Bosch LV009, LV012, LV007, LV018, LV024 Installation And Maintenance Manual

...

LV MODEL

Installation and Maintenance Manual

8733944336 (2016/09)

2 | LV Heat Pump Series

CONTENTS

Key to Symbols...................................................................3

Safety Warnings.................................................................3

Model Nomenclature...........................................................4

General Description............................................................5

Moving and Storage............................................................5

Installation.........................................................................5

Step1 Check Job Site....................................................5

Step 2 Check Unit.........................................................5

Step 3 Locate Unit...................... ...................................6

Step 4 Mount The Unit...................................................7

Hanging Bracket Kit.......................................................8

Step 5 Check Duct System......... .....................................9

Step 6 Install Condensate Drain................. ......................9

Step 7 Pipe Connections..............................................10

Step 8 Wire Power Supply............................................10

Step 9 Wire Field Controls............................................12

Unit Controls ECM-UPM....................................................12

ECM Interface Board...................................................12

Safety Devices and the UPM control..............................12

Safety Features..........................................................13

Freeze Sensor............................................................14

Intelligent Reset..........................................................14

Lockout reset.............................................................14

Pre- Start- Up..................... ...............................................15

Air Coil......................................................................15

Units Mounted Non-Fused Disconnect Switch.................22

Hot Gas Reheat..........................................................24

Hot Gas Bypass..........................................................25

Internal 2-Way Water Valve..........................................25

Economizer...............................................................25

Certified Performance Table.............................................26

Fan Motors Options...........................................................27

Permanent Split Capacitor Motors (PSC)........................27

Constant Torque Motors (ECM).....................................28

Constant Airflow Motors (ECM).....................................30

Standard Blower Motor................................................32

Constant Torque ECM Blower Motor..............................33

Constant CFM ECM Blower Motor..................................34

Troubleshooting...............................................................35

Temperature Pressure Table.............................................40

Waterside pressure Drop Table..........................................46

Compressor Characteristics..............................................47

Corner Weights (HZ).........................................................48

Water Coil Volume............................................................48

Wiring Diagrams...............................................................49

Dimensional Drawings......................................................56

Vertical............................................................................56

Horizontal........................................................................57

Start Up...........................................................................15

Operating Limits........................................................ 15

Environment..............................................................15

Power Supply.............................................................15

Unit Starting Conditions...............................................15

Scroll Compressor Rotation..........................................16

Sequence Of Operation UPM........................................17

Sequence Of Operation ECM.......... ...............................18

Unit Start Up Cooling Mode...........................................19

Unit Start Up Heating Mode................. ..........................19

Flow Regulation..........................................................19

Antifreeze..................................................................20

Application Considerations...............................................20

Well Water Systems....................................................20

Cooling Tower/Boiler Systems......................................21

Geothermal Closed Loop Systems.................................21

Open Well Water Systems............................................22

Water Quality...................................................................22

Water Quality Table..........................................................23

Condensate Connections..................................................23

Piping..............................................................................24

Options............................................................................24

Extended Range.........................................................24

Maintenance....................................................................59

Information On Decommissioning......................................59

Protecting The Environment..............................................59

Components..............................................................59

Refrigerant................................................................59

Terminology.....................................................................60

Unit Check Out Sheet........................................................61

Notes...............................................................................62

LV Heat Pump Series8 733 944 336 (2016/09) Subject to change without prior notice

Key to Symbols | 3LV Heat Pump Series

KEY TO SYMBOLS

Warnings

Warnings in this document are identified by

a warning triangle printed against a grey

background. Keywords at the start of the

warning indicate the type and seriousness

of the ensuing risk if measures to prevent

the risk are not taken.

The following keywords are defined and can be used in

this document:

• DANGER indicates a hazardous situation which, if

not avoided, will result in death or serious injury.

• WARNING indicates a hazardous situation which, if

not avoided, could result in death or serious injury.

• CAUTION indicates a hazardous situation which, if

not avoided, could result in minor to moderate

injury.

• NOTICE is used to address practices not related to

personal injury.

Important Information

This symbol indicates important information where

there is no risk to property or people.

SAFETY WARNINGS

IMPORTANT: Read the entire instruction

manual before starting installation.

DANGER: Improper installation,

adjustment, alteration, service,

maintenance, or use can cause explosion,

fire, electrical shock or other conditions

which may cause personal injury or property

damage. Consult a qualified installer,

service agency, or your distributor or branch

for information or assistance. The qualified

installer or agency must use factoryauthorized kits or accessories when

modifying this product. Refer to the

individual instructions packaged with the

kits or accessories when installing.

WARNING: Before performing service or

maintenance operations on the system, turn

off main power to the unit. Electrical shock

could cause personal injury or death.

WARNING: When working on equipment,

always observe precautions described in

the literature, tags, and labels attached to

the unit. Follow all safety codes. Wear

safety glasses and work gloves. Use a

quenching cloth for brazing, and place a fire

extinguisher close to the work area.

NOTICE: To avoid the release of refrigerant

into the atmosphere, the refrigerant circuit

of this unit must be serviced only by

technicians who meet local, state, and

federal proficiency requirements.

NOTICE: All refrigerant discharged from this

unit must be recovered WITHOUT

EXCEPTION. Technicians must follow

industry accepted guidelines and all local,

state, and federal statutes for the recovery

and disposal of refrigerants. If a compressor

is removed from this unit, refrigerant circuit

oil will remain in the compressor. To avoid

leakage of compressor oil, refrigerant lines

of the compressor must be sealed after it is

removed.

NOTICE: To avoid equipment damage, DO

NOT use these units as a source of heating

or cooling during the construction process.

Doing so may affect the unit’s warranty. The

mechanical components and filters will

quickly become clogged with construction

dirt and debris, which may cause system

damage.

WARNING: Installation and servicing of this

equipment can be hazardous due to system

pressure and electrical components. Only

trained and qualified personnel should

install, repair, or service the equipment.

8 733 905 683 (2016/09)LV Heat Pump Series

//9 97& )/738% ;; 6$0;; ; ; $;; ; ;; ; ; 6%$

GENERAL ELECTRICAL OPTIONS (UP TO 5 AVAILABLE PER UNIT)

A-EMS RELAY

B-BLOWER MONITOR RELAY

C-COMPRESSOR MONITOR RELAY

D-PHASE MONITOR

E-PUMP/VALVE RELAY

G-BOILERLESS CONTROL

H-FLOW PROVING SWITCH

J-DISCONNECT SWITCH

K-FIRE ALARM RELAY/DUAL POWER

M-WIRE TO 208 V

X-AS DEFAULT FOR NON USED ELECTRICAL CODES

VOLTAGE

0 115/60/1

1 208-230/60/1

2 277/60/1

3 208-230/60/3

4 460/60/3

5 575/60/3

8 220-240/50/1

A 380-420/50/1

SIZE

007, 009, 012, 015,

018, 024, 030, 036,

041, 042, 048, 060,

070

LV

CABINET CONFIGURATION

HZ-HORIZONTAL

VT-VERTICAL

CF-COUNTERFLOW

COAX OPTIONS

C-COPPER

N-CUPRO-NICKEL

WATER CONNECTIONS

F-FRONT

B-BOTTOM

M-MARINE

RETURN AIR CONFIGURATION

L-LEFT

R-RIGHT

DISCHARGE AIR CONFIGURATION

T-TOP

S-STRAIGHT

E-END

B-BOTTOM

FAN/MOTOR OPTIONS

P-STANDARD PSC

A- CONSTANT AI RFLOW ECM

T-CONSTANT TORQUE ECM

AIR COIL

U-UNCOATED

D-DUOGUARD

REVISION LEVEL

B-CURRENT

ELECTRIC HEAT

(SINGLE POINT)

X-NONE

A-5kW

B-7.5kW

C-10kW

CABINET CONSTRUCTION

A-GALVANIZED STEEL/1/2” STANDARD 1.5LB DUAL DENSITY FIBERGLASS

C-A-GALVANIZED STEEL/1/2” CLOSED CELL FOAM

D-A-GALVANIZED STEEL/1/2” STANDARD 1.5LB DUAL DENSITY FIBERGLASS, EXTRA QUIET

F-A-GALVANIZED STEEL/1/2” CLOSED CELL FOAM, EXTRA QUIET

APPLICATION

T-TXV OPTION

S-STANDARD RANGE

G-EXTENDED RANGE

AIR FILTRATION

1- STANDARD THROWAWAY FILTER W/4 SIDED FILTER RACK

4-MERV8-2” W/4 SIDED FILTER RACK

5-MERV13-2” W/4-SIDED FILTER RACK

REFRIGERATION CIRCUIT OPTIONS

X-NONE

H-HOT GAS REHEAT-ON OFF

B-HOT GAS BYPASS

C-HOT GAS BYPASS WITH HOT GAS REHEAT

S-STRAIGTH COOL

CONTROLS

X-NONE

M-DDC(MULTI PROTOCOL)(BACNET, MODBUS, N2

L-DDC-LONWORKS

WATER FLOW CONTROL OPTIONS

X-NONE

2-2 WAY SOLENOID VALVE

3-MEASURE FLOW (3GPM/TON)

4-2 WAY SOLENOID +MEASUREFLOW

6-WATER REGULATING VALVE CONNECTION

TRANSFORMER

4-40 VA

5-50 VA

7-75 VA

1-100 VA

STANDARD/SPECIAL

S-STANDARD

A-SPECIAL #1

B-SPECIAL #2

AGENCY OPTIONS

X-ETL (UL 1995)

C-CE (50 HZ ONLY)

