Page 1

2. Technical System Description 1/2003 2 - 1

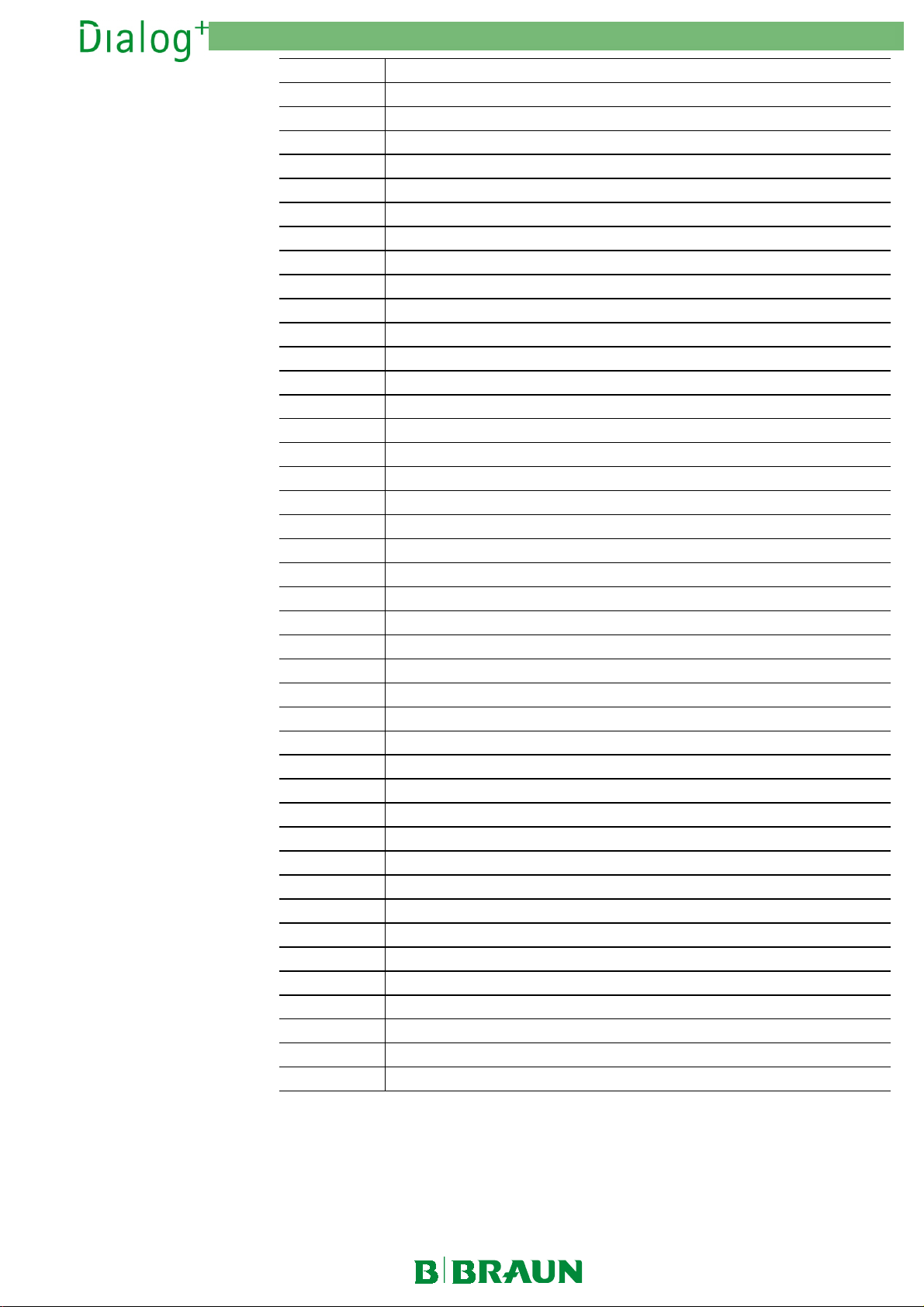

Table of Content s Page

General Information 2-7

2.1 Overview Sub-Racks 2-8

2.1.1 Legend Overview Sub-Racks 2-8

2.2 Top Level Sub-Rack 2-9

2.2.1 Legend Top Level Sub-Rack 2-9

2.3 UF Sub-Rack 2-10

2.3.1 Legend UF Sub-Rack 2-10

2.4 DF Sub-Rack 2-11

2.4.1 Legend DF Sub-Rack 2-11

2.5 Water Inlet Sub-Rack 2-12

2.5.1 Legend Water Inlet Sub-Rack 2-12

2.6 Rinsing Bridge 2-13

2.6.1 Legend Rinsing Bridge 2-13

2.7 Rear Door 2-14

2.7.1 Legend Rear Door 2-14

2.8 TFT Monitor 2-15

2.8.1 Legend TFT Monitor 2-15

2.9 Power Board 1 PB1 2-16

2.9.1 Legend Power Board 1 PB1 2-16

2.10 Power Board 2 PB2 2-17

2.10.1 Legend Power Board 2 PB2 2-17

2.11 Supervisor Board SB 2-18

2.11.1 Legend Supervisor Board SB 2-18

2.12 Controller Board CB 2-19

2.12.1 Legend Controller Board CB 2-19

2.13 Switch Mode Power Supply SMPS (Benning) 2-20

2.13.1 Legend Switch Mode Power Supply SMPS 2-20

2.14 Front Door 2-21

2.14.1 Legend Front Door 2-21

2.15 Flow Diagram 2-22

MT-MD-DE08C M.KAY

Dialog+_sm_Chapter 2_1-2003.doc/pdf <011003> ddmmyy

B. Braun Medizintechnologie GmbH

Page 2

2. Technical System Description 1/2003 2 - 2

2.15.1 Legend Flow Diagram 2-23

2.16 Description Flow Diagram 2-25

2.16.1 Water Inlet Section with Upline Tank 2-25

2.16.2 Degassing Circuit with Temperature System 2-26

2.16.3 Dialysate Processing 2-27

2.16.4 Central Bicarbonate and Concentrate Supply 2-28

2.16.5 BIC Cartridge Holder 2-28

2.16.6 Balance Chamber System 2-29

2.16.7 Working Principle Balance Chamber System 2-29

2.16.8 Ultrafiltration and Rinsing Bridge 2-31

2.16.9 Disinfection and Cleaning Program 2-31

2.17 Block Diagram 2-32

2.17.1 Legend Block Diagram 2-33

2.18 TFT Monitor 2-35

2.18.1 Description TFT Monitor 2-35

2.19 ABPM Option (Non-Invasive Blood Pressure Measurement) 2-37

2.19.1 Wiring Diagram ABPM Option 2-37

2.20 bioLogic RR Option (Automatic Blood Pressure Stabilisation) 2-38

2.21 Supervisor Board SB 2-39

2.21.1 Supervisor 2-39

2.21.1.1 Block Diagram Supervisor 2-39

2.21.1.2 Description Supervisor 2-39

2.22 Bicarbonate Conductivity Measurement 2-41

2.22.1 Block Diagram Bicarbonate Conductivity Measurement 2-41

2.22.2 Description Bicarbonate Conductivity Measurement 2-41

2.23 END Conductivity Measurement Controller 2-42

2.23.1 Description END Conductivity Measurement Controller 2-42

2.23.2 END Conductivity Measurement Supervisor 2-42

2.23.3 Block Diagram END Conductivity Measurement Supervisor 2-42

2.23.4 Description END Conductivity Measurement Supervisor 2-42

2.24 Temperature Measurement 2-43

2.24.1 Block Diagram Degassing Temperature Measurement 2-43

2.24.2 Design Degassing Temperature Measurement 2-43

2.24.3 Description Bicarbonate Temperature Measurement 2-43

MT-MD-DE08C M.KAY

Dialog+_sm_Chapter 2_1-2003.doc/pdf <011003> ddmmyy

B. Braun Medizintechnologie GmbH

Page 3

2. Technical System Description 1/2003 2 - 3

2.24.4 Description Dialysate Controller Temperature Measurement 2-43

2.24.5 Block Diagram Dialysate Supervisor Temperature

2-44

Measurement

2.24.6 Description Temperature Measurement Dialysate Supervisor 2-44

2.25 Level Measurement 2-44

2.25.1 Block Diagram Level Measurement Upline Tank 2-44

2.25.2 Description Level Measurement Upline Tank 2-44

2.26 Reed Contacts 2-45

2.26.1 Block Diagram Coupling Status 2-45

2.26.2 Description Coupling Status 2-45

2.27 Pressure Measurement 2-45

2.27.1 Block Diagram Venous Pressure Measurement 2-45

2.27.2 Description Venous Pressure Measurement 2-45

2.27.3 Block Diagram Arterial Pressure Measurement 2-46

2.27.4 Description Arterial Pressure Measurement 2-46

2.28 Blood Inlet Pressure Measurement 2-46

2.28.1 Block Diagram Blood Inlet Pressure Measurement 2-46

2.28.2 Description Blood Inlet Pressure Measurement 2-46

2.29 Level Sensors 2-47

2.29.1 Block Diagram Level Sensors Air Separator 2-47

2.29.2 Description Level Sensors Air Separator 2-47

2.30 Red Detector 2-47

2.30.1 Block Diagram Red Detector 2-47

2.30.2 Description Red Detector 2-47

2.31 Degassing Pressure Measurement and Dialysate Pressure

2-48

Measurement

2.31.1 Block Diagram Pressure Measurement 2-48

2.31.2 Description Pressure Measurement 2-48

2.32 Monitoring Analogue 12 V Voltage Supply 2-48

2.32.1 Block Diagram Monitoring of Analogue 12 V Voltage Supply 2-48

2.32.2 Description Monitoring of Analogue 12 V Voltage Supply 2-48

MT-MD-DE08C M.KAY

Dialog+_sm_Chapter 2_1-2003.doc/pdf <011003> ddmmyy

B. Braun Medizintechnologie GmbH

Page 4

2. Technical System Description 1/2003 2 - 4

2.33 Safety Air Detector SAD and Venous Red Detector RDV 2-49

2.33.1 Block Diagram SAD/RDV 2-49

2.33.2 General Information SAD 2-49

2.33.3 Description Safety Air Detector SAD 2-50

2.33.4 Description Venous Red Detector RDV 2-52

2.34 Blood Leak Detector 2-53

2.34.1 Block Diagram Blood Leak Detector 2-53

2.34.2 Description Blood Leak Detector 2-53

2.35 Controller Board CB 2-54

2.35.1 Block Diagram Controller Board 2-54

2.35.2 Description Controller Board 2-55

2.36 Power Board 1 PB1 2-57

2.36.1 Block Diagram Power Board 1 2-57

2.36.2 Description Power Board 1 2-57

2.37 Power Board 2 PB2 2-59

2.37.1 Block Diagram Power Board 2 2-59

2.37.2 Description Power Board 2 2-60

2.38 Heparin Pump Compact 2-62

2.38.1 Block Diagram Heparin Pump Compact 2-62

2.38.2 Description Heparin Pump Compact 2-62

2.39 Single Needle Cross Over 2-64

2.39.1 Block Diagram SN Cross Over 2-64

2.39.2 Description SN Cross Over 2-65

2.40 Staff Call (Option) 2-66

2.40.1 Block Diagram Staff Call 2-66

2.40.2 Description Staff Call 2-66

2.40.3 Operating Modes Staff Call System 2-67

2.40.4 Block Diagram Alarm Monitoring 2-67

2.40.5 Pin Assignment 2-67

2.41 Switch Mode Power Supply SMPS (Benning) 2-68

2.41.1 Block Diagram Switch Mode Power Supply 2-68

2.41.2 System Integration 2-69

2.41.3 Layout Switch Mode Power Supply SMPS 2-70

2.41.4 Wiring Diagram Switch Mode Power Supply SMPS with

Battery Option

2.41.5 Description Switch Mode Power Supply 2-72

MT-MD-DE08C M.KAY

Dialog+_sm_Chapter 2_1-2003.doc/pdf <011003> ddmmyy

2-71

B. Braun Medizintechnologie GmbH

Page 5

2. Technical System Description 1/2003 2 - 5

2.41.6 Pin Assignment Switch Mode Power Supply 2-72

2.42 Safety Concept 2-77

2.42.1 Block Diagram Safety Concept 2-77

2.42.2 Description Safety Concept 2-78

MT-MD-DE08C M.KAY

Dialog+_sm_Chapter 2_1-2003.doc/pdf <011003> ddmmyy

B. Braun Medizintechnologie GmbH

Page 6

2. Technical System Description 1/2003 2 - 6

with the options:

Double Pump

•

BIC Cartridge Holder

•

Central Concentrate Supply

•

MT-MD-DE08C M.KAY

Dialog+_sm_Chapter 2_1-2003.doc/pdf <011003> ddmmyy

B. Braun Medizintechnologie GmbH

Page 7

General Information

2. Technical System Description 1/2003 2 - 7

Operation is accomplished via a touch screen (TFT monitor). Two

microprocessor systems control and monitor the machine.

The hardware concept consists of the following systems:

Top Level System

•

Low Level System

•

Top Level System

Low Level System

The top level system consists of the following components:

Communication module

•

Top level controller TLC (motherboard)

•

Hard disk drive

•

Floppy disk drive

•

ABPM (option)

•

The communication between the user and the machine is performed via the

top level.

Example data exchange to communication module:

Entry via input mask of the touch screen or keyboard

•

Output via the output mask of the TFT monitor

•

Example data exchange to low level:

Transmitting and receiving of data from/to low level controller

•

The low level system consists of the following components:

Low level controller LLC

•

Supervisor SB

•

Power board PB1 and power board PB2

•

The low level controls and monitors all functions.

Example data exchange to top level controller:

Transmitting and receiving of data from/to low level controller

•

Example data exchange low level controller to supervisor:

Transmitting and receiving messages, data and commands from/to supervisor

•

All sensors are connected to the processor system via the supervisor board. The

actuators, motors and valves are driven via the power boards 1 and 2.

