Page 1

User’s Guide

Agilent Technologies 14761A

Harmonic and Flicker Emissions Tests

for

EN 61000-3-2, EN 61000-3-3,

and EN 60555 Part 2

Agilent Part No. 5962-0831

Microfiche Number 5962-0832

Printed in USA May, 2000

Page 2

Notice

This document contains proprietary information protected by copyright. All rights are reserved. No part of this

document may be photocopied, reproduced, or translated into another language without the prior consent of Agilent

Technologies. The information contained in this document is subject to change without notice.

Copyright 1995 -1998, 2000 Agilent Technologies, Inc.

Windows is a registered trademark of Microsoft Corporation.

Warranty

This Agilent Technologies software product is warranted against defects in materials and workmanship for a period

of 90 days from date of delivery. During the warranty period, Agilent Technologies will, at its option either repair or

replace parts which prove to be defective.

Agilent Technologies makes no express or implied warranty of any kind, including, but not limited to the implied

warranties of merchantability or fitness for a particular purpose, with regard to the program material contained

herein. Agilent Technologies shall not be liable for incidental or co nsequential damages in connection with or arising

out of the furnishing, performance, or use of this software.

Use of the supplied manual and software is restricted to Agilent ac source products only. The software is copyrighted

and may not be copied except for archival purposes, to replace a defective copy, or for program error verification.

Agilent Technologies warrants that this software designed for use with a personal computer, will execute its

programming instructions when properly installed on that personal computer. Agilent Technologies does not warrant

that the operation of the personal computer , software, or ac source will be uninterrupted or error free.

Limitation of Warranty

The foregoing warra nty shall not apply to defects resulting from: misuse, unauthorized modifica tion, operation or

storage outside the environmental specifications for the product, in-transit damage, improper maintenance, or defects

resulting from use of non-Agilent software, accessories, media, or such items not designed for use with the product.

Revisions

Revision codes on the Agilent 14761A HFTS software indicate the current revision. Minor changes to the software

such as bug fixes usually do not require a change to the manual. Therefore, the revision number of the software may

be higher than the software revision number shown below, yet the information in the manual still applies.

Software changes that require a change to the manual will be accompanied either by a new edition of the manual or

an update packet documenting the changes. In that case, the software revision number shown below will be updated

to agree with the revision number of the software.

This manual applies to software revision... A.05.03

Printing History

The manual printing date indicates the current edition. The printing date changes with each new edition or update.

Update packets or change sheets may be issued between editions to correct or add information. Minor corrections

incorporated at reprint do not cause a new edition.

August, 1995.........First Edition

October, 1995........Update 1

February, 1997.......Second Edition

June, 1997..............Third Edition

December, 1998......Fourth Edition

May, 2000...............Fifth Edition

2

Page 3

Table of Contents

Notice 2

Warranty 2

Limitation of Warranty 2

Revisions 2

Printing History 2

Table of Contents 3

1 INTRODUCTION 7

How to Use this Manual 7

The Agilent 6800-Series AC Power Source/Analyzer 8

The Agilent 14761A Harmonic/Flicker Test System Software 8

EN 61000-3-2 and EN 60555 Part 2 Regulations 9

Compliance Testing Implementation 9

EN 61000-3-3 Regulation 10

Compliance Testing Implementation 10

2 INSTALLATION 11

Install the Software 11

Connect the Equipment 11

Installing Interface Card Drivers for Windows 3.1 or 3.11 Systems 12

Installing Interface Card Drivers for Windows 95 Systems 12

Installing Interface Card Drivers for Windows NT 4.0 Systems 12

Verify the Configuration 12

Default Settings 14

Getting Around in the Application 14

Drop-down Menu 14

Menu Tabs 16

3 SETTING UP THE TEST 17

Select a Test Type 17

Create a Template 19

Select the Test Setup Options for Quasi-stationary or Fluctuating Harmonics 20

Standard Test Options 20

Advanced Test Options 21

Test Termination Options 23

Select the Test Options for Voltage Fluctuations 24

Standard Test Options 24

Advanced Test Options 25

Test Termination Options 26

4 RUNNING THE TEST 27

To Run a Pre-test for Quasi-stationary or Fluctuating Harmonics 27

Pre-Te st Summary 27

Pre-Test Power Statistics 29

Pre-Test Source Harmonics 30

To Run a Pre-test for Voltage Fluctuations 31

Pre-Te st Summary 31

Pre-test Measurements 32

To Run a Test 33

Test Status Information 35

Validation Mode 36

3

Page 4

5 VIEWING TEST DATA 37

Navigator Toolbar 37

Viewing Quasi-stationary and Fluctuating Harmonics 38

Graph Display 38

Table Display 41

Time-Series Display 42

Statistics Display 45

Probability Display (for Quasi-stationary or Fluctuating harmonics) 46

Viewing 2.5 Minute Window Failures 47

Viewing Voltage Fluctuations 49

Pst Display 49

Probability Display (for Voltage Fluctuations and Flicker) 50

Distribution Display 52

RMS Display 53

Flicker Display 54

Editing the Graph Attributes 56

Copying Graphs and Tables to the Clipboard 57

Using the Print Screen keyboard key 57

Using the Copy Commands 57

Viewing Reports 58

Causes for Non-compliant EN 61000-3-2 or EN 60555-2 Tests 58

Causes for Non-compliant EN 61000-3-3 Tests 58

Short Form Report 59

Long Form Report 60

Remarks Report 63

6 SEARCHING FOR SPECIFIC TEST DATA 65

Searching for Data While the Test is Running 65

Searching for Data After the Test has Completed 65

Using the Span Control 66

Using the Zoom Control 67

Obtaining Detailed Failure and Error Information 68

7 PRINTING 69

Printing Graphs and Tables 69

Using the Print Pre-test command 69

Using the Print Graph/Table command 69

Printing Reports 69

From the File menu 69

From the Report window 70

Printing Reports to a File 70

A SPECIFICATIONS 73

Supported or Referenced EN 61000-3-2 and EN 60555 Part 2 Standards 73

Supported or Referenced EN 61000-3-3 Standards 73

PC Requirements 73

Supported GPIB Interfaces 73

Supported Equipment 73

Equipment Specifications (IEC Mode) 74

B GLOSSARY 77

4

Page 5

C IEC MODE COMMAND SUMMARY 81

Introduction 81

Using the SENSe:CURRent:ACDC:RANGe command 81

CALCulate:INTegral:TIME 83

CALCulate:SMOothing 83

CALCulate:LIMit:UPPer 84

FORMat 85

FORMat:BORDer 86

MEASure:ARRay:CURRent:HARMonic? 87

MEASure:ARRay:VOLTage:FLUCtuations:ALL? 88

MEASure:ARRay:VOLTage:FLUCtuations:FLICker? 90

MEASure:ARRay:VOLTage:FLUCtuations:PST? 91

SENSe:CURRent:PREFerence 92

SENSe:WINDow 92

SYSTem:CONFigure 93

D CLASS DETERMINATION 95

Class A Device Selected 96

Class B Device Selected 97

Class C Device Selected 98

Class D Device Selected 99

EN 60555 Part 2 Regulation Selected 100

INDEX 101

5

Page 6

Page 7

1

Introduction

How to Use this Manual

This manual describes the operation of the Agilent 14761A Harmonic/Flicker Test System (HFTS)

software when used in conjunction with the Agilent 6800-Series AC Power Source/Analyzers. Its

primary function is as a reference manual. If you have a question about a specific screen or how to

perform a certain task, simply turn to the appropriate section of the manual. The manual is organized

according to the procedure that you would follow if you were to run a compliance test. This manual

assumes that you are familiar with the EN 61000-3-2 and EN 61000-3-3 regulations and their

requirements. It also assumes that you are familiar with operating a personal computer in a Microsoft

Windows environment.

The manual is organized as follows:

Chapter 1 provides an overview of the regulations and how compliance testing to these regulations is

implemented with the Agilent 14761A HFTS software.

Chapter 2 describes how to install the software and get it running. It describes some pitfalls to avoid so

that operation of the software will be glitchless and error-free.

Chapter 3 describes what you need to do to before you can run a test. There is certain information that

you need to provide about the Device Under Test as well as setting up the Agilent 6800-Series AC Power

Source/Analyzer.

Chapter 4 explains what happens when the pre-test and the compliance test is run.

Chapter 5 describes how to view the test data both while the test is running and after the test completes.

Chapter 6 describes the software tools available to find and display specific test data.

Chapter 7 explains how to print graphs and test reports.

Appendix A lists the product specifications

Appendix B is a glossary of terms related to the EN 61000-3-2 and EN 61000-3-3 Regulations.

Appendix C is for programmers. It describes the SCPI programming commands that implement the

harmonic/flicker tests.

Appendix D explains the class determination logic of the Agilent 14761A HFTS software, and how this

logic is used to set test limits.

7

Page 8

1 - Introduction

The Agilent 6800-Series AC Power Source/Analyzers

The Agilent 6800-Series AC Power Source/Analyzers are specifically designed for testing products

compliant to the IEC low-frequency emissions regulations for quasi-stationary current harmonics,

fluctuating current harmonics, and voltage fluctuations and flicker. The following models provide up to

full power coverage of the single-phase regulatory requirements:

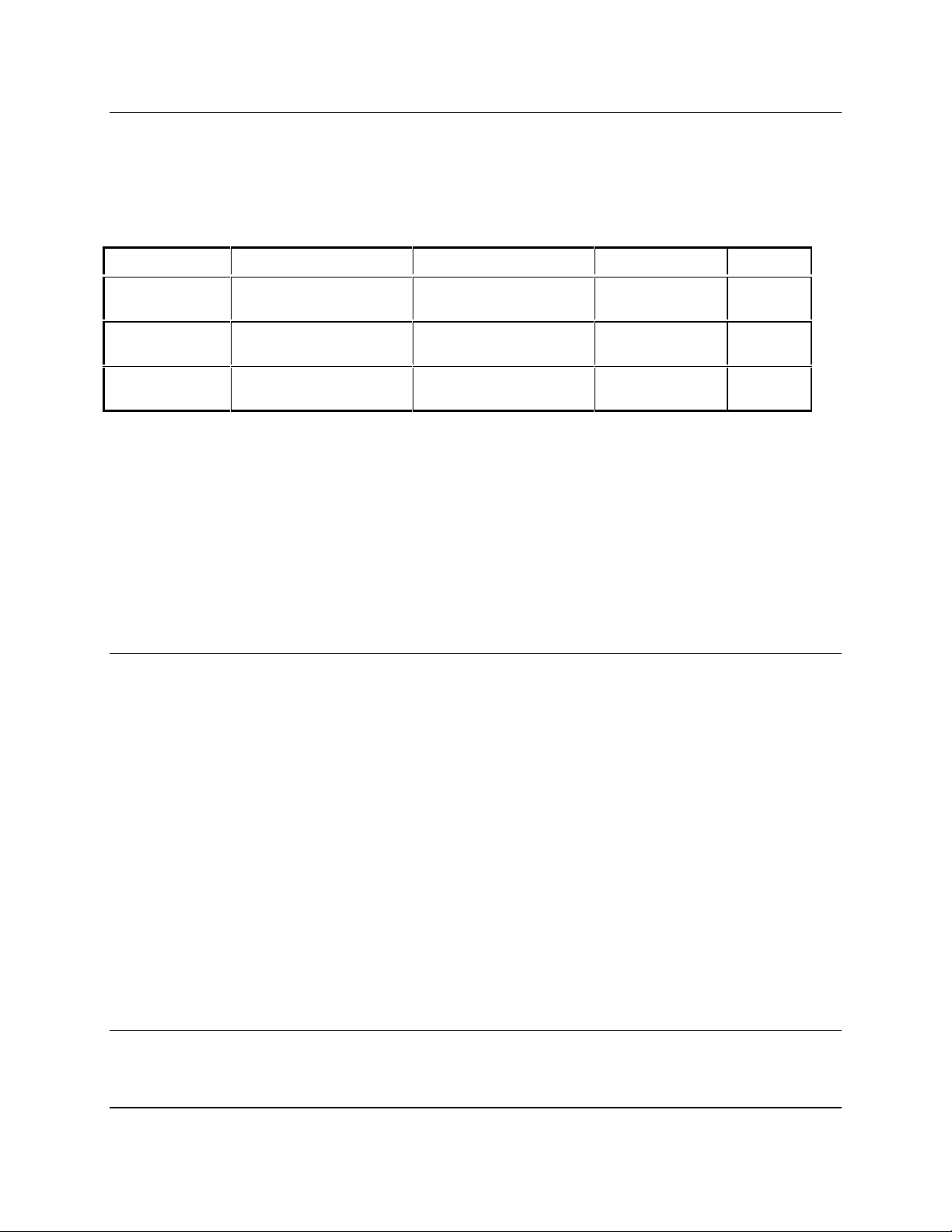

Model rms Voltage rms Current peak Current VA

Agilent 6812B

Agilent 6841A

Agilent 6813B

Agilent 6842A

Agilent 6843A

230 Vrms (compliance)

300 Vrms (maximum)

230 Vrms (compliance)

300 Vrms (maximum)

230 Vrms (compliance)

300 Vrms (maximum)

3.3 Arms (compliance)

6.5 Arms (maximum)

7.6 Arms (compliance)

13 Arms (maximum)

16 Arms (compliance)

32 Arms (maximum)

40 A 750 VA

80 A 1750 VA

96 A (low range)

48 A (high range)

4800 VA

Each one-box test system contains the capabilities of a stand-alone ac source, power analyzer, flicker

meter, and line impedance network. Unlike multiple-box ac source and measurement configurations, the

power generation and measurement of the Agilent 6800-Series are controlled by a common internal

timebase, and are truly synchronized. This allows precise measurement of harmonics.

In addition to compliance testing, you can also use the Agilent 6800-Series AC Power Source/Analyzers

as standard ac sources. The units have a SYSTem:CONFigure command that that lets you switch

between IEC mode and Normal mode (the default), where the units behave as standard ac sources. When

you run the Agilent 14761A HFTS software, the units automatically switch from Normal to IEC mode.

