Page 1

use and maintenance

DSULOLD

part#

8202101

Area 51

Page 2

© 1998 aprilia s.p.a. - Noale (VE)

This manual is to be considered an integral part of the vehicle,

which must be delivered complete with it also in case of resale.

aprilia s.p.a. reserves the right to modify its models at any time,

without prejudice to the main characteristics here described.

All rights as to electronic storage, reproduction and total or par-

tial adaptation, with any means, are reserved for all Countries.

The mention to products or services supplied by third parties is

made only for information purposes and is not binding in any

case.

aprilia s.p.a takes no responsibility as to the performance or the

use of said products.

First edition: may 1998

Reprint:

Produced and pri nted by:

6WXGLR 7HFQR 3XEOLF

Viale del Progresso - 37038 Soave (VR) - Italy

Tel. +39 (0)45 -76 11 911

Fax +39 (0)45 -76 12 241

www.stp.it

E-mail: customer@stp.it

On behalf of:

DSULOLD VSD

via G. Galilei, 1 - 30033 Noale (VE) - Italy

Tel. +39 (0)41 - 58 29 111

Fax +39 (0)41 - 44 10 54

www.aprilia.com

use and maintenance Area 51

2

Page 3

)25(:25'

★

Before starting the engine, carefully read this manual, paying

particular attention to the chapter "RIDING SAFELY".

Your and other people’s safety depends not only on your quickness of reflexes and on your agility, but also on what you know

about the vehicle, on its efficiency and on your knowledge of the

basic information for RIDING SAFELY.

Therefore, get a tho rough knowledge of the vehic le, in such a

way as to be able to drive in the traffic safely.

For the controls and repair s not expressly describe d in th is man ual, for the purchase of aprilia Genuine Spare Parts, accessories and other products, as well as for specific technical advice,

contact only aprilia Authorized Outlets a nd O ffi ci al D ea ler s, w ho

can ensure you reliabl e and prompt servicing.

Thank you for choosing aprilia. We wish you a nice ride.

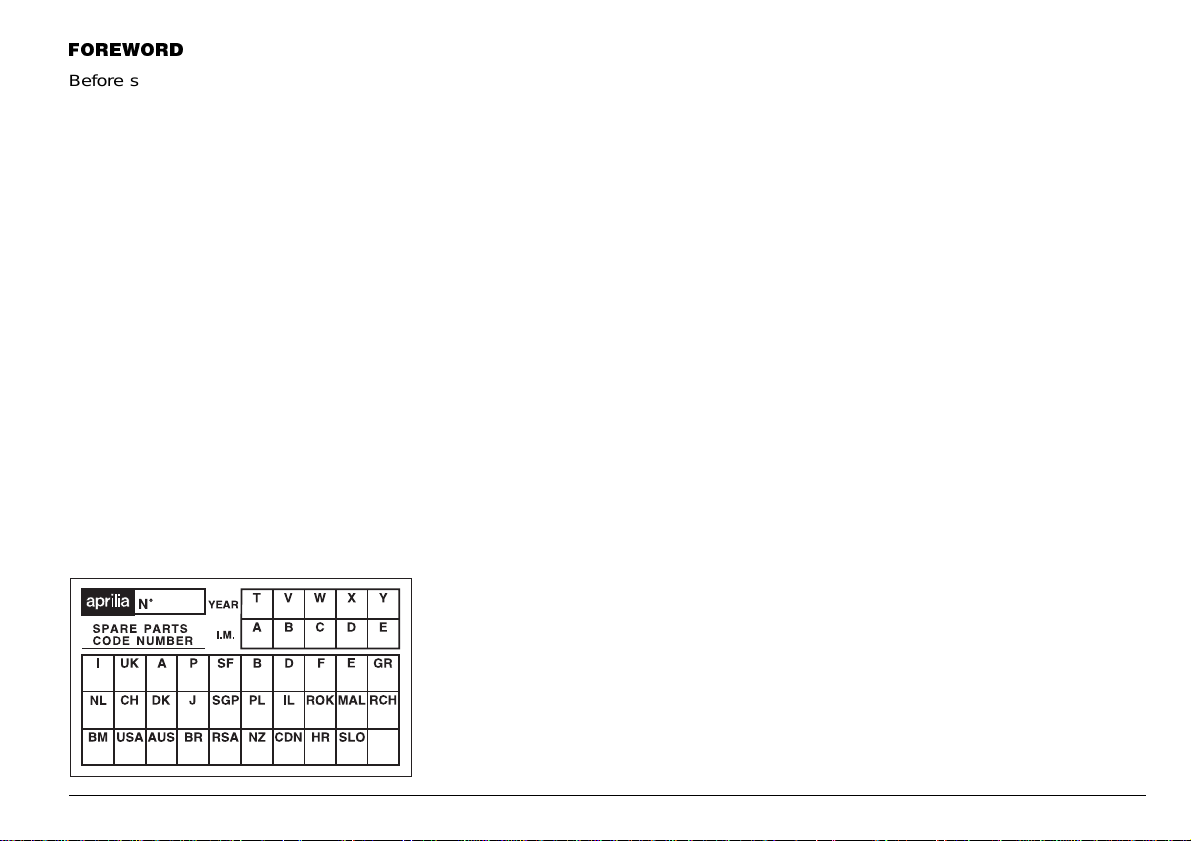

IMPORTANT:

When asking your Dealer for sp are parts, specify the spare parts

code indicated on t he SPARE PARTS I DENTIFICATION LABEL. Write down the iden tification code in the space here below ,

in order to remember it also in case of loss or deterioration of the

label.

The label is glued onto the right beam of the frame; to be able to

read it, remove the front inspection cover, see p. 46 (REMOVING

THE FRONT INSPECTION COVER).

Carefully observe the instructions preceded by the following

warning signs:

Safety norms and regulations to protect the driver

and other people from severe injuries or grave risks.

Indications to make the operations easier. Technical

informat i on.

The operations preceded by this symbol must be repeated on the opposite side of the vehicle.

In this manual the vario us version s are indi cated by the follow ing

symbols:

automatic light switching v ersi on (Automat ic Swit ch-on De vic e)

j

optional

-

catalyti c ve r s ion

#

VERSION:

Italy

United Kingdom

Austria

Portugal

Finland

Belgium

i

Germany

France

Spain

Greece

$

4

2

,

1

0

.

