Page 1

CL8543131

11/2016 rev 0

LADY 5

EN

UNIONE NAZIONALE COSTRUTTORI

AUTOMATISMI PER CANCELLI, PORTE

SERRANDE ED AFFINI

Page 2

Page 3

1008

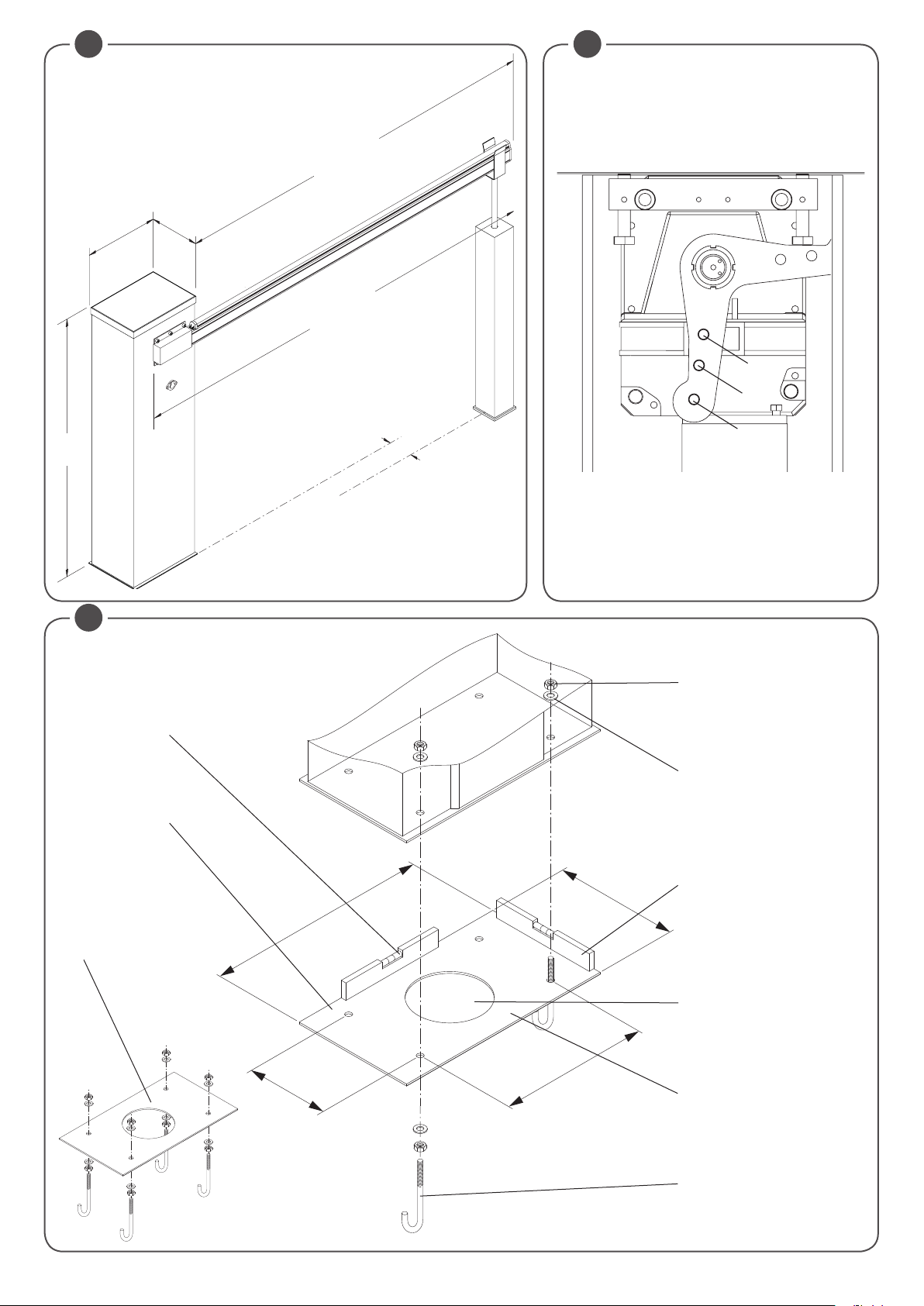

1

320

135

222

200

2

MIN. 2,0m

MAX. 4,0m

222

324

MIN. 2,2m

MAX. 4,2m

C

B

3

Livella.

Spirit level

Wasserwaage

Niveau

Nivel

Poziomnica

Accessorio VE.PS

Accessory VE.PS

Zubehör VE.PS

Accessoire VE.PS

Accesorio VE.PS

Akcesoriów VE.PS

VE.PS Kit

VE.PS Kit

VE.PS Kit

VE.PS Kit

VE.PS Kit

VE.PS Kit

40

Dimensioni d’ingombro

Overall dimensions

Platzbedarf

Dimensions d’encombrement

Dimensiones totales

Wymiary gabarytowe

A

Dado M12 UNI 5588.

Nut M12 UNI 5588.

Mutter M12 UNI 5588.

Ecrou M12 UNI 5588.

Tuerca M12 UNI 5588.

Nakrętka M12 UNI 5588

Rosetta Ø13x24 UNI 6592.

Washer Ø13x24 UNI 6592.

Unterlegscheibe Ø13x24 UNI 6592.

Rondelle Ø13x24 UNI 6592.

Arandela Ø13x24 UNI 6592.

Podkładka Ø 13x24 UNI 6592

Mettere in piano la piastra tramite livella

Lay the plate flat using a spirit level

Die Platte mit Hilfe einer Wasserwaage gerade ausrichten

Mettre la plaque de niveau avec un

niveau à bulle

Nivelar horizontalmente la placa

con el nivel

Wypoziomować płytę za pomocą

poziomnicy.

Foro per passaggio cavi

Hole for passing cables

Loch für Kabeldurchgang

Trou pour passage des câbles

Orificio para el paso de cables

Otwór do przepuszczania kabli.

Piastra di fondazione

Foundation plate

Fundamentplatte

Plaque de fondation

Placa de cimentación

Płyta montażowa.

Staffa a cementare

Cementing-in bracket

Bügel zum Einbetonieren

Patte à sceller

Estribo a cimentar.

Kotwa do zabetonowania.

3

Page 4

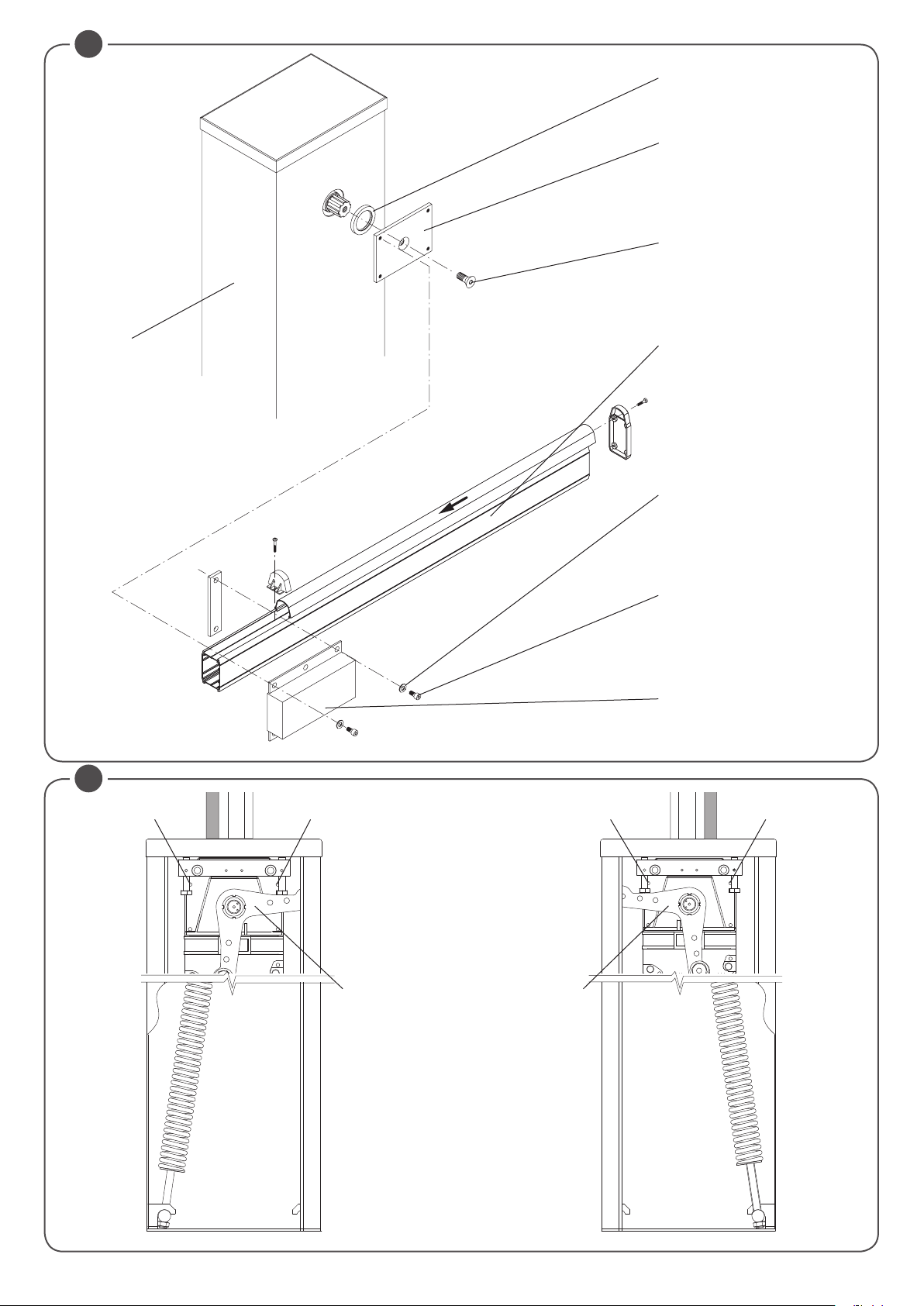

4

V ring (V 60A)

Piastra.

Plate.

Platte.

Platine

Placa.

Płyta

Vite M14x30 UNI 5933.

Screw M14x30 UNI 5933.

Schraube M14x30 UNI 5933.

Vis M14x30 UNI 5933.

Tornillo M14x30 UNI 5933.

