Page 1

50/60 Hz

ecocirc PREMIUM

Series

WET ROTOR CIRCULATORS FOR

HEATING, COOLING AND SANITARY SYSTEMS

ErP 2009/125/EC

Cod. 191007301 Rev. B Ed.03/2015

Page 2

ecocirc PREMIUM SERIES

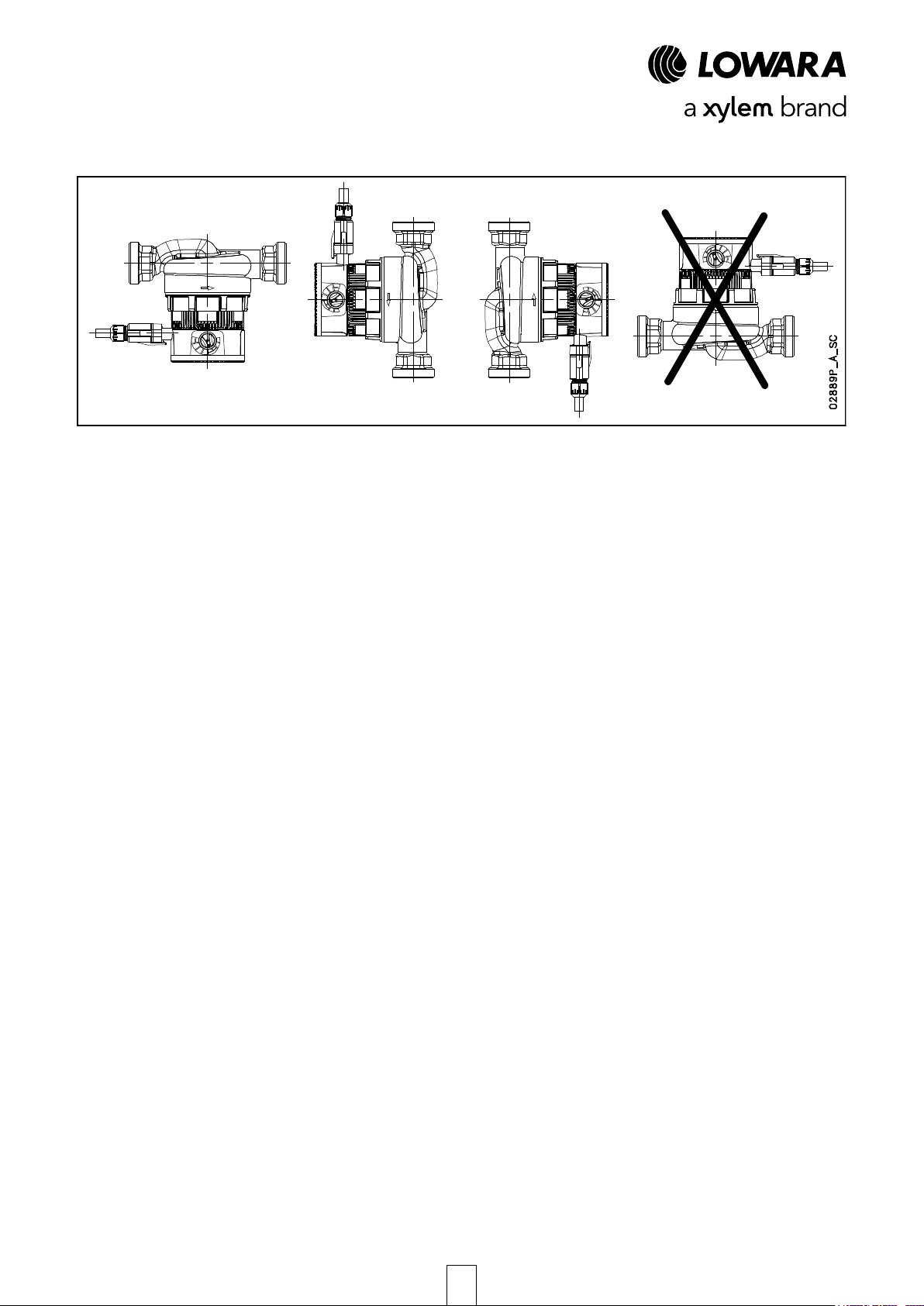

INSTALLATION POSITIONS

Lowara, ecocirc, Xylect are trademarks of Xylem Inc. or one of its subsidiaries.

