Page 1

BROOKFIELD DIGITAL VISCOMETER

MODEL DV-II+

Operating Instructions

Manual No. M/92-161-I496

BROOKFIELD ENGINEERING LABORATORIES, INC.

240 Cushing Street, Stoughton, MA 02072 USA

Phone: 617-344-4310/4313 800-628-8139 (U.S. except MA); Fax: 617-344-7141

Telex: 924497 BRENLAB STOU (Western Union); 200195 BEL (RCA)

- 1 -

Page 2

TABLE OF CONTENTS

I. INTRODUCTION ........................................................................... 3

1 DV-II+ Components .......................................................................... 3

2 Utilities .............................................................................................. 4

3 Specifications .................................................................................... 4

4 DV-II+ Set-Up................................................................................... 4

5 Key Functions.................................................................................... 5

II. GETTING STARTED..................................................................... 6

1 Autozero ............................................................................................ 6

2 Spindle Selection ............................................................................... 7

3 Speed Selection & Setting ................................................................. 8

4 Display Selection............................................................................. 10

5 Autorange and CGS or SI Units Selection ...................................... 10

6 Out of Range.................................................................................... 11

7 Temperature Display ....................................................................... 12

8 Printing ............................................................................................ 13

9 Operation ......................................................................................... 14

10 Timed Modes for Viscosity Measurement ...................................... 14

Appendix A - Cone/Plate Viscometer Set-Up....................................... 20

Appendix B - Viscosity Ranges ............................................................ 26

Appendix C - Variables in Viscosity Measurements ............................ 29

Appendix D - Spindle and Model Codes .............................................. 31

Appendix E - Calibration Procedures ................................................... 34

Appendix F - Special Speed Sets.......................................................... 40

Appendix G - Communications............................................................. 41

Appendix H - Model A Laboratory Stand............................................. 45

Appendix I - DVE-50 Probe Clip ........................................................ 47

Appendix J - Fault Diagnosis and Troubleshooting ............................ 48

Appendix K - Warranty Repair and Service ......................................... 51

- 2 -

Page 3

I. INTRODUCTION

The Brookfield DV-II+ Viscometer measures fluid viscosity at given shear rates. Viscosity is a

measure of a fluid’s resistance to flow. You will find a detailed description of the mathematics of

viscosity in the Brookfield publication ”More Solutions to Sticky Problems” a copy of which was

included with your DV-II+.

The principal of operation of the DV-II

+ is to drive a spindle (which is immersed in the test fluid)

through a calibrated spring. The viscous drag of the fluid against the spindle is measured by the spring

deflection. Spring deflection is measured with a rotary transducer. The measurement range of a DV-

II+ (in centipoise or milliPascal seconds) is determined by the rotational speed of the spindle, the

size and shape of the spindle, the container the spindle is rotating in, and the full scale torque of the

calibrated spring.

There are four basic spring torque series offered by Brookfield:

Spring Torque

Model dyne-cm milli Newton - m

LVDV-II

RVDV-II

+ 673.7 0.0673

+ 7,187.0 0.7187

HADV-II+ 14,374.0 1.4374

HBDV-II+ 57,496.0 5.7496

The higher the torque calibration, the higher the measurement range. The measurement range for

each torque calibration may be found in Appendix B.

All units of measurement are displayed according to either the CGS system or the SI system.

1. Viscosity appears in units of centipoise (shown as “cP”) or milliPascal-seconds (shown

as mPa•s) on the DV-II+ Viscometer display.

2. Shear Stress appears in units of dynes/square centimeter (“D/cm2”) or Newtons/square

meter (“N/m2”).

3. Shear Rate appears in units of reciprocal seconds (“1/SEC”).

4. Torque appears in units of dyne-centimeters or Newton-meters (shown as percent “%”

in both cases) on the DV-II+ Viscometer display).

The equivalent units of measurement in the SI system are calculated using the following conversions:

SI CGS

Viscosity: 1 mPa•s = 1 cP

Shear Stress: 1 Newton/m

2

= 10 dyne/cm

2

Torque: 1 Newton-m = 107 dyne-cm

References to viscosity throughout this manual are done in CGS units. The DV-II+ Viscometer

provides equivalent information in SI units.

I.1 Components

1) DV-II+ Viscometer

2) Model A Laboratory Stand

3) Spindle Set with Case (4 spindles for LVDV-II+; 7 Spindles for RV, HA and HBDV-II+).

For Cone/Plate versions: a spindle wrench, one cone spindle and sample cup (Part No. CP44Y) replace the spindle set.

4) Power cord

5) RTD Temperature Probe and DVE-50 Probe Clip

6) Guard Leg (LVDV-II+ and RVDV-II+ only)

7) Carrying Case

- 3 -

Page 4

Please check to be sure that you have received all components, and that there is no damage. If you

are missing any parts, please notify Brookfield Engineering or your local Brookfield agent immediately. Any shipping damage must be reported to the carrier.

I.2 Utilities

Input Voltage: 115 VAC or 230 VAC

Input Frequency: 50/60 Hz

Power Consumption: Less than 20 WATTS

Power Cord Color Code:

United States Outside United States

Hot (live) Black Brown

Neutral White Blue

Ground (earth) Green Green/Yellow

I.3 Specifications

Speeds: LVDV-II+: 0.0, 0.3, 0.6, 1.5, 3, 6, 12, 30, 60, 0.0,

0.5, 1, 2, 2.5, 4, 5, 10, 20, 50, 100

RV/HA/HBDV-II+: 0.0, 0.5, 1, 2, 2.5, 4, 5, 10, 20, 50, 100,

0.0, 0.3, 0.6, 1.5, 3, 6, 12, 30, 60

Weight: Gross Weight 20 lbs. 9 kg.

Net Weight 17 lbs. 7.7 kg.

Carton Volume 1.65 cu. ft. 0.05 m

3

Temperature sensing range: -100˚C to 300˚C (-148˚F to 572˚F)

Analog Torque Output: 0 - 1 Volt DC (0 - 100% Torque)

Analog Temperature Output: 0 - 4 Volts DC (10mv / ˚C)

RS232 Compatible Serial Port for use with an attached printer or PC.

I.4 Set-Up

1) Place the upright rod into the base (refer to assembly instructions in Appendix H). The rack

gear and clamp assembly should face the front of the base. The upright rod is held in place

with the jam nut which is attached from the bottom of the base. Tighten this nut with a

suitable wrench (spanner). Attach leveling feet.

2) Insert the mounting handle on the back of the DV-II+ Viscometer into the hole on the clamp

assembly. Be sure that the clamp screw, VS-24Y, is loose.

3) Tighten the VS-24Y clamp screw. Adjust viscometer to be as close to level as possible while

tightening VS-24Y.

4) Connect the RTD probe to the socket on the rear panel of the DV-II+.

5) The Viscometer must be leveled. The level is adjusted using the three leveling screws on

the base. Adjust so that the bubble level on top of the DV-II+ is centered within the circle.

Note: Check level periodically during use.

- 4 -

Page 5

6) Make sure that the AC power switch at the rear of the DV-II+ is in the OFF position.

Connect the power cord to the socket on the back panel of the instrument and plug it into

the appropriate AC line. The AC input voltage and frequency must be within the

appropriate range as shown on the name plate of the Viscometer.

Note: The DV-II+ must be earth grounded to ensure against electronic failure!!

7) Temperature monitoring is assured (after the instrument has stabilized) to within ±1.0˚C in

the range -99.9˚C to +150˚C and within ±2.0˚C in the range 150˚C to 300˚C.

8) For Cone/Plate models, refer to Appendix A.

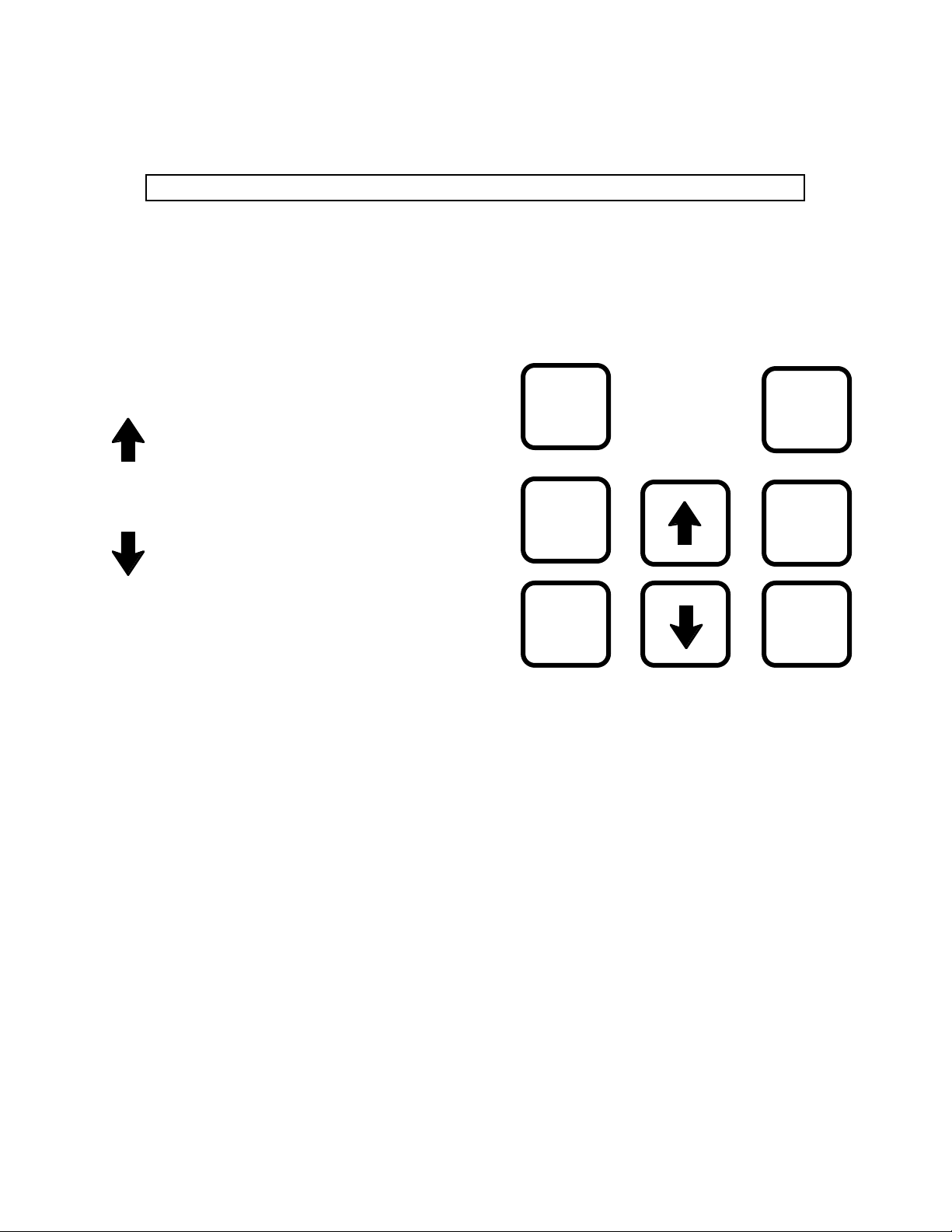

I.5 Key Functions

Figure 1 shows the control keys on the face of

the DV-II+ Viscometer. The following

describes the function of each key.

MOTOR

ON/OFF

AUTO

RANGE

UP ARROW

This key is used to scroll UP (in an increasing

value direction) through the available speed or

spindle tables.

SET

SPEED

SELECT

SPINDLE

DOWN ARROW

This key is used to scroll DOWN (in a decreasing value direction) through the available speed

or spindle tables.

SELECT

DISPLAY

MOTOR ON/OFF

Turns the motor ON or OFF.

Figure 1

SET SPEED

Causes the DV-II+ to begin running at the currently selected speed. This key is used for Time to

Torque and Timed Stop Tests (see Section II.10 - Timed Modes for Viscosity Measurement).

SELECT DISPLAY

Selects the data parameter to be displayed:

% Viscometer Torque (%)

cP Viscosity (cP or mPa.s)

SS Shear Stress (dynes/cm2 or Newtons/m2)

SR Shear Rate (1/sec)

Note: Pressing and holding the Select Display key during power on will enable the

temperature display for units of either °C or °F (see page 12).

AUTO RANGE

Presents the maximum (100% torque) viscosity attainable using the selected spindle at the current

viscometer spindle speed. This feature is functional when the motor is running.

PRINT

Note: Pressing and holding the Auto Range key during power on will enable the

display to be selected for either CGS or SI units of measurement (see page 11).

- 5 -

Page 6

SELECT SPINDLE

Initiates spindle selection on the first press and then selects the currently scrolled-to spindle when

pressed a second time. This key is used for Time to Torque and Timed Stop Tests (see Section II.10

- Timed Modes for Viscosity Measurement).

PRINT

Selects printing and non-printing modes when a printer is attached.

