Bosch Power Tools GLL2-80 User Manual

IMPORTANT: IMPORTANT : IMPORTANTE:

G

LL

2

-80

P

P

r

o

fe

s

s

ion

a

l

Read Before Using Lire avant usage Leer antes de usar

Operating/Safety Instructions

Consignes de fonctionnement/sécurité

Instrucciones de funcionamiento y seguridad

GLL2-80

GLL 2-80

Call Toll Free for

Consumer Information

& Service Locations

1-877-BOSCH99 (1-877-267-2499) www.boschtools.com

Pour obtenir des informations

et les adresses de nos centres

de service après-vente,

appelez ce numéro gratuit

Llame gratis para

obtener información

para el consumidor y

ubicaciones de servicio

For English Version Version française Versión en español

See page 5 Voir page 13 Ver la página 22

G

LL

2-8

0

P

Pr

o

f

es

s

i

o

n

a

l

4

3

2

5

6

1

1

GLL 2-80

7

8

12

11

10

9

13

14

1

1

-2-

FE

D

C

BA

-3-

P

r

of

e

ss

io

nal

20

16

BP 350

17

19

LR 2

18

15

8

8

MW 1

HG

-4-

General Safety Rules

!

WARNING

serious injury. The term “tool” in all of the warnings listed below refers to your mains-operated

(corded) tool or battery-operated (cordless) tool.

!

WARNING

ALWAYS BE AWARE of their location when using the tool.

DO NOT remove or deface any warning or caution labels. Removing labels increases the risk

of exposure to laser radiation.

Use of controls or adjustments or performance of procedures other than those specified in this

manual, may result in hazardous radiation exposure.

ALWAYS make sure that any bystanders in the vicinity of use are made aware of the dangers

of looking directly into the laser tool.

DO NOT place the laser tool in a position that may cause anyone to stare into the laser beam

intentionally or unintentionally. Serious eye injury could result.

ALWAYS position the laser tool securely. Damage to the laser tool and/or serious injury to the

user could result if the laser tool fails.

ALWAYS use only the accessories that are recommended by the manufacturer of your laser

tool. Use of accessories that have been designed for use with other laser tools could result in

serious injury.

DO NOT use this laser tool for any purpose other than those outlined in this manual. This could

result in serious injury.

DO NOT leave the laser tool “ON” unattended in any operating mode.

DO NOT disassemble the laser tool. There are no user serviceable parts inside. Do not modify

the product in any way. Modifying the laser tool may result in hazardous laser

radiation exposure.

DO NOT use the laser viewing glasses as safety goggles. The laser viewing glasses are used

for improved visualization of the laser beam, but they do not protect against laser radiation.

DO NOT use the laser viewing glasses as sun glasses or in traffic. The laser viewing glasses

do not afford complete UV protection and reduce color perception.

DO NOT use any optical tools such as, but not limited to, telescopes or transits to view the

laser beam. Serious eye injury could result.

DO NOT stare directly at the laser beam or project the laser beam directly into the eyes of

others. Serious eye injury could result.

Read all instructions. Failure to follow all instructions listed below may

result in hazardous radiation exposure, electric shock, fire and/or

The following labels are on your laser tool for your convenience and

safety. They indicate where the laser light is emitted by the tool.

Do not direct the laser beam at persons or animals and do not stare into the

laser beam yourself. This tool produces laser class 2 laser radiation and

complies with 21 CFR 1040.10 and 1040.11 except for deviations pursuant to

Laser Notice No. 50, dated June 24, 2007. This can lead to persons

being blinded.

SAVE THESE INSTRUCTIONS

-5-

Work area safety

Keep work area clean and well lit.

Cluttered or dark areas invite accidents.

DO NOT operate the laser tool around

children or allow children to operate the

laser tool. Serious eye injury could result.

Electrical safety

!

WARNING

To reduce this risk, always follow all

instructions and warnings on the battery label

and package.

DO NOT short any battery terminals.

DO NOT charge alkaline batteries.

DO NOT mix old and new batteries. Replace

all of them at the same time with new

batteries of the same brand and type.

DO NOT mix battery chemistries.

Dispose of or recycle batteries per

local code.

DO NOT dispose of batteries in fire.

Keep batteries out of reach of children.

Remove batteries if the device will not be

used for several months.

