411iedSignai

ELECTRONIC AND AVIONICS SYSTEMS

INSTALLATION MANUAL

BENDIX/KING@

KY 196/197

VHF COMMUNICA TIONS

TRANSCEIVERS

MANUAL NUMBER 006-00169-0003

REVISION 3 SEPTEMBER, 1983

WARNING

Information subject to the export control laws. This document. which includes

any attachments and exhibits hereto. contains information subject to

International Traffic in Arms Regulation (ITAR) or Export Administration

Regulation (EAR) of 1979. which may not be exported, released or disclosed to

foreign nationals inside or outside the U.S. without first obtaining an export

license. Violators of ITAR or EAR may be subject to a penalty of 10 years

imprisonment and a fine of $1,000.000 under 22 U.S.C. 2778 or Section

2410 of the Export Administration Act or 1979. Include this notIce with any

reproduced portion of this document.

COPYRIGHT NOTICE

01:>1996AlliedSignal, Inc.

Reproduction of this publication or any portion thereof by any means without

the express written permission of AlliedSignal Commercial Avionics Systems is

prohibited. For further information contact the Manager, Technical

Publications, AlliedSignal Commercial Avionics Systems, 400 North Rogers

Road, Olathe, Kansas, 66062. Telephone: (913) 782-0400.

p

2.1

2.2

2.3

2.3.1

2.3.2

2.3.3

2.3.4

2.3.5

2.4

"~

3.1

3.1.1

3.1.2

3.1 .3

3.1.4

3.1.5

Figure

2-1

2-2

2-3

2-4

2-5

2-6

2-7

2-8

2-9

2-10

2-11

2-12

2-13

~3-1

3-2

Page

2-4

2-7

2-9

2-11

2-13

2-15

2-17

2-19

2-21

2-23

2-25

OnLy 2-27

O"Ly

2-2~

3-3

~-l.

Paragraph

1.1

1.2

1.3

1.4

1.5

1.6

KING

KY 196/196E/KY 197/197E

VHF COMMUNICATIONS TRANSCEIVER

TABLE OF CONTENTS

SECTION I

GENERAL INFORMATION

Introduction

Equipment Description

Technical Characteristics

Units and Accessories Supplied

Accessories Required, but Not Supplied

License Requirements

SECTION II

INSTALLATION

General

Unpacking and Inspecting Equipment

InstaLLation

Avionics Cooling Requirements For Panel Mounted Equipment

Mounting Rack Installation

Antenna InstalLation

CabLe Harness and Connector AssembLy

KY 196/196E/197/197E InstaLLation

Post InstaLLation Check

SECTION III

OPERATION

Operating Procedure

Turn On

Transmit Indicator

Mod~ of 0peration

Remote Frequency Transfer

Remote Channel Increment

LIST OF ILLUSTRATIONS

MoLex TerminaL and TooLs (3 Sheets)

Radio Removal TooL (KPN 071-6045-00)

KPN 030-0101-02 Connector AssembLy

KY 196/196E/197/197E OutLine and Mounting Drawing

KY 196/196E/197/197E InstaLLation AssembLy Drawing

KY 197/197E Interconnect Diagram with KMA 20 (13.75VDC)

To Provide 4 ohm Speaker OutPut, Ramp HaiLer and Intercom

KY 196/196E Interconnect Diagram with KMA 20 (27.5VDC)

To Provide 4 ohm Speaker OutPut, Ramp HaiLer and Intercom

KY 197/197E Interconnect Diagram with KA 25A (1~.75VDC)

To Provide 4 ohm Speaker Output

KY 196/196E Interconnect Diagram with KA 25A (27.5VDC)

To Provide 4 ohm Speaker Output

KY 197/197E Interconnect Diagram with KA 134 (1~.75VDC)

To Provide 4 ohm Speaker Output, Ramp HaiLer, and Intercom

KY 196/196E Interconnect Diagram with KA 134 (27.5VDC)

