amada 357 Installation Guide

Vipros 357 Queen User Pre-installation Guide |

©Amada America, Inc. |

Vipros 357 Queen User Pre-installation Guide

Amada America Inc.

7025 Firestone Blvd.

Buena Park CA. 90621

Phone: (714) 739 2111

Fax.: (714) 739 4099

|

Email info@amada.com |

|

|

Print Date 03/04/99 Revision 2.0 |

Page 1 of 41 |

This document available on the World Wide Web at http://www.amada.com/support |

|

Vipros 357 Queen User Pre-installation Guide |

©Amada America, Inc. |

Warning

‰Qualified personnel must complete all work.

‰Do not apply power to the Vipros 357 Queen until an A.E.S.I. (Amada

Engineering and Service Incorporated) Engineer is present and has instructed you to do so.

Print Date 03/04/99 Revision 2.0 |

Page 2 of 41 |

This document available on the World Wide Web at http://www.amada.com/support |

|

Vipros 357 Queen User Pre-installation Guide |

©Amada America, Inc. |

Table Of Contents |

|

Warning ................................................................................................................................................................................ |

2 |

Introduction ........................................................................................................................................................................... |

5 |

Motion Package Specifications ............................................................................................................................................. |

6 |

Punching System Specifications ........................................................................................................................................... |

7 |

58 Station - 2 Auto-Index Turret Configuration ................................................................................................................. |

8 |

Fanuc O4PC Controller......................................................................................................................................................... |

9 |

Hydraulic Systems Specifications ....................................................................................................................................... |

10 |

Power Hydraulic Numerical Control ................................................................................................................................ |

10 |

Hydraulic Power Unit ...................................................................................................................................................... |

10 |

Supply Requirements.......................................................................................................................................................... |

11 |

Installing the Electrical Power Supply ............................................................................................................................. |

12 |

Installing the Air Supply .................................................................................................................................................. |

13 |

Planning the Location of the Machine................................................................................................................................. |

14 |

Lifting the Machine.......................................................................................................................................................... |

15 |

Machine Dimensions - Plan View ................................................................................................................................... |

16 |

Machine Dimensions - End View .................................................................................................................................... |

17 |

Machine Dimensions - Elevation View............................................................................................................................ |

18 |

Maintenance Areas......................................................................................................................................................... |

19 |

SBC EX 5.5 Chiller.............................................................................................................................................................. |

20 |

Chiller Connections......................................................................................................................................................... |

21 |

Chiller Placement............................................................................................................................................................ |

22 |

Foundation Requirements................................................................................................................................................... |

23 |

Machine Anchoring Requirements ...................................................................................................................................... |

24 |

Floor J-bolt Mounting Hole Detail (saw cut hole) ............................................................................................................ |

24 |

Floor J-bolt Mounting Hole Plan View (saw cut hole)...................................................................................................... |

25 |

Alternative Floor J-bolt Mounting Hole Detail (Core Drill) ............................................................................................... |

26 |

Alternative J-bolt Mounting Method Plan View (Core Drill) ............................................................................................. |

27 |

Floor J-bolt Mounting Procedure..................................................................................................................................... |

28 |

Print Date 03/04/99 Revision 2.0 |

Page 3 of 41 |

This document available on the World Wide Web at http://www.amada.com/support |

|

Vipros 357 Queen User Pre-installation Guide |

©Amada America, Inc. |

Foundation Anchoring Procedure ....................................................................................................................................... |

30 |

Foundation J-bolt Detail.................................................................................................................................................. |

30 |

Foundation Plan View..................................................................................................................................................... |

31 |

Foundation Elevation View ............................................................................................................................................. |

32 |

Removing the Protective Coating........................................................................................................................................ |

33 |

Machine Leveling ................................................................................................................................................................ |

34 |

Rocking Test................................................................................................................................................................... |

35 |

Floor Condition: Crowned ............................................................................................................................................... |

36 |

Floor Condition: Sloped .................................................................................................................................................. |

37 |

Leveling Procedure......................................................................................................................................................... |

38 |

Print Date 03/04/99 Revision 2.0 |

Page 4 of 41 |

This document available on the World Wide Web at http://www.amada.com/support |

|

Vipros 357 Queen User Pre-installation Guide |

©Amada America, Inc. |

Introduction

This manual describes the tasks that the purchaser of a Vipros 357 Queen must complete before calling the service organization to complete the installation and operator training.

