Page 1

INSTRUCTION MANUAL

IMVSR01

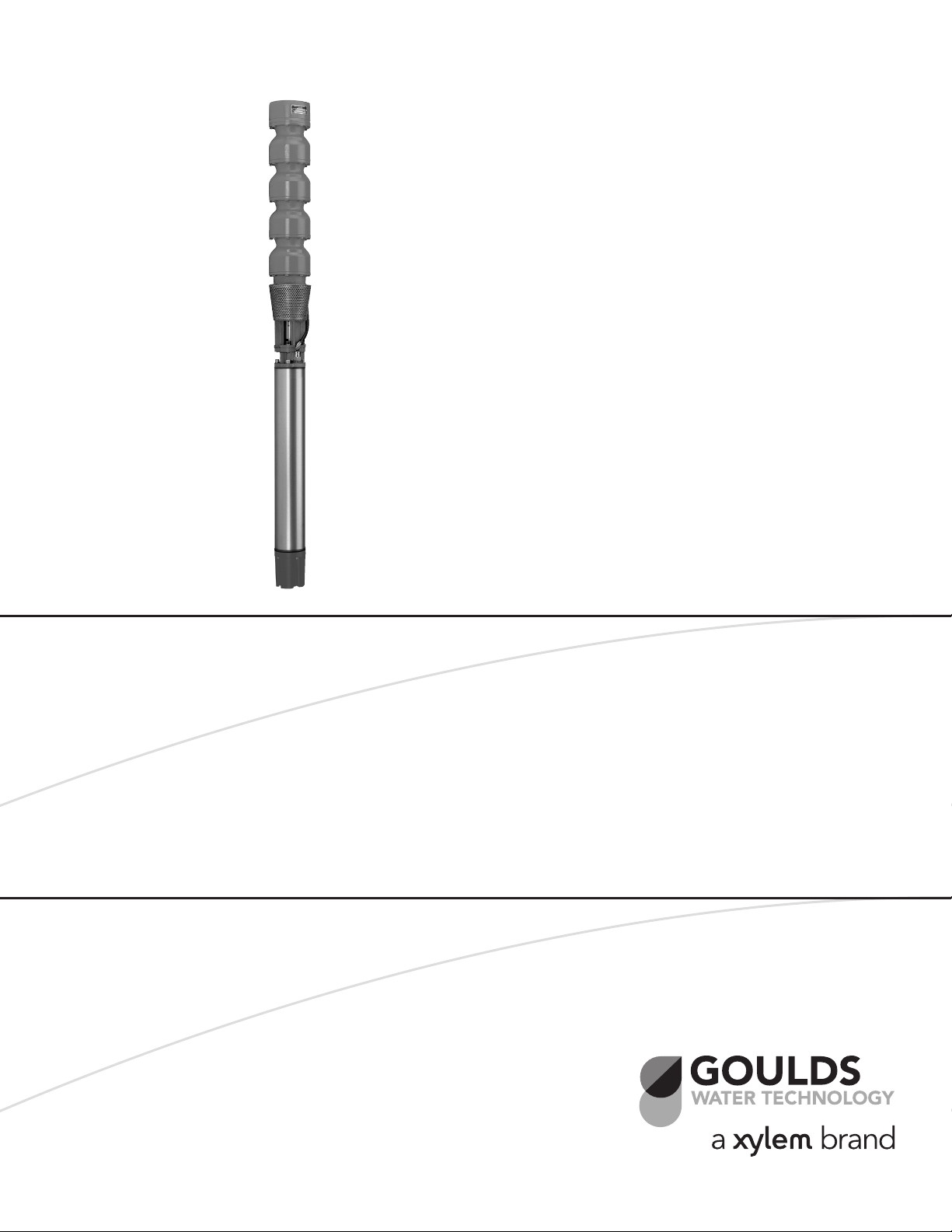

MODEL VS

VERTICAL INDUSTRIAL TURBINE PUMPS

INSTALLATION, OPERATION AND MAINTENANCE INSTRUCTIONS

Page 2

Foreward

This manual provides instructions for the Installation, Operation, and Maintenance of the Goulds Water

Technology Turbine Pumps. This manual covers a standard product. For special options, supplemental

instructions are available. This manual must be read and understood before installation and start-up.

This instruction manual covers several different pump models. Most assembly, disassembly, and inspection

procedures are the same for all the pumps. However, where there are differences, these differences will be

noted within the manual. The design, materials, and workmanship incorporated in the construction of the pumps

makes them capable of giving long, trouble-free service. The life and satisfactory service of any mechanical unit,

however, is enhanced and extended by correct application, proper installation, periodic inspection, condition

monitoring and careful maintenance. This instruction manual was prepared to assist operators in understanding

the construction and the correct methods of installing, operating, and maintaining these pumps.

The information contained in this book is intended to assist operating personnel by providing information on the

characteristics of the purchased equipment. It does not relieve the user of their responsibility of using accepted

engineering practices in the installation, operation, and maintenance of this equipment.

Goulds Water Technology shall not be liable for physical injury, damage, or delays caused by a failure to

observe the instructions for installation, operation and maintenance contained in this manual.

Warranty is valid only when genuine Goulds Water Technology parts are used.

Use of the equipment on a service other than stated in the order will nullify the warranty, unless written approval

is obtained in advance from Goulds Water Technology.

For information or questions not covered in this manual, contact Goulds Water Technology at (806) 743-5700.

THIS MANUAL EXPLAINS :

• Proper Installation • Pump Overhaul

• Start-up Procedures • Trouble Shooting

• Operation Procedures • Ordering Spare or Repair Parts

• Routine Maintenance

Pump Model Number:

Pump Serial Number:

Control Model Number:

Dealer:

Dealer Phone No.:

Date of Purchase: Installation:

Current Readings at Startup:

1 Ø 3 Ø L1-2 L2-3 L3-1

Amps: Amps:

Volts: Volts:

2

Page 3

Table of Contents

SUBJECT PAGE

Safety Instructions .........................................................................................................................................................4

Section 1 – General Information

Introduction ..............................................................................................................................................................4

Receiving and Checking ............................................................................................................................................4

Materials and Equipment Required ...........................................................................................................................4

Section 2 – Storage

Storage ......................................................................................................................................................................4

Storage Preparation ...................................................................................................................................................4

Recommended Storage Procedures ............................................................................................................................5

Preparations for Uncontrolled Long-Term Storage .....................................................................................................5

Section 3 – General Description

General Description ..................................................................................................................................................5

Drivers ......................................................................................................................................................................5

Discharge ..................................................................................................................................................................5

Bowl Assembly ..........................................................................................................................................................5

Section 4 – Preparation for Installation

Well Requirements ....................................................................................................................................................6

Preparing the Foundation .......................................................................................................................................... 6

Motor and Cable Checks and Preparation .................................................................................................................6

Section 5 – Installing the Pump......................................................................................................................................7

Section 6 – Starting the Pump ........................................................................................................................................8

Section 7 – Pump Disassembly and Reassembly

Pump Disassembly.....................................................................................................................................................8

Bowl Disassembly ....................................................................................................................................................10

Turbine Bowl – Wear Rings Removal .......................................................................................................................10

Turbine Bowl – Impeller Wear Ring Removal ..........................................................................................................10

Bowl Bearing Removal ............................................................................................................................................10

Inspection and Replacement ....................................................................................................................................10

Turbine Bowl and Impeller Wear Ring Installation ..................................................................................................10

Bowl Bearing Installation ........................................................................................................................................10

Turbine Bowl with Taperlock – Reassembly ............................................................................................................. 10

Section 8 – Troubleshooting Chart ..............................................................................................................................11

Appendix A – Assembly of Pump and Motor ...............................................................................................................12

Appendix B – Splicing Power Cable to Motor Leads ....................................................................................................12

Appendix C – Electrical Tests ......................................................................................................................................13

Limited Warranty ........................................................................................................................................................16

3

Page 4

DANGER

WARNING

CAUTION

WARNING

CAUTION

SAFETY INSTRUCTIONS

TO AVOID SERIOUS OR FATAL PERSONAL

INJURY OR MAJOR PROPERTY DAMAGE, READ

AND FOLLOW ALL SAFETY INSTRUCTIONS IN

MANUAL AND ON PUMP.

THIS MANUAL IS INTENDED TO ASSIST IN THE

INSTALLATION AND OPERATION OF THIS UNIT

AND MUST BE KEPT WITH THE PUMP.

This is a SAFETY ALERT SYMBOL.

When you see this symbol on the pump

or in the manual, look for one of the

following signal words and be alert

to the potential for personal injury or

property damage.

Warns of hazards that WILL cause

serious personal injury, death or major

property damage.

Warns of hazards that CAN cause

serious personal injury, death or major

property damage.

Warns of hazards that CAN cause personal injury or property damage.

NOTICE: INDICATES SPECIAL INSTRUCTIONS

WHICH ARE VERY IMPORTANT AND

MUST BE FOLLOWED.

THOROUGHLY REVIEW ALL INSTRUCTIONS

AND WARNINGS PRIOR TO PERFORMING ANY

WORK ON THIS PUMP.

MAINTAIN ALL SAFETY DECALS.

SECTION 1 — GENERAL INFORMATION

1–1 INTRODUCTION

The design, materials and workmanship incorporated in

the construction of Goulds Water Technology submersible turbine pumps makes them capable of giving long,

trouble-free service. The life and satisfactory service of

any mechanical unit, however, is enhanced and extended

by correct application, proper installation, periodic

inspection and careful maintenance. This instruction

manual was prepared to assist the operators in understanding the construction and correct methods of installing, operating and maintaining these pumps.

Study thoroughly Sections 1 through 8 and keep this

manual handy for reference. Further information can be

obtained by contacting Goulds Water Technology sales

office or your local branch office.

GOULDS WATER TECHNOLOGY

SHALL NOT BE LIABLE FOR ANY

DAMAGES OR DELAY CAUSED BY FAILURE TO

COMPLY WITH THE PROVISIONS OF THIS INSTRUCTION MANUAL.

1–2 RECEIVING AND CHECKING

The pump shall be carefully supported prior to unloading from the carrier. Handle all components carefully. Inspection for damage of the shipping crate shall be made

prior to unpacking the pump. After unpacking, visually

inspect the pump and check the following:

1. Contents of the pump assembly against shipping list.

2. All components for damage.

4

Any shortages or damages should be immediately called

to the attention of the local freight agent of the carrier by

which the shipment arrived and proper notation made on

the bill. This shall prevent any controversy when a claim

is made and to facilitate prompt and satisfactory adjustment.

1–3 MATERIALS AND EQUIPMENT REQUIRED

The material and equipment necessary for installation

of the pump will vary with the size of the pump and the

type of installation. The following discussion and list of

standard tools and supplies is therefore offered only as a

guide.

1. BULK MATERIAL

Anti-galling lubricant, thread compound, lubrication

oil, grease, petroleum based solvent.

