Yamaha MU-100 Service Manual

SERVICE MANUAL

TONE GENERATOR

CONTENTS

SPECIFICATIONS

···································································································

3

PANEL LAYOUT

·······································································································

4

CIRCUIT BOARD LAYOUT

···············································································

5

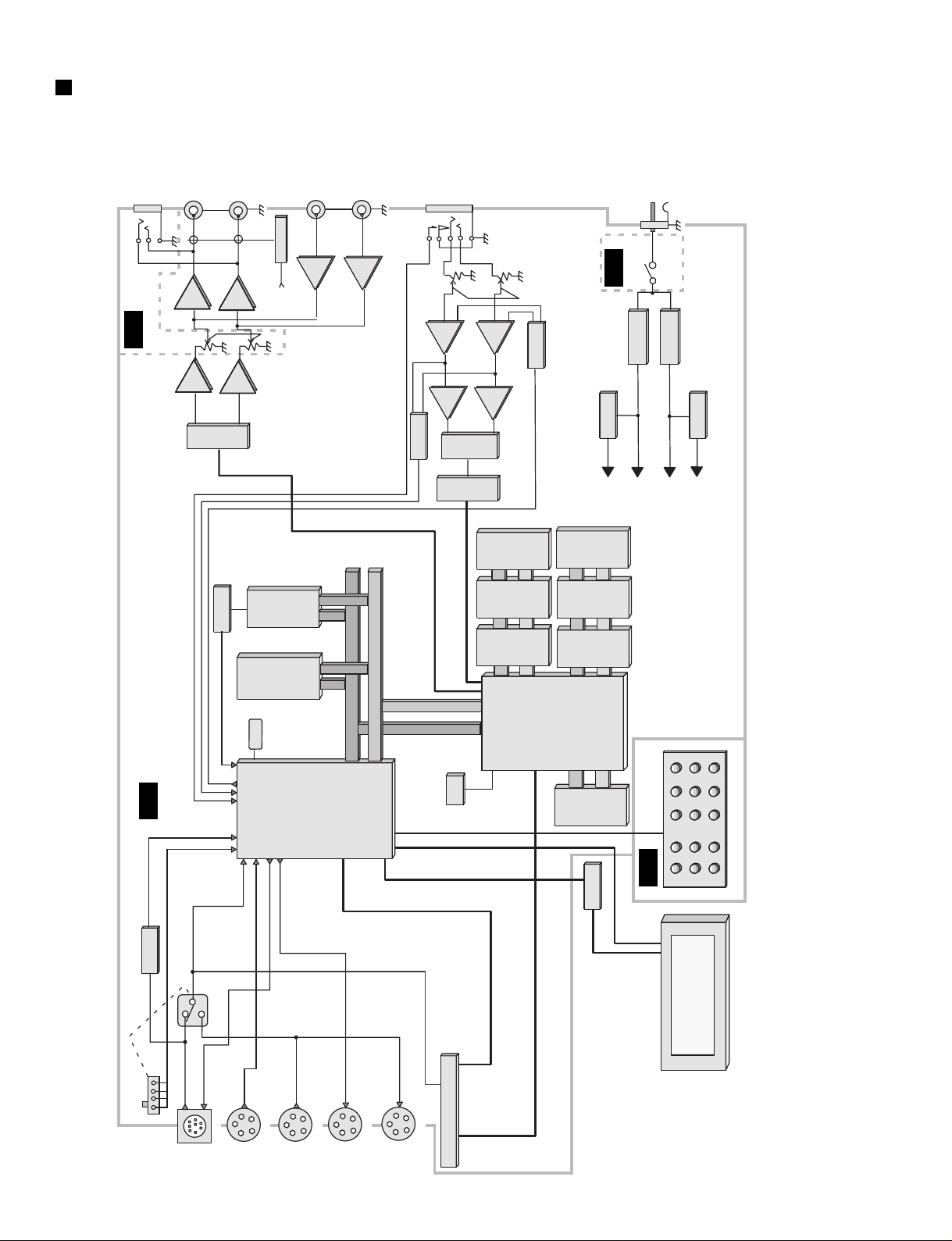

BLOCK DIAGRAM

···································································································

6

DISASSEMBLY PROCEDURE

·······································································

7

LSI PIN DESCRIPTION

····················································································

12

IC BLOCK DIAGRAM

·························································································

14

CIRCUIT BOARDS

·······························································································

16

TEST PROGRAM

··································································································

18

MIDI / COMPUTER CONNECTING CABLES

····································

23

ERROR MESSAGES

··························································································

24

INITIALIZE

·················································································································

25

MIDI IMPLEMENTATION CHART

······························································

26

OVERALL CIRCUIT DIAGRAM

···································································

27

PARTS LIST

SY

011450

PLG-100DX PLG-100VL PLG-100VH

HAMAMATSU, JAPAN

0.32K-3942 Printed in Japan '99.01

MU100

2

WARNING: CHEMICAL CONTENT NOTICE!

The solder used in the production of this product contains LEAD. In addition, other electrical/electronic and/or plastic (where

applicable) components may also contain traces of chemicals found by the California Health and Welfare Agency (and possibly

other entities) to cause cancer and/or birth defects or other reproductive harm.

DO NOT PLACE SOLDER, ELECTRICAL/ELECTRONIC OR PLASTIC COMPONENTS IN YOUR MOUTH FOR ANY REASON

WHAT SO EVER!

Avoid prolonged, unprotected contact between solder and your skin! When soldering, do not inhale solder fumes or expose eyes

to solder/flux vapor!

If you come in contact with solder or components located inside the enclosure of this product, wash your hands before handling

food.

LITHIUM BATTERY HANDLING

This product uses a lithium battery for memory back-up.

WARNING: Lithium batteries are dangerous because they can be exploded by improper handling. Observe the following

precautions when handling or replacing lithium batteries.

Leave lithium battery replacement to qualified service personnel.

Always replace with batteries of the same type.

When installing on the PC board by soldering, solder using the connection terminals provided on the battery cells.

Never solder directly to the cells. Perform the soldering as quickly as possible.

Never reverse the battery polarities when installing.

Do not short the batteries.

Do not attempt to recharge these batteries.

Do not disassemble the batteries.

Never heat batteries or throw them into fire.

ADVARSEL!

Lithiumbatteri-Eksplosionsfare ved fejlagtig håndtering. Udskiftning må kun ske med batteri af samme fabrikat og type. Levér det

brugte batteri tilbage til leverandøren.

VARNING

Explosionsfara vid felaktigt batteribyte.

Använd samma batterityp eller en ekvivalent typ som rekommenderas av apparattillverkaren.

Kassera använt batteri enligt fabrikantens instruktion.

VAROITUS

Paristo voi räjähtää, jos se on virheellisesti asennettu.

Vaihda paristo ainoastaan laitevalmistajan suosittelemaan tyyppiin.

Hävitä käytetty paristo valmistajan ohjeiden mukaisesti.

