Allison Transmission DOC 7.0 PC Tools User Guide

User Guide

TM

Allison DOC

For PC–Service Tool

Version 7.0.0

GN3433ENGN3433EN 200703 Printed in USA 200710www.allisontransmission.com

User

2007 MARCH

Guide

GN3433EN

Allison Transmission

Allison DOC™ For PC–Service Tool

Version 7.0.0

Printed in USA

1

Copyright © 2007 Allison Transmission, Inc.

TABLE OF CONTENTS

1.0 Allison DOC™ For PC–Service Tool . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

1-1. Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

1-2. Warnings and Notes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

1-3. User Guide Organization . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

1-4. Text Conventions Used in This Guide . . . . . . . . . . . . . . . . . . . . . . . . 9

1-5. System Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

1-6. Allison DOC™ For PC–Service Tool Software Installation . . . . . . . . 10

1-7. Allison DOC™ For PC–Service Tool Overview . . . . . . . . . . . . . . . . 11

1-8. Allison DOC™ For PC–Service Tool Navigation, Controls,

and Status Information. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Status Bar . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Menus. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Button and Keyboard Shortcuts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

2.0 Connecting the PC to the Control System . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

3.0 Starting Allison DOC™ For PC–Service Tool . . . . . . . . . . . . . . . . . . . . . . .

3-1. Starting the Program. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

3-2. 30-Day Trial. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

3-3. At Start-up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

4.0 Configuring and Updating Allison DOC™ For PC–Service Tool . . . . . . . . . 24

4.1. Application Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

General Tab . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Reprogramming Tab . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Update Application Tab . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

TAC Data Collection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

1000/2000 Setup and 3000/4000 Setup Tabs . . . . . . . . . . . . . . . . . . . 28

Setting up a New Data Configuration . . . . . . . . . . . . . . . . . . . . . . . . . 32

Loading a Saved Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Loading Default Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

5.0 Using Allison DOC™ For PC–Service Tool . . . . . . . . . . . . . . . . . . . . . . . . . 33

5-1. Connecting/Disconnecting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Connecting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Disconnecting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Quick Solutions for Unsuccessful Connections . . . . . . . . . . . . . . . . . 36

22

2

5-2. Viewing Diagnostic Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

5-3. DTC and General Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

DTC Grid . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Viewing Troubleshooting Manual Information for a Trouble Code . . 38

Clearing DTC Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Performance Complaint . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Failure Records . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

DTC Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Displaying the DTC Test Screen . . . . . . . . . . . . . . . . . . . . . . . . . . 42

TCM Information Grid. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Transmission Information Grid . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Shift Inhibits Grid. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

5-4. Data Monitor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Diagnostic Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Input/Output Functions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Shift Inhibits. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

5-5. Custom Data Monitor. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

To Select Custom Data Monitor Transmission Parameters. . . . . . . . . 44

To Remove Custom Data Monitor Transmission Parameters . . . . . . . 45

Preconfigured Data List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

5-6. Graphics Monitor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Displaying the Graphics Monitor . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

5-7. Strip Chart . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Displaying the Strip Chart . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Saving A Strip Chart Configuration . . . . . . . . . . . . . . . . . . . . . . . . 47

To Load or Delete a Saved Strip Chart Configuration . . . . . . . . . . 48

Data Trace Identification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

X-axis Scaling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Y-axis Scaling.. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Strip Chart Modes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Control Modes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

5-8. Calibration Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

To Display Current Calibration Information: . . . . . . . . . . . . . . . . . . . 50

5-9. Data Bus Traffic View. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Displaying the Data Bus Viewer. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Playing Back Data Bus Viewer files . . . . . . . . . . . . . . . . . . . . . . . . . . 56

3

5-10. Action Requests . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

Clutch Test Enabled . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

Solenoid Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

To Enable the Solenoid Test Function:. . . . . . . . . . . . . . . . . . . . . . 58

Reset Auto-Detect . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

Reset Auto-Detect Retarder . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

Reset Fast Adaptive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

To Reset to Fast Adaptive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

Reset Adaptive Shift Parameters. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

To Reset Adaptive Shift Parameters. . . . . . . . . . . . . . . . . . . . . . . . 60

Reset Full/Closed Throttle Calibration (TPS only). . . . . . . . . . . . . . . 62

Reset SEM Auto-Select . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

Engineering Calculations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

Transmission Fault Lamp Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

To Initiate a Fault Lamp Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

Reverse Warning Lamp Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

To Initiate a Reverse Warning Test. . . . . . . . . . . . . . . . . . . . . . . . . 65

5-11. Recording Snapshots . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

To Record an Event Driven Snapshot . . . . . . . . . . . . . . . . . . . . . . . . . 66

Triggering a Snapshot Recording (and/or setting a bookmark). . . . . . 66

To Insert a Bookmark While Recording Data . . . . . . . . . . . . . . . . 67

5-12. Stopping/Saving Snapshot Sessions . . . . . . . . . . . . . . . . . . . . . . . . . . 67

5-13. Playing Back Snapshots . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

5-14. Exporting Playback Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

6.0 Reprogramming TCM. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

6-1. Reprogramming TCM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

Enabling/Authorizing the Reprogramming Section in

Allison DOC™ For PC–Service Tool . . . . . . . . . . . . . . . . . . . . . . 73

Accessing the Reprogramming Function . . . . . . . . . . . . . . . . . . . . . . 74

Reprogramming Input/Output Configuration . . . . . . . . . . . . . . . . . . . 76

Reprogramming Customer Modifiable Constants. . . . . . . . . . . . . . . . 76

Reprogramming Package Assignments. . . . . . . . . . . . . . . . . . . . . . . . 77

Reprogramming TCM Password . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

Initiating TCM Reprogramming. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

Reprogramming Status for WTEC II, WTEC III, and CEC2 . . . . . . . 78

4

7.0 Reports . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

7-1. Diagnostic Reports . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

Saving Diagnostic Reports . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

Displaying Saved Diagnostic Reports. . . . . . . . . . . . . . . . . . . . . . . . . 81

Diagnostic Report Examples . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

7-2. TRANSHEALTH™ Report . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

Loading Saved TRANSHEALTH™ Reports . . . . . . . . . . . . . . . . . . . 88

Saving TRANSHEALTH™ Reports . . . . . . . . . . . . . . . . . . . . . . . . . 89

Printing TRANSHEALTH™ Reports . . . . . . . . . . . . . . . . . . . . . . . . 89

Closing the TRANSHEALTH™ Feature . . . . . . . . . . . . . . . . . . . . . . 89

7-3. Printing Screens . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

7-4. Exiting Allison DOC™ For PC–Service Tool. . . . . . . . . . . . . . . . . . . 90

8.0 WTEC II/III, CEC2, and CEC1 Control Systems

WTEC II/III and CEC2 Diagnostic Trouble Codes . . . . . . . . . . . . . . 91

WTEC II/III and CEC2 DTC and General Info View . . . . . . . . . . 91

Clearing Active Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 92

Clearing Inactive Codes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 92

WTEC II/III and CEC2 Diagnostic Data Monitor . . . . . . . . . . . . . . . 93

Diagnostic Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

Input and Output Wires/Functions . . . . . . . . . . . . . . . . . . . . . . . . . 93

Shift Inhibits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94

CEC1 Diagnostic Data Monitor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94

WTEC II/III and CEC2 Custom Data Monitor. . . . . . . . . . . . . . . . . . 94

WTEC II/III and CEC2 Graphics Monitor . . . . . . . . . . . . . . . . . . . . . 94

Displaying the Graphics Monitor. . . . . . . . . . . . . . . . . . . . . . . . . . 94

WTEC II/III Graphics Monitor . . . . . . . . . . . . . . . . . . . . . . . . . . . 95

ECU Calibration Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 95

WTEC II/III and CEC2 ECU Calibration Information . . . . . . . . . . . . 96

WTEC II/III and CEC2 Clutch Test . . . . . . . . . . . . . . . . . . . . . . . . . . 96

WTEC II/III Reset Fast Adaptive . . . . . . . . . . . . . . . . . . . . . . . . . . . . 97

WTEC II/III Reset Unadapted Shifts . . . . . . . . . . . . . . . . . . . . . . . . . 97

WTEC II/III and CEC2 Reset Throttle Calibration. . . . . . . . . . . . . . . 97

WTEC II/III TAC Data Collection . . . . . . . . . . . . . . . . . . . . . . . . . . . 98

. . . . . . . . . . . . . . . . .

