Page 1

Installation and Operating Instructions

Software Version 6.1

5O5XY Robot

PB0193 Issue 3

Page 2

Contents

505XY one-year warranty .................................................... Page 3

Safety .................................................... Page 3

Information for returning the robot ................................................... Page 3

Part 1: Installation

Siting .................................................... Page 4

Electrical connection .................................................... Page 4

Interfacing with the 505Di .................................................... Page 4

505Di setup procedure .................................................... Page 5

Dispensing head .................................................... Page 7

Part 2: Overview

Quick start for a pre-programmed robot ........................................... Page 8

Keypad layout .................................................... Page 8

Conventions used in the manual .................................................... Page 8

Part 3: Setup

Accessing the setup mode .................................................... Page 9

Selecting a language .................................................... Page 9

Clearing memory .................................................... Page 9

Remote control operation .................................................. Page 10

Exit setup mode .................................................. Page 10

Part 4: Setting the operating parameters

Requirements .................................................. Page 11

Setting the number of rows and columns ...................................... Page 11

Setting the tray fill pattern .................................................. Page 12

Setting up the drip delay and fill head speed ................................ Page 12

Setting the operating mode .................................................. Page 13

Setting the number of trays and the fill direction ........................... Page 14

Storing values and returning to the main menu ............................. Page 14

Setting batch fill delays .................................................. Page 15

Multiple tray setup .................................................. Page 15

Setting the XY robot filler start/end/corner points .......................... Page 15

The start point .................................................. Page 16

The end point .................................................. Page 16

The corner point .................................................. Page 17

Part 5: Operating the 505XY

Performing a test fill .................................................. Page 18

Fill in conjunction with the 505Di/L or 505Di/RL ............................ Page 18

Part 6: Memory facilities

Storing/recalling/reviewing memories ............................................ Page 20

Storing a setup in memory location ............................................... Page 20

Recalling memories .................................................. Page 21

Reviewing memories .................................................. Page 21

Error messages .................................................. Page 21

Specification .................................................. Page 22

Fill pattern examples .................................................. Page 23

Menu structure .................................................. Page 24

Outline dimensions .................................................. Page 27

Product Use and Decontamination Declaration ............................. Page 28

Declaration of Conformity .................................................. Page 29

2

Page 3

505XY one-year warranty

Watson-Marlow Limited warrants, subject to the conditions below, through

either Watson-Marlow Limited, its subsidiaries, or its authorised distributors,

to repair or replace free of charge, including labour, any part of this product

which fails within one year of delivery of the product to the end user. Such

failure must have occurred because of defect in material or workmanship

and not as a result of operation of the product other than in accordance with

the instructions given in this manual.

Conditions of and specific exceptions to the above warranty are:

· Consumable items are excluded.

· Products must be returned by pre-arrangement carriage paid to Watson-

Marlow Limited, its subsidiaries, or its authorised distributor.

· All repairs or modifications must have been made by Watson-Marlow

Limited, its subsidiaries, or its authorised distributors or with the express

permission of Watson-Marlow Limited, its subsidiaries, or its authorised

distributors.

· Products which have been abused, misused, or subjected to malicious or

accidental damage or electrical surge are excluded.

Warranties purporting to be on behalf of Watson-Marlow Limited made by

any person, including representatives of Watson-Marlow Limited, its

subsidiaries, or its distributors, which do not accord with the terms of this

warranty shall not be binding upon Watson-Marlow Limited unless expressly

approved in writing by a Director or Manager of Watson-Marlow Limited.

Safety

In the interests of safety, this unit should only be used by competent, suitably

trained personnel after they have read and understood this manual, and

considered any hazard involved.

Any person who is involved in the installation or maintenance of this

equipment should be fully competent to carry out the work. In the UK this

person should also be familiar with the Health and Safety at Work Act 1974.

Do not place any part of the body within the working envelope of the 505XY

during operation.

There are dangerous voltages (at mains potential) inside the unit. If access is

required, isolate from the mains supply before removing the cover.

Information for returning the robot

Any equipment which has been contaminated with, or exposed to, body

fluids, toxic chemicals or any other substance hazardous to health must be

decontaminated before it is returned to Watson-Marlow or its distributor.

A certificate (a suitable blank form is included at the rear of these operating

instructions), or signed statement, must be attached to the outside of the

shipping carton.

This certificate is required even if the equipment is unused. If the 505XY has

been used, the fluids that have been in contact with the 505XY and the

cleaning procedure must be specified along with a statement that the

equipment has been decontaminated.

3

Page 4

Part 1: Installation

Siting

The 505XY should be situated on a flat surface and is fitted with adjustable

feet to ensure that the unit can be levelled. Adequate area must be given to

allow tubing to pass from the 505L pumphead to the dispensing head of the

robot without kinking or unnecessary bends.

Electrical connection

The 505XY operates on single phase mains electricity only. It is fitted with a

mains voltage selector which must be set to either 120V for 100-120V

50/60Hz supplies or 240V for 220-240V 50/60Hz supplies.

The on/off switch of the 505XY is located at the mains socket as is the fuse.

A spare fuse is incorporated in the fuse holder and should be replaced with

the same value of fuse if used.

A mains cable fitted with a moulded plug is supplied with the 505XY, but if

another plug is to be fitted, the colour coding of the mains lead must be

observed.

The mains cable for 220-240V supplies is coded so that the live lead is

coloured brown, the neutral lead is coloured blue, and the earth lead is

coloured green and yellow.

The mains cable for 100-120V supplies is coded so that the live lead is

coloured black, the neutral lead is coloured white, and the earth lead is

coloured green.

Failure to

operate

Should the robot fail to operate, check that mains electricity is available at

the unit, that the voltage selector switch is in the correct position and that the

mains fuse is in tact.

There are dangerous voltages (at mains potential) inside the unit. If

access is required, isolate the pump from the mains before removing

the cover.

