Agilent Technologies ESA-E E4405B, ESA-E E4402B, ESA-E, ESA-E E4404B, ESA-L Getting Started Manual

...Page 1

Getting Started Guide

ESA Series Spectrum Analyzers

This manual provides documentation for the following instruments:

ESA-E Series

E4401B (9 kHz - 1.5 GHz)

E4402B (9 kHz - 3.0 GHz)

E4404B (9 kHz - 6.7 GHz)

E4405B (9 kHz - 13.2 GHz)

E4407B (9 kHz - 26.5 GHz)

and

ESA-L Series

E4411B (9 kHz - 1.5 GHz

E4403B (9 kHz - 3.0 GHz)

E4408B (9 kHz - 26.5 GHz)

Manufacturing Part Number: E4401-90473

Printed in USA

December 2012

Supersedes: September 2012

© Copyright 2001-2012 Agilent Technologies, Inc.

Page 2

Notice

The information contained in this document is subject to change without notice.

Agilent Technologies makes no warranty of any kind with regard to this material,

including but not limited to, the implied warranties of merchantability and fitness

for a particular purpose. Agilent Technologies shall not be liable for errors

contained herein or for incide ntal or conseq uentia l damages in connect ion with the

furnishing, performance, or use of this material.

The following safety symbols are used throughout this manual. Familiarize

yourself with the symbols and their meaning before operating this analyzer.

WARNING Warning denotes a hazard. It calls attention to a procedure which, if not

correctly p erformed or adhe r ed to, could r e sult in inj ury or lo ss of lif e. Do not

proceed beyond a warning note until the indicated conditions are fully

understood and met.

CAUTION Caution denotes a hazard. It calls attention to a procedure that, if not correctly

performed or adhered to, could result in damage to or destruction of the analyzer.

Do not proceed beyond a caution sign until the indicated conditions are fully

understood and met.

NOTE Note calls out special information for the user’s attention. It provides operational

information or additional instructions of which the user should be aware.

Additional Information

For the latest information about this analyzer, including firmware upgrades,

application information, and product information, see the following URL:

http://www.agilent.com/find/esa/

2

Page 3

Contents

1. Installation and Setup

Initial Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Power Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Checking the Fuse . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

AC Power Cord . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Turning on the Analyzer for the First Time . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Why Aren’t All the Personality Options Loaded in Memory? . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Using an External Reference . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Firmware Revision . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Running Internal Alignments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Printer Setup and Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Protecting Against Electrostatic Discharge . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Safety Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

2. Front and Rear Panel Features

Front Panel Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Front-Panel Connectors and Keys . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Display Annotations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Rear-Panel Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Key Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Front and Rear Panel Symbols . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

3. Making a Basic Measurement

Using the Front Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Entering Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Using Menu Keys . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Presetting the Spectrum Analyzer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Creating a User Preset . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Viewing a Signal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

4. Viewing Catalogs and Saving Files

File Menu Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Locating and viewing files in the catalog . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Creating a directory . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Formatting a Floppy Disk . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Saving a File . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Step 1. Set up the analyzer trace . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Step 2. Save the file . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

Loading a file . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

Renaming a File . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

Copying a File . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

Deleting a File . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

Using the Alpha Editor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

3

Page 4

Contents

5. Options and Accessories

Ordering Options and Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .66

Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .67

Option Descriptions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .70

Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .83

50 Ohm/75 Ohm Minimum Loss Pad . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .83

75 Ohm Matching Transformer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .83

AC Probe . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .83

AC Probe (Low Frequency) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .83

Broadband Preamplifiers and Power Amplifiers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .83

Carrying Strap (Part Number E4401-60028) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .84

External Keyboard . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .84

GPIB Cable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .84

USB/GPIB Cable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .84

HP/Agilent 11970 Series Harmonic Mixers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .84

HP/Agilent 11974 Series Preselected Millimeter Mixers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .85

Agilent E1779B Battery Pack . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .85

Parallel Interface Cable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .85

Printer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .85

RF and Transient Limiters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8 5

RF Bridges . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .86

RS-232 Cable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8 6

Static Safe Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .86

6. In Case of Difficulty

Types of Spectrum Analyzer Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8 9

Before Calling Agilent Technologies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .90

Check the Basics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .90

Read the Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .91

Service Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .91

Connector Care . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .91

Contacting Agilent Technologies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .91

Returning an Analyzer for Service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .92

4

Page 5

1 Installation and Setup

5

Page 6

Installation and Setup

This chapter provides the following information that you may need when you first receive your

spectrum analyzer:

• “Initial Inspection” on page 7

• “Power Requirements” on page 9

• “Turning on the Analyzer for the First Time” on page 14

• “Printer Setup and Operation” on page 18

• “Protecting Against Electrostatic Discharge” on page 21

• “Running Internal Alignments” on page 17

• “Safety Information” on page 22

6 Chapter 1

Page 7

Installation and Setup

Initial Inspection

Initial Insp ection

Inspect the shipping container and the cushioning material for signs of stress. Retain the shipping

materials for future use, as you may wish to ship the analyzer to another location or to Agilent

Technologies for service. Verify that the contents of the shipping container are complete. The

following table lists the items shipped with the analyzer.

Item Description

Accessories

Adapter, Type-N (m) to BNC (f) Not shipped with Option 1DP. Two adapters are shipped with Option

1DN.

Adapter, BNC (m) to F (f), 75 Shipped only with Option 1DP. Two adapters shipped with Option

1DQ.

Adapter, Type-N (m) to SMA (f) Shipped only with Option 1DN for Agilent E4402B, E4403B,

E4404B, E4405B, E4407B, and E4408B. Not shipped with

Option BAB.

Adapter, APC 3.5 (f) to APC 3.5 (f) Shipped only with Option BAB.

Adapter, BNC (f) to SMA (m) Shipped only with Option BAB.

Cable, BNC (m) to BNC (m), 203 mm Shipped only with Agilent E4402B, E4403B, E4404B, E4405B,

E4407B, and E4408B.

Cable, SMA (m) to Type-N (m), 220 mm Shipped only with Option 1DN for Agilent E4402B, E4403B,

E4404B, E4405B, E4407B, and E4408B.

IntuiLink Toolbar software, CD-ROM Provides a set of connectivity tools that enable yo u to easily mov e data

from your analyzer to your PC.

Power Cable (Se e Table 1-3 on page 12) Connection for po w er sou r c e.

Standard Documentation Set

Getting Started Guide Covers unpacking and set ting up the analyzer, analyzer features, and

how to make a basic measurement. Includes information on options

and accessories, and what to do if you have a problem.

User’s/Programmer’s Guide Describes analyzer features in detail, including front-panel key

descriptions, basic spectrum analyzer programming information, and

SCPI command descriptions.

Measurement Guide Provides details on how to measure various signals, and how to use

catalogs and files.

Specifications Guide Documents specifications, safety, and regulatory information.

Instrument Messages and Functional Tests Includes instrument messages (and suggestions for troubleshooting

them), and manual functi onal tests.

Programming Conversion Guide Describes SCPI programming command compatibility for 8590, ESA

series analyzers.

Chapter 1 7

Page 8

Installation and Setup

Initial Inspection

Item Description

Documentation CD-ROM Includes the docu ments in the standard set (listed above). You can

view and print the information as needed. See the CD-ROM jacket for

installation information.

NOTE If you purchased one or more optional measurement personalities, the related guides for the

options you ordered are included.

Service documentation is not included in the standard documentation set. See “Options and

Accessories” on page 65 for information on ordering.

If There Is a Problem

If the shipping materials are damaged or the contents of the container are incomplete:

• Contact the nearest Agilent Technologies office to arrange for repair or replacement. You will not

need to wait for a claim settlement.

• Keep the shipping materials for the carrier’s inspection.

• If you must return an analyzer to Agilent Technologies, use the original (or comparable) shipping

materials (see “Returning an Analyzer for Service” on page 92).

8 Chapter 1

Page 9

Installation and Setup

Power Requirements

Power Requirements

The only physical installation of your Agilent spectrum analyzer is a connection to a power source.

Line voltage does not need to be selected.

WARNING Failure to ground the analyzer properly can result in personal injury. Before

turning on the analyzer, you must connect its protective ea rth terminals to the

protective conductor of the main power cable. Insert the main power cable

plug into a socket outlet that has a protective earth contact only. DO NOT

defeat the earth-grounding protection by using an extension cable, power

cable, or autotransformer without a protective ground conductor.

If you are using an autotransformer, make sure its common terminal is

connected to the protective earth contact of the power source outlet socket.

This is a Safety Class 1 Product (provided with a protective earth ground

incorporated in the power cord). The mains plug shall only be inserted in a

socket outlet pr ovided with a prot ective ea rth contact . Any inte rruption of t he

protective conductor inside or outside of the product is likely to make the

product dangerous. Intentional interruption is prohibited.

CAUTION The Mains wiring and connectors shall be compatible with the connector used in

the premise electrical system. Failure, to ensure adequate earth grounding by not

using the correct components may cause product damage, and serious injury.

CAUTION VENTILA TION REQUIREMENTS: When installing the product in a cabinet, the

convection into and out of the product must not be restricted. The ambient

temperature (outside the cabinet) must be less than the maximum operating

temperature of the product by 4C for every 100 watts dissipated in the cabinet. If

the total power dissipated in the cabinet is greater than 800 watts, then forced

convection must be used.

This instrument has auto-ranging line voltage input, be sure the supply voltage is

within the specified range and voltage fluctuations do not to exceed 10 percent of

the nominal supply voltage.

NOTE This product is designed for indoor use only.

NOTE For more information regarding analyzer specifications, see the Specifications

guide.