2

Page 3

ErP

ready

2015

L'alta efficienza del

domani è disponibile

adesso: i nuovi

circolatori Ecocirc

sono conformi alla

Direttiva ErP per il 2015

High

efficiency

circulators

for domesting

heating

ecocirc PREMIUM

Series

MARKET SECTORS

RESIDENTIAL.

APPLICATIONS

•

Water circulation in heating and air

conditioning systems.

•

Refurbishment or extension of existing systems.

•

Recommended for facilities fitted with thermostatic valves.

•

Single-family houses or apartment buildings.

•

Floor heating systems.

SPECIFICATIONS

PUMP

• Flow rate: up to 3,2 m

• Head: up to 5,7 m.

• Maximum power consumption: 23 W (for the 4 m model)

and 42 W (for the 6 m model).

• Temperature of pumped liquid: -10°C ÷ +110°C.

Avoid condensation and ice formation.

Maximum 20% glycol and water mixture.

For glycol quantities higher than 20%, hydraulic performances

must be checked.

• Maximum operating pressure: 10 bar (PN 10).

• Rotor assembly group: made of stainless steel/composite material/carbon.

3

/h.

MOTOR

• Permanent magnet EC (Electronically Commutated) type motor with spherical

rotor/stator.

• Wet rotor with a single spherical ceramic/carbon bearing.

• Integrated motor protection; no external protection required.

• Single-phase 200-240 V 50/60 Hz power supply.

• Variable-speed motor, with automatic speed adjustment based

on system requirement.

• Insulation class F (155°C).

• Protection class IP 44.

3

Page 4

ecocirc PREMIUM

Series

CONSTRUCTION

CHARACTERISTICS

• Improved hydraulics to improved efficiency.

The cast iron pump housing is cataphoresis coated completely and is therefore

resistant to corrosion.

• The spherical rotor. The permanent magnet rotor/impeller unit is the only

moving part. Spherical motor pumps are shaftless, and therefore whisper quiet

over the whole lifetime. In case of an indicated rotor blocking, emergency

software shakes and vibrates the rotor to avoid further blocking.

• Anti-Block-Technology allows to separate the magnetic chamber from the

flow, preventing magnetite and sludge to block and damage the pump.

Blocking up, even in very old, open systems is impossible by our pump design.

• Three in one control:

- step-less manually control constant speed, (displayed by a white LED),

- automatic differential pressure, (displayed by a blue LED),

- automatic constant pressure, (displayed by a green LED).

• Digital multi-Display that shows automatically and alternatively power

consumption (Watt), head (m), and flow-rate (m3/h). The display provides also

detailed information on the air purge mode status as well as detailed error

messages.

• Optimized motor technology: Doubled electric windings combined with

the latest 32 Bit processor technology - that also makes the ecocirc even more

efficient.

• Overtemperature protection feature that slows down the circulator in

case the temperature of the electronic module is too high and shuts it down

when temperature rises above the safety limit. The circulator will automatically

restart after having cooled down.

• Always easy to access: The screw ring design results in a pump motor that

can be rotated in any position around the 360°circle. The electrical connection

as well as the control knob is therefore easy to access.

• Plug an easy and quick electrical connection. By turning the stator via the screw

ring the plug can be fixed in any position, making the installation even in the

hardest and tightest environment easy.

• Automatic air purge: Quick automatic air-venting-mode for a safe operation.

• According to EN standards 60335-1, 60335-2-51, 55014-1, 55014-2,

16297-1, 16297-2.

