Page 1

BROOKFIELD DIGITAL RHEOMETER

MODEL DV-III+ Operating Instructions

Manual No. M/98-211-A0701

Please record the Model and Serial Number of your viscometer.

Having this information readily available will help us to assist you

should there be any questions regarding your instrument.

Model No. ______________________

Serial No. ______________________

SPECIALISTS IN THE

MEASUREMENT AND

CONTROL OF VISCOSITY

BROOKFIELD ENGINEERING LABORATORIES, INC.

11 Commerce Boulevard, Middleboro, MA 02346-1031 USA

TEL508-946-6200

F

AX

508-946-6262

Brookfield Engineering Laboratories, Inc. Page 1 Manual No. M/98-211-A0701

or 800-628-8139 (USA excluding MA)

NTERNET

I

www.brookfieldengineering.com

Page 2

Contents

I. INTRODUCTION.......................................................................................................3

I.1 Components ............................................................................................................. 4

I.2 Utilities..................................................................................................................... 5

I.3 Specifications ........................................................................................................... 5

I.4 Data Retention.......................................................................................................... 5

I.5 Set-Up ...................................................................................................................... 6

I.6 Connections.............................................................................................................. 9

I.7 Key Functions ........................................................................................................ 10

II. GETTING STARTED...............................................................................................12

II.1 Autozero................................................................................................................. 12

II.2 Rheometer Display................................................................................................. 13

II.3 Spindle Entry.......................................................................................................... 15

II.4 Direct Speed Entry ................................................................................................. 16

II.5 External Control..................................................................................................... 17

III. MAKING VISCOSITY MEASUREMENTS ..............................................................19

III.1 Quick Start ............................................................................................................. 19

III.2 Preparation ............................................................................................................. 19

III.3 Selecting a Spindle/Speed...................................................................................... 20

III.4 Multiple Data Points .............................................................................................. 20

III.5 Cleaning ................................................................................................................. 20

IV. PROGRAMMING THE DV-III+ AND ANALYSIS..................................................... 21

IV.1 Programming Concept ........................................................................................... 21

IV.2 DV-III Speed/Time Pair Programming .................................................................. 22

IV.3 Bevis Programs ...................................................................................................... 34

IV.4 Choosing the Best Data Collection Method........................................................... 36

IV.5 Data Analysis ......................................................................................................... 37

V. OPTIONS ................................................................................................................ 40

V.1 Set Up..................................................................................................................... 40

V.2 Print ........................................................................................................................41

V.3 Alarms .................................................................................................................... 42

V.4 Set Temperature ..................................................................................................... 43

V.5 Data ........................................................................................................................ 43

V.6 Timed data collection ............................................................................................. 44

VI. RHEOLOADER USER'S MANUAL ........................................................................ 47

VI.1 Description of B.E.V.I.S. Commands .................................................................... 47

VI. 2 Example Programs ................................................................................................. 50

APPENDIX A - Cone/Plate Rheometer Set-Up..................................................................... 52

APPENDIX B

APPENDIX C - Variables in Viscosity Measurements .......................................................... 61

APPENDIX D - Spindle and Model Codes ............................................................................ 63

APPENDIX E - Calibration Procedures ................................................................................ 67

APPENDIX F - VS-27Y Clamp Assembly............................................................................ 74

APPENDIX G - DV-III+ to Computer Command Set .......................................................... 75

APPENDIX H - Fault Diagnosis and Troubleshooting.......................................................... 77

APPENDIX I - Warranty Repair and Service ....................................................................... 80

- Viscosity Ranges.......................................................................................... 56

Brookfield Engineering Laboratories, Inc. Page 2 Manual No. M/98-211-A0701

Page 3

I. INTRODUCTION

The Brookfield DV-III+ Programmable Rheometer measures fluid parameters of Shear Stress and

Viscosity at given Shear Rates. Viscosity is a measure of a fluid’s resistance to flow. You will find

a detailed description of the mathematics of viscosity in the Brookfield publication “More Solutions

to Sticky Problems”, a copy of which was included with your DV-III+.

The principle of operation of the DV-III+ is to drive a spindle (which is immersed in the test fluid)

through a calibrated spring. The viscous drag of the fluid against the spindle is measured by the

spring deflection. Spring deflection is measured with a rotary transducer. The measuring range of

a DV-III+ (in centipoise) is determined by the rotational speed of the spindle, the size and shape of

the spindle, the container the spindle is rotating in, and the full scale torque of the calibrated spring.

There are four basic spring torque series offered by Brookfield:

Spring Torque

Model dyne•cm mN•m

LVDV-III+ 673.7 0.0673

RVDV-III+ 7,187.0 0.7187

HADV-III+ 14,374.0 1.4374

HBDV-III+ 57,496.0 5.7496

The higher the torque calibration, the higher the measurement range. The measurement range for

each torque calibration may be found in Appendix - B.

All units of measurement are displayed according to either the CGS system or the SI system.

1. Viscosity appears in units of centipoise (shown as “cP”) or milliPascal-seconds (shown

as mPa•s).

2. Shear Stress appears in units of dynes/square centimeter (“D/cm

2

”) or Newtons/square

meter (“N/m2”).

3. Shear Rate appears in units of reciprocal seconds (“1/SEC”).

4. Torque appears in units of dyne-centimeters or Newton-meters (shown as percent “%”

in both cases).

The equivalent units of measurement in the SI system are calculated using the following conversions:

SI CGS

Viscosity: 1 mPa•s = 1 cP

Shear Stress: 1 Newton/m

2

= 10 dyne/cm

2

Torque: 1 N•m = 107 dyne•cm

References to viscosity throughout this manual are done in CGS units.

WARNING: Use of this instrument in a manner not specified by Brookfield may result in incorrect

readings or instrument failure. Please read this manual prior to using the instrument.

Brookfield Engineering Laboratories, Inc. Page 3 Manual No. M/98-211-A0701

Page 4

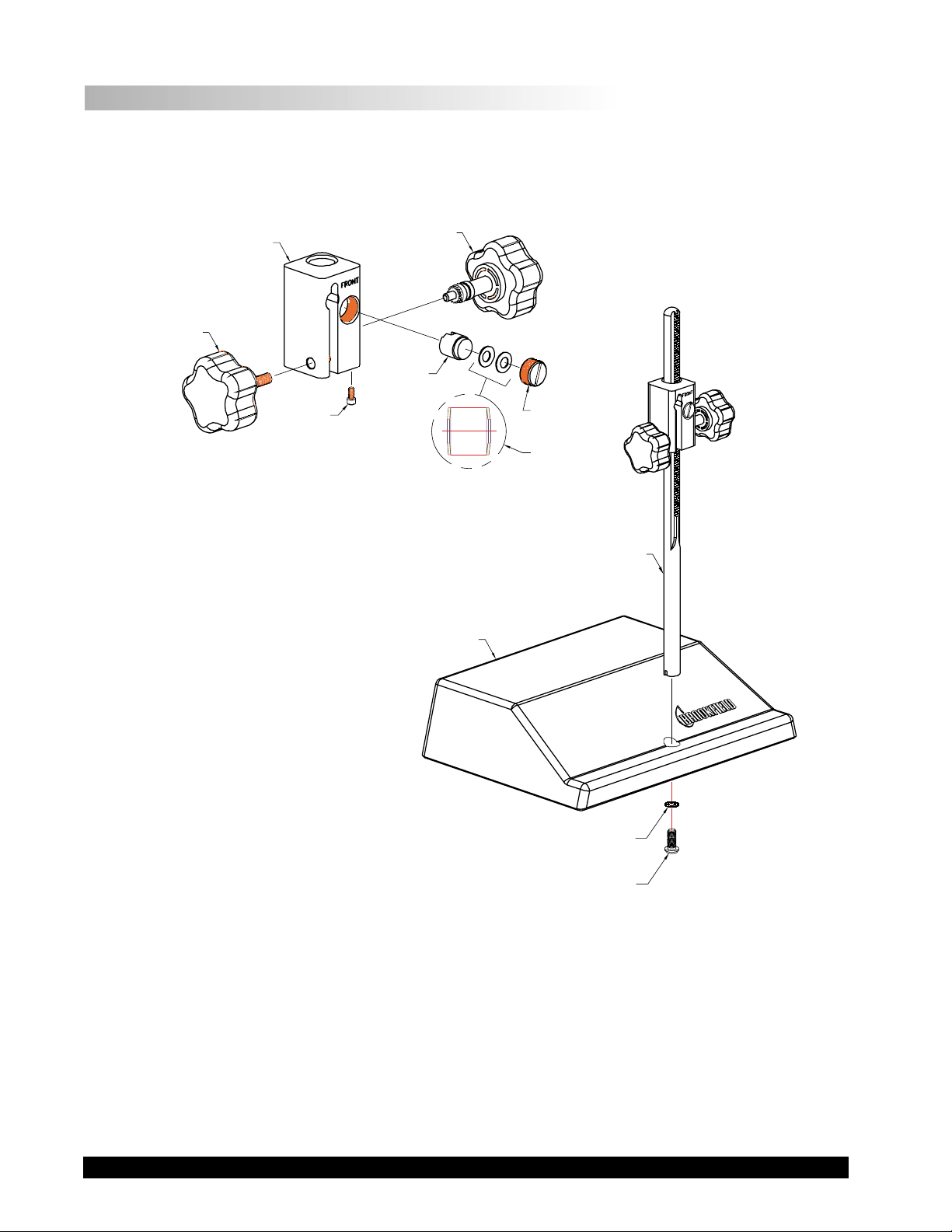

I.1 Components

Component Part Number

DV-III+ Rheometer depends on model

Powerbase DVP-2Y

includes:

Leveling Screws (3) VS-3

Upright Rod VS-20

Jam Nut VS-21

Clamp Assembly VS-27Y

Spindle Set with Case

LVDV-III+ set of four spindles or SSL

RVDV-III+ set of seven spindles or SSR

HA/HBDV-III+ set of seven spindles SSH

For Cone/Plate versions: a spindle wrench, one cone spindle and sample cup Part No.

CPE-44Y replace the spindle set.

Power Cord

for 115 VAC DVP-65

for 230 VAC DVP-66

RTD Temperature Probe DVP-94Y

Ribbon Cable DVP-145

Guard Leg:

LVDV-III+ B-20Y

RVDV-III+ B-21Y

Carrying Case DVP-71Y

RHEOLOADER Software DVP-201Y

Cable (DV-III+ to Computer) DVP-80

Operator Manual M/98-211

Please check to be sure that you have received all components, and that there is no

damage. If you are missing any parts, please notify Brookfield Engineering or your local

Brookfield agent immediately. Any shipping damage must be reported to the carrier.

Brookfield Engineering Laboratories, Inc. Page 4 Manual No. M/98-211-A0701

Page 5

I.2 Utilities

Autosensing Power Supply:

Input Voltage: 90 - 260 VAC

Input Frequency: 50 - 60 Hz

Power Consumption: Less than 220 UA

Power Cord Color Code:

United States Outside United States

Hot (live) Black Brown

Neutral White Blue

Ground (earth) Green Green/Yellow

I.3 Specifications

Speed Range: 0.01-250 RPM, 0.01 RPM increments from 0.01 to 0.99 RPM,

0.1 RPM increments from 1.0 to 250 RPM

Viscosity Accuracy: ± 1.0% of full scale range for a specific spindle running at a

specific speed.

Temperature sensing range: - 100°C to 300°C (-148°F to 572°F)

Temperature accuracy: ± 1.0°C from -100°C to 150°C

± 2.0°C from +150°C to 300°C

Analog Torque Output: 0 - 1 Volt DC (0 - 100% torque)

Analog Temperature Output: 0 - 4 Volts DC (10mv / °C)

Printer Output: Centronics, serial

Computer Interface: RS232

Weight: Gross Weight: 35 lbs. 15.9 kg

Net Weight: 32 lbs. 14.5 kg

Carton Volume: 2.0 cu. ft. 0.057 m

3

I.4 Data Retention

The DV-III+ will save spindle parameters (used to calculate centipoise, shear rate and shear stress),

default settings and the test data from the last program test run when the rheometer is turned off or

there is a power failure.

Brookfield Engineering Laboratories, Inc. Page 5 Manual No. M/98-211-A0701

Page 6

I.5 Set-Up

1) Place the upright rod into the hole at the front of the base. The rack gear and clamp assembly

should face the rear of the base (see Figure 1). The upright rod is held in place with the jam nut

which is attached from the bottom of the base. Tighten this nut with a suitable wrench (spanner).

VS-41Y

CLAMP KNOB

ASSEMBLY

VS-35

UNIVERSAL

CLAMP

50S044012E140

4-40 x 3/8 LG.

SOC. HD. CAP SCREW

VS-40Y

GEAR SCREW

ASSEMBLY

VS-29

TENSION

INSERT

BASE UNIT

VS-28

TENSION

SCREW

VS-29W

WASHER

(2 REQ'D.)

VS-34

UPRIGHT ROD

502020032S34Z

WASHER, EXT. TOOTH,

5/16 O.D. x 5/32 I.D.

50S311B24S06B, SCREW,

5/16 - 18x3/8 LG. SLT. PAN HD.

