Page 1

MotionSuite™ Series Machine Controller

Programming Manual

Page 2

MotionSuite ™ Series Machine Controller Programming Manual Table of Contents /P reface

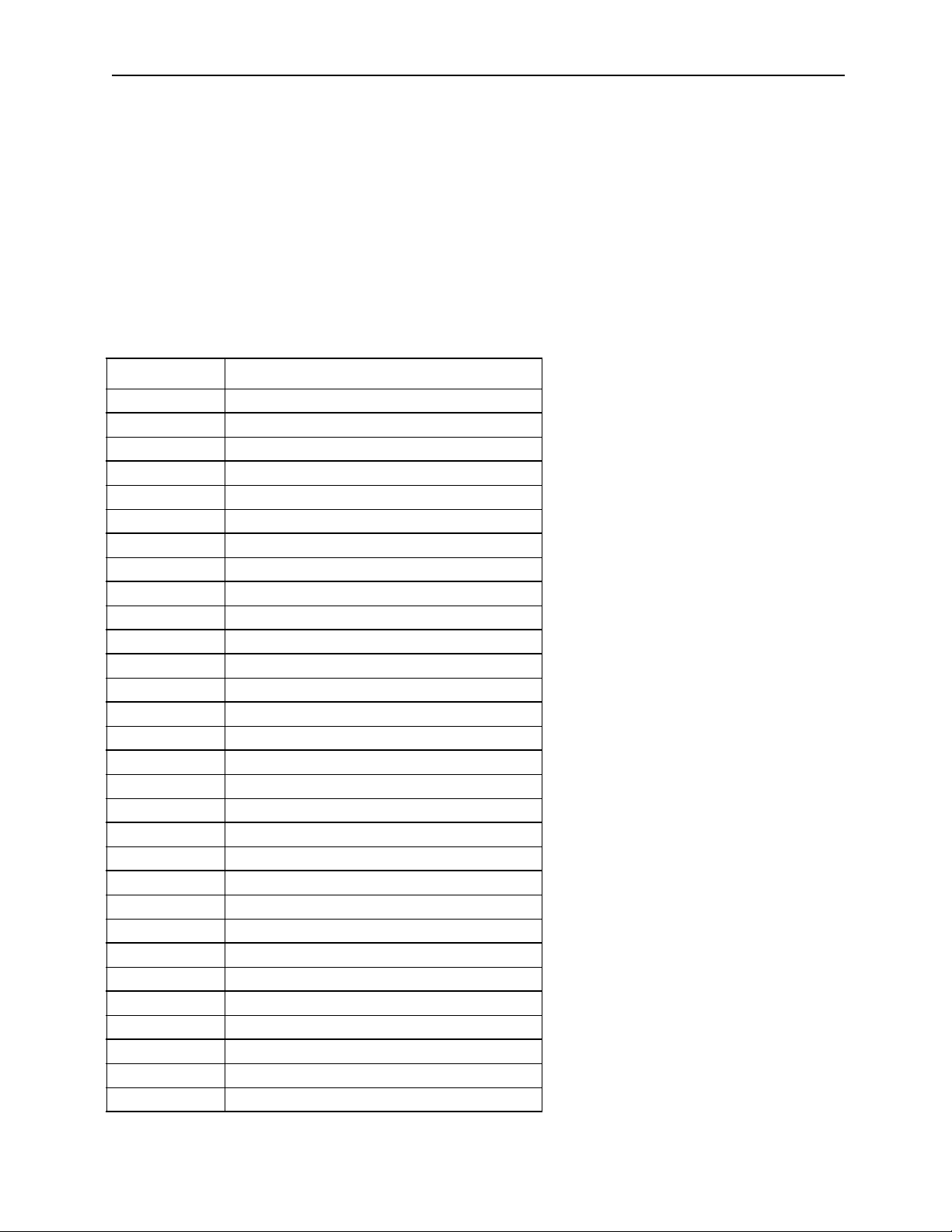

1 Motion Programming Outline........................................................................... ........ 1-1

1.1 What is a Motion Program .................................................................................. 1-2

1.1.1 Capabilities of Motion Programs ...............................................................1-2

1.1.2 Basic P rog ram Str u ct u re ......... .................. ................... ........................ ...... 1-3

1.1.3 Function Performance List ......................................................................... 1-5

1.1.4 Motion P ro g ram Star t ............... .................. ......................... .................. .... 1-6

1.1.5 Parallel Program Operation ....................................................................... 1-7

1.1.6 Program Editor ..........................................................................................1-7

1.2 Motion Programming Method ....................................... .......... .......... .......... .......1-9

1.2.1 Input Format .............................................................................................. 1-9

1.2.2 Con trol Axes .................... .............. ................... .............. .................... .....1-15

1.2.3 Feed Sp ee d ...... ...... .................. ......................... .................. .................. .... 1-21

1.2.4 Motion Co m m a n d Li st .............. .................. ......................... .................. .. 1-26

2 Motio n Co m m a n d s ................ .............. .................... ............. .................... .............. .2-1

2.1 Axial Motion Commands .................................................................................... 2-2

2.1.1 Positi o n i n g (MOV) ......................... ......................... .................. ................ 2-2

2.1.2 Linear Interpolation (MVS) ....................................................................... 2-7

2.1.3 Circul ar Inter p o l ation (MC W , MCC) .............. ........................ ................ 2-11

2.1.4 Helical Interpolation (MCW, MCC) ........................................................ 2-19

2.1.5 Ze ro-po i n t Re tur n (ZRN) . ...... .................. ......................... .................. .... 2-22

2.1.6 Skip Command (SKP) ............................................................................. 2-28

2.1.7 Time Designation Positioning (MVT) ..................................................... 2-29

2.1.8 External Positioning (EXM) .................................................................... 2-31

2.2 Con trol Comm a n d ................ .................. ......................... .................. ................ 2-32

2.2.1 Absolute (ABS) Mode ............................................................................. 2-32

2.2.2 Incremental (INC) Mode ......................................................................... 2-34

2.2.3 Current Value Change (POS) .................................................................. 2-36

2.2.4 Coordinate Plane Designation (PLN) ...................................................... 2-39

2.2.5 Machin e Co o r d in ate Comma n d ( MV M) ...... ......................... .................. 2-40

2.2.6 Program Current Position Update (PLD) ................................................. 2-42

2.2.7 Timed Wait (TIM) ................................................................................... 2-43

2.2.8 Program End (END ) ......... .................. ......................... .................. .......... 2-44

3 Advanc e d P ro g r a m m ing .................... ........................ ................... .................. .......... 3-1

3.1 Ad v an c e d Co n t rol Comman d s ... .................. ......................... .................. ............ 3-2

3.1.1 In-Pos ition Check (PFN) Co m m a n d ........... ................... ........................ .... 3-2

3.1.2 Second In-Position Check (INP) Command . ............................................. 3-5

3.1.3 Ignore Single Block (SNG) Command ...................................................... 3-7

3.1.4 User Function Call-out (UFC) Command ................................................. 3-8

3.1.5 I/O Vari ab le Wait (IOW) Co mmand ........ ................... .................. .......... 3-17

i

Page 3

MotionSuite ™ Series Machine Controller Programming Manual Table of Contents /P reface

3.1.6 Sub-p rog ram Call -o u t (MSEE) Co m m a n d ........................ ...................... 3-18

3.1.7 Sub-program End (RET) Command ........................................................ 3-19

3.1.8 1-scan Wait (EOX) Command ................................................................. 3-20

3.1.9 Branc h (IF ELSE IEND ) Command ..... ...... ................... ........................ .. 3-22

3.1.10 Re p e at (W H I LE WEND ) Co m m a n d ........................... ........................ .... 3-24

3.1.11 Parallel Execution (PFORK, JOINTO, PJOINT) Command .................. 3-26

3.1.12 Selec ti v e Execut i o n (S FORK, JOIN TO, SJOI N T) Comman d ................ 3-31

3.2 Speed/Acceleration Commands ........................................................................ 3-34

3.2.1 A cc e l e r a t i o n Time Change (ACC) Co m mand ........ .............. ...................3-34

3.2.2 S-Curve Time Constant Change (SCC) Command .................................3-36

3.2.3 Feed Sp ee d Ch an g e (V EL) Comm a n d ...... ................... .................. .......... 3-38

3.2.4 Interpolation Feed Speed Ratio Setting (IFP) Command ........................ 3-40

3.2.5 Maximum Interpolation Feed Speed Setting (FMX) Command ............. 3-42

3.2.6 Interpolation Acceleration Time Change (IAC) Command .................... 3-44

3.2.7 Interpolation Deceleration Time Change (IDC) Command .................... 3-46

4 Sequence Commands ................................................................................................4-1

4.1 Se q u e n ce Co m m a n d O u tli n e ................. ................... .................. ........................ 3-2

4.1.1 Calculation Commands .............................................................................. 4-2

4.1.2 Arithmetic Calculation Combination ......................................................... 4-4

4.1.3 Logical Calculation Combination .............................................................. 4-5

4.2 Aritmetic Calculations.........................................................................................4-6

4.2.1 Substitution (=) .........................................................................................4-6

4.2.2 Addition (+) ............................................................................................... 4-7

4.2.3 Subtraction (–) ........................................................................................... 4-8

4.2.4 Multipl icatio n (* ) ...................... .................. ................... ........................ .... 4-9

4.2.5 D i v i sion (/) ...... ...... ........................ ................... .................. ...................... 4-10

4.2.6 Remainder (MOD) ................................................................................... 4-11

4.3 Logical Calculations..........................................................................................4-12

4.3.1 Lo g i c a l OR (| ) .......................... .............. ................... .............. .................4-12

4.3.2 Logical AND (&) ..................................................................................... 4-13

4.3.3 Exclusive OR (^) ......................................................................................4-14

4.3.4 N O T (!) ................ .............. .................... ............. .................... .............. ...4-15

4.4 Value Comparisons............................................................................................4-16

4.4.1 V alue Comp a ri son Comma n d ( = =, < >, > , < , >= , <=) .......................... .4-16

4.5 Data Oper at io n s .................. .................. .................. ......................... .................. 4-18

4.5.1 Bit Right-shift (SFR) Co m m a n d ........... ................... .................. .............. 4-18

4.5.2 Bit Left-shift (SFL) Command ................................................................ 4-20

4.5.3 Block Transfer (BLK) .............................................................................. 4-22

4.5.4 Clear (CLR) ............................................................................................. 4-24

ii

Page 4

MotionSuite ™ Series Machine Controller Programming Manual Table of Contents /P reface

4.6 Basi c F u n c t i o n s................ .............. .................... ............. .................... .............. .4-26

4.6.1 Sine (SIN) ................................................................................................4-26

4.6.2 Cosine (COS) ........................ .................. ................... ........................ ...... 4-28

4.6.3 Tangent (TAN) ........................................................................................4-30

4.6.4 Arc Sine (ASN) ........................................................................................4-31

4.6.5 A rc Cosine (ACS) ........... ........................ ................... .................. ............ 4-32

4.6.6 A rc Tangent (ATN) ...... .................. ................... ........................ .............. 4-33

4.6.7 Square Ro o t (S Q T) ................... ......................... .................. .................. .. 4-35

4.6.8 BCD→BIN (BI N ) ......................... ................... .................. ...................... 4-37

4.6.9 BIN→BCD (BCD) ............ ........................ ................... .................. .......... 4-38

4.6.10 Desig n at e d Bi t ON (S{ }) ... ........................ ................... .................. ........ 4-39

4.6.11 Designated Bit OFF (R{ }) ...................................................................... 4-40

5 Varia b l e s (Regist ers) .................. .................. ................... ........................ .................. 5-1

5.1 Outline ................................................................................................................. 5-2

5.1.1 V ariabl e O v e r v iew ........ .................. ................... .................. ...................... 5-2

5.1.2 G l o b a l a n d Lo ca l V ariable s .............. ......................... .................. .............. 5-4

5.2 Ho w to U se the Variables .......................... ................... ........................ .............. 5-8

5.2.1 Syste m Variable s .............. .................. ................... ........................ ............ 5-8

5.2.2 Data Variables (M Registers) .................................................................... 5-9

5.2.3 Input Variables (I registers) ..................................................................... 5-10

5.2.4 O u t p u t V a riables (O Re g i sters) ............... ......................... .................. ...... 5-12

5.2.5 Constant Variables (C Registers) ............................................................. 5-13

5.2.6 D V ariable s (D Regist e rs) ................... ................... ........................ .......... 5-14

iii

Page 5

MotionSuite ™ Series Machine Controller Programming Manual Table of Contents /P reface

Outline of Manual

!

This manual is a collection of data regarding the design and maintenance of the MotionSuite™ series machine controller. The following items are included in this manual:

• Product outline, specifications and programming methods

• Basic programming

• Advanced programming

!

Read this manual thoroughly so as to ensure proper use of the controller. Furthermore,

store this manual properly so that it can be referenced whenever necessary .

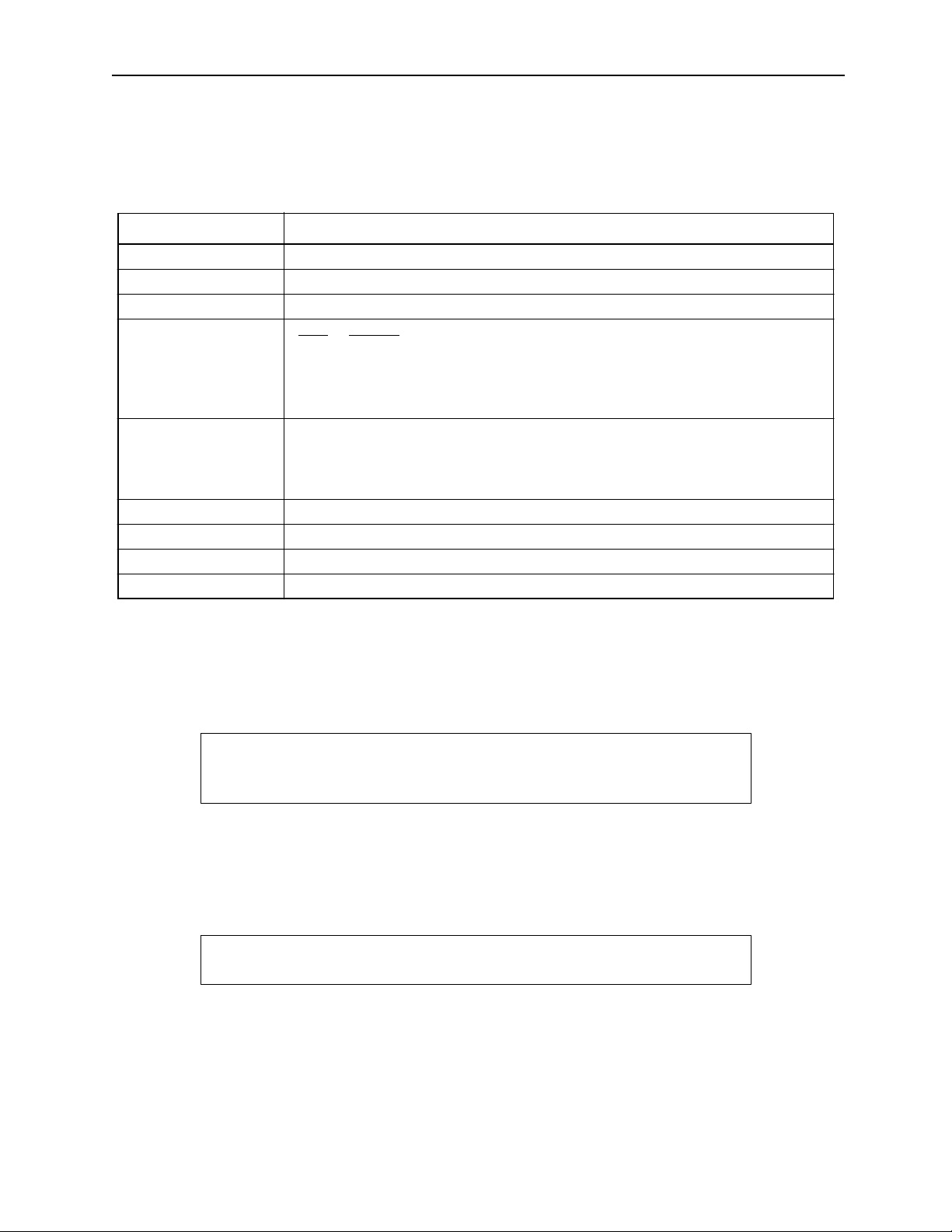

Related Manuals

!

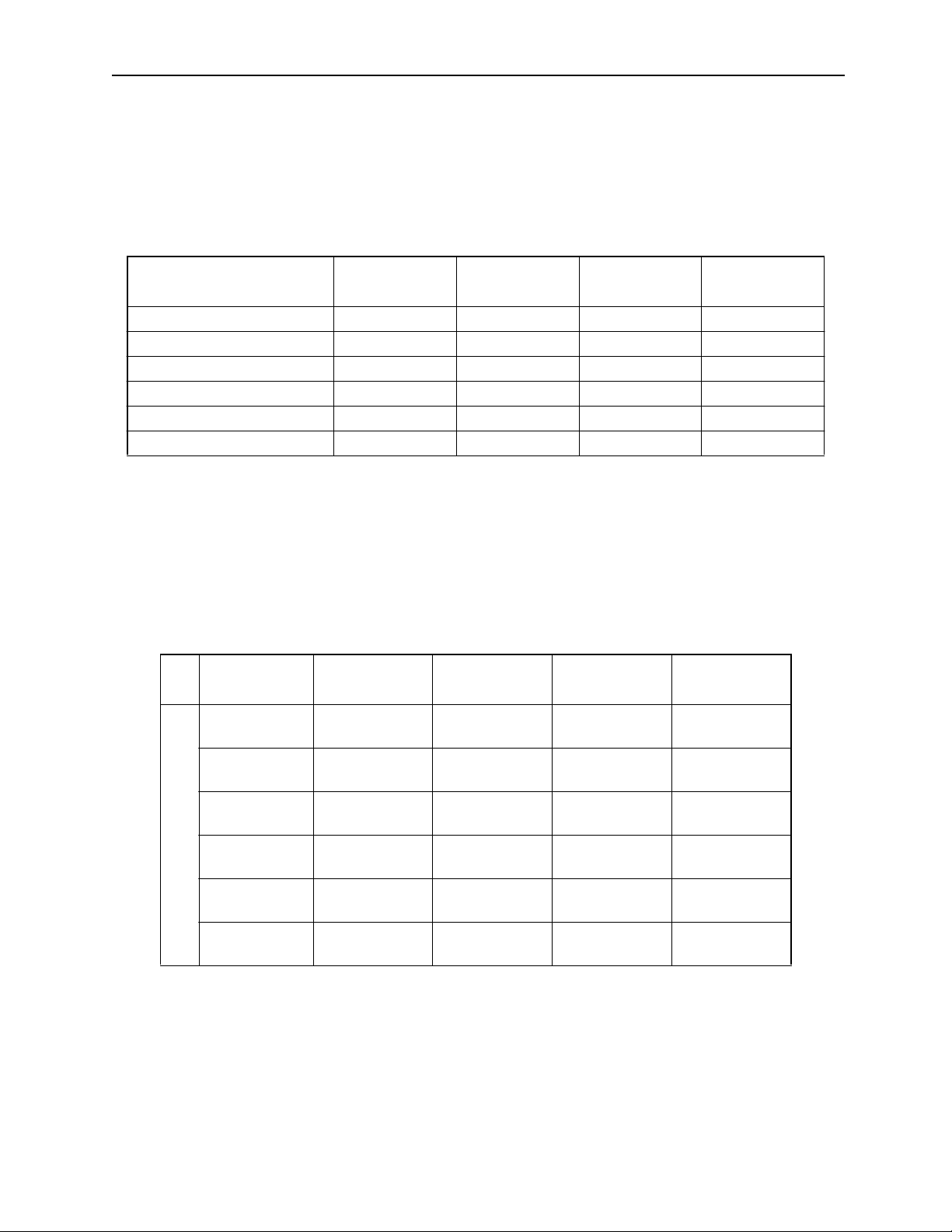

Related manuals are shown in the following table.

