TECHNICIANS’ GUIDE

INSPECTION AND ANALYSIS OF THE

ALLISON 4000 & B500

PRODUCT FAMILIES

GN4065EN

(5/05)

INSPECTION AND ANALYSIS OF THE

ALLISON 4000/B 500 PRODUCT FAMILIES

i

2005 General Motors Corporation.

ALLISON TRANSMISSION TECHNICIANS’ GUIDE

NOTICE: This guide is intended

for use by technicians skilled

in diagnosis and repair of

automatic transmissions.

Contact an authorized Allison

Transmission service outlet for

further information or

clarification if required. All

specifications provided in this

manual are subject to change

without notice.

Glossary Of Terms . . . . . . . . . . . 2

Introduction T o

Inspection & Analysis . . . . . . . . 3

General Inspection

Guidelines for

Q

Cast Parts & Machined

Surfaces . . . . . . . . . . . . . . . . . . 4

Q

Gears . . . . . . . . . . . . . . . . . . . . 5

Q

Splines . . . . . . . . . . . . . . . . . . . 6

Q

Bearings . . . . . . . . . . . . . . . . 7-8

Q

Bushings . . . . . . . . . . . . . . . . . 9

Q

Retaining Rings . . . . . . . . . . 10

Q

Thrust Washers . . . . . . . . . . . 11

Q

Clutch Plates . . . . . . . . . . 12-13

Q

Springs . . . . . . . . . . . . . . . . . 14

Q

Valves and Valve Bores . . . . 15

Control Module . . . . . . . . . . 16-21

Torque Converter

Module . . . . . . . . . . . . . . . . . 22-27

Torque Converter

Housing Module . . . . . . . . . 28-30

Standard Rear Cover and

P3 Planetary Module . . . . . 31-38

Retarder Module . . . . . . . . . 39-42

Close Ratio Main

Shaft Module . . . . . . . . . . . . . . 43

Wide Ratio Main

Shaft Module . . . . . . . . . . . . . . 44

P2 Planetary Module . . . . . 45-46

P1 Planetary Module . . . . . 47-48

Front Support & Oil

Pump Module . . . . . . . . . . . 49-52

Rotating Clutch Module . . . 53-58

C3/C4 Clutch Module . . . . . 59-64

Main Housing . . . . . . . . . . . 65-66

C6 Adapter Housing . . . . . . 67-69

Wear Limits and

Spring Data . . . . . . . . . . . . . 70-77

Abrade - Scrape off

Battering - Wear or damage due to

hard usage or repeated blows

Brinelling - Permanent deformation

of a bearing surface where rollers or

balls contact a race; Results from

excessive load or impact;

Characterized by indentations

on a bearing surface

Burr - Sharp metal extending

beyond normal surface

Chipped - Having a small piece

broken off

Cone - A shape whose base is a

circle and whose sides taper up

to a point

Crimped - Pinched or pressed

together tightly

Crocus cloth - Fine grit cloth

Discoloration - Change in color

Distortion - Change from original

shape

Erosion - Gradual uneven removal

of material

Fracture - A break or crack

Gall - Wear between parts such

that metal transfer occurs

Grooves - Long narrow

depressions

Inadequate - Not enough

Light Stoning - Using a

medium India oilstone to

remove material

Metal T ransfer - Metal from one

component embedded in a mating

component

Nick - Small notch

Pit - Local areas where material has

been removed

Porosity - Porous area where air,

fluid, or light may pass through

Score - Deep scratch

Scuff - Wear due to two moving

parts coming together with no

lubricant

Spalled - Damage characterized by

metal flaking or breaking down on

a wear surface; Similar to pitting

damage

Stripped - Threads broken or

damaged so part will not hold

torque

TAN - Total Acid Number;

Oil acidity should not change by

more then 3 from the new fluid

TAN when oil sampling is used to

determine oil change intervals

Twisted - Bent from original shape

ALLISON 4000/B500 PRODUCT FAMILIES

GLOSSARY OF TERMS

2

2005 General Motors Corporation.

ALLISON TRANSMISSION TECHNICIANS’ GUIDE

The Technicians’ Guide is

intended to provide additional

guidance with the inspection and

analysis of transmission parts.

This guide should be used by

technicians who overhaul Allison

4000/B 500 automatic

transmissions in conjunction with

the 4000/B 500 Service Manual

(SM2457EN) when inspecting parts

to determine their serviceability

and reuse.

General Rework Guidelines

Replace parts that cannot be

re-worked as outlined in this

manual and Service Manual

SM2457EN. A soft stone or crocus

cloth can be used to attempt

removal of “high spots” from

transmission parts. After the

attempted rework, the part must

meet specification if it is going to

be reused. Some seal surfaces (for

example the output yoke sealing surface

and the converter pump hub sealing

surface) cannot be reworked.

Both of these seal surfaces have a

controlled finish that can result in a

fluid leak if the part is altered by

rework.

ALLISON 4000/B500 PRODUCT FAMILIES

INTRODUCTION TO INSPECTION & ANALYSIS

3

2005 General Motors Corporation.

ALLISON TRANSMISSION TECHNICIANS’ GUIDE

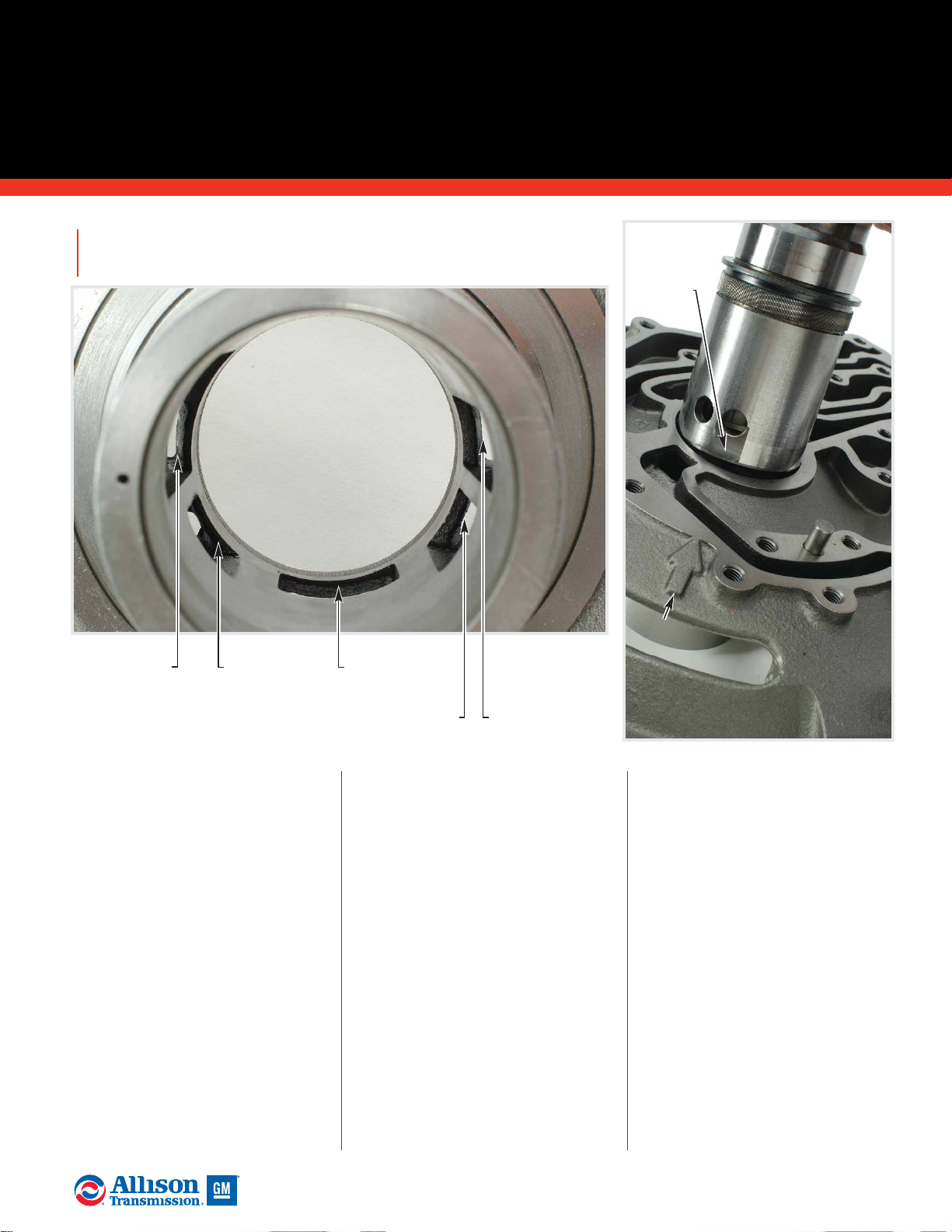

A. Replace housings or other cast

parts that are cracked or broken.

Inspect clutch housing sealing

surfaces for imperfections that

could damage the piston seals or

interfere with mating parts.

Inspect threaded holes for bad

threads. Clean damaged threads

with the correct size tap.

B. Inspect all machined surfaces

for damage that could cause fluid

leakage. Inspect mounting faces

and bores for damage.

C. Inspect all fluid passages for

obstructions, porosity, broken

lands, cracks and land surface

imperfections.

D. Replace housings that have

splines worn beyond wear limits.

Refer to the Wear Limits Table

(7-1) in Service Manual SM2457EN.

NOTE: Some parts have Spiralock®

threaded holes . A standard tap will

eliminate the locking feature

requiring the reworked part to be

replaced. For repair, use a

Spiralock® tap to repair Spiralock®

threaded holes. As of this printing,

the following parts have Spiralock®

threaded holes:

Q

Torque converter front cover

flexplate adapter bolt holes and

lockup clutch backplate bolt

holes.

Q

Output shafts using a single bolt

for flange or yoke retention.

4

2005 General Motors Corporation.

ALLISON TRANSMISSION TECHNICIANS’ GUIDE

ALLISON 4000/B500 PRODUCT FAMILIES

GENERAL INSPECTION GUIDELINES FOR

CAST PARTS & MACHINED SURFACES

C. Fluid

Passages

A. Cast

Part

A. Housings

D. Splines

C. Fluid

Passages

B. Machined

Surfaces

ALLISON 4000/B500 PRODUCT FAMILIES

GENERAL INSPECTION GUIDELINES FOR

GEARS

5

2005 General Motors Corporation.

ALLISON TRANSMISSION TECHNICIANS’ GUIDE

A. Inspect gears for damaged or

broken teeth. Inspect gear teeth for

wear that has changed the original

tooth shape. If this condition is noted,

replace the gear. Inspect gears for load

pattern and signs of distress. Any

signs of distress indicate the gear may

fail during operation. Reusing

distressed gears is an individual

customer decision based on

experience. Backlash cannot be used

to establish critical gear wear. Pits,

scuffs, scores or galling are typically

evident long before backlash exceeds

specification.

B. Inspect the thrust face of gears

for damage. If these defects cannot

be removed with a soft stone, replace

the gear.

Check gears for

damaged or

missing teeth.

A. Gear

Teeth

B. Thrust Face

Surface

A. Gear

Teeth

6

2005 General Motors Corporation.

ALLISON TRANSMISSION TECHNICIANS’ GUIDE

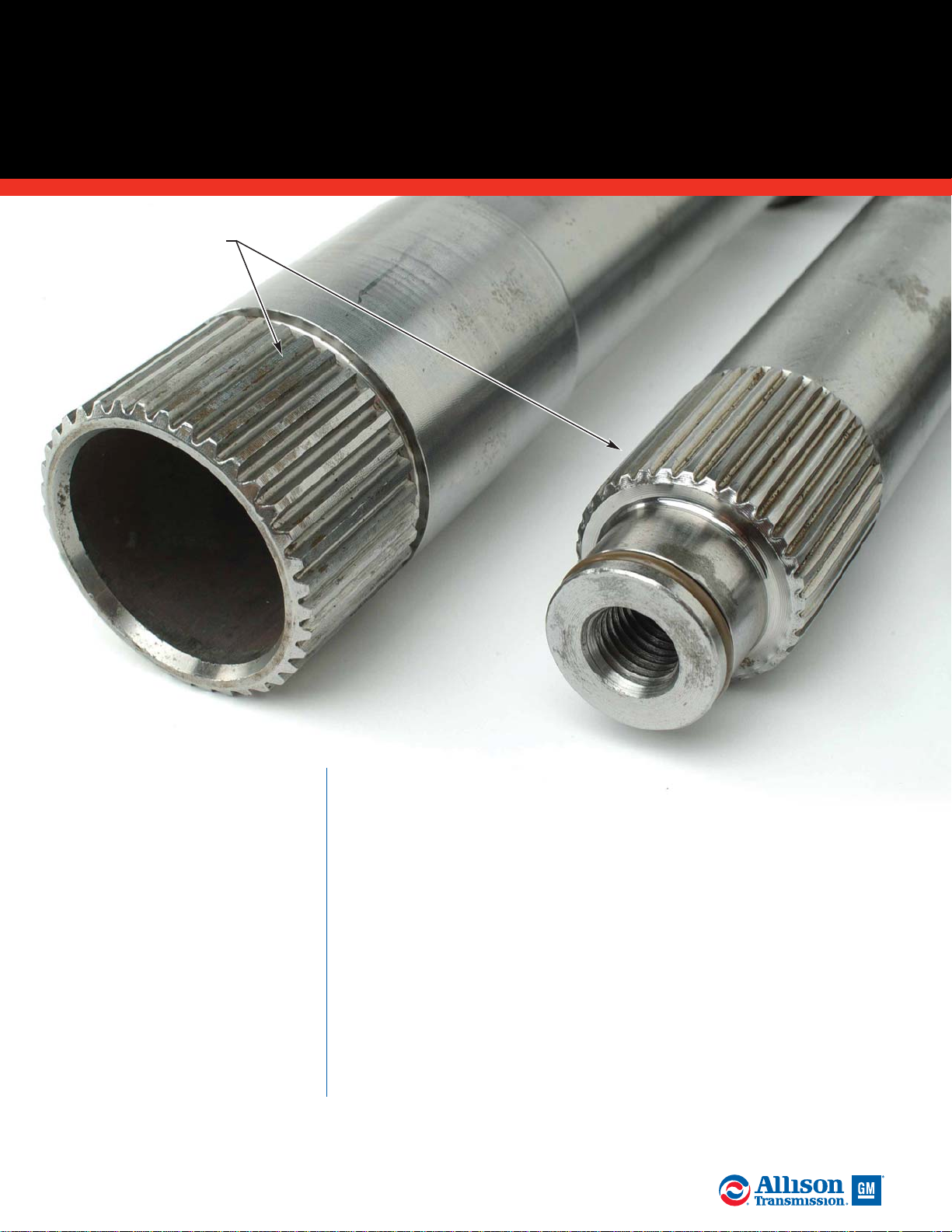

A. Inspect splined parts for

damage. Remove burrs with a soft

stone. Spline wear is not considered

harmful except where it affects the

fit of the splined parts. Spline wear

is determined by comparing feeler

gauge thickness with the thickness

of the worn area on the spline.

Replace parts having excessive

spline wear. The maximum

movement allowed at the splines is

0.38 mm (0.015 inches) if not

otherwise listed in Wear Limits

Table 7-1 in Service Manual

SM2457EN. Do not reuse a splined

part that exceeds the published

maximum spline wear. Backlash

cannot be used to establish critical

spline wear. Accurate backlash

measurement requires the mating

parts to be concentrically located.

ALLISON 4000/B500 PRODUCT FAMILIES

GENERAL INSPECTION GUIDELINES FOR

SPLINES

Inspect splined parts

for burrs, damage

and excessive wear.

