SERVICE MANUAL

EF3000iSE

7WL-28197-E0

310140

FOREWORD

HOW TO USE THIS MANUAL

This manual was written by the Yamaha Motor

Company primarily for use by Yamaha dealers

and their qualified mechanics. It is not possible

to put an entire mechanic’s education into one

manual, so it is assumed that persons using

this book to perform maintenance and repairs

on Yamaha generators have a basic understanding of the mechanical precepts and procedures inherent to generator repair

technology. Without such knowledge,

attempted repairs or service to this model may

render it unfit for use and/or unsafe.

Yamaha Motor Company Ltd. is continually

striving to further improve all models manufactured by Yamaha. Modifications and significant

changes in specifications or procedures will be

forwarded to all Authorized Yamaha dealers

and will, where applicable, appear in future

editions of this manual.

NOTE:

This Service Manual contains information

regarding periodic maintenance to the emission control system. Please read this material

carefully.

PARTICULARLY IMPORTANT

INFORMATION

This material is distinguished by the following

notation.

The Safety Alert Symbol means ATTENTION!

BECOME ALERT! YOUR SAFETY IS

INVOLVED!

WARNING

Failure to follow WARNING instructions could

result in severe injury or death to the machine

operator, a bystander, or a person inspecting

or repairing the machine.

CAUTION:

A CAUTION indicates special precautions that

must be taken to avoid damage to the

machine.

NOTE:

A NOTE provides key information to make procedures easier or clearer.

EF3000iSE

SERVICE MANUAL

©2002 by Yamaha Motor Co., Ltd.

1st Edition, October 2002

All rights reserved. Any reprinting or

unauthorized use without the written

permission of Yamaha Motor Co., Ltd.

is expressly prohibited.

Printed in Japan

MANUAL FORMAT

The procedures in this manual are organized

in a sequential, step-by-step format. The information has been compiled to provide the

mechanic with an easy to read, handy reference that contains comprehensive explanations of all disassembly, repair, assembly, and

inspection operations.

In this revised format, the condition of a faulty

component will precede an arrow symbol and

the course of action required will follow the

symbol, e.g.,

•Bearings

Pitting/damage → Replace.

EXPLODED DIAGRAM

Each chapter provides exploded diagrams

before each disassembly section for ease in

identifying the correct disassembly and

assembly procedures.

12

GEN

INFO

INSP

ADJ

34

ENG

ELEC

–+

5

SPEC

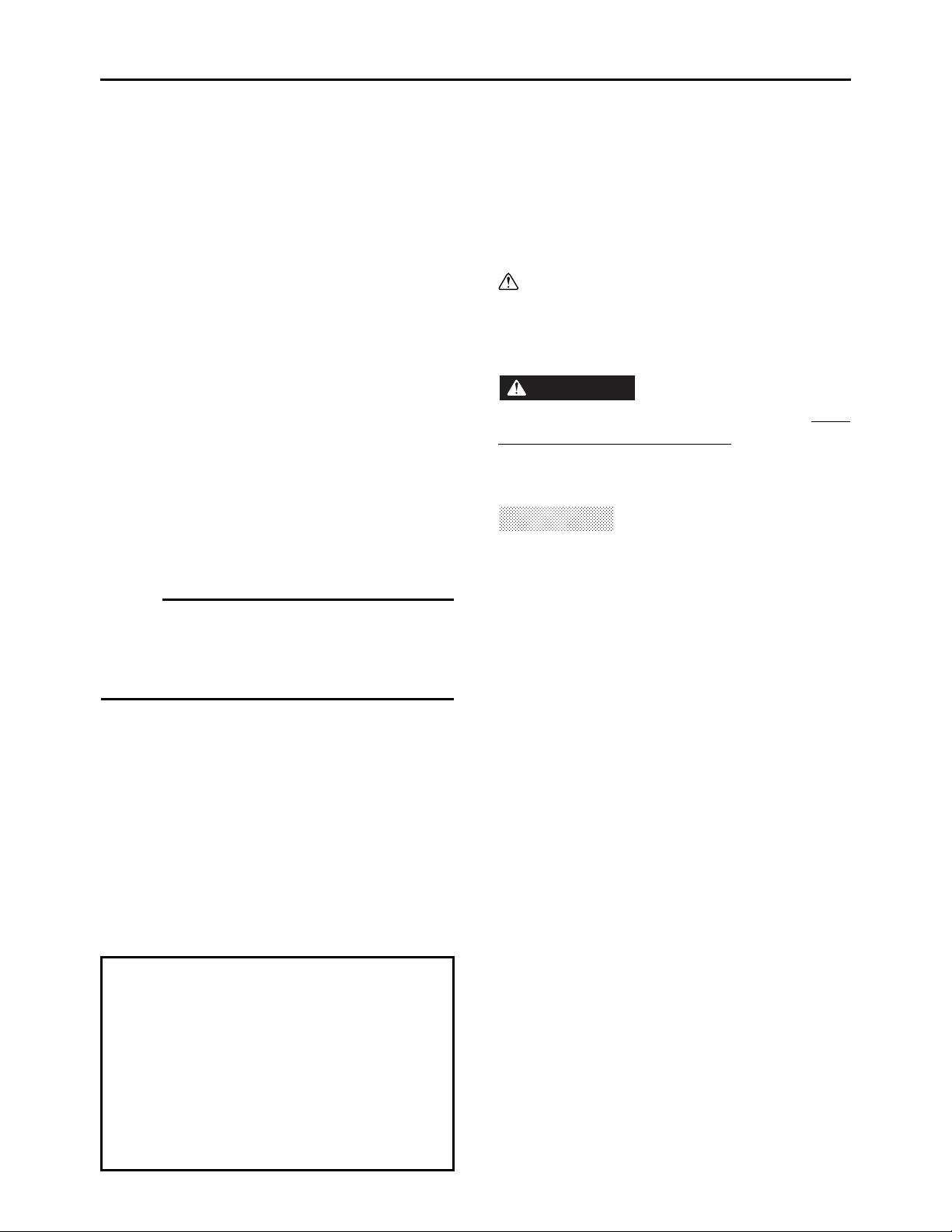

ILLUSTRATED SYMBOLS

(Refer to the illustration)

Illustrated symbols 1 through 5 are designed

as thumb tabs to indicate the chapter’s number

and content.

General information

1

Periodic inspections and adjustments

2

Engine

3

Electrical

4

Specifications

5

67

89

T

.

R

.

0A

B

CDE

E

G

M

FGH

B

LS

M

IJK

LT

4

New

Illustrated symbols 6 through B are used to

identify the specific tools and test equipment.

Filling fluid

6

Lubricant

7

Special tool

8

Tightening

9

Wear limit, clearance

0

Engine speed

A

, V, A

Ω

B

Illustrated symbols C through K in the

exploded diagram indicate the grades of lubricant and the locations of the lubrication points.

Apply engine oil

C

Apply gear oil

D

Apply molybdenum disulfide oil

E

Apply wheel bearing grease

F

Apply lightweight lithium-soap base grease

G

Apply molybdenum disulfide grease

H

Apply a locking agent (LOCTITE

I

Apply Yamaha bond

J

Use a new one

K

®

)

INDEX

GENERAL

INFORMATION

PERIODIC INSPECTIONS

AND ADJUSTMENTS

ENGINE

ELECTRICAL

SPECIFICATIONS

CHAPTER 1.

GENERAL INFORMATION

MACHINE IDENTIFICATION

SERIAL NUMBER ...............................1-1

STARTING SERIAL NUMBER ............ 1-1

IMPORTANT INFORMATION

PREPARATION FOR REMOVAL

AND DISASSEMBLY

CAUTION ON SERVICE ..................... 1-2

NOTES ON SERVICE ......................... 1-2

ALL REPLACEMENT PARTS .............1-3

GASKETS, OIL SEALS,

AND O-RINGS ..................................... 1-3

BEARINGS AND OIL SEALS .............. 1-3

SPECIAL TOOLS AND TESTERS

....................1-1

..................1-2

...........1-4

CHAPTER 2.

PERIODIC INSPECTIONS

AND ADJUSTMENTS

INTRODUCTION

MAINTENANCE INTERVALS CHART

(For Canada)

PERIODIC MAINTENANCE/

LUBRICATION INTERVALS

COVERS, PANELS, AND CAPS

ENGINE

....................................................2-3

ENGINE OIL LEAKAGE CHECKING ..2-3

OIL LEVEL CHECKING ....................... 2-3

OIL REPLACEMENT ...........................2-4

FUEL LEAKAGE .................................. 2-5

FUEL TANK FILTER ...........................2-6

FUEL PIPE STRAINER ....................... 2-7

AIR FILTER ELEMENT .......................2-8

MUFFLER ............................................2-9

VALVE CLEARANCE

ADJUSTMENT ..................................2-10

AIR GAP BETWEEN TCI UNIT

AND FLYWHEEL MAGNETO ...........2-13

COMPRESSION PRESSURE ...........2-14

ENGINE SPEED (NO LOAD) ............ 2-16

ECONOMY ENGINE SPEED ............ 2-16

CHOKE CABLE ................................. 2-17

BREATHER HOSE ............................2-17

.......................................2-1

............................................2-1

....................2-1

..............2-2

ELECTRICAL

SPARK PLUG ................................... 2-18

MAIN SWITCH .................................. 2-19

ECONOMY SWITCH ........................ 2-20

PILOT LIGHT .................................... 2-20

OVERLOAD WARNING LIGHT ........ 2-20

DC CIRCUIT BREAKER ................... 2-21

DC CIRCUIT BREAKER

(120 V-60 Hz) .................................... 2-21

RECEPTACLE .................................. 2-22

AC SWITCH (NFB)

(120 V-60 Hz/23.5 A) ........................ 2-22

AC SWITCH (NFB)

(120 V-60 Hz/15 A) ........................... 2-23

FUSES .............................................. 2-23

BATTERY .......................................... 2-25

BATTERY TERMINAL ...................... 2-25

BATTERY ELECTROLYTE ............... 2-26

BATTERY CHARGING ..................... 2-29

......................................... 2-18

CHAPTER 3.

ENGINE

PANELS AND COVERS

CONTROL PANEL

FUEL TANK AND CONTROL BOX

AIR FILTER ASSEMBLY

AND CONTROL UNIT

120 V-60 Hz, 220 V-50 Hz .................. 3-7

AIR FILTER ASSEMBLY, CONTROL UNIT

AND NOISE FILTER

230 V-50 Hz ........................................ 3-8

RECOIL STARTER

AND FLYWHEEL MAGNETO

RECOIL STARTER REMOVAL ........ 3-12

FLYWHEEL MAGNETO

REMOVAL ......................................... 3-12

FLYWHEEL MAGNETO

INSTALLATION ................................. 3-13

RECOIL STARTER

DISASSEMBLY ................................. 3-14

RECOIL STARTER INSPECTION .... 3-14

RECOIL STARTER ASSEMBLY ....... 3-15

ENGINE ASSEMBLY

CHASSIS AND CASTERS

MUFFLER

MUFFLER INSTALLATION ............... 3-20

.............................................. 3-19

.......................... 3-1

................................... 3-3

......... 3-5

.............................. 3-7

................................ 3-8

.................. 3-9

............................. 3-17

..................... 3-18

GENERATOR .........................................3-21

GENERATOR ASSEMBLY

REMOVAL .........................................3-22

GENERATOR ASSEMBLY

INSTALLATION .................................3-23

CYLINDER HEAD COVER

AND CYLINDER HEAD ..........................3-25

CYLINDER HEAD REMOVAL ...........3-26

PUSH ROD INSPECTION ................. 3-26

CYLINDER HEAD INSPECTION ......3-26

CYLINDER HEAD ASSEMBLY ......... 3-27

BREATHER HOSE ............................3-27

VALVE ....................................................3-28

VALVE AND VALVE SPRING

REMOVAL .........................................3-29

VALVE AND VALVE SPRING

INSPECTION .....................................3-29

LOCKER ARM INSPECTION ............3-30

VALVE SEAT INSPECTION .............. 3-31

VALVE LAPPING ..............................3-32

VALVE AND VALVE SPRING

ASSEMBLY .......................................3-33

CRANKCASE COVER

AND CAMSHAFT ...................................3-34

CRANKCASE COVER REMOVAL ....3-35

CAMSHAFT INSPECTION ................3-35

VALVE LIFTER INSPECTION ........... 3-36

CAMSHAFT ASSEMBLY ..................3-36

CRANKCASE COVER

INSPECTION .....................................3-36

CRANKCASE COVER

INSTALLATION .................................3-36

PISTON, CONNECTING ROD,

CRANKSHAFT AND CRANKCASE ...... 3-37

CRANKCASE (CYLINDER)

INSPECTION .....................................3-38

PISTON AND PISTON PIN

INSPECTION .....................................3-38

PISTON RING INSPECTION ............ 3-40

CRANKSHAFT INSPECTION ........... 3-41

CONNECTING ROD OIL

CLEARANCE INSPECTION .............. 3-42

PISTON RING

AND PISTON ASSEMBLY ................3-43

CRANKSHAFT ASSEMBLY ..............3-44

CARBURETOR ...................................... 3-45

FLOAT HEIGHT INSPECTION ......... 3-49

CHOKE CABLE INSTALLATION ...... 3-50

THROTTLE CONTROL MOTOR ...... 3-50

TROUBLESHOOTING ........................... 3-51

THROTTLE CONTROL SYSTEM ..... 3-56

CHAPTER 4.

ELECTRICAL

ELECTRICAL COMPONENTS ................ 4-1

120 V-60 Hz ........................................ 4-1

220 V-50 Hz ........................................ 4-2

230 V-50 Hz ........................................ 4-3

SWITCHES ............................................... 4-4

CHECKING SWITCH CONTINUITY ... 4-4

IGNITION SYSTEM .................................. 4-5

TROUBLESHOOTING CHART ........... 4-5

ELECTRIC STARTING SYSTEM ........... 4-11

TROUBLESHOOTING CHART ......... 4-11

STARTER MOTOR ........................... 4-14

CHARGING SYSTEM ............................ 4-17

TROUBLESHOOTING CHART ......... 4-17

GENERATOR SYSTEM ......................... 4-20

TROUBLESHOOTING CHART ......... 4-20

CHAPTER 5.

SPECIFICATIONS

GENERAL SPECIFICATIONS ................. 5-1

MAINTENANCE SPECIFICATIONS ........ 5-4

ENGINE .............................................. 5-4

GENERATOR AND ELECTRICAL ...... 5-7

LUBRICATION POINTS

AND LUBRICANT TYPES ....................... 5-8

TIGHTENING TORQUE ........................... 5-9

GENERAL TORQUE

SPECIFICATIONS ................................. 5-11

DEFINITION OF UNITS ......................... 5-11

WIRE ROUTING DIAGRAM ................... 5-12

1

MACHINE IDENTIFICATION

GENERAL INFORMATION

MACHINE IDENTIFICATION

SERIAL NUMBER

The serial number is printed on a label

which is affixed to the generator as shown.

NOTE:

The first three characters of this number are

SWL1010T

for model identification, the remaining digits

are the unit production number.

GEN

INFO

1

SWL1020J

STARTING SERIAL NUMBER

Model Code

120 V-60 Hz 7WL2 7WL-220101~

220 V-50 Hz 7WL3 7WL-330101~

230 V-50 Hz 7WL3 7WL-300101~

230 V-50 Hz 7WL3 7WL-350101~

NOTE:

Designs and specifications are subject to

change without notice.

Starting serial

number

1-1

SVU1030

SVU1040

SVU1050

GEN

IMPORTANT INFORMATION

IMPORTANT INFORMATION

PREPARATION FOR REMOVAL AND DISASSEMBLY

CAUTION ON SERVICE

1. Fire prevention

When servicing the engine, always keep the engine and yourself

away from fire.

NOTES ON SERVICE

1. Correct tools

Be sure to use the correct special tool for the job to guard

against damage.

2. Oil, grease and seals

Be sure to use genuine Yamaha oils, grease and sealers, or the

equivalents.

INFO

SVU1060

SVU1070

SVU1080

3. Expendable parts

Always replace the gaskets, O-rings, cotter pins and circlips with

new parts when servicing engine.

4. Tightening torque

Be sure to follow torque specifications. When tightening bolts,

nuts or screws, start with the largest-diameter fastener and work

from an inner position to an outer position in a crisscross pattern.

5. Notes on disassembly and assembly

a. Parts should be cleaned in solvent and blown dry with com-

pressed air after disassembly.

SVU1090

SVU1100

b. Contact surfaces of moving parts should be oiled when reas-

sembled.

c. Make sure that the parts move smoothly after each section of

the machine is assembled.

1-2

SVU1110

GEN

IMPORTANT INFORMATION

ALL REPLACEMENT PARTS

We recommend the use of genuine Yamaha parts for all replacements. Use oil and/or grease, recommended by Yamaha, for

assembly and adjustment.

GASKETS, OIL SEALS, AND O-RINGS

1. All gaskets, seals, and O-rings should be replaced when an

engine is overhauled. All gaskets surfaces, oil seal lips, and Orings must be cleaned.

2. Properly oil all mating parts and bearings during reassembly.

Apply grease to the oil seal lips.