!

Use this product with full knowledge of the product specifications, usage limits, etc.

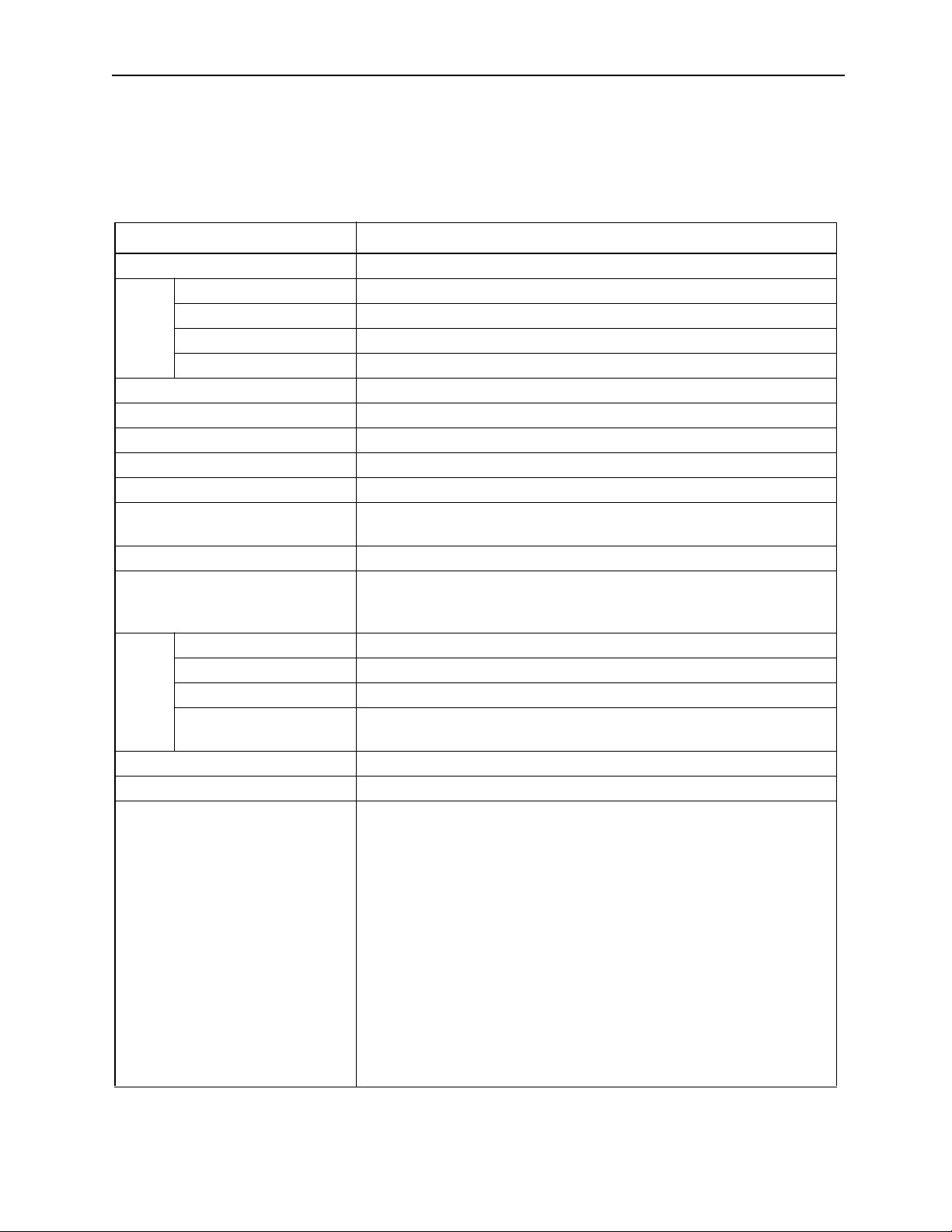

Document Name Document Number Content

MP930 Machine Controller

Hardware Manual

MP930 Machine Controller

Ladder Programming

MotionSuite™ Seri es Machine

Controller Software Manual

• YEA-SIA-C887-1.1 B Describes in detail the functions, specifications and usage methods of the MP930

• Functions/Specifications

• Setup procedures, etc .

• SIEZ-C887-1.2 Describes in detail the operation co mmands

used in MP930 ladder program m ing

• YEA-SIA-C887-1.4B Descri bes in detail the process control commands used in MotionWorks™ software

iv

Page 6

MotionSuite ™ Series Machine Controller Programming Manual Table of Contents /P reface

Using this Manual

!

Users of this manual

This manual is to be used by the following personnel:

• Persons designing MotionSuite™ systems

• Persons writing MotionSuite™ motion programs

!

Abbreviations

The following abbreviations are used in this manual:

• MC Unit: MC unit used is the MotionSuite™ motion controller

• I/O Unit: I/O unit used is the I/O expansion module (model: JEPMC-IO350)

• PP: Programming Panel

• PC: Personal Computer

v

Page 7

MotionSuite ™ Series Machine Controller Programming Manual Table of Contents /P reface

Safety Notes

This chapter deals with the cautionary items regarding the safe and proper use of this

device. Be sure to thoroughly read the directions in this manual and all associated

materials prior to mounting, running, storage/inspection, and then execute the contents

of these manuals correctly. Use the MotionSuite™ series machine controller after

thorough study of all device data, safety information, and cautionary items.

Cautions on Usage

!!!!

!

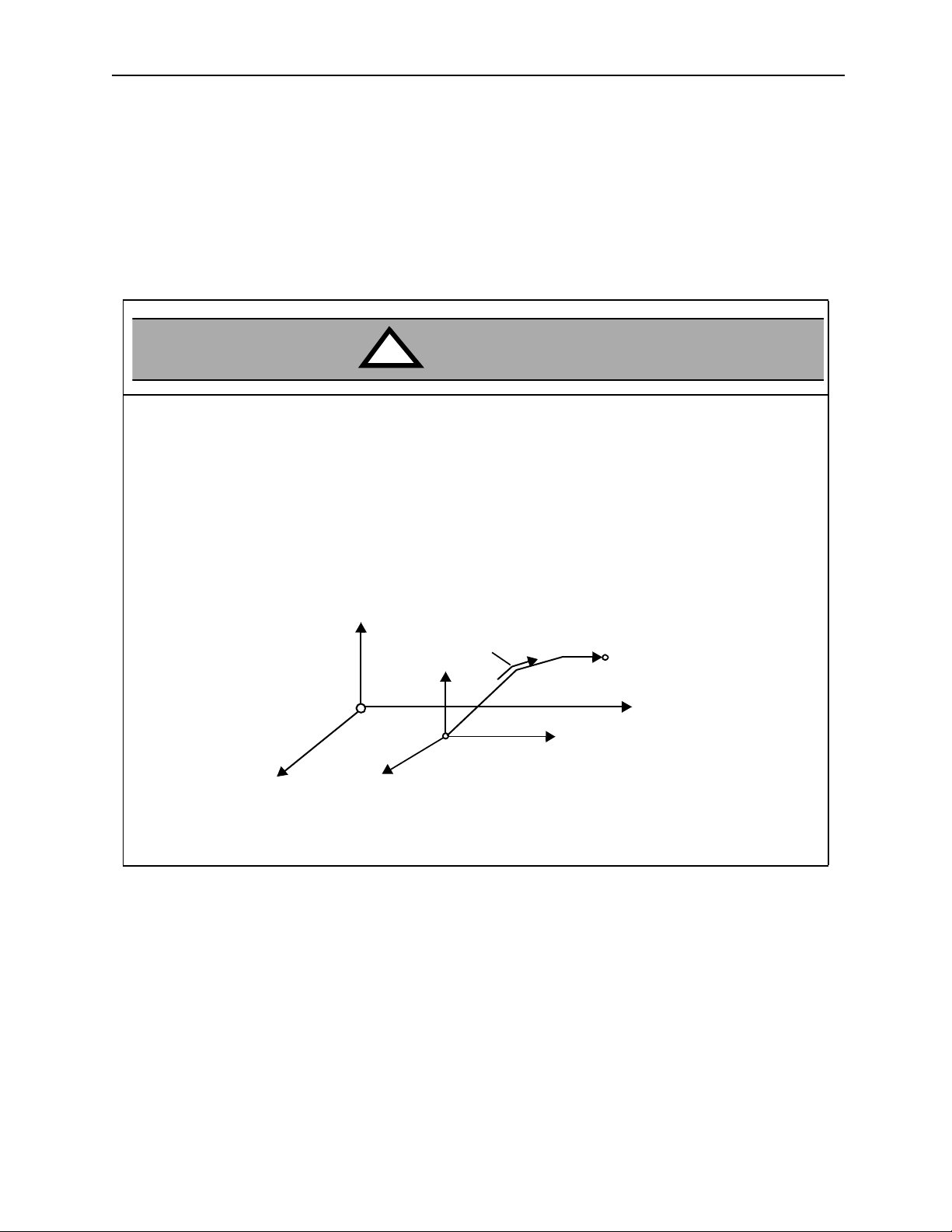

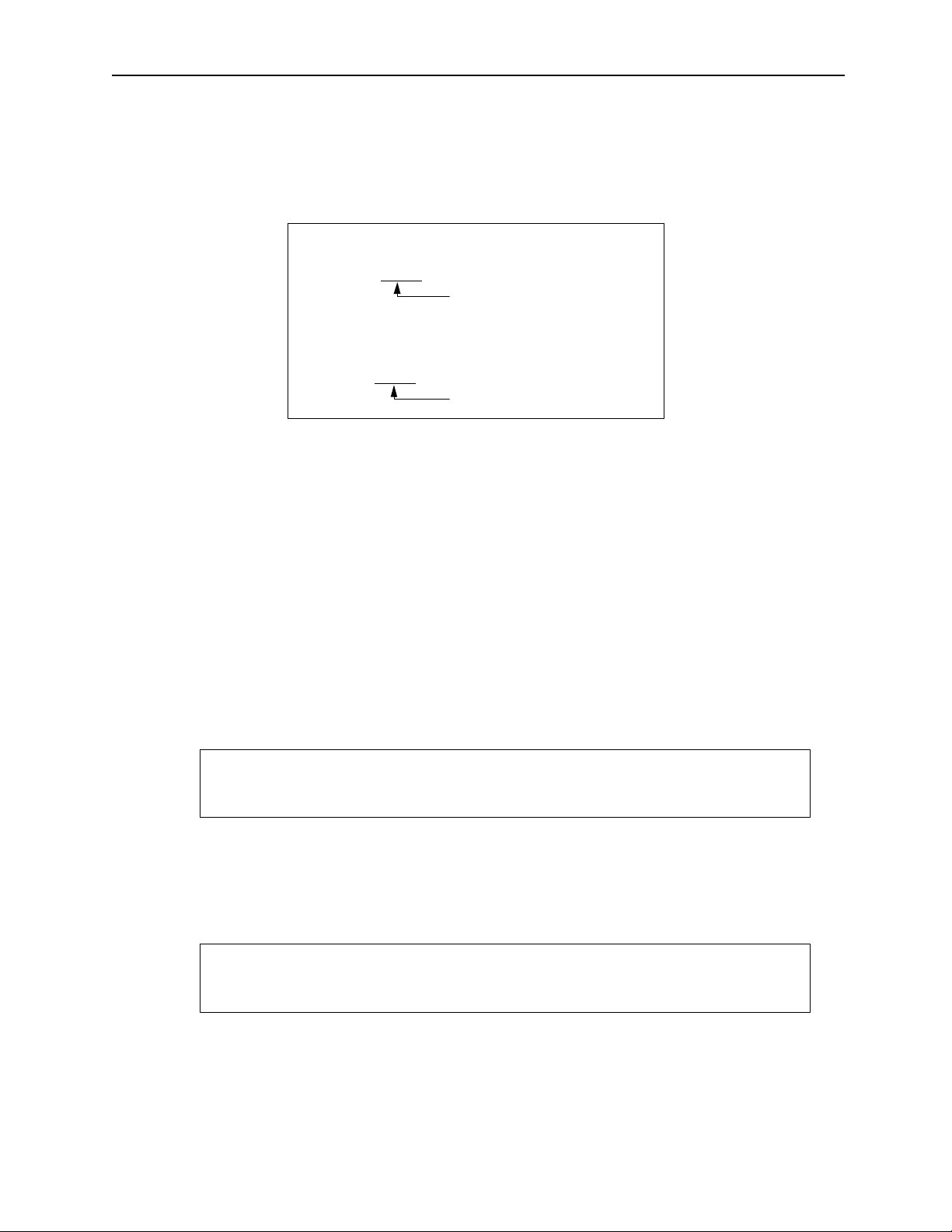

During programming of the following axi s motion commands, be sur e to che ck the move path to make

•

sure that the tool does not interfere with the work.

Commands requiring such checks:

• Positioning (MOV) commands

• Linear Interpolation (MVS) commands

• Ci r cular Interpol ation (MCC, MCW) commands

• He lical Interpolation (MCC, MCW) commands

• Time Designated Positioning (MVT) commands

• Skip (SKP) commands

CAUTION

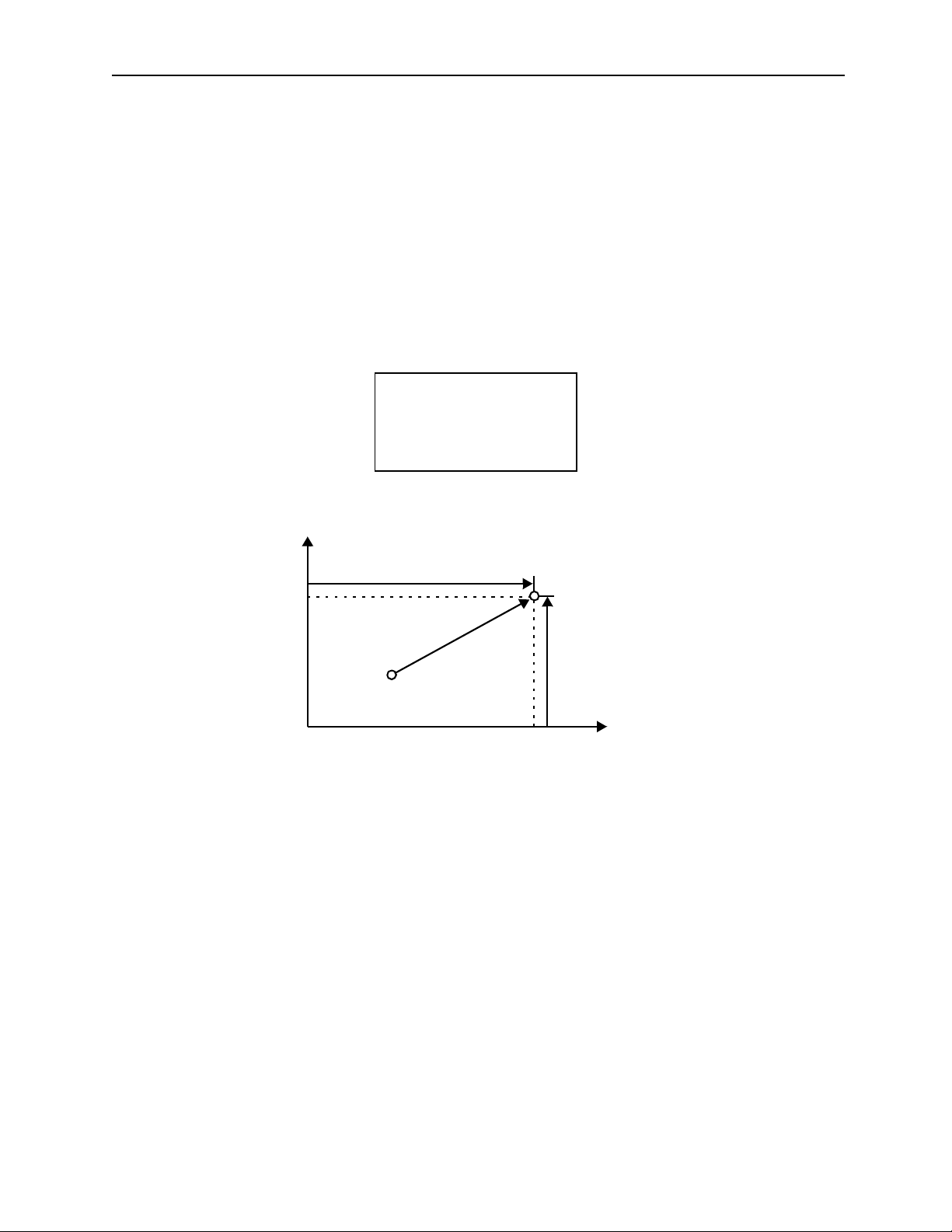

Example

axis2

axis3

axis2

Each axis is moving independent ly

by feed speed

axis3

Positioning motion

Current position

End position

axis1

axis1

Move Path Based on the MOV Command

Forgetti ng this check may result in tool dam age , or bodily injury.

vi

Page 8

MotionSuite ™ Series Machine Controller Programming Manual Table of Contents /P reface