A. Splines

7

2005 General Motors Corporation.

ALLISON TRANSMISSION TECHNICIANS’ GUIDE

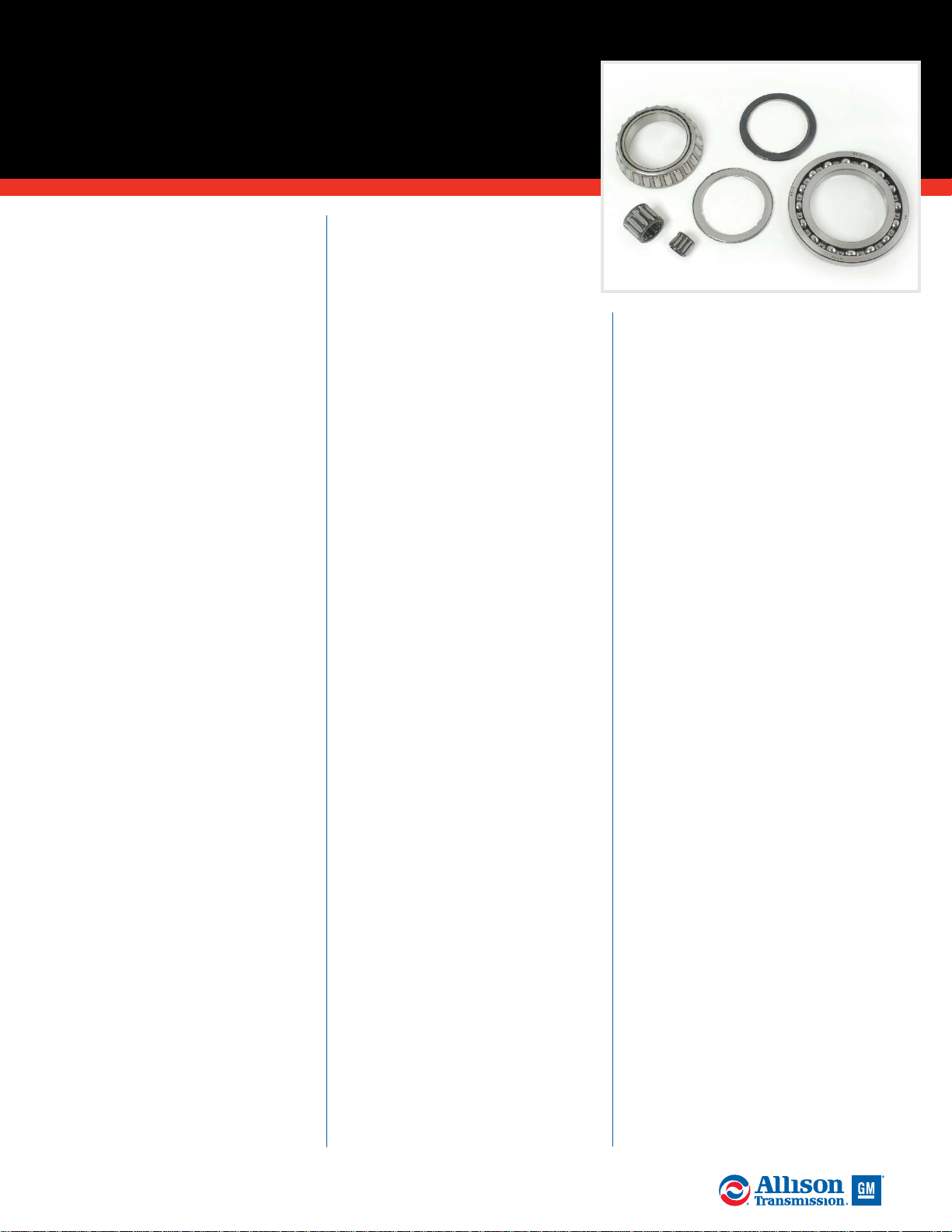

A. Replace the bearing if any

rollers/balls are rusted. Replace the

bearing if balls/rollers have a feeling

of looseness in the retainer or race

compared to a new bearing. Replace

the bearing if balls/rollers are

discolored from heat, lack of

lubrication or debris lapping in the

balls/rollers. Replace the bearing if

the balls/rollers are worn, galled or

abraded. Replace the bearing if it

catches or feels rough after being

thoroughly cleaned.

B. Replace the bearing if any

races are rusted. Replace the

bearing if the bearing balls/rollers

have a feeling of looseness in the

raceway compared to a new

bearing. Replace the bearing if races

are discolored from heat, lack of

lubrication or debris lapping in the

race. Replace the bearing if the

races are worn, galled or abraded.

Replace the bearing if it catches or

feels rough after being thoroughly

cleaned.

C. Replace the bearing if any

retainer or retainer clip is

fractured, bent, dented or missing.

Replace the bearing if any retainer

is rusted. Replace the bearing if

there is a feeling of looseness

between the retainer and ball/roller

compared to a new bearing. Replace

the bearing if it catches or feels

rough after being thoroughly

cleaned.

ALLISON 4000/B500 PRODUCT FAMILIES

GENERAL INSPECTION GUIDELINES FOR

BEARINGS

A. Rollers

B. Bearing

Race

C. Retainer

B. Bearing

Race

B. Bearing Race

(continued)

C. Retainer

C. Retainer

8

2005 General Motors Corporation.

ALLISON TRANSMISSION TECHNICIANS’ GUIDE

General Bearing Handling

& Storage

Dirt is the greatest single enemy

of any antifriction bearing.

Cleanliness - using clean tools in a

clean environment - is at the top

of the list of good service

techniques. Keep bearings sealed in

original containers. Do not allow

anyone to open boxes and handle

bearings. A new bearing, if not

protected, can quickly pick up

enough dust even in an apparently

clean place to seriously affect its life

and operation. Minimize the

possibility of rusting or lubricant

aging in storage by using the oldest

bearings in stock first.

If any part of a bearing assembly

has been compromised, replace all

detail parts in the assembly

(example - races, retainers and the

bearing itself). Most bearings fail

from preventable causes. Follow a

regular system for inspection. Look

for bearings with obvious damage

first.

General Bearing Inspection

Do not try to judge the condition of

a bearing until after cleaning. Do

not spin bearings while cleaning

them. Rotate them slowly while

washing. Do not spin any bearings

with air pressure. Put bearings

under axial pressure while rotating

to bring the balls and races firmly in

contact with each other. For single

row angular contact bearings,

pressure must always be applied on

thrust faces.

When immersing in solvent, place

bearings in a wire basket so there is

plenty of space for cleaner to reach

all parts. Tanks should have a

screened false bottom to prevent

settled debris from being stirred up

into the bearings. Agitate the

basket frequently until grease, oil or

sludge is thoroughly loosened and

can be flushed out. Blow solvent

out of bearings using dry, filtered

air. Be careful not to spin the

bearing using air pressure.

Lubricate bearings immediately

after drying to avoid rust.

NOTE: Wear eye protection and

follow the appropriate safety

guidelines when using solvents to

clean components.

Badly discolored rollers and races

are usually a sign of inadequate

lubrication. Replace badly

discolored bearings. Moderately

discolored rollers, cages and races

do not necessarily mean that the

bearing needs replacement.

Technicians should always try to

determine the root cause of failure

when inspecting failed components.

It’s important the root cause be

identified and repaired to avoid the

same failure in the future. Bearings

should be replaced for the

following reasons:

Rusted rollers, balls or

raceways -

rusted rollers, balls or

raceways are usually caused by

water passing worn or defective

seals, or by condensation inside the

housing.

Fractured races - a fractured race

can be caused by forcing a cocked

bearing on or off a shaft. An

excessively tight press fit can also

cause a race to fracture.

Worn, galled or abraded

surfaces - worn, galled or abraded

surfaces on a bearing may be the

result of a loose fit on a shaft or in a

housing. A locked bearing spinning

on a shaft or in a housing can also

create this type of damage.

General feeling of roughness -

inspect for a general feeling of

roughness which remains

unchanged by thorough cleaning.

This condition generally indicates

damage to raceways or rollers

caused by dirt, pitting, brinelling or

corrosion.

Catchy feeling - inspect for a

catchy feeling at one or more points

which repeated flushing will not

remove. This condition generally

indicates a spalled or fatigued spot

on the race. Thorough flushing is

necessary to be sure the catchy or

rough feeling is not caused by

foreign debris in the bearing.

Excessive looseness - inspect for

excessive looseness which indicates

lapping by dirt or an abrasive

contaminate in the lubricant. If in

doubt, compare the end play

against the end play of an identical

new bearing. The races, balls and

rollers will appear dull gray when

lapped by dirt.

ALLISON 4000/B500 PRODUCT FAMILIES

GENERAL INSPECTION

GUIDELINES FOR BEARINGS

(continued)

9

2005 General Motors Corporation.

ALLISON TRANSMISSION TECHNICIANS’ GUIDE

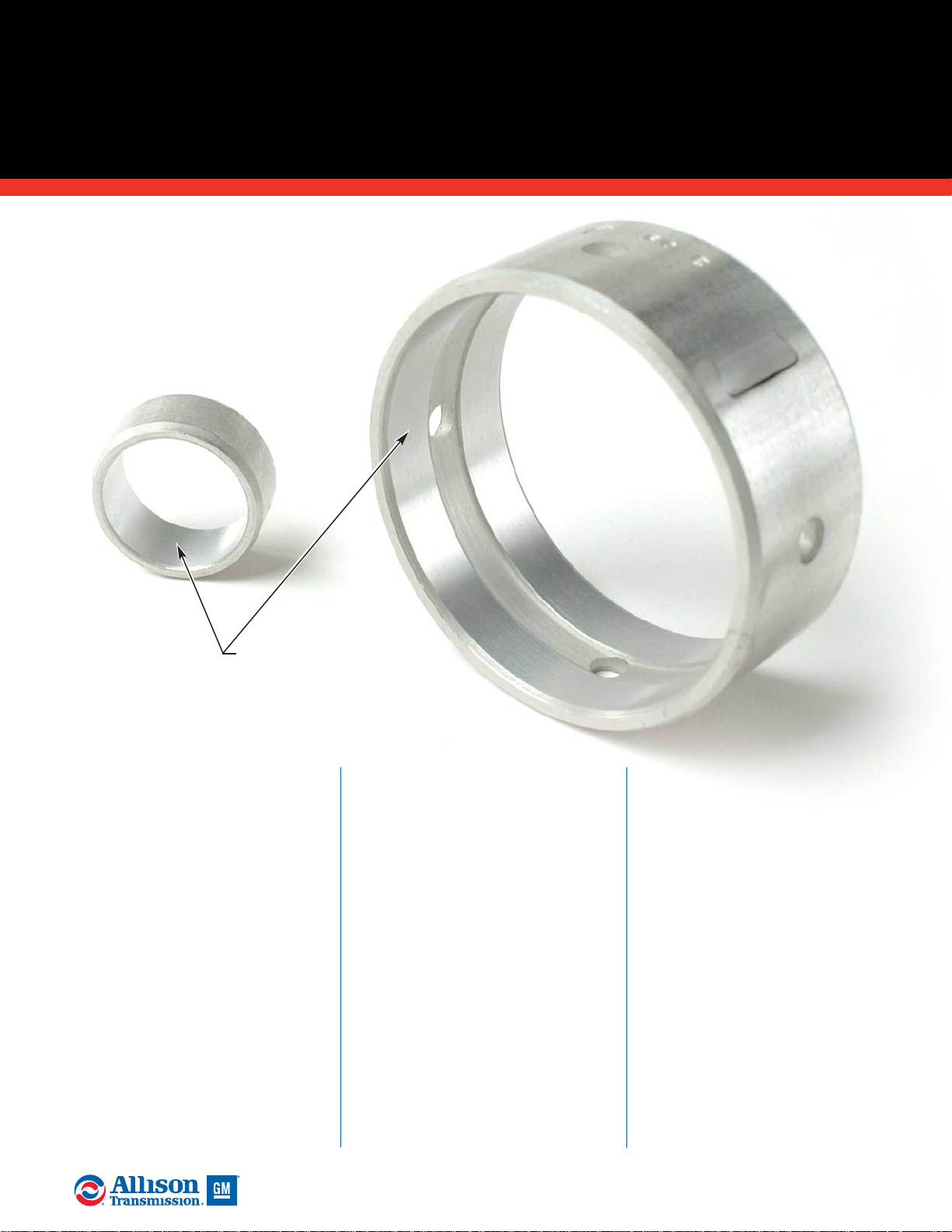

A. Inspect bushings for wear

beyond service limits. Replace any

bushing which is excessively worn.

Inspect bushings for discoloration

and surface damage due to lack of

lubrication. Replace any bushing

which is damaged.

General Bushing Information

Mechanically, bushings are the

simplest type of journal bearing and

are often referred to as “plain”

bearings. A bushing is simply a

sleeve of bearing material, such as

bronze or aluminum, in which a

component rides. Bushing wear is

strongly influenced by the quantity

and condition of the lubricant.

Bushing bearing surfaces are

sometimes grooved to better

distribute lubrication across the

bearing surface.

Some bushings are susceptible to

material leaching. This can be

caused by oxidized oil that has

turned acidic combined with heat

and mechanical loading. The TAN

(Total Acid Number) of the

transmission oil should not change

by more than 3 from the baseline

(new fluid) TAN. Changing

transmission oil per recommended

change intervals or based on a

successful oil sampling program

will help prevent material leaching.

ALLISON 4000/B500 PRODUCT FAMILIES

GENERAL INSPECTION GUIDELINES FOR

BUSHINGS

Bushing wear is strongly

influenced by the

quantity and condition

of the lubricant.

A. Bushing

10

2005 General Motors Corporation.

ALLISON TRANSMISSION TECHNICIANS’ GUIDE

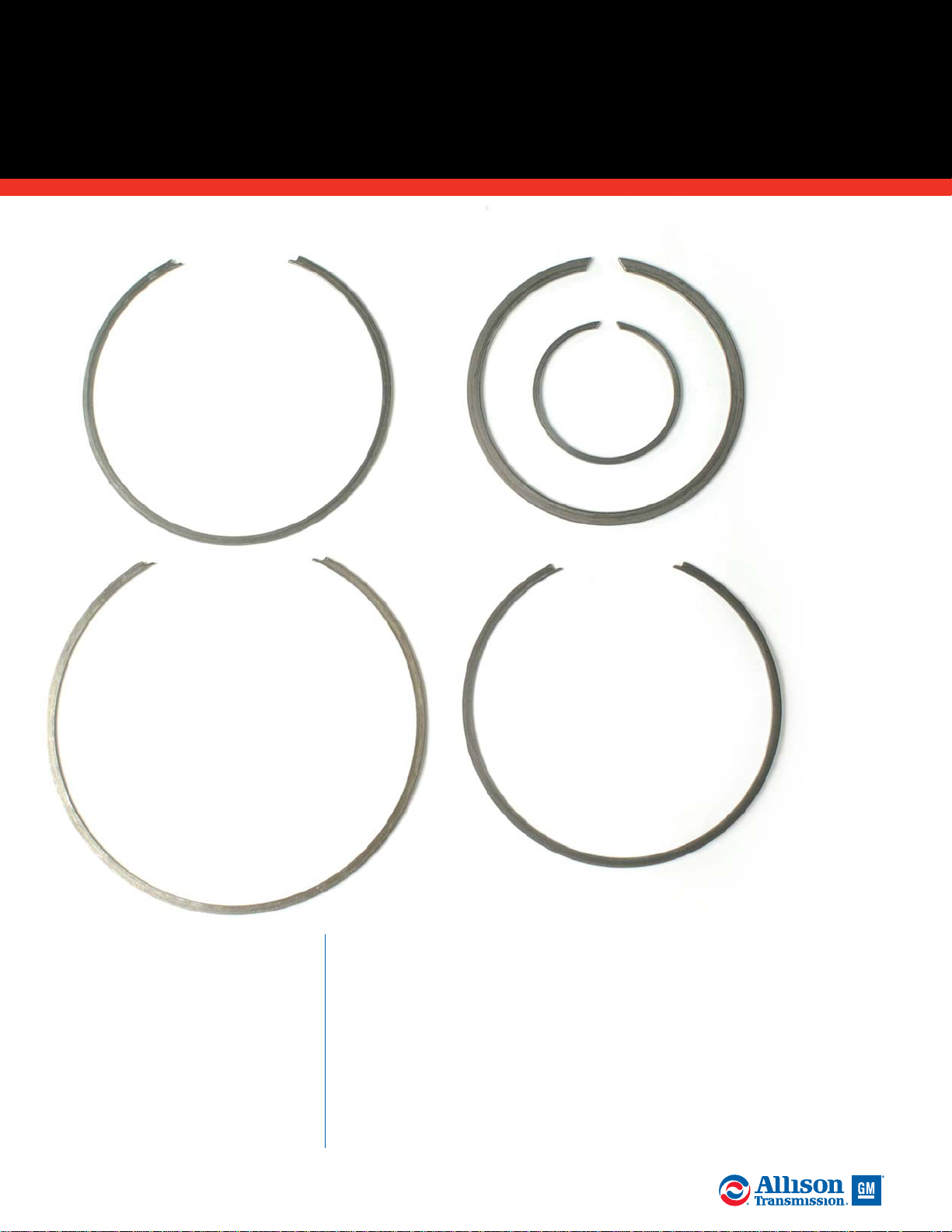

A. Inspect retaining rings for

damage, distortion and excessive

wear. Replace retaining rings if

damage cannot be repaired using a

soft stone or crocus cloth.

