Page 1

INSTRUCTION MANUAL

IM024

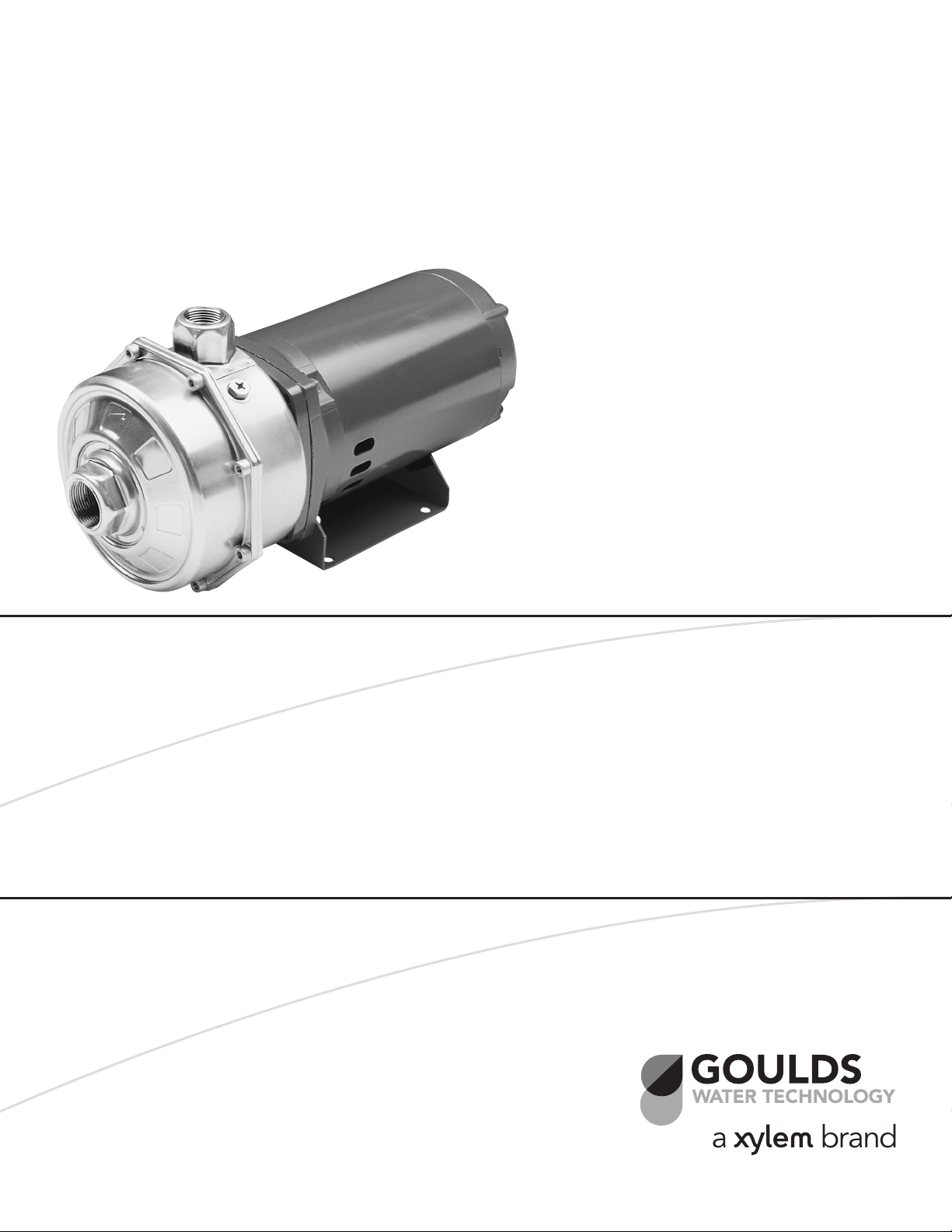

Model LC

INSTALLATION, OPERATION AND MAINTENANCE INSTRUCTIONS

Page 2

SUBJECT PAGE

Safety Instructions ........................................................................................................................................................ 3

Important ..................................................................................................................................................................... 3

Installation ................................................................................................................................................................... 3

Suction Piping .............................................................................................................................................................. 3

Discharge Piping........................................................................................................................................................... 4

Rotation ....................................................................................................................................................................... 4

Operation ..................................................................................................................................................................... 4

Maintenance................................................................................................................................................................. 4

Disassembly .................................................................................................................................................................. 4

Reassembly ................................................................................................................................................................... 5

Troubleshooting ........................................................................................................................................................... 5

Parts List ...................................................................................................................................................................... 6

Mechanical Seal Application Chart ............................................................................................................................... 6

Limited Warranty ......................................................................................................................................................... 6

Declaration of Conformity ......................................................................................................................................... 21

Pump Model Number:

Pump Serial Number:

Dealer:

Dealer Phone No.:

Date of Purchase:

Date of Installation:

Current Readings at Startup:

1 Ø 3 Ø L1-2 L2-3 L3-1

Amps: Amps:

Volts: Volts:

2

Page 3

SAFETY INSTRUCTIONS

DANGER

WARNING

CAUTION

WARNING

Hazardous fluids

can cause fire,

burns or death.

CAUTION

CAUTION

CAUTION

TO AVOID SERIOUS OR FATAL PERSONAL

INJURY OR MAJOR PROPERTY DAMAGE, READ

AND FOLLOW ALL SAFETY INSTRUCTIONS IN

MANUAL AND ON PUMP.

THIS MANUAL IS INTENDED TO ASSIST IN THE

INSTALLATION AND OPERATION OF THIS UNIT

AND MUST BE KEPT WITH THE PUMP.

This is a SAFETY ALERT SYMBOL.

When you see this symbol on the pump

or in the manual, look for one of the

following signal words and be alert

to the potential for personal injury or

property damage.

Warns of hazards that WILL cause

serious personal injury, death or major

property damage.

Warns of hazards that CAN cause

serious personal injury, death or major

property damage.

Warns of hazards that CAN cause personal injury or property damage.

NOTICE: INDICATES SPECIAL INSTRUCTIONS

WHICH ARE VERY IMPORTANT AND

MUST BE FOLLOWED.

THOROUGHLY REVIEW ALL INSTRUCTIONS

AND WARNINGS PRIOR TO PERFORMING ANY

WORK ON THIS PUMP.

MAINTAIN ALL SAFETY DECALS.

UNIT NOT DESIGNED FOR USE

WITH HAZARDOUS LIQUIDS OR

FLAMMABLE GASES. THESE

FLUIDS MAY BE PRESENT IN

CONTAINMENT AREAS.

1.3 Motors must be wired for proper voltage. Motor wir-

ing diagram is on motor nameplate. Wire size must

limit maximum voltage drop to 10% of nameplate

voltage at motor terminals, or motor life and pump

performance will be lowered.

1.4 Always use horsepower-rated switches, contactor and

starters.

1.5 Motor protection:

1.5.1 Single-phase: Thermal protection for single-

phase units is sometimes built in (check nameplate). If no built-in protection is provided, use

a contactor with a proper overload. Fusing is

permissible.

1.5.2 Three-phase: Provide three-leg protection with

properly sized magnetic starter and thermal

overloads.

1.6 Maximum Operating Limits:

Liquid Temperature: 220°F (110°C)

Working Pressure: 125 PSI

Starts per Hour: 20, evenly distributed.

1.7 Regular inspection and maintenance will increase

service life. Base schedule on operating time. Refer to

Section 8.

2. INSTALLATION

2.1 Locate pump as near liquid source as possible (below)

level of liquid for automatic operation.

2.2 Protect from freezing or flooding.

2.3 Allow adequate space for servicing and ventilation.

2.4 All piping must be supported independently of the

pump, and must “line-up” naturally.

NEVER DRAW PIPING INTO PLACE BY

FORCING THE PUMP SUCTION AND

DISCHARGE CONNECTIONS.

DESCRIPTION and SPECIFICATIONS:

The Model LC is a close-coupled, end suction, two stage

centrifugal for general liquid transfer service, booster

applications, etc. Liquid-end construction is all AISI Type

304 stainless steel, stamped and welded. Impellers are

fully enclosed, non-trimable to intermediate diameters.

Casings are fitted with diffusers for efficiency and for

negligible radial shaft loading.

All units have NEMA 48Y and 56Y motors with square

flange mounting and threaded shaft extension.

1. IMPORTANT

1.1 Inspect unit for damage. Report any damage to car-

rier/dealer immediately.

1.2 Electrical supply must be a separate branch circuit

with fuses or circuit breakers, wire sizes, etc., in

compliance with National and Local electrical codes.

Install an all-leg disconnect switch near pump.

ALWAYS DISCONNECT ELECTRICAL

POWER WHEN HANDLING PUMP OR

CONTROLS.

2.5 Avoid unnecessary fittings. Select sizes to keep

friction losses to a minimum.

2.6 Units may be installed horizontally, inclined or

vertically.

DO NOT INSTALL WITH MOTOR BELOW PUMP. ANY LEAKAGE OR CON-

DENSATION WILL AFFECT THE MOTOR.

2.7 Foundation must be flat and substantial to eliminate

strain when tightening bolts. Use rubber mounts to

minimize noise and vibration.

2.8 Tighten motor hold-down bolts before connecting

piping to pump.