MT-MD-DE08C M.KAY

Dialog+_sm_Chapter 2_1-2003.doc/pdf <011003> ddmmyy

B. Braun Medizintechnologie GmbH

Page 8

2. Technical System Description 1/2003 2 - 8

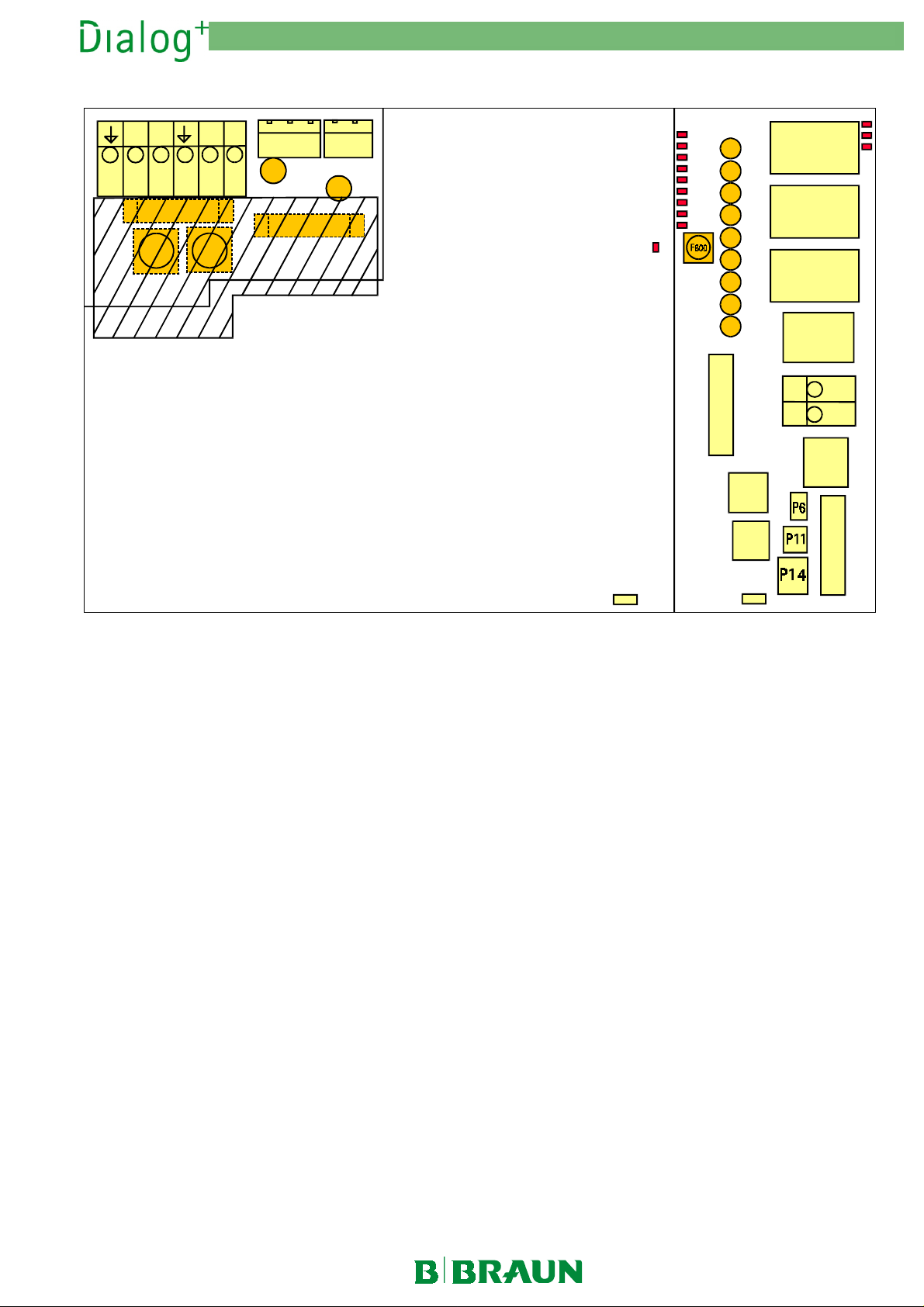

2.1 Overview Sub-Racks

Fig. : Overview Sub-Racks Rear View Dialog+

2.1.1 Legend Overview Sub-Racks

MT-MD-DE08C M.KAY

Dialog+_sm_Chapter 2_1-2003.doc/pdf <011003> ddmmyy

Top Level Sub-Rack

1

UF Sub-Rack

2

DF Sub-Rack

3

Water Inlet Sub-Rack

4

B. Braun Medizintechnologie GmbH

Page 9

2. Technical System Description 1/2003 2 - 9

2.2 Top Level Sub-Rack

12

Fig. : Top Level Sub-Rack

2.2.1 Legend Top Level Sub-Rack

1

1 Hard Disk Drive

11

2222 Motherboard

MT-MD-DE08C M.KAY

Dialog+_sm_Chapter 2_1-2003.doc/pdf <011003> ddmmyy

B. Braun Medizintechnologie GmbH

Page 10

2. Technical System Description 1/2003 2 - 10

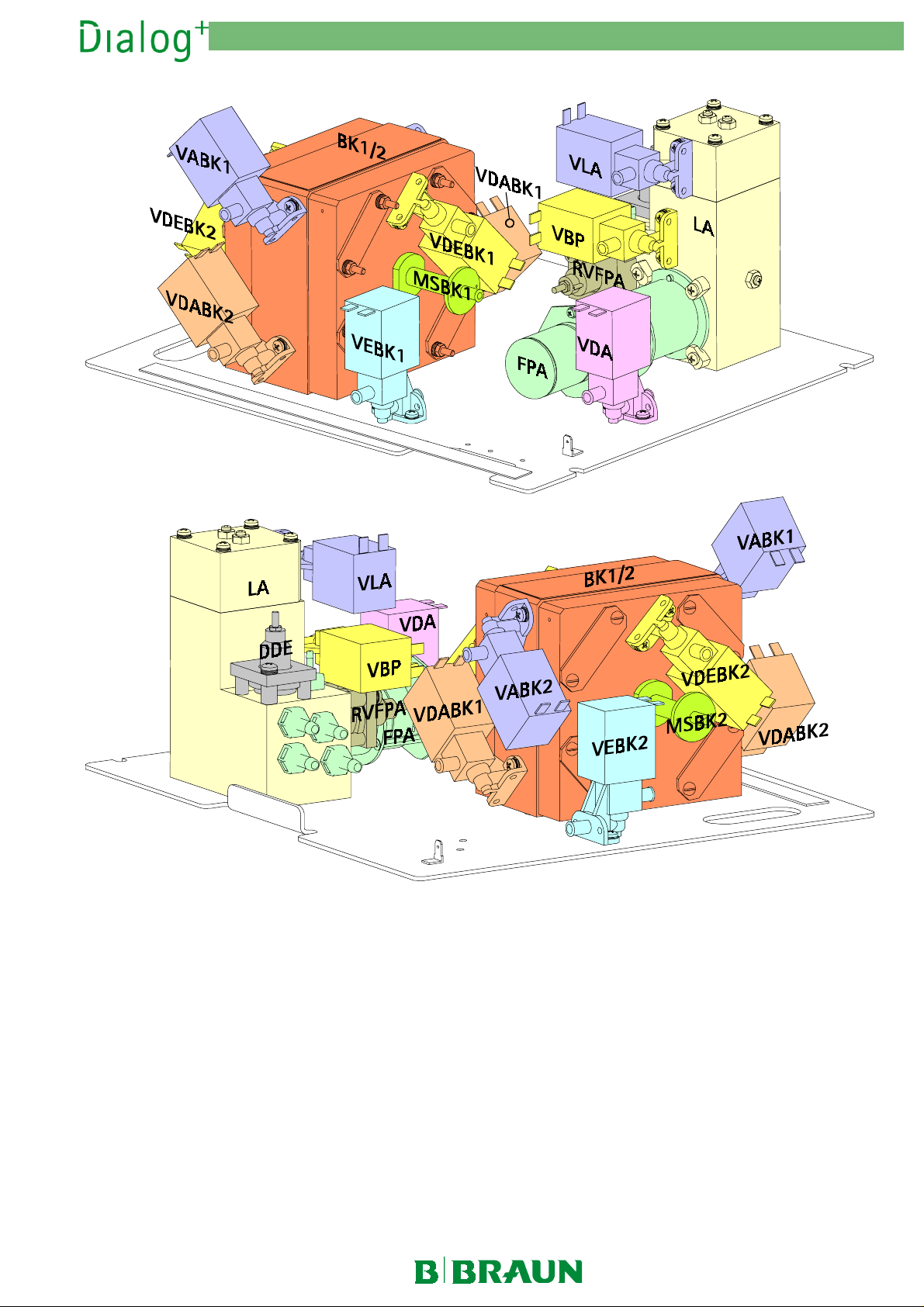

2.3 UF Sub-Rack

Fig. : UF Sub-Rack

2.3.1 Legend UF Sub-Rack

Air Separator LA

Air Separator Valve VLA

Balance Chamber BK1/2

Bypass Valve VBP

Dialyser Inlet Throttle DDE

Dialyser Inlet Valve VDEBK1

Dialyser Inlet Valve VDEBK2

Dialyser Outlet Valve Balance Chamber VABK1

MT-MD-DE08C M.KAY

Dialog+_sm_Chapter 2_1-2003.doc/pdf <011003> ddmmyy

LA

LALA

VBP

VBPVBP

VLA

VLAVLA

BK1/2

BK1/2BK1/2

VDEBK1

VDEBK1VDEBK1

VDEBK2

VDEBK2VDEBK2

DDE

DDEDDE

VABK1

VABK1VABK1

Dialyser Outlet Valve Balance Chamber VABK2

Dialyser Dialyser Outlet Valve Balance Chamber VDABK1

Dialyser Dialyser Outlet Valve Balance Chamber VDABK2

Inlet Valve Balance Chamber VEBK1

Inlet Valve Balance Chamber VEBK2

Membrane Position Sensor Balance Chamber MSBK1/2

Outlet Flow Pump FPA

Outlet Flow Pump Throttle RVFPA

FPA

FPAFPA

VEBK1

VEBK1VEBK1

VEBK2

VEBK2VEBK2

RVFPA

RVFPARVFPA

VABK2

VABK2VABK2

VDABK1

VDABK1VDABK1

VDABK2

VDABK2VDABK2

MSBK1/2

MSBK1/2MSBK1/2

B. Braun Medizintechnologie GmbH

Page 11

2. Technical System Description 1/2003 2 - 11

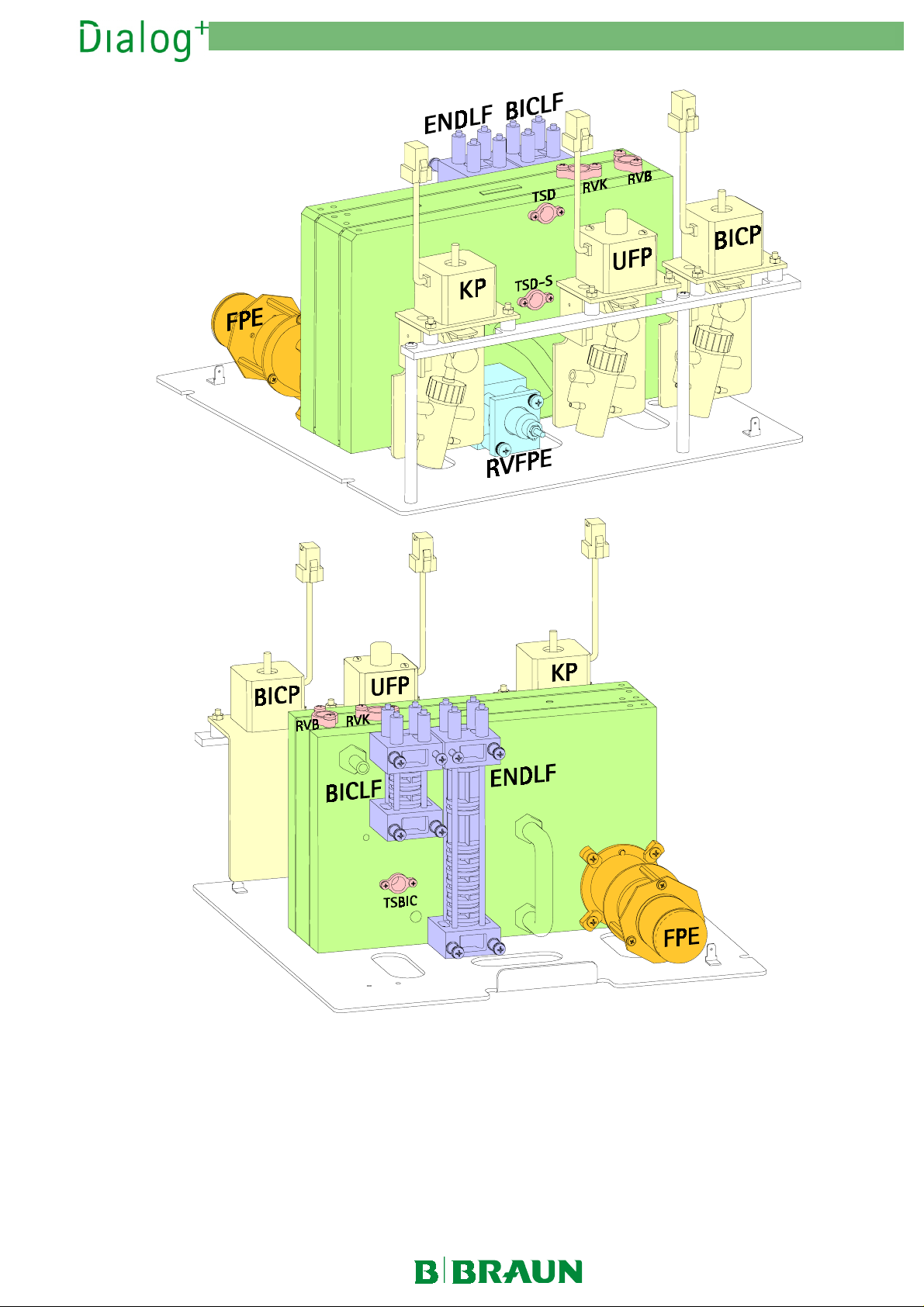

2.4 DF Sub-Rack

Fig. : DF Sub-Rack

2.4.1 Legend DF Sub-Rack

BIC Pump BICP

Bicarbonate Conductivity BICLF

Bicarbonate Temperature Sensor TSBIC

Bicarbonate Throttle RVB

Concentrate Pump KP

Concentrate Throttle RVK

Degassing Chamber EK

Degassing Control Valve RVE

MT-MD-DE08C M.KAY

Dialog+_sm_Chapter 2_1-2003.doc/pdf <011003> ddmmyy

BICP

BICPBICP

KP

KPKP

RVB

RVBRVB

EK

EKEK

RVK

RVKRVK

BICLF

BICLFBICLF

RVE

RVERVE

TSBIC

TSBICTSBIC

Degassing Pressure Sensor PE

Degassing Pump EP

Dialysate Temperature Sensor Supervisor TSD-S

Dialysate Temperature Sensor TSD

END Conductivity/Supervisor ENDLF/ENDLF-S

Inlet Flow Pump FPE

Inlet Flow Pump Throttle RVFPE

UF Pump UFP

UFP

UFPUFP

EP

EPEP

FPE

FPEFPE

PE

PEPE

TSD

TSDTSD

ENDLF/ENDLF-S

ENDLF/ENDLF-SENDLF/ENDLF-S

RVFPE

RVFPERVFPE

TSD-S

TSD-STSD-S

B. Braun Medizintechnologie GmbH

Page 12

2. Technical System Description 1/2003 2 - 12

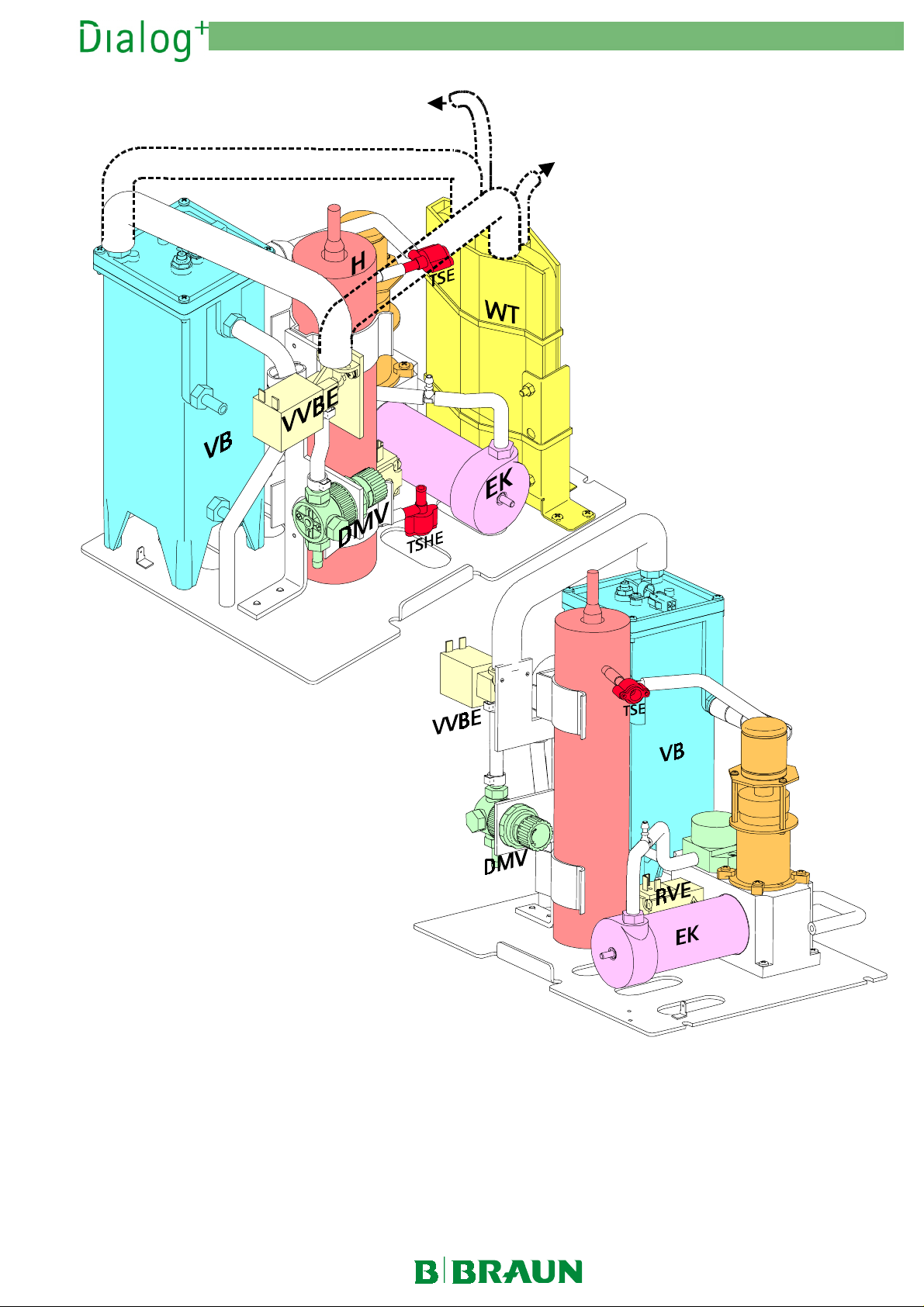

2.5 Water Inlet Sub-Rack

RVDA

Outlet

Ausgang

Fig. : Water Inlet Sub-Rack (with and without Heat Exchanger WT Option)

