Page 1

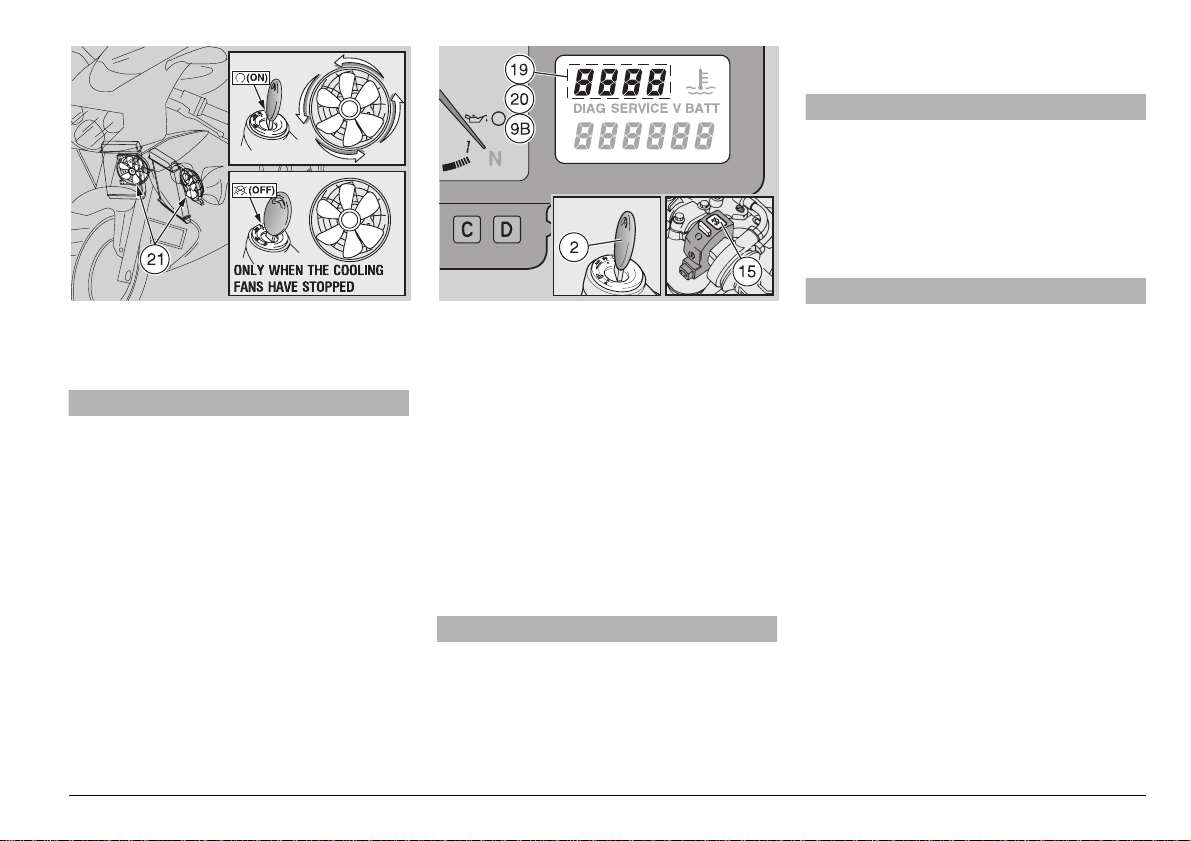

NOTE The coolin g fans (21) funct ion only

when the ignition key (2) is in the “

position.

+” (ON)

aCAUTION

Do not leave the ignition key in the “-”

(OFF) position since the cooling fans

will not run regardless of the coolant

temperature. T his will cause the c oolant temperature to continue to rise.

If, before shutting off the engine, you hear

the cooli ng fans fun ctioning, stop the e n-

gine but leave the ignition key to “

position. This will allow the cooling fans to

draw air through the radiators, and lower

the temperature. Turn the ignition key to

-” (OFF) position only when the cooling

“

fans have stopped.

If, while riding, the right side of the multi-

function display shows a temperature of 115

– 120 °C (239 – 248 °F) (19), stop riding the

vehicle, stop the engine, turn the ignition

+” (ON) position and wait until the

key to “

+” (ON)

cooling fans have sto pped, then turn the ig nition key to “

the coolant level, see p. 56 (COOLANT).

If the symbol “///” (20) is displayed , stop

riding the vehicle and let the engine run at

3,000 rpm for approximately two minutes,

thus allowing the coolant to circulate normally in the cooling system. Then move the engine stop switch to position “

check the coolant level, see p. 5 6 (C OO LANT).

If the symbol “

after the coolant l evel has been che cked,

contact your Local aprilia Dealer.

-” (OFF) positio n and check

m” (OFF) and

///” (20) is still displayed

aWARNING

Do not operate the vehicle if the maxi-

mum temperature [120 °C (248 °F)] is exceeded. Serious engine damage or even

seizure may result which can cause an

upset and serious injury or even death.

Whenever the ignition key (2) is turned to

+” (ON), the right sid e o f th e m ult ifu nction

“

display wi ll show “HIL” (9B) for about

three seconds.

aCAUTION

If the symb ol “HIL” (9B) is displayed

during the normal running of the engine, this means that the electronic unit

has detected an anomaly. In many cases, the engine keeps running with reduced performance levels; immediately

contact your Local APRILIADealer

.

aWARNING

Avoid opening and clo sing the throttle

repeatedly and continuously. Failure to

head this warning can cause you to accidentally lose control of your vehicle.

When you have to brake, close the

throttle and apply both brakes simultaneously in order to obtain the best

brake performance.

By applying only the front brake or only

the rear brake, you re duce the braking

performance considerably and run the

risk of locking up one wheel which can

cause an upset and subsequent serious

injury or even death.

If you stop on an up hill, us e brakes only

to slow the vehicle and to keep it in

place. Slipping the clutch to keep the

vehicle in one place on an uphill grade

will very quickly ruin the clutch and

overheat the engine.

Before enteri ng a turn, slow down, using the brakes and the engine, to a constant speed and then accelerate slightly

use and maintenance RSV mille

-

67

Page 2

through the turn. Av oid braking at the

last moment. Thi s can cause you to

lose control of your vehicle.

If the brakes are operated continuously

on downhill grades, the discs and pads

will overheat, reducing the braking efficiency. Use engine compre ssion and

downshift to retard your vehicle while

going downhill. Use the brakes as little

as possible to maintain a safe speed.

Never coast downhill with the e ngine off

and/or the clutch disengag ed or the

transmission in neutral.

On roads that are wet or covered with

snow, ice or mud, ride very slowly,

avoiding braking or accelerating or maneuvering quickly. Hold the handlebars

firmly.

Failure to heed these warnings can

cause an upset with su bsequent serious injury or death.

Pay very close attention to any obstacles or variations of the road surface.

Uneven roads, rails, manhole covers,

painted traffic stripes, traffic dots all be come slippery when wet. Avoid partic ularly steel pl ates which are som etimes

used during r oad maintenanc e. They

become more slippery than ice once

they are wet by rain. If you must ride on

such surfaces, decrease your speed

and operate the throttle, brakes and

steering very gently.

Always use the turn signals any time

you intend to change lanes or change

direction, and avoid sudden or abrupt

turning.

use and maintenance RSV mille

68

-

Switch off the direction indicators as

soon as you have changed direction.

Overtake and pass only with care, especially in rainy weather when a water

cloud created by larger vehicles reduces

visibility and the slip stream could cause

you to lose control of your vehicle.

25..).').

The internal parts of the engine and transmission must be properly run-in to ensure

their long life and dependable operation.

If possible, while breaking in your vehicle,

ride on hilly roads a nd/ or roa ds w it h many

curves so that the engine and transmission undergo lots of speed changes. It i s

also important that, during the r un-in period, the suspension and brak es be treated

gently to allow the mating parts to bed.

Therefore, avoid hard braking, high

speeds or very bumpy roads during the

break in period.

NOTE Only after the first 937 mi (1500

km) of running-in you can expect the best

performance from the vehicle.

During break in, obey the following rules:

◆

Do not open the throttle abruptly or fully

at low engine speed. This rule applies

even after break in has been completed.

◆

During the first 62 mi (100 km), apply the

brakes with caution, avoid sudden and

prolonged braking. This ensures correct

bedding in of the pads on the discs.

◆

During the first 625 mi (1,000 km), never

exceed 6,000 rpm.

aWARNING

After the vehicle has been operated for

625 mi (1,000 km) perform the “checking

operations” shown in column “After running-in” of the REGULAR SERVICE INTERVALS CHART, see p. 74. Rectify any

faults found. Failur e to heed this warning could lead to damage to your vehicle

or engine s eizure or o ther malfun ction

which could cause an upset and lead to

serious injury or even death.

◆

Between the first 625 mi (1,000 km) and

937 mi (1,500 km) drive more briskly,

changing speed and using maximum acceleration for only a few seconds. Never

exceed 7,500 rpm.

◆

After the first 937 mi (1,500 km) if you

have followed the above break in schedule, the engine should be fully broken in,

and will deliver maxi mum performance.

However, never exceed the ma ximum allowed rpm (10,500 rpm).

Engine maximum rpm

for the running-in

Mileage mi (km) Max. rpm

0 – 625 (0 – 1,000) 6,000

625 – 937

(1,000 – 1,500)

over 937 (1,500) 10,500

7,500

Page 3

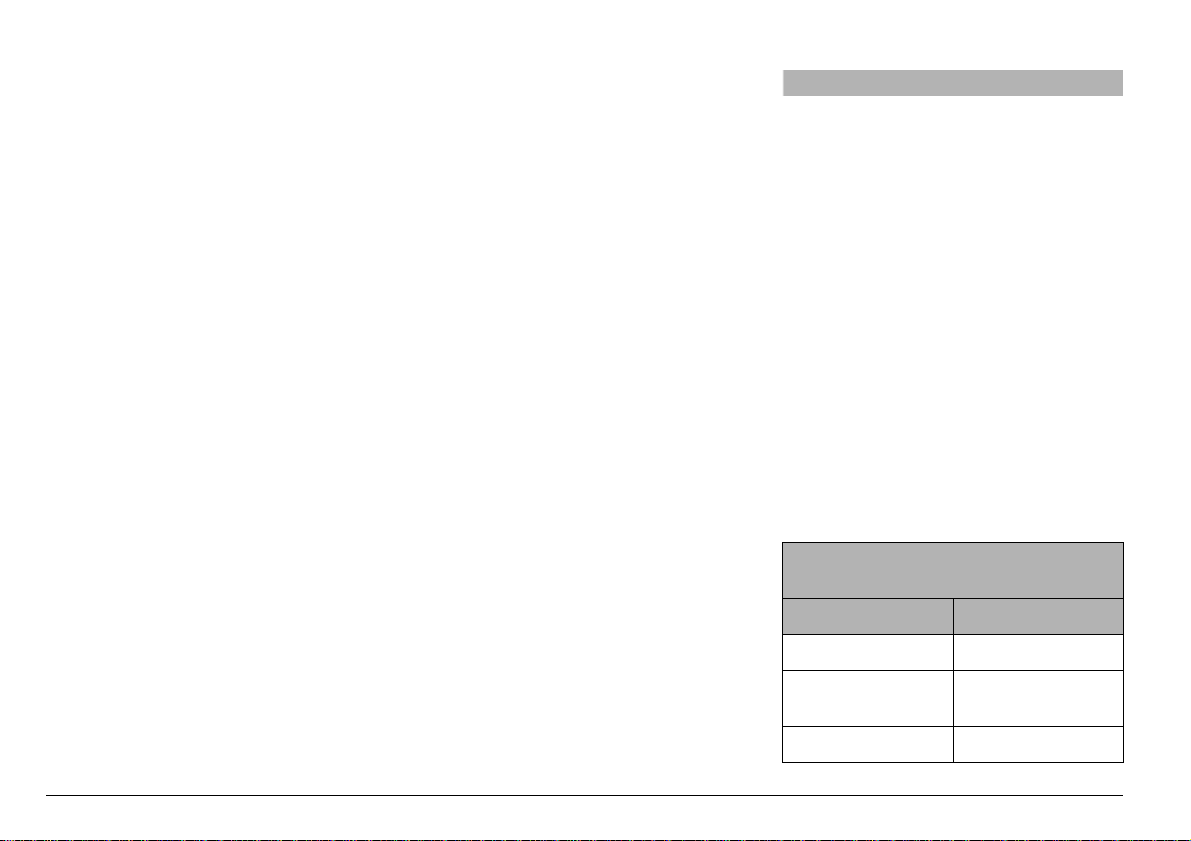

34/00).'

aWARNING

If possible, avoid stopping abruptly,

slowing down suddenly and braking at

the last moment.

Failure to comply wi th these instructions may cause an accident with consequent risk of serious injuries or even

death.

◆

Release the throttle grip (1) (Pos. A),

gradually put on the brakes and at the

same time shift down in or der to decrease the speed, see p. 64 (RIDING).

Once the speed has decrea sed, before

stopping the vehicle:

◆

Pull in the clutch lever (2) (Pos. B) in or-

der to prevent the engine dying.

When the vehicle has come to rest:

◆

Position the shift lever (3) in neutral

(green warning light “

◆

Release the clutch lever (2) (Pos. C).