Stay alert, watch what you are doing and

use common sense when operating a

tool. Do not use a tool while you are tired

or under the influence of drugs, alcohol

or medication. A moment of inattention

while operating a tool may result in serious

personal injury or incorrect

measurement results.

Use safety equipment. Always wear eye

protection. Safety equipment such as dust

mask, non-skid safety shoes, hard hat, or

hearing protection used for appropriate

conditions will reduce personal injuries.

Magnets

• Keep the tool and laser target plate 15

away from magnetic data medium and

magnetically-sensitive equipment. The

effect of the magnets of the tool and laser

target plate can lead to irreversible

data loss.

Batteries can explode or

leak, cause injury or fire.

Personal safety

Keep the tool and laser

target plate 15 away from

cardiac pacemakers. The

magnets of the tool and laser

target plate generate a field

that can impair the function of

cardiac pacemakers.

Noise Information

The A-weighted sound pressure level of the

audio signal at one meter distance is

80dB(A).

Do not hold the measuring tool close to

your ear!

Use and care

Use the correct tool for your application.

The correct tool will do the job better

and safer.

Do not use the tool if the switch does not

turn it on and off. Any tool that cannot be

controlled with the switch is dangerous and

must be repaired.

Store idle tool out of the reach of children

and do not allow persons unfamiliar with

the tool or these instructions to operate

the tool. Tools are dangerous in the hands

of untrained users.

Maintain tools. Check for misalignment or

binding of moving parts, breakage of

parts and any other condition that may

affect the operation. If damaged, tool

repaired before use. Many accidents are

caused by poorly maintained tools.

Use the tool, accessories, etc., in

accordance with these instructions and in

the manner intended for the particular

type of tool, taking into account the

working conditions and the work to be

performed. Use of the tool for operations

different from those intended could result in a

hazardous situation.

Service

Have your tool serviced by a qualified

repair person using only identical

replacement parts. This will ensure that the

safety of the tool is maintained.

Develop a periodic maintenance schedule

for tool. When cleaning a tool be careful

not to disassemble any portion of the tool

since internal wires may be misplaced or

pinched or may be improperly mounted.

Certain cleaning agents such as gasoline,

carbon tetrachloride, ammonia, etc. may

damage plastic parts.

SAVE THESE INSTRUCTIONS.