ALLISON 4000/B500 PRODUCT FAMILIES

GENERAL INSPECTION GUIDELINES FOR

RETAINING RINGS

Examine retaining

rings for damage,

distortion or

excessive wear.

A. Retaining

Rings

11

2005 General Motors Corporation.

ALLISON TRANSMISSION TECHNICIANS’ GUIDE

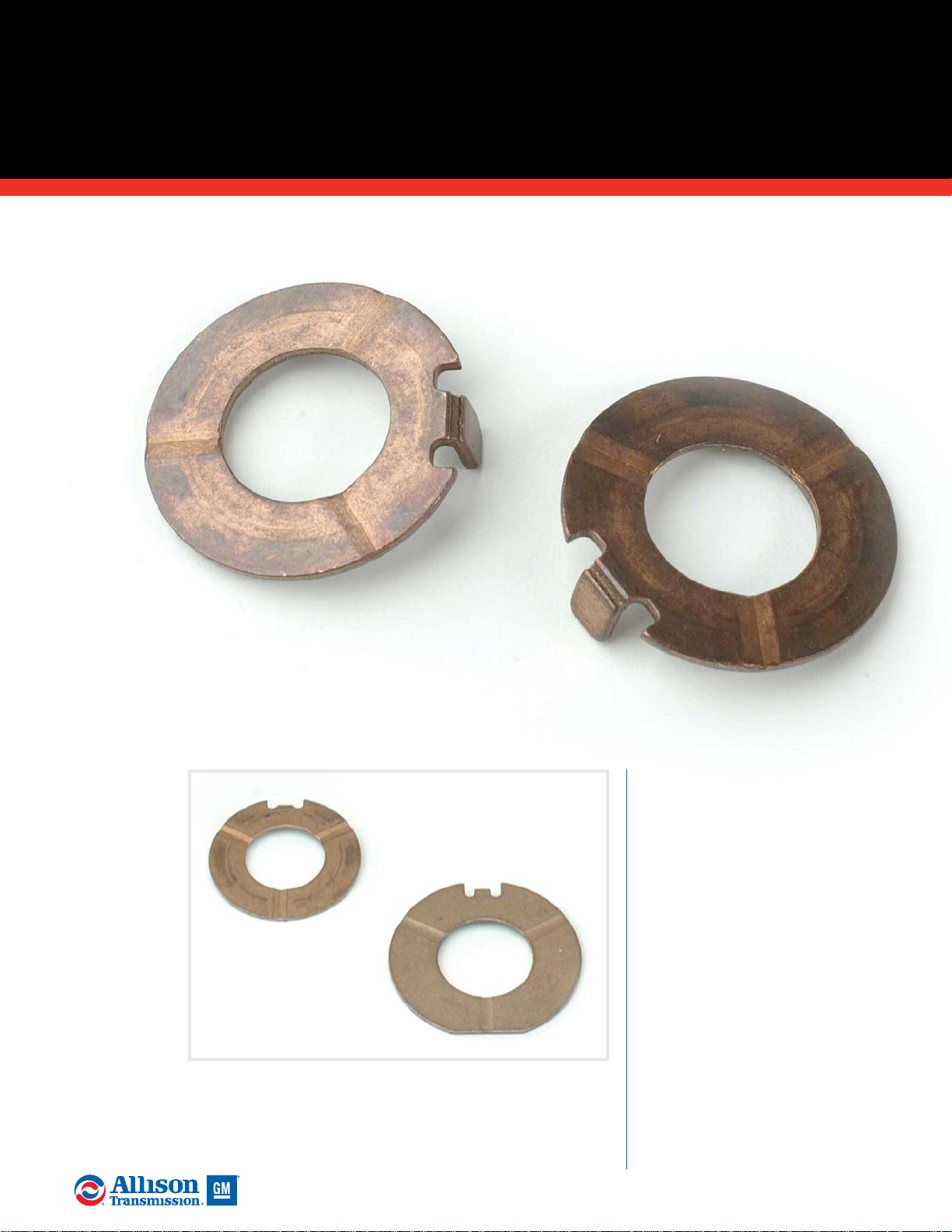

A. Replace thrust washers if they

are worn beyond service limits.

Replace thrust washers if they are

galled, abraded or distorted.

Replace thrust washers if they are

damaged due to a lack of

lubrication.

ALLISON 4000/B500 PRODUCT FAMILIES

GENERAL INSPECTION GUIDELINES FOR

THRUST W ASHERS

A. Thrust

Washers

Thrust

Washers

12

2005 General Motors Corporation.

ALLISON TRANSMISSION TECHNICIANS’ GUIDE

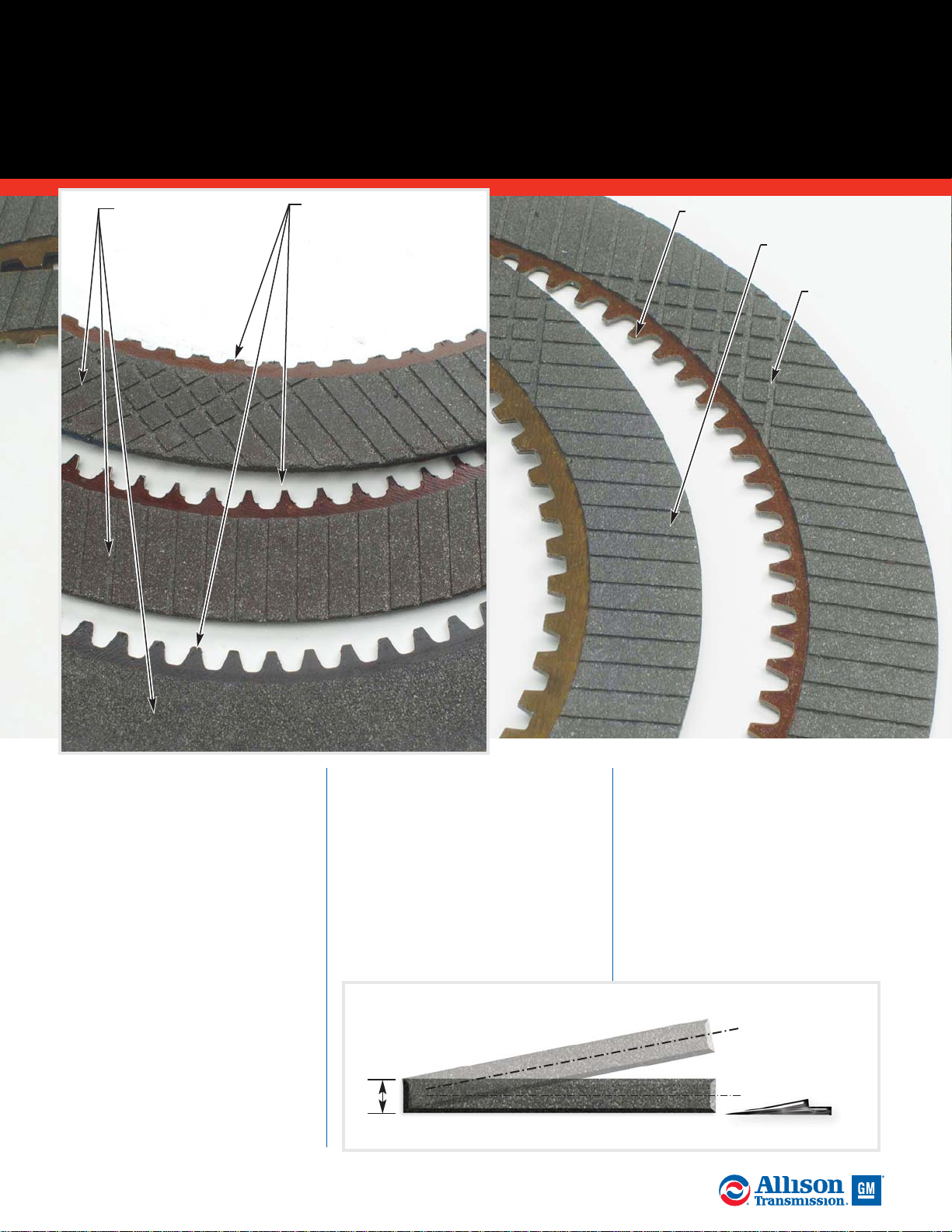

A. Contact

Surface

C. Oil

Groove

Depth

D. Spline

Teeth

A. Inspect friction plate contact

faces and splines for excessive

wear, damage and coning. Inspect

the plates for burrs, pitted faces,

cracks, distortion and damaged

spline teeth.

B. Measure friction plate

thickness and coning. Reference

the Service Manual for minimum

thickness and maximum coning

specifications. Do not reuse friction

plates that do not meet published

specifications. If reused plates are

slightly coned (within

specification), make sure each plate

is stacked with the cone facing the

same direction.

C. Measure friction plate oil

groove depth. Replace any plates

that are not within Service Manual

minimum groove depth

specification.

D. Inspect spline teeth for

excessive wear and battering.

Replace the clutch plate if damage

cannot be repaired using a soft

stone or crocus cloth. Replace the

clutch plate if spline teeth are

broken or missing.

NOTE: Anti-freeze (glycol) and/or

water can adversely affect the

bonding agent between the friction

material and steel core. Replace any

friction plates which have been

exposed to water and/or glycol.

ALLISON 4000/B500 PRODUCT FAMILIES

GENERAL INSPECTION GUIDELINES FOR

CLUTCH PLATES

B. Clutch Plate

Thickness and

Coning

Check Using

Feeler Gauge

Thickness

Coned Plate

Flat Plate

(continued)

Oil grooves

appear shallow

or worn away measure plate

thickness and

groove depth.

Spline teeth battered

and worn - may be an

indication of driveline

issues. Replace

clutch plates and

check driveline.

13

2005 General Motors Corporation.

ALLISON TRANSMISSION TECHNICIANS’ GUIDE

NOTE: The current clutch friction plates

were implemented April of 2000 starting

with s/n 6610062126. Current clutch

friction plates will have two or more

missing splines. Former friction plates

will either have one spline missing or

none missing. Any 4000/B 500 model

transmission may be updated from former

C5 friction plates to current C5 frictions

without recalibrating the transmission

ECU. The rest of the clutches in the main

housing (C1 through C4) must be

updated with current friction plates if

any other individual clutch besides C5 is

updated from former to current friction

plates. Any update from former frictions

to current frictions in C1 through C4 for

a 4000 Series or B500 with a WTEC II

ECU will require a new ECU calibration

from Allison Transmission. Any update

from former frictions to current frictions

in C1 through C4 for a 4000 Series or

B500 with a WTEC III ECU with a

calibration prior to October 25, 1999 will

require an updated ECU calibration from

Allison Transmission. Do not intermix

both former and current friction plates in

a clutch pack.

The P3 ring gear changed to a harder ring

gear on s/n 6610027070. The current P3

ring gear identifier is a groove machined

around the outer diameter of the gear.

The P3 ring gear with a groove identifier

requires the C5 friction with two missing

splines if updating from former C5

frictions. If any 4000/B500 series model

without the harder ring gear (no groove

on O.D.) is being updated with current

C5 frictions, then it will require the C5

friction that has three missing internal

splines. The C5 friction plate missing

three splines will exhibit spline wear if

used with the current P3 ring gear with a

groove identifier on the O.D. The former

P3 ring gear (no groove on O.D.) will

exhibit premature wear if used with the

current C5 friction with two missing

internal splines. No ECU calibration is

necessary for updating C5 clutch plates.

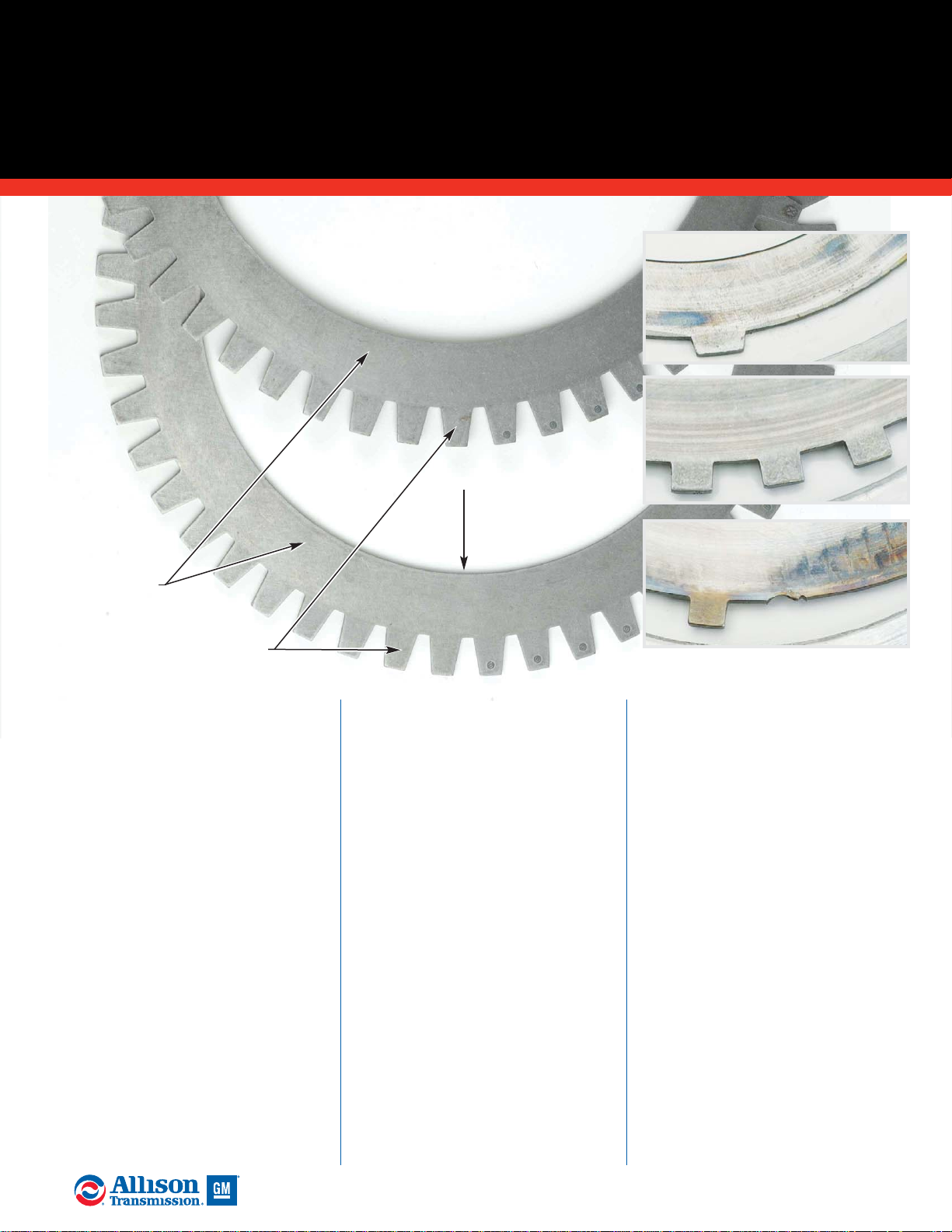

A. Inspect reaction plates for

excessive wear, warping, coning

and surface damage. Replace any

plate with wear exceeding service

limits or with damage which

cannot be repaired using a soft

stone or crocus cloth..

B. Measure reaction plate

thickness and coning. Reference

the Service Manuals for minimum

thickness and maximum coning

specifications. Do not reuse plates

that do not meet published

specifications. If reused plates are

slightly coned (within

specification), make sure each plate

is stacked with the cone facing the

same direction.

C. Inspect reaction plate tangs

for damage. Replace the plate if

damage cannot be repaired using a

soft stone or crocus cloth.

ALLISON 4000/B500 PRODUCT FAMILIES

GENERAL INSPECTION GUIDELINES FOR

(continued)

CLUTCH PLATES

A. Contact

Surfaces

B. Thickness

& Coning

(see prior

page graphic)

C. Tangs

Acceptable

discoloration reuse plates.

Excessive scoring replace plates.

Broken tangs replace plates.

14

2005 General Motors Corporation.

ALLISON TRANSMISSION TECHNICIANS’ GUIDE

A. Inspect springs for permanent

set and wear due to rubbing

adjacent parts. Replace the spring if

any of these defects are identified or

if the spring fails to meet published

service limits. Reference the Spring

Data Charts in Service Manual

SM2457EN for spring identification

and service limit specifications.

