Page 1

MotionWorks+™ Windows Software and

Icon-Based Programming Manual

Page 2

Page 3

MotionWorks+™

WARNING

YASKAWA manufactures component parts that can be used in a wide variety

of industrial applications. The selection and application of YASKAWA

products remain the responsibility of the equipment designer or end user.

YASKAWA accepts no responsibility for the way its products may be incorporated into the final system design.

Under no circumstances should any YASKAWA product be incorporated into

any product or design as the exclusive or sole safety control. Without

exception, all controls should be designed to detect faults dynamically under

all circumstances. All products designed to incorporate a component part

manufactured by YASKAWA must be supplied to the end user with appropriate warnings and instructions as to that part’s safe use and operation. Any

warnings provided by YASKAWA must be promptly provided to the end user.

YASKAWA offers an express warranty only as to the quality of its products in

conforming to standards and specifications published in YASKAWA’s

manual. NO OTHER WARRANTY, EXPRESS OR IMPLIED, IS OFFERED.

YASKAWA assumes no liability for any personal injury, property damage,

losses, or claims arising from misapplication of its products.

i

Page 4

Notes

MotionWorks+™

ii

Page 5

MotionWorks+™

Contents

1. MotionWorks+™............................................................................................. 3

1.1 System Requirements ...............................................................................................3

1.2 Installation.................................................................................................................3

1.3 Introduction To Software Features.........................................................................4

1.4 Creating A Project ....................................................................................................6

1.5 Saving A Project........................................................................................................8

1.6 The Project Explorer ................................................................................................9

1.6.1 HMI Data .........................................................................................................38

1.6.2 Import/Export Initiation...................................................................................42

1.7 Scope ........................................................................................................................51

1.8 The Block Toolbar ..................................................................................................58

1.9 The Properties Window..........................................................................................59

1.10 The Program Window ............................................................................................60

1.11 Expression Builder..................................................................................................62

1.12 Cross Reference.......................................................................................................65

1.13 Search and Replace.................................................................................................66

1.14 Connecting To The Controller...............................................................................67

1.15 Compiling A Program ............................................................................................71

1.16 Downloading a Project ...........................................................................................72

1.17 Saving a Project to Flash........................................................................................73

1.18 Electronic Cam Tool...............................................................................................74

1.19 Archive...................................................................................................................101

2. Icon-Based Motion Control Programming ...............................................103

2.1 Programming Tools ..............................................................................................103

3. Programming Concept ................................................................................ 105

iii

Page 6

MotionWorks+™

3.1 User Unit Conversion ...........................................................................................127

3.2 Block Reference.....................................................................................................130

3.2.1 CALL SUBROUTINE...................................................................................132

3.2.2 CAM ..............................................................................................................133

3.2.3 CAM SHIFT ..................................................................................................135

3.2.4 CHANGE DYNAMICS ................................................................................137

3.2.5 DEFINE POSITION ......................................................................................138

3.2.6 END ...............................................................................................................139

3.2.7 GEAR.............................................................................................................140

3.2.8 GEAR RATIO ..............................................................................................141

3.2.9 HOME AXIS .................................................................................................142

3.2.10 IF EVENT......................................................................................................144

3.2.11 IF FAULT ......................................................................................................145

3.2.12 INPUT............................................................................................................146

3.2.13 JOG AXIS......................................................................................................147

3.2.14 LATCH ..........................................................................................................148

3.2.15 LATCH TARGET .........................................................................................150

3.2.16 LAUNCH PROGRAM ..................................................................................153

3.2.17 MOVE AXIS .................................................................................................154

3.2.18 PLS.................................................................................................................156

3.2.19 RESET FAULT .............................................................................................158

3.2.20 SCALE CAM.................................................................................................159

3.2.21 SERVO ..........................................................................................................160

3.2.22 SET VARIABLE ...........................................................................................161

3.2.23 SLAVE OFFSET ...........................................................................................162

3.2.24 START...........................................................................................................163

3.2.25 STOP MOTION.............................................................................................164

3.2.26 SUSPEND PROGRAM.................................................................................165

3.2.27 TIMER ...........................................................................................................166

3.2.28 TORQUE .......................................................................................................167

Appendix A Operational Examples .......................................................................................169

Appendix B Standardized Template Project........................................................................177

B.1 Summary........................................................................................................178

B.2 Programs ........................................................................................................179

B.3 Subroutines ....................................................................................................186

Appendix C MW+ Camming 101...........................................................................................201

Index......................................................................................................225

iv

Page 7

MotionWorks+™

Introduction

This manual is divided into two sections. The first section covers the user interface and other features

of the Windows application. The second section covers machine functions in general, and contains

details about the icon-based programming environment and its interface to the controller. Program

examples are included in the appendix.

This manual was updated to correspond with the software version 2.83.

1

Page 8

Notes

MotionWorks+™

2

Page 9

MotionWorks+™ System Requirements

1. MotionWorks+™

1.1 System Requirements

* Microsoft(R) 95/98/NT/2000 operating systems.

* Minimum - 133MHz, 64MB memory, 100MB hard disk space.

* Recommended 350MHz, 128MB memory, 500MB hard disk space.

* High Color (16-bit) Color Palette display setting.

* Microsoft (R-compatible mouse).

* 100MB of free disk space to install the application and all supporting libraries.

1.2 Installation

The installation of MotionWorks+™ consists of three separate programs, which are

automatically installed by the Install Wizard. They are: MotionWorks+™, Electronic

CamTool, and CimScope.

First, remove any previous versions. When removing MotionWorks+™, these three

programs must be removed using the Add/Remove Programs feature of the Windows

control panel. After installation, Windows must be restarted for the installation to be

complete.

3

Page 10

Introduction To Software Features MotionWorks+™

1.3 Introduction To Software Features

MotionWorks+™ incorporates the following features and tools to aid in the creation of

motion control programs.

1. Project Window

Displays and allows editing of application information in a file manager-type

structure.

2. Properties Window

Used to edit and view block information. These are called properties.

3. Program Window

Shows the graphical program layout; i.e., motion control programs are created by

connecting blocks together.

4. Block Toolbar

Used to drag and drop blocks on the Program Window.

4

Page 11

MotionWorks+™ Introduction To Software Features

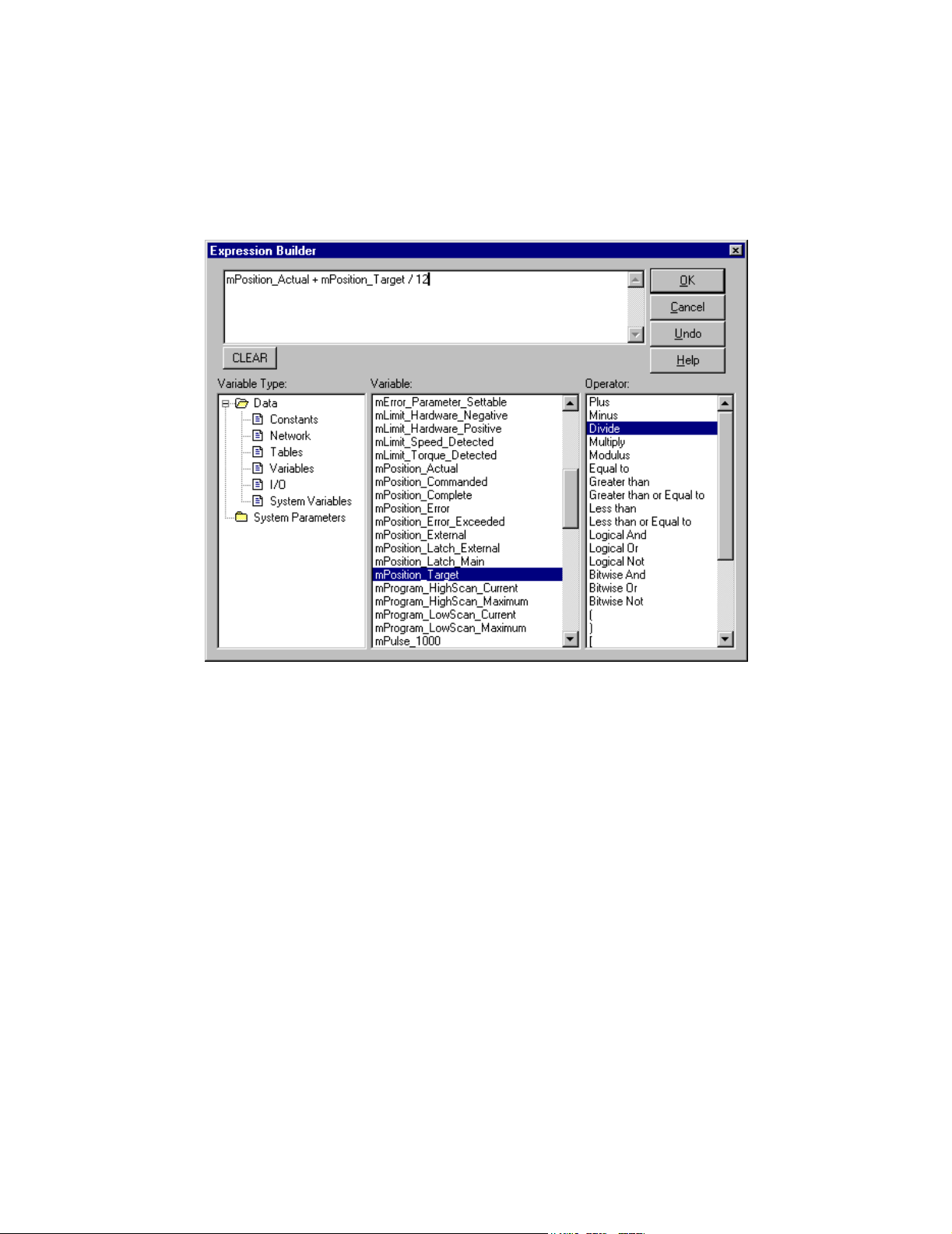

5. Expression Builder (below)

Accessible by double-clicking on block properties. It aids in creating calculations for

a variety of purposes.

6. The Debugging Tools consist of the following:

• Monitoring / Data - View and change data values online.

• Monitoring / I/O - Displays a graphical view of I/O data and other system variables

for verification of hardware connections and debugging.

• Monitoring / Program - Displays current block numbers for all active programs and

shows the program and subroutine names.

• Monitoring/Scope - Records specific information in the controller, then uploads it to

MW+ for display as a graph.

5

Page 12

Creating A Project MotionWorks+™

1.4 Creating A Project

A project is a collection of files, all of which pertain to a specific job. Each project

occupies its own directory for easy portability.

Accessibility

To access the New Project dialog box select:

• From the Main Menu > File > New Project

• From the Standard Toolbar > New > New Project (from the drop down list)

• Hot Key: Ctrl+N

1. Input the project name and file system location. The length of the project name may be up

to 255 characters, including spaces. Characters not allowed in the project name are /, \, :,

*, ?, “, <, >, and |.

2. Display the New Program dialog box to add a program to the project. This can be done

either from the main menu, or from the Project Explorer by selecting Project > Add - Program > New Program. The following window appears:

3

2

4

5

1

6

Page 13

MotionWorks+™ Creating A Project

1. New Program Name

The character restrictions applying to the project name apply to the program name.

Characters not allowed in the project name are /, \, :, *, ?, “, <, >, and |.

2. Program Number

In addition to creating a name, select a program number. Add programs to empty

locations or replace existing programs by clicking any of the program numbers in the

list.

3. Scan Type

There are two choices for scan speed: high and low. Priority levels must be

considered when selecting scan speed. For example, high speed is recommended for

critical I/O that must be monitored frequently. Low speed is sufficient for low priority

events such as operator push buttons. Each program executes one block in the scan

period.

Note: High and low scans must be an even multiple of each other. For eaxmple: 2/10,

4/16, etc.

4. Active

Select the Active checkbox to indicate whether the program is to be incorporated

during project compilation. During project debugging, it may be helpful to deactivate

certain programs to isolate problems. Deactivated programs will not be compiled or

downloaded.

5. Autostart

The Autostart checkbox indicates whether the program automatically executes its

START block when the power is initially turned on. If Autostart is not selected,

programs can be launched later by incorporating a LAUNCH PROGRAM block in

another program. At least one program in the project must be selected for autostart in

order to ensure execution.

7

Page 14

Saving A Project MotionWorks+™

1.5 Saving A Project

All files contained in the project are saved when the SAVE icon is pressed. If the project

is not saved before exiting MotionWorks+™, a Save Project window appears. All the

files that have been changed are displayed. Select the files to be saved at this time. (The

default is to save all changed files.) The user must de-select the names of any files that

are not to be saved. The Cancel button aborts closing MotionWorks+™, and does not

save any files.

Accessibility

To save a project, select

• From the Main Menu > File > Save Project

• From the Standard Toolbar > Save

8

Page 15

MotionWorks+™ The Project Explorer

1.6 The Project Explorer

Project Explorer is used to navigate among windows in the main programming area.

This window can be dragged, resized, docked, and undocked. All folders and their

documents are shown below. To view any of the items below, double-click on the file.

Accessibility

To open the Project Explorer, select

• From the Main Menu View > Project Explorer

Programs

This folder contains a list of all programs within the project. A maximum of eight

programs can be created.

Accessibility

To view programs and create new programs:

• Right-click on the project name or the Programs folder. Select New Program from

the sub-menu.

9

Page 16

The Project Explorer MotionWorks+™

Program Definition

The Program Definition window displays the properties of each program within the

project. The properties may be edited on this screen.

Accessibility

The Program Definition window is displayed as follows:

• Automatically appears when a new program is created

• From Project Explorer > right-click on the project name > select Program Definition

from the sub-menu

• From Project Explorer > right-click on Programs > select Program Definition from

the sub-menu

• From the Main Menu > Project > Program > Definition

Scan Type

Select either High or Low scan for each of the projects programs. This configuration

determines the interval that blocks are executed.

Active

This setting controls if a program is included in the compile & download. Useful for

debugging.

10

Page 17

MotionWorks+™ The Project Explorer

Auto Start

The setting controls which programs start executing automatically when the power is

applied. Programs set to “Auto Start=false” can be started later using the LAUNCH

block.

Subroutine Definition

When New Subroutine is selected, a new untitled program window is added to the

project; the START and END blocks automatically appear. The File > Save Subroutine

As function is recommended at this time. The new subroutine does not appear in Project

Explorer until it has been named.

Accessibility

To access the subroutine definitions, select:

• From the Main Menu > Project > New

• From the Standard Toolbar > New > Subroutine

• From the Project Explorer > right-click on the project name > Subroutine > New

Configuration

System Parameters

The system parameters are mainly comprised of tuning gains and limit settings. The

tool tip of each parameter shows the operation mode in which each gain applies. The

parameters can be written to the hard disk. Parameters can also be read from or written to the controller.

Accessibility

To access the system parameters, select:

• From the Project Explorer > Configuration > System Parameters

• From the Main Menu > Project > Configuration > System Parameters

11

Page 18

The Project Explorer MotionWorks+™

Important Note!!

Parameters are updated in the controller after a value is changed if MotionWorks+™ is online with the controller. However, if the new values are to be saved

with the project and retained after power cycle, the project must be downloaded.

12

Page 19

MotionWorks+™ The Project Explorer

System Properties

Systems properties allow the controller to be configured using the windows shown

below.

Accessibility

To access the System Properties, select

• From the Project Explorer > Configuration > System Properties

• From the Main Menu > Project > Configuration > System Properties

• System Properties already open, but not visible; From the Main Menu > Window

List

Right clicking on any of the modules will display a menu with following choices:

• Get from the controller

• Import

• Export

• Restore default

• Send to controller

These menu items are available when right clicking on any of the components in system

properties. Their actions affect only the component selected.