3. SUCTION PIPING

3.1 Low static suction lift and short, direct, suction pip-

ing is desired. Consult pump performance curve for

Net Positive Suction Head Required.

3.2 Suction pipe must be at least as large as the suction

connection of the pump. Smaller size will degrade

performance.

3

Page 4

CAUTION

CAUTION

CAUTION

3.3 If larger pipe is required, an eccentric pipe reducer

(with straight side up) must be installed at the pump.

3.4 Installation with pump below source of supply:

3.4.1 Install full flow isolation valve in piping for

inspection and maintenance.

DO NOT USE SUCTION ISOLATION

VALVE TO THROTTLE PUMP.

3.5 Installation with pump above source of supply:

3.5.1 Avoid air pockets. No part of piping should be

higher than pump suction connection. Slope

piping upward from liquid source.

3.5.2 All joints must be airtight.

3.5.3 Foot valve to be used only if necessary for

priming, or to hold prime on intermittent

service.

3.5.4 Suction strainer open area must be at least

triple the pipe area.

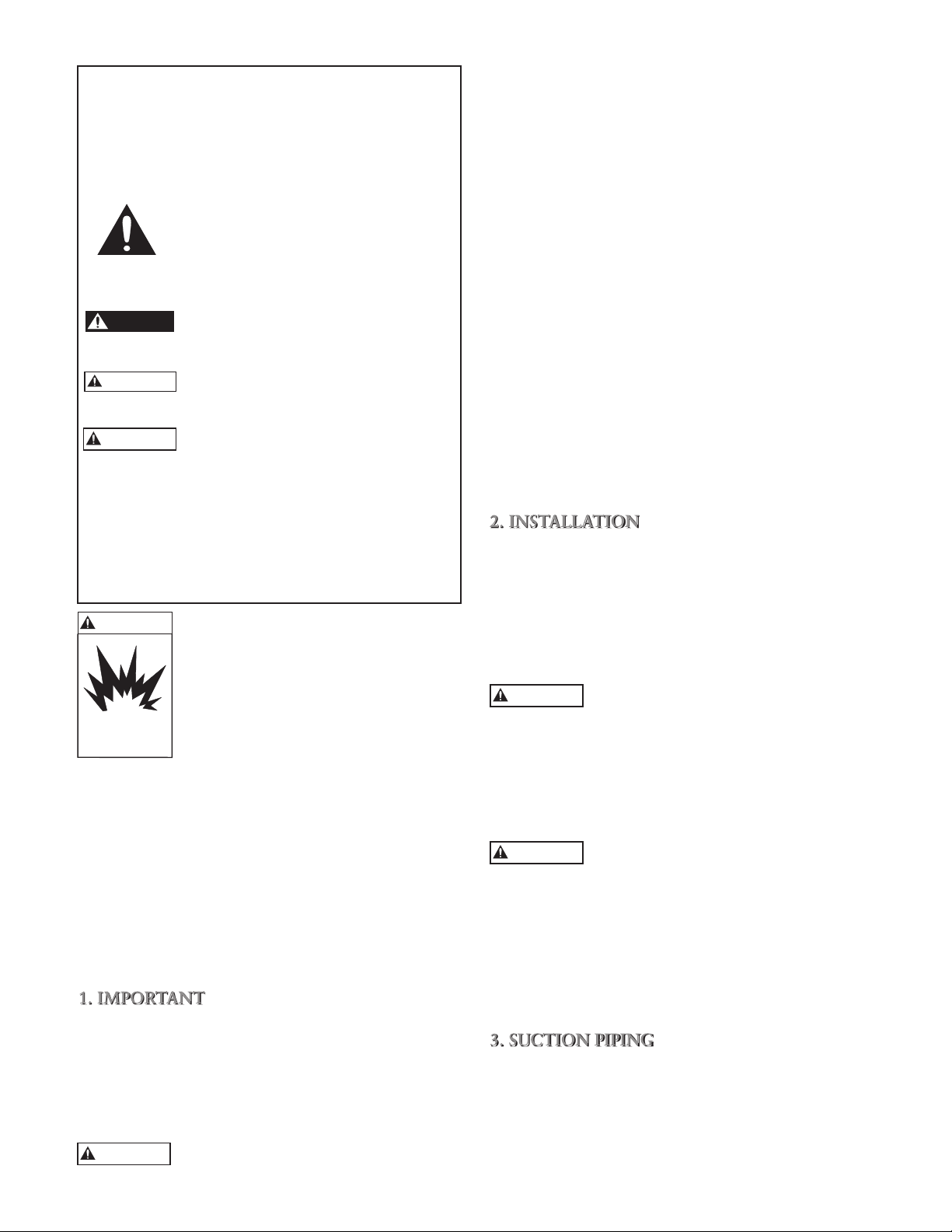

3.6 Size of inlet from liquid source, and minimum sub-

mergence over inlet, must be sufficient to prevent air

entering pump through vortexing. See Figures 1-4.

3.7 Use 3-4 wraps of Teflon™ tape to seal threaded

connections.

H min.

D

Figure 1 Figure 2

3.0D

min.

1.5D

min.

H min.

D min.

D D

2

H min.

H

16

15

14

13

12

11

10

9

8

7

6

5

4

3

2

H = Min. Submergence in feet

1

1234567891011 12131415 16

V = Velocity in feet per second

= GPM x 0.321

Area

GPM x 0.4085

D

V

2

D

Figure 3 Figure 4

4. DISCHARGE PIPING

4.1 Allowance should be made for disconnecting dis-

charge piping near casing to allow for pump disassembly.

4.2 Arrangement must include a check valve located

between a gate valve and the pump. The gate valve

is for regulation of capacity, or for inspection of the

pump or check valve.

4.3 If an increaser is required, place between check valve

and pump.

4.4 Use 3-4 wraps of Teflon tape to seal threaded

connections.

4

5. ROTATION

5.1 Correct rotation is right-hand (clockwise when

viewed from the motor end). Switch power on and

off quickly. Observe shaft rotation. To change rotation:

5.1.1 Single-phase motor: Non-reversible

5.1.2 Three-phase motor: Interchange any two

power supply leads.

6. OPERATION

6.1 Before starting, pump must be primed (free of air

and suction pipe full of liquid) and discharge valve

partially open.

6.2 Make complete check after unit is run under operat-

ing conditions and temperature has stabilized. Check

for expansion of piping.

7. MAINTENANCE

7.1 Ball bearings are located in and are part of the mo-

tor. They are permanently lubricated. No greasing

required.

PUMPED LIQUID PROVIDES LUBRICA-

TION. IF PUMP IS RUN DRY, ROTATING PARTS WILL SEIZE AND MECHANICAL SEAL

WILL BE DAMAGED. DO NOT OPERATE AT OR

NEAR ZERO FLOW. ENERGY IMPARTED TO THE

LIQUID IS CONVERTED INTO HEAT. LIQUID MAY

FLASH TO VAPOR. ROTATING PARTS REQUIRE

LIQUID TO PREVENT SCORING OR SEIZING.

8. DISASSEMBLY

8.1 Complete disassembly of the unit will be described.

Proceed only as for as required to perform the maintenance work required.

8.1.1 Turn off power.

8.1.2 Drain system and flush if necessary.

8.1.3 Disconnect discharge pipe from pump.

8.1.4 Remove motor hold-down bolts.

8.2 Disassembly of Liquid End

8.2.1 Remove casing screws and nuts.

8.2.2 Remove back pull-out assembly from casing.

8.2.3 Remove the first stage diffuser cover and casing

o-ring.

8.2.4 Remove motor fan cover to expose wrench flats

or slot on shaft end.

8.2.5 Hold shaft at flats to resist rotation, and

remove impeller nut and washer.

DO NOT INSERT SCREWDRIVER

BETWEEN THE FAN BLADES TO PREVENT ROTATION.

NOTE: Notice the location of anti-rotation tabs and

holes on items 10, 11, 12 and 13 these must be

aligned and engaged for reassembly.

8.2.6 Remove the first stage impeller, impeller spacer,

intermediate diffuser and last stage diffuser

cover.

Page 5

8.2.7 Remove the last stage impeller and last stage

diffuser.

NOTE: Further disassembly will require removal of the

mechanical seal. It is recommended that a new

mechanical seal be installed at reassembly.

8.2.8 Lubricate the shaft with a 50/50 solution of

glycerin and water. Remove the rotary portion

of the mechanical seal.

8.2.9 Remove the pump body and motor adapter as-

sembly from the motor.

8.2.10 Remove the stationary portion of the mechan-

ical seal from the pump body.

8.2.11 Remove the motor adapter from the pump

body.

8.2.12 To remove the pump shaft from the motor.

Heat must be applied to the pump shaft at the

largest diameter. This is required to break the

bond of the Loctite® #271 between the pump

and motor shafts.

9. REASSEMBLY

9.1 All parts should be cleaned before reassembly.

9.2 Refer to parts list to identify required replacement

items. Specify pump index or catalog number when

ordering parts.

9.3 Reassembly is the reverse of disassembly.

Observe the following when reassembling the pump:

9.4 Check the shaft runout. Maximum permissible is

.010” TIR at the end of the shaft.

9.5 Apply Loctite ‘PrimerN’ and Loctite® #271 to motor

shaft, thread pump shaft in place and torque to 30 lb.

of torque.

