Page 1

L8542881

02/2016 rev 4

KMB24

UNIONE NAZIONALE COSTRUTTORI

AUTOMATISMI PER CANCELLI, PORTE

SERRANDE ED AFFINI

Page 2

Page 3

ENG

The product shall not be used for purposes or in ways other than those for which the product is intended for and as

described in this manual.

Incorrect uses can damage the product and cause injuries and damages.

The company shall not be deemed responsible for the non-compliance with a good manufacture technique of gates as

well as for any deformation, which might occur during use.

Keep this manual for further use.

This manual has been especially written to be use by qualified fitters.

Installation must be carried out by qualified personnel (professional installer, according to EN 12635), in compliance with

Good Practice and current code.

Make sure that the structure of the gate is suitable for automation.

The installer must supply all information on the automatic, manual and emergency operation of the automatic system and

supply the end user with instructions for use.

The manufacturer also supply further documentation (for example handover pack or a CD with the standards) to safely

set up the gate automation (machine).

Packaging must be kept out of reach of children, as it can be hazardous.

For disposal, packaging must be divided the various types of waste (e.g. carton board, polystyrene) in compliance with

regulations in force.

Do not allow children to play with the fixed control devices of the product.

Keep the remote controls out of reach of children.

This product is not to be used by persons (including children) with reduced physical, sensory or mental capacity, or who

are unfamiliar with such equipment, unless under the supervision of or following training by persons responsible for their

safety.

Apply all safety devices (photocells, safety edges, etc.) required to keep the area free of impact, crushing, dragging and

shearing hazard.

Bear in mind the standards and directives in force, Good Practice criteria, intended use, the installation environment, the

operating logic of the system and forces generated by the automated system.

Installation must be carried out using safety devices and controls that meet standards EN 12978 and EN 12453.

Only use original accessories and spare parts, use of non-original spare parts will cause the warranty planned to cover

the products to become null and void.

All the mechanical and electrical parts composing automation must meet the requirements of the standards in force and

outlined by CE marking.

An omnipolar switch/section switch with remote contact opening equal to, or higher than 3mm must be provided on the

power supply mains.

Make sure that before wiring an adequate differential switch and an overcurrent protection is provided.

Pursuant to safety regulations in force, some types of installation require that the gate connection be earthed.

During installation, maintenance and repair, cut off power supply before accessing to live parts.

Also disconnect buffer batteries, if any are connected.

The electrical installation and the operating logic must comply with the regulations in force.

The leads fed with different voltages must be physically separate, or they must be suitably insulated with additional

insulation of at least 1 mm.

The leads must be secured with an additional fixture near the terminals.

During installation, maintenance and repair, interrupt the power supply before opening the lid to access the electrical parts

Check all the connections again before switching on the power.

The unused N.C. inputs must be bridged.

WASTE DISPOSAL

As indicated by the symbol shown, it is forbidden to dispose this product as normal urban waste as some parts might

be harmful for environment and human health, if they are disposed of incorrectly.

Therefore, the device should be disposed in special collection platforms or given back to the reseller if a new and similar

device is purchased.

An incorrect disposal of the device will result in fines applied to the user, as provided for by regulations in force.

Descriptions and figures in this manual are not binding. While leaving the essential characteristics of the product unchanged, the

manufacturer reserves the right to modify the same under the technical, design or commercial point of view without necessarily

update this manual.

WARNING

3

Page 4

GENERAL RECOMMENDATIONS

Automatismi Benincà SpA is not liable for damage caused by improper use or by incorrect installation of products or components.

WARNING: Important safety instructions. Follow all instructions since incorrect installation can lead to severe injury.

If this is the first time you realise an automation for swing gates with KMB24, we recommend that you read this manual carefully as

it contains important advice and information for the realisation of the plant in safe conditions.

Keep the various components on hand to gain confidence with them while reading this manual.

Keep this manual for future use

Attention!

Potentially dangerous operations. Scrupulously respect the indications given.

Useful indication.

Suggestions and recommendations for simplifying and/or improving the installation operations.

The automation of a door cannot be considered the only device for protection against intrusion.

Do not use any of the components in unsuitable environments (salty, acid or potentially explosive atmosphere)

All operations that require the protection shells of the devices opened, must take place without mains power supply.

Check that the temperature range marked on the drive is suitable for the location.

The drive cannot be used with a driven part incorporating a wicket door (unless the drive cannot be operated with the wicket door

open).

Ensure that entrapment between the driven part and the surrounding fixed parts due to the opening movement of the driven part is

avoided.

After installation, ensure that the mechanism is properly adjusted and that the protection system and any manual release function

correctly.

PRODUCT DESCRIPTION

DESTINATION OF USE

This product is destined exclusively for the opening and closure of swing doors for residential use, characterised by dimensional

limits and weight as indicated in this manual in the “Limits of use” paragraph”.

No other use is allowed.

BENINCÀ is not liable for uses that are not in compliance with those indicated in these instructions.

The kit is made up from two electromechanical operators with 24Vdc motor (LOW VOLTAGE), which allows movement of the leaves

via an articulated anti-shearing arm. The irreversible electromechanical gear motori keeps the gate locked in the closing and opening

positions.

Functioning is controlled by and electronic control unit, installed in one of the two operators.

The control unit commands the movement of the two motors and the functioning of the various accessories.

PRELIMINARY CHECKS

Before installation it is indispensable to perform several checks:

• Check the solidity of the structure installed in relation to the forces generated by the motor. Attach the motor stably using adguate

materials.

• The pillars supporting the leaves must be suitable for fixing the gear motors.

• If avialable, check the contenent of the EC declaration of conformity of the manual gate.

• If necessary, carry out the structural calculation and attach it to the technical file.

• Carry out the analysis of the risk and choice of solutions in accordance with the Machinery Directive 2006/42/CE and the standards

EN 13241-1, EN 12453, EN 12445.