Chapter 1 9

Page 10

Installation and Setup

Power Requirements

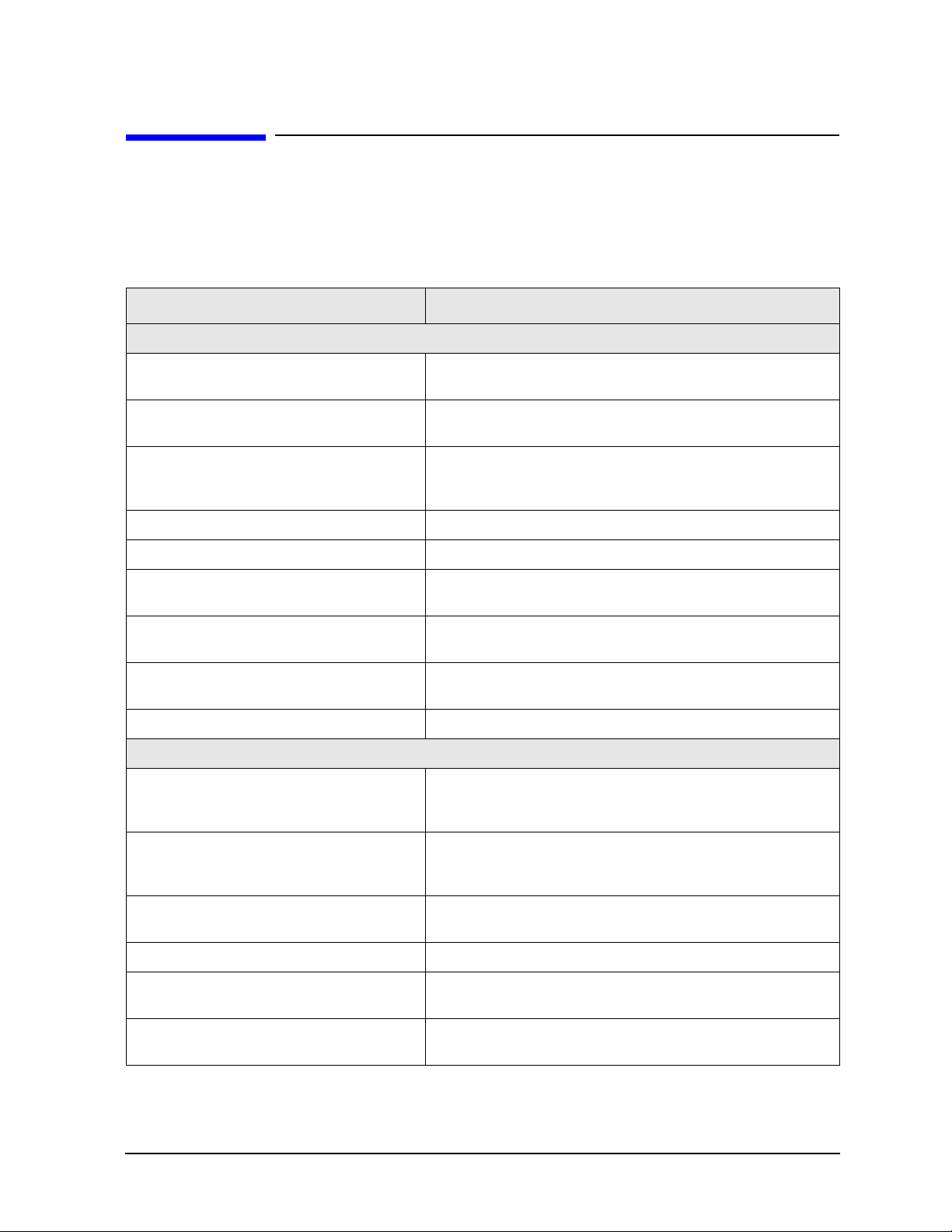

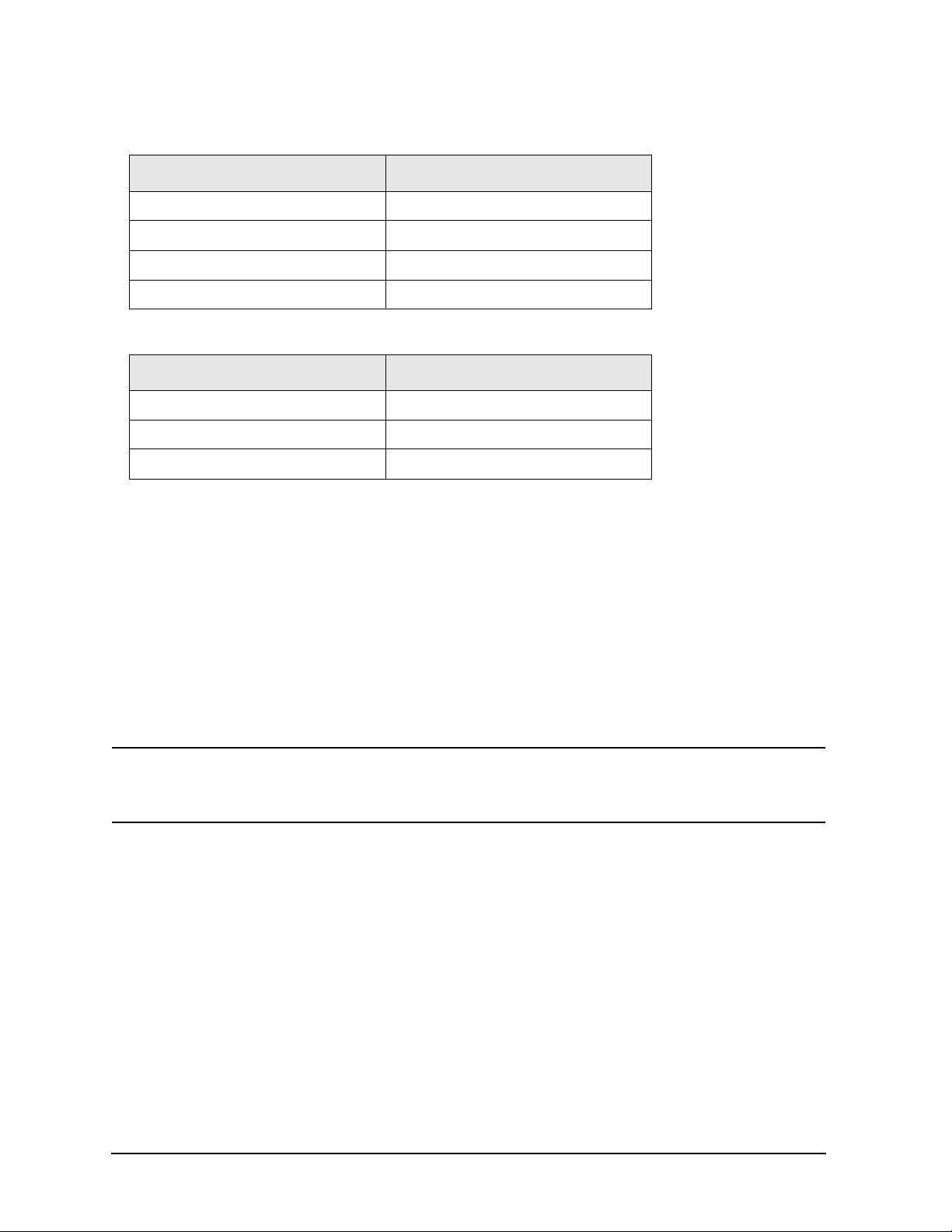

Table 1-1 AC Power Requirements

Description Specifications

Voltage 90 to 132 Vrms (47 to 440 Hz)

Vol tage 195 to 250 Vrms (47 to 66 Hz)

Power Consumption, On < 300 W

Power Consumption, Standby < 5 W

Table 1-2 DC Power Requirements

Description Specifications

Voltage 12 to 20 Vdc

Power Consumption < 200 W

Power Consumption, Standby < 5 W

Checking the Fuse

Where IEC regulations apply, use a 5 by 20 mm, rated F5A, 250 V IEC approved fuse. This fuse may

be used with input line voltages of 115 V or 230 V. Its part number is 2110-0709.

Where UL/CSA regulations apply, use a 5 by 20 mm rated fast blow, 5 A, 125 V UL/CSA approved

fuse (part number 2110-0756). This fuse may only be used with an input line voltage of 115 V.

The line fuse is housed in a fuse holder in the upper left hand corner of the rear panel.

To remove the fuse, first disconnect the power cord from the analyzer. Then insert the tip of a

screwdriver into th e s lot at the middle of the fuse holder, and turn counterclockwise to exte nd the fuse

holder.

WARNING For continued protection against fire hazard, replace fuses, and or circuit

breakers only with same type and ratings. The use of other fuses, circuit

breakers or materials is prohibited.

10 Chapter 1

Page 11

Installation and Setup

Power Requirements

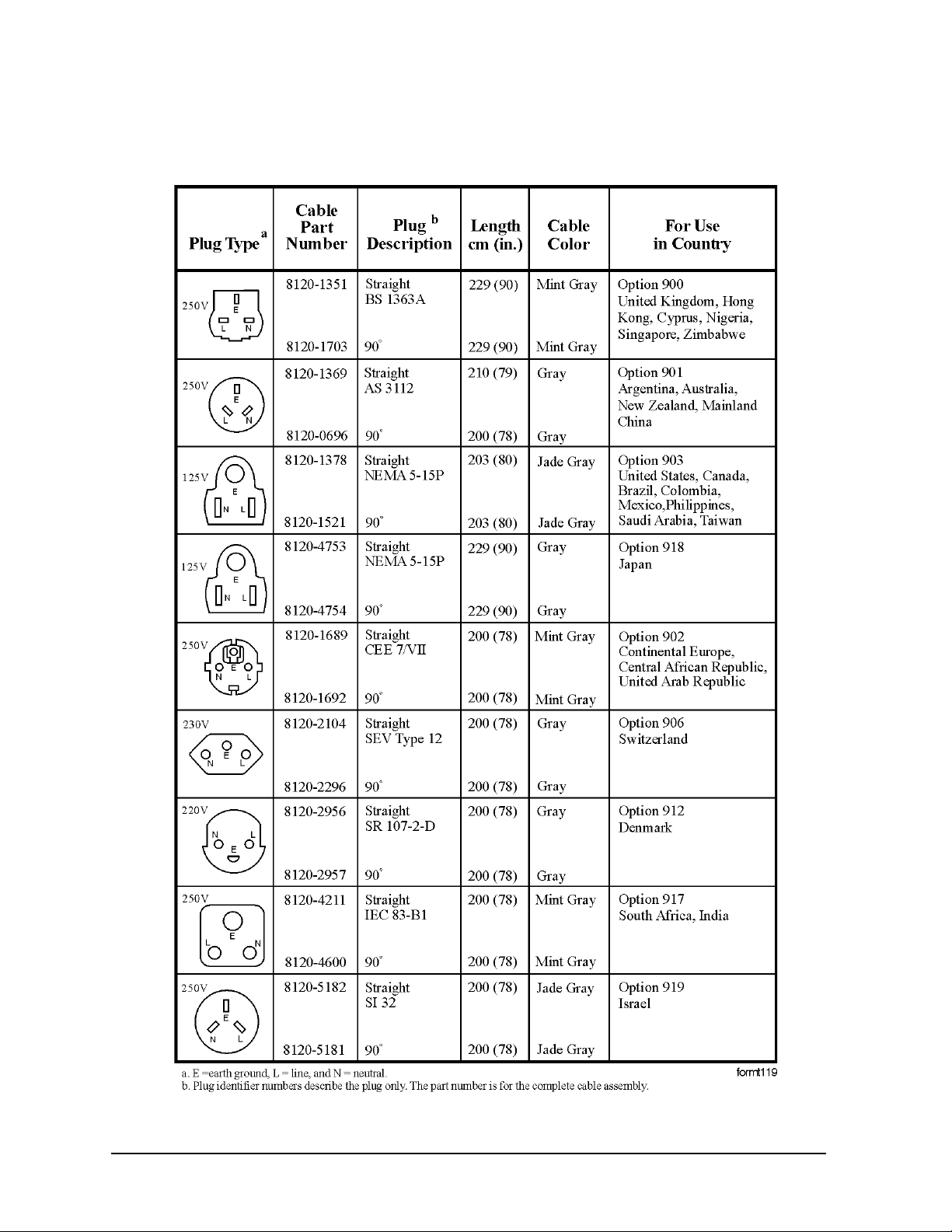

AC Power Cord

The analyzer is equipped with a three-wire power cord, in accordance with international safety

standards. This cable grounds the analyzer cabinet when connected to an appropriate power line

outlet. The cable appropriate to the original shipping location is included with the analyzer.