CONTROL MODES

• Automatic regulation: the pump automatically adjusts the working conditions

based on the requirement of the system. When the pump detects a decrease

in the flow, the inverter reduces the differential pressure of the pump until it

reaches the required head.

ACCESSORIES

• Pipe unions.

• Insulation shell.

INSTALLATION

• Suitable for installation in vertical or horizontal piping, in this last case

not with the motor housing upward.

4

Page 5

ecocirc PREMIUM SERIES

Ecocirc MATERIAL TABLE

MATERIAL

Cast iron ( EN-GJL-200 )

cataphoretically coated

Stainless steel

Composite material

Carbon

Ceramics

EPDM Rubber

Aluminum ( AlSi11Cu2 )

Aluminum ( AlMgSi05 )

Polyamide

ecocircP-50-en_a_tm

Plug

PART

Bearing

Pump body

Rotor assembly group

Gaskets

Motor housing

Screw ring

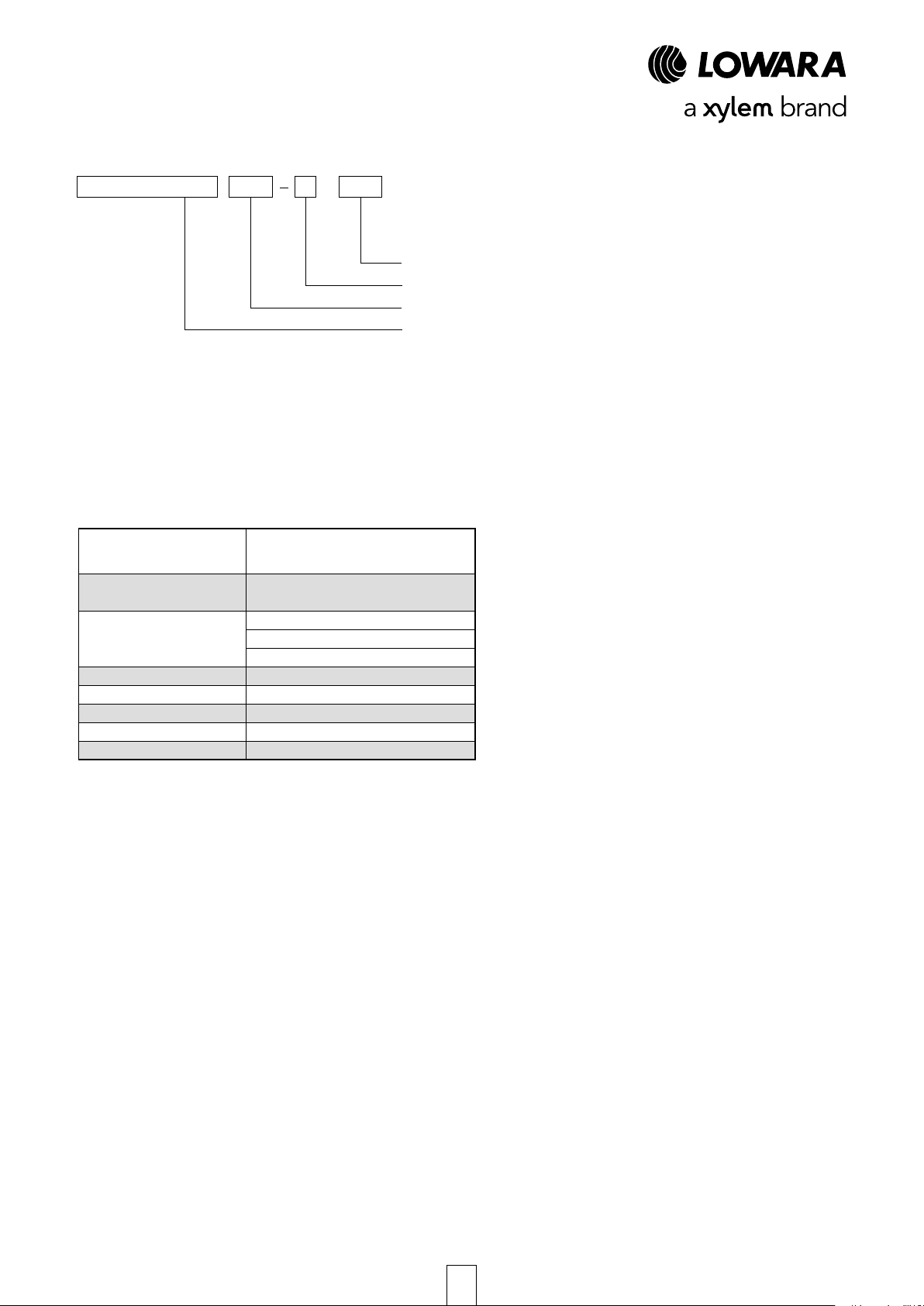

IDENTIFICATION CODE

ecocirc PREMIUM

EXAMPLE : ecocirc PREMIUM 25-4/130

Electronic circulator of the ecocirc PREMIUM series, port nominal diameter = 25,

max head = 4 m, with port to port distance 130 mm.

25

4 130

/

PORT TO PORT DISTANCE IN mm.

MAXIMUM HEAD IN m.

PORT NOMINAL DIAMETER

SERIES NAME

TABLE OF MATERIALS

Regulations (EC) n. 641/2009 and (EU) n. 622/2012 – Annex I – point 2 (Product information

requirements)

a) Energy efficiency index: see the EEI column in the tables in the Hydraulic performance section.

b) “The benchmark for most efficient circulators is EEI ≤ 0,20”.