To Provide 4 ohm Speaker Output, Ramp HaiLer, and Intercom

KY 196/196E Interconnect to Provide Intercom and Headphone Output

KY 197/197E Interconnect to Provide Intercom and Headphone Output

Frequency Mode

Program Mode/Memory Mode

Rev. 3, September, 1983

IM0035-2

Paqe

1-1

1-1

1-2

1-4

1-4

1-4

2-1

2-1

2-1

2-1

2-1

2-1

2-2

2-3

2-3

3-1

3-1

3-1

3-1

3-3

3-3

KY 196

064-1019-00

Non-Glare lens

KY 196E

064-1019-01

Non-Glare lens

KY 196

064-1019-02

Standard lens

KY 196

064-1019-05

Non-Glare lens,

Memory

Channels

KY 196E

064-1019-06

Non-Glare lens,

Memory

Channels

KY 196

064-1019-07

Standard lens,

Memory

Channels

KY 196

064-1019-10

Non-Glare lens,

Memory

Channels,

Remote

Transfer/Inc

KY 196E

064-1019-11

Non-Glare lens,

lIo1emory

Channels,

Remote

Transfer/Inc

KY 196

064-1019-12

Standard lens,

Memory

Channels,

Remote

Transfer/Inc

KY 197

064-1021-00

Non-Glare

lens

KY 197E

064-1021-01

Non-Glare

Lens

KY 197

064-1021-05

Non-Glare

lens,

Memory Channels

KY 197E

064-1021-06

Non-Glare

lens,

Memory

Channels

KY 197

064-1021-10

Non-Glare

lens,

Memory

Channels,

Remote

Transfer/Inc

KY 197E

064-1021-11

Non-Glare

lens,

Memory

Channels,

Remote

Transfer/Inc

1.2

EQUIPMENT

DESCRIPTION

KING

KY 196/196E/KY 197/197E

VHF COMMUNICATIONS TRANSCEIVER

SECTION I

GENERAL INFORMATION

1.1 INTRODUCTION

This manual contains information relative to the physical, mechanical, and electrical characteristics of

the King Radio Corporation Silver Crown KY 196/196E/197/197E 720 channel VHF communications transceivers.

Installation and operating procedures are also included. Information relative to t"e

maintenance,

alignment, and procurement of replacement parts may be found in KY 196/196E/197/197E Maintenance/Overhaul

Manual.

The units covered are as follows:

NOTE

All KY 196/196E RADIOS ARE 27.5 VDC, All KY 197/197E RADIOS ARE

13.75 VDC.

The KY 196/196E/197/197E transceiver is a TSO'd 720 channel communications transceiver and is desiqned to

provide two-w::lYvoice communication within the frequency range of

11~.OOOMHz

to B,).975MHz in ~5KHz

increments.

The KY 196/196E/197/197E is a panel mounted unit. Connections to the unit are made throuqh a 20 pin

Molex printed circuit board edge connector and a BNC coax connector at the rear of t"e unit.

ElectricaLLy, the KY 196/196E/197/197E consists of four sections: receiver, transmitter, frequency

synthesizer, and gas-discharge display circuitry. The only difference between the KY 196/197 and I<Y

196E/197E lies in their selectivity specifications (see Section 1.3). The only difference between the KY

196/196E and KY 197/197E is thei r rated t ransmi tter power out out and power requi r~ments (see Secti on

1.3) .

The KY 196/196E (-aS, -06, -07) and the KY 197/197E (-OS, -06) "ave the capability of oreproqra~minq UP

to nine memory channel frequencies for later recall. Channel frequency information is stored in ::I

non-volatile earom memory so that when the radio is turned off and then back on, channel information is

retained.

The KY 196/196E (-10, -11, -12) and the KY 197/197E (-10, -11) have the capability of remote transfer of

use and standby frequencies and the remote recall of channel frequency information.

Rev. 3, September, 1983

IM0035-3

Paqe 1-1

KY 1961196E:

(27.5V)

Receive

-

.4AMP

Transmit

-

5.0AMP

KY 197/197E:

(13.75V)

