Page 1

Aprilia Consumer Service Spa

Technical Service and Training

Release 4 july 99

RSV 1000 Technical Training Course

RSV Mille

This material is didactic and

may be changed following the technical

development of the product

Page 2

Aprilia Consumer Service Spa

Technical Service and Training

Release 4 july 99

RSV 1000 INTRODUCTION

Open your third eye !

The originality of the technical decision the

systematic use of solutions borrowed from the

Racing Department and, above all, the passion and

commitment applied to make every detail exclusive,

form the basis of Aprilia's constructive philosophy. In

particular, the RSV Mille embodies and enhances

the most significant characteristics of this company's

heritage, with its high-level technology, superior

quality of construction and its unique and

unmistakable design.

The RSV Mille brings a substantial change on the

scene of bigh-powered super-sport motorcycles. lts

manoeuvrability and easy riding - typical of two

cylinder bikes - are wedded with the versatility and

The RSV Mille is the best production line bike for

use on the track.

A bike that guarantees a pleasant ride, on either

track or road, to satisfy even the most demanding

rider who wants the best as regards easy bandling,

performance, exclusive quality and technology. lt is

decidedly original, exclusive and performing. A

motorcycle in which the love of the racing world is

translated into a wealth of important details. A bike

with a superior performance, occupying a price

range in line with the best of Japanese competitors.

A product which represents, to all effects, a decision

in style for the buyer and, for Aprilia, the first stage of

further development linked with highpowered bikes.

For Aprilia, "the sense of wonder' means breaking

away from set patterns, having the courage to face

new challenges, in this case shaking off a

paradoxically conservatile universe such as the

world of high-powered super-sports motorcycles.

The RSV Mille marks a turning point, opens a new

chapter and becomes the new point of reference

This material is didactic and

may be changed following the technical

development of the product

Page 3

Aprilia Consumer Service Spa

Technical Service and Training

Release 4 july 99

Design Concept:

Aprilia’s aim in making RSV Mille was to create a

motorcycle with extremely compact dimensions, one

that could cleave the air in an optimumn fashion and

protect the rider against the impact of the wind and

high speeds.

The flow inside the front ait intakes has been

optimazed too, as well as the position of the intakes

on the fairing.

As regards the aereodynamic result obtained, the

achivied CXs value of 0,3010 is the new reference

point for the category.

This material is didactic and

may be changed following the technical

development of the product

Page 4

Aprilia Consumer Service Spa

Technical Service and Training

Release 4 july 99

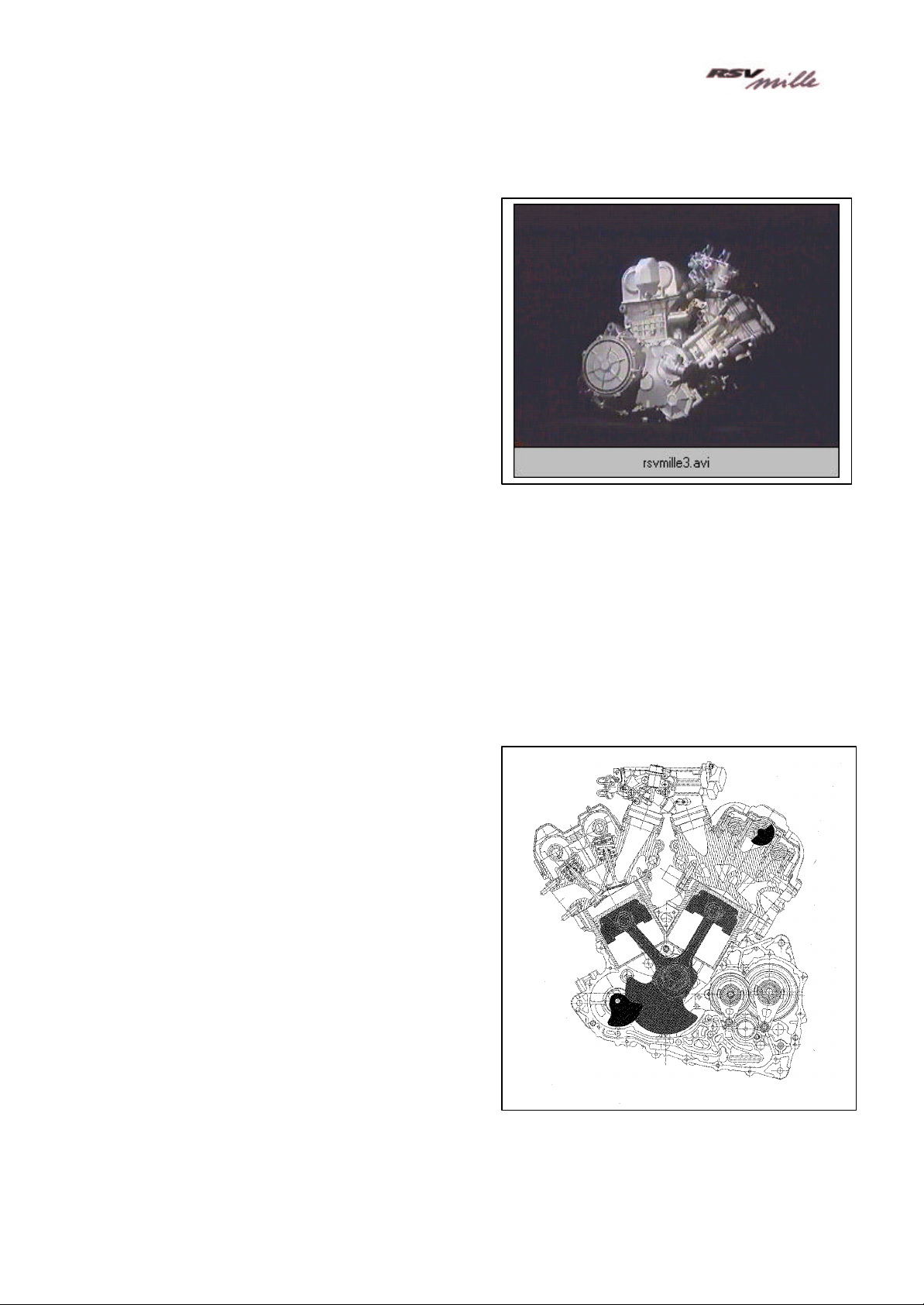

THE ENGINE

The engine fitted on the RSV Mille is a completely

new type, conceived and developed by Aprilia's

engineers. It is a 60°V-formation longitudinal two

cylinder engine, with 4 distribution valves per cylinder

and a double camshaft at the head, controlled by a

mixed chain and gear system. lt is fed by electronic

ignition with air input through a system of dynamic

air intakes. lgnition is of the CDI type, where the load

of air and petrol is fired by the TSI system (Twin

Spark lgnition) which uses two spark plugs per

cylinder. lgnition is controlled by the integrate engine

management system, which also controls injection.

While it is true that the 90' V engine is itrinsically balanced (the first order forces generated during

the movement of the internal organs automatically cancel one another), it is equally true that the

dimensione of the engine are penalized by the size of the angle between the cilinders.

The decision to use a 60° V-formation two-cylinder engine responds perfectly to the need for a

lightweight, compact engine, so as not to sacrifica the design of the cycle parts with tecnical

solutions and weight distribution that are not optimum.

The countershafts

The problem of the vibrations which are created

inside a 60 V engine gave the designers a lot of

work. The possibility of offsetting the pins of the

connecting rod was discarded, as it would have

required excessive widening of the dimension of the

motor crankcase.

The solution found was the use of the exclusive

AVDC patent (Anti-Vibration Double

Countershaft).This system uses an anti-vibration by

turning countershaft which, in the opposite direction

to the engine shaft, balances the first order forces.

The moment generated by the countershaft is, in

turn, balanced by fitting a second countershaft

(Smaller than the main one) inside the head of the

rear cylinder. The result of adopting this technology

is an engine with excellent characteristics of power,

torque, with extremeily reduced vibrations.

This material is didactic and

may be changed following the technical

development of the product

Page 5

Aprilia Consumer Service Spa

Technical Service and Training

Release 4 july 99

The dry sump

A further innovation brought by Aprilia in producing this new engine is the use of dry-sump

lubrication, which allows a more rigid and compact engine block that the "wet-sump" solution. The

system makes use of a second trochoid pump for recovery and an external oil tank, as well as a

radiator positioned in front of the engine.

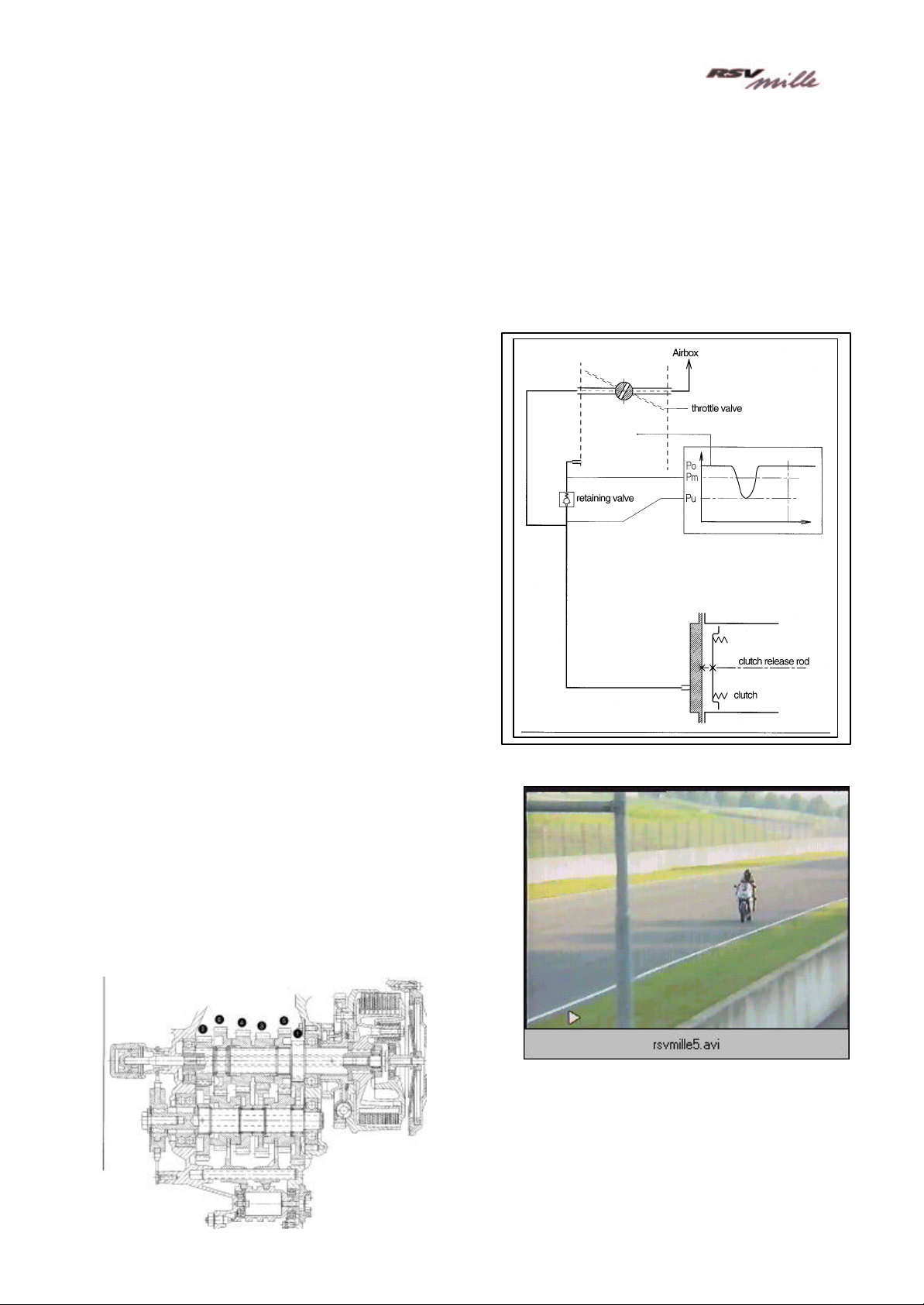

The power clutch

The RSV Mille has a clutch with hydraulic control,

assisted by the esclusive PPC patent (Pneumatic

Power Clutch) to check bouncing of the rear wheel.

When decelerating suddenly, the weight of the

motorcycle is transferred instantly to the front,

lightening the rear axle. In high-powered twocylinder engines this phenomenon is accentuated by

the high “engine braking" effect; this can cause the

so-called bouncing, or the tendency of the rear

wheel to block and lift off the ground, endangering

the stability of the bike and, consequently, the

vehicle's performance and safety.

Aprilia has found the ideal solution to this problem

exploiting the variations in pressure which occur in

the intake ducts when the throttle is opened and

closed, to lighten the load on the clutch springs. By

connecting the intake ducts to a "lung" situated at the

side of the clutch group, the vacuum created when

the throttle is closed decreases the load exerted on

the disks by the springs, while when the throttle is

opened again the clutch resumes operation under

normal weight conditions, thus transferring all the

power to the rear wheel.

This system also allows reduction of the force

applied on the lever on the handlebar, when the bike

is running at low rev speeds.

This material is didactic and

may be changed following the technical

development of the product

Page 6

Aprilia Consumer Service Spa

Technical Service and Training

Release 4 july 99

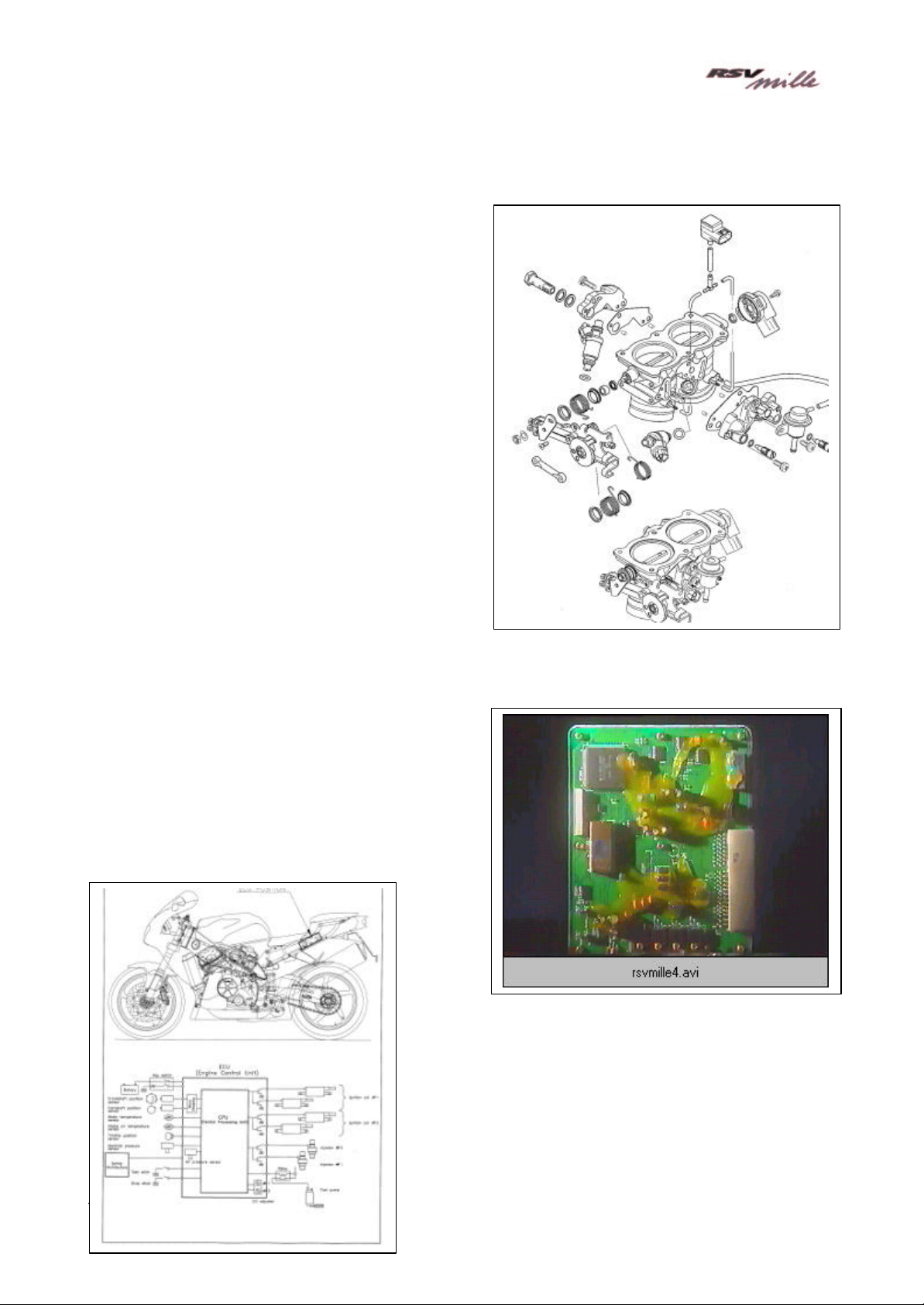

lnjection

The need for suitable control of the powerful engine

of the RSV Mille led the Aprilia designers to adopt

an electronic management system built into the

engine. All the fondamental operating parameters

are constantly monitored by a sophisticated

electronic controls unit which, on the basis of the

data received, control operation of both the injection

system and the ignition system.