The following information complies with Dutch Official Gazette 1995. 45; ESSENTIALS OF ORDER ON THE COLLECTION OF

BATTERIES.

•Please refer to the diassembly procedure for the removal of Back-up Battery.

•Leest u voor het verwijderen van de backup batterij deze beschrijving.

IMPORTANT NOTICE

This manual has been provided for the use of authorized Yamaha Retailers and their service personnel. It has been assumed that

basic service procedures inherent to the industry, and more specifically Yamaha Products, are already known and understood by

the users, and have therefore not been restated.

WARNING: Failure to follow appropriate service and safety procedures when servicing this product may result in personal

injury, destruction of expensive components and failure of the product to perform as specified. For these

reasons, we advise all Yamaha product owners that all service required should be performed by an authorized

Yamaha Retailer or the appointed service representative.

IMPORTANT: This presentation or sale of this manual to any individual or firm does not constitute authorization, certification,

recognition of any applicable technical capabilities, or establish a principal-agent relationship of any form.

The data provided is belived to be accurate and applicable to the unit(s) indicated on the cover. The research engineering, and

service departments of Yamaha are continually striving to improve Yamaha products. Modifications are, therefore, inevitable and

changes in specification are subject to change without notice or obligation to retrofit. Should any discrepancy appear to exist,

please contact the distributor's Service Division.

WARNING: Static discharges can destroy expensive components. Discharge any static electricity you body may have

accumulated by grounding yourself to the ground buss in the unit (heavy gauge black wires connect to this

buss.)

IMPORTANT: Turn the unit OFF during disassembly and parts replacement. Recheck all work before you apply power to the

unit.

SPECIFICATIONS

MU100

3

Tone Generation Method

AWM2 (Advanced Wave Memory 2)

Maximum Simultaneous Polyphony

64-note

Sound Module Modes

XG, TG300B, C/M, and Performance

Multi-timbral Capacity

32-Part (on 32 MIDI channels; with element reserve priority for later notes and dynamic Voice allocation)

Internal Voice/Program Structure

Normal Programs

Total Voices···································· 1267

XG mode········································· 1074

TG300B mode ································ 614

C/M mode······································· 128 (Parts 1 — 9), 64 (Parts 11 — 16)

Drum Programs

Total Kits········································ 46

XG mode········································· 36

TG300B mode ································ 10

C/M mode······································· 1

Performance Programs

Up to four Voices plus all effect settings can be memorized to a Performance.

Preset Programs······························ 100

User Programs ································ 100

Effects

Six sections of multi-effects: Reverb (12 Types), Chorus (14 Types),

Variation (70 Types), Insertion 1, 2 (43 Types), Multi EQ (4 Types), and Part EQ (1 Type)

Display

Custom back-lit LCD

Controls

POWER/VOL control, A/D INPUT level control; Mode select buttons: PLAY, UTIL (UTILITY), MODE, EDIT, EFFECT, EQ; other buttons:

MUTE/SOLO, ENTER, EXIT, PART

,

SELECT , VALUE

Jacks and Terminals

Front panel: PHONES jack (Stereo Mini-pin), A/D INPUT (stereo 1/4” plug)

Rear panel: OUTPUT R,L (RCA-pin), INPUT R, L (RCA-pin); DC IN jack; TO HOST terminal; HOST SELECT switch; MIDI IN-A/B, MIDI OUT

and MIDI THRU terminals

Computer/MIDI Interface

Direct connection to host computer port (RS-232C, RS-422); MIDI terminals allow connection to MIDI sequencer or MIDI controller

Data Transfer (Baud) Rate

MIDI — 31,250 bps (bits per second)

Mac — 31,250 bps

PC-1 — 31,250 bps

PC-2 — 38,400 bps

Power Supply

Yamaha PA-5B AC Adaptor (included)

Dimensions (W X D X H)

220 X 210 X 44 mm (8-11/16" X 8-1/4" X 1-3/4")

Weight

1.3 kg (2 lbs., 14 oz.)

Included Accessories

Owner’s Manual, Yamaha PA-5B AC Adaptor,

XGtools Setup Guide, CD-ROM “XGtools”

Output Level

Refer to the TEST PROGRAM section of this manual on page,19 and 20.

