Page 1

INSTRUCTION MANUAL

IM045

READ COMPLETE INSTRUCTIONS CAREFULLY BEFORE ATTEMPTING ANY WORK

High Head

Effluent Pumps

INSTALLATION AND OPERATION INSTRUCTIONS

Page 2

DANGER

WARNING

CAUTION

WARNING

Hazardous fluids

can cause fire,

burns or death.

DANGER

Owner’s Information

Please fill in information and give this booklet to

homeowner.

Model Number:

Serial Number:

Dealer:

Dealer’s Phone No.

Date of Purchase: Installation:

Table of Contents

SUBJECT PAGE

Safety Instructions ................................................. 2

Description and Specifications ............................... 2

Important Precautions ........................................... 2

Piping .................................................................... 2

Wiring and Grounding .......................................... 2

Motor Cable Installations ...................................... 3

Pump Installation .................................................. 4

Tank with effluent filter ......................................... 4

Troubleshooting .................................................... 5

Motor Insulation Resistance Readings ................... 5

SAFETY INSTRUCTIONS

TO AVOID SERIOUS OR FATAL PERSONAL INJURY OR MAJOR PROPERTY DAMAGE, READ

AND FOLLOW ALL SAFETY INSTRUCTIONS IN

MANUAL AND ON PUMP.

THIS MANUAL IS INTENDED TO ASSIST IN THE

INSTALLATION AND OPERATION OF THIS UNIT

AND MUST BE KEPT WITH THE PUMP.

THOROUGHLY REVIEW ALL INSTRUCTIONS

AND WARNINGS PRIOR TO PERFORMING ANY

WORK ON THIS PUMP.

MAINTAIN ALL SAFETY DECALS.

This is a SAFETY ALERT SYMBOL.

When you see this symbol on the pump

or in the manual, look for one of the

following signal words and be alert

to the potential for personal injury or

property damage.

Warns of hazards that WILL cause

serious personal injury, death or major

property damage.

Warns of hazards that CAN cause

serious personal injury, death or major

property damage.

Warns of hazards that CAN cause personal injury or property damage.

NOTICE: INDICATES SPECIAL INSTRUCTIONS

WHICH ARE VERY IMPORTANT AND

MUST BE FOLLOWED.

PUMPING HAZARDOUS LIQUIDS

OR FLAMMABLE GASES CAN

CAUSE FIRE, BURNS OR DEATH.

DESCRIPTION AND SPECIFICATIONS

Assembled pump/motor units purchased from the factory

are UL® and CSA listed. ALL Franklin Electric motors are

UL® recognized and CSA listed.

INSPECT UNIT FOR DAMAGE AND REPORT ALL

DAMAGE TO THE CARRIER IMMEDIATELY.

IMPORTANT PRECAUTIONS

All electrical work must be performed by a qualified

technician. Always follow the National Electrical Code

(NEC), or the Canadian Electrical Code, as well as all

local, state and provincial codes. Code questions should

be directed to your local electrical inspector. Failure to

follow electrical codes and OSHA safety standards may

result in personal injury or equipment damage. Failure to

follow manufacturer’s installation instructions may result

in electrical shock, fire hazard, personal injury or death,

damaged equipment, provide unsatisfactory performance,

and may void manufacturer’s warranty.

2

Page 3

Standard units are not designed for use in

WARNING

WARNING

WARNING

WARNING

WARNING

Hazardous voltage

can shock, burn or

cause death.

WARNING

Hazardous

voltage

WARNING

swimming pools, open bodies of water,

hazardous liquids, or where flammable

gases exist. These fluids and gases may

be present in contaminant areas. Tank or

wetwell must be vented per local codes.

Only pumps specifically Listed for Class

1, Division 1 are allowable in hazardous

liquids and where flammable gases may

exist. See specific pump catalog bulletins

or pump nameplate for all agency listings.

Disconnect and lockout electrical power

before installing or servicing any electrical

equipment. Many pumps are equipped

with automatic thermal overload protection which may allow an overheated

pump to restart unexpectedly.

PIPING

• System piping MUST conform to all local and national

plumbing codes and practices.

WIRING AND GROUNDING

Important notice: Read Safety Instructions before proceeding with any wiring.

Use only stranded copper wire

to pump/motor and ground.

The ground wire must be at

least as large as the power supply wires. Wires should be color

coded for ease of maintenance

and troubleshooting.

• This pump is provided with a means for grounding. To

reduce the risk of electrical shock from contact with

adjacent metal parts, bond supply box to the pumpmotor-grounding means and to all metal parts accessible at the tank, including metal discharge pipes, and

the like, by means of:

1. An equipment grounding conductor at least the size

of the power cable conductors to the pump.

2. A clamp, a weld or both if necessary, secured to the

equipment grounding terminal, or the grounding

conductor on the pump housing. The equipment

grounding lead, if one is provided, is the conductor

that has an outer surface of insulation that is green

with or without one or more yellow stripes.-UL 778

MOTOR CABLE INSTALLATIONS

• Prepare the motor cable by stripping off ½" (13 mm) at

the end of each conductor’s insulation.

NOTICE: FOLLOW THE SPLICE KIT

MANUFACTURER’S INSTRUCTIONS.

• Where cables are spliced or connected to the motor

leads, splices MUST be water tight. Commercially

available potting or heat shrinking kits may be used, if

allowed by local or federal regulations.

• To ensure proper sealing, immerse splice in a metal

container filled with water for ten minutes, then take a

resistance reading between the metal container and the

cable conductor. Resistance should read 2 megohms or

higher. Redo splice as required.

• Two wire motors do not require a control box.

Install wire and ground according to the National

Electrical Code, as well as all local, state and provincial codes.

