Page 1

Disc

The disc inserted in the front cover contains the user manual of the models APEX10,

APEX15 and APEX20. The user manual is available in the following languages:

The disc also contains quick-reference instructions for the replacement of the pump

hose. This replacement instruction is only for users that are familiar with the

replacement procedures in the user manual.

How to use the disc

1 Put the disc in the disc drive.

2 Close the disc drive.

The disc will start automatically.

3 Wait until the various language versions appear on screen.

4 Select the required language (click 1x with the left mouse button).

The PDF reader program will automatically start and the required user manual

appears on screen.

Shortcuts

In the left margin you will find the various chapters and paragraphs. These can be

accessed directly by clicking on the required chapter or paragraph.

In the text you will find hyperlinks to chapters or paragraphs. These hyperlinks are linked

with the required chapters or paragraphs. By clicking a shortcut the required chapter or

paragraph appears on screen.

System requirements

The program on the disc requires a PC with the following minimum system

requirements:

• CD drive

The following software must be installed on the PC:

• PDF reader program

• an internet browser

1

Page 2

2

Page 3

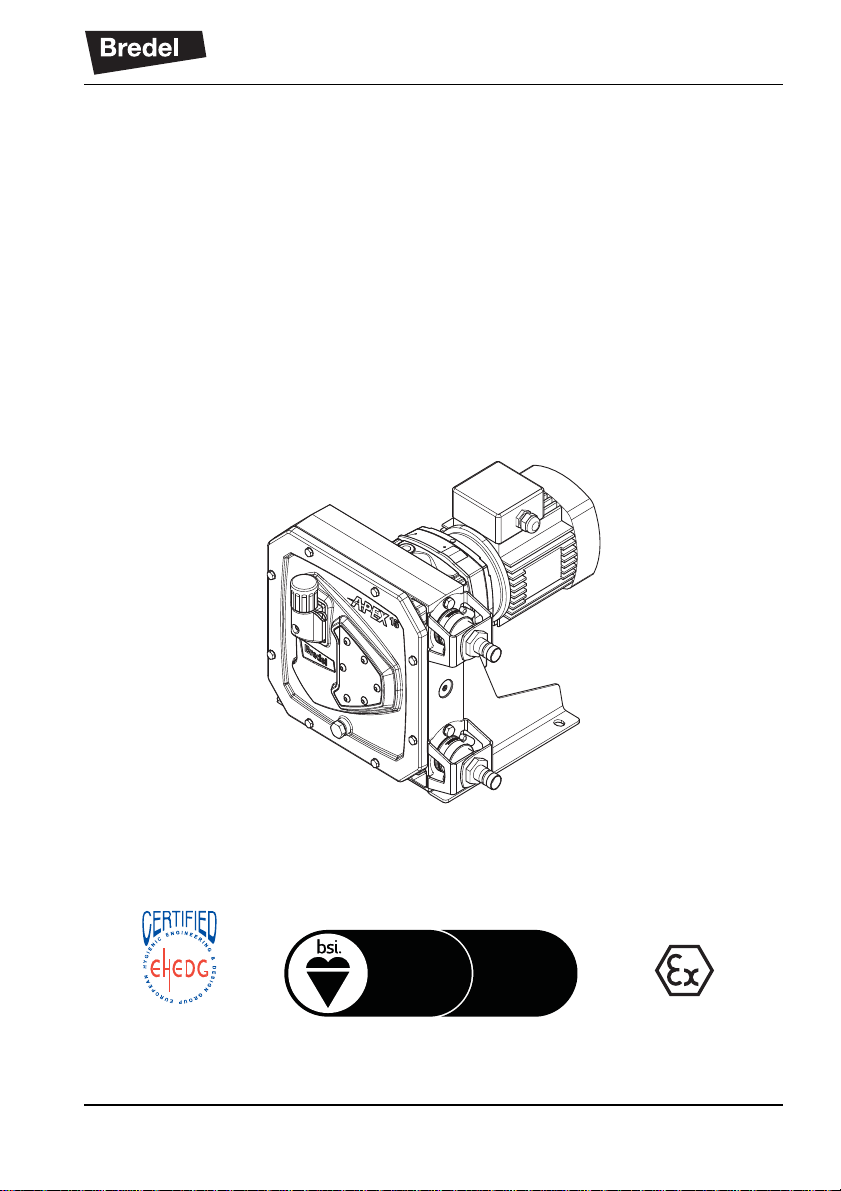

Hose pump series

TYPE EL - CLASS I

AUGUST 2012

Environmental

Management

ISO

14001

Quality

Management

ISO

9001

APEX10, APEX15 and APEX20

Manual

3

Page 4

© 2014 Watson-Marlow Bredel B.V.

All rights reserved.

The information provided herein may not be reproduced and/or published in any form,

by print, photoprint, microfilm or any other means whatsoever (electronically or

mechanically) without the prior written authorisation of Watson-Marlow Bredel B.V.

The information provided can be changed without prior notification. Watson-Marlow

Bredel B.V. or one of its representatives cannot be held liable for possible damage

resulting from use of this manual. This is an extensive limitation of the liability which

applies to all damage, inclusive of (without limitation) compensating, direct, indire ct or

consequential damage, loss of data, income or profit, loss or damage to possessions

and claims of third parties.

Watson-Marlow Bredel B.V. provides the information in this manual "as is" and does not

take any responsibility and does not give any guarantee on this manual o r its content.

Watson-Marlow Bredel B.V. rejects all responsibilities and guarantees. Furthermore,

Watson-Marlow Bredel B.V. does not take responsibility for and does not guarantee that

the information in this manual is accurate, complete or up to date.

Names, trade names, brands, etc. used by Watson-Marlow Bredel B.V. may not, as per

the legislation concerning the protection of trade names, be considered as available.

4

Page 5

CONTENTS

1GENERAL

1.1 How to use this manual .................................. ........................................ 8

1.2 Original instructions ................................................................................ 8

1.3 Other supplied documentation ................................................................ 8

1.4 Service and support .................................................................... ... ... ...... 8

1.5 Environment and disposal of waste ........................................................ 9

2SAFETY

2.1 Symbols ................................................................................................ 10

2.2 Intended use ......................................................................................... 10

2.3 Use in potentially explosive atmospheres ............................................. 11

2.4 EHEDG compliance .............................................................................. 11

2.5 Responsibility ........................................................................................ 12

2.6 Qualification of the user ........................................................................ 12

2.7 Regulations and instructions ................................................................. 12

3 WARRANTY CONDITIONS

4 DESCRIPTION

4.1 Identification of the product ................................................................... 14

4.1.1 Identification of the product ....................................................... 14

4.1.2 Identification of the pump .......................................................... 14

4.1.3 Identification of the gearbox ...................................................... 14

4.1.4 Identification of the electric motor .............................................. 15

4.1.5 Identification of the frequency controller .................................... 15

4.1.6 Identification of the pump hose ................................................. 15

4.2 Construction of the pump ...................................................................... 16

4.3 Operation of the pump .......................................................................... 17

4.4 Pump hose ...................................... .. ..................................... ... ............ 18

4.4.1 General ...................................................................................... 18

4.4.2 Hose compression force adjustment ......................................... 19

4.4.3 Lubrication and cooling ............................................................. 19

4.5 Gearbox ................................................................................................ 20

4.6 Electric motor ........................................................................................ 20

4.7 Available options ................................................................................... 20

5

Page 6

5 INSTALLATION

5.1 Unpacking ............................................................................................ 21

5.2 Inspection ............................................................................................. 21

5.3 Installation conditions ........................................................................... 21

5.3.1 Ambient conditions .................................................................... 21

5.3.2 Setup ......................................................................................... 21

5.3.3 Pipework ................................................................................... 22

5.3.4 Motor ......................................................................................... 23

5.3.5 Frequency controller ................................................................. 23

5.4 Lifting and moving the pump ................................................................ 24

5.5 Placing the pump .................................................................................. 24

6 COMMISSIONING

6.1 Preparations ......................................................................................... 25

6.2 Commissioning ..................................................................................... 26

7 OPERATION

7.1 Temperature ......................................................................................... 27

7.2 Power rating ................................................. ... ... .................................. 27

7.3 Performance graphs ........................................ ..................................... 28

7.4 Dry running ........................................................................................... 30

7.5 Hose failure ...................................................................................... ... . 31

7.6 Fluid leakage ........................................................................................ 33

8 MAINTENANCE

8.1 General ................................................................................................. 34

8.2 Maintenance and periodic inspections ................................................. 34

8.3 Cleaning the pump hose ...................................................................... 36

8.4 Changing lubricant ............................................................................... 36

8.5 Replacing the pump hose ..................................................................... 37

8.5.1 Removing the pump hose ......................................................... 37

8.5.2 Cleaning the pumphead ............................................................ 38

8.5.3 Fitting the pump hose ................................................................ 39

8.6 Exchanging replacement parts ............................................................. 41

8.6.1 Replacing rotor, bearings and seal ring .................................... 41

8.7 Fitting options ....................................................................................... 44

8.7.1 Fitting a high-level float switch .................................................. 44

8.7.2 Replacing the revolution counter ............................................... 46

6

Page 7

9 STORAGE

9.1 Hose pump ........................................................................................... 48

9.2 Pump hose ...................................... .. ..................................... ... ............ 48

10 TROUBLESHOOTING

11 SPECIFICATIONS

11.1 Pumphead ............................................................................................ 54

11.1.1 Performance .............................................................................. 54

11.1.2 Materials .................................................................................... 55

11.1.3 Surface treatment ...................................................................... 56

11.1.4 Lubricant table pump ................................................................. 56

11.1.5 Weights ..................................................................................... 57

11.1.6 Torque figures ........................................................................... 58

11.2 Gearbox ................................................................................................ 59

11.3 Electric motor ........................................................................................ 59

11.4 Variable Frequency Drive (VFD) (optional) ........................................... 60

11.5 Parts list ................................................................................................ 60

11.5.1 Ordering parts .................................................................... ... ... . 60

11.5.2 Overview ................................................................................... 61

11.5.3 Cover assembly ......................................................................... 62

11.5.4 Pumphead assembly ................................................................. 63

11.5.5 Support assembly ...................................................................... 64

11.5.6 Barbed nipple assembly (PTFE/PDVF) ..................................... 65

11.5.7 Barbed or threaded nipple assembly

(stainless steel/PP/PVC) ........................................................... 66

11.5.8 Flange assembly with insert with collar ..................................... 67

11.5.9 Flange assembly with threaded nipple ...................................... 68

11.5.10Lubricant ................................................................................... 68

EC DECLARATION OF CONFORMITY OF THE MACHINERY

SAFETY FORM

NOTES

7

Page 8

GENERAL

1GENERAL

1.1 How to use this manual

This manual is intended as a reference book by means

of which qualified users are able to install, commission

and maintain the hose pumps mentioned on the front

cover.

1.2 Original instructions

The original instructions for this manual have been

written in English. Other language versions of this

manual are a translation of the original instructions.

1.3 Other supplied documentation

Documentation of components such as the gearbox, the

motor and the frequency controller is not included in this

manual. However, if additional documentation is

supplied, you must follow the instructions in this

additional documentation.

1.4 Service and support

For information with respect to specific adjustments,

installation, maintenance or repair jobs which fall

beyond the scope of this manual, contact your Bredel

representative. Make sure you have the following data

at hand:

• Serial number of the hose pump

• Article number of the pump hose

• Article number of the gearbox

• Article number of the electric motor

• Article number of the frequency controller

You will find these data on the identification plates or

stickers on the pumphead, the pump hose, the gearbox

and the electric motor. Refer to § 4.1.1.

8

Page 9

1.5 Environment and disposal of waste

CAUTION

Always observe the local rules and

regulations with respect to processing (non

reusable) parts of the hose pump.

Enquire within your local government about the

possibilities for reuse or environment-friendly

processing of packaging materials, (contaminated)

lubricant and oil.

GENERAL

9

Page 10

SAFETY

2SAFETY

2.1 Symbols

In this manual the following symbols are used:

WARNING

Procedures which, if not carried out with

the necessary care, may result in serious

bodily harm.

CAUTION

Procedures which, if not carried out with

the necessary care, may result in serious

damage to the hose pump, the surrounding

area or the environment.

Remarks, suggestions and advice.

2.2 Intended use

The hose pump is exclusively designed for pumping

suitable products. Every other or further use is not in

conformance with the intended use.

Flammable fluids are not suitable products to be

pumped by this hose pump. This pump is not intended

to operate in potentially explosive atmospheres.

The "Intended use" as laid down in EN 292-1 is "... the

use for which the technical product is intended in

accordance with the specifications of the manufacturer,

inclusive of his indications in the sales brochure". In

case of doubt it is the use, which appears to be its

intended use judging from the construction, execution

and function of the product, and its description in the

user's documentation.

Only use the pump in conformance with the intended

use described above. The manufacturer cannot be h eld

responsible for damage or harm resulting from use that

10

Page 11

is not in conformance with the intended use. If you want

to change the application of your hose pump, contact

your Bredel representative first.

2.3 Use in potentially explosive atmospheres

The pumphead and drive mentioned in this manual may

be configured to be suitable for use in a potentially

explosive atmosphere. Such a pump meets the

requirements as stated in the European Directive 94/9/

EC (ATEX Directive). Such a pump belongs to: Group II

appliances, category 2 GD bck T5.