Holland

Switzerland

Denmark

Japan

Singapore

Poland

Israel

South Korea

Malaysia

Chile

/

h

l

p

r

m

o

q

n

Bermuda

United States

of America

Australia

Brazil

South Africa

New Zealand

Canada

Hungary

Slovenia

use and maintenance Area 51

3

Page 4

7$%/( 2) &217(176

SAFE DRIVE

BASIC SAFETY RU L ES ............... .. ............... 6

CLOTHING .................................................... 9

ACCESSORIES ................ ................. .......... 10

LOAD .......... ......................... ........................ 10

ARRANGEMENT OF THE MAIN ELEMENTS

ARRANGEMENT OF THE INSTRUMENTS

INSTRUMENTS AND INDICATORS

INSTRUMENT AND INDICATOR TABLE ...15

PROGRAMMIN G PUSH BUTTONS ............ 16

MAIN INDEPENDENT CONTROLS

CONTROLS ON THE LEFT SIDE

OF THE HANDLEBAR ................................. 18

CONTROLS ON THE RIGHT SIDE

OF THE HANDLEBAR ................................. 19

IGNITION SWITC H ... ................................... 20

STEERING LOCK ........................................ 20

AUXILIARY EQUIPMENT

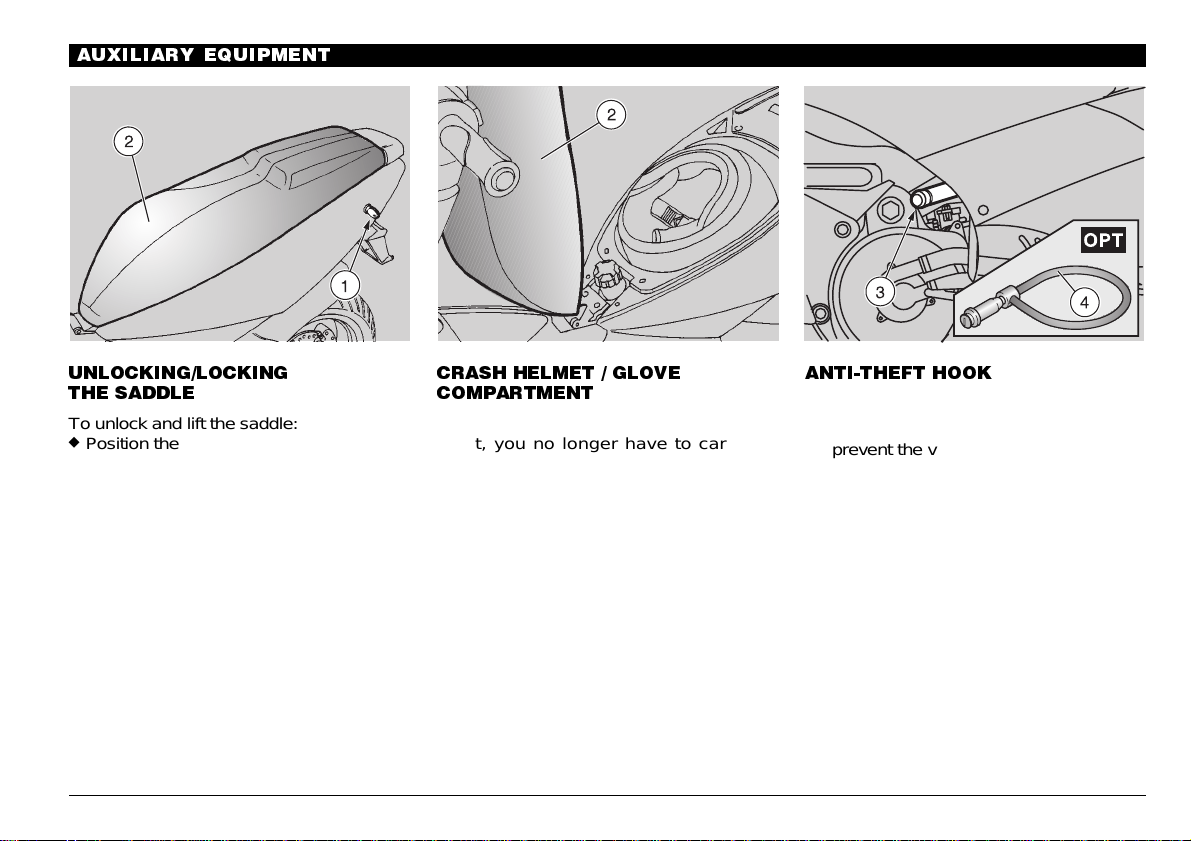

UNLOCKING/LOCKING

THE SADDLE ..............................................21

CRASH HELMET / GLOVE

COMPARTMEN T ...... ...... .. ...... ...... ..... ...... ... . 21

ANTI-THEFT HOOK ....................................21

TOOL KIT ....................................................22

REAR MUDGUARD EXTENSION ...............22

MAIN COMPONENTS

FUEL .............. ..... ......... ........ ......... ........ ...... .23

2 STROKE OIL TANK .................................. 24

BRAKE FLUID - recommendations ............. 24

DISC BRAKES ............................................. 25

COOLANT ................................................... 26

TYRES ........... .............. ................. ............... 27

AUTOMATIC

LIGHT SWITCHING VERSION

CATALYTIC SILENCER

........................................................... ...5

.................14

..................18

................ ................. . 21

................ ......... ........ ....... 23

............ 28

j

...................... 28

#

.. 12

...... 14

INSTRUCTIONS FOR USE

PRELIMINARY CHECKIN G OPERATIONS 29

STARTING ..... ..............................................30

DEPARTURE AND DRIVE ...........................32

RUNNING-IN .............. .............. .............. ......33

STOPPING ..... ............ .............. .............. ......33

PARKING ......................................... ............33

POSITIONING THE VEHICLE

ON THE STAND ...........................................34

SUGGESTIONS

TO PREVENT THEFT ..................................34

MAINTENANCE

REGULAR SERVICE INTERVALS CHART .35

IDENTIFICATION DATA ..............................3 6

AIR CLEANER ................................. ............37

CHECKING

THE TRANSMISSION OIL LEVEL ...............38

CHANGING

THE TRANSMISSION OIL ...........................39

FRONT WHEEL ........... ... .................... .........40

REAR WHEEL ..............................................42

CHECKING THE BRAKE PAD WEAR .........43

REMOVING THE FRONT AND REAR

BRAKE CALIPERS ......................................43

CHECKING THE STEERING .......................44

CHECKING

THE ENGINE FULCRUM AXIS ....................44

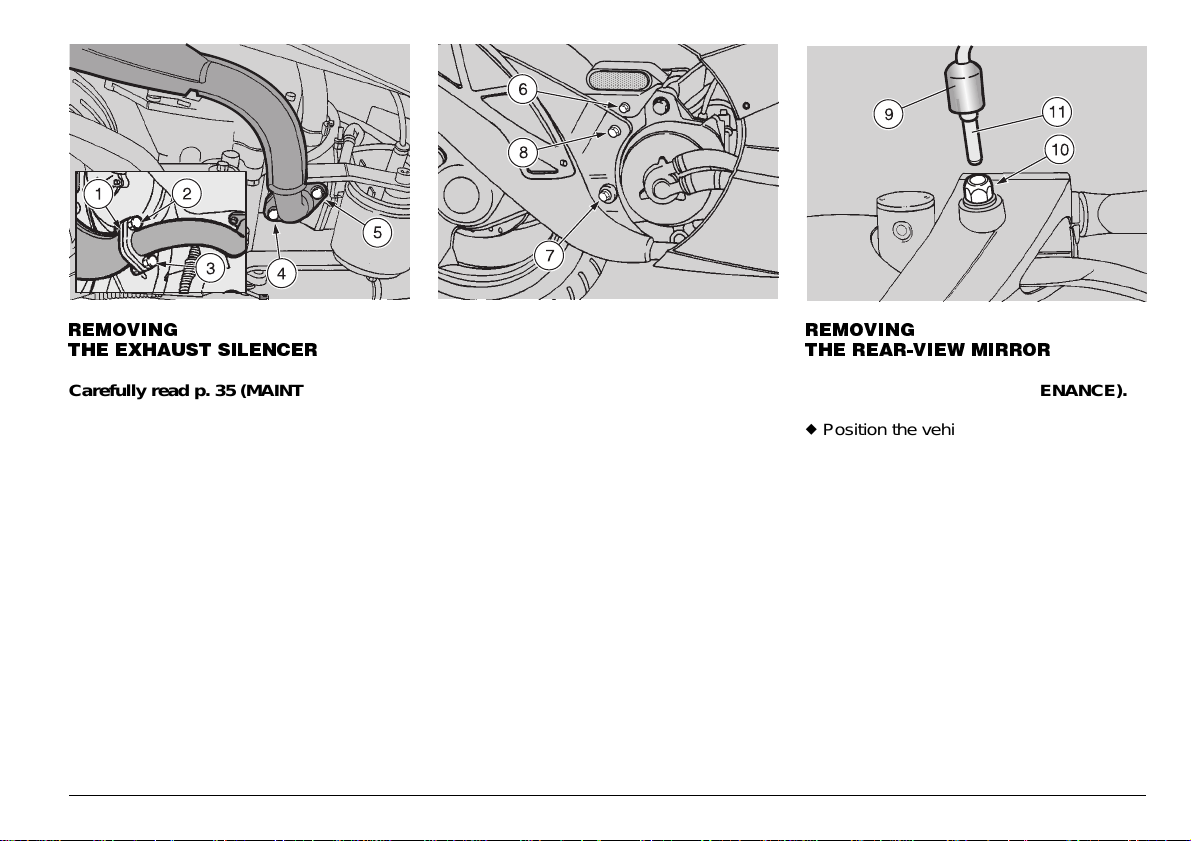

REMOVING THE EXHAUST SILENCER .....45

REMOVING THE REAR-VIEW MIRROR .....45

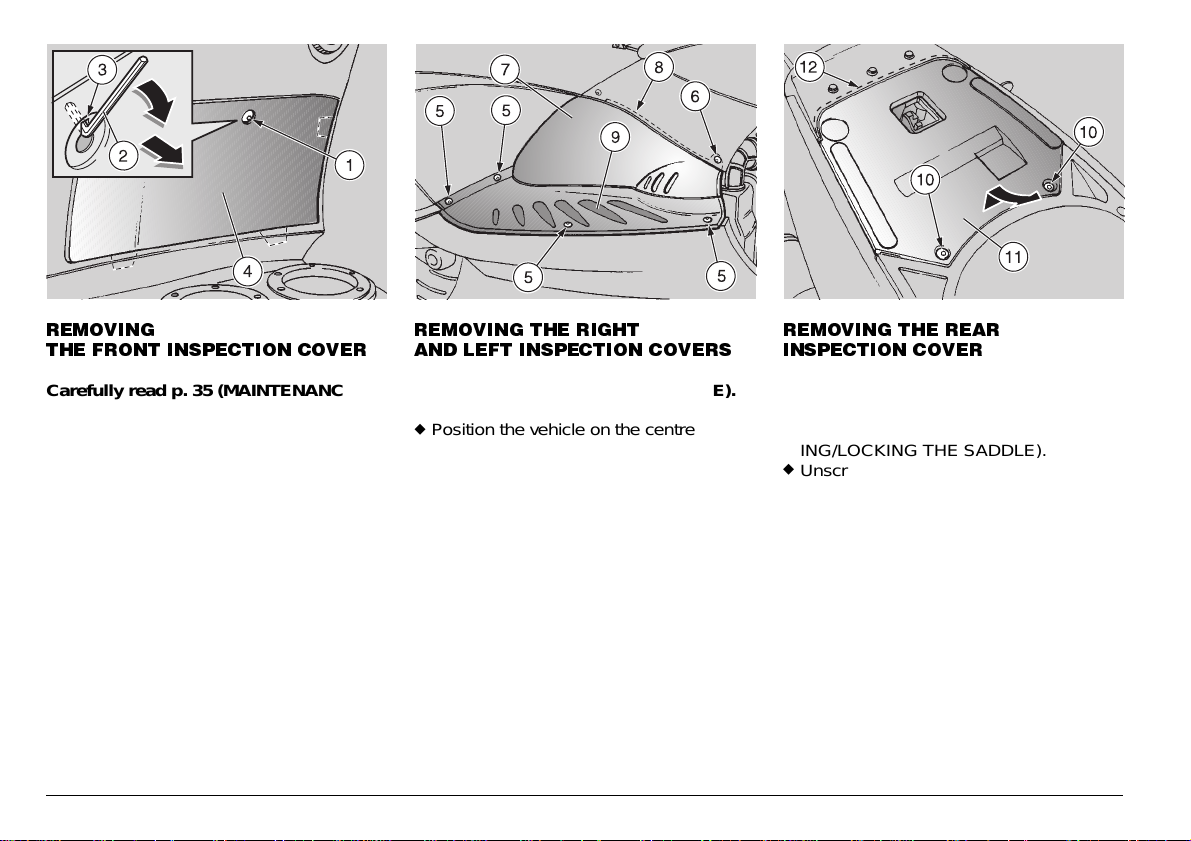

REMOVING

THE FRONT INSPECTION COVER ............46

REMOVING THE RIGHT

AND LEFT INSPECTION COVERS .............46

REMOVING THE REAR

INSPECTION COVER ..................................46

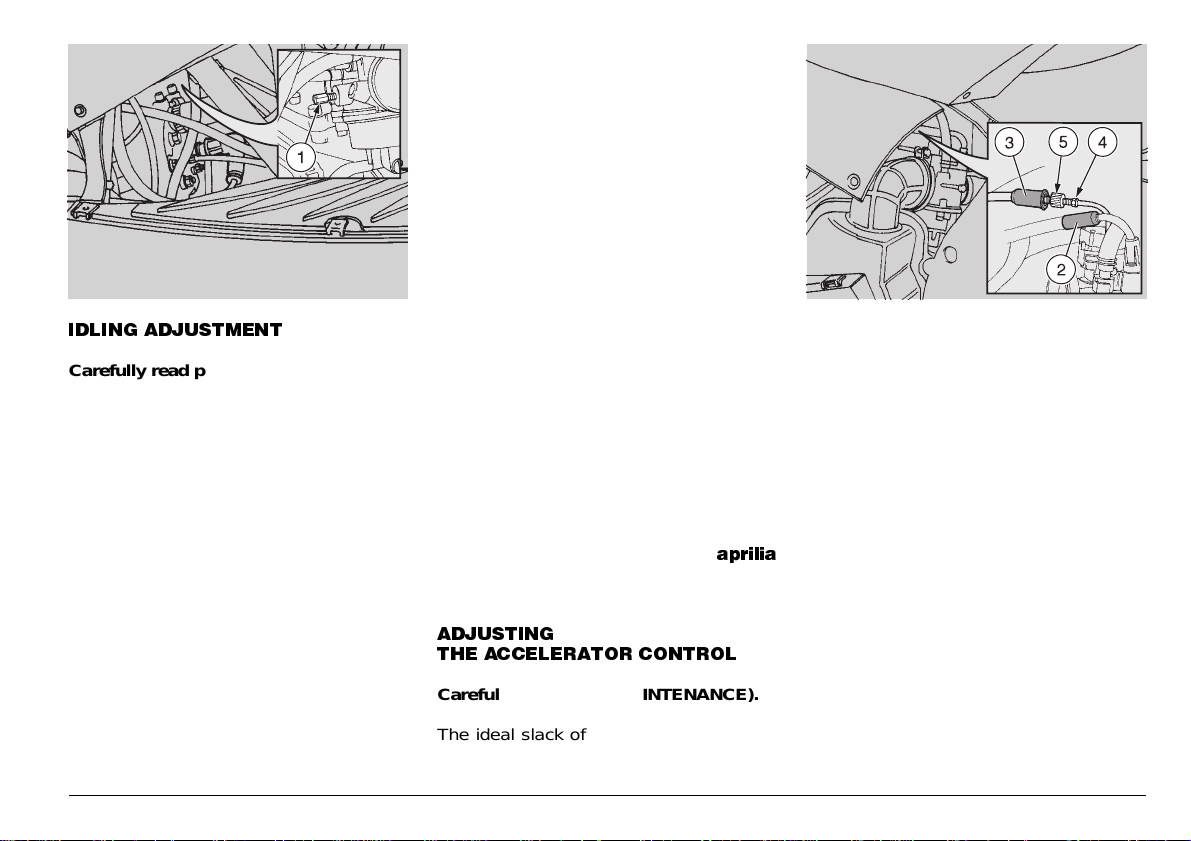

IDLING ADJUSTMENT ................................47

................ ..... ...... ... ..... ...... ..... ... .35

................................29

ADJUSTING

THE ACCELERATOR CONTROL ............... 47

SPARK PLUG ..................... ................. ........ 48

BATTERY .................................................... 49

LONG INACTIVITY

OF THE BATTERY ......................................49

CHECKING AND CLEANING

THE TERMINALS ........................................50

REMOVING THE BATTERY ........................50

CHECKING

THE ELECTROLYTE LEVEL .......................51

RECHARGING THE BATTERY ................... 51

INSTALLING T HE BATTERY ................. ... .. 51

CHANGING THE FUSE ............................... 52

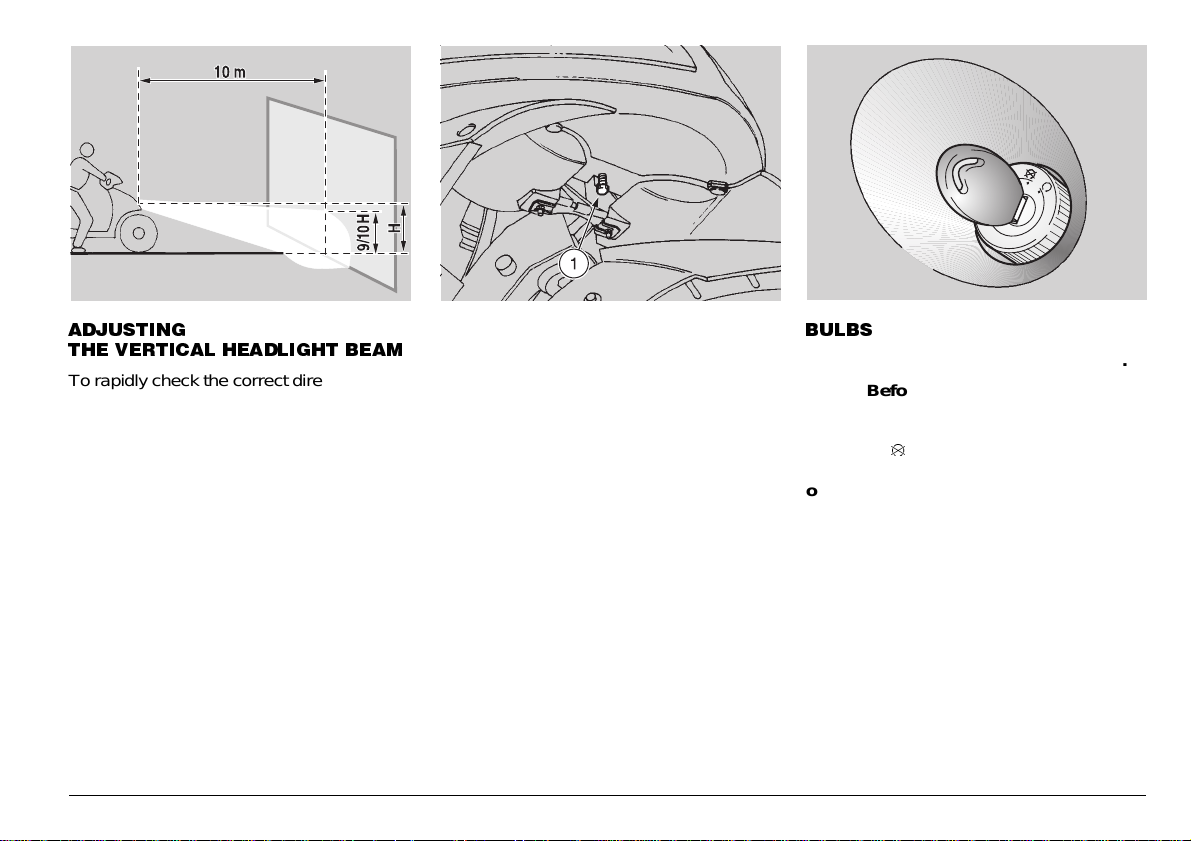

ADJUSTING

THE VERTICAL HEADLIGHT BEAM ..........53

BULBS ....... ............................ ...................... 53

CHANGING THE HEADLIGHT BULBS .......54

CHANGING

THE REAR LIGHT BULB ............................. 56

CHANGING THE NUMBER PLATE BULB

, 1 j

TRANSPORT

DRAINING THE FUEL TANK ......................57

CLEANING

LONG PERIODS OF INACTIVITY ...............59

AFTER A PERIOD OF INACTIVITY ............ 59

TECHNICAL DATA

LUBRICANT CHART ...................................64

Importers .... ......... ..... ......... ........ ........ ......66- 67

WIRING DIAGRAM Area 51 ........................68

WIRING DIAGRAM KEY Area 51 ................69

..................................................... 57

................ ................... .................... .. 58

................ ................ 56

................. ...................... ..... 60

use and maintenance Area 51

4

Page 5

safe drive

Page 6

%$6,& 6$)(7< 58/(6

To drive the vehicle it is necessary to be in

possession of all the r equirements prescribed by law (driving licence, minimum

age, psychophysical ability, insurance,

state taxes, vehic le registration, n umber

plate, etc.).

Gradually get to know the vehicle by driving it first in areas with low tra ffic and/or pri vate areas.

use and maintenance Area 51

6

The use of medicins, alcohol and drugs or

psychotropic su bstanc es no tably in crease s

the risk of accidents.

Be sure that yo u are in good ps ychoph ysical conditions and f it for driving a nd pay

particular attention to physical weariness

and drowsiness.

Most road accidents ar e caused by the

driver’s la ck of experience.

NEVER lend the vehicle to beginners and,

in any case, make sure that the driver has

all the requirements for driving.

Page 7

¡

STOP150 m

150m

STOP

Rigorously observe all road signs and national and local road regulations.

Avoid abrupt movements that can be dangerous for yourself and other people (for

example: rearing up on the back wheel,

speeding, etc. ), and give d ue co nside rati on

to the road surface, visibility and other dri ving conditions.

Avoid obstacles that could damage the vehicle or make you lose control.

Avoid riding in the slipstream created by

preceding veh icles in order to incr ease

your speed.

Always drive with both hands on the handlebars and both feet on the footrests, in

the correct driving posture.

Avoid standing up or stretching your limbs

while driving.

use and maintenance Area 51

7

Page 8

OIL

COOLER

The driver should pay attention and avoid

distractions caused by people, things and

movements (never smok e, eat, drink , read,

etc.) while driving.

use and maintenance Area 51

8

Use only the veh ic le’ s s pe cific fuels and lubricants (indicated in the “LUBRICANT

CHART”); check all oil, fuel and coolant

levels regularly.

If the vehicle has been involved in an accident, make sure that no damage has occurred to the control levers, pipes, wires,

braking system and vital parts.

If necessary, have the ve hicle ins pecte d by

an aprilia Official Dealer, who should carefully check the frame, handlebars, suspensions, safety parts and all the de vices that

you cannot check by yourself.

Always remember to report any malfunction to the technicians to help them in their

work.

Never use the vehicle when the amount of

damage it has suffered endangers your

safety.

Page 9

A12

345

ONLY ORIGINALS

Never change the position, inclination or

colour of: number plate, direction indicators, lights and horns.

Any modification of the vehicle will result in

the invalidity of the guarantee.

Any modification of the engine or of other

members whic h is aimed at increas ing the

speed or the power of the vehic le is p roh ibited by the law; in fact, any modification resulting in an increase of the maximum

speed or of the eng ine displacement would

change the scooter into a motorcycle,

which implies the following obligations for

the owner:

– new homologation;

– new registration;

– appropriate driving license.

Further, said modifications cause the loss

of the insurance cover, since insurance

policies expressly prohibit to make technical changes aimed at increasing the vehicle performance levels.

For the reasons stated abov e, the fai lure to

comply with the tampering prohibition is

punished by law with app osite sanctions

(including the confiscation of the vehicle),

which, according to the case, can be combined with the sanctions provided for not

using the crash helmet and/or the number

plate, for the violation of fiscal obligations

(ownership tax) and with penal sanctions

provided for using the vehicle without driving license.

Never race with other vehicles.

Avoid off-road driving.

