Amana GUIA090A50, GUIA115A40, GUIA045A30, GUIA090A30, GUIA115A50 Service Instructions Manual

...

Service

A

t

Instructions

40" 80% Gas Furnaces

GUIA, GCIA, GUIB, GCIB, GUIC, GCIC

GUID, GUIS, GCIS, GUIV & Accessories

Model and Manufacturing

numbers listed on page 4&5

This manual is to be used by qualified HVAC

technicians only. Amana does not assume

any responsibility for property damage or

personal injury for improper service

procedures done by an unqualified person.

®

Heating n Air Conditioning

higher standard of comfor

RS6620002

Revision 2

December 1998

INDEX

Important Safety Information .................................................................................... 3

Product Identification................................................................................................ 4-15

Furnace Specifications............................................................................................. 16-26

Blower Performance Specifications.......................................................................... 27-34

Combustion and Ventilation air ................................................................................ 35-37

Product Design ........................................................................................................ 38-46

System Operation .................................................................................................... 47-64

Polarization and Phasing ......................................................................................... 65

Scheduled Maintenance........................................................................................... 66-67

Servicing .................................................................................................................. 68-89

Wiring Diagrams ...................................................................................................... 90-97

Schematics.............................................................................................................. 98-106

REV. 2 Added new models to manual

2 Rev. 2

IMPORTANT INFORMATION

Pride and workmanship go into every product to provide our customers with quality products. It is possible, however, that

during its lifetime a product may require service. Products should be serviced only by a qualified service technician who

is familiar with the safety procedures required in the repair and who is equipped with the proper tools, parts, testing

instruments and the appropriate service manual. REVIEW ALL SERVICE INFORMATION IN THE APPROPRIATE SERVICE MANUAL BEFORE BEGINNING REPAIRS.

IMPORTANT NOTICES

IF REPAIRS ARE ATTEMPTED BY UNQUALIFIED PERSONS,

WARNING

CAUTION

YOUR OWN PRODUCT, YOU ASSUME RESPONSIBILITY FOR ANY PERSONAL INJURY

OR PROPERTY DAMAGE WHICH MAY RESULT.

DANGEROUS CONDITIONS (SUCH AS EXPOSURE TO ELECTRICAL SHOCK) MAY RESULT. THIS MAY CAUSE SERIOUS INJURY

OR DEATH.

AMANA WILL NOT BE RESPONSIBLE FOR ANY INJURY OR

PROPERTY DAMAGE ARISING FROM IMPROPER SERVICE OR

SERVICE PROCEDURES. IF YOU PERFORM SERVICE ON

To locate an authorized servicer, please consult your telephone book or the dealer from whom you purchased this

product. For further assistance, please contact:

CONSUMER AFFAIRS DEPT. OR 1-319-622-5511

AMANA HEATING & AIR CONDITIONING CALL and ask for

AMANA, IOWA 52204 Consumer Affairs

If outside the United States contact:

AMANA HEATING & AIR CONDITIONING

A TTN: INTERNATIONAL DIVISION

AMANA, IOWA 52204, USA

T elephone: (319) 622-551 1

Facsimile: (319) 622-2180

RECOGNIZE SAFETY SYMBOLS, WORDS AND LABELS

DANGER

WARNING

DANGER - Immediate hazards which WILL result in

severe personal injury or death.

WARNING - Hazards or unsafe practices which COULD

result in severe personal injury or death.

CAUTION

CAUTION - Hazards or unsafe practices which COULD

result in minor personal injury or product or property damage.

3 Rev. 2

PRODUCT IDENTIFICATION

The model and manuacturing number are used for positive identification of component parts used in manufacturing. At which

time engineering and manufacturing changes take place where interchangeability of components are affected, the

manufacturing number will change.

It is very important to use the model and manufacturing numbers at all times when requesting service or parts information.

MODEL M/N

GUIA045A30 P1177301F

GUIA070A30 P1177302F

GUIA070A40 P1177303F

GUIA090A30 P1177304F

GUIA090A50 P1177305F

GUIA115A40 P1177306F

GUIA115A50 P1177307F

GUIA140A50 P1177308F

GUIA045B30 P1206601F

GUIA070B30 P1206602F

GUIA070B40 P1206603F

GUIA090B30 P1206604F

GUIA090B50 P1206605F

GUIA115B40 P1206606F

GUIA115B50 P1206607F

GUIA140B50 P1206608F

GUIA045CA30 P1207201F

GUIA070CA30 P1207202F

GUIA070CA40 P1207203F

GUIA090CA30 P1207204F

GUIA090CA50 P1207205F

GUIA115CA40 P1207206F

GUIA115CA50 P1207207F

GUIA140CA50 P1207208F

GCIA045A30 P1177401F

GCIA070A30 P1177402F

GCIA070A40 P1177403F

GCIA090A30 P1177404F

GCIA090A50 P1177405F

GCIA115A40 P1177406F

GCIA115A50 P1177407F

GCIA140A50 P1177408F

GCIA045CX30 P1207301F

GCIA070CX30 P1207302F

GCIA070CX40 P1207303F

GCIA090CX30 P1207304F

GCIA090CX50 P1207305F

GCIA115CX40 P1207306F

GCIA115CX50 P1207307F

GCIA140CX50 P1207308F

MODEL M/N MODEL M/N

GUIB045A30 P1186401F

GUIB070A30 P1186402F

GUIB070A40 P1186403F

GUIB090A30 P1186404F

GUIB090A50 P1186405F

GUIB115A40 P1186406F

GUIB115A50 P1186407F

GUIB140A50 P1186408F

GUIB045B30 P1206801F

GUIB070B30 P1206802F

GUIB070B40 P1206803F

GUIB090B30 P1206804F

GUIB090B50 P1206805F

GUIB115B50 P1206807F

GUIB045CX30 P1207701F

GUIB070CX30 P1207702F

GUIB070CX40 P1207703F

GUIB090CX30 P1207704F

GUIB090CX50 P1207705F

GUIB115CX50 P1207707F

GCIB045A30 P1186501F

GCIB070A30 P1186502F

GCIB070A40 P1186503F

GCIB090A30 P1186504F

GCIB090A50 P1186505F

GCIB115A40 P1186506F

GCIB115A50 P1186507F

GCIB140A50 P1186508F

GUIC045CA30 P1207601F

GUIC070CA30 P1207602F

GUIC070CA40 P1207603F

GUIC090CA30 P1207604F

GUIC090CA50 P1207605F

GUIC115CA40 P1207606F

GUIC115CA50 P1207607F

GUIC140CA50 P1207608F

GUIC045CX30 P1207401F

GUIC070CX30 P1207402F

GUIC070CX40 P1207403F

GUIC090CX30 P1207404F

GUIC090CX50 P1207405F

GUIC115CX40 P1207406F

GUIC115CX50 P1207407F

GUIC140CX50 P1207408F

GUIC045DA30 P1222501F

GUIC070DA30 P1222502F

GUIC070DA40 P1222503F

GUIC070DA40 P1222509F

GUIC090DA30 P1222504F

GUIC090DA50 P1222505F

GUIC115DA40 P1222506F

GUIC115DA50 P1222507F

GUIC140DA50 P1222508F

GUIC045DX30 P1222601F

GUIC070DX30 P1222602F

GUIC070DX40 P1222603F

GUIC070DX40 P1222609F

GUIC090DX30 P1222604F

GUIC090DX50 P1222605F

GUIC115DX40 P1222606F

GUIC115DX50 P1222607F

GUIC140DX50 P1222608F

GUIC045DA30 P1226601F

GUIC070DA30 P1226602F

GUIC070DA40 P1226603F

GUIC070DA40 P1226609F

GUIC090DA30 P1226604F

GUIC090DA50 P1226605F

GUIC115DA40 P1226606F

GUIC115DA50 P1226607F

GUIC140DA50 P1226608F

GUIC140DA50 P1226612F

GUIC045DX30 P1226701F

GUIC070DX30 P1226702F

GUIC070DX40 P1226703F

GUIC070DX40 P1226709F

GUIC090DX30 P1226704F

GUIC090DX50 P1226705F

GUIC115DX40 P1226706F

GUIC115DX50 P1226707F

GUIC140DX50 P1226708F

GUIC045DX30 P1226801F

GUIC070DX30 P1226802F

GUIC070DX40 P1226803F

GUIC090DX30 P1226804F

GUIC090DX50 P1226805F

GUIC115DX40 P1226806F

GUIC115DX50 P1226807F

GUIC140DX50 P1226808F

4 Rev. 2

PRODUCT IDENTIFICATION

The model and manuacturing number are used for positive identification of component parts used in manufacturing. At which

time engineering and manufacturing changes take place where interchangeability of components are affected, the

manufacturing number will change.

It is very important to use the model and manufacturing numbers at all times when requesting service or parts information.

MODEL M/N MODEL M/N MODEL M/N

GCIC045CX30 P1207501F

GCIC070CX30 P1207502F

GCIC070CX40 P1207503F

GCIC090CX30 P1207504F

GCIC090CX50 P1207505F

GCIC115CX40 P1207506F

GCIC115CX50 P1207507F

GCIC140CX50 P1207508F

GCIC045DX30 P1222701F

GCIC070DX30 P1222702F

GCIC070DX40 P1222703F

GCIC070DX40 P1222709F

GCIC090DX30 P1222704F

GCIC090DX50 P1222705F

GCIC115DX40 P1222706F

GCIC115DX50 P1222707F

GCIC140DX50 P1222708F

GUID045CA30 P1212401F

GUID070CA30 P1212402F

GUID070CA40 P1212403F

GUID090CA30 P1212404F

GUID090CA50 P1212405F

GUID115CA50 P1212407F

GUID045CA30 P1220601F

GUID070CA30 P1220602F

GUID070CA40 P1220603F

GUID090CA30 P1220604F

GUID090CA50 P1220605F

GUID115CA50 P1220607F

GUID045CX30 P1212501F

GUID070CX30 P1212502F

GUID070CX40 P1212503F

GUID090CX30 P1212504F

GUID090CX50 P1212505F

GUID115CX50 P1212507F

GUID045CX30 P1220501F

GUID070CX30 P1220502F

GUID070CX40 P1220503F

GUID090CX30 P1220504F

GUID090CX50 P1220505F

GUID115CX50 P1220507F

GUID045DA30 P1222801F

GUID070DA30 P1222802F

GUID070DA40 P1222803F

GUID070DA40 P1222809F

GUID090DA30 P1222804F

GUID090DA50 P1222805F

GUID115DA50 P1222807F

GUID045DX30 P1222901F

GUID070DX30 P1222902F

GUID070DX40 P1222903F

GUID070DX40 P1222909F

GUID090DX30 P1222904F

GUID090DX50 P1222905F

GUID115DX50 P1222907F

GUID045DA30 P1226901F

GUID070DA30 P1226902F

GUID070DA40 P1226903F

GUID070DA40 P1226909F

GUID090DA30 P1226904F

GUID090DA50 P1226905F

GUID115DA50 P1226907F

GUID090DA50 P1226910F

GUID115DA50 P1226911F

GUID045DX30 P1227001F

GUID070DX30 P1227002F

GUID070DX40 P1227003F

GUID070DX40 P1227009F

GUID090DX30 P1227004F

GUID090DX50 P1227005F

GUID115DX50 P1227007F

GUIS070CA35 P1211003F

GUIS090CA30 P1211004F

GUIS090CA50 P1211005F

GUIS115CA50 P1211007F

GUIS140CA50 P1211008F

GUIS070CX35 P1211103F

GUIS090CX50 P1211105F

GUIS115CX50 P1211107F

GUIS070DA35 P1223003F

GUIS090DA30 P1223004F

GUIS090DA50 P1223005F

GUIS115DA50 P1223007F

GUIS140DA50 P1223008F

GUIS070DX35 P1223103F

GUIS090DX30 P1223104F

GUIS090DX50 P1223105F

GUIS115DX50 P1223107F

GUIS070DA35 P1227103F

GUIS090DA30 P1227104F

GUIS090DA50 P1227105F

GUIS115DA50 P1227107F

GUIS140DA50 P1227108F

GUIS070DX35 P1227203F

GUIS090DX30 P1227204F

GUIS090DX50 P1227205F

GUIS115DX50 P1227207F

GCIS070CX35 P1211203F

GCIS090CX50 P1211205F

GCIS070DX35 P1223203F

GCIS090DX50 P1223205F

GCIS070DX35 P1227303F

GCIS090DX50 P1227305F

GUIV070DX40 P1221103F

GUIV090DX50 P1221105F

GUIV115DX50 P1221107F

GUIV140DX50 P1221108F

GUIV070DX40 P1227403F

GUIV090DX50 P1227405F

GUIV115DX50 P1227407F

GUIV140DX50 P1227408F

5 Rev. 2

PRODUCT IDENTIFICATION

The model and manuacturing number are used for positive identification of component parts used in manufacturing. At which

time engineering and manufacturing changes take place where interchangeability of components are affected, the

manufacturing number will change.

