Page 1

g

+

Dialo

SW 9.xx

Service Manual

English

Edition 1 -2010

M.KAY Dialog+ SW9xx SM EN 1-2010

Page 2

Dialog

+

SW 9.xx

Service Manual 1/2010

I

Contact your Local

B. Braun Representative

for Service Support

B. Braun Avitum AG

BA-TE-DE08C M.KAY -

34209 Melsungen

Germany

Tel. No.: +49 5661 713500 (Günter Ni ssen)

E-Mail: guenter.nissen@bbra un.com

Dialog+ SW9xx_sm_TOC_1-2010.doc/pdf <100329> yymmdd

B. Braun Avitum AG

Page 3

Dialog

+

SW 9.xx

Service Manual 1/2010

Valid for the following machine type:

For Software ≥ 9.xx

Dialog+: from serial no. 100000

Dialog+ HDF-Online: from serial no. 150000

II

BA-TE-DE08C M.KAY -

Registration Number:

Service Manuals with a registr ation nu mber a re inclu ded in the upda te serv ice!

Dialog+ SW9xx_sm_TOC_1-2010.doc/pdf <100329> yymmdd

B. Braun Avitum AG

Page 4

+

Dialog

Prevent Electrical Shock H azard

SW 9.xx

Commissioning and Service Only trained personnel must service the Dialog+, i.e. repair, maintenance, software

!

Protective Conductor in TFT Housing

TSM Service Progr am

Prevent Chemical Burns and Scalding During servicing on running machines: prevent chemical burns and scalding of the skin

Contaminated Machines Protective gear should be worn in case of servicing of assumed contaminated

Disposal and Taking Back

System Configuration The system configuration saved on a diskette must be downloaded to an other Dialog+

Service Manual 1/2010

Copyright This document is the pr operty of B. Braun Avitu m AG with all rights reserved.

installation, firmware update, r etrofitting and commissioning of th e Dialog+.

Servicing must only be performed with proper tools, calibration equipment and be in

accordance with the most recent revision of this service manual/technical information,

which must be clearly and thoroughly understood.

Switch off the Dialog+ and disconnect unit from mains if you have to open the

machine for servicing. Do not touch any exposed wiring or conductive surfaces while

the Dialog+ is opened. The voltages present when electrical power is connected to the

Dialog+ can ca use serious injury or death.

ESD Information Pay attention to ESD information, because electronic components are sensitive to

electrostatic discharges.

High Voltage

in TFT Monitor

Software

Therapy Mode

Calibration

Tubing

Wiring

Cover in Rear Door Servicing of mechanical assembly groups (components in contact with fluid): the cover

O-Rings Always check o-rings from disassembled groups/components and replace if necessary.

Figures The displayed figures can differ slightly from the machines on site, due to different

Fuses If fuses are replaced they must exactly match the type and rating specified by the

Spare Parts Only use original spare parts manufactured and sold by B. Braun Avitum AG.

of Spare Parts

Function Check Check the respective function of the assembly group/component after servicing. A

If a battery option is present in the machine:

High voltage can be present at the backlight inverter board BIB in the TFT monitor,

even if the machine has been disconnected from mains. Pull out the battery

compartment in the base platform and switch off the battery voltage before opening

the machine.

If the TFT housing had to be opened during a service job, the tight seat of the

protective conductors in the TFT housing must be checked.

Only activate the TSM service program for service activities. It is prohibited to connect

a patient to the Dialog+ and to run a therapy if the TSM service program is activated

in the Dialog+. If the TSM service program is activated the complete alarm system is

disabled. The TSM service program is started in the service mode: digital board, service

switch S1, position 2.

The software is installed in the software mode: digital board, service switch S1,

position 3.

After completion of all procedures switch back to the therapy mode: digital board,

service switch S1, position 0.

Only perform a calibration after the Dialog+ has reached working temperature and the

machine was disinfected and decalcified. Save the calibration data (CFC) before you

exit the TSM service program:

Tubing must be replaced only by the same tubing type/length and identical installation

manner.

Make sure that the tubings in the machine are not kinked or twisted after servicing

(e.g. if sub-racks are pulled out and inserted again). The tubing must not touch

moving/rotating co mponents (e.g. motors of gear pumps).

Wiring must be replaced only by the same cable type/length and identical installation

manner. The cables must not touch moving/rotating components (e.g. motors of gear

pumps).

due to the penetration of disinfectant or hot liquid.

machines.

for the switch mode power supply microcontroller SMPS-MC in the rear door must be

assembled during servicing because it serves as a spray protection.

hardware statuses.

manufacturer in the spare parts list/technical information. Where applicable: fuses

must be approved by UL/CSA.

Dispose spare parts (e.g. boards or batteries) according to local disposal guidelines or

send back to B. Braun Avitum AG free of charge (see chapter 7).

machine only if:

•

the hardware matches and

•

the identical software version number is present.

complete function check must be performed after every service, according to the

operating manual.

TSM Main Menu, File Operations, Save Calibration Data

III

.

BA-TE-DE08C M.KAY -

Dialog+ SW9xx_sm_TOC_1-2010.doc/pdf <100329> yymmdd

B. Braun Avitum AG

Page 5

Dialog

+

SW 9.xx

Service Manual 1/2010

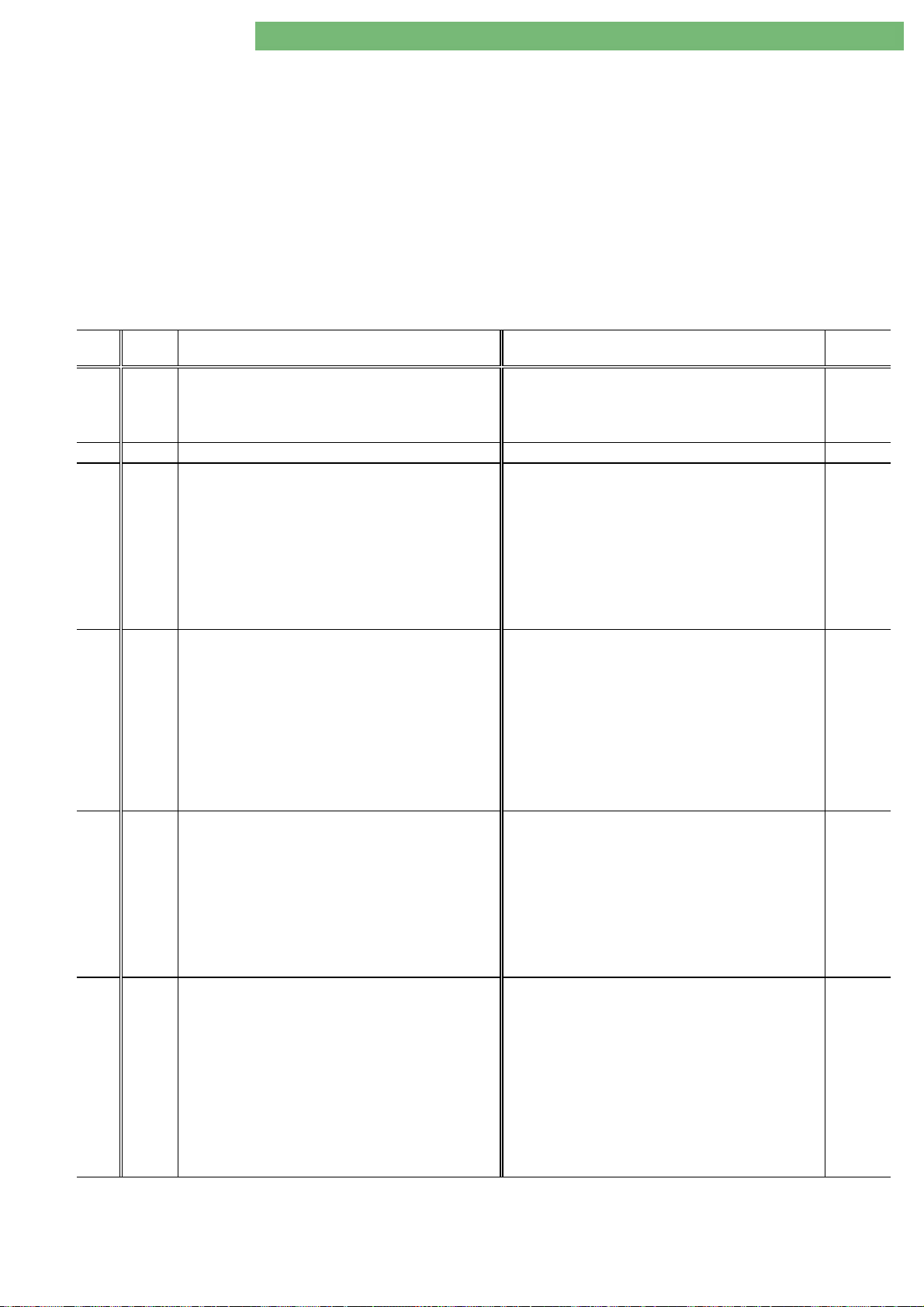

Table of C ont e nt s Pa ge

IV

1. Installation and Commissioning

2. Technical System Description

3. Repair Instructions

4. TSM Service Program

5. Technical Safety Inspection with Preventive Maintenance

6. Flow, Wiring and Tubing Diagrams

7. Spare Parts List

8. Appendix

8.1 ESD/EMC Information

8.1.1 Electrostatic Discharge ESD

8.1.2 Electromagnetic Compatibility EMC

1-1

2-1

3-1

4-1

5-1

6-1

7-1

8-1

8-2

8-2

8-4

8.2 Technical Information

8.3 Assembly Instructions

8.4 Field Service Information

8.5 Instruction Leaflets

9. Edition/Updates Service Manual

-

-

-

-

9-1

BA-TE-DE08C M.KAY -

Dialog+ SW9xx_sm_TOC_1-2010.doc/pdf <100329> yymmdd

B. Braun Avitum AG

Page 6

V

Dialog

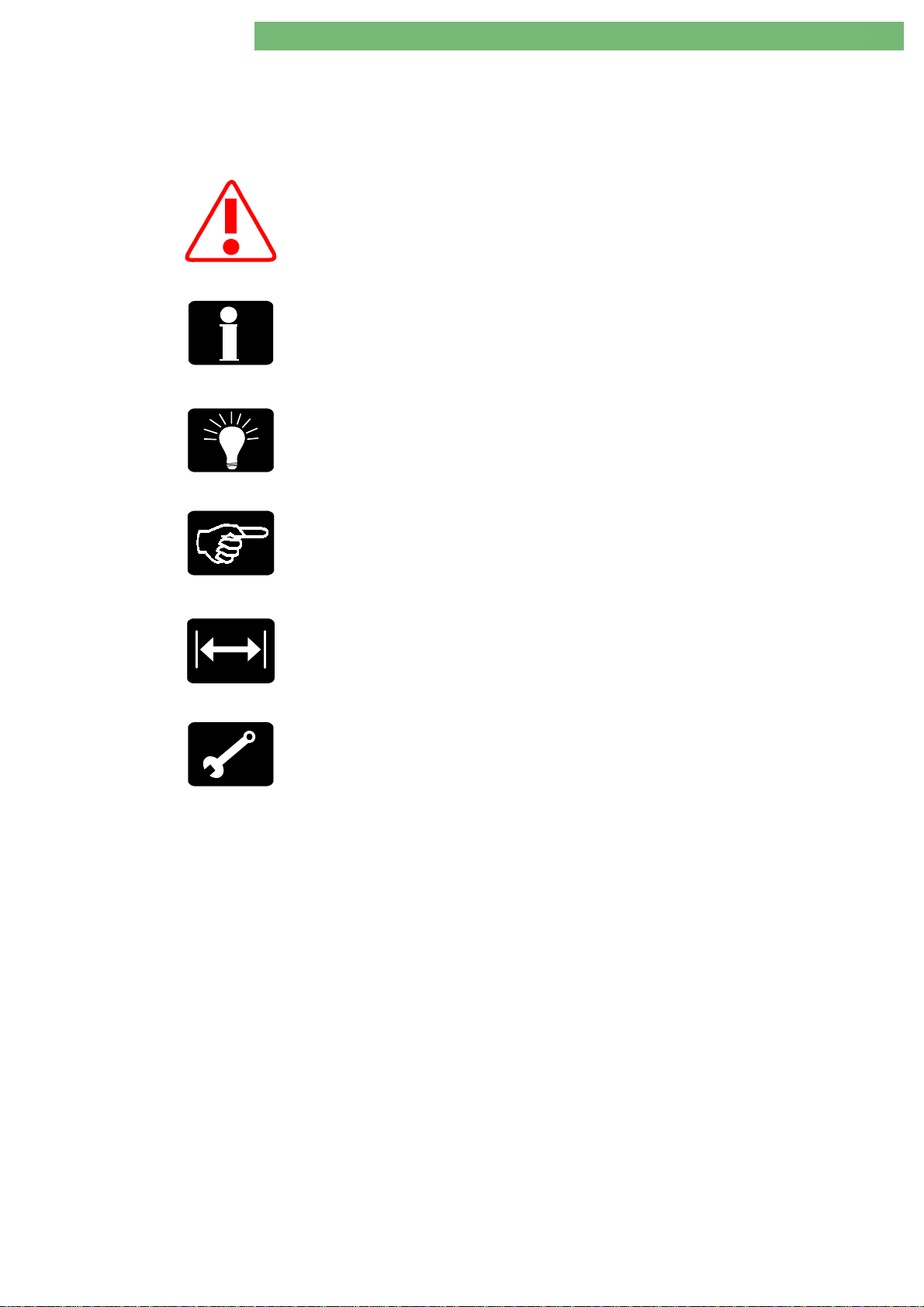

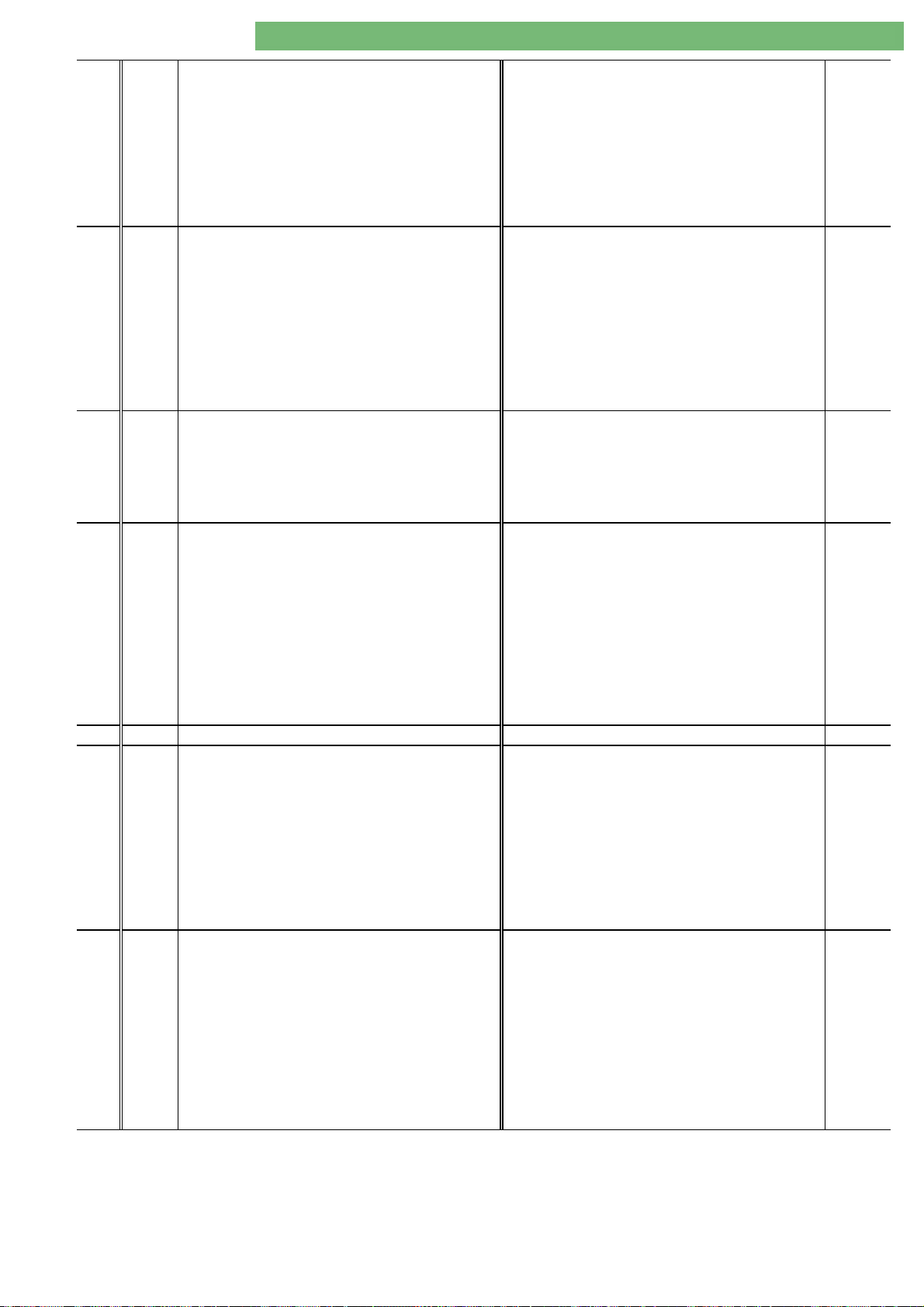

Conventions

+

SW 9.xx

Service Manual 1/2010

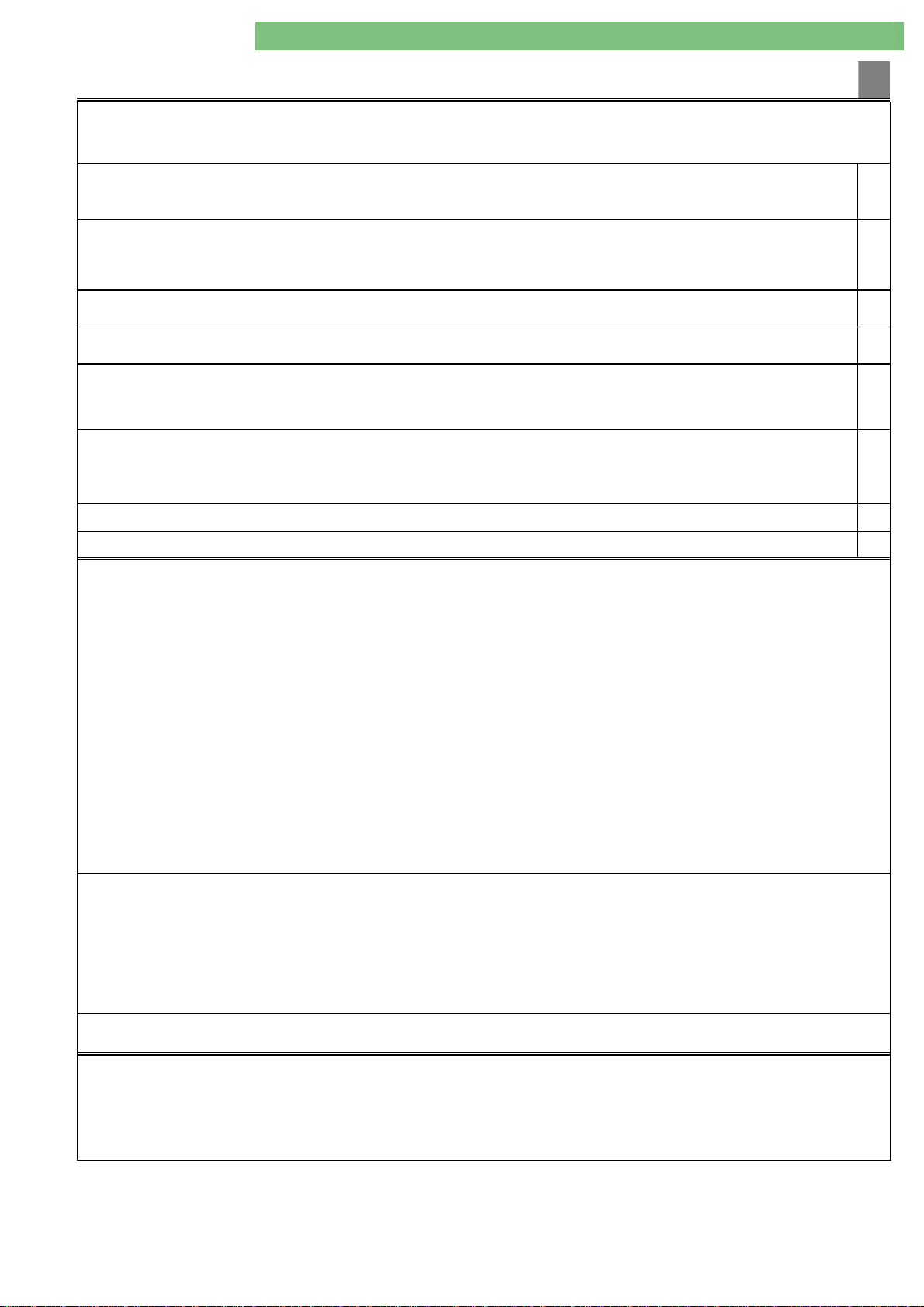

Symbol Description

Attention

The symbol gives information, which are safety relevant for

the Dialog+ and must be observed.