2. HAND TOOLS

Pipe wrenches, two chains tongs, mechanic's hand

tools and machinist level.

3. INSTRUMENTS

One megger, or similar instrument indicating electrical

resistance, clamp-on ammeter, voltmeter and a good

grade of pipe joint compound should be available to

facilitate assembly and possible future disassembly.

4. INSTALLATION EQUIPMENT

Wooden friction blocks or steel clamps, steel column

lifting elevators of approved type and of proper size

for the column pipe, and cable sling approximately 10

feet long of adequate size for the loads involved.

Although portable derricks are sometimes used, a

properly designed pump setting rig is recommended.

It must be possible to erect the crown block to a

height so as to allow the load hook to be raised about

three feet higher than the longest piece. The lifting

device must be of sufficient strength and rigidity to

raise the total weight of the unit safely.

REMEMBER – REGARDLESS OF THE

TYPE OF LIFTING EQUIPMENT, OR

THE TYPE OF PUMPING EQUIPMENT, THE PRIMARY RULE IS: SAFETY FIRST.

SECTION 2 — STORAGE

2–1 STORAGE

Goulds Water Technology carefully preserves and protects its products for shipment. However, the effective

life of the preservatives applied at the factory can vary

from 3 to 18 months depending on the severity of the environment in which the equipment is stored. This section

provides procedures for preparation prior to storage and

maintenance during storage of Goulds Water Technology pumps. These procedures are necessary to protect

the precision parts of the pumps. Specific procedures

for storing motors should be obtained from the motor

manufacturer. This section is intended to be of general

assistance to users of Goulds Water Technology pumps. It

shall not modify, amend, and/or otherwise alter the scope

of the Goulds Water Technology warranty in anyway

whatsoever.

2–2 STORAGE PREPARATION

Goulds Water Technology submersible pumps require

proper preparation for storage. The pump shall be

Page 5

considered in storage when it has been delivered to the

job site and is awaiting installation. If a pump has been

installed, but is not in regular operation, such as seasonal

shutdown or an extended period of time, it is suggested

that the pump be operated for at least 15 minutes every

two weeks if possible.

2–3 RECOMMENDED STORAGE PROCEDURES

1. Controlled storage facilities should be maintained at

an even temperature 10º F (5.6°C) or more above the

dew point with relative humidity less than 50% and

little or no dust. (If these requirements cannot be met

the pump is to be considered in uncontrolled storage.)

2. For uncontrolled storage periods of six months or less,

the pump is to be inspected periodically to insure that

all preservatives are intact.

3. All pipe threads and flanged pipe covers are to be

sealed with tape.

4. The pump must not be stored closer than six inches to

the ground.

2–4 PREPARATIONS FOR UNCONTROLLED

LONG TERM STORAGE

Storage periods over six months require the preceding

uncontrolled storage procedure plus the following:

1. Inspect the assembly and recoat periodically to prevent

corrosion.

2. Place ten pounds of moisture absorbing desiccant or

five pounds of vapor phase inhibitor crystals near the

center of the pump. If the pump is assembled, place an

additional one pound in the discharge nozzle securely

fastened to the discharge flange.

3. Install a moisture indicator near the perimeter of the

pump. Cover the pump with 6 mils (0.15 mm) minimum thickness black polyethylene or equal and seal

it with tape. Provide a small ventilation hole approximately ½ inch diameter.

4. Provide a roof or a shed shelter to protect from direct

exposure to the elements.

SECTION 3 — GENERAL DESCRIPTION

3–1 GENERAL DESCRIPTION

Goulds Water Technology model VS pump is a submersible turbine pump designed for maximum dependability.

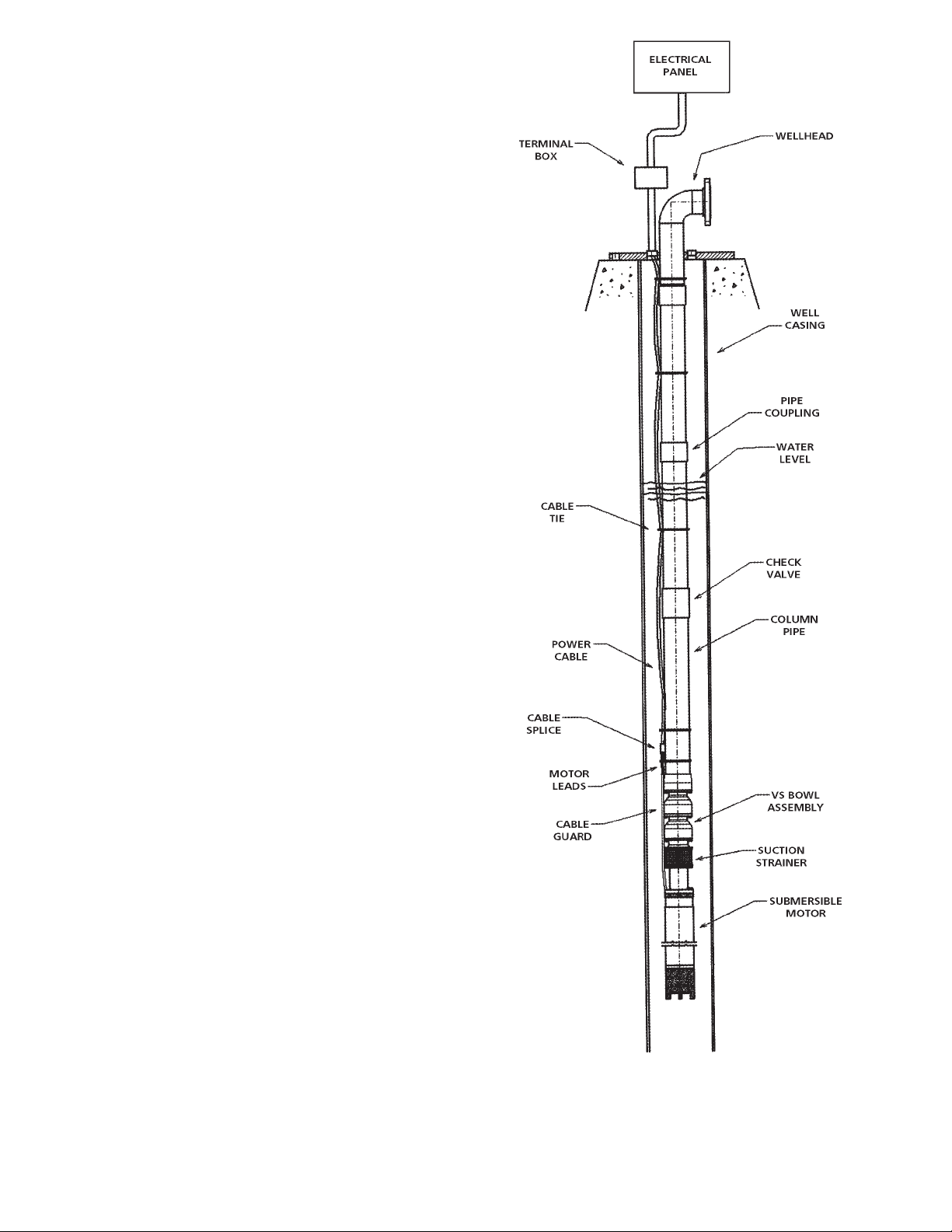

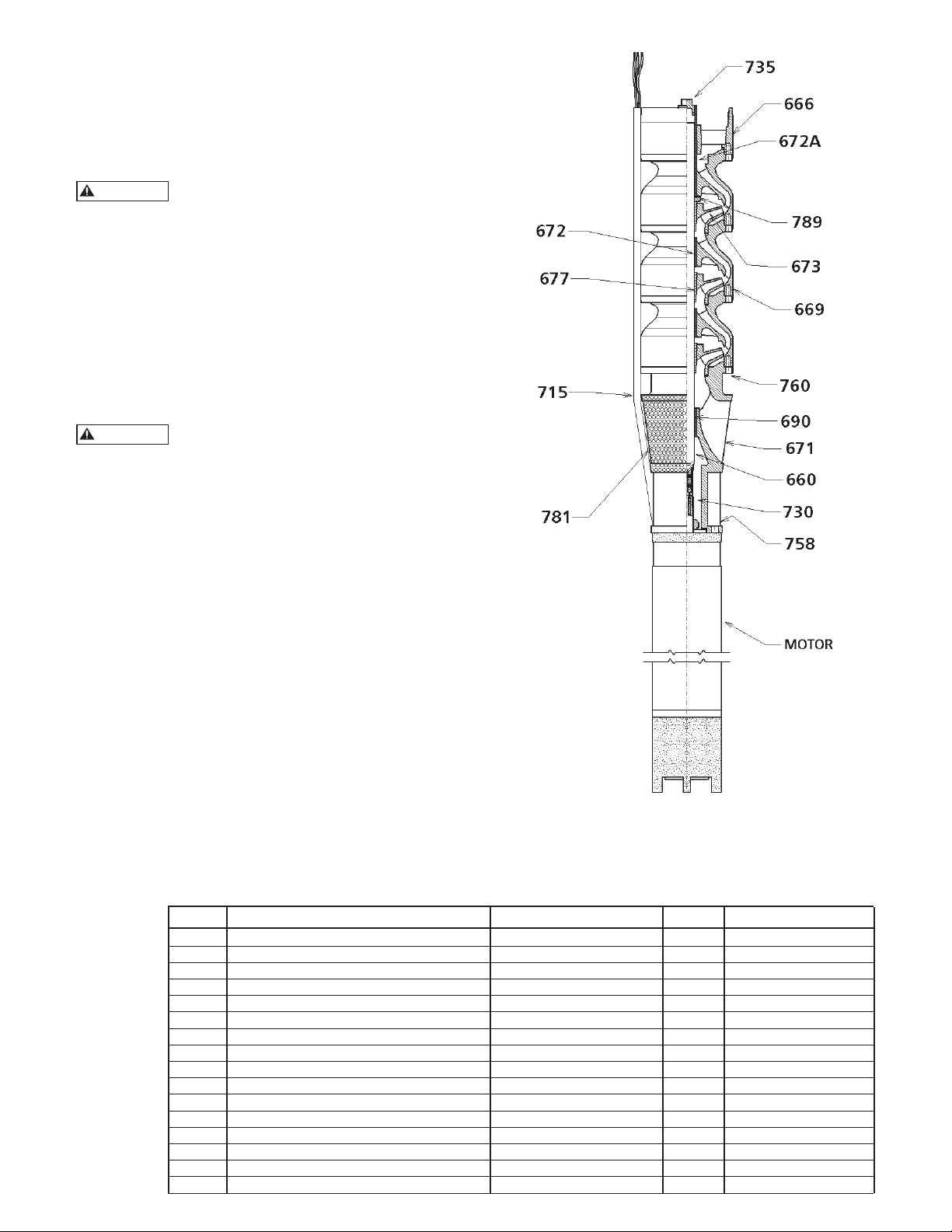

See Figure 1 for typical VS pump.