Figure 1

Brookfield Engineering Laboratories, Inc. Page 6 Manual No. M/98-211-A0701

Page 7

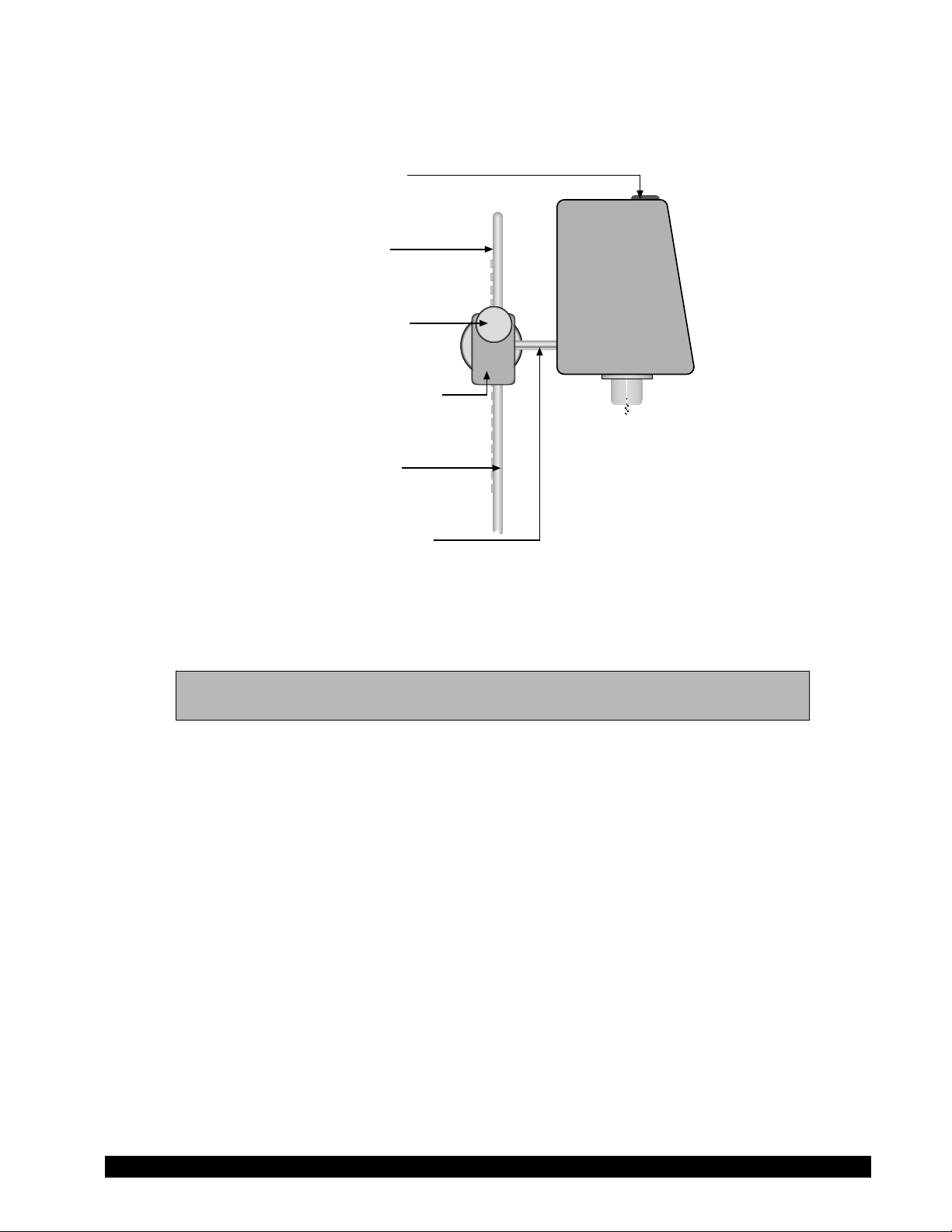

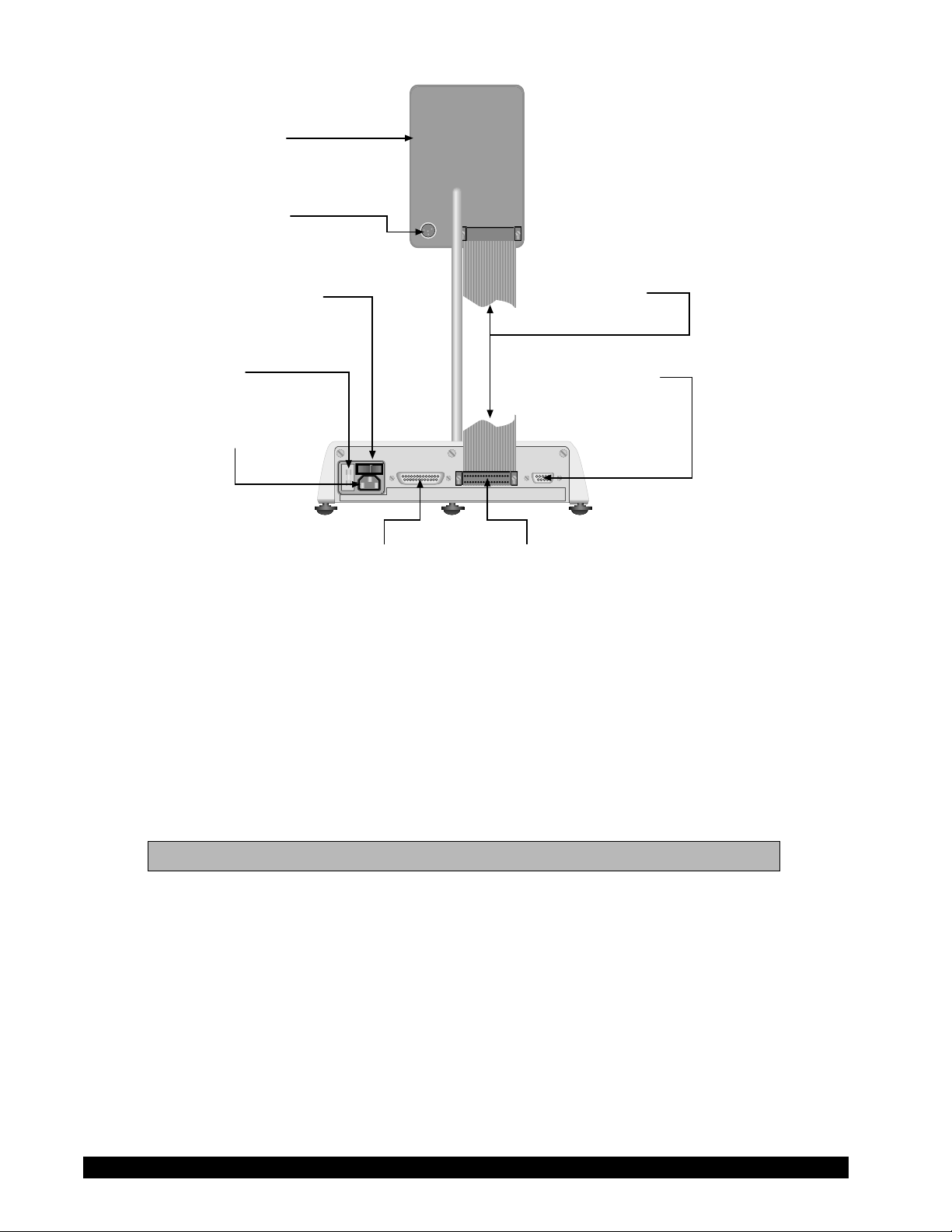

2) Insert the mounting handle on the back of the DV-III+ into the hole on the clamp assembly

(Figure 2).

Bubble Level

Rack Gear

Clamp Screw

Clamp Assembly

Upright Rod

Mounting Handle

Figure 2

3) Tighten the DV-III+ clamp Screw (Figure 2).

Note: If the clamp assembly moves along the upright rod too freely, tighten the

tension screw (see Appendix F).

4) Insert the ribbon cable into the DV-III+ Rheometer head. Insert the other end of the ribbon

cable into the connector on the DV-III+ base (see Figure 3).

Brookfield Engineering Laboratories, Inc. Page 7 Manual No. M/98-211-A0701

Page 8

Rheometer Head

RTD Temperature

Probe Connector

Power ON/OFF Switch

AC Fuse(s)

AC Power Connector

100-240 VAC 50/60 HZ 220VA

Connector Connector

Parallel Printer Ribbon Cable

MODEL DV-III BASE UNIT

Ribbon Cable

Connector

RS-232 Serial

Printer/Computer

Analog Output(s)

240 CUSTHING ST.

STOUGHTON, MA USA 02072

Figure 3

5) Connect the RTD probe to the socket on the back side of the DV-III+ Rheometer (Figure 3).

6) The Rheometer must be leveled before the instrument is zeroed and readings are taken. The level

is adjusted using the three leveling screws on the base. Adjust so that the bubble level on top of

the DV-III+ (Figure 2) is centered within the circle.

7) Make sure that the AC power switch at the rear of the base unit is in the OFF position. Connect

the AC plug to the socket on the back of the DV-III+ base and plug it into the appropriate AC line.

The DV-III+ must be earth grounded to ensure against electronic failure!!

8) Temperature monitoring is assured (after the instrument has stabilized) to within ±1.0°C in the

range -100°C to +150°C and within 2°C in the range 150°C to 300°C.

9) For Cone/Plate models refer to Appendix A.

10) For printers, software and temperature controllers, refer to Section 1.6, Connections.

Brookfield Engineering Laboratories, Inc. Page 8 Manual No. M/98-211-A0701

Page 9

I.6 Connections

The DV-III+ Rheometer is capable of communicating with several external devices to enhance

operation. The cables and connections required for proper communication are detailed below.

RHEOLOADER SOFTWARE

DVP-80 cable is used to connect the RS232 serial port on the DV-III+ base to Com Port 1 or Com

Port 2 on the computer. This cable is supplied with the DV-III+.

RHEOCALC SOFTWARE

DVP-80 cable is used to connect the RS232 serial port on the DV-III+ base to Com Port 1 or Com

Port 2 on the computer. This cable is supplied with the RHEOCALC software.

PARALLEL PRINTER

CAP-86 cable is used to connect the 25-pin parallel port on the DV-III+ base with the Centronics

port on the printer.

SERIAL PRINTER

DVP-81 cable is used to connect the 9-pin serial port on the DV-III+ with the 25-pin serial port on

a printer.

THERMOSEL CONTROLLER, MODEL HT-106

TC-200/TC-500/TC-201P/TC-501P BATH, MODEL HT-107

DVP-141 cable is used to connect the serial port on the DV-III+ base to the serial port on the

controller. This cable is supplied with the controller/bath.

Be sure that the controller temperature probe is properly located in the control device (Thermosel

or bath) and connected to the controller.

Notes: 1. The controller may alternately communicate with Rheocalc V 2.0 soft-

ware. In this configuration, the controller is connected to the computer

through either Com Port 1 or Com Port 2. The DV-III+ is also connected

to a computer Com Port.

2. The controller must also be connected to the control device (Thermosel or

bath) with the appropriate load cable.

STRIP CHART RECORDER

DVP-96Y cable is used to connect the serial port on the DV-III+ to the input block of the strip chart

recorder. This cable is supplied with a Brookfield strip chart recorder.

Brookfield Engineering Laboratories, Inc. Page 9 Manual No. M/98-211-A0701

Page 10

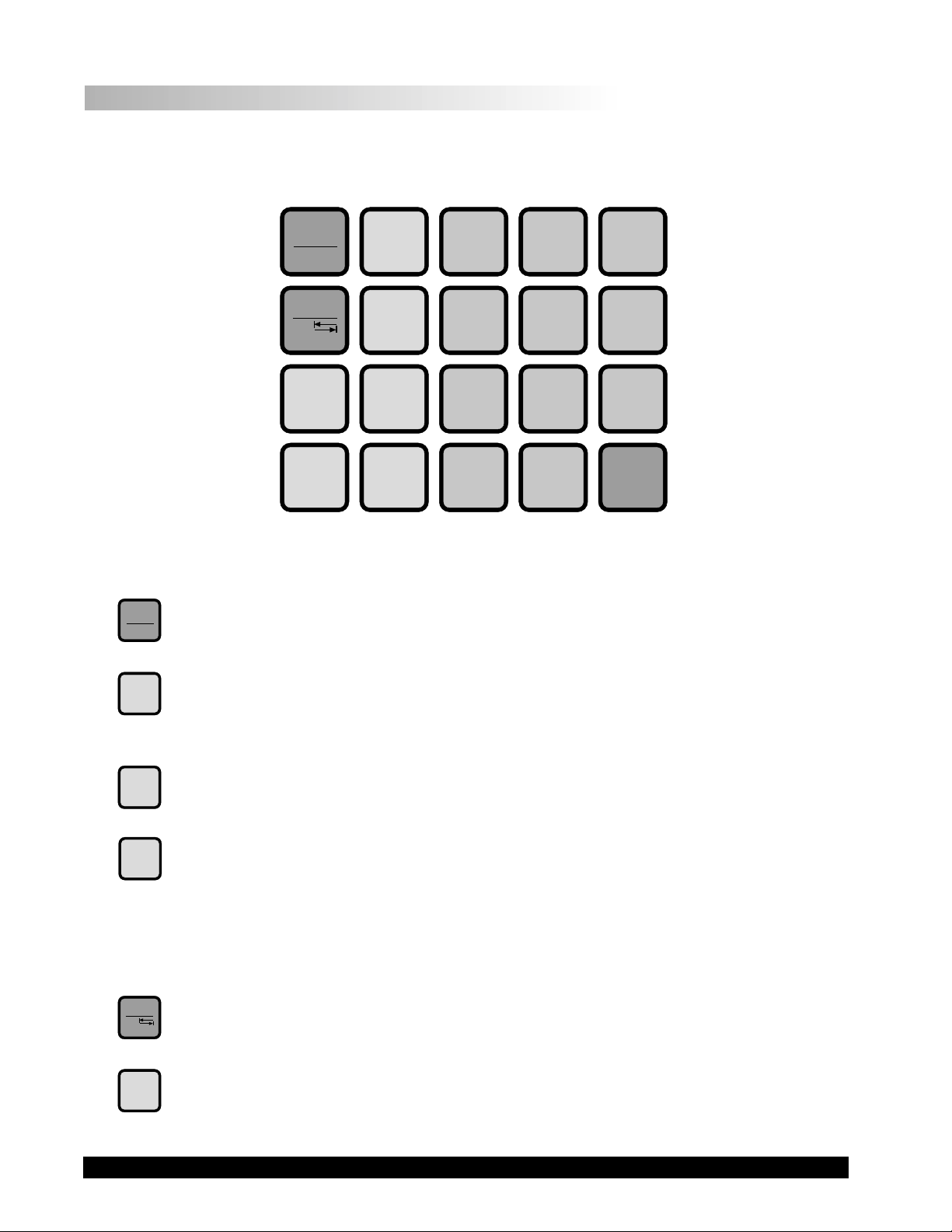

I.7 Key Functions

Figure 4 shows the control keys on the face of the DV-III+ Rheometer. The following describes

each key’s function.

MOTOR

ON/OFF

ESCAPE

MOTOR

ON/OFF

ESCAPE

OPTION

TAB

SELECT

SPDL

SELECT

DISP

AUTO

RANGE

PROG

PROG

RUN

PRINT

789

456

1

YES NO

.

2

0

3

ENTER

Figure 4

MOTOR ON/OFF, ESCAPE

Turns the motor on or off. Cancels any operation, returns the user to the previous screen.

RANGE

SELECT

SELECT

OPTION

TAB

AUTORANGE

AUTO

Presents the maximum (100% torque) viscosity attainable using the selected spindle at

the current speed.

SELECT SPDL

SPDL

Allows selection of the spindle to be used.

SELECT DISP

DISP

Selects the parameter to be displayed:

% Rheometer Torque (%)

cP Viscosity (cP or mPa.s)

SS Shear Stress (Dynes/cm2 or Newtons/m2)

SR Shear Rate (1/Sec)

OPTION, TAB

Accesses options menu. See Section V. Toggles between selectable items when indicated.

PRINT

PRINT

Sends a single line of data to an attached printer. Selects printing and non-printing mode as

selected in the Options menu.

Brookfield Engineering Laboratories, Inc. Page 10 Manual No. M/98-211-A0701

Page 11

PROG

PROG

Access the Programs menu for program creation, running or deleting. Contstructs a test

program. Allows you to review/modify an existing test program. Execute a Bevis program.

PROG

PROG RUN

RUN

Execute DV-III speed/time pair program.

0

NUMBER KEYS (0 through 9)

Sets speeds and choose items from various dialog screens and the option menu.

ENTER

ENTER

Functions as an ENTER key similar to a computer by serving to accept a keyboard entry.

