Page 1

BROOKFIELD DV-III ULTRA

Programmable Rheometer

Operating Instructions

Manual No. M98-211-E0912

SPECIALISTS IN THE

MEASUREMENT AND

CONTROL OF VISCOSITY

with offices in

Boston • Chicago • London • Stuttgart • Guangzhou

:

BROOKFIELD ENGINEERING LABORATORIES, INC.

11 Commerce Boulevard, Middleboro, MA 02346 USA

TEL 508-946-6200

F

AX 508-946-6262

or 800-628-8139 (USA e xcluding MA)

http://www.brookfieldengineering.com

I

NTERNET

Brookeld Engineering Laboratories, Inc. Page 1 Manual No. M98-211-E0912

Page 2

Brookeld Engineering Laboratories, Inc. Page 2 Manual No. M98-211-E0912

Brookeld Engineering Laboratories, Inc. Page 2 Manual No. M/98-211-B0104

Page 3

Table of Contents

I. Introduction .......................................................................................................... 5

I.1 Torque Measurement ................................................................................................................. 5

I.2 Viscosity Units of Measurement ................................................................................................5

I.3 Yield Stress Measurement ........................................................................................................6

I.4 Components ..............................................................................................................................7

I.5 Dimensional Information ............................................................................................................ 8

I.6 Utilities ....................................................................................................................................... 9

I.7 Specication ..............................................................................................................................9

I.8 Safety Symbols and Precautions ............................................................................................. 11

I.9 Data Retention ......................................................................................................................... 11

I.10 Set-Up ................................................................................................................................... 11

I.11 Connections ........................................................................................................................... 15

I.12 Key Functions ........................................................................................................................ 16

I.13 Cleaning .................................................................................................................................17

II. Getting Started ................................................................................................... 18

II.1 Autozero .................................................................................................................................18

II.2 Rheometer Display ................................................................................................................. 18

II.3 Spindle Entry ..........................................................................................................................21

II.4 Direct Speed Entry .................................................................................................................23

II.5 External Control ...................................................................................................................... 24

II.6 Preventative Maintenance ...................................................................................................... 25

III. Making Viscosity and Yeild Measurements .................................................... 27

III.1 Quick Start ............................................................................................................................. 27

III.2 Preparations for Making Measurements ................................................................................28

III.3 Selecting a Spindle/Speed ....................................................................................................30

III.4 Multiple Data Points ...............................................................................................................30

IV. Programming the DV-III Ultra and Data Collection Methods/Analysis ......... 31

IV.1 Programming Concepts ......................................................................................................... 31

IV.2 DV-III Speed/Time Pair Programs for Making Viscosity Measurements ...............................32

IV.3 Bevis Programs for Making Viscosity Measurements ...........................................................42

IV.3.1 Setting Up Bevis Programs ............................................................................................42

IV.3.1.1 Description of B.E.V.I.S. Commands ......................................................................43

IV.3.1.2 Example Programs ................................................................................................. 46

IV.3.2 Running Bevis Programs in Standalone Mode ............................................................... 47

IV.4 Choosing the Best Data Collection Method for Viscosity Tests ............................................. 49

IV.5 Data Analysis for Viscosity Tests ........................................................................................... 50

IV.6 Automated Data Gathering and Analysis using Rheocalc .....................................................50

IV.7 Math Models ..........................................................................................................................50

IV.7.1 The Power Law (Ostwald) Model ...................................................................................42

IV.7.2 The Herschel/Bulkley Model ...........................................................................................42

IV.7.3 The Bingham Model .......................................................................................................42

IV.7.4 The Casson Model .........................................................................................................42

Brookeld Engineering Laboratories, Inc. Page 3 Manual No. M98-211-E0912

Brookeld Engineering Laboratories, Inc. Page 3 Manual No. M/98-211-B0104

Page 4

Table of Contents (cont'd)

IV.7.5 Other Common Rheological Models ..............................................................................42

IV.8 Yeild Stress Test Programs and Test Samples ...................................................................... 53

IV.8.1 Test Parameter Description ............................................................................................ 53

IV.8.2 Toolbar and Menu Options .............................................................................................57

IV.8.3 Data Page ......................................................................................................................60

IV.8.4 Graphs Page ..................................................................................................................62

IV.8.5 Examples of Yield Test Programs ................................................................................... 65

IV.8.5.1 Example Application: Hair Gel .............................................................................. 65

IV.8.5.2 Example Application: Hand Cream ....................................................................... 66

IV.8.5.3 Example Application: Ketchup .............................................................................. 66

IV.8.5.4 Torque vs. Time for Various Food Products ........................................................... 68

IV.8.6 Running Yield Test Programs in Stand-Alone Mode ..................................................... 69

IV.8.6.1 Data Output ...........................................................................................................73

IV.8.6.2 Printing A Program ................................................................................................73

IV.8.6.3 Test Results ........................................................................................................... 75

V. OPTIONS ............................................................................................................. 77

V.1 Set Up ....................................................................................................................................77

V.2 Print ........................................................................................................................................77

V.3 Alarm ......................................................................................................................................78

V.4 Set Temperature ..................................................................................................................... 79

V.5 Data ........................................................................................................................................79

V.6 Timed Data Collection ............................................................................................................81

Appendix A - Cone/Plate Rheometer Set-Up ...................................................................83

A.1 Electronic Gap Setting Features ............................................................................................83

A.2 Set-Up .....................................................................................................................................84

A.3 Setting the Gap .......................................................................................................................85

A.4 Verifying Calibration ................................................................................................................86

Appendix B - Viscosity Ranges ........................................................................................87

Appendix C - Variables in Viscosity Measurements .......................................................93

Appendix D1 - Spindle and Model Codes for Viscosity Tests .......................................95

Appendix D2 - Spindle Codes and Speeds for Yeild Tests ............................................99

Appendix E - Calibration Procedures .............................................................................102

Appendix F - The Brookeld Guardleg ..........................................................................107

Appendix G - DV-III Ultra Stand Assembly .....................................................................109

Appendix H - DVE-50A Probe Clip ..................................................................................110

Appendix I - DV-III Ultra to Computer Command Set .................................................... 111

Appendix J - Fault Diagnosis and Troubleshooting .....................................................115

Appendix K - Online Help and Other Resources ........................................................... 118

Appendix L - Warranty Repair and Service .................................................................... 119

Viscosity Test Report .........................................................................................Tear out page

Brookeld Engineering Laboratories, Inc. Page 4 Manual No. M98-211-E0912

Page 5

I. INTRODUCTION

The Brookeld DV-III Ultra Programmable Rheometer measures uid parameters of Shear Stress

and Viscosity at given Shear Rates. Viscosity is a measure of a uid’s resistance to ow. You will

nd a detailed description of the mathematics of viscosity in the Brookeld publication “More

Solutions to Sticky Problems”, a copy of which was included with your DV-III Ultra.

The principle of operation of the DV-III Ultra is to drive a spindle (which is immersed in the test

uid) through a calibrated spring. The viscous drag of the uid against the spindle is measured

by the spring deection. Spring deection is measured with a rotary transducer. The viscosity

measurement range of the DV-III Ultra (in centipoise or cP) is determined by the rotational speed

of the spindle, the size and shape of the spindle, the container the spindle is rotating in, and the full

scale torque of the calibrated spring.

The DV-III Ultra can also measure yield stress (in Pascals or Pa). See Section I.3 for more information

on yield stress.

I.1 Torque Measurement

There are four basic spring torque models offered by Brookeld:

Spring Torque

Model dyne•cm mN•m

LVDV-III Ultra 673.7 0.0673

RVDV-III Ultra 7,187.0 0.7187

HADV-III Ultra 14,374.0 1.4374

HBDV-III Ultra 57,496.0 5.7496

The higher the torque calibration, the higher the viscosity measurement range. The viscosity

measurement range for each spring torque model may be found in Appendix B.

I.2 Viscosity Units of Measurement

All units of measurement are displayed according to either the CGS system or the SI

system.

1. Viscosity appears in units of centipoise (shown as “cP”) or milliPascal-seconds (shown

as mPa•s).

2

2. Shear Stress appears in units of dynes/square centimeter (“D/cm

2

meter (“N/m

”).

”) or Newtons/square

3. Shear Rate appears in units of reciprocal seconds (“1/SEC”).

4. Torque appears in units of dyne-centimeters or Newton-meters (shown as percent “%”

in both cases).

The equivalent units of measurement in the SI system are calculated using the following

conversions:

SI CGS

Viscosity: 1 mPa•s = 1 cP

Shear Stress: 1 Newton/m

2

= 10 dyne/cm

2

Torque: 1 N•m = 107 dyne•cm

References to viscosity throughout this manual are done in CGS units.

Brookeld Engineering Laboratories, Inc. Page 5 Manual No. M98-211-E0912

Brookeld Engineering Laboratories, Inc. Page 5 Manual No. M/98-211-B0104

Page 6

I.3 Yield Stress Measurement

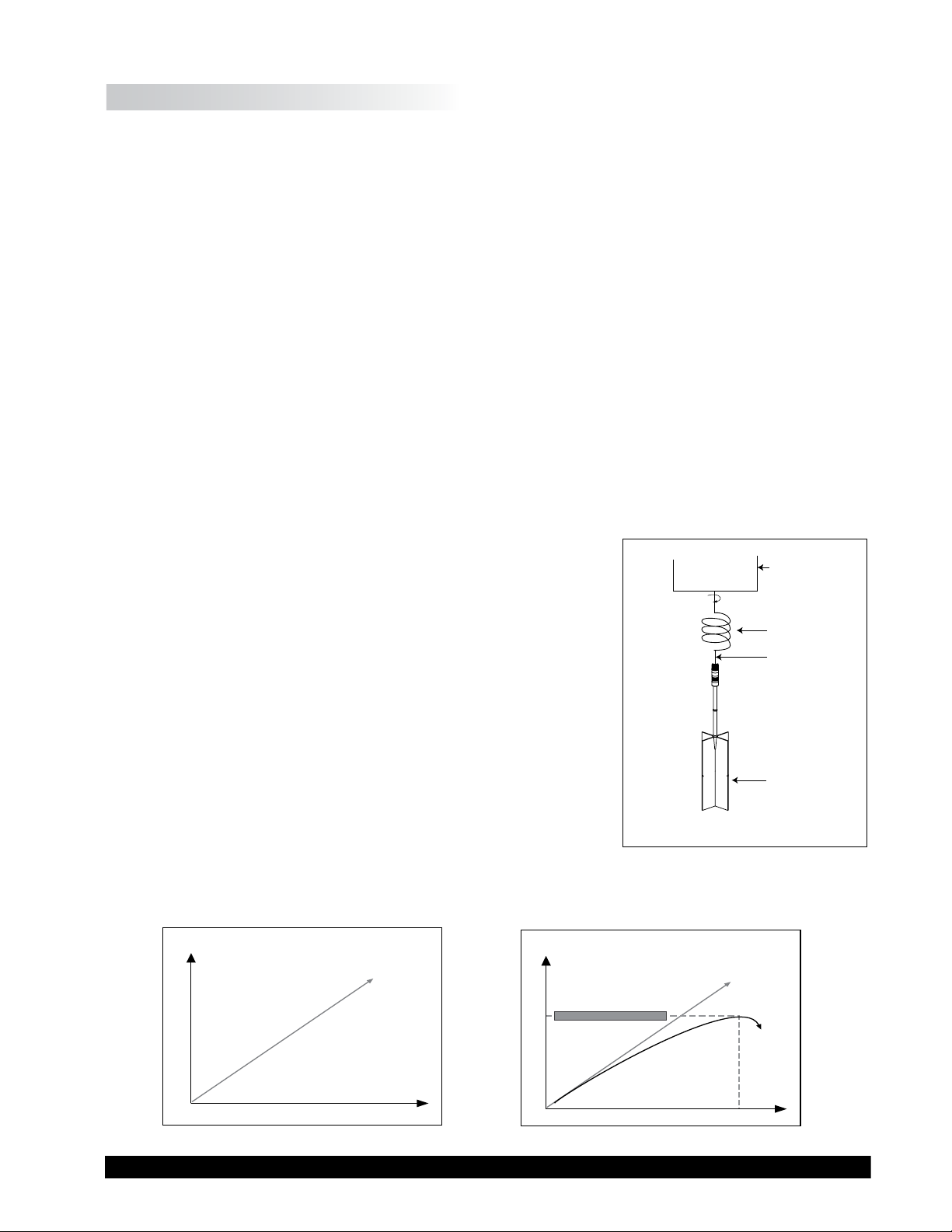

Motor

Calibrated

Spiral Spring

Drive

Shaft

Vane

Spindle

Maximum Torque Value

TIME

TORQUE

TIME

TORQUE

Another feature now available in the DV-III Ultra Rheometer is the yield stress test.

