Allison Transmission HT 700, HTB 700, CLT 700, CLBT 700 Service Manual

Mechanic’s

Tips

Allison Transmission

Division of General Motors Corporation

P.O. B ox 894 Indianapolis, Indiana 46206-0894

Printed in U.S.A. Copyright © 1995 General Motors Corp.

i

IT IS YOUR RESPONSIBILITY to be completely familiar with the warnings and

cautions described in this handbook. It is, however, important to understand that these

warnings and cautions are not exhaustive. Allison Transmission could not possibly

know, evaluate, and advise the service trade of all conceivable ways in which service

might be done or of the possible hazardous consequences of each way. Consequently,

Allison Transmission has not undertaken any such broad evaluation. Accordingly,

ANYONE WHO USES A SERVICE PROCEDURE OR TOOL WHICH IS NOT

RECOMMENDED BY ALLISON TRANSMISSION MUST rst be thoroughly

satised that neither personal safety nor equipment safety will be jeopardized by the

service methods selected.

Proper service and repair is important to the safe, reliable operation of the equipment.

The service procedures recommended by Allison Transmission and described in this

handbook are effective methods for performing service operations. Some of these

service operations require the use of tools specially designed for the purpose. The

special tools should be used when and as recommended.

Three types of headings are used in this manual to attract your attention. These

warnings and cautions advise of specic methods or actions that can result in personal

injury, damage to the equipment, or cause the equipment to become unsafe.

WARNING: A warning is used when an operating procedure, practice,

etc., if not correctly followed, could result in personal injury or loss of life.

CAUTION: A caution is used when an operating procedure,

practice, etc., if not strictly observed, could result in damage to or

destruction of equipment.

NOTE:

A note is used when an operating procedure, practice, etc., is

essential to highlight.

ii

Paragraph Description Page

1–1. Periodic Inspection and Care . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

1–2. Importance of Proper Transmission Fluid Level . . . . . . . . . . . . 1

1–3. Transmission Fluid Check Procedures. . . . . . . . . . . . . . . . . . . . 2

1–4. Keeping Transmission Fluid Clean . . . . . . . . . . . . . . . . . . . . . . 5

1–5. Automatic Transmission Fluid Recommendations . . . . . . . . . . 5

1–6. Transmission Fluid and Filter Change Intervals . . . . . . . . . . . . 6

1–7. Fluid Temperatures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

1–8. High-Efficiency, Main-Pressure External Filter Change. . . . . . 8

1–9. Transmission Fluid Contamination . . . . . . . . . . . . . . . . . . . . . . 8

1–10. Transmission Fluid and Filter Change Procedure . . . . . . . . . . . 9

1–11. Auxiliary Filter. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

1–12. Breather . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

1–13. Transmission Stall Test and Neutral Cool-Down Check . . . . . . 10

2–1. Draining Transmission. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

2–2. Disconnecting Controls . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

2–3. Uncoupling From Driveline, Engine, and Vehicle. . . . . . . . . . . 14

2–4. Removing the Transmission. . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

2–5. Removing Input and Output Flanges or Yokes . . . . . . . . . . . . . 14

2–6. Rebuild, Overhaul Instructions . . . . . . . . . . . . . . . . . . . . . . . . . 15

3–1. Checking Input Components . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

3–2. Installing Output Flange and Input Flange

(Remote-Mounted Transmission) . . . . . . . . . . . . . . . . . . . . . . . 16

3–3. Installing PTO . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

3–4. Installing Transmission Fill Tube and Seal . . . . . . . . . . . . . . . . 18

3–5. Checking Plugs, Openings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

iii

Paragraph Description Page

4–1. Engine, Transmission Adaptation Requirements. . . . . . . . . . . . 19

4–2. Checking Flexplate Drive Assembly . . . . . . . . . . . . . . . . . . . . . 20

4–3. Checking Input Drive Components

(Remote-Mounted Transmissions). . . . . . . . . . . . . . . . . . . . . . . 20

4–4. Chassis and Driveline Inspection . . . . . . . . . . . . . . . . . . . . . . . . 22

4–5. Cooler, Filter, and Lines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