II. GETTING STARTED

II.1 Autozero

Before readings may be taken, the Viscometer must be Autozeroed. This action is performed each

time the power switch is turned on. The display window on the Viscometer will guide you through

the procedure as follows:

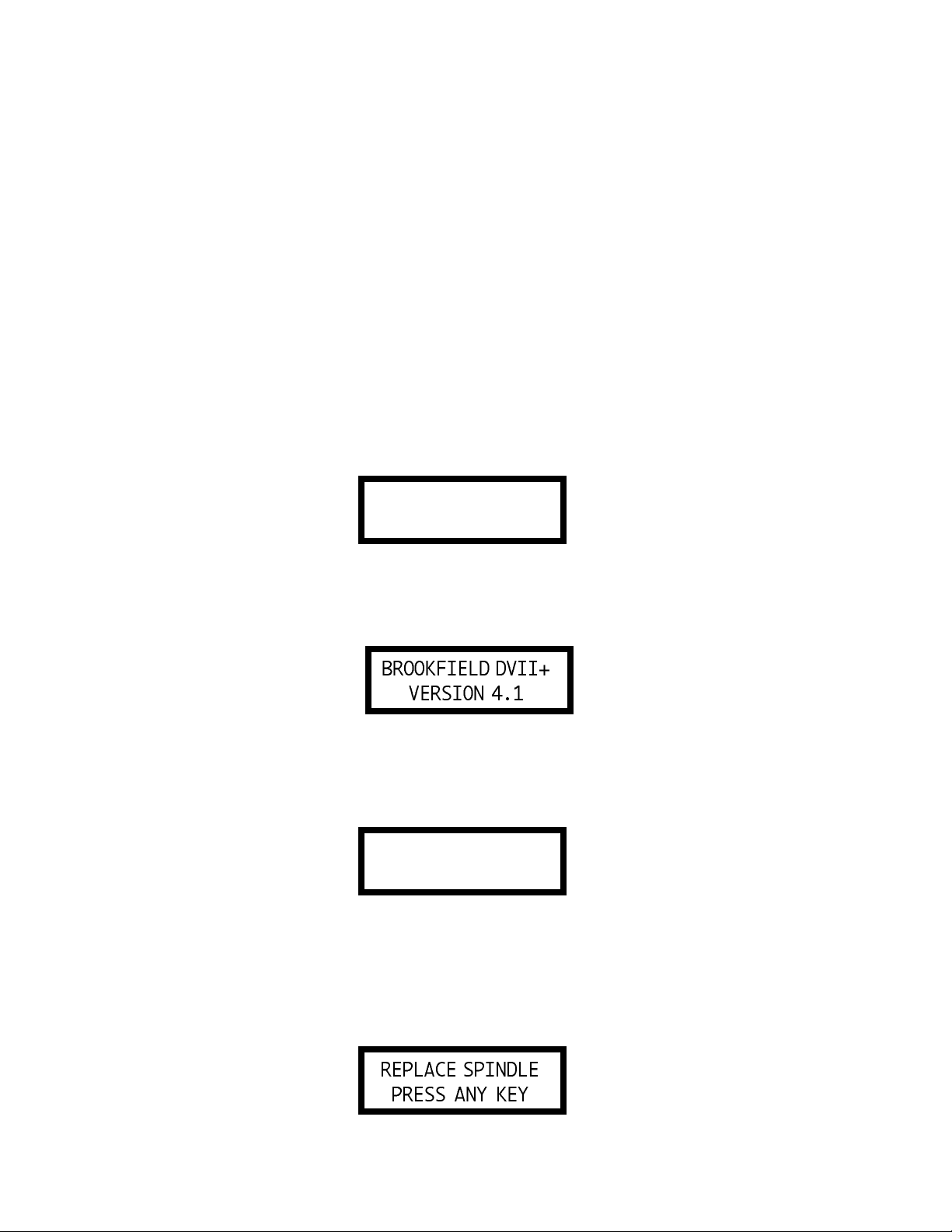

Turn the power switch (located on the rear panel) to the ON position. This will result in the following

screen display:

BROOKFIELD DVII+

RV VISCOMETER

Figure 2

After a few seconds, the following screen appears:

Figure 3

No key press is required at this point. After a short time, the display will clear and the following

will be displayed:

REMOVE SPINDLE

PRESS ANY KEY

Figure 4

After removing the spindle and pressing any key, the DV-II+ begins its Autozero. The screen will

flash "Autozeroing."

After approximately 15 seconds, the display shows “Replace Spindle Press Any Key”.

Figure 5

- 6 -

Page 7

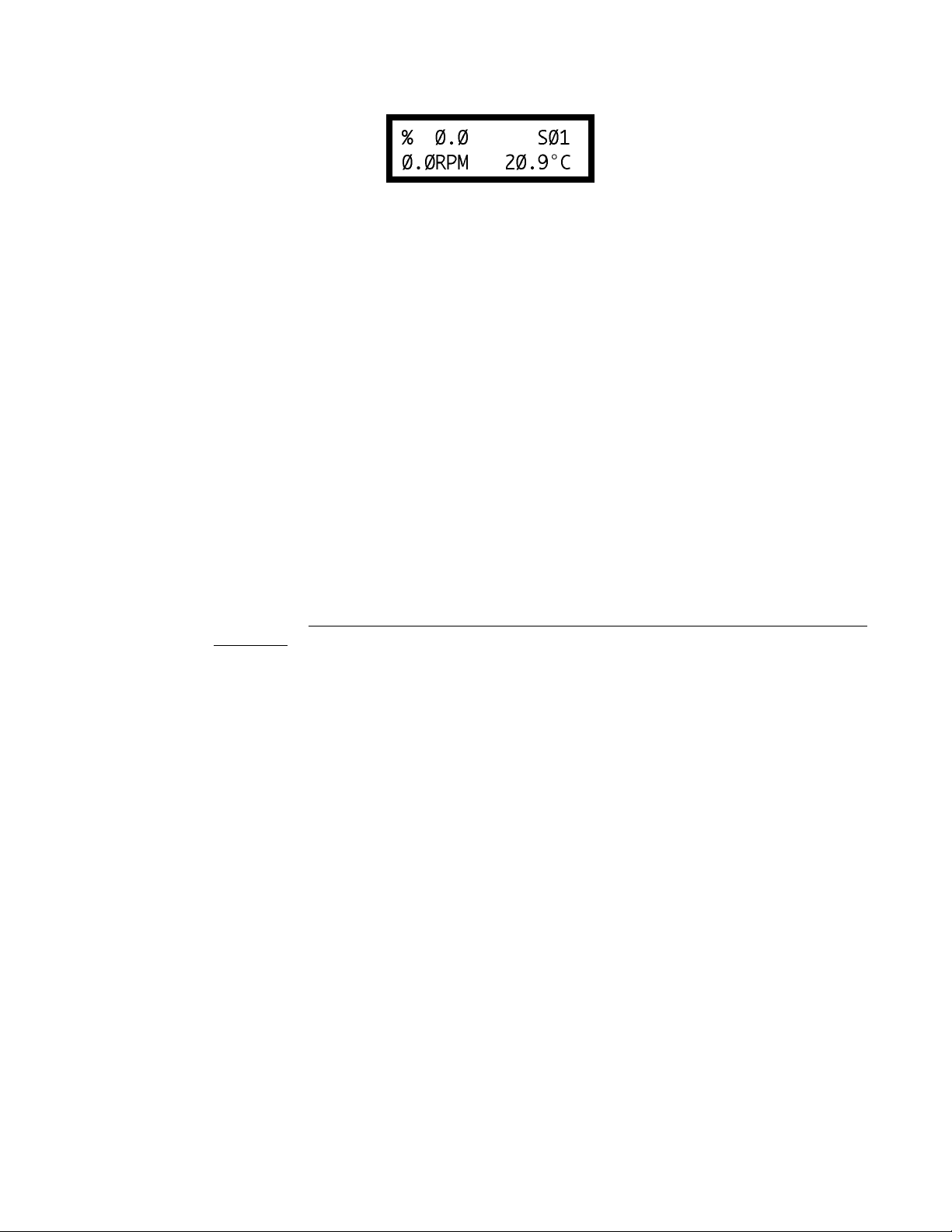

Pressing any key at this point results in the display of the DV-II+ default screen:

Figure 6

The display will vary slightly depending upon the status of temperature and last spindle entered.

II.2 Spindle Selection

LVDV-II+ Viscometers are provided with a set of four spindles and a narrow guardleg; RVDV-II+

Viscometers come with a set of seven spindles and a wider guardleg; HADV-II+ and HBDV-II+

Viscometers come with a set of seven spindles and no guardleg. (See Appendix E for more

information on the guardleg.)

The spindles are attached to the viscometer by screwing them to the lower shaft. Note that the

spindles have a left-hand thread. The lower shaft should be held in one hand and the spindle screwed

to the left. The face of the spindle nut and the matching surface on the lower shaft should be smooth

and clean to prevent eccentric rotation of the spindle. Spindles can be identified by the number on

the side of the spindle coupling nut.

The DV-II+ must have a Spindle Entry Code number to calculate Viscosity, Shear Rate and Shear

Stress values. The DV-II+ memory contains parameters for all standard Brookfield spindles and the

two digit entry code for each spindle (the complete list of entry codes may be found in Appendix D).

Note: The DV-II+ will remember the Spindle Entry Code which was in use when the power was

turned off.

Pressing the SELECT SPINDLE key will cause the character S on the top line of the display to begin

to blink . It will blink for about three seconds. If the UP or DOWN Arrow keys are pressed (while

S is blinking) the two character spindle value to the right of the S character will begin to change (in

either an increasing or decreasing direction depending upon which Arrow key is pressed) for each

press of the key. If the Arrow key is pressed and held, the display will scroll through the spindle codes

for as long as the Arrow key is depressed. When it reaches the last item in the list (either at the top

or bottom of the list) the spindle code displayed will “roll-over” to either the first or last spindle code

and the scroll action will continue.

When the desired spindle code is displayed, release the Arrow key to halt further scrolling. Press

the SELECT SPINDLE key once again. This will cause the S character to cease blinking and the

new spindle code will be accepted for use in viscometer calculations.

Note: You have approximately three seconds in which to press the SELECT SPINDLE key

before the blinking stops. If you fail to press the SELECT SPINDLE key before the

blinking stops you will have to repeat the above steps and re-select the desired spindle.

The DV-II+ will begin to calculate using the new spindle parameters as soon as the SELECT

SPINDLE key is pressed the second time.

Note: The number 99 spindle is for use with special spindles when using Brookfield’s

DVGATHER+ or WINGATHER computer programs. Refer to the DVGATHER+ or

WINGATHER manuals for further information on using “99” spindles.

- 7 -

Page 8

The DV-II+ may also be programmed at Brookfield Engineering for “special” user spindles. These

“special” spindles will show up on the spindle scroll list starting with designation “AA” and

continuing through “AZ”. Contact Brookfield Engineering regarding your needs for special

spindles.

II.3 Speed Selection & Setting

There are 18 speeds programmed into the standard DV-II+. These speeds correspond to the standard

LVT, RVT, HAT, HBT, LVF and RVF dial models. If the DV-II

at speed 0.0. It will then scroll up through the LV speeds, pass through speed 0.0 again, and then scroll

up through the RV speeds at which point it will pass through speed 0.0 again and will then repeat the

above sequence. If the DV-II

The DV-II+ will start at 0.0 and scroll through the RV speeds, pass through 0.0 again and then scroll

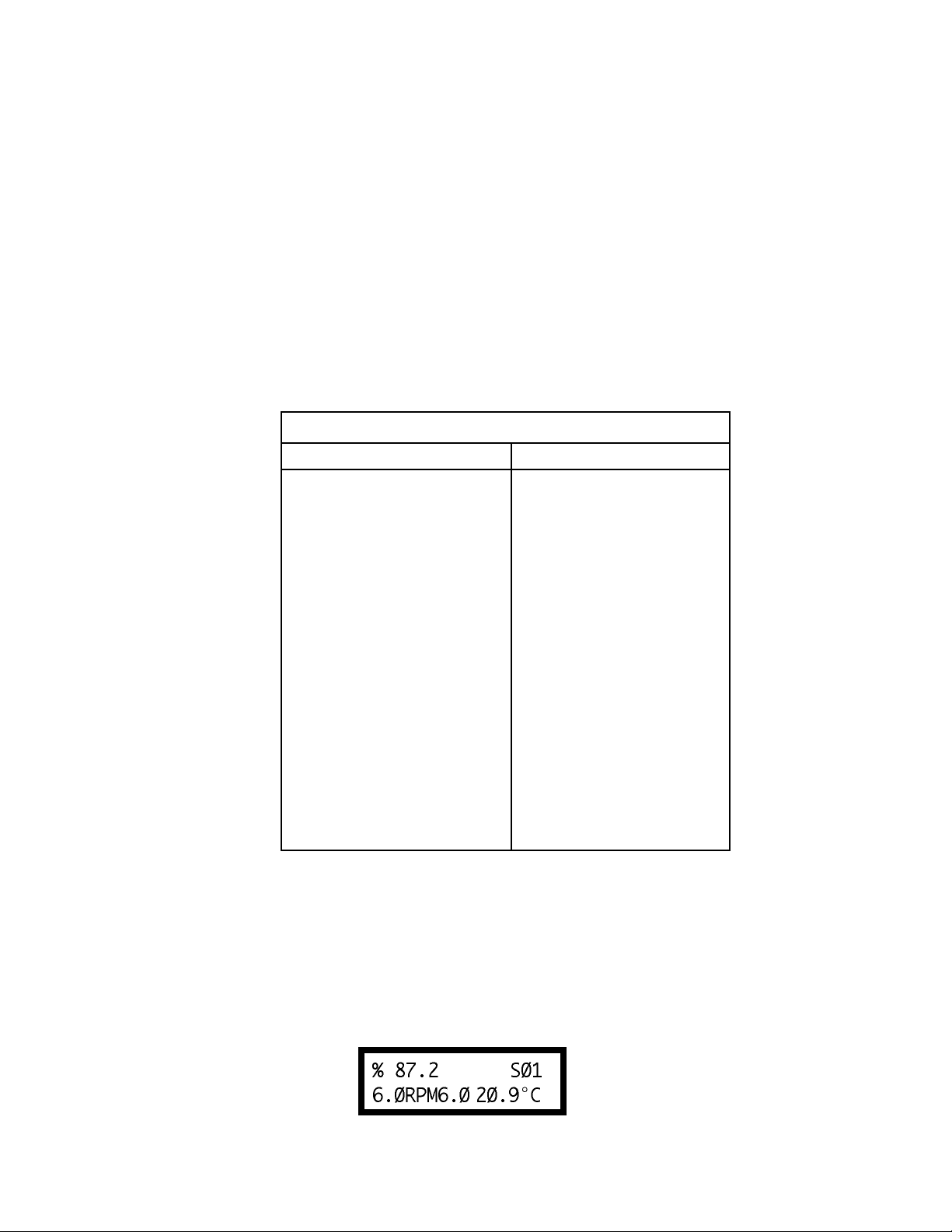

through the LV speeds until it again reaches speed 0.0. The speed sets are described in Table 1.

