Bosch GLM 150 Professional, GLM 250 VF Professional User guide [ml]

OBJ_BUCH-1044-001.book Page 1 Tuesday, October 13, 2009 9:53 AM

Robert Bosch GmbH

Power Tools Division

70745 Leinfelden-Echterdingen

Germany

www.bosch-pt.com

1 609 929 T68 (2009.10) T / 64 XXX

GLM Professional

150 | 250 VF

en Original instructions

fr Notice originale

th

หนังสือคู่มือการใช้งานฉบับต้นแบบ

id Petunjuk-Petunjuk untuk Penggunaan Orisinal

OBJ_BUCH-1044-001.book Page 2 Tuesday, October 13, 2009 9:49 AM

2 |

English . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Page 7

Français . . . . . . . . . . . . . . . . . . . . . . . . . . . . Page 22

ภาษาไทย . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . หน้า 37

Bahasa Indonesia . . . . . . . . . . . . . . . . . . Halaman 50

1 609 929 T68 | (13.10.09) Bosch Power Tools

OBJ_BUCH-1044-001.book Page 3 Tuesday, October 13, 2009 9:49 AM

3 |

hi

g

f

e

a

3

2

1

18

GLM 250 VF

Professional

28

29

d

b

c

9

8

7

6

5

4

10

11

12

13

14

15

1617

22

23

21

20

19

0 VF

nal

25

io

s

LM

G

es

of

r

P

082

3D1

<1 mW, 635 nm

IEC 60825-1:07

erdingen

elden-Echt

mbH

ery 4x1.5V LR03 (AAA)

GLM 250 VF

Laser Klasse 2

nicht in den Strahl blicken

Laserstrahlung

Batt

ert Bosch G

ricado na

Made in

Fab

D-70745 Leinf

Rob

Hecho en

24

27

26

25

24

10

1 609 929 T68 | (13.10.09) Bosch Power Tools

1.6 ft

1.6 ft

1.6 ft

1.6 ft

1.6 ft

OBJ_BUCH-1044-001.book Page 4 Tuesday, October 13, 2009 9:49 AM

4 |

BA

1.6 ft

1.6 ft

1.6 ft

DC

1.6 ft

FE

min

1.6 ft

1 609 929 T68 | (13.10.09) Bosch Power Tools

1

E

3

2

90˚

90˚

1

3

2

1

E

3

2

90˚

1

3

2

1

E

3

2

90˚

1

32

1

E

2

90˚

1

2

OBJ_BUCH-1044-001.book Page 5 Tuesday, October 13, 2009 9:49 AM

5 |

G

I

max

H

2

E

90˚

1

J

E

3

E

1

90˚

2

3

2

90˚

1

LK

E

A

3

1 609 929 T68 | (13.10.09) Bosch Power Tools

2

90˚

90˚

1

B

3

B

1

B

2

OBJ_BUCH-1044-001.book Page 6 Tuesday, October 13, 2009 9:49 AM

6 |

M

2.0 ft

2.0 ft

N

30

BS 150

0 601 096 974

O

31

2 607 990 031

32

2 607 001 391

1 609 929 T68 | (13.10.09) Bosch Power Tools

OBJ_BUCH-1044-001.book Page 7 Tuesday, October 13, 2009 9:49 AM

English | 7

en

Safety Notes

Working safely with the measuring

tool is possible only when the

operating and safety information

are read completely and the in-

structions contained therein are

strictly followed. Never make warning labels

on the measuring tool unrecognisable.

SAVE THESE INSTRUCTIONS.

f Caution – The use of other operating or ad-

justing equipment or the application of other

processing methods than those mentioned

here, can lead to dangerous radiation exposure.

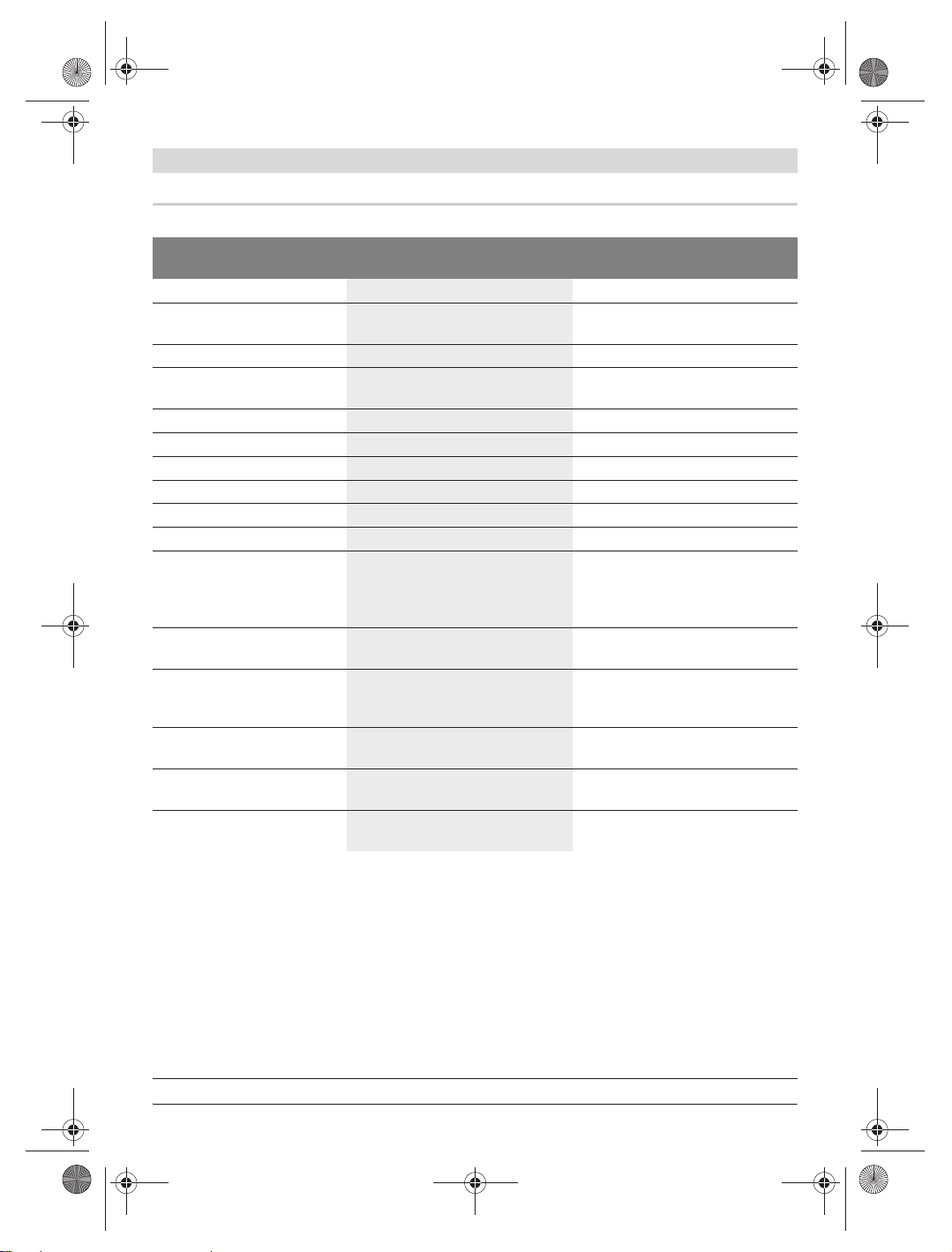

f The measuring tool is delivered with a warn-

ing label in German language (marked with

the number 19 in the representation of the

measuring tool on the graphic page).

f Before putting into operation for the first

time, attach the supplied sticker in your national language over the German text on the

warning label.

f Do not direct the laser beam at persons or

animals and do not stare into the laser

beam yourself. This measuring tool produc-

es laser class 2 laser radiation according to

IEC 60825-1. This can lead to persons being

blinded.

f Do not use the laser viewing glasses as

safety goggles. The laser viewing glasses are

used for improved visualisation of the laser

beam, but they do not protect against laser

radiation.

f Do not use the laser viewing glasses as sun

glasses or in traffic. The laser viewing glasses

do not afford complete UV protection and reduce colour perception.

f Have the measuring tool repaired only

through qualified specialists using original

spare parts. This ensures that the safety of

the measuring tool is maintained.

f Do not allow children to use the laser meas-

uring tool without supervision. They could

unintentionally blind other persons or themselves.

f Do not operate the measuring tool in explo-

sive environments, such as in the presence

of flammable liquids, gases or dusts. Sparks

can be created in the measuring tool which

may ignite the dust or fumes.

Functional Description

Please unfold the fold-out page with the representation of the measuring tool and leave it unfolded while reading the operating instructions.

Intended Use

The measuring tool is intended for measuring

distances, lengths, heights, clearances, and for

the calculation of areas and volumes. The measuring tool is suitable for measuring indoors and

outdoors.