91

5

9.0 1000/2000 (Pre-Allison 4th Generation Controls) Control System . . . . . . . . 100

Diagnostic Trouble Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100

Reset Adaptive Shift Parameters. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100

1000/2000 Throttle Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 101

Clutch Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 102

10.0 CEC Control System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 103

CEC Snapshot Record . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 103

Reports . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 104

11.0 Using Allison DOC™ For PC–Service Tool Demos . . . . . . . . . . . . . . . . . . . 105

12.0 HELP System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 107

Help Topics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 107

Video-Based Training Materials . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 108

Demo . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 108

DTC Lookup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 108

Troubleshooting Manuals. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 109

Access To Allison Transmission Web Site

(requires an internet connection) . . . . . . . . . . . . . . . . . . . . . . . . . . 109

Hydro Schematics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 109

Allison Transmission Calc . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 110

About Allison DOC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 110

13.0 Diagnostic Data Definitions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 111

13-1. Customer Modifiable Constants (CMC) . . . . . . . . . . . . . . . . . . . . . . . 111

13-2. SEM/LRTP. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 123

WTEC III Control Systems Specific Parameters . . . . . . . . . . . . . . . . 134

1000/2000 (Pre-Allison 4th Generation Controls)

Specific Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 135

6

1.0 ALLISON DOC™ FOR

PC–SERVICE TOOL

1–1. INTRODUCTION

The Allison DOC™ (Diagnostic Optimized Connection) For PC–Service Tool is a

diagnostic system designed for use with Allison’s 3000/4000 Product Families

transmissions, 1000/2000 Product Families transmissions, and transmissions using

CEC2/CEC1 controls. This PC-based diagnostic program is capable of

communicating with Allison 4th Generation Control System Module TCMs,

WTEC II and WTEC III Electronic Control Units (ECU), 1000/2000 (Pre-Allison

4th Generation Controls) TCMs, CEC2, and CEC1 Electronic Control Units (ECU).

Allison DOC™ For PC–Service Tool performs the following:

• Monitors 3000/4000 Product Families Transmission Control Module

(TCM) data

• Monitors 1000/2000 Product Families Transmission Control Module

(TCM) data

• Monitors CEC2 Electronic Control Unit (ECU) data

• Monitors CEC Electronic Control Unit data, using a proprietary protocol

and the Allison CEC translator device

• Displays multiple transmission parameters

• Displays a graphical instrument panel with analog and digital gauges

• Displays a graphical strip chart

• Records and plays back diagnostic sessions

• Prints diagnostic reports

• Reprograms selected TCM parameters (requires completion of Allison

Transmission training).

Allison DOC™ For PC–Service Tool provides the following features:

• A Microsoft Windows®/PC look and feel

• Security measures to control reprogramming TCM/ECU parameters

• Integrated Help with training videos

• Diagnostic Trouble Code information with a direct link to 3000/4000

Product Families Troubleshooting Manuals

7

• Diagnostic Trouble Code information with a direct link to the 1000/2000

Product Families Troubleshooting Manual

• Diagnostic Trouble Code information with a direct link to CEC2

Troubleshooting Manuals

• A demo mode using prerecorded data

• SmartConnect for detecting the PC-to-vehicle translation device and

communication link

• Communication troubleshooting wizard for those cases where the tool is

unable to connect to a control module

• Allison DOC™ For PC–Service Tool is compliant with applicable TMC

Recommended Practices, GM Online Standards, SAE Standards, and CE

Standards

• Allison DOC™ For PC–Service Tool is RP1210A compliant

1–2. WARNINGS AND NOTES

WARNING:

use or read the diagnostic tool while the vehicle is moving. Doing so

may result in loss of vehicle control, which may cause personal injury

and vehicle damage.

WARNING:

diagnostic tool.

WARNING:

vehicle while an assistant performs the diagnostic evaluations.

NOTE:

have a basic working knowledge of the Microsoft® Windows 2000®

Professional/XP® Professional®/Vista® Home Basic Operating

System(s) and Adobe Acrobat Reader®.

NOTE:

transmission controller has continuous power and ignition voltage

supplied at all times.

To avoid personal injury, the vehicle operator must not

Personnel other than the vehicle operator must use the

The vehicle operator must maintain control of the

Allison DOC™ For PC–Service Tool users are assumed to

During a TCM/ECU reprogramming event, make sure the

8

Trademark Information

Windows 2000® Professional, Windows Explorer®, Windows XP® Professional,

Windows Vista® Home Basic, and Windows Media Player® are registered

trademarks of Microsoft Corporation.

Adobe Acrobat® is a registered trademark of Adobe Corporation.

Allison DOC™ is a trademark of General Motors Corporation.

InstallShield® is a registered trademark of InstallShield Software Corporation.

1–3. USER GUIDE ORGANIZATION

This user guide for Allison DOC™ For PC–Service Tool is organized with

information pertaining to the most current control system, Allison 4th Generation

Controls, appearing in the main body of the user guide. The functions and features

described are similar for all control systems except were indicated. Information

specific to an earlier control system is presented in a section devoted to that control

system.

1–4. TEXT CONVENTIONS USED IN THIS GUIDE

The following text conventions are used in this Guide to more clearly describe using

Allison DOC™ For PC–Service Tool:

• Screen button and keyboard key names are in bold capitals—

• Menu names are presented as displayed—File, Edit, etc.

• Menu items are presented as displayed—Exit.

• File names that may change with use are in lowercase italics—

• File names, usually system files, that do not change are in initial capitals—

Acrobat.pdf.

• Titles of windows are as they appear in the window.

OK, RETURN

snapshot.ad

1–5. SYSTEM REQUIREMENTS

• Microsoft® Windows XP® Professional, Windows 2000® (SP4 or later)

Professional, and Windows Vista® Home Basic (or better)

• 20 GB Hard Drive, (40 GB or greater recommended)

• 600 MB free hard drive space required to install the program (after software

installation, the operating system requires sufficient free hard disk space to

run the program)

• 1GHz (or greater) 32-bit (x86) or 64-bit (x64) processor

9

.

.

• 512MB of RAM system memory (1GB recommended)

• One available USB port—USB 1.1 (USB 2.0 recommended)

• A serial port is required if connecting legacy CEC1 controllers, or if using the

J 44652-A - SPX J1850-VPW (Class 2) translator device

• 16x CD-ROM, (48x or greater recommended)

• Full administrative privileges are required to install, use, and update the

Allison DOC™ For PC–Service Tool

• Internet connection capability (Internet Explorer® 5.0.1 or greater)

(NOTE: A broadband internet connection is recommended for receiving

updates and file downloads)

• Windows® Media Player® is installed by default

• Adobe® Acrobat Reader® is installed by default

1–6. ALLISON DOC™ FOR PC–SERVICE TOOL SOFTWARE

INSTALLATION

This section explains how to install the Allison DOC™ For PC–Service Tool

software on your PC from the Allison DOC™ For PC–Service Tool CD-ROM.

Before attempting to install this software, make sure that:

• Your computer satisfies the PC Platform requirements listed on the “System

Requirements” section.

• You have

• For more information, see your network administrator.

full PC Administrator privileges

.

NOTE

: The newest version of Allison DOC™ For PC will

automatically supersede any previous version of this application. There

is no need to uninstall earlier versions of this application. The software

authorization (or password requirement) status will be maintained.

To install the Allison DOC™ For PC–Service Tool software on your PC:

1. Insert the Allison DOC™ For PC–Service Tool CD-ROM into your

CD-ROM drive. If the installation process does not begin momentarily, select

Start

->

Run

from the task bar. Click

installation CD, and click OK.

NOTE

: This process may take several minutes; please be patient.

Interrupting the installation process could cause issues such as error

messages, unable to connect, blank screens, problems during future

updates, etc.

10

Browse

, locate the

Setup.exe

file on the

2. Follow On-Screen instructions.

3. Finally, the InstallShield® Wizard Complete window displays to indicate that

the installation has completed successfully. Select the “

my computer now

setup process and restart your PC.

NOTE

• Allison DOC™ For PC automatically installs the RP1210A

• To use any other RP1210 translator device listed in the latest

NOTE

procedures when using the Dearborn DPA4 USB adapter, please refer

to the “

Guide

Electronic Tools | Translator Devices.

” option (default). Click the

:

drivers for the following adapters: (1) DPA4 USB Translator

Device (essential-rated tool for Allison Transmission), and

(2) SPX J1850 VPW translator Device.

Allison DOC™ Service Information Letters (SIL), the

corresponding device drivers must be installed separately. Make

sure to install the drivers before attempting to use the translator

device with Allison DOC™ For PC–Service Tool.

: For more information on installation and troubleshooting

DPA4 USB Translator Device (J-47943) Quick Reference

” document available at www.allisontransmission.com | Service |

FINISH

Yes, I want to restart

button to exit the

1–7. ALLISON DOC™ FOR PC–SERVICE TOOL OVERVIEW

Allison DOC™ For PC–Service Tool has been designed to aid you, the technician,

in troubleshooting and maintaining Allison transmissions equipped with Allison 4th

Generation Controls, WTEC II, WTEC III, CEC2, CEC1, and 1000/2000 (PreAllison 4th Generation Controls) systems. Allison DOC™ For PC–Service Tool can

be used with a desktop PC or with a laptop PC in the cab of a vehicle.

WARNING:

use or read the tool while the vehicle is moving. Doing so may result

in loss of vehicle control, which may cause personal injury and

property damage.

Allison DOC™ For PC–Service Tool aids you by providing:

• Displays of real-time and prerecorded transmission operating data.

• The ability to display and record user-selectable transmission data.

• The ability to display and record data bus traffic.