◆

If you are stopping just briefly and not

q” (4) on).

shutting down the engine, keep one

brake applied.

use and maintenance RSV mille

-

69

Page 4

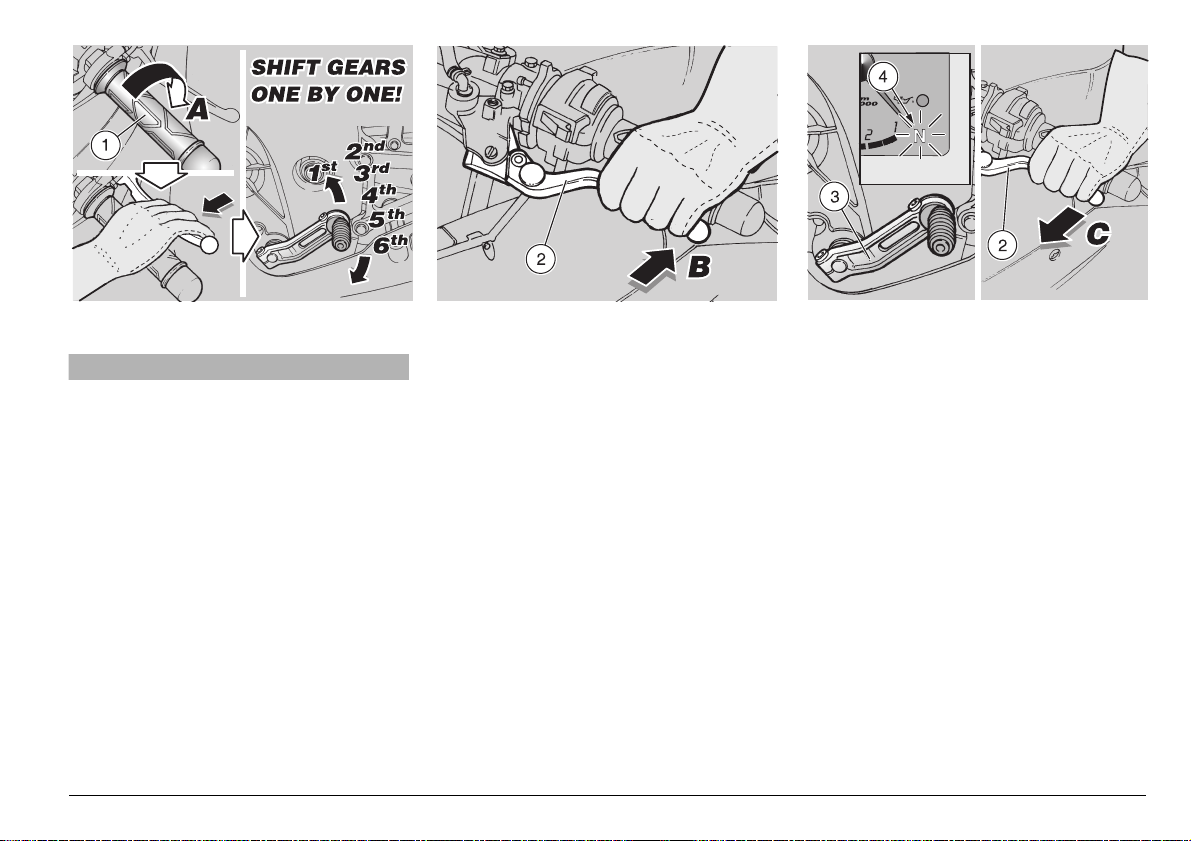

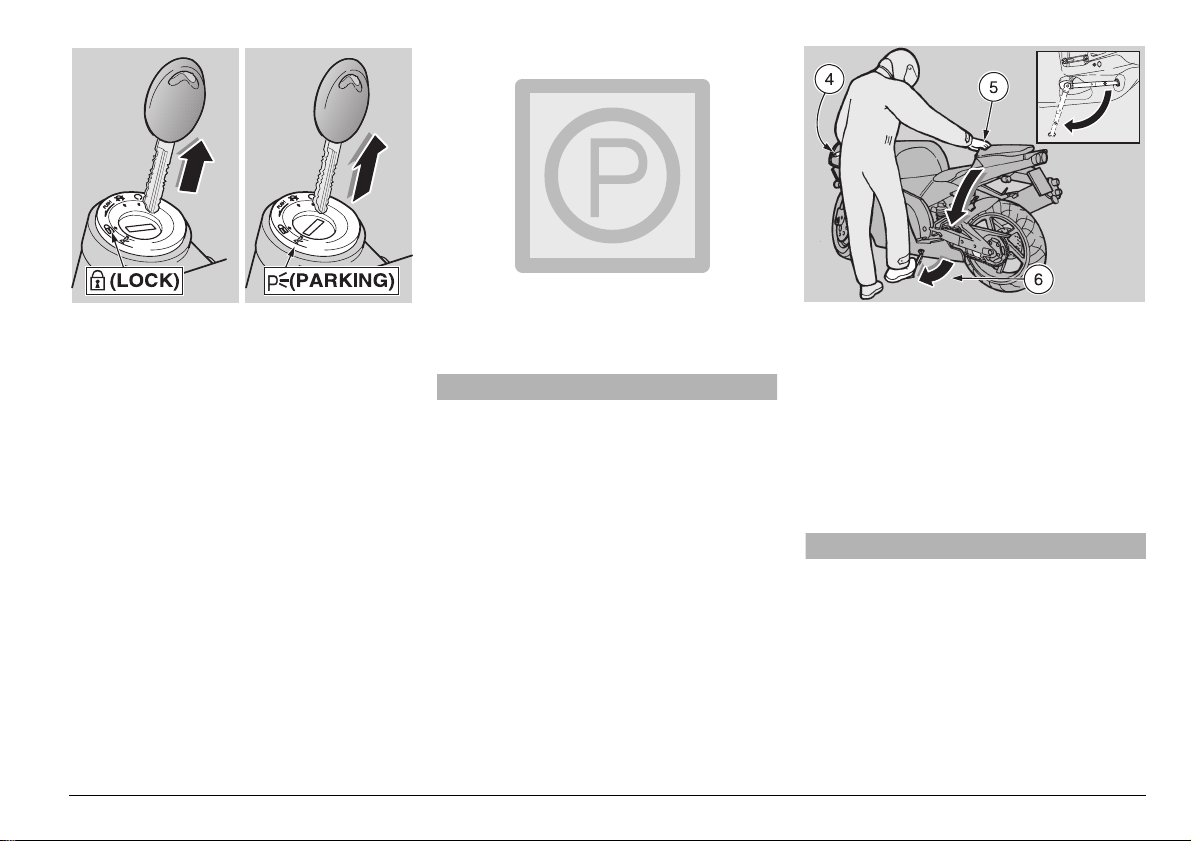

0!2+).'

aWARNING

Park the vehicle only on firm flat

ground, otherwise it could fall over.

Do not lean the vehicle agains t walls, d o

not lay it on the ground.

Park your vehicle away from children

and pedestrians, so that they will not

come in contact with hot parts.

Do not leave you r vehicle unat tended

with the engine running or with the key

in the ignition switch.

Do not sit o n the ve hicle wh en the s ide

stand is down.

Do not get too close to the cooling fans

(A). Even though they are not moving,

they could start automatically and suck

clothing, hair, etc. into the fan.

If the vehicle falls over, it will leak gasoline which is extremely flammable.

Flames or sparks could cause a fire

which could destroy not only your vehicle but also buildings arou nd it and

cause injury or even death to people as

well.

◆

Stop the vehicle, see p . 69 (STOPPIN G).

◆

Move the engine stop switch (1) to the

m” (OFF) position.

“

aCAUTION

Do not leave the ignition on if you have

stopped the engine by moving the engine stop switch to the “

tion as this will discharge the battery.

When the vehicle has come to rest after

stopping the engine with the engine

stop switch, turn the ignition switch (3)

to the “

m” (OFF) position.

◆

Rotate the key (2) and move the ignition

switch (3) to the “

◆

Position your vehicle on the stand, see

p. 71 (POSITIONING THE VEHICLE ON

THE STAND).

m” (OFF) posi-

m” (OFF) position.

use and maintenance RSV mille

70

-

Page 5

NOTE Neve r leave th e key in the igniti on

switch.

◆

Lock the steering, see p. 40 (STEERING

LOCK) and extract the key.

When you have to park your vehicle in a

dark or badly lighted area (parking lot or

street), it is sometimes useful to leave the

parking lights on s o that you r vehicle will be

easily visible.

To leave the parking lights on: see p. 40

(PARKING LIGHTS).

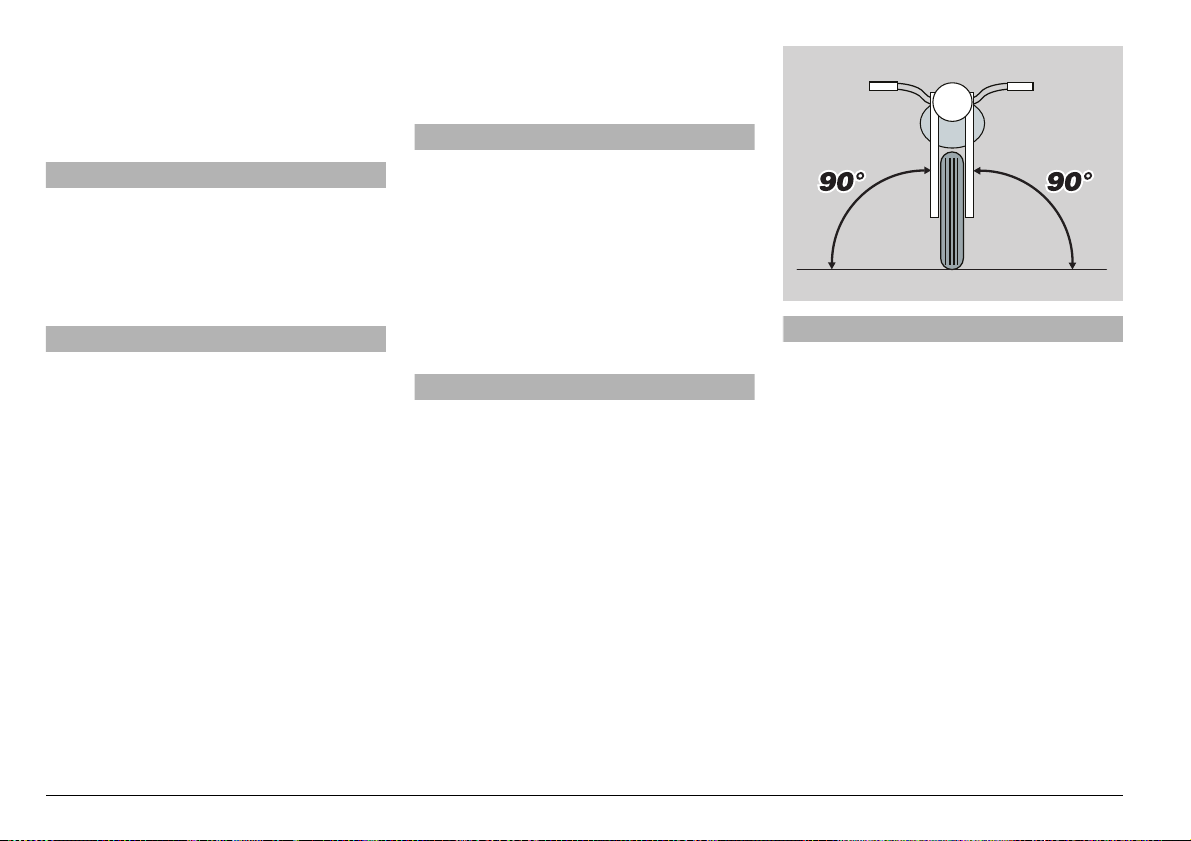

0/3)4)/.).'4(%6%()#,%

/.4(%34!.$

aWARNING

Position the vehicle on firm and flat

ground.

SIDE STAND

◆

Grab the left handle gri p (4) a nd th e pa ssenger grab strap (5).

◆

Put the side stand (6) down with your

right foot. Make sure it i s exte nded completely and all the way forward.

◆

Lean the vehicle to th e left u ntil the stand

rests firmly on the ground.

◆

Turn the handlebars completely against

the left stop.

aWARNING

Make sure the vehicle is stable when

parked. If it falls down, it will certainly

be damaged and could injure others as

well.

use and maintenance RSV mille

-

71

Page 6

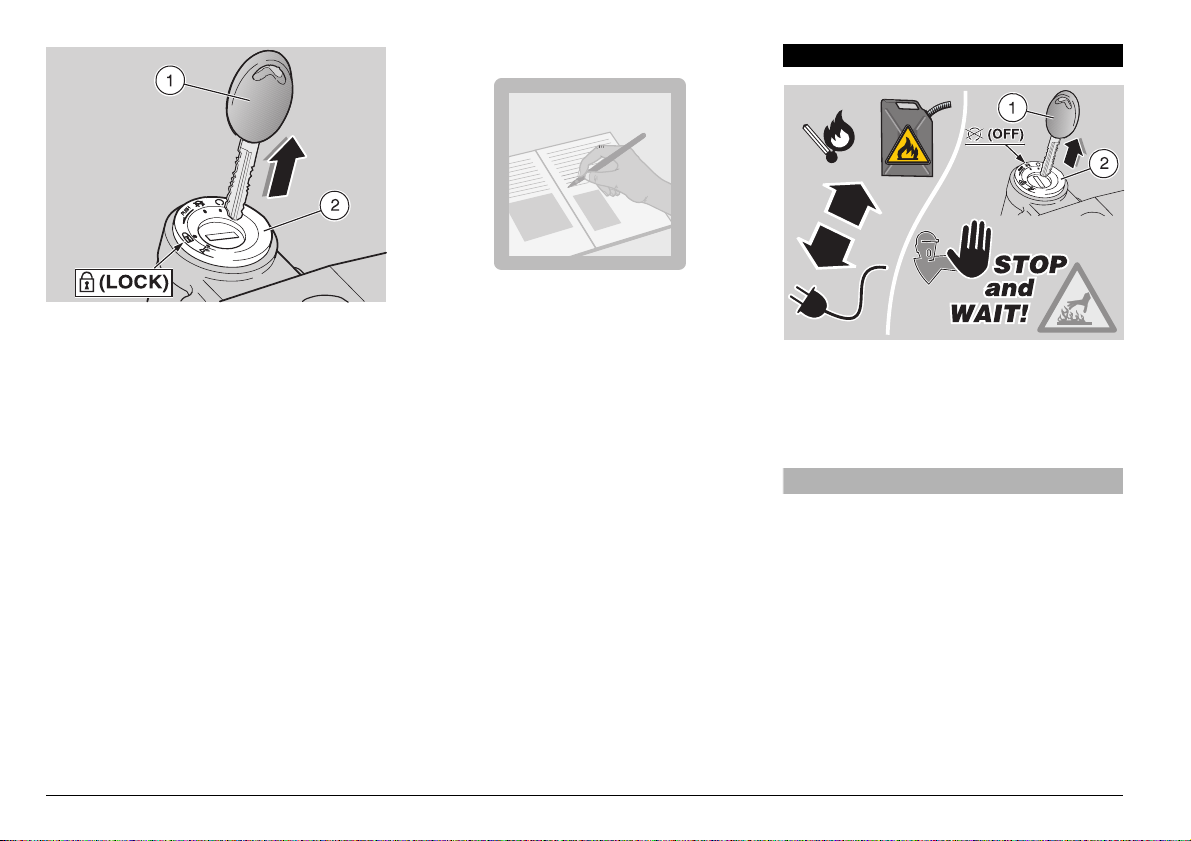

-!).4%.!.#%

35''%34)/.3

4/02%6%.44(%&4

NEVER leave the key (1) in the ignition

switch (2), always use the steering lock “

(LOCK).

Try to park your ve hicle in a safe place, if

at all possible, in a garage or other pro tected place.

Lock your vehicle up using a chain and

padlock around the rear wheel. Chain t he

rear wheel to the swinging arm.

Make sure that all le gal req uire ments : reg istration, license plates, insurance, etc. are

in order.

use and maintenance RSV mille

72

-

Write down your name, address and telephone number and the vehicle identification number in the space below, to facilitate finding the owner in case your vehicle

s”

is recovered after theft.

SURNAME: ...............................................

NAME: ......................................................

ADDRESS: ...............................................

...................................................................

TELEPHONE NO.: ...................................

NOTE Ver y often stolen vehicles are

identified thanks to the data written in the

use/maintenance manual.

Carefully read p. 2 (FOREWORD) and

(INTRODUCTION), p. 3 (SAFETY WARNINGS) and (GENERAL SAFETY RULES),

p. 5 (WARN INGS - PRECAUTIONS GENERAL ADVICE).

aWARNING

Risk of fire.

Keep fuel and other flammable sub-

stances away from the electrical components.

Before beginning any main tenance operation or any inspection of the vehicle,

stop the engine, remove the key (1)

from the ignition swi tch (2), wait until

the engine and the e xhaust syst em have

cooled down and if possible lift the vehicle by means of the pro per equipment, on firm and flat ground.