It is very important to use the model and manufacturing numbers at all times when requesting service or parts information.

FURNACE ACCESSORY KITS

FTK__ Furnace Twinning Kit (Not for use with GUIS/GCIS/GUIV Furnace)

HANG__ High Altitude Nat Gas Kit

HALP__ High Altitude LP Kit

LPTK__ LP Conversion Kit

HAC1PS__ High Altitude Press Switch Kit

Note: See servicing section for available kits and usage.

ADDITIONAL FURNACE ACCESSORIES

ACG_ Accomodator (Filter Cabinet)

CVK_ Common Vent Kit

DEHUM_ Dehumidistat

EAC_ Electronic Air Cleaner

EFR_ External Filter Rack Kit

HR _ Horizontal Filter Housing

MAC_ Media Air Cleaner

MAF_ Media Air Filter (Replacement Filter for MAC_)

Note: For additional accessory kits listed above, see product identification

section pages 12, 13, 14 and 15 for available accessories and usage.

6 Rev. 2

PRODUCT IDENTIFICATION

G U I A 045 C A 50

Product Type

G: Gas Furnace

Supply Type

U: Upflow/Horizontal

C: Counterflow/Horizontal

Furnace Type

I: Induced Draft (80%)

Model Family

A/C : Air Command 80 SSE cat 1

B/D: Air Command 80 SV cat 1

S: Air Command 80 SSE II cat 1

V: Air Command 80 SSE IIQ cat 1

* This model identifier not used on early models.

Airflow Capability

25: 2.5 Tons

30: 3.0 Tons

35: 3.5 Tons

40: 4.0 Tons

50: 5.0 Tons

Additional Features *

A: Standard Unit

X: NOx Models

Design Series

A: Initial Design

B: Second Design Series

C: Third Design Series

D: Fourth Design Series

Nominal Input

045: 45,000 Btuh

070: 70,000 Btuh

090: 90,000 Btuh

115: 115,000 Btuh

140: 140,000 Btuh

7 Rev. 2

PRODUCT IDENTIFICATION

FOR YOUR SAFETY

READ BE F ORE OPERATI NG

WARNING:

explosion may result causing property

pers on al inju r y or

A. This appliance does not have a pilot. It is equipped

with an ignition device which automatically lights

the burner.

B.

BEFORE OPERATING

area for gas. Be sure to smell next to the floor

because some gas is heavier than air and will

settle on the floor.

WH AT TO DO IF YOU SMELL GAS

C. Use only your hand to push in or turn the gas control lever.

Never use tools. If the lever will not push in or turn by

hand, don't try to repair it, call a qualified service

technician. Force or attempted repair may result in a fire

or explosion.

D. Do not use this appliance if any part has been underwater.

Immediately call a qualified service technician to inspect

the appliance and to replace any part of the control

syst em and any gas control which has been underwater.

If you do not follow these instructions

damage,

loss of life.

try

to ligh t the burner by ha nd.

not

Do

Do not try to light any appliance.

Do not touch any electric switch;

do not use any phone in your building.

Immediately call your gas supplier from a neighbor's

phon e. Fol low the gas suppl ie r 's ins truc ti ons .

If you cannot reach your gas supplier,

call the fire department.

smell all around the appliance

LIRE AVANT DE METTRE

EN MA RCHELIRE

AVERTISSEMENT:

la let tre l es instruct ions da ns le pr ésent m anuel

risque de déclecher un incendie ou une explosion

ent raîna nt des d ammag es matériels, de s lésions

cor p o relle s ou l a perte de vi es hu m a ines.

Cet appareil ne comporte pas de veilleuse. Il est

A.

muni d'un dispositif d'allumage qui allume

automatiquement le brûleur. Ne

d'allumer le brûleur manuellement.

B. AVANT DE LE FAIRE FONCTIONNER,

renifler tout autour de l'appariel pour déceler

une odeur de gaz. Renifler près du plancher, car

certains gaz sont plus lourds que l'air et

peuvent s'accumuler au niveau du so.l

Quiconque ne respecte pas á

tenter

pas

QUE FAIRE S'IL Y A UNE ODEUR DE GAZ

Ne pas tenter d'allumer l'appariel

Ne toucher aucun interrupteur électri que;

n'utiliser aucun téléphone dans le bâtiment.

Appeler immédiatement le fournisseur de gaz

en employant le téléphone dún voisin.

Respecter à la lettr e les inst ructions du

C

qu'à la main; ne jamais emploer d'outil à cet effet

Si la manette reste coincée, ne pas tenter de la

réparer; appeler un technicien qualifié. Quiconque

tente de forcer la manette ou de la reparer peut

déclencher une explosion ou un incendie.

D.

dans l'eau, complètement ou en partie. Appeler un

technicien qualifié pour inspecter l'appareil et

remplacer tout partie du système de contrôle et

toute commande qui ont été plongés dans

fournisseur de gaz.

Si personne ne répond, appeler le service des

incendies.

Ne pousser ou tourner le levier d'admission du gaz

.

Ne pas se servir de cet appareil s'il a été plongé

l'eau.

.

OPERATING INSTRUCTIONS

1.

this label.

2. Set the thermostat to lowest setting.

3. Turn off all power to the appliance.

4. This appliance is equipped with an ignition

device which automatically lights the burner.

Do

5. Push the gas control lever to

Do

6. Wait five (5) minutes to clear out any gas. Then

smell for gas, including near the floor. If you

then smell gas,

in the safety information above

on this Label. If you don't smell

to next step.

7. Push gas control lever

to

8. R eplace access panel.

9. Turn on all electric

power to the appliance.

10.Set thermostat to desired setting.

11.If the appliance will not operate,

follow the instructions "To Turn

Off Gas To Appliance" and call your

service technician or gas company.

Read the safety information above on

STOP!

not

try to light the burner by hand.

not

force.

Follow

STOP!

.

"ON"

"OFF"

"B"

gas, go

GAS

INLET

ARRIVEE

DU GAZ

Position.

TO TURN OFF GAS TO APPLIANCE

1. Set the thermostat to lowest setting.

2. Turn off all electric power to the appliance

if service is to be perfo rm ed .

3. Push the gas control lever to

Do not force.

4. Replace control access panel.

"OFF"

.

Position.

ROBINET A GAZ

MANUEL, EN POS

"ON/MARCHE"

*

*

*

MANUAL GAS

LEVER SHOWN

IN ON POSITION

1

M

O

F

3

P

F

2

C

ON

*

MISE EN MARCHE

ARRETÊR!

1.

la portion supérieure de cette étiquette.

2. R égler le thermo stat à la tempér atur e la plus ba sse

.

3. Couper l'alimentation électrique de l'appareil.

4. Cet appareil ménager étant doté d'un système

d'allumage automatique, ne

allumer le brûleur manuellement.

5. Pousse le levier du contrôle du gaz à

position.

6. Attendre cinq (5) minutes pour laisser echapper tout le

gaz. Renifler tout autour de l'appareil, y compris près du

plancher, pour déceler une odeur de gaz. Si c'est le cas,

ARRETER!

sur la portion supérieure de cette étiquette.

*

S'il n'y a pas d'odeur de gaz, passer à l'étape suivanté.

*

7. Pousse le levier du contrôle du gaz à

position.

8. Remettre en place le panneau d'accés.

9. Mettre l'appareil sous tension.

10. Régler le thermostat à la température desirée.

*

11. Si l'appareil ne se met pas en marche, suiyre les

instructions intitulées. Comment coupler l'admission

de gaz de l'appereil et appeler un technicien

qualifié ou le fourrnisseur de gaz.

Lisez les instructions de sécurité sur

s

essayer à

pa

"OFF/ ARRET"

Passer à l'étape B des instructions de sécuritié

"ON/MARCHE"

POUR COUPER L'ADMISSION

DE GAZ DE L'APPAREIL

1. Ré gl er le therm ostat à la tem pérature la plus basse.

2. Couper l'alimenta tion électrique de l'appareil s'il

faut procéder à des opérations d'entretien.

3. Po usse le levier du contrôle du gaz à "OFF / ARRET"

position.

Ne pas forcer.

4. Re mettr e en place le pa nneau d'accès.

11072707

8 Rev. 2

PRODUCT IDENTIFICATION

FOR YOUR SAFETY

READ BEF ORE OPERATING

WARNING:

explosion may result causing property

pers on al injury or

A. This appliance does not have a pilot. It is equipped

with an ignition device which automatically lights

the burner.

B.

BEFORE O P ERAT ING

area for gas. Be sure to smell next to the floor

because some gas is heavier than air and will

settle on the floor.

WHAT TO DO IF YOU SMELL GAS

C. Use only your hand to turn the gas control knob.

Never use tools. If the knob will not turn by

hand, don't try to repair it, call a qualified service

technician. Force or attempted repair may result in a fire

or explosion.

D. Do not use this appliance if any part has been underwater.

Immediately call a qualified service technician to inspect

the appliance and to replace any part of the control

syst em and any gas control which has been un derwater.

If you do not follow these instructions

damage,

loss of life.

try

to light the burner by hand.

not

Do

Do not try to light any appliance.

Do not touch any electric switch;

do not use any phone in your building.

Immediately call your gas supplier from a neighbor's

phon e. Fol low the gas suppl ier's ins tr uct i ons .

If you cannot r each your gas supplier,

call the fire department.

smell all around the appliance

LIRE AVANT DE METTRE

EN MA RCHELIRE

AVERTISSEMENT:

la lettre les instructions dans le présent manuel

risque de décl echer un incendie ou une explosion

entraînant des dammages matériels, des lésions

corp ore ll e s ou la perte de vies hum ain es .

Cet appareil ne comporte pas de veilleuse. Il est

A.

muni d'un dispositif d'allumage qui allume

automatiquement le brûleur. Ne

d'allumer le brûleur manuellement.

B. AVANT DE LE FAIRE FONCTIONNER,

renifler tout autour de l'appariel pour déceler

une odeur de gaz. Renifler près du plancher, car

certains gaz sont plus lourds que l'air et

peuvent s'accumuler au niveau du so.l

Qui c onque n e respecte pas á

tenter

pas

QUE FAIRE S'IL Y A UNE ODEUR DE GAZ

Ne pas tenter d'allumer l'appariel

Ne toucher aucun interrupteur électri que;

n'utiliser aucun téléphone dans le bâtiment.

Appeler immédiatement le fournisseur de gaz

en employant le téléphone dún voisin.

Re specter à la lettre les instructions du

C

qu'à la main; ne jamais emploer d'outil à cet effet

Si la manette reste coincée, ne pas tenter de la

réparer; appeler un technicien qualifié. Quiconque

tente de forcer la manette ou de la reparer peut

déclencher une explosion ou un incendie.

D.

dans l'eau, complètement ou en partie. Appeler un

technicien qualifié pour inspecter l'appareil et

remplacer tout partie du systèm e de contrôle et

toute commande qui ont été plongés dans

fournisseur de gaz.

Si personne ne répond, appeler le service des

incendies.

Ne pousser ou tourner le robinet d'admission du gaz

.

Ne pas se servir de cet appareil s'il a été plongé

l'eau.

.

OPERATING INSTRUC TIONS

1.

this label.

2. Set the thermostat to lowest setting.

3. Turn off all power to the appliance.

4. This appliance is equipped with an ignition

device which automatically lights the burner.

Do

5. Turn the gas control knob clockwise to

"OFF"

6. Wait five (5) minutes to clear out any gas. Then

smell for gas, including near the floor. If you

then smell gas,

information above o

If you don't smell

next step.

7. Turn gas control knob

counterclockwise to

8. R eplace access panel.

9. Turn on all electric

power to the appliance.

10.Set thermostat to desired setting.

11.If the appliance will not operate,

follow the instructions "To Turn

Off Gas To Appliance" and call your

service technician or gas company.