Install an all leg disconnect switch where required

by code.

Disconnect and lockout electrical power before

performing any service or installation.

The electrical supply voltage and phase must

match all equipment requirements.

Incorrect voltage or phase can cause fire, motor

and control damage, and voids the warranty.

All splices must be waterproof. If using splice kits

follow manufacturer’s instructions.

Seal all controls from gases present which

may damage electrical components.

FAILURE TO PERMANENTLY

GROUND THE PUMP, MOTOR AND

CONTROLS BEFORE CONNECTING

TO ELECTRICAL POWER CAN

CAUSE SHOCK, BURNS OR DEATH.

Reduced risk of electrical shock during

operation of this pump requires the provisions of acceptable grounding.

3

Page 4

PUMP INSTALLATION

WARNING

Hazardous voltage

can shock, burn or

cause death.

NOTICE: PROTECT ALL PIPING, FITTINGS AND

SYSTEM COMPONENTS FROM FREEZING.

DO NOT LIFT, CARRY OR HANG

PUMP BY THE ELECTRICAL CABLE.

DAMAGE TO THE ELECTRICAL

CABLE CAN CAUSE SHOCK, BURNS

OR DEATH.

IT IS RECOMMENDED THAT ANY

INSTALLATION AND SERVICING

BE BY A CERTIFIED INSTALLER.

NOTICE: THE MODEL IS ASSEMBLED WITH LEFT

HAND THREADS. HOLD THE PUMP

WITH A WRENCH ON THE DISCHARGE

HEAD WHILE INSTALLING THE DISCHARGE PIPE OR CONNECTOR.

• Ensure that the pump and motor are free to rotate by

turning the shaft by hand.

• Connect drop pipe or discharge pipe to pump and

lower pump into tank.

• The pump must be protected from solids and debris.

The effluent must pass through an approved filter before reaching the pump.

• Using waterproof plastic electrical tape, fasten the

electrical cable to the drop pipe at approximately three

foot intervals.

• The pump MUST be submerged at all times for proper

operation. Do not run dry. Ensure that the float

switches are set so that the pump cuts out before the

pump runs dry or breaks suction. Adjust the floats as

necessary for proper operation.

• If pump is to be operated with an open discharge, a

discharge valve MUST be installed. Before startup,

open this valve approximately 1⁄3 of the way, then start

the pump. SLOWLY open the valve until the desired

flow rate is achieved. Final setting MUST be within the

pumps recommended operating range.

• The motor bearings are lubricated internally. No other

motor or pump maintenance is required or possible.