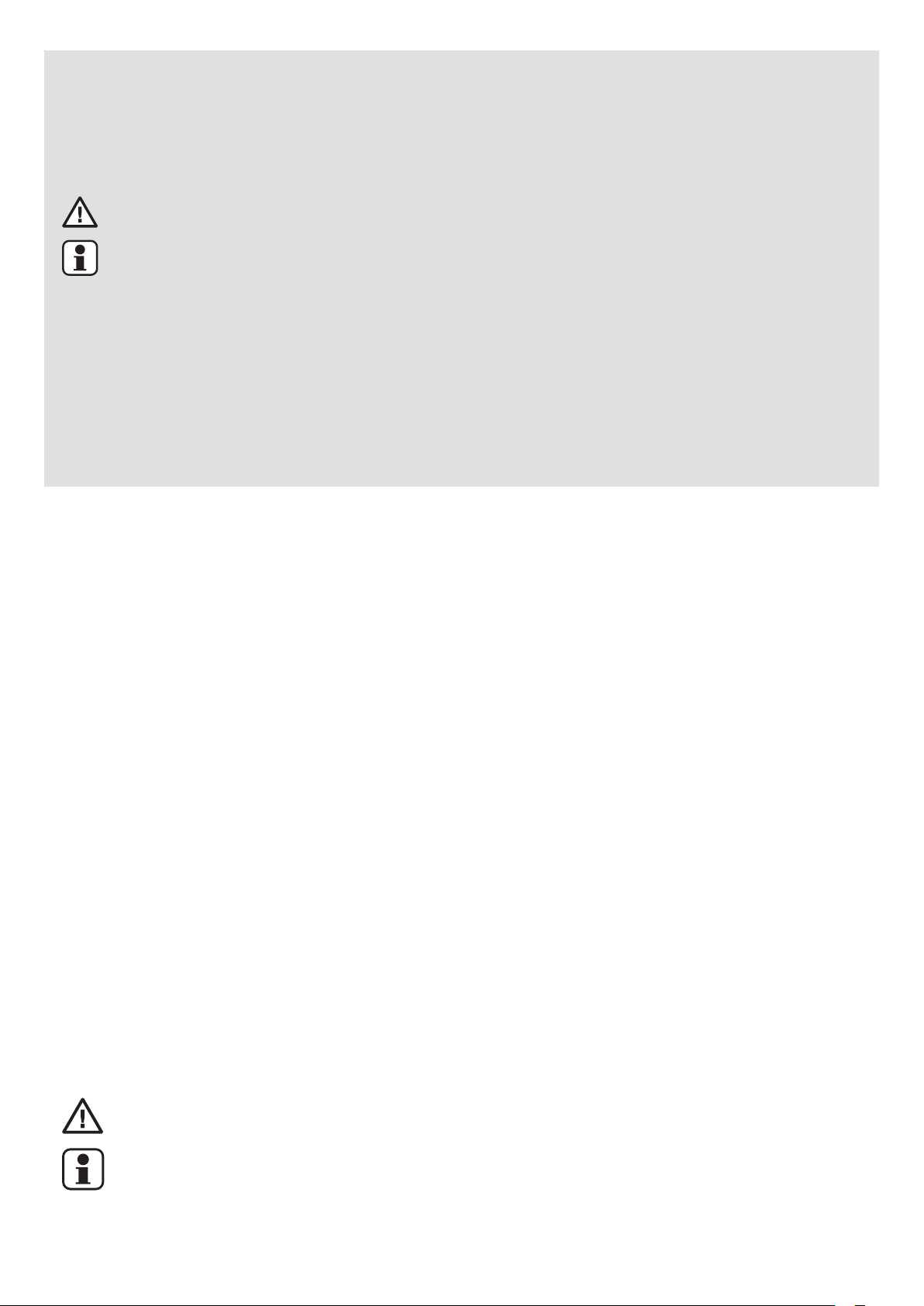

Referer to Fig.4:

A - Impact and crushing of the main closing edge.

B - Impact and crushing in the area of opening.

C - Impact in the area of closure.

the KMB24 has been built to guarantee the PL c (Performance Level c), category 2, according to the EN 13849-1 standard(Safety

of Machinery).

• Try and open the gate manually, the leaves must move without effort and without points of resistance for the entire run.

• When left in any intermediate position the leaf must not move.

• The hinges and components subject to wear must be in perfect working condition. If this is not the case, replace the faulty parts.

• With the gate completely closed, check that the leaves are aligned perfectly along their entire length.

• The presence of a opening and closing stop is indispensable (Fig.3 ref. 5 and 8). It mist be installed if not present.

The reliability and safety of the automation depend on the state of the gate structure.

Check that there is enough space for installation of the operator in safe and comfortable conditions.

4

Page 5

A

C

DE B

184

234

28

1 2

10

184

234

28

245

184

35

95

α°

A (mm) B (mm) C (mm) D (mm) E (mm)

Door leaf max. rotation

90° 0 470 350 243 140

350

350

90° 50 470 339 255 140

90° 100 470 331 262 140

90° 150 470 328 264 140

90° 185 470 356 237 160

90° 200 440 410 160 200

110° 0 420 244 318 200

105° 100 420 262 310 200

3

A

11

H

I

12

M

4

D

9

F

A

1

7

8

3

L

5

2

B

6

5

E

C

G

5

Page 6

4

57

27,5

140 mm min.

A

B

C

B

5

5

6

6

Page 7

57

27,5

140 mm min.

7

Articulated bracket

Bracket

8 9

YES!

NO!

10

Screw M8x65

A

Fixing bracket

Self locking nut M8

7

Page 8

1 2

see label manual relase

11 12

GND

LN

T

SN

S

Customized key C

A

P

B1

T1

N

R

D

S1

B2

Lever L

13

GND

14

SWC2 (17) SWO2 (16) COM (13) M2 (3,4)

Cavi

LN

Cables

MBE24V

MB24V

8

Page 9

15

Key

Lower cam

Key

Upper cam

Open.

Close.

Upper cam

Microswitch

Key

Lower cam

Open.

Upper cam

Key

Close.

Lower cam

16

MB24

MBE24

Inside.

Open. Open.

Left Right

9

Page 10

17

F2:1.6AT (230V)

F2:3.2AT (115V)

N

L

+-

24Vac

II°CH/SERL

ANT

ANT

SHIELD

32313029

T 2A

F1

Code

____

J1 DAS

Close

DAS 8K2

DAS

J1 DAS

Open

DAS N.C.

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26

U11

2827

RADIO

2827

DAS

8k2

M1 M2

SCA

LAMP

Lock 12Vdc

24Vdc

10

10W (5s)

PHOTO

TEST

(+) (-)

24Vac/dc

500mA max

COM

SWC1

SWO1

P.P.

STOP

SWO2

PHOT

SWC2

PHOTC

OPEN

PED

CLOSE

COM +

Page 11

18

TX2

TX1

PHOT C

RX2

PHOT

RX1

PHOTOCELLS ACTIVE IN OPENING AND CLOSING PHOTOCELLS ACTIVE IN OPENING AND CLOSING

PHOTOTEST

24Vac

11

12 11 1213 18 13 199 10

test1:on test2:ON

COM PHOT COM PHOT-C

PHOTOTEST

24Vac

9 10

19

24Vac 24Vac

NC NO

RX1TX1

SCA

24Vac/dc

500mA max

11 12

AUX1:0

32313029

COM

24Vac 24Vac

SERVICE/ZONE LIGHT

Relè 24Vac

24Vac/dc

500mA max

11 12

L N

32313029

Service Light

Service/Zone

Light

230Vac

NC NO

COM

RX2TX2

AUX1:2

Zone Light

AUX1:3

11

Page 12

Display OFF

Power ON

Firmware Ver. (3s)

Diagnostic

v1.05

8888

PAR

tca

tm1

tm2

tped

pmo1

pmc1

pmo2

pmc2

tdmo

40

50

50

50

50

50

PRG

5

5

2

PRG

PRG

PRG

PRG

PRG

PRG

PRG

PRG

LOG

tca

IBL

IBCA

SCL

PP

PRE

ham

blco

blcc

tdmc

tls

tloc

sld1

sld2

spd1

spd2

pso1

psc1

pso2

60

50

50

99

99

20

20

20

3

5

PRG

PRG

PRG

PRG

PRG

PRG

PRG

PRG

PRG

PRG

soft

ltca

htr

imot

cvar

mloc

bb

2ch

tst1

tst2

tstm

rem

TCA

TCA

psc2

seau

sear

tinc

20

0

0

250

PRG

PRG

PRG

PRG

radi

LOG

12

Page 13

on PRG

RADI

pp

PUSH OK

OFF PRG

OFF PRG

OFF PRG

OFF PRG

OFF PRG

OFF PRG

off PRG

off PRG

OFF PRG

Off PRG

off PRG

off PRG

par

Nman

MACI

RES

AUTO

CODE

2ch

ped

clr

rtr

PUSH OK

PUSH OK

PUSH OK

rtr PRG OK

0012 3456

OFF PRG

res PRG

PUSH

0000 conf OK

2 Cycle

OPEN/CLOSE

OK

9000 9C5a

RE-ENTER

CODE

Display OFF

off PRG

off PRG

off PRG

OFF PRG

Off PRG

off PRG

off PRG

off PRG

Legenda

Press key (-)