Use in potentially explosive atmospheres

requires special configuration of the pump

unit. Contact your Bredel representative for

use in explosive atmospheres.

See Bredel’s ATEX Instruction manual which is supplied

with pumps configured as mentioned above.

2.4 EHEDG compliance

SAFETY

The hose connections of the pumphead described in

this manual are EHEDG compliant when stainless steel

nipples are applied and the connections are properly

created. This only concerns the connection between

nipple and pump hose.

WARNING

The user is responsible for the EHEDG

compliance of the connection between

nipple and suction or discharge line if

compliance is needed.

See the user guide “NBR Hoses For Food Contact”

supplied with F-NBR hoses for a description of a proper

hose connection.

11

Page 12

SAFETY

2.5 Responsibility

The manufacturer does not accept any responsibility for

damage or harm caused by not observing the safety

regulations and instructions in this manual and other

supplied documentation, or by negligence during

installation, use, maintenance and repair of the hose

pumps mentioned on the front cover. Depending on the

specific working conditions or accessories used,

additional safety instructions can be required.

Immediately contact your Bredel representative if you

notice a potential danger while using your hose pump.

WARNING

The user of the hose pump is fully

responsible for observing local safety

regulations and directives. Observe these

safety regulations and directives when

using the hose pump.

2.6 Qualification of the user

The installation, use and maintenance of the hose

pump should only be performed by well-trained and

qualified users. Temporary staff and persons in training

may use the hose pump only under the supervision and

responsibility of trained and qualified users.

2.7 Regulations and instructions

• Everyone who works with the hose pump must

be aware of the contents of this manual and

observe the instructions with great care.

• Never change the order of the actions to be

carried out.

• Always store the manual near the hose pump.

12

Page 13

3 WARRANTY CONDITIONS

The manufacturer offers a two-year warranty on all

parts of the hose pump. This means that all parts will be

repaired or replaced free of charge, with the exception

of consumables such as pump hoses, hose clamps, ball

bearings, wear rings, seals and rubber bushes, or parts

which have been used wrongly, misused, whether or

not they have been intentionally damaged. If genuine

Watson-Marlow Bredel B.V. (hereafter called Bredel)

parts are not used, any warranty claim is void.

Damaged parts which are covered by the applicable

warranty conditions can be returned to the

manufacturer. The parts must be accompanied by a

fully filled in and signed safety form, as present in the

back of this manual. The safety form must be applied to

the outside of the shipping carton. Parts which have

been contaminated or which have been corroded by

chemicals or other substances which can pose a health

risk must be cleaned before they are returned to the

manufacturer. Furthermore, it should be indicated on

the safety form which specific cleaning procedure has

been followed, and that the equipment has been

decontaminated. The safety form is required even if the

parts have not been used.

WARRANTY CONDITIONS

Warranties purporting to be on behalf of Bredel made

by any person, including representatives of Bredel, its

subsidiaries, or its distributors, which do not accord with

the terms of this warranty shall not be binding upon

Bredel unless expressly approved in writing by a

Director or Manager of Bredel.

13

Page 14

DESCRIPTION

min-1

N

o

i

D A

B

E

C

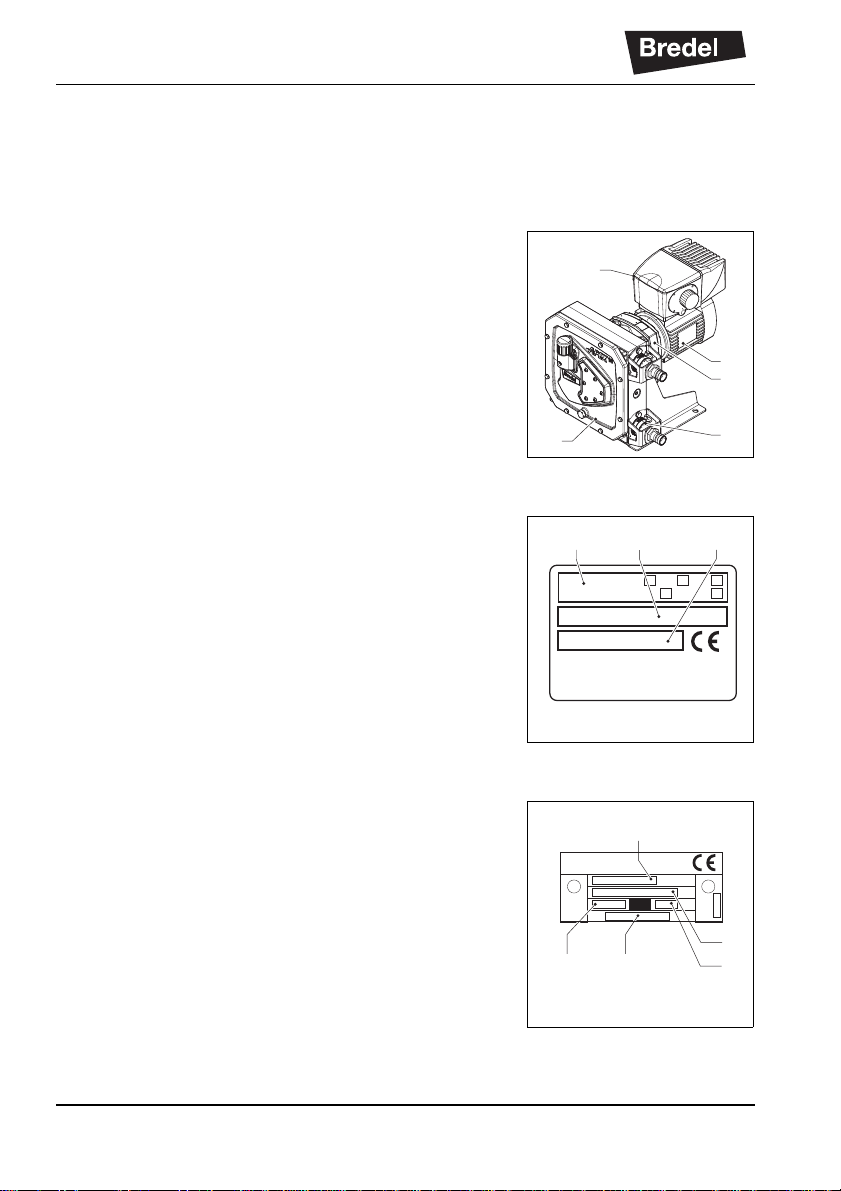

4 DESCRIPTION

4.1 Identification of the product

4.1.1 Identification of the product

The hose pump can be identified by identification plates

or stickers on:

A Pumphead

B Gearbox

C Electric motor

D Pump hose

E Frequency controller (option)

E

C

B

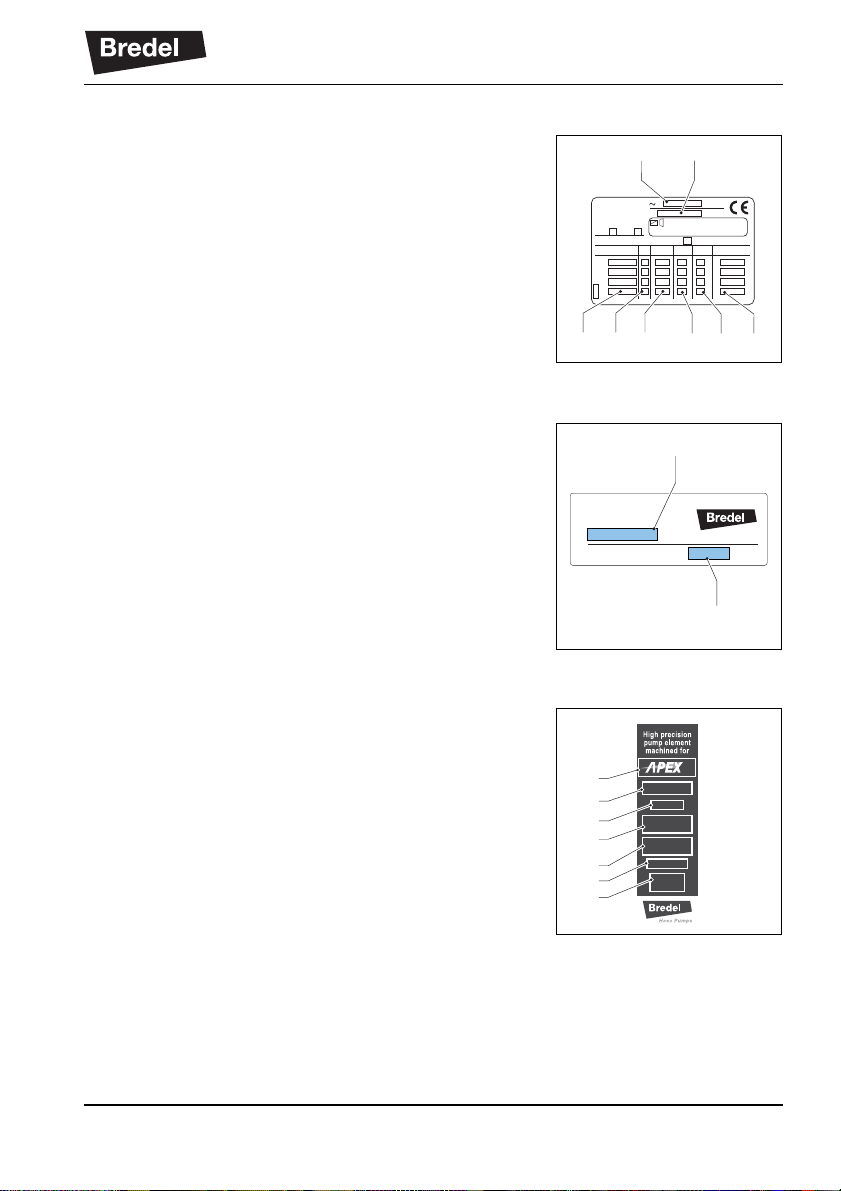

4.1.2 Identificati on of the pump

The identification plate on the pumphead contains the

following data:

A Pump type, hose diameter and rotor type (low

or medium pressure)

B Serial number

C Year of manufacture

4.1.3 Identification of the gearbox

The identification plate on the gearbox contains the

following data:

A Article number

B Serial number

C Type number

D Reduction ratio

E Number of revolutions per minute

A

A C

APEX

Serial No:.

YEAR:

Watson-Marlow Bredel B.V.

Sluisstraat 7-Delden-NL

www.bredel.com

B

10 15 20

LOW

D

MED.

14

Page 15

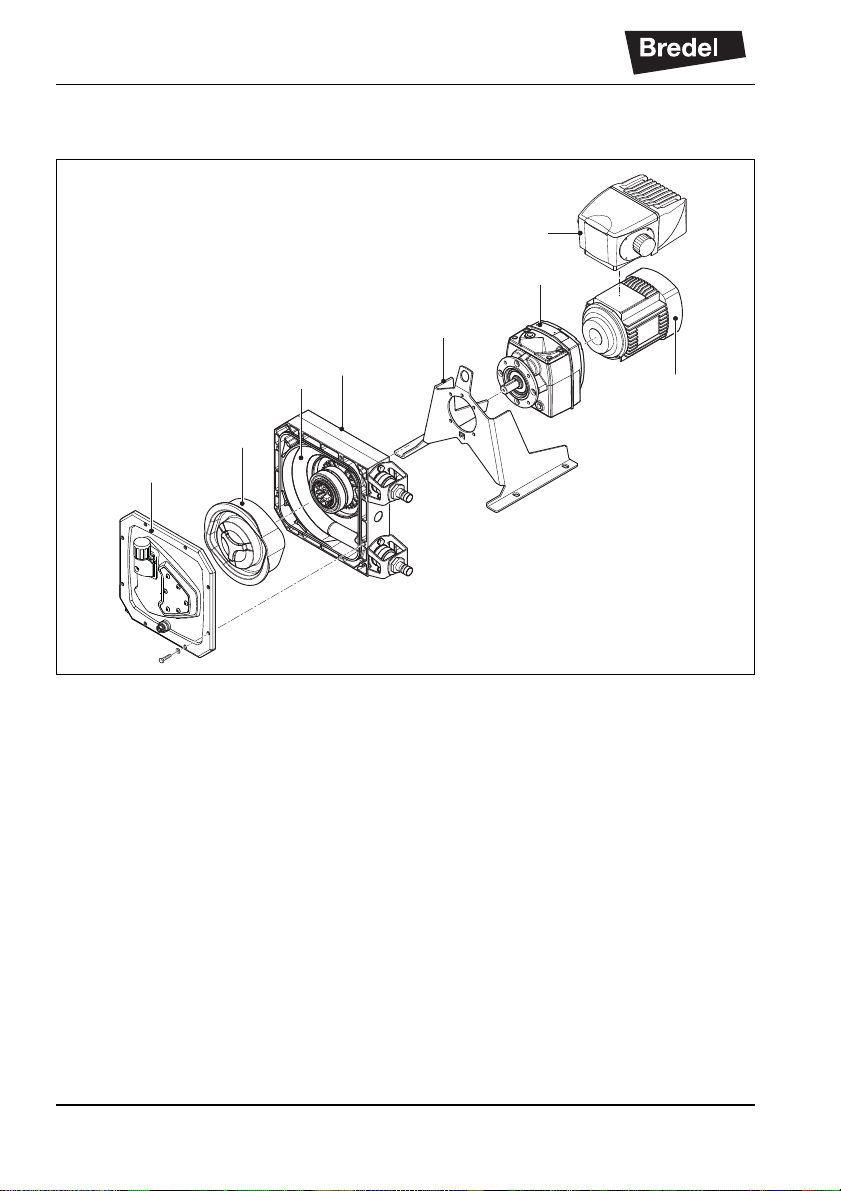

4.1.4 Identification of the electric motor

V

S

IP IK

Hz min-1 kW A

COS

C/h%

N

o

U

N

V

P

Mf

Nm

CF

o

D E F

GH I

C

B

The identification plate on the electric motor contains

the following data:

