Mechanic’s Tips

MT(B) 600

Series Transmissions

MT1357EN

Mechanic’s

Tips

Allison Transmission

MT 640, MT 643, MTB 643(R),

MT 644, MT 647, MTB 647,

MT 650, MT 653DR, MTB 653DR,

MT 654CR, MTB 654CR

MT1357EN

Division of General Motors Corporation

P.O. Box 894 Indianapolis, Indiana 46206-0894

Printed in U.S.A. Copyright © 1997 General Motors Corp.

July, 1997

Revised 199906

WARNINGS, CAUTIONS, AND NOTES

IT IS YOUR RESPONSIBILITY to be completely familiar with the warnings

and cautions described in this handbook. It is, however, important to understand that

these warnings and cautions are not exhaustive. Allison Transmission could not

possibly know, evaluate, and advise the service trade of all conceivable ways in

which service might be done or of the possible hazardous consequences of each

way. Consequently, Allison Transmission has not undertaken any such broad

evaluation. Accordingly, ANYONE WHO USES A SERVICE PROCEDURE OR

TOOL WHICH IS NOT RECOMMENDED BY ALLISON TRANSMISSION

MUST first be thoroughly satisfied that neither personal safety nor equipment safety

will be jeopardized by the service methods selected.

Proper service and repair is important to the safe, reliable operation of the

equipment. The service procedures recommended by Allison Transmission and

described in this handbook are effective methods for performing service operations.

Some of these service operations require the use of tools specially designed for

the purpose. The special tools should be used when and as recommended.

Three types of headings are used in this manual to attract your attention. These

warnings and cautions advise of specific methods or actions that can result in

personal injury, damage to the equipment, or cause the equipment to become unsafe.

WARNING:

etc., if not correctly followed, could result in personal injury or loss of life.

CAUTION:

etc., if not strictly observed, could result in damage to or destruction of

equipment.

NOTE:

essential to highlight.

A warning is used when an operating procedure, practice,

A caution is used when an operating procedure, practice,

A note is used when an operating procedure, practice, etc., is

ii

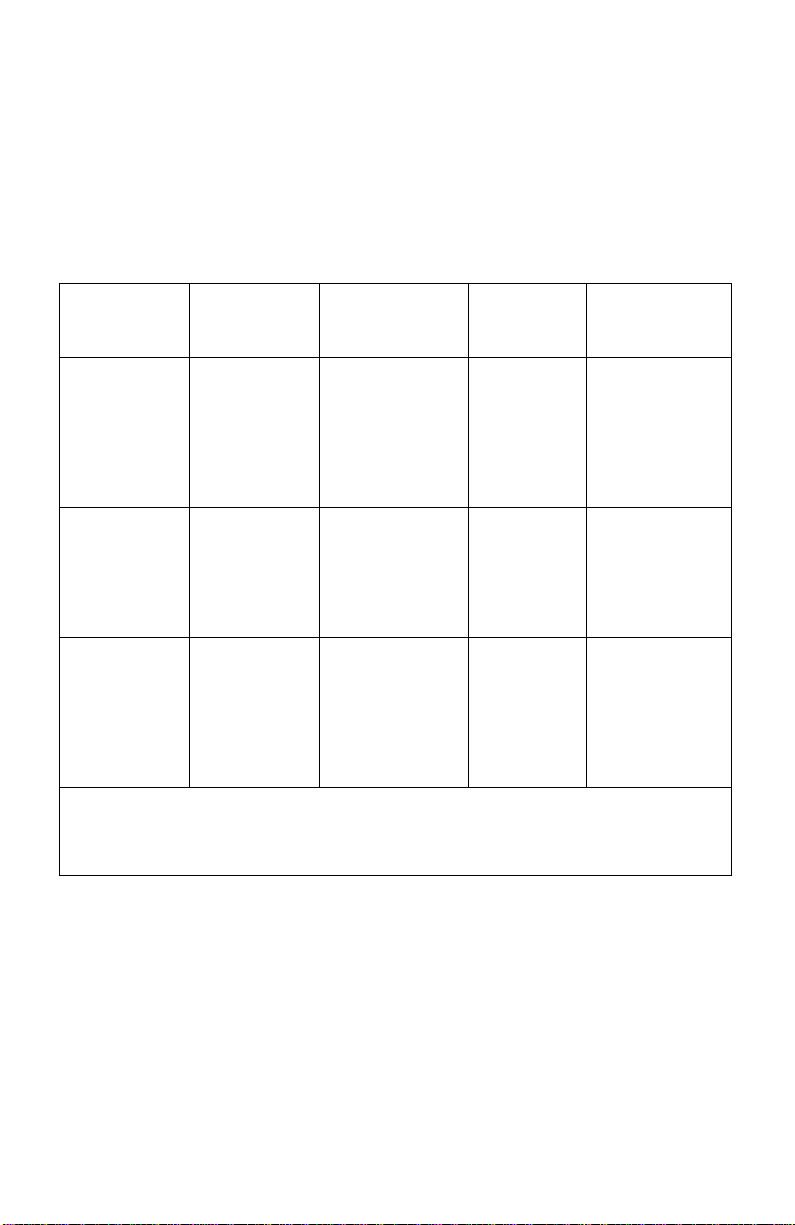

TABLE OF CONTENTS

Paragraph Description Page

Section I PREVENTIVE MAINTENANCE

1–1 Periodic Inspection and Care . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