Sruba M14x30 UNI 5933

Colonna

Column

Säule

Fût

Columna

Kolumna

Asta LADY.A.

Bar LADY.A.

Stange LADY.A.

Lisse LADY.A.

Asta LADY.A.

Ramię LADY.A

Rosetta Ø8.4x17 UNI 6592.

Washer Ø8.4x17 UNI 6592.

Unterlegscheibe Ø8.4x17 UNI 6592.

Rondelle Ø8.4x17 UNI 6592.

Arandela Ø8.4x17 UNI 6592.

Podkładka Ø 8.4x17 UNI 6592

Vite M8x16 UNI 5931.

Screw M8x16 UNI 5931.

Schraube M8x16 UNI 5931.

Vis M8x16 UNI 5931.

Tornillo M8x16 UNI 5931.

Sruba M8x16 UNI 5931

Supporto.

Support.

Auflage.

Support.

Soporte.

Wspornik

5

F2F1

Barriera sinistra

Left barrier

Schrank links

Barrière gauche

Barrera izquierda

Bariera lewa

Barriera destra

Right barrier

Schranke rechts

Barrière droite

Barrera derecha

Bariera prawa

F2F1

L L

4

Page 5

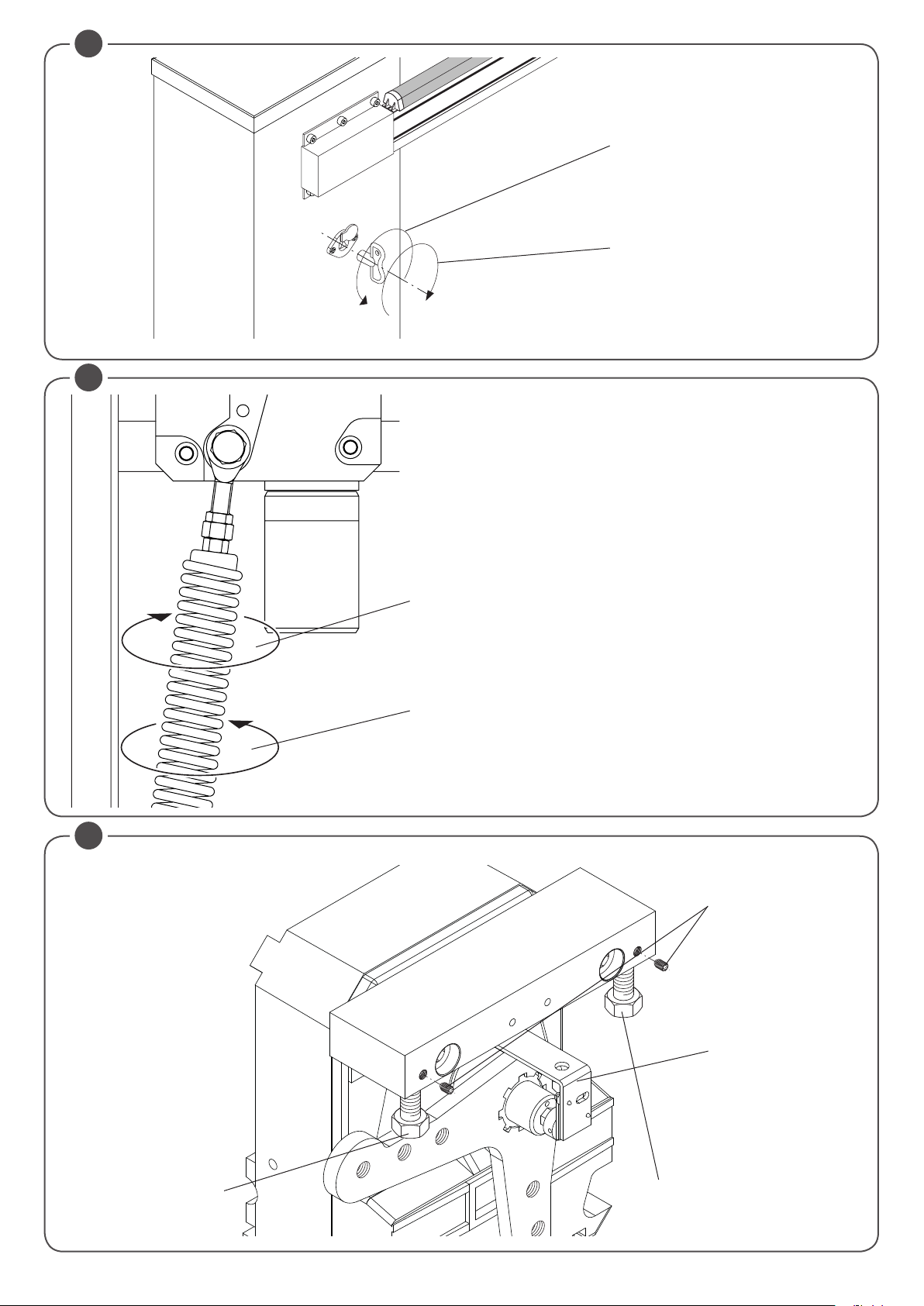

6

Ripristino automatismo

Reset automation

Reset des Automatismus

Réinitialisation automatisme

Reactivación del automatismo

Przywrócenie działania automatyzmu

Sblocco di emergenza

Emergency release

Notentriegelung

Déblocage de secours

Desbloqueo de emergencia

Rozsprzęglanie awaryjne

7

Con motoriduttore sbloccato:

With geared motor released:

Bei entriegeltem Getriebemotor:

Avec l’opérateur débloqué :

Con motorreductor desbloqueado:

Z motoreduktorem odblokowanym:

Se l'asta tende a chiudere, aumentare la tensione della molla (distendere la molla con rotazione oraria)

If the bar tends to close, increase the spring tension (extend the spring by turning clockwise)

Wenn die Stange dazu neigt, zu schließen, die Spannung der Feder erhöhen (durch Drehen im Uhrzeigersinn

entspannen)

Si la lisse a tendance à s’abaisser, augmenter la tension du ressort (détendre le ressort en tournant

dans le sens des aiguilles d’une montre)

Si el asta tiende a cerrarse, aumentar la tensión del muelle (descomprimir el muelle girándolo a la derecha)

Jeśli ramię szlabanu ma tendencję do zamykania się, należy zwiększyć napięcie sprężyny (rozkuźnić

sprężynę przez pokręcanie zgodnie z ruchem wskazówek zegara)

Se l'asta tende ad aprire, diminuire la tensione della molla (comprimere la molla con rotazione antioraria)

If the bar tends to open, decrease the spring tension (compress the spring by turning anti-clockwise)

Wenn die Stange dazu neigt, zu öffnen, die Spannung der Feder vermindern (durch Drehen im

Gegenuhrzeigersinn komprimieren)

Si la lisse a tendance à se lever, diminuer la tension du ressort (comprimer le ressort en tournant

dans le sens inverse des aiguilles d’une montre)

Si el asta tiende a abrirse, disminuir la tensión del muelle (comprimir el muelle girándolo hacia la izquierda)

Jeśli ramię szlabanu ma tendencję do otwierania się, należy zmniejszyć napięcie sprężyny (scisnąć

sprężynę poprzez pokręcanie w kierunku odwrotnym do ruchu wskazówek zegara)

8

Grani di bloccaggio

Blocking dowels

Arretierstifte

Goujons de blocage

Tornillos sin cabeza de bloqueo

Kołki blokujące

Fermo meccanico apertura

Mechanical stop on opening

Mechanische Feststellvorrichtung Öffnen

Butée mécanique en ouverture

Tope mecánico de apertura

Blokada mechaniczna otwarciu

Encoder assoluto

Absolute encoder

Absolut-Encoder

Encodeur absolu

Codificador absoluta

Enkodera absolutnego

Fermo meccanico chiusura

Mechanical stop on closing

Mechanische Feststellvorrichtung Schließen

Butée mécanique fermeture

Tope mecánico de cierre

Blokada mechaniczna zamknięcia

5

Page 6

2

3

3x1

2x1

2x1

4

6

7

1

2x1

4x1

2x1.5

230 V

5

8

Mod. VE.AF / VE.AFS (Optional)

9 10

Slow-down

O

Open (SLDo)

C

O

Slow-down

Close (SLDC)

C

11

6

Page 7

12

+ -

2xDA.BT2

(Optional)

SIS

(Optional)

ANT

SHLD

M3

J1

P. P.

RADIO

CLOSE

OPEN

- 24V +

STOP

PHOT

ABS. ENCODER

SWC

U5

MOTAUX

COM

SWO

MENC

F1

BLINKAUX2

M2

CP.EVA2

ANT

ANT

SHLD

-

+

24Vdc

500 mA

- 24V +

M

MOTAUX

BAR

LIGHT

24Vdc

LAMP.