Press key (+)

Press key (PG)

Press simultaneously keys (+) and (-)

Increase/decrease the value with keys (+) and (-)

Press the transmitter key, which is to be assigned to function

13

Page 14

INDEX

1) LIMITS FOR USE....................................................................................................................................................................................... 15

2) OVERALL DIMENSION (FIG.1) .................................................................................................................................................................... 15

3) INSTALLATION DIMENSIONS (FIG.2) .......................................................................................................................................................... 15

4) TOOLS AND MATERIALS ........................................................................................................................................................................... 15

5) STANDARD INSTALLATION (FIG.3).............................................................................................................................................................15

6) ANCHORING OF BRACKETS (FIG.6-7) ........................................................................................................................................................ 15

7) POSITIONING THE GEARED MOTOR (FIG.10) .............................................................................................................................................15

8) POSITIONING THE ARTICULATED ARM BA (FIG.11) .................................................................................................................................... 15

9) MANUAL AND EMERGENCY OPERATION (FIG.12) ......................................................................................................................................16

10) WIRE CONNECTIONS (FIG.3) ................................................................................................................................................................... 16

11) ADJUSTING THE LIMIT SWITCHES (FIG.15) ............................................................................................................................................. 16

12) CHECKS ................................................................................................................................................................................................ 16

12.1) CHECKS INSTALLING POSITIONS ....................................................................................................................................................16

12.2) CHECK MOTOR AND LIMIT SWITCHES CONNECTIONS ..................................................................................................................... 17

13) SAFETY DEVICES (FIG.16) ....................................................................................................................................................................... 17

14) CP.MBY24 CONTROL UNIT ..................................................................................................................................................................... 17

14.1) AUTOSET FUNCTION ....................................................................................................................................................................... 17

14.2) WIRE DIAGRAM .............................................................................................................................................................................. 18

15) PROGRAMMING ..................................................................................................................................................................................... 19

16) PARAMETERS, LOGIC AND SPECIAL FUNCTIONS ....................................................................................................................................19

16.1) PARAMETERS (PAR) ....................................................................................................................................................................... 19

16.2) LOGIC (LOG)...................................................................................................................................................................................20

16.3) RADIO (RAD) .................................................................................................................................................................................. 22

16.4) CYCLES NUMBER (NMAN) ............................................................................................................................................................... 22

16.5) MAINTENANCE CYCLES (MACI) ...................................................................................................................................................... 22

16.6) RESET (RES) .................................................................................................................................................................................. 22

16.7) AUTOSET (AUTO) ........................................................................................................................................................................... 22

16.8) PROTECTION CODE (CODE) ............................................................................................................................................................ 23

17) TRANSMITTERS REMOTE LEARNING ......................................................................................................................................................23

18) FUSES ................................................................................................................................................................................................... 23

19) EMERGENCY BATTERY OR SOLAR PANEL ............................................................................................................................................... 23

20) DIAGNOSTICS ........................................................................................................................................................................................ 23

21) ERROR MESSAGES ................................................................................................................................................................................ 24

22) INSPECTION AND COMMISSIONING ........................................................................................................................................................ 24

TECHNICAL DATA

Power supply

Motor feed

Power drawn

Current drawn

Torque max.

Noise level

Working Temperature

Operating time at 90°

Door leaf max. weight

Door leaf max.

Duty cycle

Lubrication

Index Protection

Weight

Built-in release:

14

MBE24 (With Control Unit) MB24

230 Vac ± 10%

24 Vdc

160 W

0,76 A

180 Nm

<70 dB

-20°C/+50°C

10 s (with slowdown disabled)

300 kg (see limits for use)

3,0 m (see limits for use)

30 min. ON /30 min. OFF

Permanent grease

IP44

10,7 kg

Customized key

10 s (with slowdown disabled)

300 kg (see limits for use)

3,0 m (see limits for use)

30 min. ON / 30 min. OFF

24 Vdc

160 W

6,2A

180 Nm

<70 dB

-20°C/+50°C

Permanent grease

IP44

9 kg

Customized key

--

Page 15

1) LIMITS FOR USE

Do not use the automation on leaves with dimensions / weights above the values indicated in the below enclosed table chart:

Door leaf width

(m)

1

1,5

2

2,3

Door leaf weight

(kg)

300

250

215

200

2) OVERALL DIMENSION (FIG.1)

On Fig 1 main overvall dimensions are indicated, value to be in millimiters.

3) INSTALLATION DIMENSIONS (FIG.2)

On Fig. 2 and enclosed table chart , different installation dimensions are indicated.

Any change on the A, B, E dimensions, C and D dimensions changes accordingly.

Verify to have enough space to guarantee the necessary articulated arm movement before proceeding with the installation.

4) TOOLS AND MATERIALS

Make sure that there are all tools and materials necessary for installation (fig.5). Also check that they are in compliance with Standards and in perfect working order.

Use suitable individual protection devices I.P.D. (goggles, gloves, etc)

The length and type of connection cables depend on the accessories installed (see “Electric connections” paragraph).

The fixing screws for the gear motor are not supplied as they depend on the features of the materials used for the pillars

and the leaves.

5) STANDARD INSTALLATION (FIG.3)

On Fig. 3 a standard installation complete with the main accessories is showed.

Keys

1 MBE.24 with control unit CP.MBY24

2 MB.24

3 Wall Photocell transmitter TX1

4 Wall Photocell receiver RX1

5 Opening leaf stop

6 Internal Photocell transmitter TX2

7 Internal Photocell receiver RX2

8 Closing leaf stop

9 Key selector

10 Flashing signal light connection with aerial

11 Safety edge Left leaf

12 Safety edge Right leaf

6) ANCHORING OF BRACKETS (FIG.6-7)

Once the fixing value “E”(fig.2) it taken from the relevant table, and considering a minimum height from floor of 100mm, fit the bracket

to the pillar by means of the screws M8 with relevant screw anchors.

Once the fixing value “B” is calculated, fit the articulated bracket to the gate with the same screws M8 and relevant screw anchors

or weld it to the gate by aligning the articulation bracket to the fitting bracket for the pillar, as shown in the drawing. Reinforce the

fitting areas which are not sufficiently thick, or in any case not strong enough.

7) POSITIONING THE GEARED MOTOR (FIG.10)

Place the geared motor in the fitting bracket for assembly to pillar by using the special nuts and screws supplied.

8) POSITIONING THE ARTICULATED ARM BA (FIG.11)

- Release the gear motor (see paragraph “Emergency manual operation”)

- Insert pin P in the hole of the motor shaft A

- Join arm B1 to arm B2 and lock them by means of pin T1 and lock ring S1

- Fix the arms to the motor shaft A and lock them by means of nut D by inserting washer R and ring N

- Hook the arm to bracket SN and lock it by means of pin T1 and release ring S1.