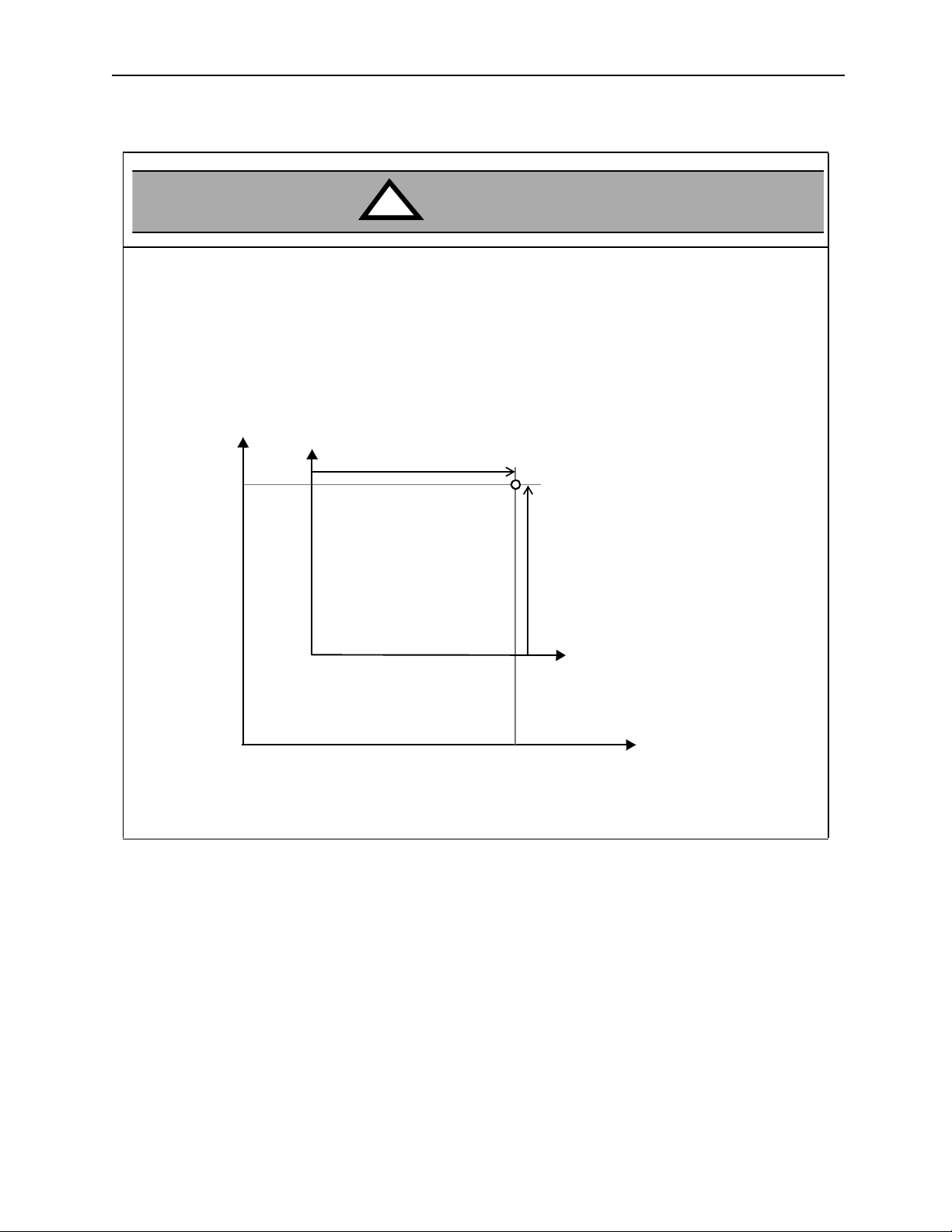

!

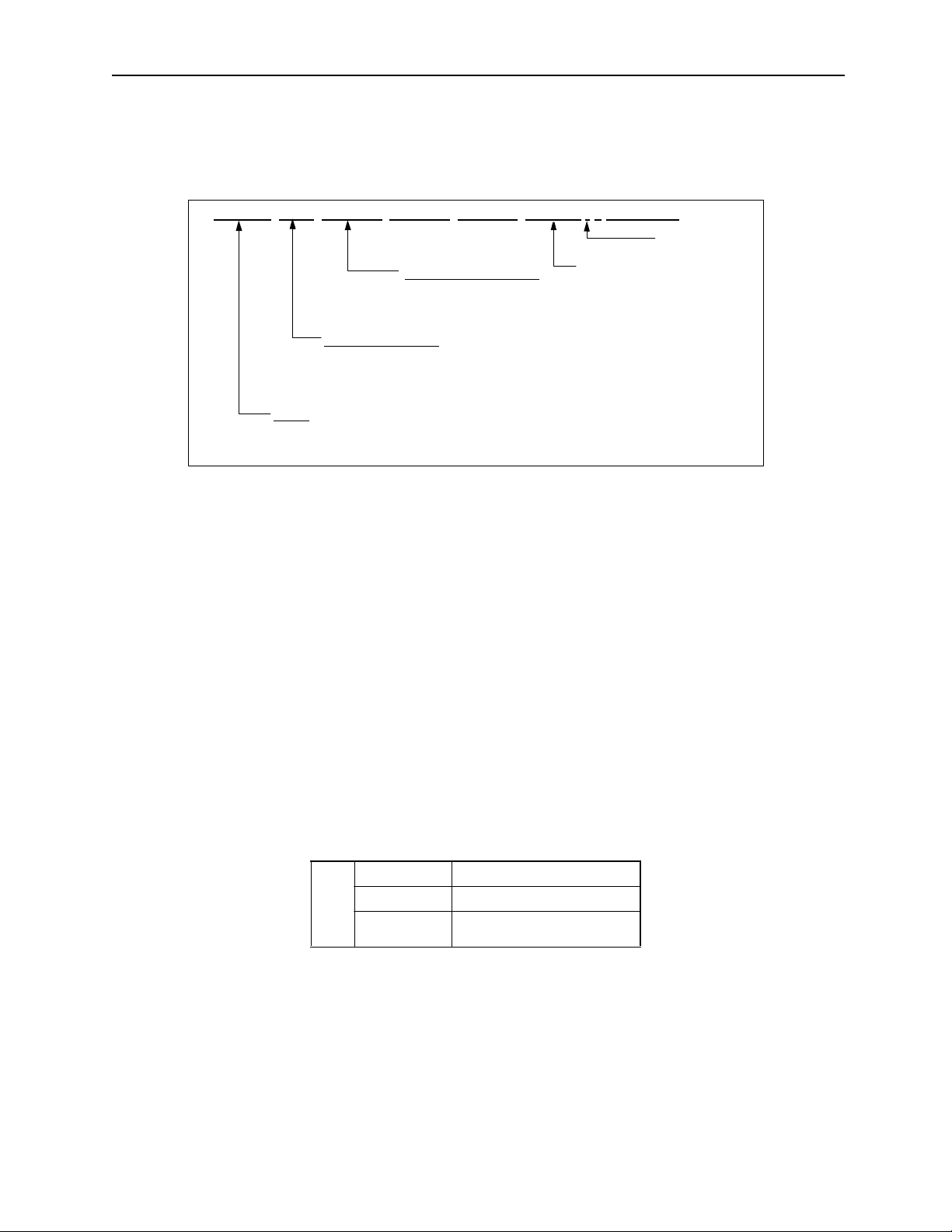

• I f the f o ll owing co m m a nd s are erroneously designat ed , the subsequ en t mo tio n o peratio n w il l b e co m pletely incorrect. V erify prior to running that these commands have been correctly designated

The following commands require such checks:

CAUTION

• Absolute mode (ABS)

• Incremental mode (INC)

• Current value change (POS)

• Machine coordinate designation (MVM)

Example

axis2

axis2

(0,0)

Y

axis1

Work coordinate

Current pos ition

axis2

axis1

(0,0)

POS Command (current value change)

Forgetti ng this step may result in tool damage, or bodily injury.

vii

axis1

Page 9

MotionSuite ™ Series Machine Controller Programming Manual Table of Contents /P reface

!

! General Cautionary Items

!!

Cautions During Use

• The MotionSuite™ was n either designed nor manufactured for use in devices or systems under such critical

conditions as fol low: Transporta tion s yst ems, m edic al dev ices, aeros pace, nu cl ear powe r contro l, submari ne

relay devices, etc . Please contact Yaskaw a whe n cons idering any such special application.

• Although the MotionSui te™ is manufa cture d unde r rigorous qualit y con trol, pu t in pl ace sa fety appara tus s o

that a major accident c annot occur when apply ing the Moti onSuit e™ in an insta ll ation where the occurre nce

of major facilities damage or serious, life-threatening injury is anticipated due to the fai lure of the MotionSuite™.

• The pictures and diagrams in this manual are representative examples, and may differ from the product

received.

• These manuals may be changed as needed due to product improvements, specification change, or for

improvement in ease of use of the manual.

• These changes are made following updating of the document number of the manual, and its issua nce as a

revised edition. The publication number of the re vised edition is written on the manual cover.

• When ordering new manuals due to damage or loss, contact a Yaskawa dealer or the nearest Yaskawa corporate office li s ted on the cover, and give the document number.

• If the nameplate mounted on the product becomes illegible or damaged, order another nameplate from a

Yaskawa dealer or Yaskawa cor po r a te offic e li s t ed on th e co v e r.

• Any product modified by the custome r fall beyond Yaskawa’s product warranty . Yaskawa shoulder s no

responsibility for any injury or damage resulting from modified products.

viii

Page 10

MotionSuite ™ Series Machine Controller Programming Manual Chapter 1: Motion Programmming Outline

1 Motion Programming Ou tline

This chapter deals with the methods of creating motion programs. Motion programs are created using MotionWorks™ (Programming Unit); the programs are

executed after transfer to the MotionSuite™ series machine controller.

1.1 What is a Motion Program .................................................................................. 1-2

1.1.1 Capabilities of Motion Programs ...............................................................1-2

1.1.2 Basic P rog ram Str u ct u re ......... .................. ................... ........................ ...... 1-3

1.1.3 Function Performance List ......................................................................... 1-5

1.1.4 Motion P ro g ram Star t ............... .................. ......................... .................. .... 1-6

1.1.5 Parallel Program Operation ....................................................................... 1-7

1.1.6 Program Editor ..........................................................................................1-7

1.2 Motion Programming Method ....................................... .......... .......... .......... .......1-9

1.2.1 Input Format .............................................................................................. 1-9

1.2.2 Con trol Axes ........ .................... .............. ................... .................... ...........1-15

1.2.3 Feed Sp ee d ...... ...... .................. ......................... .................. .................. .... 1-21

1.2.4 Motion Co m m a n d Li st .............. .................. ......................... .................. .. 1-26

1-1

Page 11

MotionSuite ™ Series Machine Controller Programming Manual Chapter 1: Motion Programmming Outline

1.1 What is a Motion Program?

A general description of motion programming is presented in this chapter. Be sure to read

this section before doing any programming.

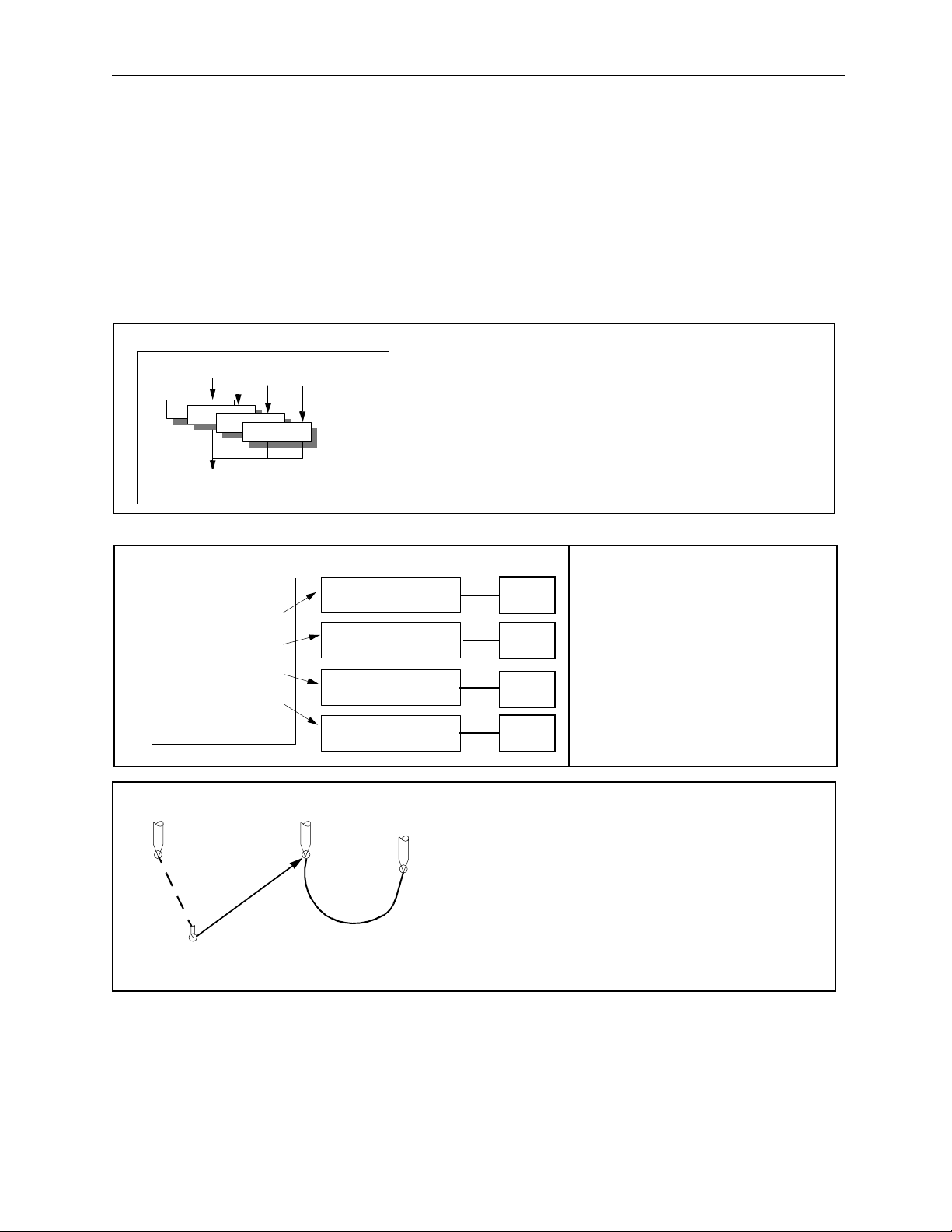

1.1.1 Capabilit ies of Motion Programs

Using MotionSuite™, it is possible to program the specific motions necessary for

industrial machines. The main characteristics of motion progr ams are provi ded below

for reference:

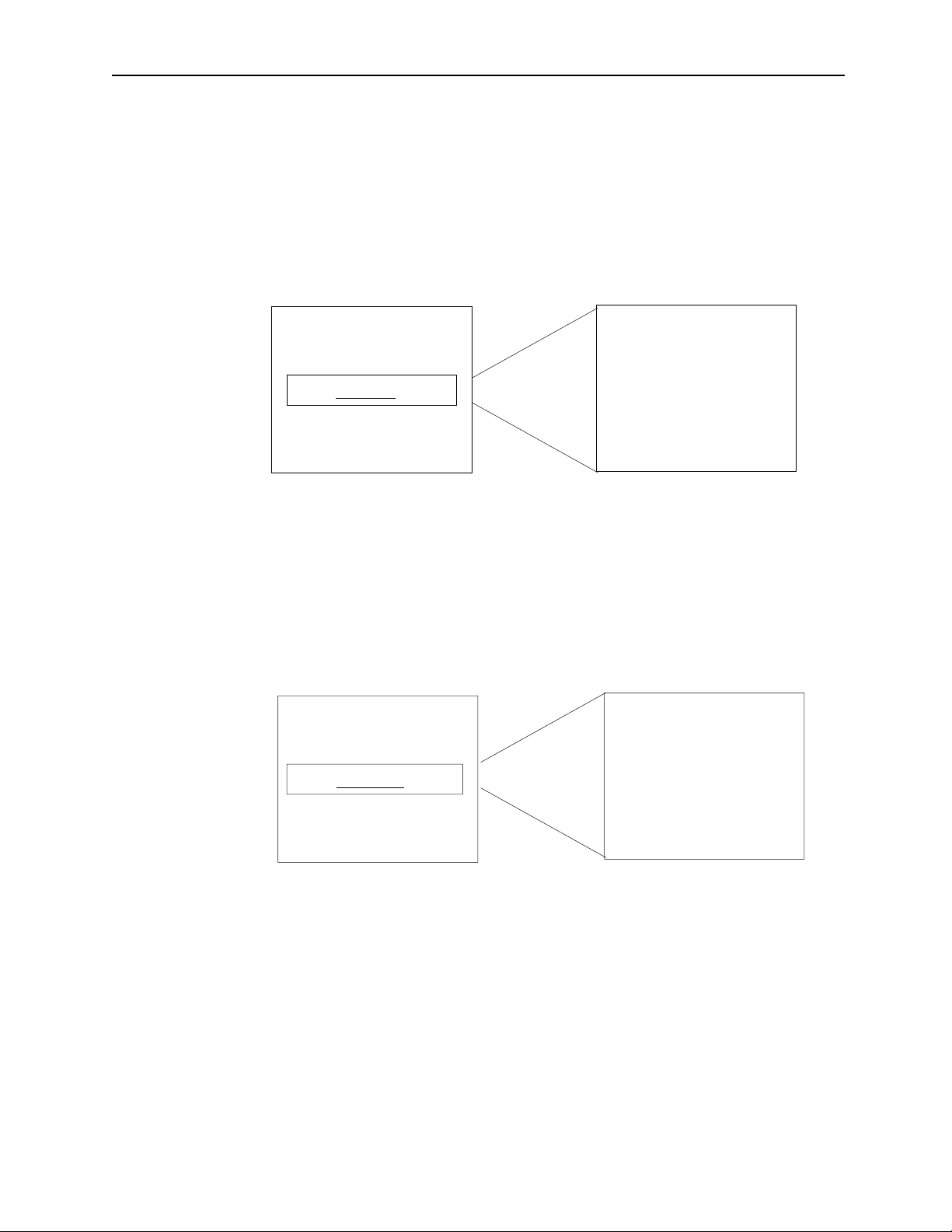

Motion Program MPM001

PFORK S1, S2, S3, S4

S1

S2

S3

S4

S5: PJOINT

Ladder Program

MSEE MP M001 DA0000

MSEE MP M002 DA0002

MSEE MP M003 DA0004

MSEE MP M004 DA0006

Motion Program

Motion Pro gram

Motion Pro gram

Motion Pro gram

Motion Pro gram

MPM001

MPM002

MPM003

MPM004

Parallel Operation 1

• A maxi mum of fou r pro grams c an be operat ed in par allel

using the PFORK command within a si ngle motion program.

• Axes may be freely combined in up to four groups.

Machine

Simultaneous Control of

Multiple Machines

MC-1

MC-2

• Several prog rams can be op e r at ed in

parallel.

• A maximum of 14 axes can be controlled.