24Vdc

LED 2

Advantouch

- BAT

+ BAT

SA.24V

-

+

LED 1

+

-

M1

F1

N

- +- +

P. P.

CLOSE

OPEN

PHOT

STOP

SWC

SWO

COM

BLINKAUX2

L

100÷250 Vac

7

Page 8

PUSH OK

PUSH OK

0012

PUSH OK

PUSH OK

PUSH OK

Display OFF

Power ON

v1.05

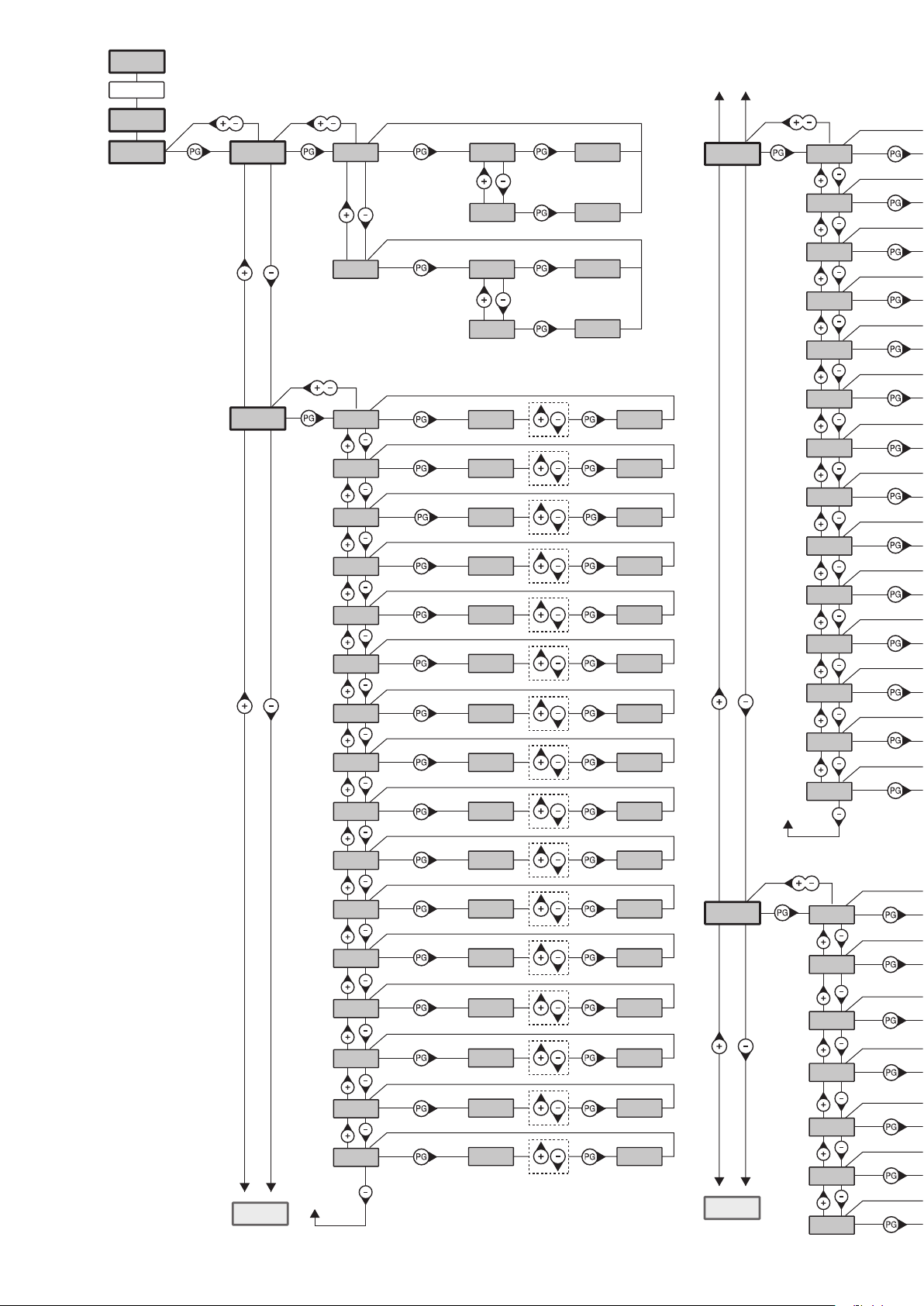

Schema menu di programmazione - Menu programming layout

Diagramm Programmiermenü - Menu de programmation

Menú de la carta de programación - Układ menu programowania

Diagnostic

8888

Inst

PAR

Boom

POS

tca

fsts

sldo

sldc

tsmo

3-5 ok

7-8

0---

---0

20

99

50

50

20

ok

ok

ok

PRG

PRG

PRG

PRG

PRG

LOG

tca

IBL

IBCA

SCL

PP

PRE

htr

ltca

tst1

tstm

tsmc

pmo

pmc

pso

psc

seav

sear

TLS

saso

20

20

20

20

20

60

cvar

PRG

lbar

PRG

aopf

PRG

rem

PRG

PRG

0

0

0

PRG

PRG

PRG

PRG

RADI

TCA

pp

OPen

Clse

2ch

sasc

AUX1

TCA

0

0

LOG

8

PRG

PRG

nman

n TX

clr

rtr

Page 9

on PRG

OFF PRG

OFF PRG

OFF PRG

OFF PRG

OFF PRG

OFF PRG

off PRG

off PRG

OFF PRG

Inst

Nman

MACI

RES

AUTO

CODE

BUS

0012 3456

OFF PRG

res PRG

PUSH

0000 conf OK

ID

Loc

2 Cycle

OPEN/CLOSE

OK

9000 9C5a

0

OFF

RE-ENTER

PRG

PRG

id

CODE

Display OFF

ON PRG

off PRG

off PRG

off PRG

PUSH OK

PUSH OK

PUSH OK

PUSH OK

0012

PUSH OK

rtr PRG OK

Legenda

Premere il tasto (-) / Press key (-) / Die Taste (-) drücken

Appuyez sur la touche (-) / Presionar la tecla (-) / Wcisnąć przycisk (-)

Premere il tasto (+) / Press key (+) / Die Taste (+) drücken

Appuyez sur la touche (+) / Presionar la tecla (+) / Wcisnąć przycisk (+)

Premere il tasto (PG) / Press key (PG) / Die Taste (PG) drücken

Appuyez sur la touche (PG) / Presionar la tecla (PG )/ Wcisnąć przycisk (PG)

Premere simultaneamente (+) e (-) / Press simultaneously keys (+) and (-)

Gleichzeitig (+) und (-) drücken / Presser simultanément (+) et (-)

Presionar simultáneamente (+) y (-) / Naciskać jednocześnie (+) i (-)

Selezionare il valore desiderato con i pulsanti (+) e (-)

Increase/decrease the value with keys (+) and (-)

Mit den Tasten (+) und (-) kann man eingerichtete Werte ändern

Régler la valeur désirée avec les touches (+) et (-)

Establecer con las teclas (+) y (-) el valor deseado

Nastawia przyciskami (+) i (-) obraną wartoś

Selezionare il pulsante del trasmettitore da associare alla funzione

Press the transmitter key, which is to be assigned to function

Taste des Sendegeräts drücken, dem diese Funktion zugeteilt werden soll.

Appuyer sur la touche du transmetteur qu’e l’on désire affecter à cette fonction.

Presionar la tecla del transmisor que se desea asignar a esta función.

Wcisnąć przycisk nadajnika, który zamierza się skojarzyć z tą funkcją.

9

Page 10

13

PHOTOTEST

24Vdc

+

-

24V ac 24V ac

AUX1

COM

AUX1:0004

tst1:on

PHOT

NC NO

COM

RXTX

SCA

24Vdc

+

-

SERVICE LIGHT

24Vdc

+

-

Relè

24Vdc

AUX1:0000

AUX1

24Vac

LAMP

AUX1:0003

AUX1

L N

230Vac

LAMP

14

MASTER

Menu BUS

ID=0

GND B A GND B A

SIS

3x0,5mm

Menu BUS

SLAVE

ID=1

SIS

10

Page 11

ENG

GENERAL INFORMATIONS

The product shall not be used for purposes or in ways other than those for which the product is intended for and as described in this manual.

Incorrect uses can damage the product and cause injuries and damages.

The company shall not be deemed responsible for the non-compliance with a good manufacture technique of gates as well as for any deformation, which might occur during use. Keep this manual for further use.

INSTALLER GUIDE

This manual has been especially written to be use by qualified fitters. Installation must be carried out by qualified personnel (professional

installer, according to EN 12635), in compliance with Good Practice and current code. Make sure that the structure of the gate is suitable

for automation. The installer must supply all information on the automatic, manual and emergency operation of the automatic system and

supply the end user with instructions for use.

GENERAL WARNINGS

Packaging must be kept out of reach of children, as it can be hazardous. For disposal, packaging must be divided the various types of

waste (e.g. carton board, polystyrene) in compliance with regulations in force. Do not allow children to play with the fixed control devices of

the product. Keep the remote controls out of reach of children. This product is not to be used by persons (including children) with reduced

physical, sensory or mental capacity, or who are unfamiliar with such equipment, unless under the supervision of or following training by

persons responsible for their safety. Apply all safety devices (photocells, safety edges, etc.) required to keep the area free of impact, crushing, dragging and shearing hazard. Bear in mind the standards and directives in force, Good Practice criteria, intended use, the installation

environment, the operating logic of the system and forces generated by the automated system. Installation must be carried out using safety

devices and controls that meet standards EN 12978 and EN 12453. Only use original accessories and spare parts, use of non-original spare

parts will cause the warranty planned to cover the products to become null and void. All the mechanical and electrical parts composing

automation must meet the requirements of the standards in force and outlined by CE marking.

ELECTRICAL SAFETY

The box containing the control unit is secured to barrier case with two screws to avoid damage during transport. Once the barrier has been

positioned it possible to remove the screws and to unhook the box from the case so as to facilitate wiring operations and the preparation

of the control unit. On completing installation, secure the box to the barrier case again.

An omnipolar switch/section switch with remote contact opening equal to, or higher than 3mm must be provided on the power supply mains.

Make sure that before wiring an adequate differential switch and an overcurrent protection is provided.

Pursuant to safety regulations in force, some types of installation require that the gate connection be earthed. During installation, maintenance

and repair, cut off power supply before accessing to live parts. Also disconnect buffer batteries, if any are connected. The electrical installation

and the operating logic must comply with the regulations in force. The leads fed with different voltages must be physically separate, or they

must be suitably insulated with additional insulation of at least 1 mm. The leads must be secured with an additional fixture near the terminals.

During installation, maintenance and repair, interrupt the power supply before opening the lid to access the electrical parts

Check all the connections again before switching on the power. The unused N.C. inputs must be bridged.

Consult the control unit instructions manual as regards the regulation of the operating times and logic, the connection of the accessories

and of the safety devices, etc.

WASTE DISPOSAL

As indicated by the symbol shown, it is forbidden to dispose this product as normal urban waste as some parts might be harmful for environment and human health, if they are disposed of incorrectly. Therefore, the device should be disposed in special collection platforms

or given back to the reseller if a new and similar device is purchased. An incorrect disposal of the device will result in fines applied to the

user, as provided for by regulations in force.

Descriptions and figures in this manual are not binding. While leaving the essential characteristics of the product unchanged, the manufacturer reserves

the right to modify the same under the technical, design or commercial point of view without necessarily update this manual.

WARNING

QUICK PROGRAMMING

- Press the <PG> button, the display goes to the "INST" menu

- Enter the INST menu

- Verify that the parameter BOOM is correct: 3-5 for all LADY models (factory settings).