-6-

Intended Use

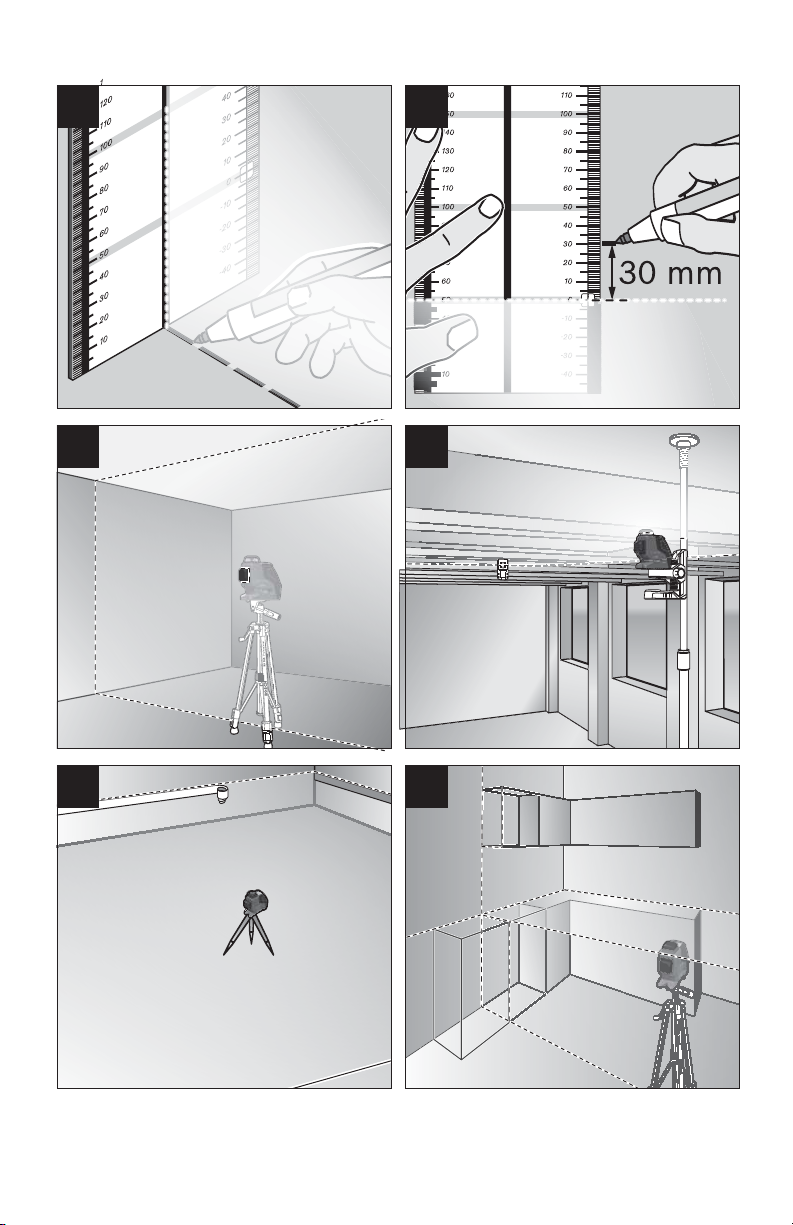

The tool is intended for determining and checking horizontal and vertical lines.

Preparation

Inserting/Replacing the Battery

Alkaline batteries are recommended for

the tool.

To open the battery compartment 12, slide

the latch 11 in the direction of the arrow and

fold the battery lid up. Insert the batteries.

When inserting, pay attention to the correct

polarity according to the representation on

the inside of the battery lid.

When the batteries become weak, a single 5

s audio signal will sound. The battery low

indicator 2 continuously flashes red. The tool

Features

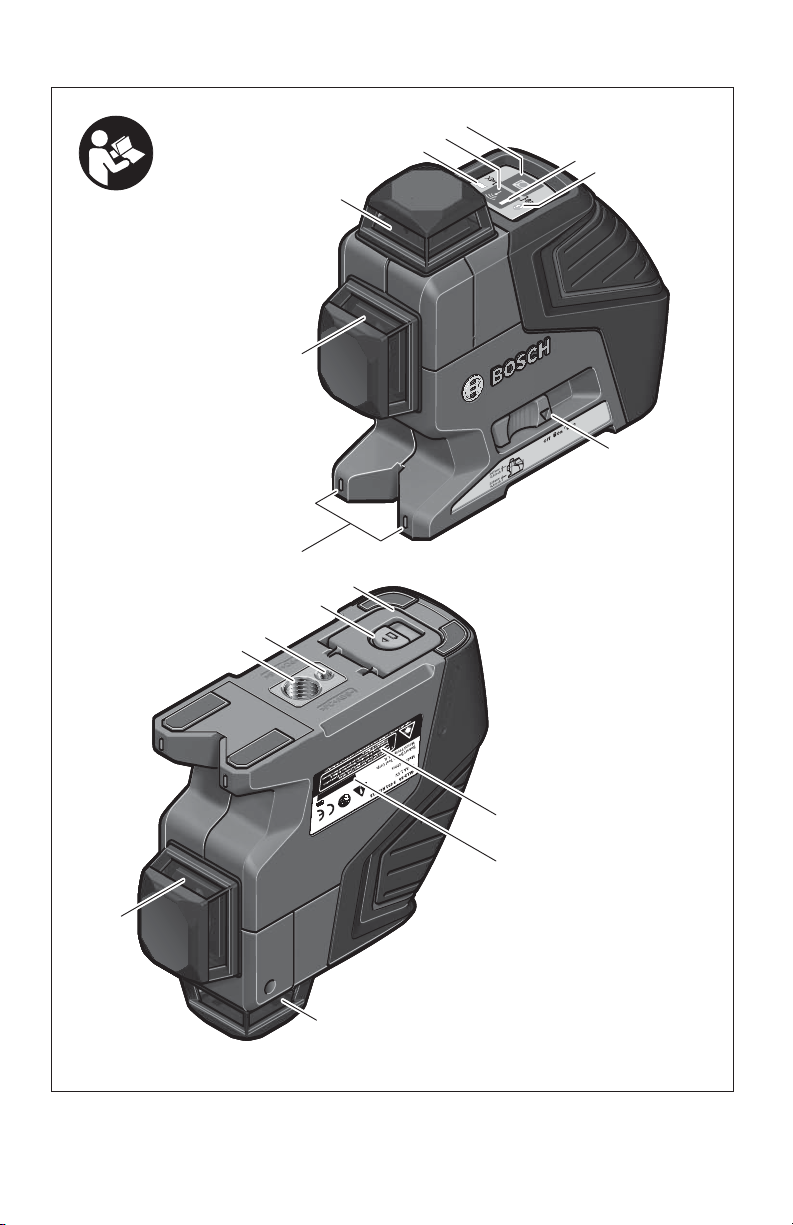

The numbering of the product features shown

refers to the illustration of the tool on the

graphic page.

