Page 1

600479-001 Rev 2 1/147

Operation Manual

Page 2

600479-001 Rev 2 2/147

Copyright © 2009 ZOLL Circulation, Inc..

All rights reserved. Printed in U.S.A.

Trademarks

Alsius, CoolGard, CoolGard 3000, Thermogard XP, Cool Line, Fortius, and

Icy are trademarks of ZOLL Circulation, Inc.

Mallinckrodt is a registered trademark of Mallinckrodt Inc.

Windows is a registered trademark of Microsoft Corporation.

Other products and names listed in this document may be trademarked by their

owners and no representation is made by ZOLL Circulation, Inc. as to rights

thereto.

U.S. Patents Pending

This product is covered by or for use under one or more of the following U.S.

patents. Other U.S. and foreign patents pending:

4,290,428 4,648,384 4,689,041 4,850,969 4,865,581

4,917,667 4,927,412 5,011,468 5,033,998 5,059,167

5,908,407 6,019,783 6,126,684 6,149,670 6,165,207

6,287,326 6,290,717 6,299,599 6,338,727 6,368,304

6,393,320 6,405,080 6,409,747 6,416,533 6,419,643

6,432,124 6,436,130 6,447,474 6,450,990 6,451,045

6,454,792 6,454,793 6,458,150 6,460,544 6,494,903

6,516,224 6,520,933 6,529,775 6,530,945 6,530,946

6,554,797 6,572,640 6,581,403 6,582,398 6,585,692

6,589,271 6,602,243 6,620,131 6,641,602 6,641,603

6,645,233 6,645,234 6,652,565 6,682,551 6,699,268

6,706,060 6,709,448 6,716,188 6,716,236 6,719,724

6,726,653 6,726,710 6,733,517 6,749,585 6,749,625

6,755,851 6,786,916 6,796,995 6,872,222 6,878,156

6,893,419 6,893,454 6,942,644 7,001,418 7,014,651

7,070,612 7,090,792 7,097,657 7,101,388 7,144,407

ZOLL Circulation, Inc.

650 Almanor Avenue

Sunnyvale, California 94085

U.S.A.

Telephone: +1-408-541-2140

Facsimile: +1-408-541-1030

Page 3

600479-001 Rev 2 3/147

Contents

1. Safety Information

2. Introduction

3. Receiving, Inspection, and Assembly

4. Operation

Overview

Alarms & Alerts

Your First Case

Setup - Variations

Ending Treatment

Temperature Trend Data

Mechanical Components

Accessory: HMIA

5. TempTrend CSV Program User’s Guide

6. Alarms and Corrective Actions

7. Troubleshooting

8. Maintenance

9. Warranty and Service

10. Specification

Page 4

Safety Information

600479-001 Rev 2 4/147

Safety Information

1

Page 5

Safety Information

600479-001 Rev 2 5/147

Contents

Safety Information 3

Overview 3

Warnings, Cautions, and Notes 3

Definitions of Symbols and Labels Used on the Product and in the Manual 4

General Safety Precautions 5

Shipping and Storage Conditions 6

Ignition of Flammable Anesthetic Mixtures 6

Electrical Hazards 6

Primary Patient Temperature Probe (T1) Failure 7

Configuration Changes 7

Priming the Saline Circuit 7

Air Entry Into the Tubing Circuit 8

Check the Integrity of the Catheter 8

Check the Integrity of the Start-up Kit Tubing 8

Interference 9

Product Label 9

2

Page 6

Safety Information

600479-001 Rev 2 6/147

Safety Information

Overview

Safety is of primary concern to ZOLL Circulation, Inc.. This chapter provides

information on safely using the System. You must read and understand the

information in this chapter before operating the System. Always follow the

warnings, cautions, and notes throughout this document.

If you have questions about the safe or effective use of the System, please

contact the manufacturer.

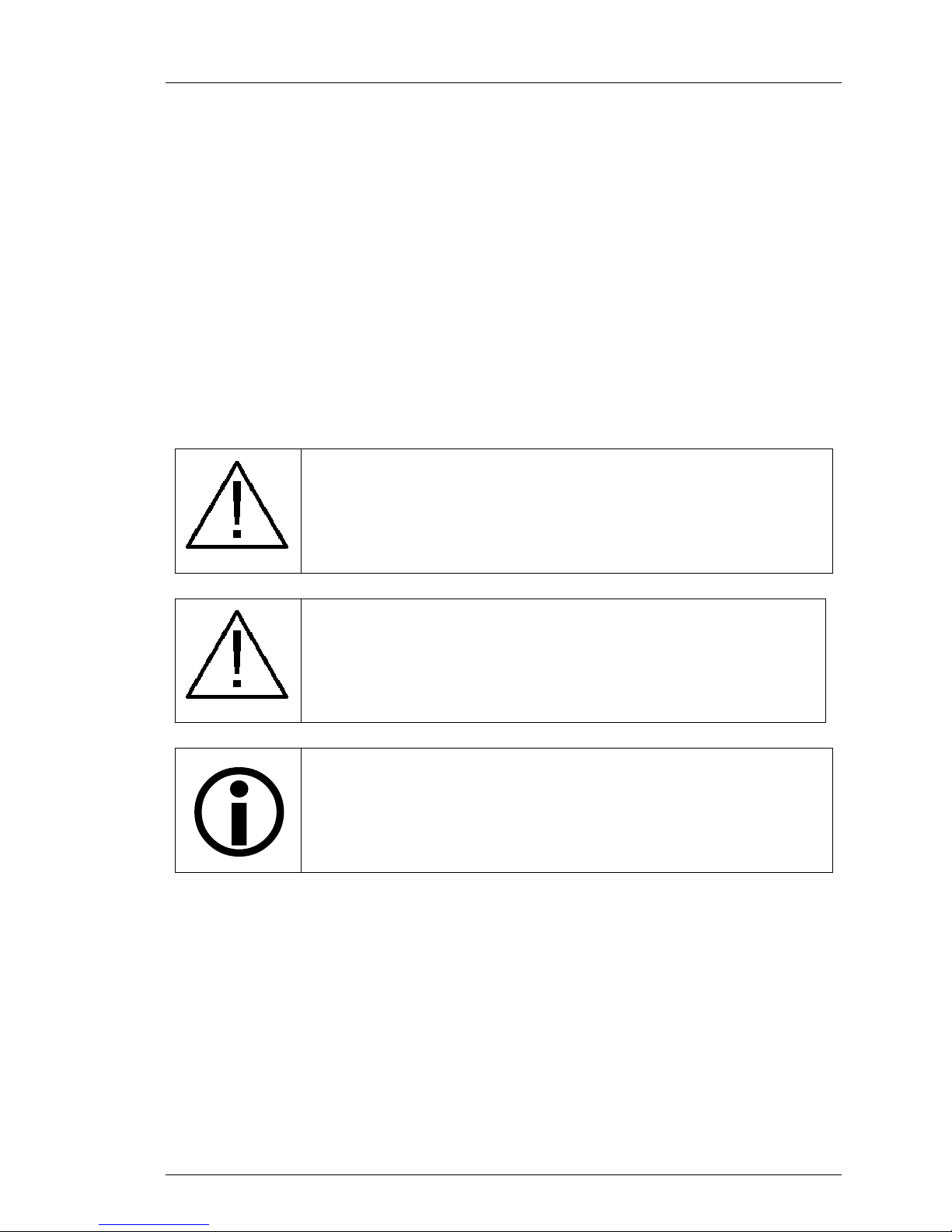

Warnings, Cautions, and Notes

This document uses the following conventions to indicate important information.

WARNING!

Warnings are accompanied by symbols surrounded by a triangle and are

printed in the text in bold italics. Warnings indicate events or conditions

that can result in serious injury or death or severe damage to the

equipment.

CAUTION!

Cautions are accompanied by symbols surrounded by a triangle and are

printed in the text in bold italics. Cautions indicate information for safe

operation, proper performance, or avoiding actions that may result in

damage to the equipment.

NOTE:

Notes are accompanied by a symbol of the letter “i” surrounded by a circle

and are printed in the text in italics. Notes clarify understanding, aid in the

proper operation of the product, and prevent problems or errors from

occurring.

3

Page 7

Safety Information

600479-001 Rev 2 7/147

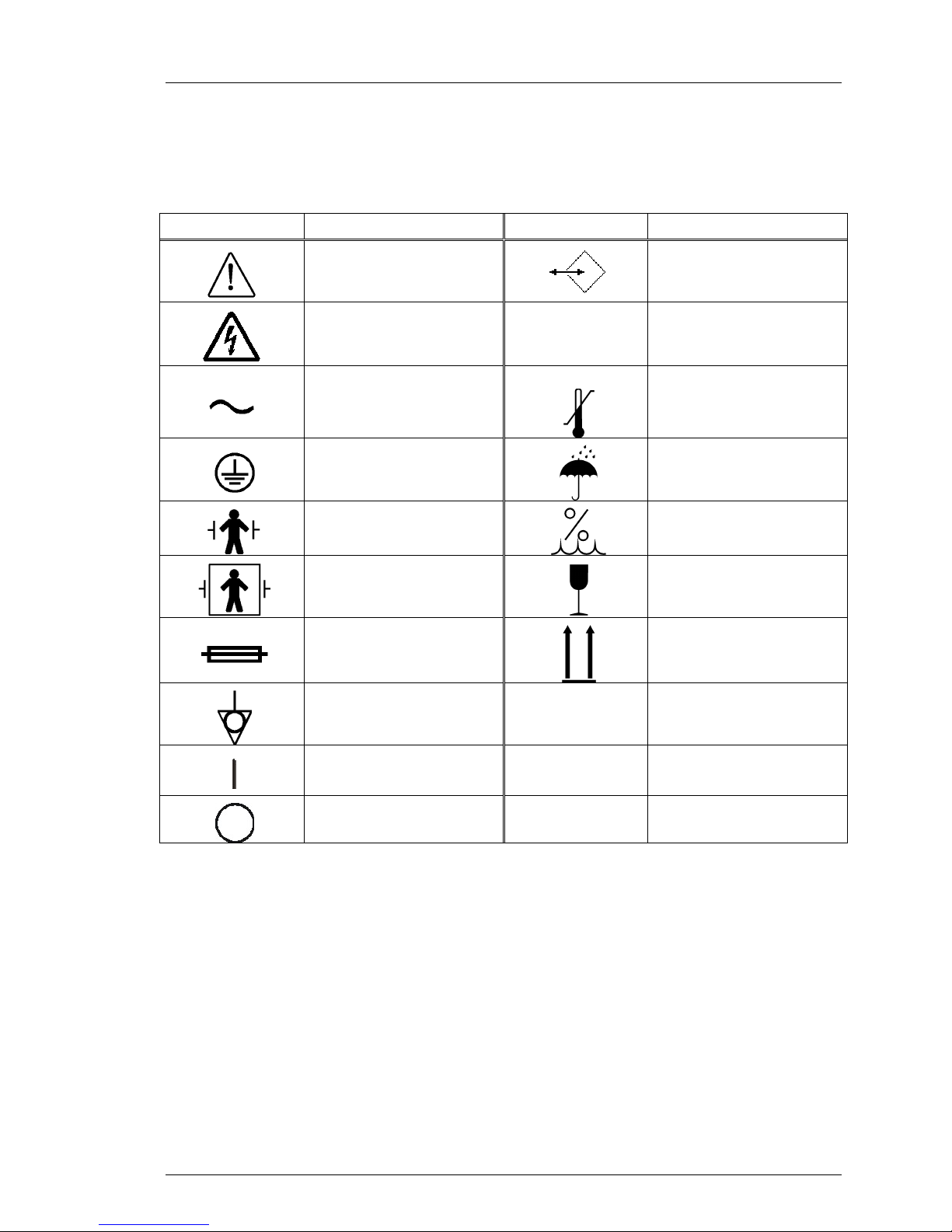

Definitions of Symbols and Labels Used on

the Product and in the Manual

Symbol Definition Symbol Definition

Attention. Consult

accompanying

documents.

Electrical warning or

electrical caution.

Alternating current.

Protective earth (ground).

Type B applied part.

Defibrillator protected.

Type BF applied part.

Defibrillator protected.

Fuse.

This symbol designates

the connector for the data

acquisition cable.

Indicates notes intended

to clarify understanding.

Temperature and

pressure range.

Do not allow liquids to spill

on the product or

package.

Humidity range.

Fragile contents.

Top facing up.

Ground equipment.

On.

Off.

Lo

Hi

The low patient

temperature alarm limit.

The high patient

temperature alarm limit.

4

Page 8

Safety Information

600479-001 Rev 2 8/147

General Safety Precautions

WARNING! SYSTEMIC HYPOTHERMIA RISKS.

Systemic hypothermia may cause cardiac arrhythmia, patient shivering, or

other system or organ complications. Systemic hypothermia should only be

utilized under the supervision of a qualified physician.

When treating a patient with the System, appropriately qualified medical staff

must routinely and closely monitor the patient and must comply with the following

procedures:

Audible and visual alarms generated by the System require the

authorized individual to remain in close proximity to the patient

throughout the procedure.

Always verify the function of the System prior to insertion of an Alsius

catheter. In the event of a malfunction, have other means of cooling

available.

When combining the use of the System and other adjunctive means

of cooling, ensure that close observation of the patient is maintained.

Do not use the ZOLL System in conjunction with other temperature

maintenance devices that have an automatic temperature controller.

Temperature oscillations may occur that are dangerous to the

patient.

Performance of installation, operation, or maintenance procedures

other than those described in this manual may create hazards and

may cause the manufacturer’s warranty to become void.

Sterile components are designed for a single use only. If

unauthorized disposable components are used, proper operation

cannot be guaranteed and harm to the patient may result.

Proper aseptic technique must be used while making all sterile

connections to the System.

Never operate damaged or leaking equipment.

Never operate the equipment without coolant fluid in the coolant well.

Never use pure water, pure propylene glycol, or alcohol as a coolant

fluid.

Never operate the equipment while smoking or in the presence of

open flame.

5

Page 9

Safety Information

600479-001 Rev 2 9/147

Shipping and Storage Conditions

When shipping or storing the System, follow these recommendations:

Temperature range: -20ºC (-4ºF) to 60ºC (140ºF).

Atmospheric pressure range: 50 kPa to 106 kPa.

Do not allow liquids to spill on the System or its packaging.

Humidity range: 10% to 90% noncondensing.

Fragile contents, handle with care.

Always handle and store with the top facing up.

Ignition of Flammable Anesthetic Mixtures

The System is not category AP or APG equipment and must not be used in

environments where flammable anesthetic gas mixtures are present.

Electrical Hazards

This equipment has been tested and found to comply with the EMC limits of the

international standard EN 60601-1-2. These limits are designed to provide

reasonable protection against interference in a typical medical installation. The

equipment can radiate radio frequency energy if not installed in accordance with

the instructions, and may cause harmful interference to other devices in the

vicinity. There is no guarantee that interference will not occur in a particular

installation. Always comply with the following:

To avoid the risk of electrical shock, do not remove any panels of the

product.

Refer servicing to qualified personnel.

Never operate equipment with damaged power line cords.

Refer service and repairs to a qualified technician.

CAUTION! ELECTRIC SHOCK HAZARD.

Electric shock hazard. Always turn off the System and disconnect the

power line cord from the source before performing any service or

maintenance procedures, or before moving the System.

6

Page 10

Safety Information

600479-001 Rev 2 10/147

Primary Patient Temperature Probe (T1)

Failure

The System relies upon the patient temperature reading from a YSI-400 type

thermistor connected to the Primary Patient Temperature Probe (T1). There are

rare failures of this type of thermistor that cannot be detected by the System with

100% reliability. Failure of the T1 can result in either patient hypo- or hyper-

thermia. Death or serious injury to the patient may result. A secondary patient

temperature probe (T2) connection is therefore built into the system. For patient

safety, either use both the T1 and T2 connections or employ the T1 probe with

an independent frequent check of patient core temperature.