The Agilent 14761A Harmonic/Flicker Test System Software

The Agilent 14761A Harmonic/Flicker Test System (HFTS) software application supports EN 61000-32,

EN 61000-3-3, and EN 60555 Part 2 compliance testing requirements. The Agilent 14761A HFTS

software provides an intuitive graphical user-interface from which you can:

ñ Set up and run compliance-level tests. The setting up of many IEC details is facilitated through

the use of embedded standards expertise.

ñ Collect real-time test data from the Agilent 6800-Series AC Power Source/Analyzer.

ñ Display and monitor ongoing test results.

ñ Save test results.

ñ Terminate tests based on user-defined criteria.

ñ Analyze failures or marginal results using advanced test, display, and search options.

ñ Evaluate the long-term test results compared to pass/fail criteria.

ñ Print reports and graphs.‘

See Appendix A for a complete list of supported standards and regulations.

Note A selection in the Options/Default menu lets you compliance test to the older

EN 60555 Part 2 (IEC 555-2) regulation. The EN 60555-3 (IEC 555-3) regulation is no

longer a requirement and has officially been replaced by EN 61000-3-3.

8

Page 9

Introduction - 1

EN 61000-3-2 and EN 60555 Part 2 Regulations

EN 61000-3-2 and EN 60555 Part 2 regulate the magnitude of harmonic currents drawn by products

from the ac line. For example, harmonic currents can occur as a result of high peak currents drawn by

switch-mode power supplies. Power companies, particularly in Europe, have led a regulatory initiative to

limit harmonic current generation at the product level because of a variety of undesirable effects on the

mains environment such as: interference with other equipment, overheating of conductors and power

factor correction networks, and power transmission losses. Personal computers, peripherals, and variable

speed motor drives are examples of the types of products addressed by the regulations.

EN 61000-3-2 and EN 60555 Part 2 actually cover two categories of harmonic currents: quasi-stationary

harmonics and fluctuating harmonics. Power supply manufacturers, for example, may be concerned

primarily with the first category while product manufacturers may be concerned with both categories.

Different measurement techniques are used for determining compliance for the two categories, with more

stringent testing requirements applied to testing fluctuating harmonics. In particular, compliance testing

for fluctuating harmonics requires non-stop harmonic analysis over extended periods of time. The EN

61000-3-2 regulation applies to class A, B, C, D, and motor-driven equipment.

The EN 60555 Part 2 regulation only applies to class A and class B equipment. This regulation is

selected in the Options/Defaults menu. See appendix D for information about class determination.

Compliance Testing Implementation

The Agilent 14761A HFTS software compliance tests to EN 61000-3-2 / EN 60555 Part 2 as follows:

ñ It initializes and programs the Agilent 6800-Series AC Power Source/Analyzer.

ñ After the pre-test, the software displays one cycle of voltage and current, which represents the

average of all half-cycle measurements made during the pre-test, with Class D envelope

information superimposed over the waveshapes. Rms voltage, frequency, rms current, peak

current, real power, apparent power, power factor, voltage distortion, current distortion, and

percent in envelope are displayed as well. An additional display indicates if the harmonic-by-

harmonic voltage distortion is either “IN SPEC” or ”OUT OF SPEC” as per the regulations for

source distortion. This is based on the worst-case results obtained during the pre-test.

ñ During the compliance test, the software produces a real-time bar graph that represents either the

absolute magnitudes of 40 harmonics, or the magnitudes of 40 harmonics expressed as a

percentage of the applicable limits. The graph display shows both the maximum measured value

and the value of the present data record. The value of the present data record is continually

updated while the test is running. A time-series graph is available to display test data for a

specific harmonic.

ñ The software also produces a table that displays either the absolute magnitudes of 40 harmonics,

or the magnitudes of 40 harmonics expressed as a percentage of the applicable limits in real-time.

The table shows both the peak data values and the present data values. Note that you can also

display the data of any individual harmonic versus time, either as an absolute magnitude or as a

percentage of the allowable limits.

ñ When testing fluctuating harmonics, the software uses a 2.5 minute sliding window. Within this

window harmonic peaks of up to 150% of the steady-state harmonic limits are allowed, provided

that these samples do not total more than 10% of the total samples (or 15 seconds of time) within

any 2.5 minute observation period. Samples that contribute to a 2.5 minute window failure must

fall between 100% and up to 150% of the steady-state harmonic limits. Values greater than 150%

of the limits are counted as individual failures.

9

Page 10

1 - Introduction

EN 61000-3-3 Regulation

EN 61000-3-3 regulates the magnitude, rate, and time-duration of voltage fluctuations and flicker

caused by products connected to the ac line. Voltage fluctuations are created by time-varying current

drains working against branch circuit impedance that exists in all power distribution networks. Flicker

occurs when an incandescent lamp changes in intensity due to the frequency and amplitude of voltage

fluctuations in the same branch circuit.

Because flicker is annoying, and for certain individuals presents a health hazard, the regulation seeks to

regulate flicker generation to an imperceptible level. A specialized instrument called a flickermeter,

which is built into the Agilent 6800-Series AC Power Source/Analyzer, is used to measure flicker in

terms of human perceptibility. A perceptibility level of 1 represents the threshold of perception for the

average individual.

Note that the EN 60555-3 (IEC 555-3) regulation is no longer a requirement and has officially been

replaced by EN 61000-3-3.

Compliance Testing Implementation

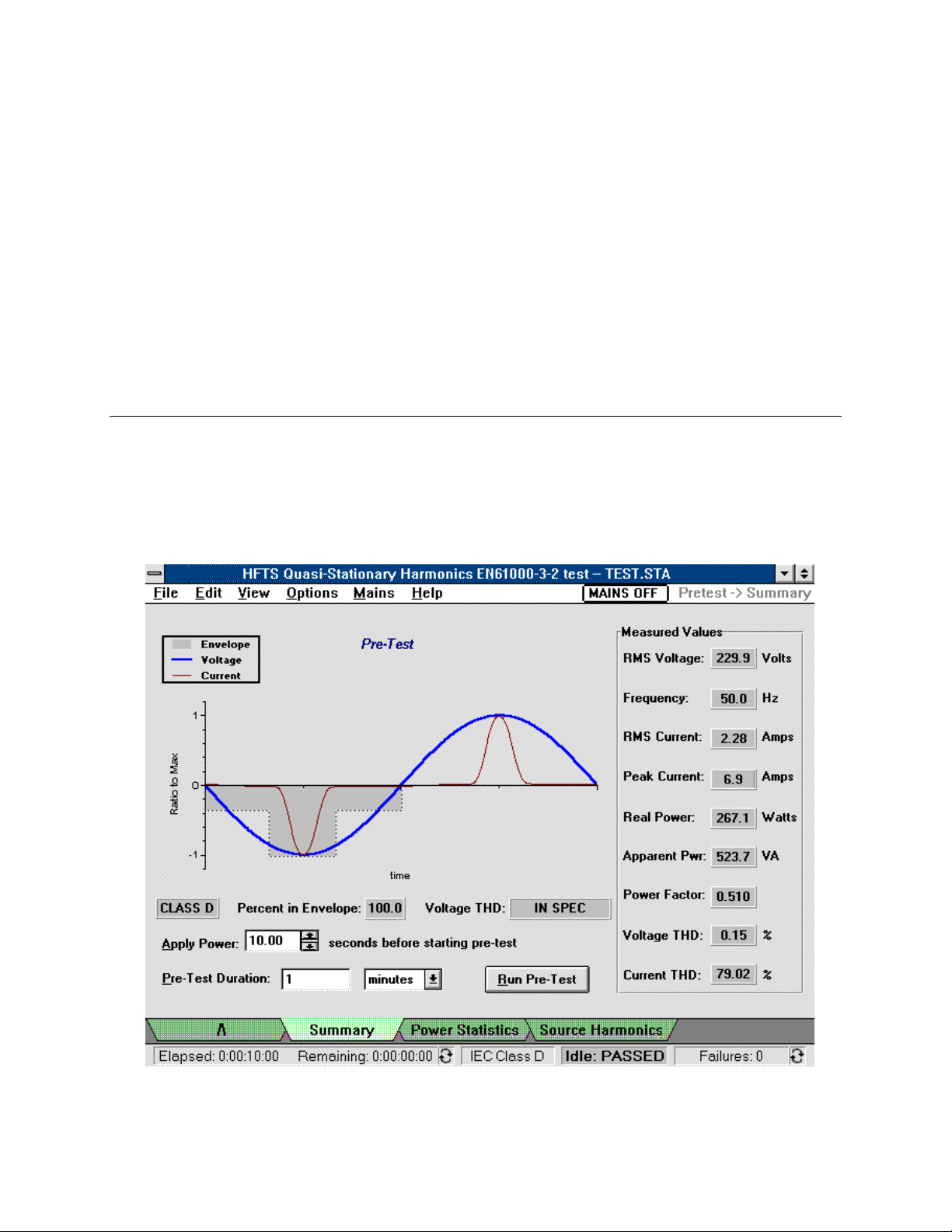

The Agilent 14761A HFTS software compliance tests to EN 61000-3-3 as follows:

ñ It initializes and programs the Agilent 6800-Series AC Power Source/Analyzer.

ñ After the pre-test, the software shows one cycle of voltage and current, which represents the

average of all half-cycle measurements made during the pre-test, with Class D envelope

information superimposed over the waveshapes. Note that the envelope waveshape is provided

for information only, the regulation does not require Equipment Under Test (EUT)

classification. Therefore, no Percent in Envelope information or Volt THD IN SPEC/OUT of

SPEC information is provided. However, information about rms voltage, frequency, rms current,

peak current, real power, apparent power, power factor, voltage distortion, and current distortion

is provided.

ñ When the compliance test is run, the software generates a bar graph which displays the short-

term flicker (Pst) compared to the predetermined test limits at the end of each integration period.

The graph shows the maximum measured value and the present value .

ñ During the compliance test, the software produces a bar graph that displays the selected time

range of rms voltage values. This graph effectively shows the time-series of rms voltage

variations produced by the varying load currents flowing through the reference impedance.

ñ Probability and distribution graphs reflect a statistical view of the raw data used to generate the

Pst graph at the end of each integration period. Note that long term flicker (Plt) data is generated

during post processing after the test has completed . This information is included in the long

form report.

ñ Summary values for maximum rms voltage deviation (Dmax), steady-state voltage change (Dc),

and the time interval during which the voltage deviation exceeds the prescribed limit (Dt), are

displayed at the bottom of each display. These are the maximum values for each parameter

within the presently displayed integration period.

ñ The software also displays the time-series for instantaneous flicker, which can be useful for

diagnosing faults in the equipment under test.

10

Page 11

Installation

Install the Software

NOTE: A README.TXT file is included on the installation disks. It contains product updates or

corrections that are not documented in this manual. Use any text editor to read this file.

The Agilent 14761A HFTS software (p/n 5063-2363) comes on two disks. When installed, it requires 5

Mbytes of hard disk space, 8 Mbytes of RAM, and 512 Kbytes of conventional memory. It also requires

the correct interface card drivers to be installed on your PC. See “Installing Interface Card Drivers”.

1. Place Disk #1 in the A drive of your computer.

2. In the Windows Program Manager, run A:\SETUP

3. Follow the directions on your screen. During the installation procedure, you will be asked to

specify an installation directory on your hard disk (the default is C:\HFTS5).

4. You will also be asked to select default voltage and frequency settings for the equipment that you

will be testing (choose either 120 Vac/ 60 Hz or 230 Vac/ 50 Hz). This option may help in avoiding

the accidental applications of damaging voltages to the equipment under test. This option may

changed at any time in the Standard Test Options window.

2

NOTE: Before you run the Agilent 14761A HFTS software, make sure that:

ñ No LAN software is running

ñ No screen savers are running. Press Ctrl Esc to check the Windows Task List. Also

check the Control Panel Desktop application.

ñ If you have Power Management Software running on your PC, make sure that any power

management modes such as Sleep or Standby are turned off while the tests are running.

Connect the Equipment

To use the Agilent 14761A HFTS software, install or connect the following equipment to your computer.

1.Make sure that an Agilent GPIB or a National GP-IB interface card with the appropriate drivers has

been installed in your computer. See “Installing Interface Card Drivers”.

2 Install the Agilent 6800-Series AC Power Source/Analyzer and connect it to the computer.

3.Set up the AC Power Source/Analyzer for remote sensing at the input terminals of the equipment

under test. Failure to do this will result in inaccurate output voltage programming.

4.Turn on your computer and Agilent 6800-Series AC Power Source/Analyzer. Setup is complete.

However, in order for this software to operate, you must install a driver for your GPIB card.

11

Page 12

2 - Installation

Installing Interface Card Drivers for Windows 3.1 or 3.11 Systems

ñ If you are using an Agilent 82335 GPIB card, install the driver software from the I/O Libraries

CD-ROM (E2094) that came with the card. Open the \win31\disk1 directory on the CD-ROM

and run setup.exe. If you do not have this CD-ROM, you may purchase it through a local Agilent

Sales and Support office.

ñ If you are using an Agilent 82340, 82341, or 82350 GPIB card, the CD-ROM that came with the

card (Agilent E2094F) may contain driver software only for Windows 95 and Windows NT. In

that case you should obtain the latest version of this CD-ROM (Rev F.01.02 or later), which also

contains drivers for Windows 3.1. Open the \win31\disk1 directory on the CD-ROM and run

setup.exe.

ñ If you are using a National Instruments GPIB card, install the associated Windows 3.x driver.

You may have received a disk containing this driver when you purchased the card. Also, at the

time this guide was written, the newest drivers were available from www.ni.com. Install the

latest version of NI-488.2.

Installing Interface Card Drivers for Windows 95 Systems

ñ If you are using an Agilent 82335, 82340, 82341, or 82350 GPIB card, install the driver software

from the I/O Libraries CD-ROM that came with the card. If this CD-ROM is an E2094F or later,

run setup.exe in the CD-ROM’s root directory. If the CD-ROM is an E2094E, open the

\win95nt\disk1 directory on the CD-ROM and run setup.exe. If you do not have this CD-ROM,

you may purchase it through a local Agilent Sales and Support office.