Various AC power cables are available that are unique to specific geographic areas. You can order

additional AC power cables for use in different areas. AC Power Cords, on page 12 lists the available

AC power cables, illustrates the pl ug conf igurations, and identifie s the geogr aphi c ar ea in which each

cable is appropriate.

NOTE The front panel switch is a standby switch only; it is not a LINE switch (power

disconnecting device).

WARNING Install the product so that the detachable power cord is readily identifiable

and easily reached by the operator. The detachable power cord is the

instrument disconnecting device. It disconnects the mains circuits from the

mains supply before other parts of the instrument. The front panel switch is

only a standby switch and is not a LINE switch. Alternatively, an externally

installed switch or circuit breaker (which is readily identifiable and is easily

reached by the operator) may be used as a disconnecting device.

CAUTION Always use the three-prong AC power cord supplied with this product. Failure to

ensure adequate earth grounding by not using this cord can cause product damage.

CAUTION This instrument has auto-ranging line voltage input, be sure the supply voltage is

within the specified range and voltage fluctuations do not to exceed 10 percent of

the nominal supply voltage.

Chapter 1 11

Page 12

Installation and Setup

Power Requirements

Table 1-3 AC Power Cords

12 Chapter 1

Page 13

Installation and Setup

Power Requirements

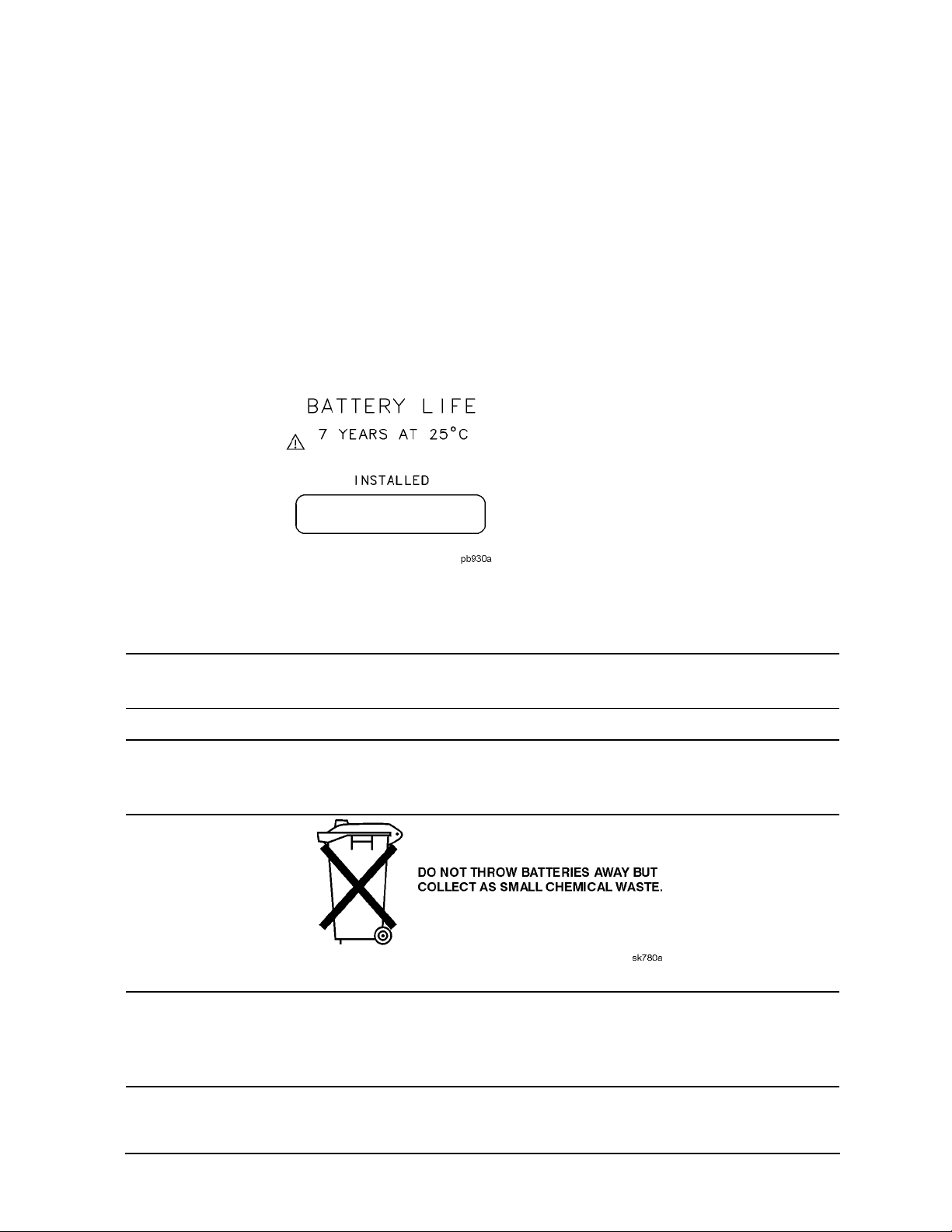

Battery Information

The analyzer uses a lithium battery to enable the internal memory to retain data. The date when the

battery was installed is on a label on the rear panel of the analyzer. See Figure 1-1

The minimum life expectancy of the battery is 7 years at 25 C , or 1 year at 55 C . If you experience

problems with the battery or the recommended time period for battery replacement has elapsed, see

“Returning an Analyzer for Service” on page 92.

If you wish to replace the battery yourself, you can purchase the service documentation that provides

all necessary test and maintenance information.

After replacing the analyzer battery, write the date of battery replacement on the rear-panel label.

Figure 1-1 Rear-Panel Battery Information Label

You can order the service documentation for Agilent spectrum analyzers through your Agilent Sales

and Service office. The documentation is described under “Options and Accessories” on page 65.

NOTE If the analyzer’ s clock d oes not wor k, the prob lem is the battery. See “Returning an

Analyzer for Service” on page 92.

WARNING Danger of explosion if battery is incorrectly replaced. Replace only with the

same or equivalent type recommended. Discard used batteries according to

the manufacturer’s instructions.

WARNING The Agilent Technologies E4402B, E4403B, E4404B, E4405B, E4407B,

E4408B, E4411B, E7402A, E7405A may be used with an E1779B

Rechargeable Battery Pa ck wh ich co ntains a Ni- Cd batt ery. The battery must

be recycled or disposed of properly.

Chapter 1 13

Page 14

Installation and Setup

Turning on the Analyzer for the First Time

Turning on the Analyzer for the First Time

❏ Plug in th e power cord.

WARNING If this product is to be energized via an external auto transformer for voltage

reduction, make sure that its common terminal is connected to a neutral

(earthed pole) of the power supply.

CAUTION The analyzer is shipped with a a transportation disk inserted in the disk drive to

prevent damage to the di sk dri ve dur ing t ranspo rtat ion. This trans portat ion di sk, or

a blank floppy disk, should be inse rt ed i n the disk drive whenever transporting the

analyzer.

NOTE Do not connect anything else to the analyzer yet.

❏ Choose a power on pr eference usin g the s witch on the rea r panel (refer to “Rear-Panel Features” on

page 31, item 14). The

PWR ALWAYS ON setting turns the analyzer on whenever external power

is applied. This mode is useful if an external power switch is used to control a rack of several

instruments. Neverthel ess, if you set the anal yzer to standby us ing the front pa nel

Standby key and

the external power is r emoved an d rest ored wi thin 20 second s, the a nalyze r will remai n in st andby.

PWR NORM setting assigns analyzer on/off control to the front-panel On and Standby keys

The

(see “Front-Panel Connectors and Keys” on page 24, item 23). If the analyzer is on and the

external power is removed and restored within 20 seconds, the analyzer will turn on. On the other

hand, if the external power is removed and restored after 20 seconds, the analyzer will remain in

standby regardless of the front-panel switch settings.

❏ Press the (On) key to turn the analyzer on.

Information Screen: An information screen appears during the initialization process. The information

screen contains the analyze r produc t number and a URL for accessi ng produc t suppor t in formati on on

the World Wide Web. See “Additional Information” on page 2.

NOTE The information screen displays for approximately 10 seconds before the

initializat i on process is complete.

Record the firmware revision and serial number, and keep it for reference. If you

should ever need to call Agilent Technologies for service or with any questions

regarding your analyzer, it will be helpful to have this information readily

available. You can also obtain the f irmware re visio n and se rial number b y pr essin g

System, More, Show System.

❏ Allow the analyzer to wa rm-u p for 5 minute s befo re making a cali brate d measur ement. To meet its

specifications, the analyz er mu st meet operat in g temperat ure conditions.

14 Chapter 1

Page 15

Installation and Setup

Turning on the Analyzer for the First Time

If the analyzer is an Agilent Technologies E4402B, E4403B, E4404B, E4405B, E4407B, or

E4408B, connect a BNC cable from the AMPTD REF OUT to INPUT 50 using an adapter.

After a 5 minute warm-up, press

System, Alignments, Align Now, All.

CAUTION When operating in dc coupled mode on analyzers with Option UKB ensure

protection of the input mixer by limiting the input level to 0 Vdc, +30 dBm.

When operating in ac coupled mode, ensure protection of the input mixer by

limiting the input level to 50 Vdc, +30 dBm.

NOTE It is normal to hear clicking when the Auto Alignment function is on. See

“Running Internal Alignments” on page 17 for more information.

Why Aren’t All the Personality Options Loaded in Memory?

Many measurement personality options are available for use with this instrument. If the option is

loaded in the instrument, you must also have a license key entered, to use it.

Some versions of instrument hardware my not have enough memory to accommodate all the options

that you have ordered. If this is the case you will need to swap the applications in/out of memory, as

needed. It may also be possible to upgrade your hardware to have more memory. Contact your local

sales/service office.

Using an External Reference

If you wish to us e an ext ernal 1 0 MHz sour ce as t he refe rence frequenc y, connect an external refere nce

source to the

dBm.

NOTE It is not necessary to connect the 10 MHz REF OUT to t he 10 MHz REF I N on the

1. T o use an ext ernal freque ncy ref erence , con nect it to the EXT REF IN connector on the rear panel

(see “Rear-Panel Features” on page 31).

10 MHz REF IN connector on the rear panel. The signa l le vel shou ld be grea ter tha n –15

rear of the analyzer. Doing so results in a “Frequency Reference Error” message.

Chapter 1 15

Page 16

Installation and Setup

Firmware Revision

Firmware Revision

To view the firmware revision of your analyzer, press System, More, Show System. If you call

Agilent Technologies regarding your anal yzer, it is helpful to have this revisi on and t he anal yzer seri al

number available.

TIP You can get automatic electronic notification of new firmware releases and other

product updates/information by subscribing to the Agilent Technologies Test &

Measurement E-Mail Notification Service for the PSA and ESA Series at

http://www.agilent.com/find/notifyme

16 Chapter 1

Page 17

Installation and Setup

Running Internal Alignments

Running Intern al Ali g nments

Each time the analyzer is powered on, the internal alignment routine runs automatically.

The analyzer was shipped from the factory with the Alignments mode set to

Align All.

