Zoll Base Powercharger Service manual

ZOLL Base Powercharger

Service Manual

4x4

9650-0072-01 Rev. E

GENERAL INFORMATION

SECTION I

GENERAL INFORMATION

TABLE OF CONTENTS

DESCRIPTION SECTION

I. General Information

• Table of Contents .............................................................................I-1

• Safety Considerations ...................................................................... I-3

• How to Use This Manual .................................................................. I-5

• Symbols used on the Equipment......................................................I-7

• Service Policy ................................................................................... I-8

II. Checkout Procedures

• Leakage Current Test...................................................................... II-2

• Functional Tests ..............................................................................II-2

• Manual Test ..................................................................................... II-3

• Checkout Procedure........................................................................II-4

III. Troubleshooting Guides

• TroubleShooting Table ................................................................... III-2

• Fault Codes Table .......................................................................... III-3

• Definition of Fault Code..................................................................III-4

IV. Functional Descriptions

• System........................................................................................... IV-2

• Common Circuitry Description....................................................... IV-3

• Bay Circuitry Description ............................................................... IV-5

• LED PCB ..................................................................................... IV-12

V. Schematic Drawings

• Display / Keyboard. ........................................................................ V-3

• System............................................................................................ V-4

VI. Component Layout Drawings

• LED................................................................................................ VI-3

• System .......................................................................................... VI-4

I-1

VII. Disassembly Procedures

• Removing the Base Pan................................................................ VI-3

• Removing the Main PCB Assembly ............................................. VI-5

• Removing the Heat Sink................................................................ VI-7

• Removing the Transformer............................................................ VI-9

• Removing the Power Entry Module............................................. VI-12

• Removing the Battery Harness and Contact Pins....................... VI-14

VIII. Replacement Parts

• Field Replaceable Units .............................................................. VIII-2

APPENDIX A OPERATOR'S MANUAL

GENERAL INFORMATION

I-2

GENERAL INFORMATION

SAFETY CONSIDERATIONS

WARNINGS

General

• The following is a list of service related safety considerations. For

operation related safety considerations see the Base

PowerCharger

aware of all safety considerations prior to servicing the equipment.

• THE BASE POWERCHARGER

SERVICED BY QUALIFIED PERSONNEL ONLY! Unauthorized

persons should not attempt to service this device.

• The Base PowerCharger

radio frequency emissions typical of two-way radios used in

emergency service/public safety activities. Users of the Base

PowerCharger

environment of use for the possibility of radio frequency interference

from high-power sources.

4x4

Operator's Guide. Service Technicians should be

4x4

DEVICE SHOULD BE

4x4

is protected against interference from

4x4

should assess the devices’ performance in their

• Use only the AC power line cord supplied with the device. Failure to

use the proper line cord could result in excess leakage currents and

reduced safety.

• Only Qualified Personnel should disassemble the PowerCharger

4x4

.

A shock hazard exists. Refer all problems to ZOLL Technical

Service.

• Follow all recommended maintenance instructions. If a problem

occurs, obtain service immediately. Do not use the Base

PowerCharger

4x4

until the unit has been inspected by the appropriate

personnel.

• Do not place anything on top of the Base PowerCharger

4x4

. Doing so

may block the vents on the unit, preventing proper dissipation of heat

during operation.

• Do not sterilize the Base PowerCharger

4x4

.

• Do not use alcohol or ketones (MEK, acetone, etc.) on the Base

PowerCharger

• Always wait until the Base PowerCharger

4x4

.

4x4

has completed its

charge cycle before removing batteries.

• Repeated use of partially charged batteries will reduce their capacity

and operating life.

I-3

Operator Safety

GENERAL INFORMATION

• Do not operate the Base PowerCharger

4x4

in the presence of

flammable agents (such as gasoline), oxygen-rich atmospheres, or

flammable anesthetics. Using the device near the site of a gasoline

spill may cause an explosion.

• Do not immerse or set the Base PowerCharger

4x4

in fluid. Using the

device near or within puddles of water is a shock hazard to the

operator, patient, and nearby personnel.

Patient Safety

• Do not mount the device directly above the patient. Locate the Base

PowerCharger

harm the patient if they fall.