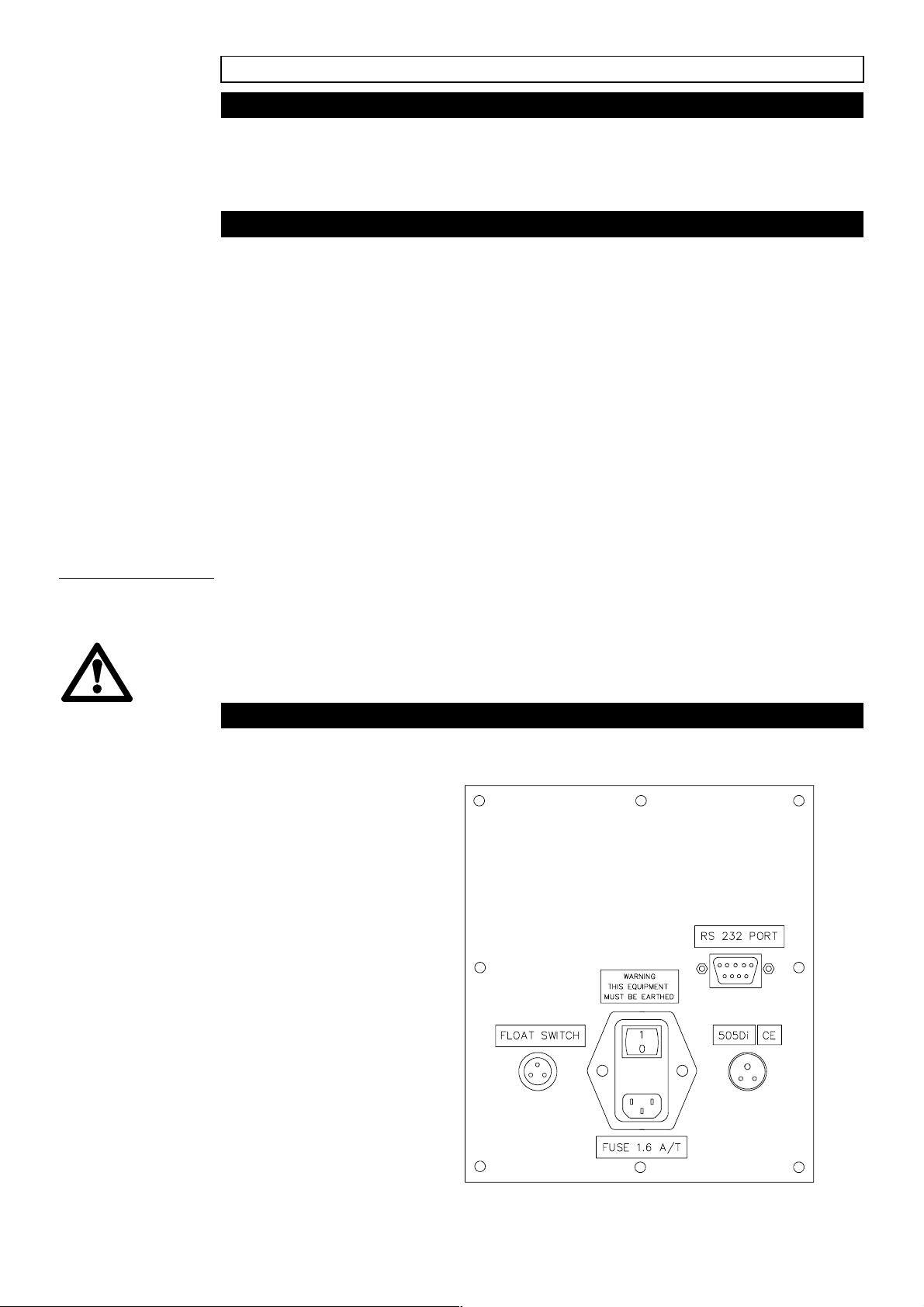

Interfacing with the 505Di

The 505XY has four connector/sockets on the rear panel.

· Mains socket

· 505Di socket

· RS 232 connector

· Floatswitch socket

4

Page 5

· Ensure that the voltage selector, found on the underside of the unit, is

switched to the appropriate voltage - either 120V for 110V-120V

operation, or 240V for 220-240V operation.

· Plug the mains power lead into mains socket at rear of unit.

· Level the robot using the adjustable feet.

· Connect the interface lead into socket at rear of unit marked 505Di

socket. Connect the other end into the 25 pin Dee connector on the rear

panel of the 505Di using the interface lead provided, Watson-Marlow part

number 059.7021.000.

· An RS 232 connector is provided to allow connection to a P.C. for remote

control.

· The float switch socket enables a remote stop facility to be set up

providing an over-ride to a preset dispensing run.

· Attach the delivery end of the tubing from the 505L pumphead to the

dispensing head of the XY Robot.

505Di setup procedure

The 505Di which is to be used in conjunction with the 505XY should be fitted

with EPROM version 2.03.

Ensure that mains power to the 505Di is on and the interface lead to the

505XY is correctly in position. The main menu of the pump will display:

D D S E C A L M A N U A L

N E T W O R K S E T U P

Step to SETUP and press Enter.

R O M D A T E / T I M E

B E E P R A M P D R I P >

B A U D = 9 6 0 0 A U X I L

P U M P = 1 M A X >

Using the step key, step through to AUXIL and press Enter, you will be given

an option under Line 1 of Dose or Motor:

L I N E 1

D O S E M O T O R

Press Enter at Dose.

The pump will then display the following message:

L I N E - 1

H I G H = R U N S T O P

5

Page 6

Step to Stop and press Enter.

L I N E - 2 D I R E C T I O N

H I G H = C W

Press Enter at CW. The pump can be set to operate in a counter-clockwise

or clockwise direction for this setup procedure. The following screens will

then be called:

L I N E - 1 H I G H = S T O P

L I N E - 2 H I G H = C W

B A U D = 9 6 0 0 A U X I L

P U M P = 1 M A X >

Press Main Menu calling up the display:

D D S E C A L M A N U A L

N E T W O R K S E T U P

The 505Di can now be calibrated and the dosing parameters set in the

normal way. (For more information reference the 505Di operating instruction.

