3M 7800S User Manual

7000 Series

Respirator Full Facepiece

User Instructions for 3MTM Silicone, Small 7800S, Silicone, Medium 7800S, Silicone, Large 7800S Full Facepieces

Important: Keep these User Instructions for reference.

1

GENERAL SAFETY INFORMATION

Intended Use

The 3M TM 7000 Series Full Facepiece Respirators are NIOSH approved and designed to help provide respiratory protection against certain airborne contaminants when used in accordance with all use instructions and limitations and applicable safety and health regulations.

This respirator helps protect against certain airborne contaminants. Misuse may result in sickness or death. For proper use, see supervisor, or User Instructions , or call 3M

These User Instructions provide information about facepiece use only. Important information is provided in the User Instructions with each of the air filtration/supplied air systems. Failure to follow the User Instructions for the air filtration/supplied air systems being used may result in sickness or death.

Do not clean respirator with solvents. Cleaning with solvents may degrade some respirator components and reduce respirator effectiveness. Inspect all respirator components before each use to ensure proper operating conditions.

CAUTION:

This product contains natural rubber latex which may cause an allergic reaction.

2

USE INSTRUCTIONS AND LIMITATIONS

Important

Before use, the wearer must read and understand these User Instructions . Keep these instructions for reference.

Use For

Respiratory protection from certain airborne contaminants according to NIOSH approvals, OSHA limitations, in Canada CSA standard Z94.4 requirements, other applicable regulations and 3M instructions.

Do Not Use For

Concentrations of contaminants which are immediately dangerous to life or health, are unknown

or when concentrations exceed 10 times the permissible exposure limit (PEL) in air-purifying mode when qualitatively fit tested, 50 times the PEL in air-purifying mode when quantitatively fit tested, 1000 times the PEL in powered air-purifying or supplied air mode, or according to specific OSHA standards or applicable government regulations, whichever is lower.

Use Instructions

1.Failure to follow all instructions and limitations on the use of this respirator and/or failure to wear this respirator during all times of exposure can reduce respirator effectiveness and may result in sickness or death.

2.Before using this respirator, a written respiratory protection program must be implemented meeting all the requirements of OSHA 29 CFR 1910.134 such as medical evaluation, training and fit testing and applicable OSHA substance specific standards. In Canada, CSA standard Z94.4 requirements must be met.

3.The airborne contaminants which can be dangerous to your health include those that are so small you cannot see them.

4.Leave contaminated area immediately and contact supervisor if you smell or taste contaminants or if dizziness, irritation, or other distress occurs.

5.Store respirator away from contaminated areas when not in use.

6.Dispose of used product in accordance with applicable regulations.

Use Limitations

1.This respirator does not supply oxygen when used in air-purifying mode. Do not use in atmospheres containing less than 19.5% oxygen.

2.Do not use when concentrations of contaminants are immediately dangerous to life and health, are unknown or when concentrations exceed 10 times the permissible exposure limit (PEL) in airpurifying mode when qualitatively fit tested, 50 times the PEL in air-purifying mode when quantitatively fit tested, 1000 times the PEL in powered air-purifying or supplied air mode, or according to specific OSHA standards or applicable government regulations, whichever is lower.

3.Do not alter, abuse or misuse this respirator.

4.Do not use with beards or other facial hair or other conditions that prevent a good seal between the face and the faceseal of the respirator.

Time Use Limitations

1.If respirator becomes damaged, leave the contaminated area immediately and repair or replace the respirator.

2.Replace filters in accordance with the filter Time Use Limitation.

3

3.Replace cartridges in accordance with an established change schedule or earlier if smell, taste or irritation from contaminants is detected.

NIOSH Cautions and Limitations

The following restrictions may apply. See NIOSH approval label.

A– Not for use in atmospheres containing less than 19.5 percent oxygen. B– Not for use in atmospheres immediately dangerousto life or health.

C– Do not exceed maximum use concentrations established by regulatory standards.

D– Air-line respirators can be used only when the respirators are supplied with respirable air meeting the requirements of CGA G-7.1 Grade D or higher quality.

E– Use only the pressure ranges and hose lengths specified in the User’s Instructions.

