Page 1

Page 2

Read and Follow

Safety Instructions!

DANGER

WARNING

CAUTION

This is the safety-alert symbol. When you see this symbol on your system or in this

manual, look for one of the following signal words and be alert to the potential for

personal injury;

DANGER warns about hazards that will cause serious personal injury, death or

major property damage if ignored.

WARNING warns about hazards that could cause serious personal injury, death or

major property damage if ignored.

CAUTION warns about hazards that may result in minor or moderate injury or

property damage if ignored.

This label NOTICE indicates special instructions which are important but not related

to hazards.

Carefully read and follow all safety instructions in this manual or on system.

Keep safety labels in good condition.

Replace missing or damaged safety labels.

Safety Instructions

1. WARNING - THESE WATER TANKS ARE DESIGNED FOR

2. It is your responsibility to make sure your installation meets all national and

3.

4. If a captive air water systems tank replaces a standard galvanized tank on a

5.

OPERATION ON AMBIENT TEMPERATURE WATER SYSTEMS LIMITED

TO A MAXIMUM WORKING PRESSURE OF 125 POUNDS PER SQUARE INCH

GAUGE (PSIG). IF YOUR SYSTEM HAS THE ABILITY TO EXCEED 125 PSIG

WORKING PRESSURE (100 PSIG IF THIS IS A PUMP MOUNTED UNIT), A

SUITABLE SAFETY DEVICE MUST BE INSTALLED. THIS CAN BE EITHER A

HIGH PRESSURE ELECTRICAL CUT-OFF SWITCH AND/OR A PRESSURE

RELIEF VALVE. FAILURE TO FOLLOW THESE INSTRUCTIONS CAN CAUSE

TANK RUPTURE AND RESULT IN PERSONAL INJURY AND/OR PROPERTY

DAMAGE.

local plumbing and electrical codes.

DANGER - Before installing or servicing your pump or tank be sure power

source is disconnected.

submersible pump installation, bleeder orifices or other air charging devices

must be removed. Air charging devices on jet pumps must be removed.

CAUTION - Storage tanks are designed for use on ambient temperature

- (maximum temperature of 120

this product on other applications could cause tank failure and possibly

personal injury. Use of this tank on other applications voids the warranty.

o

F, effective Feb. 2001) water systems. Use of

6. Complete pump, tank and piping system must be protected against freezing.

Failure to do so will cause severe damage and voids the warranty.

7.

DANGER - Tank contains air pressure. Do not puncture. Never throw tank

into fire or incinerator.

2

Page 3

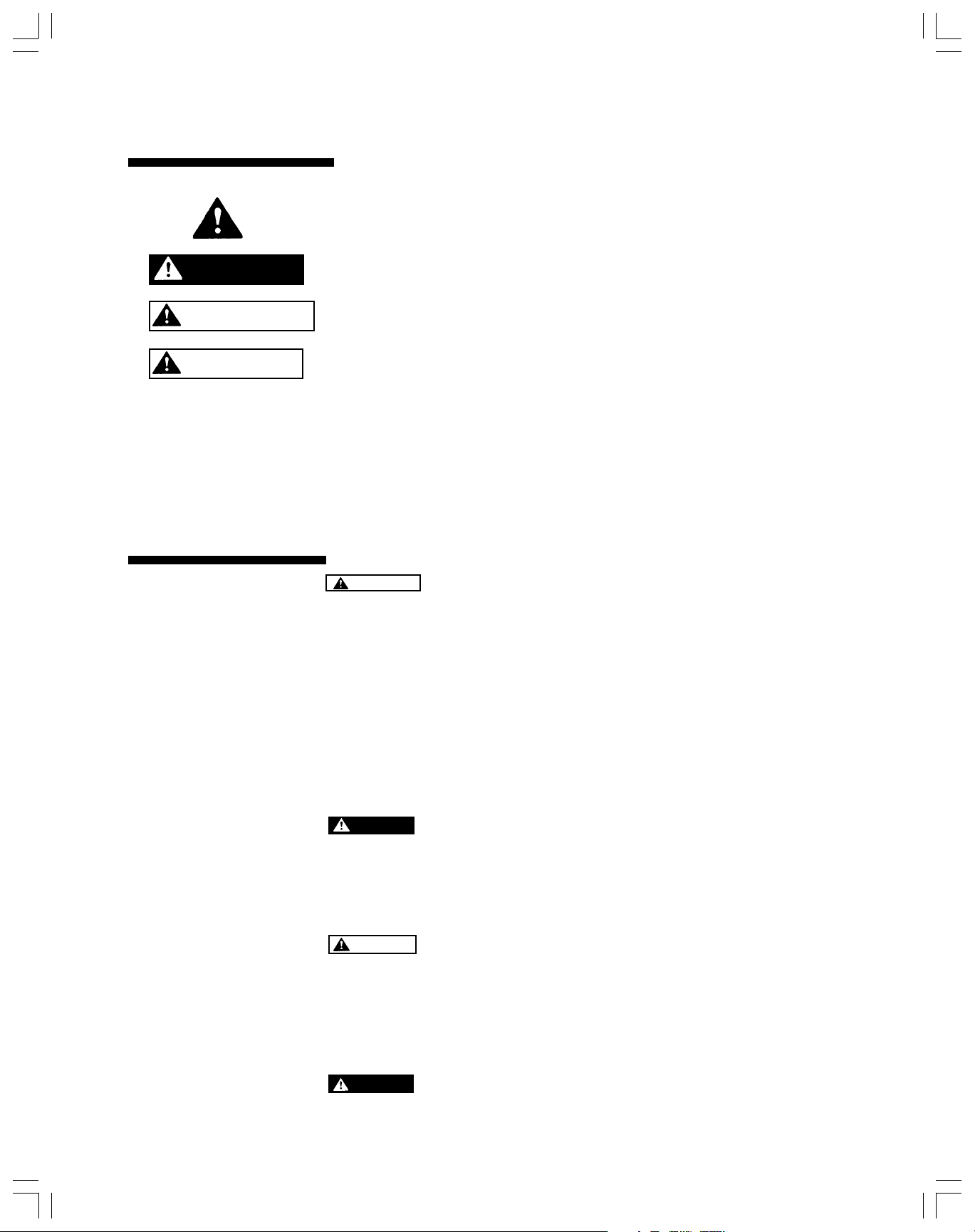

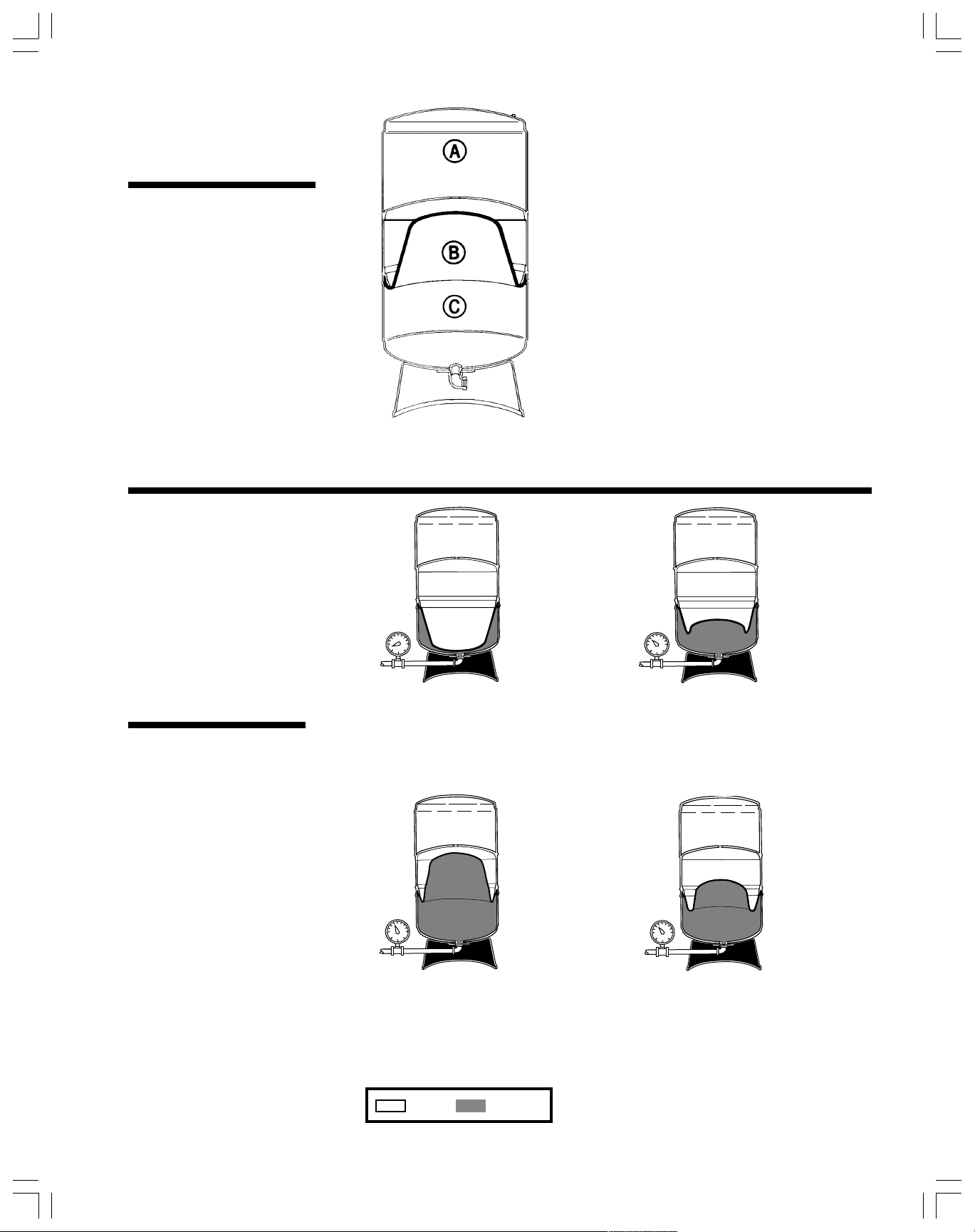

The water systems

40

45

tank

concept

Here’s how the

tank works for a

The water system tank does more than simply

store water. It helps to protect the system

components. A properly sized tank will provide

adequate flow even when the pump is not

running. It saves energy by reducing the

number of pump starts. Another benefit is

increased system component life due to fewer

pump cycles.

The water system tank consists of a steel tank

(A) containing a sealed-in-place heavy duty

diaphragm (B) which separates air from the

water. The portion of the tank where water is

stored (C) is lined to isolate water from the

metal tank. This protects the tank from

corrosion.

water system

designed to

operate at a

30/50 psig

pressure

switch

setting.

30

Prior to shipping, the tank

1.

is pressurized to a standard

precharge as defined in

“OPERATION” part of this

manual.

50

As water enters the tank, the

2.

air above the diaphragm is

compressed and its volume

is reduced by the volume of

water that enters.

The pressure in the tank

3.

rises. Water continues to

enter until the pump cut-out

pressure is reached. The

pump shuts off and the tank

is now filled.

AIR WATER

The pressure in the air chamber

4.

forces water into the system

when a demand is made

without causing the pump to

operate immediately. When

the pressure in the chamber

finally drops to the pump cutin pressure, the pump switch

activates the pump and

3

repeats the filling cycle.