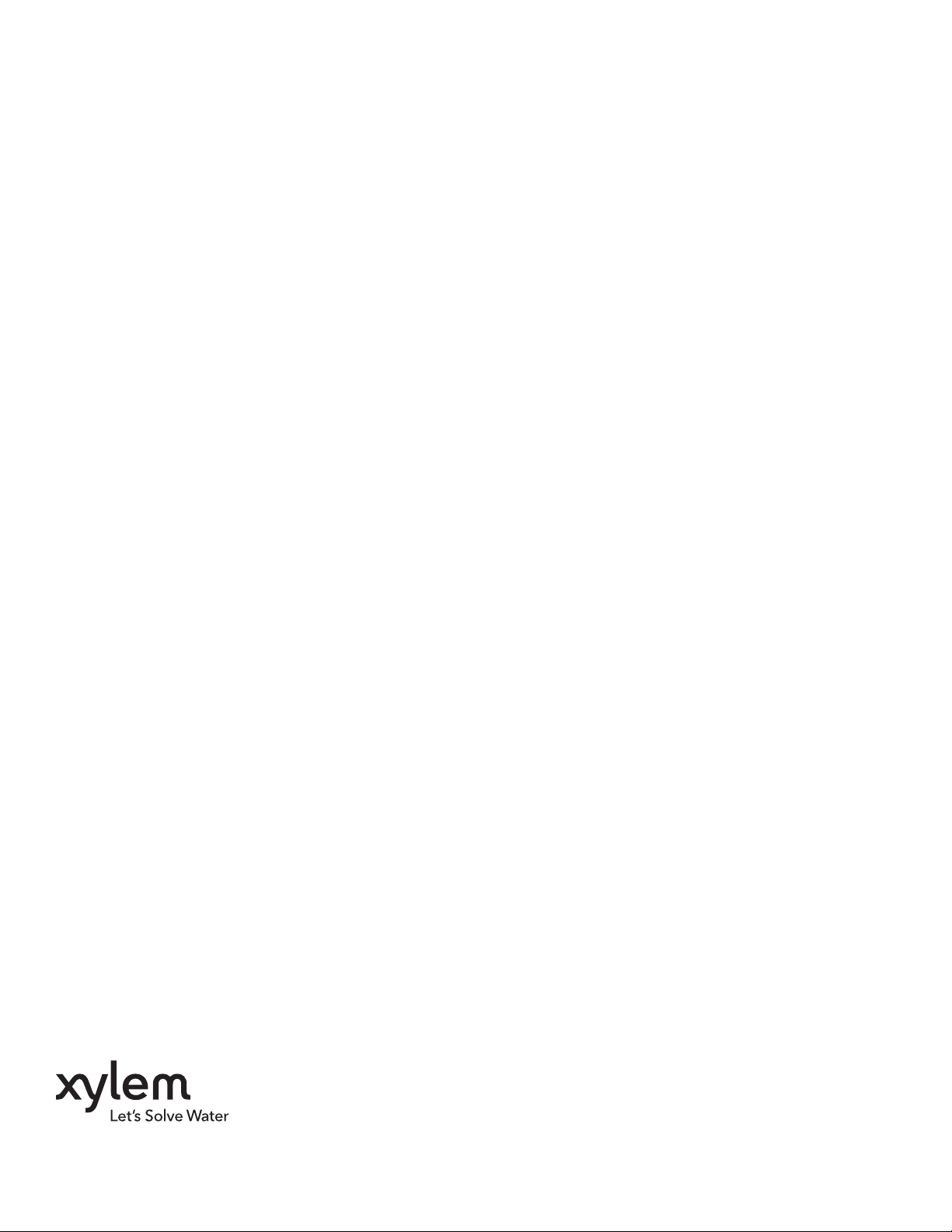

TANK WITH EFFLUENT FILTER

INLET

BAFFLE

EFFLUENT

FILTER

FILTERED

PUMP VAULT

4

Page 5

TROUBLESHOOTING

WARNING

Hazardous

voltage

Symptom Probable Cause Recommended Action

PUMP MOTOR

NOT RUNNING

LITTLE OR NO LIQUID

DELIVERED BY PUMP

DISCONNECT AND LOCKOUT ELECTRICAL POWER BEFORE ATTEMPTING

ANY SERVICE. FAILURE TO DO SO CAN CAUSE SHOCK, BURNS OR DEATH.

1. Motor thermal protector tripped

a. Incorrect or faulty electrical connections

b. Faulty thermal protector

c. Low voltage

d. Pump bound by foreign matter

e. Inadequate submergence

2. Open circuit breaker or blown fuse 2. Have a qualified electrician inspect and repair,

3. Power source inadequate for load 3. Check supply or generator capacity

4. Power cable insulation damage

5. Faulty power cable splice

1. Faulty or incorrectly installed check valve

2. Pump air bound

3. Lift too high for pump

4. Pump bound by foreign matter

5. Pump not fully submerged

6. Filter/screen plugged

7. Excessive pump wear

1. Allow motor to cool, thermal protector will

automatically reset.

a-e. Have a qualified electrician inspect and

repair, as required.

f. Pull pump, clean, adjust set depth

as required.

g. Confirm adequate unit submergence

in pumpage.

as required

4. & 5. Have a qualified electrician inspect and

repair, as required

1. Inspect check valve, repair as required

2. Successively start and stop pump until flow is

delivered

3. Review unit performance, check with dealer

4. Pull pump, clean, adjust set depth as required

5. Check float settings, lower pump if possible

6. Clean filter

7. Pull pump and repair as required

MOTOR INSULATION RESISTANCE READINGS

Condition of Motor and Leads OHM Value Megohm Value

New motor, without power cable 20,000,000 (or more) 20.0

Used motor, which can be reinstalled in tank 10,000,000 (or more) 10.0

Motor in tank – Readings are power cable plus motor

New motor 2,000,000 (or more) 2.0

Motor in reasonably good condition 500,000 to 2,000,000 0.5 – 2.0

Motor which may be damaged or have damaged power cable

Do not pull motor for these reasons

Motor definitely damaged or with damaged power cable

Pull motor and repair

Failed motor or power cable –

1

Courtesy of Franklin Electric Company

Pull motor and repair

Less than 10,000 0 – 0.01

1

20,000 to 500,000 0.02 – 0.5

10,000 to 20,000 0.01 – 0.02

Xylem, Inc.

www.completewatersystems.com

© 2012 Xylem Inc. IM045 Revision Number 3 July 2012

5

Page 6

MANUAL DE INSTRUCCIÓN

IM045

LEA CUIDADOSAMENTE TODAS LAS INSTRUCCIONES ANTES DE INTENTAR

REALIZAR CUALQUIER TRABAJO

Bomba para

efluente filtrado

INSTRUCCIONES DE INSTALACIÓN Y FUNCIONAMIENTO

Page 7

PELIGRO

ADVERTENCIA

CUIDADO

ADVERTENCIA

Los fluidos peligrosos

pueden causar

incendios, quemaduras

o la muerte.

PELIGRO

Información del propietario

Sírvase completar la información y dé este folleto al

propietario de la casa.

Número de Modelo:

Número de Serie:

Agente:

No. telefónico del agente:

Fecha de compra: Instalación:

Índice

TEMA PÁGINA

Instrucciones de seguridad ..................................... 7

Descripción y especificaciones ............................... 7

Precauciones importantes ...................................... 7

Tuberías ................................................................. 7

Alambrado y conexión a tierra .............................. 8

Instalaciones del cable del motor ........................... 8

Instalación de la bomba ......................................... 9

Tanque con filtro para efluente .............................. 9

Identificación y resolución de problemas ............. 10

Lecturas de resistencia de aislamiento del motor .. 10

INSTRUCCIONES DE SEGURIDAD

PARA EVITAR LESIONES PERSONALES GRAVES

O AÚN FATALES Y SERIOS DAÑOS MATERIALES,

LEA Y SIGA TODAS LAS INSTRUCCIONES DE

SEGURIDAD EN EL MANUAL Y EN LA BOMBA.

ESTE MANUAL HA SIDO CREADO COMO UNA

GUÍA PARA LA INSTALACIÓN Y OPERACIÓN DE

ESTA UNIDAD Y SE DEBE CONSERVAR JUNTO A

LA BOMBA.

Éste es un SÍMBOLO DE ALERTA DE

SEGURIDAD. Cuando vea este símbolo

en la bomba o en el manual, busque

una de las siguientes palabras de señal y

esté alerta a la probabilidad de lesiones

personales o daños materiales.

Advierte los peligros que CAUSARÁN

graves lesiones personales, la muerte o

daños materiales mayores.

Advierte los peligros que PUEDEN

causar graves lesiones personales, la

muerte o daños materiales mayores.

