Page 1

INSTRUCTION MANUAL

IM023

Model 45HB-70HB

MULTI-STAGE CENTRIFUGAL BOOSTER PUMP

INSTALLATION, OPERATION AND TROUBLESHOOTING MANUAL

Page 2

GENERAL INFORMATION

GENERAL INFORMATION

Models 45HB and 70HB are multi-stage, high-pressure,

general-purpose centrifugal booster pumps, using enclosed impellers. Applicable for clear, non-hazardous

liquids in general industrial services up to 180°F (82°C).

Particularly suited for high-pressure booster services.

All models are close-coupled to electric motors containing prelubricated bearings designed for continuous service. Threaded shaft extension is protected by a stainless

steel sleeve/coupling combination.

All models are equipped with single, unbalanced mechanical shaft seals.

Units are shipped completely assembled and ready for

installation.

IMPORTANT

IMPORTANT

1. Inspect unit for shipping damage.

2. Read all instructions carefully.

3. ALWAYS disconnect all electrical power when handling pump, motor, or controls.

4. Do not run unit dry or against a closed discharge.

This will result in damage to mechanical seal and

pump.

5. Never pump hazardous liquids or solvents.

6. Maximum liquid temperature: 180°F (82°C).

7. Maximum inlet pressure: 100 PSI.

INSTALLATION

INSTALLATION

Location: Locate pump as near the liquid source as prac-

tical. Allow adequate room for servicing and ventilation.

Protect the unit from cold weather freezing and water

damage due to rain or flooding. Pump may be mounted

horizontal; or vertical with motor on top provided a

drip-shield is used for motor protection.

Foundation: Foundation surface must be flat so there is

no distortion and/or strain developed when tightening

the foundation bolts. CAUTION: Bolting and/or piping

must not put strain on liquid end. The pumps are quiet

and smooth running, but rubber mounting is recommended on foundations susceptible to sound effect.

Alignment: No filed alignment is necessary as pumps are

close-coupled.

Piping: Suction pipe must be at least equal in size to

suction connection of pump and provide positive suction head (intake pressure) to the pump. Avoid using the

pump for applications requiring suction lift. Never use a

gate valve in the suction line to throttle the pump. CAUTION: Piping must not put strain on the liquid end.

Wiring: Electrical power supply must be a separate

branch circuit equipped with proper starters, fuses or

circuit breakers, wire size, etc., conforming to National

Electrical Code plus local codes. Power supply voltage,

phase and controls must match motor nameplate requirements. Low voltage and phase-loss (3 phase) protection is

recommended.

Motors: Single-phase 3 HP motors are dual voltage

115/230 volts, 60 Hz, A.C. Single-phase 5 HP motors are

230 volts, 60 Hz, A.C. All other motors are three-phase,

dual voltage 230/460 volts, 60 Hz, A.C. The higher voltages are recommended where available.

Rotation: Three-phase rotation must be checked at installation my momentarily energizing the completely filled

pump and observing the rotation. Rotation is clockwise

looking into the motor shaft, end-bell side (remove protective cap to observe shaft). Rotation must correspond

to rotation arrow. Rotation of three-phase units can be

reversed by interchanging any two (2) electrical power

leads. CAUTION: Do Not run in reverse rotation or

damage will result.

OPERATION

OPERATION

Fill suction line and pump with liquid to be pumped to

insure mechanical seal will not run dry. With pump and

suction line completely filled, and motor properly wired,

the unit may be started. Be sure pump is not started

against a closed valve in the discharge line.

MAINTENANCE

MAINTENANCE

1. Lubrication

Pumps should require no maintenance other than the

motor bearings: In hot or severe service, lubricate

every 3 months. Follow motor manufacturer’s instructions to determine lubrication schedule. Lubricate with

power off and motor warm. Remove upper and lower

plugs at both bearing. Free lower relief hole of hard

grease. Install clean grease-fitting on upper hole and

add grease with a low-pressure grease gun. Run motor

30 minutes. Stop motor and remove drained grease.

Replace all plugs. CAUTION: Do Not over-grease.

DISASSEMBLY

DISASSEMBLY

1. Turn off all electrical power.

2. Drain system.

3. Disconnect piping.

4. Remove bolts holding motor to foundation.

5. Remove shaft snap ring (1) within discharge head (2).

6. Use a torch on both ends of casing to break-down

thread sealant at casing threads.

7. Use wrenches on suction housing (21) and discharge

head (2) to unscrew (counter-clockwise) discharge

head and casing. Casing is threaded inside each end

and sealed with thread sealant. The casing may come

off with the discharge head or stay on the suction

housing. If the casing remains on the suction housing

it may be removed with a strap wrench. CAUTION:

Do Not use a pipe wrench on the casing or damage will result. The unbroken thread sealant may be

removed by applying heat with a torch.

8. Remove shaft sleeve (4) from shaft.

9. Stages, each consisting of a bowl, impeller, and diffuser, can now be removed.

2

Page 3

10. Remove motor end-plug to expose slot in end of motor shaft.

11. Heat shaft sleeve/coupling with a torch by directing a

flame through hole in suction housing (21). This will

break down Loctite® thread locking compound to

allow removal of the sleeve/coupling. NOTE: Thread

is right-hand. Turn counter-clockwise to loosen.

12. Remove shaft assembly, including rotating portion

of mechanical seal, by holding motor shaft with a

screw-driver in motor shaft slot while turning pump

shaft assembly counter-clockwise with a ½” wrench.

NOTE: Due to the applied heat, the mechanical seal

must be discarded and replaced with a new mechanical seal.

13. Remove bolts holding adapter to motor.

14. Remove suction housing/adapter combination from

motor.

15. Place suction housing/adapter on a flat surface and

push out stationary portion of mechanical seal.

REASSEMBLY

REASSEMBLY

1. Clean all parts, especially pump and motor register

fits, seal seat counter bore in suction housing, and

shaft (in particular where shaft sleeve/coupling fits

against shaft shoulder).