4–6. Checking Controls . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

5–1. Handling. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

5–2. Mounting to Engine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

5–3. Installing Transmission Mounting Components . . . . . . . . . . . . 28

5–4. Coupling to Driveline. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

5–5. Coupling to Engine (Remote-Mounted Transmission) . . . . . . . 28

5–6. Connecting Input Retarder Control . . . . . . . . . . . . . . . . . . . . . . 29

5–7. Connecting Output Retarder Control . . . . . . . . . . . . . . . . . . . . . 29

5–8. Connecting Power Takeoff Controls . . . . . . . . . . . . . . . . . . . . . 29

5–9. Connecting Parking Brake Control . . . . . . . . . . . . . . . . . . . . . . 30

5–10. Connecting Cooler, Filter. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

5–11. Installing Auxiliary Filter. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

5–12. Connecting Speedometer Drive . . . . . . . . . . . . . . . . . . . . . . . . . 30

5–13. Installing Temperature and Pressure Sensors,

Connecting Electrical Components . . . . . . . . . . . . . . . . . . . . . . 32

5–14. Filling the Hydraulic System . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

6–1. Installation Checklist . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

6–2. Road Test and Vehicle Operation Checklist . . . . . . . . . . . . . . . 35

7–1. Owner Assistance. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

7–2. Service Literature. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

iv

This handbook is a mechanic’s reference for removing, installing, and maintaining

the HT, HTB, CL(B)T 700 Commercial Electronic Control Series Automatic

Transmissions. All features of the transmission and vehicle involved in installation

procedures are discussed. The information presented will help the mechanic to

remove, install, and maintain the transmission in a manner that assures satisfactory

operation and long service life. For additional detailed information, refer to HT, HTB

700 Electronic Control Series Service Manual SM2004EN or CL(B)T 700 Series

Service Manual SM1314EN and CL(B)T 755 Electronic Control Series Service

Manual Supplement SM1992EN. Troubleshooting the electronic control system is

presented in Troubleshooting Manual TS2712EN.

DEXRON® is a registered trademark of General Motor Corporation.

Loctite® is a registered trademark of the Loctite Corporation.

Teon® is a registered trademark of the DuPont Corporation.

Pro-Link® is a registered trademark of Micro Processor Systems, Inc.