It is a recommended that a trial run of the 505XY setup is completed before

full process operation. This will ensure that the traversing limits of the 505XY

have been programmed correctly. (Refer to Part 5 of this operating

instruction).

Following calibration and dose setup the pump screen will indicate:

* * * *

M L

* * * * *

D O S E

P R E S S S T A R T

The GO button can then be pressed on the 505XY Robot and dispensing will

commence.

The 505Di should be set up normally as if for a manual dispensing run. The

505XY robot filler controls when the pump should start dispensing ensuring

that the pump will always wait for the dispensing head to finish moving to the

next position before it starts pumping again.

Note: If the 505Di setup is complete and the pump is ready to start a

dispensing cycle, turning the mains power of the 505XY robot on or off will

initiate a single dose from the 505Di.

6

Page 7

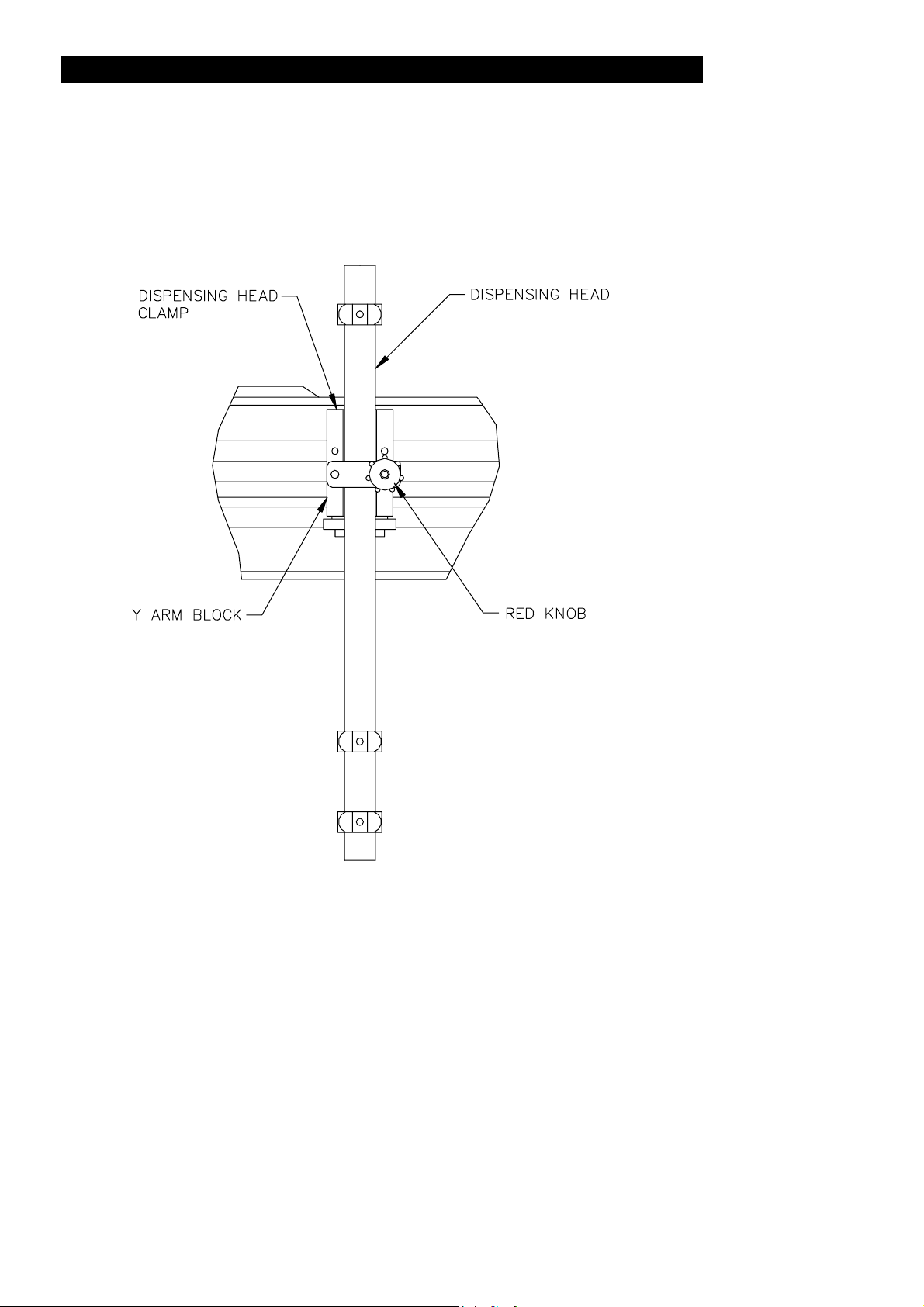

Dispensing head

The appropriate dispensing head for the size of tubing being used should be

attached to the Y arm block by loosening the red knob and lifting the

dispensing head clamp.

The dispensing head can then be inserted into the slot, the clamp lowered

and the red knob re-tightened.

In order to obtain the correct dispensing height, adjustable feet are fitted to

the base of the system.

An adjustable tray guide is also fitted to ensure that the filler trays locate

correctly.

Fine adjustment can be made using the dispensing head. It can be raised or

lowered by simply undoing the adjustable red knob, and sliding the guide to

the correct (200mm max) height, then re-tighten.

7

Page 8

Part 2: Overview

Quick start for a pre-programmed robot

To initiate a fill sequence on a pre-programmed XY robot filler switch on

power to the unit and the following screen will be displayed:

S O F T W A R E V E R X . X

M E M O R Y S E T U P G O

Ensure that the vial tray is located correctly within the tray guides

and press the 'GO' button to begin a fill cycle.

The remainder of the manual explains how to program the system

for a variety of filling applications using different tray sizes and

equipment configurations.