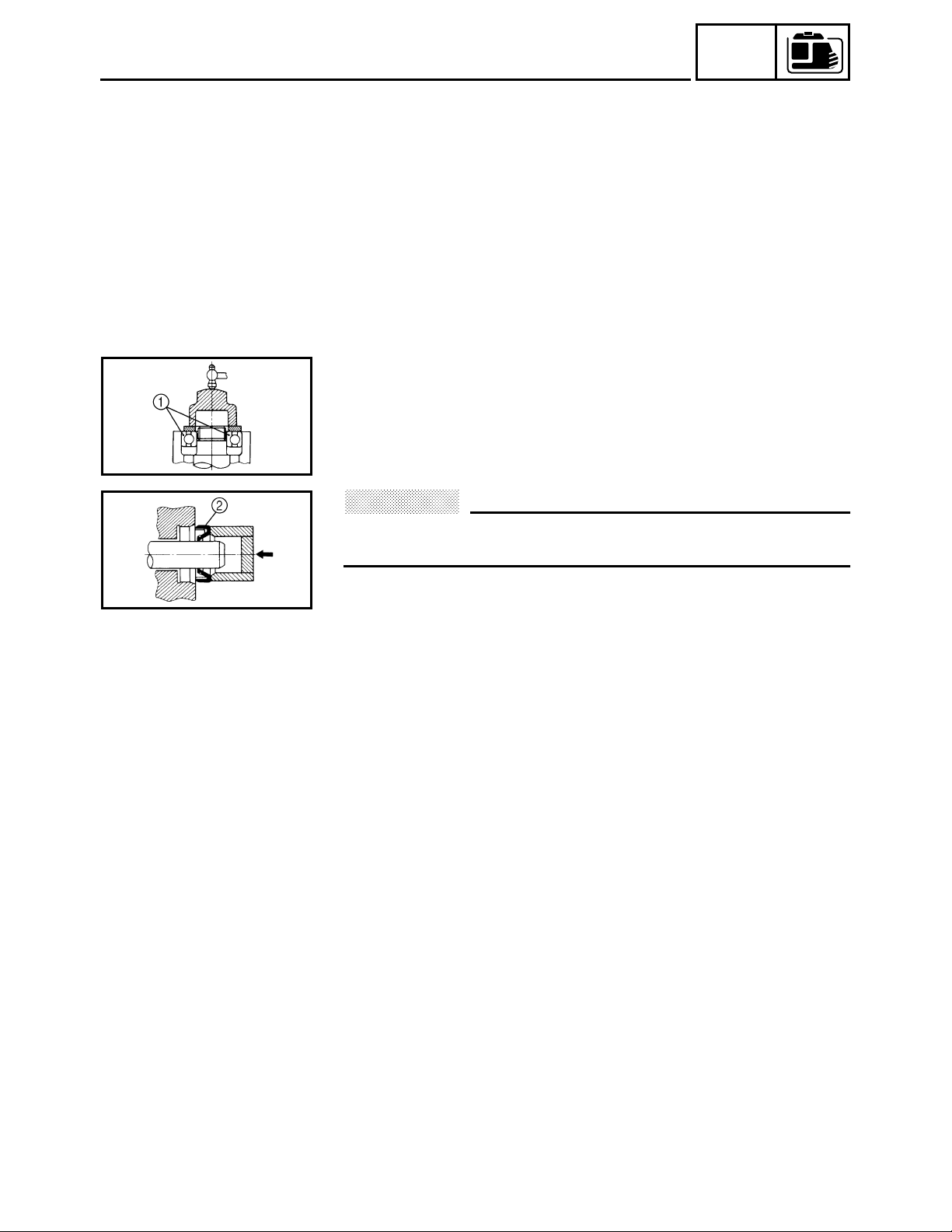

BEARINGS AND OIL SEALS

Install the bearing(s) 1 and oil seal(s) 2 with their manufacture’s

marks or numbers facing outward. (In other words, the stamped letters must be on the side exposed to view.) When installing oil

seal(s), apply a light coating of light-weight lithium base grease to

the seal lip(s). Oil the bearings liberally when installing.

INFO

SVU1120

CAUTION:

Do not use compressed air to spin the bearings dry. This

causes damage to the bearing surfaces.

1-3

SVU1130

GEN

SPECIAL TOOLS AND TESTERS

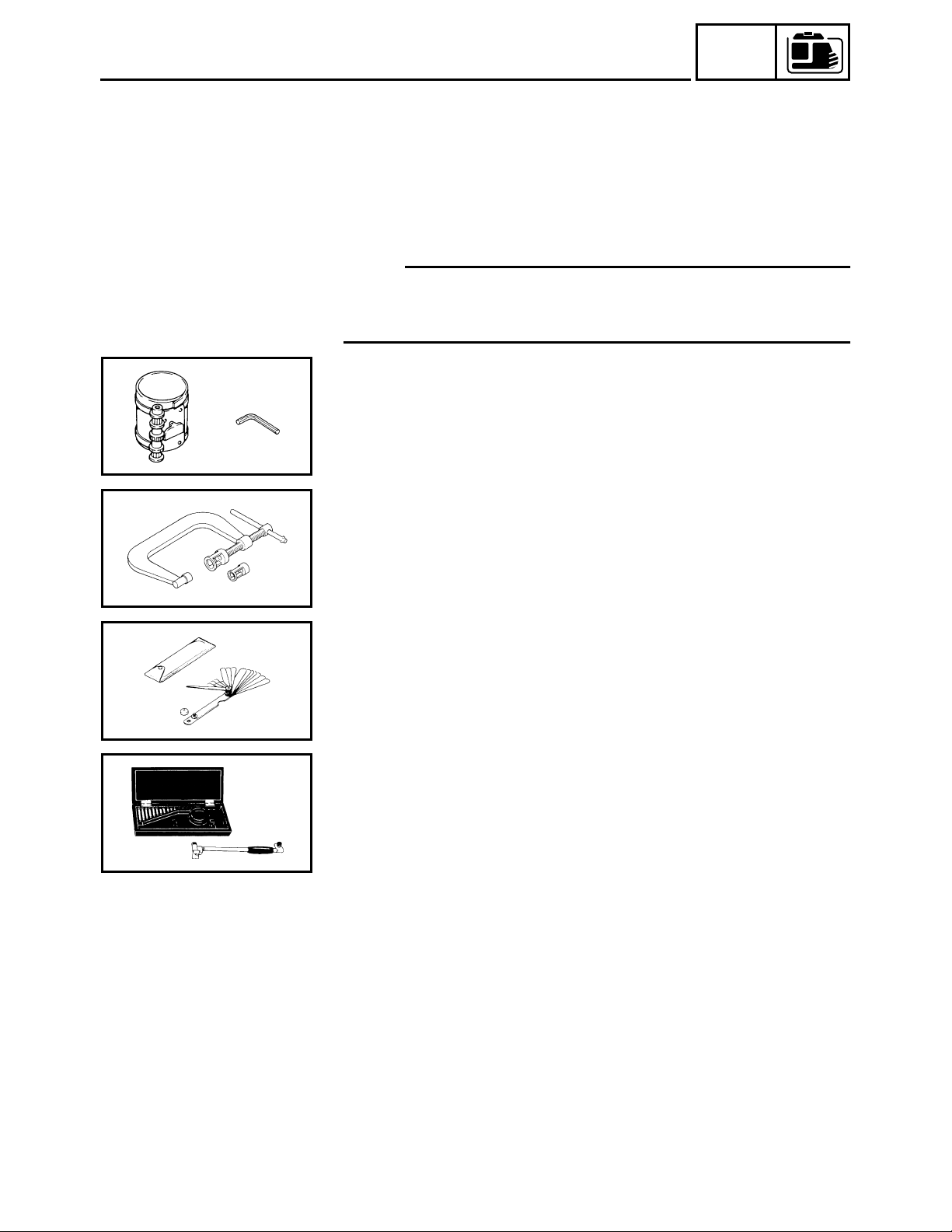

SPECIAL TOOLS AND TESTERS

The proper special tools are necessary for complete and accurate

tune-up and assembly. Using the correct special tool will help prevent damage caused by the use of improper tools or improvised

techniques. The shape and part number used for the special tool

differ by country, so two types are provided. Refer to the list provided to avoid errors when placing an order.

NOTE:

• For USA and Canada, use part number starting with “YM-”, “YU-”

or “YS-”.

• For others, use part number starting with “90890-”.

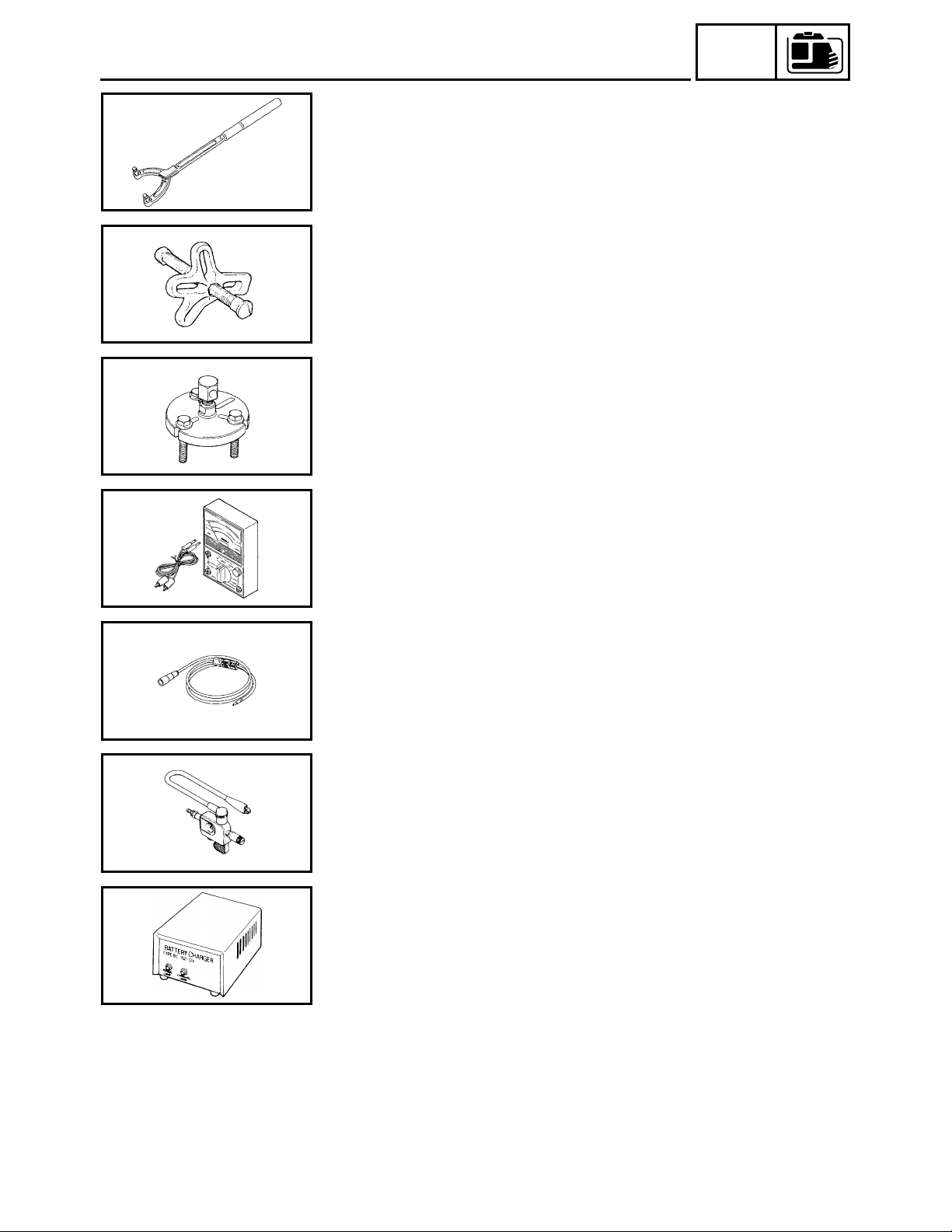

1. Piston ring compressor

P/N. YU-33294, 90890-05158

This tool is used to compress the piston rings when installing the

piston.

INFO

SVU1140

SVU1150

SVU1160

2. Valve spring compressor

P/N. YM-01253, 90890-01253

This tool is used to remove the valve springs.

3. Thickness gauge

P/N. YU-26900-9, 90890-03079

This gauge is used to adjust valve clearance, piston clearance

and piston ring end gap.

4. Cylinder gauge

Commercially available

This instrument is used for checking cylinder bore size and condition.

1-4

SPECIAL TOOLS AND TESTERS

GEN

INFO

1

2

3

4

SWL1010

SWL1020

SWL1040

5. Inductive self-powered tachometer

1

P/N. YU-8036-B

Engine tachometer

2

P/N. 90890-03113

3

P/N. 90793-80009

4

P/N. 90793-80032

This instrument is used for reading engine r/min.

SWL1050

SVU1180

SVU1190

SVU1200

6. Compression gauge 1

P/N. YU-33223, 90890-03081

Adapter 2

P/N. YU-33223-3, 90890-04082

This gauge is used for checking engine compression.

7. Dial gauge

P/N. YU-03097, 90890-03097

This instrument is used for checking crankshaft side clearance.

8. Piston pin puller

P/N. YU-01304, 90890-01304

This tool is used to remove the piston pin.

9. Sheave holder

P/N. YS-01880-A, 90890-01701

This tool is necessary for holding the flywheel or rotor.

SVU1205

1-5

SWL1030

SPECIAL TOOLS AND TESTERS

10.Rotor assembly holder

Commercially available

This tool is necessary for holding the rotor.

GEN

INFO

1

2

1

SVU1210

SVU1220

SVU1230

SVU1240

11.Rotor puller

1

P/N. YU-33270-B

2

P/N. 90890-01362

This tool is necessary for removing the flywheel.

12.Pocket tester

P/N. YU-03112-C, 90890-03112

This instrument is necessary for checking the electrical system.

13.Dynamic spark tester 1

P/N. YM-34487

Ignition checker 2

P/N. 90890-06754

This instrument is necessary for checking the ignition system

components.

2

SVU1250

14.MF Battery charging

Commercially available

This instrument is necessary for charging the electrical system.

SWL1060

1-6

INSP

ADJ

INTRODUCTION/MAINTENANCE INTERVALS CHART (For Canada)/

PERIODIC MAINTENANCE/LUBRICATION INTERVALS

PERIODIC INSPECTIONS AND ADJUSTMENTS

INTRODUCTION

This chapter includes all information necessary to perform recommended inspections and adjustments. These preventive maintenance procedures, if followed, will ensure more reliable machine

operation and a longer service life. The need for costly overhaul work will be greatly reduced. This

information applies to machines already in service as well as new machines that are being prepared

for sale. All service technicians should be familiar with this entire chapter.

MAINTENANCE INTERVALS CHART (For Canada)

Proper periodic maintenance is important. Especially important are the maintenance services

related to emissions control. These controls not only function to ensure cleaner air but are also vital

to proper engine operation and maximum performance. In the following maintenance tables, the

services related to emissions control are indicated as “*” in the chart.

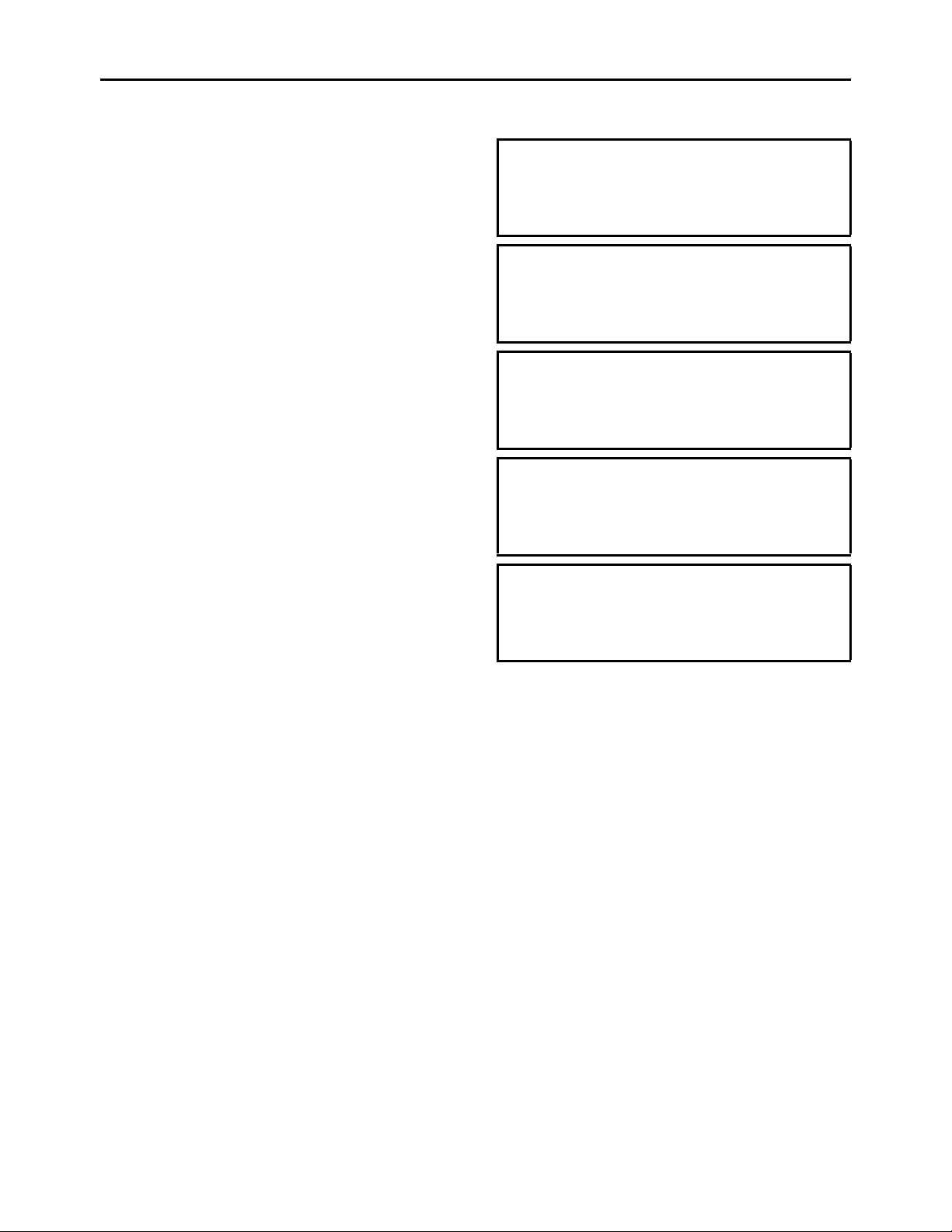

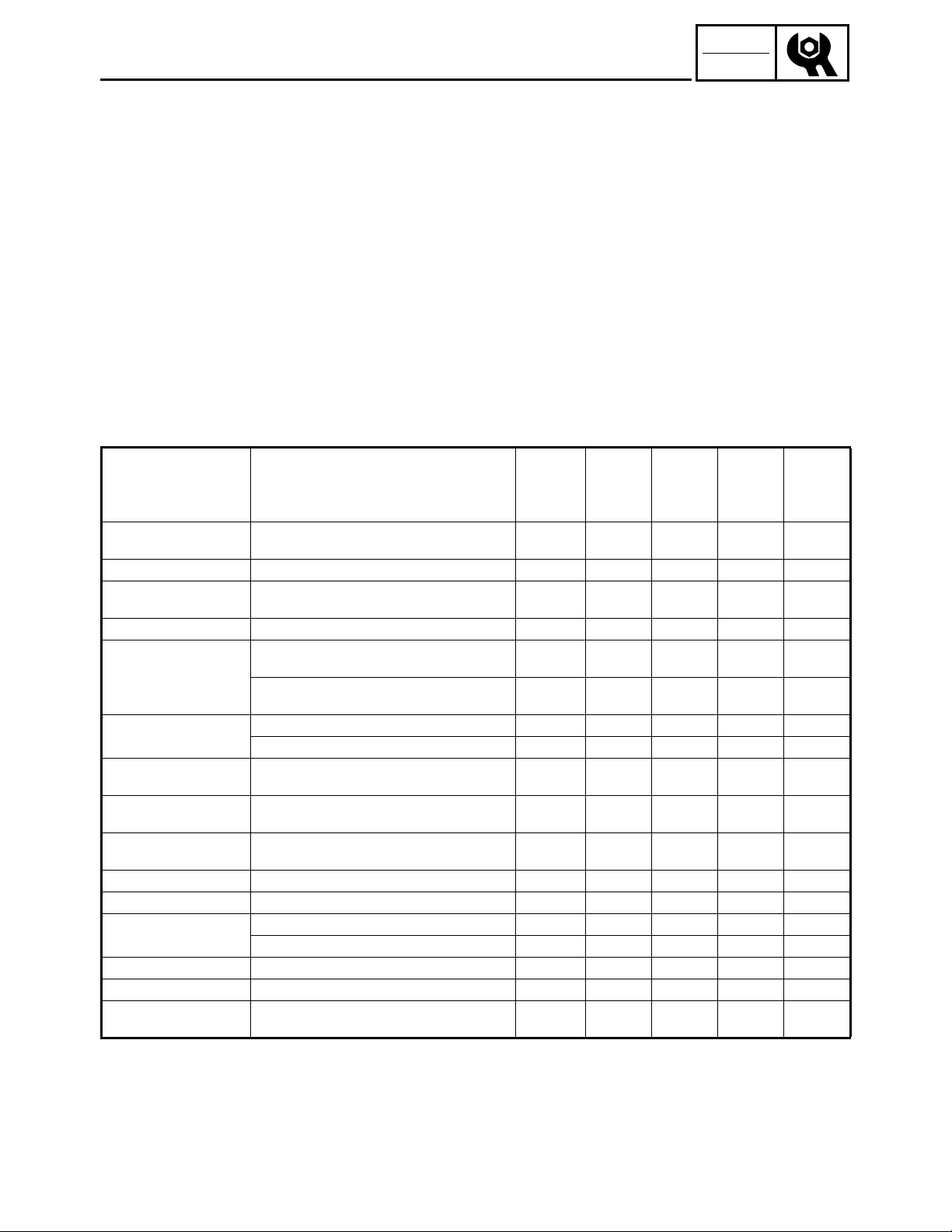

PERIODIC MAINTENANCE/LUBRICATION INTERVALS

ÈÉÊËÌÍ

Item Remarks

Ï

*Spark Plug

Ð

*Valve Clearance Check and adjust when engine is cold.