ñ If you are using a National Instruments GPIB card, install the associated Windows 95/98 driver.

You may have received a disk containing this driver when you purchased the card. Also, at the

time this guide was written, the newest driver was available from www.ni.com. Install the latest

version of NI-VISA or NI-488.2.

Installing Interface Card Drivers for Windows NT 4.0 Systems

ñ If you have an Agilent 82335 GPIB card, this card will NOT operate under Windows NT. You

should purchase an Agilent 82340, 82341, or 82350 GPIB card through a local Agilent Sales and

Support office.

ñ If you are using an Agilent 82340, 82341, or 82350 GPIB card, install the software from the I/O

Libraries CD-ROM that came with the card. If this CD-ROM is an Agilent E2094F or later, run

setup.exe in the CD-ROM’s root directory. If this CD-ROM is an E2094E, open the

\win95nt\disk1 directory on the CD-ROM and run setup.exe. If you do not have this CD-ROM,

you may purchase it through a local Agilent Sales and Support office.

ñ If you are using a National Instruments GPIB card, install the associated Windows NT driver.

You may have received a disk containing this driver when you purchased the card. Also, at the

time this guide was written, the newest driver was available from www.ni.com. Install the latest

version of NI-VISA or NI-488.2.

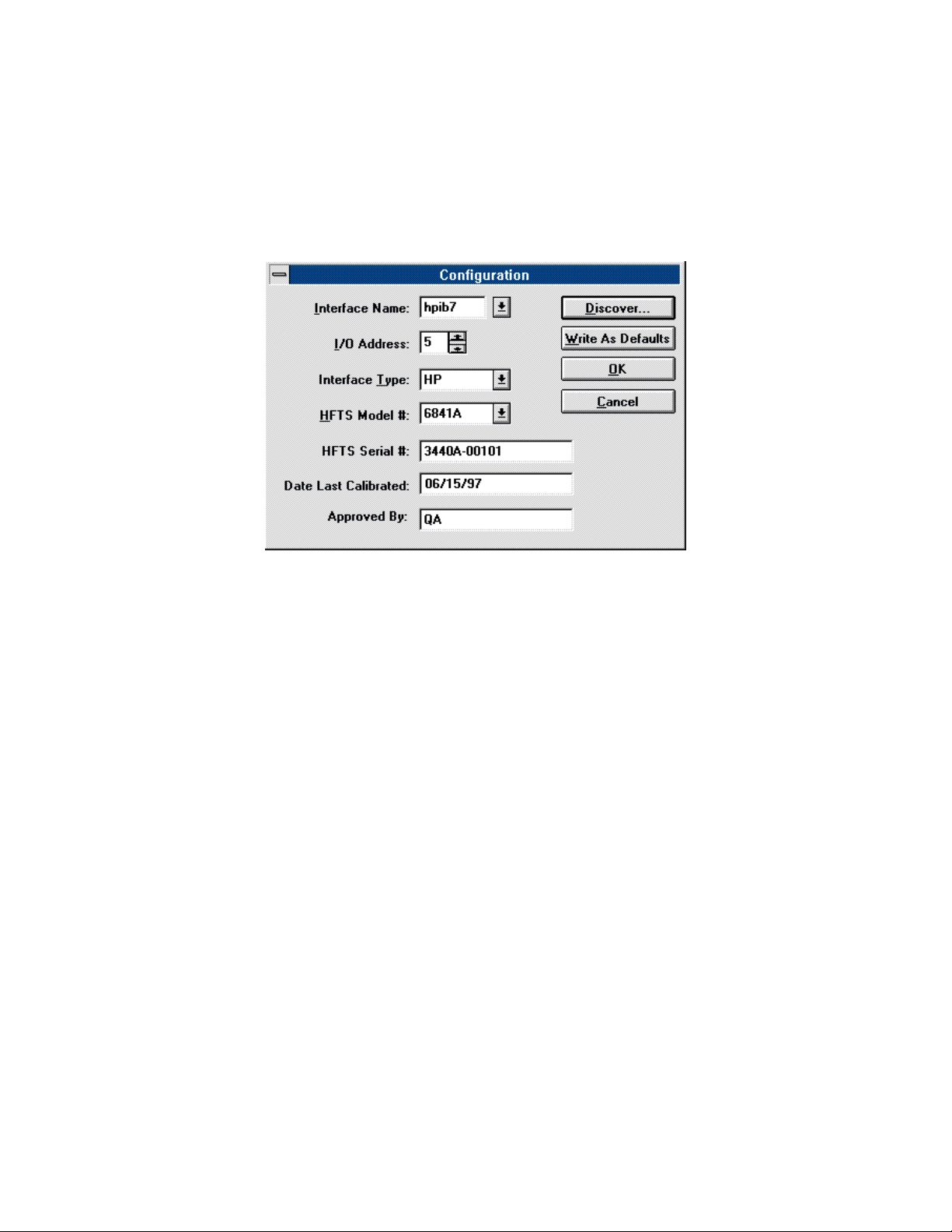

Verify the Configuration

Once your equipment and software are installed, click on the Start button and select Programs |

Regulatory Test Solution | Harmonic and Flicker Emissions. (For Windows 3.1, click on the HFTS

12

Page 13

Installation - 2

icon to run the software.) When the software is run, it automatically searches for an interface card and

queries the Agilent 6800-Series AC Power Source/Analyzer for its model number. Verify that your

configuration is correct as follows:

1. Select the New button in the Welcome Window

2. In the Options menu, select the Configure... command. This displays a Configuration dialog box

on the screen. The Configuration Dialog box contains the following fields:

ñ The Interface Name identifies the interface session when using an SICL interface. The

application determines the default interface name by checking which interface driver is installed

in your system. If “HP” is the interface type, the Interface Name list box displays all of the SICL

names presently configured in the Windows 95 system. (SICL interface names are assigned to

the ac source in the interface card’s configuration utility.) For Windows NT systems, the list box

displays hpib7 as the default interface name. If “National” is the interface type, the Interface

Name box displays the following pre-defined GPIB names: GPIB0, GPIB1, GPIB2,or GPIB3.

ñ The I/O Address displays the address of the Agilent 6800-Series AC Power Source/Analyzer.

The instrument address can be read or set using the front panel Address key.

ñ The Interface Type is either HP, National, or File only.

ñ The HFTS Model # is the instrument model that you are controlling.

ñ The HFTS Serial # is where you enter the serial number of instrument that you are

controlling.(this is optional)

ñ Enter the date the instrument was last calibrated (this is optional)

ñ Enter the calibration approvel name (this is optional)

Pressing the Discover button causes the software to search for an interface card and query the Agilent

6800-Series AC Power Source/Analyzer for its model number. Any equipment that is located is then

displayed in the appropriate fields in the configuration dialog box.

Pressing Write as Defaults updates the HFTS.INI file with the information that has been entered in this

dialog box either by the user or by the Discover feature. These default values are used during subsequent

start-ups of the Agilent 14761A HFTS software to confirm system configuration.

Press OK to accept the changes, or Cancel to cancel the changes and exit the dialog box.

13

Page 14

2 - Installation

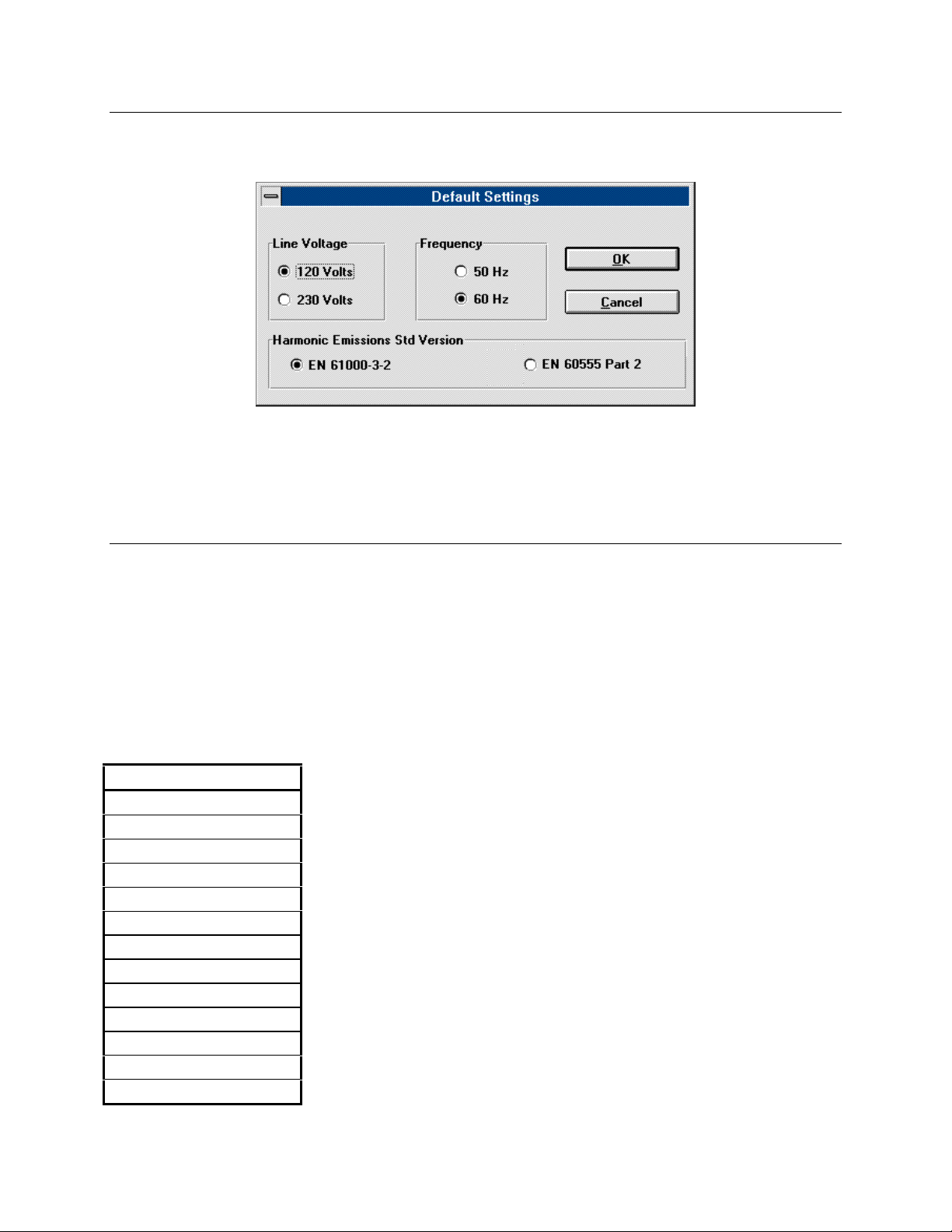

Default Settings

In the Options menu, select Defaults to view the default settings. The following settings are configurable:

ñ The line voltage and frequency that will be applied to the equipment under test.

ñ The quasi-stationary/fluctuating harmonics regulations version that you will be testing to.

Select either EN 61000-3-2 or the older EN 60555 Part 2 regulation.

Press OK to accept the defaults, or Cancel to cancel the changes and exit the dialog box.

Getting Around in the Application

There are two ways to access the various functions of this application:

1. From the drop-down menus at the top of the screen, or

2. From the menu tabs at the bottom of the screen.

The menu tabs at the bottom of the screen are the same as the View menu commands.

Drop-down Menu

The following commands are located in the drop-down menus at the top of the screen.

File

New...

New From Template...

Open...

Save

Save As...

Lock Test File

Edit Template..

Save As Template...

Print Pre-test

Print Report...

Print Graph/Table...

Printer Setup...

Exit

Lets you select a new test

Lets you select a new test but applies an existing set-up template

Opens an existing test

Saves the presently opened test

Saves the present test under a new name

Sets the attribute of a completed test file to read only

Lets you edit a template

Saves only the template information of the presently opened test

Lets you print the currently displayed pre-test screen

Lets you print the currently displayed report

Lets you print the currently displayed graph or table

Lets you change the printer setup

Exits the application

14

Page 15

Edit

Copy Table

Copy Graph

View

Main

Test Setup >

Pre-test

Test

Display >

Report >

Options

Local Lockout

Validation Mode

Configure...

Defaults...

Installation - 2

Copies highlighted information from the table to the Clipboard

Copies the presently displayed graph to the Clipboard

Lets you select the type of test to run

Lets you select the test set-up parameters

Lets you run the pre-test

Lets you run the test

Lets you view specific test results

Lets you view the test report

Lets you disable the front panel keys of the Agilent 6800-Series AC Power

Source/Analyzer.

Lets you run a special mode used to validate current harmonics testing

methodology.

Lets you specify the I/O slot address of the interface, the instrument address,

the interface type, and the Agilent 6800-Series AC Power Source/Analyzer

model number.

Lets you view and change the default values for line voltage, frequency, and

test standards.

Mains

Auto On/Auto Off

Auto On/Manual Off

Manual On/Auto Off

Manual On/Manua l O ff

Help

Contents

Using Help

About

Mains ON/ Mains Off

Automatically controls the output of the Agilent 6800-Series AC Power

Source/Analyzer while the test is running.

Lets you manually turn off the output of the Agilent 6800-Series AC Power

Source/Analyzer from the Test window. Provides automatic turn-on at the

beginning of pretests and tests.

Lets you manually turn on the output of the Agilent 6800-Series AC Power

Source/Analyzer from the Test window. Provides automatic turn-off at the

completion of pretests and tests.

Lets you manually control the output of the Agilent 6800-Series AC Power

Source/Analyzer from the Test window.

Accesses the Help contents.

Explains how to use the on-line help.

Displays the Agilent 14761A HFTS software revision.

Indicates the present state of the ac source output.