- Set the barrier position by means of the menu POS, by default the barrier is set as RIGHT BARRIER

- Enter the menu AUTO, confirm with <PG> and wait until the barrier has carried out the autoset of the parameters

- By means of the menus PAR and LOG, select the parameters and the logic functions wanted according to the type of installation

in object

IMPORTANT: After every change of the parameters FSTS. SLDO, SLDC, TSMO, TSMC, the barrier executes an opening maneuver

followed by a closing one in order to acquire the new values of current and torque, on the screen will appear the message <PRG>

20

Page 12

1) TECHNICAL DATA

LADY5

Feed 230 Vac

Motor feed 24 Vdc

Motor consumption 1,6 A

Torque 205 Nm

Degree of protection IP44

Jogging Intensive use

Operation temp. -20°C/+50°C

Opening time min. 3,6"

Lubrication Permanent grease

Noise level <70dB (A)

Weight 50 kg

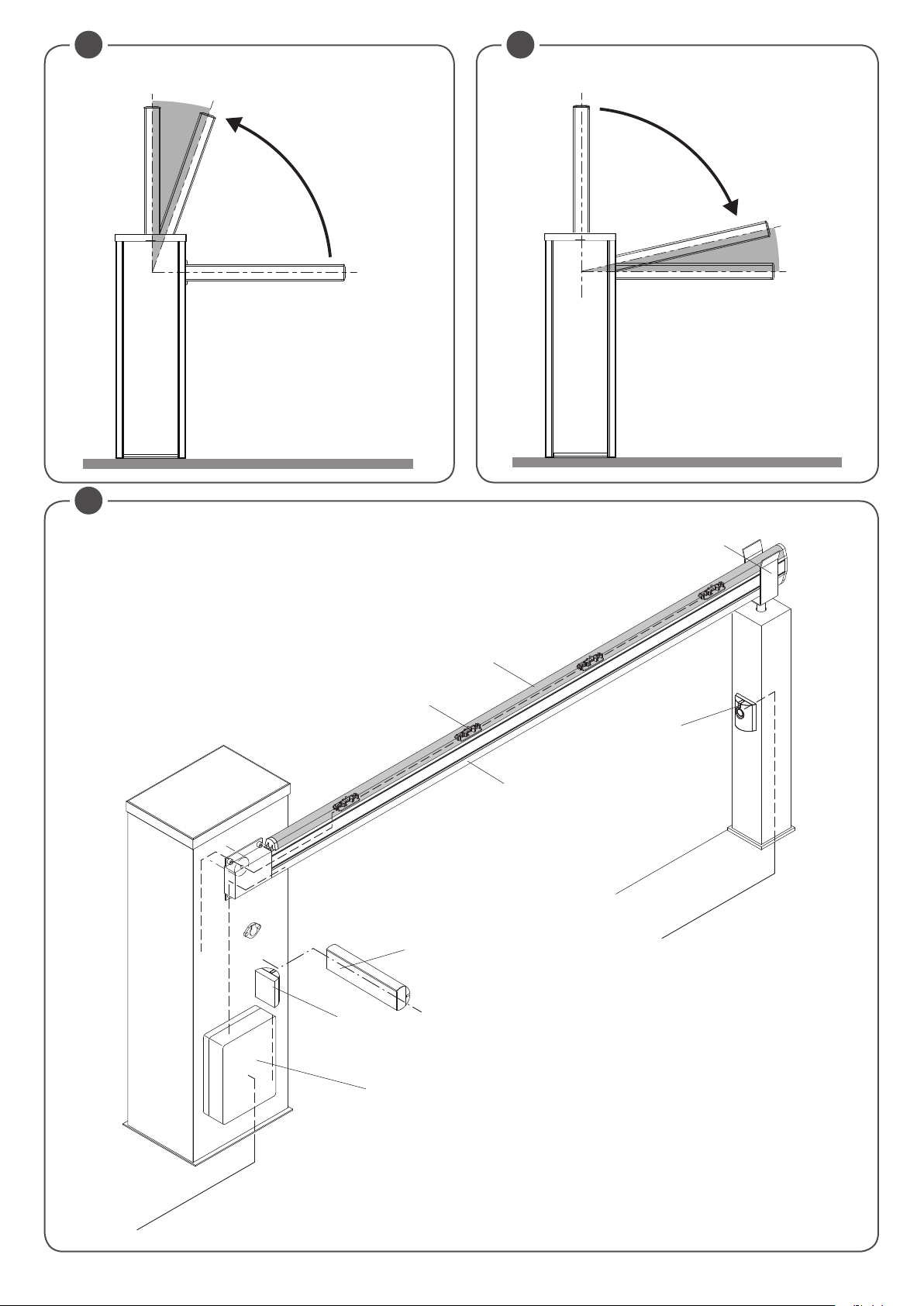

2) POSITIONING THE SPRING AND THE ACCESSORIES FOR USE

Depending on the length of the bar and on the type of accessories installed, before putting the spring under tension it is necessary to choose the correct

point in which to attach the spring to the lever.

The correct fastening point (“A”, “B” or “C” - Fig.1), must be chosen in table 1, depending on the length of the bar and on the type of accessories you

intend to install.

TAB. 1

Accessories for use

NA

LADY.P(1)

LADY.P(2)

VE.RAST

LADY.P(1) + VE.RAST

LADY.P(1) + VE.AM

LADY.P(2) + VE.AM

LADY.P(1) + VE.RAST + VE.AM

SC.RES

LADY.P (1) + SC.RES

SC.RES + VE.AM

LADY.P(1)+ SC.RES + VE.AM

VE.RAST + VE.AM

Key

NA

No accessories

LADY.P(1)

LADY.P(2)

VE.RAST

VE.AM

SC.RES

Attention:

The installation of the

The installation of the

Protection profile (only upper).

Protection profiles (upper and lower).

Aluminium skirt.

Mobile support for bar.

Sensitive resistive edge (complying EN12878).

VE.RAST

LADY.L

interferes with the use of the

lights kit does not influence the balancing of the bar

2,2 2,7 3,2 3,7 4,2 4,7 5,2

C C B B B A

C C C B B A A

C C C B B A A

C C B B A A

C C B A A

C C C B A A A

C C B B A A

C B B A A

C C B B A A

C C B A A

C B B A A

C B B A A

C B B A A

SC.RES

and vice versa.

LADY5/LADY5.I

Bar lenght (m)

3) LAYING THE FOUNDATION PLATE (FIG.3)

After having arranged the passage of the cables (power supply, accessories, etc.), put the foundation plate in position, referring to the measurements in fig.3.

4) FIXING THE BAR (FIG.4)

The bar is fixed to the plate using the support and the screws provided, as illustrated in Fig.4. We recommend installing any accessories for the bar

(protective profiles, lights, edge, skirt, etc.) before fixing it to the plate.

5) PREPARING THE BARRIER FOR RIGHT OR LEFT (FIG.5)

If the opening direction reversion is required, proceed as follows. If it is not necessary, go to the next section:

• Entirely unload the spring by loosening it and unhooking it from the “L” anchoring lever

• with reference to Fig. 5, invert the position of the “F1” and “F2” mechanical stoppers. Before loosening the stoppers, back-off the related locking

grains (see section HOW TO ADJUST THE MECHANICAL STOPERS)

• unlock the geared motor (see “Manual Operation”) insofar as to render the L hooking lever idle.

• according to the length of the road barrier arm and accessories used, choose the correct hooking position, as indicated in paragraph “Positioning of

the spring and accessories”.

• hook the spring in the new position. Fig. 5 shows the differences between a right-hand road barrier and a left-hand one.

21

Page 13

6) MANUAL AND EMERGENCY MANOEUVRES

In the event of a power cut or of abnormal operation, it is possible to release the bar and move it by hand (Fig. 6).

Using the key provided:

• To release the bar, turn the key in a clockwise direction until you fell a certain resistance.

• To restore the automatic movement of the bar, turn the key in an anti-clockwise direction until it is blocked.

7) BALANCING (FIG. 7)

For good operation of the barrier it is fundamental for the bar to be suitably balanced by the action of the spring. To check this, proceed as follows:

• Ensure that the spring is fixed to the correct point of the lever (see paragraph 2).

• Mechanically release the barrier using the release key.

• The correctly balanced bar must stay still in whichever point it is positioned:

- if it tends to open, decrease the tension of the spring

- if it tends to close, increase the tension of the spring

The tension of the spring may be regulated by manually screwing (anti-clockwise rotation) or unscrewing (clockwise rotation) the spring itself. Once

you have regulated the spring tension, block it, screwing down the nut “D” until it makes contact with the cap T.

8) REGULATING THE MECHANICAL STOPS (FIG.8)

The inertial movement of the bar after the motor stops is blocked using the adjustable mechanical stops shown in Fig.8.

After having regulated the opening/closing limit stop cam, bring the respective closing mechanical stop into contact with the lever. The opening mechanical stop is of the damped type.