B Serial number

C Article number

D Mains

E Frequency

F Speed

G Power

H Power factor

I Current

4.1.5 Identification of the frequency controller

The identification of the Bredel Variable Frequency

Drive (VFD) can be found inside the VFD. Remove the

cover by loosening the two screws. The identification

sticker contains the following data:

A Article number

B Serial number

DESCRIPTION

B

LS serial number

sn20837003969

Bredel article number E384083

A

4.1.6 Identif ication of the pump hose

The identification sticker on the pump hose contains the

following data:

A: Pump type

B: Part code

C: Internal diameter

D: Type of material of inner liner

E: Remarks, if applicable

F: Maximum permissible working pressure

G: Production code

A

B

C

D

E

F

G

15

Page 16

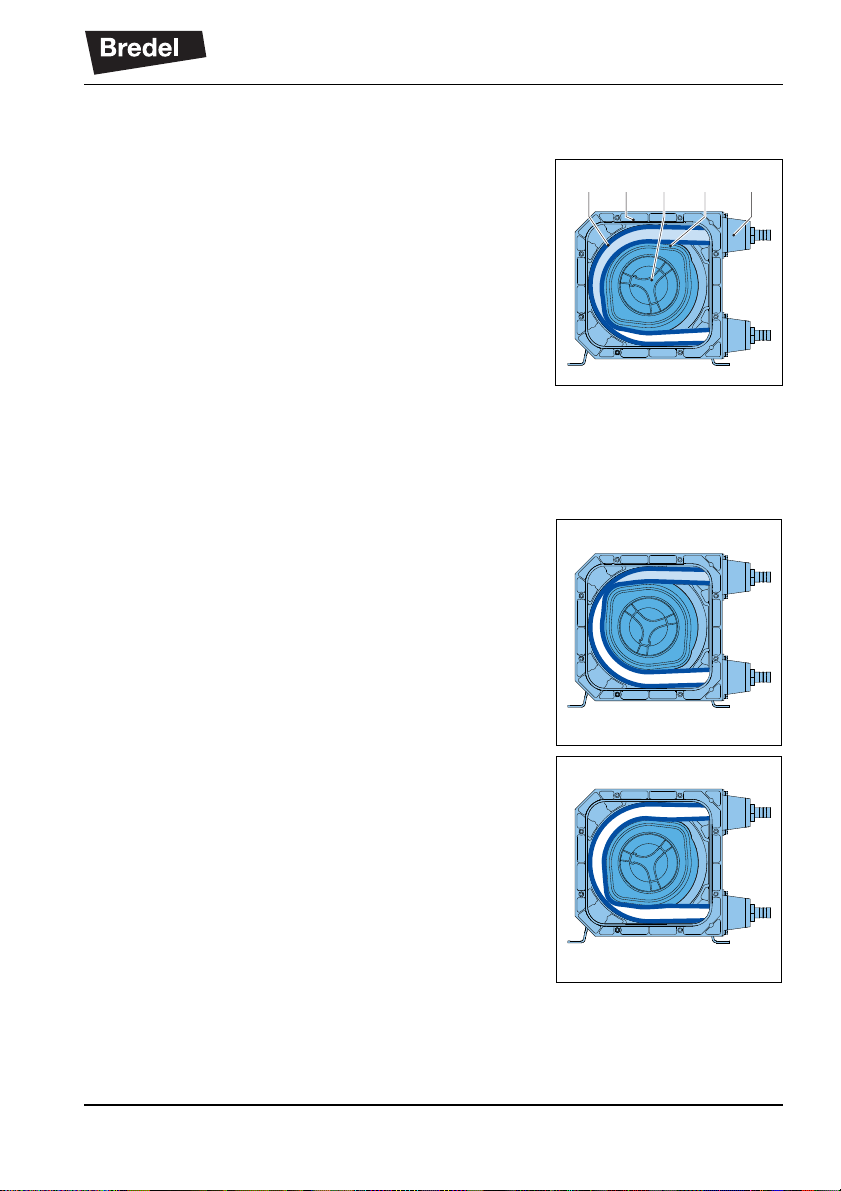

DESCRIPTION

4.2 Construction of the pump

C

B

A

H

F

E

D

G

A Cover

B Rotor

C Pump hose

D Pump housing

E Support

F Gearbox

G Electric motor

H Frequency controller

16

Page 17

4.3 Operation of the pump

The heart of the pumphead consists of a specially

constructed pump hose (A) which lies against the inside

of the pump housing (B). The ends of the hose are

connected to the suction and discharge lines (C). A

bearing-mounted rotor (D) with two facing integral

pressing shoes (E) is in the centre of the pumphead. It

rotates clockwise.

In phase 1 the lower shoe compresses the pump hose

by the rotational movement of the rotor, forcing fluid

through the hose. As soon as the shoe has passed, the

hose recovers to its original shape due to the

mechanical properties of the material and fluid is drawn

into the hose.

In phase 2 fluid is drawn through the hose by the

(continuous) turning motion of the rotor.

DESCRIPTION

AB E CD

In phase 3, the second integral pressing shoe

compresses the pump hose. Due to the continuous

rotating movement of the rotor new fluid is sucked in

and fluid that is previously drawn in is pressed out by

the shoe. When the first shoe leaves the pu mp hose,

the second shoe has already occluded the pump hose

and fluid is prevented from flowing back. This method of

liquid displacement is known as the "positive

displacement principle".

17

Page 18

DESCRIPTION

4.4 Pump hose

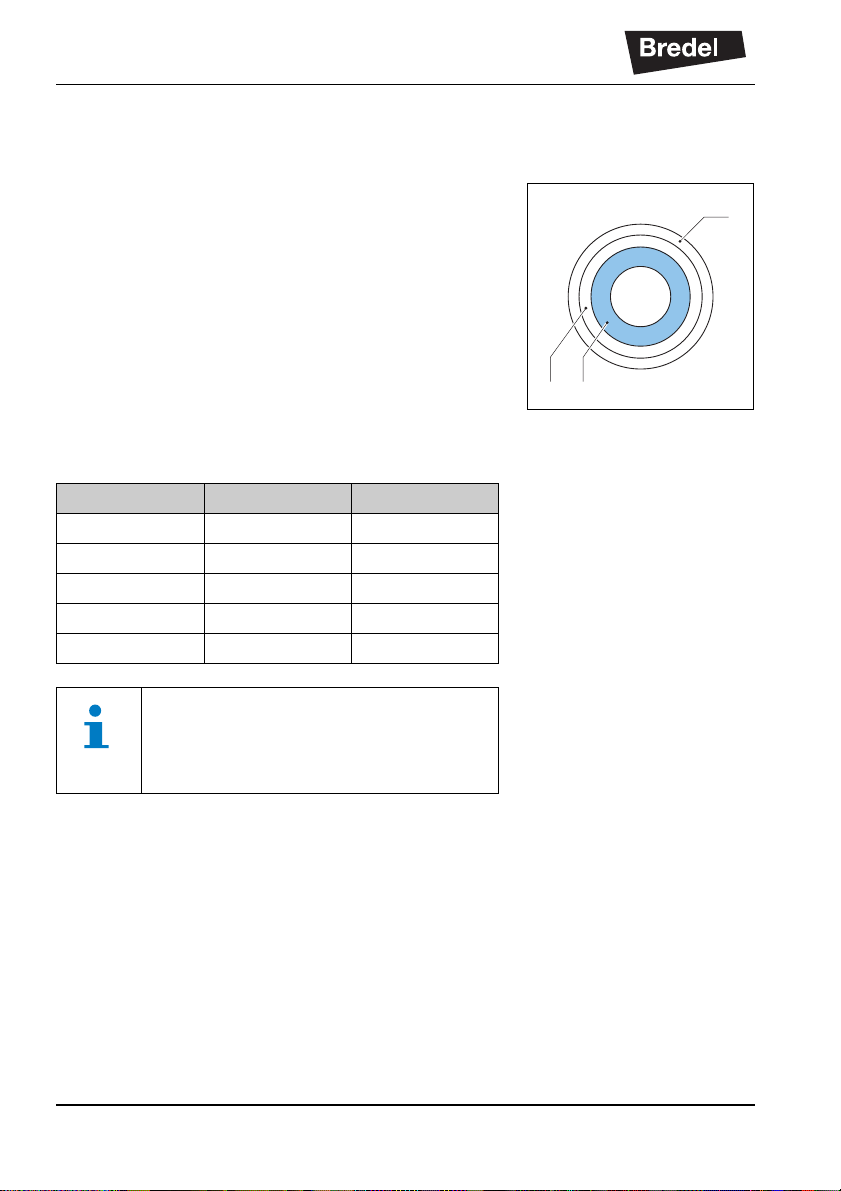

4.4.1 General A Extruded outer layer made of natural rubber B Two nylon reinforcement layers C Extruded inner liner

The pump hose liner material should be chemically

resistant to the product being pumped. For each pump

model various hose types are available. Choose the

most appropriate for your application.

The material of the inner liner of the pump hose

determines the hose type. Each hos e ty pe i s marked by

a unique colour code.

Hose type Material Colour code

NR Natural rubber Purple

NBR Nitrile rubber Yellow

F-NBR Nitrile rubber Yellow

EPDM EPDM Red

CSM CSM Blue

A

B C

Consult your Bredel representative for

more detailed information about the

chemical and temperature resistance of

pump hoses.

Bredel pump hoses have been carefully machined to

achieve minimum tolerances in wall thickness. It is very

important to guarantee the correct compression of the

pump hose, because:

• When the compression is too high, it creates an

excessive load on the pump and pump hose,

which may reduce the life of the pump hose and

bearings.

• When the compression is too low, it cuts

capacity and causes backflow. Backflow

reduces the life of the pump hose.

18

Page 19

4.4.2 Hose compress ion force adjustment

The compression force on the pump hose can be

adjusted by installing a rotor with a different dimension

between the tips of the integral pressing shoes. The

rotor is chosen to achieve an optimal life of the pump

hose for the intended use of the hose pump. Each hose

size (10, 15 or 20 mm inner diameter) has its own lowpressure and medium-pressure rotors. This means

there are six types of rotors available. If you want to

change the application of your hose pump or if you want

to change the hose size, contact your Bredel

representative.

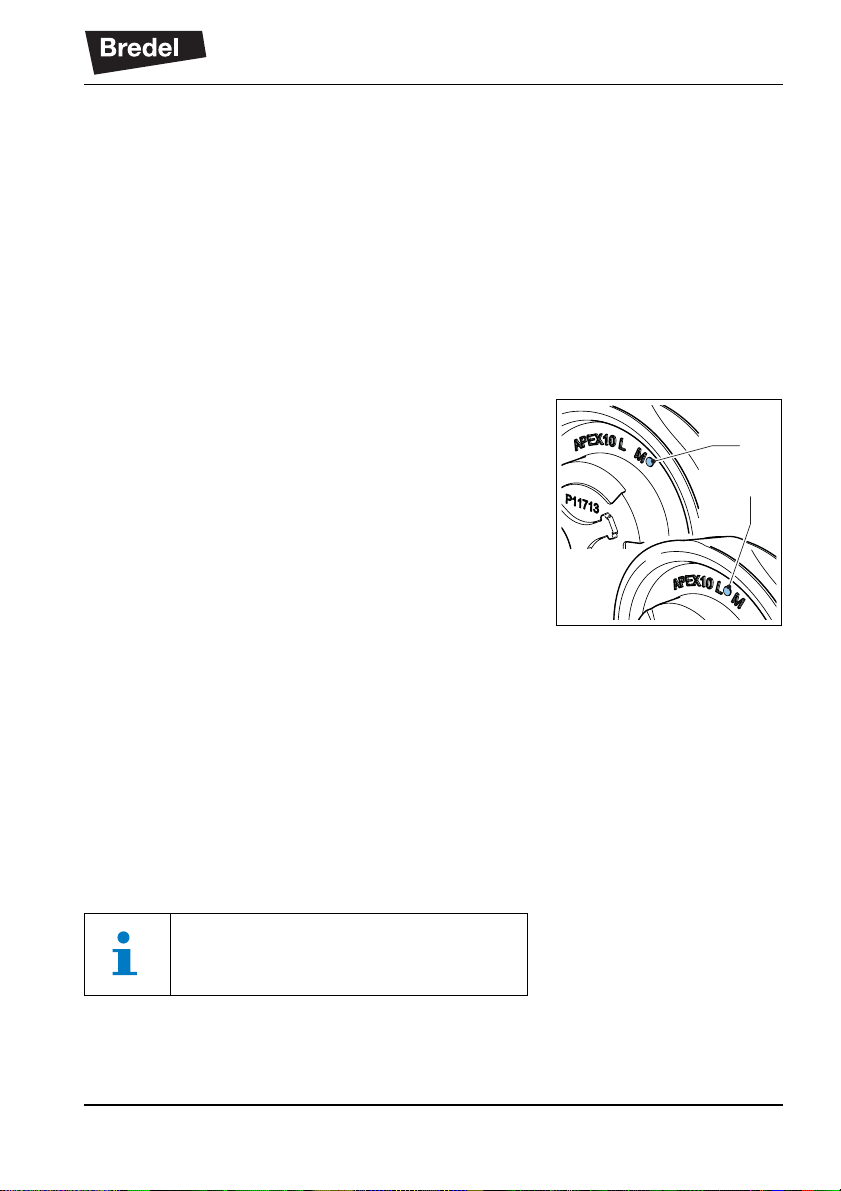

Low-pressure and medium-pressure rotors can be

recognized by a marked hole near the “L” for “Lowpressure” (B) or near the “M” for “Medium-pressure” (A)

on the rotor.