1 Exit opening for laser beam

2 Battery low indicator

3 Pulse-function button

4 Operating mode button

5 Pulse-function indicator

6 Working without automatic leveling

indicator

7 On/Off switch

8 Magnets

9 Tripod mount 5/8"

Technical Data

can be operated for less then 2 h.

When the batteries are weak when switching

on the tool, the 5 s audio signal will sound

directly after switching on the tool.

Always replace all batteries at the same time.

Only use batteries from one brand and with

the identical capacity.

• Remove the batteries from the

tool when not using it for extended

periods. When storing for extended

periods, the batteries can corrode and

discharge themselves.

10 Tripod mount 1/4"

11 Latch of battery lid

12 Battery lid

13 Laser warning label

14 Serial number

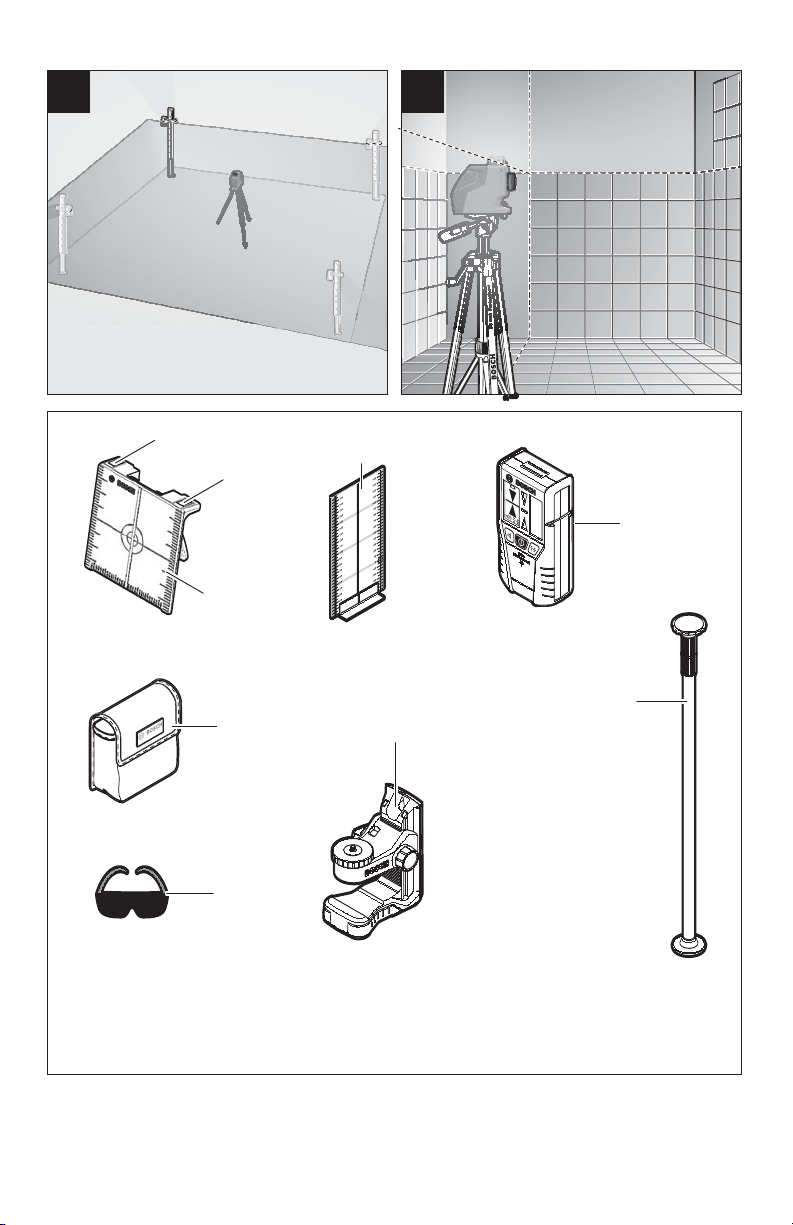

15 Laser target plate

16 Measuring plate with stand*

17 Laser receiver*

18 Protective pouch*

19 Universal holder*

20 Laser viewing glasses*

21 Tripod* (not shown)

*The accessories illustrated or described are

not included as standard delivery.