c) Information relevant for disassembly, recycling or disposal at end-of-life: observe the current laws and by-laws

governing sorted waste disposal. Consult the product operating manual.

d) Information for circulators specifically designed to potable water uses: note not applicable to these products.

5

Page 6

ecocirc PREMIUM...4/ SERIES

TABELLA DI PRESTAZIONI IDRAULICHE CIRCOLATORI SERIE Ecocirc..4 (Costante) Monofase 50 Hz

TABELLA DI PRESTAZIONI IDRAULICHE CIRCOLATORI SERIE Ecocirc..4 (Costante) Monofase 50 HzTABELLA DI PRESTAZIONI IDRAULICHE CIRCOLATORI SERIE Ecocirc..4 (Costante) Monofase 50 Hz

TABELLA DI PRESTAZIONI IDRAULICHE CIRCOLATORI SERIE Ecocirc..4 (Costante) Monofase 50 Hz

0,690,69

2,52,5

15-4/130

20-4/130

25-4/130

25-4/180

TABELLA DI PRESTAZIONI IDRAULICHE CIRCOLATORI SERIE Ecocirc PREMIUM..4 (Proporzionale) Monofase 50 Hz

TABELLA DI PRESTAZIONI IDRAULICHE CIRCOLATORI SERIE Ecocirc PREMIUM..4 (Proporzionale) Monofase 50 HzTABELLA DI PRESTAZIONI IDRAULICHE CIRCOLATORI SERIE Ecocirc PREMIUM..4 (Proporzionale) Monofase 50 Hz

TABELLA DI PRESTAZIONI IDRAULICHE CIRCOLATORI SERIE Ecocirc PREMIUM..4 (Proporzionale) Monofase 50 Hz

0,690,69

2,52,5

15-4/130

20-4/130

25-4/130

25-4/180

HYDRAULIC PERFORMANCE TABLES

(CONSTANT SPEED) (CONSTANT PRESSURE)

PUMP SPEED

TYPE EEI ≤

ecocirc PREMIUM MIN MAX

230V 50Hz (1) W W

0,21

0,21

0,21

0,21

32-4/180

Performances according to standards EN 16297-2. (1) Energy efficiency index. ecocircP4-c-50-en_c_th