1–2 Importance of Proper Fluid Level . . . . . . . . . . . . . . . . . . . . . . . 1

1–3 Dipstick Markings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

1–4 Fluid Check Procedure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

1–5 Keeping Fluid Clean . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1–6 Recommended Automatic Transmission Fluid

and Viscosity Grade. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1–7 Fluid and Filter Change Intervals. . . . . . . . . . . . . . . . . . . . . . . . 6

1–8 Fluid and Filter Change Procedure . . . . . . . . . . . . . . . . . . . . . . 8

1–9 Fluid Contamination . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

1–10 Auxiliary Filter. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

1–11 Breather . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

1–12 Transmission Stall Test and Neutral

Cool–Down Check. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Section II REMOVING TRANSMISSION

2–1 Draining Transmission. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

2–2 Disconnecting Controls . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

2–3 Uncoupling From Engine And Driveline. . . . . . . . . . . . . . . . . 16

2–4 Removing Mounting Bolts. . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

2–5 Removing Transmission . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

2–6 Repair Instructions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Section III PREPARING TRANSMISSION FOR INSTALLATION

3–1 Checking Input Components . . . . . . . . . . . . . . . . . . . . . . . . . . 20

3–2 Checking Torque Converter Position. . . . . . . . . . . . . . . . . . . . 20

3–3 Installing Parking Brake and Output Flange . . . . . . . . . . . . . . 21

3–4 Installing Shift Selector Lever . . . . . . . . . . . . . . . . . . . . . . . . . 22

3–5 Installing Power Takeoff (PTO). . . . . . . . . . . . . . . . . . . . . . . . 23

3–6 Installing Shift Modulation Control. . . . . . . . . . . . . . . . . . . . . 25

3–7 Installing Fill Tube and Drain Plug . . . . . . . . . . . . . . . . . . . . . 25

3–8 Installing Neutral Start and Reverse Signal Switches . . . . . . . 26

3–9 Checking Breather . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

iii

Paragraph Description Page

Section IV PREPARING VEHICLE FOR TRANSMISSION

INSTALLATION

4–1 Checking Flexplate, Engine Features. . . . . . . . . . . . . . . . . . . . 28

4–2 Checking Chassis, Driveline . . . . . . . . . . . . . . . . . . . . . . . . . . 32

4–3 Checking Cooler, Tubes, Hoses, Fittings. . . . . . . . . . . . . . . . . 33

4–4 Checking Controls . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

4–5 Mounting Adapter or Spacer . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Section V INSTALLING TRANSMISSION INTO VEHICLE

5–1 Handling. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

5–2 Coupling to Engine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

5–3 Mounting Output Retarder. . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

5–4 Installing Transmission Mounting Components . . . . . . . . . . . 36

5–5 Coupling to Driveline. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

5–6 Connecting Cooler, Vacuum Lines, Air Lines. . . . . . . . . . . . . 36

5–7 Connecting Shift Selector Control. . . . . . . . . . . . . . . . . . . . . . 37

5–8 Installing Vacuum or Air Modulator Control . . . . . . . . . . . . . 38

5–9 Installing, Adjusting Mechanical Modulator Control . . . . . . . 39

5–10 Connecting Power Takeoff Controls . . . . . . . . . . . . . . . . . . . . 40

5–11 Connecting Parking Brake Control . . . . . . . . . . . . . . . . . . . . . 40

5–12 Connecting Speedometer Drive . . . . . . . . . . . . . . . . . . . . . . . . 40

5–13 Filling the Transmission. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Section VI CHECKS AND ADJUSTMENT

6–1 Installation Checklist . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

6–2 Road Test and Vehicle Operation Checklist . . . . . . . . . . . . . . 44

Section VII CUSTOMER SERVICE

7–1 Owner Assistance. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

7–2 Service Literature. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

iv

PREFACE

This handbook is a ready reference for the mechanic removing, installing, or maintaining MT(B) 600 Series Automatic Transmissions. All features of both the vehicle

and transmission that become involved in the installation procedures are discussed.

The information presented will help the mechanic to remove, install, and maintain the

transmission in a manner that assures satisfactory operation and long service life.