Brookfield Engineering Laboratories, Inc. Page 11 Manual No. M/98-211-A0701

Page 12

II. GETTING STARTED

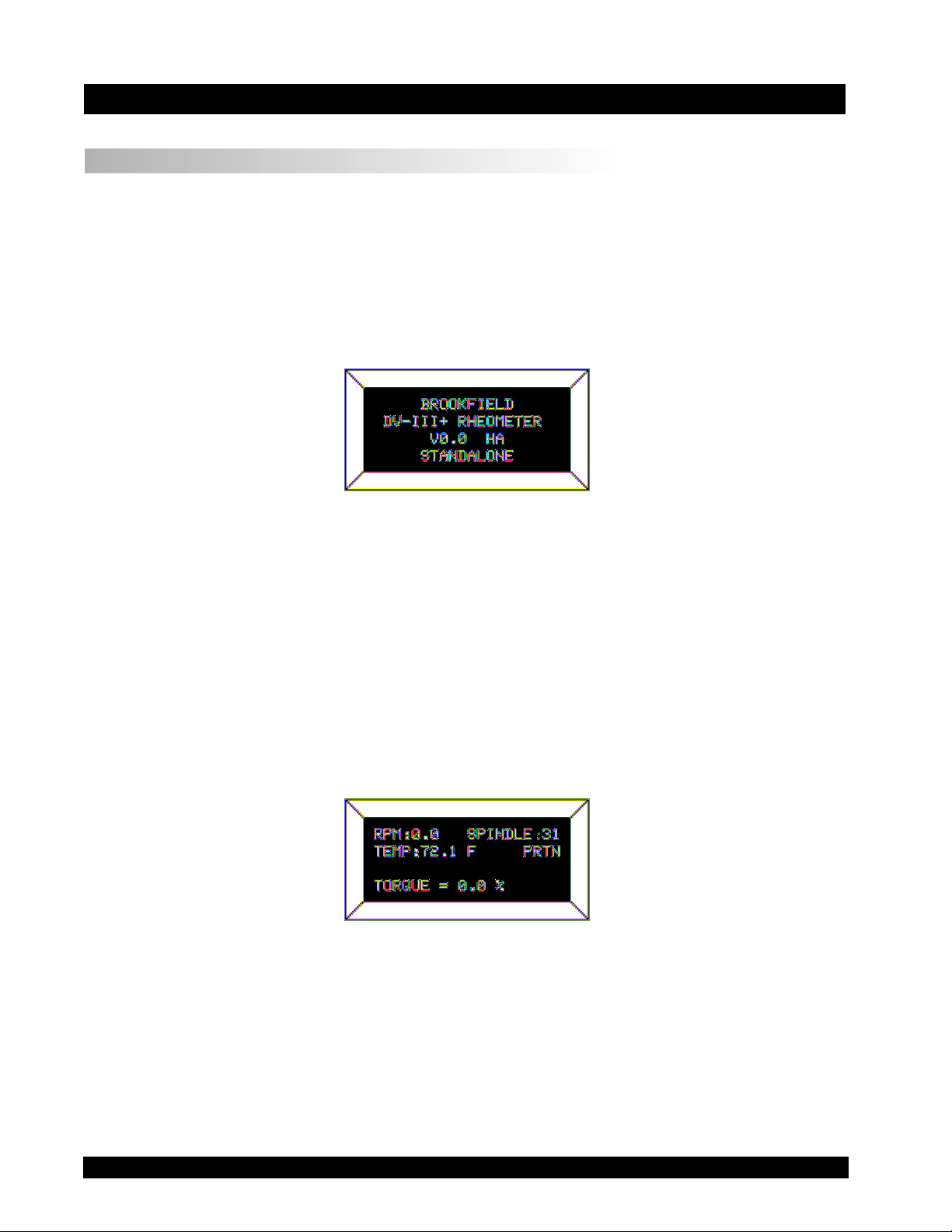

II.1 Autozero

Before readings may be taken, the Rheometer must be autozeroed. This is done each time the power

switch is turned on. The Rheometer will guide you through the procedure, as follows:

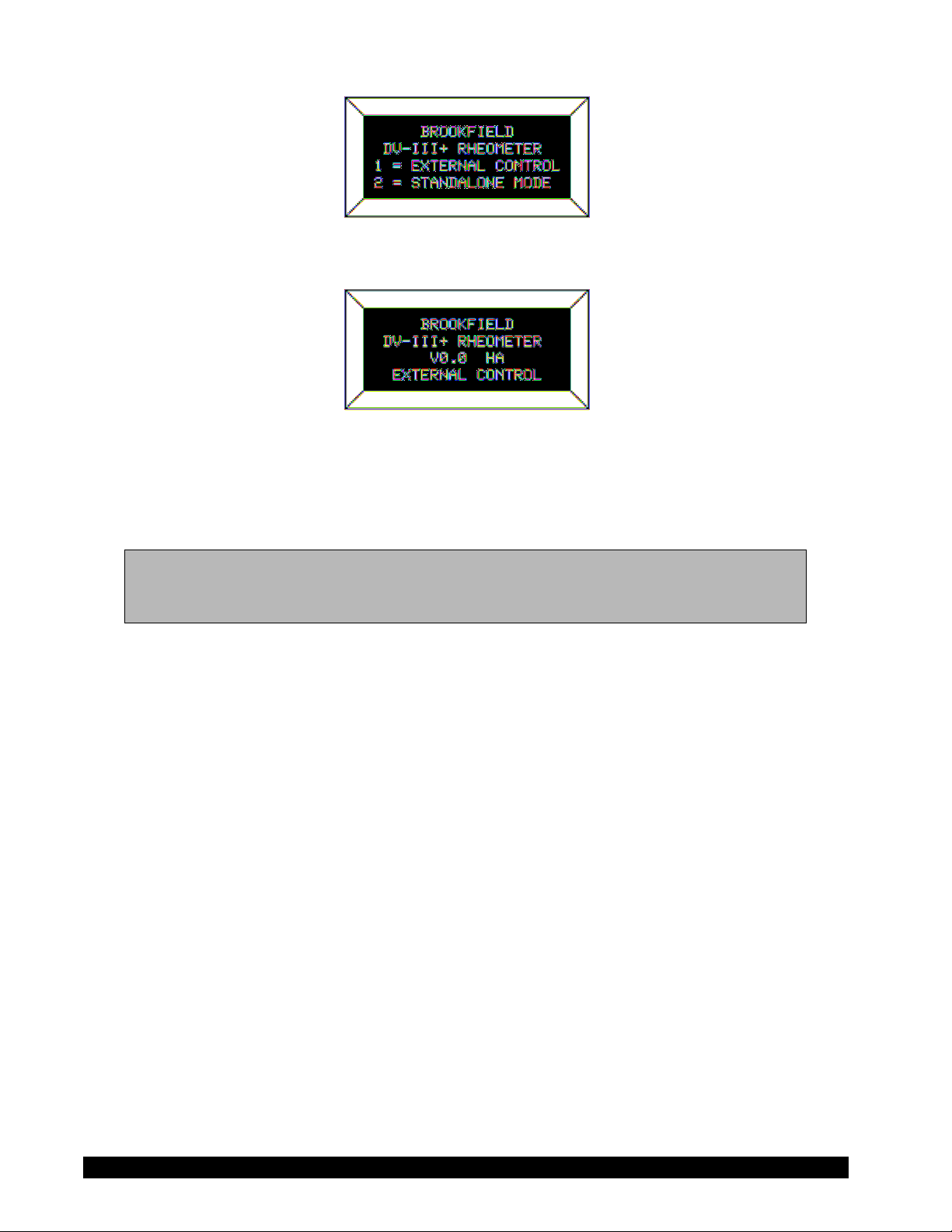

Turn power switch on; as shown in Figure 5, the screen indicates that the DV-III+ is in the standalone

mode (is not connected to a computer) and gives the version of the operating firmware (the built in

program which controls the instrument) and a two-digit alphanumeric code which indicates the

Model number (see Table D2 in Appendix D; the code tells the spring torque rating of your

Rheometer).

Figure 5

No key press is necessary. After a short pause the display will read “REMOVE SPINDLE, LEVEL

RHEOMETER AND PRESS THE MOTOR ON/OFF KEY TO AUTOZERO.” Before beginning the autozero

procedure, Brookfield recommends that you allow 10 minutes for the instrument to warm up.

After pressing the MOTOR ON/OFF key, the screen “flashes” for approximately 15 seconds while

the DV-III+ autozeros.

After 15 seconds the display reads “AUTOZERO IS COMPLETE REPLACE SPINDLE AND PRESS ANY

KEY.” Press a key.

The main screen is displayed and the DV-III+ is ready for use (Figure 6).

Figure 6

Brookfield Engineering Laboratories, Inc. Page 12 Manual No. M/98-211-A0701

Page 13

II.2 Rheometer Display

The DV-III+ Rheometer is supplied with a 4-line display. The basic set of information is called "The

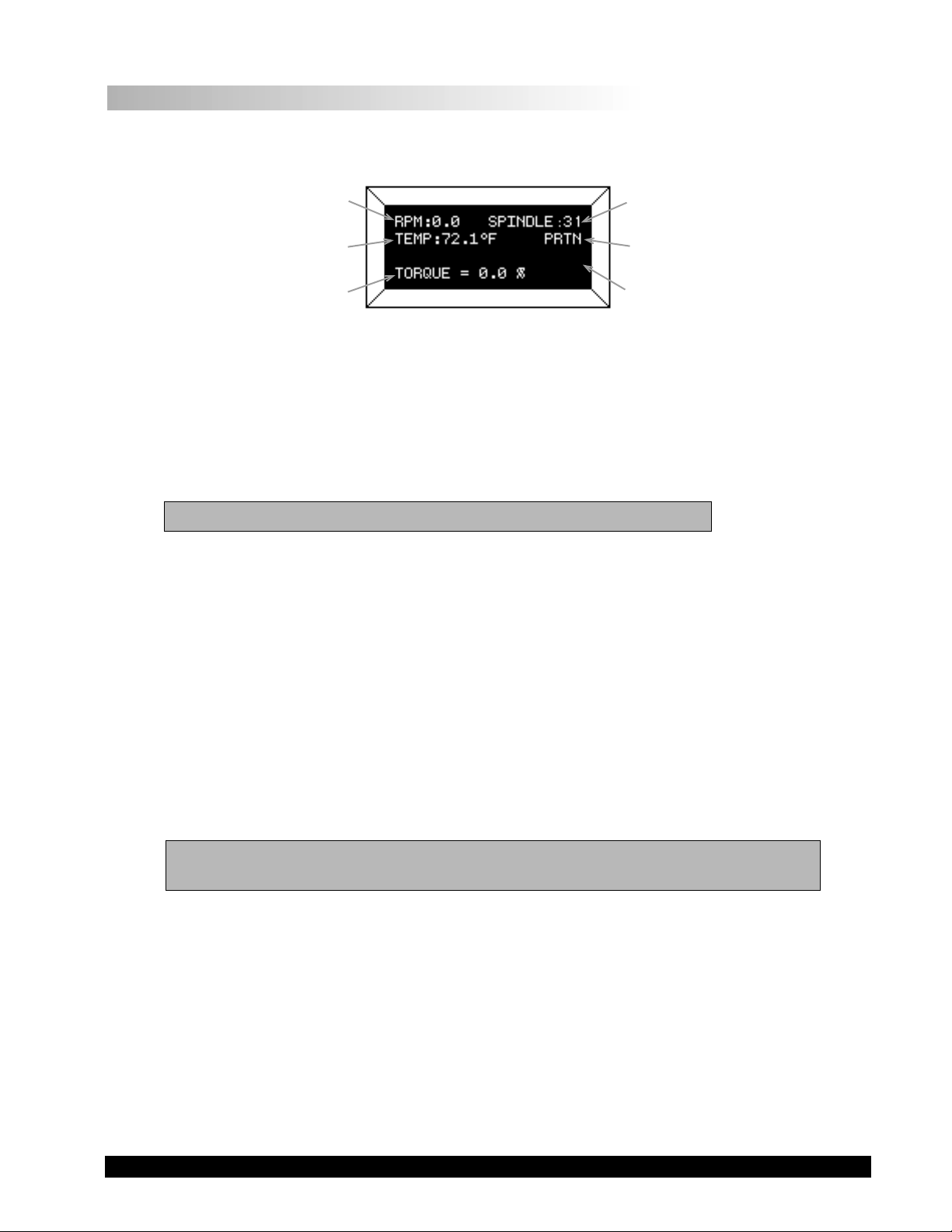

Default Screen" and is shown in FIGURE 7. The parameters are detailed below:

1

3

5

2

4

6

Figure 7

1. Motor Status and Current Rheometer Speed

The DV-III+ motor can be OFF, ON at 0.0 rpm or ON at a speed greater than 0.0 rpm. When the

motor is OFF, "OFF" will be displayed and no speed entry will be accepted. When the motor is

ON, the actual speed of rotation will be displayed. When the motor is switched from ON to OFF,

the speed of rotation will be remembered; when the motor is turned ON again, the DV-III+ will

operate at that same speed. The rheometer motor is set to "OFF" after AUTOZERO.

Note: Motor OFF and a speed setting of 0.0 are essentially the same.

2. Spindle Number

The currently-selected spindle. Viscosity, shear rate, and shear stress values will be calculated

based on this number. See Section II.3.

3. Measured Temperature

The current temperature as measured by the attached temperature probe. If no probe is connected,

four dashes "----" will be displayed.

4. Printing Status

Indicates the currently-selected method of printing. See Section II.5.

5. Measured Data

Instrument Torque (%), Viscosity (cP), Shear Stress (D/cm2), Shear Rate (s-1)

The parameters are toggled from one to another using the Select Display key.

Note: Shear Stress and Shear Rate data cannot be calculated for some spindle

geometries. In these cases, the display will show 0.0.

6. Blank Line

This line is used to display entry data when selecting a spindle or speed of rotation. Additionally,

selected programs available for running will be identified here when in the Program mode. (See

Section IV.2).

The default screen will appear at the completion of the AUTOZERO sequence each time the DVIII+ is turned ON in the standalone mode (see Section II.6 for external control mode). The displayed

data may be changed as described in the following sections.

The format for data displayed in the default screen and all other screens is described in Table 1. For

appearance sake, the entries in the table have been decimal point aligned. Actual rheometer display

will have all fields left justified.