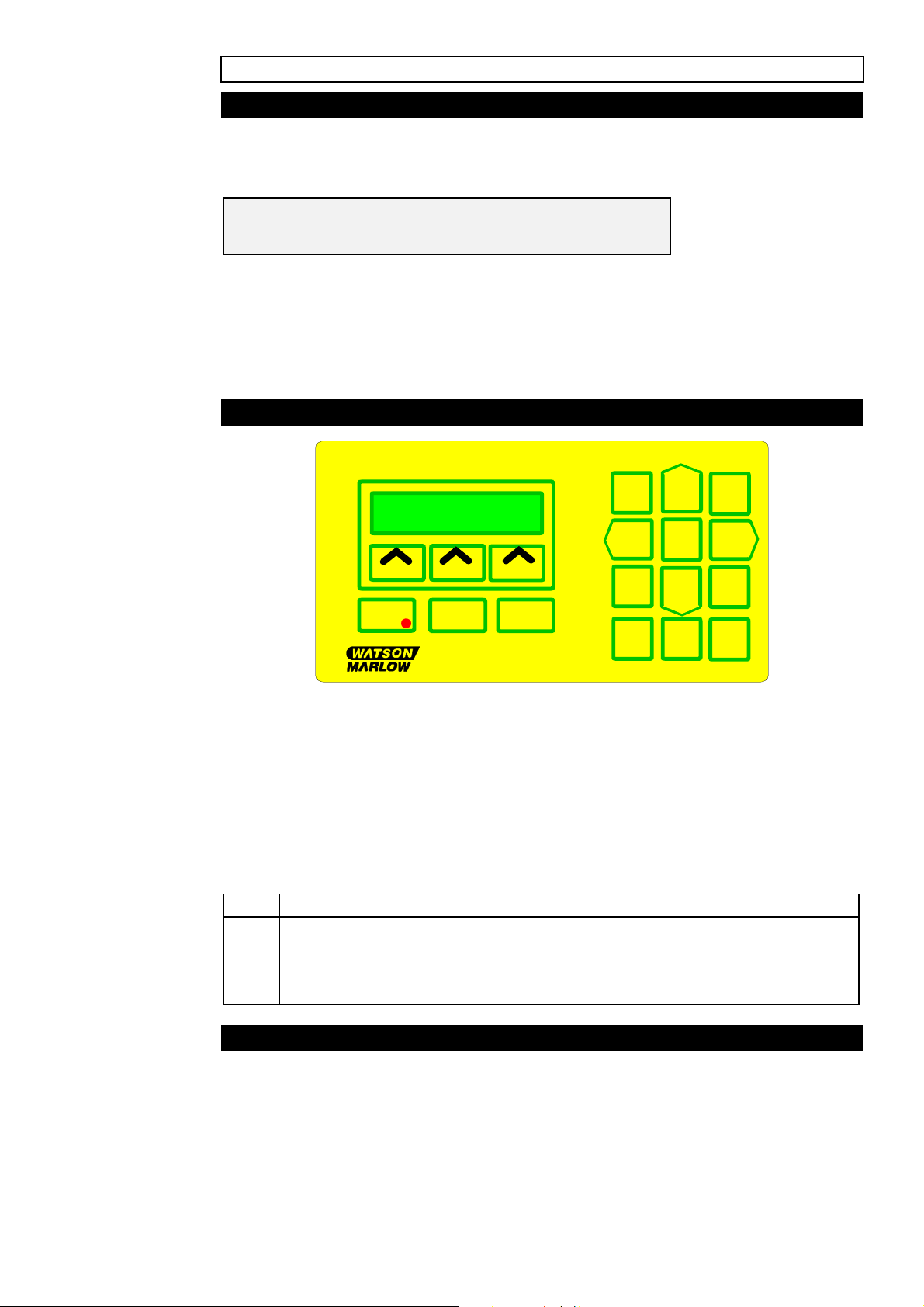

Keypad layout

1

4

7

Power

Start

505XY

Beneath the display are three rectangular soft function keys. The function of

each key at any one time in a procedure is denoted by the text in the bottom

line of the LCD display.

The keypad serves two functions;

· To enable parameters to be entered into the operating programme of the

XY robot.

· To enable the operator to move the fill head

· The keys and functions are listed below::

Key Function

2 Move fill head to fill rear of XY robot filler

4 Move fill head left

6 Move fill head right

8 Move the fill head forwards (towards the front of the XY robot filler)

Stop

Enter

Robot

2

5

8

0

3

6

9

.

Conventions used in the manual

Throughout the manual conventions are used to describe the keyboard keys:

The soft keys are referred to as 'buttons', e.g. from the main menu press the

MEMORY button.

The keypad keys and the START/STOP keys are shown enclosed thus

<START>.

8

Page 9

Part 3: Setup

Accessing the setup mode

This section illustrates how various parameters such as language used and

serial communication speed are set up upon receipt of a new machine. It

also shows that this procedure need only be carried out once, as all

parameters are stored, even when the unit is switched off.

Setup mode is accessed by holding down the soft key, which is positioned to

the extreme left of the three keypad softkeys, whilst the power is switched on

at the rear of the machine. When the key is released the display will show

the following message:

S E T U P P R O G R A M M E

E N T E R P A S S W O R D

Enter the system password (1212) the display will show the following

message:

S E T U P P R O G R A M M E

C O U N T R Y M E M O R Y N E X T

Selecting a language

Press the key beneath the "country" option on the display. The display will

show the following message:

E N G L I S H N E X T A C C E P T

Press the NEXT button to step through each available language option.

Press ACCEPT to select the desired option and return to the setup menu.

Clearing memory

NOTE. This should only be necessary after maintenance work or after a

software upgrade. This operation will erase all settings stored in the

module.

At the setup menu press the MEMORY button. The display will show the

following message:

E R A S E M E M O R Y

A C C E P T Q U I T

Press the ACCEPT button to erase all memory locations, or the QUIT button

to cancel the operation and return to the setup menu. After pressing the

NEXT button, the display will show:

9

Page 10

S E T U P P R O G R A M M E

R S 2 3 2 R E M O T E N E X T

Press the RS232 button, the display will show:

1 2 0 0 B P S N E X T A C C E P T

Press the NEXT button until the desired baud rate is shown in the display.