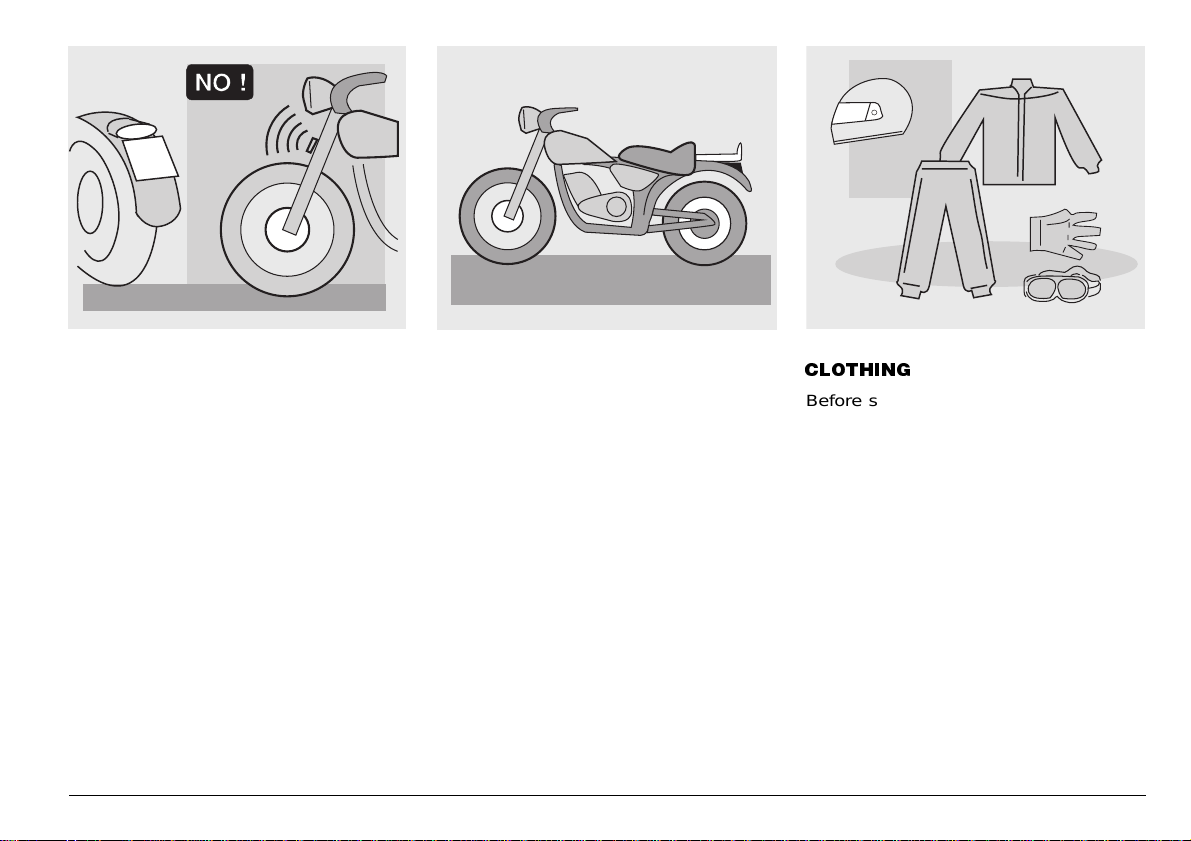

&/27+,1*

Before starting, always wear a correctly

fastened crash helmet. Make sure that it is

homologated, in good shape, of the right

size and that the visor is clean.

Wear protective clothing, preferably in light

and/or reflecting colours. In this way you

will make yourself more visible to the other

drivers, thus notably reducin g the risk of

being knocked down, and you will be more

protected in case of fall. This clothing

should be very tight-fitting and fastened at

the wrists and ankles. Strin gs, belts and

ties should not be hanging loose; prevent

these and other objects from interfering

with driving by getting entangled with moving parts or driving mechanisms.

use and maintenance Area 51

9

Page 10

Do not keep objects that can b e dangerous

in case of fall, for example pointed objects

like keys, pens , glass vials etc. in your

pockets (the same recommendations also

apply to passengers).

use and maintenance Area 51

10

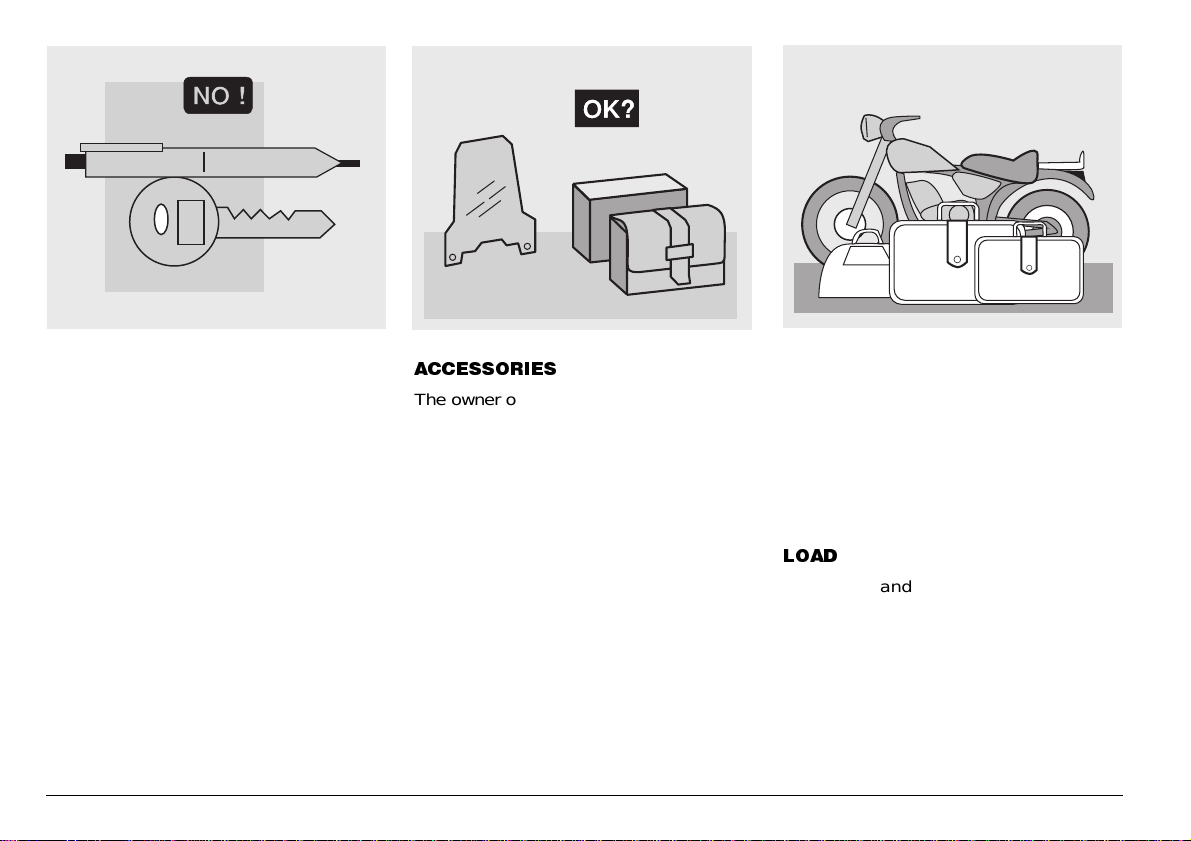

$&&(6625,(6

The owner of the vehicle is responsible for

the choice, installation and use of any accessory.

Avoid installing accessories that cover

horns or lights or that could impair their

functions, limit the suspension stroke and

the steering angle, ham per the operatio n of

the controls and reduce the distance from

the ground and the angle of inclination in

turns. Avoid using accessories that hamper

access to the controls, since this can prolong reaction times during an emergency.

Large fairings and windscreens assembled

on the vehicle can produce aerodynamic

forces capable of compromising the stability of the vehicl e while drivin g. Make sure

that the equipment is well fastened to the

vehicle and not dangerous during driving.

Do not install electrical devices and do not

modify those alr ead y exis ting t o avoid electrical over load s, b ecau se t he v ehic le c ould

suddenly stop or there could be a dangerous current shor t age in th e horn an d in t he

lights. aprilia recommends the use of

“aprilia genuine accessories”.

/2$'

Be careful and moderate when loading

your luggage. Kee p a ny luggage loaded as

close as possible to the centre of the vehicle and distribute the load uni formly on

both sides, in order to reduce imbalance to

the minimum. Furthermore , mak e su re tha t

the load is firmly secured to the vehicle, es pecially during long trips.

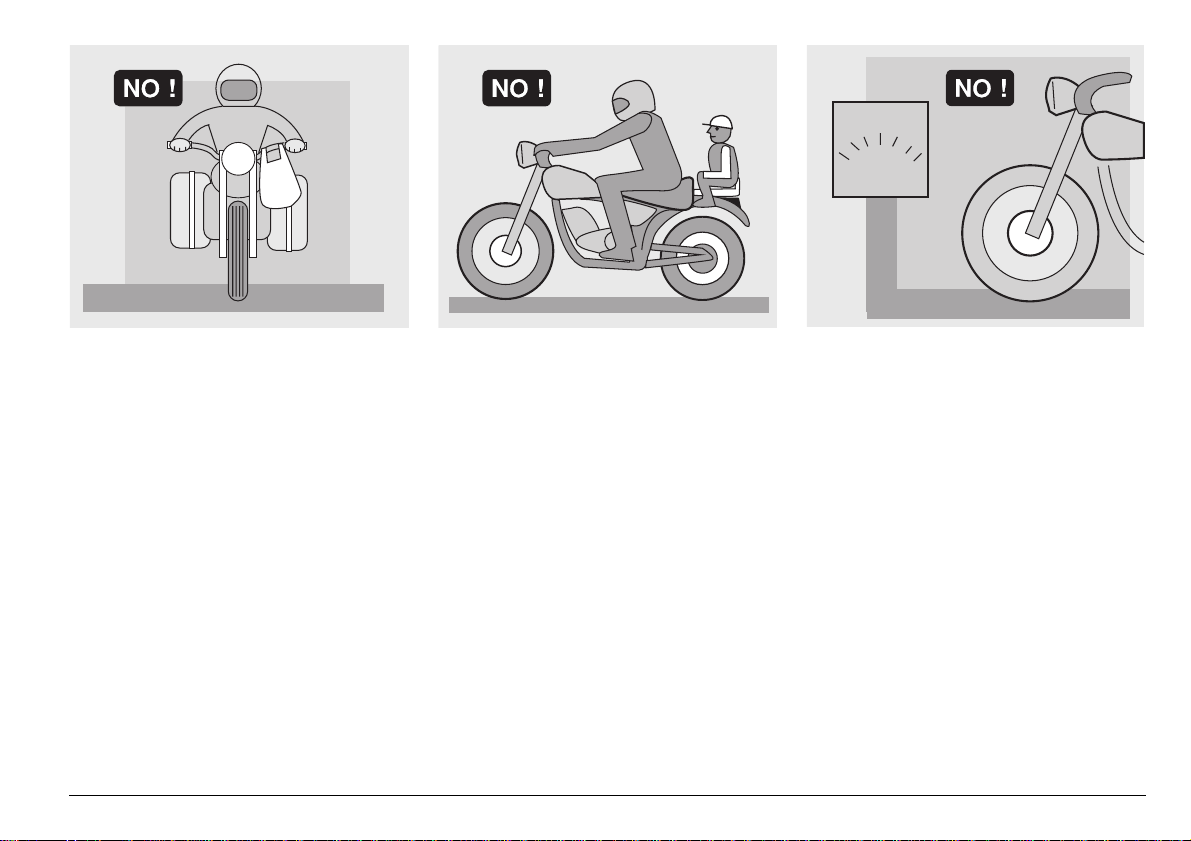

Page 11

Avoid hanging bulky, hea vy and/ or danger-

KG!

ous objects on the handlebars, mudguards

and forks, because the vehicle might respond more slowly in turns and its manoeuvrability could be unavoidabl y impaired.

Do not place bags th at a r e too bu lk y on the

vehicle sides, because it co uld hit people

or obstacles making you los e co ntro l of the

vehicle.

Do not carry any bag if it is not tightly secured to the vehicle.

Do not carry bags w hich protrude too muc h

from the luggage-ra ck or which cover the

lights, horn or indicators.

Do not carry animals or childre n on the

glove compartment or o n the luggag e-rack .

Do not exceed the maximum load allowed

for each side-bag.

When the vehicle is over loade d, its s tab ility

and its manoeuvrability can be compromised.

use and maintenance Area 51

11

Page 12

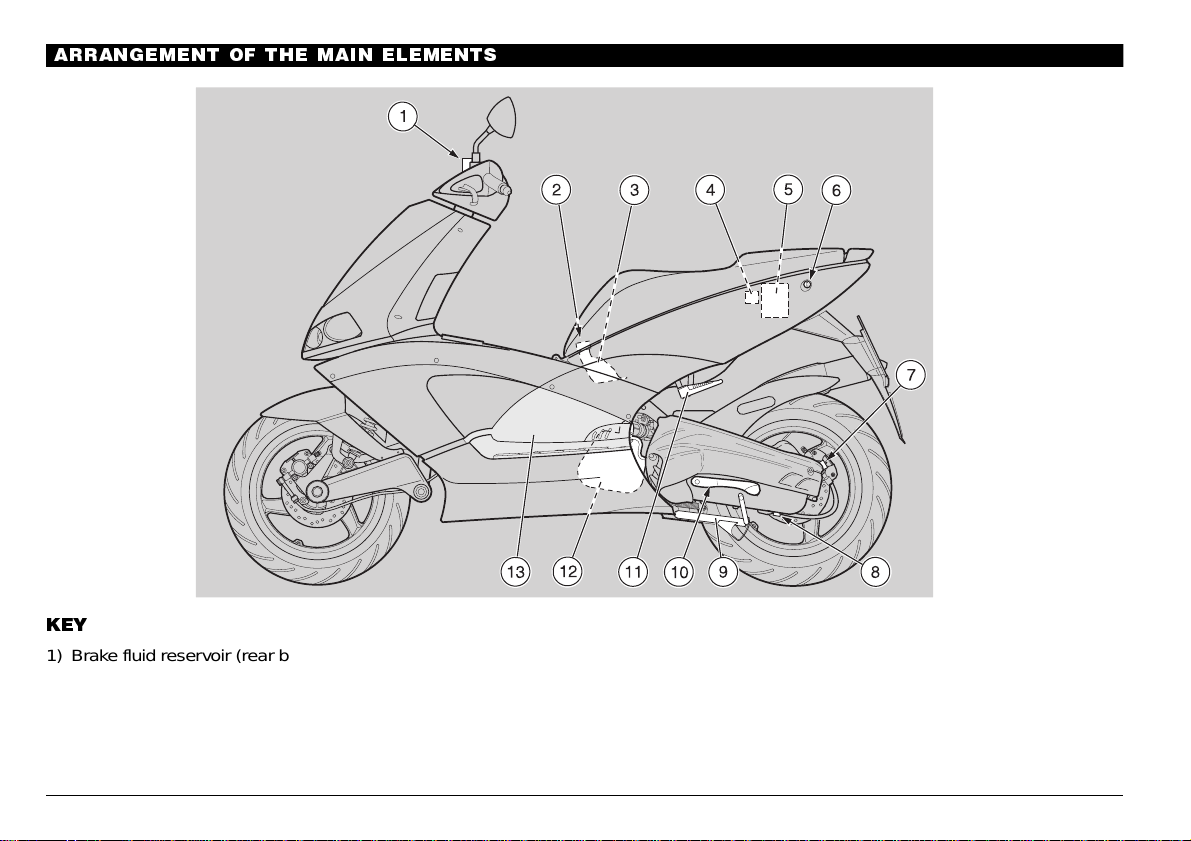

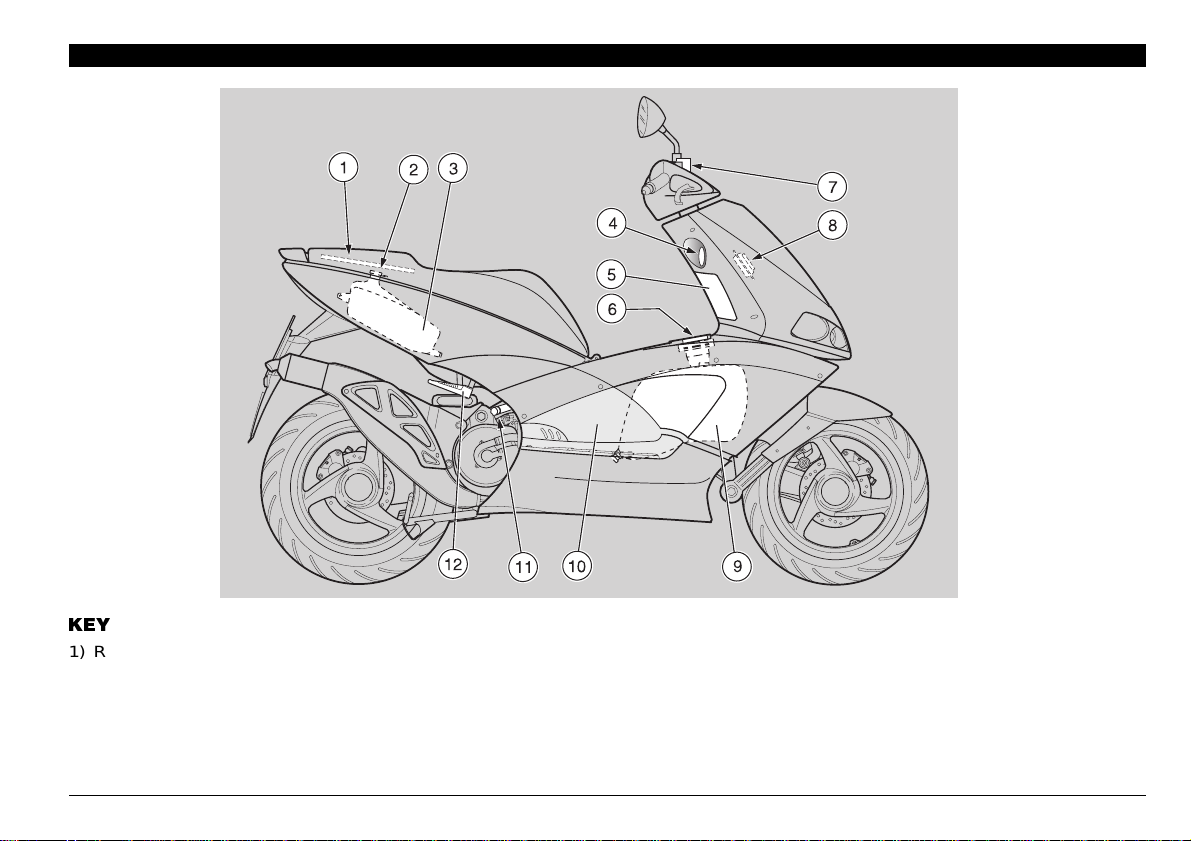

$55$1*(0(17 2) 7+( 0$,1 (/(0(176

.(<

1) Brake fluid reservoir (rear brake)