4x4

and ZOLL resuscitation devices where they cannot

Caution

• Do not discharge a PD 4410 battery pack except in a Base

PowerCharger

device.

• Safety and effectiveness data submitted to the Food and Drug

Administration (FDA) under section 510(K) of the Medical Device Act

by ZOLL Medical Corporation to obtain approval to market is based

upon the use of ZOLL accessories such as disposable electrodes,

patient cables and batteries. ZOLL cannot make representations as

to safety and clinical effectiveness when a device is used with nonZOLL accessories. Users assume all responsibility for the safety and

effectiveness of ZOLL products if used with non-ZOLL accessories.

Further, ZOLL disclaims all implied and expressed warranties,

including warranties of fitness and merchantability, and all product

liability to the extent possible in the event of the use of a non-ZOLL

accessory.

4x4

or compatible ZOLL Battery Charging/Testing

• The equipment may only be used with disposables, accessories, and

consumable items when an agency, accredited for the testing of the

equipment, has established that those items, in their intended use,

meet its safety requirements.

I-4

Who it is for

GENERAL INFORMATION

HOW TO USE THIS MANUAL

The Base PowerCharger

designed for biomedical engineering personnel whose responsibilities include

maintenance and repair of medical equipment.

Purpose

Its purpose is to provide the basic information needed to allow biomedical engineering

personnel to identify and/or repair the Base PowerCharger

(printed circuit board) level.

Recommended Use

The Service Manual should be readily available in the facility's equipment maintenance

library. It will be used for preventive maintenance checks and for troubleshooting when

problems are reported.

The Operator's Guide, included as Appendix A, will be used in training new operators

and for operational reference. This copy should be kept with the Base PowerCharger

Service Manual. A separately bound copy should be kept with the Base PowerCharger

device.

The Service Manual consists of several key sections:

Section I: General Information

This section contains a number of important notices and reference material, including

safety warnings and ZOLL's warranty statement. Be sure to review this section

thoroughly before attempting to use or service the Base PowerCharger

4x4

Service Manual is a basic technical reference document

4x4

to the sub-assembly

4x4

device.

4X4

4X4

Section II: Checkout Procedures

This section contains information you need in order to verify that the Base

PowerCharger

PowerCharger

4X4

is functioning properly, and procedures for checking the Base

4X4

.

For daily inspection and operational checks, see the Operator's Manual.

Section III: Troubleshooting Guides

This section contains an operational troubleshooting section, for use by non-technical

personnel to respond to common problems detected during Base PowerCharger

4X4

operational use.

Section IV: Functional Descriptions

This section provides a basic technical description of the Base PowerCharger

4X4

main

subassembly modules. The information should be thoroughly reviewed before servicing.

Section V: Schematic Drawings

Major circuit board schematics are included for troubleshooting purposes.

I-5

GENERAL INFORMATION

Section VI: Component Layout Drawings

Major component layout drawings are included for troubleshooting purposes.

Section VII: Disassembly Procedures

Step-by-step instructions are provided for removing subassemblies in the event of failure.

Refer to the Service Policy in Section I for return and repair information.

Section VIII: Replacement Parts

This section contains a detailed listing of ZOLL part numbers for field replaceable parts

available for the Base PowerCharger

4x4

and will allow the service person to identify and

order replacement parts. No attempt to replace parts at the component level should be

attempted or the ZOLL warranty may be voided.

Appendix A: Operation

The Operator's Manual has been reproduced here for convenience and consistency. It

should be read and understood before attempting any service procedure.

I-6

GENERAL INFORMATION

SEE FILE PG7_C.PM5

FOR THIS PAGE AND ALL OF THE

SYMBOLS

I-7

SERVICE POLICY

WARRANTY

In North America: Consult your purchasing agreement for terms and conditions

associated with your warranty.

Outside of North America: Consult ZOLL authorized representative.

In order to maintain this warranty, the instructions and procedures contained in this

manual must be strictly followed.