The yield point is the point at which a material begins to ow. The associated properties are the

yield stress and yield strain. The yield stress is the critical shear stress, applied to the sample, at

which the material begins to ow as a liquid. The yield strain is the deformation in the material,

resulting from the applied stress prior to the start of ow.

Many materials are designed to have a yield point, so that the behavior of their products satises

various customer needs. Foods often have yield points. Ketchup in particular must ow out of a

bottle when shaken or squeezed, but then solidify on the targeted food such as french fries. Shaking

or squeezing the bottle stresses the ketchup so that it ows; after the ketchup settles on the fries, its

structure rebuilds so the ketchup “sits” in place rather than owing off the fries like water. Puddings

have yield points, as well. The “body” of the pudding appeals to consumers – it is solid at rest,

yet it’s easily spooned out of its cup and is easy to eat. Thus, the yield behavior of many foods

contributes to the food texture that we like.

Many paints have low yield stresses. Many latex house paints, for example, are easily stirred or

poured. Brushing or spraying provides enough stress so that the paint ows easily and smoothly

over a painted wall. However, a thin layer of applied paint (if a good one!), that is allowed to rest

undisturbed on the surface, regains its structure quickly so that there is very little unsightly “dripping”

afterwards. The smooth appearance of the painted surface is very appealing to the homeowner.

The operating principle is to drive a vane spindle through the

calibrated spiral spring connected to a motor drive shaft (see

Figure I-1). The vane spindle is immersed in the test material.

The resistance of the material to movement is measured by

observing increasing torque values as the DV-III Ultra motor

rotates. The amount of shaft rotation is measured by the deection

of the calibrated spiral spring inside the instrument. Spring

deection is measured with a rotary transducer.

If the vane spindle did not move at all, the data would look like

the graph in Figure I-2. The data often looks like the graph in

Figure I-3 because there is usually some deformation of the test

material due to the increasing force imparted by the vane spindle.

The maximum torque value is the yield point. The straight line

in Figure I-3 is a repeat of what was shown in Figure I-2. An

algorithm in the rmware converts the maximum torque value

into a yield stress value.

Figure I-1

The shear stress measurement range of the DV-III Ultra (in Pascals) is determined by the size and

shape of the vane spindle and the full scale torque range of the calibrated spring.

Brookeld Engineering Laboratories, Inc. Page 6 Manual No. M98-211-E0912

Figure I-2

Figure I-3

Page 7

I.4 Components

Component Part Number

DV-III Ultra Rheometer depends on model

Powerbase DVP-2Y

includes:

Leveling Screws (3) VS-3

Upright Rod VS-20

Jam Nut VS-21

Clamp Assembly VS-27Y

Spindle Set with Case

LVDV-III Ultra set of four spindles or SSL

RVDV-III Ultra set of six spindles or SSR

HA/HBDV-III Ultra set of six spindles SSH

Optional Vane Set of three spindles SSVANE

For Cone/Plate versions: a spindle wrench, one cone spindle and sample cup Part No.

CPE-44Y replace the spindle set.

Power Cord

for 115 VAC DVP-65

for 230 VAC DVP-66

RTD Temperature Probe DVP-94Y

Ribbon Cable DVP-145

Guard Leg:

LVDV-III Ultra B-20Y

RVDV-III Ultra B-21Y

Carrying Case DVP-71Y

RHEOLOADER Software, EZ-Yield Software CD-PROGA

RS-232 Cable (DV-III Ultra to Computer) DVP-80

USB Cable DVP-202

Operator Manual M98-211

Please check to be sure that you have received all components, and that there is no

damage. If you are missing any parts, please notify Brookeld Engineering or your local

Brookeld agent immediately. Any shipping damage must be reported to the carrier.

Brookeld Engineering Laboratories, Inc. Page 7 Manual No. M98-211-E0912

Page 8

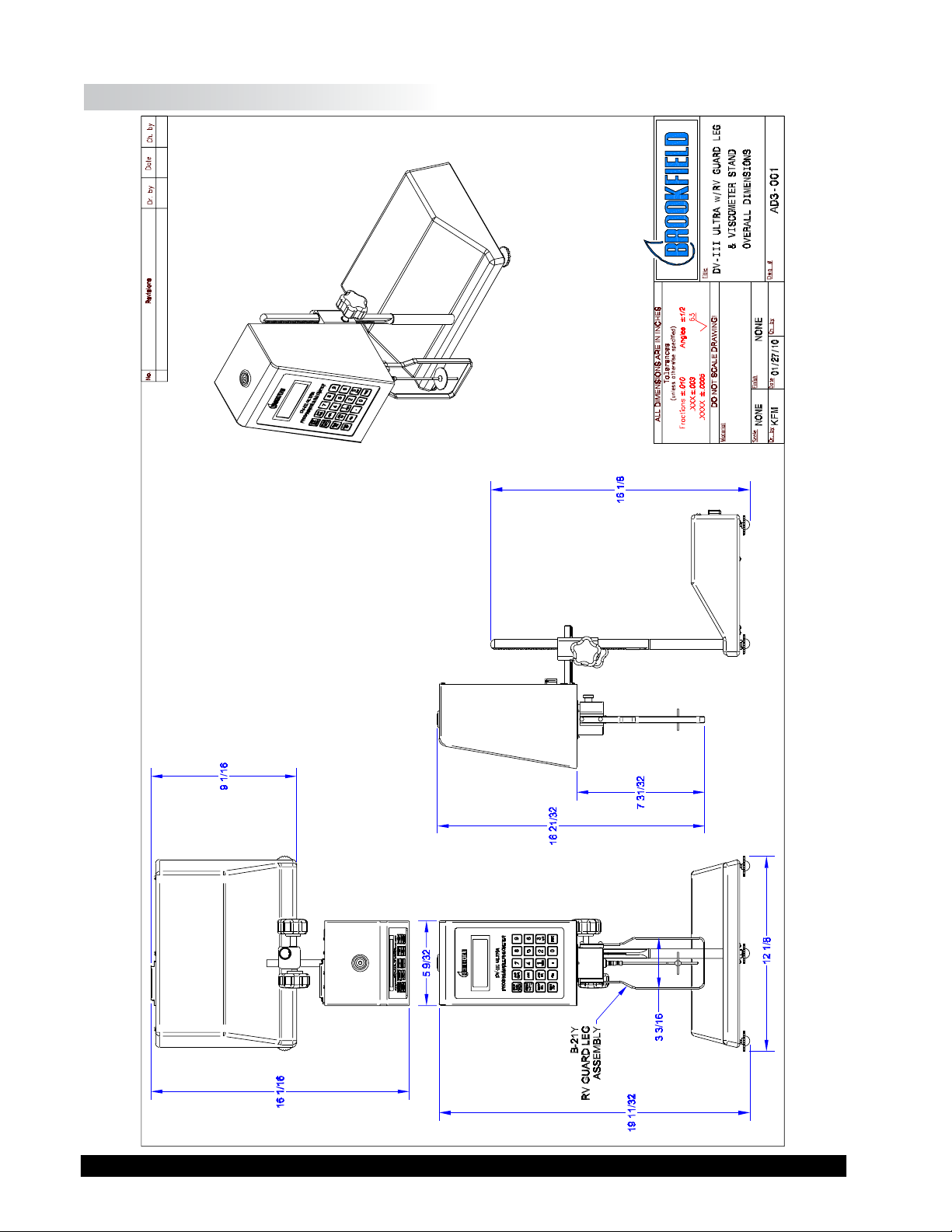

I.5 Dimensional Information

Brookeld Engineering Laboratories, Inc. Page 8 Manual No. M98-211-E0912

Brookeld Engineering Laboratories, Inc. Page 8 Manual No. M/98-211-B0104

Page 9

I.6 Utilities

Auto-sensing Power Supply:

Input Voltage: 90 - 260 VAC

Input Frequency: 50 - 60 Hz

Power Consumption: Less than 220 VA

Main supply voltage uctuations are not to exceed ± 10% of the nominal supply voltage.

Power Cord Color Code:

United States Outside United States

Hot (live) Black Brown

Neutral White Blue

Ground (earth) Green Green/Yellow

I.7 Specication

Speed Ranges 0.01-250 RPM, 0.01 RPM increments from 0.01 to 0.99 RPM,

for viscosity tests: 0.1 RPM increments from 1.0 to 250 RPM

Speed Ranges Pre Shear 0.01 to 200 rpm

for yield tests: Zero 0.01 to 0.5 rpm

Yield Test 0.01 to 5 rpm

Time Intervals 100 msec - 1000 msec

for yield tests:

Viscosity Accuracy: ± 1.0% of full scale range for a specic spindle running at a

specic speed.

Temperature sensing range: - 100°C to 300°C (-148°F to 572°F)

Temperature accuracy: ± 1.0°C from -100°C to 150°C

± 2.0°C from +150°C to 300°C

Analog Torque Output: 0 - 1 Volt DC (0 - 100% torque)

Analog Temperature Output: 0 - 4 Volts DC (10mv / °C)

Printer Output: Centronics, parallel or serial

Computer Interface: RS-232

USB

Torque Accuracy: ±1.0% of full scale range

Torque Repeatability: ±0.2%

Brookeld Engineering Laboratories, Inc. Page 9 Manual No. M98-211-E0912

Page 10

Operating Environment: Use indoors only.

5 °C to 40 °C temperature range (41 °F to 104 °F)

20% - 80% R.H.: non-condensing atmosphere

Pollution Degree II

Installation Category II

Altitude up to 2000 meters (max).

Weight: Gross Weight: 35 lbs. 15.9 kg

Net Weight: 32 lbs. 14.5 kg

Carton Volume: 2.0 cu. ft. 0.057 m

3

Ball Bearing Option:

If you ordered the ball bearing suspension system with your new instrument, please note the

following:

1) The ball bearing suspension in your Brookeld instrument is noted on the serial tag on

the back of the head by the letter "B" after the mode.

2) When attaching and detaching the spindle, it is not necessary to lift the coupling where

the spindle connects to the instrument.

3) The Oscillation Check explained in the Appendix J - Fault Diagnosis and Troubleshooting

does not pertain to this instrument.

Electrical Certication:

This product has been certied to the applicable CSA and ANSI/UL Standards, for use in

Canada and the U.S. (cCSAus).