TRADEMARKS USED

DEXRON-III

®

Loctite

Teflon

is a registered trademark of the Loctite Corporation

®

is a registered trademark of the DuPont Corporation

®

is a registered trademark of General Motors Corporation

v

vi

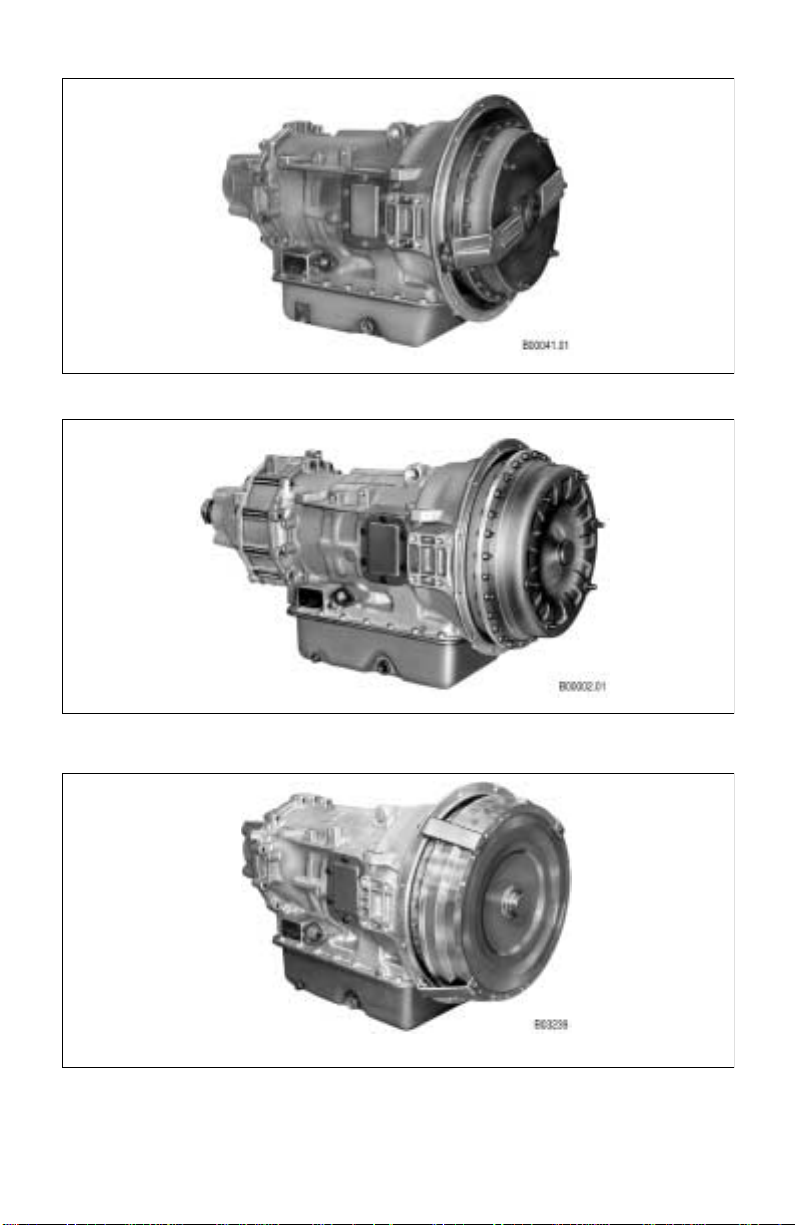

Model MT 643 Transmission — Right-Front View

Model MT 653 Transmission — Right-Front View

Model MTB 644/647 Transmission — Right-Front View

PREVENTIVE

MAINTENANCE

S

I

ECTION

1–1. PERIODIC INSPECTION AND CARE

Clean and inspect the exterior of the transmission at regular intervals. The severity

of service and operating conditions will determine the frequency of such

inspections. Inspect the transmission for the following items:

•

Loose bolts (transmission and mounting components)

•

Fluid leaks (correct immediately)

•

Shift linkage freely positioned by transmission detent

•

Full (and ease of) movement of mechanical modulator linkage

•

Leaks in the vacuum or air line and modulator

•

Damaged or loose fluid lines

•

Worn or frayed electrical connections

•

Worn, out-of-phase driveline U-joints and slip fittings

•

Loose or missing speedometer cable and fittings

•

Damaged PTO linkage and driveline

Check transmission fluid regularly . Once consistent daily hot le vel checks ha ve been

established, and daily inspection shows no sign of transmission leakage, less

frequent checks can be made.

1–2. IMPORTANCE OF PROPER FLUID LEVEL

Because the transmission fluid cools, lubricates, and transmits hydraulic

power, it is important that the proper fluid level be maintained at all

times. If the fluid level is too low, the input pump will draw air into the

system and the converter and clutches will not receive an adequate

supply of fluid. If the level is too high, clutch rotation will aerate the

fluid, the transmission will overheat, and fluid may be expelled through

the breather or dipstick tube. Check the transmission fluid for changes in

viscosity or color. Thin, milky fluid indicates aeration is occurring due

to improper fluid, incorrect fluid level, or a defectiv e or missing sealring

on the intake pipe of the internal filter.

