Page 1

Disc

The disc inserted in the front cover contains the user manual of the models Bredel 10,

Bredel 15 and Bredel 20. The user manual is available in the following languages:

The disc also contains quick-reference instructions for the replacement of the pump

hose. This replacement instruction is only for users that are familiar with the

replacement procedures in the user manual.

How to use the disc

1 Put the disc in the disc drive.

2 Close the disc drive.

The disc will start automatically.

3 Wait until the various language versions appear on screen.

4 Select the required language (click 1x with the left mouse button).

The PDF reader program will automatically start and the required user manual

appears on screen.

Shortcuts

In the left margin you will find the various chapters and paragraphs. These can be

accessed directly by clicking on the required chapter or paragraph.

In the text you will find hyperlink s to chapter s or para graphs . These hy perli nks are li nked

with the required chapters or paragraphs. By clicking a shortcut the required chapter or

paragraph appears on screen.

System requirements

The program on the disc requires a PC with the following minimum system

requirements:

• Disc drive

The following software must be installed on the PC:

• PDF reader program

• An Internet browser

1

Page 2

2

Page 3

Hose pump series

Bredel 10, Bredel 15 and Bredel 20

Manual

3

Page 4

© 2013 Watson-Marlow Bredel B.V.

All rights reserved.

The information provided herein may not be reproduced and/or published in any form,

by print, photoprint, microfilm or any other means whatsoever (electronically or

mechanically) without the prior written authorisation of Watson-Marlow Bredel B.V.

The information provided can be changed without prior notification. Watson-Marlow

Bredel B.V. or one of its representatives cannot be held liable for possible damage

resulting from use of this manual. This is an extens ive limitation of the liability which

applies to all damage, inclusive of (without limitation) compensating, direct, indirect or

consequential damage, loss of data, income or profit, loss or damage to possessions

and claims of third parties.

Watson-Marlow Bredel B.V. provides the information in this manual "as is" and does not

take any responsibility and does not give any guarantee on this manual or its content.

Watson-Marlow Bredel B.V. rejects all responsibilities and guarantees. Furthermore,

Watson-Marlow Bredel B.V. does not take responsibility for and does not guarantee that

the information in this manual is accurate, complete or up to date.

Names, trade names, brands, etc. used by Watson-Marlow Bredel B.V. may not, as per

the legislation concerning the protection of trade names, be considered as available.

4

Page 5

CONTENTS

1 GENERAL

1.1 How to use this manual .......................................................................... 8

1.2 Original instructions .......................................................... ...... ..... ........... 8

1.3 Other supplied documentation ................................................................ 8

1.4 Service and support ................................................................................ 8

1.5 Environment and disposal of waste ........................................................ 9

2SAFETY

2.1 Symbols ................................................................................................ 10

2.2 Intended use ......................................................................................... 11

2.3 Use in potentially explosive atmospheres ............................................. 11

2.4 Responsibility ........................................................................................ 12

2.5 Qualification of the user ........................................................................ 12

2.6 Regulations and instructions ................................................................. 12

3 WARRANTY CONDITIONS

4 DESCRIPTION

4.1 Identification of the product ................................................................... 14

4.1.1 Identification of the product ....................................................... 14

4.1.2 Identification of the pump .......................................................... 14

4.1.3 Identification of the rotor ............................................................ 14

4.1.4 Identification of the gearbox ...................................................... 15

4.1.5 Identification of the electric mo tor .................... ...... ...... ..... ......... 15

4.1.6 Identification of the frequency controller .................................... 16

4.1.7 Identification of the pump hose ................................................. 16

4.2 Construction of the pump ...................................................................... 17

4.3 Operation of the pump .......................................................................... 17

4.4 Pump hose ............................................................................................ 19

4.4.1 General ...................................................................................... 19

4.4.2 Hose compression force adjustment ......................................... 20

4.4.3 Lubrication and cooling ............................................................. 20

4.5 Gearbox ................................................................................................ 20

4.6 Electric motor ........................................................................................ 21

4.7 Frequency controller ............................................................................. 21

4.8 Available options ................................................................................... 21

5

Page 6

5 INSTALLATION

5.1 Unpacking ............................................................................................ 22

5.2 Inspection ............................................................................................. 22

5.3 Installation conditions ........................................................................... 22

5.3.1 Ambient conditions .................................................................... 22

5.3.2 Set-up ........................................................................................ 22

5.3.3 Pipework ................................................................................... 23

5.3.4 Frequency controller ................................................................. 24

5.4 Lifting and moving the pump ................................................................ 25

5.5 Placing the pump .................................................................................. 25

6 COMMISSIONING

6.1 Preparations ......................................................................................... 26

6.2 Commissioning ..................................................................................... 26

7 MAINTENANCE

7.1 General ................................................................................................. 28

7.2 Maintenance and periodic inspections ................................................. 28

7.3 Additional maintenance in potentially explosive environments ............ 30

7.4 Cleaning the pump hose ...................................................................... 30

7.5 Changing lubricant ............................................................................... 31

7.6 Replacing pump hose ................................. .......................................... 31

7.6.1 Removing pump hose ............................................................... 31

7.6.2 Cleaning the pump head ........................................................... 33

7.6.3 Fitting the pump hose ...................... ..... ..................................... 33

7.7 Exchanging replacement parts ............................................................. 35

7.7.1 Replacing rotor, bearings and seal ring .................................... 35

7.8 Fitting options ....................................................................................... 39

7.8.1 Fitting a high-level float switch .................................................. 39

7.8.2 Revolution counter .................................................................... 40

8 STORAGE

8.1 Hose pump ........................................................................................... 41

8.2 Pump hose ........................................................................................... 41

9 TROUBLESHOOTING

10 HAZARDOUS ENVIRONMENTS (ATEX)

10.1 ATEX compliance ................................................................................. 47

10.2 Identification ......................................................................................... 47

6

Page 7

10.2.1 Pump head ................................................................................ 47

10.2.2 Gearbox ..................................................................................... 48

10.2.3 Electric motor ............................................................................ 48

10.2.4 Frequency controller ....................... ...... ...... ..... ...... .................... 48

11 SPECIFICATIONS

11.1 Pump head ........................................................................................... 49

11.1.1 Performance .............................................................................. 49

11.1.2 Materials .................................................................................... 50

11.1.3 Surface treatment ...................................................................... 51

11.1.4 Lubricant table pump ................................................................. 51

11.1.5 Weights ..................................................................................... 51

11.1.6 Torque figures ........................................................................... 52

11.2 Gearbox ................................................................................................ 52

11.3 Electric motor ........................................................................................ 53

11.4 Variable Frequency Drive (VFD) (optional) ........................................... 53

11.5 Parts list ................................................................................................ 54

11.5.1 Overview ................................................................................... 54

11.5.2 Cover assembly .......................................... ............................... 55

11.5.3 Pump head assembly ................................................................ 56

11.5.4 Support assembly ...................................................................... 57

11.5.5 Barbed nipple assembly (PTFE/PDVF) ..................................... 58

11.5.6 Barbed or threaded nipple assembly (stainless steel) ............... 59

11.5.7 Flange assembly (1) .................................................................. 60

11.5.8 Flange assembly (2) .................................................................. 61

11.5.9 Revolution counter assembly ................................ ...... .............. 62

11.5.10Lubricants ................................................................................. 62

EC DECLARATION OF CONFORMITY OF THE MACHINERY

SAFETY FORM

NOTES

7

Page 8

GENERAL

1 GENERAL

1.1 How to use this manual

This manual is intended as a reference book by means

of which qualified users are able to install, commission

and maintain the hose pumps mentioned on the front

cover.

1.2 Original instructions

The original instructions for this manual have been

written in English. Other language versions of this

manual are a translation of the original instructions.

1.3 Other supplied documentation

Documentation o f co mpone nt s su ch as th e gearb ox, the

motor and the frequency co ntrolle r is not inc luded in this

manual. However, if additional documentation is

supplied, you must follow the instructions in this

additional documen t ati on.

1.4 Service and support

For information with respect to specific adjustments,

installation, maintenance or repair jobs which fall

beyond the scope of this manual, contact your Bredel

representative. Make sure you have the following data

at hand:

• Serial number hose pump

• Article number pump hose

• Article number gearbox

• Article number electric motor

• Article number frequency controller

You will find these data on the identification plates or

stickers of the pumphead, the pump hose, the gearbox

and the electric motor. Refer to § 4.1.1.

8

Page 9

1.5 Environment and disposal of waste

CAUTION

Always observe the local rules and regulations with respect to processing (non reusable) parts of the hose pump.

Enquire within your local government about the

possibilities for reuse or environment-friendly

processing of packaging materials, (contaminated)

lubricant and oil.

GENERAL

9

Page 10

SAFETY

2SAFETY

2.1 Symbols

In this manual the following symbols are used:

WARNING

Procedures which, if not carried out with

the necessary care, may resu lt in serious

damage to the hose pump or in serious

bodily harm.

CAUTION

Procedures which, if not carried out with

the necessary care, may resu lt in serious

damage to the hose pum p, the surrounding

area or the environment.

Remarks, suggestions and advice.

10

WARNING

Procedures, remarks, suggestions or

advice which refer to use in potentially

explosive atmos phe res in a ccordance with

the ATEX Directive 94/9/EC.

Page 11

2.2 Intended use

The hose pump is exclusively designed for pumping

suitable products. Every other or further use is not in

conformance with the intended use.

The "Intended use" as laid down in EN 292-1 is "... the

use for which the technical product is intended in

accordance with the specifications of the manufacturer,

inclusive of his indications in the sales brochure". In

case of doubt it is the use which appears to be its

intended use judging from the construction, execution

and function of the product . Observing the i nstructions

in the user's documentation also belongs to intended

use.