Working range (typical)

–Standard .................................... 65 ft (20m)

–With pulse function .................... 50 ft (15m)

–With laser receiver............16-260 ft (5-80m)

Leveling Accuracy

(typical) ..............................up to 1/4 at 100 ft

Self-leveling range (typical).......................±4°

Leveling duration, (typical) ...................... <4s

Operating temperature ........... 14 °F ~113 °F

(–10 °C ~ +45 °C)

Storage temperature............... -4 °F ~ 158 °F

(–20 °C ~ +70 °C)

Relative air humidity, max. ....................90 %

Laser class ................................................. 2

Laser type ...........................640 nm, <1 mW

Tripod mount .........................1/4-20, 5/8-11

Batteries ..........................4 x 1.5 V LR6 (AA)

Operating lifetime in operating mode

–With 2 laser planes..................................9 h

–With 1 laser plane .................................18 h

Weight ..................................... 1.54lb (700g)

Dimensions ........................ 6.2” x 5.5” x 2.1”

(159x 141 x 54mm)

Degree of protection ............................. IP 54

(dust and splash water protected)

1) The working range can be decreased by

unfavourable environmental conditions

(e.g. direct sun irradiation).

Please observe the article number on the

type plate of your tool. The trade names of

the individual tools may vary.

The tool can be clearly identified with the

serial number 14 on the type plate.

-7-

Operation

Initial Operation

• Loud audio signals will sound under

certain conditions while operating the

tool. Therefore, keep the tool away from

your ear or other persons. The loud

audio signal can cause hearing damage.

Protect the tool against moisture and

direct sun light.

• Do not subject the tool to extreme

temperatures or variations in

temperature.

As an example, do not leave it in vehicles

for longer periods. In case of large

variations in temperature, allow the

tool to adjust to the ambient temperature

before putting it into operation. In case of

extreme temperatures or variations in

temperature, the accuracy of the tool can

be impaired.

• Avoid heavy impact or dropping of the

tool. After heavy exterior impact on the

tool, an accuracy check should always be

carried out before continuing to work (see

“Leveling Accuracy”).

• Switch the tool off during transport.

When switching off, the leveling unit,

which can be damaged in case of intense

movement, is locked.

Switching On and Off

To switch on the tool, slide the On/Off

switch 7 to the “ on”. position (when

working without automatic levelling) or to the

“ on” position (when working with

automatic levelling). Immediately after

switching on, the tool sends laser beams out

of the exit openings 1.

• Do not point the laser beam at persons

or animals and do not look into the

laser beam yourself, not even from a

large distance.

To switch off the tool, slide the On/Off

switch 7 to the “off” position. When switching

off, the levelling unit is locked.

When exceeding the maximum permitted

operating temperature of 45 °C, the tool

switches off to protect the laser diode. After

cooling down, the tool is ready for operation

and can be switched on again.

Deactivating the Automatic Shut-off

When no button on the tool is pressed for

approx. 30 minutes, the tool automatically

switches off to save the batteries.

To switch on the tool after automatic shut-off,

either slide the On/Off switch 7 to the “off”

position and then switch the tool on again or

press the operating mode button 4 once or

press teh pulse-function button 3 once.

To deactivate the automatic shut-off, keep

the operating mode button 2 pressed for at

least 3 s (while the tool is switched on).

Deactivation of the automatic shut-off is

confirmed by brief flashing of the laser

beams.

• Do not leave the switched on tool

unattended and switch the tool off after

use.

To activate the automatic shut-off, switch the

tool off and then on again.

Deactivating the Signal Tone

After the tool has been switched on,the audio

signal is always activated.

To deactivate/activate the audio signal, press

and hold the operating mode button 4 and

the pulse-function button 3 at the same time

for at least 3 s.

The audio signal activation and deactivation

are both confirmed by three short beeps.