The injectors are fed by a pump which produces a

constant pressure of 330 Kpa. The throttle bodies

have a diameter of 51 mm. Fresh air is taken in

through ducts which make use of dynamic pressure

when the motor-cycle is moving, sending fresh air

into a large volume airbox.

The entire injection/ignition system is also equipped

with a continuous Selfdiagnosis circuit (both on

starting and when the bike is running); this is able to

indicate any malfunctions of the system directly on

the dashboard, without the aid of complicated and

expensive external equipment.

This material is didactic and

may be changed following the technical

development of the product

Page 7

Aprilia Consumer Service Spa

Technical Service and Training

Release 4 july 99

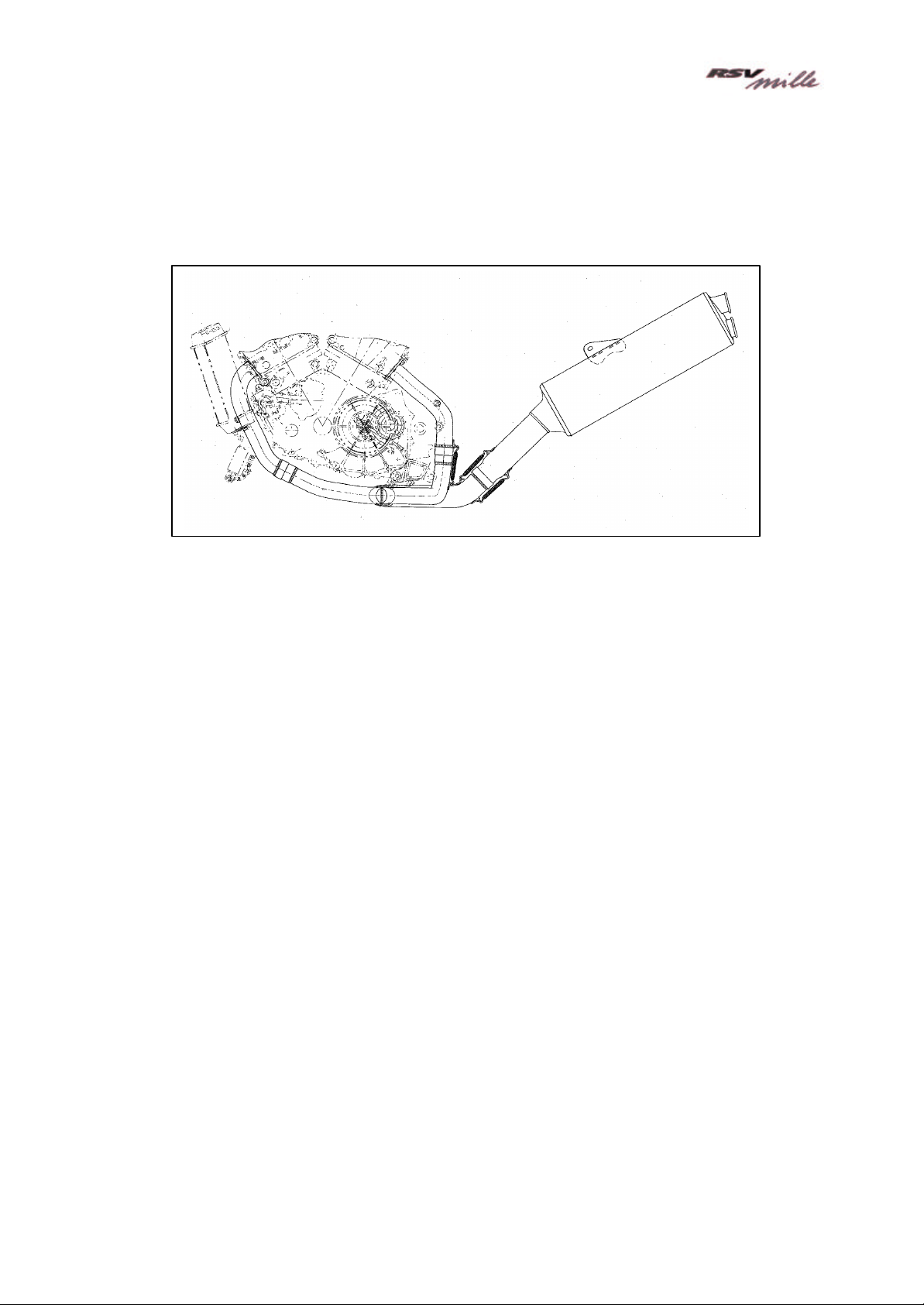

The exhaust

The exhaust system of the RSV Mille originates as the reply to four very precise requests: light

weight, aerodynamic line, respect for the environment and for approval standards.

The choice of the "2 in 1 " exhaust proved to be the most appropriate since, while obtaining an

internal volume of over 9 litres, the bulk and weight are lower than those of a l'2 in 2" exhaust.

The exhaust of the RSV Mille made completely of stainless steel, which ensures long life and

lasting good looks.

This material is didactic and

may be changed following the technical

development of the product

Page 8

Aprilia Consumer Service Spa

Technical Service and Training

Release 4 july 99

As regards respect for the environment, the engine of the RSV Mille complies with the parameters

of the future European standards (EURO 1, which comes into force in 1999); this result is achieved

without the aid of any type of catalyst, as a further guarantee of performance and attention to these

problems.

This material is didactic and

may be changed following the technical

development of the product

Page 9

Aprilia Consumer Service Spa

Technical Service and Training

Release 4 july 99

CYCLE PARTS

Jewel within the jewel, the cycle parts of the RSV

Mille must be considered to all effects a true

masterpiece of engineering. As beautiful as a work

of art, impeccably but above all efficiently finished,

instinctive and easy to drive, to quarantee optimum

exploitation of all the engine power.

The best engineers in the Aprilia racing department

designed the frame, giving it the most in terms of

planning and knowledge of structures, choice of

materials, weight distribution and dynamic

behaviour.

Particular care was taken with the torsional stiffness (with a record value of 650 Kgm) and bending

resistance of tbc frame, fondamental elements as regards riding precision and safety.

The splendid rear fork with differentiated arms

controls, by means of linka-ges, a multiadjustable shock-absorber with built-in "piggyback" tank. The rear wheel bump position is

135 mm.

At the front the 43 mm Showa "upside-down"

fork allows a bump position of 120 mm.

The cycle parts of the RSV Mille are

supported by a dry weight of only 189 kg,

optimally distributed with 49.2% on the front

axle and 50.8% on the rear axle.

This material is didactic and

may be changed following the technical

development of the product

Page 10

Aprilia Consumer Service Spa

Technical Service and Training

Release 4 july 99

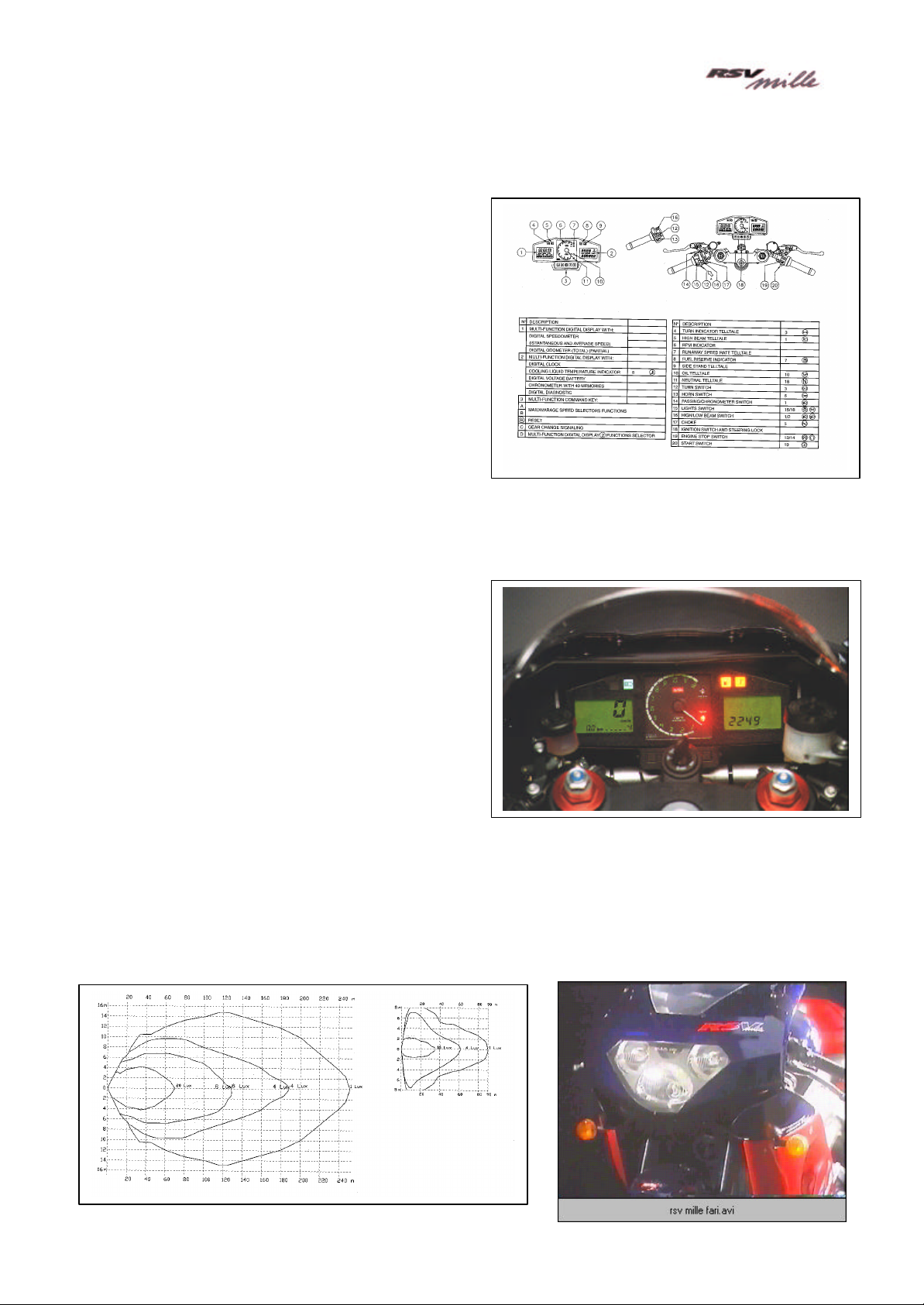

COMPONENTS

Every slightest detail of the RSV Mille receives the

same meticulous care from Aprilia, to transfer dove,

care and enthusiasm into every bike that the

company produces.

Many parts contribute to make the RSV Mille a

unique and unrivalied rnotorcycle: the aluminium rear

frame that supports the saddle, the beautiful

exposed welds, the adiustable controls on both

handlebar and pedals (where micrometric

adjustment by means of a cam offers a solution to

satisfy even the most demanding motorcyclist), the

Brembo wheels in aluminium alloy and the steering

shock absorber. These are only some of the most

significant details.

Another great innovation of this rnotorcycle is the

analog and digital dashboard. It is to all effects a real

computer on board, able to supply the rider wíth all

the information ho needs at any time.

A sophisticated, exclusive digital chronometer/clock,

controlled by the flashing of the main beam headlamp, is

able to store up to 40 lap times. The "red zone" on the rev

counter is indicated by the flashing of a warning light

(which may be set by the rider at the desired rev speed),

allowing him to choose the best moment to change gear

and gain precious seconds when performing the operation.

The headlamp

The headlamp is a particulary distinctive feature of the RSV Mille, characterizing its

appearance and making it immediately recognizable as soon as it starts flashing. lt is a triple

headlamp, in which the power of the main beam allows a broad, powerful and homogeneous beam

of light, to make night riding even more safe and effective. Two 55 Watt halogen lamps are housed

inside parabolas developed on the computer with the technology of complex surfaces.

This material is didactic and

may be changed following the technical

development of the product

Page 11

Aprilia Consumer Service Spa

Technical Service and Training

Release 4 july 99

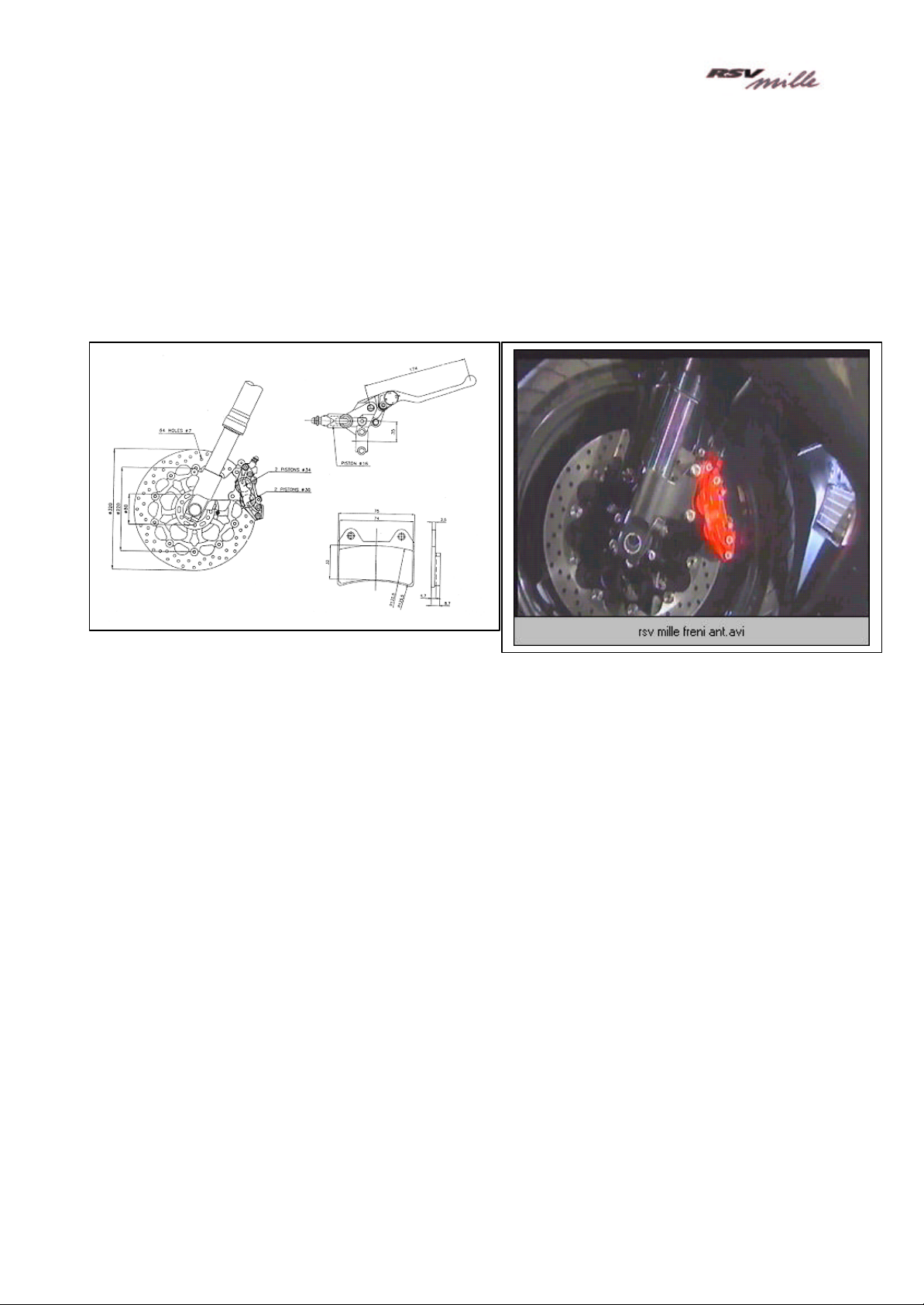

The Brakers:

The Brakers of RSV, developed in close collaboration between Brembo and Aprilia, have calipers at

the front with 4 piston with different diameters (34 and 30 mm) wich act on steel disks with diameter

of 320 mm.

