3M 6900, 6901, 8900, 8901, 6900-1K-S User Manual

...

3

Crimplok™ Connectors

Quick, easy installation and superior performance

To successfully design, install or operate today’s fiber optic networks, you need components that offer speed and reliability – from the fiber itself all the way down to the connectors. That’s why 3M developed a connector that combines the speed of non-adhesive connectors with the performance characteristics

of epoxy and hot melt connectors. 3M™ Crimplok™ Connectors are the ideal solution for quickly making fiber connections at the desk or for emergency restoration work.

Crimplok connectors were designed to:

•Save time in installation

•Provide rugged, reliable performance, meeting or exceeding current EIA/TIA-568B.3 specifications

•Install cleanly and simply with fewer parts and tools

Saves time

Available in both SC and ST, single-mode and multimode connector versions, Crimplok connectors are faster to install than epoxy connectors since there is no set-up or curing time. Crimplok connectors do not require special heating tools or ovens, so time spent searching for electrical outlets is eliminated. Polishing the connector is also a simple process that can be performed in seconds.

Provides reliable performance

The Crimplok connector incorporates proven 3M malleable metal element fiber gripping technology. There is no fiber splice or second joint inside the connector, so there is no added attenuation at the connection.

When the conformable metal element closes, it grips a length of the fiber, eliminating fiber movement associated with other crimp-style connectors.

The strength of the metallic element ensures that Crimplok connectors meet industry standards for temperature and humidity.

The plastic buffer retention insert also prevents fiber movement by gripping the buffer without crushing it when the crimp ring is crimped. On jacketed cable, the crimp ring also grips the Kevlar® strands and

3M™ Crimplok™ ST Connector Multimode

3M™ Crimplok™ SC Connector Single-mode

cable jacket to prevent the fiber connection from breaking when the cable is pulled.

The buffer retention insert and the crimp ring combine to ensure that Crimplok connectors perform extremely well and meet rigorous tensile strength requirements in building wiring applications.

Installs cleanly and simply

Preparing and installing Crimplok connectors is as simple as the concept behind them.

During installation, the fiber passes through the back end of the connector, through the metallic element and extends beyond the end of the activation tool. Pressing the activation tool locking arm closes the metal element around the fiber. It’s that simple.

The few tools required for installing a Crimplok connector can be conveniently stored in a small tool pouch.

3M™ Crimplok™ Connectors

Features |

Benefits |

Easy to install |

Saves time |

Meets EIA/TIA-568A specifications |

Rugged, reliable performance |

Non-adhesive design |

Clean and simple terminations |

Intermateability with standard connectors |

Convenience, quick restoration of existing systems |

No workstation setup required |

Saves time and money |

Minimal tools required |

Low-cost kit |

No electricity required |

Installation anywhere |

Pre-radiused PC zirconia ceramic ferrule |

Assured contact of fibers; stability through temperature change; quality performance |

