Page 1

1.31.0

Perfusor® Space

Service Manual

Version 1.3 English

Page 2

1.21.0

0

This Service Manual is valid for: Designation Part No.

Infusion syringe pump Perfusor® Space . . . . . . . . . . . . 0871 3030

This Service Manual is available under

the following part number:

Languages of this Manual The Service Manual for this unit can be supplied in the following

Designation Part No.

Service Manual Perfusor® Space, English. . . . . . . . . . . 8713 9020

languages:

Designation Part No.

Service Manual Perfusor® Space, German . . . . . . . . . . 8713 9010

Service Manual Perfusor® Space, English (US). . . . . . 8713 9020U

Service Manual Perfusor® Space, French . . . . . . . . . . . 8713 9030

2 Perfusor® Space, 1.2 gb

Page 3

1.01.0

0-Table of Contents

0

Important Preliminary Remarks Service Work Page 0 - 5

Technical Safety Checks Page 0 - 5

Current Versions Page 0 - 5

Revision Service Page 0 - 5

Quality Management Page 0 - 6

Checks and Repair Page 0 - 6

Notes on ESD Page 0 - 6

Spare Parts and Test Equipment Page 0 - 7

Setting Off Page 0 - 7

Contact Persons Technical Training Page 0 - 11

Entry for Technical Training Page 0 - 11

Ordering of Spare Parts and Test Equipment Page 0 - 11

Service Hotline International Page 0 - 11

Return of Spare Parts and Test Equipment Page 0 - 11

Safety Officer

(§ 30 MPG) Page 0 - 11

Translation Page 0 - 11

System Overview Description Page 1 - 1

System Overview Page 1 - 1

Physical Construction Page 1 - 2

Function Page 1 - 3

Unit Software Page 1 - 6

Service Program Page 1 - 7

Technical Data Page 1 - 12

Options Page 1 - 12

Accessories Page 1 - 12

Unit Diagnosis / Calibration General Page 2 - 1

Alarms and Error Codes Page 2 - 3

The Most Important Error Modes Page 2 - 8

Device Check Page 2 - 9

Calibration Page 2 - 14

Procedural Instructions for Calibration Page 2 - 14

Trouble Shooting Page 2 - 29

Disassembly / Assembly General Page 3 - 1

Battery Module Page 3 - 9

Unit Foot Page 3 - 11

Operating Unit Page 3 - 12

Upper Part of Housing Page 3 - 17

Release Button Page 3 - 19

Loudspeaker Page 3 - 19

Drive Page 3 - 20

Syringe Holder with Piston Brake Page 3 - 27

Processor PCB Page 3 - 34

Assembly / Installation Page 3 - 35

Checks after Repair Page 3 - 47

Perfusor® Space, 1.0 gb 0- 3

Page 4

1.01.0

0

Table of Contents

Servicing the Unit Cleaning Page 4 - 1

Servicing the Battery Page 4 - 1

Technical Safety Check (TSC) Perfusor® Space 1

Technical Safety Check (TSC) Power Supply SP 1

Procedural Instructions on the TSC Visual Inspection Page 7 - 1

Electrical Safety

according to IEC/EN 60601-1

or VDE 0750 and VDE 0751 Page 7 - 2

Functional Inspection Perfusor® Space Page 7 - 3

Functional Inspection Power Supply SP Page 7 - 6

Test Equipment and Special Tools Test equipment Page 8 - 1

Special Tools Page 8 - 3

Spare Parts List Page 9 - 1

Revision Documentation Description of Version Page 10 - 1

Version List of the Individual Pages Page 10 - 1

Index Page 11 - 1

0- 4 Perfusor® Space, 1.0 gb

Page 5

1.11.0

0-Important Preliminary Remarks

0

Service Work The present manual is for your information only. The possession of

this manual does not authorize the performance of service work.

Service tasks may only be executed by persons, who

- have received appropriate training on the system from

B. Braun

- are included in the revision service

- possess the necessary test equipment and mechanical aids,

and

- fulfill the personal requirements (training and knowledge).

Technical Safety Checks The user is obliged to perform or to have performed the Technical

Safety Checks on those medial products for which these checks

have been prescribed by the manufacturer and to carry them out

according to the indications of the manufacturer as well as the

generally approved technical standards while adhering to the

periods stated (§ 6 MP BetreibV).

B. Braun also recommends training on the Technical Safety

Checks, or to perform at least the steps indicated in the current

version of the manual, as:

- the TSC requires that the instructions in the manuals are

observed

- the manuals are a reference for measurements

- depending on the unit type, the Service Program must be

called which may lead to a dangerous unit condition in case

of inappropriate operation. Furthermore, a special service

connector may be necessary.

Current Versions This manual version corresponds to the state when the manual

was written. B Braun reserves the right to make technical

modifications. The state of the revision is indicated by the index

number in the footer of every page.

Revision Service The possession of this manual does not automatically mean

inclusion in the revision service. You will be included in the

revision service after:

- technical training by B. Braun Melsungen or

- a written order placed with the sales department of B. Braun

(fee required).

Perfusor® Space, 1.1 gb 0- 5

Page 6

1.11.0

0

Important Preliminary Remarks

Responsibility of the Manufacturer The manufacturer, person who assembles, installs or imports the

device can only be held responsible for safety, reliability and

performance if

- mounting, enhancements, new settings, changes or repairs

are carried out by duly authorized persons,

- the electrical installation in the corresponding room meets

the requirements of the VDE 0107, VDE 0100 part 710 or

IEC 60364-7-710 and the national standards,

- the device is used in accordance with the instructions for use

and the Service Manual,

- the Technical Safety Checks are performed at regular

intervals,

- a current manual which corresponds to the revision state is

used when carrying out maintenance, repair and service,

- the service technician takes part in the revision service,

- the technician has participated in a technical training course

for the specific B. Braun unit.

Quality Management B. Braun is certified in accordance with DIN EN ISO 9001 and

ISO 13485. This certification also includes maintenance and

service.

The unit has the CE label. The CE label confirms that the device

corresponds to the “Directive of the Council for Medical Products

93/42/EC” of June 14, 1993.

Checks and Repair Training may only be performed by B. Braun. The possession of the

manual does not authorize the performance of repairs. The

instructions on electrostatic sensitive components (ESD

standards) must be observed.

After repair a device check or diagnosis is to be carried out.

Notes on ESD Semiconductors can be destroyed by electrostatic discharge.

Especially MOS components can be damaged by interference from

electrostatic fields, even without discharge via contact. This type

of damage is not immediately recognizable. Unit malfunctions

can even occur after a longer period of operation.

0- 6 Perfusor® Space, 1.1 gb

Page 7

1.1

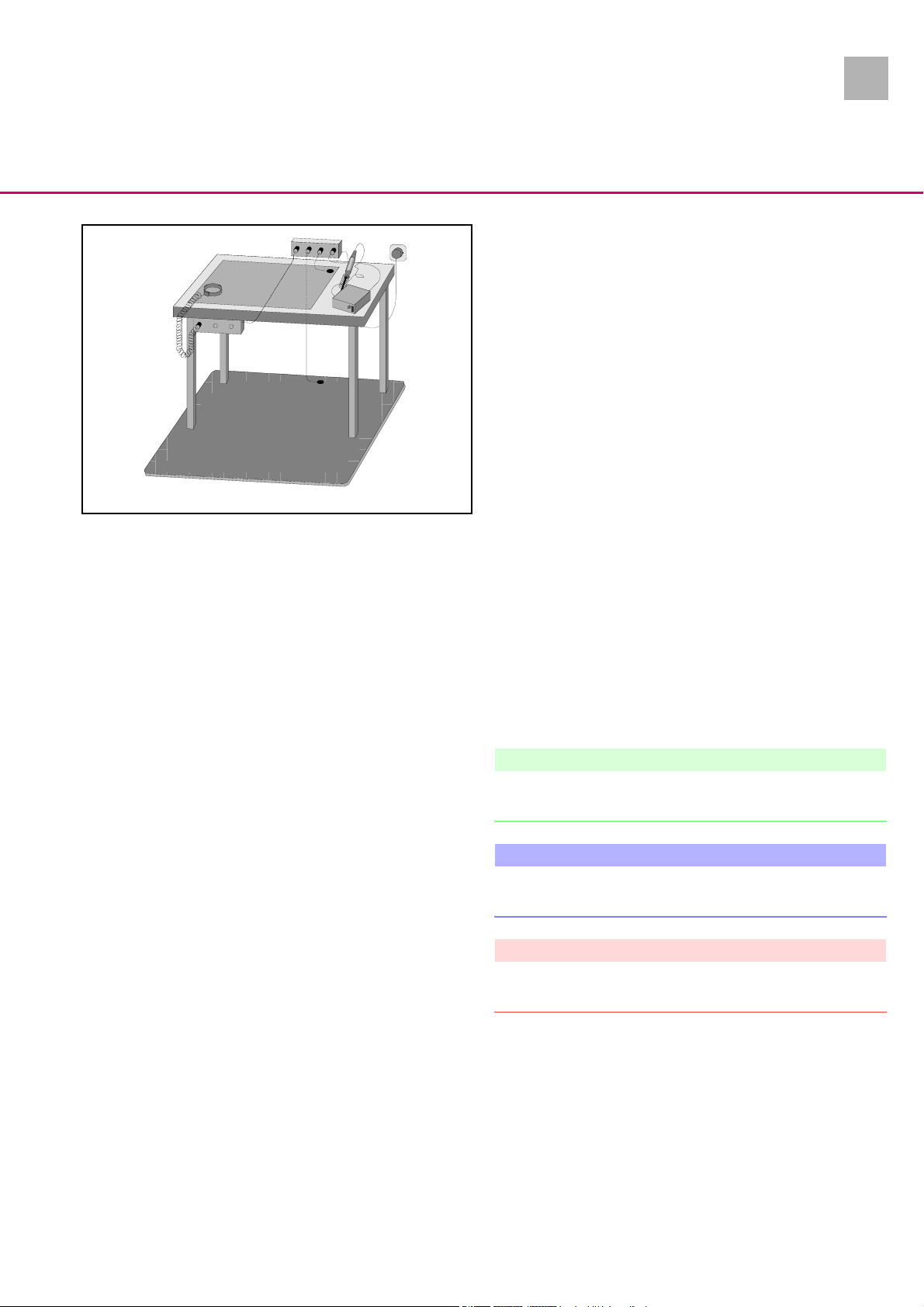

Fig.: 0 - 1

Important Preliminary Remarks

Each workstation must be equipped according to the

recommendations with the necessary static protective measures,

if ESD components or boards are handled.

Each workstation must be equipped with a conductive table

surface. The conductive surface, the soldering iron or the

soldering stations must be grounded via protective resistors.

Chairs must be of antistatic design. The floor or floor mats should

be of electrically conductive material.

Personnel must wear conductive wristbands which are connected

to a central ground potential via protective resistors, e.g. the

ground contact of a wall outlet. Furthermore it is recommended

that personnel wear cotton clothing and electrically conductive

shoes to prevent electrostatic charge.

0

Spare Parts and Test Equipment Only use original spare parts from the manufacturer. Do not

tamper with assembly groups which can only be exchanged

completely. The spare parts required are listed in the repair

descriptions.