Only use the pump in conformance with the intended

use described above. The manufacturer cannot be held

responsible for damage or harm resulting from use that

is not in conformance with the intended use. If you want

to change the application of your hose pump, contact

your Bredel representative first.

2.3 Use in potentially explosive atmospheres

SAFETY

Refer to chapter 10 for a description of pump

configurations th at are suitable in a potentially exp losiv e

atmosphere. Such configurations are suitable for use in

a potentially explosive atmosphere. For use in Europe,

the pump complie s with the European Directi ve 94 /9/EC

(ATEX).

The pumps belong to:

• Group II Appliances, category 2 GD bck T5

Use in Potentially explosive atmospheres

requires special configuration of the pump

unit. Contact y our Bredel rep resentativ e for

use in explosive atmosphe res .

11

Page 12

SAFETY

2.4 Responsibility

The manufacturer does not ac ce pt any resp ons ib ili ty for

damage or harm caused by not (strictly) observing the

safety regulations and instructions in this manual and

the also supplied documentation, or by negligence

during installation, use, maintenance and repair of the

hose pumps mentioned on the front cover. Depending

on the specific working conditions or accessories used,

additional safety instructions can be required.

Immediately contact your Bredel representative, if you

noticed a potential danger while using your hose pump.

WARNING

The user of the hose pump is always fully

responsible for observing the local valid

safety regulations and directives. Observe

these safety regulation s and directives

when using the hose pump.

2.5 Qualification of the user

The installation, use and maintenance of the hose

pump should only be performed by well-trained and

qualified users. Temporary staff and persons in training

may use the hose pump only under the supervision and

responsibility of trained and qualified users.

2.6 Regulations and instructions

• Everyone who works with the hose pump must

be aware of the contents of this manual and

observe the instructions with great car e.

• Never change the order of the actions to be

carried out.

• Always store the manual near the hose pump.

12

Page 13

3 WARRANTY CONDITIONS

The manufacturer offers a two-year warranty on all

parts of the hose pum p. Thi s m ean s th at al l parts will be

repaired or replaced free of charge, with the exception

of consumables, such as pump hoses, hose clamps,

ball bearings, wear rings, and seals, or parts which

have been misused or have been intentionally

damaged.

If parts are used that are not Watson-Marlow Bredel

B.V. (hereafter called Bredel) parts, every warranty

becomes void.

Damaged parts which are covered by the applicable

warranty conditions can be returned to the

manufacturer. The parts must be accompanied by a

fully filled in and signed safety form, as present in the

back of this manual. The safety form must be applied to

the outside of the shipping carton. Parts which have

been contaminated or which have been corroded by

chemicals or other substances which can pose a health

risk, must be cleaned before they are returned to the

manufacturer. Furthermore, it should be indicated on

the safety form which spec ific cleaning procedure has

been followed, and it should be indicated that the

equipment has been decontaminated. The safety form

is required at all items, even if the parts have not been

used.

WARRANTY CONDITIONS

Warranties purporting to be on behalf of Bredel, made

by any person, including representatives of Bredel, its

subsidiaries, or its distributors, which do not accord with

the terms of this warranty shall not be binding upon

Bredel unless expressly approved in writing by a

Director or Manager of Bredel.

13

Page 14

DESCRIPTION

4 DESCRIPTION

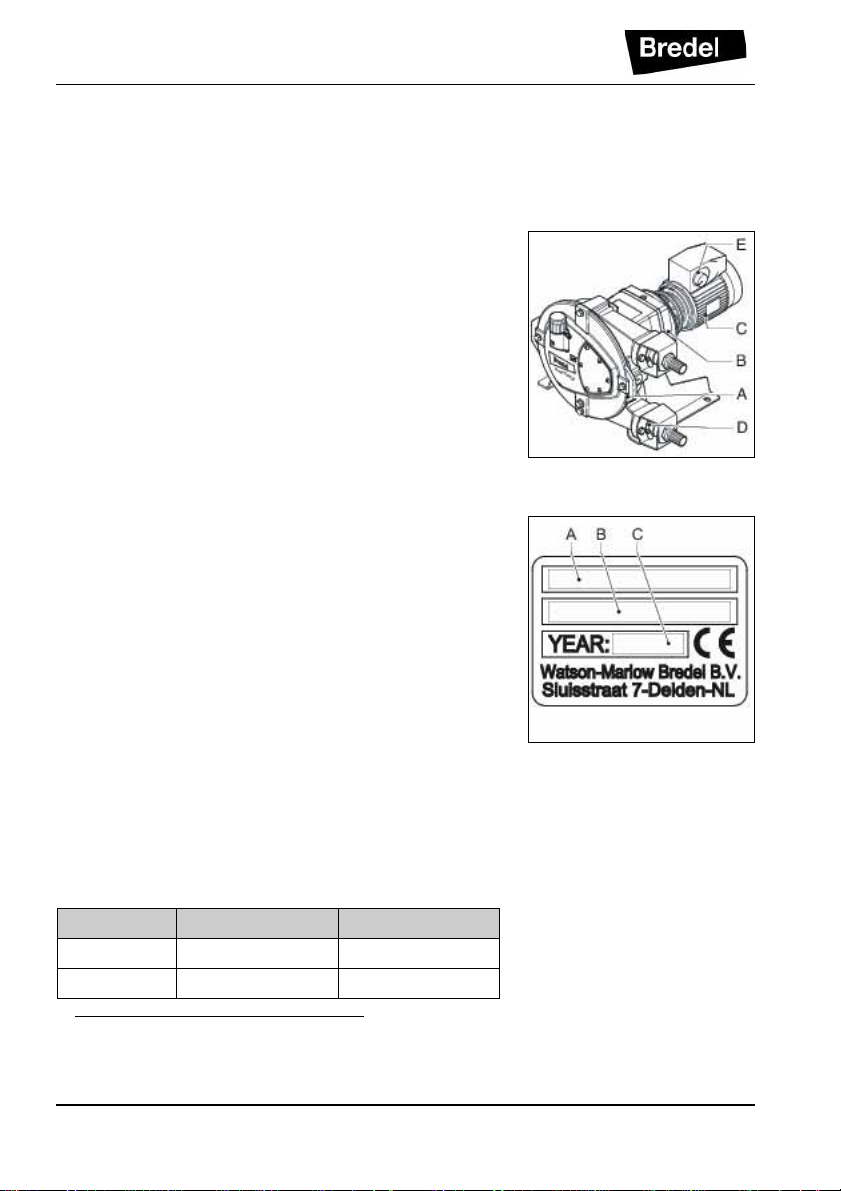

4.1 Identification of the product

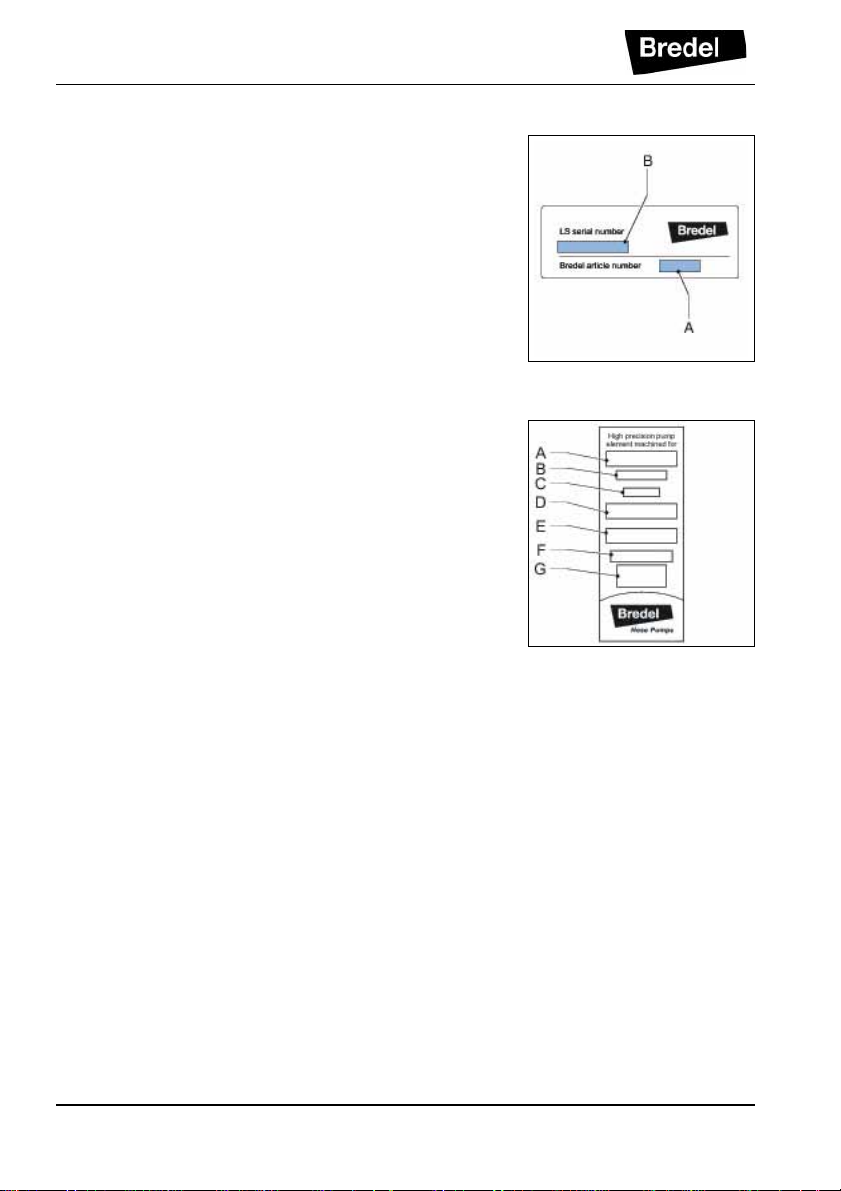

4.1.1 Identification of the product

The hose pump can be identified based on the

identification plates or stickers on:

A: Pump head

B: Gearbox

C: Electric motor

D: Pump hose

E: Frequency controller (option)

4.1.2 Identification of the pump

The identification plate on the pump head contains the

following data:

A: Pump type

B: Serial number and rotor identification letter

1

C: Year of manufacture

4.1.3 Identification of the rotor

The rotor identification letter identifies which type of

rotor is mounted to the pump. The table below shows

the rotor identification letter and the article number of

the mounted rotor. Also refer to 11.5.3.

