Page 1

Machine Controller MP2300S

Basic Module

USER'S MANUAL

Model: JEPMC-MP2300S-E

MP2300S

YAS KAWA

BATTERY

M-

I/II

RDY

RUN

ALM

ERR

MTX

BAT

TRX

IP

STOP

SUP

INT

SW

CNFG

1

MON

TEST

NO

E-INT

E-TEST

ON

SW

2

NO

ON

Specifications and Functions

Overview

Mounting and Wiring

RLY

OUT

Ethernet

LINK

DC

24V

DC

0V

100M

Outline of Motion Control Systems

System Start Up and

Easy Programming

Built-in Ethernet Communications

Slave CPU Synchronous Function

Maintenance and Inspection

Troubleshooting

1

2

3

4

5

6

7

8

9

MANUAL NO. SIEP C880732 00C

Appendices

A

Page 2

Copyright © 2007 YASKAWA ELECTRIC CORPORATION

All rights reserved. No part of this publication may be reproduced, stored in a retrieval system, or

transmitted, in any form, or by any means, mechanical, electronic, photocopying, recording, or otherwise, without the prior written permission of Yaskawa. No patent liability is assumed with respect to

the use of the information contained herein. Moreover, because Yaskawa is constantly striving to

improve its high-quality products, the information contained in this manual is subject to change without

notice. Every precaution has been taken in the preparation of this manual. Nevertheless, Yaskawa

assumes no responsibility for errors or omissions. Neither is any liability assumed for damages resulting from the use of the information contained in this publication.

Page 3

Using this Manual

The MP2300S is a compact Machine Controller that contains the power supply, the CPU, I/O, and the communication

functions in one single unit.

Please read this manual to ensure correct usage of the MP2300S system and apply to your manufacturing system for

control. Keep this manual in a safe place for future reference.

Basic Terms

Unless otherwise specified, the following definitions are used:

• MP2300S: MP2300S Machine Controller

• MPE720: The Programming Device Software or a Programming Device (i.e., a personal computer) running the

Programming Device Software

• PLC: Programmable Logic Controller

Manual Configuration

Read the chapters of this manual as required by the purpose.

Selecting

Chapter

Chapter 1

Overview

Chapter 2

Specifications and Functions

Chapter 3

Mounting and Wiring

Chapter 4

System Start Up and Easy

Programming

Chapter 5

Outline of Motion Control

Systems

Chapter 6

Built-in Ethernet Communications

Chapter 7

Slave CPU Synchronous

Function

Chapter 8

Maintenance and Inspection

Chapter 9

Troubleshooting

Appendices A to G −−√−√√

Models and

Peripheral

Devices

√−−−−−

√√√√−−

−√√√−−

√−−−√−

−−√−√−

−−√−√−

−−−−√−

−−−−√√

−−−−

Studying

Specifications

and Ratings

Designing

the System

Installation

and Wiring

Trial Oper-

ation

√

Maintenance

and Inspec-

tion

√

For information on motion parameters and motion commands, refer to Machine Controller MP2000-series SVB/SVB01 Motion Module User’s Manual (manual number: SIEP C880700 33).

Engineering Tool Used in this Manual

The displays for MPE720 version 6 are used for descriptions in this manual.

If you are using MP720 version 5, interpret the displays according to MPE720 version 5.

Indication of Reverse Signals

In this manual, the names of reverse signals (ones that are valid when low) are written with a forward slash (/) before

the signal name, as shown in the following example:

Notation Examples

• S-ON

• P-CON

= /S-ON

= /P-CON

iii

Page 4

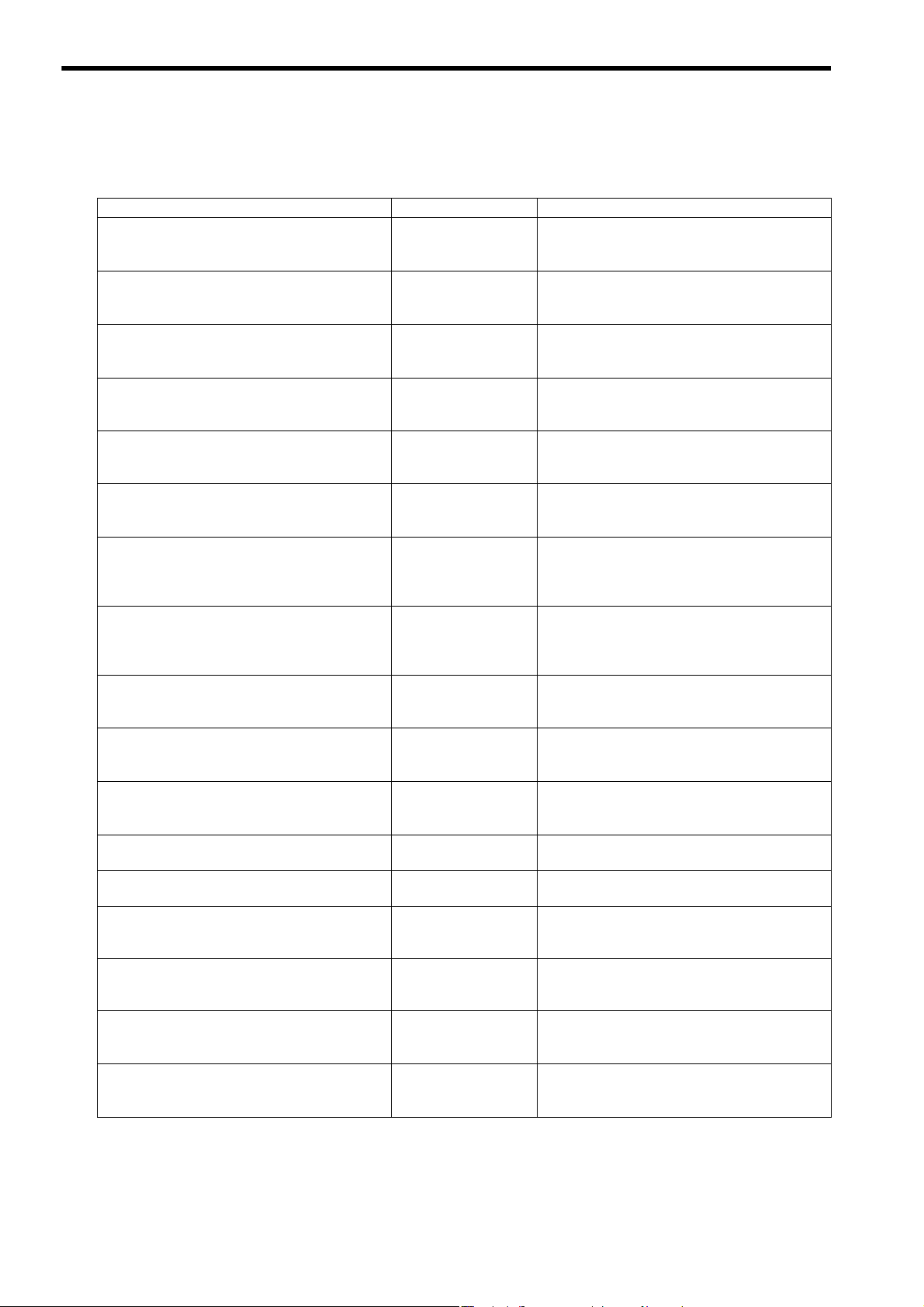

Related Manuals

The following table lists the manuals relating to the MP2300S. Refer to these manuals as required.

Manual Name Manual Number Contents

Machine Controller MP2000 Series

SVA-01 Motion Module

User’s Manual

Machine Controller MP2000 Series

Built-in SVB/SVB-01 Motion Module

User's Manual

Machine Controller MP2000 Series

SVC-01 Motion Module

User's Manual

Machine Controller MP2000 Series Pulse Output

Motion Module PO-01 User's Manual

Machine Controller MP2000 Communication

Module User’s Manual

Machine Controller MP2300S/MP2310/MP2400

Basic Module Supplement for Ethernet

Communications

Machine Controller MP2000 Series 262IF-01

FL-net Communication Module User's Manual

Machine Controller MP2000 Series 263IF-01

EtherNet/IP Communication Module User's

Manual

Machine Controller MP2000 Series I/O Module

User's Manual

Machine Controller MP2000 Series

Analog Input/Analog Output Module

AI-01/AO-01 User’s Manual

Machine Controller MP2000 Series

Counter Module CNTR-01

User's Manual

Machine Controller MP900/MP2000 Series

User’s Manual, Ladder Programming

Machine Controller MP2000 Series

User's Manual, Motion Programming

Engineering Tool for MP2000 Series Machine

Controller MPE720 Version 6 User's Manual

Machine Controller MP900/MP2000 Series

MPE720

User’s Manual

Machine Controller MP900/MP2000 Series

New Ladder Editor User’s Manual

Programming Instructions

Machine Controller MP900/MP2000 Series

New Ladder Editor User’s Manual

Operation

Software fo

r Programming Device

SIEP C880700 32

SIEP C880700 33

SIEP C880700 41

SIEP C880700 28

SIEP C880700 04

SIEP C880700 37

SIEP C880700 36

SIEP C800700 39

SIEP C800700 34

SIEP C800700 26

SIEP C800700 27

SIEZ-C887-1.2

SIEP C880700 38

SIEP C880700 30

SIEP C880700 05

SIEZ-C887-13.1

SIEZ-C887-13.2

Describes the functions, specifications, and application methods of the MP2000-series SVA-01 Motion

Module.