- Apply cover C and fix it by means of the two screws V.

The gear motor can be installed on the other gate leaf (Fig. 6) in a similar way. The only difference between right-hand and left-hand

leaves relies in the position of arm B2.

With released gear motor, completely open the gate and check the operating clearances of the two arms.

15

Page 16

9) MANUAL AND EMERGENCY OPERATION (FIG.12)

To manually open or close the door in case of power failure or faults, two solutions are possible:

• Built-in release

Introduce the customized key C, turn it clockwise and pull lever L. At this point the geared motor is released and the gate can be

manually pushed.

To reset the normal operation, close lever L again and turn key C anticlockwise. Manually move the gate until the geared motor

is engaged again.

• Rope external release: optional

It is available for fitting to external wall or with accessory to be mounted flush (see MB.SE).

10) WIRE CONNECTIONS (FIG.3)

The cables necessary for the installation can vary according to the accessories installed.

No connection cable is supplied.

Fig. 3 indicates the cables for standard installation.

List of cables

Connection Type Maximum length and notes

A Mains power supply (MBE.24 with control unit CP.MBY24) 3x1,5mm

B Motor connection (MB.24 without control unit) 5x1,5mm

C Wall Photocell transmitter connection 2x0,5mm

D Wall Photocell receiver connection 4x0,5mm

E Column Photocell transmitter connection 2x0,5mm

F Column Photocell receiver connection 4x0,5mm

G Key selector connection for external command 4x0,5mm

H Flashing signal light connection 2x1,0mm

I Connection of the aerial built-in the flashing light RG 58

L Connection for safety edge Right leaf 2x1,0mm

M Connection for safety edge Left leaf 2x1,0mm

2

2

2

2

2

2

2

2

2

2

30m - [1]

15m - [2]

20m

20m

20m

20m

20m

10m

10m

10m

Note

An omnipolar switch should be provided with the contact opening of at least 3 mm, provided with overload protection and able to cut off the system from the mains.

[1]

Means for disconnections must be incorporated in the fixed wiring in accordance with the wiring rules.

The MBE24 gear motor can be installed indifferently on the right of left leaf.

It is preferable to install it on the leaf that is most easily reached by the electricity line.

It is recommended not to exceed 15 m in length. If it is indispensable to exceed this limit, increase the section of the

[2]

cable.

The cables used must be suitable for the type of connection. For example, for connection protected by raceways

use H03VV-F cables, for cables in the outdoor environment always use the H07RN-F type.

11) ADJUSTING THE LIMIT SWITCHES (FIG.15)

N.B.: The position of the cams referring to micro-switches varies according whether the installation of the geared motor is

lefthand or righthand, view from inside. Pay attention to diagrams.

• Closing limit switches

Release the geared motor and manually close the door.

Turn the related cam to the position shown by using the special key supplied, until the micro-switch is activated. Lock the cam

by tightening the central screw supplied.

• Opening limit switches

Release the geared motor and manually open the door.

Turn the related cam to the position shown by using the special key supplied, until the micro-switch is activated. Lock the cam by

tightening the two screws supplied.

12) CHECKS

12.1) CHECKS INSTALLING POSITIONS

1) Check that the arms are perfectly horizontal using a spirit level (fig.8).

If the arms are not perfectly horizontal, malfunctioning and breakage can occur. The shape of the holes on the fixing plate allows

any minimum adjustments.

2) With both gear motors released, take the leaves into the completely open position and check that the arms do not strike any

obstacle during movement.

Fig.9 represents the two motors installed, the dotted line indicates the two arms with the leaves in the opening position.

Control the presence and functionality of the mechanical block in closing “A”.

16

Page 17

12.2) CHECK MOTOR AND LIMIT SWITCHES CONNECTIONS

1) Cut-off power supply.

2) Manually release the wings, move them to approx. half-stroke and lock them again.

3) Restore power supply.

4) Send a step-by-step control signal by pressing the <-> push-button.

5) The leeaves must move in OPENING.

In case this does not happen, it is sufficient to invert among them the motor run wires. (1<>2 for M1 motor, and 3<>4 for M2

motor) and, if used, the relative Limit switch inputs (14<>15 for M1 motor, and 16<>17 for M2 motor).

13) SAFETY DEVICES (FIG.16)

IMPORTANT!

READ CAREFULLY!

Measure opening and closing forces (by means of the special instrument required by the standard EN 12445).

If the values of the forces are higher, install a protective device in accordance with the standard EN 12978 (for example

a sensitive edge) and repeat the measurement.

The dynamic forces can be reduced, for example, by reducing the speed of the leaf or using a sensitive edge wit high

elastic deformation.

BENINCÀ can provide all the devices necessary for your installation and relative accessories , contact your trusted

supplier for any further information.

On fig.16 an example of application on the primary closing edges.

To prevent the impact in the area of closure (figure 4, risk C) install a pair of photocells (recommended height 500 mm) so as to sense

the presence of the test paralleledpipe height 700 mm (in according to MD).

To reduce further the possibility of impact in the area of opening (figure 4, risk B) install a pair of photocells (recommended height

500 mm) in the area of movement of the gate, so as to sense the presence of the test paralleledpipe height 700 mm (in according

to MD).

We suggest to connect photocells in phototest mode (see Fig.18 and set logics TST1=ON e TST2=ON), or check the if photocell

working correctly at least every 6 months.

14) CP.MBY24 CONTROL UNIT

14.1) AUTOSET FUNCTION

IMPORTANT:

type of installation.

The AUTOSET function must be repeated at every function parameter change or upon change of automation conditions. See the

AUTO menu for further information.

The first and most important function to program is the self-regulation of the parameters, which allows the control unit to automatically set the end run points, the torque applied to the leaf and the slowing phases*.

To carry out autoset, proceed as follows:

a) Ascertain that no obstacles of any nature are present in the manoeuvre area, if necessary, block off the area in order to prevent

access from people, animals, vehicles, etc.

During autoset phase, the anti-crushing function is not active.

b) Select the AUTO function and press OK.

c) Select with the <+> or <-> button the submenu LSW.

LSW: if the motor is equipped with Limit switch.

d) once selected press OK to begin the autoset phase.

The control unit carries out a series of manoeuvres for learning of the run of the leves and for parameter configuration.

Perform an autostop procedure after every maintenance intervention or modification of the door.

After every autoset procedure and/or PMO/PMC,PSO/PSC parameters changing, measure opening and closing forces (by means

of the special instrument required by the standard EN 12445).

The control unit is equipped with the Autoset function to automatically set the main functioning values based on the

During the autoset operations, the control unit automatically performs several opening and closure manoeuvres.

Before proceeding, check that no person, animal or obstacle is or can be in the door manoeuvre area.

All the accessories provided for the system should be already connected to the control unit. If further accessories should

be added, self-adjustment must be repeated.

17

Page 18

14.2) WIRE DIAGRAM

Wire connections shown in Fig. 18 are described hereunder:

Terminal No. Function Description

1-2 Motor 1 Connection, motor 1: 24VDC PRE-WIRED

3-4 Motor 2 Connection, motor 2: 24VDC MB24

5-6 Flashing light Connection, flashing light 24VDC 15W max.

7-8 Lock Output, 12Vdc/10W power supply for electric lock (7:0V, 8:+12V)

Contact free from N.O. Voltage, may be configured as open gate indicator or photocell

test.