Auto,

NOTE When the Alignment routine runs, you will hear the attenuator settings changing,

which generates noise. This is not an indication of trouble.

Manually Performing an Alignment

If the analyzer is an Agilent Technologies E4402B, E4403B, E4404B, E4405B, E4407B, or E4408B,

connect a BNC cable from the AMPTD REF OUT to INPUT 50 using an adapter. After a 5 minute

warm-up, press

System, Alignments, Align Now, All.

NOTE It is normal to hear clicking when the Auto Alignment function is on. During the

interval between sweeps, portions of the analyzer’s circuitry are realigned. Some

of the circuitry is controlled by relays. It is the rapid switching of these relays

between sweeps which causes the clicking sound. Under normal operation, these

relays will last over 50 years.

To eliminate the clicking sound, turn off the automatic alignment. (See the

Alignments key description in your User’s guide.”) With

Auto Align turned off,

however, the Align Now All function should be performed periodically. For more

information on how often to perform Align Now All when the Auto Alignment

function is of f, refer to the appropriate “S pecifications and Characteri stics” chapt er

in your specifications guide.

If

Auto Align, Off is selected, refer to the Specifications guide for t he co ndi tions required to main tai n

calibration.

Chapter 1 17

Page 18

Installation and Setup

Printer Setup and Operation

Printer Setup and Operation

A printer can be connecte d to your analyzer if it is eq uipped with an external I/O i nte rface. Supported

printers accept Hewlett-Packard Printer Control Language Level 3 (PCL3) or 5 (PCL5). Refer to the

documentation or specifications supplied with your printer, or contact the manufacturer to identify

your printer’s language.

Equipment

• IEEE 1284 compliant printer cable.

• Supported and tested printers are listed below. Note that there are many PCL3/5 printers that may

work with your analyzer, however, they have not been tested.

— PCL3 printers include most HP DeskJet printers.

— PCL5 printers include most HP LaserJet printers.

NOTE The following printers are not compatible with your analyzer:

HP Deskjet 720C, 722C, 820C and 1600C

Epson MX-80, FX-85, Stylus, and LQ-570

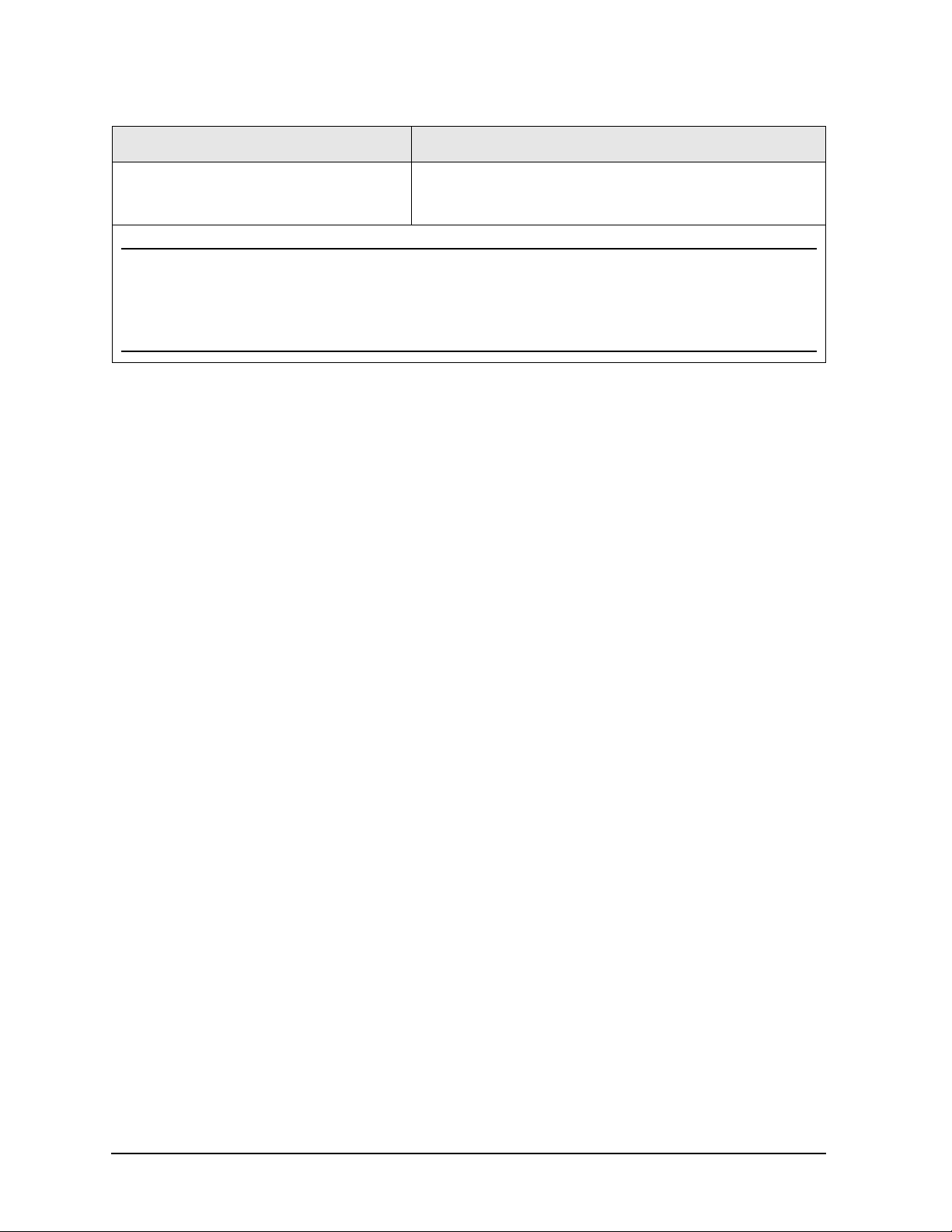

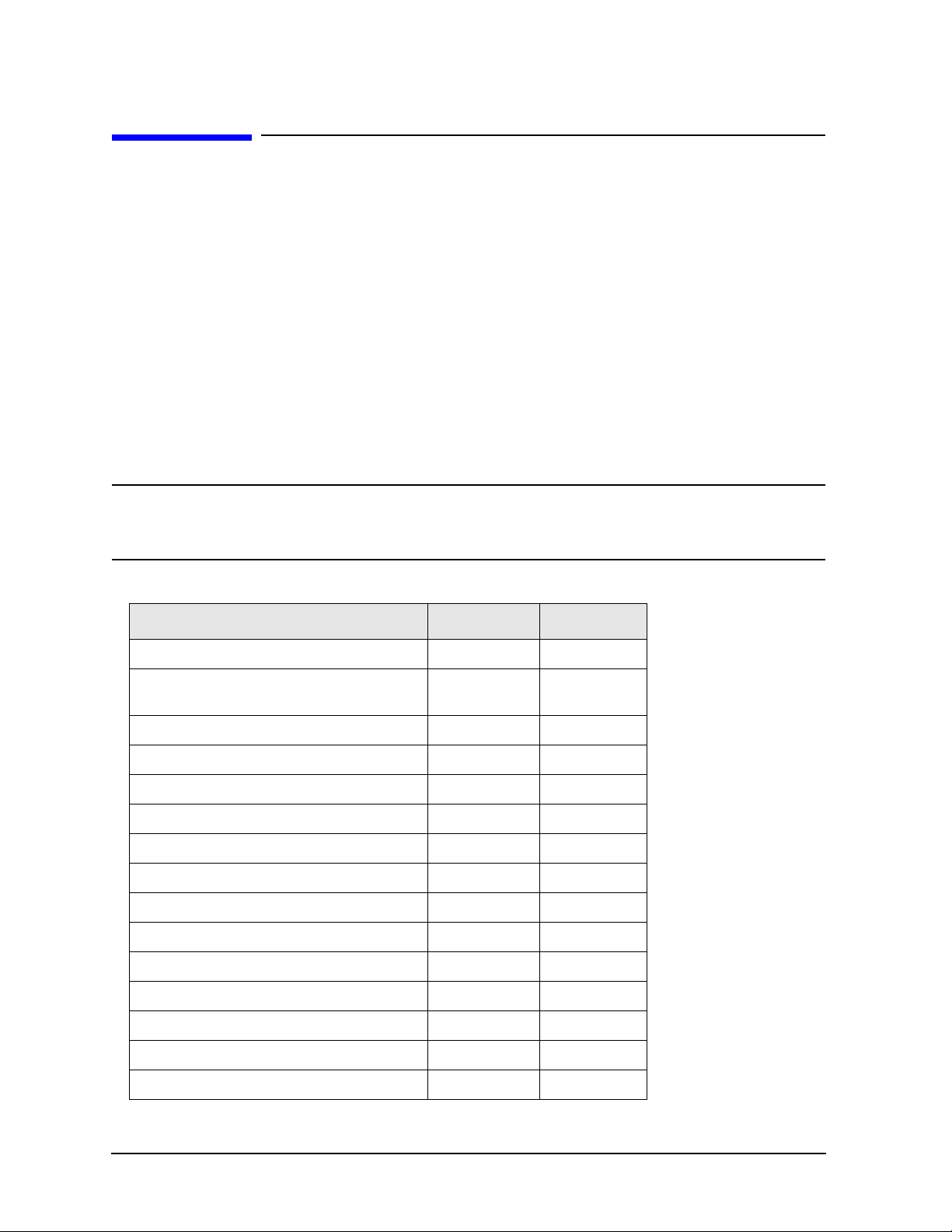

Printer Models Language Type Color Capable

HP DeskJet 310, 320, 350C, 400L PCL3 yes

HP DeskJet 500C, 550C, 600, 660C, 672C, 680C,

682C, 690C, 693C

HP DeskJet 840C, 850 C, 870C, 890C, 895C PCL3 yes

HP DeskJet 935C, 970C, 990C PCL3 yes

HP DeskJet 1120C, 1150C PCL3 yes

HP Inkjet 2000C PCL 3 yes

HP LaserJet III PCL3/5 no

HP LaserJet 4P PCL3/5 no

HP LaserJet 5L, 5M, 5N, 5P, 5SI PCL3/5 no

HP LaserJet 6L, 6MP PCL5 no

HP LaserJet 2100 Series, PCL3/5 no

HP LaserJet 4050N PCL3/5 yes

HP LaserJet 5000GN PCL3/5 yes

HP Professional Series 2500CM PCL3 yes

PCL3 yes

HP Professional Series 2500CM PCL3 yes

18 Chapter 1

Page 19

Installation and Setup

Printer Setup and Operation

Interconnection and Setup

1. Turn off the printer and the analyzer.

2. Connect the printer to the analyzer parallel I/O interface connector using an IEEE 1284 compliant

parallel printer cable.

3. If appropriate, configure your printer using configuration menus or switches. Refer to your

printer’s documentation for more specific information on configuring your printer.

4. Turn on the analyzer and printer.

5. Press

Print Setup on the front panel and then press the Printer Type menu key. Printer Type

accesses the following keys:

None None disables the an alyzer from attempting to print to a printer. This is the

appropriate setting if no printer is connected to the analyzer.

Custom Custom allows you to access the Define Custom menu keys. The Define

Custom

menu keys allow you to specify printer characteristics such as PCL

Level and printer color capability.