Bosch Power Tools 1 609 929 T68 | (13.10.09)

OBJ_BUCH-1044-001.book Page 8 Tuesday, October 13, 2009 9:49 AM

8 | English

Technical Data

Digital Laser Rangefinder GLM 150

Professional

Article number

3 601 K72 070 3 601 K72 170

GLM 250 VF

Professional

Optical sight

(magnification 1.6-fold)

Measuring range

Measuring accuracy

(typically)

A)

B)

Lowest indication unit

Operating temperature

0.05– 150 m (0.16 –492 ft) 0.05– 250 m (0.16 –820 ft)

±1.0 mm (± 1/32 in) ±1.0 mm (± 1/32 in)

1/32 in; 0.001 ft; 0.1 mm 1/32 in; 0.001 ft; 0.1 mm

–10°C...+50°C

– z

C)

–10°C...+50°C

Storage temperature –20 °C ... +70 ° C –20 °C ... +70 ° C

Relative air humidity, max.

Laser class

Laser type

635 nm, <1 mW 635 nm, <1 mW

90 % 90 %

22

Laser beam diameter

(at 25 ° C), approx.

– at 10 m (33 ft) distance

– at 150 m (492 ft) distance

Batteries

Rechargeable batteries

Battery live, approximately

– Individual measurements

– Continuous measurement

6 mm (1/4 in)

90 mm (3 1/2 in)

4x1.5VLR03(AAA)

4x1.2VHR03(AAA)

D)

30000

D)

5h

6 mm (1/4 in)

90 mm (3 1/2 in)

4x1.5VLR03(AAA)

4x1.2VHR03(AAA)

30000

5h

Weight according to

EPTA-Procedure 01/2003

Dimensions

(2 19/32 x 4 23/32 x 1 15/32 in)

Degree of protection

splash water protected)

A) The working range increases depending on how well the laser light is reflected from the surface of the target (scattered, not reflective) and with increased brightness of the laser point to the ambient light intensity (interior spaces,

twilight). In unfavourable conditions (e.g. when measuring outdoors at intense sunlight), it may be necessary to use

the target plate.

B) In unfavourable conditions (e. g. at intense sunlight or an insufficiently reflecting surface), the maximum deviation

±20 mm per 150 m (± 0.8 in per 492 ft). In favourable conditions, a deviation influence of ± 0.05 mm/m

is

±0.0006 in/ft) must be taken into account.

(

C) In the continuous measurement function, the maximum operating temperature is +40 ° C.

D) Less measurements are possible when using 1.2 V rechargeable batteries than with 1.5 V batteries. The battery

life listed refers to measurements without display illumination and audio signal.

Please observe the article number on the type plate of your measuring tool. The trade names of the individual measuring tools may vary.

The measuring tool can be clearly identified with the serial number 20 on the type plate.

0.24 kg (8.5 oz) 0.24 kg (8.5 oz)

66 x 120 x 37 mm

66 x 120 x 37 mm

(2 19/32 x 4 23/32 x 1 15/32 in)

IP 54 (dust and

IP 54 (dust and

splash water protected)

C)

D)

D)

1 609 929 T68 | (13.10.09) Bosch Power Tools

3

OBJ_BUCH-1044-001.book Page 9 Tuesday, October 13, 2009 9:49 AM

English | 9

Product Features

The numbering of the product features shown

refers to the illustration of the measuring tool

on the graphic page.

1 Latch of the positioning pin

2 Button for continuous laser beam

3 Function-mode button

4 Button for length, area and volume

measurement

5 Result button

6 Plus button

7 Button for measuring and continuous

measuring

8 Button for selection of the reference level

9 Display

10 View finder of the optical sight

(GLM 250 VF)

11 Display-illumination button

12 Minus button

13 Button for minimum and maximum

measurement

14 Spirit level

15 Button for measured-value list

16 On/Off and memory delete button

17 Fixture for carrying strap

18 Positioning pin

19 Laser warning label

20 Serial number

21 1/4" thread

22 Battery compartment

23 Locking knob of the battery compartment

24 Alignment aid

25 Optical sight window (GLM 250 VF)

26 Reception lens

27 Laser beam outlet

28 Protective pouch

29 Carrying strap

30 Tripod*

31 Laser viewing glasses*

32 Laser target plate*

* The accessories illustrated or described are not

included as standard delivery.

Display Elements

a Measured-value lines

b “ERROR” indication

c Result line

d Measured-value list indicator

e Measuring modes

Length measurement

Area/surface measurement

Volume measurement

Continuous measurement

min

max Minimum/maximum measurement

2

1

Simple Pythagoras measurement

1

Double Pythagoras measurement

32

3

2

Combined Pythagoras measurement

1

2

Trapezium measurement

1

Timer function

Wall-surface measurement

Mark-out mode

f Battery low indicator

g Measurement reference level

h Laser switched on

i Temperature warning

Assembly

Inserting/Replacing the Battery

Using alkali-manganese or rechargeable batteries is recommended for operation of the measuring tool.

Fewer measurements are possible when using

1.2 V rechargeable batteries as compared with

1.5 V batteries.

To open the battery compartment 22, turn the

locking knob 23 to position and pull out the

battery compartment.

When inserting the batteries/rechargeable batteries, pay attention to the correct polarity according to the representation on the inside of

the battery compartment.

When the battery symbol appears for the first

time on the display, at least 100 individual

measurements are still possible. The continuous

measurement mode is deactivated.

Bosch Power Tools 1 609 929 T68 | (13.10.09)

OBJ_BUCH-1044-001.book Page 10 Tuesday, October 13, 2009 9:49 AM

10 | English

When the battery symbol flashes, the batteries/rechargeable batteries must be replaced.

Measurements are no longer possible.

Replace all batteries/rechargeable batteries at

the same time. Do not use different brands or

types of batteries/rechargeable batteries together.

f Remove the batteries/rechargeable batter-

ies from the measuring tool when not using

it for longer periods. When storing for longer

periods, the batteries/rechargeable batteries

can corrode and discharge themselves.

Operation

Initial Operation

f Protect the measuring tool against mois-

ture and direct sun light.

f Do not subject the measuring tool to ex-

treme temperatures or variations in temperature. As an example, do not leave it in

vehicles for longer periods. In case of large

variations in temperature, allow the measuring tool to adjust to the ambient temperature

before putting it into operation. In case of extreme temperatures or variations in temperature, the accuracy of the measuring tool can

be impaired.

f Avoid heavy impact to or falling down of the

measuring tool. After severe exterior effects

to the measuring tool, it is recommended to

carry out an accuracy check (see “Accuracy

Check of the Measuring Tool”, page 19) each

time before continuing to work.

Switching On and Off

For switching on the measuring tool, the following possibilities are given:

– Pressing the On/Off button 16: The measur-

ing tool is switched on and is in length measurement mode. The laser is not activated.

– Briefly pressing the measuring button 7:

Measuring tool and laser are switched on.

The measuring tool is in length measurement

mode.

– Pressing the measuring button 7 for several

seconds: Measuring tool and laser are

switched on. The measuring tool is in continuous measurement mode.

f Do not point the laser beam at persons or

animals and do not look into the laser beam

yourself, not even from a large distance.

To switch off the measuring tool, press the

On/Off button 16 for a few seconds.

When no button on the measuring tool is

pressed for approx. 5 minutes, the measuring

tool automatically switches off to save the

batteries.

When switching off automatically, all stored

values are retained.

Measuring Procedure

After switching on, the measuring tool is always

in length measurement or continuous measurement mode. Other measuring modes can be

switched to by pressing the respective mode

button (see “Measuring Functions”, page 12).

After switching on, the rear edge of the measuring tool is preset as the reference level for the

measurement. By pressing the reference level

button 8, the reference level can be changed

(see “Selecting the Reference Level”, page 11).

Upon selection of the measuring function and

the reference level, all further steps are carried

out by pushing the measuring button 7.

With the reference level selected, place the

measuring tool against the desired measuring

line (e.g. a wall).

Briefly press the measuring button 7 to switch

on the laser beam.

1 609 929 T68 | (13.10.09) Bosch Power Tools

OBJ_BUCH-1044-001.book Page 11 Tuesday, October 13, 2009 9:49 AM

English | 11

f Do not point the laser beam at persons or

animals and do not look into the laser beam

yourself, not even from a large distance.

Aim the laser beam at the target surface. Briefly

press the measuring button 7 again to initate

the measurement.

When the laser beam is switched on permanently, the measurement already starts after the first

actuation of the measuring button 7. In continuous measurement mode, the measurement

starts immediately upon switching on.

Typically, the measured value appears after 0.5

and latest after 4 seconds. The duration of the

measurement depends on the distance, the light

conditions and the reflection properties of the

target surface. The end of the measurement is

indicated by a signal tone. The laser beam is

switched off automatically upon completion of

the measurement.

When no measurement has taken place approx.

20 seconds after sighting, the laser beam is

switched off automatically to save the batteries.