Read the safety information above on

STOP!

not

try to light the burner by hand.

Position.

not

Do

STOP!

n this Label.

gas, go to

force.

Follow

"ON"

"B"

.

in the safety

TO TURN OFF GAS TO APPLIANCE

1. Set the thermostat to lowest setting.

2. Turn off all electric power to the applian ce

if service is to be perfo rm ed .

3. Turn the gas control knob clockwise to

"OFF"

4. Re pl ace contr ol acce ss panel.

Position.

Do not force.

.

*

*

*

*

PILOT ADJ

*

*

MANUAL GAS

KNOB SHOWN

IN "ON" POSITION

ROBINET A GAZ

MANUEL, EN POS

"ON/MARCHE"

*

ON

INLET

OFF

ARRIVEE

*

*

DU GAZ

MISE EN MARCHE

ARRETÊR!

1.

la portion supérieure de cette étiquette.

2. R égler le thermo stat à la tempér atur e la plus ba sse

.

3. Couper l'alimentation électrique de l'appareil.

4. Cet appareil ménager étant doté d'un système

d'allumage automatique, ne

allumer le brûleur manuellement.

Torner le robinet a gaz dans le sens des aigilles

5.

d'une montre

6. Attendre cinq (5) minutes pour laisser echapper tout le

gaz. Renifler tout autour de l'appareil, y compris près du

plancher, pour déceler une odeur de gaz. Si c'est le cas,

ARRETER!

sur la portion supérieure de cette étiquette.

S'il n'y a pas d'odeur de gaz, passer à l'étape suivanté.

GAS

7. T

ourner le robinet a gaz dans le sens inverse des

aigilles d'ne montre en pos

8. Remettre en place le panneau d'accés.

9. Mettre l'appareil sous tension.

10. Régler le thermostat à la température desirée.

11. Si l'appareil ne se met pas en marche, suiyre les

instructions intitulées. Comment coupler l'admission

de gaz de l'appereil et appeler un technicien

qualifié ou le fourrnisseur de gaz.

Lisez les instructions de sécurité sur

s

essayer à

pa

en position

Passer à l'étape B des instructions de sécuritié

"OFF/ARRET"

"ON/MARCHE".

POU R CO UP E R L'ADM ISSION

DE GAZ DE L'APPAREIL

1. Ré gl er le therm ostat à l a température la plus basse.

2. Couper l'alimentation électrique de l'appareil s'il

faut pro céder à des opérat ions d'entr etie n.

3.

Torner le robinet a gaz dans le sens des aigilles

d'une montre en position

Ne pas forcer.

4. Re mettr e en place le pa nneau d'accès.

"OF F/ARRET ".

11072707

9 Rev. 2

PRODUCT IDENTIFICATION

GUI_ 80% Upflow/Horizontal

1 1/2

1 5/8

3/4

Upflow

Left Side View

28-3/4

28

20

Supp l y

14

1

Electrical

Hole "Low

Voltage"

Gas

Supply

Hole

4-5/8

23

Side

Cut-Out

23 1/2

Bottom Knock-Out

Knock-Out

4 5/8

28-1/4

For

Venting

Electrical

Hole "High

Voltage"

31-5/8

3/4

40

37-3/8

Upflow

Front View

A

B

C

D

Bottom Knock-Out

3/4

Upflow

Right Side View

E

4 11/16

Supply

2-1/2

31

34-5/8

Side

Cut-Out

GUI_ DIMENSIONS

FURNACE

MODEL

GUI__045

GUI__070

ABCDE

16-1/2 15 5-1/4 12-5/8 4 4

Minimum

Vent

Diameter

GUI__090

GUI__115

GUI__140

20-1/2 19 7-1/4 14-5/8 4 4

24-1/2 23 9-1/4 18-5/8 4 5

CLEARANCES TO COMBUSTIBLE SURFACES

GUI_ MODEL FURNACES

UPFLOW

FRONT

RIGHT

LEFT

REAR

TOP

FLUE

FLOOR

1

= 3 inch when using Type B-1 vent is used.

2

= 1 inch when Type B-1 vent is used.

C = If placed on combustible floor, floor MUST be wood ONLY.

1

6

0612

0126

000

166

2

6

CCC

ACCESSIBILITY CLEARANCES (MINIMUM)

36" at front is required for servicing or cleaning.

NOTE: In all cases accessiblility clearance shall take precedence over clear-

ances from the enclosure where accessibility clearances are greater.

All dimensions given in inches.

HORIZONTAL

LEFT

Alcove Alcove

2

6

HORIZONTAL

RIGHT

2

6

10 Rev. 2

3/4

g

1

2

COUNTERFLOW

3/4

40

FRONT VIEW

A

B

A Raytheon Company

D

UNFOLDED

FLANGES

E

FOLDED

FLANGES

GCI_ 80% Counterflow/Horizontal

FURNACE

MODEL

GCI__045

GCI__070

PRODUCT IDENTIFICATION

COUNTERFLOW

LEFT SIDE VIEW

28 3/4

28

3/4

20 1/8

KNOCK-OUT

FOR HORIZONTAL

VENTING

GAS

SUPPLY

HOLE

ELECTRICAL

SUPPLY

HOLE "LOW

VOLTAGE"

18 5/8

UNFOLDED

FLANGES

20 1/8

FOLDED

FLANGES

4 5/8

Units are shipped with

unfolded bottom flan

GCI_ DIMENSIONS

ABC

16-1/2 15 5/3/8 13-1/2 15 4

4 3/4

22

28 1/4

31 5/8

ELECTRICAL

HOLE "HIGH

VOLTAGE"

es.

D

UnfoldedEFolded

COUNTERFLOW

RIGHT SIDE VIEW

3"

34 5/8

31

SUPPLY

1 3/4

2 1/2

4 5/8

Minimum

Vent

Diameter

GCI__090

GCI__115

GCI__140

20-1/2 19 7-3/8 17-1/2 19 4

24-1/2 23 9-3/8 21-1/2 23 5

CLEARANCES TO COMBUSTIBLE SURFACES

GCI_ MODEL FURNACES

HORIZONTAL

LEFT

Alcove Alcove

FRONT

UPFLOW

1

6

RIGHT 0612

LEFT 0126

REAR 000

TOP 166

FLUE

2

6

2

6

FLOOR CCC

= 3 inch when using Type B-1 vent is used.

= 1 inch when Type B-1 vent is used.

C = If placed on combustible floor, floor MUST be wood ONLY.

ACCESSIBILITY CLEARANCES (MINIMUM)

36" at front is required for servicing or cleaning.

NOTE: In all cases accessiblility clearance shall take precedence over clear-

ances from the enclosure where accessibility clearances are greater.

All dimensions given in inches.

HORIZONTAL

RIGHT

2

6

11 Rev. 2

(

)

g

(2)

MAC1

MEDIA AIR CLEANER

SPECIFICATIONS

CAPACITY 600-2000CFM

MEDIA SERVICE LI FE

MEDIA LISTING

DIMENSIONS

A

B

C 22-1/8

D 22-5/8

E

RESISTANCE

CFM INCHES W.C.

600

800

1000 .09

1200

1400

1600

1800

2000

All dimensions given in inches.

12 MO.NOMINAL

MAC1

MEDIA AIR CLEANER

Used On Models

GUI_ / GCI_

PRODUCT IDENTIFICATION

ACCESSORIES

MEDIA AIR CLEANER

A

UL CLASS 2

7-1/4

25

17-11/16

.04

.05

.12

.15

.18

.22

.27

C

B

E

D

ELECTRONIC AIR CLEANER

RATED CAPACITY

MAX. PRESSURE DROP

CELL WEIGHT

UNIT WEIGHT

POWER CONSUMPTION

ELECTRICAL INPUT

ELECTRICAL OUTPUT

A

B

C

D

E

F

G

H

EAC5

SPECIFICATIONS

2000 CFM

.13 in. w.

12 lbs. each

46 lbs.

48 watts maximum

120 V , 60 HZ, 1 PH

DIMENSIONS

3.2 MA @ 6200 V D C

24-7/16

20-5/16

All dimensions given in inches.

. @ 2000 CFM

4-1/2

7-3/16

20-3/4

22-1/2

17-3/4

3400 M3/HR

25

EAC5

ELECTRONIC AIR CLEANER

Used On Models

GUI_ / GCI_

12 Rev. 2

ELECTRONIC AIR CLEANER

A

30°

2-1/8 "

B

C

H

3-1/2 "

G

F

E

D

PRODUCT IDENTIFICATION

ACCESSORIES

EXTERNAL FILTER RACK

14.500

23.567

EFR01

EXTERNAL FILTER RACK

Used On Models

GUI_

INTERNAL

FILTER

RETAINERS

(80% MODELS

ONLY)

FRONT

OF UNIT

BASE

OF UNIT

INTERNAL FILTER

RETAINER SCREWS

(80% MODELS ONLY)

UNIT SIDE

PANEL

RETURN AIR

CUTOUT AREA

SLOTS IN FILTER

CLEAR SCREWS

ON UNIT

BLOWER DECK

LOWER EDGE

SCREW

SCREWS

FILTER RACK ASSEMBLY

(FACE FILTER OPENING

TOWARDS FRONT

OF UNIT)

"A"

"B"

21 1/8

6 21/32

"C"

COUNTERFLOW SUBBASE

"D"

28 1/4

6 15/32

Furnace

Model

GCI_070

GCI_090 21 19 20-1/8 21-1/4

GCI_115

GCI_140

All dimensions given in inches.

Subbase adjustable to fit all 3 cabinet sizes.

Detailed installation instructions ship with the subbase.

ASB01

SUBBASE DIMENSIONS

Dim. "A"

Subbase

Width

Dim. "B"

Plenum

Chamber

Dim. "C"

Floor

Opening

17 15 16-1/8 21-1/4

25 23 24-1/8 21-1/4

Dim. "D"

Floor

Opening

13 Rev. 2

ACG1625 AND ACG2025

ACCOMODATOR

Used on Models

GUI_045_30

GUI_070_30

GUI_070_40

GUI_090_30

GUI_090_50

GUI_115_40

GUI_115_50

GUI_140_50

GUI_090_50

GUI_115_40

GUI_115_40

GUI_140_50

Filter Base

Required

ACG1625-3

ACG1625-6

ACG2025-3

ACG2025-6

All dimensions given in inches.

Short base handles 1" & 2" filters. Height 3-3/4".

Tall base handles 1", 2" & 4" filters. Height 5-3/4".

PRODUCT IDENTIFICATION

ACCESSORIES

ACCOMODA TOR

A

C

or

or

ACG1625 AND ACG2025

ACCOMODATOR DIMENSIONS

Model

Number

Overall Opening Top

ABCDEFG

ACG1625-3 17-3/8 28-3/8 3-3/4 14-7/8 26 1-1/2 1 1425

ACG1625-6 17-3/4 28-3/8 5-3/4 14-7/8 26 1-1/2 1 1625

ACG2025-3 21-3/8 28-3/8 3-3/4 18-7/8 26 1-1/2 1 2025

ACG2025-6 21-3/8 28-3/8 5-3/4 18-7/8 26 1-1/2 1 2025

D

F

Filter

Size

B

E

G

HORIZONTAL FILTER HOUSING

D

E

B

A

MODEL HR

HR AND HRB

HORIZONTAL FILTER HOUSING DIMENSIONS

Model

Number

HR20 6-5/8 25-1/2 22 19-3/4 19 20x25

HR25 6-5/8 20-1/2 27 19-3/4 19 20x25

HRB20 6-5/8 25-1/2 22 - - 20x25

HRB25 6-5/8 20-1/2 27 - - 20x25

All dimensions given in inches.

Uses Standard Filter Sizes: 1", 2" or 4".

Overall Duct Opening

ABCDE

C

C

B

Filter

Size

MODEL HRB

HR AND HRB

HORIZONTAL FILTER HOUSING

Used On Models

GUI_

A

14 Rev. 2

Vent Damper

PRODUCT IDENTIFICATION

ACCESSORIES

COMMMON VENT KIT

NO

YES

YES

To Chimney

From furnace Flow To Chimney

COMMON VENT KITS

Kit Model

Numbers

CVK 4 4

CVK 5 5

CVK 6 6

CVK 7 7

NO

Install vent damper

with actuator to

sides of vent only.

Do not mount vent

damper with

actuator above

or below the vent.