DESCRIPTION

A

B

4.4.3 Lubrication and cooling

The pumphead is filled with Bredel Genuine Hose

Lubricant. This lubricant lubricates the shoes and

dissipates the heat generated by the movement of the

pressing shoes against the pump hose.

The lubricant is food grade. The user is responsible to

ensure the chemical compatibility of the lubricant with

the fluid to be pumped. Refer to § 11.1.4 for the

required quantity and NSF registration.

Refer to § 7.5 for the consequences of a hose failure.

Consult your Bredel representative for

lubrication recommendations when

operating the hose pump below 2 rpm.

19

Page 20

DESCRIPTION

4.5 Gearbox

The hose pump types described in this manual use

helical gearbox units. Other gearbox types are available

as option. The gearboxes are fitted with a flange

connection. Refer to § 11.2 for specifications. Refer to

the documentation supplied with the gearbox for

installation and maintenance information. In case of

doubt, consult your Bredel representative.

4.6 Electric motor

The standard electric motor is a completely enclosed

three-phase asynchronous motor. The motor

connection must meet the local applicable regulations.

Refer to the documentation supplied with the electric

motor for installation and maintenance information. In

case of doubt consult your Bredel representative. Refer

to § 5.3.4 and § 6.1 for installation and connection

information.

4.7 Available options

The following options are available for the hose pump:

• High (lubricant) level float switch

• Revolution counter

• Medium- or low-pressure rotor (depending on

the discharge pressure)

• Frequency controller

1

• Three hose sizes

• Five hose types

• Various types of hose connection

• Worm gear drive

• Special configuration for use in explosive

atmospheres

1 Refer to the supplier’s documentation and § 11.4.

20

Page 21

5INSTALLATION

5.1 Unpacking

Follow the unpacking instructions on the packaging or

on the hose pump, the gearbox and the electric motor.

5.2 Inspection

Check that your delivery is correct and check it for any

transport damage. When replacing parts, check that the

delivery is correct and check these parts for any

transport damage. Refer to § 4.1.1. Report any damage

immediately to your Bredel representative.

5.3 Installation conditions

5.3.1 Ambient conditions

Make sure that the hose pump is in an area where the

ambient temperature during operation is not lower than

-20 °C and not higher than +45 °C.

INSTALLATION

5.3.2 Setup

• The pump materials and protective layers are

suitable for indoor setup and a protected

outdoor setup. Under certain conditions the

pump is suitable for limited outdoor setup or a

salty or aggressive atmosphere. Consult your

Bredel representative for more information.

• Make sure that the floor surface has a

maximum slope of 10 mm per metre.

• Make sure that there is sufficient room around

the pump to carry out the necessary

maintenance.

• Make sure that the room is sufficiently

ventilated, so that the heat developed by the

pump and drive can be dissipated. Keep some

distance between the ventilation cover of the

electric motor and the wall to allow the supply of

cooling air.

21

Page 22

INSTALLATION

5.3.3 Pipework

When determining and connecting suction and

discharge lines consider the following points:

• It is recommended that the bore size of the

suction and discharge lines is larger than the

bore size of the pump hose. For more

information consult your Bredel representative.

• Limit the presence of sharp bends in the

discharge line. Make sure that the radius of any

bend is as large as possible. Use Y-connections

instead of T-connections.

• It is recommended to use a minimum of three

quarters (3/4) of the hose length as flexible

hose in the suction or discharge line. This

avoids the need to remove the connection l ines

when changing a pump hose.

• Keep the delivery and suction lines as short and

direct as possible.

• Select the correct mounting material for flexible

hoses and make sure that the installation is

suited for the design pressure of the system.

• Do not exceed the maximum working pressure

of the hose pump. Refer to § 11.1.1. If

necessary fit a pressure relief valve.

CAUTION

Consider the maximum permissible

working pressure on the discharge side.

Exceeding the maximum working pressure

may lead to serious damage to the pump.

• Make sure that the maximum forces on the

flanges are not exceeded. The permissible

loads are given in the following table.

22

Page 23

Maximum permissible loads [N] on the

pump connections

Force APEX10, 15, 20

F1 600

F2 120

F3 300

5.3.4 Motor

The motor connection must meet the local applicable

regulations. A thermal safety device should reduce the

risk of a motor overload. For connecting PTC

thermistors (if present) a special thermistor relay must

be used. In case of doubt, contact your Bredel

representative for advice. Refer to § 11.3 for

specifications.

Refer to the documentation supplied with the electric

motor for information on how to connect the motor to

your power supply.

INSTALLATION

F2

F1

F3

5.3.5 Frequency controller

WARNING

A frequency controller that is fitted without

manual control can start the pump

automatically when power is applied.

If the hose pump is fitted with a frequency controller,

consider the following points:

• Take precautions so the motor does not restart

automatically after an unscheduled stop.

In the event of a power or mechanical failure,

the frequency controller stops the motor. When

the cause of the failure is removed, the motor

can restart automatically. The automatic restart

can be dangerous in certain pump installations.

23

Page 24

INSTALLATION

• All control cables outside the enclosure must be

shielded and have a cross sectional area

between 0.22 mm

must be connected to earth at both ends. In

case of doubt, consult your Bredel

representative.

5.4 Lifting and moving the pump

The pump support has a lifting eye (A) for lifting and

moving the hose pump.

The complete hose pump, i.e. pumphead, gearbox and

electric motor, must be lifted using the lifting eye plus

additional support using suitably rated straps or

slings (A). For the weights, refer to § 11.1.5.

2

and 1 mm2. The shielding

A

A

WARNING

If the pump is to be lifted ensure that all

standard lifting practices are adhered to

and carried out by qualified personnel only.

5.5 Placing the pump

Position the pump on a horizontal surface. Use suitable

anchor bolts to attach the pump to the floor surface.

24

Page 25

6 COMMISSIONING

6.1 Preparations

WARNING

A frequency controller that is fitted without

manual control can start the pump

automatically when power is applied.

WARNING

Disconnect and lock the power supply to

the pump drive before any work is carried

out.

In case the motor is fitted with a frequency

controller and has a single-phase power

supply, wait two minutes to make sure that

the capacitors have discharged.

1. Connect the electric motor and, if present, the

frequency controller in conformance with the

locally applicable rules and regulations. Refer to

§ 5.3.4 and § 5.3.5. Have the electrical

installation work carried out by qualified

personnel.

COMMISSIONING

2. Check that the lubricant level is above the

minimum level line in the inspection window. If

necessary refill with Bredel Genuine Hose

Lubricant via the breather plug. Also refer to

§ 8.4.

25

Page 26

COMMISSIONING

6.2 Commissioning

1. Connect the pipework.

2. Make sure that there are no obstructions such

as closed valves.

3. Switch on the hose pump.

4. Check the rotation of the rotor.

5. Check the capacity of the hose pump. If the

capacity differs from your specification, follow

the instructions in chapter 10 or consult your

Bredel representative.

6. If a frequency controller is present, check the

capacity range. In case of any deviations

consult the supplier’s documentation.

7. Check the hose pump in accordance with points

2 to 4 of the maintenance table at § 8.2.

26

Page 27

7 OPERATION

7.1 Temperature

The pump will heat up during normal operation. Heat is

generated in the contact zone between the pressing

shoe and the hose. The heat is removed by the

lubricant and transported to the pump casing and cover.

This will result in a temperature higher than the ambient

temperature.

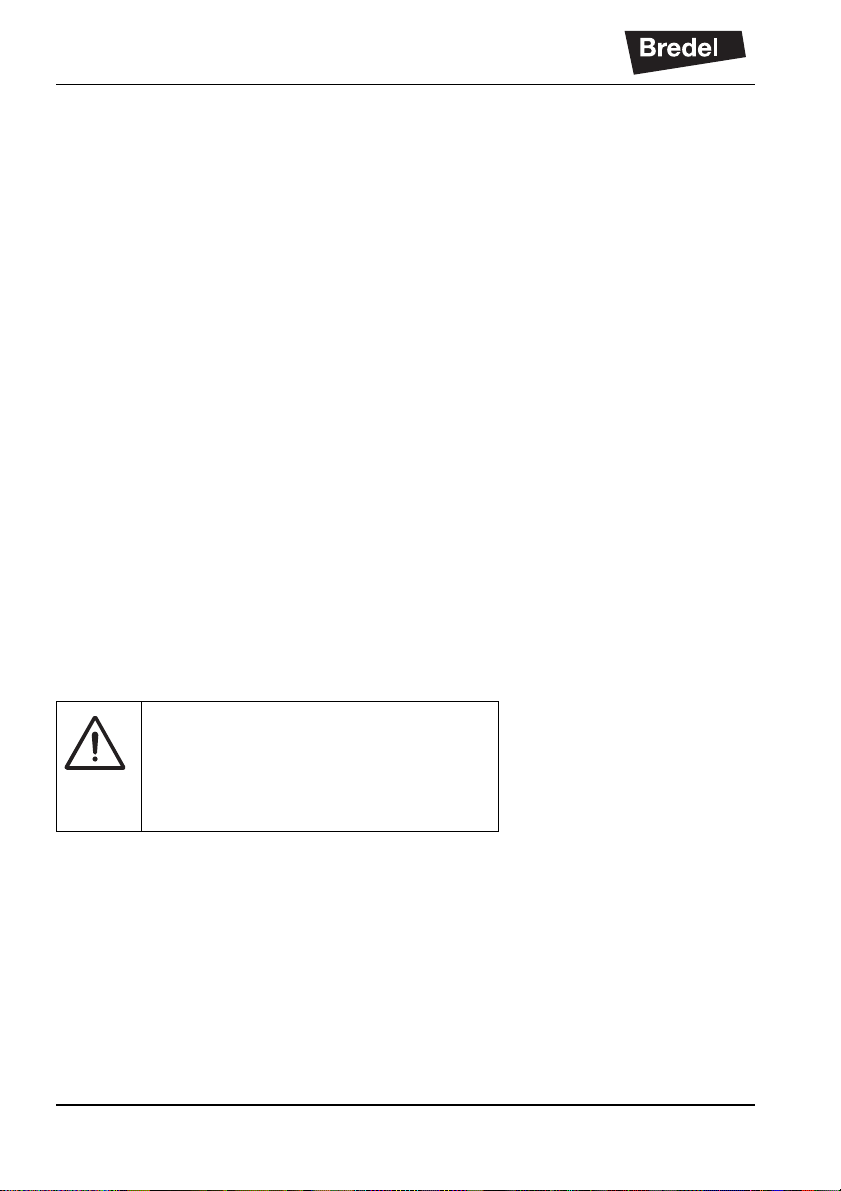

WARNING

Avoid contact with the casing and cover

under conditions of high pressure and

running speed.

7.2 Power rating

The pump requires a certain amount of power for the

specified operating condition(s). The gearbox and

motor should be capable of handling that power at the

given revolution speeds. Refer to § 7.3 to determine the

required power.

OPERATION

WARNING

Overloading the motor can lead to serious

motor damage. Do not exceed the

maximum power rating of the motor.

WARNING

Overloading the gearbox leads to

increased tooth wear and shortened

bearing life. This can lead to serious

gearbox damage. Do not exceed the

maximum power rating of the gearbox.