Receive

-

.~AMP

Transmit

-

6.0AMP

KING

KY 196/196E/KY 197/197E

VHF COMMUNICATIONS TRANSCEIVER

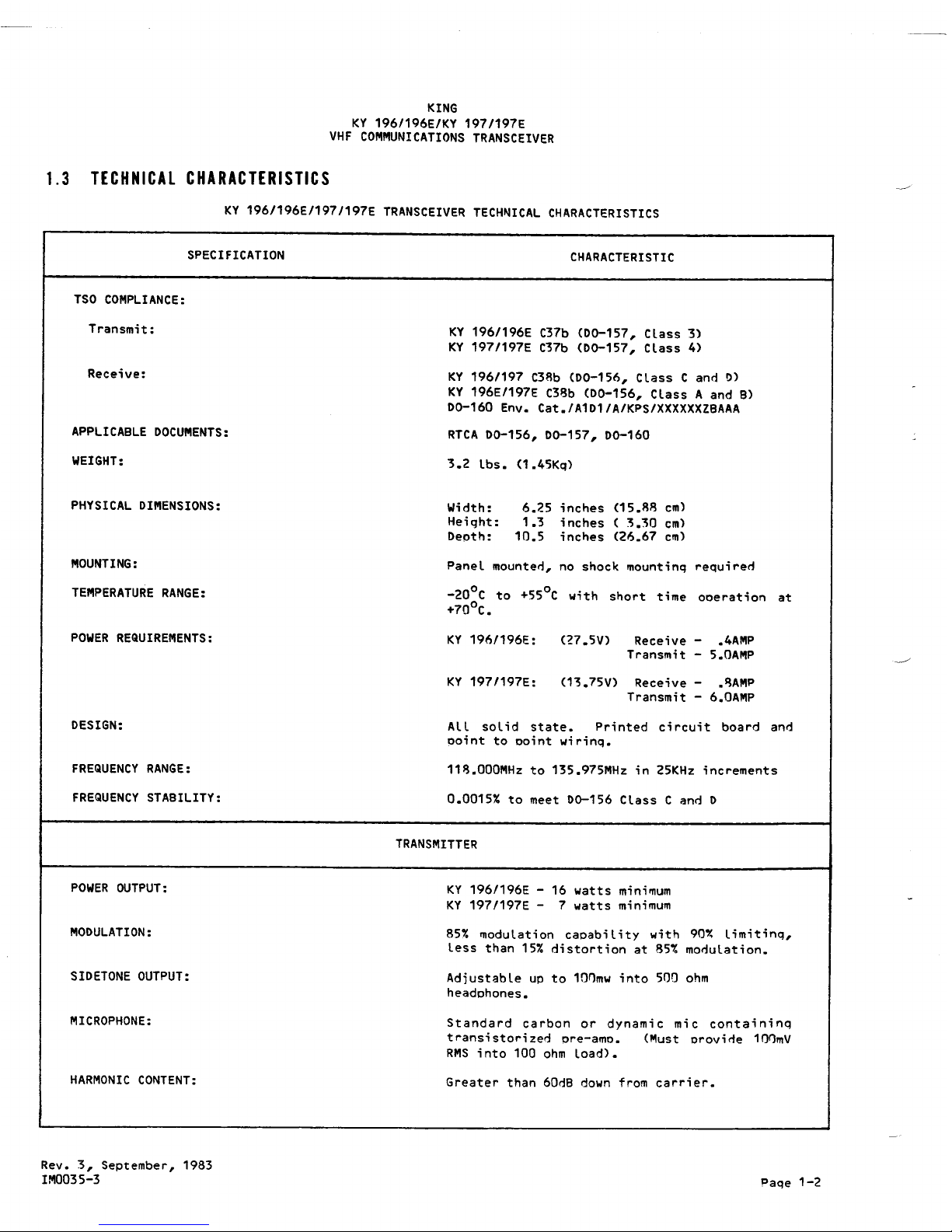

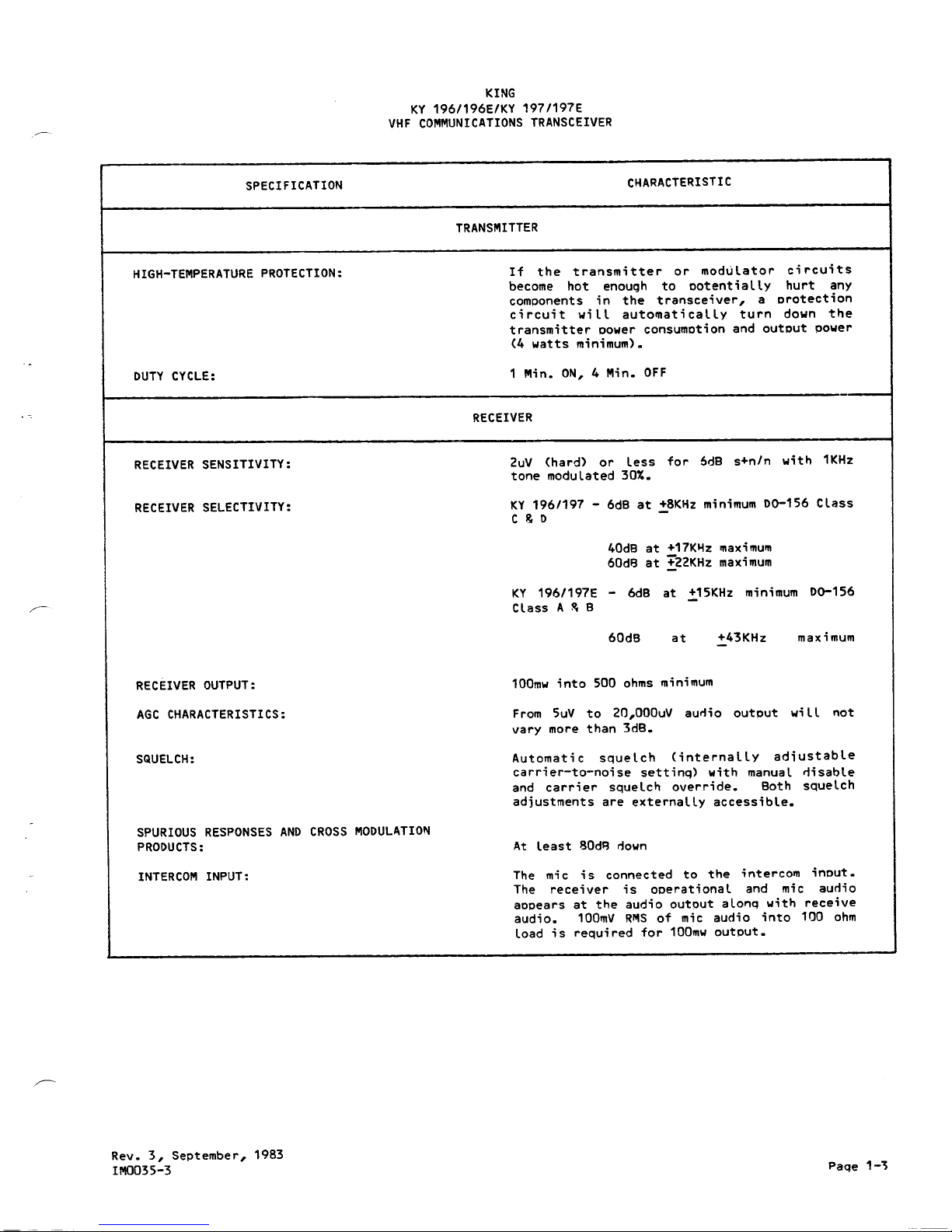

1.3 TECHNICAL CHARACTERISTICS

KY 196/196E/197/197E TRANSCEIVER TECHNICAL CHARACTERISTICS

SPECIFICATION

CHARACTERISTIC

TSO COMPLIANCE:

Transmit:

KY 196/196E C37b (00-157, Class 3)

KY 197/197E C37b (00-157, Class 4)

KY 196/197 C38b (00-156, Class C and D)

KY 196E/197E C38b (DO-156, Class A and B)

00-160 Env. Cat./A1D1/A/KPS/XXXXXXZBAAA

RTCA 00-156, DO-157, 00-160

Receive:

APPLICABLE DOCUMENTS:

WEIGHT:

3.2 lbs. (1.45Kq)

PHYSICAL DIMENSIONS:

Width:

Height:

Depth:

6.~5 inches (15.88 cm)

1.3 inches

(

3.30 cm)

10.5 inches (26.67 cm)

MOUNTING:

TEMPERATURE RANGE:

Panel mounted, no shock mounting required

-200C to +550C with short time operation at

+700C.

POWER REQUIREMENTS:

DESIGN:

All solid state. Printed circuit board and

point to point wirinq.

FREQUENCY RANGE:

118.000MHz to 135.975MHz in 25KHz increments

FREQUENCY STABILITY:

0.0015% to meet 00-156 Class C and D

TRANSMITTER

POWER OUTPUT:

KY 196/196E - 16 watts minimum

KY 197/197E - 7 watts minimum

MODULATION:

85% modulation capabi l ity with 90Y. l imitinq,

less than 15% distortion at 85% modulation.

SIDETONE OUTPUT:

Adjustable up to 1a~mw into 500 ohm

headphones.

MICROPHONE:

Standard carbon or dynamic mic containinq

transistorized pre-amp. (Must provide 10~mV

RMS into 100 ohm load).

HARMONIC CONTENT:

Greater than 60dB down from carrier.

