Page 1

YASKAWA AC Drive 1000-Series Option

Modbus TCP/IP

Installation Manual

Type: SI-EM3

To properly use the product, read this manual thoroughly and retain

for easy reference, inspection, and maintenance. Ensure the end user

receives this manual.

安川インバータ1000シリーズオプション

Modbus TCP/IP通信

取扱説明書

形 式

SI-EM3

製品を安全にお使い頂くために,本書を必ずお読みください。

また,本書をお手元に保管していただくとともに,最終的に本製品をご使用になる

ユーザー様のお手元に確実に届けられるよう,お取り計らい願います。

MANUAL NO. TOBP C730600 57B

Page 2

Copyright © 2012 YASKAWA ELECTRIC CORPORATION

All rights reserved. No part of this publication may be reproduced, stored in a retrieval system, or

transmitted, in any form or by any means, mechanical, electronic, photocopying, recording, or otherwise,

without the prior written permission of Yaskawa. No patent liability is assumed with respect to the use of the

information contained herein. Moreover, because Yaskawa is constantly striving to improve its high-quality

products, the information contained in this manual is subject to change without notice. Every precaution has

been taken in the preparation of this manual. Yaskawa assumes no responsibility for errors or omissions.

Neither is any liability assumed for damages resulting from the use of the information contained in this

publication.

2 YASKAWA ELECTRIC TOBP C730600 57B 1000-Series Option SI-EM3 Installation Manual

Page 3

Table of Contents

1 PREFACE AND SAFETY . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

2 PRODUCT OVERVIEW . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

3 RECEIVING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

4 OPTION COMPONENTS. . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

5 INSTALLATION PROCEDURE . . . . . . . . . . . . . . . . . . . . . . . 13

6 RELATED DRIVE PARAMETERS . . . . . . . . . . . . . . . . . . . .31

7 MODBUS TCP/IP MESSAGING . . . . . . . . . . . . . . . . . . . . . . 35

8 WEB INTERFACE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .40

9 TROUBLESHOOTING. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

10 SPECIFICATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

YASKAWA ELECTRIC TOBP C730600 57B 1000-Series Option SI-EM3 Installation Manual 3

Page 4

1 Preface and Safety

1 Preface and Safety

Yaskawa manufactures products used as components in a wide variety of industrial systems

and equipment. The selection and application of Yaskawa products remain the responsibility

of the equipment manufacturer or end user. Yaskawa accepts no responsibility for the way its

products are incorporated into the final system design. Under no circumstances should any

Yaskawa product be incorporated into any product or design as the exclusive or sole safety

control. Without exception, all controls should be designed to detect faults dynamically and

fail safely under all circumstances. All systems or equipment designed to incorporate a

product manufactured by Yaskawa must be supplied to the end user with appropriate

warnings and instructions as to the safe use and operation of that part. Any warnings

provided by Yaskawa must be promptly provided to the end user. Yaskawa offers an express

warranty only as to the quality of its products in conforming to standards and specifications

published in the Yaskawa manual. NO OTHER WARRANTY, EXPRESS OR IMPLIED, IS

OFFERED. Yaskawa assumes no liability for any personal injury, property damage, losses,

or claims arising from misapplication of its products.

◆ Applicable Documentation

The following manuals are available for the SI-EM3 Option:

SI-EM3 Option

Yaskawa AC Drive

1000-Series Option

SI-EM3 Modbus TCP/IP

Installation Manual

Manual No: TOBP C730600 57

(This book)

Yaskawa AC Drive

1000-Series Option

SI-EM3 Modbus TCP/IP

Technical Manual

Manual No: SIEP C730600 57

4 YASKAWA ELECTRIC TOBP C730600 57B 1000-Series Option SI-EM3 Installation Manual

Read this manual first.

The installation manual is packaged with the

option and contains information required to

install the option and set up related drive

parameters.

The technical manual contains detailed

information about the option. Access the

following sites to obtain the technical

manual:

U.S.: http://www.yaskawa.com

Europe: http://www.yaskawa.eu.com

Japan: http://www.e-mechatronics.com

For questions, contact your local Yaskawa

sales office or the nearest Yaskawa

representative.

Page 5

Yaskawa Drive

1 Preface and Safety

Yaskawa AC Drive

1000-Series

Quick Start Guide

Yaskawa AC Drive

1000-Series

Quick Start Guide

The drive manuals cover basic installation, wiring,

operation procedures, functions, troubleshooting, and

maintenance information.

The manuals also include important information about

parameter settings and drive tuning.

Access these sites to obtain Yaskawa instruction manuals:

U.S.: http://www.yaskawa.com

Europe: http://www.yaskawa.eu.com

Japan: http://www.e-mechatronics.com

Other areas: contact a Yaskawa representative.

◆ Terms

Note: Indicates supplemental information that is not related to safety messages.

Drive: Yaskawa AC Drive 1000-Series

Option: Yaskawa AC Drive 1000-Series Option SI-EM3 Modbus TCP/IP

◆ Registered Trademarks

• Modbus TCP/IP is a trademark of Modbus-IDA.

• All trademarks are the property of their respective owners.

YASKAWA ELECT RIC TOBP C730600 57B 1000-Series Option SI-EM3 Installation Manual 5

Page 6

1 Preface and Safety

W ARNING

CAUTION

NOTICE

◆ Supplemental Safety Information

Read and understand this manual before installing, operating, or servicing this option. The

option must be installed according to this manual and local codes.

The following conventions are used to indicate safety messages in this manual. Failure to

heed these messages could result in serious or possibly even fatal injury or damage to the

products or to related equipment and systems.

DANGER

Indicates a hazardous situation, which, if not avoided, will result in death or serious

injury.

Indicates a hazardous situation, which, if not avoided, could result in death or

serious injury.

Indicates a hazardous situation, which, if not avoided, could result in minor or

moderate injury.

Indicates an equipment damage message.

6 YASKAWA ELECTRIC TOBP C730600 57B 1000-Series Option SI-EM3 Installation Manual

Page 7

1 Preface and Safety

DANGER

NOTICE

■ General Safety

General Precautions

• The diagrams in this section may include options and drives without covers or safety shields to illustrate details.

Reinstall covers or shields before operating any devices. The option should be used according to the instructions

described in this manual.

• Any illustrations, photographs, or examples used in this manual are provided as examples only and may not apply

to all products to which this manual is applicable.

• The products and specifications described in this manual or the content and presentation of the manual may be

changed without notice to improve the product and/or the manual.

• When ordering new copies of the manual, contact a Yaskawa representative or the nearest Yaskawa sales office and

provide the manual number shown on the front cover.

Heed the safety messages in this manual.

Failure to comply will result in death or serious injury.

The operator is responsible for injuries or equipment damage caused from failure to heed

the warnings in the manual.

Do not modify the drive or option circuitry.

Failure to comply could result in damage to the drive or option and will void warranty.

Yaskawa is not responsible for any modification of the product made by the user. This

product must not be modified.

Do not expose the drive or option to halogen group disinfectants.

Failure to comply may cause damage to the electrical components in the option.

Do not pack the drive in wooden materials that have been fumigated or sterilized.

Do not sterilize the entire package after the product is packed.

YASKAWA ELECT RIC TOBP C730600 57B 1000-Series Option SI-EM3 Installation Manual 7

Page 8

2 Product Overview

2 Product Overview

◆ About This Product

This option provides a communications connection between the drive and a Modbus TCP/IP

network. The option connects the drive to a Modbus TCP/IP network and facilitates the

exchange of data.

This manual explains the handling, installation and specifications of this product.

The option is a communications link to connect industrial devices (such as smart motor

controllers, operator interfaces, and variable frequency drives) as well as control devices

(such as programmable controllers and computers) to a network. The option is a simple,

networking solution that reduces the cost and time to wire and install factory automation

devices, while providing interchangeability of like components from multiple vendors.