2) Coolant expansion tank plug

3) Coolant expansion tank

4) Fuse carrier

5) Battery

6) Saddle lock

7) Transmission oil filling cap

use and maintenance Area 51

12

8) Transmission oil drain plug

9) Centre stand

10) Kick starter

11) Passenger left footrest (snapping, closed/open)

(in the countries where required)

12) Air cleaner

13) Left inspection cover

Page 13

.(<

1) Rear inspection cover

2) Mixer oil tank plug

3) Mixer oil tank

4) Ignition switch/steering lock

5) Front inspection cover

6) Fuel tank plug

7) Brake fluid reservoir (front brake)

8) Horn

9) Fuel tank

10) Right inspection cover

11) Anti-theft hook (for the aprilia “Body-Guard” armored cable

12) Passenger right footrest (snapping, closed/open)

(in the countries where required)

-

)

use and maintenance Area 51

13

Page 14

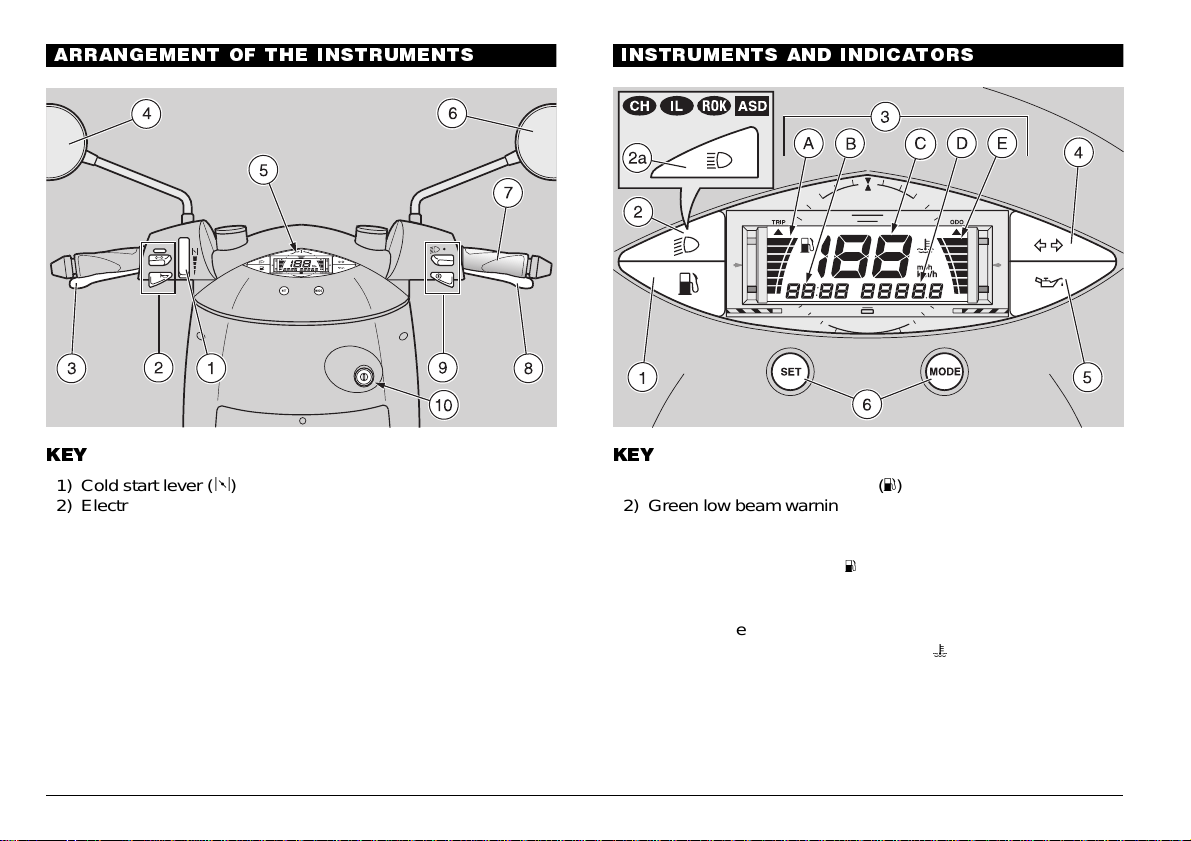

$55$1*(0(17 2) 7+( ,167580(176

,167580(176 $1' ,1',&$7256

.(<

1) Cold start lever ()

2) Electric controls on the left side of the handlebar

3) Rear brake lever

4) Left rear-view mirror (not provided in the

5) Instruments and indicators

6) Right rear-view mirror (in the countries where required)

7) Throttle grip

8) Front brake lever

9) Electric controls on the right side of the handlebar

10) Ignition switch/steering lock (

use and maintenance Area 51

14

- - +)

version)

.(<

1) Amber low fuel warning light ()

2) Green low beam warning light ()

2a) Blue high beam warning light (

3) Multifunction digital display:

A - Fuel level indicator (

B-Clock

C - Speedometer

D - Odometer (Mileage counter for the

E - Coolant temperature indicator (

(indicator scale on the right

4) Green direction indicator warning light (

5) Red 2 stroke oil reserve warning light (

6) SET and MODE programming push buttons

) , 1

) (indicator scale on the left)

)

(

j

only)

)

)

Page 15

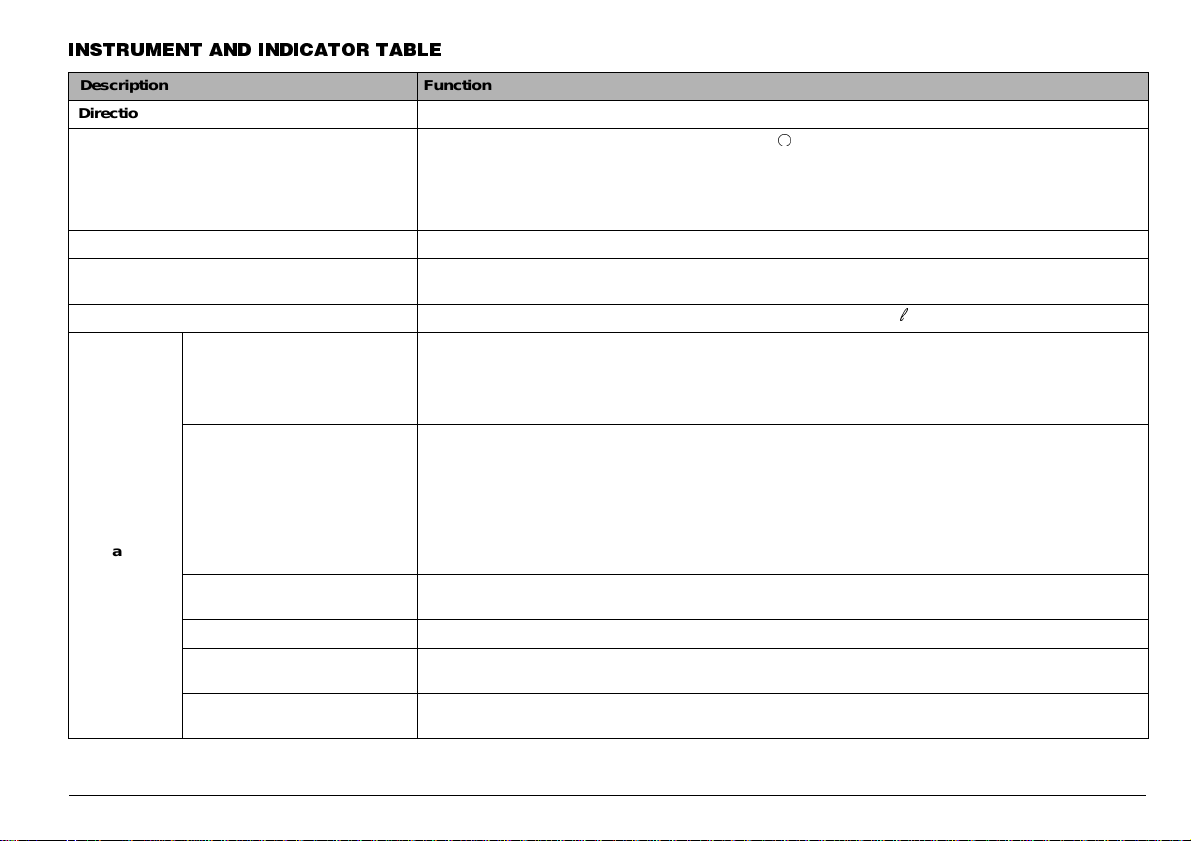

,167580(17 $1' ,1',&$725 7$%/(

Description Function

Direction indicator warning light

2 stroke oil reserve warning light

(

It blinks when the direction indicators are on.

It comes on when the ignition switch is in position

If the LED does not come on during the starting, contact an

Low beam warning light

High beam warning light

, 1 j

Low fuel warning light

Fuel level indicator

Coolant temperature

indicator

Multifunction digital

display

Speedometer

Odometer

Mileage counter

(for the

Clock

only)

It comes on when the headlight is in low beam position.

It comes on when the headlight in high beam position.

It comes on when the quantity of fuel left in the tank is about 2±0,5 E.

It indicates the approximate fuel level in the tank.

When the fuel tank is full, the indicator scale is completely lit up in correspondence with the gray refer-

ence mark (on the left upper side).

As the fuel level decreases, the lit area decrea ses as well; wh en it reac hes the r ed mark (on the left

lower side), the low fuel warning light “

It indicates the approximate temperature of the coolant in the engine.

When the indicator scale starts to light up ( light blue reference mark on the right lower side), the coolant temperature is sufficient to ensure the trouble-free r unning of the vehicle.

If the lit area on the scale reaches the red mar k (on the r ight upper s ide) and blinks, stop the engine

and check the coolant level, see p.26 (COOLANT).

It indicates the instantaneous driving speed in kilometres (or miles for the

presetting, see p. 16 (PROGRAMMING PUSH BUTTONS).

It indicates the total or partial number of kilometres covered.

It indicates the total or partial number of miles covered.

It indicates the hour and minutes according to the presetting, see p. 16 (PROGRAMMING PUSH BUT-

TONS).

“”

, thus checking the proper functioning of the LED.

aprilia

Authorized Dealer

If the warning light comes on and does not go out after the check, or if it comes on during normal functioning, this means that the 2-stroke oil reserve is being used; in this

case, top up the 2-stroke oil tank, see p. 24 (2 STROKE OIL TANK).

” comes on.

If the maximum allowed temperature is exceeded (indicator scale completely lit up), the

engine may be seriously damaged.

.

only) according to the

use and maintenance Area 51

15

Page 16

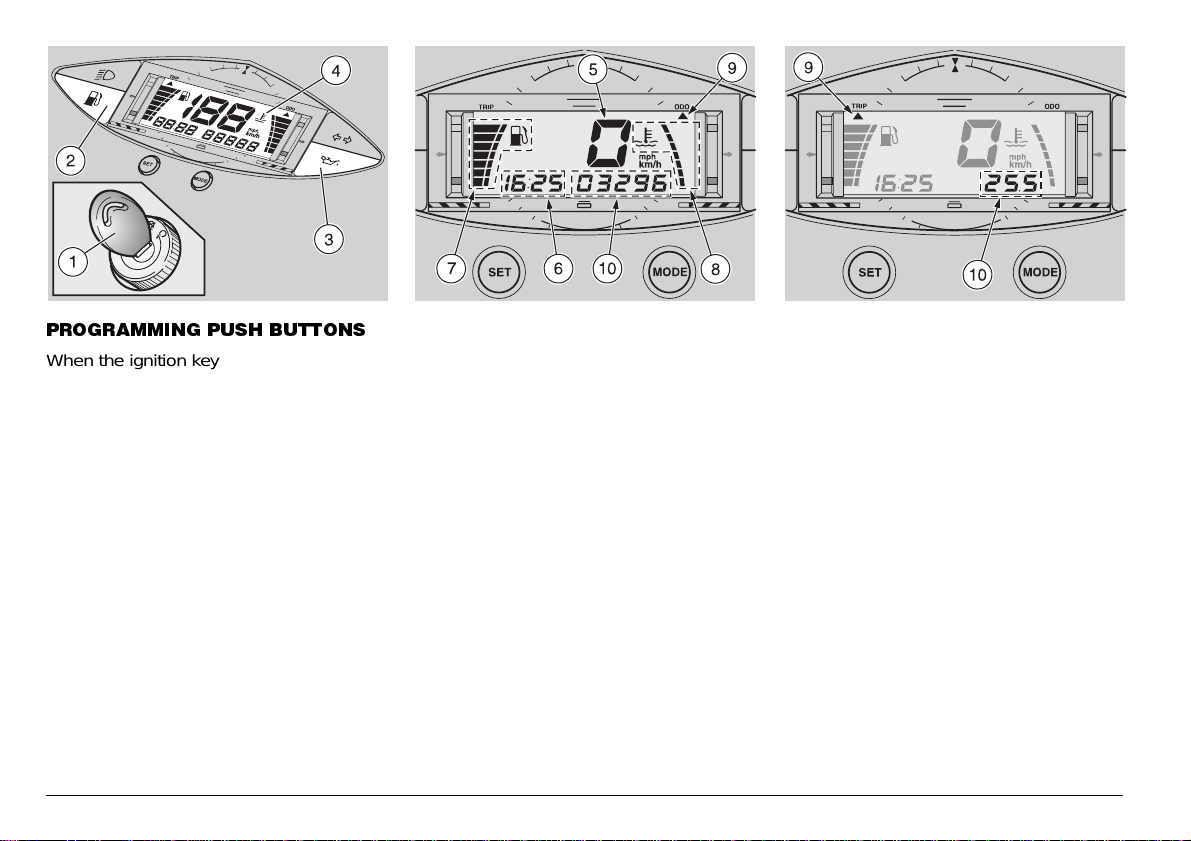

352*5$00,1* 386+ %877216

When the ignition key (1) is turned to position “

multaneously on the dashboard:

– amber low fuel warning light (

– red 2-stroke oil reser ve warning light

– the entire display (4) for approximately

pends on the last s etting made , see be-

16

”, the following lights come on si-

) (2);

) (3);

(

three seconds , afte r w hi ch the sp ee dom eter (5) will indicate “

ing functions will re main on: the cloc k (6),

the symbols corresponding to the fuel

level indicator “

temperature i ndicato r “” (8), the arrow

“▲” (9) under the writing ODO (or TRIP)

and the segments (10) indicating the total (or partial) number of kilometres

(miles for the

The position of the arrow “▲” (9)

under the writing O DO or TRIP de -

use and maintenance Area 51

” and the follow-

” (7) and to the coolant

only) covered.

low (SWITCHING FROM TOTAL KILOMETRES ODOMETER TO TRIP ODOMETER

(TO TAL MILEA GE COUNTER / TRIP MILE-

only).