2.5.1 Legend Water Inlet Sub-Rack

Degassing Chamber EK

Degassing Control Valve RVE

Degassing Pressure Sensor PE

Degassing Pump EP

Degassing Temperature Sensor TSE

Heat Exchanger WT

EK

EKEK

RVE

RVERVE

EP

EPEP

WT (Option)

WTWT

PE

PEPE

TSE

TSETSE

H

PE

Heater HHHH

Heater Inlet Temperature Sensor TSHE

Heater Temperature Sensor TSH

Pressure Reducer Valve DMV

Upline Tank Inlet Valve VVBE

Upline Tank VB

VB

VBVB

DMV

DMVDMV

VVBE

VVBEVVBE

TSH

TSHTSH

TSHE

TSHETSHE

EP

MT-MD-DE08C M.KAY

Dialog+_sm_Chapter 2_1-2003.doc/pdf <011003> ddmmyy

B. Braun Medizintechnologie GmbH

Page 13

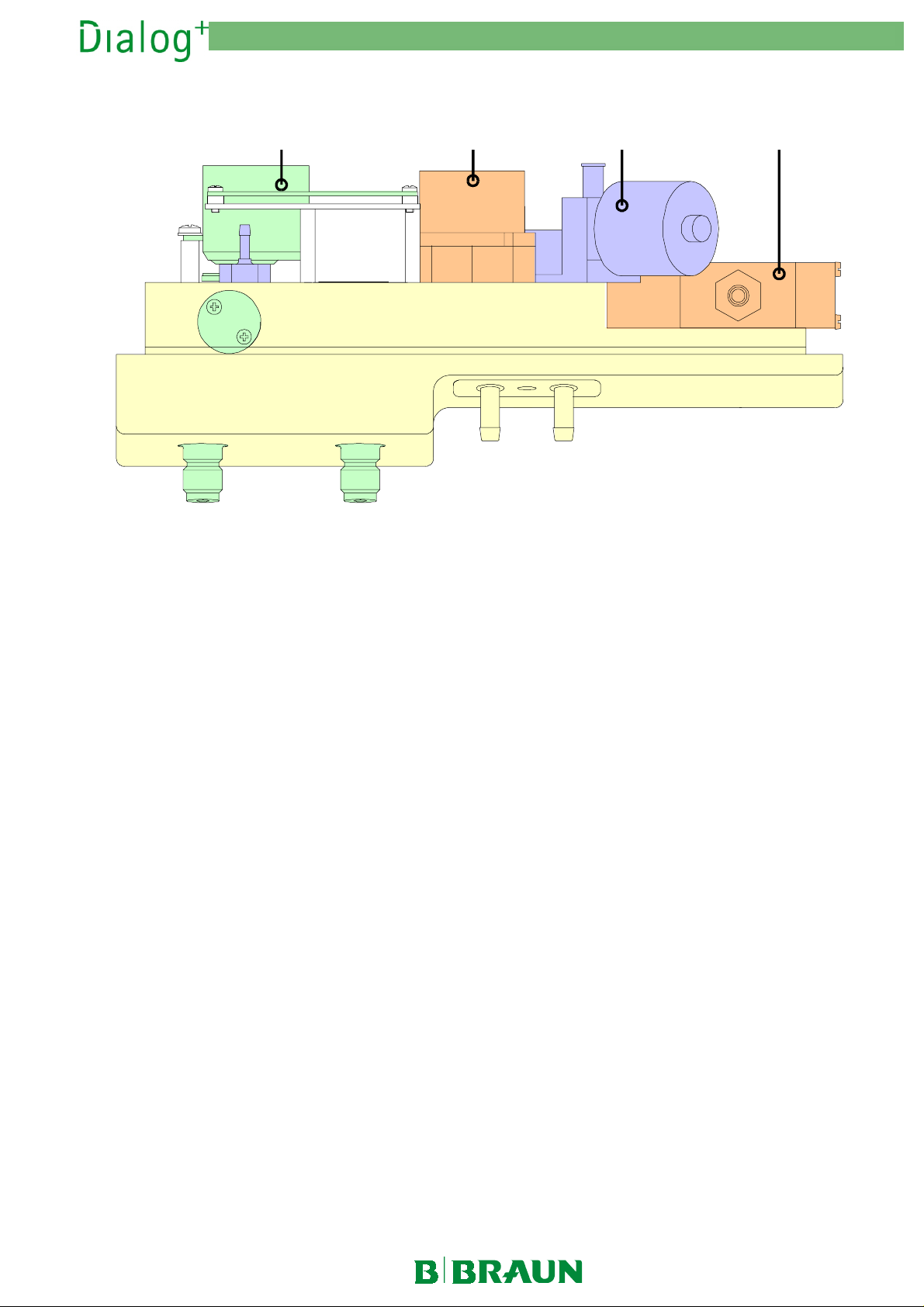

2.6 Rinsing Bridge

2. Technical System Description 1/2003 2 - 13

1

VD

Fig. : Rinsing Bridge

2.6.1 Legend Rinsing Bridge

234

PDA

VDE

BL

1

1 Disinfection Valve VD

11

2222 Pressure Sensor Dialysate Outlet PDA

VD

VDVD

PDA

PDAPDA

3333 Dialyser Inlet Valve VDE

4444 Blood Leak Detector BL

VDE

VDEVDE

BL

BLBL

MT-MD-DE08C M.KAY

Dialog+_sm_Chapter 2_1-2003.doc/pdf <011003> ddmmyy

B. Braun Medizintechnologie GmbH

Page 14

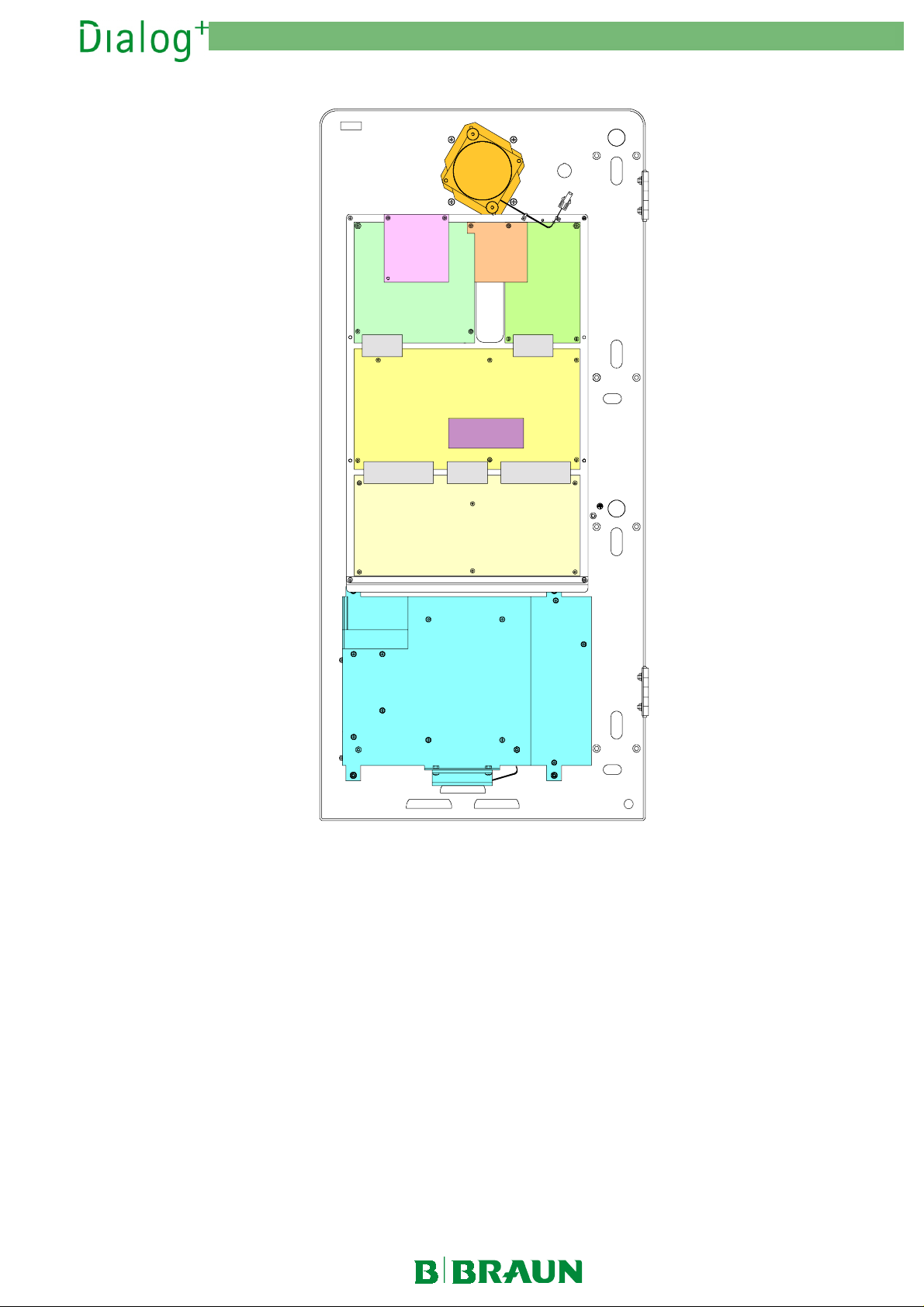

2.7 Rear Door

2. Technical System Description 1/2003 2 - 14

1

HOP

PB2

BIC-KV

PB1

SB

2

CB

SMPS

Fig. : Rear Door

2.7.1 Legend Rear Door

MT-MD-DE08C M.KAY

Dialog+_sm_Chapter 2_1-2003.doc/pdf <011003> ddmmyy

BIC Cartridge Holder Board BIC-KV

Controller Board CB

HDF Online Power Board HOP

HFS 2 Board HFS2

Fan (1111)

Power Board 1 PB1

CB

CBCB

HFS2 with TSHE (Option) (2222)

HFS2HFS2

PB1

PB1PB1

BIC-KV (Option)

BIC-KVBIC-KV

HOP (Option)

HOPHOP

Power Board 2 PB2

SAKA Board SAKA

Switch Mode Power Supply SMPS

Supervisor Board SB

Heater Inlet Temperature Sensor Board TSHE

PB2

PB2PB2

SAKA with TSHE (Option) (2222)

SAKASAKA

SMPS

SMPSSMPS

SB

SBSB

TSHE (2222)