2. Clean shaft sleeve/coupling threads and motor shaft

threads. Clean old Loctite from threads with a wire

brush. Apply Locquic Primer T®, (Loctite® Product

No. 74756 available in Automotive Parts and Hardware stores) and allow to dry.

3. Lubricate counterbore of suction housing (21) and

rubber bushing of new stationary seal seat with

light oil or soapy water and press into counterbore

squarely and evenly. CAUTION: Do Not mar or

contaminate the lapped face of the new mechanical

seal seat.

4. With motor in vertical position, remount suction

housing/adapter on motor. Make certain the motor shaft does not dislocate the new mechanical seal

stationary seat.

5. Apply a thin coat of light oil or soapy water to outer

surface of sleeve/coupling and inside diameter of rubber portion of the new rotating seal member.

6. Slide spring retainer, spring and rotating member of

the new mechanical seal over the sleeve/coupling,

making certain the seal face stays in the holding

collar, and spring retainer is squarely seated against

shoulder of sleeve/coupling. CAUTION: Take care

to prevent damage or dirt on lapped faces of the new

mechanical seal.

7. Coat motor shaft threads with Loctite® 271.

8. Thread the shaft sleeve/coupling, with rotating portion of mechanical seal in place, onto the threaded

motor shaft until the sleeve/coupling bottoms on the

motor shaft shoulder. Use screwdriver in motor shaft

slot to hold while tightening the shaft assembly with

a ½” wrench.

9. Use a straight edge across face of suction housing to

check location of outboard end of shaft sleeve/coupling. Due to variations in motor shaft lengths and

pump parts, it will be from 0.080” short (below the

straight edge) to flush.

10. If sleeve/coupling is below the straight edge, add

0.010” shims until top face of shims are one (1) shim

higher than straight edge (interferes with straight

edge).

11. Reassemble stages on shaft, checking impeller hub

height after each stage. Hub must be flush with

straight edge or higher. Add 0.010” shims as necessary.

11a. On 10 HP models install bearing spider at half way

point in the stack, use shaft sleeve (13) and shim

accordingly.

12. Install shaft sleeve (4) on shaft.

13. Apply thread sealant (Loctite® HVV Pipe Sealant) to

suction housing (21) threads plus discharge head (2)

threads and reassemble casing to pump. (Tighten to

50 foot pounds torque.) CAUTION: Do Not apply

sealant to casing threads.

14. Turn pump by hand with a ½” socket over the end

of the pump shaft inside the discharge head (2). Turn

counter-clockwise. Unit should turn with resistance

of only the mechanical shaft seal.

14a. Replace snap ring (1) on shaft.

15. Replace motor end plug.

16. Do not start unit until suction line and pump are

completely filled with water. Refer to OPERATION

Section.

3

Page 4

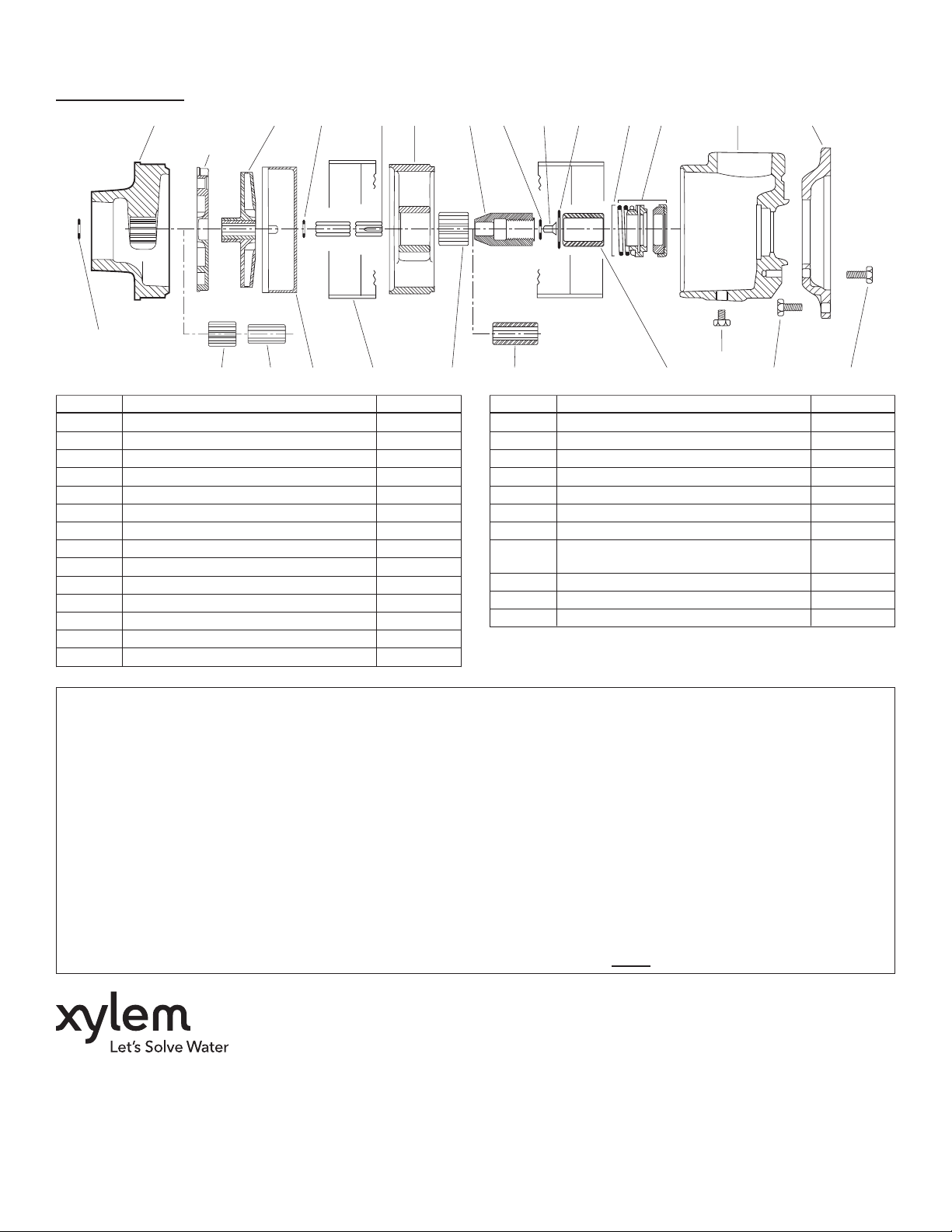

REPAIR PARTS

REPAIR PARTS

2

1

8

6

10

11

14 15 16 17 19 20 21 22

5

25

3 4 7 9 12 13 18 23 24

Item No. Part Name Pattern No.