By installing the option to a drive, it is possible to do the following from a Modbus TCP/IP

master device:

• drive operation

• drive operation status monitoring

• changing parameter settings.

◆ Applicable Models

The option can be used with the drive models in Tab le 1 .

Table 1 Applicable Models

Drive Series

A1000

Z1000 CIMR-ZA ≥ 1014

<1> See “PRG” on the drive nameplate for the software version number.

8 YASKAWA ELECTRIC TOBP C730600 57B 1000-Series Option SI-EM3 Installation Manual

Drive Model Number Software Version <1>

CIMR-A2A ≥ 1010

CIMR-A4A0002 to 4A0675 ≥ 1010

CIMR-A4A0930 and 4A1200 301

CIMR-A5A 504

Page 9

3 Receiving

NS MS

MANUAL

3 Receiving

Please perform the following tasks upon receipt of the option:

• Inspect the option for damage. Contact the shipper immediately if the option appears

damaged upon receipt.

• Verify receipt of the correct model by checking the model number printed on the name

plate of the option package.

• Contact your supplier if you have received the wrong model or the option does not

function properly.

◆ Option Package Contents

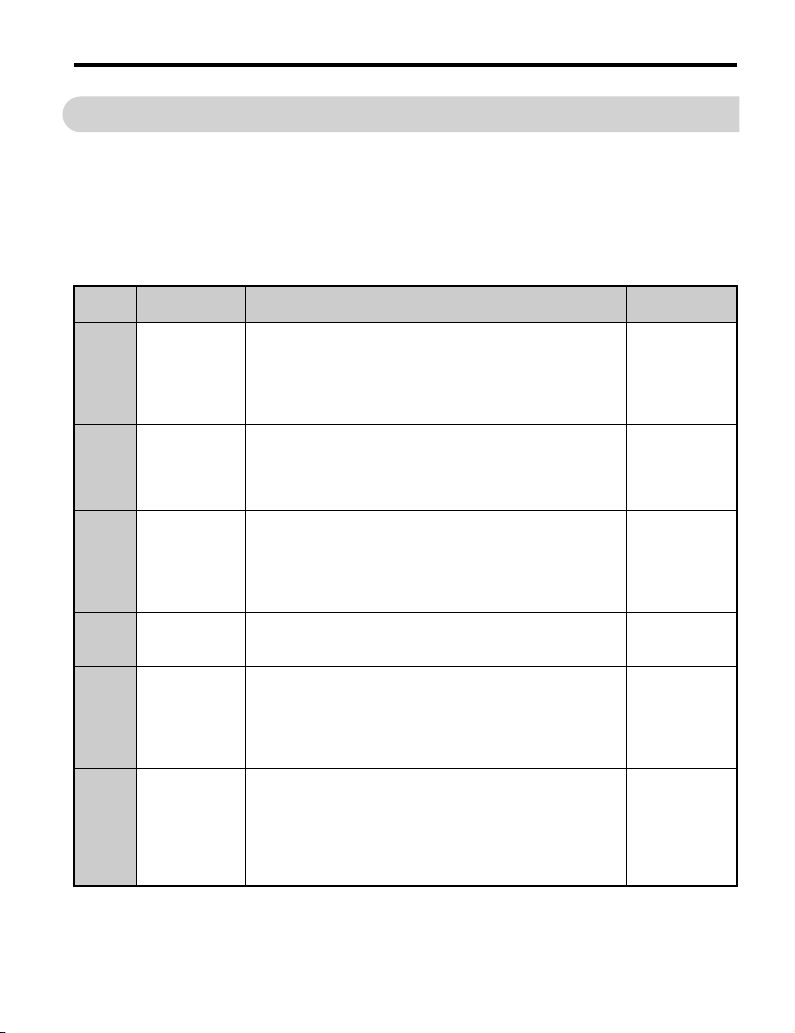

Table 2 Option Package Contents

Description: Option

_

Quantity: 11311

Ground

Wire

◆ Tools Required for Installation

• A Phillips screwdriver (M3 metric/#1, #2 U.S. standard size <1>) is required to install the

option and remove drive front covers.

• Diagonal cutting pliers. (required for some drive models)

• A small file or medium grit sandpaper. (required for some drive models)

Screws

(M3)

LED Label

Installation

Manual

<1> Screw sizes vary by drive capacity. Select a screwdriver appropriate for the drive capacity.

Note: Tools required to prepare option networking cables for wiring are not listed in this manual.

YASKAWA ELECT RIC TOBP C730600 57B 1000-Series Option SI-EM3 Installation Manual 9

Page 10

4 Option Components

E

Underside

A

F

B

G

H

D C

A1000

4 Option Components

◆ SI-EM3 Option

Figure 1

A – Connector (CN5)

B – Installation hole F – Communication connector CN1 (RJ45)

C – LED (MS)

D–LED (NS)<1> H – LED (10/100) <1>

<1> Refer to Option LED Display on page 12 for details on the LEDs

<2> The ground wire provided in the option shipping package must be connected during installation

10 YASKAWA ELECTRIC TOBP C730600 57B 1000-Series Option SI-EM3 Installation Manual

<1> G – LED (LINK/ACT) <1>

Figure 1 SI-EM3 Option Components

E – Ground terminal and installation hole

<2>

Page 11

4 Option Components

◆ Communication Connector CN1

The communication connector on the option is a modular RJ45 female connector designated

CN1.

CN1 is the connection point for a customer supplied male Modbus network communication

cable.

Table 3 Male, 8-way Ethernet Modular Connector (Customer Supplied)

Male Ethernet 8-Way Modular Connector Pin Description

1 (Pair 2) Transmit data (TXD) +

2 (Pair 2) Transmit data (TXD) -

3 (Pair 3) Receive data (RXD) +

4 (Pair 1) Not used

5 (Pair 1) Not used

6 (Pair 3) Receive data (RXD) -

7 (Pair 4) Not used

8 (Pair 4) Not used <1>

<1> Not used for 10 Mbps and 100 Mbps networks.

<1>

<1>

<1>

YASKAWA ELECT RIC TOBP C730600 57B 1000-Series Option SI-EM3 Installation Manual 11

Page 12

4 Option Components

◆ Option LED Display

The option has four LEDs:

Bi-color Status LEDs:

• Module status (MS) red/green

• Network status (NS) red/green

Green Ethernet LEDs:

• Network speed-10/100 (MS) green

• Link status and network activity-Link/Act (NS) red/green

The operational states of the option LEDs after the power-up diagnostic LED sequence is

completed are described in Table 4. Wait at least 2 seconds for the power-up diagnostic

process to complete before verifying the states of the LEDs.

Table 4 Option LED States

Name

MS

NS

10/100

<1>

LINK/ACT

<1>

<1> Remove the drive front cover to check the status of the LED. Be careful not to touch the main circuit terminals or

the control board in the drive.

Indication

Color Status

– OFF Power supply OFF Power is not being supplied to the drive

Green ON Option operating The option is operating normally

Green Flashing Option initializing The option is configuring an IP address

Red ON Fatal error occurred

Red Flashing Non-fatal error occurred

– OFF Offline or power supply OFF –

Green ON

Green Flashing Control connection active

Red ON Communications error (fatal) The option detected a duplicate IP address

Green OFF 10 Mbps is established

Green ON 100 Mbps is established

Green OFF Link is not established

Green ON Link is established

Green Flashing

Operating Status Remarks

The option has detected a fatal

(unrecoverable) error

The option has detected a non-fatal

(recoverable) error

Online communications

established

Link is established and there is

network activity

The option is online and has established

connections

The option is online and has an established

and active control connection.

