3000 AND 4000 ELECTRONIC CONTROLS TROUBLESHOOTING MANUAL

PREFACE

Welcome to the TS2973EN Troubleshooting Manual. We make every effort to keep our service

information current and accurate. Because of the time lag involved with writing and printing processes,

the transmission TCM may report a code that has not yet been added to this document. If you encounter

a code that is not yet in this publication, please call the Allison Transmission Technical Assistance Center

at 1-800-252-5283.

Go to the Table of Contents.

Copyright© 2005 General Motors Corp.

2005 OCTOBER

Troubleshooting

REV. 1 OCTOBER 2006

Manual

TS2973EN

Allison Transmission

VOCATIONAL MODELS

3000 VOCATIONAL MODELS

3000 HS 3500 RDS B 300(P)(R)

3000 RDS 3500 EVS B 400(P)(R)

3000 EVS T 200

3000 MH T 300

3000 PTS

3000 TRV

3200 SP 3500 SP 3700 SP

3200 TRV

MD 3060 MD 3560 MD 3070PT

MD 3066

4000 VOCATIONAL MODELS

4000 EVS 4500 EVS 4700 EVS 4800 EVS B 500

4000 HS 4500 HS 4700 RDS

4000 MH 4500 RDS

4000 RDS 4500 SP

4000 TRV 4500 TRV

HD 4060 HD 4560 HD 4070 HD 4076 B 500P

HD 4060P HD 4560P HD 4070P B 500R

HD 4060R HD 4560R HD 4070R B 500PR

HD 4060PR HD 4560PR HD 4070PR T 425

T 450

Allison Transmission, General Motors Corporation

P.O. Box 894 Indianapolis, Indiana 46206-0894

www.allisontransmission.com

Printed in USA

Copyright © 2005 General Motors Corporation

WTEC III ELECTRONIC CONTROLS TROUBLESHOOTING MANUAL

FOREWORD—How to Use This Manual

This manual provides troubleshooting information for the 3000 and 4000 Product Families Transmissions. Service

Manuals SM2148EN and SM2457EN, plus Parts Catalogs PC2150EN and PC2456EN may be used in conjunction

with this manual.

This manual includes:

•

Description of the WTEC III electronic control system.

•

Description of the electronic control system components.

•

Description of diagnostic codes, system responses to faults, and troubleshooting.

•

Wire, terminal, and connector repair information.

Specific instructions for using many of the available or required service tools and equipment are not included in

this manual. The service tool manufacturer will furnish instructions for using the tools or equipment.

Additional information may be published from time to time in Service Information Letters (SIL) and will be

included in future revisions of this and other manuals. Please use these SILs to obtain up-to-date information

concerning Allison Transmission products.

This publication is revised periodically to include improvements, new models, special tools, and procedures. A

revision is indicated by a new date on the title page and in the lower left corner of the rear cover. Contact your

Allison Transmission service outlet for the currently applicable publication. Additional copies of this publication

may be purchased from authorized Allison Transmission service outlets. Look in your telephone directory under

the heading of Transmissions—Truck, Tractor, etc.

Take time to review the Table of Contents and the manual. Reviewing the Table of Contents will aid you in quickly

locating information.

NOTE: Allison Transmission is providing for service of wiring harnesses and wiring harness components as

follows:

•

Repair parts for the internal wiring harness and for wiring harness components attached to the shift selector

will be available through the Allison Transmission Parts Distribution Center (PDC). Use the P/N from your

appropriate parts catalog or from Appendix E in this manual. Allison Transmission (AT) is responsible for

warranty on these parts.

•

Repair parts for the external harnesses and external harness components must be obtained from St. Clair

Technologies Inc. (SCTI). SCTI provides parts to any Allison customer or OEM and is responsible for

warranty on these parts. SCTI recognizes AT, manufacturers, and SCTI part numbers. SCTI provides a

technical HELPLINE at 519-627-1673 (Wallaceburg). SCTI will have parts catalogs available. The SCTI

addresses and phone numbers for parts outlets are:

St. Clair Technologies, Inc.

920 Old Glass Road

Wallaceburg, Ontario, N8A 4L8

Phone: 519-627-1673

Fax: 519-627-4227

St. Clair Technologies, Inc.

Calle Damanti S/N Col

Guadalupe—Guaymas

Sonora, Mexico CP85440

Phone: 011-526-2222-43834

Fax: 011-526 2222-43553

•

St. Clair Technologies, Inc. stocks a WTEC III external harness repair kit, P/N 29532362, as a source for

some external harness repair parts. SCTI is the source for external harness repair parts.

ii Copyright © 2005 General Motors Corp.

WTEC III ELECTRONIC CONTROLS TROUBLESHOOTING MANUAL

IMPORTANT SAFETY NOTICE

IT IS YOUR RESPONSIBILITY to be completely familiar with the warnings and cautions

used in this manual. These warnings and cautions advise against using specific service

procedures that can result in personal injury, equipment damage, or cause the equipment to

become unsafe. These warnings and cautions are not exhaustive. Allison Transmission could

not possibly know, evaluate, or advise the service trade of all conceivable procedures by which

service might be performed or of the possible hazardous consequences of each procedure.

Consequently, Allison Transmission has not undertaken any such broad evaluation.

Accordingly, ANYONE WHO USES A SERVICE PROCEDURE OR TOOL WHICH IS NOT

RECOMMENDED BY ALLISON TRANSMISSION MUST first be thoroughly satisfied

that neither personal safety nor equipment safety will be jeopardized by the service

procedures used.

Also, be sure to review and observe WARNINGS, CAUTIONS, and NOTES provided by the

vehicle manufacturer and/or body builder before servicing the Allison transmission in that

vehicle.

Proper service and repair is important to the safe and reliable operation of the equipment.

The service procedures recommended by Allison Transmission and described in this manual

are effective methods for performing troubleshooting operations. Some procedures require

using specially designed tools. Use special tools when and in the manner recommended.

The WARNINGS, CAUTIONS, and NOTES in this manual apply only to the Allison

transmission and not to other vehicle systems which may interact with the transmission. Be

sure to review and observe any vehicle system information provided by the vehicle

manufacturer and/or body builder at all times the Allison transmission is being serviced.

WARNINGS, CAUTIONS, AND NOTES

Three types of headings are used in this manual to attract your attention:

WARNING!

Is used when an operating procedure, practice, etc., which, if not correctly followed,

could result in injury or loss of life.

CAUTION:

NOTE: Is used when an operating procedure, practice, etc., is essential to highlight.

Is used when an operating procedure, practice, etc., which, if not strictly observed, could

result in damage to or destruction of equipment.

Copyright © 2005 General Motors Corp. iii

,

WTEC III ELECTRONIC CONTROLS TROUBLESHOOTING MANUAL

TRADEMARKS USED IN THIS MANUAL

The following trademarks are the property of the companies indicated:

•

Allison DOC

•

DEXRON

®

•

LPS

Cleaner is a registered trademark of LPS Laboratories.

•

Loctite

•

MagiKey

•

•

®

Teflon

TranSynd

TM

is a trademark of General Motors Corporation.

®

is a registered trademark of General Motors Corporation.

®

is a registered trademark of the Loctite Corporation.

®

is a registered trademark of NEXIQ Technologies, Inc.

is a registered trademark of the DuPont Corporation.

TM

is a trademark of Castrol Ltd.

SHIFT SELECTOR TERMS AND DISPLAY INDICATIONS

Shift selector terms and displays are represented in this manual as follows:

Button Names —

•

•

Transmission Ranges— D (Drive), N (Neutral), R (Reverse), 1 (First), 2 (Second), etc.

•

Displays—“ o , L ”; “ o , K ”, etc. (Display occurs one character at a time.)

, “display mode”, MODE , etc.

↑

↓

iv Copyright © 2005 General Motors Corp.

WTEC III ELECTRONIC CONTROLS TROUBLESHOOTING MANUAL

3000 AND 4000 ELECTRONIC CONTROLS TROUBLESHOOTING MANUAL

TABLE OF CONTENTS

Foreword. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ii

SAFETY INFORMATION

Important Safety Notice . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .iii

Warnings, Cautions, and Notes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .iii

TRADEMARKS USED IN THIS MANUAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .iv

SHIFT SELECYOR TERMS AND DISPLAY INDICATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .iv

SECTION 1. GENERAL DESCRIPTION

1–1. TRANSMISSION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1–1

1–2. ELECTRONIC CONTROL UNIT (ECU) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1–3

1–3. SHIFT SELECTOR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1–3

A. Pushbutton Shift Selector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1–3

B. Lever Shift Selector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1–4

1–4. THROTTLE POSITION SENSOR. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1–5

1–5. SPEED SENSORS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1–5

1–6. CONTROL MODULE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1–6

1–7. WIRING HARNESSES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1–8

A. External Wiring Harness . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1–8

B. Internal Wiring Harness. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1–10

1–8. VEHICLE INTERFACE MODULE. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1–10

1–9. AUTODETECT FEATURE (V8, V8A, V9A SOFTWARE) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1–11

A. Retarder . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1–11

B. Oil Level Sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1–11

C. Throttle Source (V8, V8A Software—See Paragraph 1–10C For V9A). . . . . . . . . . . . . . . . . . 1–12

D. Engine Coolant Temperature Sensor Source . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1–12

1–10. AUTODETECT FEATURE (V9A, V9B, AND V9C SOFTWARE) . . . . . . . . . . . . . . . . . . . . . . . 1–12

A. Retarder . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1–12

B. Oil Level Sensor (OLS) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1–12

C. Throttle Source (Also Applies to V9 Software). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1–13

D. Engine Coolant Temperature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1–13

1–11. TRANSID FEATURE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1–13

A. General Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1–13

B. Transmission Changes Versus TransID Number . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1–14

C. Compatibility Between TransID Level And ECU Calibration Level . . . . . . . . . . . . . . . . . . . . 1–16

Page

Copyright © 2005 General Motors Corp. v

WTEC III ELECTRONIC CONTROLS TROUBLESHOOTING MANUAL

3000 AND 4000 ELECTRONIC CONTROLS TROUBLESHOOTING MANUAL

TABLE OF CONTENTS(Cont'd)

SECTION 2. DEFINITIONS AND ABBREVIATIONS

2–1. CHECK TRANS LIGHT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2–1

2–2. ALLISON TRANSMISSION DIAGNOSTIC TOOL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2–1

Basic Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2–1

PC Platform. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2–2

2–3. ABBREVIATIONS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2–3

SECTION 3. BASIC KNOWLEDGE

3–1. BASIC KNOWLEDGE REQUIRED . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3–1

3–2. USING THE TROUBLESHOOTING MANUAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3–2

3–3. SYSTEM OVERVIEW. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3–2

3–4. IMPORTANT INFORMATION IN THE TROUBLESHOOTING PROCESS . . . . . . . . . . . . . . . . 3–2

3–5. BEGINNING THE TROUBLESHOOTING PROCESS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3–3

Page

SECTION 4. WIRE TESTING PROCEDURES

4–1. TESTING FOR OPENS, SHORTS BETWEEN WIRES, AND SHORTS-TO-GROUND . . . . . . . 4–1

4–2. TESTING AT TRANSMISSION CONNECTOR AND THE INTERNAL HARNESS

FOR OPENS, SHORTS BETWEEN WIRES, AND SHORTS-TO-GROUND . . . . . . . . . . . . . . . . 4–3

SECTION 5. OIL LEVEL SENSOR

5–1. INTRODUCTION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5–1

5–2. ELECTRONIC FLUID LEVEL CHECK (SHIFT SELECTOR). . . . . . . . . . . . . . . . . . . . . . . . . . . 5–3

A. Fluid Level Check Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5–3

5–3. ELECTRONIC FLUID LEVEL CHECK (ALLISON DOC™ FOR PC–SERVICE TOOL) . . . . . 5–5

A. Fluid Level Check Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5–5

SECTION 6. DIAGNOSTIC CODES

6–1. DIAGNOSTIC CODE MEMORY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6–1

6–2. CODE READING AND CODE CLEARING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6–1

6–3. DIAGNOSTIC CODE RESPONSE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6–3

6–4. SHIFT SELECTOR DISPLAYS RELATED TO ACTIVE CODES . . . . . . . . . . . . . . . . . . . . . . . . 6–4

6–5. DIAGNOSTIC CODE LIST AND DESCRIPTION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6–4

6–6. DIAGNOSTIC CODE TROUBLESHOOTING. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6–16

A. Beginning the Troubleshooting Process . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6–16

B. Solenoid Locations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6–16

C. Diagnostic Code Schematics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6–16

D. Wire/Terminal Numbering Scheme . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6–17

vi Copyright © 2005 General Motors Corp.

WTEC III ELECTRONIC CONTROLS TROUBLESHOOTING MANUAL

3000 AND 4000 ELECTRONIC CONTROLS TROUBLESHOOTING MANUAL

TABLE OF CONTENTS(Cont'd)

SECTION 7. INPUT AND OUTPUT FUNCTIONS

7–1. INPUT FUNCTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7–1

7–2. OUTPUT FUNCTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7–3

SECTION 8. GENERAL TROUBLESHOOTING OF PERFORMANCE COMPLAINTS

APPENDICES

A. IDENTIFICATION OF POTENTIAL CIRCUIT PROBLEMS. . . . . . . . . . . . . . . . . . . . . . . . . . . .A–1

B. MEASURING CLUTCH AND RETARDER PRESSURES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B–1

C. SOLENOID AND CLUTCH CHART . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C–1

D. WIRE/CONNECTOR CHART. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .D–1

E. CONNECTOR PART NUMBERS, TERMINAL PART NUMBERS,

TOOL PART NUMBERS, AND REPAIR INSTRUCTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . E–1

F. THROTTLE POSITION SENSOR ADJUSTMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . F–1

G. WELDING ON VEHICLE/VEHICLE INTERFACE MODULE . . . . . . . . . . . . . . . . . . . . . . . . . .G–1

H. HYDRAULIC SCHEMATICS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .H–1

J. 3000 AND 4000 PRODUCT FAMILIES WIRING SCHEMATIC . . . . . . . . . . . . . . . . . . . . . . . . . J–1

K. TRANSID 1 TEMPERATURE SENSOR AND SOLENOID RESISTANCE CHARTS . . . . . . . .K–1

L. EXTERNALLY-GENERATED ELECTRONIC INTERFERENCE . . . . . . . . . . . . . . . . . . . . . . . . L–1

M. DIAGNOSTIC TREE—HYDRAULIC SYSTEM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . M–1

N. DIAGNOSTIC TOOL INFORMATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .N–1

P. INPUT/OUTPUT FUNCTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . P–1

Q. TRANSID 2 AND 3 THERMISTOR TROUBLESHOOTING INFORMATION . . . . . . . . . . . . . .Q–1

R. SAE J1939 COMMUNICATION LINK . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . R–1

Page

Copyright © 2005 General Motors Corp. vii

WTEC III ELECTRONIC CONTROLS TROUBLESHOOTING MANUAL

NOTES

viii Copyright © 2005 General Motors Corp.

WTEC III ELECTRONIC CONTROLS TROUBLESHOOTING MANUAL

ECTION

S

1—GENERAL DESCRIPTION

1–1. TRANSMISSION

The World Transmission Electronic Controls (WTEC III) system features closed-loop clutch control to provide

superior shift quality over a wide range of operating conditions. The 3000 and 4000 Product Families transmissions

configurations can be programmed to have up to six forward ranges, neutral, and one reverse range. The MD 3070,

3700 SP, HD 4070/4076, 4700 RDS, 4700/4800 EVS, 4700/4800 SP have up to seven forward ranges and one

reverse.