ONLY)).

ONLY)

AGE COUNTER FOR THE

SWITCHING FROM TOTAL KILOMETRES

ODOMETER TO TRIP ODOMETER (TOTAL MILEAGE COUNTER / TRIP MILEAGE COUNTER FOR THE

◆

Press and release the MODE push button; the arrow “▲” (9) will move from under the writing ODO to under the writing

TRIP (or viceversa) , and at the same

time the segments (10) will indicate the

total or partial number of kilometres

(miles for the

ODO = total kilometres odometer (total

mileage counter for the only).

TRIP = trip odometer (trip mileage coun-

ter for the

only) covered.

pressed and released.

The selected setting app ears every time

the vehicle is started.

To set the trip odometer (trip mileage

counter for the

ceed as follows:

◆

◆

The arrow “▲” (9) will move every time the MODE push button is

only) to zero, pro-

Press and release the MODE push button, in such a way as to move the arrow

“▲” (9) under the writing TRIP.

Press the SET push button for about

three seconds and the segments (10) will

be set to zero.

Page 17

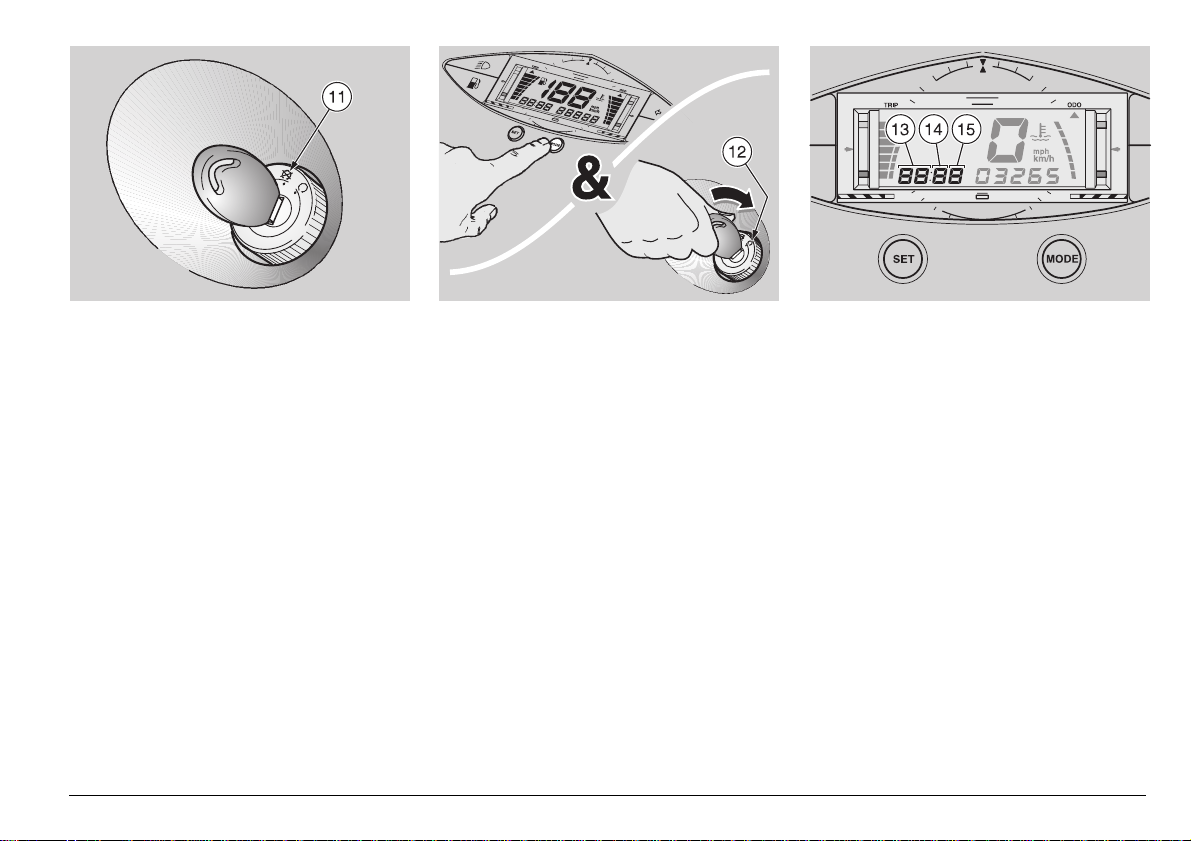

SWITCHING FROM KILOMETRES (km/h)

TO MILES (MPH) FOR THE

◆

Turn the ignition switch to position “”

(11) .

◆

Keep the MODE push button pressed

while turning the ignition switch to position “

” (12).

For the rever se switching, repeat

these operations.

ONLY

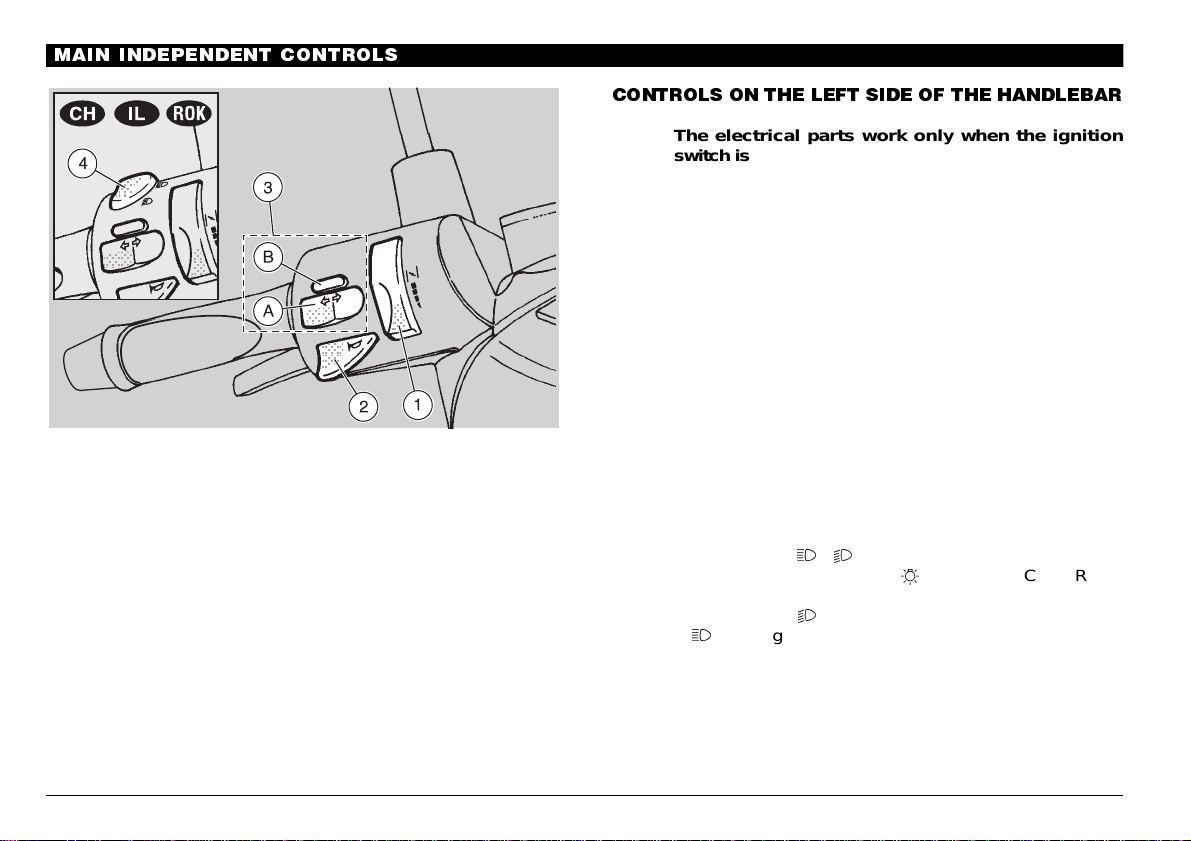

SETTING THE CLOCK

(HOURS AND MINUTES)

◆

Press the MODE push button for more

than three seconds, the segments corresponding to the hours (13) will blink.

are changed one by one, while if the

SET push button is kept pressed, the

data flip over in cyclical sequences.

◆

◆

If the SET push button is

pressed and relea sed, the data

Press the SET push button and select

the desired hour.

To confirm the hour setting, press the

MODE push button for less than three

seconds: the segment corresponding to

the tens of minutes (14) will blink.

◆

Press the SET push button and select

the desired figure for the tens of minutes.

◆

To confirm the setting of the tens of minutes, press the MODE push button for

less than three seconds: the segment

corresponding to the minutes (15) will

blink .

◆

Press the SET push button and select

the desired minutes.

◆

To conf ir m the mi nute se tting, press and

release the MODE push button.

use and maintenance Area 51

17

Page 18

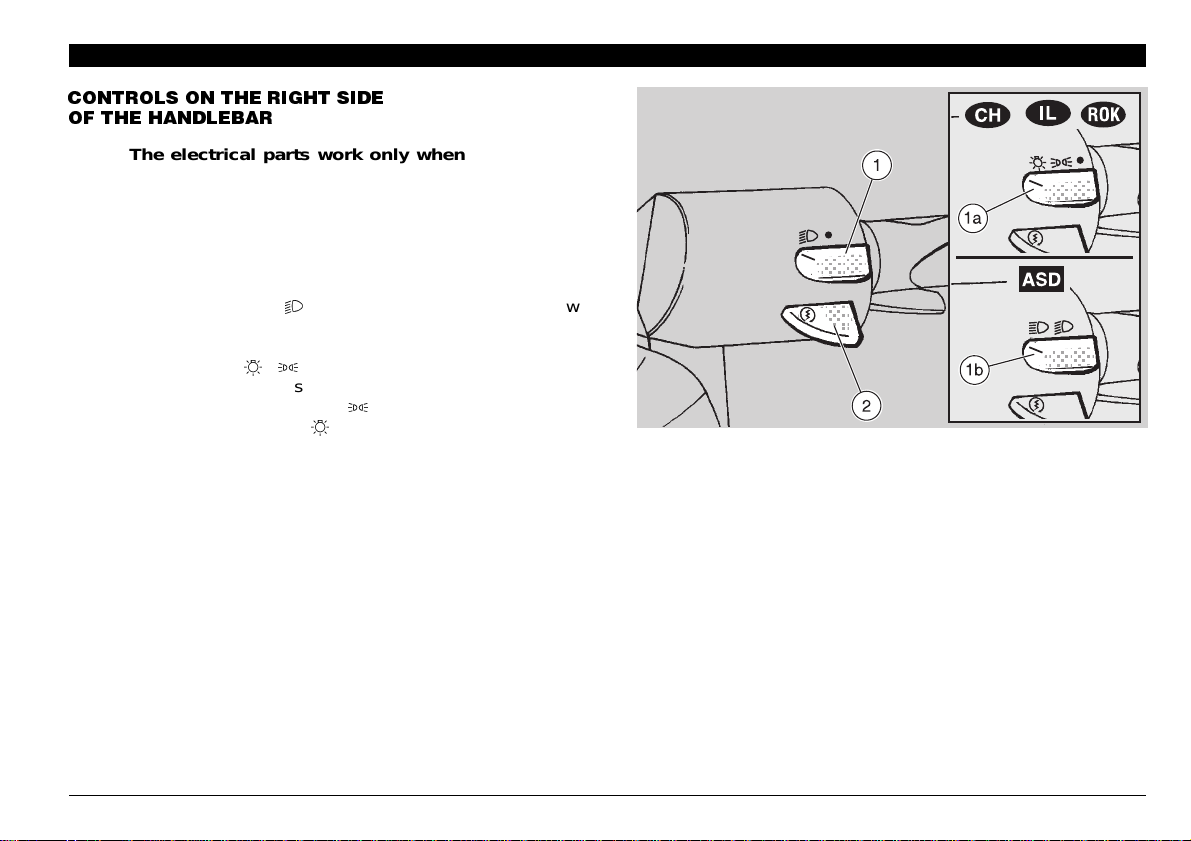

0$,1 ,1'(3(1'(17 &21752/6

&21752/6 21 7+( /()7 6,'( 2) 7+( +$1'/(%$5

The electrical parts work only when the ignition

switch is in position “”.

The lighting system works only when the engi ne is

running.

18

use and maintenance Area 51

1) COLD START LEVER (

The starter for the c old start of t he eng ine is opera ted by rota ting the lever upwards.

To disco nnect t he cold star t, brin g the l ever to its init ial pos ition.

2) HORN PUSH BUTTON (

The horn is activated when the push button is pressed.

3) DIRECTION INDICATOR SWITCH (

To indicate the turn to the left, move the switch (A) to the left;

to indicate the turn to the right, move the switch (A) to the

right.

To turn off the direction indicator, press the push button (B).

4) DIMMER SWITCH (

With the light switch in position “”, see p. 19 (CONTROLS

ON THE RIGHT SIDE OF THE HANDLEBAR): if the dimmer

switch is in positi on “

sition “

”, the high beam is on.