For use as “Open gate indicator” the TEST1 and TEST2 logics must be OFF

For use as photocell test it is sufficient to activate one or both TEST logics and connect

9-10

SCA/

PHOTO TEST

the photocells as indicated in Fig.3.

Output, accessory power supply, 24VAC/0.5A max.

11-12 24 Vac/dc

IMPORTANT: If the battery charger board is installed, the output (without mains power

connected) has a 24Vdc polarised voltage.

Make sure the devices are correctly connected (i.e. 11:+24Vdc / 12:-0Vdc).

13 COM Common for limit switch and all the command inlets.

14 SWO1 Motor 1 OPEN limit switch input (N.C. contact) PRE-WIRED.

15 SWC1 Motor 1 CLOSE limit switch input, (N.C. Contact) PRE-WIRED

16 SWO2 Motor 2 OPEN limit switch input, (N.C. Contact).

17 SWC2 Motor 2 CLOSE limit switch input, (N.C. Contact)

18 PHOT Input, photocell activated in both opening and closing phases

19 PHOT C Input, photocell activated in closing phase only (Normally closed contact)

20 STOP Input, STOP push-button (Normally closed contact)

21 OPEN

Input, OPEN push-button (Normally open contact).

It is possible to connect a timer for opening in time slots.

22 CLOSE Input, CLOSE push-button (Normally open contact)

23 PED

Pedestrian button input (N.O. Contact), controls the motor 1 opening, see TPED parameter.

24 Step-by-Step Input, step-by-step push button (Normally open contact)

25 COM Common for Limit switch and all the command inputs.

26 N/A N/A

Input, sensitive edge contact

Resistive edge 8K2: “DAS” Jumper closed (see paragraph 13 “SAFETY DEVICES”).

Mechanical edge N.C.: “DAS” Jumper open

When the edge is activated, the gate movement is stopped and reversed for about 3s.

27-28

SENSITIVE

EDGE

(DAS)

N.O. Contact free from Voltage, may be configured as second radio channel or service

29-30 II°CH/SERL

light. For use as second radio channel the 2CH logic must be ON.

For use as courtesy light the 2CH logic must be OFF.

31-32 Antenna Connection to the built-in radio receiver card (30-signal/31-screen).

+ / - 24VAC/dc

U11

18

CONFIGURATION

MEMORY

Input, 24VAC/24VDC power supply.

In case of use of plug batteries connect the battery charging card as indicated in the

specific installation instructions.

Extractable Eprom Memory. Contains all the control unit configurations (logics, parameters, etc.), including the radiotransmitters. In case of faults it is possible to extract Eprom

and insert it into a different control unit, avoiding reprogramming.

Page 19

15) PROGRAMMING

The programming of the various functions of the control unit is carried out using the LCD display on the control unit and setting the

desired values in the programming menus described below.

The parameters menu allows you to assign a numerical value to a function, in the same way as a regulating trimmer.

The logic menu allows you to activate or deactivate a function, in the same way as setting a dip-switch.

Other special functions follow the parameters and logic menus and may vary depending on the type of control unit or the software

release.

TO ACCESS PROGRAMMING:

1 – Press the button <PG>, the display goes to the first menu, Parameters “PAR”.

2 – With the <+> or <-> button, select the menu you want (PAR>LOG>RAD>NMAN>MACI>RES>AUTO>CODE).

3- Press the button <PG>, the display shows the first function available on the menu.

4 - With the <+> or <-> button, select the function you want.

5 - Press the button <PG>, the display shows the value currently set for the function selected.

6 - With the <+> or <-> button, select the value you intend to assign to the function.

7 - Press the button <PG>, the display shows the signal “PRG” which indicates that programming has been completed.

NOTES:

Simultaneously pressing <+> and <-> from inside a function menu allows you to return to the previous menu without making any

changes. Hold down the <+> key or the <-> key to accelerate the increase/decrease of the values.

After waiting 120s the control unit quits programming mode and switches off the display.

When the board is switched on, the software version is displayed for around 5 sec

Hold down the <+> key or the <-> key to accelerate the increase/decrease of the values.

16) PARAMETERS, LOGIC AND SPECIAL FUNCTIONS

The tables below describe the individual functions available in the control unit.

16.1) PARAMETERS (PAR)

MENU

TCA

TM1

TM2

Tped

PMo1

PMC1

PMo2

PMc2

TDMo

TDMC

TLS

TLOc

SLD1

Automatic closing time. Active only with logic “TCA”=ON.

At the end of the set time the control unit orders a closing manoeuvre.

Operating time, motor 1. The operating time is adjusted at normal speed during

motor 1 opening and closing phases. See Paragraph “Adjustment of the gate leaf

speed”.

By setting the value to 0, the operation is performed with around 2 seconds of

pick-up and then the movement is carried on at reduced speed for the entire

stroke. In the motors with encoder, the value is expressed in percentage. In motors without encoder the value is expressed in seconds.

Operating time, motor 2. The operating time is adjusted at normal speed during

motor 2 opening and closing phases. See Paragraph “Adjustment of the gate leaf

speed”.

By setting the value to 0, the operation is performed with around 2 seconds of

pick-up and then the movement is carried on at reduced speed for the entire

stroke. In the motors with encoder, the value is expressed in percentage. In motors without encoder the value is expressed in seconds.

Adjusts the motor 1 opening percentage (pedestrian function).

The value is expressed in seconds. In the motors with encoder, the value is

expressed in percentage. In motors without encoder the value is expressed in

seconds.

The anti-crash device (amperometric sensor) operation is adjusted in the opening

phase, at normal speed - Motor 1.

The anti-crash device (amperometric sensor) operation is adjusted in the closing

phase, at normal speed - Motor 1.

The anti-crash device (amperometric sensor) operation is adjusted in the opening

phase, at normal speed - Motor 2.

The anti-crash device (amperometric sensor) operation is adjusted in the closing

phase, at normal speed - Motor 2.

Mot.2 opening delay time.

Regulates the delay time of motor 2 on opening with respect to motor 1

Mot.1 closing delay time

Regulates the delay time of motor 1 on closing with respect to motor 2

SERL contact activation time (Service light) 29/30 terminals.

At each manoeuvre the contact closes for the set time.

See Figure 19 connection scheme.

Electric lock activation time. The value is expressed in 1/10s (0=0s - 50=5s) 0-50 (5=0,5s)

Adjusts motor 1 speed during slowing phases.

This value is expressed in percentage.

FUNCTION MIN-MAX-(Default) MEMO

1-240-(40s)

0-99-(5)

0-99-(5)

1-99 (50)

1-99-(50%)*

1-99-(50%)*

1-99-(50%)*

1-99-(50%)*

0-15-(2s)

0-40-(3s)

1-240-(60s)

30-70 (50%)

19

Page 20

SLD2

SpD1

SpD2

Pso1

Psc1

Pso2

Psc2

SeaU

SEAR

tinc

* 1: minimum force/torque - 99: maximum force/torque.

MENU FUNCTION ON-OFF-(Default) MEMO

TCA

IbL

ibca

SCL

PP

PRE

HAM

Blco

Blcc

Adjusts motor 2 speed during slowing phases.

This value is expressed in percentage.

Adjusts motor 1 speed during normal speed phase.

Value expressed in percentage.

Adjusts motor 2 speed during normal speed phase.