E-ETL W/E-HEAT AND SINGLE POINT POWER

ECONOMIZER

X-NONE

E-ECONOMIZER WITH 3 WAY VALVE AND CONTROLS

CODE STRING LEVEL

CHANNEL

B-BOSCH

4 | Model Nomenclature LV Heat Pump Series

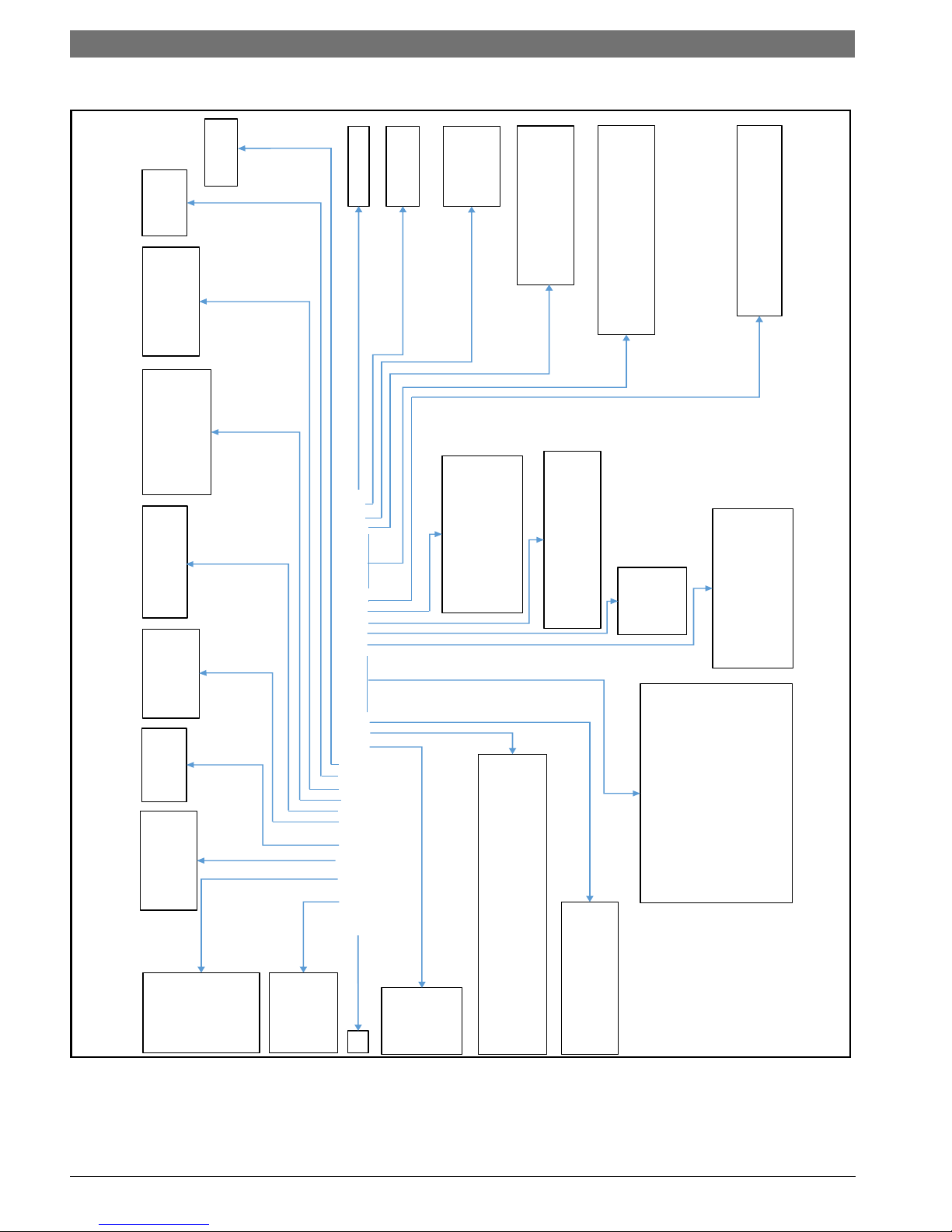

MODEL NOMENCLATURE

Not all Options are available on all models.

Figure # 1

LV Heat Pump Series8 733 944 336 (2016/09) Subject to change without prior notice

General Description | 5LV Heat Pump Series

GENERAL DESCRIPTION

The LV series water-to-air heat pump provides an

unmatched combination of performance, features and

flexibility for both high performance new construction

applications and replacement of existing water-to-air

heat pumps. All units are certified by the Air

conditioning, Heating and Refrigeration Institute (AHRI)

to AHRI/ANSI/ASHRAE/ISO standard 13256-1 for waterto-air and brine-to-air heat pumps at both Water Loop

Heat Pump and Ground Loop Heat Pump application

points.

All Water-to-Air Heat Pumps conform to UL 1995

standard and are certified to CAN/CSA C22.2 No 236 by

Intertek-ETL.

These units meet all current applicable requirements of

ASHRAE 90.1.

LV series units are designed to operate with entering

fluid temperatures between 50°F and 100°F in cooling

and 50°F and 80°F in heating with the base

configuration. With the extended range option, LV series

models can operate with entering fluid temperatures

between 50°F and 110°F in cooling and between 20°F

and 80°F in heating. LV units can accommodate a wide

range of air temperatures, however, standard LV models

should not be used for 100% outside air without

consulting the factory applications group. 100% outside

air routinely requires higher levels of dehumidification

than is available from equipment designed for return air

applications.

LV series units are available in three basic

configurations: vertical top supply air (VT), horizontal

end supply air or straight through supply air (HZ) and

counter flow down supply air (CF). Each of these

configurations are available with either left or right hand

return air. HZ models can have the supply air field

converted from end discharge air to straight through

with no extra parts required.

LV units are designed and rated for indoor installation

only. LV units should not be installed in environments

that fall below freezing or exceed 100°F ambient. LV

cabinets are constructed of heavy gauge G-90 galvanized

steel and will resist most common types of corrosion for

the life of the equipment.

LV series units are offered with a wide range of factory

installed options including: PSC, constant torque ECM

or constant air flow ECM fan motors; hot gas reheat; hot

gas bypass; internal 2 way valves; tin plated air coils;

2“4-sided filter racks; MERV 13 filters (with constant

airflow ECM motors); on board DDC controls; copper or

cupro nickel water coils; water-side economizers and

more refer to the unit model number for installed

options..

Note that some options are offered in limited sizes

and/or voltages.

On board safety features will protect the major unit

components from damage under most foreseeable

installation and operation problems.

MOVING AND STORAGE

If the equipment is not needed for immediate

installation upon arrival at the job site, it should be left

in its packaging and stored in a clean, dry area.

Units must be moved and stored in the normal upright

position at all times.

Use caution to avoid damage to filter racks and duct

flanges when storing or handling units.

NOTICE: Never lift or move units by filter

racks, external piping or attached options/

accessories.

NOTICE: Never stack units when

transporting them.

NOTICE: When storing units:

Do not stack units larger than 6 tons

capacity!

Do not stack vertical or counter flow units

under 6 tons capacity more than 2 high

Do not stack horizontal units 6 tons capacity

more than 3 high

INSTALLATION

Step 1- Check Job Site

Installation, operation and maintenance instructions are

provided with each unit. Before unit start-up, read all

manuals and become familiar with unit and its operation.

Thoroughly check out the system before operation.

Complete the inspections and instructions listed below

to prepare a unit for installation.

Horizontal Units

LV units are designed for indoor installation only. Be

sure to allow adequate space around the unit for

servicing.

Vertical Counter flow Units

LV Units are designed for indoor installations only.

While vertical units are typically installed in a floor-level

closet or a small mechanical room, the unit access

guidelines for these units are very similar to those

described for horizontal units.

Step 2- Check Unit

Upon receipt of shipment at the job site, carefully check

the shipment against the bill of landing. Make sure all

units have been received. Inspect each unit for damage.

Ensure the shipping company makes proper notation of

any shortages or damage on all copies of the freight bill.

Concealed damage not discovered during unloading

must be reported to the shipping company.

Please inspect the product carefully for any defects or

discrepancies.

Should you identify any issue, contact the Bosch

Wholesaler / Distributor you purchased the unit from.

8 733 905 683 (2016/09)LV Heat Pump Series

6 | Installation LV Heat Pump Series

1. Be sure that the location chosen for unit installation

provides ambient temperatures maintained above

freezing.

2. Be sure the installation location is isolated from

sleeping areas, private offices and other acoustically

sensitive spaces.

3. Be sure unit is mounted at a height sufficient to

provide an adequate slope of the condensate lines.

If an appropriate slope cannot be achieved, a fieldsupplied condensate pump may be required.

4. On horizontal units, allow adequate room below the

unit for condensate drain trap and do not locate the

unit above supply piping.

5. Provide sufficient space for duct connection. do not

allow the weight of the duct work to rest on the unit.

6. Provide adequate clearance for filter replacement

and drain pan cleaning. Do not allow piping,

conduit, etc. To block filter access.

7. Provide sufficient access to allow maintenance and

servicing of the fan and fan motor, compressor and

coils. Removal of the entire unit from the closet

should not be necessary.

8. Provide an unobstructed path to the unit within the

closet or mechanical room. Space should be

sufficient to allow return air to freely enter the

space.

9. Provide ready access to water valves, fittings, and

screwdriver access to unit side panels, discharge

collar, and all electrical connections.

10. Where access to side panels is limited, pre-removal

of the control box side mounting screws may be

necessary for future servicing.

Protection

Once the units are properly positioned on the job site,

cover them with either a shipping carton, vinyl film, or an

equivalent protective covering. Cap opens ends of pipes

stored on the job site. This precaution is especially

important in areas where painting, plastering or spraying

of fireproof material, etc. Is not yet complete. Foreign

material that accumulates within the units can prevent

proper start-up and require costly clean-up operations.

Before installing any of the systems components, be

sure to examine each pipe, fitting valves and remove any

dirt or foreign material found in or on these components.

Inspect Unit

1. Compare the electrical data on the unit nameplate

with ordering and shipping information to verify that

the correct unit has been shipped.

2. Verify that the unit is the correct model for the

entering water temperature of the job.

3. Do not remove the packaging until the unit is ready

for installation.

4. Verify that the refrigerant tubing is free of kinks or

dents, and that it does not touch other unit

components.

5. Inspect all electrical connections. Be sure

connections are clean and tight at the terminals.

6. Remove any blower support styrofoam from

underneath the blower.

7. Remove any shipping brackets from the unit

attached to the pallet.

Step 3- Locate the Unit

Locate the unit in an indoor area that allows easy access

to the filter, front access panel and blower access panel,

and has enough room for service personnel to perform

maintenance and repair work. Provide sufficient room to

make fluid, electrical and duct work connections.

Locate the unit in conditioned space and avoid

installation in corrosive environments.

If the unit is installed in a confined space, such as a

closet, provisions must be made for return air to freely

enter the face of the unit’s air coil.

Unit condensate drains are not internally trapped.

Allow room below the unit base for horizontal and

counter flow models for an adequate condensate trap.

NOTICE: These units are not approved for

outdoor installation; therefore, they must

be installed inside the structure being

conditioned space. Do not locate in areas

that are subject to freezing.

NOTICE: Do not locate the unit above

supply piping.

Do not locate the unit in areas subject to

freezing or in areas subject to temperature

or humidity extremes.

NOTICE: LV series packaged units are not

approved for outdoor installation. Units

must be installed in conditioned space that

is not subject to extremes of temperature or

humidity to avoid cabinet sweating and/or

equipment damage.

NOTICE: Do not use LV series units for

temporary heating, air conditioning or

ventilation during construction, especially

when plastering, sanding or painting. Care

should be taken to avoid introduction of

dust, paint or debris into the air coil.

LV Heat Pump Series8 733 944 336 (2016/09) Subject to change without prior notice

Installation | 7LV Heat Pump Series

Vibration

Mounting

Pad

Step-4 Mount The Unit

Duct Flanges

The Unit heat pump feature foldout return and supply air

duct flanges. These fold-out flanges allow the heat

pumps to more easily fit through doorways and other

tight spaces, and also prevent damage in shipping and

handling.

It is recommended that all fold-out flanges be folded out

once the heat pump is installed to ensure that return and

supply airflow is not obstructed. These Flanges can be

easily folded using standard or duckbill pliers.Once

folded out these flanges can be used to support light

duct work loads.