With reference to Fig.8:

• Slacken the blocking dowel

• Tighten /unscrew the mechanical stop until the desired position of intervention is obtained

• Tighten the blocking dowel

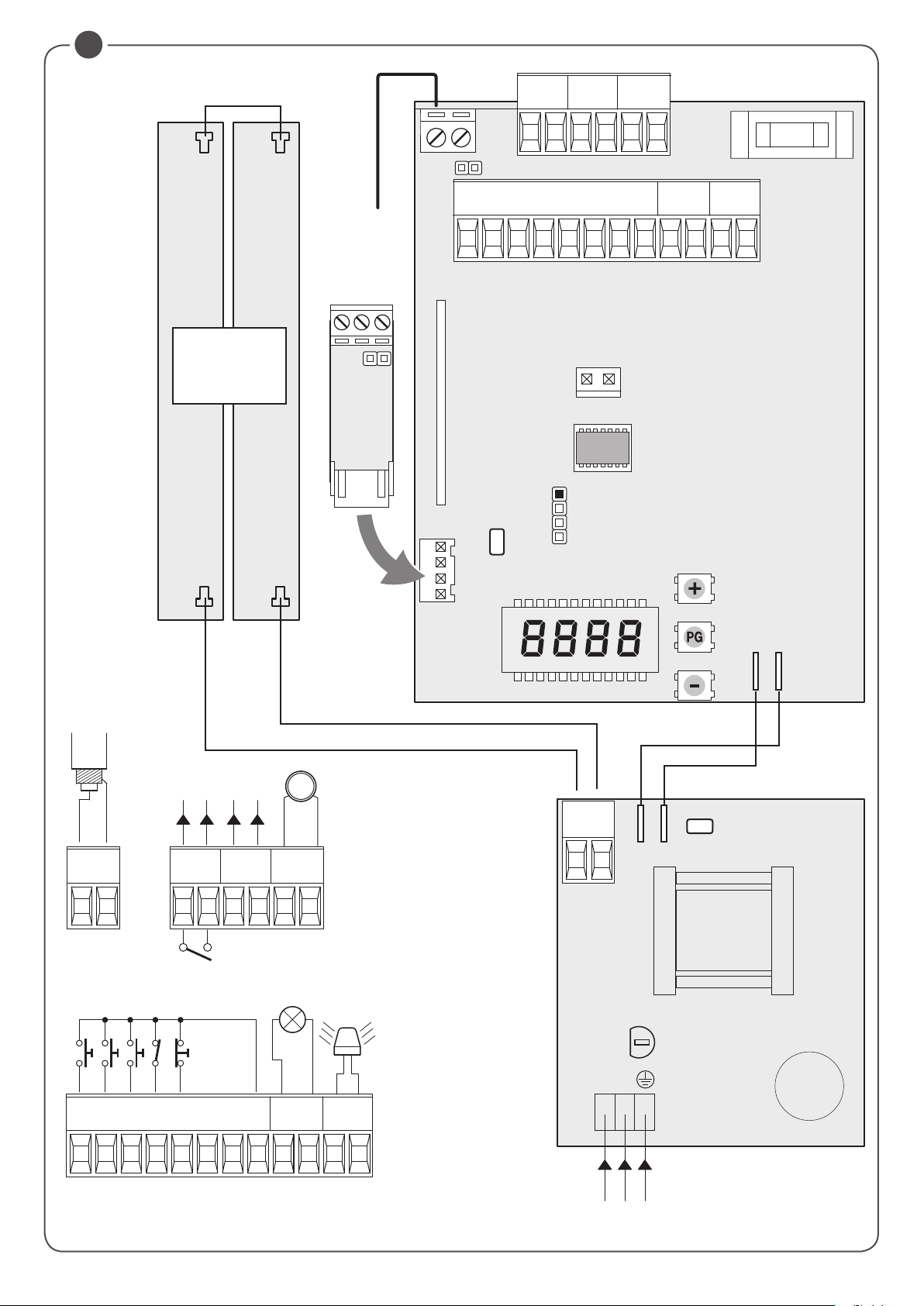

9) WIRE DIAGRAM (FIG.11)

1 Control unit CP.EVA2

2 Transmitting photocell FTC

3 Receiving photocell FTC

4 Blinking lights LADY.L

5 Photocell column for barrier LADY.COL

6 Bottom/top rubber protection LADY.P

7 Resistive edge SC.RES

8 Mod. VE.AF / VE.AFI accessory

10) CP.EVA2 CONTROL UNIT WIRE DIAGRAM

Wire connections shown in Fig. 12 are described hereunder:

SA.24V

TERMINALS Function Description

L-N-GND Power supply Mains input 100÷250Vac 50/60Hz

+ - Output 24Vdc Controller CP.1524 power supply output 24 Vdc

BAT-BAT Batteries Clamp input for connection of back-up batteries (accessory).

CP.EVA2

TERMINAL BLOCK M1

M1 24Vdc INPUT

TERMINAL BLOCK M2

P.P. Step by step Input for step by step command (N.O. contact) .

CLOSE Close Input for close command (N.O. contact) .

OPEN Open Input for open command (N.O. contact), It is possible to connect a timer for programmed openings.

PHOT Photocell Input for photocells enabled during opening and closing phase (N.C. contact).

STOP STOP Input for STOP command (N.C. contact).

SWC Closing limit switch

SWO Opening limit switch

COM Common Common for all the input commands and the limit switches .

AUX2 24Vdc output for bar light

BLINK Blinker

24Vdc input for powering the CP.EVA2.In case of use of the SUN SYSTEM it is necessary to connect

the 24Vdc output of the SUN.SY to M1 (see the KSUN instructions)

Input for closing limit switch (N.C. contact).

To be used ONLY FOR BARRIER WITH ELECTROMECHANICAL LIMIT SWITCHES. If not used it is NOT

NECESSARY TO BRIDGE the input to the common COM.

Input for opening limit switch (N.C. contact).

To be used ONLY FOR BARRIER WITH ELECTROMECHANICAL LIMIT SWITCHES. If not used it is NOT

NECESSARY TO BRIDGE the input to the common COM.

24Vdc output for the bar flashing light EVA.L (max 2), the flashing mode can be set by means of the

logic LBAR.

Output 24Vdc 15W max. for flashing light connection (EVA.LAMP) to be installed on the top cover of

the barrier.

22

Page 14

TERMINAL BLOCK M3

ANT-SHIELD Antenna

AUX Auxiliary output AUX 1 Output with N.O. contact configurable by means of the logic AUX 1

24V 24 Vdc Accessory power supply 24Vdc 500 mA maximum

MOT Motor Motor connection: 24Vdc.

TERMINAL MENC

ABS ENC Encoder input Absolute encoder input, pre-cabled by factory.

Connection for the antenna of the built in receiver (ANT-signal/SHIELD-shield).

In case of use of an external antenna it is necessary to remove the pre-cabled cable from the terminal ANT

11) PROGRAMMING

The programming of the various functions of the control unit is carried out using the LCD display on the control unit and setting the desired values in

the programming menus described below.

The parameters menu allows you to assign a numerical value to a function, in the same way as a regulating trimmer.

The logic menu allows you to activate or deactivate a function, in the same way as setting a dip-switch.

11.1) TO ACCESS PROGRAMMING

1 -Press the <PG> button to enter the first Installation menu “INST”.

2 -Choose with <+> or <-> button the menu you want to select

3 - Press the button <PG>, the display shows the first function available on the menu.

4 - With the <+> or <-> button, select the function you want.

5 - Press the button <PG>, the display shows the value currently set for the function selected.

6 - With the <+> or <-> button, select the value you intend to assign to the function.

7 - Press the button <PG>, the display shows the signal “PRG” which indicates that programming has been completed.

11.2) PROGRAMMING NOTES

Simultaneously pressing <+> and <-> from inside a function menu allows you to return to the previous menu without making any changes. Hold down

the <+> key or the <-> key to accelerate the increase/decrease of the values.

Hold down the <+> key or the <-> key to accelerate the increase/decrease of the values.

After waiting 120s the control unit quits programming mode and switches off the display.

When the board is switched on, the software version is displayed for around 5 sec

The pre-set logic functions and parameters are made taking account of a typical installation.

12) PARAMETERS, LOGICS AND SPECIAL FUNCTIONS

The following tables describe the functions available on the control unit

12.1) INSTALLATION (inst)

MENU FUNCTION MIN-MAX-(Default) MEMO

Select the length of the boom installed on the barrier.

BOOM

Value expressed in meter from 3m to 5m (all LADY models) or from 7m to 8m (other models)

According to the selected boom length, the optimal value of speed will be set.

Set the closing direction of the barrier.

The symbol 0--- indicates right barrier (R/RIGHT) DEFAULT

The symbol ---0 indicates left barrier (L/LEFT)

Verify the opening direction of the boom and in case reverse it. Every change of this function automatically implies the starting of a new AUTOSET procedure.

Pos

LADY - RIGHT

(STANDARD)

MENU FUNCTION MIN-MAX-(Default) MEMO

TCA

FSTS

Automatic closing time. Enabled only with logic “TCA”=ON.

At the end of the set time, the control unit commands a closing maneuver .

Adjusts the opening and closing speed of the barrier (standard speed, before the slowdown

phase).

LADY - LEFT

12.2) PARAMETERS (PAR)

3/5 -7/8 (7-8)

0--- = RIGHT

---0 = LEFT

( RIGHT )

1-240-(20s)

50-99-(99)

sldo

sldc

tsmo

tsmc

Adjusts the slowdown speed of the barrier during the opening phase* (Fig.9 -slow Open). 20-70-(50)

Adjusts the slowdown speed of the barrier during the closing phase * (Fig.10 -slow Close). 20-70-(50)

Sets the starting point of the slowdown during the opening phase (Fig.9- beginning of the slow

Open). The value is expressed in percentage on the entire stroke.

Sets the starting point of the slowdown during the closing phase (Fig.10- beginning of the slow

Close). The value is expressed in percentage on the entire stroke.

1-99-(20)

1-99-(20)

23

Page 15

PMO

PMC

PSO

PSC

SeaU

SEAR

tls

saso

sasc

aux1

* ATTENTION: A WRONG SETTING OF THESE PARAMETERS CAN BE DANGEROUS.

RESPECT THE REGULATION IN FORCE!

After each Autoset procedure and/or PMO/PMC/PSC, PSO changing parameters, proceed with verification of impact forces as required by EN12445.

Adjusts the motor torque applied to the barrier during the opening phase.* 1-99-(20)

Adjusts the motor torque applied to the barrier during the closing phase.* 1-99-(20)

Adjusts the motor torque applied to the barrier during the slowdown in opening phase * (Fig.9

- Slow Open).

Adjusts the motor torque applied to the barrier during the slowdown in closing phase * (Fig.10Slow Close).

Adjusts the intervention threshold of the anti crushing device (Encoder) during the normal speed*.

0:Off -1: minimum sensitivity - 99: maximum sensitivity

Adjusts the intervention threshold of the anti crushing device (Encoder) during the slowdown

speed*.

0:Off -1: minimum sensitivity - 99: maximum sensitivity

Activation time of the courtesy light contact. Value expressed in seconds. At the beginning of

each maneuver the contact latches for the set time.

See the description of AUX1 parameter.

Sets a short reversion after reaching the limit switch in open position. Can be useful for facilitating the manual release.

Sets a short reversion after reaching the limit switch in close position. Can be useful for facilitating the manual release.

Selects the functioning mode of the auxiliary output 1 (N.O. clean contact)

0: Open barrier light, close contact when the barrier is open, open contact when the barrier is

close, intermittent during the maneuver (fig. 13, SCA)

1: Second radio cannel of the built in receiver

2: Boom light, for controlling the LED light installed on the BOOM (EVA.LED), see also the parameter LBAR.