Value expressed in percentage.

The anti-crash device (amperometric sensor) operation is adjusted in the opening

phase, at reduced speed - Motor 1.

The anti-crash device (amperometric sensor) operation is adjusted in the closing

phase, at reduced speed - Motor 1.

The anti-crash device (amperometric sensor) operation is adjusted in the opening

phase, at reduced speed - Motor 2.

The anti-crash device (amperometric sensor) operation is adjusted in the closing

phase, at reduced speed - Motor 2.

NOT USED 0-99-(0%)

NOT USED 0-99-(0%)

NOT USED 1-250-(250)

16.2) LOGIC (LOG)

Enables or disables automatic closing

On: automatic closing enabled

Off: automatic closing disabled

Enables or disables condominium function.

On: condominium function enabled. The step-by-step impulse or transmitter

impulse has no effect during the opening phase.

Off: condominium function disabled.

The multi-flat function is enabled or disabled during the TCA counting.

On: the bloc of flat function is enabled. The Step-by-Step signal or the transmitter

signal has no effect during the TCA counting.

Off: the bloc of flat function is disabled.

Enables or disables rapid closing

On: rapid closure is enabled. With open gate, or in the opening phase, the

activation of the photocell causes the automatic closure 3sec after the total

opening of the gate. It is activated only with TCA:ON

Off: rapid closing disabled.

Selects the operating mode of the ”Step by step button” and of the transmitter.

On: Operation: OPEN > CLOSE > OPEN >

Off: Operation: OPEN > STOP > CLOSE > STOP >

Enables or disables pre-blinking.

On: Pre-blinking enabled. Blinking is activated 3s before the motor starts.

Off: Pre-blinking disabled.

Enables or disables the inversion stroke function

On: Function enabled. Before each opening manoeuvre the control unit orders a

manoeuvre of 2s in the opposite direction to facilitate the release of the electric

lock.

Off: Function disabled.

Enables or disables the block function in opening.

On: Block function enabled. After the intervention of the opening Limit switch the

control unit delays arrest by about 0.5s, so to allow a better strike of the shutter

on the stop locks.

Off: Block function disabled

Enables or disables the block function in closing.

On: Block function enabled. After the intervention of the opening Limit switch the

control unit delays arrest by about 0.5s, so to allow a better strike of the shutter

on the stop locks.

Off: Block function disabled.

30-70 (50%)

30-99 (99%)

30-99 (99%)

1-99-(20%)*

1-99-(20%)*

1-99-(20%)*

1-99-(20%)*

(ON)

(OFF)

(OFF)

(OFF)

(OFF)

(OFF)

(OFF)

(OFF)

(OFF)

20

Page 21

SOFT

LTCA

htr

1mot

Cvar

mloc

BB

2ch

TST1

TST2

TSTm

rem

Enables or disables start at decreased speed.

On: Executes start ups at decreased speed for 2 seconds to then shift to normal

speed.

Off: Start at decreased speed not active.

Selects the operating mode of the blinking light during the time TCA

On: Blinking light on during TCA

Off: Blinking light off during TCA

Enabled or disables HOLD-TO-RUN function

On: HOLD-TO-RUN function.

The pressure of the OPENS/CLOSES button must be maintained throughout the

entire manoeuvre. The opening of the STOP input stops the motor. All the safety

inputs are deactivated, except for the Limit switch inputs /SW01/SW02/SWC1/

SWC2).

Off: Automatic/semiautomatic function

The operating mode with 1 or 2 motors is selected:

On: The motor operation is synchronised. This function must be used in the following cases:

- for each single motor, connect it to M1: Terminals 1/2.

- for two synchronised motors (e.g. balancing doors), connect one motor to M1:

terminals 1/2 and the other to M2: terminals 3/4. Adjust the parameters related to

motor 1, the M2 limit switch inputs are deactivated. TDMO and TDMC must be 0.

Off: For two non-synchronised motors, e.g. overlapping gate leaves, adjust TDMO

and TDMC on the desired values.

The code programmable transmitters is enabled or disabled.

On: Radio receiver enabled only for rolling-code transmitters.

Off: Receiver enabled for rolling-code and programmable code transmitters (selflearning and Dip Switch).

Selects the type of electric lock used.

On: Magnetic electric lock, normally fed at 12Vdc.

Power is cut off to the electric lock output before each opening and closing

operation.

Off: Electric lock with latch, normally not fed.

Before each opening manoeuvre power is fed at 12Vdc for the time set by the

parameter TLOC.

Activates or deactivates the push in closing function. Only with logic SLD:ON

On: The last second of the manoeuvre in closing phase is carried out at normal

speed (disabling slowing) to favour a better hook of the electric lock.

Off: Function disabled.

Enables or disables the second radio channel on terminals 29/30.

On: Exit 29/30 configured with function as second radio channel.

Off: Exit 29/30 takes on function of service light (see parameter TLS).

Enables or disables checking of photocells on PHOT input, active both in closing

and in opening.

On: Check enabled. If the check has a negative result, no manoeuvre is commanded. See Fig.18 - “PHOTO TEST”.

Off: Checking of photocells disabled at each manoeuvre.

Enables or disables checking of photocells on PHOT-C inputs, active only in closing.

On: Check enabled. If the check has a negative result, no manoeuvre is commanded. See Fig.18 - “PHOTO TEST”.

Off: Checking of photocells disabled at each manoeuvre.

NOT USED (OFF)

(Enables or disables remote radiotransmitters learning, as indicated in the paragraph “Remote transmitters learning”.

On: Remote learning enabled.

Off: Remote learning not enabled.

(OFF)

(OFF)

(OFF)

(OFF)

(OFF)

(OFF)

(OFF)

(OFF)

(OFF)

(OFF)

(OFF)

21

Page 22

16.3) RADIO (RAD)

MENU

By selecting this function, the receiver goes in waiting (Push) for a transmitter code to assign to the step-step function.

PP

2Ch

ped

CLR

RTR

Displays the number of complete cycles (open+close) carried out by the automation.

When the <PG> button is pressed for the first time, it displays the first 4 figures, the second time it shows the last 4. Example

<PG> 0012 >>> <PG> 3456: made 123.456 cycles.

Press the key of the transmitter to assign to this function.

If the code is valid, it is memorised and the message OK is displayed

If the code is not valid, the message Err is displayed

By selecting this function, the receiver goes into waiting (Push) for a transmitter code to assign to the second radio

channel.

Press the key of the transmitter to assign to this function.

If the code is valid, it is memorised ad the OK message is displayed

If the code is not valid, the message Err is displayed.

By selecting this function, the receiver goes into waiting (Push) for a transmitter code to assign to the pedestrian

opening function (see parameter TPED).

Press the key of the transmitter to assign to this function.

If the code is valid, it is memorised ad the OK message is displayed

If the code is not valid, the message Err is displayed.

By selecting this function, the receiver goes into waiting (Push) for a transmitter code to erase from the memory.

If the code is valid, it is erased and the message OK is displayed

If the code is not valid or not present in memory, the message Err is displayed

Completely erases memory of the receiver. Confirmation of the operation is requested.

By selecting this function the receiver goes into waiting (Push) for a new PGM pressure to confirm the operation.

At end of erasing the OK message is displayed

16.4) CYCLES NUMBER (NMAN)

FUNCTION

16.5) MAINTENANCE CYCLES (MACI)

This function enables to activate the maintenance request notice after a number of manoeuvres determined by the installer.