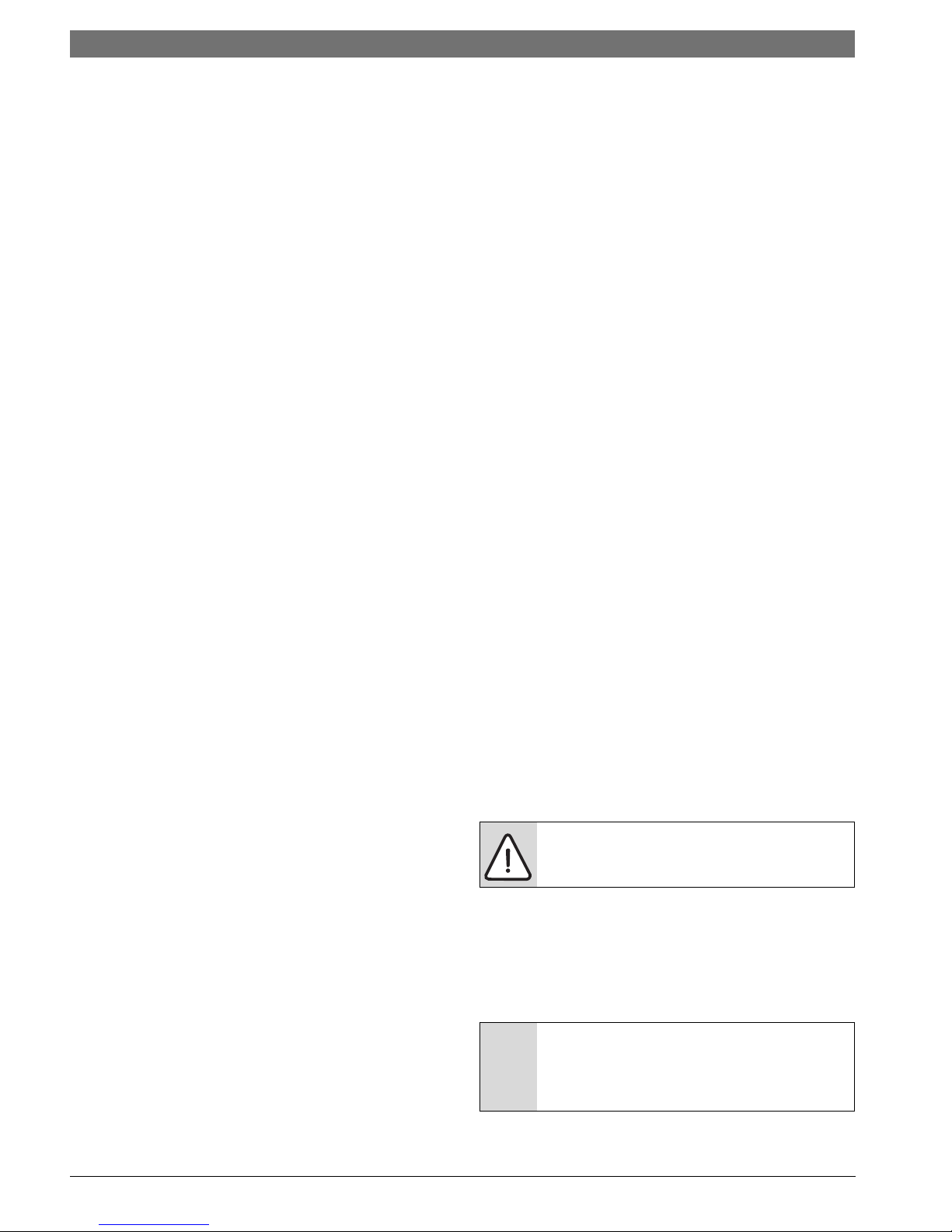

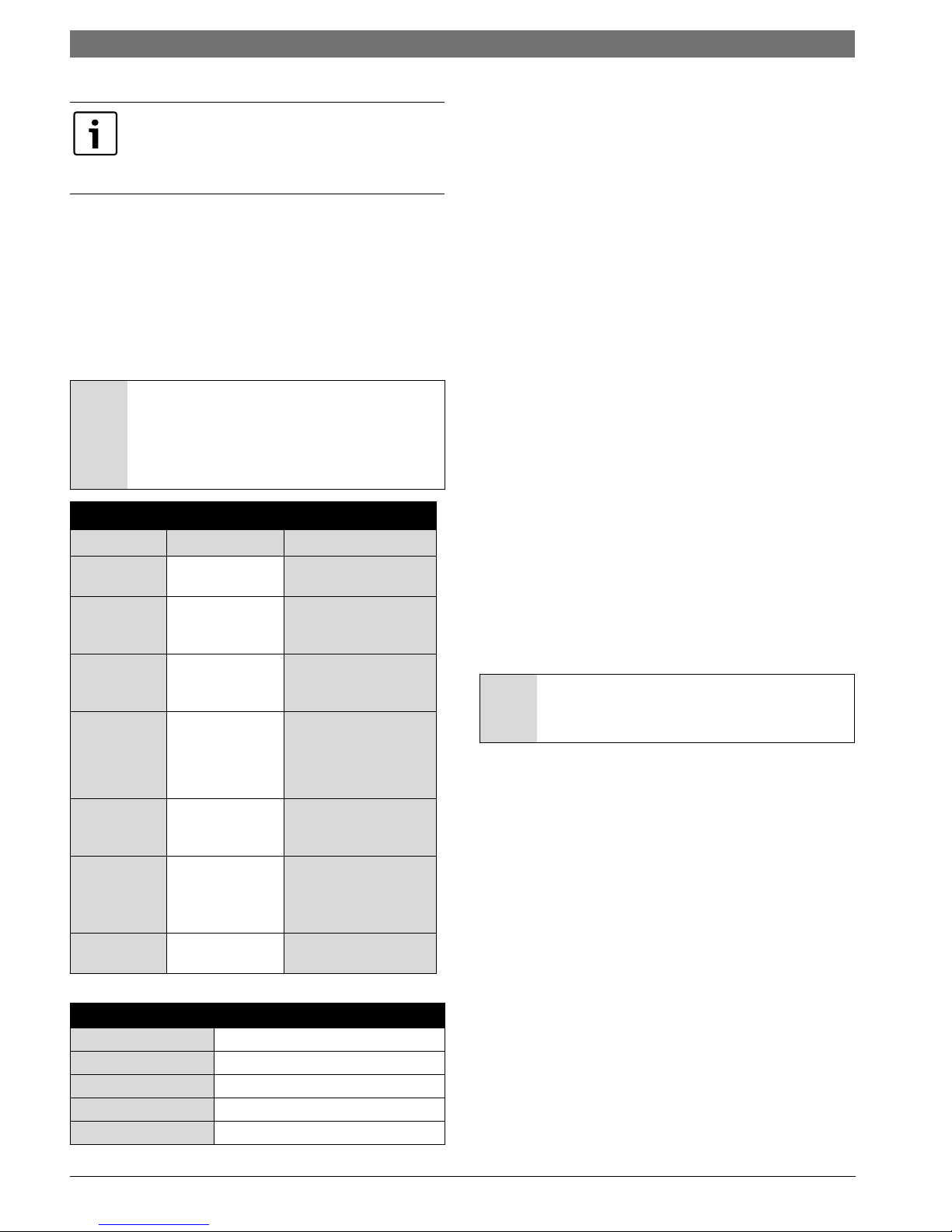

Mounting Vertical Units

LV Series vertical and counter flow units should be

mounted level on a vibration absorbing pad slightly

larger than the unit base in order to minimize vibration

transmission from the unit to the building structure. See

Figure #2 It is generally not necessary to anchor the unit

unless required by local code.

All major service access for the LV Series vertical and

counter flow models is from the front side of the unit.

When installing the unit in a confined space such as a

closet, ensure that the service panel screws are

accessible, that the filter can be replaced without

damage and that water and electrical connections are

accessible. For models with a unit mounted disconnect

switch, make sure the switch can be easily seen and

operated.

To reduce sound transmission, units should be installed

using flexible electrical conduit and hose kits. Care

should be taken to ensure that no part of the unit

cabinet is touching part of the building structure. For

ducted return applications, a flexible duct connection

should be used.

Mounting Horizontal Units

While horizontal units may be installed on any level

surface strong enough to hold their weight, they are

typically suspended above a ceiling by threaded rods.

The rods are usually attached to the unit corners by

hanger bracket kits included with the unit.

NOTICE: Horizontal (HZ) units must be

installed pitched toward the condensate

drain connection 1/8” per foot.

Horizontal units installed above the ceiling must

conform to all local codes. An auxiliary drain pan if

required by code, should be at least four inches larger

than the bottom of the heat pump.

Plumbing connected to the heat pump must not come in

direct contact with joists, trusses, walls, etc. Some

applications require an attic floor installation of the

horizontal unit. In this case the unit should be set in a full

size secondary drain pan on top of a vibration absorbing

mesh.

The secondary drain pan prevents possible condensate

overflow or water leakage damage to the ceiling. The

secondary drain pan is usually placed on a plywood base

isolated from the ceiling joists by additional layers of

vibration absorbing mesh. In both cases, a 3/4” drain

connected to this secondary pan should be run to an

eaves at a location that will be noticeable.

NOTICE: If the unit is located in a crawl

space, the bottom of the unit must be at

least 4" above grade to prevent flooding of

the electrical parts due to heavy rains.