An overview of the preparations is as follows:

ˆPlan the location of the Vipros 357 Queen in the shop, taking into account all the maintenance areas indicated on the floor plan.

ˆPrepare the Vipros 357 Queen floor or foundation as required.

ˆUncrate the Vipros 357 Queen and Fanuc O4PC control and place them on the foundation, but do not fill the anchorbolt holes (if used) until after A.E.S.I. completes the initial installation.

ˆInstall the Vipros 357 Queen and SBC EX 5.5 Chiller electrical supply.

ˆInstall the air supply.

ˆRemove the protective coating from the surface of the Vipros 357 Queen

Note: It is the purchaser’s responsibility to install any safety devices to ensure the safety area.

Print Date 03/04/99 Revision 2.0 |

Page 5 of 41 |

This document available on the World Wide Web at http://www.amada.com/support |

|

|

Vipros 357 Queen User Pre-installation Guide |

|

©Amada America, Inc. |

|

Motion Package Specifications |

||

|

|

|

|

|

Travel Method |

X and Y axes work piece movement |

|

|

|

|

|

|

Control Method |

X, Y, T & C |

|

|

|

|

|

|

Drive Motors |

Fanuc AC Servo (X, Y, T, C) |

|

|

|

|

|

|

Maximum Sheet Size |

50" (Y) x 144" (X) with one repositioning cycle |

|

|

|

|

|

|

Maximum Sheet Thickness |

0.250" |

|

|

|

|

|

|

Maximum Material Weight |

220 lb. |

|

|

|

|

|

|

Maximum Axis Travel |

72" (X) by 50" (Y) |

|

|

|

|

|

|

Max. Linear Table Speed |

3929 IPM |

|

|

|

|

|

|

Punching Accuracy |

±0.004" |

|

|

|

|

|

|

Positioning Accuracy |

±0.001" |

|

|

|

|

|

|

Repeatability |

±0.001" |

|

|

|

|

|

Print Date 03/04/99 Revision 2.0 |

Page 6 of 41 |

This document available on the World Wide Web at http://www.amada.com/support |

|

|

Vipros 357 Queen User Pre-installation Guide |

|

|

|

|

©Amada America, Inc. |

|

Punching System Specifications |

|

|

|

||

|

|

|

|

|

|

|

|

Press Capacity |

33 Tons |

|

|

|

|

|

|

|

|

|

|

|

|

Press Stroke |

1.575" |

|

|

|

|

|

|

|

|

|

|

|

|

Stroke Rate (X/Y) |

Pitch |

|

Stroke |

Stroke Rate |

|

|

|

|

|

|

|

|

|

|

0.079" |

|

0.118" |

520/420 |

|

|

|

|

|

|

|

|

|

|

1.000" |

|

0.315" |

275/240 |

|

|

|

|

|

|

|

|

|

Maximum Hole Diameter |

4.500" |

|

|

|

|

|

|

|

|

|

|

|

|

Tool Type |

Amada Thick Turret |

|

|

|

|

|

|

|

|

|

|

|

|

Turret Rotation Speed |

30 RPM |

|

|

|

|

|

|

|

|

|

|

|

Print Date 03/04/99 Revision 2.0 |

Page 7 of 41 |

This document available on the World Wide Web at http://www.amada.com/support |

|

Vipros 357 Queen User Pre-installation Guide |

©Amada America, Inc. |

58 Station - 2 Auto-Index Turret Configuration

A/I

A/I

220

220

219 |

|

|

318 |

217 |

116 |

|

||

|

333 |

336 |

237 |

340 |

|

|

|

|

|

|

|

|

342 |

|

|

||

|

|

|

|

|

|

|

||

331 |

|

235 |

|

239 |

|

|

|

|

|

|

|

|

|

345 |

|

|

|

|

|

|

|

|

|

|

|

|

230 |

132 |

134 |

|

138 |

141 |

244 |

|

|

|

|

|

|

|

|

|

|

|

129 |

|

|

|

|

143 |

|

|

|

228 |

|

|

|

|

246 |

|

||

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

349 |

|

|

|

|

|

|

|

|

248 |

|

|

|

|

|

|

|

|

147 |

|

|

|

|

|

|

|

|

|

351 |

|

|

|

|

|

|

|

150 |

|

|

|

|

|

|

|

|

152 |

253 |

|

|

|

|

|

|

|

|

|

PEGA 345, PEGA 345 King, PEGA 357, PEGA 367 COMA 555, COMA 557, COMA 567, COMA 588 VIPROS 345, VIPROS 357, VIPROS 367 VIPROS 357 Queen, VIPROS 367 Queen

354

1000mm disc |

255 |

|

58 STATION 2 AUTO INDEX |

||

|

114 |

|

|

|

|

|

A/I |

|

|

|

315 |

|

|

|

|

|

256 |

|

|

|

|

|

|

|

|

|

|

|

|

|

111 |

|

|

|

|

|

|

|

|

NUMBER OF |

212 |

|

|

|

|

|

|

MAXIMUM SIZE |

||

313 |

|

|

|

|

|

|

STATIONS |

||

|

|

|

|

|

|

|

ROUND |

||

|

|

|

|

|

|

|

|

( KEYED ) |

|

210 |

|

|

|

|

|

264 |

|

|

|

107 |

|

|

|

|

|

|

|

||

|

|

|

|

|

165 |

A |

1/2" ( 12.7mm ) |

36 ( 12 ) |

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|||

208 |

105 |

|

|

168 |

266 |

B |

1 1/4" ( 31.7mm ) |

12 ( 12 ) |

|

309 |

|

|

102 |

|

|

|

|||

|

|

|

170 |

|

|

2" ( 50.8mm ) |

|

||

|

|

|

|

367 |

C |

4 ( 4 ) |

|||

|

|

|

|

|

|||||

|

|

|

|

|

|

||||

|

|

306 |

203 |

|

271 |

369 |

D |

3 1/2" ( 88.9mm ) |

2 ( 2 ) |

|

|

|

201 |

||||||

|

|

|

|

|

|||||

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

E |

4 1/2" ( 114.3mm ) |

|

|

|

|

|

304 |

|

372 |

|

2 ( 2 ) |

||

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

AUTO INDEX |

B |

1 1/4" ( 31.7mm ) |

2 ( 2 ) |

Print Date 03/04/99 Revision 2.0 |

Page 8 of 41 |

This document available on the World Wide Web at http://www.amada.com/support |

|

|

Vipros 357 Queen User Pre-installation Guide |

|

©Amada America, Inc. |

|

Fanuc O4PC Controller |

||

|

|

|

|

|

Model |

Fanuc O4PC(with PHNC) |

|

|

|

|

|

|

Control Function |

X, Y, T & C |

|

|

|

|

|

|

Input Method |

MDI, Paper Tape, DNC |

|

|

|

|

|

|

Minimum Command Unit |

0.001" (X, Y) .010 (C) |

|

|

|

|

|

|

Minimum Travel Unit |

0.001" (X, Y) .010 (C) |

|

|

|

|

|

|

Operating Modes |

Automatic, MDI & Manual |

|

|

|

|

|

|

Display Modes |

Program Contents, Position Information, Program |

|

|

|

Check, Parameters, Tool Hit Counter, Self |

|

|

|

Diagnostics |

|

|

|

|

|

|

Interlock Displays |

Oil Temperature, Door Open |

|

|

|

|

|

Print Date 03/04/99 Revision 2.0 |

Page 9 of 41 |

This document available on the World Wide Web at http://www.amada.com/support |

|

Vipros 357 Queen User Pre-installation Guide |

|

|

©Amada America, Inc. |

|||

Hydraulic Systems Specifications |

||||||

|

Power Hydraulic Numerical Control |

|

|

|

||

|

|

|

|

|

|

|

|

Ram Cycle Patterns |

65 total |

|

|

|

|

|

|

Punching |

2 |

|

|

|

|

|

Nibbling |

1 |

|

|

|

|

|

Forming |

50 |

|

|

|

|

|

Marking |

4 |

|

|

|

|

|

Knockouts |

4 |

|

|

|

|

|

Slitting |

4 |

|

|

|

|

|

|

|

|

|

|

|

Minimum Increment |

0.01mm |

|

|

|

|

|

|

|

|

|

|

|

|

Hydraulic Power Unit |

|

|

|

||

|

|

|

|

|

|

|

|

Model |

|

Yuken |

|

|

|

|

|

|

|

|

||

|

Dual Operating Pressure |

|

100 kgf cm² & 195 kgf cm² |

|

||

|

|

|

|

|

||

|

Oil Type |

|

Mobil DTE® Excel 46 (formerly called Mobil Hydraulic Oil NZ 46) |

|||

|

|

|

|

|

|

|

|

Oil Capacity |

|

40 Gallons |

|

|

|

|

|

|

|

|

|

|

Print Date 03/04/99 Revision 2.0 |

Page 10 of 41 |

This document available on the World Wide Web at http://www.amada.com/support |

|

|

Vipros 357 Queen User Pre-installation Guide |

|

|

©Amada America, Inc. |

|

Supply Requirements |

|

|

|

|

|

|

|

|

|

Electrical Power Supply |

Vipros 357 Queen |

230 / 460 3ph ±10%, 30 KVA |

|

|

|

SBC EX 5.5Chiller* |

230 or 460 3ph ±10%, 15 kVA |

|

|

|

|

|

|

|

Air Supply |

|

80 psi @ 8.8 ft³/min. |

|

|

|

|

|

|

*The SBC EX 5.5 Chiller voltage must be specified when machine is ordered.

Print Date 03/04/99 Revision 2.0 |

Page 11 of 41 |

This document available on the World Wide Web at http://www.amada.com/support |

|

Vipros 357 Queen User Pre-installation Guide |

©Amada America, Inc. |

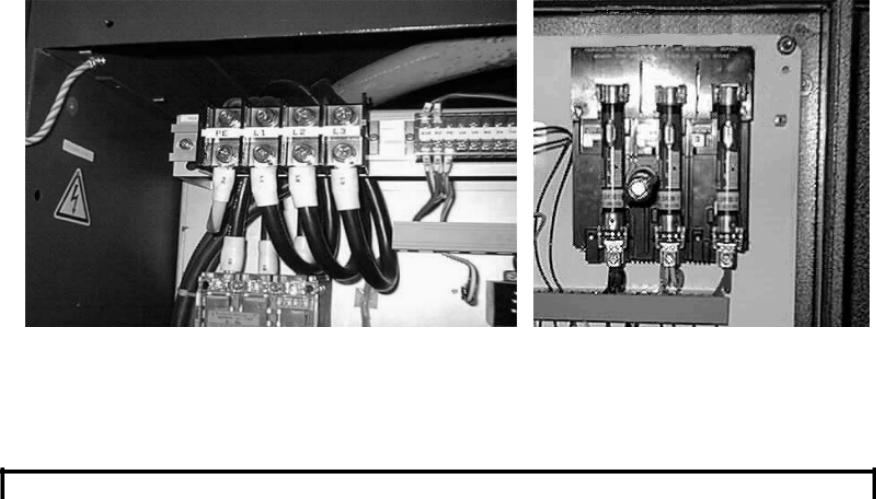

Installing the Electrical Power Supply

The Vipros 357 Queen requires two separate electrical power sources. The first power source is supplied to the Fanuc O4PC. The other supply source must go to the SBC EX 5.5 Chiller. The Vipros 357 Queen should be supplied from a power line separate from those for welding machines or other machines that produce electrical noise.

ˆThe Vipros 357 Queen Electrical inlet is 64" above floor level at the rear of the Fanuc O4PC control.

ˆThe SBC EX 5.5 Chiller Electrical inlet is approximately 53" above floor level.

Vipros 357 Queen electrical enclosure |

SBC EX 5.5 Chiller electrical enclosure |

Main electrical

connection È

Main electrical connection È

Print Date 03/04/99 Revision 2.0 |

Page 12 of 41 |

This document available on the World Wide Web at http://www.amada.com/support |

|

Vipros 357 Queen User Pre-installation Guide |

©Amada America, Inc. |

Installing the Air Supply

The Vipros 357 Queen must be connected to a compressed air system by hose or pipe. The compressed air must be clean and dry.

Please note the following:

ˆThe minimum inner pipe diameter is ½".

ˆThe air pressure required is 80 psi.

ˆThe air volume required is 8.8 ft³/min..

The air inlet is approximately 16" above the floor level at the rear of the Vipros 357 Queen

Print Date 03/04/99 Revision 2.0 |

Page 13 of 41 |

This document available on the World Wide Web at http://www.amada.com/support |

|

Loading...

Loading...