Dometic 2500 User Manual

A&E CATALINA 2500

A&E Systems

A&E Systems

USA

Service Office

The Dometic Corp.

509 South Poplar St.

LaGrange, IN 46761

CANADA

Dometic Dist.

866 Langs Dr.

Cambridge, Ontario

CANADA N3H 2N7

INSTALLATION & OPERATING |

Catalina |

||||

|

|

INSTRUCTIONS |

2500 |

||

REVISION |

|

|

|

|

|

Form No. 3103624.023 |

|

3/98 |

|

|

|

(Replaces 3103624.015) |

|

|

|

|

|

(French 3108310.024) |

|

|

|

|

|

|

|

|

|||

©1998 The Dometic |

Corporation |

1 |

|

|

|

LaGrange, IN 46761 |

|

|

|

||

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

A&E CATALINA 2500

A&E CATALINA 2500

INSTALLATION/OPERATION

APPLICATION

The A&E Catalina 2500 Case Awning is designed and intended for direct mounting on straight and most curved mini-motorhomes, pick-up campers, vans, van conversions and pop-up tent trailers.

The optional Universal Van Adapter Kit, A&E Part No. 930035 allows permanent or temporary mounting to vans with rain gutters without drilling holes in the van.

Important: Read the entire installation procedure before starting installation.

Note: The Dometic Corporation assumes no liability for damages or injuries resulting from installation or operation of this product.

The Dometic Corporation reserves the right to modify appearances and specifications without notice.

INSTALLATION

Tools Required: |

|

ο Measuring Tape |

ο Pencil |

ο Electric Drill |

ο Pop Rivet Gun (Necessary |

ο Drill Bits #& or 3/6”, 1/8” |

only if Backing Plate is |

ο Center Punch |

needed) |

ο Phillips Screw Driver |

ο Silicone Sealant |

For Direct Wall Mounting:

Note: When determining location for awning make sure to consider door clearance, if required, and location of other vehicle components like compartment doors, mirrors, etc..

1.A. Install C-Channel of awning case into awning rail by inserting C-Channel into one end of awning rail and sliding awning case into position (FIG. 1A), or by tilting case up and inserting entire C-Channel into awning rail and rotating case down into position (FIG. 1B).

B.Using the end caps as templates, drill one 1/8” Dia. hole into vehicle for each end cap (FIG. 1A). Secure each end cap using one #10 x 3/4” Phillips pan head sheet metal screw with a small dab of silicone sealant on each screw (FIG 1A & 1B).

Note: Awning must be mounted with case back parallel to side wall of vehicle.

|

|

Shim not supplied |

NO |

YES |

YES |

Note: Be sure to use a dab of silicone sealant on every screw where a hole has been drilled in the side of the vehicle. This will prevent possible water leakage.

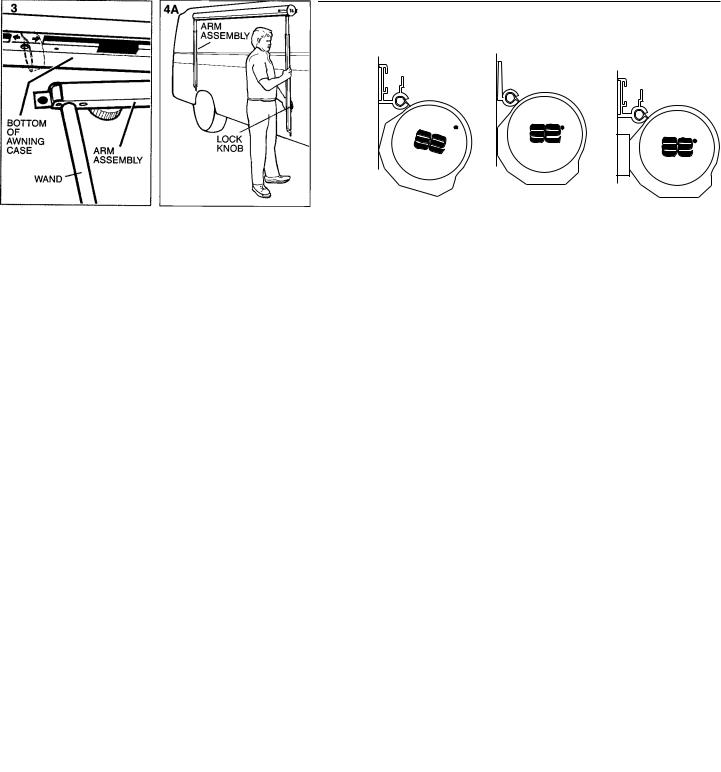

2.Using the wand, open awning case by inserting the pin on the end of the wand into hole in arm assembly indicated by arrows on bottom of case (FIG. 2)

3.Lower arm assembly out of awning case (FIG. 3)

4.A. Allow arm to hang freely from case. Tighten lock knob (FIG. 4A). Repeat for other side.