0,21

POWER Q = DELIVERY

ABSORBED

min

l/s 0

l/s 0 0,06

l/s 0l/s 0

3333

/h 0

/h 0

mmmm

/h 0/h 0

0,06 0,11

0,11 0,17

0,17 0,22

0,060,06

0,110,11

0,2

0,2 0,4

0,4 0,6

0,20,2

0,40,4

H = TOTAL HEAD METRES COLUMN OF WATER

0,40,5 0,4

0,22 0,28

0,170,17

0,220,22

0,6 0,8

0,60,6

0,4 0,3

0,8 1,0

0,80,8

4 23

3,6 3,4 3,1 2,7 1,32,5 2,4

0,28 0,31

0,31 0,44

0,280,28

0,310,31

1,0 1,1

1,1 1,6

1,01,0

1,11,1

0,2 0,2

0,44 0,56

0,56 0,69

0,440,44

0,560,56

1,6 2,0

2,0 2,5

1,61,6

2,02,0

1,82,9

0,69

2,5

0,5max

(PROPORTIONAL PRESSURE)

PUMP SPEED

TYPE EEI ≤

ecocirc PREMIUM MIN MAX MIN MAX

230V 50Hz (1) W W A A

POWER

ABSORBED

CURRENT Q = DELIVERY

ABSORBED

l/s 0

l/s 0 0,06

l/s 0l/s 0

3333

/h 0

/h 0

mmmm

/h 0/h 0

0,06 0,11

0,11 0,17

0,17 0,22

0,22 0,28

0,060,06

0,110,11

0,170,17

0,2

0,2 0,4

0,4 0,6

0,40,4

0,6 0,8

0,60,6

0,20,2

H = TOTAL HEAD METRES COLUMN OF WATER

0,220,22

0,8 1,0

0,80,8

0,28 0,33

0,280,28

1,0 1,2

1,01,0

0,33 0,44

0,44 0,56

0,330,33

0,440,44

1,2 1,6

1,6 2,0

1,21,2

1,61,6

0,56 0,69

0,69

0,560,56

2,5

2,0 2,5

2,02,0

0,21

0,21

0,21

0,21

32-4/180

Performances according to standards EN 16297-2. (1) Energy efficiency index. ecocircP4-p-50-en_c_th

0,21

0,09 0,284 23

max

0,52

1,53 1,70 1,94 2,25 1,28

0,52 0,49 0,45

0,53

0,43

0,39min

1,75 0,552,62 2,45 2,20

6

Page 7

ecocirc PREMIUM...4/ SERIES

024681012

0246810

024681012

0246810

024681012

0246810

SINGLE-PHASE OPERATING CHARACTERISTICS

ecocirc BASIC/PREMIUM

15-4/13 - 25-4/180

20-4/130 - 32-4/180 - 25-4/130

4

H [m]

7

3

6

5

2

4

3

1

2

1

0

30

P [W]

7

20

6

5

4

10

3

2

1

0

0,0 0,5 1,0 1,5 2,0 2,5 3,0

0,0 0,2 0,4 0,6 0,8

ecocirc PREMIUM

15-4/130 - 25-4/180

20-4/130 - 32-4/180 - 25-4/130

4

H [m]

7

3

6

These performances are valid for liquids with density ρ = 1.0 Kg/dm3 and kinematic viscosity ν = 1 mm2/sec.

Pump operates steplessly. Lines correspond to knob settings and are for reference only.

5

2

4

3

1

2

1

0

30

P [W]

7

20

6

5

10

4

3

2

1

0

0,0 0,5 1,0 1,5 2,0 2,5 3,0

0,0 0,2 0,4 0,6 0,8

EN 16297-2

Q [Imp gpm]

Q [US gpm]

Q [m3/h]

Q [l/s]

EN 16297-2

Q [Imp gpm]

Q [US gpm]

Q [m3/h]

Q [l/s]

ecocirc BASIC/PREMIUM

15-4/130 - 25-4/180

20-4/130 - 32-4/180 - 25-4/130

H [ft]

H [kPa]

12

30

10

8

20

6

4

10

2

0

0

02982C_F_CH

H [ft]

H [kPa]