–

12 YASKAWA ELECTRIC TOBP C730600 57B 1000-Series Option SI-EM3 Installation Manual

Page 13

5 Installation Procedure

W ARNING

5 Installation Procedure

◆ Section Safety

DANGER

Electrical Shock Hazard

Do not connect or disconnect wiring while the power is on.

Failure to comply will result in death or serious injury.

Disconnect all power to the drive and wait at least the amount of time specified on the

drive front cover safety label.

After all indicators are off, measure the DC bus voltage to confirm safe level, and check

for unsafe voltages before servicing. The internal capacitor remains charged after the

power supply is turned off.

Electrical Shock Hazard

Do not remove the front covers of the drive while the power is on.

Failure to comply could result in death or serious injury.

The diagrams in this section may include options and drives without covers or safety

shields to show details. Be sure to reinstall covers or shields before operating any devices.

The option should be used according to the instructions described in this manual.

Do not allow unqualified personnel to use equipment.

Failure to comply could result in death or serious injury.

Maintenance, inspection, and replacement of parts must be performed only by authorized

personnel familiar with installation, adjustment, and maintenance of this product.

Do not touch circuit boards while the power to the drive is on.

Failure to comply could result in death or serious injury.

YASKAWA ELECT RIC TOBP C730600 57B 1000-Series Option SI-EM3 Installation Manual 13

Page 14

5 Installation Procedure

NOTICE

W ARNING

Do not use damaged wires, place excessive stress on wiring, or damage the wire

insulation.

Failure to comply could result in death or serious injury.

Fire Hazard

Tighten all terminal screws to the specified tightening torque.

Loose electrical connections could result in death or serious injury by fire due to

overheating of electrical connections.

Damage to Equipment

Observe proper electrostatic discharge (ESD) procedures when handling the option,

drive, and circuit boards.

Failure to comply may result in ESD damage to circuitry.

Never shut the power off while the drive is outputting voltage.

Failure to comply may cause the application to operate incorrectly or damage the drive.

Do not operate damaged equipment.

Failure to comply may cause further damage to the equipment.

Do not connect or operate any equipment with visible damage or missing parts.

Do not use unshielded cable for control wiring.

Failure to comply may cause electrical interference resulting in poor system performance.

Use shielded twisted-pair wires and ground the shield to the ground terminal of the drive.

14 YASKAWA ELECTRIC TOBP C730600 57B 1000-Series Option SI-EM3 Installation Manual

Page 15

5 Installation Procedure

NOTICE

Properly connect all pins and connectors.

Failure to comply may prevent proper operation and possibly damage equipment.

Check wiring to ensure that all connections are correct after installing the option

and connecting any other devices.

Failure to comply may result in damage to the option.

YASKAWA ELECT RIC TOBP C730600 57B 1000-Series Option SI-EM3 Installation Manual 15

Page 16

5 Installation Procedure

F

H

L

M

N

K

I

B

C

D

E

A

G

J

NS MS

◆ Installing the Option to A1000 Drive

■ Prior to Installing the Option

Prior to installing the option, wire the drive, make necessary connections to the drive

terminals, and verify that the drive functions normally without the option installed. Refer to

the Quick Start Guide packaged with the drive for information on wiring and connecting the

drive.

Figure 2 shows an exploded view of the drive with the option and related components for

reference.

Figure 2

A – Insertion point for CN5 connector H – Included screws

B – SI-EM3 option I – Ground wire

C – Drive front cover J – Option modular connector CN1

D – Digital operator K – Drive grounding terminal (FE)

E – LED label L – Connector CN5-A

F – Drive terminal cover M – Connector CN5-B

G – Removable tabs for wire routing N – Connector CN5-C

16 YASKAWA ELECTRIC TOBP C730600 57B 1000-Series Option SI-EM3 Installation Manual

Figure 2 Drive Components with Option

Page 17

5 Installation Procedure

C

D

F

A1000

■ Installing the Option

Remove the front covers of the drive before installing the option. Refer to the drive Quick

Start Guide for directions on removing the front covers. Cover removal varies depending on

drive size. This option can be inserted only into the CN5-A connector located on the drive

control board.

DANGER! Electrical Shock Hazard. Do not connect or disconnect wiring while the power is on. Failure to

comply could result in death or serious injury. Before installing the option, disconnect all power to the drive

and wait at least the amount of time specified on the drive front cover safety label. After all indicators are off,

measure the DC bus voltage to confirm safe level, and check for unsafe voltages before servicing. The

internal capacitor remains charged after the power supply is turned off.

1. Shut off power to the drive, wait the appropriate amount of time for voltage to

dissipate, then remove the digital operator (D) and front covers (C, F). Refer to the

Quick Start Guide packaged with the drive for directions on removing the front

covers. Cover removal varies depending on drive size.

NOTICE: Damage to Equipment. Observe proper electrostatic discharge procedures (ESD) when handling

the option, drive, and circuit boards. Failure to comply may result in ESD damage to circuitry.

Figure 3

Figure 3 Remove the Front Covers and Digital Operator

YASKAWA ELECT RIC TOBP C730600 57B 1000-Series Option SI-EM3 Installation Manual 17

Page 18

5 Installation Procedure

A1000

2. With the front covers and digital operator removed, apply the LED label (E) in the

Figure 4

appropriate position on the drive top front cover (C).

C

NS MS

Figure 4 Apply the LED Label

E

18 YASKAWA ELECTRIC TOBP C730600 57B 1000-Series Option SI-EM3 Installation Manual

Page 19

5 Installation Procedure

A1000

3. Make sure the screws on the left and right sides of the option terminal block (J) are

tightened with a tightening torque of 0.5 to 0.6 Nxm (4.4 to 5.3 in lbs), then insert the

option (B) into the CN5-A connector (L) located on the drive and fasten it using one

Figure 5

of the included screws (H).

B

L

H

J

Figure 5 Insert the Option

YASKAWA ELECT RIC TOBP C730600 57B 1000-Series Option SI-EM3 Installation Manual 19

Page 20

5 Installation Procedure

A1000

4. Connect the ground wire (I) to the ground terminal (K) using one of the remaining

provided screws (H). Connect the other end of the ground wire (I) to the remaining

ground terminal and installation hole on the option (B) using the last remaining

Figure 6

provided screw (H) and tighten both screws to 0.5 to 0.6 Nxm (4.4 to 5.3 in lbs).

B

K

I

H

Figure 6 Connect the Ground Wire

Note: There are two screw holes on the drive for use as ground terminals (K). When connecting three

options, two ground wires will need to share the same drive ground terminal.

20 YASKAWA ELECTRIC TOBP C730600 57B 1000-Series Option SI-EM3 Installation Manual

Page 21

5 Installation Procedure

B

A

5. Route the option wiring.

Depending on the drive model, some drives may require routing the wiring through

the side of the front cover to the outside to provide adequate space for the wiring.

Refer to the Peripheral Devices & Options section of the drive Quick Start Guide or

Technical Manual for more information on wire routing of specific models.

Route the wiring through the side of the front cover to the outside. In these cases,

using diagonal cutting pliers, cut out the perforated openings on the left side of the

drive front cover as shown in Figure 7-A. Sharp edges along the cut out should be

smoothed down with a file or sand paper to prevent any damage to the wires.

Route the wiring inside the enclosure as shown in Figure 7-B for drives that do not

require routing through the front cover.

Note: Separate communication cables from main circuit wiring and other electrical lines.

Figure 7

A – Route wires through the openings

provided on the left side of the

front cover.

<1> The drive will not meet NEMA Type 1 requirements if wiring is exposed outside the enclosure.

YASKAWA ELECT RIC TOBP C730600 57B 1000-Series Option SI-EM3 Installation Manual 21

<1>

Figure 7 Wire Routing Examples

B – Use the open space provided

inside the drive to route option

wiring.