Press the ACCEPT button to store the selected value. The previous setup

menu will be displayed.

Remote control operation

Press the REMOTE button, the display will show:

X Y K E Y P A D M O D E

N E X T A C C E P T

Press the NEXT to alternate between XY keypad and XY remote mode,

followed by the ACCEPT button to store the selected value and return to the

setup menu.

NOTE: After selecting XY remote mode, the keypad will become redundant,

all control will be via a remote keypad. For diagnostic help, refer to the

engineering mode flow chart on page 24.

Exit setup mode

To exit the setup mode press the ACCEPT button, the XY robot filler will

reset and display the following screen, prompting to press <START> to move

the dispensing head to the home position.

P R E S S < S T A R T >

T O H O M E M A C H I N E

When the dispensing head has been moved to the home position the main

menu will be called:

S O F T W A R E V E R X . X

M E M O R Y S E T U P G O

10

Page 11

Part 4: Setting the operating parameters

Requirements

Before a fill sequence the XY robot filler needs to know the following:

1. Size of fill in rows & columns.

2. Fill pattern, the way the tray of bottles are arranged.

3. The delay from the end of dispensing liquid to moving to the next fill point

drip delay.

4. The speed at which the head will move from one fill point to the next.

5. Whether the XY robot filler will run continuously after finishing a fill pattern

or stop.

6. The number of trays to be placed within the working envelope.

7. The direction of the fill sequence.

8. The start point for each tray.

9. The end point, for each tray position.

10.The corner point, for each tray position.

Setting the number of rows and columns

Initially the screen will show:

S O F T W A R E V E R X . X

M E M O R Y S E T U P G O

Press the SETUP button and the display will show:

S E T U P / T E S T T R A Y N O 1

T E S T L I M I T S O P T I O N S

From the setup menu select OPTIONS, calling the display:

S E T U P F I L L O P T I O N S

C O L U M N S R O W S N E X T

P R E S S E N T E R T O R E T

C O L U M N S R O W S N E X T

The option to return to the previous setup/test menu will also toggle with this

display.

Press the COLUMNS button to call the display:

E N T E R N O O F C O L S 0 0

A C C E P T Q U I T

11

Page 12

The display will show the previously entered value (if any). Enter the

number of columns to be filled using the keypad (between 01 & 99). Press

the ACCEPT button to store the value, or the QUIT button to return to the

previous setup/fill/options menu without changing any settings. Press the

ROWS button to call the display:

E N T E R N O O F R O W S 0 0

A C C E P T Q U I T

Again, using the keypad, enter the number of rows to be filled and press the

ACCEPT button to store the value, or the QUIT button to return to the

previous setup/fill/options menu without changing any settings.

NOTE: Using the QUIT button provides a quick verification of the set number

of rows and columns.

Press the NEXT button, the display will show:

S E T U P F I L L O P T I O N S

P A T T E R N D R I P D E L N E X T

P R E S S E N T E R T O R E T

P A T T E R N D R I P D E L N E X T

The option to return to the previous setup/fill/options menu will also toggle

with this display.

Setting the tray fill pattern

The XY robot may, in addition to a straight fill, perform fill sequences on

trays with bottles arranged in a honeycomb pattern. Four distinct patterns

are available and these are shown on page 23, together with their

associated start/end points and number of columns/rows.

Press the PATTERN button, the display will show:

0 0 0 0 0 0 S T R A I G H T F I L L

0 0 0 0 0 0 N E X T A C C E P T

The display will show the previously entered fill pattern (if any), if no pattern

was previously stored the straight pattern will be displayed.

Press the NEXT button to scroll through the available fill patterns, press the

ACCEPT button to store the desired pattern. The previous setup/fill/options

menu will then be displayed.

Setting up the drip delay and fill head speed

The drip delay, is the time period between the XY robot filler completing one

delivery, and moving to the next fill point. Press the DRIPDEL button and the

display will show:

12

Page 13

D R I P D E L A Y 0 . 1 S

A C C E P T Q U I T

The previously entered drip delay (if any) will be shown. Enter the drip delay

in multiples of 0.1 seconds and press either the ACCEPT button to store the

new value, or the QUIT button to return to the previous setup/fill/options

menu without making any changes.

NOTE: Using the QUIT button provides quick verification of drip delay.

Press the NEXT to call the display:

S E T U P F I L L O P T I O N S

S P E E D M O D E N E X T

P R E S S E N T E R T O R E T

S P E E D M O D E N E X T

The option to return to the previous setup/fill/options menu will also toggle

with this display.

Press the SPEED button, the display will show:

S E T P O S I T I O N E R S P E E D

X . X C M / S N E X T A C C E P T

Use the NEXT button to select the desired filler head traversing speed.

Options of 6, 9 or 12cm/s are available. Press the ACCEPT button to store

the selected speed and return to the previous setup/fill/options menu.

Setting the operating mode

There are two modes of operation with the XY robot. Batch mode is where the

XY robot will perform a fill sequence and then stop, whilst continuous mode is

where the XY robot will repeat its fill sequence until stopped manually.

Press the MODE button, the display will show:

B A T C H M O D E

N E X T A C C E P T

Press the NEXT button to change the operating mode to continuous. Press

the ACCEPT button to store the selected mode and the previous

setup/fill/options menu will be displayed.

Press the NEXT button, the display will show:

13

Page 14

S E T U P F I L L O P T I O N S

T R A Y S S T E P D I R N E X T

P R E S S E N T E R T O R E T

T R A Y S S T E P D I R N E X T

The option to return to the previous menu will also toggle with this display.

Setting the number of trays and the fill direction

In order for the XY robot to operate correctly, it needs to know the number of

individual trays within the working envelope which are to be part of a fill

sequence.

For example, if three tray positions have been programmed into the system

setup, and all three are to be filled, then by setting the number of trays as 3,

all three trays will be filled.