To avoid personal injury, the vehicle operator must not

11

• The ability to clear transmission trouble codes.

• Automatic recording of failure records.

• Automatic triggering of snapshot recording when a DTC is detected.

• Access to TCM configuration data.

• With Allison Transmission approved training, the ability to change

TCM/ECU configuration such as I/O functions and CMCs (this calibration

configuration change is called Reprogramming).

• A graphic data display.

• Strip chart data graphing.

• A variety of reports such as:

◊

Failure Records

◊

Autodetect Information

◊

Shift Inhibits

◊

I/O Functions

◊

TRANSHEALTH™ Report

NOTE

: Contact your nearest Allison Distributor for additional Allison

DOC™ For PC–Service Tool training. Allison Distributors are listed on

the Allison web site at www.allisontransmission.com.

◊

Diagnostic Data

◊

Customer Modifiable Constants (CMC)

◊

Trouble Codes

◊

DTC Test

1–8. ALLISON DOC™ FOR PC–SERVICE TOOL NAVIGATION,

CONTROLS, AND STATUS INFORMATION

Allison DOC™ For PC–Service Tool displays the following navigation, control, and

status information items regardless of what is displayed in the main Allison DOC™

For PC–Service Tool window.

Status Bar

The status bar provides information about the connection between Allison DOC™

For PC–Service Tool and the controller. It is located in the upper portion of the main

Allison DOC™ For PC–Service Tool window. The fields in the status bar are not

labeled, but their content adequately indicates their purpose.

Allison DOC™ For PC–Service Tool Status Bar

12

Allison DOC™ For PC–Service Tool Connect Time Display

Allison DOC™ For PC–Service Tool Status Bar Fields:

• Control System Information

◊

Transmission Control System, Calibration Identification Number, and

software level, example: 1K2K—120004A002K / D71

• Application Status

◊

Connected—Allison DOC™ For PC–Service Tool is actively connected

to a control system and receiving live data.

◊

Off-Line—Allison DOC™ For PC–Service Tool is not actively connected

to a control system and it’s not receiving live data.

◊

Playback—The displayed data is part of a snapshot or Demo file

previously recorded.

◊

Recording—Displayed data is live data and is being recorded.

• Event Status (during a live connection)

◊

Diagnostic—Diagnostic data is being displayed.

◊

Shift Inhibit—Diagnostic data is being displayed, and a shift inhibit is

currently present.

◊

Action Request—Diagnostic data is being displayed, and the user is

commanding an action request.

◊

Reprogramming—the Reprogramming screen is being displayed.

• Event Status (during Playback)

◊

Diagnostic—Diagnostic data is being displayed. No action requests were

being performed at the time of the recording and no shift inhibits were

present.

◊

Shift Inhibit—Diagnostic data is being displayed. A shift inhibit was

active at the time of the recording.

◊

Action Request—Diagnostic data is being displayed which was recorded

while an action request was being performed.

• DTC Status

◊

Active Codes—One or more Active DTCs are present. Inactive DTCs

may also be present.

◊

No Active Codes—No Active DTCs are present. Inactive DTCs may be

present.

13

Menus

The menu bar at the top of the Allison DOC™ For PC–Service Tool window, above

the Status bar, displays the following drop-down menus:

File

• TCM Reflash (PCCS)—Opens up the TCM Reflash (PCCS) application, only

if it’s installed in the PC.

• Data Bus Viewer—Opens up the Data Bus Traffic Viewer. This option is

disabled during a live connection of the tool.

• Exit—Exits the Allison DOC™ For PC–Service Tool program

Reprogram

• When enabled, displays the TCM/ECU Reprogramming section. Users need

special training to enable this section of the tool.

Action Items

• Clutch Test Enabled—For Allison 4th Generation Control systems and

1000/2000 (Pre-Allison 4th Generation Controls) systems, it displays the

Clutch Test floating tool bar. For all other control system (i.e. WTEC II,

WTEC III, and CEC2), it controls the Clutch Test mode.

• Solenoid Test…—Displays the Solenoid Test screen (not available for

WTEC II/III, CEC1, and CEC2).

• Reset Adaptive Shift Parameters—(not available for WTEC II/III, CEC1, and

CEC2) Displays the Reset Adaptive Shift Parameters window, where

transmission adaptive data can be reset to factory values per shift.

• Reset Unadapted Shifts—(only available for WTEC II and WTEC III) Resets

all transmission adaptive data to factory values.

• Reset Fast Adaptive—(not available for 1000/2000 Pre-Allison 4th

Generation Controls and CEC2 systems) Activates the Fast Adaptive logic in

the TCM/ECU.

• Reset Full Throttle Calibrations (TPS only)—(not available for WTEC II,

WTEC II, and CEC2 control systems) Resets upper limit of the TPS

calibration.

• Reset Closed Throttle Calibrations (TPS only)— (not available for WTEC II,

WTEC II, and CEC2 control systems) Resets the lower limit of the TPS

calibration.

• Reset Throttle Calibration—(only available for WTEC II, WTEC III, and

CEC2) Resets the throttle position sensor calibration.

• Transmission Fault Lamp Test—(only available for Allison 4th Generation

Controls systems) Enables the transmission Fault Lamp Test.

14

• Reverse Warning Lamp Test—(only available for Allison 4th Generation

Controls systems) Enables the Reverse Warning Lamp Test.

• Reset Auto-Detect—(not available for the 1000/2000 Pre-Allison 4th

Generation controls system) Clears and resets the TCM auto-detect

information.

• Reset Auto-Detect Retarder—(only available for the 3000/4000 Allison 4th

Generation Controls system) Clears and resets auto-detection of transmission

retarder.

• Reset SEM Auto-Select—(only available for Allison 4th Generation Controls

systems) Clears and resets auto-selection of Shift Energy Management.

• Engineering Calculations—Provides means to calculate converter speed

ratio, vehicle speed, and acceleration in g’s.

Snapshot

• Record

◊

Record Options—Displays the recording options window.

◊

Stop Recording—Halts recording.

◊

Add Bookmark—Displays the bookmark window.

• Playback

◊

Open Playback File—Displays the Open window and the content of the

Log folder.

◊

Play—Plays a recorded data file.

◊

Rewind—Starts the playback at the beginning.

◊

Stop—Stops a playback.

◊

Fast forward—Plays a recorded data file at four times the normal speed.

◊

Continuous—Plays a recorded data file continuously, a looped playback.

• Email—Displays the Compose Email window. This section requires the user

to fill out some networking information that might require the assistance

from the user’s IT department.

• Export—(only available for Allison 4th Generation Controls system) Exports

data from a playback file for inclusion into a spreadsheet.

Reports

• Diagnostic Reports—displays the Report Sections window. Refer to

Section 7–1 for more information.

• TRANSHEALTH™ Report— (not available for Allison 4th Generation

Controls systems) when available, it displays the TRANSHEALTH™

feature. Refer to Section 7–2 for more information.

15

Software Configuration

• Displays the Software Configuration dialog box.

Help

• Help Topics—displays the Help Topics window.

• Video-based Training Materials

◊ Allison DOC™ Training Videos—displays the new/enhanced software

training videos

◊ Circuit Checks—Displays the Circuit Checks training video with

Microsoft® Media Player®

◊ Circuit Basics—Displays the Circuit Basics training video with

Microsoft® Media Player®

• Demo—displays the Choose Demo window

• DTC Lookup—displays the Trouble Code Lookup window for various

control systems

• Troubleshooting Manuals

◊ WTEC III—opens up the WTEC III Troubleshooting Manual

◊ 3000/4000 (4th Gen)—opens up the 3000/4000 (Allison 4th Generation

Controls) Troubleshooting Manual

◊ 1000/2000 (Pre-4th Gen)—opens up the 1000/2000/2400 Series™

Troubleshooting Manual

◊ 1000/2000 (4th Gen)—opens up the 1000/2000 (Allison 4th Generation

Controls) Troubleshooting Manual

◊ WTEC II—opens up the WTEC II Troubleshooting Manual

◊ CEC2 Off-Highway—activates the Adobe Acrobat reader to display the

CEC2 Troubleshooting Manual

• Access to Allison Transmission Web Site—Connects to the ALLISON

TRANSMISSION web site, www.allisontransmission.com

• Hydraulic Schematics

◊ 3000/4000 (4th Gen)—displays the Allison 4th Generation Controls

3000/4000 hydraulic schematics

◊ 1000/2000 (4th Gen)—displays the Allison 4th Generation Controls

1000/2000 hydraulic schematics

◊ 1000/2000 (Pre-4th Gen)—displays 1K2K (Pre-Allison 4th Generation

Controls) hydraulic schematics

◊ WTEC III—displays WTEC hydraulic schematics

• Allison Transmission Calc—displays the Allison Transmission Calculation

application.

• About Allison DOC—displays information about this version of Allison

DOC™ For PC–Service Tool

16

Print Screen

• Prints the displayed screen

Button and Keyboard Shortcuts

The following buttons are always available in the primary Allison DOC™ For PC–

Service Tool window. Clicking the button or pressing the associated function key

displays the listed menu.