Figure # 2 Mounting Vertical Units

8 733 905 683 (2016/09)LV Heat Pump Series

8 | Installation LV Heat Pump Series

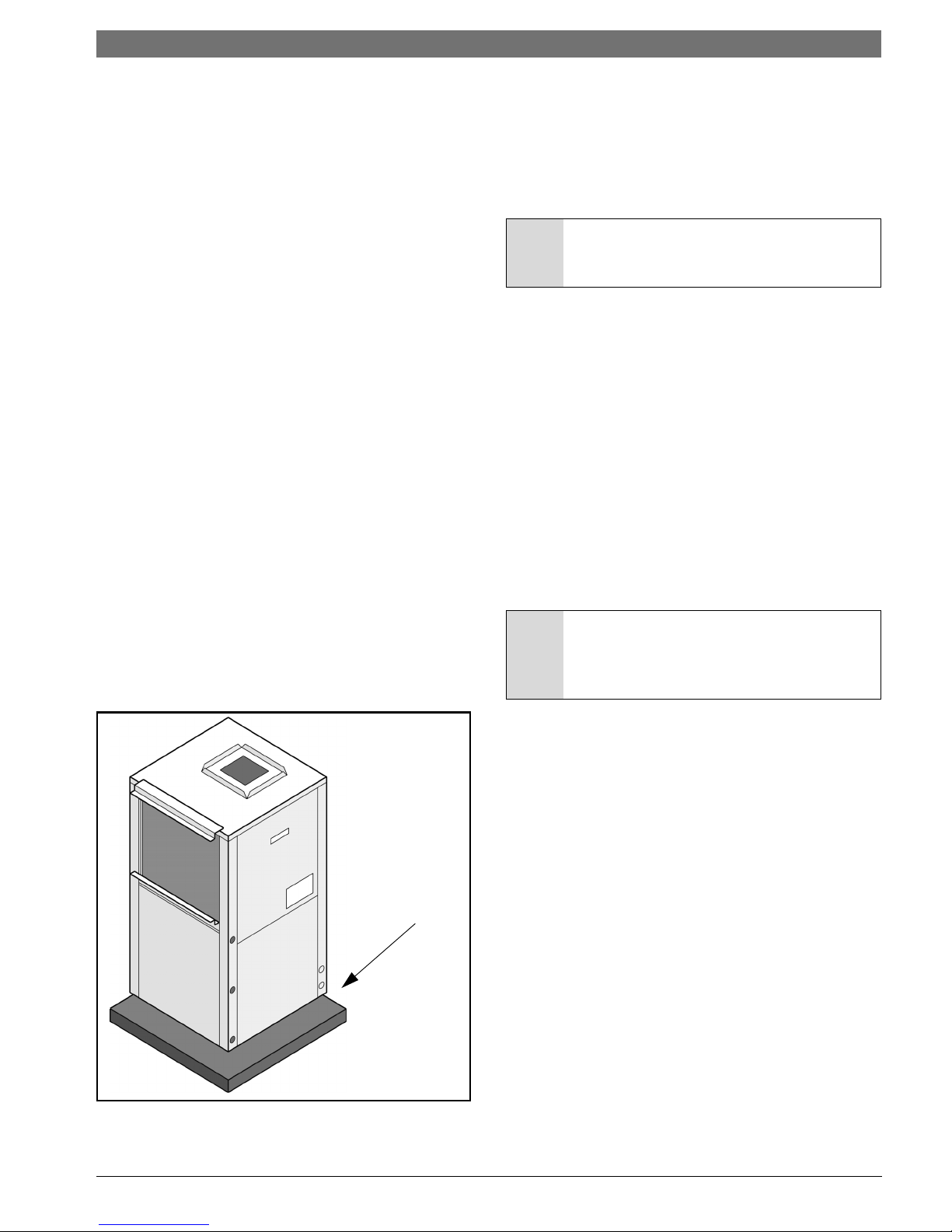

Hanging Brackets Locations

Hanging Bracket Kit

Installation instructions

All horizontal units come with Hanging Bracket Kit

to facilitate suspended unit mounting using threaded

rod. Hanging Brackets are to be installed as shown in

Figure#3

Figure # 3

This kit includes the following:

(5) Brackets

(5) Rubber Vibration Isolators

(8) Screws # 10x1/2”

(10) Bolts 1/4-28x1/2” hex Bolt (not used on this

model)

The following are needed and are to be field provided:

Threaded rod (3/8” max dia)

Hex Nuts

Washers (1-3/4” min O.D.)

1. Remove and discard factory provided screws from

location where Hanging Brackets will be installed shown

in Figure#4

2. Mount 4 Brackets to unit corner post using the bolts

provided in the kit as shown on Figure # 5

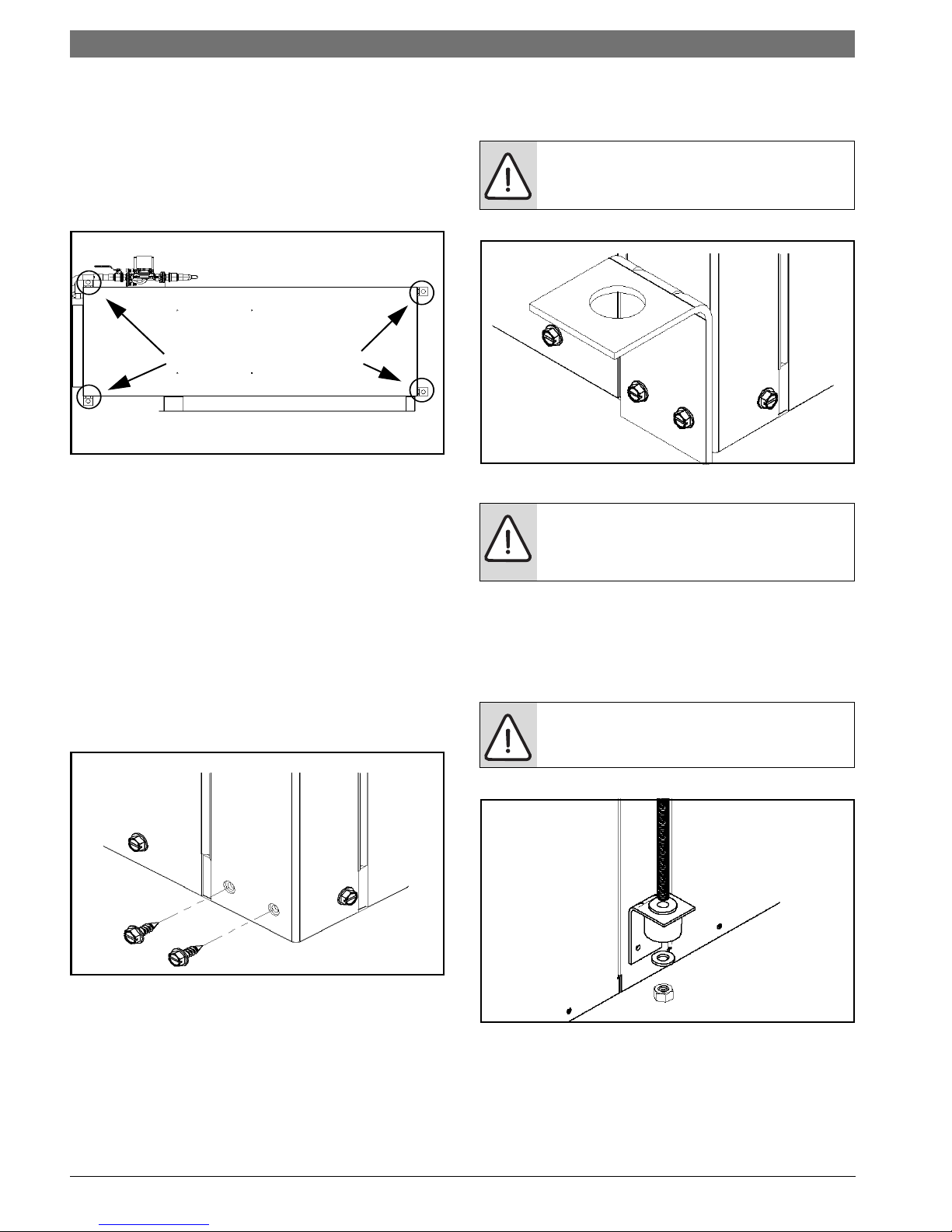

WARNING: Do not re-use screws removed

from the unit on step 1 to mount the

hanging Brackets to the unit.

Figure # 5

WARNING: Follow all applicable codes

requirements when hanging this unit.

Selecting threaded rod material, etc.

3. Install Rubber Grommet on the bracket as shown in

Figure# 6.

4. Hang the unit and assemble the field provided Thread

Rod, Nuts and Washers on to the Brackets as shown in

Figure# 6.

DANGER: Rods must be securely anchored

to the ceiling.

Figure # 4

Figure # 6

LV Heat Pump Series8 733 944 336 (2016/09) Subject to change without prior notice

Installation | 9LV Heat Pump Series

Step-5 Check Duct System

All units are provided with a return air duct flange and

supply air duct connections. Refer to unit dimensional

drawings (Page# 55).

A flexible duct connector is recommended for supply

and return air duct connections on metal duct systems.

All metal ducting should be insulated with a minimum of

1”inch duct insulation to avoid heat loss or gain and

prevent condensate from forming during the cooling

operation. Application of the unit to uninsulated duct

work is not recommended as the unit’s performance will

be adversely affected.

If the unit will be installed in a new installation with new

duct work, the installation should be designed using

current ASHRAE procedures for duct sizing. If the unit

will be connected to an existing duct system, a check

should be made to assure that the duct system has the

capacity to handle the air required for the unit

application. If the duct system is too small, larger duct

work must be installed. Be certain to check for existing

leaks and repair.

The duct system and all diffusers should be sized to

handle the designed air flow quietly. To maximize sound

attenuation of the unit blower, the supply and return air

plenums should be insulated. There should be no direct

straight air path through the air grill into the heat pump.

The return air inlet to the heat pump must have at least

one 90° turn away from the space return air grill. If air

noise or excessive air flow are a problem, the blower

speed can be changed to a lower speed to reduce air

flow.

6. Turn the blower panel 180

support brackets are now at the bottom of the

blower.

7. Insert the blower panel with the blower and motor

into the desired location. Be careful not to damage

the refrigerant coils or any other internal unit

components. Screw the panel into place.

8. Replace the wires between the blower motor and

electrical box. Make sure to connect wires to the

proper speed taps.

9. Replace the blower access panel.

10. Reconnect power to the unit.

°

so that the blower

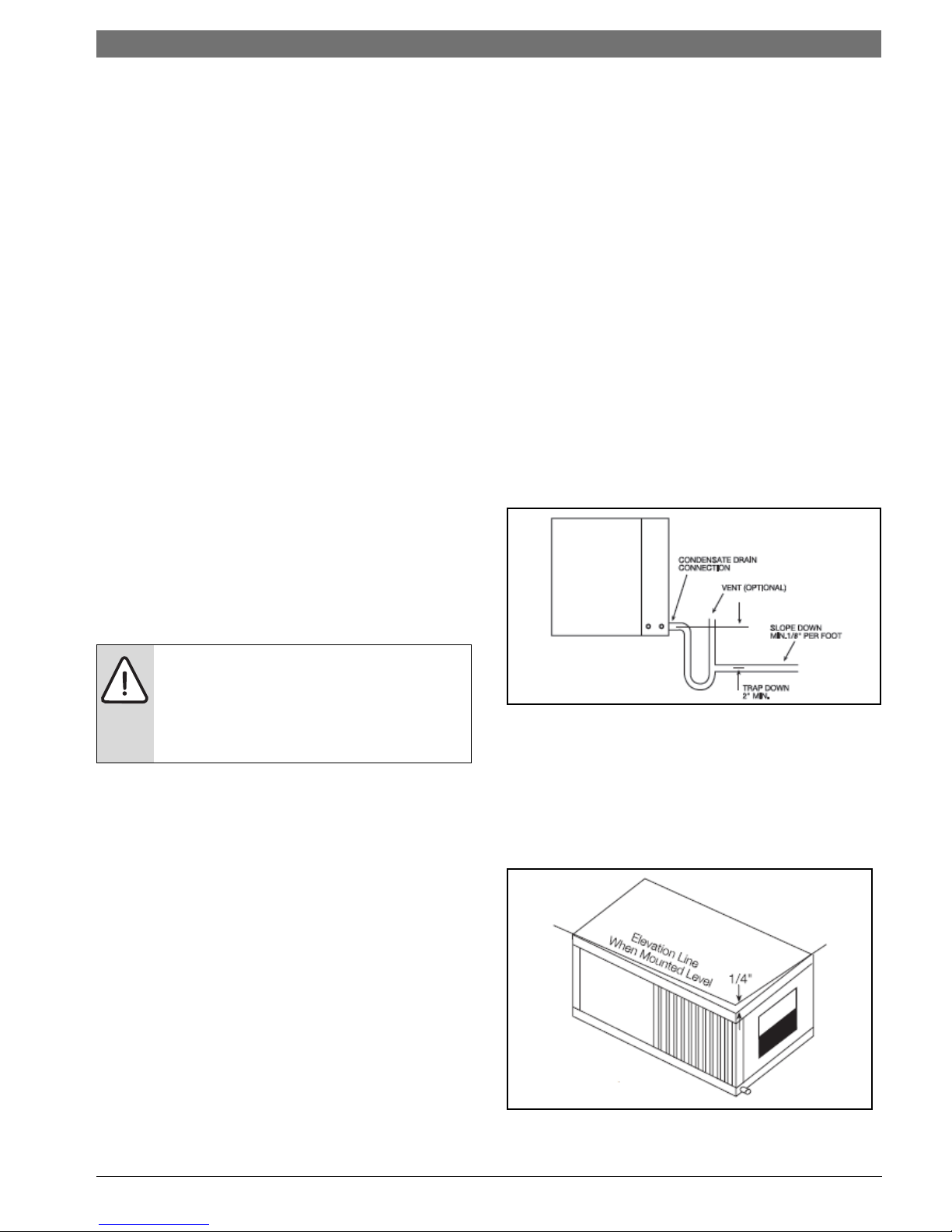

Step 6-Install Condensate Drain.