+ is an RV (HA and HB) “type”, the inverse of the above will occur.

+ is an LV, the speed set will start

Table 1

DV-II+ Speed Sets

LV Instruments RV/HA/HB Instruments

0.0 0.0

0.3 0.5

0.6 1.0

1.5 2.0

3.0 2.5

6.0 4.0

12.0 5.0

30.0 10.0

60.0 20.0

0.0 50.0

0.5 100.0

1.0 0.0

2.0 0.3

2.5 0.6

4.0 1.5

5.0 3.0

10.0 6.0

20.0 12.0

50.0 30.0

100.0 60.0

The DV-II+ may also be programmed with “special” speed sets. A list of special speed sets is

included in Appendix F. Please consult Brookfield Engineering or your local dealer/distributor for

any special speed requirements not addressed by the standard or special speed sets.

To select a Viscometer speed first press either the UP or DOWN arrow keys which will cause the

area to the right of RPM (on the bottom line) to display the currently selected speed. Figure 7 shows

the DV-II+ had been operating at 6.0 RPM, and the current selected speed is 6.0 RPM.

Figure 7

- 8 -

Page 9

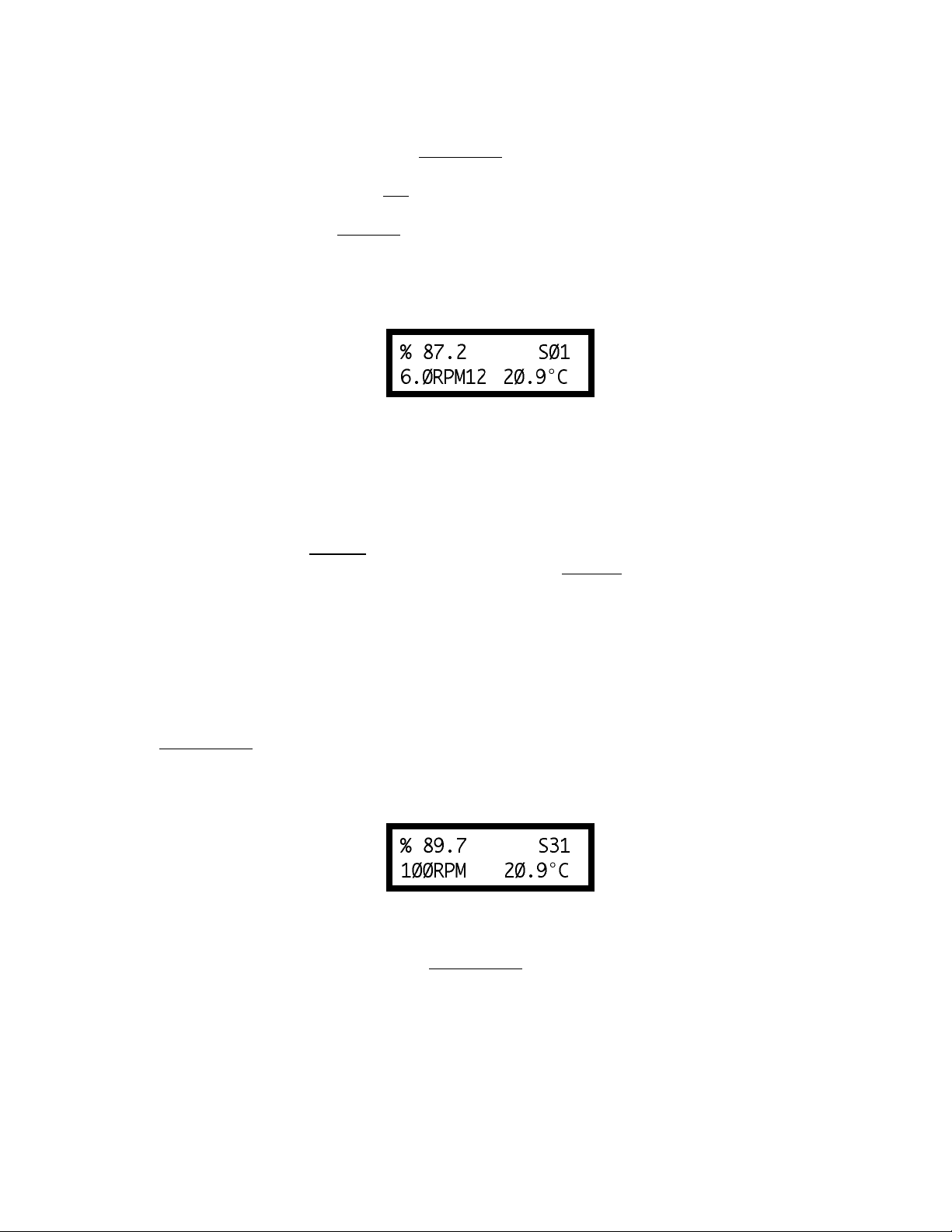

If the Arrow key is pressed just once and then released, the characters RPM will blink for three

seconds, then will cease blinking resulting in no change to the speed entry.

Note: The speed selection process remembers the last value of scrolled-to speed so that the next

time you initiate a speed change (by pressing an Arrow key), the DV-II

scroll display from the last entered value.

The last-scrolled-to speed does not necessarily have to be the same as the speed at which the DV-

II

+ is currently running. The user may operate at a given speed and pre-set the DV-II+ to the next

desired speed before that speed will be used. For example, if the DV-II+ is currently running at 6.0

RPM and was previously scrolled to 12 RPM, a single press of either Arrow key would result in the

Figure 8 screen display:

Figure 8

Pressing the SET SPEED key would cause the DV-II+ to begin running at 12 RPM.

If the user did not press the SET SPEED key, the DV-II+ would continue to run at its current speed

of 6 RPM. In fact, you may scroll to a new speed (12 RPM in this example) and press the SET SPEED

key at any future time (without further pressing an Arrow key) to immediately cause the DV-II+ to

run at the new speed. Pressing the Arrow key at any time reminds the operator of what was selected

for the next speed.

+ will begin its

If an Arrow key is pressed and held the DV-II+ will scroll up (or down) through the speed table.

When it reaches the last speed in the list (either at the top or bottom of the list) the speed displayed

will ”roll-over” to either the first or last speed in the table and the scroll action will continue.

When the required speed is displayed, release the Arrow key to halt further scrolling. You have

approximately two seconds (before the blinking RPM stops) in which to press the SET SPEED key

to immediately begin rotation at the new speed.

Pressing the MOTOR ON/OFF key stops the Viscometer spindle rotation. Pressing this key sets

the DV-II+ to 0.0 RPM and causes the screen display to change as shown in Figure 9:

Figure 9

Pressing the MOTOR ON/OFF again immediately starts the DV-II+ running at the last scrolledto-speed. If you had been running at 12 RPM, pressed MOTOR ON/OFF and then re-started the

DV-II+ by pressing MOTOR ON/OFF once again, you would again be running at 12 RPM.

However, if while the motor was off you had scrolled to a new speed of 0.5 RPM, pressing the

MOTOR ON/OFF key would start the DV-II+ running at 0.5 RPM.

Note: During both spindle or speed selection and scrolling operations, the DV-II+ will continue

to calculate and display Viscometer data as selected.

- 9 -

Page 10

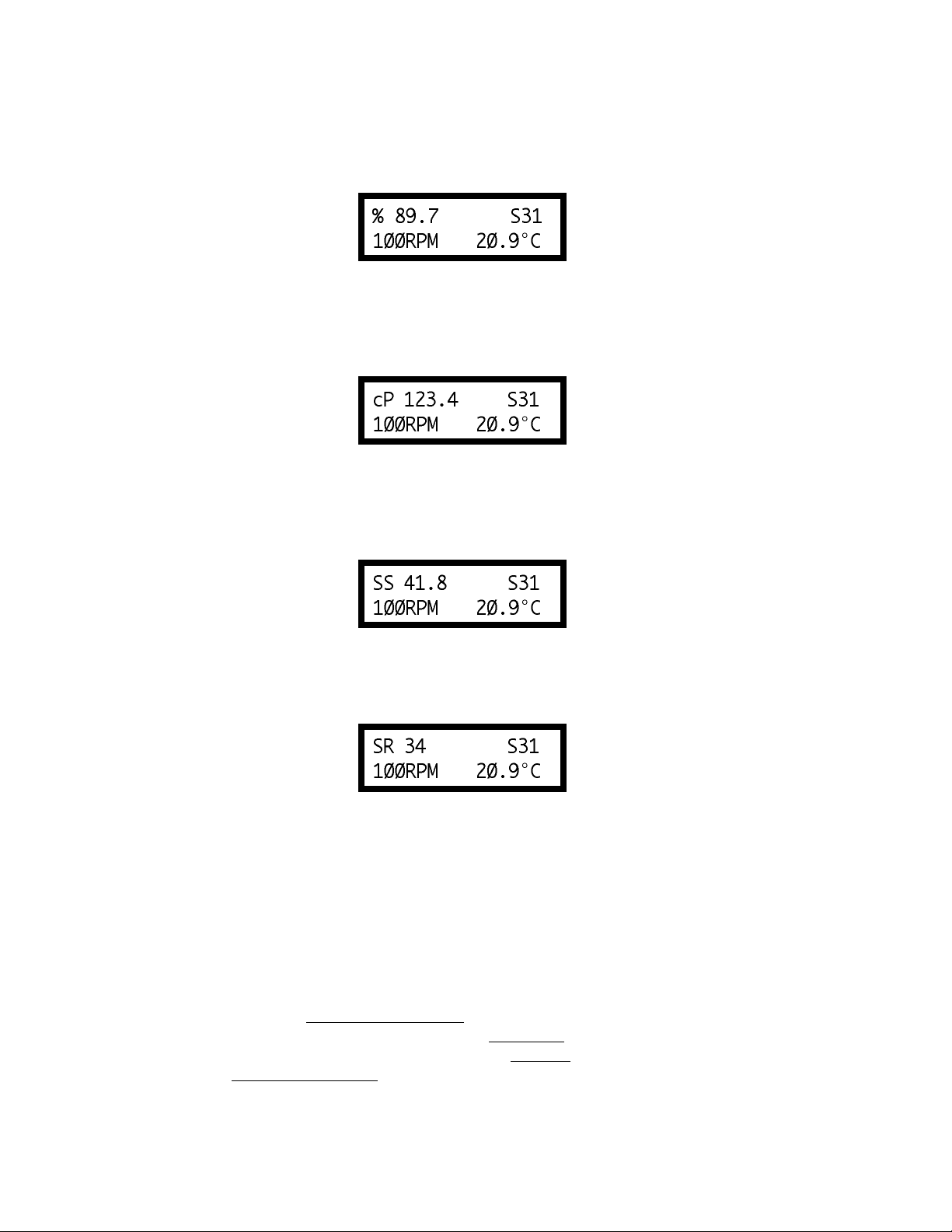

II.4 Display Selection

Viscometric data (%, cP, SS, SR) is displayed on the left side of the top line. You may “step” through

the four display options by pressing the SELECT DISPLAY key. For example, if the DV-II+ were

currently displaying % (Torque) as shown in Figure 10:

Figure 10

The first press of the SELECT DISPLAY key would display viscosity in cP (or mPa.s), see Figure

11:

Figure 11

The next press of the SELECT DISPLAY key would display SS (Shear Stress) in Dynes/Cm2 (or

Newtons/m2).

Figure 12

The next press of the SELECT DISPLAY key would display SR (Shear Rate) in 1/Sec.

Figure 13

One more press of the SELECT DISPLAY key would result in a re-display of the % (Torque)

screen, as shown in Figure 10.

Note: You may step through the display at any time. This will not interrupt any Viscometer

calculations that are in progress.