ALLISON 4000/B500 PRODUCT FAMILIES

GENERAL INSPECTION GUIDELINES FOR

SPRINGS

Inspect springs for signs of

overheating, permanent set

or wear due to rubbing

adjacent parts.

A. Springs

Reference the Service Manual

Spring Data Charts for spring

identification and specifications.

15

2005 General Motors Corporation.

ALLISON TRANSMISSION TECHNICIANS’ GUIDE

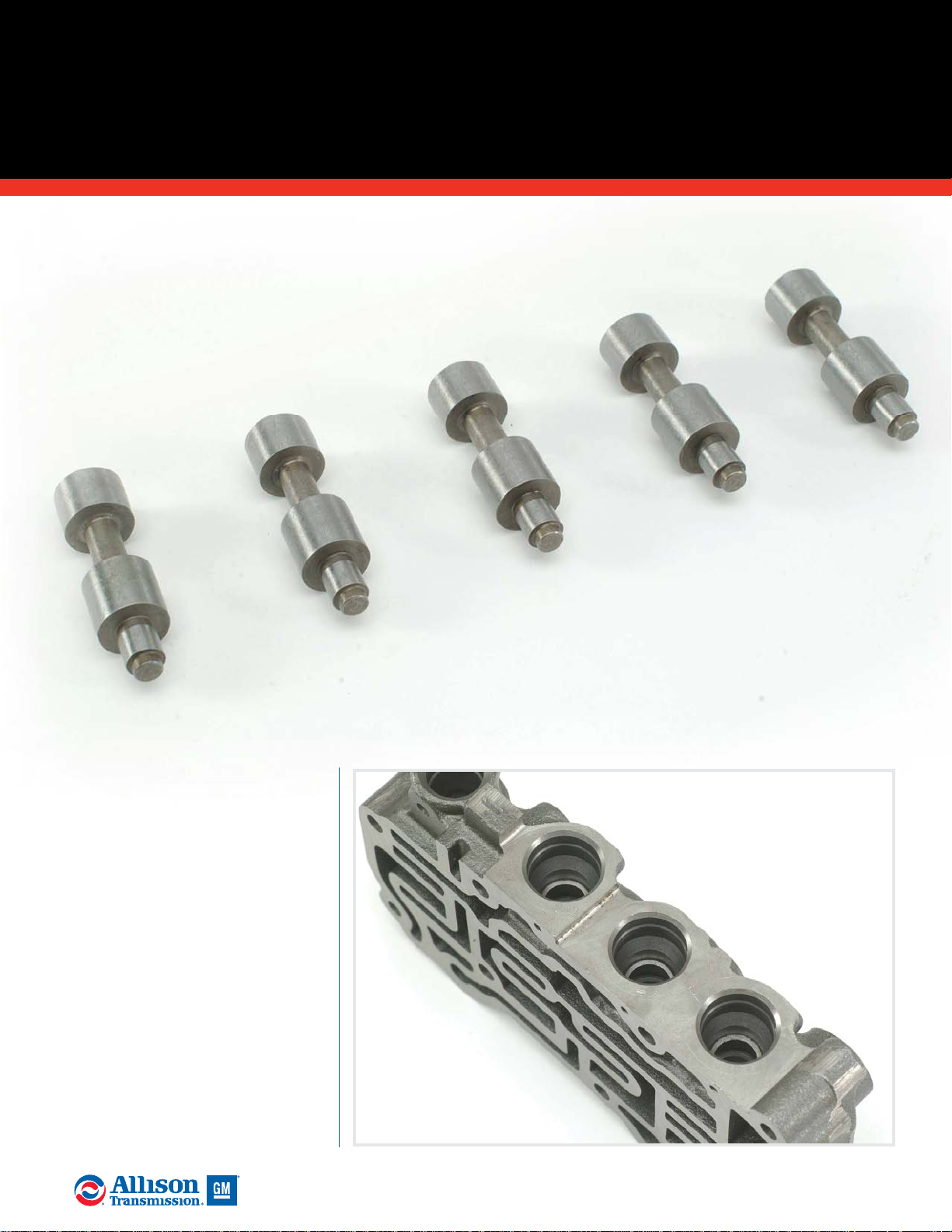

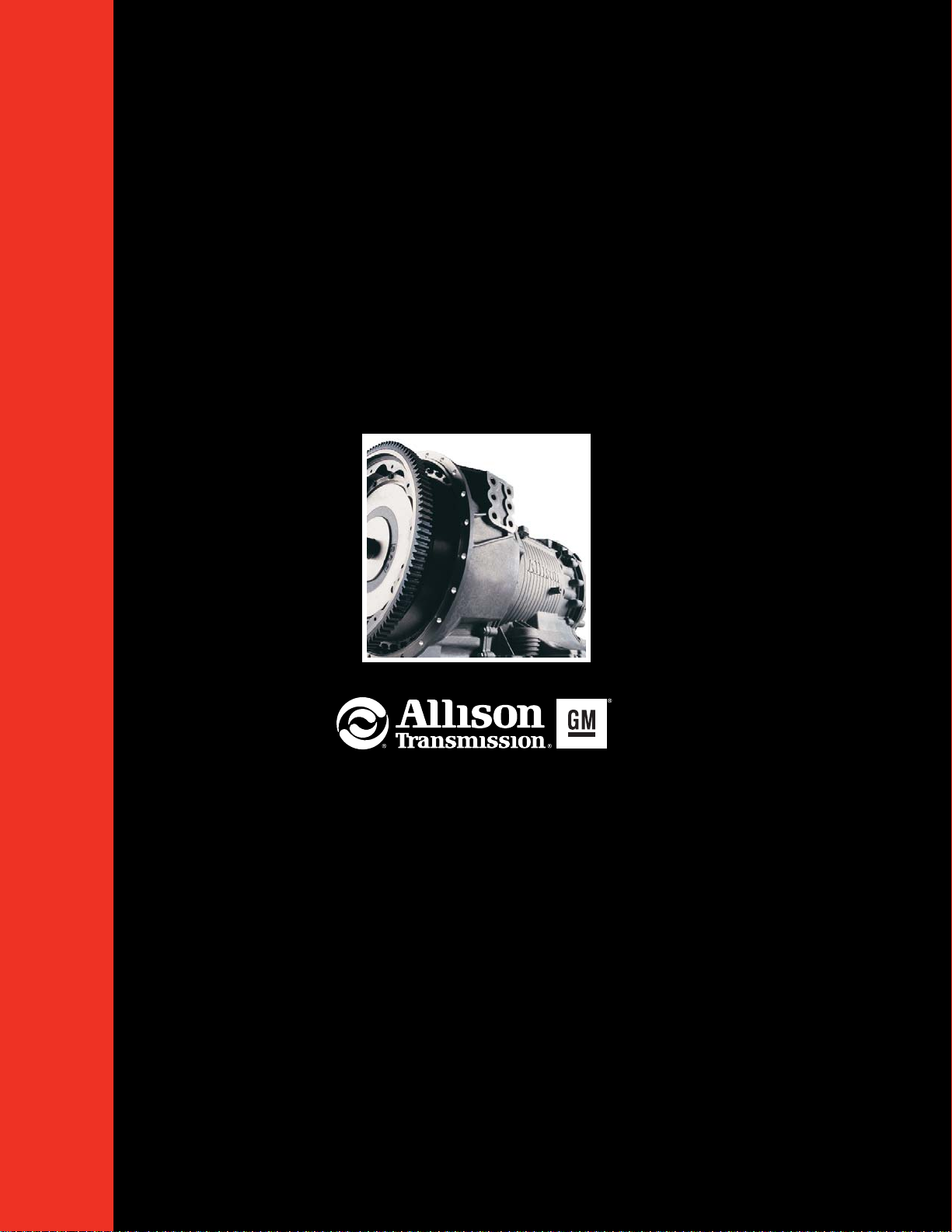

A. Valves must be free of nicks,

burrs and scoring and operate

smoothly in their bores without

sticking. Dry valves must move

freely in their bores by their own

weight. Replace damaged valves. A

soft stone or crocus cloth can be

used in an attempt to repair slight

irregularities.

B. Valve bores must be free of

nicks, burrs and scoring. No honing

of any kind is allowed. A soft stone

or crocus cloth can be used in an

attempt to repair slight

irregularities.

ALLISON 4000/B500 PRODUCT FAMILIES

GENERAL INSPECTION GUIDELINES FOR

VALVES & VALVE BORES

Valves should move freely in

their bores, when dry, under

their own weight.

Valve bores must

be free of nicks,

burrs and scoring.

A. Valves

B. Valve

Bores

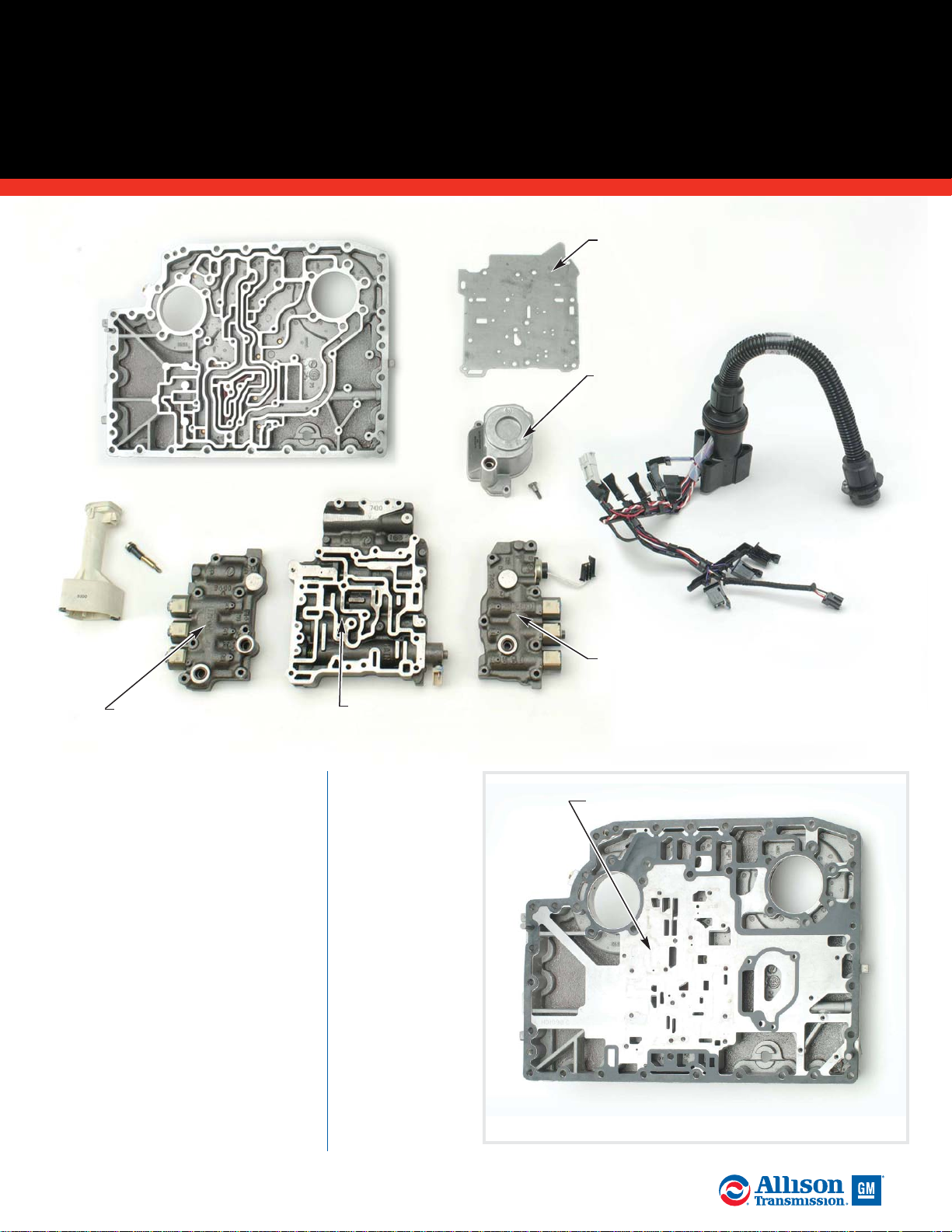

A. Inspect the channel plate for

damage. All passages must be clear

of debris. Inspect all machined

surfaces for burrs, nicks or scoring.

Light stoning and crocus cloth may

be used to eliminate minor high

spots. If a channel plate cannot be

repaired so that all machined

surfaces can seal correctly to their

mating parts, or if thread damage

cannot be repaired, replace the

channel plate.

NOTE: Do not use impact guns (air

wrenches, electric impact

wrenches, etc.) when working with

aluminum threads or when torque

sequencing bolts.

B. Inspect both

separator

plates for dents,

nicks, burrs and

other damage or

distortion.

Replace the

plate if it has

damage which

cannot be

repaired using a

soft stone or

crocus cloth. All

passages must

be clean and

debris free.

A. Channel

Plate

B. Solenoid

Separator Plate

D. Internal

Wiring

Harness

C. Suction

Filter

Assembly

E. Rotating

Clutch Body

Assembly

F. Main Valve

Body Assembly

G. Stationary Clutch

Valve Body Assembly

H. Oil Level

Sensor

ALLISON 4000/B500 PRODUCT FAMILIES

CONTROL MODULE

16

2005 General Motors Corporation.

ALLISON TRANSMISSION TECHNICIANS’ GUIDE

B. Separator Plate

Separator plate and gasket installed

on channel plate.

(continued)

ALLISON 4000/B500 PRODUCT FAMILIES

(continued)

CONTROL MODULE

17

2005 General Motors Corporation.

ALLISON TRANSMISSION TECHNICIANS’ GUIDE

C. Replace the suction filter

assembly during overhaul.

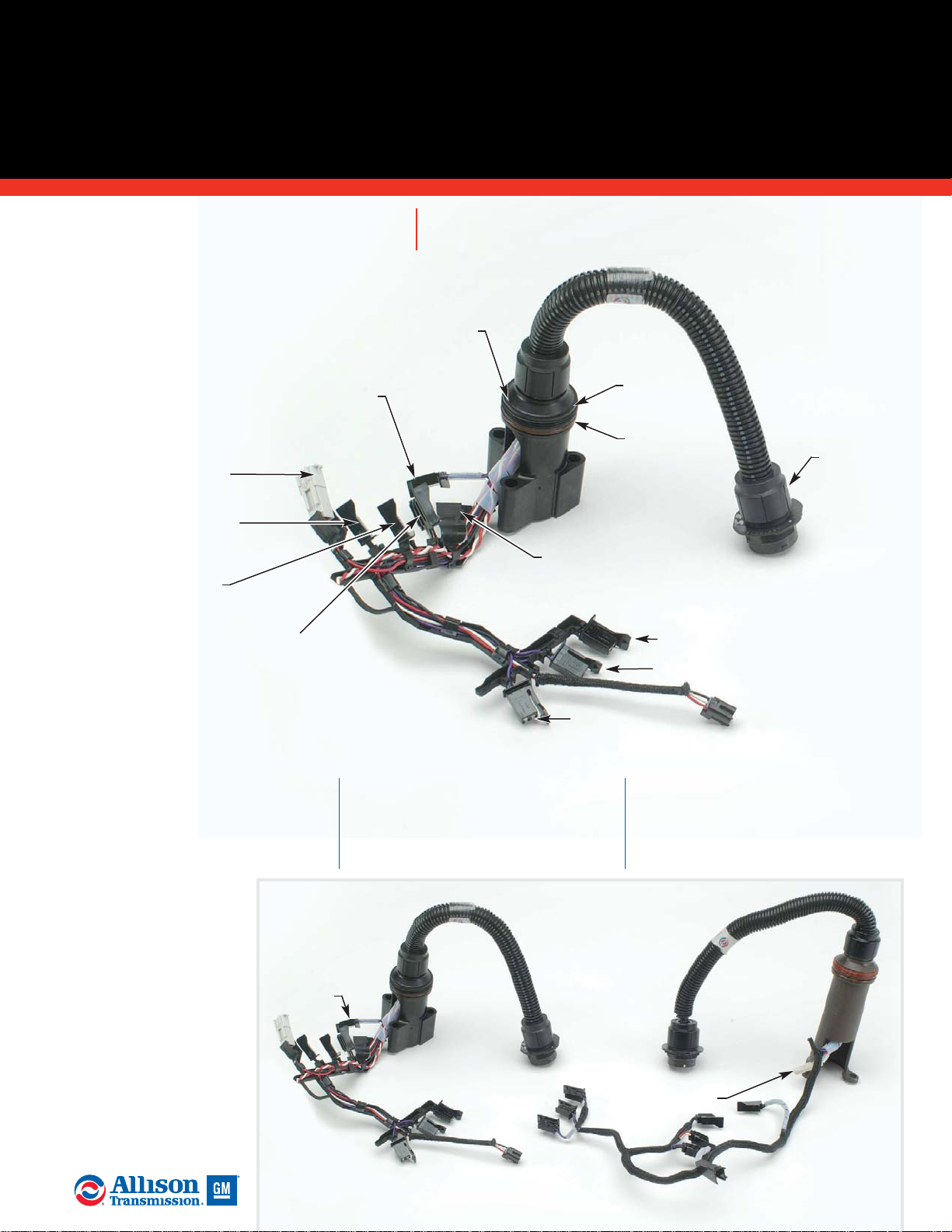

D. Replace or repair the control

module wiring harness if the

wires, terminals or

connectors are visibly

damaged. Inspect the

molded harness channel

for cracks or breaks.

