Page 1

English

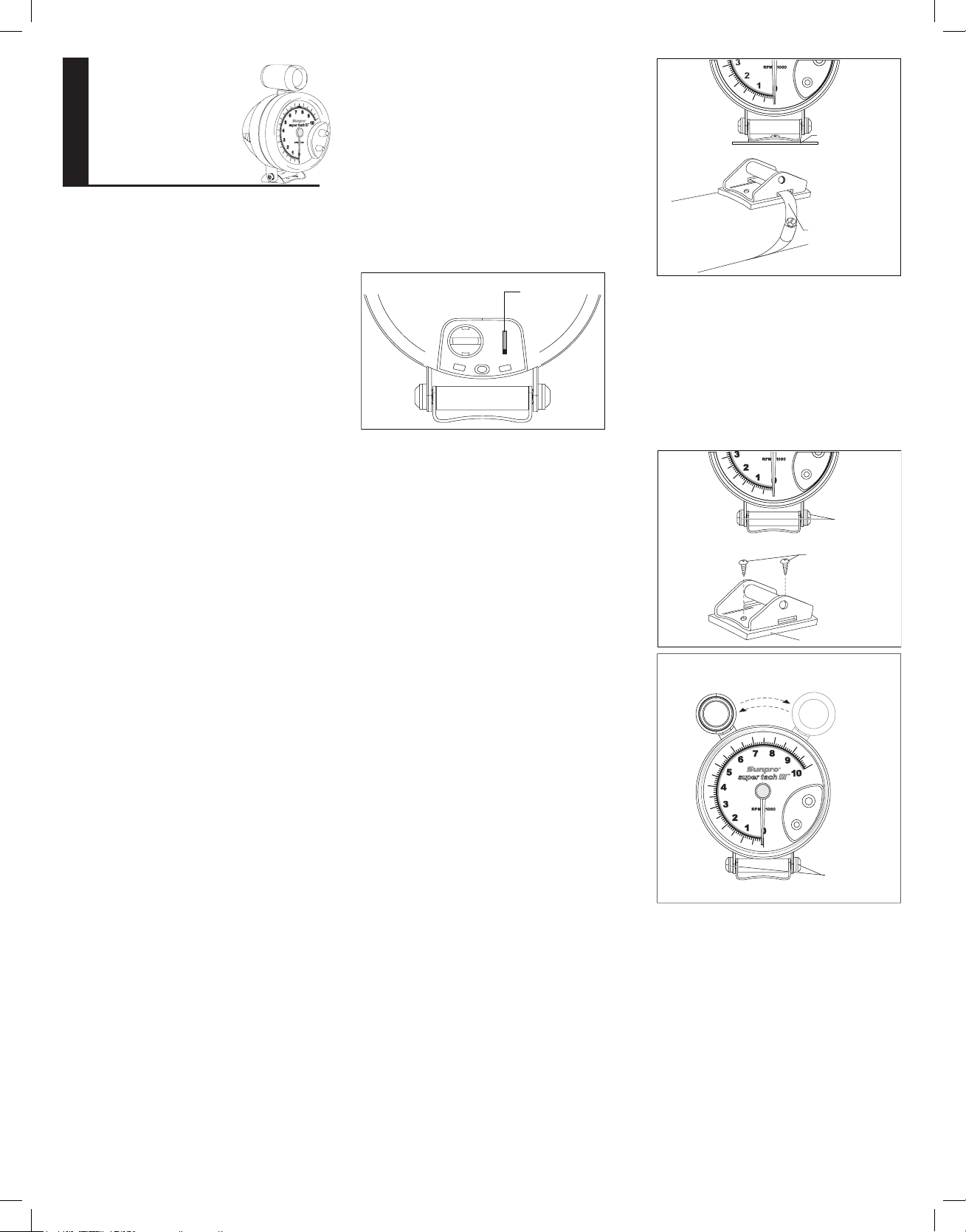

If #10 screws are used, mark hole locations, and drill

holes using #18 or 11/64” drill bit.

1. Loosen both button head screws on the mounting

bracket. Now, tachometer can tilt back and forth (see

gure 3).

2. Install #10 screws (see gure 3).

3. Slide the Shift Light around the tachometer to desired

position (see gure 4).

4. Tighten both button head screws on the mounting

bracket (see gure 4).

Fig. 2

STEERING

COLUMN

Hose cl amp mount

(Hose Cla mp not incl uded)

Suface m ount

STEP 4

Tighten button

head screws

STEP 3

Slide Shift Light

around tachometer

Fig. 4

Fig. 3

STEP 1

Loosen button

head screws

STEP 2

Install #10 screws to

mount the tachometer

MOUNTING BASE PAD

ELECTRICAL CONNECTIONS

CAUTION

For your own personal safety, and to prevent possible

damage to the electrical system of your vehicle during

the installation, disconnect the negative (-) battery cable.

Reconnect this cable after installation is complete.

Do not route wires along or against sharp edges, hot

engine surfaces, or near spark plug wires. If needed, drill

a 3/8” hole for the grommet (included).

NOTE: If additional wire is needed, use #18 or #20 AWG

stranded automotive primary wire.

High voltage — 30,000 to 50,000 volts — is present in

the ignition coil, distributor cap, ignition wires and

spark plugs. When handling ignition wires while the

engine is running, use insulated pliers to avoid a shock.

While not lethal, a shock may cause you to jerk

involuntarily and hurt yourself.

Never crawl under vehicle or run engine while vehicle

is on a jack.

CYLINDER SELECTION

Check t he c ylinder setting before installat ion. T he

Cylinder Selector Switch is located on the back of the

tachometer, behind the door (see gure 1). The Factory

Setting is 8 Cylinders. Change the setting if necessary.

•

•

CYLINDER

SELECTION

SWITCH

Fig. 1

4

2

CYL.

8

6

DISTRIBUTOR EQUIPPED ENGINES

Set the switch to match the number of cylinders in the

engine.

DISTRIBUTORLESS IGNITION SYSTEM

EQUIPPED ENGINES

The tachometer-ignition connection for some 4 Cylinder

and 6 Cylinder DIS (Distributorless Ignition S ystem)

engines requires that you use the 2 Cylinder setting.

Depending on which type of system you have, set the

switch as follows:

If your vehicle’s DIS ignition system has a tachometer

output lead set the switch to the 4 Cylinder position for the

4 cylinder engines and to the 6 Cylinder position for the

6 cylinder engines. When connecting tachometer wires

(see EL ECTRICA L CO NNEC T I ONS), conn e ct the

tachometer GREEN wire to the vehicle’s tachometer

output lead.

If your vehicle’s DIS ignition system does not have a

tachometer output lead but allows access to the driver

wires from the vehicle computer to the ignition module,

set the switch to the 2 Cylinder position regardless of the

number of cylinder s in the engine. When connecting

tachometer wires (see ELECTRICAL CONNECTIONS),

connect the tachometer GREEN wire to either of the

driver wires.

FUNCTIONAL QUICK CHECK

It is sug geste d that the tach ometer be ele ctr ica ll y

connected to the vehicle, (using alligator clip leads or

other suitable means) following the steps below, and an

electrical functional check of the tachometer be made,

prior to making a permanent installation.

Start the vehicle’s engine. Conrm the operation of the

tachometer. Disconnect tachometer.

MOUNTING THE TACHOMETER

Your t achometer is designed to be mounted on any

at or curved surface, or on the steering column (see

gure 2).

SUNPRO

®

SUPER TACH III

™

5” TACHOMETER

CP7914

INSTALLATION INSTRUCTIONS

GENER AL INFORMATION

Ple ase read this instr uc ti on manual and rev iew the

installation procedures carefully before attempting the

installation of your tachometer.

CAUTION

This unit is designed for use on 12-volt negative (-) ground

4- cycle automotive t ype engines. The tachometer is

compatib le wit h most distrib ut or and distr ib utorles s

ignition systems.

PACKAGE CONTENTS

Contains Installation Hardware Kit consisting of:

Tachometer Mounting Base Pad....................................1 ea

1/4” Quick Connect Receptacle......................................1 ea

Grommet...........................................................................1 ea

Hex Key Wrench..............................................................1 ea

Wire Splices.....................................................................2 ea

Ring Terminals.................................................................2 ea

#10 X 5/8” Self-tapping Screw........................................2 ea

SAFETY GUIDELINES

To prevent accidents that could result in serious injury and/

or damage to your vehicle or tachometer, carefully follow

these safety rules and test procedures.

Fire Extinguisher

Never work on your vehicle without having a suitable

re extinguisher handy. A 5-lb or larger CO2 or dry

chemical unit specied for gasoline/chemical/electrical

res is recommended.

Safety Goggles

We recommend wearing safety goggles when working

on your vehicle, to protect your eyes from battery acid,

gasoline, and dust and dir t ying off moving engine

parts.

Be very careful not to get your hands, hair or clothes

near any moving parts such as fan blades, belts and

pulleys or throttle and transmission linkages. Never wear

neckties or loose clothing when working on your

vehicle.

Never wear wrist watches, rings or other jewelry when

working on your vehicle. You’ll avoid the possibility

of catching on moving parts or causing an electrical

short circuit which could shock or burn you.

The carbon monoxide in exhaust gas is highly toxic. To

avo id asphyxi at ion , al ways oper at e vehic le in a

well-ventilated area. If vehicle is in an enclosed area,

exhaust should be routed directly to the outside via

leakproof exhaust hose.

Make sure that your vehicle is in Park or Neutral, and

that the parking brake is rmly set.

Avoid contact with hot sur faces such as exhaust

manifolds and pipes, muf ers (catalytic converters),

radiator and hoses.

Never smoke while working on your vehicle. Gasoline

vapor is highly ammable, and the gas formed in a

charging battery is explosive.

Do no t l ay to ols o r e quipme nt on the ba t ter y.

Accidentally grounding the “HOT” battery terminal

can shock or burn you and damage wiring,the battery

or your tools and testers. Be careful of contact with

battery acid. It can burn holes in your clothing and burn

your skin or eyes.

•

•

•

•

•

•

•

•

•

Page 2

Fig. 10

STEP 1

Press and turn coin

counter clockwise to

unlock rear cap

STEP 3

Pull lamp

straight out

STEP 2

Pull rear

cap out

LAMP SOCKET

LAMP

Fig. 9

BACKLIGHTING

LAMP SOCKET

4

2

CYL.

8

6

FULL ON E (1) YEAR WARRANTY

Sunpro, a busi ness unit of SPX Corporation, 15825 I ndustrial Parkway,

Clevelan d, Ohio 44135, warrant s to the user that this unit will be fr ee from

defect s in materials and work manship for a period of one (1) year from the

date of ori ginal purchase.

Any unit that fails wit hin this peri od will be repair ed or replaced at Sunpro’s

option and wi thout charge when returned to the Fac tory. Sunpro requests

that a co py of the origina l, dated sales re ceipt be return ed with the unit t o

determine if the w arranty peri od is still in effe ct.

This warranty does not apply to damage s c aused by accid ent, alterations, or

improp er or unreasonable use. Expendab le items, such as batteries, fuses,

lamp bulb s, ash tubes are al so excluded from t his warranty.

Sunpro, a b usiness unit of S PX Corporatio n DISCLAIM S ANY LIABILI TY

FOR INCIDENTAL OR CON SEQUENTIAL DAMAGES FOR BR EACH OF

ANY WRIT TEN WARR ANTY ON THE UNIT. Some states do not allow the

disclaimer of liability for incident al or consequent ial damages, so the above

disclaimer may or may not appl y to you. This warra nty gives specic le gal

rights , and you may also have ri ghts, which var y from state to sta te.

SHIFT LIGHT L AMP REPL ACEMENT

The External Shift Light also uses a wedge base lamp

for illumination.

To replace the Shift Light lamp, follow steps to open

the shift light (see gure 10). Remove the lamp from

its socket by pulling it straight out. Replace the lamp

with a #194 automotive lamp. Reassemble the shift light by

reversing the steps.

BLACK, RED, AND WHITE WIRE CONNECTIONS

– ALL SYSTEMS

1. Connect the BLACK wire to the negative (-) battery

terminal, or a clean unpainted chassis ground using a

ring terminal or other suitable means (see gure 5.)

Make the following connections with wire splices, or

by an alternative method if desired (see gure 6.)

2. Connect the RED wire to any vehicle harness wire

which is energized with battery voltage, ONLY when the

ignition key is in the ON (RUN) position, NOT OFF OR

ACCESSORIES (see gure 5.)

3. Connect the WHITE wire to the instr ument panel

lighting circuit that is controlled by the instrument panel

dimmer control (see gure 5.)

Some vehicles (typically imported) wire the dimmer control

into the ground side of the instrument panel lighting

circuit, as opposed to the more conventional “hot” or 12-volt

side. In vehicles which use this circuit, connect the WHITE

wire to a circuit which is energized by the headlamp switch.

VEHICLE

HARNESS WIRE

PIERCING

CLIP

Fig. 6

CONNECTOR

WIRE SPLICE

LIP UNLOCKED

TACHOMETER

WIRE

WIRE SPLICE

LOCKED

ELECTRICAL

TAPE

CRIMP ENDS

SOLDER

Fig. 5

RED WIRE

TO BATTERY

VOLTAGE

GROMMET

RING

TERMINAL

WHITE

WIRE

BLACK

WIRE TO GROUND

SEE THE GREEN

WIRE CONNECTION

SECTION OF

THIS MANUAL

INSTRUMENT

LAMP

WIRE

SPLICE

TO DIMMER

SWITCH

GREEN WIRE CONNECTION

The GREEN wire provides the tachometer with the engine

RPM (speed) signal.

DISTRIBUTOR EQUIPPED ENGINES

Connect the GREEN wire to the negative (-) side of the

ignition coil. This terminal may also be referred to as the

TACH, TACH TEST, DEC, or ECU terminal.

DISTRIBUTORLESS IGNITION SYSTEM EQUIPPED

ENGINES

If your vehicle’s DIS ignition system has a tachometer

output lead set the switch to the 4 Cylinder position for the

4 cylinder engines and to the 6 Cylinder position for the

6 cylinder engines. Connect the tachometer GREEN wire

to the vehicle’s tachometer output lead.

If your vehicle’s DIS ignition system does not have a

tachometer output lead but allows access to the driver

wires from the vehicle computer to the ignition module,

set the switch to the 2 Cylinder position regardless of the

number of cylinders in the engine. Connect the tachometer

GREEN wire to either of the driver wires.

MULTIPLE SPARK DISCHARGE IGNITION

SYSTEM EQUIPPED ENGINES

For Multiple Spark Discharge ignition systems, connect

the GREEN wire only to the tachometer output terminal on

the ignition module. Do NOT connect to the ignition coil.

SHIFT LIGHT RPM TRIP POINT SET-UP

Some possible uses for the Shift Light are:

Engine RED LINE (maximum safe operating speed of

the engine)

En g ine maximu m to r que R PM ( for m a ximu m

performance shifting) and desired shift speed.

NOTE: You will nee d both ha nds free to s et the

tachometer (see gures 7 and 8).

•

•

Fig. 8

1. Push and hold

lower knob

To set Shift Light

trip point

2. At the same time

push and rotate

upper knob

To view Shift Light trip point

Push and hold lower knob

Fig. 7

1. Turn the ignition key to the ON position. The engine does

not have to be running.

2. Push and keep the LOWER knob depressed.

3. Push in and rotate the UPPER control knob until the

tachometer pointer indicates the RPM trip point at

which the Shift Light should turn ON.

4. Release both the LO WER knob and the UPPER

control knob.

Note:

If at any time the tach pointer appears to freeze

beyond the 10,000 RPM marker: 1) Turn on the ignition

2) Push and hold both knobs 3) Turn the UPPER knob

fully clockwise and then return to the desired trip point.

BACKLIGHTING L AMP

SUBSTITUTION OR REPLACEMENT

The t achometer is supplied with a #168 wedge base

lamp. If the light is too bright, replace with a lamp of less

intensity such as a #194 or #161.

The lamp socket is located in the rear of the housing

of the tachometer (see gure 9). To remove the lamp, gently

grasp the black lamp socket (use pliers if necessary)

and twist it c ounterc lock wise approximately 1/8 turn

until it stops. Pull the socket with lamp straight out of the

tachometer housing. Remove the lamp from its socket

by pulling it straight out. Replace the lamp. Reinstall the

socketed lamp by rotating it against the tachometer’s

internal PC board until it drops into place, and then rotate

it approximately 1/8 turn clockwise until it reaches its

mechanical stop.

0002-00 0- 304 5

Sunpro, a business unit of SPX Corporation

1-800-228 -7667

Loading...

Loading...