Operating Modes

The tool has three operating modes between

which you can switch at any time:

– Horizontal operation: generates a

horizontal laser plane.

– Vertical operation: generates a vertical

laser plane.

– Cross-line operation: generates a

horizontal and vertical laser plane.

After switching on, the tool is in horizontal

operation. Press the operating mode button

4 to change the operating mode.

All three operating modes can be selected

either with or without automatic levelling.

Pulse Function

When working with the laser receiver 17,

the pulse function must be activated,

–independent of the selected operating

mode.

In pulse function, the laser lines flash at very

high frequency and thus become detectable

by the laser receiver 17.

To switch on the pulse function, press button

3. When the pulse function is switched on,

the pulse-function indicator 5 lights up green.

-8-

When the pulse function is switched on, the

visibility of the laser lines is reduced for the

human eye. Therefore, shut off the pulse

function by pushing button 3 again when

working without laser receiver. When the

pulse function is switched off, the pulsefunction indicator 5 is deactivated.

Automatic Leveling

Working with Automatic Leveling

Position the tool on a level and firm support,

attach it to the holder 19 or to the tripod 21.

When working with automatic levelling, push

the On/Off switch 7 to the “ on” position.

After switching on, the leveling function

automatically compensates irregularities

within the self-leveling range of ±4°. The

leveling is finished as soon as the laser

beams do not move any more.

If automatic leveling is not possible, e.g.

because the surface on which the tool stands

deviates by more than 4° from the horizontal

plane, the laser lines begin to flash rapidly.

When the audio signal is activated, a fastbeat signal sounds for 30 s (maximum). This

alarm is deactivated within 10 s after

switching on, in order to allow adjustment of

the tool.

Set up the tool in level position and wait for

the self-leveling to take place. As soon as the

tool is within the self-leveling range of ±4°, all

laser beams light up continuously and the

audio signal is switched off.

In case of ground vibrations or position

changes during operation, the tool is

automatically levelled in again. To avoid

errors, check the position of the horizontal

and vertical laser

line with regard to the reference points upon

releveling.

Working without Automatic Leveling

For working without automatic leveling, slide

the On/Off switch 7 to the “ on” position.

When automatic leveling is switched off,

indicator 6 lights up red and for the first 30 s

laser beams flash slowly.

When the automatic leveling is switched off,

the tool can be held by hand or placed on an

inclined surface. In cross-line operation, the

two laser lines do not necessarily run at a

right angle to each other.

Working Advice

• Always use the center of the laser point

for marking. The size of the laser point

changes with the distance.

Leveling Accuracy

Influences on Accuracy

The ambient temperature has the greatest

influence. Especially temperature differences

occurring from the ground upward can divert

the laser beam.

Because the largest difference in

temperature layers is close to the ground,

the tool should always be mounted on a

tripod when distances exceeding 20 m. If

possible, also set up the tool in the center of

the work area.

Apart from exterior influences, devicespecific influences (such as heavy impact or

falling down) can lead to deviations.

Therefore, check the accuracy of the tool

each time before starting your work.

Firstly, check the leveling accuracy of the

horizontal laser line and then the leveling

accuracy of the vertical laser line.

Should the tool exceed the maximum

deviation during one of the tests, please

have it repaired by a Bosch after-sales

service.