27

Page 28

OPERATION

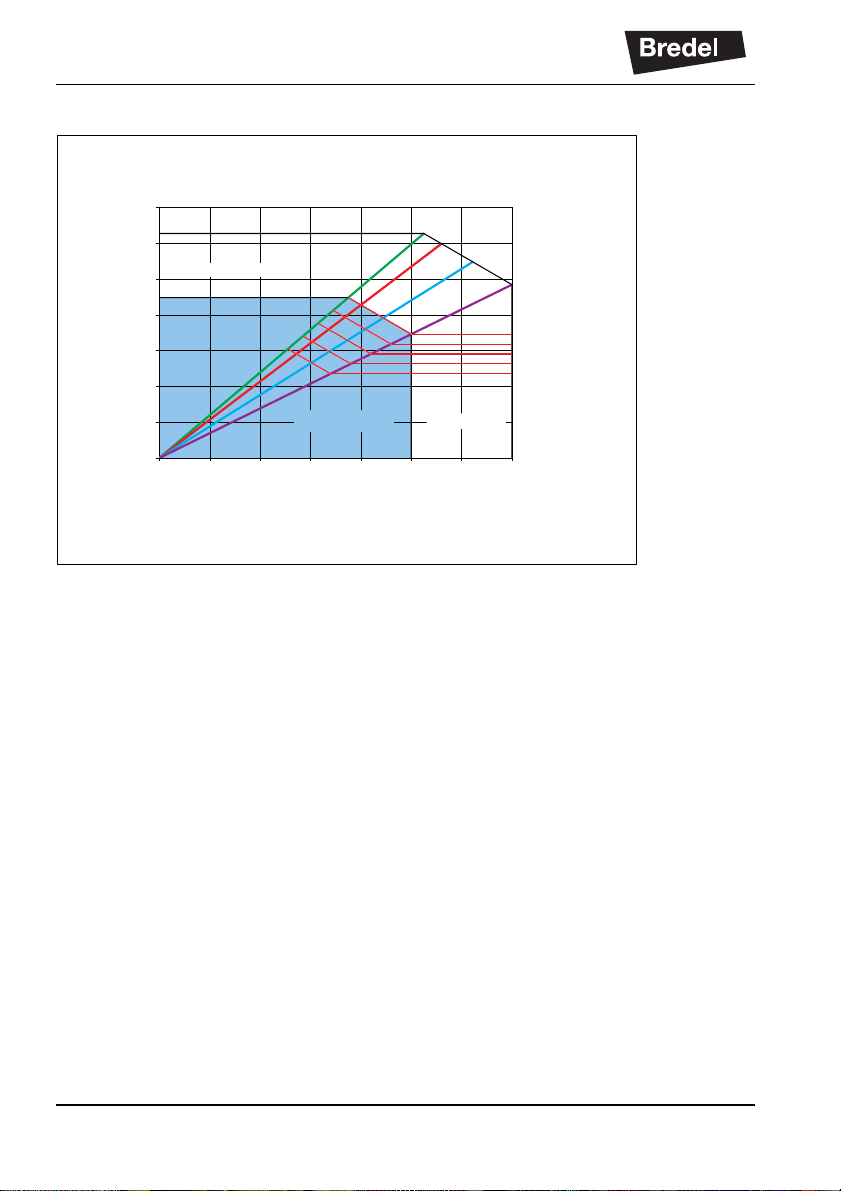

7.3 Performance graphs

Useful operating duties can be found in the

performance graphs in which discharge-pressure

curves are displayed in a speed-power diagram.

Even at 0 kPa discharge pressure a certain torque is

required to let the pump rotor rotate. The pump and

hose are designed to handle a discharge pressure up to

800 kPa. The triangular area between the 0 kPa and the

800 kPa lines describes the allowed performance area.

The required duty points have to fall within this area.

In the direction of higher speeds and powers, pump

operation is limited by the heat generated, the product

temperature and the ambient temperature. Producttemperature lines determine a distinction between

areas of continuous operation and intermittent

operation in the graphs. The graphs apply for a

maximum ambient temperature of 40 °C.

If the duty for an application is specified in the area of

intermittent operation, let the pump stand still to cool

down for at least one hour after three hours of

operation.

28

Page 29

7.3.1 Performance graph APEX10:

0.00

02040

40

50

60

70

80

60 80 100 120 140

0 55 110 165 220 275 330 385

0.05

0.10

0.15

0.20

0.25

0.30

0.35

0.40

0.45

0.50

Pump Speed [rpm]

Capacity [L/h]

Required Motor Power [kW]

0 kPa

300 kPa

600 kPa

800 kPa

Intermittent Duty

Continuous Duty

100 kPa =1 bar

Product

temperature

(°C)

0.00

0 20 40 60 80 100 120 140

0 110 220 330 440 550 660 770

0.10

0.20

0.30

0.40

0.50

0.60

Pump Speed [rpm]

Capacity [L/h]

Required Motor Power [kW]

0 kPa

300 kPa

600 kPa

800 kPa

Intermittent Duty

Product

temperature

(°C)

40

50

60

70

80

Continuous Duty

100 kPa =1 bar

7.3.2 Performance graph APEX15:

OPERATION

29

Page 30

OPERATION

0,00

0,10

0,20

0,30

0,40

0,50

0,60

0,70

02040

40

50

60

70

80

60 80 100 120 140

0 175 350 525 700 875 1050 1225

Pump Speed [rpm]

Capacity [L/h]

Required Motor Power [kW]

0 kPa

300 kPa

600 kPa

800 kPa

Intermittent Duty

Continuous Duty

100 kPa =1 bar

Product

temperature

(°C)

7.3.3 Performance graph APEX20:

7.4 Dry running

Dry running is a running condition of the pump when no

fluid is flowing through the pump. Bredel peristaltic

pumps are very suitable for dry run nin g.

Dry running imposes an additional thermal load on the

pump hose, because a part of the internal heat

associated with repetitive hose compression is normally

removed by the process fluid. So dry running increases

the wear on the hose. The thermal load depends on the

running speed of the pump, the hose size (10, 15, 20

mm) as well as the rotor type (low pressure or medium

pressure). To minimise the extra wear, it is advisable to

minimise dry running periods.

30

Page 31

7.5 Hose failure

Cause of a hose failure

The hose in a peristaltic pump has to withstand many

load cycles of considerable magnitude. The repetitive

stress cycles will cause the hose to deteriorate and

eventually fail.

Result of a hose failure

A hose failure will result in direct contact between the

pump lubricant and the pumped fluid.

Consequences of a hose failure

In general, this will not cause a hazardous situation

because the Bredel Genuine Hose Lubricant is

harmless (approved by the United States Food and

Drug Administration). However, there is an exception in

case of pumping a strong oxidiser or a strong acid.

Refer to § 11.1.4 about chemical compatibility.

OPERATION

31

Page 32

OPERATION

• Hazardous situations

WARNING

Avoid direct contact between a strong

oxidiser or a strong acid and Bredel

Genuine Hose Lubricant. This can cause

unwanted chemical reactions. Use an

alternative lubricant to avoid hazardous

situations. Contact your Bredel

representative for more details.

• Additional downtime

Hose failure will result in additional downtime,

because you must clean the pump before a new

hose installation.

Regularly replace the hose to avoid hose

failure and additional downtime. Hose life

depends on the operating condition,

process fluid and hose material. The enduser should be aware of this and establish

the frequency of preventive hose

replacement. Contact your Bredel

representative for advice.

• Large spill of product

In case the pressure in the process line

(reservoir) is above the pressure in the pump

housing (ambient pressure), the process fluid

can enter the pump housing. If there is no check

valve in the process line a serious amount of

fluid can flow from the reservoir into the pump

housing and escape through the breather onto

the floor. This could lead to a large spill of

product outside the pump. Reversed flow

protection is advised. This is not part of the

scope of delivery.

32

Page 33

7.6 Fluid leakage

The APEX pump uses a lubricated rotor to compress

the hose. This means the pumphead must be filled with

sufficient lubricant during operation. This lubricant is

contained in the pump housing by the front cover and

by a dynamic seal on the back. The gearbox is filled

with gearbox lubricant.

Seal damage can occur due to normal wear in time, but

is seriously accelerated if the seal gets in contact with

contaminated lubricant. Thorough cleaning of the pump

housing after a hose failure and regular replacement of

the lubricant is strongly advised.

The pumphead and gearbox are directly coupled to

each other. A special feature is included in the

pumphead to allow early detection of seal damage of

the pump or gearbox.

This feature is called the leakage zone. Drops of

lubricant visible at the back of the pump indicate likely

seal failure. To avoid consequential damage, the pump

must be stopped and lubricant levels of the pumphead

and gearbox must be checked. The damaged seal

should be replaced.

OPERATION

Regularly inspect the pump for fluid

leakage.

WARNING

Risk of injury from falling! Process fluid

mixed with pump lubricant that is leaking

from the pump can make floors slippery.

33

Page 34

MAINTENANCE

8 MAINTENANCE

8.1 General

WARNING

Disconnect and lock the power supply to

the pump drive before any work is carried

out.

In case the motor is fitted with a frequency

controller and has a single-phase power

supply, wait two minutes to make sure that

the capacitors have discharged.

WARNING

Do not remove the pump cover if the power

cable is connected to the motor. Do not

connect the power cable to the motor if the

pump cover is removed.

Only use original Bredel parts when maintaining the

hose pump. Bredel cannot guarantee correct operation

and any consequential damage that occurs from the

use of non-original Bredel components. Also refer to

chapters 2 and 3.

Check that your delivery of original parts is correct and

check it for any transport damage. If parts are

damaged, consult your Bredel representative.

Before installation, always check the

condition of the supplied parts. Do not

install damaged parts. In case of doubt,

contact your Bredel representative.

8.2 Maintenance and periodic inspections

The following diagram shows the maintenance and

periodic inspection that need to be carried out on the

hose pump to guarantee optimal safety, operation and

life of the pump.

34

Page 35

MAINTENANCE

Point Action To be carried out Remark

1 Checking the lubricant

level.

2 Checking the pump-

head for any leakage of

lubricant around the

cover, the brackets and

the rear of the pumphead.

3 Checking the gearbox

for any leakage.

4 Checking the pump for

deviating temperature or

strange noises.

5 Checking the rotor with

integral pressing shoes

for excessive wear.

6 Internal cleaning of the

pump hose.

7 Replacing the pump

hose.

8 Changing lubricant. After every second hose

9 Replacing the seal ring. If necessary. Refer to § 8.6.1.

Before starting the pump

and at scheduled intervals during operation.

Before starting the pump

and at scheduled intervals during operation.

Before starting the pump

and at scheduled intervals during operation.

At scheduled intervals

during operation.

When replacing the

pump hose.

Cleaning of the system

or fluid change.

Preventive, this means

after 75% of the hose life

of the first hose.

change or after 5,000

service hours, whichever

comes first, or after hose

rupture.

Make sure that the lubricant level is above the

minimum level line in the

inspection window.

If necessary refill the

lubricant. Also refer to

§ 8.4.

Refer to § 10.

In case of leakage consult your Bredel representative.

Refer to § 10.

Refer to § 8.5.

Refer to § 8.3.

Refer to § 8.5.

Refer to § 8.4

35

Page 36

MAINTENANCE

Point Action To be carried out Remark

10 Replacing the rotor with

integral pressing shoes.

Wear on the running surface of the pump hose

and/or seal ring.

11 Replacing the bearings. If necessary. Refer to § 8.6.1.

8.3 Cleaning the pump hose

The inside of the pump hose can be easily cleaned by

rinsing the pump with clean water. If a cleaning fluid is

added to the water, check if the hose liner material is

resistant to it. Also check if the pump hose can resist

the cleaning temperature. Special cleaning balls are

also available. Contact your Bredel representative for

more details.

8.4 Changing lubricant

1. Place a tray (A) under the drain plug, which is in

the cover of the pump. Remove the drain plug

(B). Drain the lubricant from the pump housing

into the tray. Place back the drain plug and

tighten it.

2. The pump housing can be filled with lubricant

via the breather (A) on the cover. For this

purpose remove the breather cap (B) and

position a funnel (C) in the breather. Pour the

lubricant into the pump housing through the

funnel.

36

B

A

C

B

A

Page 37

3. Keep on pouring until the lubricant level has

B

A

risen above the level line in the inspection

window. Place back the breather cap.

For the required quantity of lubricant, refer

to § 11.1.4.

8.5 Replacing the pump hose

8.5.1 Removing the pump hose

1. Isolate the pump from the electrical supply .

2. Close any shut-off valves in the suction and

discharge line to minimise product loss.

3. Place a tray (A) under the drain plug in the

bottom of the pumphead. The tray must be

large enough to contain the lubricant, possibly

contaminated with product fluid, from the

pumphead. Remove the drain plug (B). Catch

the lubricant from the pump housing in the tray.

Check that the breather mounted on the cover

is not obscured. Place back the drain plug and

tighten it.

4. Disconnect the suction and discharge lines.

MAINTENANCE

B

A

5. Loosen the hose clamp (A) of the inlet and

outlet ports by loosening the bolt (B).

37

Page 38

MAINTENANCE

A

6. Loosen the bolts (A) of the bracket (B) and

remove the bolts.

7. Pull the bracket and hose clamp from the ho se.

Then pull off the rubber bush (C).

Do steps 6 to 7 for both the inlet and outlet

ports.

8. Switch on the electrical supply.

9. Drive out the hose (A) from the pump chamber

by jogging the drive motor.

WARNING

During jogging the drive:

- Do not stand in front of the pump

ports.

- Do not try to guide the hose by

hand.

8.5.2 Cleaning the pumphead

1. Isolate the pump from the electrical supply.

2. Remove the cover (B) by loosening the bolts

(A).

3. Check the cover seal (C) and replace it if

necessary.

A

B

C

C

A

4. Rinse the pumphead with clean water and

remove all residues. Clean the pockets in the

pump housing. Make sure that no rinsing water

remains in the pumphead.

38

B

A

Page 39

5. Check the rotor for wear or damage and replace

A

the rotor if necessary. Also refer to the

maintenance diagram in § 8.2.

CAUTION

When the rotor is worn the compression

force of the hose decreases. If the

compression force is too low, this results in

a loss of capacity because of the backflow

of the liquid to be pumped.

Backflow results in a reduction of the life of

the pump hose.

6. Place back the cover and fasten the retaining

bolts to the correct torque. Refer to § 11.1.6.