TSHETSHE

B. Braun Medizintechnologie GmbH

Page 15

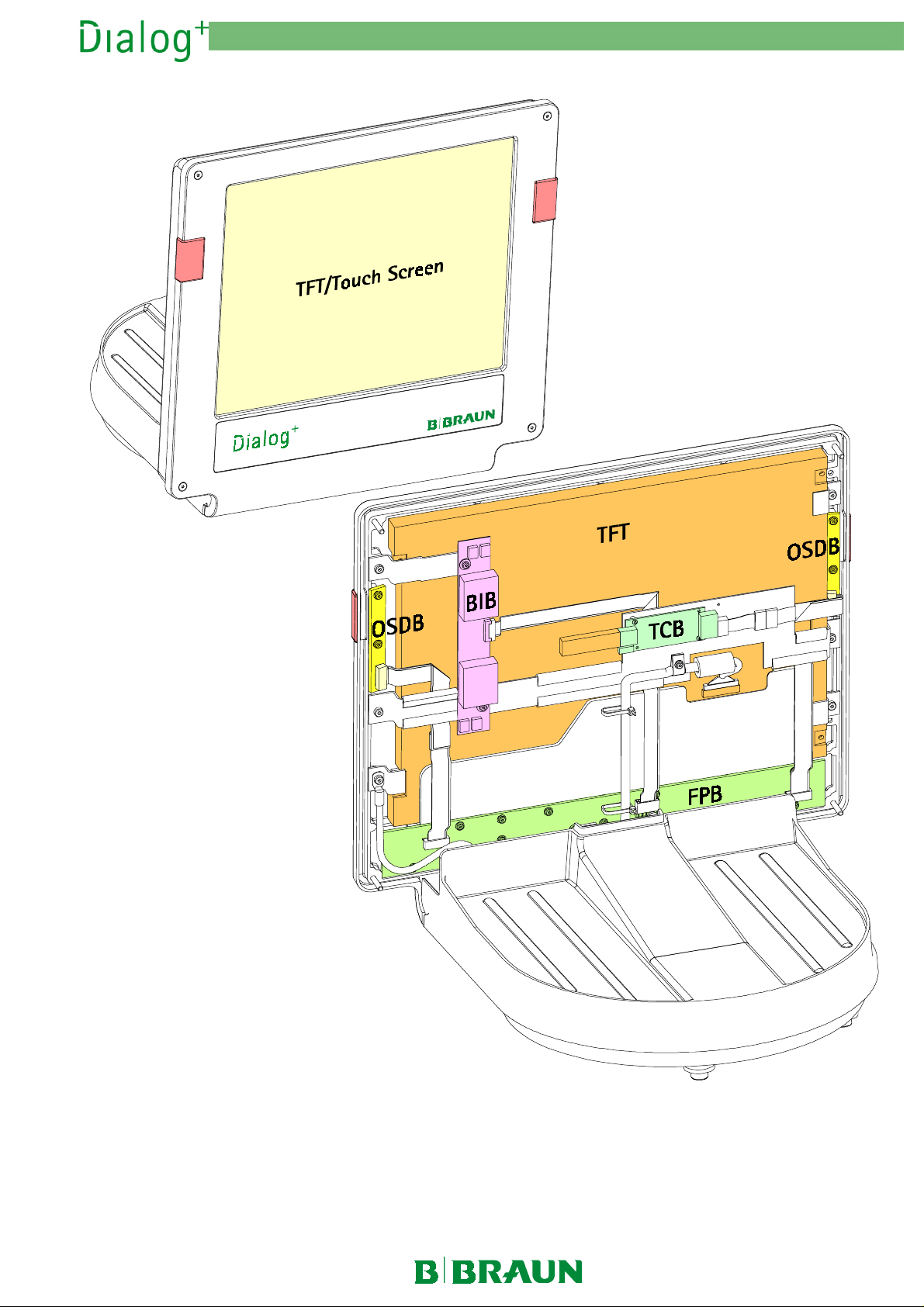

2.8 TFT Monitor

2. Technical System Description 1/2003 2 - 15

Fig. : TFT Monitor

2.8.1 Legend

MT-MD-DE08C M.KAY

Dialog+_sm_Chapter 2_1-2003.doc/pdf <011003> ddmmyy

TFT Monitor

Backlight Inverter Board

Front Panel Board

TFT Monitor

FPB

TFT

BIB

Optical Status Display Board

Touch Controller Board

Touch Screen

TCB

OSDB

B. Braun Medizintechnologie GmbH

Page 16

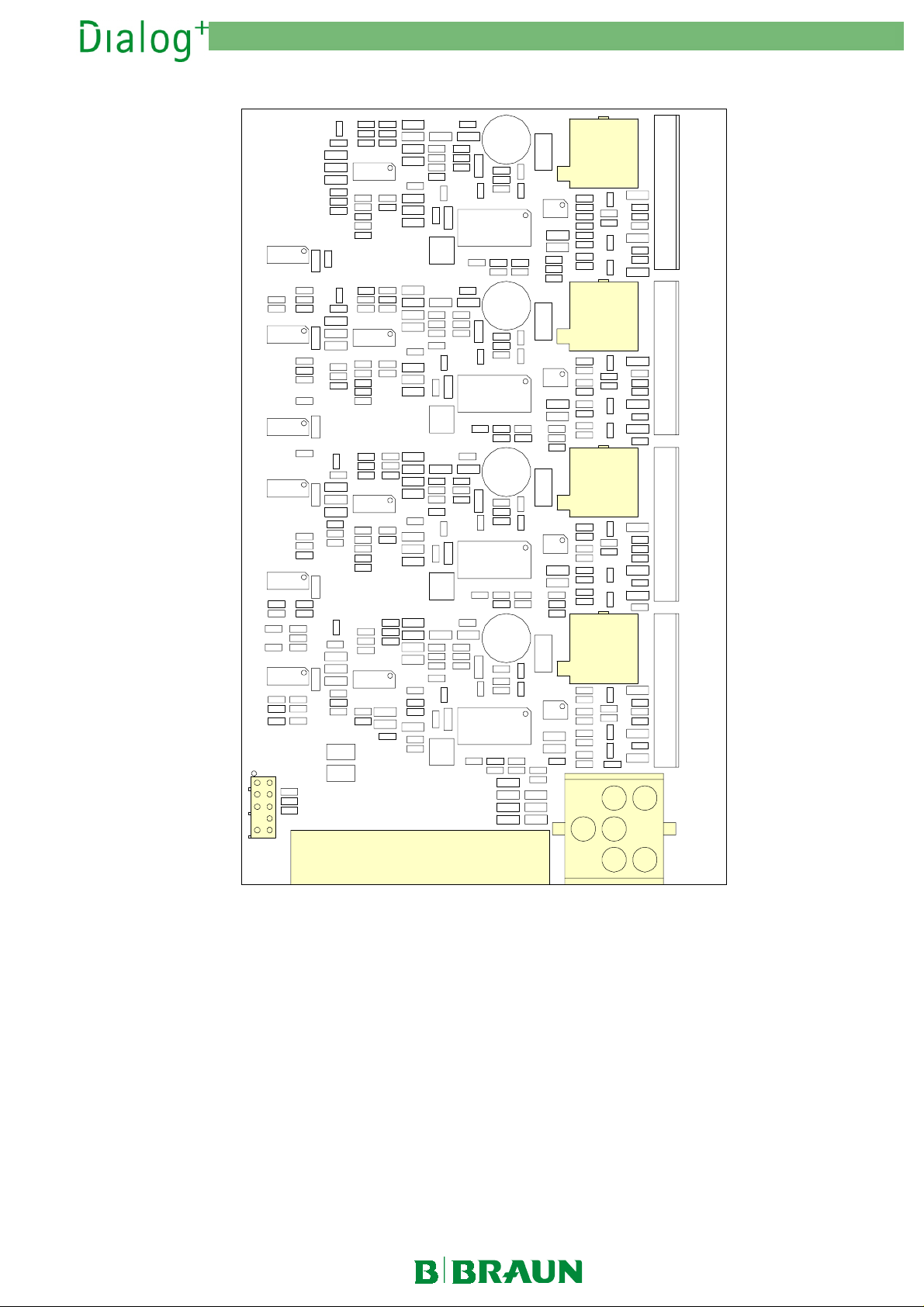

2.9 Power Board 1 PB1

2. Technical System Description 1/2003 2 - 16

V7

C37

V22

V20

R75

C50

R71

V5

V21

P5

R312

C148 C147 C146

V10

C93

V13

V4

C124C117

C39

C62

V24

V23

C65

C64

C86

V27

V26

R186

C89

C34

C15

V19

V17

R14R131

C18

R127 R1

V8

V25

C128C127C126 C125

R182

V11

V28

V1

V18

P6

P7

U15U14U13 U12

V40

V39V38V37 V36 V35V34 V33 V32 V31 V30 V29

P1

P4

P4

Fig. : Power Board 1 PB1

2.9.1 Legend Power Board 1 PB1

P1

P1 Arterial Blood Pump BPA

P1P1

P2

P2 Supervisor Board SB

P2P2

P3

P3 Voltage Supply

P3P3

P4

P4 Sensors Blood Pump

P4P4

Cover switch

SB

SBSB

BPA

BPABPA

P2

C17

P3

P5

P5 Inlet Flow Pump FPE

P5P5

P6

P6 Outlet Flow Pump FPA

P6P6

P7

P7 Degassing Pump EP

P7P7

FPE

FPEFPE

EP

EPEP

FPA

FPAFPA

MT-MD-DE08C M.KAY

Dialog+_sm_Chapter 2_1-2003.doc/pdf <011003> ddmmyy

B. Braun Medizintechnologie GmbH

Page 17

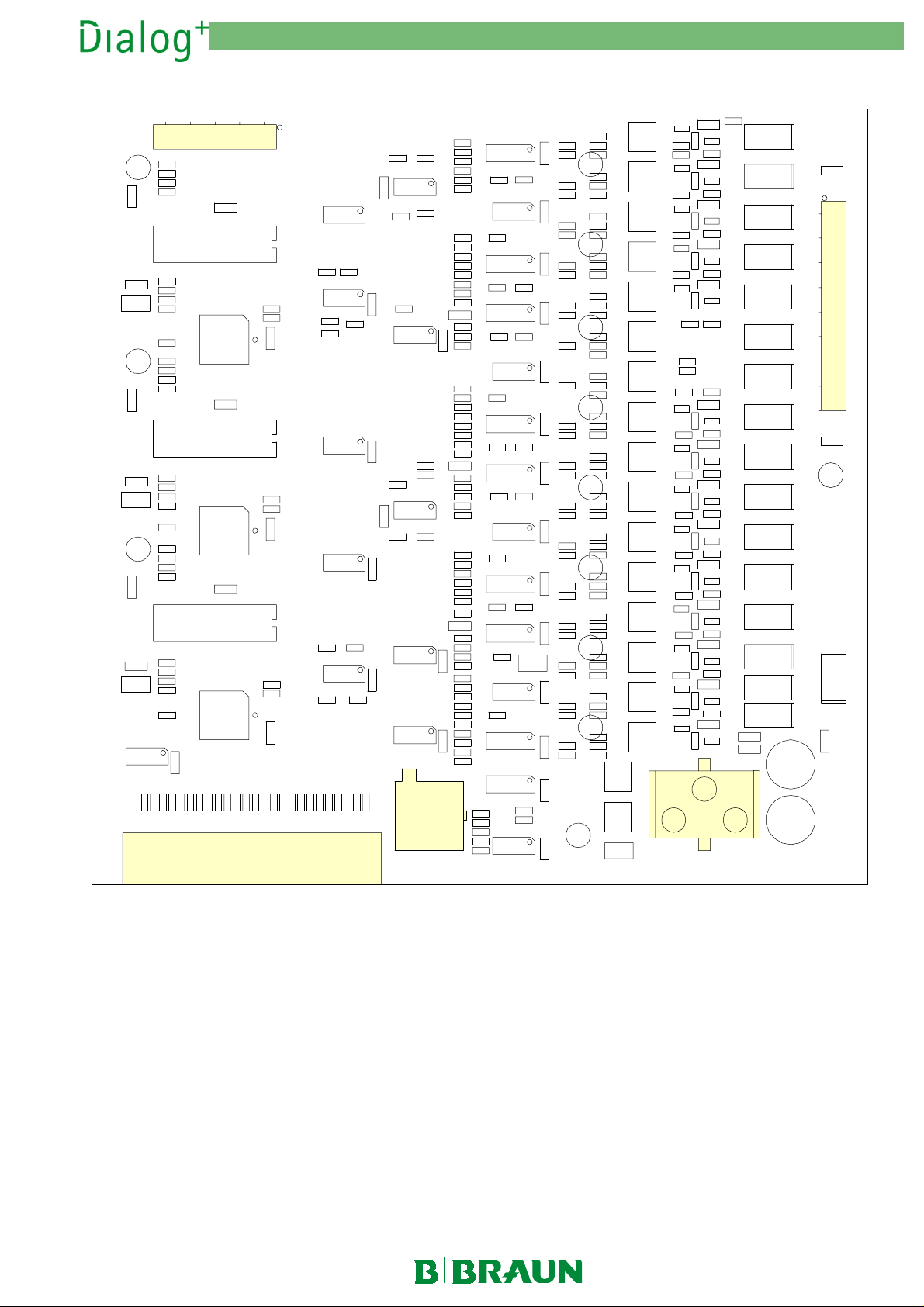

2.10 Power Board 2 PB2

P3

C78

2. Technical System Description 1/2003 2 - 17

P1

U26U25U24

P2

Fig. : Power Board 2 PB2

2.10.1 Legend Power Board 2 PB2

P1

P1 for Valves and SAKV:

P1P1

Upline Tank Inlet Valve RVVB

Degassing Control Valve RVE

Venous Tubing Clamp Currentles Closed SAKV-SG

Dialyser Outlet Valve VDA

Dialyser Inlet Valve VDE

Balance Chamber Valves VABK1/2, VDABK1/2, VEBK1/2, VDEBK1/2

Air Separator Valve VLA

Circulation Valve VZ

Bypass Valve VBP

VBP

VBPVBP

P5

RVVB

RVVBRVVB

RVE

RVERVE

SAKV-SG

SAKV-SGSAKV-SG

VDA

VDAVDA

VDE

VDEVDE

VABK1/2, VDABK1/2, VEBK1/2, VDEBK1/2

VABK1/2, VDABK1/2, VEBK1/2, VDEBK1/2VABK1/2, VDABK1/2, VEBK1/2, VDEBK1/2

VLA

VLAVLA

VZ

VZVZ

V47V46V45V44V43V42V41V40V39V38V37V36V35V34V33V32

P4

P2

P2 Supervisor Board SB

P2P2

P3

P3 Piston Pumps:

P3P3

Concentrate Pump KP

Bicarbonate Pump BICP

Ultrafiltration Pump UFP

P4

P4 Voltage Supply

P4P4

P5

P5 Disinfection Valve VD

P5P5

SB

SBSB

VD

VDVD

KP,

KPKP

BICP,

BICPBICP

UFP

UFPUFP

V3

C93

C83

MT-MD-DE08C M.KAY

Dialog+_sm_Chapter 2_1-2003.doc/pdf <011003> ddmmyy

B. Braun Medizintechnologie GmbH

Page 18

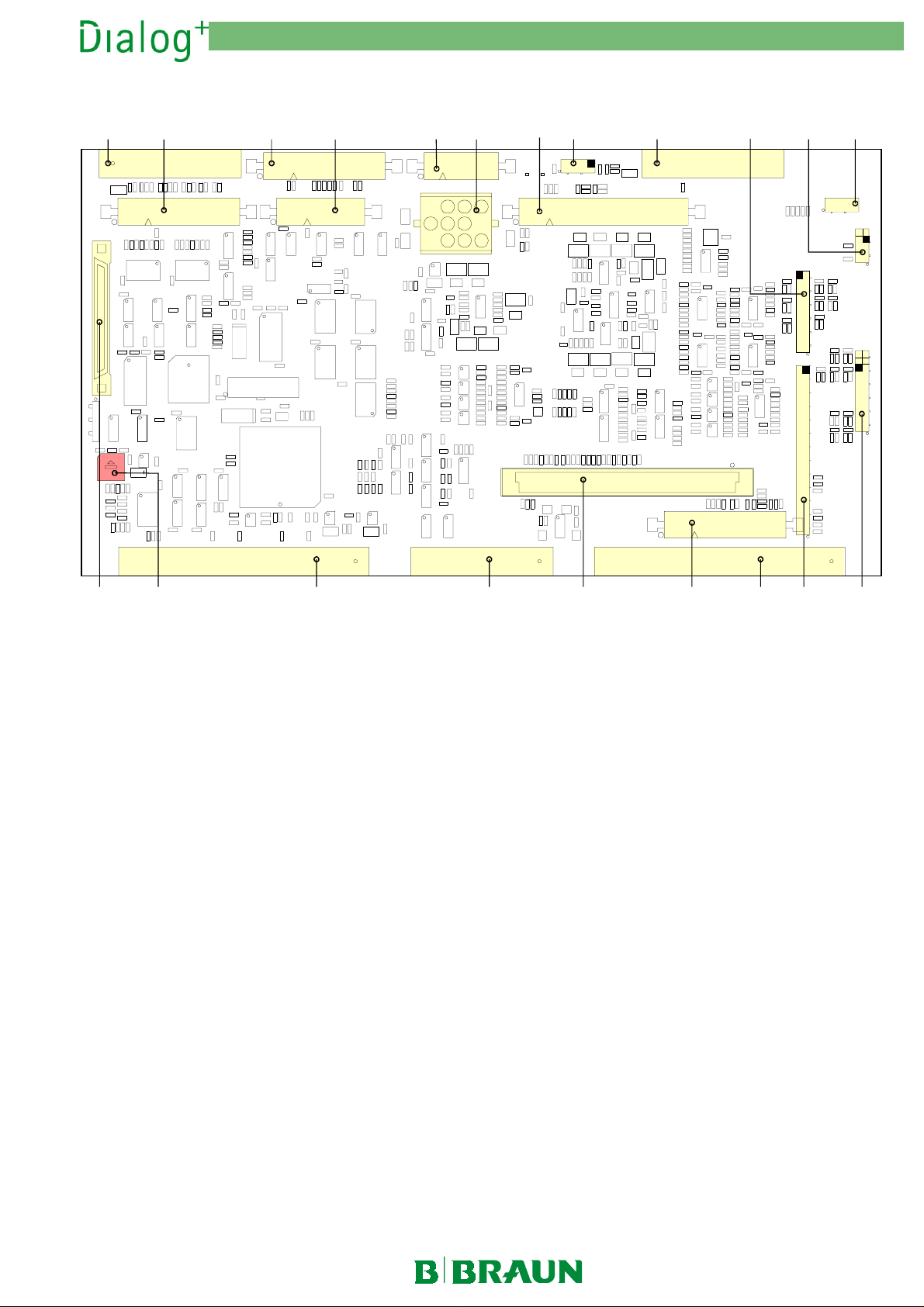

2.11 Supervisor Board SB

2. Technical System Description 1/2003 2 - 18

P11 P12 P8 P5

P9

14 P7

P6

P10 P15

P13P17

P19 K1 P2 P3 P18 P23 P1 P4 P16

Fig. : Supervisor Board SB

2.11.1 Legend Supervisor Board SB

P13

P1/P2/P3

P1/P2/P3 Controller Board CB

P1/P2/P3P1/P2/P3

P4

P4 BICSS/KSS/RDVLED/SAD RTS/TX/CTS/RX Signals

P4P4

P5

P5 Staff Call Signals

P5P5

P6

P6 BPV/PBS/SAKA Signals

P6P6

P7

P7 BL Signals

P7P7

P8

P8 REM/HOFF/HREL Signals

P8P8

P9

P9 SCB-RX/TX/CTS/RTS Signals

P9P9

P10

P10 BP/EP/FP Signals

P10P10

P11

P11 VVBE/KP/BICP/UFP/SKAV/VDE/VDA Signals

P11P11

P12

P12 Heparin Pump Signals

P12P12

CB

CBCB

P13 Pressure Sensor PBE

P13P13

P14

P14 Voltages +5 V/+24 VL/+24 VGB/+12 VAN/-12 VAN

P14P14

P15

P15 ENDLF/ENDLF-S/BICLF/TSD/TSD-S/TSBIC/TSE Signals

P15P15

P16

P16 Voltages +5 VREF/+12 VAN/-12 VAN

P16P16

P17

P17 Voltages +5 V/12 VD/-12 VD

P17P17

P18

P18 Extension Connector

P18P18

P19

P19 Communication Program Adapter

P19P19

K1

K1 Hardware Switch:

K1K1

Position 0: Therapy Mode

Position 2: TSM Service Program Mode

Position 3: Software Update Mode

PBE

PBEPBE

MT-MD-DE08C M.KAY

Dialog+_sm_Chapter 2_1-2003.doc/pdf <011003> ddmmyy

B. Braun Medizintechnologie GmbH

Page 19

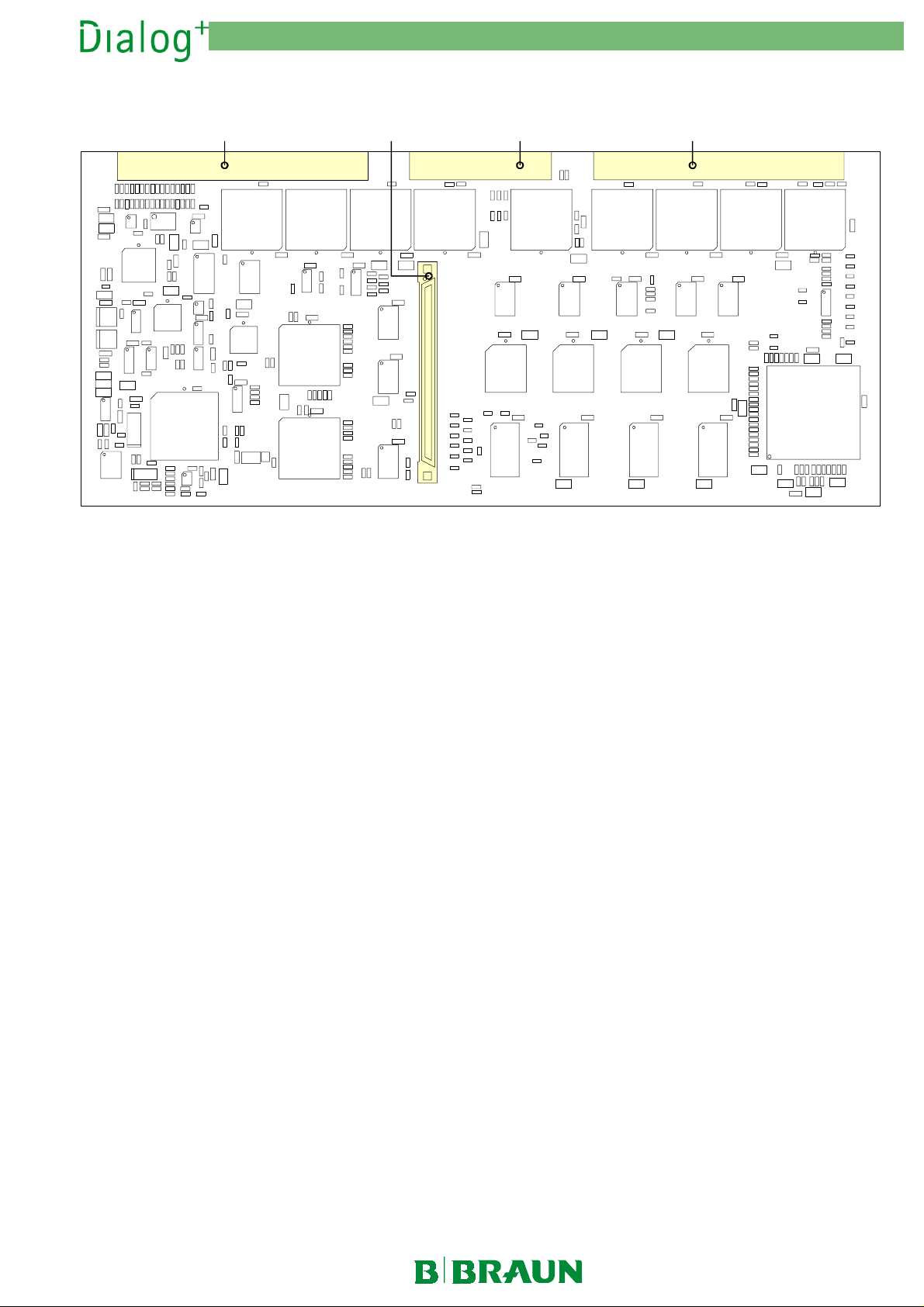

2.12 Controller Board CB

2. Technical System Description 1/2003 2 - 19

P1P3P5P2

U9 U8U6

U22

U25

U51

Fig. : Controller Board CB

U18

U26

U33

2.12.1 Legend Controller Board CB

P1/P2/P3

P1/P2/P3 Supervisor Board SB

P1/P2/P3P1/P2/P3

U2

U5

SB P5

SBSB

U3

P5 Program Adapter with Memory Card

P5P5

U12U11 U10

U1

MT-MD-DE08C M.KAY

Dialog+_sm_Chapter 2_1-2003.doc/pdf <011003> ddmmyy

B. Braun Medizintechnologie GmbH

Page 20

2. Technical System Description 1/2003 2 - 20

2.13 Switch Mode Power Supply SMPS (Benning)

PE3 N3 L3 N2 L2

X3

PE L N PE L1 N1

X1.3 X1.1 X1.2 X1.6 X1.5 X1.4

F4

X1

F5

F6

F1

Fig. : Switch Mode Power Supply SMPS (Benning)

F2

F3

X2

F1 T6.25A 6.3x32

F2 T6.25A 6.3x32

F3 T3.15A TR5

F4 T3.15A TR5

F5/F6 - 110/ 120V: F20A 6.3x32

- 230V: M10A 6.3x32

F301 T3.15A TR5

F302 T5.0A TR5

F303 T3.15A TR5

F304 T3.15A TR5

F401 T1.25A TR5

F402 T5.00A TR5

F403 T1.25A TR5

F500 T3.15A TR5

F600 M10.00A 6.3x32

F601 T3.15A TR5

F602 T3.15A TR5

+12VD / F401 - T1.25A TR5

+12VD / F402 - T5.00 A TR5

+12VAN / F4 03 - T1.25A TR5

+5VD / F303 - T3.15A TR5

+5VD / F30 2 - T5 . 00A TR5

+5VD / F301 - T3.15A TR5

+5VD / F304 - T3.15A TR5

+24 VGB / F602 - T3.15A TR5

+24VGB / F601 - T3.15A TR5

+24V

X100

LED

P13

F401

F402

F403

F303

F302

F301

F304

F602

F601

1

3

1

P7

P8

P101

1

3

1

3

1

3

P3

1

3

P12

P10

P4

1

P5

3

2

1

-

+

1

P9

4

1

1

2

P2

1

3

1

2.13.1 Legend Switch Mode Power Supply

SMPS

X1

X1 Mains Input, Heater

X1X1

X2

X2 -

X2X2

X3

X3 Fluid Warmer (via Relay)

X3X3

P2

P2 Supervisor/Watchdog, Service Board

P2P2

P3

P3 Battery Connection (Screw Terminal)

P3P3

P4

P4 Power Board 1/2

P4P4

P5

P5 Supervisor/Controller Board

P5P5

P6

P6 Floppy Disk Drive

P6P6

P7

P7 Options, Service Board (Service Tool)

P7P7

F1/F2

F1/F2 6.25 AT (6.3x32), Mains Input

F1/F2F1/F2

F3/F4

F3/F4 3.15 AT (TR5), Fluid Warmer + Monitor

F3/F4F3/F4

F5/F6

F5/F6 10 AM (6.3x32), Heater 1800 W (240 V)

F5/F6F5/F6

20 AF (6.3x32), Heater 1800 W (110/120 V)

F301

F301 3.15 AT (TR5), +5 VD

F301F301

F302

F302 5.00 AT (TR5), +5 VD

F302F302

F303/

F303/ 3.15 AT (TR5), +5 VD

F303/F303/

F304

F304

F304F304

P8

P8 ABPM

P8P8

P9

P9 Fan, Mains Switch

P9P9

P10

P10 PC

P10P10

P11

P11 Hard Disk Drive

P11P11

P12

P12 Options

P12P12

P13

P13 -

P13P13

P14

P14 EXT ON

P14P14

P101

P101 Service Watchdog

P101P101

X100

X100 Fan

X100X100

F401

F401 1.25 AT (TR5), +12 VD

F401F401

F402

F402 5.00 AT (TR5), +12 VD

F402F402

F403

F403 1.25 AT (TR5), +12 VAN

F403F403

F600

F600 10 AM (6.3x32), +24 VL

F600F600

F601/

F601/ 3.15 AT (TR5), +24 VGB

F601/F601/

F602

F602

F602F602

MT-MD-DE08C M.KAY

Dialog+_sm_Chapter 2_1-2003.doc/pdf <011003> ddmmyy

B. Braun Medizintechnologie GmbH

Page 21

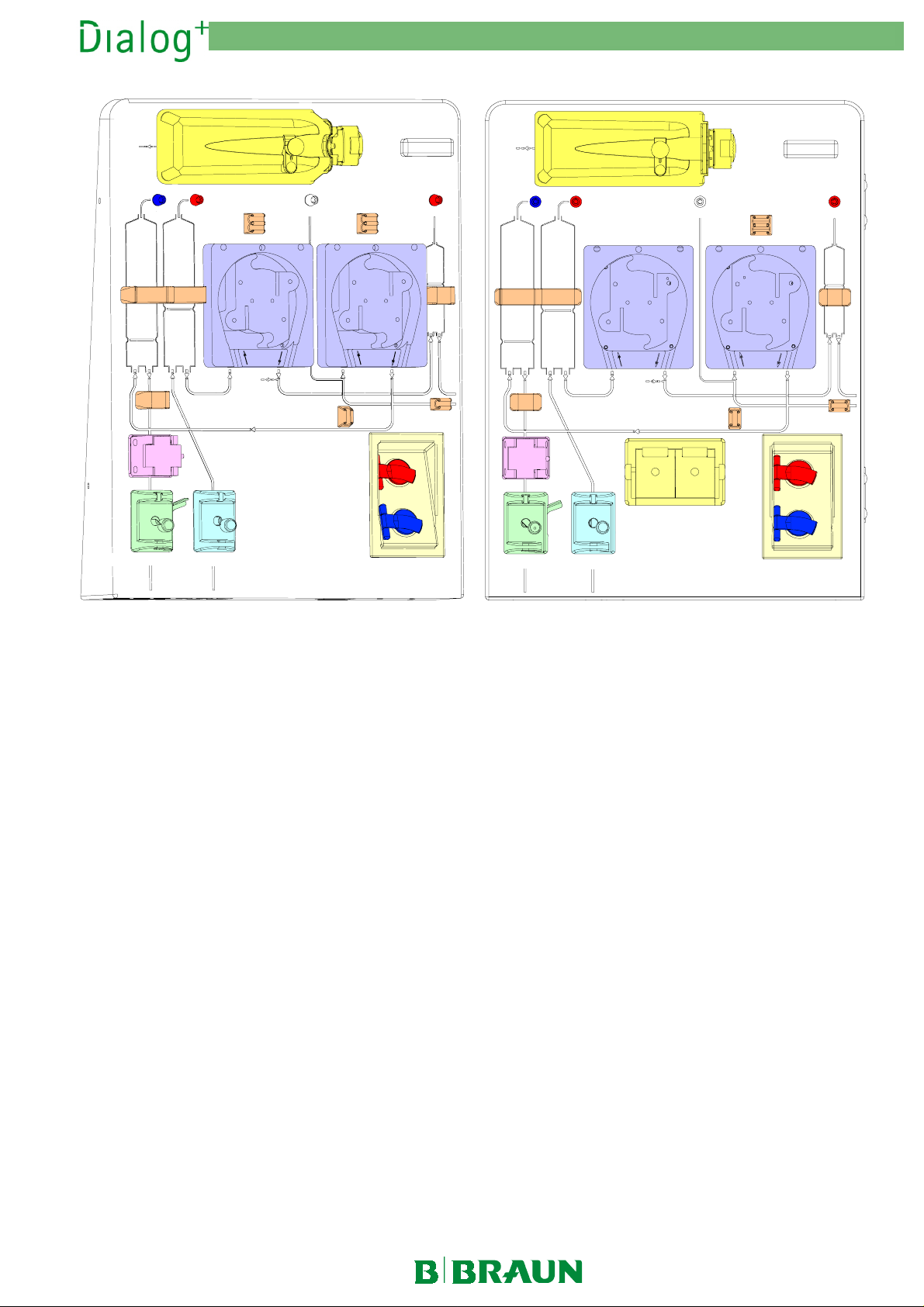

2.14 Front Door

2. Technical System Description 1/2003 2 - 21

HP

PV PA PBS/SN PBE

SN

SN

PBA PBV

SAD

SAKV-SG

SAKA

HP

PV PA

SN

SAD

SN

PBA PBV

PBS/SN

PBE

1111

2222

SAKASAKV-SG

2222

Fig. : Front Door

2.14.1 Legend Front Door

Arterial Blood Pump BPA

Arterial Pressure Sensor PA

Arterial Tubing Clamp SAKA-SG

BPA

BPABPA

PA

PAPA

SAKA-SG

SAKA-SGSAKA-SG

Cover for Suction Rods 2222

Heparin Pump Compact HP

Pressure Sensor PBE

PBE

PBEPBE

HP

HPHP

Pressure Sensor PBS/SN

Safety Air Detector SAD

PBS/SN

PBS/SNPBS/SN

SAD/Venous Red Detector RDV

SADSAD

RDV

RDVRDV

Substitution Port 1111

Venous Blood Pump BPV

Venous Pressure Sensor PV

Venous Tubing Clamp Currentles Closed SAKV-SG

BPV

BPVBPV

PV

PVPV

SAKV-SG

SAKV-SGSAKV-SG

MT-MD-DE08C M.KAY

Dialog+_sm_Chapter 2_1-2003.doc/pdf <011003> ddmmyy

B. Braun Medizintechnologie GmbH

Page 22

MT-MD-DE08C M.KAY

Dialog+_sm_Chapter 2_1-2003.doc/pdf <011003> ddmmyy

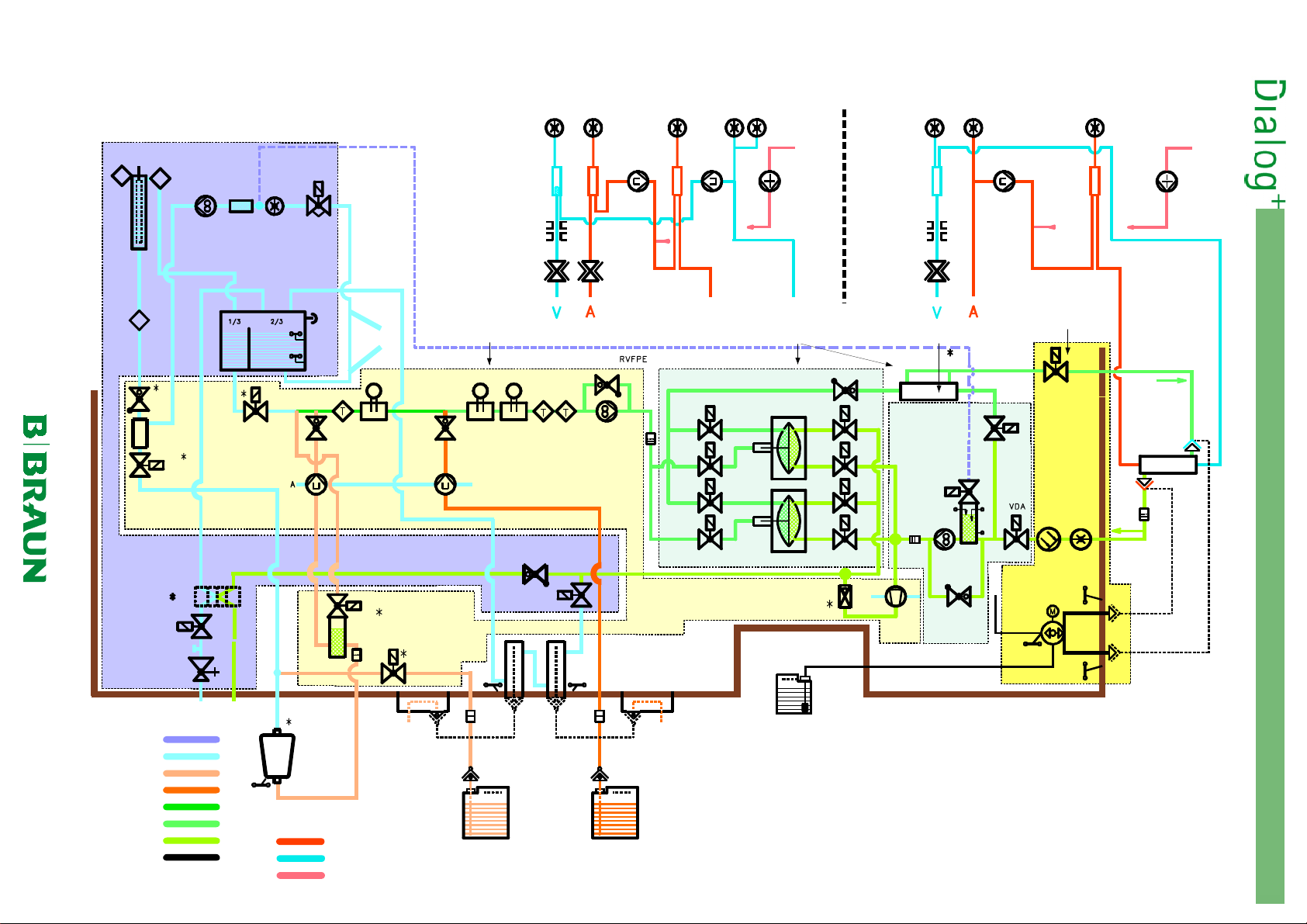

2.15 Flow Diagram

PA

PBE

PVPVPA

PBE

Double-NeedlePBS

TSETSH

T

T

EP EK PE

H

Water Sub-Rack

Wasser-Einschub

TSHE

T

DBK

LAB1

VBKO

WT

B. Braun Medizintechnologie GmbH

VVBE

DMV

VVB

BICP

RVE

SAD

RDV

SAKV-SG

SAKA

VB

DF Sub-Rack

DF-Einschub

NSVB

C

A

BPVBPA

Single-Needle

HP

UF Sub-Rack

UF-Einschub

SAD

RDV

SAKV-SG

Pyrogen Fi l t er

Pyrogenfilter

BPA

HP

Rinsing Bridge

Spülbrücke

2. Technical System Description 1/2003 2 - 22

DDE

RVB

TSBIC

BICLF

RVK TSD TSD-S

ENDLF-SENDLF

B

FPE

FBK1

VDEBK1

VEBK1

VDEBK2

MSBK1

BK1

VABK1

VDABK1

VABK2

VBP

VLA

VDE

V.D.

