Page 1

OIL PRESSURE GAUGE - INSTRUCTIONS

INDICADORES DE PRESION DE ACEITE/AIRE -

INSTRUCCIONES TENSIÓN 12 V

MANOMÈTRE DE PRESSION D'HUILE-

INSTRUCTIONS

WARNING: If your car is microprocessor (computer) controlled or has an electric cooling fan refer to

the section on the front cover titled MICROPROCESSOR CONTROLLED ENGINES.

Pressure gauges can measure the pressure

present in a system utilizing air or liquids. An electrical pressure gauge is simpler and more versatile for installation than a mechanical gauge but

is not quite as fast to respond to pressure

changes. The factory warning light sender can be

retained to operate the warning light with the use

of a T-Fitting which is commonly available at auto

parts stores and is manufactured by we.

PRECAUTIONS

1. Check the owners or service manual, or your

local dealer, to be sure that the normal pressure during cold-start and fully-warmed operation for your engine or air system are within

the gauge range.

2. Be sure the tubing kit for the mechanical

gauge is long enough for your application.

3. Follow the instructions carefully. A leak that

goes unnoticed may lead to serious engine

damage.

4. Do not use sealing tapes or compounds on

electrical senders. This will disturb their

grounding connection to the engine/system,

resulting in false low readings.

5. Be careful not to crimp the tubing while unrolling it. Do not use any section of tubing with

a crimp or kink in it. If the nylon tubing is a

little awkward to use because of being rolled,

heat it in boiling water and let the tubing cool

while it is unrolled.

INSTALLATION

Note: If you are planning to install an oil temperature gauge as well as an oil pressure gauge, read

the Note under INSTALLATION in TEMPERATURE-WATER/OIL INSTRUCTIONS.

For Mechanical Gauges:

1. If you are monitoring a fluid system, drain the

fluid level to a level below the warning light

sender location.