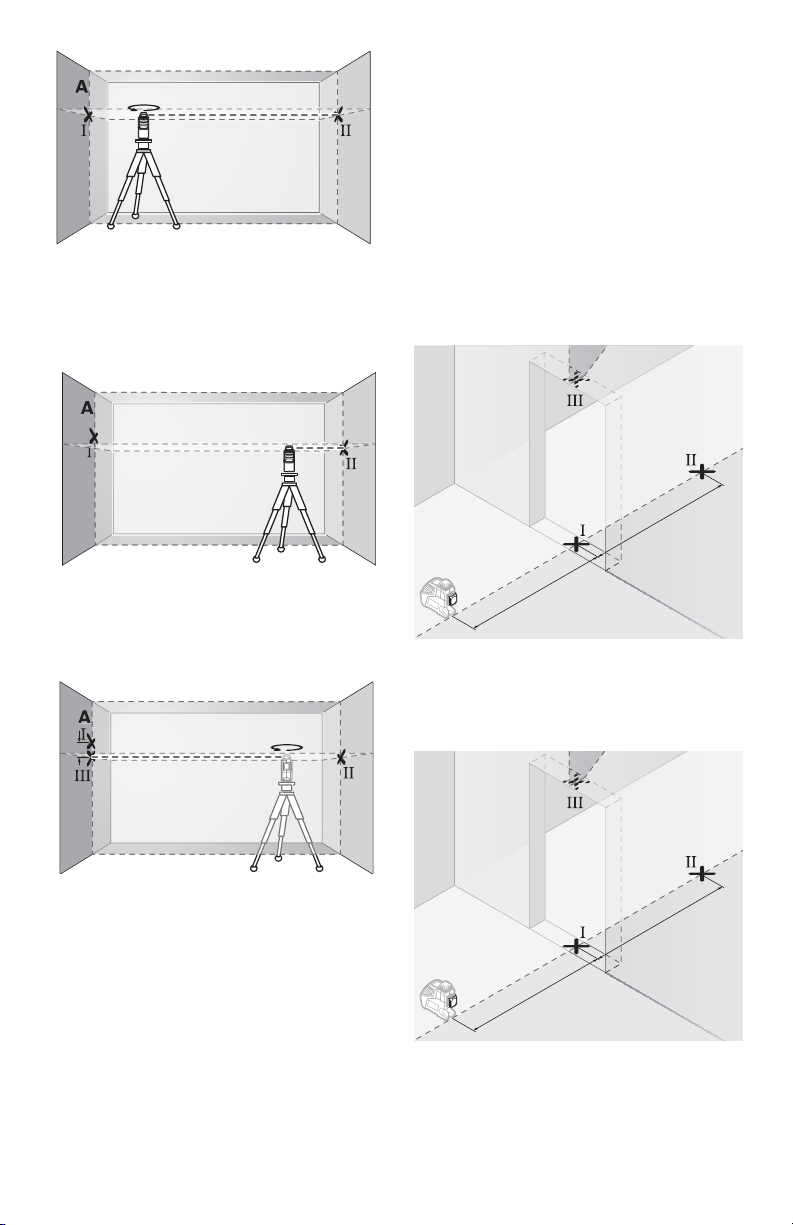

Checking the Horizontal Leveling

Accuracy.

A free measuring distance of 16 ft on a firm

surface in front of two walls A and B is

required for the check.

– Mount the tool onto a tripod, or place it

on a firm and level surface close to the

wall A. Switch the tool on. Select crossline operation with automatic leveling.

B

16 ft (5m)

– Direct the laser against the close wall A

and allow the tool to level in. Mark the

center of the point where the laser lines

cross each other on the wall (point I).

-9-

– Turn the tool by 180°, allow it to level in

B

180˚

B

B

dd

180˚

8ft

8ft

8ft

8ft

and mark the cross point of the laser lines

on the opposite wall B (point II).

– Without turning the tool, position it close to

wall B. Switch the tool on and allow it to

level in.

– Align the height of the tool (using a tripod

or by underlaying, if required) in such a

manner that the cross point of the laser

lines is projected against the previously

marked point II on the wall B.

32ft x ±0.0024in/ft = ±5/64 (0.078 in)

Thus, the difference d between points I and

III must not exceed 5/64 in (max.).

Checking the Leveling Accuracy of the

Vertical Line

For this check, a door opening is required

with at least 8 ft of space (on a firm surface)

to each side of the door.

– Position the tool on a firm, level surface

(not on a tripod) 8ft away from the door

opening. Allow the tool to level in while in

vertical operation with automatic leveling,

and direct the laser beam at the

door opening.

– Mark the center of the vertical laser line at

the floor of the door opening (point I), at a

distance of 8ft beyond the other side

of the door opening (point II) and at the

upper edge of the door opening (point III).

– Without changing the height, turn around

the tool by 180°. Direct it against the wall A

in such a manner that the vertical laser line

runs through the already marked point I.

Allow the tool to level in and mark the

cross point of the laser lines on the wall A

(point III).

– The difference d of both marked points I

and III on wall A results in the actual height

deviation of the tool alongside the

lateral axis.

On the measuring distance of 2 x 16ft = 32ft,

the maximum allowable deviation is:

– Rotate the tool by 180° and position it on

the other side of the door opening directly

behind point II. Allow the tool to level in

and align the vertical laser line in such a

-10-

Loading...

Loading...