Z.D.

Dialysator

Dialyser

KP

LAB2

VBICP

FBIC

VBKS

Zentrale

Bicarbonat-

Versorgung

Central

Bicarbonate

Supply

RVDA

UFP

FBK2

LAFS

FPA

RVFPA

BL PDA

LA

Luft

SBS1

Air

VD

LVD

SBS2

VEBK2

MSBK2

VDABK2

BK2

FM

CB

VZ

FVD

S1

S2

Luft

Air

Wasser

Water

Bicarbonat

Bicarbonate

Konzentrat

Concentrate

Dialysierfluß 1

Dialysate Flow 1

Dialysierfluß 2

Dialysate Flow 2

Dialysierflüssigkeit

Dialysate

Desinfektionsmittel

Disinfectant

Optionen

Options

Wasser Z U

Water Inlet

*

Dialysat AB

Dialysate Outlet

BKUS

Blut Arteriell

Blood Arterial

Blut Venös

Blood Venous

Heparin

BVA

BICSS

FB

BE

BIC-Konzentrat

BIC Conce ntrate

KSS

FK

KE

Konzentrat

Säurekonzentrat

Concentrate

Aci d C oncentrat e

KVA

Zentrale

Konzentrat-

Versorgung

Central

Concentrate

Supply

FD

Disinfectant

(Rear Side of Unit)

Desinfektionsmittel

(Geräterückseite)

Page 23

2.15.1 Legend Flow Diagram

Abbreviation Description

2. Technical System Description 1/2003 2 - 23

BE

BICLF

BICP

BICSS

BK1

BK2

BL

BPA

BPV

BVA

DBK

DDE

DMV

EK

ENDLF

ENDLF-S

EP

FB

FBIC

FBK1

FBK2

FK

FM

FPA

FPE

FVD

H

HP

KE

KP

KSS

KVA

LA

LAB1

LAB2

LAFS

LVD

MSBK1

MSBK2

NSVB

PA

PBE

PBS

PDA

PE

PV

Bicarbonate Withdrawal Rod

Bicarbonate Conductivity

Bicarbonate Pump

Bicarbonate Rinsing Connection Sensor

Balance Chamber 1

Balance Chamber 2

Blood Leak Detector

Arterial Blood Pump

Venous Blood Pump

Bicarbonate Supply Connection (Central Supply)

Throttle Bicarbonate Cartridge Holder

Throttle Dialyser Inlet

Pressure Reducer Valve

Degassing Chamber

END Conductivity

END Conductivity Supervisor

Degassing Pump

Filter Bicarbonate

Filter Bicarbonate Cartridge

Filter Balance Chamber 1

Filter Balance Chamber 2

Filter Concentrate

Flowmeter

Outlet Flow Pump

Inlet Flow Pump

Filter from Dialysate

Heater

Heparin Syringe Pump

Concentrate Withdrawal Rod

Concentrate Pump

Concentrate Rinsing Connector Sensor

Concentrate Supply Connector (Central Supply)

Air Separator

Air Separator BIC Cartrige Holder 1

Air Separator BIC Cartrige Holder 2

Air Separator Level Sensors

Light Barrier Disinfection Valve

Membrane Position Sensor Balance Chamber 1

Membrane Position Sensor Balance Chamber 2

Level Sensor Upline Tank

Arterial Pressure Sensor

Pressure Sensor Blood Inlet

Blood Pressure Control Sensor

Pressure Sensor Dialysate Outlet

Degassing Pressure Sensor

Venous Pressure Sensor

MT-MD-DE08C M.KAY

Dialog+_sm_Chapter 2_1-2003.doc/pdf <011003> ddmmyy

B. Braun Medizintechnologie GmbH

Page 24

2. Technical System Description 1/2003 2 - 24

RDV

RVB

RVDA

RVE

RVFPA

RVFPE

RVK

RVUF

SAD

SAKA

SAKV-SD

SBS1

SBS2

TSBIC

TSD

TSD-S

TSE

TSH

TSHE

UFP

VABK1

VABK2

VB

VBICP

VBKO

VBKS

VBP

V.D.

VD

VDA

VDABK1

VDABK2

VDE

VDEBK1

VDEBK2

VEBK1

VEBK2

VLA

VVB

VVBE

VZ

WT

Z.D.

Venous Red Detector

Throttle Bicarbonate

Throttle Dialysate Valve

Degassing Control Valve

Throttle Flow Pump Outlet

Throttle Flow Pump Inlet

Throttle Concentrate

Throttle Ultrafiltration

Safety Air Detector

Arterial Tubing Clamp

Venous Tubing Clamp Currentles Closed

Rinsing Bridge Connector Sensor 1

Rinsing Bridge Connector Sensor 2

Bicarbonate Temperature Sensor

Dialysate Temperature Sensor

Dialysate Temperature Sensor Supervisor

Degassing Temperarture Sensor

Thermal Fuse Heater Element

Heater Inlet Temperature Sensor

Ultrafiltration Pump

Outlet Valve Balance Chamber 1

Outlet Valve Balance Chamber 2

Upline Tank

Bicarbonate Pump Valve

Bicarbonate Cartridge Holder Top Valve

Bicarbonate Cartridge Holder Concentrate Rod Valve

Bypass Valve

Dialyser Coupling (from Dialysate)

Disinfection Valve

Dialyser Outlet Valve

Dialyser Outlet Valve Balance Chamber 1

Dialyser Outlet Valve Balance Chamber 2

Dialyser Inlet Valve

Dialyser Inlet Valve Balance Chamber 1

Dialyser Inlet Valve Balance Chamber 2

Inlet Valve Balance Chamber 1

Inlet Valve Balance Chamber 2

Air Separator Valve

Upline Tank Valve

Upline Tank Inlet Valve

Circulation Valve

Heat Exchanger

Dialyser Coupling (to Dialysate)

MT-MD-DE08C M.KAY

Dialog+_sm_Chapter 2_1-2003.doc/pdf <011003> ddmmyy

B. Braun Medizintechnologie GmbH

Page 25

2. Technical System Description 1/2003 2 - 25

2.16 Description Flow Diagram

The flow diagram can be divided into six sections:

2.16.1 Water Inlet Section with Upline

Tank

The water inlet section has the following components

Water Inlet Section with Upline Tank

•

Degassing Circuit with Temperature System

•

Dialysate Processing

•

Balance Chamber

•

Ultrafiltration

•

Rinsing Bridge

•

TSE

VB

WT

Pressure Reducer Valve DMV

•

Upline Tank Inlet Valve VVVVVBE

•

Upline Tank VB

•

Level Sensors Upline Tank NSVB

•

Heat Exchanger WT

•

VB

VBVB

DMV

DMVDMV

WT (Option)

WTWT

KSS

NSVB

RVE

RVB

VBE (2/2 way valve)

VBEVBE

NSVB

NSVBNSVB

Pressure Reducer Valve DMV

Pressure Reducer Valve DMV

Pressure Reducer Valve DMVPressure Reducer Valve DMV

The pressure reducer valve DMV limits the

pressure of the inlet water (e.g. osmosis water)

to a maximum of approx. 1.3 bar.

Upline Tank Inlet Valve

Upline Tank Inlet Valve VVVVVBE

Upline Tank Inlet Valve Upline Tank Inlet Valve

The valve VVBE is time-delayed controlled via

the level sensor NSVB (top) in the upline tank

VB. The delay time depends on the dialysate

flow.

Level Sensors Upline Tank NSVB

Level Sensors Upline Tank NSVB

Level Sensors Upline Tank NSVBLevel Sensors Upline Tank NSVB

The level sensors are mounted in the upline

tank.

VBE

VBEVBE

VZ

VVBE

DMV

Fig. : Water Inlet with Upline Tank

MT-MD-DE08C M.KAY

Dialog+_sm_Chapter 2_1-2003.doc/pdf <011003> ddmmyy

RVDA

NSVB

NSVB top:

NSVBNSVB

closed - VVBE is closed

NSVB

NSVB bottom (monitoring low water level):

NSVBNSVB

closed (alarm) - Water inlet is disturbed

- Heater is switched off

Heat Exchanger WT (Option)

Heat Exchanger WT (Option)

Heat Exchanger WT (Option)Heat Exchanger WT (Option)

The cold inlet water can be warmed up via the

optional heat exchanger WT. Thereby the heat

consumption to heat up the water can be

reduced.

B. Braun Medizintechnologie GmbH

Page 26

2.16.2 Degassing Circuit with

Temperature System

2. Technical System Description 1/2003 2 - 26

The degassing circuit with temperature system has the following components:

Degassing Control Valve RVE

•

RVE

RVERVE

Degassing Control Valve RVE

Degassing Control Valve RVE

Degassing Control Valve RVEDegassing Control Valve RVE

Degassing Pressure Sensor PE

Degassing Pressure Sensor PE

Degassing Pressure Sensor PEDegassing Pressure Sensor PE

Degassing Pump EP

Degassing Pump EP

Degassing Pump EPDegassing Pump EP

Heater Element H

Heater Element H

Heater Element HHeater Element H

Thermal Fuse Heater Element TSH

Thermal Fuse Heater Element TSH

Thermal Fuse Heater Element TSHThermal Fuse Heater Element TSH

Degassing Temperature Sensor TSE

Degassing Temperature Sensor TSE

Degassing Temperature Sensor TSEDegassing Temperature Sensor TSE

Degassing Pressure Sensor PE

•

Degassing Chamber EK

•

Degassing Pump EP

•

Thermal Fuse Heater Element TSH

•

Temperature Sensor Heater Inlet TSHE

•

Heater Element HHHH

•

Degassing Temperature Sensor TSE

•

The control valve RVE, pressure sensor PE, degassing chamber EK and degassing

pump EP produce and measure a negative pressure respectively. The negative

pressure is produced to separate the dissolved gas from the water.

The control valve RVE reduces the flow (throttle principle) depending on the

measured pressure at the pressure sensor PE. Thereby the desired negative

pressure is gained between the control valve RVE and the degassing pump EP.

The value of the negative pressure is approx. -500 mmHg and thus always

higher than the lower pressure of the dialysate behind the dialyser. The

degassing pump works with constant speed, which is determined by the

dialysate, unless the negative pressure is insufficient at the smallest opening of

RVE. Then the speed of EP is increased.

The heater H has an integrated thermal fuse TSH as a thermal cut-off. The

temperature sensor TSE measures the actual temperature posterior to the

heater.

EP

EPEP

EK

EKEK

PE

PEPE

TSH

TSHTSH

TSE

TSETSE

TSHE

TSHETSHE

TSE

T

Temperature Control

Temperature Control The temperature of the water inlet determines the amount of heat which the

Temperature ControlTemperature Control

heater must supply, to replace the amount of heat (dialysate flow and dialysate

temperature) withdrawn by the drainage.

The differential temperature between the heater inlet (TSHE) and the heater

outlet (TSE) determines the controlled variable for the heater, depending on the

dialysate flow and dialysate temperature.

VLA

TSH

T

EP

EK

PE

RVE

H

T

TSHE

zum VB/to VB

Fig. : Degassing Circuit with Temperature System

MT-MD-DE08C M.KAY

Dialog+_sm_Chapter 2_1-2003.doc/pdf <011003> ddmmyy

vom VB/f rom VB

B. Braun Medizintechnologie GmbH

Page 27

2.16.3 Dialysate Processing

2. Technical System Description 1/2003 2 - 27

The dialysate processing has the following components:

The main components of the dialysate preparation are the bicarbonate

Bicarbonate Concentrate Pump BICP

•

Bicarbonate Throttle RVB

•

Bicarbonate Temperature Sensor TSBIC

•

Bicarbonate Conductivity BICLF

•

Concentrate Pump KP

•

Concentrate Throttle RVK

•

END Conductivity ENDLF

•

END Conductivity Supervisor ENDLFS

•

Dialysate Temperature Sensor TSD

•

Dialysate Temperature Sensor Supervisor TSDS

•

Inlet Flow Pump FPE

•

Inlet Flow Pump Throttle RVFPE

•

concentrate pump BICP and the concentrate pump KP, with the conductivity

cells BICLF and ENDLF and a flow pump FPE. The flow pump FPE delivers the

dialysate. The bicarbonate concentrate, which is added via the bicarbonate

pump BICP, is measured by the conductivity measurement cell BICLF. Thereby

the pump can control the given conductivity set-point value.

KP

KPKP

ENDLF

ENDLFENDLF

FPE

FPEFPE

RVB

RVBRVB

RVK

RVKRVK

BICLF

BICLFBICLF

ENDLFS

ENDLFSENDLFS

RVFPE

RVFPERVFPE

TSD

TSDTSD

BICP

BICPBICP

TSBIC

TSBICTSBIC

TSDS

TSDSTSDS

vom VB

from VB

TSBIC

The concentrate or acid concentrate addition has the same working principle.

The nonreturn valves RVB and RVK stablise the dosage of the bicarbonate and

concentrate.

The temperature sensors TSBIC and TSD are responsible for:

the temperature compensation of the conductivity measurement and

•

temperature measurement TSD after the addition of cold concentrate

•

(second measurement sensor for temperature system) and thus

compensation of temperature loss.

The conductivity sensor ENDLFS is an independent monitoring unit (supervisor).

The geometry of the ENDLFS sensor is different (but has the same cell constant)

than the ENDLF sensor of the controller. Thereby a deposit on the sensor can be

identified. The temperature compensation is carried out by the temperature

sensor TSDS. The temperature sensor additionally monitors the dialysate flow

temperature for the supervisor. The ENDLFS and TSDS sensors have no influence

on the respective control.

The throttle RVFPE prevents a high pressure build-up and thus a bursting of

tubing if the flow path is blocked behind FPE. If the set pressure is reached

RVFPE is opened and the fluid can circulate.

RVFPE

BICLF

ENDLF

ENDLF-S

TSD

TSD-S

T

RVB

BICP

vom Bicarbonat

Fig. : Dialysate Processing

MT-MD-DE08C M.KAY

Dialog+_sm_Chapter 2_1-2003.doc/pdf <011003> ddmmyy

from Bicarbonate

RVK

KP

vom Konzentrat

from Concentrate

T

T

zu Bilanzierungskamme rn

FPE

to Bal ance Chambers

B. Braun Medizintechnologie GmbH

Page 28

2.16.4 Central Bicarbonate and

Concentrate Supply

2.16.5 BIC Cartridge Holder

2. Technical System Description 1/2003 2 - 28

A canister or central supply can be selected via the bicarbonate and

concentrate supply connetion BVA and KVA. The supply connection is an option.

The flow pump FPE guarantees a continuous control of the desired dialysate

flow into the balance chambers.

The flow rate is determined by the filling time of the balance chamber. The flow

pump FPE is controlled via the predetermined volume of the chamber and a

continuous detection of the position of the membrane.

DBK

DBK Throttle Bicarbonate Cartridge Holder

DBKDBK

LAB1

LAB1 Air Separator BIC Cartrige Holder 1

LAB1LAB1

VBKO

VBKO Bicarbonate Cartridge Holder Top Valve

VBKOVBKO

VBKS

VBKS Bicarbonate Cartridge Holder Concentrate Rod Valve

VBKSVBKS

Throttle Bicarbonate Cartridge Holder

Throttle Bicarbonate Cartridge HolderThrottle Bicarbonate Cartridge Holder

DBK ensures a constant pressure (approx. 200 mmHg) during the filling of the

bicarbonate cartridge.

Air Separator BIC Cartrige Holder 1

Air Separator BIC Cartrige Holder 1Air Separator BIC Cartrige Holder 1

LAB1 ensures that only fluid can enter the bicarbonate cartridge.

Bicarbonate Cartridge Holder Top Valve

Bicarbonate Cartridge Holder Top ValveBicarbonate Cartridge Holder Top Valve

The bicarbonate cartridge is filled to the limit presure (200 mmHg) after VBKO

opens.

