BLAUPUNKT VXW 250, VXW 300, VXW 380 User Manual

GB

D

F

Notes on installation and operation Hinweise zur Installation und Bedienung Conseils pour l’installation et l’utilisation

VXW 250, VXW 300, VXW 380

GB

Thanks for choosing Velocity!

Congratulations on your purchase of your new Velocity product! We have invested tremendous effort in the de-sign process of the new Velocity subwoofer series, in order to achieve superior musical performance.

For maximum performance and reliability we highly recommend that your new Velocity subwoofers be installed by an authorised Velocity dealer. By using our Velocity line component speakers and amplifiers you can be as-sured of making the best out of your high-quality audio hi-fi system without spoiling the sound by using com-ponents of inferior quality.

For additional information on the Velocity Product Line (technical data, user notes and soon also a simulation programme for subwoofer housings) visit our Internet site at: http://www.velocity.de.

NEW COMPONENT FEATURES

High Power handling

Incredibly flexible installation: The new Velocity subwoofers perform well in sealed, vented and bandpass boxes.

Due to the low resonance values, the new Velocity subwoofers also work well in infinite baffle installations in which the woofer is mounted on the rear deck, using the trunk of the car for its acoustical enclosure.

New ultra-linear long-throw suspension.

Corrugated mica polypropylene design yields tremendous rigidity.

Additional loudness is achieved through longer cone travel, so we designed the Velocity subwooferswith 6 to 9 mm peak-to-peak excursion.

The new reinforced spider renders spider tears a thing of the past.

Butyl rubber surrounds offer linear cone movement without compression or the risk of tearing from over-excursion even for longer cone travel.

New strontium ceramic ferrite magnets yield smaller magnet sizes without reduced magnet strength but retain their magnet power far beyond the expected life of the woofer.

Four layers of high-temperature wire on DuPont Kapton Polyamide voice coil bobbins allow for voice coil temperatures exceeding nearly 225 degrees Celsius without damage.

Rear vented T-yokes allow fresh air to move in from behind the woofer to cool the voice coil.

Safety precautions

Before starting to mount your speakers, please read carefully the instructions on installation and connection.

Disconnect the negative terminal of the battery before carrying out installation and connection work. Observe the vehicle manufacturer’s safety instructions (regarding airbags, alarm systems, trip computers, vehicle immobilisers).

When drilling holes, take care to avoid damage to vehicle components (battery, cables, fuse boxes). Do not mount the subwoofer onto flexible rear decks (hatchback vehicles) or anywhere where they may fall for-ward.

8 622 401 256

2

DUAL VOICE COIL ADVANTAGES

The dual voice coil woofer is actually quite old in the home audio industry but still relatively new to the car audio world. The largest advantage of the DVC woofer is in the flexibility in installation. In order to raise the sound pressure level (loudness) in a car, you can either add more speakers or add more amplifier power to drive a single speaker. Many cars cannot fit two subwoofers and their necessary enclosure volumes but can easily fit large power amplifiers and a single woofer. Simply speaking, the

DVC woofer allows you to make up for speaker deficiencies with additional amplifier power.

SUBWOOFER ENCLOSURE TYPES

Sound is created by the movement of the woofer cone back and forth. If a woofer cone moves forward creating a positive pressure wave, this same motion creates a negative pressure at the back of the woofer. If these two waves combine due to the lack of a wall separating the front of the speaker sound from the back, the output from the woofer is effectively cancelled thus substantially reducing the bass output of the speaker. This wall is absolutely necessary and is referred to as an acoustical „baffle“. It can be accomplished using a box of some kind or simply the rear package shelf of an automobile to isolate the front and back waves of the speaker.