Advierte los peligros que PUEDEN

causar lesiones personales o daños

materiales.

AVISO: INDICA INSTRUCCIONES ESPECIALES

QUE SON MUY IMPORTANTES Y QUE SE

DEBEN SEGUIR.

EXAMINE BIEN TODAS LAS INSTRUCCIONES Y

ADVERTENCIAS ANTES DE REALIZAR CUALQUIER TRABAJO EN ESTA BOMBA.

MANTENGA TODAS LAS CALCOMANÍAS DE

SEGURIDAD.

BOMBEAR LÍQUIDOS PELIGROSOS

O GASES INFLAMABLES

PUEDE PRODUCIR INCENDIO,

QUEMADURAS O AÚN LA MUERTE.

DESCRIPCIÓN Y ESPECIFICACIONES

Las unidades de bombas/motores armadas compradas

de la fábrica están aprobadas por UL® y CSA. TODOS

los motores Franklin Electric son reconocidos por UL® y

aprobados por CSA.

INSPECCIONE LA UNIDAD PARA DETERMINAR SI

ESTÁ DAÑADA Y NOTIFIQUE TODOS LOS DAÑOS

DE INMEDIATO A LA COMPAÑÍA TRANSPORTISTA.

PRECAUCIONES IMPORTANTES

Todo el trabajo eléctrico debe ser

realizado por un técnico calificado.

Siempre siga el Código Eléctrico de EE.UU. (NEC) o

el Código Eléctrico Canadiense, además de todos los

códigos locales, estatales y provinciales. Las preguntas

acerca del código deben ser dirigidas al inspector

eléctrico local. Si se hace caso omiso a los códigos

eléctricos y normas de seguridad de OSHA, se pueden

producir lesiones personales o daños al equipo. Si se

Page 8

ADVERTENCIA

Tensión

peligrosa

ADVERTENCIA

Un voltaje peligroso puede

producir golpes eléctricos,

quemaduras o la muerte.

ADVERTENCIA

ADVERTENCIA

hace caso omiso a las instrucciones de instalación del

ADVERTENCIA

ADVERTENCIA

ADVERTENCIA

fabricante, se puede producir electrochoque, peligro de

incendio, lesiones personales o aún la muerte, daños al

equipo, rendimiento insatisfactorio y podría anularse la

garantía del fabricante.

TUBERÍAS

• Las tuberías del sistema DEBEN cumplir con todos los

ALAMBRADO Y CONEXIÓN A TIERRA

Aviso importante: Lea las instrucciones de seguridad antes

de proseguir con el cableado.

8

Las unidades estándar no están diseñadas

para usarse en albercas, masas abiertas

de agua, líquidos peligrosos o donde

existan gases inflamables. Estos fluidos

y gases podrían estar presentes en áreas

de contención. El tanque o pozo debe

ser ventilado de acuerdo con los códigos

locales.

En lugares con líquidos inflamables o

donde pudiese haber gases inflamables

sólo deben usarse bombas específicamente

clasificadas para áreas de Clase 1,

División 1. Consulte los boletines de

catálogos de bombas específicas o la

placa de identificación de la bomba con

respecto a las listas de agencias.

Desconecte y bloquee la corriente

eléctrica antes de instalar o dar servicio

a cualquier equipo eléctrico. Muchas

bombas están equipadas con protección

automática contra la sobrecarga

térmica, la cual podría permitir que una

bomba demasiado caliente rearranque

inesperadamente.

códigos y prácticas de plomería locales y nacionales.

Use únicamente alambre

trenzado de cobre para la

bomba/motor y la conexión a

tierra. El alambre de conexión

a tierra debe ser al menos

del mismo tamaño que los

alambres de la fuente de

alimentación. Los alambres

deben codificarse con colores

para facilitar el mantenimiento

y la identificación y resolución

de problemas.

Instale los cables y la conexión a tierra de acuerdo con el Código Eléctrico de EE.UU. (NEC),

además de todos los códigos locales, estatales y

provinciales.

Instale un desconectador de todos los circuitos

donde el código lo requiera.

Desconecte y bloquee la corriente eléctrica

antes de instalar o dar servicio.

La tensión y fase de la fuente de alimentación

debe corresponder con todos los requerimientos del equipo. La tensión o fase incorrecta

puede producir incendio, daño al motor o a los

controles y anular la garantía.

Todos los empalmes debe ser impermeables. Si

utiliza juegos de empalme, siga las instrucciones

del fabricante.

Selle todos los controles de los gases

presentes que pudiesen dañar los

componentes eléctricos.

LA FALLA DE CONECTAR A TIERRA

PERMANENTEMENTE LA BOMBA,

EL MOTOR Y LOS CONTROLES,

ANTES DE CONECTAR LA

CORRIENTE ELÉCTRICA PUEDE

CAUSAR ELECTROCHOQUE,

QUEMADURAS O LA MUERTE.

• Esta bomba está equipada con un medio de puesta

a tierra. Para reducir el riesgo de electrochoque del

contacto con partes metálicas adyacentes, conecte la

caja de suministro al medio de puesta a tierra de la

bomba-motor y a todas las partes metálicas accesibles

en el tanque, incluso las tuberías de descarga metálicas

y artículos similares, mediante lo siguiente:

1. Un conductor de puesta a tierra de equipo cuyo

tamaño sea al menos igual a los conductores del cable

de alimentación a la bomba.

2. Una abrazadera, soldadura o ambas si es necesario,

sujeta al terminal de puesta a tierra del equipo o al

conductor de puesta a tierra en la caja de la bomba.