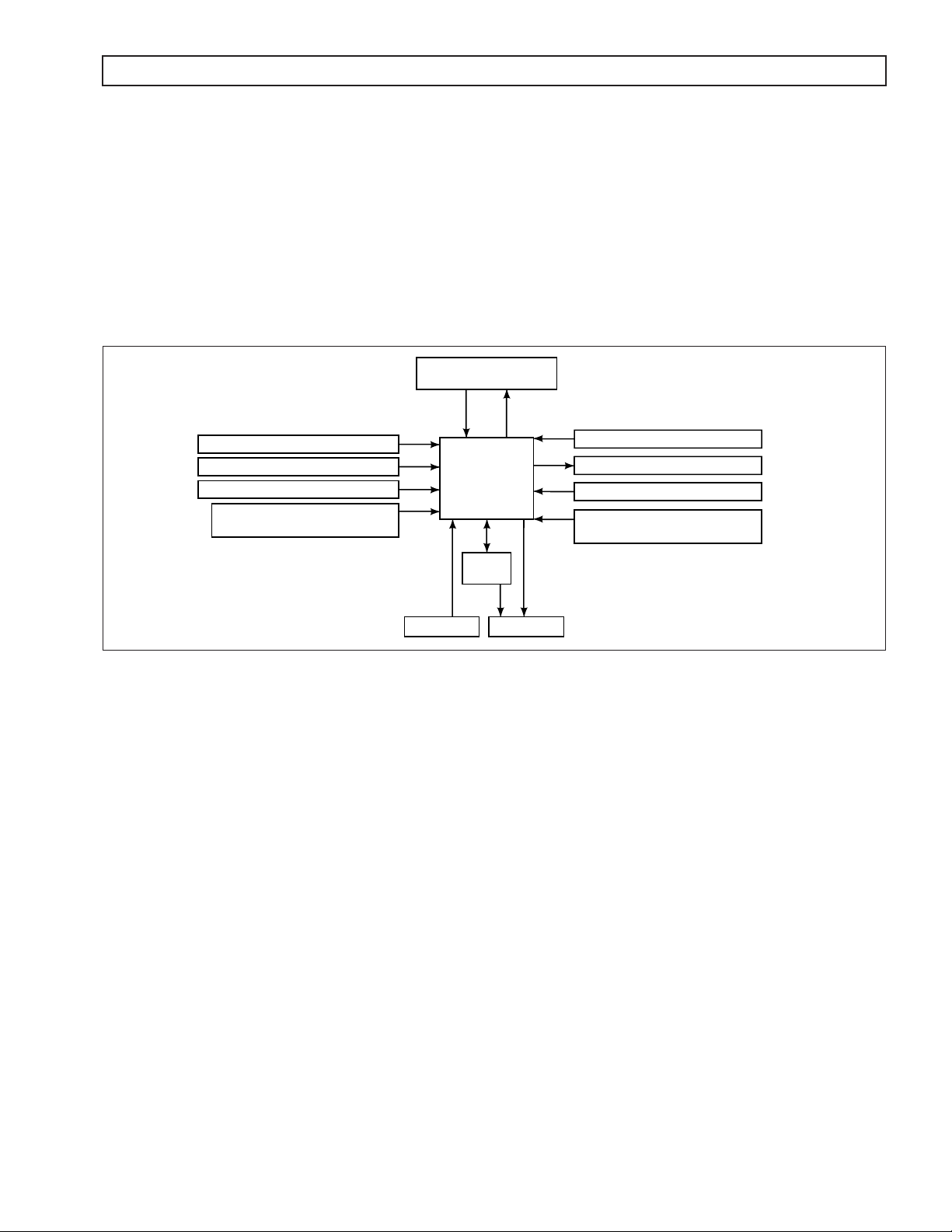

Figure 1–1 is a block diagram of the basic system inputs and outputs.

SHIFT SELECTOR

RANGE AND

MODE SWITCH

SPEED SENSORS

THROTTLE POSITION SENSOR

RETARDER MODULAT ION

VEHICLE/ENGINE

COMMUNICATION LINKS

Figure 1–1. Electronic Control Unit Block Diagram

ECU

VIM

INPUTS OUTPUTS

DISPLAY

Figure 1–2 shows WTEC III electronic control components.

WTEC III Electronic Controls consist of the following elements:

•

Remote 12/24V Max Feature Sealed Electronic Control Unit (ECU)

Remote Pushbutton or Lever Shift Selector

•

•

Optional Secondary Shift Selector

OIL LEVEL SENSOR

SOLENOIDS

C3 PRESSURE SWITCH

TEMPERATURE SENSOR

(SUMP/RETARDER)

V03469

NOTE:

•

Throttle Position Sensor (TPS) (or electronic engine throttle data or PWM signal)

Engine, Turbine, and Output Speed Sensors

•

Control Module (Electro-Hydraulic Valve Body)

•

•

Wiring Harnesses

Vehicle Interface Module (VIM)

•

•

Autodetect Feature

•

TransID Feature

Optional Retarder Controls

•

•

Optional Engine Coolant Temperature Input.

All external harnesses are OEM supplied

•

•

The VIM is an OEM option

Copyright © 2005 General Motors Corp. 1–1

WTEC III ELECTRONIC CONTROLS TROUBLESHOOTING MANUAL

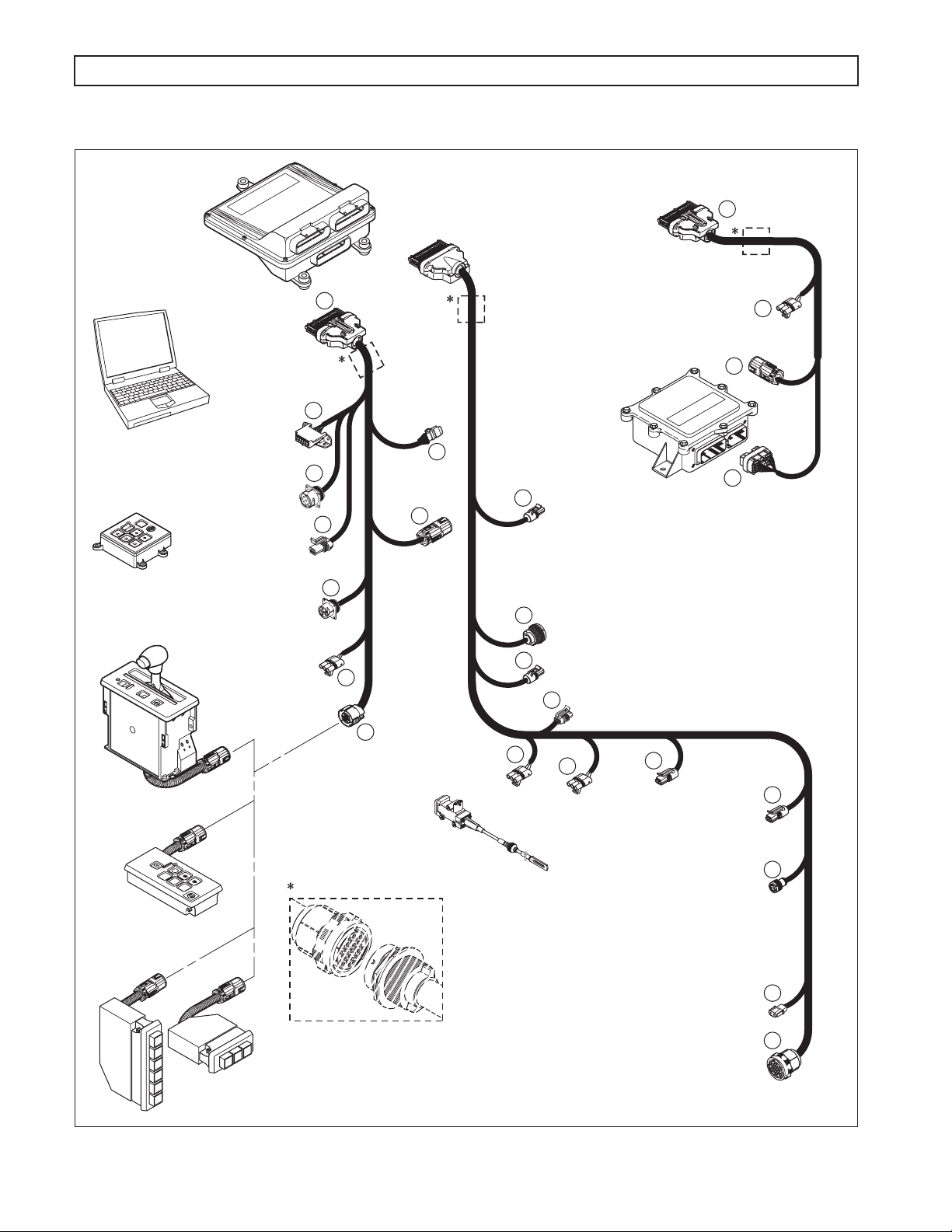

R

MODE

N

D

BLUE

BLUE

BLACK

GRAY

GENERAL DESCRIPTION

ELECTRONIC

CONTROL

UNIT

(ECU)

ALLISON DOC

FOR PC

™

SELECTOR (S)

GRAY

TRANSMISSION (T)

BLACK

BLUE

BLUE

1

HARNESS

“T”

CONNECTOR

(BLUE)

VEHICLE (V)

HARNESS

“V”

CONNECTOR

(GRAY)

1

TPS

CONNECTOR

(OPTIONAL)

4

HARNESS

CONNECTOR

“S”

(BLACK)

VEHICLE

INTERFACE

MODULE

(VIM)

17

COMPACT

PUSHBUTTON

SELECTOR

MODE

REMOTE LEVER

SELECTOR

DIAGNOSTIC

TOOL

CONNECTOR

DEUTSCH 9-PIN

DIAGNOSTIC TOOL

CONNECTOR

SCI (J 1587)

CONNECTOR

(OPTIONAL)

DEUTSCH

DIAGNOSTIC TOOL

CONNECTOR

(OPTIONAL)

RETARDER

MODULATION

REQUEST (RMR)

CONNECTOR

25

17

19

17

18

J 1939

CONNECTOR

(OPTIONAL)

3

VIW

CONNECTOR

6

RETARDER ACCUMULATOR

CONNECTOR

7

SENSOR HARNESS

CONNECTOR (OPTIONAL)

OUTPUT

8

SPEED SENSOR

CONNECTOR

9

RETARDER TEMP. SENSOR CONNECTOR

16

REMOTE

PUSHBUTTON

SELECTOR

SELECT

SHIFT

SELECTOR

CONNECTOR

MODE

R

N

D

Bulkhead Connector (Optional)

THROTTLE POSITION

SENSOR (TPS)

CONNECTOR

THROTTLE

POSITION

SENSOR (TPS)

4

RMR

CONNECTOR

(OPTIONAL)

15

SPEED SENSOR

14

TURBINE

CONNECTOR

(4000 PRODUCT

FAMILY)

RETARDER “H” SOLENOID

(4000 PRODUCT FAMILY)

VIW

CONNECTOR

3

5

VIM

CONNECTOR

ENGINE

SPEED

SENSOR

CONNECTOR

CONNECTOR

13

13

STRIP PUSHBUTTON

SHIFT SELECTORS

(EUROPEAN

OEM)

(4000 PRODUCT FAMILY) PRE-TRANSID & TID 1

1

2

3

D

N

R

.

R

N

D

NOTE: Illustration is not to scale. Actual harness

configuration may differ from this illustration.

Figure 1–2. WTEC III Electronic Control Components

1–2 Copyright © 2005 General Motors Corp.