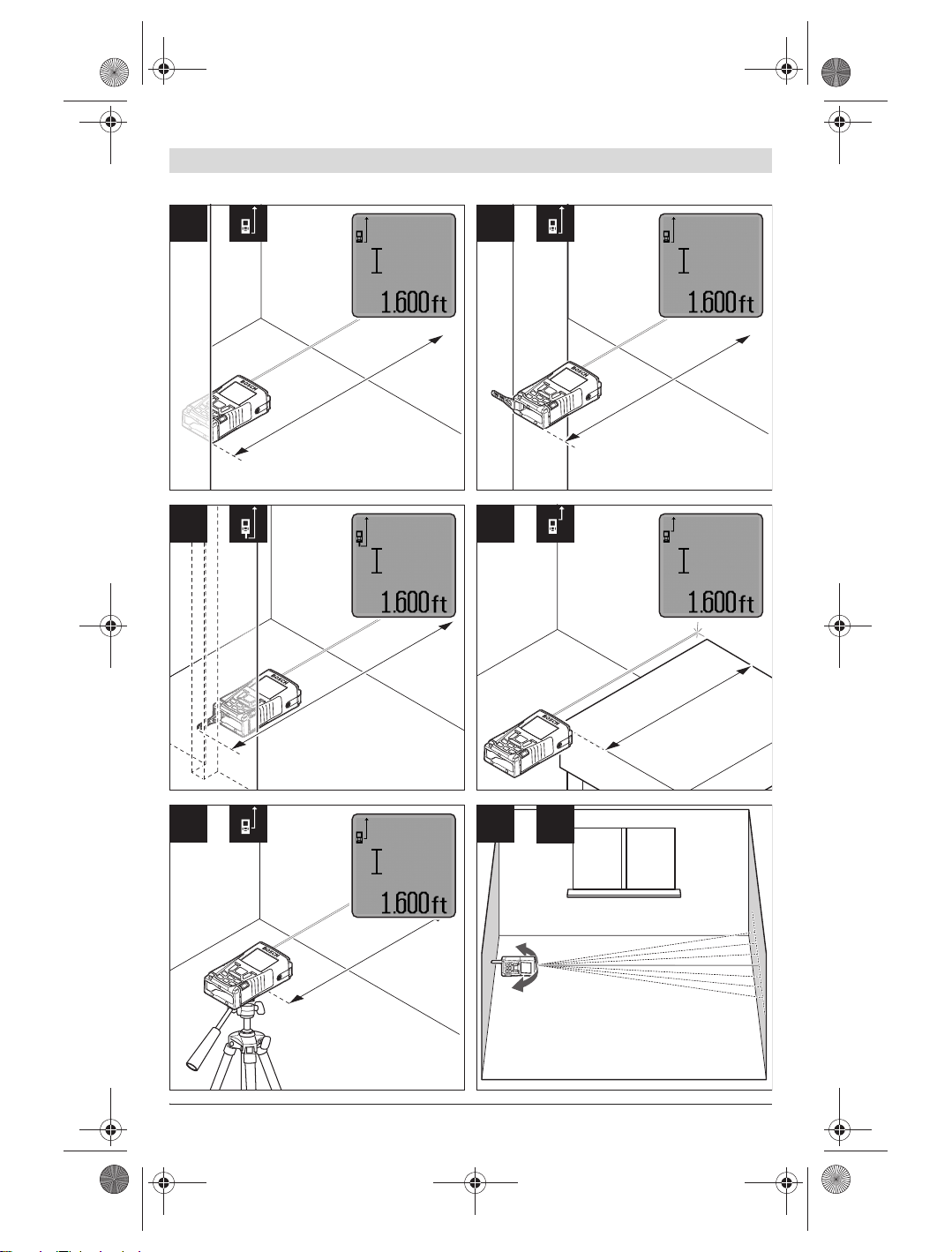

Selecting the Reference Level

(see figures A – E)

For measuring, you can select between four

different reference planes:

– The rear edge of the measuring tool or the

front edge of the laterally folded-out positioning pin 18 (e.g. when measuring onward

from outer corners),

– The tip of the folded-out positioning pin 18

(e.g. when measuring from a corner),

– The front measuring-tool edge (e. g. when

measuring onward from a table edge),

–The thread 21 (e. g. for tripod measure-

ments).

To select the reference level, press button 8 until the requested reference level is indicated on

the display. Each time after switching on the

measuring tool, the rear end of the measuring

tool is preset as the reference level.

Subsequent changing of the reference level for

measurements that have already been carried

out (e.g. when indicating measuring values in

the measured-value list) is not possible.

Continuous Laser Beam

If required, the measuring tool can also be

switched to the continuous laser beam mode.

For this, push the button for continuous laser

beam 2. “LASER” lights up continuously in the

display.

f Do not point the laser beam at persons or

animals and do not look into the laser beam

yourself, not even from a large distance.

In this setting, the laser beam also remains

switched on between measurements; for measuring, it is only required to press the measuring

button 7 once.

To switch off the continuous laser beam, press

button 2 again or switch the measuring tool off.

Switching off the continuous laser beam during

a measurement automatically ends the measurement.

Display Illumination

The display illumination is switched on and off

by pressing button 11. When no button is

pressed 10 s after switching on the display illumination, it is switched off to save the batteries.

Audio Signal

To switch the audio signal on

and off, press the functionmode button 3 until the “audio-signal adjustment” indication appears on the display.

Select the required setting by

pressing the plus button 6 or

the minus button 12.

The selected audio-signal adjustment is retained

when switching the measuring tool off and on.

Bosch Power Tools 1 609 929 T68 | (13.10.09)

OBJ_BUCH-1044-001.book Page 12 Tuesday, October 13, 2009 9:49 AM

12 | English

Changing the Unit of Measure

For indication of the measured values, the unit

of measure can be changed at any time.

The following units of measure are possible:

– Length measurement: m, cm, mm, ft, ft 1/32,

in, in 1/32, yd,

– Area/surface measurement: m

– Volume measurement: m

3

, ft3.

2

, ft2,

To to change the unit of measure, press the function-mode

button 3 until the “change

unit of measure” indication

appears on the display. Select

the required unit of measure

by pressing the plus button 6

or the minus button 12.

The unit-of-measure setting is retained when

switching the measuring tool on or off.

Measuring Functions

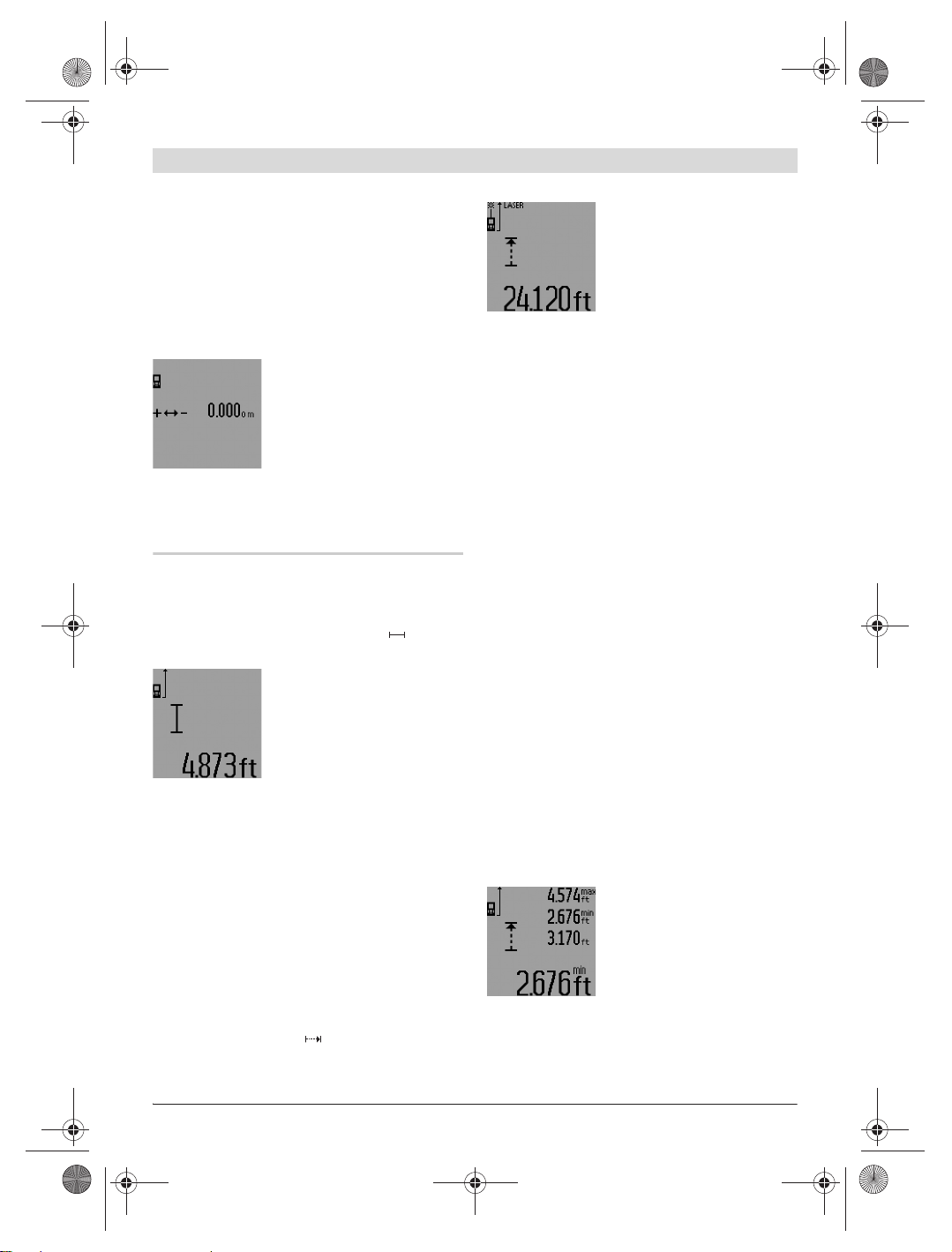

Simple Length Measurement

For length measurements, press button 4 until

the “length measurement” indication appears

on the display.