Describes the functions, specifications, and application methods of the MP2000-series Motion Module

that is built into the SVA, SVB-01, and SVR Module.

Describes the functions, specifications, and application methods of the MP2000-series SVC-01 Motion

Module.

Describes the functions, specifications, and application methods of the MP2000-series PO-01 Motion

Module.

Describes the functions, specifications, and application methods of the MP200 Communication Modules (217IF, 218IF, 260IF, 261IF).

Describes how to communicate with devices (PLCs,

Windows computers, etc.) connected to the

MP2300S/MP2310/MP2400 by Ethernet.

Describes the specifications and communication

methods of an FL-net Communication Module that

can connect to an MP2000-series Machine Controller.

Describes the specifications and communication

methods of an EtherNet/IP Communication Module

that can connect to an MP2000-series Machine Controller.

Describes functions, specifications, and application

methods of the MP2000-series I/O Modules (LIO-01,

LIO-02, LIO-04, LIO-05, LIO-06, and DO-01).

Describes the functions, specifications, and communication methods of the MP2000-series I/O Modules

(Al-01 and AO-01).

Describes the functions, specifications, and application methods of the MP2000-series CNTR-01

Counter Module.

Describes the instructions used in MP900/MP2000

ladder programming.

Describes the motion language used with an

MP2000-series Machine Controller.

Describes the installation and operation of the engineering tool for MP2000-series Machine Controller

MPE720 Version 6.

Describes how to install and operate the MP900/

MP2000-series programming system (MPE720).

Describes the programming instructions of the New

Ladder Editor, which assists MP900/MP2000-series

design and maintenance.

Describes the operating methods of the New Ladder

Editor, which assists MP900/MP2000-series design

and maintenance.

iv

Page 5

Manual Name Manual Number Contents

Machine Controller MP900/MP2000 Series

User’s Manual, MECHATROLINK System

Machine Controller MP900/MP2000 Series

Linear Servomotor Manual

Terms Used to Describe “Torque”

Although the term “torque” is commonly used when describing rotary servomotors and “force” or “thrust” are used

when describing linear servomotors, this manual uses “torque” when describing both (excluding parameters).

Copyrights

• DeviceNet is a registered trademark of the ODVA (Open DeviceNet Venders Association).

• PROFIBUS is a trademark of the PROFIBUS User Organization.

• Ethernet is a registered trademark of the Xerox Corporation.

• Microsoft, Windows, Windows NT, and Internet Explorer are registered trademarks of the Microsoft Corporation.

• Pentium is a registered trademark of the Intel Corporation.

• Other product names and company names are the trademarks or registered trademarks of the respective company. “TM” and the

® mark do not appear with product or company names in this manual.

SIEZ-C887-5.1

SIEP C880700 06

(cont’d)

Describes MECHATROLINK distributed I/O for

MP900/MP2000-series Machine Controllers.

Describes the connection methods, setting methods,

and other information for Linear Servomotors.

v

Page 6

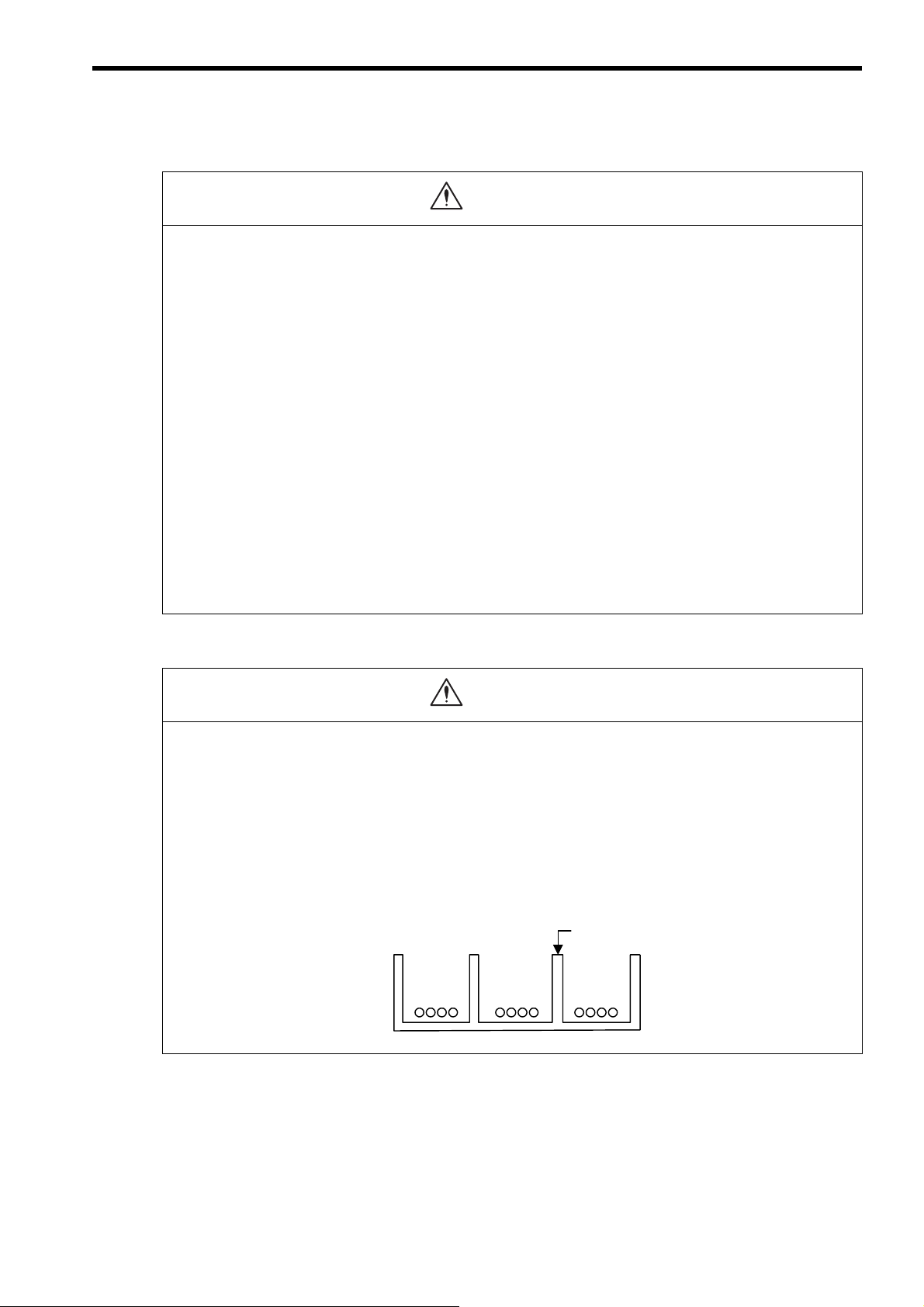

WARNING

CAUTION

CAUTION

PROHIBITED

MANDATORY

Safety Information

The following conventions are used to indicate precautions in this manual. These precautions are provided to ensure

the safe operation of the MP2300S and connected devices. Information marked as shown below is important for the

safety of the user. Always read this information and heed the precautions that are provided.

The conventions are as follows:

Indicates precautions that, if not heeded, could possibly result in loss of life, serious injury, or property damage.

Indicates precautions that, if not heeded, could result in relatively serious or minor injury,

or property damage.

If not heeded, even precautions classified under can lead to serious results

depending on circumstances.

Indicates prohibited actions. Specific prohibitions are indicated inside .

For example, indicates prohibition of open flame.

Indicates mandatory actions. Specific actions are indicated inside .

For example, indicates mandatory grounding.

vi

Page 7

WARNING

Safety Precautions

The following precautions are for checking products on delivery, storage, transportation, installation, wiring, operation,

application, inspection, and disposal. These precautions are important and must be observed.

General Precautions

Before connecting the machine and starting operation, ensure that an emergency stop procedure has been

provided and is working correctly.

There is a risk of injury.

Do not touch anything inside the MP2300S.

There is a risk of electrical shock.

Always keep the front cover attached when power is being supplied.

There is a risk of electrical shock.

Observe all procedures and precautions given in this manual for trial operation.