Rev. 3, September, 1983

IM0035-3

Paqe 1-2

KING

KY 196/196E/KY 197/197E

VHF COMMUNICATIONS TRANSCEIVER

SPECIFICATION

CHARACTERISTI C

TRANSMITTER

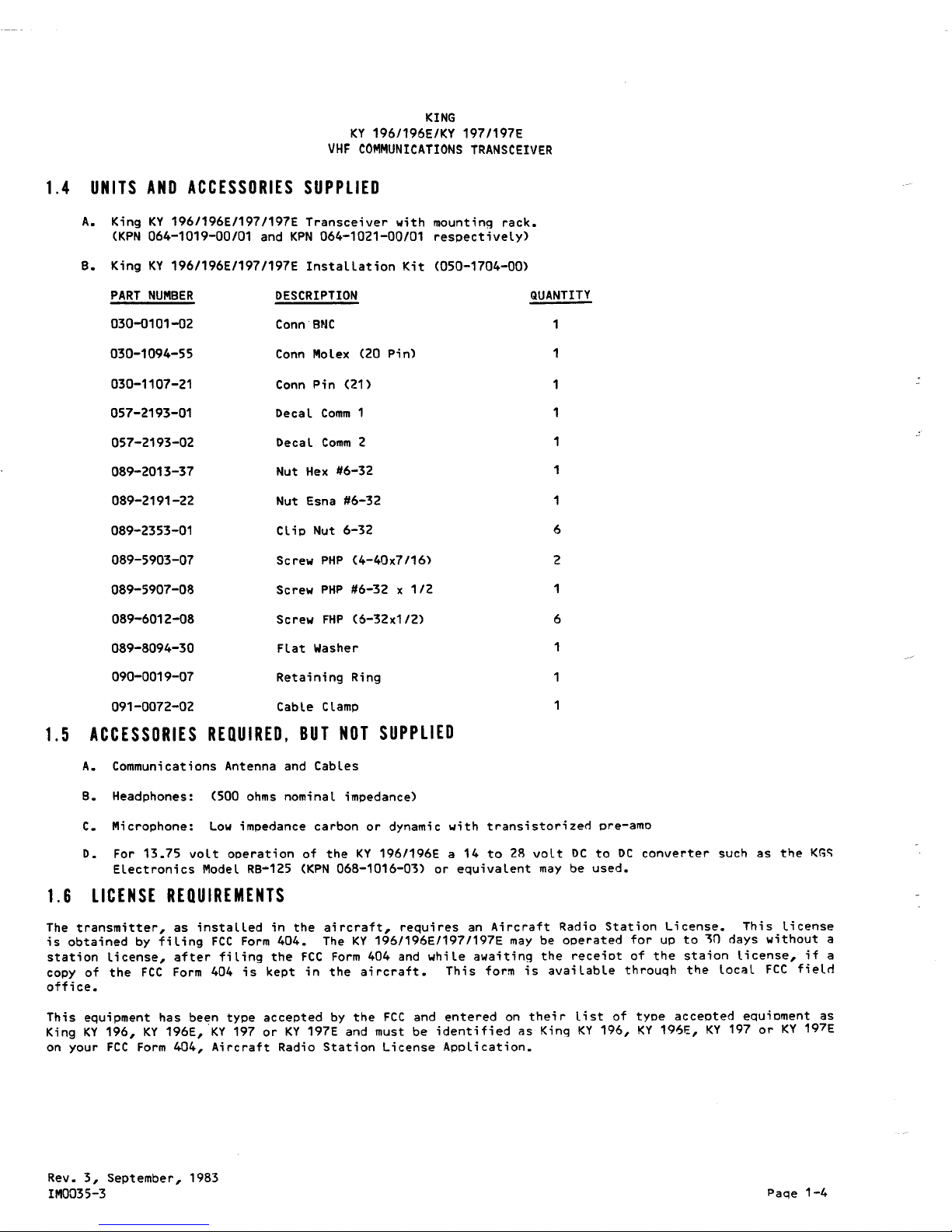

HIGH-TEMPERATURE PROTECTION:

If the transmitter or modulator circuits

become hot enough to ootentially hurt any

components in the transceiver, a protection

ci rcuit wi II automati cally turn down the

transmitter oower consumotion and output power

(4 watts minimum).

DUTY CYCLE:

1 Min. ON, 4 Min. OFF

--

RECEIVER

RECEIVER SENSITIVITY:

2uV (hard) or less for 6dB s+n/n with 1KHz

tone modulated 30%.

RECEIVER SELECTIVITY:

KY 196/197 - 6dB at !8KHz minimum 00-156 Class

C & 0

40dB at +17KHz maximum

60d8 at !22KHZ maximum

KY 196/197E - 6dB at +15KHz minimum 00-156

Class A ~ B

60dB

at

+43KHz

maximum

RECEIVER OUTPUT:

100mw into 500 ohms minimum

AGC CHARACTERISTICS:

From 5uV to 20,000uV aurlio output wi II not

vary more than 3dB.

SQUELCH:

Automatic squelch (internally ad;ustable

carrier-to-noise settinq) with manual rlisable

and carrier squelch override. Both squelch

adjustments are externally accessible.

SPURIOUS RESPONSES AND CROSS MODULATION

PRODUCTS:

At least 80d8 down

INTERCOM INPUT:

The mic is connected to the intercolII input.

The receiver is operational and mic aurlio

appears at the audio output alonq with receive

audio. 100",V RMS of mic audio into 100 ohm

load is required for 100mw output.

Rev. 3, September, 1983

lM0035-3

Paqe 1-~

PART NUMBER DESCRIPTION

030-0101-02 Conn BNC

030-1094-55

Conn

Molex

(20

Pin)

030-1107-21

Conn Pin (21)

057-2193-01

Decal

Comm 1

057-2193-02

Decal Comm 2

089-2013-37

Nut

Hex #6-32

089-2191-22

Nut Esna #6-32

089-2353-01

Clip Nut 6-32

089-5903-07 Screw PHP (4-40x7/16)

089-5907-08 Screw PHP

#6-32 x 1/2

089-6012-08 Screw FHP

(6-32x1/2)