15

Page 16

2 - Installation

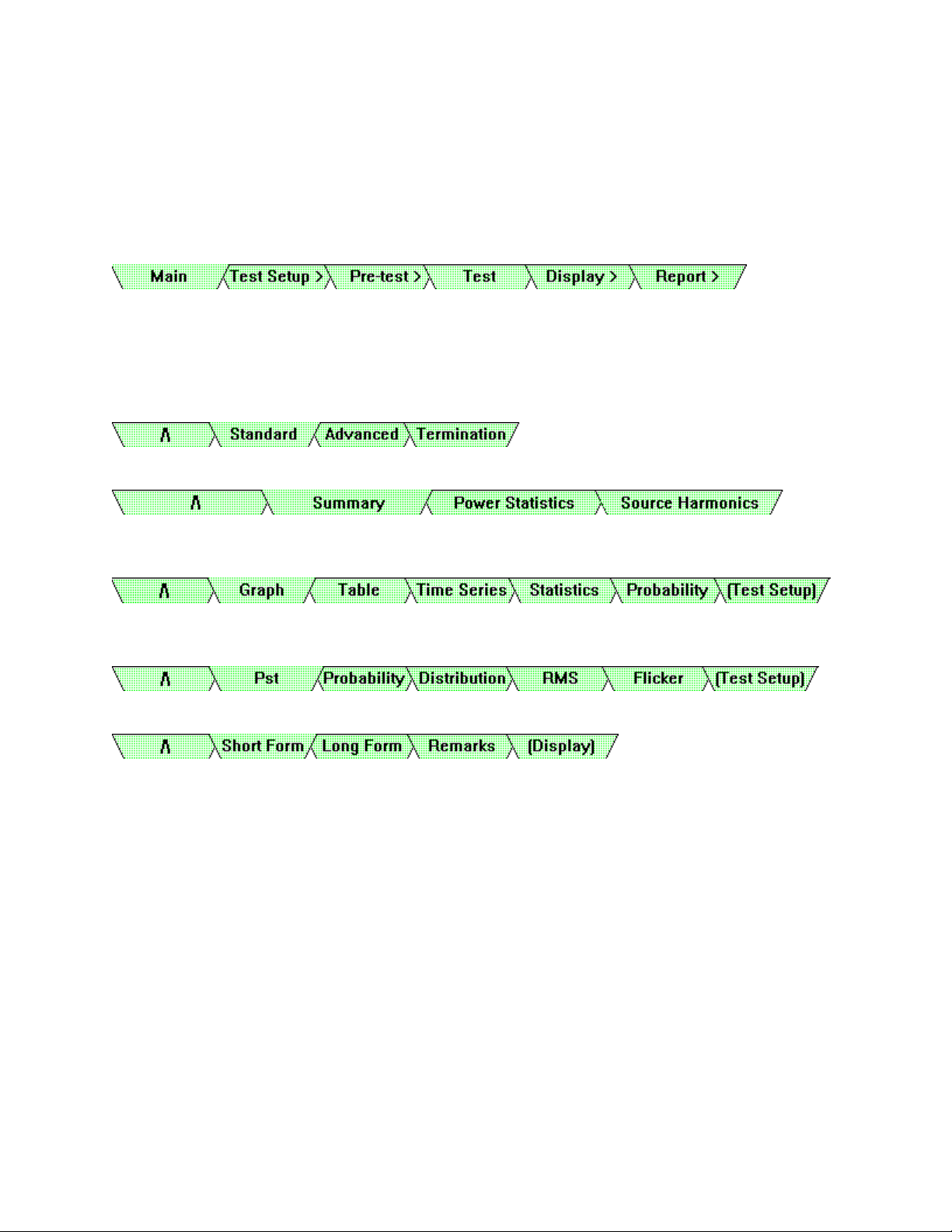

Menu Tabs

The menu tabs that are located at the bottom of the screen let you easily access the primary functions of

the Agilent 14761A HFTS software. These functions are also available from the file menus. Altogether,

there are five groups of menu tabs:

The Main level group accesses the following functions:

The > symbol in the tab label indicates a lower-level of tabs, which access a number of additional

screens. Once at the lower level, the /\ tab returns you to the Main Level. When active, the [last tab] in

the series jumps to the last lower-level tabs that you had previously accessed.

The following tabs appear in the Test Setup> group. Each tab accesses its respective function.

The following tabs appear in the Pre-test> group. Each tab accesses its respective function.

The following tabs appear in the Display> group for Quasi-stationary or Fluctuating Harmonic testing.

Each tab accesses its respective function.

The following tabs appear in the Display> group for Voltage Fluctuation testing. Each tab accesses its

respective function.

The following tabs appear in the Report> group. Each tab accesses its respective function.

16

Page 17

3

Setting Up the Test

If you have not already done so, click on the Agilent HFTS icon to run the software. Now you can set up your

test. If the Agilent HFTS icon does not appear on your computer, go back to chapter 2 and install the Agilent

14761A HFTS software.

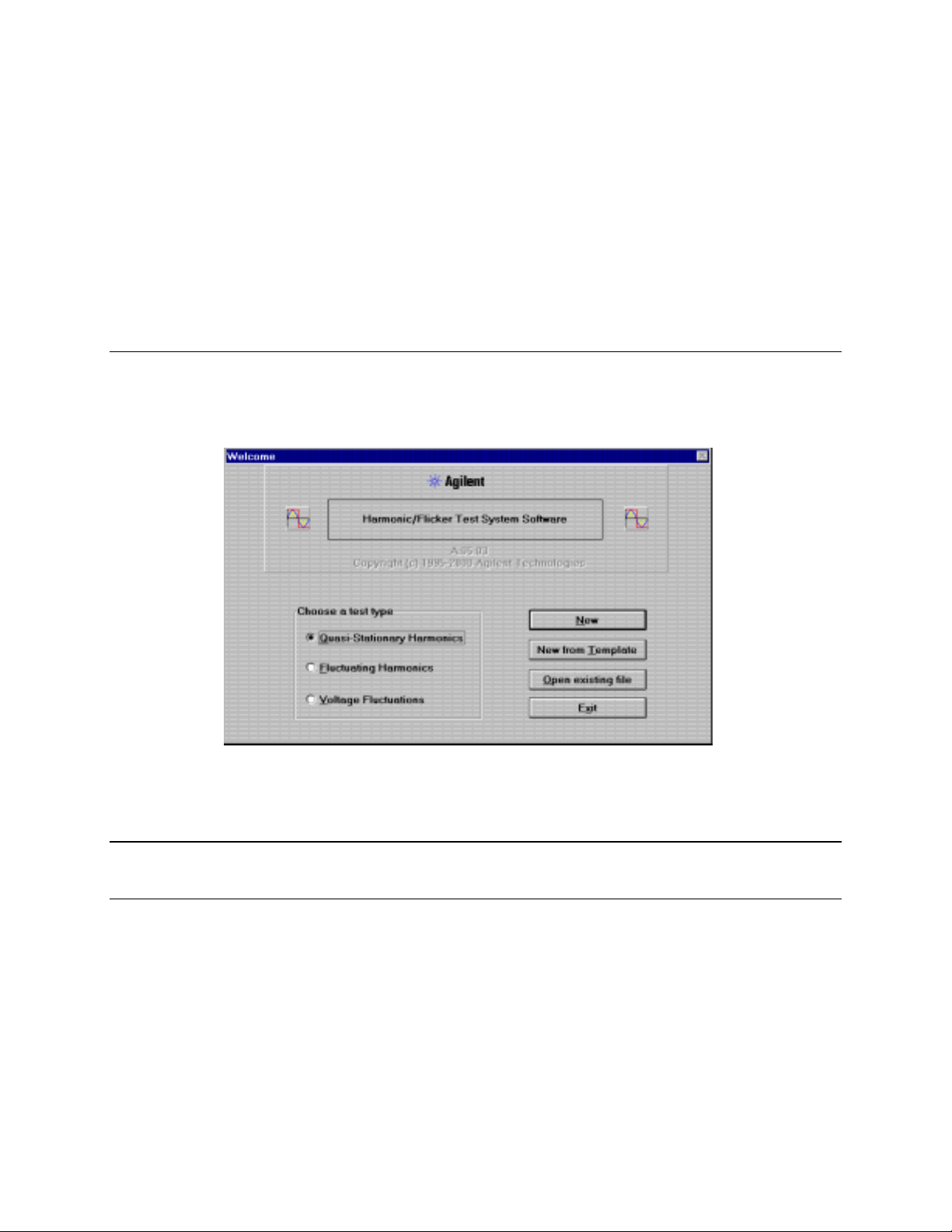

Select a Test Type

When you first run the Agilent 14761A HFTS software, the Welcome window appears.

Select a test type from the Welcome Window.

1. Click on either Quasi-stationary Harmonics, Fluctuating Harmonics, or Voltage Fluctuations

Note To select a different test after you get past the Welcome window, use the drop-down File

menu commands

2. Choose to configure a new test, run an existing test, or configure a new test based on an existing

template. Note that these selections are also available in the File menu.

ñ Selecting New opens the Main window, in which you start entering test setup information about

the test that you will be running. If you want to run other tests of the same type using the same

setup information, consider saving this information to a template file once the setup has been

established.

17

Page 18

3 - Setting Up the Test

ñ Selecting New From Template opens a dialog box that lets you select a template file which

contains previously-configured test setup information. This template information will be copied

into your new data file. The template itself is not changed unless you make subsequent changes

to your setup and save them into the template using “Save as Template.”. When you run the test,

the test data will then be added to the information obtained from the template. You can modify

the template defaults and set up data as required for the new test or use the values supplied by the

template. The following file extensions are used to identify template files:

.stt template files for quasi-stationary harmonic tests

.flt template files for fluctuating harmonic tests

.fkt template files for voltage fluctuation tests

The default directory for template files is C:\hfts\template

ñ Selecting Open Existing File opens a dialog box that lets you select a data file which contains

setup information and may or may not contain pre-test as well as test data. This lets you examine

previously run test data or replace old test data with data obtained from a new test run. The

following file extensions are used to identify data files:

.sta data files for quasi-stationary harmonic tests

.flu data files for fluctuating harmonic tests

.flk data files for voltage fluctuation tests

The default directory for data files is C:\hfts

Note Running a pre-test or a test after opening an existing file will cause all existing data to be

overwritten with new data. You can prevent this from occurring by checking the Make

test data read-only option in the Test window before running a test, or by using the

Lock Test File command in the File menu.

18

Page 19

Setting Up the Test - 3

Create a Template

Template files contain setup information for the test that you will be running. Using templates can save

valuable time by eliminating the need to enter repetitive data each time you set up a test.

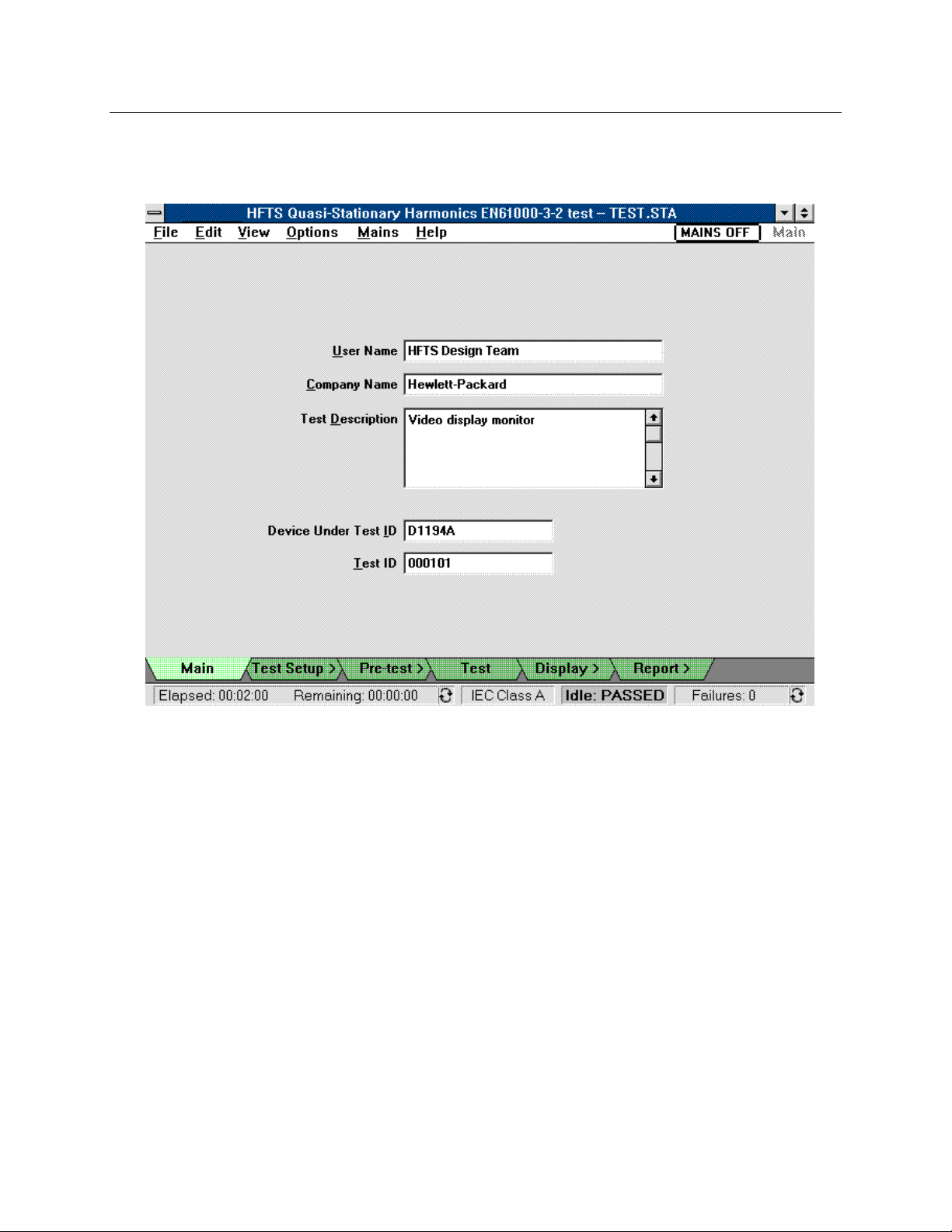

Create a template by entering information into the Main and the Test Setup windows. Use the Tab key

to move among the different fields.