WARNING! NEVER CLINICALLY USE A RESISTOR IN PLACE

OF THE T1 TEMPERATURE PROBE

ZOLL supplies fixed value resistors and variable resistor test boxes (e.g the

TP-400 FOGG Box) for testing, training and demonstration purposes. These

can be plugged into the Primary Patient Temperature Probe T1 connection on

the front of the System to represent a patient. Never use this device, or other

method, to circumvent the normal patient temperature feedback control when

the system is connected to the patient. Doing so exposes the patient to the

hazards associated with hypo- or hyper- thermia. Death or serious injury may

result.

Configuration Changes

CAUTION! CONFIGURATION CHANGES MUST BE

CERTIFIED.

Equipment connected to the analog and digital interfaces must be certified to

the respective IEC standards (i.e., IEC 950 for data processing equipment

and IEC 60601-1 for medical equipment). Furthermore, all configurations shall

comply with the system standard IEC 60601-1. Any person who connects

additional equipment to the signal input part or the signal output part configures a medical system and is therefore responsible that the system complies with the requirements of the system standard IEC 60601-1.

Priming the Saline Circuit

WARNING! DO NOT PRIME THE SALINE CIRCUIT WHILE

CONNECTED TO A PATIENT

During the priming operation, the air-trap alarm will be disabled. Air present in

the saline line may be circulated through the indwelling catheter.

Before priming the circuit or during troubleshooting for possible leak,

disconnect the heat exchange catheter, then connect the inflow and outflow

luer fittings of the saline circuit together.

7

Page 11

Safety Information

600479-001 Rev 2 11/147

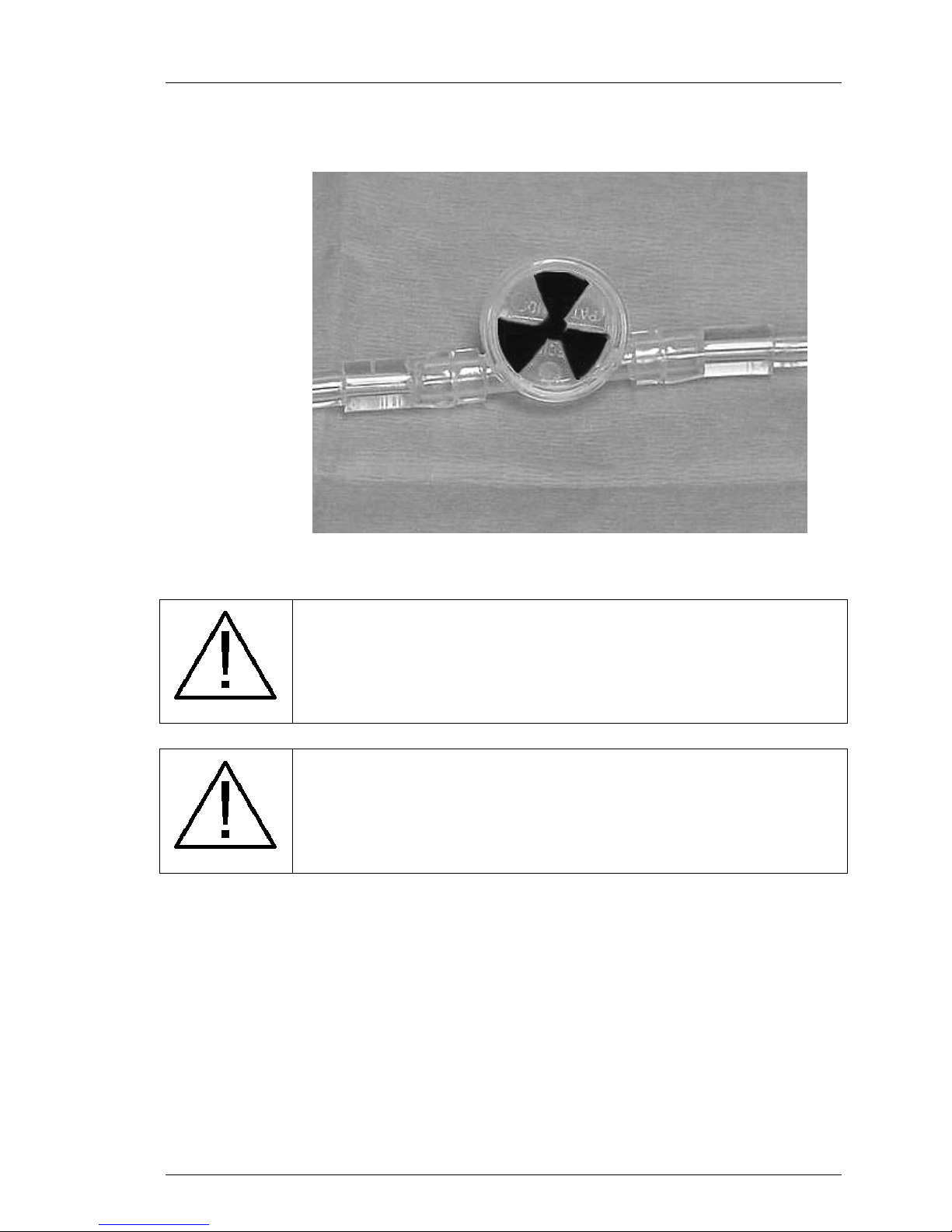

Air Entry Into the Tubing Circuit

Air entry may occur with the failure of any part of the start-up kit, between the

saline bag and the outflow of the pump. In such cases, the integrity of the

catheter prevents air entry into the patient. In the rare event of a second,

simultaneous failure of the catheter, air entry into the patient is possible.

Air entry into the tubing circuit will usually, but not always, be associated with an

air trap alarm that will stop the System. Always investigate air trap alarms. The

cooling circuit is a closed loop–usually air trap alarms indicate a breach

somewhere in this closed loop (occasionally an air trap alarm can be caused by

condensation forming on the air trap exterior). With any air trap alarm, check both

the integrity of the catheter and the start-up kit (see below).

Periodically check the start-up kit for significant air bubbles and re place the kit if

necessary.

WARNING! NEVER CLINICALLY CIRCUMVENT THE AIR

TRAP ALARM

ZOLL supplies air trap “dummies” for testing, training and demonstration

purposes. These are fluid filled air trap assemblies that are separate from a

standard Start-up Kit assembly. Never use this device, or other method, to

circumvent the air trap alarm when the system is connected to the patient.

Doing so exposes the patient to the hazards associated with air embolism

should the catheter fail. Death or serious injury may result.

Check the Integrity of the Catheter

To check the integrity of the catheter, perform these steps in the indicated order:

1. Stop the System.

2. Using aseptic technique, disconnect the tubing from the catheter and

properly cap both the catheter and the tubing set.

3. Fill a sterile 10 ml syringe with sterile saline.

4. Connect the syringe to the INFLOW lumen of the catheter and

disconnect the outflow cap.

5. Infuse the 10 ml of saline – it should flow out the outflow lumen.

6. Cap the OUTFLOW lumen and pull and hold 5 ml of vacuum for at least

10 seconds. Approximately 4 ml of saline, but not blood, should enter the

syringe and you should be able to maintain the vacuum.

7. Ease the vacuum, disconnect the syringe, and recap the INFLOW lumen.

Check the Integrity of the Start-up Kit Tubing

To check the integrity of the start-up kit tubing, perform these steps in the

indicated order:

1. Stop the System.

2. Look for obvious leakage.

3. Remove the tubing from the pump and check it for damage. Replace it in

the pump if it is undamaged.

4. Inspect the tubing from the pump to the patient for sources of fluid loss:

8

Page 12

Safety Information

600479-001 Rev 2 12/147

Look for damage to the tubing and/or the presence of air inside the

tubing.

Inspect, and tighten if necessary, each Luer fitting (do not use

instruments to tighten the fittings).

5. Inspect the tubing that returns to the pump from the patient.

6. Examine the saline bag to ensure that it has not been accidentally

compromised (for example, the spike may have damaged the bag wall).

7. Inspect the tubing from the saline bag to the saline reservoir and the

pump.

Interference

If this equipment does cause interference with other devices, which can be

determined by turning the equipment off and on, the user is encouraged to try to

correct the interference by one or more of the following measures:

Reorient or relocate the receiving device.

Increase the separation between the equipment.

Connect the equipment into an outlet on a circuit different from that

to which the other device(s) is connected.

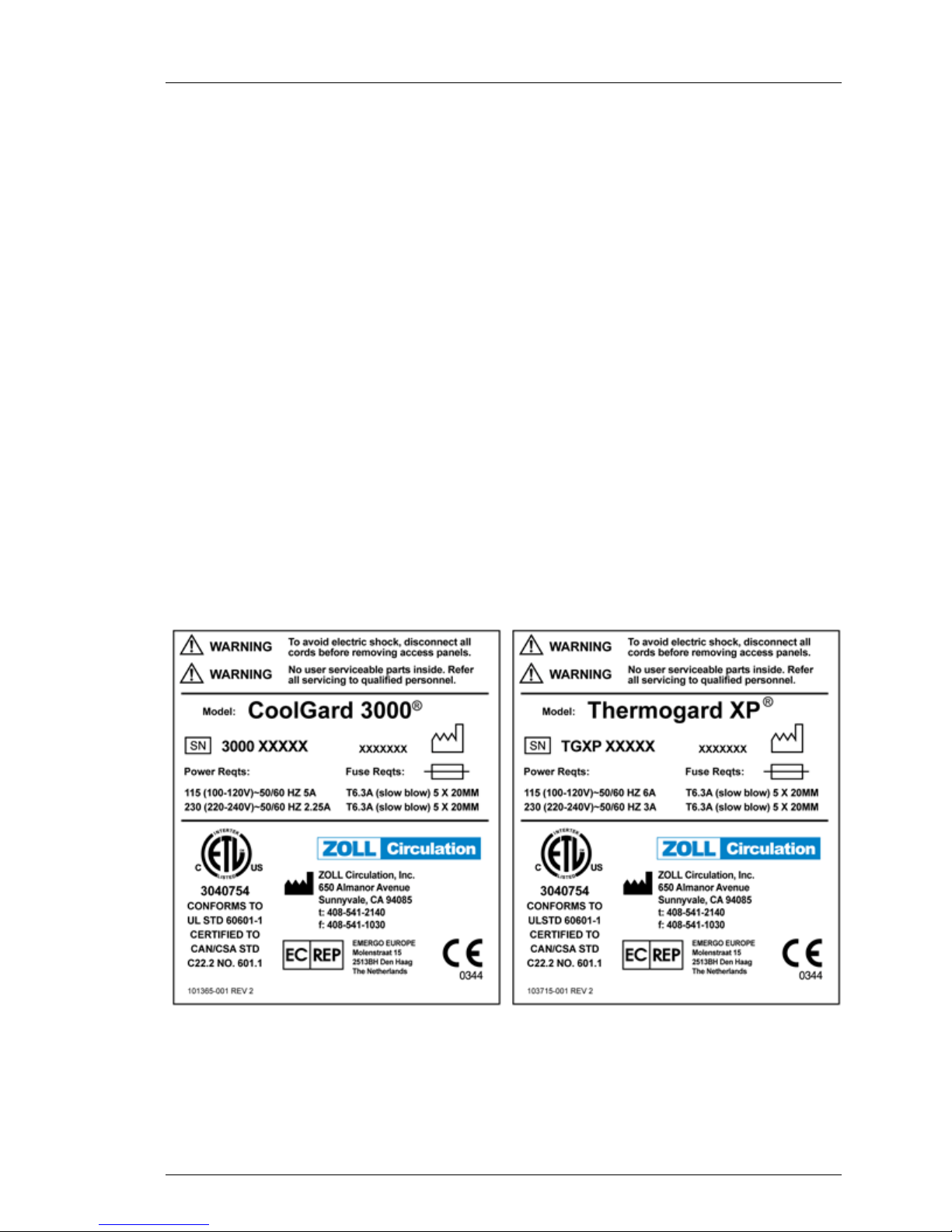

Product Label

An identifying label is attached to the outside of the System console near the

power cord inlet. The label is illustrated in Figure 1-1.

The label provides safety information and identifies the manufacturer, model

number, serial number, power requirements, fuse capacity, and m anufacturing

date for the System.

9

Figure 1-1. Product Label .

Page 13

Introduction

600479-001 Rev 2 13/147

Introduction

1

Page 14

Introduction

600479-001 Rev 2 14/147

Contents

Introduction 3

Use of the System 3

Operating Life 3

Functional Description 3

System Components 4

Controls and Display 4

Display 4

Power Indicators 5

Alarm Indicators 5

Control Buttons 5

Control Knob 6

Serial Interface Connector 6

Recirculating Chiller 6

Temperature Controller 7

Temperature Probe Connectors 7

Pump 7

Prime Switch 8

Start-up Kit 9

Data Memory 10

Saline Circuit Diagram 10

2

Page 15

Introduction

600479-001 Rev 2 15/147

Introduction

Use of the System

WARNING! PATIENTS MUST BE CONTINUOUSLY MONITORED.

Patients being treated with the System must be checked frequently (hourly)

when the System is operating. It is possible for malfunctions or misuse of the

System to result in patient injury or death.

The ZOLL Thermal Regulating System is comprised of an external heat

exchange system (CoolGard 3000 or Thermogard) and an Alsius endovascular

heat-exchange catheter connected via a sterile heat exchanger and tubing circuit

(the Alsius Start-up Kit). These components together comprise a patient

temperature-regulation apparatus employing feedback control. The catheter and

the Start-up Kit (its heat exchange coil, air trap, and tubing) are single-use

disposable devices.

This manual provides operating instructions for the System and the start-up kit.

Catheter components are referenced where it is necessary to assure proper use

with the system components. Always refer to the catheter’s Instructions for Use

for additional specific information.

Operating Life

The operating life of the catheters may vary according to design as indicated by

the model designation. Always refer to the catheter’s Instructions for Use for

information about the catheter’s operating life.

The disposable components of the Alsius start-up kit are designed for continuous

use for a period not to exceed seven (7) days. After seven days of use, all startup kit components must be removed and replaced with component s from a new

start-up kit.

CAUTION! START-UP KIT LIFETIME IS SEVEN (7) DAYS.

The designed operating lifetime for start-up kit components is seven (7) days

of continuous operation. If a patient must be treated for a longer period, a new

start-up kit must be installed in the System. Failure to adhere to this time limit

may cause injury to the patient.

Functional Description

The System can be described in terms of three major components: a

recirculating chiller, a sterile fluid roller pump, and a temperature control system.

The System is connected to the temperature-controlled catheter by two smallbore plastic tubes. One tube supplies temperature-controlled sterile saline

solution to the catheter, and the other tube returns the saline solution to the

System. The sterile saline is pumped through a continuous recirculating loop by a

peristaltic pump inside the console. The saline solution acts as an intermediate

heat-transfer medium between the patient and the System. Sterile saline is used

because it is biologically compatible with the patient and in the unlikely event of a

leak in the catheter, the possibility of harming the patient is reduced to a practical

minimum.

3

Page 16

Introduction

600479-001 Rev 2 16/147

Patient temperature feedback is used to control the system. The patient’s

temperature is measured by an indwelling YSI 400 thermistor temperature

sensor. In response to the patient’s measured temperature, the System employs

both cooling and heating. Cooling occurs when the patient’s temperature is

above the set point target temperature. Heating occurs when the patient’s

temperature is below the set point target temperature. The amount of heating or

cooling power is proportional to the difference in temperature between the set

point target temperature and the patient’s measured temperature.