1

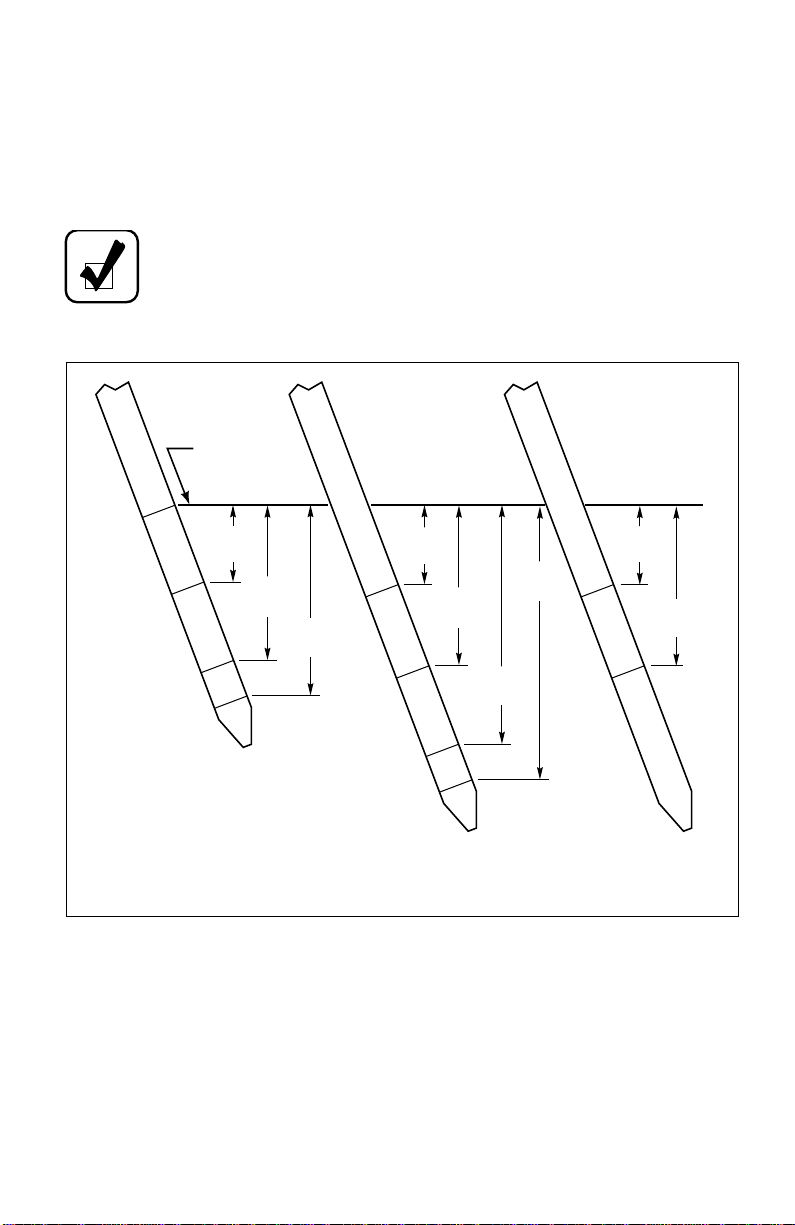

1–3. DIPSTICK MARKINGS

Earlier models use a dipstick marked FULL and ADD. Later models use a dipstick

marked REF FILL (COLD RUN) and HOT RUN. Figure 1–1 shows typical dipstick

markings for MT 600 Series transmissions. Figure 1–2 illustrates the marks in

relation to the transmission.

NOTE:

The ADD and FULL dimensions on earlier dipsticks coincide

with the HOT RUN band dimension on later dipsticks. If desired, the

dipstick on earlier models can be recalibrated to show HOT RUN and

REF FILL (COLD RUN).

CHECK IN NEUTRAL

AT IDLE

TRANSMISSION

OIL PAN

SPLITLINE

HOT RUN

(19.0 mm)

0.75"

REF

FILL

4.34 in.

OIL PAN

1.50"

(38.0 mm)

(45.7 mm)

CHECK IN NEUTRAL AT IDLE

0.75"

(19.0 mm)

HOT RUN

1.80"

1.50"

(38.0 mm)

REF

FILL

CHECK IN NEUTRAL AT IDLE

2.55"

(64.8 mm)

2.22"

(57.1 mm)

HOT RUN

0.75"

(19.0 mm)

1.50"

(38.0 mm)

5.10 in.

OIL PAN

Figure 1–1. Typical Dipstick Markings

2

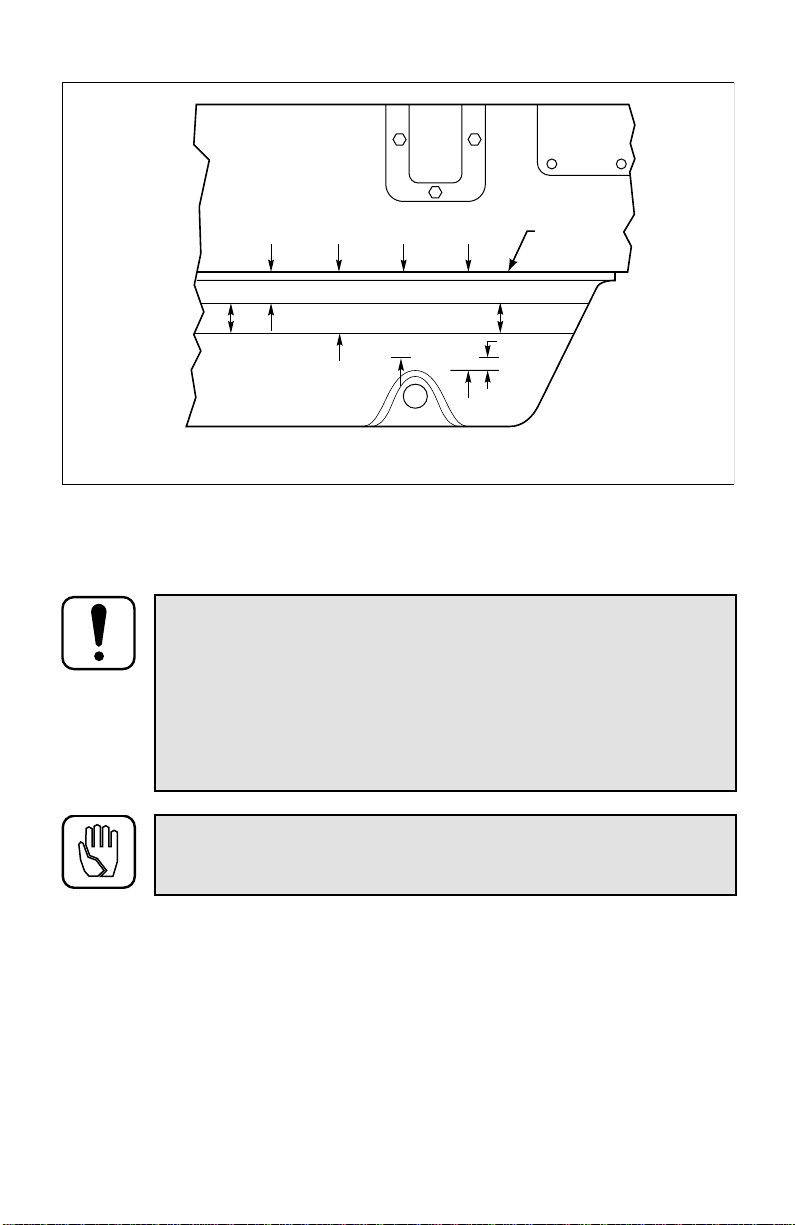

7 in.