Information

The symbol gives additional information, which should be

observed.

Tips

The symbol gives additional hints, which can be helpful.

Handling

The symbol gives information for a handling at or in the

machine, i.e. during a calibration, disassembly or assembly.

Calibration

The symbol appears for necessary calibration measures.

Calibration Equip m ent / Tools

The symbol gives remarks for necessary calibration

equipment/tools, i.e. during a calibration, disassembly or

assembly.

BA-TE-DE08C M.KAY -

Dialog+ SW9xx_sm_TOC_1-2010.doc/pdf <100329> yymmdd

B. Braun Avitum AG

Page 7

V

Dialog

+

SW 9.xx

Service Manual 1/2010

I

Service Manual

Service Training

The edition of this service manual is for the maintenance and repair of the

Dialog+ machine with a software ≥ 9.01. The service manual is subject to

amendments.

A service training is essential to meet the B. Braun standard operating

procedures for qualified service and support.

The user of this documentation should only use this documentation in

combination with a participation in a B. Braun service training.

The user of this documentation should h ave the following qualifications and

prerequisites:

1. Mechanics, digital/analogue techniques, optoelectronics, measurement and

PC techniques.

2. Participation in a B. Braun service training to accomplish qualified

maintenance, repair and service support.

3. Availability of approved and calibrated test equipment and tools given in

this service manual.

Contact your local B. Braun representative or dealer for detailed inform ation

concerning training courses.

B. Braun Avitum AG

34209 Melsungen, Germa ny

Tel.: +49 5661 712718

Fax.: +49 5661 752718

E-Mail: marina.ritz-nickel@bbraun.com

Technical Safety Inspection

Instructions for Use

ESD/EMC Information

Spare Parts

Perform regular technical safety inspections as described in chapter 5 of this

service manual to ensure the safety of the machine.

An instructions for use can be ordered at your local B. Braun representative or

dealer.

Please observe the ESD/EMC information (see appendix for additional

information):

• ESD: electrostatic discharge

• EMC: electromagnetic compatibility

Only original spare parts manufactured and sold by B. Braun are applicable.

Please provide part number and description respectively when ordering any

spare parts. Please order your spare parts at your local B. Braun representative

or dealer.

B. Braun Avitum AG

34209 Melsungen, Germa ny

Tel. No.: +49 5661 713662

E-Mail: heike.sinning@bbraun.com

dialysetechnik.melsungen@bbraun.com

The main assembly groups are defined according to the spare parts list. The

main assembly groups are especially:

• All pcb's (printed circuit boards)

• Pumps

• DF block

• Ultrafiltration

• Blood leak detector

• Safety air detector

• Heater

Tamper or repairs in these assembly groups are not permissible (due to

calibration, ESD, multi-layer pcb's and the application of SMT (SMT = surface

mounted technology).

Calibration Serv ice

BA-TE-DE08C M.KAY -

Dialog+ SW9xx_sm_TOC_1-2010.doc/pdf <100329> yymmdd

All calibration devices must be approved and registered with an identification

number. The calibration equipment is subjec t to the B. Braun calibration service

and must be checked and recalibrated in regular intervals, to meet th e B. Braun

standard operating procedures SOPs. Only approved and registered calibration

equipment must be applied for servicing.

B. Braun Avitum AG

Page 8

1. Commissioning 1/2010 1 - 1

Dialog

Copyright

Commissioning and Service

Prevent Electrical Shock Hazard

ESD Information

High Voltage

in TFT Monitor

Protective Conductor in TFT Housing

TSM Service Program

Software

Therapy Mode

Calibration

Prevent Chemical Burns and Scalding

Contaminated Machines

Cover in Rear Door

Tubing

Wiring

Fuses

Spare Parts

Instructions for Use

Check Machine

Commissioning

Electrical Installation

Mains Voltage Supply

Ambient Temperature

Water Installation

Water Quality

Central Hot Cleaning System

+

SW 9.xx

This document is the property of B. Braun Avitum AG with all rights reserved.

Only trained personnel must service the Dialog+, i.e. repair, maintenance, software installation, firmware

update, retrofitting and commissioning of the Dialog+.

Servicing must only be performed with proper tools, calibration equipment and be in accordance with the

most recent revision of this service manual/technical information, which must be clearly and thoroughly

understood.

Switch off the Dialog+ and disconnect unit from mains if you have to open the machine for servicing.

Do not touch any exposed wiring or conductive surfaces while the Dialog+ is opened. The voltages present

when electrical power is connected to the Dialog+ can cause serious injury or death.

Pay attention to ESD information, because electronic components are sensitive to electrostatic discharges.

If a battery option is present in the machine:

High voltage can be present at the backlight inverter board BIB in the TFT monitor, even if the machine has

!

been disconnected from mains. Pull out the battery compartment in the base platform and switch off the

battery voltage (remove fuse) before opening the machine.

If the TFT housing had to be opened during a service job, the tight seat of the protective conductors in the

TFT housing must be checked.

Only activate the TSM service program for service activities. It is prohibited to connect a patient to the

Dialog+ and to run a therapy if the TSM service program is activated in the Dialog+. If the TSM service

program is activated the complete alarm system is disabled. The TSM service program is started in the service

mode: digital board, service switch S1, position 2.

The software is installed in the software mode: digital board, service switch S1, position 3.

After completion of all procedures switch back to the therapy mode: digital board, service switch S1,

position 0.

Only perform a calibration after the Dialog+ has reached working temperature, and the machine was

disinfected and decalcified. You should save the calibration data to the hard disk drive before you exit the

TSM service program:

During servicing on running machines: prevent chemical burns and scalding of the skin due to the

penetration of disinfectant or hot liquid.

Protective gear should be worn in case of servicing of assumed contaminated machines.

Servicing of mechanical assembly groups (components in contact with fluid): the cover in the rear door must

be assembled during servicing because it serves as a spray protection for the SMPS-MC.

Tubing must be replaced only by the same tubing type/length and identical installation manner.

Make sure that the tubings in the machine are not kinked or twisted after servicing (e.g. if sub-racks are

pulled out and inserted again). The tubing must not touch moving/rotating components (e.g. motors of gear

pumps).

Wiring must be replaced only by the same cable type/length and identical installation manner. The cables

must not touch moving/rotating components (e.g. motors of gear pumps).

If fuses are replaced they must exactly match the type and rating specified by the manufacturer in the spare

parts list/technical information. Where applicable: fuses must be approved by UL/CSA.

Only use original spare parts manufactured and sold by B. Braun Avitum AG.

Please pay attention to the information in the instructions for use

Check completeness of machine and transport damages after unpacking.

Do not start machine if a safe operation is not guaranteed.

The electrical installation must correspond with national regulations for initial operation of the unit (e.g. IEC

publications). The machine must not be operated in hazardous locations or rooms. The potential equalisation

must be in accordance with national requirements (e.g. IEC publications)

The mains voltage supply must correspond with the mains voltage on the unit type plate!

Before the Dialog+ is switched on the machine must have room temperature (see instructions for use,

chapter 15).

The installation must be in accordance with national regulations e.g. DVGW work sheet W503 for

haemodialysis equipment and VDE 0753 (rules of application for haemodialysis equipment).

A pipe disconnector is not necessary if a water softener or water softener with built-in reverse osmosis

system is installed. A nonreturn valve and a bleed pipe are adequate. Please see DVGW work sheet W 503,

section 4.4 and VDE 0753 part 4 (Rules of application for haemodialysis equipment).

Only water of the highest quality should be applied. Please consider the following, especially for bicarbonate

dialysis:

• Inlet water shall be free of Mg

If the machine is connected to a central hot cleaning system a high temperature tubing must be used for the

water inlet.

TSM Main Menu, File Operations, Save Calibration Data

++

and Ca++.

.

BA-TE-DE08C M.KAY Dialog+ SW9xx_SM_Chapter 1-1_1-2010.doc/pdf <110301> yymmdd B. Braun Avitum AG

Page 9

1. Commissioning 1/2010 1 - 2

1

Dialog

+

SW 9.xx

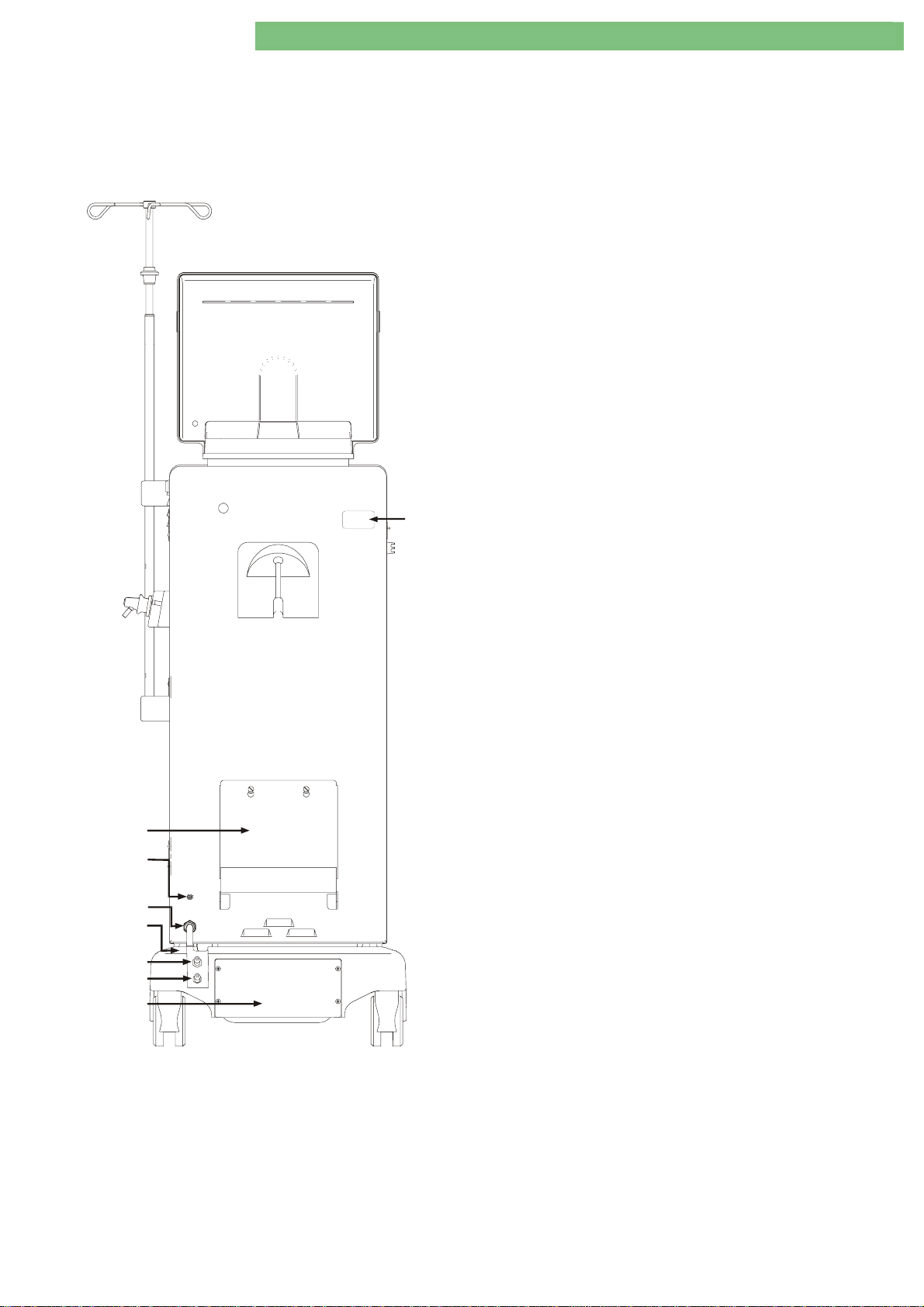

Legend

1. Type Plate

2. Canister Holder

3. Potential Equalisation Bolt

4. Main Cord

2

3

4

5

5. Central Concentrate Supply Option

6. Tubing Connection Water Inlet

• PVC tubing 10 x 3 mm (red)

(fasten with two single ear clamps 19.5)

• Tubing length: approx. 3 m

6.1 Tubing Connection Water Inlet for Osmosis Device

with Hot Disinfection of the Loop Line

• Silicone tubing 8 x 3.2 mm (high temperature tubing, red)

(fasten with two single ear clamps 19.5)

7. Tubing Connection Dialysate Outlet

• PVC tubing 10 x 3 mm (black)

(fasten with a single ear clamp 19.5 and a tubing clamp 1220 mm)

• Tubing length: approx. 3 m

• Drain height: max. 80 cm

8. Emergency Power Supply/Battery Option

6

7

8

Fig.: Dialog+ Rear View

BA-TE-DE08C M.KAY Dialog+ SW9xx_SM_Chapter 1-1_1-2010.doc/pdf <110301> yymmdd B. Braun Avitum AG

Page 10

1. Commissioning 1/2010 1 - 3

Dialog

+

SW 9.xx

Table of Contents Page

1.1 Commissioning Check List

1.1.1 Measurement Circuits for the Measurement of the Electrical

Safety According to EN 62353/60601-1

1-4

1-6

BA-TE-DE08C M.KAY Dialog+ SW9xx_SM_Chapter 1-1_1-2010.doc/pdf <110301> yymmdd B. Braun Avitum AG

Page 11

1. Commissioning 1/2010 1 - 4

Dialog

+

SW 9.xx

1.1 Commissioning Check List

For Dialog+ SW 9.xx

REF {Type/Typ}:................................................. SN {Serien-No./Nr.}: ................................................

Year of Purchase: ....................... Responsible Organisation (User): .....................................................

.........................................................................................................................................................................

Operating Hours: .................................... h Inventory No.: ..................................................................

SW Version: ...........................................

The commissioning (putting into service) shall be performed and documented before the machine

is handed over to the responsible organisation (user), according to the specified check list, with

reference to the service manual and instructions for use.

Manufacturer:

B. Braun Avitum AG

34209 Melsungen, Germany

Check List

Note: Text in { } brackets is information for the execution of the check list!

1. Visual Inspection

1.1 {Machine: clean/complete; no damages/moisture influences or loose assemblies; no moveable parts touching tubings or wires; casters are moveable;

type plate legible}

1.2 {Check tight seat and damages of mains supply (power supply cord, strain relief), potential equalisation cable, staff call/data lines (if present) and

connectors}

2. Protective Earth Resistance According to EN 62353

2.1 Protective Earth Resistance:

< 0.3 [Ω] {note highest value}: ................................................ [Ω]

{(Machine in cl. power supply cord. Move the power supply cord during the check. Thus possible loose connections can be detected. Data lines and

potential equalisation cable must not be connected during the check of the of the protective earth resistance (see figure 1)}

{Measurement points:}

{Exterior: Potential equalisation bolt, rinsing bridge (dialyser inlet and outlet)}

{Interior: Heater body (top), rear door (top left corner), frame (rear), housing cover (top left), front door (top left)}

{Monitor: Monitor (one of the screws in the front panel/housing}

3. Install Machine

3.1 {Connect water inlet to the metal tubing connector and fasten with single ear clamp.

Connect dialysate outlet to plastic tubing connector and fasten with tubing clamp.}

3.2 {Connect central supply for concentrate (central supply option) and deaerate tubings}

3.3 {Assemble holder for disinfectant (if option present)}

3.4 {Assemble dialyser holder}

3.5 {Assemble filter holder. Insert DF filter (option)}

3.6 {Assemble DF filter/HDF filter (if option present)}

OK

4. Function Inspection

{Pay attention to the filling procedure of the machine to prevent dry run of the heater!}

4.1 Switch on machine, fill and rinse: - {Switch machine in Test 1.10 Degassing and Heating menu and fill with water until

water flows out of the dialysate outlet. Then rinse in disinfection (approx. 5 minutes).}

4.2 Automatic Blood Pressure Measurement ABPM

4.2.1 ABPM Option: - Measurement on a test person is plausible

4.3 Customer Specific System Setting: - {Switch machine in TSM Service Program: Execute Treatment Support (calibrate PE offset for

altitudes > 1000 m}

Option present no yes

BA-TE-DE08C M.KAY Dialog+ SW9xx_SM_Chapter 1-1_1-2010.doc/pdf <110301> yymmdd B. Braun Avitum AG

Page 12

1. Commissioning 1/2010 1 - 5

Dialog

Check List

+

SW 9.xx

OK

Note: Text in { } brackets is information for the execution of the check list! SN {Serien-No./Nr.}............................................

5. Setting into Service According to Instructions for Use with Electrical Safety Check According to

EN 62353/EN 60601-1

5.1 Applied Accessories/Disposables:

- Applied line system:

Name: ......................................................................................................................................................................................

5.2 Switch on machine: - Self-test passed {and 15 minutes therapy with UF safety check}

- Ultrafiltration comparison measurement 15 minutes with UF rate 500 ml/h: ......................... [ml]

(125 ml UF volume ±15 ml)

5.3 Temperature: - Comparison measurement {at dialyser coupling}, at 37 oC (-1.5; +0.5): ......................... [oC]

5.4 Conductivity: - Comparison measurement {at dialyser coupling}, e.g. 14.3 mS/cm (±0.2): ................. [mS/cm]

5.5 Equipment Leakage Current:

{All water connections and data lines must be connected during the check of the equipment leakage current (see figure 2)}

≤ 0.5 [mA] - During heat-up phase {change mains polarity and note highest value}: ....................... [mA]

5.6 Patient Leakage Current:

{All water connections and data lines must be connected during the check of the patient leakage current (see figure 3)}

< 10 [µA] AC - Under normal conditions {at dialyser coupling}, conductivity at 13 – 15 mS/cm: ........................ [µA]

5.7 Safety Air Detector (SAD): - Test alarm function (visual/audible) passed

5.8 Disinfection: - Start

Applied Measurement Equipment:

Electrical Safety: ........................................................................................ * ID/Serial No.: .................................

Conductivity: ............................................................................................... * ID/Serial No.: .................................

Temperature: ............................................................................................... * ID/Serial No.: .................................

Pressure: ....................................................................................................... * ID/Serial No.: .................................

Balance: ........................................................................................................ * ID/Serial No.: .................................

Pressure Manometer: ............................................................................... * ID/Serial No.: .................................

Other Measurement Device: ................................................................... * ID/Serial No.: .................................

......................................................................................................................... * ID/Serial No.: .................................

* If applicable, please enter the type and identification number of the equipment used.

Comments:

..........................................................................................................................................................................................................................................................

..........................................................................................................................................................................................................................................................

..........................................................................................................................................................................................................................................................

Next Inspection Date:

The commissioning was performed and the

machine was hand over to the responsible

organisation (user).

............................................................................................................................................................

Name Service Technician: Name of Company:

...................................................................................

................................................................................... .................................................................