If however, only tray 1 of the three trays was required to be filled, then by

setting the number of trays as 1 then this will be achieved.

This is a general setting applicable to fill sequences which can be set under

any individual tray setup option.

Press the TRAYS button, the display will show:

N O O F T R A Y S 1

A C C E P T Q U I T

Use the numeric keypad to enter the number of trays to be filled. Press the

ACCEPT button to exit and store the value, or the QUIT button to exit

without changing anything. The previous menu will be displayed.

Storing values and returning to the main menu

The XY robot can work either forwards (starting at the start point), or

backwards (starting at the end point). Press the STEP-DIR button, the display

will show:

N O R M A L T R A Y S T E P

A C C E P T N E X T

With NORMAL TRAY STEP displayed as shown below, the XY robot will

start at the nearest point to home and proceed from there.

Press the NEXT button to change the option to REVERSE TRAY STEP.

R E V E R S E F I L L

A C C E P T N E X T

Press the ACCEPT button to exit and store the selection and the previous

setup/fill/options menu will be displayed.

14

Page 15

Press the NEXT to call the following screen:

S E T U P F I L L O P T I O N S

D E L A Y N E X T

Setting batch fill delays

Press the DELAY button and the display will show:

B A T C H F I L L D E L A Y O O S

A C C E P T Q U I T

Set the time delay between each batch fill sequence in seconds using the

numeric keypad. Press ACCEPT to store the value or QUIT to return to the

previous display without changing any settings.

When all parameters have been entered the program will return to the setup

menu, from here press <ENTER> to return to the main menu.

If the limits have been set outside the fill area, or the start is further than the

end point an appropriate error message will appear on the display for

approximately 1.5 seconds. These setting errors must be rectified before

the program will return to the main menu.

Multiple tray setup

The setup for multiple trays within the fill area is identical to the setup of an

individual tray. Each individual setup procedure must be repeated for the

relevant position of each individual tray. Each tray number should be

entered at the following screen prior to its positional information being

inputed. Fill tests on specific trays can be carried out by entering the relevant

tray number and then running the fill test procedure.

S E T U P / T E S T T R A Y N O 1

T E S T L I M I T S O P T I O N S

The "1" in the figure above shows that the limits for a tray No.1 can be

changed. Pressing the <2> key will increase the number up to a maximum of

nine pressing the <8> key will decrease the number back down to "1".

Setting the XY robot filler start/end/corner points

S E T U P / T E S T T R A Y N O 1

T E S T L I M I T S O P T I O N S

Press the LIMITS button and the following display will be called:

S E T F I L L L I M I T S - 1

S T A R T E N D C O R N E R

15

Page 16

P R E S S E N T E R T O R E T

S T A R T E N D C O R N E R

The option to return to the previous setup/test menu will also toggle with this

display.

The start point

NOTE. The start point is always nearest the home position. When using a

honeycomb fill pattern refer to page 23 for an illustration of various patterns

and start/end points.

Press the START button, the display will show:

M O V E T O S T A R T P O I N T

A C C E P T Q U I T H O M E

The fill head will move to the previously set start point. Using the keypad

cursor keys move the fill head to the first fill point.

Press the ACCEPT button to store the setting. The XY robot will warn the

operator that the Y corner point has been reset by calling the display:

Y C O R N E R P O I N T R E S E T

Press the HOME button to move the fill head to the home position, or the

QUIT button to return to the previous menu without changing any settings.

NOTE. If the start point is moved, the end point will move with respect to the

change in co-ordinates. This is useful if the same tray is used but positioned

in a different position as the start point is then the only change required.

The end point

Press the END button, the display will show:

M O V E T O E N D P O I N T

A C C E P T Q U I T H O M E

The fill head will move to the previously set end point. Using the keypad

cursor keys move the fill head to the last fill point. Press the ACCEPT button

to store the setting. The XY robot will warn the operator that the X corner

point has been reset by calling the display:

X C O R N E R P O I N T R E S E T

16

Page 17

Press the HOME button to move the fill head to the home position, or the

QUIT button to return to the previous set fill limits menu without changing any

settings.

The corner point

The corner point feature is generally the point furthest away (in a horizontal

line) from the first fill point. When using a honeycomb fill pattern refer to

page 23 for an illustration of various patterns and start/end points.

NOTE: The corner point will be calculated by the robot and will generally not

need altering. The feature is included to allow for possible tray misalignment.

Press the CORNER button, the display will show:

M O V E T O C O R N E R P O I N T

A C C E P T Q U I T H O M E

The fill head will move to the corner point which has been calculated using

the START and END point settings. If tray misalignment is experienced use

the cursor keys to move the fill head to the actual corner point (the point

furthest left along the first fill row).

Press the HOME button to move the fill head to the home position, or the

QUIT button to return to the previous menu without changing any settings.

Press the <ENTER> key to return to the set fill limits menu. Within the setup

menu option the <2>and <8> keys can be used to select any one of a

number of possible trays within the fill area. Please refer to the section

covering multiple tray setup.

17

Page 18

Part 5: Operating the 505XY

Performing a test fill

Press the SETUP button, the display will show:

S E T U P / T E S T T R A Y N O 1

T E S T L I M I T S S I Z E

The display shows that the LIMITS and TEST options refer to tray No 1,

pressing key <2> increases the value up to 9, pressing key <8> decreases

the value down to 1. With the tray number shown as '1', pressing key <8>

will change the display to 'TEST ALL TRAYS', this allows the testing of the

programmed fill sequence for the number of trays entered.

Press the TEST button, the display changes to show the fill status:

0 0 : R X C F F T R A Y X

· 00 is the number of the current memory setup.

· R is the programmed number of rows in the tray.

· C is the programmed number of columns in the tray.

· FF is the tray fill pattern, e.g.

ST = Straight

H1 - H4 = Honeycomb

· TRAY X shows the tray number that is currently being filled.

A test fill sequence is now performed with the head passing over the

vials/bottles without the XY robot operating.