II.5 Autorange and CGS or SI Units Selection

The AUTO RANGE key allows you to determine the maximum calculated viscosity (full scale

reading) possible with the current spindle/speed setting. Pressing the key at any time will cause the

current viscosity display to change and show that maximum viscosity. The screen area formerly

displaying temperature display will now display a flashing “%100.0” to indicate this special

condition. This maximum viscosity and flashing %100.0 value will be displayed for as long as the

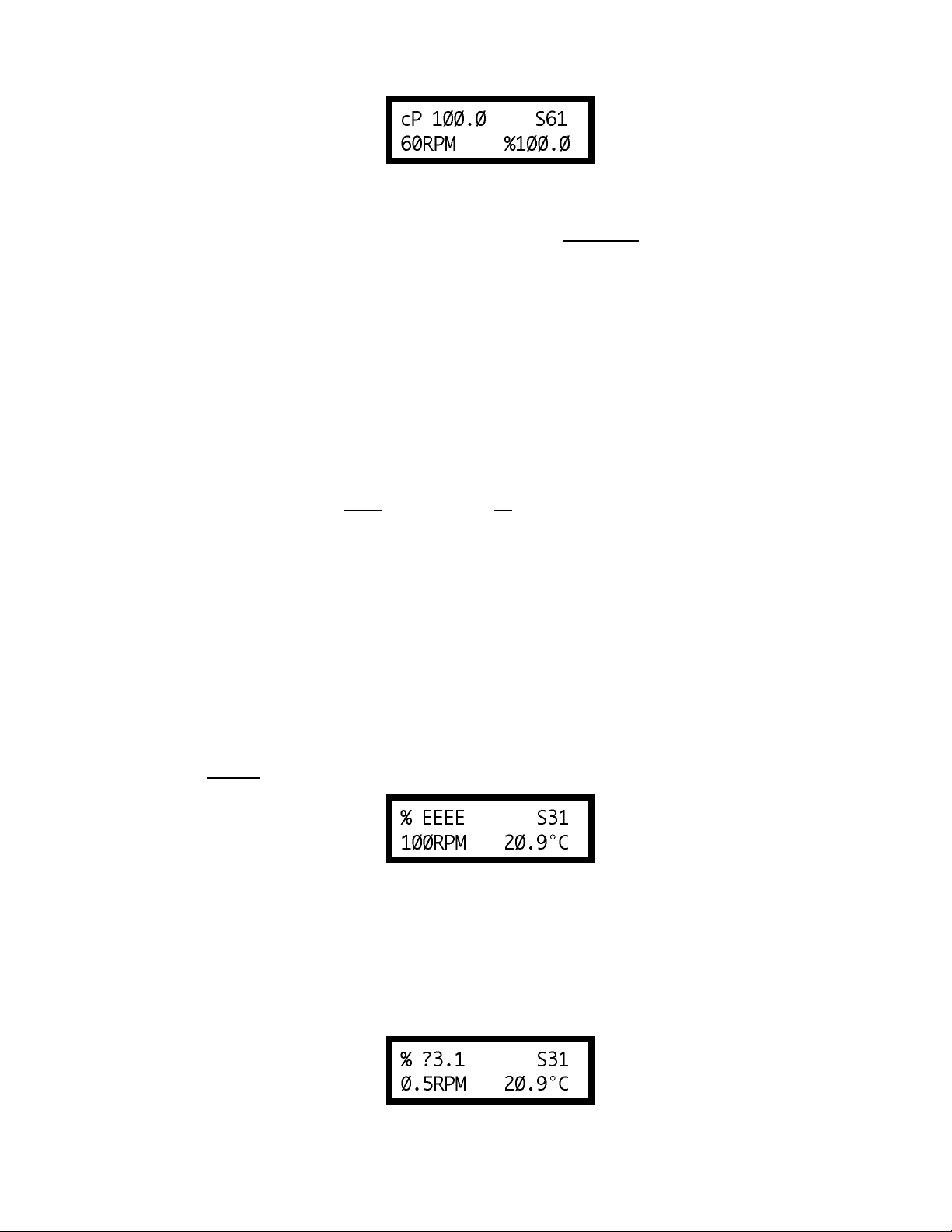

AUTO RANGE key is depressed. Figure 14 shows the AUTO RANGE function for the situation

where the No. 1 LV spindle is rotating at 60 rpm. The full scale range is 100.0 cP (or 100.0 mPa.s).

- 10 -

Page 11

Figure 14

Note: 1. If the MOTOR is OFF or the RPM is 0.0, the maximum viscosity displayed will be 0.0

cP (or 0.0 mPa.s).

2. While the Viscometer is in the Auto Range mode, any data sent to an attached printer or

computer reflects the displayed values (i.e. Auto Range values).

Pressing and holding the AUTO RANGE key during power on will enable the selectable display to

be read in either CGS or SI units. To change the unit format:

1. Turn the power off.

2. Press and hold the AUTO RANGE key and turn the power ON.

The DV-II+ will retain the unit selection when the viscometer is turned OFF.

CGS SI

Viscosity cP mPa.s

Shear Stress dyne/cm

Shear Rate sec

-1

2

N/m

sec

2

-1

Torque % %

DV-II+ Viscometers without this function can be updated. Contact Brookfield or your local

Brookfield dealer for this service.

II.6 Out of Range

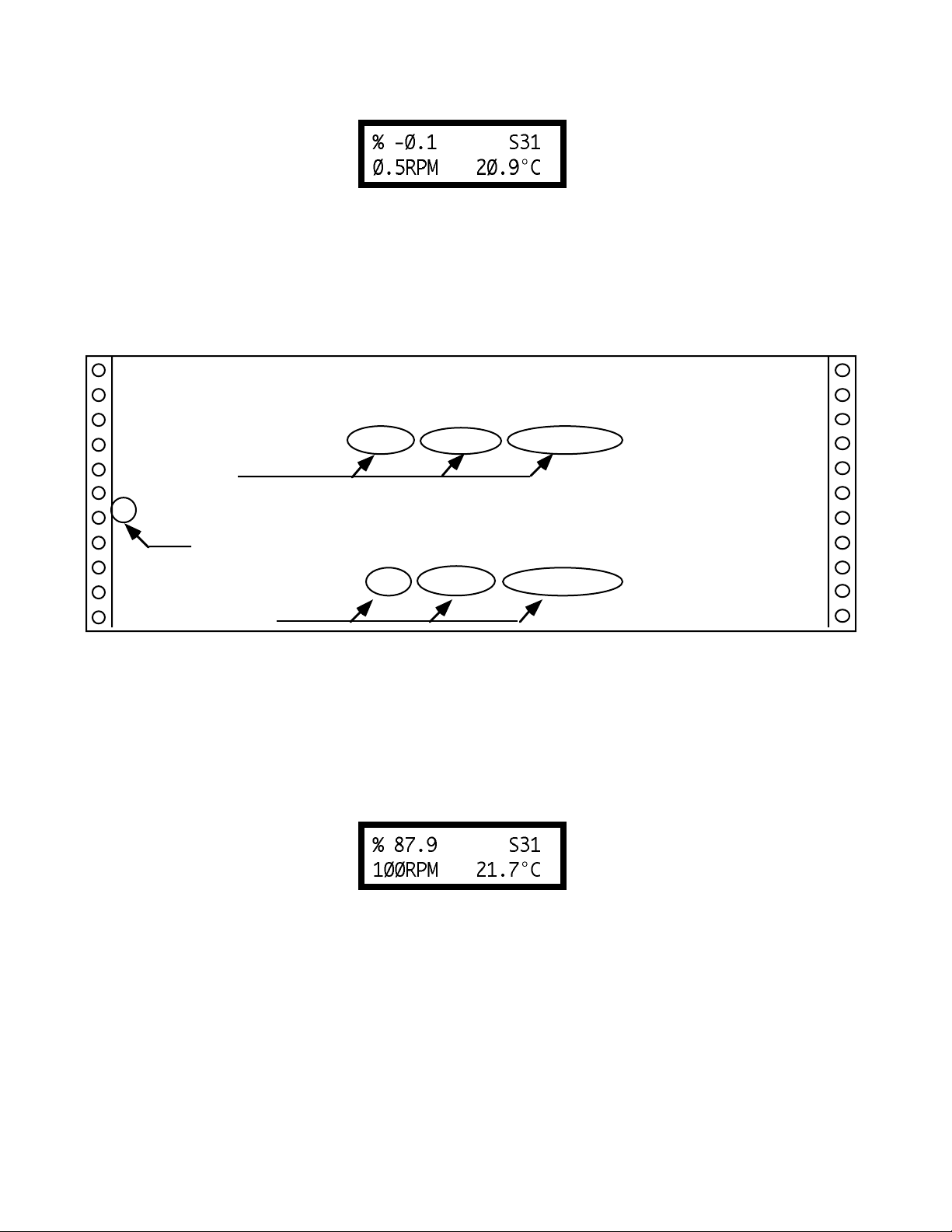

The DV-II+ gives indications for out of specification or out-of-range operation. When % (Torque)

readings exceed 100.0 % (over-range), the display changes to that shown in Figure 15:

Figure 15

EEEE will also appear when viscosity or shear stress are over range. You must change either speed

or spindle to correct this condition. If you operate at spindle speeds that produce % (Torque) below

10.0 % (under-range), the DV-II+ displays % (Torque), cP (Viscosity) and SS (Shear Stress)

preceded by a “?” as shown in Figure 16:

Figure 16

- 11 -

Page 12

Negative % (Torque) will be displayed as shown in Figure 17:

Figure 17

cP (Viscosity) and SS (Shear Stress) values will be displayed as "- - - -" when the % (Torque) is

below zero.

Figure 18 is an example of the printed output of each of the above conditions.

RPM=50 MD=RV SPDL=29 %=51.4 cP=10280 D/CM2=1285 1/SEC=12.5 T=25.5C

Normal Print String

RPM=50 MD=RV SPDL=29 %=EEEE cP=EEEE D/CM2=EEEE 1/SEC=12.5 T=25.5C

Over-Range

?RPM=50 MD=RV SPDL=29 %=5.2 cP=1040 D/CM2=130 1/SEC=12.5 T=25.5C

Under-Range

RPM=50 MD=RV SPDL=29 %=-0.1 cP=---- D/CM2=---- 1/SEC=0.0 T=25.5C

Negative Torque

Figure 18

II.7 Temperature Display

The DV-II+ will display the temperature measured by its RTD temperature probe. Temperature may

be displayed in either ˚C (Centigrade) or ˚F (Fahrenheit) units depending upon the start-up

operations. If the DV-II+ is started normally, the default temperature display will be in ˚C

(Centigrade) units as shown in the Figure 19:

Figure 19

However, if you press and hold the SELECT DISPLAY key while turning on the DV-II+ the

temperature will be displayed in ˚F (Fahrenheit).

If you turn on the DV-II+ with the temperature probe disconnected, or remove the temperature probe

at any point after power-up, the display will indicate “- - - -°C”.

The four “dashes” indicate the absence of the probe. If you were displaying temperature in

Fahrenheit units the C would be displayed as an F.

- 12 -

Page 13

TABLE 2

Temperature Accuracies For

Digital Viscometer Model DV-II+

Temperature Range Temperature Accuracy

-100°C to +150°C ±1.0°C

+150°C to +300°C ±2.0°C

II.8 Printing

The DV-II+ will print data to an attached Serial printer. The printer must be attached to the rear panel

SERIAL AND ANALOG output connector. See Appendix G for the connection requirements.

The printer must be configured as follows:

Baud Rate 9600

Data Bits 8

Stop Bits 1

Parity None

Handshake None

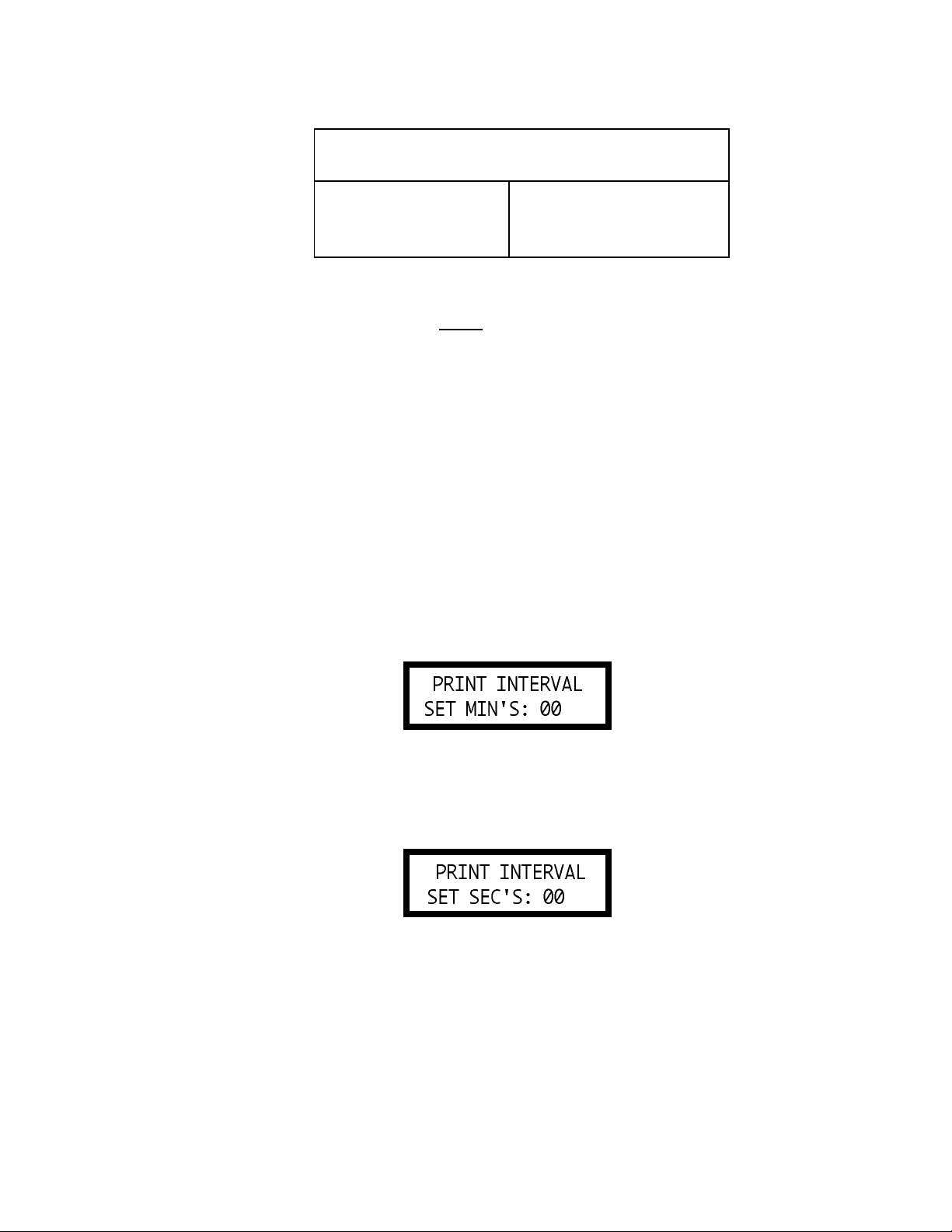

Data may be printed in two ways:

1. Pressing the PRINT key once (for less than three (3) seconds) will result in the printing of one

standard print line.