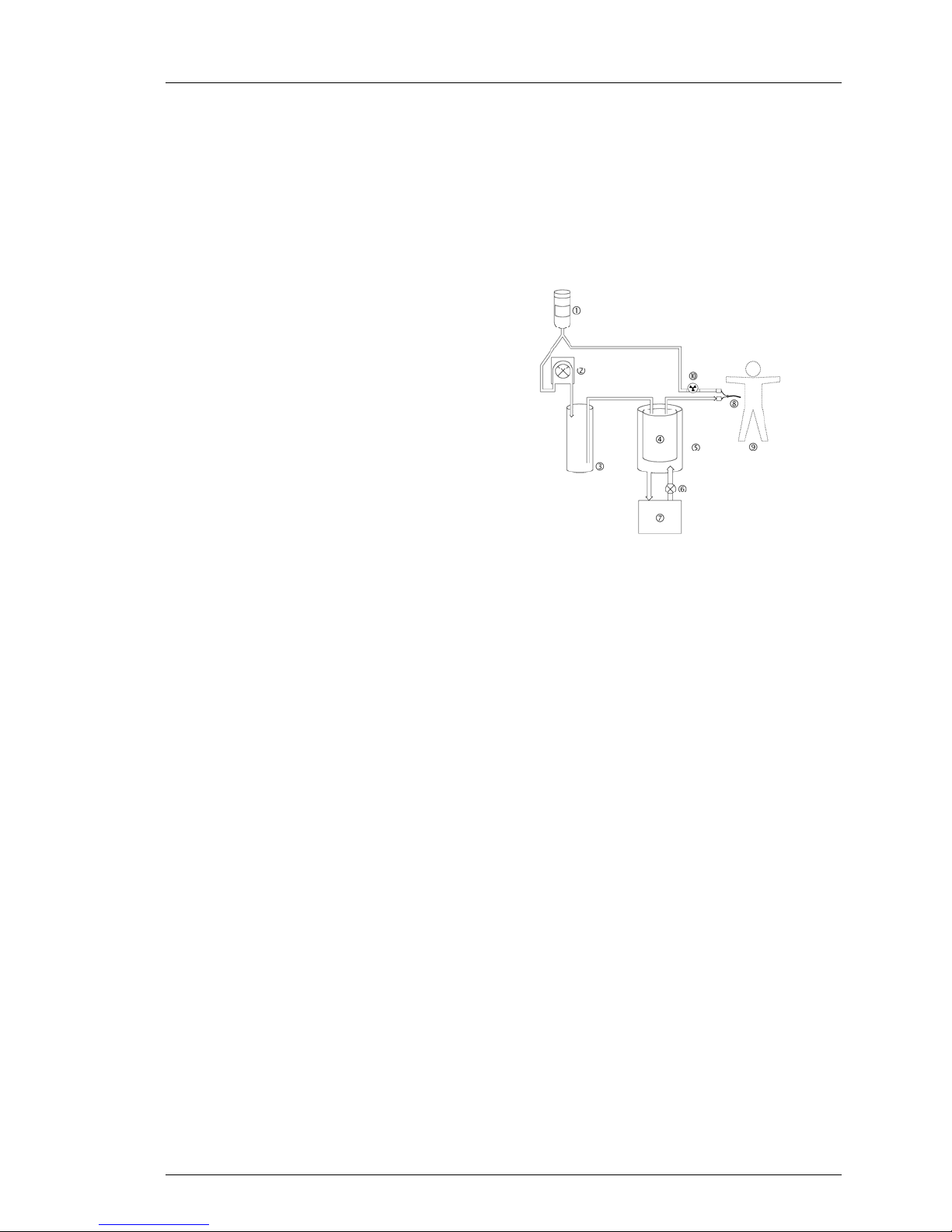

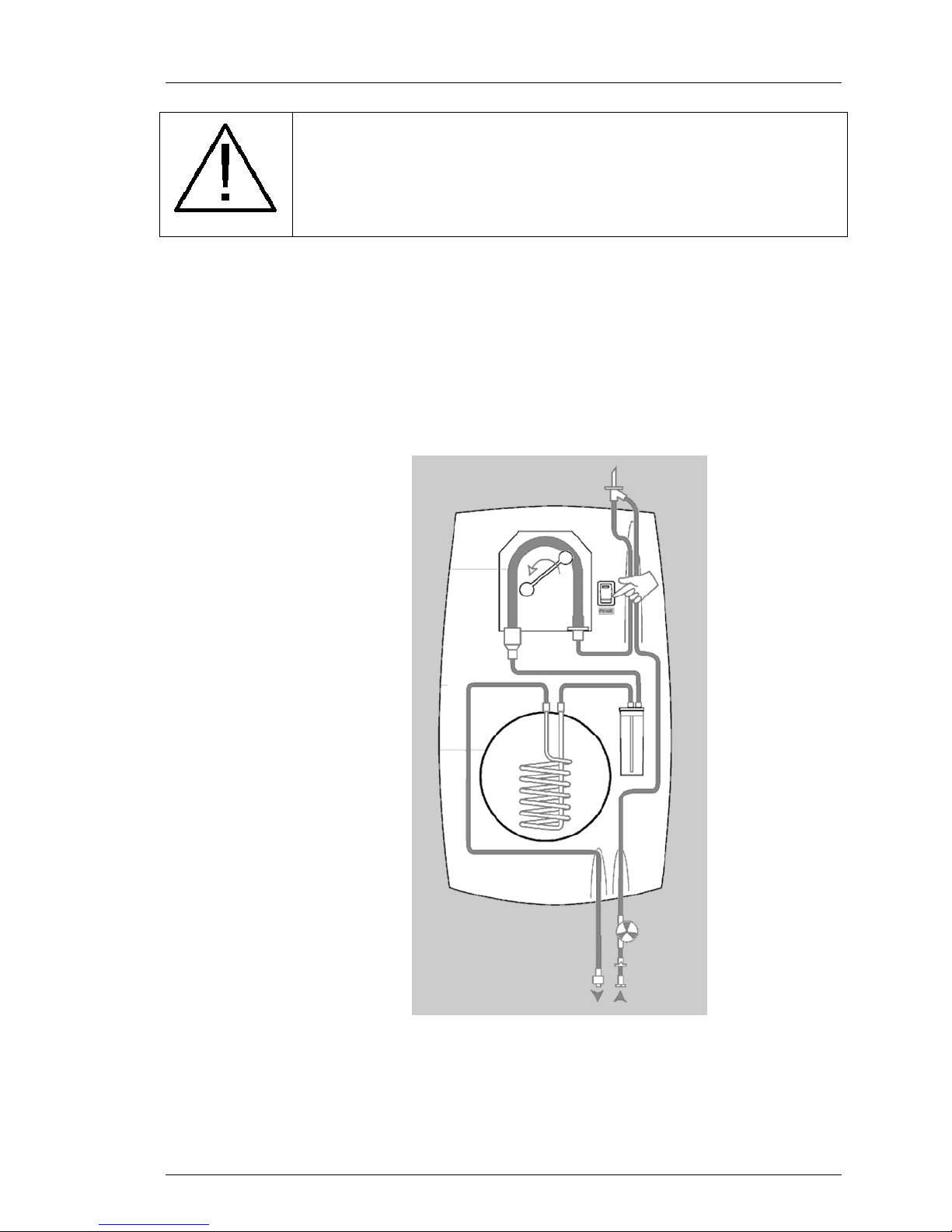

A basic diagram of the System is illustrated in the following figure.

1. Saline bag.

2. Peristaltic pump

3. Air trap

4. Heat exchange coil

5. Coldwell

6. Coolant pump

7. Chiller & Heater

8. Catheter

9. Patient

10. Pin wheel flow indicator

Figure 2-1. Simplified Flow Diagram.

System Components

Controls and Display

The operator’s display panel contains four buttons and one knob used to access

functions and adjust settings with the aid of the menus and messages displayed

on the screen. The controls and display are illustrated in figure 2-2 and explained

in the following text.

Display

The display is a backlit color LCD panel that can be easily read in all ambient

lighting conditions. It is used to display status, menus, messages, alarms, and

patient temperature trend graphs.

The display head is attached to the mast by an adjustable swivel/tilt mounting

clamp. The user can adjust the tilt and rotation of the display head and lock it into

position by using this clamp.

4

Page 17

Introduction

600479-001 Rev 2 17/147

1. Display Screen

2. Alarm Indicator LED.

3. Mute Button

4. Power On Indicator LED.

5. Target Temp Button.

6. Standby / Run Button.

7. Rate Deg / HR Button.

8. Press for Menu / Enter Knob

Figure 2-2. Controls and Display.

Power Indicators

An indicator lamp on the control panel is illuminated when power is switched on.

A second power-on indicator is mounted directly above the power swit ch on the

rear of the console.

Alarm Indicators

The System typically notifies users of alarm conditions in two ways. When an

alarm occurs, the screen displays an alarm message, and an alarm annunciator

produces an audible alarm tone (beep). The alarm tone can be temporarily

muted by the user, but it cannot be turned off.

If the nature of the failure prevents the System from displaying an alarm

message, the alarm indicator on the control panel will be illuminated.

Control Buttons

The display head features four pushbuttons that are used to control System

functions. To provide confirmation, each time a button is pressed, a “key click”

sound is produced by the annunciator.

Target Temp

Press the “Target Temp” button to display a screen that allows you to set the

patient’s target temperature. You may set a target temperature between 31º C

and 38º C (87.8º F and 100.4º F).

Rate Deg/Hr

Press the “Rate Deg/Hr” button to display a screen that allows you to set the

cooling/warming rate (expressed in degrees per hour). You may set a cooling/

warming rate between 0.10º C/hr and 0.65º C/hr (0.18º F/hr and 1.17º F/hr).

Standby/Run

5

Page 18

Introduction

600479-001 Rev 2 18/147

Press the “Standby/Run” button to toggle the operation of the System between

standby mode (the pump is stopped) or run mode.

An alarm or fault can place the System into standby mode automatically. After

remedying the condition that caused the alarm, press this button to return to run

mode.

Silence Alarm

Press the silence alarm button to silence the audible alarm tone for two minutes

(120 seconds). If the alarm condition has not been cleared during this two -minu te

period, the audible alarm will sound again.

Control Knob

The “Press for Menu/Enter” control is a dual-function control knob and

pushbutton.

Press the knob to display a menu screen or to indicate the completion of a

selection.

Turn the knob to scroll between selections or to scroll temperature trend graphs.

Serial Interface Connector

A female 9-pin subminiature D connector is mounted on the lower left corner of

the rear of the display head. Use this connector to attach a serial interface cable

between the System and a laptop computer. Once connected, the computer can

download patient temperature trend data stored by the System.

Recirculating Chiller

The chiller consists of an air-cooled refrigeration system, reservoi r heater,

circulation pump, stainless steel reservoir, reservoir cover, and a temperature

controller.

6

Figure 2-3. Serial Interface Connector.

Page 19

Introduction

600479-001 Rev 2 19/147

Temperature Controller

The temperature controller uses input from the patient’s temperature probe and

the operator-selected patient temperature setpoint to regulate the coolant

temperature of the recirculating chiller. The temperature controller constantly

adjusts the coolant temperature by means of a closed-loop control system. The

operator enters a setpoint that represents the patient’s target temperature. The

controller cools or heats the coolant, in a range between 0º and 42º C (32º and

107.6º F) to optimally achieve and maintain the target temperature. The controller

constantly displays the measured patient temperature and the target

temperature.

An optional mode can command the controller to approach the target

temperature at a user-selected rate.

Temperature Probe Connectors

The front of the System console features two connectors, labeled “T1” and “T2”

which are used for connection to patient temperature probes. The primary patient

temperature probe is plugged into connector T1. The secondary probe is plugged

into connector T2.

Pump

Sterile saline solution is circulated through the heat exchanger coil and the

catheter by a high-performance, compact roller pump. It pumps by peristaltic

action on the tubing installed in the pump head. The pump rotation speed is

accurately controlled by an electronic speed control system. The pump flow rate

can be selected by the user.

7

Figure 2-4. Temperature Probe Connectors.

Page 20

Introduction

600479-001 Rev 2 20/147

WARNING! FINGER INJURIES

Be careful when inserting the pump tubing that you do not catch your fingers

with the roller.

When the System is operating DO NOT attempt to circumvent the safety

interlocks on the peristaltic pump lid. DO NOT place fingers or foreign objects

into the pump raceway when the pump is turning. The peristaltic pump has

sufficient torque to severely damage a finger.

If a tubing leak or failure occurs in the pump raceway, the saline solution will

cause corrosion in the moving parts of the rotor.

1. Remove the pump rotor (refer to Pump Rotor removal instructions in

System Service Manual).

2. Rinse the rotor in clean water and thoroughly dry the rotor.

3. Apply a few drops of light machine oil to the moving parts of the rotor.

4. Reinstall the rotor (refer to pump rotor installation instructions in System

Service Manual).

Prime Switch

The prime switch is located next to the pump under the top cover. The switch is

used to operate the pump to prime the tubing with sterile saline solution from the

saline source. When the switch is held down, the pump runs; when the switch is

released, the pump stops.

8

Figure 2-5. Pump.

Page 21

Introduction

600479-001 Rev 2 21/147

Start-up Kit

The Alsius start-up kit contains the sterile disposable components for this

system. Each kit contains a heat exchanger coil, air trap, saline coolant delivery

lines, saline container connectors, catheter connectors, and the roller pump

tubing. These components are described in detail in later chapters of this

document. The components in the start-up kit are designed to operate

continuously for seven days, after which they must be replaced.

Figure 2-6. Prime Switch

.

9

Figure 2-7. Start-up Kit.

Page 22

Introduction

600479-001 Rev 2 22/147

CAUTION! START-UP KIT LIFETIME IS SEVEN (7) DAYS.

The designed operating lifetime for start-up kit components is seven (7) days

of continuous operation. If a patient must be treated for a longer period, a new

start-up kit must be installed in the System. Failure to adhere to this time limit

may cause injury to the patient.

Data Memory

The System is capable of continuously recording patient temperature and system

activity for up to 21 days. This stored data can be downloaded to an attached

computer over a serial interface using optional software furnished by ZOLL.

Saline Circuit Diagram

A flow diagram is printed on the inside of the top cover. Use this diagram to

assure that the start-up kit has been installed correctly.

10

Figure 2-8. Flow Diagram.

Page 23

Introduction

600479-001 Rev 2 23/147

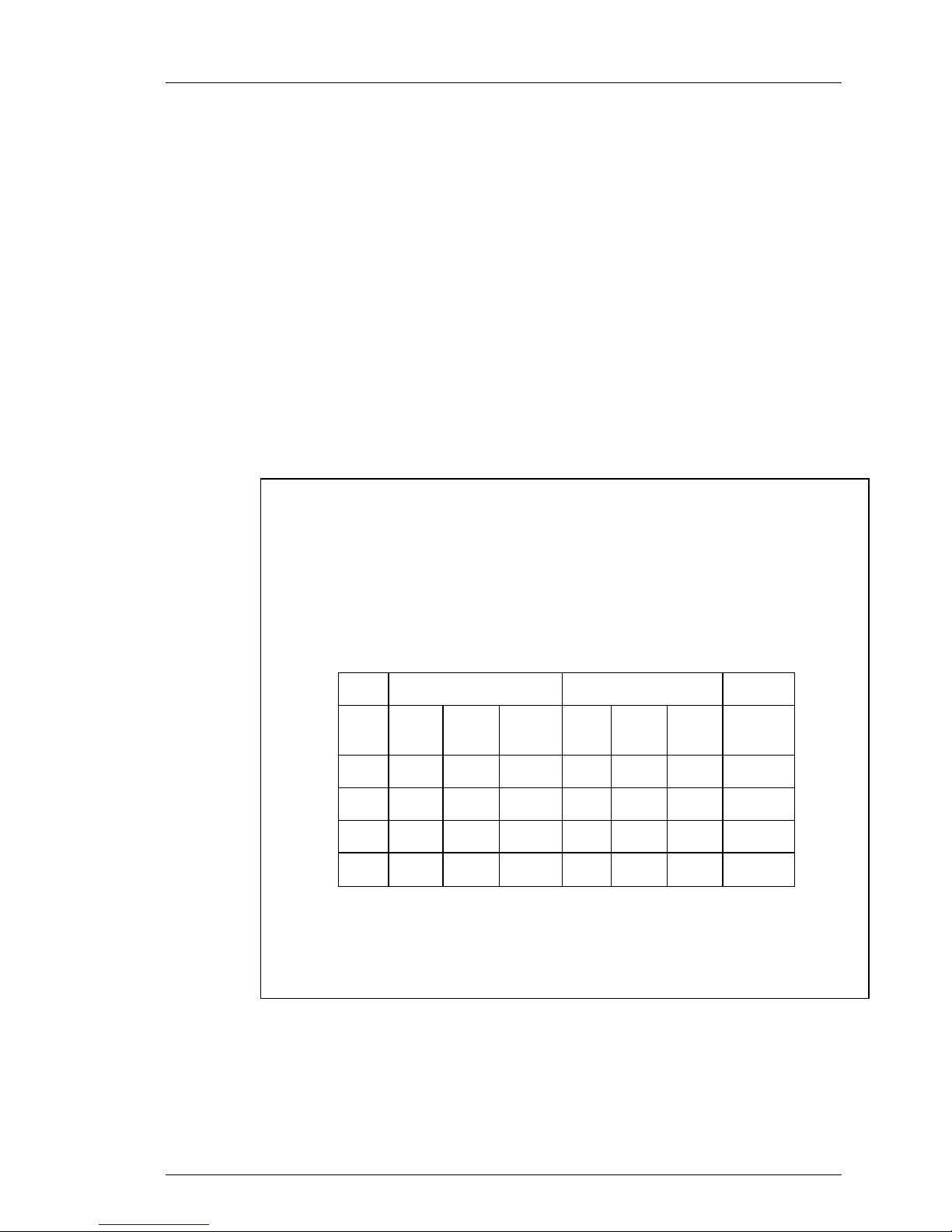

Indications for Use - USA

The Indications for Use listed below have clearance within the USA for the

following models of ZOLL Thermal Regulation System:

The CoolGard 3000

The Thermogard XP

These systems can be used with any of the Alsius Catheters. The indications for

use are specific to the catheter. Please refer to the Indications for Use statement

in the catheter specific Instructions for Use.