Replace the harness if

the molded channel is

damaged. Check sump

temperature resistance

following the guidelines

and specifications listed

in the Service Manual

and Troubleshooting

Manual.

NOTE: Transmissions built prior to

S/N 6610014067 used the former

design sump temperature sensor.

Sensor resistance specifications

differ between the former and

current designs. Be sure to use the

correct resistance specification

chart for the sensor being checked.

Sump Temperature

Sensor (TID 2, 3)

D Solenoid (C4)

C Solenoid (C3)

E Solenoid

(C5)

F Solenoid

(Lockup)

Oil Level

Sensor

Feed

Through

Stand-Off

C3 Pressure

Switch

A Solenoid

(C1)

Feed

Through

Harness

B Solenoid

(C2)

G Solenoid

(C2 Latch)

Identification Detail:

Internal Wiring Harness

Current TID2/TID3

Harness

Former TID1

Harness

TID1 Sump

Temp. Sensor

(continued)

Dust

Seal

O-Ring

Seal

TID 2, 3

Sump Temp.

Sensor

ALLISON 4000/B500 PRODUCT FAMILIES

CONTROL MODULE

(continued)

18

2005 General Motors Corporation.

ALLISON TRANSMISSION TECHNICIANS’ GUIDE

E, F, G. Valves, valve body bores

and oil passages must be free of

debris, nicks, burrs, scoring and

galling. Valves should move freely

in their bores, when dry, under

their own weight. Repair or replace

valves and/or valve bodies failing to

meet these requirements.

Valve body machined surfaces

must be free of debris, nicks, burrs

and scoring. Light stoning of these

machined surfaces is permitted to

correct minor defects. Replace any

valve body that cannot be repaired.

Inspect all threaded holes for

damage and debris. Replace the

valve body if the thread damage

cannot be repaired.

NOTE: Do not use impact guns (air

wrenches, electric impact

wrenches, etc.) when working with

aluminum threads or when torque

sequencing bolts.

Replace valve springs which are

broken, permanently set or worn

due to rubbing adjacent parts.

Reference the Spring Data Charts in

the Service Manual for spring

specifications and identification.

Valve stops and retention pins

must not be damaged or battered.

Replace valve stops or pins which

have damage that cannot be

removed using a soft stone or

crocus cloth.

Replace solenoids if they are visibly

damaged. Proper solenoid

resistance is 3 to 4 ohms measured

between the two solenoid

terminals. Check resistance

between each solenoid terminal and

the solenoid body. Replace the

solenoid if resistance measures less

than 100k ohms.

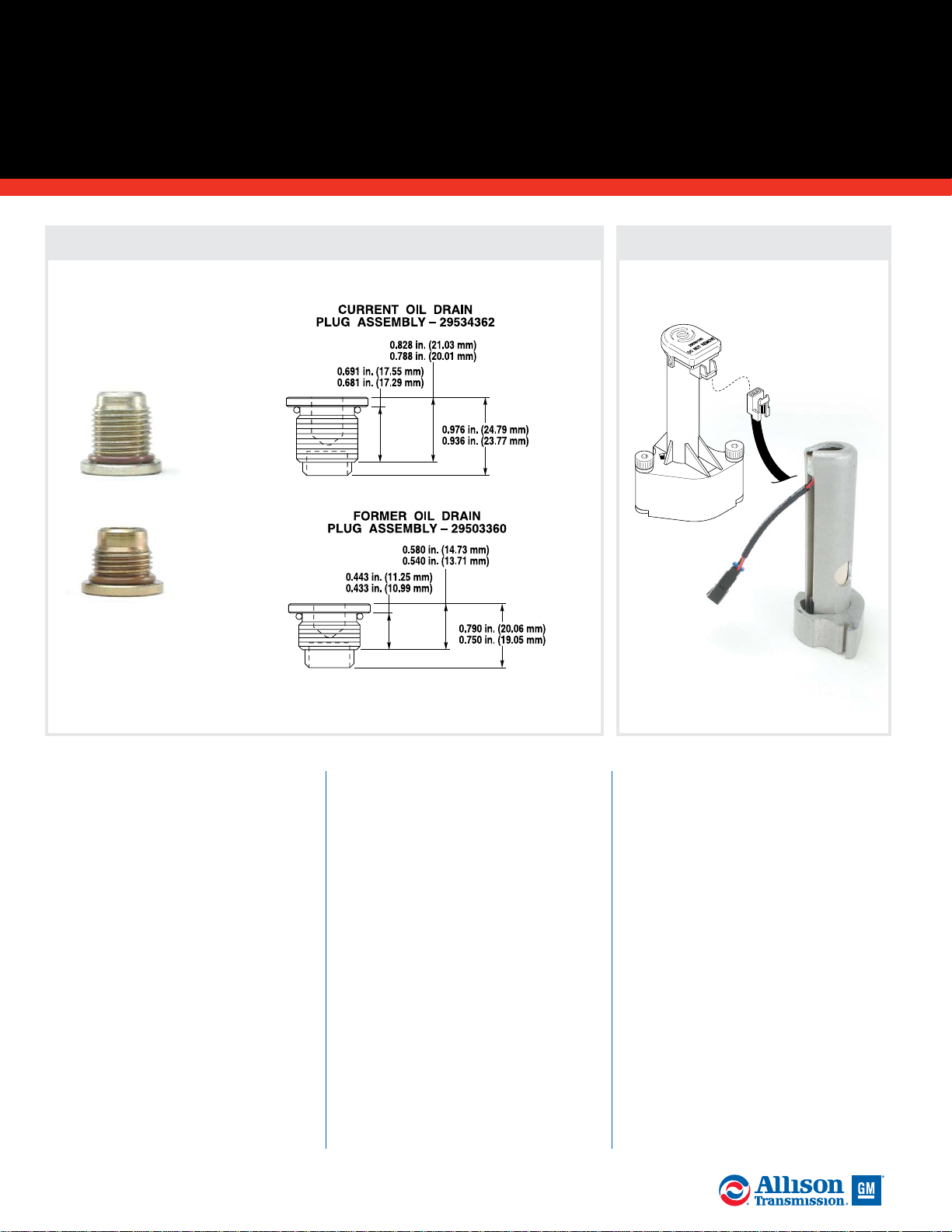

Supersession Information

Oil Drain Plug Redesign SIL 5-WT-98, Rev. A

Current plug is

backward compatible

with all control

modules.

Supersession Information

Oil Level Sensor Redesign SIL 19-WT-99

Kit must be used when

replacing former sensor

with current sensor.

Current

Former

(continued)

Replace the C3 pressure switch if

it is visibly damaged. Resistance

between the two switch terminals

should measure 20k ohms or higher

when the switch is open (and no

pressure is present). Resistance

between the two terminals should

not exceed 2 ohms when the switch

is closed (159 kPa-255 kPa or 23-37

psi present).

H. Replace the optional oil level

sensor if it is determined it is not

functioning correctly.

ALLISON 4000/B500 PRODUCT FAMILIES

(continued)

CONTROL MODULE

19

2005 General Motors Corporation.

ALLISON TRANSMISSION TECHNICIANS’ GUIDE

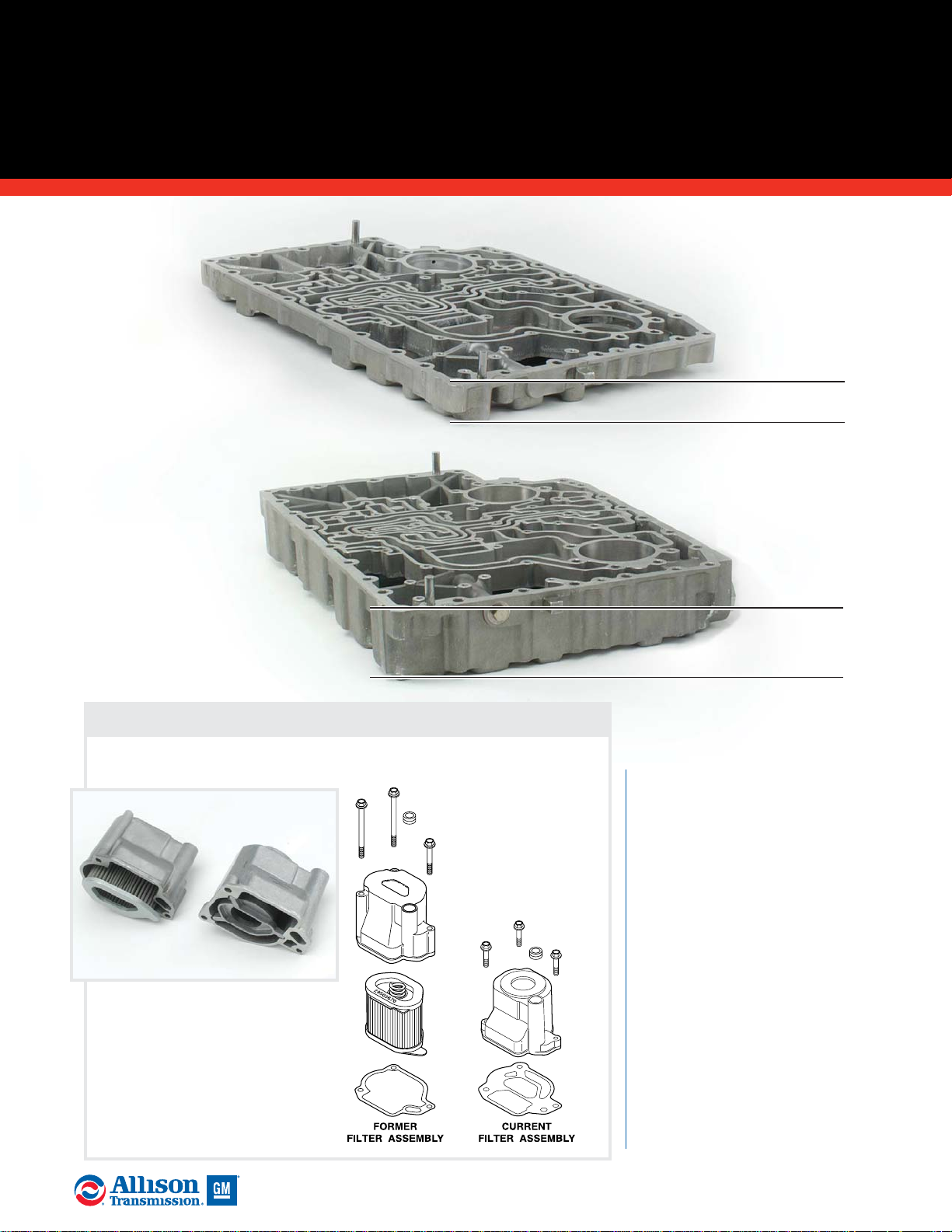

4” Channel

Plate

2” Channel

Plate

Supersession Information

Suction Filter Redesign - SIL 1-WT-00

Replace the

assembly

during

overhaul.

Current

Former

(continued)

ALLISON 4000/B500 PRODUCT FAMILIES

CONTROL MODULE

(continued)

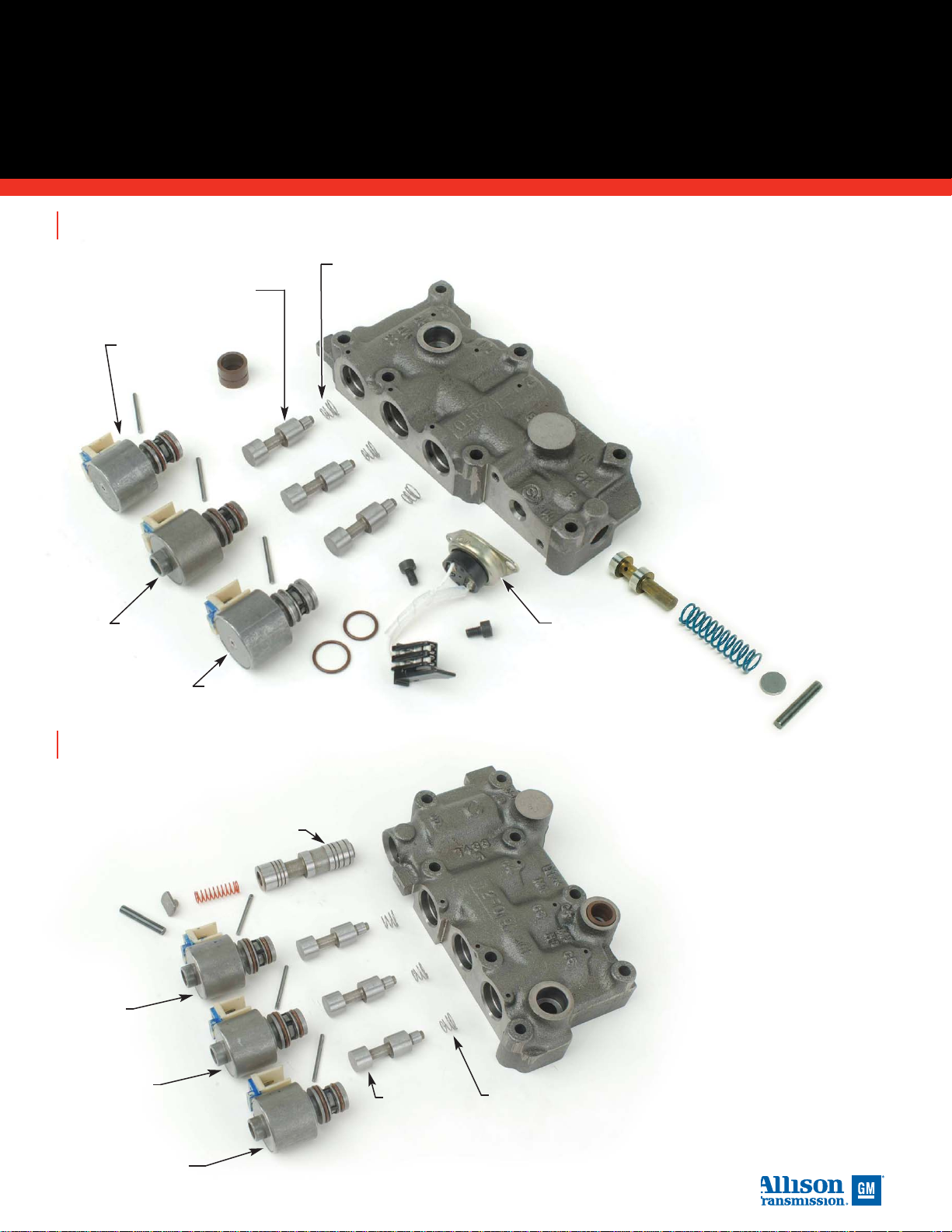

B Solenoid

(C2)

F Solenoid

(Lockup)

A Solenoid

(C1)

Rotating

Clutch V alve

Body

Solenoid

Regulator

Valves

C3

Pressure

Switch

Solenoid

Regulator

Springs

Identification Detail: Rotating Clutch Valve Body Assembly

D Solenoid

(C4)

C Solenoid

(C3)

E Solenoid

(C5)

