Xylem Flygt Concertor 6020 Installation, Operation And Maintenance Manual

Installation, Operation,

and Maintenance Manual

Concertor

™

6020

Table of Contents

1 Introduction and Safety..............................................................................................................3

1.1 Introduction.......................................................................................................................... 3

1.2 Safety terminology and symbols........................................................................................3

1.3 User safety.............................................................................................................................4

1.4 Special hazards.....................................................................................................................4

1.5 Protecting the environment................................................................................................5

1.6 Spare parts............................................................................................................................5

1.7 Warranty................................................................................................................................5

2 Transportation and Storage...................................................................................................... 6

2.1 Inspect the delivery..............................................................................................................6

2.1.1 Inspect the package..................................................................................................... 6

2.1.2 Inspect the unit..............................................................................................................6

2.2 Transportation guidelines...................................................................................................6

2.2.1 Lifting..............................................................................................................................6

2.3 Temperature ranges for transportation, handling and storage.....................................7

2.4 Storage guidelines...............................................................................................................7

Table of Contents

3 System Description.....................................................................................................................9

3.1 System overview...................................................................................................................9

3.1.1 Concertor™ N.................................................................................................................9

3.1.2 Concertor™ EA............................................................................................................ 10

3.1.3 Concertor™ DP............................................................................................................ 11

4 Product Description................................................................................................................. 13

4.1 The pump............................................................................................................................13

4.1.1 Pump design............................................................................................................... 13

4.1.2 The data plate............................................................................................................. 16

4.1.3 Product denomination............................................................................................... 16

4.2 The gateways......................................................................................................................17

4.2.1 Product design............................................................................................................17

4.2.2 Approvals.....................................................................................................................17

4.2.3 Parts..............................................................................................................................18

4.2.4 The data plate............................................................................................................. 18

5 Mechanical Installation............................................................................................................ 19

5.1 Precautions......................................................................................................................... 19

5.2 Requirements..................................................................................................................... 20

5.3 Make the mechanical installation.....................................................................................20

5.3.1 Prepare the site: new P-installation.......................................................................... 20

5.3.2 Install the pump: P-installation..................................................................................21

5.3.3 Install the pump: S-installation..................................................................................22

5.3.4 Install the gateway...................................................................................................... 23

6 Electrical Installation................................................................................................................ 24

6.1 Precautions......................................................................................................................... 24

6.2 Requirements..................................................................................................................... 25

6.3 Make the electrical connections...................................................................................... 26

6.3.1 Prepare the SUBCAB® cables....................................................................................26

6.3.2 Connect the motor cable to the pump.................................................................... 27

Concertor™ 6020 Installation, Operation, and Maintenance Manual 1

Table of Contents

6.3.3 Connect the motor cable to mains and to the monitoring equipment............... 28

6.3.4 Connect the gateway................................................................................................. 28

6.4 Cable charts........................................................................................................................30

7 Operation.................................................................................................................................. 32

7.1 Precautions......................................................................................................................... 32

7.2 Start the pump....................................................................................................................32

7.3 Alarm handling...................................................................................................................33

7.3.1 Alarms and messages................................................................................................ 33

7.3.2 Service in case of alarm..............................................................................................33

8 Maintenance..............................................................................................................................34

8.1 Torque values.....................................................................................................................35

8.2 Maintenance intervals....................................................................................................... 36

8.2.1 Inspection.................................................................................................................... 36

8.2.2 Major overhaul............................................................................................................ 37

8.3 Drain the liquid from the stator housing.........................................................................37

8.4 Change the oil....................................................................................................................38

8.5 Replace the impeller......................................................................................................... 41

8.5.1 Remove the impeller.................................................................................................. 41

8.5.2 Install the impeller...................................................................................................... 41

9 Troubleshooting....................................................................................................................... 44

9.1 The pump does not start...................................................................................................44

9.2 The impeller does not rotate............................................................................................45

9.3 The pump starts but stops after 10 seconds.................................................................. 45

9.4 The pump stops................................................................................................................. 45

9.5 The pump does not receive commands from the gateway......................................... 46

9.6 The pump starts-stops-starts in rapid sequence............................................................46

9.7 The pump delivers too little or no water.........................................................................46

10 Technical Reference...............................................................................................................48

10.1 The pump......................................................................................................................... 48

10.1.1 Motor data.................................................................................................................48

10.1.2 Application limits......................................................................................................48

10.2 The gateways................................................................................................................... 48

10.2.1 Dimensions................................................................................................................48

10.2.2 Environmental requirements.................................................................................. 48

10.2.3 IP-rating......................................................................................................................49

10.2.4 Electrical data............................................................................................................49

10.2.5 Terminals................................................................................................................... 49

10.2.6 Source code.............................................................................................................. 50

2 Concertor™ 6020 Installation, Operation, and Maintenance Manual

1 Introduction and Safety

1.1 Introduction

Purpose of the manual

The purpose of this manual is to provide necessary information for working with the unit.

Read this manual carefully before starting work.

Read and keep the manual

Save this manual for future reference, and keep it readily available at the location of the

unit.

Intended use

WARNING:

Operating, installing, or maintaining the unit in any way that is not covered in this manual

could cause death, serious personal injury, or damage to the equipment and the

surroundings. This includes any modification to the equipment or use of parts not

provided by Xylem. If there is a question regarding the intended use of the equipment,

please contact a Xylem representative before proceeding.

1 Introduction and Safety

Other manuals

See also the safety requirements and information in the original manufacturer's manuals

for any other equipment furnished separately for use in this system.

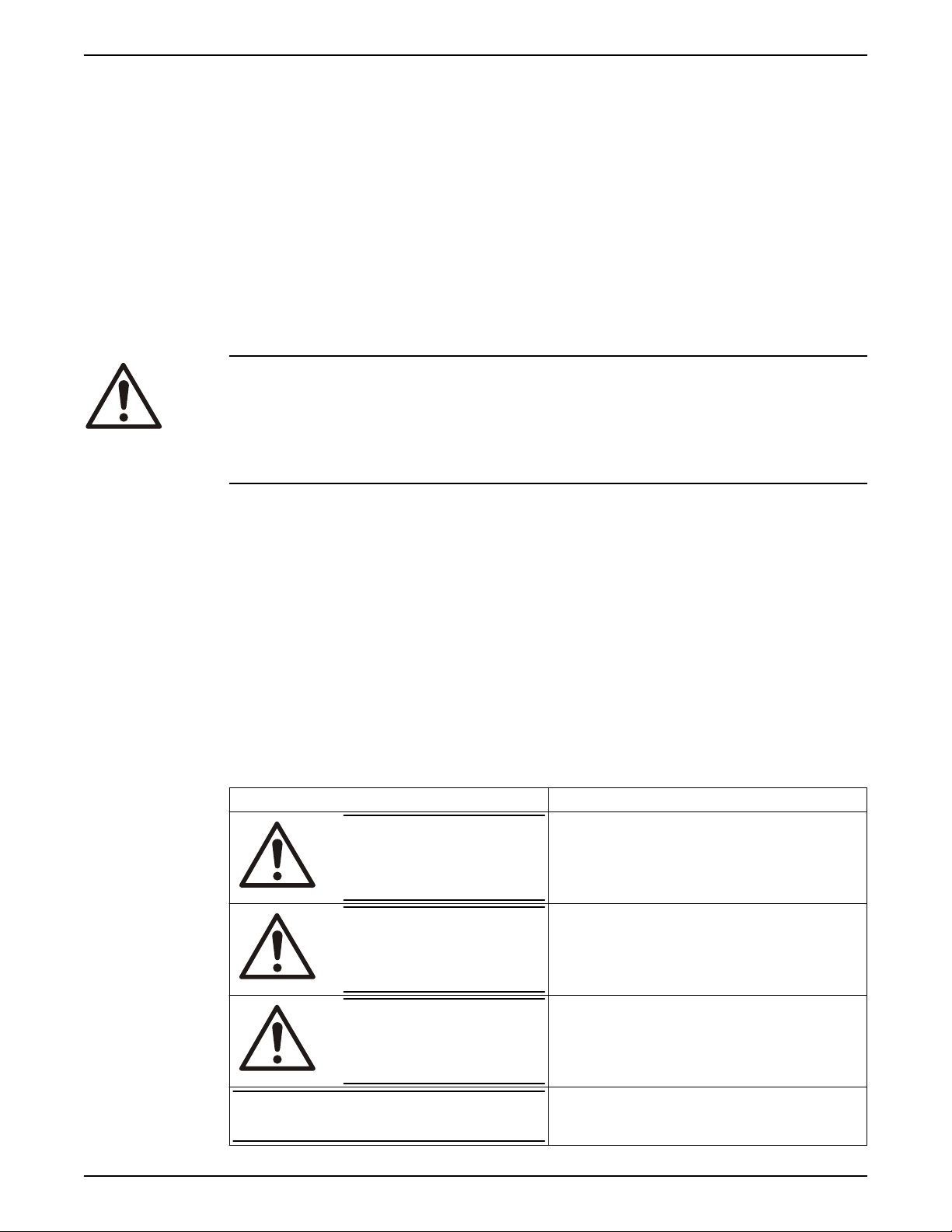

1.2 Safety terminology and symbols

About safety messages

It is extremely important that you read, understand, and follow the safety messages and

regulations carefully before handling the product. They are published to help prevent

these hazards:

• Personal accidents and health problems

• Damage to the product and its surroundings

• Product malfunction

Hazard levels

Hazard level Indication

DANGER:

WARNING:

A hazardous situation which, if not avoided, will result in

death or serious injury

A hazardous situation which, if not avoided, could result

in death or serious injury

CAUTION:

NOTICE:

Concertor™ 6020 Installation, Operation, and Maintenance Manual 3

A hazardous situation which, if not avoided, could result

in minor or moderate injury

Notices are used when there is a risk of equipment

damage or decreased performance, but not personal

injury.

1 Introduction and Safety

Special symbols

Some hazard categories have specific symbols, as shown in the following table.

Electrical hazard Magnetic fields hazard

Electrical Hazard:

1.3 User safety

All regulations, codes, and health and safety directives must be observed.

The site

• Observe lockout/tagout procedures before starting work on the product, such as

transportation, installation, maintenance, or service.

• Pay attention to the risks presented by gas and vapors in the work area.

• Always be aware of the area surrounding the equipment, and any hazards posed by

the site or nearby equipment.

Qualified personnel

This product must be installed, operated, and maintained by qualified personnel only.

Protective equipment and safety devices

• Use personal protective equipment as needed. Examples of personal protective

equipment include, but are not limited to, hard hats, safety goggles, protective gloves

and shoes, and breathing equipment.

• Make sure that all safety features on the product are functioning and in use at all times

when the unit is being operated.

CAUTION:

1.4 Special hazards

Biological hazards

The product is designed for use in liquids that can be hazardous to your health. Observe

these rules when you work with the product:

• Make sure that all personnel who may come into contact with biological hazards are

vaccinated against diseases to which they may be exposed.

• Observe strict personal cleanliness.

WARNING: Biological Hazard

Infection risk. Rinse the unit thoroughly with clean water before working on it.

Wash the skin and eyes

Follow these procedures for chemicals or hazardous fluids that have come into contact

with your eyes or your skin:

Condition Action

Chemicals or hazardous fluids in

eyes

Chemicals or hazardous fluids on

skin

1. Hold your eyelids apart forcibly with your fingers.

2. Rinse the eyes with eyewash or running water for at least 15 minutes.

3. Seek medical attention.

1. Remove contaminated clothing.

2. Wash the skin with soap and water for at least 1 minute.

3. Seek medical attention, if necessary.

4 Concertor™ 6020 Installation, Operation, and Maintenance Manual

1.5 Protecting the environment

Emissions and waste disposal

Observe the local regulations and codes regarding:

• Reporting of emissions to the appropriate authorities

• Sorting, recycling and disposal of solid or liquid waste

• Clean-up of spills

Exceptional sites

CAUTION: Radiation Hazard

Do NOT send the product to Xylem if it has been exposed to nuclear radiation, unless

Xylem has been informed and appropriate actions have been agreed upon.

1.6 Spare parts

CAUTION:

Only use the manufacturer’s original spare parts to replace any worn or faulty

components. The use of unsuitable spare parts may cause malfunctions, damage, and

injuries as well as void the warranty.

1 Introduction and Safety

1.7 Warranty

For information about warranty, see the sales contract.

Concertor™ 6020 Installation, Operation, and Maintenance Manual 5

2 Transportation and Storage

2 Transportation and Storage

2.1 Inspect the delivery

2.1.1 Inspect the package

1. Inspect the package for damaged or missing items upon delivery.

2. Note any damaged or missing items on the receipt and freight bill.

3. File a claim with the shipping company if anything is out of order.

If the product has been picked up at a distributor, make a claim directly to the

distributor.

2.1.2 Inspect the unit

1. Remove packing materials from the product.

Dispose of all packing materials in accordance with local regulations.

2. Inspect the product to determine if any parts have been damaged or are missing.

3. If applicable, unfasten the product by removing any screws, bolts, or straps.

For your personal safety, be careful when you handle nails and straps.

4. Contact the local sales representative if there is any issue.

2.2 Transportation guidelines

Precautions

DANGER: Crush Hazard

Moving parts can entangle or crush. Always disconnect and lock out power before

servicing to prevent unexpected startup. Failure to do so could result in death or serious

injury.

Position and fastening

The unit can be transported either horizontally or vertically. Make sure that the unit is

securely fastened during transportation, and cannot roll or fall over.

2.2.1 Lifting

Always inspect the lifting equipment and tackle before starting any work.

WARNING: Crush Hazard

1) Always lift the unit by its designated lifting points. 2) Use suitable lifting equipment and

ensure that the product is properly harnessed. 3) Wear personal protective equipment. 4)

Stay clear of cables and suspended loads.

NOTICE:

Never lift the unit by its cables or hose.

Lifting equipment

Lifting equipment is always required when handling the unit. It must fulfill the following

requirements:

• The minimum height (contact your local sales and service representative for

information) between the lifting hook and the floor must be sufficient to lift the unit.

• The lifting equipment must be able to hoist the unit straight up and down, preferably

without the need for resetting the lifting hook.

• The lifting equipment must be securely anchored and in good condition.

6 Concertor™ 6020 Installation, Operation, and Maintenance Manual

2 Transportation and Storage

• The lifting equipment must support the weight of the entire assembly and must only

be used by authorized personnel.

• Two sets of lifting equipment must be used to lift the unit for repair work.

• The lifting equipment must be dimensioned to lift the unit with any remaining pumped

media in it.

• The lifting equipment must not be oversized.

CAUTION: Crush Hazard

Over-dimensioned lifting equipment can lead to injury. A site-specific

risk analysis must be done.

2.3 Temperature ranges for transportation, handling and storage

Handling at freezing temperature

At temperatures below freezing, the product and all installation equipment, including the

lifting gear, must be handled with extreme care.

Make sure that the product is warmed up to a temperature above the freezing point

before starting up. Avoid rotating the impeller/propeller by hand at temperatures below

the freezing point. The recommended method to warm the unit up is to submerge it in the

liquid which will be pumped or mixed.

NOTICE:

Never use a naked flame to thaw the unit.

Unit in as-delivered condition

If the unit is still in the condition in which it left the factory - all packing materials are

undisturbed - then the acceptable temperature range during transportation, handling and

storage is: –50°C (–58ºF) to +60°C (+140ºF).

If the unit has been exposed to freezing temperatures, then allow it to reach the ambient

temperature of the sump before operating.

Lifting the unit out of liquid

The unit is normally protected from freezing while operating or immersed in liquid, but

the impeller/propeller and the shaft seal may freeze if the unit is lifted out of the liquid

into a surrounding temperature below freezing.

Units equipped with an internal cooling system are filled with a mixture of water and 30%

glycol. This mixture remains a flowing liquid at temperatures down to –13°C (9°F). Below –

13°C (9°F), the viscosity increases such that the glycol mixture will lose its flow properties.

However, the glycol-water mixture will not solidify completely and thus cannot harm the

product.

Follow these guidelines to avoid freezing damage:

1. Empty all pumped liquid, if applicable.

2. Check all liquids used for lubrication or cooling, both oil and water-glycol mixtures, for

the presence of unacceptable amounts of water. Change if needed.

2.4 Storage guidelines

Storage location

The product must be stored in a covered and dry location free from heat, dirt, and

vibrations.

NOTICE:

Protect the product against humidity, heat sources, and mechanical damage.

Concertor™ 6020 Installation, Operation, and Maintenance Manual 7

2 Transportation and Storage

NOTICE:

Do not place heavy weights on the packed product.

Long-term storage

If the unit is stored more than six months, then the following apply:

• Before operating the unit after storage, it must be inspected with special attention to

the seals and the cable entry.

• The impeller/propeller must be rotated every other month to prevent the seals from

sticking together.

Packaging material stacking limit

If the packaging material has an indicated stacking limit, then it is valid for 23°C (73°F) and

50% relative humidity. Depending on the material, other temperature and humidity

ranges can reduce the stacking limit.

8 Concertor™ 6020 Installation, Operation, and Maintenance Manual

3 System Description

WS009752A

3

1

2

3.1 System overview

Concertor™ is a wastewater pumping system with integrated intelligent technology. The

system is available in different configurations depending on requirements in the pumping

applications.

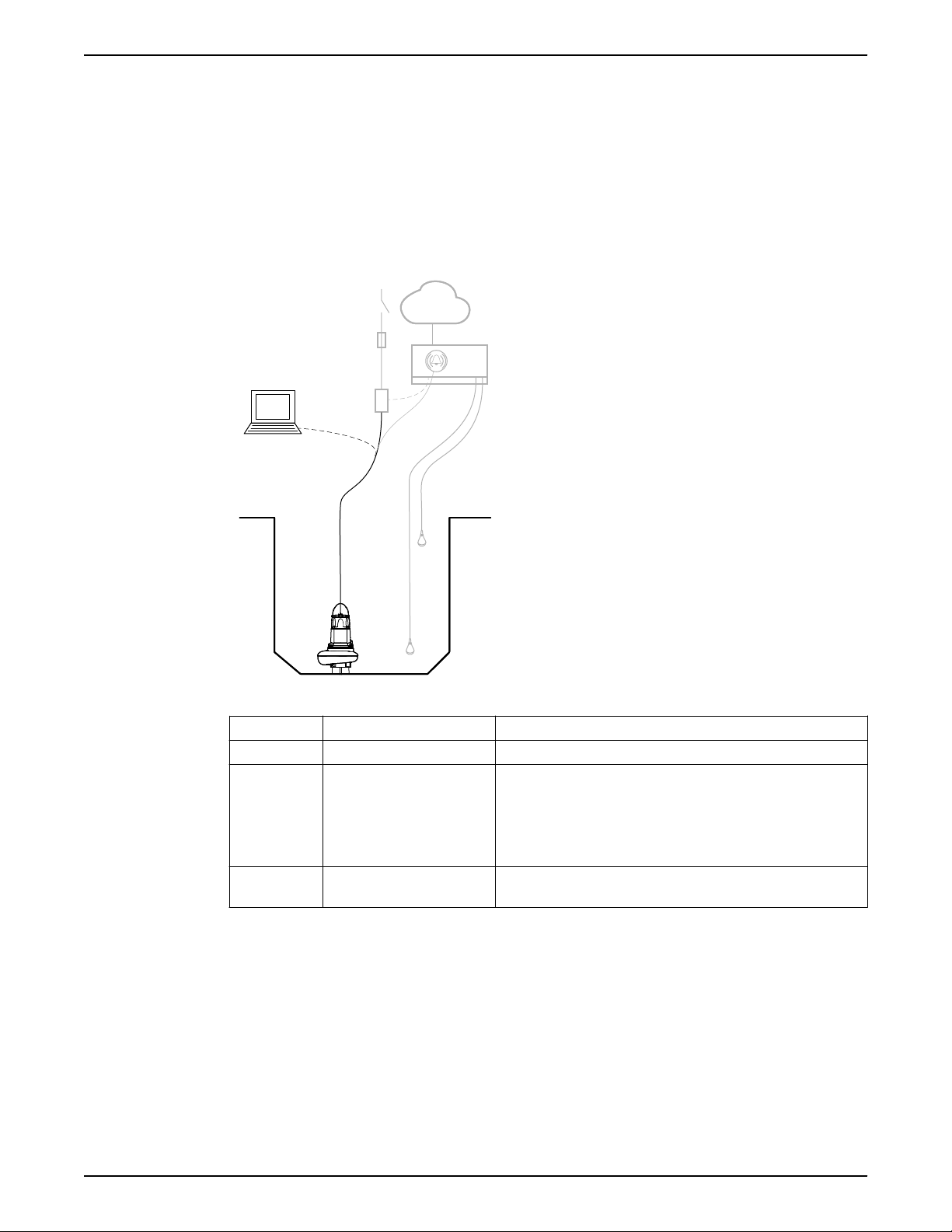

3.1.1 Concertor™ N

3 System Description

Parts

Number Part Description

1 Pump A pump in the Concertor™ system series.

2 Components outside of the

Concertor™ system

3 PC application Dirigo™ Service Tool gives access to settings and log files.

Functions

• Pump clog detection

• Pump cleaning

• Soft-start

• Constant power

• Always correct rotation

• Pump sum-alarm I/O

• Change pump performance, Dirigo™ Service Tool

• Contactors, fuses, relays

• Control system

• Level sensors

• Cloud services

• Pump sum-alarm I/O

Connection is made through T3 and T4.

Concertor™ 6020 Installation, Operation, and Maintenance Manual 9

WS009753A

34

1

2

3 System Description

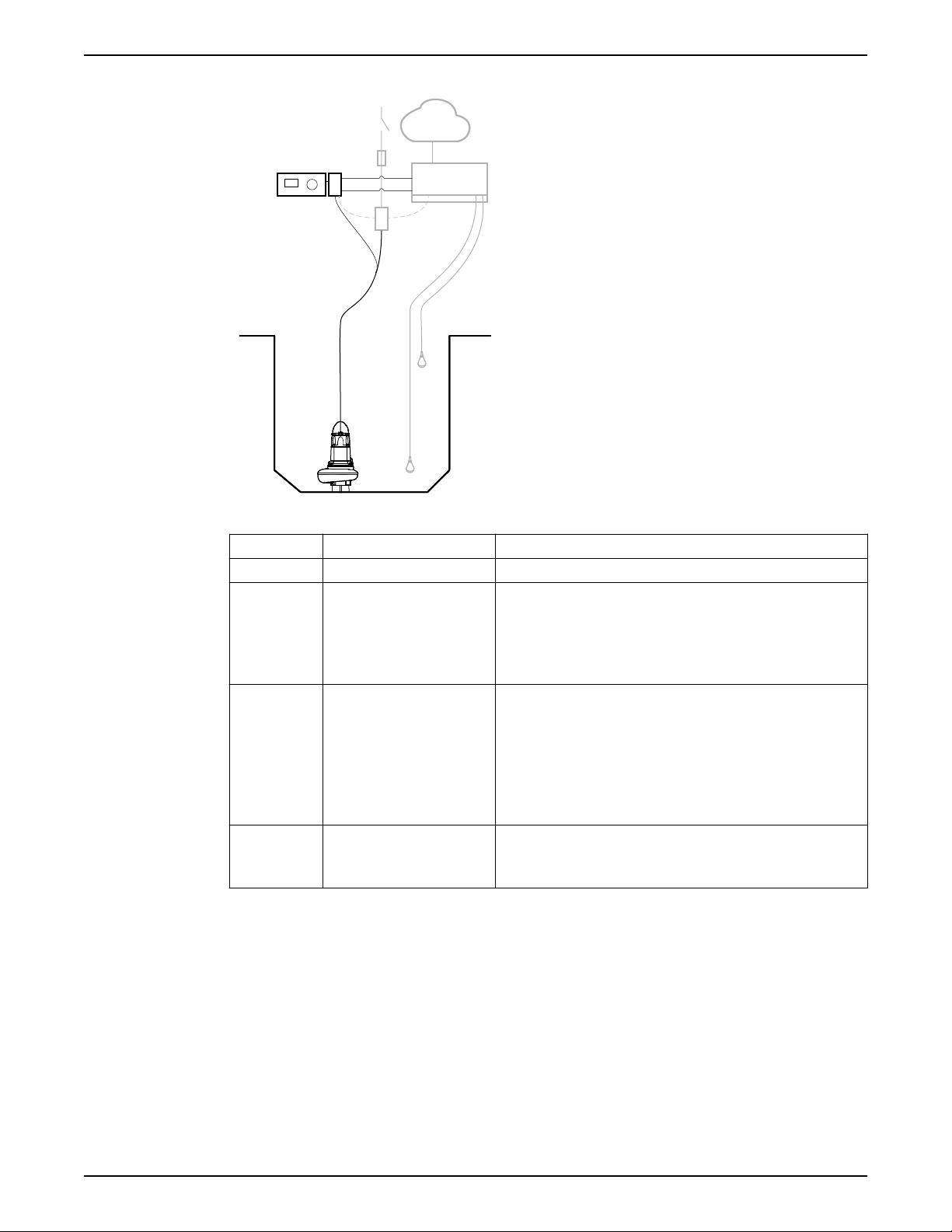

3.1.2 Concertor™ EA

Parts

Functions

Number Part Description

1 Pump A pump in the Concertor™ system series.

2 Components outside of the

Concertor™ system

• Contactors, fuses, relays

• Control system

• Level sensors

• Cloud services

• Pump sum-alarm I/O

3 Gateway, FPG 411 • The gateway starts and stops the pump based on the input

signal from the external control system.

– Digital input signal

– Modbus

• All the alarms are sent back to the external control system.

• The operator changes the pump settings through the gateway.

• Data is logged by and stored in the gateway.

4 HMI, FOP 312 The HMI is handheld, or mounted inside the cabinet or in the

cabinet door.

The HMI is optional.

• Pump clog detection

• Pump cleaning

• Soft-start

• Soft-stop

• Constant power

• Always correct rotation

• Set-up wizard

• Set pump performance (pump stopped)

• Pump alarms with priority A or B, I/O

• Pump and motor control alarms, HMI or Modbus

10 Concertor™ 6020 Installation, Operation, and Maintenance Manual

• Alarm handling

WS009754A

34

1

2

• Status and history

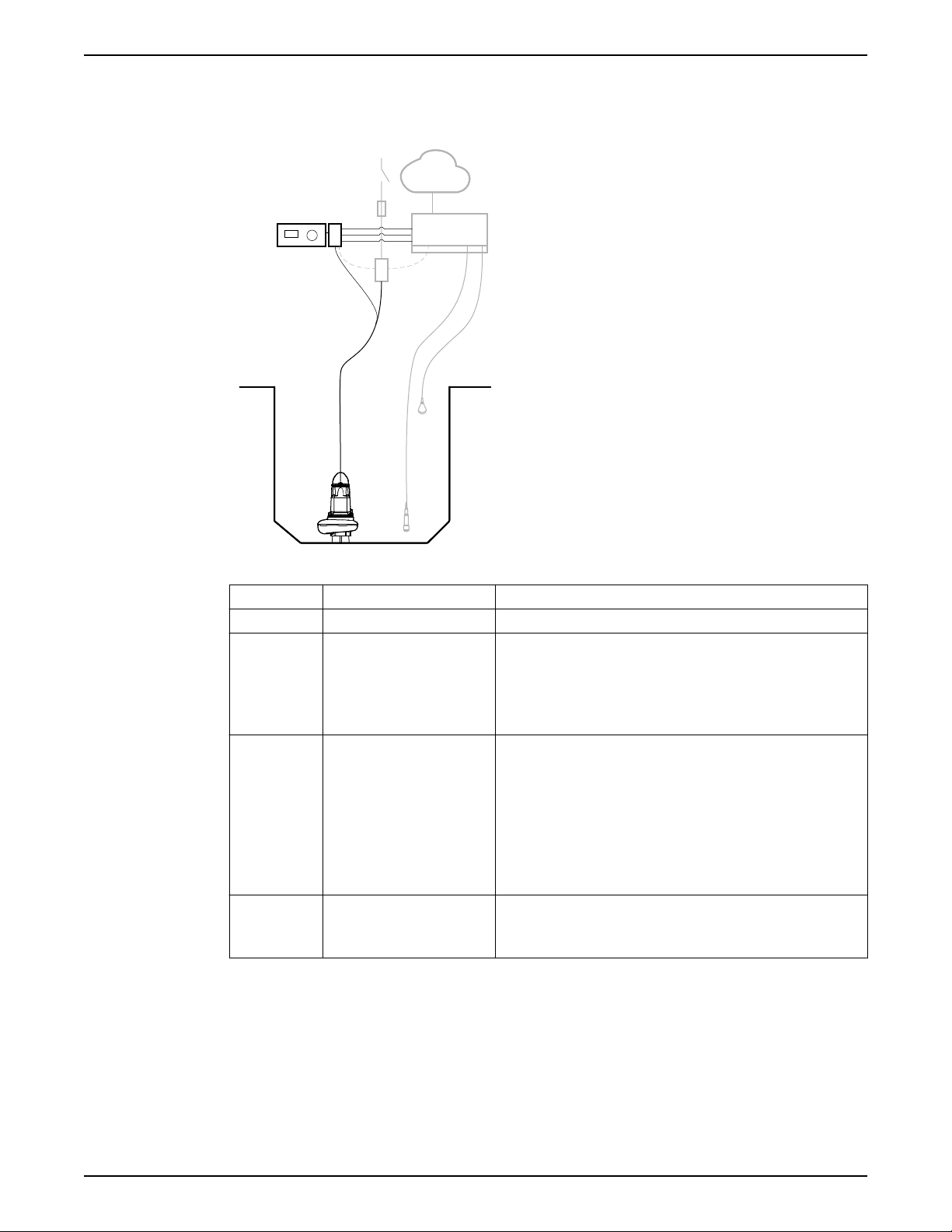

3.1.3 Concertor™ DP

3 System Description

Parts

Functions

Number Part Description

1 Pump A pump in the Concertor™ system series.

2 Components outside of the

Concertor™ system

• Contactors, fuses, relays

• Control system

• Level sensors

• Cloud services

• Pump sum-alarm I/O

3 Gateway, FPG 412 • The gateway starts and stops the pump based on the input

signal from the external control system.

– Digital input signal

– Analog input signal

– Modbus

• All the alarms are sent back to the external control system.

• The operator changes the pump settings through the gateway.

• Data is logged by and stored in the gateway.

4 HMI, FOP 312 The HMI is handheld, or mounted inside the cabinet or in the

cabinet door.

The HMI is optional.

• Pump clog detection

• Pump cleaning

• Soft-start

• Soft-stop

• Constant power

• Always correct rotation

• Set-up wizard

Concertor™ 6020 Installation, Operation, and Maintenance Manual 11

3 System Description

• External process control for dynamic pump performance, 4–20 mA or Modbus

• Pump alarms with priority A or B, I/O

• Pump and motor control alarms, HMI or Modbus

• Alarm handling

• Status and history

12 Concertor™ 6020 Installation, Operation, and Maintenance Manual

4 Product Description

Products included

System Pump version Gateway

Concertor™ N 6020.180 –

Concertor™ EA 6020.180 FPG 411

Concertor™ DP 6020.180 FPG 412

4.1 The pump

4.1.1 Pump design

The pump is designed for submersible use, and driven by a control system that is

connected to a permanent-magnet synchronous motor. For motor data, see Technical

Reference on page 48.

Intended use

The product is intended for moving waste water, sludge, raw and clean water. Always

follow the limits given in Technical Reference on page 48. If there is a question regarding

the intended use of the equipment, please contact a local sales and service representative

before proceeding.

4 Product Description

DANGER: Explosion/Fire Hazard

Special rules apply to installations in explosive or flammable atmospheres. Do not install

the product or any auxiliary equipment in an explosive zone unless it is rated explosionproof or intrinsically-safe. If the product is EN/ATEX-, MSHA- or FM-approved, then see

the specific EX information in the Safety chapter before taking any further actions.

Concertor™ 6020 Installation, Operation, and Maintenance Manual 13

WS009987A

8

10

11

12

13

9

5

4

3

15

2

1

6

7

RS485

DI

1

2

3

4

GND

A

AI

AO

HMI

1

2

3

4

5

B

GND

24VDC

+

_

+

_

+

_

PWR

DI1

DI2

DI3

DI4

DO1

DO2

DO3

DO4

ALARM A

ALARM B

PUMP RUN/CLEAN

PUMP COMMS

RS485

USB

NODE

ADDRESS

ON

OFF

MASTER

SLAVE

TERM

RS485

DO1

NO

COM

NO

GND

T4

T3

GND

DO2

DO1

NO

COM

NO

GND

DO2

ETHERNET

Concertor™

FPG411

1

2

3

4

5

6

7

8

9

0

14

4 Product Description

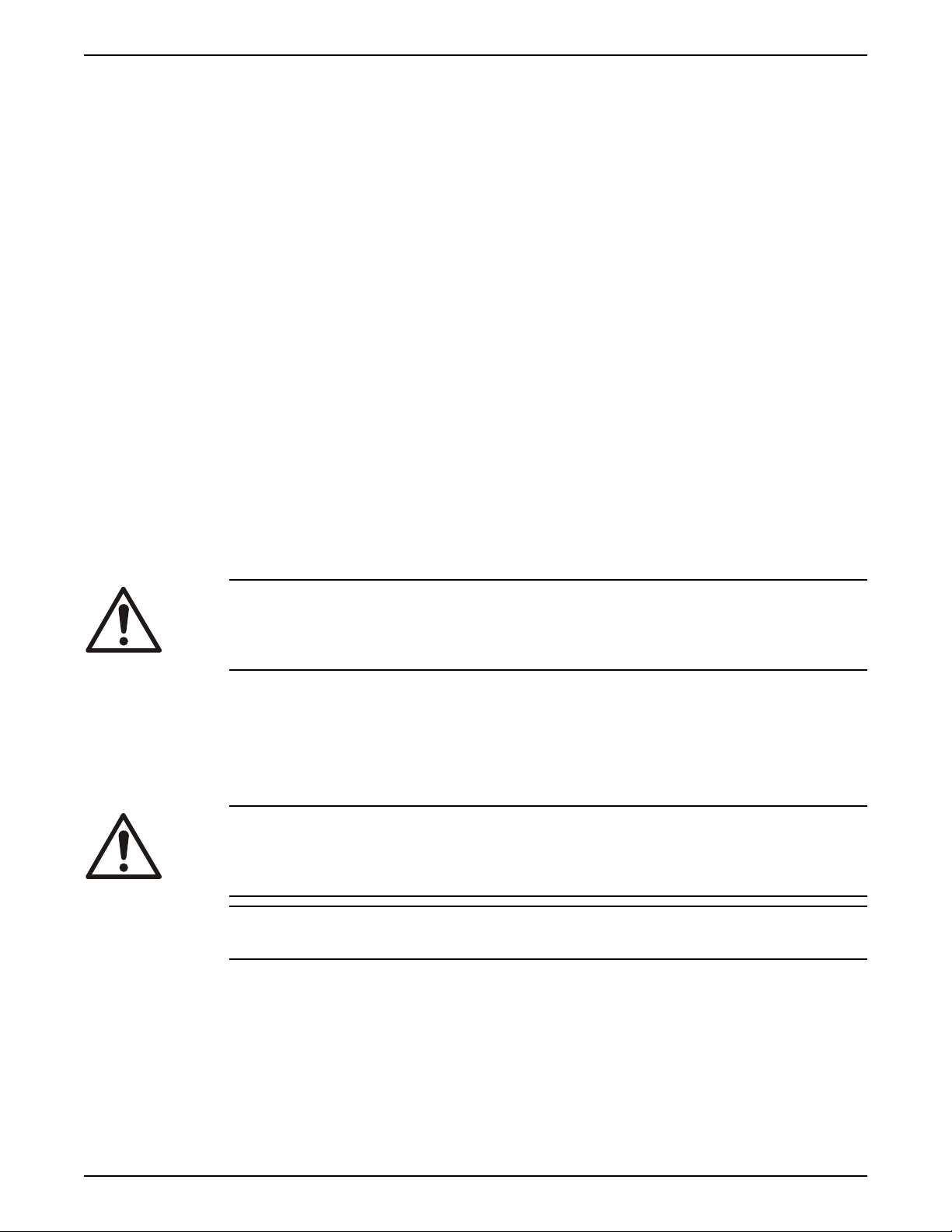

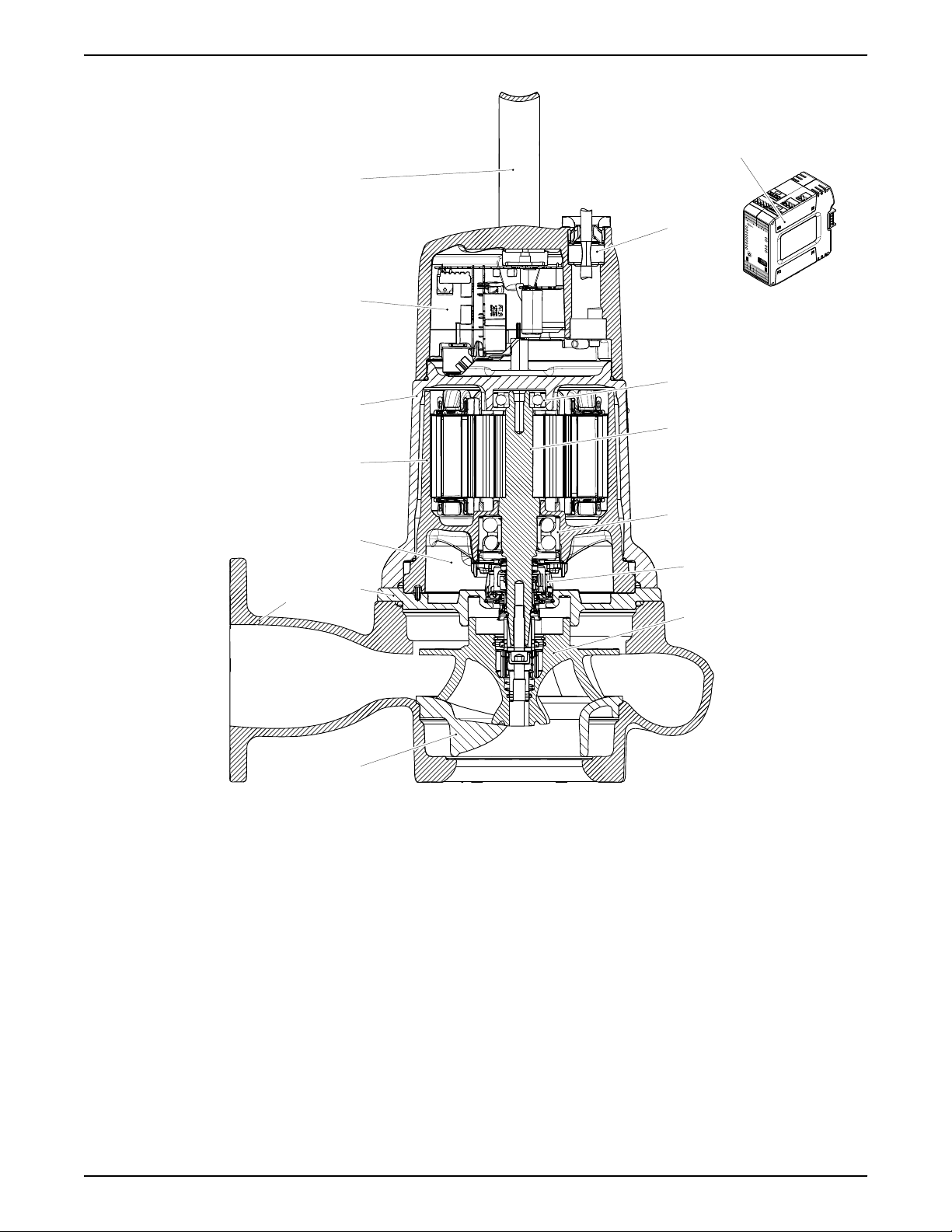

Illustrations

Figure 1: N 6020.180 MT/100, iron

14 Concertor™ 6020 Installation, Operation, and Maintenance Manual

WS009767A

8

10

11

12

13

9

5

4

3

15

2

1

6

7

RS485

DI

1

2

3

4

GND

A

AI

AO

HMI

1

2

3

4

5

B

GND

24VDC

+

_

+

_

+

_

PWR

DI1

DI2

DI3

DI4

DO1

DO2

DO3

DO4

ALARM A

ALARM B

PUMP RUN/CLEAN

PUMP COMMS

RS485

USB

NODE

ADDRESS

ON

OFF

MASTER

SLAVE

TERM

RS485

DO1

NO

COM

NO

GND

T4

T3

GND

DO2

DO1

NO

COM

NO

GND

DO2

ETHERNET

Concertor™

FPG411

1

2

3

4

5

6

7

8

9

0

14

4 Product Description

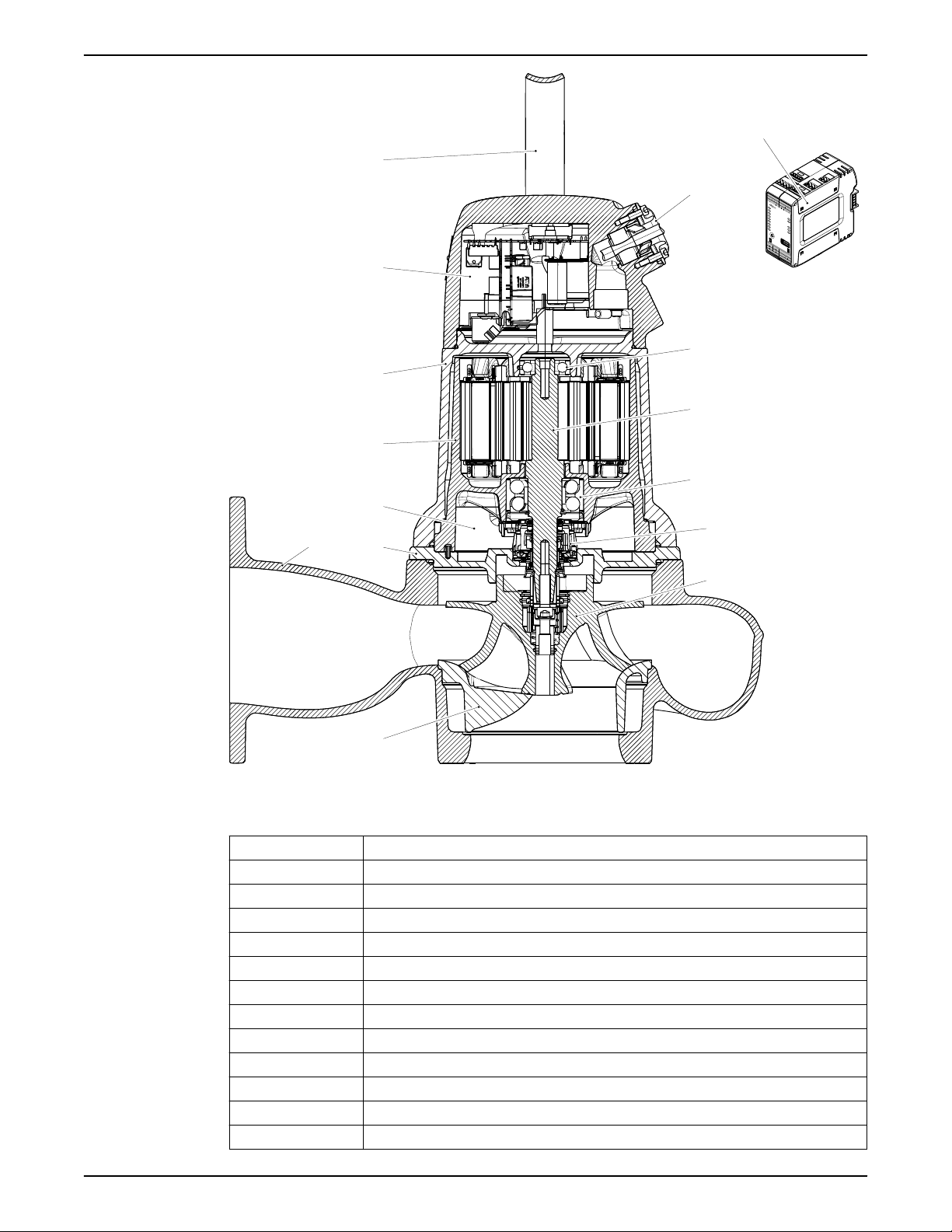

Parts

Figure 2: N 6020.180 LT/150, aluminum

Position Part

1 Insert ring with a guide pin

2 Pump housing, without flush valve connection

3 Seal housing cover

4 Stator housing unit with a leakage sensor

5 Cooling jacket

6 Connection housing with integrated control system

7 Lifting handle

8 Cable entry

9 Support bearing

10 Shaft unit with a permanent magnet rotor

11 Main bearing

12 Mechanical seal

Concertor™ 6020 Installation, Operation, and Maintenance Manual 15

Loading...

Loading...