7. Switch on the electrical supply to the pump.

8.5.3 Fitting the pump hose

1. Clean the (new) pump hose on the outside and

fully lubricate the outside with Bredel Genuine

Hose Lubricant.

MAINTENANCE

2. Fit the pump hose (A) via one of the ports.

3. Run the motor so that the ro tor pulls the hose

into the pump housing. Stop the motor when the

hose sticks out equally from both sides of the

pump housing.

WARNING

During jogging the drive:

- Do not stand in front of the pump

ports.

- Do not try to guide the hose by

hand.

39

Page 40

MAINTENANCE

A

BB

A

B

A

4. Check that the rubber bushes (A) are not

deformed or damaged and replace them if

necessary.

5. Check that the hose clamps (B) are not

damaged and replace them if necessary.

6. First fit the inlet port.

Slide the rubber bush (D) over the hose. Push

the bracket (A) and the hose clamp (B) over the

hose together. Align the holes in the bracket

with the ones at the front of the port. Position

the two bolts (C) and tighten them. Make sure

the bolts are tightened to the correct torque.

Refer to § 11.1.6.

7. Turn the rotor in such a way that the hose (A) is

pressed firmly against the bracket (B).

B

A

A

B

B

D

C

A

C

8. Place the hose clamp accurately on the track in

the rubber bush. Tighten the bolt (B) of the hose

clamp (A). Make sure the bolt is tightened to the

correct torque. Refer to § 11.1.6.

9. Now fit the other port in the same way.

10. Fill the pump housing with Bredel Genuine

Hose Lubricant. Refer to § 8.4.

1 1. Connect the suction and discharge lines.

40

Page 41

8.6 Exchanging replacement parts

8.6.1 Replacing rotor, bearings and seal ring

1. Remove the pump hose. Refer to § 8.5.1.

2. Isolate the pump from the electrical supply .

3. Remove the cover (B) by loosening the

retaining bolts (A).

4. Check the cover seal (C) and replace it if

necessary.

5. Put the hose pump on blocks, on its side as

shown. Make sure the space between the

blocks is wide enough for the rotor to fall into.

MAINTENANCE

C

B

A

6. Remove the nuts (B), the washers (C) and the

pump drive (A).

A

B

C

41

Page 42

MAINTENANCE

7. Put a plastic or wooden drive pin (A) on the

rotor.

8. Hit the drive pin firmly with a hammer to remove

the rotor.

9. Put the hose pump upright on the support.

10. Dismount the circlip (A) with the correct tool.

11. Dismount the bearings (A), the spacer ring (B)

and the retaining ring (C) with the correct tool.

Clean the hub.

A

A

12. Remove the seal ring (A). Clean and degrease

the bore. The holes in the pump housing can be

used to drive out the old seal.

42

ACB A

A

Page 43

13. Fit a new seal ring (A) using g ood engineering

A

practices. The seal ring must be fitted in the

correct orientation (B). Make sure that the open

side points to the pump cover.

14. Slightly oil the inne r ring of the (new) bearings

and the seat on the hub. Fit the bearings and

the rings.

The bearings are placed on the hub with a slight

interference fit. Use a pressing tool to press the

bearings on the hub.

15. Mount the circlip (A).

MAINTENANCE

B

A

16. Fit the rotor (A). The rotor is placed on the

bearings with a loose fit. Press the rotor on the

hub until it clicks on the retaining ring.

A

43

Page 44

MAINTENANCE

17. Put the hose pump on two blocks, on its side as

shown.

18. Fit the pump drive (A) with the nuts (B) and

washers (C). Make sure the coupling and rotor

are correctly oriented such that they fit onto

each other. Tighten to the specified torque

settings. Refer to § 11.1.6.

19. Put the hose pump upright on the support.

20. Refit the cover (B). Make sure that the eight

bolts (A) are refitted and that they are tightened

in the correct order, diagonally opposite each

other. Refer to § 11.1.6.

21. Switch on the electrical supply to the pump.

22. Fit the (new) pump hose. Refer to § 8.5.3.

8.7 Fitting options

8.7.1 Fitting a high-level float switch

1. Dismount the standard breather (A) on the

cover of the pumphead.

A

B

C

B

A

44

A

Page 45

2. Mount the breather (A) with high-level float

switch.

3. Connect the high-level float switch to the

auxiliary power circuit via the 1.5 metre long

PVC cable (2 x 0.34 mm

2

). Bear in mind that

the electrical contact of the float switch is

normally closed (NC). The knob is upwards for

normally closed operation. When the lubricant

level is (too) high the contact will open.

Specifications

*

Voltage: Max. 230 V AC/DC

Current: Max. 2 A

Power: Max. 40 VA

* For use in non-explosive atmospheres.

MAINTENANCE

A

NC

Where the float switch is constructed to

stop the equipment, operating has to be

arranged so that the stop function locksout, preventing the equipm en t from being

re-started without re-setting. Check if the

float switch is mounted with the NC sign at

the top.

45

Page 46

MAINTENANCE

8.7.2 Replacing the revolution counter

1. Jog the rotor until the pressing shoe is clearly

visible through the inspection window. Now the

pressing shoe faces the position of the sensor.

2. Remove the lubricant. Refer to 8.4.

3. Remove the cover (B) by loosening the

retaining bolts (A).

4. Remove the nut (A) and the old sensor (B).

C

B

A

5. Mount the nut (B) and the sealing ring (A) on the

new sensor (C).

6. Place the sensor (C) in the pump housing.

46

A

B

A

B

C

Page 47

MAINTENANCE

7. Tighten the nuts so that the distance between

the sensor and the rotor (X) is between 0.75

mm and 1.25 mm.

8. Check if the revolution counter works properly:

1 The sensor needs to send signals.

2 The rotor should be able to rotate freely.

9. Refit the cover (B). Make sure that the eight

bolts (A) are refitted and that they are tightened

in the correct order, diagonally opposite each

other. Refer to §11.1.6.

10. Refill the pumping house with lubricant. Refer to

8.4.

11. Connect the sensor electrically via the 2 metre

long PVC cable (3 x 0.34 mm

2

). Refer to the

connection scheme, right.

Specifications

*

Voltage 10 ... 30 V DC

Current Max. 200 mA

* For use in non-explosive atmospheres.

pnp

X

B

A

BN

BU

BK

+

47

Page 48

STORAGE

9STORAGE

9.1 Hose pump

• Store the hose pump and pump parts in a dry

area. Make sure that the hose pump and pump

parts are not exposed to temperatures lower

than -40 °C or higher than +70 °C.

• Cover the openings of the inlet and outlet ports.

• Prevent corrosion of untreated parts. For this

purpose use the correct protection or

packaging.

• After a long period of standstill or storage, the

static load on the pump hose may have caused

permanent deformation, which will reduce the

life of the pump hose. To prevent this, remove

the pump hose when the pump is not going to

be used for more than one month.

9.2 Pump hose

• Store the pump hose in a cool and dark room.

After two years the hose material will age, which

will reduce the life of the hose.

48

Page 49

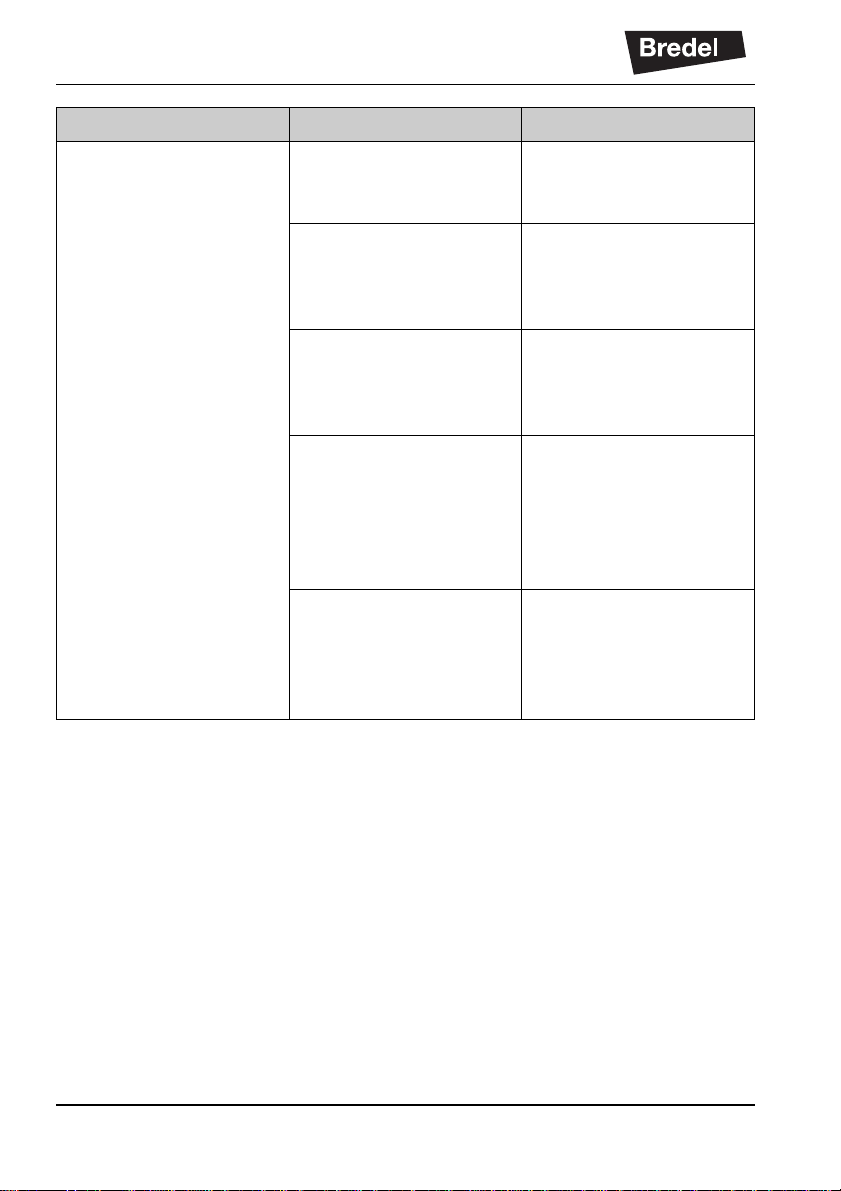

TROUBLESHOOTING

10 TROUBLESHOOTING

WARNING

Disconnect and lock the power supply to the pump drive before any work is

carried out.

In case the motor is fitted with a frequency controller and has a singlephase power supply, wait two minutes to make sure that the capacitors

have discharged.

If the hose pump does not function (correctly), consult the following checklist to see if

you can remedy the error yourself. If you cannot, contact your Bredel representative.

Problem Possible cause Correction

Failure to operate. No voltage. Check if the power supply

switch is on.

Check if the electrical sup-

ply is available at the

pump.

Stalled rotor. Check if the pump is

stalled by incorrect fitting of

the hose.

Check the VFD settings, if

applicable.

Lubricant level monitoring

system has been activated.

Check if the lubricant level

monitoring system has

stalled the pump.

Check the functioning of

the lubricant level monitoring system, and check the

lubricant level.

49

Page 50

TROUBLESHOOTING

Problem Possible cause Correction

High pump temperature. Non-standard hose lubri-

cant used.

Low lubricant level. Add Bredel Genuine Hose

Fluid temperature too high . Consult your Bredel repre-

Internal friction on the hose

caused by blocked or poor

suction characteristics.

High pump speed. Reduce pump speed to a

Consult your Bredel representative for the correct

lubricant.

Lubricant. For the required

amount of lubricant refer to

§ 11.1.4.

sentative about the maximum temperature range of

the fluid.

Check pipework/valves for

blockages. Ensure that the

suction pipework is as

short as possible and that

the diameter is large

enough.

minimum. Consult your

Bredel representative for

advice on optimum pump

speeds.