*Crankcase breather

Ñ

system

Ò

*Idle speed Check and adjust engine idle speed.

Ó

*Exhaust System

Ö

Engine Oil

Ù

*Air Filter

Ú

Fuel Filter

Û

Fuel Line

Ü

*Choke knob Check choke operation.

Ý

Cooling System Check for fan damage.

Þ

Starting System

Á

*Decarbonization More frequently if necessary.

+

Generation Check the pilot light comes on.

,

Fittings/Fasteners

Check condition. Adjust gap and clean.

Replace if necessary.

Check breather hose for cracks or damage.

Replace if necessary.

Check for leakage.

Ô

Retighten or replace gasket if necessary.

Check muffler screen and spark arrester.

Õ

Clean/replace if necessary.

×

Check oil level.

Ø

Replace.

Clean.

Replace if necessary.

Clean fuel tank filter.

Replace if necessary.

Check fuel hose for crack or damage. Replace

if necessary.

ß

Check recoil starter operation.

À

Check electric starter operation.

Check all fittings and fasteners.

Correct if necessary.

Pre-Opera-

tion check

(daily)

●

●

●

●

●

●

●

Î

Initial

1 month

or 20 Hr

●●

Every

3 months

or 50 Hr

●

●

Every

6 months

or 100 Hr

●

●

Every

12 months

or 300 Hr

●

●

●

●

●

●

*: Related to emission control system.

2-1

INSP

ADJ

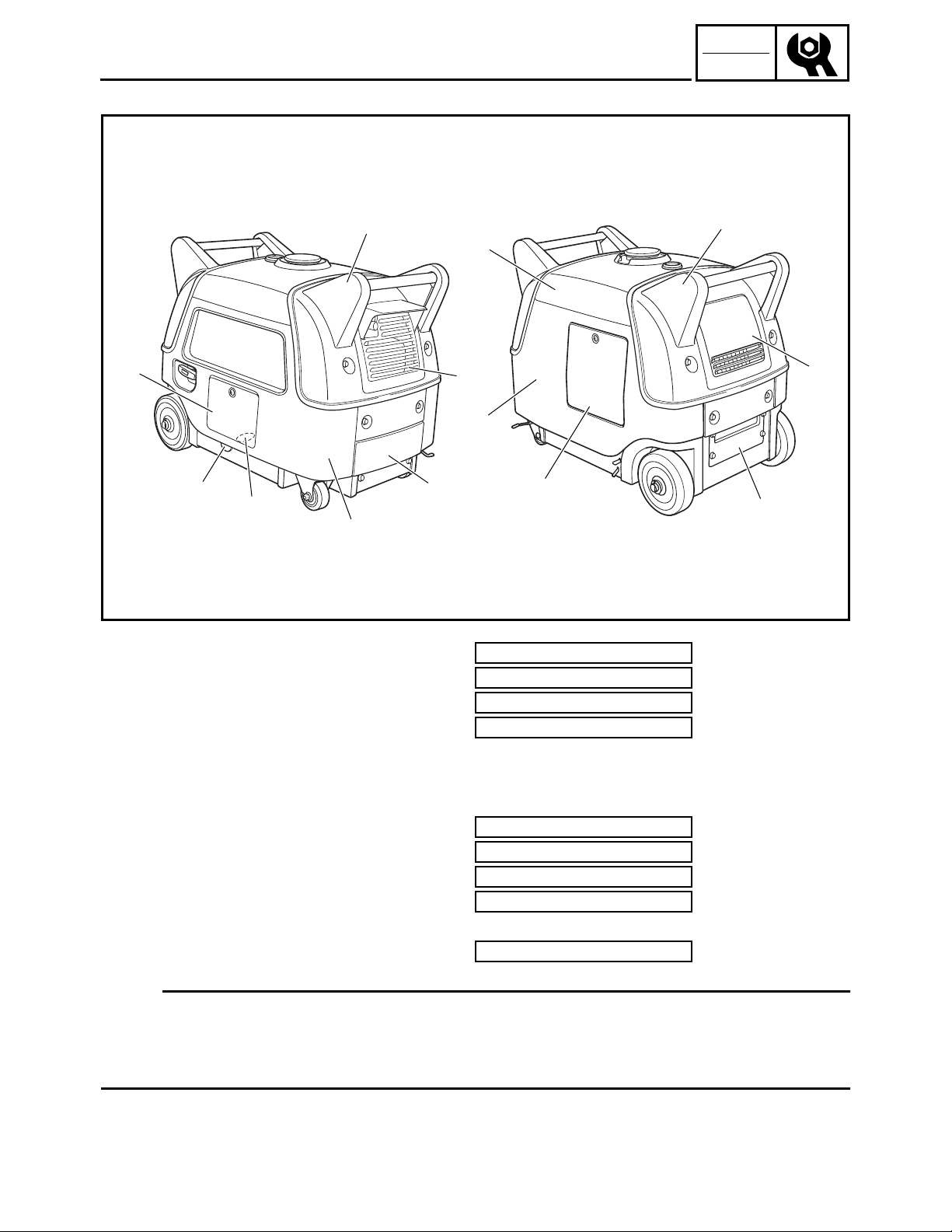

COVERS, PANELS, AND CAPS

COVERS, PANELS, AND CAPS

7

Front right view

6

5

4

1

3

2

Rear left view

9

8

0

C

B

A

SWL2180T

1

Cover 1

2

Panel 1

3

Cover 2

4

Cover 3

5

Cap 1

6

Cap 2

7

Panel 2

8

Cover 4

9

Cover 5

0

Panel 3

A

Battery bracket

B

Panel 4

C

Cover 6

7.0 Nm (0.7 m · kg, 5.1 ft · lb)

7.0 Nm (0.7 m · kg, 5.1 ft · lb)

7.0 Nm (0.7 m · kg, 5.1 ft · lb)

7.0 Nm (0.7 m · kg, 5.1 ft · lb)

7.0 Nm (0.7 m · kg, 5.1 ft · lb)

7.0 Nm (0.7 m · kg, 5.1 ft · lb)

7.0 Nm (0.7 m · kg, 5.1 ft · lb)

7.0 Nm (0.7 m · kg, 5.1 ft · lb)

7.0 Nm (0.7 m · kg, 5.1 ft · lb)

NOTE:

• The EF3000iSE are equipped with soundproof covers and panels that cover the engine and

frame.

• To make periodic maintenance checks easy, remove the applicable cover or panel.

• For cover or panel removal and installation, refer to “PANELS AND COVERS” in CHAPTER 3.

2-2

INSP

ADJ

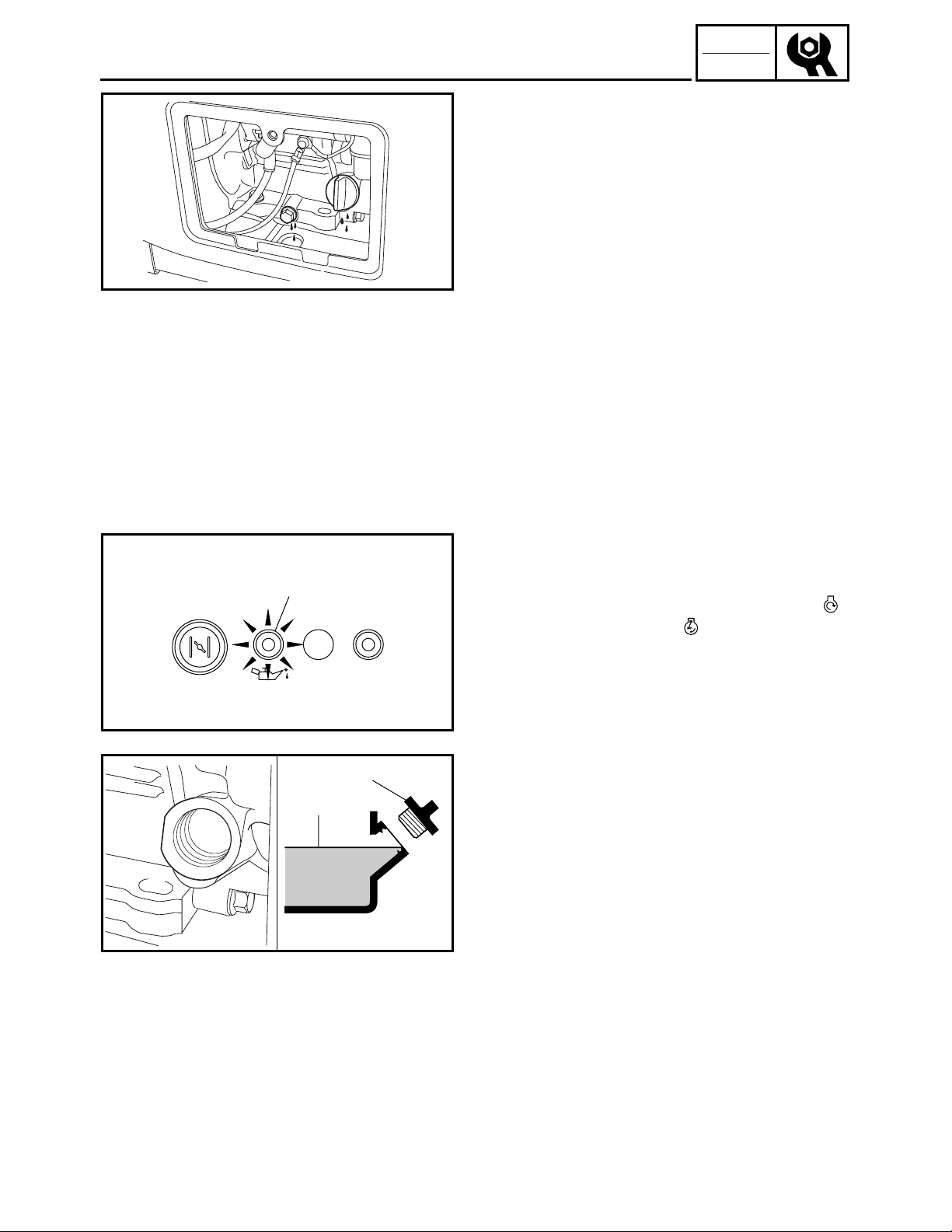

ENGINE OIL LEAKAGE CHECKING/

OIL LEVEL CHECKING

ENGINE

ENGINE OIL LEAKAGE CHECKING

1. Remove:

• Panel 2

• Panel 4

Refer to “COVERS, PANELS, AND

CAPS”.

2. Check the areas outside of the engine for

SWL2020J

oil leakage.

Oil leakage → Replace the gasket, oil

seal, or O-ring.

3. Install:

• Panel 4

• Panel 2

Refer to “COVERS, PANELS, AND

CAPS”.

1

a

1

SWL2010T

SWL2040J

OIL LEVEL CHECKING

1. Check:

• Oil level with oil level warning light 1

• Set the main switch to “START” “”

or set it to “ON” “” and pull the recoil

starter to check that the oil level warning light 1 flashes.

Oil level warning light flashes → Add

oil.

Oil level warning light does not flash

OK

2. Remove:

• Panel 2

Refer to “COVERS, PANELS, AND

CAPS”.

• Oil filler cap 1

3. Check:

• Check that the engine oil is at the specified level a.

Oil level checking steps:

• Place the generator on a level surface.

• Warm up the engine for several minutes.

• Stop the engine.

• Check that the engine oil is at the specified

level a. Add oil if necessary.

→

2-3

INSP

ADJ

OIL LEVEL CHECKING/

OIL REPLACEMENT

4. Install:

• Oil filler cap

• Panel 2

Refer to “COVERS, PANELS, AND

CAPS”.

NOTE:

Tighten the oil filler cap securely by hand.

OIL REPLACEMENT

1. Warm up the engine for several minutes.

2. Stop the engine.

3. Remove:

• Panel 2

• Cap 2

• Cap 1

Refer to “COVERS, PANELS, AND

CAPS”.

4. Place a receptacle under the engine.

5. Remove:

• Oil drain bolt

6. Tilt the engine to drain the oil completely.

7. Tighten:

• Oil drain bolt

1

SWL2060J

È

1

1

SWL2050J

Oil drain bolt:

17 Nm (1.7 m · kg, 12 ft · lb)

T

.

R

.

8. Remove:

• Oil filler cap 1

9. Fill:

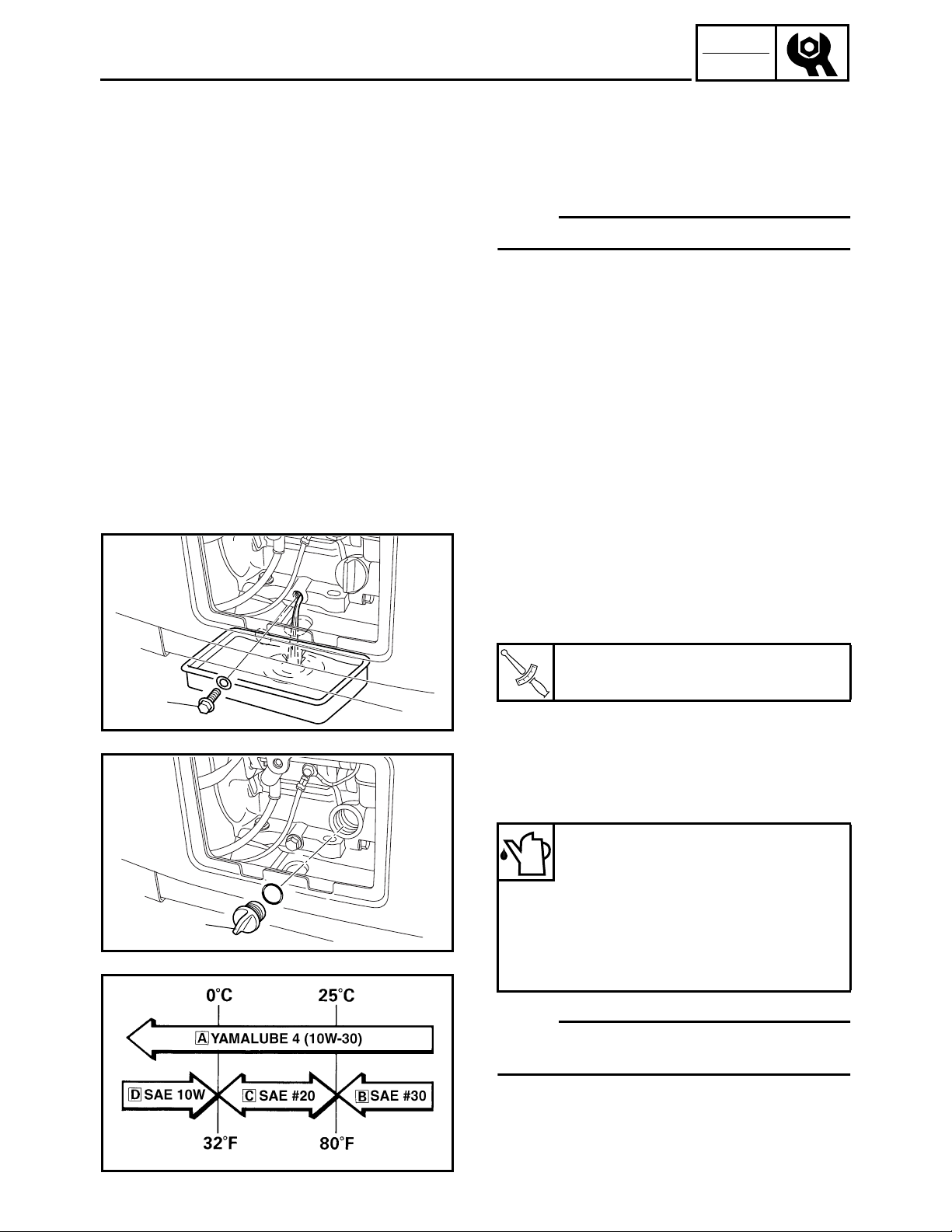

Recommended oil:

È YAMALUBE 4 (10W-30) or SAE

10W-30 type SE

É SAE #30

Ê SAE #20

Ë SAE 10W

Engine oil quantity:

0.6 L (0.53 Imp qt, 0.63 US qt)

NOTE:

Recommended engine oil classification:

API Service “SE” or “SF”, if not available, “SD”.

SVU2060

2-4

INSP

ADJ

OIL REPLACEMENT/

FUEL LEAKAGE

É

SVW2070T

Recommended oil:

SAE #30 or 10W-30

È

or 10W-40

SAE #20 or 10W-30

É

or 10W-40

SAE 10W or 10W-30

Ê

or 10W-40

SAE #40: Above 35 °C (95 °F)

Engine oil quantity:

0.6 L (0.53 Imp qt, 0.63 US qt)

NOTE:

Recommended engine oil classification:

API Service “SE” or “SF”, if not available, “SD”.

For Canada

È

Except for Canada

É

10.Install:

• Oil filler cap

NOTE:

Tighten the oil filler cap securely by hand.