RETARDER TEMPERATURE

SENSOR CONNECTOR

TRANSMISSION

FEEDTHROUGH

HARNESS

CONNECTOR

11

10

V07347.04.00

BLUE BLUE

BLACK GRAY

WTEC III ELECTRONIC CONTROLS TROUBLESHOOTING MANUAL

GENERAL DESCRIPTION

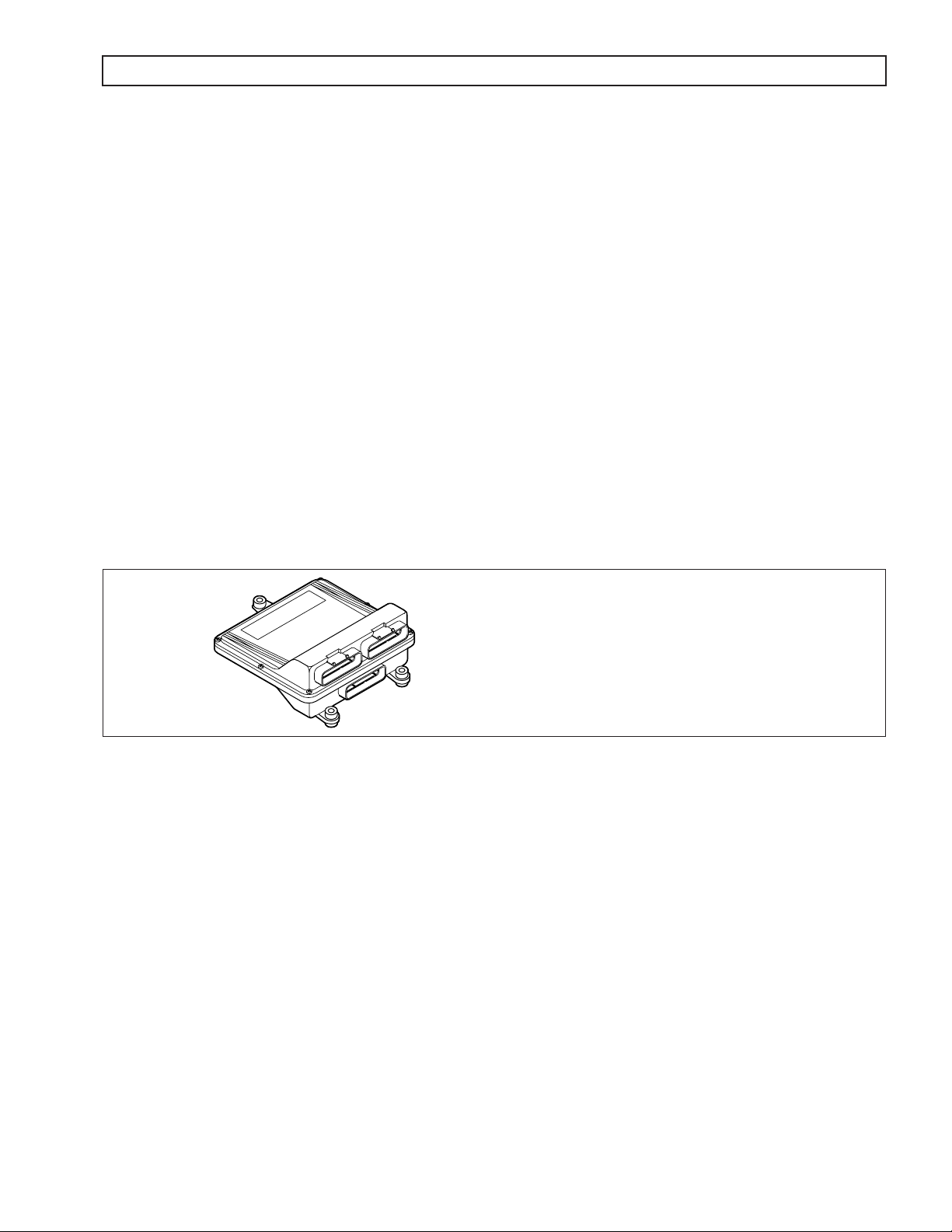

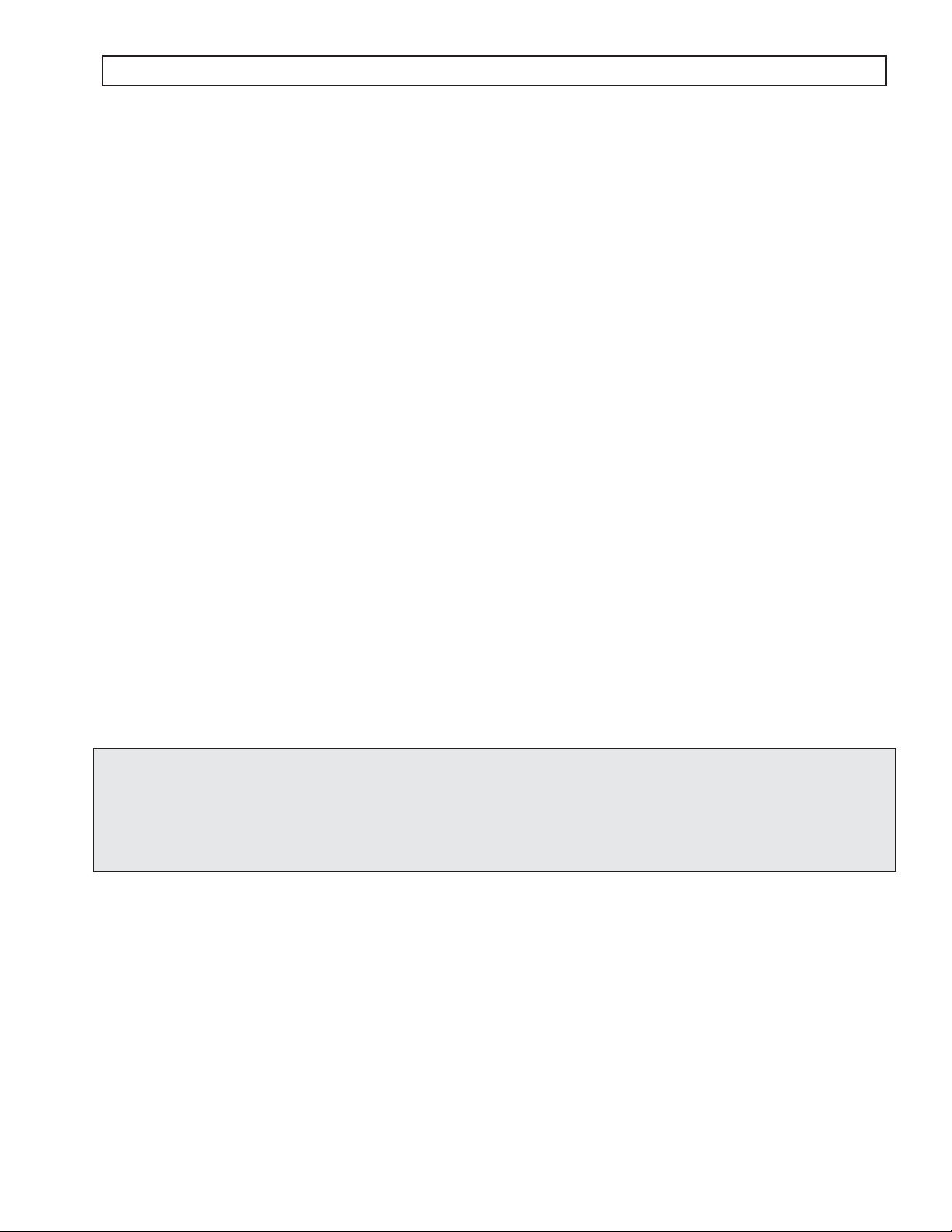

1–2. ELECTRONIC CONTROL UNIT (ECU)

The ECU (Figure 1–3) contains the microcomputer which is the brain of the control system. The ECU receives and

processes information defining:

Shift selector

•

•

Throttle position

•

Sump/retarder temperature

Engine speed

•

Turbine speed

•

•

Transmission output speed.

The ECU uses the information to:

•

Control transmission solenoids and valves

• Supply system status

• Provide diagnostic information.

Each ECU has a date code stamped on the label which is attached to the outer case of the ECU. This is the date

when the ECU passed final testing. This date is commonly used to denote the change configuration level of the

ECU. It is normal for the ECU date displayed electronically to be a few days prior to the date shown on the label.

NOTE: ECU wiring harness connector retainers are individually

keyed and color-coded to ensure that the proper

connector is attachedto the correct ECU socket.

The color of the connector retainer should

match the color of the connector strain relief

BLUE

ECU

Figure 1–3. Electronic Control Unit (ECU)

(see Appendix E, Paragraph 1–1).

V07346.00.01

1–3. SHIFT SELECTOR

Pushbutton and lever shift selectors for the WTEC III Series are remote mounted from the ECU and connected to

the ECU by a wiring harness. All shift selectors except the strip-type pushbutton have a single digit LED display

and a mode indicator (LED). During normal transmission operation, illumination of the LED mode indicator shows

that a secondary or special operating condition has been selected by pressing the MODE button. During diagnostic

display mode, illumination of the LED indicator shows that the displayed diagnostic code is active. Display

brightness is regulated by the same vehicle potentiometer that controls dash light display brightness. More

information on both types of shift selectors is continued below.

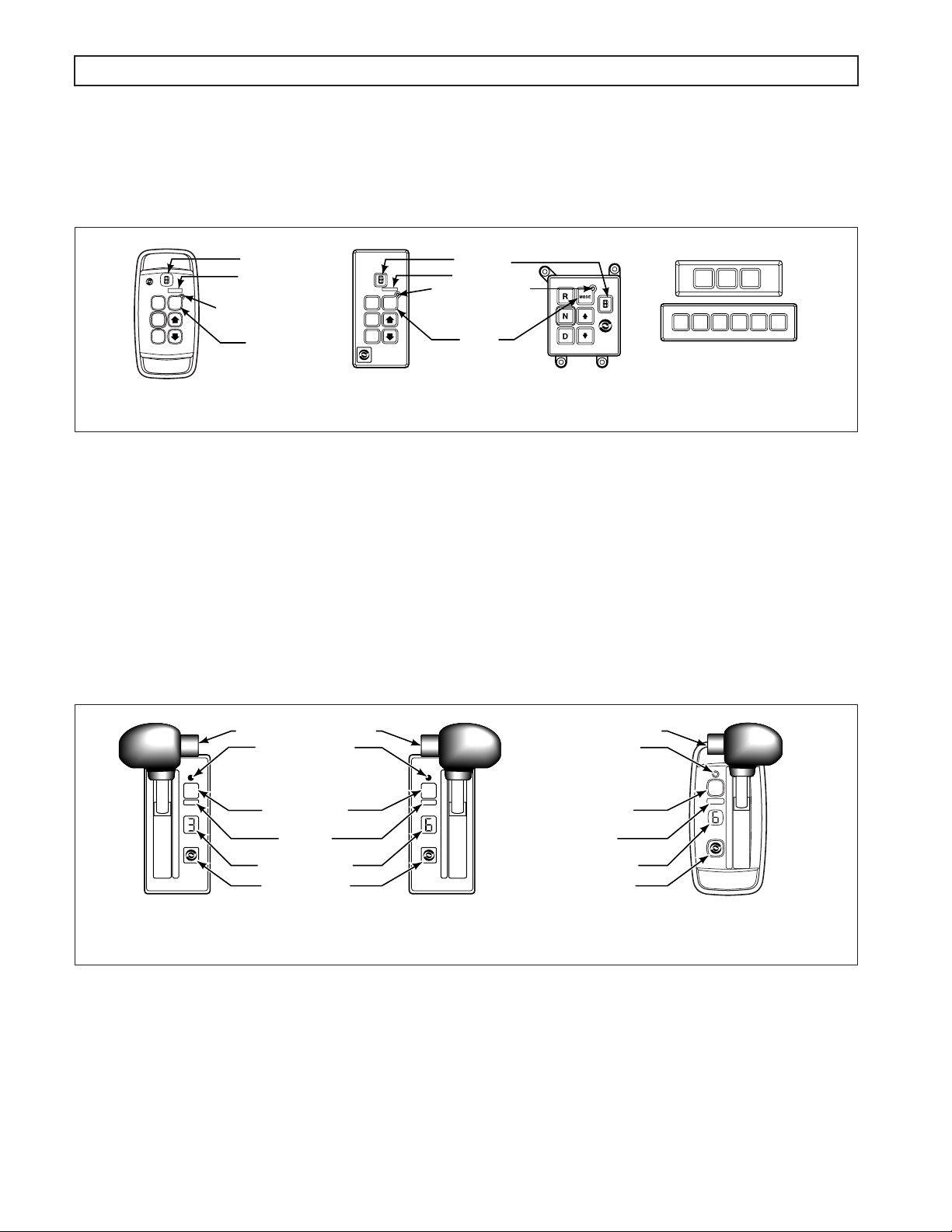

A. Pushbutton Shift Selector (Figure 1–4)

There are three full-function pushbutton shift selectors and a strip pushbutton shift selector. Strip

pushbutton shift selectors are used by European OEMs. A full-function shift selector has a MODE

button and diagnostic display capability through the single digit LED display. The strip pushbutton

shift selector does not have a MODE button, diagnostic capability, or adjustable illumination. The

full-function pushbutton shift selector has six (6) pushbuttons which are R (Reverse), N (Neutral),

D (Drive),

by pressing the

has a raised lip to aid in finding it by touch. The MODE button is pressed to select a secondary or

special operating condition, such as ECONOMY shift schedule. Diagnostic and oil level (if sensor is

present) information is obtained by pressing the

↓ (Down), ↑ (Up), and MODE. Manual forward range downshifts and upshifts are made

↓ (Down) or ↑ (Up) arrow buttons after selecting D (Drive). The N (Neutral) button

↓ (Down) and ↑ (Up) arrow buttons at the same time.

Copyright © 2005 General Motors Corp. 1–3

WTEC III ELECTRONIC CONTROLS TROUBLESHOOTING MANUAL

GENERAL DESCRIPTION

The strip pushbutton shift selector has either three or six range selection positions as shown in Figure

1–4. When a strip pushbutton shift selector is used, diagnostic information must be obtained by using

the Allison DOC™ For PC–Service Tool, or a customer-furnished remote display.

DISPLAY

MODE ID

MODE

R

N

D

MODE INDICATOR

(LED)

MODE

BUTTON

CONTOURED VERSION

B. Lever Shift Selector (Figure 1–5)

The lever shift selector can have as many as six forward range positions (seven for the 7-speed

models), as well as R (Reverse) and N (Neutral). There is a hold override button which must be

pressed and held in order to move between certain selector positions. The hold override button must

be pressed when shifting between R, N, and D. The hold override button is released when the desired

selector position is reached. The selector lever can be moved freely between D and the numbered

forward ranges without pressing the hold override button. The lever selector can be chosen with the

lever on the left side or on the right side and with the R (Reverse) position toward the front or toward

the rear of the selector. Diagnostic and oil level (if sensor is present) information is obtained from the

LED display by pressing the DISPLAY MODE/DIAGNOSTIC button.

DISPLAY

MODE ID

MODE

R

N

D

MODE INDICATOR

(LED)

MODE

BUTTON

REGULAR COMPACT

PUSHBUTTON

SELECTORS

Figure 1–4. Pushbutton Shift Selectors

R

D

N

21 3DNR

STRIP PUSHBUTTON

SHIFT SELECTORS

V07178

HOLD OVERRIDE BUTTON

1

MODE

2

3

4

5

D

N

R

SIX-SPEED, LEFT-HAND

LEVER SELECTOR

WITH REVERSE TO REAR

MODE INDICATOR

(LED)

MODE BUTTON

MODE ID

DIGITAL DISPLAY

DISPLAY MODE/

DIAGNOSTIC BUTTON

Figure 1–5. Typical Lever Shift Selector

R

MODE

N

D

5

4

3

2

1

SIX-SPEED, RIGHT-HAND

LEVER SELECTOR

WITH REVERSE TO FRONT

HOLD OVERRIDE BUTTON

MODE INDICATOR

(LED)

MODE BUTTON

MODE ID

DIGITAL DISPLAY

DISPLAY MODE/

DIAGNOSTIC BUTTON

R

MODE

N

D

5

4

3

2

1

CONTOURED VERSION

V07177

1–4 Copyright © 2005 General Motors Corp.

WTEC III ELECTRONIC CONTROLS TROUBLESHOOTING MANUAL

GENERAL DESCRIPTION

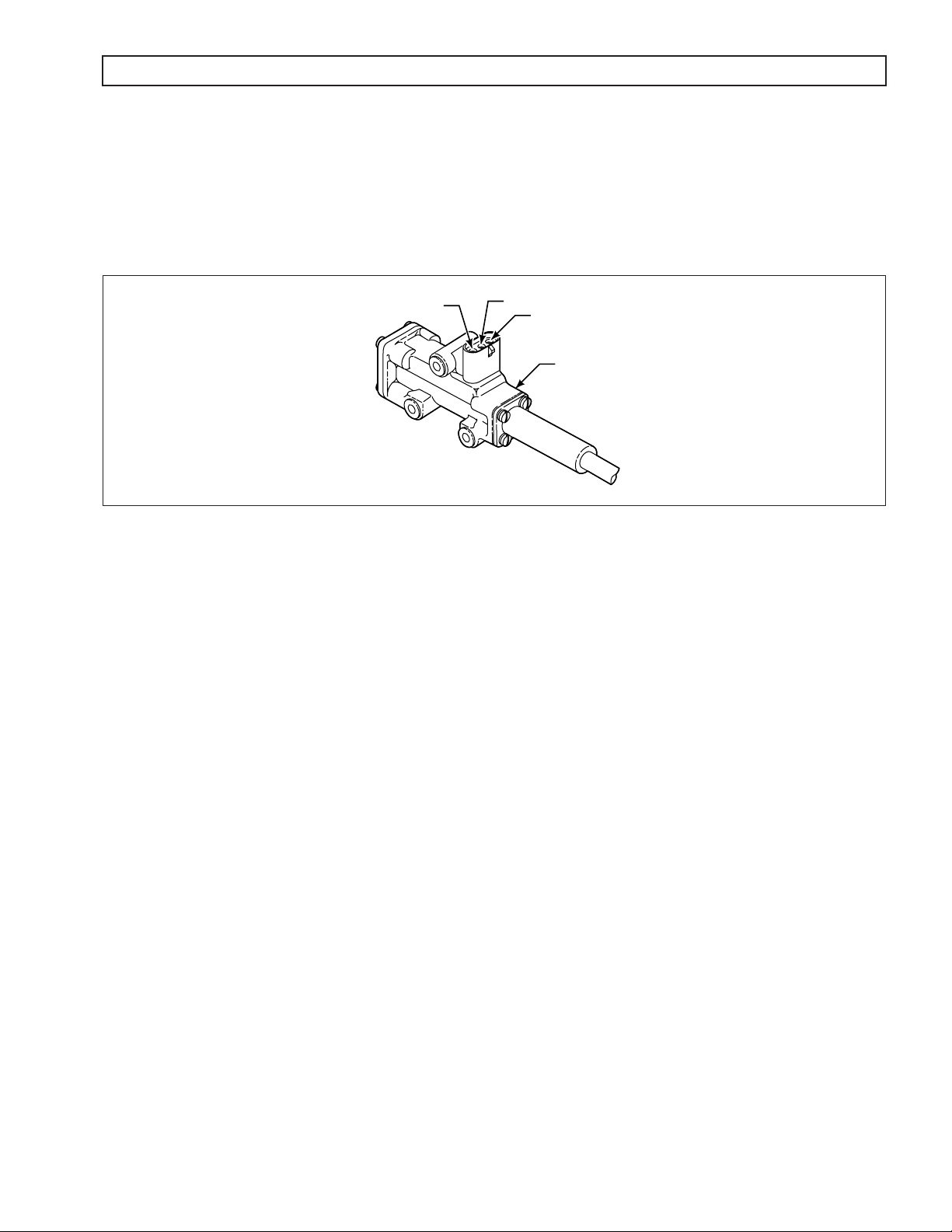

1–4. THROTTLE POSITION SENSOR (Figure 1–6)

The Throttle Position Sensor (TPS) can be mounted to the engine, chassis, or transmission. The TPS contains a pull

actuation cable and a potentiometer. One end of the cable is attached to the engine fuel lever and the other, inside a

protective housing, to the TPS potentiometer. Output voltage from the TPS is directed to the ECU through the

external harness. The voltage signal indicates the throttle position and, in combination with other input data,

determines shift timing.