12

30

10

8

20

6

4

10

2

0

0

02980PC_A_CH

4

H [m]

3

7

6

2

1

0

30

P [W]

20

10

0

0,0 0,5 1,0 1,5 2,0 2,5 3,0

0,0 0,2 0,4 0,6 0,8

5

4

3

2

1

7

6

5

4

3

2

1

EN 16297-2

Q [Imp gpm]

Q [US gpm]

Q [m3/h]

Q [l/s]

H [ft]

H [kPa]

12

30

10

8

20

6

4

10

2

0

0

02980P_F_CH

7

Page 8

ecocirc PREMIUM...6/ SERIES

TABELLA DI PRESTAZIONI IDRAULICHE CIRCOLATORI SERIE Ecocirc PREMIUM..6 (Costante) Monofase 50 Hz

TABELLA DI PRESTAZIONI IDRAULICHE CIRCOLATORI SERIE Ecocirc PREMIUM..6 (Costante) Monofase 50 HzTABELLA DI PRESTAZIONI IDRAULICHE CIRCOLATORI SERIE Ecocirc PREMIUM..6 (Costante) Monofase 50 Hz

TABELLA DI PRESTAZIONI IDRAULICHE CIRCOLATORI SERIE Ecocirc PREMIUM..6 (Costante) Monofase 50 Hz

0,890,89

3,23,2

15-6/130

20-6/130

25-6/130

25-6/180

TABELLA DI PRESTAZIONI IDRAULICHE CIRCOLATORI SERIE Ecocirc PREMIUM..6 (Proporzionale) Monofase 50 Hz

TABELLA DI PRESTAZIONI IDRAULICHE CIRCOLATORI SERIE Ecocirc PREMIUM..6 (Proporzionale) Monofase 50 HzTABELLA DI PRESTAZIONI IDRAULICHE CIRCOLATORI SERIE Ecocirc PREMIUM..6 (Proporzionale) Monofase 50 Hz

TABELLA DI PRESTAZIONI IDRAULICHE CIRCOLATORI SERIE Ecocirc PREMIUM..6 (Proporzionale) Monofase 50 Hz

0,830,83

3,03,0

15-6/130

20-6/130

25-6/130

25-6/180

HYDRAULIC PERFORMANCE TABLES

(CONSTANT SPEED) (CONSTANT PRESSURE)

PUMP SPEED

TYPE EEI ≤

ecocirc PREMIUM MIN MAX

230V 50Hz (1) W W

0,23

0,23

0,23

0,23

32-6/180

Performances according to standards EN 16297-2. (1) Energy efficiency index. ecocircP6-c-50-en_c_th

0,23

POWER

ABSORBED

4 42

l/s 0

l/s 0 0,06

0,06 0,11

l/s 0l/s 0

0,060,06

3333

0,2

0,2 0,4

0,20,2

/h 0

/h 0

mmmm

/h 0/h 0

min 0,5 0,5

5,9 5,6

0,11 0,17

0,110,11

0,4 0,6

0,40,4

H = TOTAL HEAD METRES COLUMN OF WATER

0,4 0,10,4 0,3

Q = DELIVERY

0,17 0,22

0,22 0,31

0,170,17

0,220,22

0,6 0,8

0,8 1,1

0,60,6

0,80,8

0,31 0,44

0,44 0,56

0,310,31

0,440,44

1,1 1,6

1,6 2,0

1,11,1

1,61,6

0,56 0,69

0,69 0,89

0,560,56

0,690,69

2,0 2,5

2,5 3,2

2,02,0

2,52,5

0,89

3,2

0,9max 4,3 3,65,3 5,0 4,7 3,0 2,1

(PROPORTIONAL PRESSURE)