Service personnel are responsible for the calibration of their test

equipment. Original test equipment can be calibrated at the

works of B. Braun. Further information is available upon request.

Setting Off Additional notes and warnings are set off as follows:

Note

Is used for additional or special notes concerning information and

working steps.

CAUTION

Is used for working steps which may result in damage to the unit,

system or to a connected device.

WARNING

IS USED FOR WORKING STEPS WHICH MAY RESULT IN PERSONAL

INJURY.

Perfusor® Space, 1.1 gb 0- 7

Page 8

1.11.0

0

Important Preliminary Remarks

References to chapters are shown as follows

(see “Setting Off“ ➨ pg. 0 - 7)

References to figures and tables are shown as follows

Fig.: 2 - 3 or Table 2 - 1

References to item numbers in figures are shown as follows

(Fig.: 1 - 1 / Item 1)

In this case “Fig.: 1 - 1“ is the figure number and “Item 1“ the item

number within the figure.

When the Service Manual is stored as pdf-file, these references

are displayed green. Click with the mouse button on a reference

to jump to the corresponding source.

Menu commands are described as:

Menu

File

.

0- 8 Perfusor® Space, 1.1 gb

Page 9

1.2

Important Preliminary Remarks

0

List of Abbreviations Abbreviations which are not generally known, but are used in this

manual, are listed below.

CAN Controller Area Network

CE Communauté Européenne

(European Communities)

CS Calibration Step

DIN Deutsche Industrie Norm

(German Industrial Standard)

EN European Standard

ESD Electrostatic Discharge

FuP Function Microprocessor

IEC International Electrotechnical

Commission

ISO International Standardization

Organization

ISP Infusomat® Space

ISPS Infusomat® Space, Silicon

ISPP Infusomat® Space, PVC

KuP Monitoring Microprocessor

LCD Liquid Crystal Display

MOS Short for the following

company name:

MOS Technology, Inc.

(Commodore Semiconductor

Group)

PCA Patient-Controlled Analgesia

PSP Perfusor® Space

SP Space (System)

SPC SpaceCover

SPCC SpaceCover comfort

SPCS SpaceCover standard

SPCO SpaceCom

SPCT SpaceControl

SPS SpaceStation

TEMP Temperature

TS Troubleshooting Step

TSC Technical Safety Checks

Perfusor® Space, 1.2 gb 0- 9

Page 10

1.21.0

0

Important Preliminary Remarks

UTS Unit Test Step

VDE Verband der Elektrotechnik,

Elektronik und

Informationstechnik e.V.

(German electrical engineering

association)

0- 10 Perfusor® Space, 1.2 gb

Page 11

1.3

0-Contact Persons

0

Technical Training Via local representative.

Entry for Technical Training Application for a technical training course must be made via the

responsible representative.

Ordering of Spare Parts and Test Equipment Please contact your local B. Braun subsidary.

International Technicians (Intercompany)

Nadja Machal

Fax: +49 5661 / 75 - 47 89

e-mail: nadja.machal@bbraun.com

Service Hotline International Karl Tippel, Tanja Kördel

Fax: +49 5661 / 71 - 35 26

e-mail: karl.tippel@bbraun.com

e-mail: tanja.koerdel@bbraun.com

Return of Spare Parts and Test Equipment B. Braun Melsungen AG

Schwarzenberger Weg 73-79

Wareneingang Werk C

34 212 Melsungen

Germany

Safety Officer (§ 30 MPG)

Translation Cs2 Informatik GmbH & Co. KG, Germany

Dr. Ludwig Schütz

e-mail: ludwig.schuetz@bbraun.com

Perfusor® Space, 1.3 gb 0- 11

Page 12

1.0

0

For your notes:

Contact Persons

0- 12 Perfusor® Space, 1.0 gb

Page 13

1.0

Description

System Overview

1

2

3

4

Fig.: 1 - 1 Space system

Legend of fig. 1 - 1:

ItemDesignation

1 SpaceCover

2 Infusion pump Infusomat® Space

3 Infusion syringe pump Perfusor® Space

1-System Overview

The Perfusor® Space (PSP) is according to IEC/EN 60601 resp. IEC/

EN 60601-2-24 a transportable infusion syringe pump for

administrating fluids in the nutritional therapy and infusion

technique as well as for home care applications.

The medical specialist must decide on suitability for application

on the basis of the warranted properties and the technical data.

The Space system is a modular design of modern infusion

technology for stationary, mobile or private use. The key modules

and their connection to the peripheral devices are shown in

Fig.: 1 - 1.

All the pump types, Perfusor® Space, Infusomat® Space and

Infusomat® Space P, as well as the other devices of the system are

of modular design. Up to three pumps can be connected together

mechanically using L rails on the bottom of the unit and grooves

on the top. They can then be fastened to a drip stand or

appropriate rail using the pole clamp.

The SpaceControl module can be used to extend operation. One

single pump can be inserted onto this module. The pump is then

connected via connectors to the module.

The SpaceStation module allows the set-up of a complete pump

system with up to 24 pumps. Up to four pumps can be installed in

every SpaceStation. The pumps are supplied with power via the

integrated power supply and the built-in connectors. The pumps

5

are connected to the optional SpaceCom via these connectors.

SpaceControl can also be integrated into the system.

Up to six SpaceStations can be set-up as a column with a total of

24 pumps. SpaceStation placed next to each other can be

connected via special connection cables, if the maximum number

of 24 pumps in maximum three columns is not exceeded.

SpaceCover Standard or SpaceCover Comfort forms the top of

each column. Alarms are signalled by a row of LEDs and a

loudspeaker in the SpaceCover Comfort.

1

4 SpaceControl

5 SpaceStation

Perfusor® Space, 1.0 gb 1- 1

Page 14

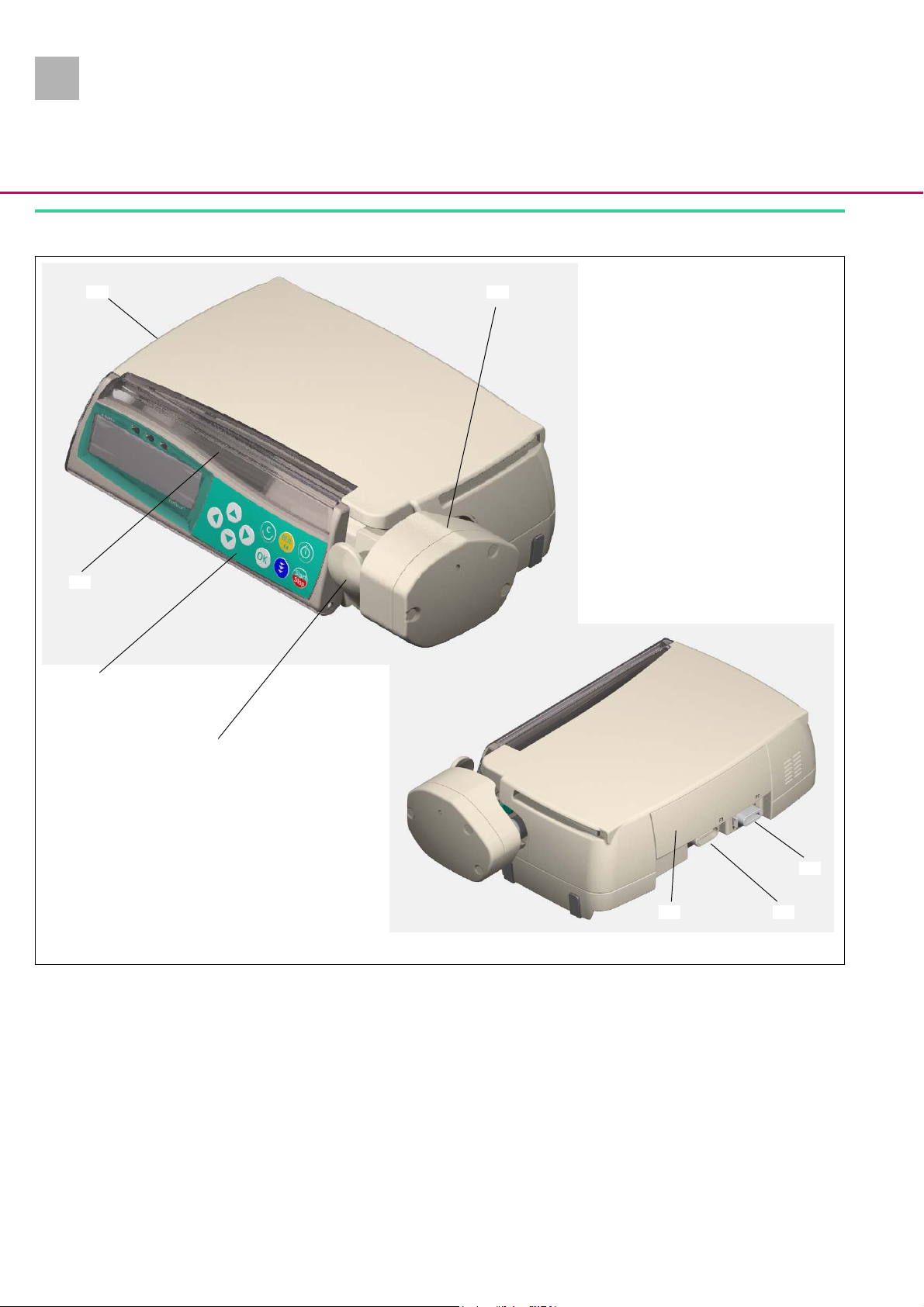

1.0

1

System Overview

Physical Construction

1

2

5

4

3

Fig.: 1 - 2 Perfusor® Space

Legend of fig. 1 - 2:

ItemDesignation

1 Perfusor® Space

2 Drive head

3 Syringe holder with piston brake

4Operating Unit

5 Syringe area

6

78

6 Connector “P2“ for SpaceStation module, external 12 V DC

and accessories

7 Connector “P3“, connection to SpaceControl module

8 Battery compartment cover

1- 2 Perfusor® Space, 1.0 gb

Page 15

1.0

System Overview

The Perfusor® Space housing mainly consists of the bottom part

and the upper part.

The battery module is inserted in the rear of the housing upper

part. The opening is covered by the battery compartment cover.

The operating unit is attached to the front of the bottom part with

two hinges. This operating unit covers the area for the syringes.

The complete drive assembly, consisting of lead screw and drive

head with driving tube is located directly behind the syringe area

in the bottom part of the housing. The housing bushing for the

driving tube is located in the side of the housing.

The syringe holder is mounted in the right side of the housing

bottom part.

The processor PCB with the permanently connected external

connectors “P2” and “P3” is located at the bottom of the housing

bottom part.