9.6 Lubricate pump shaft and pump body stationary seat

holder with a 50/50 glycerin and water solution prior

to installation of mechanical seal components.

9.7 Inspect casing o-ring and impeller o-rings for damage

or wear and replace if necessary.

9.8 O-rings may be lubricated with glycerin and water

solution or petroleum jelly to ease assembly.

9.9 Tighten casing screws to 10 lb.ft. of torque using a

star pattern to prevent o-ring binding.

10. TROUBLESHOOTING CHART

MOTOR NOT RUNNING

(See causes 1 through 6)

LITTLE OR NO LIQUID DELIVERED

(See causes 7 through 17)

POWER CONSUMPTION TOO HIGH

(See causes 4, 17, 18, 19, 22)

EXCESSIVE NOISE AND VIBRATION

(See causes 4, 6, 9, 13, 15, 16, 18, 20, 21, 22)

PROBABLE CAUSE

1. Tripped thermal protector

2. Open circuit breaker

3. Blown fuse

4. Rotating parts binding

5. Motor wired improperly

6. Defective motor

7. Not primed

8. Discharge plugged or valve closed

9. Incorrect rotation

10. Foot valve too small, suction not submerged,

inlet screen plugged

11. Low voltage

12. Phase loss (3-phase only)

13. Air or gasses in liquid

14. System head too high

15. NPSHA too low:

Suction lift too high or suction losses excessive

Check with vacuum gauge

16. Impeller worn or plugged

17. Incorrect impeller diameter

18. Head too low, causing excessive flow rate

19. Viscosity or specific too high

20. Worn bearings

21. Pump or piping loose

22. Pump and motor misaligned

5

Page 6

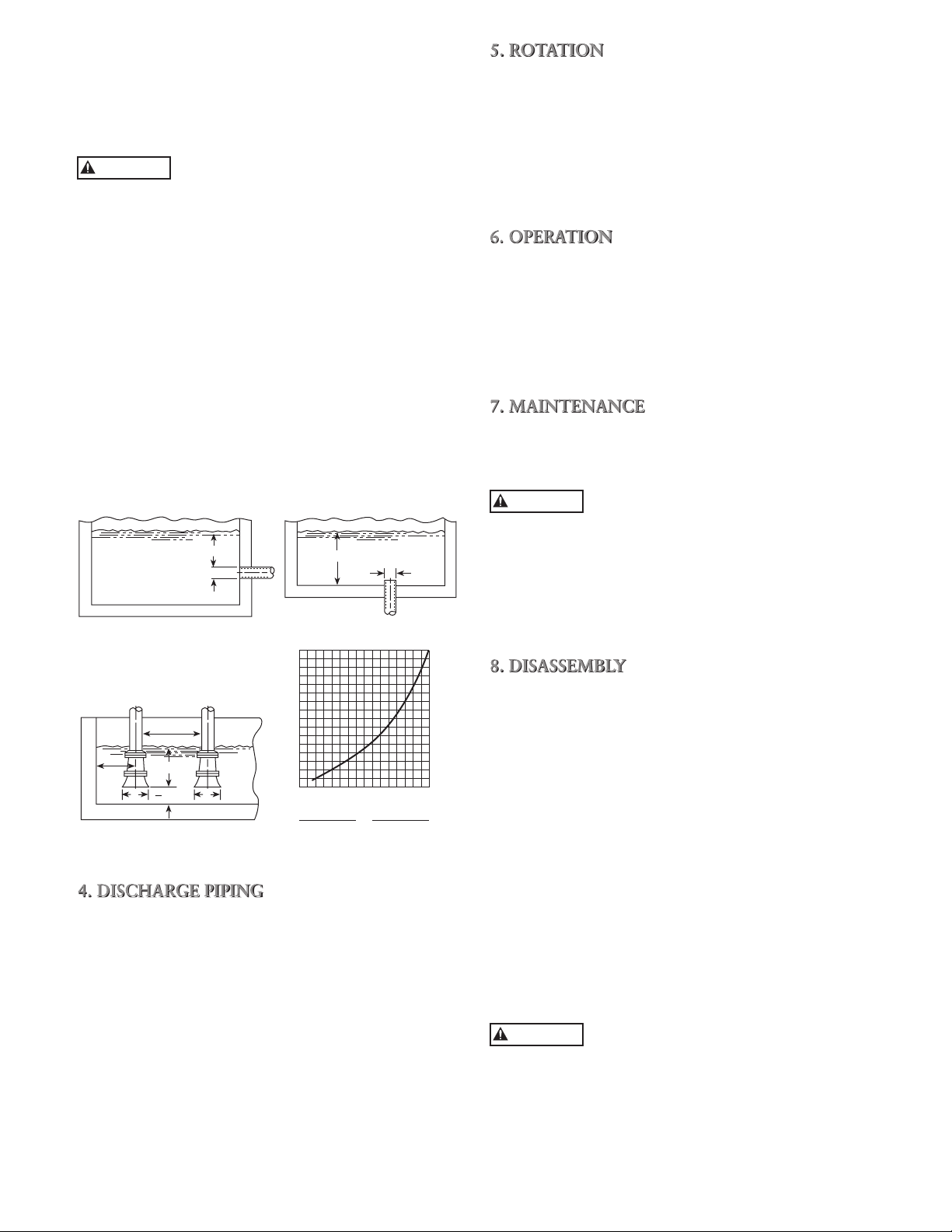

PARTS LIST

Item No. Description Materials

1 Screw, casing 304SS

2 Pump casing, suction 304SS

Viton

3 O-ring, casing Optional EPR

Optional BUNA

4 Diffuser cover, first stage 304SS

Viton

5 O-ring, impeller Optional EPR

Optional BUNA

6 Impeller nut 304SS

7 Impeller lock washer 400SS

8 Impeller 304SS

9 Impeller spacer 304SS

10 Diffuser, intermediate 304SS

11 Diffuser cover, last stage 304SS

12 Diffuser, last stage 304SS

MECHANICAL SEAL APPLICATION CHART

Rotary Stationary Elastomer Metal Parts Part No.

Silicon carbide Viton

Silicon carbide 10K88

Carbon Silicon carbide EPR 10K89

Ceramic 10K92

Carbon

10K87

316SS

Item No. Description Materials

13 Mechanical seal Varies

14 Fill and drain plug 304SS

15 O-ring, fill and drain plug Viton

16 Pump body with plug 304SS

17 Motor adapter Cast iron

18 Locknut, motor adapter to pump Steel

19 Shaft, pump 304SS

20 Key, impeller 304SS

21 Foot, pump Steel

22 Spacer Rubber

23 Screw, motor adapter to pump Steel

Motor, 3 phase ODP

Motor, 1 phase ODP

24

Motor, 3 phase TEFC

Motor, 1 phase TEFC

25 Nut, casing screw 304SS

23

20

19

14

303SS

24

13

15

10

8

4

2

1

6

9

7

5

3

5

11

12

8

25

16

15

14

18

17

22

21

6

Page 7

GOULDS WATER TECHNOLOGY LIMITED WARRANTY

This warranty applies to all water systems pumps manufactured by Goulds Water Technology.

Any part or parts found to be defective within the warranty period shall be replaced at no charge to the dealer during the warranty period. The warranty period shall exist for a

period of twelve (12) months from date of installation or eighteen (18) months from date of manufacture, whichever period is shorter.

A dealer who believes that a warranty claim exists must contact the authorized Goulds Water Technology distributor from whom the pump was purchased and furnish complete

details regarding the claim. The distributor is authorized to adjust any warranty claims utilizing the Goulds Water Technology Customer Service Department.

The warranty excludes:

(a) Labor, transportation and related costs incurred by the dealer;

(b) Reinstallation costs of repaired equipment;

(c) Reinstallation costs of replacement equipment;

(d) Consequential damages of any kind; and,

(e) Reimbursement for loss caused by interruption of service.

For purposes of this warranty, the following terms have these definitions:

(1) “Distributor” means any individual, partnership, corporation, association, or other legal relationship that stands between Goulds Water Technology and the dealer in

purchases, consignments or contracts for sale of the subject pumps.

(2) “Dealer” means any individual, partnership, corporation, association, or other legal relationship which engages in the business of selling or leasing pumps to customers.

(3) “Customer” means any entity who buys or leases the subject pumps from a dealer. The “customer” may mean an individual, partnership, corporation, limited liability

company, association or other legal entity which may engage in any type of business.

THIS WARRANTY EXTENDS TO THE DEALER ONLY.

Xylem, Inc.

2881 East Bayard Street Ext., Suite A

Seneca Falls, NY 13148

Phone: (800) 453-6777

Fax: (888) 322-5877

www.xyleminc.com/brands/gouldswatertechnology

Goulds is a registered trademark of Goulds Pumps, Inc. and is used under license.