Installation Category II, Pollution Degree 2, Altitude 2000m (max).

NOTICE TO CUSTOMERS:

This symbol indicates that this product is to be recycled at an appropriate collection center.

Users within the European Union:

Please contact your dealer or the local authorities in charge of waste management on how to

dispose of this product properly. All Brookeld ofces and our network of representatives

and dealers can be found on our web site: www.brookeldengineering.com

Users outside of the European Union:

Please dispose of this product according to your local laws.

Brookeld Engineering Laboratories, Inc. Page 10 Manual No. M98-211-E0912

Brookeld Engineering Laboratories, Inc. Page 10 Manual No. M/98-211-B0104

Page 11

I.8 Safety Symbols and Precautions

Safety Symbols

The following explains safety symbols which may be found in this operating manual.

Indicates hazardous voltages may be present.

Refer to the manual for specic warning or caution information to avoid personal injury

or damage to the instrument.

Precautions

If this instrument is used in a manner not specied by the manufacturer, the protection

provided by the instrument may be impaired.

This instrument is not intended for use in a potentially hazardous environment.

In case of emergency, turn off the instrument and then disconnect the electrical cord

from the wall outlet.

The user should ensure that the substances placed under test do not release poisonous,

toxic or ammable gases at the temperatures which they are subjected to during the

testing.

Instrument intended for indoor use only.

I.9 Data Retention

The DV-III Ultra will save spindle parameters (used to calculate centipoise, shear rate and shear

stress), default settings and the test data from the last program test run when the rheometer is turned

off or there is a power failure.

I.10 Set-Up

Note: "IQ,OQ,PQ", a guideline document for installation, operation and

performance validation for your DV-III Ultra Rheometer, can be

downloaded from our website: www.brookeldengineering.com

Brookeld Engineering Laboratories, Inc. Page 11 Manual No. M98-211-E0912

Page 12

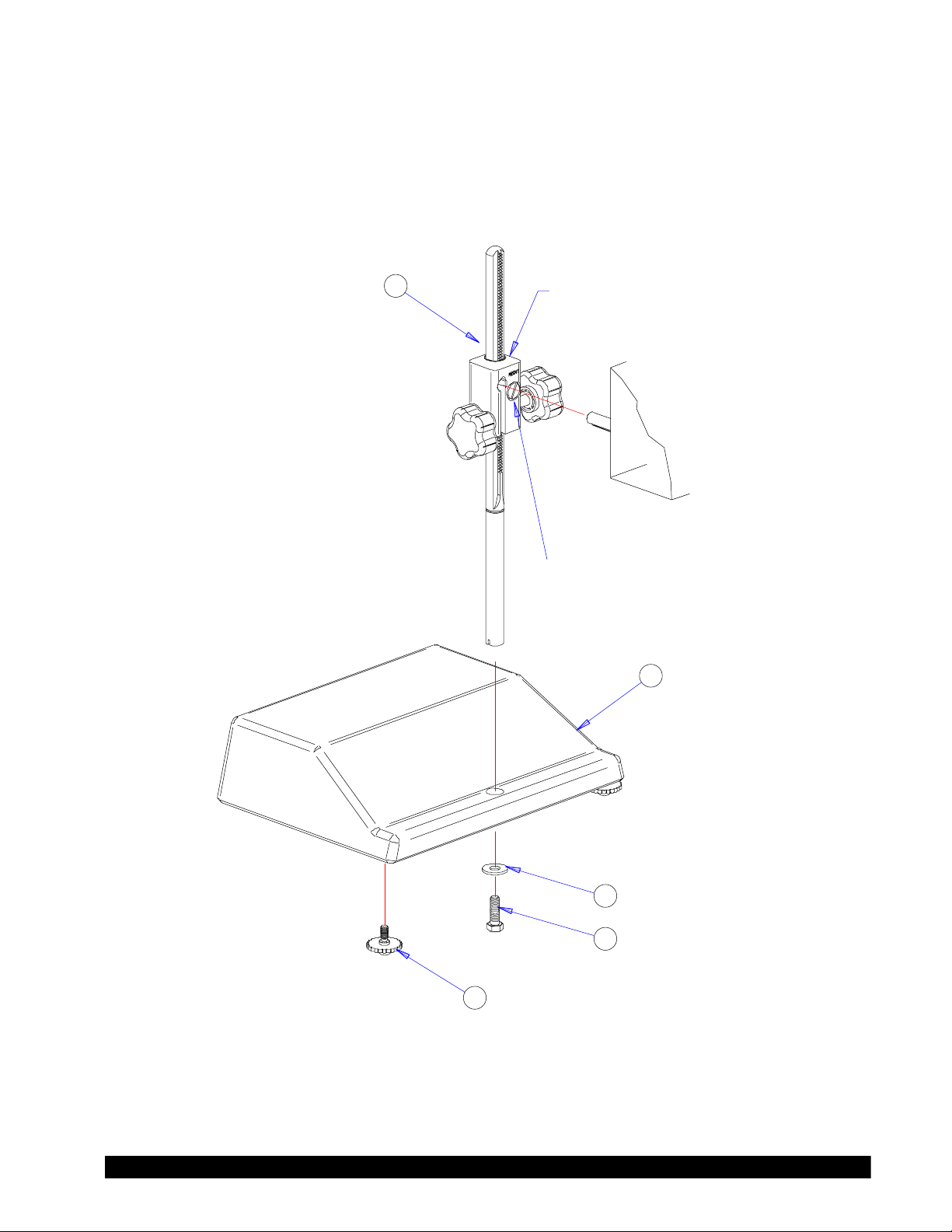

1) Place the upright rod into the hole at the front of the base. The rack gear and clamp assembly

DV-III Ultra Stand Assembly

should face the rear of the base (see Figure I-4). The upright rod (item #1) is held in place

with the jam nut (item #4) which is attached from the bottom of the base. Tighten this nut

with a suitable wrench (spanner).

1

CLAMP ASSEMBLY

NOTE: “FRONT” FACES TOWARD YOU.

DV-III Ultra

HEAD UNIT

TENSION SCREW

2

3

4

5

Figure I-4

Brookeld Engineering Laboratories, Inc. Page 12 Manual No. M98-211-E0912

Page 13

Bubble Level

Rack Gear

Clamp Assembly

Clamp Screw

Upright Rod

Mounting Handle

Figure I-5

2) Insert the mounting handle on the back of the DV-III Ultra into the hole on the clamp assembly

(SEE Figure I-5).

3) Tighten the DV-III Ultra clamp Screw (SEE Figure I-5).

Note: If the clamp assembly moves along the upright rod to freely, tighten the

tension screw (See Appendix G)

4) Insert the ribbon cable into the DV-III Ultra Rheometer head. Insert the other end of the

ribbon cable into the connector on the DV-III Ultra base (see Figure I-6).

5) Connect the RTD probe to the socket on the back side of the DV-III Ultra Rheometer (see

Figure I-6).

6) The Rheometer must be leveled before the instrument is zeroed and readings are taken. The

level is adjusted using the three leveling screws on the base. Adjust so that the bubble level

on top of the DV-III Ultra (see Figure I-5) is centered within the circle.

7) Remove the grey shipping cap which secures the lower coupling nut on the Rheometer to the

pivot cup

Brookeld Engineering Laboratories, Inc. Page 13 Manual No. M98-211-E0912

Brookeld Engineering Laboratories, Inc. Page 13 Manual No. M/98-211-B0104

Note: Check level periodically during use

8) Make sure that the AC power switch at the rear of the base unit is in the OFF position. Connect

the AC plug to the socket on the back of the DV-III Ultra base and plug it into the appropriate

AC line. Allow at least 10 minutes for warm up; 30 minutes is preferable.

Page 14

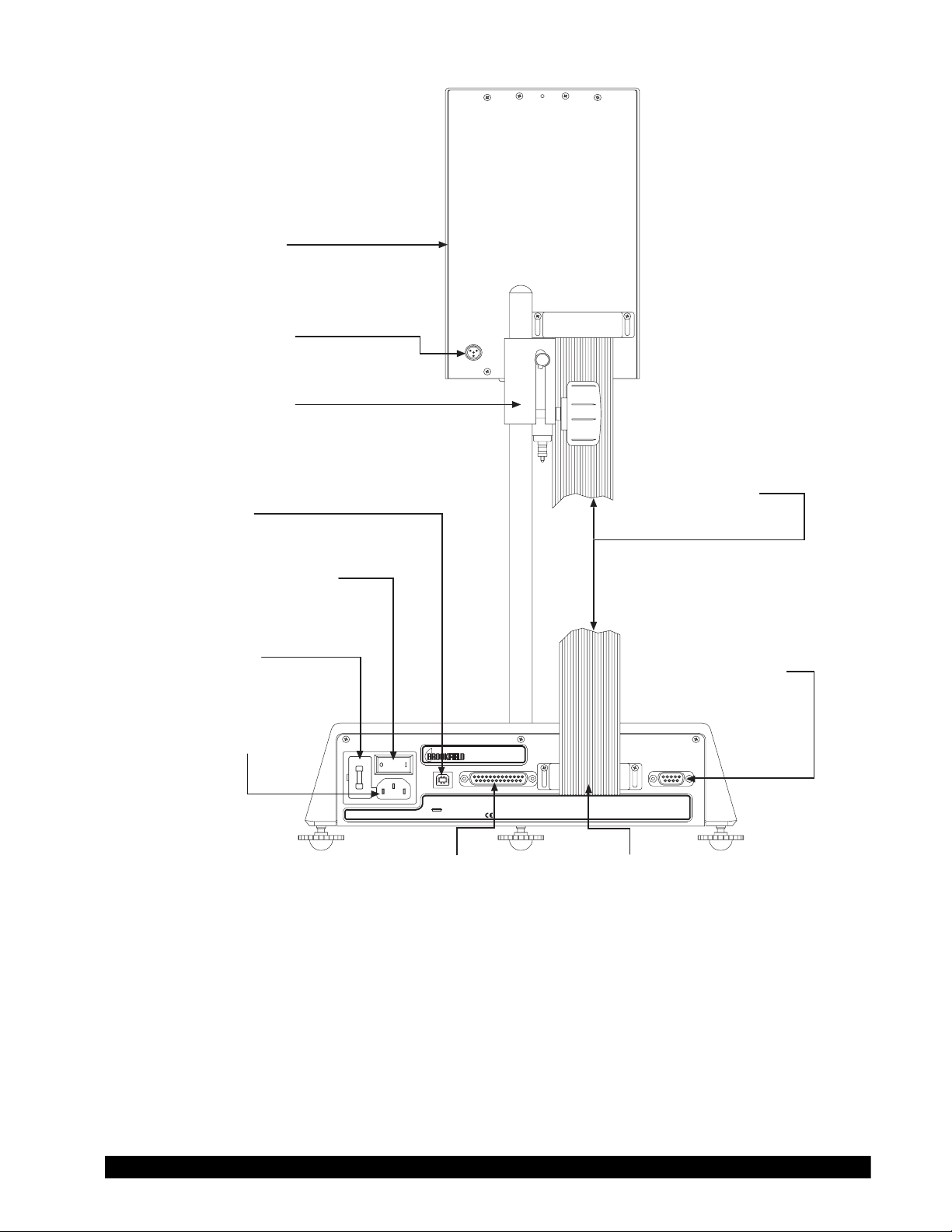

Rheometer Head

RTD Temperature

Probe Connector

Adjustment Knob

Connector

USB Cable

Power ON/OFF Switch

AC Fuse(s)

AC Power Connector

ELECTRIC RA TINGS (AUTORANGING)

90-260V AC 50/60Hz 220V A

11 COMMERCE BLVD.

MIDDLEBORO , MA 02346 U.S.A .