Page 22

5 Installation Procedure

Drive

M

U

V

W

R

S

T

CN5-A

FE

<1>

ModbusTCP/IP Master

Modbus TCP/IP Cable

MotorPower

SI-EM3

Modbus

TCP/IP

Option

CN1

A1000

6. Connect the Ethernet communication cable to the option modular connector (CN1).

To connect the option to a network, insert the RJ45 communication connector of the

Cat 5e patch cable into the option modular female connector (CN1). Ensure the

cable end is firmly connected (see Figure 7).

Communication Cable Specifications

Only use cable recommended for Modbus TCP/IP™. Using a cable not specifically

recommended may cause the option or drive to malfunction.

Connection Diagram

<1> The ground wire provided in the option shipping package must be connected during installation.

Figure 8 Option Connection Diagram

22 YASKAWA ELECTRIC TOBP C730600 57B 1000-Series Option SI-EM3 Installation Manual

Page 23

5 Installation Procedure

F

C

D

A1000

7. Replace and secure the front covers of the drive (C, F) and replace the digital

Figure 8

operator (D).

Figure 9 Replace the Front Covers and Digital Operator

Note: Take proper precautions when wiring the option so that the front covers will easily fit back onto

the drive. Make sure no cables are pinched between the front covers and the drive when

replacing the covers.

8. Set drive parameters in Table 5 for proper option performance.

YASKAWA ELECT RIC TOBP C730600 57B 1000-Series Option SI-EM3 Installation Manual 23

Page 24

5 Installation Procedure

A1000

◆ Installing the Option to Z1000 Drive

■ Prior to Installing the Option

Prior to installing the option, wire the drive, make necessary connections to the drive

terminals, and verify that the drive functions normally without the option installed. Refer to

the User Manual packaged with the drive for information on wiring and connecting the

drive.

Figure 10 shows an exploded view of the drive with the option and related components for

reference.

Figure 9

A

B

C

D

E

J

I

A – Drive grounding terminal (FE) F – LED label

B – Option card G – Ground wire

C – Mounting screw H – Terminal block CN1

D – Drive front cover I – Insert connector CN5 here

E – HOA keypad J – Connector CN5

24 YASKAWA ELECTRIC TOBP C730600 57B 1000-Series Option SI-EM3 Installation Manual

H

G

Figure 10 Drive Components with Option

F

NS MS

Page 25

5 Installation Procedure

A1000

■ Installing the Option

Remove the front cover of the drive before installing the option. Refer to the drive User

Manual for directions on removing the front covers. Cover removal varies depending on

drive size. This option can be inserted only into the CN5-A connector located on the drive

control board.

DANGER! Electrical Shock Hazard. Do not connect or disconnect wiring while the power is on. Failure to

comply could result in death or serious injury. Before installing the option, disconnect all power to the drive

and wait at least the amount of time specified on the drive front cover safety label. After all indicators are off,

measure the DC bus voltage to confirm safe level, and check for unsafe voltages before servicing. The

internal capacitor remains charged after the power supply is turned off.

1. Shut off power to the drive, wait the appropriate amount of time for voltage to

dissipate, then remove the HOA keypad (E) and front cover (D).

NOTICE: Damage to Equipment. Observe proper electrostatic discharge procedures (ESD) when handling

the option, drive, and circuit boards. Failure to comply may result in ESD damage to circuitry.

Figure 10

D

E

Figure 11 Remove the Front Cover and HOA Keypad

YASKAWA ELECT RIC TOBP C730600 57B 1000-Series Option SI-EM3 Installation Manual 25

Page 26

5 Installation Procedure

NS MS

F

D

A1000

2. With the front cover and HOA keypad removed, apply the LED label (F) in the

Figure11

appropriate position on the drive front cover (D).

Figure 12 Apply the LED Label

26 YASKAWA ELECTRIC TOBP C730600 57B 1000-Series Option SI-EM3 Installation Manual

Page 27

5 Installation Procedure

A1000

3. Make sure the screws on the left and right sides of the option terminal block (H) are

tightened with a tightening torque of 0.5 to 0.6 Nxm (4.4 to 5.3 in lbs), then insert the

option (B) into the CN5 connector (J) located on the drive and fasten it using one of

Figure 12

the included screws (C).

J

B

C

H

Figure 13 Insert the Option

YASKAWA ELECT RIC TOBP C730600 57B 1000-Series Option SI-EM3 Installation Manual 27

Page 28

5 Installation Procedure

G

C

A

A1000

4. Connect the ground wire (G) to the ground terminal (A) using one of the remaining

provided screws (C). Connect the other end of the ground wire (G) to the ground

terminal and installation hole on the option using the last remaining provided screw

Figure 13

(C) and tighten both screws to 0.5 to 0.6 Nxm (4.4 to 5.3 in lbs).

Figure 14 Connecting the Ground Wire

5. Wire the communication cables.

Note: Separate communication cables from main circuit wiring and other electrical lines.

28 YASKAWA ELECTRIC TOBP C730600 57B 1000-Series Option SI-EM3 Installation Manual

Page 29

5 Installation Procedure

A1000

6. Connect the Ethernet communication cable to the option modular connector (CN1).

To connect the option to a network, insert the RJ45 communication connector of the

Cat 5e patch cable into the option modular female connector (CN1). Ensure the

cable end is firmly connected (see Figure 15).

Communication Cable Specifications

Only use cable recommended for Modbus TCP/IP™. Using a cable not specifically

recommended may cause the option or drive to malfunction.

Connection Diagram

R

S

T

U

V

W

Drive

<1>

CN5-A

SI-EM3

Modbus

TCP/IP

ModbusTCP/IP Master

<1> The ground wire provided in the option shipping package must be connected during installation.

Modbus TCP/IP Cable

Figure 15 Option Connection Diagram

Option

CN1

FE

M

MotorPower

YASKAWA ELECT RIC TOBP C730600 57B 1000-Series Option SI-EM3 Installation Manual 29

Page 30

5 Installation Procedure

A1000

7. Replace and secure the front cover of the drive (D) and replace the HOA Keypad

Figure 14

(E).

D

E

Figure 16 Replace the Front Cover and HOA Keypad

Note: Take proper precautions when wiring the option so that the front covers will easily fit back onto

the drive. Make sure no cables are pinched between the front covers and the drive when

replacing the covers.

8. Set drive parameters in Table 6 for proper option performance.

30 YASKAWA ELECTRIC TOBP C730600 57B 1000-Series Option SI-EM3 Installation Manual

Page 31

6 Related Drive Parameters

6 Related Drive Parameters

The following parameters are used to set up the drive for operation with the option.

Parameter setting instructions can be found in the drive Quick Start Guide or Technical

Manual.

Confirm proper setting of all the parameters in Table 5 using the digital operator, before

starting network communications.

Table 5 Related Parameter Settings

No.

(Addr. H)

b1-01

(180)

<1>

b1-02

(181)

<1>

F6-01

(3A2)

F6-02

(3A3)

F6-03

(3A4)

F6-06

(3A7)

<3>

Name Description Values

Selects the frequency reference input source.

Frequency

Reference

Selection

Run Command

Selection

Operation

Selection after

Communications

Error

External Fault

Detection

Conditions (EF0)

Stopping Method

for External

Fault from the

Communication

Option

Torque

Reference/

Torque Limit

Selection from

the

Communication

Option

0: Operator - Digital preset speed d1-01 to d1-17

1: Terminals - Analog input terminal A1 or A2

2: MEMOBUS/Modbus communications

3: Option

4: Pulse Input (Terminal RP)

Selects the run command input source.

0: Digital Operator - RUN and STOP keys

1: Digital input terminals S1 to S8

2: MEMOBUS/Modbus communications

3: Option

Determines drive response when a bUS error is detected during

communications with the option.

0: Ramp to Stop

1: Coast to Stop

2: Fast-Stop

3: Alarm Only

Sets the condition for external fault detection (EF0).