A

Figure 1–6. Throttle Position Sensor (Without Mounting Brackets)

B

C

THROTTLE SENSOR

V00628

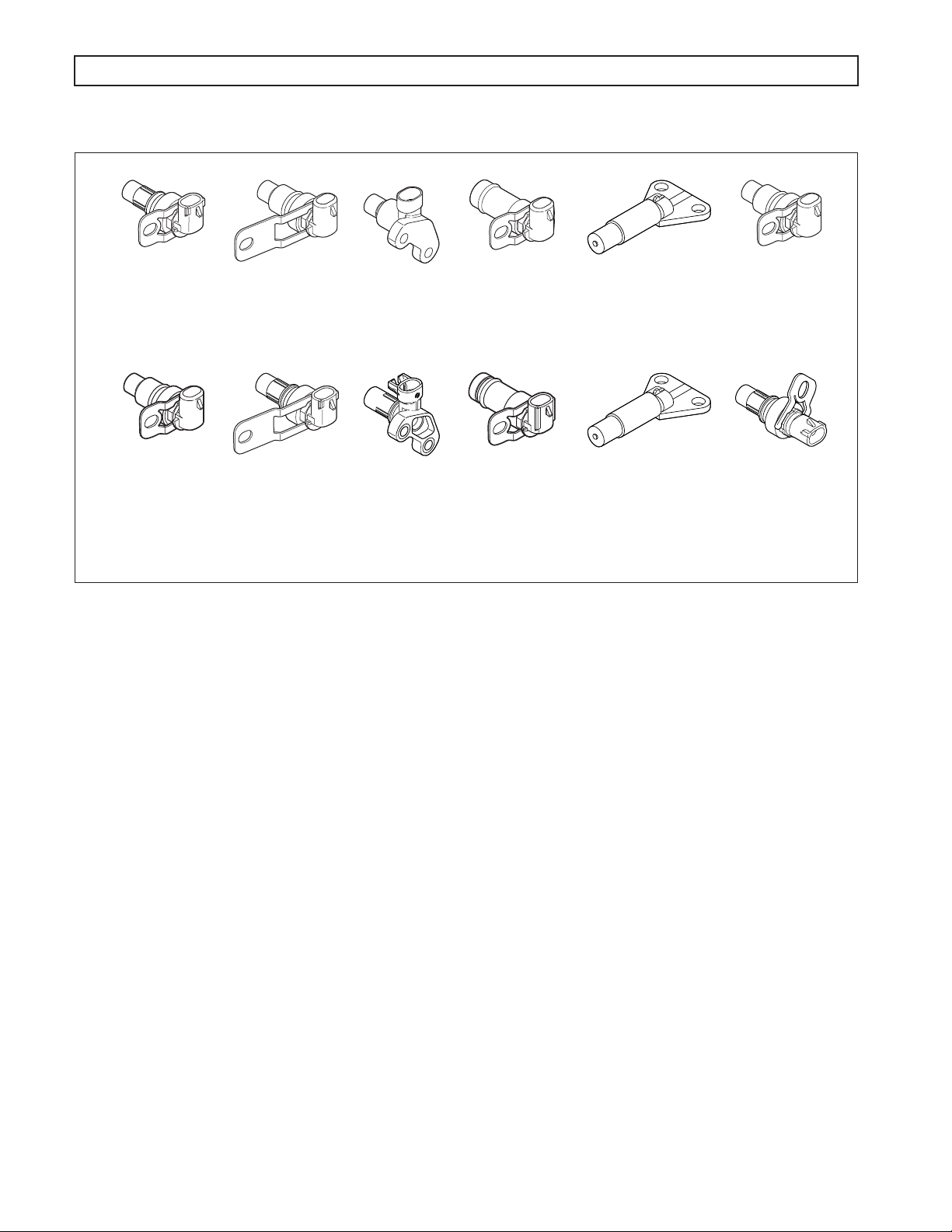

1–5. SPEED SENSORS (Figure 1–7)

The following three sensors provide information to the ECU:

• Engine speed−signal is generated by ribs on the torque converter pump.

• Turbine speed−signal is generated by the rotating-clutch housing spline contours.

• Output speed−signal is generated by a toothed member attached to the output shaft (except for the

3000 Product Family 7-speed models, where the toothed member is the transfer case idler gear).

The speed ratios between the various speed sensors allow the ECU to determine if the transmission is in the

selected range. Speed sensor information is also used to control the timing of clutch apply pressures, resulting in

the smoothest shifts possible. Hydraulic problems are detected by comparing the speed sensor information for the

current range to that range’s speed sensor information stored in the ECU memory.

Copyright © 2005 General Motors Corp. 1–5

WTEC III ELECTRONIC CONTROLS TROUBLESHOOTING MANUAL

GENERAL DESCRIPTION

MD/HD/B 300/B 400

ENGINE

(EXTERNAL)

HD/B 500

TURBINE

(EXTERNAL)

MD/B 300/B 400

TURBINE

(INTERNAL)

MD/B 300/B 400

(EXCEPT 7-SPEED)

RETARDER OUTPUT

(EXTERNAL)

MD 3070PT

OUTPUT

(INTERNAL)

MD/HD/B

OUTPUT

(EXTERNAL)

FORMER (BEFORE APPROXIMATELY JANUARY 1, 2006

MD/HD/B

ENGINE

(EXTERNAL)

HD/B 500

TURBINE

(EXTERNAL)

MD/B 300/B 400

TURBINE

(INTERNAL)

MD/B 300/B 400

(EXCEPT 7-SPEED)

RETARDER OUTPUT

(EXTERNAL)

MD 3070PT 7-SPEED

OUTPUT

(INTERNAL HD)

MD/HD/B

OUTPUT

(EXTERNAL)

RETARDER

CURRENT (AFTER APPROXIMATELY JANUARY 1, 2006)

SENSORS

Figure 1–7. Speed Sensors

V09818.00.00

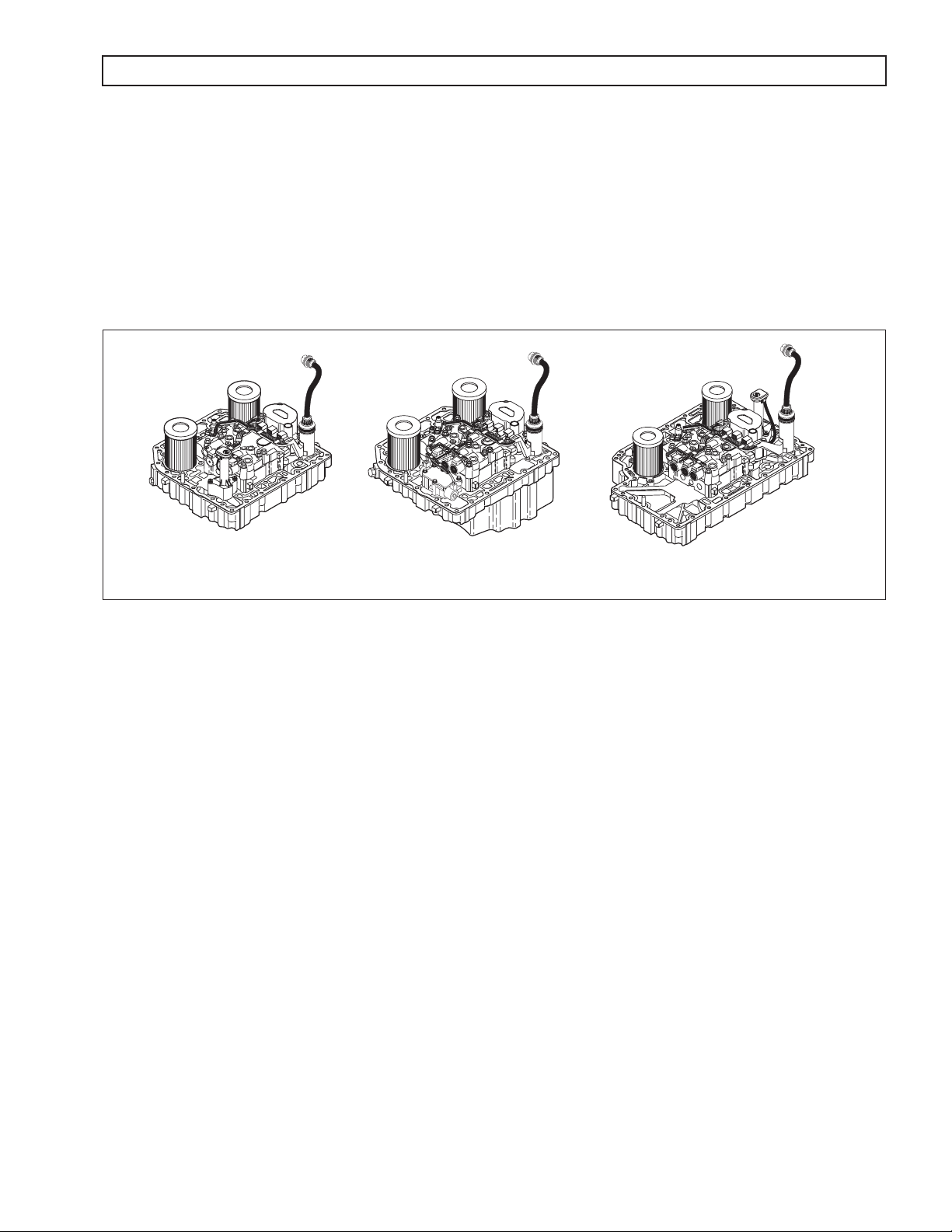

1–6. CONTROL MODULE (Figure 1–8)

Pulse width modulated solenoids are used in the valve bodies. For valve locations, refer to SIL 27-WT-93.

The WTEC III Series transmission control module contains a channel plate on which is mounted a:

• Main valve body assembly.

• Stationary-clutch valve body assembly.

• Rotating-clutch valve body assembly.

The main valve body assembly contains:

• G solenoid and the C1 and C2 latch valves controlled by the solenoid.

• Main and lube regulator valves.

• Control main and converter regulator valves.

• Converter flow valve and exhaust backfill valves.

The stationary-clutch valve body assembly contains:

• C solenoid (C3)

• D solenoid (C4)

• E solenoid (C5)

• Solenoid regulator valves controlled by the solenoids

• C3 accumulator relay valve

1–6 Copyright © 2005 General Motors Corp.

WTEC III ELECTRONIC CONTROLS TROUBLESHOOTING MANUAL

GENERAL DESCRIPTION

The rotating-clutch valve body assembly contains:

• A solenoid (C1)

• B solenoid (C2)

• F solenoid (lockup)

• Solenoid regulator valves controlled by the solenoids

• C3 pressure switch

The low valve body assembly (3000 and 4000 Product Families 7-speed) contains N and J solenoids.

3000 PRODUCT FAMILY CONTROL MODULE

(EXCEPT 7-SPEED MODELS)

3000 PRODUCT FAMILY 7-SPEED 4000 PRODUCT FAMILY CONTROL MODULE

V07349.00.00

Figure 1–8. WTEC III Control Modules

A temperature sensor (thermistor) is located in the internal wiring harness. Changes in sump fluid temperature are

indicated by changes in sensor resistance which changes the signal sent to the ECU. Refer to Figure 6–8 in

Section 6, Code 24.

The oil level sensor (OLS) is a float type device mounted on the control module channel plate. The OLS senses

transmission fluid level by electronically measuring the buoyancy forces on the float. The sensor operates on

5 VDC supplied by the ECU. The oil level sensor is standard on 3000 and 4000 Product Families transmissions.

An OLS is required on all models with a shallow sump but is optional on other models. The oil level sensor is not

available on the 3000 Product Family 7-speed models.

The C3 pressure switch is mounted on the rotating-clutch valve body assembly and indicates when pressure exists

in the C3 clutch-apply passage. An accumulator/relay valve is in-line ahead of the C3 pressure switch and prevents

high frequency hydraulic pulses generated by the C3 solenoid from cycling the C3 pressure switch.

Also mounted on the control module is the turbine speed sensor for the 3000 Product Family transmissions. The

turbine speed sensor is directed at the rotating-clutch housing. The turbine speed sensor on the 4000 Product

Family transmissions is located on the outside of the main housing.