Letter Bredel 10 Bredel 15-20

blank no rotor no rotor

A 210103L 215103L

1 For information on the rotor identification letter, refer

to 4.1.3.

14

Page 15

Letter Bredel 10 Bredel 15-20

B 210103H 215103H

C - 220103L

D - 220103H

E 210103X 215103X

F - 220103X

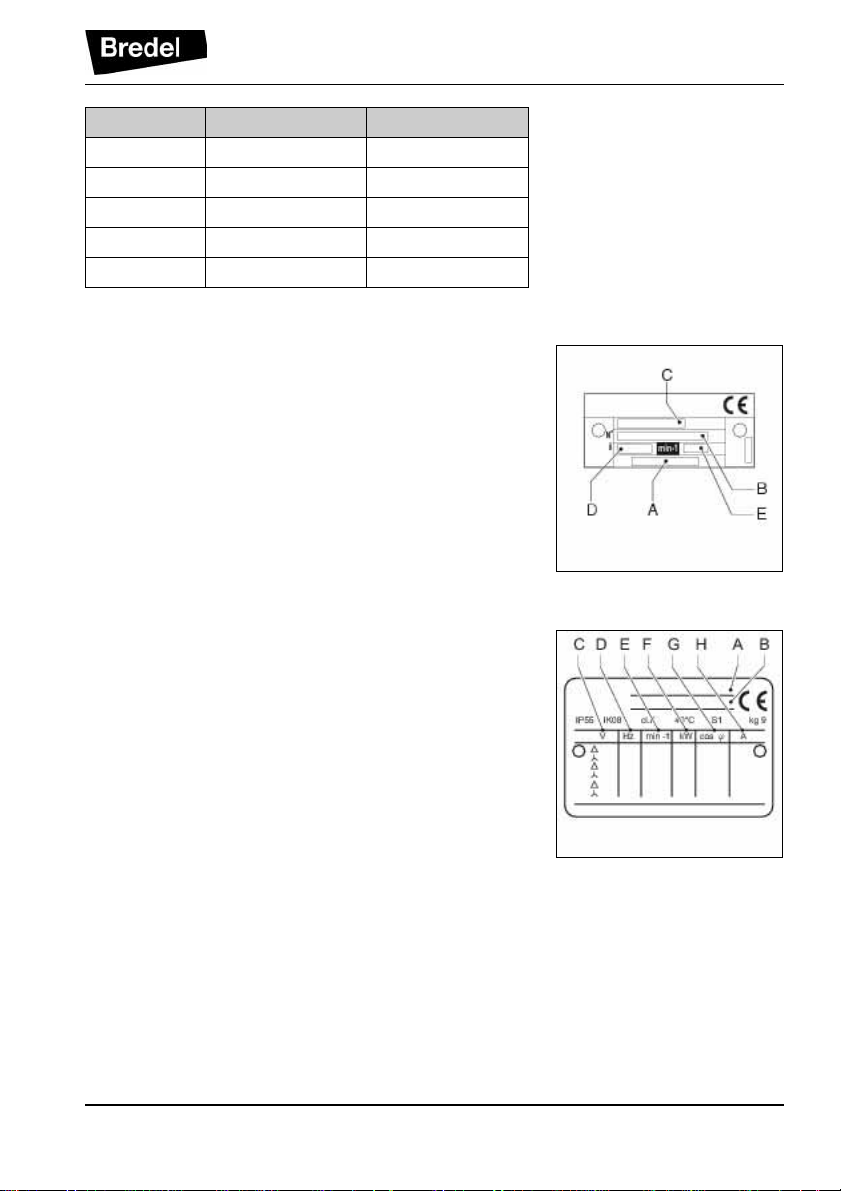

4.1.4 Identification of the gearbox

The identification plate on the gearbox contains the

following data:

A: Article number

B: Serial number

C: Type number

D: Reduction ratio

E: Number of revolutions per minute

4.1.5 Identification of the electric motor

The identification plate on the electric motor contains

the following data:

A: Type number

B: Serial number

C: Article number

D: Mains

E: Frequency

F: Speed

G: Power

H: Power factor

I: Current

DESCRIPTION

15

Page 16

DESCRIPTION

4.1.6 Identification of the frequency controller

The identification of the Bredel Variable Frequency

Drive (VFD) can be found inside the VFD. Remove the

cover by loosening the two screws. The identification

sticker contains the following data:

A: Article number

B: Serial number

4.1.7 Identification of the pump hose

The identification st icker on the pump hose contains the

following data:

A: Pump type

B: Reorder number

C: Internal diameter

D: Type of material of inner liner

E: Remarks, if applicable

F: Maximum permissible working pressure

G: Production code

16

Page 17

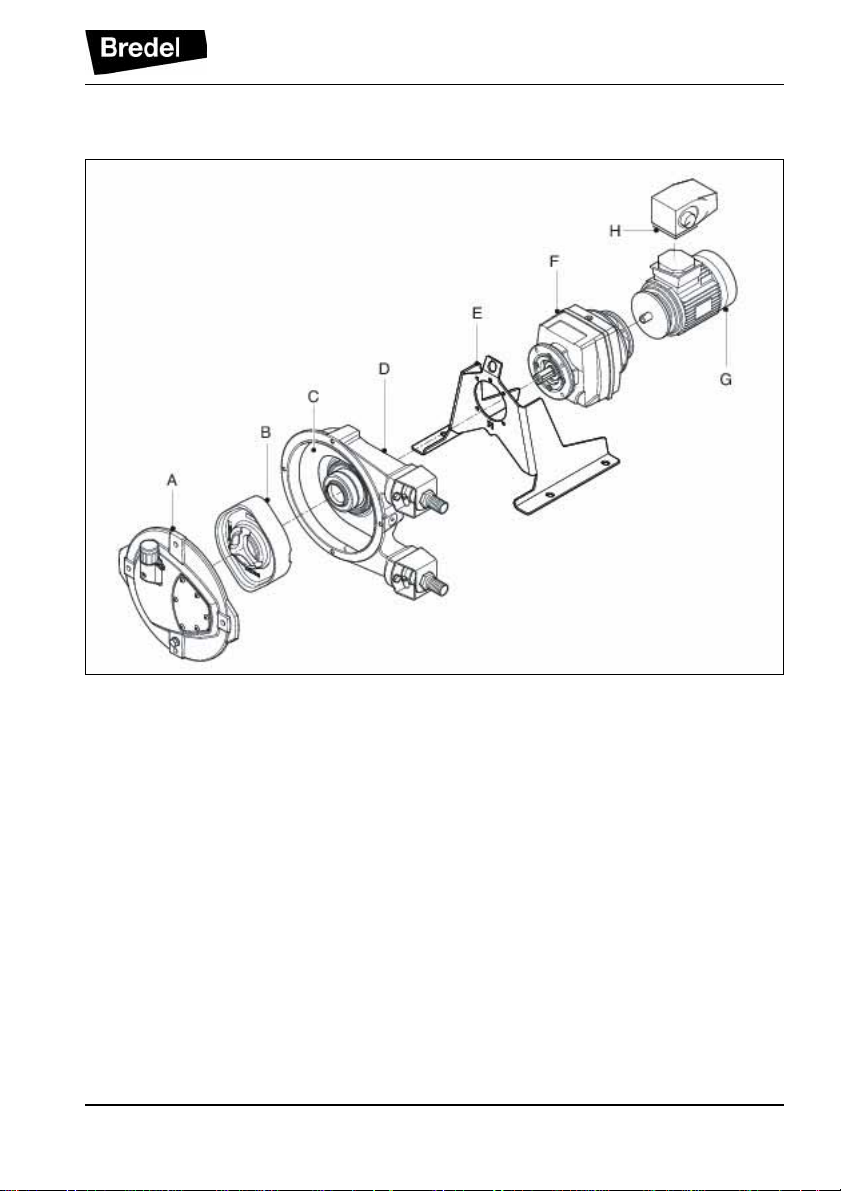

4.2 Construction of the pump

DESCRIPTION

A: Cover

B: Rotor

C: Pump hose

D: Pump housing

E: Support

F: Gearbox

G: Electric motor

H: Frequency controller

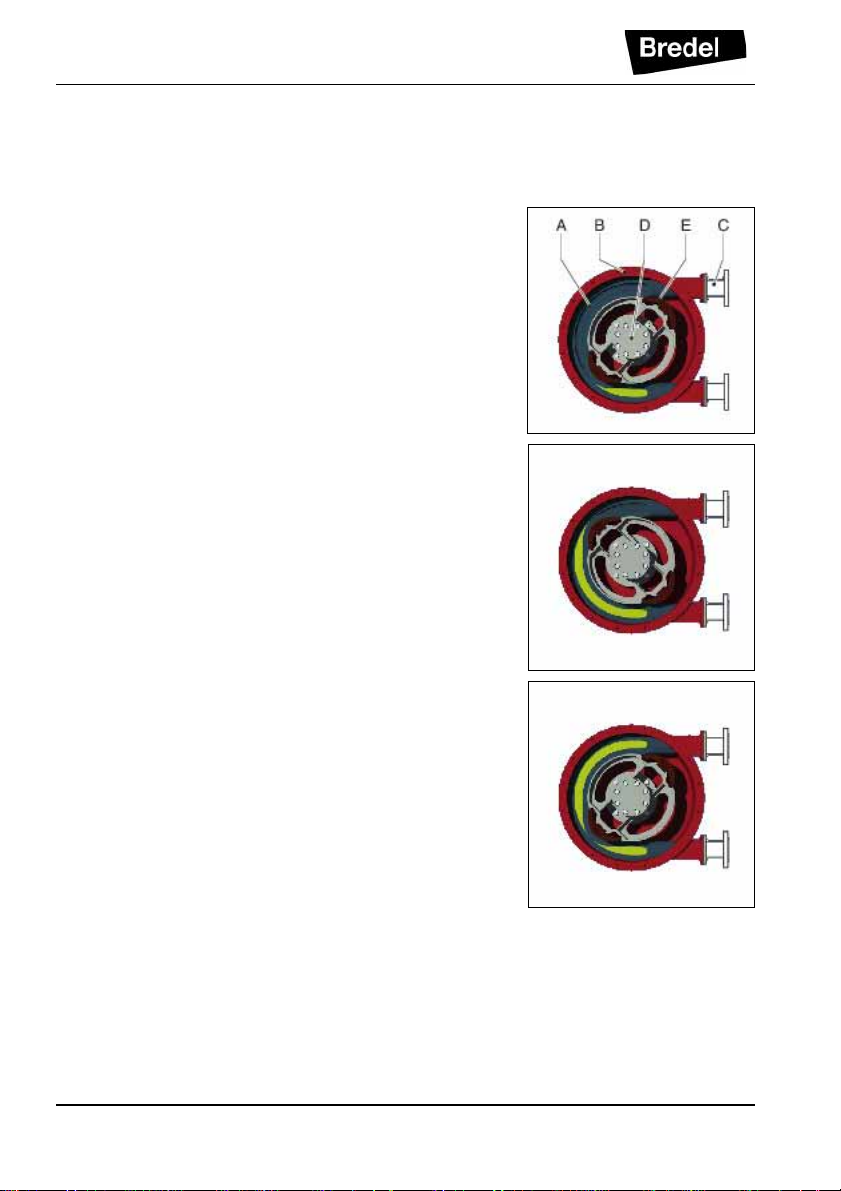

4.3 Operation of the pump

The heart of the pump head consists of a specially

constructed pump hose (A) which lies contorted against

the inside of the pump housing (B). Both ends of the

hose are c onnected to the suction and discha rge lines

17

Page 18

DESCRIPTION

(C). A bearing-mounted rotor (D) with two facing

integral pressing shoes (E) is in the centre of the pump

head.

In phase 1 the lower shoe compresses the pump hose

by the rotational movement of the rotor, forcing the fluid

through the hose. As soon as the shoe has passed, the

hose recovers to its original shape due to the

mechanical properties of the material.

In phase 2 the product is drawn into the hose by the

(continuous) turning motion of the rotor.

In phase 3, the second integral pressing shoe will

subsequently compress the pump hose. Due to the

continuous rotating movement of the rotor not only new

product is sucked in, but also the already present

product is pressed out by the shoe. When the first shoe

runs from the pump hose, the second shoe has already

closed the pump hose and the product is prevented

from flowing back . T his m ethod of liquid displacement is

also known as the "positive displacement principle".

18

Page 19

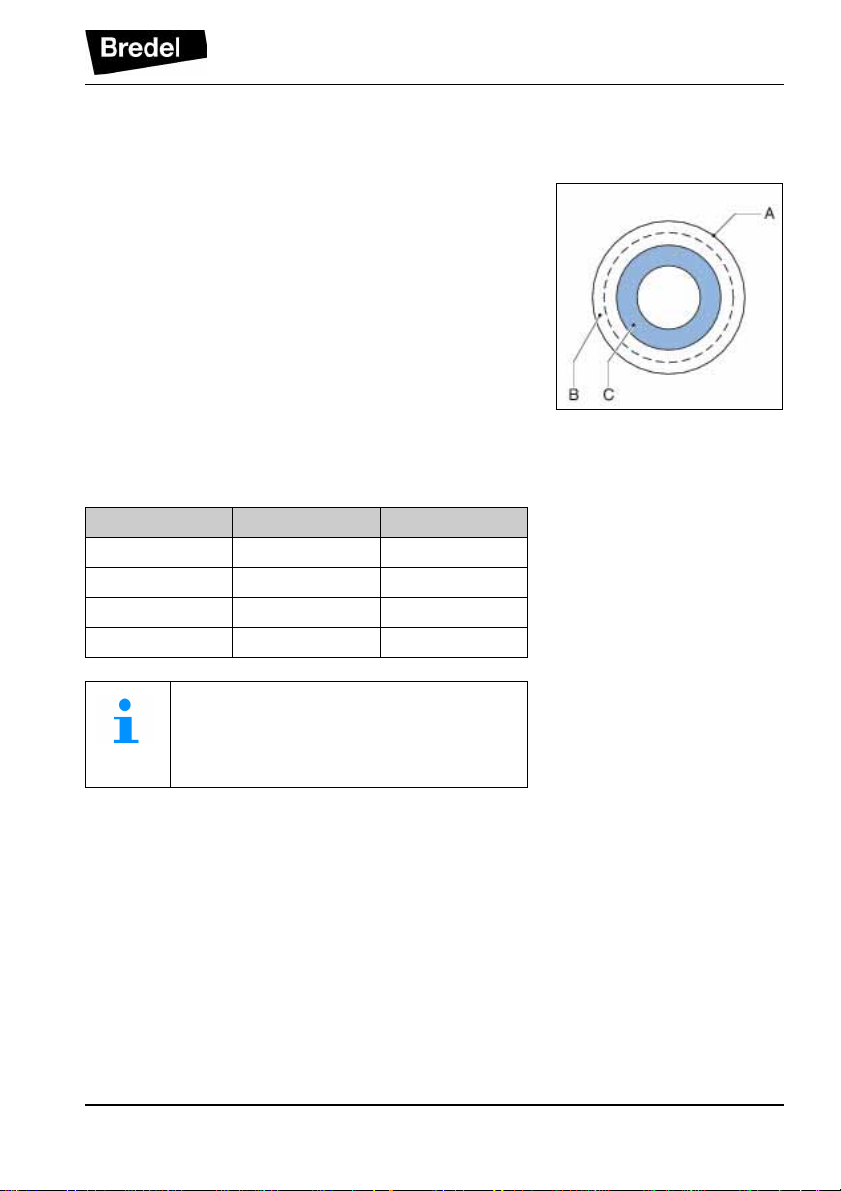

4.4 Pump hose

4.4.1 General A: Outer extruded layer made of natural rubber B: Two nylon reinforcement layers C: Inner extruded liner

The pump hose liner material should be chemically

resistant with the product to be pumped. Dependent on

the specific requirements of your application a

corresponding pump hose must be selected. For each

pump model various hose types are available.

The material of the inner liner of the pump hose

determines the hose type. Each hose type is marked by

a unique colour code.

Hose type Material Colour code

NR Natural rubber Purple

NBR Nitrile rubber Yell ow

EPDM EPDM Red

CSM CSM Blue

DESCRIPTION

Consult your Bredel representative for

more detailed information about the chemical and temperature resistance of pump

hoses.

The Bredel pump hoses have been carefully machined,

therefore there are minimum tolerances in wall

thickness. It is very important to guarantee the cor rect

compression of the pump hose, because:

• When the compression is too high, it creates a

too high load of the pump and pump hose,

which may result in a reduction of the life of the

pump hose and bearings.

19

Page 20

DESCRIPTION

• When the compression is too low, this will result

in loss of capacity and backflow. Backflow

results in a reduction of the life of the pump

hose.

4.4.2 Hose compression force adjustment

The compression force of the pump hose can be

adjusted by installing a rotor with a different dimension

between the tips of the integral pressing shoes. The

rotor is chosen to achieve an optimal life of the pump

hose for the intended us e of th e hos e pu mp . If yo u w ant

to change the application of your hose pump, contact

your Bredel representative .

4.4.3 Lubrication and cooling

The pumphead, in which the rotor and pump hose can

be found, is filled with Bredel Genuine Hose Lubricant.

This lubricant lubricates the movement between the

hose and the pressing shoes and dissipates the

generated heat via the pump housing and the cover.

The lubricant is food grade. See §11.1.4 for the

required quantity an d NSF registration.

Consult your Bredel representative for

lubrication recommendations when operating the hose pump below 2 rpm.

4.5 Gearbox

The hose pump types described in this manual use

helical gearbox units. The gearboxes are fitted with a

flange connection. Refer to § 11.2 for specifications. If

the pump is to be used in potentially explosive

atmospheres, refer to chapter 10.

20

Page 21

4.6 Electric motor

If the electric motor has been standard supplied by the

manufacturer, it is a standardized squirrel-cage motor.

Refer to § 11.3 for specifications. If the pump is to be

used in potentially explosive atmospheres, refer to

chapter 10.