3: Courtesy light, the contact remains close according to the parameter TLS (fig.13 SERVICE

LIGHT)

4: Photocells test, see wiring diagram in Fig.13 (PHOTOTEST)

5: Close contact with open barrier

6: Close contact with close barrier

1-99-(20)

1-99-(20)

0-99-(0%)

0-99-(0%)

1-240 (60)

0-5 (0)

0-5 (0)

0-6-(0)

12.3) LOGICS (LOG)

MENU FUNZIONE ON-OFF-(Default) MEMO

Enables or disables automatic closing

TCA

IbL

ibca

SCL

PP

PRE

htr

ltca

TST1

On: automatic closing enabled

Off: automatic closing disabled

Enables or disables condominium function.

On: condominium function enabled. The step-by-step impulse or transmitter impulse has no

effect during the opening phase.

Off: condominium function disabled.

The multi-flat function is enabled or disabled during the TCA counting.

On: the bloc of flat function is enabled. The Step-by-Step signal or the transmitter signal has no

effect during the TCA counting.

Off: the bloc of flat function is disabled.

Enables or disables rapid closing

On: rapid closure is enabled. With open bar, or in the opening phase, the activation of the photocell causes the automatic closure 3sec after the total opening of the gate. It is activated only

with TCA:ON

Off: rapid closing disabled.

Selects the operating mode of the ”Step by step button” and of the transmitter.

On: Operation: OPEN > CLOSE > OPEN >

Off: Operation: OPEN > STOP > CLOSE > STOP >

Enables or disables pre-blinking.

On: Pre-blinking enabled. Blinking is activated 3s before the motor starts.

Off: Pre-blinking disabled.

Enabled or disables HOLD-TO-RUN function

On: HOLD-TO-RUN function.

The pressure of the OPENS/CLOSES button must be maintained throughout the entire manoeuvre.

The opening of the STOP input stops the motor. All the safety inputs are deactivated.

Off: Automatic/semiautomatic function

Selects the operating mode of the blinking light during the time TCA

On: Blinking light on during TCA

Off: Blinking light off during TCA

Enables or disables checking of photocells on PHOT input, active both in closing and in opening.

On: Check enabled. If the check has a negative result, no manoeuvre is commanded. See Fig.13

- “PHOTO TEST”.

Off: Checking of photocells disabled at each manoeuvre.

(ON)

(OFF)

(OFF)

(OFF)

(OFF)

(OFF)

(OFF)

(OFF)

(OFF)

24

Page 16

Enables or disables motors check.

TSTm

Cvar

lBAR

aopf

rem

On: Check enabled. If the check has a negative result, no manoeuvre is commanded.

Off: Check disabled.

The code programmable transmitters is enabled or disabled.

On: Radio receiver enabled only for rolling-code transmitters.

Off: Receiver enabled for rolling-code and programmable code transmitters (self-learning and

Dip Switch).

Selects the functioning mode of the boom light (24Vdc output on AUX2 or N.O. contact on the

output AUX 1 when configured at 2).

On: The boom light is off when the barrier is close, it turns on when the barrier is in movement

or open.

On: The boom light flashes slowly when the barrier is close (1s pause), it flashes quickly (0,5s

pause) when the barrier is in movement or open.

The “forced opening in case of power cut-off” function is activated or deactivated (it can be

activated only with connected and operating emergency batteries).

On: Activated function. In the event of power failure, the control unit causes an opening operation.

The barrier remains open until the power supply is back.

Off: Deactivated function.

Enables or disables remote radiotransmitters learning, as indicated in the paragraph “Remote

transmitters learning”.

On: Remote learning enabled.

Off: Remote learning not enabled.

12.4) RADIO (RADi)

MENU FUNZIONE

By selecting this function, the receiver goes in waiting (Push) for a transmitter code to assign to the step-step function.

PP

OPen

close

2Ch

ntx

CLR

RTR

Press the key of the transmitter to assign to this function.

If the code is valid, it is memorised and the message OK is displayed

If the code is not valid, the message Err is displayed

By selecting this function, the receiver goes in waiting (Push) for a transmitter code to assign to the OPEN function.

Press the key of the transmitter to assign to this function.

If the code is valid, it is memorised and the message OK is displayed

If the code is not valid, the message Err is displayed

By selecting this function, the receiver goes in waiting (Push) for a transmitter code to assign to the CLOSE function.

Press the key of the transmitter to assign to this function.

If the code is valid, it is memorised and the message OK is displayed

If the code is not valid, the message Err is displayed

By selecting this function, the receiver goes into waiting (Push) for a transmitter code to assign to the second radio channel.

Press the key of the transmitter to assign to this function.

If the code is valid, it is memorised ad the OK message is displayed

If the code is not valid, the message Err is displayed.

By selecting this function the LCD screen shows the number of transmitters memorized into the receiver.

By selecting this function, the receiver goes into waiting (Push) for a transmitter code to erase from the memory.

If the code is valid, it is erased and the message OK is displayed

If the code is not valid or not present in memory, the message Err is displayed

Completely erases memory of the receiver. Confirmation of the operation is requested.

By selecting this function the receiver goes into waiting (Push) for a new PGM pressure to confirm the operation.

At end of erasing the OK message is displayed

(OFF)

(ON)

(OFF)

(OFF)

(OFF)

12.5) CYCLES NUMBER (Nman)

Displays the number of complete cycles (open+close) carried out by the automation.

When the <PG> button is pressed for the first time, it displays the first 4 figures, the second time it shows the last 4. Example <PG> 0012 >>> <PG>

3456: made 123.456 cycles.

12.6) MAINTENANCE CYCLES (maci)

This function enables to activate the maintenance request notice after a number of manoeuvres determined by the installer.

To activate and select the number of manoeuvres, proceed as follows:

Press button <PG>, the display will show OFF, which indicated that the function is disabled (default value).

With the buttons <+> and <-> select one of the numeric values proposed (from OFF to 100). The values are intended as hundreds of cycles of manoeuvres (for example: the value 50 indicates 5000 manoeuvres).

Press the OK button to activate the function. The display will show the message PROG.

The maintenance request is indicated to the user by keeping the indicator lamp lit up for other 10 sec after the conclusion of the opening or closing

operation.

12.7) RESET (RES)

RESET of the control unit. ATTENTION!: Returns the control unit to the default values.

Pressing the <PG> button for the first time causes blinking of the letters RES, pressing the <PG> button again resets the control unit. Note: The transmitters are not erased from the receiver nor is the access password.

All the logics and all the parameters are brought back to default values, it is therefore necessary to repeat the autoset procedure.

25

Page 17

12.8) AUTOSET (AUTO)

This function sets the optimal functioning values of the installation, at the end of the procedure, it sets the average values of torque (PMO/PMC and

PSO/PSC).

To carry out the AUTOSET, proceed as follow:

a) Make sure that during the autoset there is no obstacle is in the maneuver area, if necessary, fence off the area so that persons, animals, cars, etc.,

cannot interrupt the procedure.

During the AUTOSET procedure, the anti crushing feature is not enabled.

b) select the function AUTO and press PG.

c) the control unit waits the confirmation to start the procedure “PUSH”

c) press PG to start the AUTOSET procedure.

The control unit performs few maneuvers for the stroke learning and the configuration of the parameters.

In case that the procedure is not successful the message ERR will be shown. Repeat the procedure after checking the wirings and the possible

presence of obstacles.

12.9) PASSWORD (CODE)

It allows to type in an access protection code to the programming of the control unit.

A four-character alphanumeric code can be typed in by using the numbers from 0 to 9 and the letters A-B-C-D-E-F.

The default value is 0000 (four zeros) and shows the absence of a protection code.

While typing in the code, this operation can be cancelled at any moment by pressing keys + and – simultaneously. Once the password is typed in,

it is possible to act on the control unit by entering and exiting the programming mode for around 10 minutes in order to allow adjustments and tests

on functions.

By replacing the 0000 code with any other code, the protection of the control unit is enabled, thus preventing the access to any other menu. If a

protection code is to be typed in, proceed as follows:

- select the Code menu and press OK.

- the code 0000 is shown, also in the case a protection code has been previously typed in.

- the value of the flashing character can be changed with keys + and -.

- press OK to confirm the flashing character, then confirm the following one.

- after typing in the 4 characters, a confirmation message “CONF” appears.

- after a few seconds, the code 0000 appears again

- the previously stored protection code must be reconfirmed in order to avoid any accidental typing in.

If the code corresponds to the previous one, a confirmation message “OK” appears.

The control unit automatically exits the programming phase. To gain access to the Menus again, the stored protection code must be typed in.

IMPORTANT: TAKE NOTE of the protection code and KEEP IT IN A SAFE PLACE for future maintenance operations.

To remove a code from a protected control unit it is necessary to enter into programming with the password and bring the code back to

the 0000 default value.

IF YOU LOOSE THE CODE, PLEASE CONTACT THE AUTHORISED SERVICE CENTER FOR THE TOTAL RESET OF THE CONTROL UNIT.

12.10) SYNCHRONIZATION (BUS)

MENU FUNZIONE

id

loc

Sets the synchronizing number. It is possible to set a numeric value from 0 to 16.

If the ID parameter is to 0 the control unit is set as MASTER, all the other values set the barrier as SLAVE.

Allows a barrier set as SLAVE to receive local commands.

See paragraph 12.4 “SYNCHRONIZATION OF TWO OPPOSED BARRIERS”

13) SYNCHRONIZATION OF TWO OPPOSED BARRIERS

It is possible to manage a system composed of two barriers by using for each CP.EVA2 the specific optional control unit SIS, which must be plugged

into the appropriate connector as shown in Fig. 12.

Each SIS unit must be connected to the other one by means of 3 wires by 0,5 sq.mm each, as shown in Fig.12.

One of the control unit must be set as MASTER (ID=0) and the other one as SLAVE (ID>0).

All the commands (commands given by transmitters, push buttons or safety devices) received by the MASTER barrier are sent to the SLAVE barrier,

which will replicate instantaneously the behavior of the MASTER.

The logic LOC can be set in two ways:

ON: the SLAVE barrier can accept a local command and execute an opening/closing maneuver with no effect on the MASTER barrier.

OFF: the SLAVE barrier do not accept any local command and so it will replicate exclusively the behavior of the MASTER barrier.