3–2 DRIVERS

Goulds Water Technology furnishes only internationally

recognized motors designed for continuous operation

under any thrust which may develop throughout the

performance curve. Impeller adjustment and type of

coupling, splined or clamped, is dependent on the

specific motor being used.

3–3 DISCHARGE

The discharge bowl provides an NPT or BSP thread for

connecting to the well head or the first section of column

pipe.

Figure 1 – Typical Submersible Pump Installation

3–4 BOWL ASSEMBLY

The bowls are generally flanged construction for accurate

alignment and ease of assembly and disassembly. Impellers may be enclosed or open type. Impeller position is

set at factory. No field adjustment is required.

5

Page 6

CAUTION

CAUTION

CAUTION

WARNING

CAUTION

SECTION 4 — PREPARATION FOR

INSTALLATION

4–1 WELL REQUIREMENTS

1. The well should be developed with a test pump prior

to installing the submersible pump. Test pumping the

well serves several purposes. It removes the excess

sand encountered during the initial pumping of the

well. Pumping sand or other abrasives with a submersible pump will shorten the life of the pump and can

void the warranty.

DO NOT INSTALL THE UNIT WITH

THE MOTOR IN THE MUD, SAND

OR RESTING ON THE BOTTOM OF THE WELL.

IT IS IMPORTANT TO PREVENT THE WELL FROM

SANDING UP AT ANY TIME TO THE POINT THAT

THE MOTOR BECOMES EVEN PARTIALLY BURIED.

2. The test pumping also provides a means of determin-

ing the capacity and drawdown. The well capacity

should equal or exceed the pump capacity. If the pump

removes water at a higher rate than the well produces,

the drawdown will be excessive and the pump will

cavitate or 'starve' resulting in damage of the pump

and motor.

3. The well must be deep enough so that the pump suc-

tion is at least 10 feet below the expected drawdown

level. If the well screen or water producing aquifer is

above the pumping level, the required submergence of

the pump suction would be over 20 feet.

NEVER INSTALL UNIT WITH THE

BOTTOM OF THE MOTOR CLOSER

THAN FIVE FEET FROM THE BOTTOM OF THE

WELL.

4. The motor must always be immersed in flowing water.

The flow rate must be over .5 ft./sec. If the pump is set

below the well screen openings or other conditions exist that caused the water to be supplied from above the

pump, a flow induce sleeve should be used.

5. The inside diameter of the well casing must be large

enough to allow lowering the unit into the well without damage to the power cable, the splice between the

power cable and the motor leads. Many wells have

more than one size of casings installed and frequently

the lower sections are smaller in diameter than the

upper casing.

6. The submersible pump/motor unit must be operated

in a straight portion of the well. Exerted pressures can

and will cause misalignment of bearings or coupling.

When the straightness of the well is not known, it is

recommended to lower a test blank with the same

diameter and length as the pump/motor assembly with

electrical leads into the well to the desired depth. If

there is any doubt about straightness, gagging and

plotting are recommended.

4–2 PREPARING THE FOUNDATION

The foundation must be rigid, level and of adequate

strength to support the complete weight of the pump,

motor, column, plus the weight of the liquid passing

through it. It is recommended the foundation be constructed of solid concrete, however, adequate beams or

6

timbers may be used. A common foundation consists of

the following concrete mixture:

1. One part cement

2. Two parts sand

3. Four parts gravel

4. With sufficient water to make a stiff mix

4–3 MOTOR AND CABLE CHECKS AND

PREPARATION

DO NOT USE MOTOR LEADS TO

LIFT OR HANDLE THE MOTOR. THE

MOTOR LEADS ARE EASILY DAMAGED. THEY

SHOULD BE PROTECTED AND HANDLED WITH

CARE AT ALL TIMES.

1. MOTOR SERVICING

Consult the motor manual and perform any preinstallation servicing that is required. Some motors may

require filling with oil or water.

2. ASSEMBLE OF MOTOR TO PUMP

If the pump and motor have not already been assembled, assemble per the instructions given in Appendix

A. For extra long units, it may be more practical to assemble the pump to the motor in the vertical position

at the installation site.

3. TESTING BEFORE SPLICING POWER CABLE TO

MOTOR LEADS

Perform the following tests before making the splice

between the motor leads and the drop cable. Instructions for performing resistance tests and evaluating

the results are given in Appendix C.

MOTOR TESTS

• Measure the resistance between each motor lead

and ground with the motor submerged in water.

See Appendix C.

• Measure the resistance of the motor windings. See

Appendix C. Record the values for future reference.

• Secure the pump and motor with chain tongs to

resist torque. Energize the motor momentarily (on

and immediately off) to check the rotation.

GROUND THE UNIT WHEN TEST-

ING. FAILURE TO GROUND THE

UNIT PROPERLY CAN RESULT IN SERIOUS OR

FATAL SHOCK. ALSO, THE HIGH STARTING

TORQUE OF THE MOTOR WILL CAUSE IT TO

'KICK' WHEN POWER IS APPLIED. THE UNIT

SHOULD BE RESTRAINED SUFFICIENTLY TO PREVENT DAMAGE TO THE EQUIPMENT OR PERSONAL INJURY.

NOTE: ROTATION WILL BE COUNTERCLOCK-

WISE WHEN VIEWED FROM THE DISCHARGED BOWL.

On three phase unit, if rotation is wrong, interchange

any two of the motor leads at the control panel.

CORRECT ROTATION IS OF EX-

TREME IMPORTANCE. EXCESSIVE

OVERLOADS MAY BE DEVELOPED UNDER OPERATING CONDITIONS WITH REVERSE ROTATION.

Page 7

CAUTION

CAUTION

WARNING

DROP CABLE TEST

• Measure the resistance between the cable conductors and ground with the cable submerged in water.

See Appendix C.

4. SPLICING POWER CABLE TO MOTOR LEADS

A waterproof splice must be made to connect the

power cable to the motor leads. A properly made

splice will last the life of the pump. An improperly

made splice will become a service problem. Make the

splice per instructions supplied with the drop cable

or per instructions in the pump motor manual. The

splice should be located above the pump bowl. It

should be as compact as possible. A compact splice is

less likely to be damaged as the pump is being lowered

into the well. See Appendix B for instruction on splic-

ing the cable.

5. TESTING AFTER SPLICING POWER CABLE TO

MOTOR LEAD

Perform the following test after making the splice, but

before lowering the pump into the well.

• Check that the splice is waterproof by immersing it

in a container of water for approximately one hour

and then taking resistance readings between each

cable conductor and the water. See Appendix C.

• Measure the total resistance of the complete drop

cable and motor circuit to insure that a good splice

was made. Record the values for future reference.

THE MINIMUM READING FOR EACH

LEAD TO GROUND SHOULD BE 50

MEGOHMS.

SECTION 5 — INSTALLING THE PUMP

1. Check the pump and motor shaft to make sure it turns

free before installation. For some models, it may be

necessary to remove the suction screen in order to

check the shaft. Be sure to reinstall the suction screen.

2. Raise the bowl/motor assembly with the shipping skids

still in place. Remove the shipping skids and lower assembly into the well, clamping the bowl assembly near

the top.

3. Attach the elevators to the bottom column pipe imme-

diately below the column coupling. Hoist the column

section into place above the well and the top of the

bowl assembly, providing a soft board or pipe dolly

for the end of the column pipe to slide in on so that

threads will not be damaged while the section is being

raised. Clean all threads with thread lubricant. Thread

the pipe into the discharge bowl connection and make

up tight, using one set of chain tongs for backup.

THE PUMP MOTOR WILL EXERT

A TORQUE THAT WILL TEND TO

UNSCREW THREADED COLUMN PIPE CONNECTIONS. FOR THE REASON, THREADED COLUMN

JOINTS MUST BE TIGHTENED.

THE FOLLOWING TABLE GIVES THE NORMAL

AMOUNT OF THREAD ENGAGEMENT NECESSARY TO MAKE A TIGHT JOINT FOR THE NPT

THREAD JOINT:

Pipe Length of Number

Size Thread (in.) of Threads

3" 1" 8

4" 11/8" 9

5" 11/4" 10

6" 15/16" 101/2

8" 17/16" 111/2

10" 15/8" 13

4. Install a cable clamp on each side of the cable splice.

See Figure 1. Be careful not to damage the cable. If

an air line is to be installed, route it beside the cable,

making sure that it is not pinched by the clamps. If

there is any danger that the splice will rub against the

well casing during installation, it should be protected

by thick rubber chaffing pads or by a steel shield.

Check that the grounding system is in place.

FAILURE TO GROUND THE UNIT

PROPERLY CAN RESULT IN SERIOUS

OR FATAL SHOCK. REFER TO ELECTRICAL CODE

REQUIREMENTS.

5. Slowly lower the unit into the well (or sump) adding

joints of column pipe as the unit is lowered. Tighten

each joint securely. See note above. Remove slack from

the power cable and attach a cable clamp approximately every 20 feet. For units with large heavy power

cable, additional cable clamp may be required to give

additional support. Line up the cable on one side of

the pump and maintain as much clearance as possible

on that side when lowering the pump in the well. BE

EXTREMELY CAREFUL NOT TO SCRAPE OR

DAMAGE THE POWER CABLE, CABLE SPLICE

OR GROUNDING SYSTEM WHEN LOWERING

THE PUMP. Hold the power cable up away from the

well casing as lowering the pump into the casing.

6. If the pump does not have a built-in check valve, a line

check valve should be installed within 25 feet above

the pump bowl assembly. For a deep setting pump, a

line check valve is recommended for every 200 feet

of column pipe, However, no check valve should be

installed above the pumping level.

7. As soon as the splice joint is submerged in the water,

take a resistance reading between the power cable

conductors and ground to assure that the insulation

and the cable or the splice was not damaged during

installation.

8. After the last piece of column pipe has been installed,

install the well head. Install a cable clamp between the

last column pipe coupling and the well head base. See

Figure 1. Route the power cable and grounding system

through the large threaded hole in the head base.

Route the air line (if used) through one of the smaller

threaded holes in the head base. The remaining small

threaded hole is for connection of a well vent or other

accessories. All of these holes are threaded with standard NPT or BSP pipe threads. If a gasket is required

between the head base and its mounting surface, the

gasket should be placed on the foundation prior to

installing the well head.

7

Page 8

WARNING

CAUTION

9. After the well head has been properly tightened,

carefully rotate the entire unit in the well until the

discharge flange is facing in the desired direction. Push

the unit to one side of the well, providing the maximum clearance for the drop cable when rotating the

unit.

10. Slowly lower the well head onto its mounting

surface. BE CAREFUL NOT TO DAMAGE THE

GROUNDING SYSTEM OR PINCH THE POWER

CABLE BETWEEN THE SURFACE PLATE AND

THE WELL CASING. If a gasket or other seating

device is used, be sure that it is aligned properly and

that it is not damaged. Install the mounting bolts.