MC-3

MC-4

Maximum 14

axes simultaneo u s

positioning

Maximum 14

axes simultaneo u s

linear interpolation

2 axes

simultaneous

circular interpolation

Enhanced Motion Commands

• Positionin g 14 axes maximum

• Linear Interpolation 14 axes maximum

• Circular Interpolation 2 axes

• Helical Interpolation 3 axes

1-2

Page 12

MotionSuite ™ Series Machine Controller Programming Manual Chapter 1: Motion Programmming Outline

Example of Operation Com ma nds:

MW81D=AB01H*SIN(100)+50;

MW5=BCD (1W0001);

IF CF476 <> DF897;

IF MW0001 > 7;

IF 0B0 == 1;

0B0 = (IB0 | IB2 | IB3) & 1B1;

MW6 = SQT (MW809);

Conditional Branching Commands

IF <Conditional>

•

• Processed when conditions established

•

•

ELSE

•

• Processed when conditions not established

•

•

IEND

Repeat Commands

WHILE <Conditional>

•

• Processing

•

•

WEND

Calculations are Flexible and Dependable

• Integer arithmetic operations

• Real number arithmetic opera tions

• Logical operations

• Trigonometric operations

• Exponents

• Logarithms

•etc.

Control Commands

• Conditional branching comm ands (IF /ELSE)

• Repeat commands (WHILE)

• Timer commands (TIM )

• Subroutines (MSEE)

• Parallel execution com mands (PFORK)

• Selection execution commands (SFORK)

1.1.2 Basic Program Structure

a. Motion programs are written in a text format motion language. Up to 256 of

these motion programs can be created separately.

b. Motion programs are of the following two types: Main programs (MPM

which can be called out from DWG.H, and sub-programs (MPS

can be called out from the main program.

Important Point

Numbers of the MPM and MPS programs cannot be duplicated.

1-3

"""

"""

) which

)

Page 13

MotionSuite ™ Series Machine Controller Programming Manual Chapter 1: Motion Programmming Outline

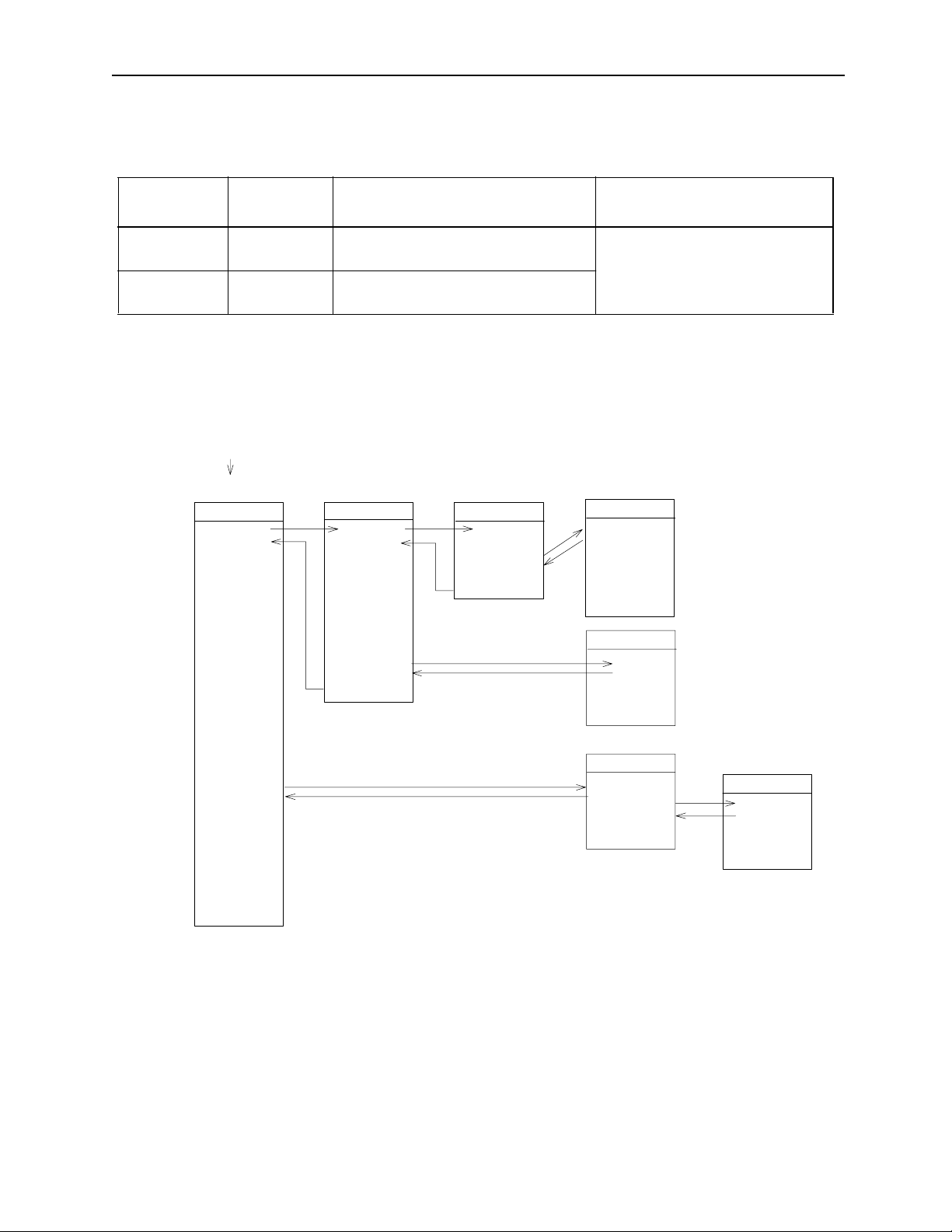

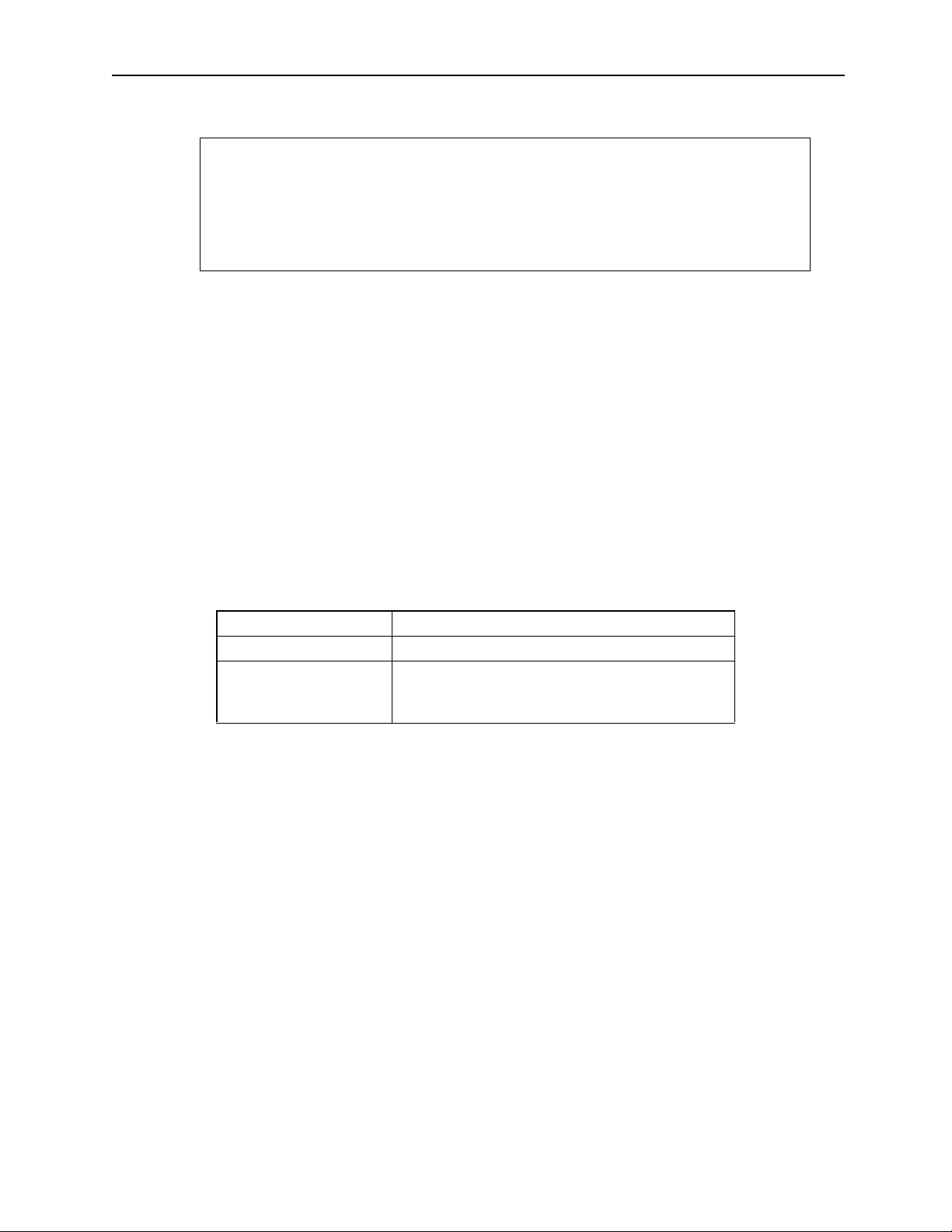

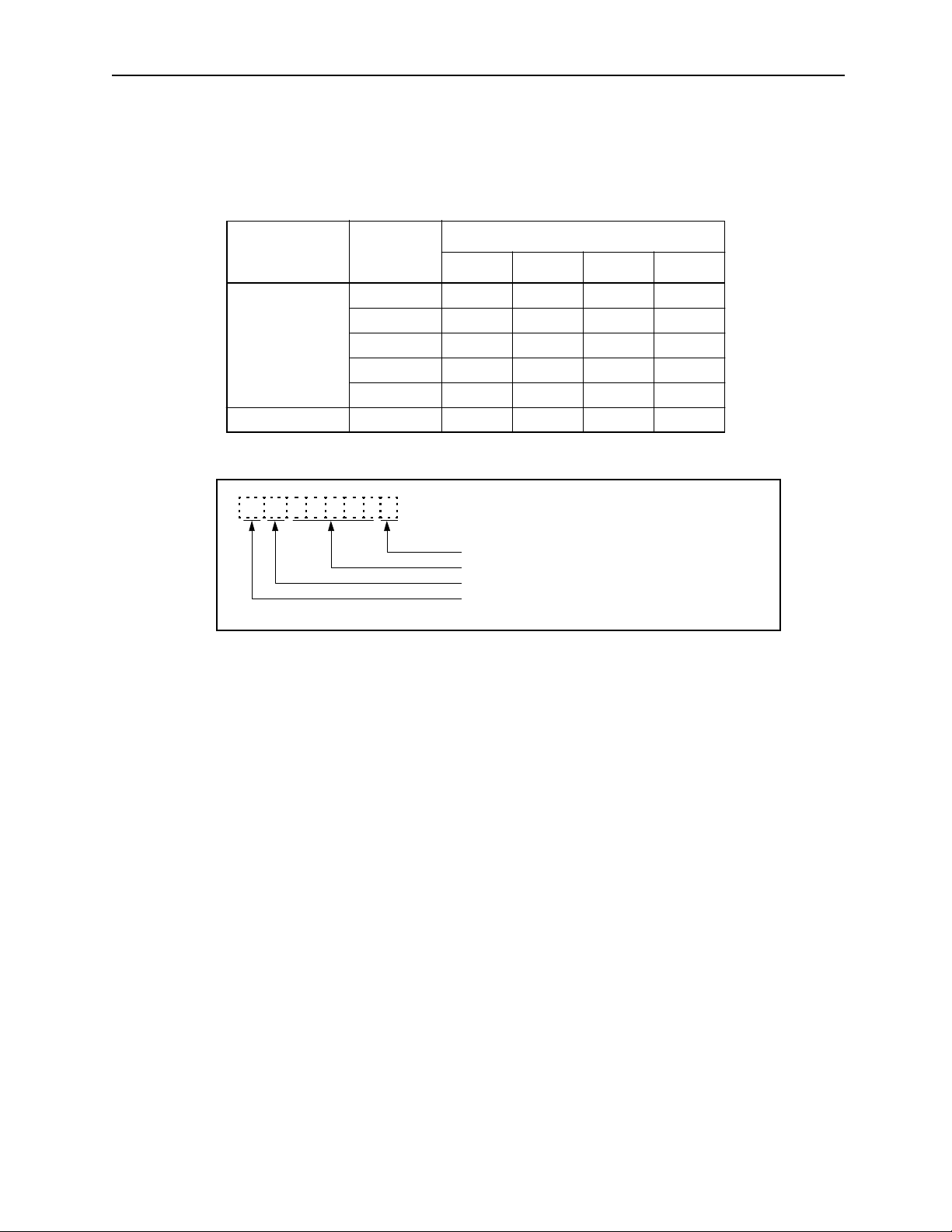

Motion Program Types

Classification

Designation

Method

Main Program MPM"""

1~256

Sub-Program MPS"""

1~256

c. Motion Program Execution Processing Format

Always refer to the motion program from the H drawing by using the MSEE

command. H drawings can be referenced from source drawings, sub-drawings,

or sub-sub-drawings.

System program starts by

operating conditions

Source Drawing

DWG.H

SEE H.01

Characteristics

Number of Programs

Can be called out from an H drawing A maximum of 256 combined

main programs and sub-programs

Can be called out from a main program

Sub-drawing

DWG.H01

SEE H01.01

Sub-sub-drawing

DWG.H01.01

MSEE MPM001

DEND

can be created.

Motion Program

MPM001

VEL [a1]5000 [b 1]..

FMX T100000000;

IAC T25;

IDC T30;

MOV [a1]300. [b1]..

MVS [a1 ]20 0. [b1]..

•

•

END

MPM002

MSEE MP M0 0 2

DEND

END

MPM003

MSEE MPM003

MSEE MPS001

END

DEND

Subroutine

MPS001

RET

Figure 1.1: Motion Program Execution Processing Format

Supplement

See Section 3.4 “User Programs” in the MP930 Machine Controller Hardware Manual for details regarding this figure.

1-4

Page 14

MotionSuite ™ Series Machine Controller Programming Manual Chapter 1: Motion Programmming Outline

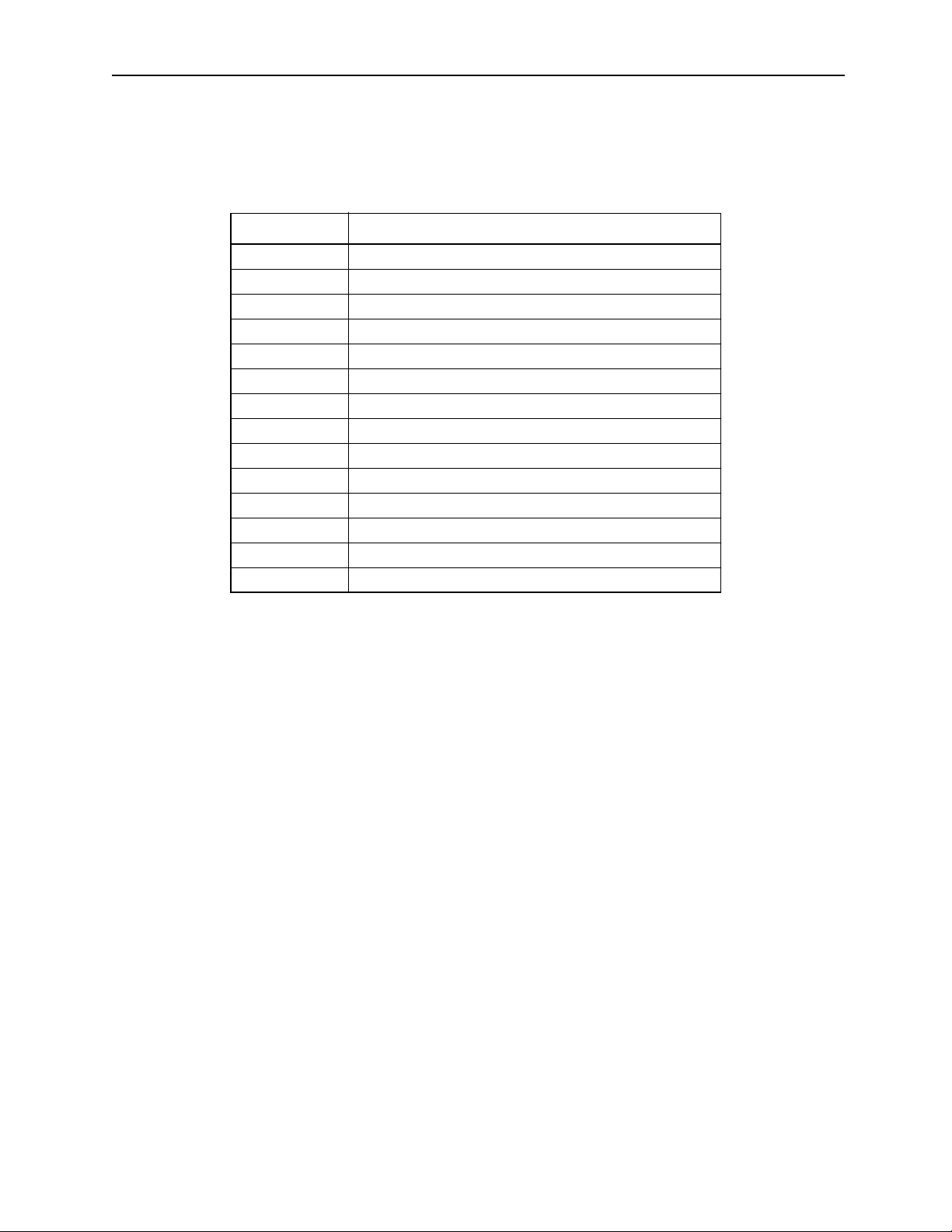

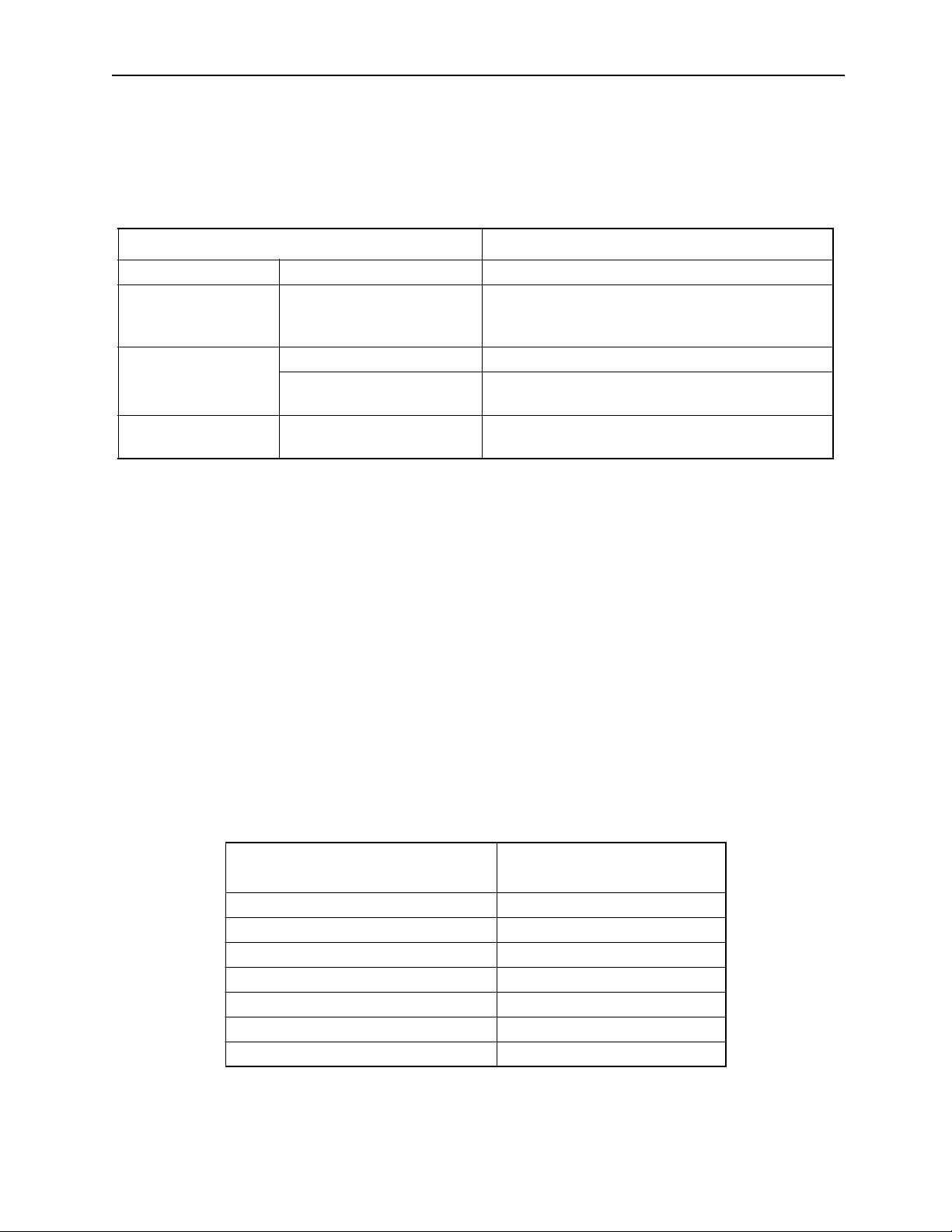

1.1.3 Function Performance List

The MP9xx motion program function specifications are as follows:

MP9xx Motion Control Function Specifications

Item Specifications

Number of Control Axes 1~14 maximum

Position Control Linear, rotational, unlimited, independent axis

Interpolation Linear: 14 axes, Circular: 2 axes, Helical: 3 axes

Speed Control None

Specs

Control

Torque Limit Limited (torque limit set by parameters only)

Command Unit mm, inch, deg, pulse

Minimum Command Setti ng Unit 1, 0.1, 0.01, 0.001, 0.0001, 0.00001

Maximum Command Value -2147483648~+2147483647 (with 32-bit symbols)

Speed Command Unit mm/min, inch/min, deg/mi n, pulse/min

Accel/Decel Type Linear, S-curve, separate accel/decel

Override Functions Positioning: 0.01~100.00% of axis uni t

Interpolation: 0.01~100.00% of group unit

Coordinates Cartesian Coordinates

Zero-Point Return 4 Types:

Torque+C-phase, zero-point LS, torque+zero-point LS, C-phase

There is a zero-point setting function

Language Dedicated motion language

Number of Tasks A maximum of four programs can be simultaneously execut ed in parallel.

Number of Programs 256 maximum

Programs

Program Volume 80 Kbytes (characters)

(Adjustable by the volume of ladder progra m used: 100 Kbyte maximum)

Applied Servo Amplifier SGD-"""N/SGDB-""AN

Encoder Incremental/Absolute

Command Language Axis Motion Commands : 8 types

MOV, MVS, MCW , MCC, ZRN, SKP, MVT, EXM

Basic Control Commands : 5 types

ABS, INC, POS, PLN, MVM

Speed/ Accel/D ecel Commands : 7 types

ACC, SCC, VEL, I A C, IDC, IFP, FMX

Advanced Control Commands : 4 types

PFN, INP, SNG, UFC

Control Commands : 9 types

MSEE, TIM, IOW, END, RET, IF ELSE IEND, WHILE WEND,

PFORK JOINTO PJOINT, SFORK JOINTO SJOINT

Operation/Sequence Control Commands : 36 types

=, +, -, *, /, MOD, |, ^, &, !, (), S{}, R{}, SIN, COS, TAN, ASN, ACS,

ATN, SQRT, BIN, BCD, ==, <>, >, <, >=, <=, TON, TOF, SFR, SFL,

PON, NON, BLK, CLR

1-5

Page 15

MotionSuite ™ Series Machine Controller Programming Manual Chapter 1: Motion Programmming Outline

1.1.4 Motion Program Start

The motion program is started from an “H” drawing ladder program. Start is initiated

by motion program start commands (MSEE) from within the ladder program and a

low to high transition of the program run start request bit. Motion programs are designated directly by the program number and indirectly by the register number containing

the program number.

ABS;

MOV X_Y_

MVS X_Y_F

MSEE MPM001 DA0000

IOW MB0001

MOV X_Y_

•

•

Ladder Program

Motion Control Program

Figure 1.2: Motion Program Start by Direct Designation

ABS;

•

MOV X_Y_

MVS X_Y_F

MSEE MW00200 DA0000

MPM Number is in MW00200

Ladder Program Motion Contro l Pr ogram

IOW MB0001

MOV X_Y_

•

Figure 1.3: Motion Program Start by Indirect Designation

1-6

Page 16

MotionSuite ™ Series Machine Controller Programming Manual Chapter 1: Motion Programmming Outline

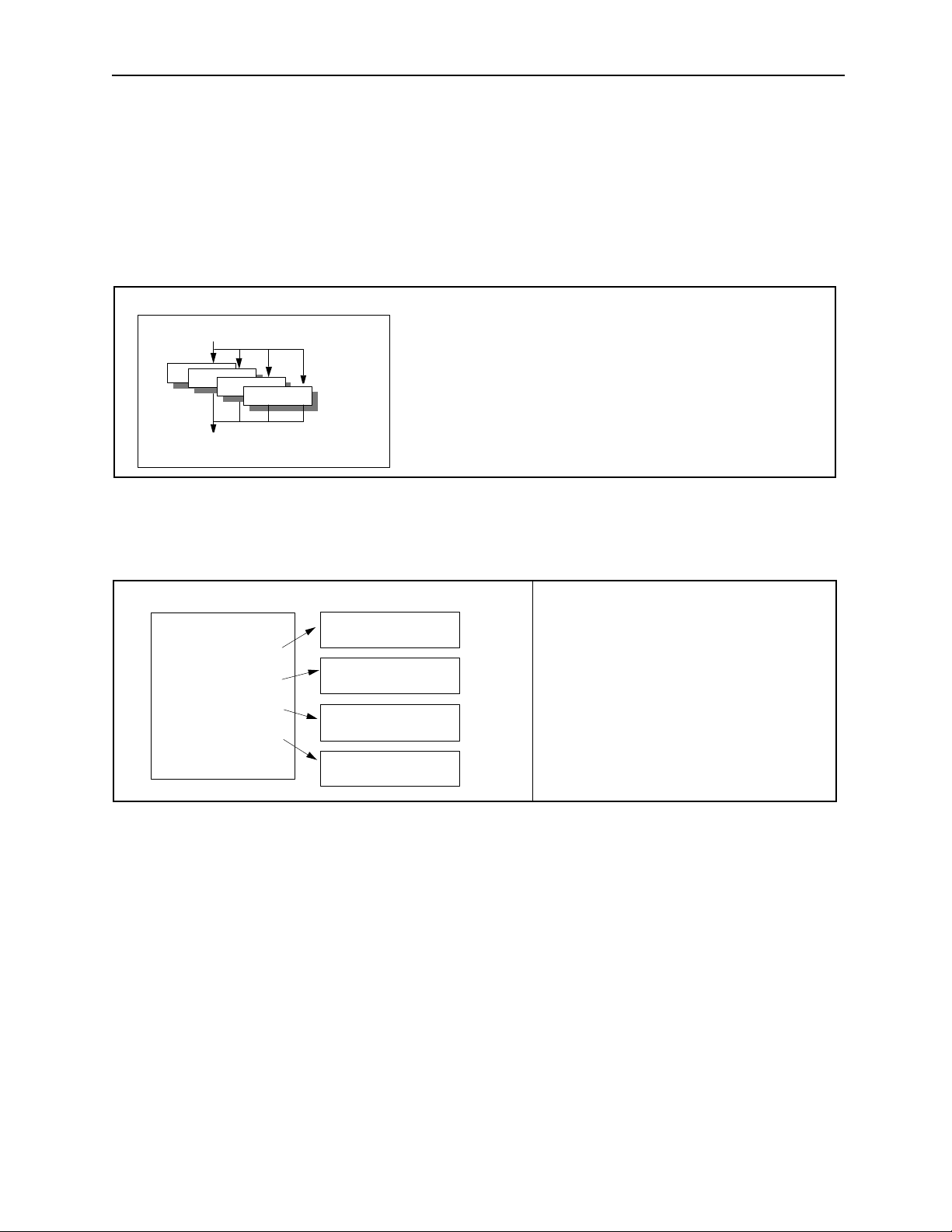

1.1.5 Parallel Program Operation

With MP9xx, it is possible to program freely with various machine activities, due to

capabilities for parallel running that make complex motion control possible. Parallel

running of motion programs is available in the two following forms.

a. With motion program PFORK commands, parallel running of a maximum of 4

programs within 1 program is possible.

Motion Program MPM001

PFORK S1, S2, S3, S4

S1

S2

S3

S4

S5: PJ O INT

b. With ladder program MSEE commands, parallel running of multiple motion pro-

grams is possible. (When automatically generated with MotionWorks™ group

setting display , parallel running of a maximum of 4 programs is possible.)

Ladder Program

Motion Program

MSEE MPM 00 1 DA 00 00

MSEE MPM 00 2 DA 00 02

MSEE MPM 00 3 DA 00 04

MSEE MPM 00 4 DA 00 06

Motion Program

Motion Program

Motion Program

MPM001

MPM002

MPM003

MPM004

Parallel Operation 1

• A maximum of four (4) programs can be operated i n parallel us ing the PFORK command within a single motion

program. The PFORK command must be ended with the

PJOINT command.

Parallel Operation 2

• Several programs can be operated in parallel

by using the ladder program MSEE command.

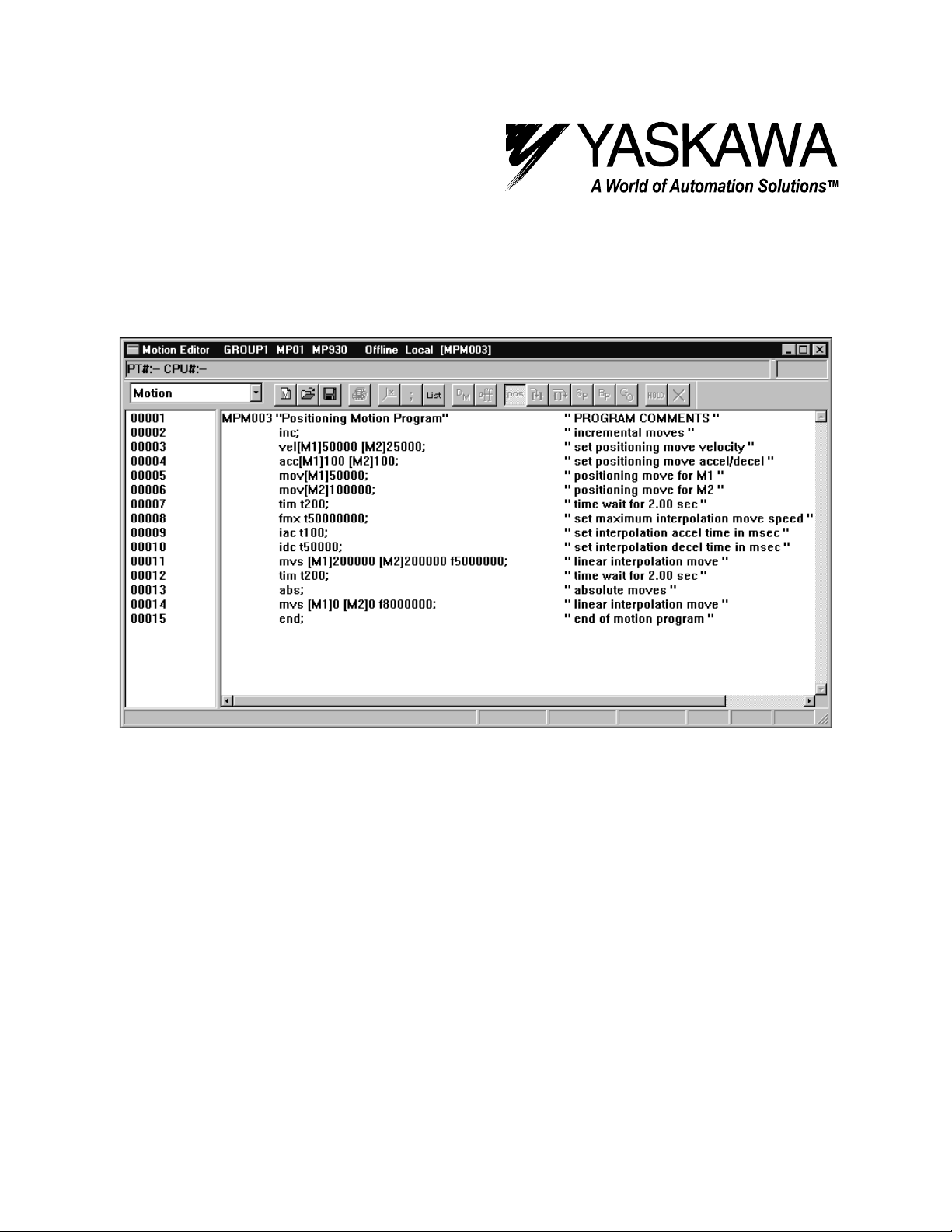

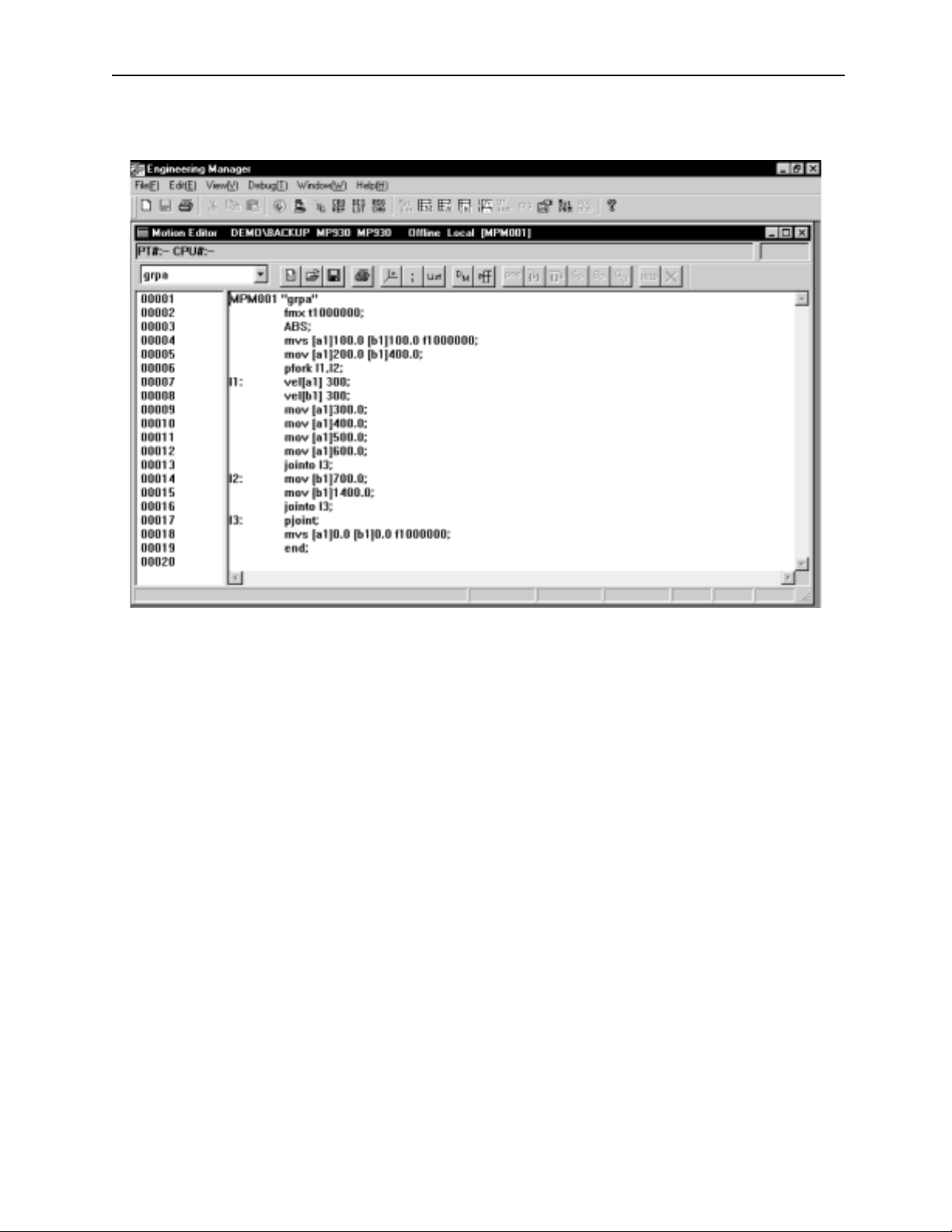

1.1.6 Program Editor

The motion program editor is generated on the MotionWorks™ (programming device)

motion program editor display. The editing display contains the following functions.

a. The same functions as the text editor, such as cut & paste, look-up, replace, and

jump

b. Special functions such as debugging operations and program instruction moni-

toring

c. Function for importing and reading text editor files

1-7

Page 17

MotionSuite ™ Series Machine Controller Programming Manual Chapter 1: Motion Programmming Outline

d. Function for writing and exporting motion program files as text files.

Figure 1.4: MotionWorks™ Motion Program Editor Display

Supplement

For motion program editor function details, please refer to the MotionSuite™ Series

Machine Controller Software Manual.

1-8

Page 18

MotionSuite ™ Series Machine Controller Programming Manual Chapter 1: Motion Programmming Outline

1.2 Motion Programming Method

This section deals with the basic rules for creating motion programs. Read this section

thoroughly prior to program execution.

1.2.1 Input Format

! Motion Program Sample

Motion programs are created in variable-length block format.