2. If the PRINT key is pressed and held for more than three (3) seconds, the user will be presented

with the following screen:

Figure 20

Here the user is being asked to enter the time interval (in minutes and seconds) between

successive print strings. First, as depicted above the user is asked for the minutes entry and then

by pressing the print key the seconds entry as shown below:

Figure 21

The print interval maximum limits are 99 minutes and 59 seconds.

3. The method for entering the minutes and seconds values is accomplished by using the UP or

DOWN arrow keys. The PRINT key is used to advance from the minutes to seconds entries and

as the exit key after the user has input the seconds value.

Note: The value for minutes or seconds must be other than zero or you will not be able to exit

this mode.

- 13 -

Page 14

4. After the final press of the PRINT key, the DV-II+ will immediately begin sending out print

strings at the selected user print rate. To stop continuous printing, the user must press and hold

the PRINT key for three (3) seconds.

5. Only after the user again presses and holds the PRINT key for three (3) seconds will you be asked

for the minute and seconds entries. The previously selected values for time interval will be

retained in EEPROM so as to be available at the next power-up. Thus, if the user wishes to again

print continuously at the previous print interval, you will only have to press the PRINT key three

(3) times; once to accept the minutes entry; once to accept the seconds entry, and once to exit and

begin printing.

Note: On DV-II+ Viscometers with serial number DE27812 or higher, the RS-232 output

is automatically active after Auto Zero is executed.

The RS-232 output MUST be active (printing continuously) when using a computer

and DVGATHER+ software.

II.9 Operation

The following general procedure is used for making viscosity measurements. Brookfield recommends the use of a 600 ml Low Form Griffin type beaker when using LV/RV/HA/HB spindles in

order to obtain data that verifies proper calibration of the DV-II+ Viscometer (see Appendix E).

1. Mount the guardleg on the DV-II+ Viscometer (LV and RV series). Attach the spindle to the

lower shaft. Lift the shaft slightly, holding it firmly with one hand while screwing the spindle

on with the other (note left-hand thread). Avoid putting side thrust on the shaft.

2. Insert and center spindle in the test material until the fluid's level is at the immersion groove in

the spindle's shaft. With a disc-type spindle, it is sometimes necessary to tilt the instrument

slightly while immersing to avoid trapping air bubbles on its surface. (You may find it more

convenient to immerse the spindle in this fashion before attaching it to the Viscometer.)

3. To make a viscosity measurement, follow the instructions in II.2 and II.3. Allow time for the

indicated reading to stabilize. The time required for stabilization will depend on the speed at

which the Viscometer is running and the characteristics of the sample fluid. For maximum

accuracy, readings below 10% should be avoided.

4. Press the MOTOR ON/OFF key and turn the motor "OFF" when changing a spindle or changing

samples. Remove spindle before cleaning.

5. Interpretation of results and the instrument's use with non-Newtonian and thixotropic materials

is discussed in the booklet, "More Solutions to Sticky Problems", and in Appendix C, Variables

in Viscosity Measurements.

II.10 Timed Modes for Viscosity Measurement

The Timed Modes allow the viscometer user to implement Timed Stop and Time to Torque

capabilities with the DV-II+ Viscometer. These features will allow the user to set up the viscometer

(i.e. select spindle and speed) and then record readings for a fixed period of time (Timed Stop) or

until a set torque value is attained (Time to Torque). A series of menus will ask the user to input

minutes and seconds (Timed Stop) or % torque (Time to Torque) and will then begin timing when

the user presses the MOTOR ON/OFF key to ON. A message will be displayed showing time

remaining (or time elapsed) and the appropriate display item (viscosity or torque) will be updated

- 14 -

Page 15

continuously during the event. Upon completion, the viscometer will display a screen stating that

the test is complete and will also display the final recorded value for the viscosity in the first case,

and the time in minutes and seconds to reach the torque limit in the second case. Pressing the UP

or DOWN arrow keys will allow alternate data to be examined and pressing any other key (except

the PRINT key) will bring the user back to the default (normal) viscometer display with the motor

OFF. If the user wishes to run another test, repeat the above steps.

II.10.1 Set Up

1. The user must first select the temperature scale in °C or °F and the display unit option: CGS or

SI.

2. The user then selects (via the UP and DOWN arrows) the spindle speed.

Note: If 0.0 RPM is the selected speed setting (the default after executing AUTOZERO) the

timed modes can be executed; however, the results will be meaningless showing no

viscosity values.

3. Next, the user selects the spindle number corresponding to the spindle attached.

4. Now, the user presses the MOTOR ON/OFF key to ensure that the motor is OFF. Setting the

motor to the OFF condition sets up the viscometer for executing the Timed Modes.

5. The user presses the SET SPEED and SELECT SPINDLE keys simultaneously to enter either

of the timed test modes. Immediately the following screen appears:

Figure 22

6. The user presses either the UP or DOWN arrow key to select the test method of choice and is

immediately presented with the corresponding opening screen.

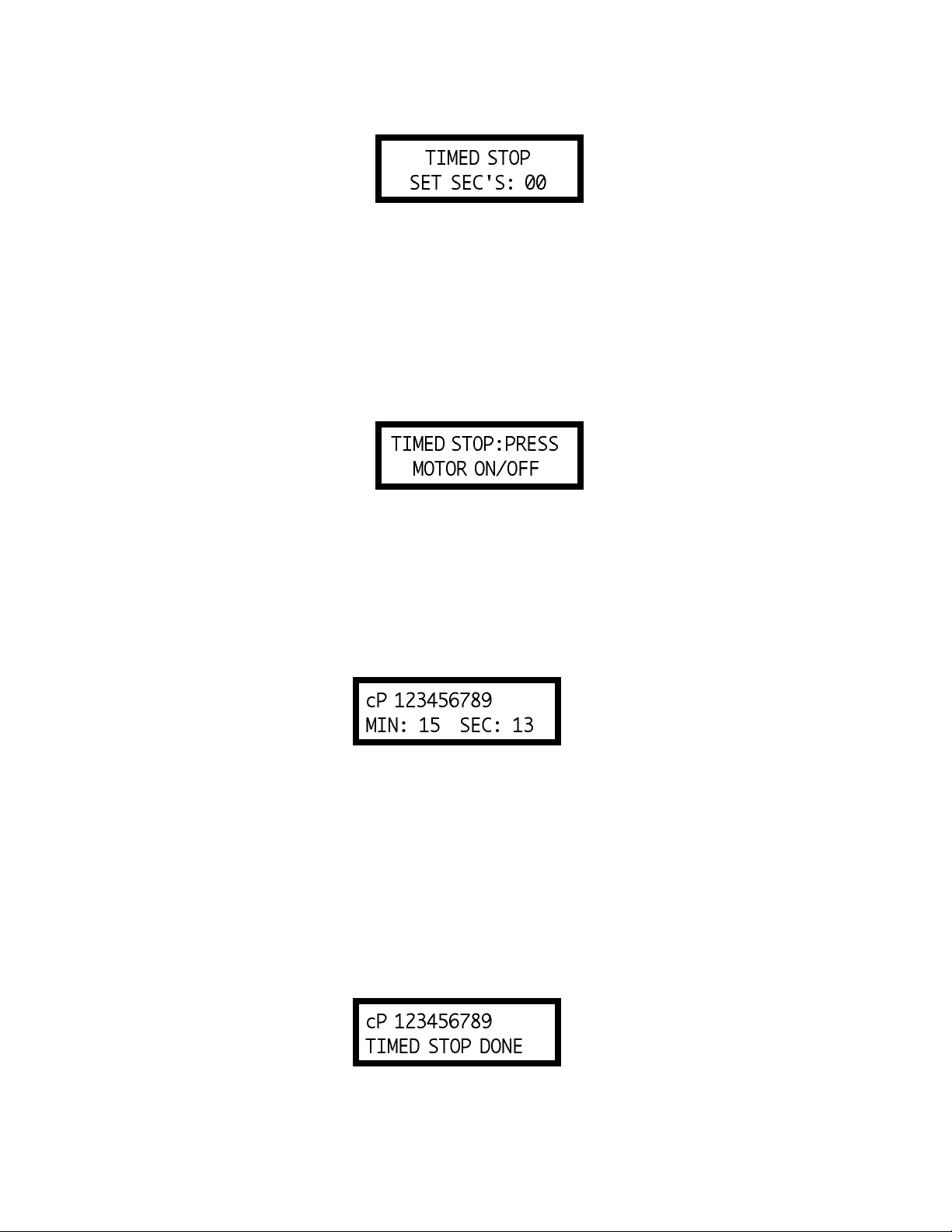

II.10.2 Timed Stop Implementation

1. After pressing the UP arrow key when in the display of Figure 23, the user is presented with the

following screen:

Figure 23

Using the UP and DOWN arrow keys, the user enters a value for the minutes portion of the time

to stop. This value can be as high as 99 minutes.

- 15 -

Page 16

2. When satisfied, the user presses the SELECT SPINDLE key again to enter the seconds setting

display:

Figure 24

Using the UP and DOWN arrow keys, the user enters a value for the seconds portion of the time

to stop. This value will be between 0 and 59 seconds.

Note: The value for minutes or seconds must be other than zero or you will not be able to exit

this mode.

The user presses the SELECT SPINDLE key one more time to end his time input at which point

the viscometer will display the following screen:

Figure 25

3. At this point, the user need only press the MOTOR ON/OFF key to begin the timed stop

operation. Any other key will abort the process and the user will have to begin again by

simultaneously pressing the SET SPEED and SELECT SPINDLE keys.

4. We will assume that the user pressed the MOTOR ON/OFF key to ON and is now presented with

the following screen for the duration of the timed run:

Figure 26

Note:

1. When this mode has begun, a press of the MOTOR ON/OFF key will interrupt the Timed

Stop sequence and return the user to normal operation.

2. Also see Comments on Print Mode Operation in Section II.10.4 for a description of print

options available on DV-II+ during the Timed Stop run.

The seconds display will decrement from 59 to zero (0) in one (1) second intervals. When seconds

reaches zero (0), the minutes value will decrement by one (1) minute. This will continue until all

of the time has elapsed at which point the viscometer will display the following screen:

Figure 27

- 16 -

Page 17

At this point, the viscometer will stop the motor and continue to display this screen until any key

except the UP or DOWN arrow key or the PRINT key is pressed. The user presses the UP or

DOWN arrow keys to view the Torque and Speed that were current at the Timed Stop completion.

This display would appear as follows:

Figure 28

The display will switch between that of Figures 27 and 28 for each press of either the UP or

DOWN arrow key. Pressing any key except the UP or DOWN arrow keys or PRINT key will

cause the viscometer to exit the Timed Stop mode and resume normal operation.

Note:

1. The user can press the PRINT key while in either of these two screens (Figures 27 and 28)

to send one standard print string to the attached printer as many times as the user presses

the PRINT key. Pressing any other key will exit this mode and return the viscometer to

normal operation.

2. For the Timed Stop method, the DV-II+ Viscometer will retain the last value for the time

interval in EEPROM so that it will become the default the next time the user elects to use

this method.

II.10.3 Time to Torque Implementation

1. After pressing the DOWN arrow key when in the display of Figure 22, the user is presented

with the following screen:

Figure 29

Using the UP and DOWN arrow keys, the user enters a value for the torque level which the

viscometer must achieve. This value can be as high as 99%.

Note: The value for torque must be other than zero or you will not be able to exit this mode.

2. The user presses the SELECT SPINDLE key one more time to end the torque input at which

point the viscometer will display the following screen:

Figure 30

The time to torque value can be as high as 99 minutes and 59 seconds.

- 17 -

Page 18

3. At this point, the user need only press the MOTOR ON/OFF key to begin the timed torque

operation. Any other key will abort the process and he will have to begin again by simultaneously

pressing the SET SPEED and SELECT SPINDLE keys.