Operating mistakes while the servomotor and machine are connected may damage the machine or even cause accidents resulting in injury or death.

There is a risk of electrical shock.

Do not remove the front cover, cables, connector, or options while power is being supplied.

There is a risk of electrical shock.

Do not damage, pull on, apply excessive force to, place heavy objects on, or pinch cables.

There is a risk of electrical shock, operational failure or burning of the MP2300S.

Do not attempt to modify the MP2300S in any way.

There is a risk of injury or device damage.

Do not approach the machine when there is a momentary interruption to the power supply. When power is

restored, the MP2300S and the device connected to it may start operation suddenly. Provide safety measures in advance to ensure human safety in the event that operation restarts suddenly.

There is a risk of injury.

Do not allow installation, disassembly, or repairs to be performed by anyone other than specified person-

nel.

There is a risk of electrical shock or injury.

vii

Page 8

CAUTION

CAUTION

Storage and Transportation

Do not store or install the MP2300S in the following locations.

There is a risk of fire, electrical shock, or device damage.

Direct sunlight

Ambient temperature exceeds the storage or operating conditions

Ambient humidity exceeds the storage or operating conditions

Rapid changes in temperature or locations subject to condensation

Corrosive or flammable gas

Excessive dust, dirt, salt, or metallic powder

Water, oil, or chemicals

Vibration or shock

Do not overload the MP2300S during transportation.

There is a risk of injury or an accident.

Do not under any means subject the MP2300S to an atmosphere that contains halogen gas (fluorine, chlo-

ride, bromine, iodine, etc.) during storage, transportation, or installation.

There is a risk of damage or malfunction.

If disinfectants or insecticides must be used to treat packing materials such as wooden frames, pallets, or

plywood, the packing materials must be treated before the product is packaged, and methods other than

fumigation must be used.

Example: Heat treatment, where materials are kiln-dried to a core temperature of 56°C for 30

minutes or more.

If the electronic products, which include stand-alone products and products installed in machines, are packed with

fumigated wooden materials, the electrical components may be greatly damaged by the gases or fumes resulting from

the fumigation process. In particular, disinfectants containing halogen, which includes chlorine, fluorine, bromine, or

iodine can contribute to the erosion of the capacitors.

Installation

Never use the MP2300S in locations subject to water, corrosive atmospheres, or flammable gas, or near

burnable objects.

There is a risk of electrical shock or fire.

Do not step on the MP2300S or place heavy objects on the MP2300S.

There is a risk of injury.

Do not block the air exhaust port or allow foreign objects to enter the MP2300S.

There is a risk of element deterioration inside, an accident, or fire.

Always mount the MP2300S in the specified orientation.

There is a risk of an accident.

Do not subject the MP2300S to strong shock.

There is a risk of an accident.

viii

Page 9

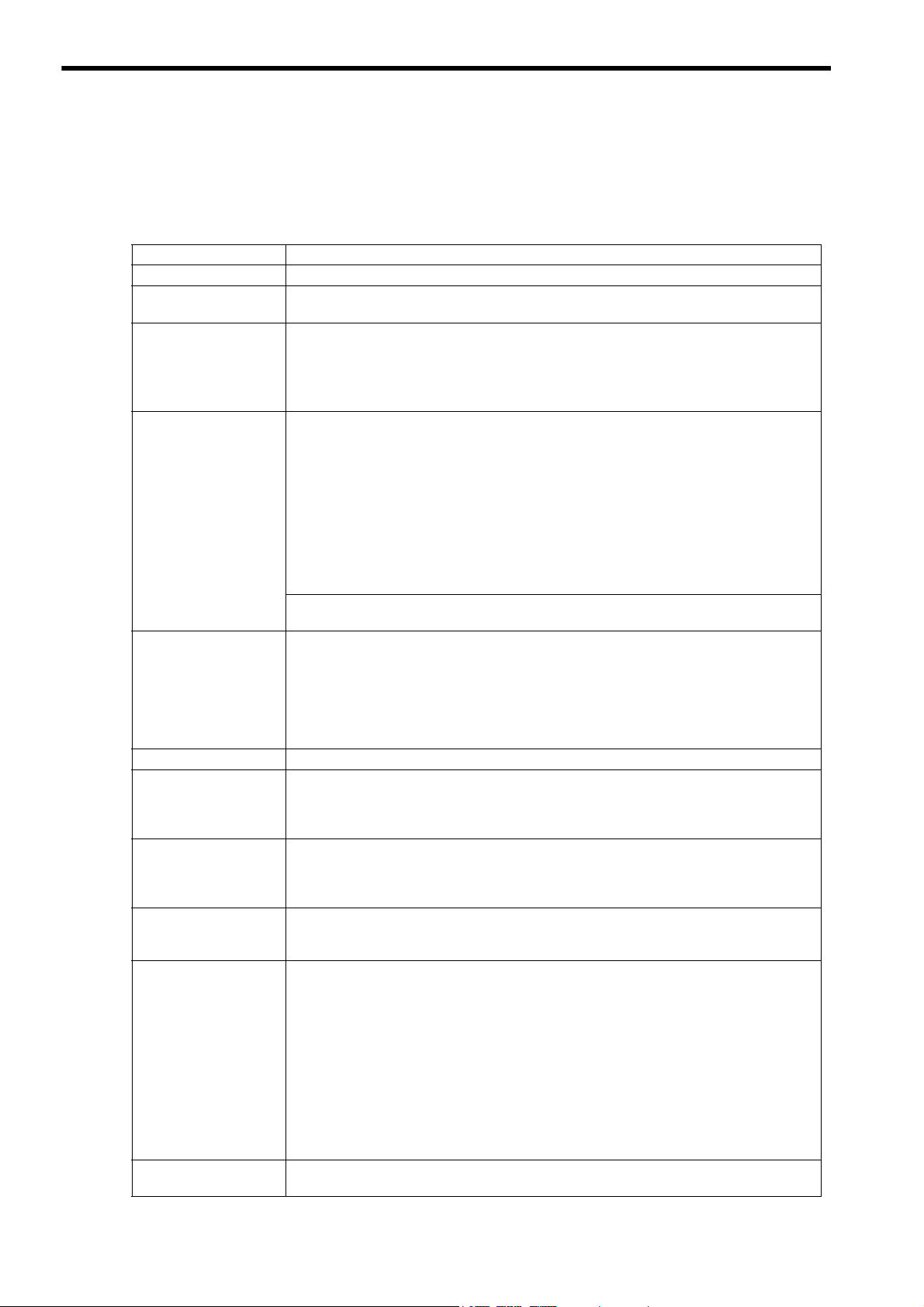

CAUTION

CAUTION

鉄板製のセパレータ

ディジタル

入出力信号

ケーブル

一般制御回路

のケーブル

動力回路

の

ケーブル

外部配線

の分離例

Example of Separated External Cables

Steel separator

Power

circuit

cables

General

control circuit cables

Digital I/O

signal

cables

Wiring

Check the wiring to be sure it has been performed correctly.

There is a risk of motor run-away, injury, or an accident.

Always use a power supply of the specified voltage.

There is a risk of burning.

In places with poor power supply conditions, take all steps necessary to ensure that the input power supply

is within the specified voltage range.

There is a risk of device damage.

Install breakers and other safety measure to provide protection against shorts in external wiring.

There is a risk of fire.

Provide sufficient shielding when using the MP2300S in the following locations.

There is a risk of device damage.

Noise, such as from static electricity

Strong electromagnetic or magnetic fields

Radiation

Near to power lines

When connecting the battery, connect the polarity correctly.

There is a risk of battery damage or explosion.

Only qualified safety-trained personnel should replace the battery.

If the battery is replaced incorrectly, machine malfunction or damage, electric shock, or injury may result.

When replacing the battery, do not touch the electrodes.

Static electricity may damage the electrodes.

Selecting, Separating, and Laying External Cables

Consider the following items when selecting the I/O signal lines (external cables) to connect the MP2300S

to external devices.

Mechanical strength

Noise interference

Wiring distance

Signal voltage, etc.

Separate the I/O signal lines from the power lines both inside and outside the control box to reduce the

influence of noise from the power lines.

If the I/O signal lines and power lines are not separated properly, malfunctioning may result.

ix

Page 10

CAUTION

CAUTION

Maintenance and Inspection Precautions

Do not attempt to disassemble the MP2300S.

There is a risk of electrical shock or injury.

Do not change wiring while power is being supplied.

There is a risk of electrical shock or injury.

When replacing the MP2300S, restart operation only after transferring the programs and parameters from

the old Module to the new Module.

There is a risk of device damage.

Disposal Precautions

Dispose of the MP2300S as general industrial waste.

A lithium battery is built into the MP2300S. After replacing the battery, dispose of the old battery separate

from regular waste and in accordance with local regulations.

