Page 1

Operator’s Manual

3000 and 4000

Product Families

International Models

OM4119ENOM4119EN 200805 Printed in USA 200806www.allisontransmission.com

Page 2

Operator’s

2008 MAY

Manual

OM4119EN

Allison Transmission

INTERNATIONAL MODELS

3000 and 4000 Product Families

Allison 4th Generation Controls

and Model Year 2009 Prognostics

3000 3000 SP

3200 3200 MH 3200 ORS 3200 SP

3500 3500 ORS 3500 SP

3700 3700 SP

4000 4000 MH 4000 ORS 4000 SP

4200 ORS

4430 ORS

4440 ORS

4500 4500 ORS 4500 SP

4600 ORS

4700 4700 OFS 4700 SP

4800 4800 SP

Printed in USA

Copyright © 2008 Allison Transmission, Inc.

Page 3

NOTES

2

Page 4

TABLE OF CONTENTS

INTRODUCTION

KEEPING THAT ALLISON ADVANTAGE . . . . . . . . . . . . . . . . . . . . . . . . 7

A BRIEF DESCRIPTION OF THE ALLISON TRANSMISSION . . . . . . . . . . 10

ALLISON 4

TH

GENERATION ELECTRONIC CONTROL SYSTEM . . . . . . . 15

ALLISON 4

TH

GENERATION MODEL YEAR 2009 PROGNOSTICS

FUNCTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

TORQUE CONVERTER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

PLANETARY GEARS AND CLUTCHES . . . . . . . . . . . . . . . . . . . . . . . . 19

COOLER CIRCUIT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

RETARDER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

TRANSFER CASE (DROPBOX) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

SHIFT SELECTORS

INTRODUCTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

DESCRIPTION OF AVAILABLE ALLISON 4

TH

GENERATION

SHIFT SELECTOR TYPES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

DESCRIPTION OF AVAILABLE ALLISON 4

TH

GENERATION MY09

PROGNOSTICS SHIFT SELECTOR TYPES . . . . . . . . . . . . . . . . . . . . . . 27

RANGE SELECTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

DRIVING TIPS

CHECK TRANS LIGHT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

DIAGNOSTIC CODES OVERVIEW . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

ALLISON 4

TH

GENERATION CONTROLS DIAGNOSTIC CODE DISPLAY

PROCEDURE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

ALLISON 4

TH

GENERATION MY09 PROGNOSTICS DIAGNOSTIC CODE

DISPLAY PROCEDURE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

ACCELERATOR CONTROL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

RANGE SHIFTS AND INHIBITS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

USING THE ENGINE TO SLOW THE VEHICLE . . . . . . . . . . . . . . . . . . . 47

USING THE HYDRAULIC RETARDER . . . . . . . . . . . . . . . . . . . . . . . . . 48

RANGE PRESELECTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

COLD WEATHER STARTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

DRIVING ON SNOW OR ICE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

ROCKING OUT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

HIGH FLUID TEMPERATURE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

PARKING BRAKE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

TOWING OR PUSHING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

TURNING OFF THE VEHICLE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

PRIMARY/SECONDARY SHIFT SCHEDULES . . . . . . . . . . . . . . . . . . . . 56

CRUISE CONTROL OPERATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

3

Page 5

OPERATING DOWN STEEP GRADES

(REAR-DISCHARGE MIXER) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

POWER TAKEOFF OPERATION

ENGINE-DRIVEN POWER TAKEOFF (PTO) . . . . . . . . . . . . . . . . . . . . . 58

CARE AND MAINTENANCE

PERIODIC INSPECTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

PREVENT MAJOR PROBLEMS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

IMPORTANCE OF PROPER FLUID LEVEL . . . . . . . . . . . . . . . . . . . . . . 60

ALLISON 4

TH

GENERATION MY09 PROGNOSTICS DISABLED AND SEVEN

SPEED TRANSMISSION FLUID LEVEL CHECK USING ALLISON SHIFT

SELECTORS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

PROGNOSTICS FUNCTIONALITY FOR MODEL YEAR 2009 . . . . . . . . . . 64

ALLISON 4

TH

GENERATION MY09 PROGNOSTICS ENABLED FLUID LEVEL

CHECK USING ALLISON SHIFT SELECTORS . . . . . . . . . . . . . . . . . . . . 67

FLUID LEVEL CHECK USING DIAGNOSTIC TOOLS . . . . . . . . . . . . . . . 72

MANUAL FLUID CHECK PROCEDURE . . . . . . . . . . . . . . . . . . . . . . . 73

COLD CHECK . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

HOT CHECK . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

RECOMMENDED AUTOMATIC TRANSMISSION FLUID AND VISCOSITY

GRADE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

KEEPING FLUID CLEAN . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

ALLISON 4

TH

GENERATION AND MY09 PROGNOSTICS DISABLED FLUID

AND INTERNAL FILTER CHANGE INTERVAL RECOMMENDATIONS . . . . 78

ALLISON 4THGENERATION MY09 PROGNOSTICS ENABLED FLUID AND

FILTER CHANGE INTERVAL RECOMMENDATIONS . . . . . . . . . . . . . . . 85

FLUID ANALYSIS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

REFILL TRANSMISSION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

DIAGNOSTICS

DIAGNOSTIC CODES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

CUSTOMER SERVICE

OWNER ASSISTANCE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90

SERVICE LITERATURE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 92

ALLISON TRANSMISSION REGIONAL OFFICES . . . . . . . . . . . . . . . . . . 93

4

Page 6

TRADEMARK USAGE

The following trademarks are the property of the companies indicated:

• Allison DOC™ is a trademark of General Motors Corporation.

• DEXRON

®

is a registered trademark of the General Motors Corporation.

5

Page 7

WARNINGS, CAUTIONS, NOTES

IT IS YOUR RESPONSIBILITY to be completely familiar with the warnings

and cautions described in this manual. It is, however, important to understand that

these warnings and cautions are not exhaustive. Allison Transmission could not

possibly know, evaluate, and advise the service trade of all conceivable ways in

which service might be done or of the possible hazardous consequences of each

way. The vehicle manufacturer is responsible for providing information related to

the operation of vehicle systems (including appropriate warnings, cautions, and

notes). Consequently, Allison Transmission has not undertaken any such broad

evaluation. Accordingly, ANYONE WHO USES A SERVICE PROCEDURE

OR TOOL WHICH IS NOT RECOMMENDED BY ALLISON

TRANSMISSION OR THE VEHICLE MANUFACTURER MUST first be

thoroughly satisfied that neither personal safety nor equipment safety will be

jeopardized by the service methods selected.

Proper service and repair is important to the safe, reliable operation of the

equipment. The service procedures recommended by Allison Transmission (or the

vehicle manufacturer) and described in this manual are effective methods for

performing service operations. Some of these service operations require the use of

tools specially designed for the purpose. The special tools should be used when

and as recommended.

Three types of headings are used in this manual to attract your attention. These

warnings and cautions advise of specific methods or actions that can result in

personal injury, damage to the equipment, or cause the equipment to become

unsafe.

WARNING: A warning is used when an operating procedure, practice,

etc., if not correctly followed, could result in personal injury or loss of

life.

CAUTION: A caution is used when an operating procedure, practice,

etc., if not strictly observed, could result in damage to or destruction of

equipment.

NOTE: A note is used when an operating procedure, practice, etc., is

essential to highlight.

6

Page 8

INTRODUCTION

KEEPING THAT ALLISON ADVANTAGE

Allison 3000 and 4000 Product Families transmissions are rugged and designed

to provide long, trouble-free service.

This handbook will help the operator gain the maximum benefits from an Allison

transmission-equipped vehicle.