089-8094-30

Flat Washer

090-0019-07 Retaining Ring

091-0072-02

Cable Clamp

KING

KY 196/196E/KY 197/197E

VHF ~OMMUNI~ATIONS T~ANS~EIVE~

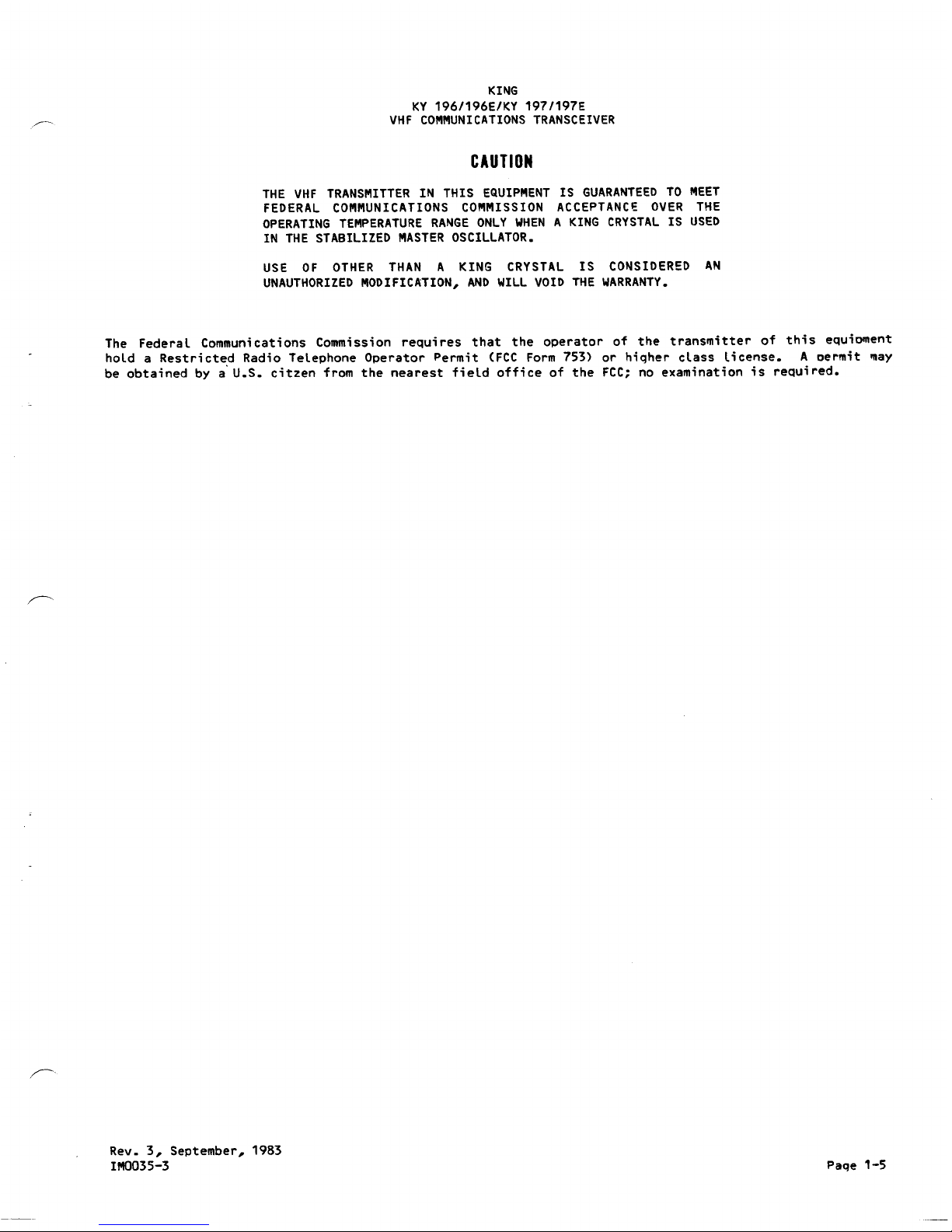

1.4 UNITS AND ACCESSORIES SUPPLIED

A. King KY 196/196E/197/197E Transceiver with mounting rack.

(KPN 064-1019-00/01 and KPN 064-1021-00/01 respectively)

B. King KY 196/196E/197/197E Installation Kit (050-1704-00)

QUANTITY

1

1

1

1

6

2

1

6

1

1.5

ACCESSORIES REQUIRED, BUT NOT SUPPLIED

A. Communications Antenna and Cables

B. Headphones: (500 ohms nominal impedance)

C. Microphone: Low impedance carbon or dynamic with transistorized pre-amo

D. For 13.75 volt operation of the KY 196/196E a 14 to 28 volt DC to DC converter such as the Kr,~

Electronics Model RB-125 (KPN 068-1016-03) or equivalent may be used.

1.6 LICENSE REQUIREMENTS

The transmitter, as instaLLed in the aircraft, requires an Aircraft Radio Station License. This License

is obtained by fiLing FCC Form 404. The KY 196/196E/197/197E may be operated for up to ~n days without a

station license, after fiLing the FCC Form 404 and while awaiting the receipt of the staion license, if a

copy of the FCC Form 404 is kept in the aircraft. This form is avaiLable throuqh the LocaL FCC field

office.

This equipment has been type accepted by the FCC and entered on their List of type accepted equioment as

King KY 196, KY 196E, 'KY 197 or KY 197E and must be identified as King KY 196, KY 196E, KY 197 or KY 197E

on your FCC Form 404, Aircraft Radio Station License AppLication.

Rev. 3, September, 1983

IM0035-3

Paqe 1-4

KHIG

KY 196/196E/KY 197/197E

VHF COMMUNICATIONS TRANSCEIVER

CAUTION

THE VHF TRANSMITTER IN THIS EQUIPMENT IS GUARANTEED TO MEET

FEDERAL COMMUNICATIONS COMMISSION ACCEPTANC~ OVER THE

OPERATING TEMPERATURE RANGE ONLY WHEN A KING CRYSTAL IS USED

IN THE STABILIZED MASTER OSCILLATOR.

USE OF OTHER THAN A KING CRYSTAL IS CONSIDERED AN

UNAUTHORIZED MODIFICATION, AND WILL VOID THE WARRANTY.

The Federal Communications Commission requires that the operator of the transmitter of this equioment

hold a Restricted Radio Telephone Operator Permit (FCC Form 753) or hiqher class license. A oermit may

be obtained by a'U.S. citzen from the nearest field office of the FCC; no examination is required.