0: Always detected

1: Detected only during operation

Determines drive response for external fault input (EF0) detection

during option communications.

0: Ramp to Stop

1: Coast to Stop

2: Fast-Stop

3: Alarm Only

0: Torque Reference/Torque Limit via network communications

are disabled

1: Torque Reference/Torque Limit via network communications

are enabled

<2>

<2>

<4>

Default: 1

Range: 0 to 4

(Set to 3)

Default: 1

Range: 0 to 3

(Set to 3)

Default: 1

Range: 0 to 3

Default: 0

Range: 0, 1

Default: 1

Range: 0 to 3

Default: 0

Range: 0, 1

YASKAWA ELECT RIC TOBP C730600 57B 1000-Series Option SI-EM3 Installation Manual 31

Page 32

6 Related Drive Parameters

No.

(Addr. H)

F6-07

(3A8)

F6-08

(36A)

F7-01

(3E5)

<5> <6>

<7>

F7-02

(3E6)

<5> <6>

<7>

F7-03

(3E7)

<5> <6>

<7>

F7-04

(3E8)

<5> <6>

<7>

F7-05

(3E9)

<7>

F7-06

(3EA)

<7>

F7-07

(3EB)

<7>

F7-08

(3EC)

<7>

F7-09

(3ED)

<7>

F7-10

(3EE)

<7>

Name Description Valu es

NetRef/ComRef

Selection

Function

Reset

Communication

Related

Parameters

IP Address 1

IP Address 2

IP Address 3

IP Address 4

Subnet Mask 1

Subnet Mask 2

Subnet Mask 3

Subnet Mask 4

0: Multi-step speed reference disabled, (F7 functionality)

1: Multi-step speed reference allowed, (V7 functionality)

Determines if communication-related parameters F6- and F7 are set back to original default values when the drive is

initialized using parameter A1-03.

0: Do not reset parameters

1: Reset parameters

Sets the static/fixed IP address.

Parameter F7-01 sets the most significant octet.

Sets the static/fixed IP address.

Parameter F7-02 sets the second most significant octet.

Sets the static/fixed IP address.

Parameter F7-03 sets the third most significant octet.

Sets the static/fixed IP address.

Parameter F7-04 sets the fourth most significant octet.

Sets the static/fixed Subnet Mask.

Parameter F7-05 sets the most significant octet.

Sets the static/fixed Subnet Mask.

Parameter F7-06 sets the second most significant octet.

Sets the static/fixed Subnet Mask.

Parameter F7-07 sets the third most significant octet.

Sets the static/fixed Subnet Mask.

Parameter F7-08 sets the fourth most significant octet.

Gateway Address 1Sets the static/fixed Gateway address.

Parameter F7-09 sets the most significant octet.

Gateway Address 2Sets the static/fixed Gateway address.

Parameter F7-10 sets the second most significant octet.

Default: 0

Range: 0, 1

<7>

Default: 0

Range: 0, 1

Default: 192

Range: 0 to 255

Default: 168

Range: 0 to 255

Default: 1

Range: 0 to 255

Default: 20

Range: 0 to 255

Default: 255

Range: 0 to 255

Default: 255

Range: 0 to 255

Default: 255

Range: 0 to 255

Default: 0

Range: 0 to 255

Default: 192

Range: 0 to 255

Default: 168

Range: 0 to 255

32 YASKAWA ELECTRIC TOBP C730600 57B 1000-Series Option SI-EM3 Installation Manual

Page 33

6 Related Drive Parameters

No.

(Addr. H)

F7-11

(3EF)

<7>

F7-12

(3E0)

<7>

F7-13

(3F1)

F7-14

(3F2)

F7-15

(3F3)

<8>

F7-16

(3F4)

H5-11

(43C)

<1> To start and stop the drive with the option master device using serial communications, set b1-02 to 3. To control

the drive frequency reference via the master device, set b1-01 to 3.

<2> If F6-01 is set to 3, the drive will continue to operate when a fault is detected. Take safety measures, such as

installing an emergency stop switch.

<3> A1000: Enabled in CLV, AOLV/PM, and CLV/PM control modes (A1-02 = 3, 6, or 7). When enabled, d5-01

determines whether the value is read as the Torque Limit value (d5-01 = 0) or read as the Torque Reference value

(d5-01 = 1). In CLV/PM, this value is read as the Torque Limit.

Z1000: Enabled in OLV/PM control modes (A1-02 = 5). When enabled, d5-01 determines whether the value is

read as the Torque Limit value (d5-01 = 0) or read as the Torque Reference value (d5-01 = 1). In V/f, this value

is read as the Torque Limit.

<4> The setting specifies that the Torque Reference or Torque Limit is to be provided via network communications

(F6-06 = 1). The motor may rotate if no torque reference or Torque Limit is supplied from the PLC.

<5> Cycle power for setting changes to take effect.

<6> If F7-13 is set to 0, then all IP Addresses (F7-01 to F7-04) must be unique.

<7> Set F7-01 to F7-12 when F7-13 is set to 0.

<8> Set F7-15 when F7-14 is set to 0 or 2.

Name Description Values

Gateway Address 3 Sets the static/fixed Gateway address.

Gateway Address 4Sets the static/fixed Gateway address.

Address Mode at

Startup

Duplex Mode

Selection

Communication

Speed Selection

Communication

Loss Time-out

Communications

ENTER Function

Selection

Parameter F7-11 sets the third most significant octet.

Parameter F7-12 sets the fourth most significant octet.

Selects how the option address is set.

0: Static <6>

1: BOOTP

2: DHCP

Selects duplex mode setting.

0: Half duplex forced

1: Auto-negotiate duplex mode and communication speed

2: Full duplex forced

Sets the communication speed.

10: 10 Mbps

100: 100 Mbps

Sets the time-out value for communication loss detection in tenths

of a second. A value of 0 disables the connection time-out.

Example: An entered value of 100 represents 10.0 seconds.

Select the function for the ENTER command that saves parameter

data to the drive.

0: Parameter changes are activated when ENTER command is

written

1: Parameter changes are activated immediately without use of

ENTER command

Default: 1

Range: 0 to 255

Default: 1

Range: 0 to 255

Default: 2

Range: 0 to 2

Default: 1

Range: 0 to 2

Default: 10

Range: 10, 100

Default: 0

Min.: 0

Max.: 300

Default: 1

Range: 0, 1

YASKAWA ELECT RIC TOBP C730600 57B 1000-Series Option SI-EM3 Installation Manual 33

Page 34

6 Related Drive Parameters

Table 6 Option Monitors

No. Name Description Value Range

U6-80 to U6-83 Online IP Address

U6-84 to U6-87 Online Subnet

U6-88 to U6-91 Online Gateway

U6-92 Online Speed Link Speed

U6-93 Online Duplex Duplex Setting 0: Half, 1: Full

U6-98 First Fault First Option Fault –

U6-99 Current Fault Current Option Fault –

IP Address currently available; U6-80 is the most

significant octet

Subnet currently available; U6-84 is the most

significant octet

Gateway currently available; U6-88 is the most

significant octet

0 to 255

0 to 255

0 to 255

10: 10 Mbps

100: 100 Mbps

34 YASKAWA ELECTRIC TOBP C730600 57B 1000-Series Option SI-EM3 Installation Manual

Page 35

7 Modbus TCP/IP Messaging

7 Modbus TCP/IP Messaging

◆ Modbus TCP/IP Overview

The Modbus TCP/IP protocol is essentially the Modbus protocol over an Modbus TCP/IP

network. A master controller (typically a PLC) sends commands to slave devices, which

then perform the specified functions and send a response to the master. The drive using the

option has slave functionality.