1. Enter the following information into the text boxes of the Main window:

your name

the company name

a brief description of the test procedure that you will be running

a device ID such as a model number

a test ID such as a serial number or test number that uniquely identifies the test

2. Use the menu tabs on the bottom of the screen to access the Test Setup windows. Note that you

can also access the Test Setup windows from the View Menu.

3. Starting with the Standard Test Setup window, select and configure each of the following Test

Setup windows as needed: Standard, Advanced, and Termination

4. Select Save as Template in the File menu to create a template file. Once created, the template

file may be used to quickly create new tests by adding or editing only the information that must

be changed for each test. This is useful if you are conducting a series of tests or testing similar

equipment that is subject to a standardized test.

19

Page 20

3 - Setting Up the Test

Select the Test Setup Options for Quasi-stationary or

Fluctuating Harmonics

Standard Test Options

Standard options specify the line voltage, line frequency, test time, and device class for compliance tests.

They are selected in the Standard window.

ñ Select the line voltage that will be applied to the equipment under test.

Selecting Variable lets you enter a value other than 120 Vac or 230 Vac.

ñ Select the line frequency (50 or 60 Hz) that will be applied to the equipment under test.

ñ Select the test duration in seconds, minutes, hours, or days.

The # of Records field displays the number of data records that will be taken during the test time

that you have specified. Note that the relationship between time and the number of records per

second is a function of line frequency and measurement window type. The measurement window

type is specified in the Advanced Test Setup window, and is set to a default of Rectangular.

ñ Select from one of the following device classes for your equipment under test to which the EN

61000-3-2 regulation applies:

Class A: All equipment except that stated in one of the remaining three classes.

Class B: Portable electrical tools, which are hand held during normal operation and used for a

short time (a few minutes) only.

Class C: Lighting equipment, including dimming devices.

20

Page 21

Setting Up the Test - 3

Class D: Equipment having an input current with a "special wave shape" (e.g. equipment with

off-line capacitor-rectifier ac input circuitry and switch-mode power supplies) and an active input

power ≤ 600 W. The active power is defined as Watts. For the Class D mA/W limits to apply, the

active power must also be greater than 75 W.

Motor Driven Device: Check this box if the equipment you are testing is a motor-driven device.

This will cause class A limits to be used in accordance with EN 61000-3-2 regardless of the input

current waveshape.

Note The EN 60555 Part 2 regulation only applies to Class A and Class B equipment. The

Agilent 14761A HFTS software will reflect this based on the regulations selection made

in the Options/Defaults menu. See appendix D for information about class

determination.

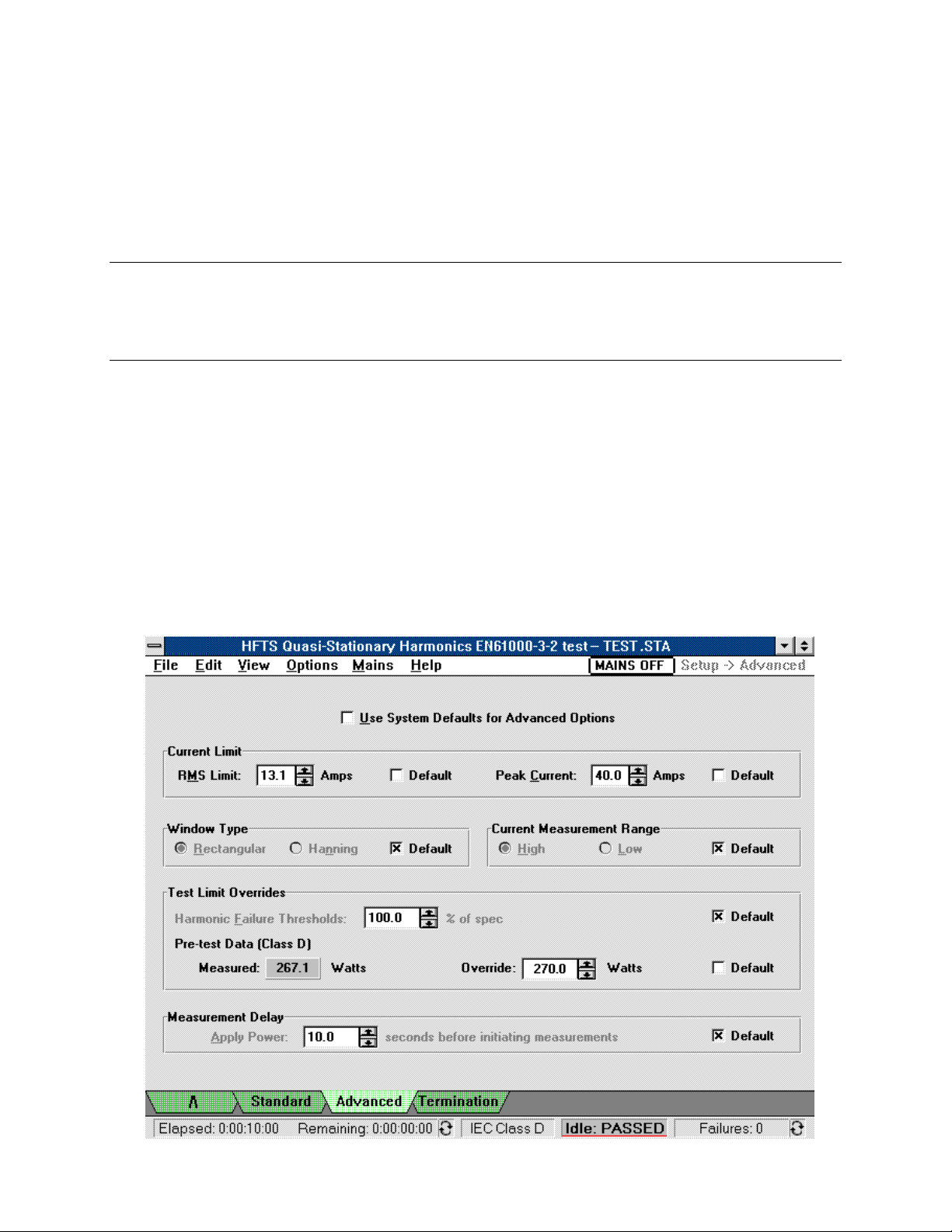

Advanced Test Options

The advanced test options may be used to modify test conditions outside the range permitted for

compliance tests. They are selected in the Advanced window. Generally, you would not change the

factory default settings if you are doing compliance testing because the changes may invalidate the test.

As an exception to the above statement, the Current Measurement Range setting and the Current Limit

settings may be changed without invalidating the compliance test as long as the changed settings do not

cause current limiting to occur during the test. Current limiting may occur during the time period when

power is initially applied but before the test is run. This time delay may be specified in the Advanced

Setup window for tests, and in the Pre-test window for pre-tests. Current limit errors are detected and

displayed if they occur during the test. Note that you can also set test limit overrides < 100% without

automatically flagging the test as non-compliant.

21

Page 22

3 - Setting Up the Test

ñ Select the rms and peak current limit of the Agilent 6800-Series AC Power Source/Analyzer that

you will be applying to the equipment under test. (The Agilent Model 6843A only has rms

current limit control, therefore, the peak current limit control does not appear.) Generally, it is

best to leave these parameters set to their maximum default values. Although the function of the

current limit is to protect the equipment under test, if the ac source goes into current limit during

a normal test the test will be invalid. Default maximum current limit values are automatically

established based on the model number that you entered into the Main window.

Note The Agilent 6800-Series AC Power Source/Analyzer can supply brief peak currents that

exceed its current capability. If this occurs for an extended time with Agilent

6812B/6841A and 6813B/6842A models, the units may activate an internal protection

circuit (the SOA limit) to turn the output off. If the equipment that you are testing causes

the Agilent 6800-Series AC Power Source/Analyzer to turn its output off, you may need

to lower the peak current limit setting. This will clip the output current of the Agilent

6800-Series AC Power Source/Analyzer during inrush but if properly set, will not

interfere with the normal running of the pre-test and tests.

ñ Select the measurement window type (Rectangular or Hanning)

ñ Select the peak current measurement range of the Agilent 6800-Series AC Power

Source/Analyzer

Low Range

High Range

6812B

6841A

8 A peak 8 A peak 9.6 A peak

80 A peak 80 A peak 96 A peak

6813B

6842A

6843A

Because of its better measurement resolution, use the low range when testing low power

equipment. However, be careful that the equipment under test never exceeds the peak currents

indicated in the above chart or the test results will be invalid.

ñ Select a test limit override for the harmonic failure threshold. This is specified as a percent of

the limit as defined by the applicable regulation. For Class C, test limits are also a function of the

measured (or user-specified) power factor and the line current at the fundamental frequency. If

necessary, you can override the power factor measured in the pre-test. For Class D, test limits are

also a function of real power (or watts). If necessary you can also override the watts measured in

the pre-test. Overrides are useful to prevent minor changes in measured values from changing the

test limits each time the test is run.

ñ Select a measurement delay from the time power is applied to the equipment under test until the

time that the Agilent 6800-Series AC Power Source/Analyzer starts measuring data. According

to EN 61000-3-2, this delay must be 10 seconds or less for compliance level fluctuating harmonic

tests. Note that the measurement delay has no consequential impact on test results. This is

because during the "delay to start of test" portion of both the pre-test and main test, test results

are not recorded and current limiting events are ignored. However, once the actual acquisition of

measurement data begins, current limit events are again treated as errors that invalidate the test.

Since high inrush currents usually occur only during the first few mains cycles following

application of mains voltage, a properly set current limit threshold will not be crossed once the

"delay to start of test" period has ended.

22

Page 23

Setting Up the Test - 3

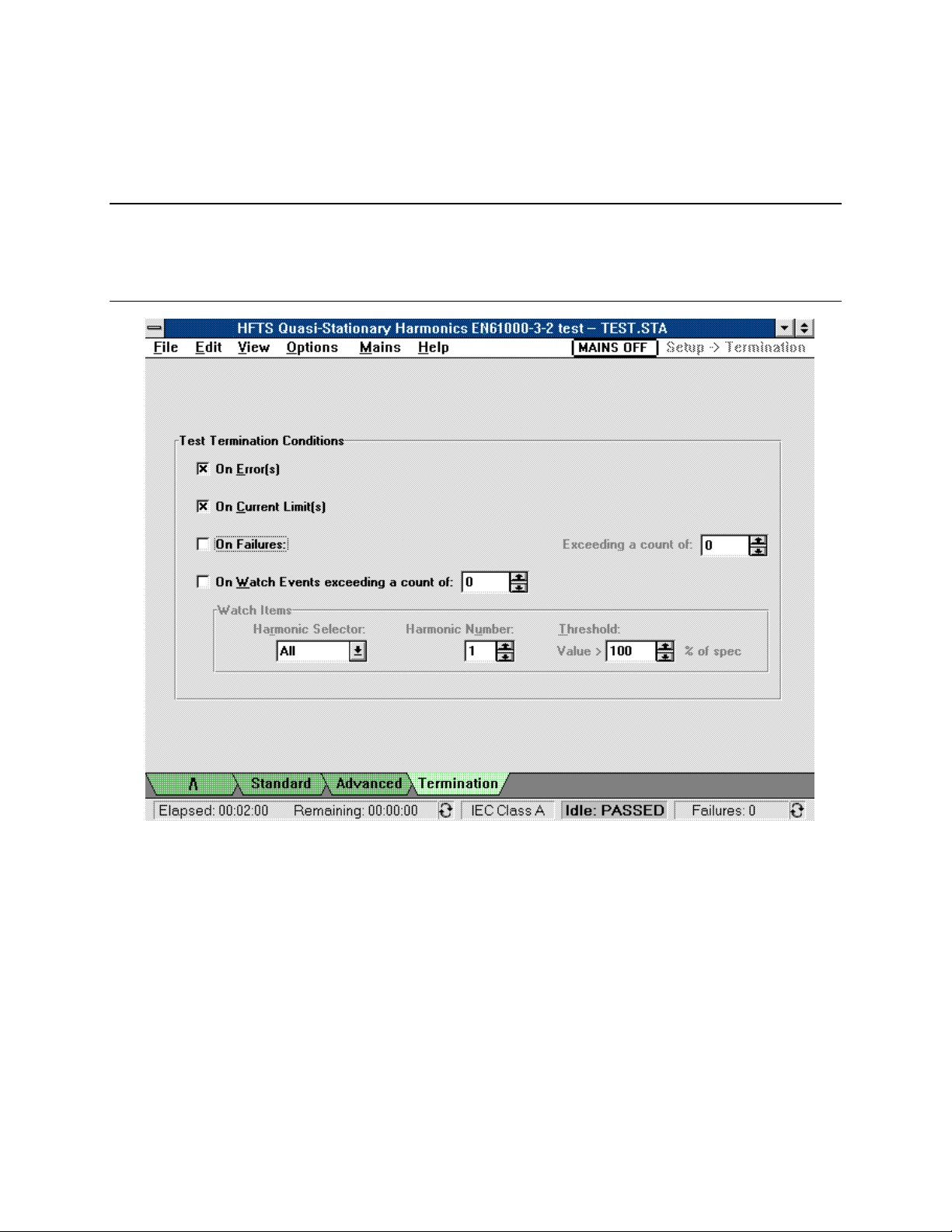

Test Termination Options

Termination options let you select the conditions that will terminate the test. They are selected in the

Termination window.

Note The following conditions terminate any test automatically if the Agilent 6800-Series AC

Power Source/Analyzer operating limits are exceeded: Rail fault condition,

Overtemperature, Overvoltage, and SOA. Refer to the applicable ac source User’s

Guide for an explanation of these conditions.

ñ Select termination on errors. One error will terminate the test when this is selected:

UNR - when the output becomes unregulated.