11. Before connecting the power cable to the control

panel:

Take a resistance reading between the power cable

conductors and ground to assure that the insulation

on the cable or splice was not damaged during installation. See Appendix C.

Measure the resistance of the power cable and motor

circuit. See Appendix C. Compare these readings with

those taken in Section 4 to assure that the splice is still

intact. Make the electrical connection between the power

cable and the control panel. It may be desirable to use a

terminal box at the well head to simplify the electrical

work required when the pump is pulled. Be sure that the

unit is grounded properly.

FAILURE TO GROUND THE UNIT

PROPERLY CAN RESULT IN SERIOUS

OR FATAL SHOCK. REFER TO ELECTRICAL CODE

REQUIREMENTS.

Be sure to connect the leads as they were marked

previously in the procedure.

SECTION 6 — STARTING THE PUMP

INITIAL STARTUP AND TESTING

MAY REQUIRE STARTING AND

STOPPING THE PUMP SEVERAL TIMES. BE SURE

TO ALLOW ADEQUATE COOLING OFF PERIOD

BETWEEN STARTS. CONSULT THE MOTOR MANUAL. IF NO INFORMATION IS GIVEN, A GOOD

RULE-OF-THUMB IS TO ALLOW A MINIMUM OF

15 MINUTES BETWEEN STARTS.

For initial startup, allow the water to be pumped out

onto the ground. A throttle valve in the discharge line is

recommended. Position the throttle valve approximately

one-forth open for startup of the pump. This will prevent

surging the well or the pump during startup.

If the pump has been in the well for several days before

the startup, check the resistance between the cable conductor and ground to assure that water has not penetrated the splice or the cable insulation. See Section 4.

Clamp the tongs of a clamp-on type ammeter around

one power lead to the pump. Set the ammeter on the

maximum scale. After the motor starts, it can be reset to

a lower scale as desired.

Refer to the motor manual and determine the normal

operating amps for the installed motor.

Start the pump and observe and record the current

readings on each conductor of the power lead. If the

8

current exceeds the normal value determined in the motor manual, stop the pump immediately. A high current

reading indicates that something is wrong. Among the

potential problems are:

• Incorrect pump rotation (3 phase only)

• Improper voltage

• Sand locked pump

• Improper cable size or leak in cable

• Mechanical damage

In any case, the problem must be corrected before the

pump can be operated.

On three phase units, if water does not appear within

one minute (deeper settings may require approximately

one half minute per 100 feet setting) the motor may be

running backwards. Stop the pump and interchange any

two of the three cable connections. If there is any doubt

about the proper rotation, run the motor in one direction

and then the other. The rotation that gives the highest

pressure and flow is always the correct one.

Check the voltage. The voltage when the pump is running should be within 5% of the pump motor nameplate

voltage.

Open the throttle valve. If a flow meter is available, open

the throttle valve to rated flow of the pump. If sand appears in the water, throttle the pump at approximately

80% of full flow until the sand clears. If excessive noise

develops, pressure fluctuates or water appears foamy

white, the pump is probably cavitating and the flow

should be throttled until the noise diminishes, the pressure remains steady and the water is clear.

On three phase units, check for current unbalance.

Details of the current unbalance test are given in the Appendix C. THE MAXIMUM ALLOWABLE CURRENT

UNBALANCE IS 5%. If the current unbalance exceeds

5% after rolling the leads and connecting them for the

lowest unbalance, the pump should be stopped and corrective action taken. Current unbalance in excess of 5%

can be expected to cause excessive heating in the motor

and premature failure. Operation with a current unbalance in excess of 5% will void the warranty.

After the unit is operating properly, a performance test

should be considered. If a performance test is conducted

when the pump is new, subsequent tests can be used to

determine the degree of wear or deterioration of the

pump without removing it from the well. After the unit

has been in operation for approximately one week, perform the routine tests.

SECTION 7 — PUMP DISASSEMBLY AND

REASSEMBLY

1. Clear a large area adjacent to the pump as storage

space for pump parts as they are disassembled. If the

pump has a long column, arrange parallel timbers on

the ground to support the pump column horizontally.

After disassembly for repair or replacement of pump

components, reassemble in all cases in the reverse

order of disassembly.

NOTE: PUMP COMPONENTS SHOULD BE

MATCH-MARKED PRIOR TO

DISASSEMBLY.

Page 9

2. It is recommended that maintenance personnel be-

WARNING

WARNING

come thoroughly familiar with the VS pump before

performing any removal of the components. Consult

the manufacturer's instructions for detailed disassembly information for the motor.

A. Remove the electrical connection at the conduit box

and tag electrical leads at the motor.

BEFORE OPENING THE CONDUIT

BOX OF AN ELECTRICAL MOTOR,

BE SURE THE CURRENT TO THE MOTOR IS SHUT

OFF. SEVERE INJURY TO PERSONNEL COULD

RESULT IF CONTACT WITH LIVE MOTOR LEADS

IS MADE.

LOCK OUT SHOULD BE INSTALLED BEFORE ANY

ELECTRICAL WORK IS PERFORMED.

NOTE: MATCH-MARK PARTS IN SEQUENCE OF

DISASSEMBLY TO AID IN THE REASSEMBLY PROCEDURE.

B. Disconnect the discharge piping from the well head.

DO NOT WORK UNDER A HEAVY

SUSPENDED OBJECT UNLESS THERE

IS A POSITIVE SUPPORT UNDER IT WHICH WILL

PROTECT PERSONNEL SHOULD A HOIST OR

SLING FAIL.

3. PUMP DISASSEMBLY

In the following pump disassembly procedures, references are made to installation sections of this manual.

These sections will aid in the disassembly of the

pump.

A. Disconnect well head and begin removal of column

sections. Refer to Section 5, #7.

B. For removal of bowl/motor assembly, hoist the

bowl/motor assembly from the well, using elevator clamps. Hoist in the same manner as for the

column. For the keyed motor shaft, loosen the

setscrews on the motor end of the shaft coupling.

Remove the motor lead from the cable guard.

Disassemble the bowl assembly from the motor by

removing the connecting bolts at the flange joint.

For the short assembly, laying the bowl/motor assembly on the ground to perform these works. For

the long or large size assembly, it is recommended

to perform these works while the assembly is in the

vertical position. Refer to Section 4, #3. Proceed to

disassemble the bowl assembly as follows.

Figure 2 – Bowl and Motor Assembly

ITEM NAME MATERIAL GPI ASTM

666 Bowl Discharge Iron 1003 A48 CL30

669 Bowl - Intermediate Cast Iron - Glassed 6911 A48 CL30

672 Bearing - Intermediate Bowl Bronze 1109 B584 C90300

672A Bearing Discharge Bronze 1109 B584 C90300

690 Bearing Subadapter Bronze 1109 B584 C90300

760 Capscrews - Grade 8 Steel 2298 SAE J429 GR8

758 Capscrews SST 304 2228 A276 S30400

730 Coupling Motor SST 416 2218 A582 S41600

715 Guard Cable SST 304 3215 A240 S30400

673 Impeller Bronze 1102 B584 C87600

781 Screen Suction SST 304 3215 A240 S30400

660 Shaft SST 416 2227 A582 S41600

671 Subadapter Duct Iron 1018 A536 65-45-12

677 Taperlock Steel 2242 A108 G10180

789 Washer Upthrust HDPE 6266 Polyethylene

735 Pipe Plug Iron 1046 A197

9

Page 10

4. BOWL DISASSEMBLY

The bowl assembly shown in Figure 2 is composed of

a discharge bowl (for the model with built-in check

valve, it would be column adapter), intermediate

bowl, impellers with taper collects, motor adapter,

bearings and pump shaft.

A. Begin disassembly by removing the capscrews that

secure the top stage intermediate bowl and the second stage intermediate bowl and slide the discharge

and top intermediate bowls off the pump shaft

together. Remove the thrust washer.

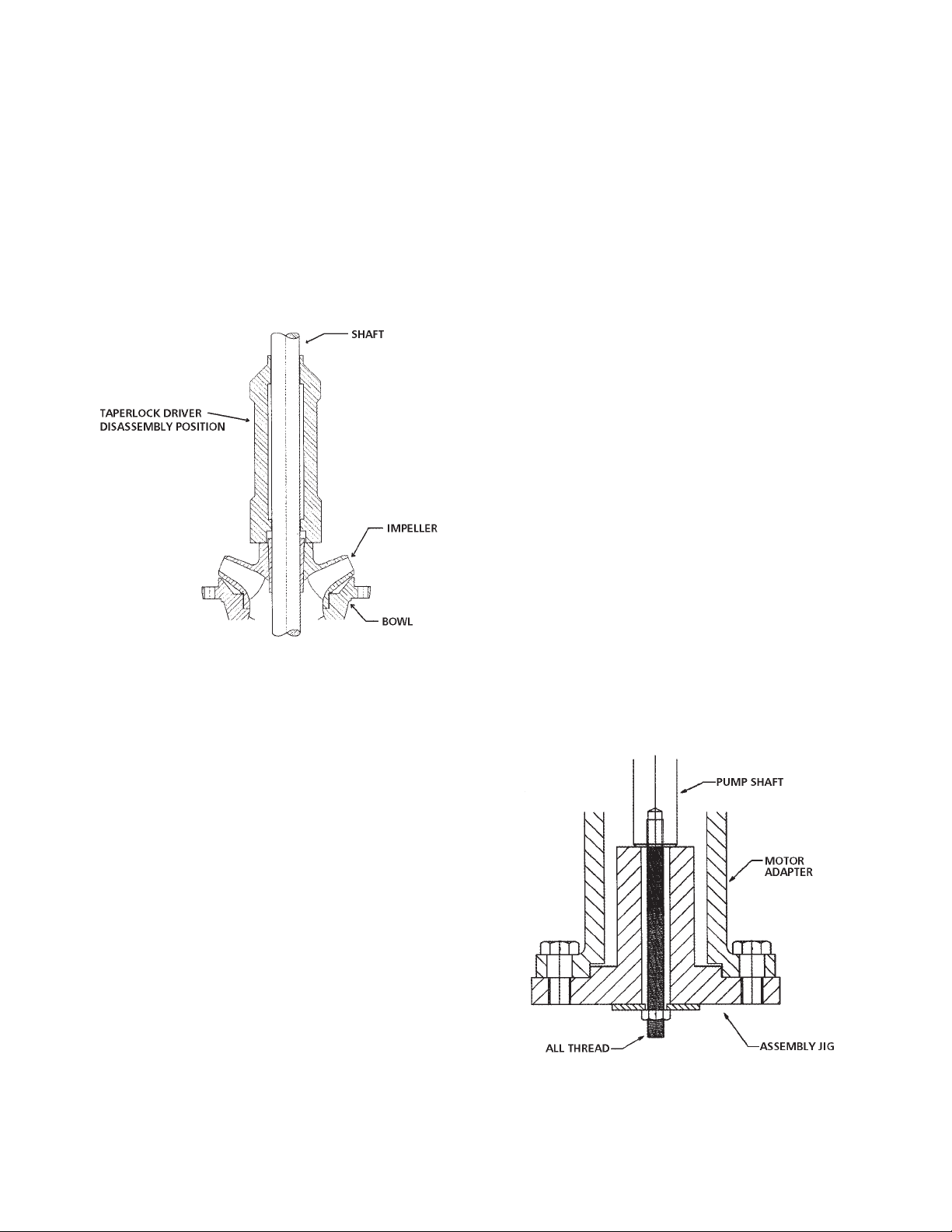

B. Pull shaft out as far as possible and strike impeller

hub utilizing a taperlock driver or equivalent sliding

along the pump shaft to drive the impeller off the

taperlock. See Figure 3.