4.7 Frequency controller

Refer to the also s upp lie d documentation of the supplier

and § 11.4. If the pump is to be used in potentially

explosive atmospheres, refer to chapter 10.

4.8 Available options

The following options are available for the hose pump:

• High (lubricant) level float switch

• Revolution counter

• Low, medium, or high pressure rotor

• Rotor and coupling for heavy duty

• Frequency controller

• Special configuration for use in explosive

atmospheres

DESCRIPTION

21

Page 22

INSTALLATION

5 INSTALLATION

5.1 Unpacking

When unpacking carefully follow the instructions as

given on the packaging or on the hose pump.

5.2 Inspection

Check that yo ur deliv ery is c orrect an d check i t for any

transport damage. Refer to § 4.1.1. Report any damage

immediately to your Bredel representative.

5.3 Installation conditions

5.3.1 Ambient conditions

Make sure that the hose pump is in an area where the

ambient temperature during operation is not lower than

-20 °C and not higher than +45 °C.

5.3.2 Set-up

• The pump materials and protective layers are

suitable for indoor set-up and a protected

outdoor set-up. Under certain conditions the

pump is suitable for limited outdoor set-up or a

salty or aggressive atmosphere. Consult your

Bredel representative for more information.

• Make sure that the floor surface is horizontal

and has a maximum slope of 10 mm per metre.

• Make sure that there is sufficient room around

the pump to carry out the necessary

maintenance activitie s.

• Make sure that the room is sufficiently

ventilated, so that the heat developed by the

pump and drive can be discharged. Keep some

distance between the ventilation cover of the

electric motor and wall to enable the supply of

necessary cooling air.

22

Page 23

5.3.3 Pipework

When determining and connecting suction and

discharge lines consider the following points:

• The bore size of the suction and disch arge line s

must be larger than the bore size of the pump

hose. For more information consult your Bredel

representative.

• Limit the presence of sharp bends in the

discharge line. Make sure that the radius of the

bent discharge line is as large as possible

(preferably 5S). It is recommended to use Y-

connections instead of T-connections.

• It is recommended to use a minimum of three

quarters (3/4) of the hose length as flexible

hose in the suction or discharge line. This

avoids the need to remove the connection lines

when changing a pump hose.

• Keep the delivery a nd suction lines as short and

direct as possible.

• Select the correct mounting material for flexible

hoses and make sure that the installation is

suited for the design pressure of the system.

• Prevent any possibilities of exceeding the

maximum worki ng pressure of the ho se pump.

Refer to § 11.1.1. If necessary fit a pressure

relief valve.

INSTALLATION

CAUTION

Consider the maximum permissible working pressure on the discharge side.

Exceeding the ma ximu m wo rking press ure

may lead to serious damage to the pump.

• Make sure that the maximum forces on the

flanges are not exceeded. The permissible

loads are given in the following table.

23

Page 24

INSTALLATION

Maximum permissible loads [N] on the

pump connections

Force Bredel 10 Bredel 15 Bredel 20

F1 600 600 600

F2 300 300 300

F3 120 120 120

5.3.4 Frequency controller

WARNING

A frequency controller that is fitted without

the manual control can start automatically

when power is applied.

If the hose pump is fitted with a frequency controller,

consider the following points:

• Take precautions so the motor does not re-start

automatically af ter an uns ch eduled stop.

In the event of a power or mechanical failure,

the frequency controller controls the motor to

stop. When the cause of the failure is removed,

the motor can restart automatically. The

automatic restart can be dangerous in certain

pump installations.

• All control cables outside the enclosure must be

shielded and have a cross sectional area

between 0.22 and 1 mm

be connected to earth at both ends.

2

. The shielding must

24

Page 25

5.4 Lifting and moving the pump

For lifting and movi ng the hos e pump, the pump s upport

has a lifting eye (A).

The complete hose pump, i.e. pump head, gearbox and

electric motor, must be lifted using the lifting eye plus

additional support using suitably rated straps or

slings (A). For the weights, refer to § 11.1.5.

WARNING

If the pump is to be lifted ensure that all

standard lifting practises are adhered to

and carried out by qualified personnel only.

INSTALLATION

5.5 Placing the pump

Position the pump on a horizontal surface. Use suitable

anchor bolts to attach the pump to the floor surface.

25

Page 26

COMMISSIONING

6 COMMISSIONING

6.1 Preparations

WARNING

A frequency controller that is fitted without

manual control can start the pump auto-

matically when power is applied.

WARNING

Disconnect and lock the power supply to

the pump drive before any work is carried

out.

In case the motor is fitted with a frequency

controller and has a single-phase power

supply, wait two minutes to make sure that

the capacitors have discharged.

1. Connect the electric motor and, if present, the

frequency controller in conformance with the

locally applicab le rules an d regulati ons. Refer to

§ 5.3.4. Have the electrical installation work

carried out by qualified perso nne l.

2. Check that the lubricant level is above the

minimum leve l line in the inspec tion window. If

necessary refill with Bredel Genuine Hose

Lubricant via the breather plug. S ee also § 7.5.

6.2 Commissioning

1. Connect the pipework.

2. Make sure that there are no obstructions such

as closed valves.

3. Switch on the hose pump.

4. Check the rotation of the rotor.

26

Page 27

5. Check the capacity of the hose pump. If the

capacity differs from your specification, follow

the instructions in chapter 9 or consult your

Bredel representative.

6. Check the capacity range of the frequency

controller. In case of any deviations consult the

documentation of the supplier.

7. Check the hose pump in acc orda nc e w it h po in ts

2 to 4 of the maintenance table from §7.2.

COMMISSIONING

27

Page 28

MAINTENANCE

7 MAINTENANCE

7.1 General

WARNING

Disconnect and lock the power supply to

the pump drive before any work is carried

out.

In case the motor is fitted with a frequency

controller and has a single-phase power

supply, wait two minutes to make sure that

the capacitors have discharged.

WARNING

Only use original Bredel parts when maintaining the hose pump. Bredel cannot

guarantee correct operation and any consequential damage that occurs from the

use of non-original Bredel components.

See also chapters 2 and 3.

7.2 Maintenance and periodic inspections

The following maintenance scheme shows the

maintenance and periodic inspection that need to be

carried out on the hose pump to guarantee optimal

safety, operation and life of the pump.

28

Page 29

MAINTENANCE

Point Action To be carried out Remark

1 Check the lubricant

level.

Before startup of the

pump and on a scheduled interval duri ng o peration.

Make sure that the lubricant level is above the

minimum level lin e in the

inspection window.

If necessary refill the

lubricant. See also § 7.5.

2 Check the pump head

for any leakage of lubricant around the cover,

the brackets an d the rear

Before startup of the

pump and on a scheduled interval duri ng o peration.

See § 9.

of the pump head.

3 Check the gearbox for

any leakage.

Before startup of the

pump and on a scheduled interval duri ng o per-

In case of leakage consult your Bredel representative.

ation.

4 Check pump for deviat-

ing temperature or

On a scheduled interval

during operation.

See § 9.

strange noises.

5 Check rotor with integral

pressing shoes for

When replacing the

pump hose.

See § 7.6.

excessive wear.

6 Internal cleaning of the

pump hose.

7 Replacing pump hose. Preventive, this means

Cleaning of the system

or product change.

See § 7.4.

See § 7.6.

after 75% of the hose li fe

of the first hose.

8 Changing lubricant. After every 2

nd

hose

See § 7.5

change or after 5,000

service hours, whic hever

comes first or after hose

rupture.

9 Replacing seal ring. If necessary. See § 7.7.1.

29

Page 30

MAINTENANCE

Point Action To be carried out Remark

10 Replacing rotor with i nte-

gral pressing shoes.

11 Replacing bearings. If necessary. See § 7.7.1.

7.3 Additional maintenance in potentially explosive environments

The following maintenance scheme shows the

additional maintenance and periodic inspections that

need to be carried out on the hose pump to guarantee

an optimal safety, operation and life of the pump in a

potentially explosive environment.

Point Action To be carried out Remark

1 Replacing bearings. According to ATEX regu-

2 Cleaning the hose

pump.

Wear on the runni ng s urface of the pump hose

and/or seal ring.

See § 7.7.1.

lations after 40,000 hrs.

service or wh en damage is suspected.

In potentially explosive

(dust) atmospheres, the

dust must be removed

regularly.

7.4 Cleaning the pump hose

The inside of the pump hose can be easily cleaned by

rinsing the pump with clean water. If a cleaning fluid is

added to the water, check if the hose liner material is

resistant to it. Also check if the pump hose can resist

the cleaning temperature. Special cleaning balls are

also available. Contact your Bredel representative for

more details.

30

Page 31

7.5 Changing lubricant

1. Place a tray (A) under the drain plug in the

cover of the pu mp. Remove the dr ain plug (B) .

Catch the lubricant from the pump housing in

the tray. Position the drain plug and tighten it

firmly.

2. The pump housing can be filled with lubricant

via the breather (A) on the cover. For this

purpose remove the breather cap (B) and

position a funnel (C) in the breather. Pour the

lubricant in the pump housing via the funnel.

3. Keep on pouring until the lubricant level has

risen above the level line in the inspection

window. Place breather cap.

MAINTENANCE

For the required quantity of lubricant, refer

to § 11.1.4.

7.6 Replacing pump hose

7.6.1 Removing pump hose

1. Isolate the pump from the electrical supply.

2. Close any shut-off valves in both the suction

and discharge line to minimize product loss.

31

Page 32

MAINTENANCE

3. Place a tray (A) under the drain plug in the

bottom of the pump head. The tray must be

large enough to contain the lubricant, possibly

contaminated with product fluid, from the pump

head. Remove the drain plug (B). Catch the

lubricant from the pump housing in the tray.