CVK4-7

Vent Diameter

Inches

Flow

From furnace

Vertical Vent InstallationHorizontal Vent Installation

CVK4-7

COMMON VENT KITS

Used on Models

GUIA GCIA

GUIB GCIB

GUIC GCIC

GUID

Vent

Damper

Install vent damper

with actuator in

any position.

DEHUM1

DEHUMIDISTAT SPEC IFICATIONS

Model Number

Setpoint - Humidity Range 30% to 80% RH

Operating Ambient 10° to 40° C (50° to 104° F)

Differential 5%

Volts 120

Amps 1

HZ 60

DEHUM1

DEHUMIDISTAT

Used on Models

GUIV

DEHUMIDISTAT

2273W-21

15 Rev. 2

FURNACE SPECIFICATIONS

GUIA045A30

MODEL

Btuh Input (US) 46,000 69,000 69,000 92,000 92,000 115,000 115,000 140,000

Output (US) 36,800 55,200 55,200 73,600 73,600 92,000 92,000 110,400

A.F.U.E. 80% 80% 80% 80% 80% 80% 80% 80%

Rated External Static (WC) .10 - .50 .12 - .50 .12 - .50 .15 - .50 .15 - .50 .20 - .50 .20 - .50 .20 - .50

Temperature Rise °F 35 - 65 35 - 65 35 - 65 40 - 70 40 - 70 40 - 70 35 - 65 45 - 75

Pressure Switch Trip Point -1.80 -1.42 -1.42 -1.30 -1.30 -1.10 -1.10 -1.20

Blower Wheel (D x W)" 9 x 8 9 x 8 10 x 6 10 x 8 10 x 8 10 x 7 10 x 9 10 x 9

Blower Horsepower 1/3 1/3 1/2 1/2 1/2 1/2 3/4 3/4

Blower Speeds 44444444

Max CFM @ 0.5 E.S.P. 1200 1290 1450 1380 1975 1590 1985 2050

Power Supply 115-60-1 115-60-1 115-60-1 115-60-1 115-60-1 115-60-1 115-60-1 115-60-1

Min. Circuit Ampacity (MCA) 9.5 10.1 11.5 8.6 15.3 13.5 13.8 14.8

Max. Overcurrent Device 15 15 15 15 20 15 15 15

Transformer (VA) 40 40 40 40 40 40 40 40

Heat Anticipator 0.7 0.7 0.7 0.7 0.7 0.7 0.7 0.7

Limit Setting °F 250 200 210 180 190 160 180 160

Aux. Limit °F. 160 160 160 160 160 160 160 160

Fan Delay On 30 secs. 30 secs. 30 secs. 30 secs. 30 secs. 30 secs. 30 secs. 30 secs.

Off Heating * 90 secs. 90 secs. 90 secs. 90 secs. 90 secs. 90 secs. 90 secs. 90 secs.

Off Cooling 45 secs. 45 secs. 45 secs. 45 secs. 45 secs. 45 secs. 45 secs. 45 secs.

Gas Supply Pressure (Nat/LP) 7" / 11" 7" / 11" 7" / 11" 7" / 11" 7" / 11" 7" / 11" 7" / 11" 7" / 11"

Manifold Pressure (Nat/LP) 3.5 " / 10" 3.5 " / 10" 3.5 " / 10" 3.5 " / 10" 3.5 " / 10" 3.5 " / 10" 3. 5 " / 10" 3.5 " / 10"

Orifice Size (Nat/LP) #43 / #55 #43 / #55 #43 / #55 #43 / #55 #43 / #55 #43 / #55 #43 / #55 #43 / #55

Number of Burners 23344556

Vent Connector Diameter4"4"4"4"4"4"4"4"

Shipping Weight (lbs.) 140 151 152 169 178 190 194 198

GUIA045B30

GUIA045C30

GUIA070A30

GUIA070B30

GUIA070C30

GUIA070A40

GUIA070B40

GUIA070C40

GUIA090A30

GUIA090B90

GUIA090C30

GUIA090A50

GUIA090B50

GUIA090C50

GUIA115A40

GUIA115B40

GUIA115C40

GUIA115A50

GUIA115B50

GUIA115C50

GUIA140A50

GUIA140B50

GUIA140C50

* Off Heating - This fan delay timing is adjustable (60, 90, 120, 180 seconds). 90 seconds as shipped.

1. These furnaces are manufactured for natural gas operation. Optional LP Conversion Kits are available to convert to

propane gas.

2. For elevations above 2000 ft. the rating should be reduced by 4% for each 1000 ft. above sea level. The furnace must not

be derated, orifice changes should only be made if necessary for altitude.

3. The total heat loss from the structure as expressed in TOTAL BTU/HR must be calculated by the manufactures method

of in accordance with the "A.S.H.R.A.E. GUIDE" or "MANUAL J-LOAD CALCULATIONS" published by the AIR CONDITIONING CONTRACTORS OF AMERICA. The total heat loss calculated should be equal to or less than the heating

capacity. Output based on D.O.E. test procedures, steady state efficiency times output.

4. Minimum Circuit Ampacity calculated as: (1.25 x Circulator Blower Amps) + I.D. Blower Amps.

16 Rev. 2

FURNACE SPECIFICATIONS

MODEL

Btuh Input (US) 46,000 69,000 69,000 92,000 92,000 115,000 115,000 140,000

Output (US) 36,800 55,200 55,200 73,600 73,600 92,000 92,000 110,400

A.F.U.E. 80% 80% 80% 80% 80% 80% 80% 80%

Rated External Static (WC) .10 - .50 .12 - .50 .12 - .50 .15 - .50 .15 - .50 .20 - .50 .20 - .50 .20 - .50

Temperature Rise °F 35 - 65 35 - 65 35 - 65 40 - 70 40 - 70 40 - 70 35 - 65 45 - 75

Pressure Switch Trip Point -1.80 -1.42 -1.42 -1.30 -1.30 -1.10 -1.10 -1.20

Blower Wheel (D x W)" 9 x 8 9 x 8 10 x 6 10 x 8 10 x 8 10 x 7 10 x 9 10 x 9

Blower Horsepower 1/3 1/3 1/2 1/2 1/2 1/2 3/4 3/4

Blower Speeds 44444444

Max CFM @ 0.5 E.S.P. 1200 1290 1450 1380 1975 1590 1985 2050

Power Supply 115-60-1 115-60-1 115-60-1 115-60-1 115-60-1 115-60-1 115-60-1 115-60-1

Min. Circuit Ampacity (MCA) 9.5 10.1 11.5 8.6 15.3 13.5 13.8 14.8

Max. Overcurrent Device 15 15 15 15 20 15 15 15

Transformer (VA) 40 40 40 40 40 40 40 40

Heat Anticipator 0.7 0.7 0.7 0.7 0.7 0.7 0.7 0.7

Limit Setting °F 250 200 210 180 190 160 180 160

Aux. Limit °F. 160 160 160 160 160 160 160 160

Fan Delay On 30 secs. 30 secs. 30 secs. 30 secs. 30 secs. 30 secs. 30 secs. 30 secs.

Off Heating * 90 secs. 90 secs. 90 secs. 90 secs. 90 secs. 90 secs. 90 secs. 90 secs.

Off Cooling 45 secs. 45 secs. 45 secs. 45 secs. 45 secs. 45 secs. 45 secs. 45 secs.

Gas Supply Pressure (Nat/LP) 7" / 11" 7" / 11" 7" / 11" 7" / 11" 7" / 11" 7" / 11" 7" / 11" 7" / 11"

Manifold Pressure (Nat/LP) 3.5 " / 10" 3.5 " / 10" 3.5 " / 10" 3.5 " / 10" 3.5 " / 10" 3.5 " / 10" 3. 5 " / 10" 3.5 " / 10"

Orifice Size (Nat/LP) #43 / #55 #43 / #55 #43 / #55 #43 / #55 #43 / #55 #43 / #55 #43 / #55 #43 / #55

Number of Burners 23344556

Vent Connector Diameter4"4"4"4"4"4"4"4"

Shipping Weight (lbs.) 140 151 152 169 178 190 194 198

GUIA045CA30 GUIA070CA30 GUIA070CA40 GUIA090CA30 GUI A090CA50 GUI A115CA40 GUIA115CA50 GUIA140CA50

* Off Heating - This fan delay timing is adjustable (60, 90, 120, 180 seconds). 90 seconds as shipped.

1. These furnaces are manufactured for natural gas operation. Optional LP Conversion Kits are available to convert to

propane gas.

2. For elevations above 2000 ft. the rating should be reduced by 4% for each 1000 ft. above sea level. The furnace must not

be derated, orifice changes should only be made if necessary for altitude.

3. The total heat loss from the structure as expressed in TOTAL BTU/HR must be calculated by the manufactures method

of in accordance with the "A.S.H.R.A.E. GUIDE" or "MANUAL J-LOAD CALCULATIONS" published by the AIR CONDITIONING CONTRACTORS OF AMERICA. The total heat loss calculated should be equal to or less than the heating

capacity. Output based on D.O.E. test procedures, steady state efficiency times output.

4. Minimum Circuit Ampacity calculated as: (1.25 x Circulator Blower Amps) + I.D. Blower Amps.

17 Rev. 2

FURNACE SPECIFICATIONS

GUIB045A30

MODEL

Btuh Input (US) 46,000 69,000 69,000 92,000 92,000 115,000 115,000 140,000

Output (US) 36,800 55,200 55,200 73,600 73,600 92,000 92,000 110,400

A.F.U.E. 80% 80% 80% 80% 80% 80% 80% 80%

Rated External Static (WC) .10 - .50 .12 - .50 .12 - .50 .15 - .50 .15 - .50 .20 - .50 .20 - .50 .20 - .50

Temperature Rise °F 35 - 65 35 - 65 35 - 65 40 - 70 40 - 70 40 - 70 35 - 65 45 - 75

Pressure Switch Trip Point -1.80 -1.42 -1.42 -1.30 -1.30 -1.10 -1.10 -1.20

Blower Wheel (D x W)" 9 x 8 9 x 8 10 x 6 10 x 8 10 x 8 10 x 7 10 x 9 10 x 9

Blower Horsepower 1/3 1/3 1/2 1/2 1/2 1/2 3/4 3/4

Blower Speeds 4 4 4 44444

Max CFM @ 0.5 E.S.P. 1200 1290 1450 1380 1975 1590 1985 2050

Power Supply 115-60-1 115-60-1 115-60-1 115-60-1 115-60-1 115-60-1 115-60-1 115-60-1

Min. Circuit Ampacity (MCA) 9.5 10.1 11.5 8.6 15.3 13.5 13.8 14.8

Max. Overcurrent Device 15 15 15 15 20 15 15 15

Transformer (VA) 40 40 40 40 40 40 40 40

Heat Anticipator 0.7 0.7 0.7 0.7 0.7 0.7 0.7 0.7

Limit Setting °F 250 200 210 180 190 160 180 160

Aux. Limit °F. 160 160 160 160 160 160 160 160

Fan Delay On 30 secs. 30 secs. 30 secs. 30 secs. 30 secs. 30 secs. 30 secs. 30 secs.

Off Heating * 90 secs. 90 secs. 90 secs. 90 secs. 90 secs. 90 secs. 90 secs. 90 secs.

Off Cooling 45 secs. 45 secs. 45 secs. 45 secs. 45 secs. 45 secs. 45 secs. 45 secs.

Gas Supply Pressure (Nat/LP) 7" / 11" 7" / 11" 7" / 11" 7" / 11" 7" / 11" 7" / 11" 7" / 11" 7" / 11"

Manifold Pressure (Nat/LP) 3.5 " / 10" 3.5 " / 10" 3.5 " / 10" 3.5 " / 10" 3.5 " / 10" 3.5 " / 10" 3.5 " / 10" 3.5 " / 10"

Orifice Size (Nat/LP) #43 / #55 #43 / #55 #43 / #55 #43 / #55 #43 / #55 #43 / #55 #43 / #55 #43 / #55

Number of Burners 23344556

Vent Connector Diameter 4" 4" 4" 4" 4" 4" 4" 4"

Shipping Weight (lbs.) 140 151 152 169 178 190 194 198

GUIB045B30

GUIB045CX30

GUIB070A30

GUIB070B30

GUIB070CX30

GUIB070A40

GUIB070B40

GUIB070CX40

GUIB090A30

GUIB090B30

GUIB090CX30

GUIB090A50

GUIB090B50

GUIB090CX50

GUIB115A40

GUIB115B40

GUIB115CX40

GUIB115A50

GUIB115B50

GUIB115CX50

GUIB140A50

GUIB140B50

GUIB140CX50

* Off Heating - This fan delay timing is adjustable (60, 90, 120, 180 seconds). 90 seconds as shipped.