Page 4

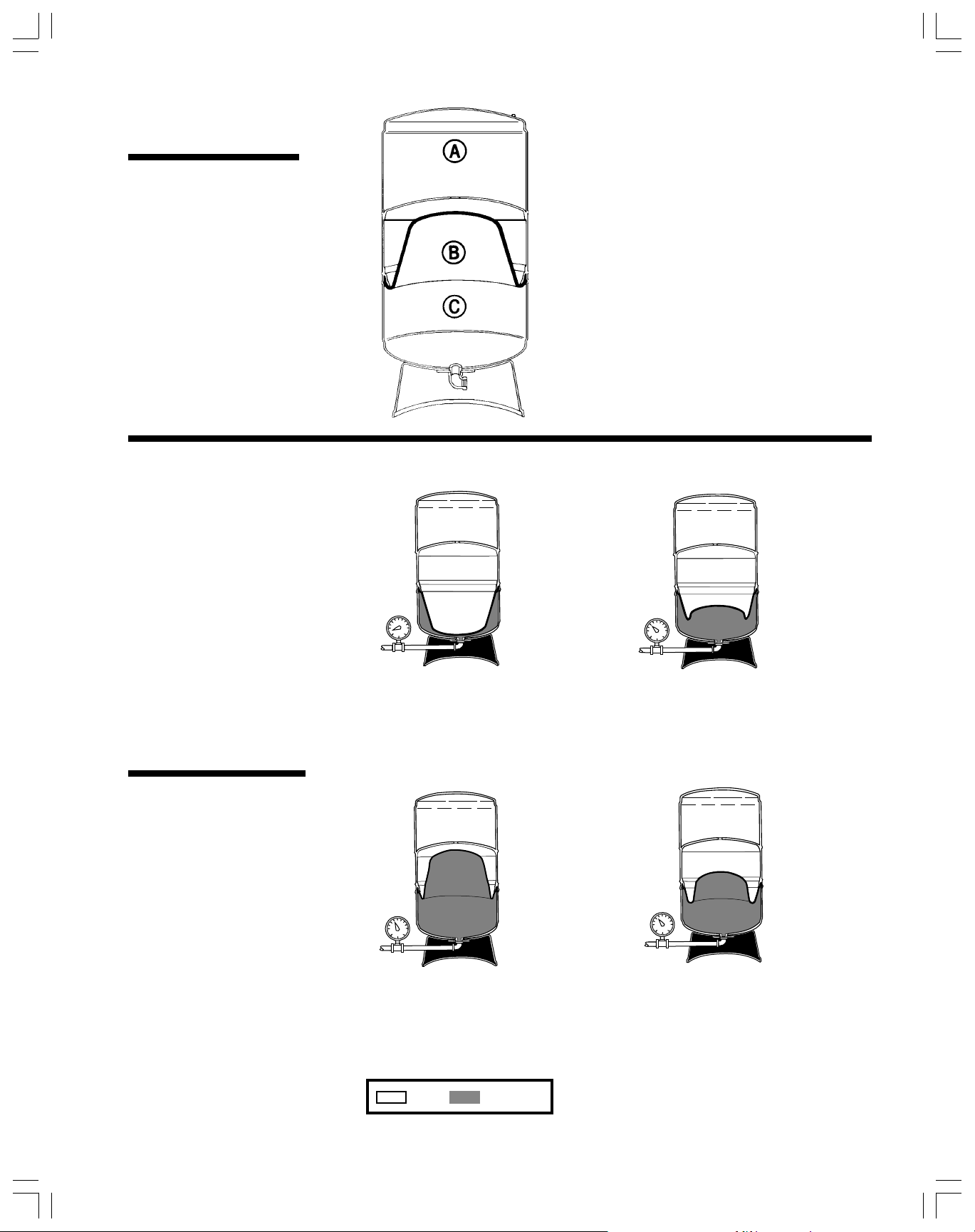

Installation Procedures

TYPICAL SUBMERSIBLE

PUMP INSTALLATION

1. The water system tank should be installed as close

as possible to the pressure switch (24 inches or less)

to reduce the adverse effect of friction loss and

elevation differences.

2. Disconnect electric power.

3. Drain system and remove old tank. On new system

installation this step is unnecessary.

4. Locate the water system tank on a firm, level surface

with adequate drainage. Typical installations are

shown in the following section.

TYPICAL JET

PUMP INSTALLATION

5. If your system is capable of exceeding a working

pressure of 125 psig (typically submersible pumps),

install a pressure relief valve (rated at 125 psig or

less, but greater than turn-off pressure) in the system

near the tank. The valve should be the same pipe

size as the tank outlet.This is not necessary on tankmounted jet pump units.

6. Connect tank to the pump discharge line using the

same size pipe as the pump tap, or larger.

WARNING: Hold 90° tank street elbow with wrench

when threading and tightening connecting pipe.

7. The tank should be flushed 5 times prior

to household use. (See operation section)

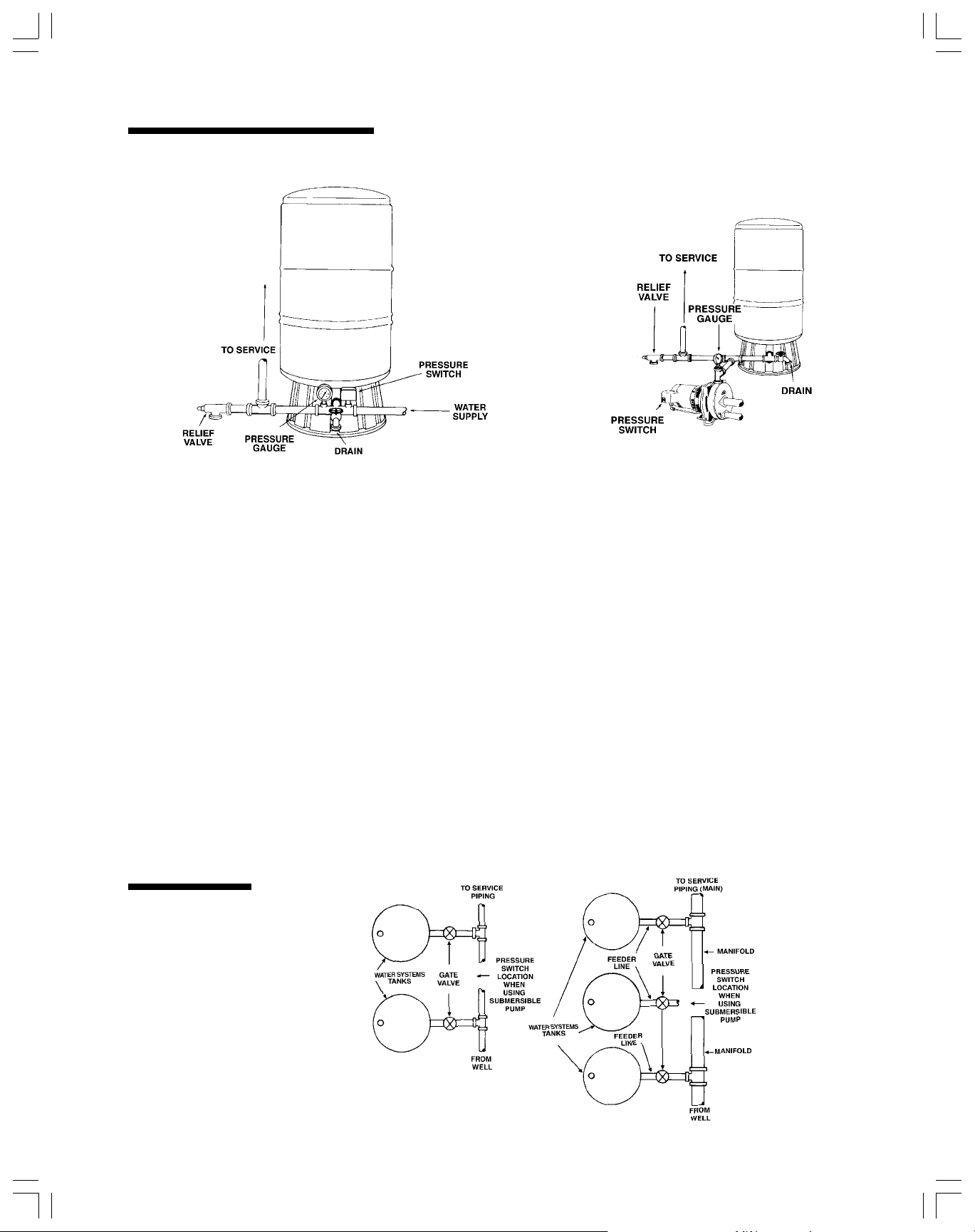

Multiple

Tank

Installation

Procedure

Water system tanks can be connected

together to increase the supply of usable

water (drawdown). Two tanks of the same

size will double the supply and three tanks

will triple the supply. When using a high

4

capacity pump, the manifold and pressure switch

assembly must be installed in the pipe line as close

to the center of the tanks as possible. Manifold and

main should be 2 times the size of the feederline.

Page 5

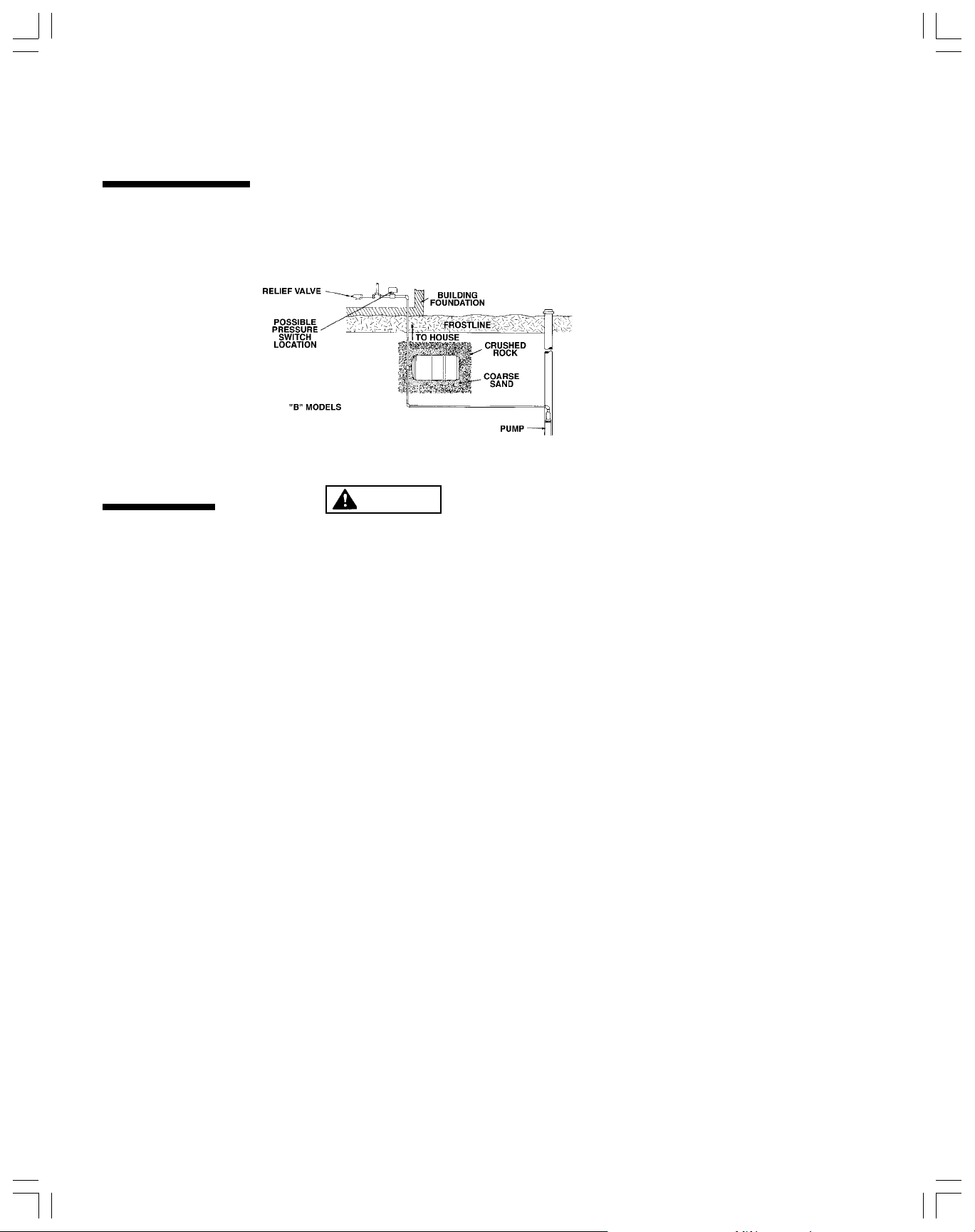

Underground

Pressure

Tanks

Operation

Buried model water system tanks are

designed for direct burial and can be

installed in the horizontal or vertical position.