Press the measuring button 7

once for sighting and once

more to take the measurement.

The measured value is displayed in the result line c.

For several subsequent length measurements,

the last measured results are displayed in the

measured-value lines a.

Continuous Measurement (Tracking)

For continuous measurements, the measuring

tool can be moved relative to the target, whereby the measuring value is updated approx. every

0.5 seconds. In this manner, as an example, you

can move a certain distance away from a wall,

while the actual distance can always be read.

For continuous measurements, firstly select the

length measuring mode and then press the

measuring button 7 until the “indicator for continuous measurement” appears on the display. The laser is switched on and the measurement starts immediately.

The current measured value is

displayed in the result line c.

Briefly pressing the measuring button 7 ends the continuous measurement. The last

measured value is displayed

in the result line c. Pressing

the measuring button 7 for several seconds restarts a continuous measuring run.

Continuous measurement automatically switches off after 5 min. The last measured value remains indicated in the result line c.

Minimum/Maximum Measurement

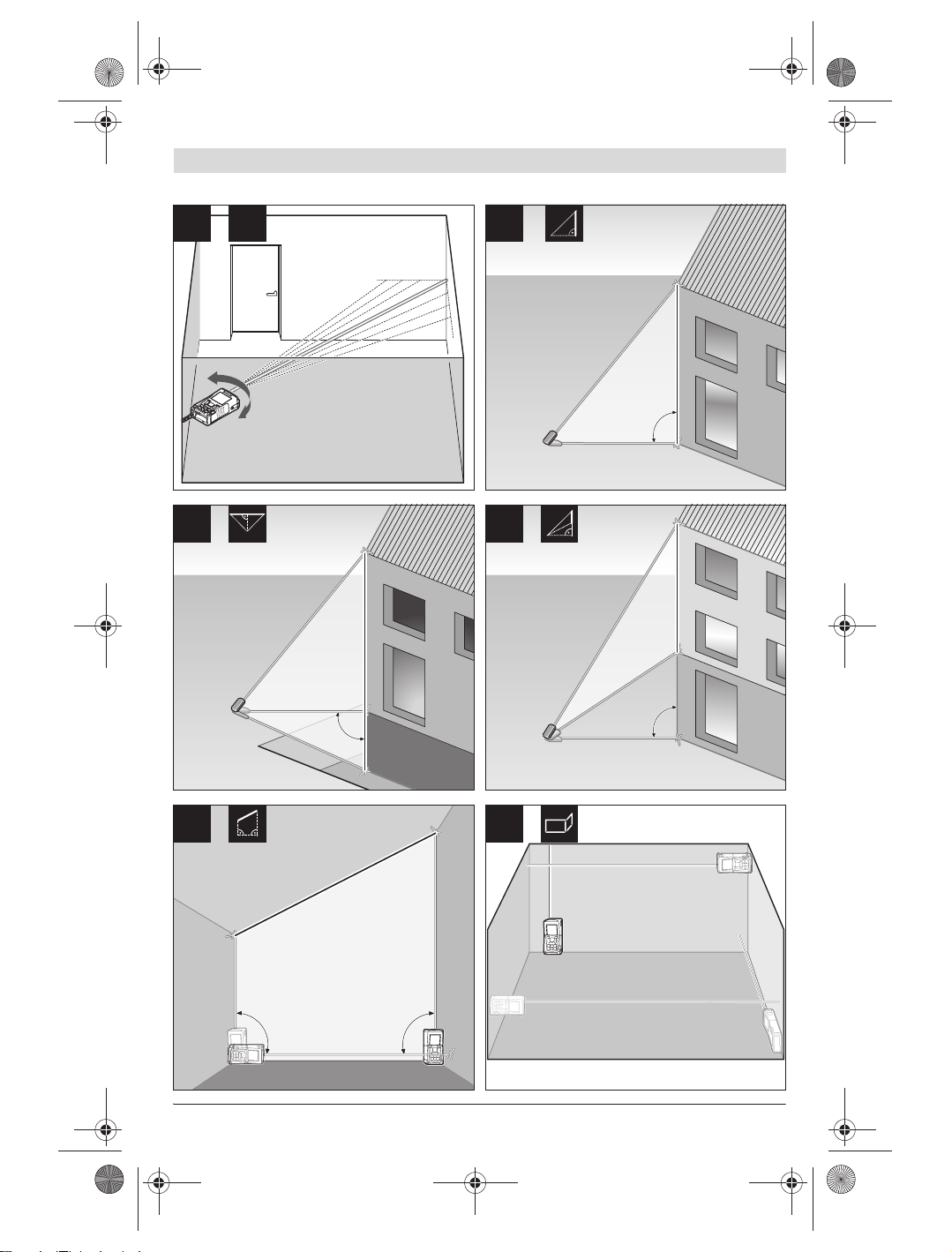

(see figure F– G)

The minimum measurement is used to determine the shortest distance from a fixed reference point. It is used, as an example, for determining plumb lines or horizontal partitions.

The maximum measurement is used to determine the greatest distance from a fixed reference point. It is used, as an example, for determining diagonals.

For simple minimum/maximum measurement,

firstly select “length measurement mode” and

then press button 13 “min” is displayed in result

line c for minimum measurement. For maximum

measurements, press button 13 again, so that

“max” is displayed in the result line. Then press

the measuring button 7. The laser is switched on

and the measurement starts.

Move the laser back and forth over the requested target (e.g., the room corner for determining

the diagonal) in such a manner that the reference point of the measurement (e.g., the tip of

the positioning pin 18) always remains at the

same location.

Depending on the set mode,

the minimum or maximum

value is displayed in the re-

sult line c. It is always over-

written, when the current

length measurement value is

less than the present minimal

or larger than the present maximal value. The

maximal (“max”), the minimal (“min”) and the

current measuring value are displayed in the

measured-value lines a.

1 609 929 T68 | (13.10.09) Bosch Power Tools

OBJ_BUCH-1044-001.book Page 13 Tuesday, October 13, 2009 9:49 AM

English | 13

To end the minimum/maximum measurement,

briefly press the measuring button 7. Pressing

the measuring button again starts a new measurement.

The minimum/maximum measurement can also

be used for length measurements within other

measuring modes (e.g. area/surface measurement). For this, press button 13 once for minimal measurement and twice for maximal measurement each time when determining individual

measured values. Then press the measuring button 7 to switch the laser beam on. Move the

measuring tool in such a manner that the desired minimum or maximum value is measured,

and press the measuring button 7 to take over

the minimum or maximum value into the current

calculation.

For time-delayed length measurements and

when in mark-out mode, minimum/maximum

measurements are not possible.

The minimum/maximum measurement automatically switches off after 5 min.