F1–Help

• Accesses the Help system

F2–TRANSHEALTH™

• Displays the TRANSHEALTH™ feature. Refer to Section 7–2 for more

detailed information.

F3–DTC Lookup

• Displays the Trouble Code Lookup window for various control systems

F4–Connect (or F4-Disconnect)

• Connect (F4-Connect) to or disconnect (F4-Disconnect) from an ECU or

TCM

F5–Trigger Recording

• Triggers the recording session of a snapshot and also inserts a trigger point in

the data stream. This constitutes the faster way to initiate a snapshot

recording session.

• If used during a recording session, inserts “bookmarks” in the data stream of

the log file. Bookmarks are sequentially numbered by the system when F6–

Bookmark # is used.

F6–Stop Recording

• Stops a snapshot recording.

Accelerator Keys—On screen buttons have shortcuts known as accelerator keys.

An underlined character in the button text identifies the button’s accelerator

keyboard key. Pressing the accelerator key activates the function associated with the

button. For example, on the button below, the P keyboard key is the accelerator key.

Dropdown menu items accelerator keys require pressing ALT before pressing the

accelerator key. After pressing the ALT/ACCELERATOR KEY combination that

menu displays.

When this button is visible, press ALT+ P to activate a print function.

17

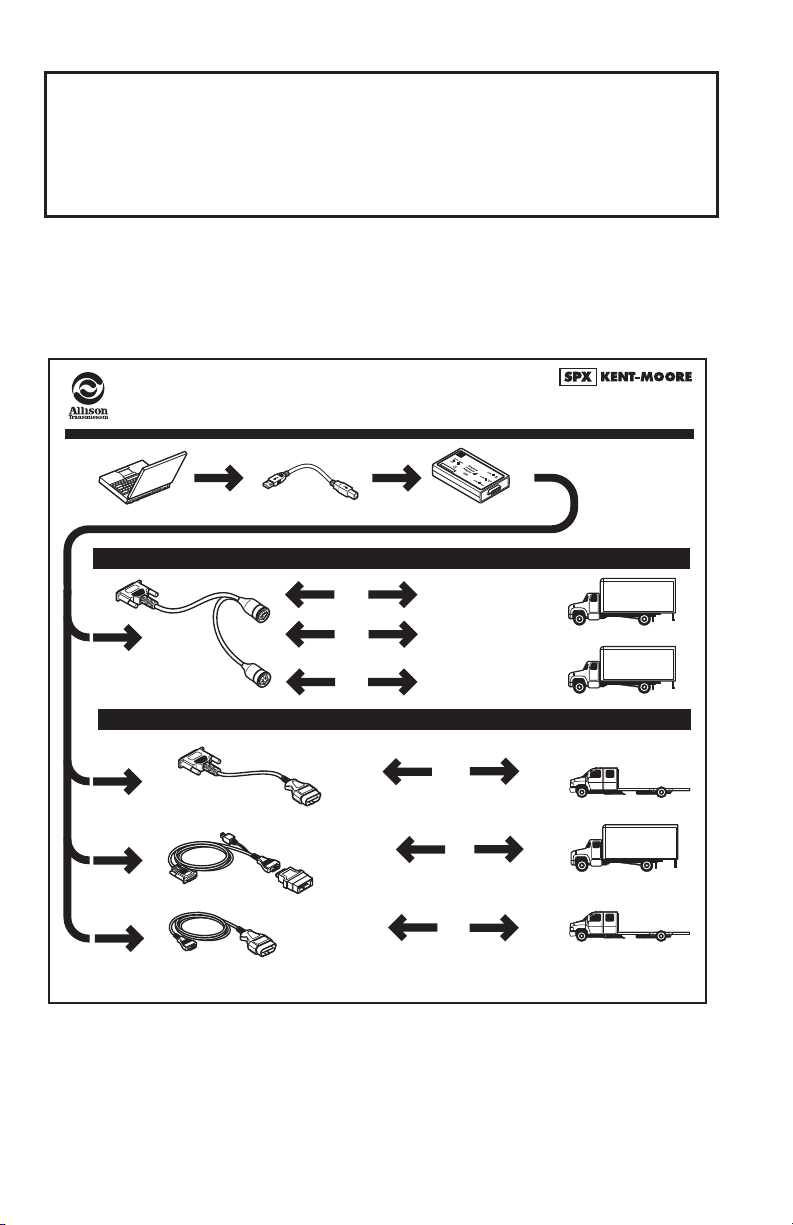

2.0 CONNECTING THE PC TO THE

CONTROL SYSTEM

The diagram below illustrates the hardware connections between the PC hosting

Allison DOC™ For PC–Service Tool, the data translator, and the vehicle control

system diagnostic connector.

J 47943

DPA4 USB

Allison DOC™ For PC–Service Tool

Connection Diagrams

J 47943-3 USB Cable

(Part of J 47943 Kit)

Used with J 47943

DB15

Connector

9-Pin

Connnector

2

-

43

9

47

J

it)

K

43

9

47

f J

t o

r

Pa

(

6-Pin

Connnector

J1939

OR

J1708

J1708

Optional Vehicle Interface Adapter Connections

SPX P/N: J 47949-A – GMLAN Cable

DB15

Connector

SPX P/N: J 38500-2 15M to 15F (Atari) Cable

Nexiq P/N: 501002

DB15 Connector

SPX P/N: J 41788

DB15 Connector

Allison 4th Generation Controls, 1000 and 2000 Product Families

(Pre-Allison 4th Generation Controls), WTEC III, WTEC II, and CEC2

OBDII/16-Pin

Connector

J 1962/B

12-Pin Packard Connector

SPX P/N: J 34812-1

Nexiq P/N: 40103

OBDII/16-Pin Connector

J 1962/A

Fax: U.S. and Canada: 1-800-578-7375 or 1-586-578-7375

D

G

D

e

htt

a

rb

p

:/

www

o

r

n

.

d

gte

G

c

r

h.

o

c

u

o

m

p

J 47943-1

Translator Device

(Part of J 47943 Kit)

Allison 4th Generation Controls

1000 and 2000 Product Families

(Pre-Allison 4th Generation Controls)

WTEC III

CEC2

WTEC III

WTEC II

CEC2

GMLAN

J170

8

J1708

Phone: U.S. and Canada: 1-866-621-2128

International: 1-507-455-7223

International: 1-507-455-7063

DPA4 USB

NOTE: Diagrams depicting

cables do not

represent actual

lengths.

Allison 4th

Generation

Controls

WTEC III

WTEC II

CEC2

WTEC III

V09364.03.01

18

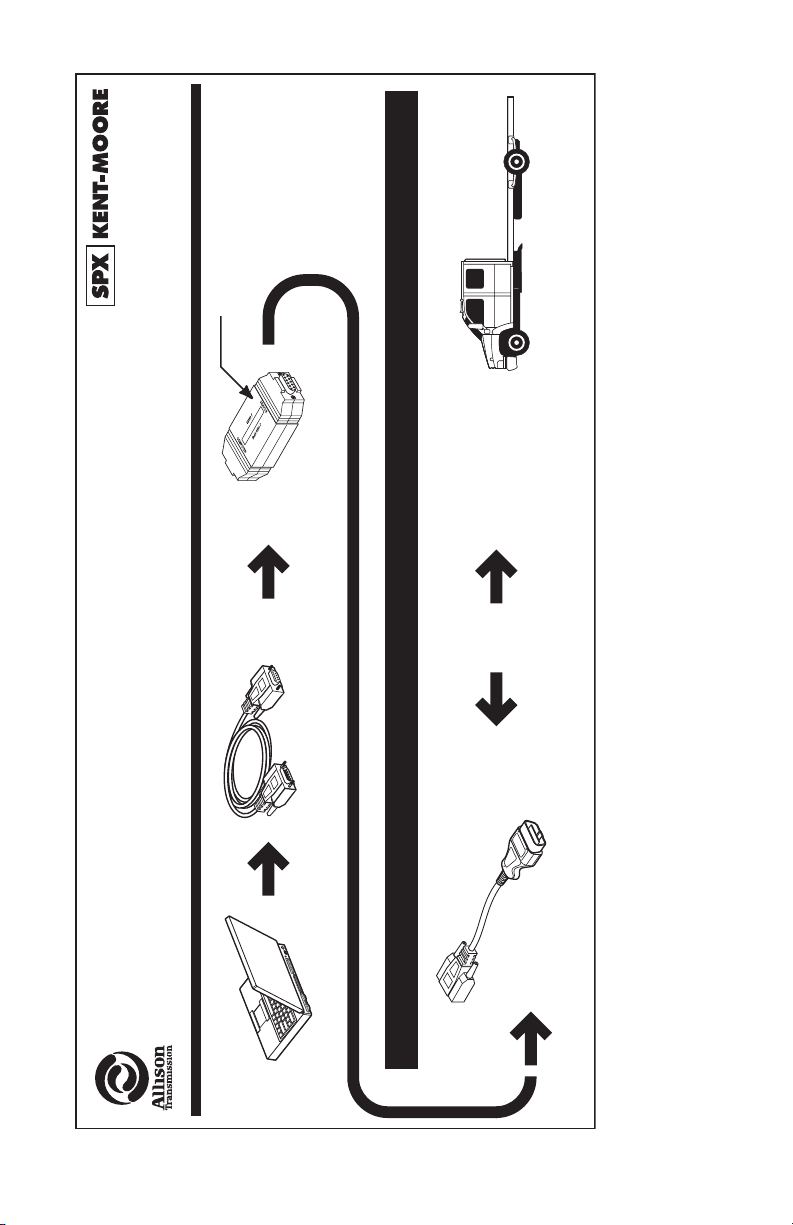

NOTE: Diagrams depicting

International: 1-507-455-7223

International: 1-507-455-7063

NOTE: “MODIFIED” must be

on the label.

cables do not

represent actual

lengths.