To eliminate the danger of freezing, tank

must be buried below frost line.

The following steps should be taken when

installing the water system tank.

1. Make sure that tank will be buried below

frost line and above water table.

WARNING

2. Use galvanized or plastic pipe

for section of pipe buried in the ground.

3. Check tank precharge. Tank precharge

must be adjusted to the pressure required

by the pressure switch setting (see section

on Operation).

4. Install tank on firm rock-free earth.

5. The water line from the pump to the

tank and from the tank to the pressure

switch location should be the same size.

6. Check system for performance

and inspect for leaks.

7. Backfill hole with sand or rock-free dirt.

Firmly tamp fill to prevent settling.

8. Make note of tank location so that it

can be easily located at a later time.

THESE WATER TANKS ARE DESIGNED FOR OPERATION ON AMBIENT TEMPERATURE WATER SYSTEMS

LIMITED TO A MAXIMUM WORKING PRESSURE OF 125 POUNDS PER SQUARE INCH GAUGE (PSIG). IF YOUR

SYSTEM HAS THE ABILITY TO EXCEED 125 PSIG WORKING PRESSURE (100 PSIG IF THIS IS A PUMP MOUNTED

UNIT), A SUITABLE SAFETY DEVICE MUST BE INSTALLED. THIS CAN BE EITHER A HIGH PRESSURE ELECTRICAL

CUT-OFF SWITCH AND/OR A PRESSURE RELIEF VALVE. FAILURE TO FOLLOW THESE INSTRUCTIONS CAN

CAUSE TANK RUPTURE AND RESULT IN PERSONAL INJURY AND/OR PROPERTY DAMAGE.

Before you operate the system you must check your water system tank and system to ensure proper operation.

All water system tanks are precharged at the factory. All 8 and 11 inch diameter tanks are precharged at 18 psig. The 15

inch diameter tanks are precharged at 28 psig while the 22 and 26 inch diameter tanks are precharged to 38 psig. The

final precharge pressure should always be 2 to 3 psig below the cut-in (pump turns on) pressure of the pressure switch.

Release air or add air as required using the following procedure.

1. Determine the pump cut-in pressure setting. The pressure switch should have this information located on/in the

cover.

2. With no water in the tank, measure the precharge of the water system tank using an accurate pressure gauge at the

air valve (similar to an auto tire gauge).

LESS

3. Release air or add air to the tank to make the pressure in the tank 2 to 3 psig

setting.

4. It will be necessary to expel air from the piping system on new installations. To do this open all faucets and turn on the

pump. Observe that a mixture of water and air will sputter from the faucet. Run the system until a steady flow of

water exists. Open and close the faucets several times to assure that all air has been removed. If streams do not

become steady, an air leak may exist. Check for leaks on suction side piping.

5. It may be necessary to make final adjustments on the system pressure switch setting because at times the actual

pressure switch setting will vary from what is stated on the cover. Such variation, though not harmful, could cause a

momentary lag of water delivery. To make this adjustment the following steps should be followed:

a. Fill the system until the pump shuts off.

b. Open a faucet and drain the water system tank until the pump starts.

c. If there is a pause in the water flow from the time the water system tank is emptied and the pump starts up

again, decrease the air pressure in the tank until it is 2 to 3 psig below the cut-in pressure setting. (See

Trouble Shooting section 3(a-b) for procedure)

d. Close the faucets and refill the water system tank. Repeat steps (b) and (c) if necessary until there no

longer is a pause in water flow.

5

than the pump cut-in pressure

Page 6

Trouble

LEDOM

.ON

SNOISNEMID

METSYSTA.SLAGNINWODWARD

:FOEGNARERUSSERPGNITAREPO

.XAM

NWODWARD

.LOV

).SLAG(

METSYS

NOITCENNOC

)SEHCNI(

RETEMAIDTHGIEHGISP04/02GISP05/03GISP06/04

SLEDOMENIL-NI

P6ET 8 61/51117.06.05.02.1MTPN"4/3

P51ET 1161/51317.14.12.17.2MTPN"4/3

P52ET 1161/1321.36.22.25.4MTPN"4/3

P54ET 8/35161/1121.53.47.34.8MTPN"1

SLEDOMGNIDNATSEERF

548/35161/51421.53.47.34.8FTPN"1

068/3518/3233.71.63.51.21FTPN"1

088/35161/9939.87.77.69.31FTPN"1

0018/3514/1748.119.96.88.31FTPN"1

0412261/9635.619.311.213.72FTPN"4/11

002228/5849.320.024.713.93FTPN"4/11

05262649.039.525.228.05FTPN"4/11

0622261/11062.132.628.227.44FTPN"4/11

0536261/3169.249.535.135.07FTPN"4/11

SLEDOMDEIRUB

B548/35161/1121.53.47.34.8MTPN"1

B068/3512/1823.71.63.51.21MTPN"1

B0412261/3235.619.311.213.72MTPN"4/11

B002224/1449.320.024.713.93MTPN"4/11

ET

ET

ET

ET

ET

ET

ET

ET

ET

ET

ET

ET

ET

Shooting

IF YOU THINK YOU HAVE A PROBLEM WITH YOUR WATER SYSTEM TANK, YOU SHOULD MAKE THE FOLLOWING

TESTS AND OBSERVATIONS BEFORE YOU CALL YOUR PROFESSIONAL DEALER.

1. Observe water system operation and note any unusual occurrence such as water spurting from a faucet rather than a

steady flow (indicates air in the system) or short cycling of the pump (rapid starts and stops).

2. In the event that evidence of a small leak near the water fitting appears, check at elbow. The introduction of cold

water to a warm tank may form condensation especially in warmer climates. It is important to provide adequate

drainage.

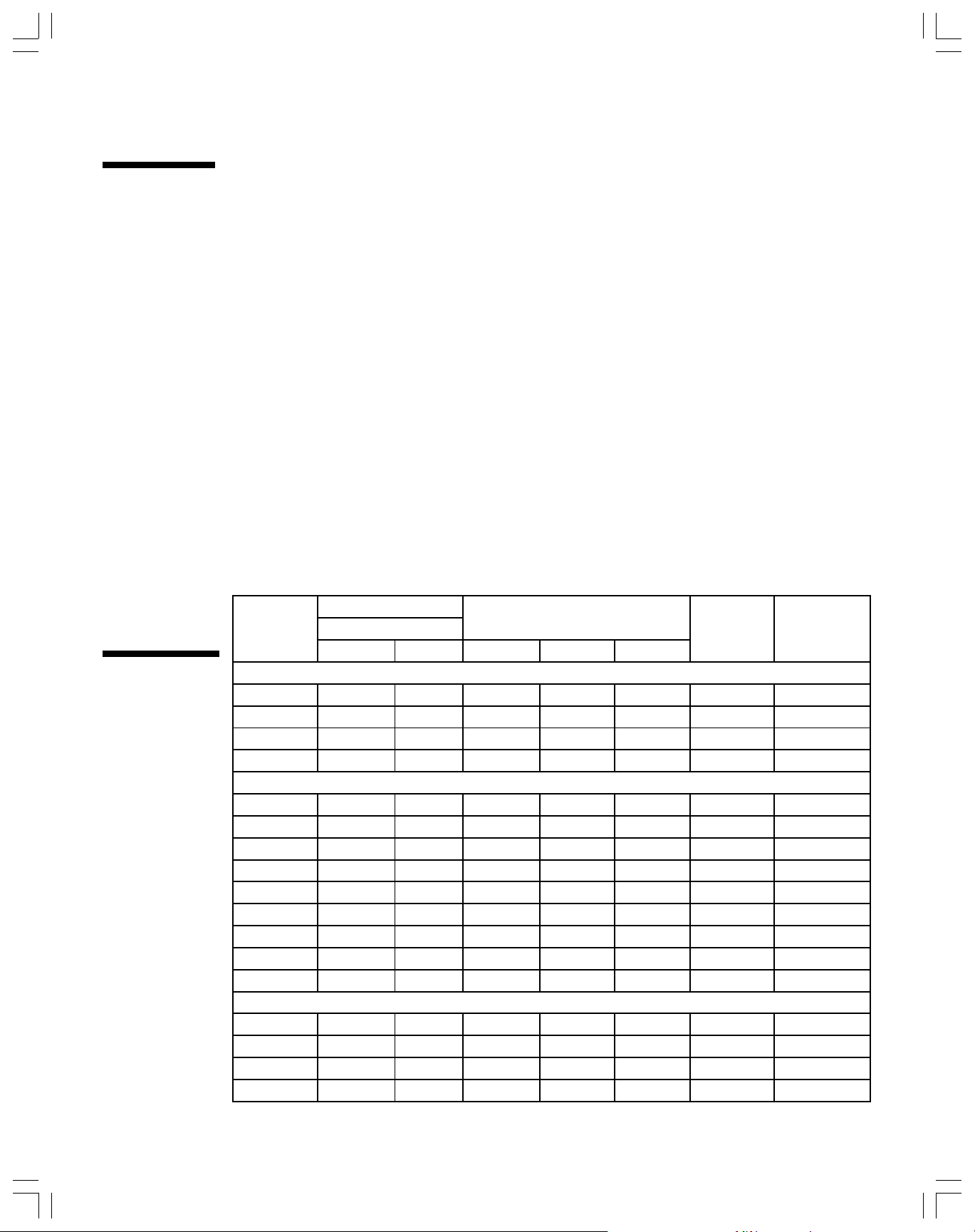

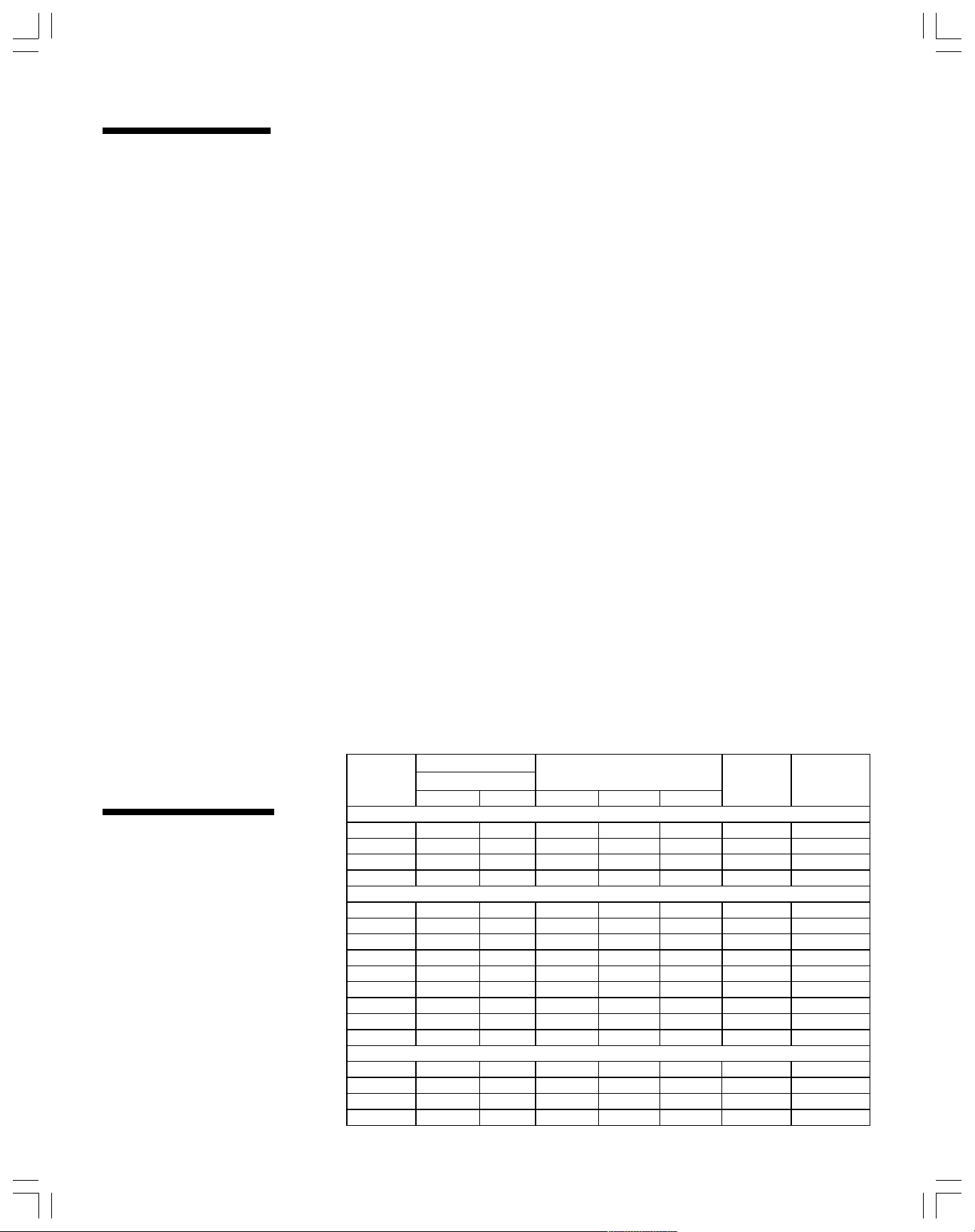

3. Measure the water drawdown by collecting water in a sufficiently sized container from the time the pump is off (cut-off