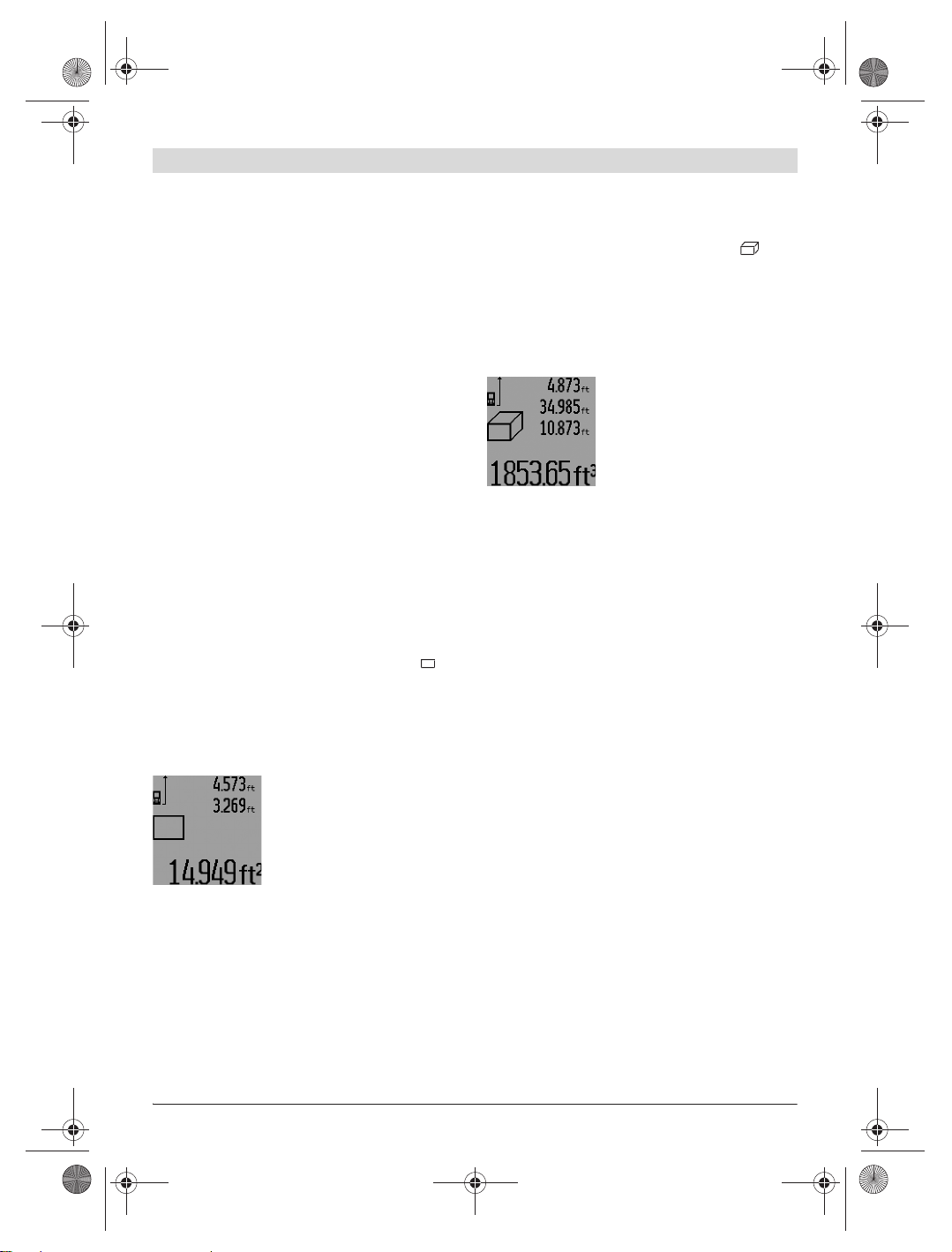

Area Measurement

For area/surface measurements, press button 4

until the indicator for area measurement appears on the display.

Afterwards, measure the length and the width,

one after another, in the same manner as a

length measurement. The laser beam remains

switched on between both measurements.

Upon completion of the second measurement, the surface is automatically calculated and displayed in the result

line c. The individual measured values are displayed in

the measured-value lines a.

Volume Measurement

For volume measurements, press button 4 until

the indicator for volume measurement appears on the display.

Afterwards, measure the length, width and the

height, one after another, in the same manner as

for a length measurement. The laser beam remains switched on between all three measurements.

Upon completion of the third

measurement, the volume is

automatically calculated and

displayed in the result line c.

The individual measured val-

ues are displayed in the

measured-value lines a.

3

Values above 999999 m

/ft3 cannot be indicated; “ERROR” and “––––” appear on the dis-

play. Divide the volume to be measured into individual measurements; their values can then be

calculated separately and then summarized.

Indirect Length Measurement

(see figures H– K)

The indirect length measurement is used to

measure distances that cannot be measured directly because an obstacle would obstruct the

laser beam or no target surface is available as a

reflector. Correct results are achieved only when

the right angles required for the respective measurement are exactly adhered to (Pythagorean

Theorem).

Pay attention that the reference point of the

measurement (e.g. the rear edge of the measuring tool) remains exactly at the same location

for all individual measurements within a measuring sequence (exception: trapezium measurements).

The laser beam remains switched on between

the individual measurements.

For indirect length measurements, four measuring modes are available. Each measuring mode

can be used for determining different distances.

To select the measuring mode, press the function-mode button 3 until the symbol of the desired measuring mode is indicated on the display.

Bosch Power Tools 1 609 929 T68 | (13.10.09)

3

OBJ_BUCH-1044-001.book Page 14 Tuesday, October 13, 2009 9:49 AM

14 | English

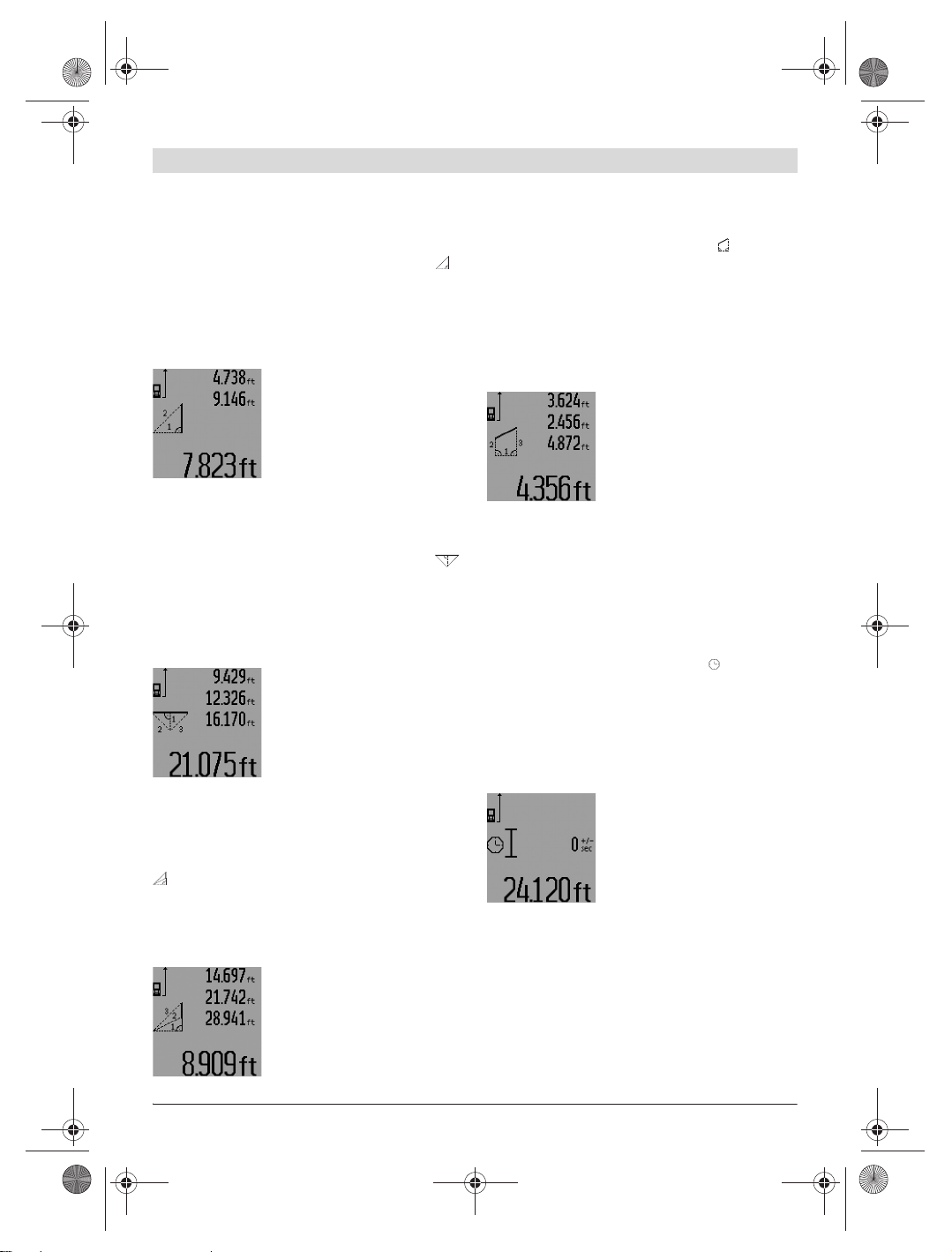

a) Simple Pythagoras Measurement

(see figure H)

Press the function-mode button 3 until the indication for simple Pythagoras measurement

2

1

appears on the display.

Measure distances “1” and “2” in this sequence

with a length measurement. Pay attention that a

right angle exists between distance “1” and the

sought distance “E”.

Upon completion of the last

measurement, the result for

the sought distance “E” is

displayed in the result line c.

The individual measured values are displayed in the

measured-value lines a.

b) Double Pythagoras Measurement

(see figure I)

Press the function-mode button 3 until the indication for double Pythagoras measurement

1

appears on the display.

Measure distances “1”, “2” and “3” in this se-

quence with a length measurement. Pay attention that a right angle exists between distance

“1” and the sought distance “E”.

Upon completion of the last

measurement, the result for

the sought distance “E” is

displayed in the result line c.