© 2012 Xylem Inc. IM024 Revision Number 6 July 2012

7

Page 8

MANUAL DE INSTRUCCIÓN

IM024

Modelo LC

INSTRUCCIONES DE INSTALACIÓN, FUNCIONAMIENTO Y MANTENIMIENTO

8

Page 9

TEMA PÁGINA

Instrucciones de Seguridad ..........................................................................................................................................10

Notas Importantes .......................................................................................................................................................10

Instalación ...................................................................................................................................................................10

Tubería de Succión ......................................................................................................................................................11

Tubería de Descarga ....................................................................................................................................................11

Rotación ......................................................................................................................................................................11

Operación ...................................................................................................................................................................11

Mantenimiento ............................................................................................................................................................11

Desarmado ..................................................................................................................................................................12

Rearmado ....................................................................................................................................................................12

Cuadro de Identificación de Problemas ........................................................................................................................12

Lista de Partes .............................................................................................................................................................13

Tabla de Aplicación del Sello Mecánico .......................................................................................................................13

Garantía Limitada .......................................................................................................................................................13

Declaración de Conformidad .......................................................................................................................................21

Número de modelo de la bomba:

Número de serie de la bomba:

Representante:

Número telefónico del representante:

Fecha de compra:

Fecha de Instalación:

Lecturas actuales de la puesta en servicio:

1 Ø 3 Ø L1-2 L2-3 L3-1

Amps: Amps:

Voltios: Voltios:

9

Page 10

INSTRUCCIONES DE SEGURIDAD

PARA EVITAR LESIONES PERSONALES GRAVES

O FATALES, Y DAÑOS SIGNIFICATIVOS A LA

PROPIEDAD, LEA Y SIGA TODAS LAS INSTRUCCIONES DE SEGURIDAD QUE SE ENCUENTRAN

EN ESTE MANUAL O EN LA BOMBA.

ESTE MANUAL TIENE LA FUNCIÓN DE ASISTIRLO

EN LA INSTALACIÓN Y OPERACIÓN DE ESTA UNIDAD Y DEBE CONSERVARSE CON LA BOMBA.

Éste es un SÍMBOLO DE ALERTA DE

SEGURIDAD. Cuando vea este símbolo

sobre la bomba o en el manual, localice

una de las siguientes palabras de señalización y esté alerta ante posibles lesiones personales o daños a la propiedad.

PELIGRO

Advierte sobre los peligros que PROVOCARÁN lesiones graves, muerte o daños

significativos a la propiedad.

ADVERTENCIA

Advierte sobre los peligros que

PUEDEN PROVOCAR lesiones graves,

muerte o daños significativos a la propiedad.

PRECAUCIÓN

Advierte sobre los peligros que PROVOCARÁN o PUEDEN PROVOCAR

lesiones o daños a la propiedad.

AVISO: INDICA QUE EXISTEN INSTRUCCIONES

ESPECIALES MUY IMPORTANTES QUE

DEBEN RESPETARSE.

EXAMINE COMPLETAMENTE TODAS LAS INSTRUCCIONES Y ADVERTENCIAS ANTES DE REALIZAR CUALQUIER TRABAJO EN ESTA BOMBA.

CONSERVE TODAS LAS CALCOMANÍAS.

ADVERTENCIA

ESTA UNIDAD NO SE ENCUENTRA

DISEÑADA PARA SER USADA CON

LÍQUIDOS O GASES INFLAMABLES.

ESTOS FLUIDOS PUEDEN ESTAR

PRESENTES EN ÁREAS CONTAMINADAS.

Los fluidos peligrosos

pueden causar

incendios, quemaduras

o la muerte.

DESCRIPCIÓN Y ESPECIFICACIONES

extremo de succión y de acoplamiento cerrado para el

servicio de transferencia general de líquidos, aplicaciones

de unidades reforzadoras, etc. El extremo de líquido es

totalmente de acero inoxidable AISI tipo 304 estampado

y soldado. Los impulsores son del tipo totalmente encerrado y no pueden regularse a diámetros intermedios. Las

carcasas están equipadas con difusores para mejorar la

eficiencia y para aplicar una carga insignificante del eje

radial.

Todas las unidades tienen motores NEMA 48Y o 56Y con

montaje de brida cuadrada y extensión de eje roscado.

1. IMPORTANTE

1.1 Inspeccione la unidad para determinar si está dañada.

Notifique cualquier daño al transportista/agente de

inmediato.

1.2 El suministro eléctrico debe ser un circuito derivado

separado con fusibles o cortacircuitos, tamaños de

alambre, etc. en cumplimiento con los códigos eléc-

tricos nacionales y locales. Instale un desconectador

de todos los circuitos, cerca de la bomba.

PRECAUCIÓN

SIEMPRE DESCONECTE LA CORRIENTE ELÉCTRICA CUANDO MANEJE

LA BOMBA O LOS CONTROLES.

1.3 Los motores deben cablearse para la tensión apro-

piada. El diagrama de cableado del motor está en la

placa del fabricante del motor. El tamaño del alambre

debe limitar la caída máxima de tensión al 10% de

la tensión de la placa del fabricante en los terminales

del motor; de lo contrario se reducirá la vida útil del

motor y disminuirá el rendimiento de la bomba.

1.4 Siempre utilice interruptores, contactadores y ar-

rancadores de potencia nominal.

1.5 Protección del motor:

1.5.1 Unidades monofásicas: A veces la protección

térmica para unidades monofásicas está incorporada (consulte la placa del fabricante). Si no

se proporciona protección incorporada, utilice

un contactador con una sobrecarga apropiada.

Se permite instalar fusibles.

1.5.2 Unidades trifásicas: Proporcione protección

de tres circuitos derivados con arrancador

magnético y sobrecargas térmicas del tamaño

adecuado.

1.6 Límites máximos de operación:

Temperatura del líquido: 220°F (110°C)

Presión de trabajo: 125 lbs./pulg. cuadrada

Arranques por hora: 20, distribuidos

uniformemente.

1.7 La inspección y el mantenimiento regulares aumen-

tarán la vida de servicio. Base la programación en el

tiempo de operación. Consulte la Sección 8.

2. INSTALACIÓN

2.1 Sitúe la bomba lo más cerca posible de la fuente de

líquido (por debajo del nivel de líquido para la operación automática).

2.2 Proteja la bomba contra la congelación o inundación.

2.3 Deje un espacio adecuado para el mantenimiento y la

ventilación.

2.4 Todas las tuberías deben apoyarse independiente-

mente de la bomba y deben “alinearse” naturalmente.

PRECAUCIÓN

EXIONES DE SUCCIÓN Y DE DESCARGA DE LA

BOMBA.

2.5 Evite el uso de accesorios innecesarios. Seleccione los

tamaños para mantener las pérdidas por fricción a un

mínimo.

2.6 Las unidades pueden instalarse horizontales, inclina-

das o verticales.

PRECAUCIÓN

FUGA O CONDENSACIÓN AFECTARÁ EL MOTOR.

NUNCA INSTALE LA TUBERÍA EN

POSICIÓN FORZANDO LAS CON-

NO INSTALAR CON EL MOTOR

DEBAJO DE LA BOMBA. CUALQUIER

10

Page 11

2.7 El cimiento debe ser plano y substancial para elimi-

nar el esfuerzo cuando se aprieten los pernos. Utilice

monturas de caucho para reducir al mínimo el ruido

y la vibración.

2.8 Apriete los pernos de sujeción del motor antes de

conectar las tuberías a la bomba.

3.6 El tamaño de la entrada de la fuente de líquido y la

sumersión mínima sobre la entrada deben ser suficientes para evitar la entrada de aire a través de un

vórtice. Consulte las figuras 1 a 4.

3.7 Aplique tres o cuatro vueltas de cinta de Teflon para

sellar las conexiones roscadas.

3. TUBERÍAS DE SUCCIÓN

3.1 Se desea una elevación de succión estática baja y una

tubería de succión corta y directa. Consulte la curva

de rendimiento de la bomba con respecto a la carga

de succión positiva neta requerida.

3.2 La tubería de succión debe ser al menos del mismo

tamaño que la conexión de succión de la bomba. Un

tamaño más pequeño degradará el rendimiento.

3.3 Si se requiere un tubo más grande, debe instalarse un

reductor de tubo excéntrico (con el lado recto hacia

arriba) en la bomba.

3.4 Instalación con la bomba debajo de la fuente de

suministro:

3.4.1 Instale una válvula de aislamiento de flujo

completo en la tubería para las operaciones de

inspección y mantenimiento.

PRECAUCIÓN

LAR LA BOMBA.

3.5 Instalación con la bomba sobre la fuente de suminis-

tro:

3.5.1 Evite las bolsas de aire. Ninguna parte de la

3.5.2 Todas las juntas deben ser herméticas.

3.5.3 Sólo debe usarse una válvula de aspiración si

3.5.4 El área abierta del colador de succión debe ser

Figura 1 Figura 2

1.5D

mín.

D D

Figura 3 Figura 4

NO UTILICE LA VÁLVULA DE AISLAMIENTO DE SUCCIÓN PARA REGU-

tubería debe estar más alta que la conexión de

succión de la bomba. Incline la tubería hacia

arriba de la fuente de líquido.

es necesario para el cebado o para retener el

cebado en servicio intermitente.

al menos el triple del área del tubo.

3.0D

mín.

H mín.

D mín.

2

H mín.

D

H mín.

H

16

15

14

13

12

11

10

9

8

7

6

5

4

3

2

H = Sumersión mín. en pies

1

1234567891011 12131415 16

V = Velocidad en pies por segundo

= GPM x 0.321

Área

GPM x 0.4085

D

V

2

D

4. TUBERÍAS DE DESCARGA

4.1 Debe incluirse un dispositivo para desconectar la

tubería de descarga cerca de la carcasa para permitir

desmontar la bomba.