v

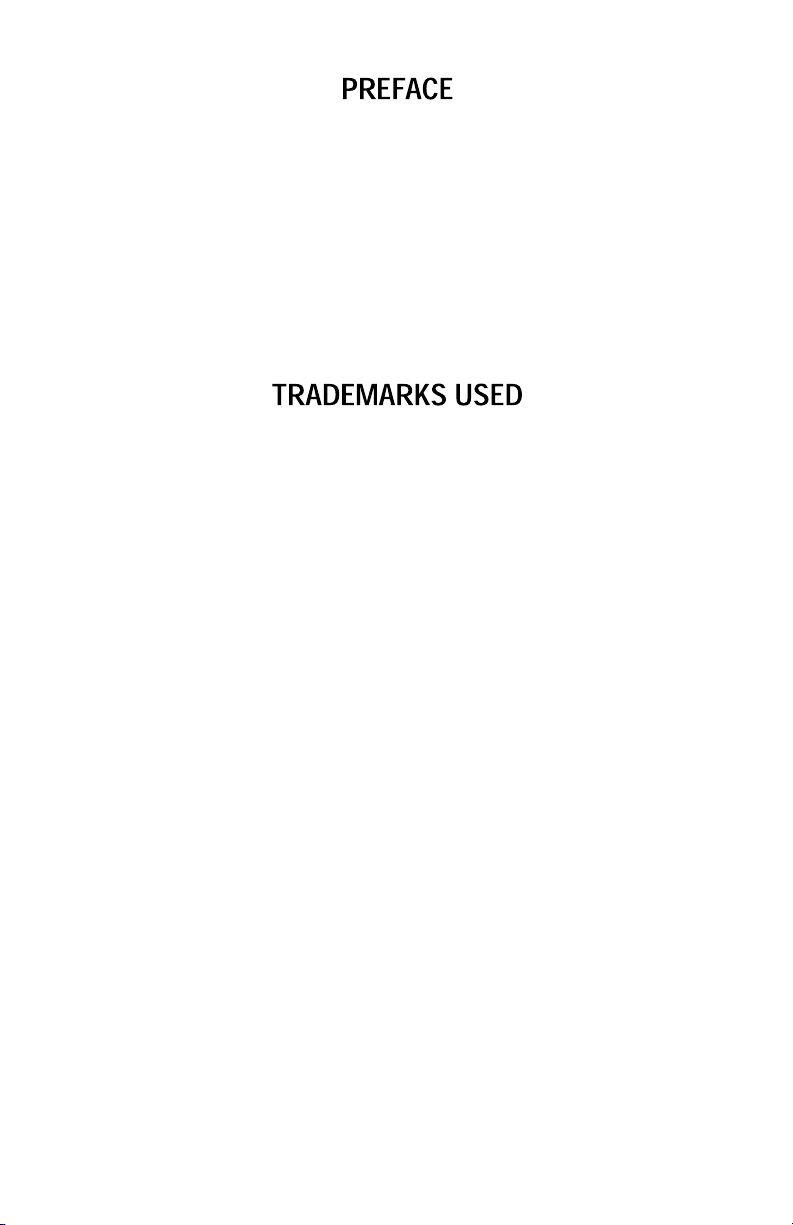

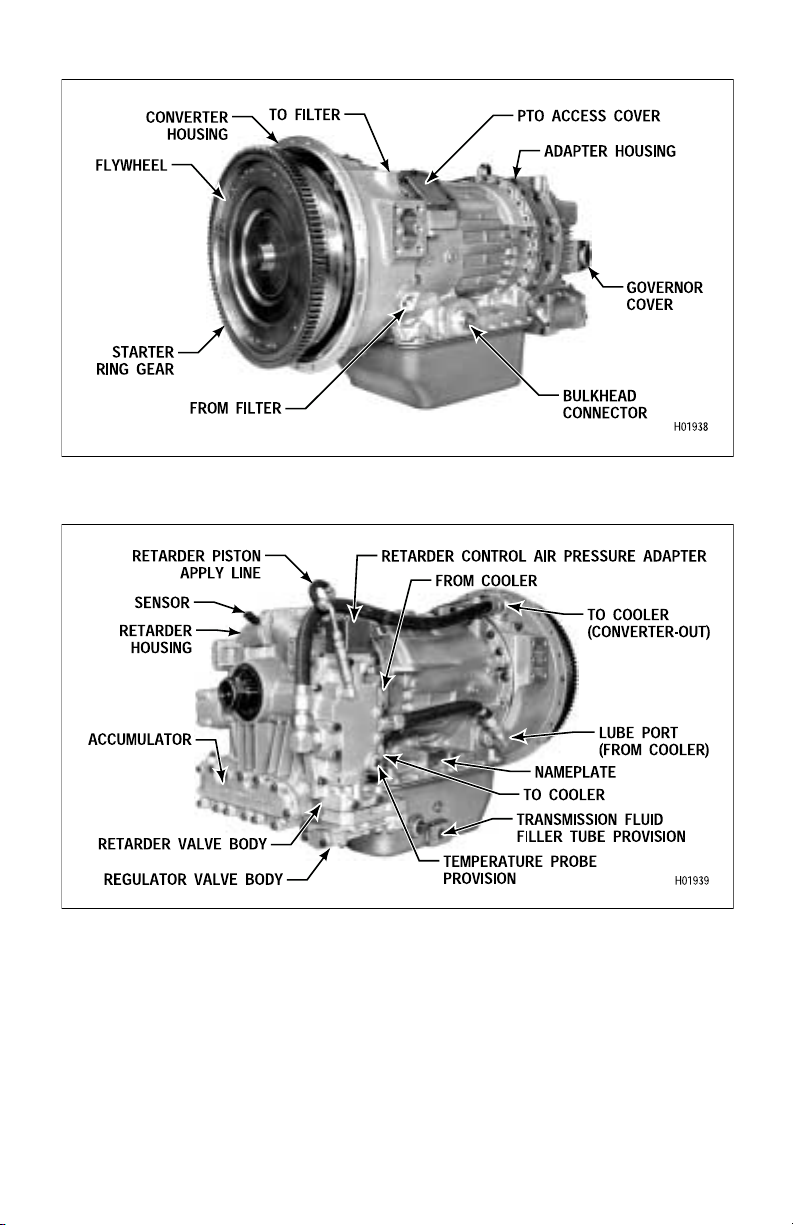

Model HT 741, 748 Transmission — Left-Rear View

Model HT 741, 748 Transmission — Right-Front View

vi

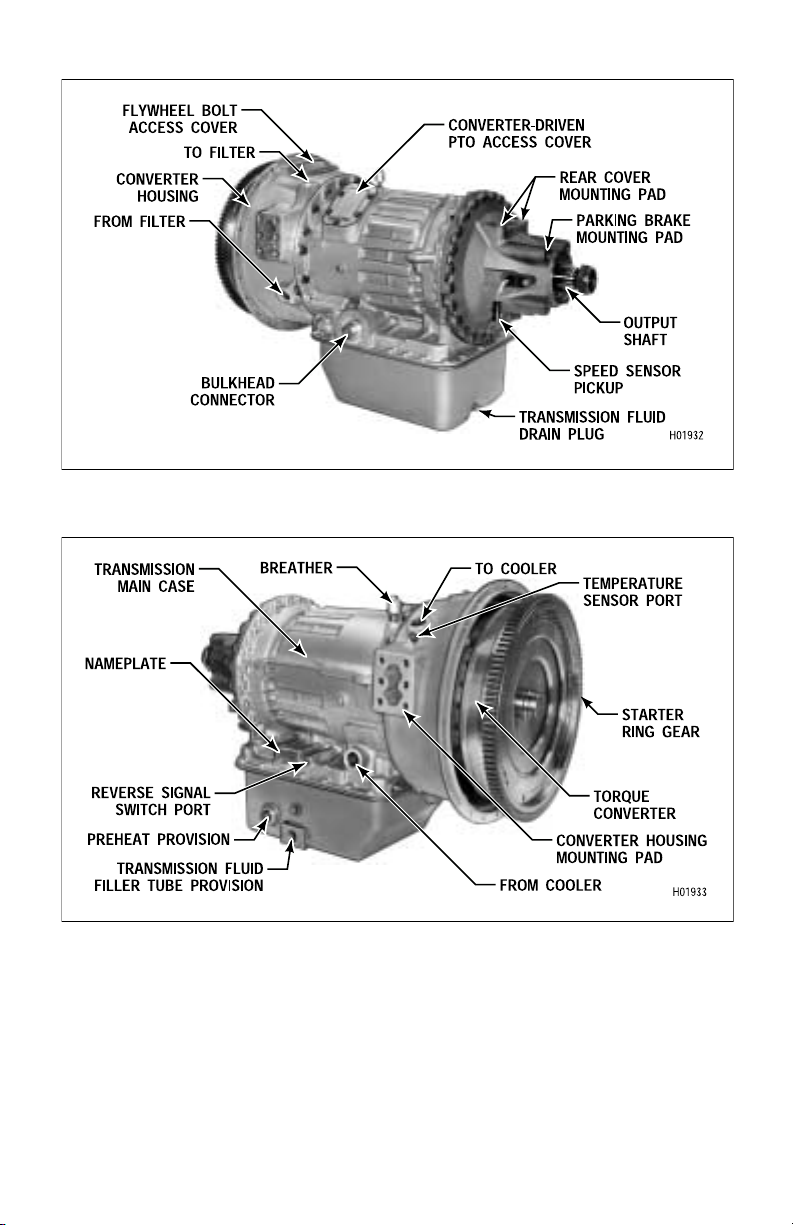

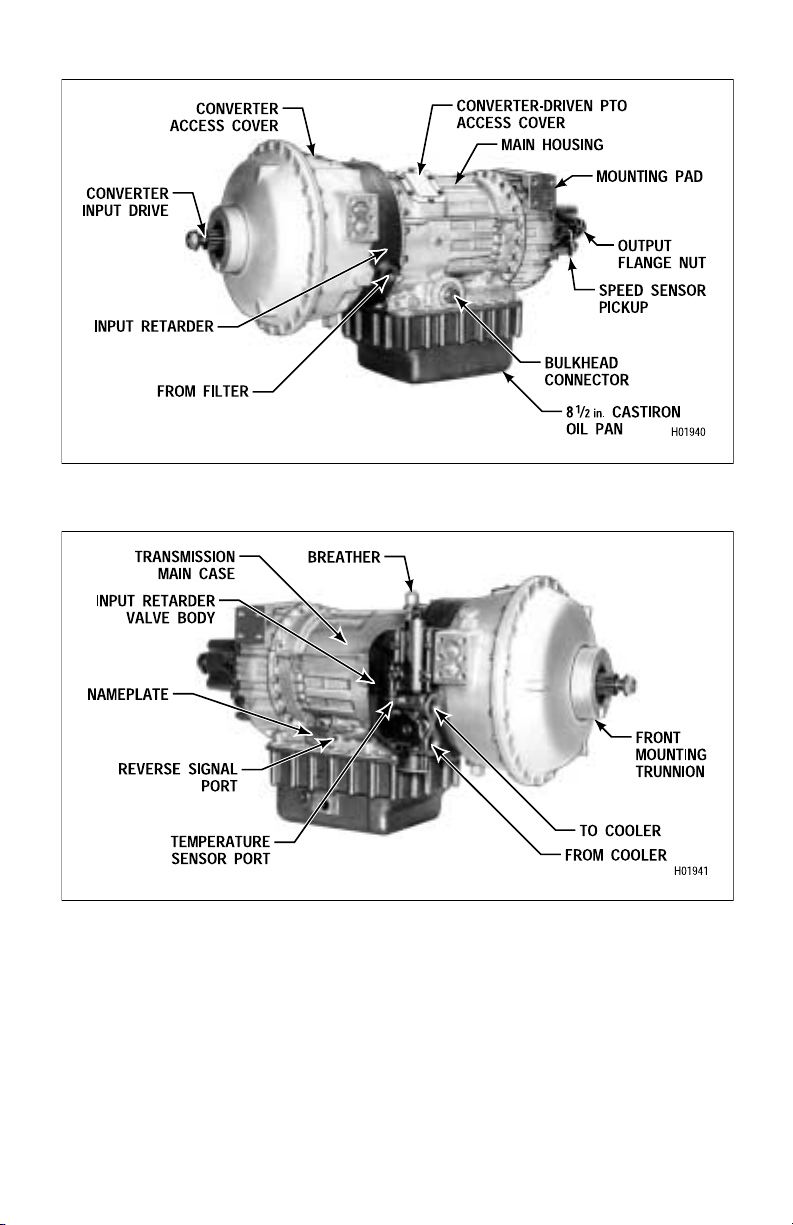

Model HT 755CR Transmission — Left-Rear View

Model HT 755CR Transmission — Right-Front View

vii

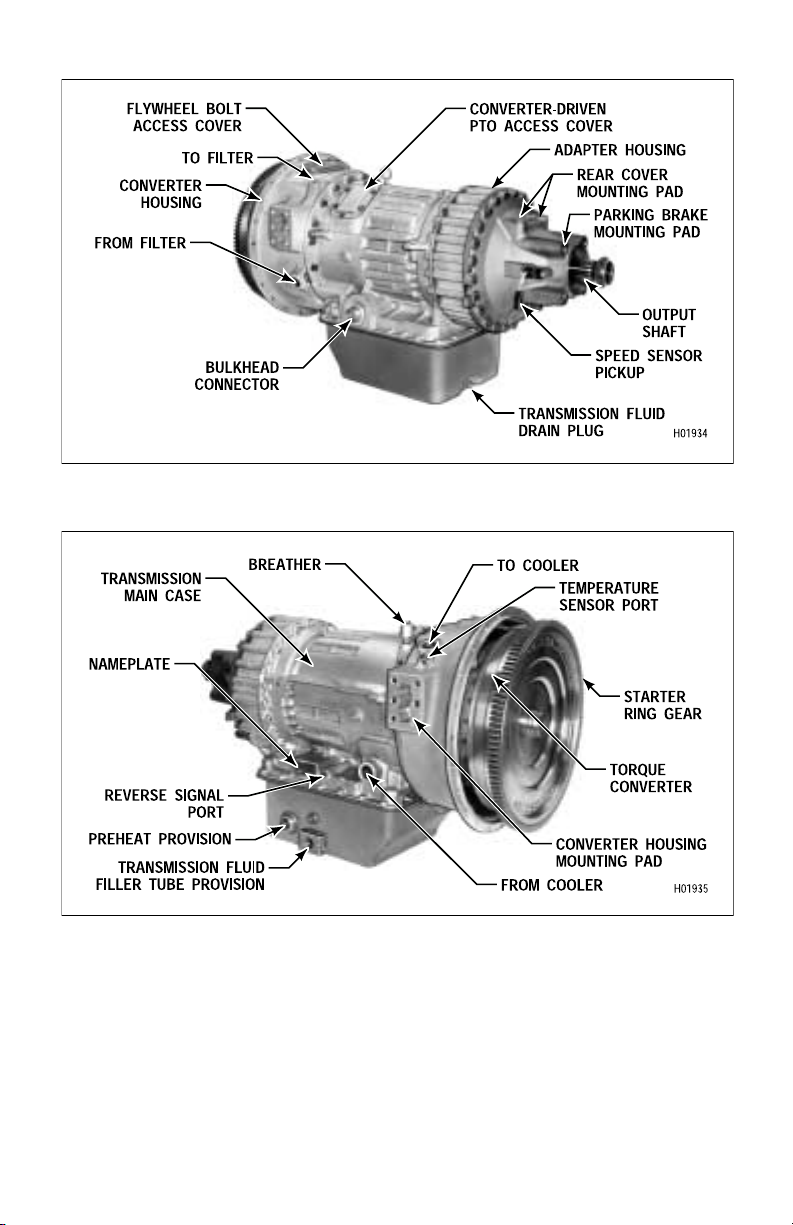

Model HT 755DR Transmission — Left-Rear View (With Input Retarder)

Model HT 755DR Transmission — Right-Front View (With Input Retarder)

viii

Model HTB 748 Transmission — Left-Front View (With Output Retarder)

Model HTB 748 Transmission — Right-Rear View (With Output Retarder)

ix