General Precautions

The products shown in illustrations in this manual are sometimes shown without covers or protective

guards. Always replace the cover or protective guard as specified first, and then operate the products in

accordance with the manual.

The drawings presented in this manual are typical examples and may not match the product you

received.

If the manual must be ordered due to loss or damage, inform your nearest Yaskawa representative or

one of the offices listed on the back of this manual.

Observe the following general precautions

to ensure safe application.

x

Page 11

Warranty

( 1 ) Details of Warranty

Warranty Period

The warranty period for a product that was purchased (hereinafter called “delivered product”) is one year from the time

of delivery to the location specified by the customer or 18 months from the time of shipment from the Yaskawa factory,

whichever is sooner.

Warranty Scope

Yaskawa shall replace or repair a defective product free of charge if a defect attributable to Yaskawa occurs during the

warranty period above. This warranty does not cover defects caused by the delivered product reaching the end of its

service life and replacement of parts that require replacement or that have a limited service life.

This warranty does not cover failures that result from any of the following causes.

1. Improper handling, abuse, or use in unsuitable conditions or in environments not described in product catalogs or

manuals, or in any separately agreed-upon specifications

2. Causes not attributable to the delivered product itself

3. Modifications or repairs not performed by Yaskawa

4. Abuse of the delivered product in a manner in which it was not originally intended

5. Causes that were not foreseeable with the scientific and technological understanding at the time of shipment from

Ya sk a wa

6. Events for which Yaskawa is not responsible, such as natural or human-made disasters

( 2 ) Limitations of Liability

1. Yaskawa shall in no event be responsible for any damage or loss of opportunity to the customer that arises due to

failure of the delivered product.

2. Yaskawa shall not be responsible for any programs (including parameter settings) or the results of program execution of the programs provided by the user or by a third party for use with programmable Yaskawa products.

3. The information described in product catalogs or manuals is provided for the purpose of the customer purchasing

the appropriate product for the intended application. The use thereof does not guarantee that there are no infringements of intellectual property rights or other proprietary rights of Yaskawa or third parties, nor does it construe a

license.

4. Yaskawa shall not be responsible for any damage arising from infringements of intellectual property rights or other

proprietary rights of third parties as a result of using the information described in catalogs or manuals.

xi

Page 12

( 3 ) Suitability for Use

1. It is the customer’s responsibility to confirm conformity with any standards, codes, or regulations that apply if the

Yaskawa product is used in combination with any other products.

2. The customer must confirm that the Yaskawa product is suitable for the systems, machines, and equipment used by

the customer.

3. Consult with Yaskawa to determine whether use in the following applications is acceptable. If use in the application

is acceptable, use the product with extra allowance in ratings and specifications, and provide safety measures to

minimize hazards in the event of failure.

• Outdoor use, use involving potential chemical contamination or electrical interference, or use in conditions or

environments not described in product catalogs or manuals

• Nuclear energy control systems, combustion systems, railroad systems, aviation systems, vehicle systems,

medical equipment, amusement machines, and installations subject to separate industry or government regulations

• Systems, machines, and equipment that may present a risk to life or property

• Systems that require a high degree of reliability, such as systems that supply gas, water, or electricity, or systems that operate continuously 24 hours a day

• Other systems that require a similar high degree of safety

4. Never use the product for an application involving serious risk to life or property without first ensuring that the system is designed to secure the required level of safety with risk warnings and redundancy, and that the Yaskawa

product is properly rated and installed.

5. The circuit examples and other application examples described in product catalogs and manuals are for reference.

Check the functionality and safety of the actual devices and equipment to be used before using the product.

6. Read and understand all use prohibitions and precautions, and operate the Yaskawa product correctly to prevent

accidental harm to third parties.

( 4 ) Specifications Change

The names, specifications, appearance, and accessories of products in product catalogs and manuals may be changed at

any time based on improvements and other reasons. The next editions of the revised catalogs or manuals will be published with updated code numbers. Consult with your Yaskawa representative to confirm the actual specifications

before purchasing a product.

xii

Page 13

Contents

Using this Manual - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - iii

Safety Information - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - vi

Safety Precautions - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - vii

Warranty - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - xi

1 Overview- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1-1

1.1 MP2300S Features- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1-2

1.2 MP2300S Configuration - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1-3

1.2.1 Basic Module Appearance - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1-3

1.2.2 MP2300S Modules - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1-4

1.3 System Configuration - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1-5

1.3.1 Example - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1-5

1.3.2 Example of Distributed Synchronizing System- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1-6

1.4 MECHATROLINK Compatible Devices - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1-7

1.4.1 MECHATROLINK-I/II Compatible Devices- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1-7

1.4.2 MECHATROLINK-III Compatible Devices - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1-8

1.5 Cables and Accessories - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1-9

1.5.1 Cables - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1-9

1.5.2 Accessories and Options - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1-10

1.5.3 Software (Programming Tool) - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1-10

2 Specifications and Functions- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2-1

2.1 Specifications- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2-2

2.1.1 General Specifications - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2-2

2.1.2 Product Specifications - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2-3

2.1.3 Function Lists - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2-4

2.2 Basic Module - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2-7

2.2.1 Outline of Functions- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2-7

2.2.2 External Appearance, LED Indicators, and Switch Settings - - - - - - - - - - - - - - - - - - - - - - - - - 2-8

2.2.3 Specifications - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2-11

2.2.4 218IFA Module (Ethernet) - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2-12