MU100

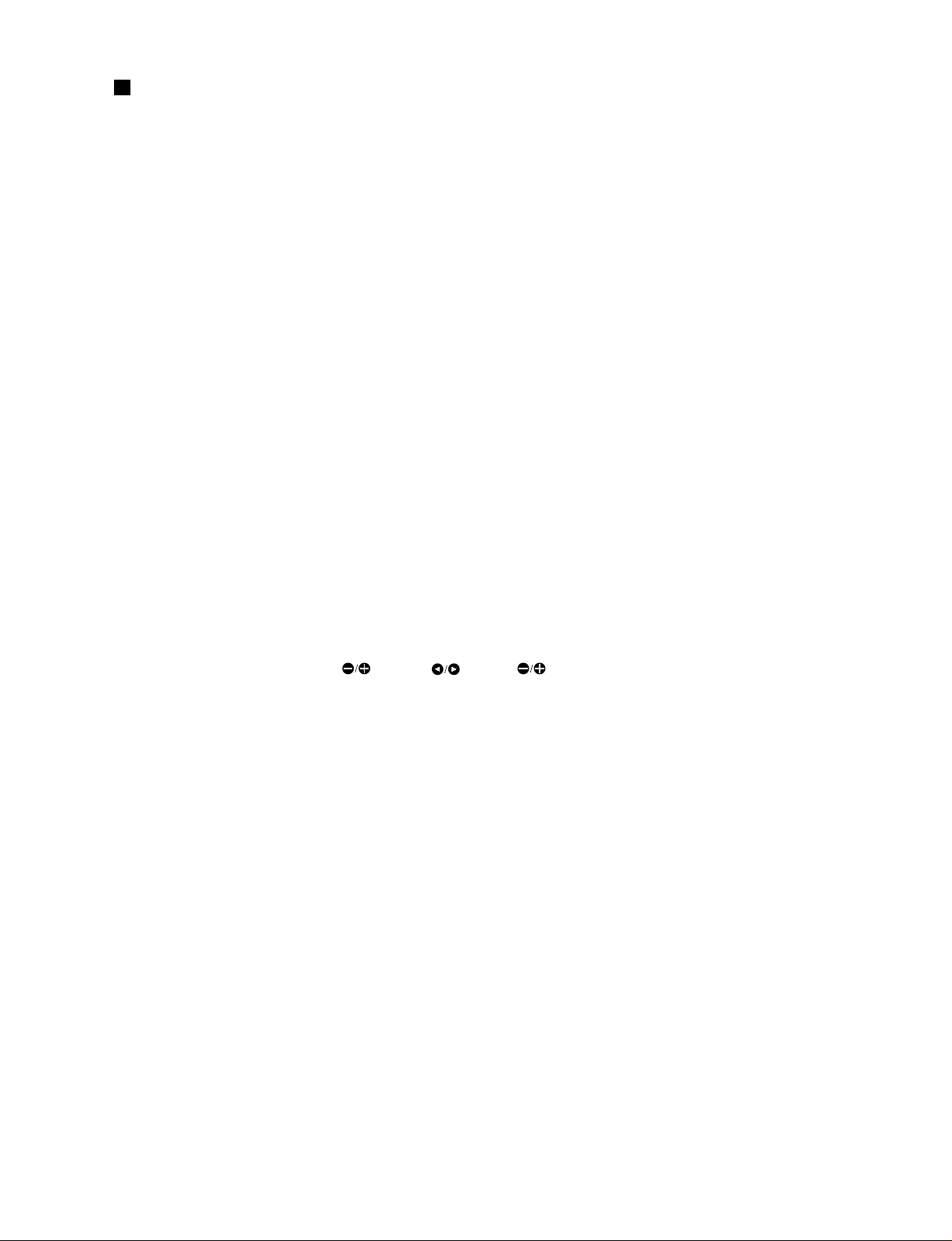

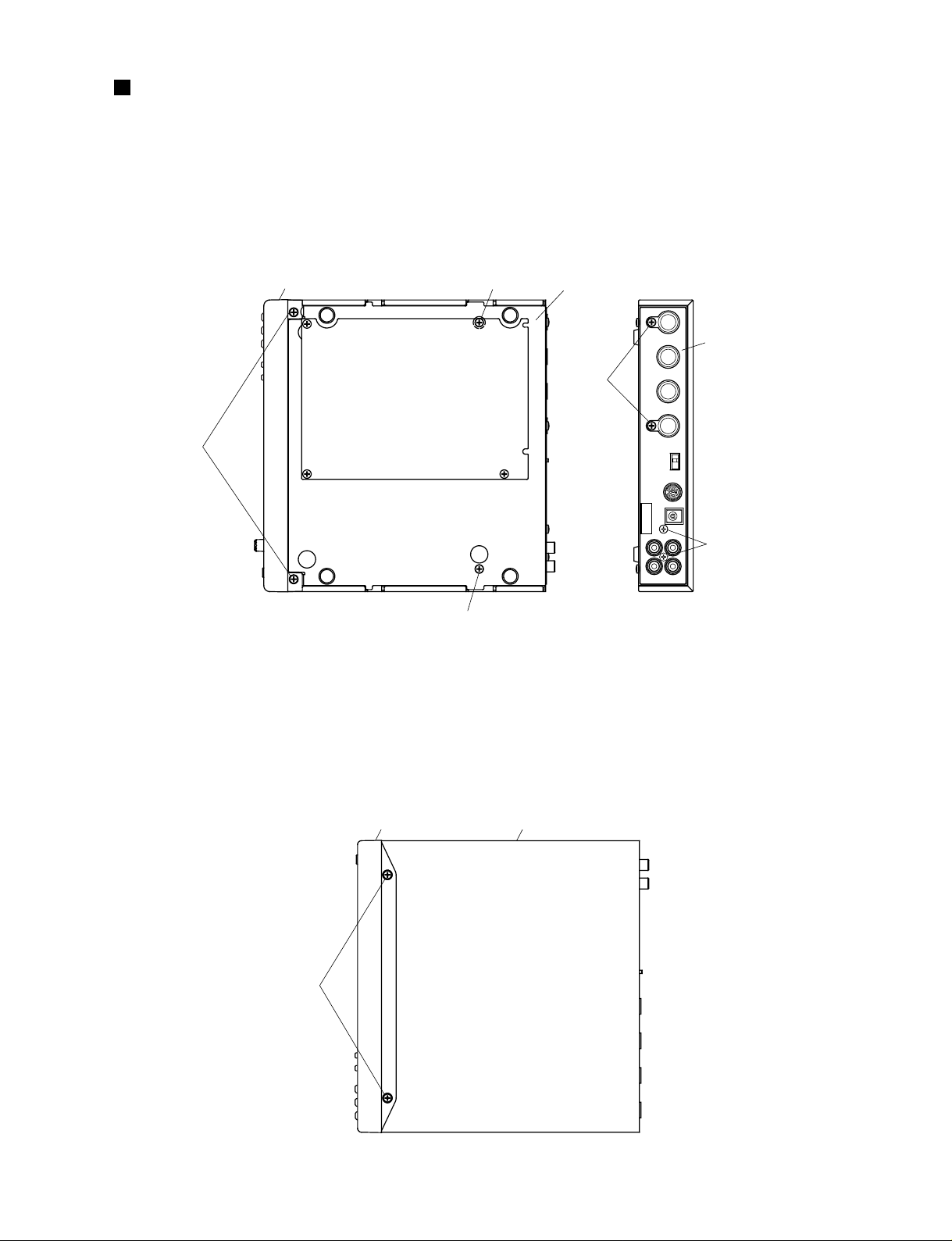

4

A/D INPUT

A/D INPUT level control

PHONES jack

POWER/VOL control

PLAY button

EDIT button

UTIL (UTILITY) button

MODE button

EQ button

MUTE / SOLO button

ENTER button

EXIT button

PART / buttons

SELECT / buttons

VALUE / buttons

EFFECT button

PANEL LAYOUT

Front Panel

MIDI THRU terminal

MIDI OUT terminal

MIDI IN-A terminal

MIDI IN-B terminal

HOST SELECT switch

TO HOST terminal

DC IN jack

OUTPUT L,R jacks (Left,Right)

INPUT L,R jacks (Left,Right)

MIDI

THRU

OUTOUT I N-AI N-A

I N-BI N-B

MIDIMIDI MacMac

PC-2PC-2 PC-1

HOST SELECT

TO HOSTTO HOST

DC INDC IN

SER NO.