Brookfield Engineering Laboratories, Inc. Page 13 Manual No. M/98-211-A0701

Page 14

p

q

y

pp

p

Item Print Format ExampleRange

RPMRPM

0.01 <= RPM <= 0.99

0.09X.XX

XX.X 0.1 <= RPM <= 99.9 2.4

XXX.X 100 <= RPM <= 250 150.0

Model

S

indle

Tor

ue

Viscosit

M

S

T

cP or mPas

XXXXX

XX

XX.X

X.XX

XXX.X

XXXXX

See Model Table D2 - A

00 <= S <= 99

-10.1 <= T <= 99.9

0 <= cP <= 9.99

10 <= cP <= 999.9

1000 <= cP <= 99999

D

31

82.4

3.16

123.8

12345

XXXeX 100000 <= cP <= 51200000000 123e3 to 8

Shear Stress

Shear Rate 1/SEC

Tem

Time

Time

erature T

D/CM2 or

N/M2 =

D/CM2/10

Z

XXX.X

XXXXX

0 <= D/CM2 <= 9.99X.XX

10 <= D/CM2 <= 999.9

1000 <= D/CM2 <= 99999

4.56

234.5

12345

XXXeX 100000 <= D/CM2 <= 999999 123e3

X.XXX 0 <= 1/SEC <= 9.999

XX.X

XXXXX

XXX.X

10 <= 1/SEC <= 99.9

100 <= 1/SEC <= 99999

-99.9 <= T <= 300.0 -10.3

1.234

20.7

200

XX:XX 00:00 <= Z <= 99.59 05:32

Table 1

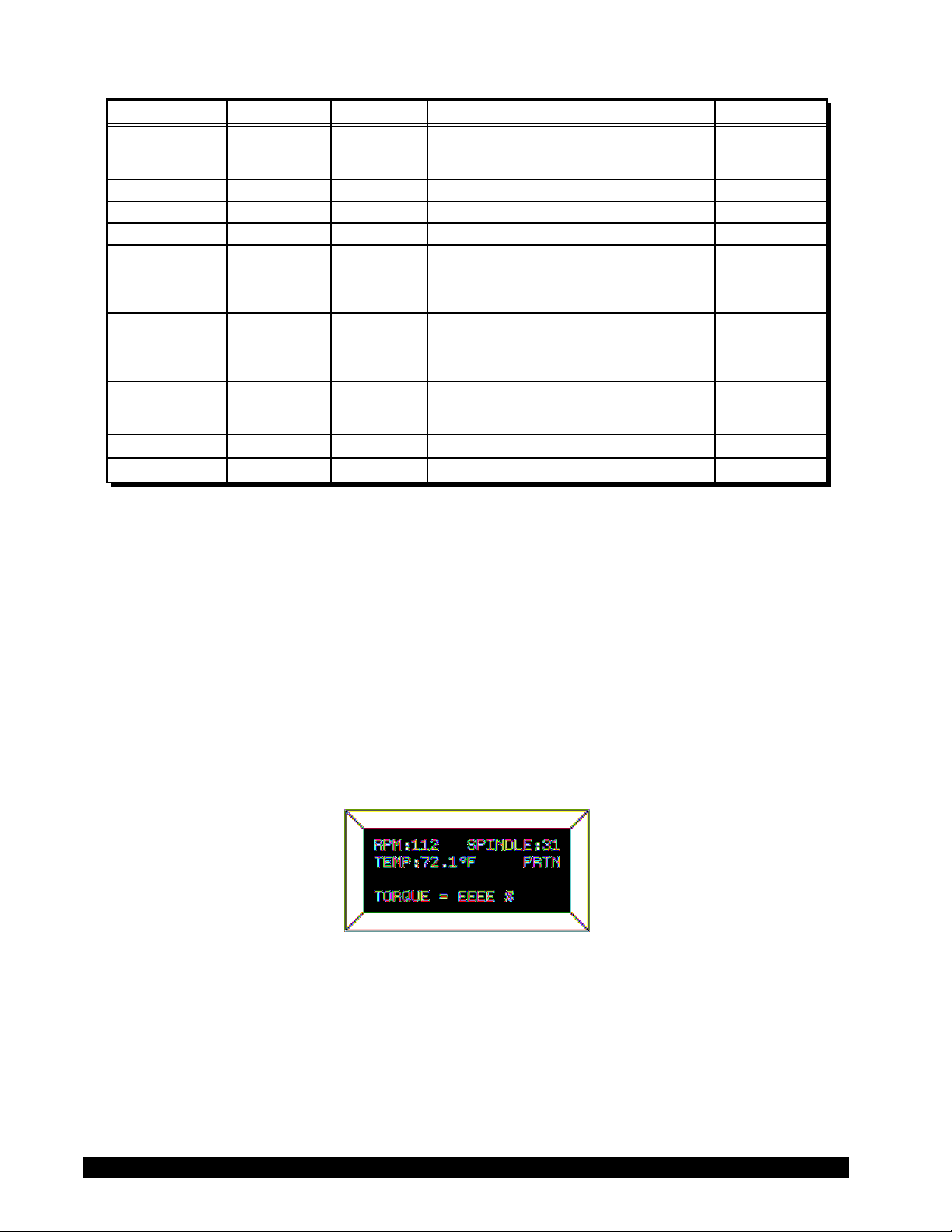

OUT OF RANGE INDICATORS

The DV-III+ is capable of measuring instrument torque within the range of 0 to 100%. Based on

this measurment, viscosity and shear stress are calculated. Brookfield recommends that data be

collected only in the range of 10 to 100%. Any data collected outside of this range is considered

invalid.

RV

The DV-III+ provides the following display indicators when the measurement point is outside of

the 10-100% acceptable range.

TORQUE GREATER THAN 100%

When Rheometer torque exceeds 100%, the parameter display field will show “EEEE” for torque,

viscosity and shear stress.

Figure 8

TORQUE LESS THAN 10%

When Rheometer torque drops below ten (10) percent, the Rheometer will continue to display

measurement (%, cP, D/cm2) values with units flashing:

Brookfield Engineering Laboratories, Inc. Page 14 Manual No. M/98-211-A0701

Page 15

Figure 9

TORQUE LESS THAN 0%

When Rheometer torque drops below zero (0) percent, the Rheometer will continue to display

torque values preceded by a minus (-) sign. The viscosity and shear stress field will display dashes

(- - - - ) as indicated in the next screen display:

Figure 10

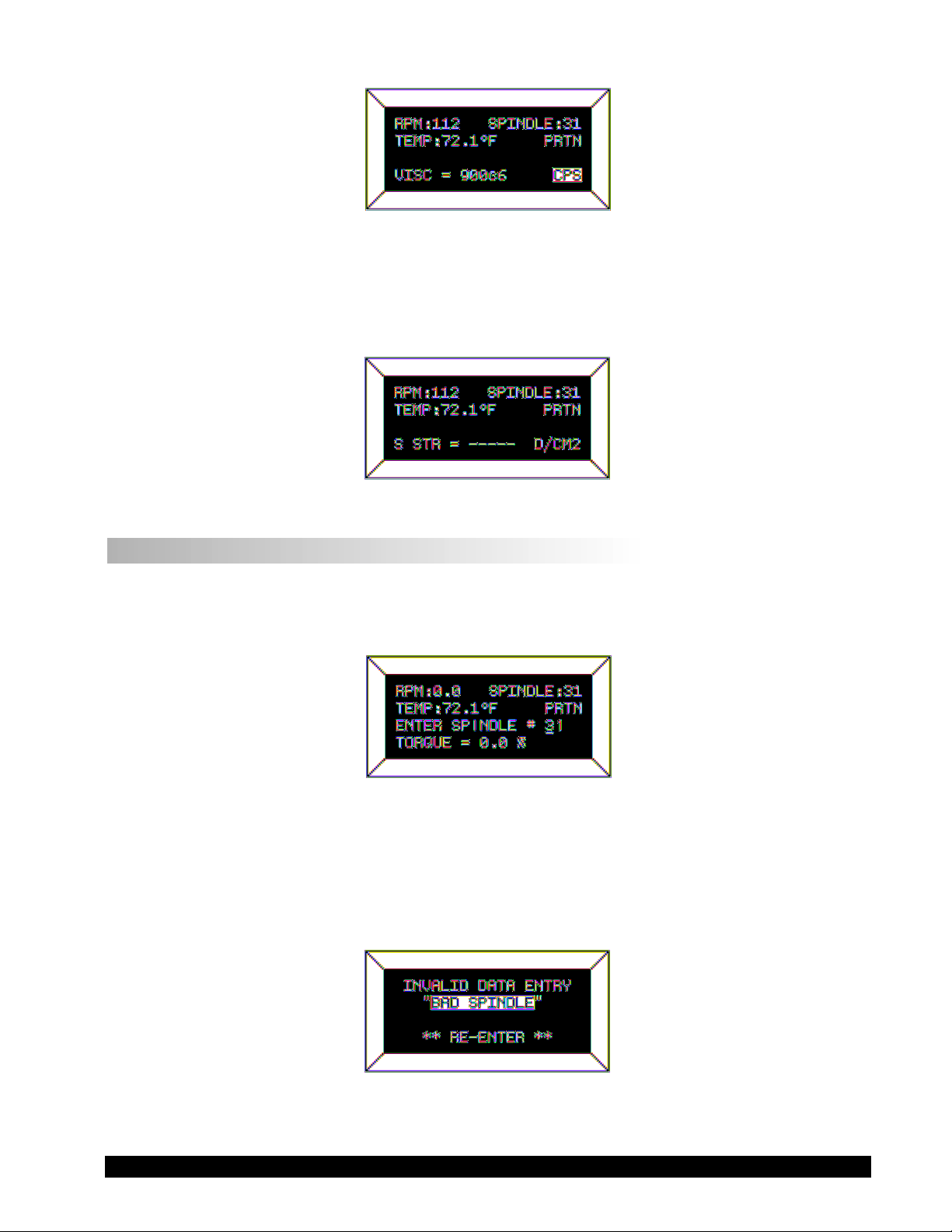

II.3 Spindle Entry

The user can elect to change the spindle selection by pressing the SELECT SPDL key. The DV-III+

control program will use the previously blank line 3 on the default display screen to record the new

spindle input as depicted in Figure 11.

Figure 11

To enter a spindle number, press the numeric keys until the desired spindle number has been entered.

Valid spindle numbers encompass the range from 00 to 99 as listed in Appendix D. Mistakes are

corrected by repeatedly pressing the numeric keys until the proper spindle value has been entered.

At that point, the user presses the SELECT SPDL key again. An invalid spindle entry will result in

a “beep” and the display of the data entry error screen as depicted below.

Figure 12

Brookfield Engineering Laboratories, Inc. Page 15 Manual No. M/98-211-A0701

Page 16

An invalid spindle entry is any two digit number in the range from 01 to 99 which is not listed in

Appendix D. This error message will be displayed for a few seconds after which the spindle entry

screen (Figure 11) will be re-displayed with a blank field for the spindle number. The user can

cancel spindle entry at any time by pressing the MOTOR ON/OFF/ESCAPE key.

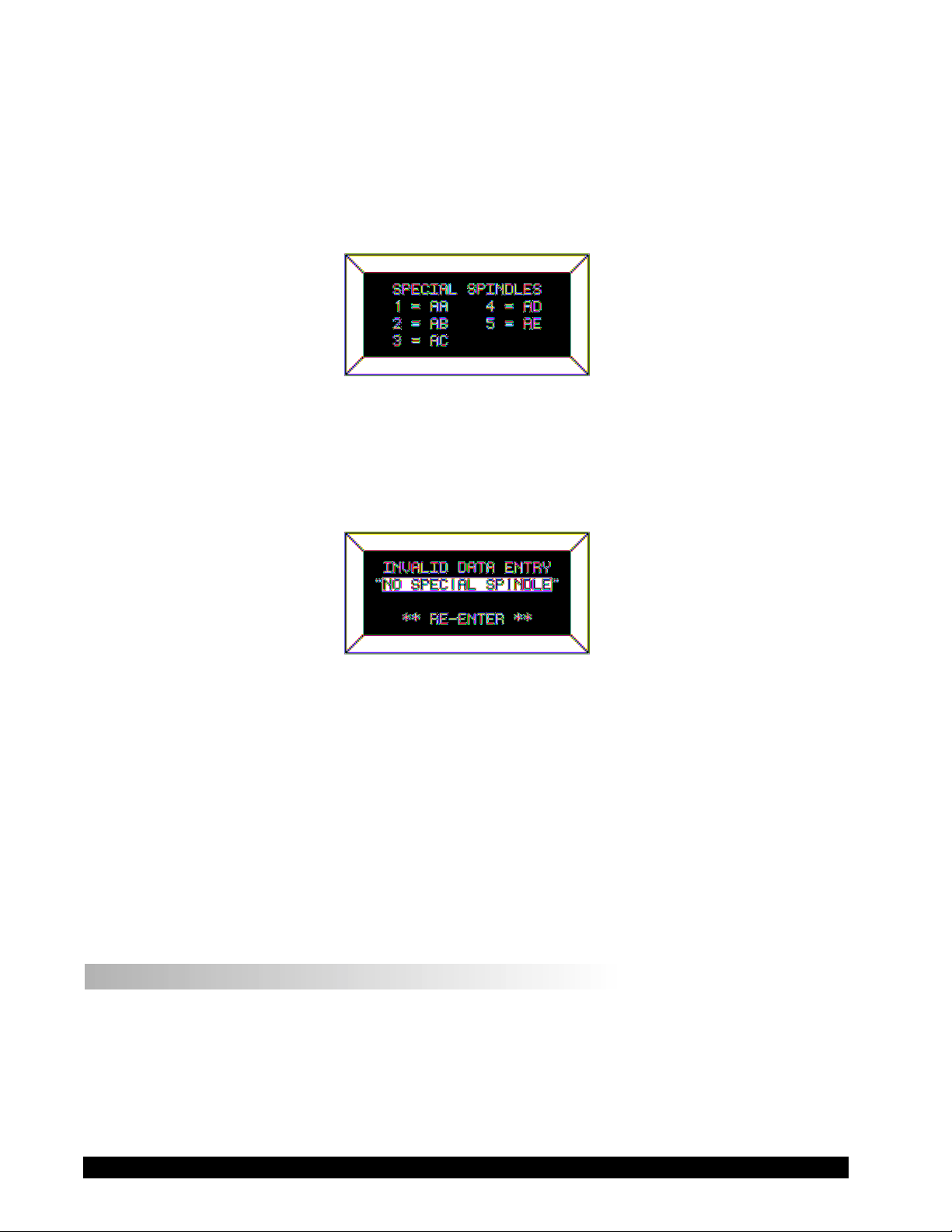

The user may elect to use a special spindle whose selection is accomplished by first entering a

spindle number of 99 and then pressing the

SELECT SPDL key. This will result in the following

display:

Figure 13

At this point, press the numeric key for the special spindle of choice. This list is created at the time

the Rheometer is manufactured. This list will therefore depend on the number of special spindles

ordered and could contain as few as one (1) or as many as five (5) spindles. If no special spindles

were purchased, the following message will be displayed if 99 is entered for a spindle number:

Figure 14

Press any key to exit this screen and to return to the spindle selection screen. The user may again

select another spindle or press the SELECT SPDL key to cancel spindle selection operation.

Successful selection of a spindle at the press of the SELECT SPDL key returns the user to the default

screen with the new spindle displayed in the upper right-hand corner. For standard spindles this

would be the two (2) digit designator used to select the spindle. In the case of special spindles, the

two (2) letters (AA, AB, AC, AD or AE) corresponding to the special spindle would be displayed

instead. The spindle number or letters will be retained in memory when power is removed. This

means that the last value entered for the spindle will be displayed the next time the Rheometer is

turned on.