2.2.5 Built-in SVB Module- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2-31

2.2.6 SVR Virtual Motion Module- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2-48

2.2.7 M-EXECUTOR Module (Motion Program Executor) - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2-51

2.3 Option Module - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2-62

2.3.1 Option Module Overview List - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2-62

2.4 External Appearance - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2-64

2.4.1 Basic Module - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2-64

2.4.2 Basic Module with Metal Fittings - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2-65

3 Mounting and Wiring - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3-1

3.1 Mounting MP2300S - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3-2

3.1.1 Method- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3-2

3.1.2 MP2300S Mount Direction - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3-7

3.1.3 Space Required for Mounting MP2300S - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3-8

3.1.4 Replacing and Adding Optional Modules - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3-9

xiii

Page 14

3.2 Basic Module Connections - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3-12

3.2.1 Connectors - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3-12

3.2.2 Power Supply Connector- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3-13

3.2.3 MECHATROLINK Connectors - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3-14

3.2.4 Ethernet Connector Details - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3-19

3.2.5 RLY OUT Connector Details - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3-23

3.2.6 System Connection Example - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3-25

4 System Start Up and Easy Programming - - - - - - - - - - - - - - - - - - - - - - - - - - - 4-1

4.1 System Startup Overview - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4-2

4.2 Preparation (step 1) - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4-3

4.2.1 Wiring - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4-3

4.2.2 Self Configuration - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4-5

4.2.3 Test Operation - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4-6

4.3 Programming (step 2) - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4-9

4.3.1 Programming Procedure - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4-9

4.4 Executing Motion (step 3) - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4-11

4.4.1 Registering Program Execution - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4-11

4.4.2 Starting a Motion Program Using the Operation Control Panel - - - - - - - - - - - - - - - - - - - - - 4-12

4.5 Starting Motion Program from an External Signal- - - - - - - - - - - - - - - - - - - - - - 4-13

4.5.1 Overview - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4-13

4.5.2 Required Equipment - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4-13

4.5.3 Creation Procedure- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4-15

5 Outline of Motion Control Systems - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5-1

5.1 Startup Sequence and Basic Operation - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5-2

5.1.1 DIP Switch Settings - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5-2

5.1.2 Startup Sequence- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5-3

5.1.3 Startup Sequence Operation Details- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5-4

5.2 User Programs- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5-5

5.2.1 Types and Execution Timing of User Program- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5-5

5.2.2 Motion Programs - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5-6

5.2.3 Sequence Program- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5-27

5.2.4 Ladder Drawings (DWG) - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5-30

5.3 Registers - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5-35

5.3.1 Types of Registers - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5-35

5.3.2 Data Types - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5-38

5.3.3 How to Use Subscripts i, j - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5-39

5.3.4 Register Designation- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5-40

5.4 Self-configuration - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5-41

5.4.1 How to Execute Self-Configuration - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5-42

5.4.2 Definition Information Updated with Self-Configuration - - - - - - - - - - - - - - - - - - - - - - - - - - - 5-50

5.5 Precaution on Using MP2300S - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5-53

5.5.1 Precautions when User Definition File is Configured/Changed - - - - - - - - - - - - - - - - - - - - - 5-53

5.5.2 Setting or Changing Module Configuration Definition Files - - - - - - - - - - - - - - - - - - - - - - - - 5-54

5.5.3 Setting and Changing the Scan Time - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5-55

xiv

6 Built-in Ethernet Communications - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 6-1

6.1 Communication Methods- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 6-2

Page 15

6.2 Communication with Other MP Series - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 6-3

6.2.1 When the MP2300S Acts as Slave (automatic receive function is used) - - - - - - - - - - - - - - - - 6-3

6.2.2 When the MP2300S Acts as Slave (ladder program which uses a MSG-RCV function) - - - - 6-17

6.2.3 When the MP2300S Acts as Master (I/O message communication function is used) - - - - - - 6-36

6.2.4 When the MP2300S Acts as Master (ladder program which uses a MSG-SND function) - - - 6-49

6.3 Communication with Touch Panel- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 6-65

6.3.1 When the MP2300S Acts as Slave (automatic receive function is used) - - - - - - - - - - - - - - - 6-65

6.4 Communication with PLC Manufactured by Mitsubishi Electric Corporation

(MELSEC protocol) - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 6-75

6.4.1 When the MP2300S Acts as Slave (automatic receive function is used) - - - - - - - - - - - - - - - 6-75

6.4.2 When the MP2300S Acts as Master (I/O message communication function is used) - - - - - - 6-83

7 Slave CPU Synchronous Function- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 7-1

7.1 Function - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 7-2

7.2 Requirements and Setting of Execution - - - - - - - - - - - - - - - - - - - - - - - - - - - - 7-3

7.2.1 Supported Version- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 7-3

7.2.2 Requirements to Execute Slave CPU Synchronous Function- - - - - - - - - - - - - - - - - - - - - - - - 7-3

7.2.3 How to Set up Slave CPU Synchronous Function- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 7-4

7.2.4 How to Execute Slave CPU Synchronous Function - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 7-7

7.3 Operation- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 7-9

7.3.1 Input/Output Register- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 7-9

7.3.2 How to Determine Slave CPU Synchronous State - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 7-15

7.3.3 Calculation of Slave CPU Synchronous Delay Time - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 7-16

7.3.4 How to Use Scan Counter - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 7-17

7.3.5 How to Determine Input Error - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 7-18

7.3.6 Management to Resume Slave CPU Synchronization - - - - - - - - - - - - - - - - - - - - - - - - - - - - 7-24

7.4 Precautions - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 7-28

7.4.1 Precautions on Usage - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 7-28

7.4.2 Effect of Error on Slave CPU Synchronous Operation- - - - - - - - - - - - - - - - - - - - - - - - - - - - 7-29

8 Maintenance and Inspection - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 8-1

8.1 Daily Inspections - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 8-2

8.2 Regular Inspections - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 8-3

8.3 Replacing the Basic Module Battery - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 8-4

9 Troubleshooting- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 9-1

9.1 Basic Flow of Troubleshooting - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 9-2

9.2 LED Indicator Meanings - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 9-3

9.3 Problem Classification- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 9-4

9.3.1 Overview - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 9-4

9.3.2 MP2300S Error Check Flowchart - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 9-5

9.4 Troubleshooting Details - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 9-6

9.4.1 Operation Errors - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 9-6

9.4.2 I/O Errors - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 9-9

9.4.3 Watchdog Timer Timeout Errors - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 9-10

9.4.4 Module Synchronization Errors (Ver. 2.75 or Later)- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 9-10

9.4.5 System Errors - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 9-11

xv

Page 16

Appendices - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - A-1

Appendix A System Registers Lists - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - A-3

A.1 System Service Registers - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - A-3

A.2 System Status - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - A-6

A.3 System Error Status - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - A-7

A.4 User Operation Error Status - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - A-9

A.5 System Service Execution Status - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - A-10

A.6 User Operation Error Status Details - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - A-11

A.7 System I/O Error Status- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - A-12

A.8 Compact Flash Card-Related System Registers

(CPU-02 and CPU-03 Modules for the MP2200 Only) - - - - - - - - - - - - - - - - - - - - - - - - - - - - A-13

A.9 Interrupt Status - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - A-14

A.10 Module Information - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - A-15

A.11 MPU-01 System Status - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - A-16

A.12 Motion Program Information - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - A-17

Appendix B SERVOPACK Parameter Data Flow- - - - - - - - - - - - - - - - - - - - - - - - A-20

B.1 Operations and Parameter Data Flow - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - A-20

Appendix C Initializing SERVOPACKs - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - A-29

Appendix D Initializing the Absolute Encoder - - - - - - - - - - - - - - - - - - - - - - - - - - A-30

D.1 Σ-V SERVOPACK - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - A-30

D.2 Σ-III SERVOPACK - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - A-31

D.3 Σ-II SERVOPACK - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - A-32

D.4 Σ-I SERVOPACK - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - A-34

Appendix E Motion Parameter Details - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - A-36

E.1 Fixed Parameter List - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - A-36

E.2 Setting Parameter List - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - A-38

E.3 Monitoring Parameter List - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - A-43

Appendix F Simple Connection Function of the Engineering Tool - - - - - - - - - - - - A-47

F.1 Preparation - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - A-47

F.2 Procedure- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - A-47

Appendix G MSG-SND/MSG-RCV Functions (Ethernet) - - - - - - - - - - - - - - - - - - A-51

G.1 Message Transmit Function (MSG-SND)- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - A-51

G.2 Message Receive Function (MSG-RCV) - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - A-86

G.3 Communication Buffer Channel - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - A-118

Appendix H Optional Functions - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - A-120

H.1 Clearing D Registers at Startup - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - A-120

H.2 Security - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - A-121

H.3 Battery Backup for Table Data - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - A-129

Appendix I Installing MPE720 Version 6 - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - A-133

INDEX

Revision History

xvi

Page 17

Overview

1

Overview

This chapter explains an overview and features of the MP2300S Machine Controller.

1.1 MP2300S Features - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -1-2

1.2 MP2300S Configuration - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -1-3

1.2.1 Basic Module Appearance - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1-3

1.2.2 MP2300S Modules - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1-4

1.3 System Configuration - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -1-5

1.3.1 Example - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1-5

1.3.2 Example of Distributed Synchronizing System - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1-6

1.4 MECHATROLINK Compatible Devices - - - - - - - - - - - - - - - - - - - - - - - - - -1-7

1.4.1 MECHATROLINK-I/II Compatible Devices - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1-7

1.4.2 MECHATROLINK-III Compatible Devices - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1-8

1.5 Cables and Accessories - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -1-9

1.5.1 Cables - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1-9

1.5.2 Accessories and Options - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1-10

1.5.3 Software (Programming Tool) - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1-10

1-1

Page 18

1.1 MP2300S Features

1.1 MP2300S Features

The MP2300S is a small all-in-one machine controller, and successor to the MP2000 series in function and performance. It is characterized by the following standard features:

Standard Feature Motion Network MECHATROLINK-II

• Controls up to 16 axes of servos supporting MECHATROLINK-II.

• Connects up to 21 stations including I/Os.

Standard Feature Ethernet (100 Mbps)

• Allows high-speed communications with the engineering tool MPE720.

• Enables communication without a ladder program by using a touch panel (automatic receive function).

• Enables communication without a ladder program by using an upper PLC (I/O message communication function).

Scalability Ensured in Preparation for Single Optional Slot

• Single optional slot ensures scalability. The existing optional modules of MP2000 series are available.

• An optional module allows the use of various open networks, such as CC-Link, DeviceNet, and PROFIBUS.

• Connecting an SVB-01 module to the optional slot allows the synchronized control of up to 32 axes of servos.

Capable of a Synchronous Distributed System with MECHATROLINK

• The MP2300S has a CPU synchronous function using MECHATROLINK communications. This is a new function in the MP2000 series Machine Controllers.

• A sync operation between slave controllers is made possible by connecting the MP2300S as a slave with an

MP2000 series model as a master via MECHATROLINK-II.

• The controller's load balancing affords a high-speed synchronization of multi-axis motions.

Simple Programming

• The operation procedures needed before performing a motion operation are significantly reduced.

• You can start up a motion program from an upper PLC without the need for programming, simply by creating the

motion program and registering execution orders.

1-2

Page 19

Overview

1.2 MP2300S Configuration

The MP2300S is configured with one Basic Module and an optional slot.

1.2.1 Basic Module Appearance

The following figure shows the external appearance of the Basic Module with metal fittings for attachment.

Also, the values in the figure do not include the length of metal fittings.

Metal fittings

for attachment

1.2 MP2300S Configuration

1.2.1 Basic Module Appearance

64 mm

LED

(8 points)

DIP switch

(6 points+4 points)

Battery cover

MECHATROLINK-Τ

connector

(1 line, 2 ports)

2-pole connector

(RLY OUT)

3-pole connector

(24-V power supply)

MP

$#66'4;

23

0

;#5-#9#

M-I/II

0

S

4&;

#./

/6:

64:

5612

572

+06

%0()

/10

6'56

470

'44

$#6

+2

59

01

10

LIO

01

.& .&

.&

.&

.&

/1&'

I/O

.&

.&

.&

130 mm

59

'

+06

6'56

E

LINK

/

thernet

01

10

&%

8

&%

0V

4.;

176

'

108 mm

Ethernet connector

with LED

Optional slot

1-3

Page 20

1.2 MP2300S Configuration

1.2.2 MP2300S Modules

1.2.2 MP2300S Modules

The following table shows the names and specifications of the Basic Module and Optional Modules.