R

L

OUTPUT INPUT

Rear Panel

MU100

5

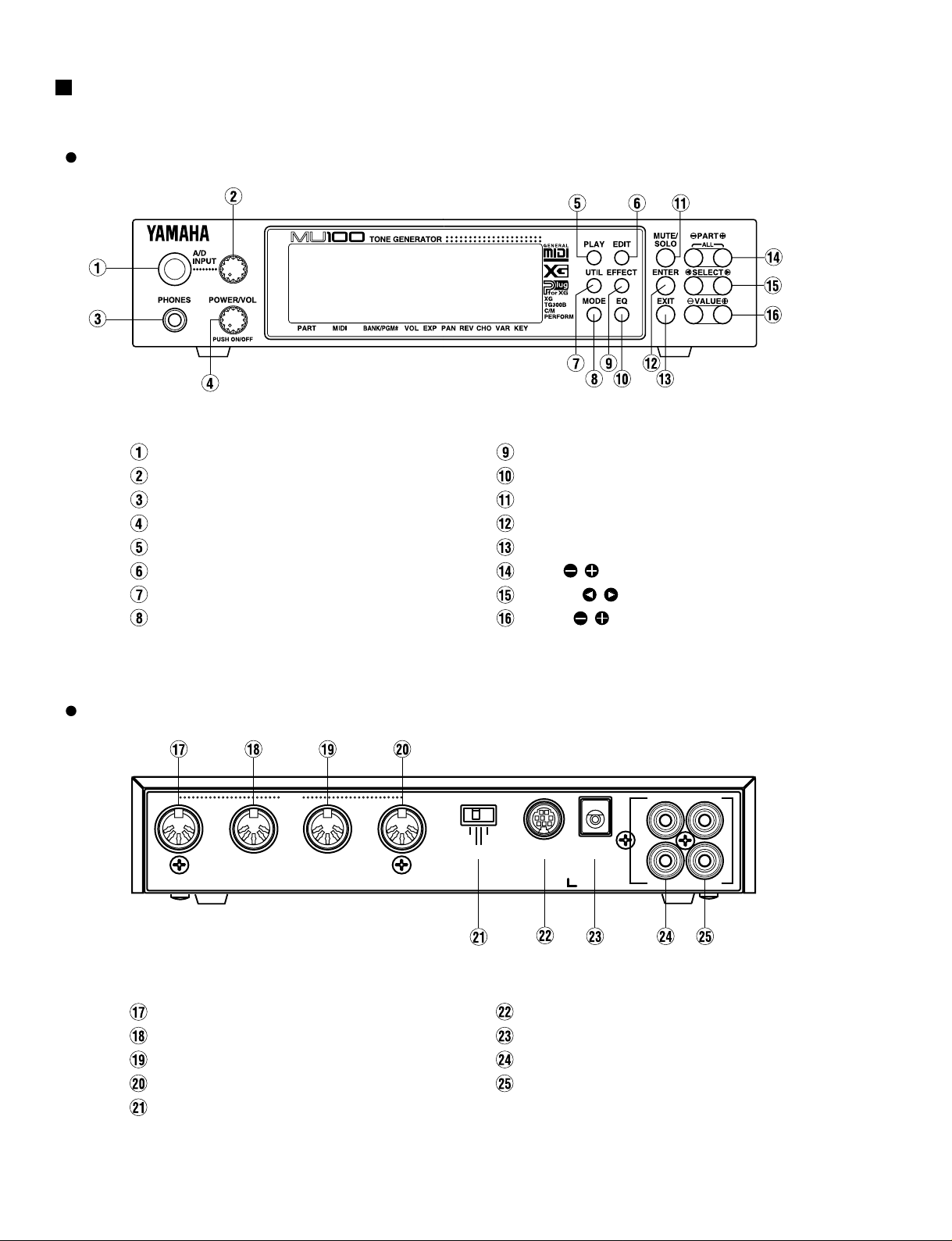

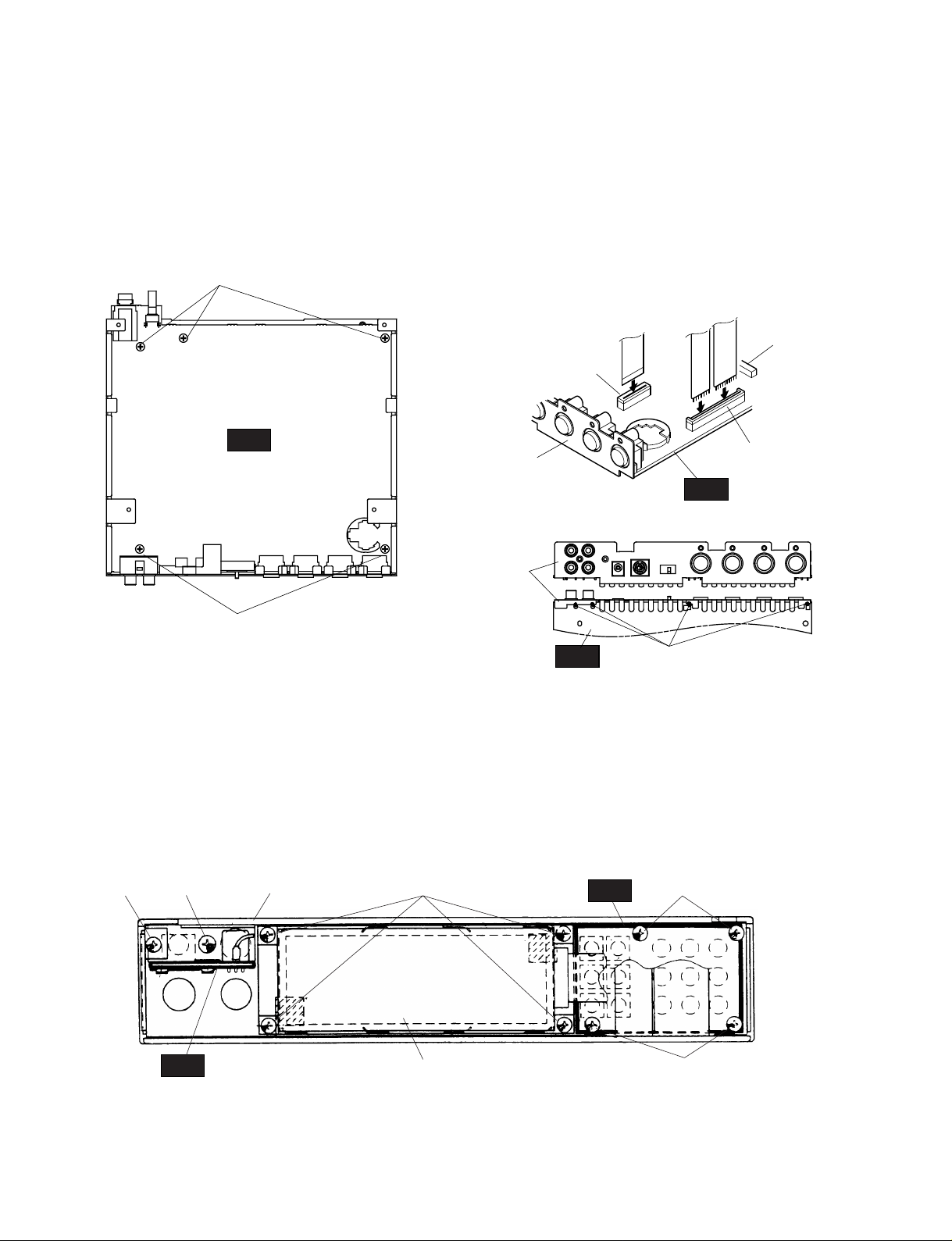

CIRCUIT BOARD LAYOUT

DM

PSWPVR

Front panel

LCD

CN10

CN 7

1

CN 14

1

CN6

CN13

CN5

CN9

1

1

1

1

VR cable

(10P)

PSW cable

(2P)

SW2 cable

(7P)

SW1 cable

(10P)