OIL PAN

V03240

0.75"

(19 mm)

FULL

ADD

1.50"

(38 mm)

MT 643 / 653

Figure 1–2. How Fluid Levels Are Established

1–4. FLUID CHECK PROCEDURE

WARNING: To help avoid injury and property damage caused by

sudden and unexpected vehicle movement, do not perform

maintenance or service procedures until you:

• Put the transmission in N (Neutral).

• Set the parking brake and service brakes, and make sure they are

properly engaged.

• Chock the wheels and take any other steps necessary to keep the

vehicle from moving.

2.22"

(57 mm)

2.55"

(65 mm)

TOP OF

OIL PAN

HOT RUN

REF FILL

V03241

CAUTION: Dirt or foreign matter must not be permitted to enter the

fluid system. It can cause valves to stick, cause undue wear of

transmission parts, or clog passages.

Always check the fluid level a minimum of two times. Consistency is important in

maintaining accuracy. If inconsistent readings persist, check the transmission

breather and the vent hole in the dipstick fill tube to ensure they are clean and free of

debris. The vent hole is located on the underside of the fill tube just below the seal

of the dipstick cap.

3

•

•

•

•

•

•

Check the fluid level by the following procedures and record any abnormal fluid

level, milky appearance, or any trace of coolant in the fluid on your maintenance

records.

a.

Cold Check

NOTE: The only purpose of the Cold Check is to determine if the

transmission has enough fluid to be safely operated until a Hot Check

can be made.

Park the vehicle on a level surface, set the parking brake and/or emergency

brakes, and chock the vehicle wheels.

Run the engine at 1000–1500 rpm for one minute to purge air from the

system. Return engine to idle, then shift to D (Drive) and then to R (Reverse)

to fill the hydraulic circuits with fluid. Then, shift to N (Neutral) and allow the

engine to idle (500–800 rpm). The sump temperature should be between

60–120°F (16–49°C).

CAUTION: The fluid level rises as sump temperature increases. DO

NOT fill above the COLD RUN band if the transmission fluid is

below normal operating temperature.

Clean around the end of the fill tube before removing the dipstick. Wipe the

dipstick clean and check the fluid level. If the fluid on the dipstick is within

the REF FILL (COLD RUN) band, the level is satisfactory for operating the

transmission until the fluid is hot enough to perform a HOT R UN check. If the

fluid level is not within the REF FILL (COLD RUN) band, add or drain fluid

as necessary to bring the level to the middle of the REF FILL (COLD RUN)

band.

Perform a hot check at the first opportunity after the normal operating sump

temperature 160–200°F (71–93°C) is reached.

b.

Hot Check

NOTE: The fluid level rises as the temperature increases. To ensure

an accurate check, operate the transmission until the sump fluid

temperature is 160–200°F (71–93°C) or converter-out temperature is

180–220°F (82–104°C).

Park the vehicle on a level surface and shift to N (Neutral). Set the parking

brake and/or emergency brakes and chock the vehicle wheels. Allow the

engine to idle (500–800 rpm).

Clean around the end of the fill tube before removing the dipstick. Wipe

the dipstick clean and check the fluid level. The safe operating range is any

4

•

•

level within the HOT RUN band on the dipstick. If the level is not within this

band, add or drain fluid as necessary to bring the level to the top of the

HOT RUN band.

1–5. KEEPING FLUID CLEAN

CAUTION: Containers or fillers that have been used to handle any

antifreeze or engine coolant solution must not be used for

transmission fluid. Antifreeze and coolant solutions contain ethylene

glycol which, if introduced into the transmission, can cause the clutch

plates to fail.

It is absolutely necessary that the fluid put into the transmission be clean. Fluid must

be handled in clean containers, fillers, etc., to prevent foreign material from entering

the transmission. Lay dipstick in a clean place while filling the transmission.

1–6. RECOMMENDED AUTOMATIC TRANSMISSION FLUID

AND VISCOSITY GRADE

RECOMMENDED AUTOMATIC TRANSMISSION FLUID AND

VISCOSITY GRADE — NON-MT 643R TRANSMISSIONS

Hydraulic fluids (oils) used in the transmission are important influences on

transmission performance, reliability, and durability.

The following transmission fluid and viscosity grades are recommended.

— DEXRON

®

-III fluids for standard duty, on-highway applications

— Type C-4 fluids (Allison approved SAE 10W or SAE 30) for severe duty

and off-highway applications

— Type C-4 SAE 30 for all applications where the ambient temperature is

consistently above 95°F (35°C)

— Type C-4 SAE 30 for dropboxes

Some DEXRON

®

-III fluids are also qualified as Type C-4 fluids. To

ensure the fluid is qualified for use in Allison transmissions, check for a

DEXRON

®

-III or C-4 fluid license, or approval numbers on the container, or

consult the lubricant manufacturer. Consult your Allison Transmission dealer

or distributor before using other fluid types; fluid types such as Type F, and

universal farm fluids may or may not be properly qualified for use in your

Allison transmission.