)

)

()

- )

, 1

”, the low beam is on, while if it is in po-

Page 19

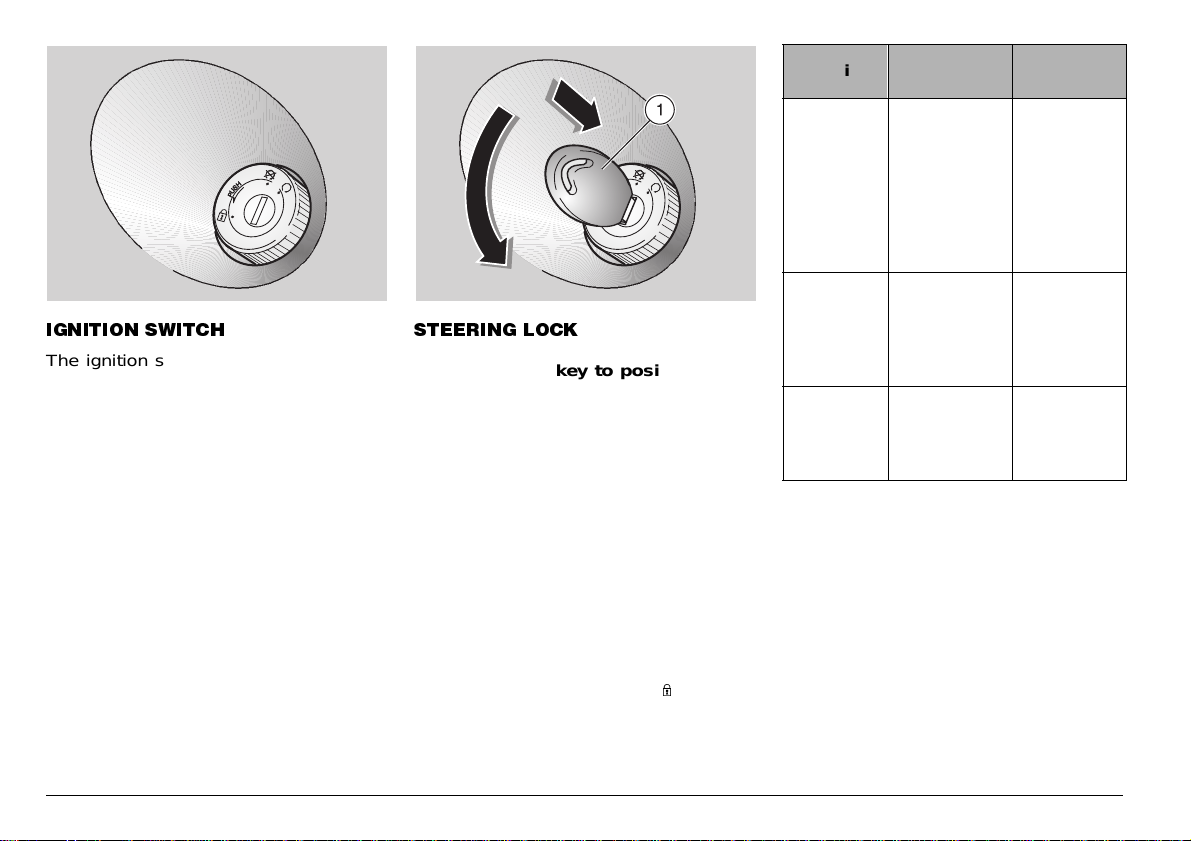

&21752/6 21 7+( 5,*+7 6,'(

2) 7+( +$1'/(%$5

1) LIGHT SWITCH (

1a) LIGHT SWITCH (

1b) DIMMER SWITCH (

2) START PUSH BUTTON (

The electrical parts work only when the ignition

switch is in position “”.

The lighting system works only when t he engine is

running.

-

)

When the light switch is in position “

the switch is in posi tion ““, the rear parking light and the lo w

beam are on.

When the light switch is in positio n “•”, the lights are off;

when the switch is i n p os i tio n “

and when it is in position “”, the parking lights and the low

or high beam are on. To turn on t he low or high beam, use

the dimmer switch, see p. 18 (CON TROLS ON THE LEFT

SIDE OF THE HANDLEBAR).

When the dimmer switch is in position “”, the low beam

and the parking lights are on; when it is in position “

high beam and the parking lights are on.

The lights can be switched off only by stopping

the engine.

•

- - •)

- )

”, the lights are off; w hen

•

, 1

”, the parking lights are on

j

)

When the start push button is pressed and one of the brake

levers (front or rear) is activated at the same time, the starter

makes the engine run.

For the starting procedure, see p. 30 (STARTING).

”, the

use and maintenance Area 51

19

Page 20

Position Function

Key

removal

,*1,7,21 6:,7&+

The ignition switch is posi tioned on the

right side, near the steering column.

saddle lock.

Two keys are supplied to gethe r with the

vehicle (one spare key).

The key (1) operates the ignition

switch/steering lock and the

67((5,1* /2&.

Never turn the key to position “

running conditions, in order to avoid

losing control of the vehicle.

OPERATION

To lock the steering:

◆

Turn the handlebar c om ple tel y le ftw ard s.

◆

Turn the key (1) to position “” and

press it.

◆

◆

Turn the key and steer the handlebar at the same time.

Rotate the key (1) anticlockwise (leftwards), steer the ha ndlebar slowly until

the key (1) reaches position “

Extract the key.

+” in

+

”.

+

Steering

lock

The steering

is locked.

It is neither

possible to

start the engine, nor to

switch on the

lights.

Neither the

engine, nor

the lights can

be switched

on.

The engine

and the lights

can be

switched on.

It is possible

to remove

the key.

It is possible

to remove

the key.

It is not possible to remove the

key.

use and maintenance Area 51

20

Page 21

$8;,/,$5< (48,30(17

81/2&.,1*/2&.,1*

7+( 6$''/(

To unlock and lift the saddle:

◆

Position the vehicle on the centre stand.

◆

Insert the key in the saddle lock (1).

◆

Turn the key clockwise and raise the

saddle (2).

not left the key in the crash helmet/glove compartment.

◆

Before lowering and locking the

saddle, make sure that you have

To lock the saddle, lower and press it

(without exerting too much pr essure),

thus making the lock snap shut.

Before leaving, make sure that

the saddle is properly locked.

&5$6+ +(/0(7 */29(

&203$570(17

Thanks to the crash helmet/glove compartment, you no longer have to carry the

crash helmet or other obj ects wit h you eve ry time you park the vehicle.

The compartment is po sitioned under the

saddle.

To reach it:

◆

Raise the saddle (2), see beside (UNLOCKING/LOCKING THE SADDLE).

shown in the figure.

Maximum allowed weight: 2.5 kg.

Position the helmet with the

opening facing upwards, as

Do not load the crash helmet/glove compartment too

much.

$17,7+()7 +22.

The anti-theft hook (3) is positioned on the

right side of the vehicle.

To prevent the vehicle from being stolen, it

is advisable to secure it with the aprilia

“Body-Guard” armored cable

able at any aprilia Official Dealer.

Do not use the hook to lift the ve-

has been parked.

hicle or for any purp ose other

than securing the vehicle once it

use and maintenance Area 51

(4), avail-

-

21

Page 22

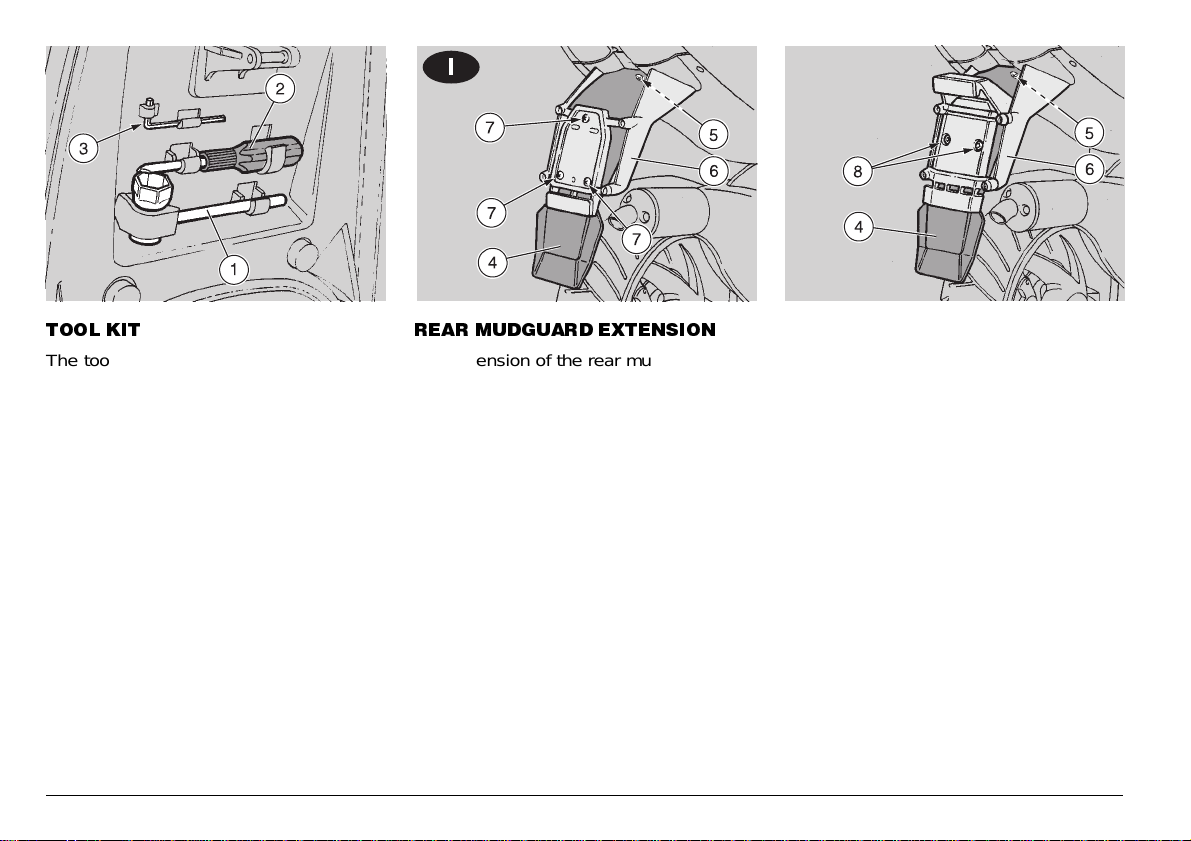

722/ .,7

The tool kit is hooked to the unde rside of

the saddle.

To reach it, proceed as follows:

◆

Lift the saddle, see p. 21 (UNLOCKING/LOCKING THE SADDLE).

The tool kit includes:

– n. 1 21 mm spark plug socket spanner

(1)

– n. 1 double-ended, cross-/cut-headed

screwdriver (2) type PH size 2 with handle

– n. 1 3 mm bent hexagon spanner (3)

use and maintenance Area 51

22

5($5 08'*8$5' (;7(16,21

The extension of the rear mudguar d (4) i s

extremely useful when the ro ad surface i s

wet, in fact it reduces the r each of t he w ater spray caused by the rear wheel.

ment and is positioned in the crash helmet / glove compartment.

For the installation, proceed as follows:

◆

◆

The rear mudguard extension (4)

is supplied as standard equip-

Raise the saddle, see p. 21 (UNLOCKING/LOCKING THE SADDLE).

Remove the rear mudguard extension

(4) together with the sc rews an d the re levant fastening nuts from the crash helmet / glove compartment.

◆

Unscrew and remove the screw (5).

◆

Position the rear mudg uard ex tensi on (4)

inside the number plate-holder support

(6).

◆

Moderately tighten the screw (5).

for the fastening of the number plate.

◆

◆

◆

◆

◆

◆

Only for : the three screws (7)

and the relevant nuts serve also

Insert the three screws (7) and s crew

the relevant nuts.

Insert the two screws (8) and screw the

relevant nuts.

Make sure that the rear mudguard extension (4) is positioned correctly.

Tighten the screw (5).

Tighten the three screws (7).

Tighten the two screws (8).

Page 23

0$,1 &20321(176

)8(/

The fuel used for inte rnal com-

ditions it can become explosive.

It is important to carry out the refuelling

and the maintenan ce operations in a

well-ventilated area, with the engine off.

Do not smoke while refuellin g or near

fuel vapours, in a ny c ase a void any contact with naked flames, sparks and any

other heat source to prevent the fuel

from catching fire or from exploding.

Further, prevent fuel from flowing out of

the fuel filler, as it could catch fire w hen

getting in contact w ith the red-hot su rfaces of the engine.

bustion engines is extremely inflammable and in particular con-

In case some fuel has accidentally been

spilt, make sure that the area has completely dried and before starting the vehicle verify that there is no fuel inside

the fuel filler neck.

Since petrol expands under the heat of

the sun and due to the effects of sun radiation, never fill the tank to the brim.

Screw the plug (3) up carefully after refuelling.

Avoid any contact of the f uel with the

skin and the inhalation of vapours; do

not swallow fuel or pour it from a rece ptacle into another by means of a tube.

KEEP AWAY FROM CHILDREN

Use only premium grade petrol (4 Stars

), in conformity with th e DIN 51600

standard, min. O.N. 98 (N.O.R.M.) and 88

(N.O.M.M.).

Use only unleaded petrol, in confo rmity

#

with the DIN 51607 standard, min. O.N. 95

(N.O.R.M.) and 85 (N.O.M.M.).

FUEL TANK CAPACITY

(reserve included): 11.5

TANK RESERVE: 2±0.5

To refuel, proceed as follows:

◆

Raise the cover (1).

◆

Insert the key (2) in the fillercap lock.

◆

Turn the key anticlockwise, pull and remove the fillercap (3).

◆

Provide for refuelling.

E

E

use and maintenance Area 51

23

Page 24

6752.( 2,/ 7$1.

Top up the mixer oil tank every 500 km.

The vehicle is provided with a separate

mixer that makes it possible to mix petrol

with oil for the lubric ation of th e engi ne, see

p. 64 (LUBRICANT CHART).

The reserve is indicated by the coming on

of the 2 stroke oil reserve warning light

“

14 and 15 (INSTRUMENTS AND INDICATORS).

If you run out of oil in the 2 stroke oil

tank or if the mixer oil pipe has been removed, it is nec essary to contac t an

DSULOLD

for bleeding the system.

This operation is indispensable, since

the operation of the engine with air in

the mixer oil system may cause serious

damages to the engine itself.

To top up the 2-stroke oil tank, proceed as

follows:

◆

◆

2 STROKE OIL TANK CAPACITY: 1.3

TANK RESERVE: 0.3

24

Remember: 1 mile = 1.6 km

1 km = 0.625 miles

” positioned on the da shboard, see p.

The use of the vehicle without 2

stroke oil caus es serious damages to the engine.

Official Dealer, who will provide

Remove the rear inspection cover, see

p. 46 (REMOVING THE REAR INSPECTION COVER).

Remove the plug (1).

E

use and maintenance Area 51

E

Wash your hands carefully after

environment.

KEEP AWAY FROM CHILDREN.

%5$.( )/8,' UHFRPPHQGDWLRQV

draulic system.

For any doubt regarding the perfec t

functioning of the braking system and

in case you are not able to carry out the

usual checking oper ations, contact

your

using the oil.

Do not dispose of the oil in the

Sudden resistanc e or clearance

problems on the brake lever m ay

be due to problems in the hy-

DSULOLD

Official De aler.

Make sure that the brake disc and the

friction eleme nts are neither oily nor

greasy, especially after maintenance or

checking operations.

Check that the brake cable is neither

twisted nor worn out.

Prevent water or dust from accidentally

getting into the circuit.

In case maint enance opera tions are to

be performed on the hydraulic circuit, it

is advisable to use latex gloves.

If the brake fluid gets in contact w ith the

skin or the eyes, it can cause serious irritations.

Carefully wash the parts of your body

that get in contact with the liquid.

Consult a doctor or an oculist if the liquid gets in contact with your eyes.

Do not dispose of the brake fluid in the

environmen t.

KEEP AWAY FROM CHILDREN

When using the brake fluid, take

rably damages them.

care not to spill it on the plastic

or painted par ts, since it ir repa-

Page 25

',6& %5$.(6

The brakes are the parts that

perfectly working.

The brake fluid mus t b e changed once a

year by an

This vehicle is provided with hydraulic disc

brakes.

When the disc pads wear out, the level of

the fluid decreases to automatically compensate for their wear.

The brake fluid reservoirs (1) are positioned on the handlebar, near the brake lever couplings. Periodically check the brake

fluid level in the reservoir (1) and the pad

wear, see p. 43 (CHECKING THE BRAKE

PAD WEAR).

most ensure your safety and for

this reason they must always be

DSULOLD

Official Dealer.

In normal operating conditions,

If it does, do not use the vehicle and

contact an

CHECKING

To check the brake fluid level, proceed as

follows:

◆

◆

◆

◆

the brake flu id never decrea ses

below the “MIN” level.

DSULOLD

Position the vehicle on the centre stand.

Rotate the handlebar leftwards, so that

the fluid containe d in the reservoir is parallel to the “MIN” mark stamped on the

glass (2).

Make sure that the lev el of the brake fl uid

contained in the tank exceeds the “MIN”

mark stamped on the glass (2).

If it does, do not use th e vehi cle a nd con tact an aprilia Official Dealer.

Official Dealer.

the circuit, contact your

Dealer, since it may be necessary to

bleed the system.