50

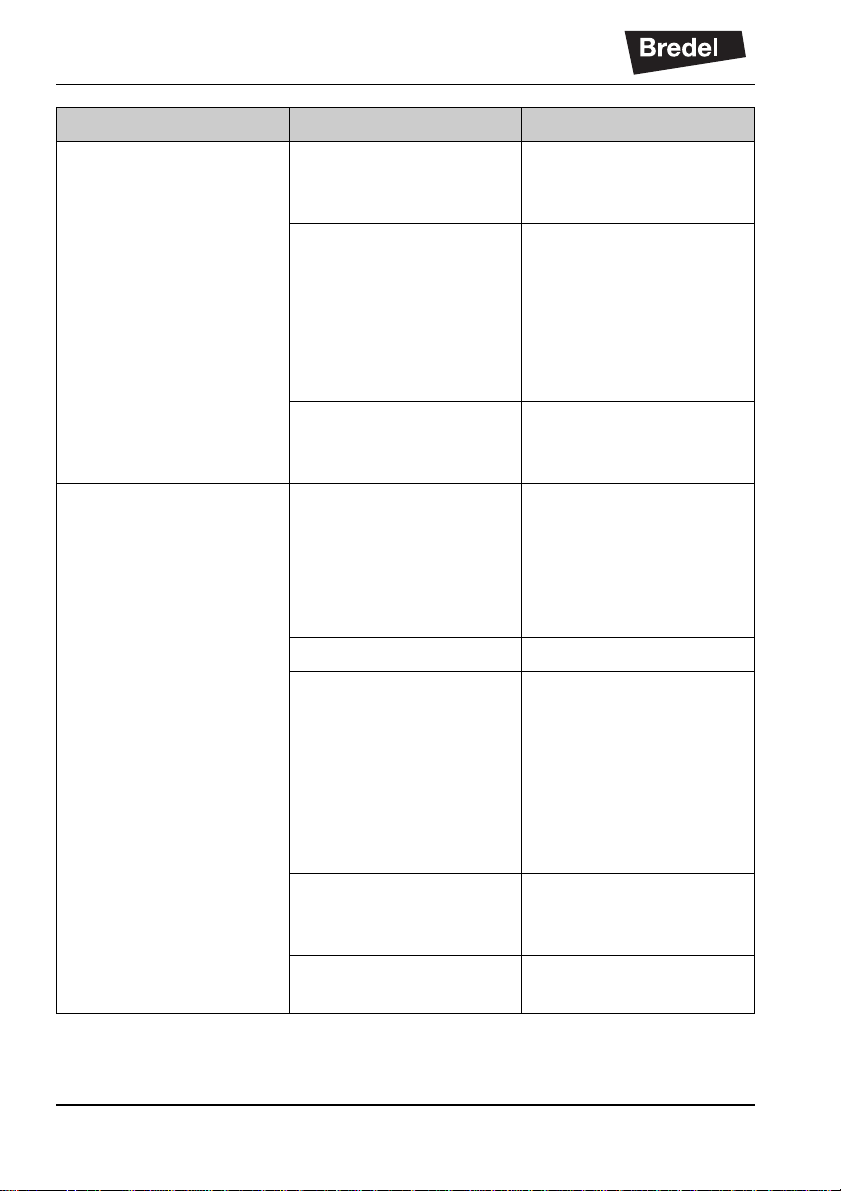

Page 51

TROUBLESHOOTING

Problem Possible cause Correction

Low capacity / pressure. Shut-off valve in the suc-

tion line (partly) closed.

Fully open the shut-off

valve.

Hose rupture or badly worn

hose.

(Partial) blockage of the

suction line or too little fluid

on the suction side.

Connections and hose

clamps not correctly

mounted, which makes the

pump suck air.

The filling degree of the

pump hose is too low,

because the speed is too

high in relation to the viscosity of the product to be

pumped and the inlet pressure.

The suction line can be too

long or too narrow or a

combination of these factors.

Replace the hose. Refer to

§ 8.5.

Ensure that the suction line

is clear of blockages and

that sufficient fluid is available.

Tighten connections and

hose clamps.

Consult your Bredel representative for a recommendation.

51

Page 52

TROUBLESHOOTING

Problem Possible cause Correction

Vibration of the pump

and pipework.

Suction and discharge

lines are not secured correctly.

Check and secure pipework.

High pump speed with long

suction and discharge lines

or high relative density or a

combination of these factors.

Too narrow diameter of

suction and/or discharge

line.

Short hose life. Chemical attack of the

hose.

High pump speed. Reduce pump speed.

High discharge pressures. Maximum working pres-

Reduce pump speed.

Reduce the line lengths on

both suction and discharge where possible.

Consult your Bredel representative for a recommendation.

Increase the diameter of

the suction/discharge lines.

Check the compatibility of

the hose material with the

fluid to be pumped. Consult your Bredel representative for correct hose

selection.

sure 800 kPa. Check that

the discharge line is not

blocked, the shut-off valves

are fully opened and the

pressure relief valve functions properly (if present in

the discharge line).

52

High product temperature. Consult your Bredel repre-

sentative for correct hose

selection.

High pulsations. Restructure the discharge

and inlet conditions.

Page 53

TROUBLESHOOTING

Problem Possible cause Correction

Hose pulled into the

pump.

Insufficient or no hose

lubricant in the pumphead.

Add extra lubricant. Refer

to § 8.4.

Lubricant leakage at

bracket.

Leakage from the rear of

the pump housing

"Buffer zone".

Lubricant leakage at

cover.

Incorrect lubricant: no

Bredel Genuine Hose

Lubricant in the pumphead.

Extremely high inlet pressure - larger than 200 kPa.

Hose blocked by an incompressible object in the

hose. The hose cannot be

compressed and will be

pulled into the pump housing.

Bolts of bracket loose. Tighten to the specified

Bolts of hose clamps loose. T ighten to the specified

Damaged seal ring. Replace seal ring.

Damaged seal ring. Replace seal ring.

Bolts not tightened. Tighten to the specified

Consult your Bredel representative for the correct

lubricant.

Reduce the inlet pressure.

Remove hose, check for

blockages and replace if

necessary.

torque settings. Refer to

§ 11.1.6.

torque settings. Refer to

§ 11.1.6.

torque settings. Refer to

§ 11.1.6.

Bolting torque too low. Tighten to the specified

torque settings. Refer to

§ 11.1.6.

53

Page 54

SPECIFICATIONS

11 SPECIFICATIONS

11.1 Pumphead

11.1.1 Performance

Description APEX10 APEX15 APEX20

∅ 10 mm ∅ 15 mm ∅ 20 mm

Max. capacity, continuous [m

Max. capacity, intermittent [m

3

/h] 0.28 0.55 0.87

3

*

/h]

0.39 0.77 1.20

Capacity per revolution [l/rev] 0.046 0.091 0.145

Max. permissible

working pressure

[kPa]

with low-pressure rotor 400 400 400

with medium-pressure

800 800 800

rotor

Permissible ambient temperature [°C] -20 to +45

Permissible fluid temperature [°C] -10 to +80

Sound level at 1 m [dB(A)] 60

* Intermittent duty: "Let the pump stand still to cool down for at least one hour after three

hours of operation".

54

Page 55

SPECIFICATIONS

10

1

5

4

8

9

2

11

7

6

7

3

7

6

7

11.1.2 Materials

Pos Description Material

1 Pump housing Aluminium

2 Cover Aluminium

3 Cover window PMMA

4 Pump rotor Cast-iron

5 Pump support Galvanised steel (AISI 316 optional)

6 Bracket AISI 316

7 Fasteners AISI 316

8 Dynamic sealing behind the rotor NBR

9 Cover seal EPDM

10 Sealing bush at hose connection EPDM

11 Coupling Steel

55

Page 56

SPECIFICATIONS

11.1.3 Surface treatment

• After surface preparation, one layer of two-component acrylate is used for

surface protection. Standard colour is RAL 3011.

• All galvanised parts have been provided with an electrolytic zinc layer of 15 - 20

microns.

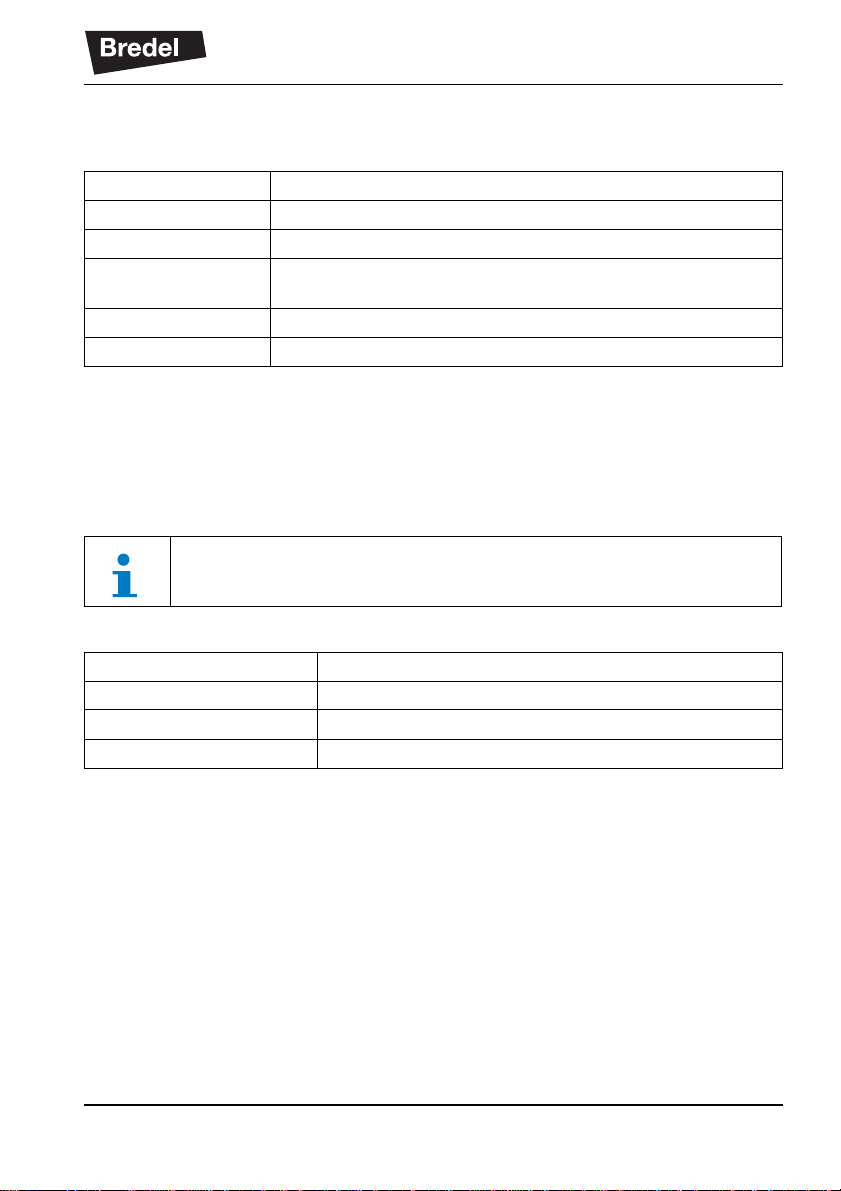

11.1.4 Lubricant table pump

APEX

Lubricant Bredel Genuine Hose Lubricant

Required quantity [litres] 1.0

Bredel Genuine Hose Lubricant is registered at NSF: NSF Registration N

Category Code H1. Also refer to: www.NSF.org/USDA.

Components:

Glycerol (C

Glycol (C

Water (H

) 50-100% w/w

3H8O3

) 2.5-10% w/w

2H6O2

O)

2

Consult your Bredel representative if you require additional information with

respect to the safety data sheet.

o

123204;

WARNING

It is the users responsibility to ensure the chemical compatibility of the fluid

to be pumped with the lubricant in the pumphead. Obey the local Health

and Safety regulations.

An alternative lubricant is available based on silicone. Also compatibility with this

lubricant must be checked if applied. Refer to the chemical compatibility chart at

www.wmpg.com/chemical or contact your Bredel representative for guidance.

56

Page 57

SPECIFICATIONS

11.1.5 Weights

Description Weight [kg]

Pumphead (inclusive of hose, lubricant and pump support) 17.6

Pump support 2.4

Rotor 4.8 ... 5.6

Hose 0.5 ... 0.7

Pump cover (complete) 1.8

Coupling 0.4

Gearbox coaxial two stages 4.7

coaxial three stages 4.8

worm gearbox 2.4

Electric motor 5.0 ... 8.3

57

Page 58

SPECIFICATIONS

1

5

3

4

2

1

3

2

6

11.1.6 Torque figures

Pos Description Bolt size

*

1Cover M6x25 10

2 Hose clamp

3 Bracket M8x20 25

**

4 Support + Gearbox nut M6 10

5 Drain plug M12x15-PA6 4

6 Inspection window M6x12 1.5

* All steel bolts are class 8.8.

** Due to creeping of the hose material, the hose clamp force initially reduces in time. If

leakage starts, re-tighten the hose clamp to the specified torque level. The listed torque

values apply to a new and properly greased hose clamp. Also refer to § 8.5.3 for extra

instructions and hose clamp installation

58

Torque [Nm]

3

Page 59

11.2 Gearbox

SPECIFICATIONS

Type Coaxial gearbox with helical gears

Number of stages Two or three

Lubrication Lubricated for life

Mounting position IM 3001 (IM B5) flanged gearbox with keyed shaft in horizontal

position.

Motor adapter Integrated

Optional motor adapter Adapter in conformance with IEC-B5 or NEMA C.

* Other gearbox types are available as option.

*

11.3 Electric motor

Standard electric motor design is an enclosed three-phase asynchronous motor. A

thermal safety device to prevent motor overload is optional.

In case of doubt about the local applicable regulations for the drive connection, contact your Bredel representative.

Protection class IP55/IK08

Insulation class F

Increase in temperature Within class B

Voltag e/frequency Refer to identification plate on motor.

59

Page 60

SPECIFICATIONS

11.4 Variable Frequency Drive (VFD) (optional)

The Bredel Variable Frequency Drive (VFD) has been preprogrammed and only needs

to be connected to the mains.

RFI filter Integrated RFI filter B (industrial applications).

Control Manual control for setting the speed and the keys for starting

forward, stop and starting reverse.

Protection class IP65

Mains power supply There are three types available; the choice depends on the

local electricity grid:

• 200-240 V ± 10%; 50/60 Hz ± 5%; 1 ph

• 200-240 V ± 10%; 50/60 Hz ± 5%; 3 ph

• 400-480 V ± 10%; 50/60 Hz ± 5%; 3 ph

11.5 Parts list

11.5.1 Ordering parts

Specify the item number, description and pump size (APEX10, APEX15 or APEX20) to

identify the component you need. Also specify the quantity you need.