4. We will assume that the user pressed the MOTOR ON/OFF key to ON and is now presented with

the following display for the duration of the timed torque run:

Figure 31

Note:

1. When this mode has begun, a press of the MOTOR ON/OFF key will interrupt the time

to torque operation and return the user to normal operation.

2. Also, see Comments on Print Mode Operation in Section II.10.4 for a description of

print options available on DV-II+ during the Time to Torque run.

The seconds display will increment from zero (0) to 59 in one (1) second intervals and the current

value of the viscometer torque will be updated continuously. When seconds reach 59, the minutes

value will increment by one (1) minute. This will continue until the user selected torque value

is attained at which point the viscometer will display the following screen:

Figure 32

At this point, the viscometer will stop the motor and continue to display this screen until the user

presses the UP or DOWN arrow keys or the PRINT key to view the viscosity that was current

at the Timed Torque completion. The display would appear as follows:

Figure 33

The display will switch between that of Figures 32 and 33 for each press of either the UP or

DOWN arrow key. Pressing any key except the UP or DOWN arrow key or the PRINT key will

cause the viscometer to exit the Timed Torque mode and resume normal operation.

Note:

1. The user can press the PRINT key while in either of these two screens (Figures 32 and 33)

to send one standard print string to the attached printer as many times as the user presses

the PRINT key. Pressing any other key will exit this mode and return the viscometer to

normal operation.

2. For the Time to Torque method, the DV-II+ Viscometer will retain the last entered torque

in EEPROM for use when the user elects to perform a time to torque test again.

- 18 -

Page 19

II.10.4 Comments on Print Mode Operation

The high-speed-print jumper (between pins four (4) and nine (9) on the RS-232 plug found on the

Brookfield PC Cable - Part No. DVP-80) is used exclusively with Brookfield’s DVGATHER+ and

WINGATHER software. This jumper if in place will override all of the above and will immediately

place the DV-II+ into the maximum print speed mode. When in this high speed print mode, the ability

to access either of the timed modes from the front panel will not be allowed and PRINT key presses

will be ignored. When the user returns to stand-alone operation with a printer, you will remove the

Brookfield PC cable (with the high-speed jumper) and replace it with the Brookfield Printer Cable

(Part No. DVP-81) or any standard serial printer cable which will re-enable the print modes described

above.

Additionally, the DV-II+ user can set up a desired print interval time, then set the viscometer to the

continuous print mode and finally initiate either of the timed modes of operation. While setting up

timed mode parameters, continuous print operation will cease. However, upon starting the timed

operation, the DV-II+ will output an initial data string to the printer and then continue printing data

strings (at the user defined time interval) for the duration of the timed run. At the end of the timed

run, continuous printing will again be disabled and the user may print single strings (of the final data

point) at your option until exiting the timed mode. Upon returning to the default operation mode,

continuous printing will again resume at the user selected time interval. In a similar manner, if the

user is in the one-print-per-key-press mode when entering the timed mode of operation, you will be

able to print data strings at any time during the timed mode by pressing the PRINT key when output

is desired.

- 19 -

Page 20

APPENDIX A - Cone/Plate Viscometer Set-Up

The Cone/Plate version of the DV-II+ Viscometer uses the same operating instruction procedures as

described in this manual. However, the gap between the cone and the plate must be mechanically

adjusted before measurements are made. This is done by moving the plate (built into the sample cup,

CP-44Y) up towards the cone until two small pins (one in the cone, the second mounted on the plate)

contact, and then separating (lowering) the plate 0.0005inch (0.013mm).

Note that the Cone/Plate Viscometer REQUIRES the use of a good circulating temperature bath

controlling temperature to within (

cup.

The following example assumes that the C/P Viscometer is set up on the Model A stand, and has been

zeroed with no cone attached. Cone CP-40 is used in the example. The water bath is on, set at the proper

temperature (the adjustment procedure must be done at test temperature) and is connected to the sample

cup. The Viscometer should be set at 0 rpm with MOTOR ON.

Connect sample cup ports to the water bath inlet and outlet, and set the bath to the test temperature. Allow

enough time for the bath to reach the test temperature (Figure A1).

+/-) 0.1 °C. The bath is connected to the ports on the CP-44Y sample

Adjusting

Ring

Adjustment Ring

Cup

Cup

Outlet

Outlet

Bath

Bath

Bath

Outlet

Outlet

PUMP

OUTLET

PUMP

INLET

Bath

Inlet

Inlet

Water

Bath

Cup

Cup

Inlet

Inlet

Sample

Sample

Cup

Cup

Figure A1

Remove sample cup and attach the cone to the Viscometer (Note: left hand threads), using the spindle

wrench to hold the Viscometer shaft (Figure A2). Note: Lift up gently on the spindle wrench.

- 20 -

Page 21

These Surfaces

These surfaes

Must be Clean!

must be clean!!!

Spindle Wrench

Spindle Wrench

Cone

Cone

Figure A2

Attach the sample cup and swing the clip under the cup to secure it in place. Take care to avoid hitting

the cone with the cup (Figure A3). Note: Do not add test sample during the gap setting procedure.

Do Not Hit

Do Not Hit

the CONE

the CONE

with the CUP!!!

with the CUP!

Figure A3

Set and start the DV-II+ running at 10 rpm. Choose to display "%" information by pressing SELECT

DISPLAY (see Section II.4 for details).

If the display reading jumps to 0.4% of scale (or higher), or will not settle to zero (indicating that the pins

on the cone and cup are hitting), unscrew the adjustment ring by turning it to the left (clockwise as you

look down on the instrument) until the reading settles at 0 (Figure A4).

- 21 -

Page 22

Adjusting Ring

Adjustment Ring

Index Mark

Index Mark

Turn Adjustment Ring Clockwise Until

the % Torque Display is Stable at 0.0%

Turn Adjusting Ring clockwise until the % torque

Figure A4

display is stable at 0.0%

Turn the adjustment ring to the right (counterclockwise as you look down on the instrument) in small

increments (one or two divisions of the ring) while watching the Viscometer display. Remember that

you are trying to lower the cone so that the pin in the cone touches the pin in the cup. Once you have

found this hit point, you can "back off" to create the desired gap between cone and cup. You must wait

at least 6 seconds between movements of the ring. Turn the adjusting ring until the display reading jumps

from 0 to 0.5% (HB Models) or from 0 to 1.0% (LV, RV and HA Models). This is the HIT POINT.

The cup may have to be adjusted up and down several times before this deflection is satisfactorily

reached. LV series DV-II+s will be the most sensitive (Figure A5).

Index Mark

Index Mark

Adjusting Ring

Adjustment Ring

Figure A5

- 22 -

Turn Adjustment Ring Counterclockwise

in Small Increments

Page 23

When you are satisfied the pins are just hitting (by observing acceptable % readings), make a pencil mark

on the adjustment ring directly under the index mark on the pivot housing (Figure A6).

Index

Mark

Index Mark

Adjustment

Adjusting Ring

Ring

Make a Pencil Mark

Directly Under the

Make a pencil

mark directly

under the

index mark

Index Mark

Figure A6

Turn the adjustment ring to the left (clockwise as you look down on the instrument) exactly the width

of one division from the pencil mark you have just made. This will separate the pins by 0.0005" (0.013

mm). Allowing the pins to touch constantly may cause wear and damage to the cone, cup and instrument.

The Viscometer is now mechanically set and ready for sample measurement (Figure A7).

Index Mark

Index Mark

Adjusting Ring

Adjustment

Ring

Figure A7

- 23 -

One Scale

One Scale

Division

Division

Turn Adjustment Ring Clockwise a

Distance Equal to One Scale Division

Page 24

Each of the five available cones has a specific sample volume, as shown in Table A1. Note that the

correct amount of sample fluid should cover the cone face and back up over the edge less than 1mm as

shown in (Figure A8).

Less than

Less Than

1 mm

Cone

Cone

Cup

Cup

Sample

Sample

1 mm

Figure A8

Notes: a) The cup may be removed without resetting the gap.

b) Remove the spindle from the viscometer when you clean it.

c) Reset the hit point every time the spindle is attached.

Table A1

Cone Sample Volume Cone Angle

CP-40 0.5 ml 0.8°

CP-41 2.0 ml 3.0°

CP-42 1.0 ml 1.565°

CP-51 0.5 ml 1.565°

CP-52 0.5 ml 3.0°

Calibration Procedure for Cone/Plate Viscometers:

1) Follow the procedures outlined in Appendix A for mechanically adjusting the setting of the cone

to the plate.

2) Refer to Table A1, and determine the correct sample volume required for the spindle to be

utilized.

3) Select a viscosity standard fluid that will give viscosity readings between 10% and 100% of full

scale range. Refer to Appendix B for viscosity ranges of cone spindles. Consult with Brookfield

or an authorized dealer to determine which fluid is appropriate.

- 24 -

Page 25

It is best to use a viscosity standard fluid that will be close to the maximum viscosity for a given

cone spindle/speed combination.

Example: LVDV-II+ Viscometer, Cone CP-42, Fluid 10

Having a viscosity of 9.7 cP at 25°C

At 60 RPM, the full scale viscosity range is 10.0 cP. Thus, the Viscometer reading should be

97% torque and 9.7 cP viscosity ± 0.197 (closer to ±0.2) cP. The accuracy is a combination of

Viscometer and fluid tolerance (refer to Interpretation of Calibration Test Results).

4) With the viscometer stopped, remove the sample cup and place the viscosity standard fluid into

the cup, waiting 10 minutes for temperature equilibrium.

5) Connect the sample cup to the Viscometer. Allow 10 minutes for temperature to reach

equilibrium.

6) Measure the viscosity and record the Viscometer reading in both % torque and centipoise (cP).

Note: The spindle must rotate at least five (5) times before a viscosity reading is taken.

- 25 -

Page 26

Appendix B - Viscosity Ranges

LV(#1-4) and RV,HA,HB(#1-7) Viscometers

Viscosity Range (cP)

Viscometer Minimum Maximum

LVDV-II+ 15 2,000,000

RVDV-II+ 100 13,300,000

HADV-II+ 200 26,600,000

HBDV-II+ 800 106,400,000

Small Sample Adapter and Thermosel

SSA & T-Sel Shear Rate Viscosity (cP)

Spindle (1/SEC) LVDV-II+

16 0 - 29.0 120 - 400,000

18 0 - 132.0 3 - 10,000

25 0 - 22.0 480 - 1,600,000

31 0 - 34.0 30 - 100,000

34 0 - 28.0 60 - 200,000

81 0 - 129.0 3.4 - 10,000

82 0 - 129.0 3.4 - 10,000

83 0 - 129.0 11.3 - 37,898

Viscosity (cP)

SSA/T-Sel Shear Rate

Spindle (1/SEC) RVDV-II+ HADV-II+ HBDV-II+

14 0 - 40.0 1,250 - 4,165,000 2,500 - 8,330,000 10,000 - 33,360,000

15 0 - 48.0 500 - 1,660,000 1,000 - 3,320,000 4,000 - 13,280,000

21 0 - 93.0 50 - 167,000 100 - 334,000 400 - 1,336,000

27 0 - 34.0 250 - 830,000 500 - 1,660,000 2,000 - 6,640,000

28 0 - 28.0 500 - 1,660,000 1,000 - 3,320,000 4,000 - 13,280,000

29 0 - 25.0 1,000 - 3,330,000 2,000 - 6,660,000 8,000 - 26,640,000

81 0 - 129.0 36.5 - 10,000 73.0 - 10,000 292.0 - 10,000

82 0 - 129.0 36.5 - 10,000 73.0 - 10,000 292.0 - 10,000

83 0 - 129.0 121.3 - 50,000 242.6 - 50,000 970.4 - 50,000

UL Adapter

Viscosity (cP)

UL Shear Rate

Spindle (1/SEC) LVDV-II+ RVDV-II+ HADV-II+ HBDV-II+

YULA-15 or 15Z 0 - 122.4 1.0 - 2,000 6.4 - 2,000 12.8 - 2,000 51.2 - 2,000

ULA-DIN-Y 0 - 129.1 1.0 - 3,800 10.6 - 5,000 21.2 - 5,000 84.8 - 2,000

- 26 -

Page 27

DIN Adapter Accessory

Viscosity (cP)

DAA Shear Rate

Spindle (1/SEC) LVDV-II+ RVDV-II+ HADV-II+ HBDV-II+

85 0 - 129 1.2 - 3,812 12.2 - 5,000 24.4 - 5,000 97.6 - 5,000

86 0 - 129 3.4 - 10,000 36.5 - 10,000 73.0 - 10,000 292.0 - 10,000

87 0 - 129 11.3 - 37,898 121.3 - 50,000 242.6 - 50,000 970.4 - 50,000

Spiral Adapter

Viscosity (cP)

Spiral Shear Rate

Spindle (1/SEC) LVDV-II+ RVDV-II+ HADV-II+ HBDV-II+

SA-70 .677 - 67.7 98.4 - 98,416 1,050- 1,050,000 2,100 - 2,100,000 8,400 - 8,400,000

(1 - 100 RPM)

The maximum viscosity ranges correspond to a spiral spindle rotational speed of 1.0 RPM. Lower

spindle speeds are possible but the pumping action within the spiral chamber may not be sufficient to

provide meaningful vicosity data.