Figure 3 – Disassemble the Impeller

C. After impeller is freed, insert a screwdriver into the

taperlock to spread it. Slide taperlock and impeller

off the pump shaft.

D. Use the preceding procedures until entire turbine

bowl assembly is completely disassembled.

5. TURBINE BOWL – WEAR RINGS REMOVAL

(OPTIONAL)

A. Utilizing a diamond point chisel, cut two V-shape

grooves on the bowl wear ring, approximately 180º

apart. Use extreme care not to damage the wear

ring seat.

B. With a chisel or equal, knock the end of half of the

ring in and pry the ring out.

C. On special materials such as chrome steel, set up the

bowl in a lathe and machine the wear ring off. Use

extreme care not to machine or damage the ring

seat.

6. TURBINE BOWL – IMPELLER WEAR RING

REMOVAL (OPTIONAL)

Set up impeller in a lathe and machine wear ring out.

Use extreme care not to machine or damage ring seat

or impeller hub. Impeller wear ring may also be removed by following steps A and B, paragraph #5.

7. BOWL BEARING REMOVAL

Utilizing an arbor press and a piece of pipe or sleeve

with outside diameter slightly smaller than the bowl

bearing diameter, press the bearing out.

8. INSPECTION AND REPLACEMENT

A. Clean all parts thoroughly with a suitable cleaner.

B. Check bearing seats for deformation and wear.

C. Check pump shaft for straightness and excessive

wear on bearing surfaces. Check straightness of the

pump shaft. The straightness should within 0.0005"/

ft. TIR.

D. Visually check impellers and bowls for cracks and

pitting. Check all bowl bearings for excessive wear

and corrosion.

9. TURBINE BOWL AND IMPELLER WEAR RING

INSTALLATION (OPTIONAL)

Place chamfered face of bowl or impeller wear ring

towards the ring seat and press. Use an arbor press or

equal. Make sure ring is flush with edge of wear ring

seat.

10. BOWL BEARING INSTALLATION

Press the bearing into all the bowls by using an arbor

press or equivalent. Press the bearing in from the

bottom end of the hub until the bottom end of the

bearing is flush with the bottom end of the hub.

11. TURBINE BOWL WITH TAPERLOCK –

REASSEMBLY

A. Secure the submersible assembly jig to the motor

end of the motor adapter. See Figure 4. Be sure

to use the proper jig for the motor frame size the

bowl assembly is intended to adapt to.

B. Put some grease in the suction bearing of the

motor adapter. Slide the shaft through the bearing. Secure the shaft in place by locking the shaft

to the assembly jig with a special long bolt or all

thread and a hex nut. See Figure 4.

Figure 4 – Assembly Jig

C. Slip impeller over the shaft. Then slip taperlock

over the shaft with smaller end towards impeller.

A screwdriver can be used to spread the taperlock

for ease in slipping over the shaft.

10

Page 11

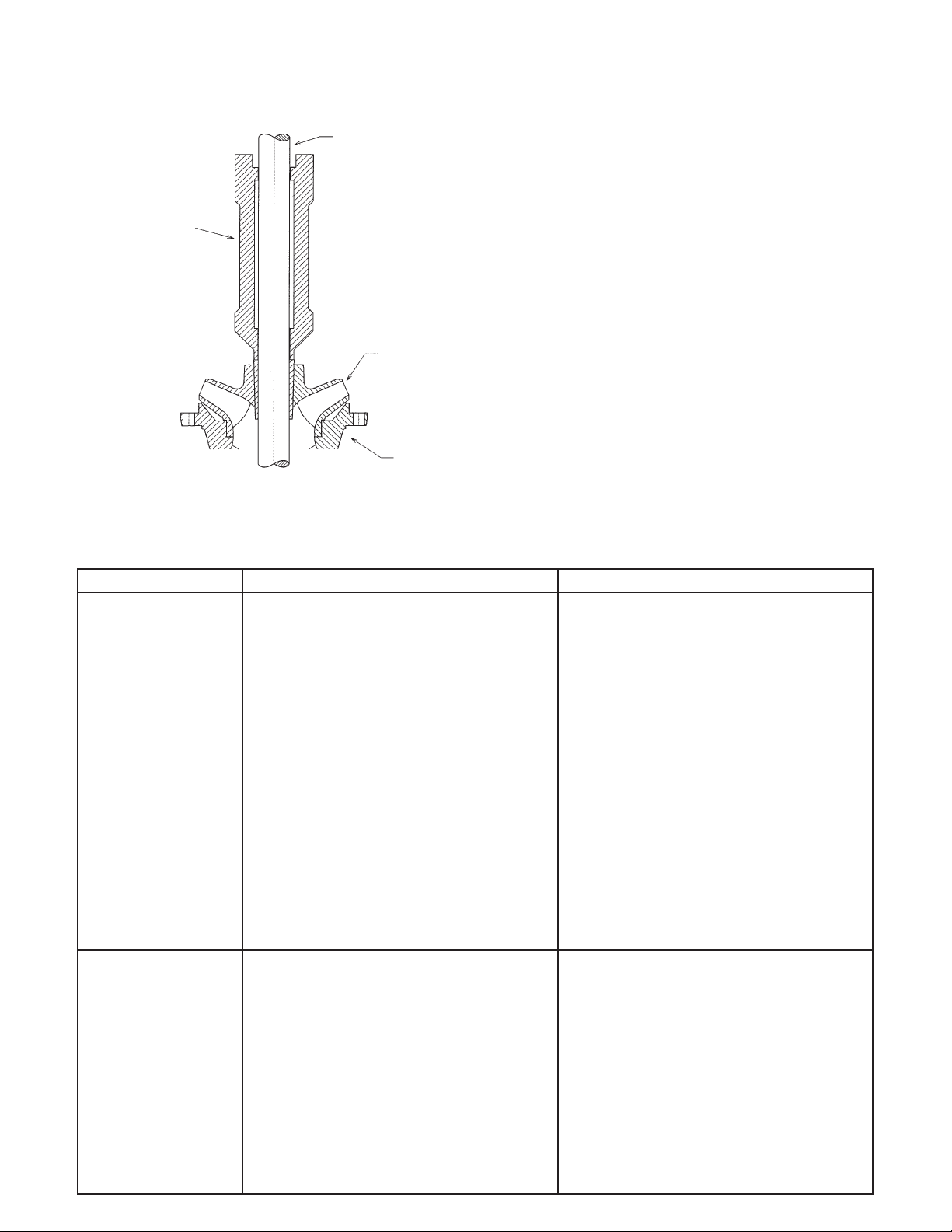

D. Hold impeller firmly against the motor adapter

and drive the taperlock into place with the taperlock driver. See Figure 5. After the impeller is

secured in position, the top end of the taperlock

should be 1/8" above the impeller hub.

SHAFT

TAPERLOCK

DRIVER

ASSEMBLY

POSITION

IMPELLER

BOWL

Figure 5 – Install the Impeller

E. Put a little grease on the shaft where the inter-

mediate bearing will be. Slip intermediate bowl

over the shaft and bolt or screw it onto the motor

adapter.

F. Place the next impeller over the shaft and continue

to assemble as explained above.

G. After assembling the last impeller, slide the up-

thrust washer over the shaft before assembling the

top intermediate.

H. Slide the discharge case and top intermediate

bowl over the shaft and bolt it to the second intermediate bowl. If the pump has a built-in check

valve, install the check valve before installing the

discharge adapter.

I. When the bowl is completely assembled, unlock

the shaft and remove the assembly jig. Rotate the

shaft by hand to see whether it rotates freely. Push

the shaft all the way in and then pull it all the

way out to check the lateral clearance. The lateral

should be between 0.187" to 0.250".

J. Install the square key in the keyway at the motor

end of the pump shaft. Slide the shaft coupling

over the shaft and secure it to the key with two

setscrews.

SECTION 8 — TROUBLESHOOTING CHART

In case of difficulties, refer to the chart to locate basic problems with the system. Once the problem is located, refer to

specific sections in this manual for details.

CONDITION PROBABLE CAUSE REMEDY

PUMP WILL 1. Motor overload protector trip 1. Allow motor to cool, overload will

NOT RUN a. Incorrect control box. automatically reset. Investigate cause

b. Incorrect connections. of overload.

c. Faulty overload protector. a-e. Have a qualified electrician inspect

d. Low voltage. and repair, as required.

e. Ambient temperature of control box

or starter too low. f. Pull the pump, examine and clean.

f. Pump bound by foreign matter. Adjust set depth as required.

2. Blown fuse, broken or loose electric 2. Check fuses, relays or heater elements

connections. for correct size capacitor and all electrical

connections.

3. Motor control box or starter not in 3. Make sure box is in upright position.

proper position.

4. Cable insulation damaged. 4. Locate and repair as per instructions.

5. Splice may be open or grounded. 5. Check resistance between cable leads

with ohmmeter. If open or grounded,

pull pump and resplice.

6. Faulty pressure switch. 6. Repair or replace.

7. Faulty liquid level control. 7. Check relay, wires and electrodes.

PUMP RUNS 1. Line check valve backward. 1. Reverse check valve.

BUT NO WATER 2. Pump is air-bound. 2. Successively start and stop pump until

water flows normally.

3. Lift too high for the pump. 3. Review performance requirement.

4. Suction screen or impeller plugged, 4. Pull the pump and clean, check well

or pump in mud or sand. depth. Raise setting if necessary.

5. Pump not submerged. 5. Check water level. Lower pump if

permissible.

6. Well may contain excessive amounts 6. Start and stop pump several times. If this

of air or gas. does not remedy conditions, pump may

not be able to cooperate because of too

much gas in the well.

7. Three-phase unit running backwards. 7. Reverse rotation.

11

Page 12

SECTION 8 — TROUBLESHOOTING CHART (continued)

CONDITION PROBABLE CAUSE REMEDY

REDUCED 1. Lift too high for the pump. 1. Check rating.

CAPACITY OR 2. Screen or impellers partly plugged. 2. Pull pump and clean.