Important Note: Performing “Send to Controller” will suffice when making changes that

are to be permanently stored in controller memory with the exception of the MP940 and

External Encoder properties. For these two modules only, the changes are only

temporary, meaning that the power on values will be from the last project download.

Machine Cycles

MW+ does not support support machine cycles with fractional pulses. This may present

a problem for applications such as flying shear / web handling / camming. In general,

axes that are set to “Rotary” mode will suffer from fractional pulses being “lost” each

machine cycle. To determine if the system has fractional pulses, perform the following

check:

Encoder

Resolution

131072

Gear Box Machine

43 Input

--------------------------

× 17×

11 Output

Cycle

Feed

Constant

360 Units

-------------------------

÷ 8710330.188888=

1 rev

Machine Cycle Counts

As can be seen from the machine cycle count, a loss of .19 cycles will occur with each

revolution. Compensate for this loss by using the Slave Offset function. For an introduction on using the Slave Offset function, see “How does SLAVE OFFSET work? How

would an application benefit from using slave offset?” on page 220.

13

Page 20

The Project Explorer MotionWorks+™

14

Page 21

MotionWorks+™ The Project Explorer

SGDH

When the SGDH module is selected, the following properties appear in the properties window: When an MP940 controller is used with an SGDH, it is recommended to set the

parameters of the amplifier through the controller instead of the front panel of the amplifier. This method ensures that parameter values are retained with the project and downloaded properly.

Property Default Min Max Details (online Help message)

Pn000 90 0 0FB1 Function Selection Basic Switches. See sections 5.1.1 and

5.3.5 of SGDH manual.

Pn001 0 0 1122 Function Selection Application Switches 1. See sections 5.1.2,

5.4.2, and 5.5.7 of SGDH manual.

Pn002 11 0 4113 Function Selection Application Switches2. See sections 5.2.8,

5.2.9, and 5.7.2 of SGDH manual.

Pn003 2 0 00FF Function Selection Application Switches 3. See section 6.5 of

SGDH manual.

Pn100 40 1 2000 Speed Loop Gain in Hz. This is an important component of

servo tuning, this parameter acts as the derivative gain. See

section 6.2.1 of SGDH manual.

Pn101 2000 15 51200 Speed Loop Integral Time Constant in 0.01ms. This is an impor-

tant component of servo tuning. See section 6.2.1 of SGDH

manual.

15

Page 22

The Project Explorer MotionWorks+™

Property Default Min Max Details (online Help message)

Pn102 40 1 2000 Position Loop Gain in 1/s. This parameter is not applicable

when using MP940. See section 6.2.1 of SGDH manual.

Pn103 100 0 10000 Inertia Ratio in percentage. See sections 6.2.1 and 6.3.3 of

SGDH manual.

Pn104 40 1 2000 2nd Speed Loop Gain in Hz. This parameter is switchable with

Pn100 based on user input. This is an important component of

servo tuning, this parameter acts as the derivative gain. See

section 6.2.1 of SGDH manual.

Pn105 2000 15 51200 2nd Speed Loop Integral Time Constant in 0.01 ms. This

parameter is switchable with Pn101. This is an important component of servo tuning. See section 6.2.1 of SGDH manual.

Pn106 40 1 2000 2nd Position Loop Gain in 1/s. This parameter is not applicable

when using MP940. See section 6.2.1 of SGDH manual.

Pn107 0 0 450 Bias in rpm. See section 6.2.4 of SGDH manual.

Pn108 7 0 250 Bias Width Addition in reference units. See section 6.2.4 of

SGDH manual.

Pn109 0 0 100 Feed Forward in percentage. This parameter is not applicable

when MP940 is used. Use pGain_FeedForward. See section

6.2.2 of SGDH manual.

Pn10A 0 0 6400 Feed-forward Filter Time Constant in 0.01ms. This parameter

is not applicable when MP940 is used. See section 5.2.5 of

SGDH manual.

Pn10B 0004 0000 2014 Gain-related Application Switches. See section 6.2.5 of SGDH

manual.

Pn10C 200 0 800 Mode Switch Torque Reference in percentage. See section

6.2.5 of SGDH manual.

Pn10D 0 0 10000 Mode Switch Speed Reference in rpm. See section 6.2.5 of

SGDH manual.

Pn10E 0 0 3000 Mode Switch Acceleration in 10rpm/s. See section 6.2.5 of

SGDH manual.

Pn10F 0 0 10000 Mode Switch Error Pulse in reference units. This parameter is

not applicable when using MP940. See section 6.2.5 of SGDH

manual.

Pn110 0012 0000 2014 Online Autotuning Switches. See section 6.3.4 of SGDH man-

ual.

Pn111 100 1 100 Speed Feedback Compensation in percentage. See section

6.2.6 of SGDH manual.

Pn200 0 0 1239 Position Control Reference Selection Switches. This parameter

is not applicable when using MP940. See section 5.2.2 of

SGDH manual.

Pn201 16384 16 16384 PG Divider in pulses per revolution. This parameter is not

applicable when using MP940. See section 5.2.3 of SGDH

manual.

Pn202 16384 16 16384 Electronic Gear Ratio (Denominator). This parameter is not

applicable when using MP940. See section 5.2.5 of SGDH

manual.

16

Page 23

MotionWorks+™ The Project Explorer

Property Default Min Max Details (online Help message)

Pn203 1 1 65535 Electronic Gear Ratio (Denominator). This parameter is not

applicable when using MP940. See section 5.2.5 of SGDH

manual.

Pn204 0 0 6400 Position Reference Accel/Decel Parameter in 0.01ms. This

parameter is not applicable when using MP940. See section

6.1.2 of SGDH manual.

Pn205 65535 0 65535 Multi-turn Limit Setting in revolutions. This parameter is not

applicable when using MP940. See section 6.1.2 of SGDH

manual.

Pn206 16384 513 65535 Reserved in pulses per revolution. This parameter is not appli-

cable when using MP940. See section 6.1.2 of SGDH manual.

Pn207 0 0 11 Position Control Function Switches. This parameter is not

applicable when using MP940. See sections 5.2.9 and 6.1.2 of

SGDH manual.

Pn208 0 0 6400 Position Reference Movement Averaging Time in 0.01ms.

This parameter is not applicable when using MP940. See sec-

tion 6.1.2 of SGDH manual.

Pn300 600 150 3000 Speed Reference Input Gain in 0.01volt / rated speed. See sec-

tion 5.2.1 of SGDH manual.

Pn301 100 0 10000 Speed 1in rpm. See section 5.2.6 of SGDH manual.

Pn302 200 0 10000 Speed 2 in rpm. See section 5.2.6 of SGDH manual.

Pn303 300 0 10000 Speed 3 in rpm. See section 5.2.6 of SGDH manual.

Pn304 500 0 10000 Jog Speed in rpm. See section 5.3.2 of SGDH manual.

Pn305 0 0 10000 Soft Start Acceleration Time in ms. See section 6.1.1 of SGDH

manual.

Pn306 0 0 10000 Soft Start Deceleration Time in ms. See section 6.1.1 of SGDH

manual.

Pn307 40 0 65535 Speed Reference Filter Time Constant in 0.01ms.

Pn308 0 0 65535 Speed Feedback Filter Time Constant in 0.01ms. See section

6.2.6 of SGDH manual.

Pn400 30 10 100 Torque Reference Input Gain in 0.1V / rated torque. See sec-

tion 5.2.7 of SGDH manual.

Pn401 100 0 65535 Torque Reference Filter Time Constant in 0.01ms. See section

6.1.5 of SGDH manual.

Pn402 800 0 800 Forward Torque Limit in % of rated torque. See section 5.1.3 of

SGDH manual.

Pn403 800 0 800 Reverse Torque Limit in % of rated torque. See section 5.1.3 of

SGDH manual.

Pn404 100 0 800 Forward External Torque Limit in % of rated torque. See sec-

tion 5.1.3 of SGDH manual.

Pn405 100 0 800 Reverse External Torque Limit in % of rated torque. See sec-

tion 5.1.3 of the SGDH manual.

Pn406 800 0 800 Emergency Stop Torque in % of rated torque. See section 5.1.2

of SGDH manual.

Pn407 10000 0 10000 Speed Limit during Torque Control in rpm. See section 5.2.7 of

SGDH manual.

17

Page 24

The Project Explorer MotionWorks+™

Property Default Min Max Details (online Help message)

Pn408 0 0 1 Torque Function Switches. See section 6.1.6 in SGDH manual.

Pn409 2000 50 2000 Notch Filter Frequency in Hz. Only effective when the SGDH is

used in torque mode. See section 6.1.6 in SGDH manual.

Pn500 7 0 250 Positioning Completed Width in pulses. It is recommended to

use sPosition_CompletionWindow instead. See section 5.5.3

of SGDH manual.

Pn501 10 0 10000 Zero Clamp Level in rpm. See section 5.4.3 in SGDH manual.

Pn502 20 1 10000 Rotation Detection Level in rpm. See section 5.5.5 of SGDH

manual.

Pn503 10 0 100 Speed Coincidence Signal Output Width in rpm. See section

5.5.4 of SGDH manual.

Pn504 7 1 250 NEAR Signal Width in pulses. See section 5.5.8 of SGDH man-

ual.

Pn505 1024 1 32767 Overflow Level in 256 pulses. This parameter is not applicable

when the SGDH is used with the MP940. See section 6.2.1 of

SGDH manual.

Pn506 0 0 50 Brake Reference Servo OFF Delay Time in 10ms. See section

5.4.4 of SGDH manual.

Pn507 100 0 10000 Brake Reference Output Speed Level in rpm. See section 5.4.4

of SGDH manual.

Pn508 50 10 100 Timing for Brake Reference Output during Motor Operation in

10ms. See section 5.4.4 of SGDH manual.

Pn509 20 20 1000 Momentary Hold Time in ms. See section 5.4.9 of SGDH man-

ual.

Pn50A 2881 0 FFFF Input Signal Selections 1. See section 5.3.3 of SGDH manual.

Pn50B 8883 0 FFFF Input Signal Selections 2. See section 5.3.3 of SGDH manual.

Pn50C 8888 0 FFFF Input Signal Selections 3. See section 5.3.3 of SGDH manual.

Pn50D 8888 0 FFFF Input Signal Selections 4. See section 5.3.3 of SGDH manual.

Pn50E 3211 0 3333 Output Signal Selections 1. See section 5.3.4 of SGDH man-

ual.

Pn50F 0 0 3333 Output Signal Selections 2. See section 5.3.4 of SGDH manual.

Pn510 0 0 33 Output Signal Selections 3. See section 5.3.4 of SGDH man-

ual.

Pn511 6541 0 FFFF Input Signal Selections 5. See section 5.3.3 of SGDH manual.

Pn512 0 0 111 Output Signal Reversal Settings. See section 5.3.4 of SGDH

manual.

Pn600 0 0 9000 Regenerative Resistor Capacity in watts. See section 5.6.1 of

SGDH manual.

18

Page 25

MotionWorks+™ The Project Explorer

COM1

When the COM1 module is selected, the following properties appear in the properties

window.

Property Default Minimum Maximum Detail

Address 1 0 63 —

Baud Rate 19200 9600 19200 —

Function Slave — — —

Protocol Memobus — — Fixed

Transmission Mode RTU — — Fixed

Address: Select between 0 and 63.

Baud Rate: The choices are 9600 and 19200bps.

Function: Fext at “Slave”.

Protocol: This is fixed at Memobus for MW+ projects.

Transmission Mode:

This is fixed at RTU for MW+ projects.

19

Page 26

The Project Explorer MotionWorks+™

COM2

When the COM2 module is selected, the following properties appear in the properties

window.

Property Default Minimum Maximum Detail

Address 1 0 63 —

Baud Rate 19200 9600 19200 bps

Function Slave — — Selection

Protocol Memobus — — Fixed

Transmission Mode RTU — — Fixed

Transmission Type RS422 RS422 RS485 Selection

Address: Select between 0 and 63.

Baud Rate: The choices are 9600 and 19200

Function: Fixed at “Slave”.

Protocol: This is fixed at Memobus for MW+ projects.

Transmission Mode:

This is fixed at RTU for MW+ projects.

Transmission Type:

RS 422 and RS 485 are the 2 choices.

20

Page 27

MotionWorks+™ The Project Explorer

MP940

When the MP940 module is selected, the following properties appear in the properties

window.

Note: When right clicking on this module, the properties can be sent to the controller,

but only to RAM. Compile & Download is required to retain values after power cycle.

Property Default Minimum Maximum Detail

Battery Test Disabled Enabled Disabled Setting

Encoder Resolution 8192 8 2147483647 Counts

Encoder Type Incremental Absolute Incremental Selection

Feed Constant 1 0.001 8338608 Constant

Gear Box Input 1 1 32767 Numerator

Gear Box Output 1 1 32767 Denominator

High Scan Setting 1 1 32 ms

Load Type Linear Linear Rotary Setting

Low Scan Setting 20 10 100 ms

Machine Cycle 1 0.001 2147483647 Modulus

Motor Rated Speed 3000 1000 10000 rpm

User Units Inch N/A N/A —

Battery Test: If enabled, the controller tests the battery voltage and sets the

battery alarm LED on the front of the controller accordingly,

and sets mAlarm_Battery.

If disabled, the battery alarm LED does not light.

Encoder Resolution:

Set the quadrature number of encoder pulses per motor revolution.

Encoder Type: Select either “incremental” or “absolute”. This setting deter-

mines whether the MP940 automatically reads the absolute

encoder at power up.

Feed Constant: The number in user units that the load travels for each revolu-

tion of the final output shaft of the mechanical system.

Final Output Shaft Detail Feed Constant

Ball screw 6mm pitch 6

Conveyor belt roller = 4in diameter

Belt and pulley last pulley = 10in diameter

4 x

10 x

π

π

Gear Box Input: If a mechanical gear box is used, enter the value which corre-

21

Page 28

The Project Explorer MotionWorks+™

sponds to the number of times the input shaft rotates for the

number of times the output shaft rotates. These are integer values. If a 10:1 gear box is used, enter “10” for the gear box

input.

Gear Box Output:

If a mechanical gear box is used, enter the value which corresponds to the number of times the input shaft rotates for the

number of times the output shaft rotates. These are integer values. If a 10:1 gear box is used, enter “1” for the gear box output.

High Scan Setting:

This value determines the interval at which blocks are executed

in high scan programs. One block from each high scan program

will execute in this time interval, some will take longer based

on specific block conditions.

Load Type: Select either linear or rotary. Linear implies an axis that has

finite travel range. Rotary implies an axis that rotates in one

direction only, but with a cyclic period. When “Rotary” is

selected, the position data is automatically modularized to fit

within one cyclic period or machine cycle.

Low Scan Setting:

This value determines the interval at which blocks are executed

in low scan programs.

Machine Cycle: This is the maximum position value of the main axis. When

this value is reached, the position will indicate “0”. Machine

cycle is only applicable if Load Type is set to “Rotary”. If the

application is a rotary table, this value may be the same as the

Feed Constant. Note: If the machine cycle in user units does

not equate to an integer number of pulses, the positioning units

will drift. In this case, program an offset at periodic intervals to

compensate for lost pulses. See note at the beginning of the

System Property section about Machine Cycle limitations.

Motor Rated Speed:

Enter the rated speed of the motor in rpm.

User units: Select from “centimeters”, “degrees”, “inches”, “microns”,

“millimeters”, or “pulses”. Custom units may also be entered.

22

Page 29

MotionWorks+™ The Project Explorer

External Encoder

When external encoder is selected, the following properties appear in the properties

window.

These properties are effective for both real and virtual encoders. A virtual encoder is

useful for simulating a machine or creating a time based cam profile. The system

properties for External encoder apply for either mode, making the user units the same.

The virtual encoder is activated by setting the system variable sExternalMode to “1”.

Note: When right clicking on this module, the properties will be sent to the controller,

but only to RAM. Compile & Download is required to retain values after power cycle.