7

Page 9

Abbreviations

ABS Anti-lock Brake System

DMD Display Mode/Diagnostic

DOC Diagnostic Optimized Connection

DTC Diagnostic Trouble Code

ECU Electronic Control Unit

EMI Electromagnetic Interference

FCC Federal Communications Commission

FM Filter Life Monitor

I/O Input/Output

KOH Potassium Hydroxide

MY09 Model Year 2009

OEM Original Equipment Manufacturer

OLS Oil Level Sensor

OM Oil Life Monitor

PTO Power Takeoff

PWM Pulse Width Modulated

RFI Radio Frequency Interference

RMR Retarder Modulation Request

SP Specialty Series

TAN Total Acid Number

TM Transmission Health Monitor

TPS Throttle Position Sensor

VIM Vehicle Interface Module

8

Page 10

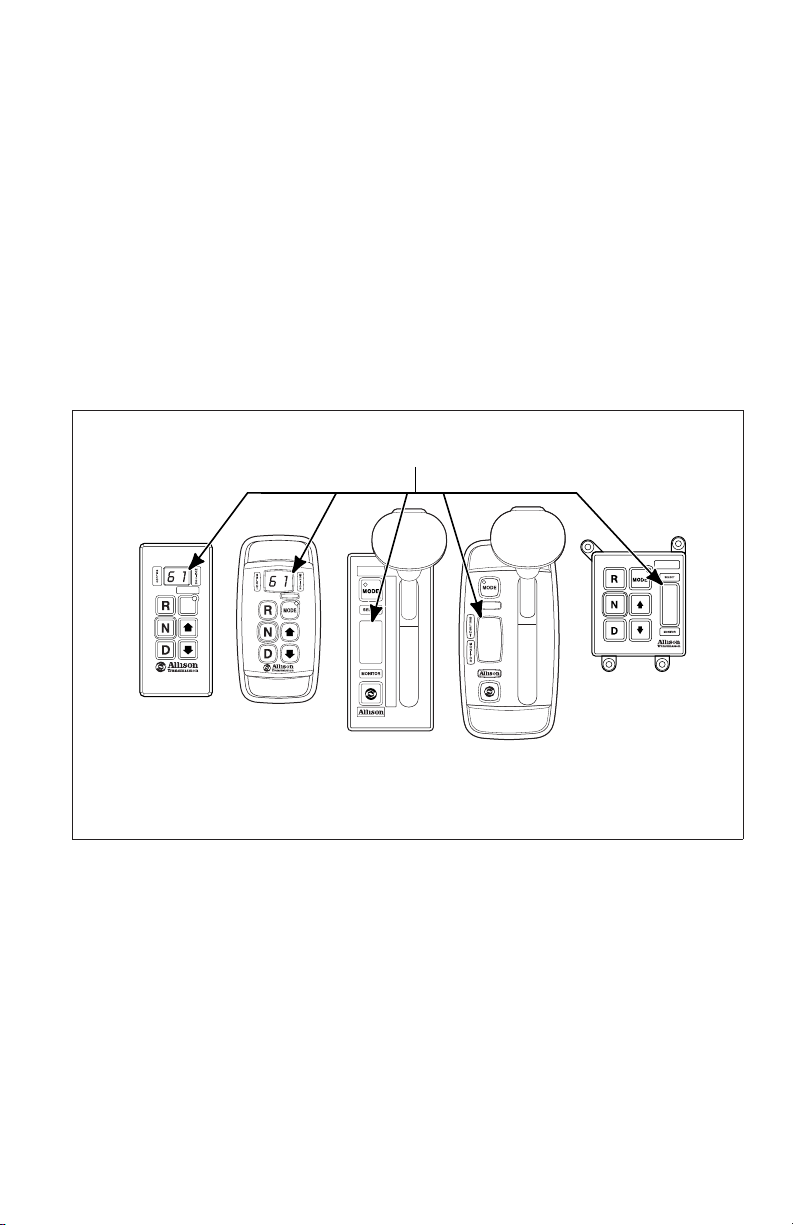

Your Allison transmission has one of two electronic control systems: Allison 4

Generation Controls, or Allison 4thGeneration MY09 Prognostics Controls. The

current electronic control system being offered is Allison 4

th

Generation MY09

th

Prognostics Controls. The MY09 Prognostics functions of this control system are

explained in Section 3, DRIVING TIPS and Section 5, CARE AND

MAINTENANCE. The operation of the shift selectors is explained in Section 2,

SHIFT SELECTORS.

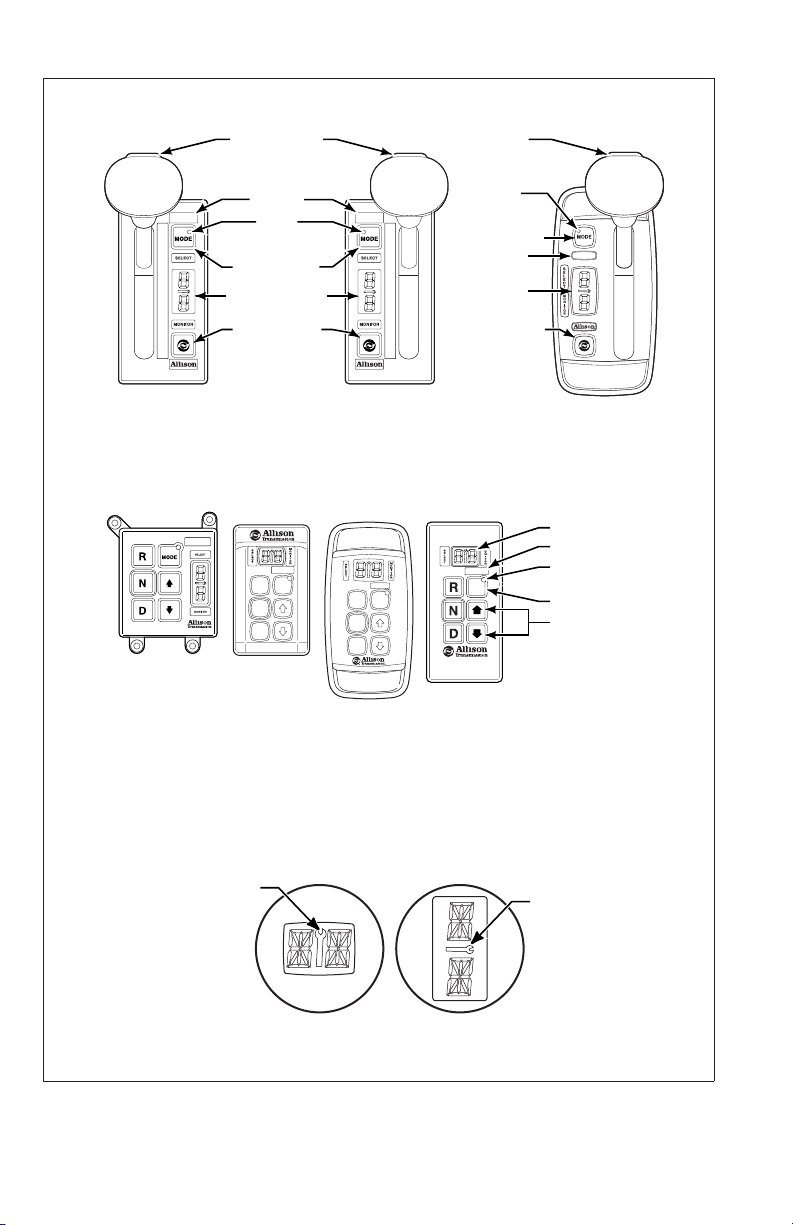

Refer to the shift selectors shown in Figure 1 and Figure 2 to identify which

system is installed in your transmission. The Allison 4

selectors have two LED digital displays (refer to Figure 1). The Allison 4

th

Generation Controls shift

th

Generation MY09 Prognostics Controls shift selectors have two LED digital

displays and a service icon in the form of an open-end wrench between the digital

displays (refer to Figure 2).

DOUBLE DIGIT LED DISPLAY

MODE

R

N

D

6

5

4

1

3

2

1

6

1

ALLISON 4TH GENERATION CONTROLS

6

1

V07344.01.01

Figure 1. Typical Allison 4thGeneration Controls Shift Selectors With

SELECT And MONITOR Digital Displays

9

Page 11

DOUBLE DIGIT LED DISPLAY

WITH SERVICE ICON

MODE

R

N

D

MODE

MODE

R

N

D

R

N

D

5

4

3

2

1

ALLISON 4TH GENERATION MY09 PROGNOSTICS CONTROLS

V11059.00.01

Figure 2. Typical Allison 4thGeneration MY 09 Prognostics Controls

Shift Selectors With SELECT And MONITOR Digital Displays and

Service Icon (open-end wrench)

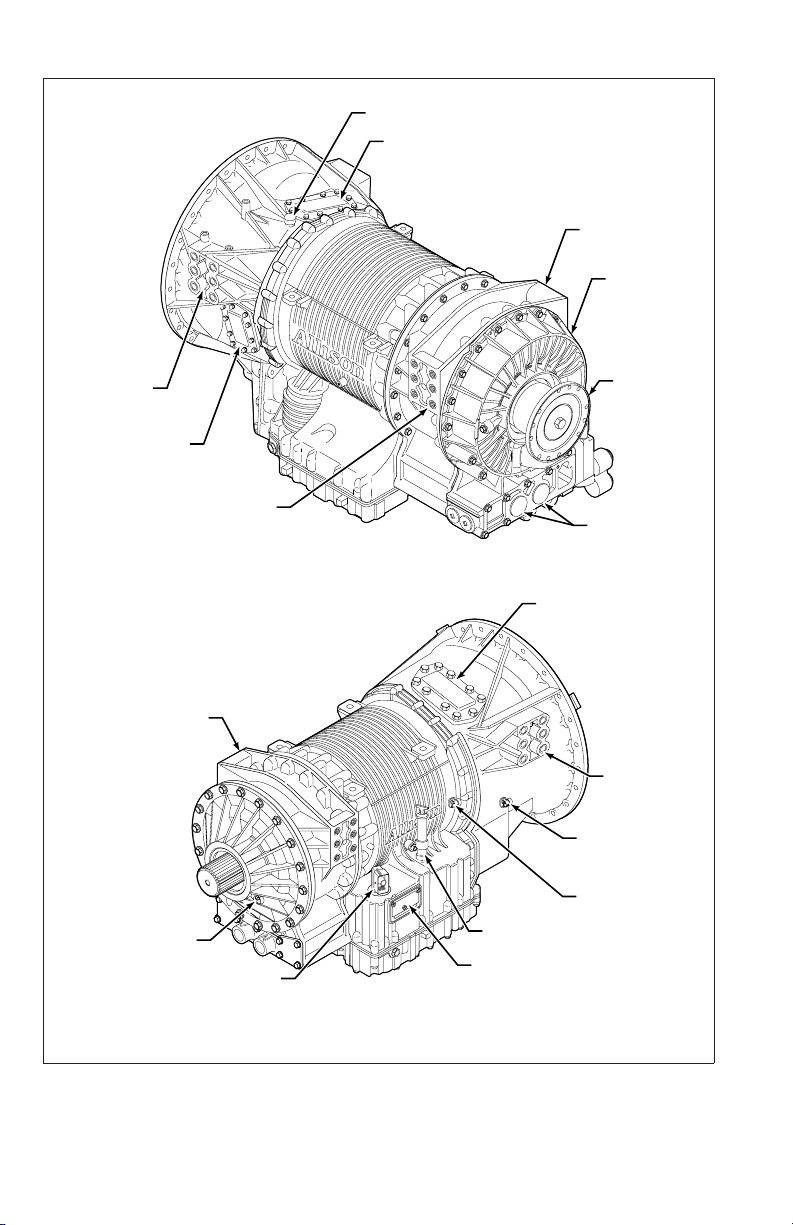

A BRIEF DESCRIPTION OF THE ALLISON TRANSMISSION

The Allison transmissions (refer to Figure 3 through Figure 6) described in this

manual include:

th

• Allison 4

• Allison 4

years)

• A torque converter with lockup clutch and torsion damper

• Three planetary gear sets (four for 4700 OFS/SP and 4800 SP)

• Five clutches (six for 4700 OFS/SP and 4800 SP)

Generation Controls

th

Generation MY09 Prognostics (not available on earlier model

An integral retarder is available as an option on all transmissions. A provision to

mount a power takeoff (PTO) is available as an option on all transmissions.

NOTE: Allison electronic controls are designed and manufactured to

comply with all FCC and other guidelines regarding radio frequency

interference/electromagnetic interference (RFI/EMI) for transportation

electronics. Manufacturers, assemblers, and installers of radio-telephone

or two-way communication radios have the sole responsibility to

correctly install and integrate those devices into Allison

transmission-equipped vehicles to customer satisfaction.

10

Page 12

BREATHER

MAIN-PRESSURE TAP

NOTE: Inch Series Threads

ASSEMBLY PADS

OUTPUT

SPEED

SENSOR

RETARDER

VALVE BODY

CONNECTOR

TACHOGRAPH PROVISION

NOTE: Metric Series Threads

TORQUE CONVERTER

WITH LOCKUP CLUTCH

AND TORSIONAL DAMPER

BREATHER

MAIN-PRESSURE TAP

NOTE: Inch series threads

COOLER PORTS

NOTE: Inch Series Threads

ASSEMBLY PADS

(BOTH SIDES)

OUTPUT

RETARDER

TO RETARDER

ACCUMULATOR

OIL FILL TUBE AND

DIPSTICK

(AVAILABLE ON

BOTH SIDES

)

V07307.02.00

Figure 3. 3200/3500 Model With Retarder

(Allison 4

th

Generation Controls)

11

Page 13

TRANSFER CASE

FEEDTHROUGH

HARNESS

CONNECTOR

BREATHER

COOLER

PORTS

OIL FILL TUBE

AND DIPSTICK

(AVAILABLE BOTH SIDES)

NAMEPLATE

SCAVENGE PUMP

PTO PROVISION

OIL FILL TUBE

AND DIPSTICK

World Transmission

M

Manufactured By

a

n

u

f

a

c

Division of General Motors CorporationDivision of General Motors Corporation

t

u

r

e

S

d

E

B

R

I

y

A

L

N

Indianapolis, IndianaIndianapolis, Indiana

O

.

XX

X

X

E

C

A

P

S

X

A

N

D

O

R

A

G

E

R

A

U

UAW

X

I

C

E

U

A

L

L

I

W

T

B

U

O

R

M

A

O

L

T

U

I

9

933

A

M

3

D

P

P

E

3

L

T

I

E

N

M

A

U

E

N

A

T

C

R

I

M

R

W

E

M

O

A

R

F

K

O

E

S

R

T

O

N

D

E

O

L

.

N

O

.

XX

X

X

X

XX

X

X

X

X

X

X

RIGHT-FRONT VIEW

ASSEMBLY PADS

(BOTH SIDES)

TRANSFER CASE

LEFT-REAR VIEW

V08626.01.01

Figure 4. 3700 SP With PTO (Allison 4thGeneration Controls)

12

Page 14

FILL TUBE

RETARDER

TEMPERATURE

CONNECTOR

SOLENOID

CONNECTOR

NAMEPLATE

TURBINE-SPEED

SENSOR

MOUNTING PAD

ENGINE-SPEED SENSOR

RIGHT-FRONT VIEW

PTO PROVISION

(TOP RIGHT POSITION)

TORQUE

CONVERTER

MODULE

BREATHER

MOUNTING PADS

(BOTH SIDES)

PTO PROVISION

MAIN-PRESSURE TAP

Figure 5. 4000/4500 Model With PTO

LEFT-REAR VIEW

(Allison 4

MOUNTING PADS

(BOTH SIDES)

PTO PROVISION

th

Generation Controls)

STANDARD

REAR

COVER

COOLER PORTS

V10695.00.01

13

Page 15

BREATHER

PTO

PROVISION

C6 ADAPTER

HOUSING

RETARDER

MOUNTING

PAD

PTO PROVISION

MOUNTING PAD

C6 ADAPTER

HOUSING

OUTPUT

SPEED SENSOR

FEEDTHROUGH

HARNESS CONNECTOR

LEFT-REAR VIEW

NAMEPLATE

RIGHT-REAR VIEW

PTO PROVISION

(TOP RIGHT

POSITION)

FILL TUBE

OUTPUT

FLANGE

COOLER

PORTS

MOUNTING

PAD

INPUT

SPEED

SENSOR

TURBINE

SPEED

SENSOR

V08619.01.01

Figure 6. 4700/4800 SP and OFS With PTO And Retarder

(Allison 4

th

Generation Controls)

14

Page 16

The TCM/ECU is programmed to provide the most suitable operating

characteristics for a specific application. This manual does not attempt to describe

all of the possible combinations. The information contained herein describes only

the operating characteristics most frequently requested by vehicle manufacturers.

ALLISON 4THGENERATION ELECTRONIC CONTROL SYSTEM

Allison 4thGeneration Controls consist of the following major components

connected by an OEM-furnished wiring harness:

• Transmission Control Module (TCM)

• Three speed sensors (refer to Figure 3 through Figure 6):

— Input

— Turbine

— Output

• Remote shift selector

• Control module which includes:

— Solenoids

— Diagnostic pressure switch

— Oil level sensor (standard on the 3000 and 4000 Product Family

transmissions through six-speed, optional on the 4700 OFS/SP and

4800 SP, and not available on 3700 SP)

— Sump temperature sensor

— Valves

— Internal wire harnesses

• Optional Allison Throttle Position Sensor (TPS)

The TCM processes information and then sends signals to actuate specific

solenoids located in the control module. These solenoids control clutch pressures

to provide closed-loop control. The closed-loop control makes “during shift”

adjustments. These adjustments in shift characteristics are based on vehicle

conditions such as grade, load, and engine power. After a shift is completed, the

TCM compares the shift to an “ideal” shift profile in the TCM calibration and

makes adjustments before the next shift of the same kind is made. This is

“adaptive logic” which establishes initial conditions for shifts.

th

The Allison 4

active within the first 30 seconds of the first 24 engine starts or 49 engine starts,

depending upon the component or sensor being detected. Autodetect searches for

the presence of the following transmission components or data inputs.

Generation Control has an “autodetect” feature. Autodetect is

15

Page 17

Retarder Present, Not Present

Oil Level Sensor (OLS) Present, Not Present

Throttle

* Analog, J1587, J1939

Engine Coolant Temperature Analog, J1587, J1939

* A pulse width modulated (PWM) throttle source is not “autodetected.” This source requires a

unique calibration or can be manually selected using Allison DOC™ For PC–Service Tool.

Even though autodetect has been completed, it can be reset to monitor an

additional group of engine starts. Reset may be necessary if a device known to be

present is not detected or if an autodetectable component or sensor was added

after the initial vehicle build.

Reset is accomplished by using the Allison DOC™ For PC–Service Tool. The

Allison DOC™ For PC–Service Tool may also be used to override autodetect and

manually enter the component or sensor to be recognized by the TCM by

changing appropriate “customer modified constants.”

ALLISON 4THGENERATION MODEL YEAR 2009 PROGNOSTICS FUNCTIONS

Allison Transmission, Inc. has introduced three new diagnostic parameters that are

available only on 3-, 4-, 5-, and 6-speed transmissions for Model Year 2009

(MY09). These new diagnostic parameters will provide indicators of required

maintenance actions and are named “Prognostics” because they predict required

transmission maintenance. These new Prognostics include the following:

• Oil Life Monitor (OM)

• Filter Life Monitor (FM)

• Transmission Health Monitor (TM)

Prognostics are designed to maximize fluid (the terms oil and fluid are used

interchangeably) and filter utilization and provide an early indication of clutch

system concerns so that an inspection may be scheduled before a clutch fails and

causes other transmission damage.

The following items are required to allow MY09 Prognostics:

• Allison approved TES 295 transmission fluid and Allison High Capacity

Filters.

• Transmission with filter life valve body and pressure switch.

• MY09 TCM.

• Filter pressure switch wiring in the OEM wiring harness from the

transmission to the TCM.

• MY09 Allison pushbutton or lever shift selector or an OEM installed shifter

plus a service indicator light or J1939 text message display. The OEM

service indicator light may also be used with a J1939 text messaging

display.

16

Page 18

Allison MY09 shift selectors contain an integrated service icon in the shape of an

open-end wrench located between the SELECT and MONITOR displays (refer to

DESCRIPTION OF AVAILABLE TYPES in the SHIFT SELECTOR section).

The vehicle manufacturer specifies whether the Allison Prognostics Feature is

made available in the calibration and, if so, whether the Prognostic function is

defaulted ON or OFF for customer use. The transmission calibration can be made

for the vehicle manufacturer (or the customer) so that the prognostics feature is in

one of the following states:

• Available and the function is defaulted ON

• Available but the function is defaulted OFF

NOTE: An Allison service outlet can assist with programming

Prognostics ON at customer expense if Allison requirements are met

prior to Prognostics features being turned ON.

• Not available in the transmission calibration.

NOTE: An Allison service outlet can assist with a transmission

calibration change so that MY09 Prognostics are available at customer

expense if Allison requirements are met prior to TCM recalibration.

The three Prognostics functions are enabled or disabled as a group and cannot be

enabled or disabled individually. The OEM may also specify whether Prognostics

may be reset by the Allison shift selector, J1939 message, or only with the use of

the Allison DOC™ For PC–Service Tool.

CAUTION: Prognostics requires the use of Allison approved

TES 295 fluids and Allison High Capacity Filters if turned ON. If

any other fluids or filters are used, the Prognostics feature MUST BE

turned OFF. Prognostics information will not be accurate with any other

transmission fluids and could result in missed maintenance activities

resulting in transmission damage. If Prognostics functions are not

programmed or are turned OFF, refer to the miles/hours/months fluid

and filter change interval charts in the CARE AND MAINTENANCE

section or visit www.allisontransmission.com, click Service, Fluid/Filter

Change Interval, then Fluids, and read the current revision of Service

Tips 1099 for details.

th

The Allison 4

Generation Controls has an “autodetect” feature. Autodetect is

active within the first 30 seconds of the first 24 engine starts or 49 engine starts,

depending upon the component or sensor being detected. Autodetect searches for

the presence of the following transmission components or data inputs.

17

Page 19

Retarder Present, Not Present

Oil Level Sensor (OLS) Present, Not Present

Throttle

* Analog, J1587, J1939

Engine Coolant Temperature Analog, J1587, J1939

* A pulse width modulated (PWM) throttle source is not “autodetected.” This source requires a

unique calibration or can be manually selected using Allison DOC™ For PC–Service Tool.

Even though autodetect has been completed, it can be reset to monitor an

additional group of engine starts. Reset may be necessary if a device known to be

present is not detected or if an autodetectable component or sensor was added

after the initial vehicle build.

Reset is accomplished by using the Allison DOC™ For PC–Service Tool. The

Allison DOC™ For PC–Service Tool may also be used to override autodetect and

manually enter the component or sensor to be recognized by the TCM by

changing appropriate “customer modified constants.”

TORQUE CONVERTER

The torque converter consists of the following four elements:

• Pump—input element driven directly by the engine

• Turbine—output element hydraulically driven by the pump

• Stator—reaction (torque multiplying) element

• Lockup Clutch—mechanically couples the pump and turbine when engaged;

controlled by TCM/ECU

When the pump turns faster than the turbine and the stator is stationary, the torque

converter is multiplying torque. When the turbine approaches the speed of the

pump, the stator starts to rotate with the pump and turbine. When this occurs,

torque multiplication stops and the torque converter functions as a fluid coupling.

The lockup clutch is located inside the torque converter and consists of the

following elements:

• Piston and backplate—driven by the engine

• Clutch plate/damper (located between the piston and the

backplate)—splined to the converter turbine

The lockup clutch/torsional damper is engaged and released in response to

electronic signals from the TCM/ECU. Lockup clutch engagement provides a

direct drive from the engine to the transmission input. This eliminates converter

slippage and maximizes fuel economy and vehicle speed. The lockup clutch

releases at lower speeds or when the TCM/ECU detects conditions requiring it to

be released.

18

Page 20

The torsional damper tries to absorb engine torsional vibration to attempt to

prevent transmitting engine torsional vibration on through to transmission

components (clutches, etc), or items bolted to the transmission (PTO, etc.).

PLANETARY GEARS AND CLUTCHES

A series of three helical, constant mesh planetary gear sets (four for 4700 OFS/SP

and 4800 SP) and shafts provides the mechanical gear ratios and direction of

travel for the vehicle. The planetary gear sets are controlled by five multi-plate

clutches (six for 4700 OFS/SP and 4800 SP) that work in pairs to produce up to

six forward speeds (seven for 4700 OFS/SP and 4800 SP) and one reverse speed.

The clutches are applied and released hydraulically in response to electronic

signals from the TCM/ECU to the appropriate solenoids.

COOLER CIRCUIT

The transmission fluid is cooled by an integral (transmission-mounted) or

remote-mounted oil cooler. Connections to the cooling circuit are located at the

front or rear of the transmission to facilitate installation of remote cooler lines. On

retarder models, only the rear cooler ports may be used. The integral cooler is

mounted on the lower rear portion of the transmission, replacing the remote cooler

manifold. Integral cooler oil ports are internal requiring coolant to be routed to

and from the cooler.

The retarder housing allows the addition of either a remote or integral cooler for

transmission sump fluid in addition to retarder out fluid. A bypass cover is placed

over the sump cooling ports when the provision is not used. The sump cooler

ports are located on the lower right rear face of the retarder housing (refer to

Figure 3 through Figure 6).

RETARDER

The self-contained retarder is at the output of the transmission and consists of a

vaned rotor which rotates in a vaned cavity. The rotor is splined to and driven by

the output shaft. When the retarder is activated, the fluid in the accumulator is

displaced into the retarder cavity. The pressurized fluid in the cavity acting against

the rotating and stationary vanes causes the retarder rotor and output shaft to

reduce speed, slowing the vehicle or limiting speed on a downhill grade. Refer to

USING THE HYDRAULIC RETARDER for additional information.

When the retarder is deactivated, the retarder cavity is evacuated and the

accumulator is recharged with fluid.

TRANSFER CASE (DROPBOX)

A transfer case (dropbox) module is provided for 3700 SP-equipped vehicles

where front and rear wheel drive is desired. The transfer case (refer to Figure 4) is

19

Page 21

merged with a six-speed close ratio gear train to produce a 7-speed configuration.

One of the two PTO drive provisions actuates a scavenge pump for the transfer

case. A remote-mounted cooler is required for a dropbox unit.

Transfer case design features include helical transfer gears and a self-contained

lubrication oil pump. The transfer gears provide a ratio of 1.2:1. The lubrication

oil pump is driven directly by the output to the drive axles. Since lubrication is

present whenever the drive axle is turning, it is not necessary to disconnect the

drivelines or axles shafts when the vehicle is towed or pushed. A torque

proportioning differential gives a front/rear torque split of 30/70 when the

differential clutch (C7) is not engaged. When the multiplate differential clutch is

engaged, the torque split becomes 50/50. The differential clutch is engaged in

difficult traction situations.

The seventh forward speed in this transmission is the lowest numerical gear ratio

provided and is intended for use in off-road conditions. This range is obtained

when a multi-plate clutch (C6) in the transfer case is applied.

20

Page 22

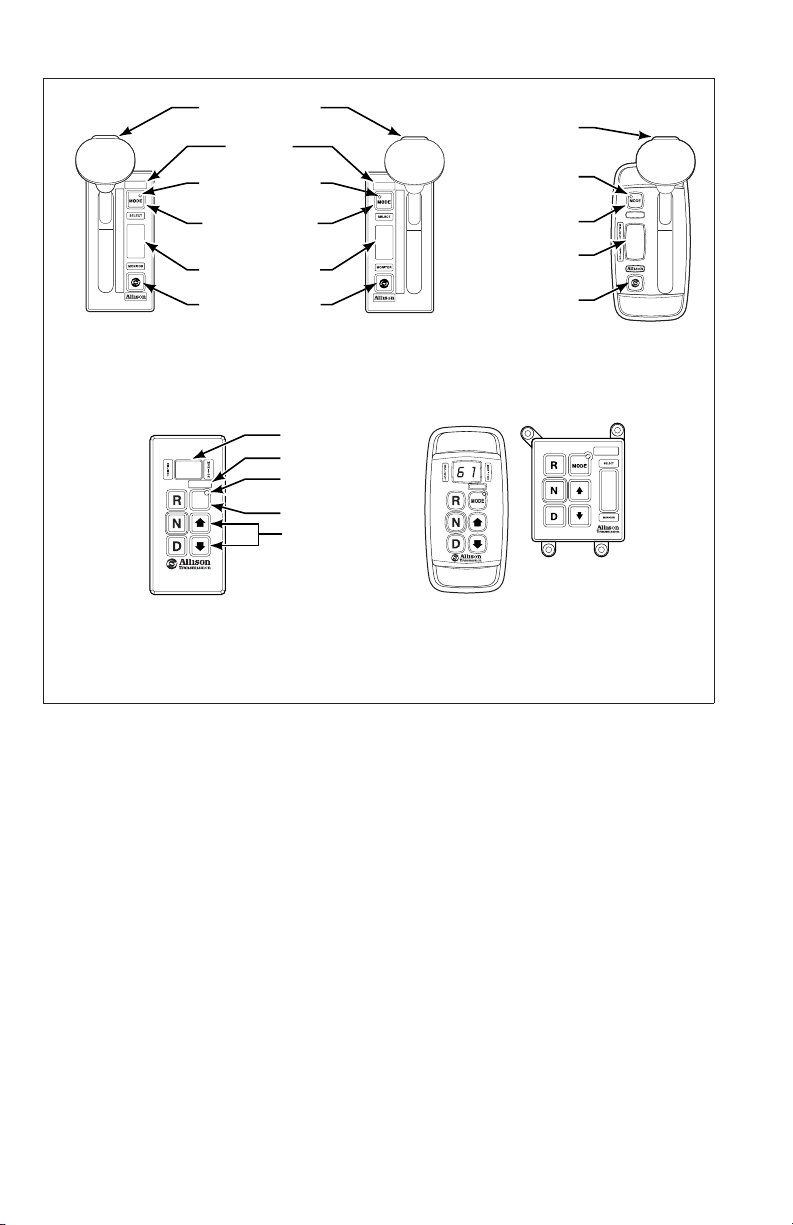

SHIFT SELECTORS

INTRODUCTION

Vehicle manufacturers may choose different types of shift selectors for their

vehicles. The shift selector in your Allison-equipped vehicle will be similar to one

of the pushbutton or lever styles (refer to Figure 7 and Figure 8) shown in the

following sections that explain each Allison shift selector.

Allison transmissions can be programmed to have up to six (seven for

4700 OFS/SP and 4800 SP) forward ranges. Shift selector positions should agree

with the programming of the TCM/ECU.

With an Allison-equipped vehicle, it is not necessary to select the right moment to

upshift or downshift during changing road and traffic conditions. The Allison

transmission does it for you. However, knowledge of the shift selector positions,

available ranges, and when to select them make vehicle control and your job even

easier. To reduce wear on service brakes, select lower ranges when descending

long grades (with or without retarder). Refer to the Range Selection table at the

end of this section for related information.

DESCRIPTION OF AVAILABLE ALLISON 4THGENERATION SHIFT SELECTOR TYPES

NOTE: This section is for Allison 4thGeneration Controls, Model Year

2009 Prognostics DISABLED, and seven-speed transmissions which

don’t have Prognostics.

21

Page 23

HOLD OVERRIDE

1

2

3

6

4

5

1

D

N

R

DIAGNOSTIC BUTTON

SIX-SPEED,

LEFT-HAND

LEVER SELECTOR

WITH REVERSE

TO REAR

7 1

MODE

BUTTON

MODE ID

MODE INDICATOR

(LED)

MODE BUTTON

DIGITAL DISPLAY

DISPLAY MODE

DIGITAL DISPLAY*

MODE ID

MODE

INDICATOR (LED)

MODE BUTTON

Push simultaneously

to enter diagnostic

mode and fluid

level check

R

N

D

6

7

5

4

1

3

*

2

1

SEVEN-SPEED,

RIGHT-HAND

LEVER SELECTOR

WITH REVERSE

TO FRONT

HOLD OVERRIDE

BUTTON

MODE INDICATOR

DIGITAL DISPLAY*

DIAGNOSTIC BUTTON

(LED)

MODE BUTTON

DISPLAY MODE

CONTOURED

6

1

PUSHBUTTON SELECTORS

NOTE:

The first number displayed in the digital display is the highest forward range available and

*

second number is range attained in selected position.

Visually confirm that the range selected was attained. If display is flashing, shift is inhibited.

6

1

BEZEL

V10694.00.01

Figure 7. Typical Allison 4thGeneration Controls Shift Selectors

LEVER SHIFT SELECTOR.

th

General Description. The Allison 4

Generation lever shift selector (refer to

Figure 7) is an electromechanical control. Typical lever positions are:

• R (Reverse)

• N (Neutral)

• D (Drive)

• Some number of lower forward range positions

Allison transmissions can be programmed to have up to six (seven for

4700 OFS/SP and 4800 SP) forward ranges. Shift selector positions should agree

with the programming of the TCM.

The lever shift selector includes the following:

• HOLD OVERRIDE button

• MODE button

22

Page 24

• Digital display

• DISPLAY MODE/DIAGNOSTIC button

Hold Override Button. The lever shift selector has three locked positions to

prevent accidentally selecting R (Reverse), N (Neutral), or D (Drive). Select

R (Reverse), N (Neutral), or D (Drive) by pressing the HOLD OVERRIDE

button and moving the lever to the desired position. Once D (Drive) is selected,

lower forward range positions may be selected without pressing the

HOLD OVERRIDE button.

MODE Button. The MODE button can allow the driver to enable a secondary

shift schedule, PTO enable, or other special functions that have been programmed

into the TCM unit at the request of the OEM. For example, a vehicle OEM may

have provided a secondary shift schedule for improved fuel economy. The name

of the special function (ECONOMY) appears on the MODE ID label adjacent to

the MODE button. Pressing the MODE button activates the ECONOMY shift

schedule and illuminates the MODE INDICATOR LED.

When the Diagnostic Display Mode has been entered, the MODE button is used

to view and toggle through diagnostic code information. The code displayed is

active if the MODE INDICATOR LED is illuminated.

NOTE: Visually observe the digital display whenever the lever is

moved. N should appear in the digital display if N is selected.

Digital Display. Allison 4thGeneration Controls contain two digital displays,

SELECT and MONITOR. During normal operation, if D (Drive) is selected, the

SELECT digital display shows the highest forward range attainable for the shift

schedule in use. The MONITOR digital display shows the lowest available

forward range.

Limited operation is indicated by the digital display as follows:

• All digital display segments are illuminated during initialization. If after

10 seconds communication is not established with the TCM, both digital

displays show

• When both digital displays show

\

/\(cateyes).

\

/\(cateyes), a selector-related fault code

has been logged.

• When the SELECT display shows R or D has been requested and the

display is flashing the selected range, then the selected range has not been

attained due to an inhibit function. Refer to RANGE SHIFTS AND

INHIBITS in the DRIVING TIPS section.

• Inhibited range, shown by a flashing SELECT digital display, is not an

indication that there is a transmission condition or problem, nor does it

indicate that a DTC has set. An inhibit means there is a vehicle or engine

condition that won’t allow range selection or direction change such as:

23

Page 25

— Too high idle speed in N to allow R or D

— Too high a throttle signal in N to allow R or D

— Too high of an output speed in N to allow R or D

— An active vehicle function or I/O function is operating which inhibits

range.

CAUTION: The transmission will not shift into range from N if a

CHECK TRANS code is active. If a CHECK TRANS code is active,

move vehicle to a safe location before turning off the engine.

Conditions which illuminate the CHECK TRANS light disable the shift selector.

The SELECT display is blank and the MONITOR display shows the range

actually attained. For a detailed explanation, refer to the CHECK TRANS LIGHT

paragraph in the DRIVING TIPS section.

Once D (Drive) is attained, the transmission will shift into the lowest forward

range programmed for the D (Drive) position, usually first-range.

Display Mode/Diagnostic Button. The DISPLAY MODE/DIAGNOSTIC button

allows access to fluid level information and diagnostic code information.

• Move the shift lever to N and apply the parking brakes.

• Press the DISPLAY MODE/DIAGNOSTIC (DMD) button once to access

oil level information (if an OLS is installed).

• Press the DMD again to access the diagnostic code information.

• Press the MODE button to view subsequent code positions d2 through d5.

• To exit the diagnostic code mode, move the shift lever to another position.

PUSHBUTTON SHIFT SELECTOR.

General Description. The pushbutton shift selector (refer to Figure 7) has the

following components:

• R (Reverse)—Press this button to select Reverse

• N (Neutral)—Press this button to select Neutral

• D (Drive)—Press this button to select Drive. The highest forward range

available will appear in the digital display window. The transmission will

start out in the lowest available forward range and advance automatically to

the highest range.

• ↑ (Up) Arrow—Press the ↑ (Up) Arrow when in D (Drive) to request the

next higher range. Continually pressing the ↑ (Up) Arrow will request the

highest range available.

• ↓ (Down) Arrow—Press the ↓ (Down) Arrow when in D (Drive) to

request the next lower range. Continually pressing the ↓ (Down) Arrow

will request the lowest range available.

24

Page 26

• MODE Button—The MODE button can allow the driver to enable a

secondary shift schedule, PTO enable, or other special functions that have

been programmed into the TCM at the request of the OEM. For example, a

vehicle OEM may have provided a secondary shift schedule for improved

fuel economy. The name of the special function (ECONOMY) appears on

the MODE ID label adjacent to the MODE button. Pressing the MODE

button activates the ECONOMY shift schedule and illuminates the MODE

INDICATOR LED. When the Diagnostic Display Mode has been entered,

the MODE button is used to view and toggle through diagnostic code

information. The code displayed is active if the MODE INDICATOR LED

is illuminated.

th

Digital Display. Allison 4

Generation Controls contain two digital displays,

SELECT and MONITOR. During normal operation, if D (Drive) is selected, the

SELECT display shows the highest forward range attainable for the shift schedule

in use. The MONITOR display shows the lowest available forward range.

Limited operation is indicated by the digital display as follows:

• All digital display segments are illuminated during initialization. If after

10 seconds communication is not established with the TCM, both digital

displays show

• When both digital displays show

\

/\(cateyes).

\

/\(cateyes), a selector-related fault code

has been logged.

• When the SELECT display shows R or D has been requested and the

display is flashing the selected range, then the selected range has not been

attained due to an inhibit function. Refer to RANGE SHIFTS AND

INHIBITS in the DRIVING TIPS section.

• Inhibited range, shown by a flashing SELECT digital display, is not an

indication that there is a transmission condition or problem, nor does it

indicate that a DTC has set. An inhibit means there is a vehicle or engine

condition that won’t allow range selection or direction change such as:

— Too high idle speed in N to allow R or D

— Too high a throttle signal in N to allow R or D

— Too high of an output speed in N to allow R or D

— An active vehicle function or I/O function is operating which inhibits

range.

CAUTION: The transmission will not shift into range from N if a

CHECK TRANS code is active. If a CHECK TRANS code is active,

move vehicle to a safe location before turning off the engine.

Conditions which illuminate the CHECK TRANS light disable the shift selector.

The SELECT display is blank and the MONITOR display shows the range

actually attained. For a detailed explanation, refer to the CHECK TRANS LIGHT

paragraph in the DRIVING TIPS section.

25

Page 27

Once D (Drive) is attained, the transmission will shift into the lowest forward

range programmed for the D (Drive) position, usually first-range.

NOTE: The oil level sensor (OLS) is standard on 3000 and 4000

Product Families transmissions (optional on the 4700 OFS/SP, 4800 SP,

not available on 3700 SP). Fluid level information is displayed by

simultaneously pressing the ↑ (Up) Arrow and ↓ (Down) Arrow

buttons. Simultaneously press both buttons again to obtain diagnostic

code information.

To display stored codes, do the following:

• Select N and apply the parking brakes.

• Simultaneously press the ↑ (Up) Arrow and ↓ (Down) Arrow buttons once

to access oil level information (if an OLS is installed).

• Simultaneously press the ↑ (Up) Arrow and ↓ (Down) Arrow buttons

again to access diagnostic codes.

• Press the MODE button to display the next code. Repeat for code positions

d3 through d5.

• Press N (Neutral) to exit the diagnostic code mode.

Refer to the CARE AND MAINTENANCE section, FLUID LEVEL CHECK

USING PUSHBUTTON OR LEVER SHIFT SELECTOR, for more information

about fluid level data. Refer to the DRIVING TIPS section, DIAGNOSTIC

CODES DISPLAY PROCEDURE, for more information about diagnostic codes

and display procedure.

26

Page 28

DESCRIPTION OF AVAILABLE ALLISON 4THGENERATION MY09 PROGNOSTICS SHIFT SELECTOR TYPES

NOTE: This section is for Allison 4thGeneration Model Year 2009

(MY09) Prognostics ENABLED. Refer to the previous section for

MY09 Prognostics DISABLED and seven-speed transmissions which

don’t have Prognostics.

LEVER SHIFT SELECTOR.

General Description. The Allison lever shift selector (refer to Figure 8) is an

electromechanical control. Typical lever positions are:

• R (Reverse)

• N (Neutral)

• D (Drive)

• Some number of lower forward range positions

Allison transmissions can be programmed to have up to six (seven for

4700 OFS/SP and 4800 SP) forward ranges. Shift selector positions should agree

with the programming of the TCM.

The lever shift selector includes the following:

• HOLD OVERRIDE button

• MODE button

• DISPLAY MODE/DIAGNOSTIC button

• SELECT and MONITOR digital displays and service icon

Hold Override Button. The lever shift selector has three locked positions to

prevent accidentally selecting R (Reverse), N (Neutral), or D (Drive). Select

R (Reverse), N (Neutral), or D (Drive) by pressing the HOLD OVERRIDE

button and moving the lever to the desired position. Once D (Drive) is selected,

lower forward range positions may be selected without pressing the

HOLD OVERRIDE button.

MODE Button. The MODE button can allow the driver to enable a secondary

shift schedule, PTO enable, or other special functions that have been programmed

into the TCM unit at the request of the OEM. For example, a vehicle OEM may

have provided a secondary shift schedule for improved fuel economy. The name

of the special function (ECONOMY) appears on the MODE ID label adjacent to

the MODE button. Pressing the MODE button activates the ECONOMY shift

schedule and illuminates the MODE INDICATOR LED.

When the Diagnostic Display Mode has been entered, the MODE button is used

to view and toggle through diagnostic code information. The code displayed is

active if the MODE INDICATOR LED is illuminated.

27

Page 29

HOLD OVERRIDE

BUTTON

HOLD OVERRIDE

BUTTON

1

2

3

4

5

D

N

R

SIX-SPEED,

LEFT-HAND

LEVER SELECTOR

MODE ID

MODE

INDICATOR

(LED)

MODE BUTTON

DIGITAL DISPLAY

DISPLAY MODE

DIAGNOSTIC

BUTTON

*

SEVEN-SPEED,

RIGHT-HAND

LEVER SELECTOR

MODE

R

N

D

MODE

R

N

D

PUSHBUTTON SELECTORS

MODE

INDICATOR

(LED)

R

N

D

6

5

4

3

2

1

MODE BUTTON

MODE ID

DIGITAL

DISPLAY

*

DISPLAY MODE

DIAGNOSTIC

BUTTON

CONTOURED

BEZEL

DIGITAL DISPLAY

MODE ID

MODE

MODE

INDICATOR (LED)

MODE BUTTON

Push simultaneously

to enter diagnostic

mode and fluid

level check

*

*NOTE:

The first number displayed in the digital display is the highest forward range available and second

number is range attained in selected position.

Visually confirm that the range selected was attained. If display is flashing, shift is inhibited.

SERVICE ICON

Location of service icon on vertical and horizontal digital display

SERVICE ICON

V11058.00.00

Figure 8. Typical Allison 4thGeneration MY09 Prognostics Shift

Selectors

28

Page 30

NOTE: Visually observe the digital display whenever the lever is

moved. N should appear in the digital display if N is selected.

Digital Display. Allison 4

th

Generation MY09 Prognostics shift selectors contain

two digital displays (SELECT and MONITOR) and a service icon (open-end

wrench) located between the two displays. During normal operation, if D (Drive)

is selected, the SELECT display shows the highest forward range attainable for

the shift schedule in use. The MONITOR display shows the lowest available

forward range.

Limited operation is indicated by the digital display as follows:

• All digital display segments are illuminated during initialization. If after

10 seconds communication is not established with the TCM, both digital

displays show

• When both digital displays show

\

/\(cateyes).

\

/\(cateyes), a selector-related fault code

has been logged.

• If the service icon is flashing or fully illuminated, a Prognostics function is

indicated. Refer to PROGNOSTICS FUNCTIONALITY FOR MY09 in the

CARE AND MAINTENANCE section of this manual to determine which

function is indicated.

• When the SELECT display shows R or D has been requested and the

display is flashing the selected range, then the selected range has not been

achieved due to an inhibit function. Refer to RANGE SHIFTS AND

INHIBITS in the DRIVING TIPS section.

• An inhibited range, shown by a flashing SELECT digital display, is not an

indication that there is a transmission condition or problem, nor does it

indicate that a DTC has set. An inhibit means there is a vehicle or engine

condition that won’t allow range selection attainment or direction change

such as:

— Too high idle speed in N to allow R or D

— Too high a throttle signal in N to allow R or D

— Too high of an output speed in N to allow R or D

— An active vehicle function or I/O function is operating which inhibits

range.

CAUTION: The transmission will not shift into range from N if a

CHECK TRANS code is active. If a CHECK TRANS code is active,

move vehicle to a safe location before turning off the engine.

29

Page 31

Conditions which illuminate the CHECK TRANS light disable the shift selector.

The SELECT display is blank and the MONITOR display shows the range

actually attained. For a detailed explanation, refer to the CHECK TRANS LIGHT

paragraph in the DRIVING TIPS section.

Once D (Drive) is attained, the transmission will shift into the lowest forward

range programmed for the D (Drive) position, usually first-range.

Display Mode/Diagnostic Button. The DISPLAY MODE/DIAGNOSTIC button

allows access to fluid level information, Prognostics information, and diagnostic

code information.

• Move the shift lever to N and apply the parking brake.

• Press the DISPLAY MODE/DIAGNOSTIC (DMD) button once to access

oil level information.

• Press the DMD again to access the Oil Life Monitor.

• Press the DMD again to access the Filter Life Monitor.

• Press the DMD again to access the Transmission Health Monitor.

• Press the DMD again to access the diagnostic code information.

• Press the MODE button to view subsequent code positions d2 through d5.

• To exit the diagnostic code mode, move the shift lever to another position.

PUSHBUTTON SHIFT SELECTOR.

General Description. The pushbutton shift selector (refer to Figure 8) has the

following components:

• R (Reverse)—Press this button to select Reverse

• N (Neutral)—Press this button to select Neutral

• D (Drive)—Press this button to select Drive. The highest forward range

available will appear in the displayed in the SELECT digital display and the

MONITOR digital display will show the lowest available forward range.

The transmission will start out in the lowest available forward range and

advance automatically to the highest range.

• ↑ (Up) Arrow—Press the ↑ (Up) Arrow when in D (Drive) to request the

next higher range. Continually pressing the ↑ (Up) Arrow will request the

highest range available.

• ↓ (Down) Arrow—Press the ↓ (Down) Arrow when in D (Drive) to

request the next lower range. Continually pressing the ↓ (Down) Arrow

will request the lowest range available.

• MODE Button—The MODE button can allow the driver to enable a

secondary shift schedule, PTO enable, or other special functions that have

been programmed into the TCM at the request of the OEM. For example, a

vehicle OEM may have provided a secondary shift schedule for improved

fuel economy. The name of the special function (ECONOMY) appears on

the MODE ID label adjacent to the MODE button. Pressing the MODE

button activates the ECONOMY shift schedule and illuminates the MODE

INDICATOR LED. When the Diagnostic Display Mode has been entered,

30

Page 32

the MODE button is used to view and toggle through diagnostic code

information. The code displayed is active if the MODE INDICATOR LED

is illuminated.

• SELECT and MONITOR digital display and service icon

Digital Display. Allison 4

th

Generation MY09 Prognostics contain two digital

displays (SELECT and MONITOR) and a service icon (open-end wrench) located

between the two displays. During normal operation, if D (Drive) is selected, the

SELECT display shows the highest forward range attainable for the shift schedule

in use. The MONITOR display shows the lowest available forward range.

Limited operation is indicated by the digital displays as follows:

• All display segments are illuminated during initialization. If after

10 seconds communication is not established with the TCM, both displays

\

/\(cateyes).

show

\

• When both displays show a

/\(cateye), a selector-related fault code has

been logged.

• If the service icon is flashing or fully illuminated, a Prognostics function is

indicated. Refer to PROGNOSTICS FUNCTIONALITY FOR MY09 in the

CARE AND MAINTENANCE section of this manual to determine which

function is indicated.

• When the SELECT display shows R or D has been requested and the

display is flashing the selected range, then the selected range has not been

attained due to an inhibit function. Refer to RANGE SHIFTS AND

INHIBITS in the DRIVING TIPS section.

• Inhibited range, shown by a flashing SELECT digital display, is not an

indication that there is a transmission condition or problem, nor does it

indicate that a DTC has set. An inhibit means there is a vehicle or engine

condition that won’t allow range selection or direction change such as:

— Too high idle speed in N to allow R or D

— Too high a throttle signal in N to allow R or D

— Too high of an output speed in N to allow R or D

— An active vehicle function or I/O function is operating which inhibits

range.

CAUTION: The transmission will not shift into range from N if a

CHECK TRANS code is active. If a CHECK TRANS code is active,

move vehicle to a safe location before turning off the engine.

Conditions which illuminate the CHECK TRANS light disable the shift selector.

The SELECT display is blank and the MONITOR display shows the range

actually attained. For a detailed explanation, refer to the CHECK TRANS LIGHT

paragraph in the DRIVING TIPS section.

31

Page 33

Once D (Drive) is attained, the transmission will shift into the lowest forward

range programmed for the D (Drive) position, usually first-range.

To display stored codes, do the following:

• Select N and apply the parking brakes.

• Simultaneously press the ↑ (Up) Arrow and ↓ (Down) Arrow buttons once

to access oil level information (if an OLS is installed).

• Simultaneously press the ↑ (Up) Arrow and ↓ (Down) Arrow buttons

again to access the Oil Life Monitor.

• Simultaneously press the ↑ (Up) Arrow and ↓ (Down) Arrow buttons

again to access the Filter Life Monitor.

• Simultaneously press the ↑ (Up) Arrow and ↓ (Down) Arrow buttons

again to access the Transmission Health Monitor.

• Simultaneously press the ↑ (Up) Arrow and ↓ (Down) Arrow buttons

again to access the diagnostic codes.

• Press the MODE button to display the next code. Repeat for code positions

d3 through d5.

• Press N (Neutral) to exit the diagnostic code mode.

Refer to the CARE AND MAINTENANCE section, FLUID LEVEL CHECK

USING PUSHBUTTON OR LEVER SHIFT SELECTOR, for more information

about fluid level data. Refer to the DRIVING TIPS section, DIAGNOSTIC

CODES DISPLAY PROCEDURE, for more information about diagnostic codes

and display procedure.

32

Page 34

RANGE SELECTION

PUSHBUTTON AND LEVER SHIFT SELECTORS

WITH DIGITAL DISPLAY

Description of Available Ranges (refer to Figure 1 through Figure 3)

WARNING: If you leave the vehicle and the engine is

running, the vehicle can move unexpectedly and you or

others could be injured. If you must leave the engine

running, do not leave the vehicle until you have

completed all of the following procedures:

1. Put the transmission in N (Neutral).

2. Be sure the engine is at low idle (500–800 rpm).

3. Apply the parking brakes and emergency brake and

make sure they are properly engaged.

4. Chock the wheels and take any other steps

necessary to keep the vehicle from moving.

R

E

V

E

R

S

E

WARNING: R (Reverse) may not be attained due to

an active inhibitor. Always apply the service brakes

when selecting R (Reverse) to prevent unexpected

vehicle movement and because a service brake inhibit

may be present. When “R” is flashing, it indicates the

shift to R (Reverse) is inhibited. Determine if

diagnostic codes are active if R (Reverse) is not

attained. Refer to DOWNSHIFT AND DIRECTION

CHANGE INHIBITOR FEATURE in the DRIVING

TIPS section.

CAUTION: Do not idle in R (Reverse) for more than

five minutes. Extended idling in R (Reverse) can cause

transmission overheating and damage. Always select

N (Neutral) whenever time at idle exceeds five minutes.

33

Page 35

PUSHBUTTON AND LEVER SHIFT SELECTORS

WITH DIGITAL DISPLAY

(cont’d)

Description of Available Ranges (refer to Figure 1 through Figure 3)

NOTE: Visually observe the digital display window

whenever a button is pushed or the lever is moved to be

R

E

V

E

R

R Completely stop the vehicle and let the engine return to idle

S

E

sure the range selected is shown (i.e., if the N (Neutral)

button is pressed, “N” should appear in the digital display).

A flashing display indicates the range selected was not

attained due to an active inhibit.

before shifting from a forward range to R (Reverse) or

from R (Reverse) to a forward range. The digital display

will display “R” when R (Reverse) is selected.

WARNING: When starting the engine, make sure the

service brakes are applied. Failure to apply the service

brakes can result in unexpected vehicle movement.

WARNING: Vehicle service brakes, parking brake, or

N

E

U

T

R

emergency brake must be applied whenever N (Neutral)

is selected to prevent unexpected vehicle movement.

Selecting N (Neutral) does not apply vehicle brakes,

unless an auxiliary system to apply the parking brake is

installed (refer to the Operator’s Manual for the vehicle).

A

L

WARNING: If you let the vehicle coast in N (Neutral),

there is no engine braking and you could lose control.

Coasting can also cause severe transmission damage. To

help avoid injury and property damage, do not allow the

vehicle to coast in N (Neutral).

34

Page 36

PUSHBUTTON AND LEVER SHIFT SELECTORS

WITH DIGITAL DISPLAY

(cont’d)

Description of Available Ranges (refer to Figure 1 through Figure 3)

N Use N (Neutral) when starting the engine, to check vehicle

accessories, and for extended periods of engine idle

operation (longer than five minutes). For vehicles equipped

N

E

U

T

R

A

L

with the pushbutton selector, N (Neutral) is selected by the

TCM/ECU during start-up. For vehicles equipped with the

lever selector, the vehicle will not start unless N (Neutral)

has been selected. If the vehicle starts in any range other

than N (Neutral), seek service immediately. N (Neutral) is

also used during stationary operation of the power takeoff

(if the vehicle is equipped with a PTO). The digital display

will show “N” when N (Neutral) is selected. Always select

N (Neutral) before turning off the vehicle engine.

WARNING: D (Drive) may not be attained due to an

active inhibitor. Always apply the service brakes when

selecting D (Drive) to prevent unexpected vehicle

movement and because a service inhibit may be

present. When “D” is flashing, it indicates the shift to

D (Drive) is inhibited. Determine if diagnostic codes

are active if D (Drive) is not attained. Refer to

DOWNSHIFT AND DIRECTION CHANGE

INHIBITOR FEATURE in the DRIVING TIPS section.

D

R

I

V

E

CAUTION: Do not idle in D (Drive) for more than five

minutes. Extended idling in D (Drive) may cause

transmission overheating and damage. Always select

N (Neutral) if time at idle exceeds five minutes.

NOTE: Turn off the vehicle HIGH IDLE switch, if present,

before shifting from N (Neutral) to D (Drive) or

R (Reverse). D (Drive) or R (Reverse) will not be attained

unless the shift is made with the engine at idle. Also, be

aware of other interlocks that would prevent attaining

D (Drive) or R (Reverse). Example: “service brakes not

applied” (service brake interlock present).

35

Page 37

PUSHBUTTON AND LEVER SHIFT SELECTORS

WITH DIGITAL DISPLAY

(cont’d)

Description of Available Ranges (refer to Figure 1 through Figure 3)

The transmission will initially attain first range when

D

R

I

D

V

E

D (Drive) is selected (except for those units programmed to

start in second-range). As vehicle speed increases, the

transmission will upshift automatically through each range.

As the vehicle or equipment slows down, the transmission

will automatically downshift to the correct range. The

digital display will show the highest range available in

D (Drive).

36

Page 38

PUSHBUTTON AND LEVER SHIFT SELECTORS

WITH DIGITAL DISPLAY

(cont’d)

Description of Available Ranges (refer to Figure 1 through Figure 3)

WARNING: The transmission incorporates a hold

feature to prohibit upshifting above the range selected

during normal driving. For downhill operation, select a

lower transmission range. If the engine governed speed

is exceeded in the held range, however, the transmission

will upshift to the next higher range to prevent engine

damage. To avoid injury and/or property damage due to

loss of vehicle control, use the vehicle brakes to prevent

exceeding engine governed speed in the held range.

M

A

N

U

A

L

S

E

L

E

C

T

+

7

6*

5*

4*

3

2

Lower ranges provide greater engine braking for going

down grades (the lower the range, the greater the braking

effect). Occasionally, it may be desirable to restrict

automatic shifting to a lower range because of:

• Road conditions.

• Load.

• Traffic conditions.

• Etc.

The pushbutton shift selector arrow buttons access

individual forward ranges. Push the ↑ (Up) or ↓ (Down)

arrow for the desired range. The digital display shows the

range chosen. Even though a lower range is selected, the

transmission may not downshift until vehicle speed is

reduced (this prevents excessive engine speed in the lower

range).

1 First-range provides the vehicle with its maximum driving

torque and engine braking effect. Use first-range when:

• Pulling through mud and deep snow.

• Maneuvering in tight spaces.

• Driving up or down steep grades.

For vehicles equipped with the pushbutton selector, push

the ↓ (Down) arrow until first-range appears in the select

window.

37

Page 39

PUSHBUTTON AND LEVER SHIFT SELECTORS

WITH DIGITAL DISPLAY

(cont’d)

Description of Available Ranges (refer to Figure 1 through Figure 3)

Transfer Case Differential—The 3700 SP transmission is

equipped with a torque proportioning differential to provide

appropriate torque and speed to the front and rear axles in

difficult traction situations. The operator can request this

function by activating a separate switch or the MODE

button on the shift selector (check your operator’s manual).

To deactivate the function, the switch is turned off or is

deactivated automatically by the ECU at a programmed

speed.

+ Only available in 4700/4800 SP and OFS, and 3700 SP.

* Actual ranges available depend on programming by vehicle manufacturer.

38

Page 40

DRIVING TIPS

CHECK TRANS LIGHT

The electronic control system is programmed to inform the operator of a problem

with the transmission system and automatically take action to protect the operator,

vehicle, and transmission. When the Electronic Control Unit (ECU) or the

Transmission Control Module (TCM) logs a DTC, the TCM/ECU:

• Restricts shifting.

• Illuminates the CHECK TRANS light on the instrument panel.

• Registers a diagnostic code.

NOTE: Some diagnostic codes may be logged without the TCM/ECU

activating the CHECK TRANS light. Your Allison Transmission

authorized service outlet should be consulted whenever there is a

transmission-related concern. They have the equipment to access and

troubleshoot diagnostic codes.

The CHECK TRANS light will illuminate each time the engine is started, then

turn off after a few seconds. This momentary lighting is to show that the status

light circuits are working properly. If the CHECK TRANS light does not

illuminate during ignition, or if the light remains on after ignition, have the

transmission inspected at the earliest opportunity by an Allison Transmission

authorized service outlet.

Continued illumination of the CHECK TRANS light during vehicle operation

(other than start-up) indicates that the TCM/ECU has signaled a diagnostic code.

The single digit shift selector display will show the actual range attained and the

transmission will not respond to shift selector requests. The dual digit shift

selector will blank the range selected and show the range attained with a CHECK

TRANS light.

Indications from the shift selector are provided to inform the operator the

transmission is not performing as designed and is operating with reduced

capabilities. Before turning off the ignition, the transmission may be operated for a

short time in the attained range in order to get the vehicle to a safe location for

39

Page 41

service assistance. Service should be performed immediately in order to minimize

the potential for damage to the transmission.

When the CHECK TRANS light is illuminated and the ignition switch is turned

off, the transmission will remain in N (Neutral) until the condition causing the

CHECK TRANS light is corrected.

Generally, while the CHECK TRANS light is on, upshifts and downshifts will be

restricted and direction changes will not occur. Lever and pushbutton shift

selectors do not respond to any operator shift requests while the CHECK

TRANS light is illuminated. The lockup clutch is disengaged when transmission

shifting is restricted.

DIAGNOSTIC CODES OVERVIEW

Diagnostic codes are numerical indications relating to a malfunction in

transmission or vehicle operation. These codes are logged in the TCM/ECU

memory with the most severe or most recent code listed first. A maximum of five

codes (numbered d1–d5) may be listed in memory at one time. As codes are

added, the oldest non-active code is dropped from the list. If all codes are active,

the code with the lowest priority that is not included on the severity list is

dropped from the list.

Diagnostic codes and code information may be accessed through the pushbutton

and lever shift selectors or the Allison DOC™ For PC–Service Tool.

The TCM/ECU separately stores the active and historical (non-active) codes. An

active code is any code that is current in the TCM/ECU decision-making process.

Historical codes (not active) are codes that are retained in the TCM/ECU memory

and will not necessarily affect the TCM/ECU decision-making process. Historical

codes are useful in determining if a DTC:

• Is isolated.

• Is intermittent.

• Results from a previous malfunction.

The TCM/ECU may automatically delete a code from memory if it has not

recurred for a period of time.

If the MODE INDICATOR (LED) is illuminated, the displayed code is active. If

the MODE INDICATOR (refer to through Figure 8) is not illuminated, the

displayed code is not active. An illuminated MODE INDICATOR during normal

operation signifies secondary mode operation.

40

Page 42

ALLISON 4THGENERATION CONTROLS DIAGNOSTIC CODE DISPLAY PROCEDURE

NOTE: Use this section for Allison 4thGeneration Controls, MY09

Prognostics DISABLED, and seven-speed transmissions which don’t

have MY09 Prognostics.

Diagnostic codes can be read and cleared by either of the following methods:

• Allison DOC™ For PC–Service Tool. For specific instructions on how to

use the Allison DOC™ For PC–Service Tool, refer to Allison Transmission

publication GN3433EN, User Guide.

• Pushbutton or lever shift selectors.

Pushbutton Shift Selector. To begin the Diagnostic Process:

1. Bring the vehicle to a stop at a safe location.

2. Shift to N (Neutral).

3. Apply the parking brake.

To Display Stored Codes (refer to Figure 7):

1. If an OLS is present, simultaneously press the ↑ (Up) and ↓ (Down)

arrow buttons twice to display the first code.

2. When the diagnostic code mode is entered, the first code (d1) is displayed

as follows:

Example–code P0722

Displays as d 1, P, 0 7, 2 2 (each item appears for about one second)

th

Allison 4

and MONITOR. Each item is displayed for about one second. The display

cycles continuously until the next code list position is accessed by

pressing the MODE button. There is a 2 minute timer that will timeout if

no buttons are pressed causing N N to display instead of the diagnostic

code.

The following example shows how the DTC P0722 is displayed on the

pushbutton shift selector.

Generation shift selectors have two digital displays, SELECT

DIGITAL DISPLAY

SELECT MONITOR

d 1

P

0 7

2 2

41

Page 43

• d 1 (code list position); the position which a code occupies in the

code list. Positions are displayed as “d1” through “d5”.

• P0722 (DTC); the diagnostic trouble code number referring to the

general condition or area of fault detected by the TCM.

3. Press the MODE button to view the next code; repeat for subsequent

codes.

NOTE: Be sure to record all codes displayed before they are cleared.

This is essential for troubleshooting.

To Clear Active Indicators and Inactive Codes then Resume Vehicle Operation:

• To clear active indicators such as the CHECK TRANS light, press and

hold the MODE button for approximately three seconds until the MODE

INDICATOR LED flashes. Release the MODE button and active indicators

will not be illuminated.

• To clear inactive codes, press and hold the MODE button for 10 seconds.

Some codes are self-clearing and others require ignition cycles to clear.

NOTE: If the condition that caused the code is still present, the code

will again become active.

Begin operating as normal. Have the transmission inspected at the earliest

opportunity by an Allison Transmission distributor or dealer.

Lever Shift Selector. To Begin the Diagnostic Process:

1. Bring the vehicle to a stop at a safe location.

2. Shift to N (Neutral).

3. Apply the parking brake.

To Display Stored Codes (refer to Figure 7):

1. If an OLS is present, press the DISPLAY MODE/DIAGNOSTIC (DMD)

button twice to display the first code.

2. Refer to the Pushbutton Shift Selector for an explanation of code displays.

3. Press the MODE button to view the next code; repeat for subsequent

codes.

NOTE: Be sure to record all codes displayed before they are cleared.

This is essential for troubleshooting.

42

Page 44

To Clear Active Indicators and Inactive Codes then Resume Vehicle Operation:

1. To clear active indicators such as the CHECK TRANS light, press and

hold the MODE button for approximately three seconds until the MODE

INDICATOR (LED) flashes. Release the MODE button and active

indicators will not be illuminated.

2. To clear inactive codes, press and hold the MODE button for 10 seconds.

3. Depending on the code(s), active indicators can be cleared:

— On successful power down

— Manually

— Self clearing.

NOTE: If the condition that caused the code is still present, the code

will again become active.

Begin operating as normal. Have the transmission inspected at the earliest

opportunity by an Allison Transmission distributor or dealer.

ALLISON 4THGENERATION MY09 PROGNOSTICS DIAGNOSTIC CODE DISPLAY PROCEDURE

NOTE: Use this section for Allison 4thGeneration MY09 Prognostics

ENABLED. Refer to the previous section for Allison 4

th

Generation

MY09 Prognostics DISABLED, and seven-speed transmissions which

don’t have MY09 Prognostics.

Diagnostic codes can be read and cleared by either of the following methods:

• Allison DOC™ For PC–Service Tool. For specific instructions on how to

use the Allison DOC™ For PC–Service Tool, refer to Allison Transmission

publication GN3433EN, User Guide.

• Pushbutton or lever shift selectors.

Pushbutton Shift Selector. To begin the Diagnostic Process:

1. Bring the vehicle to a stop at a safe location.

2. Shift to N (Neutral).

3. Apply the parking brake.

To Display Stored Codes (refer to Figure 8):

1. Simultaneously press the ↑ (Up) and ↓ (Down) arrow buttons to display

oil level information.

2. Simultaneously press the ↑ (Up) and ↓ (Down) arrow buttons again to

display Oil Life Monitor.

43

Page 45

3. Simultaneously press the ↑ (Up) and ↓ (Down) arrow buttons again to

display Filter Life Monitor.

4. Simultaneously press the ↑ (Up) and ↓ (Down) arrow buttons again to

display Transmission Health Monitor.

5. Simultaneously press the ↑ (Up) and ↓ (Down) arrow buttons again to

display diagnostic code mode.

6. When the diagnostic code mode is entered, the first code (d1) is displayed

as follows:

Example–code P0722

Displays as d 1, P, 0 7, 2 2 (each item appears for about one second)

th

The Allison 4

Generation shift selectors have two digital displays,

SELECT and MONITOR. Each item is displayed for about one second.

The display cycles continuously until the next code list position is

accessed by pressing the MODE button. The following example shows

how the DTC P0722 is displayed on the pushbutton shift selector.

DIGITAL DISPLAY

SELECT MONITOR

d 1

P

0 7

2 2

• d 1 (code list position); the position which a code occupies in the

code list. Positions are displayed as “d1” through “d5”.

• P0722 (DTC); the diagnostic trouble code number referring to the

general condition or area of fault detected by the TCM.

7. Press the MODE button to view the next code; repeat for subsequent

codes.

NOTE: Be sure to record all codes displayed before they are cleared.

This is essential for troubleshooting.

To Clear Active Indicators and Inactive Codes then Resume Vehicle Operation:

• To clear active indicators such as the CHECK TRANS light, press and

hold the MODE button for approximately three seconds until the MODE

INDICATOR LED flashes. Release the MODE button and active indicators

will not be illuminated.

• To clear inactive codes, press and hold the MODE button for 10 seconds.

Some codes are self-clearing and others require ignition cycles to clear.

44

Page 46

NOTE: If the condition that caused the code is still present, the code

will again become active.

Begin operating as normal. Have the transmission inspected at the earliest

opportunity by an Allison Transmission distributor or dealer.

Lever Shift Selector. To Begin the Diagnostic Process:

1. Bring the vehicle to a stop at a safe location.

2. Shift to N (Neutral).

3. Apply the parking brake.

To Display Stored Codes:

1. Press the DISPLAY MODE/DIAGNOSTIC (DMD) button once to

display the oil level information.

2. Press the DMD button again to display the Oil Life Monitor.

3. Press the DMD button again to display the Filter Life Monitor.

4. Press the DMD button again to display the Transmission Health Monitor.

5. Press the DMD button again to access the diagnostic code mode.

6. Press the MODE button to view the next code; repeat for subsequent

codes.

NOTE: Be sure to record all codes displayed before they are cleared.

This is essential for troubleshooting.

To Clear Active Indicators and Inactive Codes then Resume Vehicle Operation:

1. To clear active indicators such as the CHECK TRANS light, press and

hold the MODE button for approximately three seconds until the MODE

INDICATOR (LED) flashes. Release the MODE button and active

indicators will not be illuminated.

2. To clear inactive codes, press and hold the MODE button for 10 seconds.

Some codes are self-clearing and others require ignition cycles to clear.

NOTE: If the condition that caused the code is still present, the code