Copyright © 2005 General Motors Corp. 1–7

WTEC III ELECTRONIC CONTROLS TROUBLESHOOTING MANUAL

GENERAL DESCRIPTION

1–7. WIRING HARNESSES

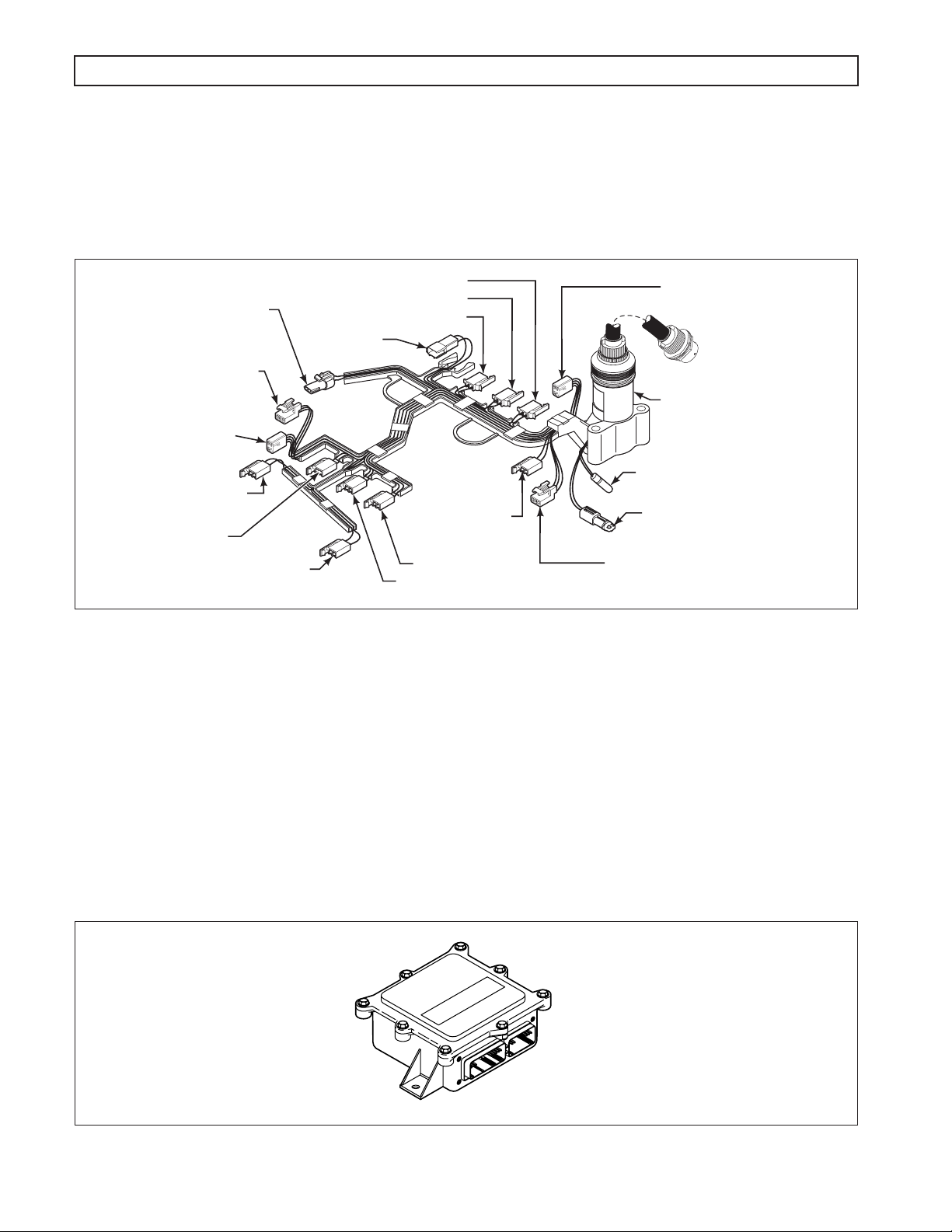

A. External Wiring Harness (Figure 1–9)

The ECU uses three connectors labeled Black, Blue, and Gray, which are used to receive input from

the following:

Transmission TPS Diagnostic tool connector

Engine Vehicle interface module (VIM) Retarder

Turbine Retarder control module Retarder temperature sensor

Output speed sensor Shift selector Accumulator

Many harnesses will include a bulkhead fitting to separate cab and chassis components. Also, many

different styles and materials for harnesses are likely to be encountered.

NOTE: Allison Transmission is providing for service of wiring harnesses and wiring harness components as

follows:

• Repair parts for the internal wiring harness and for wiring harness components attached to the

shift selector will be available through the Allison Transmission Parts Distribution Center (PDC).

Use the P/N from your appropriate parts catalog or from Appendix E in this manual. Allison

Transmission is responsible for warranty on these parts.

• Repair parts for the external harnesses and external harness components must be obtained from St.

Clair Technologies Inc. (SCTI). SCTI provides parts to any Allison customer or OEM and is

responsible for warranty on these parts. SCTI recognizes Allison Transmission, manufacturers,

and SCTI part numbers. SCTI provides a technical HELPLINE at 519-627-1673 (Wallaceburg).

SCTI will have parts catalogs available. The SCTI addresses and phone numbers for parts outlets

are:

St. Clair Technologies, Inc.

920 Old Glass Road

Wallaceburg, Ontario, Canada N8A 4L8

Phone: 519-627-1673

Fax: 519-627-4227

• St. Clair Technologies, Inc. stocks a WTEC III external harness repair kit, P/N 29532362, as a

source for some external harness repair parts. SCTI is the source for external harness repair parts.

St. Clair Technologies, Inc.

Calle Damanti S/N Col

Guadalupe—Guaymas

Sonora, Mexico CP85440

Phone: 011-526 2222-43834

Fax: 011-526-2222-43553

1–8 Copyright © 2005 General Motors Corp.

WTEC III ELECTRONIC CONTROLS TROUBLESHOOTING MANUAL

GENERAL DESCRIPTION

VEHICLE (V)

HARNESS

TRANSMISSION (T)

HARNESS

“V”

CONNECTOR

(GRAY)

RETARDER

ACCUMULATOR

CONNECTOR

TRANSFER

CASE

CONNECTOR

(3000 PRODUCT FAMILY

7–SPEED)

RETARDER

CONNECTOR

(3000 PRODUCT FAMILY)

PRE-TRANSID & TID 1

SENSOR HARNESS

CONNECTOR

(OPTIONAL)

OUTPUT

SPEED SENSOR

CONNECTOR

TPS

CONNECTOR

(OPTIONAL)

VIW

CONNECTOR

VIM

CONNECTOR

SELECTOR (S)

HARNESS

CONNECTOR

DIAGNOSTIC

CONNECTOR

DEUTSCH 9-PIN

DIAGNOSTIC TOOL

DIAGNOSTIC TOOL

6–PIN CONNECTOR

REQUEST (RMR)

“S”

(BLACK)

TOOL

CONNECTOR

SCI (J 1587)

CONNECTOR

(OPTIONAL)

DEUTSCH

(OPTIONAL)

RETARDER

MODULATION

CONNECTOR

J 1939

CONNECTOR

(OPTIONAL)

“H” SOLENOID

(4000 PRODUCT

VIW

CONNECTOR

“H” SOLENOID

(3000 PRODUCT FAMILY)

TEMPERATURE SENSOR

(4000 PRODUCT FAMILY)

PRE-TRANSID & TID 1

“T”

CONNECTOR

(BLUE)

ENGINE

SPEED

SENSOR

CONNECTOR

RETARDER

CONNECTOR

FAMILY)

RETARDER

CONNECTOR

TID 2

RETARDER

CONNECTOR

SHIFT

SELECTOR

CONNECTOR

Bulkhead Connector (Optional)

RMR

CONNECTOR

(OPTIONAL)

TURBINE

SPEED SENSOR

(4000 PRODUCT FAMILY)

NOTE: Illustration is not to scale. Actual harness configuration may differ from this illustration.

CONNECTOR

TRANSMISSION

FEEDTHROUGH

HARNESS

CONNECTOR

RETARDER TEMPERATURE

SENSOR CONNECTOR

(3000 PRODUCT FAMILY)

TID 2

THROTTLE POSITION

SENSOR (TPS)

CONNECTOR

V07086.04.00

Figure 1–9. WTEC III External Wiring Harnesses

Copyright © 2005 General Motors Corp. 1–9

WTEC III ELECTRONIC CONTROLS TROUBLESHOOTING MANUAL

GENERAL DESCRIPTION

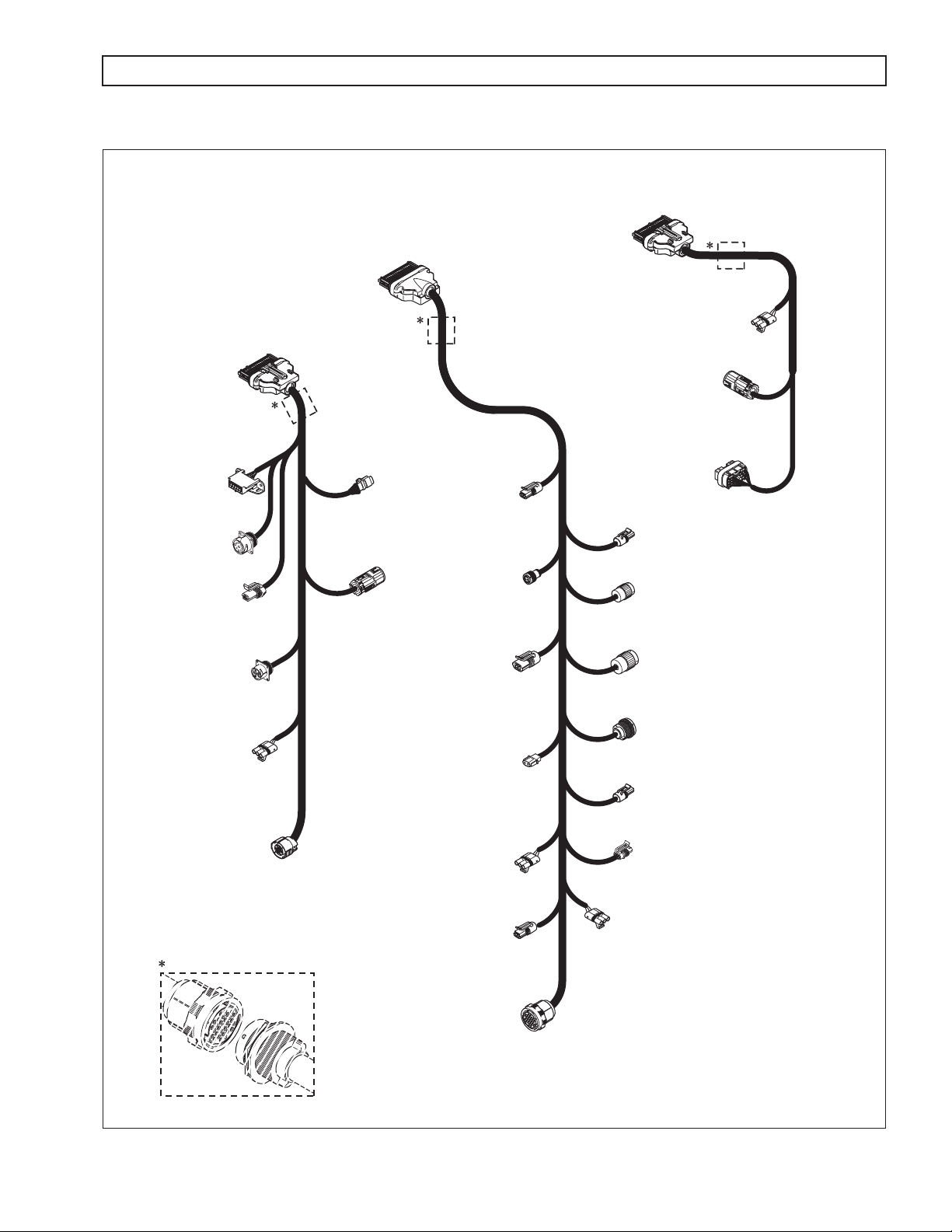

B. Internal Wiring Harness (Figure 1–10)

The internal wiring harness provides connection between the external harness, the pulse width

modulated solenoids, oil level sensor, C3 pressure switch, and the temperature sensor.

TURBINE SPEED SENSOR

3000 PRODUCT FAMILY

(Omitted in 4000 Product Family)

OIL LEVEL SENSOR

3000 PRODUCT FAMILY

(Starting with S/N 6510220479)

OIL LEVEL SENSOR

3000 PRODUCT FAMILY

(Before S/N 6510220479)

LO SIGNAL SOLENOID (N)

3000 AND 4000 PRODUCT

FAMILIES 7-SPEED

C4 SOLENOID (D)

C6 SOLENOID (J)

3000 AND 4000 PRODUCT

FAMILIES 7-SPEED

C3 PRESSURE

C2 SOLENOID (B)

LU SOLENOID (F)

C1 SOLENOID (A)

SWITCH

FORWARD

SOLENOID (G)

C5 SOLENOID (E)

C3 SOLENOID (C)

Figure 1–10. WTEC III Internal Wiring Harness

1–8. VEHICLE INTERFACE MODULE (Figure 1–11)

OIL LEVEL SENSOR

4000 PRODUCT FAMILY

(Before S/N 6610048466)

FEEDTHROUGH HARNESS

STANDOFF

(3000 and 4000

Product Families

are different heights)

TEMPERATURE SENSOR –

TRANSID 1

TEMPERATURE SENSOR –

TRANSID 2

OIL LEVEL SENSOR

4000 PRODUCT FAMILY

(Starting with S/N 6610048466)

V07381.02.00

The vehicle interface module (VIM) provides relays, fuses, and connection points for interface with

the output side of the vehicle electrical system. VIMs are available for both 12V and 24V electrical

systems. The VIM for 12V systems uses all 12V relays. The VIM for 24V systems has all 24V relays.

Refer to the Parts Catalog for the transmission assembly number that you are servicing for detailed

parts information. Refer to Pages D–30 and D–31 for VIM wire number and terminal information.

Some OEMs may provide their own equivalent for the VIM which performs the same functions as the

VIM shown in Figure 1–11.

Figure 1–11. Vehicle Interface Module (VIM)

1–10 Copyright © 2005 General Motors Corp.

V00631.02

WTEC III ELECTRONIC CONTROLS TROUBLESHOOTING MANUAL

GENERAL DESCRIPTION

1–9. AUTODETECT FEATURE (V8, V8A, V9 SOFTWARE)

Autodetect is active on the first 24 engine starts or a larger calibration number of engine starts, depending upon the

component or sensor being detected (details follow in A through D below). Autodetect takes place within the first

30 seconds of each engine start monitored. Autodetect searches for the presence of the following transmission

components or data inputs:

Retarder Present, Not Present

Oil level sensor (OLS) Present, Not Present

Throttle Analog, J1939, J1587

Engine coolant temperature Analog, J1939, J1587

Even after auotdetect has been completed, it can be reset to monitor an additional group of engine starts. Reset may

be necessary if a device known to be present is not detected or if an autodetectable component or sensor was added

after the initial vehicle build. Reset is accomplished by using Allison DOC™

AUTODETECT INFORMATION.” Allison DOC™

and manually enter the component or sensor to be recognized by the ECU by changing appropriate “customer

modifiable constants”.

For PC–Service Tool can also be used to override autodetect

For PC–Service Tool. Select “RESET

The four items above are the only customer modifiable constants (CMCs) that are autodetected. Other CMCs can

be changed at any time and are not related to autodetect. Consult Allison publication GN3433EN, User Guide, for

detailed instructions related to WTEC III “customer modified constants.” Additional details for each of the four

autodetectable features are given below.

A. Retarder

Autodetect searches for the presence of the H (retarder) solenoid during the first 24 engine ignition

cycles. The H solenoid must be present on the 24th engine start or the retarder is not detected and

will not function on subsequent engine starts.

If the retarder is present but not detected by autodetect, the retarder will not function. Be

sure to test for proper retarder function immediately after the 24th engine start. If the

WARNING

B. Oil Level Sensor (OLS)

NOTE: If an OLS is known to be present, but has not been detected, a possible cause is that the transmission

fluid level is too low. Determine the fluid level before beginning OLS troubleshooting.

retarder is not functioning, test H solenoid for open, short-to-ground, or short-to-battery

condition. Use Allison DOC™ For PC–Service Tool to reset autodetect or to manually

select the presence of the retarder after the H solenoid circuit is repaired.

No oil level sensor diagnostics take place until the OLS is detected. Frequently test for the presence of

oil level diagnostics if the transmission is known to contain an OLS. If an OLS is not detected during

the first 24 engine starts, autodetect continues for a larger calibration number of engine starts.

Autodetect stops when an OLS is detected or when the calibration number of starts is reached. When

the larger calibration number of engine starts is reached, the ECU concludes that no OLS is present. If

an OLS is known to be present, but has not been detected, troubleshooting the OLS circuit is required.

After the OLS circuit is repaired, reset autodetect or manually select the OLS function using Allison

DOC™ For PC–Service Tool.