In case of ex cessive mo vement

of the brake lever, of excessive

elasticity or in case there is air in

DSULOLD

Remember: 1 mile = 1.6 km

1 km = 0.625 miles

Official

use and maintenance Area 51

25

Page 26

&22/$17

Check the coolan t lev el eve ry 200 0 km and

after long rides; change it every 2 years.

The coolant is made up of 50% water and

50% antifreeze.

This mixture is ideal for most running temperatures and ensures good protection

against corrosion.

It is advisable to keep the same mixture

also in the hot season, since in this way

losses due to evaporation are reduced and

it is not necessary to top up very frequently.

The mineral salt deposits left in the radiator

by evaporated water are thus reduced and

the efficiency of the cooling system remains unchanged.

If the outdoor temperature is below 0°,

check the cooling circuit frequently and if

necessary increase the antifreeze concentration (up to maximum 60%).

Do not use th e vehicle if the

coolant is below the minimum

prescribed level.

Remember: 1 mile = 1.6 km

1 km = 0.625 miles

Have the coolant changed by an

DSULOLD

Official De aler.

Do not remove the e xpansion

sure and its temperature is high.

If it gets in contact with the skin or with

clothes it may cause severe burns

and/or damages.

The coolant is noxious:

DO NOT SWALLOW IT.

KEEP AWAY FROM CHILDREN.

CHECKING AND TOPPING UP

Proceed as follows:

◆

◆

tank cap when the engine is hot,

since the coolant is under pres-

Raise the saddle, see p. 21 (UNLOCKING/LOCKING THE SADDLE).

Make sure that the coolant level in the

expansion tank is included between the

"MIN" and "MAX" marks, by checking

through the special slot (1) provided on

the bottom of the crash helmet / glove

compartment.

◆

If the level is not included between the

"MIN" and "MAX" marks, provide for topping up.

TOPPING UP

Proceed with care, releasing any

◆

◆

◆

◆

◆

make sure that there are no leaks in the

circuit.

Have it repaired by an

Dealer.

residual pressure that may be

present in the system.

Loosen the plug (2), by giving it about

half a turn.

Wait for a few seconds, in order to release any residual pressure that may be

present in the system.

Unscrew and remove the plug (2).

Top up until the fluid reaches appro x. the

"MAX" notch.

Do not exceed th is level, otherw ise the

fluid will flow out o f the ta nk when the en gine is running.

Put back the filling cap (2).

In case of excessive consumption of coolant and in case the

expansion tank remains empty,

DSULOLD

Official

use and maintenance Area 51

26

Page 27

7<5(6

This vehicle is pro vided wit h tubel ess tyres.

Periodically check the tyre infla-

If the tyres are hot, the measurement is

not correct.

Carry out the measurement especially

after long rides.

If the inflation pressure is too high, the

ground unevenness cannot be dampened and is therefore transmitted to the

handlebar, thus compromising the driving comfort and reducing the road holding during turns.

tion pressure at room temperature.

If, on the contrary, the in flation pressu re

is too low, the tyre sides are under

greater stress and the tyre itself may

slip on the rim or it may become loose,

with consequent loss of control of the

vehicle.

In case of sudden braking the tyres

could even get out of the rims. Further,

the vehicle could skid while turning.

Check the surface and the wear of the

tyres, since tyres in bad conditions can

impair both the grip and the controllability of the vehicle.

Change the tyre when it is worn out or

in case of puncture on the tread side, if

the puncture is larger than 5 mm.

Use only tyres in the size suggested by

DSULOLD

Do not install tyres with ai r tube on rim s

for tubeless tyres and viceversa.

Make sure th at the tyres always have

their valve seali ng caps on, to pre vent

them from suddenly going flat.

, see p. 60 (TECHNICAL DATA).

Change, reparation, maintenance and

balancing operations are very important

and should be carried out by qualified

technicians with appropriate tools.

For this reason, it is ad visable to have

the above mentioned operations carried

out by an

qualified tyre repairer.

miles.

Do not oil the tyres with unsuitable flu-

ids.

INFLATION PRESSURE

SOLO RIDER

front:...............................180 kPa (1.8 bar)

rear:................................200 kPa (2.0 bar)

RIDER AND ONE PASSENGER

(in the countries where this is allowed)

front:...............................200 kPa (2.0 bar)

rear:................................220 kPa (2.2 bar)

MINIMUM TREAD DEPTH LIMIT

front: ..............................................1.5 mm

rear: ...............................................1.5 mm

DSULOLD

If the tyres are new, they may

still be covered with a slippery

film: drive carefully for the first

Official Dealer or by a

use and maintenance Area 51

27

Page 28

$8720$7,&

/,*+7 6:,7&+,1* 9(56,21

The vehicles provi ded with the Automa tic

Switch-on Device can be immediately recognized, since the lights co me autom atically on as soon as the engine is started.

For this reason the light switch is replaced

by a dimmer switch.

The lights can be s witche d off on ly by s topping the engine.

For the versions with high beam, proceed

as follows:

◆

Before starting the vehicle, make sure

that the dimmer switch is in position “

(front low beam).

j

&$7$/<7,& 6,/(1&(5

Avoid parking the vehicle cata-

ble to children, as the catalytic silencer

becomes extremely ho t during use; be

very careful and avoid any kind of contact before it has completely cooled

down.

The catalytic vehicle is fitted with a silenc er

with metal catalytic converter of the “platinum-rhodium bivalent” type.

This device provides for the oxi dation of

”

the CO (carbon monoxide) and of the H C

(unburned hydrocarbons) contained in the

exhaust gases, changing them into carbon

dioxide and steam, respectively.

lytic version near dry brush

wood or in plac es e asily acces si-

#

Due to the catalytic reaction, the high temperature reached by the exhaust gases

makes for the burning of the oil particles,

thus keeping the silencer clean and eliminating the exhaust fumes.

To have the catalytic converter function

correctly and for long and to reduce possible problems regarding the soiling of the

thermal unit an d o f t he exhaust, it is nec es sary to avoid covering long distances with

the engine running at constantly low rpm.

It is sufficient to alternate these periods

with periods in whic h the engine ru ns at relatively high rpm, even if only for a few seconds, but rather frequently.

What has been state d abov e assu mes pa rticular importance for the cold starting of

the engine: in this case, in order to reach a

rpm regime sufficient to enable the “priming” of the catalyt ic reaction, just make

sure that the temperat ure of the thermal

unit has reached at least 50°C, which generally occurs a few seconds after starting

the engine.

Do not use leaded petrol, since it

causes the destruction of the

catalytic converter.

use and maintenance Area 51

28

Page 29

,16758&7,216 )25 86(

Before depa rture, always c arry

functions c orrectly and sa fely, see the

following table PRELIMINARY CHECKING OPERATIONS.

The non-performance of these checking

operations can cause severe personal

injuries or damages to the vehicle.

understand about the functioning of

some controls or in case you suspect or

discover some irregularities.

It does not take long to carry out a

check-up and this op eration ensures

you much mo re safety.

out a preliminary checking of the

vehicle, to make sure that it

Do not hesitate to consult your

DSULOLD

there is something yo u do not

Official Dealer in case

35(/,0,1$5< &+(&.,1* 23(5$7,216

Component Check Page

Front and rear brake Check the functioning, the fluid level and make sure

Accelerat or Make sure that it w orks s mooth ly an d tha t it is po ssib l e to

2 stroke oil Check and/or top up, if necessar y. 24

Wheel/tyres Check the tyre surface, the inflation pressure, wear and

Brake levers Make sure that they work smoothly.

Steering Make sure that the steering rotates smoothly, without any

Centre stand Make sure that it works smoothly. When the stand is let

Fastening elements Make sure that the fastening elem ent s ar e not loose.

Fuel tank Check the fuel level and top up, if necessary.

Coolant

Lights, warning

lights, horn and

electric devices

there are no leaks.

Check the wear of the pads. Top up, if necessary.

open and close it complet ely, in all steering positions.

If necessary, adjust and/or lubricate it.

tear and any damage.

If necessary, lubricate the articul at i on s.

clearance or slackening.

up or pushed down, there must be no friction and the

spring tension must bring it back to its normal position.

If necessary, lubricate joints and hinges.

If necessary, adjust or tighten them.

Make sure there are no lea ks or occlusions in the circuit .

The coolant level in the expansion tank must be included

between t he

Top up, if necessar y.

Check the proper functio ni ng of all the devices.

Change the bulbs or intervene in case of failure. 49 ÷ 56

“

MIN

”

and

“

MAX

”

markings.

24, 25, 43

24, 25

47

27

44

—

—

23

26

use and maintenance Area 51

29

Page 30

67$57,1*

Exhaust gases contain carbon

Avoid starting the vehicle in closed or

badly-ventilated rooms.

The non-observance of this warning

may cause loss of consc iousness or

even lead to death by asphyxia.

Do not get o n the vehicle for the star ting.

ELECTRIC STARTING

◆

◆

◆

30

monoxide, which is extremely

noxious if inhaled.

Position the vehicle on the centre stand.

Make sure that the light switch (1) is in

position“

j

is in position “

”.

•

Make sure that th e dimmer s witch (2 )

use and maintenance Area 51

”.

◆

Turn the ignition switch (3) to position

”.

“

When the ignition key is rotated

stroke oil reserve warning light “” (7)

and the entire display (8) come on for a

few seconds, thus checking the oper ation of the system. If after this check the

2-stroke oil reserve warning light “

remains on, provide for topping up, see

p. 24 (2 STROKE OIL TANK).

◆

◆

to position “

warning light “

Lock at least one wheel, by pulling a

brake lever (4).

If this operation is not carried out, the

start relay receives no current and therefore the engine does not start.

Press the start push button “” (5) without accelerating, then release it as soon

as the engine starts.

”, the low fuel

” (6), the 2-

◆

If the starting is carried out with cold engine, rotate the cold start lever “

upwards.

Avoid pressing the start push

starter.

◆

”

gases and fuel consumption, warm the

engine up by running at slow speed for

the first miles.

◆

button “

running: this may damage the

Do not accelerate and pull the brake levers at the same time until you move off.

Do not start abruptly when the

engine is still cold.

To limit the emission of exhaust

Once the engine ha s warmed up, see p.

15 (Coolant temperat ure indicator “

rotate the cold start lever “” (9) downwards.

” (5) when the engine is

” (9)

”),

Page 31

KICK START

For the kick start, proceed as follows:

◆

Position the vehicle on the centre sta nd.

◆

Move to the left side of the vehicle.

◆

Make sure that the light switch (1) is in

position“

◆

j

is in position “

◆

Turn the ignition switch (3) to position

“”.

stroke oil reserve warning light “” (7)

and the entire display (8) come on for a

few seconds, thus checking the oper ation of the system. If after this check the

2-stroke oil reserve warning light “

remains on, provide for topping up, see

p. 24 (2 STROKE OIL TANK).

”.

•

Make sure that the dimmer swi tch (2)

When the ignition key is rotated

to position “

warning light “

”.

”, the low fuel

” (6), the 2-

◆

To avoid losing control of the vehicle during the starting, lo ck both wheels by

putting on the brake levers (4).

◆

STARTING AFTER A LONG PERIOD

OF INACTIVITY

After a long period of inactivity, proceed as

follows:

◆

”

◆

Do not push d ow n t he ki c k st a rt er with the engine on.

Push down the kick starter (10) with your

right foot, releasing it immediately.

If necessary, repeat the operation until

the engine starts.

Carry out the first five operations prescribed for the electric starting, see p. 30

(ELECTRIC STARTING).

Make the starter run for about 10 seconds, in order to ensure the filling up of

the float chamber.

To start the engine:

◆

Rotate the cold start lever “” (9) upwards.

◆

Slightly open the throttle, then carry out

the electric starting pro cedure (or KICK

START).

use and maintenance Area 51

31

Page 32

'(3$5785( $1' '5,9(

This vehicle is not suitable for

persons, properties and/or the vehicle

due to the imprope r use of the veh icle itself.

Release the throttle grip (pos. A), put on

the rear brake, then mo ve the vehi cle dow n

the stand.

Get on the vehicle, keeping at least one

foot on the ground in order not to lose balance.

offroad use:

responsibility for any damage to

Properly adjust the inclination of

the rear-view mirrors.

DSULOLD

declines an y

Avoid opening and closing the

cidentally lose control of the vehicle.

If you have to b rake, close the t hrottle

and put on both brakes in order t o obtain uniform deceleration, properly exerting pressure on the braking parts.

By putting on the front brake only or the

rear brake only, you reduce the braking

force considerably, thus running the

risk of locking one wheel and consequently losing grip.

Before beginning to turn, slow down or

brake driving at moderate and constant

speed or accelerating slightly; avoid

braking at the last moment: it would be

very easy to skid.

If the brakes are operated continuously

on downhill stretches, the friction surfaces can overheat, thus reducing the

braking efficiency.

Never drive with the engine off!

throttle grip repeatedly and continuously, so that you do not ac-

Uneven roads, rails, manhole covers,

indications painted on the road surface,

building site metal plates be come rather

slippery by rain. For this reason all

these obstacles have to be carefully

avoided, driving smoothly and bending

the vehicle as little as possible.

Always use the turn indicators timely

when you intend to change lane or direction, avoiding sharp and dangerous

movements.

engine, this means that the 2 stroke oil

reserve is being used; in this case, top

up the mixer oil tank, see p. 24 (2

STROKE OIL TANK).

In case of wet groun d or scarce wheel

grip (snow, ice, mud, etc.), drive slowly,

avoiding sudden brakings or manoeuvres that could make you lose grip and

fall down.

per side) and blinks, stop the engine

and check the coolant level, see p. 26

(COOLANT).

Pay the utmost attention to any

obstacle or variation of the

ground.

If the 2 stroke oil reserve warning light “

ing the normal functioning of th e

If the lit area on the coolant temperature indicator scale “

reaches the red mark (right up-

” (1) comes on dur-

” (2)

To leave, release the brake lever and accelerate by gently rotating the throttle grip

(pos. B); the vehicle will start moving.

use and maintenance Area 51

32

Page 33

5811,1*,1

P

U

S

H

2

1

ter running-in” of t he REGULAR SERV ICE INTERVALS CHART, see p. 35, in

order to avoid hurting yourself or other

people and/or damaging the vehicle.

The running-in of the engine is primary to

ensure its correct functioning and its correct

functioning. If possible, drive on hilly road s

and/or roads with many bends, so that the

engine, the suspensions and the brakes

undergo a more effective running-in.

For the first 500 km, keep to the following

indications:

0-300 km

Do not keep the throttle grip open more

than one ha lf for long st retches.

300-500 km

Do not keep the throttle grip open more

than three-fourths for long stretches.

67233,1*

◆

Remember: 1 mile = 1.6 km

1 km = 0.625 miles

After the first 50 0 kilometres,

carry out the checki ng operations indicat ed in th e colum n “Af-

If possible, avoid stopping

abruptly, slowing down suddenly

and braking at the last moment.

Release the throttle grip (pos. A) and

gradually put on the brakes to stop the

vehicle.

◆

In case of a brief stop, keep at least one

brake on.

3$5.,1*

Park the vehicle on firm and flat

Neither lean the vehicle against walls,

nor lay it on the ground.

Make sure that the vehicle and especially its red-hot parts do not represent a

danger for persons and children.

Do not leave the vehicle unattended

when the engine is on or the key is inserted into the ignition switch.

Do not sit on the vehicle whe n the stand

is down.

ground, to prevent it from falling

down.

◆

Stop the vehicle, see beside (STOPPING).

◆

Turn the ignition switch (1) to position

“”.

◆

Position the vehicle on the stand, see

p. 34 (POSITIONING THE VEHICLE ON

THE STAND).

since it is equipped with an automatic

closing system.

◆

It is not necessary to close the

fuel tap when the engine is off,

Never leave the key in the igni-

tion switch.

Lock the steering, see p. 20 (STEERING

LOCK) and extract the key (2).

use and maintenance Area 51

33

Page 34

326,7,21,1* 7+( 9(+,&/(

21 7+( 67$1'

Carefully read p. 33 (PARKING).