Before proceeding, make sure that the

room in which you are working is properly ventilated.

Page 7

Be careful to avoid hot parts of the engine and exhaust system. They are hot

enough to cause serious burns.

Avoid the temptation to hold any part of

the vehicle in your mouth . The c oati ngs

and platings used are, in some cases,

toxic.

aCAUTION

In general, reas sembly is perfor med in

the reverse order of the disassembly instructions given here.

For some maintenance operations, especially those in which your hands are

likely to come in contact with coolant,

or engine oil, or gasoline, or bra ke fl uid,

it is advisable to use thin disposable

gloves, such as thos e made of latex,

rubber or nitrile.

The routine maintenance operations described in this manual can usually be performed by the user. However, in some

cases, specific tools a nd technical expertise may be required.

Do not hesitate to contact your Local aprilia

Dealer who has all the latest factory information and tools to properly service your

vehicle.

Remember that many s ervic e opera tions, if

done improperly, can be very hazardous.

If you have any quest ions abou t your abili ty

to carry out the operations described here,

contact yo ur Local aprilia Dealer.

In all cases, personally carry out the “pre-

liminary checking operations” after any

maintenance, see p.61 (PRELIMINARY

CHECKING OPERATIONS).

aWARNING

Remember that tightening torq ue of all

fasteners on the wheels, brakes, axles,

suspension are extremel y important to

ensure safety, and must be maintained

at the prescribed values.

Check the tightening torques of the fasteners regularly, and always use a

torque wrench when installing them.

Failure to adhere to this warning could

cause the loosening and subsequent

loss of critical f asteners, which could

cause a wheel to lock or cause other

handling prob lems with consequent

overturning, and the risk of serious injury or even death.

aWARNING

Fasteners mu st be neither over tightened or undertightened. If they are

overtightened, the threads ma y be dam aged and the fa steners will be destroyed, whereas if they are undertightened, they can vibrate and become lost.

Obviously, under these circumstances,

a serious accident with resultant serious injury or death could ensue.

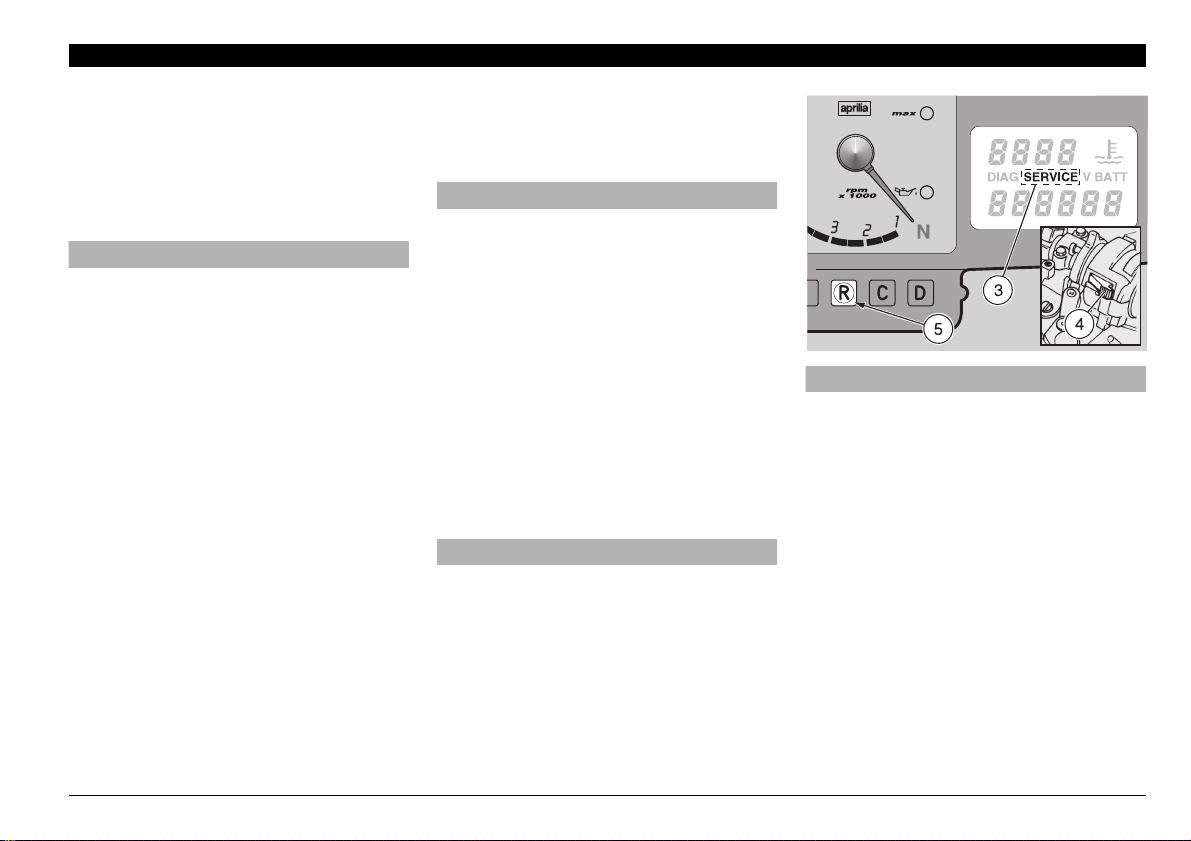

aCAUTION

After the first 6 25 mi (1,000 km) and successively every 4,687 mi (7,500 km), the

word “SERVICE” (3) appear s on the ri ght

display. In this case contact your Local

APRILIADealer, who will carry out the operations indicated in the regular service

intervals chart, see p. 74 (REGULAR SERVICE INTERVAL S CHA RT).

To make the word “SERVICE” disappear,

press the “LAP” push button (4) and then

the push butto n

pressed for about 5 seconds.

(5) and ke ep them

R

use and maintenance RSV mille

-

73

Page 8

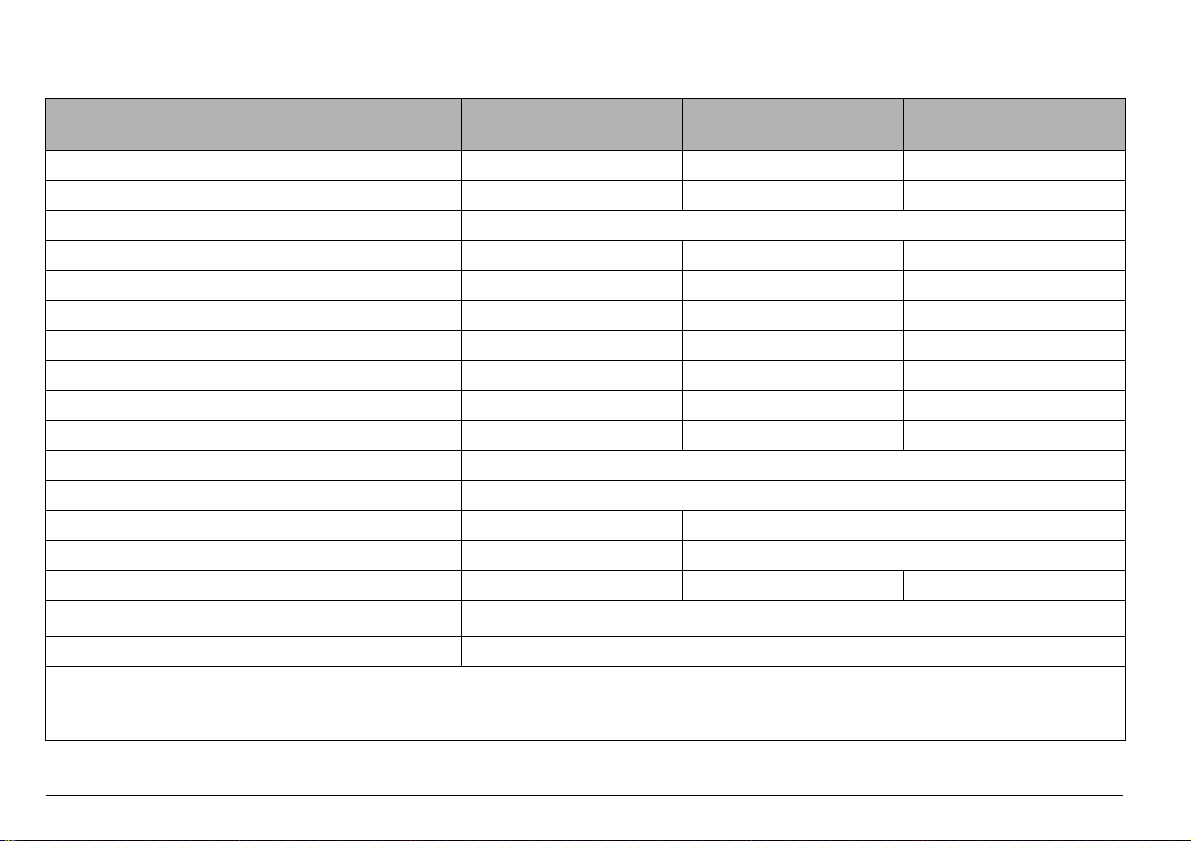

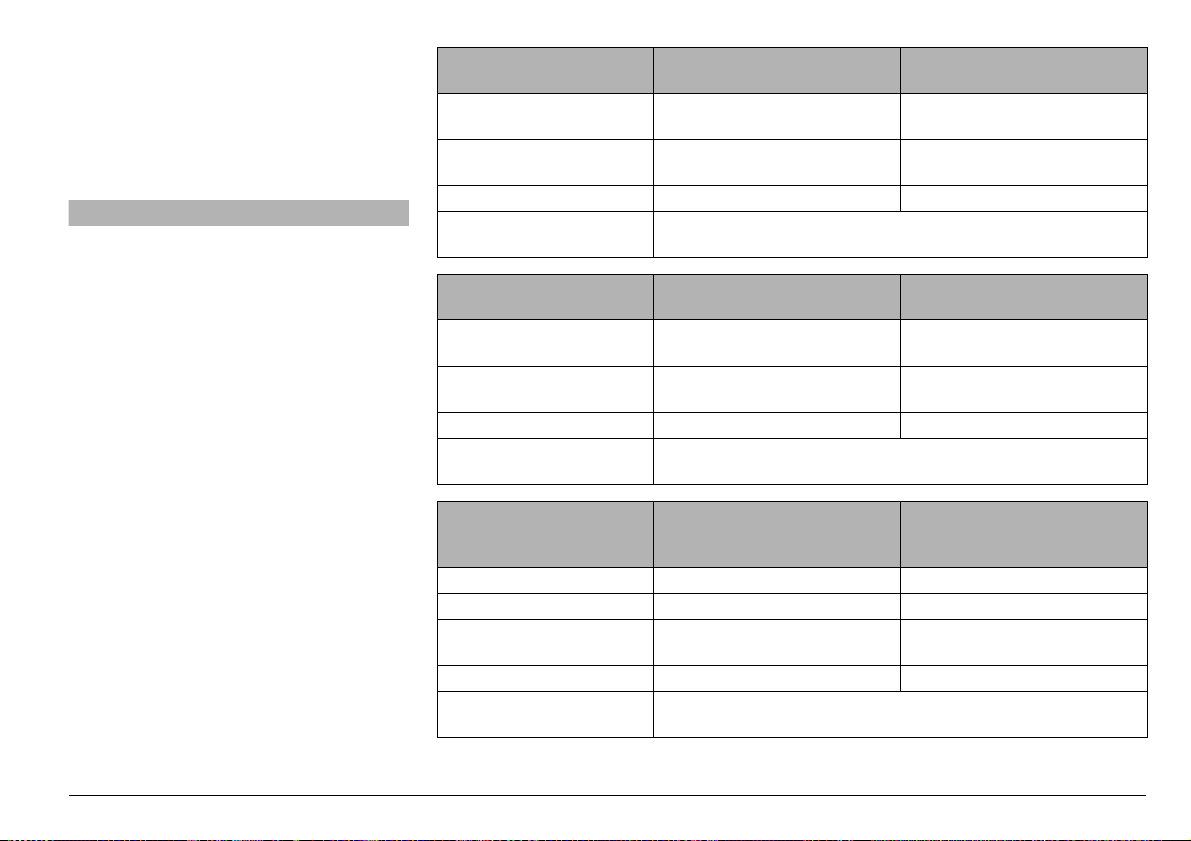

2%'5,!23%26)#%).4%26!,3#(!24

THESE OPERATIONS MAY BE CARRIED OUT BY YOUR Local APRILIADealer, OR BY THE OWNER OF THE VEHICLE

Component

Tightness of the battery termin al s C C

Spark plugs C (*) S

Drive chain, tension and lubrication every 625 mi (1,000 km): C

Air cleaner CS

Fork C

Light operation/direction C

Light system C C

Safety switches C C

Clutch fluid C

Brake fluid C

Coolant every 625 mi (1,000 km): C

Engine oil every 312 mi (500 km): C

Tires C every 625 mi (1,000 km): C

Tire pressure R every month: R

Engine idling rpm R R

Engine oil pressure warning light LED “

Front and rear brake pad wear before every trip and every 4,687 mi (7,500 km): C

C = check and clean, adjust, lubricate or change, if necessary; P = clean; S = change; R = adjust.

Perform these maintenance opera tions at on e-ha lf of he s pec ified interv als , if you r v ehi cle is often used in rainy or very dusty

conditions, on unpaved roads, or in any kind of competition.

\”

After running-in

[625 mi (1,000 km)]

Every 4,687 mi

(7,500 km) or 8 months

at every start: C

Every 9,375 mi

(15,000 km) or 16 months

(*) = For competition use, change every 2,343 mi (3,750 km).

use and maintenance RSV mille

74

-

Page 9

THESE MAINTENANCE OPERATIONS SHOULD ONLY BE PERFORMED OUT BY Local APRILIADealer.

Component

Accelerator cables (adjustmen t) C

Rear suspension linkage bearings C

Steering bearings and steering C C

Wheel bearings C

Engine oil filter S S (*)

Engine oil filter (on oil tank) P P

Engine oil S S (*)

Tappet clearance R R

Braking systems C C

Cooling system C

Clutch fluid C every 2 years: S

Brake fluid C every 2 years: S

Brake pads if worn: S

Coolant every 2 years: S

Fork oil After the frist 4,687 mi (7,500 km): S / every 14,000 mi (22,500 km): S

Wheels/tires C

Nut, bolt, screw tightening C C

Suspensio ns and attitude C C

Brake fluid bleeding C

Fuel pipes C every 4 years: S

C = check and clean, adjust, lubricate or change, if necessary; P = clean; S = change; R = adjust.

Perform these maintenance operations at one-half of he sp ecifi ed in terva ls, if y our ve hicl e is o ften us ed in rainy or very dusty

conditions, on unpaved roads, or in any kind of competition.

After running-in

[625 mi (1,000 km)]

Every 4,687 mi

(7,500 km) or 8 months

Every 9,375 mi

(15,000 km) or 16 months

(*) = For competition use, change every 2,343 mi (3,750 km).

use and maintenance RSV mille

-

75

Page 10

)$%.4)&)#!4)/.$!4!