4.2 El dispositivo debe incluir una válvula de retención

situada entre una válvula de compuerta y la bomba.

La válvula de compuerta es para regular la capacidad

o para inspeccionar la bomba o la válvula de retención.

4.3 Si se requiere un aumentador, colóquelo entre la

válvula de retención y la bomba.

4.4 Aplique tres o cuatro vueltas de cinta de Teflon para

sellar las conexiones roscadas.

5. ROTACIÓN

5.1 La rotación correcta es hacia la derecha (en el sen-

tido de las agujas del reloj cuando se mira desde el

extremo del motor). Encienda y apague el suministro

eléctrico rápidamente. Observe la rotación del eje.

Para cambiar la rotación:

5.1.1 Motor monofásico: no reversible

5.1.2 Motor trifásico: Intercambie dos conductores

de suministro eléctrico cualesquiera.

6. OPERACIÓN

6.1 Antes de arrancar, la bomba debe cebarse (sin aire y

la tubería de succión debe estar llena de líquido) y la

válvula de descarga debe estar parcialmente abierta.

6.2 Efectúe una revisión completa después de haber

hecho funcionar la unidad en las condiciones de

operación y después que se haya estabilizado la temperatura. Revise para determinar si se ha expandido

la tubería.

7. MANTENIMIENTO

7.1 Los rodamientos están situados en el motor y forman

parte del mismo. Están permanentemente lubricados.

No se requiere engrasar.

PRECAUCIÓN

SE HACE FUNCIONAR SECA, LAS PARTES GIRATORIAS SE AFERRARÁN Y SE DAÑARÁ EL SELLO

MECÁNICO. NO HAGA FUNCIONAR LA UNIDAD

CON UN FLUJO DE CERO O CERCA DE CERO. LA

ENERGÍA APLICADA AL LÍQUIDO SE CONVIERTE

EN CALOR. EL LÍQUIDO PODRÍA VAPORIZARSE

INSTANTÁNEAMENTE. LAS PARTES GIRATORIAS

REQUIEREN LÍQUIDO PARA EVITAR LAS RAYADURAS O AFERRAMIENTO.

EL LÍQUIDO BOMBEADO PROPORCIONA LUBRICACIÓN. SI LA BOMBA

11

Page 12

8. DESARMADO

8.1 Se describirá el desmontaje completo de la unidad.

Desmonte sólo lo necesario para realizar el trabajo de

mantenimiento requerido.

8.1.1 Apague la unidad.

8.1.2 Drene el sistema y enjuáguelo si es necesario.

8.1.3 Desconecte el tubo de descarga de la bomba.

8.1.4 Quite los pernos de sujeción del motor.

8.2 Desmontaje del extremo del líquido

8.2.1 Quite los tornillos y pernos de la carcasa.

8.2.2 Retire el conjunto de desmontaje trasero de la

carcasa.

8.2.3 Retire la tapa del difusor de la primera etapa y

el anillo en O de la carcasa.

8.2.4 Retire la tapa del ventilador del motor para de-

jar al descubierto las secciones planas o ranura

para la llave en el extremo del eje.

8.2.5 Sujete el eje en las secciones planas para resistir

la rotación y retire la tuerca y arandela del

impulsor.

PRECAUCIÓN

DOR PARA EVITAR LA ROTACIÓN.

NOTA: Note la ubicación de las lengüetas antirrotación

y los orificios en los artículos 10, 11, 12 y 13; estos

deben alinearse y engancharse para el rearmado.

8.2.6 Retire el impulsor de la primera etapa, espacia-

8.2.7 Retire el impulsor de la última etapa y el difu-

NOTA: El desmontaje adicional requerirá retirar el sello

mecánico. Se recomienda instalar un nuevo sello

mecánico al reensamblar.

8.2.8 Lubrique el eje con una solución 50/50 de glic-

8.2.9 Retire el cuerpo de la bomba y el conjunto del

8.2.10 Retire la parte estacionaria del sello mecánico

8.2.11 Retire el adaptador para el motor del cuerpo

8.2.12 Para retirar el eje de la bomba del motor debe

NO INSERTE UN DESTORNILLADOR

ENTRE LAS PALETAS DEL VENTILA-

dor del impulsor, difusor intermedio y la tapa

del difusor de la última etapa.

sor de la última etapa.

erina y agua. Retire la parte mecánica del sello

mecánico.

adaptador para el motor del motor.

del cuerpo de la bomba.

de la bomba.

aplicarse calor al eje de la bomba en el diámetro más grande. Esto es necesario para desprender la adherencia del compuesto Loctite

#271 entre los ejes de la bomba y del motor.

9. REARMADO

9.1 Deben limpiarse todas las partes antes del reensamb-

laje.

9.2 Consulte la lista de partes para identificar los artícu-

los de reemplazo requeridos. Especifique el número

de índice o de catálogo cuando ordene partes.

9.3 Reensamble en el orden inverso del desmontaje.

12

Observe lo siguiente cuando reensamble la bomba:

9.4 Verifique la deflexión del eje. El valor máximo per-

mitido es 0.010 pulg. TIR (lectura total del indicador) en el extremo del eje.

9.5 Aplique Loctite ‘Primer N’ y Loctite #271 al eje del

motor, atornille el eje de la bomba en posición y

torsione a 30 lbs.

9.6 Lubrique el eje de la bomba y el portaasiento esta-

cionario del cuerpo de la bomba con una solución

50/50 de glicerina y agua antes de la instalación de

los componentes del sello mecánico.

9.7 Inspeccione el anillo en O de la carcasa y los anillos

en O del impulsor para determinar si están dañados o

gastados y reemplácelos si es necesario.

9.8 Los anillos en O pueden lubricarse con una solución

de glicerina y agua o gelatina de petróleo para facilitar el montaje.

9.9 Apriete los tornillos de la carcasa a una torsión de 10

lb.-pies en una configuración de estrella para evitar el

atascamiento de los anillos en O.

10. CUADRO DE IDENTIFICACIÓN

DE PROBLEMAS

EL MOTOR NO ESTÁ FUNCIONANDO

(Ver las causas 1 a 6)

SE ENTREGA POCO O NADA DE LÍQUIDO

(Ver las causas 7 a 17)

EL CONSUMO DE ELECTRICIDAD ES DEMASIADO ALTO

(Ver las causas 4, 17, 18, 19, 22)

RUIDO Y VIBRACIÓN EXCESIVOS

(Ver las causas 4, 6, 9, 13, 15, 16, 18, 20, 21, 22)

CAUSA PROBABLE

1. Protector térmico disparado

2. Cortacircuitos abierto

3. Fusible quemado

4. Roce de las partes giratorias

5. Cableado incorrecto del motor

6. Motor defectuoso

7. Falta de cebado

8. Descarga bloqueada o válvula cerrada

9. Rotación incorrecta

10. Válvula de aspiración demasiado pequeña, la succión

no está sumergida, el filtro de entrada está tapado

11. Baja tensión

12. Pérdida de fase (unidades trifásicas únicamente)

13. Aire o gases en el líquido

14. Carga del sistema demasiado alta

15. Carga de succión positiva neta disponible (NPSHA)

demasiado baja:

Elevación de succión demasiado alta o pérdidas de

succión excesivas

Revise con un indicador de vacío

16. Impulsor gastado o taponado

17. Diámetro incorrecto del impulsor

18. Carga demasiado baja, produciendo una velocidad de

flujo excesiva

19. Viscosidad o peso específico del fluido demasiado alto

20. Cojinetes gastados

21. Bomba o tubería suelta

22. Bomba y motor desalineados

Page 13

LISTA DE PARTES

Artículo N°. Descripción Materiales

1 Tornillo, de la carcasa Acero inox. 304

2 Carcasa de la bomba, extremo de succión Acero inox. 304

Viton

3 Anillo en O, de la carcasa EPR opcional

BUNA opcional

4 Tapa del difusor, primera etapa Acero inox. 304

Viton

5 Anillo en O, del impulsor EPR opcional

BUNA opcional

6 Tuerca del impulsor Acero inox. 304

7 Arandela de seguridad del impulsor Acero inox. 400

8 Impulsor Acero inox. 304

9 Espaciador del impulsor Acero inox. 304

10 Difusor, intermedio Acero inox. 304

11 Difusor, tapa, última etapa Acero inox. 304

12 Difusor, última etapa Acero inox. 304

TABLA DE APLICACIÓN DEL SELLO MECÁNICO

Giratorio Estacionario Elastómero Partes de metal Nº de parte

Carburo de silicio Viton

Carburo de silicio

Carbón Carburo de silicio EPR 10K89

Cerámica

Carbón

10K92

Acero

inoxidable

10K88

316

10K87

Artículo N°. Descripción Materiales

13 Sello mecánico Varía

14 Tapón de llenado y drenaje Acero inox. 304

15 Anillo en O, tapón de llenado y drenaje Viton

16 Cuerpo de la bomba con tapón Acero inox. 304

17 Adaptador para el motor Hierro fundido

18 Contratuerca, adaptador para el motor a la bomba Acero

19 Eje, de la bomba Acero inox. 304

20 Chaveta, del impulsor Acero inox. 304

21 Soporte, de la bomba Acero

22 Espaciador Caucho

23 Tornillo, adaptador para el motor a la bomba Acero

Motor, trifásico, ODP

Motor, monofásico, abierto resguardado, ODP Acero inox.