El conductor de puesta a tierra del equipo, si se

suministra, es el conductor que tiene una superficie

exterior de aislamiento de color verde con o sin una o

más franjas amarillas. -UL 78

INSTALACIONES DEL CABLE

DEL MOTOR

• Prepare el cable del motor desforrando ½ pulg. (13

mm) al extremo del aislamiento de cada conductor.

AVISO: SIGA LAS INSTRUCCIONES DEL

FABRICANTE DEL JUEGO DE EMPALME.

• Cuando los cables se empalman o conectan a los

conductores del motor, los empalmes DEBEN ser

impermeables. Pueden usarse juegos de encapsulado o

de contracción por calor comercialmente disponibles si

así lo permiten los reglamentos locales o federales.

• Para asegurar un sellado apropiado, sumerja el

empalme en un recipiente de metal lleno con agua

durante diez minutos, luego mida la resistencia entre

el recipiente de metal y el conductor del cable. La

resistencia debe ser de 2 megaohmios o más. Rehaga el

empalme en la forma requerida.

• Los motores bilares no requieren una caja de control.

Page 9

INSTALACIÓN DE LA BOMBA

ADVERTENCIA

Un voltaje peligroso puede

producir golpes eléctricos,

quemaduras o la muerte.

AVISO: PROTEJA TODAS LAS TUBERÍAS,

ACCESORIOS Y COMPONENTES DEL

SISTEMA CONTRA LA CONGELACIÓN.

NO LEVANTE NI TRANSPORTE

NI CUELGUE LA BOMBA DE LOS

CABLES ELÉCTRICOS. EL DAÑO

AL CABLE ELÉCTRICO PUEDE

PRODUCIR ELECTROCHOQUE,

QUEMADURAS O AÚN LA MUERTE.

SE RECOMIENDA QUE CUALQUIER

INSTALACIÓN O SERVICIO SEA

REALIZADO POR UN INSTALADOR

CERTIFICADO.

AVISO: ALGUNOS MODELOS SE ARMAN CON

ROSCAS DE MANO IZQUIERDA. SUJETE LA

BOMBA CON UNA LLAVE EN LA CABEZA

DE DESCARGA MIENTRAS INSTALA LA TUBERÍA DE DESCARGA O EL CONECTOR.

• Asegure que la bomba y el motor giren libremente

rotando el eje con la mano.

• Conecte la placa de bajada o la tubería de descarga a la

bomba y bájela al tanque.

• La bomba debe estar protegida contra los sólidos y

residuos. El efluente debe pasar por un filtro aprobado

antes de llegar a la bomba.

• Utilizando cinta plástica aislante e impermeable, sujete

el cable eléctrico en la tubería de bajada a intervalos

aproximados de tres pies.

• La bomba DEBE estar sumergida todo el tiempo para

que funcione correctamente. No haga funcionar la

bomba seca. Asegure que los interruptores de flotador

estén ajustados de manera que la bomba se apague

antes de que funcione seca o interrumpa la succión.

Ajuste los flotadores según sea necesario para un

funcionamiento correcto.

• Si la bomba se va a operar con una descarga abierta,

DEBE instalarse una válvula de descarga. Antes de la

puesta en marcha, abra esta válvula aproximadamente

1

⁄3, luego arranque la bomba. Abra LENTAMENTE la

válvula hasta obtener la velocidad de flujo deseada. El

ajuste final DEBE estar dentro del rango de operación

recomendado de la bomba.

• Los cojinetes del motor se lubrican en forma interna.

No se requiere ni es posible ningún otro tipo de

mantenimiento del motor o la bomba.

TANQUE CON FILTRO PARA EFLUENTE

DEFLECTOR DE

ENTRADA

FILTRO DE EFLUENTE

BÓVEDA DE LA BOMBA

PARA EFLUENTE

FILTRADO

9

Page 10

IDENTIFICACIÓN Y RESOLUCIÓN DE PROBLEMAS

ADVERTENCIA

Tensión

peligrosa

Síntoma Causa probable Acción recomendada

EL MOTOR DE LA BOMBA

NO ESTÁ FUNCIONANDO

LA BOMBA ENTREGA

POCO O NADA DE

LÍQUIDO

DESCONECTE Y BLOQUEE LA CORRIENTE ELÉCTRICA ANTES

INTENTAR DAR SERVICIO. DE LO CONTRARIO, SE PUEDE PRODUCIR

ELECTROCHOQUE, QUEMADURAS O LA MUERTE.

1. Se disparó el protector térmico del motor

a. Conexiones eléctricas incorrectas o defectuosas

b. Protector térmico defectuoso

c. Baja tensión.

d. La bomba está atascada con materias extrañas

e. Sumersión inadecuada

2. Cortacircuitos abierto o fusible quemado 2. Solicite que un electricista calificado inspeccione y

3. La fuente de energía es inadecuada para la carga 3. Verifique el suministro o la capacidad del generador

4. Daño del aislamiento del cable de alimentación

5. Empalme defectuoso del cable de alimentación

1. Válvula de retención defectuosa o instalada

incorrectamente

2. La bomba está atascada con aire

3. Elevación demasiado alta para la bomba

4. La bomba está atascada con materias extrañas

5. La bomba no está completamente sumergida

6. Filtro/rejilla tapada

7. Desgaste excesivo de la bomba

1. Deje que el motor se enfríe, el protector térmico se

reposicionará automáticamente.

a-e. Solicite que un electricista calificado

inspeccione y repare, según sea requerido.

f. Retire la bomba, límpiela, ajústela, fije la

profundidad según sea requerido.

g. Confirme la sumersión adecuada de la unidad

en el agua bombeada.

repare, según sea requerido.

4. & 5. Solicite que un electricista calificado

inspeccione y repare, según sea requerido.