US BPARALLEL PRINTE RRHEOMETER UNIT SERIAL I/O

FUSE RA TINGS

F/250V 2A

-EARTH GROUNDING REQUIRE D-

Connector

Parallel Printer

MODEL DV-III ULTRA BASE UNIT Rev. B

Connector

Ribbon Cable

Figure I-6

Ribbon Cable

Connector

RS-232 Serial

Printer/Computer

Analog Output(s)

PRINTER OR COMPUTE R

ANAL OG OUTPUT S

o

TORQUE 0-1V TEMP 10MV/ C

The DV-III Ultra must be earth grounded to ensure against electronic failure!!

9) Temperature monitoring is assured (after the instrument has stabilized) to within ±1.0°C in

the range -100°C to +150°C and within 2°C in the range 150°C to 300°C.

10) For Cone/Plate models refer to Appendix A.

11) For printers, software and temperature controllers, refer to Section I.11, Connections.

Brookeld Engineering Laboratories, Inc. Page 14 Manual No. M98-211-E0912

Page 15

I.11 Connections

The DV-III Ultra Rheometer is capable of communicating with several external devices to enhance

operation. The cables and connections required for proper communication are detailed below.

S

RHEOLOADER

The DVP-202 USB Cable is used to connect the USB Port on the DV-III Ultra Base to the computer.

The DVP-80 cable is used to connect the RS-232 serial port on the DV-III Ultra base to Com Port

1 or Com Port 2 on the computer. Some PCs may also have Com Port 3 and Com Port 4. These

cables are supplied with the DV-III Ultra.

RHEOLOADER AND EZ-YIELD SOFTWARE

S

The DVP-80 cable is used to connect the RS-232 serial port on the DV-III Ultra base to Com Port

1 or Com Port 2 on the computer. Some PCs may also have Com Port 3 and Com Port 4. This

cable is supplied with the DV-III Ultra.

RHEOCALC SOFTWARE

S

The DVP-202 USB Cable is used to connect the USB Port on the DV-III Ultra Base to the computer.

The DVP-80 cable is used to connect the RS-232 serial port on the DV-III Ultra base to Com Port

1 or Com Port 2 on the computer. Both cables are supplied with the RHEOCALC software.

PARALLEL PRINTER

S

The CAP-86 cable is used to connect the 25-pin parallel port on the DV-III Ultra base with the

Centronics port on the printer.

SERIAL PRINTER

S

The DVP-81 cable is used to connect the 9-pin serial port on the DV-III Ultra with the 25-pin serial

port on a printer.

THERMOSEL CONTROLLER AND TC SERIES TEMPERATURE BATHS

S

Earlier model baths with programmable Brookeld Controllers will also work.

The DVP-141 cable is used to connect the serial port on the DV-III Ultra base to the serial port on

the controller. This cable is supplied with the controller/bath.

Be sure that the controller temperature probe is properly located in the control device (Thermosel

or bath) and connected to the controller.

Note: 1. The controller may alternately communicate with Rheocalc V.2.0 or

higher software. In this conguration, the controller is connected to the

computer through either Com Port 1 or Com Port 2 by using the DVP-80

cable. The DV-III Ultra can also be connected to a computer through

the USB Port by using the DVP-202 cable.

2. The controller must also be connected to the control device (Thermosel

or bath) with the appropriate load cable.

Brookeld Engineering Laboratories, Inc. Page 15 Manual No. M98-211-E0912

Brookeld Engineering Laboratories, Inc. Page 15 Manual No. M/98-211-B0104

Page 16

S STRIP CHART RECORDER

DVP-96Y cable is used to connect the serial port on the DV-III Ultra to the input block of the strip

chart recorder. This cable is supplied with a Brookeld strip chart recorder.

I.12 Key Functions

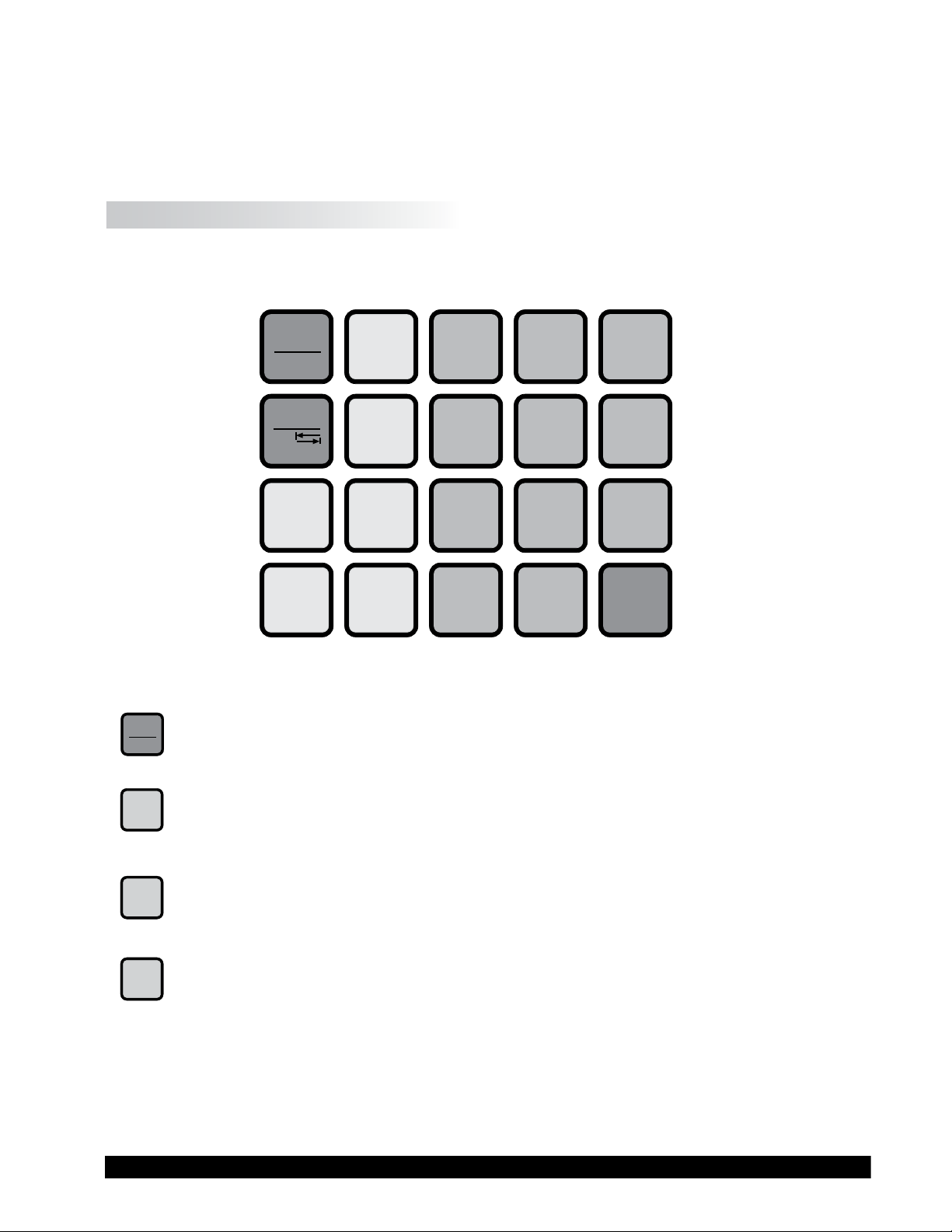

Figure I-7 shows the control keys on the face of the DV-III Ultra Rheometer. The following describes

each key’s function.

MOTOR

ON/OFF

ESCAPE

OPTION

TAB

SELECT

SPDL

SELECT

DISP

AUTO

RANGE

PROG

PROG

RUN

PRINT

789

456

1

YES NO

.

2

0

3

ENTER

Figure I-7

MOTOR

Turns the motor on or off. Cancels any operation. Returns the user to the previous screen.

MOTOR ON/OFF, ESCAPE

ON/OFF

ESCAPE

Presents the maximum (100% torque) viscosity attainable using the selected spindle at

AUTORANGE

AUTO

RANGE

the current speed.

SELECT SPDL

SELECT

SPDL

Allows selection of the spindle to be used.

Selects the parameter to be displayed:

SELECT DISP

SELECT

DISP

% Rheometer Torque (%)

cP Viscosity (cP or mPa

SS Shear Stress (Dynes/cm

.

s)

2

or Newtons/m2)

SR Shear Rate (1/Sec)

Brookeld Engineering Laboratories, Inc. Page 16 Manual No. M98-211-E0912

Page 17

OPTION

TAB F

PRINT

OPTION, TAB

Accesses options menu (see Section V). Toggles between selectable items when indicated.

PRINT

Sends a single line of data to an attached printer. Selects printing and non-printing mode as

selected in the Options menu.

PROG

PROG

Access the Programs menu for program creation, running or deleting. Constructs a test program.

Allows you to review/modify an existing test program. Execute a Bevis program.

PROG RUN

PROG

RUN

Execute DV-III Ultra speed/time pair program.

NUMBER KEYS (0 through 9)

0

Sets speeds and choose items from various dialog screens and the option menu.

ENTER

ENTER

Functions as an ENTER key similar to a computer by serving to accept a keyboard entry.

I.13 Cleaning

Make sure the instrument is in a decent working environment (dust-free, moderate

temperature, low humidity, etc).

Make sure the instrument is on a level surface.

Hands/ngers must be clean and free of residual sample. Not doing so may result in

deposit build-up on the upper part of the shaft and cause interferences between the

shaft and the pivot cup.

Be sure to remove the spindle from the instrument prior to cleaning. Severe

instrument damage may result if the spindle is cleaned in place.

Instrument and Keypad: Clean with a dry, non-abrasive cloth. Do not use solvents

or cleaners.

Immersed Components (spindles): Spindles are made of stainless steel. Clean with a

non-abrasive cloth and solvent appropriate for sample

material.

When cleaning, do not apply excessive force which may result in bending the

spindles.