LCD cable

CN1

1

CONTRAST

ADDRESS BUS

DATA BUS

16M

PROGRAM

(16bit)

1M

SRAM

(8bit)

32M

MASK

ROM

(16bit)

32M

MASK

ROM

(16bit)

4M

DRAM

(16bit)

SWP30

MPU

H8S

16MHz

33.8688

MHz

A/D INPUT

OUTPUT-L

OUTPUT-R

HEAD PHONE

PEAK

DETECT

MUTING

LPF

AMP

LPF

AMP

AMP

AMP

AMP

D/A

A/D

ANALOG

FRONT

END

GAIN

SELECT

9V

REGULATOR5VREGULATOR

5V

REGULATOR

3.3V

REGULATOR

AC-ADAPTOR

PA-5B

POWER SWITCH

MIDI-INB

MIDI-INA

MIDI-OUT

MIDI-THRU

TO-HOST

HOST-SELECT

OFF LINE

CHECK

PLUGIN BOARD CABLE

+5VA

+9VA

+5V

+3.3V

+9VA

AMP

INPUT VOL

MASTER VOL

LPF

LPF

INPUT-L

INPUT-R

32M

MASK

ROM

(16bit)

32M

MASK

ROM

(16bit)

16M

MASK

ROM

(16bit)

16M

MASK

ROM

(16bit)