11.Install:

• Cap 1

• Cap 2

• Panel 2

Refer to “COVERS, PANELS, AND

CAPS”.

FUEL LEAKAGE

1. Remove:

• Cover 1

• Cover 5

• Cover 4

Refer to “COVERS, PANELS, AND

CAPS”.

2. Remove:

• Fuel tank bolts

Refer to “FUEL TANK AND CONTROL

BOX” in CHAPTER 3.

3. Slide the fuel tank to check for leakage.

CAUTION:

When sliding the fuel tank, be sure not to

extremely bend, twist, or pull the fuel

hoses.

2-5

INSP

ADJ

SWL2070J

FUEL LEAKAGE/

FUEL TANK FILTER

4. Check:

• Leakage

Check at fuel tank, fuel cock, fuel

hoses, and carburetor.

CAUTION:

Replace the fuel hoses every four years.

5. Install:

• Fuel tank

Refer to “FUEL TANK AND CONTROL

BOX” in CHAPTER 3.

6. Install:

• Cover 4

• Cover 5

• Cover 1

Refer to “COVERS, PANELS, AND

CAPS”.

1

2

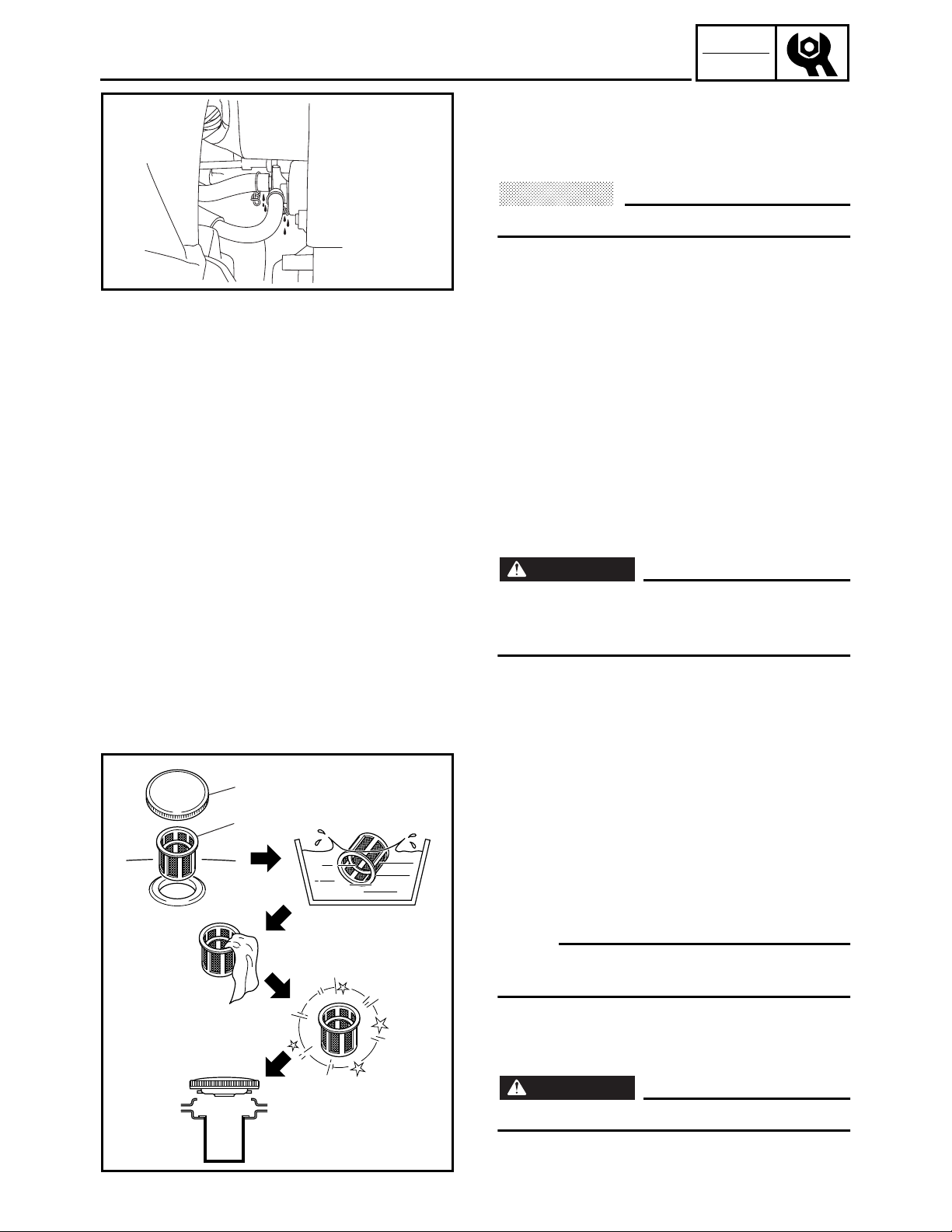

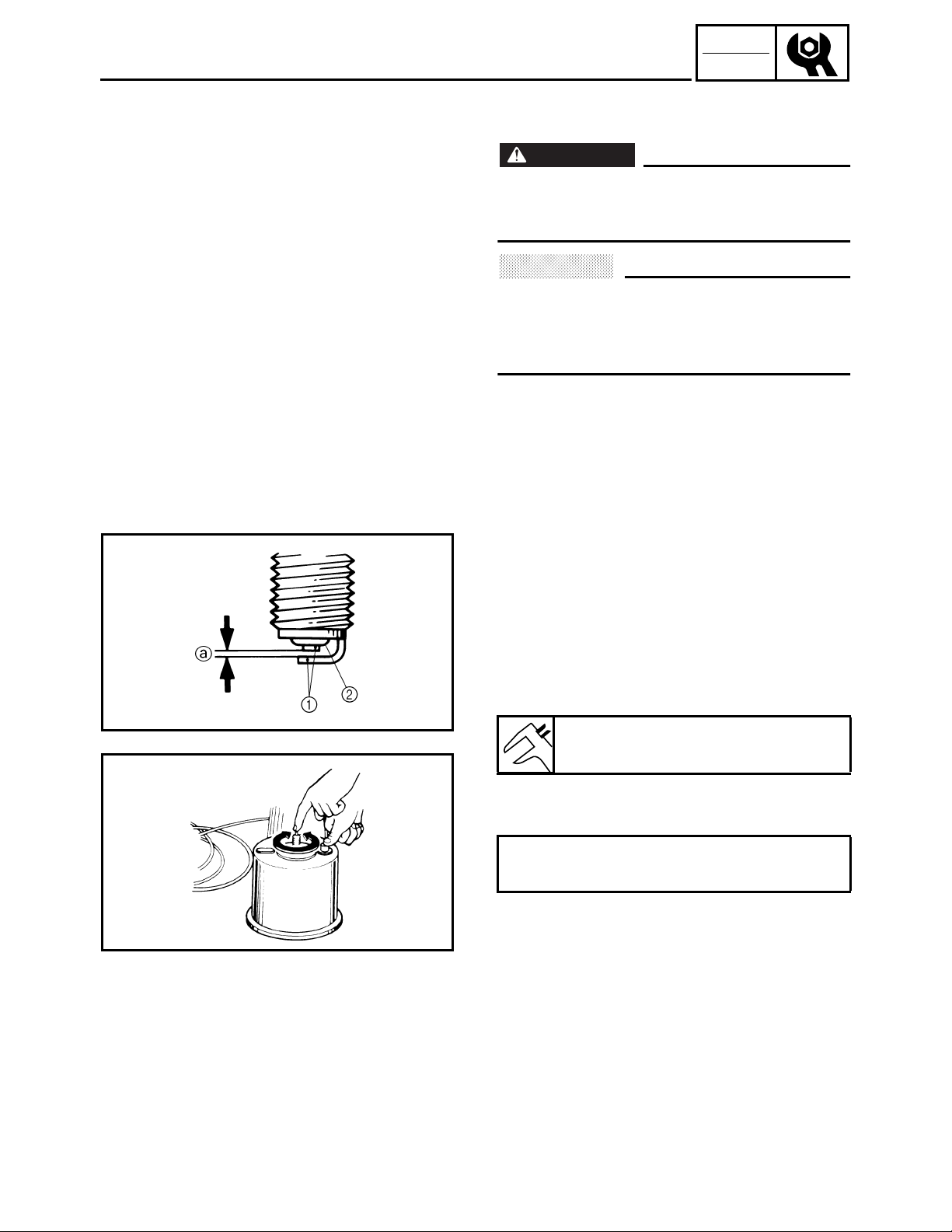

FUEL TANK FILTER

WARNING

Do not smoke, and keep away from open

flames, sparks, or any other source of fire

when handling or in the vicinity of fuel.

1. Remove:

• Fuel tank cap 1

• Fuel tank filter 2

2. Inspect:

• Fuel tank filter

Damage → Replace.

3. Clean:

• Fuel tank filter

NOTE:

Clean the fuel tank filter with solvent, and then

dry it thoroughly.

4. Install:

• Fuel tank filter

• Fuel tank cap

WARNING

Be sure the tank cap is tightened securely.

SVU2080J

2-6

INSP

ADJ

FUEL PIPE STRAINER

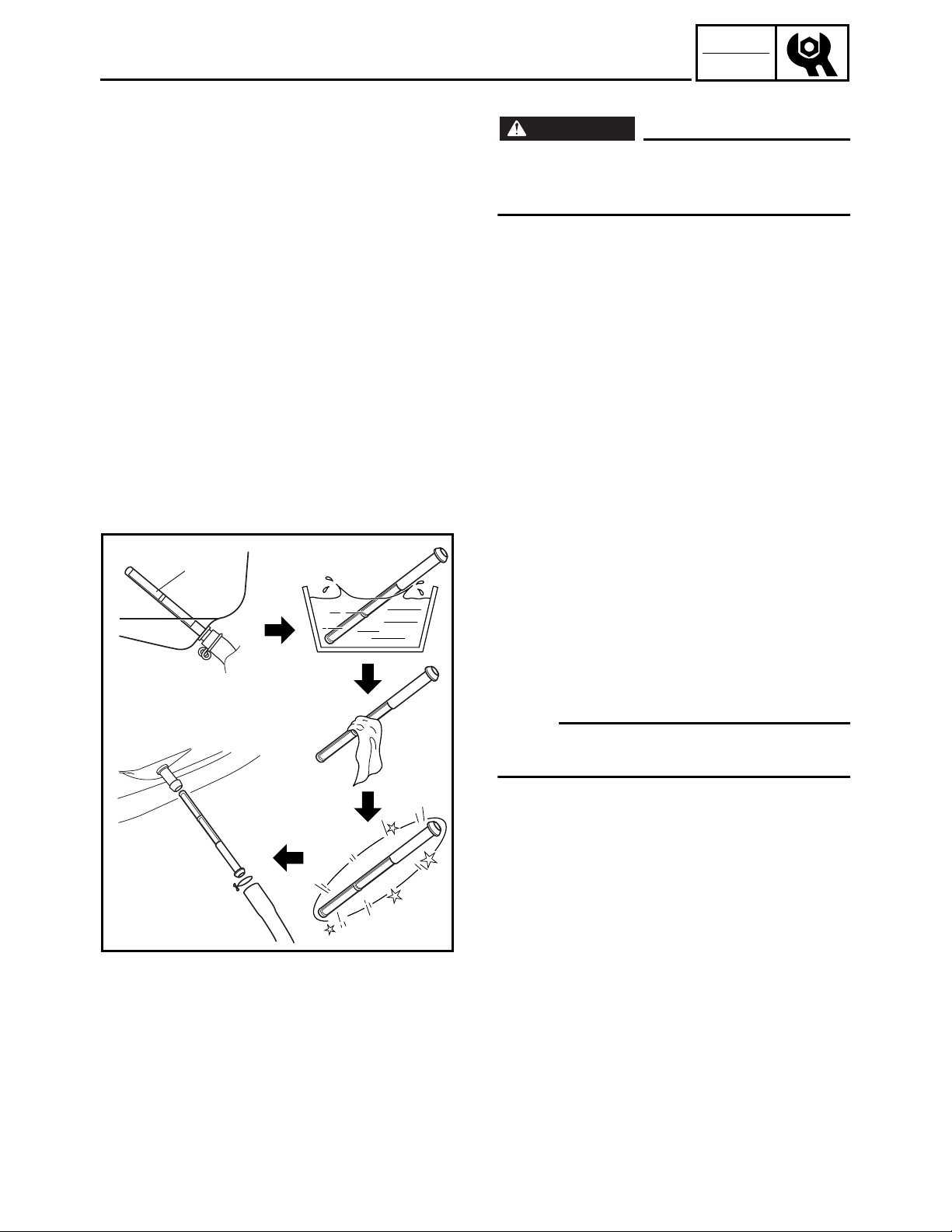

FUEL PIPE STRAINER

WARNING

Do not smoke, and keep away from open

flames, sparks, or any other source of fire

when handling or in the vicinity of fuel.

1. Drain the fuel.

2. Remove:

• Cover 1

• Cover 5

• Cover 4

Refer to “COVERS, PANELS, AND

CAPS”.

3. Remove:

• Fuel hose (fuel cock end)

• Fuel tank

Refer to “FUEL TANK AND CONTROL

BOX” in CHAPTER 3.

1

SWL2080J

4. Remove:

• Fuel hose (fuel tank end)

• Fuel pipe strainer 1

5. Inspect:

• Fuel pipe strainer

Damage → Replace.

6. Clean:

• Fuel pipe strainer

NOTE:

Clean the fuel pipe strainer with solvent, and

then dry it thoroughly.

7. Install:

• Fuel pipe strainer

• Fuel hose (fuel tank end)

8. Install:

• Fuel tank

• Fuel hose (fuel cock end)

Refer to “FUEL TANK AND CONTROL

BOX” in CHAPTER 3.

9. Install:

• Cover 4

• Cover 5

• Cover 1

Refer to “COVERS, PANELS, AND

CAPS”.

2-7

INSP

ADJ

AIR FILTER ELEMENT

2

1

1

1

2

SWL2090J

SVU2100J

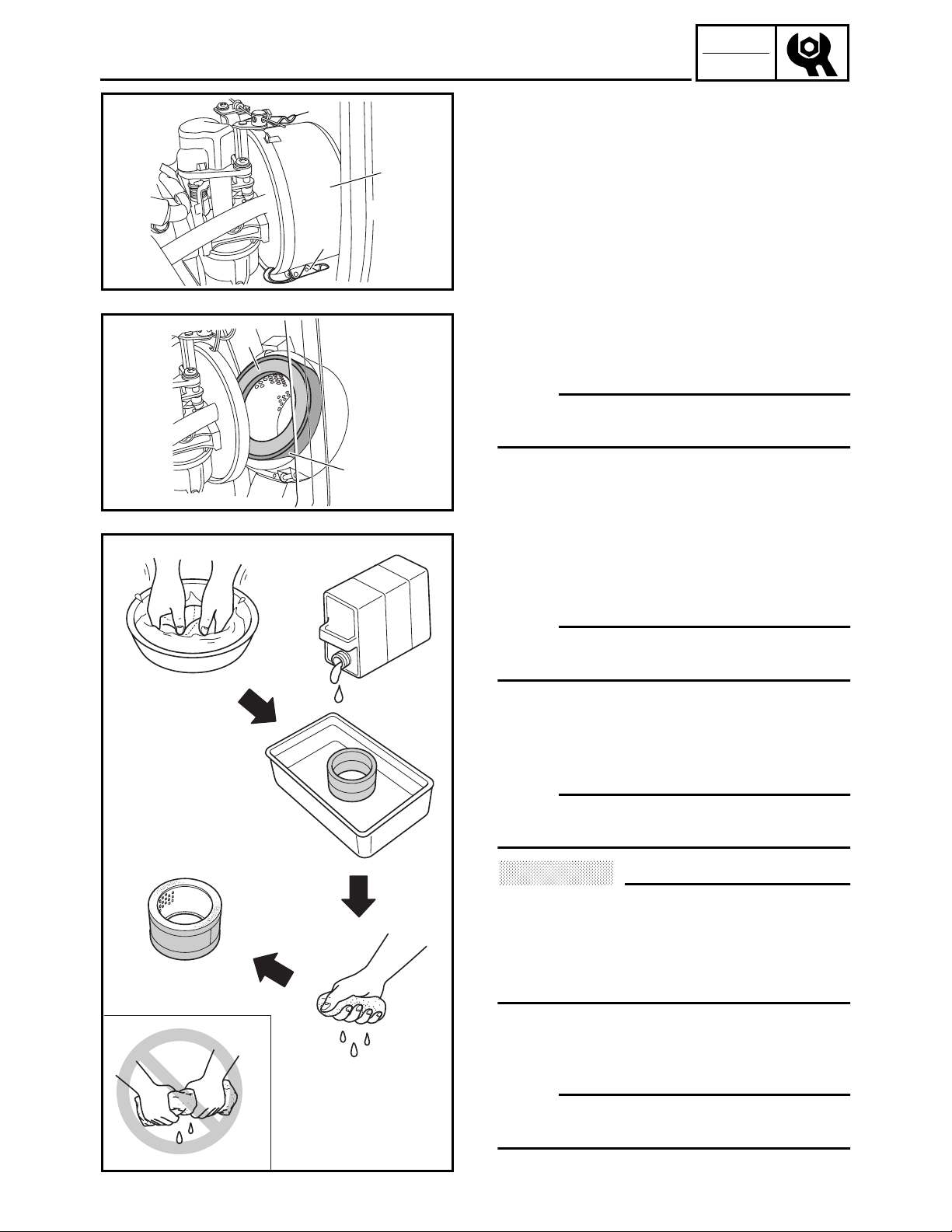

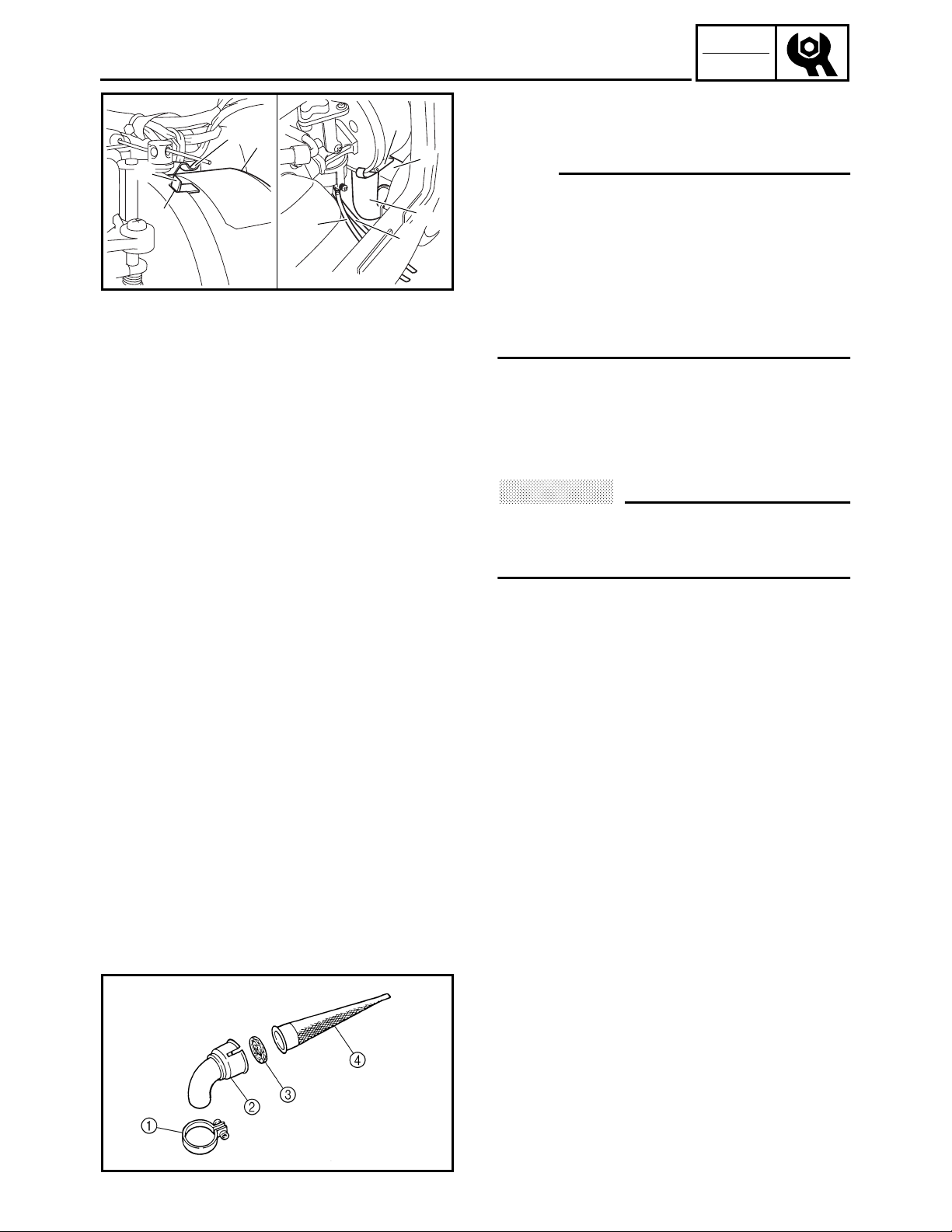

AIR FILTER ELEMENT

1. Remove:

• Panel 4

• Cover 5

Refer to “COVERS, PANELS, AND

CAPS”.