The individual measured values are displayed in the

measured-value lines a.

c) Combined Pythagoras Measurement

(see figure J)

Press the function-mode button 3 until the indication for combined Pythagoras measurement

3

2

appears on the display.

1

Measure distances “1”, “2” and “3” in this sequence with a length measurement. Pay attention that a right angle exists between distance

“1” and the sought distance “E”.

Upon completion of the last

measurement, the result for

the sought distance “E” is

displayed in the result line c.

The individual measured

values are displayed in the

measured-value lines a.

d) Trapezium Measurement (see figure K)

Press the function-mode button 3 until the indication for trapezium measurement appears

on the display.

Measure distances “1”, “2” and “3” in this sequence with a length measurement. Pay attention that the measurement of distance “3”

starts exactly at the end point of distance “1”

and that a right angle exists between distances

“1” and “2” as well as between “1” and “3”.

Upon completion of the last

measurement, the result for

the sought distance “E” is

displayed in the result line c.

The individual measured values are displayed in the

measured-value lines a.

Time-delayed Length Measurement

Time-delayed length measurement is helpful

32

e.g. when measuring at hard to reach locations

or when movements of the measuring tool during measuring are to be prevented.

For a time-delayed length measurement, press

function-mode button 3 until the indicator for

time-delayed length measurement appears on

the display.

The time period from the actuation until the

measurement takes place is displayed in the

measured-value line a. The time period can be

adjusted between 1 s and 60 s by pressing the

plus button 6 or the minus button 12.

Then press the measuring

button 7 to switch the laser

beam on and aim at the target point. Press the measuring button 7 again to actuate

the measurement. The meas-

urement takes place after the

set time period. The measured value is displayed in the result line c.

The addition and subtraction of measuring results as well as minimum/maximum measurements are not possible for time-delayed length

measurements.

2

1

1 609 929 T68 | (13.10.09) Bosch Power Tools

OBJ_BUCH-1044-001.book Page 15 Tuesday, October 13, 2009 9:49 AM

English | 15

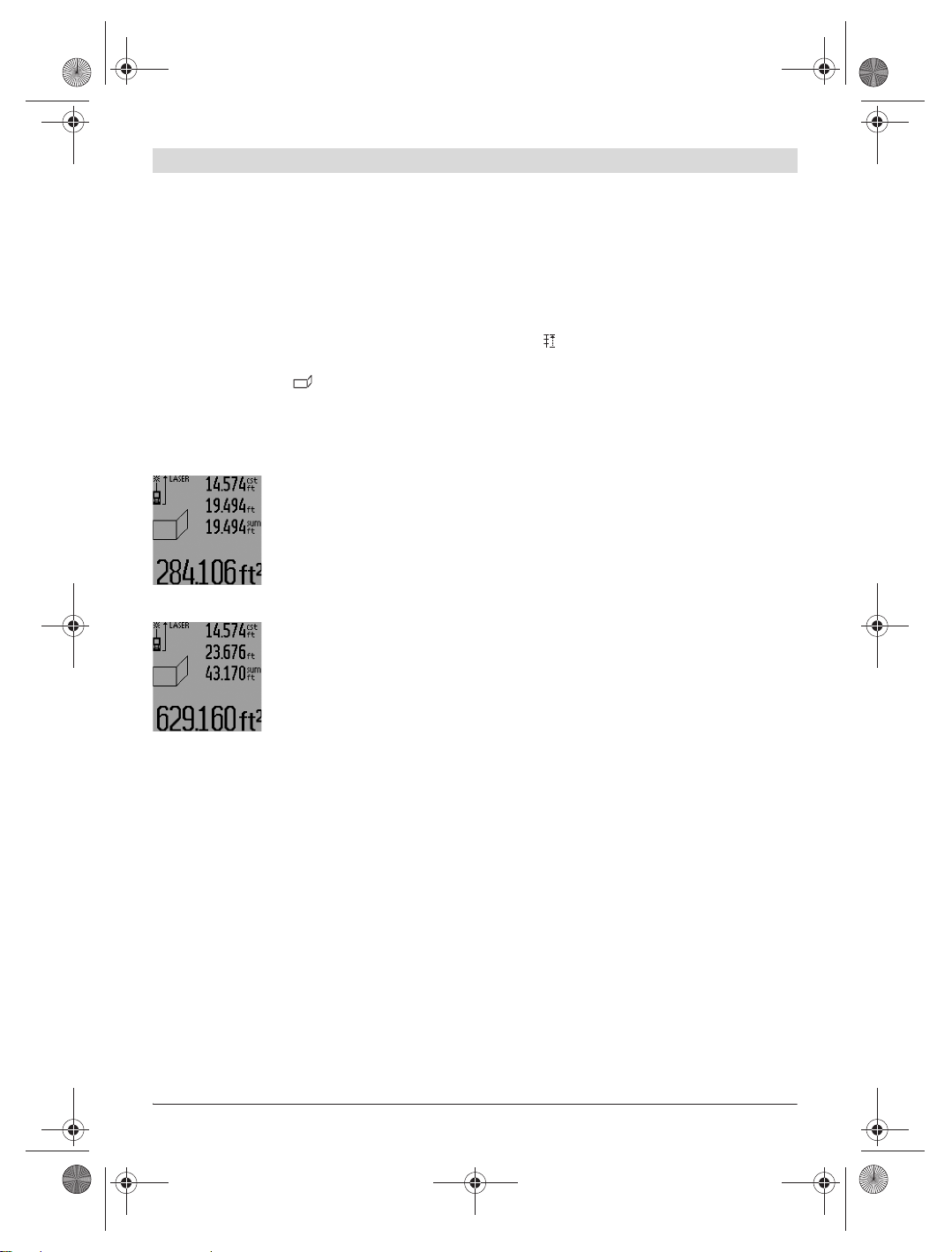

Wall Surface Measurement (see figure L)

The wall surface measurement is used to determine the sum of several individual surfaces with

a common height.

In the example shown, the total surface of several walls that have the same room height A, but

different lengths B, are to be determined.

For wall surface measurements, press the function-mode button 3 until the indicator for wall

surface measurement appears on the display.

Measure the room height A as for a length measurement. The measured value (“cst”) is dis-

played in the top measured-value line a. The laser remains switched on.

Afterwards, measure length

of the first wall. The surface

B

1

is automatically calculated

and displayed in the result line

c. The length measurement

value is displayed in the centre measured-value line a. The

laser remains switched on.

Now, measure length B

2

of

the second wall. The individually measured value displayed in the centre measured-value line a is added to

the length B

. The sum of

1

both lengths (“sum”, dis-

played in the bottom measured-value line a) is

multiplied with the stored height A. The total

surface value is displayed in the result line c.

In this manner, you can measure any number of

further lengths B

, which are automatically add-

X

ed and multiplied with height A.

The condition for a correct area/surface calculation is that the first measured length (in the example the room height A) is identical for all partial surfaces.

For a new wall surface measurement with new

room height A, press button 16 three times.