60

Page 61

11.5.2 Overview

1

3

2

4,5,6,7

8

SPECIFICATIONS

Pos. Description

1 Cover assembly. Refer to § 11.5.3.

2 Pumphead assembly. Refer to § 11.5.4.

3 Pump support assembly. Refer to § 11.5.5.

4 Barbed nipple assembly. Refer to § 11.5.6.

5 Threaded nipple assembly. Refer to § 11.5.7.

6 Flange assembly (1). Refer to § 11.5.8.

7 Flange assembly (2). Refer to § 11.5.9.

8 Lubricant. Refer to § 11.5.10.

61

Page 62

SPECIFICATIONS

1 24 3

9

8d

8b

8e

8f

5

8c

6

7

8a

11.5.3 Cover assembly

Pos. Qty. Description

1 8 Cover screw

2 8 Cover screw washer

3 1 Drain plug O-ring

4 1 Drain plug

5 1 Breather screw

61Breather

7 1 Breat he r ga s k e t

8a 1 Cover

8b 1 Inspection window

8c 1 Inspection window gasket

8d 6 Inspection window screw

8e 1 Sticker ‘Bredel’

8f 1 Sticker ‘APEX’ (pump size specific)

9 1 Cover seal

62

Page 63

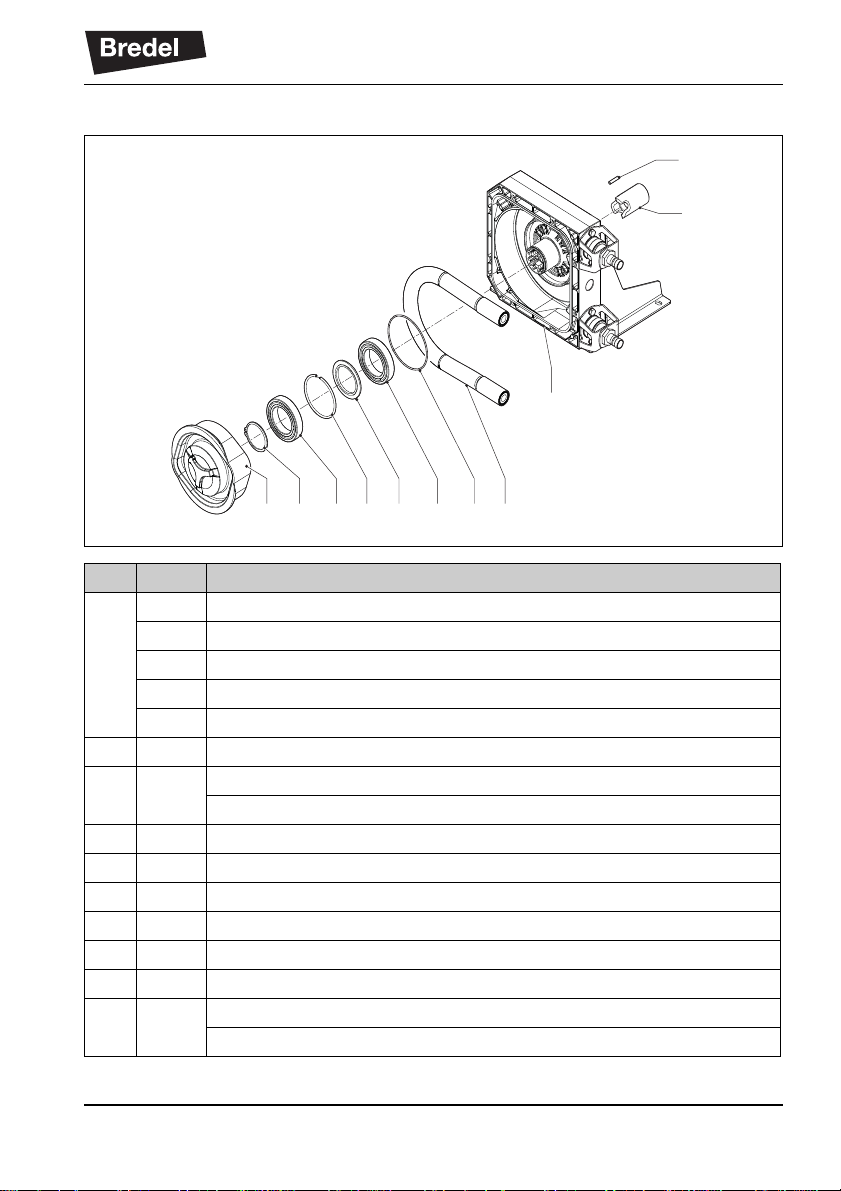

11.5.4 Pumphead assembly

12 17 14 16 15 14 13 10

11

18

19

Pos. Qty. Description

10 1 Hose NR

1Hose NBR

1Hose F-NBR

1Hose EPDM

1Hose CSM

11 1 Pump housing

12 1 Rotor, low-pressure (L)

Rotor, medium-pressure (M)

13 1 Seal ring

14 2 Bearing

15 1 Spacer ring

16 1 Retaining ring

17 1 Circlip

18 4 Support stud

19 1 Coupling, ∅ 20 x 63 mm

Coupling, ∅ 25 x 63 mm

SPECIFICATIONS

63

Page 64

SPECIFICATIONS

20

21

22

23

11.5.5 Support assembly

Pos. Qty. Description

20 1 Pump support

21 4 Support nut

22 4 Support nut washer

23 1 Orientation screw

64

Page 65

11.5.6 Barbed nipple assembly (PTFE/PDVF)

24

25

26

27

29

28

All parts differ for the APEX10, APEX15 and APEX20 except for the

bracket bolt and the bracket bolt washer.

SPECIFICATIONS

Pos. Qty. Description

24 2 Rubber bush

25 2 Hose clamp

26 2 Barbed nipple PTFE

Barbed nipple PVDF

27 2 Bracket

28 4 Bracket bolt

29 4 Bracket bolt washer

65

Page 66

SPECIFICATIONS

24

25

26

2829

27

11.5.7 Barbed or threaded nipple assembly (stainless steel/PP/PVC)

All parts differ for the APEX10, APEX15 and APEX20 except for the

bracket bolt and the bracket bolt washer.

Pos. Qty. Description

24 2 Rubber bush

25 2 Hose clamp

26 2 Barbed nipple stainless steel

*

Threaded nipple BSP stainless steel*

Threaded nipple DIN 11851 stainless steel*

Threaded nipple NPT stainless stee l*

Threaded nipple NPT PP

Threaded nipple NPT PVC

27 2 Bracket

28 4 Bracket bolt

29 4 Bracket bolt washer

* A properly created connection between a stainless steel nipple and the pump hose is

EHEDG compliant.

66

Page 67

11.5.8 Flange assembly with insert with collar

24

25

All parts differ for the APEX10, APEX15 and APEX20 except for the

bracket bolt and the bracket bolt washer.

SPECIFICATIONS

29

28

27

32

33

Pos. Qty. Description

24 2 Rubber bush

25 2 Hose clamp

27 2 Flange bracket

28 4 Bracket bolt

29 4 Bracket bolt washer

32 2 Flange ASA

33 2 Insert with collar PP

67

Page 68

SPECIFICATIONS

24

25

26

27

26

31

29

28

32

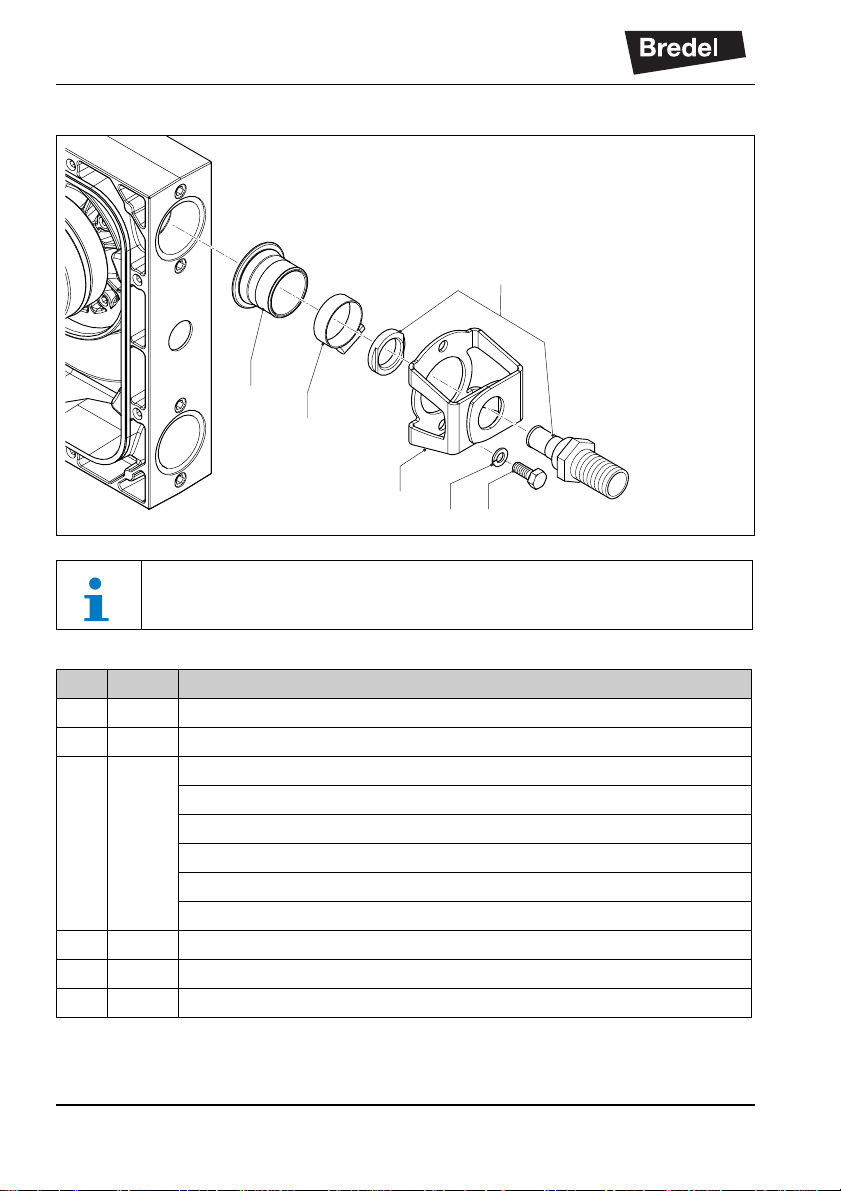

11.5.9 Flange assembly with threaded nipple

All parts differ for the APEX10, APEX15 and APEX20 except for the

bracket bolt and the bracket bolt washer.

Pos. Qty. Description

24 2 Rubber bush

25 2 Hose clamp

26 2 Threaded nipple (BSP) stainless steel

*

27 2 Bracket

28 4 Bracket bolt

29 4 Bracket bolt washer

31 2 Nipple nut

32 2 Threaded flange DIN stainless steel

2 Threaded flange ASA stainless steel

* A properly created connection between a stainless steel nipple and the pump hose is

11.5.10Lubricant

EHEDG compliant.

Pos. Qty. Description

1 1 l can Bredel Genuine Hose Lubricant

68

Page 69

ORIGINAL

Translation of original certificate

EC DECLARATION OF CONFORMITY OF THE MACHINERY

(according to Annex II.1.A. of Directive 2006/42/EC on machinery)

We,

Watson-Marlow Bredel B.V.

Sluisstraat 7

P.O. Box 47

NL-7490 AA Delden

The Netherlands

herewith declare, on our own responsibility, that the machinery:

Peristaltic hose pump: APEX10-20 series,

for the transportation of various kinds of fluids,

fulfils all the relevant provisions of Directive 2006/42/EC.

and, where appropriate, the machinery complies with the harmonised standard(s), other

standards or technical specifications, applicable requirements of these standards and/or

specifications as listed below:

EN 809

EN-ISO 12100-2

NEN-EN-IEC60204-1

Authorised to compile the technical file:

J. van den Heuvel, Sluisstraat 7, 7491GA, Delden, The Netherlands

The Netherlands, Delden

1 March 2013

J. van den Heuvel

Managing Director

69

Page 70

SAFETY FORM

Safety form

SAFETY FORM

Product Use and Decontamination Declaration

In compliance with the Health and Safety Regulations, the user is required to declare those substances that

have been in contact with the item(s) you are returning to W atson-Marlo w Bredel B.V. or any of its subsidiaries or

distributors. Failure to do so will cause delays in servicing the item or in issuing a response. Therefore, please

complete this form to make sure we have the information before receipt of the item(s) being returned. A completed copy must be attached to the outside of the p ackaging cont aining the item(s). You, the user , are responsible for cleaning and decontaminating the item(s) before returning them.

Please complete a separate Decontamination Certificate for each item returned. RGA/KBR no...................

1 Company ............................................................. .........................................................................................

Address .................... ............. ........... ............. ....... .......................... ............. ........... .......................................

Postal code.................................................. .. ... ....

Telephone.............................................................

2 Product ................................................................ 3.4 Cleaning fluid to be used if residue of chemical is

2.1 Serial Number ............. ... .. ... .................................

2.2 Has the Product been used?

YES NO

If yes, please complete all the following para-

graphs.

If no, please complete paragraph 5 only

3 Details of substances pumped 4 I hereby confirm that the only substances(s) that

3.1 Chemical Names

a) ............................ .......... ............. ........... ............

b) ............................ .......... ............. ........... ............

c) ............................ ............................. .................