V09365.01.02

Phone: U.S. and Canada: 1-866-621-2128

D

FIE

I

D

MO

Fax: U.S. and Canada: 1-800-578-7375 or 1-586-578-7375

J 44652-A

(Part of J 44652-A Kit)

Translator Device J1850-VPW

Connection Diagrams

(Part of

J 44652-A Kit)

Allison DOC™ For PC–Service Tool

th

1000 and 2000

Product Families

(Pre-Allison 4

Generation Controls)

J1850

OBDII/16-Pin

Connector

J 1962/A

Generation Controls)

th

J 44652-A

J1850-VPW

(Part of

J 44652-A Kit)

GM Applications Using 1000 and 2000 Product Families (Pre-Allison 4

Used with J 44652-A

DB9

Connector

19

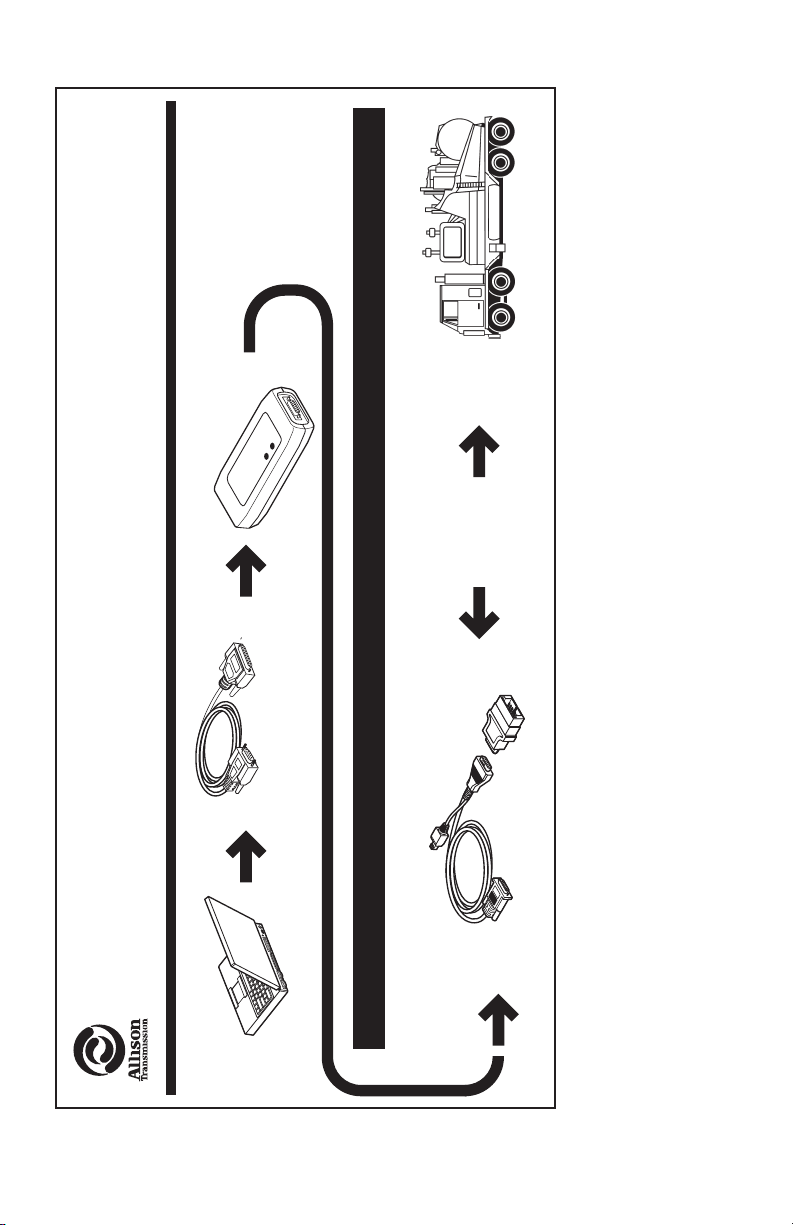

NOTE: Diagrams depicting

cables do not

represent actual

lengths.

NOTE: Cables not included

with translator device.

SGI, Inc. or SPX/Kent-Moore

Fax: 1-317-471-4996

Phone: 1-888-666-5799

For Purchase Contact:

CEC Translator Device

E

L

IC

VEH

TO

SPX P/N: J 47134

SGI P/N: CD3723EN

R

E

O

C

I

AT

V

L

E

C

S

D

E

N

R

C

RA

UTE

T

P

M

O CO

T

Commercial

9F to 25M Cable

(Modem Type)

Connection Diagrams

V09366.01.03

CEC1

Allison

Protocol

Propietary

Transmission

CEC1

12-Pin Packard Connector

SPX P/N: J 34812-1

Nexiq P/N: 40103

Allison DOC™ For PC–Service Tool

Allison

Transmission

CEC Translator

Device

Used with CEC Translator Device

15M to 15F (Atari) Cable

SPX P/N: 38500-2

Nexiq P/N: 501002

20

A fully RP1210A compliant PC-to-vehicle translator device is required to establish

communication with the TCM/ECU. Allison DOC™ For PC–Service Tool currently

supports the Dearborn Protocol Adaptor DPA4 USB (SPX P/N J47943) and other

devices listed in the latest Allison DOC™ Service Information Letter (SIL),

available on the Allison Transmission Extranet.

NOTE: For more information on installation and troubleshooting

procedures when using the Dearborn DPA4 USB adapter, please refer

to the “DPA4 USB Translator Device (J-47943) Quick Reference

Guide” document available at

www.allisontrnamission.com/Service/Electronic Tools/Translator

Devices.

In order to communicate with the CEC control system, Allison DOC™ For PC–

Service Tool requires the Allison Transmission CEC Translator Device. Refer to the

above diagrams for P/Ns and contact information. The drivers must be installed

from the Allison DOC™ For PC–Service Tool CD-ROM, located in the Noregon

RP1210A API folder.

To communicate with 1000/2000/2400 Series™ transmissions using the J1850

communication protocol (with OBDII trapezoidal diagnostic connector), Allison

DOC™ For PC–Service Tool requires the SPX J1850 VPW translator device. Refer

to the above diagrams for P/Ns and contact information. The translator device

drivers are automatically installed with Allison DOC™ For PC–Service Tool.

21

3.0 STARTING ALLISON DOC™

FOR PC–SERVICE TOOL

3–1. STARTING THE PROGRAM

There are two ways to start Allison DOC™ For PC–Service Tool:

Double-click the Allison DOC™ For PC–Service Tool icon on your PC

desktop,

or,

From your PC’s Start menu, select Programs --> Allison Transmission --> Allison

DOC™ For PC–Service Tool. If you stored Allison DOC™ For PC–Service Tool is

in another location, follow the path to that location and select Allison DOC™ For

PC–Service Tool.