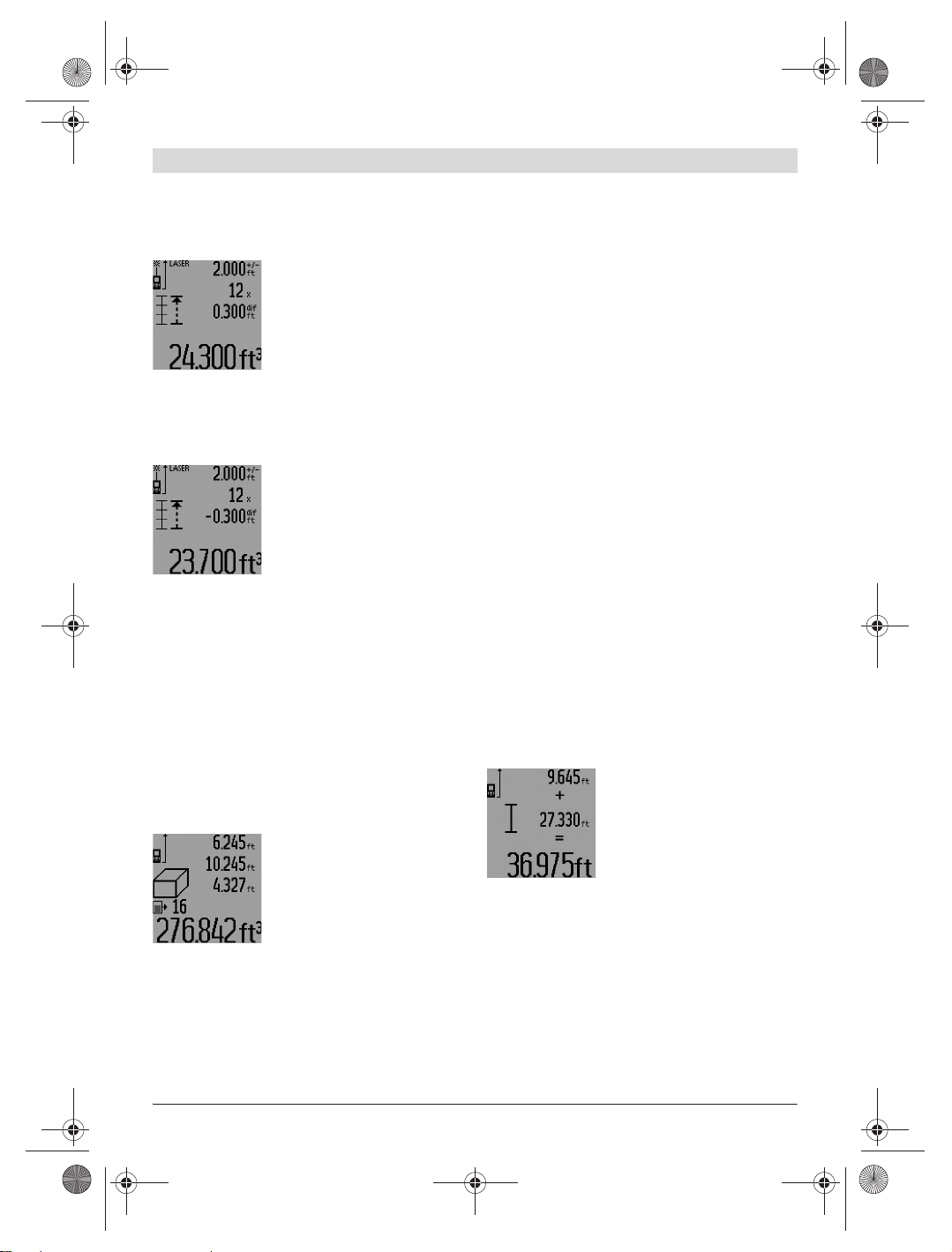

Mark-out Mode (see figure M)

Mark-out mode is used for marking off a fixed

length (mark-out value), which can either be

measured or entered. It is helpful for, e.g., marking partition spaces for drywalls.

To activate the mark-out mode, press the function-mode button 3 until the mark-out mode indication appears on the display.

The mark-out value can be adjusted as follows:

– To enter a known value, press the plus but-

ton 6 or the minus button 12 until the desired

value is displayed in the upper measured-value line a. When pressing and holding the plus

button 6 or minus button 12, the values will

continuously skip through. The laser is not

activated yet.

– For measuring the mark-out value, briefly

press the measuring button 7 once for sighting and once more for measuring. Afterwards, the laser beam remains switched on.

– The measured or entered mark-out value can

be corrected by pressing the plus button 6 or

the minus button 12.

After determining the mark-out value, press and

hold the measuring button 7 to begin the measurement.

Now, move the measuring tool in the desired direction for marking out. The current measuring

value of the complete measured distance is continuously displayed in the result line c. The selected mark-out value continues to be displayed

in the upper measured-value line a.

The factor (“x”) how often the mark-out value is

contained in the total measuring distance is displayed in the centre measured-value line, and the

difference (“dif”) between an integral multiple of

the mark-out value and the total distance is displayed in the bottom measured-value line a.

When the total measuring distance is somewhat

less than an integral multiple, then a negative

difference and the next higher multiple of the

mark-out value are displayed.

Move the measuring tool until the desired multiple of the mark-out value is displayed in the centre measured-value line a and the difference in

the bottom measured-value line is a “0.0”. Then

mark off the reference point of the measurement.

Bosch Power Tools 1 609 929 T68 | (13.10.09)

OBJ_BUCH-1044-001.book Page 16 Tuesday, October 13, 2009 9:49 AM

16 | English

Examples:

a) Positive difference:

24.3 ft = (12 x 2.0 ft) + 0.3 ft

The mark-out value 2,0 ft is

contained 12 times in a total

distance of 24,3 ft. Additionally, the total distance contains a rest of 0,3 ft. Reduce

the distance between the

measuring tool and the starting point by 0,3 ft difference,

and then mark off the length.

b) Negative difference:

23.7 ft = (12 x 2.0 ft) – 0.3 ft

For a total distance of 23,7 ft,

0,3 ft are missing for the

mark-out value 2,0 ft to be

contained 12 times. Increase

the distance between the

measuring tool and the starting point by 0,3 ft difference,

and then mark off the length.

Briefly pressing measuring button 7 ends the

mark-out mode. Pressing and holding the measuring button 7 restarts the mark-out mode anew

(with the same mark-out value).

The mark-out mode automatically switches off

after 5 min. For prior exiting of the function,

press one of the measuring-mode buttons.

List of the last Measuring Values

The measuring tool stores the last 30 measuring

values and their calculations, and displays them

in reverse order (last measured value first).

To recall the stored measurements, press button 15. The

result of the last measurement is indicated on the display, along with the indicator

for the measured-value list d

as well as a counter for the

numbering of the displayed

measurements.

When no further measurements are stored after

pressing button 15 again, the measuring tool

switches back to the last measuring function. To

exit the measured-value list, press one of the

measuring-mode buttons.

To delete the currently displayed measured-value list entry, briefly press button 16. To delete

the complete measured-value list, press and

hold the button for the measured-value list 15

and at the same time briefly press button 16.

Deleting Measured Values

Briefly pressing button 16 deletes the last indi-

vidual measuring value determined in all measuring functions. Briefly pressing the button repeatedly deletes the individual measured values

in reverse order.

In wall surface measurement mode, briefly

pressing button 16 the first time deletes the last

individually measured value; pressing the button

a second time deletes all lengths B

, and press-

X

ing the button a third time deletes all room

heights A.

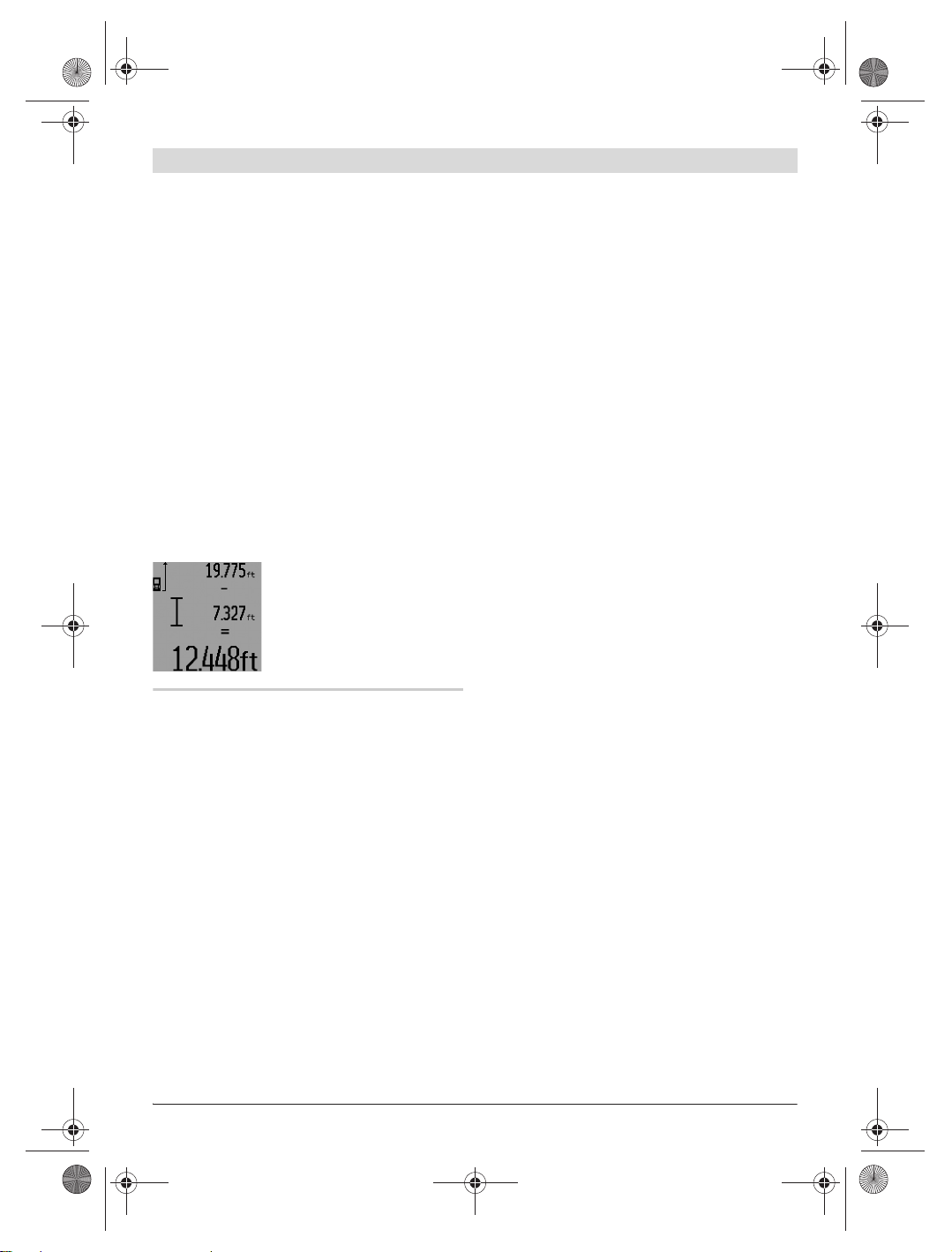

Adding Measured Values

To add measured values, firstly carry out any

measurement or select an entry from the measured-value list. Then press the plus button 6. For

confirmation, “+” appears on the display. Then

carry out a second measurement or select another entry from the measured-value list.