It is a good idea to write down the frame

and engine numbers in th e space provided below. Use the frame number (VIN) to

identify your vehicle when ordering sp are

parts.

aWARNING

In all states and countries, it is against

the law to alter the Vehicle Identification

Number (VIN). You ca n incur severe

penalties by doing this. Also, this will

immediately invalidate your warranty.

FRAME NUMBER

The frame number is stamped on the right

side of the fork head.

Frame no.

ENGINE NUMBER

The engine number is stamped on the rear

part of the left engine crankcase.

Engine no.

!)2#,%!.%2

Carefully read p. 72 (MAINTENANCE).

aWARNING

Do not use gasoline or flammable solvents to wash the air cleaner, in order to

avoid fire or explosion.

Inspect the air cleaner to ensure that it has

not become clogged every 4,68 7 mi (7,50 0

km) or 8 months of use. Renew the air

cleaner every 9,375 mi (15,000 km).

The air cle aner must be inspected mo re

frequently, cleaned if necessary, and replaced more fre quently if the vehi cle is

used on dusty or wet roads.

More frequent cleaning of the air cleaner is

suggested, especially if yo ur bike is used

under very dusty conditions.

use and maintenance RSV mille

76

-

Page 11

pressed air jets, they can cause serious

personal injur y if directed towards your

body.

◆

Grasp the air cleaner vertic ally and stri ke

it repeatedly on a clean har d horizontal

surface.

◆

If available, clean the air cleaner with a

compressed air jet, directi ng it from the

inside of the filter towards the outside.

◆

Clean the outer part of the air cleaner

with a cloth.

aCAUTION

The air cleaner must not be use d for

more than 9,375 mi (15,000 km) regardless of how many times it has been

cleaned in the interval. Under very

dusty or dirty conditions, it is advisable

to replace the air filter more often.

Before the cleaning operation, it is necessary to remove the air cleaner from the vehicle.

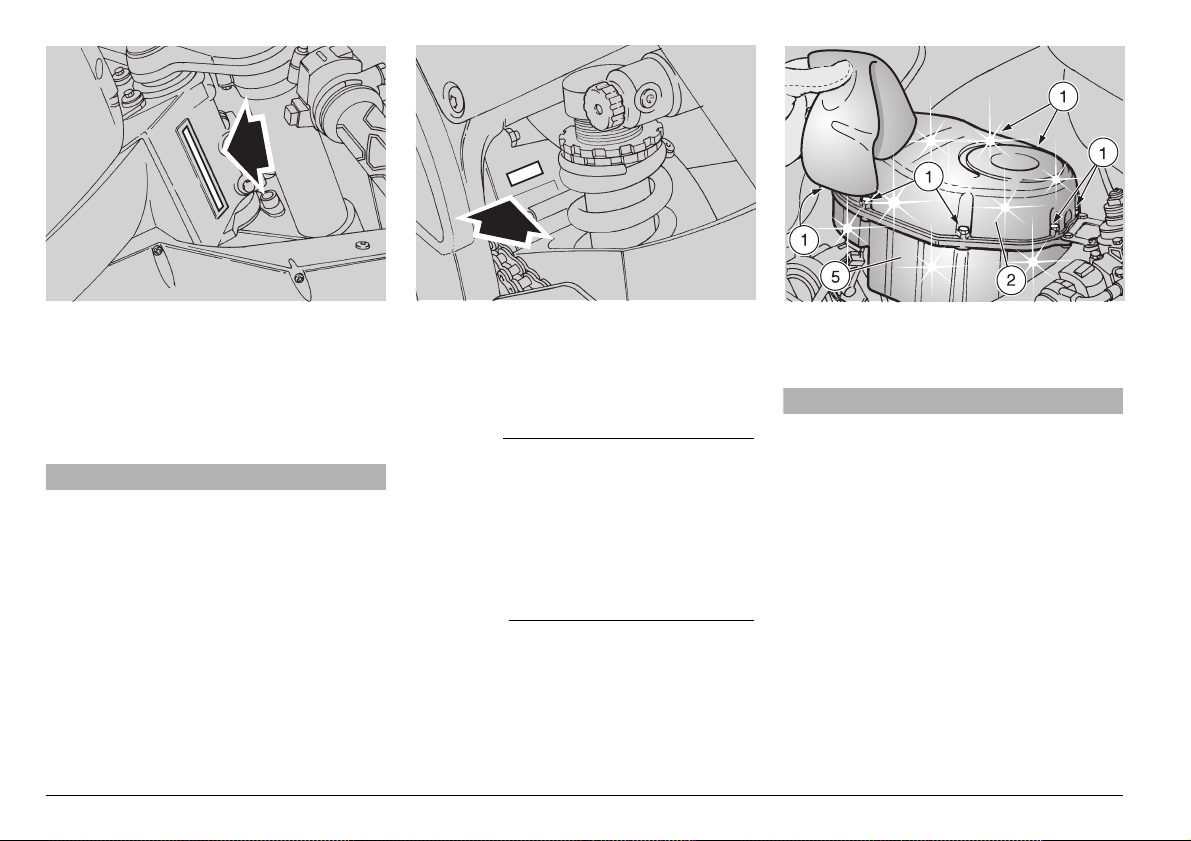

REMOVAL

◆

Lift the fuel tank, see p. 94 (LIFTING

THE FUEL TANK).

aCAUTION

Before unscrewing and removing the

screws (1), clean the filter cas e cover (2)

and the filter case (5) with a clean cloth.

Prevent any foreign matter from getting

into the inlet tubes. This could cause

severe engine damage.

◆

Unscrew and remove the seven screws

(1) that fasten the filter case cover (2).

◆

Remove the filte r case cover (2).

◆

Extract the air cleaner (3).

aCAU TION

Plug the opening with a clean cloth to

prevent any foreign matter from entering the intake tubes.

CLEANING

aCAUTION

Take great care not to deform the perforated metal outside screen. It is very

fragile and can be easily damaged. Never use a screwdriver or other sharp hard

tool to remove the air cleaner itself.

aWARNING

During this operation, always wear goggles which provide your eyes with 360°

protection. Be very careful using com-

CHANGING

◆

Replace the air cleaner with a new one

of the same type.

◆

Make sure that the gasket (4) of the filter

case (5) is intact; if it is damaged, replace it.

◆

Every 4,687 mi (7,500 km) remove the

plug (6) so that any dirt that may have

accumulated inside the filter case can be

removed.

aCAUTION

When cleaning the air cleaner, make

sure that there are no tears. Otherwise,

replace the air cleaner.

Make sure that the air cleaner is positioned correctly, in such a way as to prevent non-filtered air from entering.

Premature wear of the piston ring s, pistons and cylinders is caused by an improperly installed air cleaner.

use and maintenance RSV mille

-

77

Page 12

#(%#+).'4(%%.').%/),,%6%,

!.$4/00).'50

Carefully read p. 46 (LUBRICANTS),

p. 72 (M AINTENANCE) and p. 122 (LU BRICANT CHART) .

aWARNING

It is critical to the safe operation of your

vehicle that the proper lubricants, mai ntained at the proper levels, are used.

Failure to heed this warning can lead to

an engine seizure wit h subseq uent accident, serious injury or death.

aWARNING

Remember that the tightening torque of

all fasteners on the wheels, brakes, axles, and other components of the suspension system is very important to ensure the safety of the vehicle, and must

be kept at the prescribed values.

Check the tightening torque of the fasteners regularly, and always use a

torque wrench when reinstalling them.

Failure to comply with this warning

could allow one of these compon ents to

be lost which could lock a wheel or

cause other handling pro blems with

consequent overturning and risk of serious injury or even death.

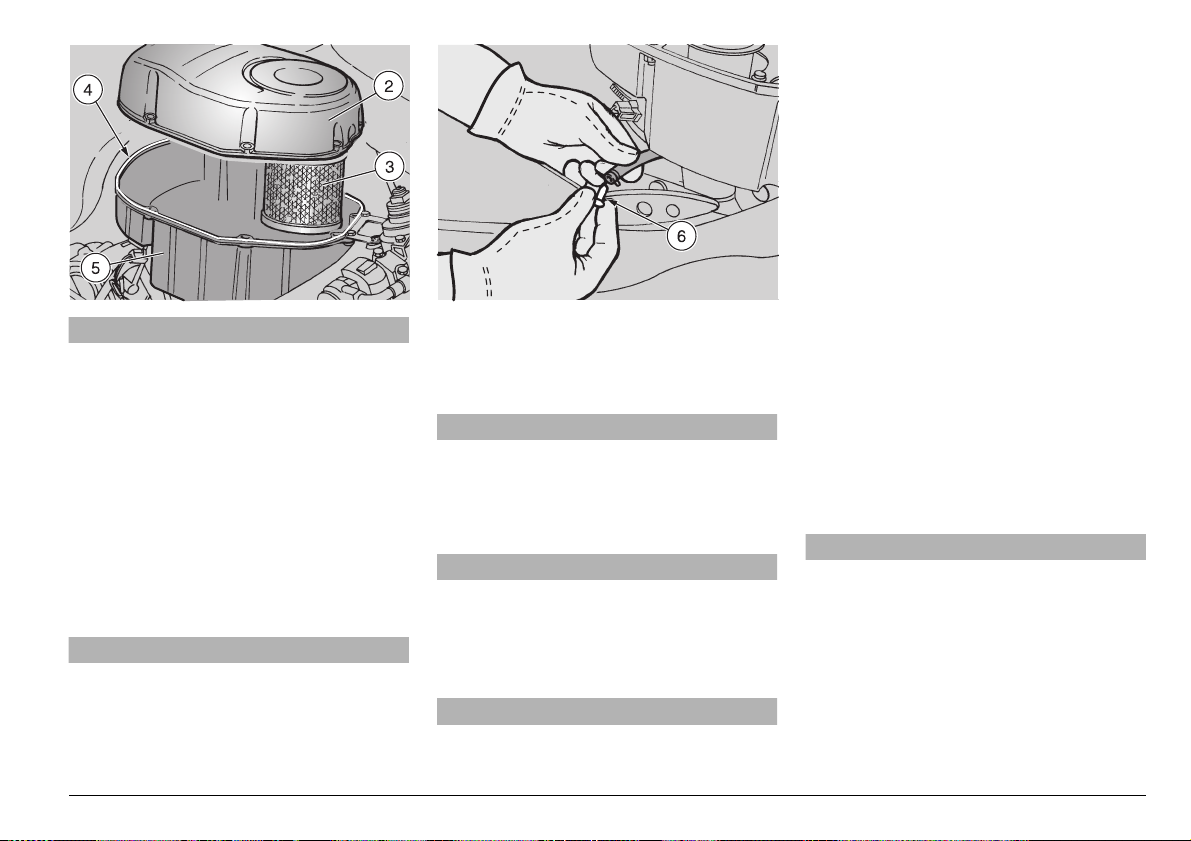

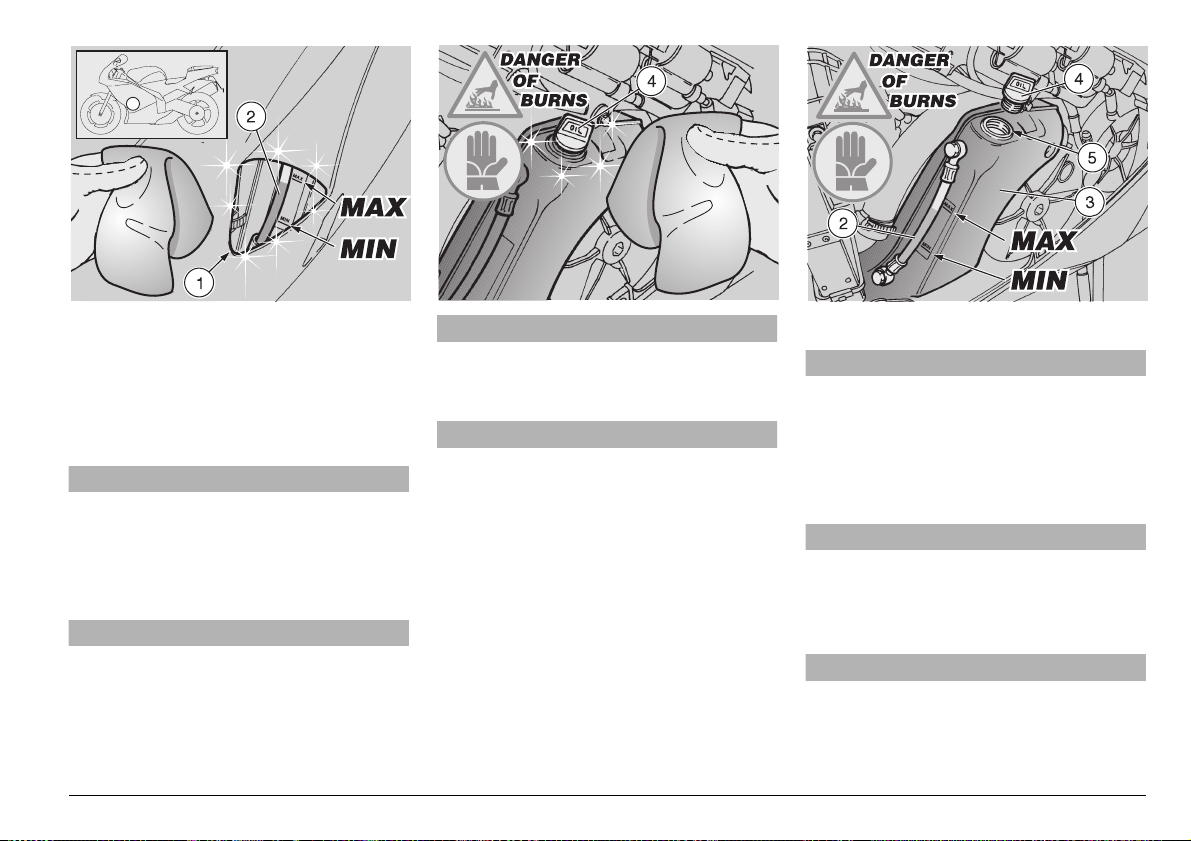

CHECKING

NOTE Positi on the vehicle on firm a nd

flat ground.

aCAUTION

The engine oil level must be checked

with warm engine.

If the check is carried out with cold engine, the oil level may temporarily lower

below the “MIN” mark.

This is not a problem, provided that the

engine oil pressure warning light LED

j” does not come on, see p. 30 (IN-

“

STRUMENTS AND INDICATORS TABLE).

aWAR NING

Exhaust gases co ntain carbon monoxide, which is extremely poisonous if inhaled.

Do not start the engine in closed or badly-ventilated rooms.

Failure to observe this warning may

cause loss of consciousness or even

lead to death by asphyxia.

◆

Check the oil when the engine is warm,

having been ridden for at least 10 mi (16

km).

NOTE If the engine is cold, warm it up

for riding, preferably on a hilly road, for approximately 10 mi (16 km) before checking

the oil.

◆

Stop the engine before checking the oil.

aWARNING

Should your vehicle overturn, it will leak

gasoline, which is extrem ely flamm able.

Flames or sparks may cause a fire,

which could destroy not on ly the vehicle, but also the bu ilding in which it is

located, and cause serious injuries or

even death.

◆

Keep the vehicle in vertical position, with

the two wheels resting on the ground.

NOTE If yo u attemp t to chec k the oil with

the vehicle leaned in either direction from

the vertical, your measurement w ill be inaccurate.

NOTE If the engine oil tank is dirty, wipe

it with a clean c loth s o th at y ou can see the

“MIN” and “MAX” marks.

◆

Look through the appropriate slot (1) in

the left fairing. Check the level of the oil

in the sight gauge (2).

use and maintenance RSV mille

78

-

Page 13

MAX = maximum level

MIN = minimum level

The difference between “MAX” and

“MIN” is about 0.53 US qt (500 cm#).

◆

The level is correct if the oil reaches approx the “MAX” mark.

aWARNING

Never exceed the “MAX” mark, nor

leave the oil below the “MIN” mark, in

order to avoid serious damage to the

engine.

If necessary, top up the engine oil tank:

aWARNING

When warmed up, the engine contains

hot oil and the engine oil tank (3) is

warm; therefore, while carrying out the

operations describe d here below be

particularly careful, in order to avoid

burns.

aCAU TION

Use thick gloves to prevent burns.

◆

Remove the left fairing, see p. 96 (REMOVING THE SIDE FAIRINGS).

aCAU TION

Before unscrewing and removing the

filler cap (4), clean it and the area of the

tank around it with a clean cloth. Prevent any foreign matter from falling into

the oil tank, this could cause serious

engine damage.

Do not use any flammable solvents

such as alcohol or gasoline when wip ing the oil tank. The oil tank is hot

enough to cause igniti on of flammable

solvents.

Use only a nature fiber cloth, i.e. cotton .

Man made fabrics such as polyester,

etc. could ignite.

◆

Unscrew and remove the filler cap (4).

aCAUTION

When topping up, never exceed the

“MAX” level.

◆

Top up the engine oil tank (3) through the

filler neck (5), with high-quality engine oil,

see p. 122 (LUBRICANT CHART).

◆

Replace and tighten the filler cap (4).

aWARNING

Tighten the filler cap (4) snugly to insure no oil leak.

◆

Replace the left fairing, see p. 96 (REMOVING THE SIDE FAIRINGS).

aWARNING

Never ride your vehicle with low engine

oil, or with contaminated oil, or with unapproved oil. Any of these will greatly

accelerate wear of yo ur engine, and

cause irreparable damage.

use and maintenance RSV mille

-

79

Page 14

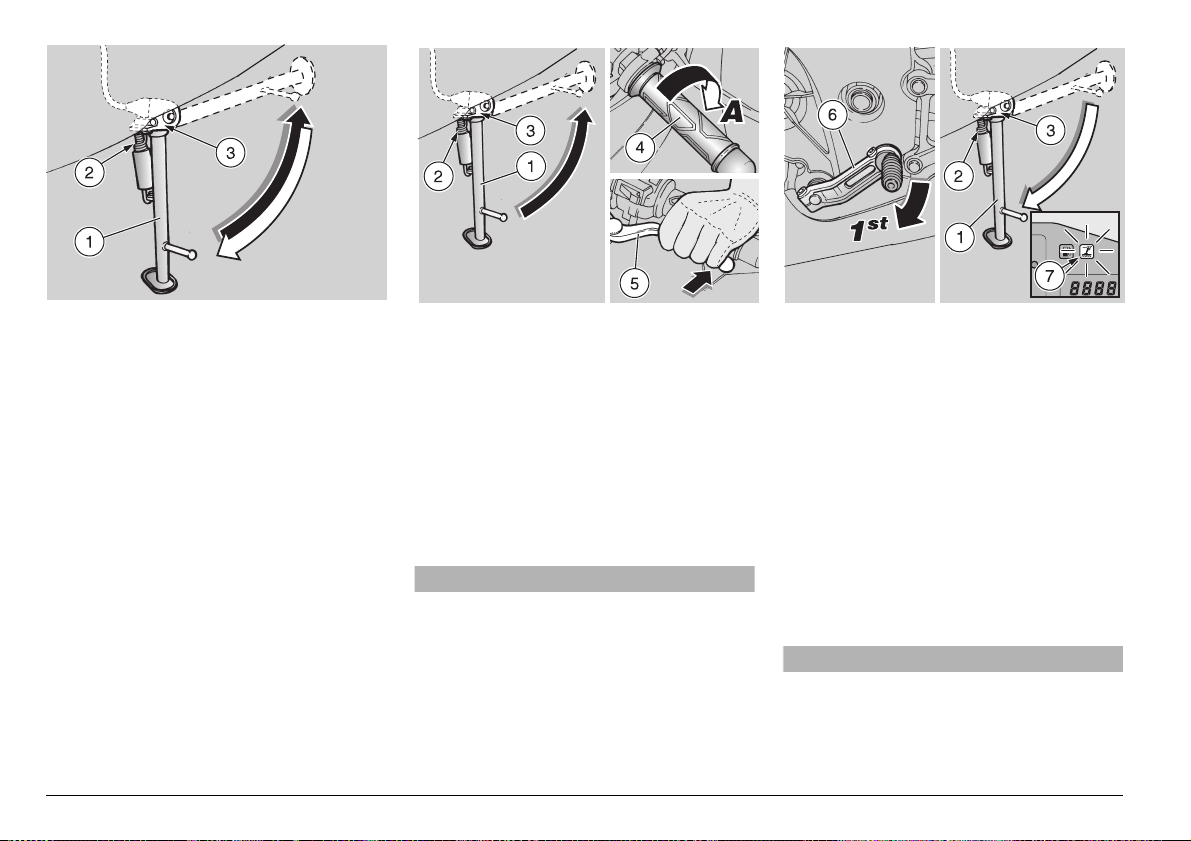

#(%#+).'4(%3)$%34!.$

Carefully read p. 72 (MAINTENANCE)

and p. 81 (CHECKING THE SWITCHES).

The side stand (1) must rotate about its

pivot smoothly and easily.

Perform the following checks:

◆

The springs (2) must be free from damage, wear, or rust, and must fully and

firmly retract the side st and when the

weight of the vehicle is lifted off of it.

◆

The side stand (1) must rotate freely

about its pivot. If necessary, lubricate

the pivot, see p. 122 (LUBRICANT

CHART).

#(%#+).'4(%&5.#4)/.).'

/&4(%3!&%4937)4#(

/.4(%3)$%34!.$

The side stand (1) is equipped with a safety system, operated by safety switch (3).

use and maintenance RSV mille

80

-

This system prevents the motor from being

started while the stand is extended unless

the transmission is in neutral. It also kills

the engine if the stand is extended while

the engine is running, unless the transmission is in neutral.

T o check the proper funct ioning of th e safety switch (3):

◆

Sit on the vehicle in the normal ridi ng position.

◆

Retract the side stand (1).

aWAR NING

Exhaust gases co ntain carbon monoxide, which is extremely poisonous if inhaled.

Do not start the engine in closed or badly-ventilated rooms.

Failure to observe this warning may

cause loss of consciousness or even

lead to death by asphyxia.

◆

Start the engine, see p. 62 (STARTING).

◆

Release the throttle grip (4) (Pos. A).

With the engine idling, pull in the clutch

lever (5) completely.

◆

Engage first gear, pushing the shift lever

(6) downwards.

◆

Extend the side stand (1).

NOTE Extending the side stand mu st kil l

the engine and the “side stand down” warning light “

gine continues to run:

◆

◆

\” (7) must come on. If the en-

Check the s afety switch (3) o n the side

stand (2), see p. 81 (CHECKING THE

SWITCHES). Perform t he necessary

cleaning or repairs.

Repeat the check.

aWARNING

If the engine does not stop when the

side stand is extended, do not ride your

vehicle. Contact your Local APRILIA

Dealer.

Page 15

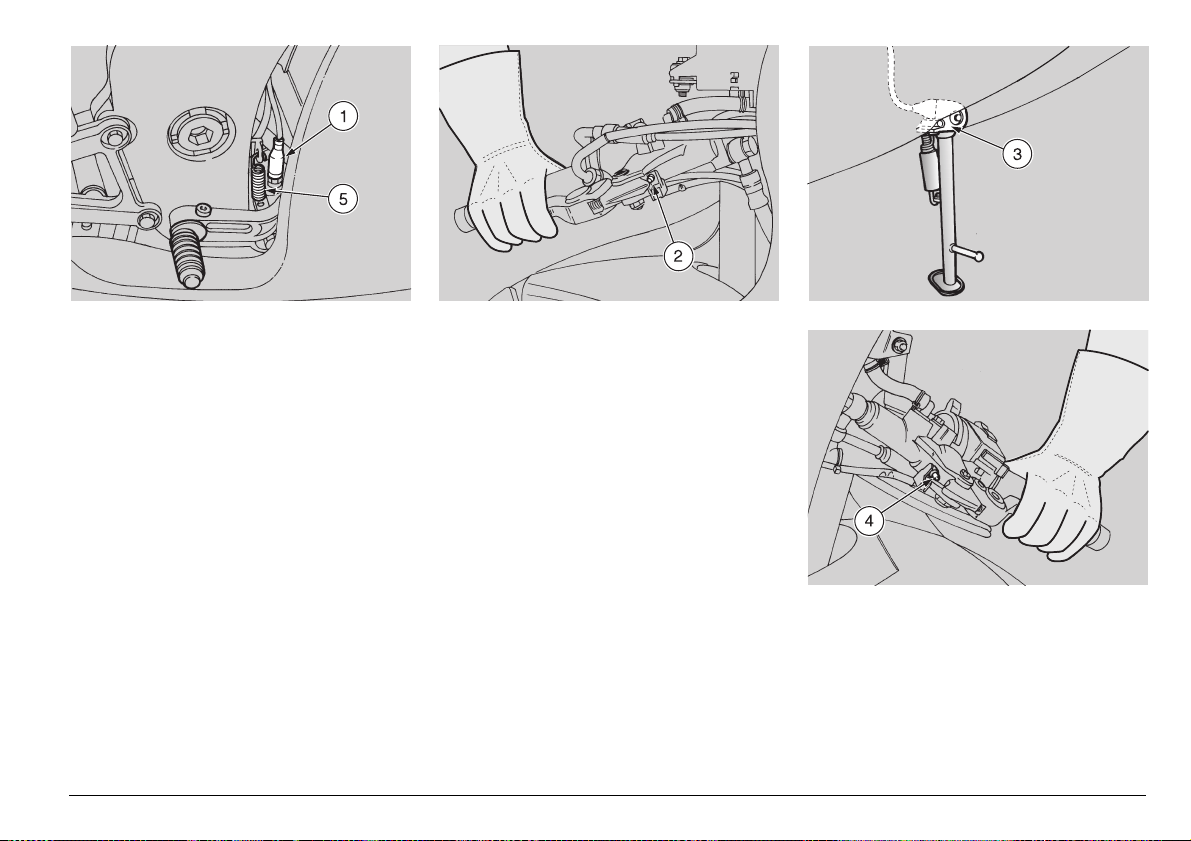

#(%#+).'4(%37)4#(%3

Carefully read p. 72 (MAINTENANCE).

Check the switches after the first 625 mi

(1,000 km) and thereafter every 4,687 mi

(7,500 km).

The vehicle is equipped with four switches:

– stoplight switch on the rear brake pedal

(1);

– stoplight switch on the front brake lever

(2);

– safety switch on the side stand (3);

– clutch lever switch (4).

◆

Make sure that there is no dirt or mud on

the switch. The switch pin must move

freely and without interference, returning

automatically to its unapplied position.

◆

Check the spring (5) ; it must not be dam aged, worn or stretched.

use and maintenance RSV mille

-

81

Page 16

).30%#4).'4(%&2/.4

!.$2%!23530%.3)/.3

aCAU TION

The front fork oil change operation

should be entrusted to your L ocal APRIL

IADealer.

Carefully read p. 72 (MAINTENANCE).

Have the front fork oil chan ged after the

4,687 mi (7,500 km) an d thereafter every

14,000 mi (22,500 km).

Every 4,687 mi (7,500 km), carry out the

following checking operations:

◆

Apply the front brake lever and push up

and down on the ha ndlebar repeate dly,

pushing the fork up and down.

The fork must move smoothl y and easily,

there must be no trace of oil on the fork

tubes.

◆

Check the t orque of all th e fasteners on

the front fork and inspect the entire front

fork to make sure that it is in good condition without leaks or dam age. Repeat for

the rear suspension and swinging arm.

aCAUTION

Do not ride your vehicl e if either suspension is damaged in any way, contact

your Local APRILIADealer.

&2/.43530%.3)/.

The front suspension consists of an hydraulic fork connected to the steering column by means of two plates.

For the setting of the vehicle attitude, each

rod of the fork is provided with an upper

screw (1) f or t he ad j us t me nt of t he hy dr a ulic damping on extension, a lower screw (2)

for the adjustment of the hydrauli c damping on compression and an upper nut (3)

for the adjustment of the spring preload.

NOTE It is possible to adj us t the atti tud e

of the vehicle, by changing the height of its

front part.

For this type of adjustment, contact your

Local aprilia Dealer.

use and maintenance RSV mille

82

-

Page 17

ADJUSTING THE FRONT FORK

The front fork is adjusted at the factory to

suit most riding conditions for most riders.

However, it is pos sible to adjust the fork s etting to your preference, and to accommodate the full range of operating conditions

that the vehicle is intended to be used for.

aCAUTION

When adjusting the fr ont fork, always

start from the most rigid setting. Do not

rotate adjusters (1) and (2) beyond their

limit position, to avoid damaging the

threads.

Use the notches (1) and (2) provided on

the adjusters as refere nce ma rks for the

adjustment of hydraulic damping on extension and hydraulic damping on compression.

Turn the adjusters (1) and (2) 1/8 turn at

a time and turn the a djus ting nut (3) one

notch at a time. Then, test the ve hicle

on the road, to ensure you have obtained the optimal adjustment.

Make sure that the spring preload and

hydraulic damping, both on extension

and compression, is the same for both

sides. A different shock absorber setting on the left and right side will decrease the stability of the vehicle.

When the spring preload is increased, it

is necessary to also increase the hydraulic damping, both on extension and

compression, to avoid a jerky unsteady

shock action while riding.

Upper screw adjusters

(1) (2.25 turns in total)

Function Increase of the hydraulic

Recommended kind

of road

Notes Rider and passenger Solo rider

Standard adjustment From the completely clockwise position, 1.5 turns counter-

Lower screw adjusters

(2) (2 turns in total)

Function Increase of the hydraulic

Recommended kind

of road

Notes Rider and passenger Solo rider

Standard adjustment From the completely clockwise position, 1.5 turns counter-

Upper adjusting

nuts (3)

(8 notches in total)

Function Spring preload increase Spring preload decrease

Attitude The vehicle is more rigid The vehicle is less rigid

Recommended kind

of road

Notes Rider and passenger Solo rider

Standard adjustment Turn the adjustin g nut 5 notch es cou nte rcl oc kwis e from the

By rotating them

clockwise (H)

damping on extension

Smooth or normal roads Roads with uneven surface

clockwise

By rotating them clockw ise

(H)

damping on compression

Smooth or normal roads Roads with uneven surface

clockwise

By rotating them clockwise

(screwing)

Smooth or normal roads Roads with uneven surface

fully clockwise setting

By rotating them

counterclockwise (S)

Decrease of the hydraulic

damping on extension

By rotating them

counterclockwise (S)

Decrease of the hydraulic

damping on compression

By rotating them

counterclockwise

(unscrewing)

use and maintenance RSV mille

-

83

Page 18

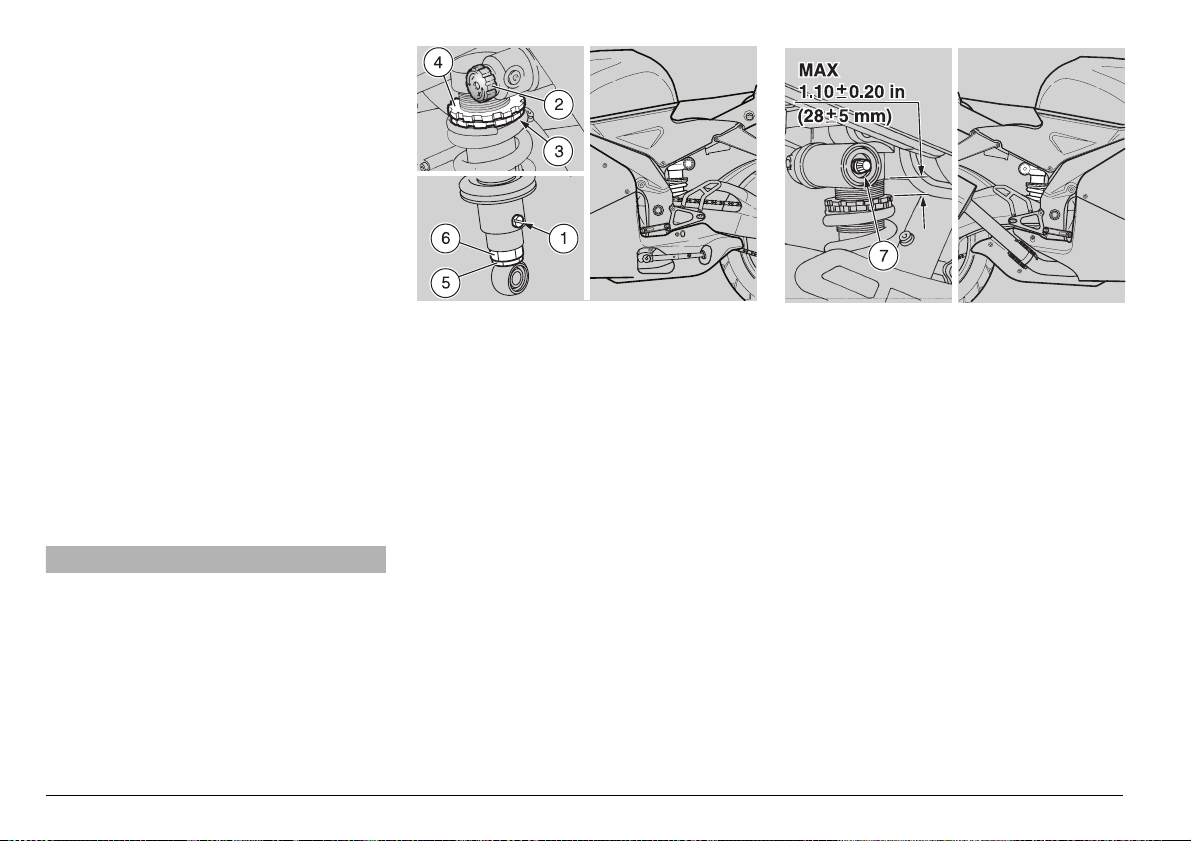

2%!23530%.3)/.

The rear suspension consists of a hydraulic shock absorber - spring unit, which is

mounted to the frame with a uniball, and to

the swinging arm by means of a system of

levers.

The ride height of the rear of the vehicle

can be set using the spring preload adjusting ring nut (3) and locking ri ng nut, (4).

The rear suspension can be tuned by adjusting the extensi on damping with a spring

adjuster (1), the damping on compression

can be adjusted by a knob (2).

ADJUSTING

THE REAR SHOCK ABSORBER

The rear shock absorber is set at the factory to satisfy most ridin g conditi ons, at either

low or high speed, and with e ithe r a li ght or

full load. However, it is pos sible to tu ne the

suspension to y our prefe rence by u sing the

above mentioned adjustments.

aCAU TION

When adjusting the rear shock absorber,

always start from the stiffest position.

This is the fully clockwise position of the

extension damper adjusti ng screw (1)

and the compression damper knob (2).

Do not rotate the extension damper adjustment screw (1) beyond its limit , this

will damage the screw and destroy your

shock absorber.

Always make sure, when adjusting

screw (1), that it clicks in to an adjustment notch, and is not at a position intermediate between adjustment notches.

The distance between the top of the adjustment ring and the top of the threads

must not exc eed 1.10 ± 0.2 0 in (28 ± 5

mm). Adjusting the nut further down on

the shock will compress the spring excessively, and result in an uneven

bumpy ride. Also, it will be impossible to

adequately adjust the extension damping using screw (1).

◆

Loosen the locking rin g nu t (4) b y m ean s

of the appropriate spanner wrench.

◆

Adjust th e adjus ting ri ng nut (3) (see figure).

◆

If necessary, adjust the extension damping screw (1) (see table p. 85).

◆

Once the ride height has been properly

adjusted, tighten the lock ring nut (4)

completely.

◆

Slightly loosen the lock nut (5).

Rotate the adjuster (6) one tu rn at a time

so that the adjusting screw (1) faces out

to the left side of the vehicle.

◆

Using the appropriate wrench, turn the

adjuster ( 6) (whi ch adjust s the ce nter to

center distance of the shock absorber

unit) (see table p. 85).

use and maintenance RSV mille

84

-

Page 19

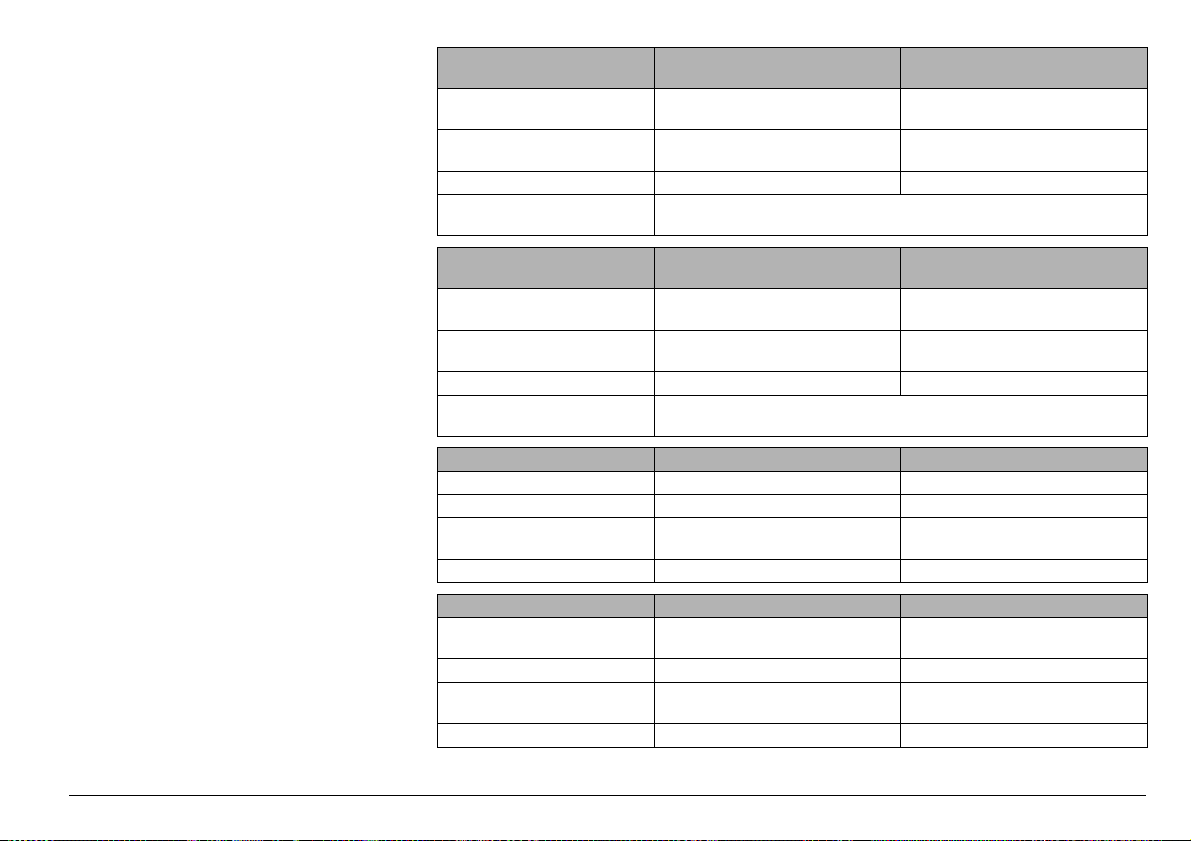

NOTE Adjust the spring preload and the

extension damping according to t he vehicle use. When the spring preload is increased, it is also necessary to increase

the extension damping in order to avoid a

bumpy uneven ride.

Especially at hi gher preload setti ngs, it is

advisable to use full extension damping

(screw (1) fully clockwise) or only a couple

of clicks clockwise, to avoid a bumpy uneven ride. If necessa ry, c on tac t y our L oc al

aprilia Dealer.

Never remove the plug (7) o r attempt to adjust the valve covered by it. This may

cause nitrogen to escape which will destroy the function of the shock absorber

and could upset the handling of your vehicle, leading to an ac ciden t with subse quent

injury or even death.

Never exceed 2-3 clicks with the extension

damping adjustment (1) or 5-6 cli cks with

the compression dampi ng a dju stmen t kn ob

(2), or one turn with the preload adjusting

nut (3) at any given ad justment attempt.

Ride the vehicle for more than just a few

miles on the road between each adjustment, to determine the adjustments most

suitable to your use.

Screw adjuster (1)

(27 clicks)

Function Increase of the hydraulic

Recommended kind

of road

Notes Rider and passenger Solo rider

Standard adjustment Turn the screw adjuster 14 clicks counterclockwise from its

Knob adjuster (2)

(40 clicks)

Function Increase of the hydraulic

Recommended kind

of road

Notes Rider and passenger Solo rider

Standard adjustment Turn the knob 10 clicks clockwise f rom its completely open,

Adjusting ring nut (3) By screwing it By unscrewing it

Function Spring preload increase Spring preload decrease

Attitude The vehic le is more rigid The vehicle is less rigid

Recommended kind of

road

Notes Rider and passenger Solo rider

Adjusting nut (6) By unscrewing it By screwing it

Function Increase the cen ter-to-center

Attitude The vehic le is highe r The vehicle is lower

Recommended kind

of road

Notes Rider and passenger Solo rider

By rotating it clockwise (H) By rotating it

damping on extension

Smooth or normal roads Roads with uneven surface

most clockwise position

By rotating it

clockwise ( +)

damping on compression

Smooth or normal roads Roads with uneven surface

most counterclockwise position

Smooth or normal roads Roads with uneven surface

mount distance

Roads with uneven surface Smooth or normal roads

counterclockwise (S)

Decrease of the hydraulic

damping on extension

By rotating it

counterclockwise (–)

Decrease of the hydraulic

damping on compression

Decrease the center-tocenter mount distance

use and maintenance RSV mille

-

85

Page 20

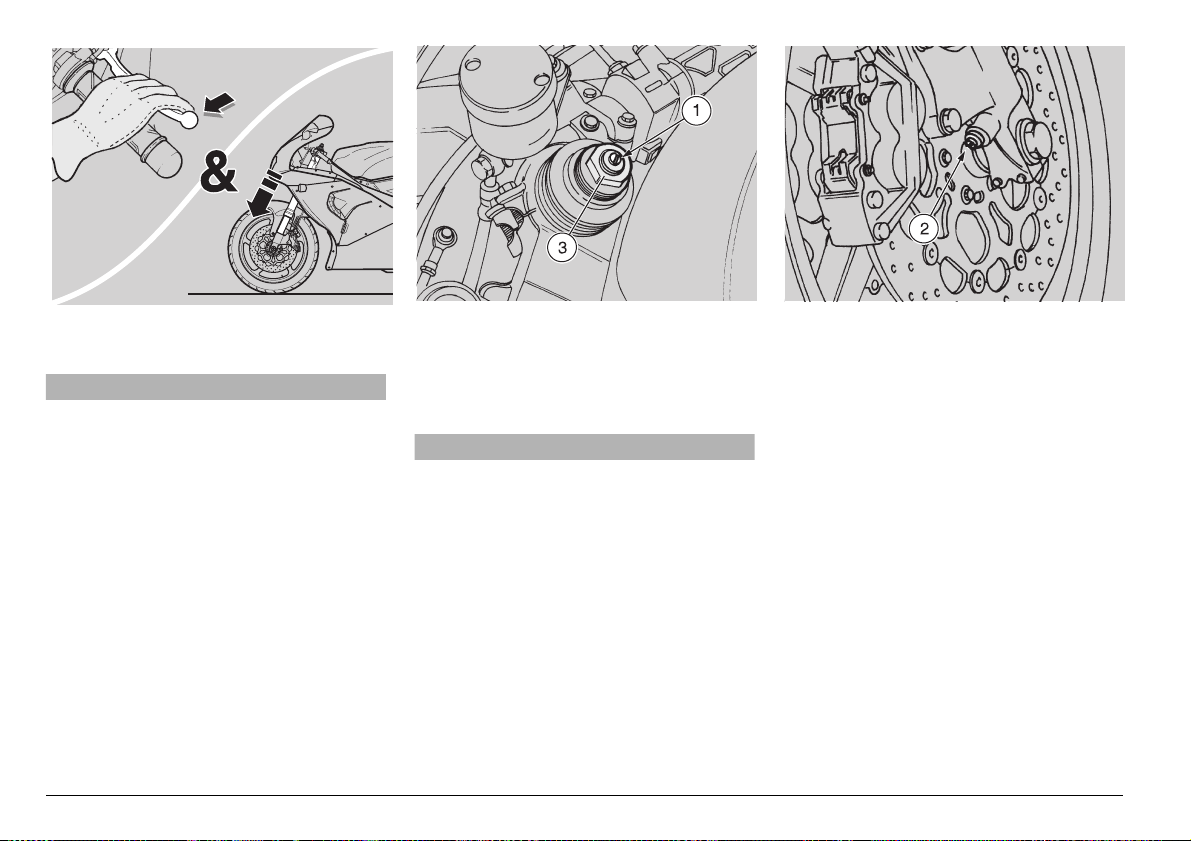

#(%#+).'4(%"2!+%0!$7%!2

Carefully read p. 47 (BRAKES), p. 48

(DISC BRAKES) and p. 72 (MAINTENANCE).

NOTE Your vehicle is equipped with

disc brakes and two separate brake systems.

The front brake system is equipped w ith

two discs, one on the right and one on the

left side of the front wheel.

The rear brake system is equipped with a

single disc on the right side of the wh eel.

The following information may re fer to a

single braking system, but is applicable for

both braking systems.

Check the brake pa d wear after the first

625 mi (1,000 km), before every trip and

thereafter every 4,687 mi (7,500 km).

The amount of wear that the brake pads

experience depends on how the vehicle is

used, how aggressively it is driven, and

the condition of the roads upon which it is

operated. Wear will be faster than no rmal

when the vehicle is driven aggressively, or

on dusty or wet roads.

aWAR NING

Check the wear o f the brake pad s before ever y trip.

CHECKING WEAR OF T HE BRAKE

PADS

◆

Place the vehicle on the stand, see p. 71

(POSITIONING THE VEHICLE ON THE

STAND).

◆

Perform a visual check of the fric tion material thickness. Use a flashlight. See

the arrows (1) and (2) above.

If the friction material on one pad of a pair,

front (3) or re ar (4) , is w orn to 0.06 in (1.5

mm) or less, replace both pads.

aWARNING

Excessive wear of the friction m aterial

would cause the contact of the pad metal support with th e disc, with consequent metallic noise and production of

sparks from the caliper; braki ng efficiency and safety will be s eriou sly com promised. This could lead to a crash,

with subsequent serious injury or

death.

aWARNING

Have the pads changed by your Local

APRILIADealer.

use and maintenance RSV mille

86

-

Page 21

#(%#+).'4(%34%%2).'

The operations necessary to this check

require specific skills and therefore

should be carried out by your Local

APRILIADealer.

#(%#+).'

4(%37).').'!2-0)6/4

The operations necessary to this check

require specific skills and therefore

should be carried out by your Local

APRILIADealer.

0/3)4)/.).'4(%6%()#,%/.

4(%2%!23500/2434!.$&

NOTE Have so meon e help you kee p the

vehicle in vertical position with the two

wheels on the ground.

aWARNING

Lift the vehicle by grasping the two pins

(1) only.

◆

Lift (Pos. A) the rear part of the stand

(2), insert it from the back of the vehicle

and position it so that the two housings

(3) of the support pins (4) hook the two

pins (1) provided on the vehicle.

If the housings (3) do not a lign with the two

pins (1):

◆

Loosen the two knob (5).

◆

Slide the two support pins (4) so that the

two housings (3) of the support pins (4)

coincide with the two pins (1).

◆

Tighten the two knobs (5).

◆

Lift (Pos. A) the rear part of the stand

(2), insert it from the back of the vehicle

and position it so that the two housings

(3) of the support pins (4) hook the two

pins (1) provided on the vehicle.

◆

Rest one foot on the rear part of the

stand (2).

◆

Push (Pos. B) the stand (2) downwards

until it reaches the end of its stroke (see

figure).

0/3)4)/.).'4(%6%()#,%/.

4(%&2/.43500/2434!.$

◆

Position the vehicle on the appropriate

rear support stand

SITIONING THE VEHICLE ON THE

REAR SUPPORT STAND

◆

Lift (Pos. C) the front part o f the stand (6)

and insert the its two ends of the stand

(7) in the two holes (8) positioned on the

lower ends of the front fork.

◆

Rest one foot on the front part of the

stand (6).

◆

Push (Pos. D) the stand (6) downwards

until it reaches the end of its stroke (see

figure).

use and maintenance RSV mille

&, see beside (PO-

&).

&

-

87

Page 22

&2/.47(%%,

aWARNING

The disassembly and reassembly of the

front wheel can be diffic ult for t hose u nfamiliar with vehicle maintenance. You

may wish to have your Local APRILIA

Dealer car ry out thes e operatio ns.

If you wish to perform these operations

yourself, caref ully read p. 72 (MAINTENANCE).

While disassembling and reassembling

the wheel, pay extra care not to damage

the brake lines, discs or pads.

Before carrying out the following ope rations, let the engine and the exhaust silencer cool down until they reach room

temperature, in order to avoid burns.

NOTE You must use the ap propriate

front and rear support stands to remove

the front wheel.

use and maintenance RSV mille

88

-

DISASSEMBLY

◆

Position the vehicle on the appropriate

rear support stand

(POSITIONING THE VEHICLE ON THE

REAR SUPPORT STAND

◆

Position the vehicle on the appropriate

front support stand & (2), see p. 87

(POSITIONING THE VEHICLE ON THE

FRONT SUPPORT STAND

& (1), see p. 87

&).

&).

aWAR NING

Make sure that the vehicle is stable.

If it falls over, it ma y cause damage to

bystanders and other p roperty, as well

as being damaged itself.

◆

Have a helper steady the handlebar in

the straight ahead position.

◆

Remove the left and right front bra ke caliper (3), see p. 98 (REMOVING THE

FRONT BRAKE CALIPERS).

aCAU TION

Never touch the front brake lever after

removing the brake calipers from the

discs. If you do, the cali per pistons ma y

be pushed out of their seats, and brake

fluid will be spilled. Shou ld you accidentally do this, take you r vehicle to

your Local APRILIADealer who will know

how to repair this damage.

◆

Place a support (4) under the front tire, in

such a way as to keep the wheel in its

position after loosening it.

◆

Hold the axle (5) from rotating with an

appropriate Allen wrench .

Wheel nut (6) tightening torque:

57.86 ftlb (80 Nm).

◆

Remove the nut (6) and washer (7).

Screw (8) tightening torque:

15.91 ftlb (22 Nm).

◆

★ Loosen the two axle c lamp screws (8),

using the appropriate Allen wrench.

Page 23

NOTE Observe the arrangement of the

left spacer ring (9) and of the right spacer

ring (10), in order to be able to reassemble

them correctly.

NOTE To facilitate the extraction of the

axle (5), slightly lift the wheel.

◆

Push the axle (5) partly out of the front

fork by tapping the threaded end with a

rubber hammer or wooden drift.

◆

Support the front wheel and remove the

axle (5) manually by pulling it from the

left side of the vehicle.

◆

Remove the wheel by pulling it forward.

NOTE The left spacer ring (9) and the

right spacer ri ng (10) remain locate d in

their seats on the wheel; but if they have

come out, replace them.

REASSEMBLY

◆

Apply a thin film of lubricating grease,

see p. 122 (LUBRICANT CHART), to the

front axle (5).

NOTE Perform the two follow opera tions

only if the left spa cer ring (9) and/or t he

right spacer ring (10) have come out of

their seats on the wheel:

aCAUTION

The left spac er ring (9) and the ri ght

spacer ring (10) have d ifferent shapes:

do not mix them up and pay extra care

to correctly install them.

◆

Install the right spacer ri ng (10) in its s eat

on the wheel (right sid e) with the larger

diameter towards t he o uts id e of the ve hi-

cle (see figure).

◆

Install th e left spacer ri ng (9) in its se at

on the whell (left side of the wheel).

aCAU TION

The arrow (11) on the wheel side indicates the rotation direction. Upon reassembly, ma ke su re th a t th e wh ee l is po sitioned correctly: the arrow must be

visible on the left side of the vehicle.

◆

Position the wheel between the fork

tubes on the support (4).

aWARNING

The front wheel is heavy and can easily

crush your fingers should you get them

between any part of the wheel and the

front fork. Do not attempt to line up the

wheel and the axle clamps with y our fingers. Failure to heed this warning can

lead to serious personal injury.

◆

Move the wheel around until the axle

hole and the axle clamps are aligned.

◆

From the left side of the vehicle, insert

the axle (5) and push in completely.

◆

Install the washer (7) and nut (6). Tighten finger tight.

◆

Hold the axle (5) from rotating using the

Allen wrench.

◆

Tighten the nut (6) to its appropriate

tightening torque.

Nut (6) tightening torque:

57.86 ftlb (80 Nm).

◆

Replace the left and r igh t fron t bra ke cal iper (3), see p. 98 (REMOVING THE

FRONT BRAKE CALIPERS).

◆

Remove the front support stand & (2),

see p. 87 (POSITIONING THE VEHICLE

ON THE FRONT SUPPORT STAND

&).

◆

Remove the rear support stand & (1),

see p. 87 (POSITIONING THE VEHICLE

ON THE REAR SUPPORT STAND

◆

Apply the front brake lever, and then

push down on the handlebars, compressing the fork springs several times.

This will align the fork tubes.

◆

★ Tighten the two axle clamp screw (8).

Screw (8) tightening torque:

15.91 ftlb (22 Nm).

&).

aWAR NING

After servicing the brakes, always

check them for function. If th e s troke of

the lever or pedal is excessive, or if you

detect that the effecti veness of the

brakes is reduced i n any w ay, ha ve you r

vehicle serviced by your Local APRILIA

Dealer. It may be necessar y to have

your dealer bleed the system, or there

may be some other problem with the

brake system.

Never ride your vehicle in traffic immediately after servicing the brakes. Always

apply the brake pedal or lever several

times before riding your vehicle. Then,

try your vehicle in a parking lot or other

safe area with little traffic to ensure that

the brakes are working properly. Failure

to observe this warning can lead to a serious accident with subseque nt serious

injury or death.

use and maintenance RSV mille

-

89

Page 24

2%!27(%%,

aWARNING

The disassembly and reassembly of the

rear wheel can be difficult for those unfamiliar with vehicle maintenance. You

may wish to have your Local APRILIA

Dealer carry out these operations.

If you wish to per form these oper ations

yourself, car efully read p. 72 (MAINTE NANCE).

While disassembling and reassembling

the wheel, pay extra care not to damage

the brake lines, discs or pads.

Before carrying out the following ope rations, let the engine and the exhaust silencer cool down until they reach room

temperature, in order to avoid burns.

NOTE You must use the appropriate rear

support stands to remove the rear wheel.

DISASSEMBLY

◆

Position the vehicle on the appropriate

use and maintenance RSV mille

90

-

rear support stand & (1), see p. 87

(POSITIONING THE VEHICLE ON THE

REAR SUPPORT STAND

&).

aWAR NING

Make sure that the vehicle is stable.

If it falls over, it may cause injury to bystanders and other property, as well as

being damaged itself.

◆

Place a support (2) under the tire, in

such a way as to keep the wheel in its

position after loosening it.

Wheel nut (3) tightening torque:

86.80 ftlb (120 Nm).

◆

Remove the nut (3) and recover the

washer (4).

NOTE To facilitate the extraction of the

axle (5), slightly lift the wheel.

◆

Remove the axle (5) from the left side of

the vehicl e.

NOTE Observe the arrangement of the

right (6) and left (7) chai n tensioners in or-

der to be able to reassemble them correctly.

◆

Remove the right (6) and left (7) chain

tensioners.

aWARNING

Keep your fingers well away from the

chain and sprocket. You could easily lose

a finger if it becomes pinched between

these two parts. Use heavy work gloves

while installing th e rear wheel. Never at tempt to line the rear wheel up using your

fingers. Failure to heed this warning can

result in serious personal injury.

◆

Remove the drive chain (8) from the rear

sprocket (9) and lay it down outside of

the rear sprocket.

NOTE Place the dr ive chai n (8) ou tsi de

of the rear sprocket (9).

◆

Move the wheel forward and pull the d rive

chain (8) away from the rear sprocket (9).

◆

Pull the wheel backwards, removing it

from the swing arm from behind, carefully

removing the disc from the brake caliper.

Page 25

aCAUTION

Never touch the rear brake pedal after removing the rear wheel . If you do, the caliper pistons may be pushe d out of their

seats, and brake fluid will be spilled.

Should you accidentally do this, take

your vehicle to your Loca l APRILIADealer

who will know how to repair this damage.

NOTE The left spacer ring (10) and the

right spacer ring (11) remain locate in their

seats on the wheel; but if they have come

out of their seats retrieve them.

REASSEMBLY

aCAUTION

While reassembling the rear wheel, be

careful not to damage the brake line , the

disc and the pads.

NOTE Perform the follow operation only

if the left spacer ring (10) and/or the right

spacer ring (11) have come out of their

seats on the wheel:

◆

Install the left (10) and right (11) spacer

rings in their seats on the wheel with the

larger diameter to wards the outside of

the vehicle (see figure).

aCAUTION

Before proceeding with the reasse mbly,

make sure that the torque plate (12) of the

brake caliper (13) is posit ioned corr ectly;

the plate slot mu st be in serted in the appropriate stop pin (14) in the inner part of

the right side of the swinging arm. Insert

the disc in the brake caliper carefully.

◆

Position the wheel centrally in the swinging arm, on the support (2).

aWARNING

Keep your fingers we ll away from the

chain and sprocket. You could easily

lose a finger if it becomes pinched between these two parts. Use heavy work

gloves while installing the rear wheel.

Never attempt to line the rear wheel up

using your fingers. Failure to heed this

warning can result in serious pers onal

injury.

◆

Move the wheel as far forward as possible, to ins tall the driv e chain (8) on the

rear sprocket (9).

◆

Pull the rear wheel backwards unti l the

bearing holes are lined up with the holes

in the swinging arm.

◆

Rotate the torque plate (12), complete with

brake caliper (13), with the stop pin (14) in

proper position until it is appropriately

aligned with the holes in the swing arm.

◆

Install the right (6 ) and left (7) c hain t ighteners in their seats on the swing arm.

◆

Apply a thin film of lubricating grease,

see p. 122 (LUBRICANT CHART), to the

rear axle (5).

NOTE To facilitate the insertion of the

axle (5), slightly lift the wheel.

◆

Install the axle (5) completely through

the wheel from the left side.

NOTE Ensure that the ax le (5) is pushe d

all the way home with the head in the appropriate seat on the left chain tightener.

◆

Install the washer (4) and tighten the nut

(3) finger tight.

◆

Remove the support (2) from under the

rear tire.

◆

Check the chain tension, see p. 92

(DRIVE CHAIN).

◆

Tighten the nut (3).

Wheel nut (3) tightening torque:

86.80 ftlb (120 Nm).

aWAR NING

After servicing the brakes, always

check them for function. If th e s troke of

the lever or pedal is excessive, or if you

detect that the effecti veness of the

brakes is reduced i n any w ay, ha ve you r

vehicle serviced by your Local APRILIA

Dealer. It may be necessar y to have

your dealer bleed the system, or there

may be some other problem with the

brake system.

Never ride your veh i c le in traffic immediately after servicing the brakes.

Always apply the brake pedal or lever

several times before riding your vehicle .

Then, try yo ur v eh i cl e in a park ing lo t or

other safe area with little t raff ic to ens ure

that the brakes are working properly.

Failure to observe this warning can lead

to a serious accident with subsequent serious injury or death.

Check the wheel centering.

Have the tightening torques, centering

and balancing of the wheel checked by

your Local APRILIA Dealer. These are critical safety operations, and failure to observe this warning could lead to an upset

with subsequent serious injury or death.

use and maintenance RSV mille

-

91

Page 26

$2)6%#(!).

Carefully read p. 72 (MAINTENANCE).

Every 312 mi (50 0 km) check the conditions, the wear, the play (tension) and the

lubrication of the drive chain.

The vehicle is equipped with an endle ss

chain. There is no master link used.

aWARNING

An excessively loose chain may cause

noise or make the c hain rattle, with consequent wear of the shoe and of the

chain guide plate.

Do not ride your vehicle with an improperly adjusted chain, see p. 93 (ADJUSTMENT).