Solenoid

Regulator

Valves

Solenoid

Regulator

Springs

Stationary

Valve Body

Overdrive Knock

Down V alve

Identification Detail: Stationar y Clutch Valve Body Assembly

20

2005 General Motors Corporation.

ALLISON TRANSMISSION TECHNICIANS’ GUIDE

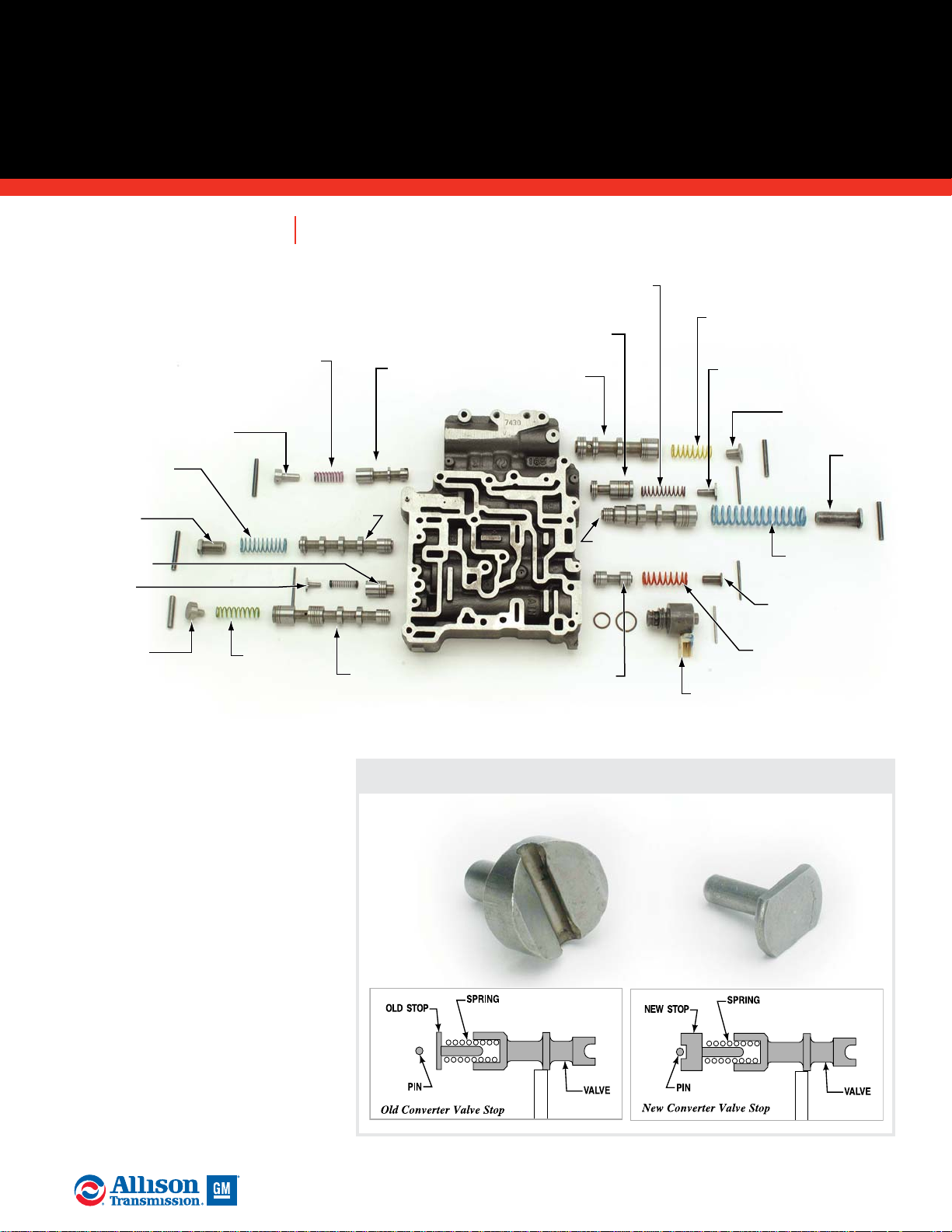

Accumulator

Relay V alve

(continued)

ALLISON 4000/B500 PRODUCT FAMILIES

(continued)

CONTROL MODULE

Converter

Regulator

Valve

Converter

Regulator

Spring

Converter

Regulator

Valve Stop

Main

Regulator

Valve Stop

Control

Main Valve

Control Main

Valve Spring

Control Main

Valve Stop

Main Regulator

Valve Spring

Lube Regulator

Valve

Lube Regulator

Valve Spring

Lube Regulator

Valve Stop

Main Regulator Valve

Lockup

Valve

Lockup

Valve Spring

Lockup

Valve Stop

C1 Latch Valve

C2 Latch

Valve

Main Valve

Body

G Solenoid

C1 Latch

Valve Spring

C2 Latch

Valve

Spring

C1 Latch

Valve Stop

C2 Latch

Valve Stop

Exhaust

Backfill

Valve Stop

Exhaust

Backfill V alve

Supersession Information

Converter Regulator Valve Stop Redesign SIL 12-WT-99

21

2005 General Motors Corporation.

ALLISON TRANSMISSION TECHNICIANS’ GUIDE

Identification Detail: Main Valve Body Assembly

Current

Stop

Former

Stop

(continued)

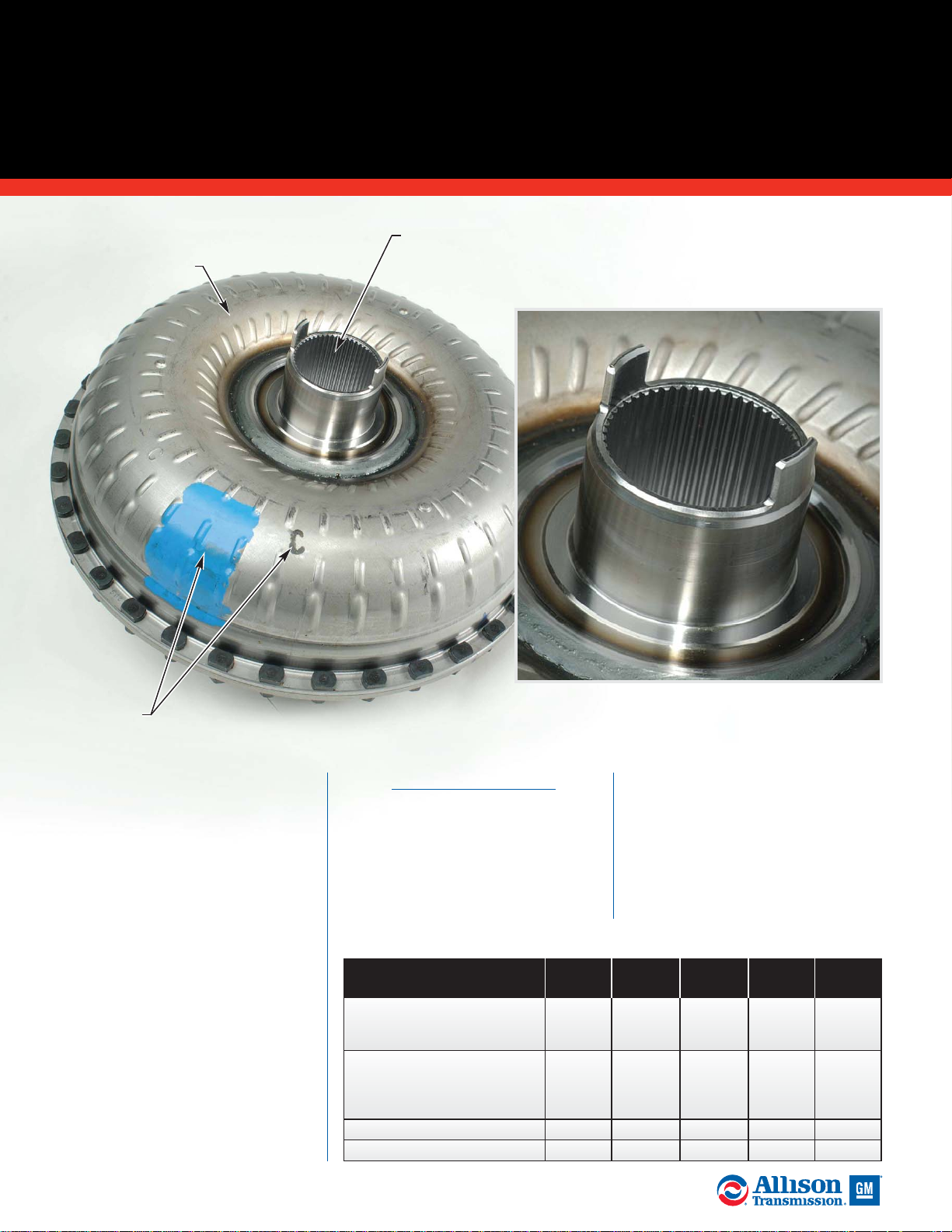

A. Converter

Pump Exterior

A.

Inspect the converter pump

exterior for dents and sealing

surface damage. Replace the

converter pump if damage cannot

be remove with a soft stone or

crocus cloth.

B. Inspect the converter pump

hub for damage and excessive wear.

Minimum pump hub diameter is

88.99 mm (3.504 inch). Inspect the

pump hub tangs for cracks, impact

damage or broken tangs. Maximum

allowable tang step wear is 0.31 mm

(0.012 inch). On PTO-equipped

models, check the splines inside

the hub for wear and damage.

Maximum spline wear is 0.38 mm

(0.015 inch).

NOTE: Do not use crocus cloth on

the converter pump hub. Polishing

the hub with crocus cloth can cause

improper input seal performance

resulting in fluid leakage.

NOTE: Pump hub tang breakage or

deformity accompanied by charging

pump bushing failure and ground

sleeve wear is often caused by poor

transmission fluid condition due to

improper maintenance intervals.

Observation of proper fluid change

intervals is key to optimum

transmission life.

Inspect the pump hub tangs for cracks,

impact damage and broken tangs.

B. Drive Hub

B. Drive

Hub

Model

Identifiers

(see chart)

Torque Converter Model

Designation

Front Cover Sticker and

Converter Paint Dot Color

(Exterior Marker)

Engraved Letter Identifiers

(Torus Ring of Converter

Pump) Ink Stamped Letter

(Exterior of Converter Pump)

Number of Stator Blades

Paint Dot Color on Stator

TC-521

Green

E

19

None

TC-531

Pink

D

19

None

TC-541

Blue

C

19

None

TC-551

Orange

B

19

None

TC-561

Yellow

A

19

None

4000 Product Family Torque Converter Identification Chart

(continued)

ALLISON 4000/B500 PRODUCT FAMILIES

TORQUE CONVERTER MODULE

22

2005 General Motors Corporation.

ALLISON TRANSMISSION TECHNICIANS’ GUIDE

C. Inspect the torque converter

front cover mounting faces for

damage. Inspect the flexplate

adapter bolt holes for stripped or

damaged threads.

D. Inspect the front cover pilot

for damage and wear. Maximum

pilot diameter is 61.77 mm (2.432

inches). Inspect the torque

converter end plug and the

retaining bolt for stripped or

damaged threads. Verify that the

correct turbine shaft selective shim

is installed following the Service

Manual procedures.

E. Inspect the engine starter ring

gear for chipped, worn or broken

teeth.

F. Inspect the flexplate adapter

mounting faces for surface damage.

Replace the adapter if damage

cannot be repaired using a soft

stone or crocus cloth. Inspect the

flexplate adapter bolt holes fro

stripped or damaged threads. Clean

damaged threads using the correct

size tap. Replace the adapter if

damage cannot be repaired.

NOTE: The flexplate adapter bolt

holes use Spiralock® threads. A

Spiralock® tap must be used when

repairing damaged threads. Using a

standard tap will destroy the

locking feature. If this occurs, the

torque converter front cover must

be replaced.

ALLISON 4000/B500 PRODUCT FAMILIES

TORQUE CONVERTER MODULE

(continued)

23

2005 General Motors Corporation.

ALLISON TRANSMISSION TECHNICIANS’ GUIDE

C. Front

Cover

Mounting

Face

Current

Plug

E. Ring

Gear

D. Pilot

F. Flexplate

Adapter

Converter

Retaining Bolt

Turbine Shaft

Selective Shim

Supersession Information

Converter Plug and Front

Cover Update SIL-21-WT-98

Model Identifiers (see

chart previous page)

The current front cover has a

threaded pilot to accept the

current converter plug. Plugs

are not interchangeable

(continued)

A. Inspect the converter pump

interior. Replace the assembly if

the vanes are damaged, cracked or

loose.

B. Replace the converter pump

assembly if the torus ring is loose

or cracked.

C. Inspect the seal surface

between the converter pump

assembly and the front cover.

Light stoning is permitted to

remove slight irregularities.

ALLISON 4000/B500 PRODUCT FAMILIES

TORQUE CONVERTER MODULE

(continued)

24

2005 General Motors Corporation.

ALLISON TRANSMISSION TECHNICIANS’ GUIDE

A. Converter

Pump Interior

Vanes

B. Torus

Ring

Replace the assembly if the vanes are

damaged, cracked or loose.

C. Seal Ring

Area

C. Front Cover-to-

Converter Pump

Sealing Surface

(continued)

A. Converter

Turbine

Blades

B. Torus

Ring

C. Rivets

D. Turbine Hub

E. Splines

Turbine

Assembly

Exterior

Turbine

Assembly

Interior

A. Inspect the converter turbine

assembly. Replace the assembly if

the blades are cracked, broken or

loose.

B. Inspect the torus ring. Replace

the turbine assembly if the torus

ring is loose or cracked.

C. Inspect the rivets. Replace the

turbine assembly if the rivets are

loose or cracked.

D. Inspect the converter turbine

hub. Replace the converter turbine

assembly if the hub is worn beyond

limits. Minimum allowable hub

diameter is 66.69 mm (2.626

inches). Inspect the sealring groove

for damage.

E. Inspect the hub splines for

damage and wear. Spline movment

between the lockup damper and

turbine hub cannot exceed 0.38

mm (0.015 inch). Replace the

turbine assembly if splines are

excessively worn.

F. Inspect the thrust bearing

following the “General Inspection

Guidelines for Bearings” section of

this manual. Replace any thrust

bearing failing these inspection

procedures.

ALLISON 4000/B500 PRODUCT FAMILIES

TORQUE CONVERTER MODULE

(continued)

25

2005 General Motors Corporation.

ALLISON TRANSMISSION TECHNICIANS’ GUIDE

Inspect the hub splines and rivets for damage and wear.

Turbine hub

sealring groove Sealring installed.

F. Thrust

Bearing

(continued)

A. Torque converter lockup

clutch components fit inside the

front cover. Install a new turbine

sealring in the converter cover bore

then measure the sealring inside

diameter. Replace the cover

assembly if diameter exceeds 61.77

mm (2.432 inch).

B. Inspect the converter cover

bushing for damage. Replace the

bushing if damage cannot be

removed with crocus cloth.

Maximum allowable bushing inside

diameter is 66.91 mm (2.634 inch).

C. Inspect the lockup clutch

piston for damage. Minimum

allowable piston thickness is 6.53

mm (0.257 inch).

D. Inspect the lockup clutch

backplate for damage, scoring and

overheating. Minimum allowable

plate thickness is 11.79 mm

(0.464 inch).

NOTE: If the backplate is within

thickness limits but has surface

damage due to metal transfer

between the backplate and lockup

damper, the plate may be reused by

turning it over so that the lockup

damper has a new contact surface.

E. Replace the lockup clutch

damper if the friction surfaces are

worn beyond service limits.

Minimum allowable friction surface

thickness is 8.51 mm (0.335 inch).

Maximum allowable damper

distortion is 0.51 mm (0.020 inch).

Maximum allowable movement

between the damper and converter

turbine splines is 0.38 mm (0.015

inch). Replace the damper if any of

these measurements are beyond

allowable limits.

F. Inspect thrust bearing

following the “General Inspection

Guidelines for Bearings” section of

this manual. Replace any thrust

bearing failing these inspection

procedures.

ALLISON 4000/B500 PRODUCT FAMILIES

TORQUE CONVERTER MODULE

(continued)

26

2005 General Motors Corporation.

ALLISON TRANSMISSION TECHNICIANS’ GUIDE

A. Sealring

Bore

D. Backplate

B. Bushing

E. Lockup

Damper

Front

Cover

Supersession Information

Lockup Clutch Damper Assembly

Update SIL-4-WT-00, Rev. B

Current damper is backward

compatible with all torque

converter assemblies. ECU

recalibration is not necessary.

C. Lockup

Clutch

Piston

F. Thrust

Bearing

(continued)

L. Retaining

Ring

D. Star

Plate

A. Stator

Race

F. Thrust

Bearing

E. Front Stator

Thrust Washer

G. Stator

Thrust Plate

B. Stator

Spring

C. Stator

Roller

A. Inspect the stator race for

damage. Replace the race if damage

cannot be repaired using a soft stone

or crocus cloth.