Cone/Plate Viscometer

Cone Shear Rate

Viscosity (cP)

Spindle (1/SEC) LVDV-II+C/P RVDV-II+C/P HADV-II+C/P HBDV-II+C/P

CP-40 0.0 -750 0.30 - 1,028 3.3 - 10,900 6.6 - 21,800 26.2 - 87,200

CP-41 0.0 -200 1.15 - 3,840 12.3 - 41,000 24.6 - 82,000 98.4 - 328,000

CP-42 0.0 -384 0.60 - 2,000 6.4 - 21,300 12.8 - 42,600 51.2 - 170,400

CP-51 0.0 -384 4.85 - 16,180 51.2 - 171,000 102.4 - 342,000 409.6 - 1,368,000

CP-52 0.0 -200 9.33 - 31,100 98.3 - 328,000 196.6 - 654,000 786.4 - 2,624,000

Helipath with T-Bar Spindles

T-Bar

Viscosity (cP)

Spindle LVDV-II+ RVDV-II+ HADV-II+ HBDV-II+

T-A 156 - 62,400 2,000 - 400,000 4,000 - 800,000 16,000 - 3,200,000

T-B 312 - 124,800 4,000 - 800,000 8,000 - 1,600,000 32,000 - 6,400,000

T-C 780 - 312,000 10,000 - 2,000,000 20,000 - 4,000,000 80,000 - 16,000,000

T-D 1,560 - 624,000 20,000 - 4,000,000 40,000 - 8,000,000 160,000 - 32,000,000

T-E 3,900 - 1,560,000 50,000 -10,000,000 100,000 - 20,000,000 400,000 - 80,000,000

T-F 7,800 - 3,120,000 100,000 -20,000,000 200,000 - 40,000,000 800,000 -160,000,000

In taking viscosity measurements with the DV-II+ Viscometer there are two considerations which

pertain to the low viscosity limit of effective measurement.

1) Viscosity measurements should be accepted within the equivalent % Torque Range from

10% to 100% for any combination of spindle/speed rotation.

2) Viscosity measurements should be taken under laminar flow conditions, not under turbulent

flow conditions.

The first consideration has to do with the precision of the instrument. All DV-II+ Viscometers have a

full scale range precision of (+/-) 1% of any spindle/speed rotation. We discourage taking readings below

- 27 -

Page 28

10% of range because the potential viscosity error of (+/-) 1% is a relatively high number compared to

the instrument reading.

The second consideration involves the mechanics of fluid flow. All rheological measurements of fluid

flow properties should be made under laminar flow conditions. Laminar flow is flow wherein all particle

movement is in layers directed by the shearing force. For rotational systems, this means all fluid

movement must be circumferential. When the inertial forces on the fluid become too great, the fluid can

break into turbulent flow wherein the movement of fluid particles becomes random and the flow can not

be analyzed with standard math models. This turbulence creates a falsely high Viscometer reading with

the degree of non-linear increase in reading being directly related to the degree of turbulence in the fluid.

For the following geometries, we have found that an approximate transition point to turbulent flow

occurs:

1) No. 1 LV Spindle: 15 cP at 60 RPM

2) No. 1 RV Spindle: 100 cP at 50 RPM

3) UL Adapter: 0.85 cP at 60 RPM

Turbulent conditions will exist in these situations whenever the RPM/cP ratio exceeds the values listed

above.

- 28 -

Page 29

Appendix C - Variables in Viscosity Measurements

As with any instrument measurement, there are variables that can affect a Viscometer measurement.

These variables may be related to the instrument (Viscometer), or the test fluid. Variables related to the

test fluid deal with the rheological properties of the fluid, while instrument variables would include the

Viscometer design and the spindle geometry system utilized.

Rheological Properties

Fluids have different rheological characteristics that can be described by Viscometer measurements. We

can then work with these fluids to suit our lab or process conditions.

There are two categories of fluids:

Newtonian - These fluids have the same viscosity at different Shear Rates (different

RPMs) and are called Newtonian over the Shear Rate range they are

measured.

Non-Newtonian - These fluids have different viscosities at different shear rates (different

RPMs). They fall into two groups:

1) Time Independent non-Newtonian

2) Time Dependent non-Newtonian

The time dependency is the time they are held at a given Shear Rate (RPM). They are non-Newtonian,

and when you change the Viscometer spindle speed, you get a different viscosity.

Time Independent

Pseudoplastic - A pseudoplastic material displays a decrease in viscosity with an increase in

shear rate, and is also known as “shear thinning”. If you take Viscometer

readings from a low to a high RPM and then back to the low RPM, and the

readings fall upon themselves, the material is time independent pseudoplastic

and shear thinning.

Time Dependent

Thixotropic - A thixotropic material has decreasing viscosity under constant shear rate. If

you set a Viscometer at a constant speed recording cP values over time and

find that the cP values decrease with time, the material is thixotropic.

Brookfield publication, “More Solutions to Sticky Problems” includes a more detailed discussion of

rheological properties and non-Newtonian behavior.

Viscometer Related Variables

Most fluid viscosities are found to be non-Newtonian. They are dependent on Shear Rate and the spindle

geometry conditions. The specifications of the Viscometer spindle and chamber geometry will affect

the viscosity readings. If one reading is taken at 2.5 rpm, and a second at 50 rpm, the two cP values

produced will be different because the readings were made at different shear rates. The faster the spindle

speed, the higher the shear rate.

The shear rate of a given measurement is determined by: the rotational speed of the spindle, the size and

shape of the spindle, the size and shape of the container used and therefore the distance between the

- 29 -

Page 30

container wall and the spindle surface.

A repeatable viscosity test should control or specify the following:

1) Test temperature

2) Sample container size (or spindle/chamber geometry)

3) Sample volume

4) Viscometer model

5) Spindle used (if using LVDV-II+ (#1-4) or RVDV-II+ (#1-7) attach the guard leg)

6) Test speed or speeds (or the shear rate)

7) Length of time or number of spindle revolutions to record viscosity.

- 30 -

Page 31

Appendix D - Spindle and Model Codes

Each spindle has a two digit entry code which is entered via the keypad on the DV-II+. The entry code

allows the DV-II+ to calculate Viscosity, Shear Rate and Shear Stress values.

Each spindle has two constants which are used in these calculations. The Spindle Multiplier Constant

(SMC) used for viscosity and shear stress calculations, and the Shear Rate Constant (SRC), used for

shear rate and shear stress calculations. Note that where SRC = 0, no shear rate/shear stress calculations

are done and the data displayed is zero (0) for these functions.

Table D1

SPINDLE ENTRY CODE SMC SRC

RV1 01 1 0

RV2 02 4 0

RV3 03 10 0

RV4 04 20 0

RV5 05 40 0

RV6 06 100 0

RV7 07 400 0

HA1 01 1 0

HA2 02 4 0

HA3 03 10 0

HA4 04 20 0

HA5 05 40 0

HA6 06 100 0

HA7 07 400 0

HB1 01 1 0

HB2 02 4 0

HB3 03 10 0

HB4 04 20 0

HB5 05 40 0

HB6 06 100 0

HB7 07 400 0

LV1 61 6.4 0

LV2 62 32 0

LV3 63 128 0

LV4 64 640 0

LV5 65 1280 0

Spiral 70 105 0.677

T-A 91 20 0

T-B 92 40 0

T-C 93 100 0

T-D 94 200 0

T-E 95 500 0

T-F 96 1000 0

ULA 00 0.64 1.223

TSEL-DIN-81 81 3.7 1.29

SSA-DIN-82 82 3.75 1.29

SSA-DIN-83 83 12.09 1.29

ULA-DIN-85 85 1.22 1.29

ULA-DIN-86 86 3.65 1.29

ULA-DIN-87 87 12.13 1.29

- 31 -

Page 32

Table D1 (continued)

SPINDLE ENTRY CODE SMC SRC

SC4-14 14 125 0.4

SC4-15 15 50 0.48

SC4-16 16 128 0.2929

SC4-18 18 3.2 1.32

SC4-21 21 5 0.93

SC4-25 25 512 0.22

SC4-27 27 25 0.34

SC4-28 28 50 0.28

SC4-29 29 100 0.25

SC4-31 31 32 0.34

SC4-34 34 64 0.28

SC4-37 37 25 0.36

CP40 40 0.327 7.5

CP41 41 1.228 2

CP42 42 0.64 3.8

CP51 51 5.12 3.84

CP52 52 9.83 2

Table D2 lists the model codes and spring torque constants for each Viscometer model.

Table D2

MODEL CODE

MODEL TK

LVDV-II+ 0.09373 LV

2.5xLVDV-II+ 0.2343 4L

5xLVDV-II+ 0.4686 5L

1/4 RVDV-II+ 0.25 1R

1/2 RVDV-II+ 0.5 2R

RVDV-II+ 1 RV

HADV-II+ 2 HA

2xHADV-II+ 4 3A

2.5xHADV-II+ 5 4A

HBDV-II+ 8 HB

2xHBDV-II+ 16 3B

2.5xHBDV-II+ 20 4B

5xHBDV-II+ 40 5B

ON DV-II+ SCREEN

- 32 -

Page 33

The full scale viscosity range for any DV-II+ model and spindle may be calculated using the

equation:

Full Scale Viscosity Range [cP] = TK SMC

*

10,000

*

RPM

Where:

TK = DV-II+ Torque Constant from Table D2

SMC = Spindle Multiplier Constant from Table D1

The Shear Rate calculation is:

Shear Rate (1/

) = SRC * RPM

Sec

Where:

SRC = Shear Rate Constant from Table D1

- 33 -

Page 34

Appendix E - Calibration Procedures

The accuracy of the DV-II+ is verified using viscosity standard fluids which are available from

Brookfield Engineering Laboratories or your local Brookfield agent. Viscosity standards are Newtonian,

and therefore, have the same viscosity regardless of spindle speed (or shear rate). Viscosity standards,

calibrated at 25°C, are shown in Table E1.

Container size: For Viscosity Standards <30,000 cP, use a 600 ml Low Form Griffin Beaker

having a working volume of 500 ml.

For Viscosity Standards ≥30,000 cP, use the fluid container.

Inside Diameter: 3.25"(8.25cm)

Height: 4.75"(12.1cm)

Note: Container may be larger, but may not be smaller.

Temperature: As stated on the fluid standard label: (±) 0.1°C

Conditions: The DV-II+ should be set according to the operating instructions. The water bath

should be stabilized at test temperature. Viscometers with the letters “LV” or

“RV” in the model designation should have the guard leg attached.

Table E1

Normal 25°C Standard Fluids

5 5,000 HT-30,000

10 12,500 HT-60,000

50 30,000 HT-100,000

100 60,000

500 100,000

1,000

Brookfield Viscosity Standard Fluid General Information

We recommend that Brookfield Viscosity Standard Fluids be replaced on an annual basis, one year

from date of initial use. These fluids are pure silicone and are not subject to change over time.

However, exposure to outside contaminants through normal use requires replacement on an annual

basis. Contamination may occur by the introduction of solvent, standard of different viscosity or

other foreign material.

High Temperature Standard Fluids

Three Viscosity/Temperatures**Viscosity (cP) Viscosity (cP)

**25°C, 93.3°C, 149°C

Refer to Brookfield catalog

for more information.

Viscosity Standard Fluids may be stored under normal laboratory conditions. Disposal should be in

accordance with state, local and federal regulations as specified on the material safety data sheet.

Brookfield Engineering Laboratories does not recertify Viscosity Standard Fluids. We will issue

duplicate copies of the Certificate of Calibration for any fluid within two years of the purchase date.

- 34 -

Page 35

Brookfield Viscosity Standard Fluids are reusable provided they are not contaminated. Normal

practice for usage in a 600 ml beaker is to return the material from the beaker back into the bottle.

When using smaller volumes in accessories such as Small Sample Adapter, UL Adapter or

Thermosel, the fluid is normally discarded.

Calibration Procedure for LV(#1-4) and RV,HA,HB(#1-7) Brookfield Spindles

1) Place the viscosity standard fluid (in the proper container) into the water bath.

2) Lower the DV-II+ into measurement position (with guard leg if LV or RV series Viscometer

is used).

3) Attach the spindle to the Viscometer. If you are using a disk-shaped spindle, avoid trapping air

bubbles beneath the disk by first immersing the spindle at an angle, and then connecting it to the

Viscometer.

4) The viscosity standard fluid, together with the spindle, should be immersed in the bath for a

minimum of 1 hour, stirring the fluid periodically, prior to taking measurements.

5) After 1 hour, check the temperature of the viscosity standard fluid with an accurate thermometer.

6) If the fluid is at test temperature (±0.1°C of the specified temperature, normally 25°C), measure

the viscosity and record the Viscometer reading.

Note: The spindle must rotate at least five (5) times before readings are taken.

7) The viscosity reading should equal the cP value on the fluid standard to within the combined

accuracies of the Viscometer and the viscosity standard (as discussed in the section entitled,

Interpretation of Calibration Test Results, page 37).

Calibration Procedure for a Small Sample Adapter

When a Small Sample Adapter is used, the water jacket is connected to the water bath and the water is

stabilized at the proper temperature:

1) Put the proper amount of viscosity standard fluid into the sample chamber. The amount varies

with each spindle/chamber combination. (Refer to the Small Sample Adapter instruction

manual).

2) Place the sample chamber into the water jacket.

3) Put the spindle into the test fluid and attach the extension link, coupling nut and free hanging

spindle (or directly attach the solid shaft spindle) to the DV-II+.

4) Allow 30 minutes for the viscosity standard, sample chamber and spindle to reach test

temperature.

5) Measure the viscosity and record the Viscometer reading.