Auto Auto enables the analyzer to automatically attempt to identify the connected

printer when the

6. Press

Printer Type to access the Printer Type menu keys. Press Auto to make the analyzer attemp t

to identify the connected printer. When you press

Print key is pressed or when Printer Type is set to Auto.

Auto, the analyzer will respond in one of the

three following ways:

•The

Print Setup menu will be displayed with the Auto key selected and no new message will

be displayed in the display status line. This indicates that the analyzer has successfully

identified the connected printer and no further setup is required. As long as

selected in the

front panel

More 1 of 3, Show System.

•The

Print Setup menu will be displayed with the Custom key selected and one of the

Printer Type menu, the analyzer w ill attempt to identify the printer when the

Print key is pressed. The selected printer will be displayed by pressing System,

Auto remains

following diagnostic messages will be displayed in the display status line:

Unknown printer, Define Custom to set up printer

No printer response, Define Custom to set up printer

Invalid printer response, Define Custom to set up printer

This indicates that the analyzer was unable to automatically identify the connected printer, and

Custom has been selected in the Printer Type menu. Press Print Setup, Define Custom to

select specific printer characteristics such as the printer language (PCL3 or PCL5) and color

printing capability. Once you have set these characteristics to match those of your connected

printer, the printer setup process is complete. As long as

Printer Type menu, the analyzer will not attempt to automatically identify the connected

printer when the front panel

•The

Print Setup menu will be displayed with the None key se lected a nd the fo llowing mes sage

Print key is pressed.

Custom remains selected in the

will appear in the display status line:

Chapter 1 19

Page 20

Installation and Setup

Printer Setup and Operation

Unsupported printer, Printer Type set to None

This indicates that the anal yzer ha s su ccessf ully identi fied t he c onnect ed print er, but the printer

is not supported by the analyzer. As long as

analyzer will respond to any print command by displaying the message Printer Type is

None in the display status line.

None is selected in the Printer Type menu, the

7. Select the desired paper size by pressing

Print Setup, More, Page Size, then choose the

appropriate page size for which your printer is configured. This setting wil l remain uncha nged with

Preset or Power Cycle.

The factory default page size is

Restore Sys Defaults is executed.

Letter. The page size will be reset to Letter if System, More,

Testing Printer Operation

When you have completed the analyzer’s printer setup, press

Print Setup, then press Print on the

front panel. If the printer is ready and the printer setup was successful, a printout of the analyzer

display will be printed. If the pri nte r is not re ady, the message Printer Timeout will appear on the

analyzer display. Printer Timeout will remain on the display unt il the printe r is rea dy or unti l you

press

ESC to cancel the printout request.

NOTE There may be some small discrepancies in the color mapping of the analyzer

display to your color printer. Due to differences in display and printer

technologies, the default display colors do not map exactly to the printer colors.

For example trace 1 is yellow on your analyzer display while it maps to green on

your printer.

20 Chapter 1

Page 21

Installation and Setup

Protecting Against Electrostatic Discharge

Protecti ng Against Electrostatic Discharge

Electrostatic discha r ge ( ESD) can damage or destr oy elec troni c component s (the po ssibi lity of unseen

damage caused by ESD is present whenever components are transported, stored, or used).

Test Equipment and ESD

To help reduce ESD damage that can occur while using test equipment:

• Before connecting any coaxial cable to an analyzer connector for the first time each day,

momentarily short the center and outer conductors of the cable together.

• Personnel should be g rou nded with a 1 M resis tor-isolated wrist-strap before touching the center

pin of any connector and before removing any assembly from the analyzer.

• Be sure that all instruments are properly earth-grounded to prevent build-up of static charge.

WARNING Do not use these first three techniques when working on circuitry with a

voltage potential greater than 500 volts.

• Perform work on all components or assemblies at a static-safe workstation.

• Keep static-generating materials at least one meter away from all components.

• Store or transport components in static-shielding containers.

• Always handle printed circuit board assemblies by the edges. This reduces the possibility of ESD

damage to components and prevent contamination of exposed plating.

For information on ordering static-safe accessories, see “Accessories” on page 83.

Additional Information about ESD

For more information about ESD and how to preve nt ESD damage, contact t he Electrostati c Discharge

Association (http:// www .esda .org). The ESD st andards devel oped by this agenc y are sanction ed by the

American National Standards Institute (ANSI).

Chapter 1 21

Page 22

Installation and Setup

Safety Information

Safety Information

WARNING This is a Safety Class 1 Product (provided with a protective earth ground

incorporated in the power cord). The mains plug shall only be inserted in a

socket outlet pr ovided with a prot ective ea rth contact . Any inte rruption of t he

protective conductor inside or outside of the product is likely to make the

product dangerous. Intentional interruption is prohibited.

If this product is not used as specified, the protection provided by the

equipment could be impaired. This product must be used in a normal

condition (in which all means for protection are intact) only.

22 Chapter 1

Page 23

2 Front and Rear Panel Features

This chapter gives you an overview of the front and rear panels of your analyzer.

For details on analyzer keys and remote programming, refer to the User’s and

Programmer’s Guide. For connector specifications (including input/output le vel s) ,

see the Specifications guide.

23

Page 24

Front and Rear Panel Features

Front Panel Overview

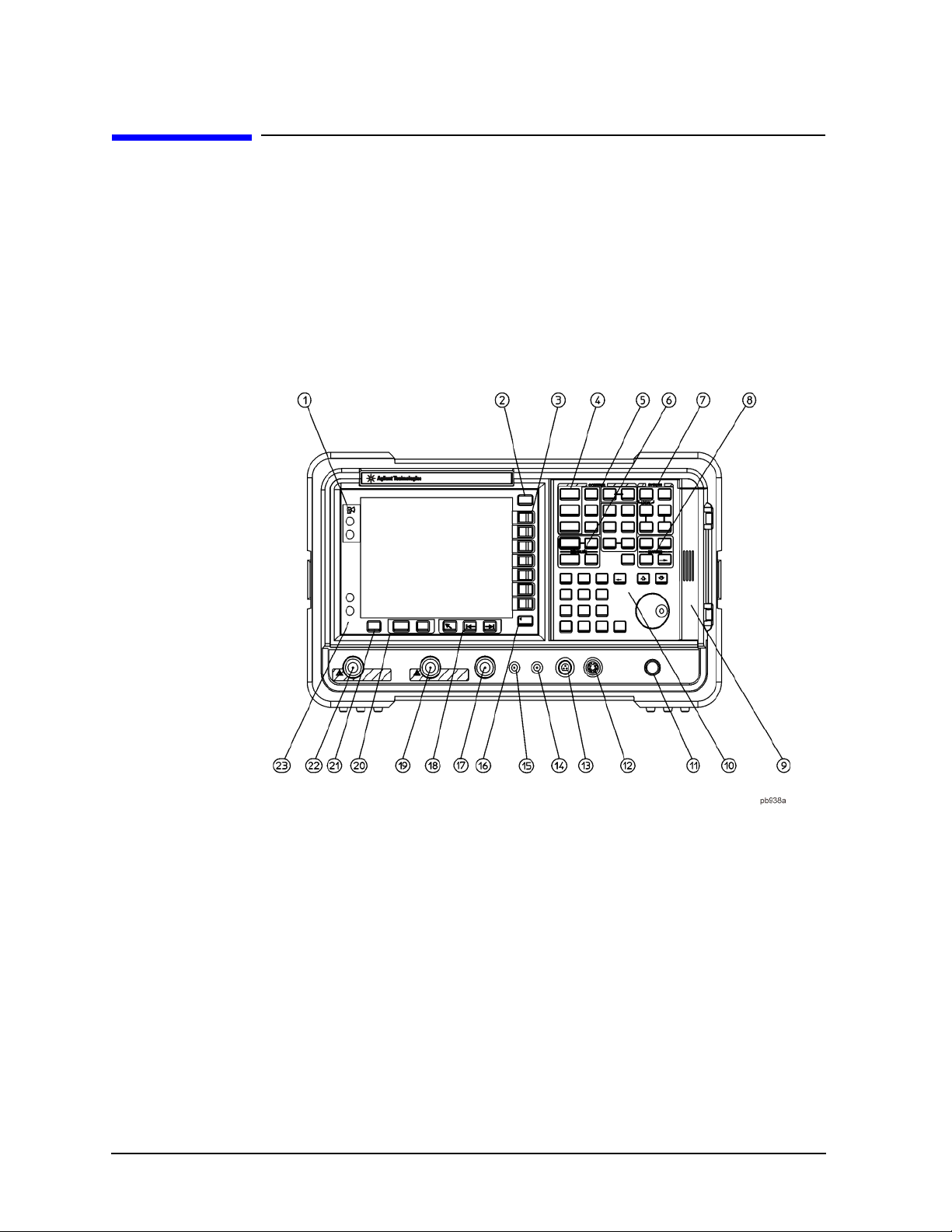

Front Panel Overview

This section provides information on the analyzer’s front panel, including:

• Front Panel Connectors and Keys, see below

• “Display Annotations” on page 28

Front-Panel Connectors and Keys

1 Viewing Angle keys adjust the display so that it can be optimally viewed from

different angles.

2 Esc. The Esc (escape) key cancels any entry in progress. Esc will abort a print (if

one is in progress) and cl ear er ror mess ages f rom the st atus l ine at the bot to m of the

display. It also clears input and tracking generator overload conditions.

3 Menu keys are the unlabeled keys next to the screen. The menu key labels are the

annotation on the scr een nex t to t he unla beled k eys. Mo st of t he lab eled ke ys o n the

analyzer front panel (also called front-panel keys) access menus of keys having

related functions.

4 FREQUENCY Channel, SPAN X Scale, and AMPLITUDE Y Scale are the three

large keys that activate the primary analyzer functions and access menus of related

functions. The secondary labels on these keys (Channel, X Scale, and Y Scale) are

24 Chapter 2

Page 25

Front and Rear Panel Features

Front Panel Overview

used in some measurements.

5 CONTROL functions access menus that adjust the resolution bandwidth, adjust the

sweep time, and control the analyzer display. They also set other analyzer

parameters needed for making measurements.

6 MEASURE accesses a menu of keys that automate some common analyzer

measurements. Once a measurement is running,

menu keys for defining your measurement.

Meas Setup accesses additional

Meas Control and Restart access

additional measurement control functions.

7 SYSTEM functions affect the state of the entire analyzer.

Various setup and alignment routines are accessed with the

The green

The

Preset key resets the analyzer to a known state.

File key menu saves/loads setups, traces, states, limit-line tables, screens,

System key.

measurement results, and amplitude correction factors to or from analyzer

memory or the floppy disk dri ve. Th e

Now

function defined under File in your User’s guide.

Print Setup menu keys configure hardcopy outputs. The Print key

The

Save key immediately exec ut es t he Save

immediately sends hardcopy data to the printer. See your User’s guide for more

details.

8 MARKER functions control t he ma rkers , read out frequ encies and ampl itude s alon g

the analyzer trace, automat icall y locat e th e signal s of highe st ampli tude, and access

functions like

9 The Media Door on the right side of the front panel ac cesses the 3.5 inch dis k drive

Marker Noise and Band Power.

and the Earphone connector. The earphone connector provides a connection for an

earphone jack which bypasses the internal speaker.