CENTRE STAND

◆

Grasp the left handgrip and the rear grab

rail (1).

◆

Push down the stand lever (2).

Make sure that the vehicle is stable.

68**(67,216

72 35(9(17 7+()7

NEVER leave the ignition key inserted and

always use the steering lock.

Park the vehicle in a safe place, pos s ibl y in

a garage or a protected place.

If possible, use the appropriate aprilia

“Body-Guard” armored cable

ditional anti-theft device.

Make sure that all documents are in order

and the road tax has been paid.

, or an ad-

-

Write down your personal data and telephone number in the sp ace p rovide d in t his

page, to facilitate the identification of the

owner in case of finding after theft.

SURNAME:................................................

NAME:........................................................

ADDRESS:.................................................

...................................................................

TELEPHONE NO.:.....................................

use and maintenance Area 51

34

ten on the use/maintenance manual.

Very often stolen vehicles are

identified thanks to the data writ-

Page 35

0$,17(1$1&(

Before beginning any mai nte-

gine, extract the key from the ignition

block, wait until the engine and the exhaust system have coole d down and if

possible lift the vehicle by means of the

proper equipment, on firm and flat

ground. Keep away from the red-hot

parts of the engine and of the exhaust

system, in order to avoid burns.

The vehicle is made up of n ot edible

parts. Never bite, suck, chew or swallo w

any part of the vehicle for any reason.

erations reversing their order.

Ordinary maintenance operations can usually be carried out by the user, but sometimes a basic knowledge of mechanic s a nd

specific tools are required.

If you need assistance or technical advice,

consult your aprilia Official Dealer, who

can ensure you prompt and accurate servicing. After any maintenance operatio n,

carry out the “Preliminary checking operations”, see p. 29 (PRELIMINARY CHECKING OPERATIONS).

nance operation or any inspection of the vehicle, stop the en-

If not expressly indicated otherwise, for the reassembly of the

units repeat the disassembly op-

Remember: 1 mile = 1.6 km

1 km = 0.625 miles

5(*8/$5 6(59,&( ,17(59$/6 &+$57

COMPONENT

Rear shock absorber C C

Battery/electrolyte level C C

Spark plug C C S

Carburettor - idling R C

Driving belt C

Steering column bearings C C

Wheel bearings C

Removal of deposits from the exhaust P

Air cleaner C P

Accelerator operation C C

Brake locking operation C C

Braking systems C C

Stop light switch C

Brake fluid every year: S

Brake fluid C

Coolant every 2000 km: C / every 2 years : S

2 stroke oil every 500 km: C

Transmission oil S

Light direction - operation C

Tyres - inflation pressure every month: R

Wheels/tyres C

Nut, bolt, screw tightening C C

Front and rear suspension C C

2 stroke oil reserve warning light C C

Fuel pipe C

Mixer oil pipe C C

Front and rear brake pad wear C every 2000 km: C

C

= check, clean, adjust, lubricate or change, if necessary;

P

= clean;S = change;R = adjust. Carry out the maintenance operations more frequently if you

use the vehicle in rainy and dusty areas or on uneven ground.

Have maintenance operations on the components indicated by

Official Dealers ONLY.

After running-in

(500 km)

Every 4000 km

or 8 months

every 3000 km

or 6 months: C

■■■

carried out by

use and maintenance Area 51

Every 8000 km

or 16 months

every 12000 km

or 2 years: S

DSULOLD

35

Page 36

,'(17,),&$7,21 '$7$

It is a good rule to w rite down the frame

and engine numbers in the space provided

in this manual.

The frame number can be used for the

purchase of spare parts.

ENGINE NUMBER

The engine number is stamped near the

transmission oil filling cap.

Engine no.

FRAME NUMBER

The frame number is stamped on the right

side of the steering column plate. To read

it, it is necessary to remove the front inspection cover, see p. 46 (REMOVING

THE FRONT INSPECTION COVER).

Do not alter the i dentification

cur severe penal and adminis trative

sanctions. In particular, th e a lteration of

the frame number results in the immed iate invalidity of the guarantee.

36

numbers if you do not want to in-

use and maintenance Area 51

Frame no.

Page 37

$,5 &/($1(5

Do not use petrol or inflammable

Carefully read p. 35 (MAINTENANCE).

Check the conditions of the air cleaner and

clean it monthly or every 4000 km, d epending on the conditions in which the vehicle is

used.

If the vehicle is us ed on dusty or wet road s,

the cleaning operations and any replacement should be carried out more frequently.

To clean the filtering element it is necessary to remove the whole filter casing from

the vehicle.

solvents to wash the air cleaner,

in order to avoid fires or explosions.

Remember: 1 mile = 1.6 km

1 km = 0.625 miles

REMOVAL

◆

Remove the left inspection cover, see

p. 46 (REMOVING THE RIGHT AND

LEFT INSPECTION COVERS).

◆

Insert the spanner in the appropriate

hole (1), whi le uns crewing and removing

the screw (2) with the relevant washer.

rectly.

◆

◆

◆

Upon reassembly, position the

rear brake cable eyelet (3) cor-

Unscrew and remove the screw (4 ) with

the relevant washer.

Loosen the screw (5) of the air manifold

clamp.

Grasp the air manifold in correspondence with the clamp and pull it, thus removing the wh ole air cleaner casing.

CLEANING THE AIR FILTER

◆

Unscrew the three screws (6).

◆

Remove the fi lter ca se co ver (7 ) and extract the filtering element (8).

◆

To clean the filtering element use clean,

non-inflamm able solvents or solvent s

with high volatility point, then let it dry

thoroughly.

◆

Apply a filter oil or a thick oil (SAE 80W-

90) on the whole surface of the filtering

element, then squeeze it to eliminate the

oil in excess.

◆

The filter must be well impregnated, though not dripping.

Clean the inside of the filter ca sin g cov er

(7) and of the filter ca sing (9) with a cloth.

use and maintenance Area 51

37

Page 38

&+(&.,1*

7+( 75$160,66,21 2,/ /(9(/

In case of oil leaks or malfunc-

DO NOT DISPOSE OF THE TRAN SMISSION OIL IN THE ENVIRONMENT.

Carefully read p. 35 (MAINTENANCE).

38

tions, contact your

cial Dealer.

Remember: 1 mile = 1.6 km

1 km = 0.625 miles

use and maintenance Area 51

DSULOLD

Offi-

To check the t ransmission oi l level, carry

out the following op erations every 3000 km

or every 6 mo nths:

◆

Drive for a few miles until the engine

reaches the normal runni ng te mperatu re,

see p. 15 (Coolant temperature indicator

”), then stop it.

“

◆

Position the vehicle on the centre sta nd.

◆

Put a graduated container (1) with at

least 120 cm! capacity under the drain

plug (2).

◆

Unscrew the filling cap (3) and the oil

drain plug (2).

◆

Let all the oil flow out of the oil pan.

◆

Measure the quantity and if it is less than

110 cm!, top up by adding the lacking

quantity, see p. 64 (LUBRICANT

CHART).

◆

Tighten the drain plug (2).

◆

Provide for fillin g u p, us ing the oil co lle cted into the graduated container (1).

◆

Tighten the filling cap (3).

Tighten the fill ing cap and the

Periodically che ck that there are no

leaks in correspondence with the oil

pan cover seal.

Do not use the vehicle with insufficient

lubrica tion or wi th cont aminat ed or un suitable lubricants, since this would accelerate the wear of the moving parts

and may also cause irreparable failures.

drain plug thoroughly and make

sure that there are no oil leaks.

Page 39

&+$1*,1*

7+( 75$160,66,21 2,/

In case of oil leaks or malfunc-

DO NOT DISPOSE OF THE TRANSMISSION OIL IN THE ENVIRONMENT.

Put it in a sealed container and take it to

the filling station where you u sua lly buy

it or to an oil salvage center.

Carefully read p. 35 (MAINTENANCE).

To ensure the efficiency and lon g life of the

vehicle, it is ne ces s ary to c hange the oil after the first 500 km and successively every

12000 km or every 2 years.

tions, contac t your

cial Dealer.

Remember: 1 mile = 1.6 km

1 km = 0.625 miles

DSULOLD

Offi-

Proceed as follows:

◆

Drive for a few miles until the engine

reaches the normal runnin g temperature ,

see p. 15 (Coolant temperature indicator

”), then stop the engine.

“

◆

Position the vehicle on the centre stand.

◆

Put a graduated container (1) with at

least 120 cm! capacity under the drain

plug (2).

◆

Unscrew the filling cap (3) and the oil

drain plug (2).

◆

Let all the oil flow out of the oil pan.

◆

Tighten the drain plug and add 110 cm

of oil, see p. 64 (LUBRICANT CHART).

◆

Tighten the filling cap (3).

Tighten the fillin g cap and the

Periodically ch eck that there are no

leaks in correspondence with the oil

pan cover seal.

Do not use the vehicle with insufficient

lubrication or with contaminated or unsuitable lubricants, since this would accelerate the wear of the moving parts

and may also caus e i rre parab le failures.

!

drain plug thoroughly and make

sure that there are no oil leaks.

use and maintenance Area 51

39

Page 40

)5217 :+((/

DISASSEMBLY

Carefully read p. 35 (MAINTENANCE).

While disassembling the wheel,

pads.

To disassemble the front wheel, proceed

as follows:

◆

200 x 200 mm.

◆

40

be careful not to damage the

brake pipe, the disc and the

Position the vehicle on the centre stand.

Prepare a 190 mm high support,

the base of which must measure

Place the support under the vehicle and

a spongy cloth between the m, so that the

front wheel can move freely and the vehicle cannot fall down.

use and maintenance Area 51

◆

◆

◆

◆

Wheel nut (4) driving torque:

120 Nm (12 kgm).

◆

be able to reassemble it correctly.

Make sure that the vehicl e is stable.

Remove the front brake caliper, see

p. 43 (REMOVING THE FRONT AND

REAR BRAKE CALIPERS).

Introduce the screwdriver in the slot (1),

lever and remove the cover (2).

Lock the wheel pin (3) by means of a

spanner.

Unscrew and remove the nut (4), taking

the washer.

Push the wheel pin (3), by carefully acting on the threaded end a nd u si ng a rubber hammer if necessary.

Check the arrangement of the

odometer control (5), in order to

◆

Support the front wheel and extract the

wheel pin (3) manually.

◆

◆

◆

Do not force the odometer control cable.

Move the wheel rightwards (in the travelling direction).

Disconnect the odometer control (5).

Remove the wheel.

Page 41

REASSEMBLY

Carefully read p. 35 (MAINTENANCE).

While reassembling the wheel, be

To reassemble the front wheel, proceed as

follows:

pin (3) and a greater quantity of grease

on the dust cover (6) of the od ometer

control (5), see p. 64 (LUBRICANT

CHART).

◆

careful not to damage the brake

pipe, the disc and the pads.

Uniformly apply a moderate

quantity of grease on t he wheel

Correctly position the odometer control

(5) with the relevant seat (7) inserted in

the antirotation pin (8), while partially introducing the wheel pin (3) from the left

side (travelling direction).

◆

Make sure that the wheel hub (9) is perfectly clean, either inside and outside.

Upon reassembly, do not force

hub (9) from damaging the teeth (10).

◆

◆

◆

Wheel nut (4) driving torque:

120 Nm (12 kgm).

the wheel against the odometer

control (5), to prevent the wheel

Bring the wheel near the end of the suspension arm, raise it and insert the wh eel

pin (3) completely.

Rotate the wheel moderately and try to

find the point in which i t can be fitted

completely, with the wheel hub (9) correctly coupled with the teeth (10).

Insert the washer, lock t he ro tati on o f th e

wheel pin (3) by means of a spanner,

screw and tighten the nut (4).

◆

Put back the cover (2) and fit it manually.

◆

Remove th e support from under the v ehicle.

After reassembly, pull the front

the braking system.

Check the wheel centering.

Have the driving torques, centering and

balancing of the wheel checked by your

DSULOLD

accidents that may be harmful for you

and/or other people.

brake lever repeatedly and

check the correct functioning of

Official Dealer, in order to avoid

use and maintenance Area 51

41

Page 42

5($5 :+((/

DISASSEMBLY

Carefully read p. 35 (MAINTENANCE).

◆

Remove the exhaust silencer, see p. 45

(REMOVING THE EXHAUST SILE NCER).

◆

Insert the screwdriver in the slot (1), lever and remove the cover (2).

of the wheel.

◆

42

To unscrew the wheel nut (3), it

is necessary to lock the rotation

Pull the rear brake lever (4) completely,

then put a small piece of cardboard (5)

on the grip and keep th e rea r brak e lever

pulled by holding it against the grip by

means of a plastic band (6).

use and maintenance Area 51

◆

Loosen the wheel nut (3).

Wheel nut (3) driving torque:

110 Nm (11 kgm).

◆

Remove the plastic band (6) and take

the piece of cardboard (5).

◆

Release the rear brake lever.

◆

Remove the rear br ak e caliper , s ee p .43

(REMOVING THE FRONT AND REAR

BRAKE CALIPERS).

◆

Unscrew and remove the wheel nut (3)

and the wash er.

grease on the wheel pin, see p. 64 (LUBRICANT CHART) and replace the

wheel nut (special type) with a new one.

◆

Upon reassembly, uniformly apply a moderate quantity of

Withdraw the wheel.

Use

the braking system.

Check the wheel centering.

Have the driving torques, centering and

balancing of the wheel checked by your

DSULOLD

accidents that may be h armful for y ou

and/or other people.

DSULOLD

only.

After reassembly, pull the rear

brake lever repeatedly and

check the correct functioning of

Official Dealer, in order to avoid

Genuine Spare Parts

Page 43

&+(&.,1*

7+( %5$.( 3$' :($5

Carefully read p. 24 (BRAKE FLUID recommendations), p. 25 (DISC

BRAKES), p. 35 (MAINTENANCE).

are valid for both.

Check the brake pad wear after the fir st

500 km and successively every 2000 km.

The wear of the brake pads depends on

the use, on the kind of drive and on the

road. The wear will be grea ter when the v ehicle is driven on dirt y or wet roads.

To carry out a rapid checking of the wear of

the front pads, proceed as follows:

◆

◆

If the thickness of th e friction material

(even of one pad only) has reduced to

about 1 mm, replace both pads.

Remember: 1 mile = 1.6 km

1 km = 0.625 miles

The following inf ormation refer

to a single braking system, but

Remove the involved brake caliper, see

beside (REMOVING THE FRONT AND

REAR BRAKE CALIPERS).

Carry out a visual check on the pads.

Have the pads changed by your

DSULOLD

Official Dealer.

5(029,1* 7+( )5217 $1' 5($5

%5$.( &$/,3(56

Carefully read p. 35 (MAINTENANCE).

Upon disassembly, take care not

are valid for both.

◆

◆

◆

Brake caliper screw (1) driving torque:

25 Nm (2.5 kgm).

to damage the brake pipe, disc

and pads.

The following information refer

to a single braking system, but

Position the vehicle on the centre stand.

Rotate the wheel manually, so that the

space between two spokes of the rim coincides with the brake caliper.

Unscrew and remove the two screws (1 ).

Never pull the rear brake lever

may go out of their seats, thus causing

the outflow of the brake fluid.

In this case consult y our

Dealer, who will carry out the proper

maintenance operation.

◆

the braking system.

after removing the brake caliper,

otherwise the caliper pistons

DSULOLD

Remove the brake calip er (2), by c arefully withdrawing it from the brake disc.

After reassembly, pull the rear

brake lever repeatedly and

check the correct functioning of

Official

use and maintenance Area 51

43

Page 44

&+(&.,1* 7+( 67((5,1*

Carefully read p. 35 (MAINTENANCE).

Every now and then it is a dvisabl e to che ck

the steering, in order to verify if ther e are

slacks.

To check the steering it is necessary to:

◆

Position the vehicle on the centre stand.

200 x 200 mm.

◆

44

Prepare a 190 mm high support,