1. Inspeccione la válvula de retención, repárela según

sea necesario

2. Arranque y detenga la bomba sucesivamente hasta

que haya flujo

3. Verifique el rendimiento de la unidad, consulte con

el agente

4. Retire la bomba, límpiela, ajústela, fije la

profundidad según sea requerido

5. Verifique los ajustes de los flotadores, baje la

bomba si es posible

6. Limpie el filtro

7. Retire y repare la bomba, según sea necesario

LECTURAS DE RESISTENCIA DE AISLAMIENTO DEL MOTOR

Condición del motor y los conductores Valor en OHMIOS Valor en Megaohmios

Motor nuevo, sin cable de alimentación 20,000,000 (o más) 20.0

Motor usado, el cual puede reinstalarse en el tanque 10,000,000 (o más) 10.0

Motor en el tanque – lecturas del cable de alimentación más el motor

Motor nuevo 2,000,000 (o más) 2.0

El motor está en relativamente buenas condiciones 500,000 a 2,000,000 0.5 – 2.0

El motor podría estar dañado o con cable de alimentación

dañado.

No retire el motor por estas razones.

Motor definitivamente dañado o con cable de alimentación

dañado.

Retire y repare el motor.

Falla del motor o del cable de alimentación –

Retire y repare el motor.

1

Cortesía de Franklin Electric Company

20,000 a 500,000 0.02 – 0.5

10,000 a 20,000 0.01 – 0.02

Menos de 10,000 0 – 0.01

1

Xylem, Inc.

www.completewatersystems.com

© 2012 Xylem Inc. IM045 Revisión Número 3 Julio 2012

Page 11

MANUEL D'UTILISATION

IM045

LIRE SOIGNEUSEMENT CHAQUE DIRECTIVE ET AVERTISSEMENT AVANT

D’EFFECTUER TOUT TRAVAIL SUR LA POMPE.

Pompe à effluents filtrés

DIRECTIVES D’INSTALLATION ET D’UTILISATION

Page 12

DANGER

AVERTISSEMENT

ATTENTION

AVERTISSEMENT

Les fluides dangereux

peuvent causer un

incendie, des brûlures

ou la mort.

Informations pour le propriétaire

Noter ci-dessous les informations pertinentes et

remettre le document à la ou au propriétaire.

Modèle de pompe :

Numéro de série :

Détaillant :

No de téléphone du détaillant :

Date d’achat : d’installation :

Table des matières

SUJET PAGE

Consignes de sécurité .......................................... 12

Description et caractéristiques ............................. 12

Précautions importantes ...................................... 12

Tuyauterie ........................................................... 12

Câblage et mise à la terre ..................................... 13

Connexion du moteur ......................................... 13

Installation .......................................................... 14

Installation type ................................................... 14

Diagnostic des anomalies ..................................... 15

Valeurs de résistance d’isolement du moteur ........ 15

CONSIGNES DE SÉCURITÉ

AFIN DE PRÉVENIR LES BLESSURES GRAVES OU

MORTELLES ET LES DOMMAGES MATÉRIELS

IMPORTANTS, LIRE ET SUIVRE TOUTES LES

CONSIGNES DE SÉCURITÉ FIGURANT DANS LE

MANUEL ET SUR LA POMPE.

LE PRÉSENT MANUEL A POUR BUT DE FACILITER

L’INSTALLATION ET L’UTILISATION DE LA

POMPE ET DOIT ÊTRE CONSERVÉ PRÈS D’ELLE.

Le symbole ci-contre est un SYMBOLE

DE SÉCURITÉ employé pour signaler

les mots-indicateurs dont on trouvera

la description ci-dessous. Sa présence

sert à attirer l’attention afin d’éviter les

blessures et les dommages matériels.

Prévient des risques qui VONT causer

des blessures graves, la mort ou des

dommages matériels importants.

Prévient des risques qui PEUVENT

causer des blessures graves, la mort ou

des dommages matériels importants.

Prévient des risques qui PEUVENT

causer des blessures ou des dommages

matériels.

AVIS : SERT À ÉNONCER LES DIRECTIVES SPÉ-

CIALES DE GRANDE IMPORTANCE QUE

L’ON DOIT SUIVRE.

LIRE SOIGNEUSEMENT CHAQUE DIRECTIVE

ET AVERTISSEMENT AVANT D’EFFECTUER

TOUT TRAVAIL SUR LA POMPE.

N’ENLEVER AUCUNE DÉCALCOMANIE DE

SÉCURITÉ.

LE POMPAGE DE LIQUIDES

DANGEREUX OU DE GAZ

INFLAMMABLES PEUT CAUSER UN

INCENDIE, DES BRÛLURES OU LA

MORT.

12

DESCRIPTION ET CARACTÉRISTIQUES

Les groupes monobloc (pompes montées sur moteurs)

provenant de l’usine sont homologués ULMD et CSA.

TOUS les moteurs Franklin Electric sont homologués

CSA et reconnus ULMD.

INSPECTER L’APPAREIL ET SIGNALER

IMMÉDIATEMENT TOUT DOMMAGE AU

TRANSPORTEUR.

PRÉCAUTIONS IMPORTANTES

L’installation électrique doit être entièrement effectuée

par un technicien qualifié. Il faut toujours suivre

les prescriptions du code provincial ou national de

l’électricité et les règlements locaux. Adresser toute

question relative au code à un inspecteur en électricité.

Le non-respect du code et des politiques de santé et de

sécurité au travail peut entraîner des blessures et des

dommages matériels. L’inobservation des directives

d’installation fournies par le fabricant peut causer par un

Page 13

choc électrique, un incendie, des blessures ou la mort,

AVERTISSEMENT

AVERTISSEMENT

AVERTISSEMENT

AVERTISSEMENT

AVERTISSEMENT

Les tensions dangereuses

peuvent causer un choc

électrique, des brûlures ou

la mort.