Brookeld Engineering Laboratories, Inc. Page 17 Manual No. M98-211-E0912

Brookeld Engineering Laboratories, Inc. Page 17 Manual No. M/98-211-B0104

Page 18

II. GETTING STARTED

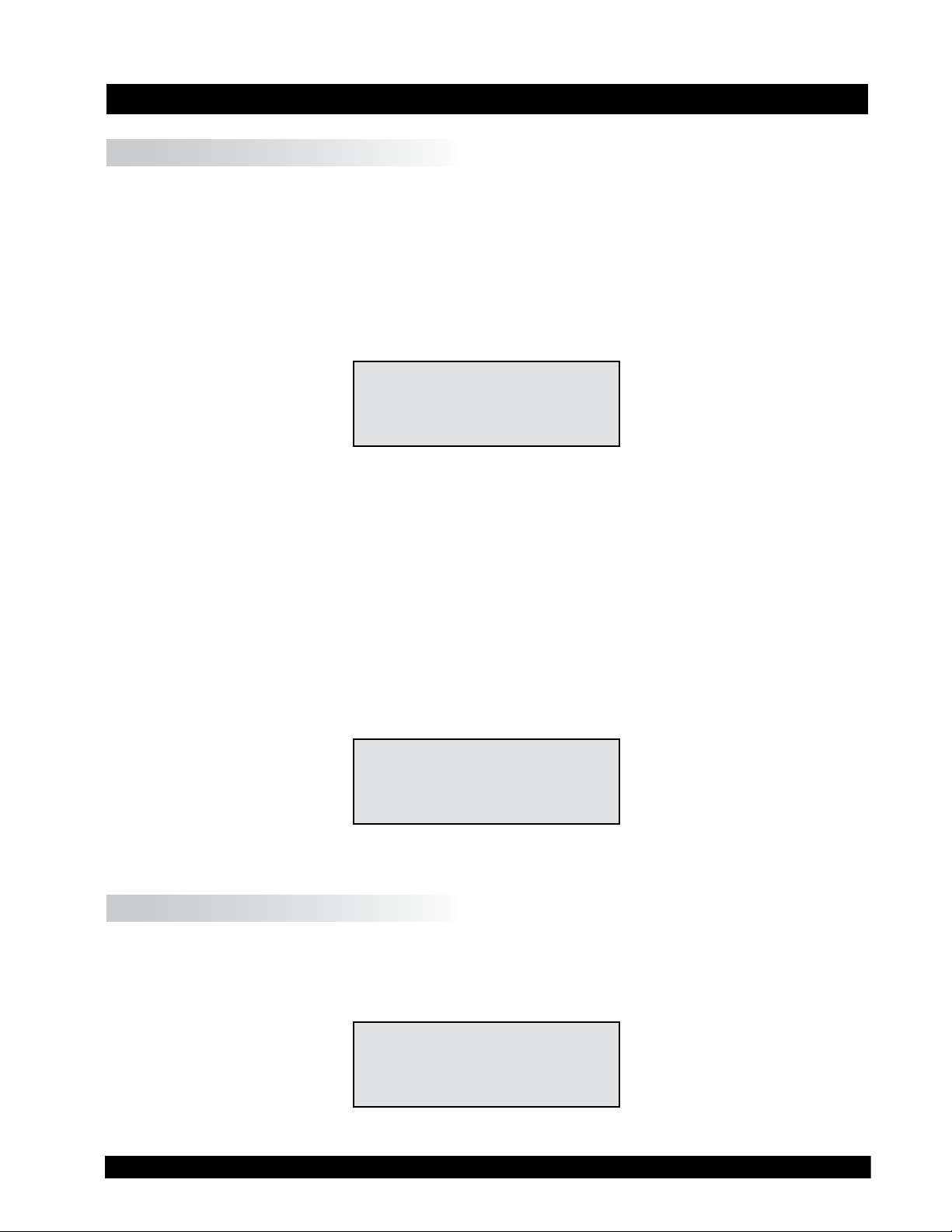

II.1 Autozero

Before readings may be taken, the Rheometer must be auto zeroed. This is done each time the

power switch is turned on. The Rheometer will guide you through the procedure, as follows:

Turn power switch on; as shown in Figure II-1, the screen indicates that the DV-III Ultra is in the

standalone mode (is not connected to a computer) and gives the version of the operating rmware

(the built in program which controls the instrument) and a two-digit alphanumeric code which

indicates the Model number (see Table D2 in Appendix D; the code tells the spring torque rating

of your Rheometer).

BROOKFIELD

DV-III ULTRA RHEOMETER

V1.0 HA

STANDALONE

Figure II-1

No key press is necessary. After a short pause the display will read “REMOVE SPINDLE, LEVEL

RHEOMETER AND PRESS THE MOTOR ON/OFF KEY TO AUTOZERO.” Before beginning the autozero

procedure, Brookeld recommends that you allow 10 minutes for the instrument to warm up.

After pressing the MOTOR ON/OFF key, the screen “ashes” for approximately 15 seconds while

the DV-III Ultra auto zeros.

After 15 seconds the display reads “AUTOZERO IS COMPLETE REPLACE SPINDLE AND PRESS ANY

KEY.” Press a key.

The main screen is displayed and the DV-III Ultra is ready for use (Figure II-2).

RPM: 0.0 SPINDLE: 31

TEMP: 72.1 F PRTN

TORQUE = 0.0 %

Figure II-2

II.2 Rheometer Display

The DV-III Ultra Rheometer is supplied with a 4-line display. The basic set of information is called

"The Default Screen" and is shown in Figure II-3. The parameters are detailed below:

RPM: 0.0 SPINDLE: 31

TEMP: 72.1°F PRTN

TORQUE = 0.0 %

Figure II-3

Brookeld Engineering Laboratories, Inc. Page 18 Manual No. M98-211-E0912

Page 19

1. Motor Status and Current Rheometer Speed

The DV-III Ultra motor can be OFF, ON at 0.0 rpm or ON at a speed greater than 0.0 rpm.

When the motor is OFF, "OFF" will be displayed and no speed entry will be accepted. When

the motor is ON, the actual speed of rotation will be displayed. When the motor is switched

from ON to OFF, the speed of rotation will be remembered; when the motor is turned ON

again, the DV-III Ultra will operate at that same speed. The rheometer motor is set to "OFF"

after AUTOZERO.

Note: Motor OFF and a speed setting of 0.0 are essentially the same.

2. Spindle Number

The currently-selected spindle. Viscosity, shear rate, and shear stress values will be calculated

based on this number. See Section II.3.

3. Measured Temperature

The current temperature as measured by the attached temperature probe. If no probe is

connected, four dashes "----" will be displayed.

4. Printing Status

Indicates the currently-selected method of printing.

5. Measured Data

Instrument Torque (%), Viscosity (cP), Shear Stress (D/cm2), Shear Rate (s-1)

The parameters are toggled from one to another using the Select Display key.

Note: Shear Stress and Shear Rate data cannot be calculated for some spindle

geometries. In these cases, the display will show 0.0.

6. Blank Line

This line is used to display entry data when selecting a spindle or speed of rotation. Additionally,

selected programs available for running will be identied here when in the Program mode.

(See Section IV.2).

The default screen will appear at the completion of the AUTOZERO sequence each time the DV-III

Ultra is turned ON in the standalone mode (see Section II.5: External Control). The displayed data

may be changed as described in the following sections.

The format for data displayed in the default screen and all other screens is described in Table 11.1.

For appearance sake, the entries in the table have been decimal point aligned. Actual rheometer

display will have all elds left justied.

Brookeld Engineering Laboratories, Inc. Page 19 Manual No. M98-211-E0912

Brookeld Engineering Laboratories, Inc. Page 19 Manual No. M/98-211-B0104

Page 20

ITEM PRINT FORMAT RANGE EXAMPLE

RPM RPM

Model M

Spindle S

Torque T

Viscosity cP or mPas

Shear Stress D/CM2 or

N/M2 =

D/CM 2/10

Shear Rate 1/SEC

Temperature T

Time Z

X.XX

XX.X

XXX.X

XXXXX

XX

XX.X

X.XX

XXX.X

XXXXX

XXXeX

X.XX

XXX.X

XXXXX

XXXeX

X.XXX

XX.X

XXXXX

XX:XX

0.01 <= RPM <= 0.99

0.1 <= RPM <= 99.9

100 <= RPM <= 250

See Model Table D-2 - Appendix D RV

00 <= S <= 99 31

-10.1 <= T <= 99.9 82.4

0 <= cP <= 9.99

10 <= cP <= 999.9

1000 <= cP <= 99999

100000 <= cP <=

51200000000

12345

123e3 to 8

0 <= D/CM2 <= 9.99

10 <= D/CM2 <= 999.9

1000 <= D/CM2 <= 99999

100000 <= D/CM2 <= 999999

12345

123e3

0 <= 1/SEC <= 9.999

10 <= 1/SEC <=99.9

100 <= 1/SEC <= 99999

-99.9 <= T <= 300.0 -10.3

00:00 <= Z <= 99.59 05:32

Table II-1

0.09

2.4

150.0

3.16

123.8

4.56

234.5

1.234

20.7

200

S

OUT OF RANGE INDICATORS

The DV-III Ultra is capable of measuring instrument torque within the range of 0 to 100%. Based

on this measurement, viscosity and shear stress are calculated. Brookeld recommends that data be

collected only in the range of 10 to 100%. Any data collected outside of this range is considered

invalid.

The DV-III Ultra provides the following display indicators when the measurement point is outside

of the 10-100% acceptable range.

S TORQUE GREATER THAN 100%

When Rheometer torque exceeds 100%, the parameter display eld will show “EEEE” for torque,

viscosity and shear stress.

RPM: 112 SPINDLE: 31

TEMP: 72.1°F PRTN

TORQUE = EEEE %

Figure II-4

S TORQUE LESS THAN 10%

When Rheometer torque drops below ten (10) percent, the Rheometer will continue to display

measurement (%, cP, D/cm2) values with units ashing:

Brookeld Engineering Laboratories, Inc. Page 20 Manual No. M98-211-E0912

Page 21

RPM: 112 SPINDLE: 31

TEMP: 72.1°F PRTN

VISC = 900@6 CPS

Figure II-5

S TORQUE LESS THAN 0%

When Rheometer torque drops below zero (0) percent, the Rheometer will continue to display

torque values preceded by a minus (-) sign. The viscosity and shear stress eld will display dashes

(- - - - ) as indicated in Figure II-6:

RPM: 112 SPINDLE: 31

TEMP: 72.1°F PRTN

S STR = ----- D/CM2

Figure II-6

II.3 Spindle Entry

The user can elect to change the spindle selection by pressing the

SELECT SPDL key. The DV-III

Ultra control program will use the previously blank line 3 on the default display screen to record

the new spindle input as depicted in Figure II-7.

RPM: 0.0 SPINDLE: 31

TEMP: 72.1°F PRTN

ENTER SPINDLE # 31

TORQUE = 0.0%

Figure II-7

To enter a spindle number, press the numeric keys until the desired spindle number has been entered.

Valid spindle numbers encompass the range from 00 to 99 as listed in Appendix D. Mistakes are

corrected by repeatedly pressing the numeric keys until the proper spindle value has been entered.

At that point, the user presses the

SELECT SPDL key again. An invalid spindle entry will result in a

“beep” and the display of the data entry error screen as shown in Figure II-8.

INVALID DATA ENTRY

"BAD SPINDLE"

** RE-ENTER **

Figure II-8

An invalid spindle entry is any two digit number in the range from 01 to 99 which is not listed in

Appendix D. This error message will be displayed for a few seconds after which the spindle entry

screen (see Figure II-7) will be re-displayed with a blank eld for the spindle number. The user

can cancel spindle entry at any time by pressing the

MOTOR ON/OFF/ESCAPE key.

To enter a new spindle into memory, use the following procedures.

Press and Hold the motor on/off and “9” key on power up. The screen in Figure II-9 appears.

Brookeld Engineering Laboratories, Inc. Page 21 Manual No. M98-211-E0912

Brookeld Engineering Laboratories, Inc. Page 21 Manual No. M/98-211-B0104

Page 22

VISCOMETER SETUP

PRESS ENTER TO START

Figure II-9

Press the

ENTER key. The screen in Figure II-10 appears. Press the "3" key for NO.

PRINT PARAM RAM?

1 = YES 3 = NO

Figure II-10

The display will now ask “SPECIAL SPINDLE?” as shown in Figure II-11. Press the “1” key

for YES.

SPECIAL SPINDLE?

1 = YES 3 = NO

Figure II-11

The display will ask “ADD A SPINDLE?” Press the “1” key for YES.

ADD A SPINDLE?

1 = YES 3 = NO

Figure II-12

The spindle number and name will be ashing. Use the “2” key for scrolling downward (ê) and

the “8” key for scrolling upward (è). The spindle name can be changed to any (2) letters from A

to Z.

Use the “tab” key to move left and right through the menu. Press the “enter” key to accept.