For additional information, please call the ZOLL Technical Service Department at

1-800-348-9011 in North America

1-781-229-0020 outside of North America

SERVICE

GENERAL INFORMATION

The Base PowerCharger

4X4

will provide trouble free operation without periodic

recalibration or adjustment. However, it is recommended that the biomedical engineering

department perform routine tests of the device to verify proper operation. (See Section

II.)

U.S.A. customers

Should the Base PowerCharger

4X4

require service, contact the ZOLL Technical Service

Department to obtain a return claim number. The unit should be returned, in its original

container, to:

ZOLL Medical Corporation

32 Second Avenue,

Burlington, Massachusetts 01803-4420,

Attn: Technical Service Department

Loaner instruments are available for use while repairs are being completed. To request

loan equipment, contact ZOLL at 1-800-348-9011 (in Massachusetts: 1-781-229-0020).

Please have the following information available to expedite service:

• Unit serial number

• A description of the problem

• Department where equipment is in use

• A Purchase Order to allow tracking of loan equipment

• A Purchase Order for systems out of warranty

I-8

International Customers

GENERAL INFORMATION

Should the Base PowerCharger

4X4

require service, it should be returned, in its original

container, to the nearest authorized ZOLL Medical Corporation service center. To

determine which authorized ZOLL Medical Corporation service center to use, write, call

or fax:

ZOLL Medical Corporation

32 Second Avenue,

Burlington, Massachusetts 01803-4420, USA

Attn: International Sales Department

1-781-229-0020 (voice)

or

1-781-272-5443 (fax)

Attn: International Sales Department

I-9

GENERAL INFORMATION

I-10

CHECKOUT PROCEDURES

SECTION II

CHECKOUT PROCEDURES

ZOLL recommends that you check your Base PowerCharger

least once every six months.

This section contains information you need in order to verify that the Base

PowerCharger

Daily operational checks are described in Section 3, Maintenance and

TroubleShooting in the Operator's Guide.

4x4

is functioning properly.

4x4

for proper operation at

TABLE OF CONTENTS

1. Leakage Current Test......................................................................................................II-2

2. Functional Test ...............................................................................................................II-2

9650-0072 II-1 Rev. D

CHECKOUT PROCEDURES

9650-0072 II-2 Rev. D

LEAKAGE CURRENT

• Perform Leakage Current Test per your manufacturer's recommended procedure

found in the Operator's Manual of your Leakage Tester.

CHECKOUT PROCEDURES

Observe:

• After the test is complete, fill in the date , operator, and Base PowerCharger

serial number on the Test Data Sheet (Page II-4). Review the results against the

limits below for any test that failed. If any test fails, circle the failed test on the

Test Data Sheet and take corrective action.

• Record results on Test Data Sheet (Page II-4).

TEST 90 - 265 VAC LIMITS

Gnd Wire Resistance N/A

Line Voltage

Hot to Neutral N/A

Hot to Gnd N/A

Neutral to Gnd N/A

Current Consumption N/A

Chassis Leakage

Normal Pol. w/Ground

Normal Pol. No/Ground

< 500 µA

< 500 µA

4x4

Reverse Pol. No/Ground

Reverse Pol. w/Ground

Ground Wire Leakage

Normal Pol. No/Ground

Reverse Pol. No/Ground

< 500 µA

< 500 µA

< 500 µA

< 500 µA

FUNCTIONAL TESTS

Continuity and Isolation Test

• Take a measurement of the Digital Volt Meter (in ohms) by shorting the two (2)

leads of the DVM.

• Record Results on Test Data Sheet (Page II-4).

• Place the red lead of the DVM on any part of the unit where there is exposed

metal, except for the battery terminals, and place the black lead of the DVM on

the ground part of the powercord.

• Record Results on Test Data Sheet (Page II-4).

• Subtract the two values and the difference should be less than 1 ohm.

9650-0072 II-3 Rev. D

• Record Results on Test Data Sheet (Page II-4).

MANUAL TEST

• Check to see that the unit is connected to live AC mains. The POWER light

• Remove all batteries from the Base PowerCharger

• Press each of the four (4) TEST buttons corresponding to each of the four (4)

• The unit will light all of the LED's associated with the compartment for a few

• Ensure that all of the FAULT indicators are off.