1

Function

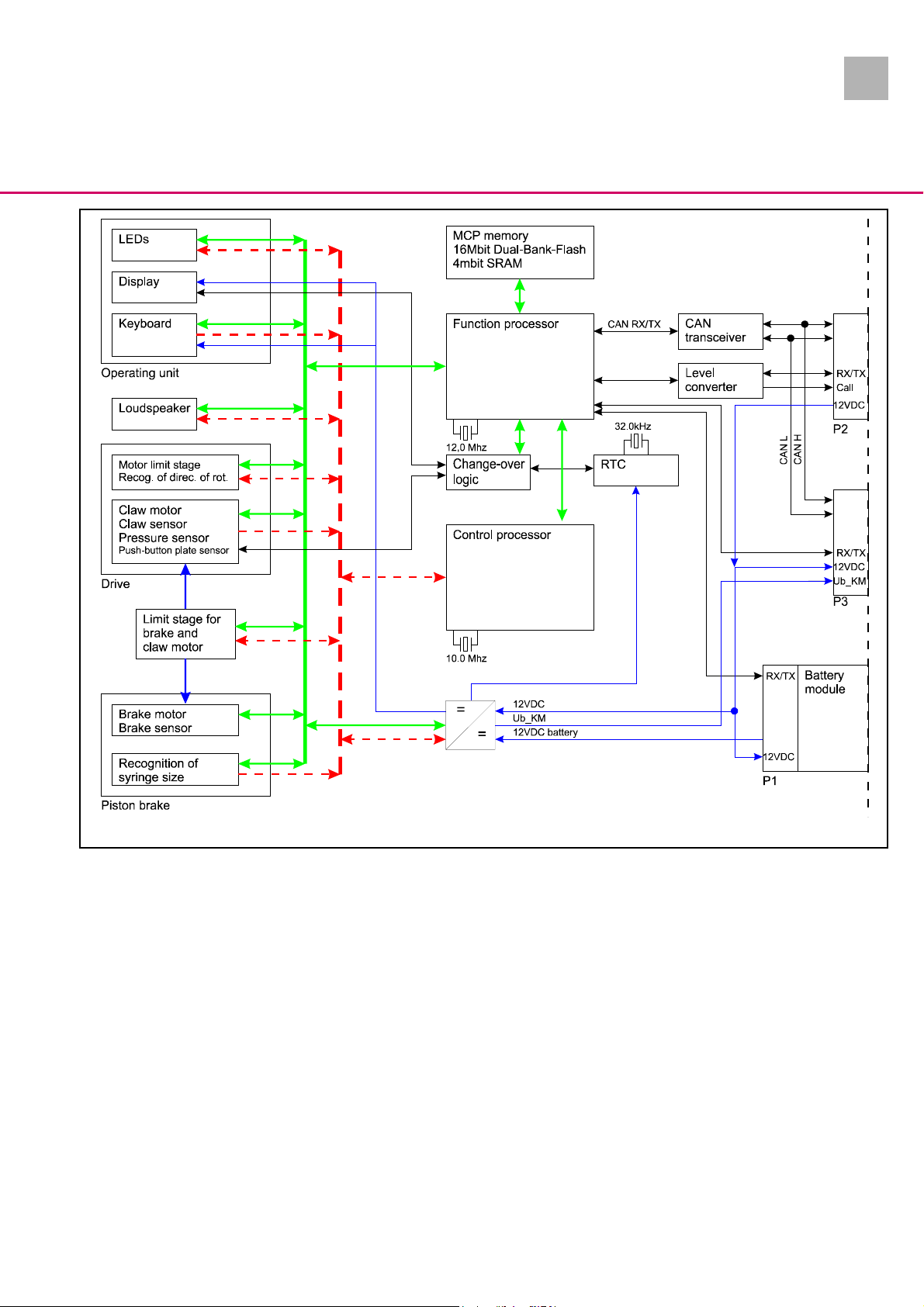

There are two power options for the Perfusor® Space:

- via the inserted battery module

- via an external 12 V DC power supply (e.g. SpaceStation,

SpaceControl, an external power supply or from an

ambulance car) connected to connector “P2”

The voltage supplied is converted to the internal voltages required

through a voltage transforming and monitoring circuit on the

processor PCB.

An independent circuit in the battery module monitors the battery

cells and controls their charge condition.

The Perfusor® Space is connected to a SpaceControl by connector

“P3”.

The function processor controls all the functions of the Perfusor®

Space. Data is stored in a non-volatile memory which also

controls the external data transfer.

The control microprocessor monitors all important responses of

the function processor to incoming information. If a response

does not correspond with that expected by the control

microprocessor, an error message is generated and the device is

switched to a safe stop state.

The drive motor is monitored by a detector for speed and direction

of rotation. The extended end position of the drive head is

detected by a switch on the processor PCB.

Perfusor® Space, 1.0 gb 1- 3

Page 16

1.0

1

System Overview

The pressure in the infusion system is measured through a strain

gauge measuring in the drive head and monitored in the device

electronics. The data from the strain gauge is continuously

compared with the limit values which are calculated dependent

on the selected syringe type and the pressure settings. When the

limit values are exceeded an alarm is automatically triggered and

the pressure in the infusion system is reduced. The maximum

pressure is additionally limited by a second, independent system.

This maximum pressure limitation is performed using the motor

current control.

The syringe size detection is performed via the syringe holder. The

syringe holder is connected to a potentiometer. The syringe size is

determined from the resistance of the potentiometer.

The syringe is fixed with the syringe holder and the axial fastening

device. The syringe piston is fastened with two claws in the drive

head. When a syringe is inserted the syringe piston is held by the

piston brake, until the piston has been caught by the claws.

Keyboard and display as well as the syringe area are illuminated.

1- 4 Perfusor® Space, 1.0 gb

Page 17

1.0

System Overview

1

Fig.: 1 - 3 Block diagram Perfusor® Space

Perfusor® Space, 1.0 gb 1- 5

Page 18

1.0

1

System Overview

Unit Software

Position 12345678910

Digit 688C030001

Revision level

Hardware

Software group

Device type: Perfusor® Space

Fig.: 1 - 4

Approved Software Versions

688A030032

- Basic software

688A030035

- Improved functions

688A030040

- Improved functions

- Languages French and Swedish added

688B030002

- Improved functions

688B030003

- CAN bus functioning

688C030001

- Dose calculation

- Changed CAN log

688D030001

- Drug list data base

- Changed user language

688E030003

- Improved functions

- Piggyback

- Soft limits

688F030006

-PCA

- Changed claw configuration

- Optimized alarm handling

688G030002

- Improved functions

1- 6 Perfusor® Space, 1.0 gb

Page 19

1.0

Service Program

System Overview

Software Update of the Unit

The instructions for updating the software are supplied with the

software itself.

CAUTION

If the device is disconnected while the software is being updated

or the device or PC is switched off, a component of the software

may be seriously damaged so that repairs are no longer possible.

In such a case the software cannot be updated via the PC and the

device must be returned to B. Braun.

Approved Version

Note

Please note that text and / or functions of the Service Program

may change depending on the software version. The following

screen illustrations are only examples and represent the state

when the manual was printed.

1

- 0.0.28

- 1.0.0

- 1.1.2

- 1.1.3

- 1.1.4

- 1.2.1

- 1.3.5

- 1.5.0

- 2.0.1

- 3.1.0

- 4.0.0

- 5.1.0

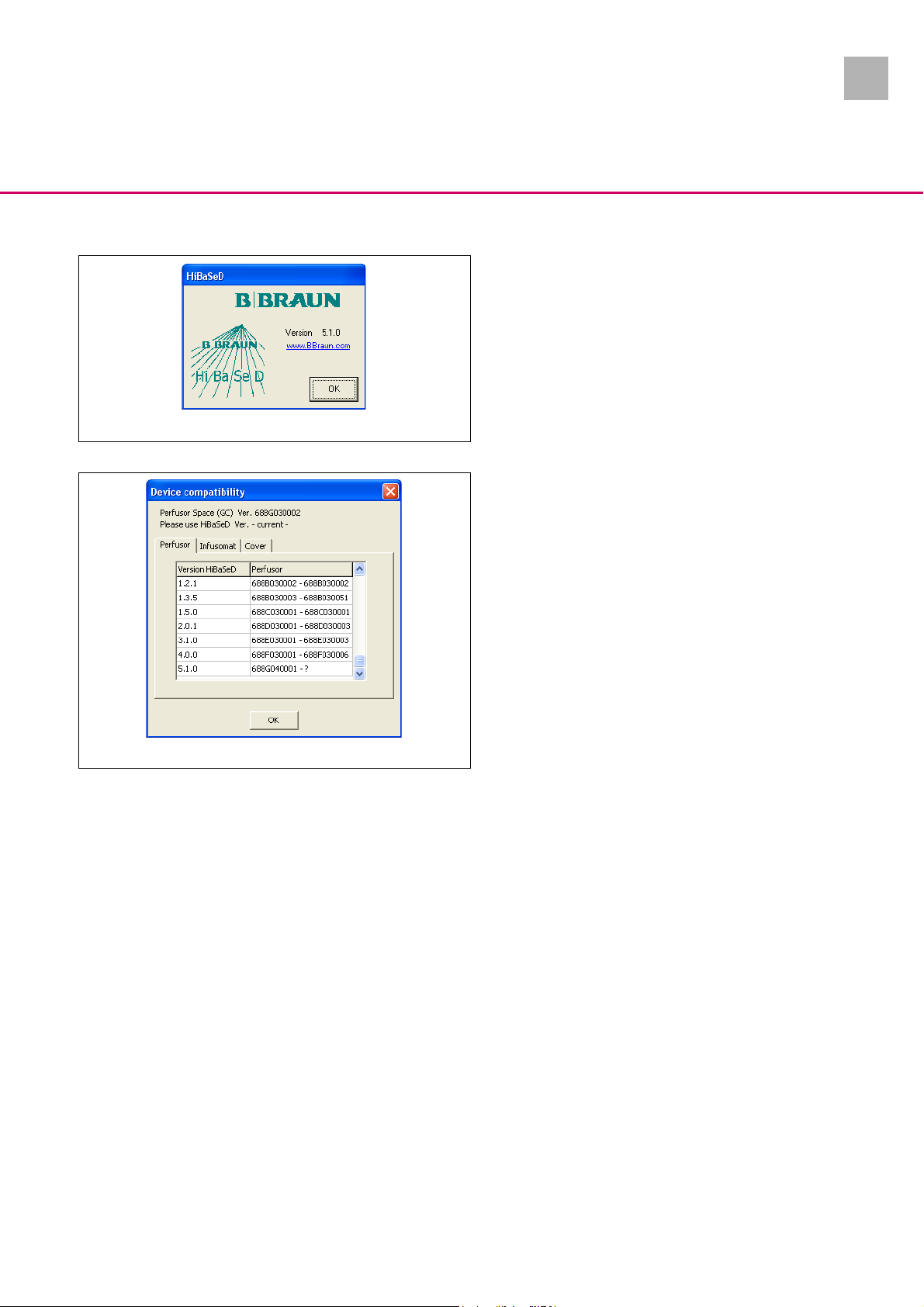

Starting the Service Program

Note

Installation and further operation of the Service Program is

described in its separate instructions for use.

Perfusor® Space, 1.0 gb 1- 7

Page 20

1.0

1

System Overview

1. Start the “HiBaSeD.exe” program (History, Barcode, Service,

D

rug list) on the PC. The Service Program is loaded and

started and the initial window of the Service Program is

displayed.

2. Read the notes carefully.

3. Mark the field “I accept all conditions” and then the field

“Yes” to confirm that you have read the notes.

Note

Click the field “English” to switch the language of the notes over

to English.