A SLAVE barrier with LOC set to ON can be useful in case it is occasionally necessary the partial opening of a passage which is usually managed by two

synchronized barriers, since that a step by step command (or OPEN/CLOSE) given to the SLAVE will have effect only on this last one, while all the other

commands given to the MASTER will be replicated by the SLAVE.

The connection of the safety devices (photocells, safety edges, etc.) can be done indifferently to the MASTER unit or to the SLAVE.

14) TRANSMITTERS REMOTE LEARNING

If an already memorised transmitter is available in the receiver it is possible to carry out remote radio learning (without needing to access the control unit).

IMPORTANT: the procedure must be carried out with barrier open.The logic REM must be ON.

Proceed as follows:

1 Press the hidden key of the transmitter which is already memorised.

2 Press, within 5s, the key of the corresponding transmitter which is already memorised to associate to the new transmitter. The flashing light will turn on.

3 Press within 10s the hidden key of the new transmitter.

4 Press, within 5s, the key of the new transmitter to associate to the channel chosen at point 2. The flashing light will turn off.

5 The receiver memorised the new transmitter and immediately exits from programming.

26

Page 18

15) FUSES

F3 CP.EVA2: T1A - Fuse for the protection of the accessories power supply

F1 SA.24V: T4A - Fuse for general protection

16) BACK UP BATTERIES

The control unit CP.EVA2 includes the power pack SA.24V predisposed for the connection of two batteries by 12Vdc 2,1Ah DA.BT2 (optional) which

guarantee the regular functioning of the automation in case of temporary power failure.

When the barrier is working with mains voltage the power pack SA.24V charges the batteries (Fig. 12).

The maximum charging current is 1A, the average charging current is 300 mA.

17) DIAGNOSTICS

SW Open

SW Close

P.P. OPEN CLOSE

LED 1 : Presence of mains voltage

LED 2 : Control unit CP.EVA2 correctly powered

To each input is associated a line of the LCD screen which in case of activation it turns on according to

the following diagram.

The N.C. inputs are represented by vertical lines.

The N.O. inputs are represented by horizontal lines.

The flashing mode of the lines SW Open (when the barrier is open) and SW Close (when the barrier is close)

PHOT

STOP

18) ERROR MESSAGES

Some messages that are displayed in case of function anomalies are listed as follows:

Err

Err1

Err2

err3

AMP

THRM

OVLD

Enc

Generic error Error inserting password or memorizing transmitter..

Motor error Verify the motor wirings, faulty motor or not connected, problem on the control unit.

Photocells error Verify connections, photocells alignment and presence of obstacles.

Absolute encoder error Verify encoder connections, verify the good functioning of the Encoder.

Amperometric sensor intervention Verify the presence of obstacles or friction points.

Thermal sensor intervention Overheating due to a too intensive use, wait the restoring.

Overload Exceeding of the maximum power. Verify the motor and presence of friction points..

Encoder Encoder threshold intervention.

27

Page 19

LADY5

User’s handbook

Safety rules

• Do not stand in the movement area of the gate.

• Do not let children play with controls and near the gate.

• Should operating faults occur, do not attempt to repair the fault but call a qualified technician.

Manual and emergency manoeuvres

In the event of a power cut or of abnormal operation, it is possible to release the bar and move it by hand.

Using the key provided:

• To release the bar, turn the key in a clockwise direction until you fell a certain resistance.

• To restore the automatic movement of the bar, turn the key in an anti-clockwise direction until it is blocked.

Maintenance

• Every month check the good operation of the emergency manual release.

• It is mandatory not to carry out extraordinary maintenance or repairs as accidents may be caused.

These operations must be carried out by qualified personnel only.

• The operator is maintenance free but it is necessary to check periodically if the safety devices and the other components

of the automation system work properly. Wear and tear of some components could cause dangers.

Waste disposal

If the product must be dismantled, it must be disposed according to regulations in force regarding the differentiated waste

disposal and the recycling of components (metals, plastics, electric cables, etc..). For this operation it is advisable to call

your installer or a specialised company.

Warning

All Benincá products are covered by insurance policy for any possible damages to objects and persons caused by construction faults under condition that the entire system be marked CE and only Benincá parts be used.

Reset automation

Emergency release

62

Page 20

19

10

11

16

9

17

13

14

15

8

18

12

Pos. Denominazione - Description - Bezeichnung - Dénomination - Denominación - Określenie Cod.

Molla

8

Leva

9

Colonna

10

Porta

11

Supporto

12

Testa a snodo

13

Leva sblocco

14

Perno sblocco

15

Flangia Sblocco

16

Chiave sblocco

17

Centrale

18

Encoder

19

Spring

Lever

Column

Door

Support

Articulated head

Release lever

Release pin

Release flange

Release key

Control unit

Encoder

Feder

Hebel

Säule

Tür

Support

Gelenkkopf

Entriegelungshebel

Entriegelungsbolzen

Entriegelungsflansch

Entriegelungsschlüssel

Zentrale

Encoder

Ressort

Levier

Fût

Porte

Support

Tête à rotule

Levier déblocage

Axe déblocage

Flasque déblocage

Clé déblocage

Boîtier logique

Encoder

Muelle

Palanca

Columna

Puerta

Soporte

Cabeza de unión

Palanca de desbloqueo

Perno de desbloqueo

Brida de desbloqueo

Llave de desbloqueo

Centralita

Encoder

Sprężyna

Uchwyt

Kolumna

Drzwiczki

Wspornik

Głowa sprężyny przegubowa

Uchwyt rozsprzęglający

Sworzeń rozsprzęglający

Kołnierz rozsprzęglający

Pilot kluczowy rozs.

Centralka

Encoder

9686183

9686248

9686180

9686181

6986184

9686666

9686190

9686191

9686192

9686193

9688241

67

Page 21

7

5

1

6

6

3

4

2

Pos. Denominazione - Description - Bezeichnung - Dénomination - Denominación - Określenie Cod.

Albero supp. ingr.

1

Guarnizione

2

Ingranaggio e piolo

3

Motore

4

Guarnizione ridut.

5

Anello di tenuta

6

Motoriduttore

7

Gear shaft

Gasket

Gear and pin

Motor

Red. unit gasket.

Lip seal

Geared motor

Welle Zahnrädersupport

Dichtung

Zahnrad und Stift

Motor

Dichtung Untersetzungs

Dichtungsring

Getriebemotor

Arbre engrenages

Garniture

Engrenage et pivot

Moteur

Garniture réduct.

Joint d’étanchéité

Motoréducteur

Eje de sop. engr.

Junta

Engranaje y espiga

Motor

Junta red.

Arandela de cierre

Motorreductor

Wał wsp. przekł.zęb.

Uszczelka

Przekładnia zębata i kołek

Silnik

Uszczelka redukt.

Pierścień uszczelniający

Motoreduktor

9686110

9686112

9686111

9686109

9686555

68

Page 22

Dichiarazione CE di Conformità

Nome del produttore: Automatismi Benincà SpA

Indirizzo: Via Capitello, 45 - 36066 Sandrigo (VI)

- Italia

Telefono: +39 0444 751030 Indirizzo e-mail: sales@

beninca.it

Persona autorizzata a coruire la documentazione

tecnica: Automatismi Benincà SpA

Tipo di prodotto: automazione per barriere radali

Modello/Tipo: LADY 5 Accessori: N/A

Il sottoscritto Luigi Benincà, in qualità di Responsabile

Legale, dichiara sotto la propria responsabilità che il

prodotto sopraindicato risulta conforme alle disposizioni

impoe dalle seguenti direttive:

Direttiva 2014/30/UE del Parlamento europeo e del

Consiglio, del 26 febbraio 2014 , concernente l’armonizzazione delle legislazioni degli Stati membri relative

alla compatibilità elettromagnetica (EMCD), secondo

le seguenti norme armonizzate:

EN 61000-6-2:2005, EN 61000-6-3:2007.

Direttiva 2014/35/EU DEL PARLAMENTO EURO-

PEO E DEL CONSIGLIO del 26 febbraio 2014 concernente l’armonizzazione delle legislazioni degli Stati

membri relative alla messa a disposizione sul mercato

del materiale elettrico deinato ad essere adoperato

entro taluni limiti di tensione (LVD), secondo le seguenti

norme armonizzate:

EN 60335-1:2012 + A11:2014; EN 60335-2-103:2015.

Direttiva 2011/65/UE del Parlamento europeo e del

Consiglio, dell’ 8 giugno 2011 , sulla rerizione dell’uso

di determinate soanze pericolose nelle apparecchiature

elettriche ed elettroniche (RoHS), secondo le seguenti

norme armonizzate:

EN 50581:2012

Direttiva 1999/5/CE del Parlamento europeo e del Con-

siglio, del 9 marzo 1999, riguardante le apparecchiature

radio e le apparecchiature terminali di telecomunicazione e il reciproco riconoscimento della loro conformità

(R&TTE), secondo le seguenti norme armonizzate:

ETSI EN 301 489-3 V1.4.1 (2002) + ETSI EN 301

489-1 V1.4.1 (2002) +

ETSI EN 300 220-3 V1.1.1 (2000) + EN 60950-1 (2001)

Direttiva 2006/42/CE DEL PARLAMENTO EURO-

PEO E DEL CONSIGLIO del 17 maggio 2006 relativa

alle macchine e che modifica la direttiva 95/16/CE,

rispettando i requisiti per le “quasi macchine”, secondo

la seguente norma: EN13241-1:2003.

• Il produttore dichiara, inoltre, che la documentazione

tecnica pertinente è ata compilata in conformità all’allegato VII B della direttiva 2006/42/CE e che sono ati

rispettati i seguenti requisiti essenziali:

1.1.1 - 1.1.2 - 1.1.3 - 1.1.5 - 1.2.1 - 1.2.3 - 1.2.6 - 1.3.1

- 1.3.2 - 1.3.3 - 1.3.4 - 1.3.7 - 1.3.9 - 1.5.1 - 1.5.2 - 1.5.4 -

1.5.5 - 1.5.6 - 1.5.7 - 1.5.8 - 1.5.10 - 1.5.11 - 1.5.13 - 1.6.1

- 1.6.2 - 1.6.4 - 1.7.2 - 1.7.4 - 1.7.4.1 - 1.7.4.2 - 1.7.4.3.