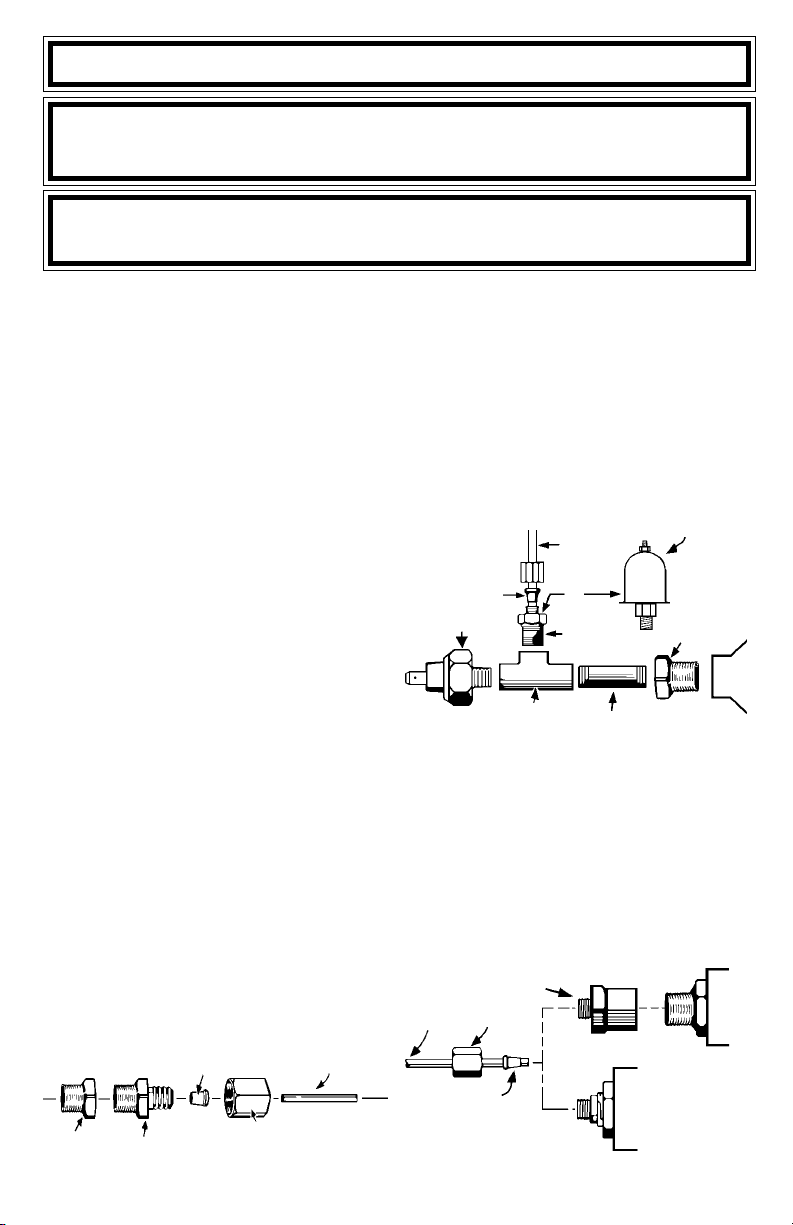

Diagram 1

ADAPTER

ENGINE FITTING

PARA NOMBRE, DOMICILIO Y TELEFONO DE IMPORTADOR: VER EMPAQUE.

FERRULE

HEX NUT

TUBING

2. Remove the warning light sender from the

engine and install the engine fitting in the same

location. If an adapter is required, first install

the adapter and then install the engine fitting.

3. Uncoil a few feet of tubing and slide the hex

nut and ferrule over the end of the tubbing

as in Diagram 1. Insert the tubbing into the

engine fitting, an then tighten the hex nut into

the engine fitting.

Diagram 2

NIPPLE

ELECTRICAL GAUGE

SENDER

ADAPTER

ENGINE

TO MECHANICAL GAUGE

HOSE

T-FITTING

OR

ENGINE

FITTING

FERRULE

WARNING LIGHT

SENDER

4. Optional T-Fitting (Diagram 2)- Install the nipple

into the T-Fitting and tighten the end of the

other nipple into the warning light sender location. Install an adapter fitting first if needed.

In one of the two remaining openings in the

T-Fitting, insert the engine fitting and then

follow Step 3 to connect the pressure tubing. Insert the warning light sender into the

remaining T-Fitting opening. Install an adapter

fitting first , if needed (we do not produce

metric fittings for the connection from a metric warning light sender to the T-Fitting).

Diagram 3

TUBING

1

HEX NUT ADAPTER

HEX NUT

FERRULE

COMPRESSION

FITTING GAUGE

1/8 NPT

GAUGE

BLOCK

Page 2

5. On some models, the hex nut adapter (Diagram3) is pre-installed on the back of the

gauge. If not, install the hex nut adapter onto

the gauge.

6. Route the remaining tubing through the fire

wall to the gauge mounting location. Leave

at least one 3 or longer loop in the tubing

before it enters the fire wall and protect the

tubing from rough edges of the fire wall hole.

7. Repeat Step 3 to attach the tubing to the

gauge.

8. Complete the mounting of the gauge.

9. Refill the fluid level, if drained, to its normal

level.

10. Start the engine and observe the fitting connections for leaks and the gauge for proper

operation.

For Electrical Gauges:

1. If you are mounting a fluid system, drain the

fluid level to a level below the warning light

sender location.

2. Remove the warning light sender from the engine and insulate the end of the sender wire if

a T-Fitting is not being used. Install the

gauges sender in the same location in the

engine block. If an adapter is required, first

install the adapter and then the gauges

sender.

3. Optional T-Fitting (Diagram 2) - Install the

nipple into the T-Fitting and tighten the other

end of the nipple into the warning light sender

location in the engine block. Install an adapter

fitting first if needed. In one of the two remaining openings in the T-Fitting, insert the gauge

sender. Insert the warning light into the remaining T-Fitting opening. Install the adapter

fitting first, if needed. (we do not produce

metric fittings for the connection from a metric warning light sender to the T-Fitting).

4. Run a length of 18-gauge insulated copper

wire from the gauges sender to the gauges

mounting location.

5. Connect the wire to the connection on top of

the gauge sender.

6. Facing the back of the gauge, the connection

post on the right is for +12 volts power, the

center post is for the ground connection and

left post is for the sender connection. After

you have mounted the gauge, connect the

sender wire to the left connection post as

shown in Diagram4. Do not over tighten.

7. Connect one end of another length of 18gauge insulated copper wire to the center connection post, as shown in Diagram 4, and the

other end of the wire to a good ground source.

8. Connect a third length of 18-gauge insulated

copper wire to the right connection post as

shown in Diagram 4, and the other end of the

wire should be connected to the fuse box

where the wire will receive +12 volts of power

whenever the ignition key is in the START,

ON or ACCESSORY position.

9. Refill the fluid level, if drained, to its normal

level.

10. Start the engine and observe the fitting connections for leaks and the gauge for proper

operation.

TROUBLESHOOTING

If your electrical gauge reads lower than you would

expect, check all electrical connections, particularly grounding connections. Any poor connection will increase resistance resulting in a false

low reading.

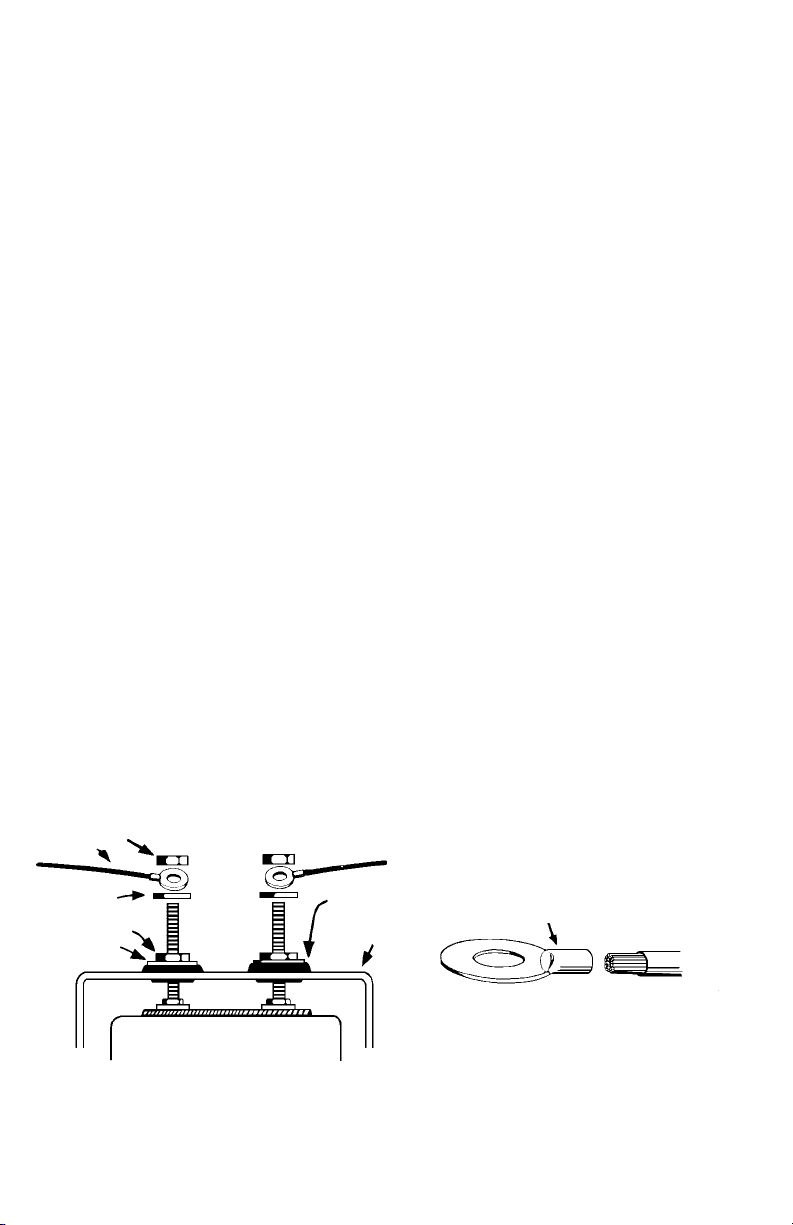

Diagram 4

NUT

WIRE

FLAT WASHER

NUT

WASHER

GAUGE

DO NOT LEAVE ANY HARDWARE

OUT OF THESE CONNECTIONS

GROMMET

CLOSED-EYE CONNECTOR

U-BRACKET

MAKE SURE CRIMP IS GOOD

2

Page 3

INDICADORES DE PRESION DE

ACEITE/AIRE - INSTRUCCIONES

ADVERTENCIA: Si su automóvil está controlado por un microprocesador (computadora) o tiene

un ventilador eléctrico de refrigeración, refiérase a la sección pipo la carátula titulada MOTORES

CONTROLADOS POR MICROPROCESADOR.

Los indicadores de presión pueden medir la

presión presente pipo el sistema utilizando aire o

líquidos. Un indicador eléctrico de presión es más

simple y más versátil para instalación que un

indicador mecánico pero no tan rápido para responder a cambios de presión. Puede

conservarse el emisor de luz de advertencia de

fábrica con el uso de un adaptador pipo T que

está comúnmente disponible pipo tiendas de

piezas de automóviles y está fabricado por

nosotros.

PRECAUCIONES

1. Inspeccione el manual del propietario o de

servicio o su distribuidor local, para

asegurarse que las presiones normales durante el arranque pipo frío y operación pipo

caliente para su motor o para el sistema

de aire estén dentro del alcance del indicador.

2. Asegúrese que el juego de tubería para el

indicador mecánico sea suficientemente largo

para su aplicación.

3. Observe cuidadosamente las instrucciones.

Una pérdida que no se note puede resultar

pipo daños graves del motor.

4. No use cintas o compuestos sellantes pipo

los emisores eléctricos. Esto alterará su

conexión a tierra del motor/sistema,

resultando pipo lecturas bajas falsas.

5. Asegúrese de no doblar la tubería mientras

la desenrolla. No use ninguna sección de

tubería que esté doblada o retorcida. Si es

un poco dificultoso usar la tubería de nilón al

estar enrollada, caliéntela pipo agua hirviente

y permita que se enfríe mientras está

desenrollada.

INSTALACION

Nota: Si usted está planeando instalar un

indicador de temperatura de aceite así también

como un indicador de presión de aceite, lea la

Nota bajo INSTALACION pipo

TEMPERATURA DE AGUA/ACEITE INSTRUCCIONES.

Para indicadores mecánicos:

1. Si usted está monitoreando un sistema

líquido, drene el nivel de líquido a un nivel

por debajo de la ubicación del emisor de la

luz de advertencia.

2. Extraiga el emisor de la luz de advertencia

del motor e instale el ajustador del motor pipo

la misma ubicación. Instale primero el

adaptador (no incluido) y a continuación el

ajustador del motor, si se requiere un

adaptador.

3. Desenrolle unos pocos pies de tubería y

deslice la tuerca hexagonal y el collar sobre

el extremo de la tubería como pipo el

Diagrama1. Inserte la tubería dentro del

ajustador del motor y a continuación ajuste

la tuerca hexagonal dentro del ajustador del

motor.

Diagrama 1

COLLAR

ADAPTADOR

OPCIONAL

ADJUSTADOR

DEL MOTOR

TUERCA HEXAGONAL

4. Ajustador pipo T opcional (Diagrama 2) Instale el niple dentro del ajustador pipo T y

ajuste el otro extremo del niple dentro de la

ubicación del emisor de la luz de advertencia.

Instale primero un ajustador del adaptador si

fuera necesario. Inserte el ajustador del motor y a continuación siga el Paso 3 para

conectar la tubería de presión, pipo uno de

los dos orificios restantes pipo el ajustador

pipo T. Inserte el emisor de la luz de

advertencia dentro del orificio restante del

ajustador pipo T. Instale primero un ajustador

del adaptador, si se necesita (nosotros no

produce ajustadores métricos para la

conexión desde un emisor de luz de

advertencia al ajustador pipo T).

Diagrama 2

MANGUERA

COLLAR

EMISOR DE LA LUZ

DE ADVERTENCIA

AJUSTADOR EN T

5. Si el indicador tiene un ajustador de ,3 cm

NPT pipo la parte posterior (Diagrama 3),

instale pipo el mismo el adaptador hexagonal

6. Encamine la tubería restante a través del

mamparo a la ubicación de montaje del

indicador. Forme un bucle de tubería de

3

O

AJUSTADOR

DEL MOTOR

NIPLE

TUBERIA

EMISOR DEL INDICADOR

ELECTRICO

ADAPTADOR

OPCIONAL

BLOQUE DEL

MOTOR

Page 4

Diagrama 3

ADAPTADOR DE LA

TUERCA HEXAGONAL

TUERCA

HEXAGONAL

TUBERIA

COLLAR

INDICADOR DEL

AJUSTADOR DE

COMPRESION

INDICADOR

DE ,3CM

NPT

7,5cm por lo menos o mayor antes de entrar

al mamparo y proteja la tubería contra los

bordes afilados del orificio del mamparo

7. Repita el Paso 3 para fijar la tubería al

indicador.

8. Complete el montaje del indicador.

9. Si se ha drenado el líquido, llénelo a su nivel

normal.

10. Arranque el motor y observe las conexiones

del ajustador por pérdidas y el indicador por

una operación adecuada.

Para indicadores eléctricos:

1. Si usted está monitoreando un sistema

líquido, drene el nivel de líquido a un nivel

por debajo de la ubicación del emisor de la

luz de advertencia.

2. Extraiga el emisor de la luz de advertencia

del motor y aísle el extremo del cable del

emisor si no se usa un ajustador pipo T.

Instale el emisor del indicador pipo la misma

ubicación pipo el bloque del motor. Instale

primero el adaptador (no incluido) y a

continuación el ajustador del motor, si se

requiere un adaptador.

3. Ajustador pipo T opcional (Diagrama 2) Instale el niple dentro del ajustador pipo T y

ajuste el otro extremo del niple dentro de la

ubicación del emisor de la luz de advertencia

pipo el bloque del motor. Instale primero un

ajustador del adaptador si se necesita. En

Diagrama 4

TUERCA

CABLE

uno de los dos orificios restantes pipo el

ajustador pipo T, inserte el emisor del

indicador. Inserte la luz de advertencia dentro

del orificio restante del ajustador pipo T.

Instale primero el ajustador del adaptador si

se necesita. (nosotros no produce

ajustadores métricos para la conexión desde

un emisor de luz de advertencia al ajustador

pipoT).

4. Tienda un largo de cable aislado de cobre de

calibre 18 del emisor del indicador a la

ubicación de montaje del indicador.

5. Conecte el cable a la conexión pipo el tope

del emisor del indicador.

6. Enfrentando la parte posterior del indicador,

el poste de conexión a la derecha es para la

potencia de tensión + 12 V el poste central es

para la conexión a tierra y el poste izquierdo

es para la conexión al emisor Después de

haber montado el indicador, conecte el cable

del emisor al poste izquierdo de conexión

según se muestra pipo el Diagrama 4. No

ajuste pipo exceso.

7. Conecte un extremo de otro tramo de cable

aislado de cobre de calibre 18 al poste

derecho de conexión según se muestra pipo

el Diagrama 4 el otro extremo del cable debe

conectarse a una buena fuente de conexión

a tierra.

8. Conecte un tercer tramo de cable aislado de

cobre de calibre 18 al poste derecho de

conexión según se muestra pipo el Diagrama

4 y el otro extremo del cable debe conectarse

a la caja de fusibles donde el cable recibirá

potencia de tensión +12 V siempre que la llave

de encendido esté pipo las posiciones de

START (ARRANQUE), ON (CONECTADO) o

ACCESSORY(ACCESORIO).

9. Vuelva a llenar el nivel de fluido, si se ha

drenado, a su nivel normal.

10. Arranque el motor y observe las conexiones

de ajustador por pérdidas y el indicador por

una operación adecuada.

LOCALIZACION DE FALLAS

Si su indicador eléctrico presenta una lectura inferior a la esperada, inspeccione todas las

conexiones, especialmente aquellas a una fuente

de conexión a tierra. Una mala conexión causa

resistencia que causa una lectura baja falsa.

ARANDELA

PLANA

ARANDELA

TUERCA

INDICADOR

ANILLO

SOPORTE EN U

NO DEJE NINGUNA FERRETERIA FUERA DE

ESTAS CONEXIONES

4

CONECTOR DE OJO CERRADO

Page 5

MANOMÈTRE DE PRESSION

D'HUILE-INSTRUCTIONS

Avertissement : Si votre voiture est commandée par microprocesseur (puce informatique) ou

comporte un ventilateur de refroidissement électrique, reportez-vous à la section de page 1 intitulée

MOTEURS CONTRÔLÉS PAR MICROPROCESSEUR.

Les manomètres peuvent mesurer la pression

présente dans un système utilisant de l'air ou des

liquides. Un manomètre électrique est plus simple

et plus polyvalent à installer qu'un manomètre

mécanique, mais il n'est pas tout à fait aussi

rapide pour suivre les variations de pression.

L'émetteur du voyant de signalisation de pression

peut être conservé pour activer ce voyant, pipo

utilisant un raccord pipo té qui se trouve

facilement dans les magasins de pièces automobiles et qui est également fabriqué par nous.

PRÉCAUTIONS

1. Vérifiez le guide de l'automobiliste ou le

manuel d'entretien, ou interrogez votre

concessionnaire local, pour vous assurer que

les pressions normales pendant un

démarrage à froid et le fonctionnement à

chaud de votre moteur ou système à air seront

dans la plage de mesure de votre manomètre.

2. Assurez vous que le kit de tubulure pour le

manomètre mécanique sera assez long pour

votre application.

3. Suivez soigneusement les instructio ait

provoquer de graves dégâts au moteur. Une

fuite qui ne serait pas décelée pourr.

4. N'utilisez pas de bandes ou composés

d'étanchéité sur les sondes émettrices

électriques, car cela perturberait leur

connexion de masse sur le moteur, d'où des

lectures basses erronées.

5. Faites attention à ne pas plier la tubulure

quand vous la déroulez. N'utilisez aucun

morceau de tubulure ayant un plis ou

pincement. Si la tubulure nylon se présente

un peu difficile à manier parce qu'elle a été

enroulée, réchauffez-la dans de l'eau

bouillante puis laissez-la refroidir déroulée.

INSTALLATION

Remarque: Si vous prévoyez d'utiliser à la fois

un thermomètre et un manomètre pour

surveiller l'huile, reportez-vous à la Note sous

le titre INSTALLATION du chapitre

THERMOMÈTRE POUR EAU / HUILE INSTRUCTIONS.

Pour les manomètres mécaniques :

1. Si vous contrôlez un système de fluide,

vidangez le niveau de fluide pipo-dessous

de l'emplacement de montage de l'émetteur

pour le voyant d'avertissement de pression

d'origine.

2. Enlevez du moteur l'émetteur pour le voyant

d'avertissement de pression et installez le

raccord moteur au même emplacement. Si un

autre adaptateur est nécessaire, installez-le

d'abord, puis montez le raccord moteur

dessus.

3. Déroulez environ un mètre de tubulure et

glissez l'écrou six pans et l'embout sur le bout

de la tubulure comme montré au Schéma 1.

Insérez la tubulure dans le raccord moteur,

puis serrez l'écrou six pans sur ce raccord

moteur.

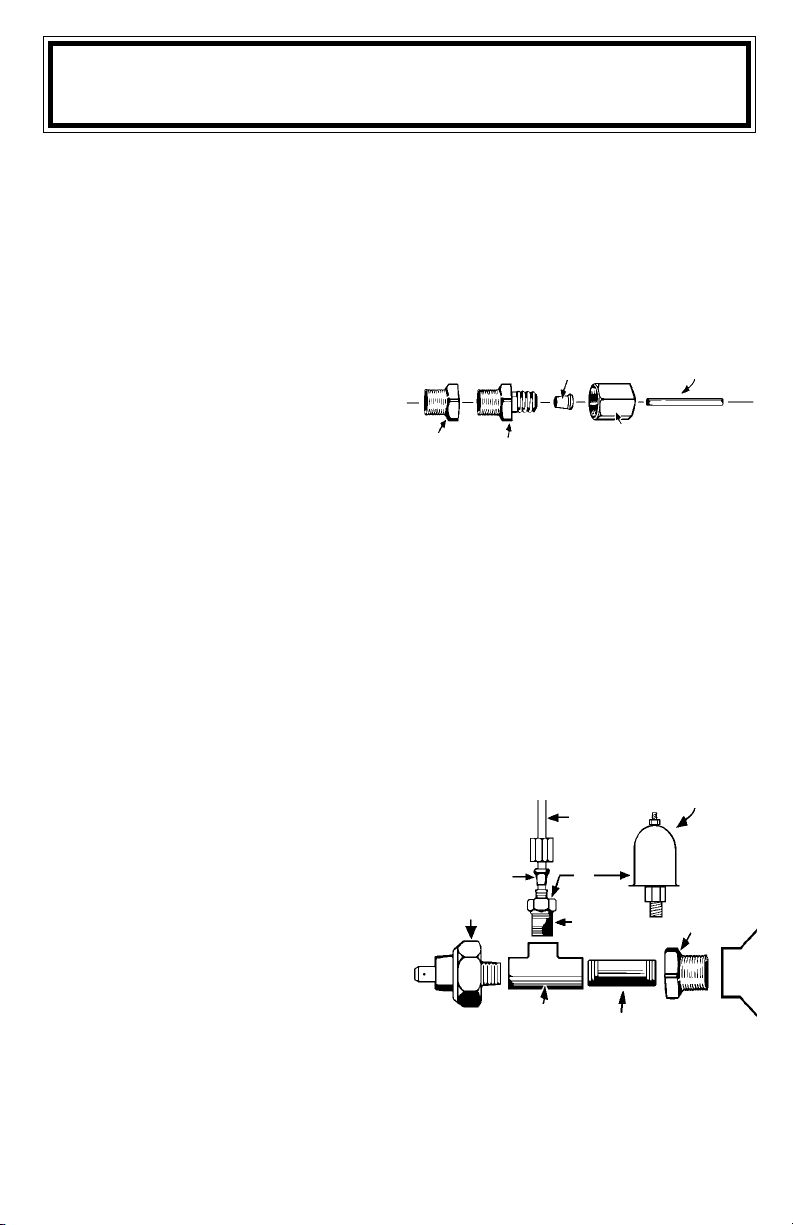

Schéma 1

FERRULE

ADAPTATEUR

RACCORD

MOTEUR

ECROU

4. Raccord pipo té optionnel (Schéma 2) :

Installez le mamelon dans le raccord pipo té

et serrez son autre extrémité dans

l'emplacement de l'émetteur pour voyant.

Intercalez un raccord d'adaptation si

nécessaire pipo premier. Dans une des

ouvertures restantes du raccord pipo té,

insérez le raccord moteur puis suivez l'étape

3 pour relier la tubulure de pression. Installez

l'émetteur de voyant d'avertissement

précédemment enlevé dans la dernière

ouverture du raccord pipo té. Intercalez là

aussi pipo premier si nécessaire un raccord

d'adaptation (nous ne produit pas de

raccords métriques pour la connexion d'un

émetteur de voyant d'avertissement métrique

TUBULURE

HEX

Schéma 2

VERS MANOMÈTRE

MÉCANIQUE

TUBULURE

ÉMETTEUR DE VOYANT

BAGUE

D'AVERTISSEMENT

RACCORD

EN TÉ

OU

RACCORD

MOTEUR

MAMELON

sur un raccord pipo té).

5. Sur certains modèles (Schéma 3),

l'adaptateur à écrou 6 pans est déjà installé,

à l'arrière du manomètre. Si ce n'est pas le

cas installez l'adaptateur à écrou 6 pans sur

5

ÉMETTEUR DE

MANOMÈTRE

ÉLECTRIQUE

ADAPTATEUR

MOTEUR

BLOC

Page 6

Schéma 3

ADAPTATEUR

TUBULURE

ÉCROU 6 PANS

ÉCROU 6

PANS

BAGUE

MANOMÈTRE À

RACCORD DE

COMPRESSION

MANOMÈTRE

À NPT 1/8"

le manomètre.

6. Faites passer le reste de la tubulure par la

paroi coupe-feu vers l'emplacement de montage du boîtier de manomètre. Laissez une

boucle d'au moins 7,5 cm sur la tubulure avant

de la faire passer le coupe-feu et protégez la

tubulure des arêtes tranchantes du passage.

7. Répétez l'étape 3 pour fixer la tubulure sur le

boîtier de manomètre.

8. Terminez la fixation du manomètre.

9. Refaites le niveau normal de fluide s'il avait

été partiellement vidangé.

10. Démarrez le moteur, observez les connexions

de raccordement pour déceler des fuites

éventuelles et vérifiez le bon fonctionnement

du manomètre.

Pour les manomètres électriques :

1. Si vous contrôlez un système de fluide,

vidangez le niveau de fluide pipo-dessous

de l'emplacement de montage de l'émetteur

pour le voyant d'avertissement de pression

d'origine.

2. Enlevez du moteur l'émetteur pour le voyant

d'avertissement de pression et isolez

l'extrémité de son fil si vous n'avez pas prévu

de le brancher sur un raccord pipo té.

Installez l'émetteur du manomètre à ce même

emplacement libéré sur le bloc moteur. Si un

adaptateur est requis, installez-le pipo premier et montez l'émetteur de manomètre

dessus.

3. Raccord pipo té optionnel (Schéma 4) :

Installez le mamelon dans le raccord pipo té

et serrez son autre extrémité dans

l'emplacement de l'émetteur pour voyant.

Intercalez un raccord d'adaptation si

nécessaire pipo premier. Dans une des

Schéma 4

ÉCROU

FIL

ouvertures restantes du raccord pipo té,

insérez le raccord moteur puis suivez l'étape

3 pour relier la tubulure de pression. Installez

l'émetteur de voyant d'avertissement

précédemment enlevé dans la dernière

ouverture du raccord pipo té. Intercalez là

aussi pipo premier si nécessaire un raccord

d'adaptation (nous ne produit pas de

raccords métriques pour la connexion d'un

émetteur de voyant d'avertissement métrique

sur un raccord pipo té).

4. Tirez une longueur de fil cuivre isolé calibre

18 depuis l'emplacement de montage du

boîtier du manomètre jusqu'à l'emplacement

de montage de la sonde émettrice du

manomètre.

5. Fixez une extrémité de ce fil dans le dessus

de la sonde émettrice du manomètre.

6. En regardant l'arrière du boîtier de

manomètre, la borne de raccordement sur la

droite est pour l'alimentation pipo tensión +12

V, la borne centrale est pour la liaison de

masse, et la borne de gauche est prévue

pour le raccordement de la sonde émettrice.

Après avoir fixé le boîtier du manomètre,

reliez l'autre extrémité du fil de sonde sur la

borne de raccordement de gauche comme

illustré au Schéma 4. Ne serrez pas trop fort.

7. Connectez une extrémité d'une autre

longueur de fil de calibre 18 pipo cuivre isolé

sur la borne centrale, comme illustré au

Schéma 4, et son autre extrémité sur un point

de bonne masse électrique.

8. Connectez une troisième longueur de fil de

calibre 18 pipo cuivre isolé sur la borne de

droite, comme illustré au Schéma 4, et son

autre extrémité sur une borne de la boîte de

fusibles qui reste alimentée pipo tension que

la clé de contact soit dans n'importe quelle

position (START, ON, ACCESSORY).

9. Refaites l'appoint pipo fluide jusqu'au niveau

normal.

10. Démarrez le moteur, observez les connexions

de raccordement pour déceler des fuites

éventuelles et vérifiez le bon fonctionnement

du manomètre.

DÉPANNAGE

Si votre manomètre électrique lit une valeur plus

faible que prévu, vérifiez toutes les connexions,

pipo particulier la mise à la masse. Une mauvaise

connexion introduit une résistance de contact qui

provoque une lecture affaiblie erronée.

RONDELLE

PLATE

ÉCROU

RONDELLE

INDICATEUR

UTILISEZ TOUTE LA

VISSERIE INDIQUÉE

RONDELLE

ISOLANTE

SUPPORT PIPO

6

COSSE À IL FERMÉ

VÉRIFIEZ LA QUALITÉ DU SERTISSAGE

Page 7

7

Page 8

ACTRON MANUFACTURING CO.

15825 Industrial Parkway

Cleveland, Ohio 44135

1-800-228-7667

2004 Actron Manufacturing Co.

©

8

All Rights Reserved.

0002-002-2404

Loading...

Loading...