Date/Signature

BA-TE-DE08C M.KAY Dialog+ SW9xx_SM_Chapter 1-1_1-2010.doc/pdf <110301> yymmdd B. Braun Avitum AG

Page 13

1. Commissioning 1/2010 1 - 6

A

A

A

Dialog

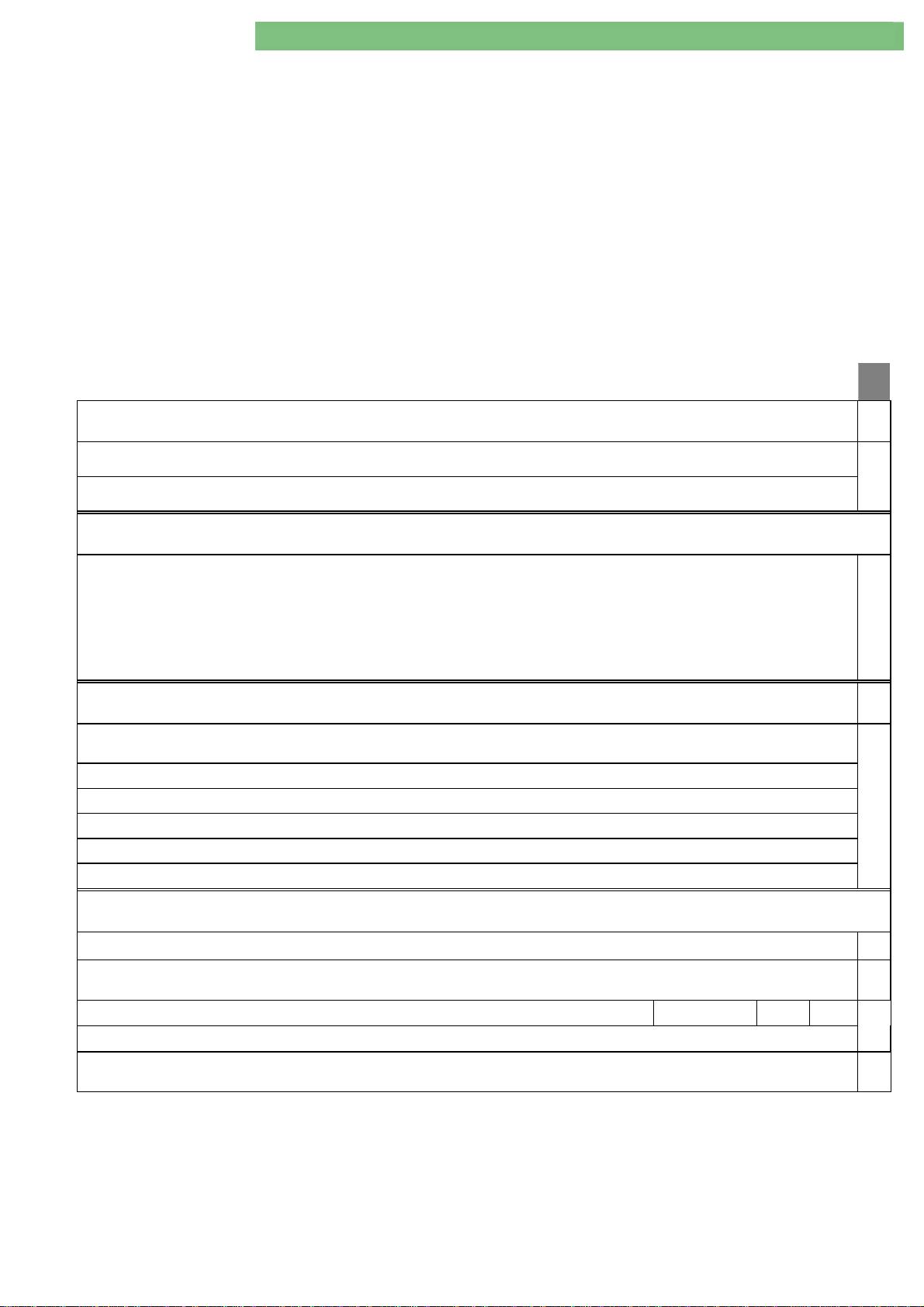

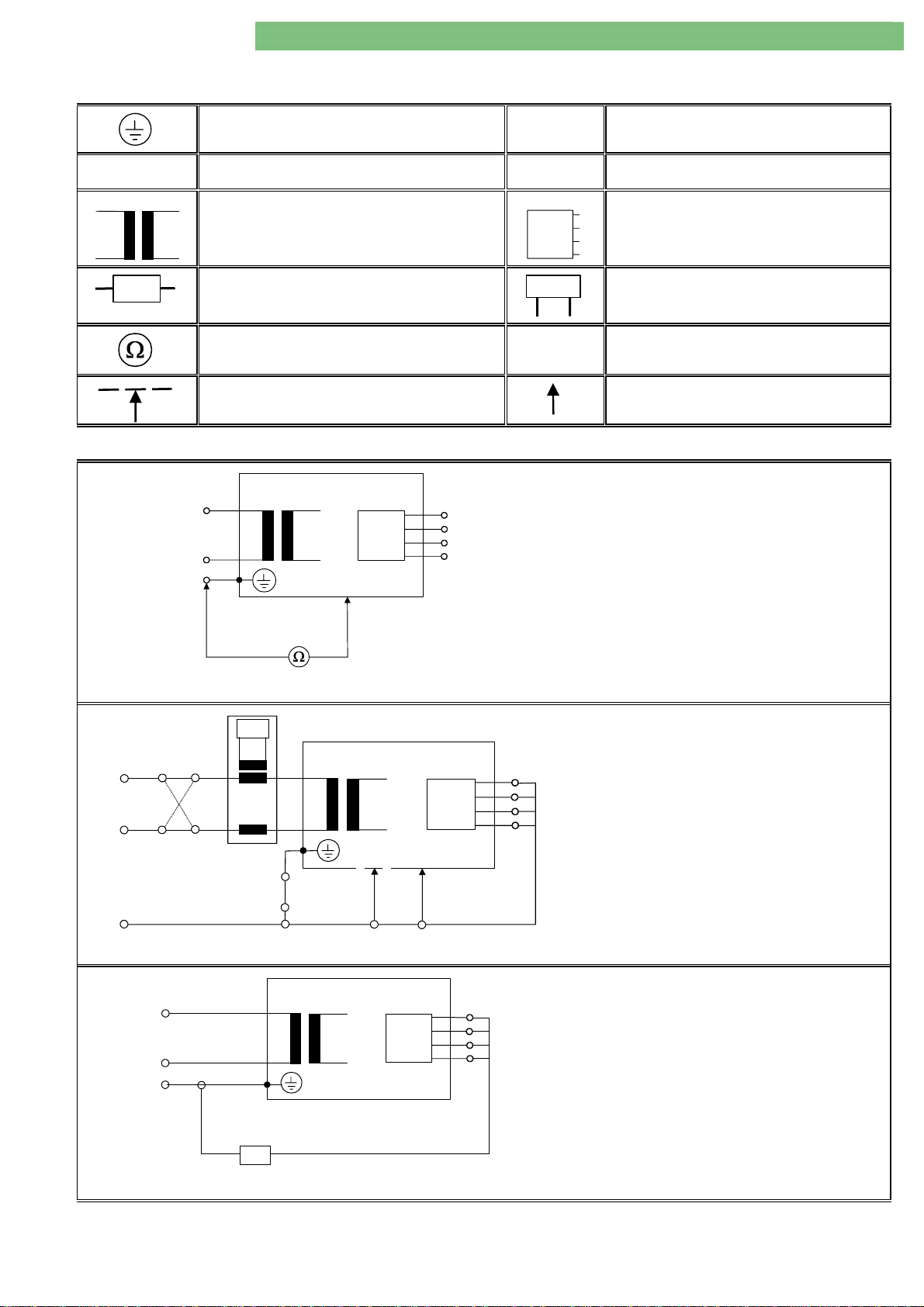

1.1.1 Measurement Circuits for Measurement of Electrical Safety

+

SW 9.xx

According to IEC 62353/60601-1

Protective earth (ground)

L, N

MP

Supply mains terminals

Mains part

MD

Measuring device

Resistance measurement equipment

Part of enclosure not protectively earthed

Table 1: Legend of Abbreviations and Symbols

L

N

PE

MP

AP

PE

P

Protective earth terminal

Applied part

M

Residual current meter with frequency

response as MD

Connection to accessible conductive parts

Protective Earth Resistance

Test current: ≥ 200 mA

The test current must be measured in both

directions.

Fig. 1: Protective Earth Resistance

L(N)

L

N

N(L)

PE

Fig. 2: Equipment Leakage Current

L

N

PE

M

MP

MP

Equipment Leakage Current:

P

• Differential Measurement

Patient Leakage Current

P

MD

Fig. 3: Patient Leakage Current

BA-TE-DE08C M.KAY Dialog+ SW9xx_SM_Chapter 1-1_1-2010.doc/pdf <110301> yymmdd B. Braun Avitum AG

Page 14

Dialog

+

SW 9.xx

2. Technical System Description 1/2010 2 - 1

Table of Content s Page

General Information 2-4

2.1 Overview Sub-Racks 2-5

2.1.1 Legend Overview Sub-Racks 2-5

2.2 Top Level Sub-Rack 2-6

2.2.1 Legend Top Level Sub-Rack 2-6

2.3 Basic Board BB 2-7

2.3.1 Legend Basic Board 2-7

2.4 Power Board Valves PBV 2-8

2.4.1 Legend Power Board Valves 2-8

2.5 Power Board Motors PBM 2-9

2.5.1 Legend Power Board Motors 2-9

2.6 Digital Board DB 2-10

2.6.1 Legend Digital Board 2-10

2.7 Analog Board AB 2-11

2.7.1 Legend Analog Board 2-11

2.8 HDF Online Board HOB 2-12

2.8.1 Legend HDF Online Board 2-12

2.9 UF Sub-Rack 2-13

2.9.1 Legend UF Sub-Rack 2-13

2.10 UF Sub-Rack HDF Online 2-14

2.10.1 Legend UF Sub-Rack HDF Online 2-14

2.11 DF Sub-Rack 2-15

2.11.1 Legend DF Sub-Rack 2-15

2.12 Water Sub-Rack 2-16

2.12.1 Legend Water Sub-Rack 2-16

2.13 Rinsing Bridge 2-17

BA-TE-DE08C M.KAY

2.13.1 Legend Rinsing Bridge 2-17

2.14 Rear Door 2-18

2.14.1 Legend Rear Door 2-18

2.15 Switch Mode Power Supply Microcontroller SMPS-MC 2-19

2.15.1 Legend Switch Mode Power Supply Microcontroller 2-19

2.16 TFT Monitor 2-20

2.16.1 Legend TFT Monitor 2-20

2.17 Front Door 2-21

2.17.1 Legend Front Door 2-21

Dialog+ SW 9xx_sm_C ha pter 2_1-2010.doc/pdf < 100329> yymmdd

B. Braun Avitum AG

Page 15

Dialog

+

SW 9.xx

2. Technical System Description 1/2010 2 - 2

2.18 Level Regulation Module 2-22

2.18.1 Legend Level Regulation Module 2-22

2.18.2 Flow Diagram Level Regulation Module 2-23

2.19 Flow Diagrams 2-24

2.19.1 Dialog+ 2-24

2.19.2 Dialog+ with BIC Option and DF Filter Option 2-25

2.19.3 Dialog+ HDF Online 2-26

2.19.4 Legend Flow Diagram 2-27

2.20 Description Flow Diagram 2-29

2.20.1 Water Inlet Section with Water Block 2-29

2.20.2 Degassing Circuit with Temperature System 2-30

2.20.3 Dialysate Processing 2-31

2.20.4 Central Bicarbonate and Concentrate Supply (Option) 2-32

2.20.5 BIC Cartridge Holder (Option) 2-32

2.20.6 Balance Chamber System 2-33

2.20.7 Working Principle Balance Chamber System 2-33

2.20.8 Ultrafiltration and Rinsing Bridge 2-35

2.20.9 Chemical Thermal Disinfection Program 2-36

2.21 Block Diagram 2-38

2.21.1 Legend Block Diagram 2-39

2.22 Switch Mode Power Supply Microcontroller SMPS-MC 2-42

2.22.1 Block Diagram SMPS-MC 2-42

2.22.2 System Integration SMPS-MC 2-43

2.22.3 Component Layout SMPS-MC 2-44

2.22.4 Wiring Diagram SMPS-MC with Battery Option 2-45

2.22.5 Description SMPS-MC 2-46

2.22.6 Fuses 2-48

2.22.7 Signals 2-49

BA-TE-DE08C M.KAY

2.22.8 Internal Signals 2-49

Dialog+ SW 9xx_sm_C ha pter 2_1-2010.doc/pdf < 100329> yymmdd

B. Braun Avitum AG

Page 16

+

Dialog

SW 9.xx

General Information

2. Technical System Description 1/2010 2 - 4

Operation is accomplished via a touch screen (TFT monitor). Two

microprocessor systems c ontr o l a nd mo ni tor the machine.

The hardware concept consists of the following systems:

Top Level System

•

Low Level System

•

The top level system consists of the following components:

Top Level Syst em

Communication module

•

Top level controller TLC (motherboard)

•

Compact flash card CFC

•

Options

•

The communication between the user and the machine is performed via the

top level.

Example data excha nge to c o mmuni c ation module:

Entry via input mask of the touch screen or keyboard

•

Output via the output mask of the TF T mo ni tor

•

Example data exchange to low level:

Transmitting and receiving data from/to low level controller and supervisor

•

on the digital board DB (LLD)

Low Level Syst em

The low level system consists of the following components:

Digital board DB (LLD)

•

Analog board AB (LLA)

•

Power board motors PBM

•

Power board valves PBV

•

The low level controls and monitors all functions.

Data exchange to top level c o ntr ol l er ( mother b oard):

Transmitting and receiving data from/to low level supervisor

•

Transmitting and receiving data from/to low level controller

•

Data exchange between low level controller to supervisor:

Transmitting and receiving messages, data and commands

•

All sensor data are sent separately, v ia two serial bus systems, to the supervisor

and controller via the analog board to the digital board. The actuators, motors

and valves are driven via the power board valves PBV and power board motors

PBM.

BA-TE-DE08C M.KAY

Dialog+ SW 9xx_sm_C ha pter 2_1-2010.doc/pdf < 100329> yymmdd

B. Braun Avitum AG

Page 17

Dialog

+

SW 9.xx

2. Technical System Description 1/2010 2 - 3

For Software

For Software

For Software For Software

9.xx

9.xx

≥≥≥≥

9.xx 9.xx

BA-TE-DE08C M.KAY

Dialog+ SW 9xx_sm_C ha pter 2_1-2010.doc/pdf < 100329> yymmdd

B. Braun Avitum AG

Page 18

Dialog

+

SW 9.xx

2. Technical System Description 1/2010 2 - 5

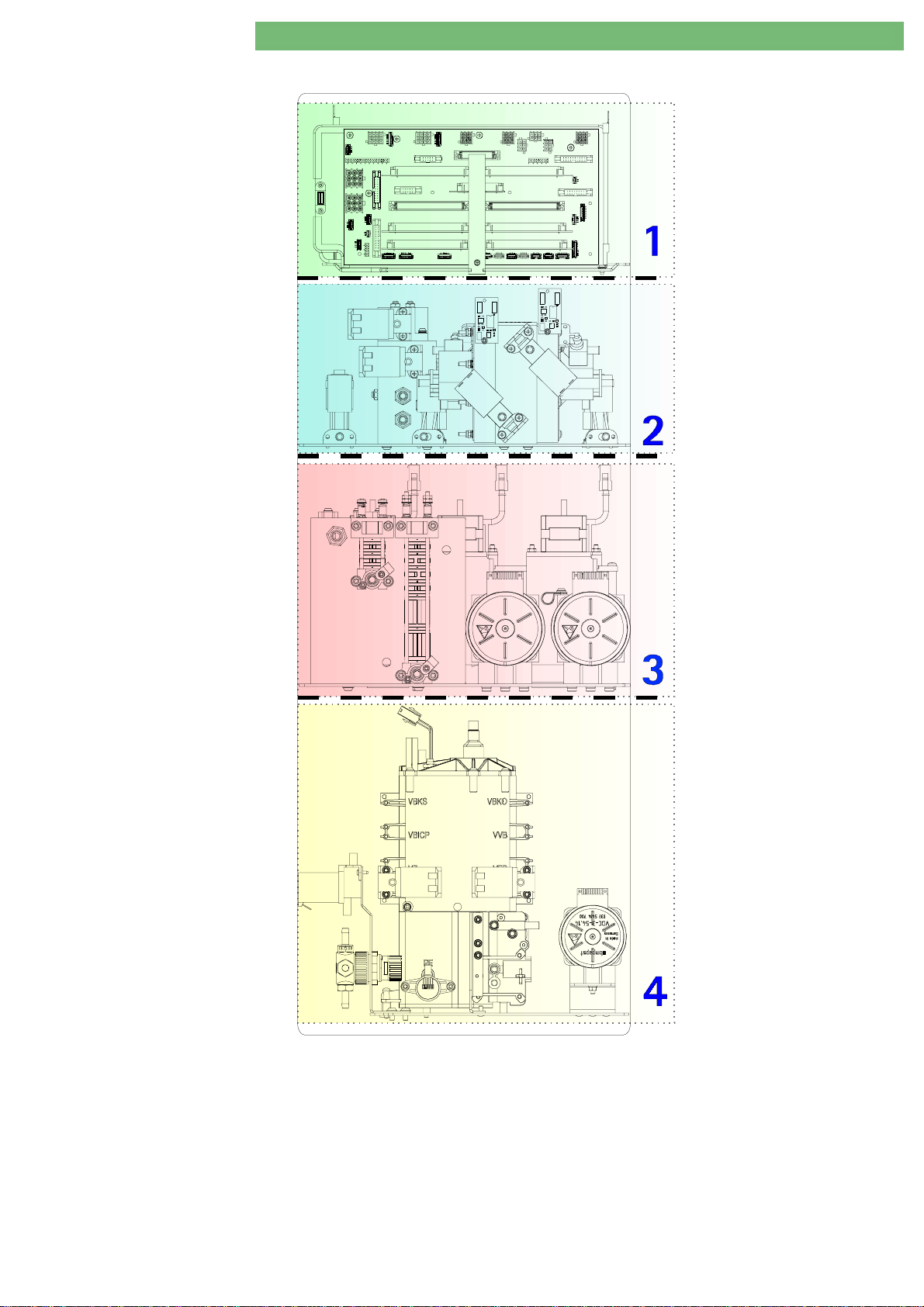

2.1 Overview Sub-Racks

4

11144

Fig. : Overview Sub-Racks Rear View Dialog+

2.1.1 Legend Ov erv iew Sub-Racks

BA-TE-DE08C M.KAY

Top Level Sub-Rack

1

UF Sub-Rack

2

Dialog+ SW 9xx_sm_C ha pter 2_1-2010.doc/pdf < 100329> yymmdd

DF Sub-Rack

3

Water Sub-Rack

4

B. Braun Avitum AG

Page 19

+

Dialog

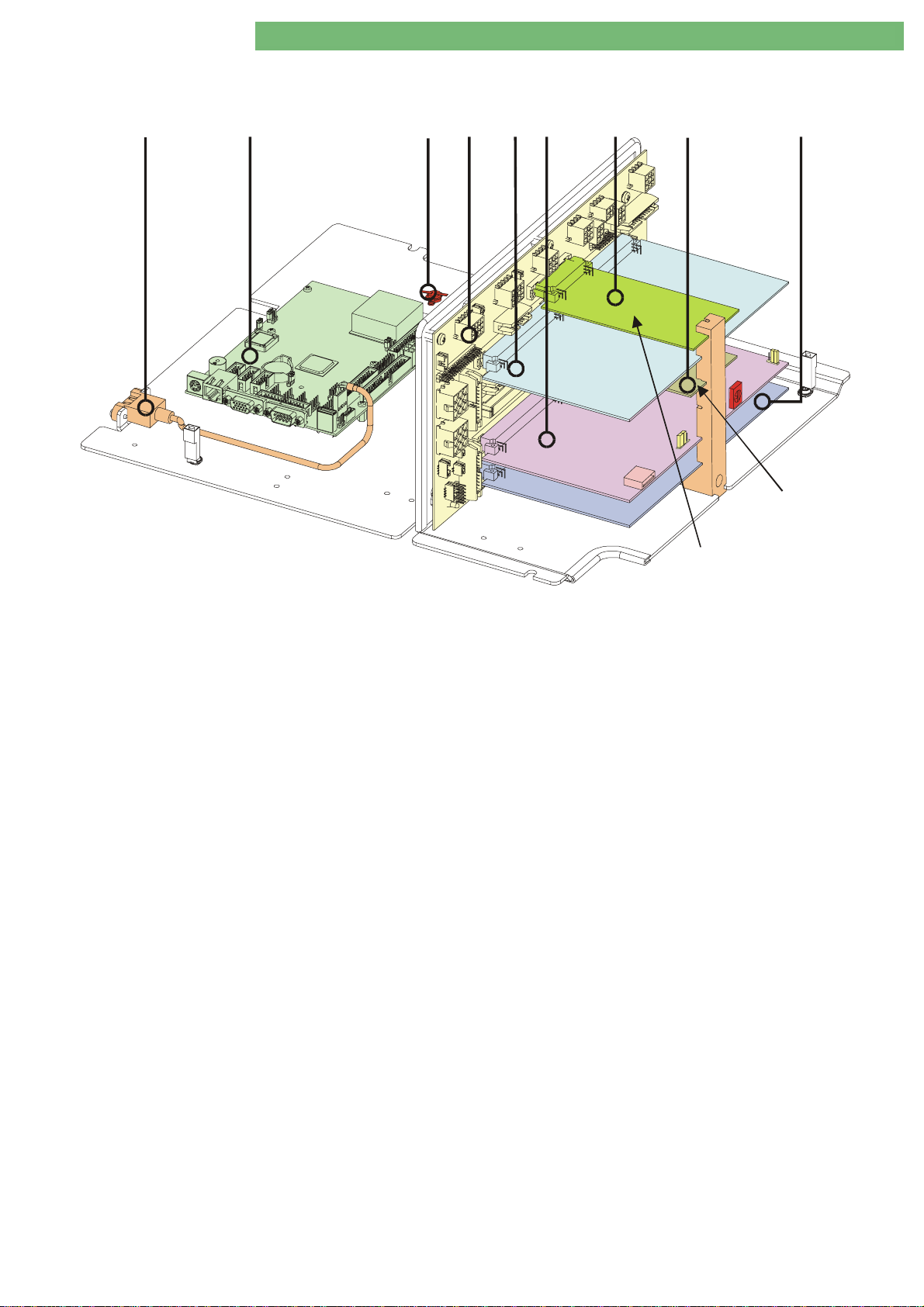

2.2 Top Level Sub-Rack

SW 9.xx

2. Technical System Description 1/2010 2 - 6

1

USB:

Service

SW

Fig. : Top Level Sub-Rack

2

Motherboard

4

3

Basic Board

5

6

Power Board

Valves

Digital Board

USB:

Analog Board

7

SW

89

JP2

S1

JP1

Power Board Motors

HDF BoardOnline

2.2.1 Legend To p Level Sub-Rack

1111 USB Port:

Service (FSU)/Software Installation TLC

2222 LX800 Motherboard

3333 Temperature Switch TS (closes at 50 ± 3

4444 Basis Board BB

5555 Power Board Valves PBV

6666 Digital Board DB (LLD):

USB Port: Software Installation LLC/LLS; Service-Switch S1; Jumper JP1/JP2

7777 HDF Online Board HOB

8888 Power Board Motor PBM

9999 Analog Board AB (LLA)

o

C, opens at 35 ± 6 oC)

BA-TE-DE08C M.KAY

Dialog+ SW 9xx_sm_C ha pter 2_1-2010.doc/pdf < 100329> yymmdd

B. Braun Avitum AG

Page 20

+

Dialog

SW 9.xx

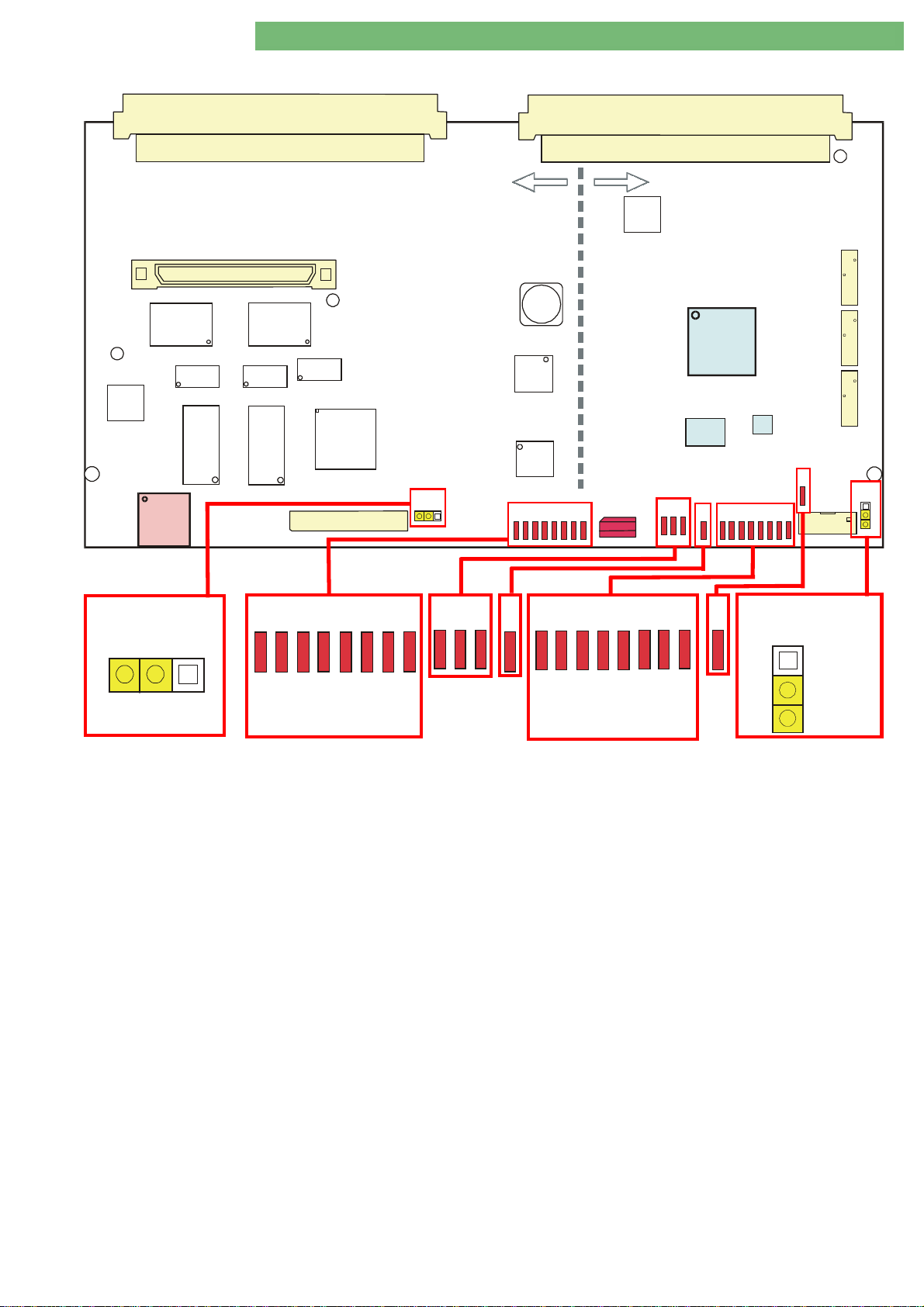

2.3 Basic Board BB

2. Technical System Description 1/2010 2 - 7

P3

P48

P26

P17

P54

P58

P31

P10

P49

P51

P32

1

P24

P6

1

1

1

P50

Fig. : Basic Board

2.3.1 Legend Basic Board

P1

P1 Degassing Pump EP

P1P1

P2

P2 Venous Blood Pump BPV

P2P2

P3

P3 Arterial Blood Pump BPA

P3P3

P4

P4 Outlet Flow Pump FPA

P4P4

P5

P5 Safety Air Detector SAD

P5P5

P6

P6 Heparin Pump HP (HEP)

P6P6

P7

P7 Air Separator Level Sensor LAFS

P7P7

P8

P8 BIC Pump BICP

P8P8

P9

P9 Concentrate Pump KP

P9P9

P10

P10 All Valves (+ Option BIC) VALVES

P10P10

P11

P11 Level Regulation LR

P11P11

P12

P12 DIABUS

P12P12

P13

P13 HDF Online Board HOB

P13P13

P14

P14 Front Panel Board FPB

P14P14

P15

P15 Valves Balance Chamber VCH

P15P15

P16

P16 UF Pump UFP

P16P16

P17

P17 Power Supply 1 PS1

P17P17

P18

P18 Not Applicable

P18P18

P19

P19 Not Applicable

P19P19

P20

P20 Inlet Flow Pump FPE

P20P20

P21/P22

P21/P22 Power Board Valves PBV

P21/P22P21/P22

P23

P23 Staff Call PERS-R

P23P23

P24

P24 Control SMPS-MS (NT)

P24P24

P25

P25 Power Board Motors PBM

P25P25

P26

P26 Disinfection Valve VD

P26P26

DIABUS

DIABUSDIABUS

SMPS-MS (NT)

SMPS-MS (NT)SMPS-MS (NT)

P59

1

BICP

BICPBICP

UFP

UFPUFP

PERS-R

PERS-RPERS-R

P23

EP

EPEP

BPV

BPVBPV

BPA

BPABPA

FPA

FPAFPA

SAD

SADSAD

HP (HEP)

HP (HEP)HP (HEP)

KP

KPKP

LR

LRLR

HOB

HOBHOB

FPB

FPBFPB

PS1

PS1PS1

FPE

FPEFPE

PBV

PBVPBV

VD

VDVD

PBM

PBMPBM

P2

P11

P21

P18

P33

LAFS

LAFSLAFS

VALVES

VALVESVALVES

VCH

VCHVCH

P47

P38P45P39 P30

P1

P13

P25

P7 P44

P27

P27 Membrane Position Sensors Balance Chamber MSBK

P27P27

P28

P28 Temperature Sensor Dialysate TSD

P28P28

P29

P29 Temperature Sensor Heater Inlet TSHE

P29P29

P30

P30 Degassing Temperature Sensor TSE

P30P30

P31

P31 Level Sensor Upline Tank NSVB

P31P31

P32

P32 Blood Leak Detector BL

P32P32

P33/P34

P33/P34 Digital Board DB

P33/P34P33/P34

P35

P35 Temperature Sensor BIC TSBIC

P35P35

P36

P36 Temperature Sensor Dialyser Inlet TSDE

P36P36

P37

P37 Temperature Sensor Dialysate Supervisor TSD-S

P37P37

P38

P38 Pressure Sensor Dialysate Outlet PDA

P38P38

P39

P39 Blood Side Pressure Sensor PBLOOD

P39P39

P40/P41

P40/P41 Analog Board AB (LLA)

P40/P41P40/P41

P42

P42 END Conductivity Sensor (Controller/Supervisor) ENDLF+S

P42P42

P44

P44 B IC Conductivity S ensor BICLF

P44P44

P45

P45 Pressure Sensor Degassing PE

P45P45

P47

P47 Speed/Rotation Direction Venous Blood Pump DZ/DR BPV

P47P47

P48

P48 Speed/Rotation Direction Arterial Blood Pump DZ/DR BPA

P48P48

P49

P49 BIC and Concentrate Sensors for Suction Rods BIC-K

P49P49

P50

P50 Rinsing Bridge Sensors SBS

P50P50

P51

P51 BIC Cartridge Holder Sensor BKUS

P51P51

P54

P54 Power Supply 2 PS2

P54P54

P57

P57 Power Supply Bedside Link BSL-PWR

P57P57

P58/P60

P58/P60 Power Supply Hall Sensors

P58/P60P58/P60

P4

P29

DB

DBDB

AB (LLA)

AB (LLA)AB (LLA)

PS2

PS2PS2

P8

P22

P19

P34

P41P40

BL

BLBL

1

P9

P15

SBS

SBSSBS

NSVB

NSVBNSVB

TSBIC

TSBICTSBIC

PBLOOD

PBLOODPBLOOD

BICLF

BICLFBICLF

PE

PEPE

BKUS

BKUSBKUS

BSL-PWR

BSL-PWRBSL-PWR

P16

TSD

TSDTSD

TSE

TSETSE

TSHE

TSHETSHE

TSDE

TSDETSDE

PDA

PDAPDA

P20

P5

P57

P60

P14

P12

P27

P42

P37P35P28

TSD-S

TSD-STSD-S

P36

MSBK

MSBKMSBK

ENDLF+S

ENDLF+SENDLF+S

DZ/DR BPV

DZ/DR BPVDZ/DR BPV

DZ/DR BPA

DZ/DR BPADZ/DR BPA

BIC-K

BIC-KBIC-K

BA-TE-DE08C M.KAY

Dialog+ SW 9xx_sm_C ha pter 2_1-2010.doc/pdf < 100329> yymmdd

B. Braun Avitum AG

Page 21

Dialog

+

SW 9.xx

2. Technical System Description 1/2010 2 - 8

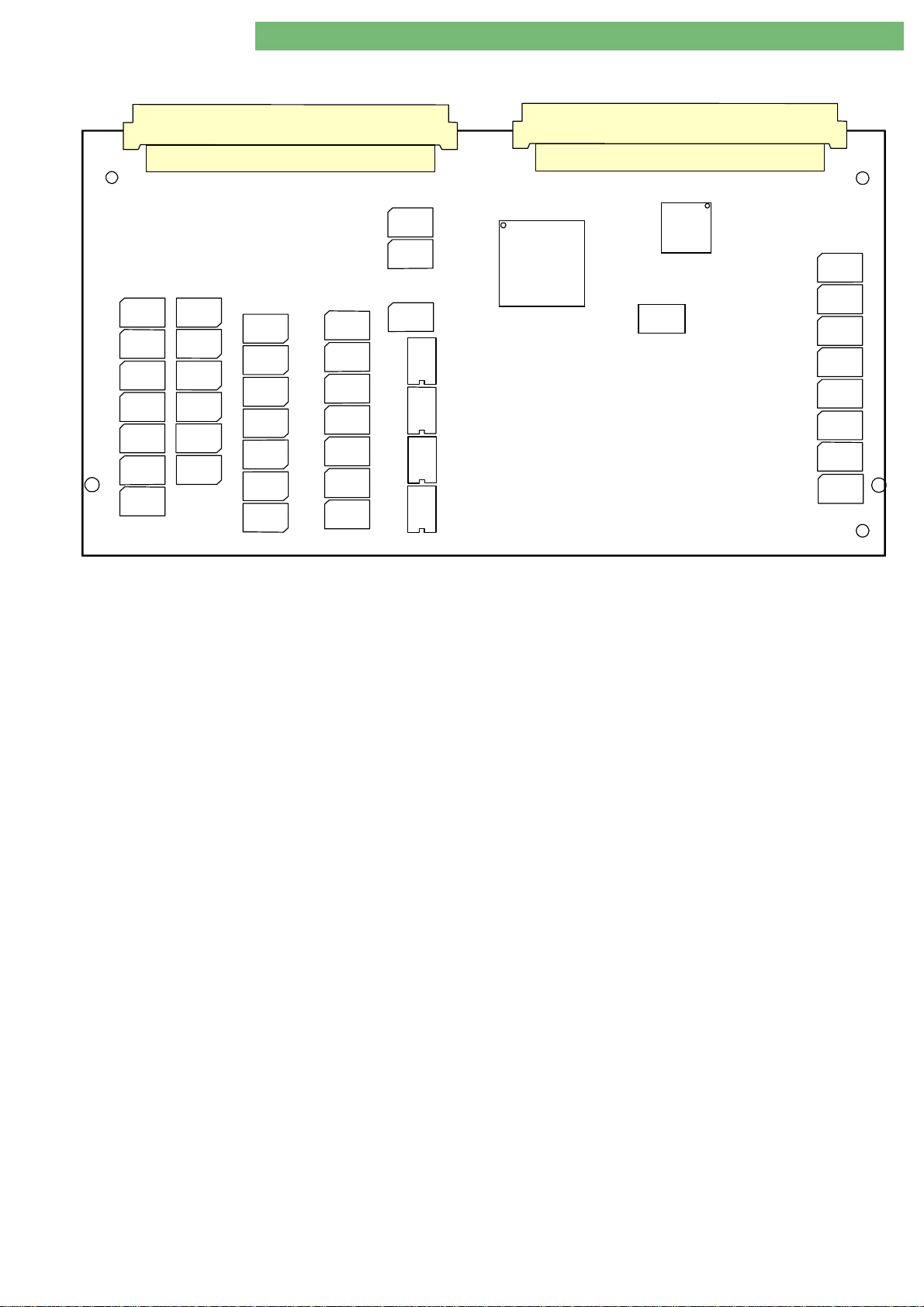

2.4 Power Board Valves PBV

Fig. : Power Board Valves

P1

P2

U3

U4

U6

U9

U13

U18

U23

2.4.1 Legend Power Boa rd Valves

P1 Valves:

Inlet Upline Tank Valve

Degassing Inlet Valve

Air Separator Valve Luftabscheide r

Dialyser Inlet Valve

Dialyser Outlet Valve

Bypass Valve

Option BIC Cartridge Valves

Disinfection Valve

Circulation Valve

Venous Tubing Clamp

Arterial Tubing Clamp

VBP

VVBE

VEB

VDE

VDA

VBICP, VBKS, VBKO, VVB

VD

VZ

SAKV

SAKA

VLA

P2 Valves:

Valve Balance Chamber

Valves Level Module

VBT, VPV, VPE, VPU, VPD, VPA

VDEBK1/2, VDABK1/2, VEBK1/2, VABK1/2

BA-TE-DE08C M.KAY

Dialog+ SW 9xx_sm_C ha pter 2_1-2010.doc/pdf < 100329> yymmdd

B. Braun Avitum AG

Page 22

Dialog

+

SW 9.xx

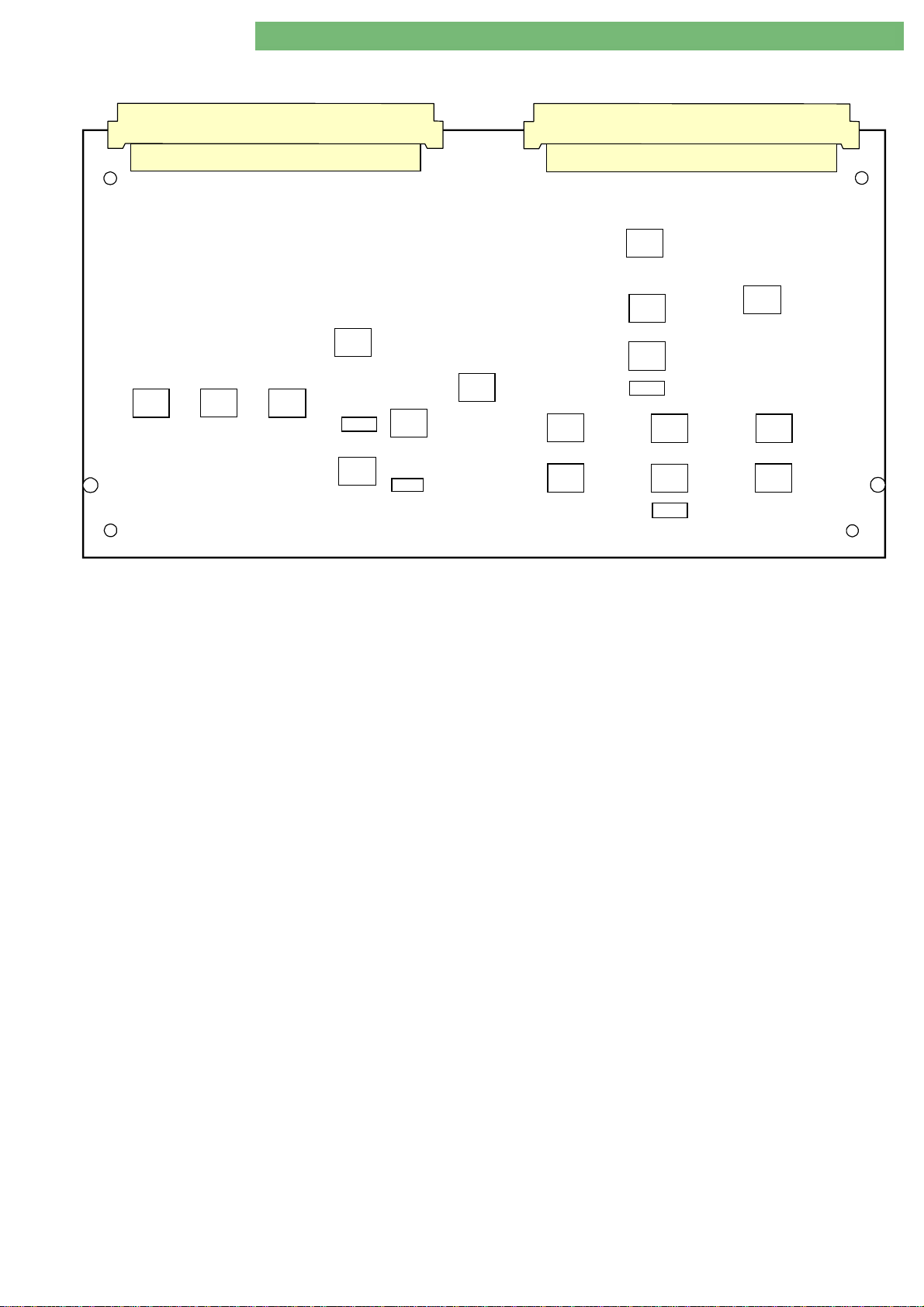

2. Technical System Description 1/2010 2 - 9

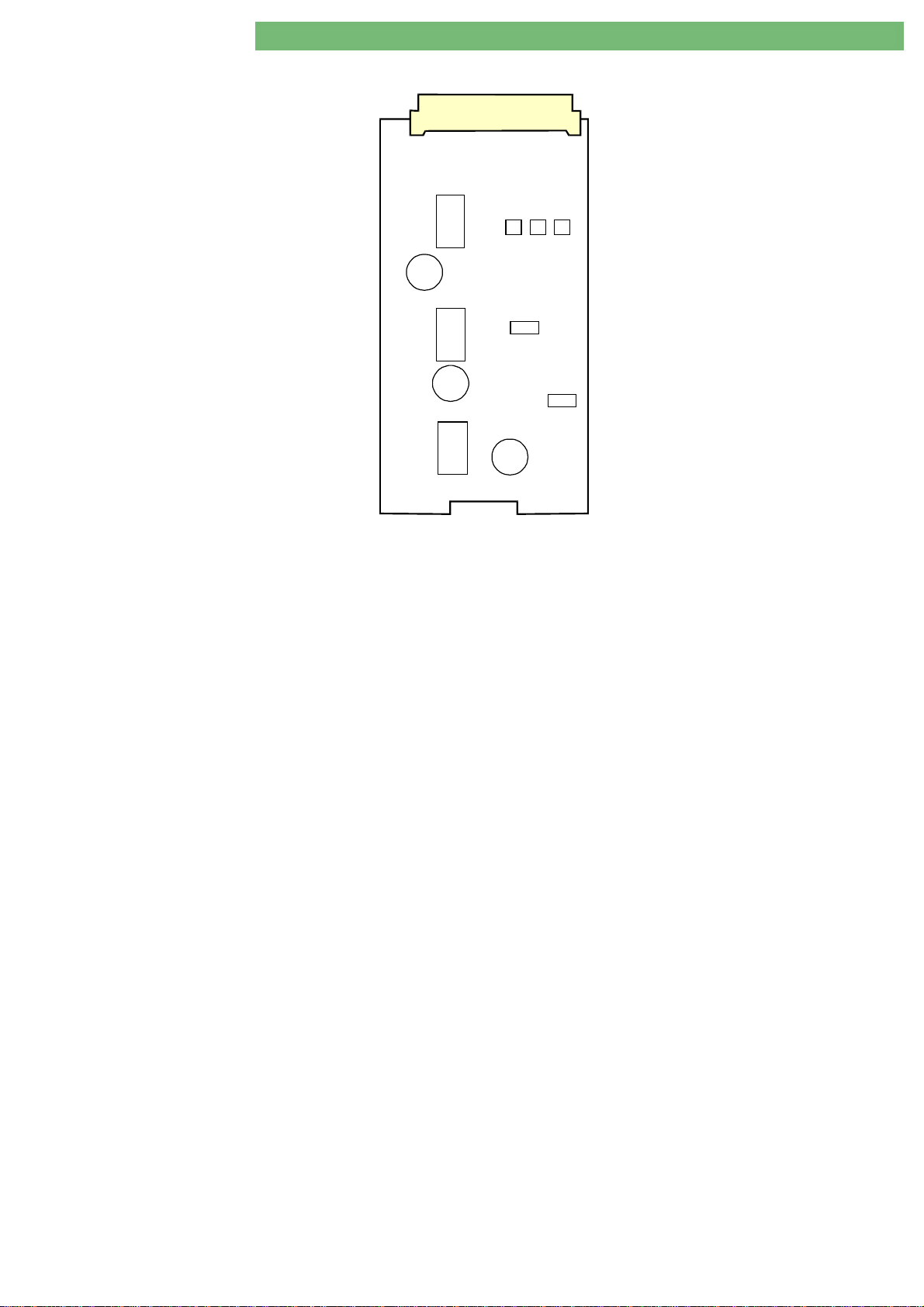

2.5 Power Board Motors PBM

P1

Fig. : Power Board Motors

2.5.1 Legend Power Board M otors

P1

P1 BIC Piston Pump BICP

P1P1

Concentrate Piston Pump KP

UF Piston Pump UFP

Level Regulation Pump (Diaphragm Pump) LRP (PPR)

BICP

BICPBICP

UFP

UFPUFP

KP

KPKP

U10

C19

U13

C26

U19

LRP (PPR)

LRP (PPR)LRP (PPR)

U2 U4 U6

U9

U12

C38

BA-TE-DE08C M.KAY

Dialog+ SW 9xx_sm_C ha pter 2_1-2010.doc/pdf < 100329> yymmdd

B. Braun Avitum AG

Page 23

+

Dialog

SW 9.xx

2.6 Digital Board DB

2. Technical System Description 1/2010 2 - 10

U39

U28

P11

U35

U55

P4

P1

U36

U56

U33

U43

P13

Controller

JP1

P2

Supervisor

U7

P5

L33

U30

FPGA

U27

U46

U53

S1

D16

D17

D18

D19

S1

D20

D21

D22

D23

D24

D25

D26

D27

U45

D28

D29

D34

D30

D35

D31

D32

D33

P6

P7

D13

JP2

P14

D16

D17

D18

D19

D20

D21

JP1

0123456

CWP

Fig. : Digital Board DB (LLD) with Controller and Supervisor

2.6.1 Legend Digital Board

Calibration Data

All calibration data are stored on the digital board. The

calibration data must be stored additionally on the compact flash

card CFC.

12 Bit AD Converter

Both supervisor and controller have a 12 bit AD converter with a

range of 0 to 4095.

P4/P5/P6/P7/P13/P14

USB Type A for SW installation with USB stick

P11

Supervisor Sensors:

BICPOS, KPPOS, UFPOS

Controller/Supervisor Sensors:

BKUS, SBS1, SBS2, BPS_IMP, BPA_DIR, BPV_IMP, BPV_DIR

Pumps:

BPA, BPV, EP, FPA, FPE

Controller Sensors:

NSVB, BICSS, KSS, MSBK1/2, RDV, SAD, BPADS, BPVDS,

BL (Controller/Supervisor Sensor Analog Board)

Controller

: not applicable

D28

D29

D30

D31

D32

D24

D25

D26

D22

D23

7

D27

01234567

D33

D34

Supervisor

Jumper JP1:

Jumper JP1:

Jumper JP1:Jumper JP1:

Default: Controller Write Protect CWP (for controller firmware)

Controller LEDs D13 – D20:

Controller LEDs D13 – D20:

Controller LEDs D13 – D20:Controller LEDs D13 – D20:

Status 0 – 7 for installation of LLC software

FPGA LEDs V7 – V9

FPGA LEDs V7 – V9: always ON

FPGA LEDs V7 – V9FPGA LEDs V7 – V9

Voltages for FPGA (U30) and periphery

(FPGA: Field Programmable Gate Array – configurable logical circuit)

LED V10

LED V10: flashes permanently

LED V10LED V10

Cycle time, system is running

Supervisor LEDs V11 – V18

Supervisor LEDs V11 – V18:

Supervisor LEDs V11 – V18Supervisor LEDs V11 – V18

Status 0 – 7 for installation of LLS software

LED V5

LED V5: always ON after loading

LED V5LED V5

The content of the memory (U45) is loaded to FPGA (U30) during

switch-on. The therapy program and the service program is stored

in the RAM (U45).

Jumper JP2:

Jumper JP2:

Jumper JP2:Jumper JP2:

Default: Supervisor Write Protect SWP (for supervisor firmware)

S1 Service Switch:

Position 0:

Position 2:

Position 3:

Therapy Mode

TSM Service Program Mode

Software Installation/Update Mode

D13

D35

JP2

SWP

BA-TE-DE08C M.KAY

Dialog+ SW 9xx_sm_C ha pter 2_1-2010.doc/pdf < 100329> yymmdd

B. Braun Avitum AG

Page 24

+

Dialog

SW 9.xx

2.7 Analog Board AB

2. Technical System Description 1/2010 2 - 11

U35

Fig. : Analog Board AB (LLA)

U36 U37

P1

U32

U40

U41

U42

U46

U39

U43

U47

U21

U33

U38

U29

P2

U44

U48

U50

U28

U45

U49

2.7.1 Legend Analog Board

P1/P2

Controller Sensors:

PBS, TSHE, TSE, TSB IC, TSD, TSDE, BICLF, ENDLF, PE, LAFS

Supervisor Sensors:

TSD-S, ENDLF-S

Controller/Supervisor Sensors:

BL, PBE, PA, PV, PDA

BA-TE-DE08C M.KAY

Dialog+ SW 9xx_sm_C ha pter 2_1-2010.doc/pdf < 100329> yymmdd

B. Braun Avitum AG

Page 25

Dialog

+

SW 9.xx

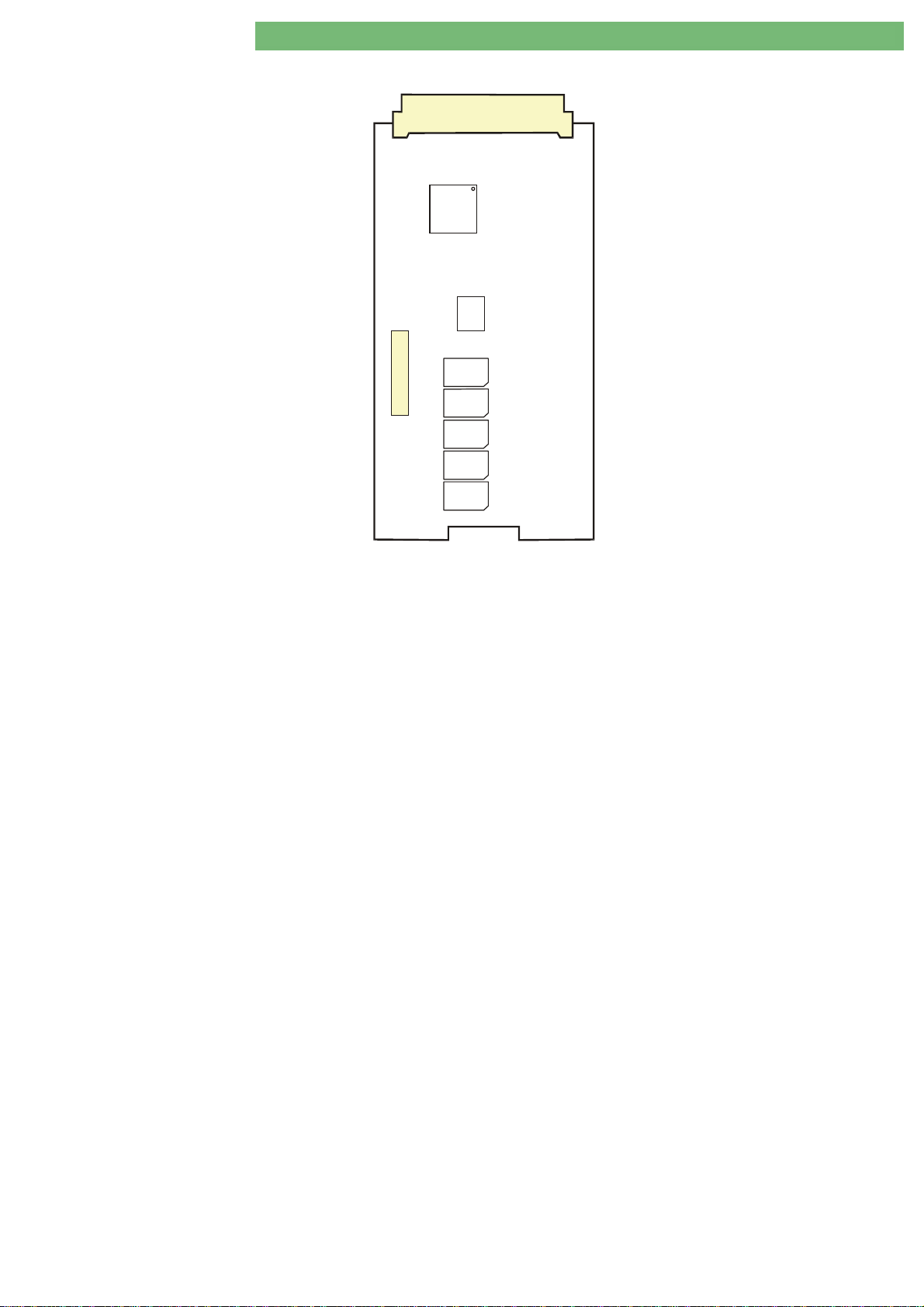

2. Technical System Description 1/2010 2 - 12

2.8 HDF Online Board HOB

P1

U2

U5

P4

Fig. : HDF Online Board

2.8.1 Legend HDF Online Board

Sensors:

P1:

PSABFS, PSAUS, PSPOSS, FEHDFS, FEDFFS P4

: Valves

VBE, VDFF, VSAA, VSAE, VSB

BA-TE-DE08C M.KAY

Dialog+ SW 9xx_sm_C ha pter 2_1-2010.doc/pdf < 100329> yymmdd

B. Braun Avitum AG

Page 26

+

Dialog

SW 9.xx

2.9 UF Sub-Rack

MSBKB1/2

2. Technical System Description 1/2010 2 - 13

VDEBK1

VDA

VLA

VEBK1

LA

VABK2

MSBK2

VDEBK2

DDE

RVFPA

VLA

VBP

VEBK2

LA

VABK1

VDABK2

VABK1

VBP

DDE

RVFPA

VDEBK2

MSBKB1/2

VABK2

VDEBK1

Fig. : UF Sub-Rack

2.9.1 Legend UF Sub-Rack

Balance Chamber BK1/2

Bypass Valve VBP

Throttle Dialyser Inlet DDE

Air Separator LA

Membrane Position Sensor Balance Chamber Board MSBKB1/2

Membrane Position Sensor Balance Chamber MSBK1/2

Non-Return Valve Outlet Flow Pump RVFPA

Outlet Balance Chamber Valve VABK1

VBP

VBPVBP

LA

LALA

BK1/2

BK1/2BK1/2

DDE

DDEDDE

VABK1

VABK1VABK1

RVFPA

RVFPARVFPA

VDA

MSBKB1/2

MSBKB1/2MSBKB1/2

MSBK1/2

MSBK1/2MSBK1/2

VEBK1

Outlet Balance Chamber Valve VABK2

Outlet Dialyser Balance Chamber Valve VDABK1

Outlet Dialyser Balance Chamber Valve VDABK2

Inlet Dialyser Balance Chamber Valve VDEBK1

Inlet Dialyser Balance Chamber Valve VDEBK2

Inlet Balance Chamber Valve VEBK1

Inlet Balance Chamber Valve VEBK2

Air Separator Valve VLA

VDABK1

VEBK1

VEBK1VEBK1

VEBK2

VEBK2VEBK2

VLA

VLAVLA

VABK2

VABK2VABK2

VDABK1

VDABK1VDABK1

VDABK2

VDABK2VDABK2

VDEBK1

VDEBK1VDEBK1

VDEBK2

VDEBK2VDEBK2

BA-TE-DE08C M.KAY

Dialog+ SW 9xx_sm_C ha pter 2_1-2010.doc/pdf < 100329> yymmdd

B. Braun Avitum AG

Page 27

Dialog

+

SW 9.xx

2. Technical System Description 1/2010 2 - 14

2.10 UF Sub-Rack HDF Online

VBE

MSBKB1/2

VABK2

MSBK2

VDEBK2

DDE

VDEBK1

VDABK2

VDA

LA

HFB

VSB

VEBK1

VSAE

VSAA

VSAE

VEBK2

VBP

VABK1

VSAA

VABK1

VLA

LA

DDE

RVFPA

VDEBK2

RVFPA

Fig. : UF Sub-Rack HDF Online

2.10.1 Legend U F Sub-Rack HDF Online

Balance Chamber BK1/2

Bypass Valve VBP

Throttle Dialyser Inlet DDE

Hydrophobic Vent Filter HFB

Air Separator LA

Membrane Position Sensor Balance Chamber Board MSBKB1/2

Membrane Position Sensor Balance Chamber MSBK1/2

Non-Return Valve Outlet Flow Pump RVFPA

Outlet Balance Chamber Valve VABK1/2

VBP

VBPVBP

LA

LALA

BK1/2

BK1/2BK1/2

DDE

DDEDDE

HFB

HFBHFB

VLA

VABK1/2

VABK1/2VABK1/2

VBP

RVFPA

RVFPARVFPA

VDA

MSBKB1/2

MSBKB1/2MSBKB1/2

MSBK1/2

MSBK1/2MSBK1/2

HFB

VEBK1

MSBKB1/2

VABK2

VDEBK1

VBE

VDABK1

VSB

Outlet Dialyser Balance Chamber Valve VDABK1/2

Inlet Dialyser Balance Chamber Valve VDEBK1/2

Inlet Balance Chamber Valve VEBK1/2

Air Separator Valve VLA

Additional Co

Substitute Bypass Valve VSB

Substitute Connection Outlet Valve VSAA

Substitute Connection Inlet Valve VSAE

Filter Vent Valve VBE

VLA

VLAVLA

mponents

mponents

mponents mponents

VBE

VBEVBE

VEBK1/2

VEBK1/2VEBK1/2

for HDF Online:

VSB

VSBVSB

VDABK1/2

VDABK1/2VDABK1/2

VDEBK1/2

VDEBK1/2VDEBK1/2

VSAA

VSAAVSAA

VSAE

VSAEVSAE

BA-TE-DE08C M.KAY

Dialog+ SW 9xx_sm_C ha pter 2_1-2010.doc/pdf < 100329> yymmdd

B. Braun Avitum AG

Page 28

+

Dialog

SW 9.xx

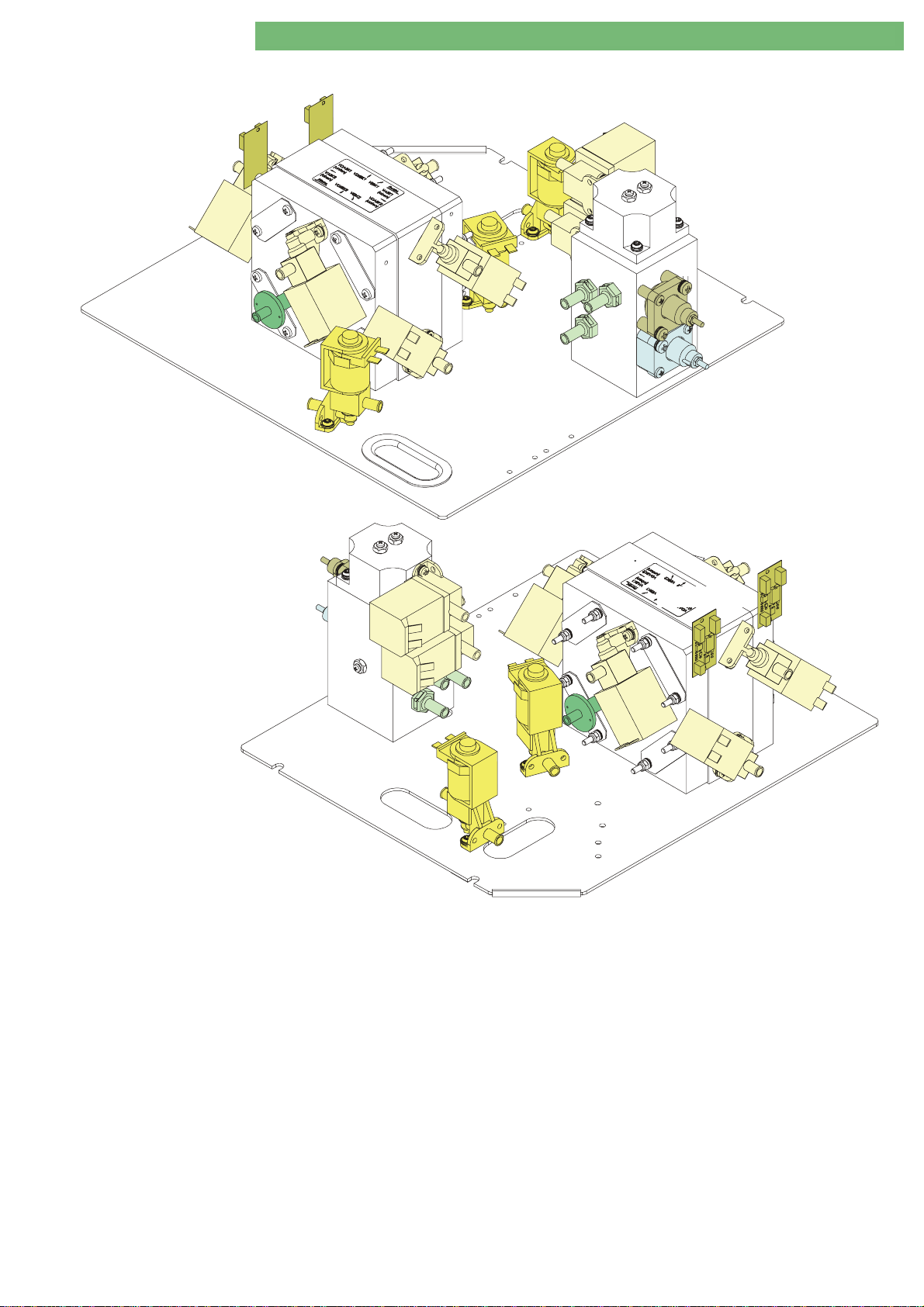

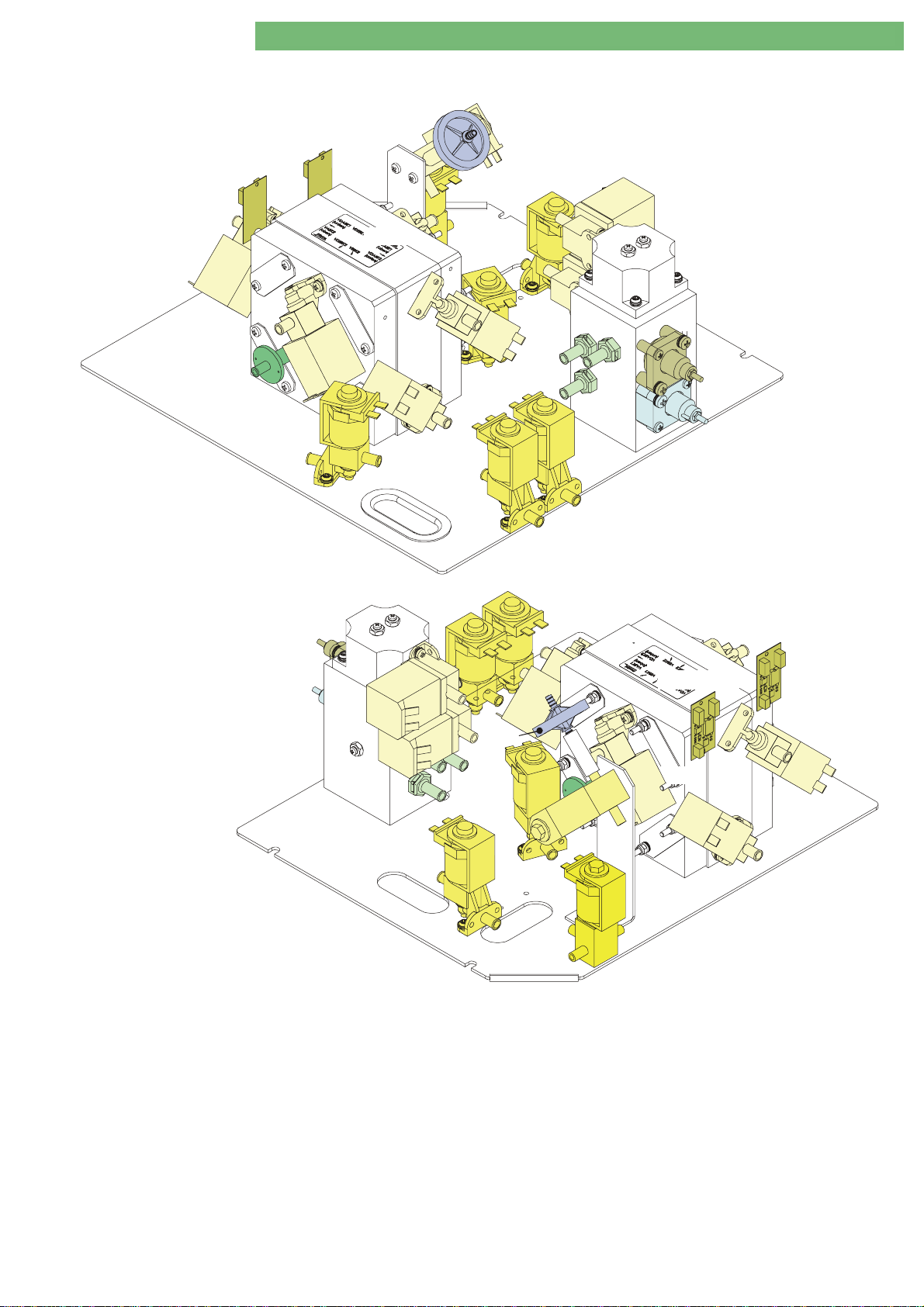

2.11 DF Sub-Rack

2. Technical System Description 1/2010 2 - 15

A

FPA

FPE

KP

ENDLF

BICLF

RVK

TSDS

RVFPE

RVB

BICP

UFP

KP

RFUFP

BICP

RVB

Fig. : DF Sub-Rack

2.11.1 Legend DF Sub-Rack

RVK

UFP

BICLF

TSBIC

ENDLF

TSD

FPE

A

FPA

BIC Pump BICP

Degassing Pressure Sensor PE

END Conductivity/Supervisor ENDLF/ENDLF-S

Outlet Flow Pump FPA

Inlet Flow Pump FPE

Concentrate Pump KP

Bicarbonate Conductivity Sensor BICLF

Bicarbonate Non-Return Valve RVB

BA-TE-DE08C M.KAY

BICP

BICPBICP

PE

PEPE

ENDLF/ENDLF-S

ENDLF/ENDLF-SENDLF/ENDLF-S

FPA (Motor Cover AAAA)

FPAFPA

FPE (Motor Cover AAAA)

FPEFPE

KP

KPKP

BICLF

BICLFBICLF

RVB

RVBRVB

Dialog+ SW 9xx_sm_C ha pter 2_1-2010.doc/pdf < 100329> yymmdd

Non-Return Valve Flow Pump Inlet RVFPE

Non-Return Valve Concentrate RVK

Non-Return Valve UF Pump RFUFP

Bicarbonate Temperature Sensor TSBIC

Dialysate Temperature Sensor TSD

Dialysate Supervisor Temperature Sensor TSD-S

UF Pump UFP

UFP

UFPUFP

RVK

RVKRVK

RFUFP

RFUFPRFUFP

TSD

TSDTSD

RVFPE

RVFPERVFPE

TSBIC

TSBICTSBIC

TSD-S

TSD-STSD-S

B. Braun Avitum AG

Page 29

+

Dialog

SW 9.xx

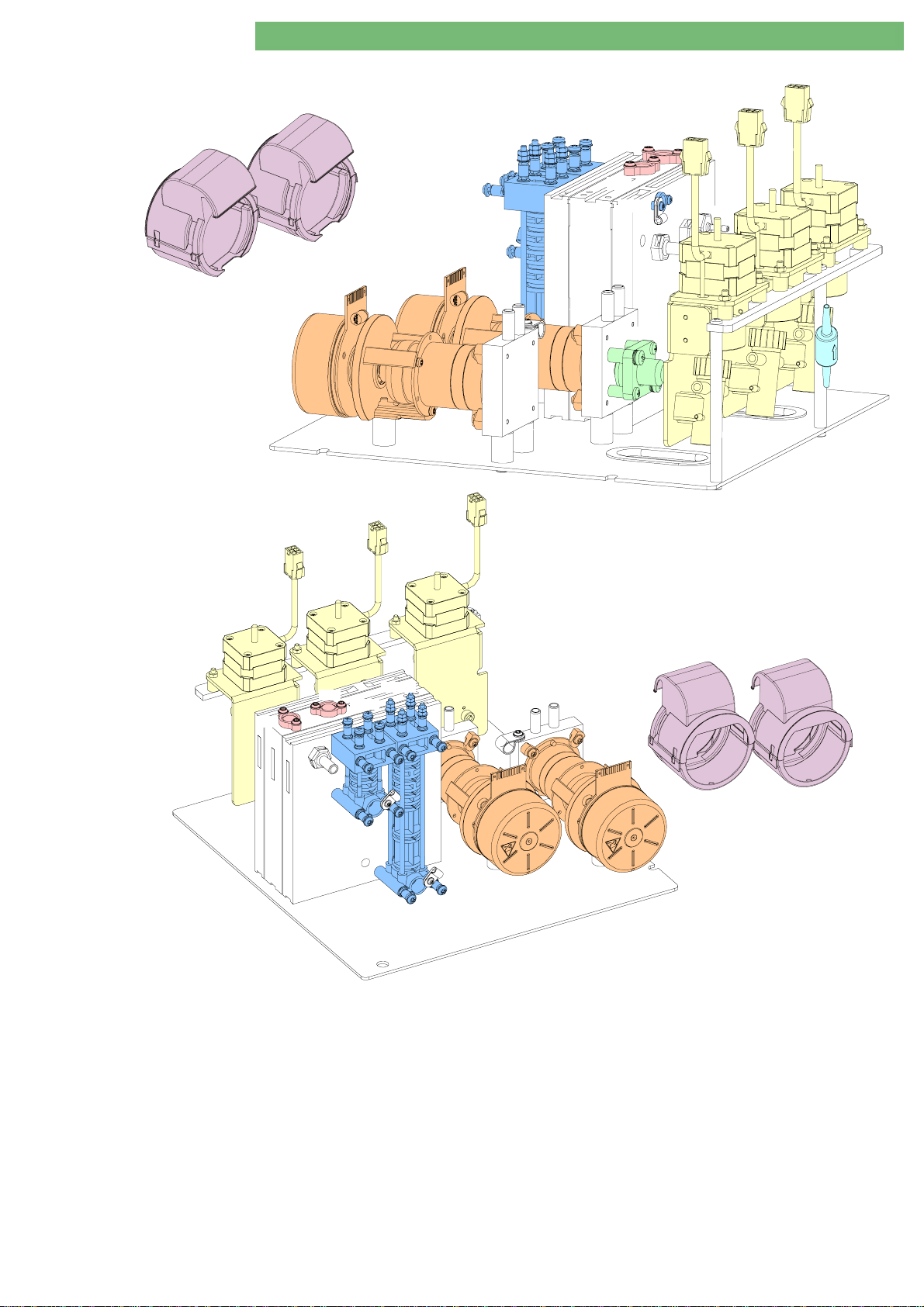

2.12 Water Sub-Rack

A

2. Technical System Description 1/2010 2 - 16

NSVB

WT

H

WAB

VEB

NSVB

VVBE

WT

EP

H

WA-Block

VZ

VEB

A

EP

RVDA

VBKS

VBICP

VZ

DBK

VBKO

VVB

VEB

DMV

PE

PE

Fig. : Water Sub-Rack Fig. : Water Block with Valves for BIC Option

2.12.1 Legend Wat er Sub -Ra c k

Water Block WAB

VB

VB and Heat Exchanger WT

VBVB

Pressure Reducer DMV

Degassing Pressure Sensor PE

Degassing Chamber EK

Degassing Pump EP

Heater HHHH

Degassing Temperature S e nso r TSE

Heater Temperature Sensor TSH

Heater Inlet Temperature Sensor TSHE

BA-TE-DE08C M.KAY

WAB (with integrated Degassing Chamber EK

WABWAB

WT)

WTWT

DMV

DMVDMV

PE

PEPE

EK

EKEK

EP (Motor Cover AAAA)

EPEP

TSE

TSETSE

TSH

TSHTSH

TSHE

TSHETSHE

Dialog+ SW 9xx_sm_C ha pter 2_1-2010.doc/pdf < 100329> yymmdd

EK, Upline Tank

EKEK

Upline Tank Inlet Valve VVBE

Upline Tank VB

Additional Components for Option BIC Cartridge:

Additional Components for Option BIC Cartridge:

Additional Components for Option BIC Cartridge:Additional Components for Option BIC Cartridge:

Throttle BIC Cartridge Holder DBK

BIC Concentrate Suction Rod Valve VBKS

Top BIC Cartridge Valve VBKS

BIC Pump Valve VBICP

Upline Tank Valve VVB

VB

VBVB

VBICP

VBICPVBICP

VVB

VVBVVB

VVBE

VVBEVVBE

VBKS

VBKSVBKS

DBK

DBKDBK

VBKS

VBKSVBKS

B. Braun Avitum AG

Page 30

+

Dialog

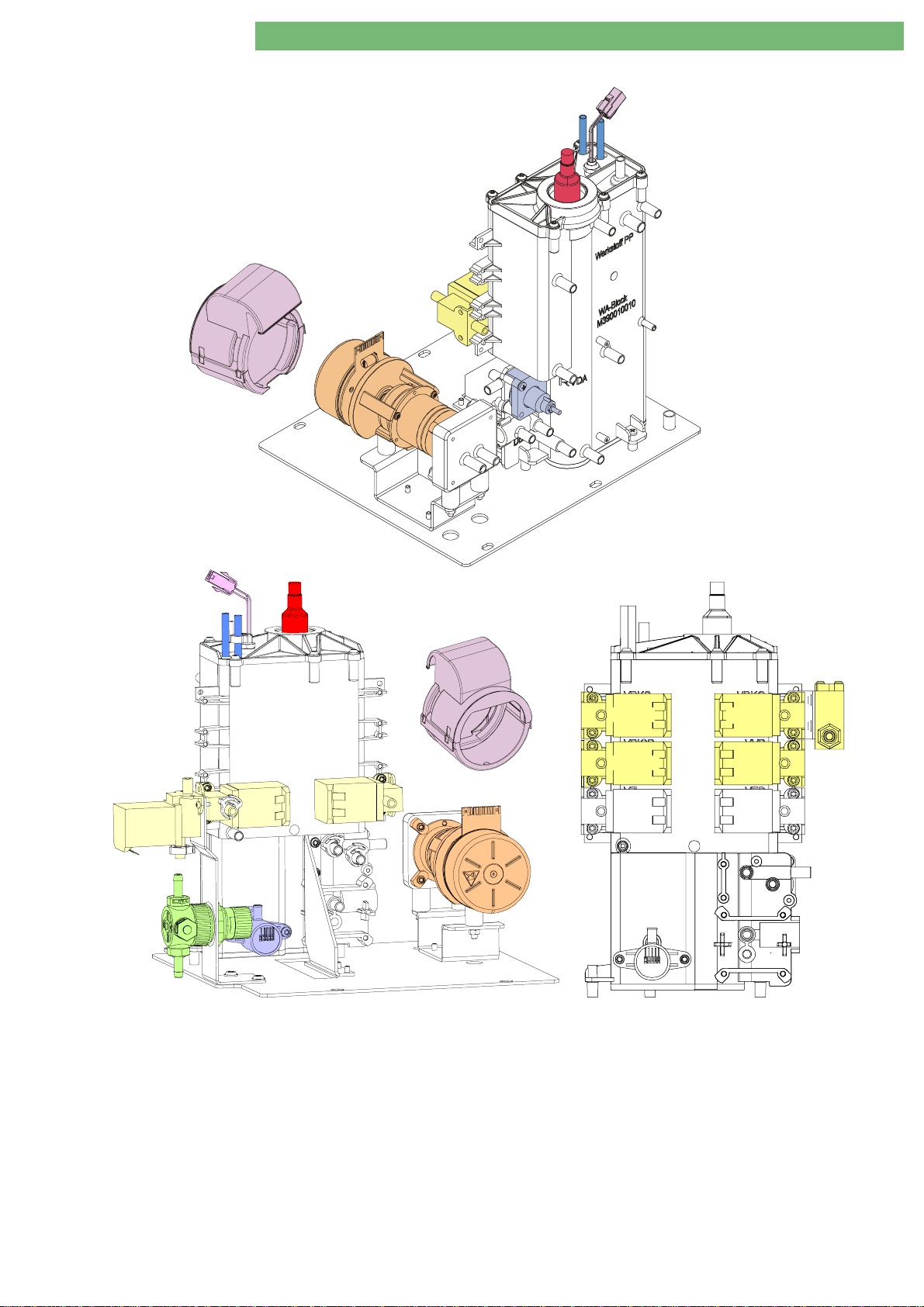

2.13 Rinsing Bridge

SW 9.xx

2. Technical System Description 1/2010 2 - 17

VD

Fig. : Rinsing Bridge

2.13.1 Legend Rinsing Bridge

1

23

PDA

54

TSDE

VDE

BL

1111 Disinfection Valve VD

2222 Pressure Sensor Dialysate Outlet PDA

3333 Dialyser Inlet Valve VDE

VD

VDVD

VDE

VDEVDE

PDA

PDAPDA

4444 Temperature Sensor Dialyser Inlet TSDE

5555 Blood Leak Detector BL

BL

BLBL

TSDE

TSDETSDE

BA-TE-DE08C M.KAY

Dialog+ SW 9xx_sm_C ha pter 2_1-2010.doc/pdf < 100329> yymmdd

B. Braun Avitum AG

Page 31

+

Dialog

SW 9.xx

2.14 Rear Door

2. Technical System Description 1/2010 2 - 18

3

12

4

Fig. : Rear Door

2.14.1 Legend Rear Doo r

Switch Mode Power Supply Microcontroller SMPS-MC

1.

2.

Fan

SMPS-MC

SMPS-MC

SMPS-MCSMPS-MC

Mains Switch

3.

Mains Cord

4.