point) to the time it turns on (cut-in point). Compare the gallons with that shown in the table below for your model of

tank. If the volume is close to that shown in the table, your system is operating properly.

a. Air charge in Tank. Turn off electric power to the pump. Open faucet nearby and drain the tank completely.

Check the pressure in the water system tank using a standard, high quality tire gauge. If the air pressure in

the tank is below the pump cut-in setting by more than 3 psi, add air to the tank to make it 2 psi less than the

cut-in setting. Replace the valve stem cap. Check around the air stem using a soapy solution to check for

leaks around welds and seams on the remainder of the tank. If a leak appears on the tank itself then

replacement of the tank will be necessary.

b. Pressure Switch Setting. Start the pump and allow the system pressure to shut off pump. Note both the

cut-in and cut-off pressure values on gauge. The difference should not exceed 25 psi. Adjust the pressure

switch if necessary after shutting off the electric power to show a difference of 20 psi. Instructions from the

pressure switch manufacturer will explain how to do this. Test the system after adjusting the limits. If the

pressure switch can’t maintain the proper differential then it may need replacement, not the tank

.

Tank

Specifications

6

Page 7

Limited

Warranty

A.O. Smith Corporation, the warrantor, extends the following LIMITED WARRANTY to the owner of this water system tank.

1. TANK

If within five years after installation the tank or a part thereof shall prove upon examination by the warrantor to be

defective in material or workmanship, the warrantor, at his option, shall exchange or repair such part or portion. The

warranty on the replacement tank will be limited to the unexpired term of the original warranty.

2. CONDITIONS AND EXPECTA TIONS

This warranty shall apply only when the tank is installed in accordance with local plumbing and building codes,

ordinances and regulations, and good industry practices. In addition, a high pressure electrical cut-off switch and/or a

pressure relief valve must be installed when the tank is installed on an ambient temperature water system whose

maximum working pressure has the ability to exceed 125 pounds per square inch gauge (psig). (100 pounds per

square inch guage (psig) on certain models)

a. This warranty shall apply only when the water system is used:

(1) on ambient temperature water systems at pressures not exceeding the working

pressure for the water system;

(2) in the United States, its territories or possessions, and Canada.

b. Any accident to the water system tank, any misuse, abuse (including freezing) or alteration of it, any operation of

it in a modified form, any attempt to repair tank leaks will void this warranty.

3. SERVICE AND REPAIR EXPENSE

Under this limited warranty the warrantor will provide only a replacement tank or part thereof. The owner is

responsible for all other costs. Such costs may include but are not limited to:

a. Labor charges for service, removal, repair, or reinstallation of the water system or any component part,

b. Shipping and delivery charges for forwarding the new tank or replacement part from the nearest distributor and

returning the claimed defective tank or part to such distributor except in the state of California where such

charges are the manufacturer’s responsibility.

4. LIMITATION ON IMPLIED WARRANTIES

Implied warranties, including any warranty of merchantability imposed on the sale of this tank under state law are

limited to five (5) year duration for the tank or any of its parts. Some states do not allow limitations on how long an

implied warranty lasts, so the above limitation may not apply to you.

5. CLAIM PROCEDURES

Any claim under this warranty should be initiated with the dealer who sold the tank, or with any other dealer handling

the warrantor’s products. If this is not practicable, the owner should contact:

a. The warrantor will only honor replacement with identical or similar tank or parts thereof which are manufactured

or distributed by the warrantor.

b. Dealer replacements are made subject to in-warranty validation by warrantor.

6. DISCLAIMERS

NO OTHER EXPRESS WARRANTY HAS BEEN OR WILL BE MADE ON BEHALF OF THE WARRANTOR WITH

RESPECT TO THE TANK OR THE INSTALLATION, OPERATION, REPAIR OR REPLACEMENT OF THE TANK.

THE WARRANTOR SHALL NOT BE RESPONSIBLE FOR WATER DAMAGE, LOSS OF USE OF THE UNIT,

INCONVENIENCE, LOSS OR DAMAGE TO PERSONAL PROPERTY, OR OTHER CONSEQUENTIAL DAMAGE.

THE WARRANTOR SHALL NOT BE LIABLE BY VIRTUE OF THIS WARRANTY OR OTHERWISE FOR DAMAGE

TO ANY PERSONS OR PROPERTY, WHETHER DIRECT OR INDIRECT, AND WHETHER ARISING IN

CONTRACT OR IN TORT.

a. Some states do not allow the exclusion or limitation of the incidental or consequential damages, so the above

limitation or exclusion may not apply to you.

. This warranty gives you specific legal rights, and you may also have other rights which vary from

b

U.S Customers Canadian Customers

A.O. Smith Corporation A.O. Smith Corporation

5621 W. 115th Street P.O. Box 310-768 Erie Street

Alsip, IL 60803 Stratford, Ontario N5A 6T3

800-323-2636 or 708-489-4600 Telephone: (519) 271-5800

state to state.

Fill in the following for your own reference. Keep it. Registration is not a condition of warranty. The model

and serial number are found on the water system tank.

Model No.______________Serial No.____________________________Date Installed_________________

Part No. 205351-000

Dealer’s Name__________________________________________________________________________

Dealer’s Address____________________________________________Phone No.____________________

City & State (Provincial)_______________________________________Zip (Postal Code)______________

Dangerous Goods Permit No. SU 5099 (Ren2) - by road or rail vehicle only, expiration date: March 31, 2003 (Pending

Renewals)

7

Page 8

Lisez et observez

les consignes de

ll s’agit là d’un symbole de mise en garde pour votre sécurité. Lorsque vous voyez ce

symbole sur votre système ou dans ce manuel, cella veut dire que vous devez faire

attention car il y a un risque de blessures.

sécurité !

DANGER

AVERTISSEMENT

ATTENTION

Consignes de

sécurité

Le mot DANGER prévient des risques qui causeront des blessures graves, la mort ou

des dommages matériels importants si l’on n’en tient pas compte.

Le mot ADVERTISSEMENT prévient des risques qui pourraient causer des blessures

graves, la mort ou des dommages matériels importants si l’on n’en tient pas compte.

Le mot ATTENTION prévient des risques qui pourraient causer des blessures

mineures ou des dommages matériels si l’on n’en tient pas compte.

Le mot AVIS attire votre attention sur des directives spéciales qui sont importantes,

mais qui ne convement pas des risque ni des dangers.

Lisez attentivement toutes les consignes de sécurité dans ce manuel et sur le

système, puis suivez-les bien.

Gardez les étiquettes de sécurité en bon état. Remplacez les étiquettes de sécurité

manquantes ou endommagées.

1. AVERTISSEMENT — CE RÉSERVOIR À EAU A ÉTÉ CONÇU POUR FONC-

TIONNER SUR UN SYSTÈME D’ALIMENTATION EN EAU À UNE TEMPÉRATURE

AMBIANTE ET À UNE PRESSION DE SERVICE MAXIMALE DE 125 lb/po

VOTRE SYSTÈME PEUT DÉPASSER UNE PRESSION DE 125 lb/po

100 lb/po

ALORS INSTALLER UN DISPOSITIF DE SÉCURITÉ APPROPRIÉ. CE DISPOSITIF

POURRAIT ÊTRE UN PRESSOSTAT ÉLECTRIQUE HAUTE PRESSION OU UNE

SOUPAPE DE SURPRESSION, OU LES DEUX. L’INOBSERVATION DE CES

CONSIGNES POURRAIT CAUSER UNE RUPTURE DU RÉSERVOIR ET ENTRAÎNER DES BLESSURES ET DES DOMMAGES MATÉRIELS.

2

S’IL S’AGIT D’UN RÉSERVOIR MONTÉ SUR UNE POMPE), IL FAUT

2

(OU DE

2

. SI

2.C’est à vous qu’incombe la responsabilité de vous assurer que votre installation est

conforme aux exigences de tous les codes nationaux et provinciaux de plomberie et

d’électricité.

3.

DANGER — Avant de procéder à l’installation ou à l’entretien de votre

pompe ou de votre réservoir, assurez-vous que son alimentation électrique a

été coupée.

4.Si un réservoir galvanisé ordinaire est remplacé par un réservoir à air captif pour

systèmes d’alimentation en eau, bouchez les orifices de purge et enlevez les régulateurs de volume d’air ou autres dispositifs d’admission d’air du système.

ATTENTION — Ce réservoir de stockage a été conçu pour les systèmes

5.

d’alimentation en eau à température ambiante (température maximale de 120

en vigueur depuis février 2001). Son emploi à d’autres fins pourrait entraîner

une défaillance du réservoir et même des blessures et annule la garantie.

6.Le système complet, c’est-à-dire la pompe, le réservoir et la tuyauterie, doit

être protégé contre le gel. Si l’on néglige cette précaution, il sera sérieusement

endommagé, et sa garantie deviendra nulle et non avenue.

7.

DANGER — Le réservoir contient de l’air sous pression. Ne le percez pas.

Ne jetez jamais le réservoir dans le feu ni dans un incinérateur.

o

F

8

Page 9

Le concept du

40

45

réservoir pour

Systèmes d’alimentation en eau

Fonctionnement du

réservoir dans un

Le réservoir pour systèmes d’alimentation en eau

ne fait pas qu’emmagasiner de l’eau ; il aide aussi

à protéger votre système d’alimentation en eau.

Le rèservoir a été mis au point pour assurer un

approvisionnement en eau adéquat avec un débit

suffisant, même quand la pompe est arrêtée, afin

d’économiser de l’énergie et de prolonger la

durée utile de son moteur, en réduisant les

démarrages donc le fonctionnement cyclique au

minimum. On protège ainsi les autres organes du

système.

Le réservoir pour systèmes d’alimentation en eau

comprend un récipient en acier (A) contenant une

membrane robuste (B) scellée en place qui

sépare l’air et l’eau. La portion du réservoir où

l’eau est emmagasinée (C) comporte un

revêtement qui isole l’eau de la paroi métallique.

Ceci protège le réservoir contre la corrosion.

système d’alimentation en eau et

dans une plage de

pression

manométrique de

30-50 lb/po

2

30

Avant l’expédition, de l’air est injecté

1.

dans le réservoir jusqu’à ce que la

pression interne atteigne la valeur

standard définie dans la section

« UTILISATION » de ce manuel.