Group Name Description Model Specifications

Basic Module

Motion

Modules

I/O Modules

Optional

Modules

Communication

Modules

Basic Module MP2300S JAPMC-MP2300S-E

MECHATROLINK

Motion Module

Analog Output Motion

Module

Pulse Output Motion

Module

I/O Module

Output Module DO-01 JAPMC-DO2300(-E) 64 outputs (sink mode output)

Analog Input Module AI-01 JAPMC-AN2300(-E) Analog input, 8 channels

Analog Output Module AO-01 JAPMC-AN2310-E Analog input, 4 channels

Counter Module CNTR-01 JAPMC-PL2300-E Reversible counter, 2 channels

Ethernet Communication Module

General-purpose Serial

Communication

Module

DeviceNet

Communication

Module

PROFIBUS

Communication

Module

FL-net Communication

Module

EtherNet/IP Communication Module

MPLINK/CP-215

Communication

Module

MECHATROLINK-I and -II Interface

Ethernet communications

SVB-01 JAPMC-MC2310(-E)

SVC-01 JAPMC-MC2320-E

SVA-01 JAPMC-MC2300(-E) Analog output, 2 axes maximum

PO-01 JAPMC-PL2310-E Pulse output, 4 axes maximum

LIO-01 JAPMC-IO2300(-E)

LIO-02 JAPMC-IO2301(-E)

LIO-04 JAPMC-IO2303(-E) 32 inputs, 32 outputs (sink mode output)

LIO-05 JAPMC-IO2304(-E) 32 inputs, 32 outputs (source mode output)

LIO-06 JAPMC-IO2305-E

218IF-01 JAPMC-CM2300(-E) RS-232C and Ethernet communications

218IF-02 JAPMC-CM2302(-E)

217IF-01 JAPMC-CM2310(-E)

260IF-01 JAPMC-CM2320(-E) RS-232C and DeviceNet communications

261IF-01 JAPMC-CM2330(-E) RS-232C and PROFIBUS communications

262IF-01 JAPMC-CM2303-E FL-net communications

263IF-01 JAPMC-CM2304-E EtherNet/IP communications

215AIF-01

JAPMC-CM2360(-E)

JAPMC-CM2361(-E)

MECHATROLINK-I and -II Interface

16 axes maximum

MECHATROLINK-III Interface

16 axes maximum

16 inputs, 16 outputs (sink mode output)

1 pulse input

16 inputs, 16 outputs (source mode output)

1 pulse input

8 inputs, 8 outputs, (sink mode output)

Analog input, 1 channel

Analog output, 1 channel

Pulse counter, 1 channel

RS-232C and Ethernet communications (100

Mbps)

RS-232C and RS-422/RS-485 communications

RS-232C, MPLINK, and CP-215 communications

1-4

Note: 1. If the model number has "-E", the product is compliant with RoHS directives.

2. If the model number has "(-E)", both RoHS-compliant and non RoHS-compliant products are available.

Page 21

Overview

1.3 System Configuration

Terminating resistor

130 Ω

Terminating resistor

130 Ω

RLY

OUT

24 VDC

FG

MPE720

MECHATROLINK-II

Ethernet

LIO-01

LIO-02

LIO-04

LIO-05

LIO-06

DO-01

AI-01

AO-01

215AIF-01

216AIF-01

260IF-01

261IF-01

262IF-01

217IF-01

218IF-01

218IF-02

Communication module

SVA-01

SVB-01

PO-01

SVC-01

Motion module

AFMP-01

Other module such as other company's module

Output

Input

RS-232C

215 communications

216 communications

Ethernet

DeviceNet

PROFIBUS

RS-422/485

FL-net

Ether Net/IP

Servo

amplifier

AnyWire

A-net/A-link

Optional module

I/O module

AFMP-02

MPANL00-0

MPALL00-0

MPAL000-0

MPAN000-0

CC-Link

Max. 21 stations including I/O.

(Max. 16 stations servo can be included.)

Ethernet Hub

Upper PLC

CNTR-01

5)&*#'

05

Inverter

I/O

Servo Servo Servo

Repeater

YASKAWA SERVOPACK

200V

SGDS-01A12A

SW1

CHARGE

C

N

3

A/B

C

N

1

C

N

2

C

N

4

L1

L2

L2C

L1C

B1/

B2

U

V

W

C

N

6

YASKAWA SERVOPACK

200V

SGDS-01A12A

SW1

CHARGE

C

N

3

A/B

C

N

1

C

N

2

C

N

4

L1

L2

L2C

L1C

B1/

B2

U

V

W

C

N

6

JEPMC-IO2310

VS mini V7

MP

/

E

thernet

LINK

0

0

23

S

&%

&%

8

4.;

176

0V

;#5-#9#

6'56

4&;

#./

/6:

64:

470

'44

$#6

+2

59

59

10

10

%0()

+06

572

/10

5612

$#66'4;

M-I/II

'

'

6'56

+06

01

01

263IF-01

1.3.1 Example

The following diagram shows an example of system configuration.

1.3 System Configuration

1.3.1 Example

1-5

Page 22

1.3 System Configuration

MP2300S

SVB-01

Module

Τ

MECHATROLINK-

Τ

MECHATROLINK-

Master

Slave

Synchronization

Synchronization

MP

/

'

VJGTPGV

.+0-

0

0

23

S

&%

&%

8

4.;

176

0V

;#5-#9#

6'56

4&;

#./

/6:

64:

470

'44

$#6

+2

59

59

10

10

%0()

+06

572

/10

5612

$#66'4;

M-I/II

'

'

6'56

+06

01

01

+

MP2300S

SVB-01

Module

Slave

MP

/

'

VJGTPGV

.+0-

0

0

23

S

&%

&%

8

4.;

176

0V

;#5-#9#

6'56

4&;

#./

/6:

64:

470

'44

$#6

+2

59

59

10

10

%0()

+06

572

/10

5612

$#66'4;

M-I/II

'

'

6'56

+06

01

01

+

MP2200

MBU-01

POWER

CPU-01

SVB-01

218IF-01

LIO-02

LIO-01

LIO-01

217IF-01

EXIOIF

260IF-01

YASKAWA

MP2100,

MP2200,

MP2300,

MP2300S,

MP2310,

MP2400,

MP2500

SVB-01

TX

ERRRUN

SPD

SIZE

M/S

ON

OFF

10

1

M-I/II

CN1

CN2

SVB-01

TX

ERRRUN

SPD

SIZE

M/S

ON

OFF

10

1

M-I/II

CN1

CN2

1.3.2 Example of Distributed Synchronizing System

For the details on the system configuration example, refer to 4.2.1 ( 1 ) System Layout Model.

Use the connecting cables and connectors recommended by Yaskawa. Always check the device to be used

and select the correct cable for the device.

Different SERVOPACKs are connected to MECHATROLINK-I (4 Mbps) and MECHATROLINK-II (10 Mbps).

Refer to 1.4.1 MECHATROLINK-I/II Compatible Devices and select the appropriate SERVOPACKs.

If devices compatible with MECHATROLINK-I and with MECHATROLINK-II are used together, make the set-

tings for MECHATROLINK-I.

The user must supply the 24-VDC power supply.

When connecting SERVOPACKs via MECHATROLINK, connect the overtravel, zero point return deceleration

limit switch, and external latch signal lines to the SERVOPACKs. For connection, refer to the SERVOPACK’s

manual.

1.3.2 Example of Distributed Synchronizing System

If some MP2300S are connected as slaves and other MP2000-series Machine Controllers are connected via MECHATROLINK-II, slaves can operate synchronously.

Distribution of the load realizes the high-speed synchronization of multiple axes.

1-6

Page 23

Overview

1.4 MECHATROLINK Compatible Devices

SERVOPACKs

Inverters

1.4.1 MECHATROLINK-I/II Compatible Devices

The following devices support MECHATROLINK communications and can be connected to the MECHATROLINK

connectors of the MP2300S and SVB-01 Module.