DM

PVR

IC2

IC16

IC17

IC18

IC35

IC34

IC39

IC38

IC37

IC20

3

3

31

21

1

IC10

28CA1-8811650

1

IC8

IC9

IC36

IC29

IC30

IC21

62

21

12

26

13

75

13275

6

67

11 6

IC11

IC12

110

62

109

105

107

30 33

63

IC12

64 111

616059

PVR

PSW

BATTERY

PANEL SW

LCD UNIT

BACK UP

MU100

BLOCK DIAGRAM

MU100

6

MU100

7

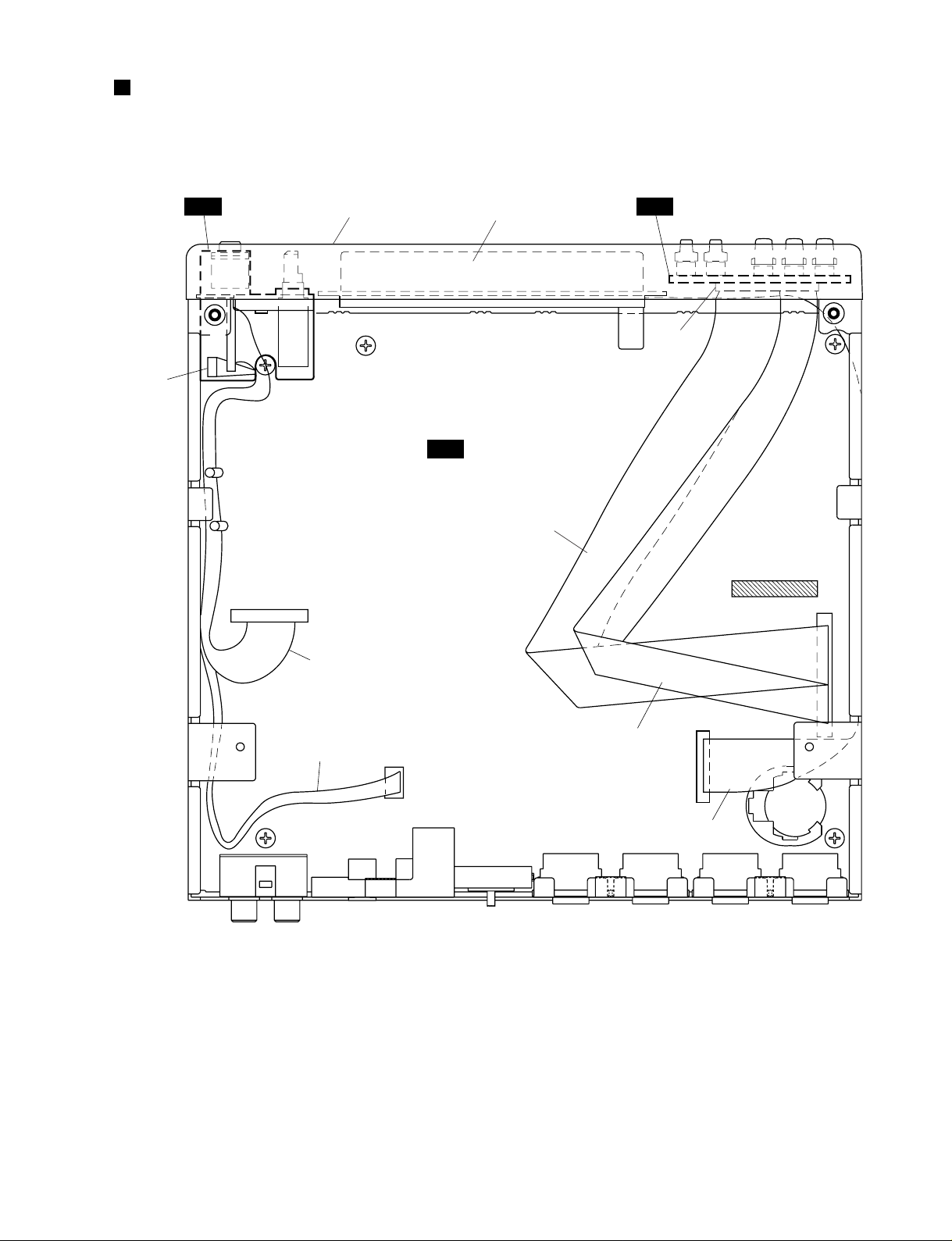

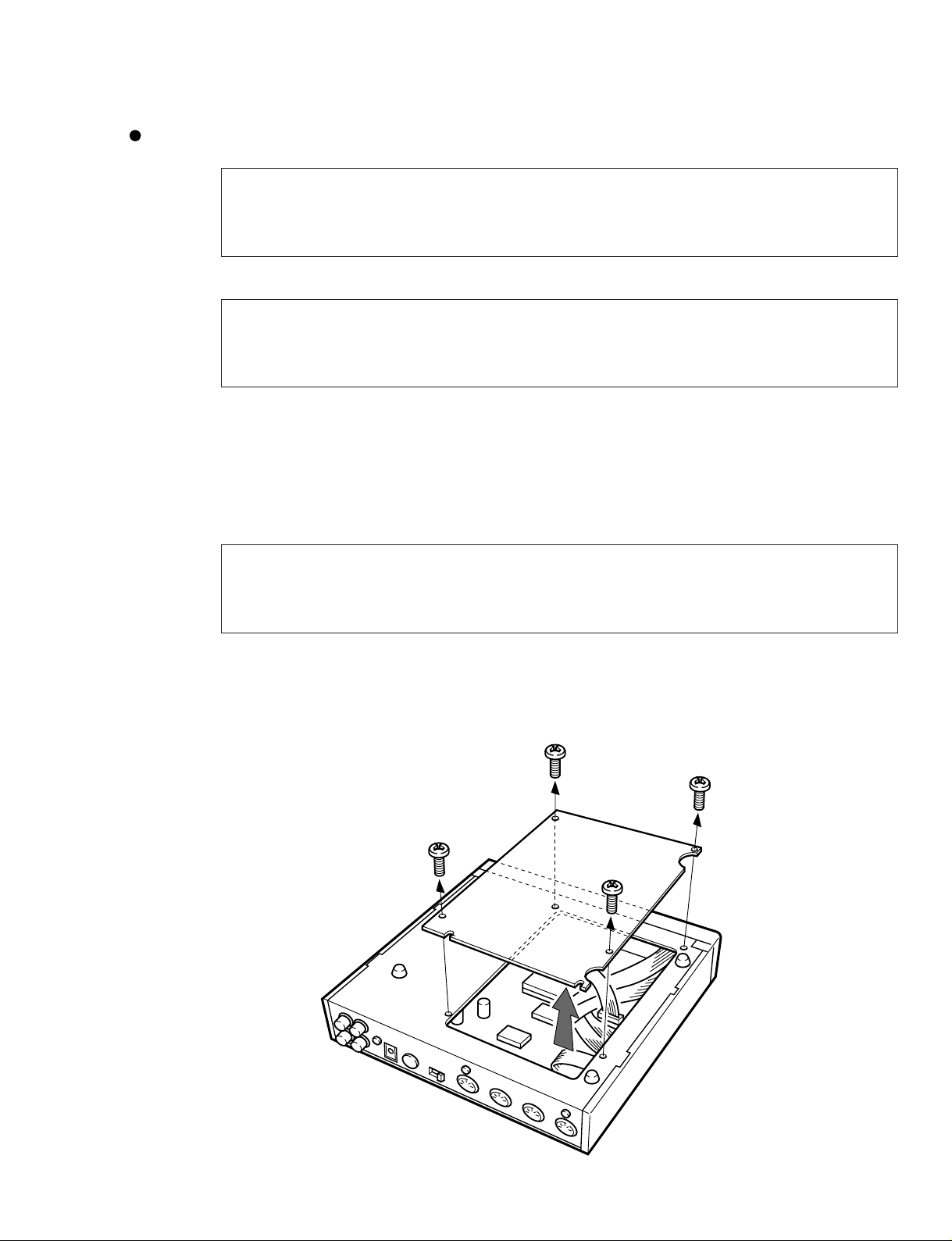

DISASSEMBLY PROCEDURE

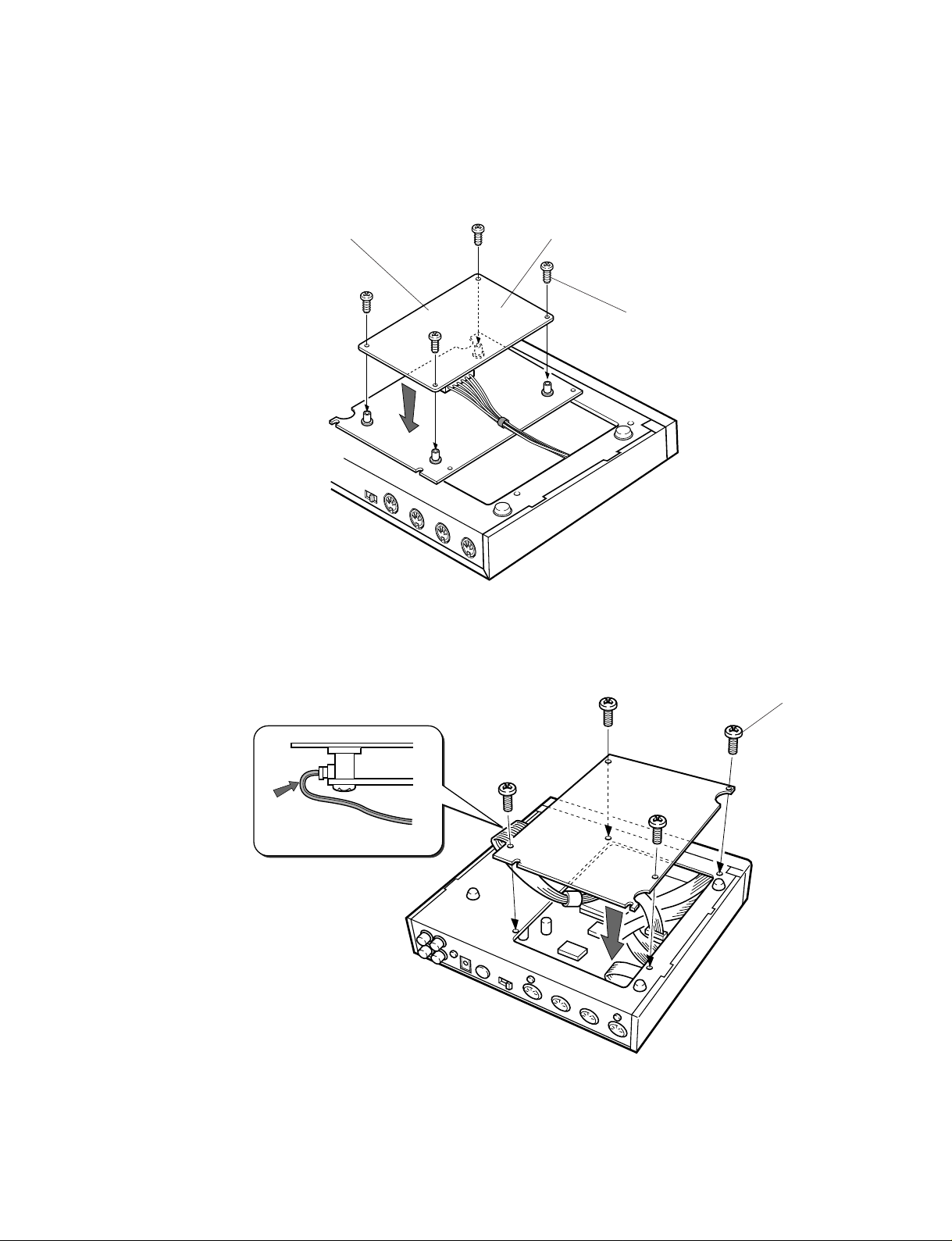

1-1 Remove the four (4) screws marked [60], the screw

marked [75], the screw marked [76] and the two (2)

screws marked [80]. The bottom assembly can then

be removed. (Fig. 1)

*

When you reattach the bottom assembly, you should

tighten the screws in the order described in figure 1.