Rev. 3, September, 1983

IMO035-3

Paqe 1-5

KING

KY 196/196E/KY 197/197E

VHF COMMUNICATIONS TRANSCEIVER

I

2.1 GENERAL

SECTION II

INSTALLATION

This section contains suggestions and fa~tors to consider before installing the KY 196/196E/197/197E.

Close adherence to these suggestions will 1assure a more satisfactory performance from the equipment.

2.2 UNPACKING AND INSPECTING EQUIPMENT

Exercise extreme care when unpacking the unit. Make a visual inspection of the unit for evidence of

damage incurred during shipment. If a claim for damage is to be made, save the shipping container to

substantiate the claim. The claim should be promptly filed with the transportation company. It would he

advisable to retain the container and packaging material after all equipment has been removed in the

event that equipment storage or reshipment should become necessary.

2.3 EQUIPMENT INSTAlLATION

The KY 196/196E/197/197E installation will conform to standards designated by the customer, installing

agency and existing conditions as to the unit location and type of installation. However, the following

suggestions should be considered before installing your KY 196/196E/197/197E. The installing agency will

supply and fabricate all external cables. The connectors required are supplien by King Radio.

Interconnect diagrams are Figures 2-6 through 2-13.

NOTE

USE GOOD

QUALITY STRANDED WIRE WITH AT LEAST

600

VOL.T

INSULATION THAT

WILL NOT SUPPORT A FLAME.

~

2.3.1 AVIONICS COOLING REQUIREMENTS

FOR PANEL MOUNTED

EQUIPMENT

The greatest single contributor to increased reliability of all modern day avionics is to limit the

maximum operating temperature of the individual units. While modern day individual circuit descdns

consume much less electrical energy, the watts per cubic inch dissipated within avionics units remains

much the same due to. high density packaging techniques utilized. Consequently, the imoortance of

providing avionics stack cooling is still with us.

While each individual unit may not reguire forced air cooling, the combined heat load of several units

operating in a typical avionics stack will significantly degrade the reliability of the avionics if

provisions for stack cooling are not incorporated in the initial installation. Recommendations on stack

cooling are contained in King Radio Installation Bullentin #55. Failure to provide stack cooling will

certainly lead to increased avionics maintenance costs and may void the King warranty.

2.3.2 Mounting Rack Installation

A. The KY 196/196E/197/197E is mounted rigidly in the aircraft panel. Select a position in the

panel that is not too close to any high external heat source. Remember to allow adequate

space for installation of cables and connectors. Avoid sharp bends and placing the cables too

near the aircraft control cables.

B. When installing two or more panel mounted units in a stack, the mounting trays shall be spaced

.050 inches (.127 cm) apart. Newer style mounting trays have had .025 inch <.064 cm) dimples

built in, top and bottom, both sides, so that two new style trays will automatically be spaced

properly.

C. Refer to Figure 2-4 for the KY 196/196E/197/197E mounting dimensions.

mounting holes.

"'ark anI"! cut the

D. Secure the mounting rack to the instrument panel per Figure 2-4. The rear mounting bosses

should be attached to the airframe by means of support brackets.

Rev. 3, September, 1983

IM0035-4

Page 2-1

KING

KY 196/196E/KY 197/197E

VHF COMMUNICATIONS TRANSCEIVER

2.3.3

ANTENNA INSTALLATION

A. A conventional 50 ohm vertically polarized

COMM

antenna is requireri with the KY

196/196E/197/197E. Vertical bent whip antennas are not recommenderi. Widehand

COMM

antennas

provide efficient operation over the

COMM

band. Antennas should be installed oer

manufacturer's recommendations. Additional recommendations are as follows.

B. Mount antenna on a flat metal surface or install a qround plane at least 18 inches square.

C. The antenna should be well removed from any projections and the engine(s) anri propeller(s).

Also, for satisfactory operation, the antenna isolation between a communications transmitter

antenna and a NAVreceiver antenna, as well as between dual

COMM

antennas, should be a minimum

of 30dB. VHF antennas mounted on top and bottom have approximately "30dB isolation. A

horizontally polarized NAVantenna and a vertical polarized

COMM

antenna will have practical

values from 10 to 30dB.

D. If both Comm antennas must be top mounted or both bottom mounteri, antenna isolation between

Comm's may not be adequate to prevent reradiation. In single audio panel installations,

reradiation can also be prevented by use of the Xmit-Rec interlock. Refer to Service Bulletin

KY 196/196E-9 or KY 197/197E-10 and Installation Bulletin 194. In dual audio panel

installations where simultaneous operation of both Comm's is desired, the Xmit-Rec interlock

is not recommended. We would recommend adequate antenna isolation, 30dB min.

2.3.4 CABLE HARNESS AND CONNECTOR ASSEMBLY

The KY 196/196E/1971197E uses a speci a l connector that mates di rect ly wi th the printed ci rcui t board

inside the unit. Assembly of the connector is as follows:

A. Contact Terminal Assembly using Molex Crimper (Figure 2-1)

1. Strip each wire 5/32" for contact terminal (KPN 030-1107-XX). (The last two digits of the

contact terminal part number indicates the number of terminals required).