( 1 ) SERVOPACKs and Inverters

1.4 MECHATROLINK Compatible Devices

1.4.1 MECHATROLINK-I/II Compatible Devices

Drive

Typ e

SGD-N

SGDB-AN

SGDH-E

JUSP-NS100

SGDH-E

JUSP-NS115

SGDS-1

SGDX-1

SJDE-AN

SGDV-1

JUSP-IM

CIMR-G7A

SI-T

CIMR-F7A

SI-T

CIMR-V7AA

SI-T/V7

( 2 ) Modules

JEPMC-IO350

JAMSC-120DDI34330

JAMSC-120DDO34340

JAMSC-120DAI53330

JAMSC-120DAI73330

JAMSC-120DAO83330

JAMSC-120DRA83030

JAMSC-120AVI02030

JAMSC-120AVO01030

JAMSC-120EHC21140

JAMSC-120MMB20230

JAMSC-IO2900-E

JAMSC-IO2910-E

Model Description MECHATROLINK-I MECHATROLINK-II

MECHATROLINK compatible AC SERVOPA CK s

SGDH SERVOPACK

NS100 MECHATROLINK-I Interface Units

SGDH SERVOPACK

NS115 MECHATROLINK-II Interface Units

SGDS SERVOPACKs

SGDX SERVOPACKs

SJDE SERVOPACKs

SGDV SERVOPACKs

MECHATROLINK-II compatible IDMs

Varispeed G7 Inverters

MECHATROLINK interface

Varispeed F7 Inverters

MECHATROLINK interface

Varispeed V7 Inverters

MECHATROLINK interface

Model Description MECHATROLINK-I MECHATROLINK-II

64-point I/O Module

24 VDC, 64 inputs, 64 outputs

DC Input Module

12/24 VDC, 16 inputs

DC Output Module

12/24 VDC, 16 outputs

AC Input Module

100 VAC, 8 inputs

AC Input Module

200 VAC, 8 inputs

AC Output Module

V

100/200

Relay Module

Wide voltage range relay contacts,

8 contact outputs

A/D Module

Analog inputs, −10 to 10 V, 4 channels

D/A Module

Analog outputs, −10 to 10 V, 2 channels

Counter Module

Reversible counter, 2 channels

Pulse Output Module

Pulse output, 2 channels

DC Input Module

12/24 VDC, 16 inputs

DC Output Module

12/24 VDC, 16 outputs

AC, 8 outputs

Ye s N o

Ye s N o

Ye s Ye s

Ye s Ye s

Ye s Ye s

No Yes

Ye s Ye s

No Yes

Ye s Ye s

Ye s Ye s

Ye s Ye s

Ye s N o

Ye s N o

Ye s N o

Ye s N o

Ye s N o

Ye s N o

Ye s N o

Ye s N o

Ye s N o

Ye s N o

Ye s N o

Ye s Ye s

Ye s Ye s

1-7

Page 24

1.4 MECHATROLINK Compatible Devices

1.4.2 MECHATROLINK-III Compatible Devices

Model Description MECHATROLINK-I MECHATROLINK-II

64-point I/O Module

JEPMC-IO2310

JEPMC-IO2330

JEPMC-PL2900

JEPMC-PL2910

JEPMC-AN2900

JEPMC-AN2910

JAPMC-MC2310 SVB-01 Motion Module

JEPMC-REP2000 MECHATROLINK-II Repeater

JEVSA-YV250 MYVIS (image processing device)

JEPMC-MC400 MP940 Motion Controller

24 VDC, 64 inputs, 64 outputs (sink mode

output)

64-point I/O Module

24 VDC, 64 inputs, 64 outputs (source

mode output)

Counter Module

Reversible counter, 2 channels

Pulse Output Module

Pulse output, 2 channels

A/D Module

Analog inputs, −10 to 10 V, 4 channels

D/A Module

Analog outputs, −10 to 10 V, 2 channels

(cont’d)

Ye s Ye s

Ye s Ye s

Ye s Ye s

Ye s Ye s

Ye s Ye s

Ye s Ye s

Ye s Ye s

No Yes

Ye s Ye s

Ye s N o

1.4.2 MECHATROLINK-III Compatible Devices

The following devices support MECHATROLINK communications and can be connected to the MECHATROLINK

connector of the SVC-01 Module.

( 1 ) SERVOPACKs

Model Description

SGDV-21

SGDV-25

( 2 ) Modules

Model Description

JAPMC-MC2320-E

SGDV SERVOPACK MECHATROLINK-III Communications

reference/rotational

SGDV SERVOPACK MECHATROLINK-III Communications

reference/linear

SVC-01 Motion Module

1-8

Page 25

Overview

1.5 Cables and Accessories

1.5.1 Cables

The following table shows the cables that can be connected to the MP2300S Basic Module and Optional Modules.

1.5 Cables and Accessories

1.5.1 Cables

Module

MP2300S

Basic Module

MP2300S

Basic Module

and SVB-01

SVA-01 CN1, CN2

LIO-01/

LIO-02

LIO-04/

LIO-05

LIO-06 CN1

DO-01 CN1, CN2

AI-01 CN1, CN2

AO-01 CN1

CNTR-01 CN1

Connector

Name

Ethernet

M-I/II

I/O

CN1, CN2

Application Model Specifications

Ethernet communication

cable

MECHATROLINK-I

cable

MECHATROLINK-I

terminator

MECHATROLINK-II

cable

MECHATROLINK-II

terminator

Cable for analog reference

input SERVOPACK

External I/O cable

External I/O cable

External I/O cable

External output cable

Analog input cable

Analog output cable

Cable for CNTR-01 Module

Provided by customers.

JEPMC-W6010-

*with a MECHATROLINK

connector and loose

wires

JEPMC-W6020 –

JEPMC-W6002-

*with MECHATROLINK

connectors on both ends

JEPMC-W6003-

*with MECHATROLINK

connectors on both ends

*with ferrite core

JEPMC-W6022 –

JEPMC-W2040-

JEPMC-W2061-

*Loose wires on one end

JEPMC-W6060-

*Loose wires on one end

JEPMC-W2064-

*Loose wires on one end

JEPMC-W6060-

*Loose wires on one end

JEPMC-W6080-

*Loose wires on one end

JEPMC-W6090-

*Loose wires on one end

JEPMC-W2063E-

*Loose wires on one end

–

Used between the devices listed below

SVB-01 and SGD-N

SVB-01 and SGDB-AN

Used between the devices listed below

SVB-01 and I/O Unit,

SVB-01 and SGDH-E+NS100

SVB-01 and SGDH-E+NS115

SVB-01 and SGDS-1

SVB-01 and SGDV-11

SVB-01 and SGDV-15

Used between the devices listed below

SVA-01 and SGDM/SGDH

SVA-01 and SGDS-01

SVA-01 and SGDS-02

Used between

LIO-01/LIO-02 and external I/O device

Used between

LIO-04/LIO-05 and external I/O device

Used between

LIO

06 and external I/O device

-

Used between

DO-01 and external I/O device

Used between

AI-01 and analog external input device

Used between

AO-01 and analog external output device

Used between

CNTR-01 and external I/O device

1-9

Page 26

1.5 Cables and Accessories

1.5.2 Accessories and Options

Module

Communication Module

218IF-01 10Base-T

218IF-02 Ethernet

217IF-01 RS-422/485

260IF-01 DeviceNet

261IF-01 PROFIBUS

262IF-01 FL-net

263F-01 EtherNet/IP

Connector

Name

PORT

(Common to all

communication modules)

Application Model Specifications

Used between

RS-232C port and 25-pin male D-sub

connector

Used between

RS-232C port and DOS/V

Cross cable (Category 3 min.)

Cross or straight cable (Category 5)

Module-side connector:

1010214-52A2JL (manufactured by 3M

Japan Limited)

Cable-side connector:

10114-3000PE (manufactured by 3M

Japan Limited)

Shell: 10314-52A0-008 (manufactured

by 3M Japan Limited)

Module-side connector:

MSTB2-5/5-GF-5.08AM

(manufactured by Phoenix Contact K.K.)

Module-side connector:

17LE-13090-27(D33C) (manufactured

by DDK Ltd.)

Cross or straight cable

(Category 5)

RS-232C communication

cable

Ethernet communication

cable

RS-422/RS-485 communication cable

DeviceNet communication

cable

PROFIBUS communication

cable

Ethernet communication

cable

JEPMC-W5310-

JEPMC-W5311-

Use a commercially available cable.

(cont’d)

1.5.2 Accessories and Options

Name Accessory/Optional Model Remarks

Battery Accessory JZSP-BA01

Power Supply Connector Accessory 721-203/026 Cable side

RLY OUT Connector Accessory 734-YE102-2 Cable side

DIN Rail Mounting Parts Accessory

Terminator

(Terminating Resistor)

Metal Fittings for Attachment Optional JEPMC-OP2300S-E –

Optional Cover Optional JEPMC-OP2300 Front cover for the empty slot

Accessory JEPMC-W6022

1.5.3 Software (Programming Tool)

The MPE720, programming tool for MP2300S, is available.