Program Sample

Block Number Program

00001 MPM001"sample” ...Program number and comment

00002 FMX=T1000000; ...Interpol ation feed high-speed setting

00003 IAC=T100; ...Interpolation feed accelerat ion time setting

00004 IDC=T100; ...Interpolation feed deceleration time setting

00005 VEL [X1]10000 [Y1]2000 [Z1]3000; ...Feed speed sett ing

00006 INC; ...Increment al mode command

00007 MOV [X1]100.[Y1]150.[Z1]200 .; ...Fas t feed

00008 MVS [X1]100.[Y1]50.F500000; ...Linear interpolation

00009 IOW IW0011=1; ...

00010 MW0100=(MW0110*100+50)/100; ...

00011 MW0200=(MW0210*100+50)/100; ...

00012 ABS; ...

00013 MOV [X1]MW0100 [Y1]MW0200; ...

00014 POS [X1]0 [Y1]0 ...

00015 PFORK LA01, LA02, LA03, LA04 ...Parallel operation command

00016 LA01: INC; ...Label

00017 MOV [X1]1000.; ...

00018 JOINTO LA05; ...

00019 LA02: INC; ...

00020 MOV [X1]2000.; ...

00021 JOINTO LA05; ...

00022 LA03: ABS; ...

00023 MV S[Z1]1500 F50000; ...

00024 MW1000=12345; ...

00025 JOINTO LA05; ...

00026 LA04: MW1100=1000; ...

00027 IOW IB101==1; ...

00028 JOINTO LA05; ...

00029 LA05:PJOINT ...Closes paral lel operation command

00030 END; ...Closes program

1-9

Page 19

MotionSuite ™ Series Machine Controller Programming Manual Chapter 1: Motion Programmming Outline

! Input Format

The variable length input formats are as given in the following table:

Variable Input Format List

Item Input Format

Program Number MPM

Label 8 char acters maximum

Motion Commands 3 alphabetical characters (some commands are other than 3 letters)

Coordinate

Language

Interpolation Fee d

Speed

Wait Time TIM T1000 10 msec units (no fractions)

Sub-program Number MPS

P Designation P100; Interpolation feed spee d ratio setting 1~100

Close Block ;

""" """

[abcd

] ± 123,456

AB C

A: Axis Name

B: Pos/Neg design ation possible

C: See Item 1.2.2 “Control Axes” for details on coordinates

F3000000

Changes accordin g to the number of places below the decim al point. (set paramete r)

3000.000mm/min when numb er of places below decimal poi nt =3

30.00000mm/min when numb er of places below decimal poi nt =5

""" """

= 1~256

= 1~256

! Leading Zero

Numbers following the characters, including program numbers and register (variable)

numbers, can omit the leading zero.

Example

[X1]00123

[X1]MW00010

MPS002

! +/- Symbol

Although the plus sign may be omitted from numbers, the negative sign may not be

omitted.

Example

[X1]00123

[X1]-123

Supplement

Decimal places cannot be used in the interpolation feed speed (Fxxxx) command.

F30000.000 is not possible; enter it as F30000000.

⇒

[X1]123

⇒

[X1]MW100

⇒

MPS2

⇒

[X1]123

⇒

[X1]-123

1-10

Page 20

MotionSuite ™ Series Machine Controller Programming Manual Chapter 1: Motion Programmming Outline

! Usable Characters

The usable characters and their meanings are given in the following table.

Usable Character List

Character Meaning

CC register

DD register

II register

MM register

OO register

SS register

F Interpolation feed speed

P Interpolation feed speed override

R Circular radius

SS Step signal number

T Timer value, number of circle turns, FMX, IAC, IDC

U Cir cular midpoint coordinate 1 (horizontal)

V Cir cular midpoint coordinate 2 (vertical)

MPS Sub-program number

1-11

Page 21

MotionSuite ™ Series Machine Controller Programming Manual Chapter 1: Motion Programmming Outline

! Function Characters

The function characters and their meanings are given in the following table.

Function Character List

Character Meaning

SP Space

TAB Tab

; End of block

ENTER

0~9 numbers

A~Z Alphabet

. Decimal point

+ Operation

- Operation

* Operation

/ Operation

| Operation

^ Operation

& Operation

! Operation

= Operation

() Operation

== Operation

> Operation

< Operation

<> Operation

>= Operation

<= Operation

S {} Operation

R {} Operation

——

Changes row

1-12

Page 22

MotionSuite ™ Series Machine Controller Programming Manual Chapter 1: Motion Programmming Outline

! Program Number Hand ling

The program number is a number for the purpose of program discrimination. There

are two kinds of programs: Main programs and sub-programs. The numbers 1~256

may be applied to each.

!

Main Programs

"""

MPM

Program number (1~256)

!

Sub-programs

"""

MPS

Program number (1~256)

Figure 1.5: Motion Program File Names

Supplemental It em

(1) The same number cannot be designated for both main programs and sub-programs.

(2) Up to 256 programs of the Main program and Subprogram combined can be

created.

! Comment Writing

It is possible to write comments within the program. These comments are saved

within the controller. There are two ways to create a comment, as follows:

1. Surrounding a comment statement with quotation marks.

“Character string”

Example

ZRN [AXIS1]0 [AXIS2]0 [AXIS3]0; “Zero return all axes”

MVS [AXIS1]100.0 [AXIS2]200.0 [AXIS3]3 00.0; “Three axis linear int erpolation”

2. All characters following the first quotation mark in a line become comments

without surrounding the line in quotation marks if

“Character string

Example

“Move to the wait machine position by linear interpolation after all axi s zero point return

ZRN [AXIS1]0 [AXIS2]0 [AXIS3]0;

MVS [AXIS1]100.0 [AXIS2]200.0 [AXIS3]3 00.0;

ENTER

ENTER

is pressed.

1-13

Page 23

MotionSuite ™ Series Machine Controller Programming Manual Chapter 1: Motion Programmming Outline

! Creation of One-Block Commands

a. A one-block command is made according to the input format list. A representa-

tive example of a single block is shown below.

LABEL: MVS [X1] 20.0 [Y1] 30.0 [Z1] 40.0 F300000 ; “ Comment”

End of block

Coordinate Language

Axis coordinate value and amount

of axial incremen tal moti o n

Motion Command

Designates motion operation type and control type.

Label

Label to be bran ched t o when us i ng paral lel

execution or selected execution commands

Interpolation fe ed s pee d

.

b. Always be sure to insert a space [SP] between the motion command and the

coordinate language.

c. Although there is no restriction on the number of characters in a single line of a

single block, we recommend that the number of characters be kept to within a

range that can be displayed on-screen for the sake of program viewability.

d. A [;] is needed any time that a block is completed.

e. The label is used as the target block for the parallel execution command

(PFORK) or selection execution command (SFORK).

! Label

A label must be us ed for the parallel execution command (PFORK) or selection execution command (SFORK). Attach a colon [:] to the end of a 1~8 character string of

alphanumeric characters or symbols. The characters that can be used in a label are

shown below. The first character in a label must be alphabetical.

Numbers 0~9

Letters A~Z, a~z

Symbols $, %, ¥, @,—, _, .

Characters

1-14

Page 24

MotionSuite ™ Series Machine Controller Programming Manual Chapter 1: Motion Programmming Outline

Example

PFORK LAB1, LAB2

LAB1: ZRN [AXIS1]0 [AXIS2]0 [AXIS3]0;

JOINTO LAB3

LAB2: MVS [AXIS1]100.0 [AXIS2]200.0 [AXIS3]300.0;

JOINTO LAB3

LAB3: PJOINT

Important Point

1. The error “Duplicate Label Defined” results if the same label is used multiple

times within a program.

2. An error results in the number of PFORK branches if the number of labels differs.

1.2.2 Control Axes

Axis Names

!

It is possible to set a desired axis name of up to eight characters. The axis names are

set in the Group Definitions Screen in MotionWorks ™. The characters that can be

used in a name, as well as the default axis names, are given below.

Usable Characters 0~9, A~Z, a~z

Axis Name Examples [AXIS1] [X1] [CONV1]

Default Axis Names If fou r axes are designated: [A1] [B1] [C1] [D1]

If eight axes are designat ed:

[A1] [B1] [C1] [D1] [E1] [F1] [G1] [H1]

Supplement

1. Always be sure to enclose axis names written in 1 ~ 8 alphanumeric characters

within [ ].

2. The same axis name cannot be set into multiple axes.

3. An error results if an axis name is designated in the motion program different

from the axis name set in the Group Definition Screen.

1-15

Page 25

MotionSuite ™ Series Machine Controller Programming Manual Chapter 1: Motion Programmming Outline

! Coordinate Language List

The motion amount and coordinate values attached to the axis name are called “coordinate language” in this book. The meanings of the coordinate language used in this

system are shown in the table below.

Coordinate La nguage Designatio n Method Meaning

Axis Name [X1], [Y1], [AXIS] Designates axis to be moved

Motion Amount or

Coordinate Value

Auxiliary Data for Circular Interpolati on and

Helical Interpola tion

Amount of External

Positioning Motion

Important Points

Direct Designation: 123.456

Variable Designation:

MW0100

R Circula r interpolation radius (set by the increm ent)

U

V

D Distance of motion after external signal input (set by

Coordinate value of designated axis , or inc rem ental

motion range

Circular interpolation center coordinate (Horizontal)

Circular interpolation center coordinate (Vertical)

the incr em e nt)

1. The 32-bit integer data type is used when the motion amount or coor dinate value

is designated by a variable.

(Ex.) ML0100

2. When there are fractions, insert zeroes for the number of places following the

decimal point.

(Ex.) Use 300000 to designate 300.000 when the number of decimal places = 3.

However, the servo parameter area (IWCxxx, OWCxxx) in the I, O registers

cannot be used for variables of the motion amount or coordinate value.

! Number of Simul taneously Controlled Axes

The number of simultaneously controlled axes designated from the motion program is

shown in the following chart.

Number of Simultaneously Controlled Axes List

Command Language

Positioning (MOV) 14 axes maximum

Linear Interpol ation (MVS) 14 axes maximum

Circular Interpolation (MCW/MCC) 2 axes

Helical Interpolation (MCW/MCC) 3 axes

Skip Command (SKP) 14 axes maximum

External Positioning (EXM) 1 axis

Time Designated Positioning (MVT) 14 axes maximum

Number of Simultaneously

Controlled Axes

1-16

Page 26

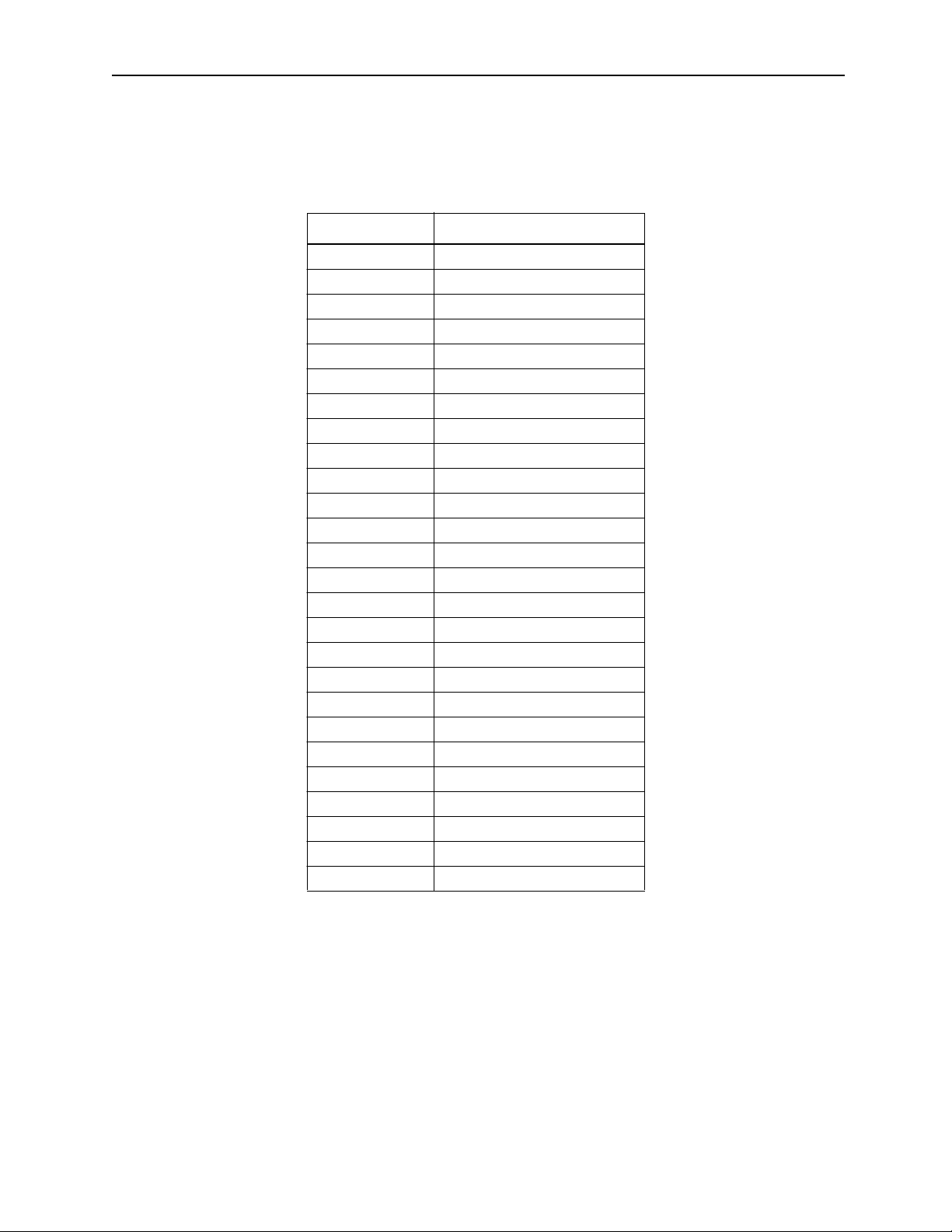

MotionSuite ™ Series Machine Controller Programming Manual Chapter 1: Motion Programmming Outline

! Command Units

The programmable command units are in accordance with the settings of b0~b3

“Command Unit Selection” of set-up parameter 17 “Servo Module Function Selection

Flag” and set-up parameter 18 “Number of Places Below Decimal Point.”

Command Unit List

Parameter Setting

# of Places Below Decimal=0 1 pulse 1mm 1º 1”

# of Places Below Decimal=1 1 pulse 0.1mm 0.1º 0.1”

# of Places Below Decimal=2 1 pulse 0.01mm 0.01º 0.01”

# of Places Below Decimal=3 1 pulse 0.001mm 0.001º 0.001”

# of Places Below Decimal=4 1 pulse 0.0001mm 0.0001º 0.0001”

# of Places Below Decimal=5 1 pulse 0.00001mm 0.00001º 0.00001”

Command Unit

Pulse

Command Unit mmCommand Unit

deg

Command Unit

inch

Supplement

The number of places below the decimal point are disabled if command unit = pulse.

The decimal points in the motion pr ogram input and posit ion monitor dis play are also

meaningless.

! Maximum Command V alue

The maximum values of single motion commands are given in the table below.

# of Decimal

Places

0 -2147483648

1 -2147483648

2 -2147483648

3 -2147483648

Limited Lengths

4 -2147483648

5 -2147483648

Command Un it

Pulse

~2147483647

~2147483647

~2147483647

~2147483647

~2147483647

~2147483647

Command Unit mmCommand Unit

deg

-2147483648

~2147483647

-2147483648

~214748364.70~3599999.9

-2147483648

~21474836.470~359999.99

-2147483648

~2147483.6470~35999.999

-2147483648

~214748.36470~3599.9999

-2147483648

~21474.836470~359.99999

0~

35999999

Command Unit

inch

-2147483648

~2147483647

-2147483648

~214748364.7

-2147483648

~21474836.47

-2147483648

~2147483.647

-2147483648

~214748.3647

-2147483648

~21474.83647

1-17

Page 27

MotionSuite ™ Series Machine Controller Programming Manual Chapter 1: Motion Programmming Outline

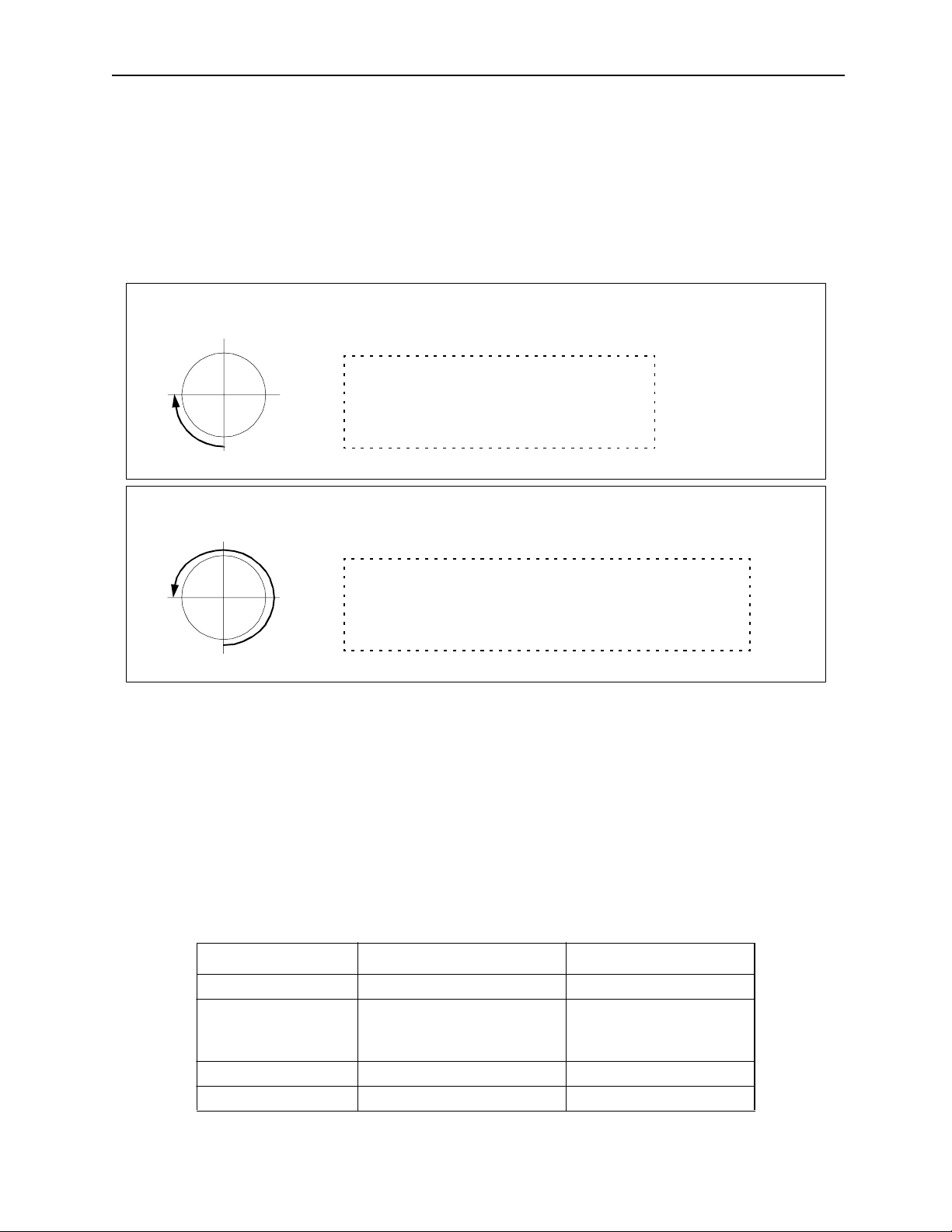

! Designation of “Absolute Mode” in a Rotary Axis

When an absolute value command (designation mode in a range of 0~359.999º) is

used in a rotary axis, the commanded +/- sign shows the rotation direction, and the

command value signifies the absolute position.