Indications for Use – Cool Line Catheters

The ZOLL Thermal Regulation System using the Alsius Cool Line™ Catheter is

indicated for use in fever reduction, as an adjunct to other antipyretic therapy, in

patients with cerebral infarction and intracerebral hemorrhage who require

access to the central venous circulation and who are intubated and sedated.

Warning – Fever Reduction

The safety of this device has not been demonstrated for fever reduction in

patients presenting with subarachnoid hemorrhage or primary trau m atic brain

injury. The safety and effectiveness of this device was examined in a randomized controlled trial of 296 patients. The mortality results reported in this trial,

for the four patient cohorts enrolled, are presented in the table below (CI –

cerebral infarction, ICH – intracerebral hemorrhage, PTBI – primary traumatic

brain injury, SAH – subarachnoid hemorrhage).

Table 1-1. Mortality by Diagnosis (ITT).

Cool Line Control

n N % n N % p-value*

CI 3 16 18.8 3 14 21.4 0.74

ICH 8 33 24.2 7 27 25.9 1.00

PTBI 10 44 22.7 4 38 10.5 0.24

SAH 13 61 21.3 7 63 11.1 0.15

*Fischer’s exact test

For more details on the results of this study please refer to Physician’s Manual –

“Normothermia for the Neuro-critically Ill Stroke Patient” #101416-001.

1

Page 24

Introduction

600479-001 Rev 2 24/147

Indications for Use – All Other Catheters

The ZOLL Thermal Regulation System, using one of the Icy ®, Quattro ™ or

Fortius

®

model catheter, is indicated for use:

in cardiac surgery patients to achieve and or maintain normothermia

during surgery and recovery/intensive care, and

to induce, maintain and reverse mild hypothermia in neurosurgery

patients in surgery and recovery/intensive care.

2

Page 25

Receiving, Inspection & Assembly

600479-001 Rev 2 25/147

Receiving, Inspection

& Assembly

1

Page 26

Receiving, Inspection & Assembly

600479-001 Rev 2 26/147

Contents

Receiving, Inspection, and Assembly 3

Overview 3

Inspection for Damage 3

Required Tools 3

Unpacking 3

Assembly 4

Hook 4

Handle 5

Control Head 5

Control Cable 6

Power Cord 7

Condensate Pan 7

Saline Container Insulating Jacket 7

2

Page 27

Receiving, Inspection & Assembly

600479-001 Rev 2 27/147

Receiving, Inspection, and Assembly

Overview

This chapter provides information on how to receive, unpack, and assemble the

System. If your System was delivered and set up by an ZOLL representative, you

may skip this chapter and turn to Chapter 4.

Inspection for Damage

Each System is carefully inspected before it is shipped. When the carrier

delivers your System, ensure that the shipping containers are not damaged.

Visually inspect the outside of the shipping container for any damage. If

damage is detected, please notify ZOLL’s customer service department and

file a damage claim with the carrier.

Required Tools

To safely unpack, inspect, and assemble the System, you will need the following

tools:

Phillips screwdriver (included in shipping container).

3/16-inch Allen wrench (included in shipping container).

5/32-inch Allen wrench (included in shipping container).

7/64-inch Allen wrench (included in shipping container).

Scissors or box knife.

Unpacking

CAUTION! AVOID LIFTING INJURY.

The System weighs 115 lb (52 kg). Never attempt to lift the equipment without

assistance. Use safe lifting practice when handling the equipment.

To unpack the System, follow these steps in the indicated order.

1. Remove the straps from the carton and pallet.

2. Open the top flaps of the carton and remove the inner carton containing

3. Remove the protective inserts and lift the outer carton up and off.

4. Use scissors or a box knife to carefully cut away the moisture barrier bag

5. With the help of an assistant, grasp the base of the console just above

the control head. This carton also contains the handle, attachment

hardware, spare fuses, the condensate pan, the saline container

insulating jacket, and other miscellaneous parts.

surrounding the console. Use care to avoid scratching the console.

the casters, carefully lift the console off the platform, and set it on the

floor.

3

Page 28

Receiving, Inspection & Assembly

600479-001 Rev 2 28/147

Figure 3-1. System Unpacked and Ready for Assembly.

Assembly

To assemble the unpacked System, follow these steps in the indicated order.

Hook

1. Attach the gray hook to the front of the mast using the short bolt

provided. Use a 7/64-inch Allen wrench to tighten the bolt securely (see

figure 3-2).

4

Figure 3-2. System With Hook Attached.

Page 29

Receiving, Inspection & Assembly

600479-001 Rev 2 29/147

Handle

2. Attach the handle to the mast using the long bolt and the short screw

provided. Use a 3/16-inch Allen wrench to tighten the bolt securely. Use

a 5/32-inch Allen wrench to tighten the screw (see figure 3-3). Do not lift

the System by the handle.

Figure 3-3. Use the Long Bolt and Center Screw to Attach the Handle.

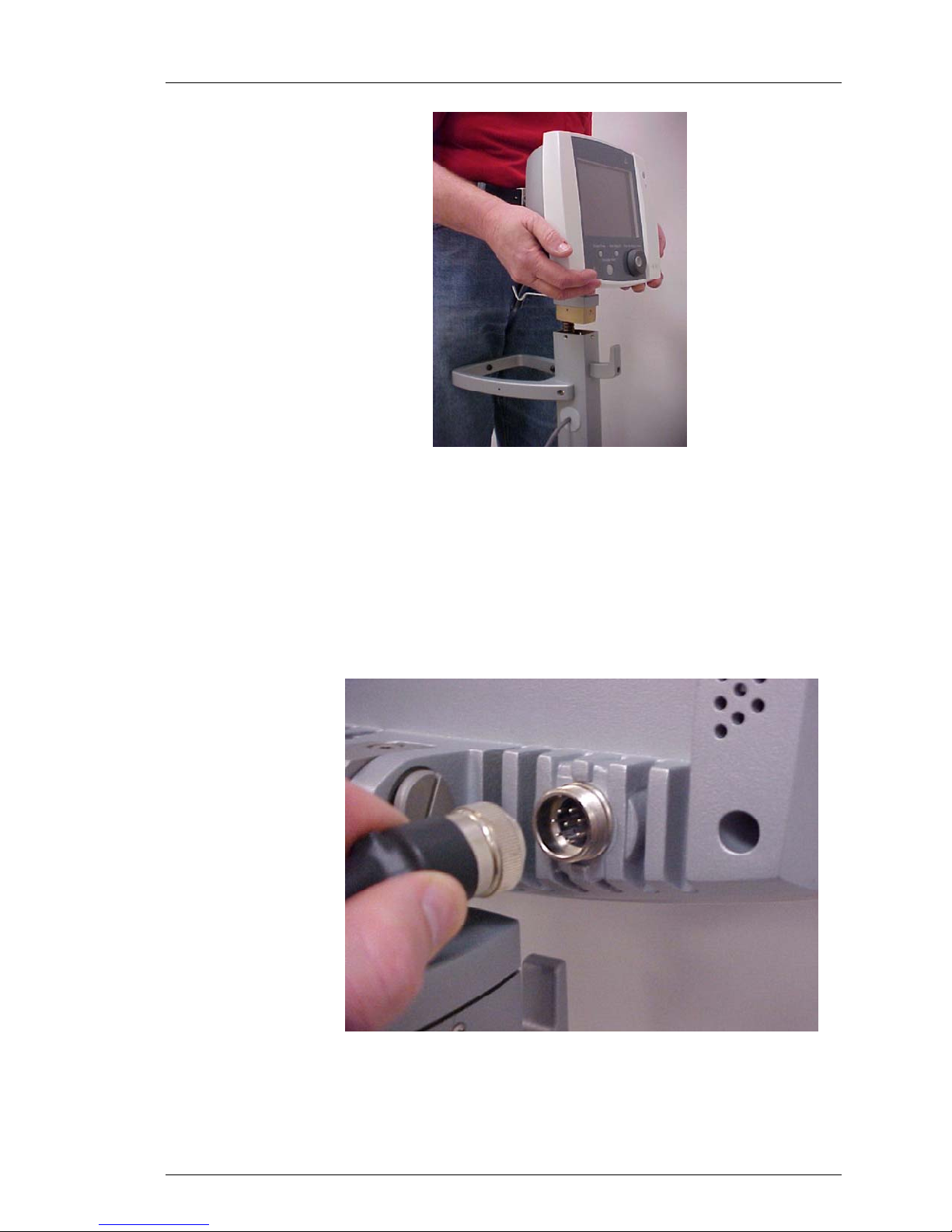

Control Head

3. Carefully remove the control head from its packaging.

4. Attach the control head to the mast. Hold the pivot assembly perfectly

vertical and slide it into the mast opening by applying even, gradual

pressure. The pivot assembly fits into the mast only in one direction.

5

Page 30

Receiving, Inspection & Assembly

600479-001 Rev 2 30/147

Figure 3-4. Attach the Control Head to the Mast.

5. Secure the control head to the mast by installing four screws in the holes

provided at the top of the mast. Use a Phillips screwdriver to tighten the

screws securely.

Control Cable

6. Connect the control cable to the socket on the lower right rear corner of

the control head. Align the plug with the socket and gently push the plug

into the socket until it is seated. Turn the retaining collar approximately

two full turns clockwise to lock the plug in the socket.

6

Figure 3-5. Plug the Control Cable Into the Socket.

Page 31

Receiving, Inspection & Assembly

600479-001 Rev 2 31/147

Power Cord

7. Plug the female end of the power cord into the recessed power inlet

connector. Wrap the power cord around the two cord hooks on the rea r

of the console.

Condensate Pan

8. Remove the condensate pan from its packaging and install it in the slot

under the front of the console (refer to figure 8-1).

Saline Container Insulating Jacket

9. Remove the saline container insulating jacket from its packaging and

hang it on the saline container hook.

Assembly is complete.

7

Page 32

600479-001 Rev 2 32/147

Operation

Operation

1

Page 33

Contents

600479-001 Rev 2 33/147

Overview 5

Operating States in the System 5

SETUP 5

STANDBY 7

RUN - Treatment Modes 8

User Interface 9

System Controls 9

The System Display Screen 10

Changing Target Temperature 11

Changing Treatment Mode 12

System Menu System 14

Hi/Lo Patient Temperature Alarms 16

Bath Pre-set 17

Time and Date 18

ºC/ºF (Temperature Notation) 19

Language 20

STANDBY Timer 20

Operation

System Self Tests 5

Thermometer Functions Self Test 5

Cooling Engine Self Test 6

Sensor Checks 6

Max Power (MAX) 8

Controlled Rate 8

FEVER (FVR) 8

Main Menu 14

Settings Menu 15

Setting the Alarms 16

Nature of the Alarm 16

Pre-Cool 18

Pre-Warm 18

None 18

Exit 18

Time Setting 18

Date Setting 19

T1/T2 Behavior - New 22

2

Page 34

First Use Warning – No T2 Probe 22

600479-001 Rev 2 34/147

T2 Probe Disconnection/Reconnection 23

Accidental Disconnection T1/T2 Probe 23

Alarms & Alerts 24

Alerts 24

Alarms 25

Your First System Case 26

What you need 26

Preparing the System for Treatment 26

Installing the Start-up Kit 32

Hang the Saline Bag 32

The Top Cover 32

The Coldwell 34

The Alsius Start-up Kit 35

The Persitaltic Pump 36

Cover the Coldwell 38

Spike the Saline Bag 38

Prime & Fill the Air Trap 39

Connecting the Patient to the System 42

Operation

Setup - Variations 45

System Setup Sequence 45

Time From Last Power Down 45

Downloading Data After Improper Shutdown 46

Ending Treatment 51

End Procedure 51

Data Download 51

New Patient – No Power Down 54

Change the Start-up Kit 54

Delete Previous Patient Data 54

Disposal of Used Components 54

Temperature Trend Data 57

Overview 57

Displaying the Temperature Trend Graph 57

3

Page 35

Temperature Trend Graph 58

600479-001 Rev 2 35/147

Patient Temperature 58

System Activity 58

Cursor 59

Status Bar 59

Setting the Time Scale 59

Mechanical Components 61

Top Cover 61

Control Head Tilt 62

Casters 63

Operation

4

Page 36

Overview

600479-001 Rev 2 36/147

This chapter explains how to start treatment and change target temperature and

rate settings during treatment. It provides instructions on the proper way to end

treatment, including how to download patient temperature trend data to a laptop

computer and how to remove used components and dispose of them safely.

Subsections at the end of this chapter provide detailed procedures for recovering

from improper shutdowns, including special procedures for downloading patient

temperature trend data.

In this Overview section, we will present the main features of system as they are

presented to the user on the display of the system. This section will help you be

familiar with the features of the System before starting to use it.

After the Overview, you will find sections that describe in detail the operation of

the System - see Operating the System. The sequence of events that you must

pass through in starting the System varies with the way it was last turned off.

Within this section we will review the different patterns of interaction you will

experience. Specifically we will review:

Your first case with the System.

Variations in the SETUP sequence of the System

Ending procedures.

Operation

Operating States in the System

The System has three operating states: SETUP, STANDBY and RUN.

SETUP

When the System is first powered up, it goes through a sequence of self tests. It

tests its own electronics and internal sensors. These tests are called the POST

(Power On Self Test). It is normal to hear two beeps during POST. Then the

System tests its thermometer functions and its cooling engine. The extent of the

testing during SETUP and the interactions required of you by the system both

vary depending upon the state of the system when it was last turned off.

You can pre-set the bath temperature so that the system is either coolingor

warming the bath in SETUP.

Patient temperature alarms are not active in SETUP.

System Self Tests

The System performs self tests both at initial power-on and then hourly during

operation. These tests allow the system to check its own performance.

Thermometer Functions Self Test

The Primary Patient Temperature monitoring circuit (T1) is checked during

SETUP and then hourly against the System internal high resolution calibration

resistor. This is a quick test.

5

Page 37

Operation

600479-001 Rev 2 37/147

Cooling Engine Self Test

During SETUP and then every four hours, during run, the System will

dynamically test its cooling engine. This test will take a few minutes.

Cooling Engine Self Test - The Pump Will Stop

Each hour the System tests its cooling engine dyn amically during RUN. These

tests are brief. The system will stop the pump during these tests to remove the

heat load from the patient during the test.

THE PUMP WILL STOP DURING THIS TEST - THIS IS NORMAL.

During these tests, the peristaltic pump is stopped (to remove the patient’s heat

load from the equation). The tests that are conducted depend upon the state of

the System at the time of the test. The test(s) done is(are) as follows:

Coolant Temperature Heating Test Cooling Test

<10 °C

10 °C - 38 °C

> 38 °C

= will be performed = will not be performed

You will not see any screen messages unless there is an abnormal result in

which case the appropriate alarm state will be called.

Sensor Checks

For the system to enter the next state, STANDBY, the following sensors must be

checked and found normal.