Check that th e breather mounted on the cover

is not obscured. Position the drain plug and

tighten it firmly.

4. Disconnect the suction and discharge lines.

5. Loosen hose clamp (A) of both the inlet and

outlet ports by loosening bolt (B).

6. Loosen the retaining bolts (A) of the bracket (B)

and remove the bolts.

7. Pull the bracket and hose clamp from the hose.

Then pull off the rubber bush (C).

Do steps 6 to 7 both for the inlet and outlet

ports.

8. Switch on the electrical supply.

9. Power out the hose (A) from the pump chamber

by jogging the drive mot or.

WARNING

During jogging the drive:

- Do not stand in front of the pump

ports.

- Do not try to guide the hose by

hand.

32

Page 33

7.6.2 Cleaning the pump head

1. Isolate the pump from the electrical supply.

2. Remove the cover (B) by loosening the

retaining bolts (A).

3. Check the gasket (C) and replace it if

necessary.

4. Rinse the pump head with clean water and

remove all residues. Make sure that no rinsing

water remains in the pump head.

5. Check the rotor for wear or d am age a nd replace

the rotor if necessary. Also see the mainten ance

scheme in § 7.2.

CAUTION

When the rotor is worn the compression

force of the hose decreases. If the compression force is too low, this results in a

loss of capacity by the ba c kflow of the liquid to be pumped.

Backflow result s in a reduct ion of the life of

the pump hose.

MAINTENANCE

6. Replace the cover and fasten the retaining bolts

with the correct torque. Refer to § 11.1.6.

7. Switch on the electrical supply to the pump.

7.6.3 Fitting the pump hose

1. Clean the (new) pump hose on the outside and

fully lubricate it with Bredel Genuine Hose

Lubricant.

33

Page 34

MAINTENANCE

2. Fit the pump hose (A) via one of the ports.

3. Let the motor run to let the rotor pull the hose in

the pump housing. Stop the motor when the

hose sticks out equally from both sides of the

pump housing.

WARNING

During jogging the drive:

- Do not stand in front of the pump

ports.

- Do not try to guide the hose by

hand.

4. Check that the rubber bushes (A) are not

deformed or damaged and replace them if

necessary.

5. Check that the hose clamps (B) are not

damaged and replace them if necessary.

6. First fit the inlet port.

Slide the rubber bush (D) over the hose.

Push the bracket (A) and the hose clamp (B)

over the hose together. Align the holes in the

bracket with the ones at the front of the port.

Position the two retaining bolts (C) and tighten

them. Make sure th e bolt s are tighte ned with the

correct torque. Refer to § 11.1.6.

34

Page 35

7. Turn the rotor in such a way that the hose (A) is

pressed firmly against the bracket (B).

8. Tighten the bolt (A) of the hos e cla mp (B). M ak e

sure the bolt is tight ened w ith th e correct t orqu e.

Refer to § 11.1.6.

9. Now fit the other port. For this port proceed in

the same way as described above for the inlet

port.

10. Fill the pump housing with Bredel Genuine

Hose Lubricant. Refer to §7.5.

11. Connect the suction and discharge lines.

MAINTENANCE

7.7 Exchanging replacement parts

7.7.1 Replacing rotor, bearings and seal ring

1. Remove the pump hose. Refer to § 7.6.1.

2. Isolate the pump from the electrical supply.

3. Remove the cover (B) by loosening the

retaining bolts (A).

4. Check the gasket (C) and replace it if

necessary.

35

Page 36

MAINTENANCE

5. Put the hose pump on blocks. Make sure the

space between the blocks is wide enough for

the rotor to fall.

6. Remove the nuts (B), the washers (C) and the

pump drive (A).

7. Put a plastic or wooden drive pin (A) on the

rotor.

8. Hit the drive pin firmly with a hammer to remove

the rotor.

9. Put the hose pump upright on the support.

10. Dismount the circlip (A) with the correct tool.

36

Page 37

11. Dismount the bearings (A), the spac er ring (B)

and the retaining ring (C) with the correct tool.

Clean the hub.

12. Remove the seal ring (A). Clean and degrease

the bore.

13. Fit a new seal ring (A) using good engineering

practises. The seal ring must be fitted in the

correct orie ntati on (B ). Ma ke sur e that th e open

side points to the pump cover.

MAINTENANCE

14. Slightly oil the inner ring of the (new) bearings

and the seat on the hub. Fit the bearings and

the rings.

The bearings are pl ac ed on th e hub with a slight

interference fit. Use a pressing tool to press the

bearings on the hub.

37

Page 38

MAINTENANCE

15. Mount the circlip (A).

16. Fit the rotor (A). The rotor is placed on the

bearings with a loose fit. Press the rotor on the

hub until it clicks on the retaining ring.

17. Put the hose pump on two blocks.

18. Fit the pump drive (A) with the nuts (B) and

washers (C). Tighten to the specified torque

settings. Refer to § 11.1.6.

19. Put the hose pump upright on the support.

20. Check the position of the rotor. If necessary

press the rotor on the hub until it clicks on the

retaining ring.

21. Refit the cover (B). Make sure that the 4 bolts

(A) are refitted and that they are tightened in the

correct order, diagonally opposite each other.

Refer to § 11.1.6.

22. Switch on the electrical supply to the pump.

23. Fit the (new) pump hose. Refer to § 7.6.3.

38

Page 39

7.8 Fitting options

7.8.1 Fitting a high-level float switch

1. Dismount the standard breather (A) on the

cover of the pump head.

2. Mount the breather (A) with high-level float

switch.

MAINTENANCE

3. Connect the high-level float switch to the

auxiliary power circuit via the 2-metre long PVC

cable (2 x 0.34mm2). Bear in mind that the

electrical contact of the float switch is normally

closed (NC). The knob is upwards for normally

closed operation. When the lubricant level is

(too) high the contact will open.

Specifications

*

Voltage: Max. 230 V AC/DC

Current: Max. 2 A

Power: Max. 40 VA

* For use in non-explosive atmospheres

39

Page 40

MAINTENANCE

Where the float switch is constructed to

stop the equipment, operating has to be

arranged so that the stop function locks

out, preventing the equipment from being

re-started without re-setting. Check if the

float switch is mounted with the NC si gn a t

the top.

7.8.2 Revolution counter

For feedback of the pump revolutions to an "intelligent"

system, the pump can be provided with an inductive

sensor (A). This sensor is mounted between the two

ports.

Connection of the revolution counter:

The speed sensor can be connected via the 2 meter

long PVC cable (3x 0.34 mm

2

).

Specifications

*

Volt ag e: 10...65 V DC

Current: Max. 200 mA

* For use in non-explosive atmospheres

Adjustment sensor:

The sensor (A) must be adjusted at an offset of 0.75-

1.25 mm to the rotor (B).

40

Page 41

8 STORAGE

8.1 Hose pump

• Store the hose pump and pump parts in a dry

area. Make sure that the hose pump and pump

parts are not exposed to temperatures lower

than -40 °C or higher than +70 °C.

• Cover the openings of the inlet and outlet ports.

• Prevent corrosion of untreated parts. For this

purpose use the correct protection or

packaging.

• After a long period of standstill or storage, the

static load on the pump hose may have caused

permanent deformation, which will reduce the

life of the pump hose. To prevent this, remove

the pump hose when the pu mp is not to b e used

for a period.

8.2 Pump hose

• Store the pump hose in a cool and dark room.

After two years th e hose materi al will age, w hich

will reduce the life of the hose.

STORAGE

41

Page 42

TROUBLESHOOTING

9 TROUBLESHOOTING

WARNING

Disconnect and loc k the power s upply to the pump drive bef ore any w ork is

carried out.

In case the motor is fitted with a frequency controller and has a singlephase power supply, wait two minutes to make sure that the capacitors

have discharged.

If the hose pump does not function (correctly), consult the following checklist to see if

you can remedy the error yourself. If this is not the case, contact your Bredel

representative.

Problem Possible cause Correction

Failure to operate. No voltage. Check that the supply

power switch is on.

Check the electrical sup-

ply is available at the

pump.

Stalled rotor. Check if the pump is

stalled by incorrect fitt ing of

the hose.

Lubricant level monitoring

system has been ac tivate d.

Check that the lubricant

level monitoring system

has stalled the pump.

Check the functioning of

the lubricant level monitoring system, or check the

lubricant level.

42

Page 43

TROUBLESHOOTING

Problem Possible cause Correction

High pump temperature. Non standard hose lubri-

cant used.

Low lubricant level. Add Bredel Genuine Hose

Consult the Bredel representative for the correct

lubricant.

Lubricant. For the required

amount of lubricant refer to

§ 11.1.4.

Product temperature too

high.

Internal friction on the hose

caused by blocked or poor

suction characteristics.

High pump speed. Reduce pump speed to a

Consult the Bredel representative about the maximum temperature rang e of

the product.

Check pipework/valves for

blockages. Ensure that the

suction pipework is as

short as poss ible and that

the diameter is large

enough.

minimum. Consult with

your Bredel pump representative for advice on

optimum pump speeds .

43

Page 44

TROUBLESHOOTING

Problem Possible cause Correction

Low capacity / pressure. Shut-off valve in th e suc-

tion line (partly) closed.

Fully open the shut-off

valve.

Hose rupture or badly worn

hose.

(Partial) blockage of the

suction line or too little

product on the suction

side.

Connections and hose

clamps not correctly

mounted, which ma kes the

pump suck air.

The filling degree of the

pump hose is too low,

because the speed is too

high in relation to the viscosity of the product to be

pumped and the inlet pressure.