Fig.: 1 - 5

Fig.: 1 - 6

4. Enter the password and confirm it by clicking the field “Start”.

The Service Program checks the PC interfaces for connected

devices of the Space system. Units that were found are

displayed for a short moment on the screen.

Fig.: 1 - 7

1- 8 Perfusor® Space, 1.0 gb

Page 21

1.0

System Overview

The work window of the Service Program appears on the

screen. All devices recognized are listed in the left column.

1

Fig.: 1 - 8

5. Activate the desired device from the list on the left in the

work window with a double-click. The device data is then

displayed below the device name.

Perfusor® Space, 1.0 gb 1- 9

Page 22

1.0

1

Fig.: 1 - 9

System Overview

If the unit software version is not compatible with the Service

Program version, a window opens prompting the operator to

change the Service Program version. This window displays a

compatibility list of the Service Program- and unit software

versions.

If Service Program- and unit software versions are

compatible, all the Service Program functions are activated.

Fig.: 1 - 10

1- 10 Perfusor® Space, 1.0 gb

Page 23

1.0

Fig.: 1 - 11

System Overview

Service Program Version

1. Open the “HiBaSeD“ window via

version of the Service Program is shown in this window.

2. Close the window by clicking “OK”.

Compatibility List

1. Open the “Unit - Compatibility” window via

Compatibility

HiBaSeD-version and the unit software version.

2. Close the window by clicking “OK”.

. This window displays the compatibility of the

Help ➨ Info ...

Help ➨

1

. The current

Fig.: 1 - 12

Quit the Service Program

1. Exit the Service Program via

2. Disconnect a power supply which might be connected from

the unit.

3. Switch off the unit.

4. Remove the battery module.

5. The device can be restarted after appr. 10 seconds.

Application ➨ Quit

.

Perfusor® Space, 1.0 gb 1- 11

Page 24

1.3

1

System Overview

Technical Data

Options

All technical data is indicated in the instructions for use.

The functions of the individual options are detailed in the

instructions for use.

Perfusor® Space

Designation Part No.:

Power supply Euro . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0871 3110A

Power supply UK. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0871 3111A

Power supply USA / Japan . . . . . . . . . . . . . . . . . . . . . . 0871 3112A

Power supply Australia. . . . . . . . . . . . . . . . . . . . . . . . . 0871 3113A

Power supply South Africa. . . . . . . . . . . . . . . . . . . . . . 0871 3115A

Accessories

Designation Part No.:

Charger SP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0871 3170

battery charging station

Connection cable staff call SP. . . . . . . . . . . . . . . . . . . . 0871 3232

Power supply cable 12 V . . . . . . . . . . . . . . . . . . . . . . . . 0871 3231

for ambulance cars

CombiLead SP 12 V . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0871 3133

connection cable, pump - pump

InterfaceLead SP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0871 3234

interface cable RS232

InterfaceLead SP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0871 3230

interface cable CAN SP

SpaceClamp SP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0871 3130

The SpaceClamp is a holder attached on beds for one

or several Space system pumps.

Short stand SP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0871 3135

Space PCA kit (PCA button) . . . . . . . . . . . . . . . . . . . . . 0871 3554

Syringe Anti Removal Cap PSP . . . . . . . . . . . . . . . . . . . 0871 3556

1- 12 Perfusor® Space, 1.3 gb

Page 25

1.1

General

2-Unit Diagnosis / Calibration

WARNING

WHILE TESTING THE UNIT AND TROUBLE SHOOTING THE

OPERATOR/SERVICE TECHNICIAN MUST WORK WITH VOLTAGES

UP TO 115 / 230 V AC. THESE VOLTAGES MAY CAUSE INJURIES

WHICH ARE DANGEROUS TO LIFE AND LIMB. THE NATIONAL AND

INTERNATIONAL SAFETY REGULATIONS ARE TO BE ADHERED TO.

Before each disassembly and assembly of a unit subsystem check

the connectors, plug contacts and connections for corrosion and

tight fit. These fault types are not described again in the following

trouble shooting list.

The following equipment and gauges are necessary for testing the

unit and/or performing troubleshooting:

2

-PC

- Service connector SP

- Service Program HiBaSeD

- Interface cable

- Syringe 2 ml / 3 ml

-Syringe 10 ml

- Syringe 30 ml

- Diameter gauge 32.0 mm

- Diameter gauge 23.4 mm

- Diameter gauge 15.7 mm

- Diameter gauge 9.0 mm

- Length gauge PSP

- Syringe gauge “#Lehre OPS 50“with push-button plate and

motor power test adapter for Perfusor® Space

There are pictures of the gauges in Chapter “Special Tools“ (➨

pg. 8 - 3).

CAUTION

Take special care when carrying out measurements on an open

and switched-on unit. Short circuits and wrong measuring

methods can cause serious damage to or destroy the subsystems

of the device.

Perfusor® Space, 1.1 gb 2- 1

Page 26

1.0

2

Unit Diagnosis / Calibration

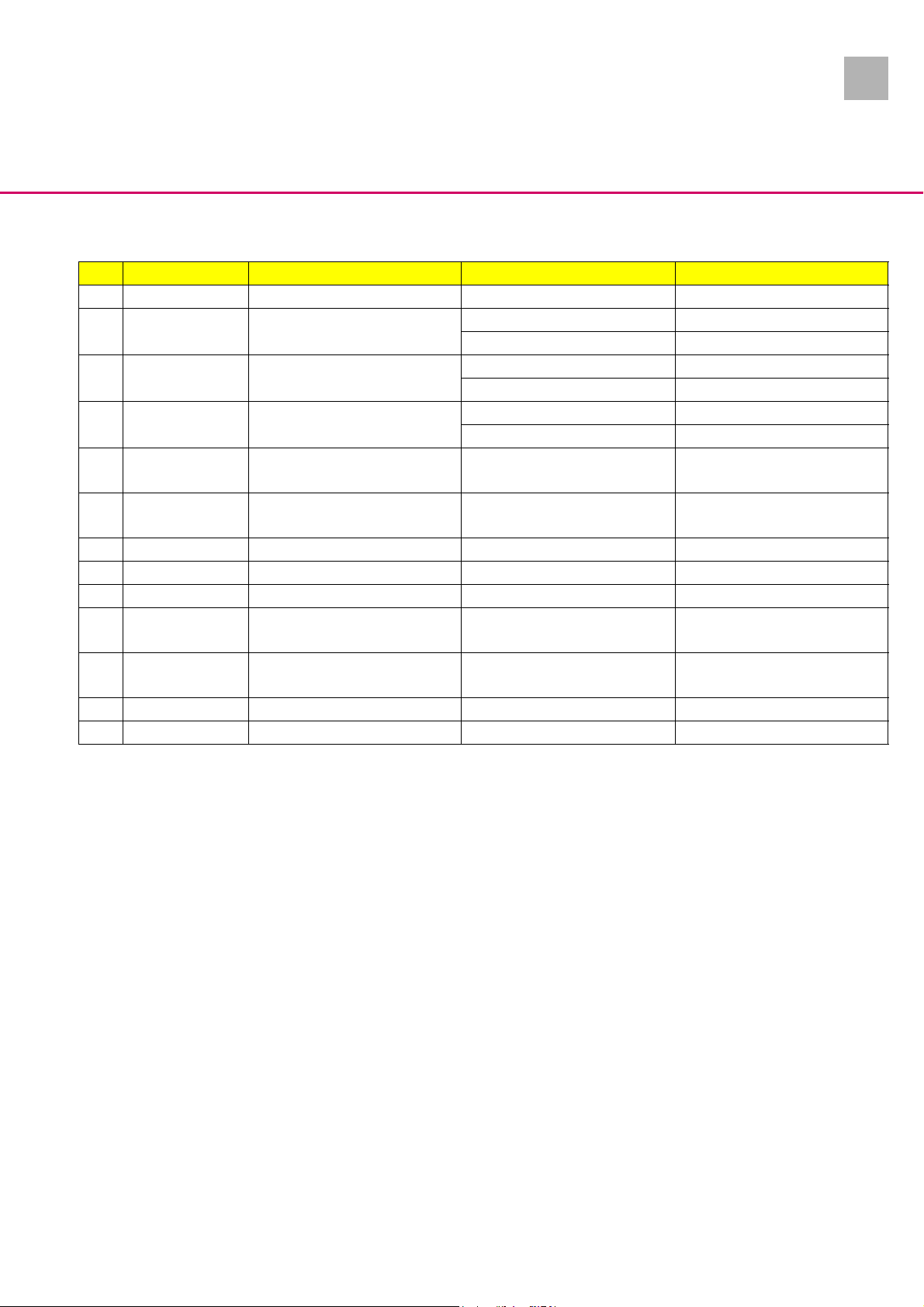

The unit check, calibration and trouble shooting are subdivided

into numbered working steps (Unit Test Step UTS, Calibration Step

CS, Trouble Shooting TS) and are based on each other.

Beginning with UTS 1 the operation described here has to be

executed. The consequences of the steps performed are listed in

the “Function“ column. If the result corresponds to the

consequence, the working step must be carried out to which

reference is made in the column “If yes”. If the result does not

correspond with the function described, the working step in

column “If no” is to be executed.

One example is given in Fig.: 2 - 1.

UTS Activity Function If yes If no

1 UTS 2

2 UTS 3 TS 1

3 UTS 4

4 UTS 5 TS 4

5

Model table 1

TS Activity Function

1 UTS 3 TS 2

2 TS 3 TS 4

3 UTS 3

4 UTS 4 TS 4

5 UTS 4

Model table 2

Fig.: 2 - 1 Model tables

Steps for which additional information is required are described

after the table in detail.

2- 2 Perfusor® Space, 1.0 gb

Page 27

1.0

Alarms and Error Codes

Unit Diagnosis / Calibration

The alarms of the Perfusor® Space are classified in 5 categories.

These categories are listed hereafter according to their

importance.

- Alarm advice

In case of unacceptable inputs corresponding messages are

displayed (e.g. “Caution! Rate out of range“, “The parameter

cannot be changed“) and a beep sounds.

-Pre-alarm

Pre-alarms are triggered several minutes (depending on the

service settings) before the operating alarms.

- Reminder alarm

A reminder alarm is triggered if the device is not operated for

two minutes when input or operation was not finished.

- Operating alarm

In case of an operating alarm the infusion is stopped. An

audible signal is released, the red LED flashes and a staff call

is triggered. The message “Alarm” and the cause of the alarm

appear on the display.

- Device alarm

The most important alarms and error codes as well as their

meaning and possible fault clearance are specified in the

following lists.

2

Note

The device should be checked after every repair or service (see

“Device Check“ ➨ pg. 2 - 9).

Perfusor® Space, 1.0 gb 2- 3

Page 28

1.0

2

Unit Diagnosis / Calibration

Alarms

Alarm Possible Cause Fault Clearance

1 Battery nearly discharged (type: pre-

alarm)

2 Battery discharged (type: operating

alarm)

3 Battery cover open (type: operating

alarm)

4 Drive blocked (type: operating alarm) ❒ The drive was manually blocked Eliminate blockage

5 Malfunction of claws (type: operating

alarm)

6 Push-button has no contact (type:

operating alarm)

7 Device alarm (type: device alarm) A serious internal fault was detected in

The device was not connected to the

mains long enough

Battery module defective or too old Replace battery module

The device was not connected to the

mains long enough

Battery module defective Replace battery module

❒ The battery compartment cover is

not correctly closed

❒ The magnet in the battery

compartment cover is missing

❒ The battery compartment cover is

not recognized by the battery

module

❒ Driving force too low Connect the unit to the mains for at least

❒ The drive is physically damaged Replace drive.