Example

When designating a position 180º from the current position:

Example of Designating the Rotary Axis Absolute Mode

0º

270º

Example of Designating the Rotary Axis Absolute Mode

270º

180º

0º

180º

90º

90º

ZRN [X1]0;

INC MOV [X1]180.0;

ABS MOV [X1]270.0; moves 90º clockwise

ZRN [X1]0;

INC MOV [X1]180.0;

ABS MOV [X1]-270.0; moves 270º counte r-clockwise

Supplement

When moving to the 0º position by designating the absolute mode in a rotary axis, -0.0

cannot be designated in a counter-clockwise motion. In this case, designate -360.0.

! Number and Variable Tabulation Method

Numbers used in motion programs are of two types: parameters and variables. The

setting method for these numbers is given below.

a. Parameters

Tabulation of Numbers that Can be Designated

Type Range Notation Example

Decimal Integers -2147483648~2147483647 0, 734, +823, -2493

Decimal Fractions -2147483.648~2147483.647

Changes accord ing to number

of decimal place s

Hexadecimal Integers 0~FFFFFFFFH FFFABCDEH, 2345H, FH

Real Numbers

1-18

763., +824.2, -234.56

-321.12345

Page 28

MotionSuite ™ Series Machine Controller Programming Manual Chapter 1: Motion Programmming Outline

b. Variables

The following types of variables exist for use in motion programs. Use them

according to the application.

Types of Variables and Tabu lation Method

Type

Global

Variables

Local Variables D Register DB DW DL DF

Variable

Type

S Register SB SW SL SF

M Register MB MW ML MF

I Register IB IW IL IF

O Register OB OW OL OF

C Register CB CW CL CF

BIT WORD LONG FLOAT

Data Type

M B 1 2 3 4 5 F

Bit Position: Enabled only with bit data

Variable Address: B, W, L, F

Data Type: B, W, L, F

Variable Name: S, M, I, O, C, D

(Ex.) MB001001=1;

MW00100=1234;

ML00100=12345678;

MF00100=1234.5678;

1-19

Page 29

MotionSuite ™ Series Machine Controller Programming Manual Chapter 1: Motion Programmming Outline

! Calculations and Functions

Calculations can combine global variables, local variables and constants with

operators and functions. The result can be substituted by a variable. Calculation and

functions use the following commands.

Type Command Name Command Format

= Substitution MW– =MW–;

+ Addition MW– =MW– +MW–;

Value Calculations

Logical Calculations

Value Comparisons

Data Operations

Basic Functions

– Subtraction MW– =MW – –MW

* Multiplication MW– =MW–*MW–;

/ Division MW– =MW–/MW–;

MOD Remainder MW– =MOD;

| OR (Logical OR) MB– =MB– | MB–;

^ XOR (Exclusive OR) MB– =MB– ^MB–

& AND (Lo gical AND) MB– =MB– &MB–;

! NOT (Invert) MB– =MB– !MB–;

= = Same IF MW– = =MW–;

< > Not same IF MW– < >MW–;

> Greater IF MW– >MW–;

<Less IF MW– <MW–;

>= Greater or equal IF MW– > =MW–;

<= Less or equal IF MW– < =MW–;

SFR Right-shift SFR MB– N– W–;

SFL Left-shift SFL MB– N– W–;

BLK B lock tra nsfer BLK M W– MW– W–;

CLR Clear CLR MB– W–;

SIN Sine SIN (MW–);

COS Cosin e COS (M W–);

TAN Tangent TAN (MF–);

ASN ARC sine ASN (MF–);

ACS AR C cosine ACS (MF–);

ATN A R C tang e nt ATN (MW– );

SQT Square root SQT (MW–);

BIN BCD→BIN BIN (MW–);

BCD BIN→BCD BCD (MW–);

S{} Designated bit ON S{MB–}=MB– &MB–;

R{} Designated bit OFF R{MB–}=MB– &MB–;

1-20

Page 30

MotionSuite ™ Series Machine Controller Programming Manual Chapter 1: Motion Programmming Outline

1.2.3 Feed Speed

! Fast Feed Speed

a. Fast feed speed is used in the following axis motions:

• Positioning (MOV) commands

• JOG run (JOG) operation

• Step run (STEP) operation

b. Set the fast feed speed in the setup parameters “Fast Feed Speed (OLxx22) or in

the motion program “Feed Speed Change Command (VEL)”.

• Fast Feed Speed Parameters (set in setup parameters)

Parameter Number Name Setting Range Unit

OLxx22 Fast Feed Speed

• Methods for setting Fast Feed Speed in the motion program

1. Direct Setting Method for Fast Feed Speed Parameters

OLC022=6000 ; Sets fast feed speed for the first axis

OLC062=5000 ; Sets fast feed s pee d for the second axis

OLC0A2=7000 ; Sets fast feed speed for the third axis

2. Setting Method Using t he F eed Speed Change Command (VEL)

VEL [X1] 6000 [Y2] 5000 [Z1] 7000

0~2

31

-1

By command unit

c. The fast feed can be switched to override within a range of 0~327.67%. This can

be set for each axis using the setup parameter “Override (OWxx2C).” There are

three override setting methods: in the motion program, in the ladder program,

and in the setup parameter.

Command Speed × Override = Output Speed

(OLxx22) (OWxx2C)

Command Speed

(OLxx22)

Override Function

Selection

Fixed Parameter 17

Bit 9

Enable

Disable

Override

(OWxx2C)

100%

Supplement

1. Override is normally enabled during run. Ladder programs and motion programs can be modified by parameter setting during axis motion.

2. When the output speed from the override setting data is outside of operable

range, the Parameter Setting Error results.

Output

Speed

1-21

Page 31

MotionSuite ™ Series Machine Controller Programming Manual Chapter 1: Motion Programmming Outline

! Interpolation Feed Speed

a. The feed speed for the interpolation feed command is set by the number follow-

ing Character (F). It is sometimes referred to as the F command.

b. The F command for linear interpolation and circular interpolation sets the tan-

gential speed.

Example

If INC MVS [X]200 [Y]500 F500;

2

F=500=

+Y

4002300

+

[mm/min]

500mm/min

300mm/min

400mm/min

+X

Figure 1.6: Tangential Speed of Two Axis Linear Interpolation

If MCC [X]--- [Y]--- I--- J--- F200;

2

F=200=

Vx2Vy

+

[mm/min]

+Y

200mm/min

V y mm/min

Vx mm/min

+X

Figure 1.7: Tangential Speed of Circular Interpolation

1-22

Page 32

MotionSuite ™ Series Machine Controller Programming Manual Chapter 1: Motion Programmming Outline

Example

If INC MVS [X]100 [Y]100 [Z]100 F400;

2

F=400=

Vx2Vy2Vz

++

[mm/min]

+Y

+X

+Z

Figure 1.8: Tangential Speed of Three-Axis Linear Interpolation

If INC MVS [X]-- [Y]-- [Z]-- [S]-- F600;

2

Vx2Vy2Vz2Vs

F=600=

Tangential Speed of Four-Axis Linear Interpolation)

(

+++

[mm/min]

1-23

Page 33

MotionSuite ™ Series Machine Controller Programming Manual Chapter 1: Motion Programmming Outline

c. The feed speed upper limit is restricted by machine and servo performance. Set

the upper limit of the feed speed by the following motion commands.

V

FMX (Maximum Interpolation Feed Speed) 200000

F Command Speed 175000

300ms

IAC (A ccelerat i on ti me)

Program Example

FMX T200000;

IAC T300;

IDC T500;

MVS [X]200, [Y]250, F175000;

500ms

IDC (Decelerati o n time)

t

Figure 1.9: Interpolation Feed Speed Limit Setting Command

An alarm results if the value of the F command exceeds the maximum interpolation feed speed.

Important Point

If interpolation commands are to be used, an FMX command must be used at the start

of a motion program.

d. F Command Units

Decimal places cannot be used in F command values.

F2000000

e. It is possible to switch the interpolation feed speed override within a range of

0~32,767%. Set the override setting in the register (default = MW00001) defined

in the Group Definitions Screen. There are three override setting methods:

motion program, ladder program, and setup parameter screen.

F reference

FMX × IFP referenceFMX × IFP reference

F refer e n c e

FMX × IFP reference

Interpolation feed speed override

×=

(MW00001)

Interpolation feed speed override

(MW00001)

1-24

Output speed

Output speed

Page 34

MotionSuite ™ Series Machine Controller Programming Manual Chapter 1: Motion Programmming Outline

Motion commands regarding the interpolation feed speed are shown as follows:

• F refer e n c e:

• IFP command:

• FMX command:

• IAC command:

• IDC command:

• SCC command:

[F reference in the interpolation command]

[Interpolation feed speed ratio setting]

[Maximum interpolation feed speed]

[Interpolation acceleration change]

[Interpolation deceleration change]

[S-curve setting value change]

Supplement

1. Override is always enabled during running.

2. An FMX clamp results when the output speed from the override setting data

exceeds the range.

Important Point

1. The motion speed of the machine does not reach the tangential speed as per the F

command when the rotating axis is included in the axes of the interpolation command.

2. A program error results if [F0] is designated in the F command.

3. Do not use the negative F command [F-

"""

]. An alarm results.

1-25

Page 35

MotionSuite ™ Series Machine Controller Programming Manual Chapter 1: Motion Programmming Outline

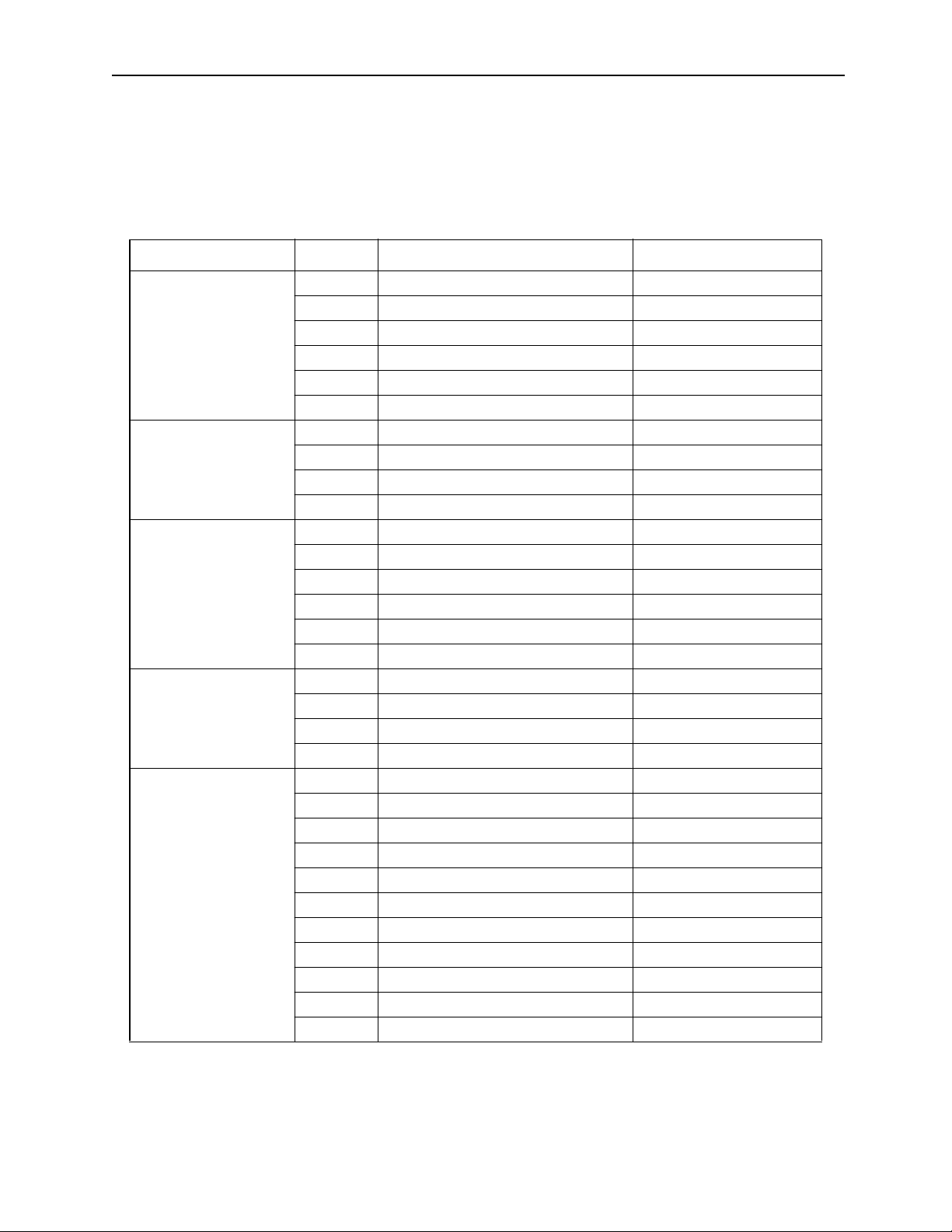

1.2.4 Motion Command List

A list of the motion commands is given in the table below:

Type Comm and Name Command Format Functio n /Mean ing

MOV Posit ioning MOV [axis1]— [axis2]— ... ;

(Up to 14 axes may be designated)

MVS Linear

MCW

MCC

MCW

MCC

ZRN Zero Point

Commands

Axis Motion

SKP Skip Com-

MVT Time

EXM External

Interpolation

Circular

Interpolation

(clockwise)

(counterclockwise)

Helical

Interpolation

(clockwise)

(counterclockwise)

Return

mand

Designation

Positioning

Positioning

MVS [axis1]— [axis2]— ... F—;

(Up to 14 axes may be designated)

MCW [axis1]— [axis2]— R— F—;

MCC [axis1]— [axis2]—U—V—

T—F—;

MCW [axis1]— [axis2]— U—V—

[axis3]—T—F—;

MCC [axis1]— [axis2]—R—

[axis3]—F—;

ZRN [axis1]— [axis2]— ...;

(Up to 14 axes may be designated)

SKP[axis1]— [axis2]— ...SS—;

(Up to 14 axes may be designated)

MVT [axis1]— [axis2]— ...T—;

(Up to 14 axes may be designated)

EXM[axis] - A~B (one axis only) Moves to designated posi tion (A)

Positioning can be simultaneously executed by fast feed for

up to 14 axes.

Linear motion can be simul taneously executed at interpolation

feed speed F for up to 14 axes.

Simultaneously executes inte rpolation for 2 axes at tangential

speed F according to a circ le of

radius R (or a designated midpoint coordinate). It is possible

to designate multiple cir cles in

T— during mid-point coordinate

designation (T— may also be

omitted).

Simultaneously mo ves 3 axes by

combining circula r interpolation

and linear interpolation outside

the cir cu la r in te r po l at io n pl an e .

It is possible to designate mult iple circles in T— during midpoint coordinate designation

(T— may also be omitted).

Returns each axis to the zero

point after [mid-p osition] positioning. Zero return is executed

immediately without mid-positioning after the first time power

is turned ON.

When the skip signal is turned

ON during linear interpolation,

the remaining motion is skipped,

and the system proceeds to the

next block. The machine records

the position a t which the skip s ignal went ON.

Executes positioning after clamping feed speed s o t hat pos ition ing

is completed in a designated

time.

if signal is not input.

Moves the incremental amount

(B) from when the signal is input .

1-26

Page 36

MotionSuite ™ Series Machine Controller Programming Manual Chapter 1: Motion Programmming Outline

Type Comm and Name Command Format Functio n /Mean ing

ABS Absolute

INC Incremental

POS Current

PLN Coordinate

Commands

Basic Control

MVM Machine

ACC Accelera-

SCC S-Curve

VEL Feed Speed

IAC Interpola-

IDC Interpola-

Commands

Speed/Accel/Decel

IPF Interpola-

FMX Interpola-

Mode

Mode

Value

Change

Plane

Designation

Coordinate

Command

tion Time

Change

Time Constant

Change

Change

tion Acceleration Time

Change

tion Deceleration Time

Change

tion Feed

Speed Rati o

Setting

tion Feed

Maximum

Speed Setting

ABS; Handles the subsequent coordi-

nate language as absolute values.

INC; Handles the subsequent coordi-

nate language as incrementa l

values.

POS [axis1]— [axis2]— ...; Simultaneously c hanges current

values for up to 14 axes to a

desired coordinate val ue. Subsequent motion commands move

based on this new coordinate system.

PLN [axis1] [axis2] Designates a coordinate plane to

be used in commands requiring a

coordinate plane.

MVM MOV [axis1]— [axis2]— ; or

MVM MVS [axis1]— [axis2]— ;

Designated when motion on a

machine coordinate plane is

desired. At zero point return, the

automatically set coordinate system is called the machine coor dinate. These coordinates are not

effe cted by POS c ommands.

ACC [axis1]— [axis2]—...; Simultaneously s ets the accel/

decel time for the linear accel/

decel of up to 14 axes.

SCC [axis1]— [axis2]—...; Simultaneously sets s-curve time

cons tant for th e av e r ag e accel/

decel for the motion of up to 14

axes.

VEL [axis1]— [axis2]—...; Sets feed speed for up to 14 axes.

IAC T— ; Sets th e acc el e ra ti o n tim e for li n -

ear accel/decel during interpolation motion.

IDC T— ; Set s th e de celerat io n ti me f o r li n -

ear accel/decel during interpolation motion.

IFP P—; Executes speed designation dur-

ing interpolation feed by designating a maximum speed %.

FMX T—; Sets the maximum speed during

interpolation feed.

The in t er p o lation accele r at io n

time is the time to reach this

speed from 0.

1-27

Page 37

MotionSuite ™ Series Machine Controller Programming Manual Chapter 1: Motion Programmming Outline

Type Comm and Name Command Format Functio n /Mean ing

PFN In-Position

Check

MVS [axis1]— [axis2]—... PFN; or

PFN [axis1] [axis2];

Proceeds to next block after an

interpolatio n motion com mand in

the same block or previous block

enters the positi oning completion area (parameter setting).