AVERTISSEMENT

ainsi que des dommages matériels, des performances non

satisfaisantes et l’annulation de la garantie du fabricant.

TUYAUTERIE

• La tuyauterie du système DOIT respecter les

CÂBLAGE ET MISE À LA TERRE

Avis important : lire les Consignes de sécurité avant de

procéder au câblage.

Les pompes standard ne sont pas

conçues pour les piscines, l’eau libre,

les liquides dangereux ni les endroits

pouvant contenir des gaz inflammables.

Ces fluides peuvent être présents dans

les installations de confinement (puits

collecteurs, réservoirs ou fosses humides).

On doit aérer ces installations suivant les

codes locaux.

Seules les pompes de classe 1, division 1,

peuvent servir dans les liquides dangereux

et les endroits pouvant contenir des gaz

inflammables. Le nom des organismes

de normalisation pertinents figure sur la

plaque signalétique de la pompe ou dans

les feuillets du catalogue décrivant les

pompes en question.

Verrouiller la source de courant en

position hors circuit avant de procéder

à l’installation ou à l’entretien de tout

dispositif électrique. Le protecteur

thermique de certains moteurs de pompe

coupe le courant lorsqu’il y a surcharge

thermique et le rétablit automatiquement,

redémarrant ainsi la pompe inopinément.

prescriptions du code provincial ou national de la

plomberie et les pratiques pertinentes.

N’utiliser que du fil torsadé en

cuivre pour la mise à la terre

et l’alimentation du moteur.

Le calibre du fil de terre doit

être au moins égal à celui des

fils d’alimentation du moteur,

et les fils devraient tous être

chromocodés pour faciliter

l’entretien et le diagnostic des

anomalies.

Poser le fil de terre et les autres fils suivant les

prescriptions du code provincial ou national de

l’électricité et les règlements locaux.

Installer un sectionneur tout conducteur si le code

l’exige.

Verrouiller la source de courant en position hors

circuit avant de procéder à l’installation ou à

l’entretien de la pompe.

Le nombre de phases et la tension d’alimentation

doivent convenir à tout l’équipement. Un nombre

de phases et une tension inappropriés annulent

la garantie et peuvent causer un incendie et des

dommages au moteur et au tableau de commande.

Chaque joint de fils doit être étanche. Si l’on

emploie un nécessaire de jonction

(« kit »), suivre les directives du fabricant.

Étancher les commandes afin d’empêcher

l’entrée de gaz pouvant en détériorer les

composants.

AVERTISSEMENT

Tension

dangereuse

L’OMISSION DE LA MISE À

LA TERRE PERMANENTE DE

LA POMPE, DU MOTEUR ET

DES COMMANDES AVANT LE

BRANCHEMENT À LA SOURCE

DE COURANT PEUT CAUSER

UN CHOC ÉLECTRIQUE, DES

BRÛLURES OU LA MORT.

Une mise à la terre acceptable réduit

les risques d’électrocution pendant

l’utilisation de la pompe.

• La pompe est munie d’une prise de terre. Pour réduire

les risques d’électrocution au contact des pièces en

métal voisines, relier la prise de terre du groupe

monobloc à la boîte d’alimentation et à toutes les

autres pièces métalliques accessibles près du réservoir, y

compris la tuyauterie de refoulement, à l’aide :

1. D’un fil de mise à la terre de l’équipement, dont le

calibre est au moins égal à celui des fils d’alimentation

du moteur ;

2. D’une borne à souder ou à dispositif de fixation, ou

les deux au besoin, assujettie à une surface de mise

à la terre de l’équipement et au fil de mise à la terre

du corps de pompe. Si le fil de mise à la terre de

l’équipement est fourni, il s’agit du fil à gaine verte

avec ou sans bande(s) jaune(s), conformément à la

norme UL 778.

CONNEXION DU MOTEUR

• Dénuder l’extrémité de chaque l de moteur sur une

longueur de 13 mm (½ po).

AVIS : SUIVRE LES DIRECTIVES DU FABRICANT DU

NÉCESSAIRE DE JONCTION DE FILS.

• Chaque jonction ou connexion des ls de moteur

DOIT être étanche. On peut employer des gaines

thermorétrécissables ou tout produit d’enrobage offerts

sur le marché s’ils sont permis par le code national ou

provincial de l’électricité.

• S’assurer de l’étanchéité des joints en plongeant ceux-

ci pendant dix minutes dans un contenant en métal

rempli d’eau, puis en mesurant la résistance électrique

entre le contenant et les fils, qui devrait être de 2

mégohms et plus. Au besoin, refaire les joints.

• Les moteurs à deux ls ne requièrent pas de boîte de

commande.

13

Page 14

AVERTISSEMENT

Les tensions dangereuses

peuvent causer un choc

électrique, des brûlures ou

la mort.

INSTALLATION

AVIS : PROTÉGER DU GEL LA TUYAUTERIE,

SES RACCORDS ET ACCESSOIRES ET LES

COMPOSANTS DU SYSTÈME.

NE PAS LEVER, TRANSPORTER

NI SUSPENDRE LA POMPE PAR

LE CÂBLE ÉLECTRIQUE, CAR

L’ENDOMMAGEMENT DE CELUICI POURRAIT CAUSER UN CHOC

ÉLECTRIQUE, DES BRÛLURES OU

LA MORT.

IL EST RECOMMANDÉ DE FAIRE

EFFECTUER L’INSTALLATION

ET L’ENTRETIEN PAR UN

INSTALLATEUR QUALIFIÉ.