50

À mesure que l’eau pénètre

2.

dans le réservoir, l’air audessus de la membrane est

comprimé et subit une diminution de volume égale au

volume de l’eau qui entre dans

le réservoir.

La pression dans le réservoir

3.

augmente. L’eau continue d’y

pénétrer jusqu’à ce que la

pression d’arrêt de la pompe soit

atteinte. La pompe s’arrête, et le

réservoir est alors plein..

AIR EAU

9

Quand on a besoin d’eau, l’air

4.

sous pression force l’eau dans le

système sans que la pompe se

mette en marche immédiatement.

Lorsque la pression de l’air baisse

au point d’atteindre la pression

d’enclenchement du pressostat

(manostat), la pompe redémarre et

répète le cycle de remplissage.

Page 10

Marche à suivre pour l’installation

INSTALLATION TYPE À POMPE

SUBMERSIBLE

1. Le réservoir pour systèmes d’alimentation en eau devrait

être installé aussi près que possible du pressostat

(24 pouces ou moins) pour diminuer l’effet nuisible de la

perte de charge par frottement et des différences

d’élévation.

2. Coupez le courant électrique.

3. Vidangez le système et enlevez le vieuxréservoir. S’il

s’agit d’une nouvelle installation, cette étape n’existe

évidemment pas.

4. Placez le réservoir sur une surface de niveau, dans un

endroit muni d’un drain suffisamment gros.

5. Si votre système est capable de dépasser une pression

de service de 125 lb/po

submersible), posez une soupape de surpression sur le

2

(habituellement avec une pompe

INSTALLATION TYPE

À POMPE À JET

système, à proximité du réservoir. Cette soupape devrait

avoir la même section de passage que la sortie du

réservoir. Cette précaution n’est pas nécessaire pour une

installation à pompe à jet montée sur le réservoir.

6. Raccordez le réservoir à la conduite de refoulement de la

pompe. Pour cela, servez-vous d’un tuyau ayant au

moins le même diamètre que l’orifice de la pompe.

AVERTISSEMENT : Quand vous vissez et serrez le tuyau

de raccordement, immobilisez à l’aide d’une clé le coude

mâle et femelle à 90 degrés du réservoir.

7. Le réservoir devrait être rincé à cinq reprises avant de

servir à des fins domestiques.

D’autres installations types sont montrées dans la section

qui suit.

Installation à

réservoirs

multiples

On peut raccorder plusieurs réservoirs pour

systèmes d’alimentation en eau pour accroître

la capacité utile du système. Deux réservoirs

de même capacité permettront de doubler le

stockage, tandis que trois le tripleront. Quand

vous utilisez une pompe à grand débit, le

10

collecteur-répartiteur et le pressostat doivent

être posés sur la canalisation, aussi près que

possible du centre des réservoirs. Le diamètre

du collecteur-répartiteur et de la canalisation

principale devrait être le double de celui de la

conduite d’alimentation.

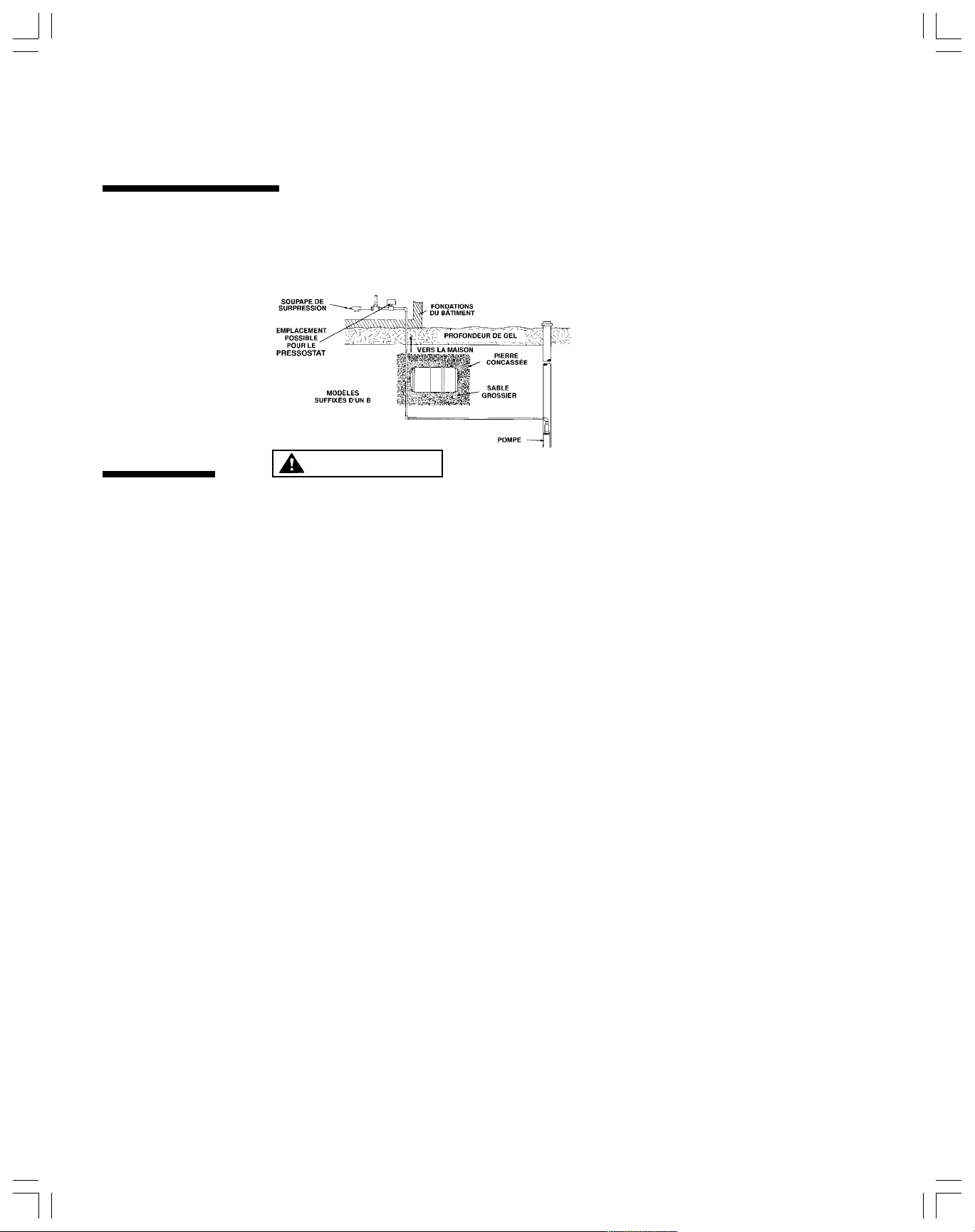

Page 11

Réservoirs avec

précompression

enterrés

Utilisation

On peut enterrer les réservoirs pour systèmes

d’alimentation en eau à l’horizontale ou à la

verticale. Afin d’éliminer les risques de gel,

tout réservoir doit être enterré en dessous de

la profondeur de gel.

Voici la marche à suivre quand on installe un

modèle suffixé d’un B :

1. Veillez à ce que le réservoir soit enterré

sous la ligne de gel, mais au-dessus de la

nappe phréatique.

2. Pour les canalisations qui seront dans le

A VERTISSEMENT

sol, utilisez des tuyaux galvanisés ou en

plastique.

3. Vérifiez la pression de l’air du réservoir. Elle

doit être réglée selon la pression de

réglage du pressostat. (Voyez la section

Utilisation.)

4. Installez le réservoir sur un lit de terre

ferme et exempte de roches et de cailloux.

5. Les tuyaux reliant la pompe, le réservoir et

le pressostat devraient avoir le même

diamètre.

6. Vérifiez les performances du système et

assurez-vous que celui-ci ne fuit pas.

7. Remblayez le trou avec du sable ou de la

terre dépourvue de roches. Pilonnez

fermement le remblai pour bien immobiliser

le réservoir.

8. Prenez note de l’emplacement du réservoir,

afin de pouvoir le retrouver facilement en

cas de besoin.

CE RÉSERVOIR À EAU A ÉTÉ CONÇU POUR FONCTIONNER SUR UN SYSTÈME D’ALIMENTATION EN EAU À UNE

2

TEMPÉRATURE AMBIANTE ET À UNE PRESSION DE SERVICE MAXIMALE DE 125 lb/po

DÉPASSER UNE PRESSION DE 125 lb/po

2

(OU DE 100 lb/po2 S’IL S’AGIT D’UN RÉSERVOIR MONTÉ SUR UNE POMPE), IL

. SI VOTRE SYSTÈME PEUT

FAUT ALORS INSTALLER UN DISPOSITIF DE SÉCURITÉ APPROPRIÉ. CE DISPOSITIF POURRAIT ÊTRE UN

PRESSOSTAT ÉLECTRIQUE HAUTE PRESSION OU UNE SOUPAPE DE SURPRESSION, OU LES DEUX. L’INOBSERVATION DE CES CONSIGNES POURRAIT CAUSER UNE RUPTURE DU RÉSERVOIR ET ENTRAÎNER DES BLESSURES ET

DES DOMMAGES MATÉRIELS.

Avant d’utiliser le système, vous devez en vérifier le bon fonctionnement et celui du réservoir pour systèmes d’alimentation en

eau.

L’air de tous les réservoirs pour systèmes d’alimentation en eau est précomprimé en usine. La pression manométrique des

2

réservoirs de 8 et de 11 pouces de diamètre est de 18 lb/po

celle des réservoirs de 22 et de 26 pouces de diamètre, de 38 lb/po

inférieure de 2 à 3 lb/po

2

à la pression d’enclenchement du pressostat (démarrage de la pompe). Au besoin, augmentez ou

, celle des réservoirs de 15 pouces de diamètre, de 28 lb/po2, et

2

. La pression de l’air précomprimé devrait toujours être

réduisez la pression de l’air comme suit :

1. Déterminez la pression de démarrage de la pompe. Vous devriez trouver ce renseignement sur ou sous le couvercle du

pressostat.

2. Le réservoir étant vide d’eau, placez un manomètre de précision pour pneus sur la valve à air comprimé du réservoir pour

systèmes d’alimentation en eau et mesurez la pression interne de l’air.

3. Relâchez de l’air ou ajoutez-en dans le réservoir pour que la pression manométrique interne soit INFÉRIEURE de 2 à 3 lb/

2

à la pression de démarrage de la pompe.

po

4. Dans le cas d’une nouvelle installation, vous devrez chasser l’air de la tuyauterie. Pour ce faire, ouvrez tous les robinets et

mettez la pompe en marche. Vous remarquerez qu’un mélange d’eau et d’air jaillira par à-coups du ou des robinets. Laissez

fonctionner le système jusqu’à ce que l’écoulement de l’eau soit stable. Ouvrez et fermez les robinets à plusieurs reprises

pour vous assurer que tout l’air a été chassé du système. Si le jet d’eau ne devient pas constant, il pourrait y avoir une fuite

d’air. Examinez bien la tuyauterie d’aspiration.

5. Il pourrait être nécessaire d’effectuer un réglage du pressostat, dont les pressions de

fonctionnement pourraient être différentes de celles qui sont indiquées sur ou sous le couvercle. Sans être dangereux, un

tel écart pourrait causer un arrêt momentané de l’écoulement de l’eau. Réglez le pressostat comme suit :

a) Faites fonctionner la pompe jusqu’à ce que le réservoir soit plein et que cette dernière s’arrête.

b) Ouvrez un robinet et videz le réservoir pour systèmes d’alimentation en eau jusqu’à ce que la pompe se remette en

marche.

c) Si l’écoulement d’eau s’arrête un peu entre le moment où le réservoir pour systèmes d’alimentation en eau est vide et le

2

redémarrage de la pompe, diminuez la pression d’air dans le réservoir jusqu’à ce qu’elle soit inférieure de 2 à 3 lb/po

à la

pression de démarrage. (Voyez le guide de dépannage, section 3 (a-b) du diagnostic des anomalies, pour savoir comment

procéder).

d) Fermez le robinet et remplissez le réservoir pour systèmes d’alimentation en eau. Au besoin, répétez les étapes b) et c)

jusqu’à ce qu’il n’y ait plus d’interruption dans l’écoulement de l’eau.