SPECIAL SPINDLE #1

NAME = D AA E

SMC =

SRC =

Figure II-13

Check the spindle constants to be entered. You must have the SMC (spindle multiplier constant)

and the SRC (the shear rate constant). Enter the rst set of numbers. Press the “enter” key to go

to the next line (example: spindle AA = SMC = 1.0 SRC = 2.0).

If you are adding additional spindles, press the “enter” key. You can enter up to 5 special

spindles.

Brookeld Engineering Laboratories, Inc. Page 22 Manual No. M98-211-E0912

Page 23

SPECIAL SPINDLE #2

NAME = D BB E

SMC = 1.000

SRC = 2.000

Figure II-14

To complete, enter 0 values for SMC and SRC.

The display may ask “ADD A SPINDLE”. You may press YES to repeat or NO to nish.

ADD A SPINDLE?

1 = YES 3 = NO

Figure II-15

If you press “3” NO, the display will ask “SAVE NEW SPINDLE?” Press the “1” YES to save or

press “3” NO.

SAVE NEW SPINDLES?

1 = YES 3 = NO

Figure II-16

The display will now say “SET UP COMPLETE”, turn power off.

You can edit any existing spindle entry names and spindle constants. If so, you will need to complete

the steps until you are prompted to “Save New Spindle”. For example, if you have three special

spindles entered and need to modify the second spindle, you will need to proceed through the third

spindle parameters by pressing “Enter” until prompted to “Save New Spindle”. This will then save

the modied spindle.

II.4 Direct Speed Entry

At this point, the user may choose to enter a speed by the so-called direct speed entry method.

Enter a valid speed in the range of 0.01 to 250 RPM by pressing the numeric keys successively.

The previously blank line 3 on the default display screen records the user’s new speed input as

depicted in Figure II-17:

RPM: 0.0 SPINDLE: 31

TEMP: 72.1°F PRTN

ENTER NEW RPM: 11_

TORQUE = 0.0 %

Figure II-17

Here, the user intends to enter a speed of 112 RPM, has pressed the “1” key twice and is about

to press the “2” key. If the user makes more than ve (5) key presses, the DV-III Ultra control

program will “roll” the cursor back to the rst character of the eld and begin to overwrite the

previous data entry.

Next the user presses the

Brookeld Engineering Laboratories, Inc. Page 23 Manual No. M98-211-E0912

Brookeld Engineering Laboratories, Inc. Page 23 Manual No. M/98-211-B0104

ENTER key to accept the speed. The motor will begin running at 112 RPM

Page 24

and the display will be updated to the next screen image:

RPM: 112 SPINDLE: 31

TEMP: 72.1°F PRTN

TORQUE = 56.3 %

Figure II-18

If the speed entered was not valid the Rheometer will display the following message:

INVALID DATA ENTRY

"BAD SPEED/TIME"

** RE-ENTER **

Figure II-19

After a few seconds, the display returns to Figure II-17 with the speed data eld cleared and just

the underscore cursor awaiting a new entry.

II.5 External Control

The DV-III Ultra Rheometer can be used in conjunction with Brookeld software, RHEOCALC

(V. 2. or higher). Through RHEOCALC, all rheometer functions are controlled by the computer.

The DV-III Ultra must be set to the external control mode to allow for proper communication with

RHEOCALC. To congure the external control mode, connect computer interface cable DVP-80

(RS-232) or DVP-202 (USB) to the port on the DV-III Ultra base before turning on the DV-III

Ultra. With the DVP-80 cable in place, the DV-III Ultra will present the screen shown in Figure

II-20 when it is turned on. If external control is selected, the DV-III Ultra will display Figure II-21

and only accept control commands from RHEOCALC software.

BROOKFIELD

DV-III ULTRA RHEOMETER

1 = EXTERNAL CONTROL

2 = STANDALONE MODE

Figure II-20

BROOKFIELD

DV-III ULTRA RHEOMETER

V0.0 HA

EXTERNAL

Figure II-21

The DV-III Ultra may be set to stand alone mode by turning it OFF and ON again and selecting

"Stand Alone" or by removing the cable (DVP-80 or DVP-202) prior to turning the DV-III Ultra

on.

Note: The DV-III Ultra cannot communicate with RHEOLOADER or EZ-

Yield software in the external control mode. Choose "Stand Alone"

when presented with Figure II-20 if you want to use RHEOLOADER

or EZ-YIELD.

Brookeld Engineering Laboratories, Inc. Page 24 Manual No. M98-211-E0912

Page 25

II.6 Preventative Maintenance

The DV-III Ultra does not require any internal maintenance or adjustment. Periodic verication

of calibration is an important procedure. We recommend that you check the calibration of

your DV-III Ultra on a regular basis. The frequency of calibration checks should be set based

on your use of the instrument and the signicance of the data. We generally recommend

a frequency of 1 month. See Appendix E - Calibration Check Procedure for information on

performing a calibration check.

Any condition that results in an out of calibration result (see Interpretation of Calibration

Results at the end of Appendix E) must be corrected by Brookeld or our authorized dealers.

Please check our web site for information on our dealers and a Laboratory Return Form;

www.brookeldengineering.com.

Preventative maintenance for the DV-III Ultra consists primarily of good practice when

using the instrument. Please follow the suggestions below.

• Long term storage: When the DV-III Ultra will be out of service for an extended period

of time, use the Instrument Carrying Case in which it was supplied. Be sure to install

the shipping cap.

• When the unit is not in use, place it on the back of the laboratory bench out of the

way of normal activity.

• Be sure that the unit is properly leveled for all measurements (Section I.10; Step 6).

• Periodically check the Tension Screw on the Clamp Assembly of the Upright Rod

Assembly (Appendix G). This screw should be tight enough to prevent the unit from

moving down the rod spontaneously but not so tight as to prevent the operator

from moving the unit with the adjustment knob.

• Keep hands free from test materials to prevent transfer of material to surfaces of

the unit.

• Keep the bottom of the unit housing clean from test samples and debris. The pivot

cup and spindle connection should be clean and free of any material. This will ensure

proper connection of the spindle to the unit and proper rotation of the spindle

(minimize run out).

• Properly clean spindles and sample chambers (optional) after each measurement.

Remove the spindle from the unit prior to cleaning, not doing so may result in the

spindle being bent. Use cleaning solvents that are compatible with 300 series

stainless steel. Do not use abrasive cloths.

• Clean keypad and display screen with a soft dry cloth. Do not use harsh solvents or

abrasive materials.

• Clean instrument surfaces with a soft dry cloth. Solvents may remove factory

paint.

• Wells/Brookeld cone spindles should be handled carefully to prevent scratches to

the measurement surface and nicks on the outer radius. Do not drop the spindle

on the lab bench or oor. We recommend placing a rubber mat in the areas around

the DV-III Ultra when these spindles are in use.

Brookeld Engineering Laboratories, Inc. Page 25 Manual No. M98-211-E0912

Page 26

• Wells/Brookeld sample cups should be handled carefully to prevent scratches or

nicks. Do not use abrasive cleaners or cloths.

• Store all spindles in the protective case in which they were supplied.

• Do not store spindles attached to the unit.

• Periodically inspect all cables for proper connection and damage.

Brookeld Engineering Laboratories, Inc. Page 26 Manual No. M98-211-E0912

Page 27

III. MAKING VISCOSITY AND YEILD MEASUREMENTS

III.1 Quick Start

Viscosity Measurement

The DV-III Ultra Rheometer uses the same methodology for viscosity measurement as the Brookeld

Dial Reading Viscometer and DV series of Digital Viscometers. If you have experience with other

Brookeld equipment, this section will give you the quick steps for taking a viscosity reading. If

you have not used a Brookeld Viscometer before, skip this section and go to Section III.2 for a

detailed description.

A) Assemble and level the rheometer (Section I.10).

B) Turn power on. Select 2 = STANDALONE MODE.

C) Autozero the rheometer (Section II.1).

D) Enter the spindle number using the SELECT SPINDLE key (Section II.3).

E) Introduce the spindle into the sample and attach the spindle to the coupling nut.

NOTE: Left-hand threads.

F) Enter the speed of rotation using the number pad and ENTER key (Section II.4).

G) Record % torque and viscosity.

Yield Measurement

The DV-III Ultra Rheometer uses the same methodology for yield measurement as the Brookeld

YR-1 Rheometer. If you have experience with the YR-1, this section will give you the quick steps

for taking a yield stress reading. If you have not used a Brookeld Viscometer before, skip this

section and go to Section IV.8 for a detailed description.

A) Assemble and level the rheometer (Section I.10).

B) Turn power on. Select 2 = STANDALONE MODE.

C) Autozero the rheometer (Section II.1).

D) Press the PROG key on the rheometer keypad. The rheometer will display the “PROGRAM

MODES” screen as shown in Figure II.20. Press the “4” key to access the Yield Program.

E) Start the EZ-Yield software program on your PC. In the upper right corner of the main screen,

set the instrument setting to “DV-III ULTRA” and the COM port setting to the appropriate

com port.

F) Click on the “Test Parameters” tab beneath the toolbar on your PC screen. Insert values for

the EZ-Yield test parameters as explained in Section I.3 and save the le if required for future

use.

G) Click the download button on the toolbar on your PC screen. The screen on the rheometer

will show “DOWNLOAD COMPLETE, PRESS ANY KEY”.

Brookeld Engineering Laboratories, Inc. Page 27 Manual No. M98-211-E0912

Brookeld Engineering Laboratories, Inc. Page 27 Manual No. M/98-211-B0104

Page 28

H) Press the ENTER button on the rheometer to run the test. The screen will then show “USE

SPINDLE #__”. Conrm that the correct spindle is attached to the rheometer and that the

sample is properly prepared and in position to begin the test. Press the ENTER button to start

the test.

I) After a few seconds, your PC will automatically show the Graphs page in the EZ-Yield software

program, indicating that the test has begun. The DV-III Ultra will send data to the PC and the

graph of the yield stress ow behavior will be captured. The Data page in the software will

record the actual numerical values for shear stress.

J) When the test is complete, a dialog box appears asking you to save the data that was just

acquired.

K) Subsequent tests can be started by either pushing the ENTER button on the DV-III Ultra or

by clicking the RUN button in the EZ-Yield software.

III.2 Preparations for Making Measurements

A) RHEOMETER: The DV-III Ultra should be turned on, leveled and auto zeroed. The level is

adjusted using the three feet on the bottom of the base and conrmed using the bubble on the

top of the head. Adjust the feet until bubble is inside the center target. Set the level prior to

autozero and check the level prior to each measurement.

Proper level is essential for correct operation of the DV-III Ultra.

B) SAMPLE: The uid to be measured (sample) must be in a container. The standard spindles

supplied with the DV-III Ultra (LV (1-4), RV (2-7), or HA/HB (2-7)) are designed to be used

with a 600 ml low form Grifn beaker (or equivalent container with a diameter of 8.25cm).

The same applies to the optional RV1, HA/HB1, and Vane spindles. Many other spindle

systems are supplied from Brookeld with specic sample chambers such as the Small Sample

Adapter, UL Adapter and Thermosel.

Brookeld recommends that you use the appropriate container for the selected spindle. You

may choose to use an alternate container for convenience, however, this may have an effect

on the measured viscosity. The DV-III Ultra is calibrated considering the specied container.

Alternate containers will provide results that are repeatable but not "true."

The LV (1-4) and RV (1-7) are designed to be used with the guardleg attached (see Appendix

F). Measurements made without the guardleg will provide repeatable results but may not

provide "true" results.

When comparing data with others, be sure to specify the sample container and presence/

absence of the guardleg.