Copyright © 2005 General Motors Corp. 1–11

WTEC III ELECTRONIC CONTROLS TROUBLESHOOTING MANUAL

GENERAL DESCRIPTION

C. Throttle Source (V8, V8A Software—See Paragraph 1–10C For V9A)

Whenever autodetect is functioning and no throttle source is found, a code 26 00 is logged. If a

datalink throttle source (J 1939 and J 1587) is detected, autodetect stops looking for that function.

However, if no analog throttle source was detected prior to engine start 25, autodetect continues for

engine starts 25 through a calibration number. Autodetect for analog throttle stops as soon as a device

is detected or when the calibration number of starts is reached. If an analog throttle source is known

to be present, but is not detected, troubleshooting of the analog throttle circuit is required. After the

analog throttle circuit is repaired, reset autodetect or manually select the analog throttle function

using Allison DOC™ For PC–Service Tool. An engine throttle source must be present.

A pulse width modulated (PWM) throttle source requires an unique calibration or must be manually

selected using Allison DOC™ For PC–Service Tool.

D. Engine Coolant Temperature Sensor Source

Autodetect looks for an engine coolant temperature source during the first 24 engine starts. However,

code 26 11 is not logged unless the calibration calls for engine coolant temperature data to be used for

retarder capacity reduction or preselected downshifts due to retarder overheating. Autodetect

remembers whatever engine coolant temperature source was present on engine start 24. If no analog

engine coolant temperature source is found on engine start 24, autodetect concludes that no sensor is

present. Therefore, if an engine coolant temperature source is known to be present at engine start 24,

but is not detected, troubleshooting of the engine coolant temperature circuit is required. After the

engine coolant temperature circuit is repaired, reset autodetect or manually select the engine coolant

temperature function using Allison DOC™ For PC–Service Tool.

1–10. AUTODETECT FEATURE (V9A, V9B, AND V9C SOFTWARE)

A. Retarder

Retarder autodetect software version V9A will countdown for a maximum of 25 ignition cycles while

recording detections of a retarder.

Retarder autodetect software version V9B and V9C will countdown for a maximum of 35 ignition

cycles while recording detections of a retarder.

A retarder will be identified as present and the retarder autodetect logic will stop once it is detected

for three consecutive ignition cycles. If the ignition cycle counter completes the 25 cycles (V9A) or

35 cycles (V9B, V9C) before there are three consecutive detections of a retarder, the software will log

that there is not retarder present and the retarder autodetect logic will stop.

B. Oil Level Sensor (OLS)

OLS autodetect will countdown for a maximum of 25 engine starts while recording detections of an

OLS. An OLS will be identified as present and the OLS autodetect logic will stop once it is detected

for:

• Five consecutive engine starts for software version V9A

• Three consecutive starts for software version V9B

• One engine start for software version V9C.

If the engine start counter completes 25 cycles before an OLS is detected (depending on the software

version specifications above), the software will log that there is not OLS present and the OLS

autodetect logic will stop. OLS detection must occur within 12.5 seconds on any given engine start.

1–12 Copyright © 2005 General Motors Corp.

WTEC III ELECTRONIC CONTROLS TROUBLESHOOTING MANUAL

GENERAL DESCRIPTION

Software version V9C will autodetect before an engine start if accumulated counts are greater than

100 or after an engine start if accumulated counts are greater than 25 but less than 100. No autodetect

occurs if accumulated counts are less than 25.

C. Throttle Source (Also Applies to V9 Software)

Throttle autodetect will increment a counter for a throttle source on each engine start during which

the possible throttle source is detected. When the counter for any of the sources indicates five

consecutive detections, the software will set a “confidence flag” to indicate that this is an available

throttle source. Multiple throttle sources can be detected on a single engine start and multiple

confidence flags can be set. There is no limit to the number of engine starts for autodetection of the

throttle source until a confidence flag is set for a source. Once a confidence flag is set for any one of

the sources, a counter begins to countdown for 15 additional engine starts. During the entire

autodetect period, the software will use the highest priority source as the throttle source if multiple

sources are detected before any confidence flags are set. Once a confidence flag is set, that source is

used as the source for the throttle signal. When the countdown period is complete, the software will

use the highest priority throttle source having a confidence flag set and the autodetect logic will stop.

D. Engine Coolant Temperature

Engine coolant temperature sensor autodetect will countdown for a total of 25 engine starts while

recording detections of engine coolant temperature sources. A “confidence flag” will be set once a

source is detected for five consecutive engine starts. Multiple sources detected before a confidence

flag is set or multiple confidence flags will result in the highest priority source being used as the

engine coolant temperature source. Multiple sources can be detected on a single engine start cycle.

1–11. TRANSID FEATURE

A. General Description

The TransID feature has been provided so that Allison Transmission can make component changes

which require calibration changes but still retain both the original transmission assembly number

(A/N) before feature based ordering (FBO) and the original calibrated ECU A/N. The purpose of

TransID is to reduce the need for OEMs to use cross-reference lists of transmission and calibrated

ECU A/Ns when such changes to the transmission are made. Since FBO began in April, 1998, the

OEM now needs to be sure the ECU being used is compatible with the TransID level stamped on the

nameplate of the transmission.

The basis for the TransID system is the creation of a TransID wire in the WTEC III system to provide

the signal to the ECU of the TransID level of the transmission. This wire will at first be connected

directly to the Analog Return (wire 135) to signal TransID level 1 (TID 1). TransID levels 2 through 8

will then be indicated by connecting the TransID wire in sequence to the return of solenoids A, B, C,

D, E, G, and F. Corresponding to the hardware changes is the ability in the V8A and later WTEC III

ECU to contain up to eight calibrations. The connection point of the TransID wire will provide the

signal to tell the ECU which calibration is required by the transmission.

Whenever a TransID level change is to be made, the new TransID level calibrations will be placed in

the PROM Calibration Configurator System (PCCS) before the change(s) is (are) made in production

to the transmissions. All ECUs programmed and sold after that date will then be loaded with the new

TransID level calibration. These ECUs will contain calibrations for the new level transmission and all

previous TransID levels and will automatically load the correct calibration for the transmission based

on the TransID signal sensed by AutoDetect during the first 25 engine starts. This eliminates worry on

the part of the OEM of coordinating the implementation of the new ECU and the new transmission

and allows their focus to be on using the stock of the earlier level ECU.

Copyright © 2005 General Motors Corp. 1–13

WTEC III ELECTRONIC CONTROLS TROUBLESHOOTING MANUAL

GENERAL DESCRIPTION

B. Transmission Changes Versus TransID Number

1. TransID 1

The internal wiring harness wiring change to make a TransID 1 (TID 1) transmission was put into

production before the introduction of the WTEC III system. The TID 1 internal harness was made

by connecting the C3 pressure switch ground (digital/signal ground; WTEC II wire 161) to the

sump temperature sensor and OLS ground (analog ground; wire 135) in the internal harness. In

WTEC II, the signal ground wire (wire 161) is routed through the transmission connector, terminal

W, and then to the ECU, terminal B27. In WTEC III, this same wire in the internal harness

becomes the TID wire (wire 195), and it goes to the ECU, terminal T13 (blue connector). The

purpose of TID 1 was to provide a common transmission for use with both WTEC II and

WTEC III systems (V7A and V8).

The only difference between a pre-TID transmission and a TID 1 transmission is the internal

wiring harness which connects the digital and analog grounds on the TID 1 harness. Adapter

harness P/N 200100 can be ordered from St. Clair Technologies to provide the same connection

outside the transmission and allow a pre-TransID transmission to be “converted” to a TransID 1

transmission.

All models of the 3000 and 4000 Product Families transmissions were built with the TID 1 internal

(feedthrough) harness beginning in September, 1996. Two changes were rolled into this update: the

wiring change for TID 1 and a change to use a molded channel rather than the braided covering

which was previously used. Both changes were rolled into the same internal harness P/N even

though there was a delay in implementing the channel which resulted in the two serial number (S/N)

breaks. Table 1–1 lists the harness P/Ns for the different transmission models along with the S/Ns

for both changes for each harness.

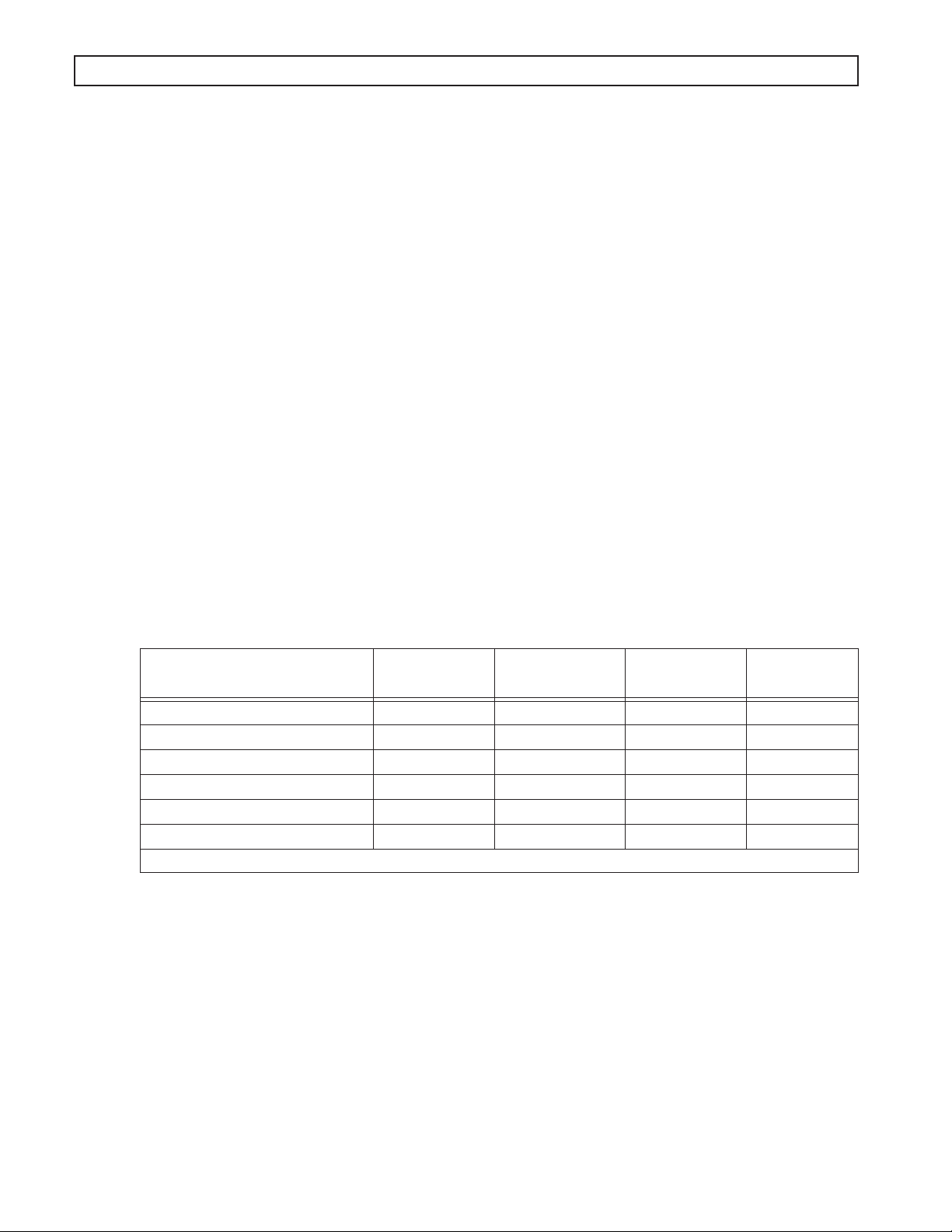

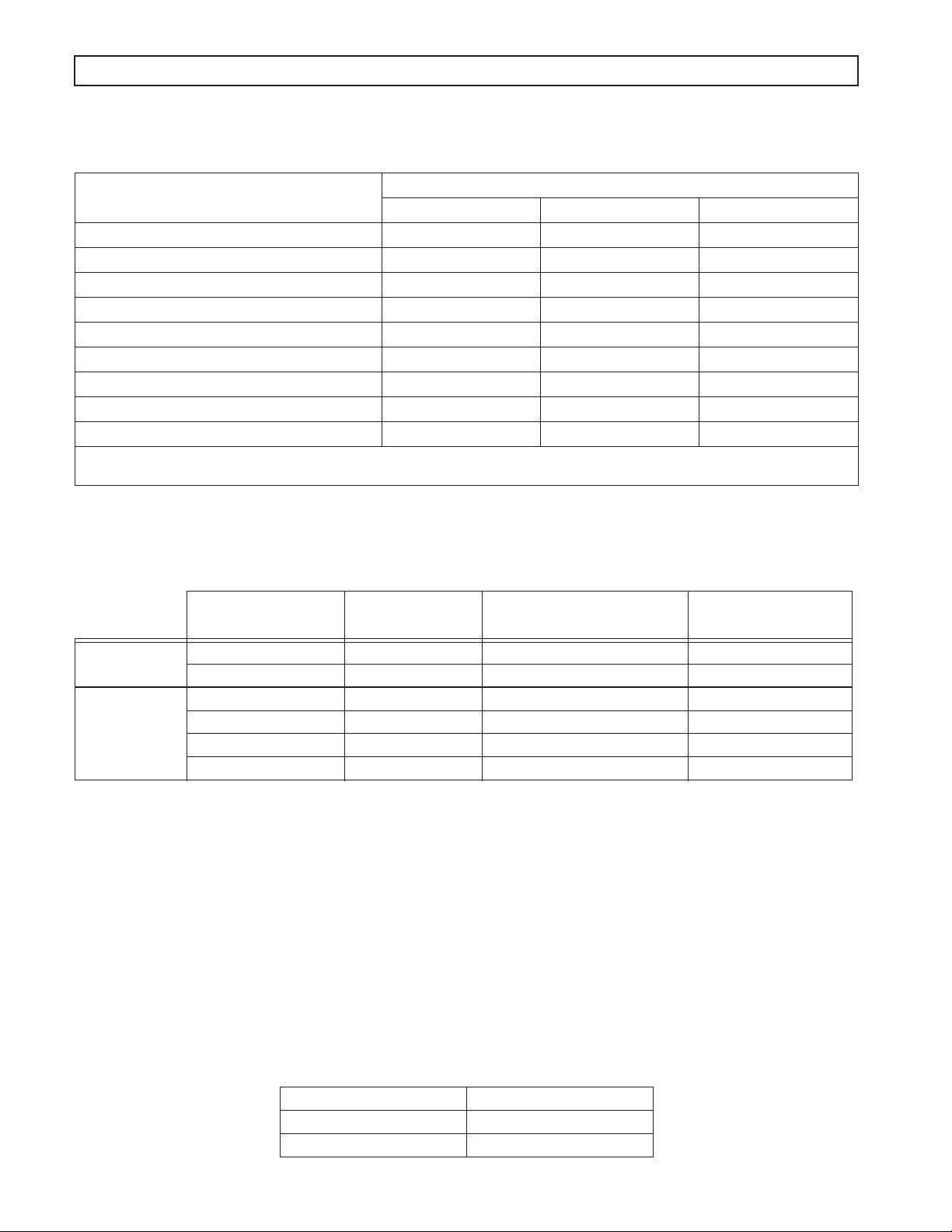

Table 1–1. TransID 1 S/N Breakpoint

Pre-TransID

Transmission Model

3000 Product Family w/ OLS 29516322 29529472 6510088864 6510096671

3000 Product Family w/o OLS 29516323 29529473 6510089316 6510096683

3000 Product Family 7-Speed 29516324 29529474 6510090786 6510096675

4000 Product Family w/ OLS 29516325 29529475 6610014067 6610015591

4000 Product Family w/o OLS 29516326 29529476 6610014084 6610015700

4000 Product Family 7-Speed N/A N/A N/A N/A

*NOTE: These P/Ns are no longer serviced, refer to Table 1–4 for current P/Ns.