❒ The syringe piston was not

recognized

❒ The claws or the claw drive are/is

damaged

❒ Negative pressure in the syringe

system

❒ Syringe was removed without

opening the syringe holder

❒ Push-button sensor defective Replace drive head

the system

Operate the device with battery until the

message “Battery discharged“ is

displayed and the unit is switched off.

Then connect the unit to the mains for at

least 6 hours.

Connect the unit to the mains for at least

6 hours

Insert the battery compartment cover

correctly

Exchange the battery compartment cover

Replace battery module

6 hours and charge battery

Re-calibrate the device

Select or insert correct syringe type

Loosen the syringe via the emergency

release button in the drive head and

insert again

Re-calibrate the device

Replace drive head

See instructions for use

See instructions for use

Switch device off and on

Carry out a device check (see “Device

Check“ ➨ pg. 2 - 9)

Table 2 - 1 Alarms

2- 4 Perfusor® Space, 1.0 gb

Page 29

1.0

Unit Diagnosis / Calibration

2

Device Alarms of the Function Processor

Error Code Definition Possible Cause Fault Clearance

1 1001 ... 1013 Internal Error

2 1014 Loudspeaker not off Loudspeaker connector Check the loudspeaker connector

Loudspeaker Check the loudspeaker

3 1015 Loudspeaker lost Loudspeaker connector Check the loudspeaker connector

Loudspeaker Check the loudspeaker

4 1016 Loudspeaker shorted Loudspeaker connector Check the loudspeaker connector

Loudspeaker Check the loudspeaker

5 1017 KuP switchoff path defect

(K_SM_CLK)

6 1018 ADC pressure out of range Pressure measurement in drive

7 1019 Internal Error

8 1020 FUP Flash Memory Error Software Software Update unit software

9 1021 FUP different version KuP to FuP Software Update unit software

10 1022 FUP pressure zero test fail Pressure measurement in drive

11 1023 FUP pressure offset test fail Pressure measurement in drive

12 1024 FUP EA key closed too long 20sec Keyboard defective Carry out device check

13 1025 Internal Error

Switch off path

Carry out calibration

head

Carry out calibration

head

Carry out calibration

head

Table 2 - 2 Device alarms of the function processor

Perfusor® Space, 1.0 gb 2- 5

Page 30

1.0

2

Unit Diagnosis / Calibration

Device Alarms of the Control Microprocessor

Error Code Definition Possible Cause Fault Clearance

1 1100 Timebase too fast Quartz of the processor PCB Exchange processor PCB

2 1101 Timebase too slow Quartz of the processor PCB Exchange processor PCB

3 1102 Timebase fail Quartz of the processor PCB Exchange processor PCB

4 1103 Keyboard High Keyboard defective Carry out device check

5 1104 EA_KEY defect 25sec Keyboard defective Carry out device check

6 1105 No keydecode Keyboard defective Carry out device check

7 1106 ROM Romtest defect Software Software Update unit software

8 1107 ROM Program defect Software Update unit software

9 1108 CM State without set

K_V_KM_ON

10 1109 MPU_Test failed Software Update unit software

11 1110 RAM_Test failed Software Update unit software

12 1111 active reset Voltage supply during operation

interrupted

13 1112 ... 1114 Internal Error

14 1115 Drive too fast Motor drive

Recognition of direction of

rotation

15 1116 Drive too slow Motor drive

Recognition of direction of

rotation

16 1117 ... 1118 Internal Error

17 1119 lcd backlight on defect LC display defective Exchange operating unit

18 1120 lcd backlight off defect LC display defective Exchange operating unit

19 1121 red led on defect LC display defective Exchange operating unit

20 1122 red led off defect LC display defective Exchange operating unit

21 1123 key pressed too long (without EA-

Key) 60sec

22 1124 ... 1127 Internal Error

23 1128 Drive motion rightless forward Motor drive

24 1129 Drive motion rightless backward Motor drive

25 1130 ... 1200 Internal Error

Table 2 - 3 Device alarms of the control microprocessor (Part 1 of 2)

Keyboard defective Carry out device check

Recognition of direction of

rotation

Recognition of direction of

rotation

Exchange processor PCB

Exchange processor PCB

Exchange processor PCB

Exchange processor PCB

2- 6 Perfusor® Space, 1.0 gb

Page 31

1.0

Unit Diagnosis / Calibration

Error Code Definition Possible Cause Fault Clearance

26 1201 different version FuP to KuP

Software

27 1202 E_ERROR_STEPMOTOR_1 Phase

not ok

28 1203 E_ERROR_STEPMOTOR_2 Current

value not 0x55

29 1204 E_ERROR_STEPMOTOR_3

K_SM_CLK defect

30 1205 E_ERROR_STEPMOTOR_4 Phase

not ok

31 1206 E_ERROR_STEPMOTOR_5

Current value not 0

32 1207 E_ERROR_STEPMOTOR_6 Current

value not 0x55

33 1208 E_ERROR_STEPMOTOR_7 Current

value not 0xAA

34 1209 E_ERROR_STEPMOTOR_8 Phases

not 0

35 1210 E_ERROR_DCMOTOR_1 Piston brake drive motor def.

36 1211 E_ERROR_DCMOTOR_2

37 1212 E_ERROR_DCMOTOR_3

38 1213 E_ERROR_DCMOTOR_4

39 1214 E_ERROR_DCMOTOR_5

40 1215 no V_MOT Voltage transformer defective Exchange processor PCB

41 1216 overvoltage test fail

42 1217 no V_MOT

43 1218 undervoltage test fail

44 1220 syringeholder defect Syringe holder or potentiometer

45 1221 syringe change timeout

46 1237 ... 1238 Internal Error

47 1239 plunger plate sensor defect Pressure measurement in drive

48 1240 ... 1254 Internal Error

Table 2 - 3 Device alarms of the control microprocessor (Part 2 of 2)

Software Update unit software

Drive motor, lead screw Exchange processor PCB

Motor drive

Recognition of direction of

rotation

Motor drive

Recognition of direction of

rotation

Motor drive

Recognition of direction of

rotation

Motor drive

Recognition of direction of

rotation

Motor drive

Recognition of direction of

rotation

Motor drive

Recognition of direction of

rotation

Motor drive

Recognition of direction of

rotation

Claw drive in drive head defective

Piston brake light barrier def.

def.

head

Carry out calibration

Carry out calibration

Carry out calibration

Carry out calibration

Carry out calibration

Carry out calibration

Carry out calibration

Replace syringe holder

Exchange processor PCB

Replace drive head

2

Perfusor® Space, 1.0 gb 2- 7

Page 32

1.0

2

Unit Diagnosis / Calibration

The Most Important Error Modes

Error Possible Cause Fault Clearance

1 The battery module discharges too fast The device was not used for a longer time.

The battery module was not discharged

and charged at regular intervals.

Table 2 - 4

The following list specifies the most important error modes and

their clearance.

Note

The device must be checked after every repair or service (see

“Device Check“ ➨ pg. 2 - 9).

❒ Discharge and charge battery module

several times

❒ Replace battery module

2- 8 Perfusor® Space, 1.0 gb

Page 33

1.1

Unit Diagnosis / Calibration

Device Check

UTS Activity Function If yes If no

1 The device is inserted in a SpaceStation or

connected to a SpaceControl.

2 Remove the device. UTS 4

3 Loosen all connections from the device. UTS 4

4 Remove syringe and close syringe holder. UTS 5

5 Plug service connector SP on connector “P2”. UTS 6

6 Connect power supply to the device via service

connector SP.

7 The battery charge state and the mains connection

8 Switch on unit. All LEDs light up (from left: yellow, green, blue). UTS 9 TS 5

9 A short deep and then a short high beep sound. UTS 10 TS 7

10 The colour of the middle LED changes from green to

11 The message “Self-test active” and the current

12 Keyboard, LC display as well as the syringe area are

13 The drive head moves to the extended end position. UTS 14 TS 11

14 The claws in the syringe head close and open. UTS 15 TS 14

15 The message “Drive moves back / Syringe change”

16 “Open syringe holder and insert syringe or press “C“

17 Open syringe holder. “Syringe change / Please insert syringe ...” is

18 Press the “>” key. The service information:

19 Insert syringe 30 ml. The syringe piston is fastened with the syringe

20 On the LC display “Brake: stopped by current”

Table 2 - 5 Device check (Part 1 of 5)

All LEDs light up for a short moment. UTS 7 TS 1

are displayed at the top left of the LC display

(without lighting).

red, then the LED goes out. The yellow and the blue

LED remain on for a short moment.

software version are displayed.

illuminated.

appears on the display.

to input parameters“ is displayed.

displayed.

- Brake: not started or active

- drivetest ok

- Size: 35.4 KuP 35.4 FuP

is displayed on the LC display.

holder blade.

appears in the line.

UTS 2 UTS 3

UTS 8 TS 5

UTS 11 TS 8

UTS 12 TS 8

UTS 13 TS 9

UTS 16 TS 16

UTS 17 TS 16

UTS 18 TS 17

UTS 19 TS 19

UTS 20 TS 21

UTS 21 TS 21

2

Perfusor® Space, 1.1 gb 2- 9

Page 34

1.1

2

Unit Diagnosis / Calibration

UTS Activity Function If yes If no

21 Insert 2 ml / 3 ml syringe. On the LC display “Brake: stopped by holder”

appears in the line.

22 Open syringe holder and remove syringe. On the LC display “Brake: stopped by light barrier”

appears in the line.

23 3.54 is shown for FuP on the LC display. The value

displayed for FuP may have a maximum tolerance of

± 0.04.

24 Close syringe holder. The value for FuP changes to 7.0 ± 0.4. UTS 25 CS 1

25 Insert diameter gauge 9.0 mm. The value for FuP changes to 9.0 ± 0.4. UTS 26 CS 1

26 Insert diameter gauge 15.7mm. The value for FuP changes to 15.7 ± 0.4. UTS 27 CS 1

27 Insert diameter gauge 23.4 mm. The value for FuP changes to 23.4 ± 0.4. UTS 28 CS 1

28 Insert diameter gauge 32.0 mm. The value for FuP changes to 32.0 ± 0.4. UTS 29 CS 1

29 The sum of the tolerances of UTS 23 to UTS 28 must

not exceed 1.0.

30 Insert 2 ml / 3 ml syringe. UTS 31

31 Press the “>” key. The syringe selection is displayed. UTS 32

32 Select a syringe. The drive head moves to the syringe piston, the

claws in the drive head close and the message

“Syringe is caught / Please wait” is displayed.

33 Test all buttons on the operating unit during a

functional check (carry out infusion).

34 Open syringe holder while the infusion is

administered.

35 Close syringe holder and continue infusion. UTS 36

36 Stop infusion. UTS 37

37 Open syringe holder. “Syringe change / Initiate change? Yes / No” is

38 Confirm with “Yes”. The claws in the drive head open and the drive head

39 Remove syringe. UTS 40

When the buttons are pressed the desired reaction

is carried out.