To inspect the conditio n of the chain,

grasp the chain where it goes around

the sprocket and try to pull it away from

the sprocket. If you can move it more

than one-eighth of a n inch away from

the sprocket, the chain is worn out and

the chain and both front and rear

use and maintenance RSV mille

92

-

sprockets must be replaced. See your

Local APRILIADealer.

aCAUTION

Lack of maintenance can cause premature wear of the chain an d damage to

the sprockets.

Maintain your chain more often if your

vehicle is used on dusty or muddy roads.

aWAR NING

Before carrying out the following operations, let the engine and the exhaust silencer cool down until they reach room

temperature, in order to avoid burns.

aWAR NING

Keep your fingers well clea r of the chain

and sprocket, especially if you are turning the rear wheel while working on the

vehicle. You can easily be seriously injured if a finger is caught between the

chain and sprocket. Use work-gloves to

carrying out these operations.

CHECKING THE PLAY

To check the play:

◆

Stop the engine.

◆

Place the vehicle on the stand, see p. 71

(POSITIONING THE VEHICLE ON THE

STAND)

◆

Shift to neutral.

◆

Check the chain play. It should be 0.98

in (25 mm) at mid-bottom span as

shown above.

◆

Move the vehicle forward or backward,

or support the rear wheel in the air and

turn the wheel to several positions, to

check the chain slack at several locations. If the slack is markedly different

with the wheel in different positions, the

chain and sprockets must be replaced.

aWARNING

Do not ever operate your vehicle with a

damaged chain. This could cause

wheel seizure which could lead to an

upset with subsequent serious injury or

death. Lubricate your chain frequently

Page 27

to minimize the possibility of this kind

of damage, see p. 93 (CLEANING AND

LUBRICATION).

If the play is the same at several locati ons, but

is more or less than 0.98 in (25 mm), adju st

it, see below (ADJUSTMENT).

ADJUSTMENT

NOTE To adjust the chain it is neces-

sary to use the a ppropriate rear su pport

stand

&.

To adjust the chain tension:

◆

Position the vehicle on the appropriate

rear support stand &, see p. 87 ( POS ITIONING THE VEHICLE ON THE REAR

SUPPORT STAND

Wheel nut (1) tightening torque:

86.80 ftlb (120 Nm).

◆

Loosen the nut (1) to several turns.

&).

NOTE In order to make wheel centering

in the swingi n g a rm ea s ie r, th ere ar e r ef er ence marks (2) and (3) on the swing arm.

See illustration above.

◆

Loosen the two lock nuts (4).

◆

Adjust the tension adjusters (5) to obtain

the appropriate chain play, ensuring that

the edge of tension adjuster is in the

same position with regard to the reference marks (2) and (3) on each side of

your vehicle.

◆

Tighten the two lock nuts (4).

◆

Tighten the nut (1).

Wheel nut (1) tightening torque:

86.80 ftlb (120 Nm).

◆

Check the chain play again, see p. 92

(CHECKING THE PLAY).

CHECKING THE WEAR OF THE CHAIN

AND SPROCKETS

In addition to the check, see p. 92 (CHECKING THE PLAY), inspect the chain an d

sprockets to make sure that there are no:

– damaged rollers;

– loose pins;

– dry, rusty, crushed or seized links;

– excessive wear;

– missing O rings;

– sprocket or teeth excessively worn or

damaged.

You may check the wear of the chain and

sprocket by grasping the chain where it con-

tacts the rear sproc ket, and pull ing it away

from the sprocket as far as you can. If you

are able to pul l the chai n far enough away

from the sprocket so that you can see light

between the side plates of the chain and the

sprocket teeth, the chain and sprocket are

worn out and should be replaced.

NOTE Always replace both sprockets

and the chain wh en any of these co mponents are replaced.

aCAU TION

If chain rollers are d amaged, the pins

and/or the O rings are loose or missing,

both sprockets as well as the chain

must be replaced.

aCAU TION

Lubricate the chain frequently, especially if it displays any rust or if it is dry to

the touch. If, after lubricating the chain,

it still has li nks which ca nnot be tu rned

easily, the chain must be replaced.

◆

Check the wear of U- sha pe d c hai n gu id e

(6).

◆

Finally, check the wear of the rear fork

protection shoe.

CLEANING AND LUBRICATION

aCAUTION

The drive chain is provided with O ri ngs

among the links, in order to keep the

grease inside them.

Carry out chain adjustment, lubrication,

cleaning and replacement with great

care. Remember to keep your fingers

clear of the chain and sprocket.

Never wash the chain with water jets,

steam jets, high-pressure water jets and

highly inflammable solvents.

◆

Wash the chain with a non-flammable

solvent. If your chain rusts quickly, lubri-

cate it more often.

Lubricate the chain every 312 mi (500 km)

or whenever it appears dry.

After washing the chain and letting it dry,

lubricate it exclusively with spray grease

for chains provided with sealing rings, see

p. 122 (LUBRICANT CHART).

aCAUTION

Make sure that the chain lubric ant you

use is appropriate for “O” ring chains.

There are some lub ricants available

which contain subst ances which will

destroy the “O” rings in your chain. If

you have any question , contact yo ur Local APRILIADealer.

NOTE Do not use the vehicle immedi-

ately after lubricat ing the ch ain , gi ve the lubricant a chance to dry, otherwise the

chain will spray the lubricant all over you

and your vehicle.

use and maintenance RSV mille

-

93

Page 28

2%-/6).'4(%2)$%23!$$,%

◆

Position the vehicle on the stand, see

p. 71 (POSITIONING THE VEHICLE ON

THE STAND).

◆

★

Partially lift the rear side edge of the

rider saddle.

◆

★

Unscrew and remove the screw (1)

and take the bushing.

Screw (1) driving torque:

8.68 ftlb (12 Nm).

◆

Lift and remove the saddle (2).

NOTE Upon reassembly, insert the front

tang of the saddle in the appropriate seat.

aCAUTION

Do not leave you r vehicle unat tended

without ensuring that the saddle (2) is

properly positioned and l ocked. Should

you forget and ride away with the saddle loose, you could be injured.

,)&4).'4(%&5%,4!.+

Carefully read p. 44 (FUEL) and p. 72

(MAINTENANCE).

aWAR NING

Risk of fire.

Wait until the engine and the exh aus t silencer have completely cooled down.

Fuel vapours are noxio us for your

health.

Make sure that the room in which you

are working is properly ventilated.

Do not inhale fuel vapours.

Do not smoke and do not use naked

flames.

DISPOSE OF UNWANTED FUEL PRO PERLY.

aCAUTION

Never drain the fuel tank, either partially

or completely. This may cause damage

to the inner components of the fuel tank,

or to other parts of the fuel system.

Always ensure that the fuel filler cap is

correctly closed.

◆

Remove the passenger saddle (or passenger saddle cover o), see p. 41 (UNLOCKING / LOCKING THE PASSENGER SADDLE).

◆

Remove the rider saddle, see beside

(REMOVING THE RIDER SADDLE).

◆

Rotate the handlebars to the straight

ahead position.

◆

Unscrew and remove the tw o screws (3)

that fasten the front part of the fuel tank (4).

◆

Remove the fuel tank support rod (7)

from its seats (5-6).

◆

Lift the front part of the fuel tank (4).

Prop it into position using the rod (7) as

shown in the figure.

use and maintenance RSV mille

94

-

Page 29

2%-/6).'4(%&2/.40!24

/&4(%&!)2).'

Carefully read p. 72 (MAINTENANCE).

◆

Position the vehicle on the stand, see

p. 71 (POSITIONING THE VEHICLE ON

THE STAND).

◆

Turn the ignition switch (1) to “m“ (OFF)

position.

◆

Unscrew and remove the two lower

screws (2).

◆

★

Unscrew and remove the side screw

(3).

aCAUTION

The rear-view mirrors remain attached to

the front part of the fairing, but they will

not be not attached firmly. Do not use

the mirrors to handle the fairing, as you

will damage both mirrors and fairing.

◆

★

Unscrew and remove the two upper

screws (4).

★ NOTE T he position of the plate (5 )

and how it fits with the seat (6) on the support frame on the front part of the fairing for

reassembly.

aCAU TION

Handle the plastic and painted components with care and avoid scraping or

damaging them.

Be very careful not to damage the electrical cables.

◆

Move the front part of the fairing (7)

slightly forward.

◆

Lift the r ubber boot (8).

◆

Disconnect the electric connector (9) of

the headlight.

aWAR NING

Upon reassembly, make sure that the

electric connector (9) is correctly coupled.

◆

Remove the front part of the fairing (7)

completely, together with the headlight

and the rear-view mirrors.

aCAUTION

Upon reassembly, tighten the screws

only moderately. Be careful not to over

tighten the screws, this will damage the

surrounding plas tic and painted components.

use and maintenance RSV mille

-

95

Page 30

2%-/6).'4(%3)$%#/6%23

Carefully read p. 72 (MAINTENANCE).

aWARNING

Before carrying out the following ope rations, let the engine and the exhaust silencer cool down until they reach room

temperature, in order to avoid burns.

◆

Position the vehicle on the stand, see

p. 71 (POSITIONING THE VEHICLE ON

THE STAND).

◆

Unscrew and remove the two screw s (1).

aCAUTION

Handle the plastic and painted components with care and avoid scraping or

damaging them.

◆

Remove the side cover (2).

NOTE Upon reassembly, make sure that

the rear coupling is positioned correctly.

Repeat these operation s to remove the

other side cover.

use and maintenance RSV mille

96

-

aCAUTION

Upon reassembly, tighten the screws

only moderately. Be careful not to over

tighten the screws, this will damage the

surrounding plas tic and painted components.

2%-/6).'

4(%2%!26)%7-)22/23

Carefully read p. 72 (MAINTENANCE).

◆

Position the vehicle on the stand, see

p. 71 (POSITIONING THE VEHICLE ON

THE STAND).

◆

Unscrew and remove the nut (3), remove

the washer (4), the spring (5) and the

half sphere (6).

aCAUTION

Handle the plastic and painted components with care and avoid scraping or

damaging them.

◆

Remove the rear-view mirror (7).

◆

If it has fallen from its seat, retrieve the

cup (8).

NOTE Repeat th ese operations to re -

move the other rear-view mirror.

aWAR NING

After reassembly, correct ly adjust the

rear-view mirrors and tighten the nuts in

such a way that the mirrors are secure.

Failure to heed this wa rning can prev ent

you from seeing danger approaching

from behind and lead to a serious accident.

2%-/6).'4(%3)$%&!)2).'3

Carefully read p. 72 (MAINTENANCE).

aWARNING

Before carrying out the following ope rations, let the engine and the exhaust silencer cool down until they reach room

temperature, in order to avoid burns.

◆

Position the vehicle on the stand, see

p. 71 (POSITIONING THE VEHICLE ON

THE STAND).

◆

Rotate the six quick turn screws (9) by

giving them 1/4 turn counterclockwise.

aCAUTION

Handle the plastic and painted components with care and avoid scraping or

damaging them.

◆

Remove the side fairing (10).

NOTE Re peat these oper ations to r e-

move the other side fairing.

Page 31

2%-/6).'4(%,/7%2&!)2).'

Carefully read p. 72 (MAINTENANCE).

NOTE To remove the lower fairing, it is

necessary to use the appropriate rear support stand

◆

Position the vehicle on the appropriate

rear support stand, see p. 87 (POSITIONING THE VEHICLE ON THE REAR

SUPPORT STAND

◆

Remove the two side fairin gs, see p. 96

(REMOVING THE SIDE FAIRIN GS) .

&.

&).

aWAR NING

Before carrying out the following operations, let the engine and the exhaust silencer cool down until they reach room

temperature, in order to avoid burns.

◆

Unscrew and remove the two front

screws (11).

◆

★

Unscrew and remove the rear screw

(12).

◆

Unscrew and remove the two screws

(13) of the rear right profile (14) (inside

the exhaust silencer).

aCAUTION

Handle the plastic and painted components with care and avoid scraping or

damaging them.

◆

Extend the side stand.

◆

Withdraw the two lines (15) and (16)

from the hole provided on the fairing.

◆

Remove the entire lower fairing (17) by

lowering it and with small movements try

to find the best position to withdraw it

from the side stand.

NOTE Upon reassembly, introduce the

two lines (15) and (16) in the hole provided

in the fairing.

◆

Take the rear right profile (14).

NOTE Upon reassembly, the upper part

of the profile (14) must be fitted between

the lower fairing (17) and the su pport pla te.

aCAUTION

Upon reassembly, tighten the screws

only moderately. Be careful not to over

tighten the screws, this will damage the

surrounding plas tic and painted components.

use and maintenance RSV mille

-

97

Page 32

◆

Remove the brake caliper (2) from the

disc, leaving it attached to its line (3).

aCAU TION

Never touch the front brake lever after

removing the brake caliper from the

disc. If you do, the calipe rs pistons may

be pushed out of their seats, and brake

fluid will be spilled. Shou ld you accidentally do this, take you r vehicle to

your Local APRILIADealer who will know

how to repair this damage.

2%-/6).'

4(%&2/.4"2!+%#!,)0%23

aWARNING

The disassembly and reassembly of the

front brake caliper s can be diffic ult for

those unfamiliar with vehicle maintenance. You may wish to have your Local APRILIADealer carry out these operations.

If you wish to perform these operations

yourself, caref ully read p. 72 (MAINTENANCE).

The front brake system is equipp ed with

two discs, one on the left and one on

the right side of the front wheel.

The following in formation may r efer to

only one brake caliper but is applicable

to both.

While disassembling and reassembling

the front brake calipers, pay extra care

not to damage the brake lines, discs or

pads.

use and maintenance RSV mille

98

-

NOTE You must use the appropriate

front support stand to remove the front

brake calipers.

DISASSEMBLY

◆

Position the vehicle on the appropriate

front support stand &, see p. 87 (POSITIONING THE VEHICLE ON THE

FRONT SUPPORT STAND

&).

aWAR NING

Make sure that the vehicle is stable.

If it falls over, it ma y cause damage to

bystanders and other p roperty, as well

as being damaged itself.

◆

Have a helper steady the handlebar in

the straight ahead position.

Brake caliper screw (1) tightening

torque: 36.16 ftlb (50 Nm).

◆

Remove the two screws (1) that fasten

the front brake caliper (2).

REASSEMBLY

aWARNING

Keep your fingers clear, do not allow

them to become crushed between the

wheel, the caliper or the fork. Do not attempt to align the holes in the caliper

using your fingers. Failure to obey this

warning can cause serious injury.

◆

Insert the brake caliper (2) on the disc

and position it so that its fastening holes

and the holes on the su pport a re a ligned .

aWARNING

When reassembling the bra ke caliper,

replace the caliper screws (1) with two

new screws of the same t ype.

◆

Tighten the two screws (1) to the appropriate torque.

Brake caliper screw (1) tightening

torque: 36.16 ftlb (50 Nm).

Page 33

aWAR NING

After servicing the brakes, always

check them for function. If th e s troke of

the lever or pedal is excessive, or if you

detect that the effecti veness of the

brakes is reduced in any w ay, ha ve you r

vehicle serviced by your Local APRILIA

Dealer. It may be necessar y to have

your dealer bleed the system, or there

may be some other problem with the

brake system.

Never ride your vehicle in traffic immediately after servicing the brakes. Always

apply the brake pedal or lever several