The suction line can be too

long or too narrow or a

combination of these factors.

Replace hose. Refer to

§ 7.6.

Ensure that the suction line

is clear of blockages and

that sufficient product is

available.

Tighten connections and

hose clamps.

Consult your Bredel representative for a recommendation.

44

Page 45

TROUBLESHOOTING

Problem Possible cause Correction

Vibration of the pump

and pipework.

Suction and discharge

lines are not secured correctly.

Check and secure pipework.

High pump speed with long

suction and discharge lines

or high relative dens ity or a

combination of these factors.

Too narrow diameter of

suction and/or discharge

line.

Short hose life. Chemical attack of the

hose.

High pump speed. Reduce pump speed.

High discharge pressures.

The hose life is reduced

significantly when the hose

has to suffer high working

pressures. The higher the

working pressure, the more

the hose life is reduced.

Reduce pump speed.

Reduce the line lengths on

both suction and discharge where possible.

Consult your Bredel representative for a recommendation.

Increase the diameter of

the suction/disc ha rge lines.

Check the compatibility of

the hose material with the

product to be pumped.

Consult your Bredel representative for correct hose

selection.

The maximum worki ng

pressure depends on the

hose type. Refer to 11.1.1.

Check that the discharge

line is not blocked, the

shut-off valve s are fully

opened and the pressure

relief valve functions properly (if present in the discharge line).

High product temperature. Consult your Bredel repre-

sentative for correct hose

selection.

High pulsations. Restructure the discharge

and inlet conditions.

45

Page 46

TROUBLESHOOTING

Problem Possible cause Correction

Hose pulled into the

pump.

Insufficient or no hose

lubricant in the pump head.

Add extra lubricant. Refer

to § 7.5.

Lubricant leakage at

bracket.

Leakage from the rear of

the pump housing

"Buffer zone".

Incorrect lubricant: no

Bredel Genuine Hose

Lubricant in the pump

head.

Extremely high inlet pressure - larger than 200 kPa.

Hose blocked by an in co mpressible object in the

hose. The hose cannot be

compressed and will be

pulled into the pump housing.

Bolts of bracket loose. Tighten to the specified

Bolts of hose clam ps loos e. Tighten to the specified

Damaged seal ring. Replace seal ring.

Consult the Bredel representative for the correct

lubricant.

Reduce the inlet pressure.

Remove hose, check for

blockages and replace if

necessary.

torque settings. Refer to

§ 11.1.6.

torque settings. Refer to

§ 11.1.6.

46

Page 47

HAZARDOUS ENVIRONMENTS (ATEX)

10 HAZARDOUS ENVIRONMENTS (ATEX)

10.1 ATEX compliance

Hose pumps that are configured for use in potentially

explosive en vi ro nm en ts co mply to CE di re ct i ve 94/9 / EC

(ATEX directive). The hose pumps as mentioned on the

front cover comply to: Group II Appliances, category

2 GD. Refer to § 10.2.1 for a more detailed definition.

10.2 Identification

10.2.1 Pump head

Hose pumps that are configured for use in potentially

explosive environments are identified by an extra ATEX

plate on the rear of the pump head on one of the ports.

The plate contains the following data:

A ATEX code

B ATEX document number

C year of manufactu re

The following table explains the ATEX code on the

ATEX plate.

II Group II equipment for use in potentially

explosive atmospheres, other than mines

susceptible to firedamp.

2 Category 2 equipment for the requisite level

of protection, even if frequently occurring disturbances or equipment faults have to be

taken into account.

G Equipment for use in expl osive atm osphe res

caused by gases, vapours or mists.

D Equipment for use in explosive atmospheres

caused by dusts.

k Equipment protected by liquid immersion.

c Equipment protected by constructional

safety.

b Equipment protected by control of ignition

source.

47

Page 48

HAZARDOUS ENVIRONMENTS (ATEX)

T5 Classification for Group II G equipment con-

cerning the maximum surface tempe rature.

T90°C Maximum surface temperature for Group II D

equipment, according to thermal test (EN

13463).

10.2.2 Gearbox

The gearbox must be selected to meet your

requirements concerning ATEX. Please contact your

Bredel representative.

10.2.3 Electric motor

The electric motor must be selected to meet your

requirements concerning ATEX. Please contact your

Bredel representative.

10.2.4 Frequency controller

The frequency controller must be selected to meet your

requirements concerning ATEX. Please contact your

Bredel representative.

48

Page 49

SPECIFICATIONS

11 SPECIFICATIONS

11.1 Pump head

11.1.1 Performance

Description Bredel 10 Bredel 15 Bredel 20

Hose inner diameter [mm] 10 15 19

3

Max. capacity, continuous [m

Max. capacity, intermittent [m

/h] 0.11 0.38 0.62

3

*

/h]

0.16 0.60 1.09

Capacity per revolution [l/rev] 0.022 0.083 0.152

Permissible ambient temperature [°C] -20 to +45

Permissible product temperature [°C] -10 to +80

Sound level at 1 m [dB(A)] 60

* Intermittent duty: "Let the pump stand still to cool down for at least 1 hour after 2 hours of

operation".

Maximum working pressure [kPa]

Description Bredel 10 Bredel 15 Bredel 20

Rotor pres sur e

Low Medium High Low Medium High Low Medium High

range

Hose

type

NR 400 800 1200 400 800 1200 400 800 1000

NBR 400 800 1200 400 800 1200 400 800 1000

EPDM 400 800 1000 400 800 1000 400 800 1000

CSM 400 800 1000 400 800 1000 400 800 1000

49

Page 50

SPECIFICATIONS

11.1.2 Materials

Pos Description Material

1 Pump housing Cast-iron

2 Cover Cast-iron

3 Pump rotor Cast-iron

4 Pump support Galvanised steel (AI SI 316 optional)

5 Bracket AISI 316

6 Fasteners AISI 316

7 Seals, gaskets NBR

8 Seals, gaskets EPDM

9 Coupling Steel

50

Page 51

SPECIFICATIONS

11.1.3 Surface treatment

• After surface preparation, one layer of two-component acrylate is used for

surface protection. Standard colour is RAL 3011, however other colours are

optional. Contact your Bredel representative for details on surface treatment.

• All galvanised parts have been provided with an electrolytic zinc layer of 15 - 20

microns.

11.1.4 Lubricant table pump

Bredel 10 Bredel 15 - 20

Lubricant Bredel Genuine

Hose Lubricant

Required quantity [litres] 0.25 0.5

Bredel Genuine Hose Lubricant is registered at NSF: NSF Registration N

Category Code H1. See also: www.NSF.org/USDA.

Should you require additional information with respect to the safety data

sheet, consult your Bredel representative.

11.1.5 Weights

Bredel Genuine

Hose Lubricant

o

123204;

Description Weight [kg]

Bredel 10 Bredel 15 - 20

Pump head (inclusive of hose, lubricant and

pump support)

Pump support 1.8 2.4

Hose 0.4 0.8

Lubricant 0.3 0.6

Pump cover (comple te) 2.3 6.0

Coupling 0.4 0.4

Gearbox GA52... 9.5 9.0

GA53... 10 10

Electric motor 4.5 6.5

12.2 18.5

51

Page 52

SPECIFICATIONS

11.1.6 Torque figures

Pos Description Torques [Nm]

Bredel 10 Bredel 15 - 20

A Cover 10 25

B Hose clamp 3 3

C Bracket 10 25

D Support 10 10

E Inspection window 1.5 1.5

11.2 Gearbox

Type Co-axial gearbox with h elic al gea rs

Number of stages Two or three

Lubrication Lubricated for life

52

Page 53

SPECIFICATIONS

Mounting position IM 2001 (IM B5) flanged gearbox with keyed shaft in hori-

zontal position.

Motor adapter Electric motor has been integrated in the gearbox hou si ng,

by which the smallest possible dimension is achieved.

Optional motor adapter Adapters in conformance with IEC-B5 or NEMA TC.

11.3 Electric motor

Standard electric motor design is an enclosed three-phase asynchronous motor. A

thermal safety device to prevent motor overload is optional.

In case of doubt ab out the l oc al a pp lic ab le regulations for the drive connection, contact your Bredel representative.

Protection class IP55/I K08

Insulation class F

Increase in temperature Within class B

Voltage/frequency 230/400 V - 3 phases - 50 Hz

11.4 Variable Frequency Drive (VFD) (optional)

The Bredel Variable Frequency Drive (VFD) has been preprogrammed and only needs

to be connected to the mains.

RFI filter Integrated RFI filter B (industrial applications).

Control Manual control for setting the speed and the keys for starting

forward, stop and starting reverse.