At the rear the bike is fitted with 220 mm disk and caliper with double opposed piston (d=30 mm)

In terms of product quality, the RSV Mille has achieved an even higher internal standard which

already places Aprilia at the top of the market. Quality means not only product quality but also, and

above all, design quality, as is demonstrated by the ISO 9001 certification obtained for ali production

phases.

To assure you that this bike is reliable and a really good buy, Aprilia covers the RSV Mille with a

MotoGo Three-Year Guarantee.

This material is didactic and

may be changed following the technical

development of the product

Page 12

Aprilia Consumer Service Spa

Technical Service and Training

Release 4 july 99

SECTION 01: INJECTION SYSTEM

1.1 PREFACE: INTRODUCTION ON THE INJECTION-IGNITION SYSTEM

The injection-ignition system is of the " alpha/n, D/J" type, in which motor speed and throttle

position are used as the main parameters for the quantity of aspirated air; knowing the quantity of

air, the fuel level is dosed as a function of the performance required. Other system sensor

atmospheric pressure, air temperature, water temperature allow basic settings to be corrected in

the event of specific conditions. In addition, motor speed and throttle angle allow the optimum spark,

advance to be calculated under any operating condition.

Electronic injection-ignition system.

The application of an electronic control injection-ignition system to eight-stroke-cycle engine,

optimizes their use, providing a higher specific horsepower together with a lower specific

consumption, and reducing the unburt elements in the exhaust gases. These advantages are got

thank to a more exact air-fuel ratio metering and a good spark advance control. This

equipment consists of three circuits: Fuel circuit, Sucked air circuit and Electric circuit.

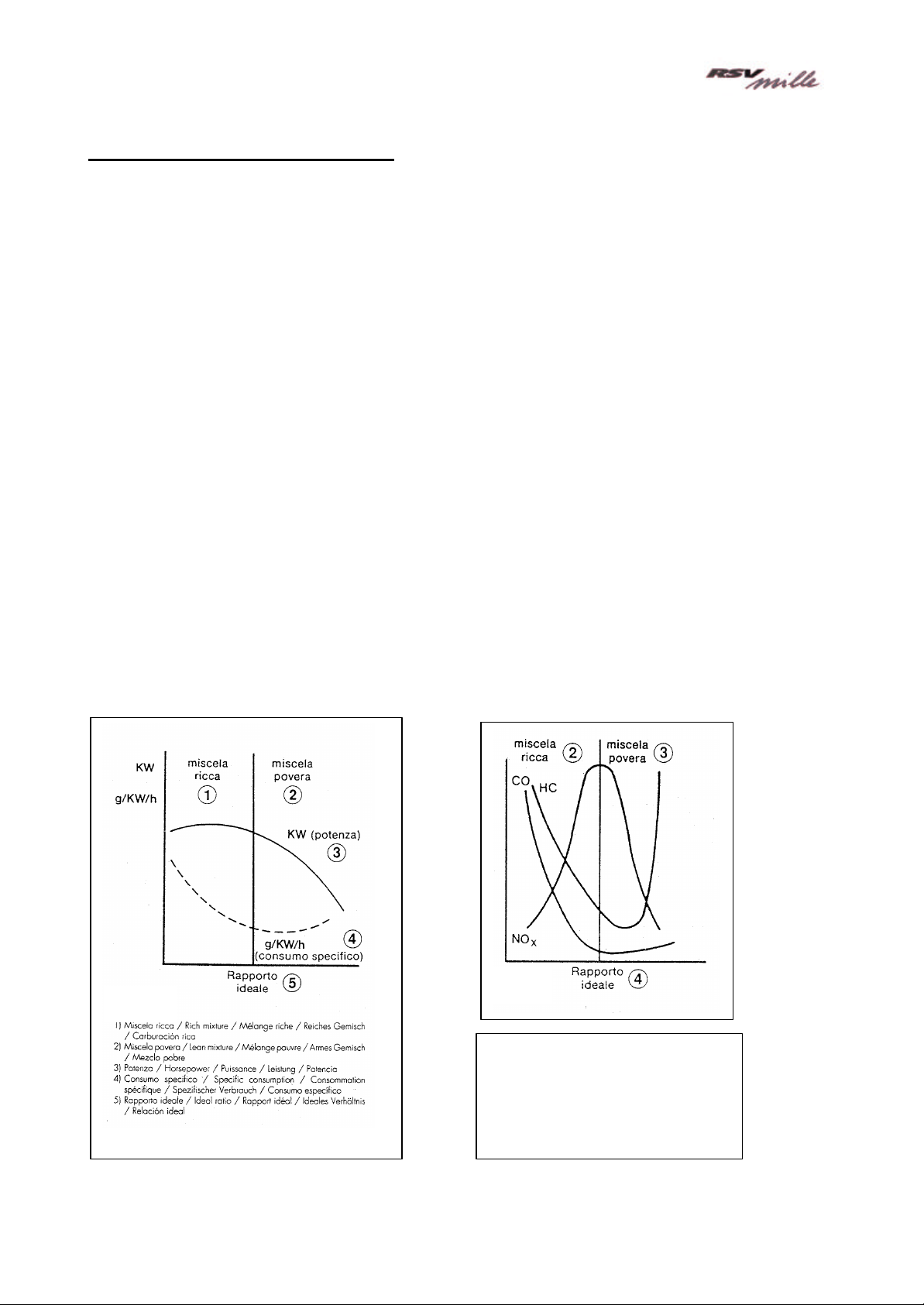

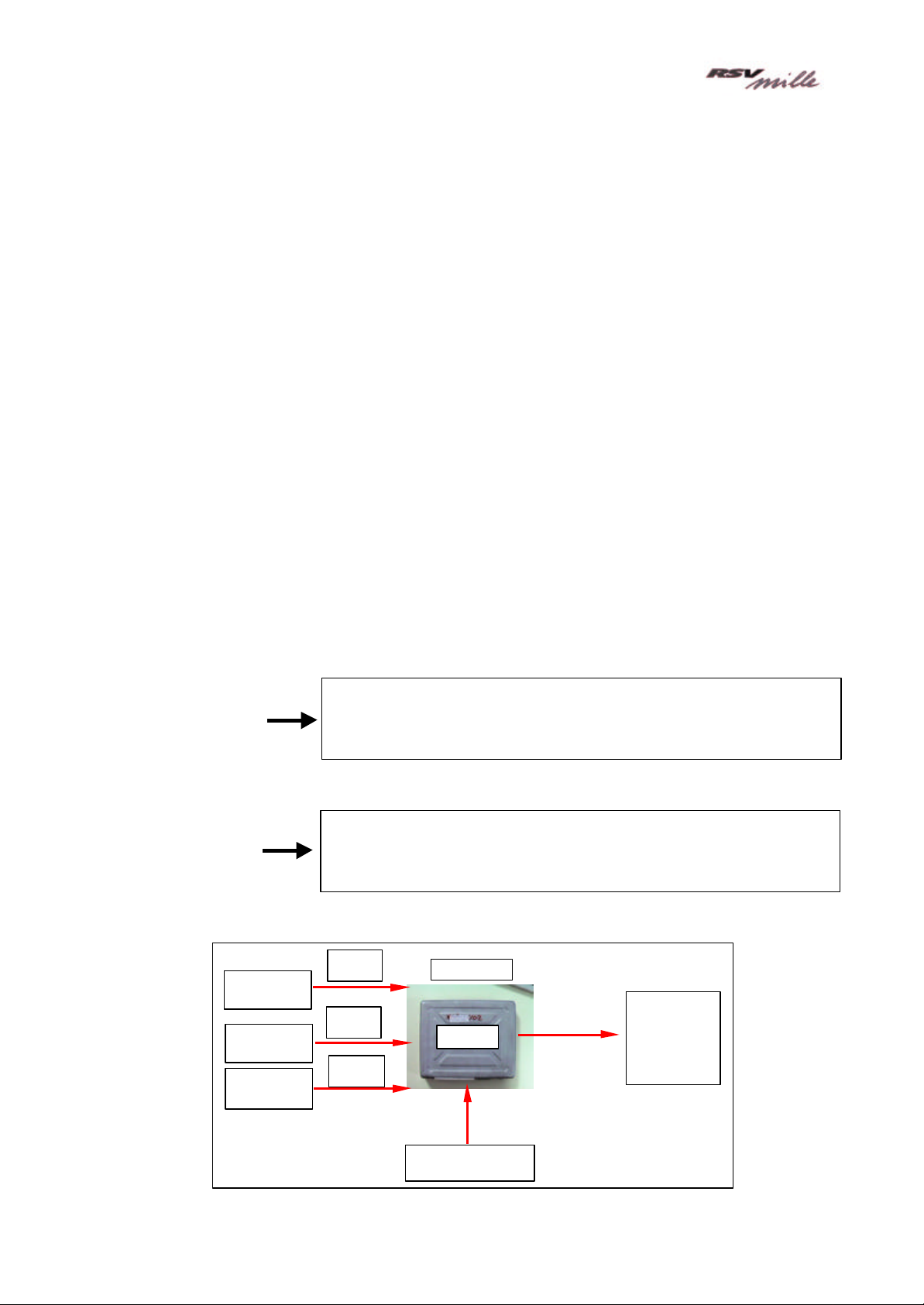

Influence of air-fuel ratio and of spark advance.

Air-fuel ratio and spark advance are key factors for the optimum functioning of the engine, and so is

their management. The air-fuel ratio is fhe ratio of air and fuel (weight) supplied to the engine: the

ideal (stechiometric) ratio is achieved when full combustion is ensured. Too much or too little air will

produce a lean or rich mixture, respectively, which affects horse power and fueI consumption (see

fig. 1, as well as the pollutant content in exhaust emissions see fig. 2).

The electronic spark advance management optimises engine performance: peak power, transient,

consumption, pollution.

Fig.1

This material is didactic and

may be changed following the technical

development of the product

Fig.2

1) Pollutants/ Polluants/ Umweltbelastende

Abgase /Contaminantes

2) Rich mixture / Melange riche / Reiches

Gemisch / Mezcla rica

3) Lean mixture / Melange pauvre / Armes

Gemisch / Mezcla pobre

4) Ideal ratio / Rapport ideal / Ideales Verhaltnis /

Proporcion ideal

Page 13

Aprilia Consumer Service Spa

Technical Service and Training

Release 4 july 99

Operation phases.

NORMAL OPERATION

When the engine has a normal temperature, the control unit –ECU- calculates the phase, the

injection time and the spark advance through interpolation of the corresponding store maps, as

function of the r.p.m/pressure (..and other input)

STARTING PHASE

When the ignition switch is operated, the control unit feeds the fuel pump for a few seconds and

receives the throttle opening angle and engine temperature signals. At the start, the control unit

receives the engine revolutions and phase signals, which allow the injection and ignition control. To

make the starting easier, in addition to the use of the Starter, the base metering is enriched,

conforming to the coolant temperature.

OPERATION DURING ACCELERATION/DECELERATION

During acceleration, the system increases the delivered fuel amount, so to have a better driving.

The acceleration condition is detected when the throttle opening angle increases remarkably; the

enrichment factor will be proportional to the pressure change and to the cooling water temperature.

A decrease of the throttle opening angle shows a deceleration and causes a reduction of the

delivered fuel.

This material is didactic and

may be changed following the technical

development of the product

Page 14

Aprilia Consumer Service Spa

α

MAPPE

SENSOR

Technical Service and Training

Release 4 july 99

1.2 RSV 1000 FUEL INJECTION SYSTEM

The main features of the RSV MILLE fuel injection system are as follows:

1. Possibility of setting the right air/fuel mixture in real time on the basis of the throttle valve

opening, the inlet manifold pressure and the engine running speed.

2. Improved performance and acceleration response thanks to the SW which compensates the

air/fuel mixture in all engine running conditions.

3. Clean exhaust emission thanks to the fuel injection system.

Variable timing, depending on engine running states. At present, the system is not set up for

the use of the Lambda probe.

To determine the injection volume, vary the opening time of the injector; the greater the volume, the

longer the injection time. To determine the injection time, there are a number of different sensors

which increase or reduce the injection volume on the basis of the atmospheric pressure,

atmospheric temperature, engine coolant temperature, intake air pressure, accelerator position and

engine rpm.

The basic volume is given by the injection mapping and the sensors send the data to the electronic

control unit to compensate this volume in line with the running conditions of the engine/bike. There

are two maps in the E-Prom:

This is the “basic” map that mainly covers the high rpm sector. The

1. Map

2. Map

n/

D/J

injector opening time, i.e. the injection volume, is determined on the basis

of the rpm and the throttle valve opening angle.

The D/J map covers the engine low/medium rpm sector. The idling

system is governed by the D/J map. The volume of fuel injected depends

on the manifold pressure and the rpm.

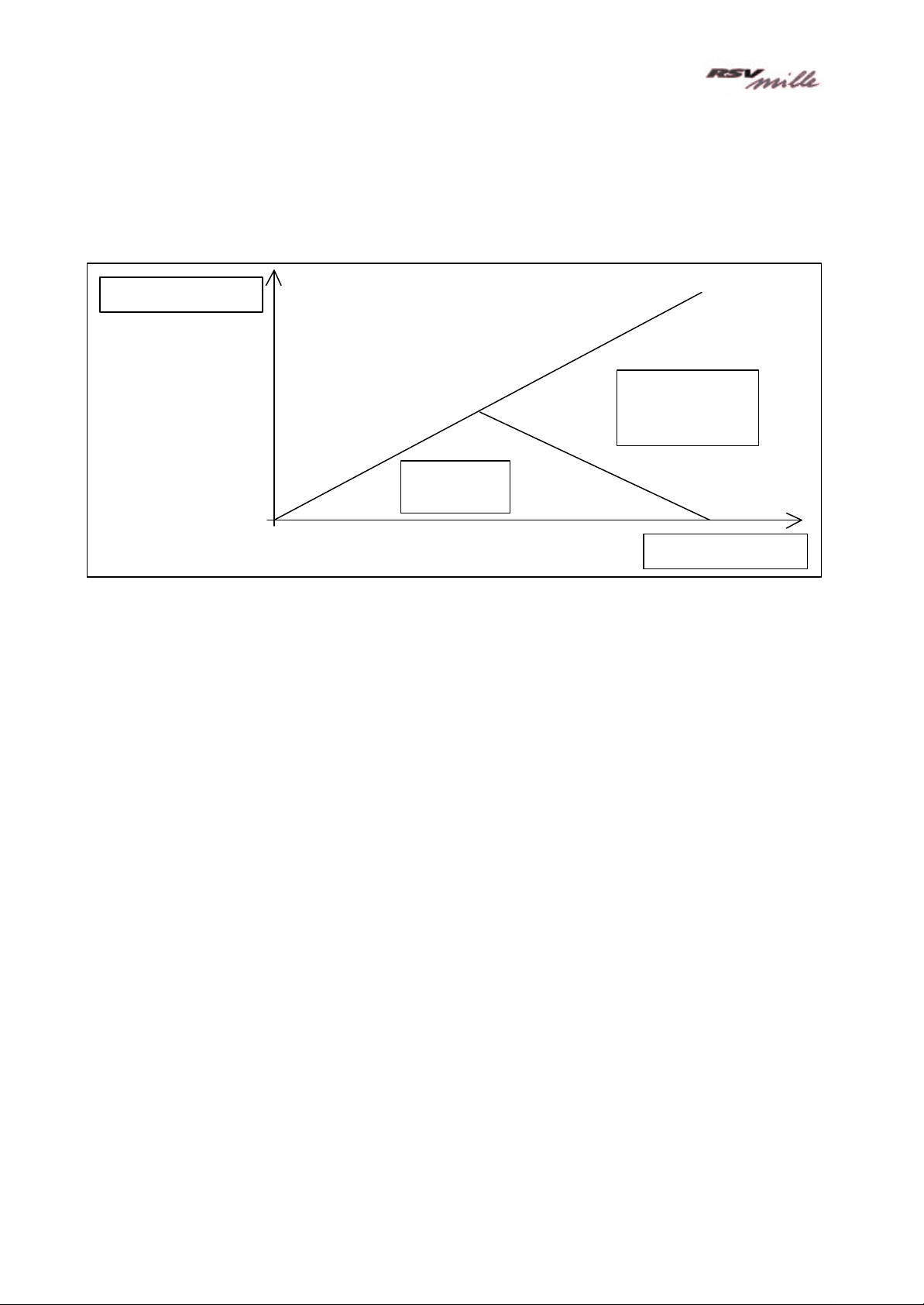

The figure shows the logic diagram for the Injection Volume calculation system.