11

Page 12

Diagnostic

des

anomalies

SI VOUS PENSEZ AVOIR UN PROBLÈME AVEC VOTRE RÉSERVOIR POUR SYSTÈMES D’ALIMENTATION EN EAU, VOUS DEVRIEZ EFFECTUER LES ESSAIS SUIVANTS AVANT D’APPELER VOTRE

DÉTAILLANT PROFESSIONNEL.

1. Observez le fonctionnement du système et prenez note de tout fait inhabituel : de l’eau jaillissant par

à-coups du robinet (présence d’air) au lieu de former un filet continu ou bien un fonctionnement

cyclique trop court (démarrages et arrêts trop fréquents).

2. S’il semble y avoir une petite fuite près d’un raccord, vérifiez d’abord le coude. L’introduction d’eau

froide dans un réservoir relativement chaud peut entraîner la formation de condensation, particulièrement dans les régions chaudes. Il est important de prévoir un drainage suffisant.

3. Mesurez la capacité utile du réservoir en en recueillant l’eau dans un récipient assez grand, à partir du

moment où la pompe s’arrête jusqu’au moment où elle se remet en marche. Comparez la quantité

recueillie avec ce qu’indique la table ci-dessus pour votre modèle de réservoir. Si le volume est à prés

égal au volume stipulé dans la table, cela veut dire que votre système fonctionne correctement, sinon

vérifiez les deux points suivants :

a) Pression d’air dans le réservoir. Coupez le courant électrique qui alimente la pompe. Ouvrez un

robinet à proximité du réservoir et videz ce dernier complètement. Au moyen d’un bon manomètre

pour pneus, vérifiez la pression d’air dans le réservoir. Si la pression d’air est bien inférieure à la

pression de démarrage de la pompe par plus de 3 lb/po

ce que la pression de l’air ait 2 lb/po

2

de moins que la pression de démarrage. Revissez le capuchon

2

, introduisez de l’air dans le réservoir jusqu’à

sur la valve à air comprimé. Avec une solution savonneuse, voyez s’il y a une fuite autour de la valve,

ainsi que près des soudures et des joints du réservoir. Si vous décelez une fuite sur le réservoir, il

faudra alors le remplacer.

b) Réglage du pressostat. Mettez la pompe en marche et laissez la pression du système arrêter la

pompe. Notez les pressions manométriques de démarrage et d’arrêt sur le manomètre. Leur diffé-

2

rence ne devrait pas dépasser 25 lb/po

le pressostat pour que la différence entre les deux pressions soit de 20 lb/po

. Au besoin, après avoir coupé l’alimentation électrique, réglez

2

. Consultez les instructions fournies par le fabricant du pressostat pour savoir comment procéder à ce réglage. Mettez le

système à l’essai après le réglage. Si le pressostat ne peut maintenir la pression différentielle appropriée, vous devrez peut-être alors le remplacer et non le réservoir.

Caractéristiques

des réservoirs

EDORÉMUN

ELÈDOM

SNOISNEMID

)SECUOP(

ERTÈMAIDRUETUAHop/bl04-02

2

2

op/bl05-03

CEVA)SUlag(ELITUÉTICAPAC

EUQIRTÉMONAMNOISSERP

:EDECIVRESED

2

op/bl06-04

NOITASILANACRUSSÉTNOMSELÈDOM

ET

P68 61/51117,06,05,02,1MTPN,4/3

ET

P511161/51317,14,12,17,2MTPN,4/3

ET

P521161/1321,36,22,25,4MTPN,4/3

ET

P548/35161/1121,53,47,34,8MTPN,1

TUOBEDSELÈDOM

548/35161/51421,53,47,34,8FTPN,1

ET

068/3518/3233,71,63,51,21FTPN,1

ET

088/35161/9939,87,77,69,31FTPN,1

ET

0018/3514/1748,119,96,88,31FTPN,1

ET

0412261/9635,619,311,213,72FTPN,4/11

ET

002228/5849,320,024,713,93FTPN,4/11

ET

05262649,039,525,228,05FTPN,4/11

ET

0622261/11062,132,628,227,44FTPN,4/11

ET

0536261/3169,249,535,135,07FTPN,4/11

ET

SÉRRETNESELÈDOM

ET

B548/35161/1121,53,47,34,8MTPN,1

ET

B068/3512/1823,71,63,51,21MTPN,1

ET

B0412261/3235,619,311,213,72MTPN,4/11

ET

B002224/1449,320,024,713,93MTPN,4/11

ÉTICAPAC

ELITU

ELAMIXAM

)SUlag(

SDROCCAR

)SECUOP(

12

Page 13

Garantie limitée

A.O. Smith Corporation, le garant, offre la GARANTIE LIMITÉE suivante au propriétaire de ce réservoir pour systèmes d’alimentation en eau.

1. RÉSERVOIR

Si, dans les cinq années qui suivent l’installation initiale, le garant constate, après examen, que le réservoir pour systèmes d’alimentation en

eau ou l’un de ses éléments est défectueux quant aux matériaux ou à la fabrication, le garant pourra, à son choix, le remplacer ou réparer

l’élément en question. La garantie pour un réservoir ainsi remplacé ou réparé sera limitée à la portion non expirée de la garantie initiale.

2. MODALITÉS ET ATTENTES

Cette garantie ne s’applique que si le réservoir pour systèmes d’alimentation en eau est installé conformément aux codes de plomberie et de

construction, ainsi qu’aux ordonnances et règlements en vigueur dans la localité et aux règles de l’industrie. En outre, il faudra que le système

soit muni d’un pressostat électrique haute pression ou d’une soupape de surpression, ou des deux, si le réservoir pour systèmes d’alimentation en eau est installé dans un système d’alimentation en eau utilisé à une température ambiante et à une pression manométrique de service

maximale pouvant dépasser 125 lb/po2 ( 100 lb/po2 pour certains modèles ).

a) La présente garantie ne s’applique que si le réservoir est utilisé :

1° avec un système d’alimentation en eau à une température ambiante à une pression ne dépassant pas la pression de service

prévue pour le réservoir ;

2° aux États-Unis et dans leurs territoires ou possessions, ainsi qu’au Canada.

b) Tout bris accidentel du réservoir pour systèmes d’alimentation en eau, tout usage incorrect ou abusif (y compris le gel), toute modification

ou toute utilisation du réservoir modifié ou bien toute tentative pour réparer une fuite dans le réservoir annulera cette garantie.

3. FRAIS D’ENTRETIEN ET DE RÉPARATION

Aux termes de la présente garantie limitée, le garant ne s’engage qu’à remplacer le réservoir pour systèmes d’alimentation en eau ou sa pièce

défectueuse. Tous les autres frais sont à la charge du propriétaire. Ces frais peuvent inclure, entre autres points :

a) les frais de main-d’œuvre pour l’entretien, la dépose, la réparation ou la réinstallation du réservoir ou de l’un de ses éléments consti

tuants ;

b) les frais d’expédition et de livraison pour l’envoi, par le distributeur le plus proche, du nouveau réservoir ou de sa pièce de rechange, et

pour le renvoi à ce distributeur de la pièce ou du réservoir jugés défectueux, sauf en Californie, où ces frais sont imputés au fabricant.

4. LIMITATION DES GARANTIES IMPLICITES

Les garanties implicites, y compris toute garantie de qualité marchande imposée en vertu d’une loi, sont limitées à une durée de cinq (5) ans

pour le réservoir et chacune de ses pièces. Comme certaines provinces ne permettent pas de limiter la durée d’une garantie implicite, il se

peut que cette limite ne s’applique pas dans votre cas.

5. RÉCLAMATIONS

Toute réclamation faite en vertu de la présente garantie doit être adressée au détaillant qui a vendu le réservoir ou à tout autre détaillant

autorisé à s’occuper des produits du garant. Si c’est impossible, le propriétaire devrait alors communiquer avec :

a) Le garant se bornera à remplacer par des articles identiques ou semblables le réservoir ou ses pièces, qui sont fabriquées ou distribuées

par lui.

b) Les remplacements effectués par un détaillant sont sujets à acceptation aux termes de la garantie par le garant.

6. LIMITATION DE RESPONSABILITÉ

AUCUNE AUTRE GARANTIE EXLICITE N’A ÉTÉ NI NE SERA FAITE AU NOM DU GARANT EN RAPPORT AVEC LE RÉSERVOIR POUR

SYSTÈMES D’ALIMENTATION EN EAU HYDRO-PRO

RÉPARATION OU SON REMPLACEMENT. LE GARANT NE POURRA ÊTRE TENU RESPONSABLE DES DOMMAGES CAUSÉS PAR

L’EAU, DE LA PERTE D’USAGE DE L’APPAREIL, DES INCONVÉNIENTS, DES PERTES OU DOMMAGES AUX BIENS PERSONNELS, NI

D’AUTRES DOMMAGES EN DÉCOULANT. LE GARANT NE SERA PAS TENU RESPONSABLE, EN VERTU DE LA PRÉSENTE GARANTIE

OU AUTREMENT, DES DOMMAGES À DES PERSONNES OU À DES BIENS, QU’ILS SOIENT DIRECTS OU INDIRECTS, ET QU’ILS

RÉSULTENT D’UNE CLAUSE CONTRACTUELLE OU D’UN DÉLIT CIVIL.

a) Comme certaines provinces ne permettent pas d’exclure ou de limiter des dommages accidentels ou consécutifs, la limitation ou

l’exclusion ci-dessus peut ne pas s’appliquer dans votre cas.

b) La présente garantie vous donne des droits légaux particuliers, auxquels peuvent s’en ajouter d’autres en vertu des lois

particulières en vigueur.

Remplissez la partie suivante pour votre usage personnel et conservez-la. La garantie n’est pas conditionnelle à l’enregistrement du produit. Les

numéros de modèle et de série sont indiqués sur la plaque signalétique du réservoir pour systèmes d’alimentation en eau.

Numéro de modèle __________________________________ Numéro de série ________________________ Date d’installation ___________

Nom du détaillant ______________________________________________________________________________________________________

A.O. Smith Corporation

P.O. Box 310

768 Erie Street

Stratford (Ontario)

N5A 6T3

Téléphone : (519) 271-5800

MC

DE GOULDS PUMPS OU SON INSTALLATION, SON FONCTIONNEMENT, SA

Adresse du détaillant _________________________________________________________________________ Téléphone _______________

Ville et province _____________________________________________________________________ Code postal _______________________

Permis pour marchandises dangereuses no SH 5099 (Ren 2) — par véhicule routier ou ferroriaire seulement ; date d’expiration : le 31 mars 2003 (renouvellement en

instance)

Formulaire no 205351-000

13

Page 14

Instrucciones

Para Instalación

de Tanques de

Presión

Subterráneos

Los Tanques para sistemas de agua están

diseñados para ser enterrados ya sea en

posición horizontal o vertical. Para eliminar el

peligro de congelamiento, el tanque debe de

enterrarse por abajo de la linea de

congelación. Los pasos siguientes deberán

tomarse al instalar un tanque “B” para

sistemas de agua.

1. Asegúrese de que el tanque sea enterrado

debajo de la linea de congelación y por

arriba de la toma de agua.

2. Use tuberia galvanizada o de plástico para

los tramos que estarán enterrados.

3. Revise la precarga del tanque. La

precarga de origen es de 28 PSI. La

precarga del tanque debe de ajustarse a

la presión requerida por la establecida en

el interruptor de presión (ver sección de

operación).

4. Instale el tanque sobre tierra firme libre de

roca, o piedras.