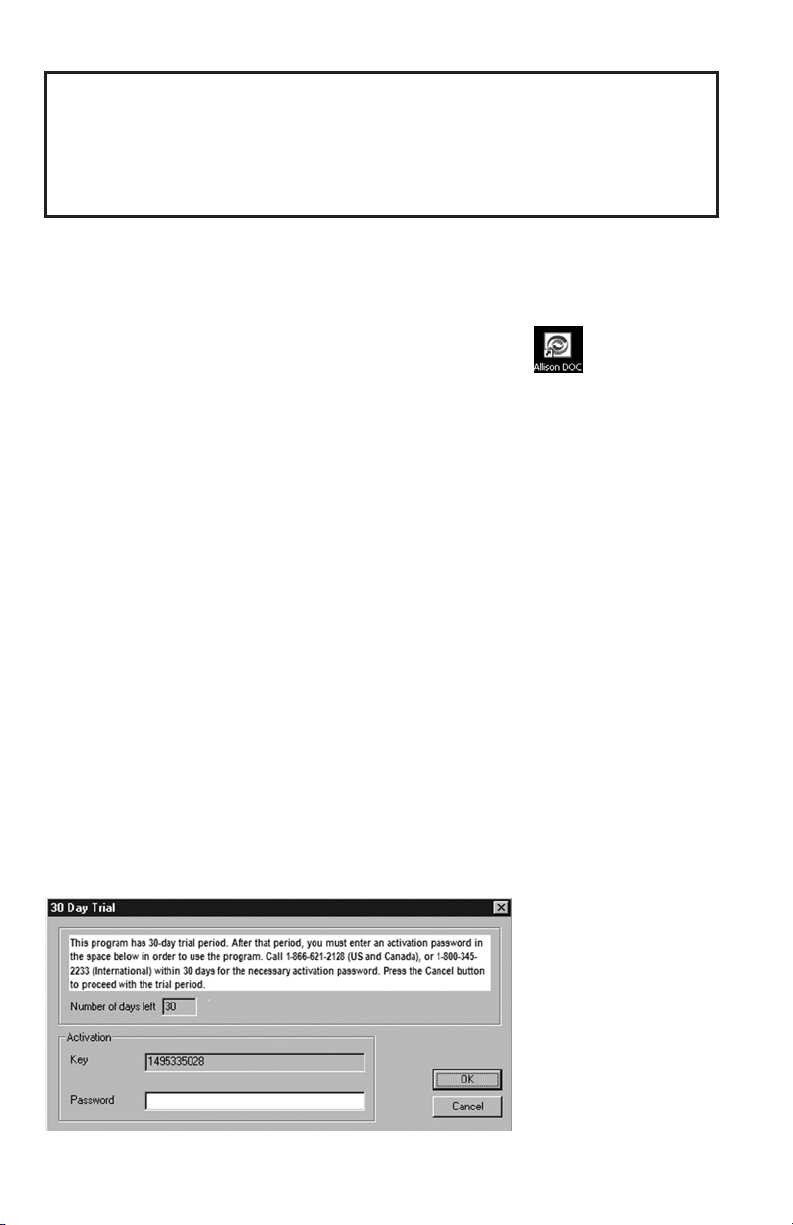

3–2. 30-DAY TRIAL

A 30-Day trial is included as part of Allison DOC™ For PC–Service Tool. The 30-day

trial window appears each time Allison DOC™ For PC–Service Tool is started, unless

the activation password has been entered. The 30-day trial window displays the

number of days remaining in the trial period. At any time before the trial period ends

you may enter the activation password. The Allison DOC™ For PC–Service Tool

application will not function after 30 days if a valid activation password has not been

entered. Contact SPX Kent-Moore (US and Canada: 1-866-621-2128, International:

1-800-345-2233) to obtain the product activation password.

Once you have the password, enter it into the Password field of the 30-Day Trial

window and press OK.

During the 30-day trial period, press CANCEL to run the Allison DOC™ For PC–

Service Tool program.

22

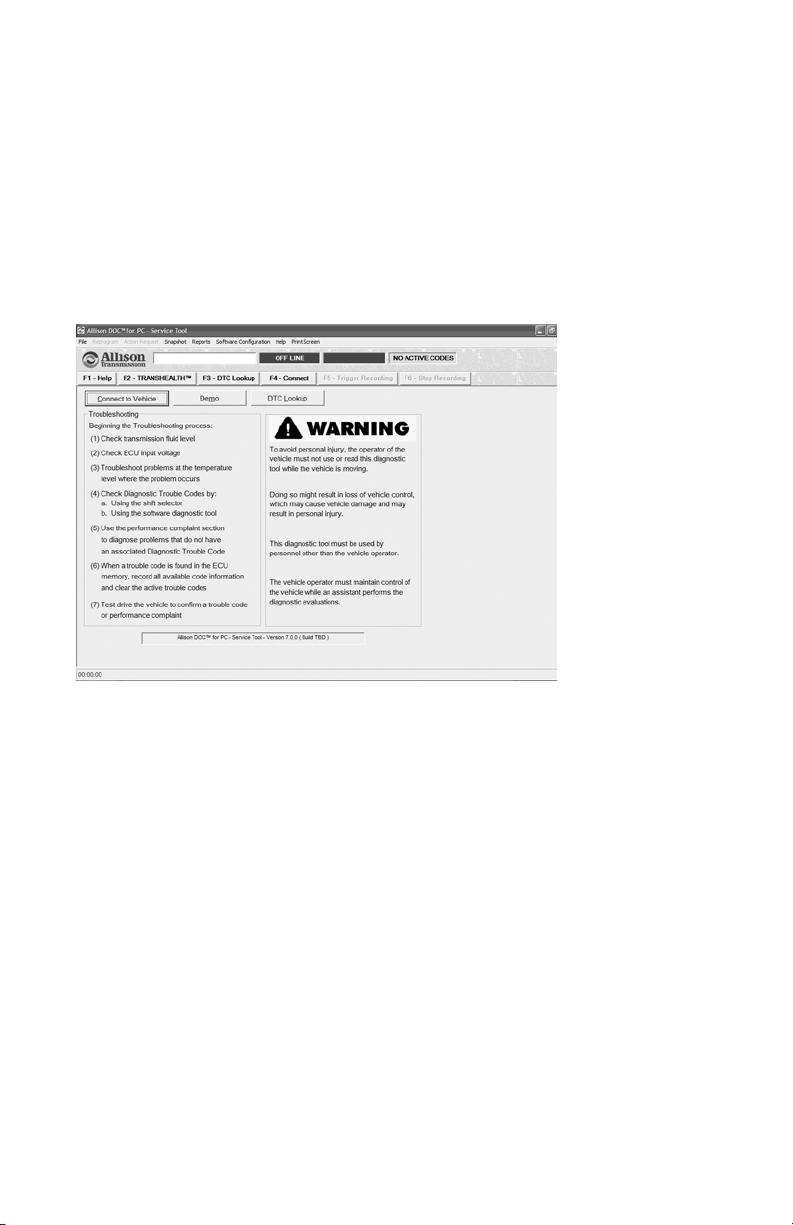

3–3. AT START-UP

When you start Allison DOC™ For PC–Service Tool, the Warning window displays

(if the activation password has been entered, otherwise the 30-Day Trial window

displays). The Warning window lists basic transmission troubleshooting tasks and

outlines basic safety considerations (see Warnings and Notes). The CONNECT TO

VEHICLE button initiates the software connection to a vehicle and the DEMO

button starts Allison DOC™ For PC–Service Tool Demos. The DTC LOOKUP

button displays the Trouble Code Lookup window for various control systems. The

Allison DOC™ For PC–Service Tool version and build are displayed at the bottom

of the Warning window.

23

4.0 CONFIGURING AND UPDATING

ALLISON DOC™ FOR PC–SERVICE TOOL

4–1. APPLICATION CONFIGURATION

The Software Configuration function allows you to tailor Allison DOC™ For

PC–Service Tool to your specific situation and to update the Allison DOC™ For

PC–Service Tool application.

From Software Configuration main menu option you can:

• Change languages—select a language that was initially selected during the

installation of the program

• Change units of measure—English or Metric

• Enter ECU/TCM Reprogramming authorization

• Update the Allison DOC™ For PC–Service Tool application

• Enter TAC Data Collection authorization

• Change the Data Configuration—select 1000/2000 and 3000/4000

th

Generation Controls system transmission parameters to be reported by the

4

TCM.

NOTE: If the Reprogramming tab is “grayed-out” or disabled, the

Reprogramming section has already been authorized.

24

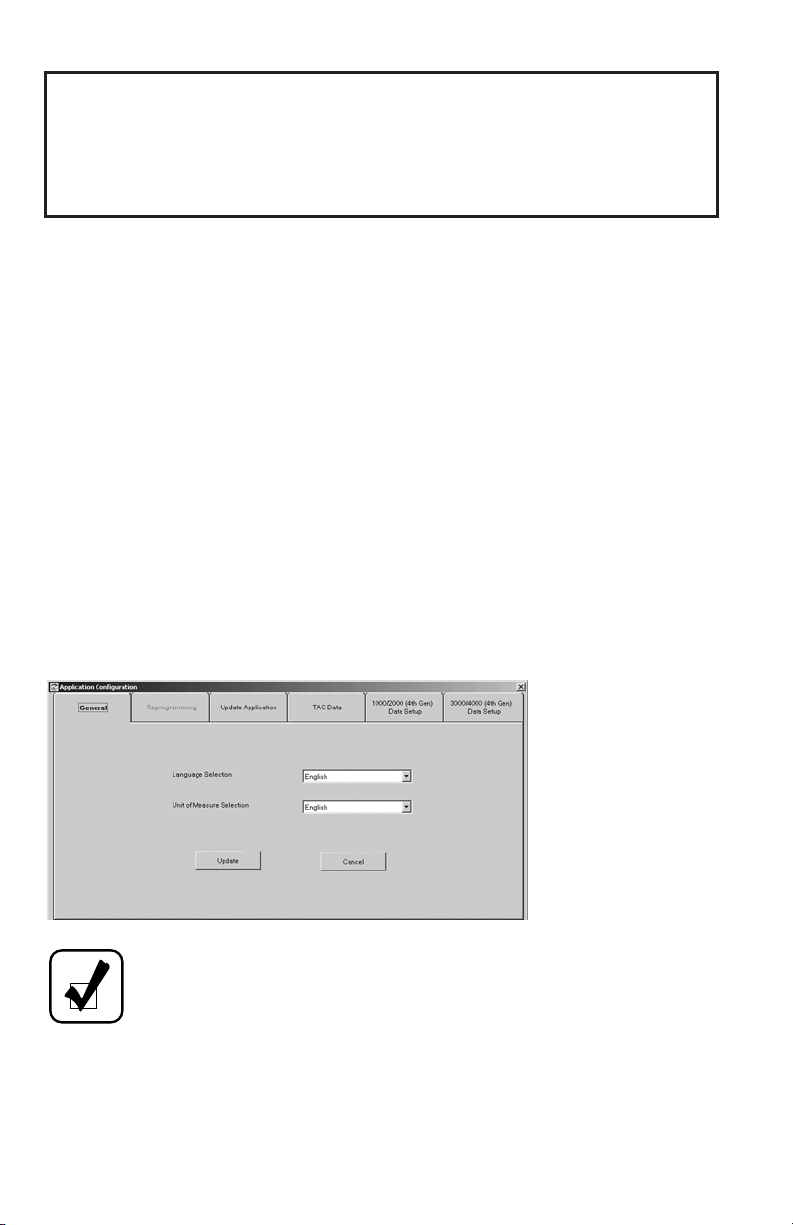

Tabs in the Application Configuration window are:

• General—the default tab

• Reprogramming

• Update Application

• TAC Data Collection

• 1000/2000 (4th Gen) Data Setup

• 3000/4000 (4th Gen) Data Setup

Access configuration items by clicking on the corresponding tab in the Application

Configuration window. An Allison logo displays next to the active tab’s title.

General Tab

From the General tab you can:

• Select a language

• Select either English or Metric units of measure.

Language Selection

1. Click on the down arrow in the Language field.

2. Click on a Language.

3. Click the UPDATE button—all text in Allison DOC™ For PC–Service Tool

is changed to the language selected.

Units of Measure Selection

1. Click on the down arrow in the Units of Measure field.

2. Click on either English or Metric.

3. Click the UPDATE button—all measurements in Allison DOC™ For PC–

Service Tool are changed to either English or Metric units.

Reprogramming Tab

TCM/ECU Reprogramming Authorization

You must obtain reprogramming authorization to reprogram TCM/ECU

information. Accessing the TCM/ECU reprogramming features of Allison DOC™

For PC–Service Tool requires an appropriate training certificate, a password, and the

Allison DOC™ For PC–Service Tool product serial number. Contact SPX

Corporation Kent-Moore Service Solutions (US and Canada: 1-866-621-2128,

International: 1-800-345-2233) for the necessary password. The product serial

number is on the installation CD-ROM jewel case.

25

To enter Reprogramming authorization information:

1. Select the Options drop-down menu.

2. Select Application Configuration menu item.

3. Click the Reprogramming tab—the Product Authorization window displays.

4. Enter Password information as provided by SPX Corporation and the Allison

DOC™ For PC–Service Tool Product Serial Number.

5. Click the APPLY button. Since this is a one-time enabling process, once the

TCM/Reprogramming section has been authorized, the Reprogramming tabs

becomes disabled (grayed out).

Update Application Tab

Allison DOC™ For PC–Service Tool Updates

Allison DOC™ For PC–Service Tool updates are stored on Allison’s Service Tool

Update Server.

NOTE: To receive updates over the Internet, your PC or laptop must

be connected to a telephone line or to some other means of accessing

the Internet. A broadband Internet connection is highly

recommended.

The Update Application function allows you to:

• Determine if an update is available.

• Download the new version and update Allison DOC™ For PC–Service Tool.

• Download the new version to your hard drive and update Allison DOC™ For

PC–Service Tool at a later time.

Checking For An Allison DOC™ For PC–Service Tool Update

Allison DOC™ For PC–Service Tool checks the Update Server for the latest version

of the software. You must have an Internet connection to access the Update Server.

1. Click on the Options Menu.

2. Select the Application Configuration menu item.

3. Click on the Update Application tab—the Application Update window

displays.

4. Click on CHECK FOR UPDATE—Allison DOC™ For PC–Service Tool

accesses the Update Server by way of the Internet. If a newer version of

Allison DOC™ For PC–Service Tool than the one you are using is found on

the update server, the newer version can be applied to your current Allison

DOC™ For PC–Service Tool or downloaded to your hard drive. If a newer

version is not found on the server, Allison DOC™ For PC–Service Tool

checks your hard drive for a newer version.

26

If an update is available, either from the server or your hard drive, the CHECK

FOR UPDATE button changes to APPLY UPDATE.

If your Allison DOC™ For PC–Service Tool is up-to-date, a message displays

indicating you do not need to update.

If the update server is not available and an update is not stored on your PC hard

drive, a message displays providing the reason for an update not being available.

Applying An Allison DOC™ For PC–Service Tool Update

Click the APPLY UPDATE button—the Update Processing window displays.

The latest version of Allison DOC™ For PC–Service Tool is loaded, either from the

update server or from your PC hard drive.

NOTE: If the tool is unable to penetrate the user’s Internet firewall,

click on the displayed URL and download the applicable update.

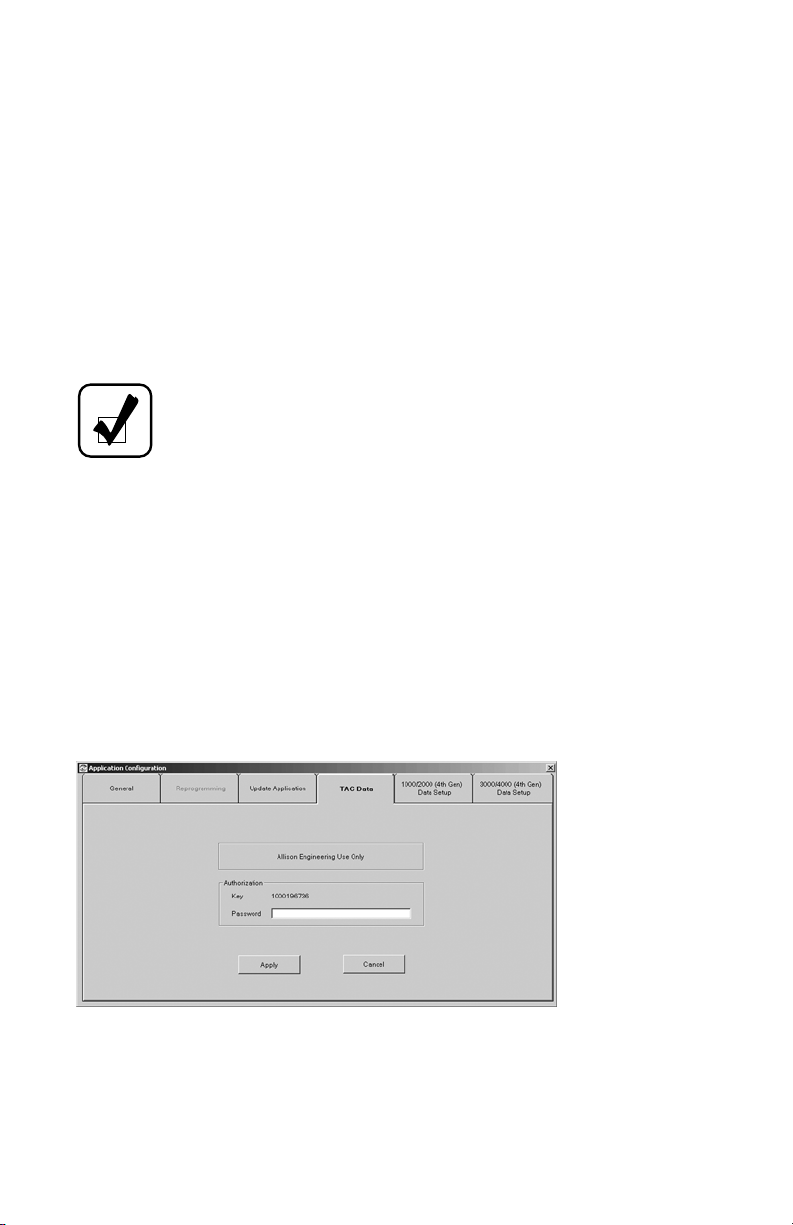

TAC Data Collection

This function shall only be used/enabled at the request of the Allison Transmission

Technical Assistance Center (TAC) to collect WTEC II/III transmission data. The

TAC Data Collection tab is only accessible after the TCM/ECU Reprogramming

section is enabled. If the TAC Data tab is disabled (grayed-out), either the user

hasn’t been authorized for the Reprogramming feature, or the TAC Data has already

been enabled.

Enabling TAC Data Collection

1. Click the TAC Data tab—the TAC Data authorization dialog box displays

with a key number.

2. After determining that you are required to use this feature in Allison DOC™,

an Allison TAC representative will contact you to enable this section based

upon the Authorization Key data.

3. Enter the password in the Password field.

27

4. Click the APPLY button—TAC Data collection may now be accessed from

the Action Request menu.