A drain line must be connected to the heat pump and

pitched away from the unit a minimum of 1/8-inch per

foot to allow the condensate to flow away from the unit.

This connection must be in conformance with local

plumbing codes. A trap must be installed in the

condensate line to ensure free condensate flow. (Heat

pumps are not internally trapped). A vertical air vent is

sometimes required to avoid air pockets.

(See figure # 7)

.

Do not connect discharge ducts directly to

the blower outlet. Use ashrae guidelines for

duct sizing

The factory filter rack should be left in place

on a free return system.

Horizontal Supply Air Configuration

Conversion

The supply air location on horizontal units can be quickly

field converted from end blow to straight through or vice

versa. To convert the supply air direction, follow the

steps below:

1. If connected to power, shut off the unit and

disconnect switch or circuit breaker.

2. Unscrew and remove the blower access panel.

3. Disconnect the wires from the unit electrical box to

the blower motor. Note which speed taps are wired

for units with PSC or constant torque motors.

4. Unscrew and carefully remove the blower panel with

the blower and motor attached. Be careful not to

damage the refrigerant coils or any other internal

unit components.

5. Remove the blower support brackets from the

bottom of the blower housing and relocate them to

the top of the blower housing.

Figure # 7 Condensate Drain

The depth of the trap depends on the amount of positive

or negative air pressure on the drain pan while the unit

fan is operating. A second Trap must not be included.

The Horizontal unit should be pitched approximately

1/4 inch towards the drain in both directions, to

facilitate condensate removal.

(see figure # 8)

Figure # 8 Pitched Unit

8 733 905 683 (2016/09)LV Heat Pump Series

10 | Installation LV Heat Pump Series

Step 7-Pipe Connections

Depending on the application there are 3 types of WSHP

piping systems to choose from: water loop, ground

water-and ground loop.

All WSHP units use female pipe thread fittings for water

connections. When making piping connections

considered the following:

• Insulation may be required on piping to avoid

condensation in the case where fluid in loop piping

operates at temperatures below dew point of

surrounding air.

• Piping systems that contains steel pipes or fittings

may be subject to galvanic corrosion. Dielectric

fittings may be used to isolate the steel parts of the

system to avoid galvanic corrosion.

Water Loop applications

Water loop applications usually include a number of

units plumbed to a common piping system. Maintenance

of any of the units can introduce air into the system.

Therefore, air elimination equipment comprises a major

portion of the mechanical room plumbing.

The flow rate is usually set between 2.25 and 3 GPM per

ton of cooling capacity. For proper maintenance and

servicing, pressure-temperature (P/T) ports are

necessary for temperature and flow verification.

In addition to complying with any applicable codes,

consider the following for system piping:

• Piping systems using water temperatures below

o

F require 1/2 inch closed cell insulation on all

50

piping surfaces to prevent pipe sweating.

• Avoid all plastic to metal threaded fittings due to the

potential for leaks.

• Teflon tape thread sealant is recommended to seal

pipe threads.

• Use Backup wrench. Do not overtighten

connections.

• Route piping to avoid service access areas to unit.

• Flush the piping system prior to operation to remove

dirt and foreign materials from the system.

Ground Loop Applications

Temperatures between 20ºand 110ºF and a cooling

capacity of 2.25 to 3 GPM of flow per ton is

recommended. In addition to complying with any

applicable codes, consider the following for system

piping:

• Limit piping materials to only polyethylene fusion in

the buried sections of the loop.

• Do not use galvanized or steel fittings at anytime

due to corrosion.

• Avoid all plastic to metal threaded fittings due to the

potential for leaks. Use a flange fitted substitute.

• Do not overtighten connections.

• Route piping to avoid service access areas to unit.

• Use pressure-temperature (P/T) plugs to measure

flow and pressure drop.

Step 8 Wire Field Power Supply

High Voltage

All field-installed wiring must comply with the National

Electric Code as well as all applicable local codes. Refer

to the unit electrical data on the unit nameplate for wire

and branch circuit protection sizing. Supply power

voltage and phasing should match the required voltage

and phasing shown on the unit nameplate. Operating the

unit below the minimum voltage, above the maximum

voltage or with incorrect phasing can result in poor

system performance or damage to the heat pump. All

field wiring should be installed by qualified and trained

personnel. Refer to the unit wiring diagram for field

connection requirements.

Power wiring to the heat pump should be enclosed in

flexible conduit to minimize the transmission of

vibration from the unit cabinet to the building.

For heat pumps with unit mounted disconnect switches,

field power should be connected to the marked

terminals on the disconnect switch. For heat pumps

without unit-mounted disconnect switches (except for

460-volt units noted below and units with dual power

supply), power is connected to the line (L) side of the

compressor contactor and the ground lug in the unit

electrical box.

Units with Dual Power Supplies

For models with dual power supplies, one power supply

feeds the compressor and a second power supply feeds

the unit fan motor and control circuit. The compressor

power supply should be connected to the line (L) side of

the compressor contactor. The fan motor and control

circuit power supply meets the voltage, amperage and

phase requirements of its load. Refer to the unit name

plates for requirements.

460-V Models with Constant Airflow Motors

The 460-V heat pumps with the constant airflow motor

option require a properly sized neutral wire with the

power supply wiring in addition to the three high voltage

wires and the ground wire. These units employ a 265-V

motor that requires power from one phase of the 460-V

supply and the neutral wire.

CAUTION: The unit ground wire should

never be used as a neutral wire

Transformer Settings for 208/230-V Units

As a factory built, all 208/230-V operation unless the

wire for 208-v option is ordered. For Job sites with a

208-V power supply, the primary leads on the unit

transformer will need to be changed from 240-V to 208V. Refer to the unit wiring diagram for details.

NOTICE: All High voltage connections must

be torqued as specified on contactor

specifications to avoid the risk of

overheating

LV Heat Pump Series8 733 944 336 (2016/09) Subject to change without prior notice

Installation | 11LV Heat Pump Series

Low Voltage

For heat pumps with PSC or constant torque fan motors,

all thermostat wiring is connected to a terminal block

located in the unit electrical box. For heat pumps with a

constant airflow fan motor thermostat wiring is

connected to a removal terminal strip located on the

ECM (Electronically Commutated Motor) control board

located in the electrical box. Refer to the unit wiring

diagram for connection details.

CAUTION: Never route control wiring

through the same conduit as power supply

wiring.

Unless provided with DDC controls, the unit heat pump

can be controlled by most commonly available singlestage heat pump thermostats. Note that the reversing

valve on the unit is energized when the unit is in the

cooling mode. Thermostats should be located on an

interior wall away from supply ducts. Avoid locations

subject to direct sunlight, drafts, external walls.

Thermostat wiring should be 18AWG (American Wire

Gage). refer to the installation instructions of the

thermostats for further details.

NOTICE: Exceptionally long runs of

thermostat wire should be avoided to

prevent voltage drops in the control circuit.

See Table #1 and #2 for recommended

length

Unit heat pumps are supplied with a 50VA control

transformer as a standard. Models with DDC, hot gas

reheat or an economizer are supplied with a 75 VA

transformer. The 75 VA and 100 VA transformers are

available as optional components for most models (size

018 and larger for 100 VA). The VA capacity of the

transformer should be considered when connecting low

voltage accessories to the heat pump such as

thermostats or solenoid valves. Table # 3 shows the VA

draw of factory mounted components in the low voltage

heat pump. The total VA draw of the heat pump internal

components plus attached accessories must be lower

than the VA capacity of the unit control transformer.

NOTICE: Exceeding the transformer

capacity can result in low control voltage,

erratic unit operation or damage to the heat

pump.

Thermostat to HVAC Equipment

The thermostat may not function properly if the total

resistance of any of the thermostat to HVAC equipment

wires exceeds 2.5 ohms. To ensure that wire length does

not cause excess resistance, refer to Table # 1and

ensure that the wires from the thermostat to the HVAC

equipment are not too long.