Bicarbonate Cartridge Holder Concentrate Rod Valve

Bicarbonate Cartridge Holder Concentrate Rod ValveBicarbonate Cartridge Holder Concentrate Rod Valve

The bicarbonate cartridge is vented during preparation and in therapy, i.e. VBKO

closes and VBKS opens for a short time. This is repeated in regular intervals

during threapy. VBKS is opened after the end of the therapy to empty the

bicarbonate cartridge.

vom Vorlau f behälter

from Upline Tank

DBK

VBICP

VBICP Bicarbonate Pump Valve

VBICPVBICP

LAB2

LAB2 Air Separator BIC Cartrige Holder 2

LAB2LAB2

VVB

VVB Upline Tank Valve

VVBVVB

VVB RVB

BICP

LAB1

Bicarbonate Pump Valve

Bicarbonate Pump ValveBicarbonate Pump Valve

If VBICP is opened the liquid level in LAB2 is increased. VBICP switches the BIC

pump in bypass after the end of the therapy to empty the bicarbonate

cartridge.

Air Separator BIC Cartrige Holder 2

Air Separator BIC Cartrige Holder 2Air Separator BIC Cartrige Holder 2

LAB2 serves as a buffer chamber for the bicarbonat e cartridge (and canis ter) to

prevent conductivity malfunctions/deviations during therapy.

Upline Tank Valve

Upline Tank ValveUpline Tank Valve

VVB cuts off the main flow after the end of the therapy to empty the

bicarbonate cartridge via FPE (VBICP and VBKS are opened).

BICLF

TSBIC

RVK

ENDLF

ENDLF-S

TSD

FPE

TSD-S

KP

VBICP

LAB2

VBKO

Fig. : BIC Cartridge Holder (Option)

MT-MD-DE08C M.KAY

Dialog+_sm_Chapter 2_1-2003.doc/pdf <011003> ddmmyy

FBIC

VBKS

BVA

FB

BE

B. Braun Medizintechnologie GmbH

Page 29

2.16.6 Balance Chamber System

2. Technical System Description 1/2003 2 - 29

The balance chamber system has the following components:

Balance Chamber BK1

•

BK1

BK1BK1

2.16.7 Working Principle Balance

Chamber System

Phase 1:

Balance Chamber BK2

•

Balance Chamber Dialyser Inlet Valve VDEBK1

•

Balance Chamber Inlet Valve VEBK1

•

Balance Chamber Membrane Position Sensor MSBK1

•

Balance Chamber Dialyser Outlet Valve VDABK1

•

Balance Chamber Outlet Valve VABK1

•

BK2

BK2BK2

VDEBK1 and VDEBK2

VDEBK1VDEBK1

VEBK1 and VEBK2

VEBK1VEBK1

VABK1 and VABK2

VABK1VABK1

VEBK2

VEBK2VEBK2

VDABK1 and VDABK2

VDABK1VDABK1

VABK2

VABK2VABK2

VDEBK2

VDEBK2VDEBK2

MSBK1 and MSBK2

MSBK1MSBK1

MSBK2

MSBK2MSBK2

VDABK2

VDABK2VDABK2

The measurement and control of the ultrafiltration rate is accomplished by the

double balance chamber system and the ultrafiltration pump UFP.

Both balance chambers BK1 and BK2 are identical. The chambers have flexible

membranes, which can be moved to both sides. The membranes devide the

chambers into two sub-compartments. The flow direction is defined by the

membranes and the eight solenoid valves. The position of the membranes is

measured by inductive membrane position sensors MSBK1 and MSBK2. The

membrane position sensors (ferrites) are connected to the membranes and each

move in a respective coil MSBK1 and MSBK2.

The balance chamber BK1 is filled with dialysate at the beginning of phase 1.

The membrane is in right position. The valves VDEBK1 and VDABK1 are opened.

The balance chamber BK1 is filled by the outlet flow pump FPA, via valve

VDABK1. Simultaneously the dialysate is removed from the balance chamber

BK1 via valve VDEBK1. Phase 1 is completed and the membrane is in left

position (see figure).

RVDA

FPE

VDEBK1

VEBK1

VDEBK2

VEBK2

VZ

MSBK1

MSBK2

The balance chamber BK2 is filled with fresh dialysate during this period. The

used dialysate from the previous phase 2 is drained (see description phase 2).

PE/RVE

BK1

BK2

VABK1

VDABK1

VABK2

VDABK2

DDE

VLA

LA_FS

FPA

UFP

LA

RVFPA

VBP

VDA

VDE

BL

open

offen

PDA

closed

geschlossen

Fig. : Phase 1 Balance Chamber

MT-MD-DE08C M.KAY

Dialog+_sm_Chapter 2_1-2003.doc/pdf <011003> ddmmyy

B. Braun Medizintechnologie GmbH

Page 30

2. Technical System Description 1/2003 2 - 30

Phase 2: After phase 1 is completed there is an automatic switch to the filled balance

chamber BK2 to obt ain a constant flow in the dialyse r. The complete cylce is

repeated in phase 2, i.e. valves VDEBK2 and VDABK2 are opened. The balance

chamber BK2 is filled via valve VDABK2. Simultaneously the dialysate is drained

from the balance chamber BK2 via valve VDEBK2. Phase 2 is completed and the

menbrane is in left position (see figure).

Simultaneously the balance chamber BK1 is filled with fresh dialysate.

Therefore valve VEBK1 is opened. Valve VABK1 is also opened, to initiate the

flow path for the used dialysate to the drain. The membrane moves to the right

position.

The outlet fluid volume is equal to the returned fluid volume, due to the closed

balance chamber system

The fluid volume removed from the closed system via the ultrafiltration pump

UFP is replaced from the blood in the dialyser and equals the precise

ultrafiltration volume.

The system is initialised in preparation, i.e. the membrane sensors are

automatically calibrated and the speed of the flow pumps FPE and FPA are

determined. Thus a synchronisation of the membranes is guaranteed, and the

pump speeds for the desired flow are determined.

FPE

RVDA

Fig. : Phase 2 Balance Chamber

VDEBK1

VEBK1

VDEBK2

VEBK2

VZ

MSBK1

MSBK2

BK1

BK2

VABK1

VDABK1

VABK2

VDABK2

DDE

VLA

LA_FS

FPA

UFP

PE/RVE

LA

RVFPA

VBP

VDA

VDE

BL

open

offen

closed

geschlossen

PDA

MT-MD-DE08C M.KAY

Dialog+_sm_Chapter 2_1-2003.doc/pdf <011003> ddmmyy

B. Braun Medizintechnologie GmbH

Page 31

2. Technical System Description 1/2003 2 - 31

2.16.8 Ultrafiltration and Rinsing Bridge

The main flow path and bypass have the following components:

Dialyser Inlet ThrottleDDE

•

DDE

DDEDDE

Dialyser Inlet Valve VDE

•

Dialyser Outlet Valve VDA

•

Bypass Valve VBP

•

Outlet Flow Pump FPA

•

VBP

VBPVBP

VDE

VDEVDE

FPA

FPAFPA

VDA

VDAVDA

The flow path for the main flow and bypass are determined by the valves VDE,

VDA and VBP. The built up flow from the flow pump FPA is stabilised by the

throttle DDE. Valves VDE and VBP are closed for sequential therapy

(ultrafiltration without dialysate flu id flow). The ultrafiltrate removal is carried

out by the ultrafiltration pump UFP.

Further components are:

Red sensitive blood leak detector BL

•

Pressure sensor PDA which monitors the dialysate pressure (also used to

•

calculate TMP)

Air separator LA with built in level sensors LAFS and air separator valve VLA

•

Throttle RVDA functions as a resistance to stabilise the flow of FPE

•

The throttle RVFPE prevents a high pressure build-up and thus a bursting of

tubing if the flow path is blocked behind FPE. If the set pressure is reached

RVFPE is opened and the fluid can circulate.

The fluid level is lowered in the air separator LA, due to air bubbles from the

dialyser (degassing or possible leakages). The air separator valve VLA is opened

if the fluid level is lower than the bottom level sensor. The fluid level is

increased, due to the negative pressure for the degassing range, until the level

reaches the upper level sensor of the air separator LA.

2.16.9 Disinfection and Cleaning Program

The user can select a disinfection or cleaning program. The position of the

couplings are checked by the sensors BICSS, KSS, SBS1 and SBS2. Then the UF

pump UFP starts running and builds up a negative pressure against the closed

disinfection valve VD. At approx. -200 mmHg VD opens and disinfectant is

sucked in by the UFP.

The circulation va lve VZ is open and fluid fl ow s i nto the upl i ne ta nk VB, because

the throttle RVDA acts as a forward resistance. Thereby a quicker heat-up in the

hot cleaning program is achieved and thus a reduction of disinfectant. There is

no flow of fluid to the drain during suction, heat-up and circulation.

MT-MD-DE08C M.KAY

Dialog+_sm_Chapter 2_1-2003.doc/pdf <011003> ddmmyy

B. Braun Medizintechnologie GmbH

Page 32

2.17 Block Diagram

2. Technical System Description 1/2003 2 - 32

Fig. : Block Diagram

MT-MD-DE08C M.KAY

Dialog+_sm_Chapter 2_1-2003.doc/pdf <011003> ddmmyy

B. Braun Medizintechnologie GmbH

Page 33

2.17.1 Legend Block Diagram

Supervisor Board SB

Controller Sensoren

Supervisor Sensors

BICLF

BICSS

ENDLF

KSS

NSVB

PBE

PE

SBS1

SBS2

TSBIC

TSD

TSE

ENDLFS

TSDS

2. Technical System Description 1/2003 2 - 33

Bicarbonate Conductivity

Bicarbonate Rinsing Connection Sensor

END Conductivity

Concentrate Rinsing Connector Sensor

Level Sensor Upline Tank

Pressure Sensor

Degassing Pressure Sensor

Rinsing Bridge Connector Sensor 1

Rinsing Bridge Connector Sensor 2

Bicarbonate Temperature Sensor

Dialysate Temperature Sensor

Degassing Temperarture Sensor

END Conductivity Supervisor

Dialysate Temperature Sensor Supervisor

Controller/Supervisor

Sensors/Actuators

BKUS

BL

FEDFFS

FEDHDFS

LAFS

MSBK1

MSBK2

PA

PDA

PSABFS

PSAUS

PV

RDV

SAD

TSHE

VBE

VBICP

VBKS

VBKO

VDFF

VSAA

VSAE

VSB

VVB

Bottom Bicarbonate Sensor

Blood Leak Detector

DF Filter Detection Sensor

HD Filter Detection Sensor

Air Separator Level Sensors

Membrane Position Sensor Balance Chamber 1

Membrane Position Sensor Balance Chamber 2

Arterial Pressure Sensor

Pressure Sensor Dialysate Outlet

Port Substition Drain Sensor

Port Substition Outlet Sensor

Venous Pressure Sensor

Venous Red Detector

Safety Air Detector

Heater Inlet Temperature Sensor

Filter Vent Valve

BIC Pump Valve

BIC Concentrate Suction Rod Valve

Top BIC Cartridge Valve

DF Filter Valve

Substitution Connection Outlet Valve (drain)

Substitution Connection Inlet Valve

Substitution Bypass Valve

Upline Tank Valve

MT-MD-DE08C M.KAY

Dialog+_sm_Chapter 2_1-2003.doc/pdf <011003> ddmmyy

B. Braun Medizintechnologie GmbH

Page 34

Power Board 1 PB1

Power Board 2 PB2

BPA

EP

FPA

FPE

BICP

KP

RVE

SAKV-SG

UFP

VABK1

VABK2

VB

VBP

VD

VDA

VDABK1

VDABK2

VDE

VDEBK1

VDEBK2

VEBK1

VEBK2

VLA

VVBE

VZ

2. Technical System Description 1/2003 2 - 34

Arterial Blood Pump

Degassing Pump

Outlet Flow Pump

Inlet Flow Pump

Bicarbonate Pump

Concentrate Pump

Degassing Control Valve

Venous Tubing Clamp Currentles Closed

Ultrafiltration Pump

Outlet Valve Balance Chamber 1

Outlet Valve Balance Chamber 2

Upline Tank

Bypass Valve

Disinfection Valve

Dialyser Outlet Valve

Dialyser Outlet Valve Balance Chamber 1

Dialyser Outlet Valve Balance Chamber 2

Dialyser Inlet Valve

Dialyser Inlet Valve Balance Chamber 1

Dialyser Inlet Valve Balance Chamber 2

Inlet Valve Balance Chamber 1

Inlet Valve Balance Chamber 2

Air Separator Valve

Upline Tanke Inlet Valve

Circulation Valve

Heparin Pump Comfort Board

SN-Crossover Board

Power Supply

HP

BPV

PBS

PBS-S

SAKA

TSH

Heparin Pump Compact

Venous Blood Pump

Pressure Single Needle

Pressure Single Needle Supervisor

Arterial Tubing Clamp

H

Heater Element

Thermal Fuse Heater Element

MT-MD-DE08C M.KAY

Dialog+_sm_Chapter 2_1-2003.doc/pdf <011003> ddmmyy

B. Braun Medizintechnologie GmbH

Page 35

2.18 TFT Monitor

2.18.1 Description TFT Monitor

2. Technical System Description 1/2003 2 - 35

TFT Monitor

TFT Monitor

TFT MonitorTFT Monitor

The 15" TFT monitor (TFT=thin film transistor) has a resolution of

1024 x 768 XGA. The TFT housing can be swivelled.

Keyboard

Keyboard

KeyboardKeyboard

The following settings can be performed via the keyboard:

Start/stop arterial blood pump BPA

•

Increase/decrease speed of arterial blood pump BPA

•

Acknowledge alarms

•

Acknowledge entries

•

Display:

+-

Battery Option

Keys:

Decrease speed of arterial blood pump BPA

Fig. : TFT Monitor witt Touch Screen

+-

. : Keyboard Membrane

Fig

stop

stop

Start and stop arterial blood pump BPA

Increase speed of arterial blood pump BPA

Acknowledge alarms

Acknowledge entries

start

stop

The

key has two integrated yellow LEDs. In both the

and keys two red LEDs are in tegrated. All keys switch a

resistor on the supervisor communication board to ground GNDD.

Optical Status Displays OSD

An optical status display OSD is integrated into the TFT hou sing

(top left and right). The red LED is cyclically checked during

therapy. The following operating statuses are displayed:

. : Rear

Fig

MT-MD-DE08C M.KAY

Dialog+_sm_Chapter 2_1-2003.doc/pdf <011003> ddmmyy

TFT Monitor

Red

Red: Alarm

RedRed

Yellow

Yellow: Warning

YellowYellow

Green

Green: Trouble-free operation

GreenGreen

Touch Screen/Touch Controller Board TCB

The touch screen has a resolution of 4096 x 4096 with a 4-wire

to technique and has an RS 232 interface (9600 Baud).

B. Braun Medizintechnologie GmbH

Page 36

2. Technical System Description 1/2003 2 - 36

Backlight Inverter Board BIB

Front Panel Board FPB

The backlight inverter board drives four lamps for the TFT

monitor.

The front panel board has five keys. If a key is pressed a signal is

generated for the TLC and LLS.

Three LEDs are integrated in each key. Thus the signals for the

TLC are generated. The alarm acknowledge key additionally

generates a signal for the LLS.

A charge LED is integrated on the FPB for the battery option.

The volume can be set with a potentiometer. A signal is

generated for the TLC. The LLS monitors the signal via the

current and the pulse.

The signals are generated for the TLC and LLS for the optical

status displays OSDs.

The signals for the brightness of the LEDs (OSD) are generated

for the TLC.

The signal (brightness for the TFT) for the backlight inverter

board BIB is generated for the TLC.

The signal for the parallel port is generated for the TLC.

The signal for the RS 232 interface is generated for the LLS.

Loudspeaker

A loudspeaker for audible alarms is either integrated in the basic

housing. The volume can be set with a potentiometer on the FPB

(TFT housing, rear bottom left).

MT-MD-DE08C M.KAY

Dialog+_sm_Chapter 2_1-2003.doc/pdf <011003> ddmmyy

B. Braun Medizintechnologie GmbH

Page 37

2. Technical System Description 1/2003 2 - 37

2.19 ABPM Option (None-Invasive Blood

Pressure Measurement)

ABPM Option

ABPM Module/ABPM Interface Board

Dialog+

Voltage Supply

Multi I/O

2.19.1 Wiring Diagram ABPM Option

Floppy Disk Drive

Diskettenlaufwerk

A none-invasive blood pressure measurement is possible with the ABPM option

(automatic blood pressure measurement). The ABPM option works on an

oscillometrical basis for the automatical control of the symptomatic hypertonia

during dialysis.