2. Remove:

• Hooks 1

• Air filter element case 2

3. Remove:

• Air filter element 1 1

• Air filter element 2 2

NOTE:

Remove air filter element 1 and air filter element 2 as a set.

4. Inspect:

• Air filter elements

Damage → Replace.

5. Clean:

• Air filter element 1

Wash the air filter elements in kerosene.

NOTE:

Be sure to squeeze the excess kerosene out of

the air filter element 1.

6. Lubricate:

• Air filter element 1

Soak the air filter element 1 in a 2–4:1

mixture of kerosene and engine oil.

NOTE:

Be sure to squeeze the excess kerosene and

engine oil out of the air filter element 1.

CAUTION:

• Do not twist the air filter elements, otherwise they can tear.

• Do not wash the air filter elements in gasoline or in acid, alkaline, or organic solvents.

7. Install:

• Air filter element 1

• Air filter element 2

NOTE:

Insert air filter element 1 into air filter element

2, and then install them into the air filter case.

SWL2110

2-8

INSP

ADJ

AIR FILTER ELEMENT/

MUFFLER

SWL2120J

a

b

2

1

6

2

5

4

3

8. Install:

• Air filter element case 1

• Hooks 2

NOTE:

• Align the projection a of the air filter case

with the slot b in the air filter element

bracket, and then install the air filter case.

• Make sure that the air intake duct 3 is

securely installed onto the frame 4.

• Make sure that the air vent hose 5 and

drain hose 6 are securely installed onto the

frame 4.

9. Install:

• Cover 5

• Panel 4

Refer to “COVERS, PANELS, AND

CAPS”.

1

CAUTION:

The engine should never run without the air

filter element installed, otherwise excessive piston and/or cylinder wear may result.

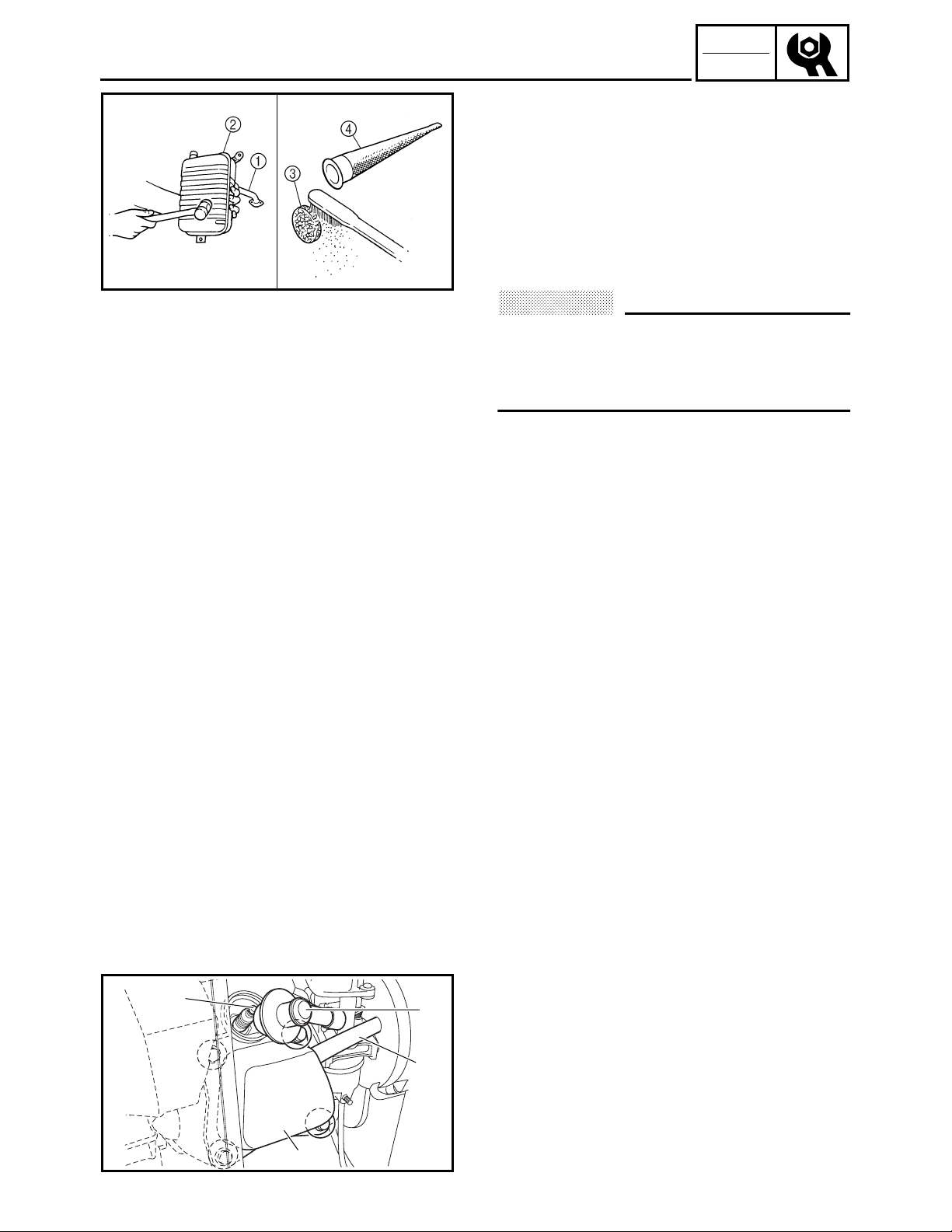

MUFFLER

1. Remove:

• Engine assembly

Refer to “ENGINE ASSEMBLY” in

CHAPTER 3.

2. Remove:

• Muffler

Refer to “MUFFLER” in CHAPTER 3.

3. Remove:

• Muffler band 1

• Muffler cap 2

• Muffler screen 3

• Spark arrester 4

SWL2400J

2-9

INSP

ADJ

MUFFLER/

VALVE CLEARANCE ADJUSTMENT

4. Decarbonize:

• Exhaust pipe 1

• Muffler 2

• Muffler screen 3

• Spark arrester 4

Tap on the muffler in the area shown in

the illustration to loosen carbon buildup,

and then shake it out of the end of the

SWL2410J

Do not use a wire to clean the muffler, otherwise the noise damping material may

come out, and the damping effect may be

reduced.

muffler.

CAUTION:

5. Install:

• Spark arrester

• Muffler screen

• Muffler cap

• Muffler band

• Muffler

Refer to “MUFFLER” in CHAPTER 3.

6. Install:

• Engine assembly

Refer to “ENGINE ASSEMBLY” in

CHAPTER 3.

4

3

2

1

SWL2130J

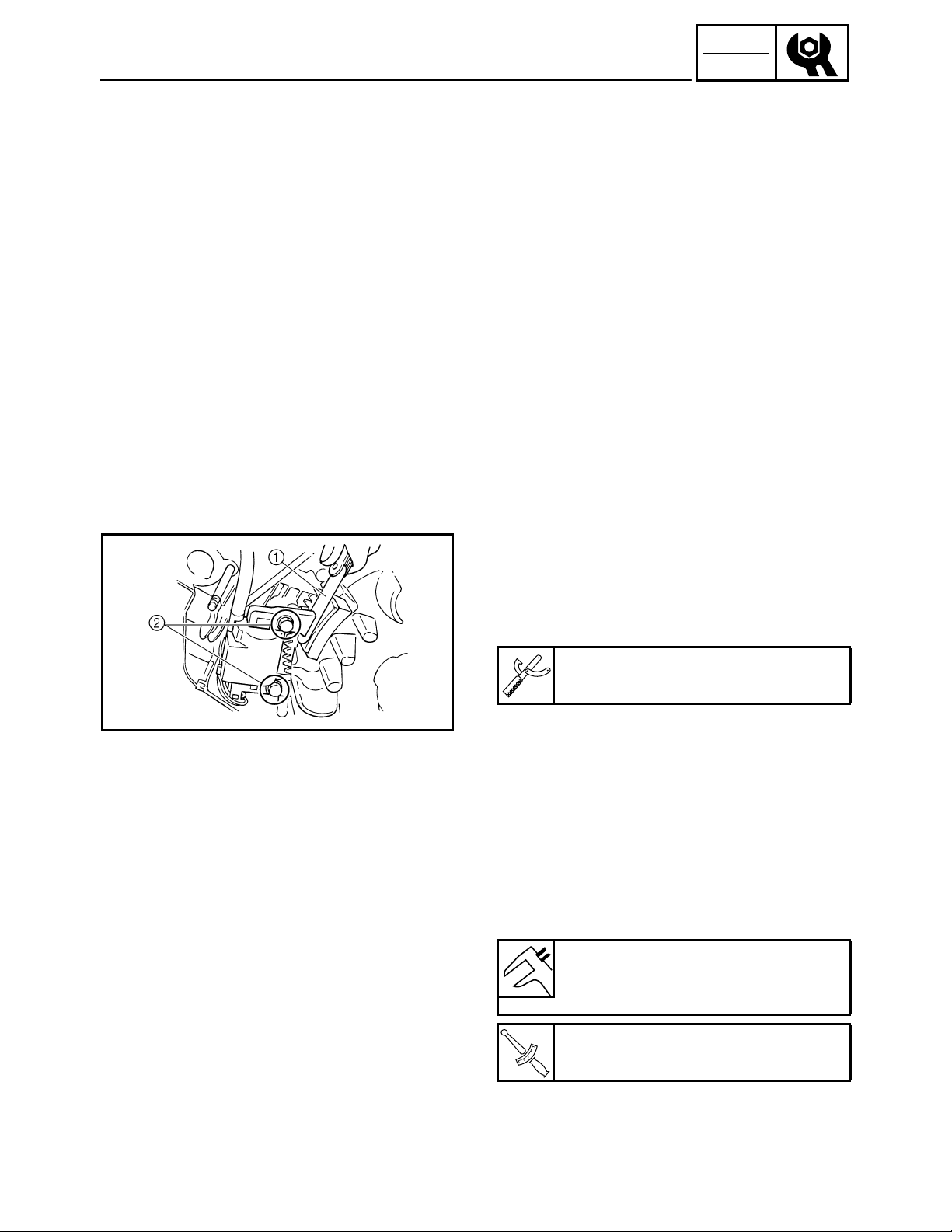

VALVE CLEARANCE ADJUSTMENT

1. Remove:

• Panel 4

Refer to “COVERS, PANELS, AND

CAPS”.

2. Remove:

• Breather hose 1

• Spark plug cap 2

• Cylinder head cover 3

• Spark plug 4

2-10

INSP

ADJ

SWL2140J

VALVE CLEARANCE ADJUSTMENT

3. Gently pull the recoil starter to bring the

piston to top dead center of its compression stroke (when the screwdriver

inserted into the spark plug hole reaches

the highest position).

NOTE:

If the piston is at top dead center of the

exhaust stroke, turn the crankshaft one full

turn (360°) to set the piston at top dead center

of the compression stroke.

SWL2150J

4. Measure:

• Valve clearance

Out of specification → Adjust.

NOTE:

Valve clearance must be measured when the

engine is cool to the touch.

Intake valve (cold):

0.18 ~ 0.22 mm (0.007 ~ 0.009 in)

Exhaust valve (cold):

0.18 ~ 0.22 mm (0.007 ~ 0.009 in)

Thickness gauge:

YU-26900-9, 90890-03079

2-11

INSP

ADJ

2

1

VALVE CLEARANCE ADJUSTMENT

5. Adjust:

• Valve clearance

Adjustment steps:

• Loosen the locknut 1.

• Turn the adjuster 2 in or out to obtain the

proper clearance.

SWL2160J

SWL2170J

1

1

2

2

3

4

SWL2180J

Adjuster Valve clearance

Turn in Decrease

Turn out Increase

• Tighten the locknut 1.

Locknut:

10 Nm (1.0 m · kg, 7.2 ft · lb)

T

.

R

.

6. Install:

• Spark plug 1

• Cylinder head cover 2

• Spark plug cap

3

• Breather hose 4

Cylinder head cover bolt:

10 Nm (1.0 m · kg, 7.2 ft · lb)

T

.

R

.

Spark plug:

18 Nm (1.8 m · kg, 13 ft · lb)

7. Install:

• Panel 4

Refer to “COVERS, PANELS, AND

CAPS”.

2-12

INSP

ADJ

AIR GAP BETWEEN TCI UNIT AND FLYWHEEL

MAGNETO

AIR GAP BETWEEN TCI UNIT AND FLYWHEEL MAGNETO

1. Remove:

• Fuel tank

Refer to “FUEL TANK AND CONTROL

BOX” in CHAPTER 3.

• Air filter element assembly

Refer to “AIR FILTER ASSEMBLY AND

CONTROL UNIT” and “AIR FILTER

ASSEMBLY, CONTROL UNIT AND

NOISE FILTER” in CHAPTER 3.

• Carburetor

Refer to “CARBURETOR” in CHAPTER

3.

• Recoil starter

• Flywheel magneto cover

Refer to “RECOIL STARTER AND FLYWHEEL MAGNETO” in CHAPTER 3.

SWL2420J

2. Measure:

• Air gap between TCI unit and flywheel

magneto

Use a thickness gauge 1.

Out of specification → Adjust.

Thickness gauge:

YU-26900-9, 90890-03079

3. Adjust:

• Air gap between TCI unit and flywheel

magneto

Adjustment steps:

• Loosen the bolts 2.

• Adjust the air gap between the TCI unit

and flywheel magneto by moving the TCI

unit up or down.

• Tighten the bolts 2.

Air gap between TCI unit and flywheel magneto:

0.5 ± 0.1 mm (0.020 ± 0.004 in)

2-13

TCI unit bolt:

10 Nm (1.0 m · kg, 7.2 ft · lb)

T

.

R

.

INSP

ADJ

AIR GAP BETWEEN TCI UNIT AND FLYWHEEL

MAGNETO/COMPRESSION PRESSURE

4. Install:

• Flywheel magneto cover

• Recoil starter

Refer to “RECOIL STARTER AND FLYWHEEL MAGNETO” in CHAPTER 3.

• Carburetor

Refer to “CARBURETOR” in CHAPTER

3.

• Air filter element assembly

Refer to “AIR FILTER ASSEMBLY AND

CONTROL UNIT” and “AIR FILTER

ASSEMBLY, CONTROL UNIT AND

NOISE FILTER” in CHAPTER 3.

• Fuel tank

Refer to “FUEL TANK AND CONTROL

BOX” in CHAPTER 3.

2

1

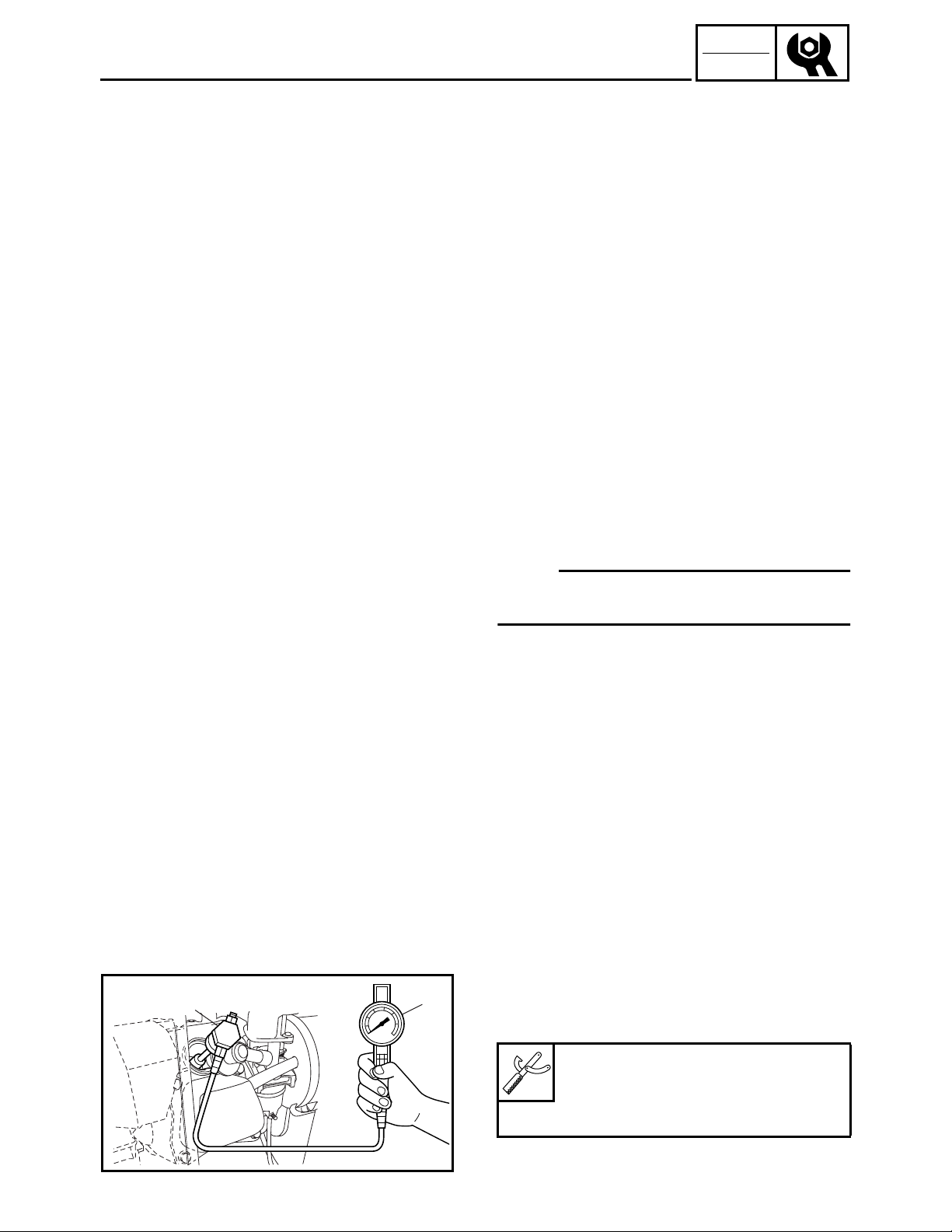

COMPRESSION PRESSURE

NOTE:

Measure the compression after checking and

adjusting the valve clearance.