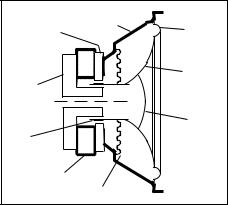

THIELE-SMALL PARAMETERS

FRONT PLATE |

FRAME |

SURROUND |

|

||

|

|

CONE |

YOKE |

|

|

VENT |

|

|

|

|

DUST CAP |

VOICE COIL |

|

|

MAGNET |

|

|

|

SPIDER |

|

Every woofer has its own electromechanical characteristics which are called THIELE-SMALL parameters. The three most important parameters include RESONANT FREQUENCY („fs“- the frequency where the speaker moves with the least mechanical resistance), TOTAL Q („Qts“- the

„magnification“ of the cone movement at its resonant frequency), and VOLUMETRIC COMPLIANCE

(„Vas“- the equivalent volume of air that the woofer cone can displace for a given power input). Using these parameters we can then calculate an optimum box volume for a particular woofer and reasonably predict its frequency response.

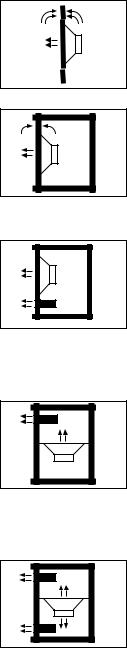

COMMON ENCLOSURE TYPES

In the car audio world there are five types of subwoofer enclosures commonly used: INFINITE

BAFFLE, SEALED BOX (closed box), VENTED BOX (bass reflex), SINGLE-VENTED BANDPASS

(often incorrectly referred to as „5th“ order), DUAL-VENTED BANDPASS (often incorrectly referred to as „7th“ order). No single design is superior because each has its own compromise in performance, power handling and design complexity. The bandpass name implies a „built-in“ acoustical response which has a natural highpass response (@ 30 Hz for example) but also a lowpass response suppressing high frequencies (e.g., > 80 Hz).

8 622 401 256

3

INFINITE BAFFLE (fig.a)designs simply use the trunk of the car for its acoustical enclosure and the rear deck to isolate the front and rear sound paths. Advantages include simple installation and adequate performance for most systems. Disadvantages include poor power handling capacity and substandard transient response.

SEALED boxes (fig.b) offer one of the best compromises in power handling and performance. Because of the „air spring“ provided by the box the advantages include simple box construction, higher power handling, excellent transient response, and smooth low frequency rolloff. Disadvantages include only moderate efficiencies at low frequencies and the need for large box volumes.

VENTED boxes (fig.c) extend the low frequency response below that of the sealed box by using a port tube. Advan-tages include extended low frequency response, lower distortion due to smaller cone movements in its passband, good efficiency, good transient response, moderate size boxes and higher power capacity. Disadvantages include increased complexity in box design and possible woofer damage due to over-excursion of the woofer cone below the cut-off frequency of the vented box.

SINGLE-VENTED BANDPASS boxes (fig.d) are relatively new

(about 5 years in the car) but offer some advantages of both the sealed and vented designs. Advantages include reasonable efficiency, small box volumes, good transient response, extended low frequency performance and can be used with very high power amplifiers. Disadvantages include slightly lower efficiency compared to a vented box and increased complexity in box design and construction.

DUAL-VENTED BANDPASS boxes (fig.e) vent the sound from the front and back of the woofer through individually tuned enclosure on the front and rear of the woofer. The advantage of this design is its high efficiency over a narrow frequency band. Disadvantages include complex design and construction, large box volumes, poor transient response and susceptibilities to cone over-excursions (damage) for sound outside its primary frequency band.

a)

b)

c)

d)

e)

8 622 401 256

4

ISOBARIC WOOFER CONFIGURATIONS

Increasing in popularity in recent years is the compound woofer design, more commonly known as the „Isobaric“ design. Isobaric actually means „constant pressure“ which is the case having two woofers moving an encapsulated pocket of air between them in the same direction.

This arrangement acts like a single speaker which effectively reduces the required box volumes for a subwoofer system by 50% which is substantial if you are space-limited. Unfortunately, the trade-off for space is the 3 dB loss in efficiency but this is usually recovered with increased amplifier power. Care must be taken to avoid air leaks between the two woofers and final speaker wiring and impedance loads must be carefully watched.