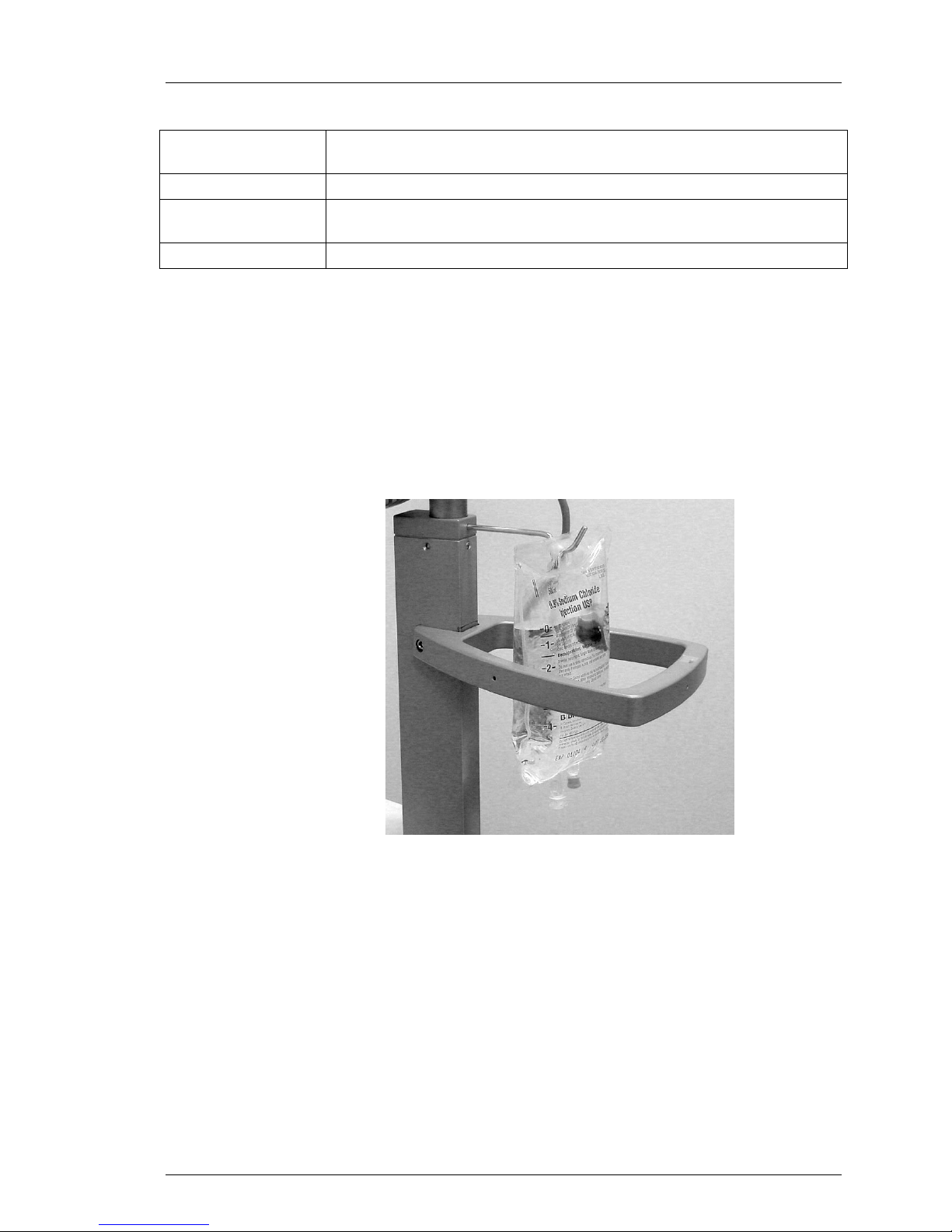

6

Figure 4-1. System Setup Screen

Page 38

Operation

600479-001 Rev 2 38/147

Table 4-1. Setup Sensor Checks

Air Trap There is no Start-up Kit installed or there is a large amount of air in the

Start-up Kit chamber.

Roller Pump Lid The clear plastic roller pump lid is not closed properly.

Check Prime Switch The Prime Switch is being depressed (as when you use it to prime the

system) or has been jammed in the ‘on” position.

Coolant The coolant level is low. Top up the coldwell with coolant.

If any of these sensor states are not correct you will see the “System Setup” and

the problem sensor state will be highlighted in red (see Figure 4-1 above). Once

you rectify the identified problems, the System will progress to STANDBY.

NOTE: Change in Design – Patient Temperature Probes

In earlier versions, the System would not enter STANDBY without at least a

Primary Patient Temperature Probe (T1) connected to the System. For XP

Systems, the System will enter STANDBY without a T1 probe being

connected; however, the System will NOT enter RUN without at least the

Primary Patient Temperature Probe (T1) connected to the System (see below:

T1/T2 Behavior - New).

STANDBY

Figure 4-2. System Operating Display - Standby

In STANDBY you can interact with the full user interface of the System. You can

select the target temperature, the rate and the treatment mode.

Patient temperature alarms are active in STANDBY if the primary patient

temperature probe (T1) is connected.

The coolant bath temperature graph is active in STANDBY (a new feature

compared to earlier versions of the System).

7

Page 39

From STANDBY you may toggle into and out of RUN. You may only return to

600479-001 Rev 2 39/147

SETUP by powering down the system.

RUN - Treatment Modes

Once you are ready to begin treatment, you may move from STANDBY to RUN.

The System will become fully operational provided that all its sensors indicate

that it is ready. Alerts will trigger if it is not.

There are three treatment modes in RUN: “Max Power”, “Controlled Rate” and

“FEVER”.

Max Power (MAX)

In this treatment option, the System seeks to make the patient’s temperature the

same as the selected target temperature. It will keep the peristaltic pump

operating unless the patient’s temperature “inverts”. This occurs whenever:

A. Bath Temperature > Patient Temperature > Target Temperature,

B. Bath Temperature < Patient Temperature < Target Temperature.

Controlled Rate

Operation

OR

In this treatment option, the System will attempt to move the patient’s

temperature to the target temperature at the programmed rate of heat exchange

(°C /hr). When the patient reaches the target temperature, the System will revert

to the MAX treatment option i.e. it will attempt to make the patient’s temperature

the same as the selected target temperature.

NOTE: Controlled Rate

Controlled rate operates in both warming and cooling modes.

FEVER (FVR)

In this treatment option, the System will start cooling the patient once the patient

temperature is above the target temperature. It does this by keeping the bath at

its coldest permissible temperature and then operating the peristaltic pump

whenever the patient’s temperature moves above the target temperature.

WARNING! “Lo” patient temperature alarm limit with “FEVER”

The System will NOT heat the patient when the “FEVER” treatment option has

been selected. The “Lo” patient temperature alarm limit ensures that an alarm

occurs should the patient stop regulating his/her own body temperature. Such

patients will cool to room temperature. This can occur when the patient dies

or becomes comatose.

INVESTIGATE ALL PATIENT TEMPERATURE ALARMS.

8

Page 40

User Interface

600479-001 Rev 2 40/147

The primary controls for the System are mounted in the display head of the

system. The next sections describe:

The controls available to the user

The System display screen

The System menu system available to the user.

System Controls

1. Display Screen

2. Alarm Indicator LED.

3. Mute Button

4. Power On Indicator LED.

5. Target Temp Button.

6. Standby / Run Button.

7. Rate Deg / HR Button.

8. Press for Menu / Enter

Knob

Operation

The use of each of the controls is described in the table below.

Power Indicator Glows green when the display has power.

System Alarm Indicator Flashes red during alarm states

Standby/Run button Toggles between RUN and STANDBY

Target Temperature button Press this to change the target temperature

Rate Deg/Hr button Press this to change the rate and/or treatment mode.

“Press & Rotate” knob This knob operates the menus on the System display.

9

Figure 4-3. Controls and Display.

Table 4-2. System Controls

Rotate the knob to scroll between selections. Press and

release the knob to select.

Page 41

The System Display Screen

600479-001 Rev 2 41/147

The System features a color display screen. The figure below shows the screen

as it appears during RUN.

Operation

Figure 4-4. Operating Screen.

The upper left hand of the screen displays:

The patient temperature

The “Lo” and “Hi” patient temperature alarm values.

The lower left hand of the screen displays:

The programmed Target Temperature for the System

The programmed treatment mode/controlled rate value

The right hand side of the screen is used either:

To display the temperature of the coolant in the System coldwell (as

depicted above), or,

To present menu selections. The main menu of the System is

presented in the figure below.

10

Page 42

Figure 4-5. System Main Menu

600479-001 Rev 2 42/147

Operation

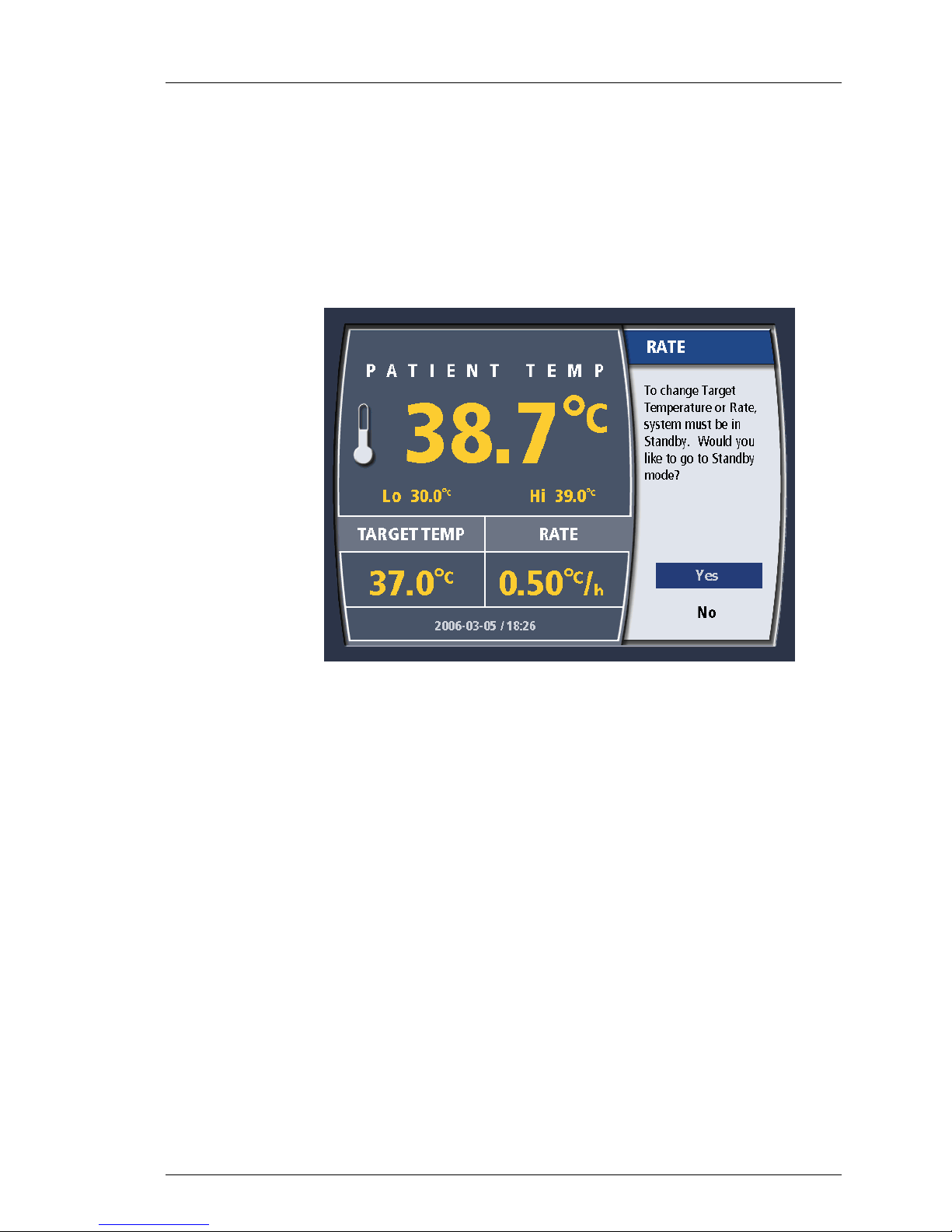

Changing Target Temperature

1. Press the Target Temp button once. If you are in RUN, you will be taken

to STANDBY. The Target Temperature value may only be changed in

STANDBY.

2. To change the target temperature, turn the knob until the desired

11

Figure 4-6. Change Target Temperature in RUN

temperature is displayed. You may choose a temperature from 31º C to

38º C (87.8º F to 100.4º F). When the correct selection is displayed,

press the knob once to enter the selection.

Page 43

3. The target temperature setting is updated on the Operating screen.

600479-001 Rev 2 43/147

Changing Treatment Mode

As explained above, there are three treatment modes: “MAX”, “Controlled

Rate” and “FEVER”. To select the Treatment Mode, including one particular

value of “Controlled Rate” you use the “Rate Deg/Hr” button.

1. Press the “Rate Deg/Hr”r button once. If you are in RUN, you will be

taken to STANDBY. The Treatment Mode value may only be changed in

STANDBY.

Operation

Figure 4-7. Change Rate/Mode Temperature in RUN

2. Turn the knob until the desired Treatment Mode selection is displayed.

When the correct selection is displayed, press the knob once to enter the

selection.

12

Page 44

Operation

600479-001 Rev 2 44/147

Figure 4-8. Select Mode

3. If you select Controlled Rate, a second menu screen will be presented.

To change the controlled cooling/rewarming rate, turn the knob until the

desired selection is displayed. You may choose a rate from 0.10º C/hr to

0.65º C/hr. When the correct selection is displayed, press the knob once

to enter the selection.

4. If you have selected FEVER Mode, you will be asked to confirm your

13

Figure 4-9. Select Controlled Rate

selection with the reminder that FEVER Mode only cools and does not

warm as per the figure below.

Page 45

Operation

600479-001 Rev 2 45/147

Figure 4-10. FEVER Mode Confirmation message

5. The Operating screen will be updated to reflect your selection.

NOTE: Target Temperature in FEVER Mode

The System keeps the bath cold and starts the peristaltic pump when the

patient temperature is greater than the target temperature

System Menu System

Main Menu

The main menu of the System is displayed in Figure 4-5 above. To call up the

main menu, press the knob from the operating screen. Some settings are

accessible only in Standby Mode.

The options available to you are as follows:

Table 4-3. System Main Menu

View Graphs

New Patient

End procedure

Settings

Exit menu

Takes you to a display of the patient temperature data log. See:

Temperature Trend Data

Indicates to the System that you are starting a new patient case.

Downloading or deleteing the existing patient data log is required

Indicates to the System that you are finishing a patient case. You will be

prompted to save the existing patient data log. See: Ending Treatment

Takes you to the Settings menu. See below

Returns you to the operating display. The bath temperature meter display

will replace the menu.