NOTE: Unlike the Reprogramming section, the TAC Data Collection

requires re-authorization once the technician uses the limited number

of exercisable data collections. TAC determines the number of times

the technician can use this feature when the authorization password is

generated.

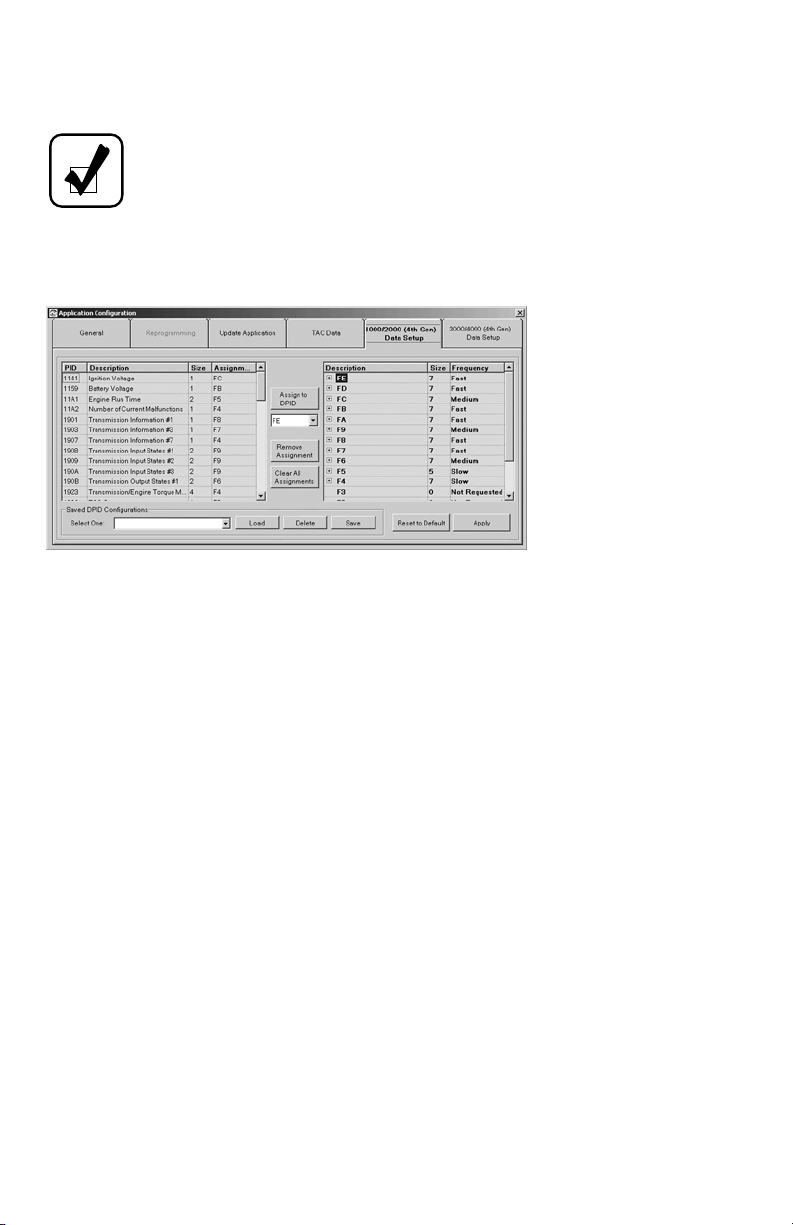

1000/2000 Setup and 3000/4000 Setup Tabs

The 1000/2000 and 3000/4000 (4th Gen) Data Setup tabs allow you to individually

select the transmission data parameters to be requested from an Allison 4th

Generation Controls system and, consequently, displayed on Allison DOC™. The

selected data is assigned to Data Packet Identifiers (DPIDs), which are identified by

an F (e.g. FE, F9, etc.). A configuration may be saved for future use. Limiting the

amount of data to request from a TCM greatly increases the rate of data refresh. In

other words, the fewer transmission data parameters you configure the tool to

request, the faster the TCM will be able to send those parameters to the tool. This is

particularly important when the user needs to closely monitor certain transmission

parameters at higher rates.

On all 4th Generation screens and reports, data that is not being requested by DPID

configuration is displayed as “Not Available.” In the graphics monitor, controls

associated with unavailable data are disabled. In the selection dialogs for the custom

data monitor, Excel export and strip chart parameters that are unavailable will not be

displayed for selection.

Anatomy of a DPID

A DPID contains one or more Parameter Identifiers (PID). A PID identifies a

specific transmission data parameter. The PID description is the designated name of

the PID. The PID size indicates how many bytes the PID uses. A DPID can only

hold up to seven bytes of data. A two-character ID, starting with an F, identifies a

DPID. Fifteen DPIDs are available: FE, FD, FC, FB, FA, F9, F8, F7, F6, F5, F4, F3,

F2, F1, and F0.

28

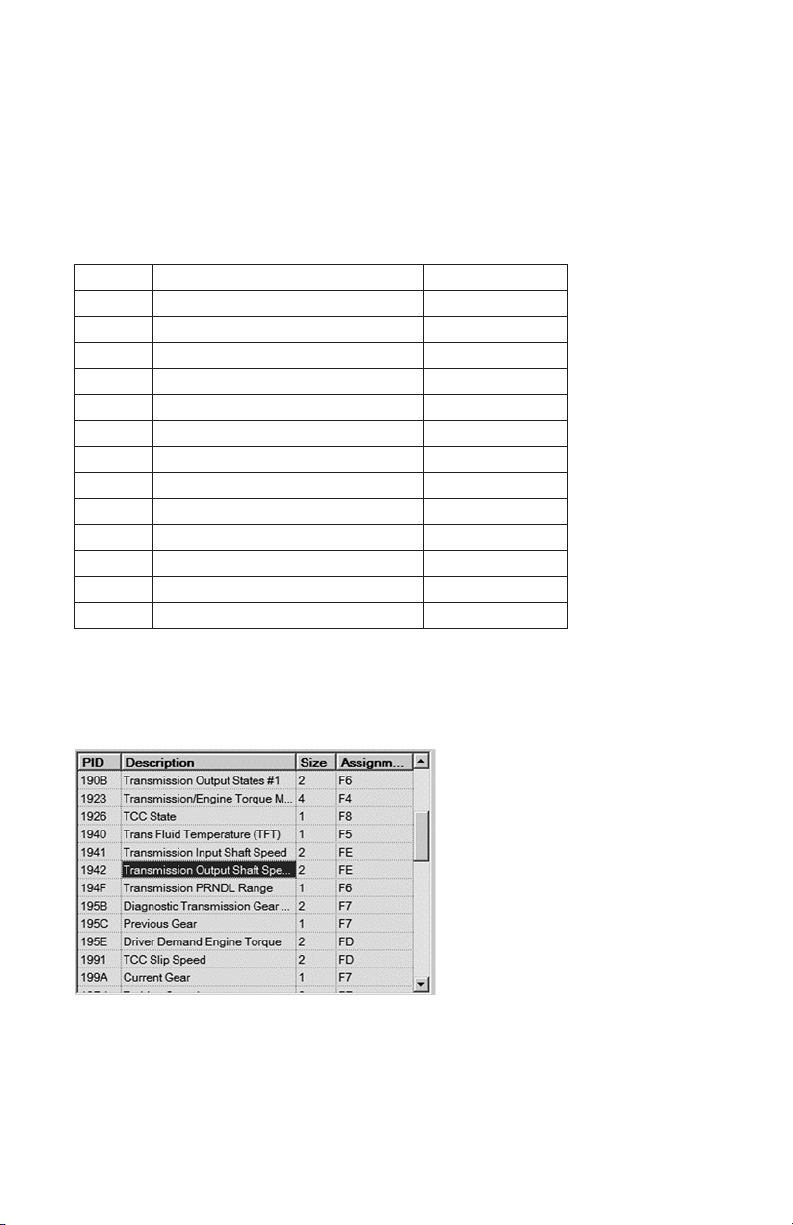

Required PID

Some PIDs are assigned by default to a DPID. The pre-assigned PIDs must always

be selected in order for certain Allison DOC™ features to work correctly. The

Allison DOC™ For PC–Service Tool allows the required PIDs to be reassigned

from their default DPID, but does not allow them to be unassigned. A message

displays if the required PIDs are not assigned to DPID. The following table lists the

required transmission data parameters (with their PID and size).

PID Description Size in Bytes

19D4 Turbine Speed

1941 Input Speed

1942 Output Speed

190B Transmission Input States #1

1909 Transmission Input States #2

190A Transmission Input States #3

3037 GPO Wire On/Off State

3036 GPI Wire On/Off State

190B Transmission Output States #1

3032 Transmission Output States #2

199A Current Gear

1A66 Gear Commanded

3038 Output Speed Acceleration

2

2

2

2

2

2

1

1

2

2

1

1

2

This feature contains the following sections:

Transmission Parameters List

A list of all selectable transmission parameters with relevant information:

• PID (Parameter Identifier)—a number that identifies the transmission

parameter

• Description—the actual designated name of the transmission parameter to

select

29

Loading...

Loading...