PUMP SPEED

TYPE EEI ≤

ecocirc PREMIUM MIN MAX MIN MAX

230V 50Hz (1) W W A A

POWER

ABSORBED ABSORBED

CURRENT Q = DELIVERY

l/s 0

l/s 0 0,06

0,06 0,11

0,11 0,17

0,17 0,22

0,22 0,28

l/s 0l/s 0

0,060,06

m3/h 0

m3/h 0 0,2

m3/h 0m3/h 0

0,2 0,4

0,20,2

0,110,11

0,170,17

0,4 0,6

0,6 0,8

0,40,4

0,60,6

H = TOTAL HEAD METRES COLUMN OF WATER

0,220,22

0,8 1,0

0,80,8

0,28 0,42

0,280,28

1,0 1,5

1,01,0

0,42 0,56

0,56 0,69

0,420,42

0,560,56

1,5 2,0

2,0 2,5

1,51,5

2,02,0

0,69 0,83

0,83

0,690,69

3,0

2,5 3,0

2,52,5

0,23

0,23

0,23

4 42 0,09

0,47

0,23

32-6/180

Performances according to standards EN 16297-2. (1) Energy efficiency index. ecocircP6-p-50-en_c_th

0,23

min

2,86

0,540,54 0,54

3,09 3,38

0,54 0,54

0,54

0,25

3,70max

2,95

2,15

1,253,70 4,05 4,38

8

Page 9

ecocirc PREMIUM...6/ SERIES

H [m]

0

1

2

3

4

5

6

0 2 4 6 8 10 12 14

H [ft]

0

5

10

15

0 2 4 6 8 10 12

H [kPa]

0

10

20

30

40

50

0,0 0,5 1,0 1,5 2,0 2,5 3,0 3,5

P [W]

0

20

40

60

0,0 0,2 0,4 0,6 0,8

02981PC_A_CH

Q [US gpm]

Q [Imp gpm]

Q [m3/h]

Q [l/s]

ecocirc PREMIUM

15-6/130 - 25-6/180

20-6/130 - 32-6/180 - 25-6/130

4

3

2

7

6

5

1

4

3

2

7

6

5

1

EN 16297-2

H [m]

0

1

2

3

4

5

6

0 2 4 6 8 10 12 14

H [ft]

0

5

10

15

0 2 4 6 8 10 12

H [kPa]

0

10

20

30

40

50

0,0 0,5 1,0 1,5 2,0 2,5 3,0 3,5

P [W]

0

20

40

60

0,0 0,2 0,4 0,6 0,8

02981P_F_CH

Q [US gpm]

Q [Imp gpm]

Q [m3/h]

Q [l/s]

ecocirc BASIC/PREMIUM

15-6/130 - 25-6/180

20-6/130 - 32-6/180 - 25-6/130

4

3

2

7

6

5

1

4

3

2

7

6

5

1

EN 16297-2

SINGLE-PHASE OPERATING CHARACTERISTICS

ecocirc BASIC/PREMIUM

15-6/130 - 25-6/180

20-6/130 - 32-6/180 - 25-6/130

0 2 4 6 8 10 12

0 2 4 6 8 10 12 14

6

H [m]

7

5

6

4

EN 16297-2

Q [Imp gpm]

Q [US gpm]

H [ft]

H [kPa]

50

15

40

5

3

4

2

3

1

2

1

0

50

7

P [W]

40

6

30

5

20

4

3

10

0

These performances are valid for liquids with density ρ = 1.0 Kg/dm3 and kinematic viscosity ν = 1 mm2/sec.

Pump operates steplessly. Lines correspond to knob settings and are for reference only.

2

1

0,0 0,5 1,0 1,5 2,0 2,5 3,0 3,5

0,0 0,2 0,4 0,6 0,8

30

10

20

5

10

0

0

Q [m3/h]

Q [l/s]

02983C_F_CH

9

Page 10

ecocirc PREMIUM SERIES

DIMENSIONI E PESI CIRCOLATORI SERIE Ecocirc PREMIUM 4 2 poli 50 Hz

p

p

p

DIMENSIONI E PESI CIRCOLATORI SERIE Ecocirc PREMIUM 6 2 poli 50 Hz

p

p

p

DIMENSIONS AND WEIGHTS

ecocirc PREMIUM...4/ TABLE

PUMP TYPE WEIGHT

ecocirc PREMIUM

15-4/130 130 65 Rp 1/2" G 1" 15 1,9

20-4/130 130 65

25-4/130 130 65 R

25-4/180 180 90 R

32-4/180 180 90 R

DIMENSIONS (mm)