To call up the sum of both

measurements, press the result button 5. The calculation

is indicated in the measuredvalue lines a, and the sum in

the result line c.

After calculation of the sum, further measured

values or measured-value list entries can be added to this result when pressing the plus button

6 prior to each measurement. Pressing the result button 5 ends the addition.

1 609 929 T68 | (13.10.09) Bosch Power Tools

OBJ_BUCH-1044-001.book Page 17 Tuesday, October 13, 2009 9:49 AM

English | 17

Notes on the addition:

– Mixed length, area and volume values cannot

be added together. For example, when a

length and area value are added, “ERROR”

briefly appears on the display after pressing

the result button 5. Afterwards, the measuring tool switches back to the last active

measuring mode.

– For each calculation, the result of one meas-

urement is added (e.g. the volume value); for

continuous measurements, this would be the

displayed measured value in result line c. The

addition of individual measured values from

the measured-value lines a is not possible.

– For time-delayed length measurements and

when in mark-out mode, additions are not

possible; when changing to these modes, begun additions are interrupted.

Subtracting Measured Values

To subtract measuring values, press minus button 12;

For confirmation, “–” is indicated on the display. The further procedure is analog to

“Adding Measured Values”.

Working Advice

General Information

The reception lens 26 and the laser beam outlet

27 must not be covered when taking a measure-

ment.

The measuring tool must not be moved while taking a measurement (except for continuous measurements, minimum/maximum measurements

and when in mark-out mode). Therefore, place

the measuring tool, as far as this is possible,

against or on a firm stop or supporting surface.

Influence Effects on the Measuring Range

The measuring range depends upon the light

conditions and the reflection properties of the

target surface. For improved visibility of the

laser beam when working outdoors and when

the sunlight is intense, use the laser viewing

glasses 31 (accessory) and the laser target plate

32 (accessory), or shade off the target surface.

Influence Effects on the Measuring Result

Due to physical effects, faulty measurements

cannot be excluded when measuring on different surfaces. Included here are:

– Transparent surfaces (e.g., glass, water),

– Reflecting surfaces (e.g., polished metal,

glass),

– Porous surfaces (e.g. insulation materials),

– Structured surfaces (e. g., roughcast, natural

stone).

If required, use the laser target plate 32 (acces-

sory) on these surfaces.

Furthermore, faulty measurements are also possible when sighting inclined target surfaces.

Also, air layers with varying temperatures or

indirectly received reflections can affect the

measured value.

Measuring with the Positioning Pin

(see figures B, C, F and G)

The positioning pin 18 is suitable for measuring

out of corners (diagonal within a space) or from

hard to reach areas, such as from roller-shutter

rails.

Press on the positioning pin latch 1 to fold it in

or out, or change its position.

For measurements starting from outer corners,

fold the positioning pin aside; for measurements from the rear edge of the positioning pin

on, fold it out to the rear.

For measurements with the positioning pin, adjust the reference plane accordingly by pressing

button 8 (for measurements with the positioning pin aside, set to measuring from the rear

edge of the measuring tool).

Aligning with the Spirit Level

The spirit level 14 allows for simple levelling of

the measuring tool. This allows for easier sighting of target surfaces, especially over longer distances.

In combination with the laser beam, the spirit

level 14 is not suitable for levelling.

Bosch Power Tools 1 609 929 T68 | (13.10.09)

OBJ_BUCH-1044-001.book Page 18 Tuesday, October 13, 2009 9:49 AM

18 | English

Sighting with the Optical Sight (GLM 250 VF)

(see figure N)

The sighting line through the optical sight and

the laser beam run parallel to each other. This

allows for precise sighting over long distances,

when the laser dot is no longer visible with the

naked eye.

For sighting, view through the viewfinder of the

optical sight 10. Take care that the optical sight

window 25 is not obstructed and clean.

Note: For close vicinities, the actual and the displayed target point are not identical.

Sighting with the Alingment Aid (see figure O)

The alignment aid 24 supports sighting over

larger distances. For this, view alongside the

alignment aid on the side of the measuring tool.

The laser beam runs parallel to this sighting line.

Working with the Tripod (Accessory)

The use of a tripod is particularly necessary for

larger distances. Position the measuring tool

with the 1/4" thread 21 onto the quick-change

plate of the tripod 30 or a commercially available

camera tripod. Tighten the measuring tool with

the locking screw of the quick-change plate.

Set the corresponding reference level for measurement with a tripod by pushing button 8 (the

reference level is the thread).

Troubleshooting – Causes and

Corrective Measures

Cause Corrective

Temperature warning indicator (i) flashing;

measurement not possible

The measuring tool is outside the operating temperature range from – 10 ° C

to + 50 ° C (in the function

continuous measurement

up to +40 °C).

Battery low indicator (f) appears

Battery voltage decreasing (measurement still

possible)

Battery low indicator (f) flashing; measurement not possible

Battery voltage too low Replace batteries/

The indications “ERROR” and “–– – ––” are

indicated in the display

The angle between the

laser beam and the target

is too acute.

The target surface reflects

too intensely (e.g. a mirror) or insufficiently (e.g.

black fabric), or the ambient light is too bright.

The laser beam outlet 27

or the reception lens 26

are misted up (e.g. due to

a rapid temperature

change).

Calculated value is greater than 999999 m/m

2

/ft3/yd.

ft/ft

Measure

Wait until the

measuring tool

has reached the

operating temperature

Replace batteries/

rechargeable batteries

rechargeable batteries

Enlargen the angle

between the laser

beam and the target

Work with the

laser target plate

32 (accessory)

Wipe the laser

beam outlet 27

and/or the reception lens 26 dry

using a soft cloth

Divide calculation

2/m3

into intermediate

/

steps

1 609 929 T68 | (13.10.09) Bosch Power Tools

OBJ_BUCH-1044-001.book Page 19 Tuesday, October 13, 2009 9:49 AM

English | 19

Cause Corrective

Measure

The indication “ERROR” flashes at the top in

the display

Addition/Subtraction of

measured values with different units of measure

Measuring result not plausible

The target surface does

not reflect correctly

(e.g. water, glass).

The laser beam outlet 27

or the reception lens 26

are covered.

Wrong reference level set Select reference

Obstruction in path of

laser beam

The measuring tool monitors the

correct function for each measurement. When a defect is determined, only the symbol shown

aside flashes in the display. In this

case, or when the above mentioned corrective

measures cannot correct an error, have the

measuring tool checked by an after-sales service

agent for Bosch power tools.

Accuracy Check of the Measuring Tool

The accuracy of the measuring tool can be

checked as follows:

– Select a permanently unchangeable measur-

ing section with a length of approx. 1 to

10 metres (3 to 30 feet); its length must be

precisely known (e.g. the width of a room or a

door opening). The measuring distance must

be indoors; the target surface for the measurement must be smooth and reflect well.

– Measure the distance 10 times after another.

Only add/subtract

measured values

with the same

units of measure

Cover off the

target surface

Make sure that the

laser beam outlet

27 or the reception lens 26 are

unobstructed

level that corresponds to measurement

Laser point must

be completely on

target surface.

The deviation of the individual measurements

from the mean value must not exceed ±1.5 mm

(±1/16 in) (max.). Log the measurements, so

that you can compare their accuracy at a later

point of time.

Maintenance and Service

Maintenance and Cleaning

Store and transport the measuring tool only in

the supplied protective pouch.

Keep the measuring tool clean at all times.

Do not immerse the measuring tool in water or

other fluids.

Wipe off debris using a moist and soft cloth. Do

not use any cleaning agents or solvents.

Maintain the reception lens 26 in particular,

with the same care as required for eye glasses

or the lens of a camera.

If the measuring tool should fail despite the care

taken in manufacturing and testing procedures,

repair should be carried out by an authorised after-sales service centre for Bosch power tools.

Do not open the measuring tool yourself.

In all correspondence and spare parts orders,

please always include the 10-digit article

number given on the type plate of the measuring

tool.

In case of repairs, send in the measuring tool

packed in its protective pouch 28.

After-sales Service and Customer

Assistance

Our after-sales service responds to your questions concerning maintenance and repair of your

product as well as spare parts. Exploded views

and information on spare parts can also be

found under:

www.bosch-pt.com

Our customer service representatives can answer your questions concerning possible applications and adjustment of products and accessories.

Bosch Power Tools 1 609 929 T68 | (13.10.09)

Loading...

Loading...