CAUTION: Disregarding minimum fluid temperature limits can

result in transmission malfunction or reduced transmission life.

5

•

N

•

•

•

•

When choosing the optimum viscosity grade of fluid to use, duty cycle,

preheat capabilities, and/or geographical location must be taken into

consideration. Table 1–1 lists the minimum fluid temperatures at which the

transmission may be safely operated in a forward or reverse range. Operation

at ambient temperatures lower than those shown will require preheating with

auxiliary heating equipment or by running the vehicle with the transmission in

(Neutral) for a minimum of 20 minutes before attempting range operation.

RECOMMENDED AUT OMA TIC TRANSMISSION FLUID AND

VISCOSITY GRADE — MT 643R TRANSMISSIONS

Due to the added heat load from the input retarder, MT 643R transmissions

require special fluid considerations. The approved fluids list is more restricti ve

than for non-retarder MT 643R transmissions. Also, the fluid change interv als

are shorter than for non-retarder MT 643R transmissions.

Only high quality, hea vy duty diesel engine oils that are appro v ed Allison C-4

fluids with a viscosity of either SAE 30 or SAE 15W-40 are recommended for

use in MT 643R transmissions. For specific name brands, contact the local

Allison Transmission Regional Office.

Refer to Table 1–1 for minimum fluid temperatures at which the transmission

may be safely operated with various fluids. Operation at ambient temperatures

lower than those shown will require preheating with auxiliary heating

equipment or by running the vehicle with the transmission in N (Neutral) for a

minimum of 20 minutes before attempting range operation.

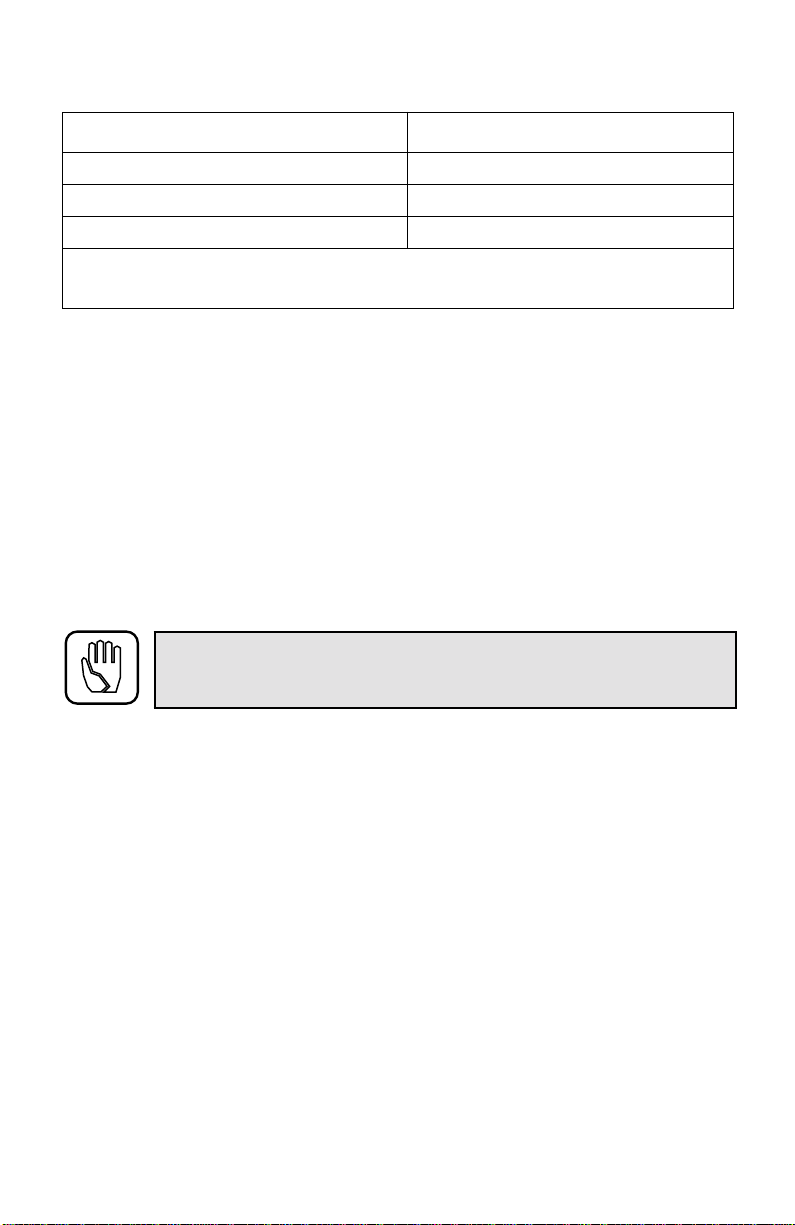

Table 1–1. Transmission Fluid Operating Temperature Requirements

Viscosity Grade

Ambient T emperatur e Below Which Preheat

Is Required

Fahrenheit Celsius

SAE 0W-20 (Arctic) –31 –35

DEXRON

®

-III

–22 –30

SAE 10W –4 –20

SAE 15W-40 5 –15

SAE 30 32 0

SAE 40 50 10

1–7. FLUID AND FILTER CHANGE INTERVALS

Fluid and filter change frequencies are determined as follows.