2. TransID 2

The purpose of the TransID 2 (TID 2) change is to indicate the use of new sump and retarder

temperature sensors (thermistors) and a new 3000 Product Family retarder design. The new

retarder requires a different calibration than the old retarder. Retarder performance complaints will

occur if the new retarder is controlled by the old retarder calibration or the old retarder is

controlled by the new retarder calibration.

TID 2 internal harnesses contain both the new sump temperature sensor and a new connection

point for the TID wire. The TID wire (195) is connected to Solenoid A ground (wire 120) to signal

TID 2 to the ECU. The new temperature sensors are discussed below.

A TID 2 transmission will only work with a V8A or later ECU (WTEC III) and V8A and later

ECUs are calibrated to accommodate both TID 1 and TID 2 transmissions. The 4000 Product

Family 7-Speed transmissions were equipped with TID 2 at the start of production. The 3000 and

4000 Product Families transmissions produced before April 3, 2000 were TID 2 units.

Harness P/N*

TransID 1

Harness*

S/N at Wiring

Change

S/N at

U-Channel

1–14 Copyright © 2005 General Motors Corp.

WTEC III ELECTRONIC CONTROLS TROUBLESHOOTING MANUAL

GENERAL DESCRIPTION

The internal harness change to all models for TID 2 production began in late December, 1997.

The S/N breakpoints are shown in Table 1–2.

Table 1–2. TransID 2 S/N Breakpoint

Transmission Model

TransID 1

Harness P/N*

TransID 2

Harness P/N*

S/N at Thermistor and

Wiring Change

3000 Product Family w/ OLS 29529472 29533652 6510141464

3000 Product Family w/o OLS 29529473 29533653 6510141470

3000 Product Family 7-Speed 29529474 29533654 6510142172

4000 Product Family w/ OLS 29529475 29533655 6610026328

4000 Product Family w/o OLS 29529476 29533656 6610026319

4000 Product Family 7-Speed N/A 29533657

*NOTE: These P/Ns are no longer serviced, refer to Table 1–4 for current P/Ns.

6610034908

(start of production)

The new retarder thermistor used on TID 2 retarder model transmissions has a molded connector

and is the same on all TID 2 retarders. The TID 1 and pre-TID retarder thermistor had a two

terminal connector attached to it when it was used on 4000 Product Family transmissions. It was

part of a retarder harness assembly when used on 3000 Product Family transmissions. Refer to

Appendix Q which describes the new and old temperature sensors. A graph and a table of

resistance values for different temperatures are also included in Appendix Q.

Table 1–3 shows the old (pre-TID and TID 1) and the new (TID 2) part numbers of the retarder

temperature sensors and the serial number when the change was made.

Table 1–3. New Retarder Temperature Sensor S/N Breakpoint

Transmission Model Former Thermistor Used

P/N Where

Former

Thermistor Used

New

Thermistor

P/N (TID 2)

First S/N

For New

Thermistor

3000 Product Family built into retarder harness 29510662 15326309 6510142059

4000 Product Family built with connector attached 29511861 15326309 6610026472

3. TransID 3

Starting April 3, 2000, the TID feature was changed from TID 2 to TID 3. A new internal harness

was released to implement the TID 3 feature. Figure J–3 (Appendix J) shows the wiring schematic

for the new internal harness. TID 1 and TID 2 internal harnesses have been maintained for service

units built before April 3, 2000. TID 3 is required to make sure that the auto-detect feature selects

the proper calibration for the new friction plate material.

Version 8A software was updated to include TID 3 capability as of October 1999. Table 1–4 shows

the new internal harness part numbers for each of the control module configurations. Also

reference Table 1–5 for transmission/ECU compatibility information. The 3000 and 4000 Product

Families transmissions produced starting April 3, 2000 were TID 3 units. All T Series

transmissions were TID 3 at introduction.

Copyright © 2005 General Motors Corp. 1–15

WTEC III ELECTRONIC CONTROLS TROUBLESHOOTING MANUAL

GENERAL DESCRIPTION

†

Table 1–4. Current Internal Harness Service Kit

3000 and 4000 Product Families Internal Harness Service Kits

Transmission

TransID 1 TransID 2 ** TransID 3***

3000 Product Family w/o OLS 29542683 29542680 29542660

3000 Product Family w/ OLS (old)* 29542682 29542677 N/A

3000 Product Family w/ OLS (new)* 29542651 29542671 29542681

3000 Product Family 7-Speed 29542684 29542679 29542687

4000 Product Family w/o OLS 29542686 29542649 29542688

4000 Product Family w/ OLS (old)* 29542685 29542648 N/A

4000 Product Family w/ OLS (new)* 29544141 29542670 29542689

4000 Product Family 7-Speed w/o OLS N/A 29542650 29542690

4000 Product Family 7-Speed w/ OLS N/A N/A 29542691

* Reference SIL 19-WT-99

** Reference SIL 7-WT-98

*** Reference SIL 4-WT-00 N/A Not Applicable

† The key words associated with this reference are “current” and “kits”.

C. Compatibility Between TransID Level And ECU Calibration Level

Table 1–5 shows the compatibility of the different ECU software levels with the different TID level

transmissions.

Table 1–5. ECU/TransID Compatibility

P/N by TransID Version

WTEC II

WTEC III

CIN Compatibility

Number

Software

Level

Compatible with

TransID Level

ECU Production

Dates

07 V6E pre-TID and TID 1 until 9/94

08 V7 and V7A pre-TID and TID 1 9/94 until 12/97

0A V8 TID 1 2/97 until 9/97

0B V8A TID 1 and 2 beginning 10/97

0C V9 TID 1, 2, and 3 beginning 4/00

0D V9A TID 1, 2, and 3 beginning 4/01

The manufacture and sale of both WTEC II and WTEC III ECUs during most of 1997 required a

means of using a common transmission with either a WTEC II or a WTEC III ECU. A TID 1

transmission is the common transmission configuration for both control systems and production

began in September, 1996 (refer to Table 1–3). A TID level 1 transmission is compatible with any

Allison-supplied ECU.

Pre-TransID transmissions are only compatible with V6E, V7, and V7A ECUs. Pre-TransID

transmissions were produced before the first S/N break in Table 1–3.

TransID level 2 transmissions were produced beginning in late December, 1997 (refer to

Table 1–5). A TransID 2 transmission is compatible with V8A and later ECUs only.

TransID level 3 transmissions were produced beginning April 3, 2000 (refer to Table 1–5). A

TransID 3 transmission is compatible with V8A and later ECUs only. Software V9 or V9A is required

to use Reduced Engine Load at Stop (RELS). Refer to Table 1–6 for S/N break points.

Table 1–6. TID 3 S/N Break Point

Model S/N Break

3000 Product Family 6510262117

4000 Product Family 6610062126

1–16 Copyright © 2005 General Motors Corp.

WTEC III ELECTRONIC CONTROLS TROUBLESHOOTING MANUAL

GENERAL DESCRIPTION

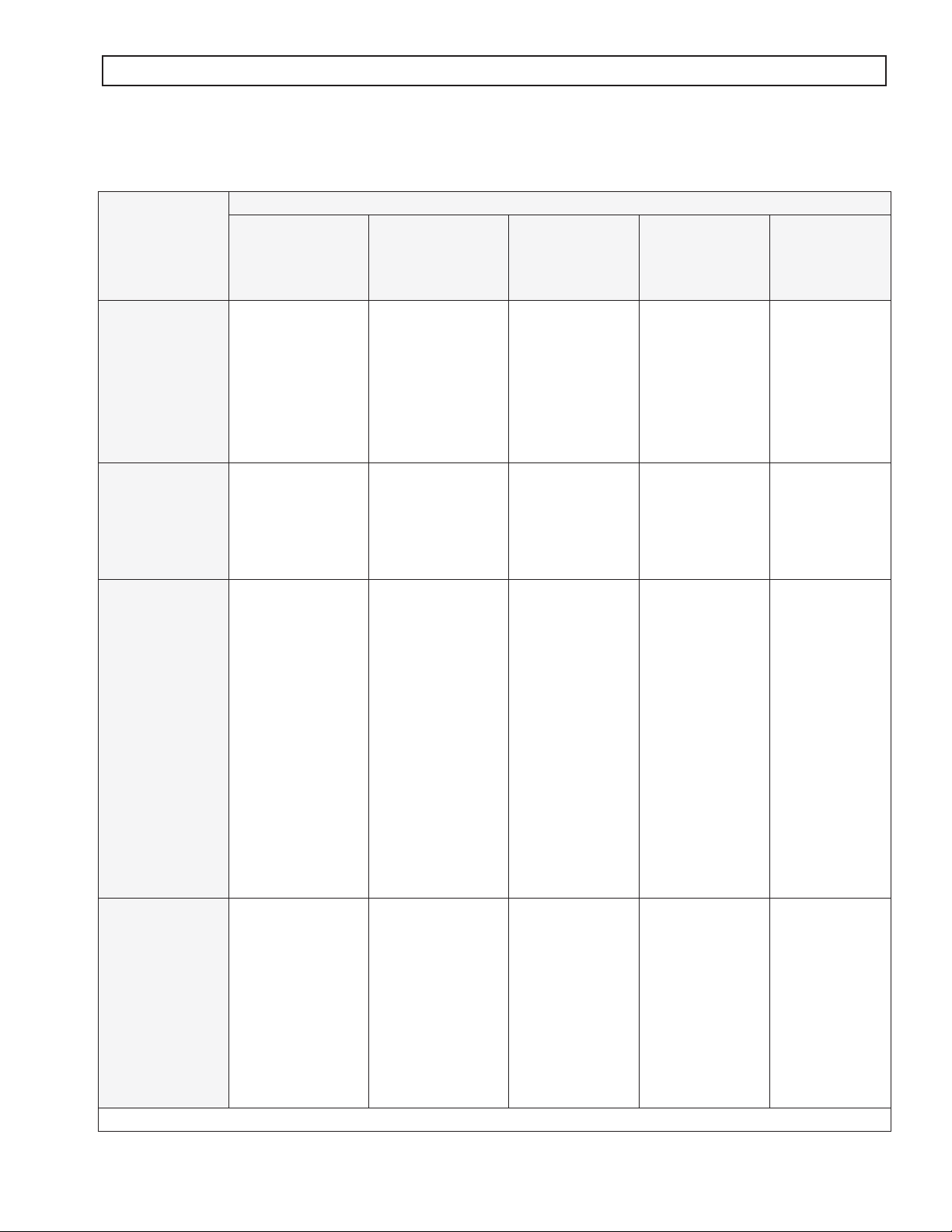

The following table shows compatibility information between transmission and vehicle configuration.

Vehicle Configuration (ECU, Shifter, and Wiring)

Transmission

Configuration

Pre-TID 3000 and 4000

Product Families;

Raybestos plates only

TID1: 3000 and 4000

Product Families;

Raybestos plates only

TID2: 3000 and 4000

Product Families; New

style sump and retarder

temp sensors; 3000

Product Family new

style retarder; Raybestos

plates only

TID2: 3000 and 4000

Product Families; New

style sump and retarder

temp sensors; 3000

Product Family new

style retarder; Dynax

plates only

*V9x refers to the latest V9 version

WTEC II, C6E;

CIN 07

everything works OK; no

cal change required or

available if Luk damper/

friction material used;

replace vehicle harness

connector with 29519127

kit

everything works OK; no

cal change required or

available if Luk damper/

friction material used;

replace vehicle harness

connector with 29519127

kit

will not work; codes 44

12, 33 23, 24 23, 33 12;

retarder codes 61 00, 62

23, and 62 12; non-rtdr

models can work if

changed back to TID1

internal harness; 4000

Product Family rtdr

models require change

back to old style retarder

temp sensor; 3000 Product

Family rtdr models

require change back to old

style retarder; no cal

change required or

available if Luk damper/

friction material used; if

converted, replace vehicle

harness connector with

2951927 kit

will not work; code 44 12

and temp sensor codes;

requires WTEC III, V8A,

V9 through V9x* system

or overhaul to change

back to Raybestos clutch

plates

WTEC II, V7;

CIN 08

everything works OK; no

cal change required or

available if Luk damper/

friction material used, but

latest cal has changes to

better match the friction

material

everything works OK;

recal if Luk damper/

friction material used,

because latest cal has

changes to better match

the friction material

will not work; codes 44

12, 33 23, 24 23, 33 12;

retarder codes 61 00, 62

23, and 62 12; non-rtdr

models can work if

changed back to TID1

internal harness; 4000

Product Family rtdr

models require change

back to old style retarder

temp sensor; 3000 Product

Family rtdr models

require change back to old

style retarder; recal if Luk

damper/friction material

used, because latest cal

has changes to better

match the friction material

will not work; code 44 12

and temp sensor codes;

requires WTEC III, V8A,

V9 through V9x* system

or overhaul to change

back to Raybestos clutch

plates

WTEC III, V8;

CIN 0A; TID1

(accommodates both

lockup clutches after 8/

25/97)

will not work unless

TID1 level trans; codes

32 xx, 55 xx; use

adapter 200100 to make

it a TID1; recal if Luk

damper/friction material

used, because latest cal

has changes to better

match the friction

material

everything works OK;

recal if Luk damper/

friction material used,

because latest cal has

changes to better match

the friction material

will not work; will use

TID1 cal and generate

codes: 33 23, 24 23, 33

12; retarder codes 61 00,

62 23, and 62 12; recal

to V8A (CIN 0B)

will not work; generate

codes: 33 23, 24 23, 33

12; retarder codes 61 00,

62 23, and 62 12; Shift

quality problems

because of clutch

material change; recal

ECU to V8A, V9

through V9x*; if RELS

required, replace ECU

with V9

WTEC III, V8A;

0B; TID1 & 2

(+TID 3 after 10/24/99,

but will not handle

TELS)

will not work unless

TID1 level trans; codes

32 xx, 55 xx; use

adapter 200100 to make

it a TID1; works with

Luk or BW damper

everything works OK;

uses TID1 cal

everything works OK;

uses TID2 cal

will not work if cal

installed before 10/24/99;

will not work with

RELS; generate code 36

01 and have shift quality

problems because of

clutch material change;

recal ECU to latest V8A

if previous cal installed

before 10/24/99; if

RELS required, replace

ECU withV9 through

V9x*

CIN 0C through 0F;

(required for RELS)

will not work unless

TID1 level trans;

codes 32 xx, 55 xx;

use adapter 200100 to

make it a TID1; works

with Luk or BW

damper

everything works OK;

uses TID1 cal

everything works OK;

uses TID2 cal

everything works OK;

uses TID3 cal

WTEC III, V9

through V9x*;

TID1, 2, & 3

Copyright © 2005 General Motors Corp. 1–17

WTEC III ELECTRONIC CONTROLS TROUBLESHOOTING MANUAL

GENERAL DESCRIPTION

level ECU and software might be found

installed in cases where the WTEC 3, V8/

V8A ECU was replaced)