II.4 Direct Speed Entry

At this point, the user may choose to enter a speed by the so-called direct speed entry method. Enter

a valid speed in the range of 0.01 to 250 RPM by pressing the numeric keys successively. The

previously blank line 3 on the default display screen records the user’s new speed input as depicted

in Figure 15:

Brookfield Engineering Laboratories, Inc. Page 16 Manual No. M/98-211-A0701

Page 17

Figure 15

Here, the user intends to enter a speed of 112 RPM, has pressed the “1” key twice and is about to

press the “2” key. If the user makes more than five (5) key presses, the DV-III+ control program

will “roll” the cursor back to the first character of the field and begin to overwrite the previous data

entry.

Next the user presses the ENTER key to accept the speed. The motor will begin running at 112 RPM

and the display will be updated to the next screen image:

Figure 16

If the speed entered was not valid the Rheometer will display the following message:

Figure 17

After a few seconds, the display returns to Figure 15 with the speed data field cleared and just the

underscore cursor awaiting a new entry.

II.5 External Control

The DV-III+ Rheometer can be used in conjunction with Brookfield software, RHEOCALC (V. 2.

or higher). Through RHEOCALC, all rheometer functions are controlled by the computer. The DVIII+ must be set to the external control mode to allow for proper communication with RHEOCALC.

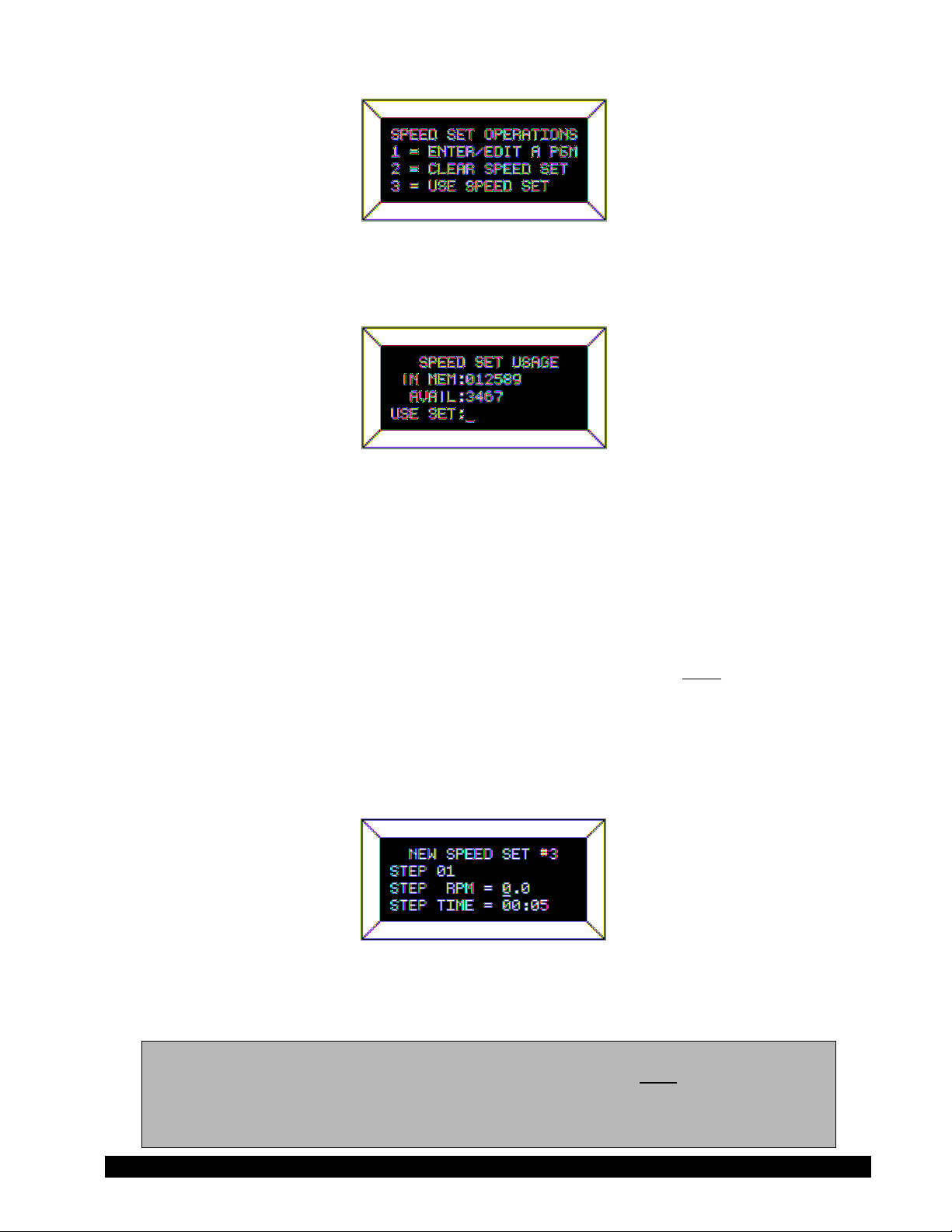

To configure the external control mode, connect cable DVP-80 to the serial port on the DV-III+ base

before turning on the DV-III+. With the DVP-80 cable in place, the DV-III+ will present the screen

shown in Figure 18 when it is turned on. If external control is selected, the DV-III+ will display

Figure 19 and only accept control commands from RHEOCALC software.

Brookfield Engineering Laboratories, Inc. Page 17 Manual No. M/98-211-A0701

Page 18

Figure 18

Figure 19

The DV-III+ may be set to stand alone mode by turning it OFF and ON again and selecting "Stand

Alone" or by removing the DVP-80 cable prior to turning the DV-III+ on.

Note: The DV-III+ cannot communicate with RHEOLOADER software in the external

control mode. Chose "Stand Alone" when presented with Figure 18 if you want

to use RHEOLOADER.

Brookfield Engineering Laboratories, Inc. Page 18 Manual No. M/98-211-A0701

Page 19

III. MAKING VISCOSITY MEASUREMENTS

III.1 Quick Start

The DV-III+ Rheometer uses the same methodology as the Brookfield Dial Reading Viscometer

and DV series of Digital Viscometers. If you have experience with other Brookfield equipment, this

section will give you the quick steps for taking a viscosity reading. If you have not used a Brookfield

Viscometer before, skip this section and go to Section III.2 for a detailed description.

A) Assemble and level the rheometer (Section I.5).

B) Autozero the rheometer (Section II.1).

C) Enter the spindle number using the SELECT SPINDLE key (Section II.3).

D) Introduce the spindle into the sample and attach the spindle to the coupling nut.

NOTE: Left-hand threads.

E) Enter the speed of rotation using the number pad and ENTER key (Section 11.4).

F) Record % torque and viscosity.

III.2 Preparation

A) RHEOMETER: The DV-III+ should be turned on, leveled and autozeroed. The level is

adjusted using the three feet on the bottom of the base and confirmed using the bubble on the

top of the head. Adjust the feet until bubble is inside the center target. Set the level prior to

autozero and check the level prior to each measurement.

Proper level is essential for correct operation of the DV-III+.

B) SAMPLE: The fluid to be measured (sample) must be in some container. Many spindle systems

from Brookfield are supplied with specific sample chambers such as the Small Sample Adapter,

UL Adapter and Thermosel. The standard spindles supplied with the DV-III+, LV (1-4), RV

(1-7) and HA/HB (1-7), are designed to be used with a 600ml low form Griffin beaker (or

equivalent container with a diameter of 8.25 cm).

Brookfield recommends that you use the appropriate container for the selected spindle. You

may choose to use an alternate container for convenience, however, this may have an effect on

the measured viscosity. The DV-III+ is calibrated considering the specified container.

Alternate containers will provide results that are repeatable but not "true."

The LV (1-4) and RV (1-7) are designed to be used with the guardleg attached. Measurements

made without the guardleg will provide repeatable results but may not provide "true" results.

When comparing data with others, be sure to specify the sample container and presence/

absence of the guardleg.

Many samples must be controlled to a specific temperature for viscosity measurement. When

conditioning a sample for temperature, be sure to temperature control the container and spindle

as well as the sample.

Please see our publication, "More Solutions to Sticky Problems", for more detail relating to

sample preparation.

Brookfield Engineering Laboratories, Inc. Page 19 Manual No. M/98-211-A0701

Page 20

III.3 Selecting a Spindle/Speed

The DV-III+ has the capability of measuring viscosity over an extremely wide range (for

example, the RVDV-III+ can measure fluids within the range of 100-40,000,000 cP) (see

Appendix B). This range is achieved through the use of several spindles over many speeds.

The process of selecting a spindle and speed for an unknown fluid is normally trial and error.

An appropriate selection will result in measurements made between 10-100 on the

instrument % torque scale. Two general rules will help in the trial and error process.

1) Viscosity range is inversely proportional to the size of the spindle.

2) Viscosity range is inversely proportional to the rotational speed.

In other words: to measure high viscosity, choose a small spindle and/or a slow speed. If the

chosen spindle/speed results in a reading above 100%, then reduce the speed or choose a smaller

spindle.

Experimentation may reveal that several spindle/speed combinations will produce satisfactory

results between 10-100%. When this circumstance occurs, any of the spindles may be selected.

Non-Newtonian fluid behavior can result in the measured viscosity changing if the spindle and/

or speed is changed. See our publication, "More Solutions to Sticky Problems," for more detail.

When viscosity data must be compared, be sure to use the same spindle, speed, container

and temperature.

III.4 Multiple Data Points

The majority of viscosity measurements are made at the quality control level and consist of a

single data point. The test is conducted with one spindle at one speed. The data point is a useful

bench mark for the go/no-go decision in a production setting. The DV-III+ can be used for

single point measurement.

Many fluids exhibit a characteristic change in viscosity with a change in applied force. This

non-Newtonian flow behavior is commonly seen in paints, coatings and food products as a

decrease in viscosity as shear rate increases. This behavior cannot be detected or evaluated with

the single viscosity point measurement.

Non-Newtonian flow is analyzed through the collection of viscosity data over a range of shear

rates and the generation of a graph of viscosity versus shear rate (a rheogram). This information

will allow for a more complete characterization of a fluid and may help in formulating and

production of the product. The DV-III+ is capable of collecting multiple data points for the

analysis of flow behavior. See Section IV on Programming and Analysis.

More information on flow behavior, shear rate and rheograms is available in our publication,

"More Solutions to Sticky Problems."

III.5 Cleaning

All immersed components are stainless steel. Use cleaning solutions that are not corrosive and

avoid scratching the measurement surfaces. The instrument housing should be cleaned with a

soft damp cloth.

Brookfield Engineering Laboratories, Inc. Page 20 Manual No. M/98-211-A0701

Page 21

IV . PROGRAMMING THE DV -III+ AND ANAL YSIS

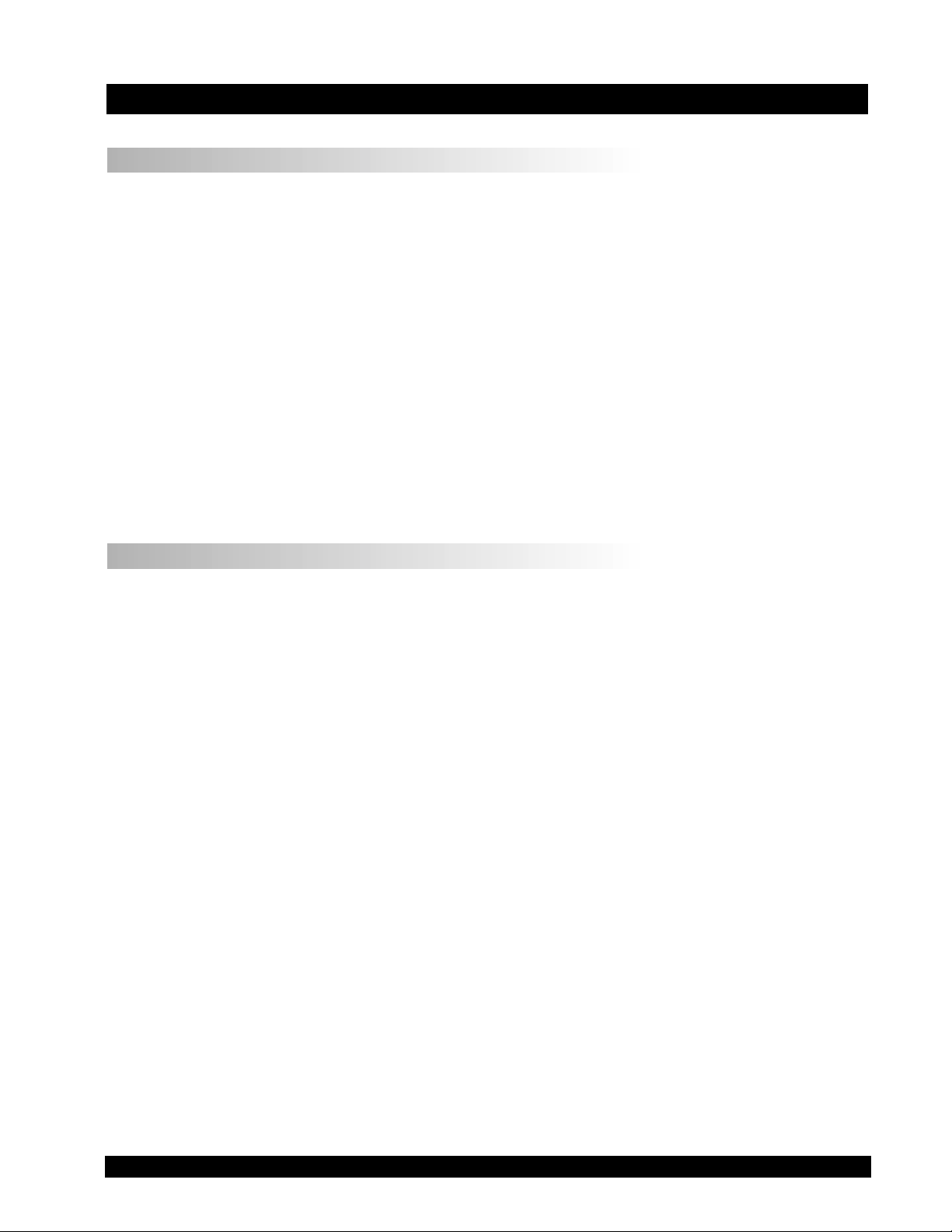

The programming and data analysis functions of the DV-III+ are accessed by pressing the PROG key

on the rheometer. The display will change to present a menu with three choices: DV-III, B.E.V.I.S., and

Models. DV-III and B.E.V.I.S. are the programming alternatives. Models will present the five math

models available for data analysis.

Figure 20

IV.1 Programming Concept

The DV-III+ may be programmed to collect viscosity data without operator involvement. The

captured data may be displayed and analyzed or output to a printer. Programs may be written using

two different methodologies, DV-III and B.E.V.I.S.