• If any of the FAULT lights are lit, the compartment is defective in some way. To

NOTE: The device under test should be at operating temperature before

CHECKOUT PROCEDURES

should be lit.

4x4

.

battery compartments.

seconds. This will be followed by a beep and then the TESTING and BATT.

READY LED's will light for a couple of seconds. Then all LED's extinguish.

identify the defect press and hold the TEST button. Illumination of specific

indicator lights together represent a specific defect. (Refer to FAULT CODES

TABLE on page III-3 to identify the fault and take corrective action).

checking/adjusting voltages. (Device powered up for a minimum of 20

minutes).

• Set the DVM to VOLTS DC.

• Test each battery compartment seperately by placing the Black lead of the DVM

on the left battery contact pin of the battery compartment and place the RED lead

of the DVM on the shrouded (middle) pin of the same battery compartment.

• The voltage measurement on the DVM should be 11.86 ± 0.10 VDC.

• Record Results on Test Data Sheet (Page II-4).

• If the voltage measurement is NOT 11.86 ± 0.10 VDC, adjust RV1 (on 9301-

0147) until the correct value is displayed.

AUTO TEST OPTION

• Install battery into any well and observe that the CHARGER ON and TESTING

LED’s are illuminated.

NOTE: The CHARGER ON and TESTING LED’s may go off within minutes,

depending on the charge state of the battery pack installed. (i.e., Fully

Charged)

QUICK CHARGE OPTION

• Install battery into any well and observe that the CHARGER ON LED remains

illuminated until the battery is “READY”.

• The TESTING LED will not

turn on by installing a battery into the charger.