To activate and select the number of manoeuvres, proceed as follows:

Press button <PG>, the display will show OFF, which indicated that the function is disabled (default value).

With the buttons <+> and <-> select one of the numeric values proposed (from OFF to 100). The values are intended as hundreds

of cycles of manoeuvres (for example: the value 50 indicates 5000 manoeuvres).

Press the OK button to activate the function. The display will show the message PROG.

The maintenance request is indicated to the user by keeping the indicator lamp lit up for other 10 sec after the conclusion of the

opening or closing operation.

16.6) RESET (RES)

RESET of the control unit. ATTENTION!: Returns the control unit to the default values.

Pressing the <PG> button for the first time causes blinking of the letters RES, pressing the <PG> button again resets the control

unit. Note: The transmitters are not erased from the receiver nor is the access password.

All the logics and all the parameters are brought back to default values, it is therefore necessary to repeat the autoset procedure.

16.7) AUTOSET (AUTO)

This function is used to set the optimal operating values of the automatic system and, at the end of the procedure, the LAG, OPERATING TIME and BRAKING parameter are adjusted.

To carry out autoset, proceed as follows:

a) Ascertain that no obstacles of any nature are present in the manoeuvre area, if necessary, block off the area in order to prevent

access from people, animals, vehicles, etc.

During autoset phase, the anti-crushing function is not active.

b) Select the AUTO function and press OK.

c) Select with the <+> or <-> button the submenu LSW.

LSW: if the motor is equipped with Limit switch.

d) once selected press OK to begin the autoset phase.

The control unit carries out a series of manoeuvres for learning of the run of the leves and for parameter configuration.

Initially both the leaves are brought to opening position, then after some opening and closing manoeuvres at different speeds, of

one or both the shutters, the control unit displays the message OK. In case the operation has no positive result, the message ERR

is displayed. Repeat the operation after re-checking the wiring and the eventual presence of obstacles.

In case parametersTM1/TM2 or the speed are changed, repeat the autoset procedure.

During the manoeuvres the display will show some abbreviations: OPM1/OPM2 during opening of the motor 1 or 2 and CLM1/

CLM2 during closing of motor 1 or 2.

22

Page 23

16.8) PROTECTION CODE (CODE)

It allows to type in an access protection code to the programming of the control unit.

A four-character alphanumeric code can be typed in by using the numbers from 0 to 9 and the letters A-B-C-D-E-F.

The default value is 0000 (four zeros) and shows the absence of a protection code.

While typing in the code, this operation can be cancelled at any moment by pressing keys + and – simultaneously. Once the password is typed in, it is possible to act on the control unit by entering and exiting the programming mode for around 10 minutes in

order to allow adjustments and tests on functions.

By replacing the 0000 code with any other code, the protection of the control unit is enabled, thus preventing the access to any

other menu. If a protection code is to be typed in, proceed as follows:

- select the Code menu and press OK.

- the code 0000 is shown, also in the case a protection code has been previously typed in.

- the value of the flashing character can be changed with keys + and -.

- press OK to confirm the flashing character, then confirm the following one.

- after typing in the 4 characters, a confirmation message “CONF” appears.

- after a few seconds, the code 0000 appears again

- the previously stored protection code must be reconfirmed in order to avoid any accidental typing in.

If the code corresponds to the previous one, a confirmation message “OK” appears.

The control unit automatically exits the programming phase. To gain access to the Menus again, the stored protection code must

be typed in.

IMPORTANT: TAKE NOTE of the protection code and KEEP IT IN A SAFE PLACE for future maintenance operations.

To remove a code from a protected control unit it is necessary to enter into programming with the password and bring

the code back to the 0000 default value.

IF YOU LOOSE THE CODE, PLEASE CONTACT THE AUTHORISED SERVICE CENTER FOR THE TOTAL RESET OF THE

CONTROL UNIT.

17) TRANSMITTERS REMOTE LEARNING

If an already memorised transmitter is available in the receiver it is possible to carry out remote radio learning (without needing to

access the control unit).

IMPORTANT: The procedure must be carried out with leaves in opening during TCA pause or with an open gate if the TCA

logic is OFF. The REM logic must be ON.

Proceed as follows:

1 Press the hidden key of the transmitter which is already memorised.

2 Press, within 5s, the key of the corresponding transmitter which is already memorised to associate to the new transmitter. The

flashing light will turn on.

3 Press within 10s the hidden key of the new transmitter.

4 Press, within 5s, the key of the new transmitter to associate to the channel chosen at point 2. The flashing light will turn off.

5 The receiver memorised the new transmitter and immediately exits from programming.

18) FUSES

F1: T2A low voltage protection.

F2: T1,6A high voltage protection.

19) EMERGENCY BATTERY OR SOLAR PANEL

Optional accessories are available for control unit power supply in case of absence of power or solar panel use.

For further information, refer to the instructions supplied with the accessory.

20) DIAGNOSTICS

SWO1 SWO2

SWC1

P.P. PED OPEN CLOSE

PHOT

PHOT-C

STOP

SWC2

DAS

One segment of the display is linked to each input. In the event of failure it switches on

according to the following scheme.

N.C. inputs are represented by the vertical segments. N.O. inputs are represented by

the horizontal segments.

The control unit sees the message AMP1 or AMP2 in case of anti-crushing ammeter

sensor intervention.

23

Page 24

21) ERROR MESSAGES

Some messages that are displayed in case of function anomalies are listed as follows:

Amp1

Amp2

Err1

Err2

Err3

Err4

Err5

Err6

Err7

Err8

thrm

Obstacle error motor 1/anti-crushing Check presence of obstacles on motor 1 leaf run

Obstacle error motor 2/anti-crushing Check presence of obstacles on motor 2 leaf run

Motor 1 circuit checking error Check motor 1 connections

Motor 2 circuit checking error Check motor 2 connections

error/fault power circuit Request technical assistance and eventually replace control unit.

PHOT photocell checking error Check connections, PHOT photocell alignment or presence of obstacles.

PHOTC photocell checking error Check connections, PHOTC photocell alignment or presence of obstacles.

Error edge active (during autoset) In autoset phase, the safety edge has intervened.

Error active stop (during autoset) In autoset phase, the STOP input has intervened.

Error active input (during autoset) In autoset phase a PP/Open/Close input has intervened.

Motor thermal protection intervention

Wait for motor cooling, in case reset does not take place, motor replacement may be necessary

22) INSPECTION AND COMMISSIONING

The respect for the indications given below is indispensable to guarantee the maximum safety of the automation.

The BENINCÀ authorised technician must perform all tests envisioned by the Law, Standards and Regulations in force

depending on the risks present, particularly respecting all requisites of the EN 12445 Standard, which establishes the test

methods for gate automations.

INSPECTION

1 Check that the model selected is suitable for the type of application and that all automation components have been installed

correctly, with respect to the indications in this manual.

2 Test opening and closure and control that the movement of the leaf is regular without friction points.

3 Check that all electric connections are made correctly and with cables that are in compliance with the Standards.

4 Check the correct functioning of photocells, transmitters, key selectors, manual release devices (see paragraph 13 “SAFETY

DEVICES”.

5 Take the measurement of the force of impact according to that indicated by the EN 12445 Standard, intervening, if necessary on

the parameters and repeat the measurement.