10 The Data Control Keys, which include the step keys, knob, and numeric keypad,

change the numeric value of an active function such as center frequency, start

frequency, resolution bandwidth, and marker position.

The data controls will change the active function in a manner prescribed by that

function. For example, y ou can change center f requency i n fine steps with th e knob,

in discrete steps with the step keys, or to an exact (1 Hz resolution) value with the

numeric keypad.

The Knob provides fine incremental changes of functions such as center

frequency, reference level, and marker position. Clockwise rotation of the knob

increases values. The extent of alteration is determined by the size of the

measurement range. The speed at which the knob is turned affects the rate at

which the values are changed.

For slow sweeps, the analyzer uses a smooth panning feature which is designed

to move the trace di splay to the la test fun ction val ue as the knob is t urned. When

center , s top or, s ta rt f re que ncy or reference level i s adj usted, the signal will shift

right or left or up or down with the rotation of the knob before a new sweep is

actually taken. An asterisk is placed in the message block (the upper right-hand

corner of the analyzer display) to indicate that the data on the screen does not

reflect da ta at the current setting.

Chapter 2 25

Page 26

Front and Rear Panel Features

Front Panel Overview

The Numeric Keypad allows entry of exact values for many of the analyzer

functions. You may include a decimal point in the number portion. If not, the

decimal point is placed at the end of the number.

Numeric entries must be terminated with a units key. When a numeric entry is

begun, the menu keys show the units key labels. The units keys change

depending on what the active function is. For example, the units keys for

frequency span are

level are

+dBm, dBm, mV, V, and A.

GHz, MHz, kHz, and Hz, whereas the units for reference

NOTE If an entry from the numeric keypad does not coincide with an allowed function

value (for example, that of a 12 MHz bandwidth), the analyzer defaults to the

nearest allowable value.

The Step Keys () increase or decrease the active function value. The step

size depends upon the current analyzer measurement. Each press results in a

single step change. For those parameters with fixed values (resolution

bandwidth), the next value in a sequence is selected each time a step key is

pressed. Step size i s predict able (e.g ., 10% of span for center freq uency) and c an

be set for some functions (i.e., center frequency). Out-of-range values or

out-of-sequence values will not occur using these keys.

11 VOLUME. The VOLUME knob adjusts the volume of the internal speaker. The

speaker is turned on and of f with the

12 EXT KEYBOARD. The EXT KEYBOARD connector is a 6-pin mini-DIN connec tor.

Speaker On Off key in the Det/Demod menu.

The keyboard can be used to enter screen titles and filenames.

NOTE To avoid damage to the analyzer, always turn off power before plugging a

keyboard into the analyzer.

13 PROBE POWER provides power for high-impedance ac probes or other

accessories. (+15 V, 12.6 V, 150 mA maximum)

14 LO OUTPUT provides the proper lo cal oscilla tor signa l for use wi th extern al mixers

(Option AYZ).

15 IF INPUT connects to the IF OUTPUT of the external mixer (Option AYZ).

16 Return. The Return key accesses the previously selected menu. Continuing to

press

Return accesses earlier menus. Ret urn als o term inate s entr y of alpha numeric

functions (e.g., Title).

17 AMPTD REF OUT provides an amplitude reference signal of 50 MHz at –20 dBm.

Agilent ESA models E4402B, E4403B, E4404B, E4405B, E4407B, and E4408B

only.

18 Tab Keys are used to move around in the Limit editor, the Correction editor and

similar table-driven forms.

19 INPUT 50 (INPUT 75 for Option 1DP) is the signal input for the analyzer.

26 Chapter 2

Page 27

Front and Rear Panel Features

Front Panel Overview

CAUTION When operating in dc coupled mode on analyzers with Option UKB, ensure

protection of the input mixer by limiting the input level to 0 Vdc, +30 dBm.

When operating in ac coupled mode, ensure protection of the input mixer by

limiting the input level to 50 Vdc, +30 dBm.

20 The Next Window key can be used to select the active window in functions which

support split-screen display modes, such as Zone markers. (Refer to “Zone” in the

User’s guide for more information.) In such modes, pressing

Zoom switches

between the split-screen and full-sized display of the active window.

21 Help. Press the Help key and then any front panel or menu key to get a short

description of the key function and the associated SCPI command. The next key

you press will remove the help window from the display.

22 RF OUT 50 for Option 1DN or RF OUT 75 (for Option 1DQ) is the source

output for the built-in tracking generator. Option 1DN or 1DQ only.

CAUTION If the tracking gen era tor output power is too high, it may damage the device under

test. Do not exceed the maximum power that the device under test can tolerate.

23 The (On) key turns the analyzer on, while the Standby key turns most of the

analyzer off. An analyzer alignment is performed (if

Auto Align is on) every time

the analyzer is turned on. After turning on the ana lyzer , allow 5 minu tes of warm-up

time to ensure the analyzer will meet all specifications.

NOTE The analyzer continues to draw power even if the line power switch is in standby.

The main power cord can be used as the system disconnecting device. It

disconnects the mains circuits from the mains supply. The front-panel switch is

only a standby switch and is not a LINE switch (disconnecting device).

Chapter 2 27

Page 28

Front and Rear Panel Features

Front Panel Overview

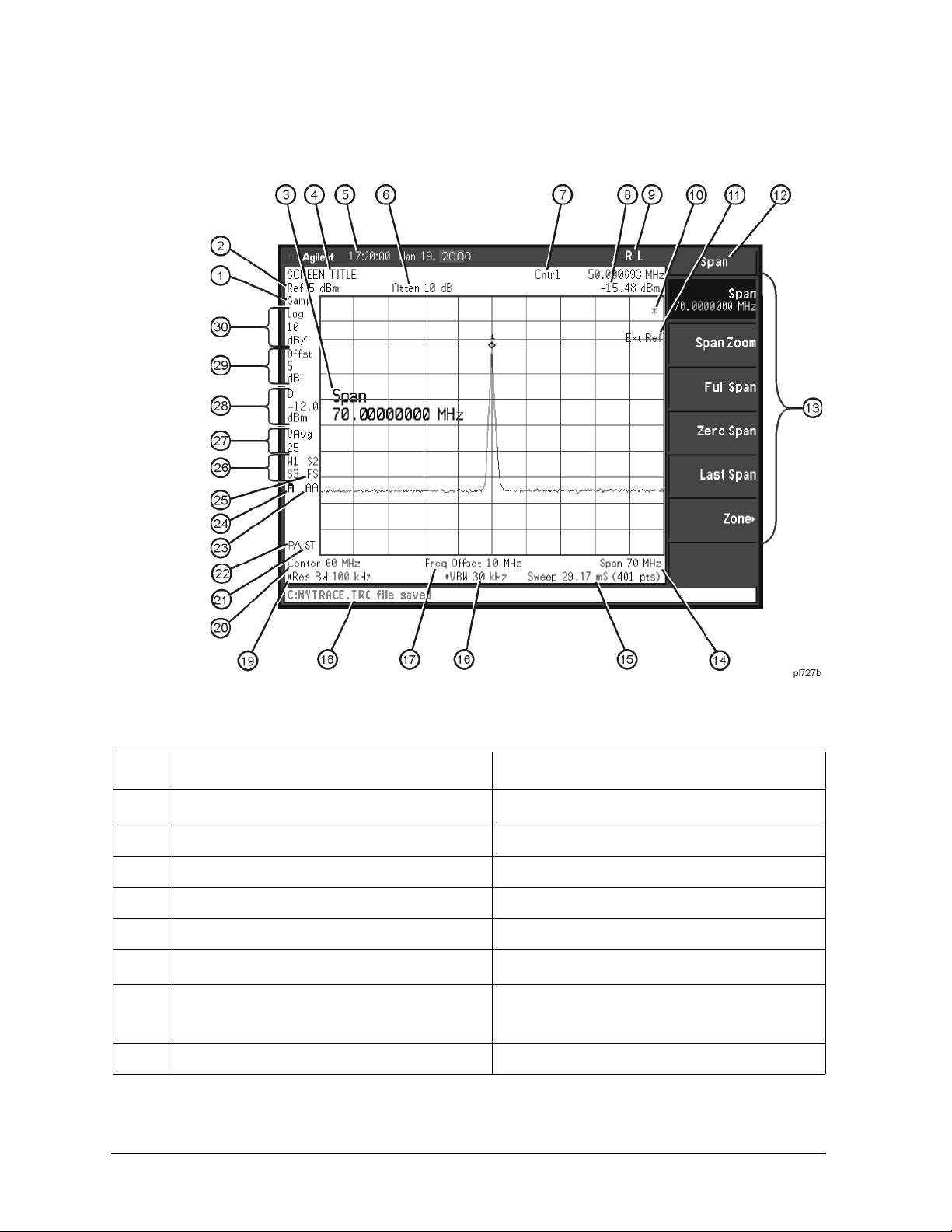

Display Annotations

Table 2-1 Screen Annotation

Item Description Associated Function Key

a

1

2 Reference level Ref Level

3 Active function block Refer to the description of the activated function.

4 Screen title

5 Time and date display Time/Date On Off

a,b

6

7 Marker frequency Marker or

8 Marker amplitude Marker

28 Chapter 2

Detector mode Detector

Change Title

RF attenuation Attenuation Auto Man

Marker Count On Off

Page 29

Front and Rear Panel Features

Table 2-1 Screen Annotation (Continued)

Item Description Associated Function Key

Front Panel Overview

9 GPIB annunciators

See programming documentation.

R - remote operation

L - GPIB listen

T - GPIB talk

S - GPIB SRQ

c

10

Data invalid indicator Sweep (Single) or View/Trace

11 Status Informational messages See your Instrument Messages and Functional

Tests manual for more information.

12 Key menu title Dependent on key selection.

13 Key menu See key label descriptions in the User’s guide for

more information.

14 Frequency span or stop frequency

Span or Stop Freq

15a Sweep time/Points Sweep Time Auto Man, Sweep Points

16a Video bandwidth Video BW Auto Man

17 Frequency offset Freq Offset

18 Display status line Displays analyzer status and error messages.

Cleared by pressing

Esc key. See your User’s

guide for more information.

19a Resolution bandwidth

Resolution BW Auto Man

20 Center frequency or start frequency Center Freq or Start Freq

21 Signal track Frequency, Signal Track

22 Internal preamp Amplitude, Int Preamp

d

23

24 Amplitude corrections are on (This indicates that

Auto alignment routine is on Auto Align

Correction On Off

the overall correction state is On. There may be

any or none of the individual corrections On.)

25 Trigger/Sweep

Trig, Sweep

F - free-run trigger

L - line trigger

V - video trigger

E - external (front) trigger

T - TV trigger (Options BAA, B7B only)

B - RF burst trigger (Opt B7E only)

C - continuous sweep

S - single sweep

Chapter 2 29

Page 30

Front and Rear Panel Features

Front Panel Overview

Table 2-1 Screen Annotation (Continued)

Item Description Associated Function Key

26 Trace mode

Trace

W - clear write

M - maximum hold

m - minimum hold

V - view

S - store blank

1 - trace 1

2 - trace 2

3 - trace 3

27 Average Average On Off

VAvg indicates video average on. PAvg indicates

power average on.