F– Do not use powered air-purifying respirators if irflowa is less than four cfm (115 lpm) for tight fitting facepieces or six cfm (170 lpm) for hoods and/or helmets.

G– If airflow is cut off, switch to filter and/or cartridge or canister and immediately exit to clean air.

H– Follow established cartridge and canister changeschedules or observe ESLI to ensure that cartridges and canisters are replaced before breakthrough occurs.

I– Contains electrical parts which have not been evaluated as an ignition source in flammable or explosive atmospheres by MSHA/NIOSH.

J – Failure to properly use and maintain this productcould result in injury or death.

L– Follow the manufacturer’s User's Instructions forchanging cartridges, canisters and/or filters. M– All approved respirators shall be selected, fitted, used, and maintained in accordance with MSHA,

OSHA, and other applicable regulations.

N– Never substitute, modify, add, or omit parts. Use only exact replacement parts in the configuration as specified by the manufacturer.

O– Refer to User’s Instructions, and/or maintenanc manuals for information on use and maintenance of these respirators.

P– NIOSH does not evaluate respirators for use assurgical masks.

S– Special or critical User’s Instructions and/or use limitations apply. Refer to User’s Instructions before donning.

S-Special or Critical User’s Instructions

3M™ Mercury Vapor Cartridge (6009 and 60929) are eq uipped with passive 3MTM End of Service Life Indicators (ESLI). The color change indicator must be readily visible when wearing the respirator without manipulation. If you cannot readily see the ESLI, do not use. Mercury vapor cartridges must be discarded when the ESLI changes color; or within 30 days of opening packaging; or when the ESLI becomes dirty or damaged; or when odors of vapors or gases become noticeable, whichever

occurs first. Mercury vapor has no odor.

3M™ Nose Cup Assembly 7881S or 7981S must be used i n all 7000 Series Full Facepiece applications except for Face-Mounted Power Air-Purifying Systems.

U.S. OSHA Standard 29 CFR 1910.134 requires that employers provide breathing air for supplied air respirator systems which shall “meet at least the r equirements of the specification for Grade D breathing air as described in the Compressed Gas Association Commodity Specification ANSI/CGA G-7.1-1997.” Testing of output air from a compressor against this standard is required prior to using with a supplied air respirator. In Canada, breathing air systems must be supplied with air which meets at least the requirements in Table 1 of CSA Standard Z180.1-00. Failure to do so may result in sickness or death.

4

Cartridge and Filter Selection and Approvals

Before using any of these products, the user must read the specific use for, use limitations and warning information or call OH&ESD Technical Service at 1-800-243-4630. In Canada, call Technical Service at 1-800-267-4414. Do not exceed maximum use concentrations established by local regulatory agencies. Cartridges/filters are approved as assemblies for use with 3M TM 7800S (S), 7800S (M) or 7800S (L) facepieces. For NIOSH approval refer to NIOSH approval label packaged with facepiece.

LIST OF PRODUCTS

3MTM 7800S Full Facepiece Respirator Parts, Filters, Chemical Cartridges, or Airline Accessories

3MTM Facepiece

Facepieces do not include filters, chemical cartridges, retainers or airline accessories.