B. Inspect the stator springs for

correct spring height following per

the Service Manual. Replace any

spring which has a free length below

17.8 mm (0.700 inch).

C. Inspect the stator rollers for

damage. Rollers should be smooth,

round and defect-free. Replace

damage or worn rollers.

D. Inspect the star plate for

excessive wear. Replace the star

plate if damage cannot be repaired

using a soft stone or crocus cloth.

E. Inspect the front stator thrust

washer for wear beyond service

limits. Replace the stator thrust

washer it is worn 0.40 mm (0.010

inch) or more. If it is within service

limits, the thrust washer can be

turned over and the un-worn surface

can be used.

F. Inspect the thrust bearings

following the “General Inspection

Guidelines for Bearings” section of

this manual. Replace any thrust

bearings failing these inspection

procedures.

G. Inspect the stator thrust plate

for damage and wear. Replace the

plate if damage cannot be removed

using a soft stone or crocus cloth.

Minimum allowable plate thickness

is 9.45 mm (0.372 inch).

H. Inspect the stator and cam

assembly for damage. Replace the

stator and cam assembly if damaged.

NOTE: Use care when cleaning the

stator and cam assembly. Hot tank

temperatures may be high enough to

release the cam assembly from the

stator.

I. Inspect the stator roller

pockets for wear and damage. Verify

correct spring-to-roller orientation.

Inspect the bottom of the cam

pocket for wear. Replace the stator

and cam assembly if it is worn 0.40

mm (0.010 inch) or more in the

bottom of the pocket.

J. Inspect tanged thrust bearing

race for damage. Replace any

damaged race.

K. Inspect shim for damage.

Replace any damaged shims. Use

procedure for shim selection in 4000

Series Service Manual.

L. Inspect the retaining ring for

damage and distortion. Replace any

distorted or damaged retaining rings.

ALLISON 4000/B500 PRODUCT FAMILIES

(continued)

TORQUE CONVERTER MODULE

27

2005 General Motors Corporation.

ALLISON TRANSMISSION TECHNICIANS’ GUIDE

H. Stator Cam

and Assembly

K. Shim

J. Tanged Thrust

Bearing Race

I. Roller

Stator

Pockets

A. Inspect for torque converter

housing damage. High spots may be

removed with crocus cloth or a soft

stone. Inspect threaded holes for

debris and thread damage. Replace

the torque converter housing if it is

cracked, if it leaks from a damaged

machined surface, or if it has thread

damage which cannot be repaired.

B. Inspect the breather for

damage and obstructions. Replace

the breather if it is damaged. Clean

the breather if it is blocked with

debris.

C. Replace the input speed sensor

if the sensor body or electrical

terminals are damaged. Speed

sensor resistance is 300 ohms (plus

or minus 30 ohms). Replace the

speed sensor if it does not meet the

service limit.

D. On PTO-equipped models,

inspect the converter housing

bearing bore for wear. Maximum

allowable bearing bore inside

diameter is 180.05 mm (7.088

inches). Replace the housing if

damage cannot be repaired using a

soft stone or crocus cloth.

E. Inspect the PTO bearing

retainer mounting face surface

and threads for damage. Replace

the housing if surface damage

cannot be repaired using a soft

stone or crocus cloth. Replace the

housing if thread damage cannot be

repaired.

ALLISON 4000/B500 PRODUCT FAMILIES

TORQUE CONVERTER HOUSING MODULE

28

2005 General Motors Corporation.

ALLISON TRANSMISSION TECHNICIANS’ GUIDE

D. Bearing

Bore

E. Retainer

Mounting

Surface

C. Speed

Sensor &

Bore

B. Breather

B. Breather

A. Torque

Converter

Housing (PTO)

A. Torque

Converter

Housing

(Non-PTO)

F. PTO Drive

Assembly

Bearing

Retainer

H. Oil

Pump

Drive

Hub

M.PTO Drive

Gear Bearings

I. PTO Gear

Teeth

J. Bearing

Surfaces

L. Splines

F. On PTO-equipped models,

inspect the PTO drive bearing

retainer housing bore for damage.

Replace the retainer if damage

cannot be repaired using a soft

stone or crocus cloth. Replace the

retainer housing if the bushing has

spun in the bushing bore.

G. Inspect the retainer housing

bushing for damage and wear.

Replace the bushing if damaged.

Maximum allowable bushing inside

diameter is 89.19 mm (3.511 inches).

Replace the bushing if it is worn

beyond service limits.

H. Inspect the oil

pump drive hub.

Replace the drive hub

if damage cannot be

repaired using a soft

stone or crocus cloth.

I. Inspect the PTO drive gear

teeth for chips, pitting and

excessive wear. Replace the gear if

damage cannot be repaired using a

soft stone or crocus cloth.

NOTE: Some axial movement of the

gear is normal, but movement

should not exceed 3.175 mm (0.125

inch). Replace the PTO bearings if

axial movement exceeds service

limit.

NOTE: Normal operating backlash

after PTO is installed is 0.1 mm to

0.66 mm (0.004 to 0.026 inch).

ALLISON 4000/B500 PRODUCT FAMILIES

(continued)

TORQUE CONVERTER HOUSING MODULE

29

2005 General Motors Corporation.

ALLISON TRANSMISSION TECHNICIANS’ GUIDE

F. Retainer

Bore

G. Bushing

(continued)

I. PTO

Gear

Teeth

K. Splines

J. Inspect the PTO drive hub

tangs for step wear, deformation

and cracks. Replace the drive hub if

tang step wear exceeds 0.38 mm

(0.015 inch) or if either tang is

deformed or cracked.

NOTE: Drive hub tang breakage or

deformity accompanied by charging

pump bushing failure and ground

sleeve wear is often caused by poor

transmission fluid condition due to

improper maintenance intervals.

Observation of proper fluid change

intervals is key to optimum

transmission life.

K. Inspect the drive hub splines

for wear. Replace the drive hub if

spline wear exceeds 0.38 mm

(0.015 inch).

L. Inspect the PTO drive gear

bearings following the “General

Inspection Guidelines for Bearings”

section of this manual. Replace

either bearing as needed.

ALLISON 4000/B500 PRODUCT FAMILIES

TORQUE CONVERTER HOUSING MODULE

(continued)

Examine the

oil pump

drive tangs

for excessive

battering.

30

2005 General Motors Corporation.

ALLISON TRANSMISSION TECHNICIANS’ GUIDE

A. Output

Speed

Sensor

B. Rear Cover

C. Piston

D. Spring

Pack

E. Retaining

Ring

F. Clutch Plates

A. Inspect the output speed

sensor for damage. Replace any

sensor that has body, terminal or

connector seat damage. Allowable

output speed sensor resistance is

300 ohms plus or minus 30 ohms.

B. Inspect the rear cover

following the “General Inspection

Guidelines for Cast Parts and

Machined Surfaces” section of this

manual. High spots on machined

surfaces can be removed using a

soft stone or crocus cloth. Inspect

the slot on the back side of the

housing where the C5 piston tang

indexes. Replace the rear cover if

damage to any machined surface

cannot be repaired using a soft

stone or crocus cloth. Replace the

rear cover if it is cracked.

C. Inspect the C5 clutch piston

following the “General Inspection

Guidelines for Cast Parts and

Machined Surfaces” section of this

manual. Replace the piston if it fails

to meet the inspection guidelines.

Inspect the C5 piston tang for

excessive wear.

D. Inspect the C5 clutch spring

pack for damage due to rubbing

adjacent parts and cracked or

broken pieces. Check springs for

wear, breakage and damage.

Reference the Spring Data Charts in

the Service Manual SM2457EN

for spring specifications and

identification.

E. Replace the C5 retaining

ring if it is bent or distorted.

ALLISON 4000/B500 PRODUCT FAMILIES

STANDARD REAR COVER &

P3 PLANETARY MODULE

31

2005 General Motors Corporation.

ALLISON TRANSMISSION TECHNICIANS’ GUIDE

(continued)

F. Clutch

Plates

F. Inspect the C5 friction clutch

plates following the “General

Inspection Guidelines for Friction

Plates” section of this manual.

Discard any plates that do not meet

the guidelines. Minimum allowable

thickness for reuse is 3.48 mm

(0.137 inch). Minimum oil groove

depth for reuse is 0.20 mm (0.0008

inch). Maximum cone for reuse is

0.25 mm (0.010 inch).

NOTE: Battered and worn spline

teeth may be an indicator of

driveline issues. Replace the clutch

plates and check the driveline.

Inspect the C5 reaction clutch

plates following the “General

Inspection Guidelines for Reaction

Plates” section of this manual.

Discard any plates that do not meet

the guidelines. Minimum allowable

thickness for reuse is 2.41 mm

(0.095 inch). Maximum cone for

reuse is 0.25 mm (0.010 inch).

NOTE: The current clutch friction

plates were implemented April of

2000 starting with s/n 6610062126.

Current clutch friction plates will

have two or more missing splines.

Former friction plates will either

have one spline missing or none

missing. Any 4000/B 500 model

transmission may be updated from

former C5 friction plates to current

C5 frictions without recalibrating

the transmission ECU. The rest of

the clutches in the main housing

(C1 through C4) must be updated

with current friction plates if any

other individual clutch besides C5

is updated from former to current

friction plates. Any update from

former frictions to current frictions

in C1 through C4 for a 4000 Series

or B500 with a WTEC II ECU will

require a new ECU calibration from

Allison Transmission. Any update

ALLISON 4000/B500 PRODUCT FAMILIES

STANDARD REAR COVER &

P3 PLANETARY MODULE

(continued)

32

2005 General Motors Corporation.

ALLISON TRANSMISSION TECHNICIANS’ GUIDE

Supersession Information

Former C5 Friction

Plate - one or no

missing splines.

Current C5

Friction Plate missing two

splines.

C5 Friction Plate Update SIL 4-WT-00, Rev. B and SIL 12-WT-03

Clutch plate identification is made by

counting the number of missing teeth.

(continued)

ALLISON 4000/B500 PRODUCT FAMILIES

STANDARD REAR COVER &

(continued)

P3 PLANETARY MODULE

33

2005 General Motors Corporation.

ALLISON TRANSMISSION TECHNICIANS’ GUIDE

Supersession Information

Use C5 friction

plate missing

3 internal teeth.

from former frictions to current

frictions in C1 through C4 for a

4000 Series or B500 with a WTEC

III ECU with a calibration prior to

October 25, 1999 will require an

updated ECU calibration from

Allison Transmission. Do not

intermix both former and current

friction plates in a clutch pack.

The P3 ring gear changed to a

harder ring gear on s/n 6610027070.

The current P3 ring gear identifier

is a groove machined around the

outer diameter of the gear. The P3

ring gear with a groove identifier

requires the C5 friction with two

missing splines if updating from

former C5 frictions. If any

4000/B500 series model without

the harder ring gear (no groove on

O.D.) is being updated with current

C5 frictions, then it will require the

C5 friction that has three missing

internal splines. The C5 friction

plate missing three splines will

exhibit spline wear if used with the

current P3 ring gear with a groove

identifier on the O.D. The former P3

ring gear (no groove on O.D.) will

exhibit premature wear if used with

the current C5 friction with two

missing internal splines. No ECU

calibration is necessary for

updating C5 clutch plates.

C5 Pressure

Oil Passage

Detail

(continued)

FORMER (NON-HARDENED)

P3 RING GEAR

HARDENED

P3 RING GEAR

IDENTIFICATION

GROOVE

Use C5 friction

plate missing

2 internal teeth.

P3 Ring Gear Update SIL 12-WT-03

ALLISON 4000/B500 PRODUCT FAMILIES

STANDARD REAR COVER &

P3 PLANETARY MODULE

(continued)

34

2005 General Motors Corporation.

ALLISON TRANSMISSION TECHNICIANS’ GUIDE

A. P3 Carrier

Assembly

(Non-Retarder)

B. Tapered

Roller

Bearing

D. P3 Planetary

Spindle

E. Thrust

Washer

G. Pinion

Roller

Bearing

I. Output Shaft

External

Retaining Ring

H. Output

Shaft

Spacer

J. Output Shaft

A.

Verify a proper press fit

between the P3 carrier and rear

cover or retarder housing by

inverting the carrier over a table or

workbench. If the P3 carrier falls

out of the rear cover or retarder

housing without using a press or

mallet, the press fit between the

tapered bearings and P3 carrier no

longer exists and the carrier must

be replaced.

Inspect the P3 carrier for spline

wear. Replace the carrier if spline

wear exceeds 0.38 mm (0.015 inch).

Inspect the pinion spindle bores in

the carrier and the pinion thrust

surfaces for excessive wear and

damage. Replace the P3 carrier if a

spindle has more than 0.051 mm

(0.002 inch) clearance in the bore.

Inspect for thread damage on the

carrier hub. Replace the carrier if

threads are damaged.

B. Inspect the tapered roller

bearings and races following the

“General Inspection Guidelines for

Bearings” section of this manual.

Replace any bearings failing to meet

the inspection guidelines. Bearing

races are located in the rear cover

housing and should also be

inspected for wear and damage.

C. Inspect the P3 indexing ring

for step wear in the area where it

contacts the spindle. Replace the

indexing ring if it is broken or if it

has excess step wear or damage

which cannot be repaired using a

soft stone or crocus cloth. Indexing

rings with acceptable wear can be

flipped during reassembly so that a

new contact surface is used.

Bearing races

located in rear

cover.

F. Pinion

Gear

C. Indexing

Ring

(continued)

D. Inspect planetary spindles for

wear and damage. Discoloration is

only a concern if spindle surface

damage exists.

E. Inspect the pinion gear thrust

washers for damage, distortion and

signs of excessive wear. Minimum

allowable thrust washer thickness

is 1.39 mm (0.054 inch). Replace

damaged or worn thrust washers.

F. Inspect the pinion gears

following the “General Inspection

Guidelines for Gears” section of this

manual. Replace any gears which

fail these inspection procedures or

if the damage cannot be repaired

using a soft stone.

G. Inspect the pinion roller

bearings following the “General

Inspection Guidelines for Bearings”

section of this manual. Replace any

bearings which fail these inspection

procedures.

H. Replace the output shaft

spacer if it is bent, cracked or if it

is distorted in any way. An attempt

can be made to repair some minor

damage using a soft stone.

I. Inspect the output shaft

external retaining ring. Replace

the retaining ring if it is distorted

or fits loosely on the shaft.

ALLISON 4000/B500 PRODUCT FAMILIES

STANDARD REAR COVER &

(continued)

P3 PLANETARY MODULE

35

2005 General Motors Corporation.

ALLISON TRANSMISSION TECHNICIANS’ GUIDE

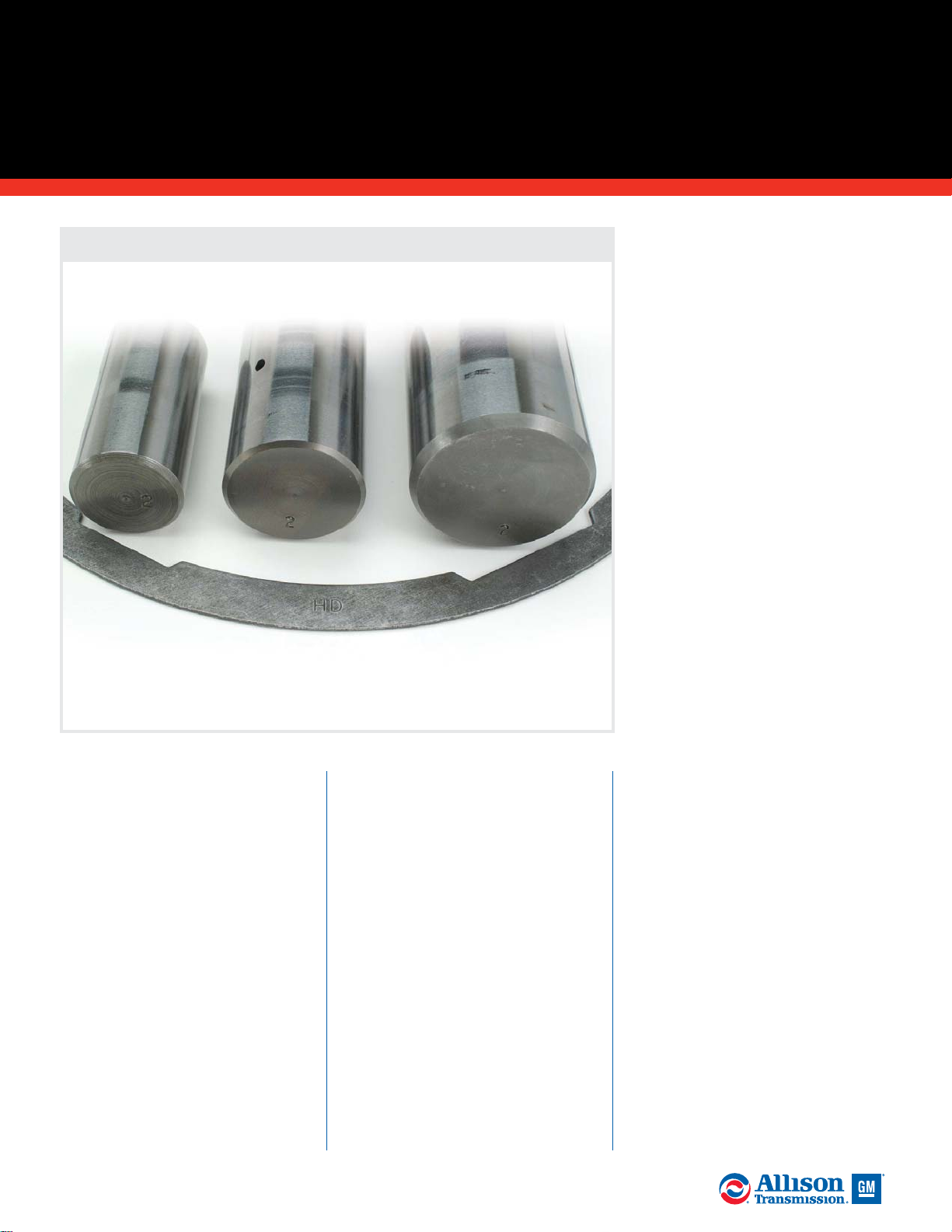

Supersession Information

P3 Carrier Update SIL 25-WT-01

Current P3 carriers use a drill point

hole and a Belleville spring washer.