Paspir.

INTAKE

PRESSURE

RPM

Pick-up

ANGLE

THROTTLE

‘SENSOR’

INJECTION

VOLUME

COMPENSATION

This material is didactic and

may be changed following the technical

development of the product

Page 15

Aprilia Consumer Service Spa

DJ/

α

Throttle angle

Technical Service and Training

Release 4 july 99

The control unit software switches between the DJ map and the alpha/n map on the basis of the

engine running conditions. The injection volume also depends on the other factors provided by the

compensation devices, illustrated later on.

The switch from D/J to alpha/n occurs gradually (See down figure) :

Injection Volume

/n

As shown in the above figure, the D/J map is almost 100% active in low load running conditions

(e.g. engine in neutral).

The alpha/N curve becomes predominant in power delivery conditions.

Remember that the control unit is connected electrically to the instrument panel, and that there is

also the self-diagnosis function. When in the diagnosis option, the panel displays the fault codes

that act as a guide in the servicing.

This material is didactic and

may be changed following the technical

development of the product

Page 16

Aprilia Consumer Service Spa

Technical Service and Training

Release 4 july 99

Compensation devices:

1. Atmospheric pressure sensor

2. Engine coolant temperature sensor

3. Intake air temperature sensor

Positioned inside the control unit box. Reads the

Patm.

The control unit normally reduces the injection volume

in low atmospheric pressure conditions

This sensor reads the coolant temperature. If the

temperature reading is low, the control unit increases

the injection times

This sensor reads the temperature of the intake air; if

the temperature is low, the injection time is increased

4. Gear position (idling switch)

Other significant compensation factors:

- Battery voltage

- Starting compensation (engine warming)

- Delta Alpha compensation:

-

- boosts the engine fuel supply during rapid acceleration

- cuts off the fuel during deceleration

This logic sensor verifies whether or not the gearbox is

in the neutral position. The signal also affects the

phasing.

This material is didactic and

may be changed following the technical

development of the product

Page 17

Aprilia Consumer Service Spa

Technical Service and Training

Release 4 july 99

-

- Timing control

The times are controlled by the reading of the position of the crankshaft and

the position of the camshaft. The control unit also detects the starting phase, injecting the fuel into

the cylinders asynchronously.

Reads the position of the crankshaft, discretizing angles of

60°

Crankshaft sensor

Camshaft position sensor

Sends a voltage to the control unit, like any pick-up.

This signal controls the fuel pump via the ECU.

Reads the position of the camshaft and sends the signal to

the ECU. The sensor reads the position of the front cylinder

only.

This material is didactic and

may be changed following the technical

development of the product

Page 18

Aprilia Consumer Service Spa

Technical Service and Training

Release 4 july 99

Injection stop control

Rpm limiter:

Software control. The control unit stops the injection if the rpm are excessive.

Deceleration:

The injector function is disabled during deceleration with the throttle valve closed.

Side stand switch:

Prevents starting when in running conditions

Switches the bike off immediately if a gear is engaged with the side stand

down

This material is didactic and

may be changed following the technical

development of the product

Page 19

Aprilia Consumer Service Spa

Technical Service and Training

Release 4 july 99

Safety systems

Kick back Prevention:

At about 300 rpm (if the rpm have been over 800 rpm) the control unit deenergizes the coil signal to prevent a possible kick-back in the pistons when turning the bike off.

Tip over sensor:

If the bike tips over, the tip over sensor stops the injectors’ control signal and

fuel pump. The sensor is a mechanical switch already used on other bikes on the market. Reset

the CPU by switching off the bike to re-enable the normal functioning of the control unit.

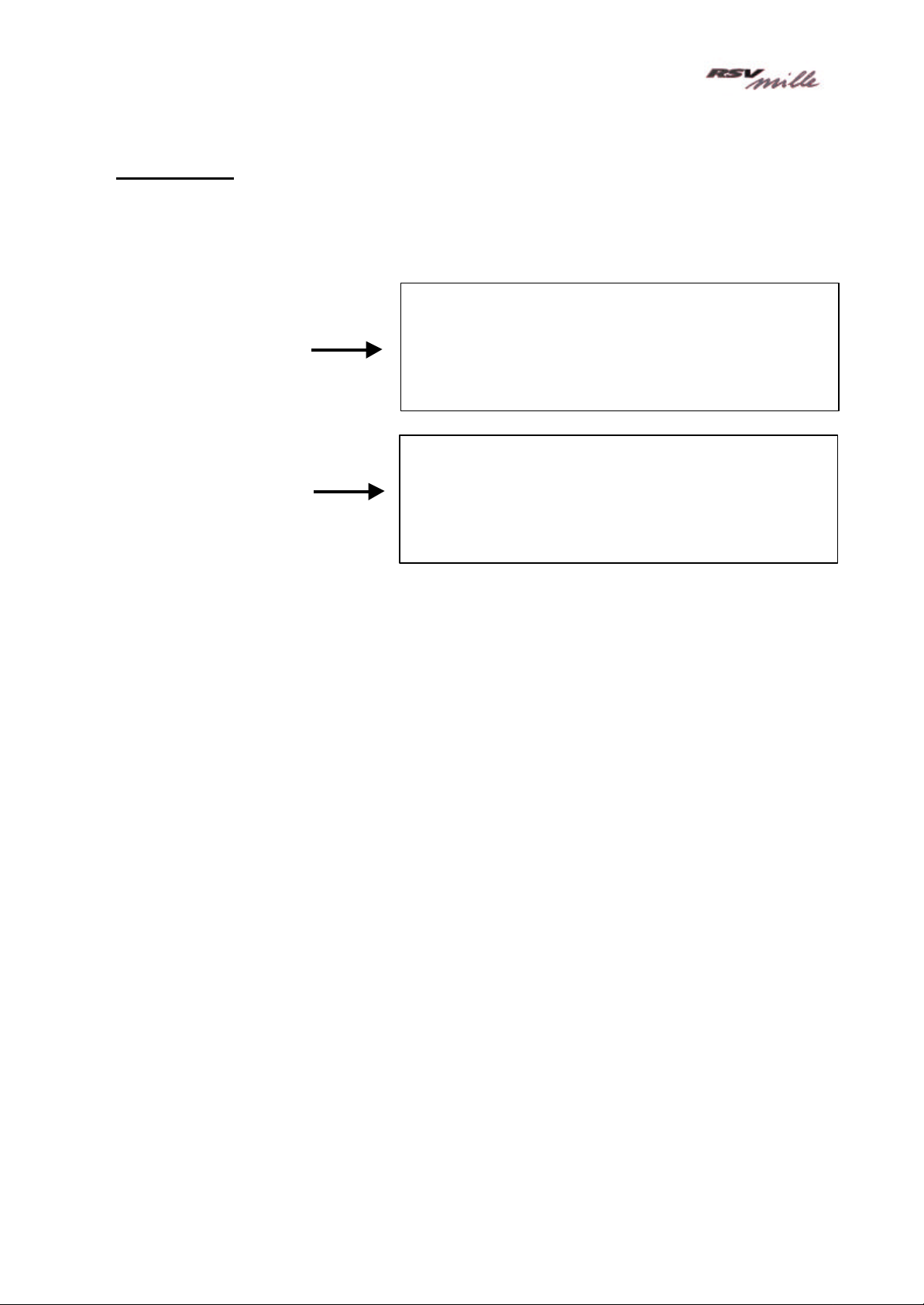

Side stand and clutch switches (possible conditions):

This material is didactic and

may be changed following the technical

development of the product

Page 20

Aprilia Consumer Service Spa

Technical Service and Training

Release 4 july 99

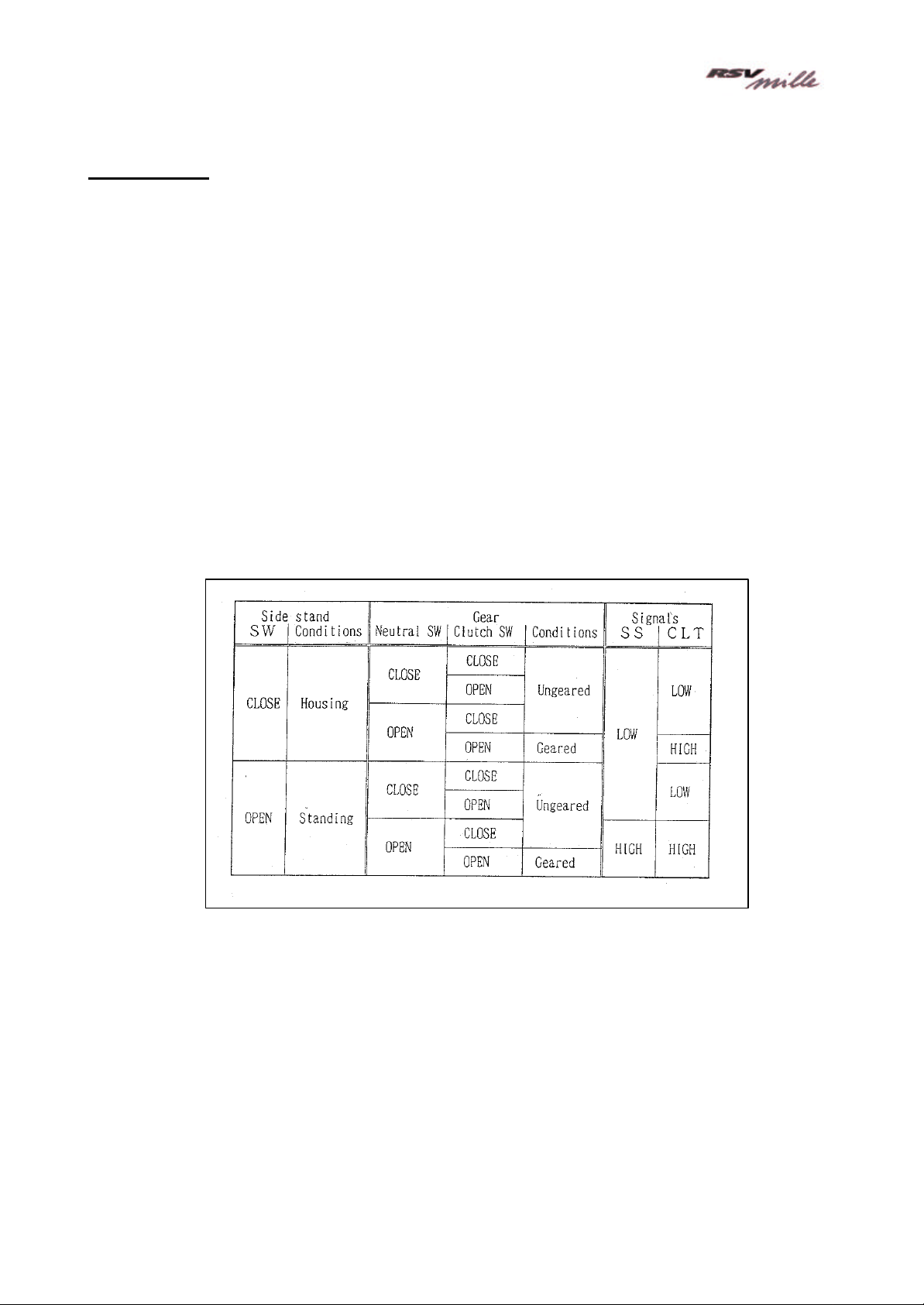

1.3 SELF-DIAGNOSTICS FUNCTION:

The self-diagnostics function is part of the ECU software and is a valid aid to trouble-shooting in the

electronic injection system.

HOW THE FUNCTION WORKS:

With the control unit and dashboard connected and the key “on”, the multi-function LCD displays

the message “EFI” instead of the temperature reading for about 3 seconds

If the EFI message disappears after 3 seconds and TEMPERATURE appears (°C, °F or COLD),

this means that the injection control unit has found no static errors in the injection components. To

check the crankshaft and camshaft sensors, make a starting attempt lasting > 4 sec.

If EFI DOES NOT appear, this means there is no connection between the display and the control

unit (DIAG lead disconnected à check wiring)

If the EFI message persists, this means that the control unit has found a fault in the

sensors/components. Go into the Dealer Mode.

The diagnostics function is divided up as follows:

- USER MODE: If there is a fault, the user will see the “EFI” message remaining on the display

after starting. This is the only sensors/coils fault message that can be seen by the user

- DEALER MODE: Using connector 68, the mechanic will be able to read the corresponding fault

code on the LCD

How to access DEALER MODE:

1- Ground the control unit diagnostics terminal via connector 68 (see diagram). The message

DIAG will appear on the display

This material is didactic and

may be changed following the technical

development of the product

Page 21

Aprilia Consumer Service Spa

Technical Service and Training

Release 4 july 99

2-If everything is functioning perfectly, the following figures may appear on the display:

-1, 0, 1 (throttle valve opening standard values – SEE CO SETTING)

3- If there are any faults, the fault codes will appear in sequence. The sequence will keep repeating

until you exit the Dealer Mode.

!!!! AFTER REPAIRING THE FAULT SWITCH THE BIKE ON AGAIN TO CHECK

IMPORTANT NOTES:

Whether or not the bike can be turned on in the Dealer Mode depends on the type of fault.