Number |

Description |

Button Color (7989) |

|

7800S (S) |

silicone, small |

red |

|

7800S |

(M) |

silicone, medium |

yellow |

7800S |

(L) |

silicone, large |

green |

Number |

|

Description |

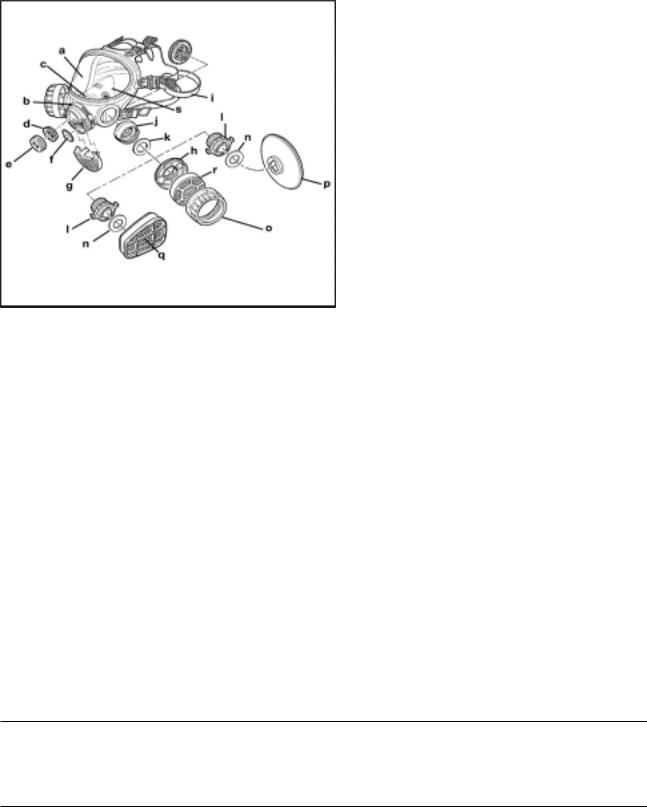

7884 |

(a) |

Lens |

7914 |

(b) |

Band Clamp |

7916 |

(c) |

Breathing Room Assembly |

7999 |

(d) |

Air Inlet Gasket |

7890 |

(e) |

F ull Face Plug |

7283 |

(f) |

Exhalation Valve |

7918 |

(g) |

Exhalation Valve Cover |

7891 |

(h) |

Cartridge Holder |

7893S |

(i) |

Head Strap Assembly, Silicone |

7886 |

(j) |

Removable DIN Connector |

7887 |

(k) |

Inhalation Valve Gasket |

701 |

(l) |

Cartridge/Filter Adapter for 3MTM 6000 Series Cartridges or 3MTM 2000 |

|

|

Series Filters |

6895 |

(n) |

Inhalation Gasket (included in 701) |

7287 |

(o) |

Cartridge Retainer for 3MTM 7000 Series Cartridges |

|

(p) |

3M TM 2000 Series Filters |

|

(q) |

3M TM 6000 Series Cartridge |

|

(r) |

3M TM 7000 Series Cartridge |

7881S |

(s) |

Nose Cup Assembly, Silicone (includes Nose Cup Valve Assembly 7882), or |

7981S |

|

Nose Cup Assembly, Silicone, Small (includes Nose Cup Valve Assembly |

|

|

7882) |

5

3MTM Accessories and Parts

Number |

Description |

Not Pictured |

Fit Test Adapter (for quantitative fit testing with 3M TM P100 Filters 2091 or 7093) |

601 |

|

7282 |

Inhalation Valve |

7288 |

Filter Retainer for Filters 7090 |

7289 |

Filter Retainer for Filters 7N11 |

7882 |

Nose Cup Valve Assembly |

7883 |

Neckstrap Assembly |

7885 |

Lens Frame Kit |

7891 |

Cartridge Holder (round) |

7894 |

Eyeglass Frame and Mount with case |

7895 |

Speaking Diaphragm Kit (includes Diaphragm, Gasket, Retainer Ring, Tool) |

7899-25 |

Lens Cover (25 pack) |

7899-100 |

Lens Cover (100 pack) |

7915 |

Tyvek ® Shroud |

7925 |

Spectacle Kit |

7930 |

Fit Test Adapter (for quantitative fit testing with 3M TM P100 Filter 7090) |

7986 |

Tinted Lens Cover (25 pack) |

7989 |

Buttons |

7990 |

Clip-on Welding Shield Kit |

7991 |

Electronic Lens Assembly |

7993 |

Welder’s Shroud |

CAUTION

Failure to properly dispose of spent cartridges, filters, or respirators contaminated by hazardous materials can result in environmental harm. Handling, transportation and disposal of spent cartridges, filters, or respirators must comply with all applicable federal, state, and local laws and regulations.

3MTM 2000 Series Filters and 3M™ Filter 7093 and 3M™ Ad apter 502

(3MTM Cartridge/Filter Adapter 701 is required. May also be used with 3MTM Adapter 502 as prefilters on 3MTM 6000 Series Cartridges).

6

Loading...

Loading...