Table 1–2 is a general guide. The fluid must be changed whenever

there is evidence of dirt or high temperature indicated by

6

•

discoloration or strong odor. More frequent changes may be required

when operations are subject to high levels of contamination or

overheating.

Fluid change intervals can be optimized by monitoring fluid oxidation

according to the tests and limits in the Fluid Contamination section of this

manual.

Table 1–2. Fluid and Filter Change Intervals

Transmission

Application

MT 600 Series

(On-Highway,

Non-MT 643R)

MT 643R After first 5000

MT 600 Series

(Off-Highway)

* Whichever occurs first.

** An Allison high-efficiency filter may be used until the Change Filter light indicates it is

contaminated or until it has been in use for 3 years, whichever occurs first. No mileage restrictions

apply.

Fluid Change

25,000 miles

(40 000 km)

or 12 months*

miles (8000 km)

then at 20,000

miles (32 000

km) or 12

months*

1000 hours

maximum or

12 months*

Internal Sump

Filter

Paper Filter:

25,000 miles

(40 000 km) or

12 months*

Stainless Steel

Screen:

At overhaul

Paper Filter:

At every other

fluid change

Stainless Steel

Screen:

At overhaul

Paper Filter:

1000 hours

maximum or 12

months*

Stainless Steel

Screen:

At overhaul

Governor

Filter

25,000 miles

(40 000 km)

or 12 months*

20,000 miles

(32 000 km) or

12 months*

1000 hours

maximum or

12 months*

External

Auxiliary

Filters**

After first 5000

miles (8 000 km)

and at normal fluid

change intervals,

thereafter*

After first 5000

miles (8000 km)

then at each fluid

change, thereafter

After first 500

hours and at

normal oil change

intervals,

thereafter*

A stainless steel screen sump filter is available for all later model MT 600 Series

transmissions except the MT(B) 654CR. This filter does not require replacement at

the regular fluid change intervals, but transmissions equipped with a sump screen

must have an auxiliary filter in the external transmission cooling circuit. Refer to

Service Information Letter (SIL) 6-TR-96 (latest revision).

7

•

•

•

•

•

•

1–8. FLUID AND FILTER CHANGE PROCEDURE

a. Drain

The transmission should be at operating temperature to assist

draining.

Remove the drain plug from the pan. In earlier models without a drain plug,

remove the fill tube.

Examine the drained fluid for evidence of contamination (refer to

Paragraph 1–9).

Remove the pan and gasket. Discard the gasket. Remove the washer head

screw that retains the filter. Remove the filter and filter tube. Discard the filter

(if being replaced) and the filter tube sealring. Clean the pan.

NOTE: Transmissions equipped with a stainless steel screen sump

filter or a 7.0 inch (180 mm) pan do not require pan removal. Refer to

Service Manual SM1317EN or SM1546EN for specific procedures.

Install a new governor feed filter at the rear of the transmission. Refer to the

latest revision of Service Manual SM1317EN or SM1546EN for the exact

location.

Install a new filter if required. Insert a new sealring onto the filter tube. Install

the filter tube and filter into the main housing. Install the pan and pan gasket if

removed. Tighten the pan screws to 10–15 lb ft (14–20 N·m).

•

•

•

•

•

NOTE: To prevent leakage, pan washer head screws must retain

a 5 lb ft (7 N·m) minimum torque after gasket sets.

Install the drain plug into the pan and tighten it to 15–20 lb ft (20–27 N·m). If

the fill tube was removed (earlier models), install the fill tube and tighten the

fill tube fitting in the pan boss to the torque shown in Paragraph 6–1.

If an external auxiliary filter is present, replace the filter element. Refer to

Table 1–2 for replacement intervals.

b.

Fill

Refill the transmission. (Refer to Paragraph 1–6 and Table 1–3.)

The refill amount is less than the initial fill because some of the fluid remains

in the external circuits and transmission cavities.

Check the fluid level as outlined in Paragraph 1–4.

8

9

Table 1–3. Transmission Fluid Refill Capacities

Pan T ype Quantity

4.3 inches (110 mm) 12 U.S. qt. (11 liters)*

5.1 inches (130 mm) 15 U.S. qt. (14 liters)*

7.0 inches (180 mm) 17 U.S. qt. (16 liters)*

* The amount of transmission fluid shown does not include the amount required to fill the

external circuits.

1–9. FLUID CONTAMINATION

a.

Examine at Fluid Change

At each fluid change, examine the fluid which is drained for evidence of dirt or

engine coolant (water). A normal amount of condensation will emulsify in the fluid

during operation of the transmission. However, if there is evidence of coolant, check

the cooler (heat exchanger) for leakage between the cooler and fluid areas. Fluid in

the coolant side of the cooler (heat exchanger) is another sign of leakage. This,

however, may indicate leakage from the engine oil system.

Metal Particles

b.

CAUTION: If excessive metal contamination has occurred,

replacement of the cooler and inspection of all bearings within the

transmission is recommended.

Metal particles in the fluid or on the magnetic drain plug (except for the minute

particles normally trapped in the filter) indicate damage has occurred in the

transmission. When these particles are found in the sump, the transmission must be

disassembled and closely inspected to find the source. Metal contamination requires

complete disassembly of the transmission and cleaning of all internal and external

circuits, cooler, and all other areas where the particles could lodge. (Refer to

Paragraph 1–10, Auxiliary Filter.)

c.