The red LED on the operating unit flashes and the

red LED of the service connector SP lights up. The

message “Alarm / Syringe holder” is displayed.

displayed.

moves to the extended end position.

UTS 22 TS 21

UTS 23 TS 21

UTS 24 CS 1

UTS 30 CS 1

UTS 33 TS 26

UTS 34 TS 29

UTS 35 TS 31

UTS 38

UTS 39

Table 2 - 5 Device check (Part 2 of 5)

2- 10 Perfusor® Space, 1.1 gb

Page 35

1.3

Unit Diagnosis / Calibration

UTS Activity Function If yes If no

40 Insert syringe gauge for the strain gauge

measurement, close syringe holder and select

syringe type „#Lehre OPS50“. The syringe gauge

must not be tipped. Therefore fix the syringe gauge

so far into the syringe recess by hand that the

piston brake moves back and the claws surrounds

the pressure element.

WARNING

DURING THE STRAIN GAUGE MEASUREMENT WITH

SYRINGE GAUGE THE SYRINGE HOLDER MUST NOT

BE OPENED. THE SYRINGE GAUGE IS UNDER VERY

HIGH PRESSURE AND MAY CAUSE INJURIES IF THE

PRESSURE IS RELIEVED SUDDENLY.

UTS 41

2

41 Input a delivery rate of 200 ml/h, select pressure

stage 1 and start infusion.

42 Confirm alarm. UTS 43

43 Select pressure stage 3 and start infusion. When the maximum pressure of this pressure stage

44 Confirm alarm. UTS 45

45 Select pressure stage 8 and start infusion. When the maximum pressure of this pressure stage

46 Confirm alarm and pull syringe holder briefly. UTS 47

Table 2 - 5 Device check (Part 3 of 5)

When the maximum pressure of this pressure stage

is reached, the delivery is stopped, the red LED on

the operating unit flashes and the message “Alarm

/ Pressure too high” is displayed.

The value read on the syringe gauge (in N) must

match the value indicated for the strain gauge

measurement of this pressure stage in the TSC.

is reached, the delivery is stopped, the red LED on

the operating unit flashes and the message “Alarm

/ Pressure too high” is displayed.

The value read on the syringe gauge (in N) must

match the value indicated for the strain gauge

measurement of this pressure stage in the TSC.

is reached, the delivery is stopped, the red LED on

the operating unit flashes and the message “Alarm

/ Pressure too high” is displayed.

The value read on the syringe gauge (in N) must

match the value indicated for the strain gauge

measurement of this pressure stage in the TSC.

UTS 42 CS 1

UTS 44 CS 1

UTS 46 CS 1

Perfusor® Space, 1.3 gb 2- 11

Page 36

1.0

2

Unit Diagnosis / Calibration

UTS Activity Function If yes If no

47 Confirm syringe change, release syringe gauge and

remove gauge.

WARNING

WHILE CHECKING THE MOTOR POWER LIMITATION

WITH THE SYRINGE GAUGE THE SYRINGE HOLDER

MUST NOT BE OPENED. THE SYRINGE GAUGE IS

UNDER VERY HIGH PRESSURE AND MAY CAUSE

INJURIES IF THE PRESSURE IS RELIEVED SUDDENLY.

48 Insert the motor power test adapter in the drive

head to check the motor power limitation.

49 Dismount the push-button plate from the syringe

gauge and insert syringe gauge.

50 Select syringe type “#Lehre OPS 50“. The threaded

end of the syringe gauge must be introduced in the

opening of the motor power test adapter. To do this,

hold on to the syringe gauge, if necessary by hand,

in the syringe area.

51 Select pressure stage 1 and start infusion. When the maximum pressure of this pressure stage

is reached, the delivery is stopped, the red LED on

the operating unit flashes and the message “Alarm

/ Drive blocked” is displayed.

The value read on the syringe gauge (in N) must

match the value indicated for the motor power

limitation in the TSC.

52 Confirm alarm. UTS 53

53 Select pressure stage 3 and start infusion. When the maximum pressure of this pressure stage

is reached, the delivery is stopped, the red LED on

the operating unit flashes and the message “Alarm

/ Drive blocked” is displayed.

The value read on the syringe gauge (in N) must

match the value indicated for the motor power

limitation in the TSC.

54 Confirm alarm. UTS 55

Table 2 - 5 Device check (Part 4 of 5)

UTS 48

UTS 49

UTS 50

UTS 51

UTS 52 CS 1

UTS 54 CS 1

2- 12 Perfusor® Space, 1.0 gb

Page 37

1.3

Unit Diagnosis / Calibration

UTS Activity Function If yes If no

55 Select pressure stage 6 and start infusion. When the maximum pressure of this pressure stage

is reached, the delivery is stopped, the red LED on

the operating unit flashes and the message “Alarm

/ Drive blocked” is displayed.

The value read on the syringe gauge (in N) must

match the value indicated for the motor power

limitation in the TSC.

56 Confirm alarm and pull syringe holder briefly. UTS 57

57 Confirm syringe change, release syringe gauge and

remove gauge.

WARNING

WHILE CHECKING THE MOTOR POWER LIMITATION

WITH THE SYRINGE GAUGE THE SYRINGE HOLDER

MUST NOT BE OPENED. THE SYRINGE GAUGE IS

UNDER VERY HIGH PRESSURE AND MAY CAUSE

INJURIES IF THE PRESSURE IS RELIEVED SUDDENLY.

UTS 56 CS 1

UTS 58

2

58 Insert syringe type 50/60 ml and lock PCA-lock with

PCA-key.

59 Open PCA-lock and remove syringe. UTS 60

60 Insert syringe type 10 ml and lock PCA-lock with

PCA-key.

61 Open PCA-lock and remove syringe. UTS 62

62 Switch device off. The message “Pump is switched off in 3 .. 2 .. 1 sec”

63 “Drive is parked .../ Please wait ...“ is displayed. The

64 The device switches off. UTS 65 TS 35

65 Pull off the power supply. The blue LED lights up for a short moment. UTS 66 TS 35

66 Switch on unit. UTS 67

67 Open the battery compartment cover when the

drive head has moved to the extended end position.

68 Remove battery. A permanent alarm is triggered. UTS 69 TS 38

69 Insert battery, close battery compartment cover and

switch on the device.

70 Switch the device off, remove service connector SP

and dismount test structure.

Table 2 - 5 Device check (Part 5 of 5)

The syringe holder cannot be opened. UTS 59 TS 32

The syringe holder cannot be opened. UTS 61 TS 32

UTS 63

is displayed.

UTS 64

drive head moves to the retracted park position.

An alarm signal sounds, the red LED flashes and

“Alarm / Battery cover open / Confirm with “OK” is

displayed.

The message “Devicealarm / 1111” is displayed. UTS 70

UTS 68 TS 36

This step terminates

the device check.

Perfusor® Space, 1.3 gb 2- 13

Page 38

1.1

2

Unit Diagnosis / Calibration

Calibration

CS Activity Function If yes If no

1 Connect unit to PC with interface cable. CS 2

2 Start Service Program on the PC (see “Starting the

Service Program“ ➨ pg. 1 - 7).

3 Start calibrating the unit (see “Starting Calibration“

➨ pg. 2 - 14).

4 Carry out calibration of the claws (see “Claw

Calibration“ ➨ pg. 2 - 23).

5 Carry out calibration of the syringe holder (see

“Syringe Holder Calibration“ ➨ pg. 2 - 23).

6 Carry out pressure calibration (see “Pressure

Calibration“ ➨ pg. 2 - 26).

7 Close the Service Program (see “Quit the Service

Program“ ➨ pg. 1 -11).

Table 2 - 6 Calibration

The desired device is found by the Service Program

and then displayed.

Calibration of the claws was terminated

successfully.

Calibration of the syringe holder was terminated

successfully.

Pressure calibration was terminated successfully. CS 7

CS 3

CS 4

CS 5

CS 6

UTS 23

Procedural Instructions for Calibration

Starting Calibration

Note

Calibration must be carried out with power supply connected,

since the calibration can be interrupted suddenly if the unit is

battery-operated and the battery gets discharged so that the

device is switched off.

Note

Please note that text and / or functions of the Service Program

may change depending on the software version. The following

screen illustrations are only examples and represent the state

when the manual was printed.

2- 14 Perfusor® Space, 1.1 gb

Page 39

1.2

Unit Diagnosis / Calibration

1. Start the Service Program (see “Starting the Service Program“

➨ pg. 1 - 7).

2. Select the unit to be calibrated in the left column of the

window with a double mouse-click. The blue and the yellow

LED blinks in opposite with the red LED.

3. Select the register tab “Calibration”.

2

Fig.: 2 - 2

4. Press the “New device” button in the frame “Calibration

procedure”. The window “Worker ID” is opened.

Note

If you do not have an allocated worker id, enter “0001”.

Perfusor® Space, 1.2 gb 2- 15

Page 40

1.2

2

Fig.: 2 - 3

Unit Diagnosis / Calibration

5. Input your user number in the window “Worker ID” as well as

the six-digit serial number of the device, if necessary.

6. Confirm the input with “OK”.

Note

If HiBaSeD could not clearly read the device serial number, the

number must be entered according to the rating plate.

Fig.: 2 - 4

Fig.: 2 - 5

If the unit is not yet switched on, the window “Device on/off”

opens and the user is asked to select the desired language.

7. Select the desired language. The respective operating steps

are explained in detail in the instructions for use.

After the language was confirmed the unit switches on and

the window “Device on/off” closes.

Note

If calibration is interrupted, data is written back to the device and

marked as invalid if this is still possible. When the Service

Program is started again the data is marked as faulty and

highlighted red when the “Modify” button is selected in the

“Calibration procedure” frame.

2- 16 Perfusor® Space, 1.2 gb

Page 41

1.2

Unit Diagnosis / Calibration

2

Fig.: 2 - 6

Perfusor® Space, 1.2 gb 2- 17

Page 42

1.2

2

Unit Diagnosis / Calibration

8. The frame “Data selection” is now activated.

Fig.: 2 - 7

If the “Modify” button was pressed in the “Calibration

procedure” frame, the desired data for editing and

transmission can now be selected in the “Data selection”

frame.

2- 18 Perfusor® Space, 1.2 gb

Page 43

1.3

Unit Diagnosis / Calibration

9. Mark at least the “Calibration data“ field in this frame if you

have not selected “New device” and confirm by clicking “OK”.

The device switches on and the drive head moves to the

extended end position. You are prompted to press the blue

connection key on the device.

Note

At the end of the line “Calibration data”, the claw configuration

is displayed by the abbreviation “(SC)” for silver claws and “(GC)”

for green claws. If this setting does not match the claws really

used, you can assign the correct claw type with the “Claw type

selection” button.

10. Press the blue connection key on the device after the drive

head has moved to the end position.

2

Fig.: 2 - 8

Perfusor® Space, 1.3 gb 2- 19

Page 44

1.2

2

Unit Diagnosis / Calibration

Fig.: 2 - 9

11. In the frame “Type of calibration” you can choose between a

complete or a partial calibration. Select the desired

calibration mode with the mouse pointer.