■ Supported Modbus TCP/IP Commands

Table 7 Supported Modbus TCP/IP Commands

Function Code Function Name

03H Read Multiple Registers

06H Write Single Register

10H Write Multiple Registers

17H Read/Write Multiple Registers

■

Drive Modbus TCP/IP Option Registers

All of the command registers, monitor registers, and parameters documented in the drive

Technical Manual are accessible via the option.

■ High Speed Access Drive Modbus TCP/IP Option Registers

Many of the registers required for control have been specially mapped to provide higher

speed access to increase network performance. Use these registers for the best response

times.

All of the drive command registers have been mapped to this high speed access area

(Modbus TCP/IP registers 01H to 01FH). In addition, the monitors shown in Table 8 are

mapped for high speed access.

YASKAWA ELECT RIC TOBP C730600 57B 1000-Series Option SI-EM3 Installation Manual 35

Page 36

7 Modbus TCP/IP Messaging

Table 8 Drive Registers

Address

(hex)

2000 4B

2001 44 Motor Speed Monitor (U1-05)

2002 48 Torque Reference Monitor (U1-09)

2003 F0 PG Count Channel 1

2004 40 Frequency Reference Monitor (U1-01)

2005 41 Output Frequency Monitor (U1-02)

2006 26

2007 4F Terminal A2 Input Level Monitor (U1-14)

2008 46 DC Bus Voltage Monitor (U1-07)

Drive

Register

(hex)

Description Bit Description

0 During Run

1 During Zero Speed

2 During Reverse Direction

3 During Fault Reset Signal Input

4 During Speed Agree

5 Drive Ready

6Alarm

Status Word

(U1-12)

Output Current

(0.01 A units for drives set to 11 kW in Heavy or Normal Duty and 0.1 A units for drives

set to 15 kW and above.)

7Fault

8 During Operation Error (oPE)

9 During Momentary Power Loss

A Motor 2 Selected

B Reserved

C Reserved

D Reserved

E ComRef Status, NetRef Status

F ComCtrl Status, NetCtrl Status

36 YASKAWA ELECTRIC TOBP C730600 57B 1000-Series Option SI-EM3 Installation Manual

Page 37

7 Modbus TCP/IP Messaging

Address

(hex)

2009 C0 Error Signal 1

200A C1 Error Signal 2

Drive

Register

(hex)

Description Bit Description

0 Reserved

1 Undervoltage (Uv1)

2 Control Power Supply Undervoltage (Uv2)

3 Soft Charge Circuit Fault (Uv3)

4 Reserved

5 Ground Fault (GF)

6 Overcurrent (oC)

7 Overvoltage (ov)

8 Heatsink Overheat (oH)

9 Heatsink Overheat (oH1)

A Motor Overload (oL1)

B Drive Overload (oL2)

C Overtorque Detection 1 (oL3)

D Overtorque Detection 2 (oL4)

E Dynamic Braking Transistor Fault (rr)

F Braking Resister Overheat (rH)

0 External Fault at input terminal S3 (EF3)

1 External Fault at input terminal S4 (EF4)

2 External Fault at input terminal S5 (EF5)

3 External Fault at input terminal S6 (EF6)

4 External Fault at input terminal S7 (EF7)

5 External Fault at input terminal S8 (EF8)

6 Cooling fan Error (FAn)

7 Overspeed (os)

8 Excessive Speed Deviation (dEv)

9 PG Disconnected (PGo)

A Input Phase Loss (PF)

B Output Phase Loss (LF)

C Motor Overheat (PTC input) (oH3)

D Digital Operator Connection Fault (oPr)

E EEPROM Write Error (Err)

F Motor Overheat Fault (PTC input) (oH4)

YASKAWA ELECT RIC TOBP C730600 57B 1000-Series Option SI-EM3 Installation Manual 37

Page 38

7 Modbus TCP/IP Messaging

Address

(hex)

200B C2 Error Signal 3

200C 4E Terminal A1 Input Level Monitor (U1-13)

200D 49 Digital Input Terminal Status (U1-10)

200E 50 Terminal A3 Input Level Monitor (U1-15)

200F F1 PG Count Channel 2

2010 4D Drive Software Number (Flash) (U1-25)

Drive

Register

(hex)

Description Bit Description

0 MEMOBUS/Modbus Communication Error (CE)

1 Option Communication Error (bUS)

2 Reserved

3 Reserved

4 Control Fault (CF)

5 Zero Servo Fault (SvE)

6 Option External Fault (EF0)

7 PID Feedback Loss (FbL)

8 Undertorque Detection 1 (UL3)

9 UL4 Undertorque Detection 2 (UL4)

A High Slip Braking Overload (oL7)

B Reserved

C Reserved

D Reserved

E Reserved

F Hardware Fault (includes oF)

38 YASKAWA ELECTRIC TOBP C730600 57B 1000-Series Option SI-EM3 Installation Manual

Page 39

7 Modbus TCP/IP Messaging

◆ Enter Command Types

The drive supports two types of Enter Commands as shown in the table below. An Enter

Command is enabled by writing 0 to register number 0900H or 0910H.

■ Enter Commands

Table 9 Enter Command Types

Register Number Description

0900H

0910H Writes data in the RAM only. Parameter changes are lost when the drive is shut off.

Note: Because the EEPROM can be written to a maximum of 100,000 times, refrain from frequently

writing to the EEPROM. An Enter Command is not required if reference or broadcast data are

sent to the drive.

Writes data into the EEPROM (non-volatile memory) of the drive and enables the data to

RAM at the same time. Parameter changes remain even if the power supply is cycled.

◆ Enter Command Settings

When replacing earlier Yaskawa drive models with a 1000 Series drive and keeping the

MEMOBUS/Modbus communications settings, parameter H5-11 needs to be set in

accordance with how the Enter Command functions in the older drive. H5-11 determines if

an Enter Command is needed or not in order to activate parameter changes in the drive.

• If upgrading from a G7 or F7 series drive to 1000 Series, set parameter H5-11 to 0.

• If upgrading from a V7 series drive to 1000 Series, set parameter H5-11 to 1.

■ H5-11 and the Enter Commands

Table 10 Enter Command Types

H5-11 Settings H5-11 = 0 H5-11 = 1

Drive being replaced. G7, F7 V7

How parameter settings

are enabled.

Upper/lower limit

check.

Default value of related

parameters.

Error handling when

setting multiple

parameters.

YASKAWA ELECT RIC TOBP C730600 57B 1000-Series Option SI-EM3 Installation Manual 39

When the Enter Command is received from

the master.

Upper/lower limit check is performed

taking the settings of related parameters into

account.

Not affected. The settings of related

parameters remain unchanged. Parameters

must be changed manually if needed.

Data is accepted even if one setting is

invalid. The invalid setting will be

discarded. No error message occurs.

As soon as the value is changed.

The upper/lower limit of the changed

parameter is checked only.

The default settings of related parameters

are changed automatically.

Error occurs if only one setting is invalid.

All data sent is discarded.

Page 40

8 Web Interface

8 Web Interface

The web server interface to the drive option allows management of diagnostic information

through a standard web browser. The embedded web pages include:

• Main page (Information)

• Drive Status page (Status, Monitor and Fault History)

• Network Monitor page (Network Monitor)

◆ Main Page (Information)

The embedded main page shows basic option information such as IP address, MAC address,

and firmware version. This page also shows the status of the option and provides links to the

other embedded web pages.

Figure 15

Figure 17 Main Page View

40 YASKAWA ELECTRIC TOBP C730600 57B 1000-Series Option SI-EM3 Installation Manual

Page 41

8 Web Interface

◆ Drive Status Page (Status, Monitor and Fault History)

The embedded drive status page shows basic I/O information and drive state information.

Figure 16

Figure 18 Drive Status Page View

YASKAWA ELECT RIC TOBP C730600 57B 1000-Series Option SI-EM3 Installation Manual 41

Page 42

8 Web Interface

◆ Network Monitor Page (Network Monitor)

The embedded network monitor page shows the status of the option network traffic and open

I/O connections.