1. Warm up the engine for several minutes.

2. Remove:

• Panel 4

Refer to “COVERS, PANELS, AND

CAPS”.

3. Remove:

• Spark plug cap

• Spark plug

4. Connect:

• Compression gauge 1

• Adapter 2

Compression gauge:

YU-33223, 90890-03081

Adapter:

YU-33223-3, 90890-04082

SWL2190J

2-14

INSP

ADJ

COMPRESSION PRESSURE

5. Measure:

• Compression

To measure the compression, set the

main switch to “START” “” or set it

to “ON” “” and pull the recoil starter

until the needle stops rising on the compression gauge.

Standard compression pressure:

400 ~ 600 kPa

(4 ~ 6 kg/cm

WARNING

To prevent sparking when cranking the

engine, ground the spark plug lead.

Testing steps (below minimum level):

• Squirt a few drops of oil into the cylinder.

• Measure the compression pressure again.

2

, 57 ~ 85 psi)

Reading Diagnosis

If higher than

without oil

• Worn cylinder, piston, and

piston ring

• Defective piston, ring(s),

If the same as

without oil

valve(s), and cylinder

head gasket

• Improper valve timing and

valve clearance

Testing steps (above maximum level):

• Check the cylinder head, valve surfaces,

and piston crown for carbon deposits.

6. Install:

• Spark plug

• Spark plug cap

Spark plug:

18 Nm (1.8 m · kg, 13 ft · lb)

T

.

R

.

7. Install:

• Panel 4

Refer to “COVERS, PANELS, AND

CAPS”.

2-15

INSP

ADJ

1

ENGINE SPEED (NO LOAD)/

ECONOMY ENGINE SPEED

ENGINE SPEED (NO LOAD)

1. Remove:

• Panel 4

Refer to “COVERS, PANELS, AND

CAPS”.

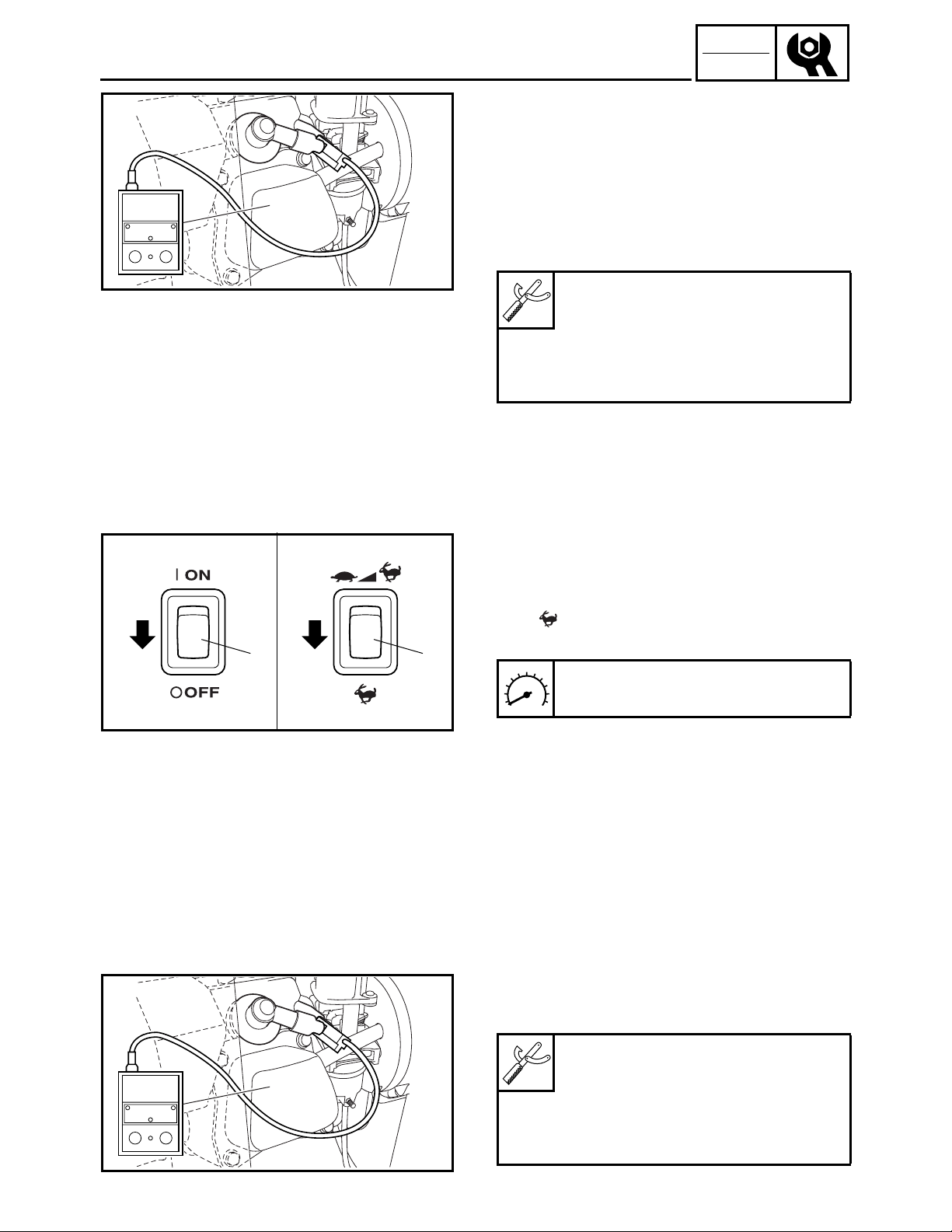

2. Connect:

• Inductive self-powered tachometer or

engine tachometer

1

SWL2200J

ÈÉ

a

1

a

1

SWL2020T

Inductive self-powered tachometer:

YU-8036-B

Engine tachometer:

90890-03113

(90793-80009, 90793-80032)

3. Inspect:

• Engine speed (no load)

Specified engine speed → OK

Out of specification → Refer to “TROU-

BLESHOOTING” in CHAPTER 3.

Inspection steps:

• Operate the engine (no load).

• Turn the economy switch 1 to “OFF”

“” a.

• Measure the engine speed (no load).

Engine speed (no load):

3,550 r/min

È

120 V-60 Hz, 220 V-50 Hz

É

230 V-50 Hz

4. Install:

• Panel 4

Refer to “COVERS, PANELS, AND

CAPS”.

ECONOMY ENGINE SPEED

1. Remove:

• Panel 4

Refer to “COVERS, PANELS, AND

CAPS”.

2. Connect:

• Inductive self-powered tachometer or

engine tachometer

1

1

Inductive self-powered tachometer:

YU-8036-B

Engine tachometer:

90890-03113

(90793-80009, 90793-80032)

SWL2200J

2-16

INSP

ADJ

ECONOMY ENGINE SPEED/

CHOKE CABLE/BREATHER HOSE

ÈÉ

a

1

a

1

SWL2050T

3. Inspect:

• Economy engine speed

Specified engine speed → OK

Out of specification → Refer to “TROU-

BLE SHOOTING” in CHAPTER 3.

Inspection steps:

• Turn the economy switch 1 to “ON”

“” a.

• Operate the engine (no load).

• Measure the economy engine speed.

Economy engine speed (no load):

2,800 ± 50 r/min

È

120 V-60 Hz, 220 V-50 Hz

É

230 V-50 Hz

4. Install:

• Panel 4

Refer to “COVERS, PANELS, AND

CAPS”.

CHOKE CABLE

1. Inspect:

• Choke knob

(pull the choke knob all the way out)

Choke knob automatically returns

Adjust.

→

1

SWL2430J

1

SWL2220J

Adjustment steps:

• Turn in the adjusting nut 1 until the choke

knob does not automatically return.

BREATHER HOSE

1. Remove:

• Panel 4

Refer to “COVERS, PANELS, AND

CAPS”.

2. Inspect:

• Breather hose 1

Cracks/damage → Replace.

Poor connection → Correct.

3. Install:

• Panel 4

Refer to “COVERS, PANELS, AND

CAPS”.

2-17

INSP

ADJ

SVU2240J

SPARK PLUG

ELECTRICAL

SPARK PLUG

WARNING

Inspect and adjust the areas around the

cylinder head after the engine has cooled

down completely.

CAUTION:

Before removing the spark plug, use compressed air to clean the cylinder head

cover to prevent dirt from falling into the

engine.

1. Remove:

• Panel 4

Refer to “COVERS, PANELS, AND

CAPS”.

2. Remove:

• Spark plug cap

• Spark plug

3. Inspect:

• Electrode 1

Wear/damage → Replace.

• Insulator color 2

4. Measure:

• Spark plug gap a

Use a wire gauge or thickness gauge.

Out of specification → Regap.

Spark plug gap:

0.7 ~ 0.8 mm (0.028 ~ 0.031 in)

SVU2250J

If necessary, clean the spark plug with a spark

plug cleaner.

Standard spark plug (with resistor):

BPR4ES (NGK)

Before installing the spark plug, clean the gasket surface and plug surface.

2-18

INSP

ADJ

SVU2280

SPARK PLUG/

MAIN SWITCH

5. Tighten:

• Spark plug

Spark plug:

18 Nm (1.8 m · kg, 13 ft · lb)

T

.

R

.

NOTE:

To prevent thread damage, finger tighten

the spark plug before tightening it to the specified torque b.

6. Install:

• Spark plug cap

7. Install:

• Panel 4

Refer to “COVERS, PANELS, AND

CAPS”.

a

ÈÉ

SWL2030T

ÈÉ

SWL2040T

MAIN SWITCH

1. Check:

• Main switch

Checking steps:

• Set the main switch to “ON” “” and pull

the recoil starter to start the engine.

• Check that the engine stops when the

main switch is set to “STOP” “” 1.

Engine does not stop → Refer to “IGNI-

TION SYSTEM” in CHAPTER 4.

È

120 V-60 Hz, 220 V-50 Hz

É

230 V-50 Hz

• Check that the engine starts when the

main switch is set to “START” “”.

Engine does not start → Refer to “ELEC-

TRIC STARTING SYSTEM” in CHAPTER

4.

È

120 V-60 Hz, 220 V-50 Hz

É

230 V-50 Hz

2-19

INSP

ADJ

ECONOMY SWITCH/PILOT LIGHT/

OVERLOAD WARNING LIGHT

ÈÉ

a

1

a

1

SWL2050T

1

ECONOMY SWITCH

1. Check:

• Economy switch 1

120 V-60 Hz, 220 V-50 Hz

È

230 V-50 Hz

É

Checking steps:

• Set the economy switch 1 to “ON”

“” a.

• Start the engine.

• Turn the switch of the electric device con-

nected to the AC outlet “ON” “”

and “OFF” “” to check whether the

engine speed increases and decreases.

Does not change → Refer to “TROUBLE-

SHOOTING” in CHAPTER 3 and “GENERATOR SYSTEM” in CHAPTER 4.

PILOT LIGHT

1. Check:

• Pilot light 1

1

SWL2060T

SWL2070T

Checking steps:

• Start the engine.

• Check that the pilot light 1 turns on.

Refer to “GENERATOR SYSTEM” in

CHAPTER 4.

OVERLOAD WARNING LIGHT

1. Check:

• Overload warning light 1

2. Remove:

• Control panel

• Overload warning light connector

Refer to “CONTROL PANEL” in CHAPTER 3.

Checking steps:

• Connect three dry cell batteries (1.5 V) to

the overload warning light lead.

• Check that the overload warning light

turns on.

Does not turn on → Replace.

3. Install:

• Overload warning light connector

• Control panel

Refer to “CONTROL PANEL” in CHAPTER 3.

2-20

1

INSP

ADJ

1

DC CIRCUIT BREAKER/

DC CIRCUIT BREAKER (120 V-60 Hz)

DC CIRCUIT BREAKER

1. Check:

• DC circuit breaker

Checking steps:

• Check if the DC circuit breaker knob 1 is

ab

SWL2080T

SWL2090T

set to “RESET” “” a.

• If the knob 1 is set to “OFF” “” b,

direct current cannot be supplied.

• Start the engine.

• Connect a pocket tester (DC 20 V) to the

DC receptacle and check if direct current

is supplied.

Pocket tester:

YU-03112-C, 90890-03112

Direct current not supplied → Replace or

refer to “GENERATOR SYSTEM” in

CHAPTER 4.

1

DC

ON OFF

a

ON

b

SVU2330C

SWL2100T

DC CIRCUIT BREAKER (120 V-60 Hz)

1. Check:

• DC circuit breaker

Checking steps:

• Set the DC circuit breaker 1 to the posi-

tion of “ON” a.

• Connect the pocket tester (DC 20 V).

Pocket tester:

YU-03112-C, 90890-03112

• Start the engine.

• Set the economy switch to “OFF”.

• Measure the DC voltage.

DC voltage:

More than 12 V at 3,550 r/min

(no load at AC output current)

• Set the DC circuit breaker 1 to “OFF” b.

Voltage is zero → OK

2-21

INSP

ADJ

RECEPTACLE/

AC SWITCH (NFB) (120 V-60 Hz/23.5 A)

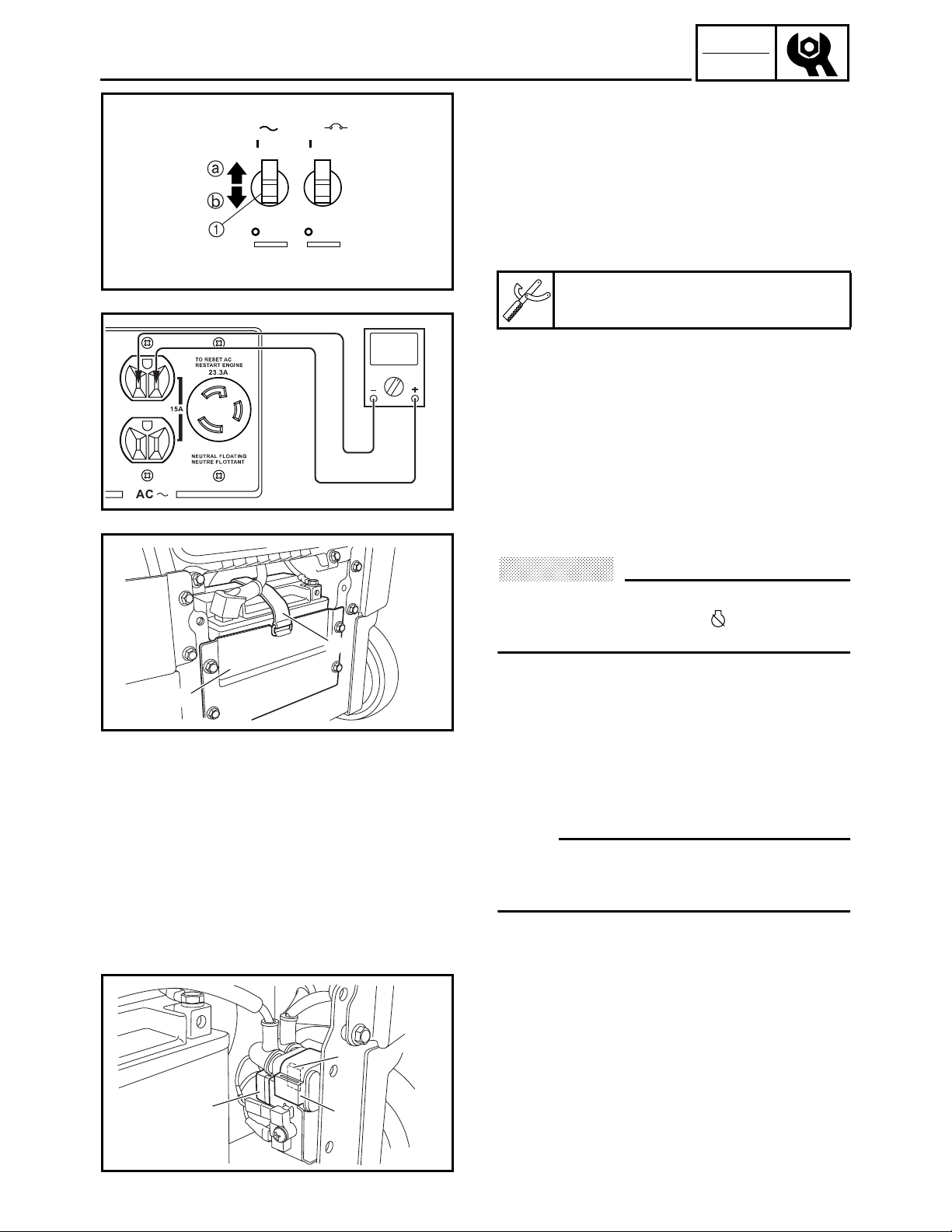

È

É

Ê

1

2

2

3

5

6

4

SWL2110T

SWL2120T

RECEPTACLE

1. Check:

• DC receptacle (12 V, 8.3 A) 1

• DC receptacle (12 V, 12 A) 2

• AC receptacles (15 A) 3

• AC receptacle (23.3 A) 4

• AC receptacles (15 A) 5

• AC receptacles (16 A) 6

Cracks/damage → Replace.

Poor connection → Correct.