2. Open the Molex hand crimper HT 1921 with the engraved side toward the operator. Place the

conductor tab section of a contact terminal on Anvi l B with the contact oortion facing

away from the operator. Close the crimper slightly untH the contact tabs touch the

female jaw.

3. Insert the stripped conductor until the insulation is even with the side of the crimper

facing the operator. Crimp the conductor tabs by squeezing the handles together until the

jaws are fully closed or a sufficient crimp is obtained.

4. Move the lead to Anvil A. Place the insulating tab section on Anvi-l A. Crimp again until

the jaws are fully closed or a sufficient crimp is obtained.

8. Contact Insertion into Molex Connector Housing

1. After the contact terminals have been installed on the

terminals can be inserted into the proper location in

030-1094-54). The terminal cannot be inserted upside down.

all the way in, until a click can be felt or heard.

wiring harness, the contact

the connector housing (KPN

8e sure to push the terminal

2. The self locking feature can be tested by gently pulling on the wire.

C. Location of Polarizing Key in Housing

1. Prior to insertion of connector into rear of unit, check polarizing key position between

contacts 3 and 4.

2. Refer to Figure 2-5 to check correct position of polarizing key.

D. Extraction of Contact from Molex Connector

1. Slip the flat narrow blade of a Molex contact e;ector tool, HT-1884

(I(PN 047-5099-01),

under the contact on the mating side of the connector. 8y turning the connector upside

down one can see the blade slide into the stoP.

Rev. 3, September, 1983

IM0035-4

Paqe 2-;:!

KING

KY 196/196E/KY 197/197E

VHF COMMUNICATIONS TRANSCEIVER

2. When the ejector is sLid into pLace, the retaining tab of the contact is raised, aLLowing

the contact to be removed by puLLing moderateLy on the Lead.

3. Neither the contact or position is damaged by removing a contact; however, the contact

shouLd be checked visuaLLy before reinstaLLing in connector to be certain that retaining

tab "A" extends as shown (see Figure 2-1) for retention in connector.

E. Coax Connector

Refer to Figure 2-3 for the ~etaiLs for mounting the right angLe coaxiaL 9~C connector to the

coax cabLe. InstaLL the connector into the mounting rack.

2.3.5 KY 196/196E/KY 197/197E INSTALLATION

A. Looking at the top of the unit, make sure the front Lobe of the hoLddown device is in a

verticaL position.

B. SLide the unit into the mouting rack untiL the front Lobe touches the mounting rack.

C. Insert a 3/32" ALLen wrench through a hoLd in the front paneL to engage the Locking screw.

Turn clockwise untiL the rear Lobe engages the mounting rack. Continue turning until the unit

is secure in the mounting rack Do not overtighten.

D. For removaL, turn the Locking screw counterclockwise, using a 3/32" ALLen wrench, untiL the

unit disengages from the mounting rack. PulL the unit out of the mounting rack by DulLing on

the metaL tabs Located behind the front paneL on each side of the unit. Radio Extractor KPN

071-6045-00 is designed to aid in the removaL of this and other King products (See Figure

2-2).

2.4

POST INST

AllA

TlON CHECK

An operation performance fLight test is recommended after the instalLation is compLeted to insure

satisfactory performance of the equipment in its normaL environment. Check all aircraft control

movements to be sure no electrical cables interfere with their operation. To check the communications

transceiver, maintain an appropriate aLtitude and contact a ground station faci l ity at a range of at

least fifty nautical miles. Contact a ground station close in. PuLL the voLume control knob out to

defeat the automatic squelch feature and listen for any unusual electrical noise which would renuce the

COMI\1

receiver sensitivity by increasing the squeLch threshold. If possible, verify the communications

capability on both the high and low end of the VHF

COMM

band.

NOTE

AS AN ADDED PRECAUTION BEFORE

THE FLIGHT, CHECK THE

ANTENNA.

VSWR SHOULD

BE

CHECKED

WITH

AN

IN-LINE TYPE WATTMETER

INSERTED IN THE

COAXIAL

TRANSMISSION LINE BETWEEN THE

TRANSCEIVER AND THE ANTENNA. ANY PROBLEM WITH THE AItITENItIA

INSTALLATION WILL MOST LIKELY BE SEEN AS A HIGH REFLECTED

?OWER. A VSWR OF 3:1 WILL RESULT IN A 25~ LOSS IN POWER.

NOTE

THE BRIGHTNESS OF THE DISPLAY CAN BE SET FOR THE MOST

PLEASING INTENSITY BY ADJUSTING R130 DURING LOW LIGHT LEVEL

CONDITIONS. R130 IS ACCESSIBLE THROUGH THE BOTTOM OF THE

RADIO WHEN IT IS PARTIALLY PULLED OUT OF THE RACK.

Rev. 3, September, 1983

I1\10035-4

Page2-~

Loading...

Loading...