The ABPM option can be retrofitted in the dialysis machine.

The ABPM option consists of the ABPM module and the ABPM interface board.

The ABPM option will be assembled in the basic housing (left side).

The ABPM module is connected to the switch mode power supply via the ABPM

interface board (connector P8).

The ABPM module is connected to the motherboard (COM3 port) via the ABPM

interface board.

ABPM Module

ABPM-Modul

left side basic housing

linke Seite Grundgehäuse

Motherboard

GX1LCD

COM3

1

COM4

COM1COM2

Fig. : Wiring Diagram ABPM Option

P1

P2

ABPM Inte rface Bo ar d

ABPM Interface-Board

Switch Mode Power Supply SMPS

Schaltnetzteil SMPS

1

1

P8

MT-MD-DE08C M.KAY

Dialog+_sm_Chapter 2_1-2003.doc/pdf <011003> ddmmyy

B. Braun Medizintechnologie GmbH

Page 38

2. Technical System Description 1/2003 2 - 38

2.20 bioLogic RR Option (Automatic Blood

Pressure Stabilisation)

The bioLogic RR option can be installed and activated subsequently. The ABPM

option must be present in the Dialog+ to run the bioLogic RR option.

The software for the bioLogic RR option is installed via an installation diskette.

The diskette is automatically marked (assigned to the machine) during

installation and subsequently can only be used for this specific Dialog+

machine.

•

Note

Note

NoteNote

If the TLC software has to be reinstalled or the hard disk drive has to be

replaced:

Activate the option bioLogic RR, i.e. use the bioLogic RR installation diskette

which belongs to the respective machine and activate again the option.

Installation diskette for bioLogic RR for SW ≥ 6.20

MT-MD-DE08C M.KAY

Dialog+_sm_Chapter 2_1-2003.doc/pdf <011003> ddmmyy

B. Braun Medizintechnologie GmbH

Page 39

2.21 Supervisor Board SB

2.21.1 Supervisor

2.21.1.1 Block Diagram Supervisor

2. Technical System Description 1/2003 2 - 39

Digitale

Eingänge

Digital

Inputs

Digitale Eingänge

Analoge Eingänge

Digital e Ausgänge

Digitale

Ausgänge

Digital

Outputs

2

E PROM

Digital Inputs

Analog Inputs

Digital Outputs

RAM

Daten/Adressbus

Data/Address Bus

CPU

80C535

Reset

Generator

Speicher-

Karte

Memory

Card

ACIA

Serielle

Schnittstelle

Serial

Interface

Serielle Schnitt stel le

Serial Interface

Datenaustausch Controller

Data Communication Controller

2

E PROM

Seriell

Serial

DIABUS

TLCB

LLCB

Fig. : Block Diagram Supervisor Board

2.21.1.2 Description Supervisor

The supervisor board connects the low level controller LLC with the peripheral.

Additionally the supervisor (monitoring microprocessor) is integrated on the

board. The following components are assembled on the board. The sensors are

directly connected:

Bicarbonate Conductivity Measurement

•

END Conductivity Measurement Controller

•

END Conductivity Measurement Supervisor

•

DegassingTemperature Measurement

•

Bicarbonate Temperature Measurement

•

Dialysate Temperature Measurement Controller

•

Dialysate Temperature Measurement Supervisor

•

Level Sensors Upline Tank

•

Reed Contacts Rinsing Bridge

•

Venous Pressure Sensor

•

Arterial Pressure Sensor

•

Level Sensors in the Air Separator

•

Red Sensors

•

Degassing Pressure Measurement

•

Blood Inlet Pressure Measurement

•

Additionally the following components are available for monitoring and control:

MT-MD-DE08C M.KAY

Dialog+_sm_Chapter 2_1-2003.doc/pdf <011003> ddmmyy

Monitoring of analogue 12 V supply voltage

•

Synchronisation of actual pump values

•

B. Braun Medizintechnologie GmbH

Page 40

2. Technical System Description 1/2003 2 - 40

The signal processing for the low level controller and supervisor are on the

supervisor board. All sensors are connected to this board via plugs. The power

board BP1 and PB2 are also connected to this board. Signals for single sensors

of the processor system are also processed separately.

Microprocessor

80C535 CPU

Address Decoding Logic

2

Serial E

PROM

The supervisor has the following components:

80C535 CPU

•

2

PROM

E

•

Connection for:

Memory Card

•

Digital Inputs and Outputs

•

Analogue Inputs

•

Serial Interface

•

Communication with the Controller

•

Reset Generator

•

The supervisor CPU (central processing unit) has the following data:

8 Bit Processor

•

256 x 8 RAM (internal)

•

6 8 Bit I/O Ports

•

3 16 Bit Counter

•

1 Serial Interface with max. 9600 Baud

•

8 Bit AD Converter with 8 Multiplexer Inputs

•

2

The processor is equipped with a 32 kB external RAM and a 1 MB E

program code is stored in the E

2

The serial E

PROM stores the supervisor sensor calibration data. The data is

2

PROM. The RAM is used to store data.

PROM. The

stored during calibration in the TSM service program and loaded before a

therapy is activated.

Digital Inputs and Outputs

Analogue Inputs

Serial Interface

Communication with the Controller

Reset Generator

Additional signal memory (latches) for the in- and outputs are available,

because the implemented ports of the 535 processor are limited. The outputs

have open colectors. All inputs have TTL level.

The processor has an internal 8 bit AD converter. The input voltage range is 0 to

5 V. The supervisor monitors the analogue sensors conductivity, temperature

and pressure, these are directly connected with the inputs.

The serial interface is used for the communication with the front panel board

FPB (via the SUPBUS). The tr ansfer rate is 9600 baud. The interface works in full

duplex mode with V 24 level.

An additional ACIA (asynchronous communications interface adapter) is

implemented for the communication with the top level controller via the

DIABUS. The ACIA works in full duplex mode with 19200 baud and 24 V level.

The communication with the controller is realised by a parallel interface. The

interface has signal memory (latches).

The reset generator resets the processor after th e su pply volt age is sw itched on.

Thereby the program can start at a predefind address.

MT-MD-DE08C M.KAY

Dialog+_sm_Chapter 2_1-2003.doc/pdf <011003> ddmmyy

B. Braun Medizintechnologie GmbH

Page 41

2.22 Bicarbonate Conductivity

Measurement

2.22.1 Block Diagram Bicarbonate

Conductivity Measurement

+5 VREF

Referenzspannung

Reference Voltage

CLK4

Takt 400 0 Hz

Cycle 4000 Hz

Geschalteter

Tiefpaß

Gleichrichter

Low-Pass

Rectifier

BIC-LF

Ausgangssignal

Output Signal

Fig. : Block Diagram Bicarbonate Conductivity Measurement

2. Technical System Description 1/2003 2 - 41

BICLF-A

Sendeelektrode

Transmitter Electrode

Switch

Verstärker

Amplifier

BICLF-C

Empfangselektrode

Receiver Electrode

2.22.2 Description Bicarbonate

Conductivity Measurement

The conductivity of the dialysate is determined by a resistance measurement.

The measurement is performed by an alternating current with approx. 4 kHz.

The calibration is accomplished by the controller. The measurement cell has two

transmitter electrodes and a receiver electrode with a fixed cell constant.

A transmitter voltage for the transmitter electrode BICLF_A signal is

•

generated from the +5 VREF reference voltage by the CLK4 signal (4000 Hz).

The signal runs through the fluid.

•

The received BICLF_C signal is amplified.

•

The switched rectifier converts the a.c. voltage to a d.c. voltage BIC_LF.

•

A d.c. voltage, which is proportional to the conductivity is fed to the AD

•

converter.

The temperature compensation and linearisation of the conductivity is

•

performed by the controller.

MT-MD-DE08C M.KAY

Dialog+_sm_Chapter 2_1-2003.doc/pdf <011003> ddmmyy

B. Braun Medizintechnologie GmbH

Page 42

2. Technical System Description 1/2003 2 - 42

2.23 END Conductivity Measurement

Controller

2.23.1 Description END Conductivity

Measurement Controller

The design of the END conductivity measurement controller is identical with

the bicarbonate conductivity measurement in paragraph 2.22.

2.23.2 END Conductivity Measurement

Supervisor

2.23.3 Block Diagram END Conductivity

Measurement Supervisor

Taktgenerator

4000 Hz

Pulse Generator

4000 Hz

Referenzspannung

Reference

Voltage

Geschalteter

END-S-LF

Ausgangssignal

Output Signal

Fig. : Block Diagram END Conductivity Measurement Supervisor

2.23.4 Description END Conductivity

Measurement Supervisor

Gleichrichter

Switch

Rectifier

ENDLF-S-A

Sendeelektrode

Transmitter Electrode

Verstärker

Amplifier

ENDLF-S-C

Empfangselektrode

Receiver Electrode

The END conductivity measurement of the dialysate by the supervisor is in

MT-MD-DE08C M.KAY

Dialog+_sm_Chapter 2_1-2003.doc/pdf <011003> ddmmyy

principle identical with the controller. The differences are:

The independent generation of the reference voltage and the clock signal

•

Dimension of the Measurement Cell

•

The calibration is

performed

by the supervisor software.

B. Braun Medizintechnologie GmbH

Page 43

2.24 Temperature Measurement

2.24.1 Block Diagram Degassing

Temperature Measurement

2. Technical System Description 1/2003 2 - 43

+5 VREF

Referenzspannung

Reference Voltage

TSE, TSHE, TSBIC, TSD

Ausgangssignal

Output Signal

Fig. : Block Diagram Degassing Temperature Measurement

U/I Wandler

U/I Converter

2.24.2 Design Degassing Temperature

Measurement

PTC

Offset

Verstärker

Amplifier

Tiefpaß

Low-Pass

The temperature of the fluid is measured by a PTC resistor (PTC positive

temperature coefficient).

2.24.3 Description Bicarbonate

Temperature Measurement

The design is identical with the degassing temperature measurement in

2.24.4 Description Dialysate Controller

Temperature Measurement

The design is identical with the degassing temperature measurement in

The PTC has a constant current flow of < 0.1 mA

•

The voltage drop is measured and amplified in a differential amplifier

•

An offset voltage is added to lift the zero point. Thereby the measurement

•

range of the AD converter has an optimal working condition.

The output voltage is fed to the AD converter on the supervisor board via a

•

low-pass filter.

paragraph 2.24.1.

paragraph 2.24.1.

MT-MD-DE08C M.KAY

Dialog+_sm_Chapter 2_1-2003.doc/pdf <011003> ddmmyy

B. Braun Medizintechnologie GmbH

Page 44

2. Technical System Description 1/2003 2 - 44

2.24.5 Block Diagram Dialysate Supervisor

Temperature Measurement

Referenz-

Spannung

Reference

U/I Wandler

U/I Converter

Voltage

PTC

Offset

Verstärker

Amplifier

TSD-S

Ausgangssignal

Output Signal

Fig. : Block Diagram Dialysate Supervisor Temperature Measurement

2.24.6 Description Dialysate Supervisor

Temperature Measurement

The temperature measurement of the supervisor has an independent reference

2.25 Level Measurement

2.25.1 Block Diagram Level Measurement

Upline Tank

Tiefpaß

Low-Pass

voltage source. Thus a cross-interference with the temperature sensors of the

controller is excluded.

+5 V

NSVBO

NSVBU

Fig. : Block Diagram Upline Tank

2.25.2 Description Level Measurement

Upline Tank

The level sensor in the upline tank has two reed contacts. The contacts are

switched by an internal magnet in a float ball. Pull-up resistors are on the

input. The query is carried out by the digital inputs of the controller.

MT-MD-DE08C M.KAY

Dialog+_sm_Chapter 2_1-2003.doc/pdf <011003> ddmmyy

B. Braun Medizintechnologie GmbH

Page 45

2. Technical System Description 1/2003 2 - 45

2.26 Reed Contacts

2.26.1 Block Diagram Coupling Status

+5 V

SBS1

SBS2

KSS

BICSS

Fig. : Block Diagram Query Reed Contacts

2.26.2 Description Coupling Status

Magnets are integrated in the dialysate couplings und concentrate couplings. If

the couplings are connected the reed contacts are switched. The query is

performed by the digital inputs of the controller and supervisor. The inputs have

pull-up resistors.

2.27 Pressure Measurement

2.27.1 Block Diagram Venous Pressure

Measurement

+5 VREF

Druckaufnehmer

Fig. : Block Diagram Venous Pressure Measurement

Pressure Sensor

2.27.2 Description Venous Pressure

Measurement

The pressure sensor has a resistance bridge. The resistance value changes in

+1,2 VREF

Offsetspannung

Offset Voltage

+5 V

Differenz

Verstärker

Differential

Begrenzer

Limiter

Ausgangssignal

Reference Voltage

Amplifier

accordance with the present pressure valu e. A constant +5 VREF is connect ed

to the bridge.

PV

MT-MD-DE08C M.KAY

Dialog+_sm_Chapter 2_1-2003.doc/pdf <011003> ddmmyy

The measurement signal is tapped and amplified in the differential amplifier.

•

An offset voltage is added to lift the zero point. Thereby the measurement

•

range of the AD converter has an optimal working condition.

The voltage is limited to +5 V by a clamp circuit on the output, in the event

•

of a fault condition. A damage of the following circuit components is

thereby prevented.

B. Braun Medizintechnologie GmbH

Page 46

2. Technical System Description 1/2003 2 - 46

2.27.3 Block Diagram Arterial Pressure

Measurement

+5 VREF

Druckaufnehmer

Fig. : Block Diagram Arterial Pressure Measurement

2.27.4 Description Arterial Pressure

2.28 Blood Inlet Pressure Measurement

2.28.1 Block Diagram Blood Inlet Pressure

Pressure Sensor

Measurement

Measurement

+2,5 VREF

The design of the arterial pressure measurement is identical with the venous

Offsetspannung

Offset Voltage

+5 V

Differenz

Verstärker

Differential

Begrenzer

Limiter

Ausgangssignal

Reference Voltage

PA

Amplifier

pressure measurement in paragraph 2.27.2, with the exception of the offset

voltage.

+5 VREF

+1,8 VREF

Druckaufnehmer

Fig. : Block Diagram Blood Inlet Pressure Measurement

2.28.2 Description Blood Inlet Pressure

Pressure Sensor

Measurement

The design of the blood inlet pressure measurement is identical with the venous

Offsetspannung

+5 V

Offset Voltage

Differenz

Verstärker

Differential

Begrenzer

Limiter

Ausgangssignal

Reference Voltage

Amplifier

pressure measurement in paragraph 2.27.2, with the exception of the offset

voltage.

PBE

MT-MD-DE08C M.KAY

Dialog+_sm_Chapter 2_1-2003.doc/pdf <011003> ddmmyy

B. Braun Medizintechnologie GmbH

Page 47

2. Technical System Description 1/2003 2 - 47

2.29 Level Sensors

2.29.1 Block Diagram Level Sensors Air

Separator

Hochpaß

High-Pass

LAFSO-EL

Oszillator

Oscillator

Hochpaß

High-Pass

Fig. : Block Diagram Level Sensors

2.29.2 Description Level Sensors Air

Separator

LAFSU-EL

Gleichrichter Tiefpaß

Rectifier Low-Pass

Gleichrichter Tiefpaß

Rectifier Low-Pass

The query of the fluid level in the air separator behind the balance chamber is

accomplished by the conductivity of the dialysate.

The oscillator generates an a.c. voltage with a frequnecy of approx. 8 kHz.

•

The d.c. voltage part is removed by a high-pass.

•

The output voltage is fed to the electrode.

•

If the electrode immerses into the fluid due to an increase of the fluid level,

•

the voltage at the electrode is decreased.

The voltage is rectified for evaluation and smothed by a low-pass

•

This d.c. voltage is compared with a reference voltage by a comparator.

•

Komparator

Comparator

Komparator

Comparator

LAFSO

LAFSU

2.30 Red Detector

2.30.1 Block Diagram Red Detector

CLK4

Ausgangssignal

RDV

Fig. : Block Diagram Red Detector

Output Signal

2.30.2 Description Red Detector

LED-

Ansteuerung

LED Drive

Tiefpaß

Low-Pass

The red detector works as a light barrier with a triggered 4 kHz green light.

The received signal from the photo transistor is amplified.

•

The signal is only evaluated, if the green LED is also driven.

•

External interferences are thereby prevented.

•