Model CLBT 755 Transmission — Left-Front View

Model CLBT 755 Transmission — Right-Front View

x

SECTION

I

Clean and inspect the exterior of the transmission at regular intervals. Severity of

service and operating conditions determine the frequency of these inspections.

Inspect the transmission for:

• loose bolts — transmission and mounting components

• uid leaks — repair immediately

• loose, dirty, or improperly adjusted throttle sensor linkage

• damaged or loose hoses

• worn, frayed, or improperly routed electrical harnesses

• worn or out-of-phase driveline U-joints and slip ttings

CAUTION: When welding on the vehicle:

• DO NOT WELD on the vehicle without disconnecting from

the ECU all control system wiring harness connectors.

• DO NOT WELD on the vehicle without disconnecting ECU

battery power and ground leads.

• DO NOT WELD on any control components.

• DO NOT CONNECT welding cables to any control components.

A label describing on-vehicle welding precautions is available from your authorized

Allison service dealer and should be installed in a conspicuous place. A vehicle used

in a vocation that requires frequent modications or repairs involving welding must

have an on-vehicle welding label.

Because the transmission uid cools, lubricates, and transmits hydraulic

power, it is important that the proper uid level be maintained at all times.

If the uid level is too low, the torque converter and clutches will not

receive an adequate supply of transmission uid, and the transmission

will overheat. If the uid level is too high, the uid aerates — causing the transmission

to shift erratically and overheat. Fluid may be expelled through the breather or

dipstick tube when the uid level is too high.

1

A severely low uid level causes the Allison Transmission Electronic Control to do

two things automatically —

• Turn on the CHECK TRANS light

• Prevent upshifting into the highest range

When the uid level is corrected, the transmission will return to normal operation.

Do not use the Electronic Control to replace regular uid level checks. Check the

level at the intervals specied in your vehicle service instructions.