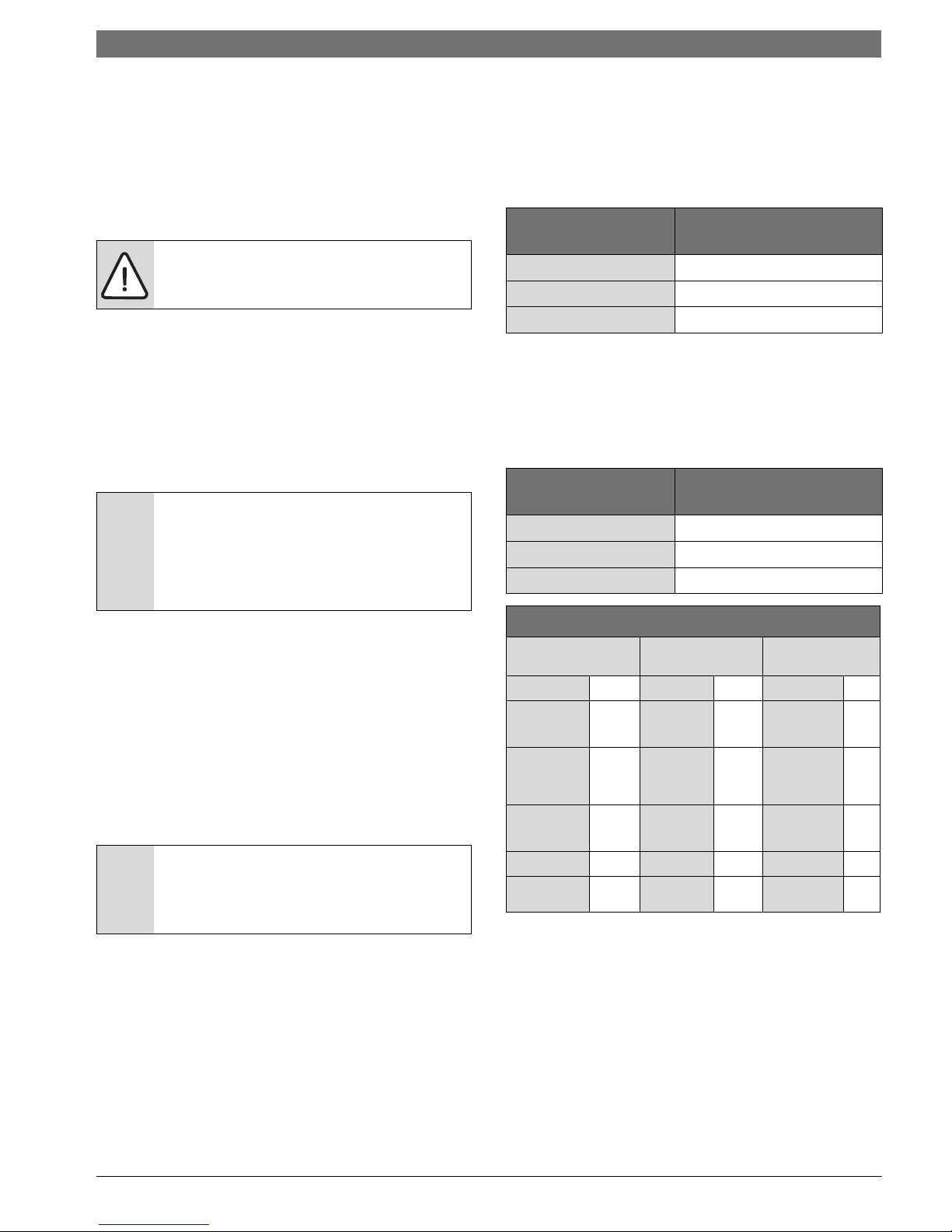

Table 1: Copper

wire size

22 AWG (0.33mm 2)

20 AWG (0.50mm 2)

18 AWG (0.75mm 2)

Maximum recommended

wire length

150 ft (46m)

240 FT (73m)

385 FT (117m)

Remote Sensor to Programmable Thermostat

Because remote temperature sensors measure

resistance, very long cable runs can cause slight errors

in the measurement. For the highest temperature

reading accuracy, avoid exceeding the maximum

recommended wire lengths show in Table # 2.

Table 2: Copper

wire size

22 AWG (0.33mm 2)

20 AWG (0.50mm 2)

18 AWG (0.75mm2)

Maximum recommended

remote sensor wire length

1000 ft (300m)

1500 FT (450m)

2500 FT (750m)

Table 3: Low Voltage VA Draw

STANDARD

CONSTRUCTION

Component VA Component VA Component VA

Blower Relay

(PSC motors

only)

Reversing

Valve

Solenoid

Compressor

Contactor

UPM Board 2

Total VA draw 22-26 Total VA

6-7 Total from

8-9 Additional

6-8 Hot Gas

HOT GAS REHEAT

OR ECONOMIZER

‘Standard’

Control

Relays

Reheat

Solenoid

draw

22-26 Monitor Relay

12-14 Internal 2

8-9 LED

42-49

OPTIONAL

COMPONENTS

(VA draw per

relay)

Way

Motorized

Valve

Annunciator

6-7

7

1

8 733 905 683 (2016/09)LV Heat Pump Series

12 | Installation LV Heat Pump Series

10

1

27

8

9

5

11

46

3

1

2

3

4

5

6

7

9

10

11

1213

17

14

15

16

8

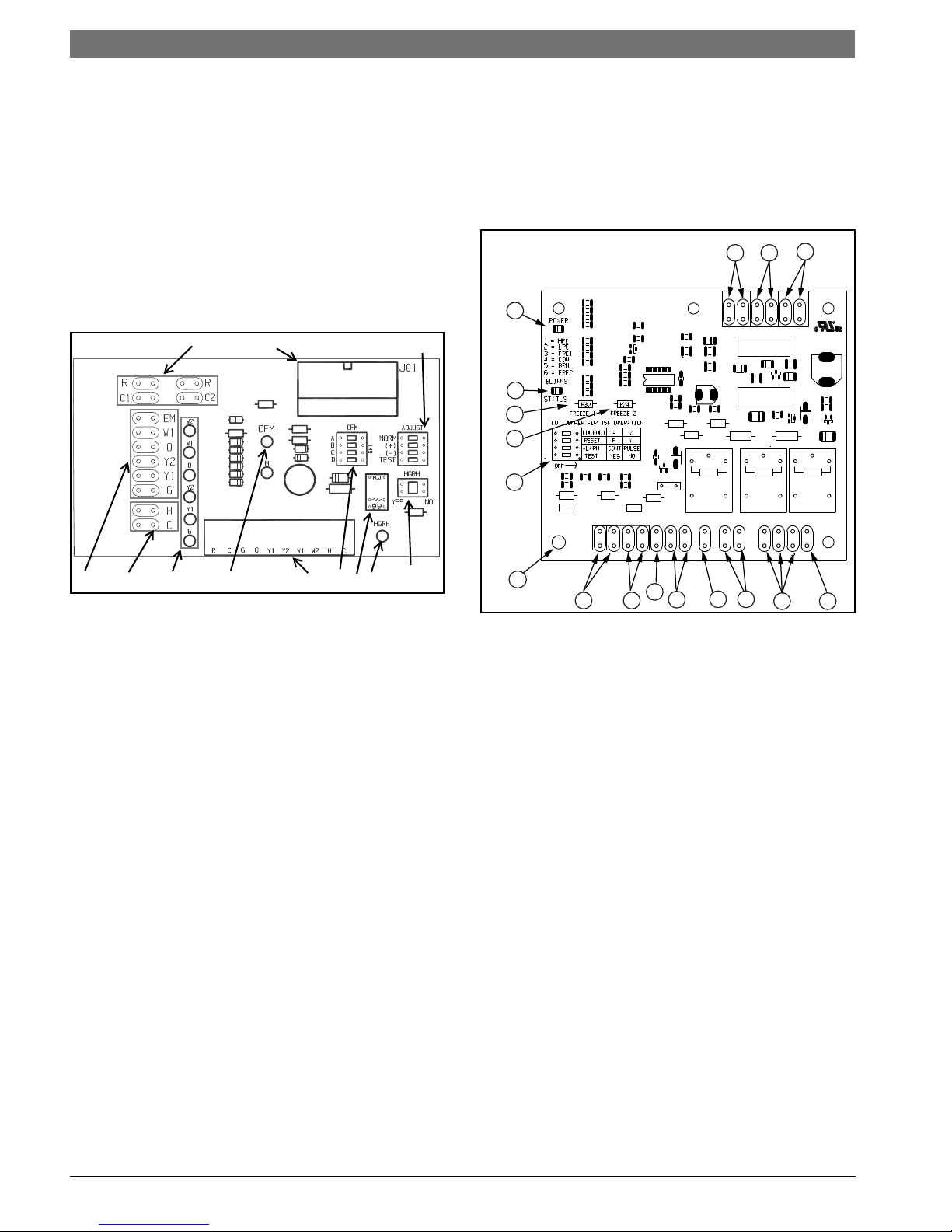

Step 9- Wire Field Controls

Units Controls ECM-UPM

ECM Interface Board

Thermostat wiring is connected to the 10 pin screw type

terminal block on the lower center portion of the ECM

Interface Board. In addition to providing a connecting

point for thermostat wiring, the interface board also

translates thermostat inputs into control commands for

the Electronic Commutated Motor (ECM) DC fan motor

and displays an LED indication of operating status. The

thermostat connections and their functions are as

shown in figure # 9

Safety devices and the UPM control

Each unit is factory provided with a UPM board

controller that controls the compressor operation and

monitors the safety.

If the unit is being connected to a thermostat with a

malfunction light, this connection is made at the unit

malfunction output or relay.

Figure # 9

[1] Motor harness plug

[2] Blower CFM adjustment

[3] Motor settings

[4] Dehumidification indication

[5] Thermostat contact inputs

[6] CFM count indicator

[7] Thermostat input status indication

[8] Reheat digital outputs

[9] Thermostat outputs

[10] 24 VAC

[11] Hot gas Re-heat enable switch

Figure # 10

[1] Board Power Indicator

[2] UPM Status LED Indicator

[3] Water Coil Freeze Protection Temperature Selection

[4] Air Coil Freeze Protection Temperature Selection

[5] UPM Board Settings

[6] Water Coil Freeze Connection

[7] Air Coil Freeze Connection

[8] LED Unit Display Connection

[9] 24VAC Power Input

[10] Compressor Contact Output

[11] High Pressure Switch Connection

[12] Call for Compressor Y1

[13] Low Pressure Switch Connection

[14] 24VAC Power Common

[15] Condensate Overflow Sensor

[16] Dry Contact

[17] UPM Ground Standoff

LV Heat Pump Series8 733 944 336 (2016/09) Subject to change without prior notice

Safety features includes the following:

• High pressure switch located in the refrigerant

discharge line and wired across the HPC terminals

on the complete UPM board

• Low pressure switch located in the unit suction line

and wired across terminals LPC1 and LPC2 on the

complete UPM Board

• Complete UPM board dry contacts are normally

open (NO).

• Water side freeze protection sensor, mounted close

to condensing water coil, monitors refrigerant

temperature between condensing water coil and

thermal expansion valve. If temperature drops

below or remains at freeze limit trip for 30 seconds,

the controller will shut down the compressor and

enter a soft lockout condition. The default freeze

limit trip is 26°F, however this can be changed to

°

F by cutting the R30 or Freeze1 resistor located

15

on top of DIP switch SW1. For resistor location. If

unit is employing a fresh water system (no antifreeze protection), it is extremely important to have

the Freeze 1 R30 resistor set to 26

°

F in order to shut

down the unit at the appropriate leaving water

temperature and protect heat pump from freezing if

a freeze sensor is included.

• Evaporator freeze sensor, mounted between the

thermal expansion device and the evaporator,

monitors refrigerant temperature between the

evaporator coil and thermal expansion valve. If

temperature drops below or remains at freeze limit

trip for 30 seconds, the controller will shutdown the

compressor and enter into a soft lockout condition.

The default freeze limit trip is 26

°

F See Figure # 10

• The condensate overflow protection sensor is

located in the drain pan of the unit and connected to

the COND terminal on the complete UPM board.