5. La distancia de la tuberia dela bomba al

tanque y del tanque al apagador de

presión debe ser la misma.

6. Revise el funcionamiento del sistema e

instalaciones si hay fugas.

7. Rellene el hoyo con arena libre de rocas o

tierra libre de rocas o piedras, aplanando

bien para evitar hundimientos.

8. Tome nota de la localización del tanque

para que se le pueda encontrar

fácilmente después.

Operacion

ESTOS TANQUES PARA AGUA ESTAN DISEÑADOS PARA OPERAR EN SISTEMAS DE AGUA Y DISEÑADOS A LA

TEMPERATURA AMBIENTE CON LIMITE DE PRESIÓN MAXIMA DURANTE SU OPERACIÓN DE 125 LIBRAS POR PULGADA

CUADRADA (PSI) SI SU SISTEMA AL FUNCIONAR PUEDE EXCEDER LA PRESIÓN DE TRABAJO DE 125 PSI (100 PSI SI ES UNA

UNIDAD CON LA BOMBA MONTADA), HABRA QUE INSTALARSE UN MECANISMO ADECUADO DE SEGURIDAD. ESTE PUEDE

SER O UN CORTA CORRIENTE (APAGADOR) DE ALTA PRESIÓN Y/O UNA VALVULA DE ESCAPE DE PRESIÓN., NO SEGUIR

ESTAS INSTRUCCIONES PUEDE CAUSAR LA RUPTURA DEL TANQUE O DAÑO PERSONAL Y/O DAÑO A LA PROPIEDAD .

Antes de operar el sistema, debe de revisar su tanque para sistemas de agua y el sistema, para asi asegurar un funcionamiento

adecuado.

Todos los tanques para sistemas de agua son precargados en la fábrica. Todos los tanques de 8 y 11 pulgadas de diametro se

precargan a 18 PSI, los de 15 pulgadas de diametro A 28 PSI y los de 22 y 26 pulgadas de diametro se precargan a 38 PSI. La

precarga de presión final deberá de ser siempre de 2 a 3 PSI debajo de la presión de arranque (Cuando se enciende la bomba) que

requiere el apagador de presión. Suelte o agregue aire seguin se reqúera, utilizando el procedimiento siguiente:

1. Determine la presión de arranque requerida por la bomba. El apagador de presión debe tener la información en o sobre la

cubierta.

2. Sin agua en el tanque, medir en la válvula de aire la precarga en el tanque para sistemas de agua con un medidor de presión

(similar al que se usa para medir la presión en las llantas de un automóvil).

3. Saque o agregue aire al tanque hasta hacer que la presión del tanque sea menor de 2 a 3 PSI a la requerida o a la indicada para

la presión de arranque de la bomba.

4. Será necesario sacar el aire de las tuberías de todas la instalaciones nuevas. Para esto hay que abrir todas las llaves y echar a

funcionar la bomba. Observará que una combinación de aire y agua saldrá a borbotones por las llaves. Deje funcionando el

sistema hasta que el agua fluya pareja e inenterrumpidamente, abra y cierre las llaves del agua varias veces hasta asegurarse

que todo el aire ha sido removido. Revise si hay fugas en las tuberias de succión latérales si no es el flujo, puede que exista una

fuga de aire.

5. Pude que sea necesario hacer ajustes finales al interruptor del sistema de presión porque a veces la presión indicada en los

interruptores varía con la mostrada en la cubierta, esta variación, aunque no peligrosa, puede ocasionar interrupciones

momentáneas en el suministro de agua. Para hacer estos ajustes favor de tomar los pasos siguientes:

a. Llene el sistema hasta que se apague la bomba.

b. Abra una llave o llaves y vacíe el tanque para sistemas de agua hasta que arranque la bomba.

c. Si se da una pausa en el flujo del agua desde que se vacía el tanque para sistemas de agua y la bomba arranca

nuevamente, disminuya la presión del tanque hasta que esté de 2 a 3 PSI debajo de la presión establecida para el

arranque. (Vea procedimiento en la sección 3 (a-b) de Buscando Fallas)

d. Cierre las llaves del agua y vuelva a llenar el tanque. Repita los pasos (b) y c) si es necesario hasta que no haya

ninguna pausa en el flujo del agua.

ADVERTENCIA

14

Page 15

El Concepto

40

45

de Tanques para

Sistemas de Agua

El tanque para sistemas de agua hace más

que el simple almacenamiento de agua; ayuda

a proteger su sistema de agua. El tanque está

diseñado para suministrar suficiente flujo de

agua, aún cuando la bomba no esté operando;

para ahorrar energia y alargar la vida del motor

minimizando el número de arranques, para

proteger los componentes del sistema

operativo minimizando el ciclo del sistema.

El tanque para sistemas de agua consiste de

un tanque de acero (A) que contiene un

diafragma de uso rudo sellado en su lugar (B)

que separa el aire del agua. La porción del

tanque donde se almacena el agua (C) está

recubierta para aislar el agua del metal del

tanque. Este recubrimiento protege el tanque

contra la corrosión.

Así es como

el tanque funciona

con un sistema

diseñado para

operar puesto a

una presión de

30/50 PSI

30

Antes de ser embarcado el tanque,

1.

es presurizado a una precarga

estándar (28 PSI o 18 PSI para

tanques pequeños) en la fábrica.

50

Conforme el agua entra en el

2.

tanque, el aire que se encuentra

arriba del diafragma es

comprimido y su volumen se

reduce en el mismo volumen del

agua que entra.

La presión en el tanque se

3.

eleva. El agua continua

entrando hasta que se alcanza

la presión que corta el

funcionamiento de la bomba la

cual se para y ahora el tanque

se encuentra lleno.

AIRE AGUA

15

La presión en la cámara de aire

4.

forza la entrada del agua en el

sistema cuando se demanda sin

que la bomba opere de inmediato.

Cuando la presión en la cámara de

aire finalmente disminuye al nivel

donde se activa el funcionamiento

de la bomba, el interruptor prende

la bomba y repite el ciclo de

llenado.

Page 16

Procedimiento de Instalación

INSTALACION TIPICA

DE BOMBA SUMERGIBLE

1. El tanque para sistemas de agua debe de instalarse

lo más cercano posible al interruptor de la presión

(24 pulgadas o menos) para reducir el efecto

adverso de pérdida de fricción y elevación de

diferencias.

2. Desconecte la energía electrica.

3. Drene el sistema y remueva el tanque viejo. En el

caso de instalaciones nuevas este paso no es

necesario.

4. Coloque el tanque para sistemas de agua sobre una

superficie firme y plana con un drenaje adecuado.

Instalaciones típicas se muestran en la sección

siguiente.

5. Si su sistema es capaz de trabajar

INSTALACION TIPICA

DE BOMBA JET

excediendo una presión de 125 PSI (Normalmente

en las bombas sumergibles) instale una válvula de

seguridad (que sea de 125 PSI o menos, pero que

sea mayor que la presión de apagado) en el sistema

cerca del tanque. La válvula tiene que ser del mismo

diámetro que la teberia de salida del tanque. Esto no

es necesario en las unidades de tanques montados

con bombas tipo “Jet”.

6. Conecte el tanque a la linea de desagúe de la bomba

usando tuberia de la misma medida de la salida de la

bomba o aún mayor. PRECAUCION: Sostenga a 90

grados el codo del tanque cuando enrosque y apriete

la tubería de conexión.

7. El tanque deberá dejarse fluir totalmente cinco veces

antes de usarse.

Instalación

Múltiple de

Tanques

Los tanques para sistemas de agua

pueden conectarse juntos para aumentar

el suministro de aqua utilizable

(extracción). Dos tanques de la misma

medida duplicarán el suministro y tres lo

triplicarán.

16

Cuando se use una bomba de alta capacidad, el

múltiple y el interruptor de presión deberán de

instalarse en la tubería lo más cercano posible al

centro de los tanques. El múltiple y principal

deben de ser 2 veces de la medida de la linea de

alimentación.

Page 17

Instrucciones

Para Instalación

de Tanques de

Presión

Subterráneos

Los Tanques para sistemas de agua están

diseñados para ser enterrados ya sea en

posición horizontal o vertical. Para eliminar el

peligro de congelamiento, el tanque debe de

enterrarse por abajo de la linea de

congelación. Los pasos siguientes deberán

tomarse al instalar un tanque “B” para

sistemas de agua.

1. Asegúrese de que el tanque sea enterrado

debajo de la linea de congelación y por

arriba de la toma de agua.

2. Use tuberia galvanizada o de plástico para

los tramos que estarán enterrados.

3. Revise la precarga del tanque. La

precarga de origen es de 28 PSI. La

precarga del tanque debe de ajustarse a

la presión requerida por la establecida en

el interruptor de presión (ver sección de

operación).

4. Instale el tanque sobre tierra firme libre de

roca, o piedras.

5. La distancia de la tuberia dela bomba al

tanque y del tanque al apagador de

presión debe ser la misma.

6. Revise el funcionamiento del sistema e

instalaciones si hay fugas.

7. Rellene el hoyo con arena libre de rocas o

tierra libre de rocas o piedras, aplanando

bien para evitar hundimientos.

8. Tome nota de la localización del tanque

para que se le pueda encontrar

fácilmente después.

Operacion

ESTOS TANQUES PARA AGUA ESTAN DISEÑADOS PARA OPERAR EN SISTEMAS DE AGUA Y DISEÑADOS A LA

TEMPERATURA AMBIENTE CON LIMITE DE PRESIÓN MAXIMA DURANTE SU OPERACIÓN DE 125 LIBRAS POR PULGADA

CUADRADA (PSI) SI SU SISTEMA AL FUNCIONAR PUEDE EXCEDER LA PRESIÓN DE TRABAJO DE 125 PSI (100 PSI SI ES UNA

UNIDAD CON LA BOMBA MONTADA), HABRA QUE INSTALARSE UN MECANISMO ADECUADO DE SEGURIDAD. ESTE PUEDE

SER O UN CORTA CORRIENTE (APAGADOR) DE ALTA PRESIÓN Y/O UNA VALVULA DE ESCAPE DE PRESIÓN., NO SEGUIR

ESTAS INSTRUCCIONES PUEDE CAUSAR LA RUPTURA DEL TANQUE O DAÑO PERSONAL Y/O DAÑO A LA PROPIEDAD .

Antes de operar el sistema, debe de revisar su tanque para sistemas de agua y el sistema, para asi asegurar un funcionamiento

adecuado.

Todos los tanques para sistemas de agua son precargados en la fábrica. Todos los tanques de 8 y 11 pulgadas de diametro se

precargan a 18 PSI, los de 15 pulgadas de diametro A 28 PSI y los de 22 y 26 pulgadas de diametro se precargan a 38 PSI. La

precarga de presión final deberá de ser siempre de 2 a 3 PSI debajo de la presión de arranque (Cuando se enciende la bomba) que

requiere el apagador de presión. Suelte o agregue aire seguin se reqúera, utilizando el procedimiento siguiente:

1. Determine la presión de arranque requerida por la bomba. El apagador de presión debe tener la información en o sobre la

cubierta.

2. Sin agua en el tanque, medir en la válvula de aire la precarga en el tanque para sistemas de agua con un medidor de presión

(similar al que se usa para medir la presión en las llantas de un automóvil).

3. Saque o agregue aire al tanque hasta hacer que la presión del tanque sea menor de 2 a 3 PSI a la requerida o a la indicada para

la presión de arranque de la bomba.

4. Será necesario sacar el aire de las tuberías de todas la instalaciones nuevas. Para esto hay que abrir todas las llaves y echar a

funcionar la bomba. Observará que una combinación de aire y agua saldrá a borbotones por las llaves. Deje funcionando el

sistema hasta que el agua fluya pareja e inenterrumpidamente, abra y cierre las llaves del agua varias veces hasta asegurarse

que todo el aire ha sido removido. Revise si hay fugas en las tuberias de succión latérales si no es el flujo, puede que exista una

fuga de aire.