9650-0072 II-4 Rev. D

CHECKOUT PROCEDURES

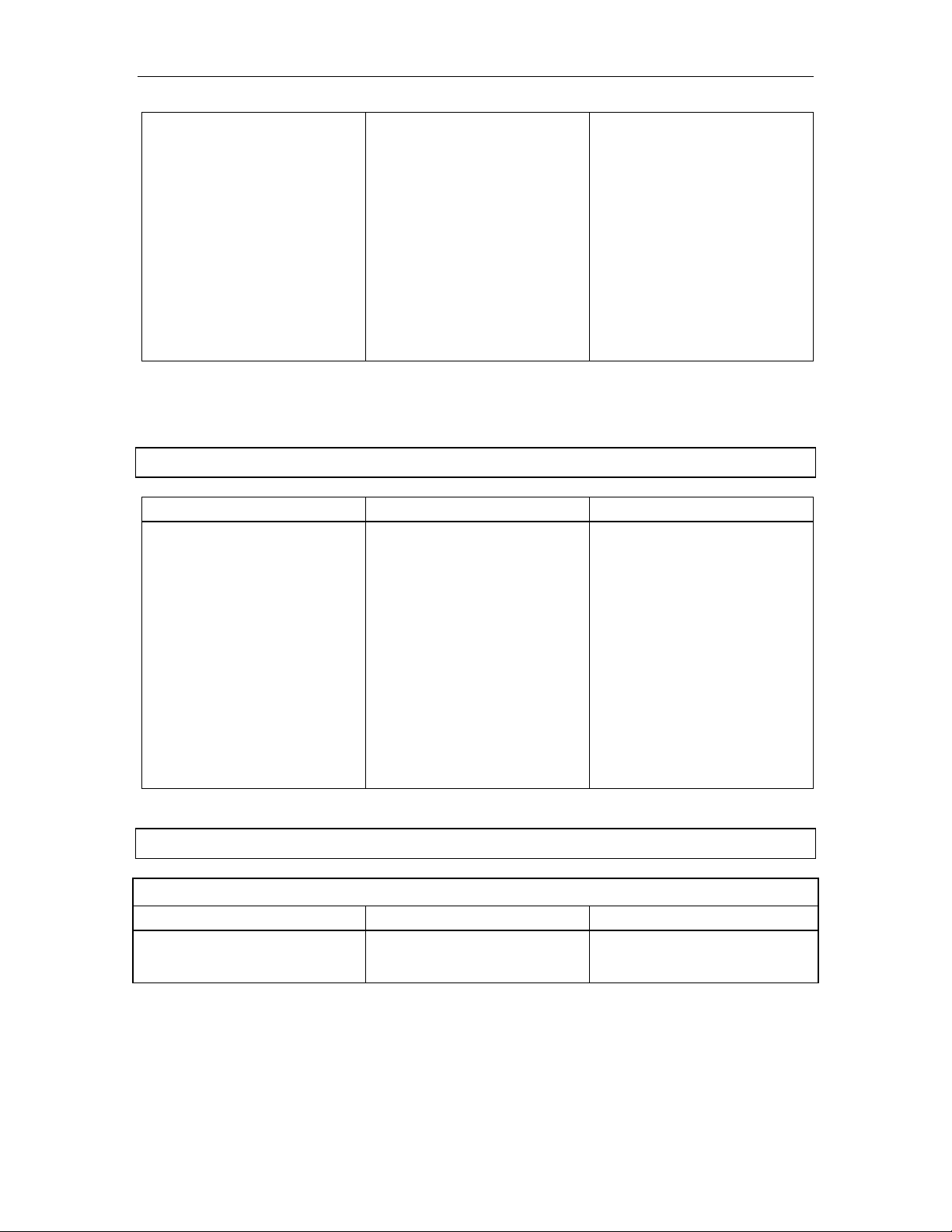

BASE POWERCHARGER

4X4

DEVICE CHECKOUT PROCEDURE

DATA SHEET

S/N___________ OPERATOR___________ DATE_________

COPY THIS FORM BEFORE USING

SECTION 1. LEAKAGE TEST

Perform this Action: Limits: Circle the Result:

1.1 Chassis Leakage

Normal Pol. w/ Ground

Normal Pol. No/ Ground

Reverse Pol. No/ Ground

Reverse Pol. w/ Ground

< 500 µA

< 500 µA

< 500 µA

< 500 µA

YES or NO

YES or NO

YES or NO

YES or NO

1.2 Ground Wire Leakage

Normal Pol. No/ Ground

Reverse Pol. No/ Ground

< 500 µA

< 100 µA

YES or NO

YES or NO

SECTION 2. FUNCTIONAL TEST

Perform this Action: Look for : Circle the Result:

9650-0072 II-5 Rev. D

CHECKOUT PROCEDURES

2.1 Continuity and Isolation

Resistance measurement

of two (2) leads shorted

to one another.

Resistance measurement

with Red lead on metal

and Black lead on

powercord ground.

Subtract the two values

above.

Record value:

________ohms

Record value:

________ohms

Difference should be < 1 ohm

YES or NO

SECTION 3. MANUAL TEST

Perform this Action: Look for : Circle the Result:

3.1 Remove all batteries from

the Base PowerCharger

Press each battery

compartment TEST

button (4).

Set DVM to VOLTS DC.

Test each battery

compartment

4x4

All LED's illuminate

momentarily, the Batt. Ready

and Testing light illuminate

alone and then, all LED's go

off.

Ensure FAULT indicators are

all off.

Voltage is 11.86 ± 0.10 VDC

YES or NO

YES or NO

YES or NO

YES or NO

YES or NO

SECTION 4. AUTO TEST

For 4 x4 base chargers that are configured as auto test units.

Perform this Action: Look for : Circle the Result:

4.1 Install Battery into any

well .

9650-0072 II-6 Rev. D

Charger on and testing LED’S

illuminate.

YES or NO

TROUBLESHOOTING GUIDES

SECTION III

TROUBLESHOOTING

This section answers many of the common problems or questions that arise during

operation.

If trouble persists after consulting this guide, contact the appropriate technical

personnel or ZOLL Technical Service Department.

TABLE OF CONTENTS

1. TroubleShooting Table.................................................................................................. III-2

2. Fault Codes Table .......................................................................................................... III-3

3. Definition of Fault Codes .............................................................................................. III-4

III-1

TROUBLESHOOTING TABLE

Symptoms TroubleShooting Method and Possible

POWER light does not illuminate.

CHARGER ON indicator light does not

illuminate when battery is inserted into

compartment.

TESTING light does not illuminate when

TEST button is pressed.

Battery fails test cycle. (FAULT light

illuminates with TESTING light).