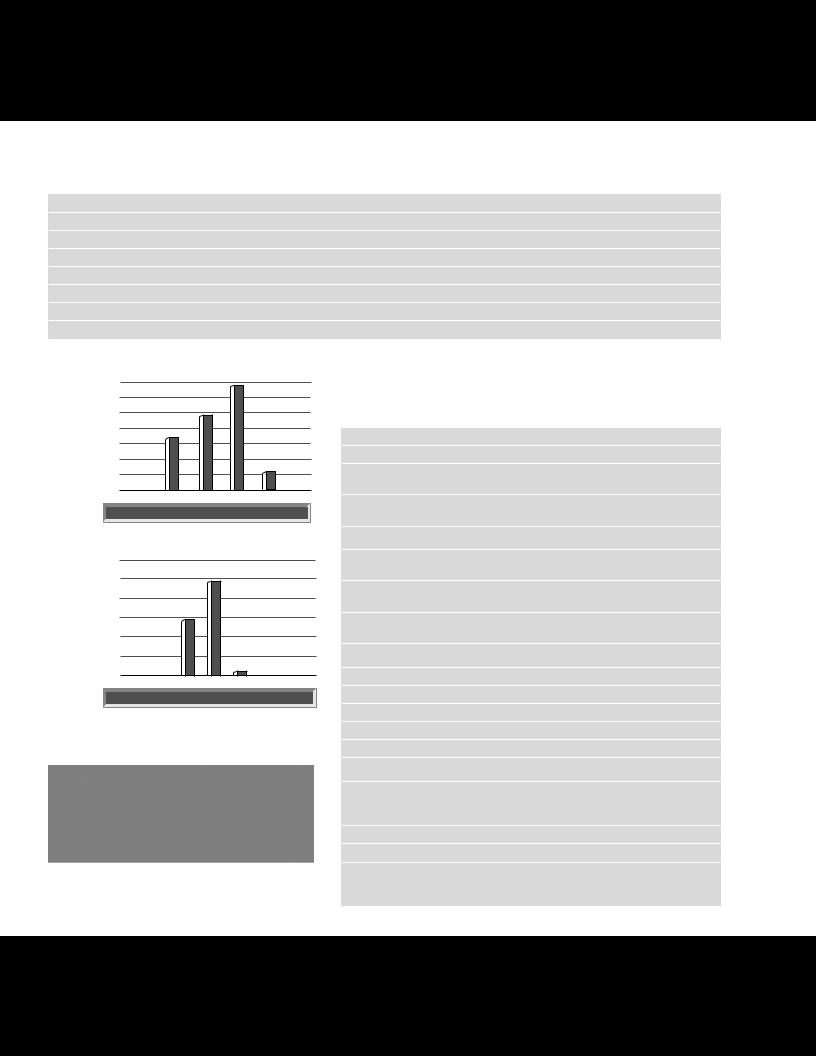

Mean 0.16 (dB)

35

|

30 |

|

|

|

Sigma 0.05 |

|

|

|

|

|

|

|

|

FREQUENCY |

25 |

|

|

|

|

|

20 |

|

|

|

|

|

|

15 |

|

|

|

|

|

|

10 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

5 |

|

|

|

|

|

|

0 |

|

|

|

|

|

|

0.05 |

.01 |

.15 |

0.2 |

0.25 |

0.3 |

Multimode ST and SC Insertion Loss (dB)

|

60 |

|

|

|

|

AVG |

28.6 |

|

|

|

|

|

|

||

|

50 |

|

|

|

|

MAX |

27 |

|

|

|

|

|

|

MIN |

30.5 |

FREQUENCY |

40 |

|

|

|

|

STD |

0.91 |

|

|

|

|

|

|

||

30 |

|

|

|

|

|

|

|

20 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

10 |

|

|

|

|

|

|

|

0 |

|

|

|

|

|

|

|

24 |

26 |

28 |

30 |

32 |

34 |

36 |

Multimode ST and SC Return Loss (dB)

3M™ Crimplok™ SC Connector

3M™ Crimplok™ SC Connector

Multimode 6900

Specifications

Attenuation @ 1300 mm (dB) |

<0.2 typical (62.5/125 µm fiber) |

Reflection (dB) |

≤-29 typical |

Operational temperature |

-10° to 60°C (14° to 140°F) |

(cable dependent) |

|

Storage temperature |

-40° to 80°C (-40° to 176°F) |

(unassembled connector) |

|

Environmental |

|

Humidity |

Max loss increase < 0.20 dB; |

|

Reflection < -25 dB |

Cold |

Max loss increase < 0.20 dB; |

|

Reflection < -25 dB |

Temperature life |

Max loss increase < 0.20 dB; |

|

Reflection < -25 dB |

Mechanical |

|

Impact |

Mean loss 0.18 dB; Mean reflection -28 dB |

Cyclic flex |

Mean loss 0.16 dB; Mean reflection -28 dB |

Twist |

Mean loss 0.16 dB; Mean reflection -28 dB |

Cable retention |

Mean loss 0.16 dB; Mean reflection -28 dB |

Mating durability 500 matings |

<0.22 change |

Materials |

|

Connector ferrule |

Zirconia ceramic |

Connector body and housing |

Thermoplastic polymer |

Boot |

Elastomeric resin |

Identification |

Black body, beige shell, black boot |

Fiber size |

125 µm multimode |

Couplings |

|

Housing |

Engineering thermoplastic |

Sleeve |

Ceramic |

Note: Testing performed on cable assemblies with 3 mm jacketed cable and 900 µm buffered fiber.

Loading...

Loading...