Note: For curved sided vehicles proceed to Step 4B. For straight sided vehicles skip to Step 5.

B.Lower arm assembly to ground. With foot still on ground raise inner arm as high as it will go (FIG. 4B).

2

A&E CATALINA 2500

Note: Make sure lock in top of awning arm assembly clears top of case lip (FIG. 4C). This is necessary for awning to open properly.

Tighten lock knob. Repeat steps 4B & 4C for other side.

C.Using wand, hook pull-strap and pull awning out about 3 feet (1 meter) (FIG. 4D).

D.While securely holding the pull-strap, tighten the lock knobs on the rafter arms (FIG. 4E).

5. |

5). |

6.Select a location for mounting of bottom mounting bracket on side of vehicle. The minimum mounting distance from the bottom of the awning case to the bottom of the bottom mounting bracket for the 2.5 meter awning is 48”. For the 3.0, 3.5 and 4.0 meter awnings it is 58” (FIG. 6).

Note: Positioning of left and right bottom mounting brackets should be at same level and centered to the awning arms (FIG. 6).

7.Loosen lock knob and extend arm assembly keeping arm perpendicular to awning case. Once location is determined, tighten lock knob (FIG. 7).

Note: The bottom mounting brackets should be mounted to the floorline of solid structural member whenever possible.

8.Using the foot and bottom mounting bracket as a template, drill a 1/8” dia. hole for the bottom screw. Secure bottom mounting bracket with foot attached to vehicle using a #10 x 1-1/2” long Phillips pan head sheet metal screw thorough the foot and the bottom mounting bracket. Use a small dab of silicone sealant on screw (FIG. 8)

9.A. Release foot from bottom mounting bracket and drill a 1/8” dia. hole for the top screw. Using a #10 x 1” long Phillips pan head sheet metal screw with a dab of silicone sealant on it, secure the top of the bottom mounting bracket to vehicle (FIG. 9A).

Repeat Steps 5 thorough 9A for other side.

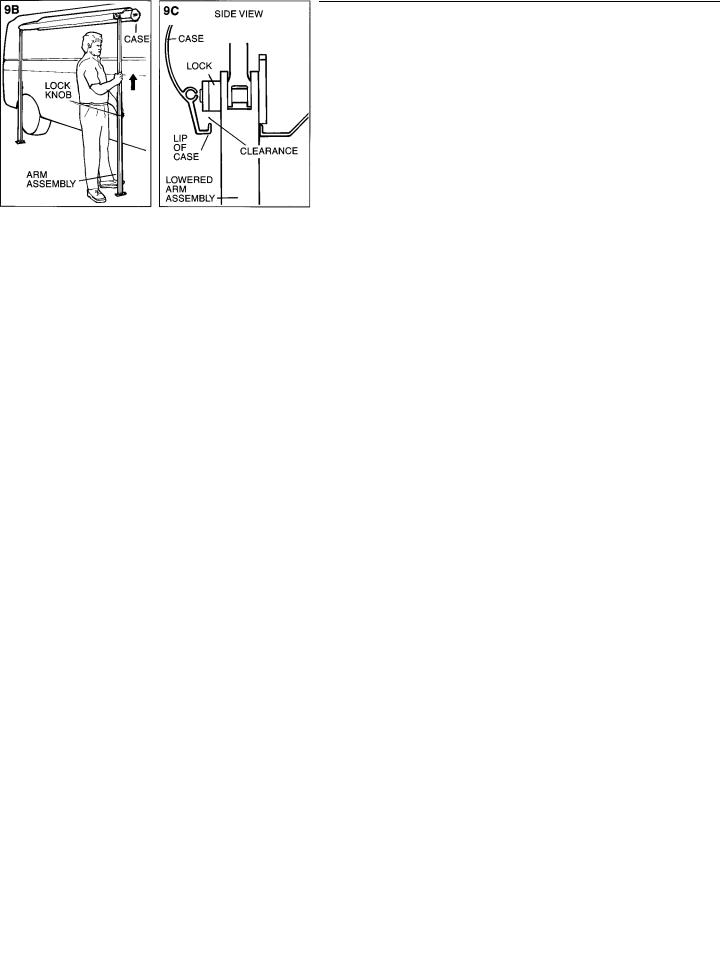

Note: For curved sided vehicles proceed to Step 9B. For straight sided vehicles skip to Step 10.

ground. With foot still on ground raise inner arm as high as it will go (FIG. 9B).

Note: Make sure lock in top of awning arm assembly clears top of case lip (FIG. 9C).

3

Loading...

Loading...