If at anytime the fill sequence must be stopped, press STOP, the display

changes to the pause screen:

P O S I T I O N E R P A U S E D

R E S U M E A B O R T

Press the RESUME button or the <START> key to continue. Press the

ABORT button to stop the test pattern.

The fill head moves to the home position after the sequence has finished or

if the sequence is aborted.

Fill in conjunction with the 505Di/L or 505Di/RL

Connect the dispenser to the XY robot using the 3 pin cable.

Setup the XY robot or load a setup from memory.

At the main menu press the GO button, the fill sequence will now begin and

the display changes to show the final status:

18

Page 19

0 0 : R X C F F T R A Y X M

M O D E

· M is the operating mode Batch/Continuous.

Pressing the MODE button will change the operating mode from Batch to

Continuous or vice versa.

If at any time the fill sequence must be stopped follow the procedure shown

on the previous page, otherwise the fill head will move to the home position

after the sequence has finished or if it is aborted.

If the XY robot detects an error in the signal from the 505Di the display will

change to show:

W A I T I N G F O R P U M P

R E S U M E A B O R T

Check the connections between the XY robot and the 505Di.

Press the RESUME button to continue or the ABORT button to reset the XY

robot and finish the fill sequence.

19

Page 20

Part 6: Memory facilities

Storing/recalling/reviewing memories

The XY robot has the ability to store and recall up to 50 settings, each setting

may have up to 20 character descriptions attached to it in order to describe

the type of fill, tray size etc. All operating information for the XY robot is

stored in a memory location, including the language in use as well as the

head speed and serial interface speed.

S O F T W A R E V E R X . X

M E M O R Y S E T U P G O

Press the MEMORY button to call the following screen:

R E C A L L / S T O R E / R E V I E W

R E C A L L S T O R E R E V I E W

P R E S S E N T E R T O R E T

R E C A L L S T O R E R E V I E W

The option to return to the previous main menu will also toggle with this

display. Press the ENTER key to return to the main menu.

Storing a setup in memory location

From the memory menu press the STORE button, the display will show:

S T O R E M E M O R Y N O 1

A C C E P T Q U I T

Enter the memory number in which you wish to store the current setup, using

the numeric keypad. Press the ACCEPT button to store the setup, or the

QUIT button to return to the previous memory menu. When the ACCEPT

button is pressed the operator is taken to the memory description screen as

shown below:

2 4 : 3 X 4 S T T R A Y 2 M

A C C E P T Q U I T

The display will show the current description stored for that location, or if the

location was previously unused the XY robot will suggest a description for

you as shown above, the format being the same as the status line when the

XY robot is operating. When the unit offers a description for a setup which is

being stored into a memory location, ensure that the description is different

from any previously stored setups to avoid any programs being overwritten.

Use the <4> and <6> keys to move the cursor left and right and the <2> and

<8> keys to increase or decrease the character to the left of the cursor.

20

Page 21

Pressing the <5> key will copy the character to the left of the cursor to the

current cursor position. Press the ACCEPT button to store the description.

The operator is returned to the memory menu.

Recalling memories

From the memory menu press the RECALL button, the display will show:

R E C A L L M E M O R Y N O 0 1

A C C E P T Q U I T

Enter the memory number to recall using the numeric keypad, press the

ACCEPT button to recall the setup, or the QUIT button to return to the

previous memory menu. If the memory number entered does not contain a

valid setup, then the display will show:

* * * E R R O R * * *

M E M O R Y I S E M P T Y

Re-enter a valid memory location number, or use the REVIEW button, as

described below, to select from the valid memories stored.

Reviewing memories

Press the REVIEW button, the display will show:

0 0 : R X C F F T R A Y X M

N E X T Q U I T R E C A L L

This is the description attached to memory location 01, pressing the NEXT

button moves to the next location with a valid setup stored in it, when the last

stored location is displayed and the NEXT button is pressed, the first

location is redisplayed. Press the RECALL button to load the contents of the

selected memory location and return to the main menu. Press the QUIT

button to return to the memory menu without recalling the memory location.

Error messages

If an attempt has been made to load an empty memory location, the display

will show:

* * * E R R O R * * *

M E M O R Y I S E M P T Y

Re-enter a valid number or use REVIEW to select. If 0 is entered as a

memory number or a the number of rows or columns the display will show:

* * * E R R O R * * *

O N L Y 0 1 - 5 0 A L L O W E D

21

Page 22

A memory number, or the number of rows/columns as has been entered as

0. Re-enter with a number between 01 and 50.

If the calculated fill area exceeds the area the XY robot can cover then

display will call:

I N V A L I D S T A R T O R E N D

P O I N T S - R E S E T L I M I T S

This can be a result of changing the START point when the END is near the

left hand limit or selecting a honeycomb pattern which has a fill point outside

the available fill area.

If the set START point is to the left of the END point the display will call:

I N V A L I D S T A R T / F I N I S H

P O I N T S - R E S E T L I M I T S

Reset so that the START point is to the right of the END point.

Specification

Power supply 110/120V&220/240V 50/60Hz Single phase

Power consumption 40W

Fuse rating T type 1.6A

Electronics Microprocessor controlled

Number of memories 50

Languages English, French, German, Spanish &

Italian(selectable)

In/Out ports Float switch, Serial RS232 300,600 1200,

2400,4800, 9600 Baud (selectable)

Dimensions Width 735mm x height 280mm x depth 385mm

Weight 14Kg

Number of fill points 99 (X), 99 (Y).

Fill patterns Straight & 4 Honeycomb patterns

Fill head speed 120mm/Sec (selectable 60, 90, 120mm/Sec,

excluding acceleration and deceleration times)

Fill direction Normal (start at start point) or Reverse (start at

end point)

Fill area 420x245 (Between fill centres)

Operating mode Batch (finishes after filling all trays), Continuous

(repeats the fill tray sequence until reset)

Positional accuracy Better than 0.3mm

Drip delay 0.0 - 0.9 Seconds (increment 0.1seconds)

Number of trays 9

Maximum vial height 200mm

Minimum vial diameter 6.5mm

22

Page 23

Fill pattern examples

23

Page 24

Menu structure

Depress and hold any of the soft keys whilst switching on the XY robot, then

release and, at the prompt, enter 1212 as the password.