Name Model Remarks

MPE720

MPE720 Version 6

CPMC-MPE720 (Ver. 5.38 or later) CD-ROM (1 disk)

CPMC-MPE720 (Ver. 6.04 or later) CD-ROM (1 disk)

ER3VC + exclusive use connector

(BA000517)

DIN rail spring Q’ty: 2

DIN rail lock Q’ty: 2

Q’ty: 1

1-10

Page 27

Specifications and Functions

2

Specifications and Functions

This chapter explains detailed specifications for the Basic Module and Optional Modules of the

MP2300S.

2.1 Specifications - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -2-2

2.1.1 General Specifications - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2-2

2.1.2 Product Specifications - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2-3

2.1.3 Function Lists - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2-4

2.2 Basic Module - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2-7

2.2.1 Outline of Functions - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2-7

2.2.2 External Appearance, LED Indicators, and Switch Settings - - - - - - - - - - - - - - - - - - - - 2-8

2.2.3 Specifications - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2-11

2.2.4 218IFA Module (Ethernet) - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2-12

2.2.5 Built-in SVB Module - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2-31

2.2.6 SVR Virtual Motion Module - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2-48

2.2.7 M-EXECUTOR Module (Motion Program Executor) - - - - - - - - - - - - - - - - - - - - - - - - 2-51

2.3 Option Module - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2-62

2.3.1 Option Module Overview List - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2-62

2.4 External Appearance - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2-64

2.4.1 Basic Module - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2-64

2.4.2 Basic Module with Metal Fittings - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2-65

2-1

Page 28

2.1 Specifications

2.1.1 General Specifications

2.1 Specifications

2.1.1 General Specifications

Item Specifications

Ambient Operating Temperature

Ambient Storage Temperature

Environmental

Conditions

Mechanical

Operating

Conditions

Ambient Operating Humidity

Ambient Storage Humidity

Pollution Level Pollution level 1 (conforming to JIS B 3501)

Corrosive Gas There must be no combustible or corrosive gas.

Operating

Altitude

Vibration

Resistance

Shock Resistance

0°C to 55°C

-25°C to 85°C

30% to 95% (with no condensation)

5% to 95% (with no condensation)

2,000 m above sea level or lower

Conforming to JIS B 3502:

• 10 to 57 Hz with single-amplitude of 0.075 mm

• 57 to 150 Hz with fixed acceleration of 9.8 m/s

• 10 sweeps each in X, Y, and Z directions

(sweep time: 1 octave/min.)

Conforming to JIS B 3502:

Peak acceleration of 147 m/s

directions

2

(15 G) twice for 11 ms each in the X, Y, and Z

2

Electrical

Operating

Conditions

Installation

Requirements

Noise Resistance

Ground Ground to 100 Ω max.

Cooling Method Natural cooling

Conforming to EN 61000-6-2, EN 55011 (Group 1, Class A)

Power supply noise (FT noise): 2 Kv min., for one minute

Radiation noise (FT noise): 1 Kv min., for one minute

2-2

Page 29

Specifications and Functions

2.1.2 Product Specifications

The following table shows the product specifications of the MP2300S.

Items MP2300S

External Dimensions

Number of Optional Slots 1 slot

Number of Basic

Control Axes

Number of

Control Axes

MECHATROLINK

Scan Interval

Setting

Communication

I/F

I/O

Memory Capacity

Maximum Number of

Control Axes

Number of Virtual Axis

Controlling Axes

Communication System

Communication Cycle

(MECHATROLINK-II)

Maximum Number of

Connectable Stations

(MECHATROLINK-II)

Slave Function √

Slave Synchronous

Function

High-speed Scan

Low-speed Scan

Ethernet

On-board I/O

Output Signal during

RUN

SDRAM 32 MB

SRAM 512 KB (Battery backup)

FLASH 8 MB

Program Capacity 5.5 MB

64 mm

× 130 mm × 108 mm

16 axes

32 axes (when one SVB-01 module is added.)

16 axes

MECHATROLINK-I,

MECHATROLINK-II (32 byte), or

MECHATROLINK-II (17 byte)

0.5 ms, 1 ms, 1.5 ms, or 2 ms

21 stations (up to 16 servo stations)

√

0.5 ms to 32 ms

(per 0.5 ms)

2.0 ms to 300 ms

(per 0.5 ms)

100Base-TX

1 port

–

(Optional)

√

2.1 Specifications

2.1.2 Product Specifications

Programming

Language

Symbols in the table mean as follows.

Ladder Language √

Motion Language √

Sequence Program √

C Language √

√: Available, –: Not available

2-3

Page 30

2.1 Specifications

2.1.3 Function Lists

2.1.3 Function Lists

( 1 ) PLC Function Specifications

The following table shows the PLC function specifications.

Item Specifications

Control Method

Programming

Language

Scan

User Drawings,

Functions and Motion

Programs

Data Memory

Trace Memory

Memory Backup

Data Types

Register Designation

Method

Instructions

Optional Functions*

Sequence: High-speed and low-speed scan methods

Ladder diagram: Relay circuit

Text-type language: Numeric operations, logic operations, etc.

Two scan levels: High-speed scan and low-speed scan

High-speed scan time setting: 0.5 to 32 ms (Integral multiple of MECHATROLINK communi-

cation cycle)

Low-speed scan time setting: 2 to 300 ms (Integral multiple of MECHATROLINK communi-

cation cycle)

Startup drawings (DWG.A):

Interrupt processing drawings

(DWG.I):

High-speed scan process drawings

(DWG.H):

Low-speed scan process drawings

(DWG.L):

Number of steps:

User functions:

Motion programs and sequence programs:

Revision history of drawings and motion programs

Security function for drawings and motion programs

Common data (M) registers:

System (S) registers:

Drawing local (D) registers:

Drawing constant (#) registers:

Input (I) registers:

Output (O) registers:

Constant (C) registers:

Data trace: 128 kwords (32 kwords × 4 groups), 16 points defined

Program memory: Flash memory: 8 MB (User area: 5.5 MB) definition files,

ladder programs, motion programs, etc.

Data other than battery backup data

Data memory: Battery backup: 512 KB, M registers, S registers, alarm history, trace data

Bit (relay): 0: OFF/1: ON

Integer: −32768 to +32767

Double-length integer: −2147483648 to +2147483647

Real number: ± (1.175E-38 to 3.402E+38)

Register number: Direct designation of register number

Symbolic designation: Up to 8 alphanumeric characters (up to 200 symbols per drawing)

With automatic number or symbol assignment

Program control instructions: 14 instructions

Direct I/O instructions: 2 instructions

Relay circuit instructions: 14 instructions (including set and reset coils)

Logic operation instructions: 3 instructions

Numeric operation instructions: 16 instructions

Numeric conversion instructions: 9 instructions

Numeric comparison instructions: 7 instructions

Data manipulation instructions: 14 instructions

Basic function instructions: 10 instructions

Table data manipulation instructions: 11 instructions

DDC instructions: 13 instructions

System functions: 9 instructions

Clearing D registers at startup

Security

64 drawings max. Up to three hierarchical drawing

levels

64 drawings max. Up to three hierarchical drawing

levels

200 drawings max. Up to three hierarchical drawing

levels

500 drawings max. Up to three hierarchical drawing

levels

Up to 1,000 steps per drawing

Up to 500 functions

A total of up to 256

64 kwords

8 kwords

Up to 16 kwords per drawing

Up to 16 kwords per drawing

32 kwords (including internal input registers)

32 kwords (including internal output registers)

16 kwords

2-4

* For details on optional functions, refer to Appendix H Optional Functions.

Page 31

Specifications and Functions

( 2 ) Motion Control Function Specifications

The following table lists the motion control function specifications for the MP2300S.

Item Specifications

Interface

Number of Controlled Axes/Module

PTP Control

Interpolation

Speed Reference Output

Torque Reference Output

Phase Control

Control

Specifications

Position

Control

Reference Unit

Reference Unit Minimum Setting

Maximum Programmable Value

Speed Reference Unit

Acceleration/Deceleration Type

Acceleration/Deceleration Reference Unit

Override Function

Coordinate System

DEC1+ Phase-C pulse Ye s

ZERO signal Ye s

DEC1+ ZERO signal Ye s

Phase-C pulse Ye s

Only Phase-C pulse Ye s

Zero

Point

Return

POT and Phase-C pulse Yes

POT Ye s

Home limit switch and Phase-C

pulse

HOME Ye s

NOT and Phase-C pulse Ye s

NOT Yes

INPUT and Phase-C pulse Ye s

INPUT Ye s

Positioning Ye s

External positioning Ye s

Zero point return Ye s

Interpolation Ye s

Interpolation with position detection function

JOG operation Ye s

STEP operation Ye s

Parameter changes

during motion command execution

MECHATROLINK-I, MECHATROLINK-II

Up to 16 axes (up to 32 axes when an SVB Modules are mounted)

Linear, rotary, and infinite-length