14

Page 46

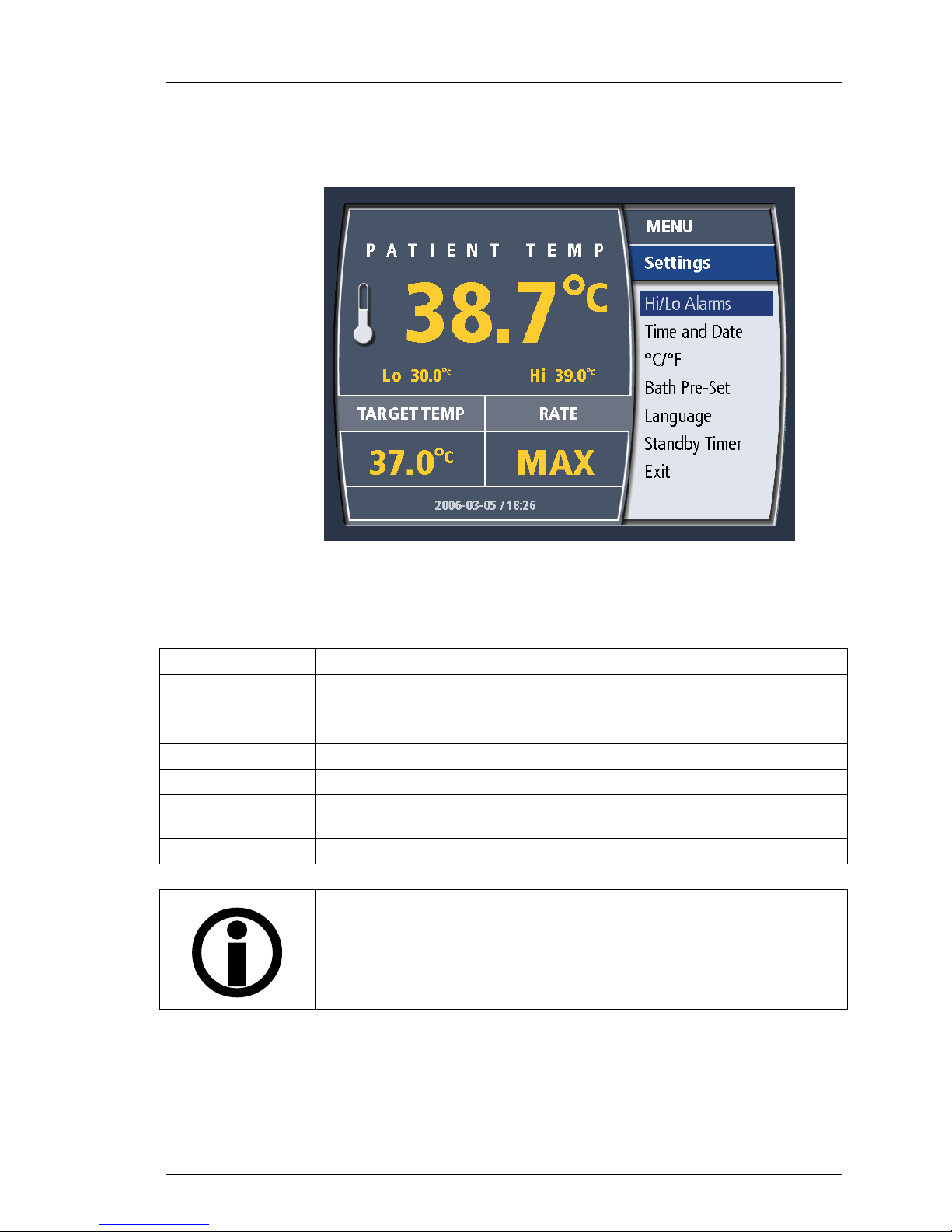

Settings Menu

600479-001 Rev 2 46/147

The settings menu allows you to modify the information displayed on the

operating display. It appears as in Figure 4-11.

Operation

The options offered by the settings menu are listed and described below.

Hi/Lo Alarms

Time and Date

°C / °F

Bath Pre-Set

Language

Standby Timer

Exit

Figure 4-11. System Settings Menu

Table 4-4. System Settings Menu

Allows you to modify the low (Lo) and high (Hi) patient temperature alarms.

Allows you to modify the System time and date.

Allows you to toggle between displaying temperatures in degrees Celsius

or degrees Farhenheit.

Allows you to set the system to either HEAT or COOL during STANDBY.

Allows you to select the display language.

Provides you with a warning alarm after the system has been in STANDBY

for either 15 or 60 minutes. This alarm can be deactivated.

Returns to the operating display.

NOTE:

There is no Pump Rate Selection in ZOLL XP systems.

ZOLL has validated that the Cool Line catheter can be safely used at a

pump rate of 240 ml/min.

15

Page 47

Hi/Lo Patient Temperature Alarms

600479-001 Rev 2 47/147

The System features two patient temperature alarms: “Hi” and “Lo”. If the alarms

are set, the System will alarm whenever the patient’s temperature is higher than

the “Hi” Patient Temperature Alarm value and whenever the patient’s

temperature is lower than the “Lo” Patient Temperature Alarm value. The range

of values for both alarms is 28 ºC – 45 ºC (82.4 ºF – 113.0 ºF).

Setting the Alarms

The alarm values are set as follows in either STANDBY or RUN mode. Set the

“Lo” and “Hi” Patient Temperature Alarms to appropriate values.

1. Press the knob and the Main Menu will appear.

2. Select the “Settings” option and press the knob.

3. Select the “Hi/Lo Alarms” option.

4. The “Lo” Alarm value will be presented. Turn the knob until the desired

value is displayed and press the knob.

5. The “Hi” Alarm value will be presented. Turn the knob until the desired

value is displayed and press the knob.

Nature of the Alarm

Operation

The alarms are both visual and audible. The alarms will not clear until the

patient’s temperature no longer triggers the alarm state.

The audible alarm may be temporarily muted for 2 minutes by pressing the Mute

button. The alarm will continue after that time unless it has cleared.

The visual alarm is effected by writing the patient temperature area on the screen

in RED text and flashing the text. The visual alarm will not stop until the alarm

has cleared.

16

Figure 4-12. “Hi” Patient Temperature Alarm

Page 48

WARNING! Change to Initial Specification of System.

600479-001 Rev 2 48/147

In the initial release of the System there were no settable patient temperature

alarms. There were fixed high and low patient temperature alarms. These

fixed alarms have been made programmable.

The patient temperature alarms MAY NOT be deactived. They may be muted

for a 2 minute period.

NOTE: Patient Temperature Alarms in STANDBY

If the System is in STANDBY and the T1 temperature probe is connected to

the System but NOT inserted into the patient you will experience “Lo” patient

temperature alarms if the ambient temperature of the exposed probe is below

the alarm limit. To avoid the annoyance of the alarm under these conditions,

simply unplug the T1 temperature probe from the System until you are ready to

connect to the patient. You may not enter RUN without the probe connected

to the System.

Bath Pre-set

Operation

The menu allows the user to select from either: Pre-Cool, Pre-Warm or None.

This selection operates only in STANDBY and is cancelled when the system

enters RUN.

Figure 4-13. Bath Pre-Set Menu

17

Page 49

Operation

600479-001 Rev 2 49/147

Pre-Cool

Pre-Warm

None

The System bath is cooled to its lowest permitted temperature and maintained

at that temperature.

The System bath is heated to its highest possible temperature and maintained

at that temperature.

The Bath Pre-set is not activated or is cancelled. If cancelled, the bath is

maintained at the temperature that was measured at the time of cancellation.

Exits the menu without a change in System status or programming.

Exit

Time and Date

This menu displays the current time and date settings.

Figure 4-14. Time and Date Settings.

The time is divided into two fields: hours (designated “HH”) and minutes (“MM”).

The System uses only 24-hour time notation (e.g., 3:00 p.m. is 15:00).

The date is divided into three fields: year (designated “YYYY”) - month

(designated “MM”) - day (designated “DD”). For example, the 24

would be shown as: 1959-02-24.

th

February, 1959

Time Setting

1. The screen first displays the message “Select Hour. Press Enter to set.”

2. The numbers displayed in the hour field will change as you turn the knob.

When the correct hour is displayed, press the knob once to enter your

selection.

3. The screen next displays the message “Select Minute. Press Enter to

set.”

4. Turn the knob until the correct minute is displayed. Press the knob once

to enter your selection.

18

Page 50

Date Setting

600479-001 Rev 2 50/147

1. The screen displays the message “Select Day. Press Enter to set.”

2. The numbers displayed in the day field will change as you turn the knob.

When the correct day is displayed in the field, press the knob once to

enter your selection.

3. The screen next displays the message “Select Month. Press Enter to

set.”

4. Turn the knob until the correct month is displayed. Press the knob once

to enter your selection.

5. The screen next displays the message “Select Year. Press Enter to set.”

6. Turn the knob until the correct year is displayed. Press the knob once to

enter your selection.

7. The time and date settings will be updated and the screen will display the

settings menu.

ºC/ºF (Temperature Notation)

This menu displays the options setting for temperature notation. The currently

selected setting is highlighted.

Operation

To keep the current selection, press the knob once. The current setting will not

be changed and the settings menu will be displayed.

To change the current setting, turn the knob to highlight the desired setting.

Press the knob once to enter the selection. The setting will be changed and the

settings menu will be displayed.

19

Figure 4-15. Temperature Notation Settings.

Page 51

Language

600479-001 Rev 2 51/147

Operation

NOTE: Change in Design – Pump Rate

In earlier versions of the System, there was the option to set the pump rate to

either 200 or 240 ml/min. ALL Alsius catheters have been validated to

operate safely at a pump rate of 240 ml/min. This control is not longer

presented to the operator.

NOTE: Change in Design - Alarm Volume & Key Press

Volume

In earlier versions of the System, there was the option to set the alarm volume

and the key press volume. In this version:

1. The Alarm Volume is always set to High

2. The Key Press Volume is always set to Medium

This menu displays the current setting for the language used for displayed text.

The currently selected setting is highlighted.

To keep the current selection, press the knob once. The current setting will not

be changed and the settings menu will be displayed.

To change the current setting, turn the knob to highlight the desired setting.

Press the knob once to enter the selection. The setting will be changed and the

settings menu will be displayed.

STANDBY Timer

The STANDBY Timer provides the User with an alarm as a reminder when the

System has been left in STANDBY for 15 or 60 minutes. The STANDBY Timer

20

Figure 4-16. Language Settings.

Page 52

Operation

600479-001 Rev 2 52/147

presents the User with the opportunity to select from the following values: No

Alarm, 15 minutes, 60 minutes.

Figure 4-17. STANDBY Timer Menu

If the system has been left in STANDBY for more than the specified time, an

alarm will sound to remind the User that the System remains in STANDBY.

Pressing the knob will reset the timer. The Standby Timer function will continue

until either:

The System is placed into RUN.

The STANDBY Timer Menu is used to deactivate the STANDBY

Timer.

The STANDBY Timer alert may be silenced for two (2) minutes by pressing the

mute button.

21

Figure 4-18. STANDBY Timer Alert

Page 53

T1/T2 Behavior - New

600479-001 Rev 2 53/147

XP Systems differ from earlier ZOLL Heat Exchange Systems in their T1/T2

behavior i.e. in how the Primary and Secondary Temperature probes are

monitored and alarmed.

WARNING! Dislodged Foley Catheter Temperature Probe

The System can detect when a patient temperature probe is dislodged

suddently from the patient.

However it is possible for the Foley catheter patient temperature probe (T1) to

become dislodged from the bladder to rest on the perineum or within the fold of

the thighs. In such a position the System may not detect the dislodgement

from the patient and will underestimate the patient’s core temperature. As a

result the System may inappropriately heat the patient.

Failure to use a second temperature probe may result in patient injury.

First Use Warning – No T2 Probe

For each time the System is powered on:

1. The System will check to see if the Primary (T1) and Secondary (T2)

Temperature Probes are present. The System will enter STANDBY

without probes being present. The System will not enter RUN unless the

T1 probe is present.

2. When the System is first put into RUN, it will check to see which probes

are present.

3. If there is no T2 present, the System will ask the User to verify that this is

intentional. See image below.

Operation

The System remembers the User’s preference.

22

Figure 4-19. No T2 Probe Connected

Page 54

T2 Probe Disconnection/Reconnection

600479-001 Rev 2 54/147

If the User connects a T2 probe at any time during the operation of the System

(in STANDBY or RUN), the System will assume that the use of the T2 probe is

desired. If the T2 probe is then disconnected the System will alarm – see below.

If the User disconnects a T2 Probe in STANDBY, the System will NOT assume

that this is intentional. When the System is placed into RUN WITHOUT a T2

Probe present, the User will again see the Warning as described above.

Accidental Disconnection T1/T2 Probe

Disconnection of the T1 probe during RUN results in

an Alarm. Press the knob to silence the alarm. The

System moves to STANDBY. Treatment cannot

continue until the T1 probe has been replaced..

Note that the patient temperature is displayed as

“---“ and the yellow warning banner covers the bath

temperature display.

Operation

Absence or disconnection of the T1 probe during

STANDBY results in a warning display WITHOUT a

persistent audible alarm. The system CANNOT

enter RUN until a T1 probe has been connected.

Note that the patient temperature is displayed as

“---“ and the yellow warning banner DOES NOT

cover the bath temperature display.

Disconnection of the T2 probe during RUN results in

an Alarm. Press the knob to silence the alarm. The

System moves to STANDBY. If you attempt to

return to RUN without reconnecting the T2 probe,

you will be asked to verify your intention.

Note that the patient temperature will be displayed

correctly if the T1 probe remains connected. The

yellow warning banner covers the bath temperature

display.

23

Page 55

Alarms & Alerts

600479-001 Rev 2 55/147

A detailed description of the alarms of the System is provided in later sections of

this manual. See:

Section 6. Alarms and Corrective Actions

Section 7. Troubleshooting

Alerts

Alerts can be cleared by reverting the state that caused them to occur. For

example, a low coolant alert can be cleared by adding coolant to the coldwell of

the System. In most cases, the System will identify and notify you to rectify alert

states at power up.

In STANDBY, Alerts are displayed across the lower half of the display screen,

with the bath temperature display not obscured, against a yellow background

(See Figure 4-20 – Right). Alerts in STANDBY are generally NOT accompanied

by an audible alarm tone.

Operation

Figure 4-20. T1 Disconnect alerts in RUN (left) and STANDBY (right)

In RUN, Alerts are displayed across the full lower half of the display screen

against a yellow background with the bath temperature display is partially

obscured (See Figure 4-20 – Left). If an alert occurs in RUN, the System will

generally revert to STANDBY and an audible alarm tone will sound. The

exception to this is that if you depress the prime switch during run – no audible

alarm will sound and the bath temperature display will not be obscured.

In both STANDBY and RUN, a message on the screen will indicate the action

required to clear the alert.

During an alert, the patient temperature display is still visible and the patient

temperature alarms are still active if the T1 Temperature probe is functional.

NOTE: In the Event of an Alert

Investigate and rectify the cause - refer to:

Section 6. Alarms and Corrective Actions

Section 7. Troubleshooting

If the alert persists, call ZOLL for service.

24

Page 56

Alarms

600479-001 Rev 2 56/147

Operation

An alarm is more serious in nature than an alert and relates to an issues that will

typically require a service call. In most cases a text message, specific to the

alarm, identifies the system code for the alarm. For example, the screen might

announce “TCM ID 01” or “MID 23” in addition to the text in the figure below.

Figure 4-21. Alarm Screen

In some cases, however, the alarm may be cleared by power cycling the system.

For example, such an alarm would occur if the pump tubing were to become

jammed in the peristaltic pump causing the pump to slow down.

If the reason for the alarm is not cleared by power cycling, the alarm will repeat

each time the System is turned back on.

During an alarm, the patient temperature display and the patient temperature

alarms are NOT active.

NOTE: In the Event of an Alarm

Investigate and troubleshoot the cause - refer to:

Section 6. Alarms and Corrective Actions

Section 7. Troubleshooting

Power cycle the System.

If the alarm persists, call ZOLL for service.

25

Page 57

Your First System Case

600479-001 Rev 2 57/147

What you need

You will need the following for each System case:

A new ALSIUS Startup Kit

A new 500ml bag of normal saline.

A YSI-400 compatable temperature probe e.g. a Foley catheter,

rectal or esophageal temperature probe

The blue patient connection cable to connect the temperature probe

to the System

An Alsius heat exchange catheter

An aseptic work area to support catheter insertion.

CAUTION! REFER TO THE CATHETER IFU

Alsius heat exchange catheters are inserted via a Seldinger technique a s a

central venous line. There are specific instructions for use included with each

catheter. Refer to these to understand the specific unique insertion

requirements of an Alsius heat exchange catheter.

Operation

Preparing the System for Treatment

To prepare the System for treatment, follow these steps in the indicated order.