The DV-III programming technique uses speed/time pairs to control the DV-III+. A program

consists of multiple lines (up to 25) instructing the rheometer to operate at a particular speed for some

period of time. As an example, we can instruct the DV-III+ to rotate the spindle at 5 RPM for 30

seconds and then change speed to 10 RPM and wait 20 seconds with the following program:

Step 1 RPM = 5 Time = 00:30

Step 2 RPM = 10 Time = 00:20

A single data point will be collected at the end of each time interval.

The B.E.V.I.S. programming technique uses a custom program language to control the DV-III+. A

program consists of a series of commands instructing the rheometer in speed control, time control,

data collection, temperature control, and output. B.E.V.I.S. offers a higher level of rheometer

control compared to the DV-III method. However, the construction of B.E.V.I.S programs is more

involved. The 2-step DV-III program previously described is duplicated using B.E.V.I.S. commands below:

SSN 5

WTI 00:30

PDN

SSN 10

WTI 00:20

PDN

END

The involved programming of B.E.V.I.S. commands is a small trade for the significant increase in

control capability over the DV-III method.

Brookfield Engineering Laboratories, Inc. Page 21 Manual No. M/98-211-A0701

Page 22

IV.2 DV-III Speed/Time Pair Programming

This programming method allows the operator to control the DV-III+ through the variables of speed

and time. These speed/time pairs instruct the rheometer to operate at a speed of rotation for a certain

period of time. Programs can be created with up to 25 steps. The DV-III+ can store up to 10

programs. Upon completion of a program, the data may be viewed on the DV-III+ display, analyzed

or printed to an attached parallel or serial printer.

Two examples of programs are shown below:

Collect Data Over Time Collect Data At Several Speeds

Step RPM Time Step RPM Time

1 100 00:12 1 2.5 01:00

2 100 00:12 2 5 00:30

3 100 00:12 3 10 00:30

4 100 00:12 4 20 00:15

5 100 00:12 5 50 00:15

Five viscosity data points Five viscosity data points will be

will be collected over collected at five speeds over

one minute. 150 seconds.

This program mode is accessed by pressing the program key and selecting number 1; 1 = DV-III.

The creation, editing and execution of DV-III programs are described in the following sections.

There are two types of test programs:

1) Next Speed Set where the test speeds are programmed, and the operator must signal the DV-

III+ to change speeds (and therefore take a reading) by pressing the ENTER key.

2) Prog Speed Set where the DV-III+ will perform the test automatically.

Each step of a program has two variables - speed and hold time. The reading is taken at the end of

the hold time interval in a Prog Speed Set or when the ENTER key is pressed in a Next Speed Set.

If the first step hold time interval is 0 seconds, the program is a Next Speed Set type. If the first step

interval is 1 second or more, the program is a Prog Speed Set type.

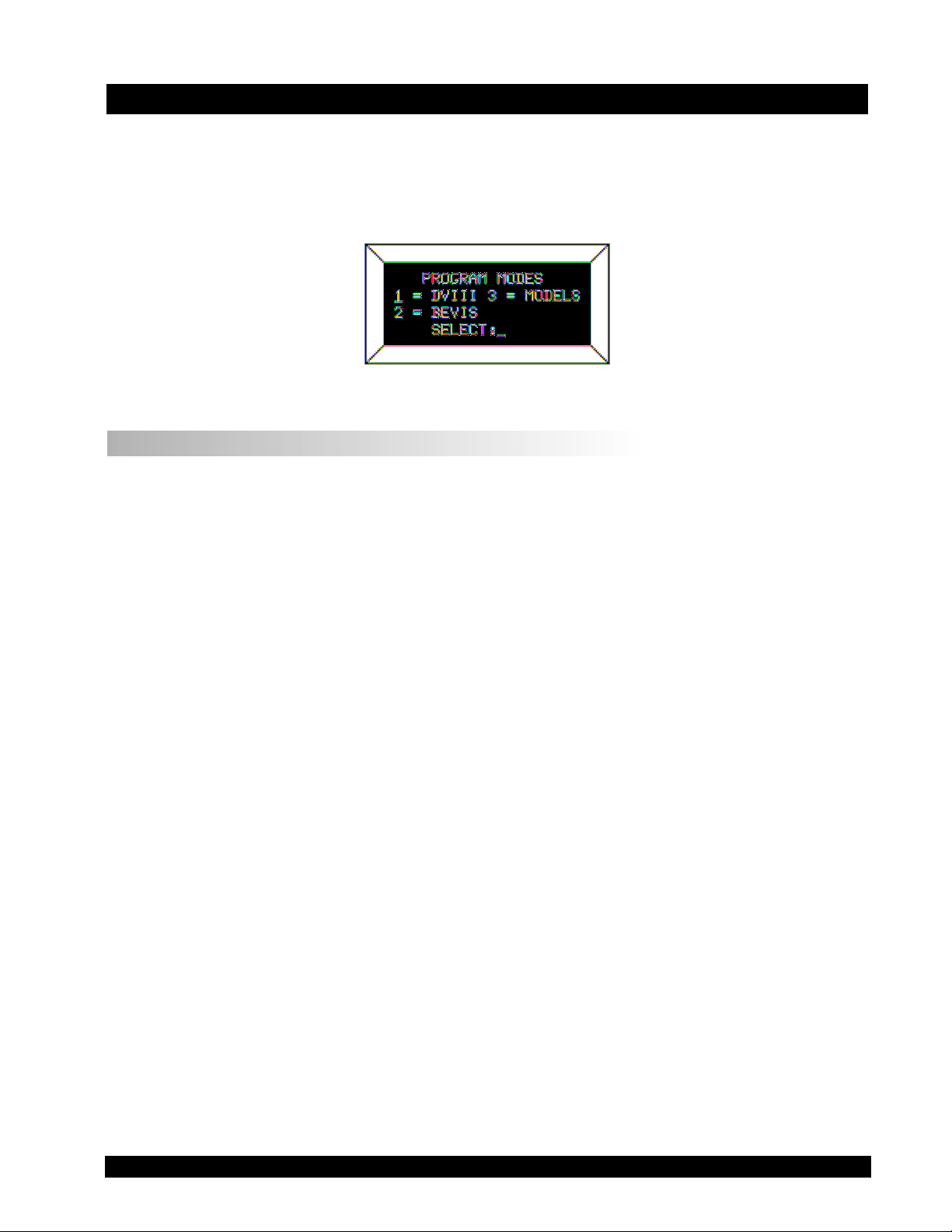

SPEED SET SELECTION AND PROGRAMMING

The DV-III+ viscometer allows for the retention of a maximum of 10 speed sets with up to 25

discrete speeds per speed set. The program locations are numbered 0 through 9. These speed sets

are retained in EEPROM memory for those times when the DV-III+ is not powered up. To access

a previously programmed speed set or to enter data for a new speed set, the user presses the “1” key

when in the display of Figure 20 and is presented with the screen shown in Figure 21:

Brookfield Engineering Laboratories, Inc. Page 22 Manual No. M/98-211-A0701

Page 23

Figure 21

At this point, the user may Enter/Edit, Clear or Use a stored program (Speed Set). Let’s startwith

Enter/Edit by pressing the “1” key:

Figure 22

In this example, the user is informed that he has 6 speed sets (0,1,2,5,8,9) pre-programmed in

memory and 4 speed sets (3,4,6,7) not programmed and available. Select any one of the ten speed

sets by pressing the appropriate numeric key. Pressing the MOTOR ON/OFF/ESCAPE key at this

point would exit the user to the default PROGRAM MODES display (Figure 20). For now let’s

assume that the user wants to program a new speed set by pressing the “3” key (the first available

program slot).

ENTERING A SPEED SET (PROGRAM)

There are two (2) types of programs available to the user: programs with finite step time intervals

and programs with zero (0) step time intervals. We will cover the inputting of finite step time

programs first.

SPEED SETS WITH FINITE STEP TIMES (PROG SPEED)

These programs when executed will automatically progress from step to step based on the time

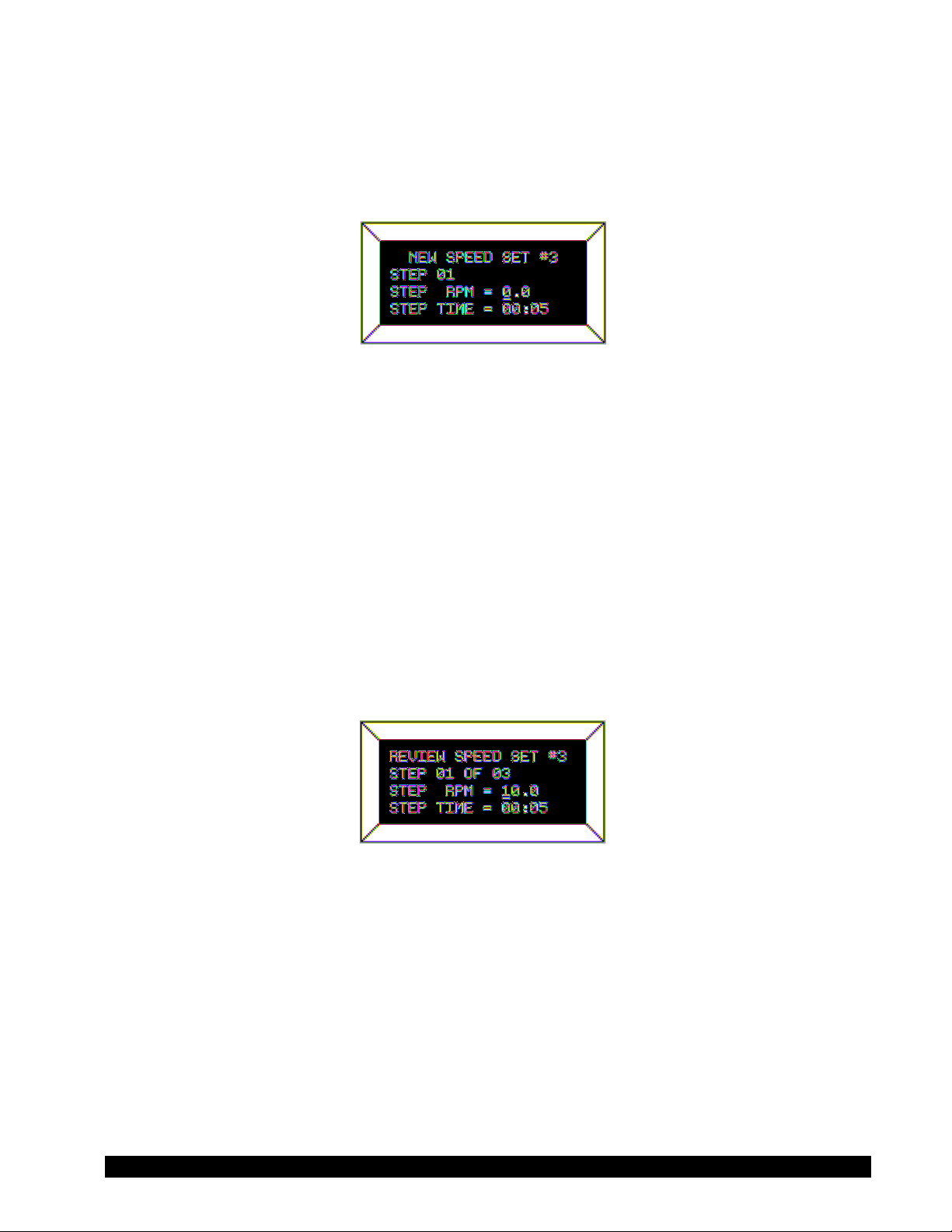

intervals programmed by the user. On pressing the “3” key in Figure 22 the user is presented with:

Figure 23

This screen reminds the user of the speed set that he has selected to program and then allows him

to change either the speed or time interval or both for that step.

Note: The time interval on entry to this screen will always be set to 00:05 seconds as the

default value. The user may of course change it to any valid time of his choice.

Whenever you change time interval, that new time becomes the default interval until

it is again changed by the user. Also, note that zero (0) times are not allowed for

program steps after the first step for Finite Step programs.

Brookfield Engineering Laboratories, Inc. Page 23 Manual No. M/98-211-A0701

Page 24

The OPTION/TAB key is used for moving from input field to input field and the ENTER key to accept

the current input for a step. On entry to this screen, the underscore cursor would be flashing (as

shown) under the first digit of the step RPM. Use the numeric keys to make changes to the step speed,

repeating the input as many times as required until satisfied.

When satisfied with the speed input, press the

OPTION/TAB key which moves the flashing cursor

down to the first character of the time field. The same procedure is used here to input the step time

as was used to enter the RPM above. Speed or time data that is out of range, as defined by Table

1, will result in the following screen:

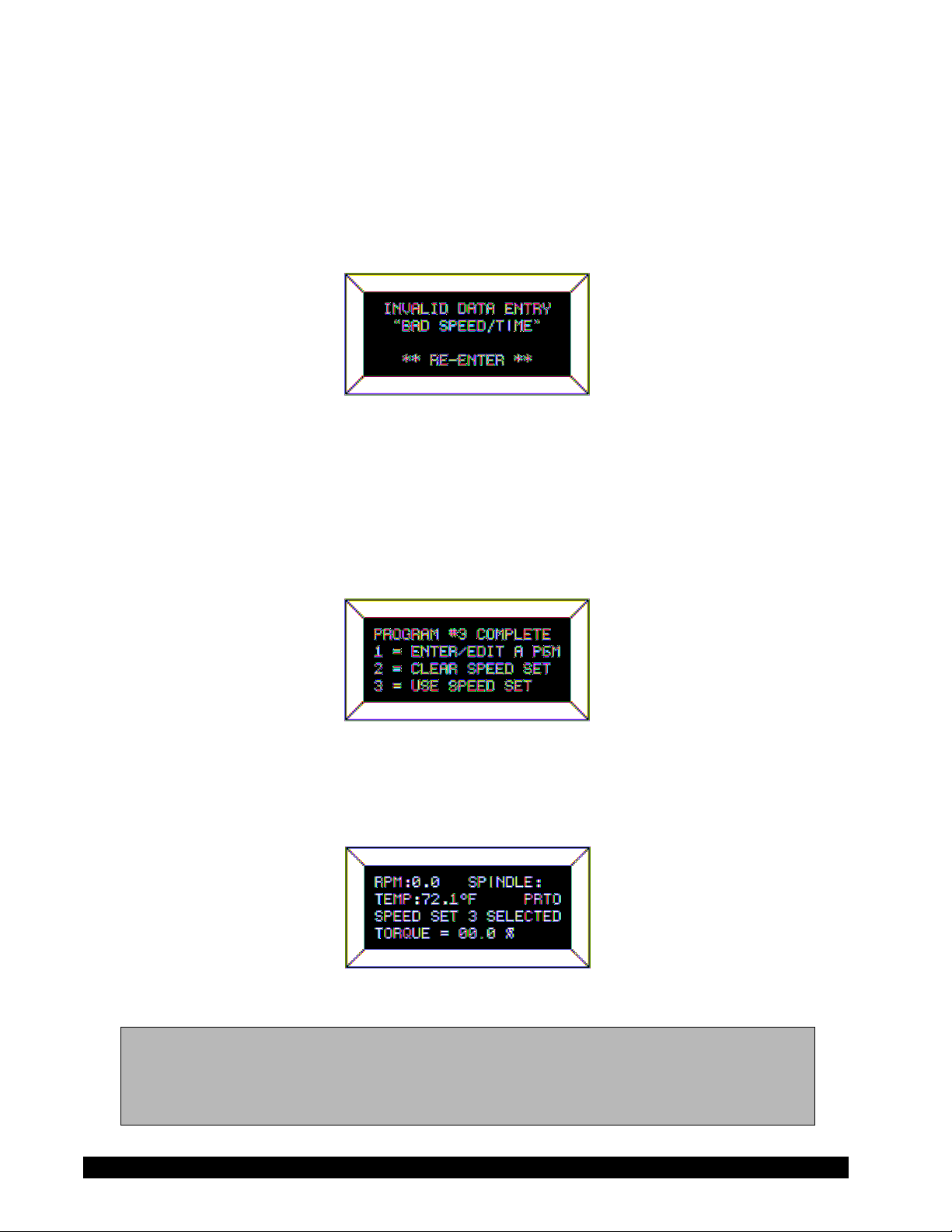

Figure 24

This screen will be displayed for 1-3 seconds.