H H1 D F DN kg

Rp 3/4"

G 1"¼ 20 2,0

1" G 1"½ 25 2,1

1" G 1"½ 25 2,4

1"¼ G 2" 32 2,4

ecocirc PREMIUM...6/ TABLE

PUMP TYPE WEIGHT

ecocirc PREMIUM

15-6/130 130 65 Rp 1/2" G 1" 15 1,9

20-6/130 130 65

25-6/130 130 65 R

25-6/180 180 90 R

32-6/180 180 90 R

DIMENSIONS (mm)

H H1 D F DN kg

Rp 3/4"

G 1"¼ 20 2,0

1" G 1"½ 25 2,1

1" G 1"½ 25 2,4

1"¼ G 2" 32 2,4

ecocircP4-2p50-en_a_td

ecocircP6-2p50-en_a_td

10

Page 11

DOCUMENTATION

11

Page 12

FURTHER PRODUCT SELECTION

AND DOCUMENTATION

Xylect

XylectTM is pump solution selection software with an extensive online database of product information across the entire

Lowara, and Vogel range of pumps and related products, with multiple search options and helpful project management

facilities. The system holds up-to-date product information on thousands of products and accessories.

TM

The possibility to search by applications and the detailed information output given makes it easy to make the optimal

selection without having detailed knowledge about the Lowara and Vogel products.

The search can be made by:

• Application

• Product type

• Duty point

XylectTM gives a detailed output:

• List with search results

• Performance curves (flow, head, power,

efficiency, NPSH)

• Motor data

• Dimensional drawings

• Options

• Data sheet printouts

• Document downloads incl dxf files

The search by application guides users not familiar with

the product range to the right choice.

12

Page 13

FURTHER PRODUCT SELECTION

AND DOCUMENTATION

Xylect

TM

The detailed output makes it easy to select the optimal pump from the given alternatives.

The best way to work with XylectTM is to create a

personal account. This makes it possible to:

• Set own standard units

• Create and save projects

• Share projects with other XylectTM users

Every user have a My Xylect space, where all projects

are saved.

For more information about XylectTM please contact

our sales network or visit www.xylect.com.

Dimensional drawings appear on the screen and can be

downloaded in dxf format.

13

Page 14

14

Page 15

Page 16

Xylem |’zīl m|

e

1) The tissue in plants that brings water upward from the roots;

2) a leading global water technology company.

We’re a global team unified in a common purpose: creating innovative solutions to meet our world’s water

needs. Developing new technologies that will improve the way water is used, conserved, and re-used in the

future is central to our work. We move, treat, analyze, and return water to the environment, and we help people

use water efficiently, in their homes, buildings, factories and farms. In more than 150 countries, we have strong,

long-standing relationships with customers who know us for our powerful combination of leading product

brands and applications expertise, backed by a legacy of innovation.

For more information on how Xylem can help you, go to xyleminc.com.

Legal head office

Xylem Water Solutions Italia Srl

Via Gioacchino Rossini 1/A

20020 – Lainate (MI) - Italy

Tel. (+39) 02 90358.1

Fax (+39) 02 9019990

www.xylemwatersolutions.com

Xylem Water Solutions Italia Srl reserves the right to make modification without prior notice.

Lowara, Xylem are trademarks of Xylem Inc. or one of its subsidiaries

© 2015 Xylem, Inc.

For information and technical support

Xylem Service Italia Srl

Via Dottor Vittorio Lombardi 14

36075 - Montecchio Maggiore (VI) - Italy

Tel. (+39) 0444 707111

Fax (+39) 0444 491043

www.lowara.com

Loading...

Loading...