120 V-60 Hz

È

220 V-50 Hz

É

230 V-50 Hz

Ê

1

AC SW

ON

ON ON

OFF

15A

ON

OFF

SWL2130T

SWL2160T

SWL2140T

AC SWITCH (NFB) (120 V-60 Hz/23.5 A)

1. Set the AC switch (NFB) 1 to the “ON”

position.

2. Connect the pocket tester (AC 120 V) to

the AC receptacle (23.3 A) and check the

AC switch (NFB) for continuity.

No continuity → Replace the AC switch

(NFB).

Pocket tester:

YU-03112-C, 90890-03112

3. Set the AC switch (NFB) 1 to the “OFF”

b position.

4. Connect the pocket tester (AC 120 V) to

the AC receptacle (23.3 A) and check the

AC switch (NFB) for continuity.

Continuity → Replace the AC switch

(NFB).

a

2-22

INSP

ADJ

AC SWITCH (NFB) (120 V-60 Hz/15 A)/

AC SWITCH (NFB) (120 V-60 Hz/15 A)

AC SW

ON

ON ON

OFF

15A

ON

OFF

SWL2170T

SWL2150T

1. Set the AC switch (NFB) 1 to the “ON”

position.

2. Connect the pocket tester (AC 120 V) to

the AC receptacle (15 A) and check the

AC switch (NFB) for continuity.

No continuity → Replace the AC switch

(NFB).

Pocket tester:

YU-03112-C, 90890-03112

3. Set the AC switch (NFB) 1 to the “OFF”

b

position.

4. Connect the pocket tester (AC 120 V) to

the AC receptacle (15 A) and check the

AC switch (NFB) for continuity.

Continuity → Replace the AC switch

(NFB).

FUSES

a

1

2

3

SWL2280J

FUSES

CAUTION:

To avoid a short circuit, always set the

main switch to “STOP” “” when check-

ing or replacing a fuse.

1. Remove:

• Cover 5

Refer to “COVERS, PANELS, AND

CAPS”.

2. Remove:

• Battery bracket 1

• Battery band 2

• Battery

NOTE:

To check the fuses, slide the battery out with

the positive battery lead and negative battery

lead connected to the battery.

3. Remove:

• Starter relay 1

• Fuse 2

• Fuse (spare)

3

2

1

SWL2290J

2-23

INSP

ADJ

FUSES

4. Check:

• Fuses

Checking steps:

• Connect the pocket tester (

and check the continuity.

NOTE:

Set the pocket tester selector to “

Pocket tester:

YU-03112-C, 90890-03112

• If the pocket tester indicates “∞”, replace

the fuse.

5. Replace:

• Blown fuse

Replacing steps:

• Set the main switch to “STOP” “”.

• Install a new fuse of the correct amperage.

• Set the main switch to “ON” “” and ver-

ify if the electrical circuit is operational.

• If the fuse immediately blows again, check

the electrical circuit.

Ω ×

1) to a fuse

Ω ×

1”

Fuse amperage:

10 A

WARNING

Never use a fuse with an amperage other

than that specified. Improvising or using a

fuse with the wrong amperage rating may

cause extensive damage to the electrical

system and could possibly cause a fire.

6. Install:

• Fuse (spare)

• Fuse

• Starter relay

7. Install:

• Battery

• Battery band

• Battery bracket

8. Install:

• Cover 5

Refer to “COVERS, PANELS, AND

CAPS”.

2-24

INSP

ADJ

DANGER/POISON

EYES

EXPLOSIVE

GASES CAN CAUSE

BLINDNESS OR INJURY

IN U.S.A., YUASA BATTERY, INC,

SERVICED BY : READING, PA. 19612

SHIELD

SPARKS

FLAMES

SMOKING

KEEP OUT OF REACH OF CHILDREN

NO

SULFURIC

ACID

CAN CAUSE

BLINDNESS OR

SEVERE BURNS

FLUSH EYES

IMMEDIATELY

WITH WATER

GET

MEDICAL

HELP

FAST

LEAD

AH17

RETURN

RECYCLE

Pb

SWL2450

BATTERY/

BATTERY TERMINAL

BATTERY

WARNING

Battery fluid is poisonous and dangerous,

causes severe burns, etc. Contains sulfuric

acid.

Avoid contact with skin, eyes or clothing.

Antidote:

EXTERNAL – Flush with water.

INTERNAL – Drink large quantities of water

or milk. Follow with milk of magnesia,

beaten egg or vegetable oil. Call a physician immediately.

Eyes: Flush with water for 15 minutes and

get prompt medical attention.

Batteries produce explosive gases. Keep

sparks, flames, cigarettes, etc. away. Ventilate when charging or using in enclosed

space. Always shield eyes when working

near batteries.

KEEP OUT OF REACH OF CHILDREN.

3

1

2

SWL2300J

SWL2310J

BATTERY TERMINAL

1. Remove:

• Cover 5

Refer to “COVERS, PANELS, AND

CAPS”.

2. Remove:

• Battery bracket 1

• Battery band 2

• Battery 3

CAUTION:

When removing the battery, disconnect the

negative lead first.

3. Check:

• Battery terminal

Dirty terminal → Clean with a wire

brush.

Poor connection → Correct.

NOTE:

After cleaning the terminals, apply grease

lightly to the terminals.

2-25

INSP

ADJ

BATTERY TERMINAL/

BATTERY ELECTROLYTE

4. Install:

• Battery

• Battery band

• Battery bracket

CAUTION:

Connect the positive lead to the battery terminal first.

5. Install:

• Cover 5

Refer to “COVERS, PANELS, AND

CAPS”.

BATTERY ELECTROLYTE

1. Fill:

CAUTION:

• Never remove the sealing sheet (aluminium seal) from the battery until the battery is filled with electrolyte.

If battery plates are exposed to air, they

will oxidize. As a result, power will not be

generated as specified.

• Add electrolyte so that its level is correct

as specified.

An incorrect electrolyte level has an

adverse effect on battery performance.

The quantity of electrolyte varies with the

type of the electrolyte container. Use

only the amount of electrolyte in the container which comes with the battery.

• Avoid using any electrolyte other than

specified.

The specific gravity of the MF battery

electrolyte is 1.320 (20 °C). (The specific

gravity of the general type battery electrolyte is 1.280.)

If the electrolyte whose specific gravity is

less than 1.320, the sulfuric acid will

decrease and thus low battery performance will result.

Should any electrolyte, whose specific

gravity is 1.320 or more, be used, the battery plates will corrode and battery life

will shorten.

2-26

INSP

ADJ

BATTERY ELECTROLYTE

a. Place the battery on a level surface.

b. Remove the sealing sheet 1.

Filler port

2

SWL2320J

c. Take the electrolyte container out of the

vinyl bag.

d. Detach the strip of caps (used as battery

plugs) 1.

Six sealed areas of container

2

NOTE:

Do not lose the strip of caps because it will be

used as battery plugs.

SWL2330J

CAUTION:

Do not peel or pierce the sealed areas.

SWL2340J

e. Turn the electrolyte container upside

down with the six sealed areas in line with

the six filler ports of the battery.

f. Push the container down strongly enough

to break the seals. The electrolyte will

start to flow into the battery.

CAUTION:

• Do not tilt the container as the electrolyte

may stop flowing.

• Never remove the container from the battery until all electrolyte has drained from

the container.

2-27

INSP

ADJ

BATTERY ELECTROLYTE

g. Leave the container in this position for

20 minutes or longer to allow proper

chemical reaction.

NOTE:

• Make sure air bubbles are rising from all six

filler ports.

• If air bubbles are not rising from a filler port,

tap the top of the container a few times.

SWL2350J

SWL2360J

• Do not cut the connected parts.

h. Be certain that all the electrolyte has been

drained from the container.

i. Fit the strip of caps (battery plugs)

securely into the filler ports. Make sure

the top of the strip is at the same level as

the top of the battery.

Press down horizontally with both hands.

1

CAUTION:

Never remove the strip of caps, nor add any

water or electrolyte.

WARNING

• Do not attempt boost charging under any

circumstances.

• Battery electrolyte is poisonous and dangerous, causing severe burns, etc. Contains sulfuric acid. Avoid contact with

skin, eyes or clothing.

Antidote: External — Flush with water.

Internal — Drink large quantities of water

or milk. Follow with milk of magnesia,

beaten egg, or vegetable oil. Call physician immediately.

Eyes: Flush with water for 15 minutes

and get prompt medical attention. Batteries produce explosive gases. Keep

sparks, flame, cigarettes, etc., away. Ventilate when charging or using in enclosed

space. Always shield eyes when working

near batteries.

KEEP OUT OF REACH OF CHILDREN.

2-28

INSP

ADJ

BATTERY ELECTROLYTE/

BATTERY CHARGING

2. Check:

• Using a digital voltmeter, the state of a

discharged MF battery can be checked

by measuring open-circuit voltage (the

voltage measured with the positive and

negative terminals being disconnected).

CAUTION:

The battery must be charged after it is filled

with electrolyte. If this is not done, the life

of the battery will be shortened drastically.

SWL2380J

SWL2390J

BATTERY CHARGING

1. Check:

• Battery voltage

Check the battery voltage using an MF

battery tester (commercially available).

Within green range → Correct

Within yellow or red range → Charge

the battery.

2. Recharge the battery using an MF battery

charger (commercially available).

• Charge the battery to the specified

electric current and to the specified voltage.

Charging amperage and charging time:

1.2 A × 5 ~ 10 hr

Charging voltage:

12.8 V or more

2-29

PANELS AND COVERS

:

7.0 Nm (0.7 m · kg, 5.1 ft · lb)

È

PANELS AND COVERS

ENGINE

È

ENG

È

È

È

5

È

8

2

7

È

4

È

3

1

È

Order Job name/Part name Q’ty Remarks

Panels and covers removal

Fuel tank/fuel hose Refer to “FUEL TANK AND CONTROL

Starter handle Refer to “RECOIL STARTER AND FLY-

1Cover 1 1

2Cover 5 1

3 Panel 1 1

4 Panel 3 1

5 Battery bracket 1

6Cover 2 1

6

È

Remove the parts in the order listed

below.

BOX”.

WHEEL MAGNETO”.

È

SWL3010

3-1

:

7.0 Nm (0.7 m · kg, 5.1 ft · lb)

È

PANELS AND COVERS

È

ENG

È

È

È

5

È

8

2

7

È

4

È

3

1

È

Order Job name/Part name Q’ty Remarks

7Cover 6 1

8Cover 3 1

6

È

NOTE:

To remove the control box, disconnect

the necessary couplers and leads. It is

not necessary to remove the cover 3 from

the control box.

For installation, reverse the removal

procedure.

È

SWL3010

3-2

CONTROL PANEL

CONTROL PANEL

ENG

1

E

4

9

8

0

A

3

120 V-60 Hz

1

2

3

4

5

6

7

3

220 V-50 Hz 230 V-50 Hz

1

9

3

D

C

2

B

3

2

1

9

D

2

2

4

5

6

7

Order Job name/Part name Q’ty Remarks

Control panel removal

Choke cable (carburetor end) Refer to “CARBURETOR”.

1 Control panel assembly 1

2 Wire harness 1

3 Ground terminal 1

4 Engine speed limiter/oil level warning

unit

4

5

6

7

F

Remove the parts in the order listed

below.

NOTE:

Disconnect all couplers and leads.

1

NOTE:

After installing all parts, refer to “WIRE

ROUTING DIAGRAM” in CHAPTER 5 to

check the cable, lead, and hose routings.

For installation, reverse the removal

procedure.

SWL3010T

3-3

CONTROL PANEL

ENG

1

4

9

120 V-60 Hz

1

8

0

A

2

3

4

5

6

7

3

220 V-50 Hz 230 V-50 Hz

1

D

9

E

3

3

C

2

B

3

2

1

D

9

2

4

2

5

6

7

4

5

6

7

F

Order Job name/Part name Q’ty Remarks

1

2

3

4

5

6

7

8

9

0

A

B

C

D

E

F

Control panel disassembly

Main switch 1

Economy switch 1

Fuel cock knob 1

Choke knob 1

Oil level warning light 1

Pilot light 1

Overload warning light 1

DC receptacle (12 V, 8.3 A) 1

DC circuit breaker 1

AC switch (NFB) (15 A) 1

AC switch (NFB) (23.5 A) 1

AC receptacle (15 A × 2) 1

AC receptacle (23.3 A) 1

DC receptacle (12 V, 12 A) 1

AC receptacle (15 A × 2) 1 For assembly, reverse the disassembly

AC receptacle (16 A × 2) 1

Remove the parts in the order listed below.

NOTE:

After installing the fuel cock knob, check it

for proper operation.

procedure.

SWL3010T

3-4

FUEL TANK AND CONTROL BOX

FUEL TANK AND CONTROL BOX

:

7.0 Nm (0.7 m · kg, 5.1 ft · lb)

È

ENG

2

3

È

a

7

1

9

,

9

+

È

4

6

5

1

9

9

10

È

8

120 V-60 Hz, 220 V-50 Hz

+

230 V-50 Hz

,

Order Job name/Part name Q’ty Remarks

Fuel tank and control box removal

Remove the parts in the order listed

below.

Cover 1/cover 5/panel 4/panel 2 Refer to “COVERS, PANELS, AND

CAPS” in CHAPTER 2.

Fuel Drain.

Choke cable (carburetor end) Refer to “CARBURETOR”.

1 Fuel hose 2

NOTE:

When removing the fuel tank, disconnect

only the fuel cock end of the fuel hose.

2 Fuel tank cap 1

3Cover 4 1

4 Fuel tank 1

5 Fuel pipe strainer 1

6 Fuel tank filter 1

SWL3020T

3-5

:

7.0 Nm (0.7 m · kg, 5.1 ft · lb)

È

FUEL TANK AND CONTROL BOX

ENG

2

È

a

7

1

9

,

9

+

10

5

1

9

9

È

8

È

6

3

4

Order Job name/Part name Q’ty Remarks

7 Fuel level gauge 1

8 Ground lead 1

9 Wire harness 1

10 Control box 1

NOTE:

To install the fuel level gauge, face the

“E” mark toward the control panel a.

NOTE:

Disconnect all couplers, leads, and con-

nectors.

NOTE:

After installing all parts, refer to “WIRE

ROUTING DIAGRAM” in CHAPTER 5 to

check the cable, lead, and hose routings.

For installation, reverse the removal

procedure.

SWL3020T

3-6

AIR FILTER ASSEMBLY AND CONTROL UNIT

AIR FILTER ASSEMBLY AND CONTROL UNIT

120 V-60 Hz, 220 V-50 Hz

:

4.0 Nm (0.4 m · kg, 2.9 ft · lb)

È

:

7.0 Nm (0.7 m · kg, 5.1 ft · lb)

É

:

10 Nm (1.0 m · kg, 7.2 ft · lb)

Ê

1

4

3

5

È

8

2

New

É

ENG

6

7

Ê

Ê

120 V-60 Hz

+

+

Ê

Order Job name/Part name Q’ty Remarks

Air filter assembly and control unit

removal

Remove the parts in the order listed

below.

Cover 5/panel 3/panel 4 Refer to “COVERS, PANELS, AND

CAPS” in CHAPTER 2.

1 Air filter assembly 1

2 Breather hose 1

3 Air intake duct 1

4 Air filter element 2

NOTE:

Remove air filter element 1 and air filter

element 2 as a set.

SWL3030T

5 Throttle control motor cover 1

6 Coupler/connector 3/1 Disconnect.

7 Control unit 1

8 Control unit cover 1

For installation, reverse the removal

procedure.

3-7

AIR FILTER ASSEMBLY, CONTROL UNIT AND NOISE

FILTER

ENG

AIR FILTER ASSEMBLY, CONTROL UNIT AND NOISE FILTER

230 V-50 Hz

:

7.0 Nm (0.7 m · kg, 5.1 ft · lb)

È

:

10 Nm (1.0 m · kg, 7.2 ft · lb)

É

1

3

6

5

8

9

6

2

New

È

4

7

É

É

É

Order Job name/Part name Q’ty Remarks

Air filter assembly, control unit, and

noise filter removal

Cover 1/cover 5/cover 4/cover 2/

cover 6/panel 3

1 Air filter assembly 1

2 Breather hose 1

3 Air intake duct 1

4 Air filter element 2

5 Throttle control motor cover 1

6 Coupler/connector 3/1 Disconnect.

7 Control unit 1

8 Coupler 1 Disconnect.

9 Noise filter 1

Remove the parts in the order listed

below.

Refer to “COVERS, PANELS, AND

CAPS” in CHAPTER 2.

NOTE:

Remove air filter element 1 and air filter

element 2 as a set.

For installation, reverse the removal

procedure.

SWL3040T

3-8

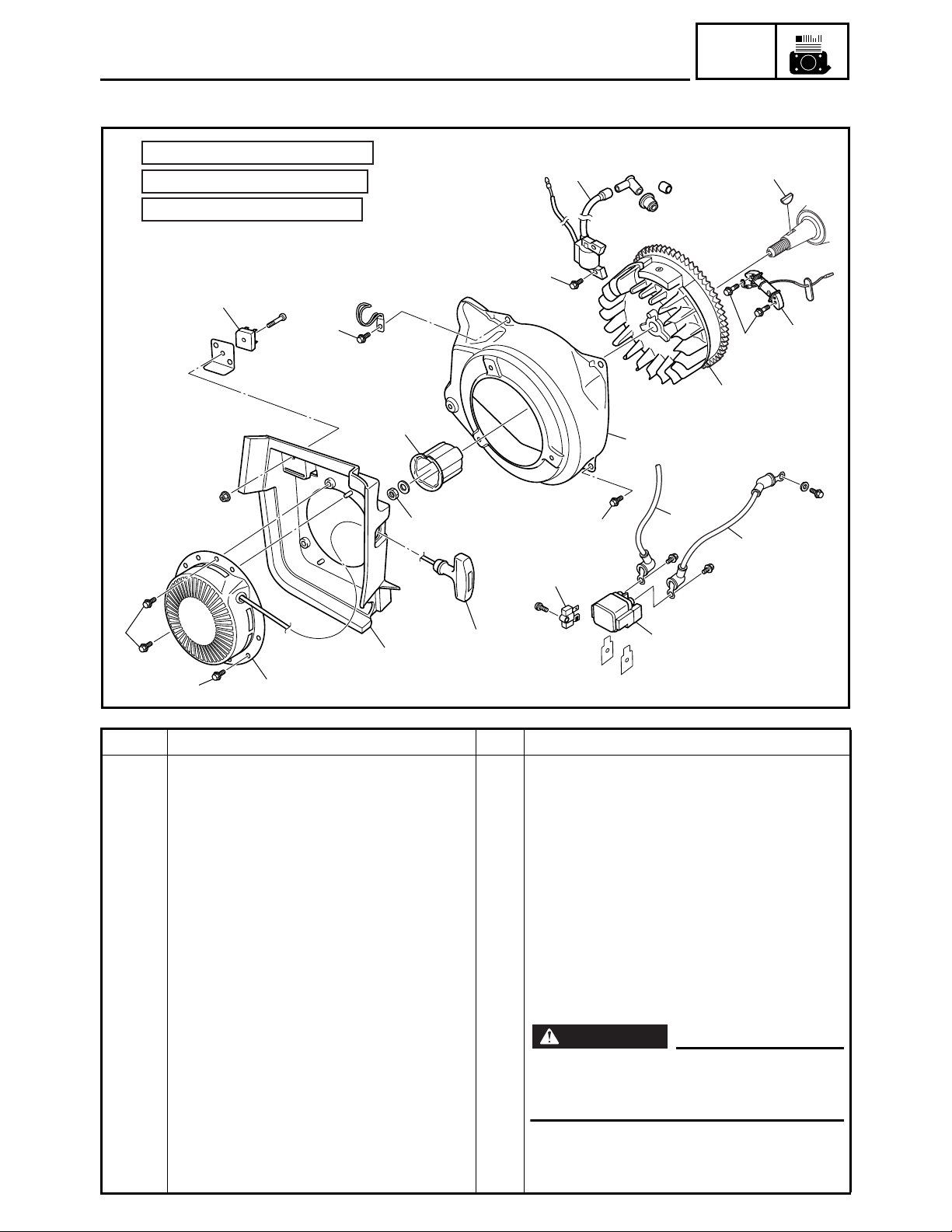

RECOIL STARTER AND FLYWHEEL MAGNETO

WARNING

RECOIL STARTER AND FLYWHEEL MAGNETO

:

7.0 Nm (0.7 m · kg, 5.1 ft · lb)

È

:

10 Nm (1.0 m · kg, 7.2 ft · lb)

É

:

65 Nm (6.5 m · kg, 47 ft · lb)

Ê

8

11

É

ENG

13

È

10

Ê

4

È

7

È

Order Job name/Part name Q’ty Remarks

Recoil starter and flywheel magneto

removal

Fuel tank Refer to “FUEL TANK AND CONTROL

Cover 3 Refer to “PANELS AND COVERS”.