1. These furnaces are manufactured for natural gas operation. Optional LP Conversion Kits are available to convert to

propane gas.

2. For elevations above 2000 ft. the rating should be reduced by 4% for each 1000 ft. above sea level. The furnace must not

be derated, orifice changes should only be made if necessary for altitude.

3. The total heat loss from the structure as expressed in TOTAL BTU/HR must be calculated by the manufactures method

of in accordance with the "A.S.H.R.A.E. GUIDE" or "MANUAL J-LOAD CALCULATIONS" published by the AIR CONDITIONING CONTRACTORS OF AMERICA. The total heat loss calculated should be equal to or less than the heating

capacity. Output based on D.O.E. test procedures, steady state efficiency times output.

4. Minimum Circuit Ampacity calculated as: (1.25 x Circulator Blower Amps) + I.D. Blower Amps.

18 Rev. 2

FURNACE SPECIFICATIONS

GUIC045CA30

MODEL

Btuh Input (US) 46,000 69,000 69,000 92,000 92,000 115,000 115,000 140,000

Output (US) 36,800 55,200 55,200 73,600 73,600 92,000 92,000 110,400

A.F.U.E. 80% 80% 80% 80% 80% 80% 80% 80%

Rated External Static (WC) .10 - .50 .12 - .50 .12 - .50 .15 - .50 .15 - .50 .20 - .50 .20 - .50 .20 - .50

Temperature Rise °F 35 - 65 35 - 65 35 - 65 40 - 70 40 - 70 40 - 70 40 - 70 45 - 75

Pressure Switch Trip Point -0.55 -0.55 -0.55 -0.55 -0.55 -0.55 -0.55 -0.55

Blower Wheel (D x W)" 9 x 8 9 x 8 10 x 6 10 x 8 10 x 8 10 x 7 10 x 9 10 x 9

Blower Horsepower 1/3 1/3 1/2 1/2 1/2 1/2 3/4 3/4

Blower Speeds 4 4444444

Max CFM @ 0.5 E.S.P. 1200 1290 1450 1380 1980 1590 1985 2050

Power Supply 115-60-1 115-60-1 115-60-1 115-60-1 115-60-1 115-60-1 115-60-1 115-60-1

Min. Circuit Ampacity (MCA) 8.7 9.3 10.7 7.8 14.5 12.7 13.0 14.0

Max. Overcurrent Device 15 15 15 15 15 15 15 15

Transformer (VA) 40 40 40 40 40 40 40 40

Heat Anticipator 0.7 0.7 0.7 0.7 0.7 0.7 0.7 0.7

Limit Setting °F 230 220 170 170 170 170 190 135

Aux. Limit °F. 160 160 160 160 160 160 160 160

Fan Delay On 30 secs. 30 secs. 30 secs. 30 secs. 30 secs. 30 secs. 30 secs. 30 secs.

Off Heating * 90 secs. 90 secs. 90 secs. 90 secs. 90 secs. 90 secs. 90 secs. 90 secs.

Off Cooling 45 secs. 45 secs. 45 secs. 45 secs. 45 secs. 45 secs. 45 secs. 45 secs.

Gas Supply Pressure (Nat/LP) 7" / 11" 7" / 11" 7" / 11" 7" / 11" 7" / 11" 7" / 11" 7" / 11" 7" / 11"

Manifold Pressure (Nat/LP) 3.5 " / 10" 3.5 " / 10" 3.5 " / 10" 3.5 " / 10" 3.5 " / 10" 3.5 " / 10" 3.5 " / 10" 3.5 " / 10"

Orifice Size (Nat/LP) #43 / #55 #43 / #55 #43 / #55 #43 / #55 #43 / #55 #43 / #55 #43 / #55 #43 / #55

Number of Burners 23344556

Vent Connector Diameter 4" 4" 4" 4" 4" 4" 4" 4"

Shipping Weight (lbs.) 140 151 152 169 178 190 194 198

GUIC045CX30

GUIC045DA30

GUIC045DX30

GUIC070CA30

GUIC070CX30

GUIC070DA30

GUIC070DX30

GUIC070CA40

GUIC070CX40

GUIC070DA40

GUIC070DX40

GUIC090CA30

GUIC090CX30

GUIC090DA30

GUIC090DX30

GUIC090CA50

GUIC090CX50

GUIC090DA50

GUIC090DX50

GUIC115CA40

GUIC115CX40

GUIC115DA40

GUIC115DX40

GUIC115CA50

GUIC115CX50

GUIC115DA50

GUIC115DX50

GUIC140CA50

GUIC140CX50

GUIC140DA50

GUIC140DX50

* Off Heating - This fan delay timing is adjustable (60, 90, 120, 180 seconds). 90 seconds as shipped.

1. These furnaces are manufactured for natural gas operation. Optional LP Conversion Kits are available to convert to

propane gas.

2. For elevations above 2000 ft. the rating should be reduced by 4% for each 1000 ft. above sea level. The furnace must not

be derated, orifice changes should only be made if necessary for altitude.

3. The total heat loss from the structure as expressed in TOTAL BTU/HR must be calculated by the manufactures method

of in accordance with the "A.S.H.R.A.E. GUIDE" or "MANUAL J-LOAD CALCULATIONS" published by the AIR CONDITIONING CONTRACTORS OF AMERICA. The total heat loss calculated should be equal to or less than the heating

capacity. Output based on D.O.E. test procedures, steady state efficiency times output.

4. Minimum Circuit Ampacity calculated as: (1.25 x Circulator Blower Amps) + I.D. Blower Amps.

19 Rev. 2

FURNACE SPECIFICATIONS

GUID045CA30

MODEL

Btuh Input (US) 46,000 69,000 69,000 92,000 92,000 115,000

Output (US) 36,800 55,200 55,200 73,600 73,600 92,000

A.F.U.E. 80% 80% 80% 80% 80% 80%

Rated External Static (WC) .10 - .50 .12 - .50 .12 - .50 .15 - .50 .15 - .50 .20 - .50

Temperature Rise °F 35 - 65 35 - 65 35 - 65 40 - 70 40 - 70 40 - 70

Pressure Switch Trip Point -0.55 -0.55 -0.55 -0.55 -0.55 -0.55

Blower Wheel (D x W)" 9 x 8 9 x 8 10 x 6 10 x 8 10 x 8 10 x 9

Blower Horsepower 1/3 1/3 1/2 1/2 1/2 3/4

Blower Speeds 444444

Max CFM @ 0.5 E.S.P. 1200 1290 1450 1380 1975 1985

Power Supply 115-60-1 115-60-1 115-60-1 115-60-1 115-60-1 115-60-1

Min. Circuit Ampacity (MCA) 8.7 9.3 10.7 7.8 14.5 13.0

Max. Overcurrent Device 15 15 15 15 15 15

Transformer (VA) 40 40 40 40 40 40

Heat Anticipator 0.7 0.7 0.7 0.7 0.7 0.7

Limit Setting °F 230 220 170 160 160 190

Aux. Limit °F. 160 160 160 160 160 160

Fan Delay On 30 secs. 30 secs. 30 secs. 30 secs. 30 secs. 30 secs.

Off Heating * 90 secs. 90 secs. 90 secs. 90 secs. 90 secs. 90 secs.

Off Cooling 45 secs. 45 secs. 45 secs. 45 secs. 45 secs. 45 secs.

Gas Supply Pressure (Nat/LP) 7" / 11" 7" / 11" 7" / 11" 7" / 11" 7" / 11" 7" / 11"

Manifold Pressure (Nat/LP) 3.5 " / 10" 3.5 " / 10" 3.5 " / 10" 3.5 " / 10" 3.5 " / 10" 3.5 " / 10"

Orifice Size (Nat/LP) #43 / #55 #43 / #55 #43 / #55 #43 / #55 #43 / #55 #43 / #55

Number of Burners 233445

Vent Connector Diameter 4" 4" 4" 4" 4" 4"

Shipping Weight (lbs.) 140 151 152 169 178 194

GUID045CX30

GUID045DA30

GUID045DX30

GUID070CA30

GUID070CX30

GUID070DA30

GUID070DX30

GUID070CA40

GUID070CX40

GUID070DA40

GUID070DX40

GUID090CA30

GUID090CX30

GUID090DA30

GUID090DX30

GUID090CA50

GUID090CX50

GUID090DA50

GUID090DX50

GUID115CA50

GUID115CX50

GUID115DA50

GUID115DX50

* Off Heating - This fan delay timing is adjustable (60, 90, 120, 180 seconds). 90 seconds as shipped.

1. These furnaces are manufactured for natural gas operation. Optional LP Conversion Kits are available to convert to

propane gas.

2. For elevations above 2000 ft. the rating should be reduced by 4% for each 1000 ft. above sea level. The furnace must not

be derated, orifice changes should only be made if necessary for altitude.

3. The total heat loss from the structure as expressed in TOTAL BTU/HR must be calculated by the manufactures method

of in accordance with the "A.S.H.R.A.E. GUIDE" or "MANUAL J-LOAD CALCULATIONS" published by the AIR CONDITIONING CONTRACTORS OF AMERICA. The total heat loss calculated should be equal to or less than the heating

capacity. Output based on D.O.E. test procedures, steady state efficiency times output.

4. Minimum Circuit Ampacity calculated as: (1.25 x Circulator Blower Amps) + I.D. Blower Amps.

20 Rev. 2

FURNACE SPECIFICATIONS

MODEL

Btuh Input (US) 69,000 69,000 69,000 69,000 69,000

Output (US) 55,200 55,200 55,200 55,200 55,200

A.F.U.E. 80% 80% 80% 80% 80%

Rated External Static (WC) .12 - .50 .12 - .50 .12 - .50 .12 - .50 .12 - .50

Temperature Rise °F 35 - 65 35 - 65 35 - 65 35 - 65 45 - 75

Pressure Switch Trip Point -0.55 -0.55 -0.55 -0.55 -0.55

Blower Wheel (D x W)" ** 10 x 8 10 x 8 10 x 8 10 x 8 10 x 8

Blower Horsepower 1/2 1/2 1/2 1/2 1/2

Blower Speeds 4 4 4 4 4

Max CFM @ 0.5 E.S.P. 1529 1529 1529 1529 1571

Power Supply 115-60-1 115-60-1 115-60-1 115-60-1 115-60-1

Min. Circuit Ampacity (MCA) 9.9 9.9 9.9 9.9 9.9

Max. Overcurrent Device 15 15 15 15 15

Transformer (VA) 40 40 40 40 40

Heat Anticipator 0.7 0.7 0.7 0.7 0.7

Limit Setting °F 215 215 215 215 215

Aux. Limit °F. 160 160 160 160 160

Fan Delay On 30 secs. 30 secs. 30 secs. 30 secs. 30 secs.

Off Heating * 90 secs. 90 secs. 90 secs. 90 secs. 90 secs.

Off Cooling 45 secs. 45 secs. 45 secs. 45 secs. 45 secs.

Gas Supply Pressure (Nat/LP) 7" / 11" 7" / 11" 7" / 11" 7" / 11" 7" / 11"

Manifold Pressure (Nat/LP) 3.5 " / 10" 3.5 " / 10" 3.5 " / 10" 3.5 " / 10" 3.5 " / 10"

Orifice Size (Nat/LP) #43 / #55 #43 / #55 #43 / #55 #43 / #55 #43 / #55

Number of Burners 3 3 3 3 3

Vent Connector Diameter 4" 4" 4" 4" 4"

Shipping Weight (lbs.) 152 152 152 152 152

GUIC070DA40 GUIC070DX40 GUID070DA40 GUID070DX40 GCIC070DX40

* Off Heating - This fan delay timing is adjustable (60, 90, 120, 180 seconds). 90 seconds as shipped.

** Note: The five models above use 10x8 blower assembly instead of 10x6 to achieve a full 4 tons of airflow.

1. These furnaces are manufactured for natural gas operation. Optional LP Conversion Kits are available to convert to

propane gas.

2. For elevations above 2000 ft. the rating should be reduced by 4% for each 1000 ft. above sea level. The furnace must not

be derated, orifice changes should only be made if necessary for altitude.