Supersession Information

Planetary Spindle and

Indexing Ring Updates SIL 10-WT-00

Planetary spindles and indexing rings are

backward compatible. Current spindles are

stamped with the number “2.” Indexing rings

are stamped with the identifier “HD5.”

P1 P2

P3

(continued)

36

2005 General Motors Corporation.

ALLISON TRANSMISSION TECHNICIANS’ GUIDE

J. Inspect the output shaft

following the “General Inspection

Guidelines for Cast Parts and

Machined Surfaces” and the

“General Inspection Guidelines for

Splines” sections of this manual.

Replace the output shaft if it fails

these inspection procedures.

Inspect the output shaft bushing

following the “General Inspection

Guidelines for Bushings” section of

this manual. Replace the bushing if

it fails these inspection procedures.

Maximum allowable bushing inside

diameter is 36.14 mm (1.423 inch).

ALLISON 4000/B500 PRODUCT FAMILIES

STANDARD REAR COVER &

P3 PLANETARY MODULE

(continued)

Supersession Information

Flange /Yoke Retaining Bolt Update - Reference SIL 1-WT-99

Single Bolt

design

increases

clamp load.

Output spacers

are not

interchangeable

between the

former and

current designs.

Supersession Information

Service Kit for Two-Bolt Ouput - SIL 15-WT-98

Kit Part Number: 29535910

J. Output Shaft

J. Inspect the output shaft

bushing for damage.

* Note: Kit contains

Belleville washers and

2 allen-head bolts to

replace original locking

tab and hex-head bolts.

(continued)

ALLISON 4000/B500 PRODUCT FAMILIES

STANDARD REAR COVER &

(continued)

P3 PLANETARY MODULE

37

2005 General Motors Corporation.

ALLISON TRANSMISSION TECHNICIANS’ GUIDE

K. Replace the output bearing

locknut retainer whenever the

locknut is removed.

L. Inspect the Belleville spring

washer for damage. Replace the

washer if it is distorted or the

tang is worn.

M. Replace the output bearing

locknut if it is cracked, distorted,

has damaged threads. The current

locknuts have three buttons in the

threaded area. This nut should be

replaced if it does not have a

minimum of 10 N.m (7.5 ft. lb.) of

running torque when threading

the nut.

(continued)

K. Locknut

Retainer

4000 Series

Wide Ratio

P3 Carrier

Assembly

4000 Series

Close Ratio

P3 Carrier

Assembly

Former output bearing

locknut and retainer

M.Output

Bearing

Locknut

L. Belleville

Spring

38

2005 General Motors Corporation.

ALLISON TRANSMISSION TECHNICIANS’ GUIDE

Supersession Information

ALLISON 4000/B500 PRODUCT FAMILIES

STANDARD REAR COVER &

P3 PLANETARY MODULE

(continued)

Supersession Information

Bearing Retainer Locknut

Update - Reference

SIL 25-WT-01

Current

bearing

retainer

locknuts

include

three

locking

buttons.

Supersession Information

Output Yoke/Flange Update Reference SIL 4-WT-03

Not all yoke / slinger combinations

can be used with all transmissions. Rear cover design determines yoke / slinger combination.

Supersession Information

Rear Cover Update - Reference SIL 4-WT-03

Current rear cover has interior cut relief to accommodate

5-ridge output seal. Former rear cover has interior cut relief to

accommodate 4-ridge output seal

(reference Output Seal Update

Supersession Information)

.

Former: No cut relief Current: Cut relief on

the exterior for a wrap

around slinger.

Former

Output Seal

Current Output Seal

(former

standard/ retarder housing)

for S/N prior to 6610116108

Current Output Seal

(current

standard/ retarder housing)

for

S/N starting with 6610116108

Output Seal Update Reference SIL 4-WT-03

Two seals are

currently available to fit former and

current rear covers.

They are NOT

interchangeable.

ALLISON 4000/B500 PRODUCT FAMILIES

RETARDER MODULE

39

2005 General Motors Corporation.

ALLISON TRANSMISSION TECHNICIANS’ GUIDE

A. Inspect the retarder housing

following the “General Inspection

Guidelines for Cast Parts and

Machined Surfaces” section of this

manual. High spots on machined

surfaces can be removed using a

soft stone or crocus cloth. Replace

the retarder housing if it is cracked

or if machined surface damage

cannot be removed using a soft

stone or crocus cloth.

Install a “known good” rotor

sealring in the retarder housing and

measure sealring inside diameter. If

the retarder housing is slightly

grooved or worn, place the sealring

directly in the grooved or worn

area. Replace the housing if sealring

inside diameter is greater than

139.72 mm (5.501 inches). A bearing

race fits into the housing and

should be inspected for damage.

B. Inspect the stator housing

following the “General Inspection

Guidelines for Cast Parts and

Machined Surfaces” section of this

manual. Some light housing

imperfections can be removed using

a soft stone. Discard and replace the

housing if damage is excessive.

NOTE: Transmissions built prior to

January 1998 included two small

check balls and retainers located in

the retarder stator housing.

Minimum allowable check ball

movement is 0.50 mm (0.020 inch).

Inspect the slot on the back side

of the housing where the C5 piston

tang indexes for excessive wear.

Replace the stator housing if

damage to any machined surface

cannot be repaired using a soft

stone or crocus cloth. Replace the

stator housing if it is cracked.

C. Inspect the retarder rotor

following the “General Inspection

Guidelines for Cast Parts and

Machined Surfaces” section of this

manual. Check for loose, cracked or

broken rivets. Replace the rotor if

movement exists between the

center hub and the vaned assembly.

Inspect the rotor splines for wear.

B. Retarder Stator

Housing

E. Autoflow V alve,

Spring & Plug

C. Retarder

Rotor

F. Retarder Temp

Sensor Assembly

A. Retarder

Housing

G. Output Speed

Sensor

(continued)

D. P3 Carrier

Assembly

(Retarder)

Supersession Information

Retarder Exhaust Backfill Valve Update Reference SIL 14-WT-02

The current stop is backward

compatible with all 4000/B500 retarder equipped transmissions.

Current

Retarder

Exhaust

Backfill

Valve Stop

Former

Retarder

Exhaust

Backfill

Valve Stop

40

2005 General Motors Corporation.

ALLISON TRANSMISSION TECHNICIANS’ GUIDE

Fluid Flow

Detail

ALLISON 4000/B500 PRODUCT FAMILIES

RETARDER MODULE

(continued)

Spline wear cannot exceed 0.38 mm

(0.015 inch). Replace the rotor if it

exceeds this wear limit.

D. Reference the “Inspection and

Analysis of the Standard Rear

Cover” section of this manual for P3

planetary carrier assembly details.

NOTE: Inspect retarder P3 carriers

for excessive step wear on the

splines of the P3 carrier hub.

Replace those P3 carriers that

exhibit step wear.

E. Inspect the retarder autoflow

valve for wear and damage. The

autoflow valve must move freely in

its bore, when dry, under its own

weight. Replace or repair the

autoflow valve and/or retarder

housing as necessary. Crocus cloth

can be used to remove slight high

spots.

Inspect the autoflow valve spring

for defects and permanent set.

Reference the Spring Data Charts in

Service Manual SM2457 for spring

specifications and identification.

Replace the spring if it fails any

inspection procedures.

F. Inspect the retarder

temperature sensor exterior for

defects. Replace the temperature

sensor if it is damaged. There are

two temperature sensor types - TID

1 and post-TID 1 (TID 2 and TID 3).

Resistance specifications vary

between the two sensor types. Be

sure to use the correct

Troubleshooting Manual chart for

the sensor being tested. Replace the

temperature sensor if its measured

resistance is not within

Troubleshooting Manual

specifications.

G. Inspect the output speed

sensor for damage. Replace the

sensor if it has body, terminal or

connector seat damage. Allowable

output speed sensor resistance is

300 ohms plus or minus 30 ohms.

Supersession Information

Retarder Sump Cooling Feature - Reference

SIL 25-WT-00, Rev. A

The sump cooling feature provides additional cooling

when the retarder is active through either an additional

auxiliary cooler or the direct mount cooler for retarder

transmissions.The direct mount cooler for retarder transmissions

works as both the main cooler and auxiliary cooler.

(continued)

Main

Control

Main

From

Cooler

To Cooler

C5 Pressure

Exhaust

Retarder

Out

Accumulator

Converter Out

(To Cooler)

Lube

Pressure

From

Cooler

To Retarder

Control Main

Main

No Sump

Cooling

Feature

Sump

Cooling

Provision

ALLISON 4000/B500 PRODUCT FAMILIES

(continued)

RETARDER MODULE

41

2005 General Motors Corporation.

ALLISON TRANSMISSION TECHNICIANS’ GUIDE

A. Inspect the retarder control

valve body following the “General

Inspection Guidelines for Cast

Parts and Machined Surfaces”

section of this manual. All passages

must be clean and debris free. Valve

bores must be free of nicks, burrs

and scoring. Crocus cloth or a soft

stone can be used to attempt

removal of slight irregularities,

however no honing of any kind is

permitted.

B & H. Inspect the retarder

control valve and exhaust backfill

valve for nicks, burrs, scoring and

other damage. A soft stone or

crocus cloth can be used to attempt

removal of slight irregularities.

Valves must move freely in their

bores, when dry, under their own

weight.

C & I. Replace the retarder

control valve spring or exhaust

backfill spring for damage or

permanent set. Reference the

Spring Data Charts in the Service

Manual for spring specifications

and identification.

D. Inspect the valve plug for

damage. Replace the plug if damage

cannot be repaired using a soft

stone or crocus cloth.

E. Inspect the channel plate

following the “General Inspection

Guidelines for Cast Parts and

Machined Surfaces” section of this

manual. Replace the channel plate if

it fails any of these inspection

procedures or if it has damage

which cannot be repaired using a

soft stone or crocus cloth.

All passages must be clean and

debris free.

K. Wiring

Harness

A. Retarder

Valve

Body

G. Retarder

Solenoid

H. Exhaust

Backfill

Valve

I. Exhaust

Backfill

Valve

Spring

L. Solenoid

Cover

E. Channel

Plate

C. Retarder Control

Valve Spring

F. Separator

Plate

J. Exhaust

Backfill V alve

Stop & Pin

D. Valve

Plug &

Retaining

Ring

B. Retarder

Control

Valve

(continued)

42

2005 General Motors Corporation.

ALLISON TRANSMISSION TECHNICIANS’ GUIDE

ALLISON 4000/B500 PRODUCT FAMILIES

RETARDER MODULE

(continued)

F. Inspect the separator plate for

nicks, burrs, scoring and distortion

(flatness). Replace the plate if

damage cannot be repaired using a

soft stone or crocus cloth.

G. Replace the retarder solenoid

if the body, connector or terminals

show visible signs of damage.

Solenoid resistance should be 3 to 4

ohms measured between the two

solenoid terminals. Check

resistance between each solenoid

terminal and the solenoid body.

Replace the solenoid if either

reading is less than 100k ohms

resistance.

J. Inspect the exhaust backfill

valve stop for damage. Replace the

stop if damage cannot be repaired

using a soft stone or crocus cloth.

Inspect the exhaust backfill valve

pin for damage. Replace the pin if it

is bent or has damage.

K. Replace or repair the wiring

harness if the wires, terminals or

connectors are visibly damaged.

Check the installed harness for

tight bends or crimps which might

damage harness wires.

L. Inspect the solenoid cover

following the “General Inspection

Guidelines for Cast Parts and

Machined Surfaces” section of this

manual. Replace the housing if it

fails any of these inspection

procedures.

Exhaust

Pressure

Retarder

Pressure

Pocket

Main

Pressure

Control

Main

Retarder

Pressure

Exhaust

Pressure

Pocket

Retarder

Pressure

Main

Pressure

Exhaust

Pressure

Exhaust

Backfill

Pressure

Exhaust

Pressure

Retarder

Pressure

Main

Pressure

(to Flow

Valve)

Main Pressure

(Feed)

Control Main

Pressure

ALLISON 4000/B500 PRODUCT FAMILIES

CLOSE RATIO MAIN SHAFT MODULE

43

2005 General Motors Corporation.

ALLISON TRANSMISSION TECHNICIANS’ GUIDE

A. Main Shaft

H. P3

Sun

Gear

D. Thrust

Bearing

F. Bearing

Spacer

G. Selective

Shim

E. P2 Sun

Gear

I. Spiral

Retaining

Ring

B. Main

Shaft

Pilots

C. Journal

B. Main

Shaft

Pilots

A. Inspect the main shaft

following the “General Inspection

Guidelines for Gears” and “General

Inspection Guidelines for Splines”

sections of this manual. Replace the

main shaft if it fails any of these

inspection procedures.

B. Inspect the front and rear

main shaft pilots for damage. The

front main shaft pilot fits inside the

turbine shaft. The rear main shaft

pilot fits inside the output shaft.

Replace the main shaft if pilot

outside diameter is less than 35.92

mm (1.414 inch).

C. Inspect the P2 bushing journal

area for damage. Replace the main

shaft if P2 planetary bushing

journal diameter is less than 52.98

mm (2.085 inch).

D. Inspect the thrust bearings

following the “General Inspection

Guidelines for Bearings” section of

this manual. Replace any bearing

that fails any of these inspection

procedures.

E. Inspect the P2 sun gear

following the “General Inspection

Guidelines for Gears” and “General

Inspection Guidelines for Splines”

sections of this manual. Replace the

gear if it fails any of these inspection

procedures.

F. Inspect the main shaft bearing

spacer following the “General

Inspection Guidelines for Cast Parts

and Machined Surfaces” and

“General Inspection Guidelines for

Splines” sections of this manual.

Replace the spacer if it fails any of

these inspection procedures.

G. Inspect the selective shim for

damage. Replace the shim if it is

distorted or if damage cannot be

removed by light stoning.

H. Inspect the P3 sun gear

following the “General Inspection

Guidelines for Gears” and “General

Inspection Guidelines for Splines”

sections of this manual. Replace the

gear if it fails any of these

inspection procedures.

I. Replace the spiral retaining

ring if it is removed.

Close Ratio Main

Shaft Module

44

2005 General Motors Corporation.

ALLISON TRANSMISSION TECHNICIANS’ GUIDE

ALLISON 4000/B500 PRODUCT FAMILIES

WIDE RATIO MAIN SHAFT MODULE

A. Main

Shaft

D. P2 Sun

Gear

E. Thrust

Bearing

F. Bearing

Spacer

G. Selective

Shim

H. Spiral

Retaining

Ring

B. Main Shaft

Pilots

C. Journal

B. Main Shaft Pilots

A. Inspect the main shaft

following the “General Inspection

Guidelines for Gears” and “General

Inspection Guidelines for Splines”

sections of this manual. Replace the