Many samples must be controlled to a specic temperature for viscosity measurement. When

conditioning a sample for temperature, be sure to temperature control the container and spindle

as well as the sample.

Please see our publication, "More Solutions to Sticky Problems", for more detail relating to

sample preparation.

C) SPINDLE ATTACHMENT: The method of spindle connection to the DV-III Ultra is specied

at the time of order as either Standard Threaded Shaft or EZ-Lock. The spindle connection

method may be changed by sending the DV-III Ultra to Brookeld or our authorized agents.

There is an adapter available to convert Standard Threaded Spindles to EZ-Lock Spindles. It

is not possible to use EZ-Lock Spindles on a Standard Threaded Unit.

Brookeld Engineering Laboratories, Inc. Page 28 Manual No. M98-211-E0912

Page 29

Note: If you are using an accessory device such as a Small Sample Adapter,

the complete kit must be congured for the EZ-Lock Unit to ensure

proper alignment and spindle immersion. Contact Brookeld for more

information.

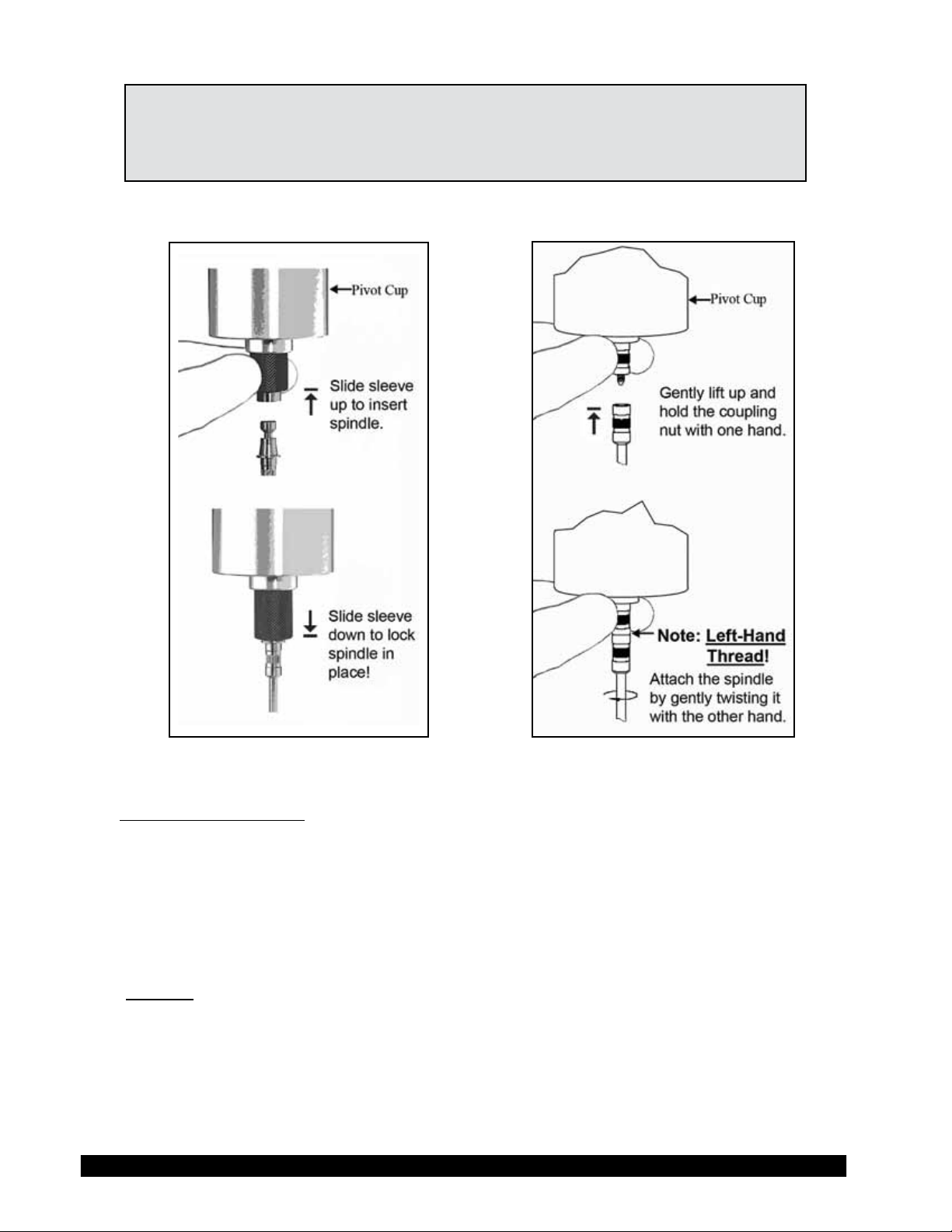

Figures III-1a and III-1b shows the method for both connection systems.

Figure III-1a: EZ-Lock Figure III-1b: Standard Spindle

Standard Threaded Shaft

The spindles are attached to the viscometer by screwing them onto the lower shaft. Note that the

spindles have a left-handed thread. The lower shaft should be secured and slightly lifted with one

hand while screwing the spindle to the left. The face of the spindle nut and the matching surface

on the lower shaft should be smooth and clean to prevent eccentric rotation of the spindle. Spindles

can be identied by the number on the side of the spindle coupling nut.

EZ-Lock

Hold the spindle with one hand while gently raising the spring-loaded outer sleeve to its highest

position with the other hand. Insert the EZ-Lock Spindle Coupling so that the bottom of the coupling

is ush with the bottom of the sleeve, and lower the sleeve. The sleeve should easily slide back

down to hold the spindle/coupling assembly in place for use. [Spindles can be identied by entry

code; look for the number on the side of the EZ-Lock spindle coupling.]

Brookeld Engineering Laboratories, Inc. Page 29 Manual No. M98-211-E0912

Brookeld Engineering Laboratories, Inc. Page 29 Manual No. M/98-211-B0104

Page 30

III.3 Selecting a Spindle/Speed

The DV-III Ultra has the capability of measuring viscosity over an extremely wide range (for example,

the RVDV-III Ultra can measure uids within the range of 100-40,000,000 cP) (see Appendix B).

This range is achieved through the use of several spindles over many speeds. When measuring

yield stress with vane spindles, a broad measurement range is also possible through the choice of

multiple spindles.

The process of selecting a spindle and speed for an unknown uid is normally trial and error. An

appropriate selection will result in measurements made between 10-100 on the instrument %

torque scale. Two general rules will help in the trial and error process.

1) Viscosity range is inversely proportional to the size of the spindle.

2) Viscosity range is inversely proportional to the rotational speed.

In other words: to measure high viscosity, choose a small spindle and/or a slow speed. If the chosen

spindle/speed results in a reading above 100%, then reduce the speed or choose a smaller spindle.

Experimentation may reveal that several spindle/speed combinations will produce satisfactory results

between 10-100%. When this circumstance occurs, any of the spindles may be selected.

Non-Newtonian uid behavior can result in the measured viscosity and yield stress changing if the

spindle and/or speed is changed. See our publication, "More Solutions to Sticky Problems," for

more detail.

When viscosity and/or yield stress data must be compared, be sure to use the same test

methodology: namely the same instrument, spindle, speed, container, temperature and test

time.

III.4 Multiple Data Points

The majority of viscosity and yield stress measurements are made at the quality control level and

often consist of a single data point. The test is conducted with one spindle at one speed. The data

point is a useful bench mark for the go/no-go decision in a production setting. The DV-III Ultra

can be used for single point measurement.

Many uids exhibit a characteristic change in viscosity and yield stress with a change in applied

force. This non-Newtonian ow behavior is commonly seen in paints, coatings and food products

as a decrease in viscosity as shear rate increases or an increase in yield stress as rotational speed

increases. This behavior cannot be detected or evaluated with the single point measurement.

Non-Newtonian ow is analyzed through the collection of viscosity data over a range of shear

rates and the generation of a graph of viscosity versus shear rate (a rheogram). The same applies to

yield stress determination by analyzing torque vs. time behavior at different rotational speeds. This

information will allow for a more complete characterization of a uid and may help in formulating

and production of the product. The DV-III Ultra is capable of collecting multiple data points for

comprehensive analysis of ow behavior. See Section IV on Programming and Analysis.

More information on ow behavior, shear rate and rheograms is available in our publication, "More

Solutions to Sticky Problems."

Brookeld Engineering Laboratories, Inc. Page 30 Manual No. M98-211-E0912

Page 31

IV. PROGRAMMING THE DV-III ULTRA AND DATA COLLECTION

METHODS/ANALYSIS

The programming and data analysis functions of the DV-III Ultra are accessed by pressing the

PROG key on the rheometer. The display will change to present a menu with four choices: DVIII, B.E.V.I.S., Models and Yield as shown in Figure IV-1. DV-III, B.E.V.I.S. and Yield are the

programming alternatives. Models will present the ve math models available for viscosity data

analysis (see IV.7 for more details about Math Models).

PROGRAM MODES

1 = DVIII 3 = MODELS

2 = BEVIS 4 = YIELD

SELECT:_

Figure IV-1

IV.1 Programming Concepts

The DV-III Ultra may be programmed to collect viscosity or yield data without operator involvement.

The captured data may be displayed and analyzed or output to a printer. Programs may be written

using three different methodologies: DV-III, B.E.V.I.S and Yield.

The DV-III Ultra programming technique uses speed/time pairs, when making viscosity measurements,

to control the DV-III Ultra. A program consists of multiple lines (up to 25) instructing the rheometer

to operate at a particular speed for some period of time. As an example, we can instruct the DV-III

Ultra to rotate the spindle at 5 RPM for 30 seconds and then change speed to 10 RPM and wait 20

seconds with the following program:

Step 1 RPM = 5 Time = 00:30

Step 2 RPM = 10 Time = 00:20

A single data point will be collected at the end of each time interval. Complete details on this

programming technique are in Section IV.2.

The B.E.V.I.S. programming technique uses a custom program language to control the DV-III Ultra.

A program consists of a series of commands instructing the rheometer in speed control, time control,

data collection, temperature control, and output. B.E.V.I.S. offers a higher level of rheometer control

compared to the DV-III method. However, the construction of B.E.V.I.S programs is more involved.

The 2-step DV-III program previously described is duplicated using B.E.V.I.S. commands below:

WTI 00:30

PDN

SSN 10

WTI 00:20

PDN

END

SSN 5

The involved programming of B.E.V.I.S. commands is a small trade-off for the signicant increase

in control capability over the DV-III method. Complete details on this programming technique are

in Section IV.3.

The yield programming technique uses three control parameters to run yield tests on the DV-III

Ultra: speed control, time control and torque change between successive data points. Complete

details on this programming technique are in Section IV.

Brookeld Engineering Laboratories, Inc. Page 31 Manual No. M98-211-E0912

Page 32

IV.2 DV-III Speed/Time Pair Programs for Making Viscosity Measurements

This programming method allows the operator to control the DV-III Ultra through the variables of

speed and time. These speed/time pairs instruct the rheometer to operate at a speed of rotation for

a certain period of time. Programs can be created with up to 25 steps. The DV-III Ultra can store

up to 10 programs. Upon completion of a program, the data may be viewed on the DV-III Ultra

display, analyzed or printed to an attached parallel or serial printer.

Two examples of programs are shown below:

Collect Data Over Time Collect Data At Several Speeds

Step RPM Time Step RPM Time

1 100 00:12 1 2.5 01:00

2 100 00:12 2 5 00:30

3 100 00:12 3 10 00:30

4 100 00:12 4 20 00:15

5 100 00:12 5 50 00:15

Five viscosity data points Five viscosity data points will be

will be collected over collected at ve speeds over

one minute. 150 seconds.