28 Display line

Display Line On Off

29 Amplitude offset Ref Lvl Offst

30 Amplitude scale Scale Type Log Lin

a. A # in front of any display annotation indicates that the function is uncoupled. (Refer to your User’s guide)

b. When the analyzer is set to the external mixer state (Option AYZ), item 6 changes to display Ext Mix in

place of Atten XdB. In addition, if Mixer Bias is on, a +I or I is appended to Ext Mix.

c. When the (*) is displayed, it means that some or all trace data may not match the anno tation due to po ssible

changes in analyzer settings.

d. AA indicates that auto alignment of all analyzer parameters, except the tracking generator and FM

demodulation options, will occur. AB indicates that auto alignment of all analyzer functions except the RF

section (and tracking generator and FM demodulation options) will occur. No indicator will appear if auto

alignment is off.

30 Chapter 2

Page 31

Rear-Panel Features

Front and Rear Panel Features

Rear-Panel Features

1 Power input is the input for the ac line power source. Make sure that the

line-power source outlet has a protective ground contact.

2 DC Power i s the inpu t for the dc power sour ce. Refer to the “Powe r Require ments”

section in the specifications guide for your analyzer.

CAUTION AC line power and dc power should not be plugged in simultaneously.

3 Line Fuse. The fuse is removed by twisting counterclockwise 1/4 turn. Replace

only with a fuse of the same rating. See the label on the rear panel.

4 Service Connector. The service connector is for service use only.

5 Inputs/Outputs (Refer to the specifications guide for more information.)

5a VGA OUTPUT drives an external VGA compatib le mo nit or wit h

a signal that has 31.5 kHz horizontal, 60 Hz vertical

synchronizing rate, non-interlaced.

5b GATE/HI SWP OUT (TTL) is high when the ana lyzer is s weeping

or when

5c GATE TRIG/EXT TRIG IN (TTL) accepts the positive edge of an

Gate (Option 1D6) is active.

external voltage input that triggers the analyzer internal sweep

source or the gate function (Time Gate, Option 1D6).

Chapter 2 31

Page 32

Front and Rear Panel Features

Rear-Panel Features

Table 2-2 and Table 2-3. show the appropriate rear panel slots to be used for the optional cards

available with the Agilent ESA Spectrum Analyzers. Refer to Table 2-2. if you have an Agilent

ESA-L Series Spectrum Analyzer. Refer to Table 2-3. if you have an Agilent ESA-E Series Spectrum

Analyzer.

(P) = Preferred Card Slot

(A) = Acceptable Card Slot

(–) = Unacceptable Card S l ot

Table 2-2 Agilent ESA-L Series (E4403B, E4408B, E4411B)

Slot # 1256

GPIB and Parallel (Option A4H) P A – –

Serial and Parallel Interface (Option 1AX) P A – –

IF, Video, and Sweep Ports (Option A4J) – – P –

Frequency Extension

a

––P

a. The Frequency Extension Assembly comes standard with the Agilent E4408B.

Table 2-3 Agilent ESA-E Series (E4401B, E4402B, E4404B, E4405B, E4407B)

Slot #

GPIB and Parallel Interface (Option A4H)

b

RS-232 and Parallel Interface (Option 1AX)b P A A A – –

Fast Time Domain Sweeps (Option AYX)

c

IF, Video, and Sweep Ports (Option A4J)c A A A A P A

FM Demodulation (Option BAA)

d

Noise Figure (Option 21 9) A A P A – –

Frequency Extension

e

Digital Signal Procession and Fast ADC

(Option B7D)

RF Communications Hardware (Option B7E) – – – – P –

a

1

23456

PAAA– –

–APA––

– APAAA

– AAAAP

–––P––

ACPR Dynamic Range Extension (Option 120) – P AAAA

Bluetooth

f

FM Demodulation (Option 106)d

,g

– APAAA

a. S ome cards may not be installed due to mechanical interference.

b. Only one optional remote interface (Option A4H or Option 1AX) can be installed at a time.

c. Only one IF and Sweep Port option (Option A4J or Option AYX) can be installed at a time.

d. Only one demod option (Option BAA or Option 106) can be installed at a time.

32 Chapter 2

Page 33

Front and Rear Panel Features

Rear-Panel Features

e. The Frequency Extension Assembly comes standard with the Agilent E4404B, E4405B and

E4407B.

f. Bluetooth

license.

g. Option 106 is required to make measurements in Bluetooth™ Measurement Personality

(Option 228)

6 GPIB and parallel interface (Option A4H) is an optional interface. GPIB supports

is a trademark owned by its proprietor and used by Agilent Technologies under

remote analyzer operation. A parallel port is included for printing only.

7 RS-232 and parallel interface (Option 1AX) is an optional interface. RS-232

supports remote analyzer operation. A parallel port is included for printing only.

NOTE Printing is only supported from the parallel port.

8 IF, Video, and Sweep Ports (Option A4J or Option AYX): (Refer to the

specifications guide for more information.)

SWP OUT provides a voltage ramp corresponding to the sweep of the analyzer

(0 V to 10 V).

HI SWP IN (TTL) can be grounded to stop and reset the sweep. Once the sweep

has been stopped, removing the ground will trigger the start of a new sweep.

HI SWP OUT (TTL) is high when the analyzer is sweeping.

AUX VIDEO OUT provides detected video output (before the analog-to-digital

conversion) proporti onal to vertic al deflecti on of the trace. Outp ut is from 0 V to

1 V. Amplitude-correction factors are not applied to this signal.

NOTE The video output signal may be blanked during retrace when automatic alignment

is on. This eff ect c an b e redu ced wit h longe r sweep times , or elimi nated by tur ning

Auto Align off. For more information, refer to the Alignments key description in

the ESA User’s and Programmers Reference, Volume 1.

AUX IF O U T is a 50 , 21.4 MHz IF output that is t he down -conve rted s ignal o f

the RF input of the analy zer. Amplitude-correction factors a re not appl ied to thi s

signal. This output is taken after the resolution bandw idth filters and step gains

and before the log amplifier.

NOTE Only one IF and Sweep Port option (Option A4J or Option AYX) can be installed

at a time.

9 FM Demod (Option BAA) demodulates, displays, and measures deviation on FM

signals. You can listen to audio signals on a built-in speaker or with an earphone.

Refer to “Det/Demod” and “FM Demodulation (Option BAA)” in the Options

chapter for more informati on.

Bluetooth

deviation on Bluetooth

Chapter 2 33

FM Demodulation (Option 106) demodulates, displays and measures

signals. Refer to “Det/Demod” and “Bluetooth FM

Page 34

Front and Rear Panel Features

Rear-Panel Features

Demodulation (Option 106)” in the Options chapter for more information.

10 Frequency Extension Assembly controls the microwave front-end components in

the Agilent E4404B, E4405B, E4407B, and E4408B.

PRESEL TUNE OUTPUT provides a signal to contr ol extern al presel ecte d mixers if

External Mixing (Option AYZ) is installed.

11 Card Slot Identification Numbers. Refer to Table 2-2 and Table 2-3 for card slot

versus option card compatibility information.

12 10 MHz REF IN accepts an ex ternal frequ ency source to prov ide the 10 MHz, 15 to

+10 dBm as a timebase.

NOTE It is not necessary to connect the 10 MHz REF OUT to t he 10 MHz REF IN on the

rear panel of the analyzer. Doing so will result in a Frequency Reference Error

message.

13 10 MHz REF OUT provides a 10 MHz, 0 dBm minimum, t imebase refer ence signal.

14 Power On Selection selects an analyzer power preference.

PWR ALWAYS ON setting turns the analyzer on whenever external power

The

is applied. This mode is useful if an external power switch is used to control a

rack of several instruments. Nevertheless, if you set the analyzer to standby

using the front panel

Standby key (see Figure 2-1. on page 22, item 23) and the

external power is removed and restored within 20 seconds, the analyzer will

remain in standby.

Power Always On

Analyzer state before removing

power

On On On

Standby Standby On

PWR NORM setting assigns analyzer on/off control to the front-panel On

The

and

Standby keys (see Figure 2-1. on page 22, item 23). If the analyzer is on

A lapse in power

< 20 sec.

A lapse in power

> 20 sec.

and the external power is removed and restored within 20 seconds, the analyzer

will turn on. On the other hand, if the external power is removed and restored

after 20 seconds, the analyzer will remain in standby regardless of the front

panel switch settings.

Power Norm

Analyzer state before removing

power

On On Standby

Standby Standby Standby

34 Chapter 2

A lapse in power

< 20 sec.

A lapse in power

> 20 sec.

Page 35

Front and Rear Panel Features

Rear-Panel Features

15 DC Fuse protects the analyzer fr om drawing to o much dc po wer . Re place onl y with

a fuse of the same rating. See the label on the rear panel.

Chapter 2 35

Page 36

Front and Rear Panel Features

Key Overview

Key Overview

The keys labeled FREQUENCY Channel, System, and Marker are all examples of front-panel keys.

The front-panel keys are dar k gray, light gray, green, or whi te in col or. Front-panel keys that are white

perform an immediate action rather than bringing up a menu. The only green key is the

which performs an analyzer reset (A summary of all front panel keys and their related menu keys can

be found in user’s guide for your analyzer). Pressing most of the dark or light gray front-panel keys

accesses menus of functions that are displayed along the right side of the display. These are called

menu keys.

Menu keys list functions ot her than tho se accesse d directl y by the front pa nel keys. To activate a menu

key function, press the key immediately to the right of the annotation on the screen. The menu keys

that are displayed depend on which front-panel key is pressed and which menu level is enabled.

If a menu key funct ion’s value can be changed, it i s cal led an ac tive functi on. The fu nctio n labe l of the

active function is highlighted after that key has been selected. For example, press

. This calls up t he menu of re lated ampl itude funct ions. Note t he fun ction label ed Ref Level (the

Scale

default selected key in the Amplitude menu) is highlighted.

Ref Level also appears in the active

function block, i ndicat ing t hat i t i s the acti ve ampl itude funct ion a nd can now be ch anged u sing any of

the data entry controls.

Preset key,

AMPLITUDE Y

A menu key with On and Off in its label can be use d to turn t he menu key’s function on or off. To turn

the function on, press the menu key so that On is underlined. To turn the function off, press the menu

key so that Off is underlined. In the manual, when On should be underlined, it will be indicated as

Function (On).

A function with Auto and Man in the label can either be auto-coupled or have its value manually

changed. The value of the function can be changed manually using the numeric keypad, knob, or step

keys. To auto-couple a function, press the menu key so that Auto is underlined. In the manual, when

Auto should be underlined, it will be indicated as Function (Auto).

In some key menus, one key label will always be highlighted to show which key has been selected.

For example, when you press

Marker, you will access a menu of keys in which some of the keys are

grouped together by a blue bar (on analyzers with a color display) on the left side of the menu. The

Normal key, which is the Marker menu default key, will be highlighted. When you press another key

within the blue bar region, such as

Delta, the highlight will move to that key to show it has been

selected.