When ready, the user may press the PROG RUN key to display the data for the next step in the

program, or the MOTOR ON/OFF/ESCAPE key (whereby none of the changes up to that point will be

accepted) to return to the screen of Figure 22. To end a program, the user simply enters and accepts

a step RPM and Time of zero (0) or continues to input step data until the program reaches the twentyfive (25) step program limit. In either case, the following screen will be displayed:

Figure 25

To use the currently selected speed set, press the “3” key in Figure 25. This would immediately

revert to the default screen modified as follows:

Figure 26

Note: If at this point, prior to using the program the user wished to enter a direct speed, a

press of any numeric key which would result in a display similar to Figure 15. At

the completion of the direct speed input, the display would revert to Figure 26 above

with the appropriate RPM displayed, and the viscometer running at that speed.

Brookfield Engineering Laboratories, Inc. Page 24 Manual No. M/98-211-A0701

Page 25

The program is initiated by pressing the PROG RUN key. See "Using Pre-programmed Speeds."

SPEED SETS WITH ZERO STEP TIMES

These programs when executed will require that the user press the ENTER key to progress from step

to step. On pressing the “3” key in Figure 22 the user is presented with the same screen that he saw

in the above description for finite step programs:

Figure 27

The user inputs his step RPM exactly as he did for finite step time programs above. However, for

time, input 00:00 and press the ENTER key. From this point forward, the user will only be able to

enter speeds since each press of the ENTER key will advance him to the next step. The OPTION/TAB

key will not be required. If the user wishes to correct the speed input, continue to press the numeric/

decimal point keys until satisfied. To correct a speed after pressing the ENTER key for that step, wait

until the program is complete and then edit the program to correct the mistake. To end a program,

simply enter and accept a step RPM of zero (0) or continue to input step data until the program

reaches the twenty-five (25) step program limit. Speed restrictions/limits are the same as for the

description just above as are the error messages.

EDITING A SPEED SET (PROGRAM)

This item is used to review a just-entered program or to review/modify (edit) a program already

stored in a memory slot. Entry to this method would typically be from Figure 22 after selecting an

“IN MEM” program slot or by pressing the “1” key in Figure 21 having just finished entering a

program. In either case, the user is presented with:

Figure 28

Operation in this mode is exactly the same as for entering a new speed set; all key actions and speed

and time limits are the same. At this point, the user may continue to review/modify the speeds

comprising speed set #3 or elect to print a listing of the speeds in this speed set. To accomplish this,

the user must be in the program Enter/Edit mode; have selected or programmed a speed set which

contains more than two (2) speeds, and then press the PRINT key. If all is well (i.e. satisfied the above

requirements) the rheometer will display:

Brookfield Engineering Laboratories, Inc. Page 25 Manual No. M/98-211-A0701

Page 26

Figure 29

This message simply asks the user to make sure the printer is ready (it’s on-line and has paper in it)

and then awaits for the PRINT key to be pressed. When it is pressed, the DV-III+ will send the

following data to the attached printer:

FOR SPEED SETS WITH FINITE STEP TIMES

Program Use: __________________________________________________

Programmer:______________________________

BROOKFIELD DV-III+ RHEOMETER — DATA FOR SPEED SET #9

SPEED #01 RPM = 2.5 TIME INTERVAL = 00:05

SPEED #02 RPM = 5.0 TIME INTERVAL = 00:05

SPEED #03 RPM = 10.0 TIME INTERVAL = 00:05

SPEED #04 RPM = 20.0 TIME INTERVAL = 00:05

SPEED #05 RPM = 50.0 TIME INTERVAL = 00:05

FOR SPEED SETS WITH ZERO STEP TIMES

Program Use: __________________________________________________

Programmer:______________________________

BROOKFIELD DV-III+ RHEOMETER — DATA FOR SPEED SET #8

SPEED #01 RPM = 10.0 TIME INTERVAL = 00:00

SPEED #02 RPM = 20.0 TIME INTERVAL = 00:00

SPEED #03 RPM = 30.0 TIME INTERVAL = 00:00

SPEED #04 RPM = 40.0 TIME INTERVAL = 00:00

Since speed sets can contain twenty-five (25) separate speeds, printing the speeds that comprise a

speed set will be of great help in allowing the user to fully exercise the power of the DV-III+. After

the printing is complete, the user will be returned to the display of Figure 28.

CLEARING A SPEED SET FROM MEMORY

Since 10 speed sets can be retained in memory, the user may eventually use all the available speed

set slots. The user may also have programmed speed sets that are no longer required and would like

to remove. Assume that the user had programmed a new speed set #3 above. If he wished to

permanently remove that new speed set, or any other IN MEMORY speed set he would, while in

the screens of Figure 21, press the “2” key and be presented with:

Figure 30

Brookfield Engineering Laboratories, Inc. Page 26 Manual No. M/98-211-A0701

Page 27

This screen advises that there are 7 speed sets in memory; speed set #3 is in use and that the DVIII+ is awaiting input for the speed set to delete.

Note: If no speed set is in use the word “NONE” will appear next to the IN USE: prompt.

At this point, the user has two options:

1. Pressing the MOTOR ON/OFF/ESCAPE key will exit from this screen and no speed sets will

be cleared. Or

2. Pressing any of the keys “0”, “1”, “2”, “3”, “5”, “8”, or “9” will delete that speed set.

Thus, to discard speed set #5, the user would press the “5” key and be presented with:

Figure 31

In which the DV-III+ is requesting that the user specifically press the “1” key in order to delete the

desired speed set.

Figure 32

Pressing the “3” key will cause the DV-III+ to take no action will return the user to the CLEAR

SPEED SET opening screen, Figure 30. Any attempt to delete an in-use speed (“3” for instance)

will cause the DV-III+ to issue a “beep” “beep” with no action being taken. Thus no active (i.e.

selected for use) program can be deleted from this screen.

USING PRE-PROGRAMMED SPEEDS

Pressing the three (3) key from Figure 21 takes the user to the speed set selection screen of Figure

22 where the user selects a new speed set. That done the user is sent to the default screen with:

“SPEED SET X SELECTED” displayed on line three (3) of the screen.

The user initiates the use of programmed speeds by pressing the PROG RUN key. If the user presses

the PROG RUN key with no speed set selected, the following error box will be displayed:

Brookfield Engineering Laboratories, Inc. Page 27 Manual No. M/98-211-A0701

Page 28

Figure 33

However, we will assume at this point that we have selected speed set #2 for use in the ensuing data

gathering operations. To initiate the use of this speed set (with finite step times or with zero step

times), the user presses the PROG RUN key and is presented with a start/end step input screen as

shown next:

Figure 34

If the user had not previously entered start and end steps, this screen will display 01 for the start step,

and the last program step (13 in this case) as the end step. The user could elect to use the entire speed

set at this point by pressing the PROG RUN key. If the user had previously selected a start and end

step, those values would be displayed upon entry to this screen instead of the program limit values

as shown above. However, while a speed set can contain up to 25 separate speeds, the user may

be in a situation where only a few contiguous steps may be required. Therefore, this screen allows

for the option of entering the range of speeds encompassed by the start step (not necessarily the first

step) and the end step (not necessarily the last step). Pressing any numeric key at this point will

erase the currently displayed start step and substitute the new value. The user may select a start step

less than the end step ( a so-called Up Ramp) or a start step greater than the end step ( a so-called

Down Ramp). Any attempt to enter a start or end speed not contained in the speed set will result

in the following display:

Figure 35

The ENTER key is used to step from the start step entry to the end step entry. Repeated pressing

of the ENTER key will allow the user to move back-and-forth between the start and end entries and

change them as required until the correct start and end step values have been entered. The selected

speed set, and the start and end steps values entered, will be retained in EEProm memory for use the

next time the viscometer is powered up in the stand-alone mode. Pressing the OPTION/TAB key at

this point results in the following screen display:

Brookfield Engineering Laboratories, Inc. Page 28 Manual No. M/98-211-A0701

Page 29

Figure 36

LOCKOUT OPTIONS

Pressing the “1” key locks out any use of the NUMERIC keys, and the PROGRAM, SELECT

SPINDLE

and OPTIONS/TAB keys. Pressing the “3” key would disable an existing lockout condition

only when in the LOCKOUT OPTIONS screen, Figure 36. After pressing the “1” or “3” keys the

user would be returned to the display of Figure 34. From Figure 34 the user runs the program by

pressing the PROGRAM RUN key which signifies that the user is satisfied with his start and stop step

values, and wishes to start running with the selected speed set. Or, he can return to the default screen

of Figure 7 by pressing the MOTOR ON/OFF/ESCAPE key. (Note: the OPTIONS/TAB key is reenabled at this point

only to allow the user to return to the LOCKOUT OPTIONS screen). In either

case, if the user has enabled the lockout mode, the top line of the default display will change as shown

in Figure 37 below:

Figure 37

The “LOCKOUT” condition will remain in effect until the user re-starts the program mode by

pressing the PROGRAM RUN key re-initiating the steps of Figures 34 through 37 above.

Once the start and end steps have been selected, the program is started by pressing the PROG RUN

key. However, if the viscometer motor was not turned on, the following message would be

displayed:

Figure 38

At this point, the user would turn the viscometer motor on by pressing the MOTOR ON/OFF/

ESCAPE key. This will cause the viscometer to start running at the first selected program speed.

Brookfield Engineering Laboratories, Inc. Page 29 Manual No. M/98-211-A0701

Page 30

USING PROGRAMMED SPEEDS WITH A ZERO TIME INTERVAL

Assume the following:

• A speed set has been selected.

• A subset of the speed set has not been selected. (i.e. we will use the entire set of speeds)

• The speed set included a time interval that was equal to zero minutes and zero seconds.

• Print mode has been set to non-continuous mode (i.e. output will be sent to the printer only

when the user presses the ENTER key).

With the above items in effect our default display screen will appear as follows after the

PROGRAM steps have been completed:

Figure 39

Or, if the user had selected the LOCKOUT option, the default screen above would appear as in

Figure 40 below:

Figure 40

Here, the LOCKOUT mode is indicated by the revision to the top line of Figure 40 where

“SPINDLE” has been contracted to “SPDL” and the two-letter combo: “LK” is being used to

indicate the “LOCKOUT” condition. Please note that while TORQUE is presently being

displayed, there is nothing to prevent the user from pressing the SELECT DISP key to change the

data display item.

The item to note here is the message being displayed on line 3 informing the user that the program

is at speed #02 of the 12 speeds comprising speed set #02. The DV-III+ will continue to operate

at 112 RPM until the ENTER key is pressed. At that point (pressing the ENTER key), two distinct

events will occur:

1. The DV-III+ will ramp up (or down) to programmed speed #03 and,

2. Since the printer is On (PRTN), the data corresponding to the last speed (112 RPM) that existed

at the time the ENTER key was pressed will be sent to the attached printer.

Thus, if 12 speeds comprised the selected speed set, then the user would be required to press the

ENTER key 12 times to exercise the entire speed set. After the last speed has been executed (i.e.

the user pressed the ENTER key for the twelfth time), the viscometer speed will be set at ZERO RPM

and the following message will be displayed:

Brookfield Engineering Laboratories, Inc. Page 30 Manual No. M/98-211-A0701

Page 31

Figure 41

Pressing the ENTER key would return the user to the default screen, as depicted in Figure 40, or to

the program start and stop limit selections of Figure 34 if the PROG RUN key is pressed.

USING PROGRAMMED SPEEDS WITH A NON-ZERO TIME INTERVAL

Assume the following:

• A speed set has been selected.

• A subset of the speed set has not been selected. (i.e. we’ll use all of the speeds in the speed set)

• The speed set included a time interval that was greater than zero (0) minutes and zero (0) seconds.

• Print mode has been set to non-continuous mode (i.e. output will be sent to the printer only when

the user presses the ENTER key).

With the above items in effect our default display screen will appear as follows after the program

steps have been completed:

Figure 42

The difference between this mode and the zero time interval mode is reflected in the message being

displayed on line three of the display where PROG has replaced ENTER indicating that the

program will be executed step-by-step without user intervention. Here the user is again informed

that he is at speed #02 of the 12 speeds comprising speed set #02. As the programmed time interval

elapses, the following will occur:

• The DV-III+ will ramp up (or down) to programmed speed #03 and,

• The data corresponding to the last speed (speed #02) that existed at the moment the step time

elapsed will be sent to the printer since the printer is ON (PRTN) (The automatic ramping to the

next speed will be interpreted by the DV-III+ as if the ENTER key had been pressed, causing the

printer output).

• At the completion of the speed set, the viscometer speed will be set at ZERO RPM

After the last speed has been executed, the viscometer speed will be set at ZERO RPM and the

following message will be displayed:

Brookfield Engineering Laboratories, Inc. Page 31 Manual No. M/98-211-A0701

Page 32

Figure 43

Pressing the ENTER key would return the user to the default screen, as depicted in its general form

in Figure 42, or to the program start and stop limit selections of Figure 34 if the PROG RUN key

is pressed.

OPERATION WITH PROGRAMMED SUBSET SPEEDS

Had the user selected a subset of a speed set (Figure 34), say speeds #04 through #08, then the

programmed mode (with a non-zero time interval) would result in the following display:

Figure 44

Here, the user is informed that speed set #2 is being used starting with speed number four and ending

at speed #08 while currently executing speed #04. After the first speed (number #04) is completed,

the display would be updated to show the new speed and the step display would now reflect the

current executing step number as in Figure 45 below.

Figure 45

If the speed set contained no time interval, the selection of a subset of speeds would result in a screen

display as shown in Figure 46.