• Il produttore si impegna a trasmettere alle autorità

nazionali, in rispoa ad una motivata richiea, le informazioni pertinenti sulla “quasi macchina”. L’impegno

comprende le modalità di trasmissione e lascia impregiudicati i diritti di proprietà intellettuale del fabbricante

della “quasi macchina”.

• Si comunica che la “quasi macchina” non deve essere

messa in servizio finché la macchina finale in cui deve

essere incorporata non è ata dichiarata conforme, se

del caso, alle disposizioni della direttiva 2006/42/CE.

• Inoltre il prodotto, limitatamente alle parti applicabili,

risulta conforme alle seguenti norme:

EN 12445:2002, EN 12453:2002, EN 12978:2003.

Benincà Luigi, Responsabile legale.

Sandrigo, 23/11/2016.

EC Declaration of Conformity

Directive 2004/108/EC(EMC); 2006/95/EC (LVD)Ma-

nufacturer's name: Automatismi Benincà SpA

Address: Via Capitello, 45 - 36066 Sandrigo (VI)

- Italia

Telephone: +39 0444 751030

Email address: sales@beninca.it

Person authorised to draft the technical documentation:

Automatismi Benincà SpA

Product type: operator for road gates

Model/type: LADY 5 Accessories: N/A

The undersigned Luigi Benincà, as the Legal Officer,

declares under his liability that the aforementioned

product complies with the provisions eablished by the

following directives:

Directive 2014/30/UE OF THE EUROPEAN PARLIAMENT AND OF THE COUNCIL of 26 February 2014,

on the harmonisation of the laws of Member States

relating to electromagnetic compatibility, according to

the following harmonised regulations:

EN 61000-6-2:2005, EN 61000-6-3:2007 + A1:2011.

Directive 2014/35/UE OF THE EUROPEAN PAR-

LIAMENT AND OF THE COUNCIL of 26 February

2014, on the harmonisation of the laws of Member

States relating to electrical equipment designed for use

with certain voltage limits, according to the following

harmonised regulations:

EN 60335-1:2012 + A11:2014; EN 60335-2-103:2015.

Directive 2011/65/EU of the European Parliament and

Council, dated 8 June 2011, on the rericted use of

certain hazardous subances in electrical and electronic

devices (RoHS), according to the following andards:

EN 50581:2012

Directive 1999/5/CE OF THE EUROPEAN PARLIA-

MENT AND COUNCIL, 9 March 1999 in relation to

radio equipment and telecommunications terminals

and the mutual recognition of their conformity, per the

following harmonised andards:

ETSI EN 301 489-3 V1.4.1 (2002) + ETSI EN 301 489-1

V1.4.1 (2002) +

ETSI EN 300 220-3 V1.1.1 (2000) + EN 60950-1 (2001)

Directive 2006/42/EC OF THE EUROPEAN PAR-

LIAMENT AND OF THE COUNCIL of 17 May

2006, on machinery, which amends Directive 95/16/

EC, and complies with the requisites for the “partly

completed machinery (almo machinery)” set forth in

the EN13241-1:2003 regulation.

• The manufacturer declares that the pertaining technical

documentation has been drawn up in compliance with

Attachment VII B of the 2006/42/ EC Directive and that

the following requirements have been complied with:

1.1.1 - 1.1.2 - 1.1.3 - 1.1.5 - 1.2.1 - 1.2.3 - 1.2.6 - 1.3.1

- 1.3.2 - 1.3.3 - 1.3.4 - 1.3.7 - 1.3.9 - 1.5.1 - 1.5.2 - 1.5.4 -

1.5.5 - 1.5.6 - 1.5.7 - 1.5.8 - 1.5.10 - 1.5.11 - 1.5.13 - 1.6.1

- 1.6.2 - 1.6.4 - 1.7.2 - 1.7.4 - 1.7.4.1 - 1.7.4.2 - 1.7.4.3.

• The manufacturer undertakes that information on the

“partly completed machinery” will be sent to domeic

authorities. Transmission ways are also included in the

undertaking, and the Manufacturer’s intellectual property

rights of the “almo machinery” are respected.

• It is highlighted that commissioning of the “partly

completed machinery” shall not be provided until the

final machinery, in which it should be incorporated, is

declared compliant, if applicable, with provisions set

forth in the Directive 2006/42/EC on Machinery.

• Moreover, the product, as applicable, is compliant with

the following regulations:

EN 12445:2002, EN 12453:2002, EN 12978:2003

Benincà Luigi, Legal Officer.

Sandrigo, 23/11/2016.

EG-Konformitätserklärung

Name des Herellers: Automatismi Benincà SpA

Adresse: Via Capitello, 45 - 36066 Sandrigo (VI)

- Italia

Telefon: +39 0444 751030

E-Mail-Adresse: sales@beninca.it

Zur Erellung der technischen Dokumentation

berechtigte Person: Automatismi Benincà SpA

Produkttypus: Wir erklären, dass: Antriebe für

Straßensperren Modell/Typus: LADY 5 Zubehör: N/A

Der Unterzeichnete Luigi Benincà, in seiner Eigenschaft

als Rechtsvertreter, erklärt eigenverantwortlich, dass

das oben angegebene Produkt den durch die folgenden

Richtlinien vorgegebene Beimmungen entspricht:

Richtlinie 2014/30/UE DES EUROPÄISCHEN

PARLAMENTS UND DES RATES vom 26. Februar

2014 zur Angleichung der Rechtsvorschriften der

Mitgliedaaten über die elektromagnetische Verträglichkeit, gemäß nachehenden Normen:

EN 61000-6-2:2005, EN 61000-6-3:2007 + A1:2011.

Richtlinie 2014/35/UE DES EUROPÄISCHEN

PARLAMENTS UND DES RATES vom 26. Februar

2014 zur Angleichung der Rechtsvorschriften der

Mitgliedaaten betreffend elektrische Betriebsmittel zur

Verwendung innerhalb beimmter Spannungsgrenzen,

gemäß nachehenden Normen:

EN 60335-1:2012 + A11:2014; EN 60335-2-103:2015.

Richtlinie 2011/65/EU des Europäischen Parlaments

und des Rates vom 8. Juni 2011 zur Beschränkung der

Verwendung beimmter gefährlicher Stoffe in Elektround Elektronikgeräten (RoHS), gemäß den folgenden

harmonisierten Normen:

EN 50581:2012

Richtlinie 1999/5/CE DES EUROPÄISCHEN PARLAMENTS UND EUROPARATS vom 9. März 1999

in Bezug auf Funkapparate und TelekommunikationsEndgeräte und die gegenseitige Anerkennung ihrer

Konformität entsprechend den folgendenharmonisierten

Normen:

ETSI EN 301 489-3 V1.4.1 (2002) + ETSI EN 301 489-1

V1.4.1 (2002) +

ETSI EN 300 220-3 V1.1.1 (2000) + EN 60950-1 (2001)

Richtlinie 2006/42/EG DES EUROPÄISCHEN PARLAMENTS UND DES RATES vom 17. Mai 2006 über

Maschinen, zur Aufhebung der Richtlinie 95/16/EG,

gemäß Anforderungen für „unvolländige Maschinen“

und nachehender Norm:

EN13241-1:2003.

• Der Hereller erklärt, dass die technischen Unterlagen

gemäß Anhang VII Teil B der Richtlinie 2006/42/EG

erellt wurden und dass das Produkt folgenden Anforderungen entspricht:

1.1.1 - 1.1.2 - 1.1.3 - 1.1.5 - 1.2.1 - 1.2.3 - 1.2.6 - 1.3.1

- 1.3.2 - 1.3.3 - 1.3.4 - 1.3.7 - 1.3.9 - 1.5.1 - 1.5.2 - 1.5.4 -

1.5.5 - 1.5.6 - 1.5.7 - 1.5.8 - 1.5.10 - 1.5.11 - 1.5.13 - 1.6.1

- 1.6.2 - 1.6.4 - 1.7.2 - 1.7.4 - 1.7.4.1 - 1.7.4.2 - 1.7.4.3.

• Der Hereller verpflichtet sich die Informationen zu

der „unvolländigen Maschine“ einzelaatlichen Stellen

auf begründetes Verlangen zu übermitteln. Durch die

Übermittlung bleibt das intellektuelle Eigentum des

Herellers der „unvolländigen Maschine“ unberührt.

• Diese „unvolländige Maschine“ darf er dann in

Betrieb genommen werden, wenn gegebenenfalls fegeellt wurde, dass die Maschine, in die die unvolländige

Maschine eingebaut werden soll, den Beimmungen der

Maschinenrichtlinie 2006/42/EG entspricht.

• Das Produkt entspricht außerdem, falls zutreffend,

folgenden Normen:

EN 12445:2002, EN 12453:2002, EN 12978:2003.

Benincà Luigi, Rechtsvertreter.

Sandrigo, 23/09/2016.

Il Certificato di Conformità di queo documento corrisponde all'ultima revisione disponibile al momento della

ampa e può risultare differente per esigenze editoriali

dall'originale disponibile presso il produttore.

Il Certificato di Conformità più completo e recente

è disponibile consultando il sito: www.beninca.com

oppure può essere richieo presso:

Automatismi Benincà S.p.A - Sandrigo VI - Italy.

.

The certificate of conformity in this document corresponds to the la review available at the time of printing and

could differ for editorial requirements from the original

available from the manufacturer.

The mo recent and complete certificate of conformity

is available consulting the site: www.beninca.com or

can be requeed from:

Automatismi Benincà SpA - Sandrigo VI - ITALY.

Die in diesem Dokument vorliegende Konformitätserklärung entspricht der neueen zum Druckzeitpunkt

erhältlichen Revision und könnte aufgrund von verlegerischen Gründen vom beim Hereller erhältlichen

Original abweichen.

Die neuee und volländige Konformitätserklärung

i auf der Internetseite: www.beninca.com erhältlich

oder kann bei folgender Adresse angefordert werden:

Automatismi Benincà SpA - Sandrigo VI - ITALY.

69

Page 23

Page 24

AUTOMATISMI BENINCÀ SpA - Via Capitello, 45 - 36066 Sandrigo (VI) - Tel. 0444 751030 r.a. - Fax 0444 759728

71

Loading...

Loading...