36 Chapter 2

Page 37

Front and Rear Panel Features

Key Overview

In other key menus, one key label will always be highli ghted to show which key ha s bee n selec ted but

the menu is immediately exited when a selection is made. For example, when you press the

Orientation key (on the Print Setup menu), it will bring up its own menu of keys. The Portrait key,

which is the Orientation menu default key, will be highlighted. When you press the

Landscape key,

the highlight will move to that key to show it has been selected and the screen will return to the

Print Setup menu.

The arrow keys locat ed be low the analyzer dis play (sometimes refer re d t o as Tab keys) ca n b e used to

navigate within tables, for example the Limit-Line table. These keys are used to move between rows.

The Left-arrow key moves up, while the right-arrow key moves down. While navigating through the

table, the cursor (inverse video highlight) stays in the same column. Navigating left or right in the

table is accomplished by choosing the desired field using the front-panel keys.

Chapter 2 37

Page 38

Front and Rear Panel Features

Front and Rear Panel Symbols

Front and Rear Panel Symbols

This symbol is used to indicate power ON (green LED).

This symbol is used to indicate power STANDBY mode (yellow LED).

This symbol indicates the input power required is AC.

The instruction documentation symbol. The product is marked with this symbol

when it is necessary for the user to refer to instructions in the documentation.

The CE mark is a registered trademark of the European Community.

The C-Tick mark is a r egistered t rademark o f the Austral ian Spectrum M anagement

Agency.

This ISM device complies with Canadian ICES-001.

Cet appareil ISM est conforme a la norme NMB du Canada.

This is also a symbol of an Industrial Scientific and Medical Group 1 Class A

product (CISPR 11, Clause 4).

The CSA mark is a registered trademark of the CSA International.

This symbol indicates separate collection for electrical and electronic equipment

mandated under EU law as of August 13, 2005. All electric and electronic

equipment are required to be separated from normal waste for disposal (Reference

WEEE Directive 2002/96/EC).

Indicates the time period during which no hazardous or toxic substance elements

are expected to leak or deteriorate during normal use. Forty years is the expected

useful life of the product.

This symbol on all pri mary and secondar y packagin g indicat es comp liance t o China

standard GB 18455-2001.

This equipment is Class A suitable for professional use and is for use in

electromagnetic environments outside of the home.

38 Chapter 2

Page 39

3 Making a Basic Measurement

This chapter provides information on basic analyzer operation. For more information on making

measurements, see the measurement guide for your analyzer.

39

Page 40

Making a Basic Measurement

This chapter is divided into the following sections:

•“Using the Front Panel” on page 41

•“Presetting the Spectrum Analyzer” on page 42

•“Viewing a Signal” on page 43

CAUTION Ensure that the t ot al power of all signals at the analyzer inp u t does not exceed +30

dBm (1 watt).

Basic Assumption

The material in this chapter is presented with the assumption that you understand the front and rear

panel layout, and display annotations of your analyzer. If you do not, refer to “Front and Rear Panel

Features” on page 23.

NOTE The display examples in this book are made using various analyzer models, you

may see some variations depending upon your analyzer.

40 Chapter 3

Page 41

Making a Basic Measurement

On Off

Signal Track

Catalog

dBm

Y Axis Units

13.2550000 GHz

CF Step

10.00 dB

Auto Man

Attenuation

Using the Front Panel

Using the Front Panel

Entering Data

When setting measurement parameters, there are several ways to enter or modify the value of the

active function:

Knob

Arrow Keys

Numeric Keypad

Unit Softkeys

Enter Key

Increments or decrements the current value.

Increments or decrements the current value.

Enters a specific value. Then press the desired terminator (either a unit

softkey, or the

Terminate a value that req uires a unit-of-measur e m e nt .

Terminates an entry when either no unit of measure is needed, or you want to

use the default unit.

Enter key).

Using Menu Keys

Menu Keys (which appear along the right side of the display) provide access to many analyzer

functions. Here are examples of menu key types:

Toggle Allows you to activate/deactivate states.

Example: Toggles the selection (underlined choice) each

time you press the key.

Submenu Displays a new menu of softkeys.

Example: A submenu key allows you to view a new menu of

softkeys rela ted to the submenu key category.

Choice Allows you to make a selection from a list of values.

Example: A choice key displays the currently selected

submenu choice, in this example, dBm. When the

choice is made, the submenu automatically

returns.

Adjust Highlights the softkey and sets the active function.

Examples: Press this type of key and enter a value.

The default for softkeys with an automatic (

or manual (

enter a value, the selection changes to manual.

You can also press the softkey twice to change to

manual.

Man) choice is automatic. After you

Auto)

Chapter 3 41

Page 42

Making a Basic Measurement

Presetting the Spectrum Analyzer

Presetting the Spectrum Analyzer

Preset provides a known starting point for making measurements. The analyzer has three types of

preset:

Factory Preset Restores the analyzer to its factory-defined state.

User Preset Restores the analyzer to a user-defined state.

Mode Preset This type of preset restores the currently selected mode to a known state.

For details, see the User’s/Programmer’s manual.

Preset Type is set to Factory, pressing the green Preset key triggers a factory preset. When

When

Preset Type is set to User, pressing Preset displays th e softkeys Factory Preset, User Preset, and

Mode Preset (if applicabl e) ; you then select the pre set you want. If Preset Type is set to Mode, but a

personality is not installed, pressing

Creating a User Preset

Preset triggers a factory preset.

If you constantly use settings which are not the factory defaults, use the following steps to create a

user-defined preset:

1. Set analyzer parameters as desired.

2. Press

System, Power On/Preset, Save User Preset to set the current parameters as the user

preset state.

3. Press

Preset to select User in the same softkey menu to enable user preset as an option.

Disabling User Preset

Go to the Power On/Preset menu (press

Factory or Mode.

System, Power On/Preset) and select a Preset Type of

42 Chapter 3

Page 43

Making a Basic Measurement

10 MHz

Viewing a Signal

Viewing a Signal

1. Press Preset. If the softkeys Factory Preset and User Preset appear, select Factory Preset.

2. Connect the analyzer’s rear panel 10 MHz REF OUT to the front-panel input.

Setting Reference Level and Center Frequency

NOTE The display examples in this section are made using various analyzer models, you

may see some variations depending upon your analyzer.

3. Set the reference level to 10 dBm: Press

4. Set the center frequency to 30 MHz: Press

AMPLITUDE, 10, dBm.

FREQUENCY, Center Freq, 30, MHz.

The 10 MHz reference signal spectrum appears on the display, as shown in Figure 3-1.

NOTE The display examples in this book are made using various analyzer models, you

may see some variations depending upon your analyzer.

Figure 3-1 10 MHz Internal Reference Signal and Associated Spectrum

Chapter 3 43

Page 44

Making a Basic Measurement

10 MHz

Viewing a Signal

Setting Frequency Span

5. Set the frequency span to 50 MHz: Press

This displays the signal as shown in Figure 3-2.

Figure 3-2 Span Changed to 50 MHz

SPAN, 5, 0, MHz.

Reading Frequency & Amplitude

6. Place a marker (labeled 1) on the 10 MHz peak, as shown in Figure 3-3.

Peak Search.

Press

Note that the frequency and amplitude of the marker appear both in the active function block, and

in the upper-right corner of the scree n. You can use the knob, the arrow keys, or th e softk eys in the

Peak Search menu to move the marker. Pressing

7. If you have moved the marker, return it to the peak of the 10 MHz signal.

Esc removes the value from the display.

Changing Reference Level

8. Press

AMPLITUDE, and note that reference level (Ref Level) is now the active function. Press

Marker ➞Mkr ➞ Ref Lvl.

Note that changing the reference level changes the amplitude value of the top graticule line.

Figure 3-4 shows the relationship between center frequency and reference level. The box

represents the analyzer display. Changing the center frequency changes the horizontal placement

of the signal on the display. Changing the reference level changes the vertical placement of the

signal on the display. Increasing the span increases the frequency range that appears horizontally

across the display.

44 Chapter 3

Page 45

Figure 3-3 A Marker on the 10 MHz Peak

Marker Active function

Making a Basic Measurement

Viewing a Signal

Figure 3-4 Relationship Between Frequency and Amplitude

Chapter 3 45

Page 46

Making a Basic Measurement

Viewing a Signal

Improving Frequency Accuracy

9. While not all of the zeros following the decimal in the active function block are significant, the

numbers after the decimal in the marker annotation (upper-right corner of screen) are significant.

To improve the accuracy of the frequency reading in the marker annotation, turn on the frequency

count function by pressing

Freq Count.

10.Note softkey

Marker Count On Off. If Off is underlined, press the softkey to toggle marker count

on.

As shown in Figure 3-5:

• The marker annotation changes from Mkr1 to Cntr1.

• The displayed resolution in the marker annotation improves.

NOTE When you use the frequency count function, if the ratio of the resolution

bandwidth to the span is less than 0.002, the following message appears on the

display: Marker Count: Widen Res BW

This indicates that the resolution bandwidth is too narrow.

11.Press

Marker ➞, Mkr ➞ CF to move the 10 MHz peak to the center of the display.

Valid Marker Count Range

12.Move the marker down the skirt of the 10 MHz peak. Note that although the readout in the active

function changes, as long as the marker is at least 26 dB above the noise, the counted value

(upper-right cor ner of disp lay) do es no t change (see Figure 3-6). For an accurate co unt, the marke r

does not have to be at the exact peak.

NOTE Marker count functions properly only on CW signals or di scret e peaks. For a valid

reading, the marker must be 26 dB above the noise.

13.Press

BW/Avg, Res BW, then enter a new value. This action makes the resolution bandwidth the

active function and allows you to experiment with different resolution bandwidth (RBW) values.

14.Press

Marker, Off to turn the marker off.

NOTE After properly sett ing t he anal yzer to dis play yo ur s ignal , you ca n save t he set ting s

as either a user preset (press

System, Power On/Preset, Save User Preset), or a

file (see “Saving a File” on page 55).

46 Chapter 3

Page 47

Figure 3-5 Increasing Marker Frequency Accuracy

Frequency Count

increases accuracy

Making a Basic Measurement

Viewing a Signal

Figure 3-6 Using Marker Counter

Chapter 3 47

Page 48

Making a Basic Measurement

Viewing a Signal

48 Chapter 3

Page 49

4 Viewing Catalogs and Sa ving Files

49

Page 50

Viewing Catalogs and Saving Files

The analyzer stores and retriev es data simi larly to the way that a personal c omputer (PC) d oes: both ha ve

internal storage and a fl oppy disk drive. While a PC has an int er nal drive, the analyzer’s internal st ora ge

is nonvolatile (fl ash) memory, which acts as an internal drive. As with a PC, both t he internal storage a nd

the floppy disk drive have directory and sub-directory capability; in the analyzer, directories and

subdirectories are called catalogs.

This chapter tells you how to:

• locate catalogs and view files, on page 51.

• save a file, on page 55.

For more information on catalogs and files, see the Measurement guide.

50 Chapter 4

Page 51

Viewing Catalogs and Saving Files

File Menu Functions

File Menu Functions