TROUBLESHOOTING GUIDES

Causes

• Check that the unit is plugged into an

appropriate power source.

• Check for defective power cord.

• Plug unit into another power source.

• Check for blown fuse. Disconnect power

cord and open fuse holder to check fuses.

• Check that the battery is properly seated

in battery compartment.

• Check that battery contacts are clean and

not damaged.

• Check that unit is plugged into an

appropriate power source.

• Test the battery compartment for

functionality.

• Place another battery in the compartment.

• Check that the battery is properly seated

in compartment.

• Check that unit is plugged into an

appropriate power source.

• Remove the battery and press the TEST

button to perform a compartment self-test.

If it does not self-test the button is

defective.

• Verify that the battery compartment is fully

operational with no defects.

• Press and hold the TEST button to

determine the fault code. (See Fault

Codes Table on Page III-3).

• If all FAULT LED's are on most likely

there is a failure in the common circuitry.

When the unit does not follow the Power-Up sequence explained elsewhere in this

manual or if a fault light comes on at any time follow the steps listed below to identify

the fault.

Note: The unit can be run through it 's self-test at any time, as long as there is no

battery installed, by pressing the TEST button. When the self-test is invoked on a

single battery compartment the unit will respond by lighting all the LED's associated

with the compartment for a few seconds. This will be followed by a beep and then the

TESTING and BATT. READY LED's will light for a couple of seconds. Then all LED's

extinguish.

Faults that may endanger the reliable charging of a battery or the ability to

charge/test successfully are latching faults that can only be cleared by power cycling

after the fault is fixed. All other faults are self-clearing as soon as the fault condition is

removed.