Note

The following description is applicable to a complete and a partial

calibration. All possible calibrations are carried out one after the

other if a complete calibration is selected. Interrupting the

calibration may trigger an alarm in the device.

2- 20 Perfusor® Space, 1.2 gb

Page 45

1.2

Fig.: 2 - 10

Unit Diagnosis / Calibration

12. Press the “OK“ button after you have selected the calibration

elements. The necessary device data is read out and stored in

the PC.

2

Fig.: 2 - 11

Fig.: 2 - 12

Fig.: 2 - 13

Perfusor® Space, 1.2 gb 2- 21

Page 46

1.2

2

Unit Diagnosis / Calibration

Fig.: 2 - 14

13. The frame “Element selection” is now activated.

If you have selected a complete calibration in the “Type of

calibration” frame, the individual calibration elements are

already selected and cannot be changed. Actuate the “OK”

button.

If you have chosen a partial calibration in the frame “Type of

calibration”, you can click the calibration element “Claw”,

“Syringe holder” and “Pressure” with the mouse pointer. A

multiple choice is possible. Press the “OK” button after you

have selected the calibration elements.

2- 22 Perfusor® Space, 1.2 gb

Page 47

1.2

Fig.: 2 - 15

Unit Diagnosis / Calibration

Claw Calibration

1. The frame “Claw calibration” is activated and calibration is

started.

2. The claws in the drive head are closed and the query “Claw

closed? Please confirm” is displayed in the frame “Claw

calibration”.

3. Check whether the claws are closed. Then actuate the “Yes”

button.

2

Fig.: 2 - 16

4. The claws in the drive head are opened and the query “Claw

open? Please confirm” is displayed in the frame “Claw

calibration”.

5. Check whether the claws are opened. Then actuate the “Yes”

button.

Syringe Holder Calibration

1. The frame “Syringe holder calibration” is activated and

calibration is started.

2. Insert diameter gauge 32.0 mm and close the syringe holder.

Note

The diameter gauge must not be held by the axial fastening of the

housing side part. They must be inserted in such a way that the

area of the diameter gauges touches the axial fastening edge.

3. Press the “OK” button.

Fig.: 2 - 17

Perfusor® Space, 1.2 gb 2- 23

Page 48

1.2

2

Fig.: 2 - 18

Unit Diagnosis / Calibration

4. Insert diameter gauge 23.4 mm and close the syringe holder.

5. Press the “OK” button.

Fig.: 2 - 19

6. Insert diameter gauge 15.7 mm and close the syringe holder.

7. Press the “OK” button.

2- 24 Perfusor® Space, 1.2 gb

Page 49

1.2

Fig.: 2 - 20

Unit Diagnosis / Calibration

8. Insert diameter gauge 9.0 mm and close the syringe holder.

9. Press the “OK” button.

2

Fig.: 2 - 21

10. Open the syringe holder and remove the diameter gauge.

Press the “OK” button.

Note

The syringe holder must always be completely turned and the

axial fastening completely opened.

Perfusor® Space, 1.2 gb 2- 25

Page 50

1.2

2

Fig.: 2 - 22

Unit Diagnosis / Calibration

11. Close the syringe holder and actuate the “OK” button.

If calibration was not terminated successfully, an error

message is displayed on the PC screen.

Fig.: 2 - 23

Pressure Calibration

Note

The term “Power gauge” in the windows of the Service Program

corresponds to the syringe gauge.

1. The frame “Pressure calibration/length/PWM” is activated

and calibration is started.

2. Insert the length gauge and close the syringe holder.

3. Press the “OK” button.

2- 26 Perfusor® Space, 1.2 gb

Page 51

1.3

Fig.: 2 - 24

Unit Diagnosis / Calibration

4. If “Insert power gauge and confirm with OK” is displayed in

the frame “Pressure calibration/length/PWM”, open the

syringe holder and remove the length gauge.

WARNING

DURING PRESSURE CALIBRATION WITH THE SYRINGE GAUGE THE

SYRINGE HOLDER MUST NOT BE OPENED. THE SYRINGE GAUGE IS

UNDER VERY HIGH PRESSURE AND MAY CAUSE INJURIES IF THE

PRESSURE IS RELIEVED SUDDENLY.

5. Insert the syringe gauge with the attached push-button plate

for the Perfusor® Space and close the syringe holder.

Note

The syringe gauge must not be tipped. Therefore fix the syringe

gauge so far into the syringe recess by hand that the piston brake

moves back and the claws surrounds the pressure element.

2

Fig.: 2 - 25

6. Press the “OK” button.

7. The power calibration is carried out. When calibration is

finished the syringe gauge is released.

8. When the drive head has moved to the extended end position,

the syringe gauge can be removed.

9. Close the syringe holder. The device can now be switched off.

Note

If the device is switched off before calibration is terminated, the

calibration is invalid and must be repeated.

Evaluation

1. At the end of calibration the result with all the values is

displayed in the frame “Calibration process completed

successfully”.

Fig.: 2 - 26

Perfusor® Space, 1.3 gb 2- 27

Page 52

1.2

2

Fig.: 2 - 27

Unit Diagnosis / Calibration

This report can be printed out by pressing the “Print” button.

2. Actuate the “OK” button to finish the calibration process and

to store the data in the device.

2- 28 Perfusor® Space, 1.2 gb

Page 53

1.0

Unit Diagnosis / Calibration

Trouble Shooting

Note

The following trouble shooting cannot be carried out

independently. It is based on the precise observance of the steps

for the device check (see “Device Check“ ➨ pg. 2 - 9). From there

reference is made to the corresponding trouble shooting steps.

TS Activity Function If yes If no

1 Replace power supply. All LEDs light up for a short moment. UTS 7 TS 2

2 At least one LED lights up for a short moment. TS 3 TS 4

3 Replace the LC display. UTS 7

4 A message is displayed on the LC display. TS 6 TS 5

5 Exchange processor PCB. All LEDs light up for a short moment and a message

is displayed on the LC display.

6 Exchange operating unit. UTS 8

7 Exchange loudspeaker and switch on unit. A short deep and then a short high beep sound. UTS 10 TS 8

8 Exchange processor PCB. UTS 10

9 Exchange operating unit. Keyboard, LC display as well as the syringe area are

illuminated.

10 Exchange processor PCB. UTS 13

11 Replace drive. TS 12

12 Switch on unit. The drive head moves to the extended end position. UTS 14 TS 13

13 Exchange processor PCB. UTS 14

14 Replace drive head. TS 15

15 Switch on unit. The claws in the syringe head close and open. UTS 15 TS 16

16 Exchange processor PCB. UTS 15

17 Replace syringe holder with piston brake. “Syringe change / Please insert syringe ...” is

displayed after the syringe holder has been opened.

18 Exchange processor PCB. UTS 18

19 Exchange processor PCB and actuate the “>”

button.

20 Exchange operating unit. UTS 19

21 Replace syringe holder with piston brake. TS 22

Table 2 - 7 Trouble Shooting (Part 1 of 2)

The service information:

- Brake: stopped by ____

- drivetest ok

- Size: 35.4 KuP 35.4 FuP

is displayed on the LC display.

UTS 7 TS 6

UTS 13 TS 10

UTS 18 TS 18

UTS 19 TS 20

2

Perfusor® Space, 1.0 gb 2- 29

Page 54

1.0

2

Unit Diagnosis / Calibration

TS Activity Function If yes If no

22 Switch on unit and insert syringe. The syringe piston is fastened with the syringe

holder blade and the default message is displayed

on the LC display.

23 Exchange processor PCB. TS 24

24 Switch on unit and insert syringe. The syringe piston is fastened with the syringe

holder blade and the default message is displayed

on the LC display.

25 Exchange piston brake ribbon cable. UTS 19

26 Exchange processor PCB. TS 27

27 Switch on unit, insert syringe and select. The drive head moves to the syringe piston, the

claws in the drive head close and the message

“Syringe change active / Syringe is caught” is

displayed.

28 Replace drive head. UTS 33

29 Exchange operating unit. TS 30

30 Test all buttons on the operating unit during a

functional check.

31 Exchange processor PCB. UTS 35

32 Exchange processor PCB. Exchange PCA-slide and

lock PCA-lock with PCA-key.

33 Exchange PCA eccentric and lock PCA-lock with

PCA-key.

34 Replace syringe holder with piston brake. UTS 59

35 Exchange processor PCB. UTS 65

36 Replace battery module. TS 37

37 Switch on unit and open the battery compartment

cover when the drive head has moved to the

extended end position.

38 Exchange processor PCB. UTS 67

39 Disconnect power supply from the device and

switch on device.

40 Charge battery module for about 16 hours in the

device with power supply connected.

41 Replace battery module. UTS 9

Table 2 - 7 Trouble Shooting (Part 2 of 2)

When the buttons are pressed the desired reaction

is carried out.

The syringe holder cannot be opened. UTS 59 TS 33

The syringe holder cannot be opened. UTS 59 TS 34

All LEDs light up for a short moment. UTS 9 TS 41

UTS 19 TS 23

UTS 19 TS 25

UTS 33 TS 28

UTS 34 TS 31

UTS 67 TS 38

TS 39

2- 30 Perfusor® Space, 1.0 gb

Page 55

1.0

3.1 General

Perfusor® Space

3-Disassembly / Assembly

Remarks on Disassembly / Assembly

Before disassembling the unit, the system must be checked (see

“Device Check“ ➨ pg. 2 - 9) to isolate the part to be exchanged.

The necessary steps to disassemble the complete unit, all its

subsystems and spare parts are detailed in the following

description. Steps that are not necessary can be skipped.

Move the drive head to the extended end position before starting

disassembly.

1. Switch the unit on. The drive head moves to the extended end

position.

2. Open the syringe holder.

3. Switch the device off when the syringe holder is opened. The

drive head stays at the extended end position.

3

WARNING

PAY ATTENTION TO THE PISTON BRAKE BLADE WHEN WORKING

ON THE PISTON BRAKE. THE BLADE IS SHARP AND MAY CAUSE

INJURIES.

Note

Special screws for plastic housings are used in this unit. Pay

attention to the corresponding notes when you fit the screws.

Perfusor® Space, 1.0 gb 3- 1

Page 56

1.2

3

Disassembly / Assembly

Preparations for Exchanging the Processor PCB

If the processor PCB is to be replaced a back-up of the pump

settings is to be carried out, if this is still possible.

1. Start the Service Program (see “Starting the Service Program“

➨ pg. 1 - 7).

2. Select the register tab “Modification data”.

Fig.: 3 - 1

3. Press the “From device” button. The data is read from the

pump.

3- 2 Perfusor® Space, 1.2 gb

Page 57

1.2

4. Select the tab “IO”.

5. Press the “To file” button.

In the window which opens now you are asked for the storage

position of the file on the PC hard disk and the file name.

Disassembly / Assembly

3

Fig.: 3 - 2

6. Press the “Print” button to transmit the device data to a

printer.

Perfusor® Space, 1.2 gb 3- 3

Page 58

1.2

3

Disassembly / Assembly

7. Actuate the “Display” button to display the device data on

screen.

With “Close” the window is closed again.

Fig.: 3 - 3

Fig.: 3 - 4

8. Select the storage position in the “Save as” window and input

a unique file name.