COMMISSIONING

Commissioning of the automation can only be performed if all of the previously-described inspection phases have had a

positive result.

1 Apply the warning plate, supplied with the automation, to the gate in a well-visible position.

2 Apply a plate to the gate that contains the following data: Type of automation, name and address of the person in charge of com-

missioning (manufacturer), serial number, year of manufacture and CE mark.

3 Realise the technical file as per indications of the EN 12445 Standard, attaching the entire drawing, electric wiring diagrams (e.g.

figure 3), risk analysis and solutions adopted, declaration of conformity of the manufacturer of the devices used (included in this

manual).

4 Fill in and supply the owner of the automation with the declaration of conformity.

5 Realise and supply the owner with the “user guide” for the automation, also using the user guide present in this manual.

6 Realise and supply the owner of the automation with the periodical maintenance plan.

7 Do not start the automation before the owner has been informed regarding the dangers and risks that are still present.

24

Page 25

KMB24

USER GUIDE

KEEP THIS GUIDE AND MAKE IT AVAILABLE TO ALL USERS OF THE AUTOMATION.

SAFETY STANDARDS

WARNING: Important safety instructions. It is important for the safety of persons to follow these instructions. Save these

instructions.

Do not stand in the movement area of the door.

Do not allow children to play with the commands or in proximity of the leaves.

Children should be supervised to ensure that they not play with appliance.

Do not allow children to play with fixed controls. Keep remote controls away from children;

In the case of functioning anomalies do not attempt to repair the fault but contact a BENINCÀ specialised technician.

MANUAL MOVEMENT FROM INSIDE

To manually open or close the door in case of power failure or faults, two solutions are possible:

• Built-in release

Introduce the customized key C, turn it clockwise and pull lever L. At this point the geared motor is released and the gate canbe

manually pushed.

To reset the normal operation, close lever L again and turn key C anticlockwise. Manually move the gate until the geared motor

is engaged again.

• Rope external release: optional

It is available for fitting to external wall or with accessory to be mounted flush (see MB.SE).

MAINTENANCE

• Periodically check the efficiency of the manual emergency release.

• The actuator does not require routine maintenance, however it is necessary to periodically check the safety devices and the other

parts of the plant that could create dangers following wear.

• Frequently examine the installation for imbalance and signs of wear or damage to cables, springs and mounting. Do not use if

repair or adjustment is necessary.

• Disconnect the supply when cleaning or other maintenance is being carried out, if the appliance is automatically controlled.

• Take good care of the maintenance book that the installer must supply you and make sure you respect the required maintenance

program.

• Check the efficiency of photocells at least every 6 months.

DISPOSAL

Whenever the product is put out of service, the legislative provisions in force must be followed regarding differentiated disposal and re-cycling of the various components (metals, plastics, electric cables, etc.). It is advised to contact a BENINCÀ

specialised technician or a specialised company that is enabled for this purpose.

C

L

25

Page 26

2

9

13

7

10

4

3

8

5

12

6

11

Pos.

1

2

3

4

5

6

7

8

9

10

11

12

13

Description

Cover

Motor

Screw

Limit stop

Microswitches

Shaft

Output shaft

Transformer

Control unit

Gasket

Release lever

Cover

Cover

1

Cod.

9686930

9686811

9686326

9686934

9686935

9686936

9686937

9686812

9686927

9686944

9686941

9686942

9686943

26

Page 27

UE Declaration of Conformity/Incorporation (DoC/DoI)

Manufacturer's name: Automatismi Benincà SpA

Address: Via Capitello, 45 - 36066 Sandrigo (VI) - Italia

Telephone: +39 0444 751030

Email address: sales@beninca.it

Person authorised to draft the technical documentation: Automatismi Benincà SpA

Product type: Electromechanical actuator 24V DC for swing gates

Model/type: KMB24

Accessories: LAMPI24.LED - PUPILLA - TO.GO WV - TOKEY

The undersigned Luigi Benincà, as the Legal Officer, declares under his liability that the aforementioned product complies with the provisions established by the following directives:

Directive 2014/30/UE OF THE EUROPEAN PARLIAMENT AND OF THE COUNCIL of 26 February 2014, on the harmonisation of the

laws of Member States relating to electromagnetic compatibility, according to the following harmonised regulations:

EN 61000-6-2:2005 + AC:2005, EN 61000-6-3:2007 + A1:2011.

Directive 2011/65/EU of the European Parliament and Council, dated 8 June 2011, on the restricted use of certain hazardous substances in

electrical and electronic devices (RoHS), according to the following standards:

EN 50581:2012

Directive 1999/5/EC OF THE EUROPEAN PARLIAMENT AND THE COUNCIL of March 9 1999 regarding radio devices and terminal

and telecommunications devices and the reciprocal recognisances of their conformity, according to the following concurred regulations:

ETSI EN 301 489-3 V1.4.1 (2002) + ETSI EN 301 489-1 V1.4.1 (2002) + ETSI EN 300 220-3 V1.1.1 (2000) + EN 60950-1 (2001)

Directive 2006/42/EC OF THE EUROPEAN PARLIAMENT AND OF THE COUNCIL of 17 May 2006, on machinery, which amends

Directive 95/16/EC, and complies with the requisites for the “partly completed machinery (almost machinery)” set forth in the EN132411:2003 regulation.

EN 60335-1:2012 + A11:2014; EN 60335-2-103:2015.

• The manufacturer declares that the pertaining technical documentation has been drawn up in compliance with Attachment VII B of the

2006/42/ EC Directive and that the following requirements have been complied with:

1.1.1 - 1.1.2 - 1.1.3 - 1.1.5 - 1.2.1 - 1.2.3 - 1.2.6 - 1.3.1 - 1.3.2 - 1.3.3 - 1.3.4 - 1.3.7 - 1.3.9 - 1.5.1 - 1.5.2 - 1.5.4 - 1.5.5 - 1.5.6 - 1.5.7 - 1.5.8

- 1.5.10 - 1.5.11 - 1.5.13 - 1.6.1 - 1.6.2 - 1.6.4 - 1.7.2 - 1.7.4 - 1.7.4.1 - 1.7.4.2 - 1.7.4.3.

• The manufacturer undertakes that information on the “partly completed machinery” will be sent to domestic authorities. Transmission

ways are also included in the undertaking, and the Manufacturer’s intellectual property rights of the “almost machinery” are respected.

• It is highlighted that commissioning of the “partly completed machinery” shall not be provided until the final machinery, in which it should

be incorporated, is declared compliant, if applicable, with provisions set forth in the Directive 2006/42/EC on Machinery.

• Moreover, the product, as applicable, is compliant with the following regulations:

EN 12445:2002, EN 12453:2002, EN 12978:2003

Benincà Luigi, Legal Officer.

Sandrigo, 08/02/2016.

The certificate of conformity in this document corresponds to the last review available at the time of printing and could differ for editorial

requirements from the original available from the manufacturer.

The most recent and complete certificate of conformity is available consulting the site: www.beninca.com or can be requested from:

Automatismi Benincà SpA - Sandrigo VI - ITALY.

Page 28

AUTOMATISMI BENINCÀ SpA - Via Capitello, 45 - 36066 Sandrigo (VI) - Tel. 0444 751030 r.a. - Fax 0444 759728

Loading...

Loading...