III-2

TROUBLESHOOTING GUIDES

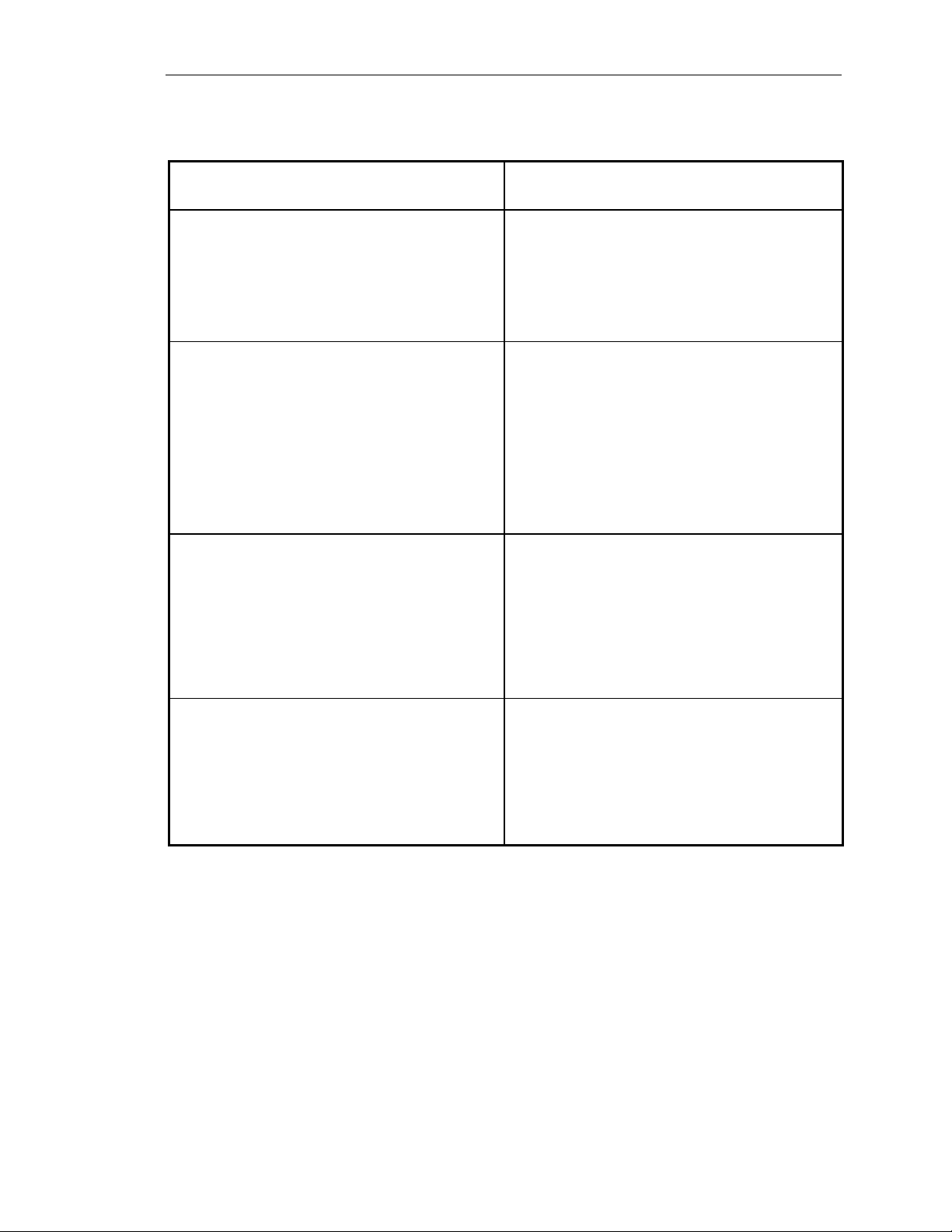

Fault Codes Table

When the FAULT indicator light illuminates, press and hold the TEST button. The

illumination of the following indicator lights together represent a specific defect

identified under the Fault Code column.

Charger On Batt. Ready Fault Testing Fault Code

ON

ON ON

ON ON ON

ON ON ON ON OverCharge

ON ON

ON

ON

ON

OFF

OFF OFF

OFF OFF OFF

OFF OFF OFF

OFF OFF

OFF

OFF

OFF

OFF

OFF OFF

ON ON ON High Battery

ON ON Low Battery

ON

ON ON Battery

ON Temperature

OFF

ON Shutdown

ON Charger

Constant

Current Voltage

Discharge

Discharge Time

Voltage

High Constant

Current

Voltage

Capacity

OFF

OFF

OFF

OFF OFF

NOTE: A battery that has failed a capacity test will display the TESTING & FAULT

LED's simultaneously. When the TEST button is pressed and held the LED pattern

will not change. This is a normal operating condition and does not reflect a fault with

the unit.

ON

ON

ON ON

OFF OFF

OFF

ON

III-3

ON Vcc Voltage

OFF

OFF

Constant

Voltage

Low Power

Supply Voltage

Low Constant

Current

Definition of Fault Codes

Constant Current The Constant Current compliance Voltage is below the specified

Voltage: range.

Discharge: Test discharge has been ineffective.

Discharge Time: The unit is unable to perform the discharge test.

OverCharge: The total delivered charge exceeds the specified range.

Temperature: Internal charger temperature deviated from specified range.

Low Battery The Battery Voltage measured was below specified range.

Voltage:

VCC Voltage: The internal five (5) volt supply deviated from specified range.

High Constant The amount of current during a charge was above specified

Current: range.

Shutdown: Safety shutdown (#2) is not operating properly (shutdown).

TROUBLESHOOTING GUIDES

High Battery The Battery Voltage was measured to be above the specified

Voltage: range.

Battery Capacity: The battery's capacity was measured to be below the specified

range.

Charger: Safety shutdown (#1) is not operating properly (charge enable).

Constant Voltage: The Constant Voltage deviated from the specified range.

Low Power The charging voltage was measured to be below the specified

Supply Voltage: range.

Low Constant The amount of current during a charge was below specified

Current: range.

III-4

FUNCTIONAL DESCRIPTION

SECTION IV

FUNCTIONAL DESCRIPTIONS

This section describes the basic operation of the circuits and supplements the

troubleshooting guides in Section III of this manual.

For additional information, refer to the associated schematics found in Section V.

TABLE OF CONTENTS

1. System. ...........................................................................................................................IV-2

2. Common Circuitry Description..................................................................................... IV-3

3. Compartment Circuitry Description............................................................................. IV-5

4. LED PCB .......................................................................................................................IV-12

IV-1

Loading...

Loading...