Property Default Minimum Maximum Detail

Enabled False False True Setting

Feed Constant 1 0.001 8338608 Constant

Gear Box Input 1 1 32767 Numerator

Gear Box Output 1 1 32767 Denominator

Machine Cycle 1 .001 2147483647 Modulus

Movement Type Rotary Linear Rotary Setting

Pulse Type Quadrature Pulse & Direction Quadrature Setting

Resolution 2048 8 2147483647 Counts

User Units Degrees N/A N/A —

Enabled:If Enabled is “True”, the MP940 expects an encoder to be con-

nected (i.e., an alarm is set if no encoder is connected). If a virtual encoder is used, set enabled=false, or an A9F alarm will

result.

Feed Constant: The number in user units that the load travels for each revolu-

tion of the final output shaft of the mechanical system.

Final Output Shaft Detail Feed Constant

Ball screw 6mm pitch 6

Conveyor belt roller = 4in diameter

Belt and pulley last pulley = 10in diameter

4 x

10 x

π

π

Gear Box Input: If a mechanical gear box is used, enter the value which corre-

sponds to the number of times the input shaft rotates for the

number of times the output shaft rotates. These are integer values. If a 10:1 gear box is used, enter “10” for the gear box

input.

23

Page 30

The Project Explorer MotionWorks+™

Gear Box Output: If a mechanical gear box is used, enter the value which corre-

sponds to the number of times the input shaft rotates for the

number of times the output shaft rotates. These are integer values. If a 10:1 gear box is used, enter “1” for the gear box output.

Machine Cycle: This is the maximum position value of the external axis. When

this value is reached, the position wraps back to “0”. Machine

cycle is only applicable if Movement Type is set to “Rotary”. If

the application involves camming, the machine cycle may be

the product length. Note: If the machine cycle in user units

does not equate to an integer number of pulses, the positioning

units will drift. In this case, program an offset at periodic intervals to compensate for lost pulses. See note at the beginning of

the System Property section about Machine Cycle limitations.

Movement Type: Select either “linear” or “rotary”. Rotary implies an axis that

rotates in one direction only, but with a cyclic period. The position data is automatically modularized to fit within one cyclic

period or machine cycle when rotary is selected.

Pulse Type: Select “Quadrature”, “Reverse Quadrature”, “Pulse & Direc-

tion”, or “Reverse Pulse & Direction”.

Resolution: The number of quadrature pulses per revolution of the external

encoder.

User Units: Select from “centimeters”, “degrees”, “inches”, “microns”,

“millimeters”, or “pulses”. Custom units may also be entered.

24

Page 31

MotionWorks+™ The Project Explorer

Network

Property Default Minimum Maximum Detail

Cycle Time 10 0 1000 mSec

Enabled False False True Setting

Function Slave Master Slave Selection

Input Words 8 0 8 / 512 Word count

Message Type Polled Polled Strobed Devicenet

Name “Network” 0 Characters 8 Characters —

Node 1 0 99 —

Output Words 8 0 8 / 512 Word count

Refresh Rate Low Low High Scan

Slave Nodes N/A 1 99 —

Type Mechatrolink DeviceNet Mechatrolink Selection

Cycle Time: Applicable for Devicenet networks when the MP940 is acting

as the master. This is the update rate of the network and effects

traffic load.

Enabled: Select whether the network is enabled or not.

Function: If Function is set to “Master”, the default Node is automatically

set to “0”. If Function is set to “Slave”, Node is automatically

set to “1” only if Node is currently set to “0”.

Message Type: The property is only applicable when the “Type” property is set

to Devicenet. Select either Polled or Strobed. This setting

determines how messages from the master are send. Strobed

can increase network efficiency if there are several identical

slaves.

Input Bytes/Words:

This property is only enabled if the Function property is set to

“Slave”. It defines the number of input bytes/words for the

MP940 as a slave. If the Function property is set to “Master”

then the total input bytes/words are determined from the Slave

Node list. Note: If network Type is set to DeviceNet, this property defines the number of Input Bytes.

Name: Provide a description of the network device that will be useful

in identifying this node. The name will also be used if the network variable “Allocation Wizard” is used.

25

Page 32

The Project Explorer MotionWorks+™

Node: Set the address of the module. The maximum value is depen-

dant on the Type property. Mechatrolink is “29”; DeviceNet is

“64”.

Output Bytes/Words:

This property is only enabled if the Function property is set to

“Slave.” It defines the number of output bytes/words for the

MP940 when configured as a slave. If the Function property is

set to “Master,” the total output words are determined from the

Slave Node list. Note: If the network Type is DeviceNet, this

property defines the number of Output Bytes.

Refresh Rate: Select either “High” or “Low” scan. This is the period in which

all network data are updated.

Slave Nodes: This property is only enabled if the Function property is set to

“Master.” It defines the number of slaves on the network. If

Function is set to “Slave,” then Nodes automatically displays

“N/A”.

Type: Select either DeviceNet or Mechatrolink.

26

Page 33

MotionWorks+™ The Project Explorer

Remote I/O

Remote I/O only appears on the System Properties window if the Network Function is

set to “Master”.

Property Default Minimum Maximum Detail

Message Type Polled Polled Strobed Devicenet

Input Words N/A 0 512 Word

Name N/A 0 characters 8 Characters —

Node 1 1 99 —

Node Type N/A See list below See list below Selection

Output Words N/A 0 512 Word

Message Type: The property is only applicable when the Network “Type” prop-

erty is set to “Devicenet.” Select either Polled or Strobed. This

setting determines how messages from the master are send.

Strobed can increase network efficiency if there are several

identical slaves.

Input Words: This property is only enabled if the Node Type property is set to

“User Defined”. This is the number of input words allocated to

this node. Note: If the network Type is DeviceNet, this property defines the number of Input Bytes.

Name: Provide a description of the network device that will be useful

in identifying this node. The name will also be used if the network variable “Allocation Wizard” is used.

Node: Set the address of the module. This applies to DeviceNet and

Mechatrolink. The maximum value is dependant on the Type

property. Mechatrolink is “29”; DeviceNet is “64.”

Node Type: This is a list of all available Mechatrolink nodes. When a par-

ticular module is selected, the input and output words are automatically set.

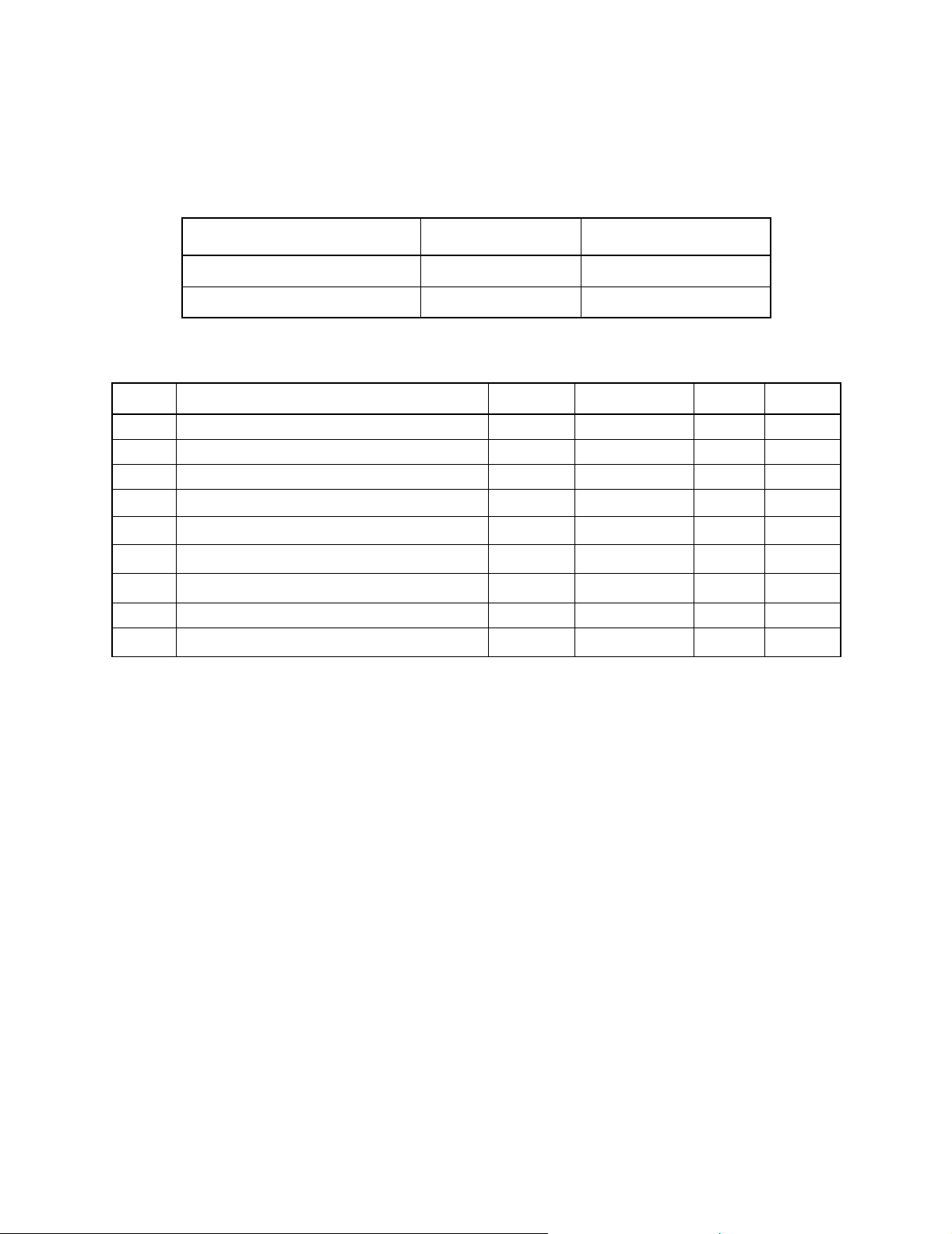

Mechatrolink Node Input Words Output Words

16pt 120VAC Input 1 0

16pt 240VAC Input 1 0

16pt Digital Input 1 0

16pt Digital Output 0 1

2ch Analog Output 2 4

4ch Analog Input 7 2

64/64pt Digital Input/Output 4 4

8pt 120-240VAC Output 0 1

27

Page 34

The Project Explorer MotionWorks+™

Mechatrolink Node Input Words Output Words

8pt Relay Output 0 1

MP940 8 8

User Defined Undefined Undefined

Output Words: This property is only enabled if the Node Type property is set to

“User Defined.” This is the number of output words allocated

to this node. Note: If the network Type is DeviceNet, this property defines the number of Output Bytes.

Data

There are six data types available for use throughout the program:

Constant

I/O

Network

System Variable

Table

Variable

Each is described in the following sections.

General Information

• Data names may be up to 32 characters.

• All names are case sensitive.

• All names must be unique across all data types.

Data Type Minimum Maximum

bit 0 1

float

integer -32768 32767

long -2147483648 2147483647

-3.402832

e-38

3.402823

e38

The resolution for data defined as “float” is seven significant digits as shown above.

To delete data, click on the gray cell to the left of the data column in the row to be

deleted, and press the Delete key.

To sort data, click on the title row of the column by which sorting should occur.

28

Page 35

MotionWorks+™ The Project Explorer

Constant Definition

Constants are added using the Constant Definition window that appears below. The

memory range for constants is 32,767 integers. If longs, floats, and bits are used, the

maximum number of constants is affected accordingly.

Accessibility

To access the constant definitions.

• From the Project Explorer > Data > Constants

• From the Main Menu > Project > Data > Constants

1

1. Name

The user-given field name of the constant.

2

3

4

5

2. Type

This field determines the potential magnitude of the constant.

3. Value

This field sets the value of the constant. Constants cannot be changed by the program

at run time.

4. Base Address

This field is a read only field indicating the register location of the constant in the

controller memory. This is provided for debugging with MotionWorks or accessing

data via Memobus serial communication.

29

Page 36

The Project Explorer MotionWorks+™

5. Comments

This field provides a location to document constant usage.

Network Definition

Network data are added using the Network Definition window that appears below.

Accessibility

To access the network definitions, select:

• From the Project Explorer > Data > Network

• From the Main Menu > Project > Data > Network

1

2

3

4

5

7

6

8

9

1. Name

The user-given name of the network data.

2. Node

This column only appears if Network Function is set to “master.” The cells in this

column contain a drop-down box that lists the remote I/O nodes configured.

3. Type

This field determines the potential magnitude of the data.

30

Page 37

MotionWorks+™ The Project Explorer

4. Initial Value

This field presets the value of the data when the power is turned on. If no initial value

is entered, the data is not initialized when the power is turned on (which is useful for

preserving data values when the power is cycled).1

5. Starting Word

The cells in this column contain a drop-down box. The contents are a list of valid

words starting at zero. The maximum value is derived from either of two places,

depending on the configuration of the controller, as follows:

• If the controller is configured as a network master, the Starting Word range is

defined by the System Properties > Remote I/O Block > Input/Output Word

properties.

• If the controller is configured as a network slave, the Starting Word range is defined

by the System Properties > Network Block > Input/Output Word properties.

6. Bit

This selection is only available if the Type is “input bit” or “output bit”. Select “0”

through “F” from the drop-down list. If a bit type variable is not defined, this cell

appears gray, and cannot be set. Also, under DeviceNet configuration, if an odd

number of bytes are defined, the drop-down list only shows “0-7” if the final “Starting

Word” is selected.

7. Base Address

This field is a read only field indicating the register location of the data in the

controller memory. This is provided for debugging with MotionWorks™ or accessing

data via Memobus serial communication. Base Address is determined by the information specified in the Node, Starting Word, and Bit columns.

8. HMI Checkbox

This field is used to set data to be written to the HMI export file.

31

Page 38

The Project Explorer MotionWorks+™

Allocation Wizard

If several network data of the same type are required, the Allocation Wizard can

automatically create data names based on user-provided input. The automaticallycreated names include the node name and I/O type.

1. Possible only when the battery option is installed to preserve RAM when power is OFF.

For example, the created names may appear as in the text box of the figure below.

2 3 4

1

1. Node

This drop-down box contains the node number and name of each slave as defined in

System Properties of the Configuration. If the controller is configured as a network

slave, the Node box is disabled.

2. Type

This field determines the potential magnitude of the data.

Data Type Minimum Maximum

bit 0 1

float

integer -32768 32767

long -2147483648 2147483647

-3.402832

e-38

3.402823

e38

3. Quantity

This entry is limited by the Network or Remote I/O configuration properties,

depending on whether the controller is configured as a master or a slave.

When a bit type is selected and the quantity is greater than the number of bits in a

word, allocation automatically proceeds to the next word in sequence. Note: for

remote I/O data, more than one data name can be assigned to the same memory

location.

4. Starting Word

32

Page 39

MotionWorks+™ The Project Explorer

This column contains a list of possible starting words. The list is created based on the

input/output properties in the configuration

I/O Definition

Digital and analog input/output names can be reviewed and edited on the window shown

below.

1

2

3

4

1. Name

he inputs/outputs are assigned default names by MotionWorks+™ when a project is

created. These names appear in the list shown below. The names can be changed to

any character string that more accurately describes their function.

2. Type

This field indicates whether the name refers to an individual input or output bit, or an

entire word, which contains up to 16 input or output bits. If the I/O is an analog type,

the 16-bit word contains the binary representation of the analog voltage.

3. Initial Value

his field only applies to outputs. Set the power ON logic state in this field. The

default output state is OFF.

5

6

33

Page 40

The Project Explorer MotionWorks+™

4. HMI Checkbox

This field is used to set data to be written to the HMI export file.

5. Cross Reference

This field retains the default I/O name assigned by MotionWorks+™ and displays the

register location of the I/O in the controller. This is provided for debugging with

MotionWorks™ or accessing data via Memobus serial communication.

6. Comments

This field provides a location for users to document I/O usage.

Table Definition

Table data is an array of values, all of which have the same name. They are accessed by

using the syntax “MOVE[i] = n”, where “i” is an integer or long, and “n” is a valid value

for the table. There are two table formats available - constant and dynamic. If a constant

table is defined (read only = true), the table data must come from a .cdd, .txt, .dat, or .csv

file. Constant table data cannot be modified by the program. If the table is configured as

a dynamic table (read only = false), the data can optionally be loaded from a file, or generated at run time with SET VARIABLE blocks. Note: Tables are zero based, and no bound-

1

2

3

4

5

6

7

8

ary checking is provided. Care must be taken by the programmer to remain within the

bounds of the table, or other data may get corrupted.

1. Table Name

The user-given name of the table.

34

Page 41

MotionWorks+™ The Project Explorer

2. Type

Select from “.cam”, “.txt”, “.dat”, “.csv”, or “Empty Table”. A CAM table is imported

from an *.cdd file and follows the cam tool format. A .csv file is an ASCII file with

data separated by commas. An empty table is either downloaded at run time or

generated within the MW+ program with SET VARIABLE blocks.

3. Data Type

This field determines the potential magnitude of each item in the table.

4. Read Only

This field determines whether items in the table can be changed by the program at run

time.

5. File Name

For Cam (.cdd) or .csv tables, select the file from which data is imported.

6. Entries

Select the maximum number of items the table can contain. If a file is imported, the

Entries property is automatically determined by the size of the file.

7. Base Address

This field is a read only field indicating the starting register location of the table in the

controller memory. This is provided for debugging with MotionWorks™ or accessing

data via Memobus serial communication.

8. HMI Checkbox

This field is used to set data to be written to the HMI export file.

35

Page 42

The Project Explorer MotionWorks+™

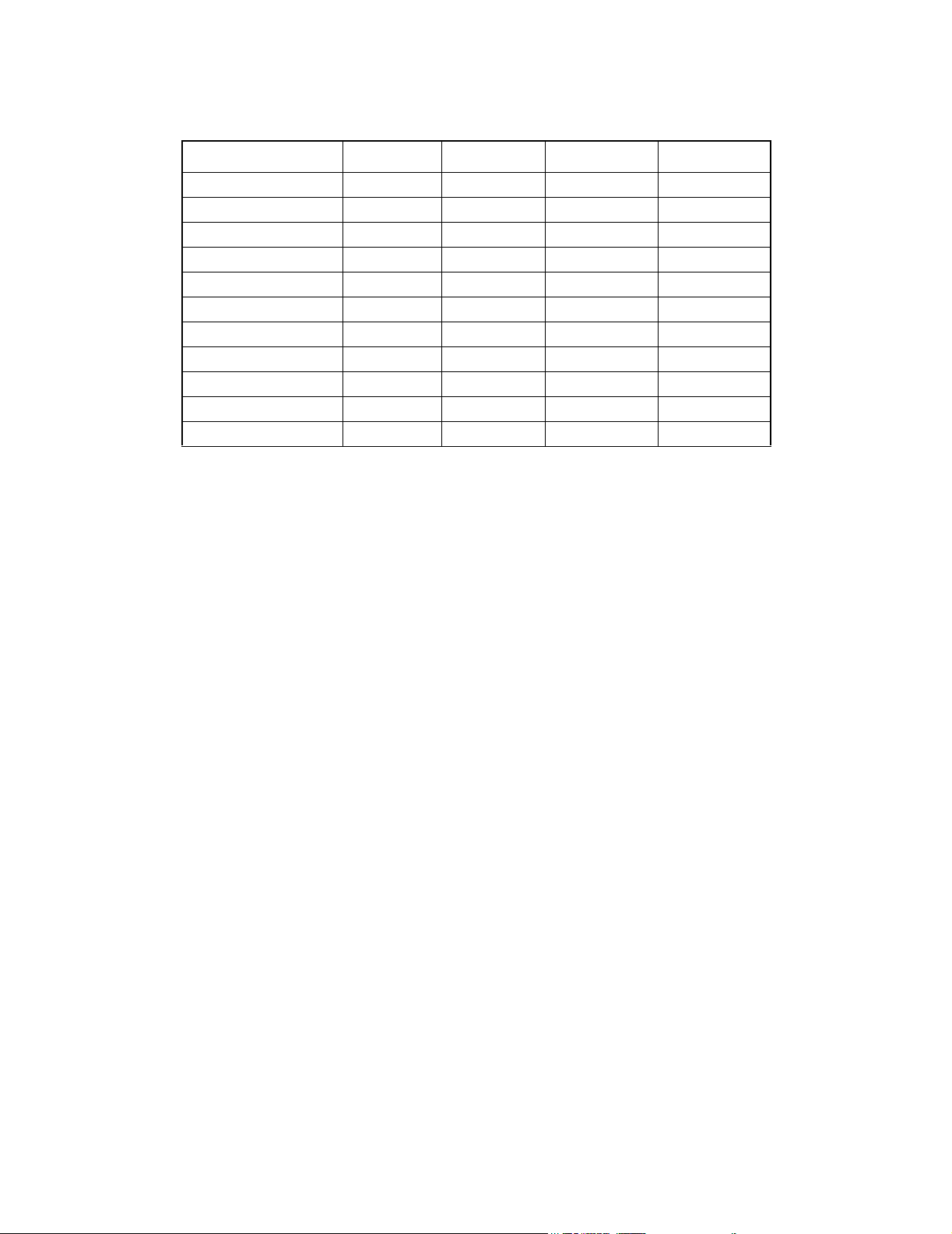

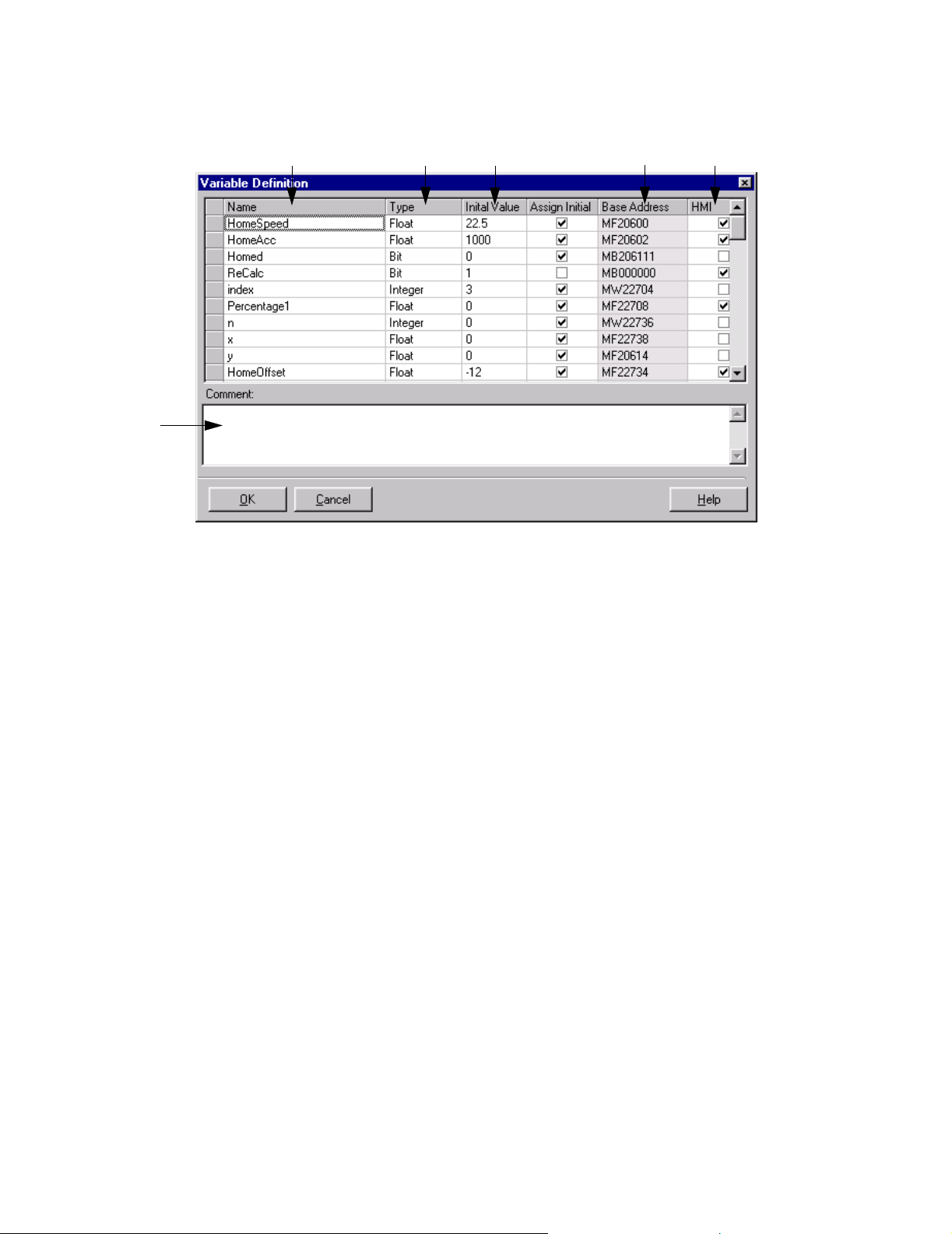

Variable Definition

6

1. Name

This field is the user-given name of the data.

1

2

3

4

5

2. Type

This field determines the potential magnitude of the data.

3. Initial Value

This field presets the value of the variable when the power is turned on. If no initial

value is entered, the data is not initialized when the power is turned on (which is useful

for preserving values when the power is cycled).

1

4. Base Address

This field is a read only field indicating the register location of the data in the

controller memory. This is provided for debugging with MotionWorks™ or accessing

data via Memobus serial communication.

Note: If a bit type variable is defined and checked as an HMI variable, the address of the

bit will be moved down to the region MB00000 ~ MB20470.

5. HMI checkbox

This field is used to set data to be written to the HMI export file.

6. Comments

This field permits users to document variable usage.

1. Possible only when the battery option is installed to preserve RAM when power is OFF.

36

Page 43

MotionWorks+™ The Project Explorer

System Variables

System variables are internal keywords which can be stored or accessed in expressions at

run time. The names of the system variables cannot be changed by the user.

37

Page 44

The Project Explorer MotionWorks+™

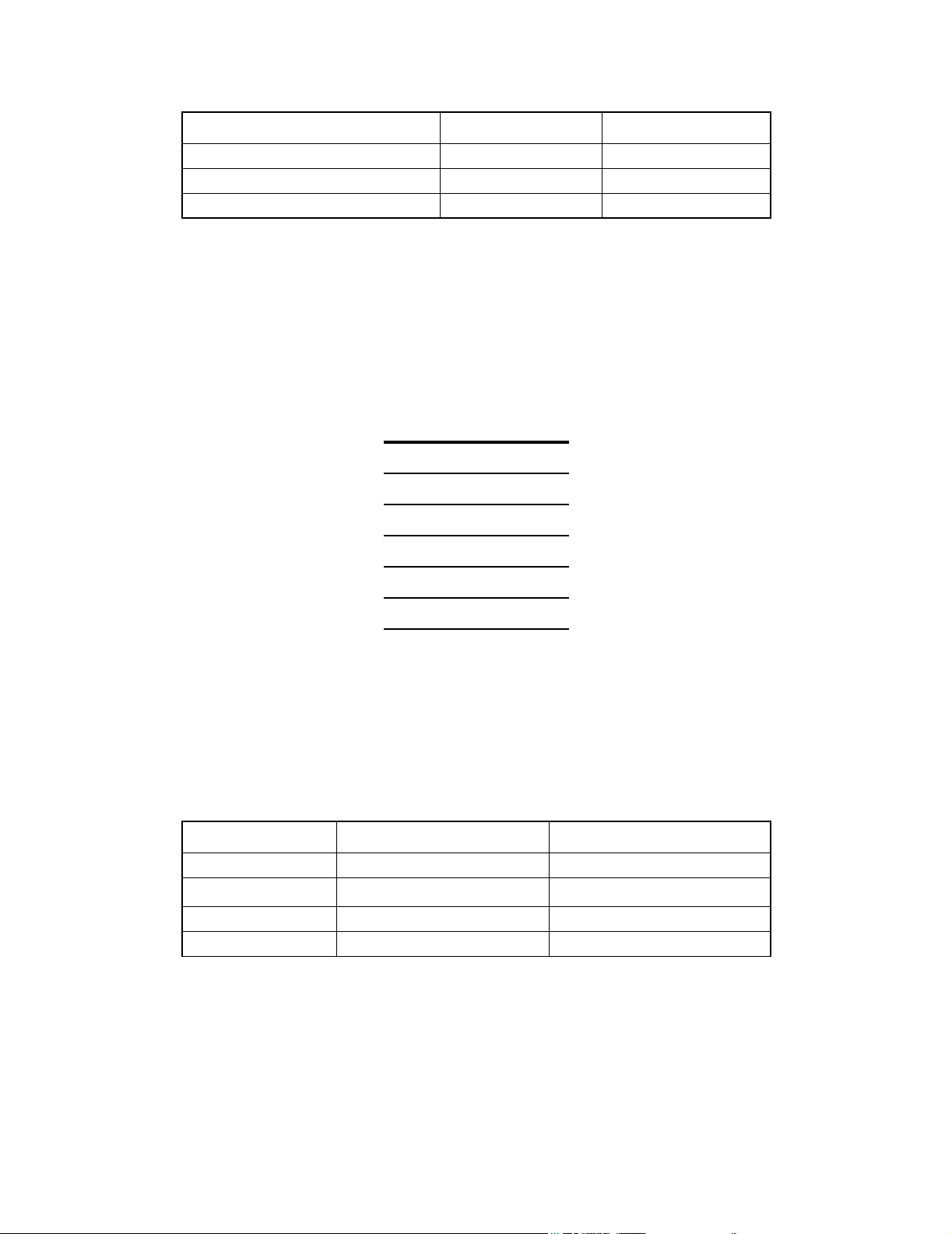

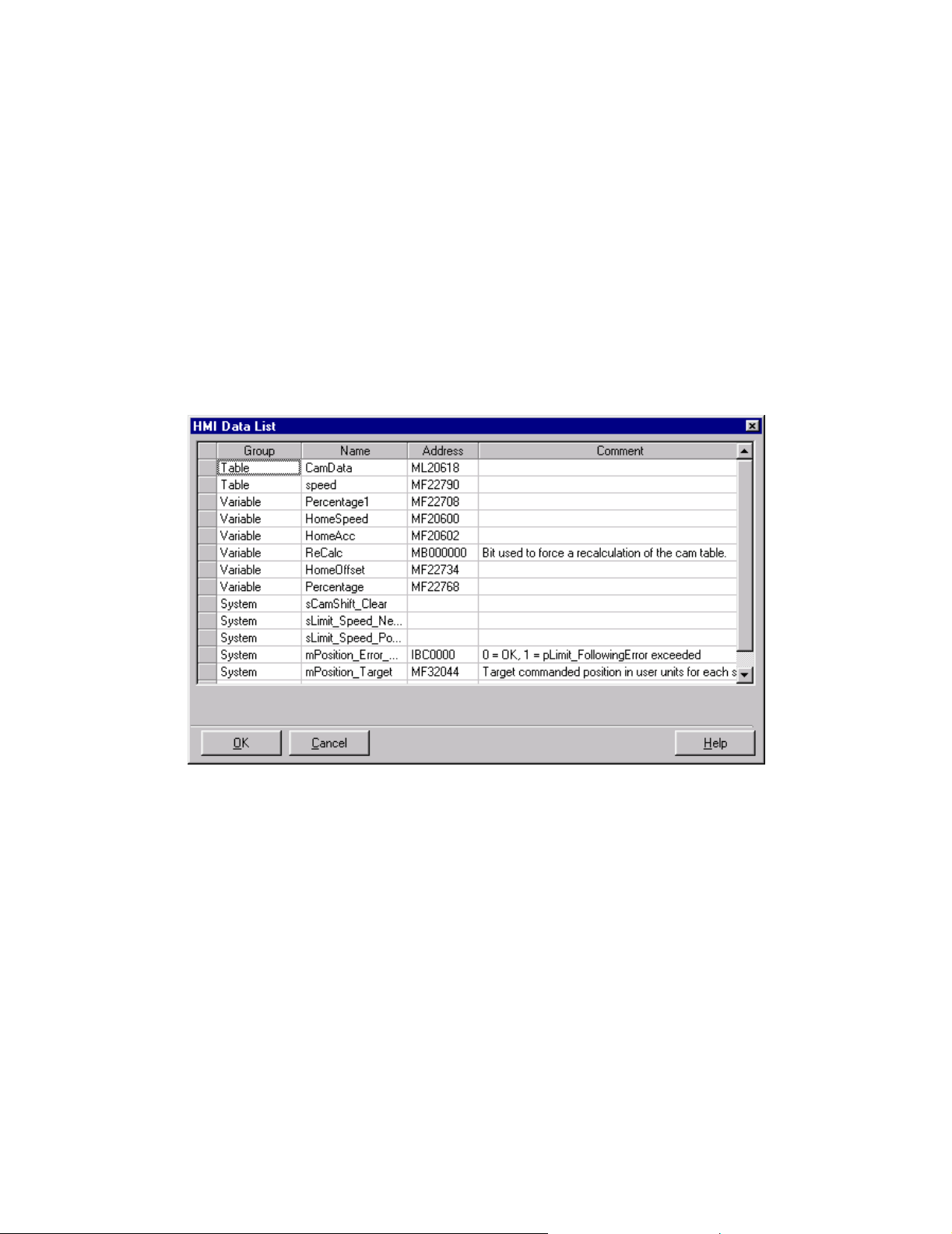

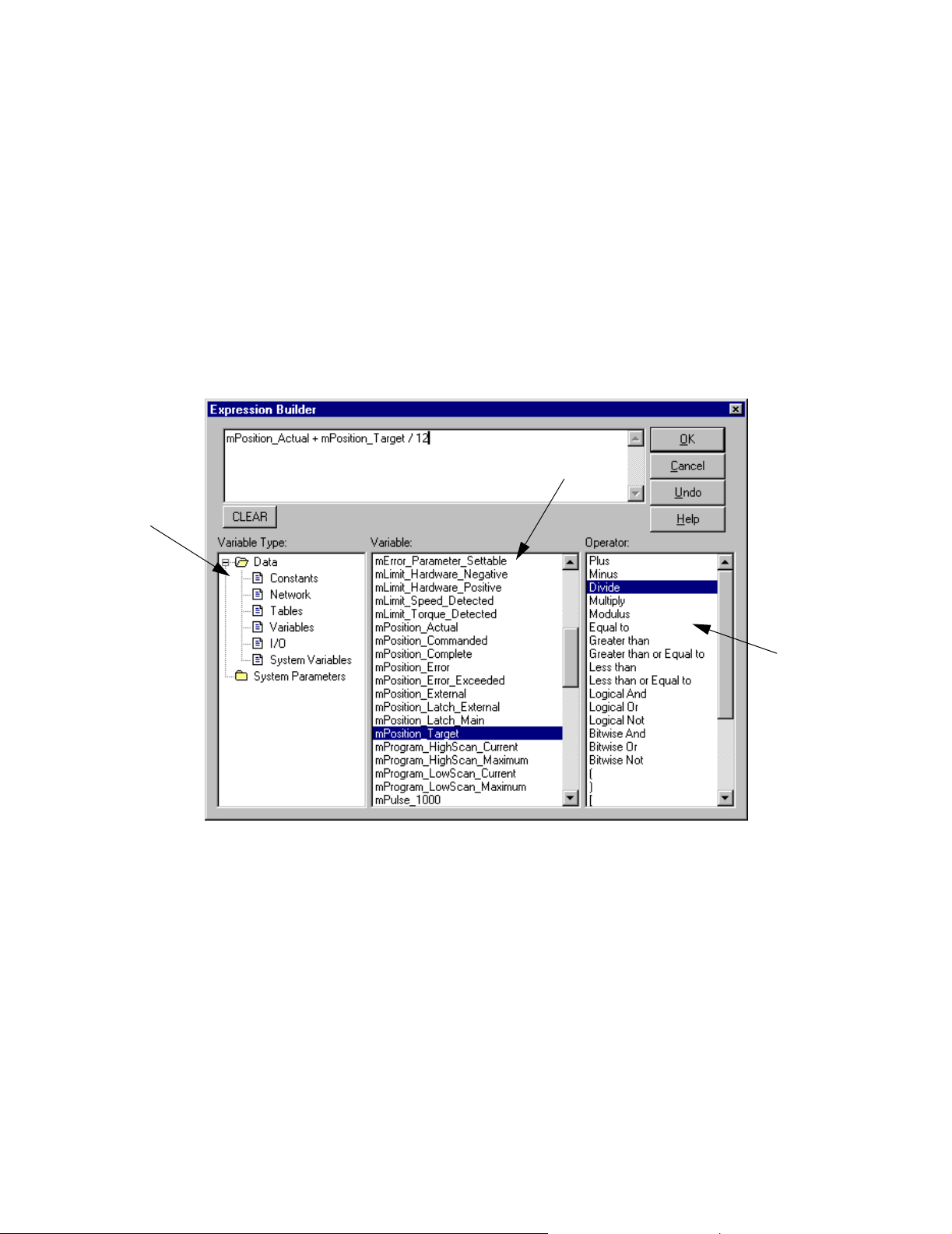

1.6.1 HMI Data

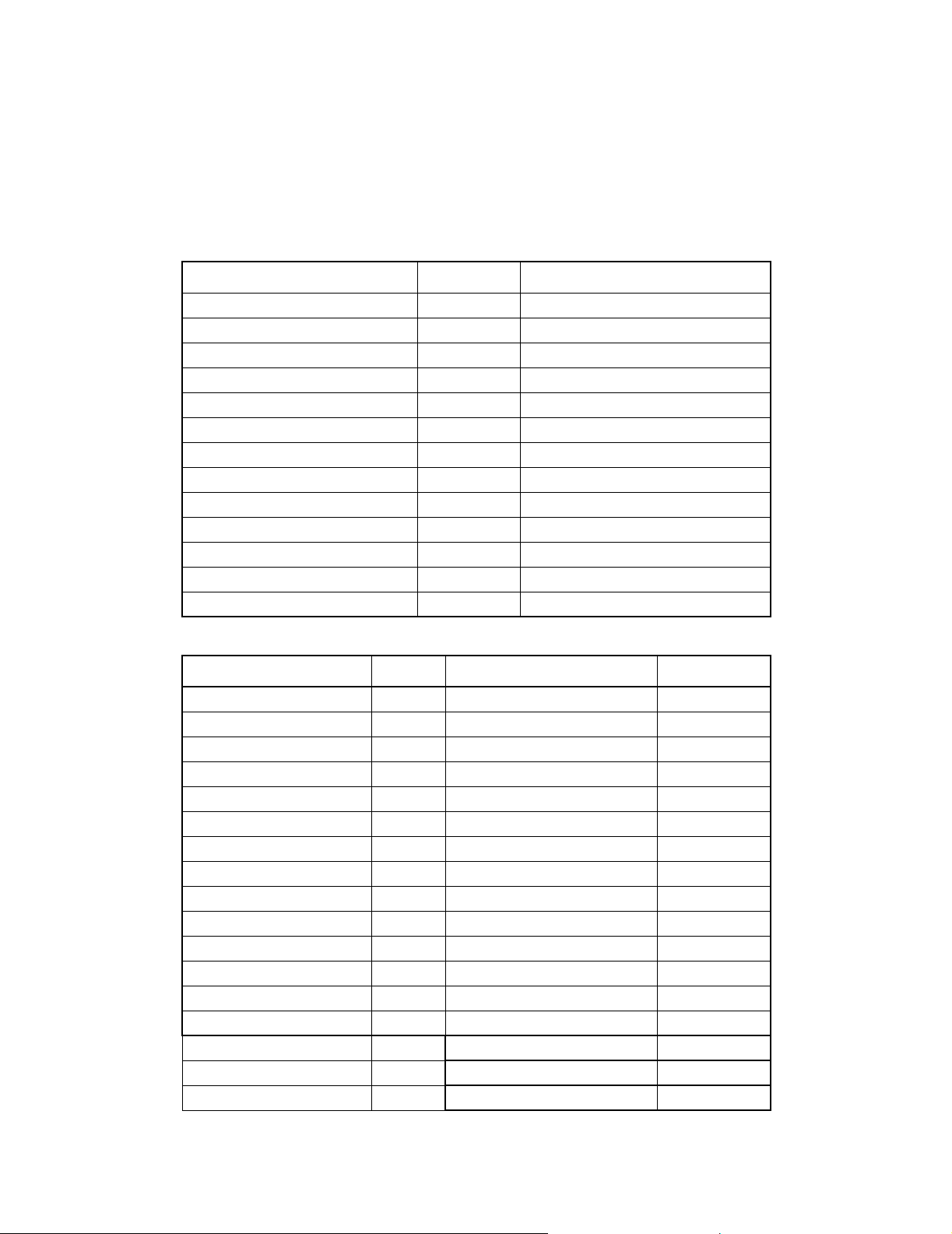

Accessibility

To access the HMI data, select:

• From the View Menu > HMI Data List

General

Each data item in the project can be identified as used in conjunction with a HumanMachine-Interface (HMI) by checking the box located next to each user variable or

system variable. The HMI data export will automatically occur each time the project is

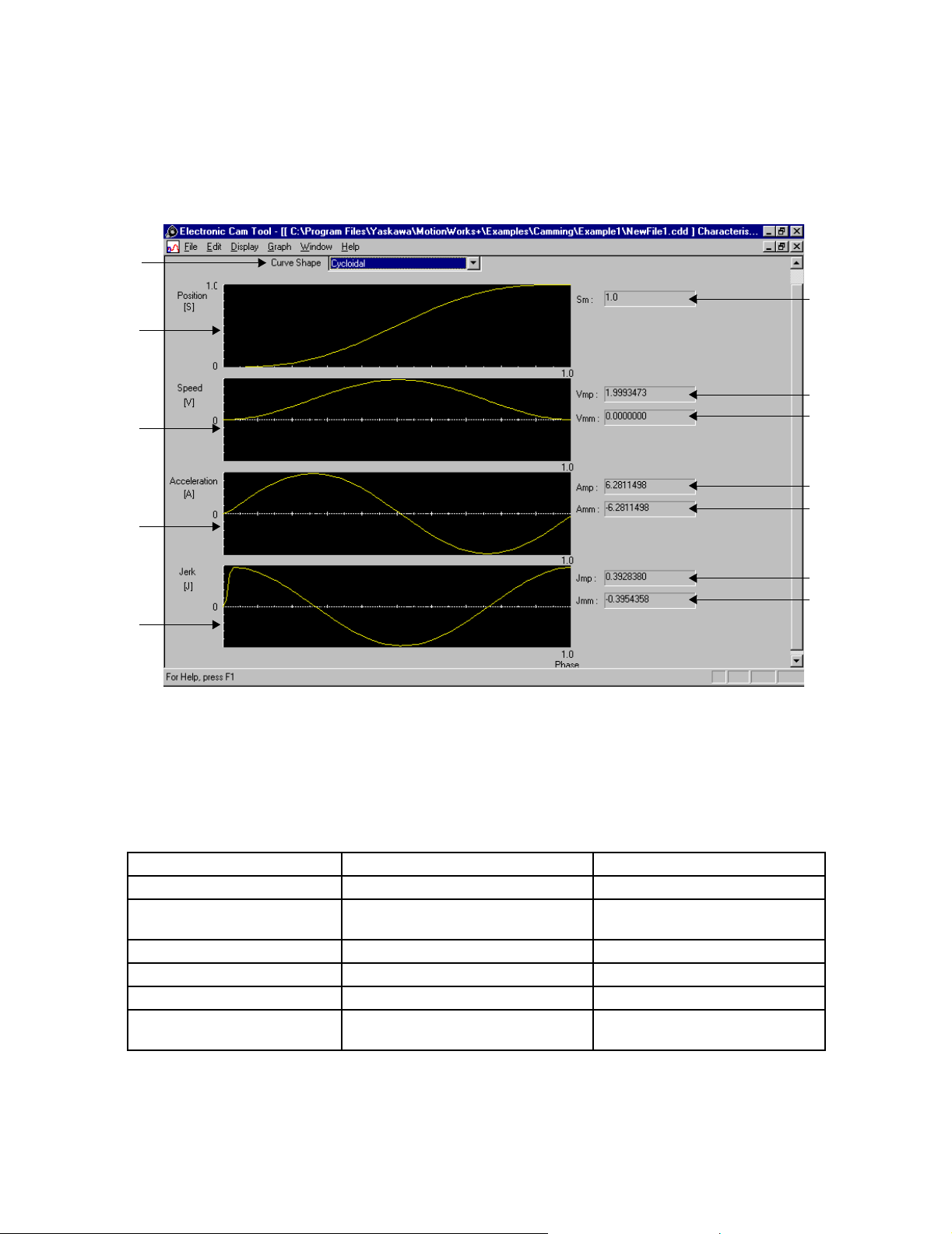

saved.

Setting data for HMI Export

Simply check the box at the right side of the row.

HMI Export File

Each data type excluding constants has a check box at the right of the line item that

can be used to identify project data as exportable to a comma separated value (CSV)

file. This file, (called HMI_xx.DAT) is automatically saved when the project is

saved. The following is a description of the file format.

38

Page 45

MotionWorks+™ The Project Explorer

Viewing HMI data

All data marked for HMI export are identified by the check mark. Alternatively, a

window is available to view all items marked for HMI export under the View menu.

Importing data is possible by reading a file with the same format that is exported. This

can be accomplished by right clicking on the Project Explorer’s Data Folder.

The data on this screen is for viewing purposes only, except that the user will be able to

remove items from the HMI data list by right clicking on one or several selected rows

and choosing “Remove from HMI list” from a sub menu. This has no effect on the data

in the project, other than to clear the checkmark on the corresponding data definition

window.

39

Page 46

The Project Explorer MotionWorks+™

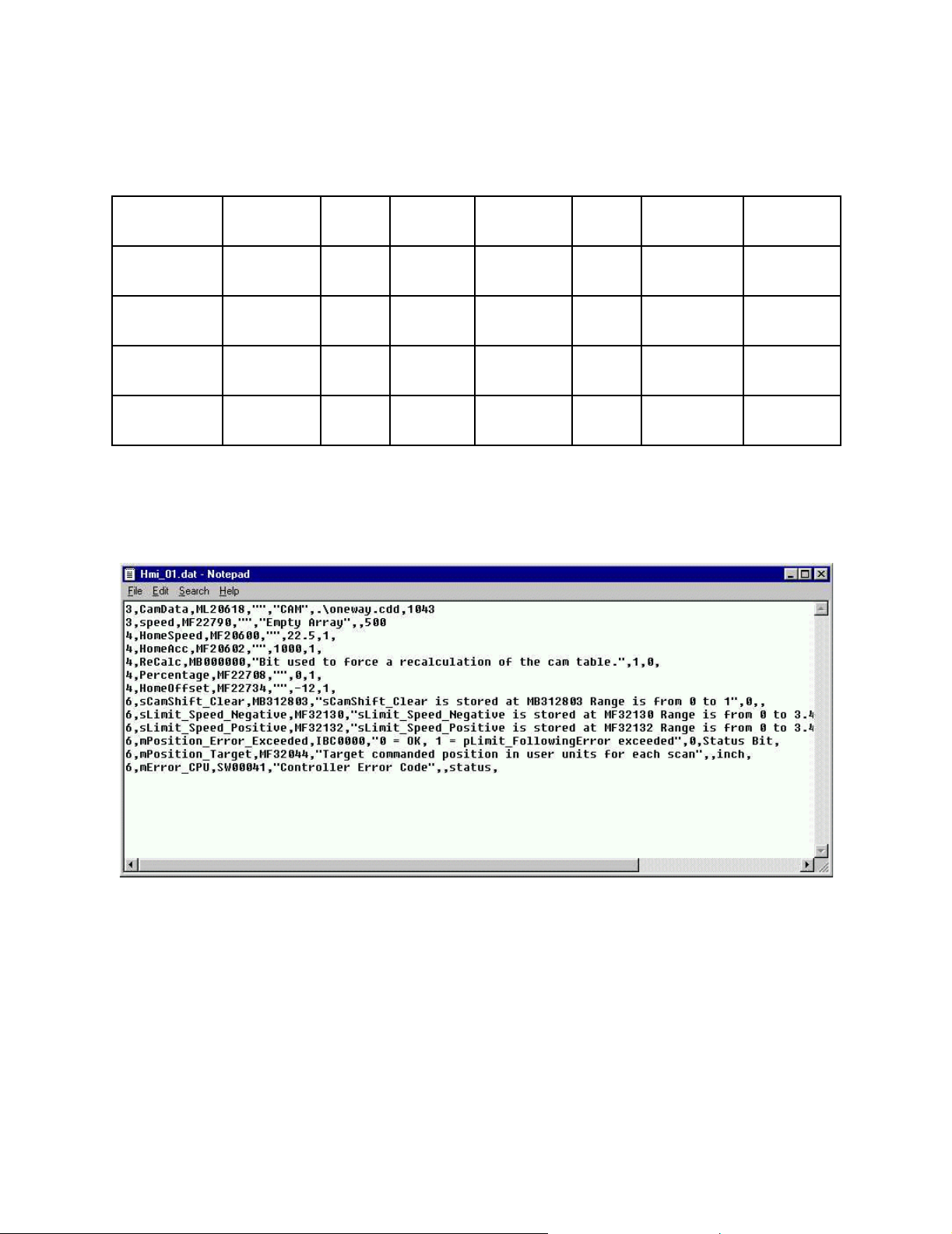

File Data Format

The imported/exported CSV file will be of the following format:

(Network)

(Table)

(Variable)

(I/O)

(System)

Code=2 Name Address Comment Initial

Value

Code=3 Name Address Comment Table

Type

Code=4 Name Address Comment Initial

Value

Code=5 Name Address Comment Initial

Value

Code=6 Name Address Comment Initial

Value

Network

Node

FileName Entries

Starting

Word

40

Page 47

MotionWorks+™ The Project Explorer

Variable Mapping

If a bit type variable is set for HMI usage, it will be mapped within the range of

MB000000 through MB02047F. This restriction will be enforced because Memobus

can only write bits in the range of MB000000 through MB04096F. When Memobus

writes bits outside of this range, the entire word is written, not just the bit, so there is a

possibility of corrupted data.

Importing an HMI Data List

Accessibility

To import an HMI data list, select:

• From the Project Menu > Data >Import HMI

• From the Project Explorer > Right click on an item in the Data folder and select

“Import.”

Import Method: If there are no variables, network, or tables in the project, the import

function will proceed without dialog for each type of item that has no existing entries. If

there are existing entries, the import will append to the list. If names already exist in the

current project, notification will be given to the user by the MW+ Importing Error dialog

box shown below.

41

Page 48

The Project Explorer MotionWorks+™

1.6.2 Import/Export Initiation

General

The import utility will determine what category each imported value falls in.

All Data Groups

Import will be initiated from Project>Data drop down menu or by right clicking on the

Data object in the Project Explorer.

Individual Data Group

Import will be initiated from Project>Data drop down menu which will expand to show

all data types when the user moves the mouse over “Data”, or by right clicking on the

specific Data object in the Project Explorer.

Name and address checking will be done on the full data area (Constants, Tables,

Network, Variables, I/O, System Variables, System Parameters, System Ladder

Registers and System Registers). The name and the address must be unique across the

full data area, with the exception of overlapping addresses in the Network data area.

The register range for MW+ system registers (MW20000 ~ MW20599) and the register

range for system ladder registers (MW30000 ~ MW32767) are reserved so that user

variables are not allowed in these areas; however, the user will be allowed to import

values for the system ladder type variables.

Constants

The name, initial value, address, and comment will be imported. The type will be

derived from the address.

Network

The name, node, initial value (if present), address, starting word, and comment will be

imported. The type and bit will be derived from the address.

If configuration for the node is completed and configuration for that node matches

configuration from the existing project, import of the network will proceed.

If the configuration for that node does not exist or does not match the configuration from

the existing project, a message box will appear stating “The data for node x cannot be

imported, because the configuration of node x is missing or does not match.” The user

can choose to cancel, skip node, or import the configuration.

1. If the name is unused, the import of that item will proceed without dialog.

42

Page 49

MotionWorks+™ The Project Explorer

2. If the imported name and address exactly match an item in the database, the value

and the comment will be imported.

3. If the imported name matches an item in the database but the address does not, the

user will be shown the following grid with the existing name and address and the

importing name and address.

A message will be displayed stating the conflict, and the user will be allowed to

choose from the following options:

Rename Existing

This button will present the user with a text box where a new name for the

existing item can be typed.

Rename Imported

This button will present the user with a text box where a new name for the

importing item can be typed.

Skip

Skips importation of this network.

Overwrite

Imports the table and removes the existing item(s).

Cancel

The import operation is canceled leaving the data area unchanged.

1. Address overlap will be allowed as currently implemented for the network data area.

43

Page 50

The Project Explorer MotionWorks+™

Table s

The name, filename (if present), address, table type, number of entries, and comment

will be imported. The type and read only status will be derived from the address. If the

filename is present the file will be copied to the project directory, and the data will be

transferred with the project.

1. If the name and the full address range is unused the import of that item will proceed

without dialog. The full address range check will look for bits, words, longs, and

floats that overlap the imported address range.

2. If the imported name and address exactly match an item in the database, the filename

(if present), and the comment will be imported.

3. If the imported name matches an item in the database but the address range does not,

the user will be shown the following grid with the existing name, number of entries

(if table type) and address and the importing name and address range.

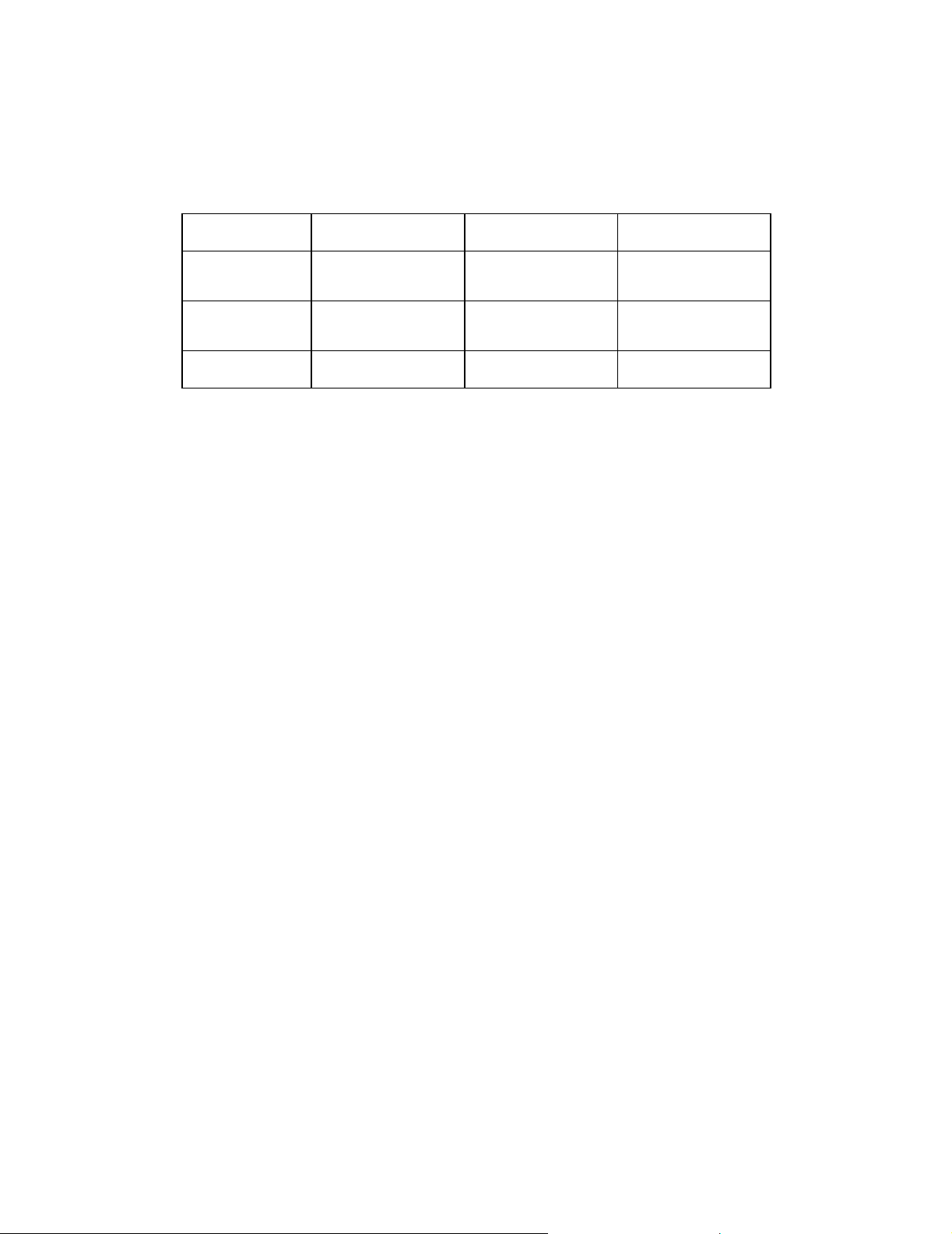

Name Entries Address Range

Imported Position 10 MW2001 ~

MW2010

Existing Position N/A MB1001

A message will be displayed stating the conflict, and the user will be allowed to choose

the following options:

Rename Existing

This button will present the user with a text box where a new name for the

existing table can be typed.

Rename Imported

This button will present the user with a text box where a new name for the

importing table can be typed.

Skip

Skips importation of this table.

Overwrite

Imports the table and removes the existing item(s).

Cancel

The entire import operation will be canceled leaving the data area unchanged.

44

Page 51

MotionWorks+™ The Project Explorer

1. If the imported address matches any existing item within the address range, the following grid will be displayed with all of the existing name(s) and address(s) and the

importing name and address.

Name Entries Address

Imported

Existing

Existing

MyTable1 100 MW1000 ~ MW

1099

MyTable2 10 MW1000 ~ MW

1009

MyWord1 N/A MW1010

A message will be displayed stating the conflict, and the user will be allowed to choose

the following options:

Re-address Existing

This button will readdress all existing data that is in the imported table space.

MW+ will preserve the order of the existing data.

Readdress Imported

This button will re-address the imported table. MW+ will find a contiguous area

of memory for the table.

Skip

Skips importation of this table.

Overwrite

Imports the table and removes the existing item(s).

Cancel

The import operation is canceled leaving the data area unchanged.

Variables

The name, initial value (if present), address, and comment will be imported. The type

will be derived from the address.

1. If the name and the full address range is unused the import of that variable will proceed without dialog. The full address range check will look for bits, words, longs,

and floats that overlap the imported address.

2. If the imported name and address exactly match a variable in the database, the value

and the comment will be imported.

45

Page 52

The Project Explorer MotionWorks+™

3. If the imported name matches an item in the database but the address does not, the

user will be shown the following grid with the existing name and address and the

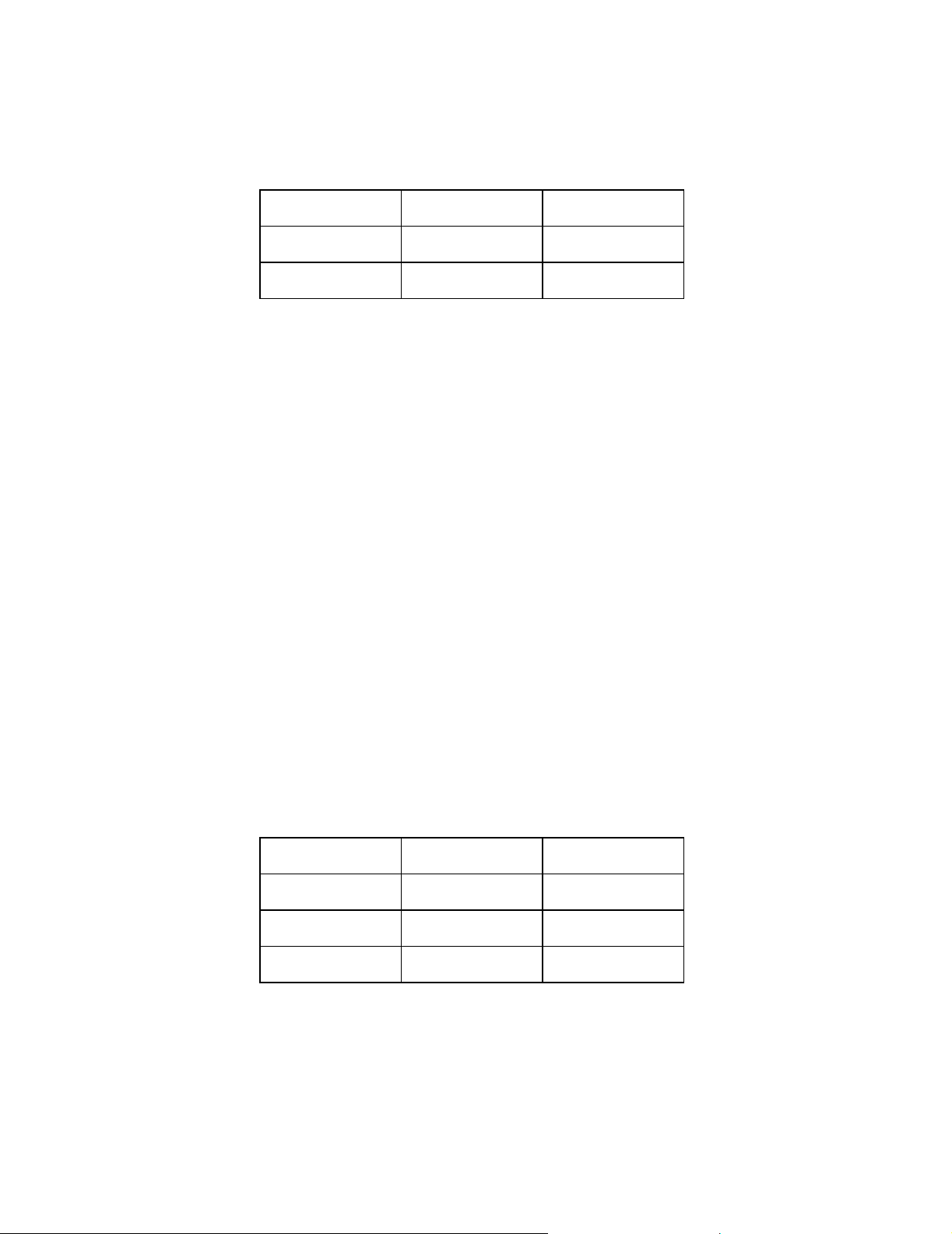

importing name and address.

Name Address

Imported MyBit1 MB2001

Existing MyBit1 MB1001

A message will be displayed stating the conflict, and the user will be allowed to choose

the following options:

Rename Existing

This button will present the user with a text box where a new name for the

existing item can be typed.

Rename Imported

This button will present the user with a text box where a new name for the

imported variable can be typed.

Skip

Skips importation of this variable.

Overwrite

Imports the variable and removes the existing item.

Cancel

The entire import operation will be canceled leaving the data area unchanged.

1. If the importing address matches any existing item within the address range, the following grid will be displayed with all of the existing name(s) and address(s) and the

importing name and address.

Name Address

Imported MWord1 MW100

Existing MyBit1 MB1001

Existing MyBit1 MB1002

A message will be displayed stating the conflict, and the user will be allowed to

choose the following options:

46

Page 53

MotionWorks+™ The Project Explorer

Readdress Existing

This button will readdress all existing data that is in the importing address space.

MW+ will preserve the order of the existing variables, so it cannot simply insert

the existing variables back into the list.

Readdress Imported

This button will readdress the imported variable.

Skip

Skips importation of this variable.

Overwrite

Imports the variable and removes the existing item.

Cancel

The entire import operation will be canceled leaving the data area unchanged.

I/O

The name, initial value (if present), address, and comment will be imported. The type

will be derived from the address.

System Variables

If a register value matches a system variable, the Name will be compared. If the names

do not match, a warning is issued to the user that a non-system variable existed in a

location reserved by MW+ for system variables.

47

Page 54

The Project Explorer MotionWorks+™

Monitoring

All monitoring functions are available only after going online with the exception of

Scope. There are 4 monitoring views available: Data, I/O, and Program and Scope.

I/O Monitoring

Accessibility

To monitor the I/O, select:

• From the Project Explorer > Monitoring > I/O

• From the Main menu > Project > Monitoring > I/O

48

Page 55

MotionWorks+™ The Project Explorer

Program Monitoring

Accessibility

To monitor the program, select:

• From the Project Explorer > Monitoring > Programs

• From the Main Menu > Project > Monitoring > Programs

2

3

1

1. Program

Select the checkbox in this column to enable monitoring for any program.

2. Name

This column displays the program or subroutine name currently active.

3. Block No.

This column displays the current block being executed and further indicates whether

the program is running.

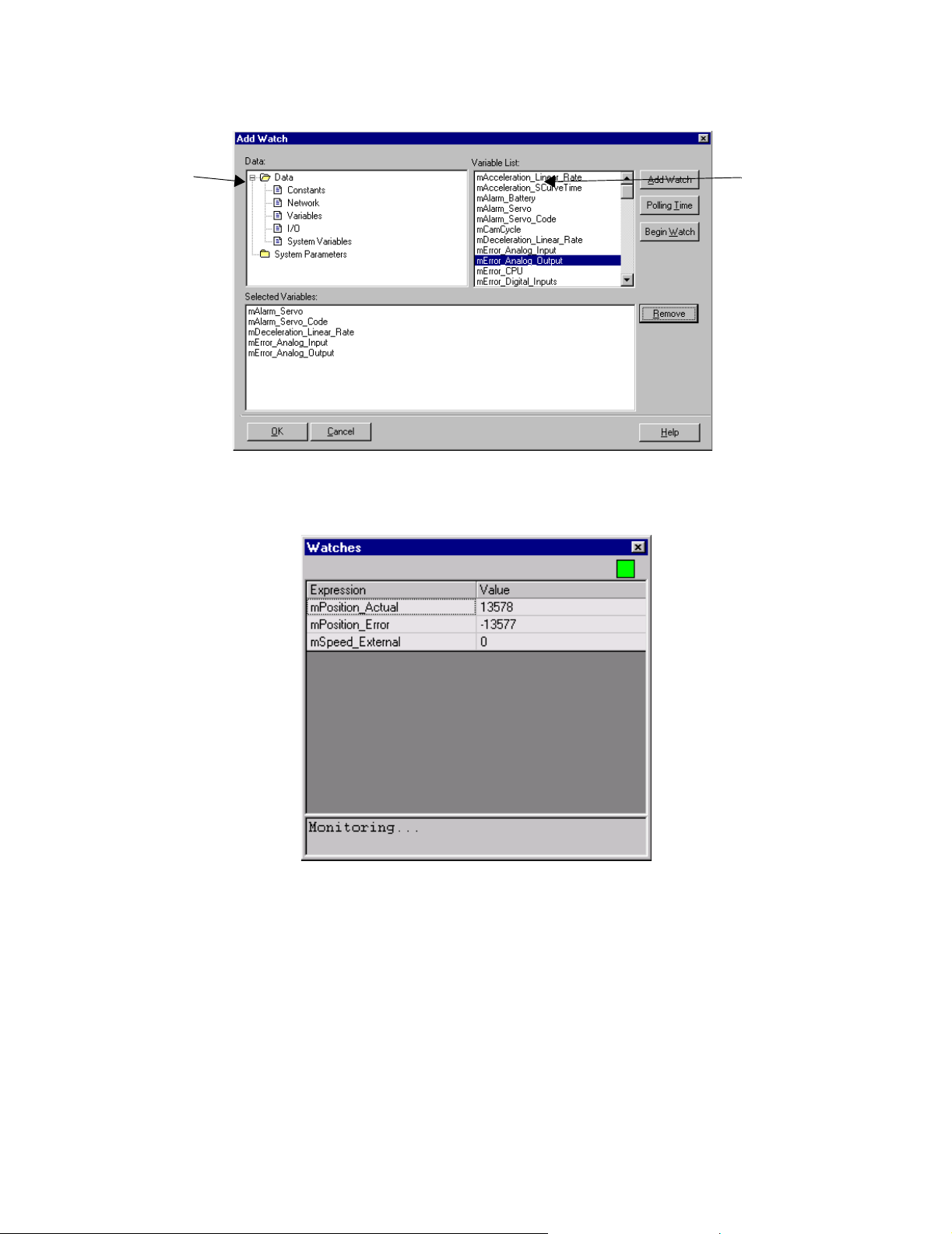

Monitoring Data

Any data can be monitored while online with the controller via the windows shown

below. Read/Write data can be changed on-the-fly using the Watch window. A list of

data selected for monitoring is saved so that the same data set can be monitored again

during future sessions with the same project.

Accessibility

To access the Watch window, select:

• From the Main Menu > Project > Monitoring > Data

49

Page 56

The Project Explorer MotionWorks+™

• From the Project Explorer > Monitoring > Data

1

2

1. Open folders from the Data text box.

2. Double-click on items in the Variable List to add them to the Watch window.

While viewing the watch window, data can be modified by typing a new value in the

right column. Variable updates occur as soon as the Enter key is pressed or the cell

loses focus. While editing data, the Variable Watch window does not update. This is

indicated by the status light in the upper right corner of the window.

50

Page 57

MotionWorks+™ Scope

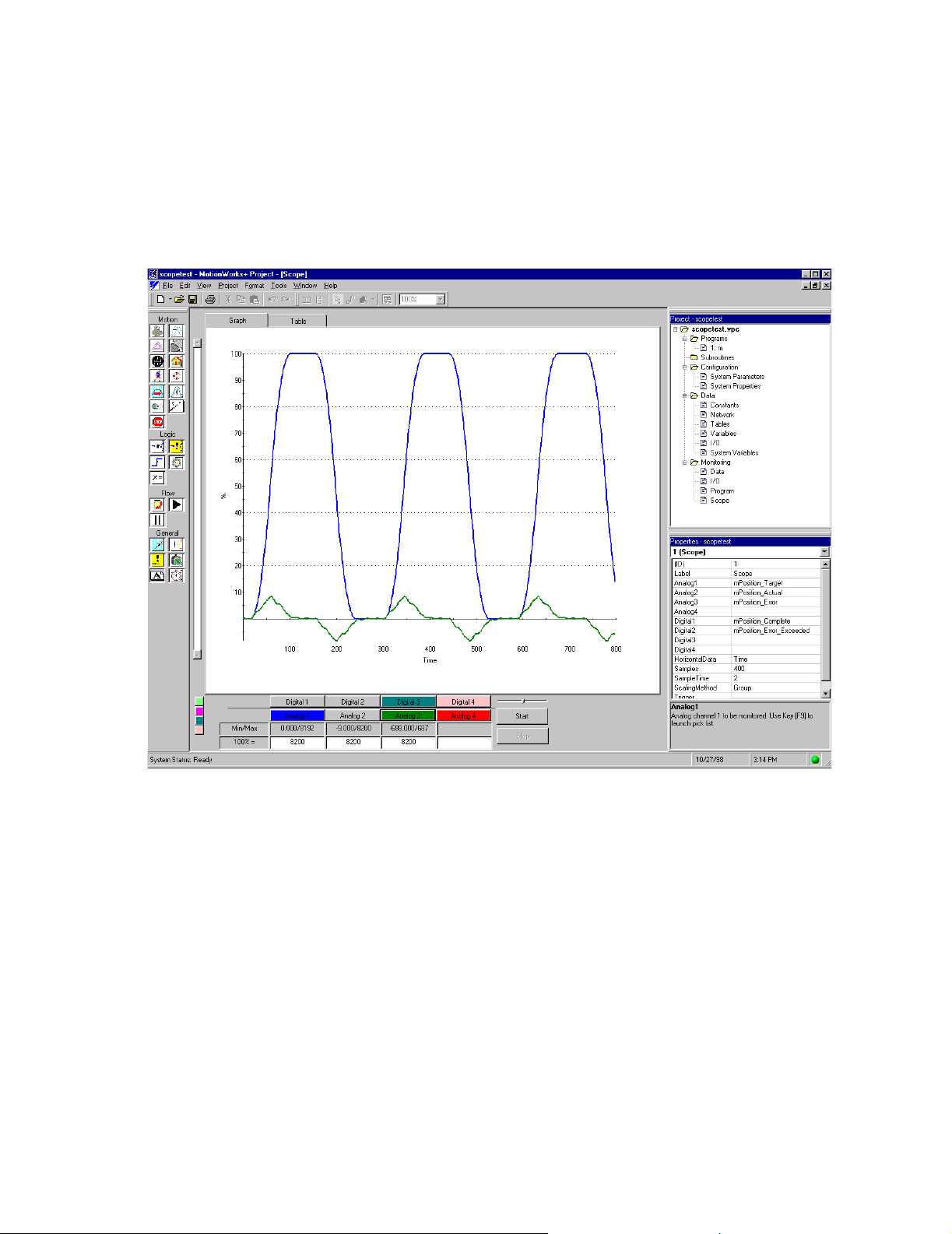

1.7 Scope

Accessibility

To view the scope display, select

• From the Main Menu > Project > Monitoring > Scope

• From the Project Explorer > Monitoring > Scope

The Scope displays recorded data. Choose data to be recorded and duration in the

properties window. The Scope has the capability to display up to eight separate data

elements.

There are tabs at the top of the graph that allow the user to switch between viewing data

graphically or in a table.

The following are the properties for the Scope. These properties are applied when the

user clicks on the start button.

51

Page 58

Scope MotionWorks+™

Properties

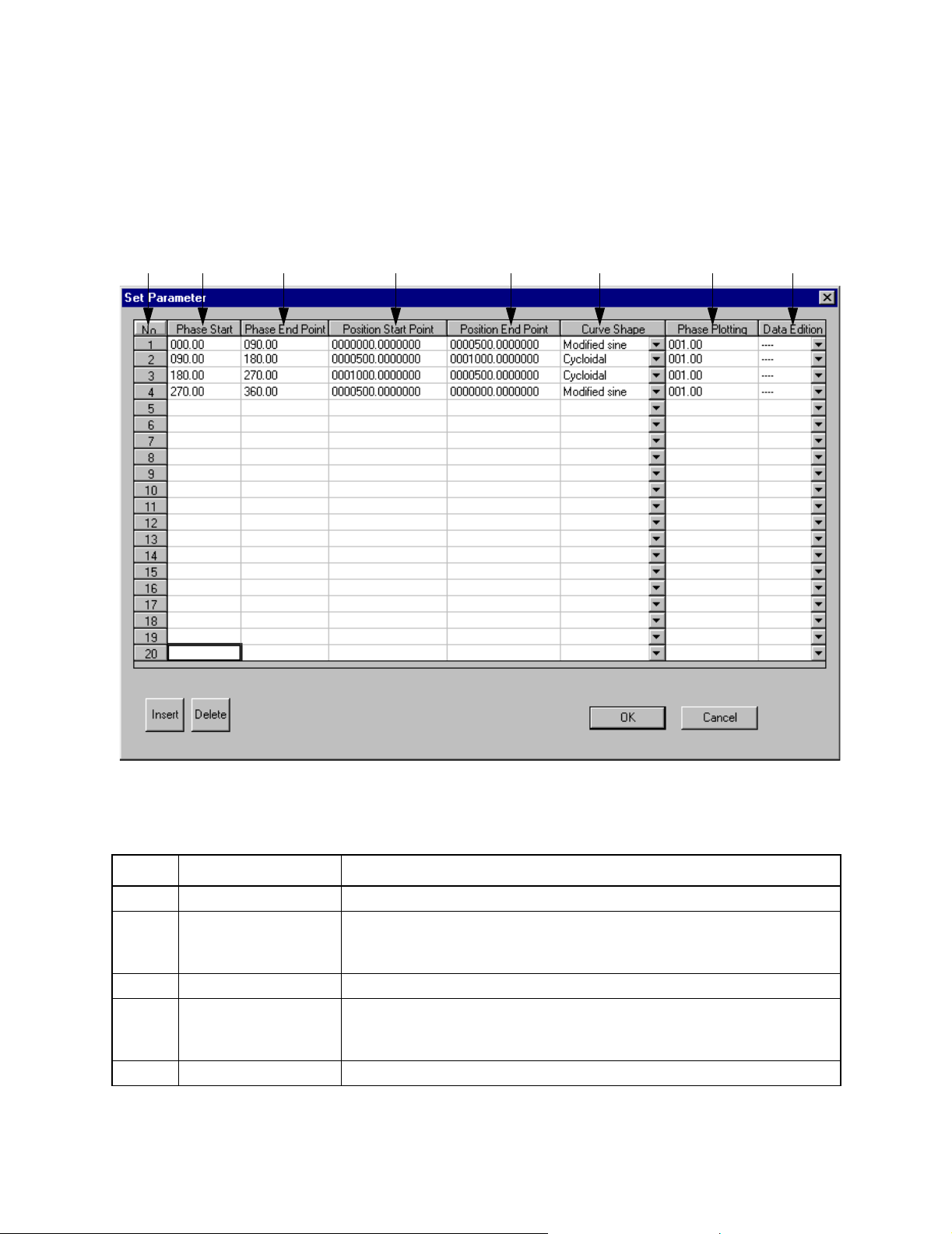

Property Default

Analog1 Nothing N/A N/A Any Data

Analog2 Nothing N/A N/A Any Data

Analog3 Nothing N/A N/A Any Data

Analog4 Nothing N/A N/A Any Data

Digital1 Nothing N/A N/A Any Bit Data

Digital2 Nothing N/A N/A Any Bit Data

Digital3 Nothing N/A N/A Any Bit Data

Digital4 Nothing N/A N/A Any Bit Data

HorizontalData

Samples 1000 10 32767 Samples / depend

SampleTime 1 0.5 5000 mSec

ScalingMethod

Time Analog1 Analog4 N/A

Custom Custom None Group, Individual,

Minimum

Value

Maximum

Value

Notes

on data types

None

Trigger Nothing N/A N/A Expression builder

Analog 1~4

Select the data that will be captured for display on this channel. To use the

expression builder, press F9.

52

Page 59

MotionWorks+™ Scope

Digital 1~4

Select the digital data that will be captured for display on this channel. When a

digital signal is displayed on the graph, it will occupy 20% of the graph height.

To use the expression builder, press F9.

HorizontalData

Normally the horizontal time scale is “Time.” It is possible to select any analog

channel data as the horizontal time scale. If only one analog channel is defined

and no digital channels are defined, the only choice is “Time.”

Samples

Specify number of points to be recorded for each channel. The maximum

number of storage words is 4096. MW+ will determine if there is enough

memory to perform the scope function based on the number of channels selected

and notify the user if there is not enough memory.

SampleTime

This is the number of milliseconds between samples. The sample time cannot be

less than the High scan setting in the MP940 system properties.

ScalingMethod

Specify how analog data is displayed on the graph. MW+ will determine the

upper and lower bounds of the Y axis and the “100% = ” number for each

channel based on the setting of this property. For all cases below, there will

always be either a 100% or a –100% boundary, or both.

53

Page 60

Scope MotionWorks+™

When this property is set to “group,” each channel will be scaled to the same

“100% =” number. Scaling is derived from the channel with the largest absolute

min/max value.

When this property is set to “individual”, each channel will be scaled to occupy

most of the graph. MW+ will calculate the “100% =” number for each channel

to obtain the best possible fit.

When this property is set to “none”, scale values will be used from the previous

Scope, and the vertical scale will be:

if all channel data are positive: 100 to 0%

if all channel data are negative:0 to -100%

else: 100 to -100%.

The vertical axis is always scaled in percent. Each channel can have a different

scale such that 100% for analog channel #1 can be different from analog channel

#2.

Trigger

The trigger is optional. If the user enters a trigger expression and clicks on start,

the Scope will not begin until the expression is true. If no trigger is entered, the

Scope will begin immediately after clicking Start.

To start Scoping, select data for at least one channel and click on the Start

button. The Scope window will display the following text messages in a text box

until data is ready to be displayed:

If a trigger is selected, and triggering has not begun

“Waiting for trigger.”

If recording data then

"Recording data."

If uploading data

"Uploading data"

54

Page 61

MotionWorks+™ Scope

Notes about Triggering:

This is the basic format of a trigger: [data] [OP] [Constant]

Example of a trigger: mSpeed_Main >= 200

The following operators may be used:

++

!=

<

>

<>

<=

=>

true

false

If the [Data] is a bit, then the [OP] must be “=”.

If the [Data] is a bit, the the [Constant] must be “ON or “OFF”.

If the [Data] is an integer, then the [Constant] must be an integer.

If the [Data] is a float, then the [Constant] can be integer, float, or in exponential

form.

Analog Channel Controls

To switch the graphed data on and off, click the Channel Display buttons. The Channel

Display buttons are the same color as the graph line. When the mouse is held over the

Channel Display button, a tool tip will display the data name.

The minimum and maximum data value is displayed for each channel.

Each channel indicates 100% value in data units. If “Scaling Method” is “none,” the

previous value is retained. If it is “group” or “individual,” the value is calculated by

MW+ to maximize the information on the screen. Adjust this value to customize the

view.

Use the horizontal slider to determine the current value of each channel at any point

along the graph. When the mouse button is held down over the horizontal slider, the

“Min/Max” field label will change to “Current value.” A vertical dashed line appears

on the graph at the slider location, and the current value is displayed in the Current Value

field. When the button is released, the “Current Value” field will revert to “Min/Max.”

55

Page 62

Scope MotionWorks+™

Digital Channel Controls

To switch digital channels ON or OFF, use the “Digital Enable” buttons at the bottom of

the Scope window. The channel display buttons are the same color as the digital graph

line. When the mouse is held over the channel display button, the data name is

displayed.

A vertical slider controls the vertical placement of the digital channels. Only one of the

four vertical slider control buttons can be active at any time. The four buttons are color

coded with the digital data colors. When the vertical slider control button for digital

channel one is active, the scroll bar indicator will be located at the zero level for digital

channel one data. It is possible to change the zero level for each digital channel by

moving the slider. This can be used to separate digital channels for easier viewing.

Graph Controls

It is possible to zoom on any portion of the graph. Enter a specific zoom percentage, Fit

in Window, or zoom on a specific range (window). To zoom into a specific range on the

graph, depress the left mouse button and drag over the graph until the desired range is

highlighted. When the button is released, the graph will display the zoomed range.

When the entire graph does not fit in the window, vertical and/or horizontal scroll bars

will appear, making it possible to access the non-displayed areas of the graph.

It is possible to display data in a graph or table by selecting the graph or table tab.

It is possible to import, export, or save recorded data by selecting items from the right

click menu while the mouse is over the graph or chart.

56

Page 63

MotionWorks+™ Scope

Scope Examples

There are two colored graph lines shown in the example below:

The darker graph line indicates Analog 1.

The lighter graph line indicates Analog 2.

57

Page 64

The Block Toolbar MotionWorks+™

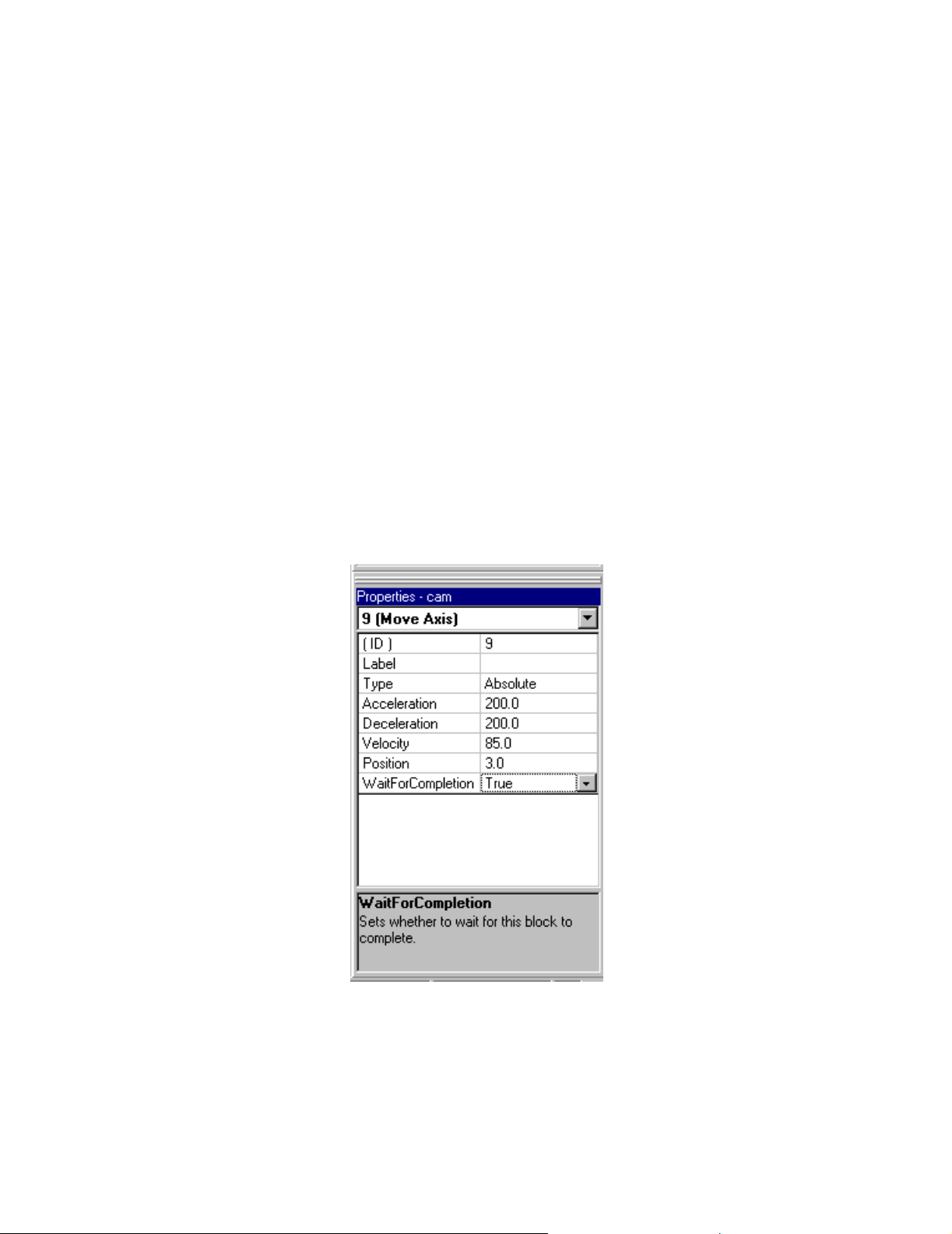

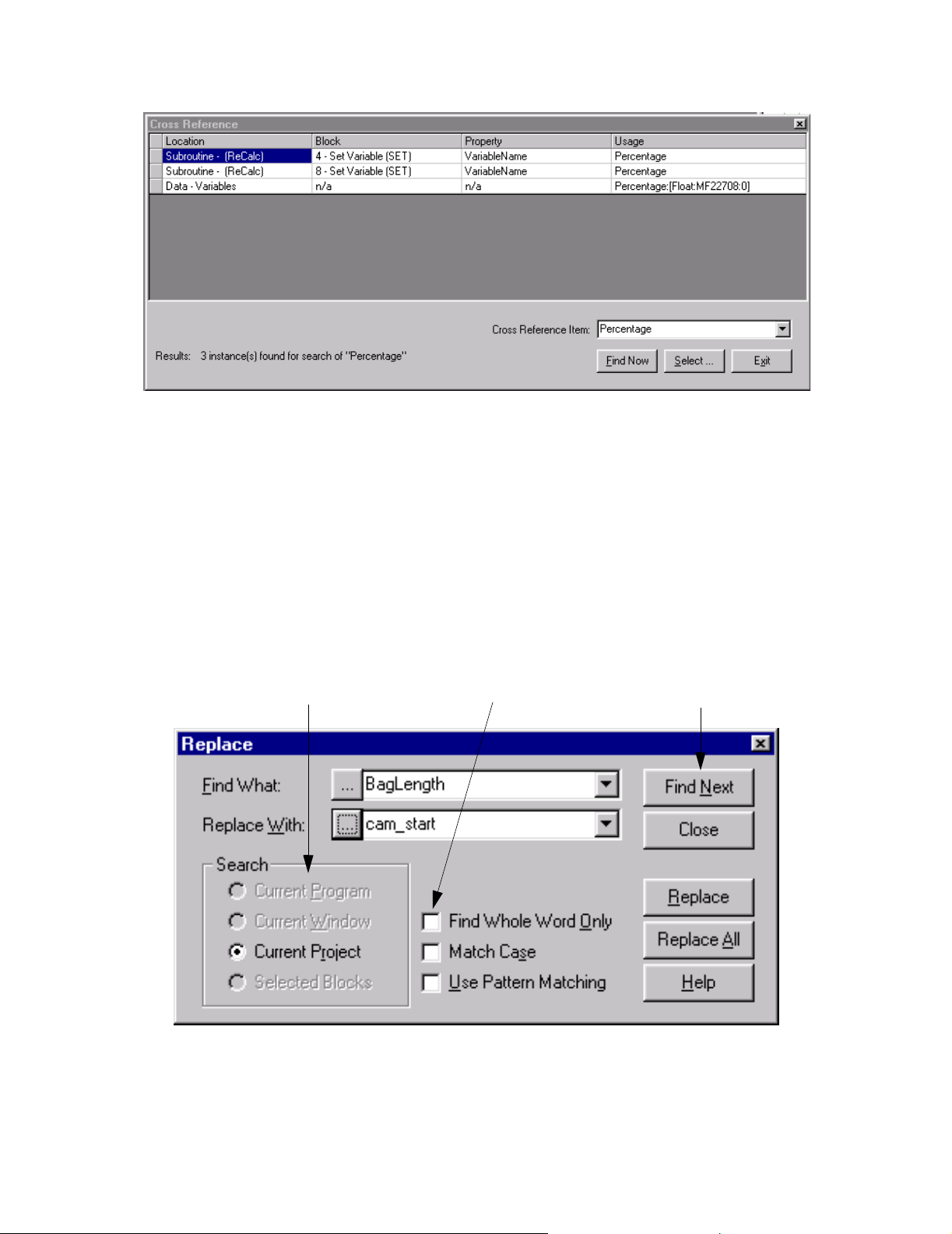

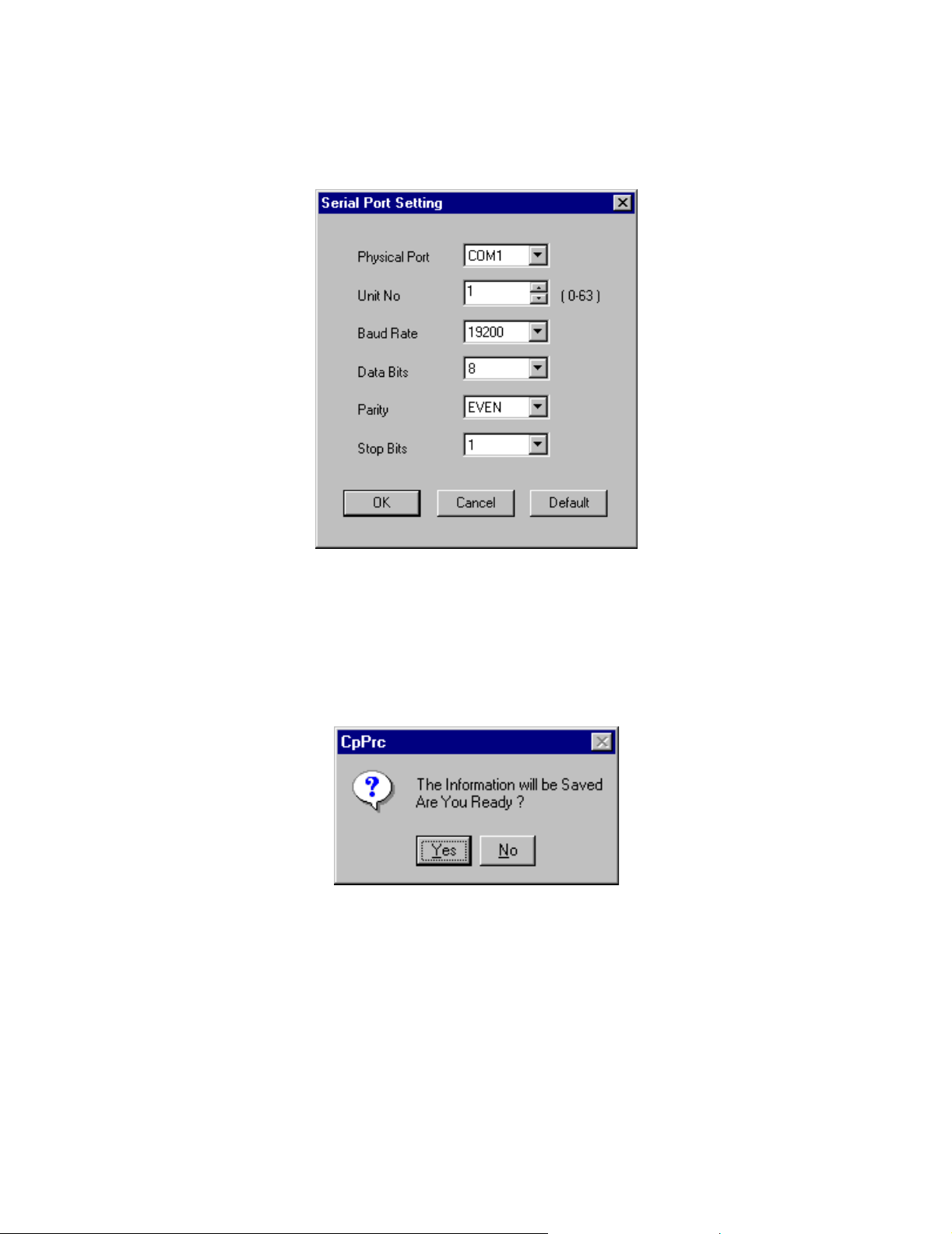

1.8 The Block Toolbar