ñ Select termination when the current limit is exceeded. The two current limit conditions that will

terminate the test when this occurs are: CL - when the output goes into current limit mode, and

CP - when the output current limit protection has tripped.

ñ Select termination upon exceeding a specified number of failures. When testing fluctuating

harmonics and this box is checked, you can specify failures:

of any type,

with a 2.5 minute window

without a 2.5 minute window.

ñ Select termination on exceeding a specified number of watch events. Each event that satisfies the

selected criteria is counted as one event occurrence.

23

Page 24

3 - Setting Up the Test

If termination On Watch Events is enabled, you can select the following Watch Items criteria:

ñ All harmonics greater than the specified percent of threshold

ñ Odd harmonics greater than the specified percent of threshold

ñ Odd ≤ 19 harmonics greater than the specified percent of threshold

ñ Even harmonics greater than the specified percent of threshold

ñ Nth, a specific Harmonic Number that is greater than the specified percent of threshold

Select the Test Options for Voltage Fluctuations

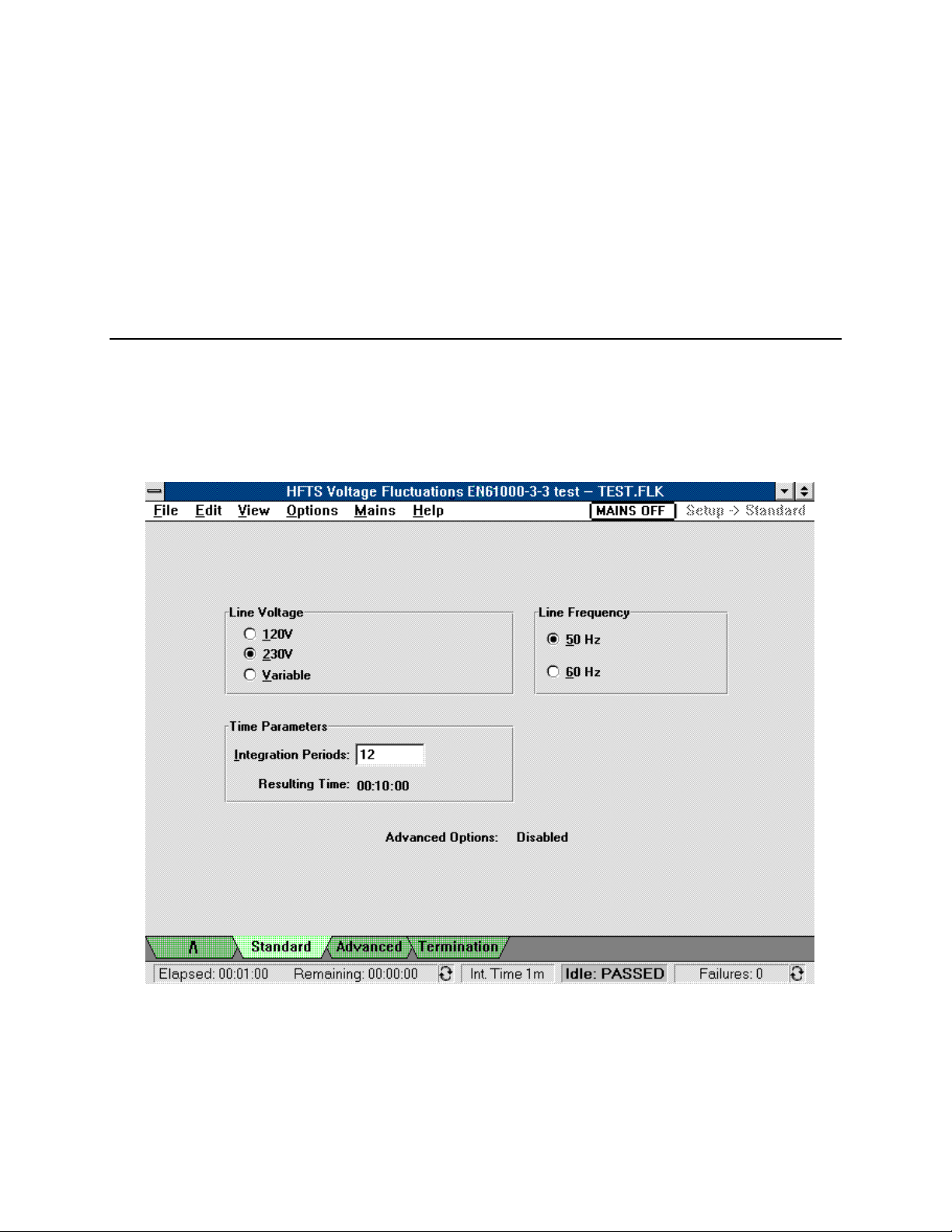

Standard Test Options

Standard options specify the line voltage, line frequency, and test time for compliance tests. They are

selected in the Standard window.

ñ Select the line voltage that you will be applying to the equipment under test.

Selecting Variable lets you enter a value other than 120 Vac or 230 Vac.

ñ Select the line frequency (50 or 60 Hz) that will be applied to the equipment under test.

24

Page 25

Setting Up the Test - 3

ñ Select the number of integration periods to be acquired during the test. The Resulting Time

field displays the test duration based on the number of integration periods as well as the Pst

integration time that you have specified in the Advanced window. The Pst integration time is set

to a default of 10 minutes with the Advanced options disabled.

Advanced Test Options

ñ Select the rms and peak current limit of the Agilent 6800-Series AC Power Source/Analyzer that

you will be applying to the equipment under test. Generally, it is best to leave these parameters

set to their maximum default values. Although the function of the current limit is to protect the

equipment under test, if the unit does go into current limit during a normal test, the test will be

invalid.

ñ Select the returned data type (All, Pst/Rms Summary, or Rms/Flicker Time Series)

ñ Select the Pst (or short-term) flicker integration time.

ñ Select a test limit override for the Pst/Plt Thresholds (short-term/long-term flicker) and Rms

Thresholds. This is specified as a percent of the specification in the applicable regulation.

ñ Select a measurement delay from the time power is applied to the equipment under test until the

time that the Agilent 6800-Series AC Power Source/Analyzer starts measuring data.

25

Page 26

3 - Setting Up the Test

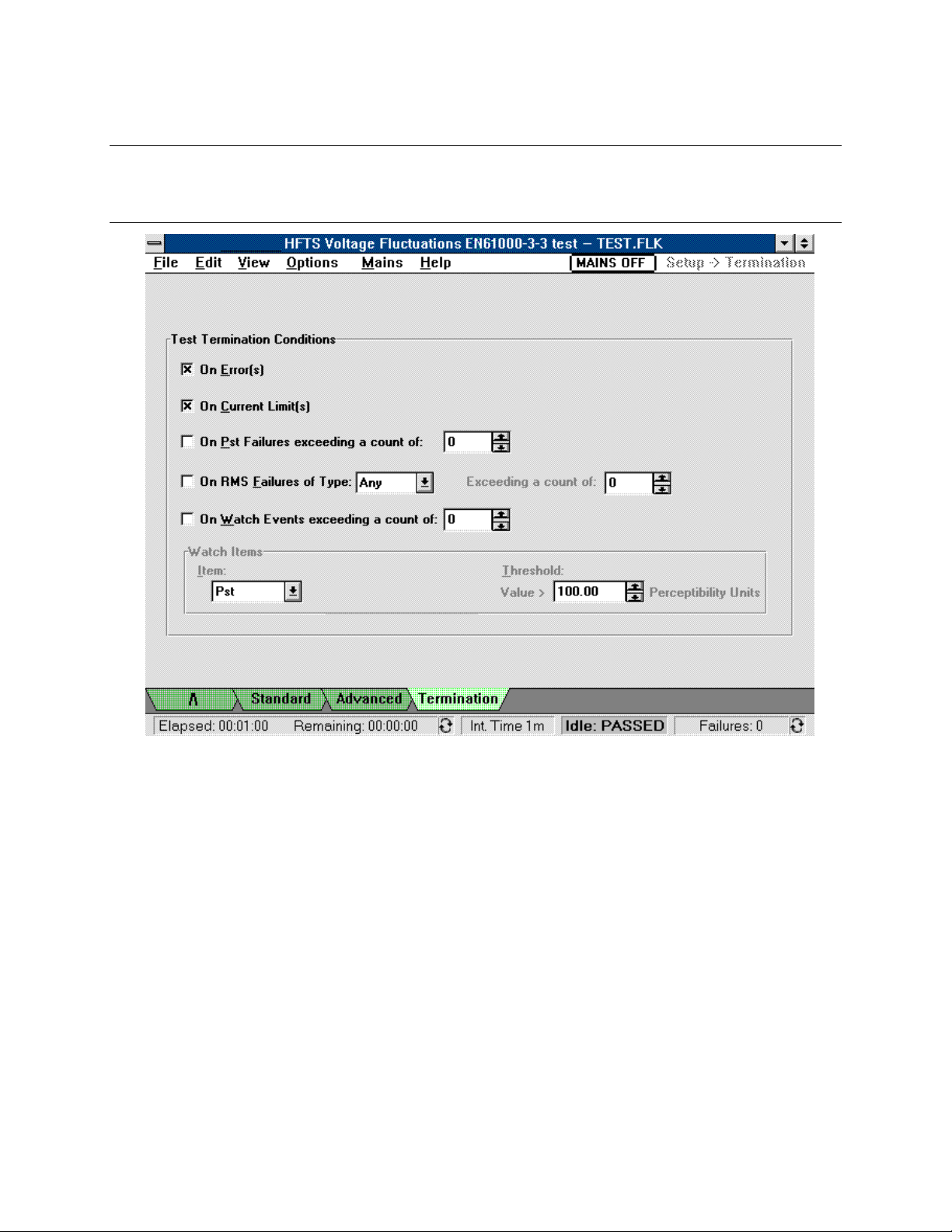

Test Termination Options

Note The following conditions terminate any test automatically if the Agilent 6800-Series AC

Power Source/Analyzer operating limits are exceeded: Rail fault condition, Overtemperature,

Overvoltage, and SOA. Refer to the ac source User’s Guide for more information.

ñ Select termination on errors. One error will terminate the test when this is selected:

UNR - when the output becomes unregulated.

ñ Select termination when the current limit is exceeded. Two current limit conditions will

terminate the test when this occurs: CL - when the output goes into current limit mode; CP when the output current limit protection has tripped.

ñ Select termination on exceeding a specified number of Pst failures

ñ Select termination on exceeding a specified number of Rms voltage failures. You can specify

Rms voltage failures: of any type

Dmax failures

Dc failures

Dt failures.

ñ Select termination on exceeding a specified number of watch events. Each event that satisfies the

selected criteria is counted as one event occurrence.

If termination On Watch Events is enabled, you can select the following Watch Items criteria:

ñ Pst values greater than the specified perceptibility units

ñ Instantaneous Flicker values greater than the specified perceptibility units

26

Page 27

4

Running the Test

Before actual test data can be acquired, the pre-test must be run. This is accomplished in the Pre-Test

window. As its name implies, the Pre-Test window centralizes functions that, following test setup, need

to be performed prior to running an actual test. This includes running preliminary tests to measure

quantities that are subsequently used to set test limits for Class C and Class D devices. Once the pre-test

data is available, the main test can be started. This is accomplished in the Test window. Test status

information is displayed in the Status bar on the bottom of the screen. Note that you must always have

pre-test results present before running the main test.

To Run a Pre-test for Quasi-stationary or Fluctuating

Harmonics

Pre-Test Summary

1. Select the Pre-test menu tab on the bottom of the screen to access the Pre-test Summary

window. You can also access the Pre-test window from the View/Pre-test menu.

2. If desired, change the time delay from when power is applied until the pre-test is run. The default

pre-test time is 10 seconds.

27

Page 28

4 - Running the Test

3. It is also possible to increase the duration of the pre-test. One purpose of running a longer pre-

test is to obtain more data over which the test results are averaged. Additional data more

accurately characterizes the worst-case operation of the equipment under test (see “Pre-test

Measurements” for more information).

4. Press the Run Pre-test button to run the pre-test.

Note Running a pre-test from a file that already contains data will not only overwrite the pre-

test data, but will also delete the existing test data.

5. Use the Print Screen command located in the File menu to print the Pre-test window.

For Quasi-stationary and Fluctuating Harmonic tests, the pre-test checks if you have correctly classified

your equipment as Class D versus any other class in the Standard Test Setup window. It displays the

input-current waveshape of the equipment under test, which lets you examine the waveshape for “fit”

into the Class D special waveshape window.

ñ The Pre-test graph displays one cycle of voltage and current, superimposed on the Class D

waveshape window. The current cycle that is superimposed in the Class D waveshape window is

the half-cycle having the highest peak value within a single 16-cycle snapshot taken at the end of

the pre-test interval (see “one-shot measurements” later in this chapter for more information).

Press the Power Statistics tab if you need to configure the active power requirements for

determining Class D limits, or if you need to display additional power measurement information.

ñ The Class Indicator displays a green background if the data collected from the equipment under

test matches the Class selection. If the data collected from the equipment under test does not

match the Class selection, the Class indicator displays a red background. In this case you should

return to the Standard Test Setup window, select the correct class, and rerun the pre-test. Refer to

appendix D for information about the class determination logic of the Agilent 14761A HFTS

software.

NOTE: Class D equipment must have input power > 75 W and ≤ 600 W, and 95% of its input-

current waveshape must fall within the Class D waveshape window. For EN 61000-3-2

testing, devices generating Class D waveforms but NOT meeting all Class D input power

criteria will be tested using Class A limit values for odd harmonics. If testing against

limits for even harmonics is also desired, select Class A. Testing a device that meets the

Class D "special waveshape" with Class A selected, results in compliant test reports if

the "Motor Driven Device" checkbox, available for EN 61000-3-2 testing, is also

selected.

ñ The Percent in Envelope indicator displays the percentage of waveform data within the Class D

waveshape standard if Class A or Class D has been selected.