INSUFFICIENT 3. Scaled or corroded discharge pipe or 3. Replace pipe and repair leaks.

TANK PRESSURE leaks anywhere in system.

4. Well may contain excessive amounts of 4. Start and stop pump several times. If this

air or gas. does not remedy conditions, pump may

not be able to cooperate because of too

much gas in the well.

5. Excess wear due to abrasives. 5. Replace worn parts.

6. Three-phase pump running backward. 6. Reverse rotation.

PRESSURE 1. Incorrect set. 1. Change settings.

SWITCH 2. Switch opening plugged. 2. Pull pump and clean.

DOES NOT 3. Leaks anywhere in system. 3. Repair leaks.

CUT OUT 4. Three-phase pump running backward. 4. Reverse rotation.

PUMP STARTS 1. Water-logged tank. 1. a. Check tank for leaks (plug at top of

TOO FREQUENTLY tank may be leaking air).

b. Be sure drain and 'Y' fittings are

functioning properly. Check operation

of snifter valve.

2. Check valve leaking. 2. Replace check valve.

3. Pressure switch out of adjustment. 3. Readjust to correct setting or replace.

4. Leaks in service line. 4. Locate and correct.

APPENDIX A — ASSEMBLY OF PUMP AND

MOTOR

Most of the time, the pump and the motor are shipped

separately in two different boxes. They need to be assembled together in the field prior to being installed in

the well. For the short pump (less than 5 stages), the motor and pump may be assembled together on the ground

horizontally. If the pump is over 6 stages long, it is recommended to assemble them in the vertical position.

1. Check that the pump shaft and the motor shaft turn

freely.

2. Clean the flange faces and the registers on the pump

and the motor. Remove all burrs from these areas.

Clean the exposed portion of the pump shaft and

motor shaft. If the pump is supplied with the coupling

assembled on the shaft, clean the inside of the motorend of the coupling.

3. Install the key on the motor shaft, if it is not the

splined shaft.

4. If the shaft coupling has setscrews in the motor half of

the coupling, loosen or remove these setscrews.

5. Align the motor with the pump and slide the motor shaft into the shaft coupling on the pump until

the shaft butts. Make sure the motor shaft lifts the

pump shaft by 1/8" to ¼" (for enclosed impeller only).

Be careful not to damage the shaft, the coupling or

the key. Orient the motor so that the motor leads

are aligned with the notch provided in the pump's

mounting flange. If the shaft coupling has setscrews

in the motor half the coupling, install and tighten the

setscrews.

6. Install and tighten the mounting bolts (or capscrews)

on the flange.

12

7. Unite the cableguard on the pump and reassemble it

with the motor leads under the cableguard to prevent

damaging the leads, when lowering the pump into the

well.

APPENDIX B — SPLICING POWER CABLE

TO MOTOR LEADS

A waterproof splice must be made to connect the power

cable to the motor leads. A properly made splice will

last the life of the pump. An improperly made splice will

become a service problem. In the market, there are different materials and methods to make waterproof cable

splices. For example: by waterproof tapes, by resin castings, by heat shrink tubes.

TAPED CABLE SPLICE:

1. Strip the insulation of each conductor of the power cable back enough to allow the conductor to extend half

way through a sleeve type connector. Crimp connector to the conductor. Strip the insulation of the motor

lead same as the power cable. Fit it into the connector

and butt against cable end. Crimp connector as before.

Pull on wire to make sure connector is firmly crimped

to both the motor lead and the power cable. Scrape

the insulation to move any loose bits of tape or thread

and roughen surface. Thoroughly clean surface with

solvent. This will insure a watertight splice.

2. Tape individual joints with rubber electrical tape. Start

at the center of the connector and tape 2" past the end

of conductor insulation end. Stretching tape about

10% while taping, overlap tapes about one half of

tape width. Make two layers. The end of second layer

should be 2" beyond the end of the first layer.

3. Tape over the rubber electrical tape with #33 Scotch

electrical tape or equivalent, using two layers as in

step #2 and making each layer overlap the end of the

preceding layer by 2".

Page 13

CAST CABLE SPLICE:

DANGER

DANGER

1. To prepare the 3-conductor power cable for splicing,

insert a sharp knife blade between the cable jacket and

lead insulation and strip the jacket back 21/2" from the

end. Taking care not to cut the lead insulation. Strip

the cambric wrapping (if any) off the conductors and

strip back rubber insulation 5/8" from the end. Assemble the cable connectors and crimp them in place using

a crimping tool.

2. Cut off the motor leads to equal length. Clean off the

ends of the leads for about a foot, using a cloth wet

with gasoline or solvent. Clean the end of the power

cable also. Insert the three motor leads into the corresponding holes in the bottom of the rubber casing

and push them several inches out the top. Crimp the

motor leads into the corresponding connectors, crimping the center one first. Bend the cables into line with

the holes in the casing and slip the casing up until the

connectors are inside the holes and about 1/4" from the

top.

3. Mix the resin as directed. Cut off a corner of the bag

and squeeze all of the resin into casing. With the roll

of tape on hand, fold the bag and tape the top of the

bag snuggly to the power cable until the resin runs

out over the top. This will assure maximum coverage

of the resin and minimum size of the finished splice.

When the resin is firm to touch, the splice may be immersed for testing.

APPENDIX C — ELECTRICAL TESTS

1. MEASURING INSULATION RESISTANCE

(GROUND TEST)

The condition of the insulation around a conductor

can be determined by measuring the electrical resistance between the conductor and ground. This measurement can be made with a megger or an ohmmeter.

The value is stated in ohms or megohms (ohms x

1,000,000). High ohm values indicate good insulation.

The basic procedure for measuring insulation resistance is given below:

A. Turn off all power and disconnect the leads to be

tested from the electrical panel. Lock out the panel.

FAILURE TO TURN OFF THE POWER

WILL DAMAGE THE METER AND

CAN CAUSE SERIOUS OR FATAL SHOCK.

Failure to disconnect the leads can result in false

readings.

B. Set the meter selector knob to RX 100K or RX

100,000 (some meters may not have RX 100K

in which case EX 10K or EX 10,000 scale can be

used). Clip the meter leads together and adjust the

meter to zero.

C. Unclip the leads and attach one of the meter leads

to one of the power cable leads or motor leads. The

other meter to the ground.

D. Do not touch any bare wires or allow bare wires

to come in contact with the ground or metal. False

readings will result.

E. If the meter needle is at either extreme end of the

scale, a more accurate reading can be obtained

by switching the selector switch to another scale.

Rezero the meter each time the selector switch is

moved.

The readings obtained from power cables and motor leads should be within the range specified in Table

C.1. Low readings indicate that the motor windings are

grounded or that the cable or splice insulation is damaged. If low or marginal readings are obtained on a new

installation the problem should be corrected before

proceeding with the installation.

2. MEASURING RESISTANCE BETWEEN LEADS

(MOTOR WINDING RESISTANCE)

The general conditions of motor windings can be

determined by measuring the resistance of the motor

windings (i.e. the resistance between the motor leads)

and comparing the measured resistance with values

given in the motor manual. The resistance is measured

with an ohmmeter and the value is stated in ohms.

The basic procedure for measuring motor winding

resistance is given below:

A. Turn off the power and disconnect the leads to be

tested from the panel. Lock out the panel.

FAILURE TO TURN OFF THE POWER

WILL DAMAGE THE METER AND

CAN CAUSE SERIOUS OR FATAL ELECTRICAL

SHOCK.

Failure to disconnect the leads can result in false

readings.

B. Set the meter selector knob to 'RX 1'. Clip the me-

ter leads together and adjust the meter to zero.

C. Unclip the meter leads and attach them to the

motor leads.

Resistance measured between the motor leads prior to

splicing the power cable to the motor leads should be

within the motor winding resistance limits specified in

the motor manual.

13

Page 14

TABLE C.1 — NORMAL INSULATION RESISTANCE VALUES BETWEEN ALL LEGS AND

GROUND

Insulation resistance does not vary with rating. Motors of all HP, voltage and phase rating have the same insulation

resistance ranges.

METER READING

R x 100,000 R x 10,000

Scale Scale

BENCH TESTS

• A new motor (without drop cable). 20,000,000+ 20+ 200+ 2000+ or 2K+

• A used motor which can be reinstalled 10,000,000+ 10+ 100+ 1000+ or 1K+

• Cable splice after immersion for one 2,000,000+ 2+ 20+ 200+

WELL TESTS Ohm readings are for drop

cable plus motor.

• A new motor or used motor in good 2,000,000+ 2+ 20+ 200+

condition.

• A motor in reasonably good condition. 500,000– 0.5–2.0 5–20 50–200

2,000,000

• A motor which may have been damaged 20,000– 0.02–0.5 0.2–5 2–50

by lightning or with damaged leads. 500,000

Do not pull the pump for this reason.

• A motor which denitely has been 10,000– 0.01–0.02 0.1–0.2 1–2

damaged or with damaged cable. The 20,000

pump should be pulled and repairs

made to the cable or the motor replaced.

The motor will not fail for this reason

alone, but will probably not operate for

long.

• A motor which has failed or with Less than 0–0.01 0–0.1 0–1

completely destroyed cable insulation. 10,000

The pump must be pulled and the

cable repaired or the motor replaced.

+ Indicates that the reading should be the value shown or greater. Higher readings indicate better insulation.

CONDITION OF MOTORS

AND LEADS

in the well.

hour in water.

OHMS MEGOHMS or or

R x 100K R x 10K

Resistance measured between the power cable leads after

splicing the power cable to the motor leads will indicate

the resistance of the power cable plus the motor windings. The motor winding resistance is obtained by the

formula below. The calculated value should be within the

limits specified in the motor manual.

Motor Winding = Reading taken – Cable Resistance

Resistance at Power Cable from Table 2.

14

A higher winding resistance than shown in the motor

manual indicates a possible burned (open) winding, an

open cable, a loose connection or the wrong motor (different HP or voltage than readings being referenced).

A considerably lower winding resistance than shown in

the motor manual indicates a possible shorted (burned

together) winding or the wrong motor.

Unequal resistance between the windings on a three

phase motor indicates a burned winding or a faulty connection.