24

Motor, trifásico, TEFC 303

Motor, monofásico, TEFC

25 Tuerca, tornillo de la carcasa Acero inox. 304

ODP = abierto resguardado

TEFC = totalmente encerrado y enfriado con ventilador

23

20

19

14

24

13

15

10

8

4

2

1

6

9

7

5

3

5

11

12

8

25

16

15

14

18

17

22

21

13

Page 14

GARANTÍA LIMITADA DE GOULDS WATER TECHNOLOGY

Esta garantía es aplicable a todas las bombas para sistemas de agua fabricadas por Goulds Water Technology.

Toda parte o partes que resulten defectuosas dentro del período de garantía serán reemplazadas sin cargo para el comerciante durante dicho período de garantía. Tal período de

garantía se extiende por doce (12) meses a partir de la fecha de instalación, o dieciocho (18) meses a partir de la fecha de fabricación, cualquiera se cumpla primero.

Todo comerciante que considere que existe lugar a un reclamo de garantía deberá ponerse en contacto con el distribuidor autorizado de Goulds Water Technology del

cual adquiriera la bomba, y ofrecer información detallada con respecto al reclamo. El distribuidor está autorizado a liquidar todos los reclamos por garantía a través del

Departamento de Servicios a Clientes de Goulds Water Technology.

La presente garantía excluye:

(a) La mano de obra, el transporte y los costos relacionados en los que incurra el comerciante;

(b) los costos de reinstalación del equipo reparado;

(c) los costos de reinstalación del equipo reemplazado;

(d) daños emergentes de cualquier naturaleza; y

(e) el reembolso de cualquier pérdida causada por la interrupción del servicio.

A los fines de esta garantía, los términos “Distribuidor”, “Comerciante” y “Cliente” se definen como sigue:

(1) “Distribuidor” es aquel individuo, sociedad, corporación, asociación u otra entidad jurídica que opera entre Goulds Water Technology y el comerciante para la compra,

consignación o contratos de venta de las bombas en cuestión.

(2) “Comerciante” es todo individuo, sociedad, corporación, asociación u otra entidad jurídica que realiza negocios de venta o alquiler-venta (leasing) de bombas a clientes.

(3) “Cliente” es toda entidad que compra o que adquiere bajo la modalidad de leasing las bombas en cuestión de un comerciante. El término “cliente” puede significar un

individuo, una sociedad, una corporación, una sociedad de responsabilidad limitada, una asociación o cualquier otra entidad jurídica con actividades en cualquier tipo de

negocios.

LA PRESENTE GARANTÍA SE EXTIENDE AL COMERCIANTE ÚNICAMENTE

Xylem, Inc.

2881 East Bayard Street Ext., Suite A

Seneca Falls, NY 13148

Teléfono: (800) 453-6777

Fax: (888) 322-5877

www.xyleminc.com/brands/gouldswatertechnology

Goulds es una marca registrada de Goulds Pumps, Inc. y se utiliza bajo licencia.

© 2012 Xylem Inc. IM024 Revisión Número 6 Julio 2012

Page 15

MANUEL D'UTILISATION

IM024

Modèle LC

DIRECTIVES D’INSTALLATION, D’UTILISATION ET D’ENTRETIEN

Page 16

SUJET PAGE

Consignes de Sécurité .................................................................................................................................................. 17

Informations Importantes ............................................................................................................................................ 17

Installation .................................................................................................................................................................. 17

Tuyauterie D'aspiration ................................................................................................................................................ 18

Tuyauterie de Refoulement .......................................................................................................................................... 18

Rotation ...................................................................................................................................................................... 18

Utilisation .................................................................................................................................................................... 18

Entretien ..................................................................................................................................................................... 18

Démontage .................................................................................................................................................................. 19

Remontage .................................................................................................................................................................. 19

Diagnostic des Anomalies ............................................................................................................................................ 19

Liste de Pièces ............................................................................................................................................................. 20

Table des Garnitures (Joints) Mécaniques .................................................................................................................... 20

Garantie Limitée..........................................................................................................................................................20

Déclaration de Conformité .......................................................................................................................................... 21

Informations pour le propriétaire

Numéro de modèle de la pompe :

Numéro de série de la pompe :

Détaillant :

Nº de téléphone du détaillant :

Date d’achat :

Date d’installation :

Courant mesuré au démarrage :

1 Ø 3 Ø L1-2 L2-3 L3-1

A : A :

V : V :

16

Page 17

CONSIGNES DE SÉCURITÉ

DANGER

AVERTISSEMENT

AVERTISSEMENT

Les fluides dangereux

peuvent causer un

incendie, des brûlures

ou la mort.

AFIN DE PRÉVENIR LES BLESSURES GRAVES OU

MORTELLES ET LES DOMMAGES MATÉRIELS

IMPORTANTS, LIRE ET SUIVRE TOUTES LES

CONSIGNES DE SÉCURITÉ FIGURANT DANS LE

MANUEL ET SUR LA POMPE.

LE PRÉSENT MANUEL A POUR BUT DE FACILITER

L’INSTALLATION ET L’UTILISATION DE LA POMPE ET DOIT RESTER PRÈS DE CELLE-CI.

Le symbole ci-contre est un SYMBOLE

DE SÉCURITÉ employé pour signaler

les mots-indicateurs dont on trouvera la

description ci-dessous. Sa présence sert à

attirer l’attention afin d’éviter les blessures

et les dommages matériels.

Prévient des risques qui VONT causer

des blessures graves, la mort ou des

dommages matériels importants.

Prévient des risques qui PEUVENT

causer des blessures graves, la mort ou

des dommages matériels importants.

ATTENTION

AVIS : SERT À ÉNONCER LES DIRECTIVES

SPÉCIALES DE GRANDE IMPORTANCE

QUE L’ON DOIT SUIVRE.

LIRE SOIGNEUSEMENT CHAQUE DIRECTIVE ET

AVERTISSEMENT AVANT D’EFFECTUER TOUT

TRAVAIL SUR LA POMPE.

N’ENLEVER AUCUN AUTOCOLLANT DE SÉCURITÉ.

Prévient des risques qui PEUVENT causer

des blessures ou des dommages matériels.

APPAREIL NON CONÇU POUR LES

LIQUIDES DANGEREUX NI POUR

LES GAZ INFLAMMABLES. CES

FLUIDES POURRAIENT ÊTRE PRÉSENTS DANS LES INSTALLATIONS

DE CONFINEMENT (PUITS COLLECTEURS).

l’électricité. Poser un sectionneur tout conducteur

près de la pompe.

ATTENTION

ON DOIT TOUJOURS COUPER LE

COURANT LORSQUE L’ON EFFECTUE

QUELQUE TRAVAIL QUE CE SOIT SUR LA POMPE

OU LES COMMANDES.

1.3. Le câblage d’alimentation du moteur doit convenir à

la tension de fonctionnement. Le schéma de câblage

se trouve sur la plaque signalétique du moteur. Les

fils doivent avoir un calibre limitant la chute de tension maximale, aux bornes du moteur, à 10 % de la

valeur de tension indiquée sur la plaque signalétique,

sinon la durée de vie du moteur et les performances

de la pompe diminueront.

1.4. Il faut toujours employer des contacteurs et des

démarreurs de puissance nominale en horse-power

(hp).

1.5. Protection du moteur

1.5.1. Moteurs monophasés – Ces moteurs sont

parfois munis d’une protection thermique intégrée (voir la plaque signalétique). Dans le cas

contraire, utiliser un contacteur à protection

appropriée contre les surcharges. Les dispositifs fusibles sont admissibles.

1.5.2. Moteurs triphasés – Employer une protec-

tion trois conducteurs appropriée contre les

surcharges thermiques ainsi qu’un démarreur

magnétique convenant à la charge électrique.

1.6. Limites d’utilisation maximales

Température du liquide : 110 °C (220 °F)

Pression : 125 lb/po

2

Démarrages par heure : 20, répartis uniformément

1.7. Une inspection et un entretien réguliers augment-

eront la durée de vie de l’appareil. Établir un programme d’entretien et d’inspection basé sur le temps

de fonctionnement. Voir la section 8.

DESCRIPTION et CARACTÉRISTIQUES

Le modèle LC est une pompe centrifuge à deux étages

formant un groupe monobloc (montée sur moteur), à

aspiration en bout, servant au transfert de liquides de

nature générale, à l’augmentation de pression, etc. La tête

de pompage est tout en inox AISI de type 304 estampé et

soudé. Les roues sont fermées et ne peuvent être réduites

à un diamètre intermédiaire. Le corps de pompe est muni

de diffuseurs pour améliorer le rendement et rendre la

charge radiale de l’arbre négligeable.

La LC est dotée d’un moteur conforme aux normes

NEMA 48Y et 56Y, muni d’une bride de fixation carrée

et d’un arbre-rallonge fileté.

1. INFORMATIONS IMPORTANTES

1.1. Inspecter l’appareil et signaler immédiatement tout

1.2. L’alimentation électrique doit être assurée par un

dommage au transporteur ou au détaillant.

circuit de dérivation distinct dont les fusibles ou les

disjoncteurs, le calibre des fils, etc. sont conformes

aux prescriptions du code provincial ou national de

2. INSTALLATION

2.1. Placer la pompe aussi près de la source de liquide

que possible (au-dessous du niveau du liquide pour

qu’elle fonctionne automatiquement).