Figure 17

Figure 19 Network Monitor Page View

Table 11 Network Monitor Explanations

Network Monitor Explanation

Msg Tx OK Cumulative number of messages transmit successfully from the option.

Msg Rx OK Cumulative number of messages received successfully to the option.

Current Connections Current number of open connections.

Control Connection

Delta Time

Msg Tx Dropped

Msg Rx Dropped

Collisions

Msg Tx Errors Cumulative number of transmit underruns and transmit stops reported by the MAC/PHY.

Msg Rx Errors

Tx Retry

The time between the last two writes to the Control register, MEMOBUS/Modbus address

0001H.

Cumulative number of messages dropped due to output network buffer being full and

unable to hold the new message.

Cumulative number of messages dropped due to input network buffer being full and

unable to hold the new message.

Cumulative number of collisions (half duplex only) reported by the MAC/PHY (Media

Access Control/Physical Connection).

Cumulative number of receive overruns, receive stops, and receive error frames reported

by the MAC/PHY.

Cumulative number of transmits in which the 1st attempt was delayed due to busy

medium reported by the MAC/PHY.

Note: Cumulative counters are reset when the power supply is cycled.

42 YASKAWA ELECTRIC TOBP C730600 57B 1000-Series Option SI-EM3 Installation Manual

Page 43

9 Troubleshooting

9 Troubleshooting

◆ Drive-Side Error Codes

Drive-side error codes appear on the drive digital operator. Causes of the errors and

corrective actions are listed in Table 12. For additional error codes that may appear on the

drive digital operator, refer to the drive Technical Manual.

■ Faults

Both bUS (Option communication error) and EF0 (External fault input from the option) can

appear as an alarm or as a fault. When a fault occurs, the digital operator ALM LED remains

lit. When an alarm occurs, the ALM LED flashes.

If communication stops while the drive is running, use the following questions as a guide to

help remedy the fault:

• Is the option properly installed?

• Is the communication line properly connected to the option? Is it loose?

• Is the controller program working? Has the controller/PLC CPU stopped?

• Did a momentary power loss interrupt communications?

Table 12 Fault Displays, Causes, and Possible Solutions

LED Operator Display Fault Name

Option Communication Error.

• After establishing initial communication, the connection was lost

bUS

• Only detected when the run command or frequency reference is assigned to the option

(b1-01 = 3 or b1-02 = 3)

Cause Possible Solution

Master controller (PLC)

has stopped

communicating

Communication cable is

not connected properly

A data error occurred due

to noise

Option is damaged

Control Connection

Timeout

• Check that power is supplied to the PLC

• Check that PLC is not in program mode

• Check for faulty wiring

• Correct any wiring problems

• Check the various options available to minimize the effects of noise

• Counteract noise in the control circuit, main circuit, and ground wiring

• If a magnetic contactor is identified as a source of noise, install a surge absorber to the

contactor coil

• Make sure the cable used meets the Modbus TCP/IP requirements

• Make sure the option ground wire is connected between option FE terminal and the

drive ground terminal connected to earth ground

If there are no problems with the wiring and the error continues to occur, replace the

option.

The control connection timer value set in F7-16 has timed out.

YASKAWA ELECT RIC TOBP C730600 57B 1000-Series Option SI-EM3 Installation Manual 43

Page 44

9 Troubleshooting

Duplicate IP Address

LED Operator Display Fault Name

Cause Corrective Action

An external fault is being

sent from the upper

controller (PLC)

Problem with the PLC

program

PLC is in the Idle Mode.

LED Operator Display Fault Name

oFA00

Cause Possible Solution

Non-compatible option

connected to the drive

LED Operator Display Fault Name

oFA01

Cause Possible Solution

Problem with the

connectors between the

drive and option

The option shares IP Address with at least one other node.

Check the setting value of F7-03 and F7-04.

Option Card External Fault

EF0

The alarm function for an external device has been triggered.

• Remove the cause of the external fault

• Reset the external fault input from the PLC device

Check the program used by the PLC and make the appropriate corrections.

• Set the PLC to the Run Mode.

• Set the drive parameter F6-54 to 0 (Enabled) not to detect errors while the PLC is in the

Idle Mode.

Option Card Connection Error (CN5-A)

Option is not properly connected.

Connect an option that is compatible with the drive.

Option Card Fault (CN5-A)

Option is not properly connected.

Turn the power off and check the connectors between the drive and option.

LED Operator Display Fault Name

oFA03

Cause Possible Solution

Option hardware fault Replace the option.

44 YASKAWA ELECTRIC TOBP C730600 57B 1000-Series Option SI-EM3 Installation Manual

Option Card Error (CN5-A)

Option self-diagnostics error.

Page 45

LED Operator Display Fault Name

oFA04

Cause Possible Solution

Option hardware fault Replace the option.

LED Operator Display Fault Name

oFA30 to

to

Option hardware fault Replace the option.

LED Operator Display Fault Name

Non-compatible option

connected to the drive.

LED Operator Display Fault Name

Options AI-A3 or DI-A3

were connected to the

CN5-B port while an

option was already

connected to CN5-A.

oFA43

Cause Possible Solution

oFb00

Cause Possible Solution

oFb02

Cause Possible Solution

Option Card Error (CN5-A)

Option flash write mode.

Option Card Connection Error (CN5-A)

Communication ID error.

Option Card Connection Error (CN5-B)

Non-compatible option is connected.

Connect the correct option to CN5-A.

Option Card Fault (CN5-B)

Two of the same options are connected at the same time.

• Only one type of AI-A3, DI-A3 or SI- option can be connected to the drive.

• The SI-EM3 option can only be connected to CN5-A.

9 Troubleshooting

YASKAWA ELECT RIC TOBP C730600 57B 1000-Series Option SI-EM3 Installation Manual 45

Page 46

9 Troubleshooting

LED Operator Display Fault Name

oFC00

Cause Possible Solution

Non-compatible option

connected to the drive.

LED Operator Display Fault Name

oFC02

Cause Possible Solution

Options AI-A3 or DI-A3

are connected to the

CN5-B port with an

option connected to CN5A.

■ Minor Faults and Alarms

LED Operator Display Minor Fault Name

CALL

Cause Possible Solution

Communication wiring is

faulty, there is a short

circuit, or improper

connection

Programming error on the

master side

Communication circuitry

is damaged.

Option Card Connection Error (CN5-C)

Non-compatible option is connected.

Connect the correct option to CN5-A.

Option Card Fault (CN5-C)

Option flash write mode.

• Only one type of AI-A3, DI-A3 or SI- option can be connected to the drive.

• The SI-EM3 option can only be connected to CN5-A

Serial Communication Transmission Error

Communication is not established.

Check for wiring errors:

• Correct the wiring

• Remove ground shorts and reconnect loose wires

Check communications at start-up and correct programming errors.

• Perform a self-diagnostics check

• Replace the drive if the fault continues to occur

Minor Fault

(H2- = 10)

YES

46 YASKAWA ELECTRIC TOBP C730600 57B 1000-Series Option SI-EM3 Installation Manual

Page 47

9 Troubleshooting

■ Option Fault Monitors U6-98 and U6-99

The option can declare error/warning conditions via drive monitor parameters on the drive

digital operator as shown in Table 13.

Table 13 Option Fault Monitor Descriptions

Fault

Condition

No Fault n/a 0 No faults

Force Fault EF0 3 Network sent a message to force this node to the fault state

Network Link

Down

Connection

Time-out

Duplicate IP

Address

Default MAC

Address

Two drive monitor parameters, U6-98 and U6-99, assist the user in network troubleshooting.

• U6-98 displays the first declared fault since the last power cycle. U6-98 is only cleared

upon drive power-up.