INP 2nd In-Posi-

tion Check

INP [axis1]— [axis2]—... PFN; Proceeds to next block afte r the

subsequently designated interpolation motion command enters

the 2nd positioning completion

area.

SNG Ignore Sin-

gle Block

Advanced Control Comm ands

SNG MVS [axis]100.

[axis2]200.F1000;

Ignores a block containing this

command, and continue s running even in the Single Block

Operation Mode.

UFC User Func-

tion Call-out

UFC user function name input data,

input address, output address

Calls out func tions crea ted by t he

user.

= Equals (Result) = (Operation) Introduces the result of an opera-

tion. Operat ions flow f rom left to

right (regardless of order of priority).

+ Ad d MW— =MW — +M W—;

MW— =MW— +123456;

MW— =123456 + MW—

Executes addition of in te gers and

real numbers. Calc ulations are

done in real number form if real

numbers and integers are mixed.

- Subtract MW— =MW— -MW—;

MW— =MW— -123456;

MW— =123456 - MW—

Executes subtraction of integers

and real numbers. Calculations

are done in real number form if

real numbers and integers are

mixed.

* Multiply MW— =MW— *MW—;

MW— =MW— *123456;

MW— =123456 * MW—

Executes multiplication of integers and real numbers. Calculations are done in real number

form if real numbers and intege rs

are mixed.

Sequ e nce Comma n ds

/ Division MW— =MW— /MW—;

MW— =MW— /123456;

MW— =123456 / MW—

Executes division of integers and

real numbers. Calc ulations are

done in real number form if real

numbers and integers are mixed.

MOD Remainder MW— =MW— /MW—;

MW— =MOD;

Saves MOD as a re m a in d er to a

designated register when commanded in the next block following division.

|OR

(logical

OR)

MB— =MB— |MB—;

MB— =MB—|1;

MW— =MW— |MW—;

Creates a bit/integer logical OR.

MW— =MW — |H00 FF;

1-28

Page 38

MotionSuite ™ Series Machine Controller Programming Manual Chapter 1: Motion Programmming Outline

Type Comm and Name Command Format Functio n /Mean ing

^ XOR

(exclusive

OR)

MB— =MB—^MB—;

MB— =MB—^1;

MW— =MW—^MW — ;

MW— =MW — ^H00FF;

& AND

(logical

AND)

MB— =MB—&MB—;

MB— =MB—&1;

MW— =MW—&M W—;

MW— =MW— &H0 0FF;

! NOT

(invert)

MB— =MB—!MB—;

MB— =MB—!1;

MW— =MW—!MW—;

MW— =MW— !H00FF;

() Parentheses MW— =MW—&

(MW—|MW—);

S{} Designated

S{MB—} = MB— &MB—; The de signa ted b it goe s ON if th e

Bit ON

R{} Designated

R{MB—} = MB— &MB—; The designat ed bit goes OFF if

Bit OFF

Sequence Commands (continued)

SIN Sine SIN(MW—);

SIN(90);

COS Cosine COS(MW—);

COS(90);

TAN Tangent TAN(MW—);

TAN(45);

ASN Arc Sine ASN(MW— );

ASN(90);

ACS Arc Cosine ACS(MW—);

ACS(90);

Creates a bit /i n teger e x cl usive

OR.

Creates a bit/integer logical

AND.

Creates a bit with a reverse va lue.

Executes operation of the logical

operation within parentheses

first.

result of the logica l operation is

true. The desi gnate d bit does not

go OFF even if the result of the

logical operation is false.

the result of the logical operation

is true. The designated bit does

not go ON even if the result of

the logical operation is false.

Calls the sine of an integer/real

number (deg), and returns a real

value.

Calls th e cos ine of a n in teg er/ rea l

number (deg), and returns a real

value.

Call s th e tangent of an in t eg er /

real number (deg), and returns a

real value.

Calls the arc sine of an integer/

real number (deg), and returns a

real value.

Call s th e ar c cos i n e o f an in t eg er /

real number (deg), and returns a

real value.

1-29

Page 39

MotionSuite ™ Series Machine Controller Programming Manual Chapter 1: Motion Programmming Outline

Type Comm and Name Command Format Functio n /Mean ing

ATN Arc Tangent ATN(MW—);

ATN(45);

Calls the arc tangent of an integer/real number (deg), and

returns a real value.

SQRT Square Root SQT(MW—);

SQT(100);

Calls the square root of an integer/real number (deg), and

returns a real value.

BIN BCD→BIN BIN (MW—); Converts BCD data to BIN data.

BCD BIN→BCD BCD (MW—); Converts BIN data to BCD data.

== Same IF MW— ==MW—;

WHILE MW— ==MW—;

Used with IF or WHILE condi-

tions. Is tru e if the left and right

are the same.

<> Not Same IF MW— <>MW—;

WHILE MW— <>MW—;

Used with IF or WHILE condi-

tions. Is tru e if the left and right

are not the same.

> Greater IF MW— >MW—;

WHILE MW— > MW—;

Used with IF or WHILE condi-

tions. Is tru e if the left is greater

than the right.

<LessIF MW— <MW—;

WHILE MW— < MW—;

Used with IF or WHILE condi-

tions. Is tru e if the left is less

than the right.

>= Equal or

Greater

IF MW— >=MW—;

WHILE MW— >=MW—;

Used with IF or WHILE condi-

tions. Is tr ue if th e le ft i s equal to

or greater than the right.

<= Equal or

Less

Sequence Commands (continued)

TON Time Limi t

ON Timer

IF MW— <=MW—;

WHILE MW— <=MW—;

Used with IF or WHILE condi-

tions. Is tr ue if th e le ft i s equal to

or less than the right.

MB— &TON(5.00 MW—); The basic timer cloc k is 10msec.

Timing occurs while the bit vari-

able is ON (wait s while bit is

OFF). The designated bit on the

left goes ON upon reaching th e

set time (parameter * clock).

Time value s (clo ck numbers ) are

stor ed in th e w o rd va r ia b le).

TOF Time Limit

OFF Timer

MB— &TOF(5.00 MW—); The basic timer cl ock is 10msec.

Timing occurs while the bit vari-

able is ON (wait s while bit is

OFF). The designated bit on the

left goes OFF upon reaching the

set time (parameter * clock).

Time value s (clo ck numbers ) are

stor ed in th e w o rd va r ia b le).

1-30

Page 40

MotionSuite ™ Series Machine Controller Programming Manual Chapter 1: Motion Programmming Outline

Type Comm and Name Command Format Functio n /Mean ing

SFR Shift Right SFR MB— N— W—; Shifts the word variable a desig-

nated amount to the right.

SFL Shift Left SFL MB— N— W—; Shifts the word variable a desig-

nated amount to the left.

PON Start-up

Detection

NON Shutdown

Detection

BLK Block

Transmission

PON (MB— MB—); A designated bit goes ON upon

start-up dete ction.

NON (MB— MB—); A designated bit goes ON upon

shutdown detection.

BLK MW— MW— MW—; Transmits a range of blocks

(parameter designation ) as the

start of a designated bit (word)

variable.

CLR Clear CLR MB— W—; Sets a group of variables to the

Sequence Commands (continued)

designated parameter OFF (0) as

the start of a designated bit

(word) variable.

MSEE Sub-pro-

MSEE MPS— 0; Executes an MPS sub-program.

gram Callout

TIM Time d Wait TIM T—; Waits for the ti me desi gnated in T

only, then proceeds to the next

block.

IOW I/O Variable

Wait

IOW MB— == ***; Stops motion pr ogram execution

until the I/O variables ful f ill conditions.

END Program

END; Ends the motion program.

END

RET Sub-pro-

RET; Ends a sub-program.

gram END

IF

ELSE

IEND

Control Commands

WHILE

WEND

Branch

Commands

Repeat

Commands

IF (conditional);

(process 1)

ELSE;

(process 2)

IEND;

WHILE (conditional);

...

WEND;

Executes (process 1) if the condi tions are satisfied, and executes

(process 2) if the conditions are

not satisfied.

Repeatedly execu tes

WHILE~WEND processing

while certain conditions continue to be satisfied.

PFORK

JOINTO

PJOINT

Parallel

Execution

Commands

PFORK Label 1, Label 2. ..;

Label 1: Process 1

JOINTO label X

Label 2: Process 2

JOINTO label X

Label ·

·

Label X: PJOINT;

Parallel executes a block designated by a label. No more than

two labels can be des ignated in

the case of sub-programs. Furthermore, motion program commands cannot be used in a block

selected by two labels. END and

RET cannot be us ed during para llel processing e xecution.

1-31

Page 41

MotionSuite ™ Series Machine Controller Programming Manual Chapter 1: Motion Programmming Outline

Type Comm and Name Command Format Functio n /Mean ing

Control Commands

SFORK

JOINTO

SJOINT

Selected

Execution

Commands

SFORK Conditional1 ? Label 1,

Conditional 2 ? La bel 2, ...;

Label 1: Process 1

JOINTO label X

Label 2: Process 2

JOINTO label X

Label ·

·

Label X: SJOINT;

Executes (process 1) if

conditiona l1 is satisfied, and executes (process 2) if conditional2

is satisfied.

1-32

Page 42

MotionSuite ™ Series Machine Controller Programming Manual Chapter 2: Motion Commands

2 Motion Commands

Programing of axial motion commands and control commands are explained in

this chapter.

2.1 Axial Motion Commands .................................................................................... 2-2

2.1.1 Positi o n i n g (MOV) ......................... ......................... .................. ................ 2-2

2.1.2 Linear Interpolation (MVS) ....................................................................... 2-7

2.1.3 Circul ar Inter p o l ation (MC W , MCC) .............. ........................ ................ 2-11

2.1.4 Helical Interpolation (MCW, MCC) ........................................................ 2-19

2.1.5 Ze ro-po i n t Re tur n (ZRN) . ...... .................. ......................... .................. .... 2-22

2.1.6 Skip Command (SKP) ............................................................................. 2-28

2.1.7 Time Designation Positioning (MVT) ..................................................... 2-29

2.1.8 External Positioning (EXM) .................................................................... 2-31

2.2 Con trol Comm a n d ................ .................. ......................... .................. ................ 2-32

2.2.1 Absolute (ABS) Mode ............................................................................. 2-32

2.2.2 Incremental (INC) Mode ......................................................................... 2-34

2.2.3 Current Value Change (POS) .................................................................. 2-36

2.2.4 Coordinate Plane Designation (PLN) ...................................................... 2-39

2.2.5 Machin e Co o r d in ate Comma n d ( MV M) ...... ......................... .................. 2-40

2.2.6 Program Current Position Update (PLD) ................................................. 2-42

2.2.7 Timed Wait (TIM) ................................................................................... 2-43

2.2.8 Program End (END ) ......... .................. ......................... .................. .......... 2-44

2-1

Page 43

MotionSuite ™ Series Machine Controller Programming Manual Chapter 2: Motion Commands

2.1 Axial Motion Commands

This section describes how to command axial motion, and gives program examples.

2.1.1 Positioning (MOV)

!

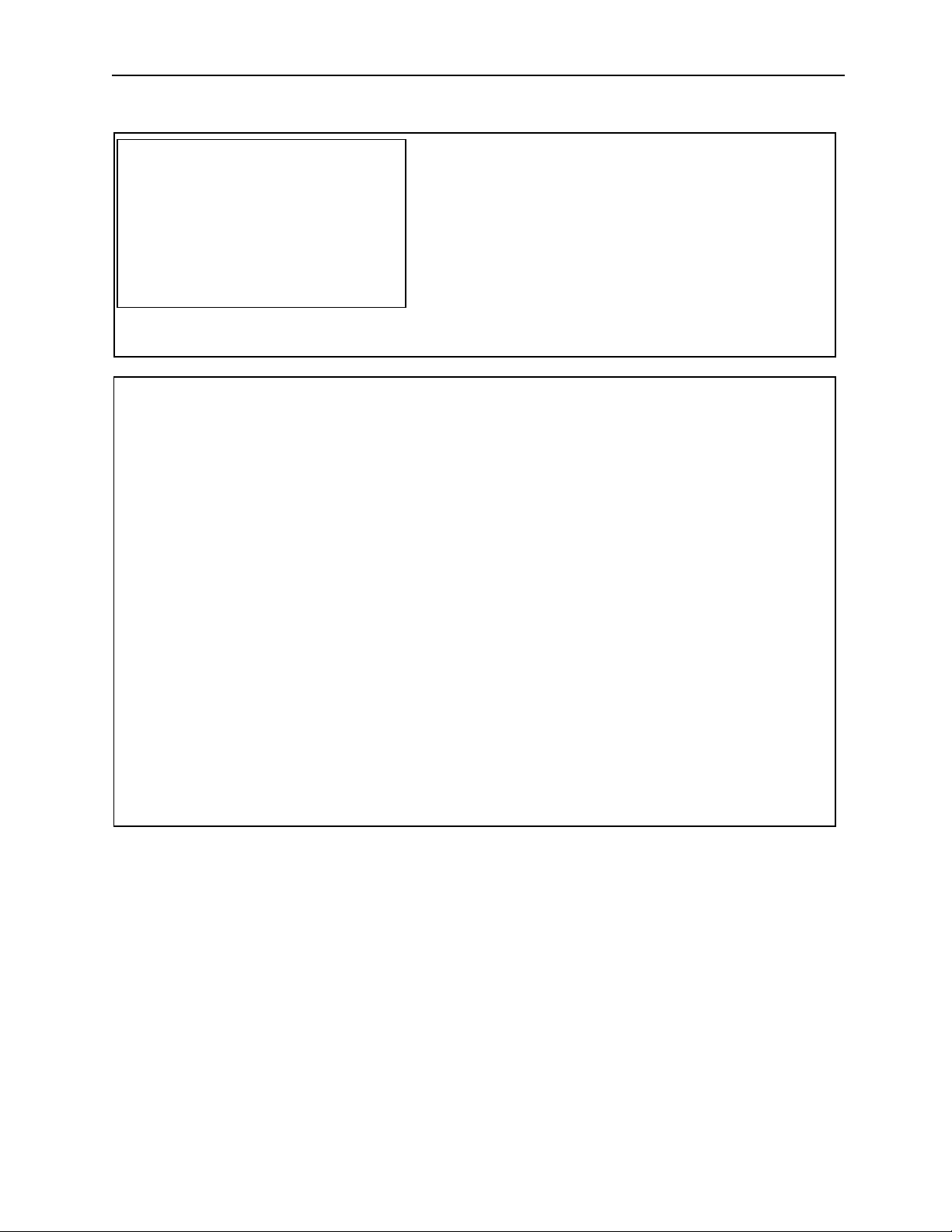

CAUTION

The move path based on the positioning (MOV) command is not

like the straight line in the linear interpolation. When programing,

the move path must be checked to avoid tools interfering with

the workpiece.

Forgetting this check carries a risk of tool damage, as well as

bodily injury due to interference.

!

! Outline

!!

The positioning command (MOV) makes each axis move independently from the current

position to the end position by fast feed speed (the speed set up in each axis’s parameter).

Up to 14 axes can be moved simultaneously. An axis that is not designated does not move.

The move path based on the MOV command does not move along the line designated by

the linear interpolation command mentioned in Item 2.1.2.

!

! Detailed Explanation

!!

The designated method of the MOV command is shown as follows:

MOV [axis1]—[axis2]—•••;

Designated position

2-2

Page 44

MotionSuite ™ Series Machine Controller Programming Manual Chapter 2: Motion Commands

The move path based on the MOV command is illustrated in the following figure:

axis2

axis3

axis2

Each axis is moving independent ly

by feed speed

axis3

Positioning motion

Current position

End position

axis1

axis1

Figure 2.1: Move Path Based on the MOV Command

• The designated position is set up as either absolute or incremental in previously

commanded ABS/INC* mode:

Absolute (AB S) mo de:

Incremental (INC) mode:

ABS/INC command

*

: Command uses either absolute value or incremental value to

Target position

Incremental amount from the current position

handle the coordinate term, which is called “modal group command.” Once designated,

it is enabled until the command is switched.

• For the axial motion based on the MOV command, execute an in-position check that

verifies whether the axial motion based on the MOV command has entered the

positioning completion range. After the in-position check, execute the next moving

command block. The following figure illustrates the motion of the in-position check.

v

Block designated by positioning

Block designated by next moving command

t

Entering the positioning completion range = In-position check completion

Figure 2.2: In-position Check Motion

• Fast feed speed is set up in parameter 30 “Fast feed speed (OLxx22)” of each axis.

Override can be set in a range of 0~327.67% to the fast feed speed. Use parameter 35

“Override (OWxx2C)” to set up the override in each axis.

2-3

Page 45

MotionSuite ™ Series Machine Controller Programming Manual Chapter 2: Motion Commands

Design ated Speed

(OLxx22)

Designated

•

For automatic accel/decel control based on the MOV command, linear accel/decel, or S-

Speed

(OLxx22)

Override

×

(OWxx2C)

=Output Speed

Overri de Function

Selection

Fixed Parameter 17

bit 9

Enable

Disable

Override

(OWxx2C)

Output

Speed

100%

curve accel/decel can be selected in the parameter settings.

•

Automatic accel/decel (in positioning) related parameters and motion commands are

shown as follows:

•

Setup parameter 11

“Linear acceleration time setting (OWxx0C)”

•

Setup parameter 18

“S-curve accel time (OWxx14)”

•

Setup parameter 29

“Servo command flag (OWxx21: b4~b7): Filter type selection”

•

Motion command

“Acceleration time change (ACC)”

•

Motion command

“S-curve time constant change (SCC)”

2-4

Page 46

MotionSuite ™ Series Machine Controller Programming Manual Chapter 2: Motion Commands

Various accel/decel patterns can be set using a combination of the above parameters and

motion commands.

No.

1 No accel/decel

2Linear

3 S-curve

Automatic

Accel/Decel Type

Related

Parameter Se tting

OWxx0C=0

OWxx21b4~b7=0

OWxx0C≠0

OWxx21b4~b7=0

OWx0C≠0

OWxx21b4~b7=2

OWxx14≠0

Note

Supplement

The setup parameter 18 “S-curve accel time (OWxx14)” is automatically tr ansferred to the

servo amplifier by the “S-curve time constant change (SCC)” motion command.

2-5

Page 47

MotionSuite ™ Series Machine Controller Programming Manual Chapter 2: Motion Commands

!

! Program Example

!!

The program example of the MOV command in the ABS mode is shown as follows:

ABS;

MOV [axis1]4000 [axis2]3000 [axis3]2000;

Start at current position: axis1 = axis2 = axis3 = 0

axis3

2000

axis2

End position

Current position

3000

Figure 2.3: Program Example of the MOV Command

4000

axis1

2-6

Page 48

MotionSuite ™ Series Machine Controller Programming Manual Chapter 2: Motion Commands

2.1.2 Linear Interpolation (MVS)

!

CAUTION

The axis that executes the linear interpolation (MVS) command