1. Bottom Assembly

Front assembly

Rear panel

[80]

[76]

[60]

[75]

[60]

[60]: Bind Head Tapping Screw-B 3.0X8 MFZN2BL (EP600190)

[75]: Bind Head Screw 3.0X6 MFZN2BL (EG330360)

[76]: Bind Head Screw 3.0X6 MFNI33 (EG330370)

[80]: Flat Head Tapping Screw-C 3.0X8 MFZN2BL (VR060800)(Fig.1)

Bottom assembly

7

8

6

4

1

3

2

5

2-1 Remove the bottom assembly. (See Procedure 1.)

2-2 Remove the two (2) screws marked [30]. The top

assembly can then be removed from the front

assembly. (Fig. 2)

2. DM Circuit Board

Front assembly

[30]

[30]: Flat Head Tapping Screw-C 3.0X8 MFZN2BL (VR060800)(Fig.2)

Top assembly

MU100

8

3. PSW & PVR circuit boards and LCD

[

F40

][

F30

] [

F90

]

[

F90

]

PVR

PSW

Front panel

LCD

[

F60

]

21

43

2

43

12

[F30]: Bind Head Tapping Screw-B 3.0X10 MFZN2Y (EP600220)

[F40]: Bind Head Tapping Screw-B 2.6X10 MFZN2Y (VD791000)

[F60]: Bind Head Tapping Screw-B 2.6X10 MFZN2Y (VD791000)

[F90]: Bind Head Tapping Screw-B 2.6X6 MFZN2Y (VC069600)

(Fig.5)

2-3 Remove the five (5) screws marked [T30]. The DM

circuit board can then be removed. (Fig. 3)

Pull off the A/D INPUT knob from the DM circuit

board.

Melt and remove the solder of the four (4) points

marked [A]. The rear shield can then be remove from

the DM circuit board. (Fig. 4-1,4-2)

* When you reattach the DM circuit board, you should

tighten the screws in the order described in figure 3.

The cables plugged into the connector CN9 should

be inserted as shown in figure 4-1.

[

T30

]

[

T30

]

[A]

DM

DM

DM

SW2

(7P)

Rear shield

Rear shield

SW1

(10P)

CN9

CN5

1

1

17

16

1

3

4

52

CN1

[T30]: Bind Head Tapping Screw-B 3.0X6 MFZN2BL (EP600230)

(Fig.4-1)

(Fig.4-2)

(Fig.3)

3-1 Remove the bottom assembly. (See Procedure 1.)

3-2 Remove the top assembly. (See Procedure 2.)

3-3 Remove the four (4) screws marked [F90]. The PSW

circuit board can then be removed. (Fig. 5)

Pull off the OP buttons and the mode buttons from

the PSW Circuit board.

3-4 Remove the screw marked [F30] and the screw

marked [F40]. The PVR circuit board can then be

removed. (Fig. 5)

3-5 Remove the four (4) screws marked [F60]. The LCD

can then be removed. (Fig. 5)

* When you reattach the circuit boards, you should

tighten the screws in the order described in figure 5.

MU100

9

Installing a Plug-in Board into the MU100

Warning

Installation and removal of a plug-in board into/from the MU100 initializes some of the setup and multipart settings of the main unit. Be sure to save any of your important settings onto a personal computer or

MIDI Data Filer MDF3 before installing or removing a plug-in board.

CAUTION!

Be careful not to injure your hands or fingers while installing or removing the plug-in board.

Be careful not to injure yourself when handling the jagged surfaces or sharp areas of the plug-in board.

CAUTION!

Accidents can occur if the plug-in board is installed or removed while the AC adaptor is connected to a

power source. Be sure to unplug the AC adaptor of the MU100 before installing or removing the plug-in

board.

Instructions

1. Turn off the power of any devices that may be connected to the MU100 and remove the MU100’s AC adaptor from its

power source.

2. Turn the MU100 upside down.

Remove the DB cover by removing the four (4) silver screws that secure it to the MU100.

Holder

Insert the connector so

that the tabs on the right

and left sides lock.

Tab

Expansion connector

XG Plug-in Connector

XG Plug-in Board

MU100

10

3. Remove the four (4), black, XG Plug-in Board installation screws that are secured to the inside of the DB cover.

Unlatch and remove the holder that secures the connector. Extend the connector.

Keep the holder for use when the XG Plug-in Board is removed.

4. Remove the XG Plug-in Board from the anti-static bag.

5. Insert the expansion connector of the MU100 into the connector of the XG Plug-in Board.

Make sure to insert the connector so that it faces the proper direction and the right and left tabs of the expansion

connector lock into place (as shown in the illustration).

CAUTION!

Before handling the XG Plug-in Board, be sure to touch a grounded, metal surface in order to remove

any static electricity from your clothes or body. Do not touch any of the patterned surfaces of the board

or its connector.