Coolant Leakage

If engine coolant leaks into the transmission hydraulic system, take immediate

action to prevent malfunction and possible serious damage. Completely

disassemble, inspect, and clean the transmission. Remove all traces of the coolant

and varnish deposits resulting from coolant contamination. Replace friction clutch

plates contaminated with ethylene glycol.

d.

Fluid Analysis

Transmission protection and fluid change intervals can be optimized by transmission

fluid analysis. Consult your local telephone directory for fluid analysis firms. Use

one fluid analysis firm as results from various firms cannot be accurately compared.

Refer to the Technicians’ Guide for Automatic T ransmission Fluid (GN2055EN) for

additional information.

To optimize transmission protection, the following is the minimum series of tests

required to properly monitor the condition of the transmission and transmission

fluid/filter system.

•

Wear Metals (ppm): Fe, Cu, Pb, Al

•

Additive and Contaminant Metals (ppm): Ba, B, Ca, Mg, P, Si, Na, Zn

•

Non-metal Contaminants: Fuel (% vol), Soot, (% wt), Water (% vol)

•

Viscosity (cSt) at 40˚C (ASTM D445)

•

Viscosity (cSt) at 100˚C (ASTM D445)

•

TAN (Total Acid Number) (ASTM D664)

•

Particle Counts (particles/ml) at >5, >10, >20, >30, and >40 microns

ppm = parts per million cSt = centiStokes ml = milliliter

10

To optimize fluid change intervals, monitor fluid oxidation per the tests and limits

shown in Table 1–4. A fluid is considered suitable for use if it meets all four limits

listed in the table, regardless of color or odor. If one of the limits is exceeded,

however, the fluid in the subject transmission should be sampled again immediately

to verify the exceeded limit. If verified, the fluid should be changed regardless of

time or mileage.

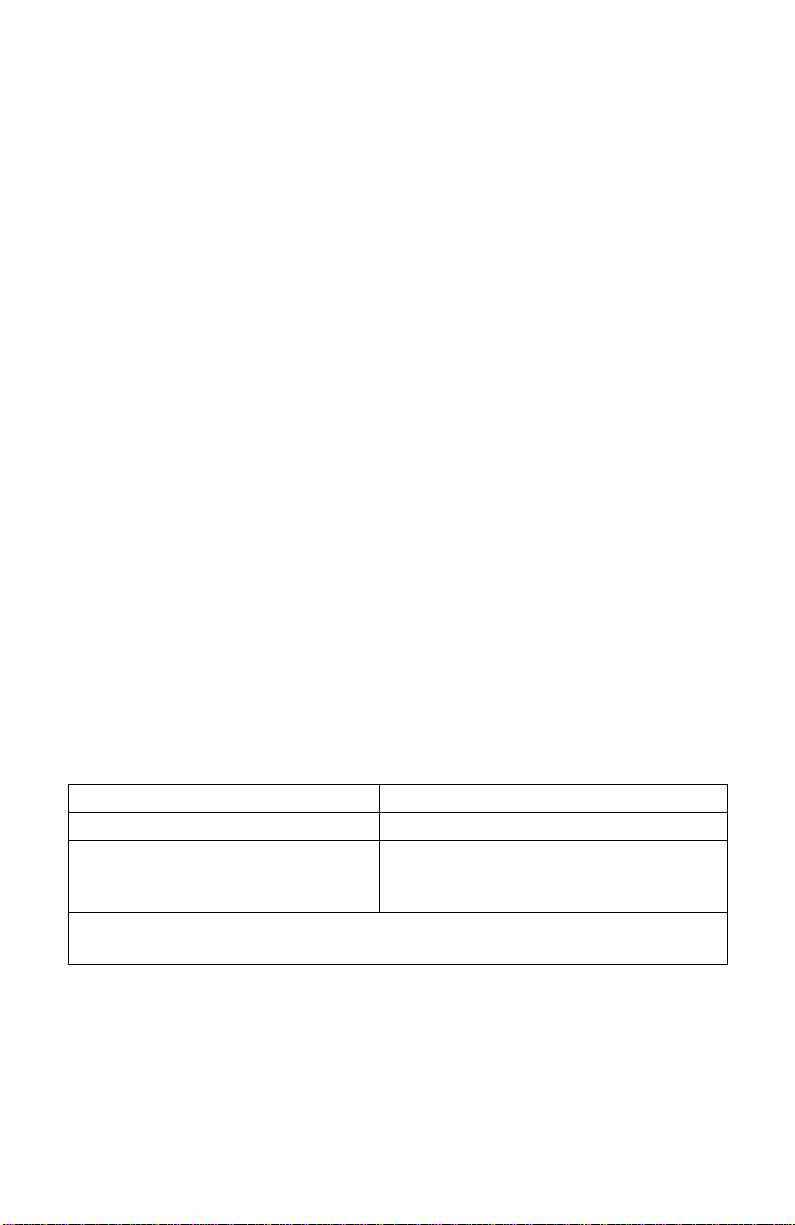

Table 1–4. Fluid Oxidation Measurement Limits

Condition Limit

Viscosity ± 25% Change From New Fluid

Carbonyl Absorbance

Total Acid Number (TAN)

Solids

* Carbonyl absorbance units/cm

** mg of KOH required to neutralize a g of fluid

+ 30* Change From New Fluid

+ 3.0** Change From New Fluid

2% By Volume Maximum

1–10. AUXILIARY FILTER

If a condition occurs that introduces debris into the transmission hydraulic system,

completely clean up the cooler and lines.

Loading...

Loading...