1 Retaining ring

2 Discharge head assembly – 2” NPT 57209

3 Marine bearing – Discharge head

4 Sleeve – Discharge head

5 Diffuser

6 Impeller

7 Bowl

8 Shim

9 Casing

10* Shaft/coupling assembly

11 Intermediate stage assembly 57203

12 Marine bearing – Intermediate stage

13 Sleeve – Intermediate stage

Part No. Part Name Pattern No.

15 Washer (coupling screw)

16 Mechanical screw

17 Retaining ring

18 Shaft sleeve

19 Spring retainer

20 Mechanical seal assembly

21 Suction housing – 2” NPT 59098

Motor adapter (210 frame) 59153

22

Motor adapter (140-180 frame) 59099

23 Hex cap screw – adapter to motor

24 Hex cap screw – adapter to suction housing

25 Pipe Plug – 1/4 NPT

* Note: Shaft assembly includes screw (16) and washer (15).

14 Coupling

GOULDS WATER TECHNOLOGY LIMITED WARRANTY

This warranty applies to all water systems pumps manufactured by Goulds Water Technology.

Any part or parts found to be defective within the warranty period shall be replaced at no charge to the dealer during the warranty period. The warranty period shall exist for a

period of twelve (12) months from date of installation or eighteen (18) months from date of manufacture, whichever period is shorter.

A dealer who believes that a warranty claim exists must contact the authorized Goulds Water Technology distributor from whom the pump was purchased and furnish complete

details regarding the claim. The distributor is authorized to adjust any warranty claims utilizing the Goulds Water Technology Customer Service Department.

The warranty excludes:

(a) Labor, transportation and related costs incurred by the dealer;

(b) Reinstallation costs of repaired equipment;

(c) Reinstallation costs of replacement equipment;

(d) Consequential damages of any kind; and,

(e) Reimbursement for loss caused by interruption of service.

For purposes of this warranty, the following terms have these definitions:

(1) “Distributor” means any individual, partnership, corporation, association, or other legal relationship that stands between Goulds Water Technology and the dealer in pur-

chases, consignments or contracts for sale of the subject pumps.

(2) “Dealer” means any individual, partnership, corporation, association, or other legal relationship which engages in the business of selling or leasing pumps to customers.

(3) “Customer” means any entity who buys or leases the subject pumps from a dealer. The “customer” may mean an individual, partnership, corporation, limited liability com-

pany, association or other legal entity which may engage in any type of business.

THIS WARRANTY EXTENDS TO THE DEALER ONLY.

Xylem, Inc.

2881 East Bayard Street Ext., Suite A

Seneca Falls, NY 13148

Phone: (800) 453-6777

Fax: (888) 322-5877

www.xyleminc.com/brands/gouldswatertechnology

Goulds is a registered trademark of Goulds Pumps, Inc. and is used under license.

© 2012 Xylem Inc. IM023 Rev. 3 February 2012

Page 5

MANUAL DE LA INSTRUCCIÓN

IM023

Modelo 45HB-70HB

BOMBA REFORZADORA CENTRÍFUGA DE ETAPAS MÚLTIPLES

MANUAL DE INSTALACIÓN, OPERACIÓN Y RESOLUCIÓN DE PROBLEMAS

Page 6

INFORMACIÓN GENERAL

INFORMACIÓN GENERAL

Los modelos 45HB y 70HB son bombas reforzadoras

centrífugas de uso general, de alta presión y de etapas

múltiples que utilizan impulsores cerrados. Se utilizan en

aplicaciones de líquidos transparentes no peligrosos en

servicios industriales generales de hasta 180°F (82°C).

Especialmente convenientes para servicios de refuerzo de

alta presión.

Todos los modelos son de acoplamiento cerrado a motores eléctricos que contienen cojinetes prelubricados

diseñados para un servicio continuo.

La extensión de eje roscado está protegida con una combinación de camisa / acoplamiento de acero inoxidable.

Todos los modelos están equipados con sellos para eje

mecánicos desbalanceados individuales.

Las unidades son enviadas completamente armadas y

listas para la instalación.

IMPORTANTE

IMPORTANTE

1. Inspeccione la unidad para determinar si resultó

dañada durante el envío.

2. Lea cuidadosamente todas las instrucciones.

3. SIEMPRE desconecte todo el suministro eléctrico

cuando maneje la bomba, el motor o los controles.

4. No haga funcionar la unidad en seco o contra una

descarga cerrada. Esto producirá daños al sello

mecánico y a la bomba.

5. Nunca bombee solventes o líquidos peligrosos.

6. Temperatura máxima del líquido: 180°F (82°C).

7. Presión máxima de entrada: 100 lbs./pulg. cuadrada

INSTALACIÓN

INSTALACIÓN

Ubicación: Sitúe la bomba lo más cerca posible a la

fuente de líquido. Deje un espacio adecuado para el

mantenimiento y la ventilación. Proteja la unidad contra

los daños causados por la congelación en tiempo frío y el

agua de lluvia o inundación. La bomba puede montarse

horizontal o vertical con el motor sobre el extremo superior, siempre que se utilice una pantalla contra goteos

para proteger el motor.

Cimiento: La superficie del cimiento debe ser plana, de

manera que no se produzca deformación o esfuerzo al

apretar los pernos de cimentación. PRECAUCIÓN: Ni el

empernado ni las tuberías deben aplicar esfuerzo sobre el

extremo del líquido. Las bombas son de funcionamiento

silencioso y suave, pero se recomienda instalar una

montura de caucho sobre los cimientos susceptibles a los

efectos sonoros.