The ECU must be on for the fault codes to be saved; if the bike is switched off (STOP Condition) the codes

memory will be erased

There is no SW/HW control on the injectors

This material is didactic and

may be changed following the technical

development of the product

Page 22

Aprilia Consumer Service Spa

Technical Service and Training

Release 4 july 99

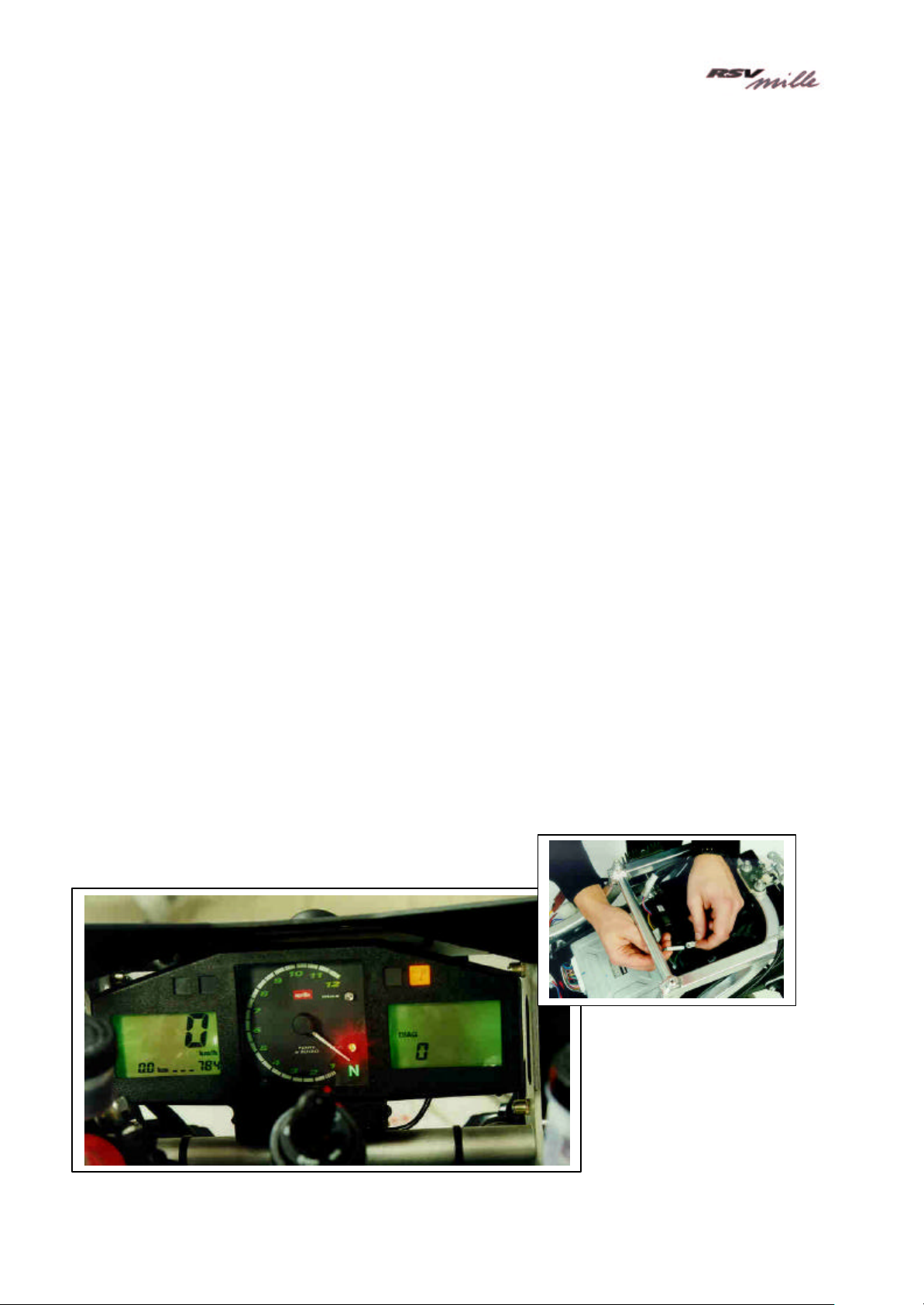

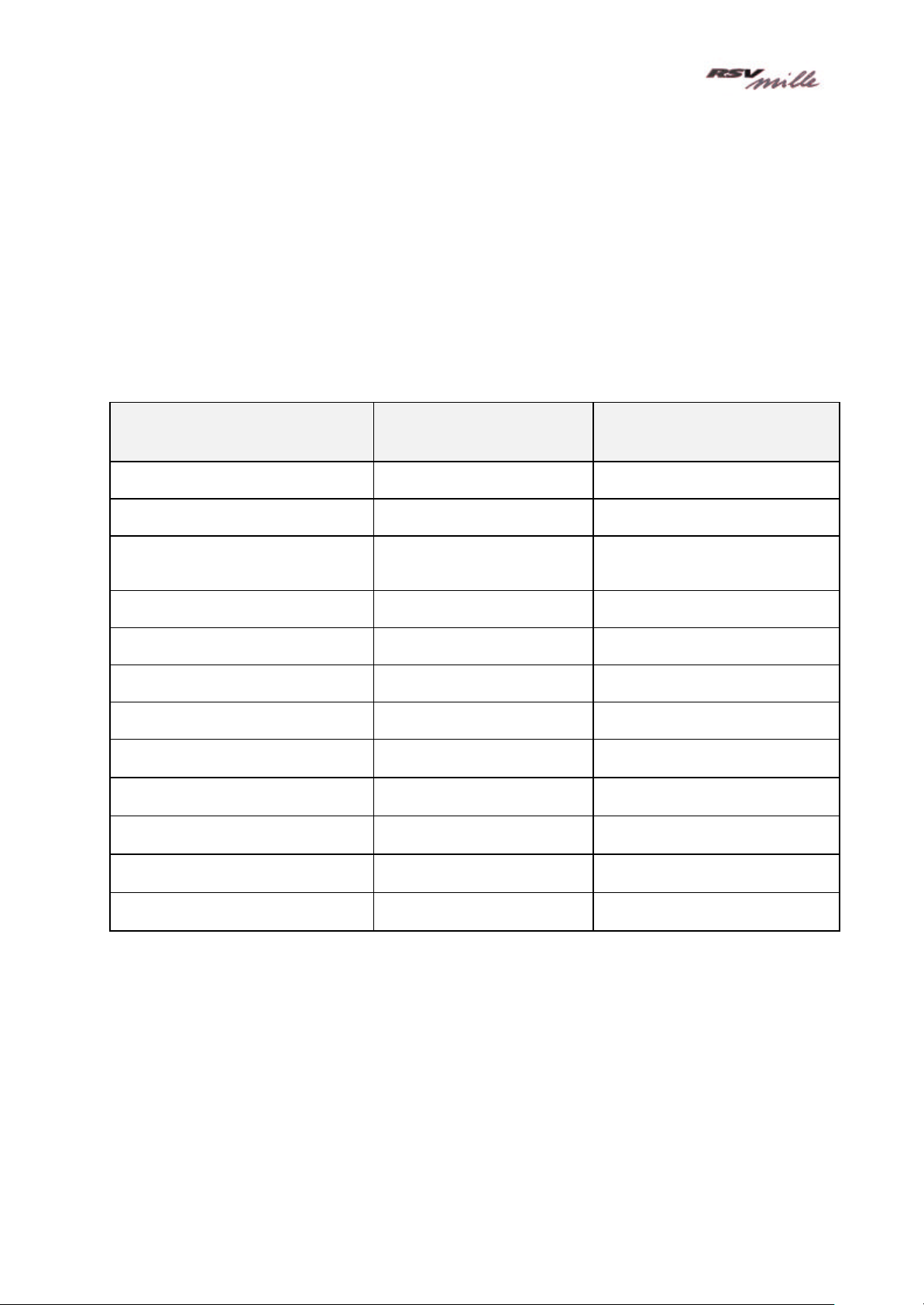

1.4 FAULTS TABLE

FAULT CODE COMPONENT INVOLVED CAUSE NOTES

11

12

13

14

15

21

22

23

33

34

35

36

41

CAMSHAFT SENSOR

CRANKSHAFT SENSOR

INTAKE PRESSURE SENSOR

INTAKE/ATMOSPHERIC PRESSURE

SENSOR

THROTTLE SENSOR

COOLANT TEMPERATURE SENSOR

AIR TEMPERATURE SENSOR

Sensor not connected, faulty

wiring, sensor broken

Sensor not connected, faulty

wiring, sensor broken

Sensor not connected, faulty

wiring, sensor broken

Increased differences

between sensor signals

Sensor not connected, faulty

wiring, sensor broken

Sensor not connected, faulty

wiring, sensor broken

Sensor not connected, faulty

wiring, sensor broken

ATMOSPHERIC PRESSURE SENSOR Sensor – inside control unit

– defective

COIL 1 CYLINDER1

COIL 2 CYLINDER 1

COIL 1 CYLINDER 2

COIL 2 CYLINDER 2

Coil not connected, faulty wiring,

sensor broken

Coil not connected, faulty wiring,

sensor broken

Coil not connected, faulty wiring,

sensor broken

Coil not connected, faulty wiring,

sensor broken

TIP OVER SENSOR NOT CONNECTED

DEFECTIVE

START ENGINE

(t>4 sec)

START ENGINE

(t>4 sec)

ENGINE RUNNING OR

ENGINE STOPPED

ENGINE RUNNING OR

ENGINE STOPPED

ENGINE RUNNING OR

ENGINE STOPPED

ENGINE RUNNING OR

ENGINE STOPPED

ENGINE RUNNING OR

ENGINE STOPPED

ENGINE RUNNING OR

ENGINE STOPPED

ENGINE RUNNING

ENGINE RUNNING

ENGINE RUNNING

ENGINE RUNNING

ENGINE RUNNING OR

ENGINE STOPPED

NO START CONDITIONS AT START - Tip over co nditions

- Safety logic not

satisfied

- Two defective coils

on same cylinder

WHAT TO DO WHEN A FAULT CODE APPEARS:

1. CHECK COMPONENT WITH TESTER

2. CHECK CONTACTS (SENSOR/WIRING– WIRING/CONTROL UNIT)

3. CHECK WIRING

This material is didactic and

may be changed following the technical

development of the product

See table

Page 23

Aprilia Consumer Service Spa

Technical Service and Training

Release 4 july 99

TROUBLE SHOOTING:

WHAT TO DO IF THE ENGINE DOESN’T START AND NO FAULT IS SHOWN ON THE SELF-DIAGNOSTICS

SYSTEM

- Check the fuel pump

- Check the injectors

- Check that the anti-theft system connector is connected

- Check the key switch

- Check the STOP-RUN control

- Check the 30 Amp fuses and 15 Amp fuses B and E

- Check the engine stop relay

- Check the battery

- Check the safety system logic (diode box, switches)

This material is didactic and

may be changed following the technical

development of the product

Page 24

Aprilia Consumer Service Spa

Technical Service and Training

Release 4 july 99

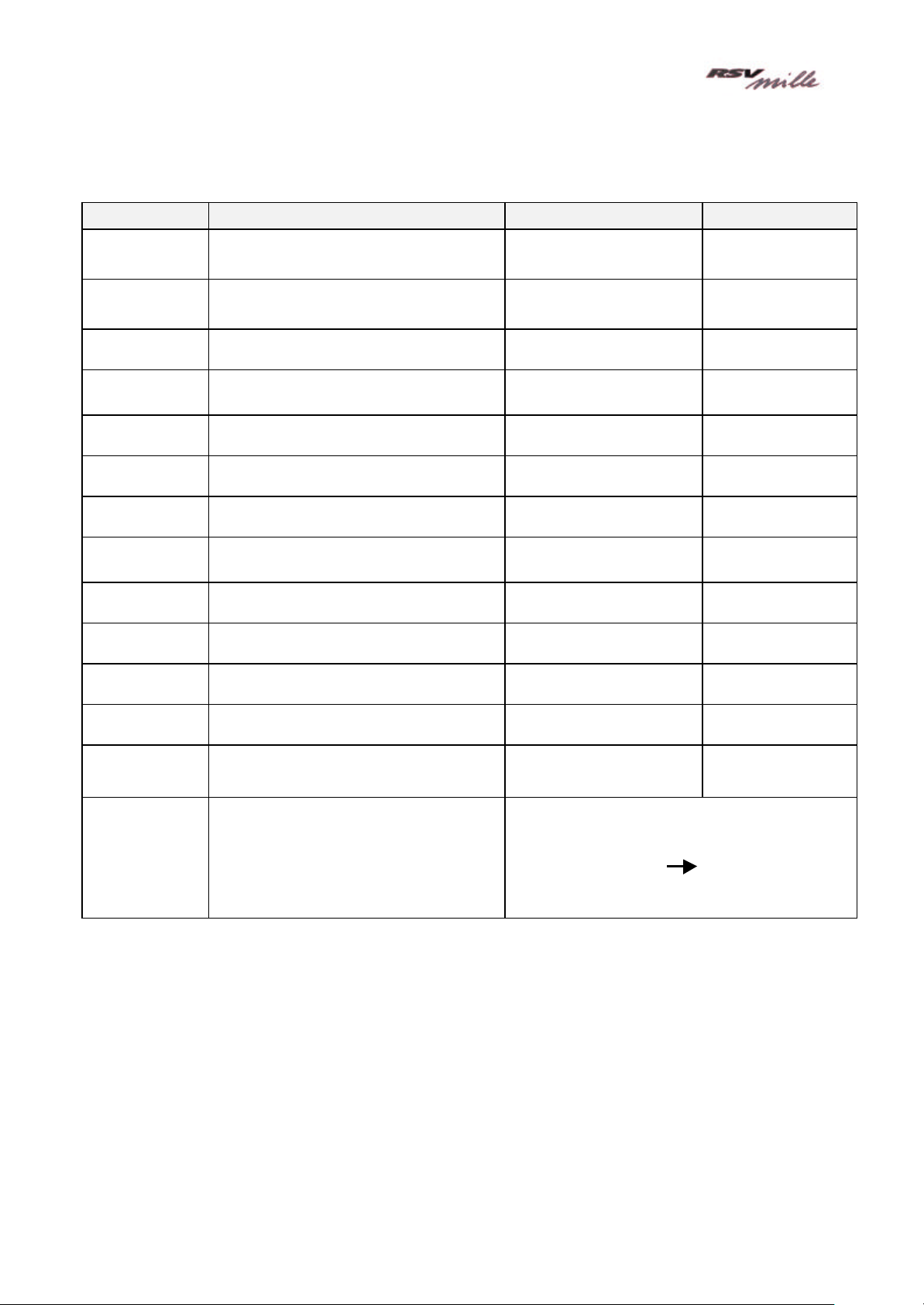

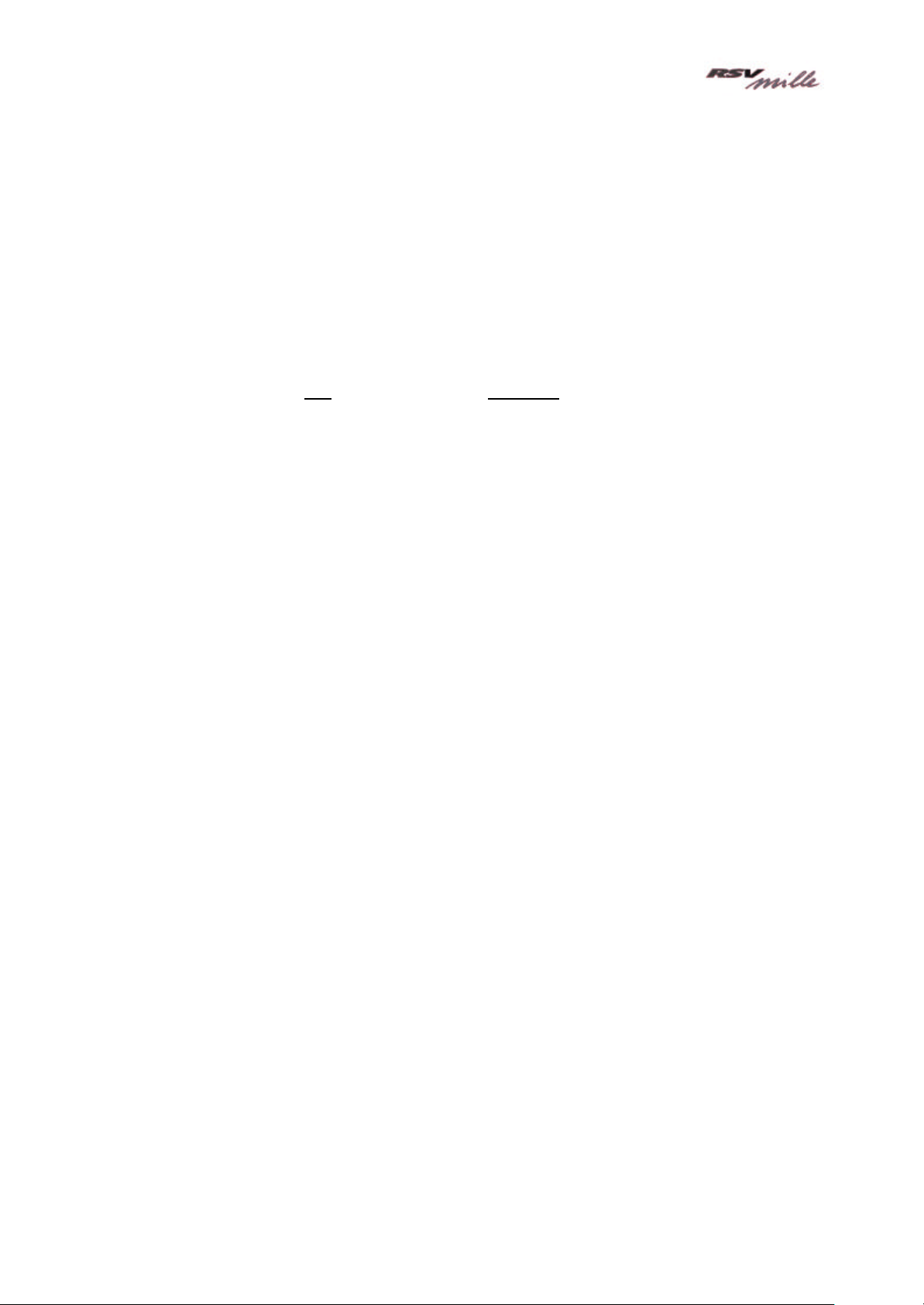

START AND RUN POSSIBILITY:

If a fault is detected, the control unit may:

- stop the bike

- allow running but not starting

- allow running and starting

as described in the table:

FAILURE START POSSIBILITY RUN POSSIBILITY

CAMSHAFT SENSOR NOT POSSIBLE POSSIBLE

CRANKSHAFT SENSOR NOT POSSIBLE NOT POSSIBLE

MANIFOLD PRESSURE SENSOR OR

PRESSURE SENSOR SIGNAL

THROTTLE POSITION SENSOR POSSIBLE POSSIBLE

COOLANT TEMPERATURE SENSOR POSSIBLE POSSIBLE

INTAKE AIR TEMPERATURE SENSOR POSSIBLE POSSIBLE

ATMOSPHERIC PRESSURE SENSOR POSSIBLE POSSIBLE

IGNITER:

IGF11 OR IGF12

IGF11 AND IGF12

POSSIBLE (ONE CYLINDER ONLY) POSSIBLE (ONE CYLINDER ONLY)

IGF21 OR IGF22

IGF21 AND IGF22

POSSIBLE (ONE CYLINDER ONLY) POSSIBLE (ONE CYLINDER ONLY)

POSSIBLE POSSIBLE

POSSIBLE POSSIBLE

POSSIBLE POSSIBLE

This material is didactic and

may be changed following the technical

development of the product

Page 25

Aprilia Consumer Service Spa

Technical Service and Training

Release 4 july 99

OPERATION - DASHBOARD KEYS

[A] [B] [R] [C] [D]

1. SEGMENTS OPERATION CHECK:

Press keys [A] and [B] and turn the key from OFF to ON: all segments stay lit as long as [A] and [B] are

pressed.

2. KM/H, MPH

Press key [A] for 5 seconds =:> numbers and km/h (mph) flash

Press key [B] to change unit of measurement

Confirm with [A] pressed for about 5 seconds.

3. INSTANTANEOUS, MAXIMUM AVERAGE SPEED (only with instantaneous S = 0)

Instantaneous speed => press key [B] for about 1 second

Maximum speed => press key [B] for about 1 second

Average speed => press key [B] for about 1 second

a) 1st partial reset:

instantaneous speed on display => press key [R] for about 3 seconds => 1st partial = 0

b) maximum speed reset:

maxS and 1st partial on display => press key [R] for about 1 second => maxS = 0.

c) average speed and 2nd partial reset :

avgS and 2nd partial on display => press key [R] for about 1 second => avgS = 0,

2nd partial = 0

With the display showing maxS or avgS and insS becomes > 0 the display shows insS.

5. EXCESS RPM WARNING LIGHT (ONLY WITH ENGINE OFF)

-Press [C] for t < 1 second => set value displayed for seconds

-Key pressed for more than 1 second - pointer moves at 1000 RPM/step as long as [C]

is pressed

-If the key is released and then pressed again within 3 seconds for less than 1 second the setting

increases by 100 RPM/pulse.

-If key [C] is not pressed for more than 3 seconds the setting is stored (confirmed by lighting of

indicator light).

This material is didactic and

may be changed following the technical

development of the product

Page 26

Aprilia Consumer Service Spa

Technical Service and Training

Release 4 july 99

6. MULTIFUNCTION

Coolant temperature and clock => [D] =>

Battery voltage => [D] =>

Set hours (Press LAP) =>

Set minutes (Press LAP) =>

Set °C/°F (Press LAP) => go back to

b) Stop watch

Press and hold [LAP] and then (within 0.7 seconds) press key [D] to start the stop watch.

b. 1) Press [LAP] ==> stop watch starts (the [LAP] key is not enabled for 10 sec.)

b.2) Starting from timing =:> press [B] => display shows first acquired time => press [LAP] to

re-display times in sequence

-Press [B] to go back to timing

-Press [A] + [LAP] for 2 seconds to zero memories

b.3) To exit timing press [D] and then [LAP] (temperature and clock will appear on display).

6. Switch off SERVICE => press [LAP] and [R] for 5 seconds.

This material is didactic and

may be changed following the technical

development of the product

Page 27

Aprilia Consumer Service Spa

POSITIVO

Technical Service and Training

Release 4 july 99

SECTION 2: IGNITION SYSTEM

The ignition system is controlled by the control unit. The system is a normal one, known as a

digital transistorised ignition system, which sets the correct timing on the basis of the engine

rpm and throttle position. It is made up of the crankshaft sensor (pick up coil), control unit, two

ignition coils and spark plugs.

MAPPING

CPU

TEMP.

SENSOR

VIBRATOR

GEAR

SWITCH

WAVE

FORM

ARRANGE

CIRCUIT

THROTTLE

POSITION

ROM

1. The ignition coil power supply is governed by the side stand safety circuit and by the gear

position.

2. The timing is constantly controlled by the throttle position and the rpm

The devices described below affect the timing in the stopping or starting of the ignition

system.

Crankshaft sensor:

The engine pick up coil produces a signal when it meets the projecting part of the

magneto flywheel.

The wave generated is sent to the control unit which calculates the engine rpm; this

signal determines the timing.

Throttle position sensor:

This sensor, mounted on the throttle body, has a variable resistance which changes the

opening value of the throttle. On the basis of this signal, the control unit sets the timing in

response to the engine rpm.

The timing mapping is made up of two factors: the throttle position and the engine rpm.

The ignition is inductive and not the capacitive discharge type. ! NEVER SHORT CIRCUIT TO

GROUND THE L.T. LEADS TO THE COILS

This material is didactic and

may be changed following the technical

development of the product

Page 28

Aprilia Consumer Service Spa

Technical Service and Training

Release 4 july 99

CONTROL STRATEGY

In the ignition phase, the control unit reads the starting, as shown in the separate figure.

BATTERIA

The ignition phase starts in this way

(asynchronous/synchronous phase):

1. The control unit reads:

- coolant temperature

- throttle angle

- engine rpm

- Patm.

RELE’

AVVIA

M

ECU

- Battery voltage

These values determine the ignition time when the engine is started.

The mapping, based on the timing, is based on

BTDC (Before top dead centre), and depends on

the throttle opening angle and the engine rpm.

Throttle

angle

rpm

This material is didactic and

may be changed following the technical

development of the product

Page 29

Aprilia Consumer Service Spa

OFF

Technical Service and Training

Release 4 july 99

2. Cylinder recognition

The camshaft and pick up sensors send signals that are clipped by the ECU.

The camshaft sensor sends one signal for each cycle (INT-COMPRESS-

IGNITION/EXPANSION-EXHAUST), corresponding to an angle of 720°

The camshaft sensor sends 12 signals for each rotation of the crankshaft, i.e. one signal every

60°.

The first camshaft pulse enables the resetting of an internal counter which starts the

synchronous ignition phase and cylinder recognition.

The following phase is known as asynchronous as both the injectors inject fuel into the ducts.

The ignition phase is illustrated in the diagram below.

spark

spark

spark

This material is didactic and

may be changed following the technical

development of the product

Page 30

Aprilia Consumer Service Spa

Technical Service and Training

Release 4 july 99

IGNITION:

The HT coils control is linked to the pick up signal after the recognition of the cylinders (see

figure above).

At low rpm (< 540) the ignition is set by the clipped signal of the pick up. The CPU gives

consensus to the ignition only. These are “fixed spark timing” and “ fixed dwell timing”

conditions.

At medium rpm levels, the spark dwell timing is fixed but the spark advance timing varies.

At high rpm (>3500) the ignition timing is calculated by the ECU and suitably compensated

(calculated spark and dwell timing conditions).

IDLING:

Applies to the 200 to 1200 rpm range. A hysterisis cycle is followed (as shown in the figure);

the spark and advance times are fixed.

540

200

1200

This material is didactic and

may be changed following the technical

development of the product

Page 31

Aprilia Consumer Service Spa

Technical Service and Training

Release 4 july 99

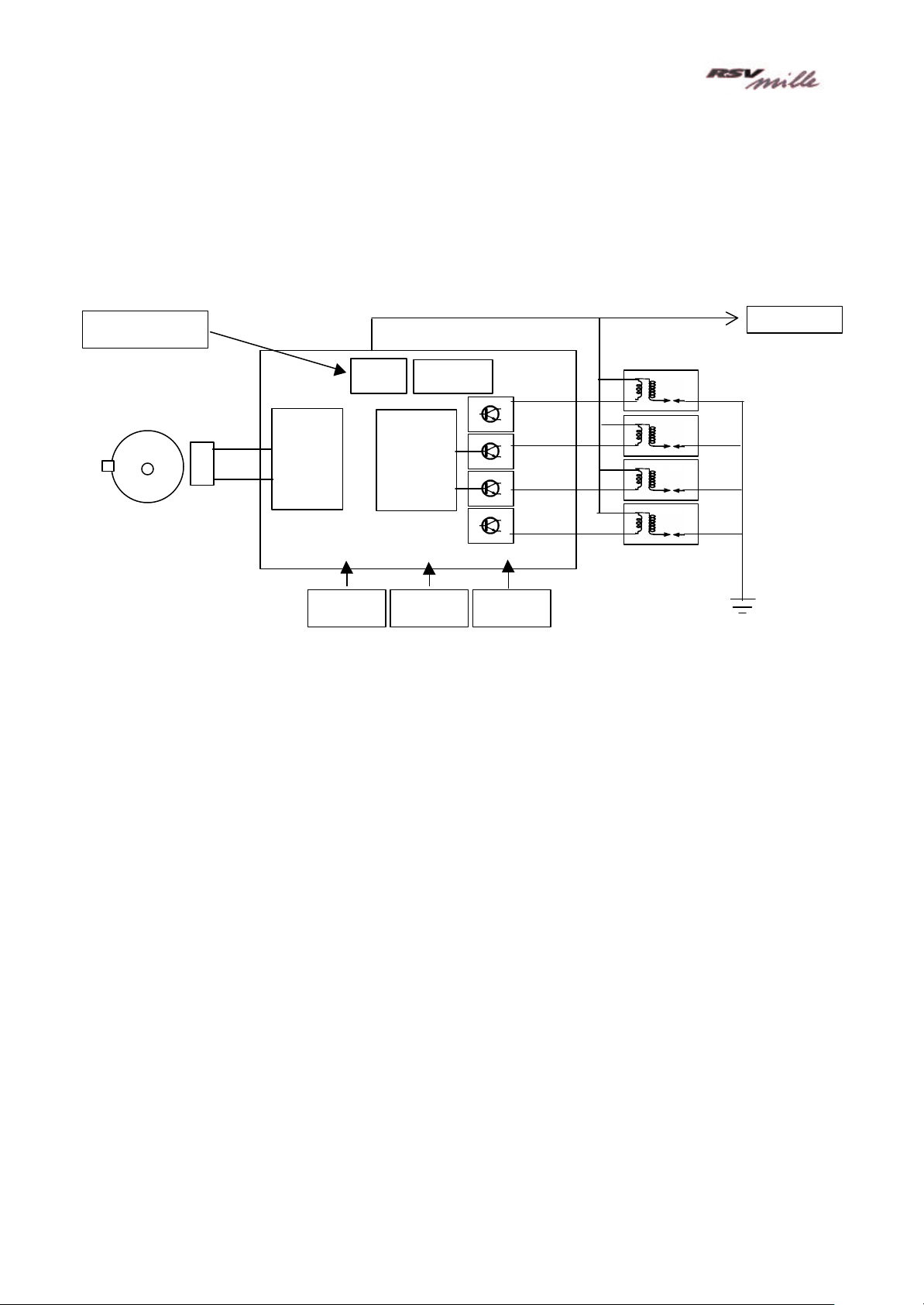

SECTION 3 : DESCRIPTION OF ELECTRONIC INJECTION SYSTEM

The RSV1000 electronic injection system is made up of the following components:

1. Electronic control unit

2. Sensors (shaft position, temperature, pressure...)

3. Actuators

4. Ignition coils

5. Fuel pump

The ECU also contains the static-inductive ignition circuit.

This material is didactic and

may be changed following the technical

development of the product

Page 32

Aprilia Consumer Service Spa

Technical Service and Training

Release 4 july 99

3.1 THE E.C.U.: ELECTRONIC CONTROL UNIT

The injection system and ignition system operation are controlled by the Nippodenso ECU, code no.

265470 (not final!!!).

The control unit is connected to the rest of the bike’s electrical system by two ‘fast’ connectors. As

well as being fed with power and receiving signals from the sensors through these connectors, the

control unit also controls the injectors and l.t. ignition coils and dialogues with the panel and, in

addition, checks that the correct torque is transmitted to the wheels. The figure below gives a basic

outline of these connections:

The ECU is governed by an 8 bit/8Mhz CPU which performs the logic and control functions. The

calculation tables and algorithms are resident in the E-PROM.

C.P.U.

Centralina ECU

Centralina ECU: C.S.

CONNETTORI ECU

E-PROM SU ZOCCOLO

This material is didactic and

may be changed following the technical

development of the product

Page 33

Aprilia Consumer Service Spa

Technical Service and Training

Release 4 july 99

In addition, the following systems/components are inside the control unit:

- coils/injectors control power circuit

- Atmospheric pressure sensor

- CO regulation trimmer

CO ECU SETTING

Trimmer regolazione CO

This material is didactic and

may be changed following the technical

development of the product

Page 34

Aprilia Consumer Service Spa

Technical Service and Training

Release 4 july 99

ECU ELECTRONIC WIRING DIAGRAM:

This material is didactic and

may be changed following the technical

development of the product

Page 35

Aprilia Consumer Service Spa

Technical Service and Training

Release 4 july 99

ONNECTORS:

The control unit is connected to the electrical circuit by plug-in connectors that plug into the ECU

printed circuit.

The connectors connect the control unit to the sensors and actuators (injectors, coils) via the

wiring.

Also, most of the connected components can be tested via the connectors, using any type of good

quality ohmic tester.

As detailed in the wiring diagram, the connectors refer to the specific components shown in the

figure:

26 WAY CONNECTOR

16 WAY CONNECTOR

IDENTIFICAZIONE

TERMINALI ECU

This material is didactic and

may be changed following the technical

development of the product

Page 36

Aprilia Consumer Service Spa

Technical Service and Training

Release 4 july 99

SECTION 4 POSITIONING OF SENSORS AND INJECTORS:

The position of each of the sensors is shown in the figure:

This material is didactic and

may be changed following the technical

development of the product

Page 37

Aprilia Consumer Service Spa

Technical Service and Training

Release 4 july 99

CAMSHAFT SENSOR:

The cam sensor is an inductive sensor installed in the front cylinder head and is identical to the

pick-up. This sensor is of fundamental importance and allows the ECU to recognise the exact

sequence of each single cylinder, resetting the internal count to zero during the asynchronous

ignition phase. The ohmic resistance of the sensor, measured at a temperature of 20 degrees, is

about 240 Ohms. This resistance can be measured either directly on the sensor wiring or at the

ECU connectors, connecting a tester between the terminals, as shown.