MU100

11

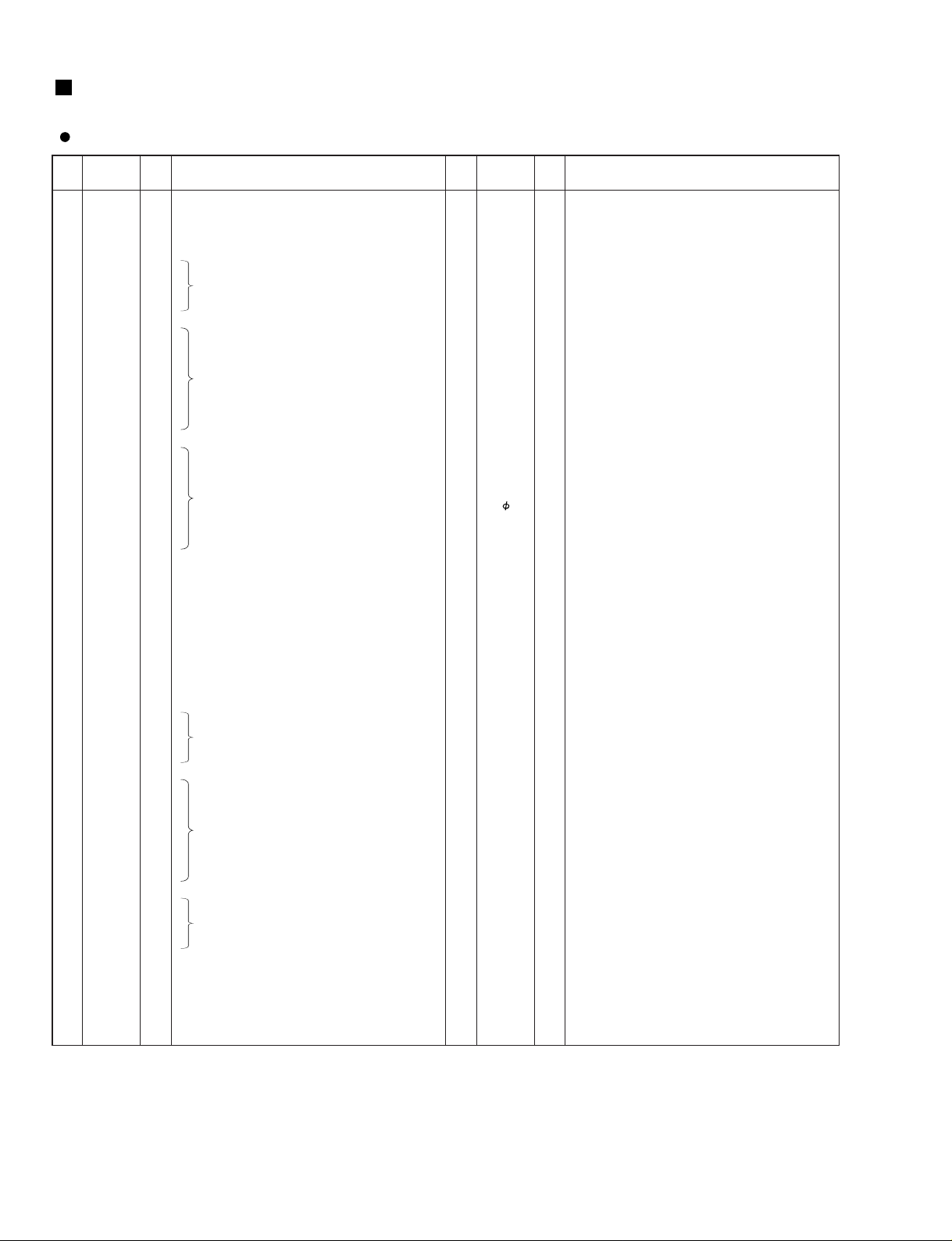

6. Attach the XG Plug-in Board to the DB cover using the four (4), black screws that were removed in Step 3.

Install the XG Plug-in Board so that the side with the IC chips is facing the DB cover.

Position the XG Plug-in Board from above, onto the DB cover, making sure to align the holes of the board with the

holes on the lid. If the holes are not properly aligned, you may damage the plug-in board.

Side without the connector

Screw (black)

XG Plug-in Board

7. Secure the DB cover back onto the MU100 by using the same four (4) silver screws that were removed in Step 2.

Secure the screws in the order shown in the illustration.

Arrange the cables of the

connector as shown, so

that they do not become

pinched or damaged.

Screw (silver)

1

2

3

4

LSI PIN DESCRIPTION

PIN

NO.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

51

52

53

54

55

56

57

58

59

60

61

62

63

64

I/O

O

O

-

-

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

I

O

O

I

O

-

O

O

-

I/O

I/O

I/O

I/O

-

I/O

I/O

I/O

I/O

I/O

I/O

I/O

I/O

-

I/O

I/O

I/O

I/O

O

O

I

I

O

O

CS1

CS0

Vss

Vss

Vcc

A0

A1

A2

A3

Vss

A4

A5

A6

A7

A8

A9

A10

A11

Vss

A12

A13

A14

A15

A16

A17

A18

A19

Vss

A20

PA5

PA6

PA7

P67

P66

Vss

Vss

P65

P64

Vcc

D0

D1

D2

D3

Vss

D4

D5

D6

D7

D8

D9

D10

D11

Vss

D12

D13

D14

D15

Vcc

TXD0

TXD1

RXD0

RXD1

P34

P35

NAME

Chip Select for System RAM (CS1)

Chip Select for System RAM (CS0)

GND

Power Supply

Address Bus

GND

Address Bus

GND

Address Bus

GND

Address Bus

Off Line Detection

Signal for Rotary encoder(REB)

Signal for Rotary encoder(REA)

Plug Detection of A/D Input

NC

GND

GND

Reset Signal for SWP30

Reset Signal for PB

Power Supply

Two Way Data Bus

GND

Two Way Data Bus

GND

Two Way Data Bus

Power Supply

Serial MIDI OUT (TXD0)

Serial Host OUT (TXD1)

Serial MIDI IN B (RXD0)

Serial MIDI IN A (RXD1) or Host IN

A/D Gain Control Signal(ADG1)

A/D Gain Control Signal(ADG2)

FUNCTION

MU100

12

HD6432655A00F (XT443A00) CPU

PIN

NO.

65

66

67

68

69

70

71

72

73

74

75

76

77

78

79

80

81

82

83

84

85

86

87

88

89

90

91

92

93

94

95

96

97

98

99

100

101

102

103

104

105

106

107

108

109

110

111

112

113

114

115

116

117

118

119

120

121

122

123

124

125

126

127

128

I/O

-

O

-

O

O

O

O

O

O

O

O

O

O

O

O

I

I

I

-

-

O

O

O

O

O

O

O

O

I

-

O

O

I

I

I

I

I

I

I

I

I

I

-

-

I/O

I/O

I/O

I/O

I/O

I/O

I/O

I/O

I

I

I

O

O

O

Vss

P60

Vss

Vss

P61

P62

P63

P27

P26

P25

P24

P23

P22

P21

P20

WDT0VF

RES

NMI

STBV

Vcc

XTAL

EXTAL

Vss

Vcc

AS

RD

HWR

LWR

PF2

PF1

PF0

TXD2

RXD2

Vss

Vss

SCK2

P53

AVcc

Vref

AN0

AN1

AN2

AN3

AN4

AN5

AN6

AN7

AVss

Vss

P17

P16

P15

P14

P13

P12

P11

P10

MD0

MD1

MD2

PG0

CS3

CS2

NAME

GND

NC

GND

GND

NC

PB Select (SW1)

PB Select (SW2)

NC

1 MHz Clock for Serial Interface

LCD Contrast (LCDC-C)

LCD Contrast (LCDC-B)

LCD Contrast (LCDC-A)

LCD Control (LCD-E)

LCD Control (LCD-R/W)

LCD Control (LCD-RS)

NC

Reset Signal

not used

not used

Power Supply

Quartz Cristal 16 MHz

Quartz Cristal 16 MHz

GND

NC

Power Supply

NC

Read Signal

Write Signal

NC

PB Select (SW4)

SW Data Read Control (SWD)

LED,SW Strobe Data Latch (SWS)

Serial Output for PB (TXD2)

Serial Input for PB (RXD2)

GND

GND

Serial Sync Clock for PB (MIDCLK)

Reset Signal for Rotary Encoder

Power Supply for A/D

Reference Voltage for A/D

Analog Level Input R

not used

Analog Level Output L

not used

Detection of Host SW Position

not used

Battery Voltage Check

ModelCheck (MU100:GND)

GND

GND

LCD Data(DB7),SW Data,LED6

LCD Data(DB6),SW Strobe Data

LCD Data(DB5),SW Strobe Data

LCD Data(DB4),SW Data,LED5

LCD Data(DB3),SW Data,LED4

LCD Data(DB2),SW Data,LED3

LCD Data(DB1),SW Data,LED2

LCD Data(DB0),SW Data,LED1

GND

GND

+5 D

PB Select (SW3)

NC

Chip Select for SWP30 (CS2)

FUNCTION

Loading...

Loading...