Figure 46

Brookfield Engineering Laboratories, Inc. Page 32 Manual No. M/98-211-A0701

Page 33

The step number would be incremented each time the user pressed the ENTER key. Assume that the

speed corresponding to step #04 was executing. If the user presses the ENTER key, our display will

be updated as shown in Figure 47

Figure 47

PROGRAMMED SPEED STOP

The user may stop program mode operation at any time by pressing the MOTOR ON/OFF/ESCAPE

key anytime during program operation. The following message would be displayed:

Figure 48

The viscometer motor would be automatically turned OFF and the default screen display (Figure

37) would show zero (0.0) RPM. At this point, the user may perform any valid viscometer operation

- load a new speed set; run a direct speed; set alarms or even re-start the current program.

PROGRAMMED SPEED HOLD

The user may interrupt program mode operation at any time by pressing the PROG key during

program execution. The following message would be displayed:

Figure 49

The viscometer motor would be automatically turned OFF and the DV-III+ would be awaiting user

key input. If the user presses the “1” key, the DV-III+ will continue executing the current program,

picking up from whichever RPM (and time, if applicable) it had been interrupted. However, if

the user had pressed the “3” key, operation would be identical to that described above for

Programmed Speed Stop mode.

Brookfield Engineering Laboratories, Inc. Page 33 Manual No. M/98-211-A0701

Page 34

IV.3 Bevis Programs

The B.E.V.I.S. Programming Method allows the operator to control the DV-III+ through the

variables of speed, temperature and time while providing for independent data collection.

Programs can include up to 25 commands with a maximum data count of 800. The DV-III+ can

store up to 10 programs. Upon completion of the program the data may be viewed on the DVIII+ display, analyzed or printed to an attached parallel or serial printer.

B.E.V.I.S. programs are created on a PC using Rheoloader software (supplied with the DVIII+). See Section VI for details. The programs are "loaded" onto the DV-III+. Loaded programs cannot be deleted, but can be overwritten.

The B.E.V.I.S. program menu is accessed by pressing the PROG key and selecting number 2, 2

= B.E.V.I.S. The loading and execution of B.E.V.I.S. programs are described in the following

sections.

B.E.V.I.S. PROGRAMS MENU

B.E.V.I.S. operations are accessed by pressing the “2” key when in the PROGRAM MODES

menu. The user is immediately presented with:

Figure 50

This screen informs the user that the B.E.V.I.S. program in storage slot 3 is current (“last used”) and

that it may be run by pressing the “2” key or another program may be selected by pressing the “2”

key. It should be noted that entrance to the B.E.V.I.S. program mode makes the last used program

available for printing or running. Thus the user, seeing that a program was resident in slot 3, could

have printed it directly from the above screen by pressing the front panel PRINT key.

SELECTING AND DOWNLOADING B.E.V.I.S. PROGRAMS

To select a program the user presses the “1” key and is presented with:

Figure 51

The user is informed that the current (or “last used”) program is no. 3; that programs 0,1,2,3 and 4

are available for immediate use and that five (5) slots: 5,6,7,8 and 9 are empty and are available for

download from a host computer. A press of the ENTER key would select the current program (i.e.

“3”) for use while a press of an appropriate numeric key 0,1,2,3 and 4 would select that specific

Brookfield Engineering Laboratories, Inc. Page 34 Manual No. M/98-211-A0701

Page 35

program slot for use. The above screen would be updated to reflect the new selection. A press of

the 5,6,7,8 or 9 keys will place the user in the B.E.V.I.S. program download mode. The following

screen appears (assuming a press of the “5” key):

Figure 52

The user’s selection “5” is flashing and is the current slot selection. When ready, the user presses

the

ENTER key to begin the program download. The following screen will appear for the duration

of the download. See Section VI. RHEOLOADER for information on creating and downloading

B.E.V.I.S. programs.

Figure 53

RUNNING B.E.V.I.S. PROGRAMS

Programs are run by pressing the “2” key when in Figure 50 which presents the user with the

following screen:

Figure 54

Here we see that our program is no. “3” and that a press of the ENTER key will start it running. As

soon as the program starts executing the user will be presented with:

Figure 55

This is a typical display for a given program step. The current step being executed (WTI0330) is

shown as well as the next step to be executed (PDN). The bottom line displays the current program

Brookfield Engineering Laboratories, Inc. Page 35 Manual No. M/98-211-A0701

Page 36

step, the total number of steps (02/39) and any time intervals if they are relevant. The WKY

command message could be displayed on the bottom line in lieu of the step and time info. This screen

stays resident until the user presses the OPTIONS/TAB key which “toggles” back-and-forth between

this screen and an amended default screen shown next:

Figure 56

The user now sees viscosity data and can use the SELECT DISPLAY key to view other viscosity

measurement parameters. Pressing the OPTIONS/TAB key from now on will toggle between the

screens of Figure 55 and Figure 56. The program code will automatically switch back to the

program progress screen, Figure 55 above, if a conditional has been reached, the end of a program

step is reached or user input is required. If no user input is required, the B.E.V.I.S. program proceeds

to the next step without switching back to the progress screen.

IV.4 Choosing the Best Data Collection Method

The DV-III+ offers 3 methods for data collection; Single Speed, DV-III Speed/Time Pairs and

B.E.V.I.S. Programs. The decision of which technique is best should be made considering the

test requirements.

SINGLE SPEED

Single speed measurements may be made by direct speed commands on the DV-III+ keypad.

Viscosity and % Torque are read directly from the display. This technique offers the simplicity of

the Brookfield Dial Viscometer. Multiple data points may be gathered by issuing multiple speed

commands.

This technique is fast and easy. It's well suited to gathering data on samples prior to establishing a test method or for performing single point tests.

DV-III SPEED/TIME PAIRS

DV-III speed/time pairs offers a simple technique to collect multiple data points. Programs can be

created and executed from the DV-III+ keypad. Results can be analyzed or output to a printer.

This technique is useful when multiple data points are required and the test method is simple.

B.E.V.I.S. PROGRAMS

B.E.V.I.S. Programs offer a command set capable of sophisticated rheometer control and data

collection. Programs are created on a PC and executed from the DV-III+ keypad. Results can be

analyzed or output to a printer.

The B.E.V.I.S. Program technique is useful when sophisticated data collection is necessary.

Brookfield Engineering Laboratories, Inc. Page 36 Manual No. M/98-211-A0701

Page 37

IV.5 Data Analysis

Data collected from DV-III speed/time pairs or B.E.V.I.S. programs may be analyzed using several

math models. These models provide a means to numerically describe the behavior of the test fluid.

In the case of viscosity measurement, a non-Newtonian fluid will produce a curve when test data

is plotted on a shear stress vs. shear rate graph. The math model will force the data into a straight

line and describe it with a slope and y intercept. The terminology associated with the slope and y

intercept vary from model to model as does the interpretation of results.

The DV-III+ does not allow for data sets to be edited. Programs must be constructed to conform

with the following data requirements if math models are to be used:

• The data set must contain non zero values for shear stress and shear rate (except for the paste

model which requires non zero viscosity and RPM).

• There cannot be two equal adjacent shear rate values (RPM values for paste model).

• % torque values of all data points must be between 0.1% and 100%.

If any of the above circumstances are violated, an error message will appear when a math

model is selected.

ERROR #1: A % torque value is less than 0.1. A shear stress or shear rate value is zero.

ERROR #2: A % torque value is greater than 100.

ERROR #3: Reserved

ERROR #4: Two adjacent speeds of equal value.

Math models for data analysis are accessed by pressing the PROG key and then 3; 3 = Models (Figure

20). If no data (i.e. no data at all or less than two(2) data points) is in the data buffer, no modeling

can be performed and Figure 57 will be displayed:

Figure 57

If there is already data in the data buffer, the user will be presented with the following screen:

Figure 58

Brookfield Engineering Laboratories, Inc. Page 37 Manual No. M/98-211-A0701

Page 38

The user is informed that there are five (5) math models which can be used on the buffer data. A

model is selected by pressing the appropriate numeric key. No matter the model selected, the

following screen will be displayed for the duration of the mathematical analysis:

Figure 59

When the calculations are complete, the results for the particular model will be displayed as follows:

Figure 60

This screen, for the Standard CASSON Model, is typical for all five (5) of the math models. Note

the cP in the upper right-hand corner to remind the user that the values are cP based. It could have

been SI (if the user had opted for SI display in the SETUP menu) as shown on the next two (2) of

the following four (4) math model screens:

The user may elect to print test results in order to obtain hard copy results. This is accomplished

by pressing the PRINT key while any of the above screens are being displayed causing the following

to be printed:

STANDARD CASSON PRINTOUT

Sample Name: ________________________________________________

Operator Name: ___________________________

Date: 01/14/1999 Time: 02:27 Math Model Results: CASSON (STANDARD)

Model: HB Spindle: 34

Plastic Viscosity: 1906.3 cP

Yield Stress: 1976.88 D/CM2

Confidence of Fit: 63.6 %

The equation for each model is described below with a definition of parameters. Please contact

Brookfield or an authorized representative if further information is required.

Note: The confidence of fit parameter used in all of the models is an indication of how well

the model fits the data set. 100% indicates the best fit.

Brookfield Engineering Laboratories, Inc. Page 38 Manual No. M/98-211-A0701

Page 39

1. Casson (Standard)

√

o

ηD

o

ηD

o

ηD

o

R

The Standard Casson equation is:

= Shear Stress

τ

= Yield Stress (stress at zero shear rate)

τo

= Plastic Viscosity

= Shear Rate

D

The calculated parameters for this model are:

Plastic Viscosity (cP or mPa•s)

Yield Stress (Dynes/cm2 or N/m2)

Confidence of Fit (%)

The Standard Casson method is a direct implementation of the original Casson equation.

2. NCA/CMA Casson (Chocolate)

This Casson method is derived from the standard set forth by the National Confectioners

Association (NCA) and the Chocolate Manufacturers Assocation (CMA). Although based on the

original Casson equation, this implementation has been tailored by the NCA and CMA

specifically to applications involving chocolate.

The Chocolate Casson equation is:

= Shear Stress

τ

= Yield Stress (stress at zero shear rate)

τo

= Plastic Viscosity

= Shear Rate

D

a = spindle (or bob) radius/ inner cup radius

τ = √τo + √η

(

1+a

)√τ = 2√τo + (

D

where:

1+a

) √η

where:

D

The calculated parameters for this model are:

Plastic Viscosity (cP or mPa•s)

Yield Stress (Dynes/cm2 or N/m2)

Confidence of Fit (%)

3. Bingham Plastic

The Bingham equation is:

= Shear Stress

τ

= Yield Stress (stress at zero shear rate)

τo

= Plastic Viscosity

= Shear Rate

D

The calculated parameters for this model are:

Plastic Viscosity (cP or mPa•s)

Yield Stress (Dynes/cm2 or N/m2)

Confidence of Fit (%)

4. Power Law

The Power Law equation is

= Shear Stress

τ

= Yield Stress (stress at zero shear rate)

D

= Plastic Viscosity

k

n = Shear Rate

τ = τo + ηD

n

τ = kD

where:

where:

Brookfield Engineering Laboratories, Inc. Page 39 Manual No. M/98-211-A0701

Page 40

The calculated parameters for this model are:

kR

Flow Index (no units)

Consistency Index (cP or mPa•s)

Confidence of Fit (%)

5. IPC Paste Analysis

This method is intended to calculate the Shear Sensitivity Factor and the 10 RPM Viscosity value

of pastes. A prime example of its use is in the solder paste industry, thus the name IPC (Institute

for Interconnecting and Packaging Electronic Circuits).

n

The Paste equation is:

= Viscosity (cP)

η

η =

kR

where:

= Consistency Multiplier

= Rotational Speed (RPM)

n

= Shear Sensitivity Factor

The calculated parameters for this model are:

Shear Sensitivity Factor (no units)

10 RPM Viscosity (cP or mPa•s)

Confidence of Fit (%)

V. OPTIONS

The DV-III+ Options Menu allows the user to execute temperature control commands and special

time tests. General rheometer settings are also accessed from this menu. The Options Menu is

shown in Figure 61. Selections are made by pressing the appropriate number key.

Figure 61

V.1 Set Up

1. Change the units of temperature. The change is selected by pressing the1 key. The change must

be confirmed by pressing the ENTER key.

2. Change the units of viscosity and shear stress (CGS System: cP, D/cm2) (SI System: mPa•s, N/

m2).

The change is selected by pressing the 2 key. The change must be confirmed by pressing the

ENTER key.

Brookfield Engineering Laboratories, Inc. Page 40 Manual No. M/98-211-A0701

Page 41

3. Change communication status with external Brookfield temperature controller. An "off"

indication means that there is no communication with a controller. Selecting this option will

make the DV-III+ try to establish communication. When communication is established, "off"

will be change to "on". Temperature control will always be set to "off" when the DV-III+ is turned

on.

When communication is established, Line 1 of the default screen will be modified. The

temperature field will show "CTLR" in place of "TEMP".

Communication may only be established with Brookfield controllers:

Thermosel Controllers: HT-106, HT-104

Bath Controllers: HT-107, HT-105

The change is selected by pressing the 3 key. Subsequent key presses required will be indicated

on the display.

4. Change the temperature display by offsetting the measured temperature to agree with an external

temperature measurement device. The adjustment will be indicated by flashing temperature

units (F or C) on the default screen (Figure 7). The adjustment will be reset to 0.0 when the DVIII+ is turned on.

The adjustment is entered using the number keys. The sign (+ or -) is selected using the OPTION/

TAB key. The change must be confirmed by pressing the ENTER key.

V.2 Print

1. Change the time interval that is used when the DV-III+ is printing continuously. Data is entered

in the format of MM:SS. For example: an interval of one minute and 30 seconds is entered as:

01:30.

The change is initiated by pressing the 1 key. Once the time interval is input, it must be accepted

by pressing the ENTER key.

2. Change the port to be used for printing, parallel or serial.

The change is selected by first pressing the 2 key and then the appropriate key for the printing

method. The change will be indicated by the position of the arrow on the right side of the display.

The change is accepted by pressing the ENTER key.

When selecting serial printing, the DV-III+ will also ask for handshaking status. Please see the

instruction manual of the printer for specification.

If the DV-III+ is communicating with an external temperature controller, serial printing will not

be available(the controller uses the serial port).

3. Enter the date and time to be shown on printed data tables. Data is entered in the format of DD/

MM/YY for date and HH:MM for time (24-hour clock). For example: 2:30 pm on January 15,

1999 is entered as 15/01/99, 14:30.

The change is initiated by pressing the 3 key. Once the data is input, it must be accepted by

pressing the ENTER key.

Brookfield Engineering Laboratories, Inc. Page 41 Manual No. M/98-211-A0701

Page 42

V.3 Alarms

There are three adjustable alarm settings: LO ALARM %, HI ALARM % and MOTOR OFF %.

The values are set in the Set Alarms mode. Alarms are used to signal the operator that the fluid is

out of the input specification. The alarms are set in % torque values, not Viscosity, Shear Stress or

Shear Rate values. The range of values which may be entered for each alarm and their default values

are:

LO ALARM HI ALARM MOTOR OFF

Minimum value: 10% Minimum value: 0% Minimum value: 0%

Maximum value: 99.9% Maximum value: 100% Maximum value: 115%