This program mode is accessed by pressing the program key and selecting number 1; 1 = DV-III.

The creation, editing and execution of DV-III programs are described in the following sections.

There are two types of test programs:

1) Next Speed Set where the test speeds are programmed, and the operator must signal the DVIII Ultra to change speeds (and therefore take a reading) by pressing the ENTER key.

2) Prog Speed Set where the DV-III Ultra will perform the test automatically.

Each step of a program has two variables - speed and hold time. The reading is taken at the end of the

hold time interval in a Prog Speed Set or when the ENTER key is pressed in a Next Speed Set.

If the rst step hold time interval is 0 seconds, the program is a Next Speed Set type. If the rst

step interval is 1 second or more, the program is a Prog Speed Set type.

S SPEED SET SELECTION AND PROGRAMMING

The DV-III Ultra viscometer allows for the retention of a maximum of 10 speed sets with up to

25 discrete speeds per speed set. The program locations are numbered 0 through 9. These speed

sets are retained in EEPROM memory for those times when the DV-III Ultra is not powered up.

To access a previously programmed speed set or to enter data for a new speed set, the user presses

the “1” key when in the display of Figure IV-1 and is presented with the screen shown in Figure

IV-2:

SPEED SET OPERATIONS

1 = ENTER/EDIT A PGM

2 = CLEAR SPEED SET

3 = USE SPEED SET

Figure IV-2

Brookeld Engineering Laboratories, Inc. Page 32 Manual No. M98-211-E0912

Brookeld Engineering Laboratories, Inc. Page 32 Manual No. M/98-211-B0104

Page 33

At this point, the user may Enter/Edit, Clear or Use a stored program (Speed Set). Let’s start with

Enter/Edit by pressing the “1” key:

SPEED SET USAGE

IN MEM: 012589

AVAIL: 3467

USE SET:_

Figure IV-3

In this example, the user is informed that he has 6 speed sets (0,1,2,5,8,9) pre-programmed in

memory and 4 speed sets (3,4,6,7) not programmed and available. Select any one of the ten speed

sets by pressing the appropriate numeric key. Pressing the MOTOR ON/OFF/ESCAPE key at

this point would exit the user to the default PROGRAM MODES display (Figure IV-1). For

now let’s assume that the user wants to program a new speed set by pressing the “3” key (the rst

available program slot).

ENTERING A SPEED SET PROGRAM

S

There are two (2) types of programs available to the user: programs with nite step time intervals

and programs with zero (0) step time intervals. We will cover the inputting of nite step time

programs rst.

S SPEED SETS WITH FINITE STEP TIMES PROG SPEED

These programs when executed will automatically progress from step to step based on the time

intervals programmed by the user. On pressing the “3” key in Figure IV-3 the user is presented

with:

NEW SPEED SET #3

STEP 01

STEP RPM = 0.0

STEP TIME = 00:05

Figure IV-4

This screen reminds the user of the speed set that he has selected to program and then allows him

to change either the speed or time interval or both for that step.

Note: The time interval on entry to this screen will always be set to 00:05

seconds as the default value. The user may of course change it to any

valid time of his choice. Whenever you change time interval, that new

time becomes the default interval until it is again changed by the user.

Also, note that zero (0) times are not allowed for program steps after

the rst step for Finite Step programs.

The OPTION/TAB key is used for moving from input eld to input eld and the ENTER key to accept

the current input for a step. On entry to this screen, the underscore cursor would be ashing (as

shown) under the rst digit of the step RPM. Use the numeric keys to make changes to the step

speed, repeating the input as many times as required until satised.

Brookeld Engineering Laboratories, Inc. Page 33 Manual No. M98-211-E0912

Page 34

When satised with the speed input, press the OPTION/TAB key which moves the ashing cursor

down to the rst character of the time eld. The same procedure is used here to input the step time

as was used to enter the RPM above. Speed or time data that is out of range, as dened by Table

II-1, will result in the following screen:

INVALID DATA ENTRY

"BAD SPEED/TIME"

** RE-ENTER **

Figure IV-5

This screen will be displayed for 1-3 seconds.

When ready, the user may press the

PROG RUN key to display the data for the next step in the

program, or the MOTOR ON/OFF/ESCAPE key (whereby none of the changes up to that point will be

accepted) to return to the screen of Figure IV-3. To end a program, the user simply enters and

accepts a step RPM and Time of zero (0) or continues to input step data until the program reaches

the twenty-ve (25) step program limit. In either case, the following screen will be displayed:

PROGRAM #3 COMPLETE

1 = ENTER/EDIT A PGM

2 = CLEAR SPEED SET

3 = USE SPEED SET

Figure IV-6

To use the currently selected speed set, press the “3” key in Figure IV-6. This would immediately

revert to the default screen modied as follows:

RPM: 0.0 SPINDLE:

TEMP: 72.1°F PRTO

SPEED SET 3 SELECTED

TORQUE = 00.0 %

Figure IV-7

Note: If at this point, prior to using the program the user wished to enter a

direct speed, a press of any numeric key which would result in a display

similar to Figure II-17. At the completion of the direct speed input, the

display would revert to Figure IV-7 above with the appropriate RPM

displayed, and the viscometer running at that speed.

The program is initiated by pressing the PROG RUN key. See "Using Pre-programmed Speeds."

S

SPEED SETS WITH ZERO STEP TIMES

These programs when executed will require that the user press the

ENTER key to progress from step

to step. On pressing the “3” key in Figure IV-3 the user is presented with the same screen that he

saw in the above description for nite step programs:

NEW SPEED SET #3

STEP 01

STEP RPM = 0.0

STEP TIME = 00:05

Figure IV-8

Brookeld Engineering Laboratories, Inc. Page 34 Manual No. M98-211-E0912

Brookeld Engineering Laboratories, Inc. Page 34 Manual No. M/98-211-B0104

Page 35

The user inputs his step RPM exactly as he did for nite step time programs above. However,

for time, input 00:00 and press the ENTER key. From this point forward, the user will only be able

to enter speeds since each press of the ENTER key will advance him to the next step. The OPTION/

TAB key will not be required. If the user wishes to correct the speed input, continue to press the

numeric/decimal point keys until satised. To correct a speed after pressing the ENTER key for that

step, wait until the program is complete and then edit the program to correct the mistake. To end

a program, simply enter and accept a step RPM of zero (0) or continue to input step data until the

program reaches the twenty-ve (25) step program limit. Speed restrictions/limits are the same as

for the description just above as are the error messages.

S EDITING A SPEED SET PROGRAM

This item is used to review a just-entered program or to review/modify (edit) a program already

stored in a memory slot. Entry to this method would typically be from Figure IV-3 after selecting

an “IN MEM” program slot or by pressing the “1” key in Figure IV-2 having just nished entering

a program. In either case, the user is presented with:

REVIEW SPEED SET #3

STEP 01 OF 03

STEP RPM = 10.0

STEP TIME = 00:05

Figure IV-9

Operation in this mode is exactly the same as for entering a new speed set; all key actions and speed

and time limits are the same. At this point, the user may continue to review/modify the speeds

comprising speed set #3 or elect to print a listing of the speeds in this speed set. To accomplish

this, the user must be in the program Enter/Edit mode; have selected or programmed a speed set

which contains more than two (2) speeds, and then press the

PRINT key. If all is well (i.e. satised

the above requirements) the rheometer will display:

PRINT SPEED SET #3

READY PRINTER THEN

PRESS PRINT KEY.

Figure IV-10

This message simply asks the user to make sure the printer is ready (it’s on-line and has paper in it)

and then awaits for the PRINT key to be pressed. When it is pressed, the DV-III Ultra will send

the following data to the attached printer:

S

FOR SPEED SETS WITH FINITE STEP TIMES

Program Use: _________________________________________________________

Programmer: _________________________________________________________

BROOKFIELD DV-III+ RHEOMETER — DATA FOR SPEED SET #9

SPEED #01 RPM = 2.5 TIME INTERVAL = 00:05

SPEED #02 RPM = 5.0 TIME INTERVAL = 00:05

SPEED #03 RPM = 10.0 TIME INTERVAL = 00:05

SPEED #04 RPM = 20.0 TIME INTERVAL = 00:05

SPEED #05 RPM = 50.0 TIME INTERVAL = 00:05

Brookeld Engineering Laboratories, Inc. Page 35 Manual No. M98-211-E0912

Page 36

S FOR SPEED SETS WITH ZERO STEP TIMES

Program Use: _________________________________________________________

Programmer: _________________________________________________________

BROOKFIELD DV-III+ RHEOMETER — DATA FOR SPEED SET #8

SPEED #01 RPM = 10.0 TIME INTERVAL = 00:00

SPEED #02 RPM = 20.0 TIME INTERVAL = 00:00

SPEED #03 RPM = 30.0 TIME INTERVAL = 00:00

SPEED #04 RPM = 40.0 TIME INTERVAL = 00:00

Since speed sets can contain twenty-ve (25) separate speeds, printing the speeds that comprise a

speed set will be of great help in allowing the user to fully exercise the power of the DV-III Ultra.

After the printing is complete, the user will be returned to the display of Figure IV-9.

S

CLEARING A SPEED SET FROM MEMORY

Since 10 speed sets can be retained in memory, the user may eventually use all the available speed

set slots. The user may also have programmed speed sets that are no longer required and would

like to remove. Assume that the user had programmed a new speed set #3 above. If he wished to

permanently remove that new speed set, or any other IN MEMORY speed set he would, while in

the screens of Figure IV-2, press the “2” key and be presented with:

CLEAR SPEED SET

IN MEM:0123589

IN USE:3

CLEAR SET:_

Figure IV-11

This screen advises that there are 7 speed sets in memory; speed set #3 is in use and that the DV-III

Ultra is awaiting input for the speed set to delete.

Note: If no speed set is in use the word “NONE” will appear next to the IN USE: prompt.

At this point, the user has two options:

1. Pressing the MOTOR ON/OFF/ESCAPE key will exit from this screen and no speed sets

will be cleared. Or

2. Pressing any of the keys “0”, “1”, “2”, “3”, “5”, “8”, or “9” will delete that speed set.

Thus, to discard speed set #5, the user would press the “5” key and be presented with:

DELETE SPEED SET 5

ARE YOU SURE?

1 = YES 3 = NO

Figure IV-12

Brookeld Engineering Laboratories, Inc. Page 36 Manual No. M98-211-E0912

Brookeld Engineering Laboratories, Inc. Page 36 Manual No. M/98-211-B0104

Page 37

In which the DV-III Ultra is requesting that the user specically press the “1” key in order to delete

the desired speed set.

CLEAR SPEED SET

IN MEM:012389

IN USE:3

CLEAR SET:_

Figure IV-13

Pressing the “3” key will cause the DV-III Ultra to take no action and will return the user to the

CLEAR SPEED SET opening screen, Figure IV-11. Any attempt to delete an in-use speed (“3”

for instance) will cause the DV-III Ultra to issue a “beep beep” with no action being taken. Thus

no active (i.e. selected for use) program can be deleted from this screen.

USING PREPROGRAMMED SPEEDS

S

Pressing the three (3) key from Figure IV-2 takes the user to the speed set selection screen of Figure

IV-3 where the user selects a new speed set. That done the user is sent to the default screen with:

“SPEED SET X SELECTED” displayed on line three (3) of the screen.

The user initiates the use of programmed speeds by pressing the

PROG RUN key. If the user presses