AVIS : LA TÊTE DE REFOULEMENT SE VISSE

À GAUCHE SUR CERTAINS MODÈLES :

L’IMMOBILISER AVEC UNE CLÉ AVANT

D’Y VISSER LE RACCORD OU LE TUYAU DE

REFOULEMENT.

• Faire tourner l’arbre de pompe à la main pour s’assurer

qu’il n’est pas grippé.

• Fixer la colonne descendante ou le tuyau de

refoulement à la pompe et descendre cette dernière

dans le réservoir.

• La pompe doit être protégée des solides et des débris :

les effluents doivent traverser un filtre approuvé avant

d’atteindre la pompe.

• À l’aide de ruban isolant (chatterton) résistant à l’eau,

fixer le câble électrique au tuyau de refoulement ou à la

colonne descendante à tous les trois pieds environ.

• La pompe DOIT être immergée en tout temps pour

bien fonctionner. Ne pas l’utiliser à sec. S’assurer de

régler la position des contacteurs à flotteur de telle

façon que la pompe marche correctement, sans risque

d’aspiration d’air ni de fonctionnement à sec.

• Si la pompe est employée sans robinet de refoulement,

on DOIT en poser un. Avant de mettre la pompe

en service, ouvrir le robinet du tiers environ, puis

démarrer la pompe. Ouvrir le robinet LENTEMENT

jusqu’à ce que le débit voulu soit atteint. Le débit choisi

DOIT se situer dans la plage de service recommandée

de la pompe.

• Les roulements du moteur sont lubriés de l’intérieur.

Aucun autre type d’entretien n’est requis ni possible sur

le moteur et la pompe.

INSTALLATION TYPE

DÉFLECTEUR

D’ENTRÉE

FILTRE À

EFFLUENTS

POMPE À EFFLUENTS

ET FILTRE

14

Page 15

DIAGNOSTIC DES ANOMALIES

AVERTISSEMENT

Tension

dangereuse

VERROUILLER LA SOURCE DE COURANT EN POSITION HORS CIRCUIT

AVANT D’EFFECTUER TOUT TRAVAIL D’ENTRETIEN SUR LA POMPE. ON

PRÉVIENDRA AINSI LES CHOCS ÉLECTRIQUES, LES BRÛLURES, VOIRE LA

MORT.

Anomalies Causes probables Correctifs recommandés

NON-FONCTIONNEMENT

DU MOTEUR DE POMPE

DÉBIT DE REFOULEMENT

FAIBLE OU NUL

1. Protecteur thermique du moteur déclenché

a) Connexions électriques défectueuses ou

incorrectes

b) Protecteur thermique défectueux

c) Basse tension électrique

d) Pompe bloquée par un corps étranger

e) Hauteur d’immersion inappropriée

2. Disjoncteur ouvert ou fusible sauté 2. Faire inspecter l’appareil par un électricien et

3. Alimentation électrique inappropriée à la charge 3. Vérifier la puissance électrique du circuit

4. Gaine du câble d’alimentation endommagée

5. Jonction du câble d’alimentation défectueuse

1. Clapet de non-retour défectueux ou mal posé

2. Poche d’air dans la pompe

3. Hauteur d’aspiration trop élevée pour la pompe

4. Pompe bloquée par un corps étranger

5. Pompe non entièrement immergée

6. Filtre(s) ou crépine obstrués

7. Usure excessive de la pompe

1. Laisser le moteur refroidir, et le protecteur thermique

s’enclenchera de nouveau automatiquement.

a) à e) Faire inspecter l’appareil par un électricien et

effectuer les réparations requises.

f ) Sortir la pompe de la fosse, la nettoyer et la

redescendre à la hauteur d’immersion requise.

g) Confirmer la bonne hauteur d’immersion dans le

liquide pompé.

effectuer les réparations requises.

d’alimentation ou de la génératrice.

4. et 5. Faire inspecter l’appareil par un électricien et

effectuer les réparations requises.

1. Inspecter le clapet de non-retour et le réparer au

besoin.

2. Démarrer et arrêter la pompe à répétition jusqu’à

ce que son débit soit bon.

3. Vérifier les performances de l’appareil et consulter

le détaillant.

4. Sortir la pompe de la fosse, la nettoyer et la

redescendre à la hauteur d’immersion requise.

5. Vérifier la position des contacteurs à flotteur et

immerger la pompe davantage si possible.

6. Les nettoyer.

7. Retirer la pompe de la fosse et effectuer les

réparations requises.

VALEURS DE RÉSISTANCE D’ISOLEMENT DU MOTEUR

État du moteur et des fils Valeurs en ohms Valeurs en mégohms

Moteur neuf sans câble d’alimentation 20 000 000 (et plus) 20,0

Moteur usagé réutilisable en fosse 10 000 000 (et plus) 10,0

Moteur en fosse — valeurs mesurées : câble d’alimentation plus moteur

Moteur neuf 2 000 000 (et plus) 2,0

Moteur dans un état raisonnablement bon 500 000 à 2 000 000 0,5 à 2,0

Moteur ou câble d’alimentation peut-être endommagé

Ne pas sortir la pompe de la fosse pour cela

Moteur ou câble d’alimentation endommagé

Sortir la pompe de la fosse et effectuer les réparations

Moteur ou câble d’alimentation défectueux

Sortir la pompe de la fosse et effectuer les réparations

1

Table publiée avec l’aimable autorisation de Franklin Electric

.

.

20 000 à 500 000 0,02 à 0,5

10 000 à 20 000 0,01 à 0,02

Moins de 10 000 0 à 0,01

1

15

Page 16

Xylem, Inc.

www.completewatersystems.com

© 2012 Xylem Inc. IM045 Révision numéro 3 Juillet 2012

Loading...

Loading...