Alineación: El alineamiento fino no es necesario ya que

las bombas son de acoplamiento cerrado.

Tuberías: La tubería de succión debe ser al menos del

mismo tamaño que la conexión de succión de la bomba

y proveer carga de succión positiva (presión de entrada)

a la bomba. Evite usar la bomba para aplicaciones que

requieran elevación de succión. Nunca use una válvula

de compuerta en la tubería de succión para estrangular

la bomba. PRECAUCIÓN: La tubería no debe aplicar

esfuerzo sobre el extremo de líquido.

Cableado: La fuente de energía eléctrica debe ser un circuito derivado separado equipado con los arrancadores,

6

fusibles o cortacircuitos apropiados, alambre de tamaño

adecuado, etc. y debe cumplir con los códigos eléctricos

nacionales y locales. La tensión, la fase y los controles

de la fuente de alimentación deben coincidir con los

requerimientos indicados en la placa de identificación del

motor. Se recomienda incluir protección contra la baja

tensión y las pérdidas de fase (tres fases).

Motores: Los motores monofásicos de 3 HP son de doble

tensión – 115/230 voltios, 60 Hz, de C.A. Los motores

monofásicos de 5 HP son de 230 voltios, 60 Hz, de C.A.

Todos los demás motores son trifásicos, de doble tensión

– 230/460 voltios, 60 Hz, de C.A. Se recomiendan las

tensiones más altas cuando estén disponibles.

Rotación: La rotación trifásica debe ser verificada en el

momento de la instalación energizando momentáneamente la bomba completamente llena y observando la

rotación. La rotación es en sentido horario cuando se

observa hacia el eje del motor, lado de la campana del extremo (retire la tapa protectora para observar el eje). La

rotación debe corresponder con la flecha de rotación. La

rotación de las unidades trifásicas puede invertirse intercambiando dos (2) conductores de alimentación eléctrica

cualquiera. PRECAUCIÓN: No haga funcionar la unidad

en rotación inversa o se producirán daños.

OPERACIÓN

OPERACIÓN

Llene la tubería de succión y la bomba con el líquido

que se va a bombear para asegurar que el sello mecánico

no funcione en seco. Con la bomba y la tubería de succión completamente llenas, y con el motor conectado

correctamente, puede ponerse en marcha la unidad.

Asegúrese de que la bomba no sea puesta en marcha contra una válvula cerrada en la tubería de descarga.

MANTENIMIENTO

MANTENIMIENTO

1. Lubricación

Las bombas no requieren mantenimiento, excepto

por los cojinetes del motor: En servicio riguroso o a

temperaturas elevadas, lubrique cada 3 meses. Siga las

instrucciones del fabricante del motor para determinar

el horario de lubricación. Lubrique con el suministro

eléctrico apagado y el motor tibio. Retire los tapones

superior e inferior en ambos cojinetes. Quite la grasa

endurecida del orificio de descarga inferior. Instale

una grasera limpia en el orificio superior y agregue

grasa con una pistola de engrase de baja presión. Haga

funcionar el motor durante 30 minutos. Detenga el

motor y quite la grasa drenada. Reinstale todos los

tapones. PRECAUCIÓN: No engrase en exceso.

DESARMADO

DESARMADO

1. Apague todo el suministro eléctrico.

2. Drene el sistema.

3. Desconecte las tuberías.

4. Quite los pernos que sujetan el motor al cimiento.

5. Retire el anillo de resorte del eje (1) dentro del cabezal de descarga (2).

6. Utilice un soplete en ambos extremos de la carcasa

para desintegrar el sellador de las roscas de la carcasa.

Page 7

7. Utilice llaves en la caja de succión (21) y en el cabezal

de descarga (2) para destornillar (en sentido contrahorario) el cabezal de descarga y la carcasa. La

carcasa está roscada en el interior de cada extremo y

está sellada con sellador de roscas. La carcasa podría

desprenderse con el cabezal de descarga o permanecer sobre la caja de succión. Si la carcasa permanece

sobre la caja de succión, puede ser retirada con una

llave de banda. PRECAUCIÓN: No utilice una llave

para tubos en la carcasa o se producirán daños. El

sellador de roscas restante puede quitarse aplicando

calor con un soplete.

8. Retire la camisa del eje (4) del eje.

9. Ahora pueden retirarse las etapas, cada una de las

cuales consta de una copa, un impulsor y un difusor.

10. Quite el tapón del extremo del motor para dejar al

descubierto la ranura en el extremo del eje del motor.

11. Caliente la camisa / acoplamiento del eje con un

soplete dirigiendo la llama a través del agujero en la

caja de succión (21). Esto desintegrará el compuesto

fijador de roscas Loctite® para permitir retirar la

camisa / acoplamiento. Nota: La rosca es de mano

derecha. Gire en sentido contrahorario para aflojar.

12. Retire el conjunto del eje, incluso la parte giratoria

del sello mecánico, sujetando el eje del motor con

un destornillador en la ranura del eje mientras gira

el conjunto del eje de la bomba en sentido contrahorario con una llave de ½ pulg. Nota: Debido al calor

aplicado, el sello mecánico debe ser desechado y

reemplazado con uno nuevo.

13. Quite los pernos que sujetan el adaptador al motor.

14. Retire la combinación de caja de succión / adaptador

del motor.

15. Coloque la caja de succión / adaptador sobre una superficie plana y empuje hacia afuera la parte estacionaria del sello mecánico.

REARMADO

REARMADO

1. Limpie todas las partes, especialmente los encajes de

registro del motor, el ensanchamiento del asiento

del sello en la caja de succión y el eje (especialmente

donde la camisa / acoplamiento del eje calza contra el

reborde del eje).

2. Limpie las roscas de la camisa / acoplamiento del

eje y las roscas del eje del motor. Limpie el Loctite

viejo de las roscas con un cepillo de alambre. Aplique

Locquic Primer T®, (Loctite® – Producto Nº 74756

– disponible en las tiendas de partes automotrices y

ferreterías) y déjelo secar.

3. Lubrique el ensanchamiento de la caja de succión

(21) y el buje de caucho del asiento del nuevo sello

estacionario con aceite liviano o agua jabonosa y

empújelo al interior del ensanchamiento en forma

perpendicular y pareja. PRECAUCIÓN: No estropee

ni contamine la cara pulida del asiento del nuevo

sello mecánico.

4. Con el motor en posición vertical, monte nuevamente la caja de succión / adaptador sobre el motor.

Asegúrese de que el eje del motor no desplace el

asiento estacionario del nuevo sello mecánico.

5. Aplique una capa delgada de aceite liviano o agua

jabonosa a la superficie exterior de la camisa / acoplamiento y al diámetro interior de la parte de caucho

del nuevo componente del sello giratorio.

6. Deslice el retén del resorte, el resorte y el componente giratorio del nuevo sello mecánico, asegurándose de que la cara del sello permanezca en

el collar de retención y que el retén del resorte esté

asentado en forma perpendicular contra el reborde

de la camisa / acoplamiento. PRECAUCIÓN: Tenga

cuidado para evitar dañar o ensuciar las caras pulidas

del nuevo sello mecánico.

7. Recubra las roscas del eje del motor con Loctite®

271.

8. Atornille la camisa / acoplamiento del eje, con la

parte giratoria del sello mecánico en posición, sobre

el eje roscado del motor hasta que la camisa / acoplamiento haga contacto con el reborde del eje del

motor. Utilice un destornillador en la ranura del eje

del motor para sujetar mientras aprieta el conjunto

del eje con una llave de ½ pulg.

9. Utilice un escantillón sobre la cara de la caja de succión para verificar la ubicación del extremo exterior

de la camisa / acoplamiento del eje. Debido a las

variaciones de las longitudes del eje del motor y las

partes de la bomba, estará situado en el intervalo de

0,080 pulg. más corto (debajo del escantillón) hasta

a ras.

10. Si la camisa / acoplamiento está debajo del escantillón, agregue planchas de relleno de 0.010 pulgada

hasta que la cara superior de las mismas sea una (1)

plancha de relleno más alta que el escantillón (interfiere con el escantillón).

11. Rearme las etapas sobre el eje, verificando la altura

del cubo del impulsor después de cada etapa. El cubo

debe estar a ras con el escantillón o más alto. Agregue

planchas de relleno de 0.010 pulgada, según sea

necesario.

11a. En los modelos de 10 HP, instale un cubo de balero

en un punto a medio camino en la pila; utilice la

camisa del eje (13) y la plancha de relleno en la

forma correspondiente.

12. Instale la camisa del eje (4) sobre el eje.

13. Aplique sellador de roscas (sellador de tubería Loctite® HVV) a las roscas de la caja de succión (21) y

a las roscas del cabezal de descarga (2) y reinstale la

carcasa en la bomba. (Apriete a una torsión de 50

pie-libras.) PRECAUCIÓN: No aplique sellador a las

roscas de la carcasa.

14. Gire la bomba a mano con una boquilla de ½ pulg.

sobre el extremo del eje de la bomba dentro del

cabezal de descarga (2). Gire en sentido contrahorario. La unidad debe girar con resistencia del sello

mecánico del eje únicamente.

14a. Reinstale el anillo de resorte (1) sobre el eje.

15. Reinstale el tapón del extremo del motor.

16. No arranque la unidad hasta que la tubería de succión y la bomba estén completamente llenas con

agua. Consulte la sección de OPERACIÓN.

7

Page 8

PARTES DE REPUESTO

PARTES DE REPUESTO

2

8

6

10

11

5

1

3 4 7 9 12 13 18 23 24

Artículo N° Nombre de la parte Patrón Nº

1 Anillo de retención

Conjunto del cabezal de descarga –

2

NPT de 2 pulg. 57209

3 Cojinete estilo marino – cabezal de descarga

4 Camisa - cabezal de descarga

5 Difusor

6 Impulsor

7 Copa

8 Plancha de relleno

9 Carcasa

10* Conjunto del eje / acoplamiento

11 Conjunto de etapa intermedia 57203

12 Cojinete estilo marino – etapa intermedia

13 Camisa – etapa intermedia

14 Acoplamiento

14 15 16 17 19 20 21 22

25

Artículo N° Nombre de la parte Patrón Nº

15 Arandela (tornillo del acoplamiento)

16 Tornillo mecánico

17 Anillo de retención

18 Camisa del eje

19 Retén del resorte

20 Conjunto del sello mecánico

21 Caja de succión – NPT de 2 pulg. 59098

Adaptador para el motor (bastidor 210) 59153

22

Adaptador para el motor (bastidor 140-180) 59099

Tornillo de cabeza hexagonal –

23

del adaptador al motor

Tornillo de cabeza hexagonal –

24

del adaptador a la caja de succión

25 Tapón de tubería – 1/4 NPT

* Nota: El conjunto del eje incluye un tornillo (16) y una arandela (15).

Esta garantía es aplicable a todas las bombas para sistemas de agua fabricadas por Goulds Water Technology. Toda parte o partes que resultaren defectuosas dentro del período

de garantía serán reemplazadas, sin cargo para el comerciante, durante dicho período de garantía. Tal período de garantía se extiende por doce (12) meses a partir de la fecha de

instalación, o dieciocho (18) meses a partir de la fecha de fabricación, cualquiera se cumpla primero.

Todo comerciante que considere que existe lugar a un reclamo de garantía deberá ponerse en contacto con el distribuidor autorizado de Goulds Water Technology del cual

adquiriera la bomba y ofrecer información detallada con respecto al reclamo El distribuidor está autorizado a liquidar todos los reclamos por garantía a través del Departamento

de Servicios a Clientes de Goulds Water Technology.

La presente garantía excluye:

(a) La mano de obra, el transporte y los costos relacionados en los que incurra el comerciante;

(b) los costos de reinstalación del equipo reparado;

(c) los costos de reinstalación del equipo reemplazado;

(d) daños emergentes de cualquier naturaleza; y

(e) el reembolso de cualquier pérdida causada por la interrupción del servicio

A los fines de esta garantía, los términos “Distribuidor”, “Comerciante” y “Cliente” se definen como sigue:

(1) “Distribuidor” es aquel individuo, sociedad, corporación, asociación u otra persona jurídica que opera en relación legal entre Goulds Water Technology y el comerciante para

la compra, consignación o contratos de venta de las bombas en cuestión.

(2) “Comerciante” es todo individuo, sociedad, corporación, asociación u otra persona jurídica que en el marco de una relación legal realiza negocios de venta o alquiler-venta

(leasing) de bombas a clientes.

(3) “Cliente” es toda entidad que compra o que adquiere bajo la modalidad de leasing las bombas en cuestión de un comerciante. El término “cliente” puede significar un

individuo, sociedad, corporación, sociedad de responsabilidad limitada, asociación o cualquier otra persona jurídica con actividades en cualquier tipo de negocios.

LA PRESENTE GARANTÍA SE EXTIENDE AL COMERCIANTE ÚNICAMENTE.

Xylem, Inc.

2881 East Bayard Street Ext., Suite A

Seneca Falls, NY 13148

Teléfono: (800) 453-6777

Fax: (888) 322-5877

www.xyleminc.com/brands/gouldswatertechnology

Goulds es una marca registrada de Goulds Pumps, Inc. y se utiliza bajo licencia.

© 2012 Xylem Inc. IM023 Rev. 3 Febrero 2012

GARANTÍA LIMITADA DE GOULDS WATER TECHNOLOGY

Page 9

MANUEL D’INSTRUCTION

IM023

Modèles 45HB et 70HB

POMPES DE SURPRESSION CENTRIFUGES MULTI-ÉTAGÉES

MANUEL D’INSTALLATION, D’UTILISATION ET DE DÉPANNAGE

Page 10

INFORMATIONS GÉNÉRALES

INFORMATIONS GÉNÉRALES

Les pompes modèles 45HB et 70HB sont des pompes de

surpression centrifuges multi-étagées, à roues fermées,

prévues pour un usage général et pour les liquides industriels limpides non dangereux de nature générale dont la

température ne dépasse pas 82 °C (180 °F). Elles conviennent particulièrement au pompage à haute pression.

Elles sont toutes montées sur un moteur électrique muni

de roulements prélubrifiés pour un service continu. Elles

possèdent un arbre-rallonge fileté, protégé par un ensemble accouplement-chemise d’arbre en inox.

Leur arbre est doté d’une garniture mécanique non compensée.

Elles sont expédiées assemblées et prêtes à installer.

INFORMATIONS IMPORTANTES

INFORMATIONS IMPORTANTES

1. Vérifier si l’appareil a été endommagé pendant le

transport.

2. Lire toutes les directives avec soin.

3. On doit TOUJOURS couper le courant lorsque l’on

effectue quelque travail que ce soit sur la pompe, le

moteur ou les commandes.

4. Ne pas faire fonctionner la pompe à sec ni quand le

liquide ne peut circuler dans la conduite de refoulement à cause d’un robinet fermé, car cela endommagerait la garniture mécanique et la pompe.

5. Ne jamais pomper de liquides dangereux ni de

solvants.

6. La température maximale du liquide pompé est de

82 °C (180 °F).

7. La pression d’aspiration maximale est de 100 lb/po2.

INSTALLATION

INSTALLATION

Emplacement : placer la pompe aussi près de la source de

liquide que possible. Prévoir assez d’espace autour de la

pompe pour l’entretien et l’aération. Protéger l’appareil

de la pluie, des inondations et du gel. On peut monter la

pompe à l’horizontale ou à la verticale, le moteur audessus, à condition que celui-ci soit protégé avec un écran

pare-gouttes.

Surface portante : la surface portante doit être plane afin

d’empêcher que le serrage des boulons d’ancrage ne cause

de déformation ni de contraintes. ATTENTION ! : le

boulonnage et la tuyauterie ne doivent appliquer aucune

contrainte sur la tête de pompage. Les pompes ont un

fonctionnement régulier et silencieux, mais on recommande de les monter sur caoutchouc si la surface portante

résonne.

Alignement : aucun alignement sur place n’est requis étant

donné que les pompes sont montées sur moteur.

Tuyauterie : le calibre du tuyau d’aspiration doit être au

moins égal à celui du raccord d’aspiration de la pompe et

permettre à la pompe d’avoir une hauteur totale de charge

absolue à l’aspiration (pression d’aspiration). Éviter les

utilisations nécessitant une hauteur d’aspiration. Ne jamais

employer un robinet-vanne sur le tuyau d’aspiration pour

réduire la section de passage vers la pompe. ATTEN-

TION ! : la tuyauterie ne doit appliquer aucune contrainte

sur la tête de pompage.

Câblage : l’alimentation électrique doit être assurée par un

circuit de dérivation distinct dont les fusibles, les disjonc10

teurs, les démarreurs, le calibre des fils, etc. sont appropriés et conformes aux prescriptions du code provincial ou

national de l’électricité. La tension d’alimentation, le nombre de phases et les commandes doivent être conformes

aux spécifications de la plaque signalétique du moteur.

Une protection contre les basses tensions électriques et les

pertes de phase (en triphasé) est recommandée.

Moteurs : les moteurs sont tous à courant alternatif, 60

Hz. Ceux de 3 hp sont monophasés bitension (115/230

V), ceux de 5 hp, monophasés à simple tension (230 V),

et tous les autres, triphasés bitension (230/460 V). Il est

recommandé d’employer la tension la plus haute quand

cela est possible.

Sens de rotation : s’il s’agit d’une pompe à moteur triphasé, on doit en vérifier le sens de rotation avant de la mettre

en service en la remplissant d’abord d’eau, puis en la

mettant en marche et en l’arrêtant immédiatement tout en

observant le sens de rotation de l’arbre de moteur, visible

une fois l’obturateur de l’extrémité d’arbre de moteur ôté.

L’arbre doit tourner en sens horaire, comme l’indique la

flèche prévue à cet effet. On peut inverser le sens de rotation en intervertissant deux (2) conducteurs d’alimentation

du moteur. ATTENTION ! : ne pas faire fonctionner la

pompe en sens antihoraire, car cela endommagerait la

pompe.

UTILISATION

UTILISATION

Remplir la conduite d’aspiration et la pompe avec le liquide à pomper pour s’assurer que la garniture mécanique

sera bien lubrifiée. Une fois la conduite et la pompe pleines

et le moteur câblé et connecté correctement, on peut

mettre la pompe en marche. S’assurer qu’aucun robinet

n’empêche la circulation du liquide dans la conduite de

refoulement.

ENTRETIEN

ENTRETIEN

Lubrification

L’appareil ne devrait nécessiter aucun entretien, sauf

pour les roulements du moteur. En service dur et à haute

température, lubrifier les roulements tous les trois (3)

mois. Suivre le calendrier de graissage recommandé par

le fabricant du moteur. Graisser les roulements quand le

moteur est chaud, après en avoir d’abord coupé le courant.

Enlever les bouchons supérieur et inférieur des orifices de

graissage de chaque roulement, puis débarrasser les orifices

inférieurs des résidus de graisse durcie. Poser un graisseur sur l’orifice supérieur et y injecter la graisse à basse

pression. Faire fonctionner le moteur pendant 30 min,

puis l’arrêter et enlever la graisse sortie des roulements.

Reposer tous les bouchons. ATTENTION ! : ne pas mettre

trop de graisse.

DÉMONTAGE

DÉMONTAGE

1. Couper le courant.

2. Vidanger le système.

3. Séparer la tuyauterie d’avec la pompe.

4. Enlever les boulons d’ancrage du moteur.

5. Enlever l’anneau élastique (1) de l’arbre par l’orifice de

la tête de refoulement (2).

6. Chauffer chaque extrémité du corps de pompe (9)

au chalumeau pour en amollir et décoller l’enduit

d’étanchéité des filets (intérieurs).

Page 11

7. À l’aide de deux clés, dévisser (en sens antihoraire) la

tête de refoulement et le corps d’aspiration (21) d’avec

le corps de pompe. Il est possible que le corps de

pompe reste fixé à la tête de refoulement ou au corps

d’aspiration. En pareil cas, utiliser un serre-tubes à

sangle sur le corps de pompe pour le dévisser. AT-

TENTION ! : ne pas employer une clé à tubes, car cela

endommagerait le corps de pompe. Chauffer les filets

au chalumeau pour en décoller l’enduit d’étanchéité.

8. Retirer la chemise d’arbre (4) de l’ensemble accouplement-arbre (10).

9. On peut maintenant retirer les étages, composés d’un

corps d’étage (« cuvette »), d’une roue et d’un diffuseur.

10. Enlever l’obturateur de l’extrémité d’arbre de moteur

pour accéder à la fente de l’arbre.

11. Chauffer l’ensemble accouplement-chemise d’arbre

au chalumeau par l’orifice du corps d’aspiration afin

d’en décoller l’enduit frein pour filets LoctiteMD et de

dévisser (sens antihoraire) et d’enlever l’ensemble.

12. Ôter l’arbre, y compris l’élément mobile de la garniture mécanique (20), en le dévissant (sens antihoraire)

avec une clé de ½ po et en bloquant l’arbre de moteur

avec un tournevis inséré dans la fente de celui-ci. Nota

: étant donné que l’on a chauffé l’arbre, donc la garniture mécanique, on doit jeter celle-ci et la remplacer

par une garniture neuve.

13. Déposer les vis de fixation (23) de l’adaptateur de

moteur (22).

14. Enlever l’ensemble corps d’aspiration-adaptateur de

moteur.

15. Placer l’ensemble corps d’aspiration-adaptateur de

moteur sur une surface plane et pousser l’élément fixe

de la garniture mécanique hors de son logement (au

centre du corps d’aspiration).

REMONTAGE

REMONTAGE

1. Nettoyer toutes les pièces et, surtout, les surfaces de

guidage moteur-pompe, les surfaces du logement de

garniture mécanique (corps d’aspiration) et l’arbre

(particulièrement l’épaulement pour l’ensemble

accouplement-chemise d’arbre).

2. Nettoyer les filets de l’arbre de moteur et de

l’ensemble accouplement-chemise d’arbre et en enlever

l’enduit Loctite avec une brosse en métal. Appliquer

de l’apprêt Primer TMD de Locquic (produit LoctiteMD no 74756, vendu dans les magasins de pièces

d’automobile et les quincailleries) sur les filets et le

laisser sécher.

3. Lubrifier les surfaces du logement de garniture mécanique et la bague en caoutchouc de l’élément fixe de la

garniture avec une huile légère ou de l’eau savonneuse,

puis pousser l’élément fixe uniformément jusqu’au

fond du logement. ATTENTION ! : ne pas abîmer

ni salir les surfaces polies de la garniture mécanique

neuve.

4. Placer le moteur à la verticale, l’arbre vers le haut, et

reposer l’ensemble corps d’aspiration-adaptateur de

moteur tout en s’assurant que l’arbre de moteur ne

déloge pas l’élément fixe de la garniture mécanique

neuve.

5. Enduire d’un peu d’huile légère ou d’eau savonneuse

la surface extérieure de l’ensemble accouplementchemise d’arbre et la surface intérieure de la partie

en caoutchouc de l’élément mobile de la garniture

mécanique neuve.

6. Enfiler l’étrier de retenue du ressort de garniture,

le ressort, puis l’élément mobile de la garniture sur

l’ensemble accouplement-chemise d’arbre, tout en

s’assurant que la surface d’étanchéité de la garniture

reste dans son collier de retenue et que l’étrier de

retenue du ressort est entièrement appuyé contre

l’épaulement de l’ensemble accouplement-chemise

d’arbre. ATTENTION ! : veiller à ne pas abîmer ni

à salir les surfaces polies de la garniture mécanique

neuve.

7. Enduire les filets de l’arbre de moteur de LoctiteMD

no 271.

8. Visser l’ensemble accouplement-chemise d’arbre (avec

l’élément mobile de la garniture mécanique) à fond

sur l’arbre de moteur avec une clé de ½ po tout en

bloquant l’arbre de moteur avec un tournevis inséré

dans la fente de celui-ci.

9. Avec une règle rectifiée, placée en travers des bords du

corps d’aspiration, vérifier la position de l’extrémité

extérieure de l’ensemble accouplement-chemise

d’arbre. En raison de variations dans la longueur de

l’arbre de moteur ou de certaines pièces de la pompe,

l’extrémité peut soit affleurer la règle, soit en être à

une distance maximale de 0,080 po (à l’intérieur).

10. Si l’extrémité de l’ensemble est à l’intérieur du corps

d’aspiration, poser des cales de 0,010 po contre

l’extrémité jusqu’à ce qu’une (1) cale dépasse le bord

de la règle rectifiée.

11. Remonter les étages de la pompe, un par un, en vérifiant la position du moyeu de roue par rapport aux

bords du corps d’étage avec une règle rectifiée. Le

moyeu doit affleurer ou dépasser le bord de la règle.

Au besoin, ajouter des cales de 0,010 po.

12. Dans le cas des modèles de 10 hp, poser une baguesupport de coussinet au milieu de la série d’étages, une

chemise d’arbre (13) et les cales nécessaires.

13. Reposer la chemise d’arbre (4).

14. Appliquer un enduit d’étanchéité pour filets (LoctiteMD

HVV pour tuyaux) sur les filets du corps d’aspiration

et de la tête de refoulement servant à visser le corps de

pompe, puis y visser ce dernier à 50 lbf·pi. ATTEN-

TION ! : ne pas mettre d’enduit d’étanchéité sur les

filets du corps de pompe.

15. Avec une douille de ½ po, enfilée sur le bout de l’arbre

de pompe par l’orifice de la tête de refoulement,

tourner l’arbre à la main en sens antihoraire. L’arbre

devrait tourner sans autre résistance que celle de la

garniture mécanique.

16. Reposer l’anneau élastique (1).

17. Remettre l’obturateur de l’extrémité d’arbre de moteur

en place.

18. Remplir la conduite d’aspiration et la pompe d’eau

avant de mettre celle-ci en marche. À ce sujet, voir la

section UTILISATION.

11

Page 12

PIÈCES DE RECHANGE

PIÈCES DE RECHANGE

2

5

1

3 4 7 9 12 13 18 23 24

8

6

10

11

14 15 16 17 19 20 21 22

25

No d’art. Nom de pièce No de moule

1 Anneau élastique

2 Tête de refoulement à orifice de 2 po, NPT 57209

3 Coussinet cannelé (tête de refoulement)

4 Chemise d’arbre (tête de refoulement)

5 Diffuseur

6 Roue

7 Corps d’étage

8 Cale

9 Corps de pompe

10* Ensemble accouplement-arbre

11 Étage intermédiaire 57203

12 Coussinet cannelé (étage intermédiaire)

13 Chemise d’arbre (étage intermédiaire)

14 Accouplement

No d’art. Nom de pièce No de moule

15 Rondelle (vis de l’accouplement)

16 Vis (accouplement)

17 Bague de retenue

18 Chemise d’arbre

19 Étrier de retenue (ressort de garniture

mécanique)

20 Garniture mécanique

21 Corps d’aspiration à orifice de 2 po, NPT 59098

22 Adaptateur de moteur (carcasse 210) 59153

Adaptateur de moteur (carcasses 140 à 180) 59099

23 Vis à tête hexagonale (adaptateur-moteur)

24 Vis à tête hexagonale (adaptateur-corps

d’aspiration)

25 Bouchon de tuyau de 1/4po, NPT

* Nota : l’ensemble comprend la rondelle (15) et la vis (16).

GARANTIE LIMITÉE DE Goulds Water Technology

La présente garantie s’applique à chaque pompe de système d’alimentation en eau fabriquée par Goulds Water Technology.

Toute pièce se révélant défectueuse sera remplacée sans frais pour le détaillant durant la période de garantie suivante expirant la première : douze (12) mois à compter de la date

d’installation ou dix-huit (18) mois à partir de la date de fabrication.

Le détaillant qui, aux termes de cette garantie, désire effectuer une demande de règlement doit s’adresser au distributeur Goulds Water Technology agréé chez lequel la pompe a

été achetée et fournir tous les détails à l’appui de sa demande. Le distributeur est autorisé à régler toute demande par le biais du service à la clientèle de Goulds Water Technology.

La garantie ne couvre pas :

a) les frais de main-d’œuvre ou de transport ni les frais connexes encourus par le détaillant ;

b) les frais de réinstallation de l’équipement réparé ;

c) les frais de réinstallation de l’équipement de remplacement ;

d) les dommages indirects de quelque nature que ce soit ;

e) ni les pertes découlant de la panne.

Aux fins de la présente garantie, les termes ci-dessous sont définis comme suit :

1) « Distributeur » signifie une personne, une société de personnes, une société de capitaux, une association ou autre entité juridique servant d’intermédiaire entre Goulds Water

Technology et le détaillant pour les achats, les consignations ou les contrats de vente des pompes en question.

2) « Détaillant » veut dire une personne, une société de personnes, une société de capitaux, une association ou autre entité juridique dont les activités commerciales sont la vente

ou la location de pompes à des clients.

3) « Client » signifie une entité qui achète ou loue les pompes en question chez un détaillant. Un « client » peut être une personne, une société de personnes, une société de

capitaux, une société à responsabilité limitée, une association ou autre entité juridique se livrant à quelque activité que ce soit.

CETTE GARANTIE SE RAPPORTE AU DÉTAILLANT SEULEMENT.

Xylem, Inc.

2881 East Bayard Street Ext., Suite A

Seneca Falls, NY 13148

Téléphone: (800) 453-6777

télécopie: (888) 322-5877

www.xyleminc.com/brands/gouldswatertechnology

Goulds est une marque déposée de Goulds Pumps, Inc., utilisée sous licence.

© 2012, Xylem Inc. IM023 Rev. 3 Février 2012

Loading...

Loading...