5. Pude que sea necesario hacer ajustes finales al interruptor del sistema de presión porque a veces la presión indicada en los

interruptores varía con la mostrada en la cubierta, esta variación, aunque no peligrosa, puede ocasionar interrupciones

momentáneas en el suministro de agua. Para hacer estos ajustes favor de tomar los pasos siguientes:

a. Llene el sistema hasta que se apague la bomba.

b. Abra una llave o llaves y vacíe el tanque para sistemas de agua hasta que arranque la bomba.

c. Si se da una pausa en el flujo del agua desde que se vacía el tanque para sistemas de agua y la bomba arranca

nuevamente, disminuya la presión del tanque hasta que esté de 2 a 3 PSI debajo de la presión establecida para el

arranque. (Vea procedimiento en la sección 3 (a-b) de Buscando Fallas)

d. Cierre las llaves del agua y vuelva a llenar el tanque. Repita los pasos (b) y c) si es necesario hasta que no haya

ninguna pausa en el flujo del agua.

ADVERTENCIA

17

Page 18

Buscando Fallas

LEDOM

.MUN

SENOISNEMID

SENOLAGNENOÍCCARTXE

ALNEAREPOAMETSISLEODNAUC

EDNÓISERPEDALACSE

.LOV.XAM

-CARTXEED

.NÓIC

).SLAG(

NÓIXENOC

AMETSISLED

)SADAGLUP(

ORTEMÁIDARUTLAGISP04/02GISP05/03GISP06/04

AENILNESOLEDOM

P68 61/51117.06.05.02.1MTPN"4/3

P511161/51317.14.12.17.2MTPN"4/3

P521161/1321.36.22.25.4MTPN"4/3

P548/35161/1121.53.47.34.8MTPN"1

EIPEDSOLEDOM

548/35161/51421.53.47.34.8FTPN"1

068/3518/3233.71.63.51.21FTPN"1

088/35161/9939.87.77.69.31FTPN"1

0018/3514/1748.119.96.88.31FTPN"1

0412261/9635.619.311.213.72FTPN"4/11

002228/5849.320.024.713.93FTPN"4/11

05262649.039.525.228.05FTPN"4/11

0622261/11062.132.628.227.44FTPN"4/11

0536261/3169.249.535.135.07FTPN"4/11

SODARRETNESOLEDOM

B548/35161/1121.53.47.34.8MTPN"1

B068/3512/1823.71.63.51.21MTPN"1

B0412261/3235.619.311.213.72MTPN"4/11

B002224/1449.320.024.713.93MTPN"4/11

ET

ET

ET

ET

ET

ET

ET

ET

ET

ET

ET

ET

ET

ET

ET

ET

ET

ESTOS TANQUES PARA AGUA ESTAN DISEÑADOS PARA OPERAR EN SISTEMAS DE AGUA Y DISEÑADOS A LA

TEMPERATURA AMBIENTE CON LIMITE DE PRESIÓN MAXIMA DURANTE SU OPERACIÓN DE 125 LIBRAS POR

PULGADA CUADRADA (PSI) SI SU SISTEMA AL FUNCIONAR PUEDE EXCEDER LA PRESIÓN DE TRABAJO DE 125

PSI (100 PSI SI ES UNA UNIDAD CON LA BOMBA MONTADA), HABRA QUE INSTALARSE UN MECANISMO

ADECUADO DE SEGURIDAD. ESTE PUEDE SER O UN CORTA CORRIENTE (APAGADOR) DE ALTA PRESIÓN Y/O

UNA VALVULA DE ESCAPE DE PRESIÓN., NO SEGUIR ESTAS INSTRUCCIONES PUEDE CAUSAR LA RUPTURA

DEL TANQUE O DAÑO PERSONAL Y/O DAÑO A LA PROPIEDAD.

1. Observe la operación del sistema de agua y vea si se dan ocasiones desacostumbradas como la salida de agua a

borbotones de alguna de las llaves en lugar de un flujo continuo e ininterrumpido (indica que hay aire en el sistema) o

si se da un ciclaje corto de la bomba (Encendidos y apagados rápidos).

2. En el caso de que tenga evidencia de una fuga pequeña cerca al cople, cheque el codo, la introducción de agua fria a

un tanque caliente puede formar condensación especialmente en climas mas calurosos. Es muy importante proveer

una drenaje adecuado.

3. Mida el suministro de agua en contenedores de tamaño adecuado, llenándolos desde que esté parada la bomba

(punto de interrupción) hasta que arranque (punto de encendido). Compare los galones con los mostrados en la tabla

mas adelante, para su modelo de tanque. Si el volumen es cercano a los que muestra la tabla, su sistema está

operando adecuadamente. Si el agua extraída es significativamente menor que la indicada, haga las pruebas

siguientes.

a. Carga de Aire en el Tanque. Interrumpa la corriente eléctrica que va a la bomba. Abra una llave cercana y

drene el tanque compltamente. Revise la presión en el tanque Goulds Pumps Hydro-Pro

estándar de alta calidad para medir presiones de aire de llantas. Si la presión de aire en el tanque está bajo lo

indicado para el arranque de la bomba por mas de 3 psi, agregue aire al tanque para que llegue a 2 PSI menos

que lo requerido para su encendido. Si se requiere, reemplace el tapón del pivote de la válvula: Revise si hay

fugas alrededor del pivote usando una solución de agua jabonosa. Si hace burbujas, esto indica que hay fuga y

en este caso es necesario despresurizar y reeplazar el pivote de la válvula con un pivote estándar de llanta

automotriz similar. Use la misma solución jabonosa para revisar si hay fugas en las costuras y soldaduras del

resto del tanque. Si aparece una fuga en el tanque, entonces éste tiene que reemplazarse necesariamente.

b. Fijación de la Presión. Arranque la bomba y permita que el sistema de presión apague la bomba. Observe en

el medidor los valores de la presión al encenderse y apagarse la bomba. La diferencia no debe de exceder 25

PSI. Si es necesario ajuste la presión apagando la corriente hasta que se mustre una diferencia de 20 PSI. Las

instrucciones para este adjuste de presión vienen con el interruptor en el instructivo de su fabricante. Pruebe el

sistema después de ajustar los limites. Si el interruptor de la presión no puede mantener los limites adecuados

entonces éste necesitará ser cambiado y no el tanque.

TM

usando un medidor

Especificaciones

del Tanque

18

Page 19

Garantia

Limitada

La corporacion A.O. Smith, la garantizadora, extiende la siguiente garantia limitada al dueño del tanque de sistema.

1. TANQUE

Si dentro de los cinco años siguientes a la fecha de instalación el tanque del sistema de agua o alguna de sus partes

resulta defectuosa al ser examinada por la garantizadora, a su opción, cambiarà o reparará las partes o porción

defectuosa. La garantía sobre el reemplazo del tanque será limitada a la parte de tiempo de la garantia original que

aún no expire.

2. CONDICIONES Y EXPECTATIVAS

Esta garantia es aplicable solo cuando el tanque de sistema de agua sea instalado de acuerdo a los còdigos

reglamentos y ordenanzas de plomeria y edificios locales, asi como a las prácticas industriales correctas. Además

se deberá instalar un interruptor de alta presión y/o una válvula de escape de presión al instalarse el tanque de

sistema de agua al sistema de agua, con temperatura ambiente, cuya capacidad de salida trabaje con presiones que

excedan PSI. (100 libras por pulgada cuadrada leídas en el manómetro (PSI) en ciertos modelos)

a. Esta garantia se aplica sòlo cuando el tanque se use:

(1) En systemas de tomas de agua de temperatura ambiental que no excedan la presión en la que

trabaja el tanque.

(2) En los Estados Unidos de Norteamérica, sus territorios a posesiones y Canadá.

b. Esta garantía no se aplica si el sistema no se usa correctamente (Incluyendo la exposición al congelamiento.),

se abusa, es alterado, es modificado en su operación o en alguna forma; también si se intenta reparar alguna

fuga en el tanque si la hubiese.

3. GASTOS DE SERVICIO Y REPARACIÓN.

Bajo esta garantía limitada, la garantizadora, reemplazará solamente el tanque de sistema o sus partes. El dueño

es responsable de otros costos los cuales son, pero no se limitan a:

a. Mano de obra por servicio, remoción, reparación o instalación del tanque tank o parte componente.

b. Cargos de embarque y entrega, por el envio y retorno al distribuidor mas cercano del nuevo tanque o parte de

reemplazo, excepto en el estado de California en cuyo caso son responsabilidad del fabricante.

4. LIMITACIÓN A LAS GARANTIAS IMPLICADAS

Las garantias implicadas, incluyendo cualquier garantía mercantil impuesta por ley estatal, se limitan a cinco años

de duración para el tanque de sistema de agua o cualquiera de sus partes. Algunos estados no permiten

limitaciones de cuanto tiempo duran las garantias implicadas por lo que en este caso la limitación anterior no aplica.

5. PROCEDIMIENTO DE RECLAMACIÓN

Cualquier reclamación amparada por esta garantía deberá iníciarse con el negocio que vendió el tanque de

sistema de agua, o con cualquier otro distribuidor que maneje los productos de la garantizadora. Si esto no es

práctico, contacte a:

a. La empresa que garantiza reemplazará, o refacciones con partes idénticas o similares manufacturadas o

distribuidas por la misma garantizadora.

b. Los reemplazos por tiendas y distribuidores de tank se hacen sujetos a la validación de la

empresa garantizadora.

6. DECLINACIONES

NINGUN OTRA GARANTIA EXPRESA HA SIDO HECHA O SERA HECHA POR CUENTA DE LA GARANTIZADORA

CON RELACION AL T ANQUE DE SISTEMA DE AGUA, SU INSTALACION, REPARACION O REEMPLAZO. LA

GARANTIZADORA NO SERA RESPONABLE DE DAÑOS POR AGUA, PERDIDA POR USO DE LA UNIDAD,

INCONVENIENCIA O PEROIDA O DAÑO A LA PROPIEDAD PERSONAL, U OTROS DAÑOS CONSECUENTES.

LA GARANTIZADORA NO EST A OBLIGADA POR VIRTUD DE ESTA GARANTIA, O EN ALGUNA OTRA FORMA, A

RESPONDER FOR DAÑOS A PERSONAS O CUALQUIER TIPO DE PROPIEDAD YA SEA DIRECTA O

INDIRECTAMENTE, O COMO RESULTADO DE CONTRATOS, DAÑOS O PERJUICIOS.

a. Algunos estados no permiten la exclusión o limitación del daño incidental o consecuente, por lo que la

exclusión anterior podria no ser aplicable a usted.

b

. Esta garantia le da derechos legales espeuficos y puede que Ud., tenga otros derechos los cuales varian de

estado a estado.

Llene lo siguiente para su propia información y referencia y consérvelo. El registro no es una condición de la garantía. El

modelo y número de serie se encuentran en el tanque para sistemas de agua.

Clientes en EUA Clientes en Canadá

A.O. Smith Corp. A.O. Smith Corp.

5621 W. 115th Street P.O. Box 310-768 Erie Street

Alsip, IL 60803 Stratford, Ontario N5A 6T3

800-323-2636 o 708-489-4600 (519) 271-5800

No. de Mod.___________________________________No. de Serie._______________________________

Fecha de Instalación_____________________________________________________________________

Nombre de la tienda o distribuidora__________________________________________________________

Dirección dela tienda o dist.__________________________________________ Tel.___________________

Ciudad y Estado (Provincia)_____________________________Código Postal_______________________

Permiso para el transporte de productos peligrosos No. SU 5099 (Ren2) - por ferrocarril o terrestre solamente, fecha de expiracíon Marzo

31 de 2003 (Renovacíon pendiente).

No. de la pieza 205351-000

19

Page 20

Red Jacket Water Products reserves the right

to make design improvements and pricing

modifications as necessary and without notice.

20

Part No. 205351-000

Loading...

Loading...