WARNING: Take the following precautions so that unexpected,

possible sudden vehicle movement is avoided. Whenever it becomes

necessary to leave the vehicle, even momentarily, while the engine is

running, place the transmission shift selector in Neutral, set the parking brake and/or emergency brakes and chock the wheels.

a. Fluid Check Procedure.

Clean all dirt from around the end of the ll tube before removing the

dipstick. Do not allow the dirt or any foreign matter to enter the

transmission. Dirt or foreign matter may cause undue wear of the

transmission parts, make valves stick, and clog passages. Check the

uid level, manually, using the following procedure and record the level in your

maintenance log. To perform the uid level check, the engine must be running at

idle speed and the transmission must be in N (Neutral).

Add transmission uid to the transmission through the ll tube opening. Be sure to

use proper transmission uid and uid containers as discussed in Sections 1–4 and

1–5. Refer to Table 1–1 for approximate transmission uid capacity.

Table 1–1. Transmission Fluid Capacity

Application U.S. Quarts Liters

41⁄2 inch (114 mm) oil pan 34 32

6 inch (152 mm) oil pan 30 28.5

7 inch (178 mm) oil pan 30 28.5

81⁄2 inch (215 mm) oil pan 43 41

NOTE: Does not include external circuits.

2

b. Cold Check.

NOTE:

The purpose of the Cold Check is to determine if the transmission

has enough fluid to be safely operated until a hot check can be

made.

• Park the vehicle on a level surface. Apply the parking brake, and chock the

wheels.

CAUTION: The uid level rises as uid temperature increases.

DO NOT ll above the “COLD RUN” band if the transmission uid is

below normal operating temperatures.

• Run the engine for at least one minute. Shift to D (Drive) and then to

R (Reverse) to clear the hydraulic circuits of air. Then shift to N (Neutral) and

allow the engine to idle (500–800 rpm).

• Insert the dipstick into the tube and remove. Check the uid level reading.

Repeat the check procedure to verify the reading.

• If the uid level is within the “COLD RUN” band, the transmission may be

operated until the uid is hot enough to perform a “HOT RUN” check. If the

uid level is not within the “COLD RUN” band, add or drain as necessary to

bring it to the middle of the “COLD RUN” band.

• Perform a hot check as soon as the normal operating temperature of

160–200°F (71–93°C) is reached.

c. Hot Check.

CAUTION: The transmission uid must be hot to ensure an accurate

check. The uid level rises as temperature increases.

• Operate the transmission in D (Drive) until normal operating temperature is

reached:

160–200°F (71–93°C) sump temperature

180–220°F (82–104°C) converter-out temperature

• Park the vehicle on a level surface and shift to N (Neutral). Apply the parking

brake, and chock the wheels. Allow the engine to idle.

• With the engine running, remove the dipstick from the tube and wipe it clean.

• Insert the dipstick into the tube and remove. Check uid level reading. Repeat

the check procedure to verify the reading.

3

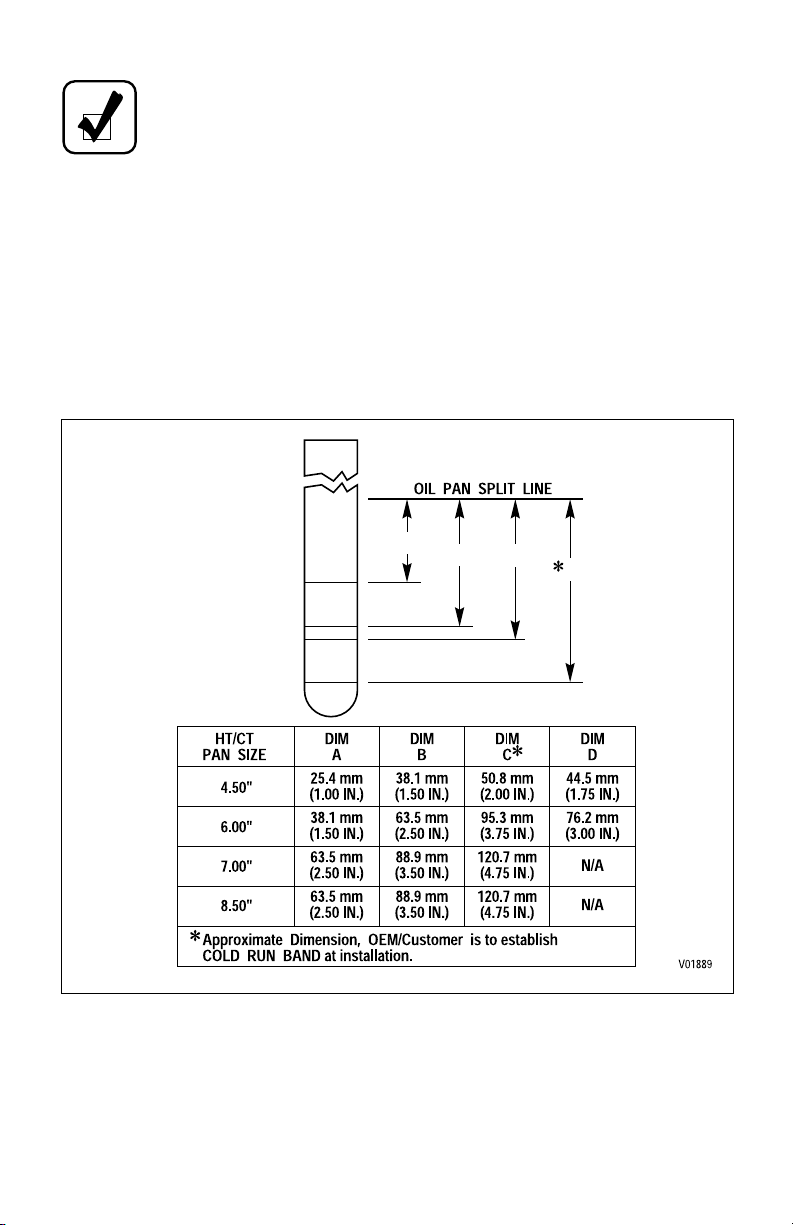

NOTE:

Safe operating level is within the “HOT RUN” band on the

dipstick, Figure 1–1.

• If the uid level is not within the “HOT RUN” band, add or drain as necessary

to bring the uid level to within the “HOT RUN” band.

d. Consistency of Readings.

• Always check the uid level at least twice and with the engine running.

Consistency is important to maintain accuracy of the reading. If inconsistent

reading persists, check the transmission breather to be sure it is clean and

unclogged.

A

B

D

C

HOT

RUN

RUN

COLD

Figure 1–1. Typical Dipstick Markings

4

CAUTION: Containers or llers that have been used for any antifreeze or engine coolant solution must not be used for the transmission uid. Antifreeze and coolant solutions contain ethylene glycol

which, if introduced into the transmission, can cause the clutch plates

to fail.

Transmission uid must be handled in clean containers, llers, etc., to prevent

foreign material from entering the transmission. Clean around the ller tube before

removing the dipstick. Lay the dipstick in a clean place while lling the

transmission.

• Hydraulic uids (oils) used in the transmission are important inuences on

transmission performance, reliability and durability. DEXRON®-III uid is

recommended for light-duty applications. Type C-4 uids are recommended

for severe-duty applications.

• Some DEXRON®-III uids are also qualied as Type C-4 uids. To ensure the

uid is qualied for use in Allison transmissions, check for a DEXRON®-III or

C-4 uid license, or approval numbers on the container, or consult the lubricant

manufacturer. Consult your Allison Transmission dealer or distributor before

using other uid types; uid types such as Type F, and universal farm uids may

or may not be properly qualied for use in your Allison transmission.

CAUTION: Disregarding minimum uid temperature limits can

result in transmission malfunction or reduced transmission life.

• When choosing the optimum viscosity grade of uid to use, duty cycle,

preheat capabilities, and/or geographical location must be taken into

consideration. Table 1–2 lists the minimum uid temperatures at which the

transmission may be safely operated. Preheat with auxiliary heating

equipment or by running the vehicle with the transmission in N (Neutral) for a

minimum of 20 minutes before attempting range operation.

5

Loading...

Loading...