Protection class IP65

Mains power su pply There are thr ee types available; the ch oice depends on the

local electricity grid:

• 200-240 V ± 10%; 50/60 Hz ± 5%; 1 ph

• 200-240 V ± 10%; 50/60 Hz ± 5%; 3 ph

• 400-480 V ± 10%; 50/60 Hz ± 5%; 3 ph

53

Page 54

SPECIFICATIONS

11.5 Parts list

11.5.1 Overview

Pos. Description

1 Cover assembly. Refer to § 11.5.2.

2 Pump head assembly. Refer to § 11.5.3.

3 Pump support assembly. Refer to § 11.5.4.

4 Barbed nipple assembly. Refer to § 11.5.5.

5 Threaded nipple assembly. Refer to § 11.5.6.

6 Flange assembly (1). Refer to § 11.5.8.

7 Flange assembly (2). Refer to § 11.5.7.

8 Lubricant. Refer to § 11.5.10.

54

Page 55

SPECIFICATIONS

11.5.2 Cover assembly

Pos. Qty. Description Bredel 10 Bredel 15 Bredel 20

1 1 Co ver 210102 215102 215102

2 2 Bolt, hex. head F504038 - -

4 - F504055 F504055

3 2 Washer F523010 - -

4 - F523012 F523012

4 1 Drain pl ug F9 11502 F911502 F911502

5 1 Gasket F342019 F342019 F342019

6 1 Insp ec tion window 210155 215155 215155

7 1 Gas ket 210156 215156 215156

8 3 Round head screw F552535 - -

6 - F552535 F552535

9 1 Breather 29093146 29093146 29093146

10 1 Gasket 29056334 29056334 29056334

11 1 Round head screw F552541 F552541 F552541

12 1 Sticker 210238 215238 220238

55

Page 56

SPECIFICATIONS

11.5.3 Pump head assembly

Pos. Qty. Description Bredel 10 Bredel 15 Bredel 20

1 1 Hose NR 010020 015020 020020

1 Hose NBR 010040 015040 020040

1 Hose EPDM 010075 015075 020075

1 Hose CSM 01007 0 015070 020070

2 1 Pump housing 210101 215101 215101

3 1 Gasket 210123 21 5123 215123

4 1 Rotor, low pressure 210103L 215103L 220103L

Rotor, medium pressure 210103H 215103H 220103H

Rotor, high pressure 210103X 215103X 220103X

5 1 Seal ring S211811 S211811 S211811

6 2 Bearing B141060 B141060 B141060

7 1 Spacer ring 29070201 29070201 29070201

8 1 Retaining ring 29080297 29080297 29080297

9 1 Circlip F343043 F343043 F343043

10 4 Stud F511001 F511001 F511001

56

Page 57

SPECIFICATIONS

Pos. Qty. Description Bredel 10 Bredel 15 Bredel 20

11 1 Coupling, ∅ 20 x 63 mm 29063255 29063255 29063255

Coupling, ∅ 20 x 68 mm 29068255 29068255 29068255

Coupling, ∅ 25 x 63 mm 29064255 29064255 29064255

Coupling, ∅ 25 x 68 mm 29069255 29069255 29069255

11.5.4 Support assembly

Pos. Qty. Description Bredel 10 Bredel 15 Bredel 20

1 1 Pum p sup port 210106 2151 06 215106

2 4 Nut, hex. head F516010 F516010 F516010

3 4 Washer F532008 F532008 F532008

4 1 Screw, countersunk head F507040 F507040 F507040

57

Page 58

SPECIFICATIONS

11.5.5 Barbed nipple assembly (PTFE/PDVF)

Pos. Qty. Description Bredel 10 Bredel 15 Bredel 20

1 2 Rubber bush 210119 215119 215119

2 2 Hose cl am p C112507 C112508 C112508

3 2 Barbe d nipple PTFE 21068801 0 215688015 215688020

Barbed nipple PVDF 210 69 0010 215690015 215690020

4 2 Brac ket 210197 215197 215197

5 4 Bolt, Hex. head F504036 F504054 F504054

6 4 Washer F532008 F532009 F532009

58

Page 59

SPECIFICATIONS

11.5.6 Barbed or threaded nipple assembly (stainless steel)

Pos. Qty. Description Bredel 10 Bredel 15 Bredel 20

1 2 Ru bbe r bush 210 119 215119 215119

2 2 Ho se clamp C112507 C112508 C112508

3 2 Brac ket 210197 215197 215197

4 4 Bolt, Hex. head F504036 F504054 F504054

5 4 Washer F532008 F532009 F532009

6 2 Thre ade d ni pple (BSP) SS 210693010 215693015 215693 020

Barbed nipple SS 210686010 215686015 215686020

Threaded nipple DIN 11851 SS210702010 215702015 215702020

Threaded nipple (NPT) PP 210696010 215696015 215696020

Threaded nipple (NPT) PVC 210697010 215697015 215697020

Threaded nipple (NPT) SS 210698010 215698015 215698020

59

Page 60

SPECIFICATIONS

11.5.7 Flange assembly (1)

Pos. Qty. Description Bredel 10 Bredel 15 Bredel 20

1 2 Rubber bush 210119 215119 215119

2 2 Hose cl am p C112507 C112508 C112508

3 2 Brac ket 210197 215197 215197

4 4 Bolt, Hex. head F504036 F504054 F504054

5 4 Washer F532008 F532009 F532009

6 2 Thre ade d ni pple (BSP) SS 210693010 215693015 215693020

7 2 Nut F519003 F519004 F519004

8 2 Flange D IN SS A304504 A 304505 A304505

2 Flange ASA SS A305504 A305505 A30 5505

60

Page 61

SPECIFICATIONS

11.5.8 Flange assembly (2)

Pos. Qty. Description Bredel 10 Bredel 15 Bredel 20

1 2 Ru bbe r bush 210 119 215119 215119

2 2 Ho se clamp C112507 C112508 C112508

3 2 Flange bracket 210197A 215197A 215197A

4 4 Bolt, Hex. head F504036 F504054 F504054

5 4 Washer F532008 F532009 F532009

6 2 Flange ASA 210199A 215199A 215199A

7 2 Insert PP 21018 9 2 15189 220189

61

Page 62

SPECIFICATIONS

11.5.9 Revolution counter assembly

Pos. Qty Description Bredel 10 Bredel 15 Bredel 20

1 1 Pum p housing 210101A 215 101 A 215101A

2 1 Revol ut i on c ounter 29060367 29060367 29060367

3 1 Gasket ring F724009 F724009 F724009

11.5.10 Lubricants

Pos. Qty. Description Bredel 10 Bredel 15 Bredel 20

- 1 0.5 l can Bredel Genuine

Hose Lubricant

901143 901143 901143

62

Page 63

ORIGINAL

EC Declaration of Co nformity for machinery

EC DECLARATION OF CONFORMITY OF THE MACHINERY

(according to Annex II.1.A. of Directive 2006/42/EC on machinery)

We,

Watson-Marlow Bredel B.V.

Sluisstraat 7

P.O. Box 47

7490 AA Delden

The Netherlands,

herewith declare, on our own responsibility, that the following machinery fulfils all the

relevant provisions of Directive 2006/42/EC:

Peristaltic hose pump: Bredel 10-20 series,

for the transportation of various kinds of fluids.

In addition, the machi nery compl ies wi th the ha rmoni sed st an dard(s) , ot her st and ards o r

technical specifications, applicable requirements of these standards and/or

specifications as listed below:

NEN-EN 809

NEN-EN-ISO 12100-2

NEN-EN-IEC 60204-1

The undersigned is responsible for compilation of the technical file and makes this

declaration on behalf of the manufacturer.

J. van den Heuvel

Managing Director

The Netherlands, Delden

1 June 2013

63

Page 64

SAFETY FORM

Safety form

SAFETY FORM

Product Use and Decontamination Declaratio n

In compliance with the Health and Safety Regulations, the user is required to declare those substances that

have been in contact with the item(s) you are returning to Watson-Marlow Bredel B.V. or any of its subsidiaries or

distributors. Failure to do so will cause delays in servicing the item or in issuing a response. Therefore, please

complete this form to make sure we have the information before receipt of the item(s) being returned. A completed copy must be attached to the outside of the packaging containing the item(s). You, the user, are responsible for cleaning and decontaminating the item(s) before returning them.

Please complete a separate Decontamination Certificate for each item returned. RGA/KBR no...................

1 Company ............................................................. .........................................................................................

Address ................. ........... .......... ........... .......... ..... .................... ..... ........... .......... ...........................................

Postal code...........................................................

Telephone .............................................................

2 Product ................................................................ 3.4 Cleaning fluid to be used if residue of chemical is

2.1 Serial Number ......................................................

2.2 Has the Product been used?

YES NO

If yes, please complete all the following para-

graphs.

If no, please complete paragraph 5 only

3 Details of substances pumped 4 I hereby confirm that the only substances(s) that

3.1 Chemical Names

a) ...................... ................ ............... ................ .....

b) ...................... ................ ............... ................ .....

c) ...................... ............................... .....................

d) ...................... ................ ............... ................ .....

3.2 Precautions to be taken in handling these substances:

a) ...................... ................ ............... ................ .....

b) ...................... ................ ............... ................ .....

c) ...................... ............................... .....................

d) ...................... ................ ............... ................ .....

3.3 Action to be taken in the event of human contact:

a) .........................................................................

b) .........................................................................

c) .........................................................................

d) .........................................................................

Fax number ..........................................................

found during servicing;

a) ........................................................................

b) ........................................................................

c) ................................................... ...... ..... ..... .....

d) ........................................................................

the equipment specified has pumped or come into

contact w it h a r e t h ose na me d , th at t h e in f or ma t ion

given is correct, and the carrier has been informed

if the consignment is of a hazardous nature.

5 Signed .................................................. ...............

Name ......................... ........................... ...............

Position ...................... ...... ..... ..... ..... .....................

Date ...................... .......................... .....................

Note:

To assist us in our servicing please describe

any fault condition you ha ve witn essed.

.............................................................................

.............................................................................

.............................................................................

.............................................................................

.............................................................................

Page 65

Notes

NOTES

NOTES

65

Page 66

NOTES

66

Page 67

NOTES

67

Page 68

Watson-Marlow Bredel B.V.

P.O. Box 47

NL-7490 AA Delden

The Netherlands

Telephone: +31 (0)74 3770000

Fax: +31 (0)74 3761175

E-mail: bredel@wmpg.com

Internet: http://www.bredel.com

68

29210309 TS04-026-C

© 2013 Watson-Marlow Bredel B.V.

Loading...

Loading...