2.2. Protéger l’appareil contre les inondations et le gel.

2.3. Prévoir assez d’espace autour de la pompe pour

l’entretien et l’aération.

2.4. La tuyauterie doit posséder ses propres supports et

« être alignée » sans contraintes sur la pompe.

ATTENTION

PLIQUER DE CONTRAINTES SUR LES RACCORDS

D’ASPIRATION ET DE REFOULEMENT DE LA

POMPE.

2.5. Ne poser aucun accessoire ni raccord de tuyauterie

superflus. Choisir le calibre approprié pour réduire

les pertes de charge au minimum.

2.6. Les pompes peuvent être installées à l’horizontale, à

la verticale ou sur une surface inclinée.

LA TUYAUTERIE DOIT ÊTRE PO-

SÉE DE FAÇON À NE JAMAIS AP-

17

Page 18

ATTENTION

NE PAS PLACER LE MOTEUR PLUS

BAS QUE LA POMPE AFIN DE LE PROTÉGER CONTRE LES FUITES ET L’EAU DE CONDENSATION.

2.7. On doit fixer l’appareil à une dalle plane et solide

pour empêcher que le serrage des boulons ne cause

de contraintes. Monter l’appareil sur caoutchouc

pour réduire le bruit et les vibrations au minimum.

2.8. Serrer les boulons de fixation du moteur avant de

raccorder la tuyauterie à la pompe.

3. TUYAUTERIE D’ASPIRATION

3.1. Une hauteur géométrique d’aspiration réduite et

une tuyauterie directe et courte sont souhaitables.

Consulter la courbe de performances de la pompe

pour obtenir la hauteur nette d’aspiration requise

(NPSHR).

3.2. Le calibre du tuyau d’aspiration doit être au moins

égal à celui du raccord d’aspiration de la pompe

pour éviter les pertes de performances.

3.3. S’il faut un tuyau plus gros, on doit installer un

raccord réducteur excentré (le côté non oblique en

haut) à la pompe.

3.4. Pompe placée plus bas que la source de liquide :

3.4.1. Poser un robinet d’isolement à passage intégral

sur le tuyau d’aspiration pour l’inspection et

l’entretien.

ATTENTION

SECTION DE PASSAGE VERS LA POMPE.

3.5. Pompe placée plus haut que la source de liquide :

3.5.1. Afin de prévenir les poches d’air, aucun élé-

3.5.2. Chaque joint doit être étanche.

3.5.3. On n’emploiera un clapet de pied que s’il est

Figure 1 Figure 2

1,5d

min.

Figure 3 Figure 4

18

NE PAS EMPLOYER LE ROBINET

D’ISOLEMENT POUR RÉDUIRE LA

ment de la tuyauterie d’aspiration ne devrait

être plus haut que le raccord d’aspiration de la

pompe. Donner à la tuyauterie une inclinaison

vers le haut à partir de la source de liquide.

requis pour amorcer la pompe ou la maintenir

amorcée pendant les arrêts.

3,0d

min.

h min.

d min.

d d

2

h min.

d

h min.

d

h

16

15

14

13

12

11

10

9

8

7

6

5

4

3

2

1

h = hauteur d’immersion minimale (pi)

1234567891011 12131415 16

v = vitesse d’écoulement (pi/s)

= gal US/min x 0,321

section de passage

gal US/min x 0,408 5

d

2

3.5.4. La section de passage de la crépine du tuyau

d’aspiration doit être au moins le triple de

celle du tuyau.

3.6. Le diamètre (d) et la hauteur d’immersion minimale

(h min.) de l’entrée du tuyau d’aspiration doivent

être suffisants pour empêcher l’aspiration d’air par

vortex (v. fig. 1 à 4).

3.7. Enrouler les raccords filetés de 3 ou 4 couches de

ruban de téflon pour les étancher.

4. TUYAUTERIE DE REFOULEMENT

4.1. Prévoir assez d’espace près du corps de pompe pour

pouvoir déconnecter le tuyau de refoulement et

démonter la pompe.

4.2. L’installation doit comporter un robinet-vanne, ainsi

qu’un clapet de non-retour placé entre le robinetvanne et la pompe. Le robinet-vanne sert au réglage

du débit et à l’inspection de la pompe et du clapet de

non-retour.

4.3. Si un raccord agrandisseur est nécessaire, le poser

entre le clapet de non-retour et la pompe.

4.4. Enrouler les raccords filetés de 3 ou 4 couches de

ruban de téflon pour les étancher.

5. SENS DE ROTATION

5.1. La rotation appropriée est en sens horaire (vers la

droite, vue de l’extrémité du moteur). Démarrer et

arrêter la pompe immédiatement tout en observant

le sens de rotation de l’arbre. Changer le sens de

rotation comme suit.

5.1.1. Moteur monophasé : irréversible.

5.1.2. Moteur triphasé : intervertir deux conducteurs

d’alimentation du moteur.

6. UTILISATION

6.1. Avant de mettre la pompe en service, on doit

l’amorcer (pour en chasser l’air), remplir de liquide

le tuyau d’aspiration et entrouvrir le robinet de

refoulement.

6.2. Faire fonctionner l’appareil dans des conditions nor-

males jusqu’à ce que sa température se stabilise, puis

vérifier tout le système. Vérifier également la dilatation de la tuyauterie.

7. ENTRETIEN

7.1. Les roulements sont situés à l’intérieur du moteur et

sont lubrifiés à vie. Aucun graissage n’est requis.

ATTENTION

À SEC, LES PIÈCES MOBILES GRIPPERAIENT, ET LA

GARNITURE MÉCANIQUE S’ENDOMMAGERAIT. IL

NE FAUT DONC PAS FAIRE MARCHER LA POMPE

LORSQUE SON DÉBIT EST NUL OU PRESQUE, CAR

LE PEU DE LIQUIDE S’Y TROUVANT ABSORBERAIT

LA CHALEUR PRODUITE PAR FROTTEMENT ET

v

POURRAIT SE CHANGER RAPIDEMENT EN VAPEUR. LES PIÈCES MOBILES DOIVENT ÊTRE LUBRIFIÉES PAR LE LIQUIDE POUR NE PAS S’ABÎMER NI

GRIPPER.

LES LIQUIDES POMPÉS SERVENT DE

LUBRIFIANT. SI LA POMPE TOURNAIT

Page 19

8. DÉMONTAGE

8.1. Le démontage complet de la pompe est décrit ci-

dessous. Ne démonter que ce qui permet de faire

l’entretien requis.

8.1.1. Couper le courant.

8.1.2. Vidanger le système. Le rincer au besoin.

8.1.3. Séparer le tuyau de refoulement d’avec la

pompe.

8.1.4. Enlever les boulons de fixation du moteur.

8.2. Tête de pompage

8.2.1. Enlever les vis et les écrous assujettissant les

demi-corps de pompe.

8.2.2. Écarter l’ensemble d’entraînement de la roue

d’avec le demi-corps de pompe, côté aspiration.

8.2.3. Enlever le couvercle du diffuseur du premier

étage et le joint torique des demi-corps de

pompe.

8.2.4. Ôter le couvercle de ventilateur du moteur

pour accéder aux méplats ou à la fente de

blocage de l’arbre, à l’extrémité de celui-ci.

8.2.5. Bloquer l’arbre, puis enlever l’écrou de

blocage des roues et la rondelle-frein.

9.3. Le remontage se fait dans l’ordre inverse du démon-

tage.

Suivre les directives ci-dessous en remontant la pompe :

9.4. Vérifier si l’arbre comporte un faux-rond : le maxi-

mum admissible est de 0,010 po au bout de l’arbre.

9.5. Enduire le bout de l’arbre de moteur d’apprêt Loc-

tite « Primer N », puis de Loctite no 271, visser

l’arbre de pompe à l’arbre de moteur et le serrer à 30

lbf·pi.

9.6. Avant de poser la garniture mécanique, lubrifier

l’arbre de pompe et le logement de garniture, au

centre du demi-corps de pompe, avec une solution

contenant moitié glycérine et moitié eau.

9.7. Inspecter le joint torique des demi-corps de pompe

et les joints toriques des roues. Les remplacer s’ils

sont endommagés ou usés.

9.8. On peut enduire les joints toriques de pétrolatum

(vaseline) ou d’une solution de glycérine et d’eau

pour en faciliter la pose.

9.9. Poser et serrer les vis des demi-corps de pompe à 10

lbf·pi, en croix, pour éviter toute déformation excessive du joint torique.

ATTENTION

POUR EMPÊCHER L’ARBRE DE TOURNER.

NOTA : Remarquer la position des pattes et des crans

antirotation des articles 10 à 13, car il faut les aligner

et les insérer correctement pour les remonter.

8.2.6. Enlever la roue du premier étage, son en-

8.2.7. Déposer la roue du second étage et son dif-

NOTA : Un démontage plus poussé nécessitera la dépose

de la garniture mécanique, qu’il est recommandé de

remplacer alors par une neuve.