SW –ECU DIAGNOSIS EXISTENT

OHMIC DIAGNOSIS

MEASURED BETWEEN

WIRES

AVERAGE VALUE 240 Ohms

2-10 (PURPLE/BLACK and

GREY/BLACK)

RIGHT-HAND CONNECTOR

This material is didactic and

may be changed following the technical

development of the product

Page 38

Aprilia Consumer Service Spa

Technical Service and Training

Release 4 july 99

THROTTLE SENSOR:

The throttle sensor, a highly reliable potentiometer, is a 4-pin resistive sensor. The sensor sends a

voltage signal, proportional to the opening angle of the throttle valve, to the control unit. The sensor

is positioned in the throttle assembly, as shown in the figure.

The figure shows the sensor connections and the sensor resistance curve/angle.

SW –ECU DIAGNOSIS EXISTENT

OHMIC DIAGNOSIS

MEASURED BETWEEN

WIRES

AVERAGE VALUE 3500 OHM

(ALPHA=0)

15 LH CONNECTORS: BLUE/RED

3 RH CONNECTORS: BROWN/WHITE

4 RH CONNS.: BROWN/YELLOW

This material is didactic and

may be changed following the technical

development of the product

Page 39

Aprilia Consumer Service Spa

Technical Service and Training

Release 4 july 99

CRANKSHAFT SENSOR: PICK - UP

An inductive sensor, already familiar from other models, positioned inside the magneto flywheel.

Sends a voltage pulse to the control unit for every 60° of rotation and is of fundamental importance,

together with the camshaft pulse, in allowing the ECU to set the injection and ignition times.

The bike will stop if this sensor breaks (see START and RUN POSSIBILITY TABLE)

SW –ECU DIAGNOSIS EXISTENT

OHMIC DIAGNOSIS

MEASURED BETWEEN

WIRES

AVERAGE VALUE 240 Ohms

9-1 (WHITE/YELLOW AND BLUE/YELLOW)

RIGHT-HAND CONNECTOR

This material is didactic and

may be changed following the technical

development of the product

Page 40

Aprilia Consumer Service Spa

Technical Service and Training

Release 4 july 99

TIP OVER SENSOR:

This is a mechanical ring-switch which stays in contact with the plastic section as long as the bike

is in a normal position. When the bike leans, the ring moves and, if the angle is greater than 44

degrees, it activates the switch terminals.

A monitoring resistor is connected in parallel to the switch, for the control unit to check the

connection to the component.

This new sensor is fitted on the battery box and reads the angle of the bike.

If the “lean” angle is greater than 44°, the switch is activated and - after a period of time set in the

control unit SW - the injection, fuel feed and ignition systems are disabled.

SW –ECU DIAGNOSIS EXISTENT

OHMIC DIAGNOSIS

MEASURED BETWEEN

WIRES

OPEN CIRCUIT

7-14 (GROUND and RED)

RIGHT-HAND CONNECTOR

This material is didactic and

may be changed following the technical

development of the product

Page 41

Aprilia Consumer Service Spa

Technical Service and Training

Release 4 july 99

ENGINE COOLANT TEMPERATURE SENSOR:

This temperature sensor has a variable resistance

which decreases with the increase in temperature.

The ECU provides the sensor with a +5 Volt signal

and measures the corresponding current, thus

calculating the temperature, based on the

characteristics of the sensor.

Each of the cylinders has one of these sensors,

although only one of them is connected to the ECU

(the other is connected to the control panel).

SW –ECU DIAGNOSIS EXISTENT

OHMIC DIAGNOSIS

MEASURED BETWEEN WIRES

AVERAGE VALUE(20C°) 2700 OHMS (DELTA CAN

BE 300 OHM)

15 LH CONNECTORS :BLUE RED

6 RH CONNECTORS: RED/BLACK

AIR TEMPERATURE SENSOR:

This temperature sensor has a variable resistance

which decreases with the increase in temperature.

The ECU provides the sensor with a +5 Volt signal

and measures the corresponding current, thus

calculating the temperature, based on the

characteristics of the sensor.

SW –ECU DIAGNOSIS EXISTENT

OHMIC DIAGNOSIS

MEASURED BETWEEN

WIRES

AVERAGE VALUE (20C°) 2700

OHMS (DELTA CAN BE 300 OHM)

15 LH CONNECTORS :BLUE RED

13 RH CONNECTORS: RED/GREEN

This material is didactic and

may be changed following the technical

development of the product

Page 42

Aprilia Consumer Service Spa

tester

Technical Service and Training

Release 4 july 99

MANIFOLD PRESSURE SENSOR:

This sensor reads the pressure in the air cleaner box and provides a linear voltage in the range of 1 to 4.2 Volts

to the control unit. It must be supplied with a continuous voltage of +5 Volts (provided by the control unit). The

operating pressure ranges from13.3 to 120 Kpa (abs).

The characteristic of the sensor is:

Vo=Vcc*(0.006*Pi+0.12) [Volts]

The figure shows the instrumental test phase for the sensor in question:

+ 5 Volt DC

Vc

Vo

GND

Pressure Range

14 to 120 KPa

This material is didactic and

may be changed following the technical

development of the product

Page 43

Aprilia Consumer Service Spa

FUEL

Technical Service and Training

Release 4 july 99

INJECTORS:

Each cylinder has an injector. The location in the throttle assembly is shown in the figure:

The injector used is made up of the following components:

1. Mesh filter

2. Compression spring

3. Valve shaft

4. Injector coil

5. Injector jet

SIGNAL

CONTROL

CIRCUIT

TRANSISTOR

+ VCC BATTERY

This material is didactic and

may be changed following the technical

development of the product

Page 44

Aprilia Consumer Service Spa

Technical Service and Training

Release 4 july 99

OTHER RELEVANT ELECTRICAL COMPONENTS:

STARTER MOTOR:

The characteristic operating curves are shown below:

This material is didactic and

may be changed following the technical

development of the product

Page 45

Aprilia Consumer Service Spa

Technical Service and Training

Release 4 july 99

DIODE MODULE:

The figure shows the electrical wiring in the module. The continuity of the diodes can be checked with a tester

or with a 4.5 - 12 Volt battery with an arbitrary load of max. 2 Watts.

Remember that the diode conducts the current one way only, as indicated by the arrow representing the

component in the diagram.

This material is didactic and

may be changed following the technical

development of the product

Page 46

Aprilia Consumer Service Spa

Technical Service and Training

Release 4 july 99

VOLTAGE REGULATOR:

The voltage regulator is situated at the rear of the bike on the right, in contact with the bodywork.

POSITIVO

This material is didactic and

may be changed following the technical

development of the product

NEGATIVO

Page 47

Aprilia Consumer Service Spa

Technical Service and Training

Release 4 july 99

TRASLATION OF LEGENDA FOR

RS 1000 ELECTRIC WIRING DIAGRAM

1 ECU

2 CAMSHAFT SENSOR

3 THROTTLE SENSOR

4 INTAKE AIR PRESSURE SENSOR

5 WATER THERMISTOR (ECU)

6 AIR THERMISTOR

7 TIP OVER SENSOR

8 DIODE MODULE

9 CLUTCH SWITCH

10 NEUTRAL SWITCH

11 RELAY R1

12 RIGHT MAIN/DIPPED BEAM SELECTOR

13 LEFT MAIN/DIPPED BEAM SELECTOR

14 ENGINE STOP RELAY

15 PUMP RELAY

16 STARTER RELAY

17 STARTER MOTOR

18 BATTERY

19 MAIN FUSES

20 FLYWHEEL

21 PICK UP

22 VOLTAGE REGULATOR

23 REAR CYL. COIL

24 REAR CYL. COIL

25 FRONT CYL. COIL

26 FRONT CYL. COIL

27 SPARK PLUG

28 VACUUM SWITCH (ISC)

29 SECONDARY FUSES

30 KEY SWITCH

31 DIPPED BEAM RELAY

32 MAIN BEAM RELAY

33 FANS RELAY

34 FRONT SIDE LIGHT

35 MAIN BEAM LIGHT

36 DIPPED BEAM LIGHT

37 FRONT RH DIRECTION INDICATOR

38 FRONT LH DIRECTION INDICATOR

39 THERMOMETER SWITCH

40 LH MAIN/DIPPED BEAM SELECTOR

41 TAILLIGHT

42 DASHBOARD

43 REAR LH DIRECTION INDICATOR

44 FRONT CYL. INJECTOR

45 REAR CYL. INJECTOR

46 FRONT BRAKE BRAKE LIGHT SWITCH

47 REAR BRAKE BRAKE LIGHT SWITCH

48 REAR RH DIRECTION INDICATOR

49 HORN

50 MULTIPLE CONNECTORS

51 FLASHER

52 FUEL PUMP

53 FUEL WARNING LIGHT SENSOR

54 OIL PRESSURE SWITCH

55 WATER TEMP. THERMISTOR

56 SPEED SENSOR

57 FUEL WARNING LIGHT

58 SIDE STAND WARNING LIGHT

59 NEUTRAL GEAR WARNING LIGHT

60 DIRECTION INDICATOR WARNING LIGHT

61 OIL PRESSURE WARNING LIGHT

62 MAIN BEAM WA RNING LIGHT

63 DASHBOARD LIGHT

64 REV COUNTER

65 MULTIFUNCTION DISPLAY

66 SPEEDOMETER DISPLAY

67 LIGHTS/LAP DIODE

68 TEST CONNECTOR

This material is didactic and

may be changed following the technical

development of the product

Page 48

Aprilia Consumer Service Spa

Technical Service and Training

Release 4 july 99

3.2 FUEL CIRCUIT

The fuel circuit is made up of the following components:

1 fuel pump

2 fuel feed pipe

3 pressure regulator

4 injector.

The fuel pump is immersed in the fuel tank and pumps the pressurised fuel to the feed pipe, where

the pressure regulator keeps the fuel pressure about 3 bars higher than the intake pressure. The

excess pressure is “vented” by the regulator and the excess fuel goes back to the tank through the

return hose. The regulator is controlled by the inlet manifold average pressure. The pressure on the

injector is thus compensated by the intake ducts pressure.

The fuel pump is the WESCO type. The functions of the pump are as follows:

1. Pressurise the fuel in the fuel feed circuit

2. Relief valve for p> 5-6 atm

3. Check valve to maintain the pressure in the circuit when the engine is turned off

There is a mesh filter at the pump inlet port; after filtering, the fuel is sent to the impeller-type pump

chamber (see fig.).

The fuel pump capacity is about 60 litres/h.

This material is didactic and

may be changed following the technical

development of the product

Page 49

Aprilia Consumer Service Spa

Technical Service and Training

Release 4 july 99

The regulator - shown in the figure - has the following components: a vacuum-operated diaphragm

and spring, and a steel ball valve with the valve seat mounted on the spring.

DEPRESSURE

FUEL TANK

FUEL TANK

This material is didactic and

may be changed following the technical

development of the product

Page 50

Aprilia Consumer Service Spa

Technical Service and Training

Release 4 july 99

POSITIONING OF ELECTRICAL COMPONENTS ON BIKE:

VOLTAGE

REGULATOR

ECU

SPEED SENSOR

This material is didactic and

may be changed following the technical

development of the product

COIL

Page 51

Aprilia Consumer Service Spa

Technical Service and Training

Release 4 july 99

THROTTLE SENSOR

ABS. PRESS. SENSOR

Temperature sensor

Oil switch

DIODE UNIT

POWER RELAY

DIAG CONNECTOR

COIL

This material is didactic and

may be changed following the technical

development of the product

STAND SWITCH

Page 52

Aprilia Consumer Service Spa

Bi/R

Bi/RGG

G

Technical Service and Training

Release 4 july 99

SECTION 5: ELECTRICAL CHECKS

Refer to the key below when consulting this chapter:

Ar= orange

Az= light blue

B= blue

Bi= white

G= yellow

Gr= grey

M= brown

N= black

R= red

R= pink

V= green

Vi= purple

CHECK 1. RECHARGE VOLTAGE TEST

V REG

V/Az

R/N

30 A 30 A

V

V

R/B

Check the electrolyte level

Check the battery voltage

Start the engine and take it up to 4000 rpm

Switch the light switch to dipped beam

test the DC voltage between the battery terminals with a tester

STANDARD VOLTAGE: 13 – 15 VOLTS

CHECK 2. ALTERNATOR CHECK

Disconnect the brown connector from the regulator

Start the engine and take it up to 4000 rpm

The voltage, measured as shown in the figure, must be not

less 60 Volts

The standard resistance of the generator coil is 0.1 – 1

Ohms.

Between cables and ground: infinite

This material is didactic and

may be changed following the technical

development of the product

Page 53

Aprilia Consumer Service Spa

Technical Service and Training

Release 4 july 99

CHECK 3: H.T. COIL CHECK:

Use the tester in the Ohms scale to check the continuity of the windings. The approx. values are as follows:

L.T. SIDE: 3-6 OHMS

H.T. SIDE: 12 – 15 KOHMS

Note: This method is NOT able to detect partial failures in the isolation

CHECK 4: TIP OVER SENSOR CHECK:

Remove the sensor plus grommet from its housing and tilt it sideways at an angle greater than 45° to simulate

a fall.

The standard reading must be 0-1 Ohms.

CHECK 5: THERMISTOR CHECK:

Check the sensor resistance, using the tester in the Ohms scale.

At 20 degrees centigrade the resistance must be about 2450 Ohms

At 40 degrees centigrade the resistance must be about 1114 Ohms

At 60 degrees centigrade the resistance must be about 584 Ohms

At 90 degrees centigrade the resistance must be about 245 Ohms

CHECK 6: THROTTLE SENSOR CHECK:

With the sensor installed, check as shown in the figure (with the throttle in any position)

Variare angolo

farfalla: La

resistenza deve

variare da 0 a "A”

This material is didactic and

may be changed following the technical

development of the product

A:Valore standard:

2,9 – 5,3 Kohm

Page 54

Aprilia Consumer Service Spa

Technical Service and Training

Release 4 july 99

Fitting the throttle sensor:

(Please see section 9 for CO regulation)

With the engine off, turn the ignition key to ON.

When positioned in the throttle body, enable the control unit diagnostics function.

If there are no errors (i.e. sensors all OK) one of three possible numbers will appear:

+1: initial angle reading too high

0: throttle position OK

-1: initial angle reading too low

Turn the sensor until the 0 appears.

Fix the sensor in position.

Next, proceed with making the fine air setting on the injectors to balance the idling rate

This material is didactic and

may be changed following the technical

development of the product

Page 55

Aprilia Consumer Service Spa

Lampadina: 12V/2Watt

Technical Service and Training

Release 4 july 99

CHECK 7: PRESSURE SENSOR CHECK:

The readings below, taken one by one, must give a value of 15 kOhms

Ohmmeter between 1-3

Ohmmeter between1-2

CHECK 8: DIODE MODULE CHECK:

Disconnect the connector from the diode module and apply the circuit described below to the different

terminals, as listed in the table:

+

NEG

The switching-on order must be as shown in the table:

This material is didactic and

may be changed following the technical

development of the product

- \ + 1 2 3 4 5

1 X On On On On

2 X

3 X

4 X

5 On X

Page 56

Aprilia Consumer Service Spa

Technical Service and Training

Release 4 july 99

This material is didactic and

may be changed following the technical

development of the product

Page 57

Aprilia Consumer Service Spa

BATT/KEY

ANTIFURTO

Vi/Gr

Ar/Gr

Technical Service and Training

Release 4 july 99

CHECK 9: FUEL PUMP CHECK:

Lift the fuel tank

Disconnect the pump assembly 3 way connector

Feed the green (+) and blue (-) wires coming from the side of the pump assembly with 12 Vdc.

Ensure that the pump works by giving a buzz and checking that the fuel comes out of the throttle assembly

(disconnect the tube).

FUEL PUMP WIRING DIAGRAM

Ar/V

CONNETTORE

Az/Gr

ECU

P

RELE’ ARRESTO

MOTORE

V/Gr

RELE’ POMPA

BENZINA

V/N

FUEL PUMP

This material is didactic and

may be changed following the technical

development of the product

Page 58

Aprilia Consumer Service Spa

Technical Service and Training

Release 4 july 99

LIGHT WIRING DIAGRAM

A

D

29

FANALE ANTERIORE

PASSING/LAP

CLAXON

LIGHTS

LIGHTS P

LIGHTS H

H - Lo

H – HI

TURN R

32

67

31

FANALE POST.