SETUP PROGRAM

ENTER PASSWORD

SETUP PROGRAM

COUNTRY MEMORY NEXT

SETUP PROGRAM

ENGLISH NEXT ACCEPT

SETUP PROGRAM

FRENCH NEXT ACCEPT

SETUP PROGRAM

GERMAN NEXT ACCEPT

SETUP PROGRAM

SPANISH NEXT ACCEPT

SETUP PROGRAM

ITALIAN NEXT ACCEPT

ERASE MEMORY

ACCEPT QUIT

SETUP PROGRAM

300BPS NEXT ACCEPT

SETUP PROGRAM

600BPS NEXT ACCEPT

SETUP PROGRAM

1200BPS NEXT ACCEPT

SETUP PROGRAM

2400BPS NEXT ACCEPT

SETUP PROGRAM

4800BPS NEXT ACCEPT

SETUP PROGRAM

RS232 REMOTE NEXT

SETUP PROGRAM

NEXT ACCEPT

XY KEYPAD MODE

NEXT ACCEPT

XY REMOTE MODE

NEXT ACCEPT

SETUP PROGRAM

960BPS NEXT ACCEPT

NOTE: Once the remote keypad option has been selected, the XY robot

keypad will become redundant.

In order to regain control, the keypad mode must be reselected. This may

only be done by switching off the machine and returning to the set-up mode

as detailed above.

24

Page 25

SOFTWARE VER X.X

MEMORY SETUP GO

PRESS ENTER TO RETURN

RECALL/STORE/REVIEW

RECALL/STORE/REVIEW

00: RxC FF TRAY X

MOVE TO START POINT

ACCEPT QUIT HOME

NUMBER OF COLUMNS 01

ACCEPT QUIT

SETUP/TEST TRAY NO. X

TEST LIMITS OPTIONS

SET FILL LIMITS-1

START END CORNER

MOVE TO END POINT

ACCEPT QUIT HOME

SETUP FILL OPTIONS

COLUMNS ROWS NEXT

NUMBER OF ROWS 01

ACCEPT QUIT

00: RxC tray x M

MODE

MOVE TO CORNER POINT

ACCEPT QUIT HOME

SETUP FILL OPTIONS

PATTERN DRIP DEL NEXT

25

Page 26

SETUP FILL OPTIONS

N

PATTERN DRIP DEL NEXT

PRESS ENTER TO RETUR

STRAIGHT FILL

NEXT ACCEPT

HONEYCOMB 1

NEXT ACCEPT

HONEYCOMB 2

NEXT ACCEPT

HONEYCOMB 3

NEXT ACCEPT

HONEYCOMB 4

NEXT ACCEPT

DRIP DELAY 0.0S

ACCEPT QUIT

SET POSITIONER SPEED

6cm/s NEXT ACCEPT

SET POSITIONER SPEED

9cm/s NEXT ACCEPT

SET POSITIONER SPEED

12cm/s NEXT ACCEPT

BATCH MODE

NEXT ACCEPT

SETUP FILL OPTIONS

SPEED MODE NEXT

SETUP FILL OPTIONS

TRAYS STEPDIR NEXT

No. OF TRAYS 1

ACCEPT QUIT

NORMALL TRAY

ACCEPT NEXT

REVERSE TRAY

ACCEPT NEXT

SETUP FILL OPTIONS

DELAY NEXT

CONTINUOUS MODE

NEXT ACCEPT

BATCH FILL DELAY 20s

ACCEPT QUIT

26

Page 27

Outline dimensions

27

Page 28

Product Use and Decontamination Declaration

In compliance with the UK Health & Safety at Work Act and the Control of Substances Hazardous to Health

Regulations you, the user are required to declare the substances which have been in contact with the product(s)

you are returning to Watson-Marlow or any of its subsidiaries or distributors. Failure to do so will cause delays in

servicing the product. Therefore, please complete this form to ensure that we have the information before

receipt of the product(s) being returned. A FURTHER COPY MUST BE ATTACHED TO THE OUTSIDE OF THE

PACKAGING CONTAINING THE PRODUCT(S). You, the user, are responsible for cleaning and

decontaminating the product(s) before returning them.

Please complete a separate Decontamination Certificate for each pump returned.

RGA No: …………………...

1 Company

Address .................................................. Postcode

Telephone ................................................... Fax Number

2 Product ...................................................

2.1 Serial Number ..............................................

(a)

...................…...............................…………….. .

2.2 Has the Product been used? (b)

....................…...............................…………….

YES NO

(c)

3.4 Cleaning fluid to be used if residue of chemical is found

during servicing;

(d)

If yes, please complete all the following Sections

If no, please complete Section 5

only

3 Details of substances pumped

3.1 Chemical names:

(a) ......................................................

(b) ......................................................

(c).......................................................

(d) ......................................................

3.2 Precautions to be taken in

handling these substances:

(a) ........................................................................

(b) ........................................................................ Note: To assist us in our servicing

(c) ........................................................................ please describe any fault condition you

(d) ........................................................................ have witnessed.

3.3 Action to be taken in the event of human

contact:

(a) ........................................................................

(b) ........................................................................

(c).........................................................................

(d) ........................................................................

4 I hereby confirm that the only substances(s) that the equipment specified

has pumped or come into contact with are those named, that the information

given is correct, and the carrier has been informed if the consignment is of a

hazardous nature.

5 Signed ………………………………………………..

Name …………………………………………………

Position ……………………………………………….

Date …………………………………………………..

Watson-Marlow Limited Falmouth Cornwall TR11 4RU England Tel: 01326 370370 Fax: 01326 376009

28

Page 29

Declaration of Conformity

29

Loading...

Loading...