8.2.8. Lubrifier l’arbre avec une solution conten-

8.2.9. Déposer l’ensemble adaptateur de moteur et

8.2.10. Extraire du demi-corps de pompe l’élément

8.2.11. Séparer l’adaptateur de moteur d’avec le

8.2.12. Pour enlever l’arbre de pompe, on doit le

NE PAS INSÉRER DE TOURNEVIS

ENTRE LES PALES DU VENTILATEUR

tretoise, son diffuseur et le couvercle du diffuseur du second étage.

fuseur.

ant moitié glycérine et moitié eau, puis ôter

l’élément mobile de la garniture mécanique.

demi-corps de pompe, côté refoulement.

fixe de la garniture mécanique.

demi-corps de pompe.

chauffer dans sa partie la plus épaisse afin

d’éliminer l’adhérence du Loctite no 271, puis

le dévisser de l’arbre de moteur.

9. REMONTAGE

9.1. Chaque pièce devrait être nettoyée avant le remontage.

9.2. Voir la liste de pièces pour déterminer les pièces de

rechange requises. Préciser le numéro de pièce ou de

catalogue de la pompe lorsque l’on commande des

pièces.

10. DIAGNOSTIC DES ANOMALIES

NON-FONCTIONNEMENT DU MOTEUR

(V. causes probables 1 à 6)

DÉBIT DE LIQUIDE FAIBLE OU NUL

(V. causes probables 7 à 17)

CONSOMMATION D’ÉNERGIE EXCESSIVE

(V. causes probables 4, 17, 18, 19 et 22)

VIBRATION ET BRUIT EXCESSIFS

(V. causes probables 4, 6, 9, 13, 15, 16, 18, 20, 21 et 22)

CAUSE PROBABLE

1. Protecteur thermique déclenché

2. Disjoncteur ouvert

3. Fusible sauté

4. Pièces mobiles grippées

5. Moteur mal connecté

6. Moteur défectueux

7. Pompe non amorcée

8. Tuyau de refoulement obstrué ou robinet fermé

9. Mauvais sens de rotation

10. Clapet de pied trop petit, entrée de tuyau

d’aspiration non immergée, crépine obstruée

11. Basse tension électrique

12. Perte de phase (moteurs triphasés seulement)

13. Présence d’air ou de gaz dans le liquide

14. Hauteur de charge du système trop élevée

15. Hauteur nette d’aspiration disponible (NPSHA) trop

faible : hauteur ou perte d’aspiration excessives – à

vérifier avec un vacuomètre

16. Roue(s) usée(s) ou engorgée(s)

17. Diamètre de roue inapproprié

18. Hauteur de charge trop faible : débit excessif

19. Viscosité ou densité trop élevées

20. Roulement(s) usé(s)

21. Pompe ou tuyauterie mal assujetties

22. Pompe et moteur désalignés

19

Page 20

LISTE DE PIÈCES

No d’art. Description Matériau

1 Vis (demi-corps de pompe) Inox 304

2 Demi-corps de pompe, côté aspiration Inox 304

Viton

3 Joint torique (demi-corps de pompe) Éthyl.-propyl. (option)

Buna (option)

4 Couvercle du diffuseur (1er étage) Inox 304

Viton

5 Joints toriques (roues) Éthyl.-propyl. (option)

Buna (option)

6 Écrou de blocage (roues) Inox 304

7 Rondelle-frein (roues) Inox 400

8 Roues Inox 304

9 Entretoise (roues) Inox 304

10 Diffuseur (1er étage) Inox 304

11 Couvercle du diffuseur (2e étage) Inox 304

12 Diffuseur (2e étage) Inox 304

TABLE DES GARNITURES MÉCANIQUES

Élément mobile Élément fixe Élastomère Métal No de pièce

Carbure de silicium Viton 10K87

Carbure de silicium

Carbone Carbure de silicium Éthyl.-propyl. 10K89

Céramique 10K92

Carbone

Inox 316

10K88

No d’art. Description Matériau

13 Garniture mécanique Voir Table...

14 Bouchons (remplissage et vidange) Inox 304

15 Joints toriques (bouchons) Viton

16 Demi-corps de pompe, côté refoulement Inox 304

17 Adaptateur de moteur Fonte

Écrou autofreiné de blocage

18

(pompe-adaptateur de moteur)

19 Arbre de pompe Inox 304

20 Clavette (roues) Inox 304

21 Plaque-support (moteur) Acier

22 Entretoise Caoutchouc

23 Vis (moteur-adaptateur de moteur) Acier

Moteur, 3 PH, abrité➀

Moteur, 1 PH, abrité

24

Moteur, 3 PH, fermé autoventilé

Moteur, 1 PH, fermé autoventilé

25 Écrous (demi-corps de pompe) Inox 304

➀

abrité = à ouvertures de ventilation protégées

Acier

Inox 303

23

20

19

14

24

13

15

10

8

4

2

1

6

9

7

5

3

5

11

12

8

25

16

15

14

18

17

22

21

20

Page 21

Declaration of Conformity

Declaration of Conformity

We at,

Goulds Water Technology/Xylem Inc.

1 Goulds Drive

Auburn, NY 13021

Declare that the following products: NPE, MCS, MCC, 3656, 3656 SP, GB, e-SV, SVI, NPO, Prime Line

SP, HB, HMS, LC, NPV, LB, LBS comply with Machine Directive 06/42/EC. This equipment is intended

to be incorporated with machinery covered by this directive, but must not be put into service until the

machinery into which it is to be incorporated has been declared in conformity with the actual provisions

of the directive.

Declaración de Conformidad

Declaración de Conformidad

Nosotros en

Goulds Water Technology/Xylem Inc.

1 Goulds Drive

Auburn, NY 13021

Declaramos que los siguientes productos: NPE, MCS, MCC, 3656, 3656 SP, GB, e-SV, SVI, NPO, Prime

Line SP, HB, HMS, LC, NPV, LB, LBS cumplen con las Directivas para Maquinarias 06/42/EC. Este

equipo ha sido diseñado para ser incorporado a la maquinaria cubierta por esta directiva pero no debe

ponerse en funcionamiento hasta que se declare que la maquinaria en la que será incorporado cumple

con las disposiciones reales de la directiva.

Déclaration de Conformité

Déclaration de Conformité

Nous, à

Goulds Water Technology/Xylem Inc.

1 Goulds Drive

Auburn, NY, U.S.A. 13021,

déclarons que les produits NPE, MCS, MCC, 3656, 3656 SP, GB, e-SV, SVI, NPO, Prime Line SP, HB,

HMS, LC, NPV, LB et LBS sont conformes à la directive 06/42/EC (législation relative aux machines). Ils

sont destinés à être intégrés dans la machinerie faisant l’objet de ladite directive, mais ne doivent pas être

mis en service tant que la machinerie en question ne sera pas déclarée conforme aux stipulations de la

directive.

21

Page 22

NOTES/NOTAS

22

Page 23

NOTES/NOTAS

23

Page 24

GARANTIE LIMITÉE DE GOULDS WATER TECHNOLOGY

La présente garantie s’applique à chaque pompe de système d’alimentation en eau fabriquée par Goulds Water Technology.

Toute pièce se révélant défectueuse durant la période de garantie sera remplacée sans frais pour le détaillant durant ladite période, qui dure douze (12) mois à compter de la

date d’installation ou dix-huit (18) mois à partir de la date de fabrication, soit la période qui expirera la première.

Le détaillant qui, aux termes de cette garantie, désire effectuer une demande de règlement doit s’adresser au distributeur Goulds Water Technology agréé chez lequel la pompe

a été achetée et fournir tous les détails à l’appui de sa demande. Le distributeur est autorisé à régler toute demande par le biais du service à la clientèle de Goulds Water

Technology.

La garantie ne couvre pas :

a) les frais de main-d’oeuvre ou de transport ni les frais connexes encourus par le détaillant ;

b) les frais de réinstallation de l’équipement réparé ;

c) les frais de réinstallation de l’équipement de remplacement ;

d) les dommages indirects de quelque nature que ce soit ;

e) ni les pertes découlant de la panne.

Aux fins de la présente garantie, les termes ci-dessous sont définis comme suit :

1) «Distributeur» signifie une personne, une société de personnes, une société de capitaux, une association ou autre entité juridique servant d’intermédiaire entre Goulds

Water Technology et le détaillant pour les achats, les consignations ou les contrats de vente des pompes en question.

2) «Détaillant» veut dire une personne, une société de personnes, une société de capitaux, une association ou autre entité juridique dont les activités commerciales sont la

vente ou la location de pompes à des clients.

3) «Client» signifie une entité qui achète ou loue les pompes en question chez un détaillant. Un «client» peut être une personne, une société de personnes, une société de

capitaux, une société à responsabilité limitée, une association ou autre entité juridique se livrant à quelque activité que ce soit.

CETTE GARANTIE SE RAPPORTE AU DÉTAILLANT SEULEMENT.

24

Xylem, Inc.

2881 East Bayard Street Ext., Suite A

Seneca Falls, NY 13148

Téléphone: (800) 453-6777

Télécopie: (888) 322-5877

www.xyleminc.com/brands/gouldswatertechnology

Goulds est une marque déposée de Goulds Pumps, Inc. et est utilisé sous le permis.

© 2012, Xylem Inc. IM024 Révision numéro 6 Juillet 2012

Loading...

Loading...