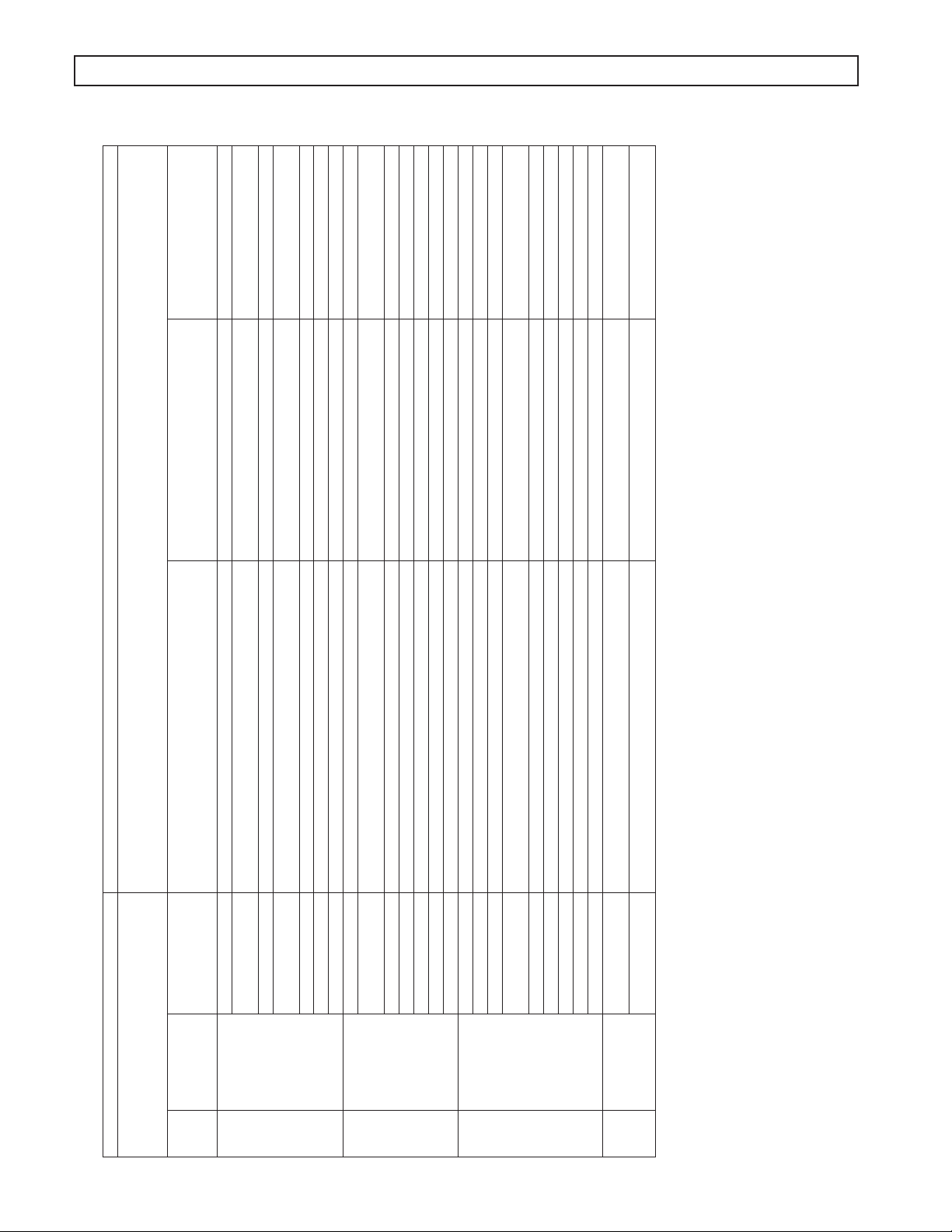

Using New Replacement Transmissions (TID 3)

one of the following modifications are necessary to make it compatible with vehicles of this configuration:

Configuration not released Configuration not released

Configuration not released Configuration not released

sensor)

sensor)

Update calibration + adapter harness (w/o temp sensor) Use adapter harness (w/o temp sensor)

sensor)

Configuration not released Update calibration if installed prior to 10/24/99 No changes needed

Configuration not released Update calibration if installed prior to 10/24/99 No changes needed

Configuration not released Update calibration if installed prior to 10/24/99 No changes needed

MD/B300 Configuration not released Update calibration if installed prior to 10/24/99 No changes needed

MDR/B300R Configuration not released Update calibration if installed prior to 10/24/99 No changes needed

MD3066/B400/3000MH Configuration not released Update calibration if installed prior to 10/24/99 No changes needed

MD3066R/B400R/

3000MHR

MD7 Configuration not released Update calibration if installed prior to 10/24/99 No changes needed

HD/B500/4000MH Configuration not released Update calibration if installed prior to 10/24/99 No changes needed

MD/B300 TID1 internal harness + Dynax cal Configuration not released Configuration not released

MDR/B300R TID1 internal harness + Dynax cal + New Rtdr cal + adapter harness (w/old temp

MD3066/B400 TID1 internal harness + Dynax cal Configuration not released Configuration not released

Transmission Configuration ECU, Shifter, Vehicle harness configuration:

retarder (pre-1998

retarder)

pre-TID • Former MD

sensors

• Former temp

Key Characteristics Model WTEC 2; CIN 07… and 08… WTEC 3; V8/V8A; CIN 0B… WTEC 3; V9/V9A; CIN 0D… (this

If this model/configuration transmission is replaced by a new

TransID 3 transmission (with Dynax clutch plates),

TID level

of origi-

nal trans

in vehicle

MD3066/B400R TID1 internal harness + New Rtdr cal + adapter harness (w/old temp sensor) Update calibration + adapter harness (w/o temp sensor) Use adapter harness (w/o temp sensor)

MDR/B300R TID1 internal harness + Dynax cal + New Rtdr cal + adapter harness (w/old temp

MD/B300 TID1 internal harness + Dynax cal Update calibration No changes needed

HD/B500 TID1 internal harness + Dynax cal Configuration not released Configuration not released

MD3066/B400R TID1 internal harness + Dynax cal + New Rtdr cal + adapter harness (w/old temp

• Post-block

HDR/B500R TID1 internal harness + Dynax cal + old rtdr temp sensor Configuration not released Configuration not released

MD7 TID1 internal harness + Dynax cal Configuration not released Configuration not released

retarder (pre-1998

retarder)

TID1 • Former MD

MD7 TID1 internal harness + Dynax cal Update calibration No changes needed

MD3066/B400 TID1 internal harness Update calibration No changes needed

sensors

• Former temp

HDR/B500R TID1 internal harness + Dynax cal + old rtdr temp sensor Update calibration+ new rtdr temp sensor connector new rtdr temp sensor connector

HD/B500 TID1 internal harness + Dynax cal Update calibration No changes needed

retarder

temperature sensors

• Current

TID2 • Current MD

HDR/B500R/4000MHR Configuration not released Update calibration if installed prior to 10/24/99 No changes needed

1–18 Copyright © 2005 General Motors Corp.

HD7 Configuration not released Update calibration if installed prior to 10/24/99 No changes needed

HD7R Configuration not released Update calibration if installed prior to 10/24/99 No changes needed

3000 Product Family—All

Models

4000 Product Family—All

retarder

• Dynax clutch plates

TID3 • Current MD

Models

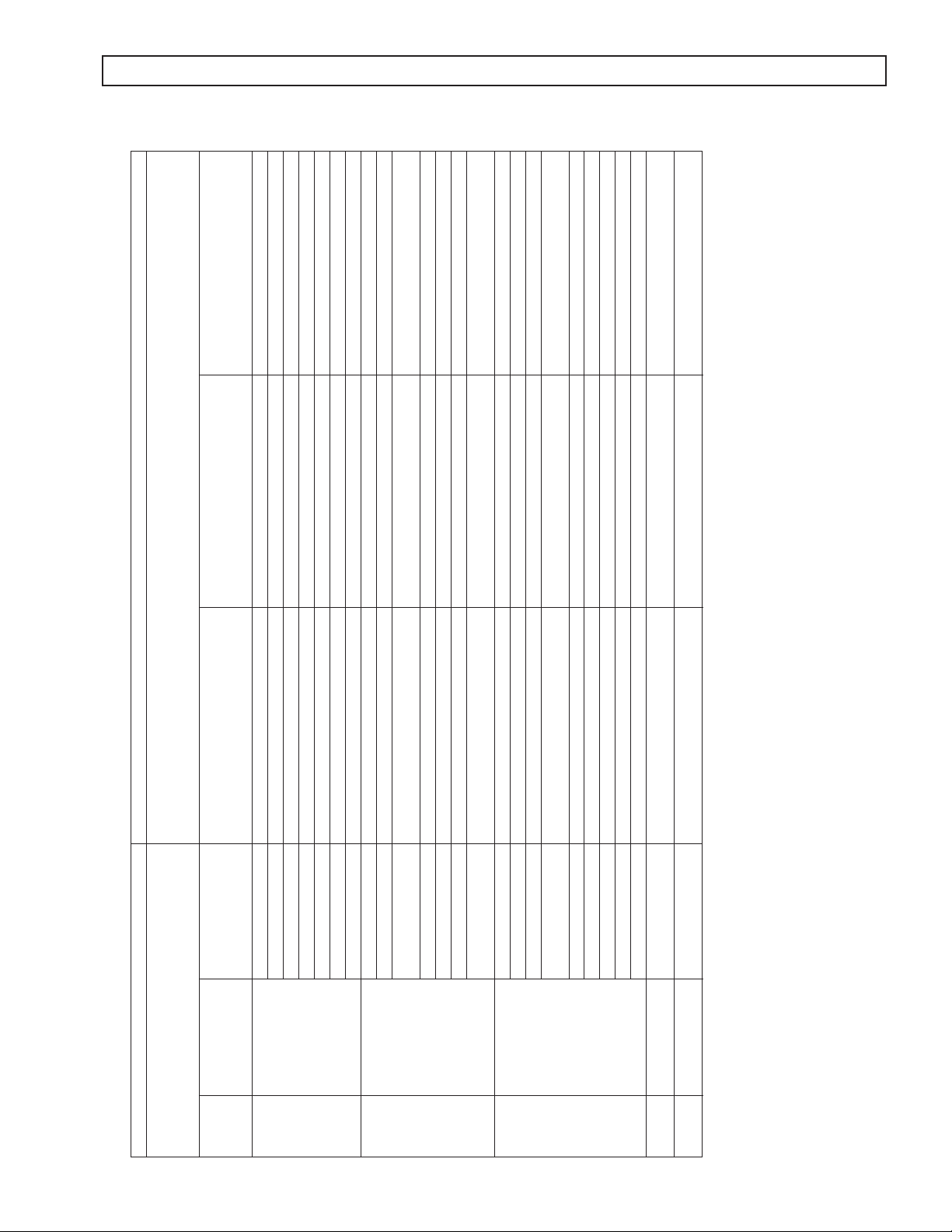

WTEC III ELECTRONIC CONTROLS TROUBLESHOOTING MANUAL

GENERAL DESCRIPTION

Retain TID 1 or install TID 3 internal harness +

ECU and software might be found installed in

cases where the WTEC 3, V8/V8A ECU was

replaced)

updated cal

TID 3 internal harness + new rtdr temp sensor

and connector

Rebuilding With Dynax Clutch Plates

one of the following modifications are necessary to make it compatible with vehicles of this configuration:

MD/B300 pre-TID or TID1 internal harness + Dynax cal Configuration not released Configuration not released

MDR/B300R pre-TID or TID1 internal harness + Dynax cal Configuration not released Configuration not released

MD3066/B400 pre-TID or TID1 internal harness + Dynax cal Configuration not released Configuration not released

MD3066/B400R pre-TID or TID1 internal harness + Dynax cal Configuration not released Configuration not released

MD7 pre-TID or TID1 internal harness + Dynax cal Configuration not released Configuration not released

HD/B500 pre-TID or TID1 internal harness + Dynax cal Configuration not released Configuration not released

HDR/B500R pre-TID or TID1 internal harness + Dynax cal Configuration not released Configuration not released

updated cal

MD/B300 Retain TID 1 + Dynax cal TID 3 internal harness + updated calibration TID 3 internal harness + updated calibration

MDR/B300R Retain TID 1 + Dynax cal TID1 internal harness + Dynax cal TID1 internal harness + Dynax cal

MD3066/B400 Retain TID 1 Retain TID 1 or install TID 3 internal harness +

MD3066/B400R Retain TID 1 Retain TID 1 Retain TID 1

connector

MD7 Retain TID 1 + Dynax cal TID 3 internal harness + updated calibration TID 3 internal harness + updated calibration

MD/B300 Configuration not released TID 3 internal harness + updated calibration TID 3 internal harness

HD/B500 Retain TID 1 + Dynax cal TID 3 internal harness + updated calibration TID 3 internal harness + updated calibration

HDR/B500R Retain TID 1 + Dynax cal TID 3 internal harness + new rtdr temp sensor and

MDR/B300R Configuration not released TID 3 internal harness + updated calibration TID 3 internal harness

MD3066/B400/3000MH Configuration not released No changes needed

Configuration not released No changes needed

MD3066R/B400R/

3000MHR

MD7 Configuration not released TID 3 internal harness + updated calibration TID 3 internal harness

HD/B500/4000MH Configuration not released TID 3 internal harness + updated calibration TID 3 internal harness

HDR/B500R/4000MHR Configuration not released TID 3 internal harness + updated calibration TID 3 internal harness

Configuration not released No changes needed No changes needed

Configuration not released No changes needed No changes needed

3000 Product Family—All

Models

4000 Product Family—All

HD7 Configuration not released TID 3 internal harness + updated calibration TID 3 internal harness

HD7R Configuration not released TID 3 internal harness + updated calibration TID 3 internal harness

Models

Transmission Configuration ECU, Shifter, Vehicle harness configuration:

Key Characteristics Model WTEC 2; CIN 07… and 08… WTEC 3; V8/V8A; CIN 0B… WTEC 3; V9/V9A; CIN 0D… (this level

If this model/configuration transmission is rebuilt with Dynax clutch

plates,

TID level

of original

trans in

vehicle

(pre-1998 retarder)

• Former MD retarder

• Former temp sensors

• Post-block

pre-TID

(pre-1998 retarder)

• Former MD retarder

• Former temp sensors

TID1

sensors

• Current MD retarder

• Current temperature

TID2

• Current MD retarder

• Dynax clutch plates

TID3

Copyright © 2005 General Motors Corp. 1–19

WTEC III ELECTRONIC CONTROLS TROUBLESHOOTING MANUAL

GENERAL DESCRIPTION

NOTES

1–20 Copyright © 2005 General Motors Corp.

WTEC III ELECTRONIC CONTROLS TROUBLESHOOTING MANUAL

SECTION 2—DEFINITIONS AND ABBREVIATIONS

2–1. CHECK TRANS LIGHT

When the ECU detects a serious fault, the CHECK TRANS light (usually located on the vehicle instrument panel)

illuminates and action is automatically taken to protect operator, vehicle, and the transmission. A diagnostic code will

nearly always be registered when the CHECK TRANS light is on; however, not all diagnostic codes will turn on the

CHECK TRANS light. Codes related to the CHECK TRANS light are detailed in the code chart (refer to Section 6).

Illumination of the CHECK TRANS light indicates that a condition was detected that requires service attention.

Operation may or may not be restricted but even when restricted will allow the vehicle to reach a service assistance

location. Depending upon the cause for the CHECK TRANS light illumination, the ECU may or may not respond

to shift selector requests. The transmission may be locked in a range. That range will be shown on the shift selector