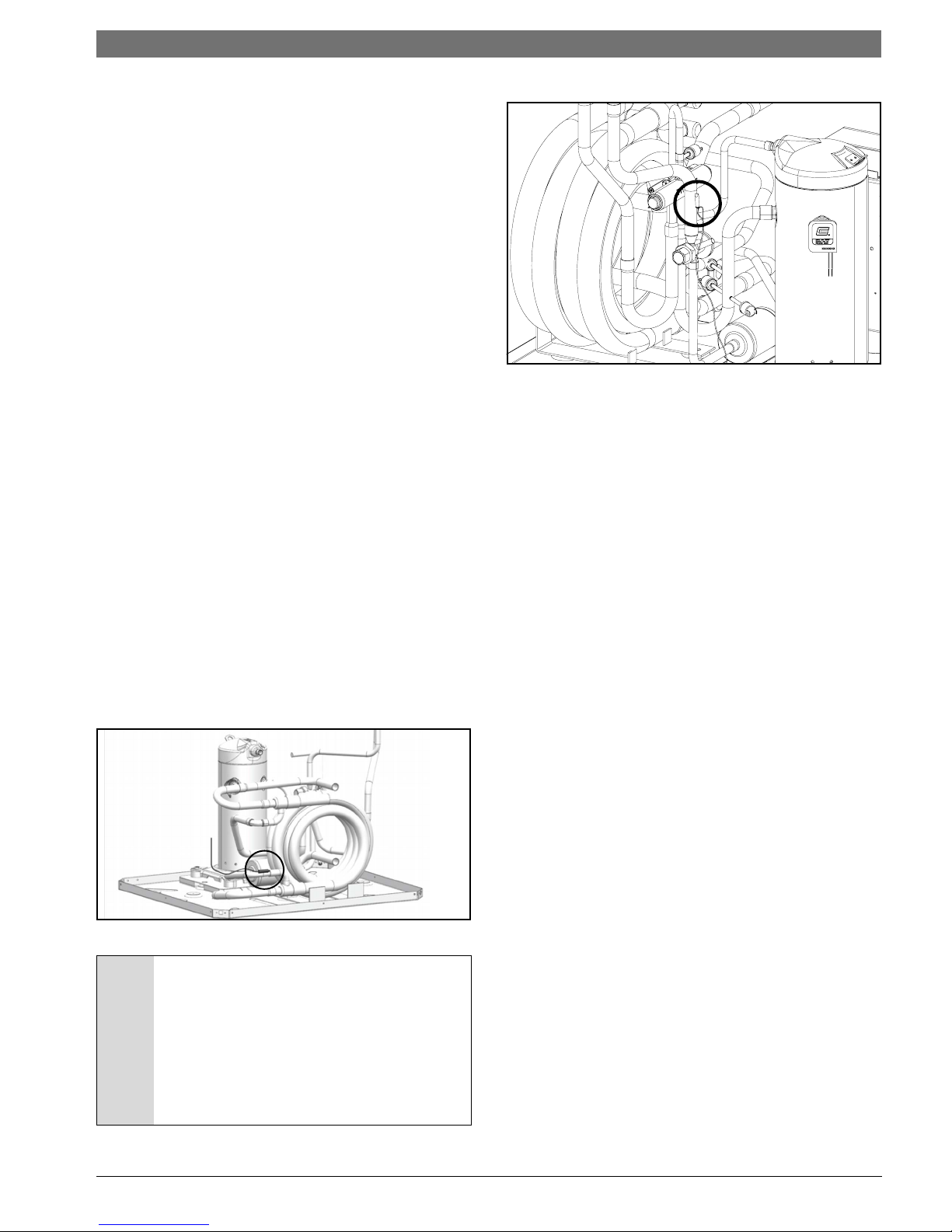

Figure # 11 Water side Freeze Protection Sensor

NOTICE: If unit is employing a fresh water

system (no anti-freeze protection), it is

extremely important to have the Freeze1

°

R30 resistor set to 26

F in order to

shutdown the unit at the appropriate

leaving-water temperature and protect your

heat pump from freezing if a freeze sensor is

included.

Installation | 13LV Heat Pump Series

Figure # 12

The UPM Board includes the following features:

• ANTI-SHORT CYCLE TIMER: 5 minute delay on

break timer to prevent compressor short cycling.

• RANDOM START: Each controller has a unique

random start delay ranging from 270 to 300 seconds

on initial power up to reduce the chance of multiple

units simultaneously starting at the same time after

power up or after a power interruption, thus

avoiding creating large electrical spike.

• LOW PRESSURE BYPASS TIMER: If the compressor

is running and the low pressure switch opens, the

controller will keep the compressor ON for 120

seconds. After 2 minutes if the low pressure switch

remains open, the controllers will shutdown the

compressor and enter a soft lockout. The

compressor will not be energized until the low

pressure switch closes and the anti-short cycle time

delay expires. if the low pressure switch opens 2-4

times in 1 hour, the unit will enter a hard lockout

power to the unit would need to be reset.

• BROWNOUT/SURGE/POWER INTERRUPTION: The

brownout protection in the UPM board will shut

down the compressor if the incoming power falls

below 18 VAC. The compressor will remain OFF until

the voltage is above 18 VAC and ANTI-SHORT CYCLE

TIMER (300 seconds) times out. The unit will not go

into a hard lockout.

• MALFUNCTION OUTPUT: Alarm output is normally

open (NO) dry contact. If pulse is selected the alarm

output will be pulsed. The fault output will depend

on the on the dip switch setting for “ALARM”. If it is

set to “CONST”, a constant signal will be produced

to indicate a fault and the unit requires inspection to

determine the type of fault. If is set to “PULSE”, a

pulse signal is produced and a fault code is detected

by a remote device indicating the fault. See LED

fault indication for blink code explanation. The

remote device must have a malfunction detection

capability when the UPM board is set to “PULSE”.

8 733 905 683 (2016/09)LV Heat Pump Series

14 | Installation LV Heat Pump Series

If 24 VAC output is needed. R must be wired to

ALR-COM terminal; 24 VAC will be available to the

ALR-OUT terminal when the unit is in the alarm

condition.

• DISPLAY OUTPUT: The display output is a pulse

output connected to the Unit Diagnostics Display

(UDD) and it pulses 24VAC when the unit is in an

lockout alarm condition.

• TEST DIP SWITCH: A test dip switch is provided to

reduce all time delays settings to 10 seconds during

troubleshooting or verification of unit operation. In

test mode the fault LED will flash 5 times in cooling

or 3 times in heating for five minutes.

NOTICE: Operation of unit in test mode can

lead to accelerated wear and premature

failure of components. The “TEST” switch

must be set back to “NO” after

troubleshooting/servicing.

Table 4: UPM Fault Blink Codes

LED Blinks Fault Fault Criteria

All fault conditions

None None

1

High Pressure

2

3

4Condensate

5 Air Coil Freeze

6Brown Out

Low Pressure

Water Coil

Freeze

Condition

Overflow

Condition

UPM Board Factory Default Settings

TEMP 26°F

LOCKOUT 2

RESET Y

ALARM PULSE

TEST NO

nominal

Refrigerant discharge

pressure has

exceeded 600 PSIG

Refrigerant suction

pressure has fallen

below 40 PSIG

Refrigerant

temperature to the

water coil has fallen

below 26°F for 30

seconds

Condensate levels in

the unit drain pan are

too high

Refrigerant

temperature to the air

coil has fallen below

26°F for 30 seconds

Control voltage has

fallen below 18 VAC

Freeze Sensor

°

The default setting for the freeze limit trip is 26

F

(sensor number 1); however this can be changed to 15°F

by cutting the R30 resistor located on top of the DIP

switch SW1, freeze limit trip should only be changed to

15°F when a closed loop system with appropriate

antifreeze mixture is used.Since freeze sensor 2 is

dedicated to monitor the evaporator coil it is

recommended to leave the factory default setting on the

board. The complete UPM controller will constantly

monitor the refrigerant temperature with the sensor

mounted close to the condensing water coil between the

thermal expansion valve and water coil. If temperature

drops below or remains at the freeze limits for 30

seconds. The controller will shut the compressor down

and enter into a soft lockout condition. Both the status

LED and the alarm contact will be active. The LED will

flash three times the code associated with this alarm

condition. If this alarm occurs 2 times (or 4 if DIP switch

is set to 4) within an hour the complete UPM controller

will enter into a hard lockout condition. It will constantly

monitor the refrigerant temperature with the sensor

mounted close to the evaporator between the thermal

expansion valve and evaporator coil as shown in figure #

11

If temperature drops below or remains at the freeze limit

trip for 30 seconds, the controller will shut the

compressor down and enter into a soft lockout

condition. Both the status LED and the alarm contact

will be active. The LED will flash three times the code

associated with this alarm condition. If this alarm occurs

2 times (or 4 if DIP switch is set to 4 within an hour the

controller will enter into a hard lockout condition.

NOTICE: It is recommended to have a flow

switch to prevent the unit from running if

water flow is lost.

Intelligent Reset

If a fault condition is initiated, the 5 minute delay on

break time period is initiated and the unit will restart

after this delays expire and if the fault condition has

been resolved. During this period the fault LED will

indicate the cause of the fault. If the fault condition still

exists or occurs 2 or 4 times (depending on 2 or 4

settings for lockout dip switch) before 60 minutes, the

unit will go into a hard lockout and requires a manual

lockout reset. A single condensate overflow fault will

cause the unit to go into hard lockout immediately, and

will require a manual lockout reset.

Lockout Reset

A hard lockout can be reset by turning the unit

thermostat off and then back on. When the RESET dip

switch is set to “Y” or by shutting off power at the circuit

breaker when the RESET DIP switch is set to “R”.

LV Heat Pump Series8 733 944 336 (2016/09) Subject to change without prior notice

THERMOSTAT OPTIONS

Y1 First Stage Compressor Operation

GFan

O Reversing Valve (energized in cooling)

W1 Auxiliary Electric Heat (runs in conjunction

with compressor)

Pre-Start-Up | 15LV Heat Pump Series

Air coil

To obtain maximum performance, clean the air coil

before starting the unit. A 10% solution of dishwasher

detergent and water is recommended for both sides of

the coil. Rinse thoroughly with water.

START-UP

Use the procedure below to initiate a proper start-up

NC Transformer 24 VAC Common (extra

connection)

C1 Transformer 24 VAC Common (primary

connection)

R Transformer 24 VAC Hot

H Dehumidification Mode

UPM DIP SWITCH DEFAULT POSITION

lockout 42

reset

alarm

test

RY

Cont pulse

yes no

PRE-START-UP

System Checkout

After completing the installation, and before energizing

the unit, the following system checks should be made

prior to initial startup:

1. Verify that the supply voltage to the heat pump is in

accordance with the nameplate ratings.

2. Make sure that all electrical connections are tight

and secure.

3. Check the electrical fusing and wiring for the correct

size.

4. Verify that the low voltage wiring between the

thermostat and the unit is correct.

5. Verify that the water piping is complete and correct.

6. Check that the water flow is correct, and adjust if

necessary.

7. Check the blower for free rotation, and that it is

secured to the shaft.

8. Verify that vibration isolation has been provided.

9. Unit is serviceable. Be certain that all access panels

are secured in place.

10. Verify that the blower support has been removed.

11. Verify that duct work has been properly fastened to

supply and return duct collars.

12. Make sure return air filters are positioned correctly

in the filter rack if removed during installation.

NOTICE: This equipment is designed for

indoor installation only

Operating Limits

Environment

This equipment is designed for indoor installation only.