• U6-99 displays the present option status. U6-99 is cleared upon a network-issued fault

reset and upon power-up.

If another fault occurs while the original fault is still active, parameter U6-98 retains the

original fault value and U6-99 stores the new fault status value.

Fault

Declared

BUS ERROR 1200 No network link to the option

BUS ERROR 1201 The control connection timer (F7-16) timed out

BUS ERROR 1202 This node and at least one other node have the same IP address

None 1203

Status Value

(U6-98/U6-99)

Description

Factory default MAC Address programmed into the option.

Contact a Yaskawa representative or the nearest Yaskawa sales

office for details.

YASKAWA ELECT RIC TOBP C730600 57B 1000-Series Option SI-EM3 Installation Manual 47

Page 48

9 Troubleshooting

◆ Option Compatibility with A1000

A limited number of options may be simultaneously connected to the A1000 depending on

the type of option. Refer to Table 14 for more information. More details can be found in the

Options and Peripheral Devices chapter of the drive Technical Manual.

Table 14 Option Installation Compatibility

Option

SI-C3, SI-EM3, SI-EN3, SI-N3, SI-P3, SI-S3, SI-W3, etc. CN5-A 1

PG-B3, PG-X3, etc. CN5-B, C 2

AI-A3 <1>, AO-A3, DI-A3 <1>, DO-A3, etc. CN5-A, B, C 1

<1> When installed in CN5-A, the AI-A3 and DI-A3 options can be used to set the frequency reference or replace the

drive analog inputs with higher resolution. When installed in CN5-B or CN5-C, these options can only be used for

monitoring; their input levels will be displayed in U1-17 or U1-21 to U1-23.

<2> Use the CN5-C connector when connecting only one option to the drive; use both CN5-B and CN5-C when

connecting two options.

Connector Number of Possible Options

<2>

48 YASKAWA ELECTRIC TOBP C730600 57B 1000-Series Option SI-EM3 Installation Manual

Page 49

10 Specifications

10 Specifications

◆ Specifications

Table 15 Option Specifications

Item Specification

Model SI-EM3

• Read Multiple Registers (03H)

• Write Single Register (06H)

Supported Messages

Option Conformance Modbus-IDA Passed

Connector Type RJ45 8-pin Shielded Twisted Pair Cat 5e cable

Physical Layer Type Isolated Physical Layer

IP Address Setting Programmable from drive keypad or network

Communication Speed

Number of Connections

Duplex Mode Half-forced, Auto-negotiate, Full-forced

Address Startup Mode Static, BOOTP, DHCP

Ambient Temperature -10 °C to +50 °C (14 ° F to 122 °F)

Humidity 95% RH or lower with no condensation

Storage Temperature -20 °C to +60 °C (-4 °F to 140 °F) allowed for short-term transport of the product

Area of Use Indoor (free of corrosive gas, airborne particles, etc.)

Altitude 1000 m (3280 ft.) or lower

• Write Multiple Registers (10H)

• Read and Write Registers (17H)

Commands that support multiple registers have a maximum Read and Write size of 16

registers.

Programmable from drive keypad or network:

10/100 Mbps, auto-negotiate.

Modbus TCP/IP: 10

Web Page Access: 2

YASKAWA ELECT RIC TOBP C730600 57B 1000-Series Option SI-EM3 Installation Manual 49

Page 50

10 Specifications

MANUAL NO. TOBP C730600 57B

Published in Japan November 2012 12-3

Date of publication

Date of original publication

Revision number

1

A1000

1

◆ Revision History

Revision dates and manual numbers appear on the bottom of the back cover.

Date of

Publication

November 2012 All Revision: Reviewed and corrected entire documentation.

March 2012 −−First edition

50 YASKAWA ELECTRIC TOBP C730600 57B 1000-Series Option SI-EM3 Installation Manual

Revision

Number

Chapter 2, 3, and 5 Addition: Z1000 drive added along with corresponding data.

Section Revised Content

Page 51

YASKAWA AC Drive 1000-Series Option

Modbus TCP/IP

Installation Manual

DRIVE CENTER (INVERTER PLANT)

2-13-1, Nishimiyaichi, Yukuhashi, Fukuoka, 824-8511, Japan

Phone: 81-930-25-3844 Fax: 81-930-25-4369

http://www.yaskawa.co.jp

YASKAWA ELECTRIC CORPORATION

New Pier Takeshiba South Tower, 1-16-1, Kaigan, Minatoku, Tokyo, 105-6891, Japan

Phone: 81-3-5402-4502 Fax: 81-3-5402-4580

http://www.yaskawa.co.jp

YASKAWA AMERICA, INC.

2121 Norman Drive South, Waukegan, IL 60085, U.S.A.

Phone: (800) YASKAWA (927-5292) or 1-847-887-7000 Fax: 1-847-887-7310

http://www.yaskawa.com

YASKAWA ELÉTRICO DO BRASIL LTDA.

Avenda Fagundes Filho, 620 Bairro Saude, São Paulo, SP04304-000, Brazil

Phone: 55-11-3585-1100

http://www.yaskawa.com.br

YASKAWA EUROPE GmbH

Hauptstrasse 185, 65760 Eschborn, Germany

Phone: 49-6196-569-300 Fax: 49-6196-569-398

http://www.yaskawa.eu.com

YASKAWA ELECTRIC UK LTD.

1 Hunt Hill Orchardton Woods, Cumbernauld, G68 9LF, United Kingdom

Phone: 44-1236-735000

http://www.yaskawa.co.uk

YASKAWA ELECTRIC KOREA CORPORATION

9F, Kyobo Securities Bldg., 26-4, Yeouido-dong, Yeongdeungpo-gu, Seoul, 150-737, Korea

Phone: 82-2-784-7844

http://www.yaskawa.co.kr

YASKAWA ELECTRIC (SINGAPORE) PTE. LTD.

151 Lorong Chuan, #04-01, New Tech Park, 556741, Singapore

Phone: 65-6282-3003

http://www.yaskawa.com.sg

YASKAWA ELECTRIC (CHINA) CO., LTD.

12F, Carlton Bld., No.21 HuangHe Road, HuangPu Distr ict, Shanghai 200003, China

Phone: 86-21-5385-2200

http://www.yaskawa.com.cn

YASKAWA ELECTRIC (CHINA) CO., LTD. BEIJING OFFICE

Room 1011, Tower W3 Oriental Plaza, No. 1 East Chang An Ave.,

Dong Cheng District, Beijing, 100738, China

Phone: 86-10-8518-4086

YASKAWA ELECTRIC TAIWAN CORPORATION

9F, 16, Nanking E. Rd., Sec. 3, Taipei, 104, Taiwan

Phone: 886-2-2502-5003

YASKAWA ELECTRIC INDIA PRIVATE LIMITED

#17/A Electronics City, Hosur Road Bangalore 560 100 (Karnataka), India

Phone: 91-80-4244-1900

http://www.yaskawaindia.in

Fax: 55-11-5581-8795

Fax: 44-1236-458182

Fax: 82-2-784-8495

Fax: 65-6289-3003

Fax: 86-21-5385-3299

Fax: 86-10-8518-4082

Fax: 886-2-2505-1280

Fax: 91-80-4244-1901

YASKAWA ELECTRIC CORPORATION

In the event that the end user of this product is to be the military and said product is to be employed in any weapons systems or the manufacture

thereof, the export will fall under the relevant regulations as stipulated in the Foreign Exchange and Foreign Trade Regulations. Therefore, be sure

to follow all procedures and submit all relevant documentation according to any and all rules, regulations and laws that may apply.

Specifications are subject to change without notice for ongoing product modifications and improvements.

© 2012 YASKAWA ELECTRIC CORPORATION. All rights reserved.

MANUAL NO. TOBP C730600 57B

Published in Japan November 2012 12-3

12-7-9

1 -0

Loading...

Loading...