SUBWOOFER ENCLOSURE CONSTRUCTION

+ |

- |

+ |

2 |

4 |

- 4 |

- |

||

|

+ |

|

|

PARALLE |

|

+ |

- |

+ |

8 |

4 |

- 4 |

- |

||

|

+ |

|

|

SERIES |

|

ISOBARIC CONFIGURATION (TANDEM)

+ |

+ |

+ |

2

- - 4 - 4

PARALLE

+ + +

8

- - 4 - 4

SERIES

Before starting final box assembly some basic construction issues should be mentioned:

-Infinite baffle construction in a car is done by simply cutting a piece of wood which will act as an acoustical divider isolating the front and rear sound of the woofer. This piece of wood is mounted inside the trunk of the car under the rear deck, or against the back of the rear seat, and should have some kind of caulking to seal off all residual air leaks.

-Box construction can take on nearly any shape since we are dealing with low frequencies. Odd shapes that are difficult to cut and glue should be avoided.

-Particle board, MDF, or high grade birch plywood are good materials to build boxes of thicknesses of 19 to 25 mm.

-All seams in the box should be glued, screwed and caulked to prevent wall separation over time due to vibration and environmental changes within the car.

-Cross bracing is important for large boxes to prevent wall vibration.

-Acoustical damping material (sheep wool or fibre-glass batting 5 to 10 cm thick), attached to 50% or more of the interior walls helps reduce box noise and also increases the box volume seen by the woofer by 10 - 20%. The application of self-adhesive damping mats to the inside walls also helps to eliminate wall resonances.

-The cables running from the amplifier to the subwoofer should be as short as possible with a cable cross section of at least 4 mm2.

-The final box should be rock solid and air tight but should also remain serviceable should a woofer be damaged for any reason.

-When possible, use 10 to 15 cm diameter port tubes to avoid wind noise from smaller diameter sizes. PVC plumbing pipe in various diameters is available at most hardware stores with „elbow“ pipes allowing you to bend the tubes inside the box.

-Try to always use active (electronic) crossovers, such as those built into our Velocity amps, for example.

8 622 401 256

5

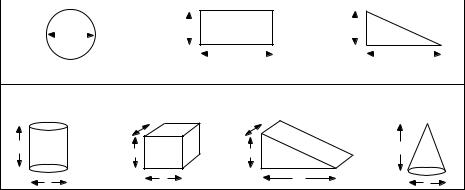

Basic Math Calculations

To build a subwoofer box some very basic math calculations must be made accurately referencing the formulas below.

Volume and Area Calculations

|

|

|

|

|

Area: |

|

|

Volume: |

||||||||

Circle (port opening) |

A = 0,79 x d x d |

|

- |

|

|

|

|

|

||||||||

Rectangle |

A = h x w |

|

- |

|

|

|

|

|

||||||||

Triangle |

A = 0,5 x h x w |

|

- |

|

|

|

|

|

||||||||

Cylinder (port tube) |

- |

|

|

|

|

|

V = 0,79 x d x d x h |

|||||||||

Rectangular box |

- |

|

|

|

|

|

V = h x w x d |

|||||||||

Triangular box |

- |

|

|

|

|

|

V = 0,5 x h x w x d |

|||||||||

Cone |

- |

|

|

|

|

|

V = 0,26 x d x d x h |

|||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

d |

|

|

h |

|

|

h |

||||||||

|

|

|

|

|

|

|

w |

|

|

|

|

|

w |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

||||||||

|

|

d |

d |

|

|

h |

|

h |

h |

|

h |

|

|

|

|

||

|

d |

w |

|

w |

d |

|

|

|

|

Speaker parameters and box calculations often need some kind of math calculations in order to make the numbers easy to work with (conversions between metric and Imperial/American units). Some common conversions are listed below:

Volume and Area Conversions

To convert from: |

multiply by: |

to get: |

Inches |

0.0254 |

Meters |

|

|

|

Meters |

39.37 |

Inches |

|

|

|

Square inches |

0.007 |

Square feet |

Square feet |

144 |

Square inches |

|

|

|

Cubic inches |

0.00058 |

Cubic feet |

|

|

|

Cubic feet |

1728 |

Cubic inches |

Liters |

0.035 |

Cubic feet |

|

|

|

Cubic feet |

28.3 |

Liters |

|

|

|

8 622 401 256

6

8 622 401 256

7

Loading...

Loading...