Note: The spindle must rotate at least five (5) times before a viscosity reading is taken.

Calibration Procedure for a Thermosel System

When a Thermosel System is used, the controller stabilizes the Thermo Container at the test temperature.

- 35 -

Page 36

1) Put the proper amount of HT viscosity standard fluid into the HT-2 sample chamber. The

amount varies with the spindle used. (Refer to the Thermosel instruction manual).

2) Place the sample chamber into the Thermo Container.

3) Put the spindle into the test fluid and attach the extension link, coupling nut and free hanging

spindle (or directly attach the solid shaft spindle) to the DV-II+.

4) Allow 30 minutes for the viscosity standard, sample chamber and spindle to reach test

temperature.

5) Measure the viscosity and record the Viscometer reading.

Note: The spindle must rotate at least five (5) times before a viscosity reading is taken.

Calibration Procedure using UL or DIN UL Adapters

When a UL or DIN UL Adapter is used, the water bath is stabilized at the proper temperature:

1) Put the proper amount of viscosity standard fluid into the UL Tube. (Refer to the UL Adapter

instruction manual).

2) Attach the spindle (with extension link and coupling nut) onto the DV-II

3) Attach the tube to the mounting channel.

4) Lower the tube into the water bath reservoir, or if using the ULA-40Y water jacket, connect the

inlet/outlets to the bath external circulating pump.

5) Allow 30 minutes for the viscosity standard, sample chamber and spindle to reach test

temperature.

6) Measure the viscosity and record the Viscometer reading.

Note: The spindle must rotate at least five (5) times before a viscosity reading is taken.

Calibration Procedure using a Helipath Stand and T-Bar Spindles

When a Helipath Stand and T-Bar spindles are used:

Remove the T-bar spindle and select a standard LV(#1-4) or RV,HA,HB(#1-7) spindle. Follow the

procedures for LV(#1-4) and RV,HA,HB(#1-7) Brookfield spindles outlined above.

T-Bar spindles should not be used for verifying calibration of the DV-II+ Viscometer.

Calibration Procedure for Spiral Adapter

+.

1) Place the viscosity standard fluid (in the proper container) into the water bath.

2) Attach the spindle to the viscometer. Attach chamber (SA-1Y) and clamp to the viscometer.

3) Lower the DV-I+ into measurement position. Operate the viscometer at 50 or 60 RPM until the

chamber is fully flooded.

- 36 -

Page 37

4) The viscosity standard fluid, together with the spindle, should be immersed in the bath for a

minimum of 1 hour, stirring the fluid periodically (operate at 50 or 60 RPM periodically), prior

to taking measurements.

5) After 1 hour, check the temperature of the viscosity standard fluid with an accurate thermometer.

6) If the fluid is at test temperature (+/- 0.1°C of the specified temperature, normally 25°C),

measure the viscosity and record the viscometer reading.

Note: The spindle must rotate at least five (5) times for one minute, whichever is greater

before readings are taken.

7) The viscosity reading should equal the cP value on the viscosity fluid standard to within the

combined accuracies of the viscometer and the standard (as discussed in the section entitled,

Interpretation of Calibration Test Results).

Calibration Procedure for Cone/Plate Viscometers:

1) Follow the procedures outlined in Appendix A for mechanically adjusting the setting of the cone

to the plate.

2) Refer to Appendix A, Table 1, and determine the correct sample volume required for the spindle

to be utilized.

3) Select a viscosity standard fluid that will give viscosity readings between 10% and 100% of full

scale range. Refer to Appendix B for viscosity ranges of cone spindles. Consult with Brookfield

or an authorized dealer to determine which fluid is appropriate.

It is best to use a viscosity standard fluid that will be close to the maximum viscosity for a given

cone spindle/speed combination.

Example: LVDV-II+ Viscometer, Cone CP-42, Fluid 10

Having a viscosity of 9.7 cP at 25°C

At 60 RPM, the full scale viscosity range is 10.0 cP. Thus, the Viscometer reading should be

97% torque and 9.7 cP viscosity ± 0.197 (closer to ±0.2) cP. The accuracy is a combination of

Viscometer and fluid tolerance (refer to Interpretation of Calibration Test Results).

4) With the viscometer stopped, remove the sample cup and place the viscosity standard fluid into

the cup, waiting 10 minutes for temperature equilibrium.

5) Connect the sample cup to the Viscometer. Allow 10 minutes for temperature to reach

equilibrium.

6) Measure the viscosity and record the Viscometer reading in both % torque and centipoise (cP).

Note: The spindle must rotate at least five (5) times before a viscosity reading is taken.

Interpretation of Calibration Test Results:

When verifying the calibration of the DV-II+, the instrument and viscosity standard fluid error must be

combined to calculate the total allowable error.

The DV-II+ is accurate to (+/-) 1% of any full scale spindle/speed viscosity range.

- 37 -

Page 38

Brookfield Viscosity Standards Fluids are accurate to (+/-) 1% of their stated value.

Example: Calculate the acceptable range of viscosity using RVDV-II+ with RV-3 Spindle at 2

RPM; Brookfield Standard Fluid 12,500 with a viscosity of 12,257 cP at 25°C:

1) Calculate full scale viscosity range using the equation:

Full Scale Viscosity Range [cP] = TK SMC

*

10,000

*

RPM

Where: TK = 1.0 from Table D2

SMC = 10 from Table D1

Full Scale Viscosity Range = = 50, 000 cP

1 10 10,000

**

2

The viscosity is accurate to (+/-) 500 cP (which is 1% of 50,000)

2) The viscosity standard fluid is 12,257 cP. Its accuracy is (+/-)1% of 12,257 or

(+/-)122.57 cP.

3) Total allowable error is (122.57 + 500) cP = (+/-) 622.57 cP.

4) Therefore, any viscosity reading between 11,634.4 and 12,879.6 cP indicates that the Viscometer

is operating correctly. Any reading outside these limits may indicate a Viscometer problem.

Contact the Brookfield technical sales department or your local Brookfield dealer/distributor with

test results to determine the nature of the problem.

The Brookfield Guardleg

The guard leg was originally designed to protect the spindle during use. The first applications of the Brookfield

Viscometer included hand held operation while measuring fluids in a 55-gallon drum. It is clear that under those

conditions the potential for damage to the spindle was great. Original construction included a sleeve that protected the

spindle from side impact. Early RV guard legs attached to the dial housing and LV guard legs attached to the bottom

of the pivot cup with a twist and lock mechanism.

The current guard leg is a band of metal in the shape of the letter U with a bracket at the top that attaches to the pivot

cup of a Brookfield Viscometer/Rheometer. Because it must attach to the pivot cup, the guard leg cannot be used with

a Cone/Plate instrument. A guard leg is supplied with all LV and RV series instruments, but not with the HA or HB series.

It’s shape (shown in Figure 1) is designed to accommodate the spindles of the appropriate spindle set; therefore, the RV

guard leg is wider than the LV due to the large diameter of the RV #1 spindle. They are not interchangeable.

The calibration of the Brookfield Viscometer/Rheometer is determined using a 600 ml Low Form Griffin Beaker. The

calibration of LV and RV series instruments includes the guard leg. The beaker wall (for HA/HB instruments) or the

guard leg (for LV/RV instruments) define what is called the "outer boundary" of the measurement. The spindle factors

for the LV, RV, and HA/HB spindles were developed with the above boundary conditions. The spindle factors are used

to convert the instrument torque (expressed as the dial reading or %Torque value) into centipoise. Theoretically, if

measurements are made with different boundary conditions, e.g., without the guard leg or in a container other than 600

ml beaker, then the spindle factors found on the Factor Finder cannot be used to accurately calculate an absolute viscosity.

Changing the boundary conditions does not change the viscosity of the fluid, but it does change how the instrument torque

- 38 -

Page 39

is converted to centipoise. Without changing the spindle factor to suit the new boundary conditions, the calculation from

instrument torque to viscosity will be incorrect.

Practically speaking, the guard leg has the greatest effect when used with the #1 & #2 spindles of the LV and RV spindle

sets. Any other LV (#3 & #4) or RV (#3 - #7) spindle can be used in a 600 ml beaker with or without the guard leg to

produce correct results. The HA and HB series Viscometers/Rheometers are not supplied with guard legs in order to

reduce the potential problems when measuring high viscosity materials. HA/HB spindles #3 through #7 are identical

to those spindle numbers in the RV spindle set. The HA/HB #1 & #2 have slightly different dimensions than the

corresponding RV spindles. This dimensional difference allows the factors between the RV and HA/HB #1 spindles

to follow the same ratios as the instrument torque even though the boundary conditions are different.

The recommended procedures of using a 600 ml beaker and the guard leg are difficult for some customers to follow. The

guard leg is one more item to clean. In some applications the 500 ml of test fluid required to immerse the spindles in

a 600 ml beaker is not available. In practice, a smaller vessel may be used and the guard leg is removed. The Brookfield

Viscometer/Rheometer will produce an accurate and repeatable torque reading under any measurement circumstance.

However, the conversion of this torque reading to centipoise will only be correct if the factor used was developed for

those specific conditions. Brookfield has outlined a method for recalibrating a Brookfield Viscometer/Rheometer to any

measurement circumstance in More Solutions to Sticky Problems, Section 3.3.10. It is important to note that for many

viscometer users the true viscosity is not as important as a repeatable day to day value. This repeatable value can be

obtained without any special effort for any measurement circumstance. But, it should be known that this type of torque

reading will not convert into a correct centipoise value when using a Brookfield factor if the boundary conditions are

not those specified by Brookfield.

The guard leg is a part of the calibration check of the Brookfield LV and RV series Viscometer/Rheometer. Our

customers should be aware of its existence, its purpose and the effect that it may have on data. With this knowledge,

the viscometer user may make modifications to the recommended method of operation to suit their needs.

RV Guardleg

LV Guardleg

- 39 -

Page 40

Appendix F - Special Speed Sets

The following special speeds sets are available from Brookfield Engineering Laboratories. All

speeds are in units of RPM.

Table F1

RPM

Step SS200 SS150 SS100 SS50 SS25 SSINT

1 0.0 0.0 0.0 0.0 0.0 0.0

2 1.0 0.8 0.5 0.2 0.1 0.3

3 1.4 1.1 0.7 0.3 0.2 0.5

4 1.8 1.4 0.9 0.4 0.3 0.6

5 2.0 1.5 1.0 0.5 0.4 1.0

6 4.0 3.0 2.0 1.0 0.5 1.5

7 6.0 4.0 3.0 1.5 0.7 2.0

8 8.0 6.0 4.0 2.0 1.0 2.5

9 10 7.5 5.0 2.5 1.2 3.0

10 20 15 10 5.0 2.5 4.0

11 40 30 20 10 5.0 5.0

12 60 40 30 15 7.5 6.0

13 80 60 40 20 10 10

14 100 75 50 25 12 12

15 120 90 60 30 15 20

16 140 105 70 35 17 30

17 160 120 80 40 20 50

18 180 135 90 45 22 60

19 200 150 100 50 25 100

SPEED SET (RPM)

Please consult Brookfield Engineering or your local dealer/distributor for any special speed requirements not addressed by either the standard speed sets shown in Table 1 (page 8) or in Table F1.

- 40 -

Page 41

Appendix G - Communications

When using the Brookfield Computer Cable (Brookfield part # DVP-80), the DV-II+ will output a

data string at a rate of approximately 2.5 times per second. When using the Brookfield Printer Cable

(Brookfield Part No. DVP-81), the output rate is 1.0 times per second. The DV-II+ uses the following RS-232 parameters to output these strings:

Baud Rate 9600

Data Bits 8

Stop Bits 1

Parity None

Handshake None

The following formulas should be used to calculate and display the Viscometer data after each

packet of data is obtained from the DV-II+.

Viscosity (cP) = 100 * TK * SMC * Torque

RPM

Shear Rate (1/

Shear Stress (

Where:

RPM = Current Viscometer spindle speed in RPM

TK = Viscometer torque constant from Appendix D, Table D2.

SMC = Current spindle multiplier constant from Appendix D, Table D1.

SRC = Current spindle shear rate constant from Appendix D, Table D1.

Torque = Current Viscometer torque (%) expressed as a number between 0 and 100.

As an example, consider an LV Viscometer using an SC4-31 spindle, running at 30 RPM and

currently returning a Torque of 62.3 (%). First we list all of the given data and include model and

spindle constants from Appendix D, Tables D1 and D2:

RPM = 30 from the example statement.

TK = 0.09373 from Appendix D for an LV Viscometer.

SMC = 32.0 from Appendix D for a type SC4-31 spindle.

SRC = 0.34 from Appendix D for a type SC4-31 spindle.

Torque = 62.3 from the example statement.

Applying this data to the above equations yields:

Viscosity (cP) =

)=RPM * SRC

Sec

Dynes

2

/

)=TK * SMC * SRC * Torque

Cm

100 * TK * SMC * Torque

RPM

Shear Rate (1/

= 100 * 0.09373 * 32.0 * 62.3

30

= 622.9 cP

)=RPM * SRC

Sec

= 30 * 0.34

= 10.2 1/

Sec

- 41 -

Page 42

Shear Stress (

Dynes

2

/

)=TK * SMC * SRC * Torque

Cm

= 0.09373 * 32.0 * 0.34 * 62.3

= 63.5

Dynes

/

Cm

2

The following is a program written in BASIC that receives these strings, parses out the appropriate