BA-TE-DE08C M.KAY

Dialog+ SW 9xx_sm_C ha pter 2_1-2010.doc/pdf < 100329> yymmdd

B. Braun Avitum AG

Page 32

Dialog

+

SW 9.xx

2. Technical System Description 1/2010 2 - 19

2.15 Switch Mode Power Supply

Microcontroller SMPS-MC

P12

P10

P4

H401

H303

H301

H302

H304

H601

H602

H402

H403

F401

F303

F301

F302

F304

F601

F602

F402

F403

H104

-

H300

K3

F600

+

+24VGB / T3.15A TR5

+24 VGD / T3.15A TR5

H600

P5

X104

H900

P8

C115

+

K4

-

C114

+

+12VAN / T1.25A TR5

+24VL / M10.00A TR5

-

X100

XP3.2

XP3.1

X103

P2

P6

P9

P14

X903

GNDAKKU

+24VAKKU

P7

P11

X101

+12VD / T3.15A TR5

+5VD / T3.15A TR5

+5VD / T3.15A TR5

+5VD / T5.00A TR5

+5VD / T3.15A TR5

+12VD / T5.00A TR5

BENNING XXXXX XXXXXX XXXXXX

Netzgerät/Power Supply

NT-Dialog-MC

XXXXXXXX

SN/SNo: XXXXXXX Bj/Year: XX/XX

TN /Item-No:XXXX XX.5 Ver/SW: Rev 1.15

Opt.: Art/mode: XX/xx

Eingang/Input Ausgang/Output

Art/Kind AC DC

Hz 50-60

V 110/12 0/230/240

A 5/2,3

H401

H303

H301

H302

H304

H601

H602

H402

H403

F401

F303

F301

F302

F304

F601

F602

F402

F403

H300

F600

F1 T6.25A 6.3x32 (X1.1: L)

F2 T6.25A 6.3x32 (X1.1: L)

F5A 110/120V: F12A 6.3x32 (X1.6: HZG1-L)

230V: T6.25A 6.3x32 (X1.6: HZG1-L )

F5B 110/120V: F12A 6.3x32 (X1.7: HZG2-L)

230V: T6.25A 6.3x32 (X1.7: HZG2-L )

F6 110/120V: F20A 6.3x32 (X1 . 5: HZG-N)

230V: F12A 6.3x32 (X1.5: HZG-N)

F301 T3.15A TR5 (+5VD1)

F302 T5.0A TR5 (+5VD2)

F303 T3.15A TR5 (+5VD3)

F304 T3.15A TR5 (+5VD4)

F401 T3.15A TR5 (+12VD1)

F402 T5.00A TR5 (+12VD2)

F403 T1.25A TR5 (+12VA)

F600 M10.00A 6.3x32 (+24VL)

F601 T3.15A TR5 (+24VGB)

F602 T3.15A TR5 (+24VGD)

H600

F5A

F5B

X1.6

LH1 LH2

F2

F1

F6

X1.3

X1.5

N

X1.4

PE1

X1.1

X1.2

LNPE

X1.8

PE

X1.7

Fig. : Switch Mode Power Supply Microcontroller SMPS-MC

2.15.1 Legend Switch Mode Power Supply

Microcontroller

X1.1

X1.1 Mains Input L

X1.1X1.1

X1.2

X1.2 Mains Input N

X1.2X1.2

X1.3

X1.3 Mains Input PE

X1.3X1.3

X1.4

X1.4 Heater PE1

X1.4X1.4

X1.5

X1.5 Heater N

X1.5X1.5

X1.6

X1.6 Heater LH1

X1.6X1.6

X1.7

X1.7 Heater LH2

X1.7X1.7

X1.8

X1.8 PE

X1.8X1.8

P2

P2 Power Supply Control from Low Level Digital Board/Basic Board

P2P2

XP3

XP3 Battery Connection (Screw Terminal)

XP3XP3

P4

P4 24 V Voltages

P4P4

F1/F2

F1/F2 6.25 AT (6.3x32), Mains Input

F1/F2F1/F2

F5A/F5B

F5A/F5B 12 AF (6.3x32), Heater 1800 W (110/ 120 V )

F5A/F5BF5A/F5B

6.25 AT (6.3x32), Heater 1800 W (230/ 240 V )

F6

F6 20 AF (6.3x32), Heater 1800 W (110/120 V)

F6F6

12 AF (6.3x32), Heater 1800 W (230/ 240 V )

F301

F301 3.15 AT (TR5), +5 VD

F301F301

F302

F302 5.00 AT (TR5), +5 VD

F302F302

Type Plate SMPS-MC

TN/Item-No (Version Numb er SM P S-M C) :

TN/Item-No (Version Numb er SM P S-M C) : e.g. XXXXXX.5 Ver/SW (SW Version):

TN/Item-No (Version Numb er SM P S-M C) :TN/Item-No (Version Numb er SM P S-M C) :

P5

P5 12 V Voltages

P5P5

P7

P7 ABPM Option

P7P7

P8

P8 DSI Option

P8P8

P9

P9 Fan, Mains Switch

P9P9

P10

P10 Motherboard, Front Panel Board

P10P10

P12

P12 Options

P12P12

P13

P13 -

P13P13

P14

P14 EXT EIN

P14P14

P101

P101 Service Watchdog

P101P101

X100

X100 Fan

X100X100

F303/F304

F303/F304 3.15 AT (TR5), +5 VD

F303/F304F303/F304

F401

F401 3.15 AT (TR5), +12 VD

F401F401

F402

F402 5.00 AT (TR5), +12 VD

F402F402

F403

F403 1.25 AT (TR5), +12 VAN

F403F403

F600

F600 10 AM (6.3x32), +24 VL

F600F600

F601/F602

F601/F602 3.15 AT (TR5), +24 VGB

F601/F602F601/F602

Ver/SW (SW Version): e.g. Rev. 1.15

Ver/SW (SW Version):Ver/SW (SW Version):

BA-TE-DE08C M.KAY

Dialog+ SW 9xx_sm_C ha pter 2_1-2010.doc/pdf < 100329> yymmdd

B. Braun Avitum AG

Page 33

+

Dialog

SW 9.xx

2.16 TFT Monitor

2. Technical System Description 1/2010 2 - 20

Fig. : TFT Monitor

2.16.1 Legend TF T M onitor

Backlight Inverter Board

Front Panel Board

BA-TE-DE08C M.KAY

TFT Monitor

FPB

TFT

Dialog+ SW 9xx_sm_C ha pter 2_1-2010.doc/pdf < 100329> yymmdd

BIB

Optical Status Display Board

Touch Controller Board

Touch Screen

TCB

OSDB

B. Braun Avitum AG

Page 34

+

Dialog

SW 9.xx

2.17 Front Door

2. Technical System Description 1/2010 2 - 21

HP

PV PA PBS/SN PBE

SN

SN

PBA PBV

SAD

SAKV-SG

SAKA

SN

SAD

HP

PV PA

SN

PBA PBV

SAKASAKV-SG

2222

Fig. : Front Door with Double Pump Fig. : Front Door for HDF Online

1111

PBS/SN

PBE

2222

PA

LRM

HP

PV

SAD

SAKV-SG

PBE

2

22

LRP

PBS/SN

PBV

1111

LRP

PBE

PBV

22222

Fig. : Front Door (Inside) with Double Pump Fig. : Front Door (Inside) for HDF Online

PBS/SN

PBA

SAKA

PBA

SAKA

PA

LRM

HP

PV

SAD

SAKV-SG

2.17.1 Legend Front Door

Cover for Suction Rods 2222

Arterial Blood Pump BPA

Venous Blood Pump BPV

Pressure Sensor PBE

Pressure Sensor PBS/SN

PBE

PBEPBE

PBS/SN

PBS/SNPBS/SN

Arterial Pressure Sensor PA

Venous Pressure Sensor PV

BA-TE-DE08C M.KAY

Dialog+ SW 9xx_sm_C ha pter 2_1-2010.doc/pdf < 100329> yymmdd

BPA

BPABPA

BPV

BPVBPV

PA

PAPA

PV

PVPV

Heparin Pump Compact HP

Arterial Tubing Clamp SAKA

Venous Tubing Clamp Current Closed SAKV-SG

Safety Air Detector SAD

HP

HPHP

SAKA

SAKASAKA

SAKV-SG

SAKV-SGSAKV-SG

SAD/Venous Red Detector RDV

SADSAD

Substitution Port 1111

Connection for concentrat e S uct i o n R o d s 2222

B. Braun Avitum AG

RDV

RDVRDV

Page 35

Dialog

+

SW 9.xx

2. Technical System Description 1/2010 2 - 22

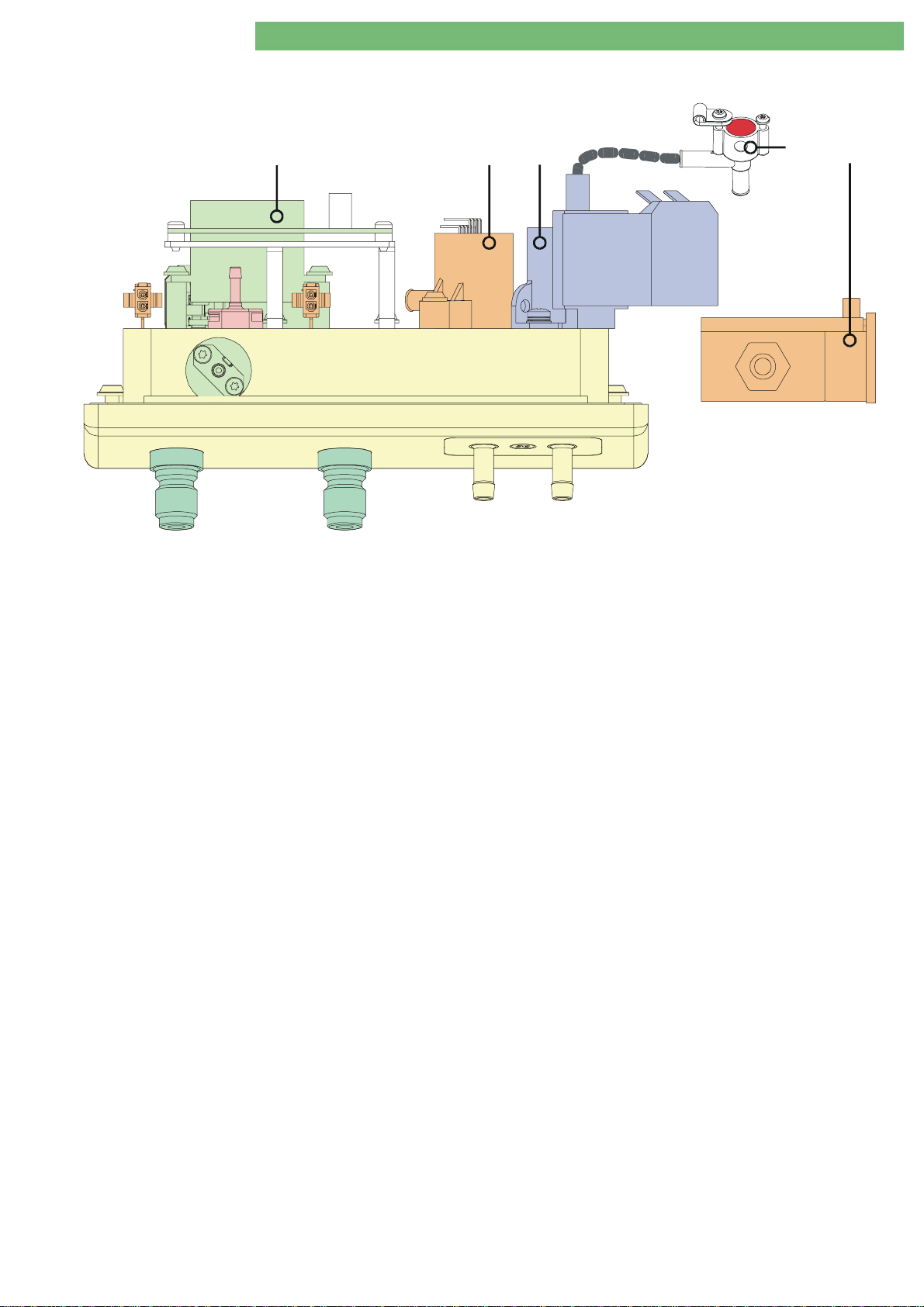

2.18 Level Regulation Module

HFE

PBS

PBE

LRP

HFS

HFP

P1

P2

V

P

E

V

P

D

V

P

U

V

P

V

P3

V

P

A

V

B

T

HFV

HFA

PV

PA

HFA

PA PV PBS PBE

HFV

PA

Fig. : Level Regulation Module and Level Regulation Pump

2.18.1 Legend Level Regula t ion Module

There are two level regulation modules with different assemblies, i.e. for machines with a sin gle blood pump and with a

double blood pump.

Inlet Pressure Sensor Valve VPE

Down Pressure Sensor Valve VPD

Up Pressure Sensor Valve VPU

Blood Control Pressure Sensor Valve VPS

Venous Pressure Sensor Valv e VPV

Arterial Pressure Sensor Valve VPA

Blood Side Test Pressure Sensor Valve VBT

PV PBE

VPE

VPEVPE

VPD

VPDVPD

VPU

VPUVPU

VPV

VPVVPV

VPA

VPAVPA

LRP

VPS (Double Pump)

VPSVPS

VBT

VBTVBT

HFS

IN

OUT

P

P

HFE

PBS

P

IN

P

OUT

Arterial Hydrophobic Filter HFA

Venous Hydrophobic Filter HFV

Blood Control Pressure Hydrophobic Filter HFS

(Double Pump)

Inlet Hydrophobic Filter HFE

Pump Hydrophobic Filter (Ceramic Filter) HFP

HFE

HFEHFE

HFA

HFAHFA

HFV

HFVHFV

HFS

HFSHFS

HFP

HFPHFP

BA-TE-DE08C M.KAY

Level Regulation Pump LRP

LRP

LRPLRP

Dialog+ SW 9xx_sm_C ha pter 2_1-2010.doc/pdf < 100329> yymmdd

B. Braun Avitum AG

Page 36

Dialog

+

SW 9.xx

2. Technical System Description 1/2010 2 - 23

2.18.2 Flow Diagram Level

Regulation

Module

Front Door

Outside

Inside

HFA

HFV

HFE

HFS

1

3

VBT

2

PA

PV

PBE

PBS

2

1

3

VPA

2

1

3

VPV

1

2

3

VPE

Level Module

1

3

1

3

VPD

VPU

HFP

P

IN

2

LRP

2

OUT

P

PA Chamber PV Chamber

Fig. : Flow Diagram Level Regulation Module

PBE Chamber

3/2 Way Solenoid Valve

There are two level regulation modules with different assemblies, i.e. for

machines with a single blood pump and with a double blood pump. The level

regulation module and the level regulation pump

inside of the rear door. The level regulation module and

functions;

Setting of the level in all blood side chambers (3/2 way solenoid valves

•

VPV, VPE, VPU, VPD

Monitoring of the blood side pressures (pressure sensors PA, PV,

•

)

PBS

Test of the blood side pressure sensors in preparation (3/2 way solenoid

•

valve

VBT

)

and diaphrag m pump

LRP

are assembled on the

LRP

have the following

LRP

)

PBE

VPA

and

,

BA-TE-DE08C M.KAY

Dialog+ SW 9xx_sm_C ha pter 2_1-2010.doc/pdf < 100329> yymmdd

B. Braun Avitum AG

Page 37

+

Dialog

SW 9.xx

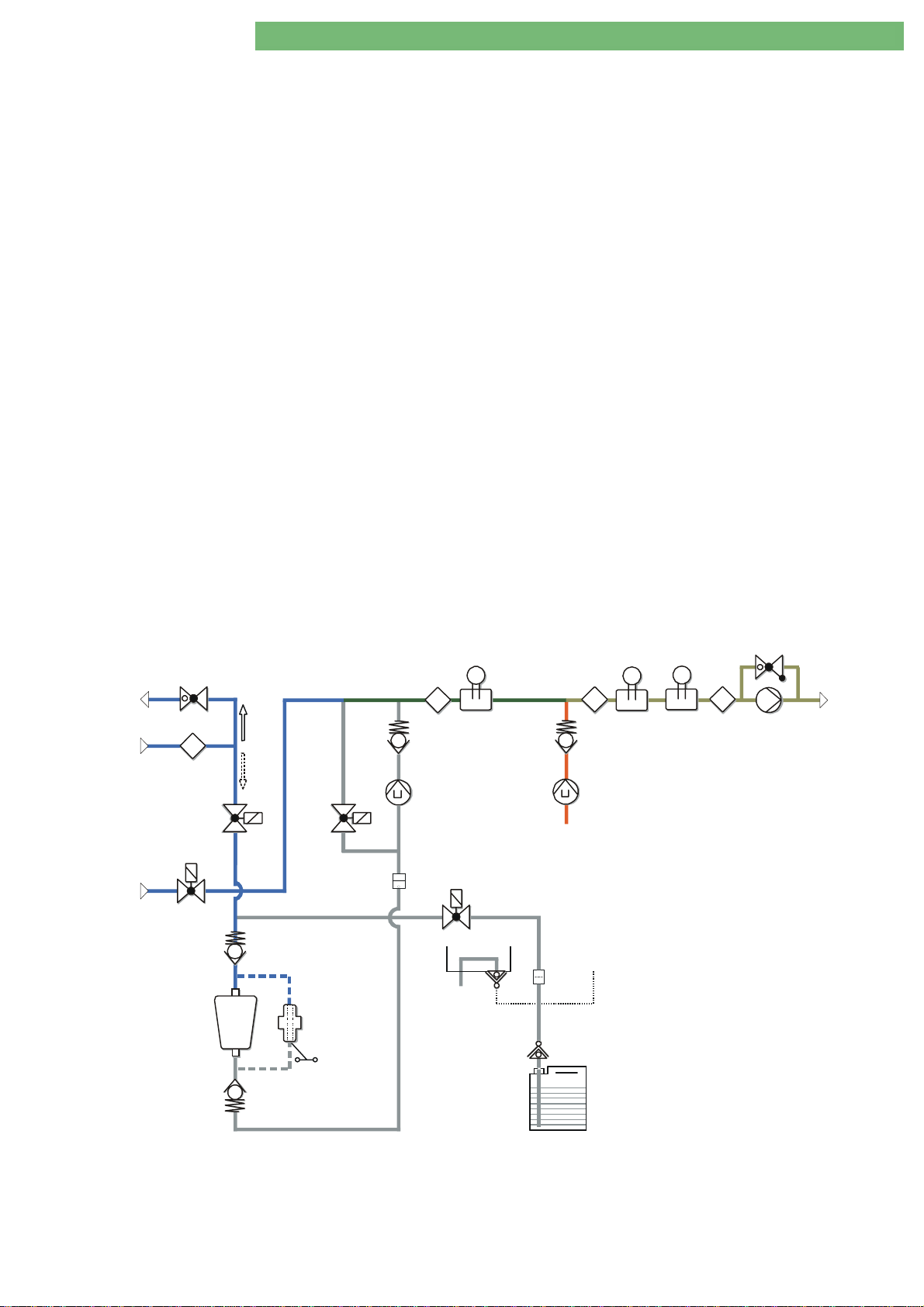

2.19 Flow Diagrams

2.19.1 Dialog+

2. Technical System Description 1/2010 2 - 24

V

Z.D.

PEV*

A

Dialyser

V.D.

FVD

SB1

SB2

Rinsing Bridge

UF Sub-Rac k

DF Sub-Rack

PDA

BL

T

VBP

VLA

LAFS

FBK2

VDABK2

VABK1

DDE VDETSDE

BK1

Balance Chamber

VDEBK1

8

RVFPE

FPE

TSD-S

ENDLF-S

ENDLFBICLFTSBIC

T T

TSD

T

VABK2

VDABK1

MSBK1

VEBK1

FBK1

RVK

VEBK2

VDEBK2

D

KP

C

SBS1

Air

VDA

LA

8

FPA

B

C

BK2

MSBK2

RVDA

SBS2

M

VD

LVD

RVFPA

UFP

RVUFP

Supply

KVABV A

Central Concentrate

KE

FKFB

KSS

VZ

SKKSSKBS

SS

BIC

BE

Supply

Central Bicarbonate

FD

(Unit Rear)

Disinfectant

KE

Acid Concentrate

BE

BIC Concentrate

KSB KSK

Disinfectant

Blood Venous

Housing

Dialysate Outlet

Water Inlet

BA-TE-DE08C M.KAY

AB

RVB

BICP

T

TSE

WAB

T

H

NSVB

Water Sub-Rack

VB WT

DMV

VVBE

EK

TSH

PE

T

A

D

TSHE

FEP

Dialog+ SW 9xx_sm_C ha pter 2_1-2010.doc/pdf < 100329> yymmdd

Air

Dialysate Flow 2

Dialysate

Blood Arterial

8

EP

VEB

Bicarbonate

Water

Concentrate

Dialysate Flow 1

B. Braun Avitum AG

Page 38

Dialog

+

SW 9.xx

2. Technical System Description 1/2010 2 - 25

2.19.2 Dialog+ with BIC Option and DF Filter Option

VA

Z.D.

PEV*

Dialyser

V.D.