Page 15

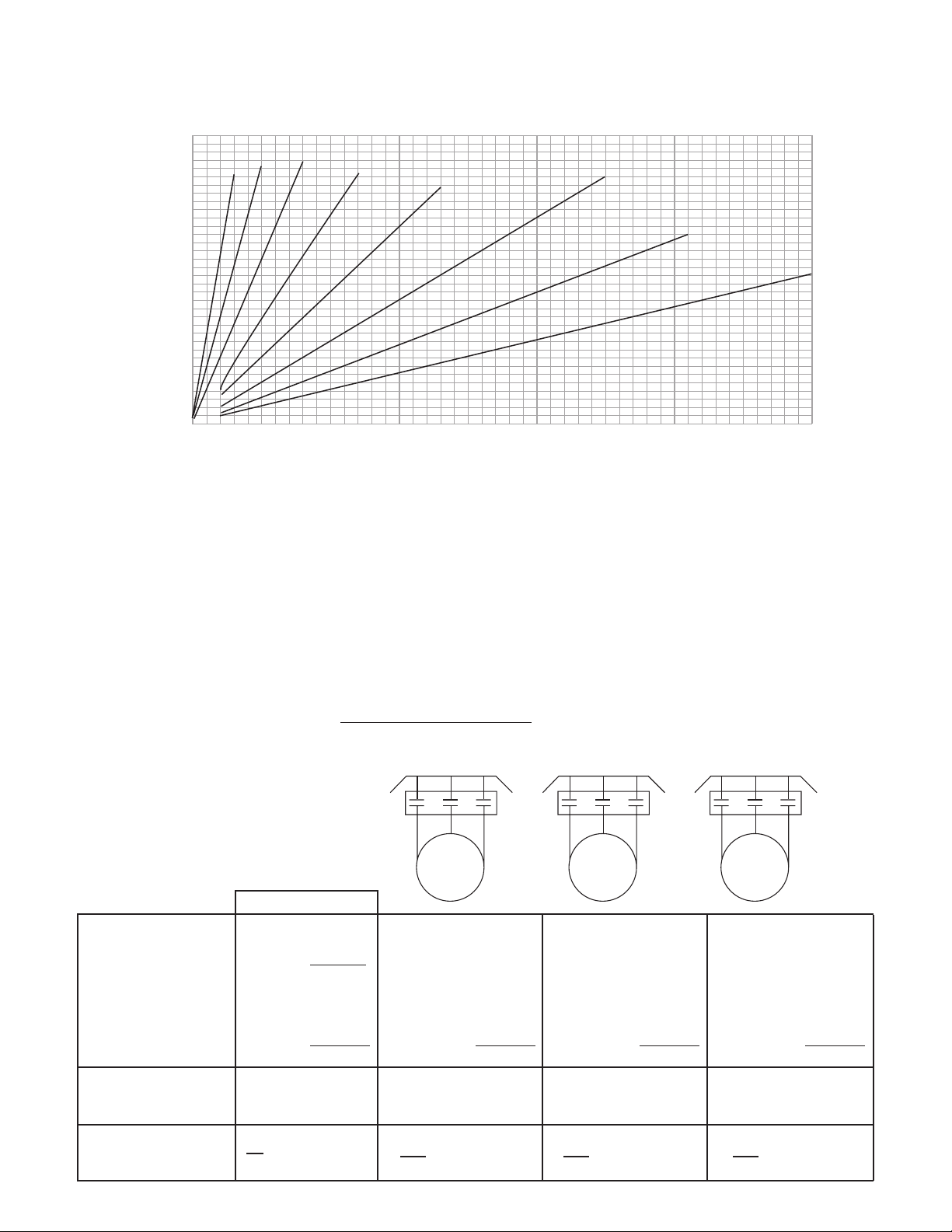

TABLE C.2 — POWER CABLE RESISTANCE

Pump Setting (feet)

1ST HOOK UP

2ND HOOK UP

3RD HOOK UP

The values below are for copper conductors. If aluminum conductor drop cable is used, the resistance will be higher

for each foot of cable of the same size. To determine the actual resistance of aluminum drop cable, divide the ohm

readings from this chart by 0.61. This chart shows total resistance of cable from control box to motor and back.

1750

1500

1250

1000

750

500

250

#0

#2

#4

#6

#8 Cable

#10 Cable

#12 Cable

#14 Cable

0

0 0.5

1

1.5 2 2.5 3 3.5 4 4.5

Power Cable Ohms

3. CURRENT UNBALANCE TEST:

A. For three phase units, after correct rotation has

been established, check the current in each of the

three motor leads and calculate the current unbalance as explained below. If the current unbalance is

2% or less, leave the leads as connected. If the current unbalance is over 2%, current readings should

be checked on each leg using one of three possible

hook-ups indicated in the table below. Roll the

motor leads across the starter in the same direction

to prevent motor rotation reversal. This procedure

is commonly known as "rolling the leads". THE

HOOKUP THAT RESULTS IN THE LOWEST

PERCENT CURRENT UNBALANCE SHOULD

BE USED FOR THE FINAL CONNECTION OF

THE POWER LEADS.

B. Current unbalance is determined by measuring

the amperage of each of the three legs and then

calculating the percent current unbalance using the

formula below. This calculation must be performed

using each of the three hookups shown.

Maximum Current difference in

Percent Current Unbalance = any leg from average current x 100

Average Current

L1 L2 L3

T2

T1 T3

L1 L2 L3

T1

T3 T2

L1 L2 L3

T3

T2 T1

SUPPLY

STARTER

MOTOR

Sample Calculation

• Measure current in T1 L1 51 amps T1 L1

each leg. T2 L2 46 amps T2 L2

T3 L3 53 amps T3 L3

• Add leg currents to 150 amps

determine total

current.

• Calculate average

leg current. 50 amps

• Determine maximum 51 – 50 = 1

difference of any one 50 – 46 = 4 max

leg from the average. 53 – 50 = 3

• Calculate percent

unbalance using

formula above.

4

x 100 = 8%

50

____________

____________

____________

T3 L1

T1 L2

T2 L3

_____________

_____________

_____________

T2 L1

T3 L2

T1 L3

_____________

_____________

_____________

÷ 3 ÷ 3 ÷ 3 ÷ 3

_____– _____= _____ _____– _____= ____ _____– _____= _____

_____– _____= _____ _____– _____= ____ _____– _____= _____

➛

_____– _____= _____ _____– _____= ____ _____– _____= _____

x 100 = %

x 100 = %

x 100 = %

15

Page 16

C. THE CURRENT UNBALANCE BETWEEN LEGS

SHOULD NOT EXCEED 5% at service factor load or

10% at rated input load. If the unbalance cannot be

corrected by rolling leads, the source of the unbalance

must be located and correct.

D. By observing where the furthest current reading from

the average is for each leg of each of the hookups, the

cause of the unbalance can be determined. If the leg

furthest from average is always on the same motor

lead, the primary source of unbalance is on the "motor

side" of the starter. In this instance, consider a damaged cable, leaking splices, poor connection or faulty

motor winding.

LIMITED WARRANTY

Company warrants title to the product(s) and, except as noted with respect to items not of Company’s manufacturer, also warrants

the product(s) on date of shipment to Purchaser, to be of the kind and quality described herein, and free of defects in workmanship

and material. THIS WARRANTY IS EXPRESSLY IN LIEU OF ALL OTHER WARRANTIES, INCLUDING BUT NOT LIMITED TO

IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS, AND CONSTITUTES THE ONLY WARRANTY OF COMPANY

WITH RESPECT TO THE PRODUCT(S).

If within one year from date of initial operation, but not more than 18 months from date of shipment by Company of any item of

product(s), Purchaser discovers that such item was not as warranted above and promptly notifies Company in writing thereof, Company

shall remedy such nonconformance by, at Company’s option, adjustment or repair or replacement of the item and any affected part

of the product(s). Purchaser shall assume all responsibility and expense for removal, reinstallation, and freight in connection with the

foregoing remedies. The same obligations and conditions shall extend to replacement parts furnished by Company hereunder. Company

shall have the right of disposal of parts replaced by it. Purchaser agrees to notify Company, in writing, of any apparent defects in design,

material or workmanship, prior to performing any corrective action back-chargeable to the Company. Purchaser shall provide a detailed

estimate for approval by the Company.

ANY SEPARATE LISTED ITEM OF THE PRODUCT(S) WHICH IS NOT MANUFACTURED BY THE COMPANY IS NOT

WARRANTED BY COMPANY and shall be covered only by the express warranty, if any, of the manufacturer thereof.

THIS STATES THE PURCHASER’S EXCLUSIVE REMEDY AGAINST THE COMPANY AND ITS SUPPLIERS RELATING TO THE

PRODUCT(S), WHETHER IN CONTRACT OR IN TORT OR UNDER ANY OTHER LEGAL THEORY, AND WHETHER ARISING

OUT OF WARRANTIES, REPRESENTATIONS, INSTRUCTIONS, INSTALLATIONS OR DEFECTS FROM ANY CAUSE. Company

and its suppliers shall have no obligation as to any products which have been improperly stored or handled, or which have not been

operated or maintained according to instructions in Company or supplier furnished manuals.

LIMITATION OF LIABILITY – Neither Company nor its suppliers shall be liable, whether in contract or in tort or under any other

legal theory, for loss of use, revenue or profit, or cost of capital or of consequential damages, or for any other loss or cost of similar type

or for claims by Purchaser for damages of Purchaser’s customers. Likewise, Company shall not under any circumstances be liable for the

fault, negligence, wrongful acts of Purchaser or Purchaser’s employees, or Purchaser other contractors or suppliers.

IN NO EVENT SHALL COMPANY BE LIABLE IN EXCESS OF THE SALES PRICE OF THE PART OR PRODUCT FOUND

DEFECTIVE.

Xylem Inc.

PO Box 5487

Lubbock, TX 79408

Phone: 1-806-763-7867

Fax: 1-800-453-4749

www.gouldswatertechnology.com

Goulds is a registered trademark of Goulds Pumps, Inc. and is used under license.

© 2012 Xylem Inc. IMVSR01 December 2012

Page 17

MANUAL DE INSTRUCCIÓN

IMVSR01

MODELO VS

BOMBAS INDUSTRIALES VERTICALES DE LA TURBINA

INSTRUCCIONES DE INSTALACIÓN, OPERACIÓN Y MANTENIMIENTO

Page 18

Prefacio

Prefacio

Este manual proporciona instrucciones para la instalación, la operación y el mantenimiento de las bombas

de turbina de pozo profundo Goulds Water Technology en su versión estándar. Para las opciones especiales

existen instrucciones complementarias. Este manual debe leerse y entenderse antes de instalar y arrancar la

bomba.

Este manual cubre diferentes modelos de bombas ya que la mayoría de los procedimientos de ensamble,

desensamble e inspección es igual para todas ellas, y donde hay diferencias se indican. Gracias al diseño,

materiales y mano de obra que se usan en su fabricación, las bombas DWT de Goulds Water Technology

pueden operar de manera continua sin presentar problemas. No obstante, la vida útil de cualquier dispositivo

mecánico se extiende y su operación mejora si se usa y se instala de manera correcta, se inspecciona

periódicamente, se monitorea sus condiciones y se le da el mantenimiento adecuado. El propósito de este

manual es ayudarles a los operadores a entender la construcción de estas bombas e indicarles los métodos

correctos de su instalación, operación y mantenimiento.

La información que contiene este instructivo pretende proporcionarle al personal de operación las

características del equipo adquirido. No libera al usuario de su responsabilidad de usar prácticas de ingeniería

aceptadas en la instalación, operación y mantenimiento de este equipo.