3. The total heat loss from the structure as expressed in TOTAL BTU/HR must be calculated by the manufactures method

of in accordance with the "A.S.H.R.A.E. GUIDE" or "MANUAL J-LOAD CALCULATIONS" published by the AIR CONDITIONING CONTRACTORS OF AMERICA. The total heat loss calculated should be equal to or less than the heating

capacity. Output based on D.O.E. test procedures, steady state efficiency times output.

4. Minimum Circuit Ampacity calculated as: (1.25 x Circulator Blower Amps) + I.D. Blower Amps.

21 Rev. 2

FURNACE SPECIFICATIONS

GUIS070CA35

MODEL

Btuh Input (US) High Fire 69,000 92,000 92,000 115,000 138,000 69,000 92,000

Output (US) High Fire 55,200 73,600 73,600 92,000 110,400 55,200 73,600

Btuh Input (US) Low Fire 48,000 64,000 64,000 80,000 96,000 48,000 64,000

Output (US) Low Fir e 38,400 51,200 51,200 64,000 76,800 38,400 51,200

A.F.U.E. 80% 80% 80% 80% 80% 80% 80%

Rated External Static (W C) .12 - .50 .15 - .50 .15 - .50 .20 - .50 .20 - .50 .12 - .50 .15 - .50

Temper ature Rise °F 30 - 60 35 - 65 35 - 65 35 - 65 45 - 75 35 - 65 45 - 75

High Pressure Switch Trip Point -0.80 -0.74 -0.74 -0.66 -0.66 -0.55 -0.55

Low Pressure Swit ch Trip Point -0.45 -0.37 -0.37 -0.37 -0.32 -0.27 -0.27

Blower Wheel (D x W)" 10 X 6 10 X 8 10 X 8 10 X 9 10 X 9 10 X 6 10 X 8

Blower Horsepower 1/2 1/2 1/2 3/4 3/4 1/2 3/4

Blower Speeds 4444444

Max CFM @ 0.5 E.S.P. 1450 1380 1975 1985 2050 1366 1780

Power Supply 115-60-1 115-60-1 115-60-1 115-60-1 115-60-1 115-60-1 115-60-1

Min. Circuit Ampacity (MCA) 10.9 8.0 14.8 13.3 14.3 10.2 14.2

Max. Overcurr ent Device 15 15 15 15 15 15 15

Transfo rmer (VA) 40 40 40 40 40 40 40

Heat Anticipator 0.7 0.7 0.7 0.7 0.7 0.7 0.7

Limit Setting °F 230 220 170 190 160 190 160

Aux. Limit °F. 160 160 160 160 160 160 160

Fan Delay On 30 secs. 30 secs. 30 secs. 30 secs . 30 secs. 30 secs. 30 sec s.

Off Heating * 90 secs. 90 secs. 90 secs. 90 secs . 90 secs. 90 secs. 90 sec s.

Off Cooling 45 secs. 45 secs. 45 secs . 45 secs. 45 secs. 45 sec s. 45 secs.

Gas Supply P ressu re (Nat/LP) 7" / 11" 7" / 11" 7" / 11" 7" / 11" 7" / 11" 7" / 11" 7" / 11"

Manifold Pressure (Nat/ L P) High Stage 3.5 " / 10" 3.5 " / 10" 3.5 " / 10" 3.5 " / 10" 3.5 " / 10" 3.5 " / 10" 3.5 " / 10"

Manifold Pressure (Nat/LP) Low Stage 1.9" / 6.0" 1.9" / 6.0" 1.9" / 6.0" 1.9" / 6.0" 1.9" / 6.0" 1.9" / 6.0" 1.9" / 6.0"

Orifice Size (Nat/LP) #43 / #55 #43 / #55 #43 / #55 #43 / #55 #43 / #55 #43 / #55 #43 / #55

Number of Burners 3445634

Vent Connector Diameter 4" 4" 4" 4" 4" 3" 3"

Shipping Weight (lbs.) 152 169 178 194 198 152 178

GUIS070CX35

GUIS070DA35

GUIS070DX35

GUIS090CA30

GUIS090DA30

GUIS090DX30

GUIS090CA50

GUIS090CX50

GUIS090DA50

GUIS090DX50

GUIS115CA50

GUIS115DA50

GUIS115DX50

GUIS140CA50

GUIS140DA50

GCIS070CX35

GCIS070DX35

GCIS090CX50

GCIS090DX50

* Off Heating - This fan delay timing is adjustable (60, 90, 120, 180 seconds). 90 seconds as shipped.

1. These furnaces are manufactured for natural gas operation. Optional LP Conversion Kits are available to convert to

propane gas.

2. For elevations above 2000 ft. the rating should be reduced by 4% for each 1000 ft. above sea level. The furnace must not

be derated, orifice changes should only be made if necessary for altitude.

3. The total heat loss from the structure as expressed in TOTAL BTU/HR must be calculated by the manufactures method

of in accordance with the "A.S.H.R.A.E. GUIDE" or "MANUAL J-LOAD CALCULATIONS" published by the AIR CONDITIONING CONTRACTORS OF AMERICA. The total heat loss calculated should be equal to or less than the heating

capacity. Output based on D.O.E. test procedures, steady state efficiency times output.

4. Minimum Circuit Ampacity calculated as: (1.25 x Circulator Blower Amps) + I.D. Blower Amps.

22 Rev. 2

FURNACE SPECIFICATIONS

MODEL

Btuh Input (US) High Fire 69,000 92,000 115,000 138,000

Output (US) High Fire 55,200 73,600 92,000 110,400

Btuh Input (US) Low Fire 48,000 64,000 80,000 96,000

Output (US) Low Fire 38,400 51,200 64,000 76,800

A.F.U.E. 80% 80% 80% 80%

Rated External Static (WC) .10 - .50 .10 - .50 .10 - .50 .10 - .50

Temperature Rise °F 30 - 60 35 - 65 35 - 65 45 - 75

High Pressure Switch Trip Point -0.80 -0.74 -0.66 -0.66

Low Pressure Switch Trip Point -0.45 -0.37 -0.37 -0.32

Blower Wheel (D x W)" 10 X 8 10 X 8 10 X 9 10 X 9

Blower Horsepower 1/2 3/4 3/4 3/4

Blower Speeds

Max CFM @ 0.5 E.S.P. 1426 1845 2059 2059

Power Supply 115-60-1 115-60-1 115-60-1 115-60-1

Min. Circuit Ampacity (MCA) 11.0 11.7 11.7 11.7

Max. Overcurrent Device 15 15 15 15

Transformer (VA) 40 40 40 40

Heat Anticipator 0.7 0.7 0.7 0.7

Limit Setting °F 230 220 190 160

Aux. Limit °F. 160 160 160 160

Fan Delay On Cooling ** 0 or 5 secs. 0 or 5 secs. 0 or 5 secs. 0 or 5 secs.

Fan Delay On Heating 30 secs. 30 secs. 30 secs. 30 secs.

Off Heating * 90 secs. 90 secs. 90 secs. 90 secs.

Off Cooling *** 0 or 45 secs. 0 or 45 secs. 0 or 45 secs. 0 or 45 secs.

Gas Supply Pressure (Nat/LP) 7" / 11" 7" / 11" 7" / 11" 7" / 11"

Manifold Pressure (Nat/LP) High Stage 3.5 " / 10" 3.5 " / 10" 3.5 " / 10" 3.5 " / 10"

Manifold Pressure (Nat/LP) Low Stage 1.9" / 6.0" 1.9" / 6.0" 1.9" / 6.0" 1.9" / 6.0"

Orifice Size (Nat/LP) #43 / #55 #43 / #55 #43 / #55 #43 / #55

Number of Burners 3 4 5 6

Vent Connector Diameter 4" 4" 4" 4"

Shipping Weight (lbs.) 152 178 194 198

GUIV070DX40 GUIV090DX50 GUIV115DX50 GUIV140DX50

Refer to notes below airflow tables on pages 31-33.

* Off Heating - This fan delay timing is adjustable (60, 90, 120, 180 seconds). 90 seconds as shipped.

** On Cooling - This fan delay timing can be set at either 0 or 5 seonds. Refer to pages 31-33 for further details.

*** Off Cooling - This fan delay timing can be set at either 0 or 45 seconds. Refer to pages 31-33 for further details.

1. These furnaces are manufactured for natural gas operation. Optional LP Conversion Kits are available to convert to

propane gas.

2. For elevations above 2000 ft. the rating should be reduced by 4% for each 1000 ft. above sea level. The furnace must not

be derated, orifice changes should only be made if necessary for altitude.

3. The total heat loss from the structure as expressed in TOTAL BTU/HR must be calculated by the manufactures method

of in accordance with the "A.S.H.R.A.E. GUIDE" or "MANUAL J-LOAD CALCULATIONS" published by the AIR CONDITIONING CONTRACTORS OF AMERICA. The total heat loss calculated should be equal to or less than the heating

capacity. Output based on D.O.E. test procedures, steady state efficiency times output.

4. Minimum Circuit Ampacity calculated as: (1.25 x Circulator Blower Amps) + I.D. Blower Amps.

23 Rev. 2

FURNACE SPECIFICATIONS

GCIA045A30

MODEL

Btuh Input (US) 46,000 69,000 69,000 92,000 92,0 00 115, 000 115,000 140,000

Output (US) 36,800 55,200 55,200 73,600 73,600 92,000 92,000 110,400

A.F.U.E. 80% 80% 80% 80% 80 % 80% 80% 80%

Rated External Static (WC) .10 - . 50 .12 - .50 .12 - .50 .15 - .50 .15 - .50 .20 - .50 .20 - .50 .20 - .50

Temperature Rise °F 35 - 65 45 - 75 45 - 75 45 - 75 45 - 75 45 - 75 45 - 75 45 - 75

Pressure Switch Trip Point -1.70 -1.42 -1.42 -1.20 -1.20 -1.15 -1.15 -1.05

Blower Wheel (D x W)" 9 x 8 9 x 8 10 x 6 10 X 8 10 x 8 10 x 7 10 x 9 10 x 9

Blower Horsepower 1/3 1/3 1/2 1/2 1/2 1/2 3/4 3/4

Blower Speeds 44444444

Max CFM @ 0.5 E.S.P. 1160 1145 1366 1265 1780 1660 1840 1845

Power Supply 115-60-1 115-60-1 115-60-1 115-60-1 115-60-1 115-60-1 115-60-1 115-60-1

Min. Circuit Ampacity (MCA) 9.5 9.3 10.7 8.6 14.7 13.1 14.5 14.5

Max. Overcurrent Device 15 15 15 15 15 15 15 15

Transformer (VA) 40 40 40 40 40 40 40 40

Heat Anticipator 0.7 0.7 0.7 0.7 0.7 0.7 0.7 0.7

Limit Setting °F 240 200 170 170 160 130 130 140

Aux. Limit °F. 160 160 160 160 160 16 0 160 160

Fan Dela y On 30 secs. 30 secs. 30 secs. 30 secs. 30 secs . 30 se cs . 30 se cs. 30 secs .

Off Heating * 90 secs. 90 secs. 90 secs. 90 secs. 90 secs. 90 secs. 90 secs. 90 secs.

Off Cooling 45 secs. 45 secs. 45 secs. 45 secs. 45 secs. 45 secs. 45 secs. 45 secs.

Gas Supply Pressure (Nat/LP) 7" / 11" 7" / 11" 7" / 11" 7" / 11" 7" / 11" 7" / 11" 7" / 11" 7" / 11"

Manifold Pressure (Nat/LP) 3.5 " / 10" 3.5 " / 10" 3.5 " / 10" 3.5 " / 10" 3.5 " / 10" 3.5 " / 10" 3.5 " / 10" 3.5 " / 10"

Orifice Size (N at/LP) #43 / #55 #43 / #55 #43 / #5 5 #43 / #55 #4 3 / #55 #43 / #55 #43 / #55 #43 / #55

Number of Burners 23344556

Vent Connector Diameter 3"3"3"3"3"3"3"3"

Shipping Weight (lbs.) 140 151 152 169 178 190 19 4 198

GCIA045CA30

GCIA045CX30

GCIA070A30

GCIA070CA30

GCIA070CX30

GCIA070A40

GCIA070CA30

GCIA070CX30

GCIA090A30

GCIA090CA30

GCIA090CX30

GCIA090A50

GCIA090CA50

GCIA090CX50

GCIA115A40

GCIA115CA40

GCIA115CX40

GCIA115A50

GCIA115CA50

GCIA115CX50

GCIA140A50

GCIA115CA50

GCIA115CX50

* Off Heating - This fan delay timing is adjustable (60, 90, 120, 180 seconds). 90 seconds as shipped.

1. These furnaces are manufactured for natural gas operation. Optional LP Conversion Kits are available to convert to

propane gas.

2. For elevations above 2000 ft. the rating should be reduced by 4% for each 1000 ft. above sea level. The furnace must not

be derated, orifice changes should only be made if necessary for altitude.

3. The total heat loss from the structure as expressed in TOTAL BTU/HR must be calculated by the manufactures method

of in accordance with the "A.S.H.R.A.E. GUIDE" or "MANUAL J-LOAD CALCULATIONS" published by the AIR CONDITIONING CONTRACTORS OF AMERICA. The total heat loss calculated should be equal to or less than the heating

capacity. Output based on D.O.E. test procedures, steady state efficiency times output.

4. Minimum Circuit Ampacity calculated as: (1.25 x Circulator Blower Amps) + I.D. Blower Amps.

24 Rev. 2

FURNACE SPECIFICATIONS

MODEL

Btuh Input (US) 46 ,0 00 69,0 00 69,0 00 92 ,0 00 92,0 00 11 5, 000 115,000 138, 000

Output (US) 37,000 55,000 55,000 74,000 74,000 92,000 92,000 110,000

A.F.U.E. 80% 80% 80% 80% 80% 80% 80% 80%

Rated External Static (WC) .10 - .50 .12 - .50 .12 - .50 .15 - .50 .15 - .50 .20 - .50 .20 - .50 .20 - .50

Temperature Rise °F 35 - 65 45 - 75 45 - 75 45 - 75 45 - 75 45 - 75 45 - 75 45 - 75

Pressure Switch Trip Point -1.30 -1.10 -1.10 -1.05 -1.05 -0.95 -0.95 -1.10

Blower Wheel (D x W)" 9 x 8 9 x 8 10 x 6 10 X 8 10 x 8 10 x 7 10 x 9 10 x 9

Blower Horsepower 1/3 1/3 1/2 1/3 1/2 1/2 3/4 3/4

Blower Speeds 44444444

Max CFM @ 0.5 E.S.P. 1160 1145 1366 1265 1780 1660 1840 1845

Power Supply 115-60-1 115-60-1 115-60-1 115-60-1 115-60-1 115-60-1 115-60-1 115-60-1

Min. Circuit Ampacity (MCA) 10.1 9.3 10.7 8.3 14.7 13.1 14.5 14.5

Max. Overcurrent Device 15 15 15 15 20 15 20 20

Transformer (VA) 40 40 40 40 40 40 40 40

Heat Anticipator 0.7 0.7 0.7 0.7 0.7 0.7 0.7 0.7

Limit Setting °F 240 200 170 170 160 130 130 140

Aux. Limit °F. 160 160 160 160 160 160 160 160

Fan Delay On 30 secs. 30 secs. 30 secs. 30 secs. 30 secs. 30 secs. 30 secs. 30 secs.

Off Heating * 90 secs. 90 secs. 90 secs. 90 secs. 90 secs. 90 secs. 90 secs. 90 secs.

Off Cooling 45 secs. 45 secs. 45 secs. 45 secs. 45 secs. 45 secs. 45 secs. 45 secs.

Gas Supply Pressure (Nat/LP) 7" / 11" 7" / 11" 7" / 11" 7" / 11" 7" / 11" 7" / 11" 7" / 11" 7" / 11"

Manifold Pressure (Nat/LP) 3.5 " / 10" 3.5 " / 10" 3.5 " / 10" 3.5 " / 10" 3.5 " / 10" 3.5 " / 10" 3.5 " / 10" 3.5 " / 10"

Orifice Size (Nat/LP) #43 / #55 #43 / #55 #43 / #55 #43 / #55 #43 / #55 #43 / #55 #43 / #55 #43 / #55

Number of Burners 23344556

Vent Connector Diameter 3" 3" 3" 3" 3" 3" 3" 3"

Shipping Weight 135 145 145 160 160 175 175 185

GCIB045A30 GCIB070A30 GCIB070A40 GCIB090A30 GCIB090A50 GCIB115A40 GCIB115A50 GCIB140A50

* Off Heating - This fan delay timing is adjustable (60, 90, 120, 180 seconds). 90 seconds as shipped.

1. These furnaces are manufactured for natural gas operation. Optional LP Conversion Kits are available to convert to

propane gas.

2. For elevations above 2000 ft. the rating should be reduced by 4% for each 1000 ft. above sea level. The furnace must not

be derated, orifice changes should only be made if necessary for altitude.

3. The total heat loss from the structure as expressed in TOTAL BTU/HR must be calculated by the manufactures method

of in accordance with the "A.S.H.R.A.E. GUIDE" or "MANUAL J-LOAD CALCULATIONS" published by the AIR CONDITIONING CONTRACTORS OF AMERICA. The total heat loss calculated should be equal to or less than the heating

capacity. Output based on D.O.E. test procedures, steady state efficiency times output.

4. Minimum Circuit Ampacity calculated as: (1.25 x Circulator Blower Amps) + I.D. Blower Amps.

25 Rev. 2

FURNACE SPECIFICATIONS

MODEL

Btuh Input (US) 46,000 69,000 69,000 92,000 92,000 115,000 115,000 140,000

Output (US) 36,800 55,200 55,200 73,600 73,600 92,000 92,000 110,400

A.F.U.E. 80% 80% 80% 80% 80% 80% 80% 80%

Rated External Static (WC) .10 - .50 .12 - .50 .12 - .50 .15 - .50 .15 - .50 .20 - .50 .20 - .50 .20 - .50

Temperature Rise °F 35 - 65 45 - 75 45 - 75 45 - 75 45 - 75 45 - 75 45 - 75 45 - 75

Pressure Switch Trip Point -0.55 -0.55 -0.55 -0.55 -0.55 -0.55 -0.55 -0.55

Blower Wheel (D x W)" 9 x 8 9 x 8 10 x 6 10 X 8 10 x 8 10 x 7 10 x 9 10 x 9

Blower Horsepower 1/3 1/3 1/2 1/3 1/2 1/2 3/4 3/4

Blower Speeds 4 4 4 44444

Max CFM @ 0.5 E.S.P. 1160 1150 1370 1270 1780 1660 1840 1850

Power Supply 115-60-1 115-60-1 115-60-1 115-60-1 115-60-1 115-60-1 115-60-1 115-60-1

Min. Circuit Ampacity (MCA) 8.7 8.5 9.9 7.8 13.9 12.3 13.7 13.7

Max. Overcurrent Device 15 15 15 15 15 15 15 15

Transformer (VA) 40 40 40 40 40 40 40 40

Heat Anticipator 0.7 0.7 0.7 0.7 0.7 0.7 0.7 0.7

Limit Setting °F 240 200 170 170 160 130 130 140

Aux. Limit °F. 160 160 160 160 160 160 160 160

Fan Delay On 30 secs. 30 secs. 30 secs. 30 secs. 30 secs. 30 secs. 30 secs. 30 secs.

Off Heating * 90 secs. 90 secs. 90 secs. 90 secs. 90 secs. 90 secs. 90 secs. 90 secs.

Off Cooling 45 secs. 45 secs. 45 secs. 45 secs. 45 secs. 45 secs. 45 secs. 45 secs.

Gas Supply Pressure (Nat/LP) 7" / 11" 7" / 11" 7" / 11" 7" / 11" 7" / 11" 7" / 11" 7" / 11" 7" / 11"

Manifold Pressure (Nat/LP) 3.5 " / 10" 3.5 " / 10" 3.5 " / 10" 3.5 " / 10" 3.5 " / 10" 3.5 " / 10" 3.5 " / 10" 3.5 " / 10"

Orifice Size (Nat/LP) #43 / #55 #43 / #55 #43 / #55 #43 / #55 #43 / #55 #43 / #55 #43 / #55 #43 / #55

Number of Burners 23344556

Vent Connector Diameter 3" 3" 3" 3" 3" 3" 3" 3"

Shipping Weight (lbs.) 140 151 152 169 178 190 194 198

GCIC045CX30 GCIC070CX30 GCIC070CX40 GCIC090CX30 GCIC090CX50 GCIC115CX40 GCIC115CX50 GCIC140CX50

* Off Heating - This fan delay timing is adjustable (60, 90, 120, 180 seconds). 90 seconds as shipped.

1. These furnaces are manufactured for natural gas operation. Optional LP Conversion Kits are available to convert to

propane gas.

2. For elevations above 2000 ft. the rating should be reduced by 4% for each 1000 ft. above sea level. The furnace must not

be derated, orifice changes should only be made if necessary for altitude.

3. The total heat loss from the structure as expressed in TOTAL BTU/HR must be calculated by the manufactures method

of in accordance with the "A.S.H.R.A.E. GUIDE" or "MANUAL J-LOAD CALCULATIONS" published by the AIR CONDITIONING CONTRACTORS OF AMERICA. The total heat loss calculated should be equal to or less than the heating

capacity. Output based on D.O.E. test procedures, steady state efficiency times output.

4. Minimum Circuit Ampacity calculated as: (1.25 x Circulator Blower Amps) + I.D. Blower Amps.

26 Rev. 2

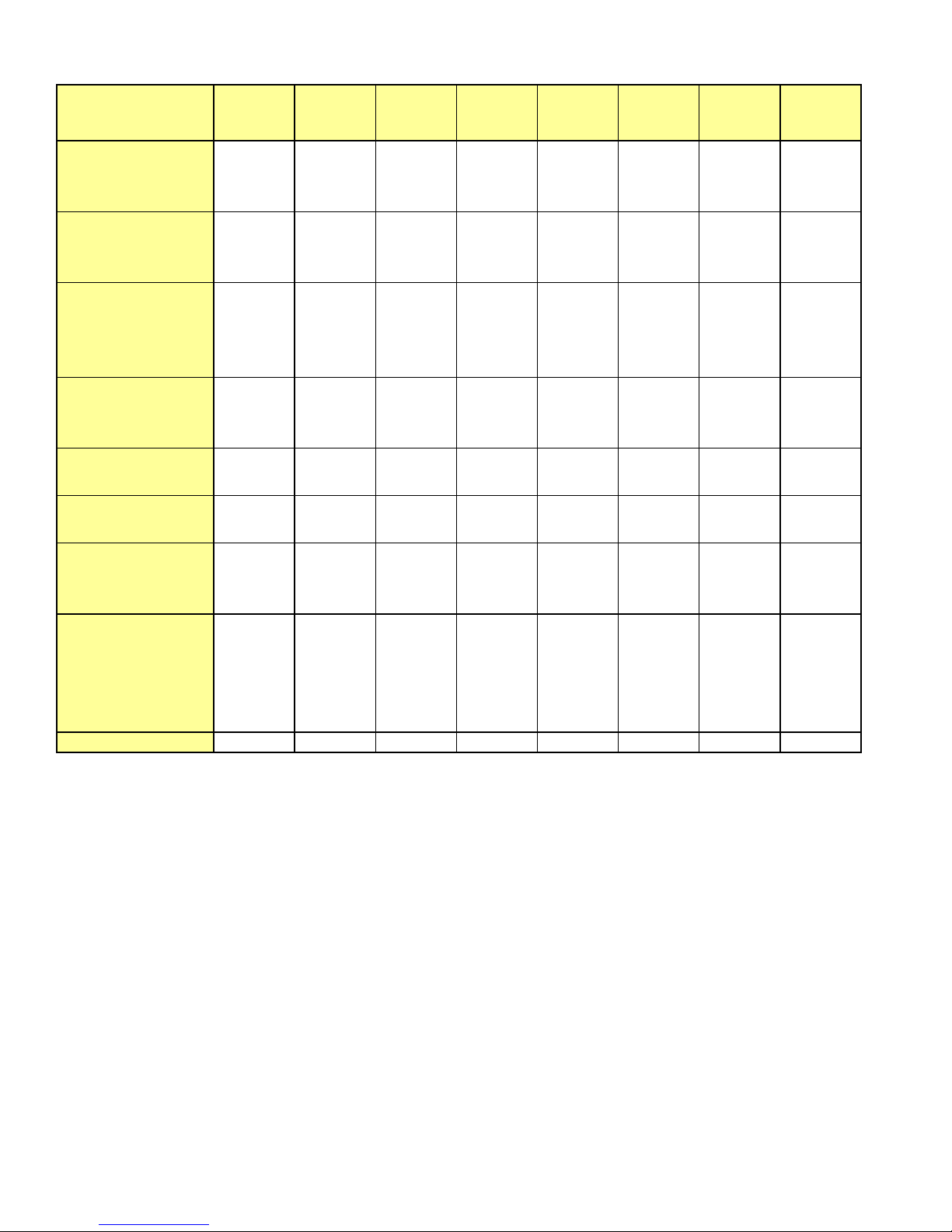

BLOWER PERFORMANCE SPECIFICATIONS

SINGLE STAGE

CFM & Temperature Rise vs. External Static Pressue

MODEL TONS AC

(Htg. Speed @ 0.5" 0.1 0.2 0.3 0.4 0.5 0.6

As Shipped) ESP CFM Rise CFM Rise CFM Rise CFM Rise CFM Rise CFM Rise

GUI_045_30

(Low) MED-LO 2.0 935 36 910 37 885 39 845 40 790 43 710 48

GUI_070_30

(Med-Lo) MED-LO 2.5 1090 47 1080 47 1055 48 1020 50 970 52 905 56

GUI_070_40

(Low) MED-LO 3.0 1235 41 1200 42 1180 43 1140 44 1115 45 1050 48

GUI_090_30

(High) MED-LO 2.0 920 - 920 - 900 - 890 - 850 - 800 -

GUI_090_50

(Med-Lo) MED-LO 3.5 1320 52 1315 52 1315 52 1315 52 1280 53 1240 55

GUI_115_40

(High) MED-LO 3.0 1320 64 1305 65 1290 66 1260 67 1200 - 1180 -

GUI_115_50

(Med-Hi) MED-LO 4.0 1875 45 1840 46 1800 47 1735 49 1685 50 1600 53

GUI_140_50

(High) MED-LO 4.0 1715 59 1700 60 1660 61 1615 63 1555 65 1470 69

MOTOR

SPEED

HIGH 3.0 1460 - 1400 - 1345 - 1280 - 1200 - 1110 -

MED-HI 2.5 1200 - 1150 - 1100 - 1050 - 980 35 900 38

LOW 1.5 700 49 685 50 665 51 635 54 575 59 425 HIGH 3.0 1555 - 1505 - 1440 35 1365 37 1290 39 1180 43

MED-HI 3.0 132538130539125041120042114044106048

LOW 2.0 760 - 750 - 750 - 735 - 700 - 645 HIGH 3.5 1695 - 1625 - 1580 - 1520 - 1450 35 1365 37

MED-HI 3.0 1485 - 1450 35 1400 36 1350 38 1295 39 1235 41

LOW 2.5 1095 46 1070 47 1050 48 1025 49 975 52 950 53

HIGH 3.5 163042156044155044146547138049127553

MED-HI 3.0 136050132551129053121556115559107064

LOW 1.5 770 - 750 - 740 - 730 - 690 - 660 HIGH 5.0 2250 - 2185 - 2120 - 2030 - 1975 - 1885 -

MED-HI 4.0 1775 - 1750 - 1735 - 1690 40 1650 41 1600 43

LOW 3.0 1180 58 1180 58 1175 58 1170 58 1140 60 1120 61

HIGH 4.0 183546178048173049166051159053153055

MED-HI 3.5 163052159553154055149057144059137562

LOW 2.5 1140 - 1145 - 1120 - 1100 - 1065 - 1030 HIGH 5.0 233036224538216539206541198543188545

MED-HI 5.0 212040207041202042194044185046177548

LOW 3.0 1290 - 1275 - 1250 - 1235 - 1210 - 1170 HIGH 5.0 2455 - 2390 - 2290 - 2200 46 2050 49 1935 52

MED-HI 5.0 205049202550196552189054181056171559

LOW 3.5 1450 70 1435 71 1415 72 1380 73 1340 - 1280 -

External Static Pressure, Inches Water Column

1. Units are shipped without filter(s). CFM in chart is without filter(s).

2. All furnaces shipped as high speed for cooling. Installer should adjust blower speeds as needed.

3. INSTALLATION IS TO BE ADJUSTED TO OBTAIN TEMPERATURE RISE WITHIN THE RANGE SPECIFIED ON THE

RATING PLATE.

4. The chart is for information only. For satisfactory operation, external static pressure not to exceed value shown on

rating plate. The shaded area indicates ranges in excess of maximum external static pressure allowed when heating.

5. The above chart is for U.S. furnaces installed at 0-2000 feet. At higher altitudes, a properly derated unit will have

approximately the same temperature rise at a particular CFM, while the ESP at that CFM will be lower.

27 Rev. 2

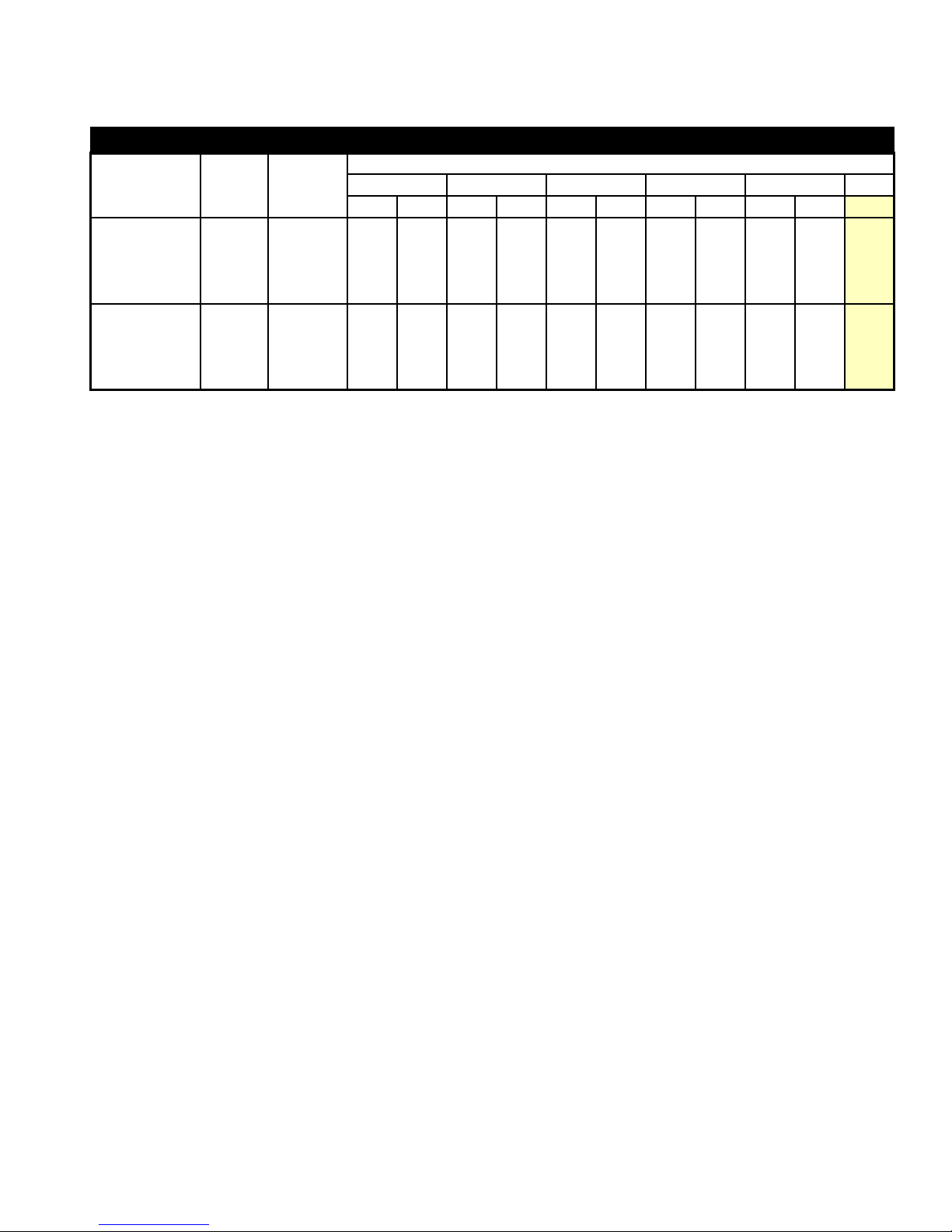

BLOWER PERFORMANCE SPECIFICATIONS

SINGLE STAGE

CFM & Temperature Rise vs. External Static Pressue

MODEL TONS AC

(Htg. Speed @ 0.5" 0.1 0.2 0.3 0.4 0.5 0.6

As Shipped) ESP CFM Rise CFM Rise CFM Rise CFM Rise CFM Rise CFM Rise

GCI_045_30

(Low) MED-LO 2.0 1010 - 980 35 940 36 880 39 810 42 700 49

GCI_070_30

(Med-Lo) MED-LO 2.5 910 56 905 56 895 57 860 59 810 63 745 68

GCI_070_40

(Low) MED-LO 3.0 1090 47 1075 47 1055 48 1015 50 975 52 915 55

GCI_090_30

(High) MED-LO 2.0 1025 67 1010 68 990 69 945 72 890 - 815 -

GCI_090_50

(Med-Lo) MED-LO 3.5 1260 54 1255 54 1230 55 1200 57 1170 58 1115 61

GCI_115_40

(High) MED-LO 3.0 1440 59 1425 60 1405 60 1380 61 1335 64 1275 67

GCI_115_50

(Med-Hi) MED-LO 4.0 1535 55 1516 56 1485 57 1455 58 1410 60 1355 63

GCI_140_50

(High) MED-LO 4.0 1845 55 1790 57 1720 59 1620 63 1525 66 1445 70

MOTOR

SPEED

HIGH 3.0 1455 - 1430 - 1360 - 1255 - 1160 - 1040 -

MED-HI 2.5 1255 - 1200 - 1150 - 1075 - 990 - 890 38

LOW 1.5 775 44 745 46 710 48 655 52 560 61 435 HIGH 3.0 1455 - 1420 - 1365 - 1275 - 1145 - 1015 50

MED-HI 3.0 1110 46 1090 47 1050 48 1015 50 935 54 845 60

LOW 2.0 730 69 715 71 710 71 680 75 645 - 490 HIGH 3.5 1655 - 1580 - 1500 - 1445 - 1366 - 1280 -

MED-HI 3.0 1530 - 1470 - 1400 - 1345 - 1280 - 1210 -

LOW 2.5 945 54 935 54 915 55 890 57 850 60 810 63

HIGH 3.5 1620 - 1550 - 1470 46 1385 49 1265 54 1165 59

MED-HI 3.0 141548135550128553121556112061101567

LOW 1.5 850 - 840 - 810 - 790 - 750 - 675 HIGH 5.0 2110 - 2030 - 1960 - 1870 - 1780 - 1680 -

MED-HI 4.0 1830 - 1765 - 1710 - 1640 - 1550 - 1470 46

LOW 3.0 1015 67 1000 68 980 70 964 71 930 73 875 HIGH 4.0 1960 - 1890 45 1825 46 1745 49 1660 51 1580 54

MED-HI 3.5 172549168550164052158553151556144059

LOW 2.5 1035 - 1025 - 1015 - 1005 - 975 - 955 HIGH 5.0 2100 - 2060 - 2000 - 1915 - 1840 46 1750 48

MED-HI 5.0 1915 - 1890 45 1840 46 1775 48 1710 50 1635 52

LOW 3.0 1175 72 115 73 1140 74 1120 - 1090 - 1060 HIGH 5.0 225545217047206549197051184555173558

MED-HI 5.0 217047204550194552185555175058165061

LOW 3.5 1425 71 1390 73 1370 74 1320 - 1265 - 1185 -

External Static Pressure, Inches Water Column

1. Units are shipped without filter(s). CFM in chart is without filter(s).

2. All furnaces shipped as high speed for cooling. Installer should adjust blower speeds as needed.

3. INSTALLATION IS TO BE ADJUSTED TO OBTAIN TEMPERATURE RISE WITHIN THE RANGE SPECIFIED ON THE

RATING PLATE.

4. The chart is for information only. For satisfactory operation, external static pressure not to exceed value shown on

rating plate. The shaded area indicates ranges in excess of maximum external static pressure allowed when heating.

5. The above chart is for U.S. furnaces installed at 0-2000 feet. At higher altitudes, a properly derated unit will have