36 34 35 35

LEGENDA:

29= SECONDARY FUSES

31= MAIN BEAM LIGHTS RELAY

32= DIPPED BEAM LIGHTS RELAY

34= FRONT SIDE LIGHTS

35= MAIN BEAM LIGHTS

36= DIPPED BEAM LIGHTS

37= TAILLIGHT

63= DASHBOARD LIGHTS

67= PASSING/LAP DIODE

D= 15 AMP FUSE

72 72 63

DISPLAY CRONOMETRO

This material is didactic and

may be changed following the technical

development of the product

Page 59

Aprilia Consumer Service Spa

SENSOR

64

66

65

16 LEFT

1LEFT

15

Technical Service and Training

Release 4 july 99

CHECK 10: WIRING AND COMPONENTS CHECK

The main electrical components’ connections to the ECU are shown in the outline wiring diagram in

fig.:

68: TEST CONNECTOR

SPEED SENSOR

RELE’

R1 11

RELE’

FUEL PUMP

HT COIL

23

HT COIL

24

HT COIL

25

HT COIL 26

19 LEFT

14 LEFT

22 LEFT

16 LEFT

1 LEFT

12 LEFT

13 LEFT

25 LEFT

2 RIGHT

10 RIGHT

15 LEFT

3 RIGHT

4 RIGHT

5 RIGHT

6 RIGHT

13 RIGHT

ECU

5 LEFT

9 RIGHT

1 RIGHT

20 LEFT

21 LEFT

CAMSHAFT

SENSOR

THROTTLE

SENSOR

INTAKE

PRESSURE

TERMISTOR

H20

AIR

TERMISTOR

SENSORE

CADUTA

VACUUM

SWITCH

2

3

4

5

6

7

28

PICK UP

8

DIODES

UNIT

44

44

45

45

This material is didactic and

may be changed following the technical

development of the product

FRONT

INIETTOR

REAR

INIETTOR

26 LEFT

8 RIGHT

9 RIGHT

11 LEFT

10 LEFT

23 LEFT

2 LEFT

CO

Page 60

Aprilia Consumer Service Spa

Technical Service and Training

Release 4 july 99

In more detail, the terminals refer to the components shown in the table; the standard ohmic values are also

given:

DESCRIPTION OF

COMPONENT

NUM.

ECU

TERMINALS

CONNECTOR

(L=LEFT, R=RIGHT)

STANDARD

VALUE

WIRE COLOUR

CAMSHAFT SENSOR 2 2

10

THROTTLE VALVE

SENSOR

3 15

3

4

INTAKE PRESSURE

SENSOR.

4 15

3

5

H20 THERMISTOR 5 15

6

AIR THERMISTOR 6 15

13

TIP OVER SENSOR 7 7

14

PICK UP 21 9

1

GND 11-10-23-2-16-7L

R

R

L

R

R

L

R

R

L

R

L

190-300

OHM

2,87 – 3,4

KOHM

AT 20 °C

(3-4 VARIABLE

RESISTANCE

FUNCTION OF

ANGLE)

10 - 15 KOHM

SEE

COMP CHECK

1,9-2,9

KOHM

IDEM

R

R

OPEN

R

R

R

190-300

OHM

PURPLE/BLACK

GREY/BLACK

BLUE/RED

BROWN/WHITE

BROWN/YELLOW

BLUE/RED

BROWN/WHITE

PINK

BLUE/RED

RED/BLACK

BLUE/RED

RED/GREEN

GROUND

RED

WHITE/YELLOW

BLUE/YELLOW

ALL BLUE/GREEN

FRONT INJECTOR 44 8

9

REAR INJECTOR 45 8

7

HT COIL 23 1

12

HT COIL 24 1

13

HT COIL 25 1

25

HT COIL 26 1

26

TEST CONNECTOR 68 19 L

VACUUM SWITCH 28 1

5

This material is didactic and

may be changed following the technical

development of the product

R

R

R

R

L

11-17 OHM

AT 20°C

11-17 OHM

AT 20 °C

3-5 OHM

L

L

3-5 OHM

L

L

3-5 OHM

L

L

3-5 OHM

L

L

L

OPEN OR

CLOSE

(NORMALLY

OPEN)

GREEN/BLACK

GREY/RED

GREEN/BLACK

BROWN/RED

GREEN/GREY

LIGHT BLUE/YELLOW

GREEN/GREY

LIGHT BLUE/WHITE

GREEN/GREY

RED/GREY

GREEN/GREY

ORANGE/WHITE

GREEN/WHITE

GREEN/GREY

GREY/YELLOW

Page 61

Aprilia Consumer Service Spa

Technical Service and Training

Release 4 july 99

This material is didactic and

may be changed following the technical

development of the product

Page 62

Aprilia Consumer Service Spa

Technical Service and Training

Release 4 july 99

This material is didactic and

may be changed following the technical

development of the product

Page 63

Aprilia Consumer Service Spa

D

56

Technical Service and Training

Release 4 july 99

DASHBOARD ELECTRIC WIRING DIAGRAM:

LEGENDA:

D=15 AMP FUSE

53= FUEL WARNING LIGHT SENSOR

54= OIL PRESSURE SWITCH

55= WATER TEMP. THERMISTOR

56= SPEED SENSOR

57= FUEL WARNING LIGHT

61= OIL PRESSURE WARNING LIGHT

64= REV COUNTER

65= MULTIFUNCTION DISPLAY

66= SPEEDOMETER

66

6564

57 61

53 55

CHECK H20 TEMPERATURE INDICATOR

DISCONNECT THE THERMISTOR CONNECTOR

Connect the following resistors to the connector and check the display reading:

COLD: R=3000 ohm

60 Degrees (err10%) with R= 580 ohm

90 Degrees (err10%) with R= 245 ohm

If the readings are correct, check the thermistor in the same way as described for the H2O thermistor

54

This material is didactic and

may be changed following the technical

development of the product

Page 64

Aprilia Consumer Service Spa

Technical Service and Training

Release 4 july 99

CHECK 11: SPEEDOMETER CHECK:

- Check the connections

WITH THE ENGINE OFF:

1) With the key ON, measure the voltage between the green/purple and blue/orange

wires without disconnecting the connectors. The reading should be more than 9 Volts

dc.

2) Measure the voltage between the grey/white and blue/orange wires without

disconnecting the connectors. The reading should be more than 6 Volts dc.

3) Starting from test 2, turn the wheel so that a screw comes on to the sensor; at that

moment the voltage should go to zero for about 2 sec. and then back to 6 Volts.

If test 1 doesn’t give the above results => dashboard defective

If test 1 is correct but test 2 wrong => sensor defective

If test s1 and 2 are correct but test 3 wrong => sensor defective

If test s1, 2 and 3 are correct but the speed isn’t shown on the dashboard =>

dashboard defective

CHECK 12: TACHOMETER CHECK:

Check that there is voltage between the green and blue/green wires with the key ON

Check the continuity (tester in ohmic scale) on the grey/purple wire between the

dashboard and the ECU

Try changing the dashboard with one you are sure that works

This material is didactic and

may be changed following the technical

development of the product

Page 65

Aprilia Consumer Service Spa

Technical Service and Training

Release 4 july 99

This material is didactic and

may be changed following the technical

development of the product

Page 66

Aprilia Consumer Service Spa

Technical Service and Training

Release 4 july 99

SECTION 6

FRAME

The RSV1000 frame is a highly rigid aluminium structure, with a flexural rigidity of 650 Kgm/°. It is

made up of a series of shell-cast parts: steering tube, engine front mounting plate, swingarm pin

mounting plate, where the rear of the shock absorber is also attached, and press-forged aluminium

plate parts; the same applies to the four sections (2 internal and 2 external) that form the side

fairings, with a special polished finish.

Given the high rigidity of the frame, there is no longer any need for the classical cradle around the

lower part of the engine, thus reducing the overall weight.

The fairings are lined inside with soundproofing material to reduce noise.

The pillar subframe is an extruded aluminium, square-section structure bolted to the central frame.

Spessore 2.5 mm

FRAME WEIGHT KG 9,9

PILLAR SUBFRAME WEIGHT KG 2.3

INSTRUMENTS SUPPORT WEIGHT KG 0,750

FORK ANGLE 25°

TRAIL mm 100

FRAME MARKING:

ITALY: ZD4ME0000TN000000

GERMANY: ZD4MEA000TN000000

FRANCE: ZD4MEC000TN000000

A=726.98 mm

B= 322.3 mm

I= 25°

20x20x2.5 mm

25x20x2.5 mm

This material is didactic and

may be changed following the technical

development of the product

Page 67

Aprilia Consumer Service Spa

Technical Service and Training

Release 4 july 99

NOTE: FOR THE REMOVAL AND REFITTING OF THE ENGINE AND SWINGARM ON THE FRAME,

SPECIAL WRENCHES MUST BE USED FOR UNSCREWING THE RING-TYPE LOCKNUTS ON THE 2

ENGINE FIXING POINTS (RH SIDE) AND ON THE RH SIDE OF THE SWINGARM PIN.

This material is didactic and

may be changed following the technical

development of the product

Page 68

Aprilia Consumer Service Spa

Technical Service and Training

Release 4 july 99

SECTION 7

BRAKING SYSTEM

The brakins systems of RSVmille are the best you can have on a production bike.

Aprilia has developed them together with Brembo, company leader in this sector, and this braking systems

offers an excellent MODULARITA’ through a 4 position adjusting lever. The braking pads are studied for

informing the rider when the thickness of the braking element is lower than 1 mm.

FRONT BRAKE

DISK: Steel

Thickness: 5 mm

Ex. diameter: 320 mm

Calipers: 4 opposite pistons

Br. pistons diam.: 2x 30 mm - 2x 34 mm

Braking pads: i/d 450FF - TOSHIBA TT 2802 (synterized)

Br. pads surface: 23,68 cm²

Br. pump diam.: 16 mm

REAR BRAKE

DISK: Steel

Thickness: 5 mm

Ex. diameter: 220 mm

Calipers: 2 opposite pistons

Br. pistons diam.: 2x 32 mm

Braking pads: i/d 450FF - TOSHIBA TT 2802

Br. pads surface: 16,17 cm²

Br. pump diam.: 11 mm

This material is didactic and

may be changed following the technical

development of the product

Page 69

Aprilia Consumer Service Spa

Technical Service and Training

Release 4 july 99

SECTION 8

REAR SHOCK ABSORBER

The rear shock absorber of the RSVmille is a modern complete adjustable unit, like the front suspension.

The shock absorber has a separate oil tank and a gas chamber to compensate the volume variations of oil due

to temperature.

Adjustments

1) Hydraulic functions

The shock absorber can be registered separately for compression effect and rebound.

B- Compression: in order to have a softer setting, turn the knob anticlockwise. Turn it clockwise for having

a hardener setting. The total setting positions are 40.

C- Rebound: in order to have a softer setting, turn the setting screw anticlockwise. Turn it clockwise for

having a hardener setting. The total setting positions are 17.

2) Mechanic functions

The shock absorber can be registered on spring preload and lenght.

A- Spring preload: in order to have a hardener response of the shock absorber, tight the preload spring

ring-nut and the lockring-nut. To set is softer untight the lockring-nut and the ring-nut.

D- Lenght: in order to set the lenght of the shock absorber, untight the locknut on the bottom. Then turn

the axle for reaching the requested position. Finally tight the locknut again. The maximum setting

lenght is 7,5 mm, for a maximum total lenght of the shock absorber of 330 mm.

This material is didactic and

may be changed following the technical

development of the product

Page 70

Aprilia Consumer Service Spa

Technical Service and Training

Release 4 july 99

This material is didactic and

may be changed following the technical

development of the product

Page 71

Aprilia Consumer Service Spa

Technical Service and Training

Release 4 july 99

FRONT FORK SPECIFICATION

BEARING PIPE DIAMETER: 43 mm

STROKE: 127 mm

REBOUND ADJ.:

COMPRESSION EFFECT: MAX 2 TURN

SPRING PRE-LOAD: MAX 2 TURN

SPRING PRE-LOAD: MAX 25 mm // MIN. 10 mm

SPRING OPERATION: 284 mm

OIL Q.TY: 520 CC

OIL LEVEL: 118 mm

This material is didactic and

may be changed following the technical

development of the product

Page 72

Aprilia Consumer Service Spa

Technical Service and Training

Release 4 july 99

SECTION 09

PBTL SYSTEM

The PBTL system on the RSV 1000 reduces the ‘braking’ torque transmitted by the engine during deceleration.

OPERATING PRINCIPLE:

Line 1 is connected to the intake passage whereas line 2 – downstream of the retaining valve – is connected to

the airbox via the throttle valve. Line 3 links line 2 to the airbox when the throttle valve opens to an angle greater

than 10-12 degrees.

During deceleration, the system configuration is as shown in the figure.

The negative pressure in the intake passages is transmitted to the clutch membrane via line 1+2.

The ‘retaining’ valve (non-return) comes into play and stabilises the pressure in the line.

Consequently, the clutch discs slip and reduce the torque.

During acceleration (throttle valve >12°), the valve, connected on the throttle unit axis, links up line 2 with the

airbox, thus cancelling out the pressing effect on the clutch unit and taking the clutch pack back to its original

position.

3

1

2

This material is didactic and

may be changed following the technical

development of the product

Page 73

Aprilia Consumer Service Spa

Technical Service and Training

Release 4 july 99

SECTION 10

FRONT CYL # 1

TIMING SETTING OF RSV MILLE ENGINE

REAR CYL # 2

This material is didactic and

may be changed following the technical

development of the product

Page 74

Aprilia Consumer Service Spa

Technical Service and Training

Release 4 july 99

1. FIXING CRANKSHAFT

1.1 REMOVE THE SCREW INDICATED WITH

THE ARROW – CLUTCH SIDE

1.2 INSERT FIXING SCREW,AFTER

REACHING THE TDC OF THE

REQUESTED CYLINDER

1.3 DETAIL OF THE FIXING POINTS ON THE

CRANKSHAFT

ATTENTION !!!

THE TIMING SETTING OF EACH CYLINDER MUST

BE DONE AFTER POSITIONING THE FIXING

SCREW ON THE RESPECTIVE T.D.C. (TOP DEAD

CENTER) POINT.

FIRST SET THE ALIGNEMENT OF THE CYLINDER

# 2 AND THEN THE ALIGNEMENT OF CYLINDER

#1.

AFTER SETTING THE ALIGNEMENT OF CYLINDER

#2 ROTATE THE CRANKSHAFT OF 420° DEGREES

AND THEN SET THE ALIGNEMENT OF CYLINDER

#1.

This material is didactic and

may be changed following the technical

development of the product

Page 75

Aprilia Consumer Service Spa

Technical Service and Training

Release 4 july 99

2. TIMING SETTING OF THE REAR CYLINDER (# 2)

3.

2.1 ALIGNEMENT OF THE INTERMEDIATE GEAR

USING THE PRINTED REFERENCES

ON CRANKCASE

2.2 ALIGNEMENT OF THE CAMSHAFT

GEARS WITH THE PRINTED REFERENCES

THE SCREWS OF THE LEFT GEAR

(EXHAUST) ARE LONGER THE THOSE ON

THE RIGHT

This material is didactic and

may be changed following the technical

development of the product

2.3 ALIGNEMENT OF THE SECONDARY

BALANCE SHAFT USING THE PAINTED

REFERENCES

Page 76

Aprilia Consumer Service Spa

Technical Service and Training

Release 4 july 99

TIMING SETTING OF THE FRONT CYLINDER (# 1)

3.1 ALIGNEMENT OF CRANKSHAFT AND

PRIMARY BALANCESHAFT WITH PAINTED

REFERENCES

3.2 ALIGNEMENT OF INTERMEDIATE GEAR

WITH THE PAINTED REFERENCE ON THE

PLATE

This material is didactic and

may be changed following the technical

development of the product

3.3 ALIGNEMENT OF THE CAMSHAFT GEARS

WITH THE PRINTED REFERENCES

Page 77

Aprilia Consumer Service Spa

Technical Service and Training

Release 4 july 99

SECTION 11: GENERAL DATA

RSV MILLE

TECHNICAL DATA

This material is didactic and