9. Press the “Save” button. The data of the pump is saved on the

PC hard disk.

3- 4 Perfusor® Space, 1.2 gb

Page 59

1.2

Disassembly / Assembly

10. Select the tab “Disposable articles”.

3

Fig.: 3 - 5

11. Actuate the “From device” button. The data is read from the

pump.

The data of the disposable articles read out is displayed on

screen.

Perfusor® Space, 1.2 gb 3- 5

Page 60

1.2

3

Disassembly / Assembly

Fig.: 3 - 6

12. Press the “Save as” button.

In the window which opens now you are asked for the storage

position of the file on the PC hard disk and the file name.

3- 6 Perfusor® Space, 1.2 gb

Page 61

1.2

Fig.: 3 - 7

Disassembly / Assembly

13. Select the storage position in the “Save as” window and input

a unique file name.

14. Press the “Save” button. The data of the pump is saved on the

PC hard disk.

15. Exit the Service Program (see “Quit the Service Program“ ➨

pg. 1 -11).

Note

When the new processor PCB has been installed the saved data

must be transferred back to the device (see “Processor PCB“ ➨

pg. 3 - 36).

3

Perfusor® Space, 1.2 gb 3- 7

Page 62

1.3

3

Disassembly / Assembly

Service Parts and Screw Kit

All small parts, such as cover caps, are contained in a Perfusor®

Space service part kit.

Designation Ord. No.

Service part kit Perfusor® Space . . . . . . . . . . . . . . . . . 3477 4270

with:

housing cover cap (40 pieces)

cover caps for operating unit (10 pieces)

cover cap for syringe holder (10 pieces)

cover cap for drive head and claw (20 pieces)

housing foot (20 pieces)

sealing strip 40 x 4 x 2 (10 pieces)

release button SP with leaf spring (2 pieces)

wing sensor holder (1 pieces)

locking clip for band PSP (10 pieces)

Cover caps for housing SP (50 pieces) . . . . . . . . . . . . . 3477 4386

Cover caps for operating unit PSP (10 pieces) . . . . . . 3477 3103

Integrated socket P2 . . . . . . . . . . . . . . . . . . . . . . . . . . . 3477 4355

Connector seal P2 (5 pieces) . . . . . . . . . . . . . . . . . . . . 3477 3102

Grease PSP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3452 1571

Set of adhesive labels Perfusor® Space . . . . . . . . . . . . 3477 0969

Claw set PSP (10 pieces), silver . . . . . . . . . . . . . . . . . . . 3477 4378

Claw set PSP (10 pieces), green (from SW “F”) . . . . . . 3477 4379

All screws used in the device are included in a Perfusor® Space

screw kit.

Screw kit Perfusor® Space . . . . . . . . . . . . . . . . . . . . . . 3477 4289

with:

screw EJOT 22x8 WN 5451 TORX 6IP (5 pieces)

screw EJOT 25x7 WN 5451 TORX 8IP (5 pieces)

screw EJOT 30x6 WN 5451 TORX 10IP (5 pieces)

screw EJOT 30x8 WN 5451 TORX 10IP (10 pieces)

screw EJOT 20x12 WN 5452 TORX 6IP (5 pieces)

screw EJOT 20x14 WN 5452 TORX 6IP (5 pieces)

screw EJOT 22x4.5 WN 5452 TORX 6IP (10 pieces)

screw EJOT 25x10 WN 5452 TORX 8IP (5 pieces)

screw EJOT 30x8 WN 5452 TORX 10IP (10 pieces)

screw EJOT 30x12 WN 5452 TORX 10IP (10 pieces)

screw EJOT 30x35 WN 5452 TORX 10IP (5 pieces)

screw EJOT 22x8 WN 5454 TORX 6IP (5 pieces)

locking ring (5 pieces)

3- 8 Perfusor® Space, 1.3 gb

Page 63

1.2

3.2 Battery Module

Disassembly / Assembly

3

Designation Ord. No.

Battery compartment cover PSP , cpl. . . . . . . . . . . . . . 3452 0872

1

2

Battery pack SP (NIMH). . . . . . . . . . . . . . . . . . . . . . . . . 0871 3180

Disassembly

Note

Move the drive head to the extended end position before starting

disassembly (see “General“ ➨ pg. 3 - 1).

1. Press the lock (Fig.: 3 - 8 / Item 2) on the battery

compartment cover (Fig.: 3 - 8 / Item 1) and remove the

battery compartment cover.

Fig.: 3 - 8

Legend of fig. 3 - 8:

ItemDesignation

1 Battery compartment cover

2 Battery compartment cover lock

Note

The battery compartment cover of more recent devices is shorter

and can only be unlocked using a pointed object.

Perfusor® Space, 1.2 gb 3- 9

Page 64

1.0

3

Disassembly / Assembly

2. Lift the lock (Fig.: 3 - 9 / Item 3) on the battery pack (Fig.: 3 -

1

3

2

9 / Item 1) and remove the battery pack out of the device.

Fig.: 3 - 9

Legend of fig. 3 - 9:

ItemDesignation

1 Battery pack

2 Battery compartment cover

3 Battery pack lock

3- 10 Perfusor® Space, 1.0 gb

Page 65

1.0

3.3 Unit Foot

Disassembly / Assembly

Designation Ord. No.

Unit foot

(see “Service Parts and Screw Kit“ ➨ pg. 3 - 8)

Disassembly

1. Pull the unit foot (Fig.: 3 - 10 / Item 1) out of the housing.

3

1

Fig.: 3 - 10

Legend of fig. 3 - 10:

ItemDesignation

1 Unit Foot

Perfusor® Space, 1.0 gb 3- 11

Page 66

1.0

3

Disassembly / Assembly

3.4 Operating Unit

Designation Ord. No.

Operating unit PSP, cpl. . . . . . . . . . . . . . . . . . . . . . . . . 3452 0970

Hinge plate PSP, left . . . . . . . . . . . . . . . . . . . . . . . . . . . 3452 1011

Hinge plate PSP, right . . . . . . . . . . . . . . . . . . . . . . . . . . 3452 1020

1

2

3

4

5

PCA-slide PSP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3452 0899

PCA-eccentric PSP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3452 0902

Rear panel, operating unit PSP . . . . . . . . . . . . . . . . . . . 3452 1003

LC display SP. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3452 0988

Front flap with keyboard PSP . . . . . . . . . . . . . . . . . . . . 3452 0996

Screws and cover caps

(see “Service Parts and Screw Kit“ ➨ pg. 3 - 8)

Note

Please pay attention to the corresponding notes during assembly

and installation (see “Assembly / Installation“ ➨ pg. 3 - 35).

6

Fig.: 3 - 11

Legend of fig. 3 - 11:

ItemDesignation

1 Cover cap

2 Screw EJOT 30x8 WN 5452 TORX 10IP A2

3 Hinge plate, right

4 PCA-eccentric

5 PCA-slide

6Operating Unit

Disassembly

1. Pierce two cover caps (Fig.: 3 - 11 / Item 1) with a small

screwdriver and remove cover caps.

2. Unscrew two screws and remove the right hinge plate

(Fig.: 3 - 11 / Item 3) carefully out of the bottom part of the

housing and pull it off the (Fig.: 3 - 11 / Item 6) operating

unit.

Note

When dismounting the operating unit pay attention to the length

of the connection cable.

3. Remove the PCA-slide (Fig.: 3 - 11 / Item 5) and the PCAeccentric (Fig.: 3 - 11 / Item 4) out of the housing bottom

part.

3- 12 Perfusor® Space, 1.0 gb

Page 67

1.0

2

Fig.: 3 - 12

Legend of fig. 3 - 12:

ItemDesignation

1 Operating unit connection cable

2 Connector lock

Disassembly / Assembly

3

4. Push the right and left connector locks (Fig.: 3 - 12 / Item 2)

1

carefully forward.

5. Disconnect the operating unit connection cable (Fig.: 3 - 12 /

Item 1) from the connector.

Perfusor® Space, 1.0 gb 3- 13

Page 68

1.2

3

Disassembly / Assembly

1

2

6. Pull the operating unit from the left hinge plate (Fig.: 3 - 13

/ Item 3).

7. Pierce two cover caps (Fig.: 3 - 13 / Item 1) with a small

screwdriver and remove cover caps.

8. Unscrew two screws and remove the left hinge plate.

3

Fig.: 3 - 13

Legend of fig. 3 - 13:

ItemDesignation

1 Cover cap

2 Screw EJOT 30x8 WN 5452 TORX 10IP A2

3 Hinge plate, left

4 Operating Unit

4

3- 14 Perfusor® Space, 1.2 gb

Page 69

1.0

Disassembly / Assembly

3

Disassembly

1

4

2

1. Pierce six cover caps (Fig.: 3 - 14 / Item 1) with a small

screwdriver and remove cover caps.

2. Unscrew six screws and remove the rear panel (Fig.: 3 - 14 /

Item 4).

Note

The three screws of the keyboard must not be loosened. A uniform

pressure point of all keys is only guaranteed when a special tool

is used for assembly.

3

Fig.: 3 - 14

Legend of fig. 3 - 14:

ItemDesignation

1Cover cap

2 Screw EJOT 22x4.5 WN 5452 TORX 6IP A2

3 Screws for keyboard: Do not loosen the screws

4 Operating unit rear panel

Perfusor® Space, 1.0 gb 3- 15

Page 70

1.0

3

Fig.: 3 - 15

Legend of fig. 3 - 15:

ItemDesignation

1 LC display connection cable lock

Disassembly / Assembly

1

3. Push the right and left connector locks of the PCB keyboard

carefully to the left.

4. Pull the LC display ribbon cable (Fig.: 3 - 16 / Item 1) out of

the connector.

2

Fig.: 3 - 16

Legend of fig. 3 - 16:

ItemDesignation

1LC display

2 Front flap with keyboard

5. Lift the LC display out of the operating unit.

Note

1

The screws of the keyboard must not be loosened. A special

procedure is required to install the keyboard, so that a uniform

pressure point is guaranteed for all keys.

3- 16 Perfusor® Space, 1.0 gb

Page 71

1.0

3.5 Upper Part of Housing

1

Disassembly / Assembly

3

Designation Ord. No.

Upper part of housing PSP . . . . . . . . . . . . . . . . . . . . . . 3452 0910

Screws and cover caps

(see “Service Parts and Screw Kit“ ➨ pg. 3 - 8)

Note

Please pay attention to the corresponding notes during assembly

and installation (see “Assembly / Installation“ ➨ pg. 3 - 35).

Disassembly

1. Pierce five cover caps (Fig.: 3 - 17 / Item 4) with a small

screwdriver and remove cover caps.

2

2. Unscrew five screws.

5

Fig.: 3 - 17

Legend of fig. 3 - 17:

ItemDesignation

1 Locking tabs

2 Housing upper part

3 Screw EJOT 30x35 WN 5452 TORX 10IP A2

4Cover cap

4

3

3. Loosen the locking tabs (Fig.: 3 - 17 / Item 1) of the upper

part of the housing (Fig.: 3 - 17 / Item 2) carefully by pressing

the left and rear outer edge of the housing upwards and

remove the housing upper part.

Note

Pay attention to the length of the connection cable and to the

connectors P2 and P3 when dismounting the housing. Do not pull