Extreme variations in temperature, humidity and

corrosive water or air will adversely affect the unit

performance, reliability and service life.

Power Supply

A voltage variation of

voltage is acceptable.

Unit Starting Conditions

Minimum ambient temperature for heating operation is

45°F. Minimum entering air for heating is 40°F. Minimum

entering water temperature for heating with standard

range units is 50°F and for extended range units is 20°F.

Air and water flow rates must be within the cataloged

range.

These operating limits are not suitable for

continuous operating conditions. Assume

that such start up conditions are for the

purpose of bringing the building space up to

occupancy temperature.

WARNING: When the disconnect switch is

closed, high voltage is present in some

areas of the electrical panel. Exercise

caution when working with the energized

equipment.

1. Restore power to system.

2. Turn thermostat fan position to ON. Blower should

start.

3. Balance airflow at registers.

4. Adjust all valves to the full open position and turn on

the line power to the heat pump unit.

5. Operate unit in the cooling cycle first, then the

heating cycle. for unit operating limits. Allow 15

minutes between cooling and heating tests for

pressure to equalize.

± 10% of nameplate utilization

8 733 905 683 (2016/09)LV Heat Pump Series

16 | Start-Up LV Heat Pump Series

Two factors determine the operating limits of a unit:

entering air temperature and water temperature.

Whenever any of these factors are at a minimum or

maximum level, the other two factors must be at a

normal level to ensure proper unit operation.

Scroll Compressor Rotation (4 and 5

Tons only)

It is important to be certain that the compressor is

rotating in the proper direction. To determine whether

or not compressor is rotating in the proper direction see

as follows:

1. Connect services gases to suction and discharge

pressure fittings.

2. Energize the compressor.

3. The suction pressure should drop and the discharge

pressure should rise, as is normal on any start up.

If the suction pressure does not drop and the discharge

pressure does not rise to normal levels:

1. Turn off power to the unit. Install disconnect tag.

2. Reverse any two of the unit power leads.

3. Reapply power to the unit and verify pressures are

correct.

The suction and discharge pressure levels should now

move to their normal start-up levels.

When the compressor is rotating in the wrong direction,

the unit makes more noise and does not provide cooling.

After a few minutes of reverse operation, the scroll

compressor internal overload protection will open, thus

activating the unit lockout. This requires a manual reset.

To reset, turn the thermostat on and then off.

There is a 5 minute time delay before the compressor

will start.

LV Heat Pump Series8 733 944 336 (2016/09) Subject to change without prior notice

Sequence Of Operation

CC

LOCKOUT CAN BE SET

TO 4 VIA DIP SWITCH

BLINK CODE ON STATUS LED

SOFT LOCKOUT

RECORD ALARM

START COUNTER (IF APPLICABLE)

CC OUTPUT = ON

NO

YES

LPC

=CLOSED

FRZ >TEMP

LIMIT

Y1 = ON

TIME > 30

SEC

CON > 0

POWER/ SWITCHES/SENSOR

STATUS CHECK

START

TIMER

NO

YES

NO

YES

NO

YES

T > ASC OR

RS SEC

YES

NO

NO

YES

START

ANTI SHORT CYCLE

INITIAL

POWER UP

YES

NO

START

RANDOM START UP

START

COUNTER

NEEDED?

YES

COUNT = 2

OR

COUNT = 4

BLINK CODE ON STATUS LED

DISPLAY OUTPUT = PULSE

ALR OUTPUT = ON/PULSE

NO

YES

HARD

LOCKOUT?

CC OUTPUT = OFF

V > 18VAC

NO

YES

YES

NO

BLINK CODE

ON STATUS LED

NO

RESET ON

Y

CLEAR FAULTS

R = 24VAC

NO

YES

NO

YES

NO

YES

HPC =

CLOSED

RESET ON R

CC OUPUT=

ON

NO

YES

TIME >

120 SEC

START

TIMER

NO

YES

CNT = CNT+1

Start-Up | 17LV Heat Pump Series

Figure # 13

8 733 905 683 (2016/09)LV Heat Pump Series

18 | Start-Up LV Heat Pump Series

Figure # 14

LV Heat Pump Series8 733 944 336 (2016/09) Subject to change without prior notice

Unit Start Up Cooling Mode

1. Adjust the unit thermostat to the warmest position.

Slowly reduce the thermostat position until the

compressor activates.

2. Check for cool air delivery at unit grille a few

minutes after the unit has begun to operate.

3. Verify that the compressor is ON and that the water

flow rate is correct by measuring pressure drop

through the heat exchanger using P/T plugs. Check

elevation and cleanliness of the condensate lines;

any dripping could be a sign of a blocked line. Be

sure the condensate trap includes a water seal.

4. Check the temperature of both supply and

discharge water.

5. Check air temperature drop across the coil when

compressor is operating. Air temperature drop

should be between 15

o

and 25oF.

Unit Start Up Heating Mode

Oper

1. Turn thermostat to lowest setting and set

2. Slowly turn the thermostat to a higher temperature

3. Check for warm air delivery at the unit grille within a

4. Check the temperature of both supply and

5. Once the unit has begun to run, check for warm air

6. Check air temperature rise across the coil when

7. Check for vibration, noise and water leaks.

Operate the unit in heating cycle after checking the

cooling cycle. Allow 5 minutes between tests for the

pressure or reversing valve to equalize.

thermostat switch to HEAT position.

until the compressor activates.

few minutes after the unit has begun to operate.

discharge water. If temperature is within range,

proceed. If temperature is outside the range, check

the heating refrigerant pressures.

delivery at the unit grille.

compressor is operating. Air temperature rise

should be between 20

°

F and 30°F after 15 minutes

load.

Start-Up | 19LV Heat Pump Series

WARNING: Open the disconnect switch and

secure it in an open position before flushing

the system.

Flushing

Once the piping is complete, units require final purging

and loop charging. A flush cart pump of at least 1.5 hp is

needed to achieve adequate flow velocity in the loop to

purge air and dirt particles from the loop. Flush the loop

to purge air and dirt particles from the loop. Flush the

loop in both directions with a high volume of water at a

high velocity.

Follow the steps below to properly flush the loop:

1. Verify that the power is off.

2. Fill loop with water from the hose through flush cart

before using flush cart pump to ensure an even fill.

Do not allow the water level in the flush cart tank to

drop below the pump inlet line to prevent air from

filling the line.

3. Maintain a fluid level in the tank above the return tee

to avoid entering back into the fluid.

4. Shutting off the return valve that connects into the

flush cart reservoir it will allow 50 psig surges to

help purge air pockets. This maintains the pump at

50 psig.

5. To purge, keep the pump at 50 psig until maximum

pumping pressure is reached.

6. Open the return valve to send a pressure surge

through the loop to purge any air pockets in the

piping system.

7. A noticeable drop in fluid level will be seen in the

flush cart tank. This is the only indication of air in the

loop.

If air is purged from the system while using a 10 inch

PVC flush tank, the level drop will only be 1 to 2

inches, since liquids are incompressible. If the level

drops more than this, flushing should continue since

air is still being compressed in the loop. If level is

less than 1 to 2 inches, reverse the flow.

Flow Regulation

Flow regulation can be accomplished by two methods.

Most water control valves have a flow adjustment built

into the valve. By measuring the pressure drop through

the unit heat exchanger, the flow rate can be

determined. Adjust the water control valve until the

desired flow is achieved. Since the pressure constantly

varies, two pressure gages may be needed in some

applications.

An alternative method is to install a flow control device.

These devices are typically an orifice of plastic material

designed to allow a specified flow rate that are mounted

on the outlet of the water control valve. Occasionally

these valves produce a flow noise that can be reduced

by applying some back pressure. To accomplish this,

slightly close the leaving isolation valve of the well water

setup.

8. Repeat this procedure until all air is purged.

9. Restore power.

Antifreeze may be added before, during or after the

flushing process. However, depending on when it is

added in the process, it can be wasted. refer to the

Antifreeze section for more detail.

Loop static pressure will fluctuate with the seasons.

Pressures will be higher in the winter months than

during the warmer months. this fluctuation is normal

and should be considered when charging the system

initially. Run the unit in either heating or cooling for

several minutes to condition the loop to a homogenous

temperature.

When complete, perform a final flush and pressurize the

loop to a static pressure of 40 to 50 psig for winter

months or 15 to 20 psig for summer months.

8 733 905 683 (2016/09)LV Heat Pump Series

20 | Application Considerations LV Heat Pump Series

After pressurization, be sure to remove the plug from the

end of the loop pump motor to allow trapped air to be

discharged and to ensure the motor housing has been

flooded. Be sure the loop flow center provides adequate

flow through the unit by checking pressure drop across

the heat exchanger.

Antifreeze

In areas where entering loop temperatures drop below

40°F or where piping will be routed through areas

subject to freezing, antifreeze is needed.

Alcohols and glycols are commonly used as antifreeze

agents. Freeze protection should be maintained to 15

°

F

below the lowest expected entering loop temperature.

For example, if the lowest expected entering loop

temperature is 30°F, the leaving loop temperature would

be 22°F to 25°F. Therefore, the freeze protection should

be at 15

°

F (30°F-15°F=15°F).

NOTICE: All alcohols should be pre-mixed

and pumped from a reservoir outside the

building or introduced under water level to

avoid build up of fumes.

1. Flex Duct Connection.

2. Low Voltage Control Connection

Figure # 15

3. Vibration Pad

Antifreeze concentration should be checked from a well

mixed sample using a hydrometer to measure specific

gravity.

4. Ball Valves

5. Solenoid Valve Slow Closing

6. Condensate Drain Connection

7. Drain Valves

Freeze Protection Selection

The 26°F FP1 factory setting (water) should be used to

avoid freeze damage to the unit.

Once antifreeze is selected. the (FP1 jumper) should be

clipped on the control to select the low temperatures

(antifreeze 15°F) set point to avoid nuisance faults.

8. Hose Kits (optional)

9. Pressure Tank (optional)

10. P/T Ports (optional)

11. Line Voltage Connection

12. Electric Heater Line Voltage Disconnect

13. Unit Line Voltage Disconnect

APPLICATION CONSIDERATIONS

Well Water Systems

Copper is adequate for ground water that is not high in

mineral content. Should your well driller express

concerns regarding the quality of the well water

available or should any know hazards exists in your area,

we recommend proper testing to assure the well water

quality is suitable for use with water source equipment.

(See water quality table on page #21) in conditions

anticipating moderate scale formation or in brackish

water a cupro-nickel heat exchanger is recommended. In

well water applications water pressure must always be

maintained in the heat exchanger. This can be

accomplished with a control valve or a bladder type

expansion tank. When using a single water well to supply

both domestic water and the heat pump care must be

taken to ensure that the well can provide sufficient flow

for both. In well water applications a slow closing

solenoid valve must be used to prevent water hammer.

Solenoid valves should be connected across Y1 and C1

on the interface board for all. Make sure that the VA

draw of the valve does not exceed the contact rating of

the thermostat.

LV Heat Pump Series8 733 944 336 (2016/09) Subject to change without prior notice

Loading...

Loading...