Goulds Water Technology no se hace responsable de lesiones físicas, daños o retrasos causados por no

observar las instrucciones de instalación, operación y mantenimiento que contiene este manual.

La garantía es válida solo cuando se usan partes de repuesto genuinas de Goulds Water Technology.

Usar el equipo en una aplicación no establecida en el pedido deja sin validez a la garantía, a menos que se haya

obtenido con anticipación una aprobación por escrito de Goulds Water Technology.

Si requiere información o tiene preguntas no tratadas en este manual, llame a Goulds Water Technology al (806)

743-5700.

ESTE MANUAL EXPLICA :

• la instalación correcta; • la revisión global de la bomba;

• el procedimientos de arranque; • la investigación y solución de fallas;

• los procedimientos de operación; • cómo pedir partes de repuesto.

• el mantenimiento de rutina;

Información del propietario

Número de modelo de la bomba:

Número de serie de la bomba:

Número de control de modelo:

Distribuidor:

No. de teléfono del distribuidor:

Fecha de compra: Instalación:

Lecturas de corriente durante el arranque:

1 Ø 3 Ø L1-2 L2-3 L3-1

Amps: Amps:

Voltios: Voltios:

18

Page 19

Tabla de contenido

CAPITULO PÁGINA

Instrucciones de seguridad ...........................................................................................................................................20

Sección 1 — Información general

Introducción ...........................................................................................................................................................20

Recepción y revisión ...............................................................................................................................................20

Materiales y equipo que se requieren ......................................................................................................................20

Sección 2 — Almacenaje

Almacenaje ..............................................................................................................................................................20

Preparación para el almacenaje ................................................................................................................................21

Procedimientos recomendados para el almacenaje ...................................................................................................21

Preparación para un almacenaje no controlado de largo plazo .................................................................................21

Sección 3 — Descripción general

Descripción general .................................................................................................................................................21

Accionamientos .......................................................................................................................................................21

Descarga .................................................................................................................................................................22

Ensamble de los tazones ..........................................................................................................................................22

Sección 4 — Preparación para la instalación

Requisitos para el pozo ...........................................................................................................................................22

Preparación de la cimentación .................................................................................................................................22

Verificación y preparación de los cables y del motor ................................................................................................22

Sección 5 — Instalación de la bomba ...........................................................................................................................23

Sección 6 — Arranque de la bomba .............................................................................................................................24

Sección 7 — Desensamble y reensamble de la bomba

Desensamble de la bomba .......................................................................................................................................25

Desensamble de los tazones .....................................................................................................................................26

Tazón de la turbina – remoción del anillo de desgaste (opcional) .............................................................................26

Tazón de la turbina – remoción del anillo de desgaste del impulsor (opcional) ........................................................26

Remoción del cojinete del tazón ..............................................................................................................................26

Inspección y reemplazo ...........................................................................................................................................26

Instalación del anillo de desgaste del tazón de la turbina y del impulsor (opcional)..................................................26

Instalación del cojinete del tazón .............................................................................................................................27

Tazón de la turbina con casquillo – reensamble .......................................................................................................27

Sección 8 — Gráfica de investigación y solución de fallas ............................................................................................28

Apéndice A — Ensamble de la bomba y del motor ......................................................................................................29

Apéndice B — Empalme del cable de potencia con los conductores del motor .............................................................29

Apéndice C — Pruebas eléctricas .................................................................................................................................30

Garantía limitada .........................................................................................................................................................34

19

Page 20

INSTRUCCIONES DE SEGURIDAD

ADVERTENCIA

PRECAUCIÓN

PELIGRO

ADVERTENCIA

PRECAUCIÓN

AVISO: INDICA INSTRUCCIONES ESPECIALES

SECCIÓN 1 — INFORMACIÓN GENERAL

1–1 INTRODUCCIÓN

Gracias al diseño, materiales y mano de obra que se usan

en su fabricación, las bombas DWT de Goulds Water

Technology pueden operar de manera continua sin presentar problemas. No obstante, la vida útil de cualquier

dispositivo mecánico se extiende y su operación mejora

si se usa y se instala de manera correcta, se inspecciona

periódicamente, se monitorea sus condiciones y se le da

el mantenimiento adecuado. El propósito de este manual

es ayudarles a los operadores a entender la construcción

de estas bombas e indicarles los métodos correctos de su

instalación, operación y mantenimiento.

Estudie detenidamente las secciones 1 a 8 y mantenga

este manual a la mano para consultas. Si requiere más

información, llame a la oficina de ventas de Goulds Water

Technology o a su sucursal.

O RETRASOS CAUSADOS POR NO CUMPLIR CON

LAS INSTRUCCIONES DE ESTE MANUAL.

1–2 RECEPCIÓN Y REVISIÓN

La bomba se debe apoyar con cuidado antes de descargarla del barco o camión. Maneje todos los componentes

con precaución. Cerciórese de que el empaque no esté

PARA EVITAR QUE EL PERSONAL SUFRA LESIONES

SERIAS O FATALES O QUE SE PRODUZCAN DAÑOS

MAYORES A LAS INSTALACIONES, LEA Y SIGA

TODAS LAS INSTRUCCIONES DE SEGURIDAD EN

ESTE MANUAL Y LAS COLOCADAS EN LA BOMBA.

EL PROPÓSITO DE ESTE MANUAL ES AYUDAR A

INSTALAR Y OPERAR ESTA UNIDAD Y SE DEBE

MANTENER CON LA BOMBA.

Este es un símbolo de alerta de seguridad. Cuando vea este símbolo en la

bomba o en el manual, busque una de las

siguientes palabras de señal y esté alerto

acerca de peligros de lesiones al personal

o de daños a la propiedad.

Advierte sobre peligros que CAUSAN

lesiones graves o la muerte, o daños

mayores a la propiedad.

Advierte sobre peligros que PUEDEN

causar lesiones graves o la muerte, o

daños mayores a la propiedad.

Advierte sobre peligros que PUEDEN

causar lesiones personales o daños a la

propiedad.

QUE SON MUY IMPORTANTES Y DEBEN

SEGUIRSE.

REVISE DETENIDAMENTE TODAS LAS

INSTRUCCIONES Y ADVETENCIAS ANTES DE

REALIZAR CUALQUIER TRABAJO EN ESTA

BOMBA.

NO QUITE LAS CALCOMANÍAS DE SEGURIDAD.

GOULDS WATER TECHNOLOGY NO

SE HACE RESPONSABLE DE DAÑOS

20

dañado, antes de desempacar la bomba. Una vez desempacada, revise lo siguiente:

1. Las partes de la bomba contra la lista de embarque.

2. Todos los componentes por si hay daños.

Avise de inmediato al agente local de embarques o al

transportista sobre cualquier falta de material o daño

que haya encontrado y anote tal situación en la factura

del embarque. Esto para evitar cualquier controversia en

caso de un reclamo, para agilizar el ajuste y que éste sea

satisfactorio.

1–3 MATERIALES Y EQUIPO QUE SE REQUIEREN

El material y el equipo necesario para la instalación de la

bomba varía con su tamaño y el tipo de instalación. Por

lo tanto, la siguiente descripción y lista de herramientas y

suministros estándar solo pretende ser una guía.

1. MATERIAL A GRANEL

Lubricante para evitar el desgaste, compuesto para

roscas, aceite de lubricación, grasa, disolvente a base

de petróleo.

2. HERRAMIENTAS DE MANO

Llaves para tubería, dos cadenas, tenazas y herramientas mecánicas de mano.

3. INSTRUMENTOS

Deben estar disponibles un megger, o instrumento

similar, que indique la resistencia eléctrica, un amperímetro de gancho, un voltímetro y un compuesto

para juntas de tubos de buena calidad para facilitar el

ensamble y el posible desensamble en el futuro.

4. EQUIPO DE INSTALACIÓN

Bloques de fricción de madera o anclas de acero,

dispositivos de levantamiento de acero del tipo y del

tamaño apropiado para los tubos de la columna, y

eslinga de cable de aproximadamente 10 pies de largo,

del tamaño adecuado para las cargas consideradas.

Aunque algunas veces se usan grúas fijas, se recomienda un dispositivo de colocación de la bomba diseñado

de manera apropiada. Debe ser posible montar el

bloque de corona a una altura tal que permita subir

que el gancho de carga cerca de 3 pies más alto que

la pieza más larga. El dispositivo de levantamiento

debe ser de suficiente fuerza y rigidez para elevar con

seguridad el peso total de la unidad.

RECUERDE – SIN IMPORTAR EL TIPO

DE EQUIPO DE LEVANTAMIENTO, O

EL EQUPO DE BOMBEO, LA REGLA PRIMARIA ES:

LA SEGURIDAD PRIMERO.

SECCIÓN 2 — ALMACENAJE

2–1 ALMACENAJE

Goulds Water Technology conserva y protege sus productos

con mucho cuidado para el embarque. No obstante, la vida

real de los preservativos aplicados en fábrica puede variar de

3 a 18 meses dependiendo de la severidad del ambiente en

el cual se almacena el equipo. Esta sección proporciona los

procedimientos para la preparación antes del almacenaje y

para el mantenimiento durante el almacenaje de las bombas

Goulds Water Technology. Estos procedimientos son necesarios para proteger las partes de precisión de las bombas. Los

procedimientos específicos para el almacenaje de motores

se obtiene del fabricante correspondiente. Esta sección

Page 21

pretende ofrecerles una ayuda general a los usuarios de las

bombas Goulds Water Technology. No modifica, incrementa

y/o de otro modo altera el alcance de la garantía de bombas

Goulds Water Technology.

2–2 PREPARACIÓN PARA EL ALMACENAJE

Las bombas sumergibles de Goulds Water Technology

requieren una preparación adecuada para su almacenaje.

Una bomba debe considerarse almacenada cuando se haya

entregado en el sitio y esté en espera de su instalación. Si

la bomba se ha instalado, pero no está en operación continua, como en un paro de temporada o por un periodo

extendido de tiempo, se sugiere que la bomba se opere por

lo menos 15 minutos cada dos semanas si es posible.

2–3 PROCEDIMIENTOS RECOMENDADOS

PARA EL ALMACENAJE

1. Las instalaciones de almacenaje controlado deben

mantenerse a una temperatura constante de 10° F ó

más sobre el punto de rocío con una humedad relativa

de menos de 50% y poco o ningún polvo. (si estos

requisitos no se pueden cumplir, la bomba se debe

considerar en almacenaje no controlado).

2. Para periodos de almacenaje no controlado de seis

meses o menos, la bomba debe inspeccionarse periódicamente para asegurar que todos los conservadores

estén intactos.

3. Todas las roscas y tapas de tuberías con bridas se deben

sellar con cintas.

4. La bomba no debe almacenarse a una altura de menos

de 6 pulgadas sobre el suelo.

3–2 ACCIONAMIENTOS

Goulds Water Technology proporciona solo motores