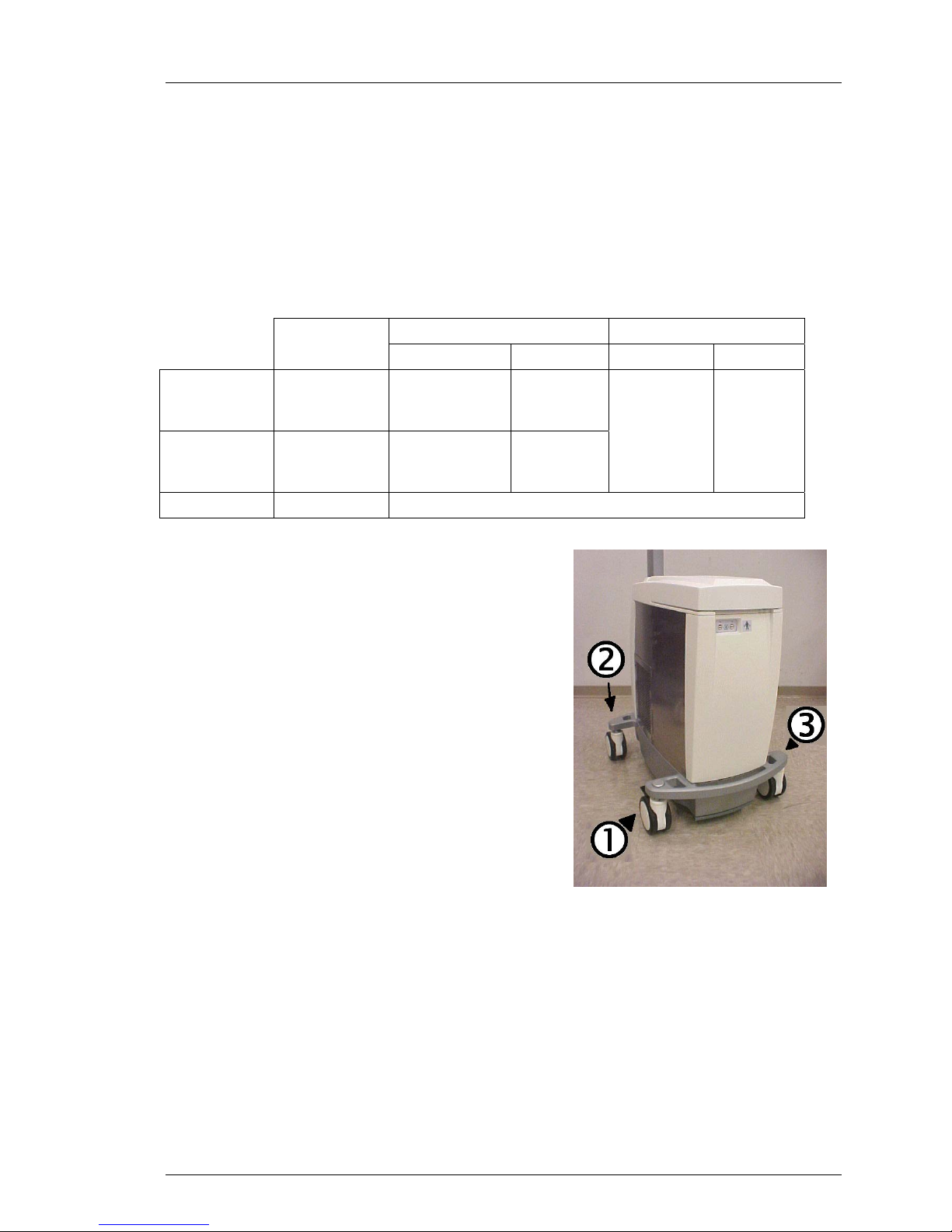

1. Roll the System to a convenient position near the patient’s bedside. Plug

the power cord into a hospital-grade receptacle.

2. Lock the right front caster by stepping down on the tab above the wheel.

3. At the rear of the console, near the upper left corner is the power on/off

switch. Turn the switch ON.

Figure 4-22. Power Switch and Power Indicator Lamp.

4. The green power indicator lamp will be illuminated and the alarm will

beep one long beep followed by a shorter softer beep.

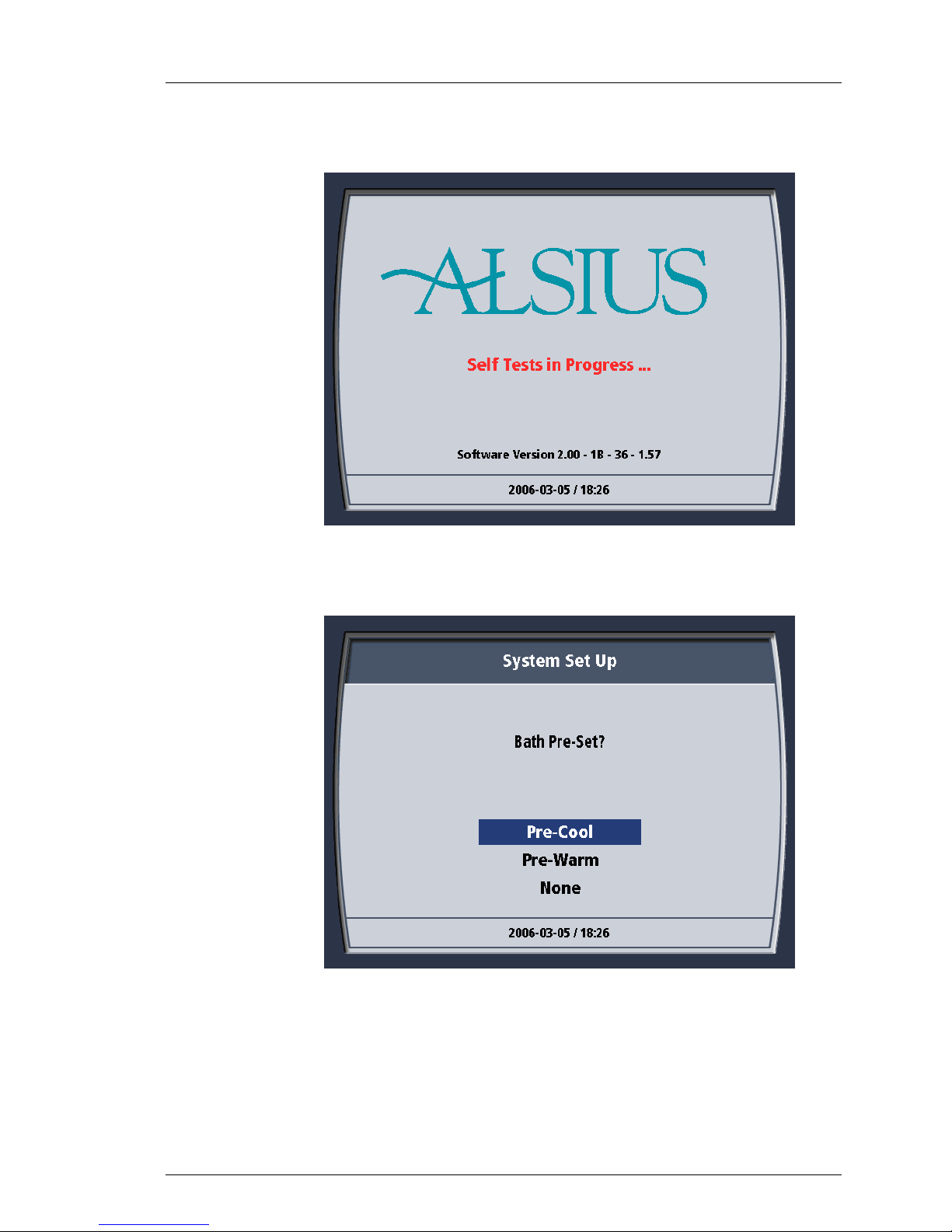

5. The System performs a self-test. During this interval, the self-test screen

appears on the display. If the self-test detects a problem, an error

26

Page 58

Operation

600479-001 Rev 2 58/147

message will be displayed. If this occurs, refer to Chapter 6–Alarms and

Corrective Actions for assistance. At the end of the self-test there will be

two short beeps.

Figure 4-23. Self-Test Screen.

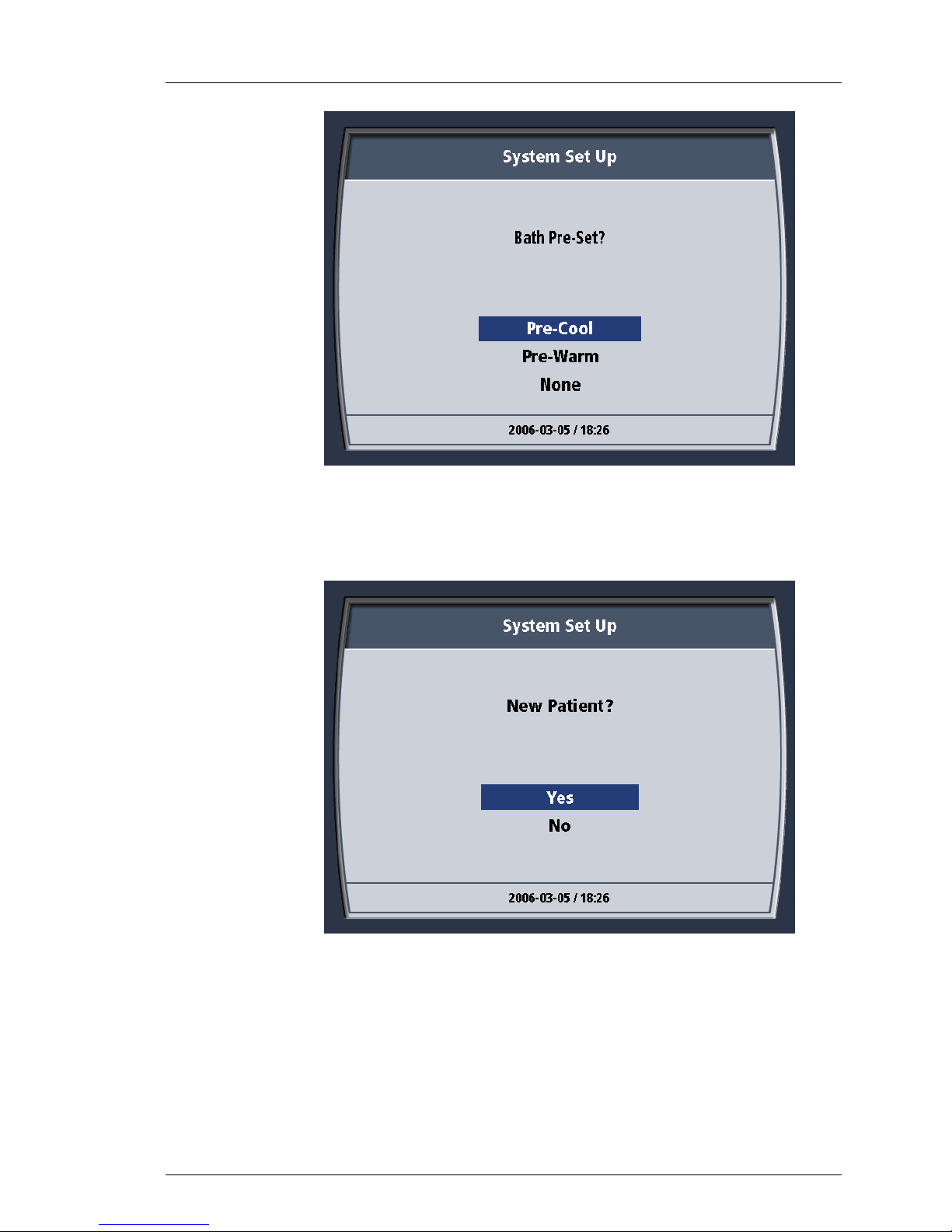

6. When the self-test is finished, the System Set Up screen displays the

message “Bath Pre-Set?”

Figure 4-24. System Pre-Cool?

7. To start cooling or heating the coolant reservoir immediately, choose the

27

desired option and press the “Press for Menu/Enter” knob (the “knob”)

once to enter the selection. If you do not wish to begin cooling or

warming the coolant reservoir now, choose “None” and press the knob

once to enter the selection.

Page 59

Operation

600479-001 Rev 2 59/147

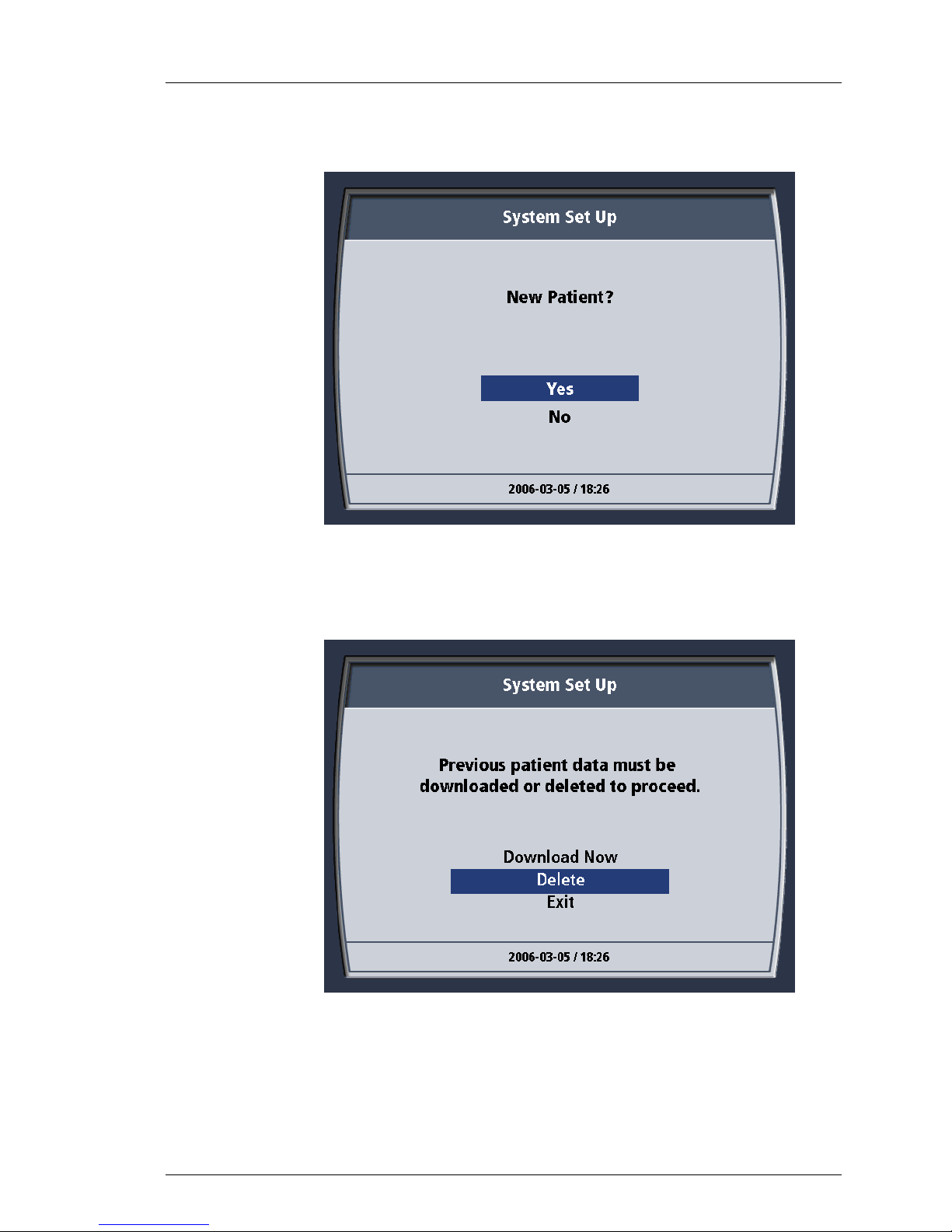

8. You may be asked questions relating to the downloading of patient data.

This is a new patient. Delete any old data left from the inservice you

received.

Figure 4-25. New Patient? Message.