Air filter assembly/control unit Refer to “AIR FILTER ASSEMBLY AND

Carburetor Refer to “CARBURETOR”.

Battery

1 Starter relay 1

2 Positive battery lead 1

6

5

Remove the parts in the order listed

below.

BOX”.

CONTROL UNIT” and “AIR FILTER

ASSEMBLY, CONTROL UNIT AND

NOISE FILTER”.

È

9

2

1

12

É

14

3

SWL3060

Remove the battery before discon-

necting the positive battery lead and

the starter motor lead.

3 Starter motor lead 1

4Rectifier 1

5 Starter handle 1

3-9

RECOIL STARTER AND FLYWHEEL MAGNETO

:

7.0 Nm (0.7 m · kg, 5.1 ft · lb)

È

:

10 Nm (1.0 m · kg, 7.2 ft · lb)

É

:

65 Nm (6.5 m · kg, 47 ft · lb)

Ê

8

É

11

ENG

13

È

10

9

Ê

È

2

4

È

5

1

7

È

6

Order Job name/Part name Q’ty Remarks

6 Recoil starter assembly 1

7 Recoil starter cover 1

8DC rectifier 1

9 Flywheel magneto cover 1

10 Starter pulley 1

11 TCI unit 1

12 Flywheel magneto 1

13 Woodruff key 1

14 Charging coil 1

NOTE:

After installing all parts, refer to “WIRE

ROUTING DIAGRAM” in CHAPTER 5 to

check the cable, lead, and hose routings.

12

É

14

3

SWL3060

3-10

For installation, reverse the removal

procedure.

RECOIL STARTER AND FLYWHEEL MAGNETO

ENG

Order Job name/Part name Q’ty Remarks

1

2

3

4

5

6

7

8

9

Recoil starter disassembly

Starter handle 1

Bolt 1

Drive plate 1

Clip 1

Drive pawl 2

Spring 2

Sheave drum 1

Starter spring 1

Starter case 1

Remove the parts in the order listed

below.

For assembly, reverse the disassembly

procedure.

SWL3070

3-11

RECOIL STARTER AND FLYWHEEL MAGNETO

RECOIL STARTER REMOVAL

1. Remove:

• Starter handle 1

NOTE:

When removing the starter handle from the

starter rope, be sure to wrap the starter rope

around a screwdriver, etc., to prevent the rope

from retracting into the starter case.

SWL3080J

ENG

1

2

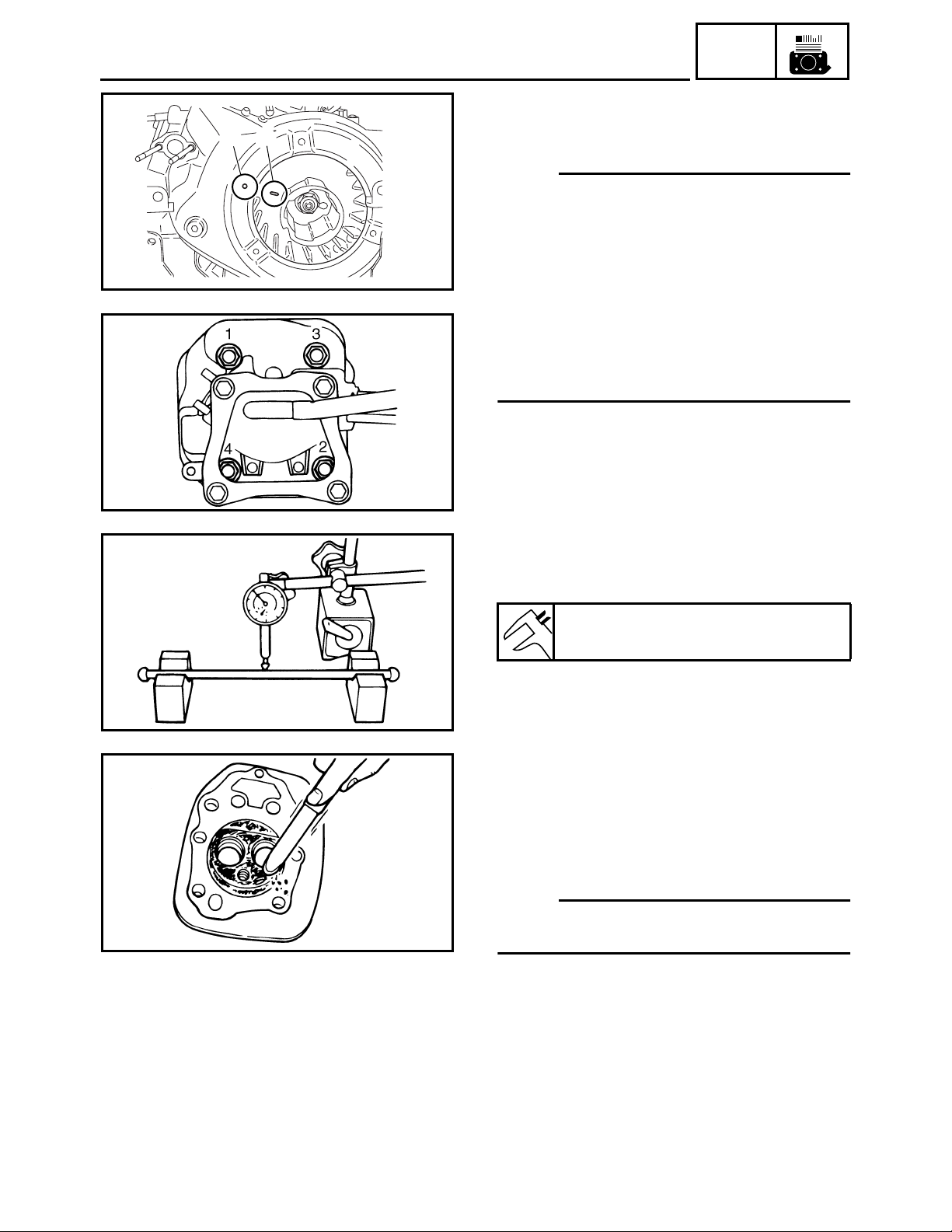

FLYWHEEL MAGNETO REMOVAL

1. Remove:

• Flywheel magneto nut 1

• Washer

• Starter pulley

NOTE:

Attach the sheave holder 2 to hold the flywheel magneto.

SWL3470J

Sheave holder:

YS-01880-A, 90890-01701

Rotor assembly holder:

(commercially available)

2. Remove:

• Flywheel magneto 1

SWL3090J

NOTE:

• Remove the flywheel magneto using a bearing puller (commercially available) 2.

• When removing the flywheel magneto, be

sure to hold it so that it does not turn.

CAUTION:

Do not hold the flywheel magneto by its

fins, otherwise the fins can be damaged.

3-12

RECOIL STARTER AND FLYWHEEL MAGNETO

FLYWHEEL MAGNETO INSTALLATION

1

2

SWL3150J

1. Install:

• Woodruff key 1

• Flywheel magneto 2

CAUTION:

Be sure to remove any oil or grease from

the tapered portion of the crankshaft using

a cloth dampened with thinner.

NOTE:

Insert the woodruff key 1 into the groove in

the flywheel magneto 2.

ENG

1

2

SWL3470J

2. Install:

• Starter pulley

• Washer

• Flywheel magneto nut 1

Flywheel magneto nut:

65 Nm (6.5 m · kg, 47 ft · lb)

T

.

R

.

NOTE:

Tighten the flywheel magneto nut 1 using the

sheave holder 2 to hold the flywheel magneto.

Sheave holder:

YS-01880-A, 90890-01701

Rotor assembly holder:

(commercially available)

3. Measure:

• Air gap between TCI unit and flywheel

magneto

Refer to “AIR GAP BETWEEN TCI

UNIT AND FLYWHEEL MAGNETO” in

CHAPTER 2.

3-13

Air gap between TCI unit and flywheel magneto:

0.5 ± 0.1 mm (0.020 ± 0.004 in)

RECOIL STARTER AND FLYWHEEL MAGNETO

RECOIL STARTER DISASSEMBLY

1. Remove:

• Starter handle 1

NOTE:

Make a knot a at the end of the starter rope to

prevent the rope from being retracted into the

starter case. Then, undo the knot b at the

starter handle to the remove the starter handle

1

.

2. Remove:

• Drum sheave 1

CAUTION:

Be sure to press down on the drum sheave,

because the spring will spring out suddenly when it is removed from the sheave

drum.

1

a

b

1

SWL3100J

SWL3110J

ENG

1

1

1

2

SVU3330J

SVU3340J

3. Remove:

• Starter spring 1

RECOIL STARTER INSPECTION

1. Inspect:

• Starter rope 1

2. Inspect:

• Starter spring

2

Damage/deterioration → Replace.

3. Inspect:

• Drive pawl 1

• Drive plate 2

Wear/damage → Replace.

2

SVU3350J

3-14

RECOIL STARTER AND FLYWHEEL MAGNETO

RECOIL STARTER ASSEMBLY

1

b

1. Install:

• Starter spring 1

• Sheave drum 2

ENG

a

1

2

3

2

a

SVU3360J

b

SWL3120J

NOTE:

Engage the starter spring outer hook a with

the groove b marked “R” on the sheave drum

2

. Carefully wind the spring counterclockwise

and place it on the sheave drum 2.

2. Install:

• Sheave drum 1

• Starter rope 2

• Starter case 3

NOTE:

• Wind the starter rope 2 clockwise two turns

on the sheave drum 1.

• Engage the starter spring inner hook a with

the strut b of the starter case 3, and then

install the parts.

2

2

1

1

a

2

SVU3380J

b

a

SVU3390J

3. Install:

• Springs 1

• Drive pawls 2

NOTE:

Install the springs 1 and drive pawls 2 at the

“R” marks a.

4. Install:

• Clip 1

• Drive plate 2

NOTE:

Align the groove a of the drive plate 2 with

the sheave drum strut b, and then install the

parts.

3-15

RECOIL STARTER AND FLYWHEEL MAGNETO

ENG

1

a

b

SWL3130J

2

SWL3140J

5. Install:

• Bolt 1

After tightening the bolt, place the

starter rope 2 in the cutout a in the

sheave drum, and wind it counterclockwise four turns.

NOTE:

Make a knot b at the end of the starter rope to

prevent the rope from being retracted into the

starter case.

3-16

ENGINE ASSEMBLY

:

7.0 Nm (0.7 m · kg, 5.1 ft · lb)

È

:

16 Nm (1.6 m · kg, 11 ft · lb)

É

ENGINE ASSEMBLY

ENG

É

É

É

2

É

È

1

È

SWL3290

Order Job name/Part name Q’ty Remarks

Engine removal

Engine oil Drain.

Fuel tank Refer to “FUEL TANK AND CONTROL

Cover 6/panel 1/battery bracket Refer to “COVERS, PANELS, AND

Air filter assembly/control unit Refer to “AIR FILTER ASSEMBLY AND

Cover 3 Refer to “PANELS AND COVERS”.

Recoil starter/recoil starter cover Refer to “RECOIL STARTER AND FLY-

1 Pipe frame 1

2 Engine assembly 1

3-17

Remove the parts in the order listed below.

BOX”.

CAPS” in CHAPTER 2.

CONTROL UNIT” and “AIR FILTER

ASSEMBLY, CONTROL UNIT AND

NOISE FILTER”.

NOTE:

Remove the cover 3 with the control box

installed.

WHEEL MAGNETO”.

For installation, reverse the removal

procedure.

CHASSIS AND CASTERS

:

7.0 Nm (0.7 m · kg, 5.1 ft · lb)

È

:

16 Nm (1.6 m · kg, 11 ft · lb)

É

CHASSIS AND CASTERS

ENG

New

1

1

1

1

2

É

5

È

É

4

É

É

3

É

5

New

SWL3490

Order Job name/Part name Q’ty Remarks

Chassis and caster removal

Engine assembly Refer to “ENGINE ASSEMBLY”.

1 Engine mount 4

2Frame 1

3Caster 1 1

4Caster 2 1

5Caster 3 2

Remove the parts in the order listed

below.

For installation, reverse the removal

procedure.

3-18

MUFFLER

MUFFLER

ENG

:

3.5 Nm (0.35 m · kg, 2.5 ft · lb)

È

:

7.0 Nm (0.7 m · kg, 5.1 ft · lb)

É

:

16 Nm (1.6 m · kg, 11 ft · lb)

Ê

6

7

8

É

5

É

É

È

É

É

10

1

É

9

4

É

Ê

3

2

Order Job name/Part name Q’ty Remarks

Muffler removal

Engine assembly Refer to “ENGINE ASSEMBLY”.

1 Exhaust pipe air shroud 1 1

2 Muffler protector 1

3 Muffler 1

4Gasket 1

5 Muffler band 1

6 Muffler cap 1

7 Muffler screen 1

8 Spark arrester 1

9 Generator cover 1

10 Exhaust pipe air shroud 2 1

Remove the parts in the order listed

below.

NOTE:

Remove the muffler nut, then the muffler

bolt.

For installation, reverse the removal

procedure.

SWL3180

3-19

SWL3190J

SWL3200J

MUFFLER

ENG

MUFFLER INSTALLATION

1. Install:

• Spark arrester

NOTE:

To install the spark arrester, align the projection a on the spark arrester with the hole b in

the muffler.

2. Install:

• Muffler cap 1

NOTE:

To install the muffler cap, align the slit in the

muffler cap with the projection c on the muffler as shown in the illustration.

SWL3210J

3. Install:

• Muffler band

NOTE:

Tighten the muffler band at the angle d shown

in the illustration. Make sure that the muffler

band opening and muffler cap slit are not covering the hole b and that the muffler cap has

not come out.

d

30 ~ 60°

Muffler band:

3.5 Nm (0.35 m · kg, 2.5 ft · lb)

T

.

R

.

4. Install:

• Muffler

NOTE:

Finger tighten the muffler nut 1 and muffler

bolt 2, and then tighten them to the specified

torques, respectively.

SWL3220J

3-20

Muffler nut:

7.0 Nm (0.7 m · kg, 5.1 ft · lb)

T

.

R

.

Muffler bolt:

16 Nm (1.6 m · kg, 11 ft · lb)

GENERATOR

:

7.0 Nm (0.7 m · kg, 5.1 ft · lb)

È

:

10 Nm (1.0 m · kg, 7.2 ft · lb)

É

:

65 Nm (6.5 m · kg, 47 ft · lb)

Ê

3

É

2

GENERATOR

4

4

ENG

Ê

Order Job name/Part name Q’ty Remarks

Generator removal

Engine assembly Refer to “ENGINE ASSEMBLY”.

Muffler Refer to “MUFFLER”.

1Fan 1

2 Generator 1

É

3

1

È

Remove the parts in the order listed

below.

CAUTION:

The magnetic force of the magneto

rotor is very strong. Therefore, be sure

to remove the magneto rotor and stator coil assembly together as a set,

otherwise they may be damaged.

SWL3230

3 Tube 2

4 Dowel pin 2

3-21

For installation, reverse the removal

procedure.

SWL3240J

GENERATOR

ENG

GENERATOR ASSEMBLY REMOVAL

CAUTION:

The magnetic force of the magneto rotor is

very strong. Therefore, be sure to remove

the magneto rotor and stator coil assembly

together as a set, otherwise they may be

damaged.

1. Remove:

• Magneto rotor nut 1

NOTE:

Attach the sheave holder 2 to hold the magneto rotor.

Sheave holder:

YS-01880-A, 90890-01701

Rotor assembly holder:

(commercially available)

SWL3250J

SWL3260J

2. Remove:

• Stator coil assembly bolts 1

NOTE:

Turn the magneto rotor until the stator coil

assembly bolts are visible through the holes in

the rotor, and then remove the bolts.

3. Remove:

• Stator coil assembly bolts 2

• Tubes

NOTE:

Turn the magneto rotor until the stator coil

assembly bolts are visible through the holes in

the rotor, and then remove the bolts.

3-22

SWL3270J

GENERATOR

ENG

4. Remove:

• Generator assembly 1

NOTE:

• Remove the magneto rotor together with the

stator coil assembly using the rotor puller 2.

• Fully tighten the tool holding bolts, making

sure that the tool body is parallel with the

magneto rotor.

CAUTION:

The magnetic force of the magneto rotor is

very strong. Therefore, do not change the

position of the magneto rotor and stator

coil assembly during or after removal, otherwise they may be damaged.

Rotor puller:

YU-33270-B, 90890-01362

SWL3480J

GENERATOR ASSEMBLY INSTALLATION

CAUTION:

Be sure to remove any oil or grease from

the tapered portion of the magneto rotor

using a cloth dampened with thinner.

1. Install:

• Generator assembly

2. Install:

• Stator coil assembly bolts 1

• Tubes

Stator coil assembly bolts:

10 Nm (1.0 m · kg, 7.2 ft · lb)

T

.

R

.

NOTE: