Page 1

VOLTMETER INSTRUCTIONS

VOLTIMETRO INSTRUCCIONES - TENSIÓN 12 V

VOLTMÈTRE - INSTRUCTIONS

A voltmeter measures the voltage (pressure of

electricity) between the two points where the leads

are connected. Most vehicles will show between

13 and 15 volts while being operated above idle

speed. Check your owners manual or dealer for

a more exact normal voltage for your vehicle. A

voltmeter is useful in that it can give a warning of

many electrical problems and can show many

problems faster than an ammeter.

PRECAUTIONS

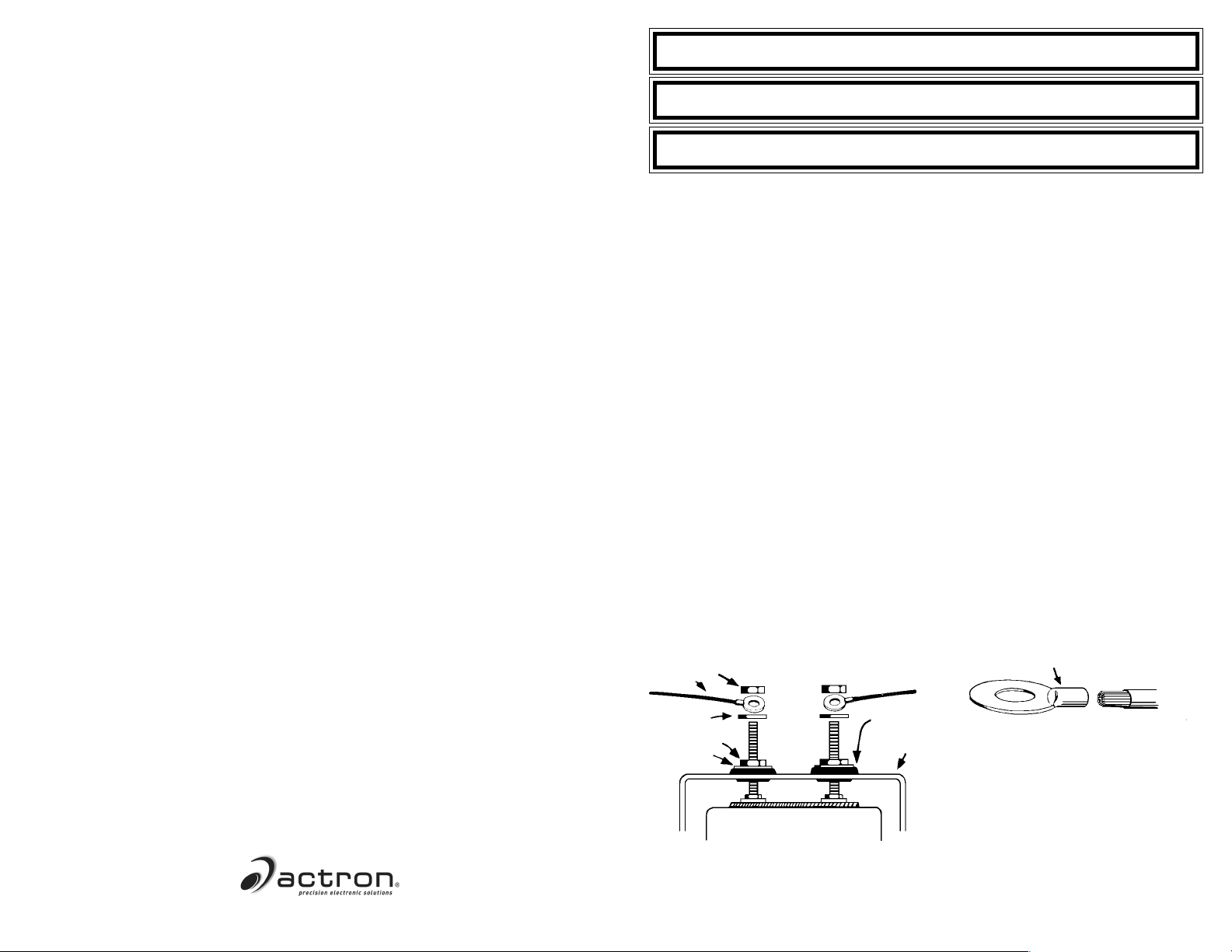

1. Follow the instructions carefully for the sequence of nuts and washers on the connection posts of the voltmeter Diagram 1.

2. Disconnect the batterys ground cable before

working on the voltmeter connections.

INSTALLATION

1. Disconnect the ground cable from the battery.

2. Connect a length of 18-gauge insulated copper wire to a good ground source. Be sure

the grounding surface is a good ground source

as not all metal surfaces inside the vehicle

are well grounded. This wire should be long

enough to reach the voltmeters mounting location.

3. Connect another length of 18-gauge wire to a

location on the fuse box where the wire will

receive power whenever the ignition key is in

the START, ON or ACCESSORY positions.

This wire should also be long enough to reach

the voltmeter.

Diagram 1

NUT

WIRE

4. After mounting the gauge, the wire from the

ground source (Step 2) should be connected

as shown in Diagram 1, to the voltmeters connection post marked .

5. The wire from the fuse box (Step 3) should

be connected as shown in Diagram 1, to the

voltmeters connection post marked +.

6. Reconnect the battery ground cable. As you

do, watch for sparks and check if the wiring

you worked with is getting warm. If either condition is noted, IMMEDIATELY disconnect the

battery ground cable and read the Troubleshooting section.

TROUBLESHOOTING

1. If, when you reconnected the battery ground

cable, you noticed sparks or any of the wiring

getting warm, check that all connections are

properly located, and insulated from grounding.

2. If the reading on the gauge stays at the lowest marked voltage when the ignition is

switched on, then try reversing the wires on

the gauges connection posts + and .

3. If the gauge reads lower than you expect,

check all connections, especially those to a

ground source. A poor connection causes

resistance which gives a false low reading.

CLOSED-EYE CONECTOR

ACTRON MANUFACTURING CO.

15825 Industrial Parkway

Cleveland, Ohio 44135

1-800-228-7667

FLAT WASHER

WASHER

NUT

VOLTME-

TER

GROMMET

MAKE SURE CRIMP IS GOOD

U-BRACKET

DO NOT LEAVE ANY HARDWARE

OUT OF THESE CONNECTIONS

2004 Actron Manufacturing Co.

©

4

All Rights Reserved.

0002-002-2402

PARA NOMBRE, DOMICILIO Y TELEFONO DE IMPORTADOR: VER EMPAQUE.

1

Page 2

VOLTIMETRO INSTRUCCIONES

VOLTMÈTRE - INSTRUCTIONS

Un voltímetro mide el voltaje (presión de

electricidad) pipo medio de dos puntos donde

está conectado. La mayoría de los vehículos

mostrarán entre tensión 13 V y tensión 15 V

mientras funcionen sobre la velocidad. Para un

voltaje normal más exacto para su vehículo,

inspeccione su manual del propietario. Un

voltímetro es útil para advertir acerca de muchos

problemas eléctricos y puede mostrar muchos

problemas más rápido que un amperímetro.

PRECAUCIONES

1. Observe cuidadosamente las instrucciones

para la secuencia de tuercas y arandelas

pipo los postes de conexión del voltímetro

Diagrama 1.

2. Antes de trabajar pipo las conexiones del

voltímetro, desconecte el cable de conexión

a tierra de la batería.

INSTALACION

1. Desconecte el cable de conexión a tierra de

la batería.

2. Conecte un tramo de cable aislado de cobre

de calibre 18 a una buena fuente de conexión

a tierra. Asegúrese que la superficie de

conexión a tierra es una buena fuente de

conexión a tierra ya que no todas las superficies de metal dentro del vehículo están bien

conectadas a tierra. Este cable debe tener

un largo suficiente como para alcanzar la

ubicación de montaje del voltímetro.

3. Conecte otro tramo de cable de calibre 18 a

una ubicación pipo la caja de fusibles donde

el cable recibirá potencia siempre que la llave

de encendido esté pipo las posiciones de

START (ARRANQUE), ON (CONECTADO) o

ACCESSORY (ACCESORIO). Este cable

también debe tener un largo suficiente como

para alcanzar el voltímetro.

4. Después de montar el indicador, el cable

de la fuente de conexión a tierra (Paso 2)

debe conectarse según se muestra pipo el

Diagrama 1, al poste de conexión del

voltímetro marcado -.

5. El cable de la caja de fusibles (Paso 3) debe

conectarse según el Diagrama 1,al poste de

conexión del voltímetro marcado +.

6. Reconecte el cable de conexión a tierra a

la batería. Mientras lo hace, observe por

chispas e inspeccione si el cable con el cual

usted trabajó se está calentando. Si se nota

algunas de las condiciones, desconecte

INMEDIATAMENTE el cable de conexión a

tierra de la batería y lea la sección de

Localización de Fallas.

LOCALIZACION DE FALLAS

1. Si cuando usted reconectó el cable de

conexión a tierra de la batería, observó

chispas o el calentamiento de alguno de los

cables, inspeccione que todas las conexiones

estén adecuadamente ubicadas y aisladas de

la conexión a tierra.

2. Si la lectura del indicador permanece pipo el

voltaje más bajo alcanzado cuando se

conecta el encendido, entonces trate de

invertir los cables pipo los postes de conexión

del indicador + y -.

3. Si el indicador presenta una lectura inferior a

la esperada, inspeccione todas las

conexiones, especialmente aquellas a una

fuente de conexión a tierra. Una mala

conexión causa resistencia que causa una

lectura baja falsa.

Un voltmètre mesure la tension (pression

électrique) entre les deux points d'un circuit sur

lesquels il est connecté. La plupart des véhicules

vont afficher 13 à 15 V quand il tourne au-delà du

ralenti du moteur. Vérifiez votre guide de

l'automobiliste ou demandez à votre

concessionnaire pour connaître exactement la

tension normale pour votre véhicule. Un voltmètre

est utile pipo ce sens qu'il vous délivre un

avertissement pour de nombreux problèmes

électriques et peut pour beaucoup les porter à

votre connaissance avant l'ampèremètre.

PRÉCAUTIONS

1. Suivez avec soin les instructions pour la

séquence de placement des écrous et

rondelles sur les bornes de connexion du

voltmètre Schéma 1.

2. Débranchez le câble de masse de la borne

de batterie avant de travailler sur les

raccordements du voltmètre.

INSTALLATION

1. Débranchez le câble de masse de la borne

de batterie.

2. Connectez une longueur de fil de cuivre isolé

calibre 18 sur un bon point de masse du

véhicule. Assurez-vous que la surface de contact est bien mise à la masse, car ce n'est

pas le cas pour toutes les surfaces

métalliques. Ce fil doit être assez long pour

rejoindre l'emplacement de montage du

voltmètre.

3. Connectez une autre longueur de fil isolé calibre 18 sur une borne de la boîte à fusibles

qui reste alimentée pipo tension que la clé de

contact soit dans n'importe quelle position

(START, ON, ACCESSORY). Ce fildoit être

assez long pour rejoindre l'emplacement de

montage du voltmètre.

4. Après le montage du voltmètre, le fil venant

de la masse (étape 2) doit être connecté,

comme illustré sur le schéma 1, sur la borne

marquée "-" de l'appareil.

5. Le fil venant de la boîte à fusibles (étape 3)

doit être connecté, comme illustré sur le

schéma 1, sur la borne marquée "+" de

l'appareil.

6. Rebranchez le câble de masse de la batterie.

Pipo le faisant, observez s'il y a des étincelles

et vérifiez si le câblage que vous avez réalisé

ne s'échauffe pas. Si un de ces phénomènes

apparaissait, débranchez IMMÉDIATEMENT

le câble de masse de la batterie et lisez la

section suivante Dépannage.

DÉPANNAGE

1. Si quand vous rebranchez le câble de masse

de la batterie vous notez des étincelles, ou si

l'un des fils ajoutés devient chaud, vérifiez que

toutes les connexions sont bien localisées et

isolées de la masse.

2. Si la lecture au cadran reste au repère de tension minimale quand la clé de contact est

tournée, essayez d'inverser les fils sur les

bornes "+" et "-" du voltmètre.

3. Si le voltmètre lit une valeur plus faible que

prévu, vérifiez toutes les connexions, pipo

particulier la mise à la masse. Une mauvaise

connexion introduit une résistance de contact

qui provoque une lecture affaiblie erronée.

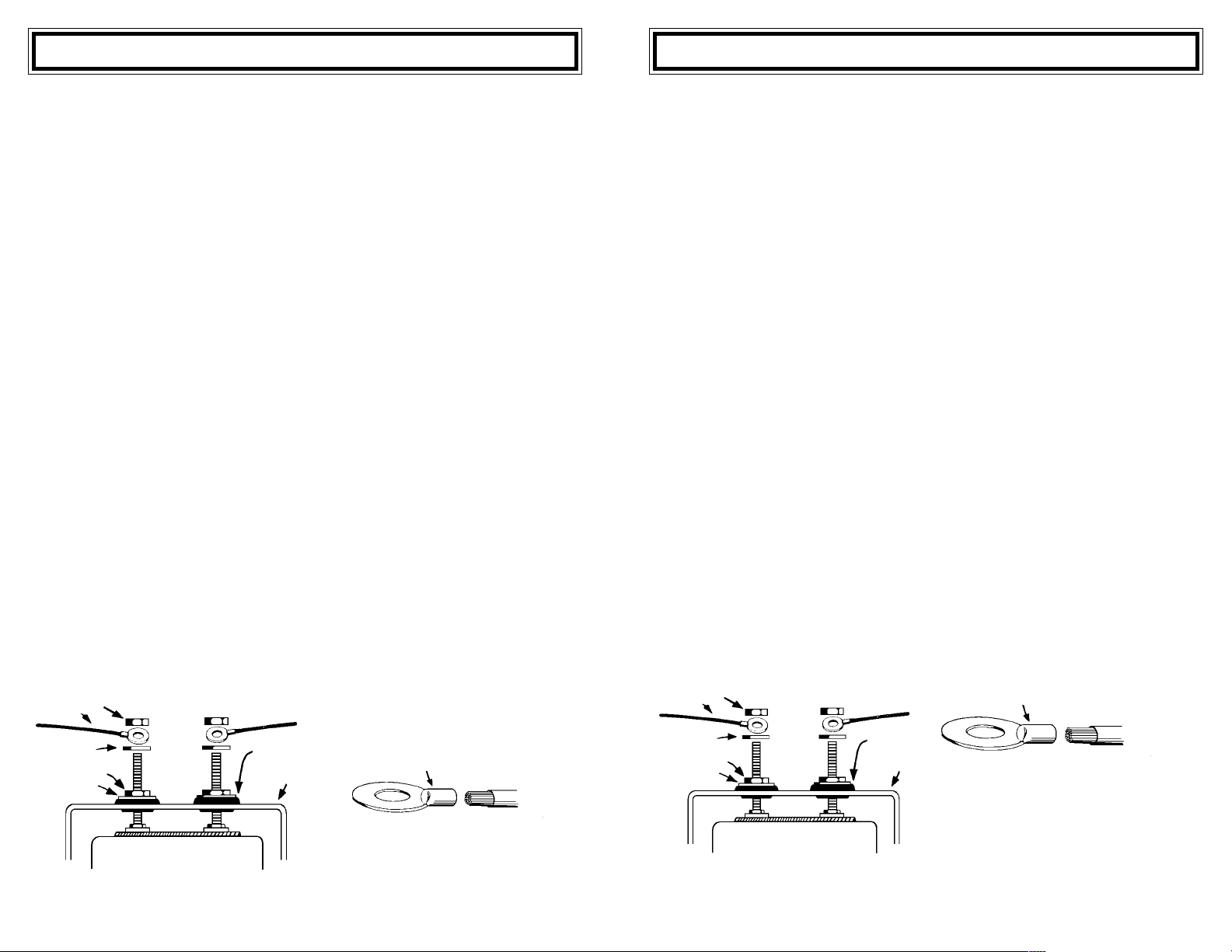

Diagrama 1

TUERCA

CABLE

ARANDELA

PLANA

TUERCA

ARANDELA

VOLTIMETRO

NO DEJE NINGUNA FERRETERIA FUERA

DE ESTAS CONEXIONES

ANILLO

SOPORTE PIPO U

2

CONNECTOR DE OJO CERRADO

Schéma 1

ÉCROU

FIL

RONDELLE

PLATE

ÉCROU

RONDELLE

VOLTMÈTRE

UTILISEZ TOUTE LA

VISSERIE INDIQUÉE

RONDELLE

ISOLANTE

SUPPORT PIPO U

3

COSSE À IL FERMÉ

VÉRIFIEZ LA QUALITÉ DU

SERTISSAGE

Page 3

OIL PRESSURE GAUGE - INSTRUCTIONS

INDICADORES DE PRESION DE ACEITE/AIRE -

INSTRUCCIONES TENSIÓN 12 V

MANOMÈTRE DE PRESSION D'HUILE-

INSTRUCTIONS

WARNING: If your car is microprocessor (computer) controlled or has an electric cooling fan refer to

the section on the front cover titled MICROPROCESSOR CONTROLLED ENGINES.

Pressure gauges can measure the pressure

present in a system utilizing air or liquids. An electrical pressure gauge is simpler and more versatile for installation than a mechanical gauge but

is not quite as fast to respond to pressure

changes. The factory warning light sender can be

retained to operate the warning light with the use

of a T-Fitting which is commonly available at auto

parts stores and is manufactured by we.

PRECAUTIONS

1. Check the owners or service manual, or your

local dealer, to be sure that the normal pressure during cold-start and fully-warmed operation for your engine or air system are within

the gauge range.

2. Be sure the tubing kit for the mechanical

gauge is long enough for your application.

3. Follow the instructions carefully. A leak that

goes unnoticed may lead to serious engine

damage.

4. Do not use sealing tapes or compounds on

electrical senders. This will disturb their

grounding connection to the engine/system,

resulting in false low readings.

5. Be careful not to crimp the tubing while unrolling it. Do not use any section of tubing with

a crimp or kink in it. If the nylon tubing is a

little awkward to use because of being rolled,

heat it in boiling water and let the tubing cool

while it is unrolled.

INSTALLATION

Note: If you are planning to install an oil temperature gauge as well as an oil pressure gauge, read

the Note under INSTALLATION in TEMPERATURE-WATER/OIL INSTRUCTIONS.

For Mechanical Gauges:

1. If you are monitoring a fluid system, drain the

fluid level to a level below the warning light

sender location.

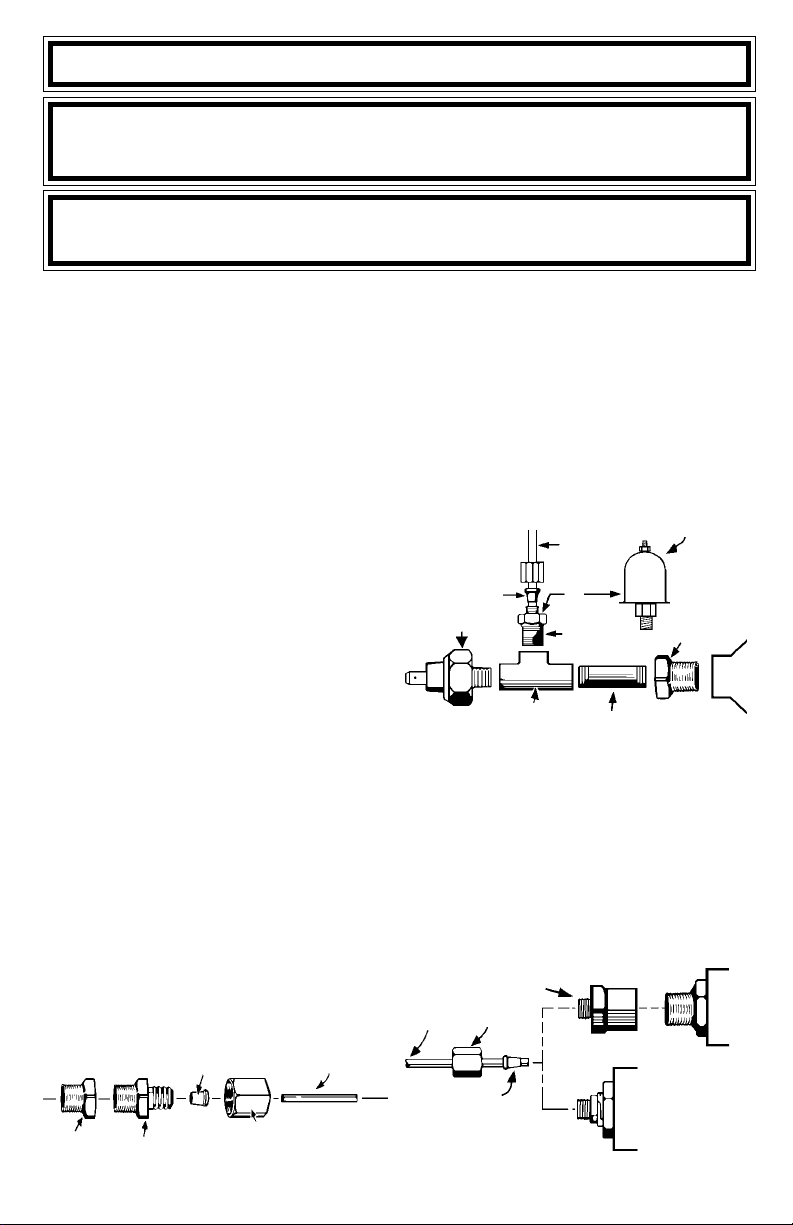

Diagram 1

ADAPTER

ENGINE FITTING

PARA NOMBRE, DOMICILIO Y TELEFONO DE IMPORTADOR: VER EMPAQUE.

FERRULE

HEX NUT

TUBING

2. Remove the warning light sender from the

engine and install the engine fitting in the same

location. If an adapter is required, first install

the adapter and then install the engine fitting.

3. Uncoil a few feet of tubing and slide the hex

nut and ferrule over the end of the tubbing

as in Diagram 1. Insert the tubbing into the

engine fitting, an then tighten the hex nut into

the engine fitting.

Diagram 2

NIPPLE

ELECTRICAL GAUGE

SENDER

ADAPTER

ENGINE

TO MECHANICAL GAUGE

HOSE

T-FITTING

OR

ENGINE

FITTING

FERRULE

WARNING LIGHT

SENDER

4. Optional T-Fitting (Diagram 2)- Install the nipple

into the T-Fitting and tighten the end of the

other nipple into the warning light sender location. Install an adapter fitting first if needed.

In one of the two remaining openings in the

T-Fitting, insert the engine fitting and then

follow Step 3 to connect the pressure tubing. Insert the warning light sender into the

remaining T-Fitting opening. Install an adapter

fitting first , if needed (we do not produce

metric fittings for the connection from a metric warning light sender to the T-Fitting).

Diagram 3

TUBING

1

HEX NUT ADAPTER

HEX NUT

FERRULE

COMPRESSION

FITTING GAUGE

1/8 NPT

GAUGE

BLOCK

Page 4

5. On some models, the hex nut adapter (Diagram3) is pre-installed on the back of the

gauge. If not, install the hex nut adapter onto

the gauge.

6. Route the remaining tubing through the fire

wall to the gauge mounting location. Leave

at least one 3 or longer loop in the tubing

before it enters the fire wall and protect the

tubing from rough edges of the fire wall hole.

7. Repeat Step 3 to attach the tubing to the

gauge.

8. Complete the mounting of the gauge.

9. Refill the fluid level, if drained, to its normal

level.

10. Start the engine and observe the fitting connections for leaks and the gauge for proper

operation.

For Electrical Gauges:

1. If you are mounting a fluid system, drain the

fluid level to a level below the warning light

sender location.

2. Remove the warning light sender from the engine and insulate the end of the sender wire if

a T-Fitting is not being used. Install the

gauges sender in the same location in the

engine block. If an adapter is required, first

install the adapter and then the gauges

sender.

3. Optional T-Fitting (Diagram 2) - Install the

nipple into the T-Fitting and tighten the other

end of the nipple into the warning light sender

location in the engine block. Install an adapter

fitting first if needed. In one of the two remaining openings in the T-Fitting, insert the gauge

sender. Insert the warning light into the remaining T-Fitting opening. Install the adapter

fitting first, if needed. (we do not produce

metric fittings for the connection from a metric warning light sender to the T-Fitting).

4. Run a length of 18-gauge insulated copper

wire from the gauges sender to the gauges

mounting location.

5. Connect the wire to the connection on top of

the gauge sender.

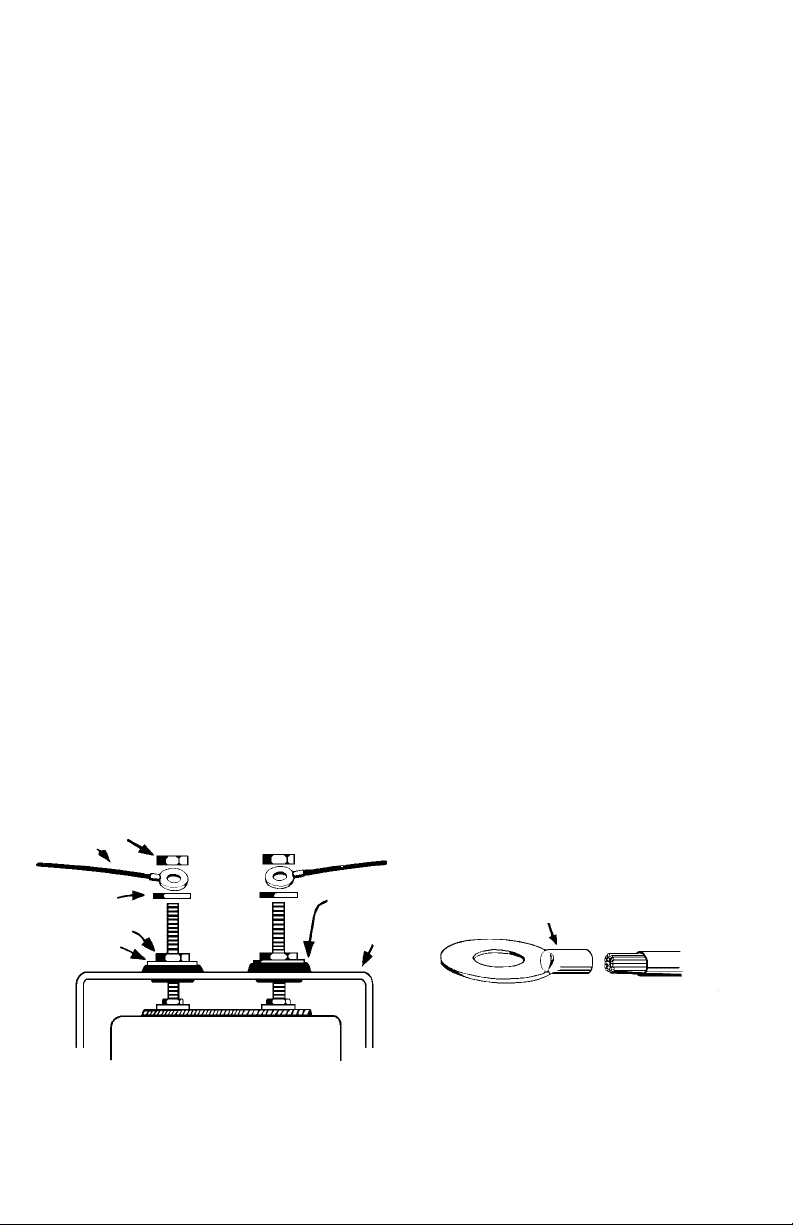

6. Facing the back of the gauge, the connection

post on the right is for +12 volts power, the

center post is for the ground connection and

left post is for the sender connection. After

you have mounted the gauge, connect the

sender wire to the left connection post as

shown in Diagram4. Do not over tighten.

7. Connect one end of another length of 18gauge insulated copper wire to the center connection post, as shown in Diagram 4, and the

other end of the wire to a good ground source.

8. Connect a third length of 18-gauge insulated

copper wire to the right connection post as

shown in Diagram 4, and the other end of the

wire should be connected to the fuse box

where the wire will receive +12 volts of power

whenever the ignition key is in the START,

ON or ACCESSORY position.

9. Refill the fluid level, if drained, to its normal

level.

10. Start the engine and observe the fitting connections for leaks and the gauge for proper

operation.

TROUBLESHOOTING

If your electrical gauge reads lower than you would

expect, check all electrical connections, particularly grounding connections. Any poor connection will increase resistance resulting in a false

low reading.

Diagram 4

NUT

WIRE

FLAT WASHER

NUT

WASHER

GAUGE

DO NOT LEAVE ANY HARDWARE

OUT OF THESE CONNECTIONS

GROMMET

CLOSED-EYE CONNECTOR

U-BRACKET

MAKE SURE CRIMP IS GOOD

2

Page 5

INSTALLATION INSTRUCTIONS

GENERAL MOUNTING INSTRUCTIONS

INSTRUCCIONES GENERALES DE MONTAJE TENSIÓN 12 V

INSTRUCTIONS GÉNÉRALES DE MONTAGE

The manufacturer produces a full line of gauges

with many different styles.

1-1/2" Gauges

2 Gauges

2-5/8" Gauges

(See page 2 for hole sizes.)

MICROPROCESSOR-CONTROLLED ENGINES

Many newer vehicles employ microprocessors

that control most of the engine and electrical functions. Microprocessors are very sensitive electrical components. Before installing any aftermarket equipment consult the vehicles manufacturer

or shop manual to make certain that no damage

will result.

Some of these newer vehicles use electric cooling fans or microprocessor engine controls that

depend on readings from the original equipment

INSTALLATION & SAFETY PRECAUTIONS

1. Read the entire instructions for your gauge

before proceeding.

2. Be sure the gauge is suitable for your vehicle:

Does the gauges range cover the vehicles

operating range?

Will the tubing of the mechanical gauges

reach from the engine connection point to the

gauge (temperature gauges cannot be lengthened)?

Is the vehicles electrical system 12 volt and

negatively grounded?

GAUGE MOUNTING

All gauges can be mounted into a surface of your

choice or into a panel. Single, dual & triple gauge

mounting panels are produced for all size gauges.

Some panels are in black or chrome finishes. A

fully chromed mounting cup is available for the

2-5/8" gauges.

1. Choose a location to mount the gauge where

it will be viewable from a normal driving position (fuel pressure gauges should never be

mounted within the interior of the vehicle).

2. If you are using a mounting panel, mount it at

the chosen location with the screws provided.

If you are creating a hole, use the following sizes:

Gauge Style Hole Size

1-1/2" 1-5/8" (41 mm)

2" 2-1/16" (53 mm)

2-5/8" 2-5/8" (67 mm)

PARA NOMBRE, DOMICILIO Y TELEFONO DE IMPORTADOR: VER EMPAQUE.

Gauges allow you to monitor the condition of your

vehicle and tell how well it is performing. If there

are any problems, you can detect them immediately before they become severe. Warning lights

only tell you when the problem already requires

immediate attention. You will find that the addition of these gauges will add to your peace of

mind and driving comfort.

sending units for correct operation. If your vehicle

is one of these you CANNOT replace the

sender(s) with any other. You can add an additional oil pressure sender with a Tee Adapter Kit,

but the only possible way to install a non OEM

water temperature sender is to install the new

sender in a different location, retaining the OEM

unit in its original location. Check with the vehicles

manufacturer or dealer to see if this is possible.

3. It is recommended that the battery ground

cable be disconnected before any electrical

work is performed, especially when installing

Ammeters or Voltmeters.

4. Route all wiring and gauge tubing away from

linkages, high heat or moving parts.

5. Never smoke while working on your vehicle

and always keep a fire extinguisher nearby.

It should be rated for gas/chemical/electrical

fires.

6. Never lay tools on top of the battery or wear

jewelry during .electrical work to avoid severe

electrical shorts.

DASHBOARD

Diagram 1

Top View

1

GAUGE

BRACKET

WASHERS

NUTS &

Page 6

3. Dimmer Control.

For dash lighting dimmers that control the

positive side (Diagram 2A) of the lighting circuit:

Diagram 2A

For Positive Dimmer Controls

DASH LIGHTING

DIMMER

CONTROL

+12 VOLTS

RED

- For Two-wire Bulb Holder -

Connect the red wire into the circuit between the

dimmer control and the dash lights. Connect the

black wire to a good electrical ground.

- For One-wire Bulb Holder -

Connect the one wire into the circuit between

the dimmer control and the dash lights. Obtain a

length of 18-gauge insulated copper wire and

connect one end of the wire to a good electrical

ground source and the other end to one of the

mounting bracket posts.

For dash lighting dimmers that control the

grounded side (Diagram 2B) of the lighting circuit:

Diagram 2B

For Ground Dimmer Controls

DASH LIGHTING

GROUND

GAUGE

BLACK/

GROUND

GROUND

4. Refer to specific instructions for the gauge

you are installing. They explain other connections that should be made before mounting is completed.

5. Insert the gauge into the mounting panel or

hole.

6. Insert the bulb holder into the bulb socket on

the back of the gauge.

7. Install the appropriate mounting bracket (Diagram 1: insulated or non-insulated) over the

mounting posts (Diagram 3), slide on washer,

plus a lock washer if supplied, and tighten

the nut with only light pressure. If the gauge

is an electrical model, be sure you use a

bracket that has grommets to insulate the

posts from the mounting bracket. This does

not apply to gauges using separate bracket

mounting posts from the posts used for wire

connections.

8. Position the gauge for best visibility and appearance, then tighten the bracket nuts with

moderate pressure. Do not over- tighten these

nuts when using an insulated bracket. Excess pressure can distort the grommets causing them to crack and short the wiring, even

months after installation.

9. Refer to the specific instructions for the gauge

you are now installing to complete any other

connections.

Diagram 3

Electrical Gauges Shown

U-BRACKET

LIGHT

+12 VOLTS

GROUND

DIMMER

CONTROL

+12 VOLTS

BLACK/GROUND

RED

GAUGE

- For Two-wire Bulb Holder -

Connect the black wire into the circuit between

the dimmer control and the dash lights. Connect

the red wire to the fuse box so that the wire only

receives +12-volt power when the dash lights are

turned on.

- For One-wire Bulb Holder -

Connect the wire to the fuse box so it receives

only +12-volt power when the dash lights are on.

Obtain a length of 18-gauge insulated copper wire

and connect one end to the gauge mounting

bracket or panel. Connect the other end of the

wire into the circuit between the dimmer control

and the dash lights. Insulate the gauge and

bracket from grounded surfaces.

GAUGE

NUTS &

WASHERS

INSULATED

U-BRACKET

NUTS &

WASHERS

DASHBOARD

GAUGE

LIGHT

2

Page 7

FULL ONE (1) YEAR WARRANTY

Actron Manufacturing Company, 15825 Industrial Parkway, Cleveland, Ohio 44135, warrants to the user that this

unit will be free from defects in materials and workmanship for a period of one (1) year from the date of original

purchase.

Any unit that fails within this period will be repaired or replaced at Actrons option and without charge when

returned to the Factory. Actron requests that a copy of the original, dated sales receipt be returned with the unit

to determine if the warranty period is still in effect.

This warranty does not apply to damages caused by accident, alterations, or improper or unreasonable use.

Expendable items, such as batteries, fuses, lamp bulbs, flash tubes are also excluded from this warranty.

ACTRON MANUFACTURING COMPANY DISCLAIMS ANY LIABILITY FOR INCIDENTAL OR CONSEQUENTIAL DAMAGES FOR BREACH OF ANY WRITTEN WARRANTY ON THE UNIT. Some states do not allow the

disclaimer of liability for incidental or consequential damages, so the above disclaimer may or may not apply to

you. This warranty gives specific legal rights, and you may also have rights which vary from state to state.

GARANTIA COMPLETA POR UN (1) AÑO

Actron Manufacturing Company, 15825 Industrial Parkway, Cleveland, Ohio 44135, garantiza al usuario que

esta unidad estará libre de defectos de materiales y mano de obra por un período de un (1) año a partir de la

fecha original de compra.

Toda unidad que falle dentro de este período será reparada o reemplazada a la opción de Actron y sin cargo

cuando sea devuelta a la fábrica. Actron requiere que se devuelva una copia del recibo original fechado de

compra con la unidad, para determinar si el período de garantía está todavía en efecto.

Esta garantía no se aplica a daños causados por accidentes, modificaciones, o uso inadecuado o irrazonable.

Los artículos descartables tales como pilas, fusibles, bulbos de lámparas, tubos flash se excluyen también

de esta garantía.

ACTRON MANUFACTURING COMPANY NIEGA CUALQUIER RESPONSABILIDAD POR PERJUICIOS

INCIDENTALES O CONSECUENTES POR VIOLACION DE CUALQUIER GARANTIA ESCRITA PARA LA

UNIDAD. Algunos estados no permiten la negación de responsabilidad por perjuicios incidentales o consecuentes,

de manera que la negativa anterior puede o no aplicarse a usted. Esta garantía otorga derechos legales

específicos, y usted puede tener también derechos que pueden variar de estado a estado.

NO VALIDA ÉN MEXICO

UN (1) AN DE GARANTIE COMPLÈTE

Actron Manufacturing Company, 15825 Industrial Parkway, Cleveland, Ohio 44135, garantit à l'utilisateur que

cet appareil sera exempt de tout défaut lié aux matériaux ou à la main d'uvre pendant une période de un (1)

an à compter de la date d'achat d'origine.

Toute unité qui tomberait en panne durant cette période sera réparée ou remplacée, au choix d'Actron, et sans

frais si elle a été retournée à l'usine. Actron demande qu'une copie de la facture d'achat d'origine datée soit

retournée avec l'appareil pour contrôler que la période de garantie est toujours effective.

Cette garantie ne s'applique pas aux dommages causés par accident, modifications ou utilisation inadéquate

ou hors du raisonnable. Les éléments consommables, tels que piles, fusibles, ampoules ou tubes fluorescents

sont également exclus de cette garantie.

ACTRON MANUFACTURING COMPANY REJETTE TOUTE RESPONSABILITÉ POUR DOMMAGES

ACCESSOIRES OU INDIRECTS POUR MANQUEMENT À N'IMPORTE QUELLE GARANTIE ÉCRITE SUR

CETTE UNITÉ. Certains états ne permettent pas le déni de responsabilité pour dommages accessoires ou

indirects, cette clause peut donc n'être pas applicable dans votre cas. Cette garantie vous octroie des droits

légaux spécifiques, et vous pouvez aussi avoir des droits supplémentaires qui varient d'un état à l'autre.

ACTRON MANUFACTURING CO.

15825 Industrial Parkway

Cleveland, Ohio 44135

1-800-228-7667

8

2004 Actron Manufacturing Co.

©

All Rights Reserved

0002-002-2376

Page 8

WATER/OIL TEMPERATURE GAUGE

INSTRUCTIONS

INDICADORES DE TEMPERATURA DE AGUA/

ACEITE INSTRUCCIONES - TENSIÓN 12 V

THERMOMÈTRE POUR EAU / HUILE -

INSTRUCTIONS

Warning: If your car is microprocessor (computer) controlled or has an electric cooling fan, refer to

the section on the front cover titled Microprocessor Controlled Engines.

Temperature gauges measure the temperature

of any liquid their sender tip is submerged in. An

electrical temperature gauge is simpler and more

versatile for installation than a mechanical gauge

but is not quite as fast to respond to temperature

changes.

PRECAUTIONS

1. A temperature gauge requires that its sender

tip have a circulating flow around it to give an

accurate reading. For this reason, a T-fitting

cannot be used because it has no circulation

therefore the original warning light sender cannot be operated off the same location. An additional location may be available on the cylinder head, intake manifold, or thermostat

housing but caution should be used in that

these locations may have different average

temperatures than the original warning light

sender location.

2. Do not over tighten the fittings or sender, particularly for mechanical gauges. The threads

are designed to strip before the engine component can be damaged. The fittings use tapered self-sealing threads and do not require

extreme force to seal properly.

3. Do not use sealing tapes or compounds on

electrical senders as this will disturb their

grounding connection to the engine resulting

in false low readings.

4. Take caution when uncoiling and routing the

mechanical gauges capillary tubing that you

do not bend it too sharply or flex it too often.

Any break in the inner tube will make the

gauge nonrepairable. A replacement service

is available only at the factory service center.

5. Always install the adapter fitting into the engine first and then tighten the captive fitting

(Diagram1) on the capillary tube to avoid

twisting the tubing.

6. Never install the captive fitting on the capillary tube directly into the engine without an

adapter, as a proper seal will not be formed.

INSTALLATION

Note: If you are planning to use both an oil

temperature gauge and an an oil pressure

gauge, some modifications may be

necessary as there is only one available hole

for both senders. Since the temperature

gauge cannot use a T-fitting, we suggest that

you install the oil temperature sender into

the oil pressure warning light sender location

in the engine block. Then obtain an adapter

(which we do not manufacture) used for oil

coolers which will give you an additional outlet

for oil pressure.

FOR MECHANICAL GAUGES:

1. Drain the fluid level in the system to below the

senders mounting location which is normally

the factorys warning light sender location.

Diagram 1

CAPILLARY TUBE TIP

2. Route the capillary tubing through the mounting hole for the gauge and then through the

firewall, protecting the tubing from rough

edges. Form at least one 3" or larger loop of

tubing as it comes through the firewall and

route the remainder to the sender mounting

locations.

CAPTIVE FITTING

CAPILLARY

TUBE

PARA NOMBRE, DOMICILIO Y TELEFONO DE IMPORTADOR: VER EMPAQUE.

1

Page 9

3. Remove the warning light sender and install

the proper adapter fitting into the engine block.

If the proper adapter fitting was not included

with the gauge, obtain the CP7555 (NPT

threads) adapter set.

4. Insert the capillary tube tip into the adapters

hole and then tighten, with moderate pressure only, the captive fitting (Diagram 1) into

the adapter. Do not over tighten. Sealing tape

or compound may be used on either connection.

5. Complete the mounting of the gauge.

6. Refill the fluid level to its normal level.

7. Start the engine and observe the fitting connections for leaks and the gauge for proper

operation.

FOR ELECTRICAL GAUGES:

1. Drain the fluid level in the system to below

the senders mounting location, which is normally the factorys warning light sender location.

2. Remove the warning light sender and insulate the end of the sender wire. Install the

proper adapter fitting (not included) into the

engine block, if needed. Obtain either the

CP7553 (NPT threads) or CP7573 (metric

threads) adapter set, if an adapter is needed.

3. Install the gauges sender into the warning

light senders mounting location in the engine

block.

4. Run a length of 18-gauge insulated copper

wire from the gauges mounting location to

the senders mounting location.

5. Attach the 18-gauge wire onto the top of the

gauges sender.

6. Facing the back of the gauge, the connection

post on the right is for the +12-volt power, the

center post is for the ground connection and

the left post is for the sender connection. After you have mounted the gauge, connect the

sender wire to the left connection post as

shown in Diagram 2. Do not over tighten.

7. Connect one end of another length of 18gauge insulated copper wire to the center

connection post, as shown in Diagram 2 and

the other end of the wire to a good ground

source.

8. Connect a third length of 18-gauge insulated

copper wire to the right connection post as

shown in Diagram 2, and the other end of the

wire should be connected to the fuse box

where the wires will receive +12 volts of

power whenever the ignition key is in a

START, ON or ACCESSORY position.

9. Refill the fluid level to its normal level.

10. Start the engine and observe the fitting/

sender connections for leaks and the gauge

for proper operation.

TROUBLESHOOTING

If your electrical gauge reads lower than you would

expect, check all electrical connections, particularly grounding connections. Any poor connection will increase electrical resistance resulting in

a false low reading.

Diagram 2

WIRE

FLAT WASHER

WASHER

NUT

GROMMET

NUT

GAUGE

DO NOT LEAVE ANY HARDWARE OUT OF

THESE CONNECTIONS

2

CLOSED-EYE CONECTOR

MAKE SURE CRIMP IS GOOD

U-BRACKET

Page 10

INSTALLATION INSTRUCTIONS

GENERAL MOUNTING INSTRUCTIONS

INSTRUCCIONES GENERALES DE MONTAJE TENSIÓN 12 V

INSTRUCTIONS GÉNÉRALES DE MONTAGE

The manufacturer produces a full line of gauges

with many different styles.

1-1/2" Gauges

2 Gauges

2-5/8" Gauges

(See page 2 for hole sizes.)

MICROPROCESSOR-CONTROLLED ENGINES

Many newer vehicles employ microprocessors

that control most of the engine and electrical functions. Microprocessors are very sensitive electrical components. Before installing any aftermarket equipment consult the vehicles manufacturer

or shop manual to make certain that no damage

will result.

Some of these newer vehicles use electric cooling fans or microprocessor engine controls that

depend on readings from the original equipment

INSTALLATION & SAFETY PRECAUTIONS

1. Read the entire instructions for your gauge

before proceeding.

2. Be sure the gauge is suitable for your vehicle:

Does the gauges range cover the vehicles

operating range?

Will the tubing of the mechanical gauges

reach from the engine connection point to the

gauge (temperature gauges cannot be lengthened)?

Is the vehicles electrical system 12 volt and

negatively grounded?

GAUGE MOUNTING

All gauges can be mounted into a surface of your

choice or into a panel. Single, dual & triple gauge

mounting panels are produced for all size gauges.

Some panels are in black or chrome finishes. A

fully chromed mounting cup is available for the

2-5/8" gauges.

1. Choose a location to mount the gauge where

it will be viewable from a normal driving position (fuel pressure gauges should never be

mounted within the interior of the vehicle).

2. If you are using a mounting panel, mount it at

the chosen location with the screws provided.

If you are creating a hole, use the following sizes:

Gauge Style Hole Size

1-1/2" 1-5/8" (41 mm)

2" 2-1/16" (53 mm)

2-5/8" 2-5/8" (67 mm)

PARA NOMBRE, DOMICILIO Y TELEFONO DE IMPORTADOR: VER EMPAQUE.

Gauges allow you to monitor the condition of your

vehicle and tell how well it is performing. If there

are any problems, you can detect them immediately before they become severe. Warning lights

only tell you when the problem already requires

immediate attention. You will find that the addition of these gauges will add to your peace of

mind and driving comfort.

sending units for correct operation. If your vehicle

is one of these you CANNOT replace the

sender(s) with any other. You can add an additional oil pressure sender with a Tee Adapter Kit,

but the only possible way to install a non OEM

water temperature sender is to install the new

sender in a different location, retaining the OEM

unit in its original location. Check with the vehicles

manufacturer or dealer to see if this is possible.

3. It is recommended that the battery ground

cable be disconnected before any electrical

work is performed, especially when installing

Ammeters or Voltmeters.

4. Route all wiring and gauge tubing away from

linkages, high heat or moving parts.

5. Never smoke while working on your vehicle

and always keep a fire extinguisher nearby.

It should be rated for gas/chemical/electrical

fires.

6. Never lay tools on top of the battery or wear

jewelry during .electrical work to avoid severe

electrical shorts.

DASHBOARD

Diagram 1

Top View

1

GAUGE

BRACKET

WASHERS

NUTS &

Page 11

3. Dimmer Control.

For dash lighting dimmers that control the

positive side (Diagram 2A) of the lighting circuit:

Diagram 2A

For Positive Dimmer Controls

DASH LIGHTING

DIMMER

CONTROL

+12 VOLTS

RED

- For Two-wire Bulb Holder -

Connect the red wire into the circuit between the

dimmer control and the dash lights. Connect the

black wire to a good electrical ground.

- For One-wire Bulb Holder -

Connect the one wire into the circuit between

the dimmer control and the dash lights. Obtain a

length of 18-gauge insulated copper wire and

connect one end of the wire to a good electrical

ground source and the other end to one of the

mounting bracket posts.

For dash lighting dimmers that control the

grounded side (Diagram 2B) of the lighting circuit:

Diagram 2B

For Ground Dimmer Controls

DASH LIGHTING

GROUND

GAUGE

BLACK/

GROUND

GROUND

4. Refer to specific instructions for the gauge

you are installing. They explain other connections that should be made before mounting is completed.

5. Insert the gauge into the mounting panel or

hole.

6. Insert the bulb holder into the bulb socket on

the back of the gauge.

7. Install the appropriate mounting bracket (Diagram 1: insulated or non-insulated) over the

mounting posts (Diagram 3), slide on washer,

plus a lock washer if supplied, and tighten

the nut with only light pressure. If the gauge

is an electrical model, be sure you use a

bracket that has grommets to insulate the

posts from the mounting bracket. This does

not apply to gauges using separate bracket

mounting posts from the posts used for wire

connections.

8. Position the gauge for best visibility and appearance, then tighten the bracket nuts with

moderate pressure. Do not over- tighten these

nuts when using an insulated bracket. Excess pressure can distort the grommets causing them to crack and short the wiring, even

months after installation.

9. Refer to the specific instructions for the gauge

you are now installing to complete any other

connections.

Diagram 3

Electrical Gauges Shown

U-BRACKET

LIGHT

+12 VOLTS

GROUND

DIMMER

CONTROL

+12 VOLTS

BLACK/GROUND

RED

GAUGE

- For Two-wire Bulb Holder -

Connect the black wire into the circuit between

the dimmer control and the dash lights. Connect

the red wire to the fuse box so that the wire only

receives +12-volt power when the dash lights are

turned on.

- For One-wire Bulb Holder -

Connect the wire to the fuse box so it receives

only +12-volt power when the dash lights are on.

Obtain a length of 18-gauge insulated copper wire

and connect one end to the gauge mounting

bracket or panel. Connect the other end of the

wire into the circuit between the dimmer control

and the dash lights. Insulate the gauge and

bracket from grounded surfaces.

GAUGE

NUTS &

WASHERS

INSULATED

U-BRACKET

NUTS &

WASHERS

DASHBOARD

GAUGE

LIGHT

2

Page 12

FULL ONE (1) YEAR WARRANTY

Actron Manufacturing Company, 15825 Industrial Parkway, Cleveland, Ohio 44135, warrants to the user that this

unit will be free from defects in materials and workmanship for a period of one (1) year from the date of original

purchase.

Any unit that fails within this period will be repaired or replaced at Actrons option and without charge when

returned to the Factory. Actron requests that a copy of the original, dated sales receipt be returned with the unit

to determine if the warranty period is still in effect.

This warranty does not apply to damages caused by accident, alterations, or improper or unreasonable use.

Expendable items, such as batteries, fuses, lamp bulbs, flash tubes are also excluded from this warranty.

ACTRON MANUFACTURING COMPANY DISCLAIMS ANY LIABILITY FOR INCIDENTAL OR CONSEQUENTIAL DAMAGES FOR BREACH OF ANY WRITTEN WARRANTY ON THE UNIT. Some states do not allow the

disclaimer of liability for incidental or consequential damages, so the above disclaimer may or may not apply to

you. This warranty gives specific legal rights, and you may also have rights which vary from state to state.

GARANTIA COMPLETA POR UN (1) AÑO

Actron Manufacturing Company, 15825 Industrial Parkway, Cleveland, Ohio 44135, garantiza al usuario que

esta unidad estará libre de defectos de materiales y mano de obra por un período de un (1) año a partir de la

fecha original de compra.

Toda unidad que falle dentro de este período será reparada o reemplazada a la opción de Actron y sin cargo

cuando sea devuelta a la fábrica. Actron requiere que se devuelva una copia del recibo original fechado de

compra con la unidad, para determinar si el período de garantía está todavía en efecto.

Esta garantía no se aplica a daños causados por accidentes, modificaciones, o uso inadecuado o irrazonable.

Los artículos descartables tales como pilas, fusibles, bulbos de lámparas, tubos flash se excluyen también

de esta garantía.

ACTRON MANUFACTURING COMPANY NIEGA CUALQUIER RESPONSABILIDAD POR PERJUICIOS

INCIDENTALES O CONSECUENTES POR VIOLACION DE CUALQUIER GARANTIA ESCRITA PARA LA

UNIDAD. Algunos estados no permiten la negación de responsabilidad por perjuicios incidentales o consecuentes,

de manera que la negativa anterior puede o no aplicarse a usted. Esta garantía otorga derechos legales

específicos, y usted puede tener también derechos que pueden variar de estado a estado.

NO VALIDA ÉN MEXICO

UN (1) AN DE GARANTIE COMPLÈTE

Actron Manufacturing Company, 15825 Industrial Parkway, Cleveland, Ohio 44135, garantit à l'utilisateur que

cet appareil sera exempt de tout défaut lié aux matériaux ou à la main d'uvre pendant une période de un (1)

an à compter de la date d'achat d'origine.

Toute unité qui tomberait en panne durant cette période sera réparée ou remplacée, au choix d'Actron, et sans

frais si elle a été retournée à l'usine. Actron demande qu'une copie de la facture d'achat d'origine datée soit

retournée avec l'appareil pour contrôler que la période de garantie est toujours effective.

Cette garantie ne s'applique pas aux dommages causés par accident, modifications ou utilisation inadéquate

ou hors du raisonnable. Les éléments consommables, tels que piles, fusibles, ampoules ou tubes fluorescents

sont également exclus de cette garantie.

ACTRON MANUFACTURING COMPANY REJETTE TOUTE RESPONSABILITÉ POUR DOMMAGES

ACCESSOIRES OU INDIRECTS POUR MANQUEMENT À N'IMPORTE QUELLE GARANTIE ÉCRITE SUR

CETTE UNITÉ. Certains états ne permettent pas le déni de responsabilité pour dommages accessoires ou

indirects, cette clause peut donc n'être pas applicable dans votre cas. Cette garantie vous octroie des droits

légaux spécifiques, et vous pouvez aussi avoir des droits supplémentaires qui varient d'un état à l'autre.

ACTRON MANUFACTURING CO.

15825 Industrial Parkway

Cleveland, Ohio 44135

1-800-228-7667

8

2004 Actron Manufacturing Co.

©

All Rights Reserved

0002-002-2376

Loading...

Loading...