ñ The Voltage THD “IN SPEC” or “OUT OF SPEC” indicator summarizes the results of testing to

determine if the output voltage of the ac source is within the harmonic voltage limits as specified

in EN 61000-3-2/EN 60555-2. The voltage THD results are based on measurements of

individual voltage harmonics up to the 40th harmonic, and a comparison of these measurements

to the limits specified in the regulations. Select the Source Harmonics tab to display the

individual worst-case voltage harmonics that occurred during the pre-test.

ñ The Measured Values area on the right side of the display summarizes nine of the most common

mains input characteristics (see “Pre-test Measurements” for more information).

28

Page 29

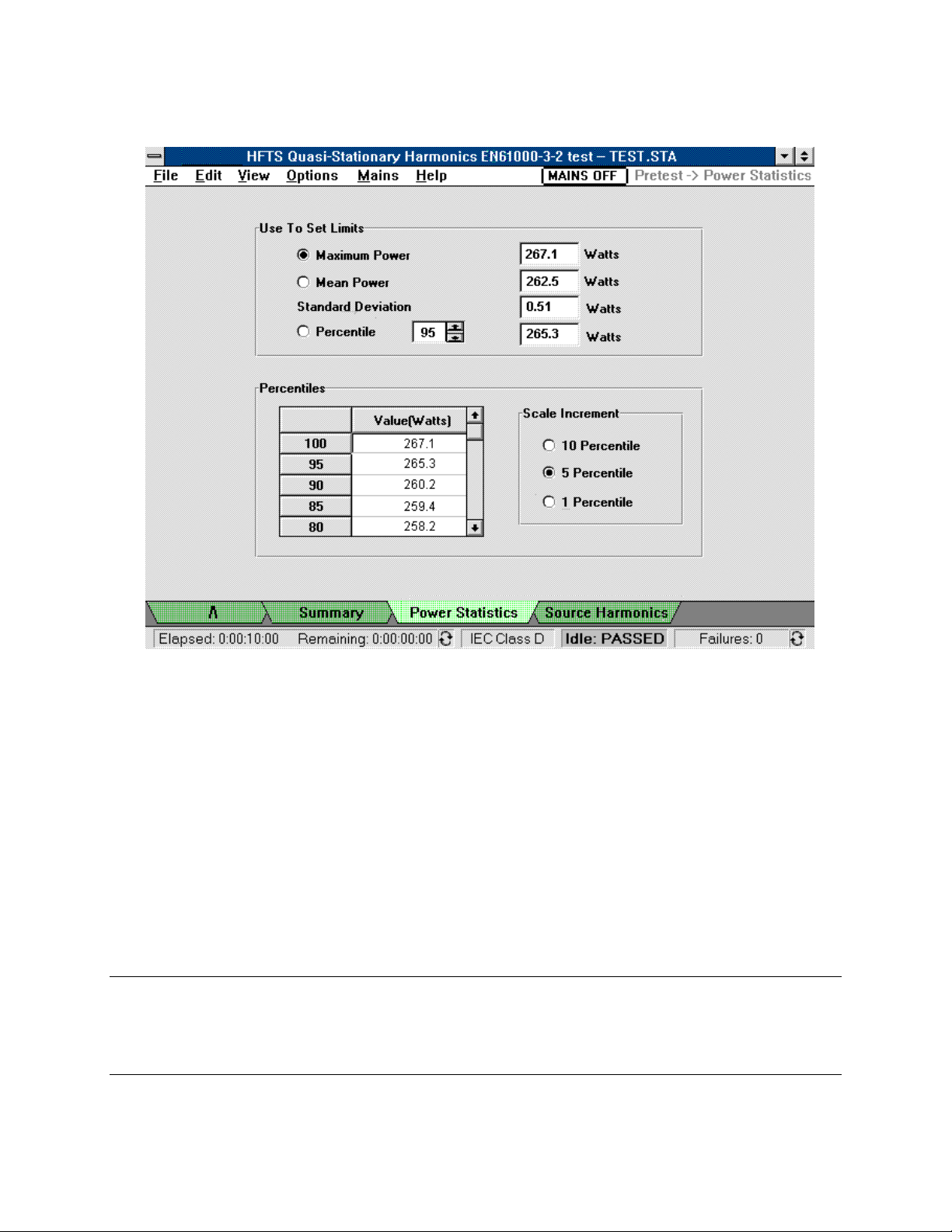

Pre-Test Power Statistics

Running the Test - 4

This screen provides additional information about the active input power of the device under test. It

displays the following power measurements, which are calculated at the end of the pre-test:

- Maximum Power in watts (default selection for setting Class D limits)

- Mean Power in watts

- Standard Deviation in watts

- specified Percentile in watts

The Percentiles area displays the results of a statistical evaluation of the active input power during the

pre-test. Percentile values are displayed according to the selected scale increment. Scale increments of

10, 5, or 1 may be specified. A scale increment of 1 displays all percentile values.

If you are testing Class D equipment, the Use to set limits area is active, letting you specify what type of

Watts measurement will be used by the Agilent 14761A HFTS software as the basis for calculating Class

D test limits. Select from: Maximum Power (the default), Mean Power, or specified Percentile. This

provides you with greater flexibility for specifying Class D test limits.

Note: Based on your selection, you can see what the Class D test limits will be by acccessing

the Display Table window. The Class D limits are shown in the Limits column.

You can also override the pre-test watts measurement later in the Advanced Test Setup

window in the Test Limit Overrides section.

29

Page 30

4 - Running the Test

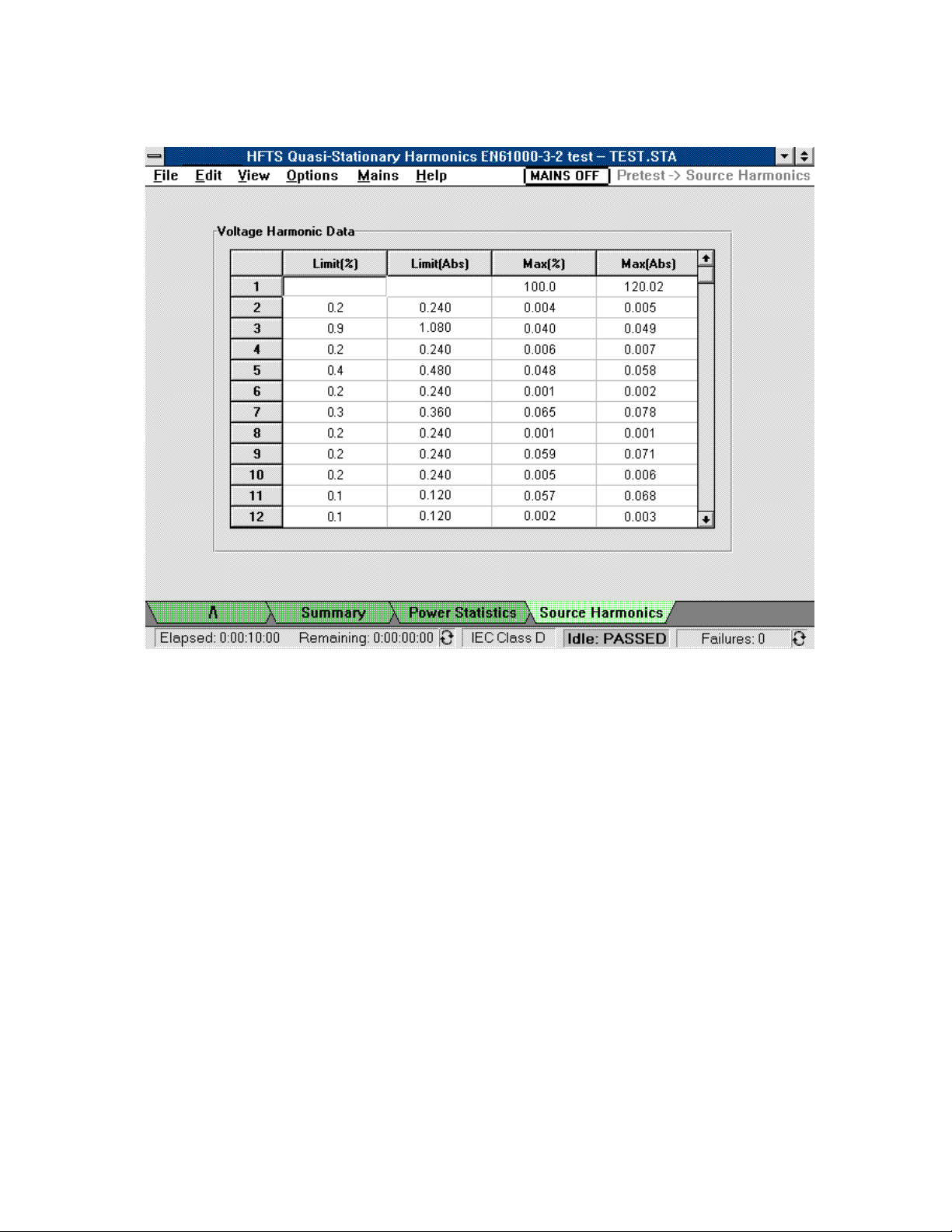

Pre-Test Source Harmonics

This screen displays the pre-test voltage data for harmonics 1-40 on a worst-case basis. The Limit(%)

column indicates the permissible limits for each harmonic expressed as percentages of the fundamental

voltage. For 230 V/50 Hz power distribution systems, these are:

- No limits for the 1st harmonic (the fundamental)

- 0.9% of V

- 0.4% of V

- 0.3% of V

- 0.2% of V

- 0.1% of V

- 0.1% of V

fundamental

fundamental

fundamental

fundamental

fundamental

fundamental

for 3rd harmonic

for 5th harmonic

for 7th harmonic

for 9th harmonic

for even harmonics from 2 to 10

for all harmonics from 11 to 40

The Limit(Abs) column indicates the permissible limits for each harmonic expressed as absolutes (in

volts). These values are obtained by multiplying the %limits divided by 100 times the measured

minimum value for the fundamental component. There are no limits for the fundamental.

The Max(%) column indicates the maximum pre-test values for harmonics 2 through 40 expressed as

percentages. These values are obtained by dividing the maximum harmonic values by the minimum

fundamental value and multiplying by 100. Failures are indicated in red.

The Max(Abs) column indicates the maximum pre-test values for harmonics 2 through 40 expressed as

absolutes (in volts). These values are simply the maximum values of the voltage harmonic data returned

during the pre-test. Failures are indicated in red.

30

Page 31

Running the Test - 4

To Run a Pre-test for Voltage Fluctuations

Pre-Test Summary

1. Select the Pre-test menu tab on the bottom of the screen to access the Pre-test Summary

window. You can also access the Pre-test window from the View/Pre-test menu.

2. If desired, change the time delay from when power is applied until the pre-test is run. The default

pre-test time is 10 seconds.

3. It is also possible to increase the duration of the pre-test. One purpose of running a longer pre-

test is to obtain more data over which the test results are averaged. Additional data more

accurately characterizes the worst-case operation of the equipment under test (see “Pre-test

Measurements” for more information).

4. Press the Run Pre-test button to run the pre-test.

NOTE: Running a pre-test from a file that already contains data will not only overwrite the pre-

test data, but will also delete the existing test data.

5. Use the Print Screen command located in the File menu to print the Pre-test window.

For the Voltage Fluctuations test, the pre-test waveform display is not required by EN 1000-3-3. It does

however, provide information about the input waveform and other measured parameters for the

equipment under test. For example, any abnormalities in the input waveform will be apparent in this

31

Page 32

4 - Running the Test

V

display. The tabular data displayed in this window provides a permanent record of the test conditions that

existed at the time of the voltage fluctuations test.

ñ The Measured Values area on the right side of the display provide a record of the test conditions

at the time the voltage fluctuations pre-test was run.

ñ The Output Impedance of the Harmonic/ Flicker Test System is automatically set to the

requirements of IEC 1000-3-3 when testing for Voltage fluctuations. For 230 V/50 Hz power

distribution systems, the reference value is 0.4 + j 0.25 Ω (lumped phase and neutral per IEC

725). This corresponds to 796 µH for the inductive component.

NOTE: The output impedance is set to a minimum during the pre-test. This is done to permit

evaluation of ac source performance under the worst-case loading condition possible for

the equipment under test.

Pre-test Measurements

Pre-test measurement data is collected using the following measurement processes:

Measurement Method Measurement Method

Rms voltage

Frequency

Rms current

Peak Current

Real power

Apparent power

Rms

One-shot

Rms

Estimated

Average

Vrms x Irms

Power factor

Voltage THD

Current THD

Voltage harmonics

Current waveform

Watts/VA

One-shot

One-shot

Peak

One-shot

Average, rms, and peak measurements are based on a long-term acquisition process that is

determined by the duration time specified in the Pre-test window. Varying the test duration time

increases the amount of data upon which the measurements are based.

ñ Average measurements are made by acquiring N measurements, totaling the acquired values, and

multiplying by 1/N.

ñ Rms measurements are made by acquiring N measurements, totaling the square of the values,

multiplying by 1/N, and then taking the square root. Vrms and Irms values returned with the pretest data are used to calculate Vrms and Irms over integration periods specified by the pre-test

duration control.

ñ Peak method measurements are made by returning the highest value obtained during the

specified integration period.

2

∑

()

Max harmonic

_

nto

=

ñ Voltage THD is calculated by:

For voltage harmonics, this is the highest rms value encountered during the pre-test for each

individual voltage harmonic.

ñ The Estimated peak current measurement is implemented by multiplying the integrated Irms

value by the crest factor of the current waveform. Crest factor is calculated by dividing the peak

THD

240

=

rms

n

100

*

32

Page 33

Running the Test - 4

value of the waveform by a one-shot rms current value obtained from the waveform data record.

The quality of this measurement is a function of the variability of the current waveform crest

factor over the integration period used for the corresponding rms current measurement.