FVD

SB1

SB2

SBS1

M

VD

Air

VDA

LA

8

FPA

B

C

BK2

RVDA

VLA

VABK2

VDEBK2

PDA

BL

LAFS

FBK2

VDABK2

MSBK2

VEBK2

RVFPE

TSDE

DF Filter *

DDE

VDE

T

VBP

VABK1

VDABK1

BK1

Balance Chamber

TSD-S

MSBK1

VEBK1

VDEBK1

FBK1

8

FPE

T

ENDLF-S

Rinsing Bridge

Rear DoorWater Sub-Rack

SBS2

LVD

RVFPA

UFP

RVUFP

Supply

KVA

Central Conc en tr a te

KE

FKFB

KSS

VZ

SKKSSKBS

FD

(Unit Rear)

Disinfectant

KE

Acid Concentrate

*

ENDLFBICLFTSBIC

WAB

VB WT

EK

D

C

RVK

AB

RVB

T

KP

Kt/V-UV*

BICP

VBICP*

VBKO*

TSH

T

A

D

TSHE

PE

FEP

T

TSD

DF Sub-Rack UF Sub-Rack

DBK*

Dialysate Outlet

Water Inlet

DMV

VVBE

T

T

TSE

H

NSVB

SS

BIC

VBKS

BVA

FBIC

RVBO*

VVB*

8

EP

VEB

BE

BIC Co n centr ate

BE

Supply

Central Bi car b ona t e

KSB KSK

Disinfectant

Blood Venous

SPA

BKUS

Dialysate Flow 2

RVBU

Water

Housing

Options

Air

Dialysate

Bicarbonate

Blood Arter ial

Concentrate

Dialysate Flow 1

BA-TE-DE08C M.KAY

Dialog+ SW 9xx_sm_C ha pter 2_1-2010.doc/pdf < 100329> yymmdd

B. Braun Avitum AG

Page 39

Dialog

+

SW 9.xx

2. Technical System Description 1/2010 2 - 26

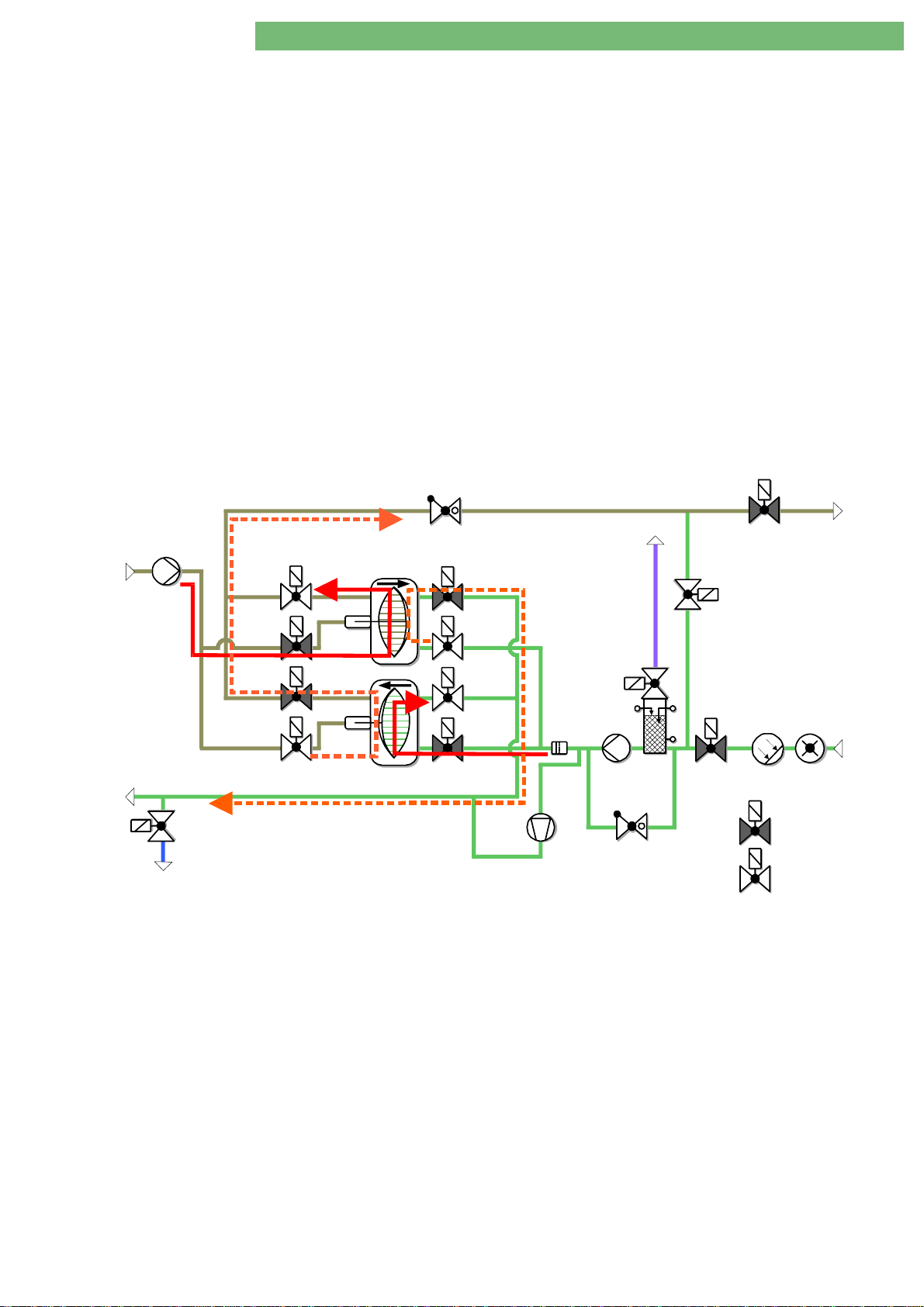

2.19.3 Dialog+ HDF Online

PSAUS

VSAEVSB

Front Door

PSABF

VSAA

FSU

VA

Z.D.

PEV*

Dialyser

V.D.

FVD

SB1

SB2

HFB

PDA

VDE

Rinsing Bridge

T

VBP

TSDE

VBE

HDF Filter

DF Filter

Rear Door

UF Sub-Rack

DDE

VDFF

VABK1

VDABK1

BK1

Balance Chamber

RVFPE

TSD-S

MSBK1

VEBK1

VDEBK1

FBK1

8

FPE

T

ENDLF-SENDLF

BL

VLA

LAFS

FBK2

VDABK2

VABK2

VEBK2

VDEBK2

SBS1

Air

VDA

LA

8

FPA

B

C

BK2

MSBK2

RVDA

SBS2

M

VD

LVD

RVFPA

UFP

RVUFP

Supply

KVABVA

Central Concentra te

KE

FK

KSS

VZ

SKKSSKBS

FD

(Unit Rear)

Disinfectant

KSK

KE

Acid Concentrate

*

FB

SS

FEP

BIC

VBKS

FBIC

RVBO*

VVB*

8

EP

VEB

T

TSD

DF Sub-Rack

DBK*

Dialysate Outlet

Water Sub-Rack

Water Inlet

DMV

VVBE

BICLFTSBIC

T

T

TSE

H

NSVB

WT

VB

EK

RVK

RVB

WAB

KP

CD

AB

BICP

VBICP*

T

TSH

T

A

D

PE

Kt/V-UV*

TSHE VBKO*

BE

BIC Concentrate

BE

Supply

Central Bicarbonate

KSB

Disinfectant

Blood Venous

SPA

BKUS

Dialysate Flow 2

RVBU

Water

Housing

Options

AirConcentrate

Dialysate

Bicarbonate

Blood Arterial

Dialysate Flow 1

BA-TE-DE08C M.KAY

Dialog+ SW 9xx_sm_C ha pter 2_1-2010.doc/pdf < 100329> yymmdd

B. Braun Avitum AG

Page 40

Dialog

+

SW 9.xx

2. Technical System Description 1/2010 2 - 27

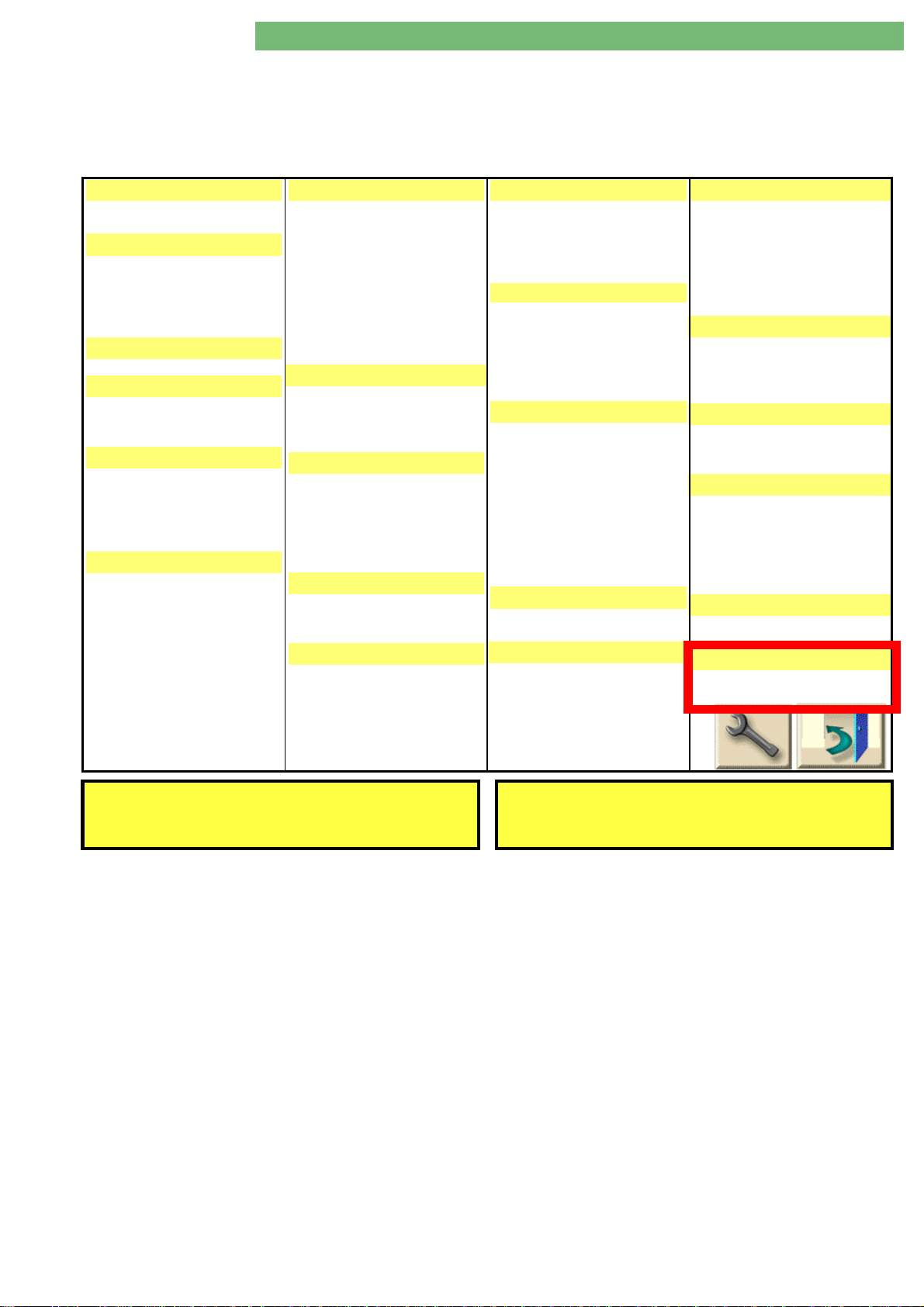

2.19.4 Legend Flow Diagram

Abbreviation

BE

BICLF

BICP

BICSS

BK1

BK2

BL

BPA

BPV

BVA

DBK

DDE

DMV

EK

ENDLF

ENDLF-S

EP

FB

FBIC

FBK1

FBK2

FEP

FK

FM

FPA

FPE

FVD

H

HP

KE

KP

KSB

KSK

KSS

KVA

LA

LAFS

LVD

MSBK1

MSBK2

NSVB

PA

PBE

PBS

PDA

PE

Bicarbonate Withdrawal

Bicarbonate Conductivity

Bicarbonate Pump

Bicarbonate Rinsing Connection Sensor

Balance Chamber 1

Balance Chamber 2

Blood Leak Detector

Arterial Blood Pump

Venous Blood Pump

Bicarbonate Supply Connection (Central Supply)

Throttle Bicarbonate Cartridge Holder

Throttle Dialyser Inlet

Pressure Reducer Valve

Degassing Chamber

END Conductivity

END Conductivity Supervisor

Degassing Pump

Filter Bicarbonate

Filter Bicarbonate Cartridge

Filter Balance Chamber 1

Filter Balance Chamber 2

Filter Degassing Pump

Filter Concentrate

Flowmeter

Outlet Flow Pump

Inlet Flow Pump

Filter from Dialysate

Heater

Heparin Syringe Pump

Concentrate Withdrawal

Concentrate Pump

Bicarbonate Rod

Concentrate Rod

Concentrate Rinsing Connector Sensor

Concentrate Supply Connector (Central Supply)

Air Separator

Air Separator Level Sensors

Light Barrier Disinfection Valve

Membrane Position Sensor Balance Chamber 1

Membrane Position Sensor Balance Chamber 2

Level Sensor Upline Tank

Arterial Pressure Sensor

Pressure Sensor Blood Inlet

Blood Pressure Control Sensor

Pressure Sensor Dialysate Outlet

Degassing Pressure Sensor

Description

BA-TE-DE08C M.KAY

Dialog+ SW 9xx_sm_C ha pter 2_1-2010.doc/pdf < 100329> yymmdd

B. Braun Avitum AG

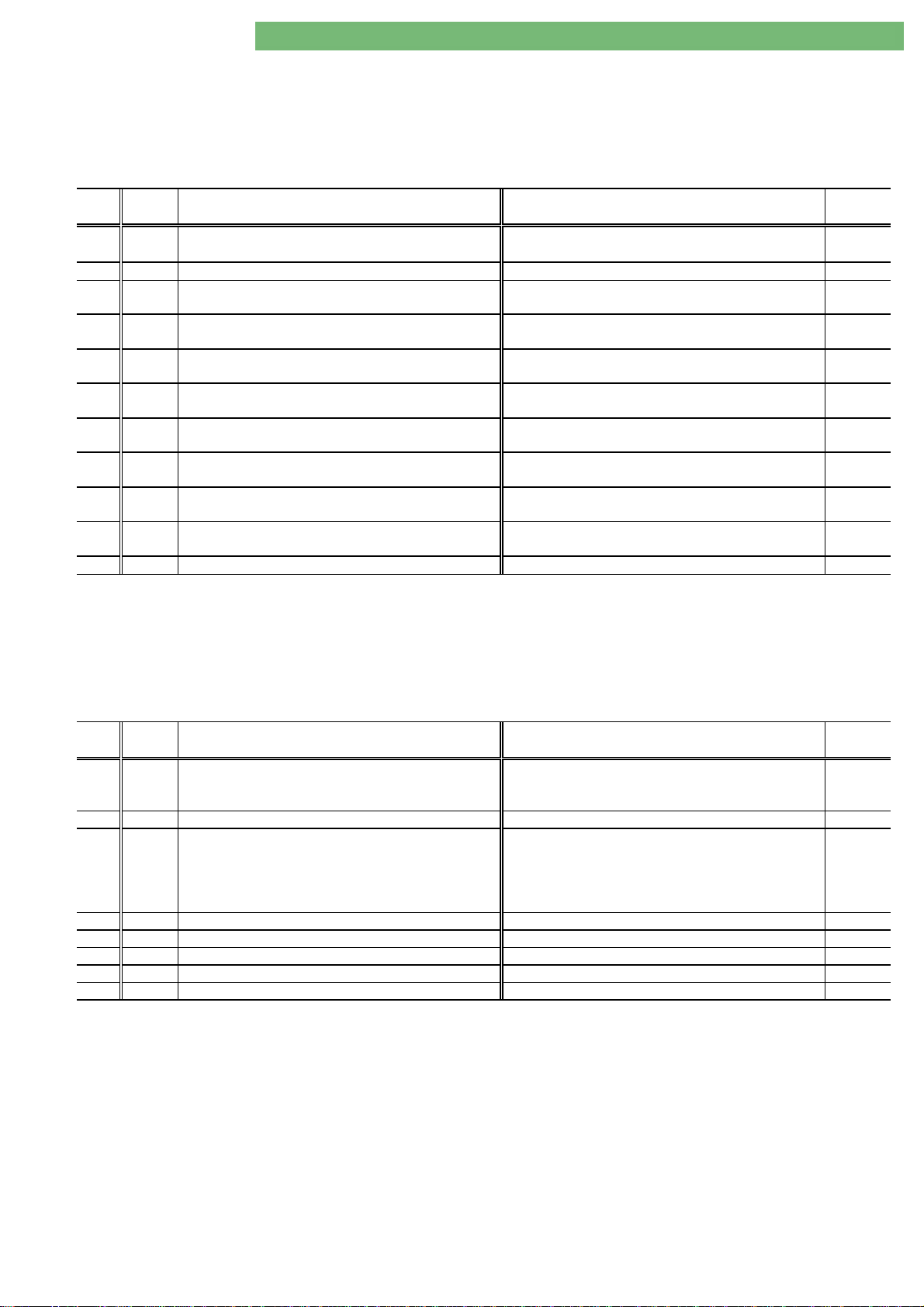

Page 41

Dialog

+

SW 9.xx

2. Technical System Description 1/2010 2 - 28

Venous Pressure Sensor

PV

RDV

RVB

RVDA

RVFPA

RVFPE

RVK

RFUFP

SAD

SAKA

SAKV-SD

SBS1

SBS2

TSBIC

TSD

TSDE

TSD-S

TSE

TSH

TSHE

UFP

VABK1

VABK2

VB

VBICP

VBKO

VBKS

VBP

V.D.

VD

VDA

VDABK1

VDABK2

VDE

VDEBK1

VDEBK2

VEB

VEBK1

VEBK2

VLA

VVB

VVBE

VZ

WA

WT

Z.D.

Venous Red Detector

Throttle Bicarbonate

Throttle Dialysate Valve

Throttle Flow Pump Outlet

Throttle Flow Pump Inlet

Throttle Concentrate

Throttle Ultrafiltration Pump

Safety Air Detector

Arterial Tubing Clamp

Venous Tubing Clamp Currentless Closed

Rinsing Bridge Connector Sensor 1

Rinsing Bridge Connector Sensor 2

Bicarbonate Temperature Sensor

Dialysate Temperature Sensor

Dialyser Inlet Temperature Sensor

Dialysate Temperature Sensor Supervisor

Degassing Temperature S ensor

Thermal Fuse Heater Element

Heater Inlet Temperature Sensor

Ultrafiltration Pump

Outlet Valve Balance Chamber 1

Outlet Valve Balance Chamber 2

Upline Tank

Bicarbonate Pump Valve

Bicarbonate Cartridge Holder Top Valve

Bicarbonate Cartridge Holder Concentrate Rod Valve

Bypass Valve

Dialyser Coupling (from Dialysate)

Disinfection Valve

Dialyser Outlet Valve

Dialyser Outlet Valve Balance Chamber 1

Dialyser Outlet Valve Balance Chamber 2

Dialyser Inlet Valve

Dialyser Inlet Valve Balance Chamber 1

Dialyser Inlet Valve Balance Chamber 2

Degassing Bypass Valve

Inlet Valve Balance Chamber 1

Inlet Valve Balance Chamber 2

Air Separator Valve

Upline Tank Valve

Upline Tank Inlet Valve

Circulation Valve

Water Block

Heat Exchanger

Dialyser Coupling (to Dialysate)

BA-TE-DE08C M.KAY

Dialog+ SW 9xx_sm_C ha pter 2_1-2010.doc/pdf < 100329> yymmdd

B. Braun Avitum AG

Page 42

Dialog

+

SW 9.xx

2. Technical System Description 1/2010 2 - 29

2.20 Description Flow Diagram

2.20.1 Water Inlet Section with Water

Block

The flow diagram can be divided into six sections:

Water Inlet Section with Water Block

•

Degassing Circuit with Temperatur e Sy stem

•

Dialysate Processing

•

Balance Chamber

•

Ultrafiltration

•

Rinsing Bridge

•

The water inlet section has the following components

Pressure Reducer Valve DMV

•

Upline Tank Inlet Valve VVVVVBE

•

Water Block WAB

•

NSVB

NSVB, Heat Exchanger WT

NSVBNSVB

WAB with integrated Upline Tank VB, Level Sensors Water Block

WABWAB

DMV

DMVDMV

VBE (2/2 way valve)

VBEVBE

WT, 2 double-stage Heater HHHH, Degassing Chamber EK

WTWT

EK

EKEK

Wate r Inlet

DMV

VVBE

EK

VB

WT

PE

A

D

TSHE

FEP

VEB

Dialysate Outlet

Pressure Reducer Valve DMV

Pressure Reducer Valve DMV

Pressure Reducer Valve DMVPressure Reducer Valve DMV

The pressure reducer valve DMV limits the pressure of the

inlet water (e.g. osmosis water) to 0.9 ±0.1 bar.

VLA

RVDA

SKBS

DBK*

H

NSVB

T

T

TSH

WAB

T

TSE

VBKO*

VVB*

TSBIC

VBICP*

Upline Tank Inlet Valve

Upline Tank Inlet Valve VVVVVBE

Upline Tank Inlet Valve Upline Tank Inlet Valve

The valve VVBE is time-delayed controlled via the level sensor

NSVB

NSVB (top) in the upline tank VB

NSVBNSVB

the dialysate flow.

Level Sensors Upline Tank NSVB

Level Sensors Upline Tank NSVB

Level Sensors Upline Tank NSVBLevel Sensors Upline Tank NSVB

The level sensors are mounted in the upline ta nk V B.

NSVB

NSVB top:

NSVBNSVB

closed - VVBE is closed

NSVB