9. Choose “Yes.”

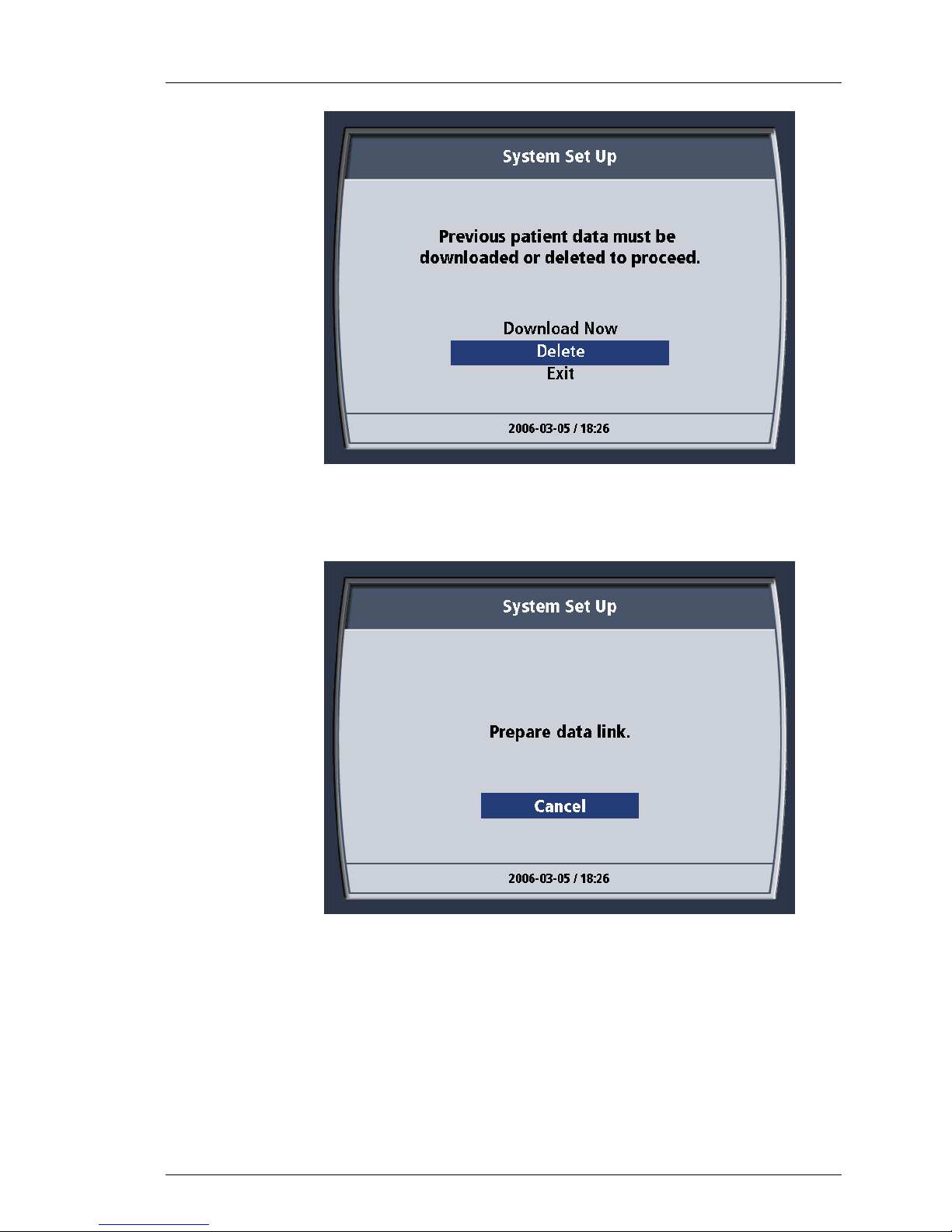

10. The screen displays the message “Previous patient data must be

downloaded or deleted to proceed.”

11. Choose “Delete”. You will be asked to confirm your choice to delete the

28

Figure 4-26. Patient Data Message.

data file. Choose “Yes”. A brief confirmation message will appear and

then automatically close. See below.

Page 60

Operation

600479-001 Rev 2 60/147

Figure 4-27. Delete Previous Patient Data

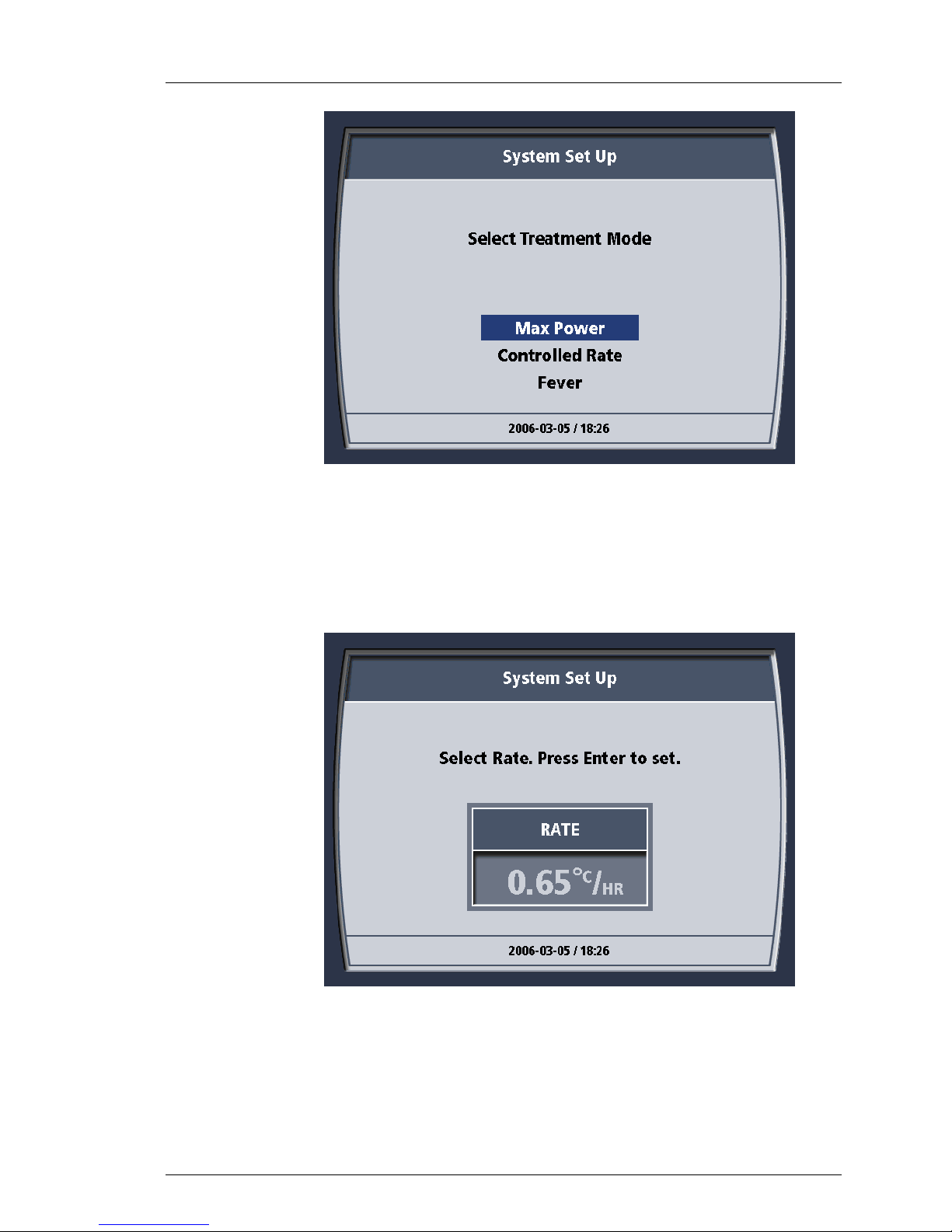

12. The System Set Up screen then displays the message “Select Target

Temp.”

13. Turn the knob until the target patient temperature is displayed. When the

14. The System Set Up screen displays the message “Select Treatment

29

Figure 4-28. Select Target Temp Message.

desired value is displayed, press the knob once to enter the selection.

Mode” Note that you have three choices: “Max Power”, “Controlled

Rate” or “FEVER”.

Page 61

Operation

600479-001 Rev 2 61/147

Figure 4-29. Select Treatment Mode Message.

15. Turn the knob to highlight the desired mode. Press the knob once to

enter the selection. Controlled rate should not be selected when using

the Cool Line catheter.

16. If you select “Controlled Rate” for the Treatment Mode, you will be

prompted to “Select Rate. Press Enter to Set”. Use the knob to scroll

through to the desired rate and then press the knob to select it.

17. If the System has not yet finished its self tests, the Self-Test screen is

30

Figure 4-30. Select Rate Screen

displayed.

Page 62

Operation

600479-001 Rev 2 62/147

Figure 4-31. Self-Test Screen.

18. Install the Start-up Kit now. If the system finishes its self test before you

complete installing the Start-up Kit, you will see the following Check

Screen. An item in RED requires your attention.

31

Figure 4-32. Check the Following Screen.

Page 63

Operation

600479-001 Rev 2 63/147

Setup Sensor Checks

Air Trap There is no Start-up Kit installed or there is a large amount of air in the

Start-up Kit chamber.

Roller Pump Lid The clear plastic roller pump lid is not closed properly.

Check Prime Switch The Prime Switch is being depressed (as when you use it to prime the

system) or has been jammed in the ‘on” position.

Coolant The coolant level is low. Top up the coldwell with coolant.

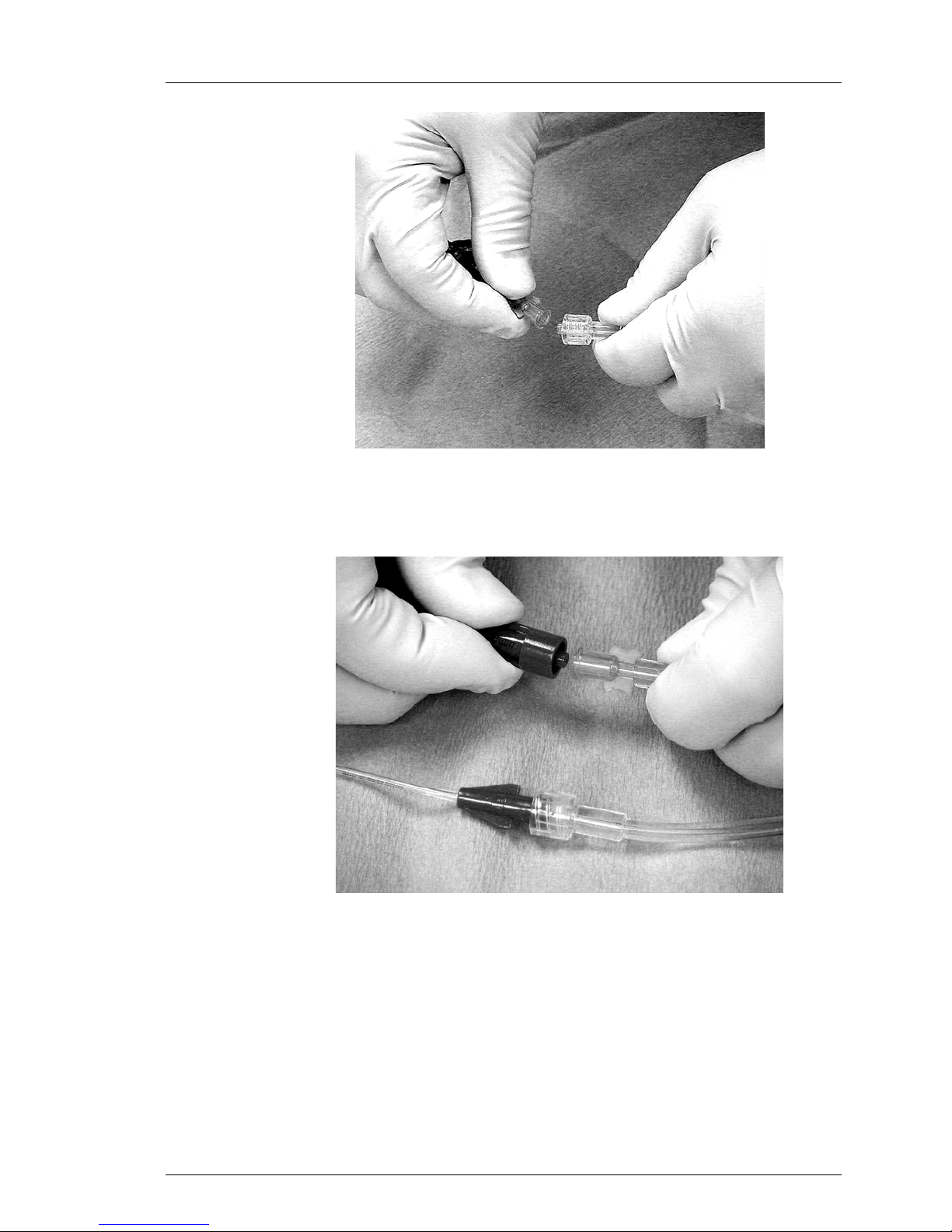

Installing the Start-up Kit

Hang the Saline Bag

To install the System Start-up Kit, follow these steps in the indicated order.

1. Obtain an IV bag or bottle of sterile normal saline solution. The bag or

bottle must contain no more than 0.5 liter (500 ml) of solution. Hang the

saline container on the hook mounted on the rear of the display post.

The container hangs inside the circumference of the handle.

The Top Cover

2. Open the top cover of the System. Open the transparent top cover of the

32

Figure 4-33. 500ml Saline Bag on Hook.

roller pump.

Page 64

Operation

600479-001 Rev 2 64/147

Figure 4-34. Covers Open.

3. A tubing circuit diagram is printed on the inside of the System top cover.

Refer to this diagram when installing the Start-up Kit.

33

Figure 4-35. Tubing Circuit Diagram.

Page 65

Operation

600479-001 Rev 2 65/147

The Coldwell

4. Remove the cap from the coolant well and set it aside in a clean location.

Figure 4-36. Coolant Well Cap.

5. Check the level of the coolant. The liquid level should be between the

two indicator lines on the wall of the coolant well. If the level is below the

bottom indicator line, add distilled water until the liquid is at the top

indicator line. If the coolant level is unusually low because of spillage,

add premixed propylene glycol and water until the liquid is at the top

indicator line.

34

Figure 4-37. Coolant Well Liquid Level Indicator Lines.

Page 66

Operation

600479-001 Rev 2 66/147

The Alsius Start-up Kit

6. Open the System Start-up Kit. For convenience and sterility, all items in

the kit are preconnected.

Figure 4-38. System Start-up Kit.

7. Insert the heat exchanger coil into the coolant well.

Figure 4-39. Installing the Heat Exchanger Coil.

8. Temporarily slide the air trap into the holder.

35

Page 67

Figure 4-40. Air Trap Placed In Holder.

600479-001 Rev 2 67/147

The Persitaltic Pump

Operation

WARNING! FINGER INJURIES

Be careful when inserting the pump tubing that you do not catch your fingers

with the roller.

When the System is operating DO NOT attempt to circumvent the safety

interlocks on the peristaltic pump lid. DO NOT place fingers or foreign objects

into the pump raceway when the pump is turning. The peristaltic pump has

sufficient torque to severely damage a finger.

9. Locate the pump tubing and route it to the right side of the roller pump.

Do not stretch or pull on the tubing. The tubing lengths and flanged

connector allow the tubing to fit into the pump in only one direction.

10. Lift the handle on the pump rollers.

36

Page 68

Operation

600479-001 Rev 2 68/147

Figure 4-41. Lift the Pump Rollers Handle.

11. Place the flanged connector of the pump tubing into the slot on the right

side of the pump head.

1. Place flanged connector

into socket on right hand

side of pump raceway.

Figure 4-42. Flanged Connector Fits Into Recess.

12. Load the pump tubing around the rollers and into the channel of the

pump head. You must turn the handle counterclockwise as you feed the

tubing into the channel. Press down firmly on the tubing until it settles

into the bottom of the channel. Once the tubing is installed, press the

handle down onto the rollers until it presses into its detent.

37

Page 69

Figure 4-43. Pump Tubing Installation.

600479-001 Rev 2 69/147

13. Close the top cover on the pump. It will snap shut.

Operation

Cover the Coldwell

14. Replace the cap on the coolant well. Position the cap so that the heat

exchanger coil and tubing fits into the notch. Press down on the cap to

create a tight seal.

Figure 4-44. Replace the Cap on the Coolant Well.

Spike the Saline Bag

15. Using aseptic technique, connect the priming line to the sterile saline

38

container. The priming line is equipped with a “spike” connector. Hang

the saline container on the hook provided.

Page 70

600479-001 Rev 2 70/147

Figure 4-45. Making a Sterile Connection to the Saline Container.

CAUTION! START-UP KIT SPIKE

Operation

The spike on the Start-up Kit is relatively long. Be careful not to puncture the

side wall of the saline bag when connecting to the Start-up Kit.

Prime & Fill the Air Trap

16. Remove the air trap from its holder and hold it upside down (with the