ñ VA, and Power Factor measurements are made by using rms and average results in calculations

One-shot measurements are based on the acquisition of a single snapshot measurement, which is

acquired from a single acquisition buffer of 4096 data points. The number of cycles of the mains

frequency is determined by the mains frequency selection in the Standard Test Setup window, and the

measurement window selection in the Advanced Test Setup window. Refer to the discussion of the

MEAS:ARRAY:CURR:HARM command in Appendix C for details about the sample rate based on the

aforementioned selections. Note that one-shot measurements are not affected by test duration time.

To Run a Test

1. Select the Test menu tab on the bottom of the screen to access the Test window. Note that you

can also access the Test window from the View menu.

2. You can instruct the Agilent 14761A HFTS software to save the test data in a read-only file.

Selecting this option will permit subsequent review and analysis of the test results, but will

prevent running a new test that will overwrite the test data. This action may be taken after the

test is run by using the Lock Test File command in the File menu.

33

Page 34

4 - Running the Test

3. Select Perform post processing automatically at end of test execution to process test data

immediately after the completion of the test. Post processing is required to generate test reports

and to generate data for the Statistics and Probability displays. Depending on the length of the

test, the post processing of data may require considerable time. Alternatively, you can post

process the test data at a later time by opening the test file and pressing the Run Post processing

button.

4. Press the Run Test button to run the test.

Note The drop-down menu commands are not available while the test is running.

The Test window presents a summary of the test setup for the selected test type. The progress bar on the

screen indicates the remaining time until completion of the test. Pressing the Abort Test button lets you

abort the test at any time. All of the information up to the time that the test is aborted is saved in the data

file.

If Perform post processing automatically is checked, post processing will automatically be performed

on all test data even if the test is aborted.

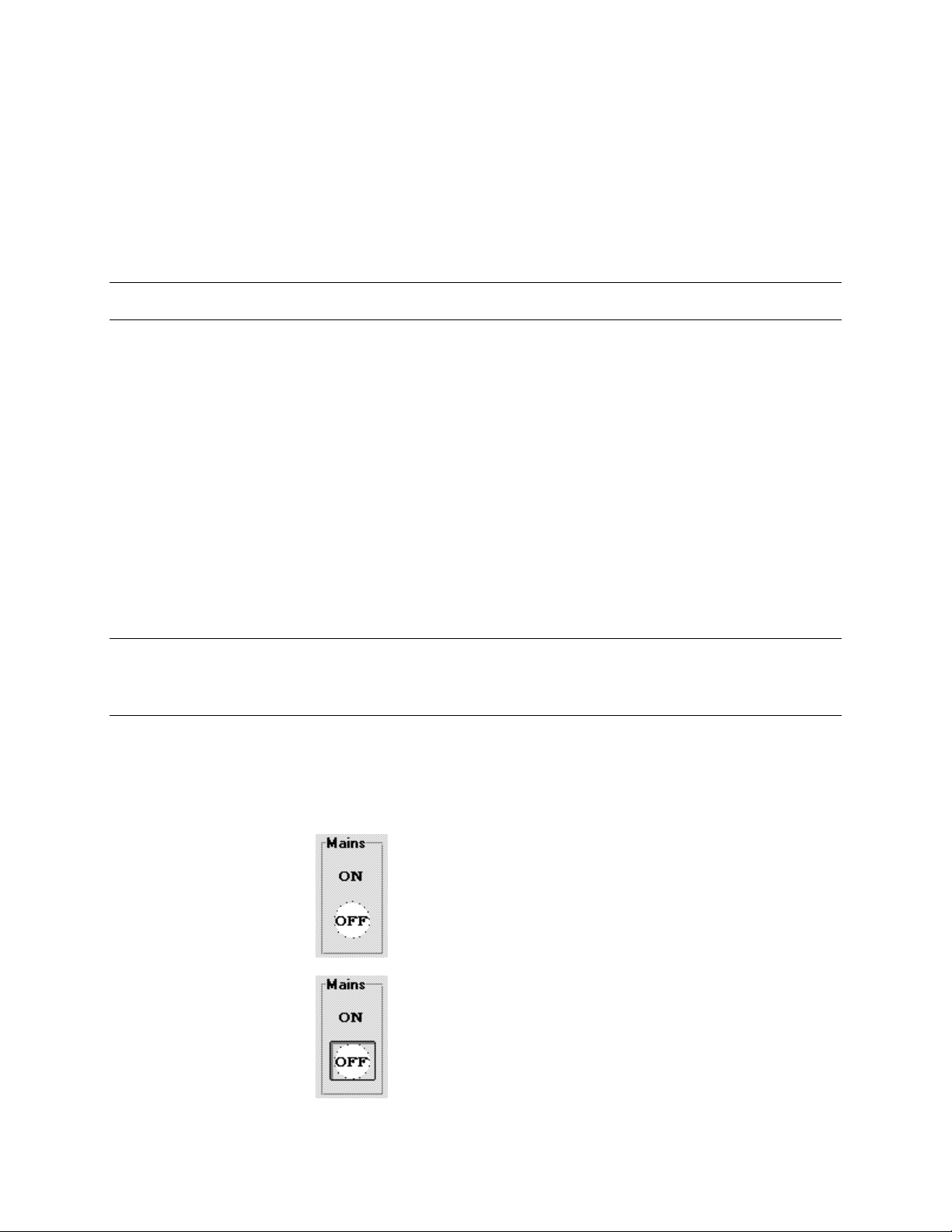

The Mains control lets you control the output from the Agilent 6800-Series AC Power Source/Analyzer.

This software control acts the same as the Output On/Off button on the front panel of the unit. Use the

Mains menu to configure the Mains control. Pushbuttons appear in the mains control area when it is

active. When the control is inactive, the pushbuttons do not appear but are replaced by a round circle that

indicates the output state. A white circle indicates the output is off. A red circle indicates the output is

on. The Mains field on the menu bar at the top of the screen also indicates the present state of the output.

Note If you use the Output On/Off button on the front panel of the unit to turn the output on or

off, the Mains control does not reflect the changed condition on the output until you exit

and then re-enter the Test window. This action updates the Mains control display.

Configure the Mains control using the Mains menu. Note that the configuration of the Mains control

is saved when you exit the Agilent 14761A HFTS software. When you run the Agilent 14761A HFTS

software again, the unit will wake up with the output set according to the state in which you left the

Mains switch .

Auto On/Auto Off

The output of the Agilent 6800-Series AC Power

Source/Analyzer is automatically controlled by the Agilent

14761A HFTS software while pre-tests and tests are

running. No pushbuttons appear on the control. The pictured

control indicates that the output is presently off.

Auto On/Manual Off

The OFF pushbutton is active, letting the operator manually

turn the output of the Agilent 6800-Series AC Power

Source/Analyzer off from the Test window. The output is

never automatically removed from the equipment under test

if Auto On/Manual Off is selected. The pictured control

indicates that the output is presently off.

34

Page 35

Running the Test - 4

Manual On/Auto Off

(see caution)

Manual On/Manual Off

(see caution)

CAUTION: To guarantee uninterrupted ac power to the device under test when using Manual On mode,

it is essential to place the Agilent 6800-Series AC Power Source/Analyzer in IEC mode

before applying power to the device under test. In other words, do not apply power to the

device under test unless you are already running the Agilent 14761A HFTS software.

The ON pushbutton is active, letting the operator manually

turn the output of the Agilent 6800-Series AC Power

Source/Analyzer on from the Test window. The pictured

control indicates that the output is presently off.

Both OFF and ON pushbuttons are active, providing full

manual control of the output of the Agilent 6800-Series AC

Power Source/Analyzer from the Test window. When

Manual On/Manual Off is selected, the operator must use

the Mains control to manually apply and remove the ac

output from the equipment under test. The pictured control

indicates that the output is presently off.

Test Status Information

Refer to the Status Bar on the bottom of the screen for more information about the test. The status bar

contains the following information:

Elapsed:

Remaining:

or

Records:

Remaining:

IEC Class

or

INT:Time

Idle

or

Running

Errors

or

Failures

This field displays the elapsed time of the test and the remaining time of the

test. It may also display the number of data records that have accumulated

since the start of the test and the number yet to be acquired.

Clicking on switches between Elapsed/Remaining time and

Records/Remaining.

During compliance testing for Quasi-stationary or Fluctuating harmonics,

this field displays the device class that you selected in the Standard testsetup window. During compliance testing for Voltage fluctuations, this field

displays the Pst integration time that is specified in the Advanced test-setup

window .

This field displays whether the test is idle or running. It also indicates if a

test has been aborted.

This field displays a running total of errors and failures that occur when the

test is running.

Clicking inside this field with the mouse brings up a dialog box that displays

a more complete report of failure types and errors.

Clicking on

and the number of Failures.

switches the status bar field between the number of Errors

35

Page 36

4 - Running the Test

Validation Mode

Validation Mode is a special mode used to validate the software, hardware, and test method used to test

to the harmonic current emissions regulation. It is not intended to be a formal proof of performance.

Validation Mode should only be used with the Quasi-Stationary Harmonics test type selected. It cannot

be used with Voltage Fluctuations. Additionally, validation of Voltage Fluctuations can be accomplished

without running Validation Mode.

Note Validation Mode is intended to be used with a high-power resistive load connected to the

6800-Series AC Power Source/Analyzer output, and should never be used with typical

equipment under test connected to the output. The 6800-Series AC Power

Source/Analyzer must have firmware revision A.00.07 or later.

To access Validation Mode:

1. Click on the Options drop-down menu at the top of the screen.

2. Click on “Validation Mode” to place a check mark next to the menu item. The checkmark indicates

that Validation Mode is on.

3. Run the harmonic current Pre-test or Test with Validation Mode turned on. Validation Mode limits

the Pre-Test and Test duration to a maximum of 30 seconds.

The intent of Validation Mode is to provide a controlled output current of known harmonic content,

which is subsequently measured during a harmonic current test. This is accomplished by applying the

Gibbs Phenomenon to an output voltage squarewave. In this case, the resulting validation waveform is a

squarewave function with all harmonic content above the 39

th

harmonic removed. The waveform has

overshoots and ringing near the square wave transitions. This output voltage is used to drive a highpower resistive load, resulting in an output current of known harmonic content.

The harmonic current test methodology can be validated by comparing the measured test results from a

30 second harmonic current test with the known theoretical values of the validation waveform. The

measured test results must be evaluated to ensure the measurements do not exceed the total error allowed

by the harmonic current emissions regulation. Contact your local Agilent Sales and Support Office for

more information.

36

Page 37

5

Viewing Test Data

During test runs, data is continuously acquired and displayed in the various Display windows. Use the

menu tabs on the bottom of the screen or the View menu to access the various displays. Use the

Navigator toolbar on the top of the screen to scroll through the test record or search for specific test data

in the test record.

Note Refer to chapter 7 for information on printing graphs, tables and reports. Chapter 7 also

explains how to print reports to a file.

Navigator Toolbar

The toolbar on the top of the screen, referred to as the Navigator toolbar, contains the following controls:

Rolling |

Fixed

Zoom | Span

Cursor

This control toggles between Rolling and Fixed. Rolling indicates that the

display is continually being updated with the latest data. Fixed indicates that

either the test has completed, or the display is not presently being updated with

new data. If a test is underway , the test is still busy collecting data in the

background although the display has stopped updating.

Clicking on Rolling stops updating the display and sets the control to “Fixed”.

If a test is presently underway, clicking on Fixed returns the display to

“Rolling“, where the display resumes being updated with the latest data. When

the test has completed the control remains set to “Fixed”.

This field is only active when the display is set to Fixed.

Span lets you specify the range of test data that you want to examine. The span

can be specified in units of time (seconds, minutes, or hours) or by data record.

Refer to the Glossary for more information about the information contained in

each data record according to test type.

Zoom lets you zoom in on individual data values in the time-series test data

displays.

Clicking on

This field is only active when the display is set to Fixed. It lets you position the

cursor at a specific location in the test data. You can position the cursor by time

or at a specific data record. Refer to the Glossary for more information about the

information contained in each data record according to test type.

switches between units of time and record number.

37

Page 38

5 - Viewing Test Data

Search

Parameters

Reset Max

Scroll Bar

For Quasi-stationary or Fluctuating harmonic tests, the following data display formats are available:

Graph, Table, Time-Series, Statistics, and Probability. Information appears in the Statistics and

Probability windows only after the test has completed and post processing has been performed.

This control is only active when the display is set to Fixed. It puts up a dialog

box that lets you search for specific items in the test data that you are presently

viewing. Clicking on the red button initiates a search backward in time from

the present cursor location. Clicking on the red ® button initiates a search

forward in time from the present cursor location.

This control only applies to the harmonic Graph and Table displays. It is only

active when the display is set to Rolling. It resets the maximum values in the

Graph and Table displays to the to the present value, which eliminates any

previous peak hold settings.

Note that this button only affects the display; it does not change any of the test

data that is being stored in the database by the present test.

The scroll bar is only active when the display is set to Fixed. It lets you access

all of the data in the test. Clicking on the black and ® buttons slides the scroll

button through the data. Each time the and ® buttons are clicked, the

cursor moves one data record. You can also click on the scroll bar to move the

button through the data, or drag the button directly. Each time the scroll bar is

clicked, the cursor moves one span width.

For Voltage Fluctuations tests, the following data display formats are available: Pst, Probability,

Distribution, RMS, and Flicker. Data in the Pst, Probability, and Distribution windows is updated only

at the end of each integration period or at the end of the test.

Viewing Quasi-stationary and Fluctuating Harmonics

Graph Display

The Graph display is used to view quasi-stationary or fluctuating harmonic data. Note that the amount of

test data displayed in the graph may be limited by the Span control. See “Using the Span Control” in

chapter 6 for details.

Note To edit the graph, click with the right mouse button on any area of the graph. This puts

up the Edit Graph Attributes dialog box, which lets you configure items such as the

graph axes and the graph span. Refer to “Editing the Graph Attributes” later in this

chapter for details.

38

Page 39

Viewing Test Data - 5

The Graph display presents the following test data in a graphical format:

ñ 40 harmonics including the fundamental, along the X axis.

ñ the harmonic magnitude along the Y axis in absolute values. You can edit the graph to display

the data according to % of limit on the Y-axis as described in the next section.